Mitsubishi Electric SW0DNC-MNETH-B, Q80BD-J71LP21S-25, Q80BD-J71LP21G, Q80BD-J71LP21-25, Q80BD-J71BR11 User Manual

...Page 1

MELSECNET/H Interface Board

User's Manual (For SW0DNC-MNETH-B)

-Q80BD-J71LP21-25

-Q80BD-J71LP21S-25

-Q81BD-J71LP21-25

-Q80BD-J71LP21G

-Q80BD-J71BR11

Page 2

Page 3

SAFETY PRECAUTIONS

(Be sure to read these instructions before using the product.)

Before using this product, read this manual and the relevant manuals introduced in this manual carefully

and handle the product correctly with full attention to safety.

Note that these precautions apply only to this product. Refer to the user's manual of the CPU module for

safety precautions on programmable controller systems.

In this manual, the safety instructions are ranked as "

WARNING " and " CAUTION".

WARNING

CAUTION

Note that failure to observe the !CAUTION level instructions may also lead to serious results depending

on the circumstances.

Be sure to observe the instructions of both levels to ensure personal safety.

Please keep this manual in accessible place and be sure to forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[Design Instructions]

!

WARNING

Make sure to see this manual for information about each station's operating status when a

communication error occurs in the network. Erroneous outputs and malfunctions may result in

serious accidents.

If a coaxial cable is disconnected, this may destabilize the line, and a data link communication

error may occur in multiple stations. Make sure to create an interlock circuit in the sequence

program so that the system will operate safely even if the above error occurs. Failure to do so

may result in a serous accident due to faulty output or malfunctions.

Provide a safety circuit outside the programmable controller so that the entire system will

operate on the safety side even when an error occurs with the personal computer.

There is a risk of an accident due to faulty output or malfunctioning.

(1) Construct circuits outside the programmable controller, including an emergency stop circuit,

protection circuit, interlock circuit for reciprocal operations such as forward and reverse, and

interlock circuit for positioning high and low limits to prevent damage to the equipment.

(2) If the station in which the board is installed is disconnected from the data link due to a data

link error, the data output from that station and written in other stations will remain the same

as immediately before the error occurred in the data link. This data will be retained until the

data link for that station is reopened (returned to system).

Provide a mechanism to monitor the status of data link and handle errors for each station

that is connected to the data link system.

A - 1 A - 1

Page 4

[Design Instructions]

!

CAUTION

Do not bunch the control wires or communication cables with the main circuit or power wires, or

install them close to each other.

They should be installed 100 mm (3.94 inch) or more from each other.

Not doing so could result in noise that would cause malfunctioning.

[Installation Instructions]

!

CAUTION

Use the board in an environment as described in the general specifications listed in this

operating manual.

If the board is used in an environment outside the ranges described in the general

specifications, it may result in an electric shock, fire, malfunctioning, damage to or deterioration

of the product.

Be sure to shut off all phases of the external power supply used by the system before installing

or removing the board. If all power is not turned off, this will result in failure of the board or

malfunctioning.

Install the board to a personal computer which is compliant with PCI standard or PCI Express

standard (Refer to "Section 2.5 Operating Environment"). Failure to do so may cause a failure or

malfunction.

Securely mount the board to the PCI slot of the mounting device.

If the board is not mounted correctly, this may lead to malfunctioning, failure or cause the board

to fall.

Insert the communication cable securely into the board connector. After it has been inserted,

check to make sure that it is not being lifted up.

A faulty connection can lead to faulty input or output.

When mounting the board, take care not to become injured by the components that are installed

or surrounding materials.

Always make sure to touch the grounded metal to discharge the electricity charged in the body,

etc., before touching the board.

Failure to do so may cause a failure or malfunctions of the board.

R

When installing the board, take care not to contact with other boards.

A - 2 A - 2

Page 5

[Wiring Instructions]

!

WARNING

Be sure to shut off all phases of the external power supply used by the system before

performing work such as installing the board and wiring.

If all power is not turned off, there is a risk of electric shock or damage to the product.

When turning on the power and operating the module after having installed the board and doing

the wiring, always attach the cover for the device module in which the board is installed.

There is a risk of electric shock if the module cover is not attached.

!

CAUTION

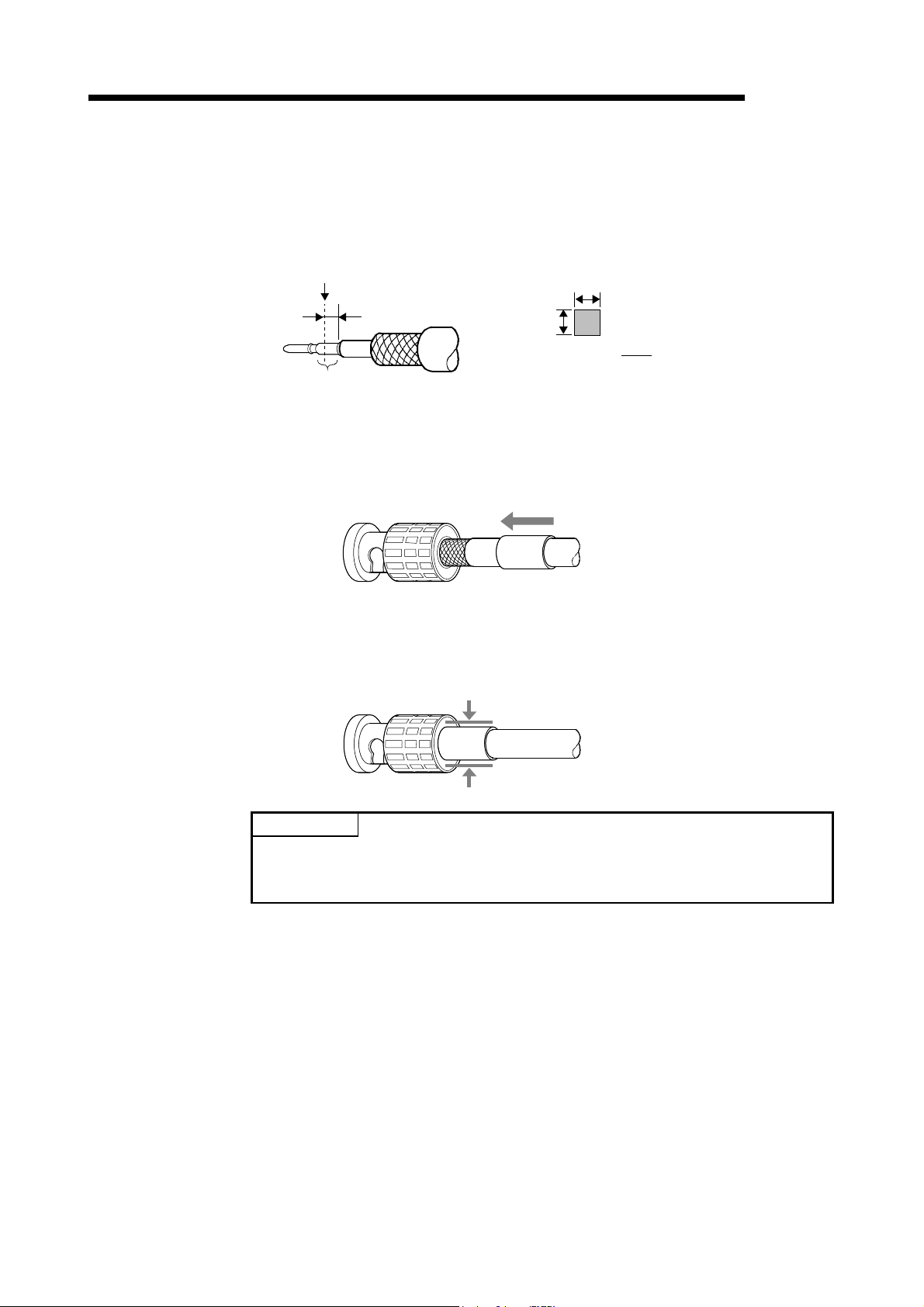

Properly solder the parts of a soldering-type coaxial cable connector. Incomplete soldering may

result in malfunction.

Crimp the parts of a crimping-type coaxial cable connector with proper force at a proper position.

Failure to do so may cause drop of the cable or malfunction.

For the communication cable, specialized skills and tools are required to connect the plug and

cable. The connector plug itself is a custom part.

When purchasing, consult your local Mitsubishi representative.

If the connection is incomplete, this can result in a short, fire or malfunction.

Be sure to fix communication cables connecting to the board by placing them in the duct or

clamping them.

Cables not placed in the duct or without clamping may be hang freely and accidentally pulled,

which may cause damage to the board or cable, or malfunction due to bad cable contacts.

When removing the cable from the board, do not pull the cable.

Pulling the cable that is still connected to the board may cause damage to the board or cable, or

malfunction due to bad cable contacts.

Prevent foreign matter such as chips or wiring debris from getting on the board.

Failure to do so can result in fire, breakdowns or malfunction.

Verify the rated voltage and pin assignment of the product and connect the external power

supply cable properly.

Connecting a power supply with a different voltage rating, imperfect cable crimping or faulty

wiring may cause a fire or failure.

Use a specified tool for crimping of the cable and contacting pin. Imperfect crimping may cause

malfunction.

Verify the pin assignment and fully insert the crimped contacting pin into the connector.

Imperfect insertion may cause failure or malfunction.

Insert the wired external power supply cable into the external power supply cable connector until

a click is heard. Imperfect insertion may cause failure or malfunction.

Keep the external power supply cable away from the main circuit cable, power cables and/or

load cables connected to other than programmable controllers. Ensure a distance of 100mm

(3.94 in.) between them. Failure to do so may result in malfunction due to noise, surge or

induction.

Always ground the personal computer. Failure to do so may cause malfunction.

A - 3 A - 3

Page 6

[Startup/Maintenance Instructions]

!

WARNING

Do not attach or remove the communication cable while the power supply is on.

This may result in malfunctioning.

Tighten the board fixing screws after turning off the power supply.

There is a risk of electric shock if the screws are tightened while power is on.

!

CAUTION

Thoroughly read the operating manual and carefully check to make sure everything is safe

before performing operations such as making changes to the program while the module is

operating, forced outputs, RUN, STOP and PAUSE.

Operation errors will result in damage to the equipment or accidents.

Do not dismantle or rebuild the board.

This will result in breakdowns, malfunctioning, injury or fire.

Be sure to shut off all phases of the external power supply used by the system before installing

or removing the board.

If all power is not turned off, this will result in failure of the board or malfunctioning.

The board internal microprocessor reaches very high temperatures when it is running. Do not

touch it directly when replacing the board.

This will result in breakdowns, malfunctioning or injury.

Always make sure to touch the grounded metal to discharge the electricity charged in the body,

etc., before touching the board.

Failure to do so may cause a failure or malfunctions of the board.

[Disposal Instructions]

!

CAUTION

When disposing of this product, treat it as industrial waste.

