Page 1

QCPU User's Manual (Multiple CPU System)

-Q00CPU -Q100UDEHCPU

-Q01CPU

-Q02(H)CPU

-Q06HCPU

-Q12HCPU

-Q25HCPU

-Q02PHCPU

-Q06PHCPU

-Q12PHCPU

-Q25PHCPU

-Q00UCPU

-Q01UCPU

-Q02UCPU

-Q03UDVCPU

-Q03UD(E)CPU

-Q04UDVCPU

-Q04UD(E)HCPU

-Q06UDVCPU

-Q06UD(E)HCPU

-Q10UD(E)HCPU

-Q13UDVCPU

-Q13UD(E)HCPU

-Q20UD(E)HCPU

-Q26UDVCPU

-Q26UD(E)HCPU

-Q50UDEHCPU

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

Overcurrent or overvoltage protection of

the power supply module is activated.

The CPU module detects an error such as a

watchdog timer error by the self-diagnostic function.

All outputs are turned off All outputs are turned off

All outputs are turned off

All outputs are held or turned off

according to the parameter setting.

Q series module AnS/A series module

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Configure external safety circuits, such as an emergency stop circuit, protection circuit, and

protective interlock circuit for forward/reverse operation or upper/lower limit positioning.

(2) The programmable controller stops its operation upon detection of the following status, and the

output status of the system will be as shown below.

All outputs may turn on when an error occurs in the part, such as I/O control part, where the

programmable controller CPU cannot detect any error. To ensure safety operation in such a case,

provide a safety mechanism or a fail-safe circuit external to the programmable controller. For a

fail-safe circuit example, refer to the QCPU User's Manual (Hardware Design, Maintenance and

Inspection).

(3) Outputs may remain on or off due to a failure of an output module relay or transistor. Configure an

external circuit for monitoring output signals that could cause a serious accident.

1

Page 4

[Design Precautions]

WARNING

● In an output module, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

● When connecting a peripheral with the CPU module or connecting an external device, such as a

personal computer, with an intelligent function module to modify data of a running programmable

controller, configure an interlock circuit in the program to ensure that the entire system will always

operate safely. For other forms of control (such as program modification or operating status change)

of a running programmable controller, read the relevant manuals carefully and ensure that the

operation is safe before proceeding. Especially, when a remote programmable controller is controlled

by an external device, immediate action cannot be taken if a problem occurs in the programmable

controller due to a communication failure. To prevent this, configure an interlock circuit in the

sequence program, and determine corrective actions to be taken between the external device and

CPU module in case of a communication failure.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm (3.94 inches) or more between them. Failure to do so may result in

malfunction due to noise.

● When a device such as a lamp, heater, or solenoid valve is controlled through an output module, a

large current (approximately ten times greater than normal) may flow when the output is turned from

off to on. Take measures such as replacing the module with one having a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

2

Page 5

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the

QCPU User's Manual (Hardware Design, Maintenance and Inspection). Failure to do so may result in

electric shock, fire, malfunction, or damage to or deterioration of the product.

● To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place. Incorrect mounting may cause malfunction, failure or drop of the

module. When using the programmable controller in an environment of frequent vibrations, fix the

module with a screw. Tighten the screw within the specified torque range. Undertightening can cause

drop of the screw, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

When using an extension cable, connect it to the extension cable connector of the base unit securely.

●

Check the connection for looseness. Poor contact may cause incorrect input or output.

● When using a memory card, fully insert it into the memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette into the cassette connector of a CPU module. After

insertion, close the cassette cover to prevent the cassette from coming off. Poor contact may cause

malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in damage to the product. A module can be replaced online (while

power is on) on any MELSECNET/H remote I/O station or in the system where a CPU module

supporting the online module change function is used. Note that there are restrictions on the modules

that can be replaced online, and each module has its predetermined replacement procedure. For

details, refer to the relevant sections in the QCPU User's Manual (Hardware Design, Maintenance

and Inspection) and in the manual for the corresponding module.

● Do not directly touch any conductive parts and electronic components of the module, memory card,

SD memory card, or extended SRAM cassette. Doing so can cause malfunction or failure of the

module.

● When using a Motion CPU module and modules designed for motion control, check that the

combinations of these modules are correct before applying power. The modules may be damaged if

the combination is incorrect. For details, refer to the user's manual for the Motion CPU module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before wiring. Failure to do so may

result in electric shock or damage to the product.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

3

Page 6

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm (3.94 inches) or more between them. Failure to do so may result in

malfunction due to noise.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor connection.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws within the specified torque range. Undertightening can cause short circuit,

fire, or malfunction. Overtightening can damage the screw and/or module, resulting in drop, short

circuit, or malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Mitsubishi programmable controllers must be installed in control panels. Connect the main power

supply to the power supply module in the control panel through a relay terminal block. Wiring and

replacement of a power supply module must be performed by qualified maintenance personnel with

knowledge of protection against electric shock. For wiring methods, refer to the QCPU User's Manual

(Hardware Design, Maintenance and Inspection).

4

Page 7

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock or cause the module to fail or malfunction.

[Startup and Maintenance Precautions]

CAUTION

● Before performing online operations (especially, program modification, forced output, and operating

status change) for the running CPU module from the peripheral device connected, read relevant

manuals carefully and ensure the safety. Improper operation may damage machines or cause

accidents.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm (9.85 inches) away in all directions from the programmable controller.

Failure to do so may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction. A module can be replaced

online (while power is on) on any MELSECNET/H remote I/O station or in the system where a CPU

module supporting the online module change function is used. Note that there are restrictions on the

modules that can be replaced online, and each module has its predetermined replacement procedure.

For details, refer to the relevant sections in the QCPU User's Manual (Hardware Design, Maintenance

and Inspection) and in the manual for the corresponding module.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module, and do not insert/remove the extended SRAM cassette to/from the

CPU module more than 50 times (IEC 61131-2 compliant) respectively. Exceeding the limit of 50 times

may cause malfunction.

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Before handling the module, touch a grounded metal object to discharge the static electricity from the

human body. Failure to do so may cause the module to fail or malfunction.

5

Page 8

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste. When disposing of batteries, separate

them from other wastes according to the local regulations. (For the Battery Directive in EU member

states, refer to the QCPU User's Manual (Hardware Design, Maintenance and Inspection).)

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. (For details of the regulated

models, refer to the QCPU User's Manual (Hardware Design, Maintenance and Inspection).)

6

Page 9

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

7

Page 10

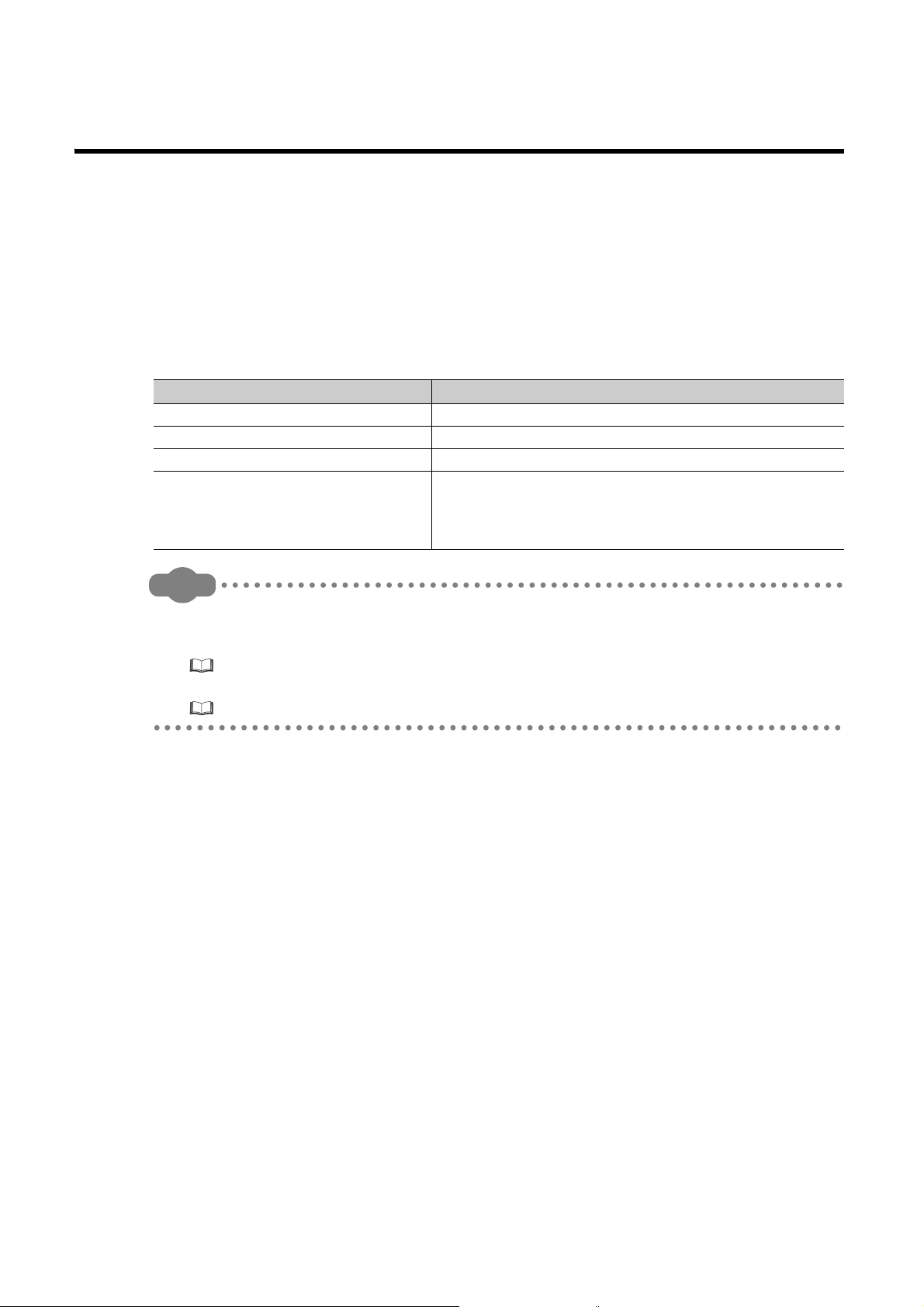

INTRODUCTION

Remark

This manual describes the system configurations, functions, and communication methods with external devices

required in a multiple CPU system.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the Q series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to the actual system, ensure the applicability and

confirm that it will not cause system control problems.

Relevant CPU modules:

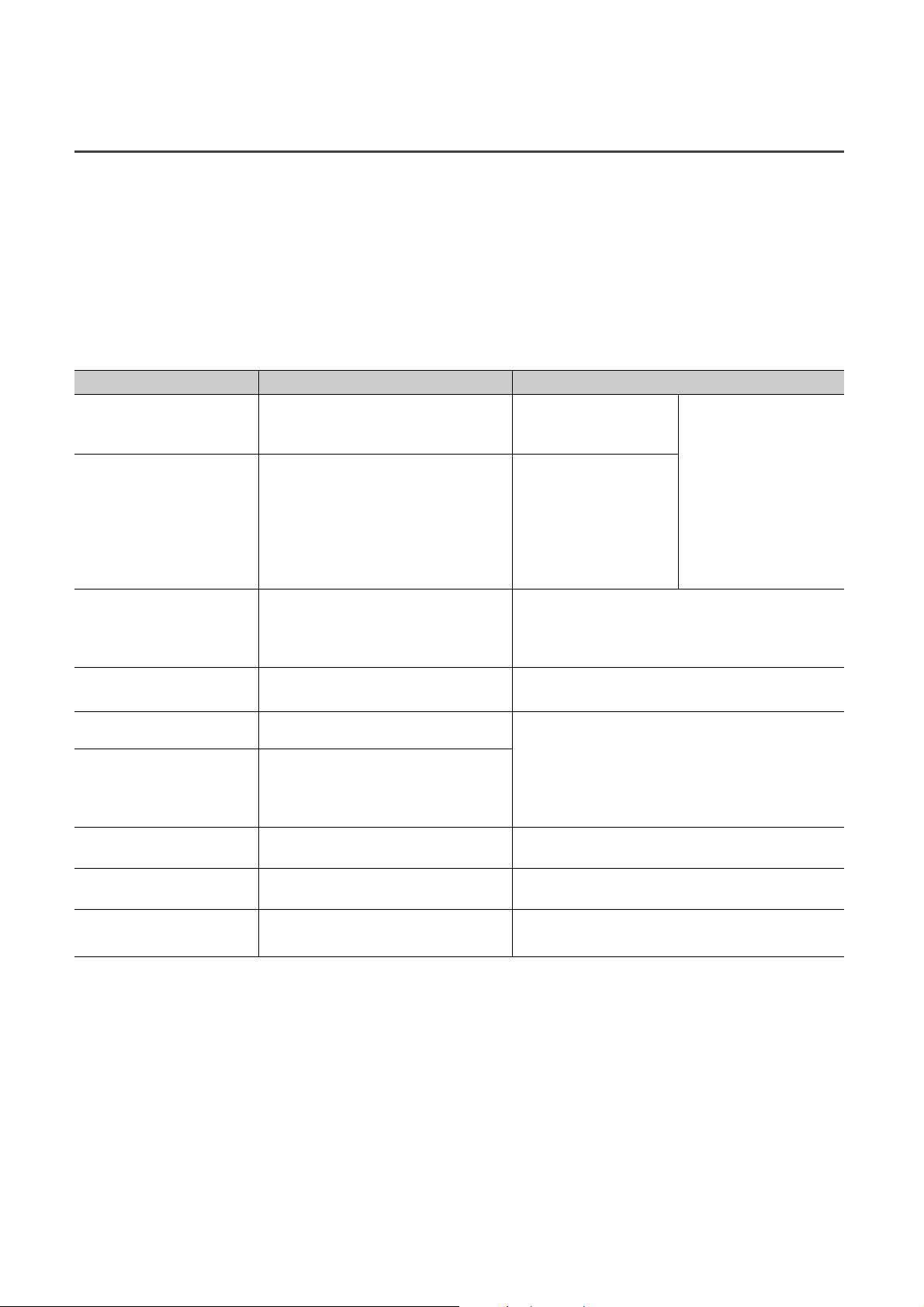

CPU module Model

Basic model QCPU Q00CPU, Q01CPU

High Performance model QCPU Q02(H)CPU, Q06HCPU, Q12HCPU, Q25HCPU

Process CPU Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU

Q00UCPU, Q01UCPU, Q02UCPU, Q03UD(E)CPU, Q03UDVCPU,

Universal model QCPU

Q04UD(E)HCPU, Q04UDVCPU, Q06UD(E)HCPU, Q06UDVCPU,

Q10UD(E)HCPU, Q13UD(E)HCPU, Q13UDVCPU, Q20UD(E)HCPU,

Q26UD(E)HCPU, Q26UDVCPU, Q50UDEHCPU, Q100UDEHCPU

● This manual does not describe the specifications and precautions of the power supply modules, base units, extension

cables, memory cards, SD memory cards, extended SRAM cassettes, and batteries as well as the peripheral

configurations.

