Mitsubishi Electric Q80BD-J71GP21-SX, Q80BD-J71GP21S-SX, Q81BD-J71GP21-SX, Q81BD-J71GP21S-SX User Manual

Page 1

CC-Link IE Controller Network Interface Board

User's Manual (For SW1DNC-MNETG-B)

-Q80BD-J71GP21-SX

-Q80BD-J71GP21S-SX

-Q81BD-J71GP21-SX

-Q81BD-J71GP21S-SX

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Be sure to read these instructions before using the product.)

Before using this product, read this manual and the relevant manuals introduced in this manual carefully

and handle the product correctly with full attention to safety.

Note that these precautions apply only to this product. Refer to the user's manual of your CPU module for

safety precautions on programmable controller systems.

In this manual, the safety instructions are ranked as " WARNING" and " CAUTION".

Note that failure to observe the CAUTION level instructions may also lead to serious results depending on the

circumstances.

Be sure to observe the instructions of both levels to ensure personal safety.

Please store this manual in a safe place for future reference. This manual must be forwarded to the end user.

A - 1

Page 4

[Design Precautions]

WARNING

Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in a personal computer. Failure to do so may result in an

accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be

configured external to the programmable controller.

(2) The station to which the board is installed may be disconnected from the data link due to a data

link error. If this occurs, the data output from the station and written to other stations before the

error will be held until the station is reconnected to the network (until its data link is restarted).

Provide a mechanism for data link status monitoring and error handling for each station that is

connected to the data link system.

For the operating status of each station after a communication failure, refer to CC-Link IE Controller

Network Reference Manual for each network. Incorrect output or malfunction due to a

communication failure may result in an accident.

When changing data during operation, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. Configure an interlock circuit in the program, and determine

corrective actions to be taken between the external device and CPU module in case of a

communication failure.

Laser diodes are used in the optical transceivers of the CC-Link IE Controller Network. The laser

class (IEC 60825-1) of these laser diodes is Class 1. Do not look directly at laser light. Doing so may

harm your eyes.

CAUTION

Do not install the external power supply or communication cables together with the main circuit lines

or power cables. Keep a distance of 100mm (3.94 in.) or more between them. Failure to do so may

result in malfunction due to noise.

[Installation Precautions]

WARNING

Shut off the external power supply for the system in all phases before installing the board to or

removing it from the personal computer.

Failure to do so may result in electric shock or cause the board to fail or malfunction.

Do not touch any connectors while power is on. Doing so may cause electric shock or malfunction.

A - 2

Page 5

CAUTION

Use the board in an environment that meets the general specifications in this manual.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

Do not directly touch any conductive parts and electronic components of the board.

Doing so may cause malfunction or failure of the board.

When installing the board, take care not to get injured by an implemented component or a

surrounding member.

Fix the board by tighten the board-fixing screws within the specified torque range.

Undertightening may cause drop of the component or wire, short circuit, or malfunction.

Overtightening may damage the screw and/or module, resulting in drop, short circuit, or malfunction.

For the tightening torque of the board-fixing screws, refer to the manual supplied with the personal

computer.

Before handling the board, touch a conducting object such as a grounded metal to discharge the static

electricity from the human body.

Failure to do so may cause the board to fail or malfunction.

Install the board to a personal computer which is compliant with PCI standard or PCI Express

standard (Section 2.5 Operating Environment). Failure to do so may cause a failure or

malfunction.

Securely insert the board into the PCI slot following the board installation instruction of the personal

computer.

Incorrect insertion of the board may lead to a malfunction, failure or drop of the board.

When installing the board, take care not to get injured by an implemented component or a

surrounding member.

When installing the board, take care not to contact with other boards.

Handle the board in a place where static electricity will not be generated.

Failure to do so may cause a failure or malfunction.

The board is included in an antistatic envelope.

When storing or transporting it, be sure to put it in the antistatic envelope.

Failure to do so may cause a failure or malfunction.

Do not drop or apply a strong impact to the board.

Doing so may cause a failure or malfunction.

®

A - 3

Page 6

[Wiring Precautions]

WARNING

Shut off the external power supply for the system in all phases before installing the board or starting

wiring.

Failure to do so may result in electric shock, damage to the product, or malfunction.

After installation of the board and wiring, attach the cover on the module before turning it on for

operation.

Failure to do so may result in electric shock.

CAUTION

Check the rated voltage and pin-out before wiring to the external power supply cable, and connect

the cables correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

Place the communication cable and the external power supply cable connected to the board in a

duct or clamp them.

If not, dangling cables may swing or inadvertently be pulled, resulting in damage to the board or

cables or malfunctions due to poor contact.

When disconnecting the cable from the board, do not pull the cable by the cable part.

Pulling the cable connected to the board may result in malfunction or damage to the board or cable.

Prevent foreign matter such as dust or wire chips from entering the personal computer.

Such foreign matter may cause a fire, failure, or malfunction.

Do not install the external power supply or communication cables together with the main circuit lines

or power cables.

Keep a distance of 100mm (3.94 in.) or more between them. Failure to do so may result in

malfunction due to noise.

Special skills and tools are required to connect the communication cable to the connector plug,

which is an exclusive product.

When purchasing it, please consult your local Mitsubishi representative.

Incomplete connection can result in a short, fire or malfunction.

Securely plug the communication cable to the connector of the board.

Then, check for any incomplete connection.

Poor contact may cause an erroneous input or output.

A - 4

Page 7

[Wiring Precautions]

CAUTION

Use a specified tool for crimping of the cable and contacting pin. Imperfect crimping may cause a

malfunction.

Verify the pin-out and fully insert the crimped contacting pin into the connector. Imperfect insertion

may cause a failure or malfunction.

Insert the wired external power supply cable into the external power supply cable connector until a

click is heard.

Imperfect insertion may cause a failure or malfunction.

Always ground the personal computer to the protective ground conductor.

Failure to do so may cause a malfunction.

[Startup/Maintenance Precautions]

WARNING

Shut off all phases of the external power supply before cleaning the board or retightening the fixing

screws. Failure to do so may result in an electric shock, or cause a failure or malfunction of the

board.

Shut off the external power supply for the system in all phases before installing the board to or

removing it from the personal computer.

Failure to do so may result in electric shock or cause the board to fail or malfunction.

Do not connect or disconnect any communication cable while power is on.

Doing so may result in a malfunction.

A - 5

Page 8

[Startup/Maintenance Precautions]

CAUTION

Thoroughly read the manual and ensure the safety before performing program modification during

operation, forced output, operation such as RUN, STOP and PAUSE.

An improper operation will result in mechanical damage or accidents.

Do not disassemble or modify the board.

Doing so may cause failure, malfunction, injury, or a fire.

Fix the board by tighten the board-fixing screws within the specified torque range. Undertightening

may cause drop of the component or wire, short circuit, or malfunction. Overtightening may damage

the screw and/or module, resulting in drop, short circuit, or malfunction.

For the tightening torque of the board-fixing screws, refer to the manual supplied with the personal

computer.

Before handling the board, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body.

Failure to do so may cause the board to fail or malfunction.

The board is included in an antistatic envelope.

When storing or transporting it, be sure to put it in the antistatic envelope.

Failure to do so may cause a failure or malfunction.

The microprocessor built in the board will reach a high temperature during operation. Do not touch it

directly when replacing the board.

Doing so may result in a failure, malfunction or injury.

[Disposal Precautions]

CAUTION

When disposing of this product, treat it as industrial waste.

A - 6

Page 9

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 7

Page 10

REVISIONS

Addition

Correction

Correction

Addition

*The manual number is given on the bottom left of the back cover.

Print Date *Manual Number Revision

APR., 2007 SH (NA)-080691ENG-A First edition

Section 8.1.2, Appendix 3

Oct., 2007 SH(NA)-080691ENG-B

Jan., 2008 SH(NA)-080691ENG-C

GENERIC TERMS AND ABBREVIATIONS,

Section 1.2, Section 1.3, Section 2.5, Chapter 5, Section 8.1.1, Section 8.1.3,

Section 8.2, Section 8.3, Section 9.2.1, Section 9.2.3, Section 10.2.1,

Section 10.2.3, Chapter 15, Section 16.2, Section 16.3.1, Appendix 4

Section 8.1.2 changed to Section 8.1.3.

"MELSECNET/G network system" (controller network) is changed to "CC-Link

IE Controller Network"

SAFETY PRECAUTIONS, PRECAUTIONS FOR USE, INTRODUCTION,

CONTENTS, MANUAL, HOW TO USE THIS MANUAL,

GENERIC TERMS AND ABBREVIATIONS, PACKING LIST, CHAPTER 1,

Section 1.1, Section 1.2, Section 1.3, Section 2.1, Section 2.2.2, Section 2.2.3,

Section 2.3, Section 2.3.2, Section 2.4, Section 2.5, Section 2.6, CHAPTER 3,

Section 3.1, Section 3.2, CHAPTER 4, Section 4.1, Section4.2, Section 4.2.1,

Section 5.1, CHAPTER 6, Section 6.1, Section 6.2, Section 6.2.1,

Section 6.2.2, Section 6.3, Section 6.4, Section 6.4.1, Section 6.5,

Section 6.5.1, Section 6.5.2, Section 6.5.3, Section 6.6, Section 6.6.1,

Section 6.6.2, CHAPTER 7, Section 7.1, Section 7.2, Section 7.3,

Section 7.3.3, Section 7.4, Section 7.5, Section 7.6, Section 7.7, Section 7.8,

Section 7.9, Section 8.1, Section 8.1.1, Section 8.1.2, Section 8.1.3,

Section 8.2, CHAPTER 9, Section 9.1, Section 9.1.1, Section 9.2,

Section 9.2.1, Section 9.2.2, Section 9.2.3, Section 9.2.4, Section 9.3,

Section 9.3.1, Section 9.3.2, Section9.3.3, Section 9.4, Section 9.4.1,

Section 9.4.6, Section 9.4.7, Section 9.4.8, Section 9.5.1, Section 9.5.3,

Section 9.5.4, Section 10.1.1, Section 10.2.1, Section 10.3, Section 10.4,

Section 10.5, CHAPTER 11, Section 11.1, Section 11.1.2, Section 11.2,

Section 12.1, Section 12.4, Section 12.5, Section 12.6, Section 12.7,

Section 12.8, Section 12.9, Section 13.1.1, Section 13.2, Section 13.2.1,

Section13.3, CHAPTER 14, Section 14.2, Section 14.2.1, Section14.2.2,

Section14.2.3, Section 14.3, CHAPTER 15, Section 16.2, Section 16.3,

Section 16.3.1, Section 16.4, Section 16.4.1, Section16.4.2, Section 16.4.3,

Section 16.4.4, Section 16.4.5, Section 16.4.6, Section 16.5.2, Section 16.5.3,

Section 16.5.4, Section 16.7, APPENDICES

Section 9.4.7

A - 8

Page 11

Print Date *Manual Number Revision

Addition

Correction

Correction

Correction

Addition

Correction

Addition

Correction

Deletion

Section 9.3.4

May., 2008 SH(NA)-080691ENG-D

Sep., 2008 SH(NA)-080691ENG-E

Oct., 2008 SH(NA)-080691ENG-F

Apr., 2009 SH (NA)-080691ENG-G

Section 2.5, Section 2.6, Section 6.5.1, Section 6.5.2, Section 6.5.3,

Section 6.6.1, Section 6.6.2, Section 7.1, Section 9.3.3, Section 9.4.1,

Appendix 6.2

Section 2.5, Section 3.2, Section 7.1, Section 9.3.1, Section 9.4.1,

Appendix 6.1

PRECAUTIONS FOR USE, GENERIC TERMS AND ABBREVIATIONS,

Section 2.5, Section 9.4.6, Section 9.4.7, Section 11.1.2

Section 7.10, Section 9.4.9, Section 16.8

SAFETY PRECAUTIONS, GENERIC TERMS AND ABBREVIATIONS,

Section 2.2.2, Section 2.3.2, Section 4.2.1, CHAPTER 5, Section 6.5.1,

Section 6.5.2, Section 6.5.3, Section 6.6.1, Section 6.6.2, CHAPTER 7,

Section 7.1, Section 7.2, Section 7.5, Section 7.6, Section 7.7, Section 8.1.1,

Section 8.1.3, Section 8.2, Section 8.3, Section 9.1.1, Section 9.2,

Section 9.3.1, Section 9.3.3, Section 9.4.1, Section 9.4.6, Section 11.1.1,

Section 11.1.2, Section 12.2, Section 12.6, Section 12.7, Section 14.3,

CHAPTER 15, Section 16.4.3, Appendix 5.6, Appendix 6.1, Appendix 6.2,

Appendix 6.4

Sep., 2009 SH (NA)-080691ENG-H

Section 6.7, Section 14.1.4

PRECAUTIONS FOR USE, Section 4.1, Section 6.1, Section 8.1.3,

Section 9.4.5, Section 9.4.6, Section 12.4, Section 13.1.1, Section 14,

Section 15.1, Appendix 2, Index

Section 14.1

Section 14.2 and 14.3 are changed to Section14.1 and 14.2.

