Page 1

Type Q80BD-J61BT11N/Q81BD-J61BT11

CC-Link System Master/Local Interface Board

User's Manual (For SW1DNC-CCBD2-B)

-Q80BD-J61BT11N

-Q81BD-J61BT11

Page 2

Page 3

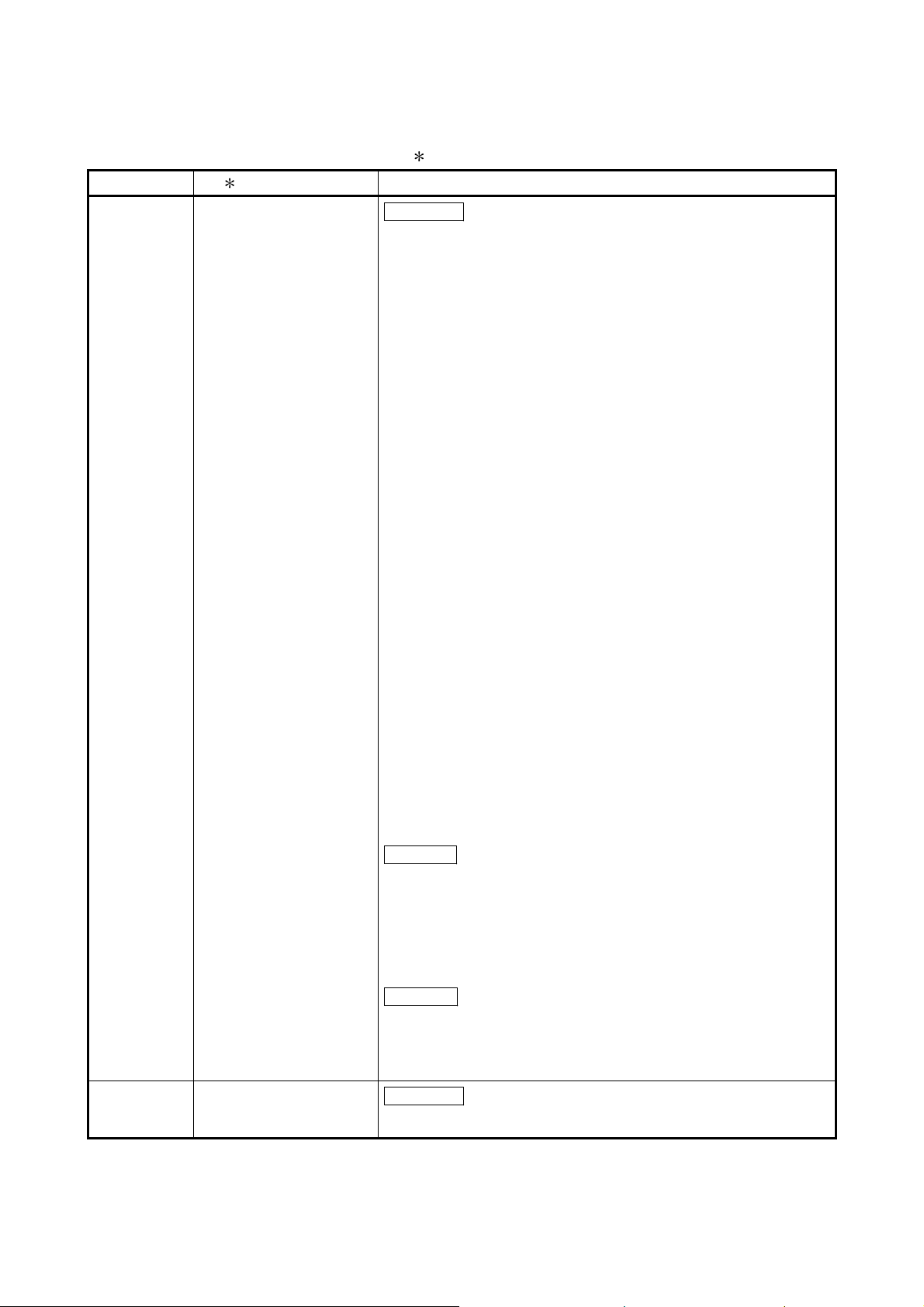

SAFETY PRECAUTIONS

(Be sure to read these instructions before using the product.)

Before using this product, read this manual and the relevant manuals introduced in this manual carefully

and handle the product correctly with full attention to safety.

Note that these precautions apply only to this product. Refer to the user's manual of the CPU module for

safety precautions on programmable controller systems.

In this manual, the safety instructions are ranked as "

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

WARNING " and "

CAUTION".

CAUTION

Note that failure to observe the !CAUTION level instructions may also lead to serious results

depending on the circumstances.

Be sure to observe the instructions of both levels to ensure personal safety.

Please keep this manual in accessible place and be sure to forward it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[DESIGN PRECAUTIONS]

!

WARNING

For details on the operating status of each station when a communication problem occurs in the

data link, refer to Section 6.5 of this manual.

If a cable dedicated to the CC-Link is disconnected, this may destabilize the line, and a data link

communication error may occur in multiple stations. Make sure to create an interlock circuit in

the sequence program so that the system will operate safely even if the above error occurs.

Failure to do so may result in a serous accident due to faulty output or malfunctions.

When performing the control of the personal computer in operation (changing data), configure

an interlock circuit in a user program so the safety of the overall system is always maintained.

When performing other controls of the personal computer in operation (changing program and

operation status (status control)), read this manual carefully and confirm if the overall safety is

maintained.

Especially, when this control is performed to a remote personal computer from an external

device, problems that have occurred on the personal computer side may not be able to

immediately be handled if there is a data communication error.

Define a troubleshooting agreement between external devices and the personal computer for

data communication error occurrences, as well as construct an interlock circuit in the user

program.

Do not write any data from the user program into the "system area" of the board buffer memory.

Writing data into the "system area" may cause a CC-Link system malfunction.

A failure in the board may cause remote I/O not to turn on or off correctly.

For critical I/O signals that may cause a serious accident, establish a circuit to externally monitor

them.

A - 1 A - 1

Page 4

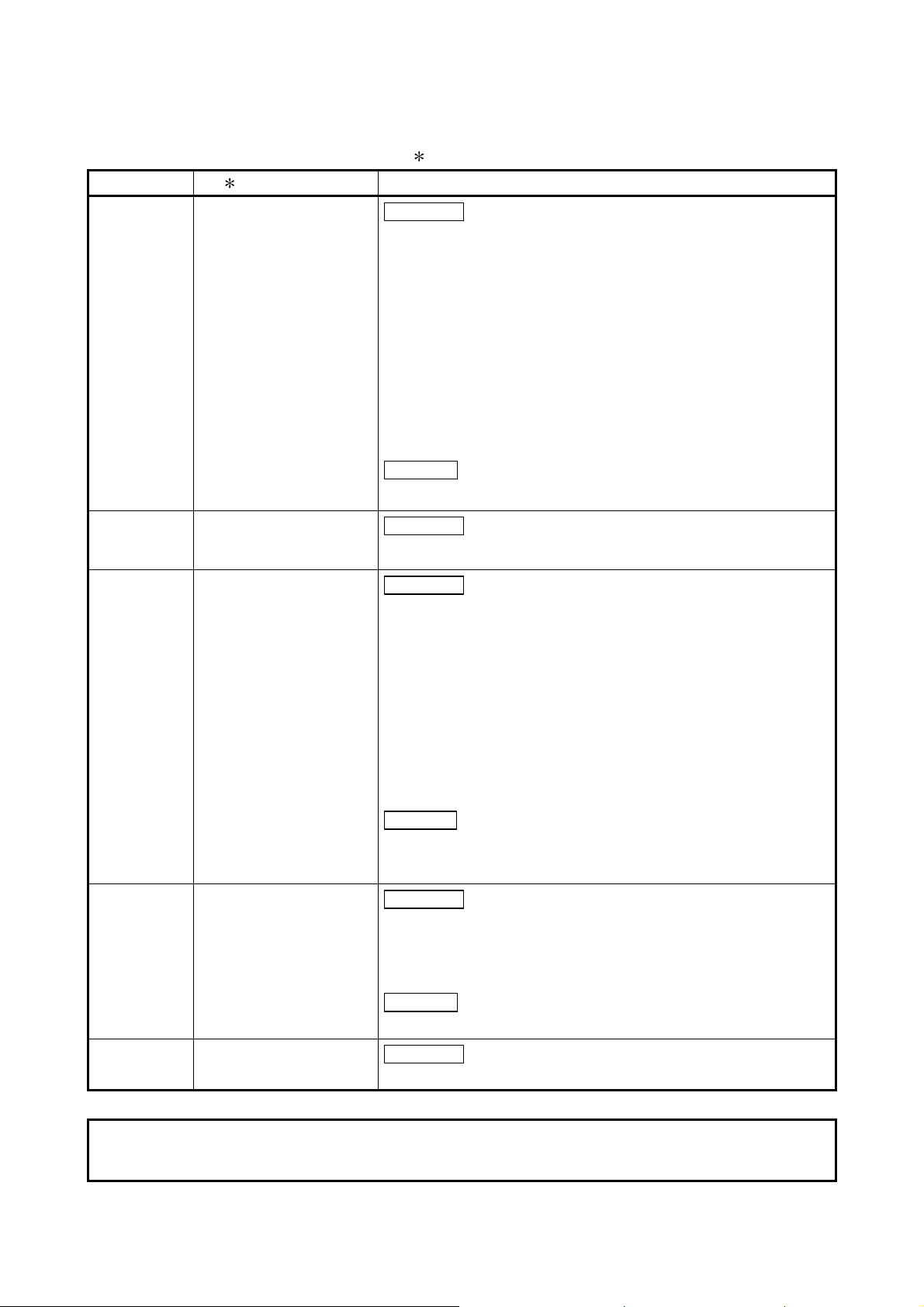

[DESIGN PRECAUTIONS]

!

CAUTION

Do not bunch the control wires or communication cables with the main circuit or power wires, or

install them close to each other.

They should be installed 100mm (3.94 in.) or more from each other.

Not doing so could result in noise that may cause malfunction.

[INSTALLATION PRECAUTIONS]

!

CAUTION

Use the board in an environment that meets the general specifications contained in this user's

manual.

Using this board in an environment outside the range of the general specifications may cause

electric shock, fire, malfunction, and damage to or deterioration of the product.

Do not directly touch the conductive area or electronic components of the board.

Doing so may cause malfunction or failure in the board.

Fix the board by tighten the board-fixing screws within the specified torque range.

Under tightening may cause drop of the component or wire, short circuit, or malfunction.

Over tightening may damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

For the tightening torque of the board fixing screws, refer to the manual supplied with the

personal computer.

Always make sure to touch the grounded metal to discharge the electricity charged in the body,

etc., before touching the board.

Failure to do so may cause a failure or malfunctions of the board.

Be sure to shut off all phases of the external power supply used by the system before installing

or removing the board. If all power is not turned off, not doing so may cause damage to the

product.

Install the board to a personal computer which is compliant with PCI standard or PCI Express

standard (Section 2.3). Failure to do so may cause a failure or malfunction.

Securely mount the board to the PCI slot of the mounting device.

If the board is not mounted correctly, this may lead to malfunctioning, failure or cause the board

to fall.

When mounting the board, take care not to become injured by the components that are installed

or surrounding materials.

When installing the board, take care not to contact with other boards.

While handling the board, be sure to keep it free of static electricity.

Static electric charges may damage the board or result in malfunction.

Be sure to turn off the power supply to the applicable station before installing or removing the

terminal block.

