Page 1

QCPU-A (A Mode)

User's Manual

-Q02CPU-A

-Q02HCPU-A

-Q06HCPU-A

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using the product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[DESIGN PRECAUTIONS]

WARNING

Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable

controller. Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Configure external safety circuits, such as an emergency stop circuit, protection circuit, and

protective interlock circuit for forward/reverse operation or upper/lower limit positioning.

(2) When the programmable controller detects the following error conditions, it stops the operation

and turn off all the outputs.

• Overcurrent or overvoltage protection of the power supply module is activated.

• The CPU module detects an error such as a watchdog timer error by the self-diagnostic

function.

All outputs may turn on when an error occurs in the part, such as I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a

safety mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe

circuit example, refer to Chapter 9 LOADING AND INSTALLATION in this manual.

(3) Outputs may remain on or off due to a failure of an output module relay or transistor. Configure

an external circuit for monitoring output signals that could cause a serious accident.

In an output module, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

A - 1

Page 4

[DESIGN PRECAUTIONS]

WARNING

Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect

output or malfunction.

For the operating status of each station after a communication failure, refer to relevant manuals for

the network.

Incorrect output or malfunction due to a communication failure may result in an accident.

When controlling a running programmable controller from a peripheral connected to the CPU module

or from a personal computer connected to a special function module, configure an interlock circuit in

the sequence program to ensure that the entire system will always operate safely.

For program modification and operating status change, read relevant manuals carefully and ensure

the safety before operation.

Especially, in the case of a control from an external device to a remote programmable controller,

immediate action cannot be taken for a problem on the programmable controller due to a

communication failure.

To prevent this, configure an interlock circuit in the sequence program , and determine corrective

actions to be taken between the external device and CPU module in case of a communication

failure.

When setting up the system, do not allow any empty slot on the base unit.

If any slot is left empty, be sure to use a blank cover (A1SG60) or a dummy module (A1SG62) for it.

Otherwise, internal parts of the module may be flied in the short circuit test or when an overcurrent or

overvoltage is accidentally applied to the external I/O section.

CAUTION

Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

When a device such as a lamp, heater, or solenoid valve is controlled through an output module, a

large current (approximately ten times greater than normal) may flow when the output is turned from

off to on.

Take measures such as replacing the module with one having a sufficient current rating.

After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size.

Design circuits so that the entire system will always operate safely, regardless of the time.

A - 2

Page 5

[INSTALLATION PRECAUTIONS]

CAUTION

Use the programmable controller under the environment that meets the general specifications in this

manual.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

To mount the CPU module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect mounting may cause malfunction, failure or a drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module

with the screw.

Tighten the screw within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Insert securely the module fixing projection at the bottom of the AnS series module into the fixing

hole in the base unit and then tighten the module fixing screw within the specified torque.

When no screw is tightened, even if the module is installed correctly, it may cause malfunctions, a

failure or a drop of the module.

Tightening the screw excessively may damage the screw and/or the module, resulting in a drop of

the module, a short circuit or malfunctions.

When using an extension cable, connect it to the extension cable connector of the base unit

securely.

Check the connection for looseness.

Poor contact may cause incorrect input or output.

When using a memory card, fully insert it into the memory card slot.

Check for incomplete connection after installing it.

Poor electrical contact may cause malfunctions.

Shut off the external power supply for the system in all phases before mounting or removing the

module.

Failure to do so may result in damage to the product.

Do not directly touch any conductive part of the module.

Doing so can cause malfunction or a failure of the module.

A - 3

Page 6

[WIRING PRECAUTIONS]

WARNING

Shut off the external power supply for the system in all phases before wiring.

Failure to do so may result in electric shock or damage to the product.

After wiring, attach the included terminal cover to the module before turning it on for operation.

Failure to do so may result in electric shock.

A - 4

Page 7

[WIRING PRECAUTIONS]

CAUTION

Ground the FG and LG terminals to the protective ground conductor dedicated to the programmable

controller.

Failure to do so may result in electric shock or malfunction.

Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting

in failure.

Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

Do not connect multiple power supply modules to one module in parallel.

The power supply modules may be heated, resulting in a fire or failure.

Connectors for external connection must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered.

Incomplete connections could result in short circuit, fire or malfunction.

Tighten the terminal screw within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure or malfunction.

A protective film is attached to the top of the CPU module to prevent foreign matter, such as wire

chips, from entering during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

Mitsubishi Electric programmable controllers must be installed in control panels.

Connect the main power supply to the power supply module in the control panel through a relay

terminal block.

Wiring and replacement of a power supply module must be performed by maintenance personnel

who is familiar with protection against electric shock. (For the wiring methods, refer to Section 9.5.)

A - 5

Page 8

[STARTUP AND MAINTENANCE PRECAUTIONS]

WARNING

Do not touch any terminal while power is on.

Doing so will cause electric shock.

Correctly connect the battery connector.

Do not charge, disassemble, heat, short-circuit, solder, or throw the battery into the fire.

Doing so will cause the battery to produce heat, explode, or ignite, resulting in injury and fire.

Shut off the external power supply for the system in all phases before cleaning the module or

retightening the terminal screws or module fixing screws.

Failure to do so may result in electric shock.

Undertightening the terminal screws can cause short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

A - 6

Page 9

[STARTUP AND MAINTENANCE PRECAUTIONS]

CAUTION

Before performing online operations (especially, program modification, forced output and operation

status change) for the running CPU module from the peripheral connected, read relevant manuals

carefully and ensure the safety.

Improper operation may damage machines or cause accidents.

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller.

Shut off the external power supply for the system in all phases before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

After the first use of the product, do not perform each of the following operations more than 50 times

(IEC 61131-2/JIS B 3502 compliant).

Exceeding the limit may cause malfunction.

• Mounting/removing the module to/from the base unit

• Mounting/removing the terminal block to/from the module

Do not drop or apply any shock to the battery to be installed in the module.

Doing so may damage the battery, causing the battery fluid to leak inside the battery. If the battery is

dropped or any shock is applied to it, dispose of it without using.

Before handling the module, touch a grounded metal object to discharge the static electricity from

the human body.

Failure to do so may cause the module to fail or malfunction.

A - 7

Page 10

[DISPOSAL PRECAUTIONS]

CAUTION

When disposing of the product, treat it as an industrial waste.

When disposing of batteries, separate them from other wastes according to the local regulations.

(For details of the Battery Directive in EU member states, refer to Appendix 7.)

[TRANSPORTATION PRECAUTIONS]

CAUTION

When transporting lithium batteries, follow the transportation regulations. (For details of the

regulated models, refer to Appendix 6.)

A - 8

Page 11

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

A - 9

Page 12

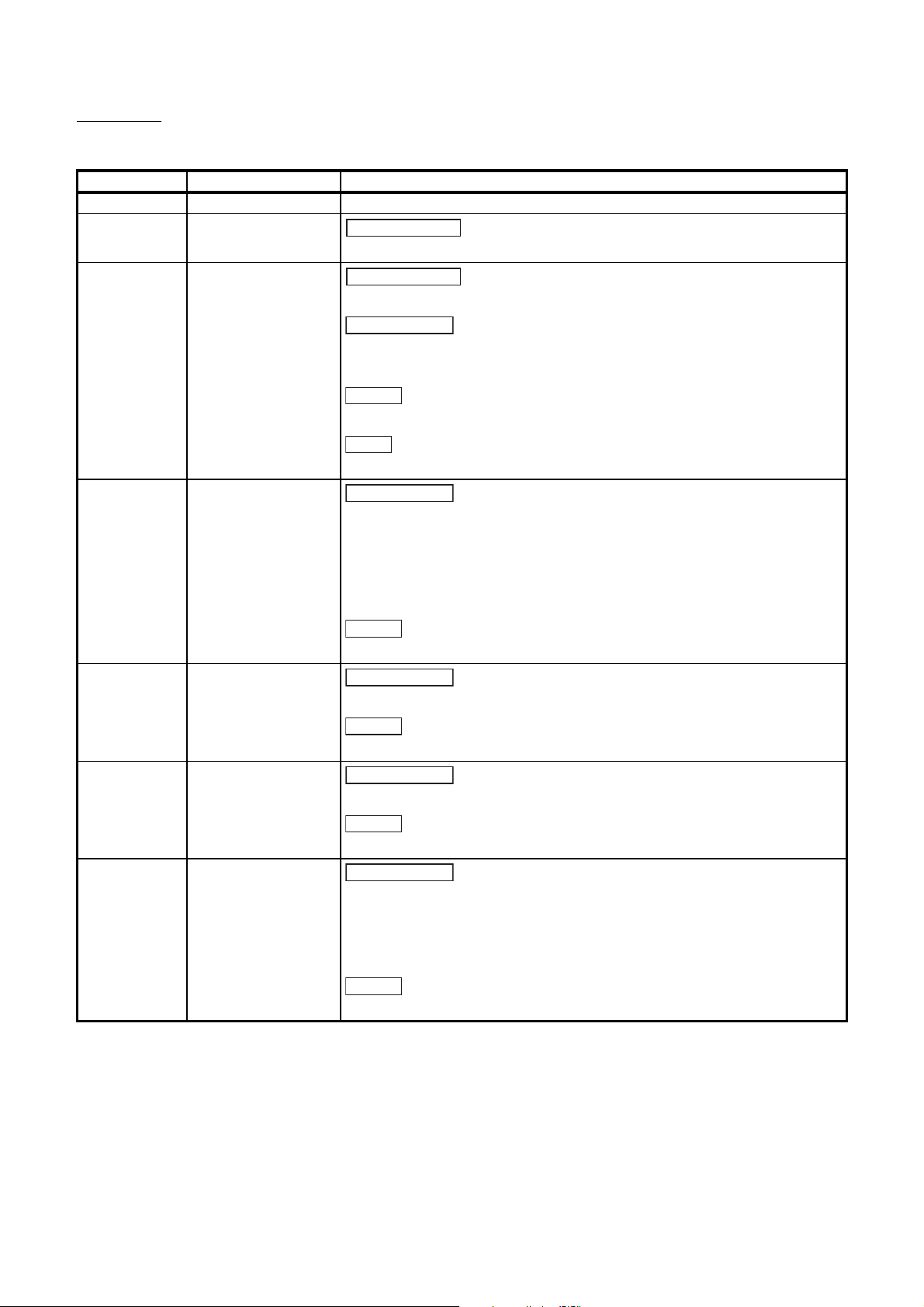

REVISIONS

Addition of model

Addition of model

Partial correction

Addition

Partial correction

Addition

Partial correction

Addition

Partial correction

Addition

Partial correction

Addition

The manual number is given on the bottom left of the back cover.

Print Date *Manual Number Revision

Dec., 1999 SH (NA) 080065-A First printing

Mar., 2000 SH (NA) 080065-B

QA1S33B

Dec., 2003 SH (NA) 080065-C

A1SY42P

About Manual, Section 2.2.1, 2.3, 3.1, 4.1.3, 6.1, 6.3, 7.2, 8.1.3, 9.1.2, 9.1.4,

9.1.5, 9.1.6, 9.2, 9.6, 11.3, 11.4.1, Appendix 2.1, 2.3, 4, 5.3

Appendix 6

Delete

Appendix 5 List of Instruction Processing Time

Oct., 2006 SH (NA) 080065-D

SAFETY PRECAUTIONS, Section 1.1, 2.2.1, 2.2.3, 2.3, Chapter 3, Section 3.1,

4.1, 4.1.1, 4.1.3, 4.1.4, 4.2.1, 4.2.2, 4.2.3, 4.2.6, 4.3, 4.4.1, 4.5, 4.6.1, 4.6.3, 5.1,

5.2, 6.1.1, 6.2, 7.2.1, 7.3, 7.7, 7.7.1, 7.7.2, Chapter 8, Section 8.1.3, 8.2.4, 8.2.6,

9.1.1, 9.1.2, 9.1.3, 9.1.4, 9.2, 9.2.4, 9.5, 9.5.1, 9.5.2, 10.3, 10.4, 11.2.8, 11.3.2,

11.4.1, Appendix 2.1, 2.3, 4.1, WARRANTY

May, 2007 SH (NA) 080065-E

Oct., 2008 SH (NA) 080065-F

Mar., 2010 SH (NA) 080065-G

Section 9.5.1, 9.5.2, 11.2.10

Section 2.3, 8.1.3, 8.2.7, 9.5.1, 9.5.2, 11.4.2

Section 8.1.7

SAFETY PRECAUTIONS, Chapter 3, Section 4.2.2, 5.1, 7.2.1, 7.7, 9.5.1, 11.4.1

Appendix 7, 7.1, 7.2

"PLC" was changed to "programmable controller".