A - 9

Page 12

Print Date *Manual Number Revision

Addition

Correction

Deletion

Correction

Correction

CONDITIONS OF USE FOR THE PRODUCT

SAFETY PRECAUTIONS, MANUAL,

GENERIC TERMS AND ABBREVIATIONS, Section 1.2, Section 2.5,

Section 3.1, Section 3.2, Section 5.1.2, Section 6.2.1, Section 6.2.2,

Section 6.3, Section 6.4, Section 6.4.2, Section 6.5.1, Section 6.5.2,

Section 6.5.3, Section 6.6.1, Section 6.6.2, Section 6.7.1, Section 7.1,

May, 2010 SH(NA)-080691ENG-I

Section 7.2, Section 7.3.1 to 7.3.3, Section 8.1, Section 8.1.1, Section 8.1.3,

Section 8.2, Section 8.3, Section 9.2.1, Section 9.2.3, Section 9.4.1,

Section 9.4.2, Section 9.5.1, Section 10.2.1, Section 10.2.3, Section 11.1.2,

CHAPTER 12, Section 12.3.3, Section 12.3.4, Section 12.9, Section 16.2,

Section 16.4.5, Appendix 3.1, Appendix 3.2

Section 12.3.5, Section 12.3.6

Section 1.3 is changed to Appendix 4.

Appendix 4 is changed to Appendix 7.

Jun., 2010 SH(NA)-080691ENG-J

Dec., 2010 SH(NA)-080691ENG-K

Section 2.6

Section 2.5

A - 10

Page 13

Print Date *Manual Number Revision

Model addition

Addition

Correction

Deletion

Correction

Addition

Correction

Correction

Q81BD-J71GP21-SX, Q81BD-J71GP21S-SX

Appendix 9.3, Appendix 9.4

SAFETY PRECAUTIONS, PRECAUTIONS FOR USE, INTRODUCTION,

MANUAL, HOW TO USE THIS MANUAL,

GENERIC TERMS AND ABBREVIATIONS, PACKING LIST, CHAPTER 1,

Section 1.1, Section 1.2, Section 2.1, Section 2.4, Section 2.5, Section 3.1,

Section 3.2, Section 5.1.1, Section 6.1, Section 6.2.1, Section 6.3,

Section 6.4.1, Section 6.4.2, Section 6.5.3, Section 6.6.1, Section 6.6.2,

Section 7.9, Section 8.1.1, Section 8.1.2, Section 8.1.3, Section 9.2.1,

Section 9.3.3, Section 9.4.1, Section 9.4.8, Section 10.2.1, Section 10.6,

Jul., 2011 SH(NA)-080691ENG-L

Section 10.7, Section 10.8, Section 10.9, CHAPTER 11, Section 11.2,

Section 12.2, Section 13.1.4, Section 13.2, CHAPTER 14, Section 14.1,

Section 14.2, Section 15.2, Section 15.3, Section 15.3.1, Section 15.4.2,

Section 15.4.4, Section 15.4.5, Section 15.5.1, Section 15.6, Appendix 1,

Appendix 2.1, Appendix 3.1, Appendix 3.4, Appendix 5, Appendix 5.1,

Appendix 5.6, Appendix 7, Appendix 8

Jan., 2012 SH(NA)-080691ENG-M

Mar., 2012 SH(NA)-080691ENG-N

Dec., 2012 SH(NA)-080691ENG-O

CHAPTER 11, Section 12.3 to Section 12.9, Section 15.1, Appendix 2.1.1,

Appendix 2.1.2

CHAPTER 12 to 16 are changed to CHAPTER 11 to 15.

Section 2.6 is changed to Appendix 4 and 7. Section 15.2 and 15.3 are

changed to Section 15.1 and 15.2. Appendix 6 is changed to Appendix 3.

Appendix 4 is changed to Appendix 6. Appendix 3 is changed to Appendix 8.

Appendix 7 is changed to Appendix 9.

PRECAUTIONS FOR USE, Section 3.1

CHAPTER 5 is changed to Appendix 9, Appendix 9 is changed to Appendix 10

Appendix 11, Appendix 12

Section 2.5, Section 7.1.1, Section 7.1.3, Section 7.2

SAFETY PRECAUTIONS, GENERIC TERMS AND ABBREVIATIONS,

Section 2.5, Section 3.1, Section 3.2, Section 5.4, Section 7.1.2, Section 11.1.1,

Section 11.3, Section 14.2, Section 14.3

A - 11

Page 14

Print Date *Manual Number Revision

Addition

Correction

Deletion

Correction

Deletion

Correction

Correction

Correction

Section 3.4, Section 5.3.3, Section 5.3.4, Section 8.2.3, Section 14.2.1,

Section 14.2.2, Section 14.3.3, Section 14.7.1, Section 14.7.2, Appendix 7.1,

Appendix 7.2, Appendix 8, Appendix 10.3

PRECAUTIONS FOR USE, HOW TO USE THIS MANUAL,

GENERIC TERMS AND ABBREVIATIONS, Section 1.2, Section 2.5,

Section 5.1 ~ 5.5, Section 6.7, Section 7.1 ~ 7.3, Section 8.2, Section 8.2.1,

Section 8.2.4, Section 8.3.1, Section 8.4.6, Section 9.2.1, Section 9.2.3,

CHAPTER 10, Section 12.1.4, Section 13.1.2, CHAPTER 14, Section 14.1,

Section 14.2.3, Section 14.3, Section 14.3.2, Section 14.6, Section 14.9,

Sep., 2013 SH(NA)-080691ENG-P

Appendix 5, Appendix 9.1, Appendix 9.2, Appendix 10, Appendix 10.1,

Appendix 10.2, Appendix 11, Appendix 11.2, Appendix 11.3

Section 5.2 is changed to Section 5.3,

Section 5.6.1 and 5.6.2 are changed to Section 5.5.4 and 5.5.5,

Section 5.7.1 is changed to Section 5.5.6,

Section 7.1.1 is changed to Section 7.2,

Section 7.1.3 is changed to Section 14.2.3,

Appendix 4 is changed to Appendix 7,

Appendix 5, 6, 7, 8, 9, 10, 11 and 12 are changed to Appendix 4, 5, 6, 9, 12, 13,

10 and 11

Jun., 2014 SH(NA)-080691ENG-Q

Jan., 2015 SH(NA)-080691ENG-R

Apr., 2015 SH(NA)-080691ENG-S

Sep., 2015 SH(NA)-080691ENG-T

Section 5.6, Section 5.7, Section 7.1.2, Section 10.1, Section 10.2,

Section 14.5.4

Section 2.5, Section 7.1, Section 7.2, Section 8.2.1, Section 8.4.1,

Section 9.1.1, Section 9.2, Section 9.3, Section 9.4, Section 9.6, Section 9.7,

Section 9.9, Section 12.1, Section 14.1, Section 14.2.2, Section 14.2.3,

Section 14.3.2, Appendix 3.1, Appendix 7.2, Appendix 9.2, Appendix 10.2,

Appendix 10.3, Appendix 11

Section 9.9 to Section 9.11 are changed to Section 9.8 to Section 9.10

Section 9.8

Section 3.2, Section 8.3.4

Section 2.5, Section 7.2, Section 9.3, Section 9.4, Section 14.3.2

Section 2.5, Section 7.1, Section 14.2.3, Appendix 8

A - 12

Page 15

Print Date *Manual Number Revision

Correction

Deletion

Correction

Correction

Section 2.5, Section 7.1, Section 7.2, Section 8.2.1, CHAPTER 9, Section 14.1,

Sep., 2016 SH(NA)-080691ENG-U

Section 14.2.3, Section 14.2.4, Appendix 8, Appendix 9.2, Appendix 10.1,

Appendix 10.2, Appendix 11

Section 9.1 to Section 9.10, Appendix 10.1

Feb., 2017 SH(NA)-080691ENG-V

Mar., 2017 SH(NA)-080691ENG-W

Section 2.5, Section 14.3.2

Section 2.5

Japanese Manual Version SH-080690-W

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses.

Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

© 2007 MITSUBISHI ELECTRIC CORPORATION

A - 13

Page 16

PRECAUTIONS FOR USE

(1) Interlink transfer and routing functions

(2) A personal computer equipped with PCI bus slot and PCI Express® slot

(3) Restrictions for functions depending on the personal computer or the

(4) Driver installation and updating

The CC-Link IE Controller Network board cannot be used as a relay station for the

interlink transfer function or the routing function.

To use these functions, set a network module as a relay station.

When CC-Link IE Controller Network board (Q80BD-J71GP21-SX,

Q80BD-J71GP21S-SX) supported with PCI bus is installed on a personal computer

®

which has both PCI bus slot and PCI Express

compared to when using a personal computer which has only PCI bus slot.

slot, link refresh time may be long

operating system

There are some restrictions for the functions or supported version depending on the

operating system or personal computer to be used.

Section 2.5 Operating Environment

Do not install or update the driver other than the method written in the troubleshooting

in this manual.

The consistency between the driver and utility cannot be identified, and CCLink IE

Controller Network board may not operate properly.

A - 14

Page 17

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric network interface boards.

Before using this product, please read this manual and the relevant manuals carefully and develop

familiarity with the functions and performance of the Q80BD-J71GP21-SX, Q80BD-J71GP21S-SX,

Q81BD-J71GP21-SX, Q81BD-J71GP21S-SX CC-Link IE Controller Network interface board to handle the

product correctly.

CONTENTS

SAFETY PRECAUTIONS ··········································································································· A - 1

CONDITIONS OF USE FOR THE PRODUCT ················································································· A - 7

REVISIONS ····························································································································· A - 8

PRECAUTIONS FOR USE·········································································································A - 14

INTRODUCTION ·····················································································································A - 15

CONTENTS ····························································································································A - 15

MANUAL ································································································································A - 20

HOW TO USE THIS MANUAL ····································································································A - 21

GENERIC TERMS AND ABBREVIATIONS ···················································································A - 22

ABBREVIATIONS AND SYMBOLS······························································································A - 23

PACKING LIST························································································································A - 23

CHAPTER 1 OVERVIEW 1 - 1 to 1 - 4

1.1 Overview ···················································································································1 - 1

1.2 Features ····················································································································1 - 2

CHAPTER 2 SYSTEM CONFIGURATION 2 - 1 to 2 - 10

2.1 System Configuration Using CC-Link IE Controller Network Board ·········································2 - 1

2.2 Single Network System ·································································································2 - 2

2.2.1 Configuration ········································································································2 - 2

2.2.2 Setting items·········································································································2 - 3

2.2.3 Available device ranges ··························································································2 - 3

2.3 Multi-Network System ···································································································2 - 4

2.3.1 Configuration ········································································································2 - 4

2.3.2 Setting items·········································································································2 - 5

2.3.3 Available device range ····························································································2 - 5

2.4 Use in Multiple CPU System or Redundant CPU System ·····················································2 - 6

2.5 Operating Environment ·································································································2 - 7

CHAPTER 3 SPECIFICATIONS 3 - 1 to 3 - 3

3.1 General Specifications ··································································································3 - 1

3.2 Performance Specifications ···························································································3 - 2

A - 15

Page 18

3.3 Optical Fiber Cable Specifications ·················································································· 3 - 3

3.4 Buffer Memory············································································································ 3 - 3

CHAPTER 4 FUNCTIONS 4 - 1 to 4 - 7

4.1 Function List ·············································································································· 4 - 1

4.2 Specifications on Cyclic Transmission Processing ····························································· 4 - 2

4.2.1 Cyclic transmission processing ················································································ 4 - 2

4.3 Driver WDT function ···································································································· 4 - 7

CHAPTER 5 PROCEDURES AND SETTINGS BEFORE OPERATION 5 - 1 to 5 - 28

5.1 Procedure before Operation ·························································································· 5 - 1

5.2 Part Names and Settings ······························································································ 5 - 3

5.3 Installation ·················································································································5 - 8

5.3.1 Handling precautions ····························································································· 5 - 8

5.3.2 Installation environment·························································································· 5 - 9

5.3.3 Board installation ·································································································· 5 - 9

5.3.4 Setting Channel Numbers ······················································································5 - 10

5.4 Wiring······················································································································5 - 11

5.4.1 Controller network system······················································································5 - 13

5.4.2 Wiring external power supply cable··········································································5 - 15

5.5 Test ························································································································5 - 17

5.5.1 Bus I/F test ·········································································································5 - 18

5.5.2 H/W test·············································································································5 - 19

5.5.3 Self-loopback test ································································································5 - 20

5.5.4 Circuit test ··········································································································5 - 22

5.5.5 Station-to-station test····························································································5 - 25

5.5.6 Communication test······························································································5 - 27

CHAPTER 6 PARAMETER SETTINGS 6 - 1 to 6 - 25

6.1 Parameter Settings (Board Information Settings) ······························································· 6 - 2

6.2 Parameter Setting Example··························································································· 6 - 8

6.3 Network Range Assignment Settings ·············································································· 6 - 9

6.3.1 LB/LW settings ····································································································6 - 10

6.3.2 LX/LY settings ·····································································································6 - 13

6.3.3 Total number of link stations···················································································6 - 15

6.3.4 Specifying I/O master station ··················································································6 - 15

6.3.5 Specifying reserved stations···················································································6 - 16

6.4 Equal Assignment Settings ··························································································6 - 17

