Page 1

<ORIGINAL>

Hot Water Heat Pump Unit QAHV

Installation/Operation Manual

QAHV-N560YA-HPB

CONTENTS

Safety Precautions ................................................................2

1. Selecting the Installation Site ............................................6

[1] Installation Conditions...................................................6

[2] Installation Space Requirements ..................................7

[3] System installation restrictions......................................9

2. Unit Installation ................................................................10

3. Water Pipe Installation.....................................................11

[1] Schematic Piping Diagram and Piping System

Components ...............................................................11

[2] Notes on Pipe Corrosion............................................. 13

[3] Water Pipe Hole Size and Location ............................ 14

[4] Pipe gradient and air venting valve (Outlet hot water

pipe)............................................................................14

[5] Outlet check valve (When installing multiple units)..... 14

[6] Secondary side control system...................................15

4. System Configurations ....................................................22

[1] Schematic Diagrams of Individual and Multiple

Systems ......................................................................22

[2] Switch Types and the Factory Settings.......................23

[3] Configuring the Settings..............................................25

[4] Air bleeding operation and flow rate adjustment

operation during test run.............................................33

5. Electrical Wiring Installation.............................................51

[1] Main Power Supply Wiring and Switch Capacity ........ 51

[2] Wiring for Configuring Secondary Side Control

System........................................................................53

[3] Cable Connections......................................................54

6. Troubleshooting...............................................................60

[1] Diagnosing Problems for which No Error Codes Are

Available .....................................................................60

[2] Diagnosing Problems Using Error Codes ................... 61

[3] Calling for Service.......................................................66

7. Operating the Unit ...........................................................67

[1] Initial Operation...........................................................67

[2] Daily Operation ........................................................... 67

[3] Using the Remote Controller.......................................68

[4] Using the Unit in Sub-freezing or Snowy Conditions .. 79

8. Main Specifications..........................................................80

Thoroughly read this manual prior to use.

Save this manual for future reference.

Some of the items in this manual may not apply to made-to-order units.

Make sure that this manual is passed on to the end users.

Page 2

Safety Precautions

All electric work must be performed by personnel certified by Mitsubishi Electric.

• Thoroughly read the following safety precautions prior to use.

• Observe these precautions carefully to ensure safety.

WARNING

CAUTION

IMPORTANT

Indicates a risk of death or serious injury

Indicates a risk of injury or structural damage

Indicates a risk of damage to the unit or other components in the system

General

WARNING

Do not use refrigerant other than the type indicated in

the manuals provided with the unit and on the

nameplate.

• Doing so may cause the unit or pipes to burst, or result in

explosion or fire during use, during repair, or at the time of

disposal of the unit.

• It may also be in violation of applicable laws.

• MITSUBISHI ELECTRIC CORPORATION cannot be held

responsible for malfunctions or accidents resulting from the

use of the wrong type of refrigerant.

Do not install the unit in a place where large amounts of

oil, steam, organic solvents, or corrosive gases, such as

sulfuric gas, are present or where acidic/alkaline

solutions or sprays containing sulfur are used

frequently.

These substances can compromise the performance of the

unit or cause certain components of the unit to corrode, which

can result in refrigerant leakage, water leakage, injury,

electric shock, malfunctions, smoke, or fire.

Do not try to defeat the safety features of the unit or

make unauthorized setting changes.

Forcing the unit to operate the unit by defeating the safety

features of the devices such as the pressure switch or the

temperature switch, making unauthorized changes to the

switch settings, or using accessories other than the ones

recommended by Mitsubishi Electric may result in smoke,

fire, or explosion.

To reduce the risk of fire or explosion, do not use volatile or

flammable substances as a heat carrier.

To reduce the risk of burns or electric shock, do not touch

exposed pipes and wires.

To reduce the risk of shorting, current leakage, electric shock,

malfunctions, smoke, or fire, do not splash water on electric

parts.

To reduce the risk of electric shock, malfunctions, smoke or

fire, do not operate the switches/buttons or touch other

electrical parts with wet hands.

To reduce the risk of electric shock and injury from the fan or

other rotating parts, stop the operation and turn off the main

power before cleaning, maintaining, or inspecting the unit.

To reduce the risk of burns or frost bites, do not touch the

refrigerant pipes or refrigerant circuit components with bare

hands during and immediately after operation.

Before cleaning the unit, switch off the power.

(Unplug the unit, if it is plugged in.)

To reduce the risk of injury, keep children away while

installing, inspecting, or repairing the unit.

Children should be supervised to ensure that they do not play

with the appliance.

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Keep the space well ventilated. Refrigerant can displace

air and cause oxygen starvation.

If leaked refrigerant comes in contact with a heat source,

toxic gas may be generated.

Always replace a fuse with one with the correct current

rating.

The use of improperly rated fuses or a substitution of fuses

with steel or copper wire may result in fire or explosion.

If any abnormality (e.g., burning smell) is noticed, stop

the operation, turn off the power switch, and consult

your dealer.

Continuing the operation may result in electric shock,

malfunctions, or fire.

Properly install all required covers and panels on the

terminal box and control box to keep moisture and dust

out.

Dust accumulation and water may result in electric shock,

smoke, or fire.

Consult an authorized agency for the proper disposal of

the unit

Refrigerant oil and refrigerant that may be left in the unit pose

a risk of fire, explosion, or environmental pollution.

CAUTION

To reduce the risk of fire or explosion, do not place flammable

materials or use flammable sprays around the unit.

Do not operate the unit without panels and safety guards

properly installed.

2

Page 3

To reduce the risk of injury, do not sit, stand, or place objects

on the unit.

Do not connect the makeup water pipe directly to the

potable water pipe. Use a cistern tank between them.

Connecting these pipes directly may cause the water in the

unit to migrate into the potable water and cause health

problems.

To reduce the risk of adverse effects on plants and animals,

do not place them where they are directly exposed to

discharge air from the unit.

Do not install the unit on or over things that are

vulnerable to water damage.

Condensation may drip from the unit.

The model of heat pump unit described in this manual is not

intended for use to preserve food, animals, plants, precision

instruments, or art work.

To reduce the risk of injury, do not touch the heat exchanger

fins or sharp edges of components with bare hands.

Do not place a container filled with water on the unit.

If water spills on the unit, it may result in shorting, current

leakage, electric shock, malfunction, smoke, or fire.

Always wear protective gears when touching electrical

components on the unit.

Several minutes after the power is switched off, residual

voltage may still cause electric shock.

To reduce the risk of injury, do not insert fingers or foreign

objects into air inlet/outlet grills.

To reduce the risk of injury, wear protective gear when

working on the unit.

Do not release refrigerant into the atmosphere. Collect

and reuse the refrigerant, or have it properly disposed of

by an authorized agency.

Refrigerant poses environmental hazards if released into the

air.

To prevent environmental pollution, dispose of brine in

the unit and cleaning solutions according to the local

regulations.

It is punishable by law not to dispose of them according to the

applicable laws.

The water heated by the heat pump is not suitable for

use as drinking water or for cooking.

It may cause health problems or degrade food.

In areas where temperature drops to freezing during the

periods of non-use, blow the water out of the pipes or fill

the pipes with anti-freeze solution.

Not doing so may cause the water to freeze, resulting in burst

pipes and damage to the unit or the furnishings.

In areas where temperature drops to freezing, use an antifreeze circuit and leave the main power turned on to prevent

the water in the water circuit from freezing and damaging the

unit or causing water leakage and resultant damage to the

furnishings.

Use clean tap water.

The use of acidic or alkaline water or water high in chlorine

may corrode the unit or the pipes, causing water leakage and

resultant damage to the furnishings.

In areas where temperature can drop low enough to

cause the water in the pipes to freeze, operate the unit

often enough to prevent the water from freezing.

Frozen water in the water circuit may cause the water to

freeze, resulting in burst pipes and damage to the unit or the

furnishings.

Periodically inspect and clean the water circuit.

Dirty water circuit may compromise the unit’s performance or

corrodes the unit or cause water leakage and resultant

damage to the furnishings.

Transportation

WARNING

Lift the unit by placing the slings at designated

locations. Support the outdoor unit securely at four

points to keep it from slipping and sliding.

If the unit is not properly supported, it may fall and cause

personal injury.

CAUTION

To reduce the risk of injury, do not carry the product by the PP

bands that are used on some packages.

Installation

WARNING

Do not install the unit where there is a risk of leaking

flammable gas.

If flammable gas accumulates around the unit, it may ignite

and cause a fire or explosion.

To reduce the risk of injury, products weighing 20 kg or more

should be carried by two or more people.

Properly dispose of the packing materials.

Plastic bags pose suffocation hazard to children.

3

Page 4

The unit should be installed only by personnel certified

by Mitsubishi Electric according to the instructions

detailed in the Installation/Operation Manual.

Improper installation may result in refrigerant leakage, water

leakage, injury, electric shock, or fire.

Any additional parts must be installed by qualified personnel.

Only use the parts specified by Mitsubishi Electric.

Take appropriate safety measures against wind gusts and

earthquakes to prevent the unit from toppling over and

causing injury.

Periodically check the installation base for damage.

If the unit is left on a damaged base, it may fall and cause

injury.

Remove packing materials from the unit before operating

the unit. Note that some accessories may be taped to the

unit. Properly install all accessories that are required.

Failing to remove the packing materials or failing to install

required accessories may result in refrigerant leakage,

oxygen starvation, smoke, or fire.

Consult your dealer and take appropriate measures to

safeguard against refrigerant leakage and resultant oxygen

starvation. An installation of a refrigerant gas detector is

recommended.

CAUTION

Do not install the unit on or over things that are

vulnerable to water damage.

When the indoor humidity exceeds 80% or if the drain water

outlet becomes clogged, condensation may drip from the

indoor unit onto the ceiling or floor.

Pipe installation

WARNING

To prevent explosion, do not heat the unit with refrigerant gas

in the refrigerant circuit.

Be sure to install the unit horizontally, using a level.

If the unit is installed at an angle, it may fall and cause injury

or cause water leakage.

The unit should be installed on a surface that is strong

enough to support its weight.

As an anti-freeze, use ethylene glycol or propylene

glycol diluted to the specified concentration.

The use of other types of anti-freeze solution may cause

corrosion and resultant water leakage. The use of flammable

anti-freeze may cause fire or explosion.

All drainage work should be performed by the dealer or

qualified personnel according to the instructions

detailed in the Installation Manual.

Improper drainage work may cause rain water or drain water

to enter the buildings and damage the furnishings.

Check for refrigerant leakage at the completion of

installation.

If leaked refrigerant comes in contact with a heat source,

toxic gas may be generated.

CAUTION

Check that no substance other than the specified

refrigerant (R744) is present in the refrigerant circuit.

Infiltration of other substances may cause the pressure to

rise abnormally high and cause the pipes to explode.

To keep the ceiling and floor from getting wet due to

condensation, properly insulate the pipes.

Electrical wiring

To reduce the risk of wire breakage, overheating, smoke, and

fire, keep undue force from being applied to the wires.

Properly secure the cables in place and provide

adequate slack in the cables so as not to stress the

terminals.

Improperly connected cables may break, overheat, and

cause smoke or fire.

To reduce the risk of injury or electric shock, switch off the

main power before performing electrical work.

Piping work should be performed by the dealer or

qualified personnel according to the instructions

detailed in the Installation Manual.

Improper piping work may cause water leakage and damage

the furnishings.

All electric work must be performed by a qualified

electrician according to the local regulations, standards,

and the instructions detailed in the Installation Manual.

Capacity shortage to the power supply circuit or improper

installation may result in malfunction, electric shock, smoke,

or fire.

To reduce the risk of electric shock, smoke, or fire, install an

inverter circuit breaker on the power supply to each unit.

Use properly rated breakers and fuses (inverter breaker,

Local Switch <Switch + Type-B fuse>, or no-fuse

breaker).

The use of improperly rated breakers may result in

malfunctions or fire.

4

Page 5

To reduce the risk of current leakage, overheating, smoke, or

fire, use properly rated cables with adequate current carrying

capacity.

Keep the unsheathed part of cables inside the terminal

block.

If unsheathed part of the cables come in contact with each

other, electric shock, smoke, or fire may result.

CAUTION

To reduce the risk of current leakage, wire breakage, smoke,

or fire, keep the wiring out of contact with the refrigerant

pipes and other parts, especially sharp edges.

Transportation and repairs

WARNING

Proper grounding must be provided by a licensed

electrician. Do not connect the grounding wire to a gas

pipe, water pipe, lightning rod, or telephone wire.

Improper grounding may result in electric shock, smoke, fire,

or malfunction due to electrical noise interference.

To reduce the risk of electric shock, shorting, or malfunctions,

keep wire pieces and sheath shavings out of the terminal

block.

The unit should be moved, disassembled, or repaired

only by qualified personnel. Do not alter or modify the

unit.

Improper repair or unauthorized modifications may result in

refrigerant leakage, water leakage, injury, electric shock, or

fire.

CAUTION

To reduce the risk of shorting, electric shock, fire, or

malfunction, do not touch the circuit board with tools or with

your hands, and do not allow dust to accumulate on the

circuit board.

IMPORTANT

To avoid damage to the unit, use appropriate tools to install,

inspect, or repair the unit.

To reduce the risk or malfunction, turn on the power at least

12 hours before starting operation, and leave the power

turned on throughout the operating season.

Recover all refrigerant from the unit.

It is punishable by law to release refrigerant into the

atmosphere.

Do not unnecessarily change the switch settings or

touch other parts in the refrigerant circuit.

Doing so may change the operation mode or damage the

unit.

To reduce the risk of malfunctions, use the unit within its

operating range.

Do not switch on or off the main power in a cycle of

shorter than 10 minutes.

Short-cycling the compressor may damage the compressor.

To maintain optimum performance and reduce the risk of

malfunction, keep the air pathway clear.

After disassembling the unit or making repairs, replace

all components as they were.

Failing to replace all components may result in injury, electric

shock, or fire.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons

in order to avoid a hazard.

To ensure proper operation of the unit, periodically

check for proper concentration of anti-freeze.

Inadequate concentration of anti-freeze may compromise the

performance of the unit or cause the unit to abnormally stop.

Take appropriate measures against electrical noise

interference when installing the air conditioners in

hospitals or facilities with radio communication

capabilities.

Inverter, high-frequency medical, or wireless communication

equipment as well as power generators may cause the air

conditioning system to malfunction. Air conditioning system

may also adversely affect the operation of these types of

equipment by creating electrical noise.

Check the water system, using a relevant manual as a

reference.

Using the system that does not meet the standards (including

water quality and water flow rate) may cause the water pipes

to corrode.

To reduce the risk of power capacity shortage, always use a

dedicated power supply circuit.

This appliance is intended to be used by expert or trained

users in shops, in light industry and on farms, or for

commercial use by lay persons.

5

Page 6

1. Selecting the Installation Site

Wind

Wind

Wind

• Install the outdoor unit in a place

where it is not exposed to direct wind,

such as behind a building.

• Install the outdoor

unit so that the outlet/

inlet faces away from

the wind.

[1] Installation Conditions

Select the installation site in consultation with the client.

Select a site to install the outdoor unit that meets the following conditions:

• This unit is for outdoor installation only.

• The unit will not be subject to heat from other heat sources.

• The noise from the unit will not be a problem.

• The unit will not be exposed to strong winds.

• Water from the unit can be drained properly.

• The space requirements (specified on pages 7 through 9) are met.

<1> Providing protection against winds

Using the figures at right as a reference,

provide adequate protection against

winds.

A unit installed alone is vulnerable to

strong winds. Select the installation site

carefully to minimize the effect of winds.

When installing a unit in a place where

the wind always blows from the same

direction, install the unit so that the outlet

faces away from the direction of the

wind.

<2> Cold Climate Installation

Observe the following when installing the units in areas where snow or strong winds prevail.

• Avoid direct exposure to rain, winds, and snow.

• Icicles that may form under the foundation can fall and inflict personal injury or property damage. Select the

installation site carefully to reduce these risks, especially when installing the unit on a roof.

• If the units are installed in the direct line of rain, winds, or snow, install the optional snow hood (on both the

discharge and suction ducts). Use a snow net or snow fence as necessary to protect the unit.

• Install the unit on a base approximately twice as high as the expected snowfall.

• If the unit is continuously operated for a long time with the outside air temperature below the freezing point, install

a heater at the base of the unit to prevent the water from freezing at the unit bottom.

• When using the unit in an outdoor temperature of -15

capacity is 320 W or more) at the bottom surface of the unit.