A - 4 A - 4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION

NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING

CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 5 A - 5

Page 8

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Nov., 2000 SH (NA)-080128-A First printing

Mar., 2001 SH (NA)-080128-B

Model addition

Q80BD-J71LP21G, Q80BD-J71LP21GE

Correction

Section 1.3, Appendix 3.1

Jun., 2001 SH (NA)-080128-C

Correction

About the Generic Terms and Abbreviations, Section 1.2, Section 1.3,

Section 2.5, Section 7.1, Section 7.1.1, Section 7.1.2, Section 7.4,

Section 8.2.3, Section 9.1.2, Section 9.2, Section 10.3.2, Section 10.4,

Appendix 3, Appendix 3.1

Addition

Section 10.8, Section 12.2, Chapter 13

Jan., 2002 SH (NA)-080128-D

Correction

Section 2.5, Section 3.1, Section 3.2, Section 5.6, Section 9.1.2,

Section 10.7, Section 12.2, Section 12.2.2

Addition

About the Generic Terms and Abbreviations, Sections 9.1.2,

Chapter 13

Dec., 2002 SH (NA)-080128-E

Correction

Safety Precautions, Section 8.2.3, Section 8.2.8, Section 8.3.3,

Section 9.1.2, Chapter 10, Section 12.2, Appendix 3.1, Appendix 4.1,

Appendix 4.2

Addition

Precautions for use, Generic Terms and Abbreviations, Section 1.2,

Section 1.3, Section 2.5, Section 5.4.2, Section 7.1.1, Section 7.1.2,

Section 7.2, Section 7.3, Section 8.1.1, Section 10.3, Chapter 13,

Section 14.3, Section 14.3.1, Section 14.5.4, Section 14.6

May, 2004 SH (NA)-080128-F

Correction

Safety Precautions, Precautions for use, Section 3.1, Section 3.2,

Section 6.3.1, Section 8.2.5, Section 8.2.10, Section 12.2, Section 12.2.1,

Section 12.2.2, Section 12.2.3, Section 12.3.3, Chapter 13,

Section 14.4.4, Section 14.7, Appendix 5.1

Addition

Generic Terms and Abbreviations, Section 1.2, Section 1.3, Section 2.4,

Section 2.5, Section 4.2.1, Section 5.2.1, Section 5.3, Section 5.4.3,

Chapter 6, Section 6.3.6, Section 8.2.1, Section 8.2.3, Section 10.3,

Section 10.3.3, Section 10.3.4, Section 10.8, Section 11.3, Chapter 12,

Section 14.4, Section 14.5.5, Section 14.6, Appendix 3

A - 6 A - 6

Page 9

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Dec., 2004 SH (NA)-080128-G Chapter numbers of 5 to 14 were changed to 6 to 15 respectively.

Correction

Precautions for use, Generic Terms and Abbreviations, Chapter 1,

Section 1.1, Section 1.2, Section 1.3, Section 2.1, Section 2.4,

Section 2.5, Section 3.2, Chapter 7, Section 7.1, Section 7.2.4,

Section 9.2.2, Section 9.2.3, Section 9.2.5, Section 9.2.10,

Section 9.2.11, Section 10.1.2, Section 10.2, Section 13.2.1,

Section 15.4.3

Addition

Section 2.6, Chapter 5, Section 15.7

Jun., 2005 SH (NA)-080128-H

Model addition

Q80BD-J71LP21S-25

Correction

SAFETY PRECAUTIONS, INTRODUCTION,

Generic Terms and Abbreviations, Product List,

Section 1.2, Section 2.1, Section 2.5, Section 3.2, Section 4.1,

Section 6.1, Section 6.3, Section 6.4, Section 6.5, Section 6.6,

Section 7.2.1, Section 8.1.2, Section 9.2.2, Section 9.2.6,

Section 9.3.5, Section 11.4, Section 11.6, Section 12.3, Chapter 13,

Chapter 14, Section 15.2, Section 15.4.4, Section 15.6, Section 15.7,

Section 15.8, Appendix 4, Appendix 5

Addition

Section 6.4.4, Section 15.6, Appendix 4, Appendix 6.2

Jul.,2005 SH(NA)-080128-I

Correction

Section 2.5, Appendix 6.2

Oct.,2005 SH(NA)-080128-J

Correction

Section 2.5, Section 8.1.1, Section 8.1.2, Section 8.3, Section 9.1,

Section 15.2

Mar., 2007 SH(NA)-080128-K

Correction

Generic Terms and Abbreviations, Section 2.2.4, Section 2.5,

Section 6.4.1, Section 6.4.2, Section 8.1.1, Section 8.1.2, Section 10.1.2,

Section 10.2, Section 11.2, Section 11.6, Section 11.8, Section 15.4.5

Addition

Section 11.3.5, Section 11.3.6, Section 11.7

Oct., 2007 SH(NA)-080128-L

Correction

Generic Terms and Abbreviations, Section 1.2, Section 1.3, Section 2.5,

Chapter 5, Section 8.1.1, Section 8.3, Section 9.1, Chapter 14,

Section 15.2, Section 15.3.1

Section 8.1.2 changed to Section 8.1.3

Addition

Section 8.1.2, Appendix 5

Jan., 2008 SH(NA)-080128-M

Correction

Generic Terms and Abbreviations, Section 2.5, Section 6.5.1,

Section 6.5.2, Section 6.5.3, Section 6.6.1, Section 6.6.2, Section 8.1.1,

Section 8.1.3, Section 10.1.2, Section 10.2, Section 11.6, Section 11.7

A - 7 A - 7

Page 10

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

May, 2008 SH(NA)-080128-N

Model addition

Q81BD-J71LP21-25

Correction

SAFETY PRECAUTIONS, Precautions for Use, INTRODUCTION,

Generic Terms and Abbreviations, Product List, Section 1.2,

Section 1.3, Section 2.1, Section 2.5, Section 3.1, Section 3.2,

Section 6.3, Section 6.4.1, Section 6.4.3, Section 6.5.1, Section 6.5.2,

Section 6.5.3, Section 6.6.1, Section 6.6.2, Section 8.1.1, Section 8.1.3,

Section 8.2, Section 8.3, Section 9.1, Section 9.1.1, Section 9.2.2,

Section 9.2.6, Section 10.1.2, Section 11.3, Section 15.2, Section 15.3,

Section 15.4.4

Appendix 3 to 6 changed to Appendix 2 to 5

Addition

Appendix 5.4

Deletion

Appendix 2, Appendix 2.1

Jun., 2008 SH(NA)-080128-O

Correction

Section 1.3, Section 2.5, Section 9.2.4, Section 15.4.4,

Appendix 4.2

Oct., 2008 SH(NA)-080128-P

Jul., 2009 SH(NA)-080128-Q

Oct., 2009 SH(NA)-080128-R

Dec., 2010 SH(NA)-080128-T

Mar., 2011 SH(NA)-080128-U

May, 2011 SH(NA)-080128-V

Addition

Generic Terms and Abbreviations, Section 2.5, Section 10.1.2

Addition

Product List, Chapter 5, Appendix 4.1

Addition

Section 8.1.3, Section 11.4, Section 13.3.4, Section 15.2

Correction

SAFETY PRECAUTIONS, Section 2.6, Section 4.1, Section 11.6,

Section 11.7, Section 12.1.1, Section 13, Section 13.1, Section 14

Correction

Section 2.5

Addition

Appendix 2

Correction

Product List, Chapter 7, Section 9.2.2, Section 15.2, Appendix 1,

Appendix 5.2

Appendix 3 to 6 changed to Appendix 4 to 7

Correction

Precautions for Use, Chapter 8

Deletion

Section 8.3

A - 8 A - 8

Page 11

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Sep., 2011 SH(NA)-080128-W

Correction

SAFETY PRECAUTIONS, INTRODUCTION, Manuals,

How to Use This Manual, Generic Terms and Abbreviations,

Product List, Section 1.2, Section 2.1, Section 2.5, Section 3.1,

Section 3.2, Section 5.1.1, Section 6.2.1, Chapter 7, Section 8.1,

Section 8.1.1, Section 8.1.2, Section 8.1.3, Section 8.2, Section 9.1.1,

Section 9.3.5, Section 9.3.6, Section 9.3.7, Section 9.3.8, Chapter 10,

Section 10.2, Section 12.3.4, Chapter 13, Section 14.2, Section 14.3.1,

Section 14.4.1, Section 14.4.2, Section 14.4.4, Section 14.4.5,

Section 14.5.1, Section 14.5.2, Section 14.5.3, Section 14.5.4,

Section 14.6, Appendix 2, Appendix 5.1,Appendix 6, Appendix 7, Appendix 8

Chapter 11 to 15 changed to Chapter 10 to 14

Section 2.6 changed to Appendix 7 and 8, Appendix 7 changed to Appendix 9

Deletion

Chapter 10, Section 11.3 to 11.9

Feb., 2012 SH(NA)-080128-X

Addition

Appendix 10, Appendix 11

Correction

Section 2.5, Section 8.1.1, Section 8.1.3, Section 8.2

Dec., 2012 SH(NA)-080128-Y

Correction

SAFETY PRECAUTIONS, GENERIC TERMS AND ABBREVIATIONS,

Section 2.1, Section 2.4, Section 2.5, Section 3.1, Section 3.2,

Section 6.4.2, Section 6.4.3, Section 8.1.2, Section 9.2.10

Sep., 2013 SH(NA)-080128-Z

Addition

Section 4.3, Section 6.3.3, Section 14.2, Section 14.2.1, Section 14.2.2,

Section 14.7.1, Section 14.7.2, Appendix 7, Appendix 9.3

Correction

SAFETY PRECAUTIONS, PRECAUTIONS FOR USE , MANUALS,

HOW TO USE THIS MANUAL, GENERIC TERMS AND ABBREVIATIONS,

Section 1.1, Section 1.2, Section 2.1, Section 2.5, Section 3.2, Section 4.1,

Section 6.1 to 6.5, Section 7.2.6, Section 7.3.1, Section 7.3.2, Section 8.1 to 8.3,

Section 9.1 to 9.2, Section 9.3.1, Chapter 10,Section 12.3.1, Section 12.3.4,

Chapter 14, Appendix ,

Section 6.6.1 to 6.6.2, changed 6.5.4 to 6.5.5, Section 8.1.3 changed 14.2.3,

Section 8.2 changed 8.3, Section 10.1 to 10.2 changed Chapter10,

Section 14.2 changed 14.1, Appendix 1 changed Section 6.3.4,

Appendix 2 changed Appendix 3, Appendix 3 to 4 changed Appendix 1 to 2,

Appendix 5 changed Appendix 8, Appendix 6 to 8 changed Appendix 4 to 6,

Appendix 9 changed Appendix 11, Appendix 10 to 11 changed Appendix 9 to 10

Deletion

Section 6.6, Section 8.1.1, Section 8.1.2, Section 9.1.3, Section 9.1.4,

Section 9.4

A - 9 A - 9

Page 12

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Apr., 2015 SH(NA)-080128-AA

Correction

GENERIC TERMS AND ABBREVIATIONS, Section 1.1, Section 2.5,

Section 8.1, Section 8.2, Section 9.1.1, Section 9.3.1, Section 9.3.2,

Section 9.3.3, Section 9.3.5, Section 9.3.6, Section 9.3.8,

Section 9.3.10, Section 14.1, Section 14.2.2, Section 14.2.3,

Section 14.3.2, Appendix 6.2, Appendix 8.2, Appendix 9.2, Appendix 9.3,

Appendix 10

Section 9.3.8 to Section 9.3.11 changed to Section 9.3.7 to Section 9.3.10

Deletion

Section 9.3.7

Sep., 2016 SH(NA)-080128-AB

Correction

Section 2.5, Section 8.1, Section 8.2, Section 9.1.1, Section 9.1.2,

Section 9.3, Section 14.1, Section 14.2.3, Section 14.2.4, Appendix 7,

Appendix 8.2, Appendix 9.1, Appendix 9.2, Appendix 10

Deletion

Section 9.3.1 to Section 9.3.10, Appendix 9.1

Sep., 2017 SH(NA)-080128-AC

Correction

Section 2.5, Section 8.1, Section 14.2.3

Japanese Manual Version SH-080129- AC

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

2000 MITSUBISHI ELECTRIC CORPORATION

A - 10 A - 10

Page 13

PRECAUTIONS FOR USE

(1) Transfer function between loops and routing transfers

(2) Remote I/O Network

(3) Restrictions for functions depending on the personal computer or

The MELSECNET/H board cannot be used as a relay station for the transfer

function between data links and during routing transfers.

If the transfer function between data links and routing transfers are used, use

the network module as a relay station.

The MELSECNET/H board cannot be used in a remote I/O net.

It can be used only in a PLC to PLC network.

the operating system

There are some restrictions for the functions or supported versions depending

on the operating system or personal computer to be used.

For the operating system, refer to Section 2.5.

(4) Driver installation and updating

Do not install or update the driver other than the method written in the

troubleshooting in this manual.

The consistency between the driver and utility cannot be identified, and CCLink IE Controller Network board may not operate properly.

A - 11 A - 11

Page 14

INTRODUCTION

Thank you for purchasing the Q80BD-J71LP21-25, Q81BD-J71LP21-25, Q80BD-J71LP21S-25, Q80BDJ71LP21G, Q80BD-J71LP21GE, Q80BD-J71BR11 MELSECNET/H Interface Board.