SAFETY PRECAUTIONS, Section 2.2.1, 2.3, 4.1, 4.2.6, 4.4.3, 4.6.1, 5.1, 7.6,

7.7.2, Chapter 8, Section 9.1.2, 9.2, 9.5.1, 11.3.2, 11.4.1, Appendix 2.1, 2.2, 4.1,

5.1, 6.1, WARRANTY

CONDITIONS OF USE FOR THE PRODUCT

A - 10

Page 13

The manual number is given on the bottom left of the back cover.

Partial correction

Addition

Partial correction

Addition

Partial correction

Partial correction

Partial correction

Partial correction

Partial correction

Print Date *Manual Number Revision

Jan., 2011 SH (NA) 080065-H

Section 4.1.4, 8.8, Chapter 9, Section 9.1, 9.1.1, 9.1.2, 9.1.3, 9.1.4, 9.1.5, 9.1.6,

Section 9.1.7, 9.1.8

Oct., 2011 SH (NA) 080065-I

Introduction, Section 2.1, 2.3, 2.4.1, Chapter 3, Section 4.5, 6.1.1, 6.1.2, 6.2,

8.1.1, 9.1.1, 9.1.2, 9.1.3, 9.3, 9.5.1, Chapter 10, Section 11.2.4, 11.2.5, 11.2.6,

11.2.7, 11.2.8, 11.2.9, 11.2.10, Appendix 2.1, 2.2, 5.2, 5.3

Section 6.4

Apr., 2012 SH (NA) 080065-J

USER PRECAUTIONS, Chapter 3, Chapter 7, Section 10.3, 10.4, 11.3.2

Feb., 2015 SH(NA)-080065-K

Chapter 3, Section 4.6.1, 5.1, 5.2, 7.2.1, 7.7.2, 8.1.3, 8.2.6, 9.5.2, Appendix 5.1

Dec., 2015 SH(NA)-080065-L

Section 2.1, 7.4, Appendix 5.3, WARRANTY

Dec., 2017 SH(NA)-080065-M

Jun., 2019 SH(NA)-080065-N

Section 7.2.1

Section 2.1, 2.3, 7.1.1, 11.2.9, Appendix 6.1

This manual confers no industrial property rights or any rights of any other kind, nor dose it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

Japanese Manual Version SH-080066-P

1999 MITSUBISHI ELECTRIC CORPORATION

A - 11

Page 14

Introduction

Thank you for purchasing the Mitsubishi Electric programmable controller MELSEC-Q series.

Before using your new programmable controller, please read this manual thoroughly to gain an

understanding of its functions so you can use it properly.

When applying the program examples introduced in this manual to the actual system, ensure the

applicability and confirm that it will not cause system control problems.

Please forward a copy of this manual to the end user.

Table of Contents

1 OVERVIEW 1 - 1 to 1 - 2

1.1 Features ........................................................................................................................................1 - 2

2 SYSTEM CONFIGURATION 2 - 1 to 2 - 23

2.1 System Configuration ....................................................................................................................2 - 1

2.2 Precautions When Configuring the System...................................................................................2 - 2

2.2.1 Hardware...............................................................................................................................2 - 2

2.2.2 Software package .................................................................................................................2 - 4

2.2.3 Precautions when using GPP function software packages and A8PUE peripheral devices

which are not compatible with AnU .......................................................................................2 - 7

2.3 System Equipment ........................................................................................................................2 - 8

2.4 System Configuration Overview ..................................................................................................2 - 22

2.4.1 QCPU-A system ..................................................................................................................2 - 23

3 SPECIFICATIONS 3 - 1 to 3 - 2

4 CPU MODULE 4 - 1 to 4 - 46

4.1 Performance Specifications...........................................................................................................4 - 1

4.1.1 Overview of operation processing.........................................................................................4 - 4

4.1.2 Operation processing of RUN, STOP, PAUSE, and STEP-RUN..........................................4 - 7

4.1.3 Operation processing upon instantaneous power failure ......................................................4 - 9

4.1.4 Self-diagnostics functions ...................................................................................................4 - 10

4.1.5 Device list ............................................................................................................................4 - 13

4.2 Parameter Setting Ranges ..........................................................................................................4 - 15

4.2.1 List of parameter setting range ...........................................................................................4 - 15

4.2.2 Memory capacity setting (for main program, file register, comment, etc.) ..........................4 - 18

4.2.3 Setting ranges of timer and counter ....................................................................................4 - 22

4.2.4 I/O devices ..........................................................................................................................4 - 24

4.2.5 I/O assignment of special function module .........................................................................4 - 25

4.2.6 MELSECNET/MINI-S3 auto refresh processing .................................................................4 - 26

4.3 Function List ................................................................................................................................4 - 31

4.4 Functions added to QCPU-A .......................................................................................................4 - 33

4.4.1 Boot operation from built-in ROM........................................................................................4 - 33

4.4.2 Usage of 1ms timer .............................................................................................................4 - 36

4.4.3 Sequence accumulation time processing............................................................................4 - 39

A - 12

Page 15

4.5 Handling Precautions ..................................................................................................................4 - 41

4.6 Part Names and Settings ............................................................................................................4 - 43

4.6.1 Part names..........................................................................................................................4 - 43

4.6.2 Switch operation after program write ..................................................................................4 - 46

4.6.3 Latch clear operation...........................................................................................................4 - 46

4.6.4 Handling of the memory card at power-on ..........................................................................4 - 46

5 POWER SUPPLY MODULE 5 - 1 to 5 - 4

5.1 Specifications ................................................................................................................................5 - 1

5.2 Part Names ...................................................................................................................................5 - 3

6 BASE UNIT AND EXTENSION CABLE 6 - 1 to 6 - 8

6.1 Specifications ................................................................................................................................6 - 1

6.1.1 Base unit specifications.........................................................................................................6 - 1

6.1.2 Extension cables specifications ............................................................................................6 - 2

6.2 Part Names and Settings ..............................................................................................................6 - 3

6.3 Setting the Extension Stage Numbers ..........................................................................................6 - 6

6.4 Voltage drop when an extension base unit is used .......................................................................6 - 7

7 MEMORY CARD AND BATTERY 7 - 1 to 7 - 13

7.1 Memory Card.................................................................................................................................7 - 1

7.1.1 Specifications ........................................................................................................................7 - 1

7.2 Battery Specifications (CPU Module and Memory Card Batteries) ...............................................7 - 2

7.2.1 Specifications ........................................................................................................................7 - 2

7.2.2 Handling precautions ............................................................................................................7 - 3

7.3 Handling Memory Cards................................................................................................................7 - 4

7.4 Part Names of Memory Card.........................................................................................................7 - 5

7.5 Installing/Removing a Memory Card .............................................................................................7 - 6

7.6 Installing Batteries (CPU Module and Memory Card Batteries) ....................................................7 - 7

7.7 Battery Replacement.....................................................................................................................7 - 8

7.7.1 Battery life .............................................................................................................................7 - 9

7.7.2 Battery replacement procedure...........................................................................................7 - 11

8 EMC AND LOW VOLTAGE DIRECTIVES 8 - 1 to 8 - 15

8.1 Requirements for Compliance with EMC Directive .......................................................................8 - 1

8.1.1 EMC Directive related standards ..........................................................................................8 - 2

8.1.2 Installation inside the control panel .......................................................................................8 - 3

8.1.3 Cable.....................................................................................................................................8 - 4

8.1.4 Power supply module ............................................................................................................8 - 9

8.1.5 Ferrite core..........................................................................................................................8 - 10

8.1.6 Noise filter (power supply line filter) ....................................................................................8 - 10

8.1.7 Power line for external power supply terminal ....................................................................8 - 11

8.1.8 Installation environment of the CC-Link/LT module and the AS-i module...........................8 - 11

8.2 Requirements for Compliance with Low Voltage Directive..........................................................8 - 12

8.2.1 Standard applied for MELSEC-AnS series programmable controller .................................8 - 12

8.2.2 Precautions when using the MELSEC-AnS series programmable controller......................8 - 12

A - 13

Page 16

8.2.3 Supply power ......................................................................................................................8 - 13

8.2.4 Control panel.......................................................................................................................8 - 14

8.2.5 Module installation ..............................................................................................................8 - 15

8.2.6 External wiring.....................................................................................................................8 - 15

9 LOADING AND INSTALLATION 9 - 1 to 9 - 30

9.1 Module Installation ........................................................................................................................9 - 1

9.1.1 Handling precautions ............................................................................................................9 - 1

9.1.2 Precautions on base unit installation.....................................................................................9 - 2

9.1.3 Installation and removal of the dustproof cover ....................................................................9 - 5

9.1.4 Installation and removal of modules......................................................................................9 - 7

9.1.5 Extension stage number setting for the extension base unit...............................................9 - 11

9.1.6 Connecting/disconnecting the extension cable ...................................................................9 - 12

9.2 Concept of Fail Safe Circuit.........................................................................................................9 - 15

9.3 Installation Environment ..............................................................................................................9 - 21

9.4 Calculation Method of Heat Amount Generated by the Programmable Controller......................9 - 22

9.5 Wiring ..........................................................................................................................................9 - 24

9.5.1 Wiring precautions ..............................................................................................................9 - 24

9.5.2 Wiring to module terminals..................................................................................................9 - 29

9.6 Precautions when Connecting the Uninterruptible Power Supply (UPS) ....................................9 - 30

10 MAINTENANCE AND INSPECTION 10 - 1 to 10 - 5

10.1 Daily Inspection ...........................................................................................................................10 - 2

10.2 Periodic Inspection ......................................................................................................................10 - 3

10.3 Operating a CPU Module After Being Stored Without a Battery .................................................10 - 4

10.4 Operating a CPU Module After Being Stored Over the Battery Life............................................10 - 5

11 TROUBLESHOOTING 11 - 1 to 11 - 27

11.1 Fundamentals of Troubleshooting...............................................................................................11 - 1

11.2 Troubleshooting...........................................................................................................................11 - 2

11.2.1 Troubleshooting flowchart ...................................................................................................11 - 2

11.2.2 Flow for actions when the POWER LED is turned off .........................................................11 - 3

11.2.3 Flow for actions when the MODE LED turns off..................................................................11 - 4

11.2.4 Flow for actions when the RUN LED is turned off...............................................................11 - 5

11.2.5 Flow for actions when the RUN LED is flashing..................................................................11 - 6

11.2.6 Flow for actions when the ERR. LED is turned on ..............................................................11 - 7

11.2.7 Flow for actions when the ERR. LED is flashing .................................................................11 - 8

11.2.8 Flow for actions when the output module's output load does not turn on ...........................11 - 9

11.2.9 Flow for actions when the program cannot be written.......................................................11 - 10

11.2.10 Flow for actions when the CPU module is not started up ................................................11 - 11

11.3 Error Code List ..........................................................................................................................11 - 12

11.3.1 Procedure to read an error code .......................................................................................11 - 12

11.3.2 Error code list for the QCPU-A (A Mode) ..........................................................................11 - 13

11.4 Fault Examples with I/O Modules ..............................................................................................11 - 22

11.4.1 Faults with the input circuit and the corrective actions ......................................................11 - 22

11.4.2 Faults in the output circuit .................................................................................................11 - 24