If the terminal block is installed or removed without turning off the power supply to the applicable

station, correct data transmission cannot be guaranteed.

A - 2 A - 2

R

Page 5

[INSTALLATION PRECAUTIONS]

!

CAUTION

Do not drop the board and the terminal block or subject it to any excessive shock.

It may damage the board and the terminal block or result in malfunction.

[WIRING PRECAUTIONS]

!

CAUTION

Be sure to shut off all phases of the external power supply used by the system before installing

or removing the board and wiring.

Not doing so may cause damage to the product.

When turning on the power and operating the module after installation and wiring, always attach

the computer's main cover.

Failure to do so may cause an electric shock.

When turning on the power and operating the module after wiring is completed, always attach

the terminal cover that comes with the product.

There is a risk of malfunction if the terminal cover is not attached.

Always ground the SLD terminal of the board and the personal computer to the protective

ground conductor.

Not doing so can cause a malfunction.

Tighten the terminal screws within the range of specified torque.

If the terminal screws are loose, it may cause short circuits or malfunction.

If the terminal screws are tightened too much, it may cause damage to the screw and/or the

board, resulting in short circuits or malfunction.

Prevent foreign matter such as swarf or wire chips from being attached onto the board.

Failure to do so may cause fires, failure or malfunction.

Be sure to fix the wires or cables connected to the board by placing them in a duct or clamping

them.

If not fixed, cables may be dangled and accidentally pulled, causing damage to the board and

cables and malfunction due to bad cable contacts.

Do not install the control lines together with the communication cables, or bring them close to

each other. Doing so may cause malfunctions due to noise.

When removing the communication cable or power supply cables from the board, do not pull the

cable.

First loosen the screws where the cable is connected to the board and then remove the cable.

Pulling the cable that is connected to the board may cause damage to the board and cable or

malfunction due to bad cable contacts.

Solderless terminals with insulation sleeve cannot be used for the terminal block. It is

recommended that the wiring connecting sections of the solderless terminals will be covered

with a marking tube or an insulation tube.

Be sure to turn off the power supply to the applicable station before installing or removing the

terminal block.

If the terminal block is installed or removed without turning off the power supply to the applicable

station, correct data transmission cannot be guaranteed.

A - 3 A - 3

Page 6

[WIRING PRECAUTIONS]

!

CAUTION

Always make sure to power off the system in advance when removing the terminating resistor to

charge the system. If the terminating resistor is removed and mounted while the system is

energized, normal data transmission will not be guaranteed.

Use applicable solderless terminals and tighten them with the specified torque.

If any solderless spade terminal is used, it may be disconnected when the terminal screw comes

loose, resulting in failure.

Be sure to tighten any unused terminal screws within a tightening torque range (0.66 to 0.89N.m).

Failure to do so may cause a short circuit due to contact with a solderless terminal.

[START UP AND MAINTENANCE PRECAUTIONS]

!

CAUTION

Do not dismantle or rebuild the board.

Doing so could cause failure, malfunction, injury or fire.

Be sure to shut off all phases of the external power supply used by the system before installing

or removing the board.

Not doing so may cause failure or malfunction of the board.

Do not touch the terminal while the power is on.

Doing so may cause malfunction.

Be sure to shut off all phases of the external power supply used by the system before cleaning

or retightening the terminal screws or module mounting screws.

Not doing so may cause damage to the product.

Fix the board by tighten the board-fixing screws within the specified torque range.

Under tightening may cause drop of the component or wire, short circuit, or malfunction.

Over tightening may damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

For the tightening torque of the board fixing screws, refer to the manual supplied with the

personal computer.

Always make sure to touch the grounded metal to discharge the electricity charged in the body,

etc., before touching the board.

Failure to do so may cause a failure or malfunctions of the board.

[DISPOSAL PRECAUTIONS]

!

CAUTION

When disposing of this product, treat it as industrial waste.

A - 4 A - 4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION

NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING

CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 5 A - 5

Page 8

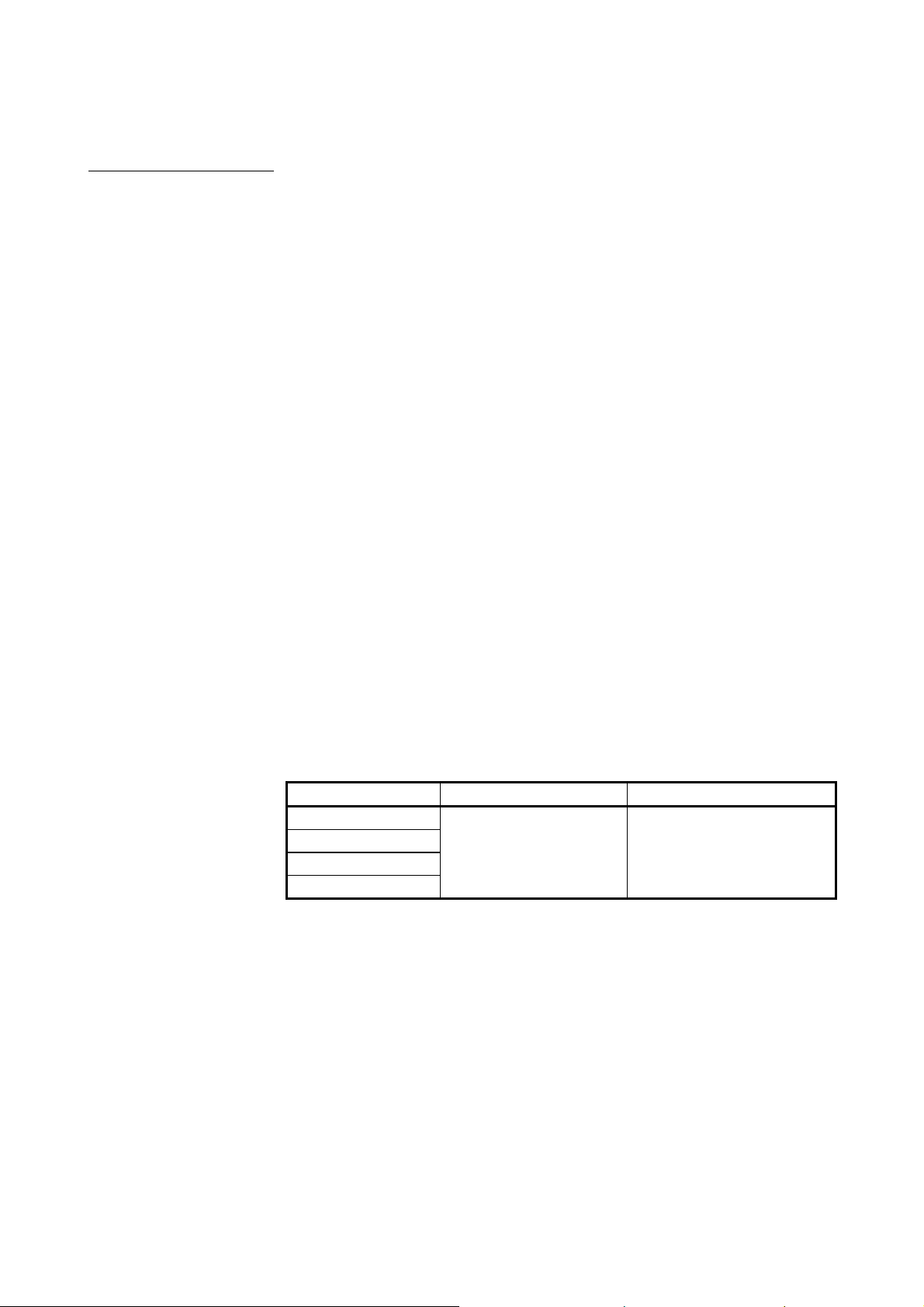

REVISIONS

The manual number is written at the bottom left of the back cover.

Print date Manual number Revision

Jun., 2005 SH (NA)-080527ENG-A First Printing

Nov., 2005 SH (NA)-080527ENG-B

Correction

Section 2.2.1, Section 8.4.1, Section 8.4.3, Chapter 9,

Section 17.1.1

Jun., 2006 SH (NA)-080527ENG-C

Correction

Section 2.2.4, Section 3.2, Section 8.6, Section 17.2.1

Mar., 2007 SH (NA)-080527ENG-D

Correction

Generic Terms and Abbreviations, Section 2.2.1, Section 8.4.1,

Section 10.1.2, Section 11.2, Section 11.4, Section 11.8

Addition

Section 11.3.5, Section 11.3.6, Section 11.7

Oct., 2007 SH (NA)-080527ENG-E

Correction

Jan., 2008 SH (NA)-080527ENG-F

Generic Terms and Abbreviations, Section 1.1,

Section 1.3, Section 2.2.1, Section 4.2.3, Chapter 7,

Section 8.4.1, Section 9.1, Section 11.3, Section 17.1.4,

Section 17.2.1, Section 17.3.1, Appendix 3.2,

Section 8.4.2 to Section 8.4.3 → Section 8.4.3 to Section 8.4.4

Addition

Section 8.4.2, Appendix 7

Correction

Precautions for use,

Generic Terms and Abbreviations, Chapter 1, Section 2.2,

Section 2.2.1, Section 2.2.3, Section 3.1, Section 4.2.1,

Section 4.2.2, Section 4.2.3, Section 4.2.4, Section 4.4.5,

Section 5.2, Section 5.2.2, Section 5.2.3, Section 5.2.4,

Section 5.3, Section 5.3.1, Section 5.3.2, Section 6.1,

Section 7.1.1, Section 7.1.2, Section 8.2.1, Section 8.2.2,

Section 8.4.1, Section 8.6, Section 9.3.6, Section 9.3.7,

Section 9.3.8, Section 9.3.11, Section 10.1.1, Section 10.1.2,

Section 12.2.1, Section 12.5.1, Section 13.1.2, Section 13.2.2,

Section 14.1.2, Section 14.2.2, Section 15.2.1, Section 16.2.1,

Section 17.1.4, Section 17.2.1, Section 17.6, Appendix 3.1.2,

Appendix 3.1.3

A - 6 A - 6

Page 9

The manual number is written at the bottom left of the back cover.

Print date Manual number Revision

May, 2008 SH (NA)-080527ENG-G

Model addition

Q81BD-J61BT11

Correction

Precautions for use, Generic Terms and Abbreviations,

Product List, Section 1.1, Section 1.3, Section 2.1, Section 2.2.1,

Section 2.2.2, Section 2.2.3, Section 2.2.4, Section 3.1,

Section 3.2, Section 4.4.7, Section 5.2, Section 8.3,

Section 8.4.1, Section 8.4.3, Section 8.4.4, Section 8.6,

Section 8.7.2, Section 9.1.1, Section 10.1.2, Section 11.3,

Section 12.1, Section 12.5.2, Section 13.1.1, Section 13.1.5,

Section 13.2.1, Section 13.2.5,Section 14.1.1, Section 14.1.5,

Section 14.2.1, Section 14.2.5,Section 15.1, Section 15.5.2,

Section 16.1, Section 16.5.2, Section 17.1.3, Section 17.3.1,

Section 17.3.2, Appendix 1.1,Appendix 1.2, Appendix 2.3,

Appendix 3, Appendix 3.2

Addition

Sep., 2008 SH (NA)-080527ENG-H

Oct., 2008 SH (NA)-080527ENG-I

Jul., 2009 SH (NA)-080527ENG-J

Oct., 2009 SH (NA)-080527ENG-K

May, 2010 SH (NA)-080527ENG-L

Appendix 8.1, Appendix 8.2

Correction

Section 3.2

Correction

Generic Terms and Abbreviations, Section 3.3, Section 10.1.2

Correction

Chapter 7, Appendix 7,1, Appendix 8.1, Appendix 8.2

Correction

Section 2.2.1, Section 8.4.1,

Section 10.1.2, Section 11.4, Section 17.1.1, Section 17.2.1,

Section 17.3.1, Appendix 4.1, Appendix 4.2

Correction

SAFETY PRECAUTIONS, Generic Terms and Abbreviations,

Section 1.1, Section 2.2.1, Section 3.1, Section 8.2.1,

Section 8.3, Section 8.4, Section 8.6, Section 10.2.1,

Section 11.3.3, Section 11.3.4, Section 11.9, Appendix 7,

Section 1.3 → Appendix 8,

Appendix 8 to Appendix 9 → Appendix 9 to Appendix 10

Addition

CONDITIONS OF USE FOR THE PRODUCT

Deletion

Section 11.3.5, Section 11.3.6

A - 7 A - 7

Page 10

The manual number is written at the bottom left of the back cover.