Before using this product, please read this manual and the relevant manuals carefully and develop

familiarity with the functions and performance of the Q80BD-J71LP21-25, Q81BD-J71LP21-25, Q80BDJ71LP21S-25, Q80BD-J71LP21G, Q80BD-J71LP21GE, Q80BD-J71BR11 MELSECNET/H Interface Board

to handle the product correctly.

CONTENTS

SAFETY PRECAUTIONS .............................................................................................................................. A- 1

CONDITIONS OF USE FOR THE PRODUCT ............................................................................................. A- 5

REVISIONS .................................................................................................................................................... A- 6

PRECAUTIONS FOR USE ............................................................................................................................ A-11

INTRODUCTION ............................................................................................................................................ A-12

CONTENTS .................................................................................................................................................... A-12

MANUALS ...................................................................................................................................................... A-17

HOW TO USE THIS MANUAL ...................................................................................................................... A-18

GENERIC TERMS AND ABBREVIATIONS ................................................................................................. A-20

MEANING AND CONTENTS OF THE TERMS ............................................................................................ A-21

PACKING LIST............................................................................................................................................... A-21

1 OVERVIEW 1- 1 to 1- 4

1.1 Overview.................................................................................................................................................. 1- 1

1.2 Features .................................................................................................................................................. 1- 2

2 SYSTEM CONFIGURATION 2- 1 to 2-12

2.1 MELSECNET/H Board System Configuration ....................................................................................... 2- 1

2.2 Single Network System ........................................................................................................................... 2- 3

2.2.1 Optical loop system .......................................................................................................................... 2- 3

2.2.2 Coaxial bus system .......................................................................................................................... 2- 3

2.2.3 Setting items ..................................................................................................................................... 2- 4

2.2.4 Usable device ranges ...................................................................................................................... 2- 4

2.3 Multiple Network System ........................................................................................................................ 2- 5

2.3.1 Configuration .................................................................................................................................... 2- 5

2.3.2 Setting items ..................................................................................................................................... 2- 6

2.3.3 Usable device range ........................................................................................................................ 2- 6

2.4 If used in a Multiple CPU System or Redundant CPU System ............................................................. 2- 7

2.5 Operating Environment ........................................................................................................................... 2- 8

3 SPECIFICATIONS 3- 1 to 3- 4

3.1 General Specifications ............................................................................................................................ 3- 1

3.2 Performance Specifications .................................................................................................................... 3- 2

3.3 Optical Fiber Cable Specification ........................................................................................................... 3- 4

3.4 Coaxial Cable Specification .................................................................................................................... 3- 4

A - 12 A - 12

Page 15

4 FUNCTION 4- 1 to 4- 6

4.1 Function List ............................................................................................................................................ 4- 1

4.2 Specifications of the Link Data Sending/Receiving Processing Time ................................................... 4- 2

4.2.1 Link data sending/receiving processing .......................................................................................... 4- 2

4.3 Driver WDT function ................................................................................................................................ 4- 5

5 EMC AND LOW VOLTAGE DIRECTIVE 5- 1 to 5- 6

5.1 Measures to comply with the EMC Directive ......................................................................................... 5- 1

5.1.1 EMC Directive related standards ..................................................................................................... 5- 2

5.1.2 Installation in a control panel ........................................................................................................... 5- 3

5.1.3 Cables ............................................................................................................................................. 5- 4

5.1.4 Ferrite core ....................................................................................................................................... 5- 5

5.1.5 Noise filter (power supply line filter) ................................................................................................. 5- 5

5.2 Requirements for Conformance to Low Voltage Directive .................................................................... 5- 6

6 PROCEDURE AND SETTINGS UP TO THE POINT OF OPERATION 6- 1 to 6-36

6.1 Procedure Up to the Point of Operation ................................................................................................. 6- 1

6.2 Part Names and Settings ........................................................................................................................ 6- 2

6.3 Installation ............................................................................................................................................... 6- 7

6.3.1 Handling precautions ....................................................................................................................... 6- 7

6.3.2 Installation environment ................................................................................................................... 6- 7

6.3.3 Board installation .............................................................................................................................. 6- 8

6.3.4 Channel No. settings ........................................................................................................................ 6- 9

6.4 Wiring ...................................................................................................................................................... 6-10

6.4.1 Optical loop system .......................................................................................................................... 6-12

6.4.2 Coaxial bus system .......................................................................................................................... 6-14

6.4.3 Connecting the connector for the coaxial cable .............................................................................. 6-19

6.4.4 External power supply cable wiring ................................................................................................. 6-23

6.5 Test .......................................................................................................................................................... 6-25

6.5.1 Self-loopback test ............................................................................................................................. 6-26

6.5.2 Internal self-loopback test ................................................................................................................ 6-28

6.5.3 H/W test ............................................................................................................................................ 6-30

6.5.4 Station to station test ........................................................................................................................ 6-31

6.5.5 Forward loop/Reverse loop test ....................................................................................................... 6-34

7 PARAMETER SETTINGS 7- 1 to 7-12

7.1 Board Information Settings ..................................................................................................................... 7- 2

7.2 Network Settings ..................................................................................................................................... 7- 3

7.2.1 Network No. ...................................................................................................................................... 7- 3

7.2.2 Station No. ........................................................................................................................................ 7- 3

7.2.3 Control station/Normal station ......................................................................................................... 7- 3

7.2.4 Group No. ......................................................................................................................................... 7- 4

7.2.5 Mode setting ..................................................................................................................................... 7- 4

7.2.6 Parameter setting example .............................................................................................................. 7- 5

A - 13 A - 13

Page 16

7.3 Common Parameters .............................................................................................................................. 7- 6

7.3.1 Send range for each station (LB/LW settings) ................................................................................ 7- 6

7.3.2 Send range for each station (LX/LY settings) ................................................................................. 7- 8

7.3.3 Total station ...................................................................................................................................... 7-10

7.3.4 Designation of the I/O master station .............................................................................................. 7-10

7.3.5 Reserved station setting .................................................................................................................. 7-10

7.3.6 Pairing Setting .................................................................................................................................. 7-10

7.4 Supplementary Setting ........................................................................................................................... 7-11

7.5 Control Station Return Setting ................................................................................................................ 7-12

8 INSTALLING AND UNINSTALLING SOFTWARE PACKAGE 8- 1 to 8- 4

8.1 Installation and Uninstallation Precautions ............................................................................................ 8- 1

8.2 Installation ............................................................................................................................................... 8- 2

8.3 Uninstallation ........................................................................................................................................... 8- 4

9 UTILITY OPERATIONS 9- 1 to 9-22

9.1 Starting and Ending Utility ...................................................................................................................... 9- 1

9.1.1 Starting a utility ................................................................................................................................. 9- 1

9.1.2 Ending a utility .................................................................................................................................. 9- 2

9.2 MNETH Utility .......................................................................................................................................... 9- 2

9.2.1 Screen configuration and basic operations ..................................................................................... 9- 3

9.2.2 Board list screen operation .............................................................................................................. 9- 4

9.2.3 Board information screen operation ................................................................................................ 9- 6

9.2.4 Routing Parameter Setting screen operation .................................................................................. 9- 8

9.2.5 Common parameter setting screen operation ................................................................................. 9- 9

9.2.6 Loop monitor screen operation ........................................................................................................ 9-13

9.2.7 Each station status screen operation .............................................................................................. 9-14

9.2.8 Error history monitor screen operation ............................................................................................ 9-15

9.2.9 Memory, I/O Test screen operation ................................................................................................. 9-18

9.2.10 Target screen operation ................................................................................................................. 9-19

9.2.11 Driver screen operation .................................................................................................................. 9-20

9.3 Device Monitor Utility .............................................................................................................................. 9-22

10 MELSEC DATA LINK LIBRARY 10- 1 to 10- 2

11 PROGRAMMING 11- 1 to 11- 6

11.1 Cautions in Programming ................................................................................................................... 11- 1

11.1.1 Interlock related signals ............................................................................................................... 11- 1

11.2 Cyclic Transmission ............................................................................................................................ 11- 3

11.2.1 Block guarantee of cyclic data per station ................................................................................... 11- 4

11.3 Link Special Relays (SB)/Registers (SW) .......................................................................................... 11- 5

A - 14 A - 14

Page 17

12 APPLICATION FUNCTIONS 12- 1 to 12-26

12.1 Direct Access to the Link Devices ...................................................................................................... 12- 1

12.2 Low-Speed Cyclic Transmission Function ......................................................................................... 12- 2

12.2.1 Send range settings ..................................................................................................................... 12- 3

12.2.2 Send timing................................................................................................................................... 12- 4

12.2.3 Startup .......................................................................................................................................... 12- 7

12.3 Transient Transmission Function ....................................................................................................... 12- 9

12.3.1 Communication function .............................................................................................................. 12-10

12.3.2 Routing function ........................................................................................................................... 12-13

12.3.3 Group function .............................................................................................................................. 12-21

12.3.4 SEND/RECV function .................................................................................................................. 12-22

12.4 Multiplex Transmission Function (Optical Loop System) .................................................................. 12-25

13 ERROR CODE 13- 1 to 13- 2

14 TROUBLESHOOTING 14- 1 to 14-28

14.1 Cause Determination Methods by Type of Trouble ........................................................................... 14- 2

14.2 Troubleshooting of Installation and Uninstallation ............................................................................. 14- 5

14.2.1 Installation failed ........................................................................................................................... 14- 5

14.2.2 Uninstallation failed ...................................................................................................................... 14- 5

14.2.3 When the instruction displayed on the screen is not effective at installation ............................. 14- 7

14.2.4 When the driver is not installed.................................................................................................... 14- 8

14.3 When MELSECNET/H Board did not Operate Normally ................................................................... 14-10

14.3.1 Checking personal computer and operating system .................................................................. 14-10

14.3.2 Checking on Event Viewer screen .............................................................................................. 14-11

14.3.3 Checking on Device Manager screen ......................................................................................... 14-13

14.4 Flowchart to Use when Data Link is not Achieved ............................................................................ 14-14

14.4.1 Flowchart to use when RUN LED is unlit .................................................................................... 14-15

14.4.2 Flowchart to use when SD/RD LED does not turn on ................................................................ 14-16

14.4.3 Flowchart to use when L.ERR. LED turns on ............................................................................. 14-17

14.4.4 Flowchart to use when unable to achieve data link for entire system ........................................ 14-18

14.4.5 Flowchart to use when unable to achieve data link for specific station ...................................... 14-20

14.5 Flowchart to Use when Error Occurred During Data Link ................................................................. 14-22

14.5.1 Flowchart to use when unexpected value is input to specific link device .................................. 14-22

14.5.2 Flowchart to use when data cannot be written or read in user program .................................... 14-22

14.5.3 Flowchart to use when communication is disabled from time to time during user program

execution ......................................................................................................................... 14-23

14.5.4 Precautions for installing other optional board ............................................................................ 14-24

14.6 When External Power Supply Function does not Work Properly ...................................................... 14-25

14.7 Troubleshooting for WDT Error Occurrence ...................................................................................... 14-26

14.7.1 Board WDT error ........................................................................................................

................... 14-26

14.7.2 Driver WDT error ........................................................................................................................... 14-26

14.8 Troubleshooting for Slow PC Operation ............................................................................................ 14-27

14.9 Information Needed when Calling with Inquiry .................................................................................. 14-28

A - 15 A - 15

Page 18

APPENDIX App- 1 to App-26

Appendix 1 Cautions for Accessing Redundant CPU System ................................................................ App- 1

Appendix 2 Host Station Status at Power ON/OFF When Using Q80BD-J71LP21S-25 ....................... App- 7

Appendix 3 Procedures for Replacing Boards ......................................................................................... App- 8

Appendix 4 Combinations of Boards with Existing Software ................................................................... App-10

Appendix 5 Checking Serial Number and Function Version .................................................................. App-11

Appendix 6 New and Improved Functions .............................................................................................. App-12

Appendix 6.1 Change of hardware function ......................................................................................... App-12

Appendix 6.2 Update of software package ........................................................................................... App-12

Appendix 7 Restrictions for Operating System ........................................................................................ App-13

Appendix 8 Warning Message Appears on Windows.............................................................................. App-14

Appendix 8.1 Overview of warning message ....................................................................................... App-14

Appendix 8.2 Methods for preventing the warning message ............................................................... App-15

Appendix 9 Behavior When Personal Computer Enters Power Save Mode or Fast Startup ................ App-20

Appendix 9.1 Behavior when the personal computer enters the power save mode

(hibernate, sleep) ............................................................................................................ App-20

Appendix 9.2 Behavior when the fast startup function is enabled ....................................................... App-21

Appendix 10 MELSECPowerManager ..................................................................................................... App-22

Appendix 10.1 Installing MELSECPowerManager............................................................................... App-22

Appendix 10.2 Uninstalling MELSECPowerManager .......................................................................... App-22

Appendix 10.3 Checking MELSECPowerManager .............................................................................. App-23

Appendix 11 External Dimensions ........................................................................................................... App-25

Appendix 11.1 Q80BD-J71LP21-25, Q80BD-J71LP21G, Q80BD-J71LP21GE................................. App-25

Appendix 11.2 Q80BD-J71LP21S-25 ..............................................................................................