A - 14

Page 17

APPENDICES Appendix - 1 to Appendix - 61

Appendix 1 Instruction List .............................................................................................................. App - 1

Appendix 1.1 Precautions for write during RUN of a dedicated instruction ............................ App - 14

Appendix 2 Lists of Special Relays and Special Registers .......................................................... App - 15

Appendix 2.1 Special relays................................................................................................... App - 15

Appendix 2.2 Special Registers ............................................................................................. App - 27

Appendix 3 Peripheral Device....................................................................................................... App - 46

Appendix 4 Precautions for Utilizing the Existing Sequence Programs for the QCPU-A.............. App - 48

Appendix 4.1 Instructions with different specifications............................................................ App - 49

Appendix 4.2 Special relays and special registers with different specifications...................... App - 50

Appendix 4.3 Parameter setting.............................................................................................. App - 50

Appendix 4.4 I/O control mode ............................................................................................... App - 51

Appendix 4.5 Microcomputer program .................................................................................... App - 52

Appendix 4.6 Index register processing.................................................................................. App - 53

Appendix 5 External Dimensions .................................................................................................. App - 54

Appendix 5.1 Q02CPU-A, Q02HCPU-A and Q06HCPU-A QCPU-A module ......................... App - 54

Appendix 5.2 A1S61PN, A1S62PN and A1S63P power supply module ................................ App - 55

Appendix 5.3 Base unit ........................................................................................................... App - 56

Appendix 6 Transportation Precautions ........................................................................................ App - 58

Appendix 6.1 Relevant models ............................................................................................... App - 58

Appendix 6.2 Transportation Guidelines................................................................................. App - 59

Appendix 7 Handling of Batteries and Devices with Built-in Batteries in EU Member States ....... App - 60

Appendix 7.1 Disposal precautions......................................................................................... App - 60

Appendix 7.2 Exportation precautions .................................................................................... App - 61

INDEX Index - 1 to Index - 3

A - 15

Page 18

About This Manual

Related manuals

The following manuals are related to this product.

Manual Name

ACPU/QCPU-A (A mode) Programming Manual (Fundamentals)

Describes programming methods necessary for creating programs, device names, parameters,

program types, memory area configuration, and so on. (Sold separately)

ACPU/QCPU-A (A mode) Programming Manual (Common Instructions)

Describes how to use the sequence instruction, basic instructions, applied instructions and

microcomputer programs. (Sold separately)

AnSHCPU/AnACPU/AnUCPU/QCPU-A (A mode) Programming Manual (Dedicated Instructions)

Describes instructions that have been expanded.

(Sold separately)

AnACPU/AnUCPU/QCPU-A (A mode) Programming Manual (PID Instructions)

Describes dedicated instructions to perform the PID control. (Sold separately)

AnS Module type I/O User's Manual

Describes the specification of the compact building block type I/O module. (Sold separately)

Manual No.

(Model Code)

IB-66249

(13J740)

IB-66250

(13J741)

IB-66251

(13J742)

IB-66258

(13J744)

IB-66541

(13JE81)

A - 16

Page 19

USER PRECAUTIONS

Precautions for using a CPU module

When a CPU module is used for the first time, data in the CPU module (built-in RAM, device

data) and in the memory card are undefined.

Before writing data (parameters, programs) to the CPU module, clear data in the built-in RAM

using a peripheral (PC memory clear operation) and also clear data using the RESET/L.CLR

switch of the CPU module (latch clear operation).

Precautions for battery

(1) Operating a CPU module after being stored without a battery

When a CPU module is operated again after being stored without a battery, data in the

CPU module (built-in RAM, device data) and a memory card may be undefined.

Before operating the CPU module again, clear data in the built-in RAM using a

peripheral (PC memory clear operation) and also clear data using the RESET/L.CLR

switch of the CPU module (latch clear operation).*

After all data are cleared, write the backed-up data in the CPU module or the memory

card.

(2) Operating a CPU module after being stored over the battery life

When a CPU module is operated again after being stored over the battery life, data in

the CPU module (built-in RAM, device data) and a memory card may be undefined.

Before operating the CPU module again, clear data in the built-in RAM using a

peripheral (PC memory clear operation) and also clear data using the RESET/L.CLR

switch of the CPU module (latch clear operation).*

After all data are cleared, write the backed-up data in the CPU module or the memory

card.

POINT

Make sure to back up each memory contents before storing the programmable

controller.

* For details of the PC memory clear operation using a peripheral, refer to the following manuals.

GX Developer Operating Manual

A6GPP/A6PHP Operating Manual

SW IVD-GPPA Operating Manual

For the latch clear operation using the RESET/L.CLR switch of the CPU module, refer to Section

4.6.3.

A - 17

Page 20

1. OVERVIEW

1 OVERVIEW

This user's manual describes the performance, functions, and handling method of the

QCPU-A, as well as the specifications and handling of the memory card, power supply

module and the base unit.

The programming modules and software packages have to be compatible with the

upgraded A2UCPU, A2UCPU-S1, A3UCPU, and A4UCPU (abbreviated as AnUCPU

hereafter).

When the conventional programming modules and software packages are used, the

usable range varies depending on the model of the CPU (programmable controller model

name).(Refer to Section 2.2.3.)

Related to each module used in the CPU modules, check "System equipment list" in

Section 2.3.

Refer to Section 2.2.1 for the special function modules which have limited usable devices

range.

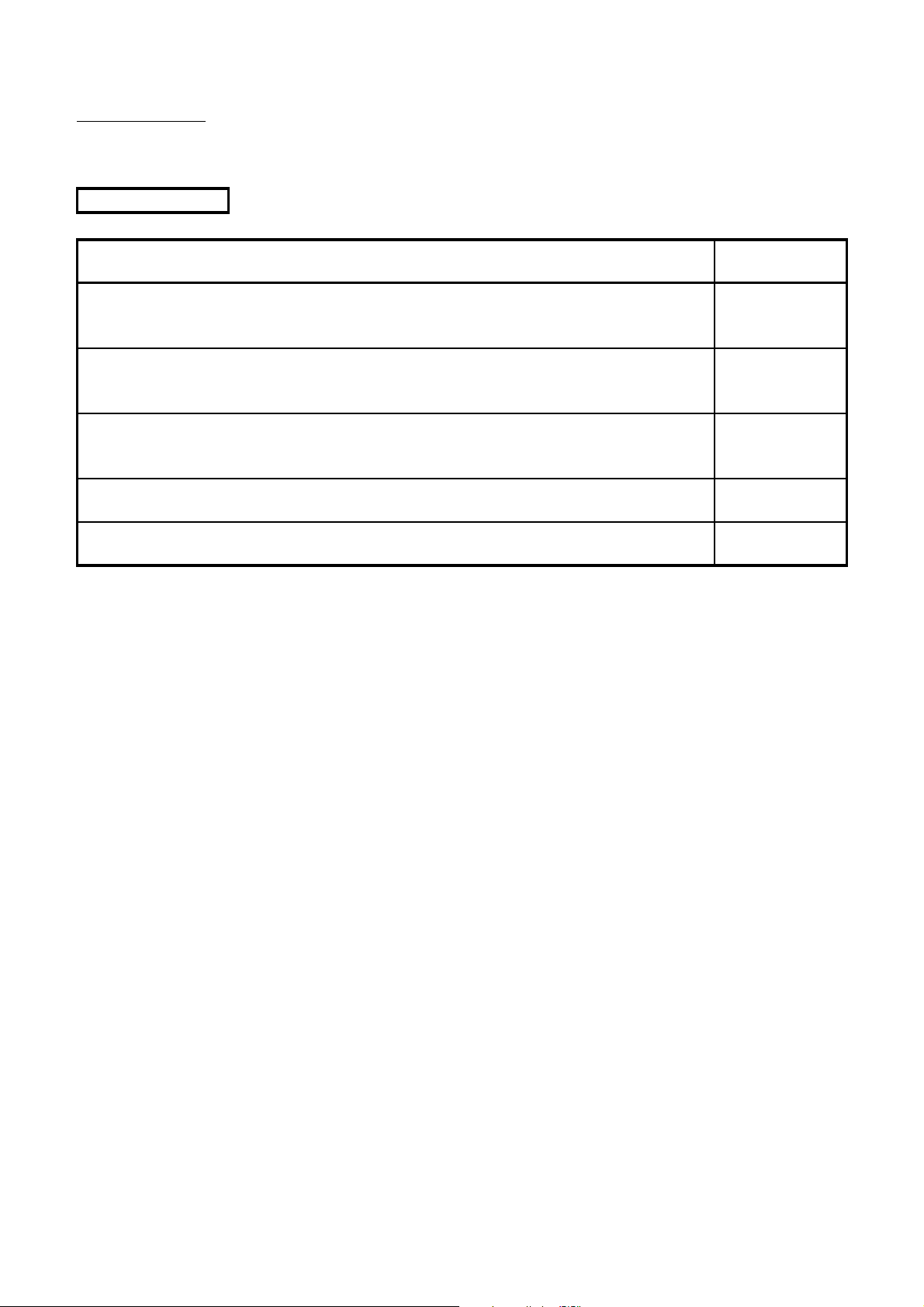

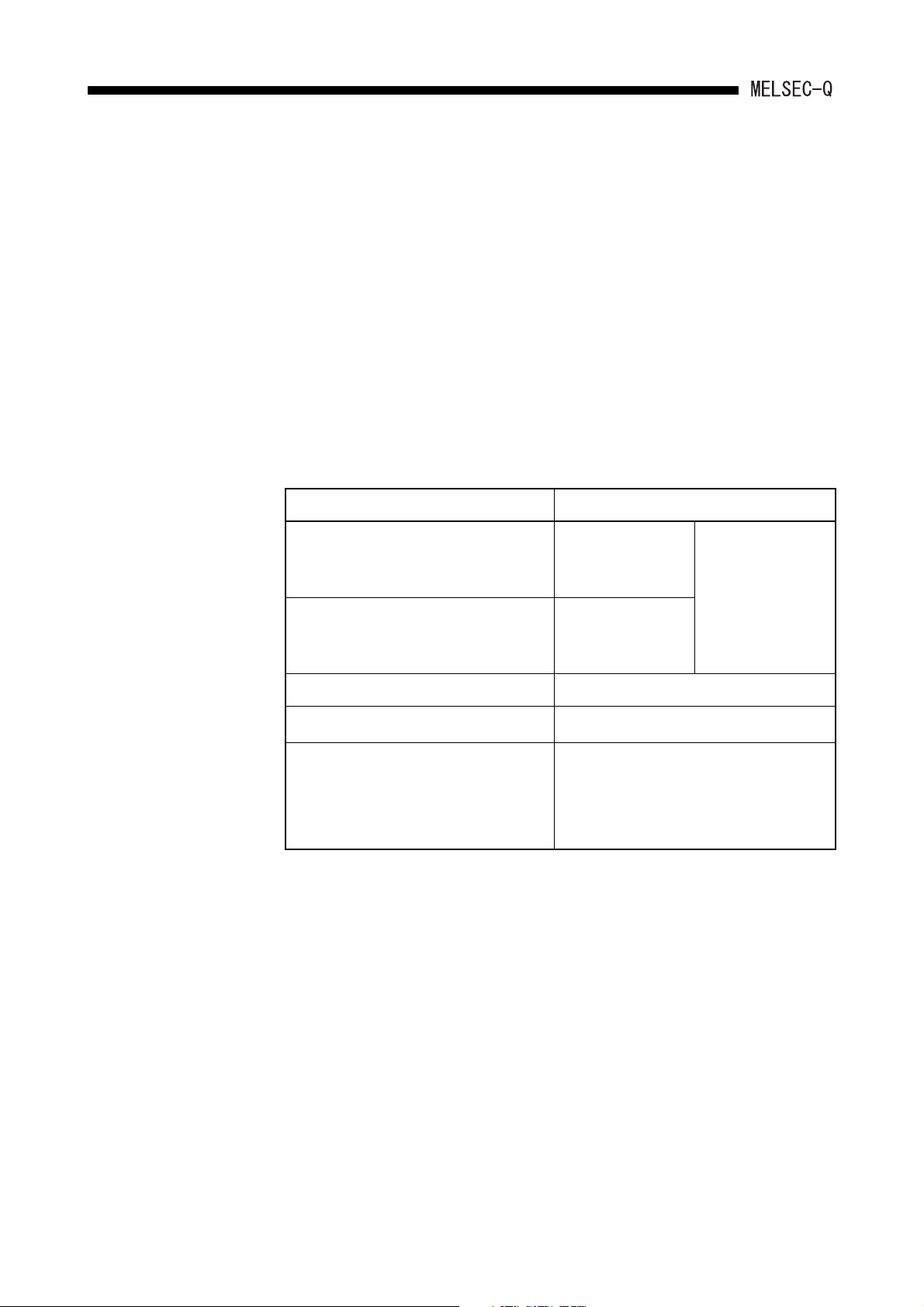

(1) Bundled parts

Product Name Model Quantity

CPU module

Battery Q6BAT 1

Q02CPU-A

1Q02HCPU-A

Q06HCPU-A

1 - 1

Page 21

OVERVIEW1.