6.5 Routing Parameter Settings ·························································································6 - 20

6.6 Supplementary Settings ······························································································6 - 21

6.7 Driver Settings···········································································································6 - 22

6.8 Event Settings ···········································································································6 - 23

6.9 Target Settings ··········································································································6 - 24

A - 16

Page 19

6.10 Refresh Parameter Setting ·························································································· 6 - 25

CHAPTER 7 INSTALLING AND UNINSTALLING SOFTWARE PACKAGES 7 - 1 to 7 - 4

7.1 Installation and Uninstallation Precautions ········································································7 - 1

7.2 Installation··················································································································7 - 2

7.3 Uninstallation ··············································································································7 - 4

CHAPTER 8 CC IE Control UTILITY 8 - 1 to 8 - 41

8.1 Overview ···················································································································8 - 1

8.1.1 List of functions ·····································································································8 - 2

8.2 Operating Procedure ····································································································8 - 3

8.2.1 Starting the utility ···································································································8 - 4

8.2.2 Ending the utility ····································································································8 - 5

8.2.3 Displaying manual ·································································································8 - 5

8.2.4 Checking the version information ··············································································8 - 6

8.3 Board Information Screens ····························································································8 - 7

8.3.1 Board list screen····································································································8 - 7

8.3.2 Channel number confirmation screen ·········································································8 - 9

8.3.3 Board detail information screen ·············································································· 8 - 10

8.3.4 Memory Test screen····························································································· 8 - 11

8.4 Setting Screen ·········································································································· 8 - 12

8.4.1 Parameter setting screen ······················································································ 8 - 12

8.4.2 Network range assignment screen ·········································································· 8 - 15

8.4.3 Equal assignment screen ······················································································ 8 - 17

8.4.4 Routing parameter setting screen············································································ 8 - 19

8.4.5 Supplementary setting screen ················································································ 8 - 20

8.4.6 Driver setting screen ···························································································· 8 - 21

8.4.7 Event setting screen ····························································································· 8 - 23

8.4.8 Target setting screen ···························································································· 8 - 25

8.4.9 Refresh parameter setting screen ···········································································8 - 27

8.5 Diagnostics Screen ···································································································· 8 - 29

8.5.1 CC-Link IE Controller Network diagnostics result screen ·············································· 8 - 29

8.5.2 Communication test screen···················································································· 8 - 36

8.5.3 Link start/stop screen ··························································································· 8 - 38

8.5.4 Logging screen ··································································································· 8 - 40

CHAPTER 9 DEVICE MONITOR UTILITY 9 - 1 to 9 - 2

CHAPTER 10 MELSEC DATA LINK LIBRARY 10 - 1 to 10 - 2

CHAPTER 11 PROGRAMMING 11 - 1 to 11 - 5

11.1 Precautions on Programming ······················································································· 11 - 1

11.1.1 Interlock related signals ························································································ 11 - 1

11.2 Cyclic Transmission ··································································································· 11 - 3

A - 17

Page 20

11.2.1 Station-based block data assurance·········································································11 - 4

11.3 Link Special Relays (SB) and Link Special Registers (SW) ·················································11 - 5

CHAPTER 12 APPLICATION FUNCTIONS 12 - 1 to 12 - 21

12.1 Transient Transmission Function···················································································12 - 2

12.1.1 Communication function ························································································12 - 3

12.1.2 Routing function··································································································· 12 - 6

12.1.3 Group function··································································································· 12 - 15

12.1.4 SEND/RECV function ························································································· 12 - 16

12.2 Event Setting Function ······························································································ 12 - 20

CHAPTER 13 ERROR CODES 13 - 1 to 13 - 11

13.1 List of Error Messages in CC IE Control Utility··································································13 - 1

13.1.1 Error messages displayed on the board information screen ··········································13 - 2

13.1.2 Error messages displayed on the setting screen ·························································13 - 3

13.1.3 Error messages displayed on the diagnostics screen ···················································13 - 7

13.2 List of Error Messages in Device Monitor Utility ······························································ 13 - 11

CHAPTER 14 TROUBLESHOOTING 14 - 1 to 14 - 29

14.1 Cause Determination Methods for Each Trouble·······························································14 - 2

14.2 Troubleshooting of Installation/Uninstallation ···································································14 - 4

14.2.1 Installation failed ··································································································14 - 4

14.2.2 Uninstallation failed ······························································································14 - 5

14.2.3 When the corrective action displayed on the screen is not effective at installation ··············14 - 6

14.2.4 When the driver is not installed ···············································································14 - 8

14.3 When CC-Link IE Controller Network Board did not Operate Normally ·································14 - 9

14.3.1 Checking personal computer and operating system·····················································14 - 9

14.3.2 Checking on Event Viewer screen ·········································································14 - 10

14.3.3 Checking on Device Manager screen ····································································· 14 - 13

14.4 Flowchart when Data Link Failed················································································· 14 - 14

14.4.1 Flowchart when RUN LED is OFF ·········································································14 - 15

14.4.2 Flowchart when SD/RD LEDs are OFF ··································································· 14 - 16

14.4.3 Flowchart when ERR. LED turned ON ···································································· 14 - 17

14.4.4 Flowchart when data link among whole system is disabled ········································· 14 - 18

14.4.5 Flowchart when data link to specific station is disabled ·············································· 14 - 20

14.4.6 Flowchart when RUN LED is flashing ····································································· 14 - 22

14.5 Flowchart for Error during Data Link············································································· 14 - 23

14.5.1 Flowchart when specific link device is not updated to the expected value ······················ 14 - 23

14.5.2 Flowchart when data cannot be written or read with user program································ 14 - 24

14.5.3 Flowchart when communications are occasionally disabled during user program

execution ········································································································· 14 - 25

14.6 When External Power Supply Function did not Correctly Operate ······································ 14 - 26

14.7 Actions for WDT Error ······························································································· 14 - 27

14.7.1 Board WDT error ······························································································· 14 - 27

14.7.2 Driver WDT error ······························································································· 14 - 27

A - 18

Page 21

14.8 Measures for Slow Personal Computer Operation ·························································· 14 - 28

14.9 Information Required for Inquiries ··············································································· 14 - 29

APPENDICES App - 1 to App - 49

Appendix 1 Precautions for Accessing Redundant CPU System ·············································· App - 1

Appendix 2 Network Status at Power ON/OFF and Board Reset During Data Linking ················· App - 10

Appendix 2.1 Network status at power ON/OFF ····························································· App - 10

Appendix 2.2 Network status at board reset··································································· App - 15

Appendix 3 File Output ·································································································· App - 16

Appendix 3.1 Parameter file ······················································································· App - 16

Appendix 3.2 SB/SW file ··························································································· App - 17

Appendix 3.3 Error log file·························································································· App - 19

Appendix 3.4 Verification result file ·············································································· App - 20

Appendix 4 Comparison with the MELSECNET/H Board ······················································ App - 21

Appendix 4.1 Comparison of boards ············································································ App - 21

Appendix 4.2 Comparison of MELSECNET utilities ························································· App - 23

Appendix 4.3 Comparison of device monitor utilities ························································ App - 23

Appendix 4.4 Precautions for replacing programs ··························································· App - 24

Appendix 4.5 Precautions for setting parameters ···························································· App - 24

Appendix 4.6 Comparison of the data link library functions ··············································· App - 25

Appendix 5 Combinations with Existing Software ································································ App - 26

Appendix 6 Checking Serial Number and Function Version ··················································· App - 27

Appendix 7 New and Improved Functions·········································································· App - 29

Appendix 7.1 Change of hardware function ··································································· App - 29

Appendix 7.2 Update of software package ···································································· App - 29

Appendix 8 Restrictions for Operating System···································································· App - 30

Appendix 9 Warning Message Appears on Windows ··························································· App - 31

Appendix 9.1 Overview of warning message·································································· App - 31

Appendix 9.2 Methods for preventing the warning message·············································· App - 32

Appendix 10 Behavior When Personal Computer Enters Power Save Mode or Fast Startup·········· App - 37

Appendix 10.1 Behavior when the personal computer enters the power save mode

(hibernate, sleep) ·················································································· App - 37

Appendix 10.2 Behavior when the fast startup function is enabled ······································· App - 38

Appendix 11 MELSECPowerManager ················································································ App - 39

Appendix 11.1 Installing MELSECPowerManager ···························································· App - 39

Appendix 11.2 Uninstalling MELSECPowerManager························································· App - 39

Appendix 11.3 Checking MELSECPowerManager ···························································· App - 40

Appendix 12 EMC AND LOW VOLTAGE DIRECTIVE ··························································· App - 42

Appendix 12.1 Requirements for Conformance to EMC Directive········································· App - 42

Appendix 12.2 Requirements for Conformance to Low Voltage Directive······························· App - 45

Appendix 13 External Dimensions ····················································································· App - 46

Appendix 13.1 Q80BD-J71GP21-SX ············································································· App - 46

Appendix 13.2 Q80BD-J71GP21S-SX ··········································································· App - 47

Appendix 13.3 Q81BD-J71GP21-SX ············································································· App - 48

Appendix 13.4 Q81BD-J71GP21S-SX ··········································································· App - 49

INDEX Index - 1 to Index - 2

A - 19

Page 22

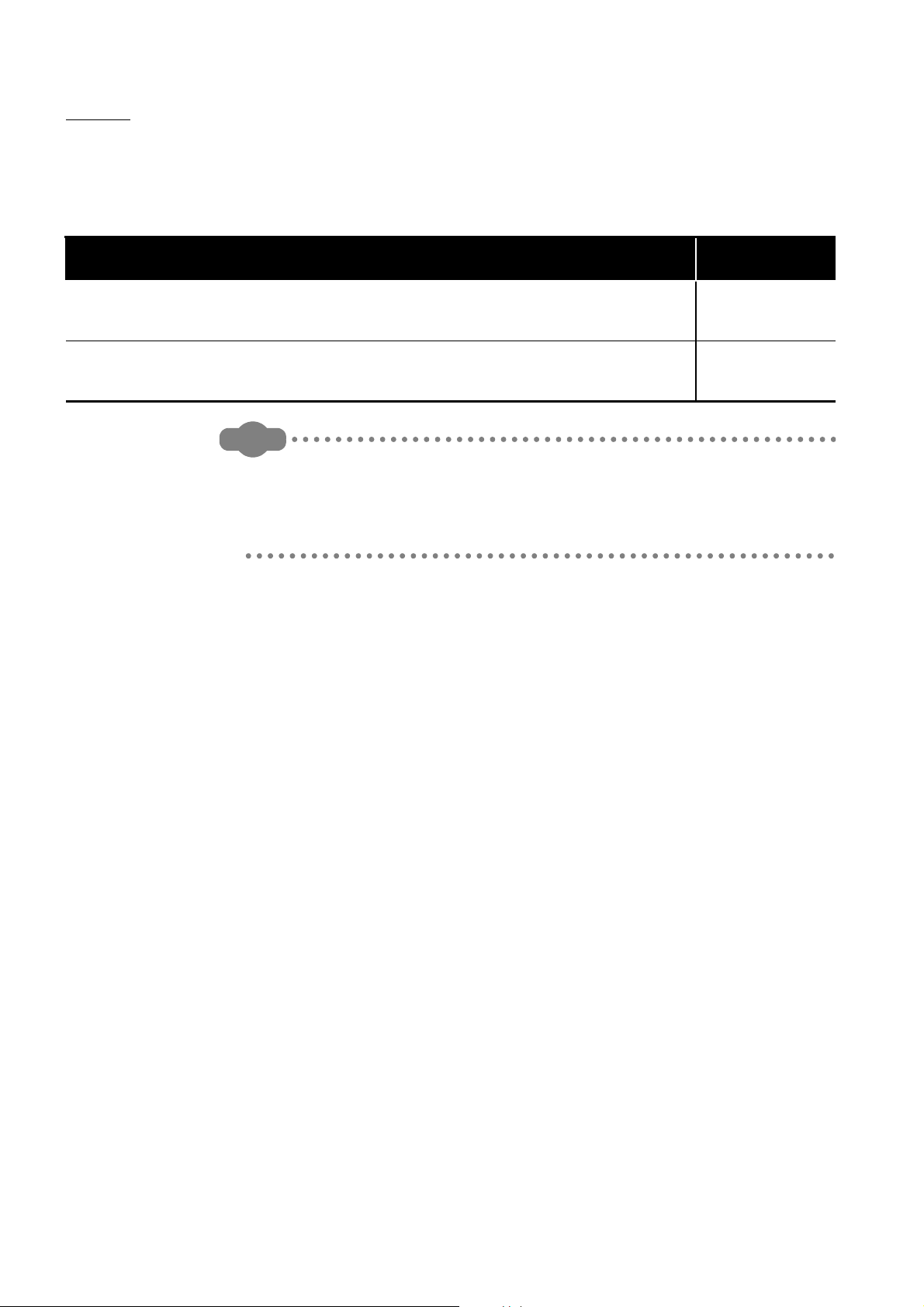

MANUAL

Remarks

The following is the manual relevant to this product.

Please purchase it if necessary.