..... App-25

Appendix 11.3 Q80BD-J71BR11 .......................................................................................................... App-26

Appendix 11.4 Q81BD-J71LP21-25 ..................................................................................................... App-26

A - 16 A - 16

Page 19

MANUALS

The following table lists the manuals relevant to this product.

You can order them as necessary.

Relevant Manuals

Manual Name

Q Corresponding MELSECNET/H Network System Reference Manual (PLC to PLC network)

This manual explains the system configuration, performance specification, function, handling, wiring and

troubleshooting for MELSECNET/H network system. (Option)

Manual Number

(Model Code)

SH-080049

(13JF92)

For QnA/A4AR MELSECNET/10 Network System Reference Manual

This manual explains the system configuration, performance specification, function, handling, wiring and

troubleshooting for MELSECNET/10 network system. (Option)

MELSEC Data Link Library Reference Manual

This manual explains the programming, function specifications, and sample programming of the

MELSEC data link library. (Option)

REMARK

MELSEC Data Link Library Reference Manual is stored on the CD-ROM of software

package with PDF file.

Manuals in printed form are sold separately for single purchase. Order a manual by

quoting the manual number (model code) listed in the table above.

IB-66690

(13JF78)

SH-081035ENG

(13JV25)

A - 17 A - 17

Page 20

HOW TO USE THIS MANUAL

"How to Use This Manual" differs depending on the purpose for which the

MELSECNET/H board is used. Use this manual with reference to the following

contents.

(1) When desiring an overview or to know the features of the

(2) When desiring to know about the system configuration

(3) When desiring to know the specifications of the MELSECNET/H

(4) When desiring to know the functions of the MELSECNET/H board

(5) When desiring to know the procedure up to the point of operation

(6) When desiring to know the parameter settings for the

Chapter 7 gives the parameter settings.

(7) When desiring to know the procedure for installing and

(8) When desiring to know the operation of each utility (Chapter 9)

(9) When desiring to know about the MELSEC data link library

MELSECNET/H board (Chapter 1)

Chapter 1 gives an overview of the MELSECNET/H board and its features.

(Chapter 2)

Chapter 2 gives the system configuration.

board (Chapter 3)

Chapter 3 gives the specifications of the MELSECNET/H board.

(Chapter 4)

Chapter 4 gives the functions of the MELSECNET/H board.

of the MELSECNET/H board and settings (Chapter 6)

Chapter 6 gives the procedures up to the point of operation and the settings.

MELSECNET/H board (Chapter 7)

uninstalling the software package (Chapter 8)

Chapter 8 gives the procedure for installing and uninstalling the software

package.

Chapter 9 gives the operation methods for each utility.

(Chapter 10)

Chapter 10 gives overview concerning the MELSEC data link library.

A - 18 A - 18

Page 21

(10) When desiring to know the interlock related signals (Chapter 11)

Chapter 11 gives the interlock related signals.

(11) When desiring to know the application functions (Chapter 12)

Chapter 12 gives the MELSECNET/H board's application functions.

(12) When desiring to know about troubleshooting (Chapter 14)

Chapter 14 gives information on troubleshooting.

A - 19 A - 19

Page 22

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and abbreviations to describe

MELSECNET/H interface board.

Generic Term/Abbreviation Description

Q80BD-J71LP21-25 Abbreviation for Q80BD-J71LP21-25 MELSECNET/H interface board.

Q80BD-J71LP21S-25 Abbreviation for Q80BD-J71LP21S-25 MELSECNET/H interface board.

Q80BD-J71LP21G Abbreviation for Q80BD-J71LP21G MELSECNET/H interface board.

Q80BD-J71LP21GE Abbreviation for Q80BD-J71LP21GE MELSECNET/H interface board.

Q80BD-J71BR11 Abbreviation for Q80BD-J71BR11 MELSECNET/H interface board.

Q81BD-J71LP21-25 Abbreviation for Q81BD-J71LP21-25 MELSECNET/H interface board.

MELSECNET/H board

SW0DNC-MNETH-B Product name of the software package for MELSECNET/H interface board.

MNETH utility Abbreviation for MELSECNET/H utility

GX Developer

MX Links

MX Component

MELSECNET/10

ACPU Generic term for the CPU of MELSEC-A series.

QnACPU Generic term for the CPU of MELSEC-QnA series.

QCPU Generic term for the CPU of MELSEC-Q series.

RCPU Generic term for R04CPU, R08CPU, R16CPU, R32CPU, and R120CPU.

QJ71LP21

QJ71BR11 Abbreviation for QJ71BR11 MELSECNET/H network module.

Network module Generic term for QJ71LP21, QJ71BR11

MELSECNET/H Abbreviation for Q corresponding MELSECNET/H network system.

MELSECNET/10 AnU corresponding, QnA/Q4AR corresponding MELSECNET/10 network system.

MELSECNET/H (10 Mbps) Abbreviation in case of using MELSECNET/H board with communication rate of 10 Mbps.

MELSECNET/H (25 Mbps) Abbreviation in case of using MELSECNET/H board with communication rate of 25 Mbps.

MELSECNET/H mode

MELSECNET/H Extended

mode

MELSECNET/10 mode

Board WDT Abbreviation for the watchdog timer that monitors the operation of network board

Driver WDT

Generic term for Q80BD-J71LP21-25, Q81BD-J71LP21-25, Q80BD-J71LP21S-25, Q80BDJ71LP21G, Q80BD-J71LP21GE, and Q80BD-J71BR11.

General product name for product model names SW8D5C-GPPW-E, SW8D5C-GPPW-EA,

SW8D5C-GPPW-EV, and SW8D5C-GPPW-EVA.

General product name for product model names SWnD5F-CSKP-E

(n denotes the version number)

General product name for product model names SWnD5C-ACT-E, SWnD5C-ACT-EA

(n denotes the version number)

Abbreviation for A70BDE-J71QLP23/A70BDE-J71QLP23G E/A70BDE-J71QBR13/A70BDEJ71QLR23 MELSECNET/10 interface board.

Abbreviation for QJ71LP21, QJ71LP21G, Q71LP21GE, QJ71LP21-25, QJ71LP21S-25,

MELSECNET/H network module.

However, if shown for a particular model, QJ71LP21, QJ71LP21G, Q71LP21GE,

QJ71LP21-25, QJ71LP21S-25 is entered.

Abbreviation in case of using MELSECNET/H board and network module with

MELSECNET/H.

Abbreviation for the extended MELSECNET/H mode, which is extended in the maximum

number of link points per station.

Abbreviation in case of using MELSECNET/H board and network module with

MELSECNET/10.

Abbreviation for the watchdog timer that monitors the communication status between a

network board and a personal computer, or operating status of a personal computer

A - 20 A - 20

Page 23

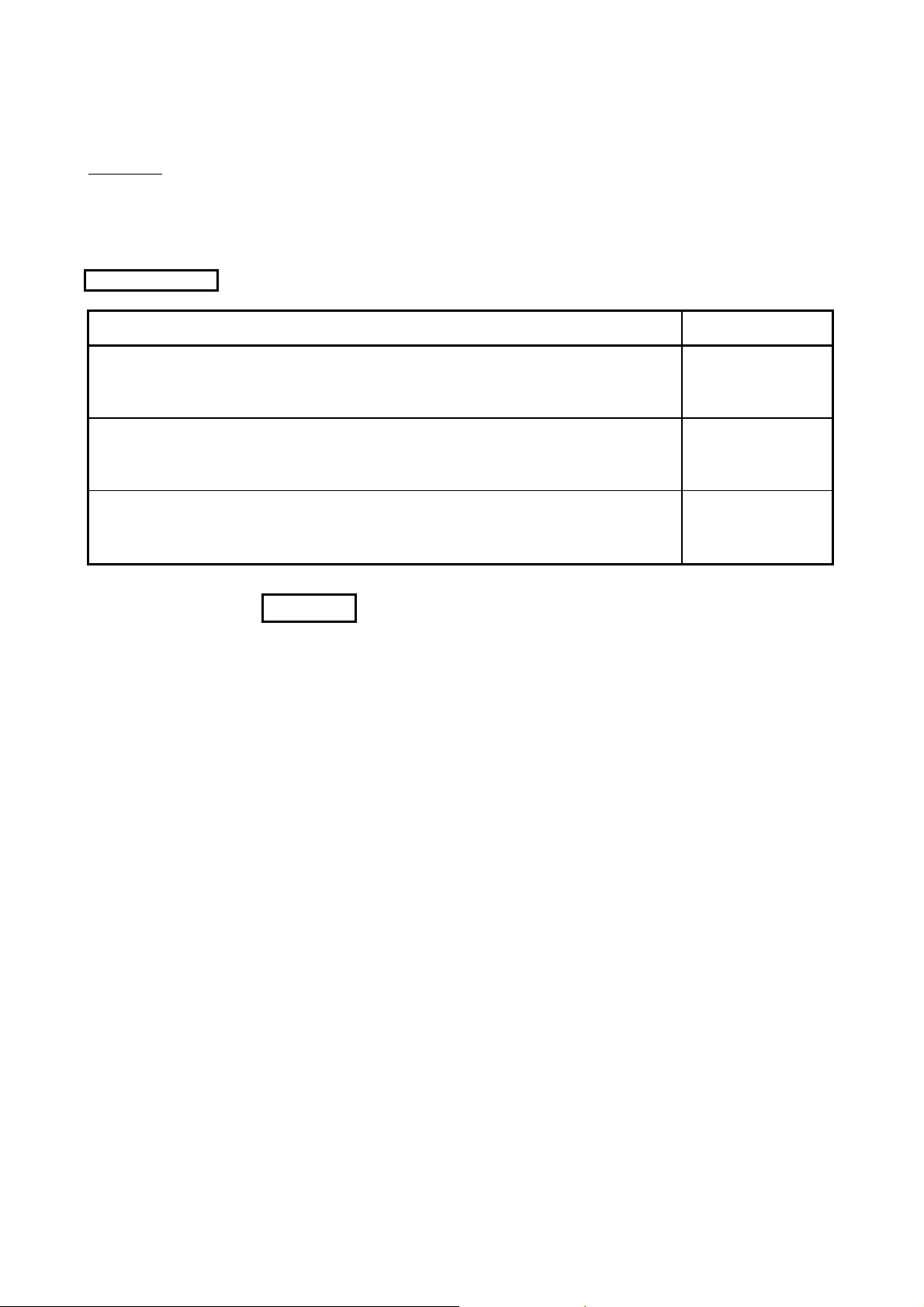

MEANING AND CONTENTS OF THE TERMS

This section describes meaning and contents of the terms in this manual.

(1) Abbreviations for control station and normal station, and symbol format

This section explains abbreviations for control station and normal station, and

symbol format to be used in this manual.

(a) Abbreviation

Abbreviation Name

MP Control station

NS Normal station (Station that can serve as a control station)

(b) Symbol format

Mp —

Group number (1 to 32) : G

Station number (1 to 64)

Abbreviation

Network No. (1 to 239)

[Example]

P

1) Network No. 3, control station, station number 6: 3M

2) Network No. 5, normal station, station number 3: 5N

6

S

3

PACKING LIST

The packing list of the MELSECNET/H board is given below.

Item Quantity

Board 1

Connector set for external power supply cable(Q80BD-J71LP21S-25 only) 1

F-type connector (A6RCON-F) (Q80BD-J71BR11 only) 1

"Before Using the Product" 1

Software Package (CD-ROM) *1 1

Software license agreement 1

1: Manuals are stored on the CD-ROM in PDF format.