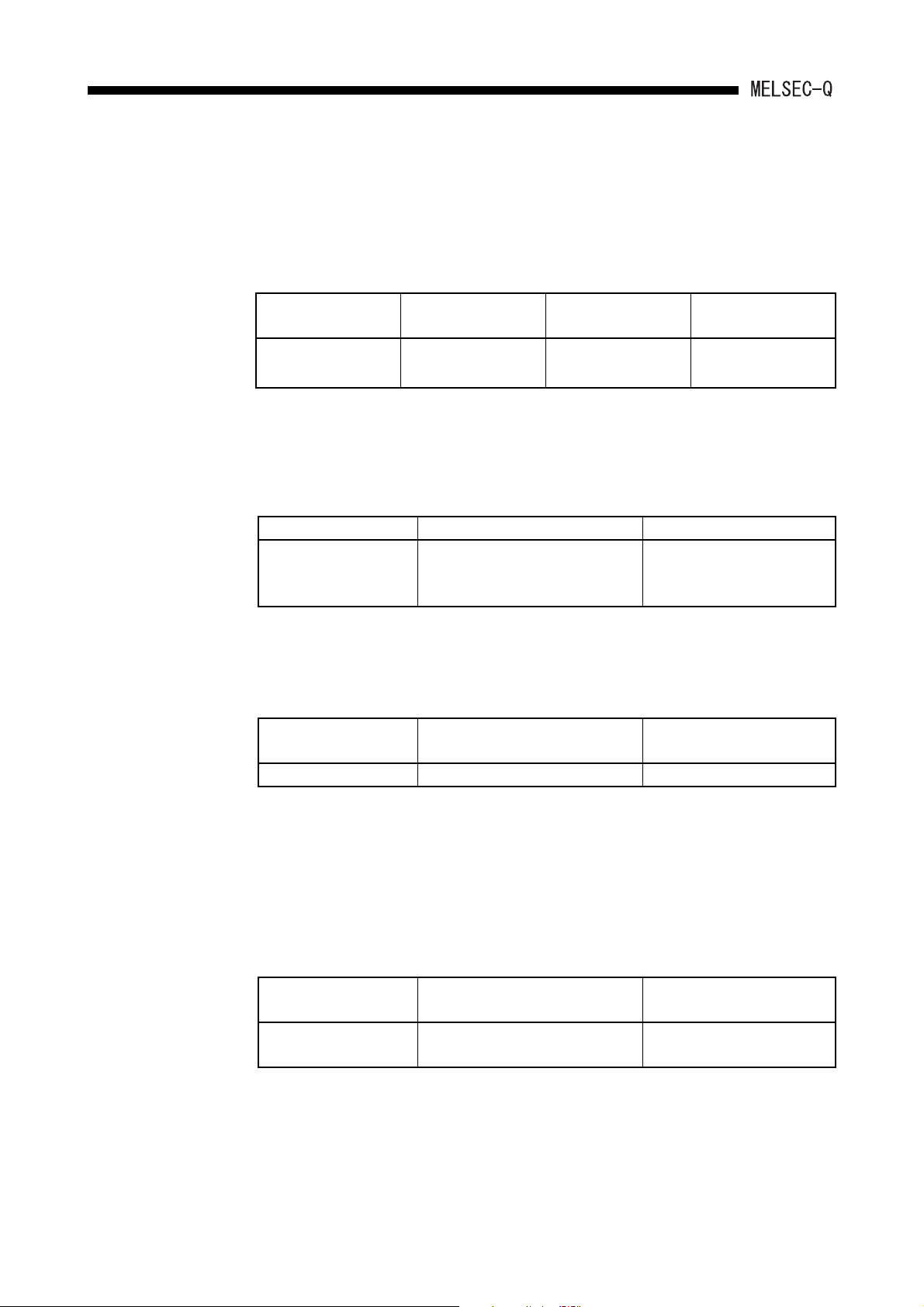

1.1 Features

QCPU-A (A mode) has the following features compared with A2USHCPU-S1.

(1) High-speed operation processing speed

QCPU-A offers significantly higher operation processing than that of A2USHCPU-S1.

Item Q02CPU-A

Operation processing

1

*

speed

*1 I/O processing: At refresh or LD instruction

79ns 34ns 90ns

Q02HCPU-A,

Q06HCPU-A

A2USHCPU-S1

(2) Greater program capacity

By using Q06HCPU-A, the program capacity can be expanded.

Moreover, Q06HCPU-A can create subprograms.

Item Q06HCPU-A A2USHCPU-S1

30k steps (Main program)

Program capacity

30k steps (Subprogram)

+

30k steps

(3) Increased actual I/O points

QCPU-A offers 4096 actual I/O points, 4 times as increased as that of A2USHCPUS1.

Item

Actual I/O points 4096 points 1024 points

Q02CPU-A, Q02HCPU-A,

Q06HCPU-A

A2USHCPU-S1

(4) Increased extension stages

Up to 7 stages of extension base unit can be added.

(5) Higher communication speed with peripheral devices

The communication speed with peripheral devices is considerably improved

compared with A2USHCPU-S1.

Item

Communication speed

(kbps)

* 1 Designate 9.6kbps when using GPP of SW3D5C-GPPW or earlier.

Q02CPU-A, Q02HCPU-A,

Q06HCPU-A

1

*

115 .2

A2USHCPU-S1

9.6

1 - 2

Page 22

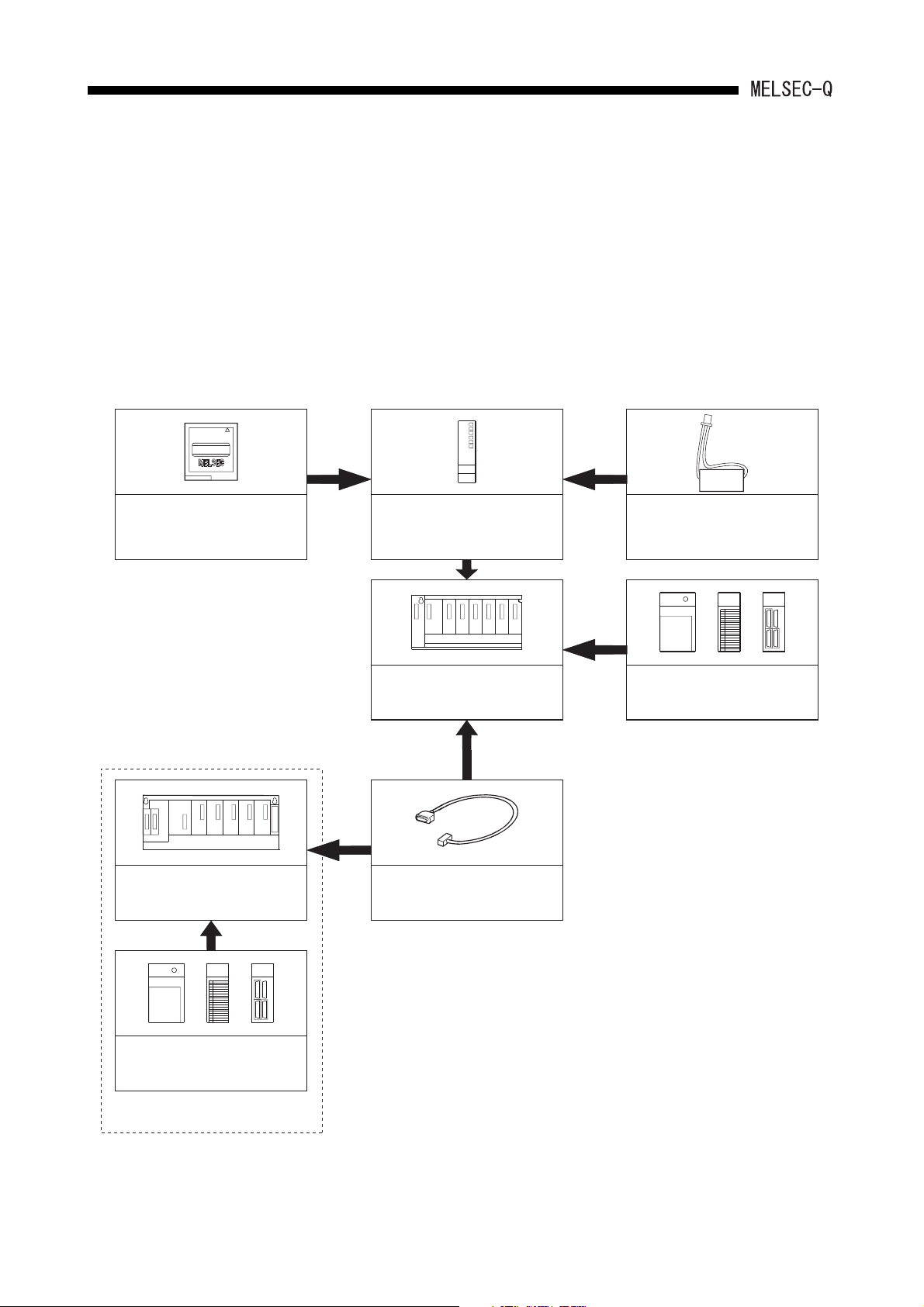

2. SYSTEM CONFIGURATION

LITHIUM BATTERY

QCPU-A

(Q02CPU-A, Q02HCPU-A,

Q06HCPU-A)

Battery

(Q6BAT)

Main base unit

(QA1S33B,QA1S35B,QA1S38B)

Extension cable

(QC05B,QC06B,QC12B,

QC30B,QC50B,QC100B)

Extension base unit

(QA1S51B,QA1S65B,QA1S68B)

Expansion of AnS series modules

*1

AnS series power supply

*2

, I/O,

or special function modules

The operation is not guaranteed

for the use of commercially

available memory cards.

*2

The power supply module cannot

be mounted on the QA1S51B.

Q series power supply, I/O, or

intelligent function modules

Memory card

*1

(Q2MEM-1MBSN,

Q2MEM-1MBS)

2 SYSTEM CONFIGURATION

This chapter shows the system configuration of QCPU-A, the relevant precautions and

system equipment.

2.1 System Configuration

This section describes the configuration of the QCPU-A system, the configuration of

peripheral devices, and the overview of the system configuration.

(1) Configuration of the QCPU-A system

2 - 1

Page 23

2. SYSTEM CONFIGURATION

2.2 Precautions When Configuring the System

The following shows the precautions when configuring the QCPU-A system:

2.2.1 Hardware

(1) Up to 64 I/O modules or special function modules can be mounted to each of the

basic base unit or the extension base unit.

(2) Up to 7 extension base units can be connected in the system.

(Up to 8 modules including the main base unit.)

(3) The total length of the extension cable should be 13.2m or less.