Relevant Manual

Manual Name

MELSEC-Q CC-Link IE Controller Network Reference Manual

This manual explains the system configuration, performance specification, functions, handling and wiring

instructions, and troubleshooting of the CC-Link IE Controller Network. (Sold separately)

MELSEC Data Link Library Reference Manual

This manual explains the programming, function specifications, and sample programming of the MELSEC data

link library. (Sold separately)

MELSEC Data Link Library Reference Manual is stored on the CD-ROM of

software package with PDF file.

Manuals in printed form are sold separately for single purchase. Order a manual

by quoting the manual number (model code) listed in the table above.

Manual Number

(Model Code)

SH-080668ENG

(13JV16)

SH-081035ENG

(13JV25)

A - 20

Page 23

HOW TO USE THIS MANUAL

Relevant sections are listed below for each purpose for using the CC-Link IE Controller

Network board.

Refer to each section when you want to know the following:

(1) Overview and features of CC-Link IE Controller Network board (Chapter 1)

Chapter 1 gives an overview of the CC-Link IE Controller Network board and its

features.

(2) System configuration (Chapter 2)

Chapter 2 explains the system configuration.

(3) Specifications of CC-Link IE Controller Network board (Chapter 3)

Chapter 3 gives the specifications of the CC-Link IE Controller Network board.

(4) Functions of CC-Link IE Controller Network board (Chapter 4)

Chapter 4 gives the functions of the CC-Link IE Controller Network board.

(5) Preparatory procedures and setting of CC-Link IE Controller Network

board (Chapter 5)

Chapter 5 gives the procedures and setting to be done before starting the operation.

(6) Parameter setting for CC-Link IE Controller Network board (Chapter 6)

Chapter 6 describes the parameter setting.

(7) Installing and uninstalling procedures of software package (Chapter 7)

Chapter 7 gives the procedure for installing and uninstalling the software package.

(8) Detailed operation method of each utility (Chapter 8 and Chapter 9)

Chapter 8 and Chapter 9 explain the detailed operation methods for each utility.

(9) MELSEC data link library (Chapter 10)

Chapter 10 gives overview of the MELSEC data link library.

(10)Interlock related signals (Chapter 11)

Chapter 11 explains the interlock related signals.

(11)Application functions (Chapter 12)

Chapter 12 explains application functions of the CC-Link IE Controller Network board.

(12)Error codes (Chapter 13)

Chapter 13 describes the error codes.

(13)Troubleshooting (Chapter 14)

Chapter 14 provides information on troubleshooting.

A - 21

Page 24

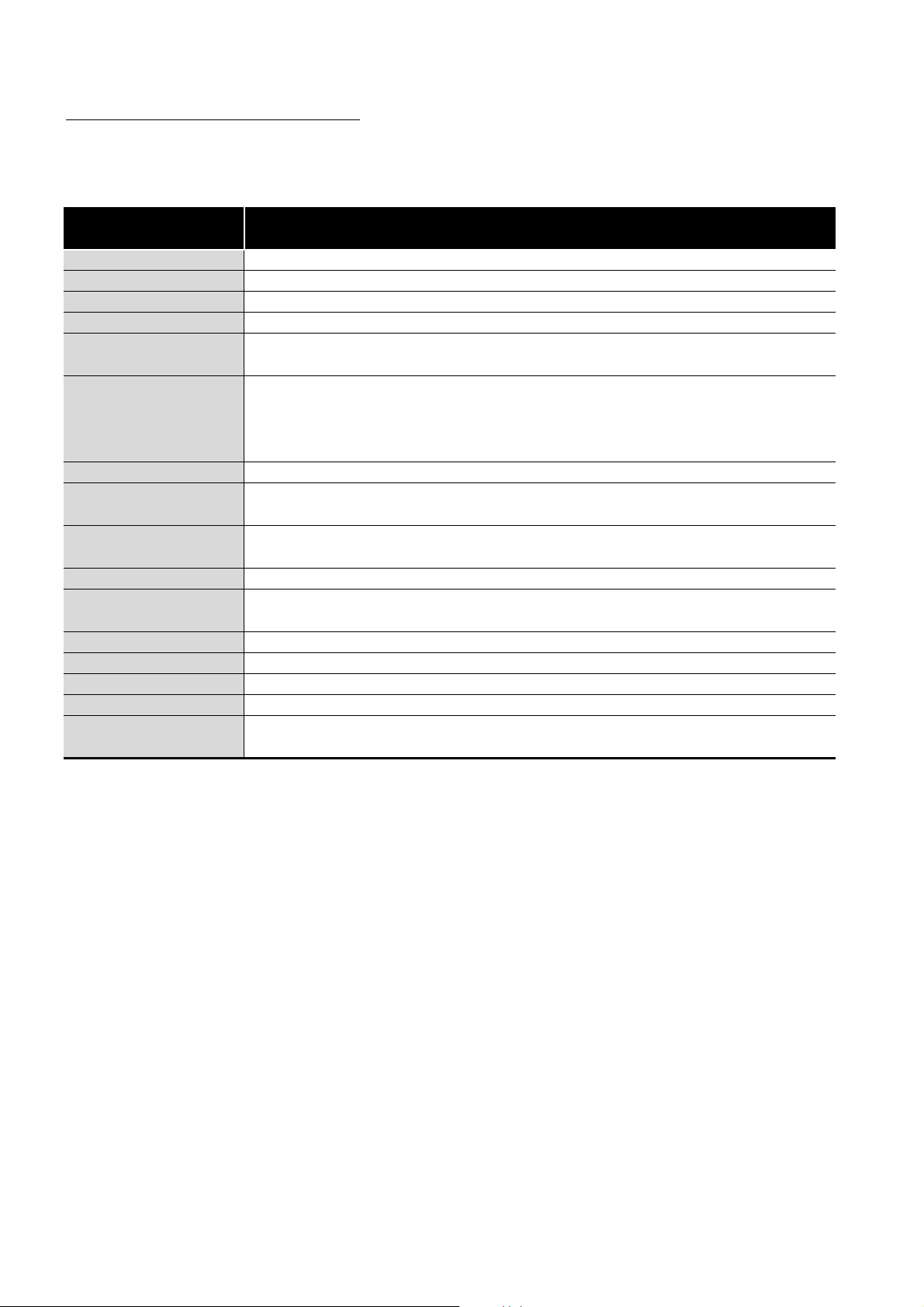

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and

abbreviations to describe the CC-Link IE Controller Network interface board.

Generic Term/

Abbreviation

Q80BD-J71GP21-SX Abbreviation for Q80BD-J71GP21-SX CC-Link IE Controller Network interface board

Q80BD-J71GP21S-SX Abbreviation for Q80BD-J71GP21S-SX CC-Link IE Controller Network interface board

Q81BD-J71GP21-SX Abbreviation for Q81BD-J71GP21-SX CC-Link IE Controller Network interface board

Q81BD-J71GP21S-SX Abbreviation for Q81BD-J71GP21S-SX CC-Link IE Controller Network interface board

CC-Link IE Controller

Network board

CC-Link IE Controller

Network board with

external power supply

function

SW1DNC-MNETG-B Product name of the software package for CC-Link IE Controller Network board

GX Developer

GX Works2

Network module Abbreviation for CC-Link IE Controller Network module

MELSECNET/H board

MELSECNET/H module Abbreviation for Q series MELSECNET/H network module

MELSECNET/H Abbreviation for Q series MELSECNET/H network system

MELSECNET/10 Abbreviation for AnU or QnA/Q4AR series MELSECNET/10 network system

Board WDT Abbreviation for the watchdog timer that monitors the operation of network board

Driver WDT

Generic term for Q80BD-J71GP21-SX, Q80BD-J71GP21S-SX, Q81BD-J71GP21-SX,

Q81BD-J71GP21S-SX CC-Link IE Controller Network interface board

Generic term for Q80BD-J71GP21S-SX, Q81BD-J71GP21S-SX CC-Link IE Controller Network

interface board

General product name for SW8D5C-GPPW-E, SW8D5C-GPPW-EA, SW8D5C-GPPW-EV,

SW8D5C-GPPW-EVA

General product name for SWnDNC-GXW2-E, SWnDNC-GXW2-EA

("n" denotes the version number.)

Generic term for Q80BD-J71LP21-25, Q81BD-J71LP21-25, Q80BD-J71LP21S-25,

Q80BDJ71LP21G, Q80BD-J71LP21GE, Q80BD-J71BR11 MELSECNET/H interface board

Abbreviation for the watchdog timer that monitors the communication status between a network

board and a personal computer, or operating status of a personal computer

Description

A - 22

Page 25

ABBREVIATIONS AND SYMBOLS

The following abbreviations and symbols are used in this manual.

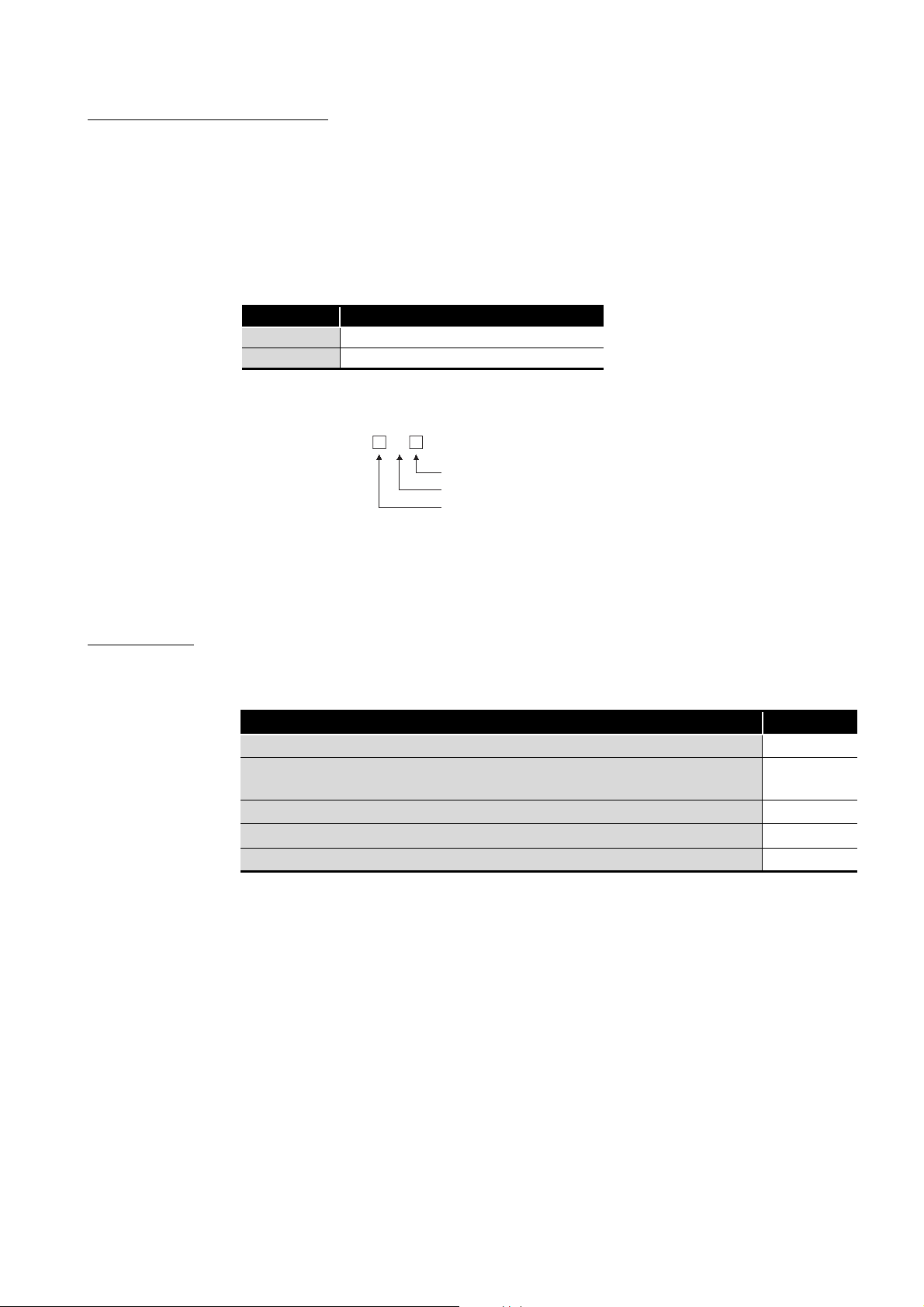

(1) Abbreviations for control station and normal station, and symbol format

This section explains abbreviations for control station and normal station, and symbol

format to be used in this manual.

(a) Abbreviations

Abbreviation Station status

MP Control station

NS Normal station

(b) Symbol format

[Example]

MP

Station number (1 to 120)

Abbreviation

Network No. (1 to 239)

PACKING LIST

1) Network No.3, control station and station number 6: 3M

2) Network No.5, normal station and station number 3: 5N

P6

S3

The packing list of the CC-Link IE Controller Network board is given below.

Item Quantity

Board 1

Connector set (for external power supply cable)

(Q80BD-J71GP21S-SX, Q81BD-J71GP21S-SX only)

"Before Using the Product" 1

Software package (CD-ROM)*

Software license agreement 1

*1: Manuals are stored on the CD-ROM in PDF format.

1

1

1

A - 23

Page 26

1

POINT

OVERVIEW

CHAPTER 1 OVERVIEW

This manual explains the specifications, functions, preparatory procedures and setting,

programming, and troubleshooting of the CC-Link IE Controller Network board.