A - 21 A - 21

Page 24

MEMO

A - 22 A - 22

Page 25

A

1 OVERVIEW

MELSEC

1 OVERVIEW

1.1 Overview

Personal Computer

MELSECNET/H Board

(Q80BD-J71LP21-25)

This is a manual you read when using the MELSCNET/H board in the MELSECNET/H

mode or MELSECNET/H Extended mode. When using the MELSCNET/H board in

the MELSCNET/H network, refer to "Q Corresponding MELSECNET/H Network

System Reference Manual (PLC to PLC network)". Also, when using the board in the

MELSECNET/10 network system, refer to "For QnA/Q4AR Corresponding

MELSECNET/10 network system reference manual".

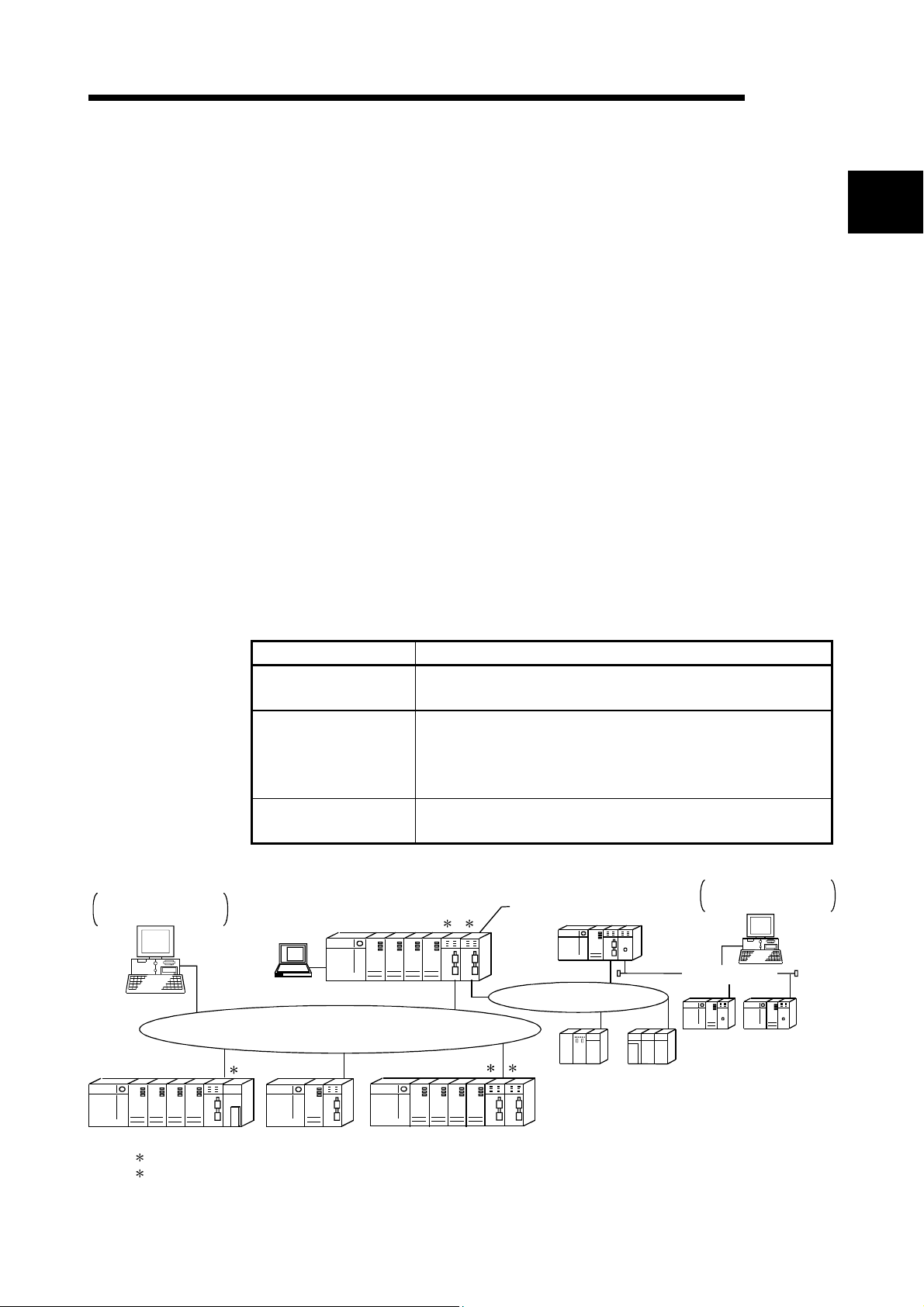

The MELSECNET/H is a network system which is used to connect multiple sequencer

modules and personal computers, and is equipped with functions and performance

realized in the MELSECNET/10 for general control of a production line.

In the MELSECNET/H, there is a network system which includes an optical loop

system (communication rates: 10 Mbps, 25 Mbps) and a coaxial bus system

(communications rate: 10 Mbps), enabling large volume communications at high

speeds.

Also, in order to improve the performance of the MELSECNET/10 network and achieve

upward compatibility, MELSECNET/H supports the MELSECNET/ H and

MELSECNET/H Extended modes (high performance, high speed mode) and the

MELSECNET/10 Mode (function compatible and performance compatible mode).

Mode Description

MELSECNET/H mode

MELSECNET/H Extended

mode

MELSECNET/10 mode

GX Developer

Set this mode when all CPUs within the network are QCPUs and

RCPUs.

The maximum number of link points per station has been increased

compared with the MELSECNET/H mode.

In excess of 2000 bytes, a maximum of 35840 bytes can be set.

Set this mode when the system uses many link points per station.

This mode is used to operate the MELSECNET/H board on a

MELSECNET/10 network.

Personal Computer

MELSECNET/H Board

(Q80BD-J71BR11)

MELSECNET /H

QCPU

1 2

MELSECNET/10

Mode

QCPU

MELSECNET /10

1

QCPU

MELSECNET/H

QCPU

1

QCPU

1 2

nU QnA

QCPUQCPU

1: The multiple CPU system compatible network module is for function version B and subsequent products.

2: In the multiple CPU system, a network module that becomes a relay station is the same as the control CPU.

1 - 1 1 - 1

Page 26

1 OVERVIEW

1

1.2 Features

MELSEC

POINT

(1) For MELSECNET/H, select QCPUs, RCPUs, and Q compatible network

modules.

(2) If QnACPU or ACPU are included in the same network, select MELSECNET/10

mode which is compatible with MELSECNET/10.

(3) All of network modules and MELSECNET/H boards within the same network

must be set to the same mode (network type)

1

.

1: MELSECNET/H mode, MELSECNET/H Extended mode and

MELSECNET/10 mode are available.

The features of the MELSECNET/H board are as shown below.

(1) A personal computer can be incorporated into MELSECNET/H.

By mounting the MELSECNET/H board in a personal computer, the personal

computer can be used as a MELSECNET/H or MELSECNET/10 control station

or normal station.

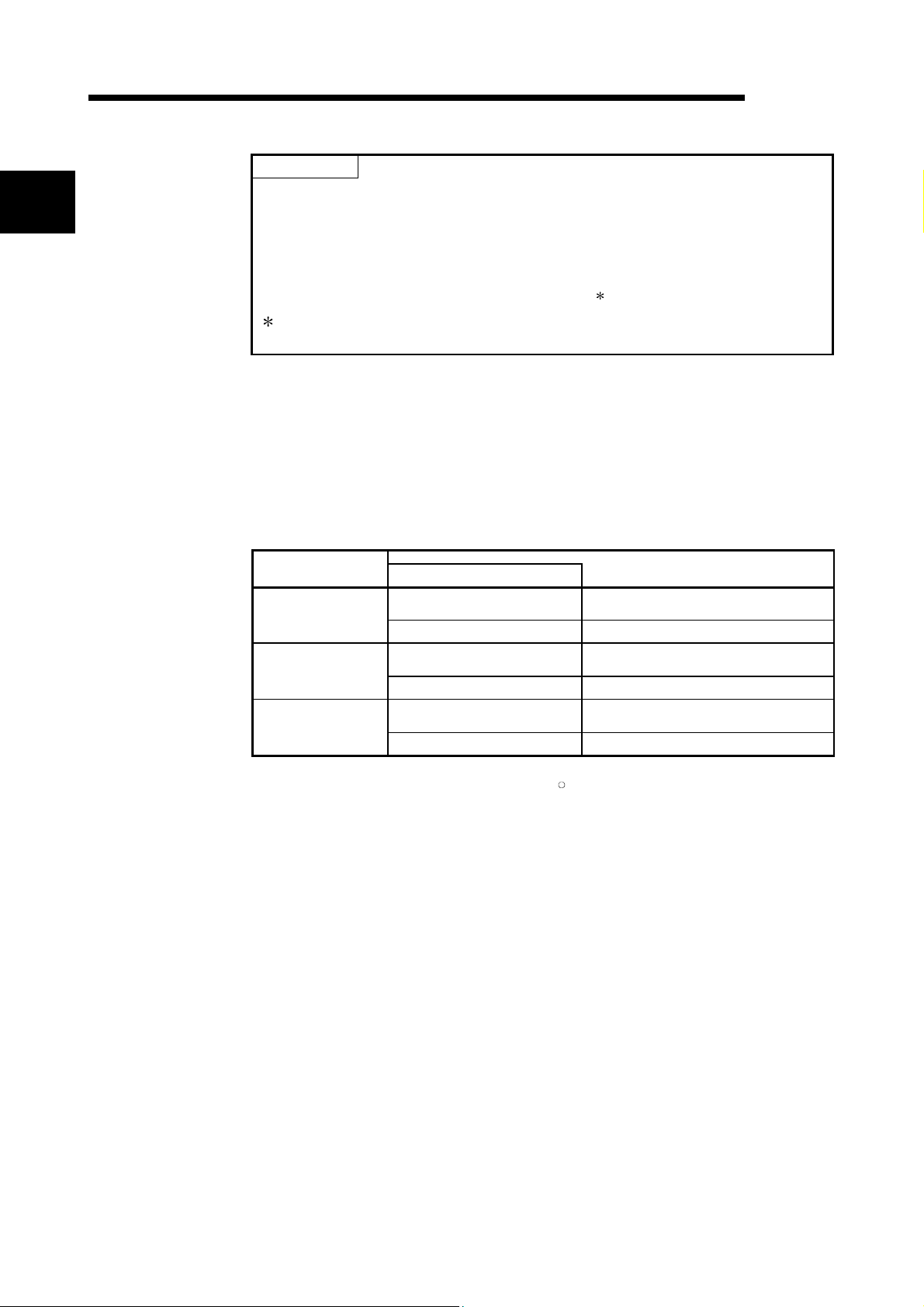

Board model name Supported network

Q80BD-J71LP21-25

Q81BD-J71LP21-25

Q80BD-J71LP21S-25

Q80BD-J71BR11

Q80BD-J71LP21G

Q80BD-J71LP21GE

MELSECNET/H Mode,

MELSECNET/H Extended Mode

MELSECNET/10 Mode MELSECNET/10 Optical Loop System

MELSECNET/H Mode,

MELSECNET/H Extended Mode

MELSECNET/10 Mode

MELSECNET/H Mode,

MELSECNET/H Extended Mode

MELSECNET/10 Mode MELSECNET/10 Optical Loop System

Mode

MELSECNET/H (10 Mbps / 25 Mbps) Optical

Loop System

MELSECNET/H (10 Mbps) Coaxial Bus

System

MELSECNET/10 Coaxial Bus System

MELSECNET/H (10 Mbps) Optical Loop

System

(2) By adopting the PCI/PCI ExpressRstandard, complicated switch

settings are no longer required.

The system can be used simply by installing the MELSECNET/H board in the

personal computer, then installing the software.

The channel No., station No. and other settings can be carried out easily in the

MNETH Utility.

(3) Compatibility with the previous MELSECNET/10 board’s operations

is maintained.

(a) Upward compatibility of user programs

Since MELSECNET/H board has the same number of the maximum

mountable board and channel number as the previous MELSECNET/10

board, the exiting user programs can be utilized.

(b) Compatible with the GX Developer, MX Links and MX

Component.