(4) The following shows the modules that have some limitations for the number of

modules to be mounted.

Module No. of Mountable Modules

MELSECNET/10 network module

A1SJ71LP21(GE), A1SJ71LR21,

A1SJ71BR11

MELSECNET(II)/B data link module

A1SJ71AP21, A1SJ71AR21,

Up to 4 modules

Up to 4 modules in

total

Up to 2 modules

A1SJ71AT21B

Interruption module: A1SI61 1 module

AnS series special function module

*

Up to 6 modules in total

1

GOT-A900 Series (Only when the bus

2

connection is used.)

GOT1000 Series (Only when the bus

connection is used.)

*1 Applies to the following modules. Any modules but the following modules do not have the

number of limitations to be mounted.

Ethernet interface module: A1SJ71E71N-B2 (-B5/-T)

Calculating machine link module: A1SJ71UC24-R2 (-R4/-PRF)

CC-Link module (in intelligent mode): A1SJ61BT11

Intelligent communication module: A1SD35ID1(2)

ID interface module: A1SD35ID1(2)

*2 Refer to the following manual for the GOT models.

• GOT-A900 Series User's Manual (GT Works Versions2/GT Designer2 Version2 Compatible

Connection System Manual)

• GOT1000 Series Connection Manual (Mitsubishi Products)

*

Connection disable

2

*

2 - 2

Page 24

SYSTEM CONFIGURATION2.

(5) The accessible device ranges have limit when the following modules are used:

Accessible Device Range in CPU

Applicable Module

Device Accessible Range

Input (X), output (Y) X/Y0 to X/Y7FF

Internal relay (M) M0 to M8191

latch relay (L) L0 to L8191

MELSECNET(II) data link module:

A1SJ71AP21, A1SJ71AR21

MELSECNET/B data link module:

A1SJ71AT21B

Link relay (B) B0 to BFFF

Timer (T) T0 to T2047

Counter (C) C0 to C1023

Data register (D) D0 to D6143

Link register (W) W0 to WFFF

Annunciator (F) F0 to F2047

(6) It is recommended that the network and data link modules are mounted to the basic

base unit.

When these modules are mounted to the extension base unit, the link refresh time

becomes longer than the case where they are mounted to the basic base unit.

2 - 3

Page 25

2. SYSTEM CONFIGURATION

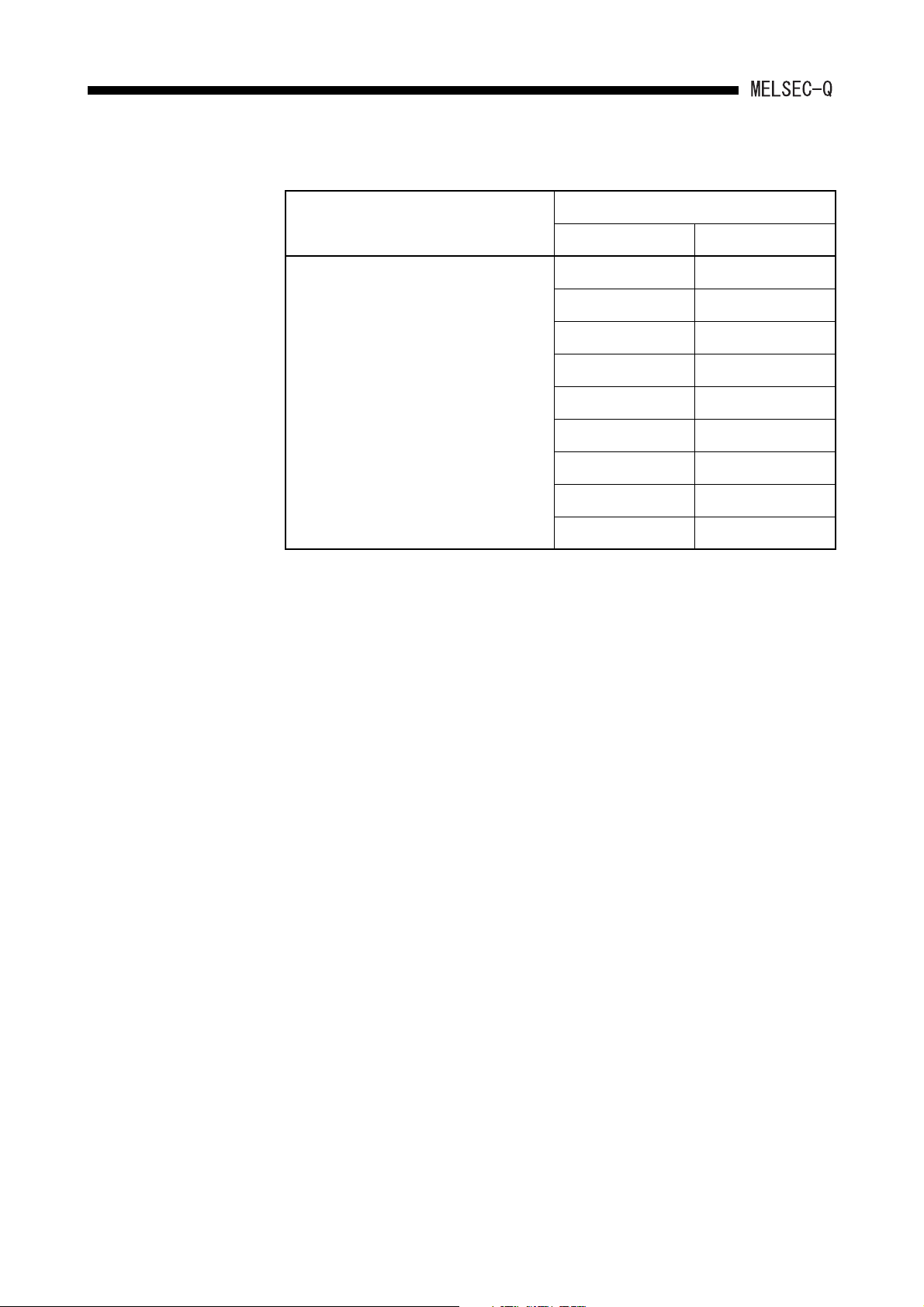

2.2.2 Software package

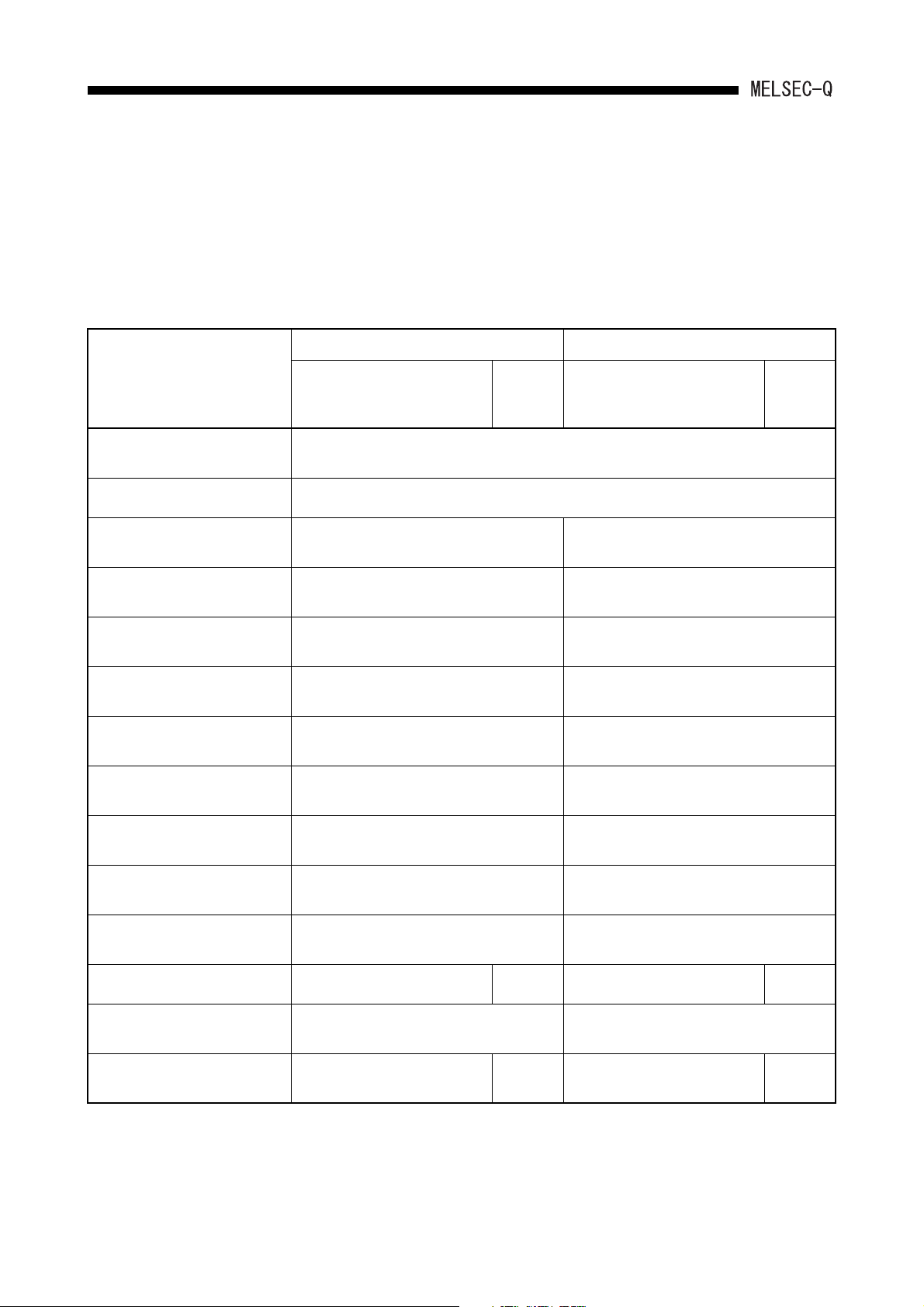

(1) GPP function software packages and model name setting at the start-up

The following table shows the GPP function software package that can be used to

create the QCPU-A program, and the programmable controller type setting at startup.

When using SW4D5C-GPPW or later, select the programmable controller type from

Q02(H)-A or Q06H-A according to the CPU to be used.

When using the peripheral devices and GPP function software package of SW3D5CGPPW or earlier, specify the programmable controller type name as "A4U". If "A4U"

is not found in PLC type names, specify "A3A." If both "A4U" and "A3A" are not

found, specify "A3H."

Note that when "A4U" is specified, the available device range is limited.

Peripheral

device

Software package for system start-up

Programmable controller CPU

model setting

Q02(H)-A Q06H-A

PC/AT

personal

computer

A6PHP SW3GP-GPPA A3H A3H

A6GPP SW3-GPPA

SW4D5C-GPPW or later Q02(H)-A Q06H-A

SW3D5 -GPPW or earlier

A4U A4U

SW IVD-GPPA

SW4GP-GPPA A3A A3A

SW1GP-GPPAU A4U A4U

SW3GP-GPPA

SW4GP-GPPA A3A A3A

SW1GP-GPPAU A4U A4U

A3H A3H

2 - 4

Page 26

SYSTEM CONFIGURATION2.

POINT

(1) Old software packages other than listed above cannot be used.

(2) To construct MELSECNET/10 network system with QCPU-A, use the AnU-

compatible GPP function software package (which includes "A4U" in its

programmable controller type name).

A network cannot be constructed with the GPP function software package

which is not compatible with AnU (which does not include "A4U" in its

programmable controller type name).

(3) Communication with GX Developer at 115.2kbps may not be available

depending on the peripheral devices. In such a case, select the lower

communication speed.

(4) When using Q02(H)CPU-A and conventional peripheral devices and setting

the programmable controller type as "A4U," designate the main program

setting to 28k steps or less with parameters. When "Main + parameter" is

written with the programmable controller with the setting of 29k steps or more,

"Cannot communicate with PC" is displayed, and writing to the CPU module is

disabled.