When applying program examples introduced in this manual to the actual system, it is

necessary to perform a sufficient examination to make sure they don't cause any error in

the system control.

For construction of the CC-Link IE Controller Network, refer to the following manual.

CC-Link IE Controller Network Reference Manual

1.1 Overview

The CC-Link IE Controller Network board allows connection of a personal computer to a

CC-Link IE Controller Network, realizing high-speed and large-volume data

communications between the computer and programmable controllers.

High-speed and

large-volume data

communication

CC-Link IE Controller Network

(CC-Link IE Controller Network board)

(1) The CC-Link IE Controller Network is a system developed to improve the

MELSECNET/H network system (PLC-to-PLC network), allowing

communications of a larger data volume at a higher speed.

For details of the comparison between the CC-Link IE Controller Network

board and the MELSECNET/H board, refer to the following Appendix.

Appendix 4 Comparison with the MELSECNET/H Board

(2) CC-Link IE Controller Network boards, MELSECNET/H boards, and

MELSECNET/H modules cannot be mixed in the same network.

(Must be separated into different networks.)

• CC-Link IE Controller Network board:

Used for CC-Link IE Controller Network

• MELSECNET/H board or MELSECNET/H module:

Used for MELSECNET/H or MELSECNET/10

1 - 1

1.1 Overview

Page 27

1

OVERVIEW

1.2 Features

1

The features of the CC-Link IE Controller Network board are shown below.

(1) Personal computer can be incorporated into CC-Link IE Controller

Network.

By installing the CC-Link IE Controller Network board to a personal computer, the

personal computer can be used as a control station or normal station of the CC-Link

IE Controller Network.

(2) Universal PCI, PCI Express® are applicable.

(a) Q80BD-J71GP21-SX, Q80BD-J71GP21S-SX

The following PCI slots are applicable.

•5 V slot

• 3.3 V slot

• 64-bit slot

•PCI-X slot

(b) Q81BD-J71GP21-SX, Q81BD-J71GP21S-SX

®

PCI Express

is applicable.

(3) Operation is easy.

To utilize the CC-Link IE Controller Network board, just install it to a personal

computer and install the software package.

Using the CC IE Control utility, various settings such as channel numbers and station

numbers can be configured easily.

2

SYSTEM

3

4

5

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

1.2 Features

PROCEDURES AND

SETTINGS BEFORE

OPERATION

6

PARAMETER

SETTINGS

7

INSTALLING AND

UNINSTALLING

SOFTWARE PACKAGES

8

CC IE Control

UTILITY

1 - 2

Page 28

1

Q80BD-

J71GP21-SX

QJ71GP21

-SX

QCPU

Q80BD-

J71GP21S-SX

Control station (No.1) Normal station (No.3)Normal station (No.2)

External power

supply

External power

supply

Normal station (No.6) Normal station (No.4)Normal station (No.5)

Q81BD-

J71GP21-SX

Q81BD-

J71GP21S-SX

QJ71GP21

-SX

QCPU

Since external power is supplied to stations No.3 and

No.5, networking of all stations continues normally.

If the boards on stations No.3 and No.5 do not have the

external power supply function, they are disconnected

from the network.

Station No.1

Disconnected

Station No.2 Station No.3

Station No.6 Station No.5 Station No.4

Personal computer

Personal computer

OVERVIEW

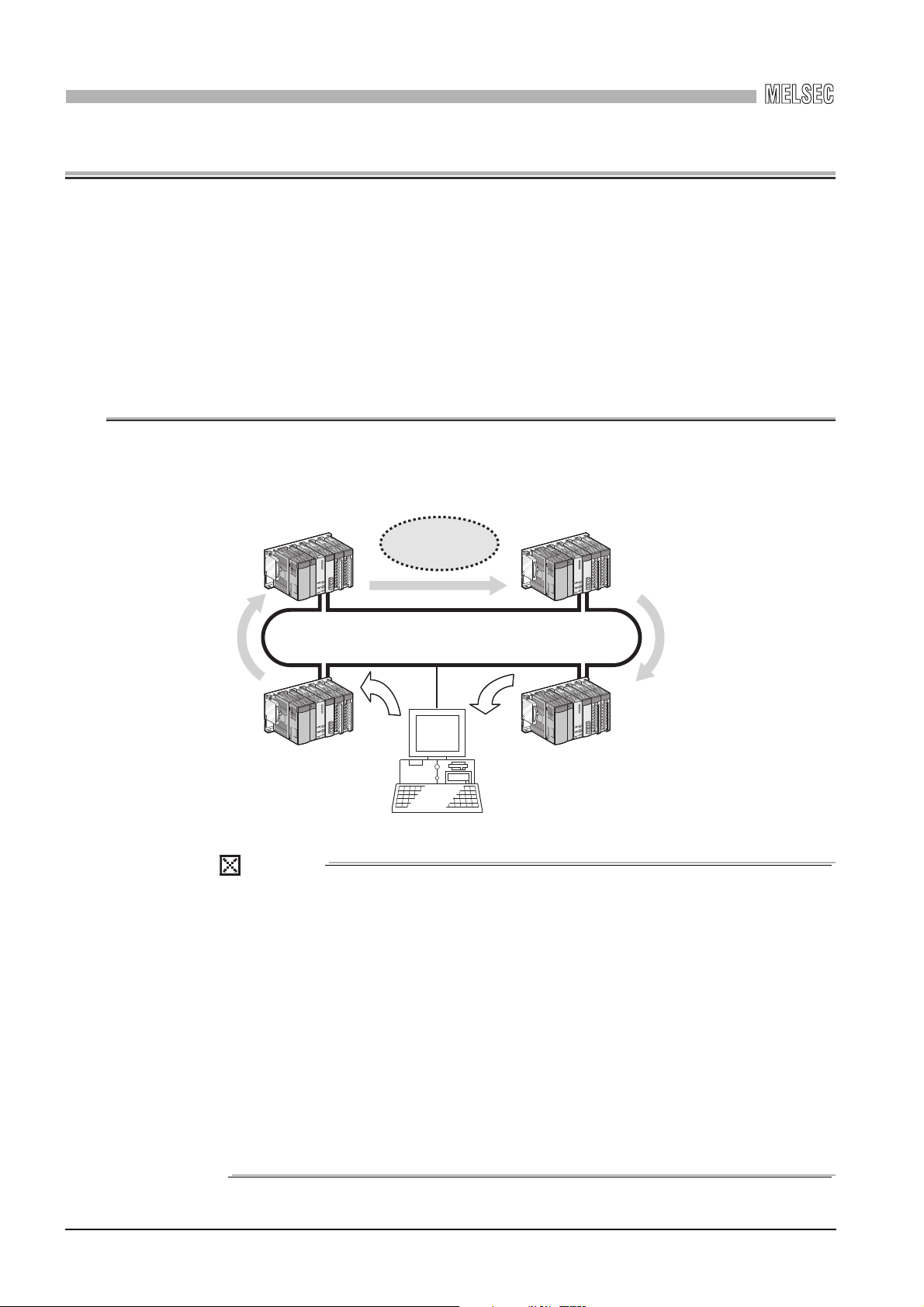

(4) External power supply allows continuous network communication even

during power-off of personal computer. (Function of the CC-Link IE

Controller Network board with external power supply function)

Since power is supplied externally, the CC-Link IE Controller Network board with

external power supply function can continue network communication (baton passing)

even if a personal computer is powered off and data link cannot be performed.

Therefore, a normally operating station connected between other stations with poweroff computers will not be disconnected from the data link.

Another advantage is that the link scan time is stabilized since loopback can be also

prevented.

When CC-Link IE Controller Network boards without the external power supply function

are installed to station number 3 and 5, and if personal computers of these stations are

1 - 3

1.2 Features

powered off, station number 3, 4, and 5 will be disconnected from the network.

Page 29

1

OVERVIEW

(5) Occupying one PCI bus slot

(6) Supporting event function

(7) Keeping application portability with MELSECNET/H board

(8) Drivers are available for each OS.

(9) User programming functions are available.

(10)Supporting Multiple CPU system

Any type of CC-Link IE Controller Network boards including those with external power

supply occupies only one slot.

The event function monitors link devices using the CC-Link IE Controller Network

board, and notifies events to the user program when the set conditions are met.

By only changing settings such as the total number of boards (CC-Link IE Controller

Network boards) installed to a personal computer and channel numbers, any existing

user program created by a MELSECNET/H or MELSECNET/10 board can be utilized.

Since various types of drivers are available, a system suitable to the user environment

can be easily constructed.

For details on the compatible operating system, refer to Section 2.5.

With supported Microsoft® Visual Basic® and Microsoft® Visual C++® functions,

remote control of programmable controllers and device reading/writing can be

performed, and user programs can be created easily.

By specifying a logical station number with the CC IE Control utility, a multiple CPU

system is accessible.