It is possible to access the programmable controller CPU using the GX

Developer, MX Links and MX Component from a personal computer where

the MELSECNET/H board is installed.

1 - 2 1 - 2

Page 27

1 OVERVIEW

MELSEC

(4) Compatible with multiple CPU systems.

By using station designations of logical station No. on the MNETH utility,

MELSECNET/H board is capable of communicating with a multiple CPU system.

(5) Compatible with redundant CPU systems.

Only by specifying whether the destination is a control or standby station using

the user program, access is simply made without considering the current

operating system state of the redundant CPU system.

(6) Compatible with MELSECNET/H Extended mode

The MELSECNET/H Extended mode is the extended MELECNET/H mode,

which is extended in the maximum number of link points per station. With this

mode, the maximum number of link points per station can be set to 2000 bytes or

more, i.e., up to 35840 bytes.

This mode is suitable for the system that needs many number of link points per

station.

(7) Drivers are provided for compatibility with each OS.

Each type of driver is provided, so it is easy to build a system that is compatible

with the user environment.

For details on the compatible operating system, refer to Section 2.5.

(8) User programming functions are provided.

Through MicrosoftRVisual BasicRand MicrosoftRVisual C++Rcompatible

functions, it is possible to carry out remote control of a programmable controller

CPU or read and write to devices, and user programs can be created easily.

1 - 3 1 - 3

Page 28

1 OVERVIEW

Personal

computer

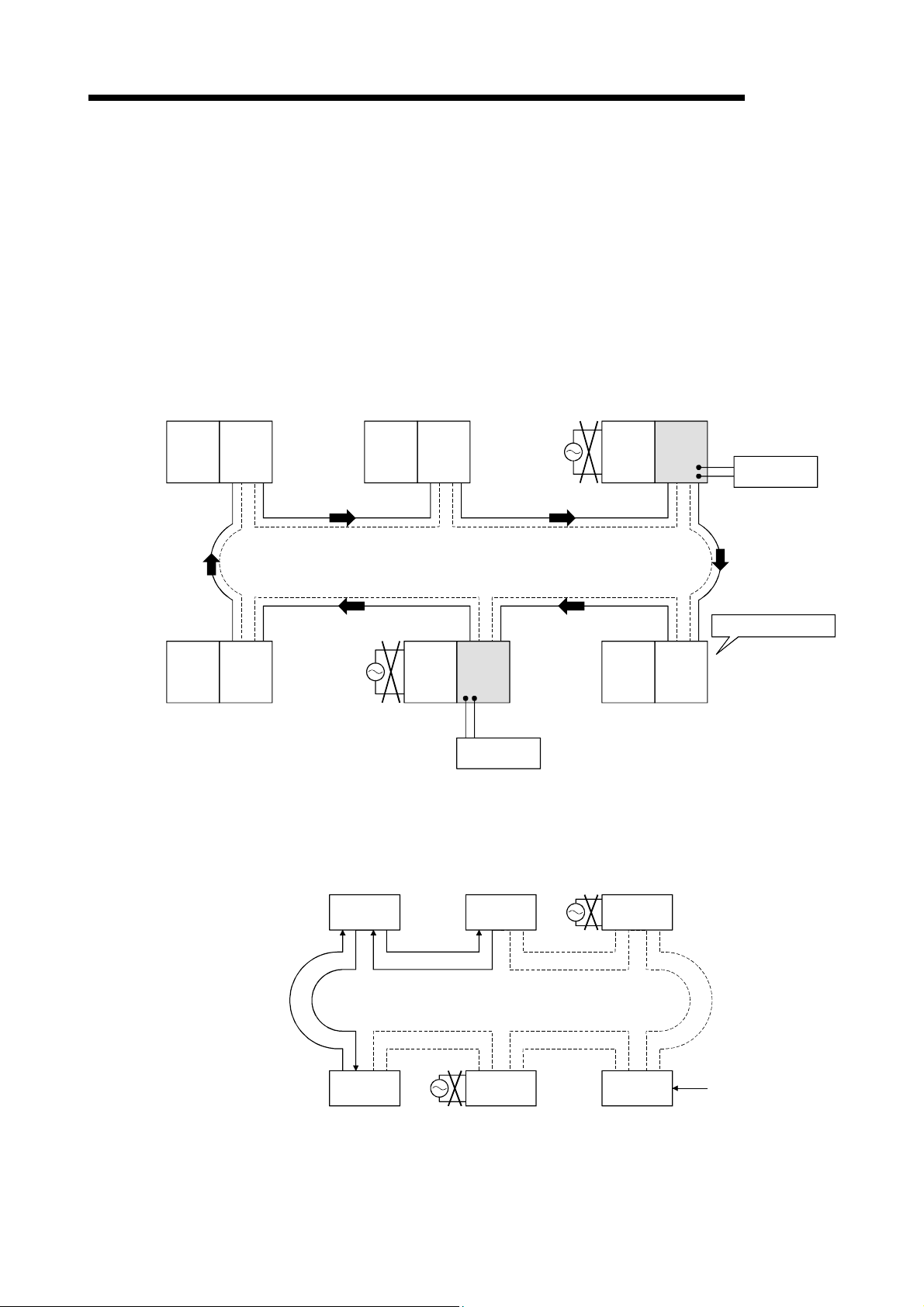

(9) External power supply allows continuous network communication

even during power-off of personal computer. (Function of the

Q80BD-J71LP21S-25)

Since power is supplied externally, the Q80BD-J71LP21S-25 can continue

network communication (baton passing) even if a personal computer is powered

off and data link cannot be performed.

Therefore, a normally operating station connected between other stations with

power-off computers will not be disconnected from the data link.

Another advantage is that the link scan time is stabilized since loopback can be

also prevented.

Personal

computer

Normal station

(Station No.3)

Q80BD

-J71

LP21S

-25

Control station

(Station No.1)

Q80BD

-J71

LP21

-25

Normal station

(Station No.2)

Q

CPU

QJ71

LP21

-25

MELSEC

External power

supply

Personal

computer

Q80BD

-J71

LP21

-25

Normal station

(Station No.6)

Data link continued

Personal

computer

Normal station

(Station No.5)

Q80BD

-J71

LP21S

-25

External power

supply

CPU

Q

Normal station

(Station No.4)

QJ71

LP21

-25

When station No. 3 and No.5 use MELSECNET/H boards without the external

power supply function and if their personal computers are powered off, station

No.4 is cut off from the network as well as No.3 and No.5.

Personal computer

Station No.1 Station No.2 Station No.3

Station No.6 Station No.5 Station No.4

Personal computer

Disconnected

1 - 4 1 - 4

Page 29

2 SYSTEM CONFIGURATION

MELSEC

2 SYSTEM CONFIGURATION

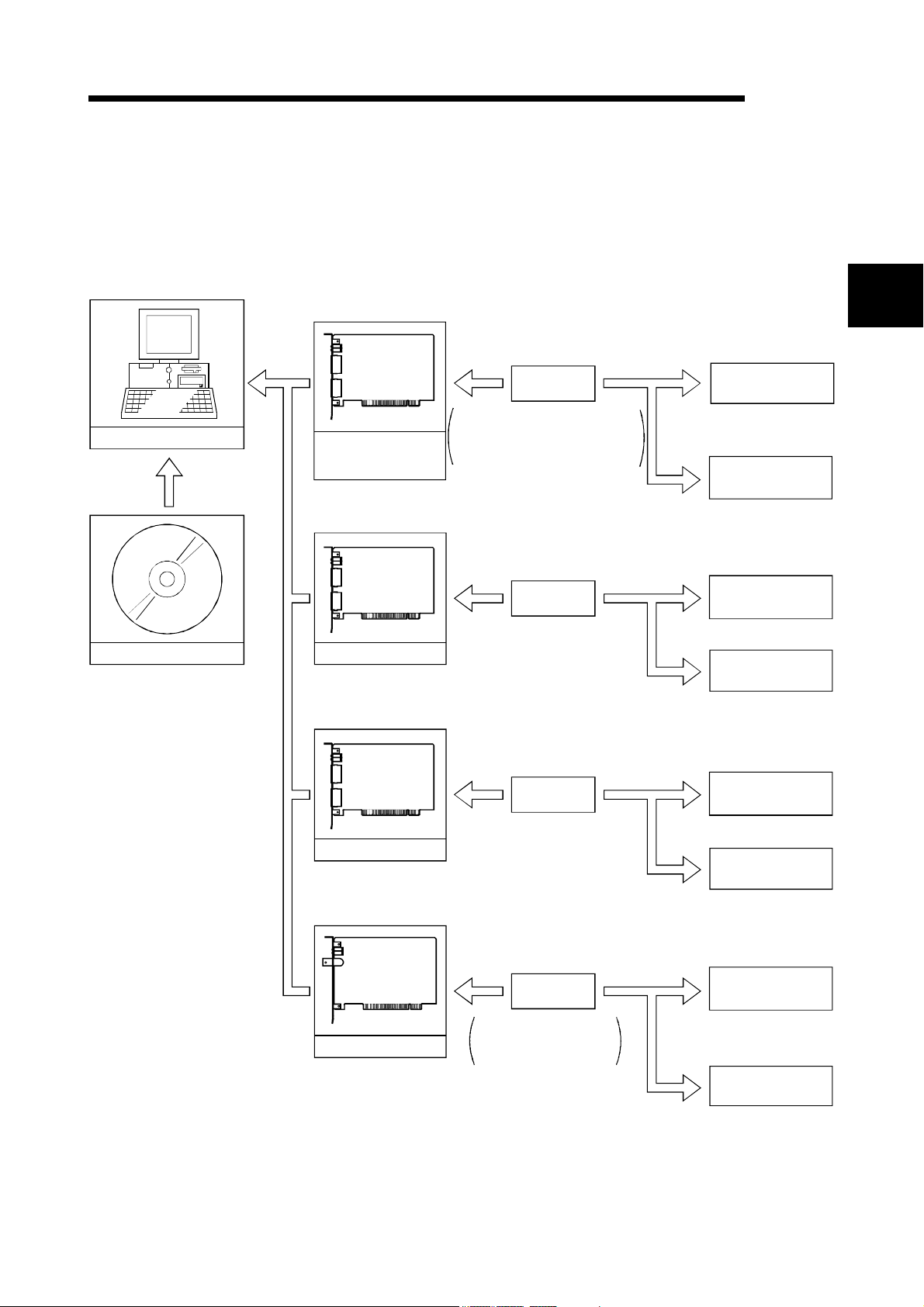

2.1 MELSECNET/H Board System Configuration

The system configuration when the MELSECNET/H board is mounted to a personal

computer is shown below.

Install

Type of cable : SI

Personal Computer

Install

SW0DNC-MNETH-B

Q

80BD-J71LP21-25

Q81BD-J71LP21-25

Q80BD-J71LP21S-25

Q80BD-J71LP21G

Q80BD-J71LP21GE

Optical fiber

cable

H-PCF

Broad-band H-PCF

QSI

Optical fiber

cable

(Type of cable : GI)

Optical fiber

cable

(Type of cable : 62.5GI)

MELSECNET/H

mode,

MELSECNET/H

Extended mode

MELSECNET/10

mode

MELSECNET/H

mode,

MELSECNET/H

Extended mode

MELSECNET/10

mode

MELSECNET/H

mode,

MELSECNET/H

Extended mode

MELSECNET/10

mode

MELSECNET/H

Optical loop system

MELSECNET/10

Optical loop system

MELSECNET/H

Optical loop system

MELSECNET/10

Optical loop system

MELSECNET/H

Optical loop system

MELSECNET/10

Optical loop system

2

MELSECNET/H

mode,

MELSECNET/H

Q80BD-J71BR11

Extended mode

Coaxial cable

Type of cable : 3C-2V

5C-2V

5C-FB

MELSECNET/10

mode

MELSECNET/H

Coaxial bus system

MELSECNET/10

Coaxial bus system

2 - 1 2 - 1

Page 30

2 SYSTEM CONFIGURATION

2

MELSEC

POINT

(1) When using the MELSECNET/H Extended mode

(a) Use the MELSECNET/H board of ROM version 2X or later and SW0DNC-

(b) When assigning 2000 bytes or more to the number of link points sent by a

(2) When using the Q80BD-J71LP21S-25

Use the SW0DNC-MNETH-B version 12N or later.