Print date Manual number Revision

Dec., 2010 SH (NA)-080527ENG-M

Correction

Section 2.2.1

May, 2011 SH (NA)-080527ENG-N

Correction

Precautions for use, Manuals, Product List, Appendix 2.3,

Appendix 7.2

Mar., 2012 SH (NA)-080527ENG-O

Correction

Section 2.2.1, Section 8.4.1, Section 8.4.2

Appendix 10 changed to Appendix 12

Addition

Appendix 10, Appendix 11

Apr., 2012 SH (NA)-080527ENG-P

Correction

SAFETY PRECAUTIONS, Manuals,

How to Read this Manual, Generic Terms and Abbreviations,

Product List, Section 1.1, Section 2.2.1, Section 3.1,

Section 4.4.7, Section 7.2.1, Section 7.4.1, Section 7.4.2,

Section 8.1.1, Section 8.1.7, Section 8.3.3, Section 8.3.5,

Section 8.3.6, Section 8.3.7, Section 8.3.8, Chapter 9,

Section 9.2, Section 10.5.2, Section 11.1.5, Section 11.2.5,

Section 12.2.5, Section 13.5.2, Section 14.5.2, Section 15.1.1,

Section 15.1.4, Section 15.2.1, Section 15.3.5, Appendix 1.1,

Appendix 3.1.4, Appendix 7.1, Appendix 8, Appendix 10,

Appendix 12.1

Chapter 7 → Appendix 10,

Chapter 8 to Chapter 9 → Chapter 7 to Chapter 8,

Chapter 11 to Chapter 17 → Chapter 9 to Chapter 15,

Appendix 9 to Appendix 12 → Appendix 11 to Appendix 14

Addition

Appendix 9

Deletion

Chapter 10, Section 11.3 to Section 11.9

Dec., 2012 SH (NA)-080527ENG-Q

Correction

HOW TO USE THIS MANUAL, GENERIC TERMS AND

ABBREVIATIONS, Section 7.7.2

A - 8 A - 8

Page 11

The manual number is written at the bottom left of the back cover.

Print date Manual number Revision

Sep., 2013 SH (NA)-080527ENG-R

Correction

SAFETY PRECAUTIONS, MANUALS, HOW TO USE THIS

MANUAL, GENERIC TERMS AND ABBREVIATIONS,

Section 1.1, Section 2.1, Section 2.3, Section 3.2.1, Section 3.4,

Section , Section 4.3.4, Section 4.4.5, Chapter 5, Section 5.1 to 5.6,

Section 6.1, Section 6.2.1, Section 6.2.2, Section 6.3.1, Section 6.3.2,

Section 6.4.1, Section 6.4.2, Section Chapter 7, Section 7.1 to 7.3,

Section 8.1 to 8.3, Section 9.1, Section 9.2, Section 10.2.1,

Section 10.2.2, Section 10.5.1, Section 11.1.2, Section 11.2.2,

Section 12.1.2, Section 12.1.3, Section 12.2.2, Section 12.2.3,

Section 13.2.1, Section 13.2.2, Section 14.2.1, Section 14.2.2,

Chapter 15, Chapter 16, Section 16.1 to 16.6, Section 2.1 changed 3.2.1,

Section 2.2.1 changed 2.3, Section 2.2.2 changed 2.2,

Chapter 7 changed Chapter 5, Section 5.2 changed 5.3,

Section 7.7 changed 5.4.4, Section 7.8.1 changed 5.5,

Section 7.8.2 changed 5.6, Section 7.4 changed Chapter 7,

Section 7.4.1 changed 7.1, 16.2.3, Section 7.4.2 changed 7.3,

Section 8.1.7 changed Appendix 10, Section 15.3.5 changed Chapter 15,

Chapter 15 changed 16, Section 15.1.1 changed 16.1,

Section 15.1.4 changed 16.3.2, Section 15.1.2 changed 16.4.3,

Section 15.3, 15.3.1, 15.3.2 changed 16.5, Section 15.6 changed 16.6,

Appendix 4, 4.1 changed 3.4, Section 2.2.4 changed Appendix 11,

Appendix 4.2 changed 1, Section15.3.3 changed Appendix 2.1,

Section 15.3.4 changed Appendix 2.2, Chapter 5 changed Appendix 3,

Appendix 6 changed 4, Appendix 1 to 3 changed Appendix 5 to 7,

Appendix 14 changed 8, Appendix 8 changed 9, Appendix 9 changed 10,

Appendix 5 changed 12, Appendix 7 changed 15, Appendix 12 changed 16,

Appendix 13 changed 17, Appendix 10 changed 18,

Appendix 11 changed 19

Addition

Section 5.3.3, Section 5.3.4, Section 5.4.3, Section 5.7, Section 6.5,

Chapter 16, Section 16.2, Section 16.2.1, Section 16.2.2,

Section 16.3, Section 16.3.3, Section 16.4, Section 16.4.1,

Section 16.4.2, Appendix 13, Appendix 13.1, Appendix 13.2,

Appendix 14, Appendix 16.3

Deletion

Section 2.2.3, Section 5.2.1 to 5.2.4, Section 8.1.3 to 8.1.6,

Section 15.1, Section 15.1.3 Section 15.2, Section 15.2.1,

Section 15.3.3 to 15.3.5, Section 15.4, Section 15.5

Jan., 2014 SH (NA)-080527ENG-S

Correction

Section 16.3.2, Appendix 2

A - 9 A - 9

Page 12

The manual number is written at the bottom left of the back cover.

Print date Manual number Revision

Jun., 2014 SH (NA)-080527ENG-T

Correction

PRECAUTIONS FOR USE,

GENERIC TERMS AND ABBREVIATIONS, Section 2.2,

Section 2.3, Section 3.2.1, Section 4.3.4, Section 4.3.5,

Section 4.3.7, Section 7.1, Section 7.2, Section 8.1.1,

Section 8.2.8, Section 8.3.1, Section 8.3.2, Section 8.3.3,

Section 8.3.5, Section 8.3.6, Section 8.3.8, Section 8.3.10,

Section 16.1, Section 16.2.2, Section 16.2.3, Section 16.3.2,

Appendix 13.2, Appendix 15.2, Appendix 16.2, Appendix 16.3,

Appendix 17

Section 8.3.8 to Section 8.3.11 → Section 8.3.7 to Section 8.3.10

Deletion

Section 8.3.7

Apr., 2015 SH (NA)-080527ENG-U

Correction

Sep., 2015 SH (NA)-080527ENG-V

Sep., 2016 SH(NA)-080527ENG-W

Sep., 2017 SH(NA)-080527ENG-X

Section 2.3, Section 3.4, Section 7.2, Section 16.3.2

Correction

Section 1.1, Section 1.2, Section 2.3, Section 4.1, Section 4.3.4,

Section 4.3.5, Section 6.1, Section 6.2.1, Section 6.2.2,

Section 6.3.1, Section 6.3.2, Section 6.4.1, Section 6.4.2,

Section 7.1, Section 8.2.1, Section 8.2.2, Section 8.2.5,

Section 10.2.2, Section 11.1.2, Section 11.2.2, Section 12.1.2,

Section 12.1.3, Section 12.2.2, Section 12.2.3, Section 13.2.2,

Section 14.2.2, Section 16.1, Section 16.2.3, Appendix 3.2,

Appendix 5.2, Appendix 7.1.2, Appendix 7.2, Appendix 8.1,

Appendix 14

Addition

Section 4.3.6, Section 16.6

Section 16.6 → Section 16.7

Correction

Section 2.3, Section 7.1, Section 7.2, Section 8.1.1,

Section 8.3, Section 16.1, Section 16.2.3, Appendix 14,

Appendix 15.2, Appendix 16, Appendix 16.1, Appendix 16.2,

Appendix 17

Deletion

Section 8.3.1 to Section 8.3.10, Appendix 16.1

Correction

Section 2.3, Section 7.1, Section 16.2.3

Japanese Manual Version SH-080526-X

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

2005 MITSUBISHI ELECTRIC CORPORATION

A - 10 A - 10

Page 13

PRECAUTIONS FOR USE

(1) Restrictions for functions depending on the personal computer or

(2) When using the CC-Link Ver.2 board as a standby master station

(3) When using the CC-Link Ver.2 board as a master station

(4) Restrictions on the CC-Link Ver.2 board installation

(5) Installation

(6) Driver installation and updating

(7) Software versions of the CC-Link system master and local modules

the operating system

There are some restrictions for the functions or supported versions depending

on the operating system or personal computer to be used. For the operating

environment, refer to Section 2.5.

Refer to Section 2.2 for combinations of modules when using the CC-Link

Ver.2 board as a standby master station.

When using the CC-Link Ver.2 board as a master station, any of local modules

cannot be used as a standby master station.

Installing the CC-Link Ver.2 board and CC-Link Ver.1 board to the same

computer and using both of them is not allowed.

When a CC-Link Ver.2 board is used on a personal computer in which

SWnDNF-CCLINK has been installed, uninstall SWnDNF-CCLINK first, then

install the SW1DNC-CCBD2-B that is provided with the CC-Link Ver.2 board.

Do not install or update the driver other than the way written in the

troubleshooting in this manual.

The consistency between the driver and utility cannot be identified, and CCLink Ver.2 board may not operate properly.

When reading/writing data from/to other stations using the transient

transmission function in the CC-Link system, there is the restriction for the

software version for the CC-Link master and local modules in the following

table.

Model name Software version Remark

AJ61QBT11

A1SJ61QBT11

AJ61BT11

A1SJ61BT11

Version N or later

Not accessible if the software

version is M or earlier.

(8) Transient transmission functions of the CC-Link board

Transient transmission is not allowed to slave station No.64 on the CC-Link

system.

(9) Performance

The system performance using the CC-Link Ver.2 board differs according to

the performance/loaded condition of the personal computer, the processing

contents of the application software, and the type of the interface board. Use

the product after reviewing the system configuration and processing contents of

the software in advance.

For details of the CC-Link Ver.2 board performance, refer to Appendix 3 DATA

LINK PROCESSING TIMES.

(10) Combination of ROM version and S/W version

When using CC-Link Ver.2 board ROM version 2B or later, use S/W package

version 1.06G or later.

A - 11 A - 11

Page 14

INTRODUCTION

Thank you for purchasing the Type Q80BD-J61BT11N, Q81BD-J61BT11 CC-Link System Master/Local

Interface Board.

Please read this manual and related manuals thoroughly to fully understand the functions and performances

of the Type Q80BD-J61BT11N, Q81BD-J61BT11 CC-Link System Master/Local Interface Board in order to

use the product properly.

Please be sure to deliver this manual to the end users.