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

● For the functions of CPU modules when used in a system other than a multiple CPU system, refer to the following.

User's Manual (Function Explanation, Program Fundamentals) for the CPU module used

8

Page 11

Memo

9

Page 12

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

MANUAL PAGE ORGANIZATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CHAPTER 1 OVERVIEW 18

CHAPTER 2 CONCEPT OF MULTIPLE CPU SYSTEM 24

2.1 CPU Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.2 I/O Number Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.2.1 I/O numbers of I/O modules and intelligent function modules . . . . . . . . . . . . . . . . . . . . . . . . 27

2.2.2 I/O numbers of CPU modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

CHAPTER 3 SYSTEM CONFIGURATION 31

3.1 System Using Basic Model QCPU as CPU No.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.1.1 Available CPU modules, base units, power supply modules, and extension cables . . . . . . . 32

3.1.2 CPU module combinations and mounting positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1.3 Available I/O modules and intelligent function modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.2 System Using High Performance Model QCPU or Process CPU as CPU No.1. . . . . . . . . . . . 41

3.2.1 Available CPU modules, base units, power supply modules, and extension cables . . . . . . . 41

3.2.2 CPU module combinations and mounting positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.2.3 Available I/O modules and intelligent function modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.3 System Using Universal Model QCPU as CPU No.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.3.1 Available CPU modules, base units, power supply modules, and extension cables . . . . . . . 53

3.3.2 CPU module combinations and mounting positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.3.3 Available I/O modules and intelligent function modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.4 Applicable Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

3.5 Precautions for System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

CHAPTER 4 STARTING UP MULTIPLE CPU SYSTEM 75

4.1 Procedure Before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.2 Operation Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.2.1 System configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.2.2 Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.3 Program Examples for Communications by Auto Refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.3.1 Program examples for Basic model QCPU, High Performance model QCPU, and Process

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

CPU

4.3.2 Program examples for Universal model QCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.4 Clock Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.4.1 Clock data of CPU modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.4.2 Clock data of intelligent function modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4.5 Resetting a Multiple CPU System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

4.6 System Operation When a Stop Error Occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

10

Page 13

CHAPTER 5 ACCESS BETWEEN CPU MODULES AND OTHER MODULES 104

5.1 Access to Controlled Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

5.2 Access to Non-controlled Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

5.2.1 Loading input (X) data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.2.2 Loading output (Y) data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.2.3 Output to output modules and intelligent function modules . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.2.4 Access to the intelligent function module buffer memory. . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.2.5 Access using the link direct device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.3 Access From a Programming Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

5.4 Accessible QCPUs when GOT is connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

CHAPTER 6 COMMUNICATIONS AMONG CPU MODULES 116

6.1 Communications Using the CPU Shared Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

6.1.1 Communications by auto refresh (using the auto refresh area) . . . . . . . . . . . . . . . . . . . . . . 122

6.1.2 Communications by auto refresh (using the multiple CPU high speed transmission area)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

6.1.3 Communications by programs using the CPU shared memory . . . . . . . . . . . . . . . . . . . . . . 150

6.1.4 Communications among CPU modules when an error is detected . . . . . . . . . . . . . . . . . . . 159

6.2 Control Directions from QCPU to Motion CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

6.3 Communications Among CPU Modules By Dedicated Instructions . . . . . . . . . . . . . . . . . . . .162

6.3.1 Reading/writing device data from/to Motion CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

6.3.2 Starting interrupt programs from QCPU to C Controller module/PC CPU module. . . . . . . . 164

6.3.3 Reading/writing device data between QCPUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6.4 Multiple CPU Synchronous Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

6.5 Multiple CPU synchronous startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

APPENDICES 170

Appendix 1 Parameters for a Multiple CPU System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Appendix 1.1 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Appendix 2 Comparison with a Single CPU System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Appendix 3 Precautions for Using AnS/A Series Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Appendix 4 Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

Appendix 4.1 Concept of scan time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Appendix 4.2 Factors that increase scan time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Appendix 4.3 Reducing processing time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

INDEX 201

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

11

Page 14

MANUALS

To understand the main specifications, functions, and usage of the CPU module, refer to the basic manuals. Read

other manuals as well when using a different type of CPU module and its functions. Order each manual as needed,

referring to the following lists.

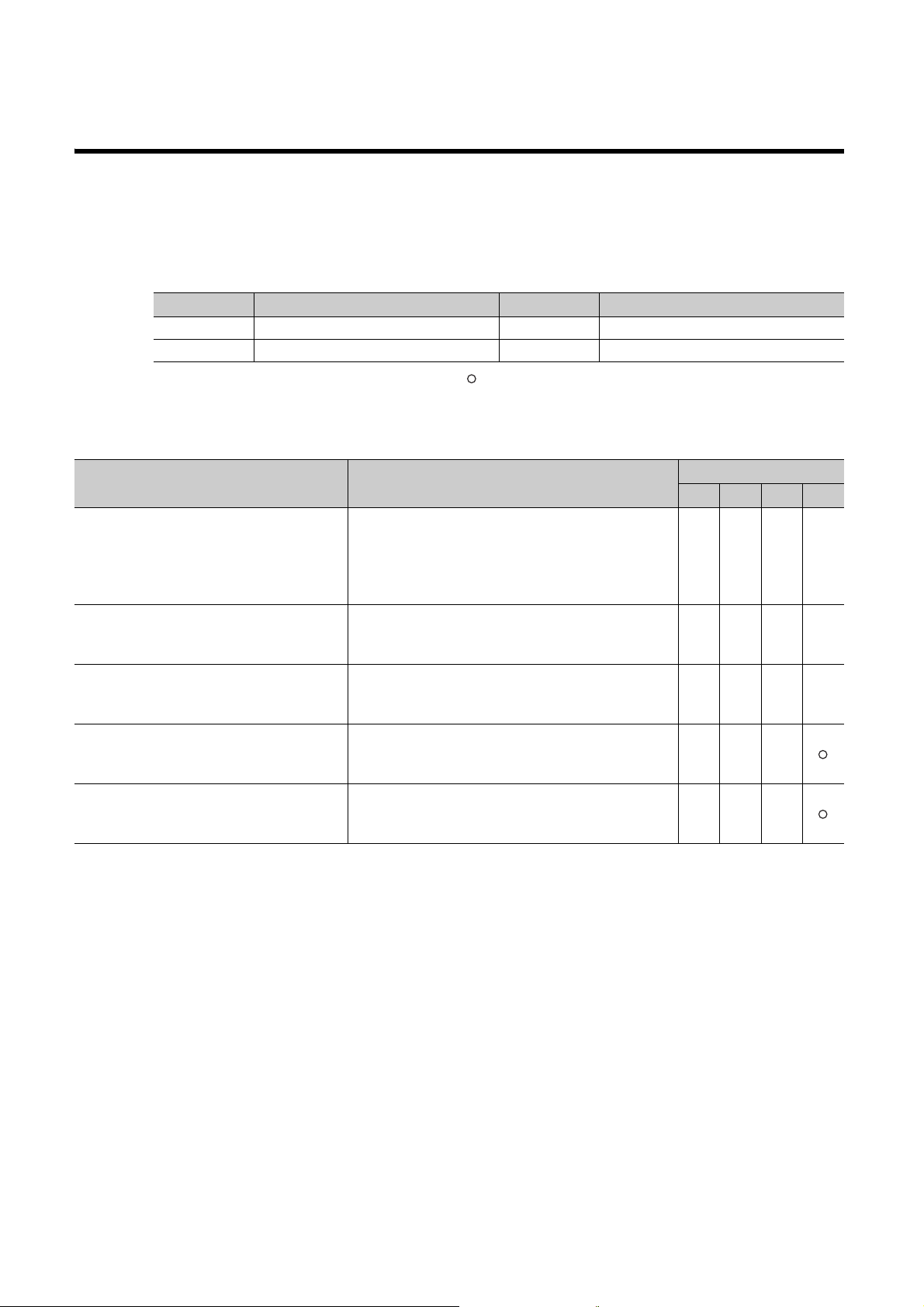

The numbers in the "CPU module" and the respective modules are as follows.

Number CPU module Number CPU module

1) Basic model QCPU 3) Process CPU

2) High Performance model QCPU 4) Universal model QCPU

●: Basic manual, : Other CPU module manuals/Use them to utilize functions.

(1) CPU module user's manual

Manual name

<manual number (model code)>

QCPU User's Manual (Hardware Design,

Maintenance and Inspection)

<SH-080483ENG (13JR73)>

QnUCPU User's Manual (Function Explanation,

Program Fundamentals)

<SH-080807ENG (13JZ27)>

Qn(H)/QnPH/QnPRHCPU User's Manual

(Function Explanation, Program Fundamentals)

<SH-080808ENG (13JZ28)>

QnUCPU User's Manual (Communication via

Built-in Ethernet Port)

<SH-080811ENG (13JZ29)>

QnUDVCPU/LCPU User's Manual (Data

Logging Function)

<SH-080893ENG (13JZ39)>

Description

Specifications of the hardware (CPU modules, power

supply modules, base units, extension cables, memory

cards, SD memory cards, and extended SRAM

cassettes), system maintenance and inspection,

troubleshooting, and error codes

Functions, methods, and devices for programming ●

Functions, methods, and devices for programming ●●●

Detailed description of communication via the built-in

Ethernet ports of the CPU module

Detailed description of the data logging function of the

CPU module

CPU module

1) 2) 3) 4)

●●●●

12

Page 15

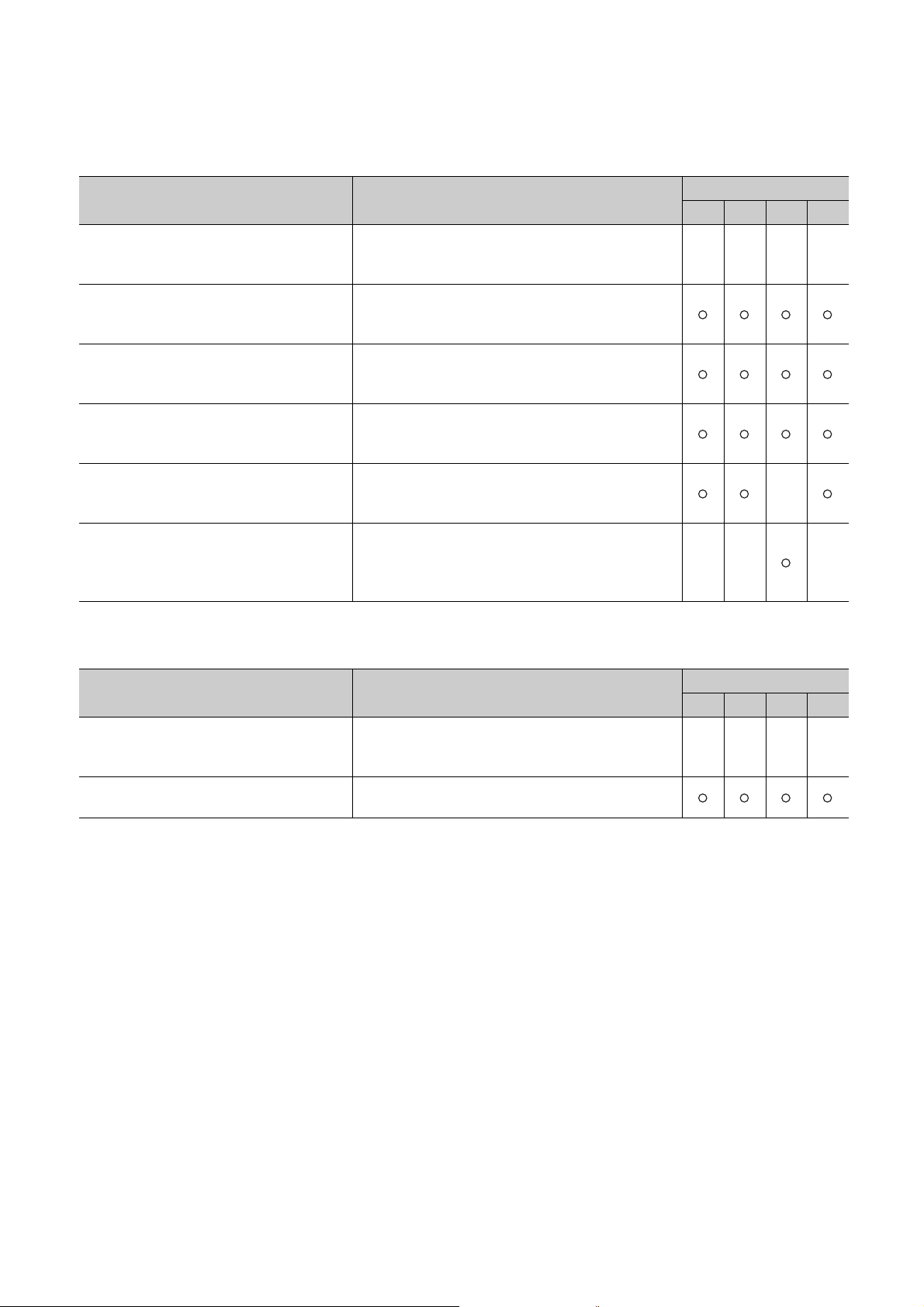

(2) Programming manual

Manual name

<manual number (model code)>

MELSEC-Q/L Programming Manual (Common

Instruction)

<SH-080809ENG (13JW10)>

MELSEC-Q/L/QnA Programming Manual

(SFC)

<SH-080041 (13JF60)>

MELSEC-Q/L Programming Manual (MELSAP-

L)

<SH-080076 (13JF61)>

MELSEC-Q/L Programming Manual (Structured

Te xt )

<SH-080366E (13JF68)>

MELSEC-Q/L/QnA Programming Manual (PID

Control Instructions)

<SH-080040 (13JF59)>

MELSEC-Q Programming/Structured

Programming Manual (Process Control

Instructions)

<SH-080316E (13JF67)>

(3) Operating manual

Description

Detailed description and usage of instructions used in

programs

System configuration, specifications, functions,

programming, and error codes for SFC (MELSAP3)

programs

System configuration, specifications, functions,

programming, and error codes for SFC (MELSAP-L)

programs

System configuration and programming using structured

text language

Dedicated instructions for PID control

Dedicated instructions for process control

CPU module

1) 2) 3) 4)

●●●●

Manual name

<manual number (model code)>

GX Works2 Version 1 Operating Manual

(Common)

<SH-080779ENG (13JU63)>

GX Developer Version 8 Operating Manual

<SH-080373E (13JU41)>

Description

System configuration, parameter settings, and online

operations (common to Simple project and Structured

project) of GX Works2

Operating methods of GX Developer, such as

programming, printing, monitoring, and debugging

CPU module

1) 2) 3) 4)