(3) When using the Q80BD-J71LP21-25, Q81BD-J71LP21-25 or Q80BD-

J71LP21S-25 at a communication speed of 25Mbps, errors may occur at all

stations if multiple boards with the same network number are installed, or the

operating systems are started up/shut down or the boards are reset

simultaneously on the adjacent personal computers. In this case, set the

communication speed to 10Mbps.

(4) If the QnACPU or ACPU are included in the same network, select

MELSECNET/10 mode which is compatible with MELSECNET/10.

MNETH-B version 11M or later.

station, set all stations including control stations and normal stations to the

MELSECNET/H Extended mode.

2 - 2 2 - 2

Page 31

r

2 SYSTEM CONFIGURATION

2.2 Single Network System

A single network system is one system that connects the control station and the normal

stations with an optical fiber cable or a coaxial cable.

2.2.1 Optical loop system

In the optical loop system, 1 control station and 63 normal stations (a total of 64

stations) can be connected. Any station number can be assigned as the control station.

However, only one station can be set as the control station per system.

In the following sample system, station number 1 has been assigned as the control

station.

Station No. 1

(control station)

Personal

computer

Q80BD-

J71LP21-25

Station No. 2

(normal station)

QCPU

Power supply

QJ71

LP21-25

Station No. 64

(normal station)

QCPU QJ71

LP21

Power supply

MELSEC

2.2.2 Coaxial bus system

In the coaxial bus system, 1 control station and 31 normal stations (a total of 32

stations) can be connected. As in the optical loop system, any station number can be

assigned as the control station. However, only 1 station can be assigned as the control

station per system.

Station No. 1

(control station)

Personal

computer

Q80BDJ71BR11

Terminal resistor

A6RCON-R75

Optical fiber cable

Station No. 2

(normal station)

QJ71

QCPU QCPU

BR11

Power supply

Coaxial cable

Station No. 32

(normal station)

QJ71

BR11

Power supply

Terminal resiste

A6RCON-R75

2 - 3 2 - 3

Page 32

2 SYSTEM CONFIGURATION

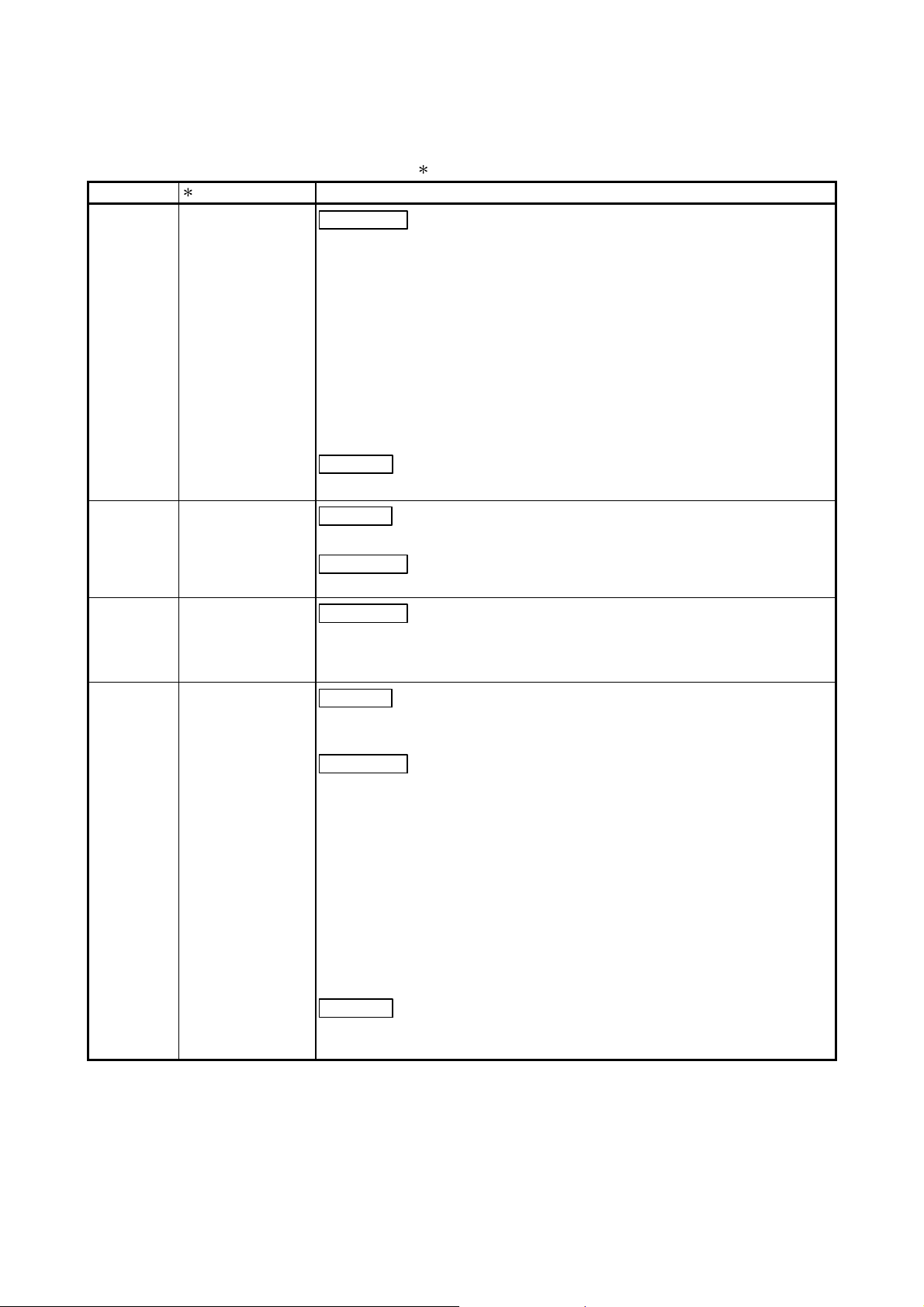

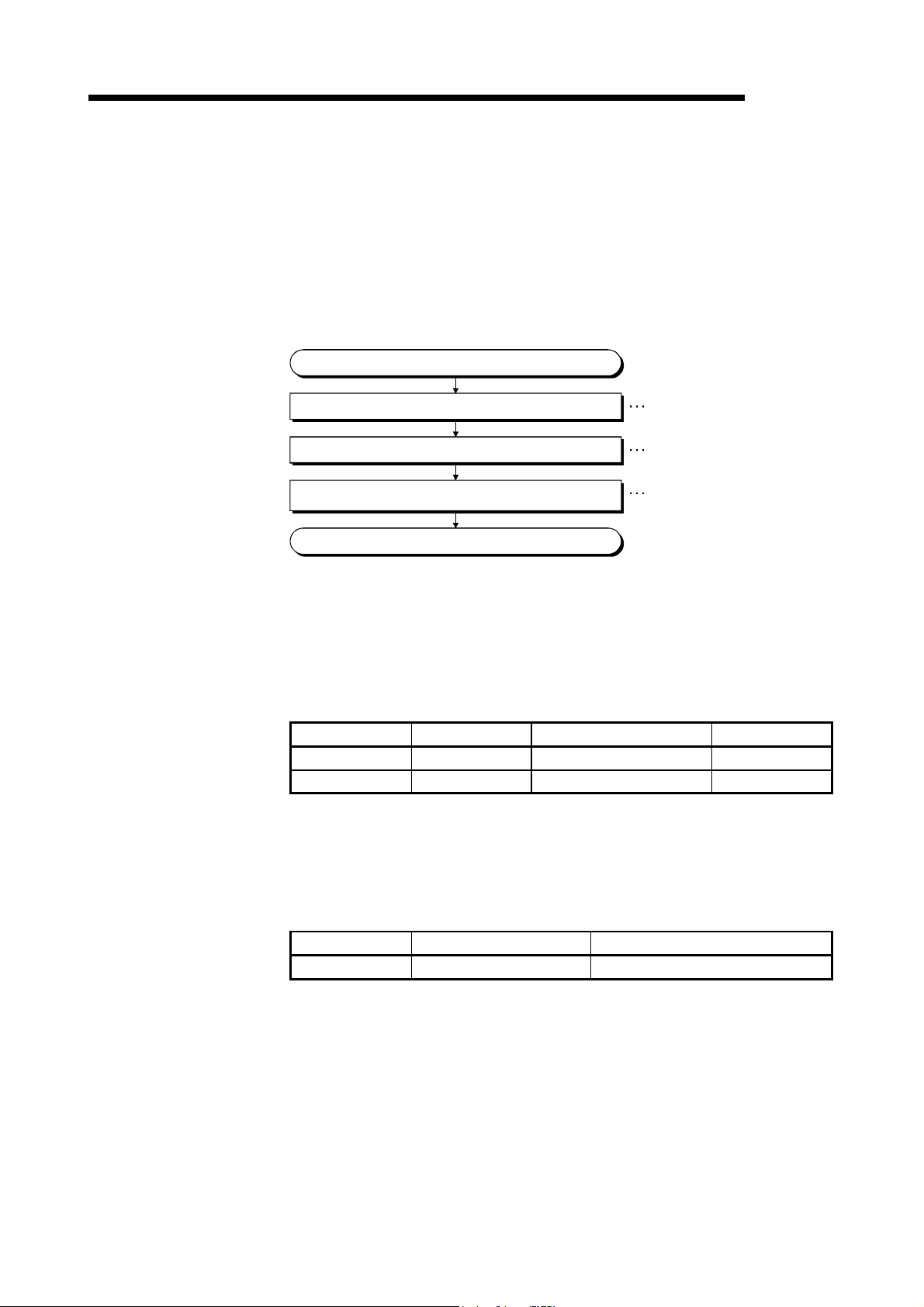

2.2.3 Setting items

In a single network system, the items which need to be set in the case that the

MELSECNET/H board is used as the control station or normal station are as follows.

MELSECNET/H board settings are set by the MNETH Utility.

Channel setting

Network No.

Group No.

Station No.

Control station/ Normal station

Mode Setting

Routing parameter setting

Common

parameter

setting

Opposite party setting

(Logical station No.)

Driver setting

2.2.4 Usable device ranges

MELSEC

Setting item Control station Normal station Reference section

Section 9.2.2

Section 9.2.3

Section 9.2.4

Section 9.2.5

Section 9.2.10

Section 9.2.11

B, W setting

X, Y setting

Reserved station setting

Supplementary setting

: Setting necessary : Set as necessary : Setting unnecessary

The MELSECNET/H board can be used within the following device ranges for the

following devices on the MELSECNET/H board.

Device Usable range

LB

LW

LX

LY

0H to 3FFFH

(16384 points)

0H to 3FFFH

(16384 points)

0H to 1FFFH

(8192 points)

0H to 1FFFH

(8192 points)

The function expansion areas of 2000H to 3FFFH are used for

the low-speed cyclic transmission. All areas can be used for the

normal cyclic transmission.

The use ranges for each MELSECNET/H board and network

module need to be assigned in the parameter settings for the

control station.

The use ranges for each MELSECNET/H board and network

module need to be assigned in the parameter settings for the

control station.

If the MELSECNET/H board is used in the MELSECNET/10 mode, the device range

for LB/LW becomes 0

H to 1FFFH (8192 points).

2 - 4 2 - 4

Page 33

2 SYSTEM CONFIGURATION

2.3 Multiple Network System

A multiple network system is a system where multiple networks are connected by relay

stations.

POINT

(1) The network No. can be set at any desired No. in the range 1 to 239.

(2) The MELSECNET/H board cannot be used as a relay station.

Please use the network module as a relay station.

2.3.1 Configuration

MELSEC

Control station

1M

P1

Personal

computer

Q80BD-

J71LP21-25

QJ71

QCPU

LP21-25

Power supply

1N

S3

Normal

station

The following example shows how three networks can be connected.

Network No.1

QJ71

BR11

Control station

3M

S2

Control station

2M

P1

QJ71

LP21

Network No.3

Q80BDJ71BR11

Personal

computer

3NS3

Normal station

Network No.2

Power supply

Normal station

1N

QCPU

QJ71

LP21

Power supply

P

1

QJ71

QCPU QJ71

BR11

Power supply

3NS2

Normal station

Normal station

Personal

computer

J71LP21-25

QCPU

LP21-25

Power supply

QCPU

BR11

3NS4

Normal station

2N

S2

Q80BD-

QJ71

Normal station

2N

S3

2 - 5 2 - 5

Page 34

2 SYSTEM CONFIGURATION

2.3.2 Setting items

Setting items in the case that the MELSECNET/H board is used as a control station or

normal station in a multiple network system are explained below.