CONTENTS

SAFETY PRECAUTIONS .............................................................................................................................. A- 1

CONDITIONS OF USE FOR THE PRODUCT ............................................................................................. A- 5

REVISIONS .................................................................................................................................................... A- 6

PRECAUTIONS FOR USE ............................................................................................................................ A-11

INTRODUCTION ............................................................................................................................................ A-12

CONTENTS .................................................................................................................................................... A-12

MANUALS ...................................................................................................................................................... A-19

HOW TO USE THIS MANUAL ...................................................................................................................... A-20

GENERIC TERMS AND ABBREVIATIONS ................................................................................................. A-21

PACKING LIST .............................................................................................................................................. A-22

1 OVERVIEW 1- 1 to 1-10

1.1 Features of the CC-Link Ver.2 Board ..................................................................................................... 1- 2

1.2 Features of the CC-Link System ............................................................................................................ 1- 3

2 SYSTEM CONFIGURATION 2- 1 to 2- 8

2.1 System Configuration Using CC-Link Ver.2 Board ................................................................................ 2- 1

2.2 Notes on the System Configuration ....................................................................................................... 2- 2

2.3 Operating Environment ........................................................................................................................... 2- 4

3 SPECIFICATIONS 3- 1 to 3-12

3.1 General Specifications ............................................................................................................................ 3- 1

3.2 Performance Specifications .................................................................................................................... 3- 2

3.2.1 Maximum number of connected modules ....................................................................................... 3- 4

3.2.2 Maximum overall cable distance (for Ver.1.00) ............................................................................... 3- 6

3.2.3 Maximum overall cable distance (for Ver.1.10) ............................................................................... 3- 8

3.3 CC-Link Dedicated Cable Specifications ............................................................................................... 3- 8

3.4 Buffer Memory List .................................................................................................................................. 3- 9

4 FUNCTIONS 4- 1 to 4-54

4.1 Function List ............................................................................................................................................ 4- 1

4.2 Basic Functions ....................................................................................................................................... 4- 3

4.2.1 Communication with remote I/O stations ........................................................................................ 4- 3

4.2.2 Communication with the remote device stations ............................................................................ 4- 5

4.2.3 Communication with the local stations ............................................................................................ 4-10

4.2.4 Communication with the intelligent device station .......................................................................... 4-16

A - 12 A - 12

Page 15

4.3 Functions for Improving System Reliability ............................................................................................ 4-22

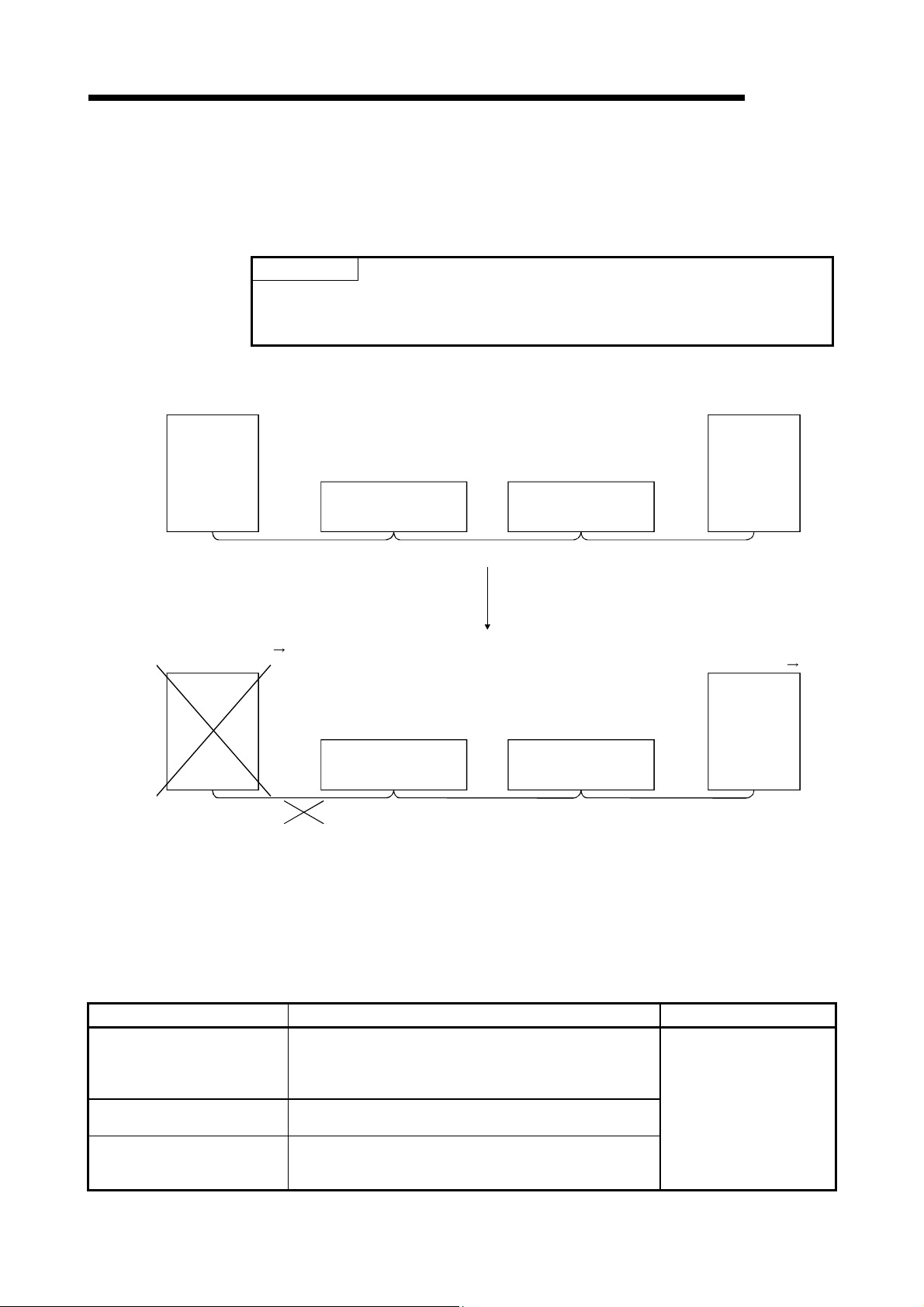

4.3.1 Disconnecting a data link faulty station and continuing the data link with only normal stations

(slave station disconnect function) .................................................................................................. 4-22

4.3.2 Automatically reconnecting a disconnected data link faulty station when it returns to normal

(auto return function) ....................................................................................................................... 4-23

4.3.3 Retaining the device status of a data link faulty station

(setting the input data status from a data link faulty station) .......................................................... 4-24

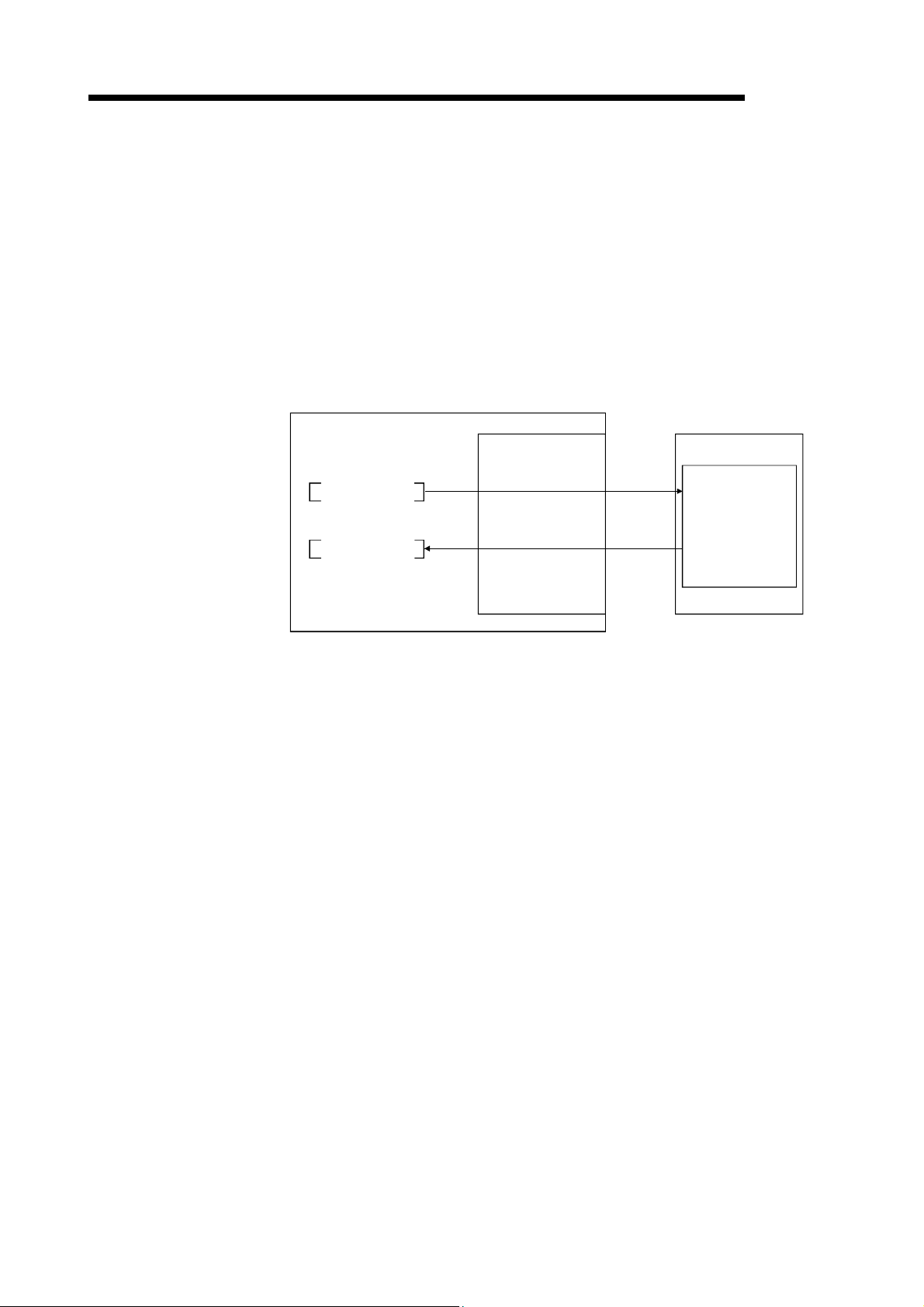

4.3.4 Continuing the data link even when the master station is faulty (standby master function) .......... 4-25

4.3.5 Monitoring the operation of the software (operating system, driver) inside the hardware

(Driver WDT function) ..................................................................................................................... 4-35

4.3.6 Station-based block data assurance function ................................................................................. 4-36

4.4 Useful Functions ..................................................................................................................................... 4-40

4.4.1 Creating a program that contains modules to be added in the future

(reserved station function) ............................................................................................................... 4-40

4.4.2 Powering off a station in operation without detecting an error

(error invalid station setting function) .............................................................................................. 4-41

4.4.3 Checking operations for each station (data link stop/restart) ......................................................... 4-42

4.4.4 Station number duplicate check ...................................................................................................... 4-42

4.4.5 Multiple CPU system support .......................................................................................................... 4-43

4.4.6 Reducing the reserved points of the remote I/O stations (Remote I/O station points setting) ...... 4-44

4.4.7 Increasing the number of cyclic points (Remote net ver.2 mode, Remote net additional mode) .. 4-45

4.5 Transient Transmission Functions ......................................................................................................... 4-54

4.5.1 Performing transient transmission (functions) ................................................................................. 4-54