●●●●

13

Page 16

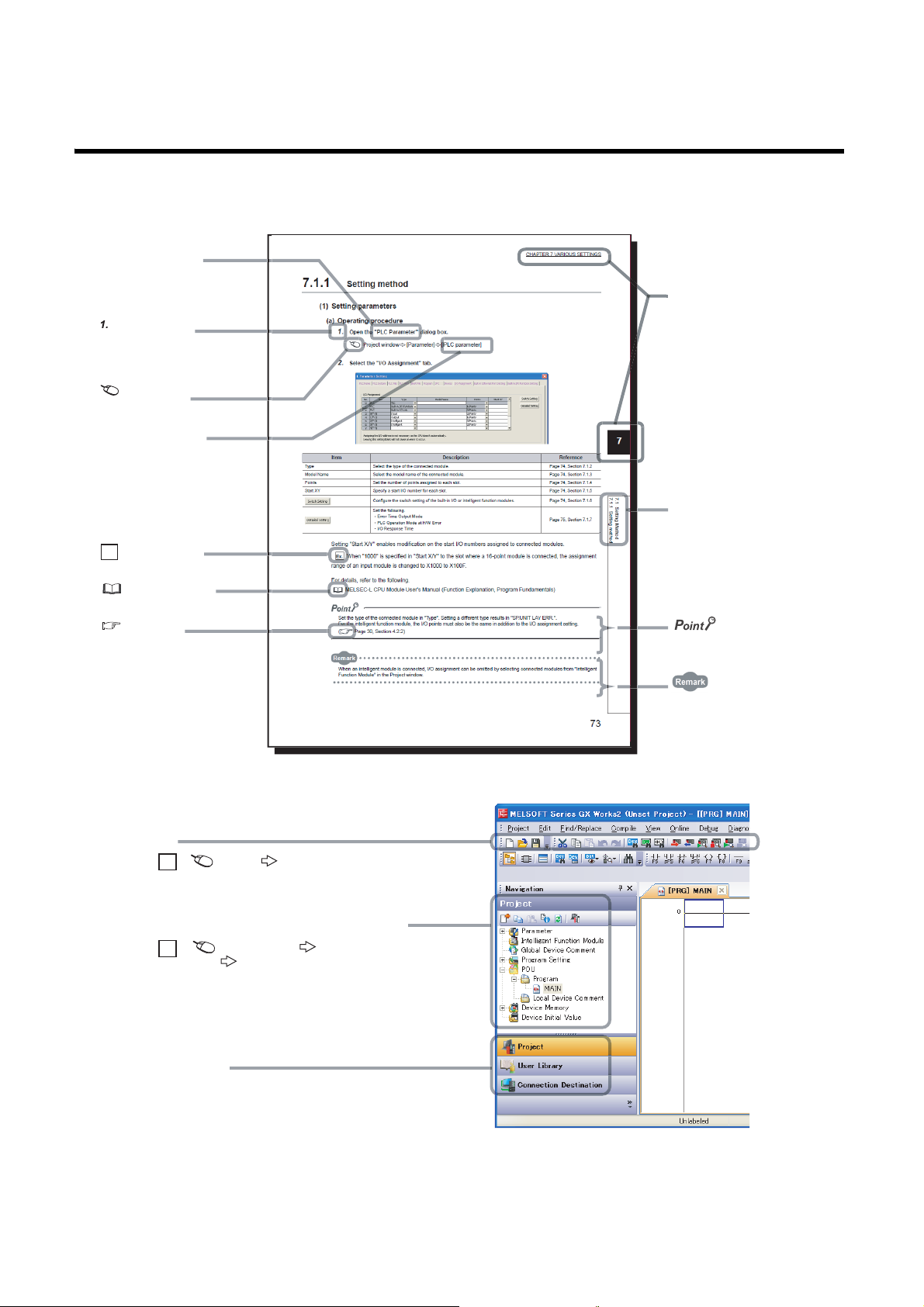

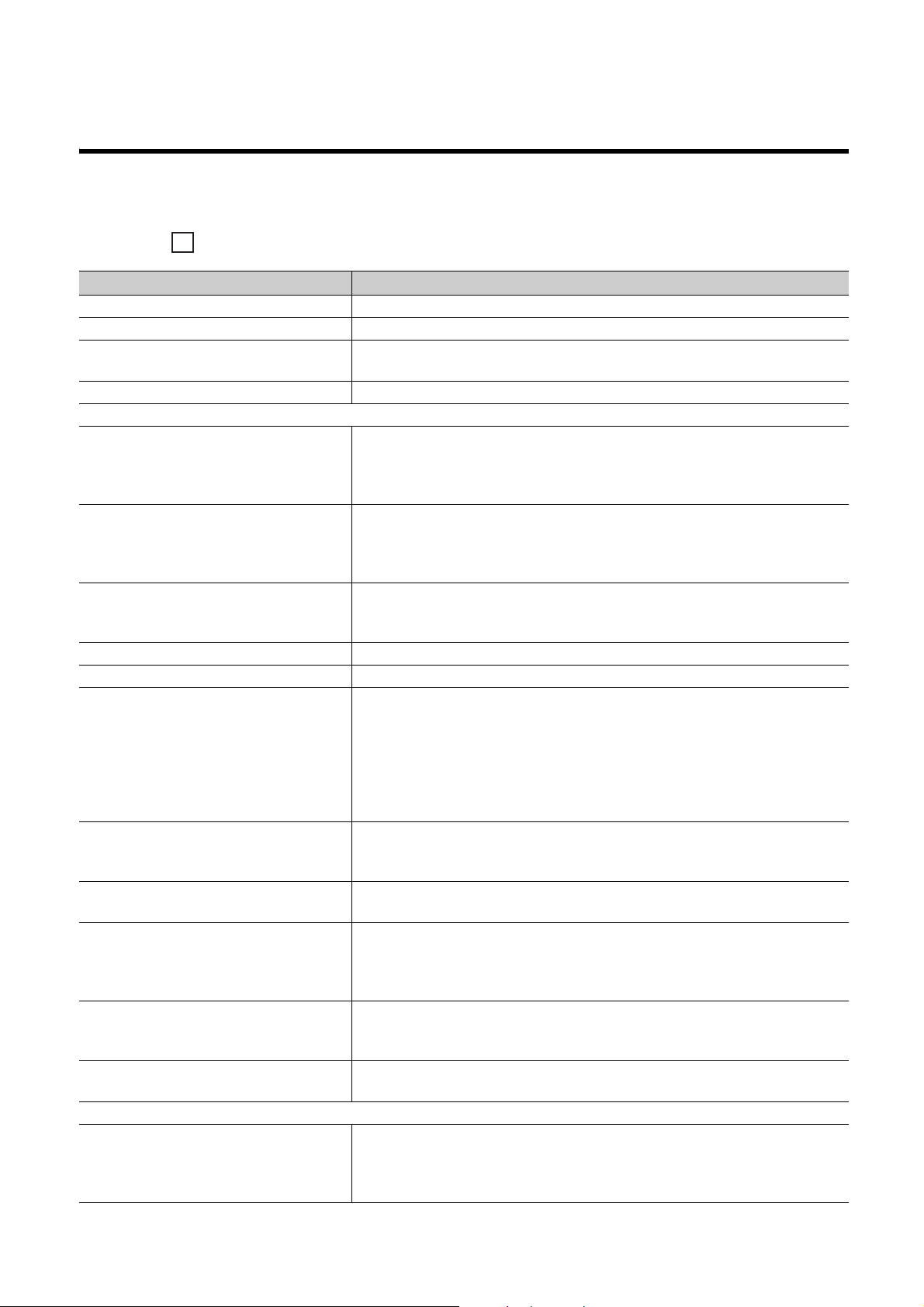

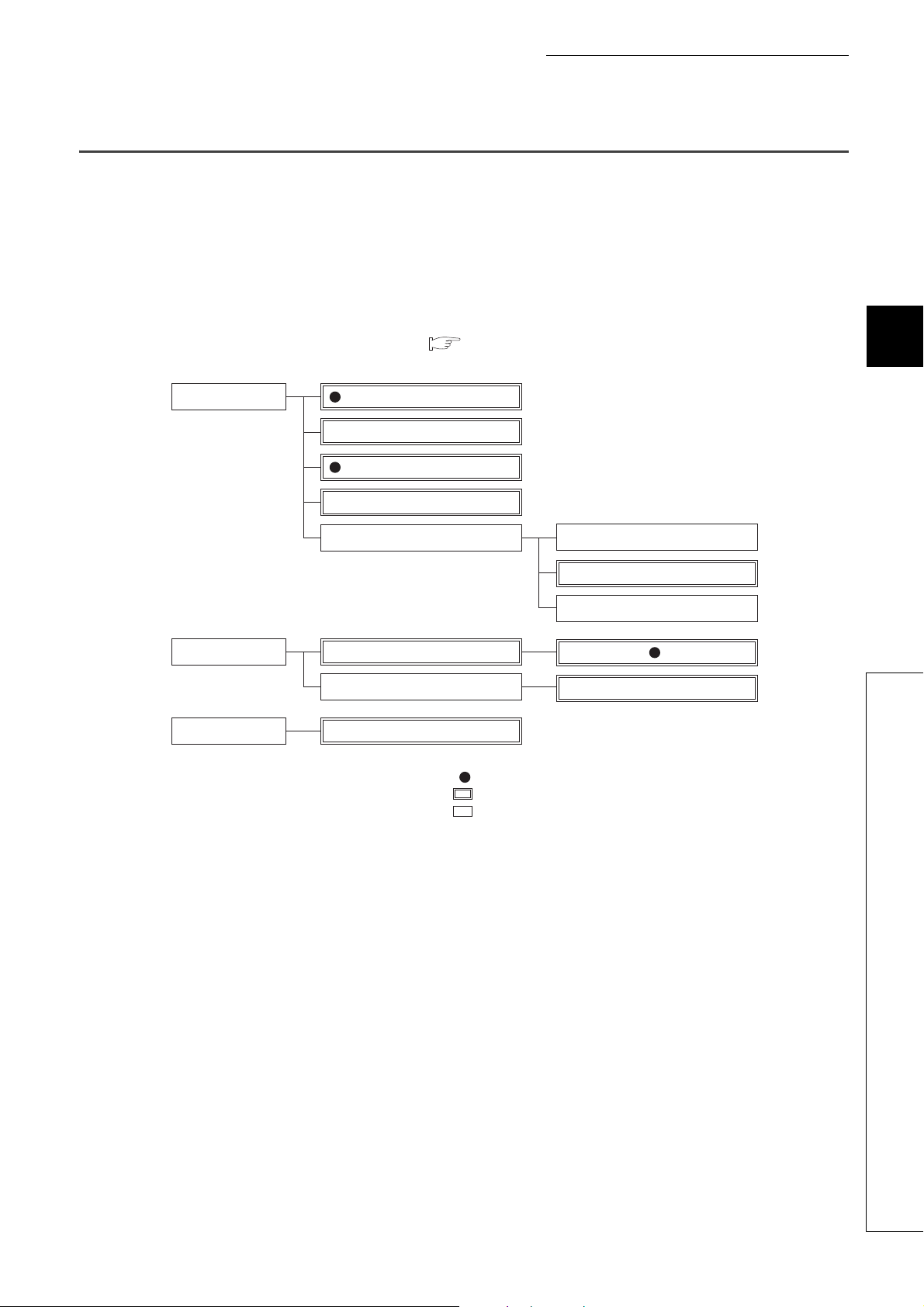

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for window

names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

A window selected in the view selection area is displayed.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[Parameter]

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

Menu bar

Ex.

Ex.

In the Project window, expand [Parameter] and

select [PLC Parameter].

In this manual, pages are organized and the symbols are used as shown below.

The following page illustration is for explanation purpose only, and is different from the actual pages.

*1 The mouse operation example is provided below. (For GX Works2)

14

Page 17

TERMS

Ex.

Unless otherwise specified, this manual uses the following generic terms and abbreviations.

* indicates a part of the model or version.

Q33B, Q35B, Q38B, Q312BQ3B

Ter m Description

Series

Q series The abbreviation for Mitsubishi MELSEC-Q series programmable controller

AnS series

A series The abbreviation for large types of Mitsubishi MELSEC-A series programmable controller

CPU module type

CPU module

QCPU

Basic model QCPU

High Performance model QCPU A generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

Process CPU A generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

Universal model QCPU

Built-in Ethernet port QCPU

High-speed Universal model QCPU

Motion CPU

PC CPU module

C Controller module

CPU module model

QnU(D)(H)CPU

The abbreviation for compact types of Mitsubishi MELSEC-A series programmable

controller

A generic term for the Basic model QCPU, High Performance model QCPU, Process

CPU, Universal model QCPU, Motion CPU, C Controller module, and PC CPU module.

The term in this manual does not include the Redundant CPU because it cannot be used

in a multiple CPU system.

A generic term for the Basic model QCPU, High Performance model QCPU, Process

CPU, and Universal model QCPU.

The term in this manual does not include the Redundant CPU because it cannot be used

in a multiple CPU system.

A generic term for the Q00CPU and Q01CPU.

The term in this manual does not include the Q00JCPU because it cannot be used in a

multiple CPU system.

A generic term for the Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU, Q03UDVCPU,

Q03UDECPU, Q04UDHCPU, Q04UDVCPU, Q04UDEHCPU, Q06UDHCPU,

Q06UDVCPU, Q06UDEHCPU, Q10UDHCPU, Q10UDEHCPU, Q13UDHCPU,

Q13UDVCPU, Q13UDEHCPU, Q20UDHCPU, Q20UDEHCPU, Q26UDHCPU,

Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU.

The term in this manual does not include the Q00UJCPU because it cannot be used in a

multiple CPU system.

A generic term for the Q03UDVCPU, Q03UDECPU, Q04UDVCPU, Q04UDEHCPU,

Q06UDVCPU, Q06UDEHCPU, Q10UDEHCPU, Q13UDVCPU, Q13UDEHCPU,

Q20UDEHCPU, Q26UDVCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

A generic term for the Q03UDVCPU, Q04UDVCPU, Q06UDVCPU, Q13UDVCPU, and

Q26UDVCPU

A generic term for the Mitsubishi motion controllers: Q172CPUN, Q173CPUN,

Q172HCPU, Q173HCPU, Q172CPUN-T, Q173CPUN-T, Q172HCPU-T, Q173HCPU-T,

Q172DCPU, Q173DCPU, Q172DCPU-S1, Q173DCPU-S1, Q172DSCPU, and

Q173DSCPU

A generic term for the MELSEC-Q series-compatible PC CPU modules manufactured by

CONTEC Co., Ltd: PPC-CPU686(MS)-64, PPC-CPU686(MS)-128, and PPC-

CPU852(MS)-512

A generic term for the C Controller modules: Q06CCPU-V, Q06CCPU-V-B, Q12DCCPU-

V, Q24DHCCPU-V, and Q24DHCCPU-LS

A generic term for the Q00UCPU, Q01UCPU, Q02UCPU, Q03UDCPU, Q04UDHCPU,

Q06UDHCPU, Q10UDHCPU, Q13UDHCPU, Q20UDHCPU, and Q26UDHCPU.