(5) Subprograms cannot be used with Q02(H)CPU-A. When using conventional

peripheral devices and setting the programmable controller type as "A4U," do

not specify any subprograms. If any subprograms are specified, "Cannot

communicate with PC" is displayed.

With Q06HCPU, subprogram 1 can be used, but subprograms 2 and 3

cannot.

When subprogram 2 or 3 is specified, the same message above is displayed.

2 - 5

Page 27

SYSTEM CONFIGURATION2.

(2) Utility package

(a) None of the following utility packages for A6GPP/A6PHP can be used:

The packages marked with * can

•SW -AD57P

• SW -UTLP-FN0

• SW -UTLP-FN1

•SW -UTLP-PID

•SW -SIMA

• SW -UTLP-FD1

•SW -SAPA

POINT

*

(1) The utility package, which specifies the device and accesses the QCPU-A,

can be used only in the device range for the A3ACPU, A3HCPU equivalent.

(Refer to Section 2.2.3.)

(2) Use an AnU-compatible utility package to use the device range for the

QCPU-A.

(Example: SW1IVD-SAP2, etc.)

*

execute the same functions using the

dedicated instructions.

For details, refer to type AnSHCPU/

AnACPU/AnUCPU/QCPU-A (A Mode)

Programming Manual (Dedicated

Instructions).

2 - 6

Page 28

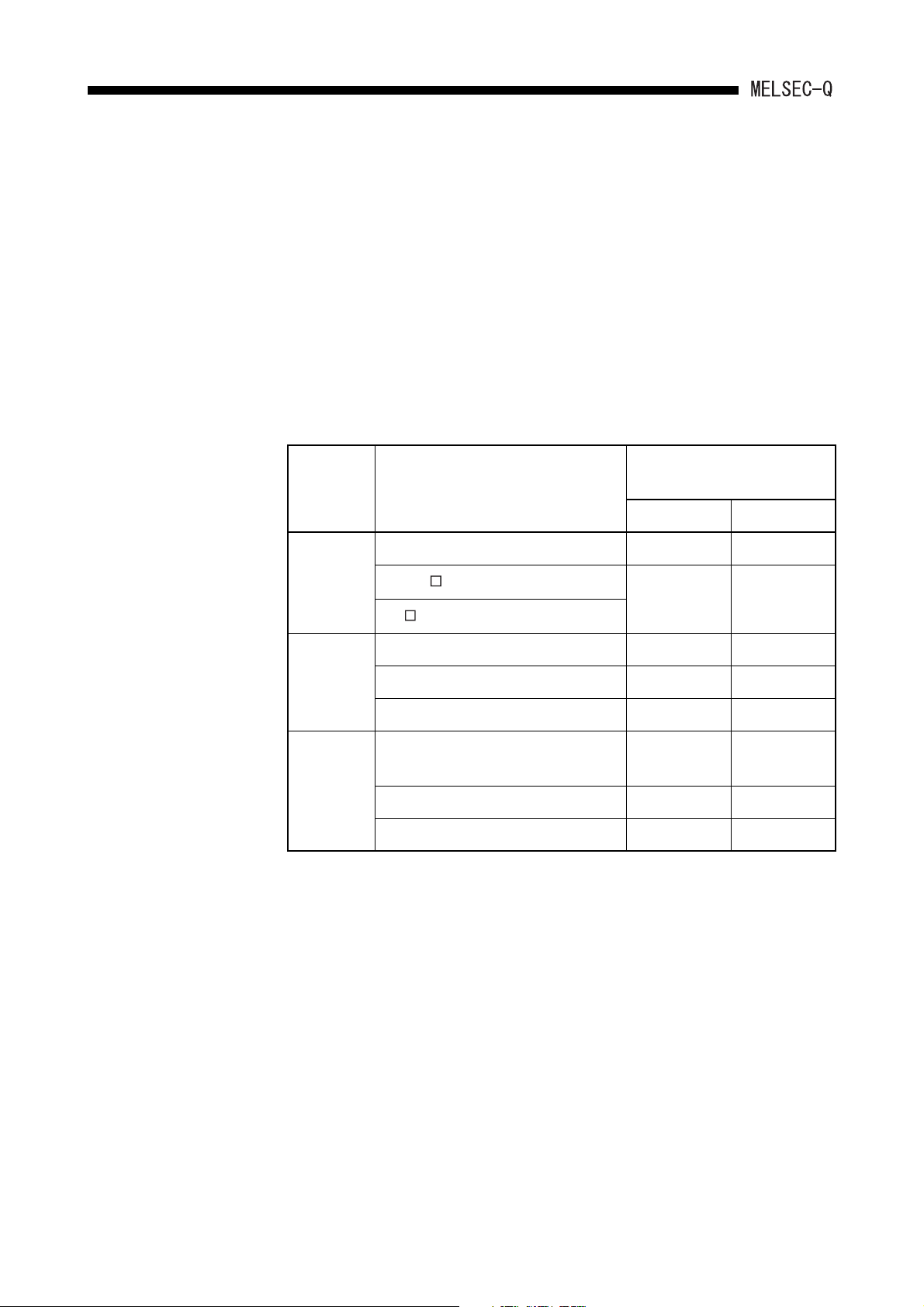

2. SYSTEM CONFIGURATION

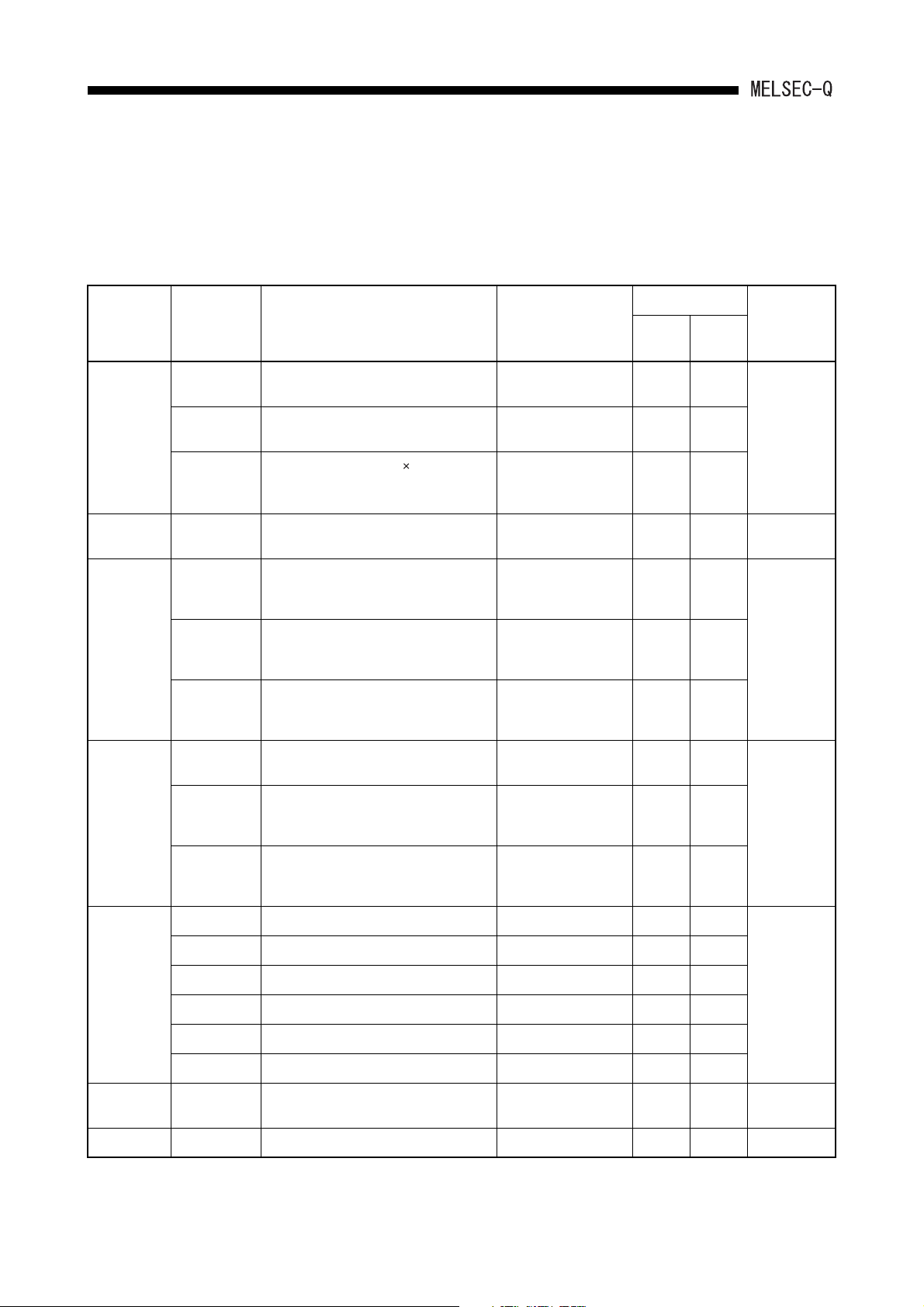

2.2.3 Precautions when using GPP function software packages and A8PUE peripheral devices which are not compatible with AnU

When starting with GPP function software packages not compatible with the AnU, QCPUA (starting with the programmable controller model name "A3A" or "A3H") or a A8PUE

peripheral device (including A7PUS), the usable device ranges are limited as follows.

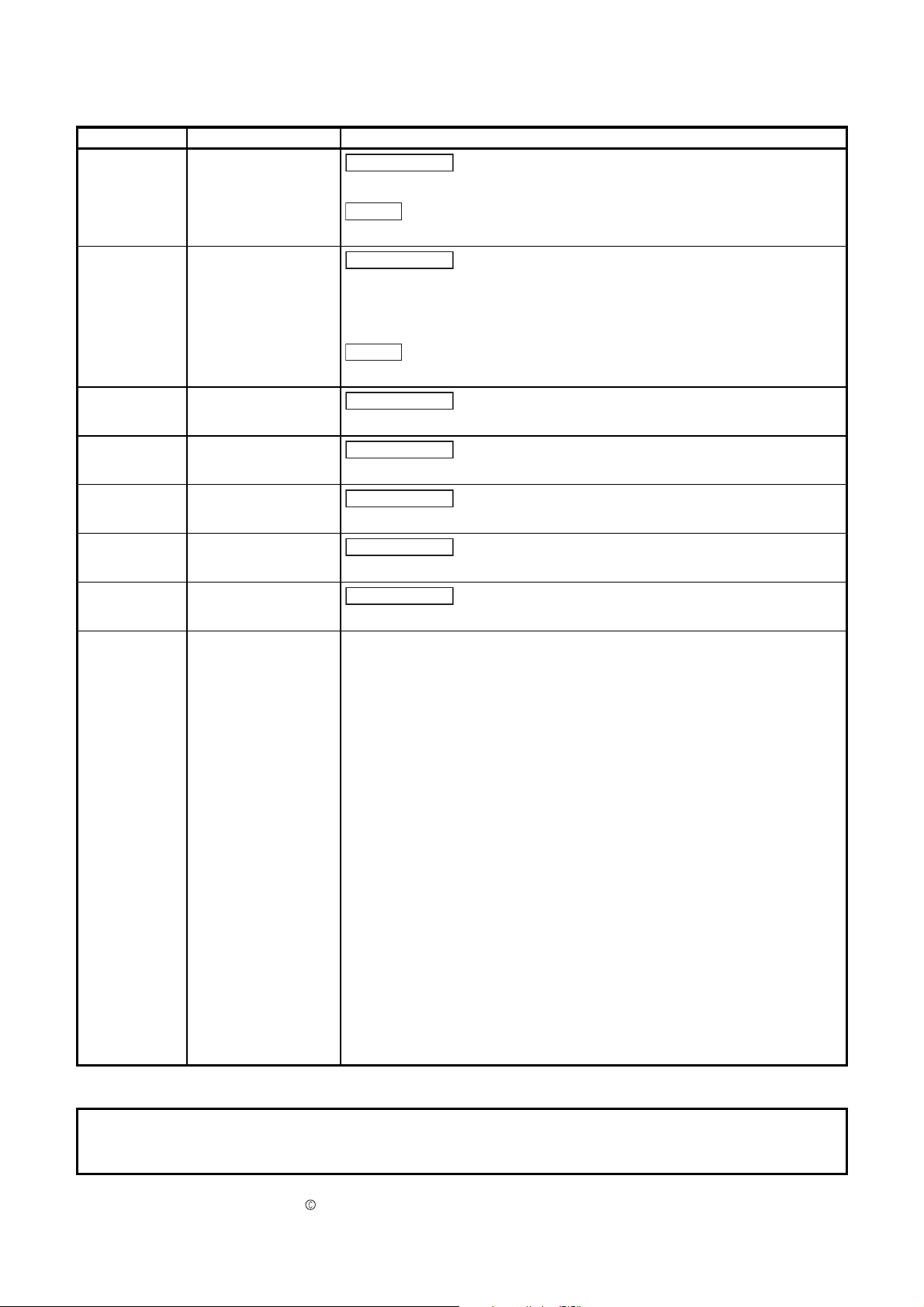

(1) List of usable device range

AnACPU-compatible Module A3HCPU-compatible Module

Item

Instruction (sequence/basic/

application/dedicated)

Program capacity Max. 14k steps can be used for the main program.