5 PROCEDURE BEFORE STARTING THE DATA LINK 5- 1 to 5-16

5.1 Procedures Before Operating the CC-Link Ver.2 Board ....................................................................... 5- 1

5.2 Component Names and Settings ........................................................................................................... 5- 2

5.3 Installation ............................................................................................................................................... 5- 4

5.3.1 Precautions on handling the CC-Link Ver.2 board ......................................................................... 5- 4

5.3.2 Installation environment ................................................................................................................... 5- 4

5.3.3 Board installation .............................................................................................................................. 5- 5

5.3.4 Setting Channel Numbers ................................................................................................................ 5- 6

5.4 Wiring ...................................................................................................................................................... 5- 7

5.4.1 Preparation before wiring ................................................................................................................. 5- 7

5.4.2 Terminal block .................................................................................................................................. 5- 8

5.4.3 Wiring procedure .............................................................................................................................. 5-10

5.4.4 T-branch connection ........................................................................................................................ 5-12

5.5 Station Number Setting ........................................................................................................................... 5-14

5.6 Transmission Rate and Mode Settings .................................................................................................. 5-15

5.7 Test .......................................................................................................................................................... 5-15

6 PARAMETER SETTINGS 6- 1 to 6-12

6.1 Parameter Setting Items ......................................................................................................................... 6- 1

6.2 Parameter Setting Examples (Remote Net Ver.1 Mode) ...................................................................... 6- 5

6.2.1 Master station network parameter settings ..................................................................................... 6- 5

6.2.2 Local station network parameter settings ........................................................................................ 6- 6

6.3 Parameter Setting Examples (Remote Net Ver.2 Mode) ...................................................................... 6- 7

6.3.1 Master station network parameter settings ..................................................................................... 6- 7

6.3.2 Local station network parameter settings ........................................................................................ 6- 8

A - 13 A - 13

Page 16

6.4 Parameter Setting Examples (Remote Net Additional Mode) ............................................................... 6- 9

6.4.1 Master station network parameter settings ..................................................................................... 6- 9

6.4.2 Local station network parameter settings ........................................................................................ 6-10

6.5 Status Difference Between a Master Station and a Slave Station at an Error ..................................... 6-11

7 INSTALLING AND UNINSTALLING THE SOFTWARE PACKAGE 7- 1 to 7- 4

7.1 Installation and Uninstallation Precautions ............................................................................................ 7- 1

7.2 Installation ............................................................................................................................................... 7- 2

7.3 Uninstallation ........................................................................................................................................... 7- 4

8 OPERATING THE UTILITY SOFTWARE 8- 1 to 8-18

8.1 Starting and Ending Utility ...................................................................................................................... 8- 1

8.1.1 Starting a utility ................................................................................................................................. 8- 1

8.1.2 Ending a utility .................................................................................................................................. 8- 2

8.2 CC-Link Ver.2 Utility ................................................................................................................................ 8- 3

8.2.1 Screen configuration and basic operations ..................................................................................... 8- 3

8.2.2 Operating the Board Information screen ......................................................................................... 8- 4

8.2.3 Operating the Other station monitor screen .................................................................................... 8- 7

8.2.4 Operating the Online operation screen ........................................................................................... 8- 9

8.2.5 Operating the Parameter Settings screen ....................................................................................... 8-10

8.2.6 Operating the Target settings screen .............................................................................................. 8-12

8.2.7 Operating the Memory I/O test screen ............................................................................................ 8-13

8.2.8 Operating the Test screen ............................................................................................................... 8-14

8.3 Device Monitor Utility .............................................................................................................................. 8-18

9 MELSEC DATA LINK LIBRARY 9- 1 to 9- 2

10 COMMUNICATION BETWEEN THE MASTER STATION AND REMOTE I/O STATIONS 10- 1 to 10- 8

10.1 Configuring a System ......................................................................................................................... 10- 1

10.2 Setting up the master station .............................................................................................................. 10- 2

10.2.1 Switch setting (channel No. setting) ............................................................................................ 10- 2

10.2.2 Parameter settings ....................................................................................................................... 10- 3

10.3 Setting up the remote I/O stations ...................................................................................................... 10- 4

10.4 Creating a Program ............................................................................................................................. 10- 5

10.5 Executing the Data Link ...................................................................................................................... 10- 6

10.5.1 Checking the data link status ....................................................................................................... 10- 6

(1) Checking the master station ................................................................................................... 10- 6

(2) Checking remote I/O stations. ................................................................................................ 10- 7

10.5.2 Confirming the operation with a user program ............................................................................ 10- 8

A - 14 A - 14

Page 17

11 COMMUNICATION BETWEEN THE MASTER STATION AND REMOTE DEVICE STATION

11- 1 to 11-16

11.1 When Using the Remote Net Ver.1 Mode ......................................................................................... 11- 1

11.1.1 Configuring a System ................................................................................................................... 11- 1

11.1.2 Setting the master station ............................................................................................................ 11- 2

(1) Switch setting (channel No. setting) ....................................................................................... 11- 2

(2) Parameter settings ................................................................................................................. 11- 3

11.1.3 Setting up the remote device station ........................................................................................... 11- 4

11.1.4 Creating a Program ...................................................................................................................... 11- 5

11.1.5 Executing the data link ................................................................................................................. 11- 7

(1) Checking the data link status ................................................................................................. 11- 7

(2) Confirming the operation with a user program ...................................................................... 11- 9

11.2 When Using the Remote Net Ver.2 Mode or Remote Net Additional Mode ..................................... 11-10

11.2.1 Configuring the system ................................................................................................................ 11-10

11.2.2 Setting the master station ............................................................................................................ 11-11

(1) Switch setting (channel No. setting) ....................................................................................... 11-11

(2) Parameter settings ................................................................................................................. 11-12

11.2.3 Setting the remote device station ................................................................................................ 11-13

11.2.4 Creating a program ...................................................................................................................... 11-14

11.2.5 Executing the data link ................................................................................................................. 11-15

(1) Checking the data link status ................................................................................................. 11-15

(2) Confirming the operation with a user program ...................................................................... 11-16

12 COMMUNICATION BETWEEN THE MASTER STATION AND LOCAL STATIONS 12- 1 to 12-16

12.1 When Using the Remote Net Ver.1 Mode ......................................................................................... 12- 1

12.1.1 Configuring the system ................................................................................................................ 12- 1

12.1.2 Setting the master station ............................................................................................................ 12- 2

(1) Switch setting (channel No. setting) ....................................................................................... 12- 2

(2) Parameter settings ................................................................................................................. 12- 3

12.1.3 Setting the local station ................................................................................................................ 12- 4

(1) Switch setting (channel No. setting) ....................................................................................... 12- 4

(2) Parameter settings ................................................................................................................. 12- 4

12.1.4 Creating a program ...................................................................................................................... 12- 5

12.1.5 Executing the data link ................................................................................................................. 12- 7

(1) Checking the data link status ................................................................................................. 12- 7

(2) Confirming the operation with a user program ...................................................................... 12- 8

12.2 When Using the Remote Net Ver.2 Mode or Remote Net Additional Mode ..................................... 12- 9

12.2.1 Configuring the system ................................................................................................................ 12- 9

12.2.2 Setting the master station ............................................................................................................ 12-10

(1) Switch setting (channel No. setting) ....................................................................................... 12-10

(2) Parameter settings ................................................................................................................. 12-11

12.2.3 Setting the local station ................................................................................................................ 12-12

(1) Switch setting (channel No. setting) ....................................................................................... 12-12

(2) Parameter settings ................................................................................................................. 12-12

12.2.4 Creating a program ...................................................................................................................... 12-13

12.2.5 Executing the data link ................................................................................................................. 12-14

(1) Checking the data link status ................................................................................................. 12-14

(2) Confirming the operation with a user program ...................................................................... 12-14

A - 15 A - 15

Page 18

13 COMMUNICATION BETWEEN THE MASTER STATION AND INTELLIGENT DEVICE STATION

(AJ65BT-R2) 13- 1 to 13-12

13.1 Configuring a System ......................................................................................................................... 13- 1

13.2 Setting the Master Station .................................................................................................................. 13- 2

13.2.1 Switch setting (channel No. setting) ............................................................................................ 13- 2

13.2.2 Parameter settings ....................................................................................................................... 13- 3

13.3 Setting up the intelligent device station .............................................................................................. 13- 4

13.4 Creating a Program ............................................................................................................................. 13- 5

13.4.1 Initialization of the AJ65BT-R2 .................................................................................................... 13- 5

13.4.2 Data transmission ........................................................................................................................ 13- 7

13.4.3 Data reception .............................................................................................................................. 13- 8

13.5 Executing the Data Link ...................................................................................................................... 13- 9

13.5.1 Checking the data link status ....................................................................................................... 13- 9

13.5.2 Confirming the operation with a user program ............................................................................ 13-11

14 COMMUNICATION BETWEEN THE MASTER STATION AND INTELLIGENT DEVICE STATION

(AJ65BT-D75P2-S3) 14- 1 to 14-16

14.1 Configuring a System ......................................................................................................................... 14- 1

14.2 Setting the Master Station .................................................................................................................. 14- 2

14.2.1 Switch setting (channel No. setting) ............................................................................................ 14- 2

14.2.2 Parameter settings ....................................................................................................................... 14- 3

14.3 Setting up the intelligent device station (AJ65BT-D75P2-S3) ........................................................... 14- 4

14.4 Creating a Program ............................................................................................................................. 14- 5

14.4.1 Initial setting .................................................................................................................................. 14- 5

14.4.2 Zero point return control ............................................................................................................... 14- 7

14.4.3 Positioning control ........................................................................................................................ 14- 9

14.4.4 JOG operation control .................................................................................................................. 14-11

14.5 Executing the Data Link ...................................................................................................................... 14-13

14.5.1 Checking the data link status ....................................................................................................... 14-13

14.5.2 Confirming the operation with a user program ............................................................................ 14-15

15 ERROR CODE 15- 1 to 15- 6

16 TROUBLESHOOTING 16- 1 to 16-28

16.1 Verification of Problem Occurrence ................................................................................................... 16- 2

16.2 Troubleshooting for Installation and Uninstallation ............................................................................ 16- 4

16.2.1 Installation failed ........................................................................................................................... 16- 4

16.2.2 Uninstallation failed ...................................................................................................................... 16- 4

16.2.3 When the instruction displayed on the screen is not effective at installation ............................. 16- 6

16.2.4 When the driver is not installed .................................................................................................. 16- 7

16.3 Troubleshooting When Personal Computer cannot be Startup or System Down Occurred ............ 16- 9

16.3.1 Checking personal computer and operating system .................................................................. 16- 9

16.3.2 Checking on Event Viewer screen .............................................................................................. 16-11

16.3.3 Checking on Device Manager screen ......................................................................................... 16-13

A - 16 A - 16

Page 19

16.4 Troubleshooting for Board and Driver ................................................................................................ 16-14

16.4.1 Board WDT error .......................................................................................................................... 16-14

16.4.2 Driver WDT error .......................................................................................................................... 16-14

16.4.3 When the RUN LED on the CC-Link Ver.2 board is flashing ..................................................... 16-15

16.5 CC-Link System Troubleshooting ...................................................................................................... 16-16

16.5.1 Verification of problem occurrence .............................................................................................. 16-16

16.5.2 Troubleshooting flow when the "ERR." LED on the master station is flashing .......................... 16-23

16.6 Measures for Slow Personal Computer Operation ............................................................................ 16-27

16.7 Information Required for Inquiries ...................................................................................................... 16-28