The term in this manual does not include the Q00UJCPU because it cannot be used in a

multiple CPU system.

15

Page 18

Term Description

QnUDVCPU

QnUDE(H)CPU

Q172CPUN(-T) A generic term for the Q172CPUN and Q172CPUN-T

Q173CPUN(-T) A generic term for the Q173CPUN and Q173CPUN-T

Q172HCPU(-T) A generic term for the Q172HCPU and Q172HCPU-T

Q173HCPU(-T) A generic term for the Q173HCPU and Q173HCPU-T

Q172DCPU(-S1) A generic term for the Q172DCPU and Q172DCPU-S1

Q173DCPU(-S1) A generic term for the Q173DCPU and Q173DCPU-S1

Base unit type

Base unit

Main base unit A generic term for the Q3B, Q3SB, Q3RB, and Q3DB

Extension base unit

Slim type main base unit Another term for the Q3SB

Redundant power main base unit Another term for the Q3RB

Redundant power extension base unit Another term for the Q6RB

Multiple CPU high speed main base unit Another term for the Q3DB

Redundant power supply base unit

Base unit model

Q3B A generic term for the Q33B, Q35B, Q38B, and Q312B main base units

Q3SB A generic term for the Q32SB, Q33SB, and Q35SB slim type main base units

Q3RB Another term for the Q38RB redundant power main base unit

Q3DB

Q5B A generic term for the Q52B and Q55B extension base units

Q6B A generic term for the Q63B, Q65B, Q68B, and Q612B extension base units

Q6RB Another term for the Q68RB redundant power extension base unit

QA1S5B

QA1S6B A generic term for the QA1S65B and QA1S68B extension base units

QA6B A generic term for the QA65B and QA68B extension base units

A5B A generic term for the A52B, A55B, and A58B extension base units

A6B A generic term for the A62B, A65B, and A68B extension base units

QA6ADP+A5B/A6B The abbreviation for A large type extension base unit where the QA6ADP is mounted

QA1S6ADP+A1S5B/A1S6B The abbreviation for A small type extension base unit where the QA1S6ADP is mounted

Power supply module

Power supply module

Q series power supply module

AnS series power supply module A generic term for the A1S61PN, A1S62PN, and A1S63P power supply modules

A generic term for the Q03UDVCPU, Q04UDVCPU, Q06UDVCPU, Q13UDVCPU, and

Q26UDVCPU

A generic term for the Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU, Q10UDEHCPU,

Q13UDEHCPU, Q20UDEHCPU, Q26UDEHCPU, Q50UDEHCPU, and Q100UDEHCPU

A generic term for the main base unit, extension base unit, slim type main base unit,

redundant power main base unit, redundant power extension base unit, and multiple

CPU high speed main base unit.

The term in this manual does not include the redundant type extension base unit

because it cannot be used in a multiple CPU system.

A generic term for the Q5B, Q6B, Q6RB, QA1S5B, QA1S6B,

QA1S6ADP+A1S5B/A1S6B, QA6B, and QA6ADP+A5B/A6B.

The term in this manual does not include the Q6WRB because it cannot be used in a

multiple CPU system.

A generic term for the redundant power main base unit and redundant power extension

base unit

A generic term for the Q35DB, Q38DB, and Q312DB multiple CPU high speed main

base units

Another term for the QA1S51B extension base unit

A generic term for the Q series power supply module, AnS series power supply module,

A series power supply module, slim type power supply module, and redundant power

supply module

A generic term for the Q61P-A1, Q61P-A2, Q61P, Q61P-D, Q62P, Q63P, Q64P, and

Q64PN power supply modules

16

Page 19

Ter m Description

A series power supply module

Slim type power supply module The abbreviation for the Q61SP slim type power supply module

Redundant power supply module A generic term for the Q63RP and Q64RP redundant power supply modules

Life detection power supply module The abbreviation for the Q61P-D life detection power supply module

Network module

CC-Link IE module

MELSECNET/H module The abbreviation for the MELSECNET/H network module

Ethernet module The abbreviation for the Ethernet interface module

CC-Link module The abbreviation for the CC-Link system master/local module

Network

CC-Link IE A generic term for the CC-Link IE Controller Network and CC-Link IE Field Network

MELSECNET/H The abbreviation for the MELSECNET/H network system

Memory extension

Memory card A generic term for SRAM card, Flash card, and ATA card

SRAM card

Flash card A generic term for the Q2MEM-2MBF and Q2MEM-4MBF Flash cards

ATA card A generic term for the Q2MEM-8MBA, Q2MEM-16MBA, and Q2MEM-32MBA ATA cards

SD memory card

Extended SRAM cassette

Software package

Programming tool A generic term for GX Works2 and GX Developer

GX Works2

GX Developer

Others

Control CPU

Controlled module I/O modules and intelligent function modules which are controlled by a control CPU

Non-controlled module

Extension cable

Battery

QA6ADP The abbreviation for the QA6ADP QA conversion adapter module

QA1S6ADP

GOT

A generic term for the A61P, A61PN, A62P, A63P, A68P, A61PEU, and A62PEU power

supply modules

A generic term for the CC-Link IE Controller Network module and CC-Link IE Field

Network module

A generic term for the Q2MEM-1MBS, Q2MEM-2MBS, Q3MEM-4MBS, and Q3MEM-

8MBS SRAM cards

A generic term for the L1MEM-2GBSD and L1MEM-4GBSD SD Secure Digital memory

cards. An SD card is a non-volatile memory card.

A generic term for the Q4MCA-1MBS, Q4MCA-2MBS, Q4MCA-4MBS, and Q4MCA-

8MBS extended SRAM cassettes

The product name for the MELSEC programmable controller software package

A CPU module which controls each I/O module and intelligent function module.

In a multiple CPU system, the CPU module which executes the control can be set for

each module.

I/O modules and intelligent function modules that are controlled by CPU modules other

than a control CPU

A generic term for the QC05B, QC06B, QC12B, QC30B, QC50B, and QC100B

extension cables

A generic term for the Q6BAT, Q7BAT, and Q8BAT CPU module batteries, Q2MEM-BAT

SRAM card battery, and Q3MEM-BAT SRAM card battery

A generic term for the QA1S6ADP and QA1S6ADP-S1 Q-AnS base unit conversion

adapter

A generic term for Mitsubishi Graphic Operation Terminal, GOT-A*** series, GOT-F***

series, and GOT1000 series

17

Page 20

CHAPTER 1 OVERVIEW

Remark

QCPU

Motion CPU

PC CPU module

1 1 1 1

In a multiple CPU system, more than one CPU module is mounted on the main base unit and each CPU module

controls I/O modules and intelligent function modules separately.

QCPUs, Motion CPUs, C Controller modules, and PC CPU modules can be used in multiple CPU systems.

( Page 31, CHAPTER 3)

This manual describes the combinations of CPU modules and communications among CPU modules in a multiple CPU

system. For the uses, functions, and instruction availabilities of each CPU module, refer to the following.

Manual for the CPU module used

For PC CPU modules, contact CONTEC Co., Ltd.

http://www.contec.com/

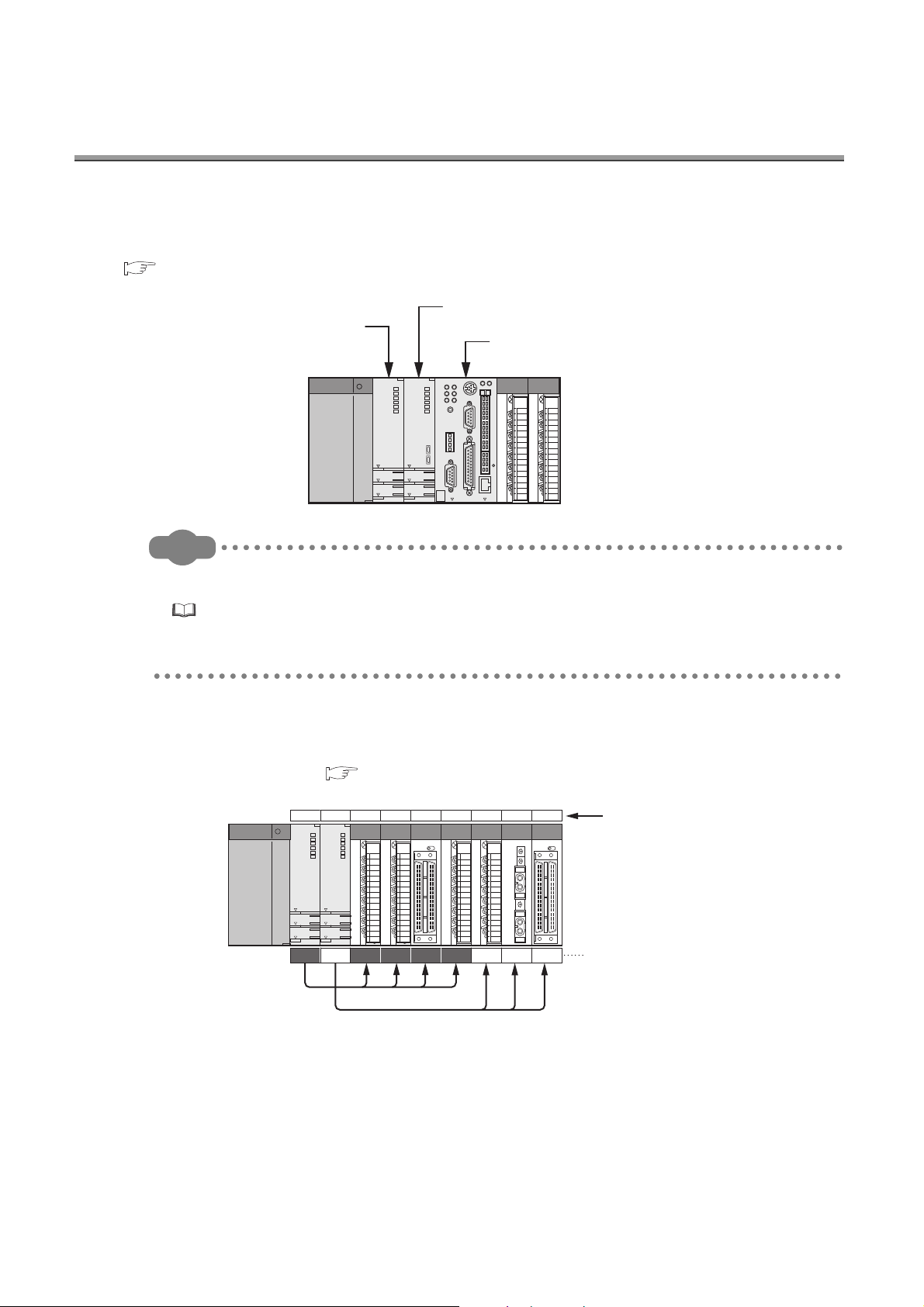

(1) Distributed control

In a multiple CPU system, control can be distributed by specifying a control CPU module for each I/O module and

intelligent function module. ( Page 24, Section 2.1)

CPU01234567

112

Controlled by CPU No.1.

Controlled by CPU No.2.

222

Distributed control provides the advantages listed on the following page.

Slot number

Control CPU setting

18

Page 21

CHAPTER 1 OVERVIEW

Data processing (low speed)

A single QCPU controls an entire system.

Machine control (high speed)

(Processing speed:

1ms or less)

CPU module for

machine control

(Processing speed:

1 to several 10ms)

CPU module for

data processing

Machine control speed is further increased with

load distribution according to the control cycle.

Free

space

Used memory

Free

space

Free

space

Used

memory

Used

memory

Memory capacity can be expanded by

using more than one CPU module.

An additional CPU module can

expand the following:

Program memory

Device memory

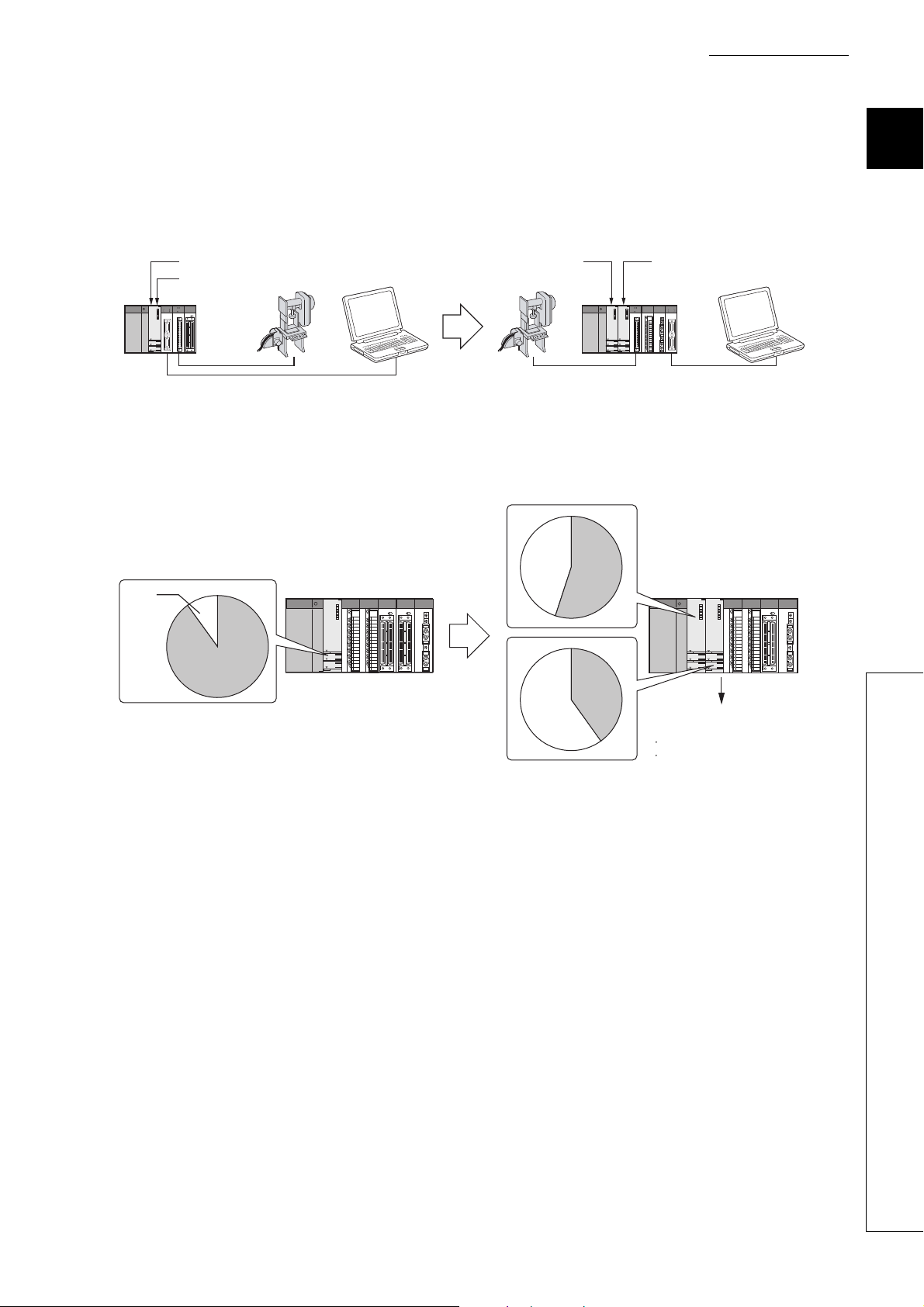

(a) Distribution of processing

The overall system scan time can be reduced by distributing the high-load processing performed in a single

CPU module over multiple CPU modules.