ºC or below, install a drain pan (with heater whose

6

Page 7

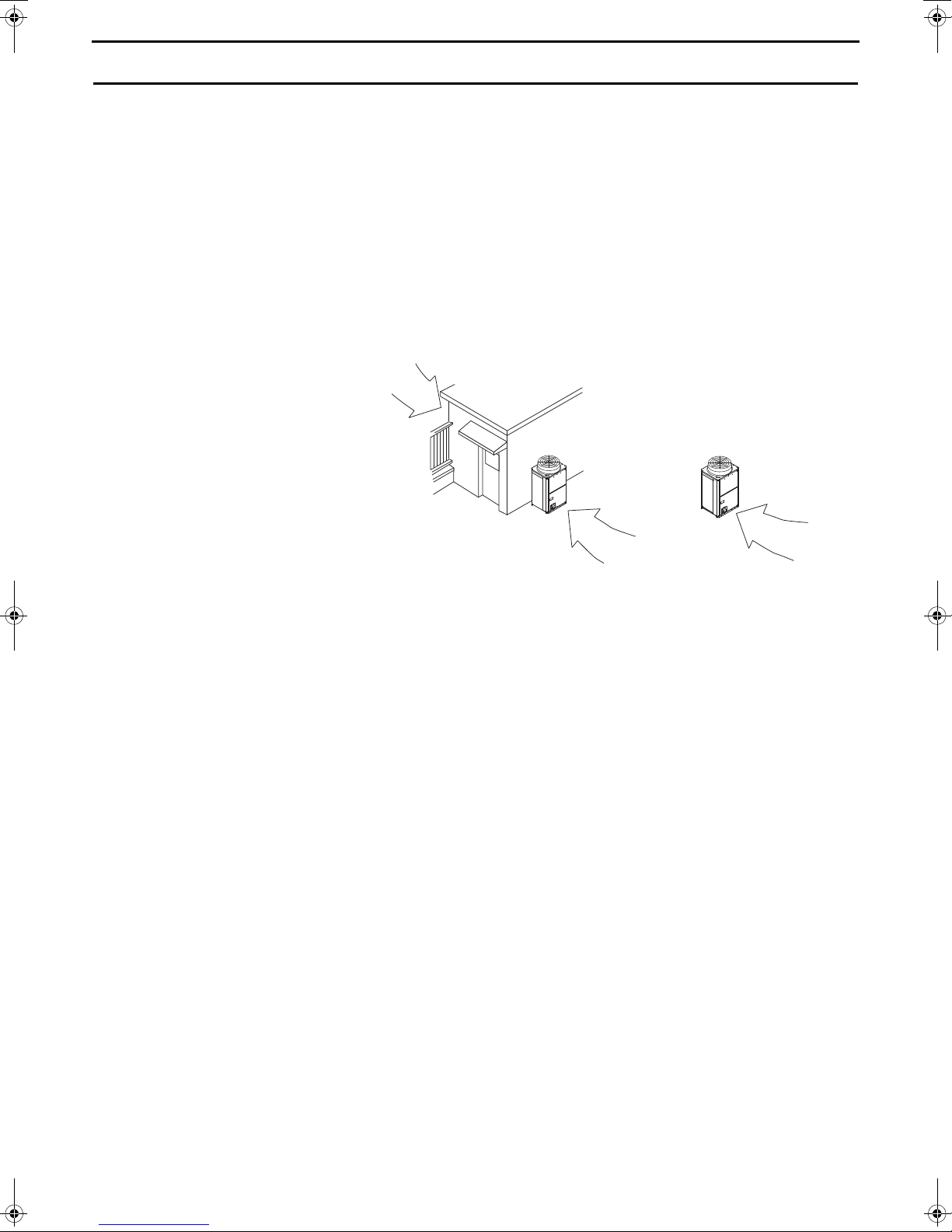

[2] Installation Space Requirements

L1

L2

L3

L3

* Height limit

Front/Right/Left Same height or lower than the overall height of the unit

Rear 500 mm or lower from the unit bottom

Unit height

Unit height

500

[mm]

When the wall(s) at the front and/or

the right/left exceed(s) their height

limits

h3

L1

L2

L3

L3

h1

Unit height

Unit height

500

When the wall at the rear exceeds

its height limit

h3

L1

L2

L3

L3

h1

L1

L2

L3

L3

h2

500

Unit height

Unit height

When all walls exceed their height

limits

L1

h3

h2

L2

L3

L3

h1

500

Unit height

Unit height

Provide sufficient space around the unit for effective operation, efficient air movement, and ease of access for

maintenance.

<1> Single unit installation

(1) When all walls are within their height limits*.

Required minimum distance [mm]

L1 (Front) L2 (Rear) L3 (Right/Left)

When the distance behind the unit (L2) needs to be small 500 300 50

(2) When one or more walls exceed their height limits*.

Add the dimension that exceeds the height limit (shown as "h1" through "h3" in the figures) to L1, L2, and L3 as

shown in the table below.

When the distance behind the unit (L2) needs to be small 500 + h1 300 + h2 50 + h3

Required minimum distance [mm]

L1 (Front) L2 (Rear) L3 (Right/Left)

7

Page 8

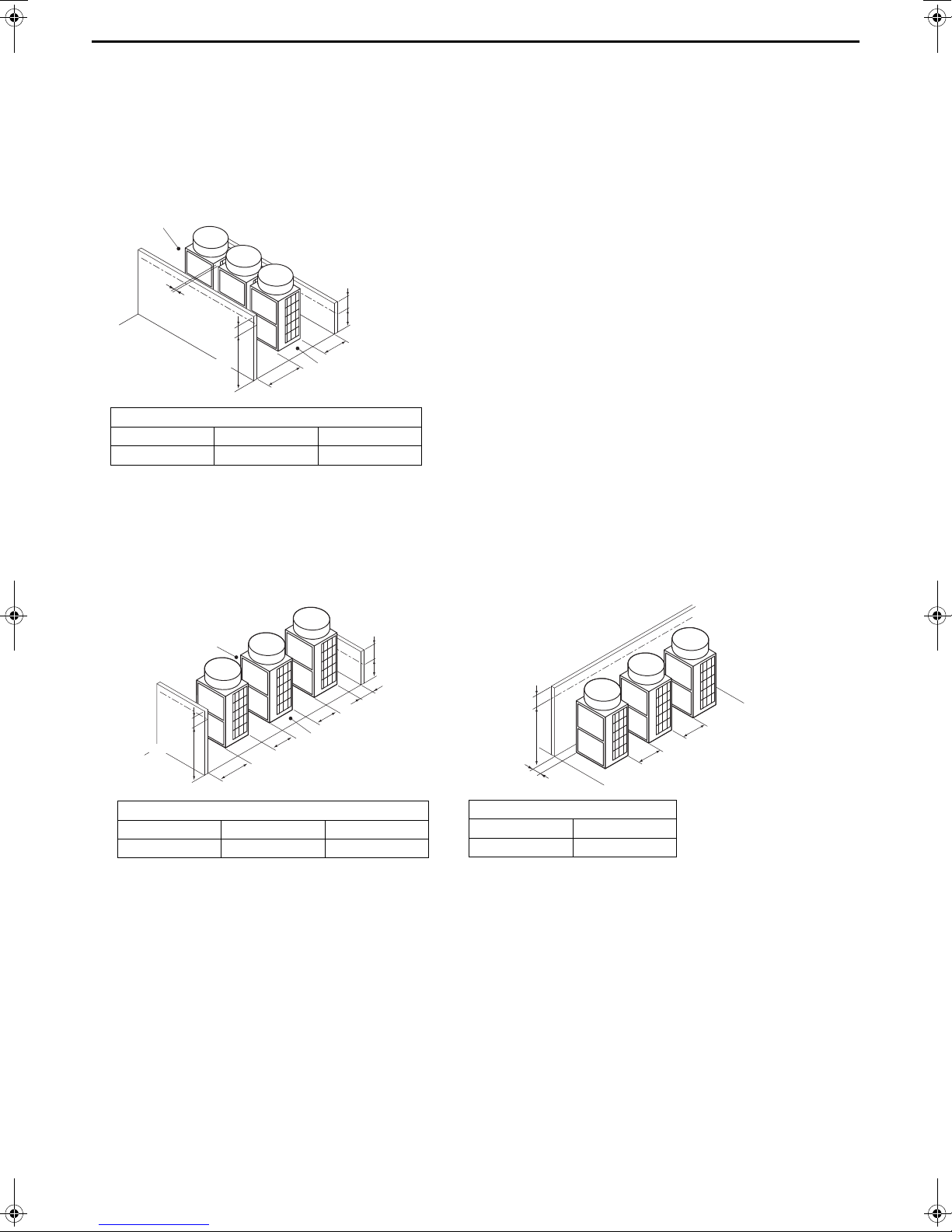

<2> Multiple unit installation

h2

L2

L1

h1

L4

Ⓐ

Ⓐ

[mm]

Unit height

500

Required minimum distance [mm]

L1 (Front) L2 (Rear) L4 (Between)

500 + h1 300 + h2 100

Ⓐ Leave open in two directions.

When there are walls in the front and rear of

the block of units

h1

h2

L1

L4

L4

L2

Ⓐ

Ⓐ

500

Unit height

Required minimum distance [mm]

L1 (Front) L2 (Rear) L4 (Between)

500 300 500

Ⓐ Leave open in two directions.

When there is a wall on either the right or left

side of the block of units

h3

L4

L3

L4

Unit height

Required minimum distance [mm]

L3 (Right/Left) L4 (Between)

50 + h3 500

When installing multiple units, make sure to take into consideration factors such as providing enough space for

people to pass through, ample space between blocks of units, and sufficient space for airflow. (The areas marked

with Ⓐ in the figures below must be left open.)

In the same way as with the single unit installation, add the dimension that exceeds the height limit (shown as "h1"

through "h3" in the figures) to L1, L2, and L3 as shown in the tables below.

(1) Side-by-side installation

(2) Face-to-face installation

8

Page 9

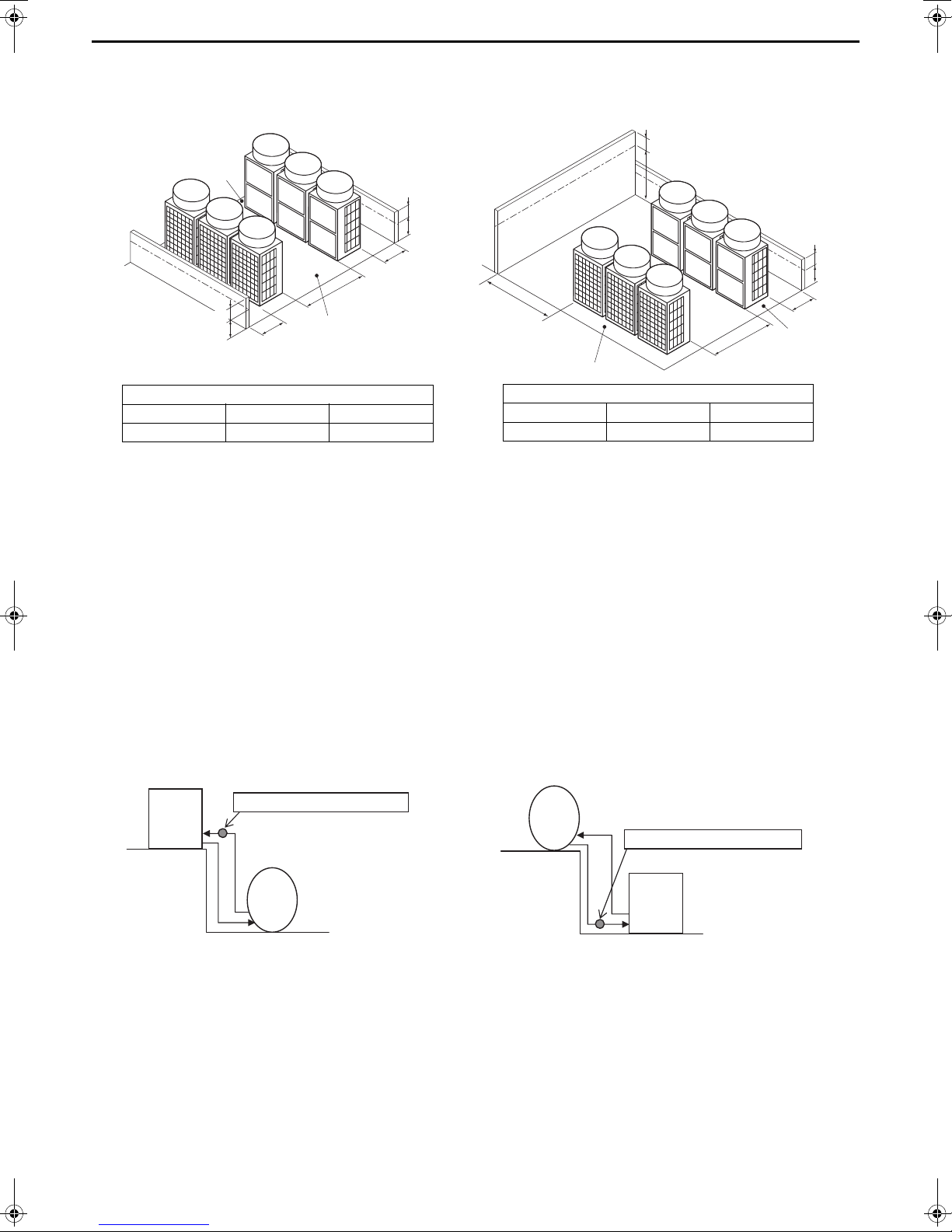

(3) Combination of face-to-face and side-by-side installations

When there are walls in the front and rear of

the block of units

h2

h2’

L2’

L4

L2

Ⓐ

Ⓐ

500

500

Required minimum distance [mm]

L2 (Right) L2’ (Left) L4 (Between)

300 + h2 300 + h2’ 1000

Ⓐ Leave open in two directions.

When there are two walls in an L-shape

h2

h3

L2

L4

L3

Ⓐ

Ⓐ

Unit height

500

Required minimum distance [mm]

L2 (Right) L3 (Right/Left) L4 (Between)

300 + h2 1000 + h3 1000

• When the unit is installed above the storage

tank

Decide the height so that the unit inlet water

pressure will not be negative for the tank

pressure.

Unit inlet water pressure > 0 MPa

Storage

tank

Heat

pump

unit

• When the unit is installed below the storage

tank

Decide the height so that the unit inlet water

pressure will be 0.5 MPa or below for the tank

pressure.

Heat

pump

unit

Storage

tank

Unit inlet water pressure < 0.5 MPa

[3] System installation restrictions

• Piping length restrictions

The maximum piping length is 60 m.

Select appropriate diameter pipes to prevent negative pressure from the pumping head and the pressure loss in the

pipes.