MELSECNET/H board settings are performed by the MNETH Utility.

Channel setting

Network No.

Group No.

Station No.

Control station/ Normal station

Mode setting

Routing parameter setting

Common

Parameter

Setting

Opposite party setting

(Logical station No.)

Driver setting

2.3.3 Usable device range

MELSEC

Setting item Control station Normal station Reference section

Section 9.2.2

Section 9.2.3

Section 9.2.4

Section 9.2.5

Section 9.2.10

Section 9.2.11

B, W setting

X, Y setting

Reserved station setting

Supplementary setting

The same device range as is used for a single network system (section 2.2.4) can be

used.

2 - 6 2 - 6

Page 35

2 SYSTEM CONFIGURATION

2.4 If used in a Multiple CPU System or Redundant CPU System

For cautions in the case of installing MELSECNET/H in a multiple CPU system or

redundant CPU system, refer to "Q Corresponding MELSECNET/H Network System

Reference Manual (PLC to PLC network)."

POINT

When accessing a multiple CPU system or Redundant CPU system, use the

MELSECNET/H board and network module of the following function versions.

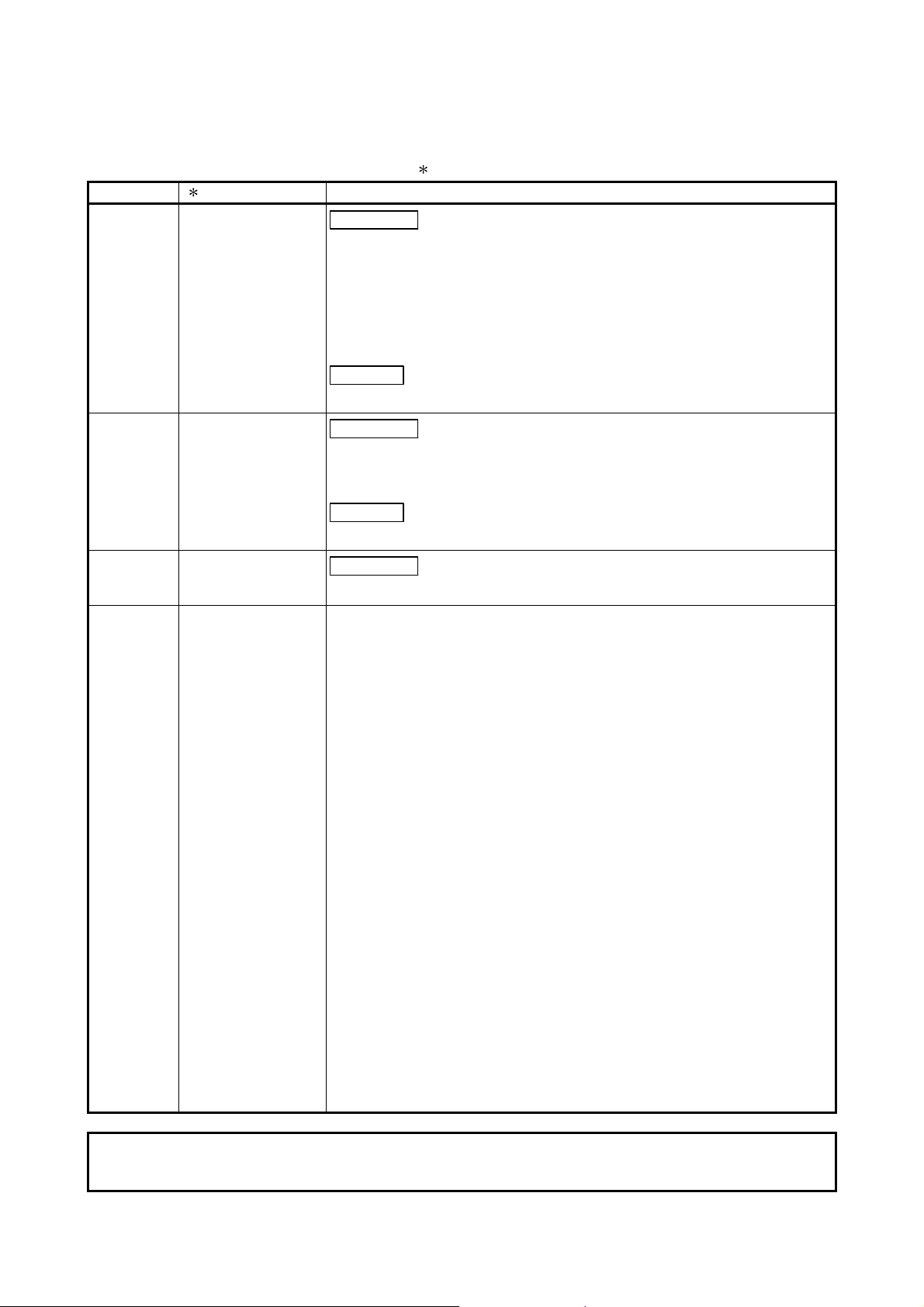

MELSEC

MELSECNET/H board

Access to multiple

CPU system

Access to Redundant

CPU system,

All versions available Function version B or later

Function version D or later1

Programmable controller

side network module

Function version D or later

1: When using a MELSECNET/H board of function version D or earlier,

access to a redundant CPU is not performed normally.

2 - 7 2 - 7

Page 36

2 SYSTEM CONFIGURATION

MELSEC

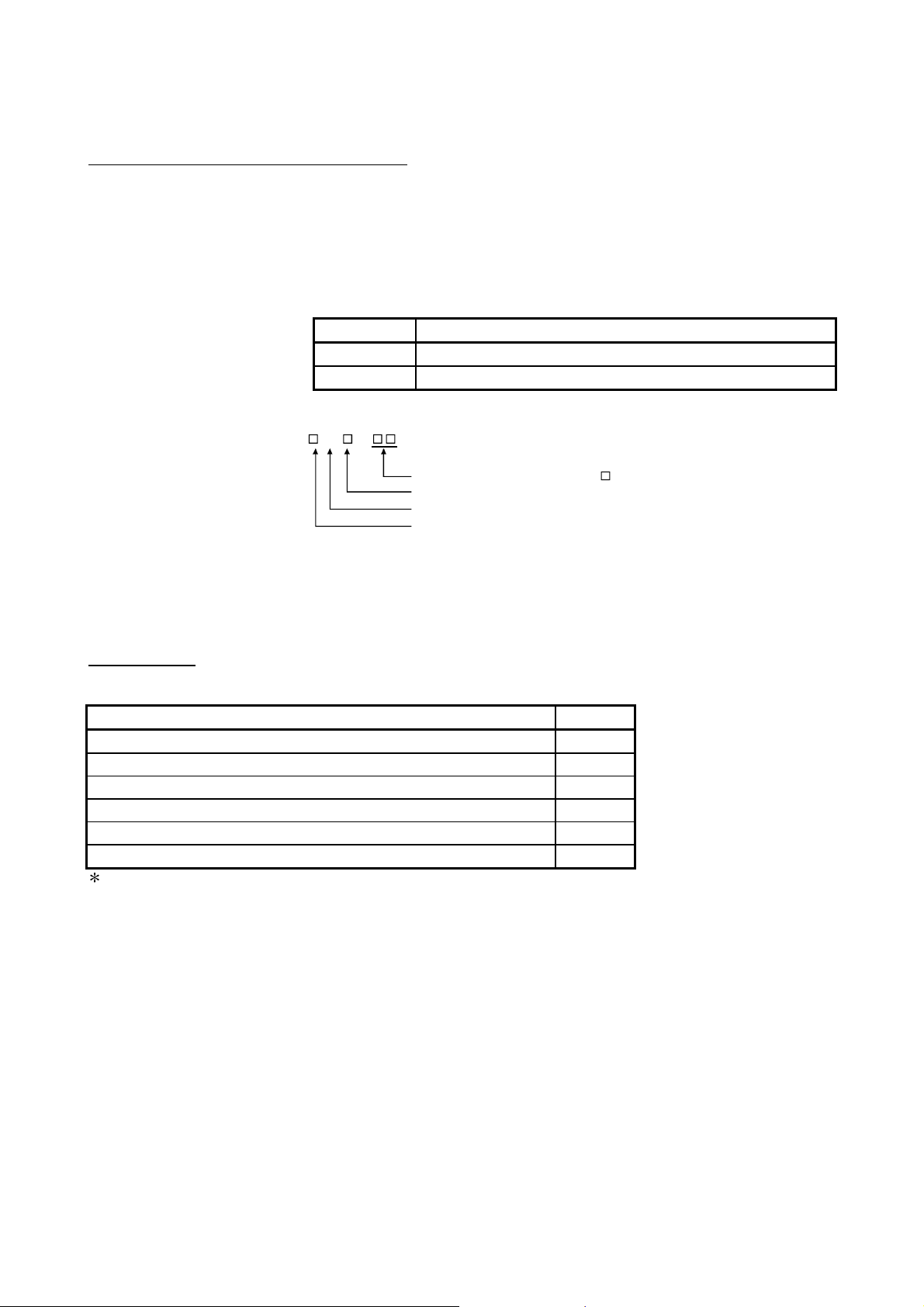

2.5 Operating Environment

The following table shows the operating environment for the MELSECNET/H board.

Item Description

Microsoft

Personal

computer

CPU

Required memory

PCI bus

specifications

PCI ExpressR

Bus specifications

System requirements of the operating system must be met.

For Q80BD-J71LP21-25, Q80BD-J71LP21S-25, Q80BD-J71LP21G, and Q80BDJ71BR11

Compliant with PCI standard Rev.2.2 (5V DC, 32-bit bus, Reference clock : 33MHz)

For Q81BD-J71LP21-25

Compliant with PCI Express

Reference clock : 100MHz)

Available hard disk space 1GB or more

Disk drive CD-ROM disk drive

Display Resolution: 800 600 dot or higher (Recommended: 1024 768 dot)

Windows 10 (Home, Pro, Enterprise, Education)

Windows 8.1, Windows 8.1 (Pro, Enterprise)

Windows Server

Windows 8, Windows 8 (Pro, Enterprise)

Windows Server 2012 (Standard)

Windows 7 (Home Premium, Professional, Ultimate, Enterprise)

Windows Server 2008 R2 (Standard, Enterprise)2

When using any of the following operating systems, use SW0DNC-MNETH-B with the

Operating system

(English version)

1

version 29F or earlier.

Windows Server 2008 (Standard (x86, x64), Enterprise (x86, x64))

Windows Vista

Windows Server 2003 R2 (Standard (x86, x64), Enterprise (x86, x64))

Windows XP

When using any of the following operating systems, use SW0DNC-MNETH-B with the

version 25B or earlier.

Windows 2000 (Professional)

Windows NT

Windows 98, Windows 98 Second Edition

Windows 95

Visual Basic

Programming language1

(English version)

Visual Studio

Visual Studio 2008, Visual Studio 2005, Visual Studio.NET 2003,

Visual Basic 6.0, Visual C++ 6.0, Visual Basic 5.0, Visual C++ 5.0

1: For a combination of the operating system and the programming language, refer to the Microsoft Knowledge Base.

2: Apply Service Pack1 and Security Update for Windows (KB3033929). Otherwise, use SW0DNC-MNETH-B with the

version 29F or earlier.

3: A 64-bit version is not supported.

POINT

For the information on how to obtain SW0DNC-MNETH-B of the version 29F or

earlier, refer to Appendix 7.

R

WindowsRsupported personal computer

R

standard Rev.1.0a (3.3 V DC, Link width : 1lane,

R

2012 R2 (Standard)

2

R

(Home Basic, Home Premium, Business, Ultimate, Enterprise)3

R

(Professional)

R

Workstation 4.0 SP3 or later

R

, Visual C++R in the following development tools

R

2015, Visual Studio 2013, Visual Studio 2012, Visual Studio 2010,

3

2 - 8 2 - 8

Page 37