(b) Distribution of memory

The memory capacity used for the entire system can be increased by distributing the memory areas over

multiple CPU modules.

1

(c) Distribution of functions

Programs can be developed easily by distributing the functions, for example, having different CPU modules

control production line A and production line B.

19

Page 22

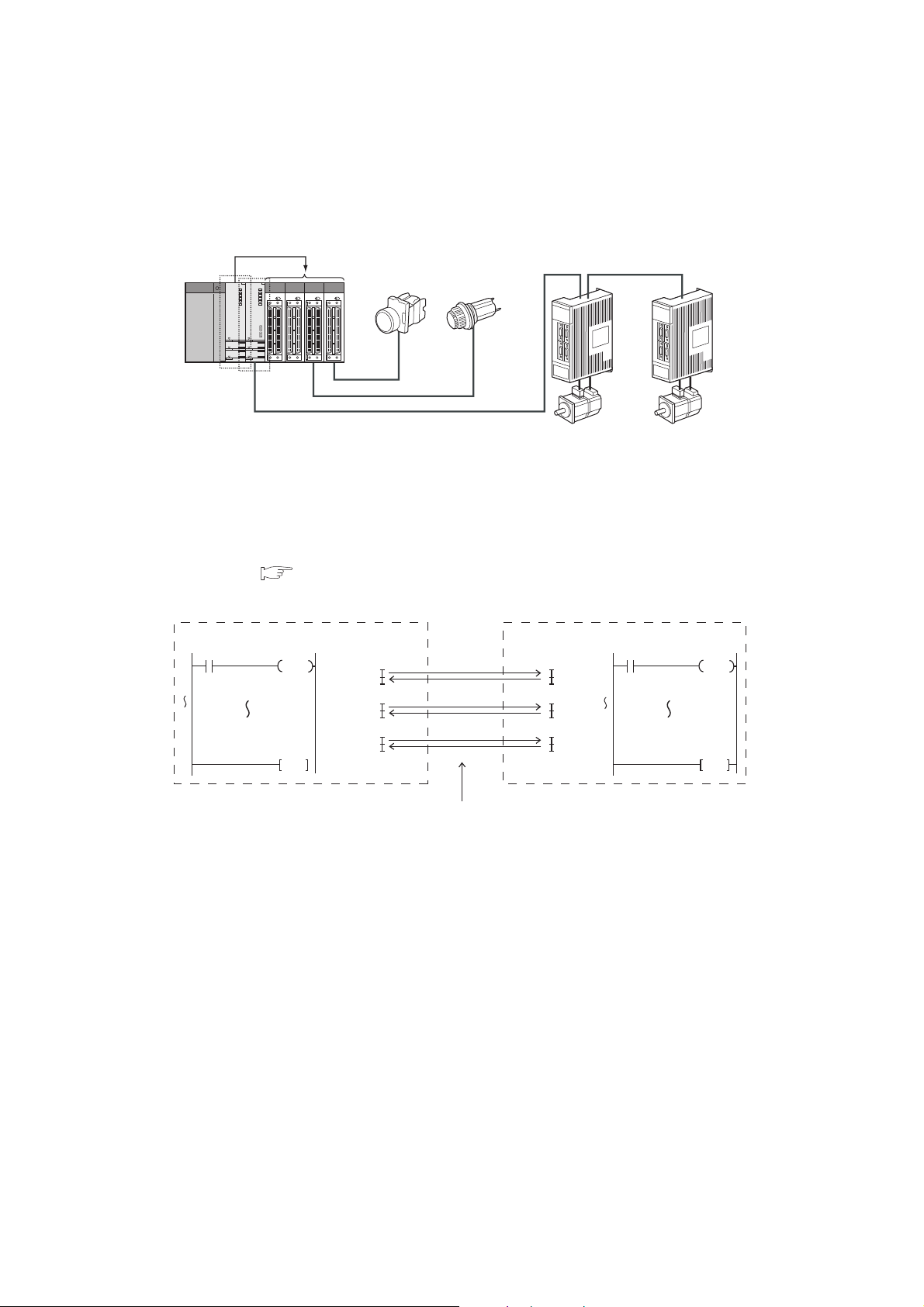

(2) Configuring sequence control and motion control systems on the same base

Control

Motion control

Sequence

control

SSCNET

Operation switch Operation status lamp

Servo

motor

Servo

motor

Servo

amplifier

Servo

amplifier

CPU No.1

Program Program

Multiple CPU high

speed transmission

Multiple CPU high

speed transmission

Data transfer

Data transfer

Data transfer

Data are transferred in parallel with programs.

X0

Y20

END

0

CPU No.2

X100

Y120

END

0

unit

In a multiple CPU system consisting of a QCPU and Motion CPU, sequence control and motion control can be

implemented together to achieve a high-level motion system.

Interaction with Motion CPUs for motion control is enhanced in Universal model QCPUs.

(a) High-speed data transfer between CPU modules

In a multiple CPU system, up to 14K-word data are transferred in parallel with programs between CPU

modules. This enables high-speed data transfer independent of scan time, and shortens the takt time of the

entire system. ( Page 150, Section 6.1.3)

20

Page 23

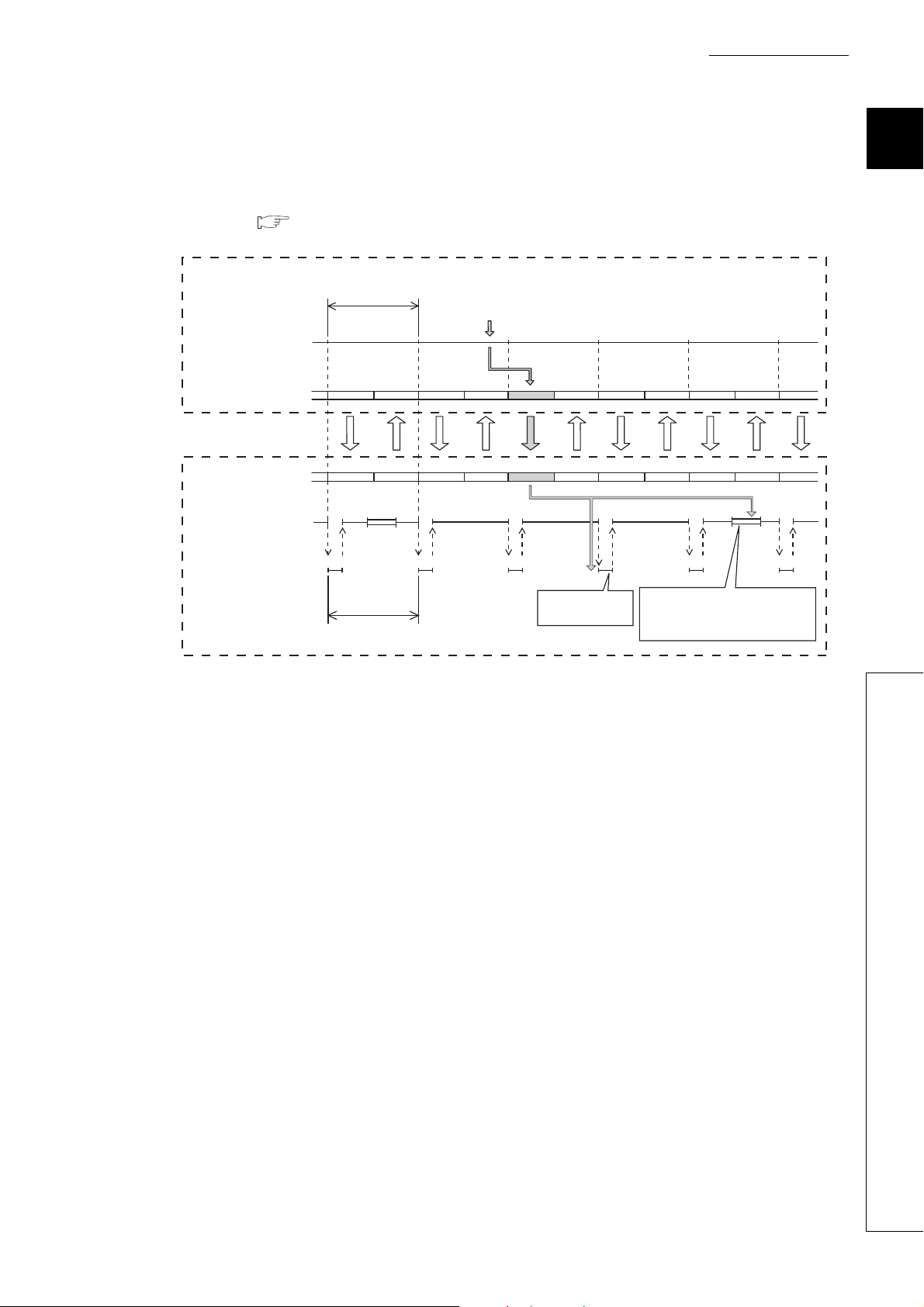

CHAPTER 1 OVERVIEW

Reading an imposition signal when

a multiple CPU synchronous

interrupt program is not used

Motion

CPU

Universal

model QCPU

Operation cycle

of a Motion CPU

Motion SFC program

Multiple CPU high

speed transmission

area

Multiple CPU high

speed transmission

Multiple CPU high

speed transmission

area

Multiple CPU

synchronous

interrupt program

Program

Reading an

imposition signal

Multiple CPU

high speed

transmission cycle

I45 IRET

END 0

I45 IRET I45 IRET

I45 IRET

END

I45 IRET

I45 IRET

Reading an

imposition signal

0

(b) Synchronous processing with a motion control

An interrupt program which is synchronized with the operation cycle of a Motion CPU (multiple CPU

synchronous interrupt program) can be executed. Command input or output from a Motion CPU can be

synchronized with the operation cycle of the Motion CPU, which enables high-speed data transfer independent

of scan time. ( Page 166, Section 6.4)

1

21

Page 24

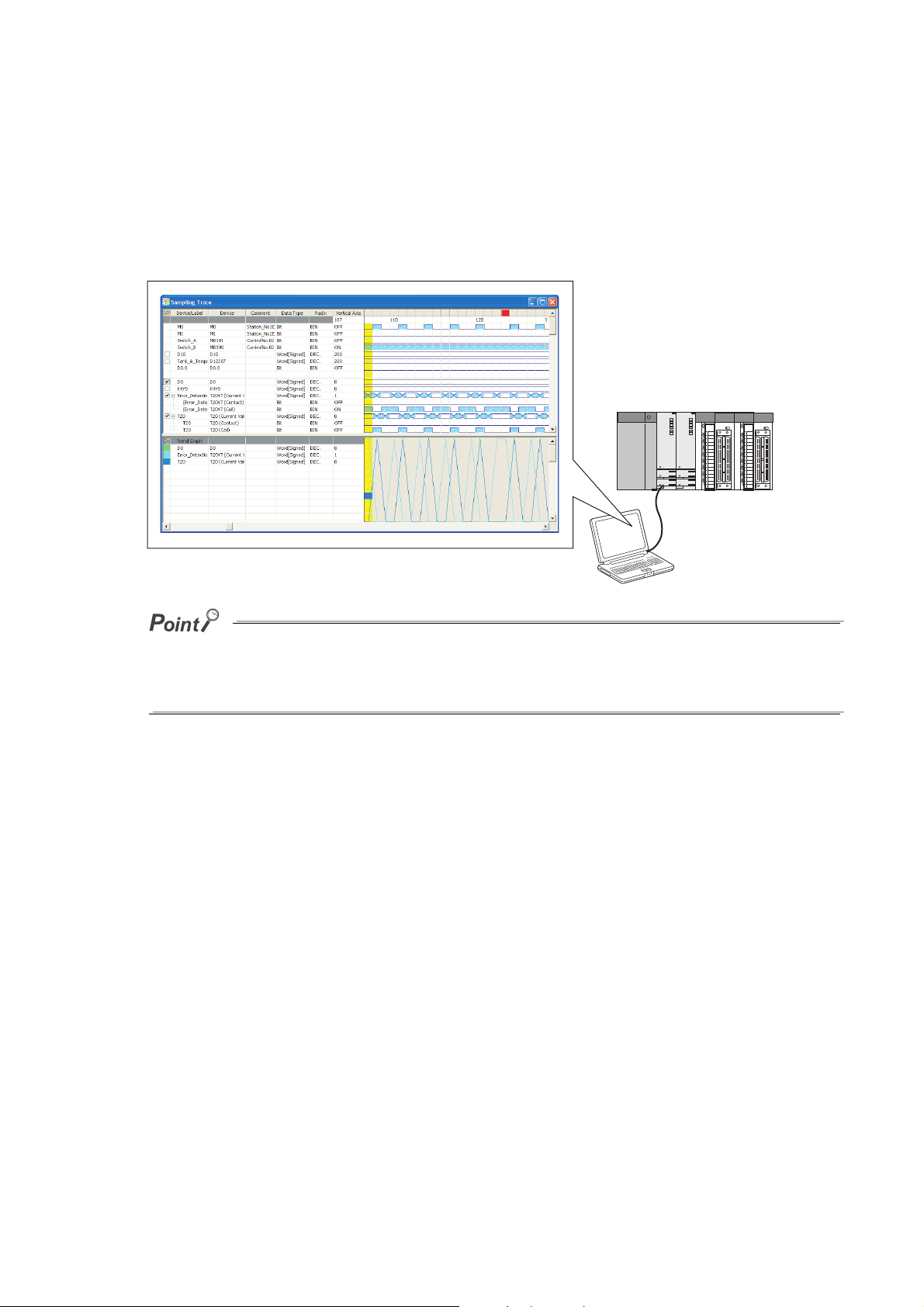

(c) Checking data send/receive timing between CPU modules

With the sampling trace function of Universal model QCPUs, the data communications timing with a Motion

CPU can be checked. Timing can also be checked between Universal model QCPUs.

The sampling trace function facilitates the processing for checking the data send/receive timing between CPU

modules, and reduces the time for debugging the multiple CPU system.

Sampling trace result display using a programming tool

The sampling trace of other CPU modules in the multiple CPU system can be executed, by specifying the following CPU

modules.

• Universal model QCPU (except the Q00UCPU, Q01UCPU, and Q02UCPU)

• Motion CPU (Q172DCPU(-S1), Q173DCPU(-S1), Q172DSCPU, or Q173DSCPU)

22

Page 25

CHAPTER 1 OVERVIEW

(3) Data communications among CPU modules

The following data communications can be performed among CPU modules in a multiple CPU system.