Pumping head (when maximum flow rate is 17

• Installation height restrictions

/min): 70 kPa

9

Page 10

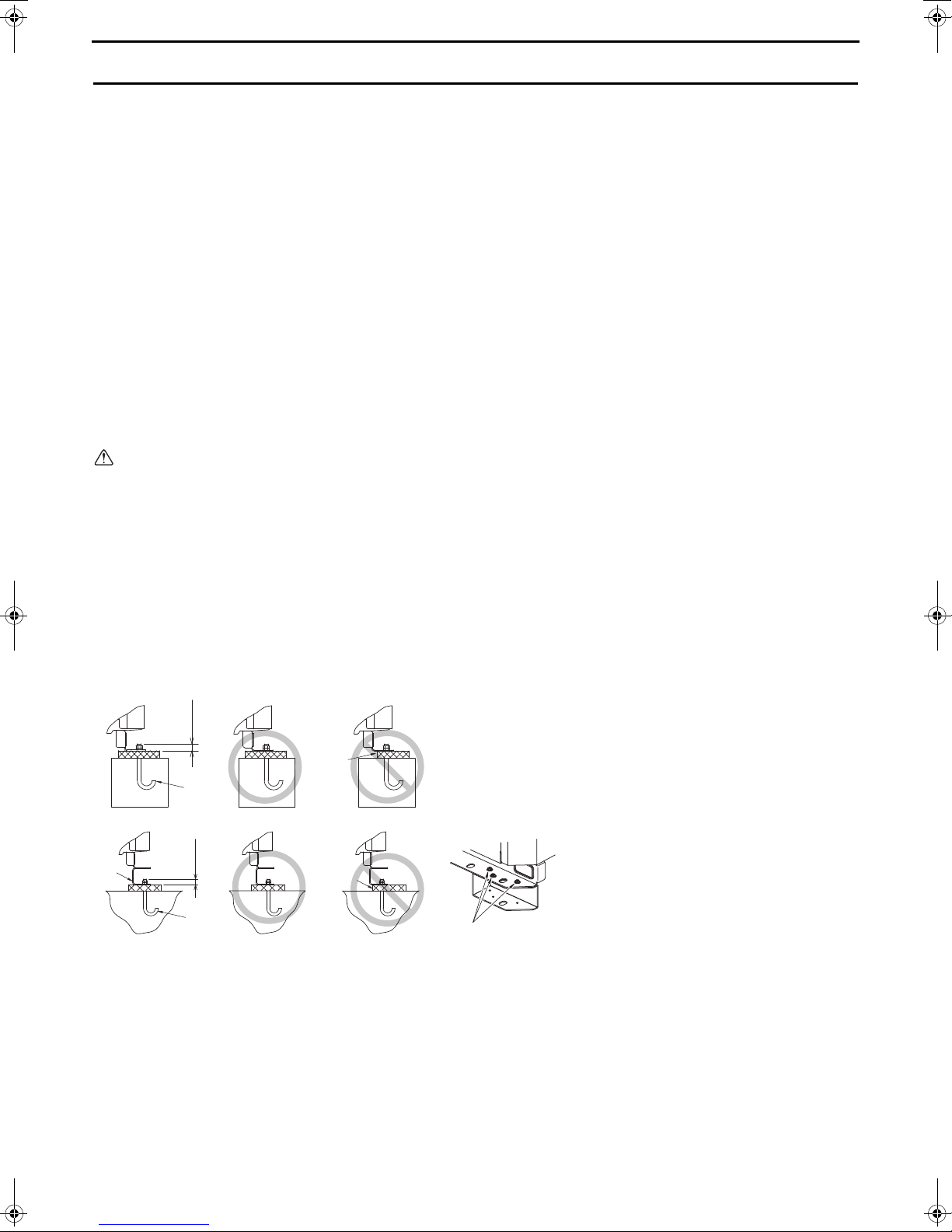

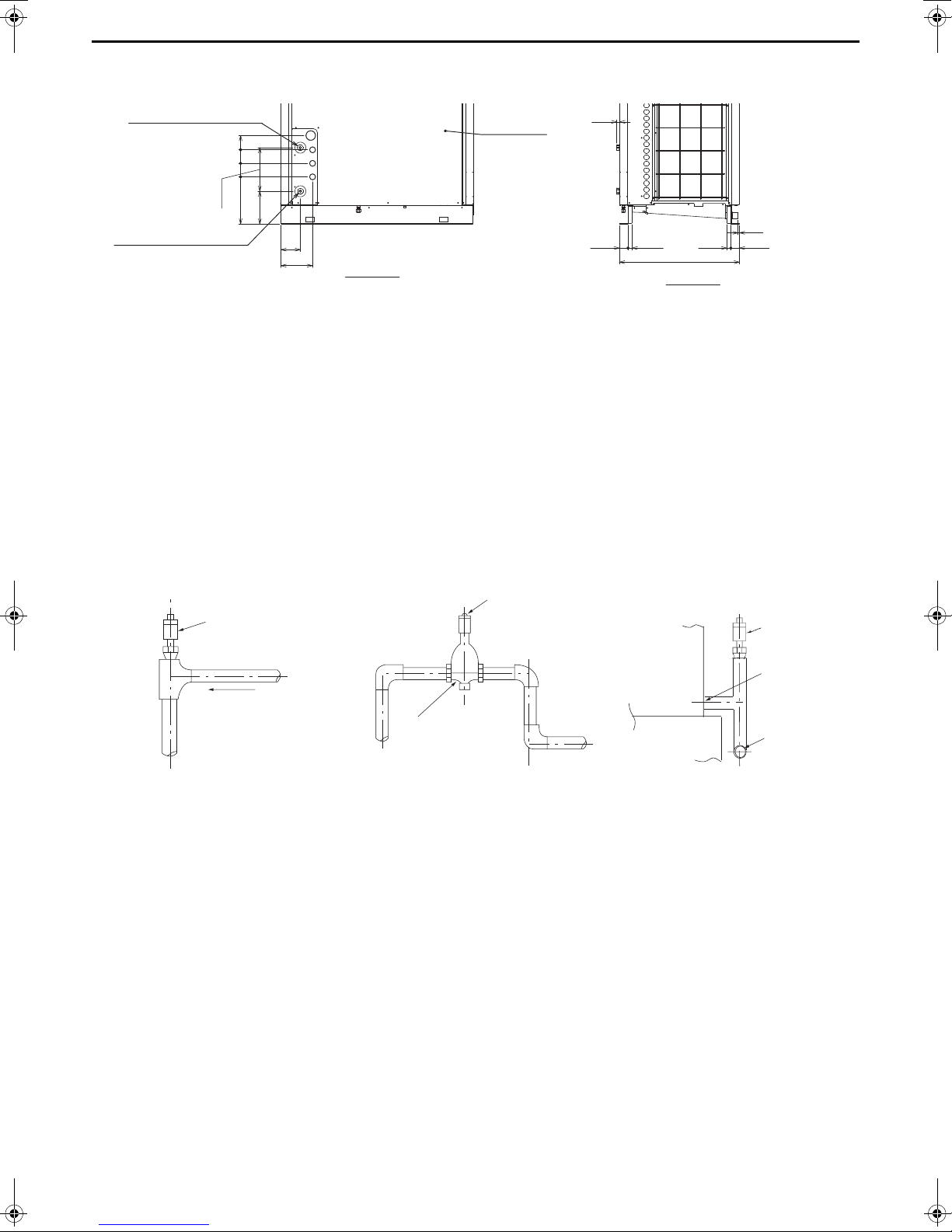

2. Unit Installation

A: M10 anchor bolt (field supply)

B: Corner is not seated.

C: Detachable leg

D: Screws

30 mm

A

30 mm

A

B

B

D

C

Units should be installed only by personnel certified by Mitsubishi Electric.

• Securely fix the unit with bolts to keep the unit from falling down during earthquakes or due to strong winds.

• Install the unit on a foundation made of concrete or iron.

• Noise and vibrations from the unit may be transmitted through the floor and walls. Provide adequate protection

against noise and vibration.

• Build the foundation in such way that the corners of the installation legs are securely supported as shown in the

figure below. When using rubber vibration isolators, make sure they are large enough to cover the entire width of

the unit's legs. If the corners of the legs are not firmly seated, the legs may bend.

• The projecting length of the anchor bolt should be less than 30 mm.

• This unit is not designed to be installed using hole-in anchor bolts unless brackets are used to support the four

corners of the unit.

• The legs on the unit are detachable.

• Detaching the legs

Loosen the three screws on the legs to detach each leg (two each in the front and back). If the finish coat becomes

damaged when detaching the legs, be sure to touch it up.

Warning:

• Be sure to install the unit on a surface strong enough to withstand its weight to keep the unit from falling

down and causing injury.

• Provide adequate protection against strong winds and earthquakes. Improper installation may cause the

unit to fall down, resulting in personal injury.

When building the foundation, take the floor strength, water drainage during operation, and piping and wiring routes

into consideration.

Precautions for routing the pipes and wires underneath the unit without detachable legs

When routing the pipes and wires underneath the unit, make sure that the foundation will not block the piping access

holes. Also, make sure the foundation is at least 100 mm high so that the piping can pass under the unit.

10

Page 11

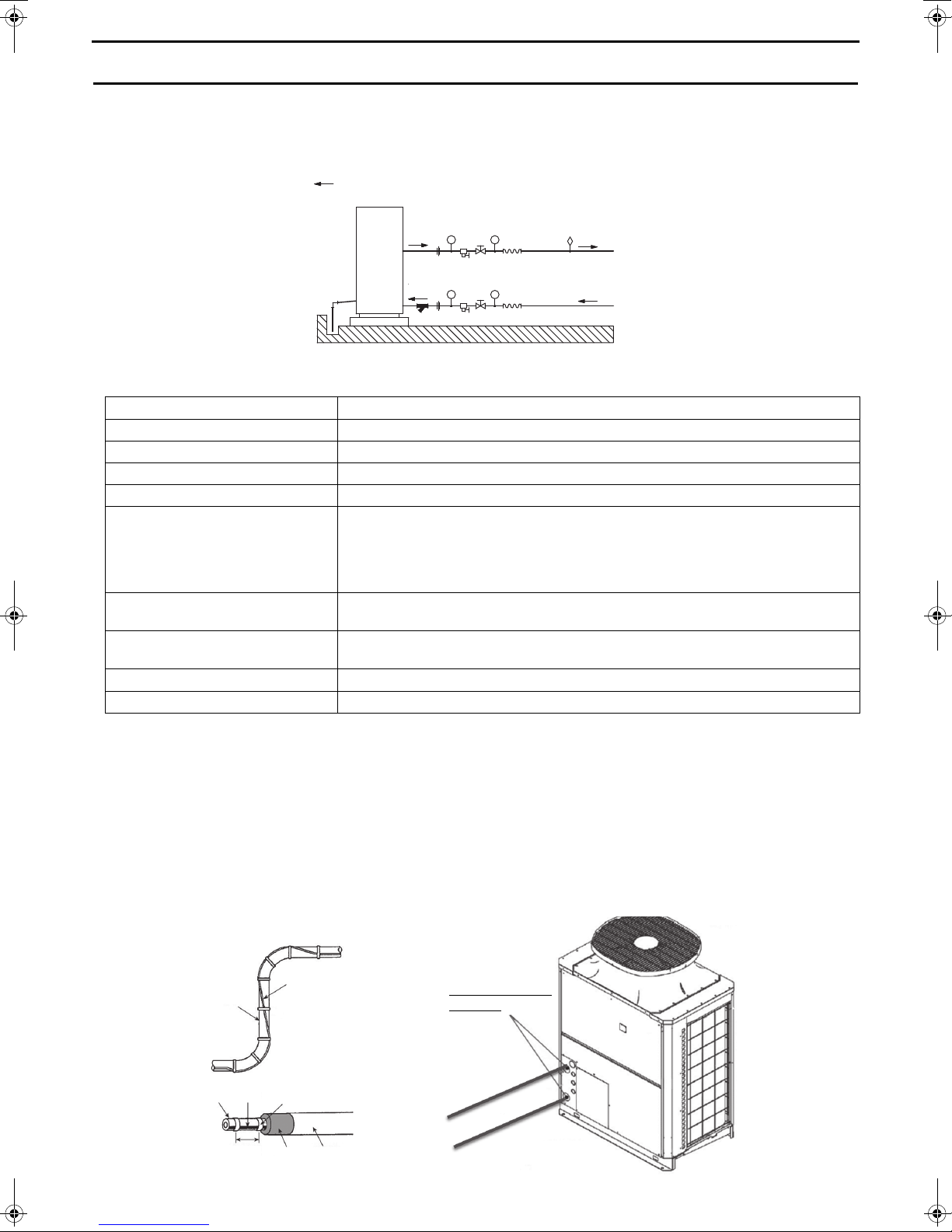

3. Water Pipe Installation

indicates the direction of the water flow.

Heat pump unit

To storage tank

Water piping diagram

From storage tank

Heater

Piping

Joint section 0ºC

or higher

Tape

Heater

Piping

250 mm

Heat insulator

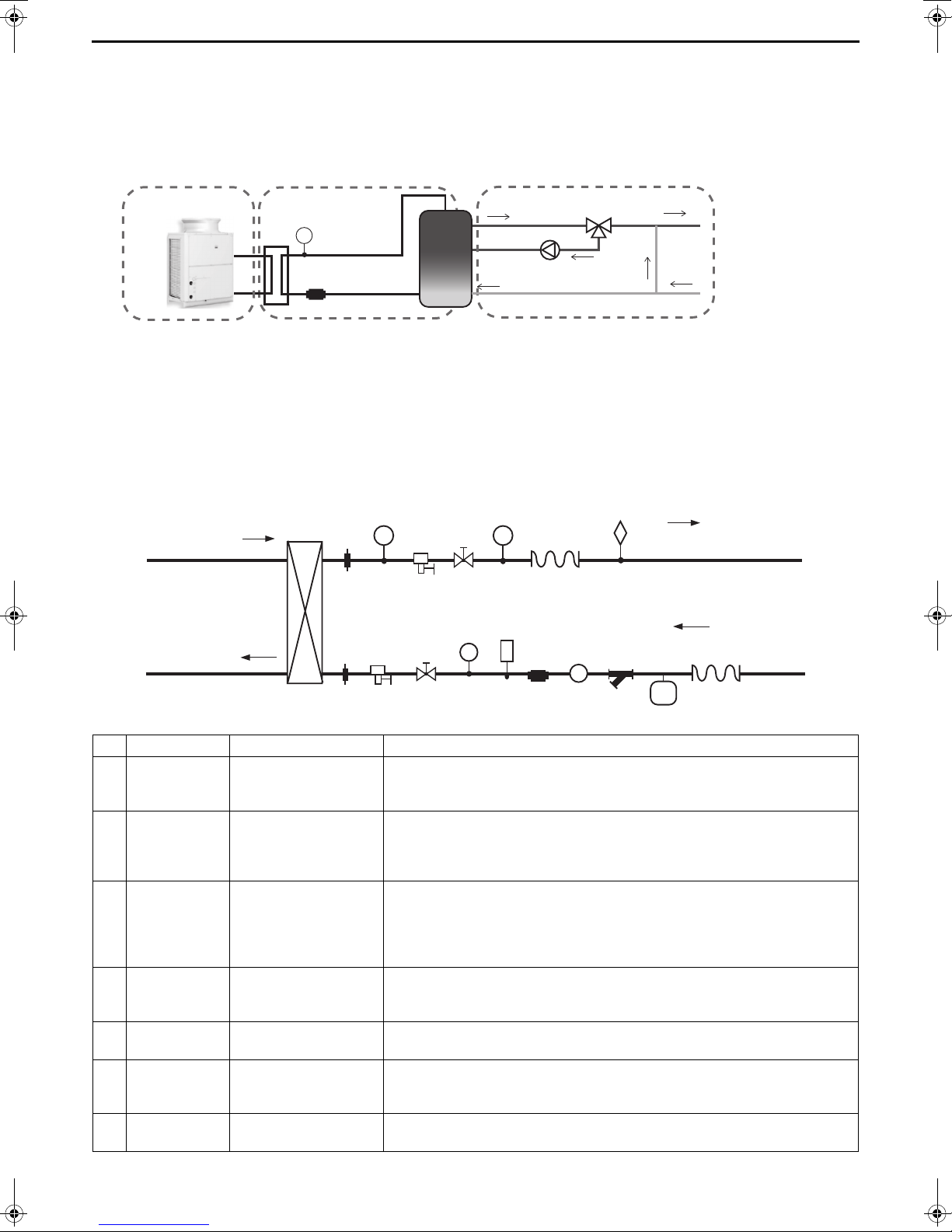

[1] Schematic Piping Diagram and Piping System Components

③

①

②

④

PT

⑤

⑧

⑨

②

⑩

④

③

PT

⑤

⑥

⑦

①

1 Union joints/flange joints Required to allow for a replacement of equipment.

2 Thermometer Required to check the performance and monitor the operation of the units.

3 Water pressure gauge Recommended for checking the operation status.

4 Valve Required to allow for a replacement or cleaning of the flow adjuster.

5 Flexible joint Recommended to prevent the noise and vibration from the pump from being transmitted.

Install the drain pipe with a downward inclination of between 1/100 and 1/200. To

prevent drain water from freezing in winter, install the drain pipe as steep an angle as

6 Drain pipe

practically possible and minimize the straight line.

For cold climate installation, take an appropriate measure (e.g., drain heater) to prevent

the drain water from freezing.

7 Strainer

8 Air vent valve

Install a strainer near the unit to keep foreign materials from entering the water-side

head exchanger (supplied).

Install air venting valves to the places where air can accumulate.

Automatic air vent valves are effective.

9 Water pipe Use pipes that allow for easy air purging, and provide adequate insulation.

0 Drain valve Install drain valves so that water can be drained for servicing.

* Installing a freezing prevention heater

1 In cold areas (where the outside temperature drops below freezing), provide a freezing prevention heater at all

local pipes to prevent spontaneous freezing.

2 After the heater is installed, check outside temperature +25ºC is ensured at the heat pump unit inlet/outlet pipe

joint section (at outside temperature -25ºC, joint section 0ºC or higher).

3 Depending on the local piping material, prevent overheating by selecting a self temperature adjustment type

heater or other method.