1

2

SYSTEM

3

4

5

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

1.2 Features

PROCEDURES AND

SETTINGS BEFORE

OPERATION

6

PARAMETER

SETTINGS

7

INSTALLING AND

UNINSTALLING

SOFTWARE PACKAGES

8

CC IE Control

UTILITY

1 - 4

Page 30

2

CC-Link IE Controller

Network board

Personal computer

Installed Connection Connection

Installed

SW1DNC-MNETG-B

Optical fiber

cable

CC-Link IE Controller Network

SYSTEM CONFIGURATION

CHAPTER 2 SYSTEM CONFIGURATION

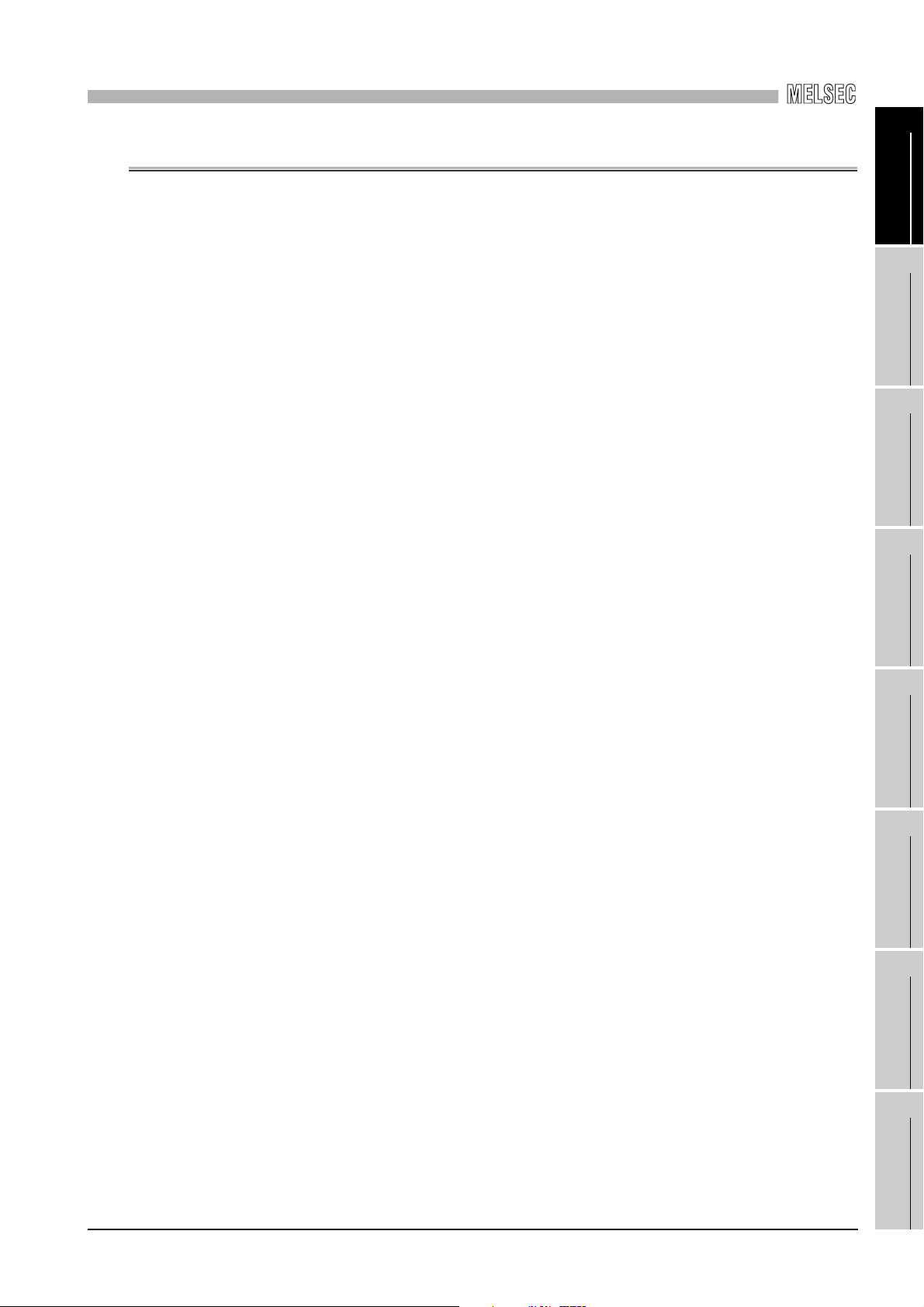

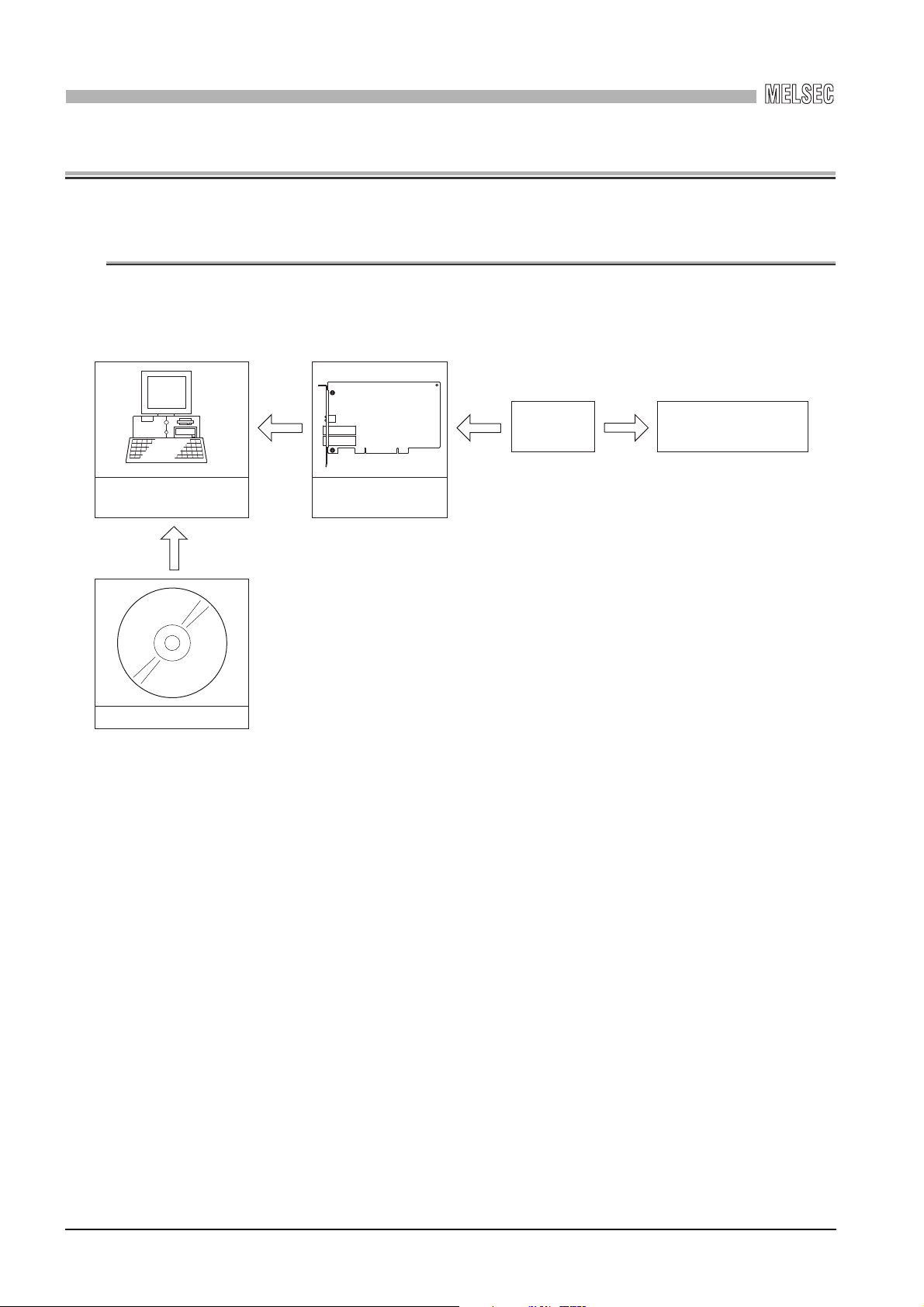

2.1 System Configuration Using CC-Link IE Controller Network

Board

A system configuration where the CC-Link IE Controller Network board is installed to a

personal computer is shown below.

2 - 1

2.1 System Configuration Using CC-Link IE Controller Network Board

Page 31

2

Q80BD-

J71GP21-SX

Control station

Station No.1

Personal

computer

Power supply

Power supply

QCPUINQJ71

GP21-SX

Normal station

Station No.2

OUT IN OUTIN OUT

QCPU QJ71

GP21-SX

Normal station

Station No.n n 120

<

SYSTEM CONFIGURATION

2.2 Single Network System

A single network system is a system that connects a control station and normal stations

with optical fiber cables.

A total of 120 stations, 1 control station and 119 normal stations, can be connected.

A control station can be any station No.s. (One control station can be connected per

network.)

In the system chart below, the station No.1 is set as the control station.

2.2.1 Configuration

A configuration example of a single network system is shown below.

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

5

PROCEDURES AND

SETTINGS BEFORE

OPERATION

6

PARAMETER

SETTINGS

7

INSTALLING AND

UNINSTALLING

SOFTWARE PACKAGES

8

2.2 Single Network System

2.2.1 Configuration

2 - 2

CC IE Control

UTILITY

Page 32

2

SYSTEM CONFIGURATION

2.2.2 Setting items

In a single network system, the following items are to be set when the CC-Link IE

Controller Network board is used as a control station or a normal station.

CC-Link IE Controller Network board settings are configured in the CC IE Control utility.

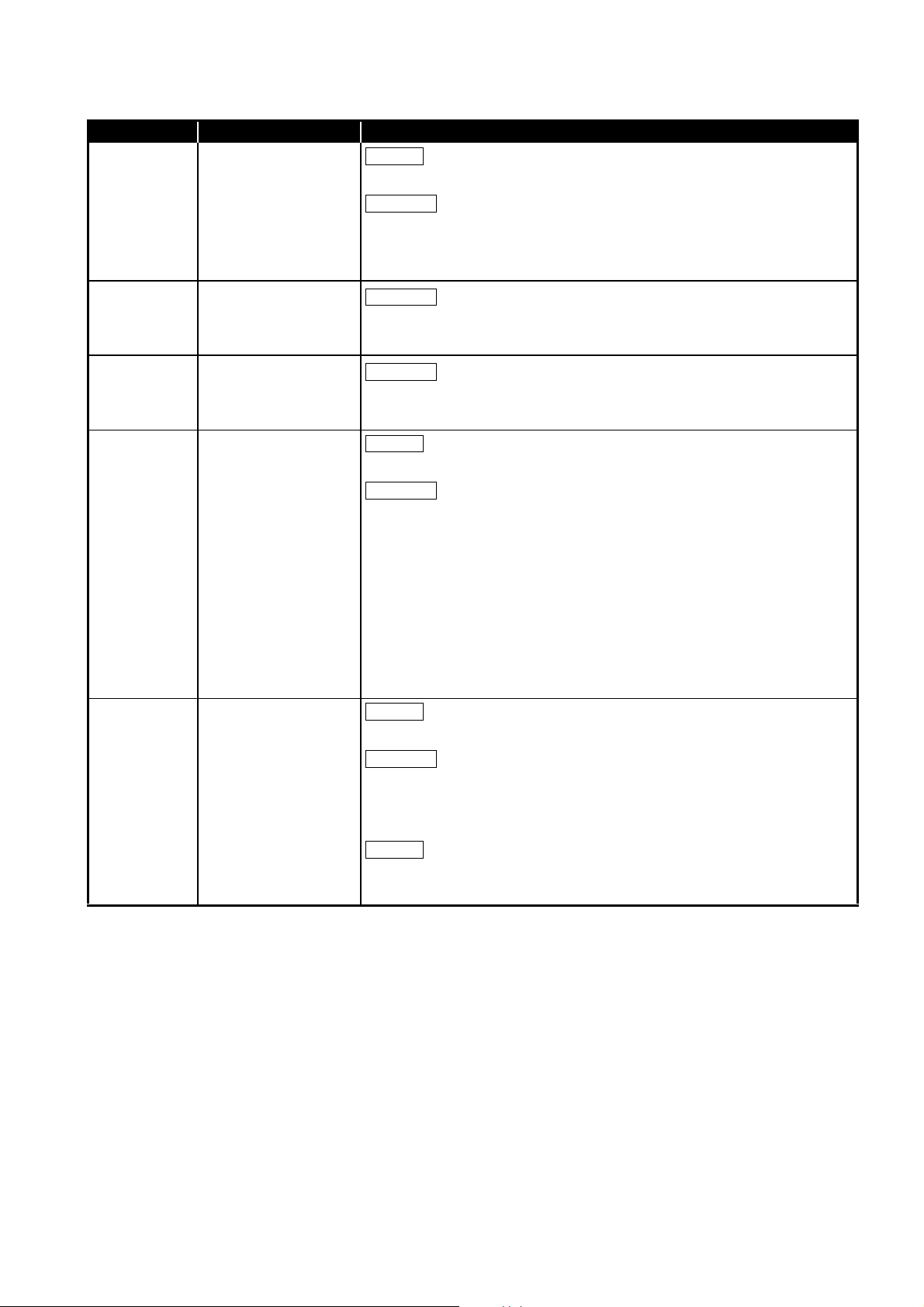

Setting item Control station Normal station Reference

Target board specification

Board

Channel No.

Network type

Operational

setting

Network

range

assignment

Driver setting Section 8.4.6

Event setting Section 8.4.7

Target setting Section 8.4.8

Refresh parameter setting Section 8.4.9

Routing parameter Section 8.4.4

Mode

Network No.

Group No.

Stati on No.

LB/LW settings

LX/LY settings

Specify reserved

station

Supplementary

setting

Section 8.4.1

Section 8.4.2

Section 8.4.5

: Setting required : Set as necessary : Setting not required

2.2.3 Available device ranges

The following device ranges can be used on the CC-Link IE Controller Network board.

Device Available range Remarks

LB 0H to 7FFFH (32768 points)

LW 0H to 1FFFFH (131072 points)

LX 0H to 1FFFH (8192 points)

LY 0H to 1FFFH (8192 points)

The ranges for each CC-Link IE Controller Network

board and network module need to be assigned in the

parameter setting for the control station.

The ranges for each CC-Link IE Controller Network

board and network module need to be assigned in the

parameter setting for the control station.

2 - 3

2.2 Single Network System

2.2.2 Setting items

Page 33

2

POINT

Q80BD-

J71GP21-SX

Control station

1M

P

1

Q80BD-

J71GP21-SX

Normal station

2N

S

2

Normal station

1NS2

Control station

2MP1

Power supply

Power supply

Power supply

QCPU QJ71

GP21-SX

QJ71

GP21-SX

Network No.1 Network No.2

Normal station

2N

S

3

QCPU QJ71

GP21-SX

Normal station

1N

S

3

QCPU QJ71

GP21-SX

SYSTEM CONFIGURATION

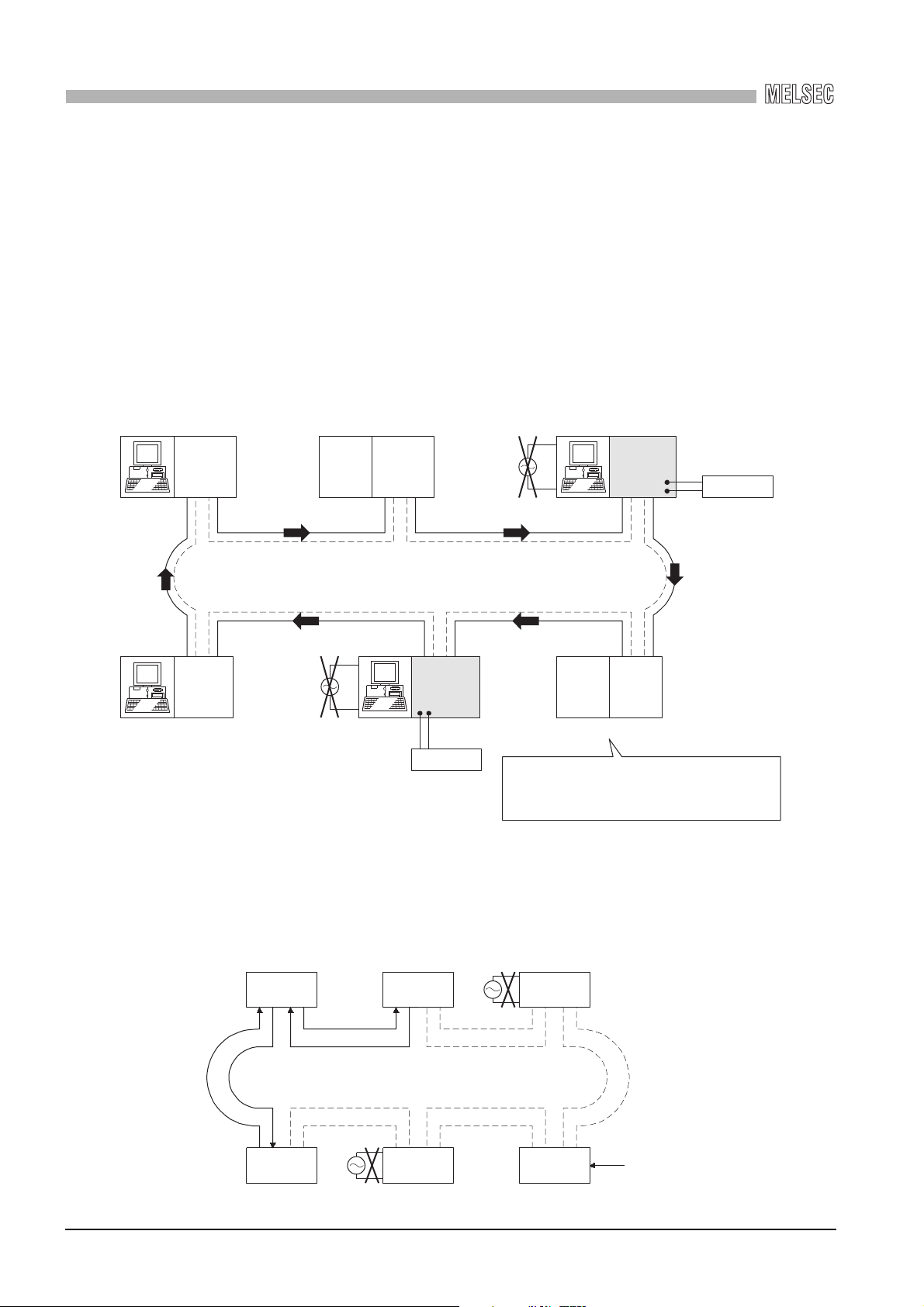

2.3 Multi-Network System

A multi-network system is composed of multiple networks that are connected by relay

stations.