(a) Transferring data among CPU modules

Data can be transferred among CPU modules by setting auto refresh using a programming tool.

( Page 122, Section 6.1.1 to Page 135, Section 6.1.2)

(b) Reading data from other CPU modules

Each CPU module can read data from other CPU modules whenever required using the following instructions.

( Page 150, Section 6.1.3)

• Read instruction from the CPU shared memory in another CPU module

• Cyclic transmission area device (U3En\G)

(c) Directing control to the Motion CPU

The QCPU can direct control to the Motion CPU using the following instruction. ( Page 160, Section 6.2)

• Motion dedicated instruction

(d) Reading/writing device data to/from the Motion CPU

The QCPU can read/write device data to/from the Motion CPU using the following instructions.

( Page 162, Section 6.3.1)

• Multiple CPU transmission dedicated instruction

• Multiple CPU high-speed transmission dedicated instruction

1

(e) Issuing events to the C Controller module or PC CPU module

The QCPU can issue events to the C Controller module or PC CPU module using the following instruction.

( Page 164, Section 6.3.2)

• Multiple CPU transmission dedicated instruction

The Universal model QCPU (except the Q00UCPU, Q01UCPU, and Q02UCPU) can execute the motion

dedicated instruction multiple times in one scan. Since the motion dedicated instruction can be executed

consecutively to different axis numbers, delay time of servo startup intervals can be shortened.

(f) Logging communication data among CPU modules

Communication data among CPU modules can be saved to an SD memory card in CSV format by logging the

cyclic transmission area device (U3EnG) using the data logging function of the CPU module.

The high-speed Universal model QCPU supports the data logging function.

( QnUDVCPU/LCPU User's Manual (Data Logging Function))

23

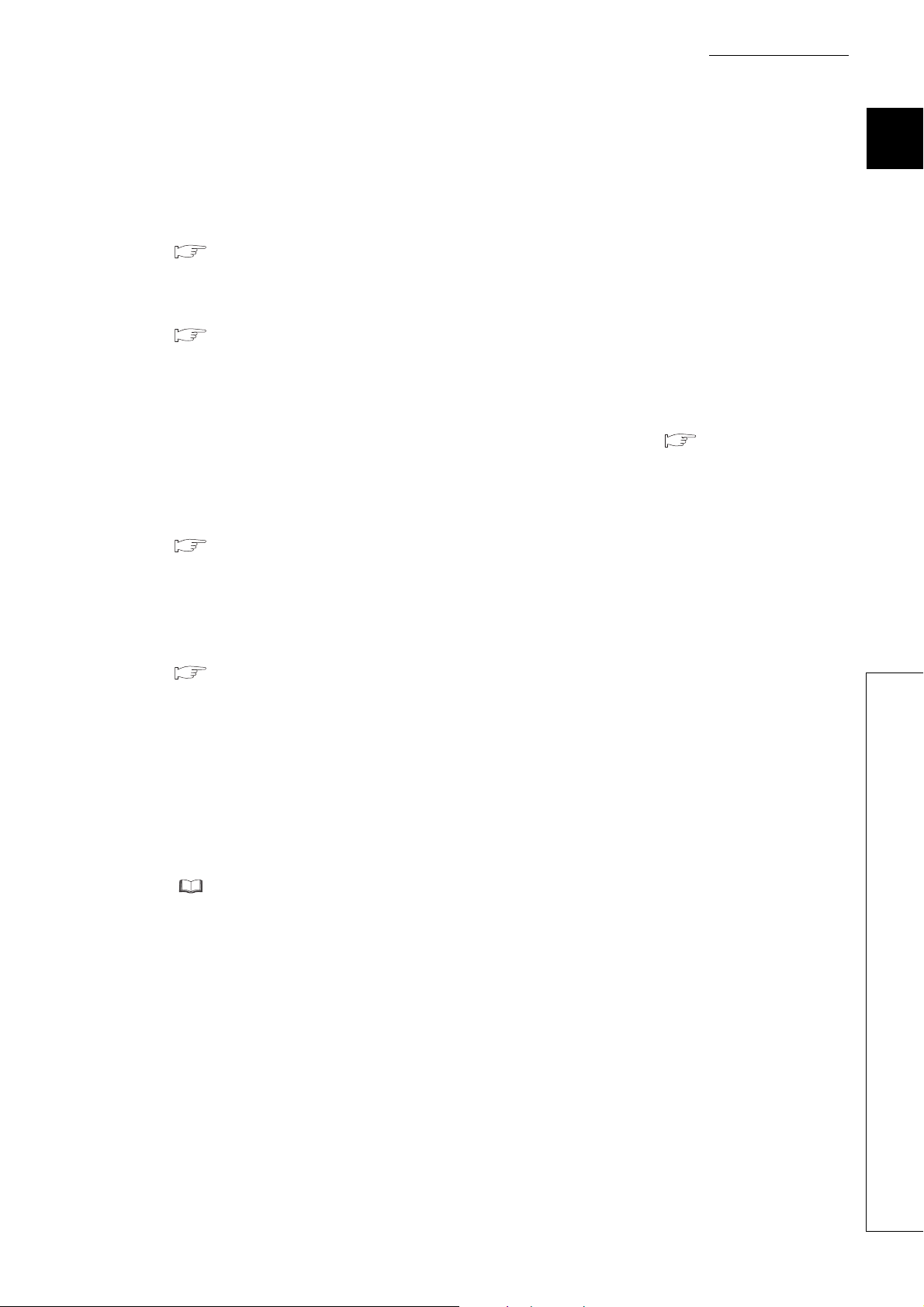

Page 26

CHAPTER 2 CONCEPT OF MULTIPLE CPU

Ex.

1

3

SYSTEM

2.1 CPU Numbers

CPU numbers are assigned to identify CPU modules contained in a multiple CPU system.

A CPU module mounted in the CPU slot of a main base unit will be CPU No.1. CPU No.2, No.3, and No.4 will be

assigned sequentially to the right of CPU No.1.

CPU slot: CPU No.1

Slot 0: CPU No.2

Slot 1: CPU No.3

Slot 2: CPU No.4

CPU 0 1 2 3 4

Slot number

2

1

4

CPU number

(1) Available CPU numbers

Available CPU numbers differ depending on the QCPU used as CPU No.1 and the main base unit used.

( Page 31, CHAPTER 3)

When a Basic model QCPU is used as CPU No.1, the total number of mountable CPU modules is three

(CPU No.1 to No.3). However, when a slim type main base unit (Q3SB) or multiple CPU high-speed

main base unit (Q3

No.1 and No.2).

DB) is used, the number of mountable CPU modules is limited to one or two (CPU

24

Page 27

(2) Uses of CPU numbers

Slot number

Control CPU setting

Controlled by CPU No.1.

Controlled by CPU No.2.

CPU01234567

11 2 1 1 1 1 222

CPU numbers are used for the following purposes.

CHAPTER 2 CONCEPT OF MULTIPLE CPU SYSTEM

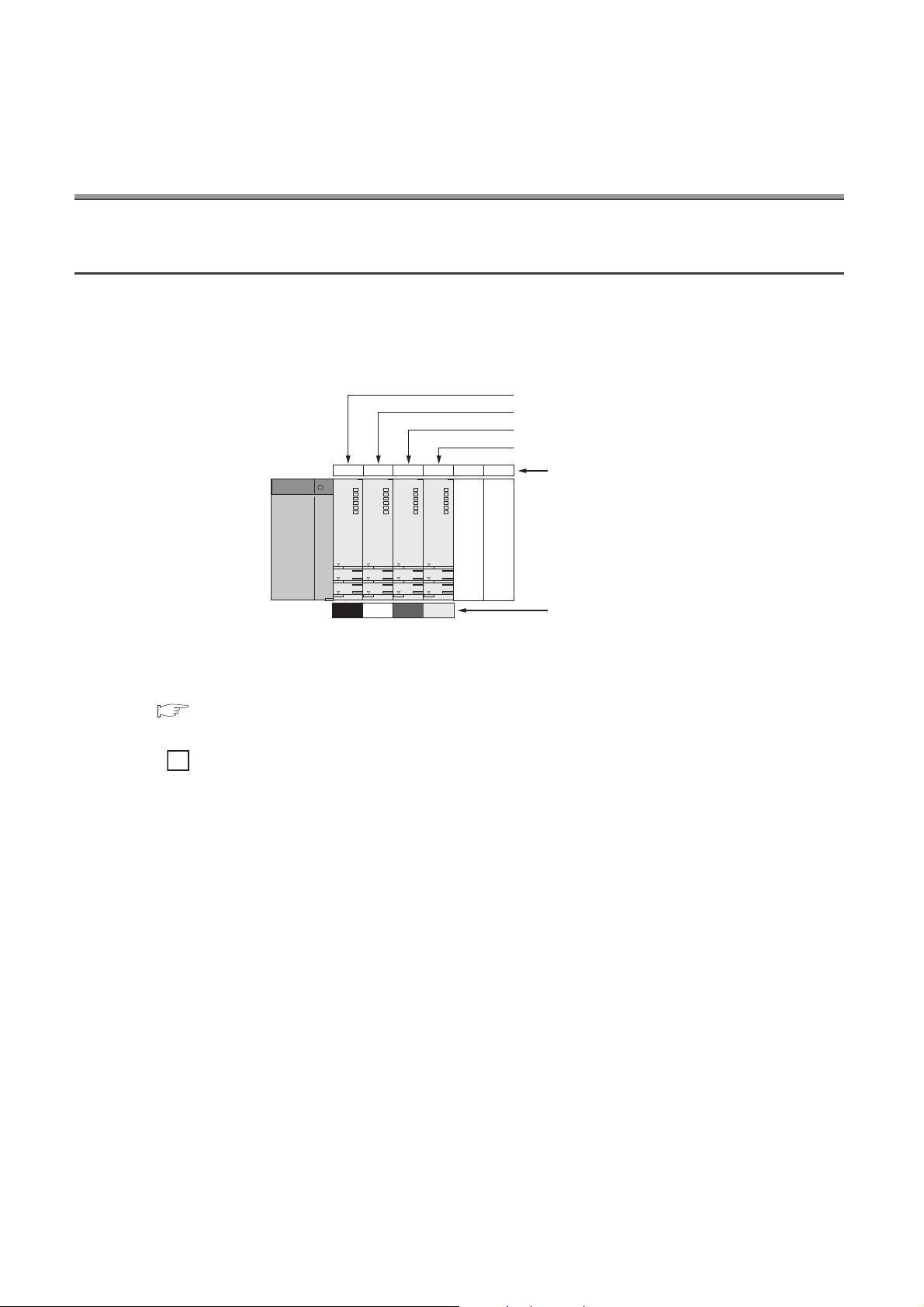

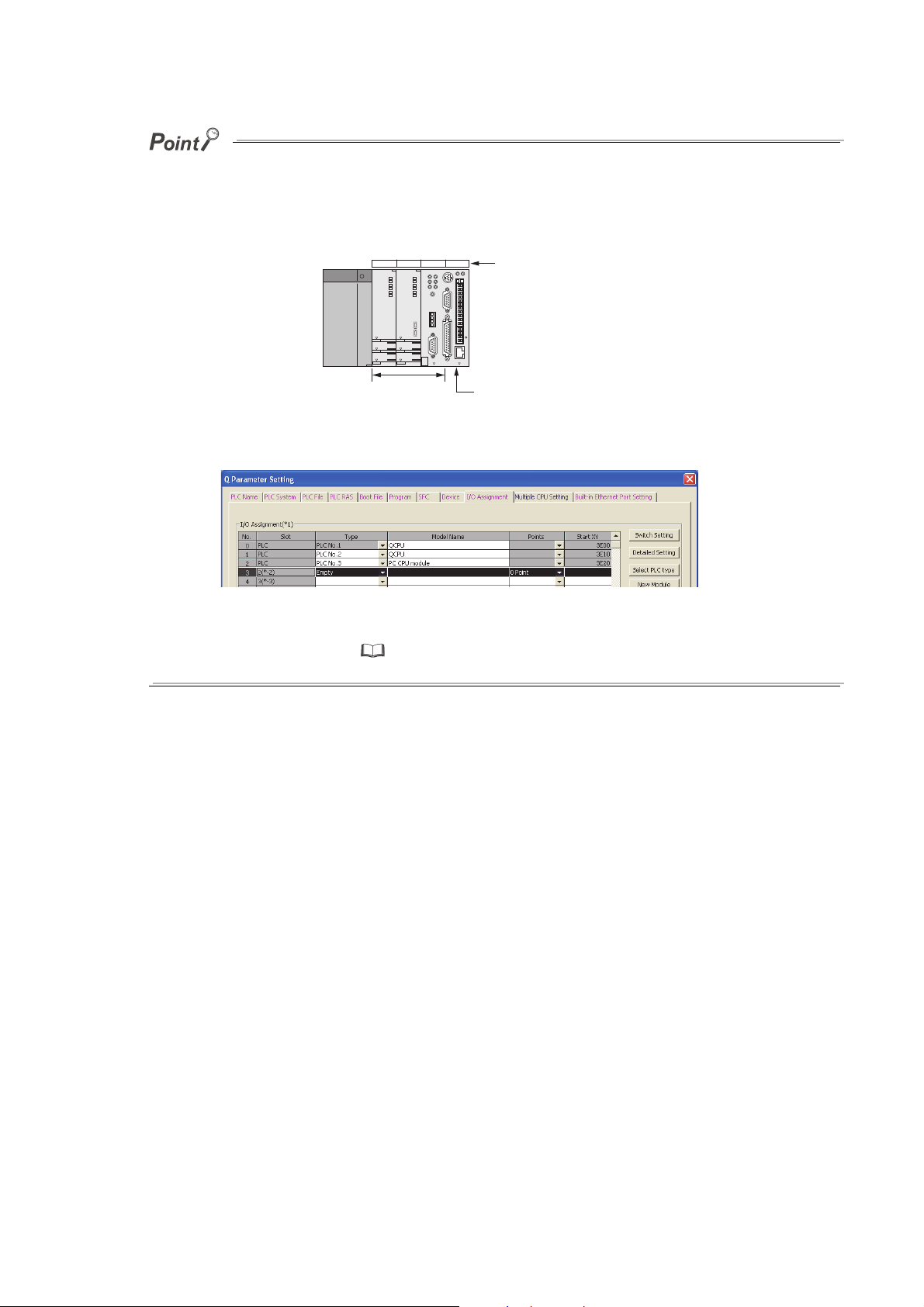

(a) Setting control CPUs

CPU numbers are used to set a control CPU for each I/O module and intelligent function module.

Set control CPUs in PLC parameter ("I/O Assignment").

Project window [Parameter] [PLC Parameter] [I/O Assignment]

Set control CPUs.