Heater installation example

11

Page 12

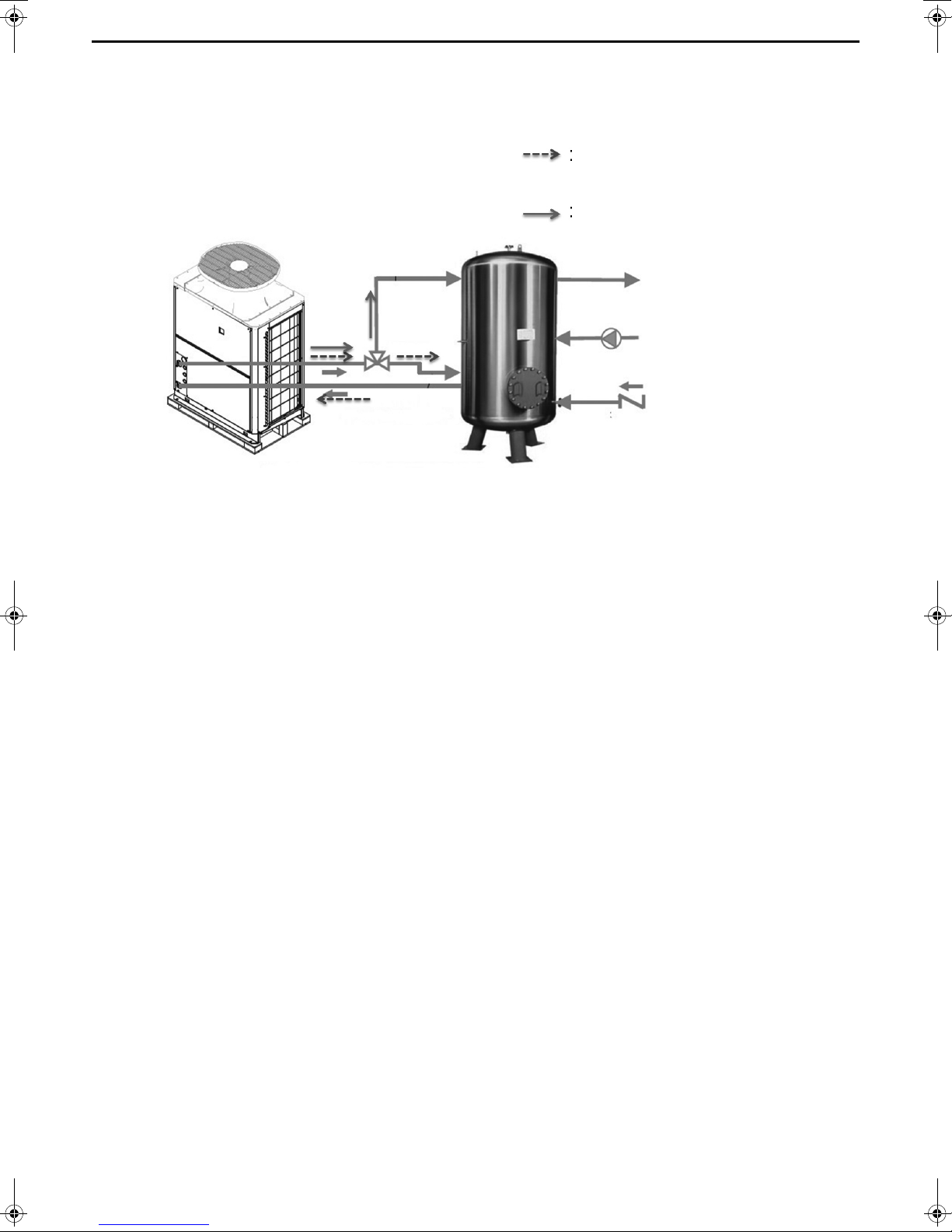

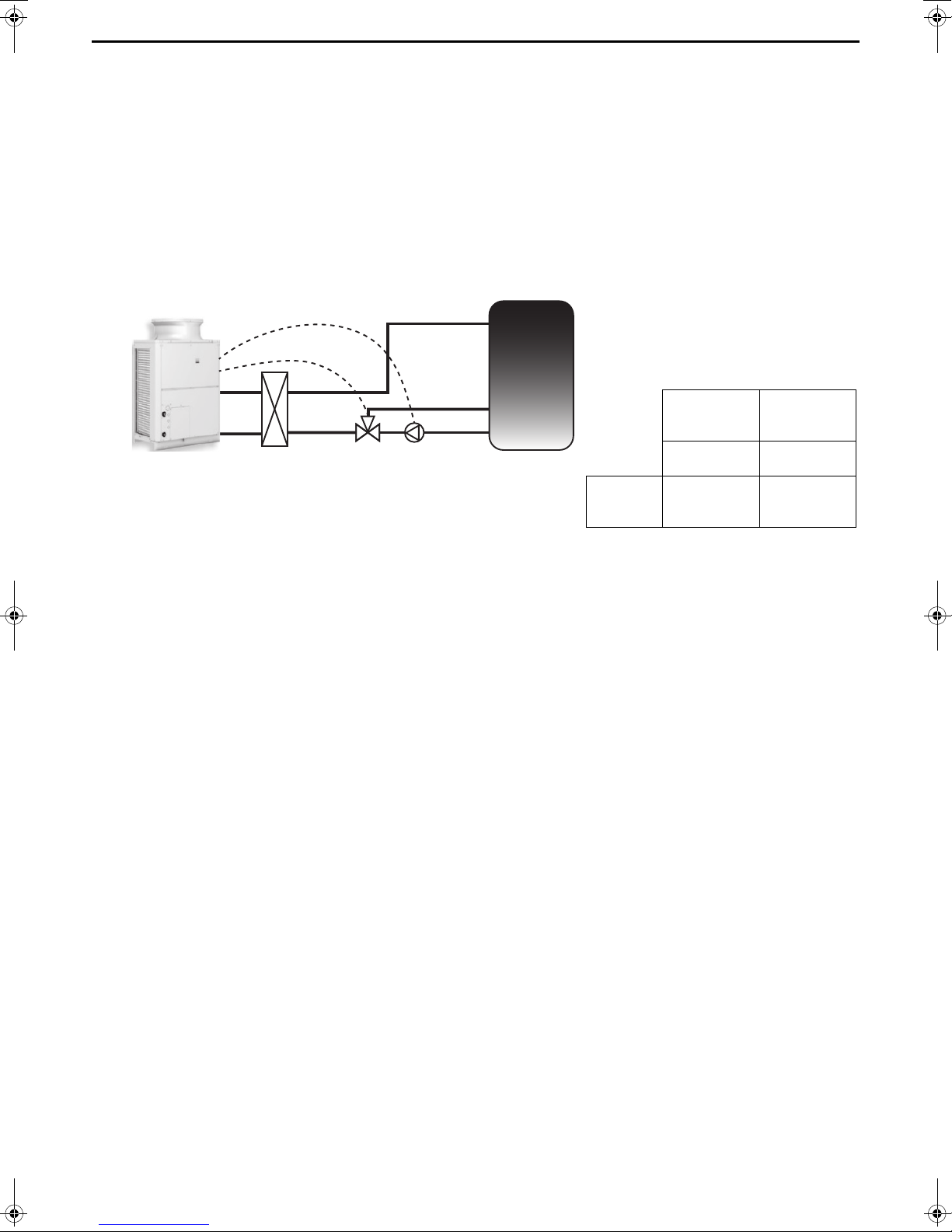

* 3-way valve installation

Hot water storage operation

Anti-freezing operation

Residual running of the pump

* The ON/OFF control of 3-way valve

depends on the output type “(r) EXTERNAL

DEVICE” on page 58.

Please connect 3-way valve on the lower part of the storage tank except when the unit is in operation. Antifreezing operation will keep the water in the tank circulated and water storage tanks can become thermally

stratified.

12

Page 13

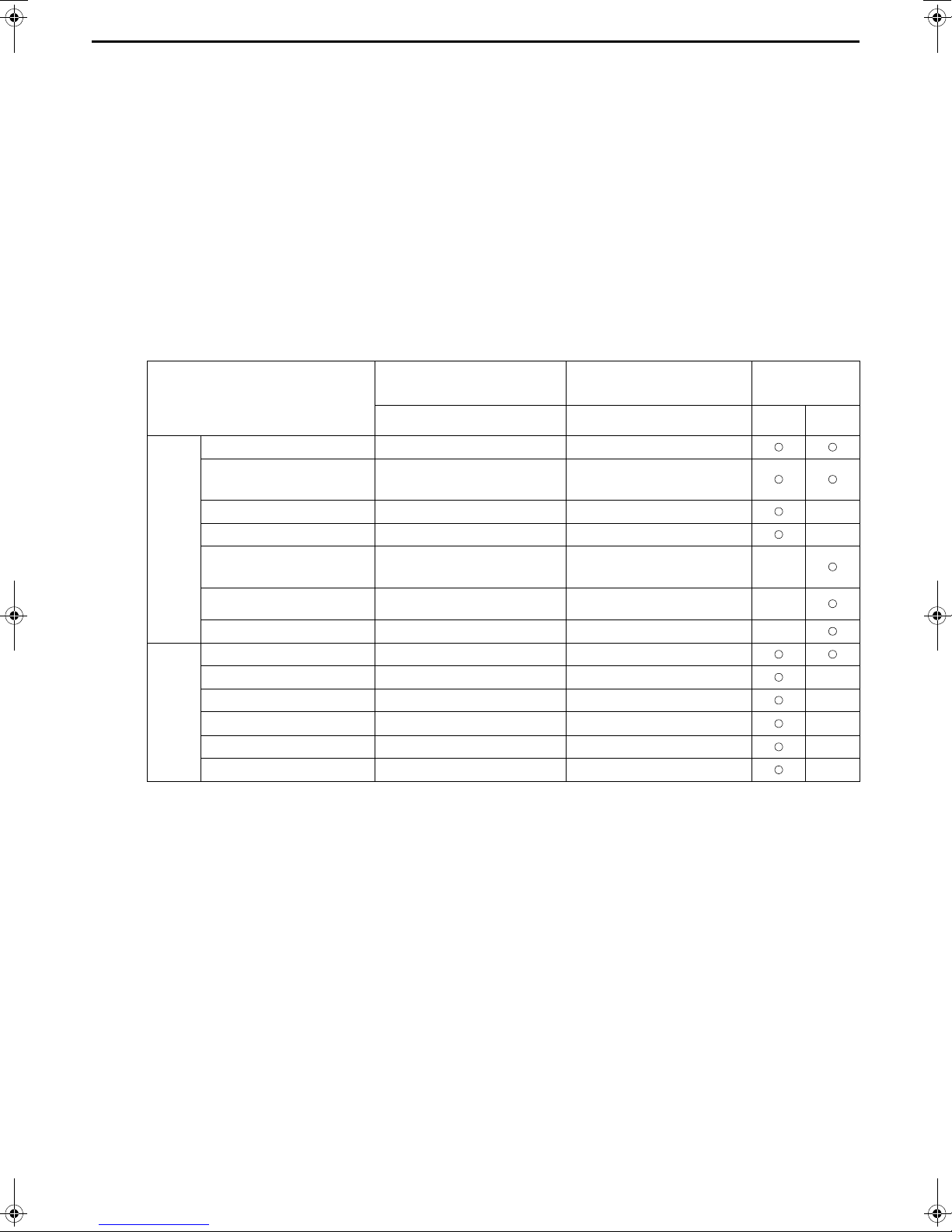

[2] Notes on Pipe Corrosion

Water treatment and water quality control

Poor-quality circulating water can cause the water-side heat exchanger to scale up or corrode, reducing heatexchange performance. Properly control the quality of the circulating water.

• Removing foreign objects and impurities in the pipes

During installation, keep foreign objects, such as welding and sealant fragments and rust, out of the pipes.

• Water Quality Control

(1) Poor-quality water can corrode or scale up the heat exchanger. Regular water treatment is recommended.

Water circulation systems using open heat storage tanks are particularly prone to corrosion.

When using an open heat storage tank, install a water-to-water heat exchanger, and use a closed-loop circuit

on the air-conditioner side. If a water supply tank is installed, keep contact with air to a minimum, and keep the

level of dissolved oxygen in the water no higher than 1 mg/.

(2) Water quality standard

Higher mid-range temperature water system

Items

pH (25˚C) 6.5 ~ 8.0 6.5 ~ 8.0

Electric conductivity (mS/m) (25˚C) 30 or less 30 or less

(µs/cm) (25˚C) [300 or less] [300 or less]

Chloride ion

Standard

items

Reference

items

Reference: Guideline of Water Quality for Refrigeration and Air Conditioning Equipment. (JRA GL02E-1994)

Sulfate ion

Acid consumption

(pH4.8) (mg CaCO

Calcium hardness

Ionic silica

Iron (mg Fe/) 0.3 or less 0.3 or less

Copper (mg Cu/) 0.1 or less 0.1 or less

Sulfide ion

Ammonium ion

Residual chlorine (mg Cl/ ) 0.1 or less 0.1 or less

Free carbon dioxide

(mg CaCO

(mg Cl

(mg SO4

(mg SiO

(mg S2-/)

(mg NH

(mg CO

-

/)

2-

/)

/)

3

/)

3

/)

2

+

/)

4

/)

2

Water Temp. > 60ºC

Recirculating water Recirculating water Corrosive

30 or less 30 or less

30 or less 30 or less

50 or less 50 or less

6.5 pH 7.5 : 90 or less

7.5 pH 8.0 : 50 or less

30 or less 30 or less

Not to be detected Not to be detected

0.1 or less 0.1 or less

10.0 or less 10.0 or less

Make-up water criteria

(with secondary side control enabled)

Water Temp. > 60ºC

250 or less

Tendency

Scale-

forming

(3) Please consult with a water quality control specialist about water quality control methods and water quality

calculations before using anti-corrosive solutions for water quality management.

(4) When replacing an air conditioner (including when only the heat exchanger is replaced), first analyze the water

quality and check for possible corrosion.

Corrosion can occur in water systems in which there has been no signs of corrosion. If the water quality level

has dropped, adjust the water quality before replacing the unit.

(5) Suspended solids in the water

Sand, pebbles, suspended solids, and corrosion products in water can damage the heating surface of the heat

exchanger and cause corrosion. Install a good quality strainer (60 mesh or better) at the inlet of the unit to filter

out suspended solids.

(6) Connecting pipes made from different materials

If different types of metals are placed in direct contact with each other, the contact surface will corrode.

Install an insulating material between pipes that are made of different materials to keep them out of direct

contact with each other.

13

Page 14

[3] Water Pipe Hole Size and Location

Water inlet

(Bronze Rc3/4, female screw)

Service panel

Front view

Side view

Hot water outlet

(Bronze Rc3/4, female screw)

Automatic air venting valve

Automatic air venting valve

Air venting valve installation example

Air separator

Automatic air

venting valve

Hot water outlet

Crosscut pipe

Base

Heat pump unit

Upward gradient 1/200

19

85 9085

274

297

206

122

199

26 5454 26

755

9

[4] Pipe gradient and air venting valve (Outlet hot water pipe)

During the hot water storage operation, the air dissolved in the water is discharged in the form of bubbling from the

outlet hot water pipe to quickly raise low-temperature water to the required temperature. When the air accumulates in

the pipe, the resistance of the water circuit will increase and the flow rate will extremely decrease. Because of this, an

installation of automatic air venting valves is required when there is a pipe that slopes down in the outlet hot water

pipe.

Install the pipe with an upward gradient of 1/200 or more toward the air vent to prevent air accumulation in the pipe.

Also, install air venting valves to the places where air can accumulate. The installation example is shown below.

Note:

• If the crosscut pipe is located lower than the hot water outlet of the heat pump unit, raise the pipe near the unit and

install an automatic air venting valve.

[5] Outlet check valve (When installing multiple units)

When connecting multiple units with pipes in parallel, install a check valve at the outlet pipe of each unit. If a check

valve is not installed, a circuit in which warm water flows back will be created in some units during the defrost cycle or

abnormal stop, and other units will come to an abnormal stop due to sudden change of the inlet water temperature.