APPENDIX App- 1 to App-93

Appendix 1 Buffer memory details............................................................................................................ App- 1

Appendix 2 Link special relays (SB) and link special registers (SW) ...................................................... App-17

Appendix 2.1 List of link special relays (SBs) ....................................................................................... App-17

Appendix 2.2 List of link special registers (SWs) ................................................................................. App-22

Appendix 3 Data link processing time ...................................................................................................... App-30

Appendix 3.1 Link scan time ................................................................................................................. App-30

Appendix 3.2 Cyclic transmission processing time .............................................................................. App-32

Appendix 3.3 Transient transmission processing time......................................................................... App-44

Appendix 4 Communication with the Redundant CPU ............................................................................ App-47

Appendix 5 Comparisons with CC-Link Ver.1 Board and CC-Link Module ............................................ App-50

Appendix 5.1 Differences from the CC-Link Ver.1 board ..................................................................... App-50

Appendix 5.2 Functional comparisons with CC-Link module .............................................................. App-52

Appendix 6 Replacing the CC-Link Board ................................................................................................ App-53

Appendix 6.1 Replacing a CC-Link Ver.1 board with a CC-Link Ver.2 board ..................................... App-53

Appendix 6.2 Replacing a CC-Link Ver.2 board with a CC-Link Ver.1 board,

or a CC-Link board with another of the same version ................................................... App-54

Appendix 6.3 Precautions ..................................................................................................................... App-55

Appendix 7 About "Parameter backup/restore tool" ................................................................................ App-56

Appendix 7.1 Operation procedure ....................................................................................................... App-56

Appendix 7.1.1 Starting and exiting the tool ......................................................................................... App-56

Appendix 7.1.2 Backing up parameters ............................................................................................... App-57

Appendix 7.1.3 Restoring parameters .................................................................................................. App-58

Appendix 7.1.4 How to check the version ............................................................................................ App-60

Appendix 7.2 Precautions when using "Parameter backup/restoration tool" ...................................... App-61

Appendix 8 Setting Checklists .................................................................................................................. App-62

Appendix 8.1 Parameter setting checklist ............................................................................................ App-62

Appendix 8.2 Station information setting checklist ............................................................................... App-63

Appendix 8.3 Device assignment checklist .......................................................................................... App-65

Appendix 9 Combinations with Existing Software .................................................................................... App-67

Appendix 10 Checking Serial Number and Function Version ................................................................. App-68

Appendix 11 CC-Link Version .................................................................................................................. App-70

Appendix 12 Mode Selection Method....................................................................................................... App-71

Appendix 13 New and Improved Functions ............................................................................................. App-72

Appendix 13.1 Change of hardware function ....................................................................................... App-72

Appendix 13.2 Update of software package ........................................................................................ App-72

Appendix 14 Restrictions for Operating System ...................................................................................... App-73

A - 17 A - 17

Page 20

Appendix 15 Warning Message Appears on Windows ........................................................................... App-74

Appendix 15.1 Overview of warning message ..................................................................................... App-74

Appendix 15.2 Methods for preventing the warning message ............................................................ App-75

Appendix 16 Behavior When Personal Computer Enters Power Save Mode or Fast Startup .............. App-80

Appendix 16.1 Behavior when the personal computer enters the power save mode

(hibernate, sleep) .......................................................................................................... App-80

Appendix 16.2 Behavior when the fast startup function is enabled ..................................................... App-81

Appendix 17 MELSECPowerManager ..................................................................................................... App-82

Appendix 17.1 Installing MELSECPowerManager .............................................................................. App-82

Appendix 17.2 Uninstalling MELSECPowerManager .......................................................................... App-82

Appendix 17.3 Checking MELSECPowerManager .............................................................................. App-83

Appendix 18 EMC and low voltage directive ............................................................................................ App-85

Appendix 18.1 Requirements for Conformance to EMC Directive ...................................................... App-85

Appendix 18.2 Requirements for Conformance to Low Voltage Directive .......................................... App-90

Appendix 19 External Dimensions ........................................................................................................... App-91

Appendix 19.1 Q80BD-J61BT11N ........................................................................................................ App-91

Appendix 19.2 Q81BD-J61BT11 .......................................................................................................... App-92

INDEX Index- 1 to Index- 3

A - 18 A - 18

Page 21

MANUALS

The following are the manuals related to this product.

Refer to the following tables when ordering required manuals.

Relevant Manuals

Manual Name

Manual Number

(Model Code)

MELSEC-Q CC-Link System Master/ Local Module User's Manual

This Manual explains system configuration, Performance specifications, functions, handling, wiring and

troubleshooting for Q series master/local module. (Sold separately)

CC-Link System Master/ Local Module type AJ61BT11/A1SJ61BT11 User's Manual

This Manual explains system configuration, Performance specifications, functions, handling, wiring and

troubleshooting for AJ61BT11 and A1SJ61BT11. (Sold separately)

CC-Link System Master/ Local Module type AJ61QBT11/A1SJ61QBT11 User's Manual

This Manual explains system configuration, Performance specifications, functions, handling, wiring and

troubleshooting for AJ61QBT11 and A1SJ61QBT11. (Sold separately)

MELSEC-L CC-Link System Master/ Local Module User's Manual

This Manual explains system configuration, Performance specifications, functions, handling, wiring and

troubleshooting for L series master/local module. (Sold separately)

MELSEC Data Link Library Reference Manual

This manual explains programming, function specifications, and sample programming for MELSEC data

link library. (Sold separately)

REMARK

SH-080394

(13JR64)

IB-66721

(13J872)

IB-66722

(13J873)

SH-080895

(13JZ41)

SH-081035ENG

(13JV25)

MELSEC Data Link Library Reference Manual is stored on the CD-ROM of the

software package in a PDF file format.

Manuals in printed form are sold separately for a single purchase. Order a manual

by quoting the manual number (model code) listed in the above table.

A - 19 A - 19

Page 22

HOW TO USE THIS MANUAL

The following lists the key items that represent the main usage of the CC-Link Ver.2 board by the purpose.

Please use the following key items to refer to the appropriate section of this manual.

(1) To learn about the features of the CC-Link Ver.2 board (Chapter 1)

The features are described in Chapter 1.

(2) To learn about the system configuration (Chapter 2)

The system configuration using the CC-Link Ver.2 board is described in

Chapter 2.

(3) To learn about specifications of the CC-Link Ver.2 board (Chapter 3)

The specifications of the CC-Link Ver.2 board are described in Chapter 3.

(4) To learn about the functions of the CC-Link Ver.2 board (Chapter 4)

The functions of the CC-Link Ver.2 board are described in Chapter 4.

(5) To learn about the settings and procedures up to operation of CC-

Link Ver.2 board (Chapter 5)

The settings and procedures up to operation of the CC-Link Ver.2 board is

described in Chapter 5.

(6) To learn about how to set parameters (Chapter 6)

How to set parameters is described in Chapter 6.

(7) To learn about how to install and uninstall utility software

(Chapter 7)

How to install and uninstall utility software is described in Chapter 7.

(8) To learn about the utility software operating procedures (Chapter 8)

The utility software operating procedures are described in Chapter 8.

(9) To learn about MELSEC data link library (Chapter 9)

The overview of MELSEC data link library is described in Chapter 9.

(10) To learn about how to communicate with each station

(Chapters 10 to 14)

Some examples of communication between the master board and each station

are described in Chapters 10 to 14.

(11) To learn about the error descriptions (Chapter 15)

The descriptions of errors are described in Chapter 15.

(12) To learn about the corrective actions to take when the system

does not operate (Chapter 16)

The troubleshooting procedures are described in Chapter 16.

A - 20 A - 20

Page 23

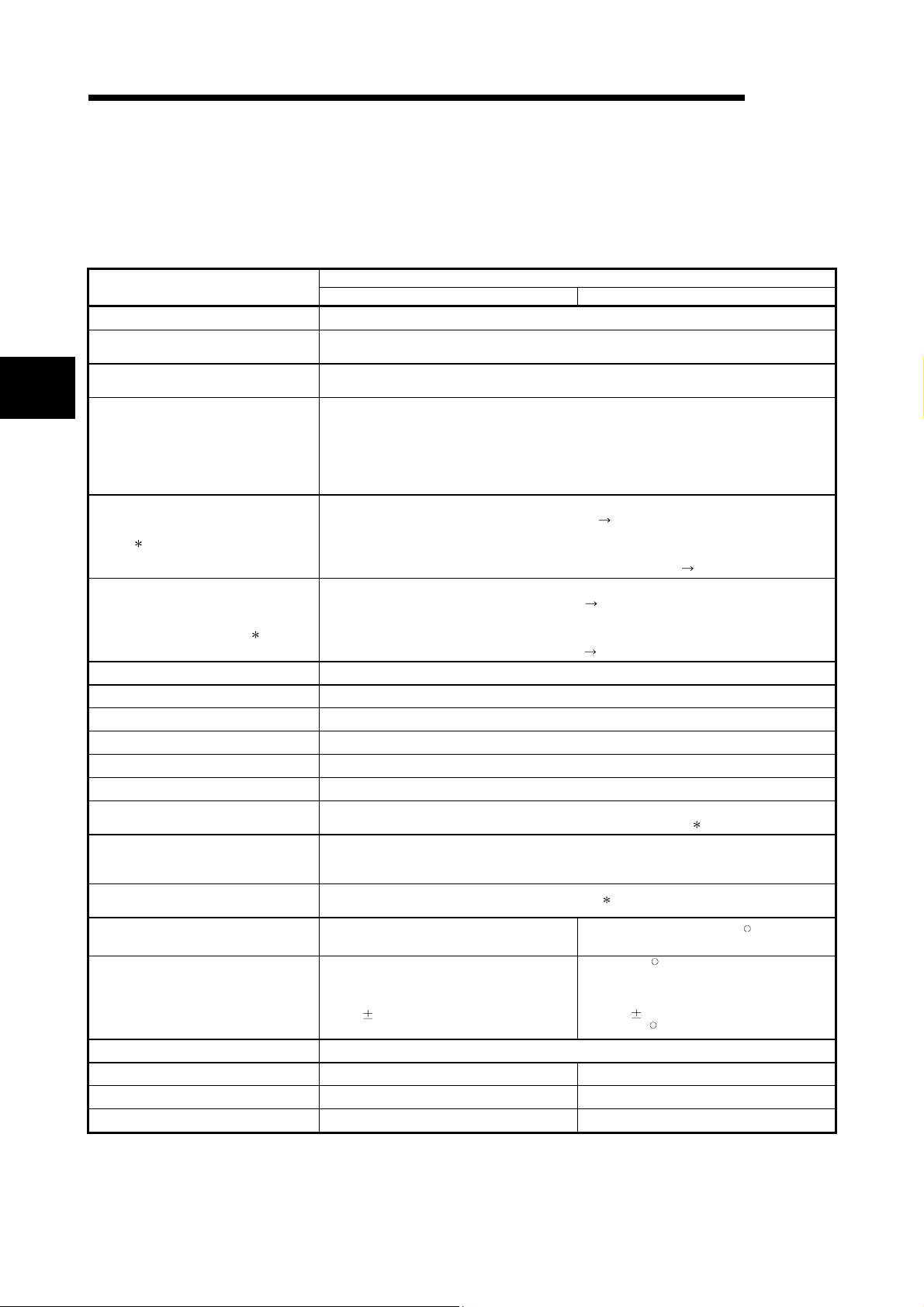

GENERIC TERMS AND ABBREVIATIONS

This manual uses the following generic terms and abbreviations to describe the Model Q80BDJ61BT11N/Q81BD-J61BT11 CC-Link System Master/Local Interface Board, unless otherwise specified.