I/O device points (X/Y)

M, L, S relay M/L/S0 to M/L/S8191 can be used.

Link relay (B)

Timer (T) T0 to T2047 can be used.

Counter (C) C0 to C1023 can be used.

Data register (D)

Programmable controller Model

"A3A"

at System FD Start-up

X/Y0 to X/Y7FF can be used.

(X/Y800 to X/Y1FFF cannot be used.)

B0 to BFFF can be used.

(B1000 to B1FFF cannot be used.)

D0 to D6143 can be used.

(D6144 to D8191 cannot be used.)

A8PUE

All instructions can be used.

Programmable controller Model

"A3H"

at System FD Start-up

X/Y0 to X/Y7FF can be used.

(X/Y800 to X/Y1FFF cannot be used.)

M/L/S0 to M/L/S2047 can be used.

(M/L/S2048 to M/L/S8191 cannot be used.)

B0 to B3FF can be used.

(B400 to B1FFF cannot be used.)

T0 to T255 can be used.

(T256 to T2047 cannot be used.)

C0 to C255 can be used.

(C256 to C1023 cannot be used.)

D0 to D1023 can be used.

(D1024 to D8191 cannot be used.)

A7PUS

Link register (W)

Annunciator (F) F0 to F2047 can be used.

Index register (V, Z) V, V1 to V6, Z, Z1 to Z6can be used.

Expanded comment Max. 3968 points – Unusable –

Latch (power failure compensation)

range

I/O assignment

The device range shown above can be latched. The device range shown above can be latched.

Possible to register occupied I/O

points and module model names.

W0 to WFFF can be used.

(W1000 to W1FFF cannot be used.)

Number of I/O occupied points can

–

W0 to W3FF can be used.

(W400 to W1FFF cannot be used.)

F0 to F255 can be used.

(F256 to F2047 cannot be used.)

V and Z can be used.

(V1 to V6, Z1 to Z6 cannot be used.)

be registered.

(1) The device range other than listed above is the same as that of QCPU-A.

(2) Refer to Operating Manual for peripheral devices to be used for available functions.

2 - 7

–

Page 29

2. SYSTEM CONFIGURATION

2.3 System Equipment

The following shows various components of each module and peripheral device which can

be used by the QCPU-A.

(1) Modules dedicated to AnS

Product Name Model Name Description

Program capacity: 28k steps, I/O points: 4096,

Processing speed for basic instruction: 79ns

Program capacity: 28k steps, I/O points: 4096,

Processing speed for basic instruction: 34ns

Program capacity: 30k steps 2 (Main/sub),

I/O points: 4096, Processing speed for basic

instruction: 34ns

SRAM type: 1MB – – –

AnS series module mounting base (power

supply module + CPU module + 3 slots for other

module)

AnS series module mounting base (power

supply module + CPU module + 5 slots for other

module)

AnS series module mounting base (power

supply module + CPU module + 8 slots for other

module)

CPU module

Memory card

Main base unit

Q02CPU-A

Q02HCPU-A

Q06HCPU-A

Q2MEM-1MBSN,

Q2MEM-1MBS

QA1S33B

QA1S35B

QA1S38B

Number of Occupied

Points (points)

[I/O Assignment

Module Type]

–0.60–

–0.64–

–0.64–

– 0.107 –

–

–

Current Consumption

5VDC(A) 24VDC(A)

0.117

(0.086)*

0.118

(0.086)*

–

–

Remark

QA1S51B

Extension base

unit

Extension cable

Battery Q6BAT

Cable QC30R2 Communication cable for peripheral devices – – –

QA1S65B

QA1S68B

QC05B 0.45m extension base cable – – –

QC06B 0.6m extension base cable – – –

QC12B 1.2m extension base cable – – –

QC30B 3.0m extension base cable – – –

QC50B 5.0m extension base cable – – –

QC100B 10.0m extension base cable – – –

AnS series module mounting base, 1 slot for

other module

AnS series module mounting base (power

supply module + CPU module + 5 slots for other

module)

AnS series module mounting base (power

supply module + CPU module + 8 slots for other

module)

Battery for retaining the contents of built-in RAM

and devices in case of power failure

–0.12–

–

–

–––

0.117

(0.088)*

0.118

(0.090)*

–

–

2 - 8

Page 30

SYSTEM CONFIGURATION2.

POINT

(1) A USB port cannot be used with QCPU-A.

(2) A RS232/422 conversion cable is required to use the conventional peripheral

devices (A6GPP, A8PUE, etc.).

Recommended cable: FA-CNV2402CBL (2m), FA-CNV2405CBL (5m)

Contact: Mitsubishi Electric Engineering Corp.

Product Name Model Name Description

A1S61PN 5VDC, 5A

Power supply

module

A1S62PN 5VDC, A/24VDC, 0.6A

A1S63P 5VDC, 5A 24VDC input

* The parenthesized values are for those which is not compliant with CE.

100/200VAC

input

Number of Occupied

Points (points)

[I/O Assignment

Module Type]

–––

Current Consumption

Remark

5VDC(A) 24VDC(A)

Installed in the

power supply

slot of the main

base and

extension base.

2 - 9

Page 31

SYSTEM CONFIGURATION2.

Product Name Model Name Description

A1SX10 16-point 100 to 120 VAC input module 16 [16 input points] 0.05 –

A1SX10EU 16-point 100 to 120 VAC input module 16 [16 input points] 0.05 –

A1SX20 16-point 200 to 240 VAC input module 16 [16 input points] 0.05 –

A1SX20EU 16-point 200 to 240 VAC input module 16 [16 input points] 0.05 –

A1SX30 16-point 12/24VDC, 12/24VAC input module 16 [16 input points] 0.05 –

A1SX40 16-point 12/24VDC input module 16 [16 input points] 0.05 –

A1SX40-S1 16-point 24VDC input module 16 [16 input points] 0.05 –

A1SX40-S2 16-point 24VDC input module 16 [16 input points] 0.05 –

A1SX41 32-point 12/24VDC input module 32 [32 input points] 0.08 –

A1SX41-S1 32-point 24VDC input module 32 [32 input points] 0.12 –

Input module

A1SX41-S2 32-point 24VDC input module 32 [32 input points] 0.08 –

A1SX42 64-point 12/24VDC input module 64 [64 input points] 0.09 –

A1SX42-S1 64-point 24VDC input module 64 [64 input points] 0.16 –

Number of Occupied

Points (points)

[I/O Assignment

Module Type]

Current Consumption

Remark

5VDC(A) 24VDC(A)

A1SX42-S2 64-point 24VDC input module 64 [64 input points] 0.09 –

A1SX71 32-point 5/12/24VDC input module 32 [32 input points] 0.075 –

A1SX80 16-point 12/24VDC sink/source input module 16 [16 input points] 0.05 –

A1SX80-S1 16-point 24VDC sink/source input module 16 [16 input points] 0.05 –

A1SX80-S2 16-point 24VDC sink/source input module 16 [16 input points] 0.05 –

A1SX81 32-point 12/24VDC sink/source input module 16 [16 input points] 0.08 –

A1SX81-S2 32-point 24VDC sink/source input module 32 [32 input points] 0.08 –

A1SX82-S1 64-point 24VDC sink/source input module 32 [32 input points] 0.16 –

2 - 10

Page 32

SYSTEM CONFIGURATION2.

Product Name Model Name Description

A1SX10 16-point relay contact output module (2A) 16

A1SY10EU 16-point relay contact output module (2A) 16

A1SY14EU 12-point relay contact output module (2A) 16

A1SY18A

A1SY18AEU

A1SY22 16-point triac output module (0.6A) 16

A1SY28A

A1SY40

A1SY40P

8-point relay contact output module (2A) for

independent contacts

8-point relay contact output module (2A) for

independent contacts

8-point triac output module (1A)

All points independent

16-point 12/24VDC transistor output module

(0.1A) sink type

16-point 12/24VDC transistor output module

(0.1A) sink type

Number of Occupied

Points (points)

[I/O Assignment

Module Type]

[16 output

points]

[16 output

points]

[16 output

points]

16

16

16

16

16

[16 output

points]

[16 output

points]

[16 output

points]

[16 output

points]

[16 output

points]

[16 output

points]

Current Consumption

5VDC(A) 24VDC(A)

0.12 0.09

0.12 0.10

0.12 0.10

0.24 0.075

0.24 0.075

(200VAC)

0.27

0.13 –

0.27 0.008

0.08 0.011

0.002

Remark

Output module

A1SY41

A1SY41P

A1SY42

A1SY50

A1SY60

A1SY60E

A1SY68A

A1SY71

A1SY80

A1SY81

32-point 12/24VDC transistor output module

(0.1A) sink type

32-point 12/24VDC transistor output module

(0.1A) sink type

64-point 12/24VDC transistor output module

(0.1A) sink type

16-point 12/24VDC transistor output module

(0.5A) sink type

16-point 24VDC transistor output module

(2A) sink type

16-point 12/24VDC transistor output module

(2A) source type

8-point 5/12/24/48VDC

transistor output module (2A) sink/source type

All points independent

32-point 5/12VDC transistor output module

(0.016A) sink type

16-point 12/24VDC transistor output module

(0.8A) source type

32-point 12/24VDC transistor output module

(0.1A) source type

32

32

64

16

16

16

16

32

16

32

[32 output

points]

[32 output

points]

[64 output

points]

[16 output

points]

[16 output

points]

[16 output

points]

[16 output

po

ints]

[32 output

points]

[16 output

points]

[32 output

points]

0.50 0.008

0.14 0.012

0.93 0.008

0.12 0.06

0.12 0.015

0.20 0.01

0.11 –

0.40 0.15

0.12 0.02

0.50 0.008

A1SY82

64-point 12/24VDC transistor output module

(0.1A) source type

2 - 11

64

[64 output

points]

0.93 0.008

Page 33

SYSTEM CONFIGURATION2.