14

Page 15

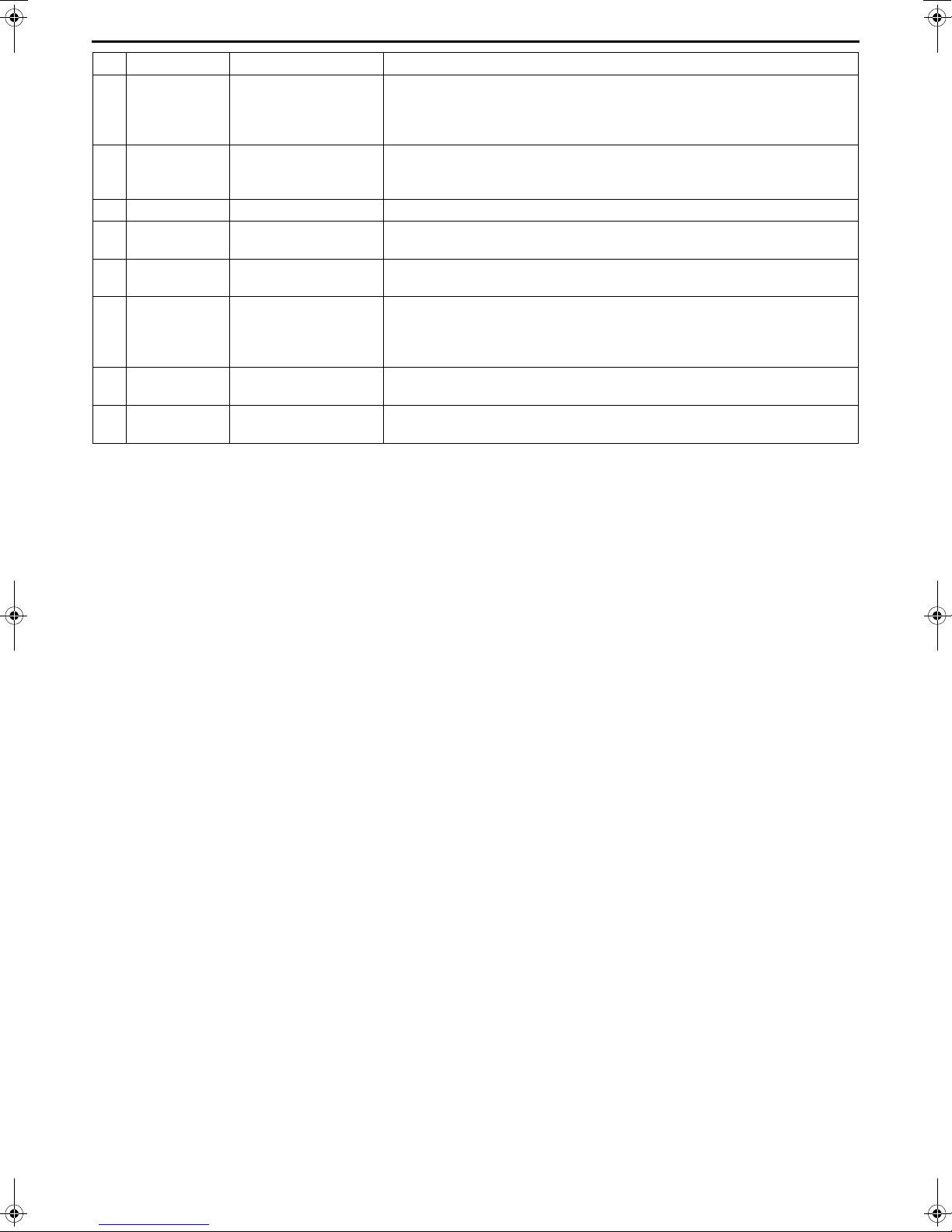

[6] Secondary side control system

T

I Unit heating circuit

II Secondary side circuit

III Hot water supply circuit

Temperature sensor

Flow sensor

䐣

䐤

䐣

䐤

䐟

T

䐠

䐥

䐬

䐦

䐨

䐩

䐧

䐪

䐡

䐢

䐫

䐭

䐥

䐬

䐦

P

䐪

䐩

P

From heat pump unit

To heat pump unit

From storage tank

To storage tank

When employing an indirect heat exchanger system using a separately sold Q-1SCK, be careful with regard to the

following points.

Install the Q-1SCK (flow sensor and temperature sensor) in the secondary side circuit as shown below to perform

control.

(1) Notes on configuring and selecting components

1 Points to note for secondary side water piping

I Details on components in the unit heating circuit

* For details, refer to page 11.

II Details on components in heat exchanger heating circuit

Schematic Piping Diagram and Piping System Components for secondary circuit

No. Component Application Remarks and notes on selecting and installing components

1

2

3

4

5 Water piping Water flow channel

6

7 Union joint

Flow sensor

(Optional parts)

Temperature

sensor

(Optional parts)

Plate heat

exchanger

Pump + Flow

rate adjustment

device

Anti-freeze

heater

Measures and controls

the secondary side flow

rate.

Measures and controls

the secondary side

outlet hot water

temperature.

Exchanges heat

between hot water

output from the unit and

water input from the

tank.

Outputs hot water from

the secondary side and

adjusts the flow rate.

Prevents pipe damage

due to freezing of the

water circuit.

Improves the workability

of replacing equipment.

P

Be sure to install this component between the downstream of the flow rate

adjustment device and the heat exchanger.

Install this component at the outlet of the heat exchanger.

Select a heat exchanger that is appropriate for the capacity.

Select a pump and flow rate adjustment device that are suitable for the system.

Install them at the lower outlet of the tank.

Be sure to perform insulation work.

Select pipes that allow for easy air bleeding.

This component needs to be installed in a location where an ambient

temperature may fall to 0˚C or less.

Install these components in the two places of the chilled water passage section

and the high temperature water passage section to enable replacement.

15

Page 16

No. Component Application Remarks and notes on selecting and installing components

Improves the workability

8 Val ve

9 Strainer

0 Air vent valve Bleeds air from the pipe. Install air vents in places where there is a risk of air accumulating.

a Flexible joint

Water pressure

b

gauge

c Expansion tank

d Drain valve

e Safety valve

of cleaning the heat

exchanger and

replacing parts.

Prevents foreign

materials from entering

into the heat exchanger.

Prevents the

propagation of vibration.

Used to check the

operation status.

Absorbs excessive

water pressure due to

expansion caused by a

rise in temperature.

Improves workability of

replacing equipment.

Prevents rupturing of

the water circuit.

Install these components in the two places of the chilled water passage section

and the high temperature water passage section to enable replacement.

Install a strainer with 60 mesh or better near the heat exchanger.

These components need to be installed in consideration of the pipe load as

pipes are easily damaged by bending.

Attach this component to each piping section to check the water pressure.

Select an expansion tank that is suitable for the system.

Install these components in the two places of the chilled water passage section

and the high temperature water passage section to enable replacement.

Be sure to provide an escape pipe to prevent discharged water from spraying on

passersby.

2 Selection criteria for heat exchanger

Step 1 Determination of prerequisites for selection

I Heat exchanger capacity 40000 W

II Estimation of outlet hot water and inlet water temperatures

As a guide, select a heat exchanger of which the temperature difference between the high temperature

section and the low temperature section will be 5˚C or below.

II-1 Outlet hot water temperature (when secondary side outlet hot water temperature is set to 65˚C (setting

at the time of shipment))

• Secondary side circuit outlet hot water temperature: 65˚C

• Unit outlet hot water temperature: 70˚C

II-2 Inlet water temperature

• Secondary side inlet water temperature: 10˚C

• Unit inlet water temperature: 15˚C

III Used flow rate

(40000 W/(70-15)˚C/4200 J/kg•K) × 60 s = 10.4 kg/min 10.4 /min

Step 2 Determination of model

Notes on selection

• Select a heat exchanger that allows water to pass through both of the flow channels.

• Select a heat exchanger so that the pressure applied to the heat exchanger in the on-site system will not

exceed the maximum operating pressure of the heat exchanger.

• Select a heat exchanger that allows flowing at a flow rate of maximum 30 /min.

• Select a heat exchanger with a capacity of at least 40000 W.

• Ensure that the shearing stress at the flow rate to be used will be 16 Pa or more. (Refer to step 4.)

* To increase the shearing stress:

• When the area per plate is equal, select a vertically long heat exchanger.

• Select a heat exchanger of which NTU is high (although the heat transfer capacity improves as NTU

increases, the pressure loss becomes high).

16

Page 17

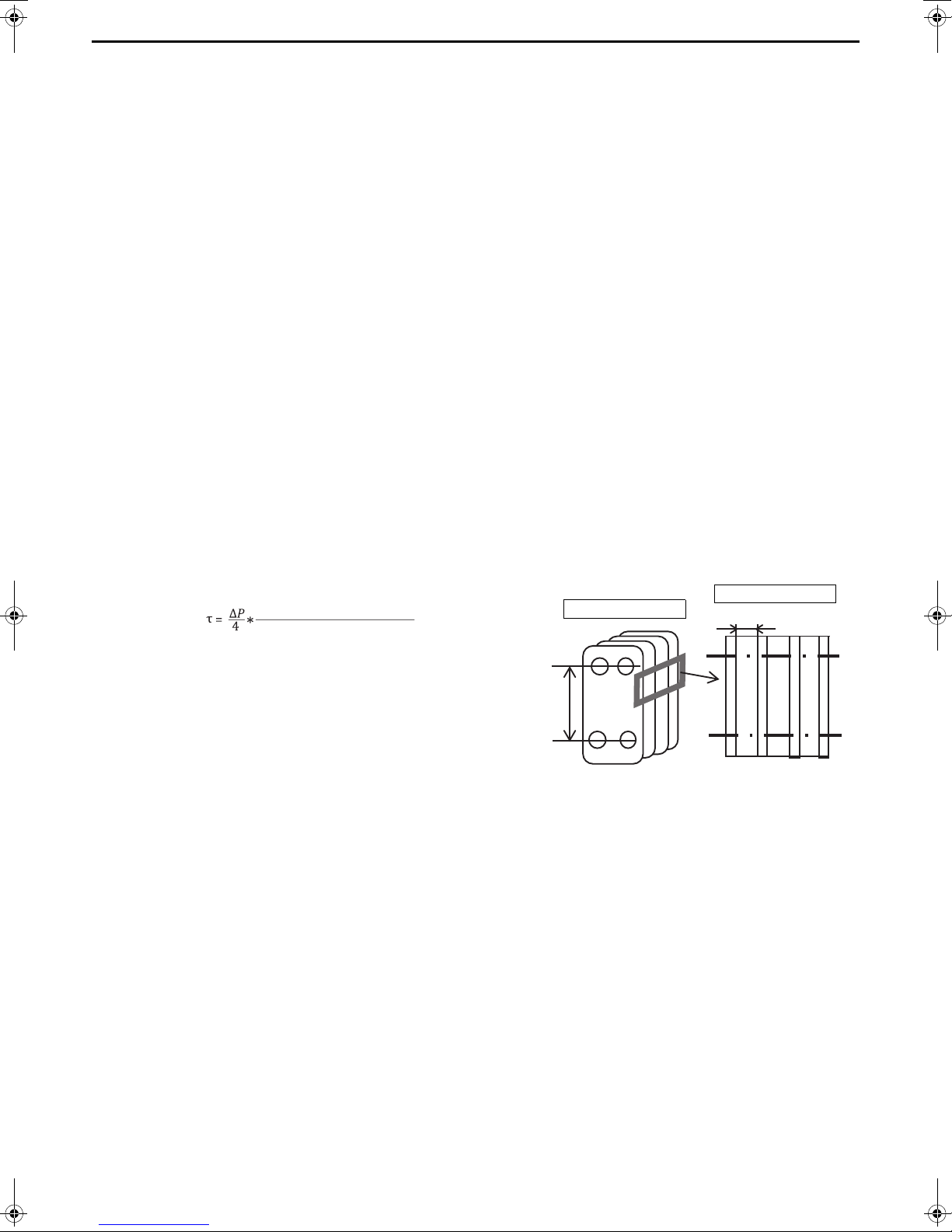

Step 3 Determination of specifications of the heat exchanger

NTU1

T1

T

-----------=

NTU2

KA

VC

------------- -

=

Effective length

Representative length of 1 channel

Effective length:

Length between water inlet and water outlet

(refer to the figure on the right)

Representative length of 1 channel:

Distance between plates

(refer to the figure on the right)

× 2

P: Pressure loss

A shearing stress of 16 Pa or higher is required to reduce the amount of scale that adheres.

If the shearing stress is low:

• Select a vertically short shape.

• Change the shape of the plates.

Reselect a heat exchanger that will increase the shearing stress by following methods described above.

Distance between plates

Effective length

Side of heat exchanger

Front of heat exchanger

Determine the model of heat exchanger and number of plates in consultation with the heat exchanger

manufacturer based on the above requirements.

* To determine the number of plates, calculate the number of plates while referring to the example below.

Values to use when determining the number of plates:

1 Overall heat transfer coefficient of corresponding heat exchanger

2 Heat transfer area per plate

Calculation method

A Obtain the data of 1 and 2 from the heat exchanger manufacturer.

B Estimate the number of plates of the heat exchanger.

C Check that the number of transfer units for the corresponding number of plates matches between

NTU1 and NTU2 (NTU1=NTU2).

If they are matched, select a heat exchanger having the corresponding number of plates. If they are

not matched, change the number of plates and then return to B to perform the calculation again.

T1: Temperature difference between inlet and

outlet

T: Temperature difference of high temperature

part (low temperature part)

K: Overall heat transfer coefficient (W/m

2

K)

A: Total heat transfer area (m

G: Total mass flow rate (kg/s)

C: Specific heat (J/kgK)

Step 4 Calculation of the shearing stress

Calculate the shearing stress using the following method.

Values required for calculation

• Relationship between flow rate and pressure loss of corresponding heat exchanger (Obtain the data

from the heat exchanger manufacturer.)

2

)

Calculation method

Calculate the shearing stress using the following formula.

17

Page 18

3 Configuration method and selection criteria of flow rate adjustment device

Overview of system

This system has a pump provided at the outlet

of the tank and a three-way valve provided

downstream of the pump, and adjusts the flow

rate by controlling the opening and closing of

the three-way valve.

Flow rate

output device

Flow rate

adjustment

device

Pump

Three-way

valve

Wiring

connection

places

1-3 of CN512 of

control board

(ON/OFF output)

Sub box

terminal block

No. 10, 11, 12

ON/OFF signal

0 to 10 V output

Three-way

valve

Pump

In this system, a flow rate adjustment device is installed in the secondary side circuit to perform secondary side

flow rate adjustment control by outputting 0 to 10 V from the unit.

* 10-V power supply is not supplied.

The following shows a system configuration example of the flow rate adjustment device and notes on the

system configuration.

The following three system types are recommended as flow rate adjustment devices:

1. System using a three-way valve

2. System using a two-way valve

3. System using an inverter

1. System using a three-way valve

Notes on selection method and system configuration

Notes on pump selection and connection

• Calculate the total pump head according to the system at the site and then select a pump capable of outputting

the minimum flow rate of about 3 /min and maximum flow rate of about 30 /min with the necessary pump head

for the piping at the site.

• When selecting the pump, please note that output at a high flow rate will not occur if the flow rate with the pump

head of the system at the site is low, and output at a low flow rate will not occur if the flow rate is too high.

• Be sure to check that the flow rate becomes 20 to 30 /min at the maximum output during a flow rate adjustment

test run (refer to page 37).

For how to check the flow rate, refer to page 38.

* If the flow rate is not within the range of 20 to 30 /min, select a different pump or adjust the maximum frequency

using an inverter, etc. so that the maximum flow rate of 20 to 30 /min is achieved.

* To select a proper pump, first select a pump that supports slightly high flow rate, and then adjust the frequency

with an inverter so that the flow rate becomes 20 to 30 /min at the maximum output.

(In that case, an inverter is necessary to be prepared separately.)

Notes on three-way valve selection and connection

• Use a valve that is capable of adjusting the flow rate with a 0 to 10 V input.

• Calculate the Cv value and select a valve that supports an appropriate rate.

• Select a valve of which the ratio of the maximum flow rate and the minimum flow rate will be at least 1:10.

• Place the three-way valve downstream of the pump. Connect one outlet to the heat exchanger.

Connect the other outlet to the lower part of the tank.

• Carefully read the instruction manual and use the three-way valve in accordance with the usage procedures.