2

2.1 CPU Numbers

25

Page 28

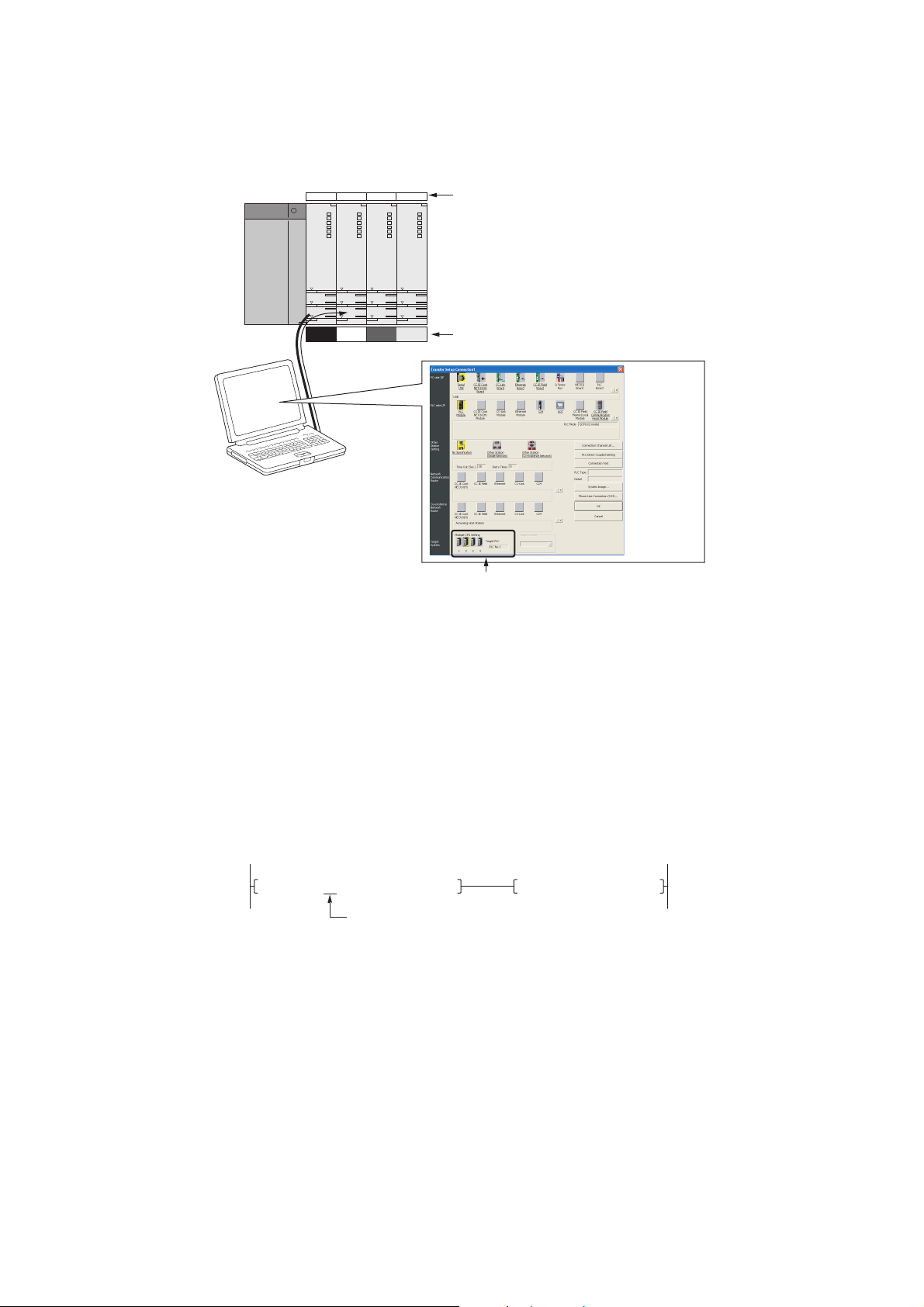

(b) Specifying a connection target using a programming tool (personal computer)

1

3

<> K1 SD395

Set the CPU number to be compared.

SET F1

CPU numbers are used to specify a CPU module to which a programming tool is connected.

CPU 0 1 2

2

A programming tool

communicates with

CPU No.2.

4

Slot number

CPU number

Specify "PLC No.2".

(3) Checking the host CPU number

The host CPU number of a QCPU is stored in SD395 (Multiple CPU system information). A host CPU number

check program (refer to an example below) should be created. If created, the following status can be checked

easily.

• Incorrect mounting status of the QCPU

• Program writing status to other CPU modules using the programming tool

In the following program, if the QCPU to which the program is written is other than CPU No.1 (if the value in

SD395 is other than "1"), the annunciator (F1) turns on. Accordingly, the USER LED of the QCPU turns on.

The corresponding annunciator number is stored in SD62 (Annunciator number).

26

Page 29

CHAPTER 2 CONCEPT OF MULTIPLE CPU SYSTEM

Ex.

2.2 I/O Number Assignment

A multiple CPU system uses the following two I/O numbers.

• I/O numbers used by CPU modules to communicate with I/O modules and intelligent function modules

( Page 27, Section 2.2.1)

• I/O numbers used by CPU modules to communicate with other CPU modules ( Page 30, Section 2.2.2)

2.2.1 I/O numbers of I/O modules and intelligent function modules

In the same way as in single CPU systems, I/O number "00H" is assigned to the I/O module or intelligent function

module mounted to the right of the CPU module. The subsequent I/O numbers are assigned sequentially to the right.

In multiple CPU systems, however, CPU modules may be mounted in slots 0 to 2 as well, and accordingly the start slot

of "00

" varies.

H

When two CPU modules are mounted

2

CPU01234567

I/O number: 00

H

Slot number

2.2 I/O Number Assignment

2.2.1 I/O numbers of I/O modules and intelligent function modules

27

Page 30

● Some CPU modules occupy two or more slots. When this type of CPU module is used, the second slot and after are

treated as empty slots.

In the case of a PC CPU module, for example, the right slot of the occupied two slots is treated as an empty slot having

16 points. (An empty slot occupies 16 points by default.)

For this reason, the start I/O number of the module mounted on the right of the PC CPU module will be "10

".

H

CPU 0 1 2

Number of

CPU modules: 3

Note that the start I/O number can be changed to "00

Slot number

Empty slot:

00

H to 0FH occupied

" by setting "0 Point" to the number of points for the right slot of the

H

PC CPU module in PLC parameter ("I/O Assignment").

● The I/O numbers of the multiple CPU system can be checked on the System monitor window using a programming tool.

● In the same way as in single CPU systems, the position of I/O number "00

" can be changed to any slot in PLC

H

parameter ("I/O Assignment"). ( User's Manual (Function Explanation, Program Fundamentals) for the CPU module

used)

28

Page 31

Ex.

Example of I/O number assignment

4th

extension

Q series power

supply module

CPU No.1

CPU No.2

CPU No.3

CPU No.4

1st

extension

2nd

extension

3rd

extension

Q312B (12 slots occupied)

Q612B (12 slots occupied)

Extension base unit .........When 32-point modules are mounted in each slot

Main base unit.........When 32-point modules are mounted in each slot

Q55B (5 slots occupied)

Q68B (8 slots occupied)

Q68B (8 slots occupied)

...... I/O number

...... Slot number

00 to 1F

20 to 3F

40 to 5F

60 to 7F

80 to 9F

A0 to BF

C0 to DF

E0 to FF

100 to 11F

120 to 13F

140 to 15F

160 to 17F

180 to 19F

1A0 to 1BF

1C0 to 1DF

1E0 to 1FF

200 to 21F

220 to 23F

240 to 25F

260 to 27F

280 to 29F

2A0 to 2BF

2C0 to 2DF

300 to 31F

320 to 33F

340 to 35F

360 to 37F

380 to 39F

3A0 to 3BF

3C0 to 3DF

3E0 to 3FF

400 to 41F

420 to 43F

4A0 to 4BF

4C0 to 4DF

4E0 to 4FF

500 to 51F

520 to 53F

440 to 45F

460 to 47F

480 to 49F

2E0 to 2FF

CPU 0 1 2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17 18 19 20 21 22 23

24 25 26 27 28

29 30 31 32 33 34 35 36

45 46 47 48 49 50 51 52

5th

extension

Q68B (8 slots occupied)

540 to 55F

560 to 57F

580 to 59F

5A0 to 5BF

5C0 to 5DF

5E0 to 5FF

600 to 61F

620 to 63F

53 54 55 56 57 58 59 60

6th

extension

Q68B (8 slots occupied)

640 to 65F

660 to 67F

680 to 69F

6A0 to 6BF

6C0 to 6DF

6E0 to 6FF

700 to 71F

720 to 73F

61 62 63

7th

extension

Q65B (5 slots occupied)

740 to 75F

760 to 77F

780 to 79F

Use prohibited

Use prohibited

37 38 39 40 41 42 43 44

If modules are

mounted, an error

occurs.

CHAPTER 2 CONCEPT OF MULTIPLE CPU SYSTEM

2

2.2 I/O Number Assignment

2.2.1 I/O numbers of I/O modules and intelligent function modules

29

Page 32

2.2.2 I/O numbers of CPU modules

In multiple CPU systems, I/O numbers are assigned to each CPU module to specify mounted CPU modules. The I/O

number for each CPU module is fixed at the corresponding slot, and cannot be changed in PLC parameter ("I/O

Assignment").

The following is the list of I/O numbers that can be assigned to CPU modules.

Item

Start I/O number

Available slots differ depending on the QCPU used as CPU No.1 and the main base unit used. ( Page 31,

CHAPTER 3)

CPU slot Slot 0 Slot 1 Slot 2

3E00

H

CPU module mounting position

3E10

H

3E20

H

(1) Uses of I/O numbers of CPU modules

The I/O numbers of CPU modules are used for the following purposes.

• Communications among CPU modules ( Page 116, CHAPTER 6)

• Specifying the communication-target CPU module under the MC protocol ( MELSEC-Q/L MELSEC

Communication Protocol Reference Manual)

3E30

H

30

Page 33

CHAPTER 3 SYSTEM CONFIGURATION

Remark

CHAPTER 3 SYSTEM CONFIGURATION

In a multiple CPU system, QCPUs, motion CPUs, C Controller modules, and PC CPU modules can be mounted in the

CPU slot to slot 2 of the main base unit.

I/O modules and intelligent function modules are mounted to the right of CPU modules.

This chapter describes the system configurations according to the QCPU used as CPU No.1.

● For a multiple CPU system using a C Controller module as CPU No.1, refer to the manual for the C Controller module

used.

● For PC CPU modules, contact CONTEC Co., Ltd.

http://www.contec.com/

3

31

Page 34

3.1 System Using Basic Model QCPU as CPU No.1

This section describes the system configuration using a Basic model QCPU as CPU No.1.

3.1.1 Available CPU modules, base units, power supply modules,

and extension cables

Available CPU modules and the number of mountable modules differ depending on the main base unit used.

(1) When a main base unit (Q3B) is used

(a) Available modules, the number of extension base units, and the number of

mountable modules

Item Description

3 CPU modules

Number of CPU

modules

Applicable CPU

*1

module

Maximum number of

extension base units

Maximum number of

mountable I/O

modules

Applicable main base

unit

Applicable extension

base unit

Applicable extension

cable

Applicable power

supply module

*1 For the CPU modules that can be combined and their mounting positions, refer to Page 37, Section 3.1.2.

*2 When using a Motion CPU, install operating system software on the CPU module. For models and versions of the

CPU No.1 (Basic model QCPU)

CPU No.2 (Motion CPU)

CPU No.3 (C Controller module or PC CPU module)

Basic model QCPU Q00CPU, Q01CPU Function version B or later

Motion CPU

C Controller module

PC CPU module

Type requiring no power supply

module (Q series)

Type requiring power supply module

(Q series)

operating system, refer to the manual for the Motion CPU used.

*2

QC05B, QC06B, QC12B, QC30B, QC50B, QC100B

Q61P-A1, Q61P-A2, Q61P, Q61P-D, Q62P, Q63P, Q64P, Q64PN

Q172CPUN(-T), Q173CPUN(-T),

Q172HCPU(-T), Q173HCPU(-T)

Q06CCPU-V, Q06CCPU-V-B,

Q12DCCPU-V, Q24DHCCPU-V,

Q24DHCCPU-LS

PPC-CPU686(MS)-64,

PPC-CPU686(MS)-128,

PPC-CPU852(MS)-512

4 extension base units

25 - (Number of CPU modules)

Q33B, Q35B, Q38B, Q312B

Q52B, Q55B

Q63B, Q65B, Q68B, Q612B

Manual for the Motion CPU

used

No function version restriction

Manual for the PC CPU

module used

32

Page 35

CHAPTER 3 SYSTEM CONFIGURATION

(b) Precautions

• If I/O modules are mounted exceeding the maximum number, "SP.UNIT LAY ERR" (error code: 2124)

occurs.

• "Number of CPU modules" indicates the number set in "No. of PLC" of PLC parameter ("Multiple CPU

Setting").

• When a C Controller module which occupies three slots is used, the maximum number of mountable I/O

modules will be two smaller than the number defined in the table on Page 32, Section 3.1.1 (1) (a).

• A PC CPU module occupies two slots. When this module is used, the maximum number of mountable I/O

modules will be one smaller than the number defined in the table on Page 32, Section 3.1.1 (1) (a).

3

3.1 System Using Basic Model QCPU as CPU No.1

3.1.1 Available CPU modules, base units, power supply modules, and extension cables

33

Page 36

(2) When a redundant power main base unit (Q3RB) is used

(a) Available modules, the number of extension base units, and the number of

mountable modules

Item Description

Number of CPU

modules

Applicable CPU

*1

module

Maximum number of

extension base units

Maximum number of

mountable I/O

modules

Applicable main base

unit

Applicable extension

base unit

Applicable extension

cable

Applicable power

supply module

CPU No.1 (Basic model QCPU)

CPU No.2 (C Controller module)

Basic model QCPU Q00CPU, Q01CPU Function version B or later

C Controller module

Type requiring no power supply

module (Q series)

Redundant power extension base unit Q68RB

QC05B, QC06B, QC12B, QC30B, QC50B, QC100B

(The Q63RP and Q64RP can be mounted on the same redundant power supply base unit.)

2 CPU modules

Q24DHCCPU-V,

Q24DHCCPU-LS

4 extension base units

25 - (Number of CPU modules)

Q38RB

Q52B, Q55B

Q63RP, Q64RP

No function version restriction

(b) Precautions

• If I/O modules are mounted exceeding the maximum number, "SP.UNIT LAY ERR" (error code: 2124)

occurs.

• "Number of CPU modules" indicates the number set in "No. of PLC" of PLC parameter ("Multiple CPU

Setting").

• When a C Controller module which occupies three slots is used, the maximum number of mountable I/O

modules will be two smaller than the number defined in the table on Page 34, Section 3.1.1 (2) (a).