Generic term/abbreviation Description of generic term/abbreviation

CC-Link Ver.1 board

CC-Link Ver.2 board

Master board Abbreviation for the CC-Link board when used as a master station.

Local board Abbreviation for the CC-Link board when used as a local station.

QJ61BT11(N)

SW1DNC-CCBD2-B

Master station The station controlling the remote station, local station, and intelligent device station.

Standby master station

Local station A station that has a CPU and can communication with the master station and local station.

Remote I/O station

Remote device station

Remote station Generic term for the remote I/O station and remote device station.

Intelligent device station A slave station such as the AJ65BT-R2 in the CC-Link system that can perform transient transmission.

Slave station

Ver.1 compatible slave station Slave station compatible with the remote net ver.1 mode.

Ver.2 compatible slave station Slave station compatible with the remote net ver.2 mode.

Master and local modules

Master module Generic term for the Master and local modules when they are used as master stations.

Local module Generic term for the Master and local modules when they are used as local stations.

Remote module

Intelligent module Generic term for modules such as the AJ65BT-R2 that can perform transient transmission.

Cyclic transmission Function that periodically updates the contents of the remote I/O and remote register.

Transient transmission

Remote net mode

Remote net ver.1 mode

Remote net ver.2 mode Select this mode when increasing the number of cyclic points and configuring a new system.

Remote net additional mode

Board WDT Abbreviation for the watchdog timer that monitors the operation of network board.

Driver WDT

Generic term for the Type A80BDE-J61BT11 CC-Link System Master/Local Interface Board and the Type

A80BDE-J61BT13 Control & Communication Link System Local Interface Board.

Abbreviation for the Type Q80BD-J61BT11N/Q81BD-J61BT11 CC-Link System Master/Local Interface

Board.

Generic term for QJ61BT11N CC-Link System Master/Local Module and QJ61BT11 CC-Link System

Master/Local Module.

Product name of the software package for CC-Link Ver.2 board.

Backup station for data link control when the link to the master station is disconnected due to a

programmable controller CPU, Master board or power supply problem.

A remote station that can only handle bit information.

(AJ65BTB

Remote station that can use bit data and word data.

(Performs input and output with external devices, and analog data conversion.)

(AJ65BT-64AD, AJ65BT-64DAV, AJ65BT-64DAI)

Generic term for remote I/O station, remote device station, local station, intelligent device station and

standby master station.

Generic term for the AJ61QBT11, A1SJ61QBT11, AJ61BT11, A1SJ61BT11, QJ61BT11, LJ61BT11,

L26CPU-BT, L26CPU-PBT, and RJ61BT11.

Generic term for AJ65BTB

A852GOT, etc.

Function by which data communications are available between 1:1stations at any given timing by

specifying a target station.

Mode that can communicate with all stations used for CC-Link (remote I/O station, remote device station,

local station, intelligent device station, and standby master station)

The remote net mode has three different modes: remote net ver.1 mode, remote net ver.2 mode, and

remote net additional mode.

Mode in which compatibility with the CC-Link Ver.1 board is achieved.

Select this mode when the number of cyclic points need not be increased or when the CC-Link Ver.2

board is used to replace the CC-Link Ver.1 board as a maintenance product.

Select this mode when adding a ver.2 compatible station to the existing system to increase the number of

cyclic points.

Abbreviation for the watchdog timer that monitors the communication status between a network board

and a personal computer, or operating status of a personal computer.

- , AJ65BTC - )

- , AJ65BTC - , AJ65BT-64AD, AJ65BT-64DAV, AJ65BT-64DAI,

A - 21 A - 21

Page 24

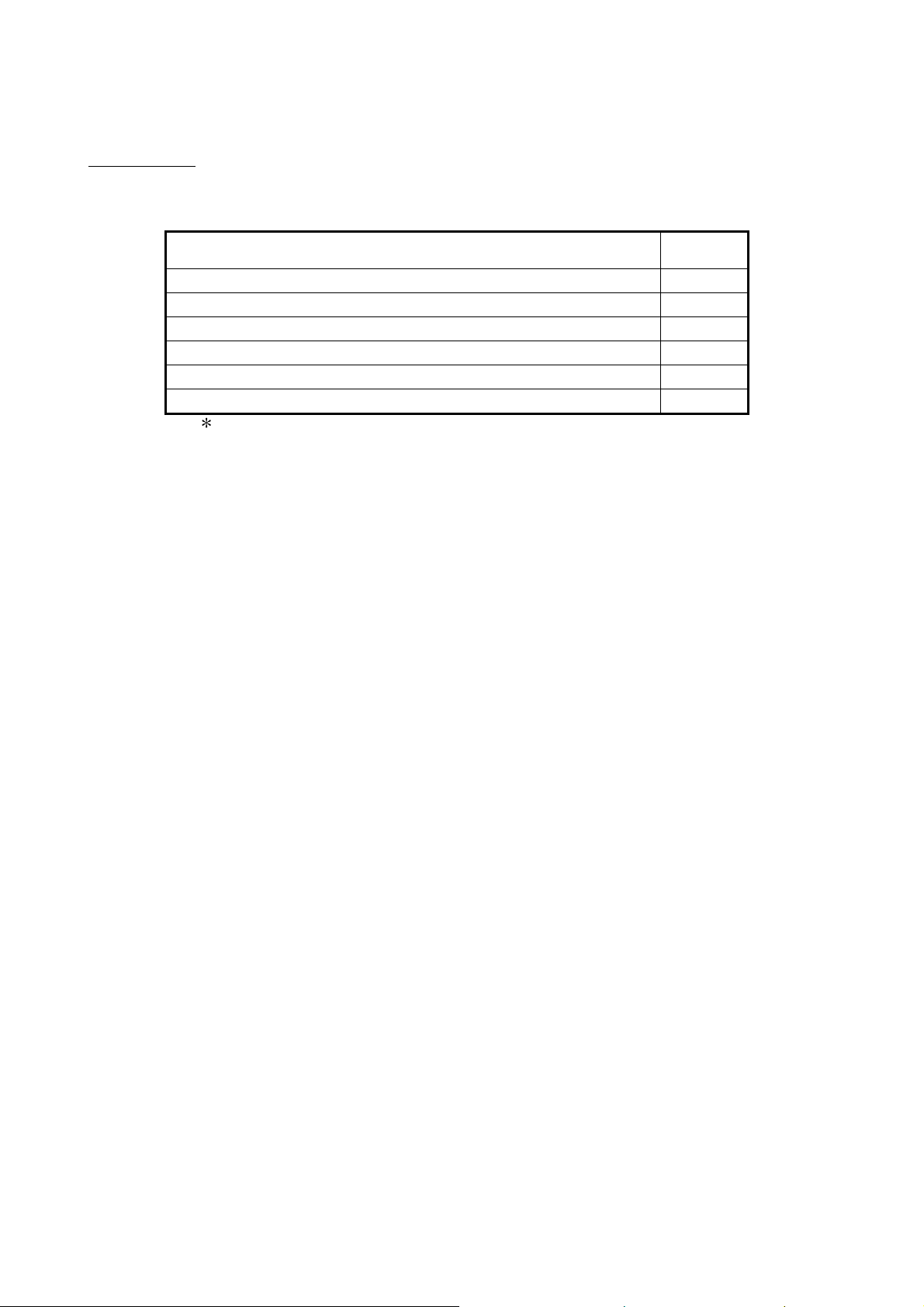

PACKING LIST

The following shows the product list of the CC-Link Ver.2 board.

Item name Quantity

CC-Link system master/local interface board 1

Terminal resistor 110Ω, 1/2 W (brown-brown-brown) 2

Terminal resistor 130Ω, 1/2 W (brown-orange-brown)

Software package (CD-ROM)

Before Using the Product 1

Software License Agreement 1

*1

1

1: The manual is stored on the CD-ROM in a PDF file format.

2

A - 22 A - 22

Page 25

1 OVERVIEW

MELSEC

1 OVERVIEW

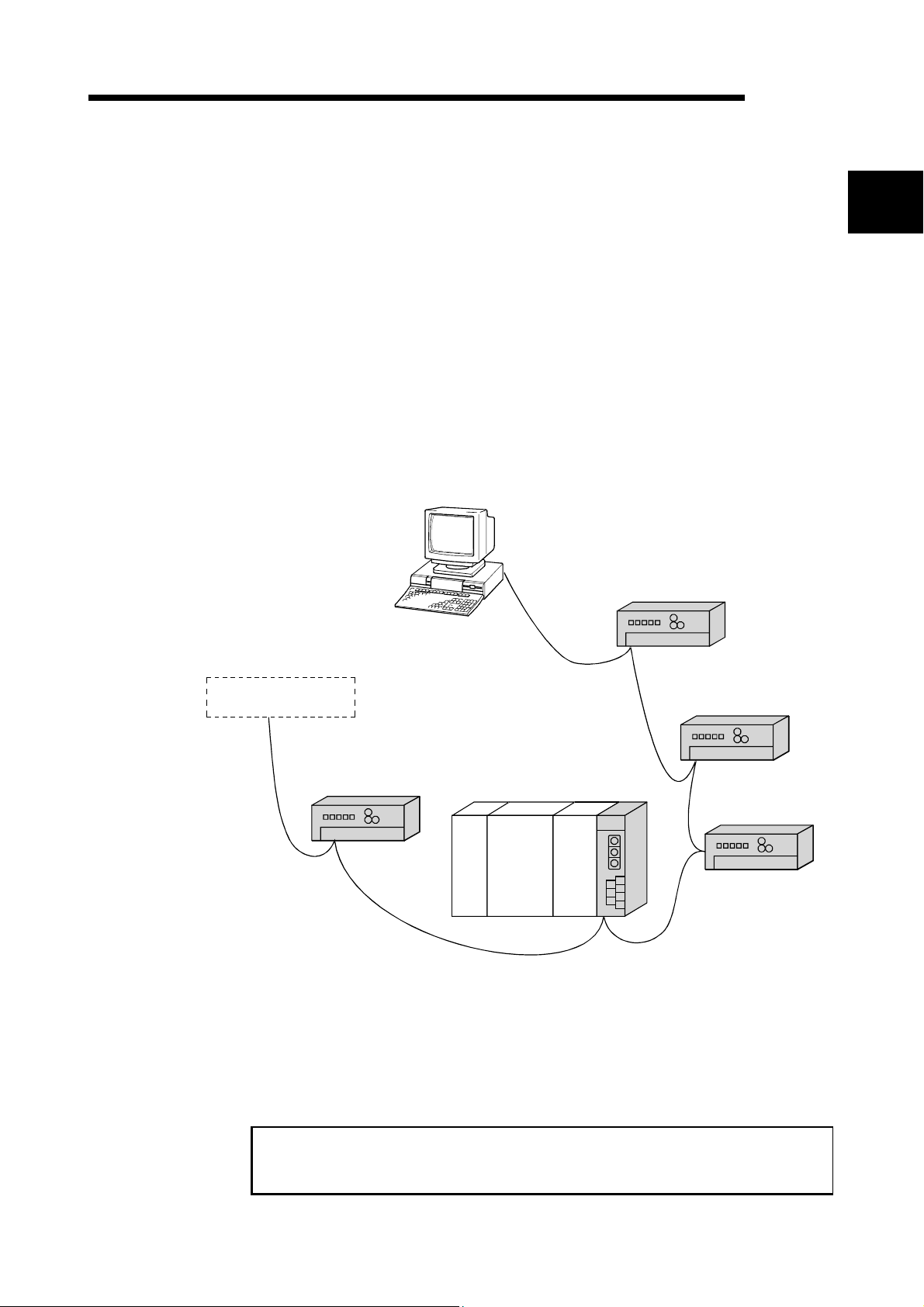

The CC-Link system connects distributed modules such as an I/O module and a

special functional module using CC-Link dedicated cables so that these modules can

be controlled by the programmable controller CPU.