18

Page 19

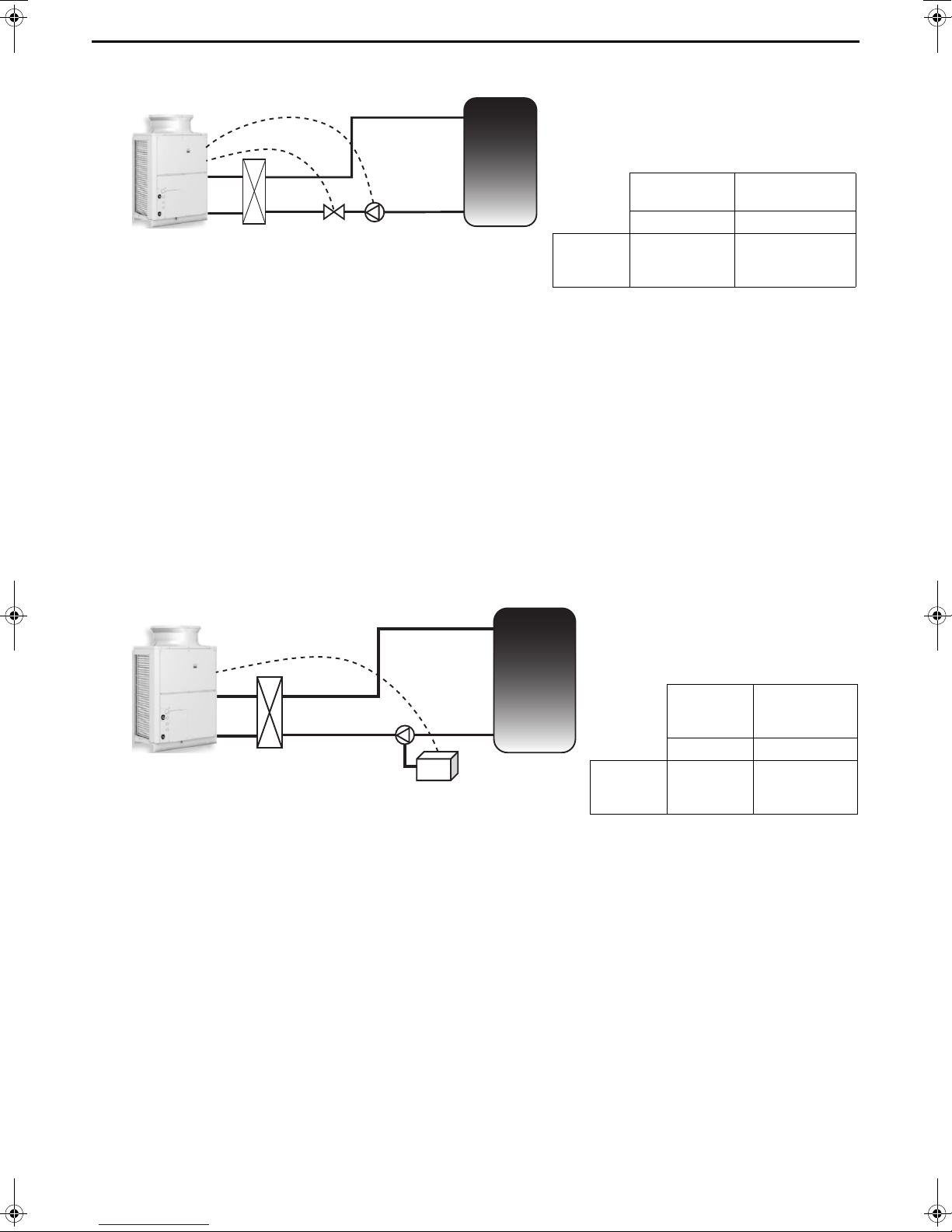

2. System using a two-way valve

Overview of system

This system has a pump provided at the outlet of the

tank and a two-way valve provided downstream of

the pump, and adjusts the flow rate by controlling the

opening and closing of the two-way valve.

Flow rate

output device

Flow rate

adjustment device

Pump Two-way valve

Wiring

connection

places

1-3 of CN512 of

control board

(ON/OFF output)

Sub box

terminal block

No. 10, 11, 12

ON/OFF signal

0 to 10 V output

Two-way

valve

Pump

Overview of system

This system has a pump provided at the outlet

of the tank and an inverter connected to the

pump, and adjusts the flow rate by changing

the frequency of the inverter.

Flow rate

output

device

Flow rate

adjustment

device

Pump Inverter

Wiring

connection

places

-

Sub box

terminal block

No. 10, 11, 12

0 to 10 V output

Pump

Inverter

Notes on pump selection and connection

Select a pump in the same way as for a system with a three-way valve.

Notes on two-way valve selection and connection

• Use a valve that is capable of adjusting the flow rate with a 0 to 10 V input.

• Calculate the Cv value and select a valve that supports an appropriate rate.

• Select a valve of which the ratio of the maximum flow rate and the minimum flow rate will be at least 1:10.

• There are various kinds of two-way valve (such as ball valve, butterfly valve, and globe valve), and there are

valves suitable for flow rate adjustment and valves that are not suitable for flow rate adjustment. Therefore be

sure to select a two-way valve of a kind capable of precisely controlling the flow rate, such as a butterfly valve or

globe valve.

• Place the two-way valve downstream of the pump.

• Carefully read the instruction manual and use the two-way valve in accordance with the usage procedures.

3. System using an inverter

Notes on pump selection and connection

Select a pump in basically the same way as for a system with a three-way valve or two-way valve.

• Select a pump that can be used also at a low frequency (6 Hz or less).

(The motor may be seized depending on the pump selected as this control is performed at a low frequency.)

• Select a pump of which flow rate at 100% output is between 20 to 30 /min.

Notes on inverter selection and connection

• The inverter needs to be able to adjust output with a 0 to 10 input.

• Select an inverter that will not cause the seizing of the motor.

• Configure the settings so that the flow rate on the secondary side will become 0 /min when the unit is not

operating.

• Carefully read the instruction manual and use the inverter in accordance with the usage procedures.

19

Page 20

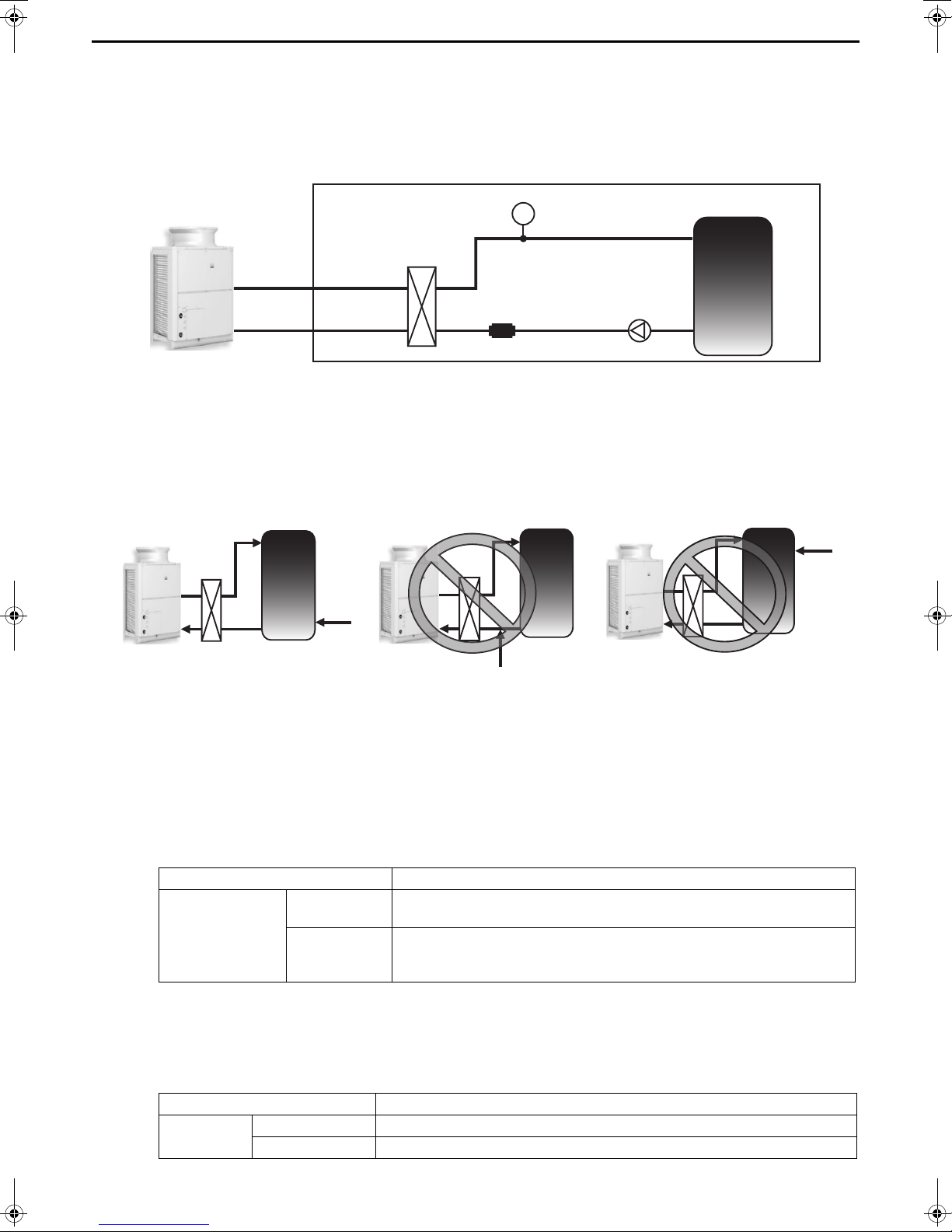

(2) Notes on other piping work

T

QAHV-N560YA-HPB

Installation indoors

Secondary side

heat exchanger

Secondary side thermistor

Secondary side flow sensor

Storage tank

Installation outdoors

Secondary side pump

QAHV-N560YA-HPB QAHV-N560YA-HPB QAHV-N560YA-HPB

Storage tank

Water

supply

Storage tank

Storage tank

Water supply

Water

supply

1 Notes on installation location of secondary side circuit

Install the secondary side heat exchanger, secondary side thermistor, secondary side flow sensor, and secondary

side pump indoors as shown in the figure for the secondary side circuit system. Also, take measures so that the

piping will not freeze.

2 Notes on hot water supply piping

Be sure to connect the hot water supply piping to the lower part of the storage tank. If you connect it to the unit

inlet pipe, an abnormal stop (high pressure or gas cooler outlet temperature) may occur or the outlet hot water

temperature may decrease due to the sudden change of the inlet water temperature (5 K/min or more

instantaneously or 1 K/min or more consecutively) during operation.

3 About anti-freezing operation

This unit performs anti-freezing operation. Furthermore, the control method can be changed according to the

system at the site. The following two items can be changed.

1. Prevent disturbance of thermal stratification in the tank

To prevent the disturbance of the thermal stratification in the tank while the indoor temperature is sufficiently high,

set the item code 1514 to "1" so that the judgment criterion for starting the anti-freezing operation of the

secondary side circuit matches with the secondary side circuit water temperature criterion.

Setting procedure and operation overview

Setting procedure Operation

0 (Initial setting)

Item code 1514

1

Performs anti-freezing operation in the secondary side circuit when the water

temperature in the unit side circuit becomes the standard value or below.

Performs

anti-freezing operation

in the secondary side circuit when the water

temperature in the secondary side circuit becomes the standard value or

below.

2. Purpose and application: Prevent piping freezing when the secondary side control is used

a risk of the piping of the primary side freezing, so set SW2-5 to "ON" so that the compressor runs during the

anti-freezing operation.

Setting procedure and operation overview

Setting procedure Operation

SW2-5

OFF (Initial setting) The compressor does not operate when the anti-freezing operation is performed.

ON The compressor operates when the anti-freezing operation is performed.

If the compressor is not run during the anti-freezing operation in the secondary side control system, there is

20

Page 21

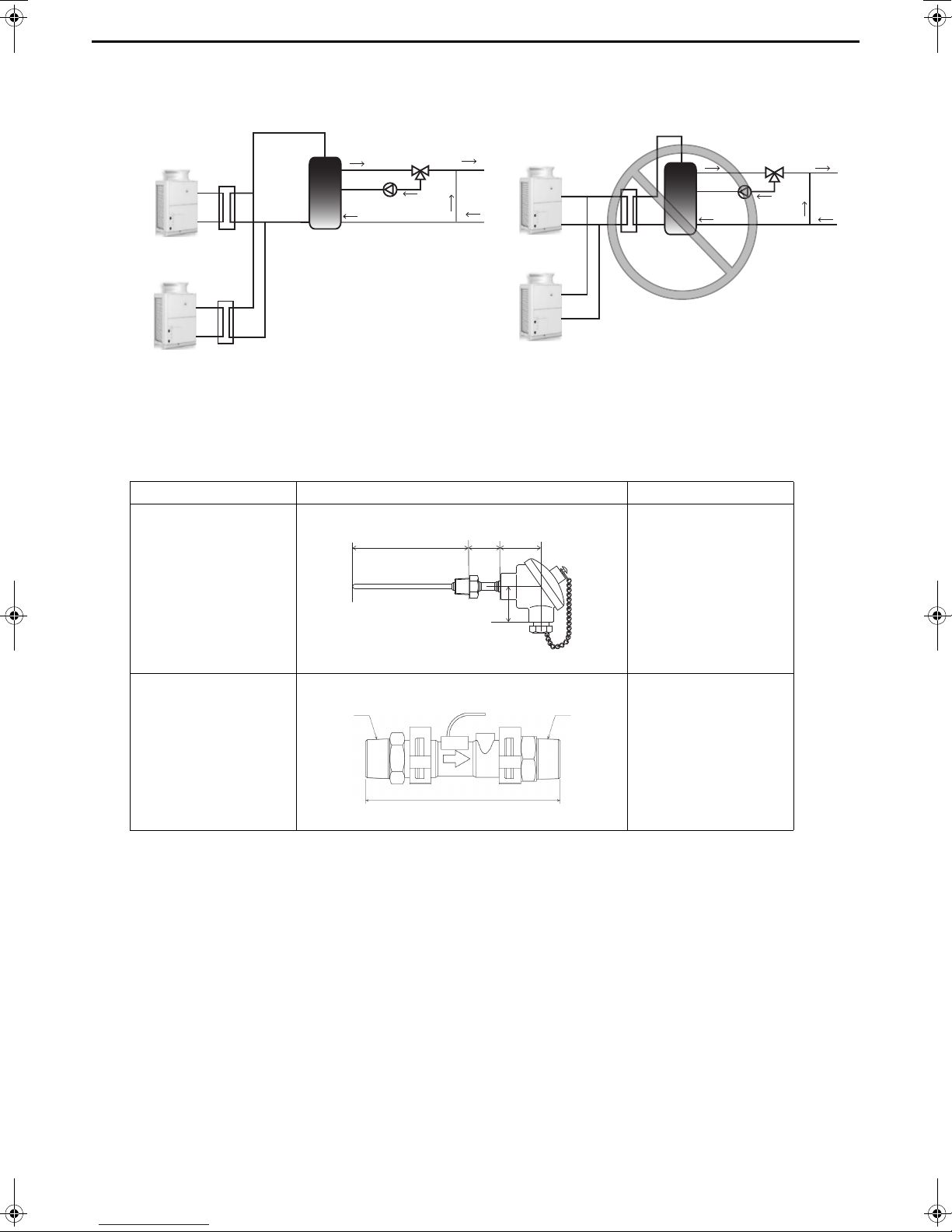

4 When connecting multiple units

QAHVN560YA-HPB

QAHVN560YA-HPB

QAHVN560YA-HPB

QAHVN560YA-HPB

Storage tank

Storage tank

ABC

D

A

BC

To connect multiple units, configure one secondary side circuit system for each unit as shown in the figure

below. (Install a heat exchanger, flow sensor, and thermistor for each unit.)

(3) Optional parts

The flow sensor and thermistor in the system are sold separately.

For the pipe connection method, refer to the manuals of the optional parts (Q-1SCK).

Secondary circuit kit Q-1SCK The size and length noted are approximate.

Parts Shape Specification

(4) Setting method for secondary side control

A: 157 mm

Thermistor

B: 42 mm

C: 54 mm

D: 48 mm

A: 129 mm

Flow sensor

B: R3/4

C: R3/4

Wiring length: 1.9 m

After configuring the secondary side control system, perform the following operation to perform the secondary side

control operation.

1. Set the digital setting item "121" to 1 (for details on the operating procedure, refer to page 28).

2. Perform a water flow rate adjustment operation (for details, refer to “Water flow rate adjustment operation (when

the secondary side control is enabled)” (page 37)).