34

Page 37

(3) When a slim type main base unit (Q3SB) is used

(a) Available modules, the number of extension base units, and the number of

mountable modules

Item Description

Number of CPU

modules

Applicable CPU

*1

module

Maximum number of

extension base units

Maximum number of

mountable I/O

modules

Applicable main base

unit

Applicable power

supply module

CPU No.1 (Basic model QCPU)

CPU No.2 (C Controller module)

Basic model QCPU Q00CPU, Q01CPU Function version B or later

C Controller module

Q32SB 1

Q33SB 2

Q35SB 4

Q06CCPU-V, Q06CCPU-V-B,

Q12DCCPU-V

2 CPU modules

Extension not allowed

Q32SB, Q33SB, Q35SB

CHAPTER 3 SYSTEM CONFIGURATION

3

No function version restriction

Q61SP

(b) Precautions

Slim type main base units do not have an extension cable connector. Therefore, no extension base unit or GOT

can be bus-connected.

3.1 System Using Basic Model QCPU as CPU No.1

3.1.1 Available CPU modules, base units, power supply modules, and extension cables

35

Page 38

(4) When a multiple CPU high speed main base unit (Q3DB) is used

(a) Available modules, the number of extension base units, and the number of

mountable modules

Item Description

Number of CPU

modules

Applicable CPU

*1

module

Maximum number of

extension base units

Maximum number of

mountable I/O

modules

Applicable main base

unit

Applicable extension

base unit

Applicable extension

cable

Applicable power

supply module

*1 For the CPU modules that can be combined and their mounting positions, refer to Page 37, Section 3.1.2.

CPU No.1 (Basic model QCPU)

CPU No.2 (C Controller module or PC CPU module)

Basic model QCPU Q00CPU, Q01CPU Function version B or later

Q06CCPU-V, Q06CCPU-V-B,

C Controller module

PC CPU module

Type requiring no power supply

module (Q series)

Type requiring power supply module

(Q series)

QC05B, QC06B, QC12B, QC30B, QC50B, QC100B

Q61P-A1, Q61P-A2, Q61P, Q61P-D, Q62P, Q63P, Q64P, Q64PN

Q12DCCPU-V, Q24DHCCPU-V,

Q24DHCCPU-LS

PPC-CPU686(MS)-64,

PPC-CPU686(MS)-128,

PPC-CPU852(MS)-512

Q52B, Q55B

Q63B, Q65B, Q68B, Q612B

2 CPU modules

4 extension base units

25 - (Number of CPU modules)

Q35DB, Q38DB, Q312DB

No function version restriction

Manual for the PC CPU

module used

36

(b) Precautions

• If I/O modules are mounted exceeding the maximum number, "SP.UNIT LAY ERR" (error code: 2124)

occurs.

• "Number of CPU modules" indicates the number set in "No. of PLC" of PLC parameter ("Multiple CPU

Setting").

• When a C Controller module which occupies three slots is used, the maximum number of mountable I/O

modules will be two smaller than the number defined in the table on Page 36, Section 3.1.1 (4) (a).

• A PC CPU module occupies two slots. When this module is used, the maximum number of mountable I/O

modules will be one smaller than the number defined in the table on Page 36, Section 3.1.1 (4) (a).

Page 39

CHAPTER 3 SYSTEM CONFIGURATION

B

B : Basic model QCPU

: Motion CPU

: C Controller module

: PC CPU module

CPU No.1 CPU No.2 CPU No.3

P

P

P

C

C

C

M

M

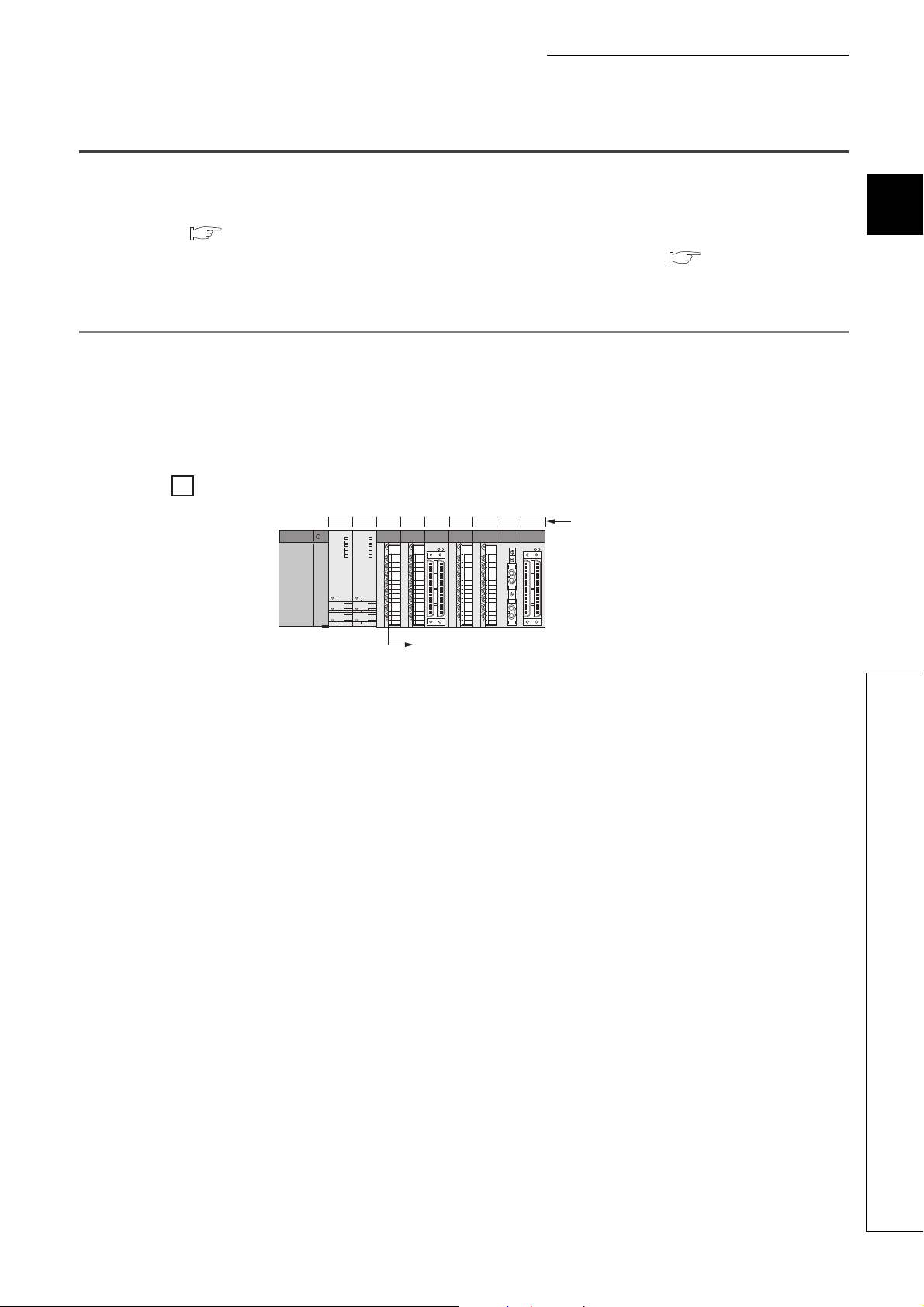

3.1.2 CPU module combinations and mounting positions

This section describes the combinations and mounting positions of CPU modules when a Basic model QCPU is used

as CPU No.1.

Note that the CPU modules that can be mounted differ depending on the main base unit used. ( Page 32, Section

3.1.1)

(1) Combinations

3

High

Performance

CPU No.1

Basic model

QCPU

model QCPU,

Process CPU,

Universal

model QCPU

Cannot be used

together.

*1 A C Controller module and a PC CPU module cannot be mounted on the same main base unit.

*2 A C Controller module (Q12DCCPU-V, Q24DHCCPU-V, or Q24DHCCPU-LS) and a Motion CPU (Q172CPUN(-T),

Q173CPUN(-T), Q172HCPU(-T), or Q173HCPU(-T)) cannot be mounted on the same main base unit.

(2) Mounting positions

The following shows the possible combinations of mounting positions of CPU modules in a multiple CPU system.

Number of CPU modules that can be mounted as CPU No.2 or others

Motion CPU

Q172CPUN(-T),

Q173CPUN(-T),

Q172HCPU(-T),

Q173HCPU(-T)

0 to 1

Q172DCPU(-S1),

Q173DCPU(-S1),

Q172DSCPU,

*2

Q173DSCPU

Cannot be used

together.

C Controller module

Q06CCPU-V,

Q06CCPU-V-B,

Q12DCCPU-V,

Q24DHCCPU-V

0 to 1 0 to 1 3

*1*2

PC CPU module

PPC-CPU686(MS)-64,

PPC-CPU686(MS)-128,

PPC-CPU852(MS)-512

*1

Maximum

number of

mountable

modules

(including

CPU No.1)

3.1 System Using Basic Model QCPU as CPU No.1

3.1.2 CPU module combinations and mounting positions

(a) Basic model QCPU

Only one Basic model QCPU can be mounted in the CPU slot (the slot on the right of the power supply module)

of the main base unit.

(b) Motion CPU

Only one Motion CPU can be mounted in slot 0 on the right of the Basic model QCPU. It cannot be mounted in

a slot other than slot 0.

37

Page 40

(c) C Controller module or PC CPU module

Ex.

Ex.

Ex.

CPU 0 1 2

Slot number

Power supply

module

Basic model

QCPU

PC CPU

module

Motion CPU

CPU 0 1 2 CPU 0 1 2

Added Motion CPU

Slot number Slot number

Power supply

module

Basic model

QCPU

PLC (Empty)

Power supply

module

Basic model

QCPU

Motion CPU

CPU 0 1 2 CPU 0 1 2

Added PC CPU module

Slot number Slot number

Power supply

module

Basic model

QCPU

Motion CPU

PLC (Empty)

Power supply

module

Basic model

QCPU

Motion CPU

PC CPU

module

CPU 0 1 2 CPU 0 1 2

Added Motion CPU

Slot number Slot number

Power supply

module

Basic model

QCPU

PLC (Empty)

PC CPU

module

Power supply

module

Basic model

QCPU

Motion CPU

PC CPU

module

Either a C Controller module or PC CPU module can be mounted on the extreme right of the other CPU

module(s). No CPU module can be mounted on the right of the C Controller module or PC CPU module.

(d) Empty slot setting

Empty slots can be reserved for future addition of CPU modules. Set the number of CPU modules including

empty slots in "No. of PLC" of PLC parameter ("Multiple CPU Setting"). Then, set "PLC (Empty)" to the type of

a target slot in PLC parameter ("I/O Assignment").

Adding a Motion CPU in slot 0 in the future

Adding a PC CPU module in slot 1 in the future

Setting "PLC (Empty)" between CPU modules

38

Page 41

CHAPTER 3 SYSTEM CONFIGURATION

● When a Basic model QCPU is used, "PLC (Empty)" can be set between CPU modules. This is useful when adding a

Motion CPU to the system where a Basic model QCPU and a C Controller module or PC CPU module are used. No

program modification is required because the CPU number of the C Controller module or PC CPU module does not need

to be changed even after the new module is added.

● For a CPU module that occupies two slots or more, secure as many empty slots as needed for the module.

3

3.1 System Using Basic Model QCPU as CPU No.1

3.1.2 CPU module combinations and mounting positions

39

Page 42

3.1.3 Available I/O modules and intelligent function modules

Remark

This section describes I/O modules and intelligent function modules that can be used.

(1) I/O modules and interrupt module

I/O modules (QX and QY) and interrupt module (QI60) can be used. Any CPU module can be set as a control

CPU.

(2) Intelligent function modules

Intelligent function modules with function version B or later can be used. Any CPU module can be set as a control

CPU.

Write parameters of each intelligent function module to the CPU module to be controlled.

The following modules can be used even if their function version is not B or later.

Module that can be used

even if its function version is not B or later

High-speed counter module (QD62, QD62D, QD62E)

Intelligent function modules with function version A (except high-speed counter modules (QD62, QD62D, and QD62E)) can

be used in the multiple CPU system only when CPU No.1 is set as a control CPU.

• External devices can access only the control CPU (CPU No.1) via a serial communication module.

• External devices cannot access CPU modules other than the control CPU (CPU No.1) via a MELSECNET/H

module or serial communication module.

• If any of CPU No.2 to No.4 is set as a control CPU, "SP.UNIT VER.ERR" (error code: 2150) will occur and the

multiple CPU system will not start up.

Modules with function version A can be used.

Any CPU module can be set as a control CPU.

Description

(3) Number of mountable modules

Refer to Page 68, Section 3.5.

(4) Access ranges of controlled and non-controlled modules

Each CPU module can access non-controlled modules by setting "I/O Sharing When Using Multiple CPUs" in

PLC parameter ("Multiple CPU Setting"). ( Page 104, Section 5.2)

40

If all of the following conditions are met, use a MELSECNET/H module with a serial number (first five digits) of "10042" or

later.

• A multiple CPU system containing a Built-in Ethernet port QCPU is configured.

• A programming tool or GOT is connected to an Ethernet port of the Built-in Ethernet port QCPU.

• A programming tool or GOT accesses another station via a MELSECNET/H module controlled by a CPU module

other than the control CPU.

• The access target on another station is an A/QnA series CPU module.

Page 43

CHAPTER 3 SYSTEM CONFIGURATION

3.2 System Using High Performance Model QCPU or

Process CPU as CPU No.1

This section describes the system configuration using a High Performance model QCPU or Process CPU as CPU

No.1.

3.2.1 Available CPU modules, base units, power supply modules,

and extension cables

Available CPU modules and the number of mountable modules differ depending on the main base unit used.

(1) When a main base unit (Q3B) is used

(a) Available modules, the number of extension bases units, and the number of

mountable modules

3

Item Description

Number of CPU

modules

Applicable CPU

*1

module

Applicable CPU

*1

module

Maximum number of

extension base units

High Performance model QCPU

Process CPU

Universal model QCPU

Motion CPU

C Controller module

PC CPU module

*2

4 CPU modules

• Function version B

Q02(H)CPU, Q06HCPU, Q12HCPU,

Q25HCPU

Q02PHCPU, Q06PHCPU, Q12PHCPU,

Q25PHCPU

Q03UD(E)CPU, Q03UDVCPU,

Q04UD(E)HCPU, Q04UDVCPU,

Q06UD(E)HCPU, Q06UDVCPU,

Q10UD(E)HCPU, Q13UD(E)HCPU,

Q13UDVCPU, Q20UD(E)HCPU,

Q26UD(E)HCPU, Q26UDVCPU,

Q50UDEHCPU, Q100UDEHCPU

Q172CPUN

Q172HCPU

Q06CCPU-V, Q06CCPU-V-B

Q12DCCPU-V

Q24DHCCPU-V

Q24DHCCPU-LS No function version restriction

PPC-CPU686(MS)-64,

PPC-CPU686(MS)-128,

PPC-CPU852(MS)-512

(-T)

, Q173CPUN

(-T)

, Q173HCPU

7 extension base units

(-T)

(-T)

,

• Function version B with a serial number

(first five digits) of "03051" or later when

used as CPU No.1 and with a PC CPU

module

No function version restriction

No function version restriction

Manual for the Motion CPU used

• Serial number (first five digits) of "10012"