(1) Any network No. can be set within the range of 1 to 239.

(2) The CC-Link IE Controller Network board cannot be used as a relay station.

Use a network module as a relay station.

2.3.1 Configuration

In the following example, two networks are connected.

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

5

PROCEDURES AND

SETTINGS BEFORE

OPERATION

6

PARAMETER

SETTINGS

7

INSTALLING AND

UNINSTALLING

SOFTWARE PACKAGES

8

2.3 Multi-Network System

2.3.1 Configuration

2 - 4

CC IE Control

UTILITY

Page 34

2

SYSTEM CONFIGURATION

2.3.2 Setting items

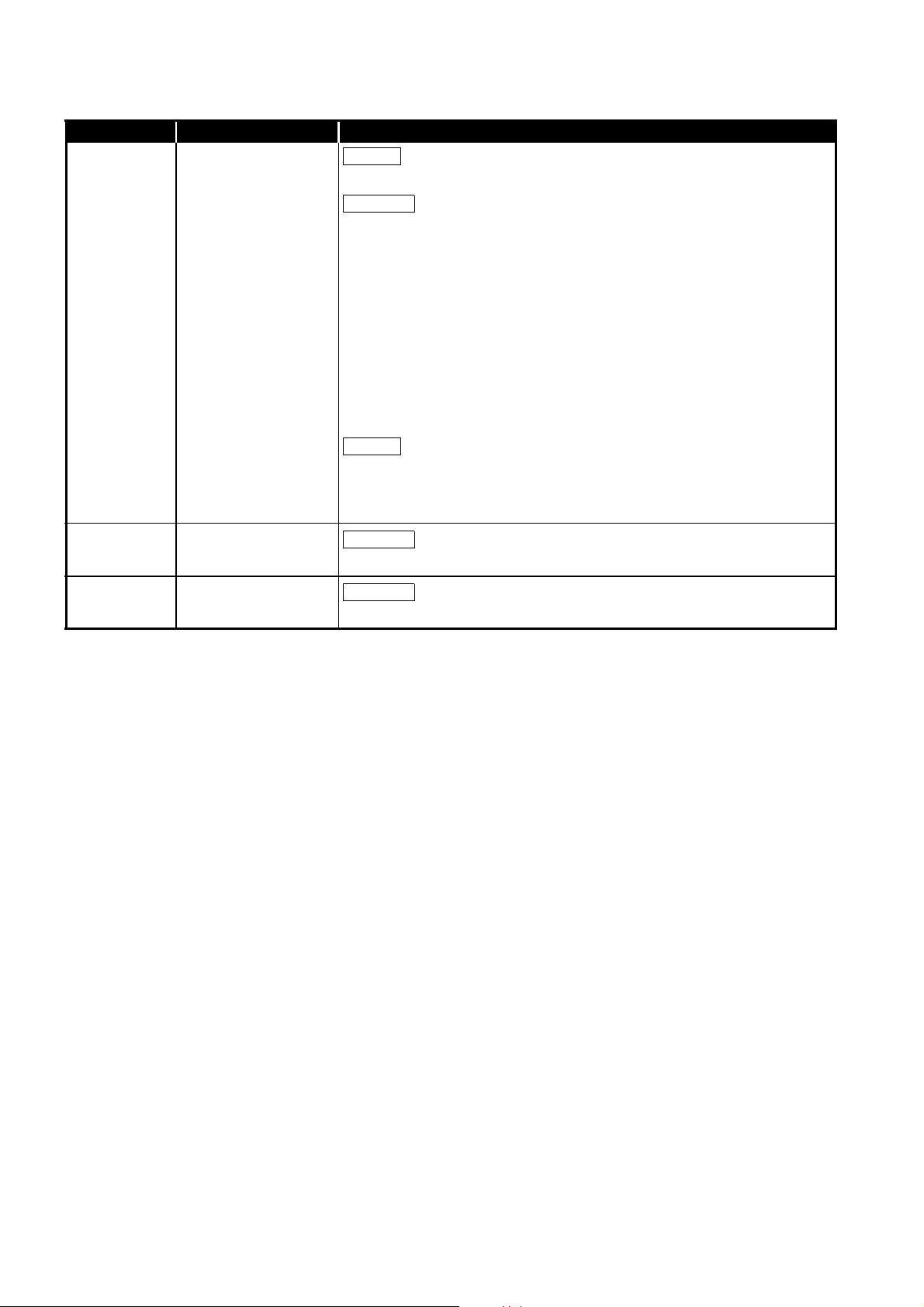

In a multi-network system, the following items are to be set when the CC-Link IE Controller

Network board is used as a control station or a normal station.

CC-Link IE Controller Network board settings are configured in the CC IE Control utility.

Setting item Control station Normal station Reference

Target board specification

Board

Channel No.

Network type

Operational

setting

Network

range

assignment

Driver setting Section 8.4.6

Event setting Section 8.4.7

Target setting Section 8.4.8

Refresh parameter setting Section 8.4.9

Routing parameter Section 8.4.4

Mode

Network No.

Group No.

Stati on No.

LB/LW settings

LX/LY settings

Specify reserved

station

Supplementary

setting

Section 8.4.1

Section 8.4.2

Section 8.4.5

: Setting required : Set as necessary : Setting not required

2.3.3 Available device range

The same device ranges as those of a single network system can be used.

Section 2.2.3 Available device ranges.

2 - 5

2.3 Multi-Network System

2.3.2 Setting items

Page 35

2

POINT

SYSTEM CONFIGURATION

2.4 Use in Multiple CPU System or Redundant CPU System

To access a multiple CPU system or redundant CPU system, the "Target setting" screen

setting must be completed.

Section 8.4.8 Target setting screen

When a CC-Link IE Controller Network board with a serial number whose first five

digits are 10091 or lower, or an SW1DNC-MNETG-B with the software Version

1.04E or earlier is used, the redundant CPU system cannot be accessed directly

with the CC-Link IE Controller Network interface board.

Relay the MELSECNET/H network system to access the redundant CPU system.

1

2

SYSTEM

3

4

OVERVIEW

CONFIGURATION

SPECIFICATIONS

FUNCTIONS

5

PROCEDURES AND

SETTINGS BEFORE

OPERATION

6

PARAMETER

SETTINGS

7

INSTALLING AND

UNINSTALLING

SOFTWARE PACKAGES

8

2.4 Use in Multiple CPU System or Redundant CPU System

CC IE Control

UTILITY

2 - 6

Page 36

2

POINT

SYSTEM CONFIGURATION

2.5 Operating Environment

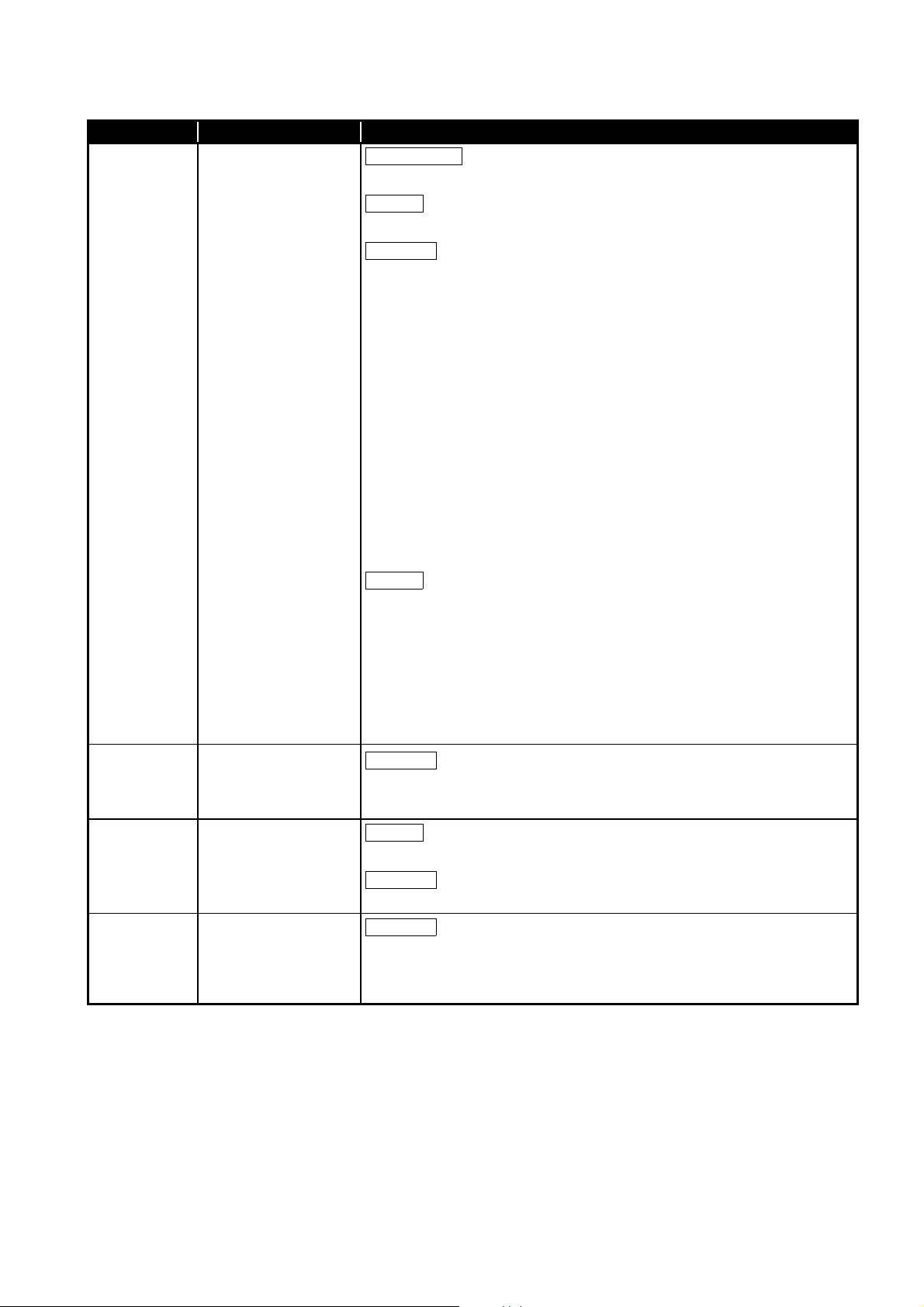

The following table shows the operating environment for the CC-Link IE Controller

Network board.