21

Page 22

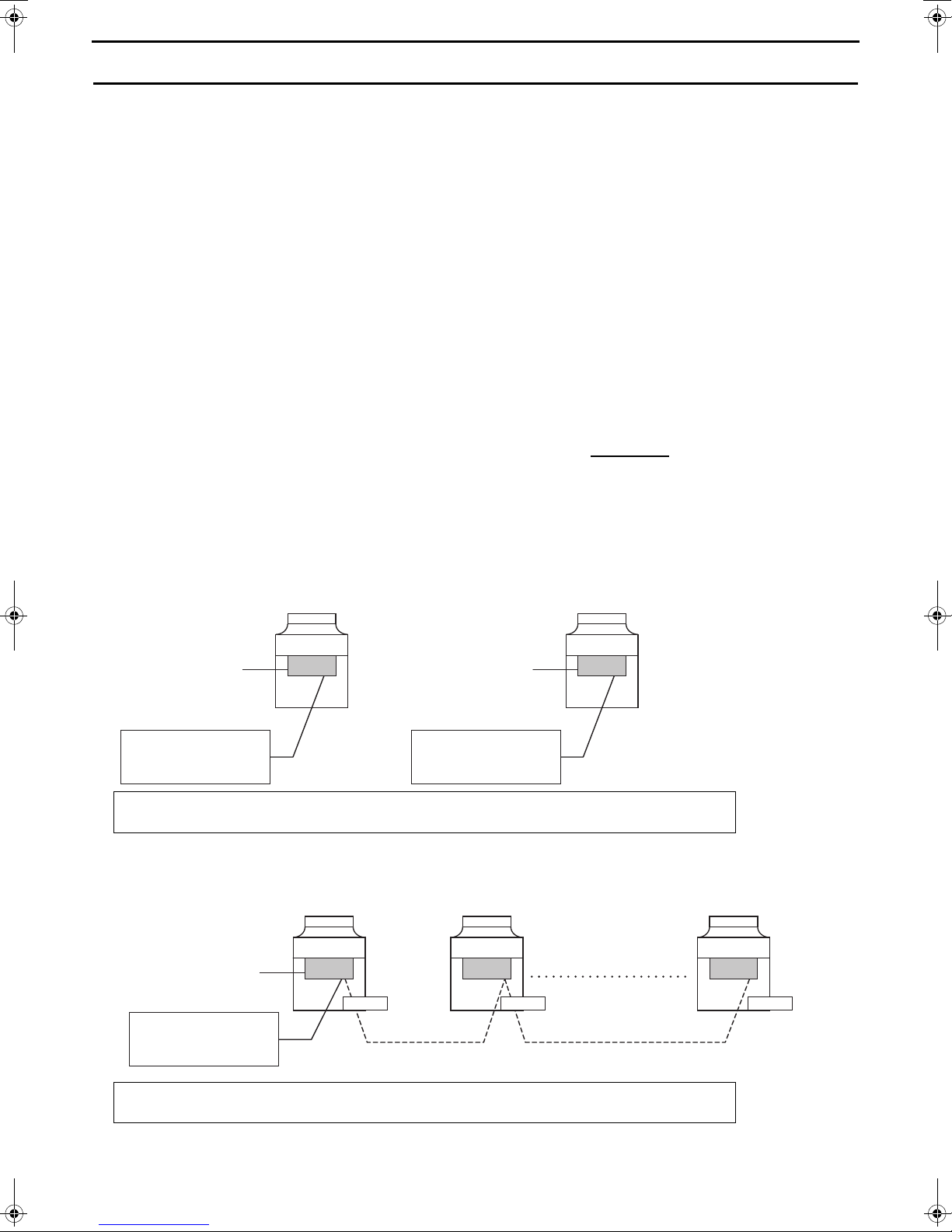

4. System Configurations

Unit (MAIN circuit)

PCB

External

temperature

sensor

Field-supplied dry contact

switch/relay or remote

controller (PAR-W31MAA) or

centralized controller (AE-200)

Field-supplied dry contact

switch/relay or remote

controller (PAR-W31MAA) or

centralized controller (AE-200)

External

temperature

sensor

Unit (MAIN circuit)

PCB

* Each unit is operated individually by connecting a dry contact switch/relay to each unit.

External

temperature

sensor

Field-supplied dry contact

switch/relay or remote

controller (PAR-W31MAA) or

centralized controller (AE-200)

MAIN

unit

SUB unit

SUB unit(s)

n units

Inter-unit wiring

(M-NET line)

Inter-unit wiring

(M-NET line)

Unit (MAIN circuit)

PCB

Unit (MAIN circuit)

PCB

Unit (MAIN circuit)

PCB

* A group of unit that consists of one main unit and up to 15 sub units is operated collectively by connecting an external water temperature sensor and a dry

contact switch/relay to the main unit.

Test run procedural flow

1.System startup (*)

Configure the settings needed for the local system.

Refer to page 23 for details.

2.Air bleeding operation

Operate the unit’s pump to perform the air bleeding operation.

Refer to page 33 for details.

3. Water flow rate adjustment operation

Adjust the unit’s pump and flow rate adjustment valve.

Refer to pages 35 and 37 for details.

* If multiple units are connected to the same water circuit, perform the water flow rate adjustment operation for each unit simultaneously.

(*)

Request at the Time of a Test Run

Set the slide switch SWS2 on the board inside the control box to the “lower side”

By default, it is set to the “upper side” for forced stop of the pump and compressor to prevent the pump being

damaged by the anti-freezing process in no water passing status or valve closed status before the test run.

during the test run.

[1] Schematic Diagrams of Individual and Multiple Systems

(1) Individual system

Refer to the sections “[2] Switch Types and the Factory Settings” (page 23) and

“(3) System configuration procedures: Individual system” (page 27) for further details.

(2) Multiple system (2-16 units)

Refer to the sections “[2] Switch Types and the Factory Settings” (page 23) and

“(4) System configuration procedures : Multiple system” (page 29) for further details.

22

Page 23

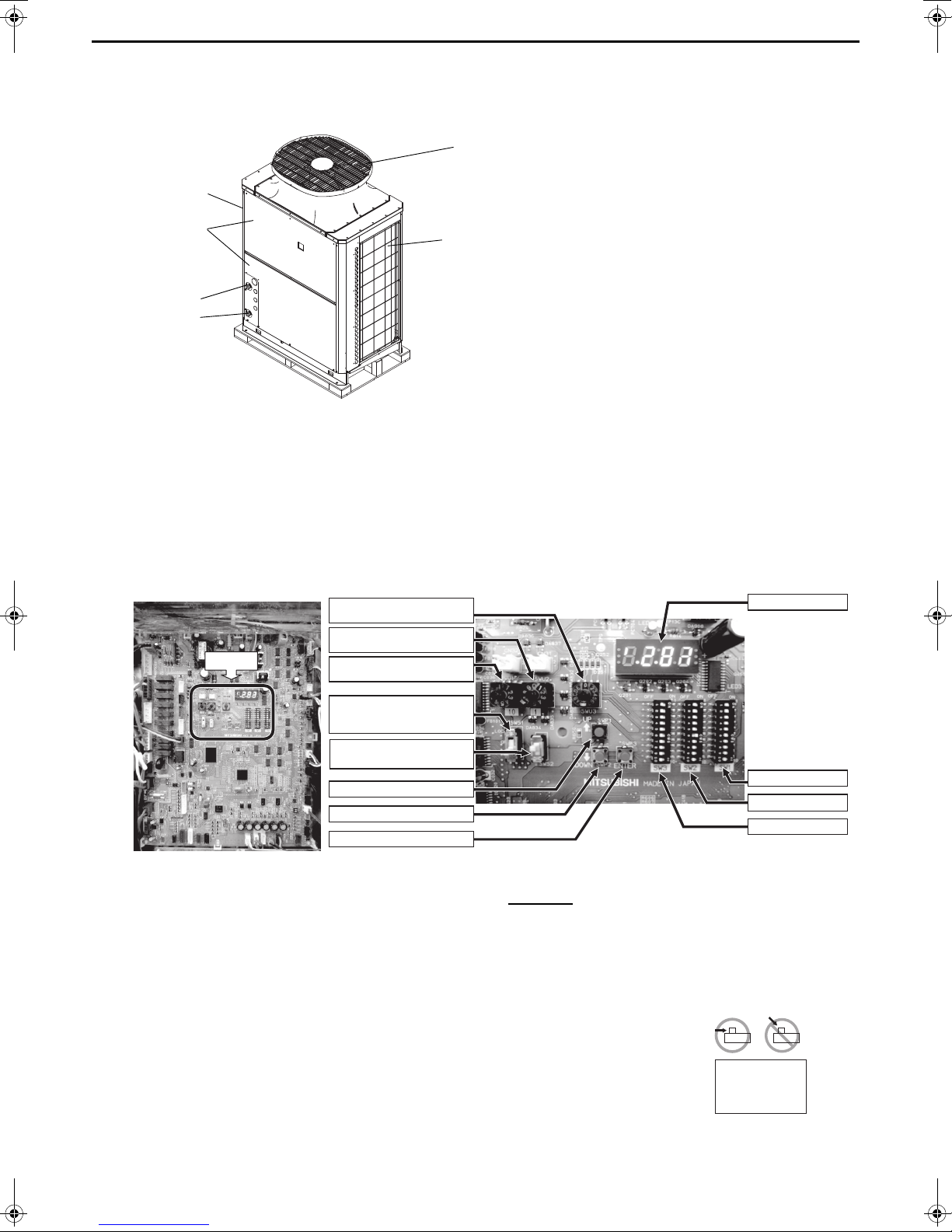

[2] Switch Types and the Factory Settings

Discharge air outlet

Service panel

Control box

Intake air inlet

Rotary switch (SWU3) (0-F)

Rotary switch (SWU2) (0-9)

Rotary switch (SWU1) (0-9)

Slide switch (SWS1)

(LOCAL, OFF, and REMOTE

from the top)

Push switch (SWP1) "UP"

Push switch (SWP2) "DOWN"

Push switch (SWP3) "ENTER"

Slide switch (SWS2) *

(A and B from the top)

Switches

[Entire view of a PCB] [Enlarged view of the switches]

LED display

Dip switch (SW1)

Dip switch (SW2)

Dip switch (SW3)

Slide the dip

switches; do not

push down the

switches.

(1) Switch names and functions

Wate r outl et

Water inlet

There are four main ways to set the settings as follows:

1Dip switches (SW1 - SW3)

2Dip switches used in combination with the push switches

3Rotary switches

4Slide switches

See below for how these switches are used to set certain items.

Different types of switches on the PCB

Set the slide switch SWS2 on the board inside the control box to the lower side during the trial run.

By default, it is set to the upper side for forced stop of the pump and compressor to prevent the pump

being damaged by the anti-freezing process in no water passing status or valve closed status before

the test run.

Upper side: A (under preparation)

Lower side: B (auto)

Always set to the lower side.

* Setting to the upper side forcefully stops the pump and compressor thus the unit does not

operate.

* When SWS2 is set to the upper side, the display shows “P.OFF” and the setting cannot be

made. When “P.OFF” appears, set SWS2 to the lower side.

23

Page 24

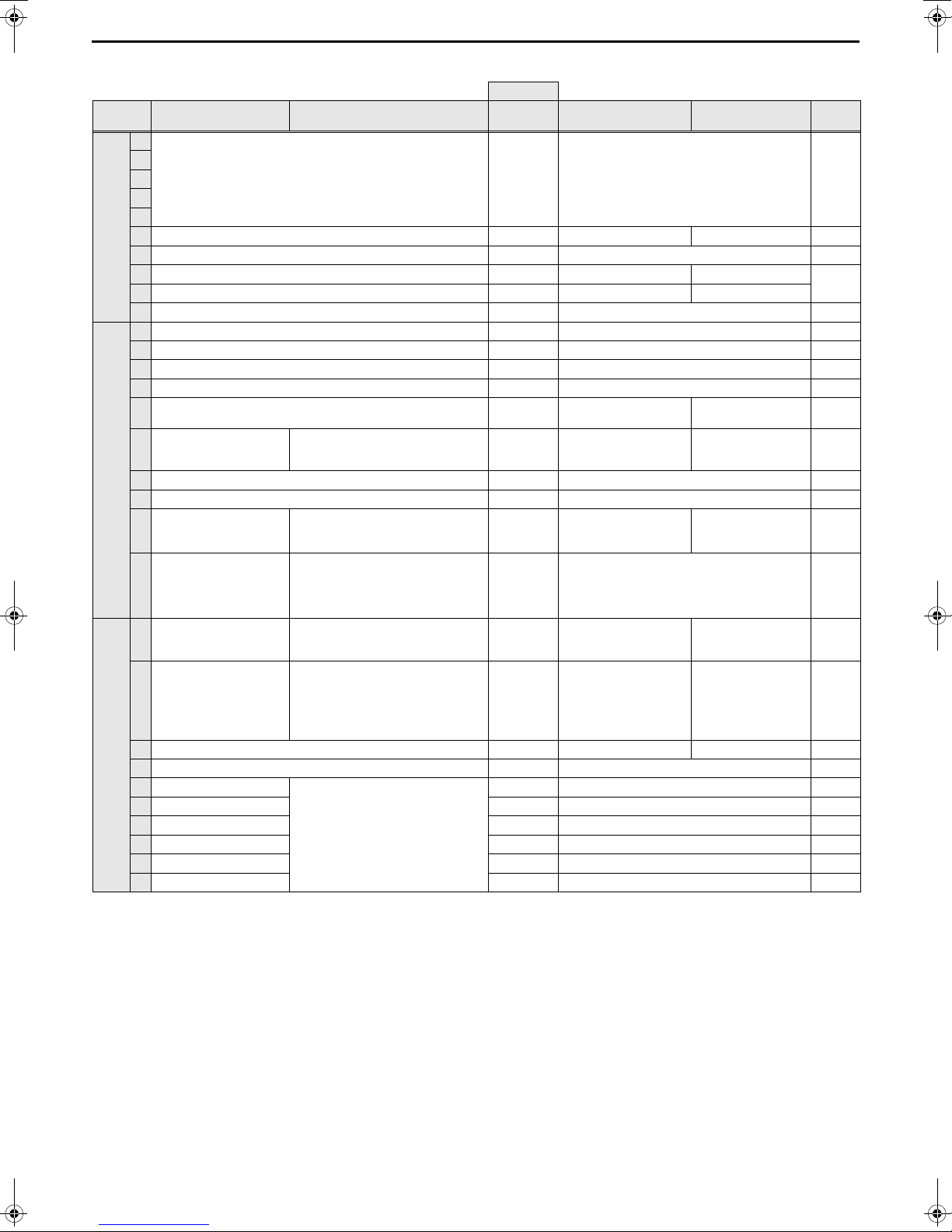

(2) Factory Switch Settings (Dip switch settings table)

Factory setting

SW Function Usage MAIN circuit OFF setting ON setting

1

2

3

Model setting

4

5

SW1

6 Test run 1 OFF - Operation during test run Any time

7 Not used OFF Leave the setting as it is. At a reset

8 Test run 2 OFF - Operation during test run

9 Test run 3 OFF - Operation during test run

10 Model setting ON Leave the setting as it is. At a reset

1 Model setting OFF Leave the setting as it is. At a reset

2 Model setting OFF Leave the setting as it is. At a reset

3 Model setting OFF Leave the setting as it is. At a reset

4 Model setting OFF Leave the setting as it is. At a reset

5 Freeze-up protection method switching OFF

Power supply option to the

6

SW2

SW3

"-" in the table indicates that the function in the corresponding row will be disabled regardless of the actual switch setting.

The factory setting for these items is OFF.

Refer to page 32 for how to reset errors.

communication circuit

7 Model setting OFF Leave the setting as it is. At a reset

8 Model setting OFF Leave the setting as it is. At a reset

1Individual/Multiple system

9

2AE connection

10 Display mode switch 7

1 Remote reset

Auto restart after power

2

failure

3 Test run 4 OFF - Operating during test run Any time

4 Function switching (Do not change this setting.) OFF Leave the setting as it is. At a reset

5 Display mode switch 1

6 Display mode switch 2 OFF Changes the 7-segment LED display mode. Any time

7 Display mode switch 3 OFF Changes the 7-segment LED display mode. Any time

8 Display mode switch 4 OFF Changes the 7-segment LED display mode. Any time

9 Display mode switch 5 OFF Changes the 7-segment LED display mode. Any time

10 Display mode switch 6 OFF Changes the 7-segment LED display mode. Any time

Switches between supplying or not

supplying power to the communication

circuit.

1Selects between individual and Multiple

system

2Selects AE connection or not

This switch is used in combination with dip

switches SW3-5 through 3-10 and push

switches SWP 1, 2, and 3 to configure or

view the settings when performing a test

run or changing the system configuration.

Enables or disables the error to be reset

from a remote location.

Enables or disables the automatic

restoration of operation after power failure

(in the same mode as the unit was in

before a power failure).

These switches are used in combination

with dip switches SW2-5 and push

switches SWP 1, 2, and 3 to configure or

view the settings when performing a test

run or changing the system configuration.

Depends on

the unit

ON

OFF Individual system

OFF Changes the 7-segment LED display mode. Any time

ON

ON

OFF Changes the 7-segment LED display mode. Any time

Leave the setting as it is. At a reset

Pump operation +

heater energization

Does not supply power to

the communication circuit.

Disables the error to be

reset from a remote

location.

An alarm will be issued

when power is restored

after a power outage.

The alarm will be reset

when the power is turned off

and then turned back on.

Compressor operation +

heater energization

Supplies power to the

communication circuit.

Multiple system or during

AE connection

Enables the error to be

reset from a remote

location.

Automatically restores

operation after power

failure.