Specified number of points

Number of Occupied

Product Name Model Name Description

32-point 12/24VDC input module

A1SH42

I/O combined

module

Dynamic input

module

Dynamic output

module

Blank cover A1SG60 Dust-proof cover for unused slot 16 [Empty] – –

A1SH42-S1

A1SX48Y18

A1SX48Y58

A1S42X

A1S42Y

32-point 12/24VDC transistor output module

(0.1A) sink type

32-point 24VDC input module

32-point 12/24VDC transistor output module

(0.1A) sink type

8-point 24VDC input module

8-point relay contact output module (2A)

8-point 24VDC input module

8-point 12/24VDC transistor output module

(0.5A)

16/32/48/64 points

12/24VDC dynamic input module

16/32/48/64 points

12/24VDC dynamic output module

Points (points)

[I/O Assignment

Module Type]

32

32

16

16

Specified number of points

[Input

Specified number of points

[Output

Specified number of points

[32 output

points]

[32 output

points]

[16 output

points]

[16 output

points]

Current Consumption

5VDC(A) 24VDC(A)

0.50 0.008

0.50 0.008

0.085 0.045

0.06 0.06

0.08 –

]

0.18 0.055

]

Remark

Dummy module A1SG62

Pulse catch

module

Analog timer

module

Interrupt

module

High-speed

counter module

A1SP60

A1ST60

A1SI61

A1SD61

A1SD62

A1SD62D

A1SD62D-S1

16-point, 32-point, 48-point, 64-point selectable

module

Short ON-time pulse input module

(pulse with a minimum of 0.5ms) 16 input points

A module whose timer setting value can be

changed for different volumes (0.1 to 1.0s, 1 to

10s, 10 to 60s, 60 to 600s)

Analog timer 8 points

Interrupt module for specifying the interrupt

program

(16-point interrupt input)

32-bit signed binary

50kBPS, 1 channel

24-bit signed binary, 2 channel

100kPPS, DC input

transistor output (sink type)

24-bit signed binary, 2 channel

200kPPS, difference input

transistor output (sink type)

24-bit signed binary, 2 channel

200kPPS, difference input

transistor output (sink type)

Specified number of points

[Input

Specified number of points

16

16

32

32

32

32

32

[16 output

points]

[16 output

points]

[32 special

points]

[32 special

points]

[32 special

po

ints]

[32 special

points]

[32 special

points]

––

]

0.055 –

0.055 –

0.057 –

0.35 –

0.1 –

0.25 –

0.27 –

A1SD62E

24-bit signed binary, 2 channel

100kPPS, DC input

transistor output (source type)

2 - 12

32

[32 special

points]

0.1 –

Page 34

SYSTEM CONFIGURATION2.

Product Name Model Name Description

4 to 20mA/0 to 10V

4 analog channels

4 to 20mA/0 to 10V

8 analog channels

4 to 20mA/0 to 10V

2 analog output channels

-10 to 10V input

8 analog output channels

4 to 20mA input

8 analog output channels

Analog input, 2 channels, simple loop control is

allowed

1 analog output channels

Analog input, 4 channels, simple loop control is

allowed

2 analog output channels

For connecting to Pt100 (3-wire)

Temperature input, 2 channels

A/D converter

module

D/A converter

module

Analog I/O

module

A1S64AD

A1S68AD

A1S62DA

A1S68DAV

A1S68DAI

A1S63ADA

A1S66ADA

A1S62RD3

Number of Occupied

Points (points)

[I/O Assignment

Module Type]

32

32

32

32

32

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

Current Consumption

Remark

5VDC(A) 24VDC(A)

0.4 –

0.4 –

0.8 –

0.65 –

0.85 –

0.8 –

0.21 0.16

0.49 –

Temperature

control module

A1S62RD4

A1S68TD Thermocouple input, 8 channels 32

A1S62TCTT-S2

A1S62TCTTBWS2

A1S62TCRT-S2

A1S62TCRTBWS2

A1S64TCTT-S1

For connecting to Pt100 (4-wire)

Temperature input, 2 channels

Transistor output, thermocouple input

2 channels/module

PID control: ON/OFF pulse

Transistor output, thermocouple input

2 channels/module

PID control: ON/OFF pulse, wire breakage

detection function

Transistor output, platinum RTD (Resistance

Temperature Detector) input

2 channels/module

PID control: ON/OFF pulse

T

ransistor output, platinum RTD input

2 channels/module

PID control: ON/OFF pulse, wire breakage

detection function

Transistor output, thermocouple input

4 channels/module

PID control: ON/OFF pulse or 2 positioning

control

32

32

32

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

0.39 –

0.32 –

0.19 –

0.28 –

0.19 –

0.28 –

0.33 –

A1S64TCTTBWS1

Transistor output, thermocouple input

4 channels/module

PID control: ON/OFF pulse or 2 positioning

control

Heater wire breakage detection function

2 - 13

32

[32 special

points]

0.42 –

Page 35

SYSTEM CONFIGURATION2.

Product Name Model Name Description

Transistor output, thermocouple input

4 channels/module

PID control: ON/OFF pulse or 2 positioning

control

Transistor output, thermocouple input

4 channels/module

PID control: ON/OFF pulse or 2 positioning

control

Heater wire breakage detection function

Transistor output,

thermocouple input, or platinum RTD input

[For standard control]

4 channels/module

PID control: ON/OFF pulse or 2 positioning

control

[For heating-cooling control]

2 channels/module

PID control: ON/OFF pulse

Transistor output,

thermocouple input, or platinum RTD input

[For standard control]

4channels/module

PID control: ON/OFF pulse or 2 positioning

control

[For heating-cooling control]

2 channels/module

PID control: ON/OFF pulse, wire breakage

detection function

Temperature

control module

A1S64TCRT-S1

A1S64TCRTBWS1

A1S64TCTRT

A1S64TCTRTB

W

Number of Occupied

Points (points)

[I/O Assignment

Module Type]

32

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

Current Consumption

5VDC(A) 24VDC(A)

0.33 –

0.42 –

0.33

(0.19)*

0.39

(0.25)*

–

–

Remark

*:When the

temperature

conversion

function of

unused channels

are not used in

the heatingcoolA1S64TCTR

TBWing control

Computer link

module

Ethernet

interface

module

Intelligent

communication

module

A1SJ71UC24-R2 Computer link function RS-232C, 1 channel 32

A1SJ71UC24PRF

A1SJ71UC24-R4

A1SJ71E71N3-T 10 Base-T 32

A1SJ71E71N-T 10 Base-T 32

A1SJ71E71N-B2 10 Base 2 (for Cheapernet) 32

A1SJ71E71N-B5 10 Base 5 (for Ethernet) 32

A1SD51S

Computer link function, printer function

RS-232C, 1 channel

Computer link function, multidrop link function

RS-422/RS-485, 1 channel

BASIC (interpreter/compiler)

R

S-232C, 2 channel

RS-422/RS485, 1 channel

[32 special

points]

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

0.1 –

0.1 –

0.1 –

0.69 –

0.56 –

0.66 –

0.57 –

0.4 –

Accessible

within the

AnACPU device

range

2 - 14

Page 36

SYSTEM CONFIGURATION2.

First half

16 empty points

Second half

32 special points

Product Name Model Name Description

1 axis positioning control, speed control and

speed-positioning control,

analog voltage output for speed-positioning

control (0 to 10V)

For positioning control, pulse output, 2-axes

(independent, 2-axis simultaneous, linear

interpolation, circular interpolation)

For positioning control, pulse output, 3-axis

(independent, 3-axis simultaneous, 2-axis linear

interpolation, 2-axis circular interpolation)

For positioning control, digital output for MR-HB/MR-J-B/MR-J2-B, 1-axis SSCNET

For positioning control, digital output, for MR-HB/MR-J-B/MR-J2-B, 2-axis SSCNET

(Independent, 2-axis simultaneous, linear

interpolation, circular interpolation)

Positioning

module

A1SD70

A1SD75P1-S3 For positioning control, pulse output, 1-axis 32

A1SD75P2-S3

A1SD75P3-S3

A1SD75M1

A1SD75M2

Number of Occupied

Points (points)

[I/O Assignment

Module Type]

48

[32 special

points]

32

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

Current Consumption

5VDC(A) 24VDC(A)

0.3 –

0.7 –

0.7 –

*

0.7

0.7 –

0.7 –

–

Remark

* When different

driver is

connected:

0.78A

ID interface

module

MELSECNET(II)

data link

module

MELSECNET/B

data link

module

B/NET data link

module

For positioning control, digital output, for MR-H-

A1SD75M3

A1SD35ID1

A1SD35ID2

A1SJ71AP21

A1SJ71AP21-S3

A1SJ71AR21

A1SJ71AT21B

A1SJ72T25B

A1SJ71B62-S3 Master module for B/NET 32

B/MR-J-B/MR-J2-B, 3-axis SSCNET

(independent, 3-axis simultaneous, 2-axis linear

interpolation, 2-axis circular interpolation)

ID interface module

One reader/writer modules can be connected.

ID interface module

Two reader/writer modules can be connected.

For the master and local stations of

MELSECNET(II) data link system (for the

optical fiber cable)

For the master and local stations of

MELSECNET(II) data link

(for the GI-type optical fiber cable)

For the master and local stations of

MELSECNET(II) data link system (for the

coaxial cable)

For the master and local stations of

MELSECNET/B data link system

For the remote I/O station of

MELSECNET/B data link system

32

32

32

32

32

32

32

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

–0.3–

[32 special

points]

0.7 –

0.25 0.17

0.25 0.33

0.33 –

0.33 –

0.8 –

0.66 –

0.08 –

Access is

allowed within

the device range

of the AnACPU.

2 - 15

Page 37

SYSTEM CONFIGURATION2.

Product Name Model Name Description

For the control, master, and normal stations of

MELSECNET/10

data link

module

CC-Link system

master module

MELSECNET/

MINI-S3 master

module

A1SJ71LP21

A1SJ71LP21GE

A1SJ71BR11

A1SJ71LR21

A1SJ61BT11

A1SJ71PT32-S3

the MELSECNET/10 data link module system

(For the dual loop SI-type optical fiber cable)

For the control, master, and normal stations of

the MELSECNET/10 data link module system

(For the dual loop GI-type optical fiber cable)

For the control, master, and normal stations of

the MELSECNET/10 data link module system

(For the single bus coaxial cable)

For the control, master, and normal stations of

the MELSECNET/10 data link module system

(For the coaxial cable dual loop)

For the master and local stations of the CC-Link

data link system

(For the twisted pair shield cable only)

For MELSECNET/MINI-S3 master stations

(max. 64 stations). Performs remote I/O and

remote terminal control of a total of 512 I/O

points.

Number of Occupied

Points (points)

[I/O Assignment

Module Type]

32

32

32

32

32

I/O mode

32 [32 special points]

Expanded mode

48 [48 special points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

[32 special

points]

Current Consumption

Remark

5VDC(A) 24VDC(A)

0.65 –

0.65 –

0.80 –

1.14 –

0.40 –

0.35 –

MELSECNET-I/

O LINK master

module

S-LINK

interface

module

AS-I interface

module

Positioning

detection

module

Programmable

controller easier

monitoring

module

Memory card

interface

module

MELSECNET-I/O LINK master station. Controls

I/O LINK remote I/O module of a maximum of

64 stations and a total of 128 I/O points.

A1SJ51T64

A1SJ71SL92N

A1SJ71AS92

A1S62LS Absolute positioning detection module 32

A1SS91

A1SD59J-S2 Memory card interface module 32

If only a few remote I/O modules are used,

perform I/O assignment with a peripheral device

to decrease the number of occupied I/O points

to 16, 32, or 48.

Master module for S-LINK

I/O total 128 points

Master module for AS-I

I/O total 496 points

Programmable controller easier monitoring

module

64

32

32

16

[64 output

points]

[32 special

points]

[32 special

points]

[32 special

points]

[16 output

po

ints]

[32 special

points]

0.115 0.09

0.20 –

0.15 –

0.55 –

0.08 –

0.05 –

The current

consumption

describes in

connecting

A1SD59J-MIF.

Simulation

module

A6SIM-X64Y64

An I/O simulation module used connected to the

base unit Debugging can be executed without

connecting the I/O module to the base unit. Use

an extension cable of the AnS series between

the main base of the AnS series and the

A6SIM-X64Y64.

2 - 16

64

64

[64 input points]

[64 output

points]

TYP. 0.3

(When all

points

"ON")

–

Page 38

SYSTEM CONFIGURATION2.

Product Name Model Name Description

PROFIBUS

interface