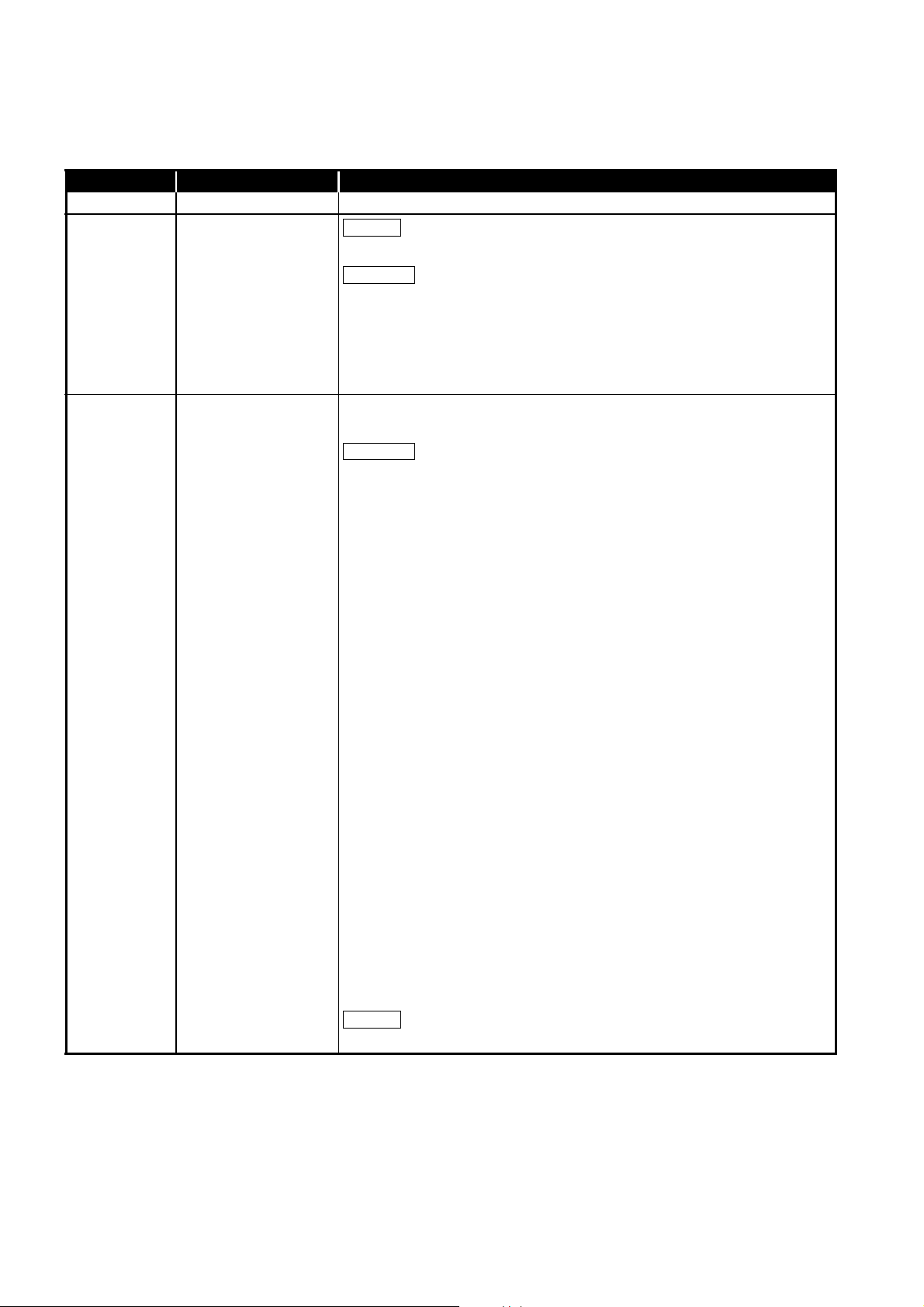

Item Description

Personal computer

CPU

Required memory

PCI bus

specifications

PCI Express®

bus specifications

Available hard disk capacity 1GB or more

Disk drive CD-ROM disk drive

Monitor Resolution: 1024 768 dots or higher

OS (English version)

Programming language

(English version)

*1

*1

Microsoft

System requirements of the operating system must be met.

For Q80BD-J71GP21-SX, Q80BD-J71GP21S-SX

• Compliant with PCI standard Rev.2.2 (3.3VDC/5VDC, 32-bit bus, Reference clock

For Q81BD-J71GP21-SX, Q81BD-J71GP21S-SX

• Compliant with PCI Express

Windows 10 (Home, Pro, Enterprise, Education)

Windows 8.1, Windows 8.1 (Pro, Enterprise)

Windows Server® 2012 R2 (Standard)

Windows 8, Windows 8 (Pro, Enterprise)

Windows Server 2012 (Standard)

Windows 7 (Home Premium, Professional, Ultimate, Enterprise)

Windows Server 2008 R2 (Standard, Enterprise)

When using any of the following operating systems, use SW1DNC-MNETG-B with the

version 1.18U or earlier.

Windows Server 2008 (Standard(x86, x64), Enterprise(x86, x64))

Windows Vista

Windows Server 2003 R2 (Standard(x86, x64), Enterprise(x86, x64)) SP2 or later

Windows XP® (Professional) SP2 or later

When using any of the following operating systems, use SW1DNC-MNETG-B with the

version 1.15R or earlier.

Windows 2000 (Professional)SP4 or later

Visual Basic® and Visual C++® in the following Microsoft Visual Studio®:

Visual Studio® 2015, Visual Studio 2013, Visual Studio 2012, Visual Studio 2010,

Visual Studio 2008, Visual Studio 2005, Visual Studio.NET 2003,

Visual Basic 6.0, Visual C++ 6.0

*1: For a combination of the operation system and the programming language, refer to the Microsoft

*2: Apply Service Pack1 and Security Update for Windows(KB3033929 or KB3125574). Otherwise,

*3: 64-bit version is not supported.

*4: Applicable to Q80BD-J71GP21-SX, Q80BD-J71GP21S-SX only.

®

Windows® supported personal computer

33MHz)

®

standard Rev.1.1 (3.3VDC, Link width 1lane, Reference

clock 100MHz)

®

(Home Basic, Home Premium, Business, Ultimate, Enterprise)

Knowledge Base.

use SW1DNC-MNETG-B with the version 1.18U or earlier.

*2

*2

*3

*3

*4

2 - 7

For the information on how to obtain SW1DNC-MNETG-B version 1.18U or

earlier, refer to the following section.

Appendix 8 Restrictions for Operating System

2.5 Operating Environment

Page 37

2

SYSTEM CONFIGURATION

(1) Instructions for personal computer

(a) PCI standard

When a personal computer which is not compliant with the PCI or PCI Express

standard is used, troubles caused by failures such as a contact failure or

operation error may occur.

For details of the number of boards that can be installed, installation slots, and

occupied slots, refer to the performance specifications in Section 3.2.

(b) Added operating environment

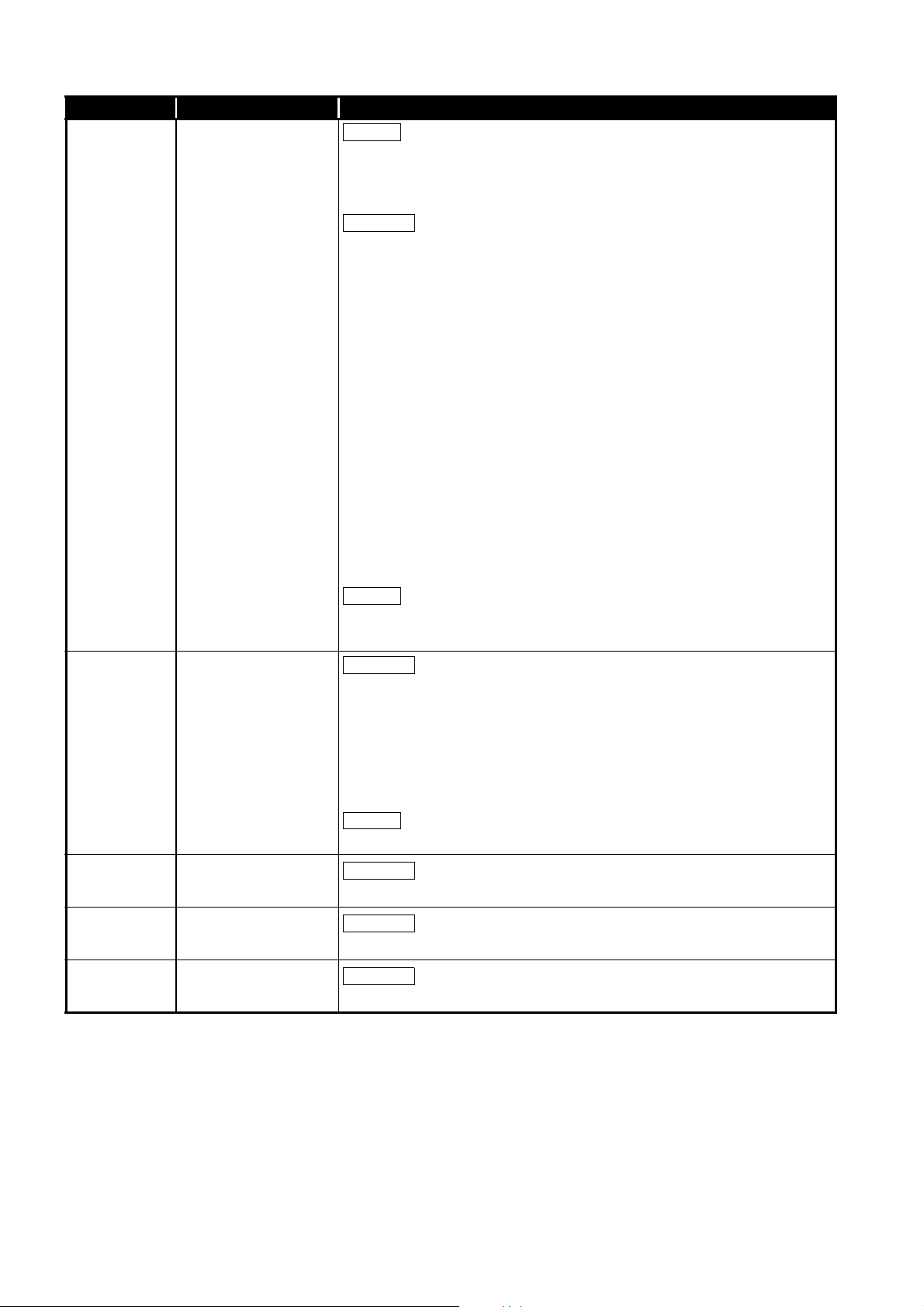

Operating environment Supported version of SW1DNC-MNETG-B

Multiprocessor Version 1.05F or later

(2) Instructions for operating system

(a) Supported version of SW1DNC-MNETG-B

Operating system

Windows 10 1.22Y or later 1.22Y or later

Windows 8.1, Windows Server 2012 R2 1.17T or later 1.17T or later

Windows 8, Windows Server 2012 1.16S or later 1.16S or later

Windows 7 (64-bit version),

Windows Server 2008 R2

Windows 7 (32-bit version) 1.11M or later

Windows Server 2008 (64-bit version) 1.12N to 1.18U

Windows Server 2008 (32-bit version) 1.11M to 1.18U

Windows Vista 1.02C to 1.18U

Windows Server 2003 R2 (64-bit version) 1.12N to 1.18U

Windows Server 2003 R2 (32-bit version)

Windows XP

Windows 2000

(b) User authority

Log on as a user having administrator authority.

• Installation, uninstallation and usage of utilities are available only by the

administrator's authority.

• Installation and uninstallation are available only by the administrator's

authority.

• The Usage of utilities is available only by the administrator's authority.

(c) Secure Boot function

For the following operating system, disable UEFI (BIOS) Secure Boot function or

use SW1DNC-MNETG-B Version 1.24A or later.

• Windows 10 Version 1607 (Build number '14393' or higher)

*1: It is not included when upgrading from Windows 10 Version 1511 or others by using Windows 10

Anniversary Update.

For the method for checking the version of an operating system and the status of

Secure Boot, refer to technical bulletin FA-A-0235.

Supported version of SW1DNC-MNETG-B

Q80BD-J71GP21-SX,

Q80BD-J71GP21S-SX

1.12N or later

1.18U or earlier

1.15R or earlier (Not supported)

Q81BD-J71GP21-SX,

Q81BD-J71GP21S-SX

1.12N or later

1.12N to 1.18U

*1

1

®

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

FUNCTIONS

5

PROCEDURES AND

SETTINGS BEFORE

OPERATION

6

PARAMETER

SETTINGS

7

INSTALLING AND

UNINSTALLING

SOFTWARE PACKAGES

8

2.5 Operating Environment

CC IE Control

UTILITY

2 - 8

Page 38

2

Remarks

SYSTEM CONFIGURATION

(d) .NET Framework 3.5

When using one of the following operating system, .NET Framework 3.5 is required.

• Windows 10

• Windows 8.1

• Windows Server 2012 R2

• Windows 8

• Windows Server 2012

Enable the .NET Framework 3.5 (including .NET 2.0 or 3.0) in "Turn Windows

features on or off" on the control panel.

(e) Upgrading and updating an operating system

Upgrading an operating system and updating from Windows 8 to Windows 8.1 are

not supported.

Install SW1DNC-MNETG-B by following the procedure:

1. Uninstall SW1DNC-MNETG-B.

2. Upgrade or update the operating system.

3. Install SW1DNC-MNETG-B with the software version supporting the changed

operating system.

(f) The functions cannot be used

If an attempt is made to use any of the following functions, this product may not

operate normally.

• Activating the application with Windows compatible mode.

• Simplified user switch-over

• Remote desktop

• Power save mode (Hibernate, Sleep)

• Fast startup

• The language switching function set by Regional and Language Options

• Windows XP Mode

• Windows Touch or Touch

• Modern UI

• Client Hyper-V

• Server Core Installation

• Tablet mode

• Virtual desktop

In the following cases, the screen of this product may not work properly.

• The size of the text and/or other items on the screen are changed to values

other than default values (such as 96 DPI, 100%, and 9 pt).

• The resolution of the screen is changed in operation.

• The multi-display is set.

2 - 9

• When exiting the operating system, always shut down the computer.

• For the behavior when entering the power save mode, refer to the

following section.

Appendix 10 Behavior When Personal Computer Enters Power Save

Mode or Fast Startup

2.5 Operating Environment

Page 39

2