Setting

timing

Any time

At a reset

Any time

At a reset

At a reset

Any time

24

Page 25

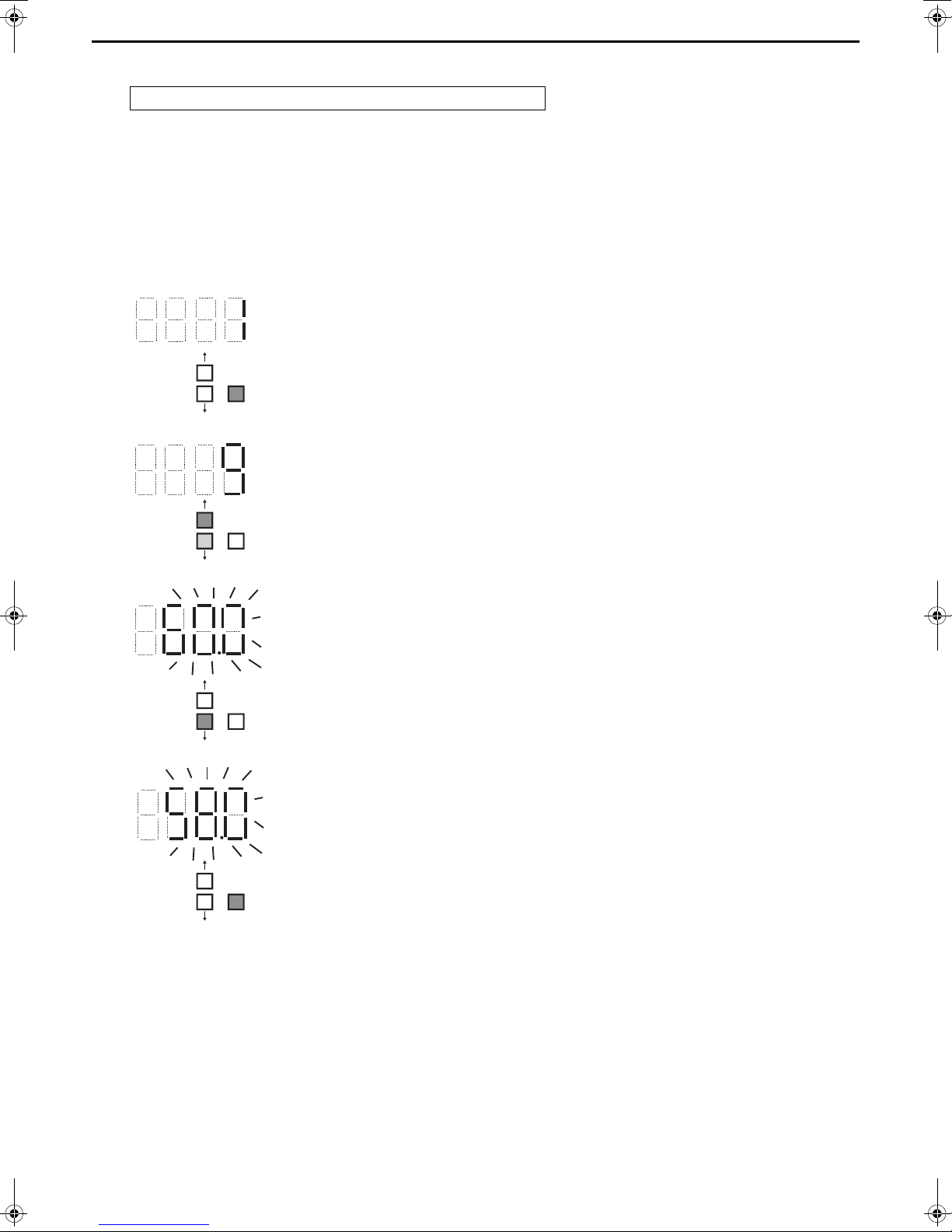

[3] Configuring the Settings

The settings must be set only by a qualified personnel.

<1> Making the settings

Use the LED display and the three push switches (SWP1 (), SWP2 (), and SWP3 (Enter)) to change the current

settings on the circuit board and to monitor various monitored values.

(1) Setting procedures

Take the following steps to set the push switches SWP1 through SWP3. These switches must be set after the dip

switches SW2 and SW3 have been set.

1 Normally an item code appears on the display.

(The figure at left shows the case where item code 1 is displayed.) Press SWP3

(Enter) to advance the item code.

SWP1

SWP2

SWP3

Enter

2 The left figure shows a display example (Code 9 Outlet hot water temperature

SWP1

SWP2

SWP3

Enter

Press SWP3 (Enter) until the item code appears that corresponds to the item to change or

monitor its value.

setting).

Press either SWP1 () or SWP2 () to display the value that corresponds to the

selected item.

3 The current setting value will blink.

The left figure shows that the current setting value is "60.0."

To decrease this value to 58.0, for example, press SWP2 ().

Press SWP1 () to increase the value.

SWP1

SWP2

SWP3

Enter

4 <To change the settings>

When the desired value is displayed (58.0 in the example at left), press SWP3 (Enter).

The displayed value will stop blinking and stay lit.

A lit LED indicates that the new setting has been saved.

SWP1

SWP2

SWP3

Enter

* Pressing SWP1 () or SWP2 () will change the blinking setting value, but the

change will not be saved until SWP3 (Enter) is pressed.

If SWP3 is not pressed within one minute, the change will not be saved and the

display will return to the item code display mode.

Press and hold SWP1 () or SWP2 () for one second or longer to fast forward

through the numbers.

<To view the monitored data>

Press SWP3 (Enter) while the LED display is blinking (see step 3 above) to stop the

blinking.

* The values of the items that can only be monitored will not change when SWP1 ()

or SWP2 () is pressed.

The display will stop blinking and stay lit after a minute, and the display will

automatically return to the item code display regardless of the type of values

displayed.

To change the values of other items, repeat the steps from step 2 above.

25

Page 26

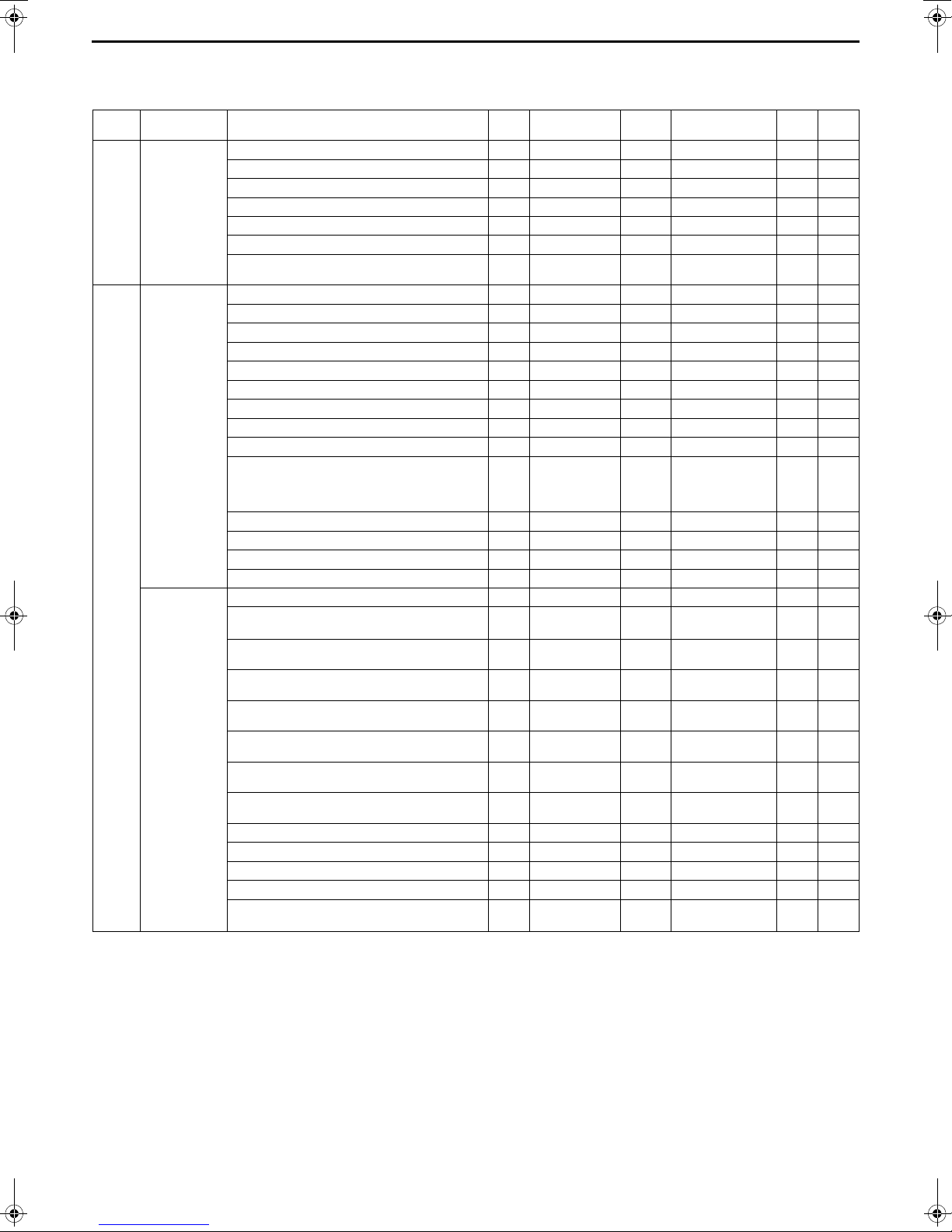

(2) Table of settings items

Set the dip switches SW2 and SW3 as shown in the table below to set the value for the items in the "Setting item" column.

Basic

settings

Basic

settings

Dip switch

settings

SW2-10: OFF

SW3-5, 6, 7: OFF

SW3-8, 9, 10: ON

SW2-10: OFF

SW3-5~8, 10:

OFF

SW3-9: ON

SW2-10: OFF

SW3-5~7, 9, 10:

OFF

SW3-8: ON

Setting item

Unit address 105 - 1 8 2

Number of connected GS to M-NET 106 - 0 16 1

AE-200 connection (0: Not connected, 2: Connected) 107 - 0 2 0

Function 1 (Sub sensor: 2, Main sensor: 1, Sub unit: 0) 110 - 0 2 0

M-NET address of main sensor of own tank 111 - 1 50 1

Address of sensor connection unit 112 - 1 51 51

Secondary control availability

(0: Not available 1: Available)

Model display 0 - - - -

Current time 1 Hour and minutes 0:00 23:59 -

Current inlet water temperature (display function only) c01 ºC - - -

Current outlet water temperature (display function only) c02 ºC - - -

Outdoor temperature (display function only) c03 ºC - - -

Storage tank water temperature (display function only) c04 ºC - - -

Demand control - maximum capacity setting 2 % 0 100 100

Demand control - start time 3 Hour and minutes 0:00 23:59 13:00

Demand control - end time 4 Hour and minutes 0:00 23:59 16:00

Outlet hot water temperature (boiling temperature) 9 ºC 40

High- and low-pressure display interval P 1051 Seconds 0 100 3

Low noise operation - maximum capacity 1054 % 0 100 70

Low noise operation - start time 1058 Hour and minutes 0:00 23:59 0:00

Low noise operation - end time 1059 Hour and minutes 0:00 23:59 0:00

Thermo-ON prohibition time Sjs1 1025 Seconds 0 480 60

Sensor method setting

(0: Local control, 1: Three-sensor, 2: Six-sensor)

Mode 1 Thermo-ON thermistor selection 1500 - 1

Mode 1 Thermo-OFF thermistor selection 1501 - 1

Mode 2 Thermo-ON thermistor selection 1502 - 1

Mode 2 Thermo-OFF thermistor selection 1503 - 1

Mode 3 Thermo-ON thermistor selection 1504 - 1

Mode 3 Thermo-OFF thermistor selection 1505 - 1

Number of water control modes 1507 - 1 3 1

Mode 1 Thermo differential value 1508 - 0 30 10

Mode 2 Thermo differential value 1509 - 0 30 10

Mode 3 Thermo differential value 1510 - 0 30 10

Anti-freezing setting

(0: Outdoor, 1: Indoor)

Item

code

121 - 0 1 0

1214 - 0 2 0

1514 - 0 1 0

Unit

Lower

limit

Upper limit

Secondary contlol

disabled: 90.0

Secondary contlol

enabled: 80.0

Six-sensor system: 6

Other system: 3

Six-sensor system: 6

Other system: 3

Six-sensor system: 6

Other system: 3

Six-sensor system: 6

Other system: 3

Six-sensor system: 6

Other system: 3

Six-sensor system: 6

Other system: 3

Initial

value

65

3

3

1

2

1

3

Setting

value

26

Page 27

(3) System configuration procedures: Individual system

A

ON

1

2345678910

ON

1

2345678910

ON

1

2345678910

10’s digit (0) 1 ’s digit (1)

(0)

10’s digit (0) 1’s digit (1)

(0)

1. Set the dip switches on the MAIN circuit board.

Set the dip switches (labeled A in the figure at right) that correspond to the

local system.

Refer to “Factory Switch Settings (Dip switch settings table)” (page 24) for

further details.

• When AE-200 is connected, set the dip switch 2-9 to ON.

2. Switch on the power to the unit.

Check for loose or incorrect wiring, and then switch on the power to the

unit.

When the power is switched on, the following codes will appear on the LED:

• [EEEE] will appear on LED1 in the circuit board (labeled A in the figure

at right).

[--ng] is displayed before the water flow rate adjustment operation is

performed. Cancel the [--ng] display by using one of the following

methods.

•Press SWP3.

•Press SWP1 or SWP2.

A

ON

ON

1

2345678910

ON

1

1

2345678910

2345678910

27

Page 28

3. Set the preset values with the switches on the circuit board.

10’s digit (0) 1’s digit (1)

(0)

B

(1) Set the dip switches SW2 and SW3 by following the procedure in

page 49. (Set the dip switches 3-8, 3-9, and 3-10 to ON.)

* [EEEE] will disappear, and an item code ([101]) will appear on LED1

(labeled B in the figure at right).

(2) Use SWP3 to toggle through the item codes and select an item code to

ON

1

1

2345678910

2345678910

change its current value. (The item codes will appear in the following

order: [101][104][105][106] [107]....)

(3) Use SWP1 to increase the value and SWP2 to decrease the value.

(4) Press SWP3 to save the changed value.

(5) Set the dip switches 3-8, 3-9, and 3-10 to OFF.

(6)

When connecting AE-200, perform the procedures described in 4 on

A

page 31.

Following the steps above, set the value for the following items as necessary.

[101] Not used

[104] Not used

[105] Function setting (When AE-200 is not connected to QAHV, the values set by rotary switches SWU1 and SWU2

are set as the preset values. When AE-200 is connected to QAHV, set the preset values referring to the notes

below.)

[106] Total number of units in the system (Initial value: 1) (Leave it as it is.)

[107] “2” when connected to AE-200 (Initial value: 0)

[108] Not used

[109] Not used

[110] Function setting (“1” when connected to AE-200) (Initial value: 0)

[111] M-NET address of main sensor of own tank (Initial value: 1)

[112 to 120] Not used

[121] Secondary side control is enabled when “1” is set. (Initial value: 0)

ON

ON

1

2345678910

ON

2345678910

1

The figure at left shows that the switches 1 through 5 are set to ON and 6 through 10 are set to OFF.

* When connecting AE-200 and remote controller (PAR-W31MAA) simultaneously, make the settings above, and

then turn off the power, turn it back on, and set “1” for item code [105]. After these settings, perform the

procedures described in (5) on page 32.

* Set SWS1 to OFF from the remote controller or with the local switch.

Settings cannot be changed unless the ON/OFF switch is set to OFF.

28

Page 29

(4) System configuration procedures : Multiple system

External

water

temperature

sensor

Field-supplied dry contact

switch/relay or remote

controller (PAR-W31MAA) or

centralized controller (AE-200)

SW2-9: ON

Address: 1

SW2-6: OFF

SW2-9: ON

Address: 2

SW2-6: OFF

SW2-9: ON

Address: 1 + n

Inter-unit wiring

(M-NET line)

* The main unit is the unit to which an external water temperature sensor is connected.

Main

unit

Sub unit

"n"th unit

Unit (MAIN circuit)

PCB

Unit (MAIN circuit)

PCB

Sub unit

Unit (MAIN circuit)

PCB

10’s digit (0) 1’s digit (1)

(0)

10’s digit (0) 1’s digit (1)

(0)

1. Set the dip switches and rotary switches.

(Switches on the main unit* AND on all sub units)

System configuration diagram

Setting the switches on the main unit

Set the dip switch SW2-9 to ON. (multiple unit control) (labeled A in the figure

at right)

Refer to “Factory Switch Settings (Dip switch settings table)” (page 24) for

further details.

Make sure the address of the main unit is set to "1" (labeled B in the figure at

right).

ON

2345678910

1

The figure at left shows that the switches 1 through 5 are set to ON and 6 through 10 are set to OFF.

Setting the switches on all sub units

(1) Set the dip switch SW2-9 to ON. (multiple unit control) (labeled A in the figure

at right)

(2) Set the addresses with the rotary switches. (labeled B in the figure at right).

Set the 10's digit with SWU1, and set the 1's digit with SWU2. Assign

sequential addresses on all sub units starting with 2.

(3) Set the dip switch SW2-6 to OFF. (power supply to communication circuit)

29

ON

ON

1

2345678910

ON

1

1

2345678910

2345678910

AB

ON

ON

1

2345678910

ON

1

1

2345678910

2345678910

AB

Page 30

2. Switch on the power to the unit.

ON

1

2345678910

ON

1

2345678910

ON

1

2345678910

[EEEE] [EEEE]

ON

1

2345678910