(1) By distributing each module to facility equipment such as a conveyor line and a

machine device, the entire system can be connected in the most efficient manner.

(2) The on/off information of input/output and numeric data handled by modules can

easily be sent and received at high speed.

(3) A simple distributed system can be configured by connecting multiple personal

computers and programmable controller CPUs.

(4) By connecting various devices made by Mitsubishi's partner manufacturers, the

system that can provide flexible solutions to meet a wide range of user needs may

be configured.

Master station

Master/local interface board

Remote I/O station

1

Device manufactured by

a partner manufacturer

Master station The station that controls the data link system.

Remote I/O station A remote station that handles bit unit data only.

Remote device station A remote station that handles bit unit and word unit data.

Local station A station having a programmable controller CPU and the

Intelligent device station A station that can perform transient transmission.

When applying the program examples and sample programs explained in this

manual to the actual system, make sure that there is no any problem regarding

control on the target system.

Remote I/O station

Remote device station

Local station

Programmable

controller CPU

ability to communicate with the master and other local

stations.

Intelligent device station

1 - 1 1 - 1

Page 26

1 OVERVIEW

1.1 Features of the CC-Link Ver.2 Board

MELSEC

1

The features of the CC-Link Ver.2 board are as follows:

(1) Personal computers can be incorporated into the CC-Link system.

Installing a CC-Link Ver.2 board into a personal computer allows the PC to be

used as a master station, standby master station, or local station compatible with

CC-Link Ver.2.

By using the CC-Link Ver.2 board as a master station, Ver.2 compatible remote

I/O stations, remote device stations, intelligent device stations and local stations

can be controlled from the PC.

(2) Programs in the CC-Link Ver.1 board can also be used in the CC-

Link Ver.2 board.

Programs developed for the CC-Link Ver.1 board can be used for the CC-Link

Ver.2 board.

(3) Parameters set for the CC-Link Ver.1 board can also be used for

the CC-Link Ver.2 board.

Parameters set for the CC-Link Ver.1 board can be reused for the CC-Link Ver.2

board. (Refer to Appendix 7)

(4) PCI/PCI ExpressRis applicable.

For Q80BD-J61BT11N, PCI is applicable.

For Q81BD-J61BT11, PCI Express

R

is applicable.

(5) Parameters can easily be set.

The parameters necessary for the operation of the CC-Link system can easily be

set with a CC-Link Ver.2 utility program; thus, programming is simplified.

(6) Test and monitoring information related to the CC-Link system can

be displayed.

The test and monitoring states in the CC-Link system can be easily displayed on

a personal computer.

(7) Support for a multiple CPU system

By specifying the logical station number via the CC-Link Ver.2 utility, a multiple

CPU system can be accessed.

(8) It provides the functions that support user programming.

It is possible to perform the remote control of remote I/O stations, remote device

stations, intelligent device stations, and local stations, as well as reading and

writing of devices using the functions that support Microsoft

Microsoft

Example:

R

Visual BasicR. Thus, user program can easily be created.

Control of the input signal X and output signal Y of a remote I/O station

Analogue voltage output control of a remote device station (analogue module)

Communication control of an intelligent device station (RS-232C module)

R

Visual C++Rand

(9) It provides the drivers for various operating systems.

Various drivers are provided for easy system configuration according to the user

environment.

For details on the compatible operating system, refer to Section 2.3.

(10) Prevent separation of cyclic data by each station

In the CC-Link Ver.2 utility, cyclic data can be assured only by enabling the

parameter of block data assurance per station setting.

1 - 2 1 - 2

Page 27

1 OVERVIEW

1.2 Features of the CC-Link System

This section explains the features of the CC-Link System.

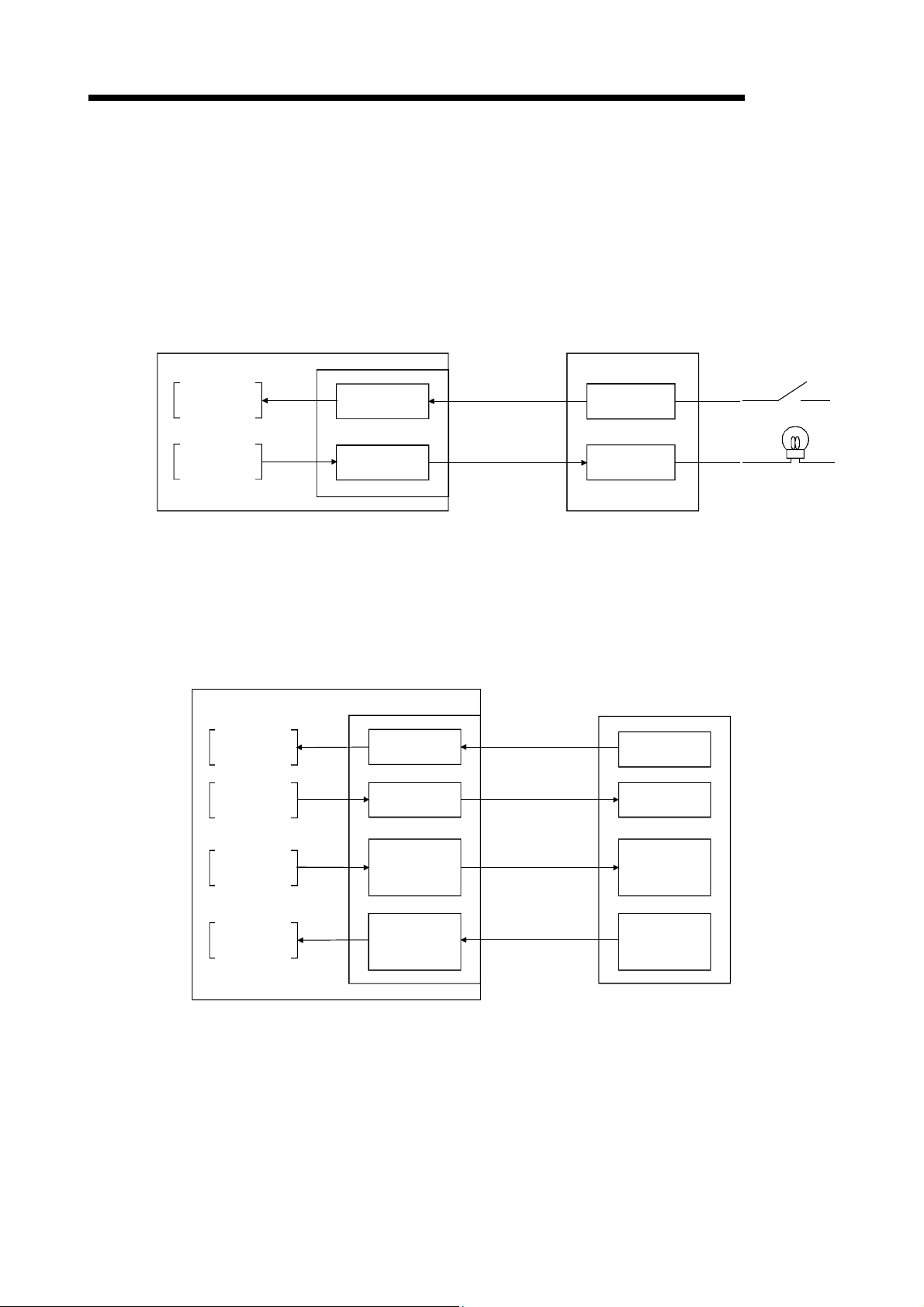

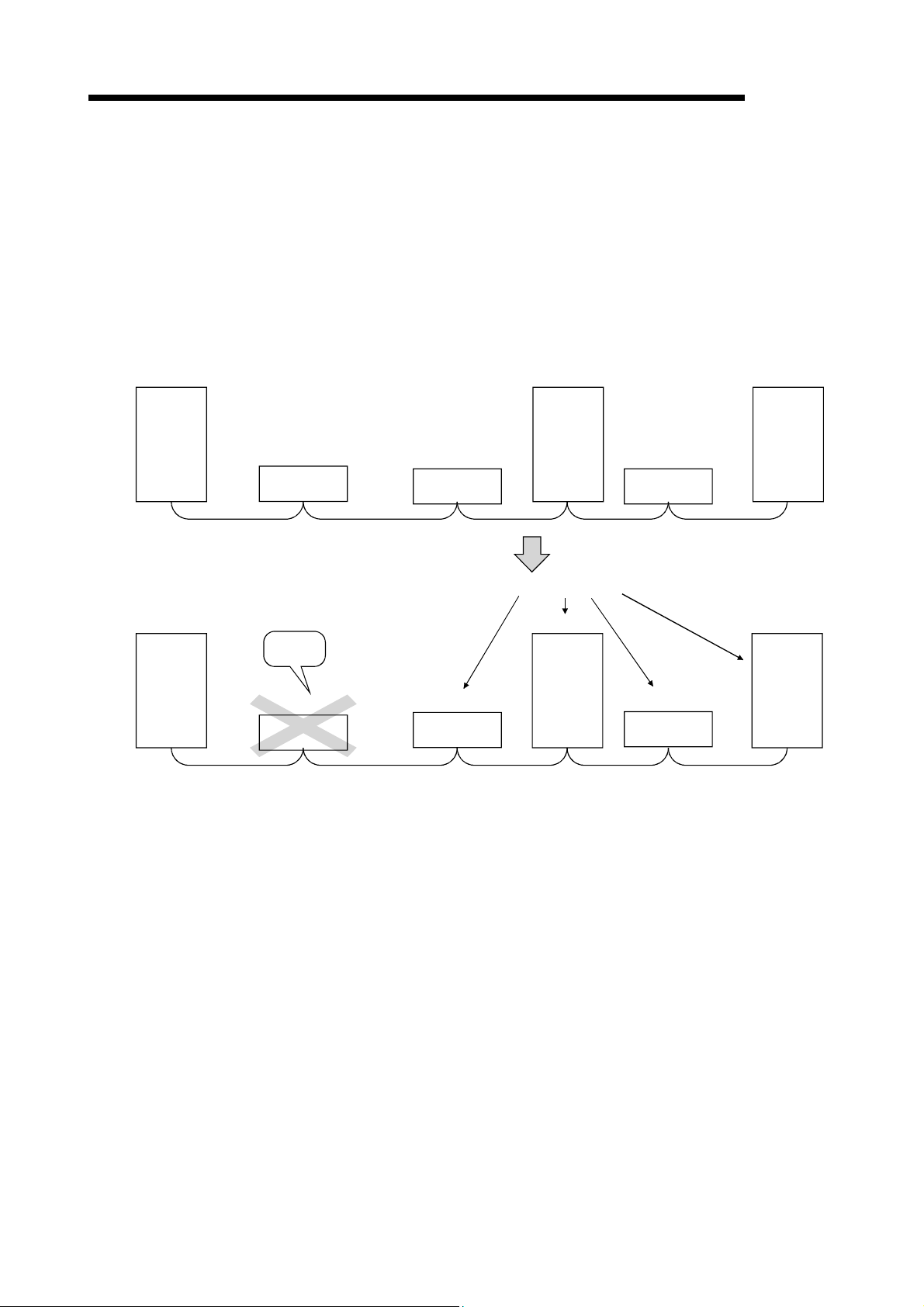

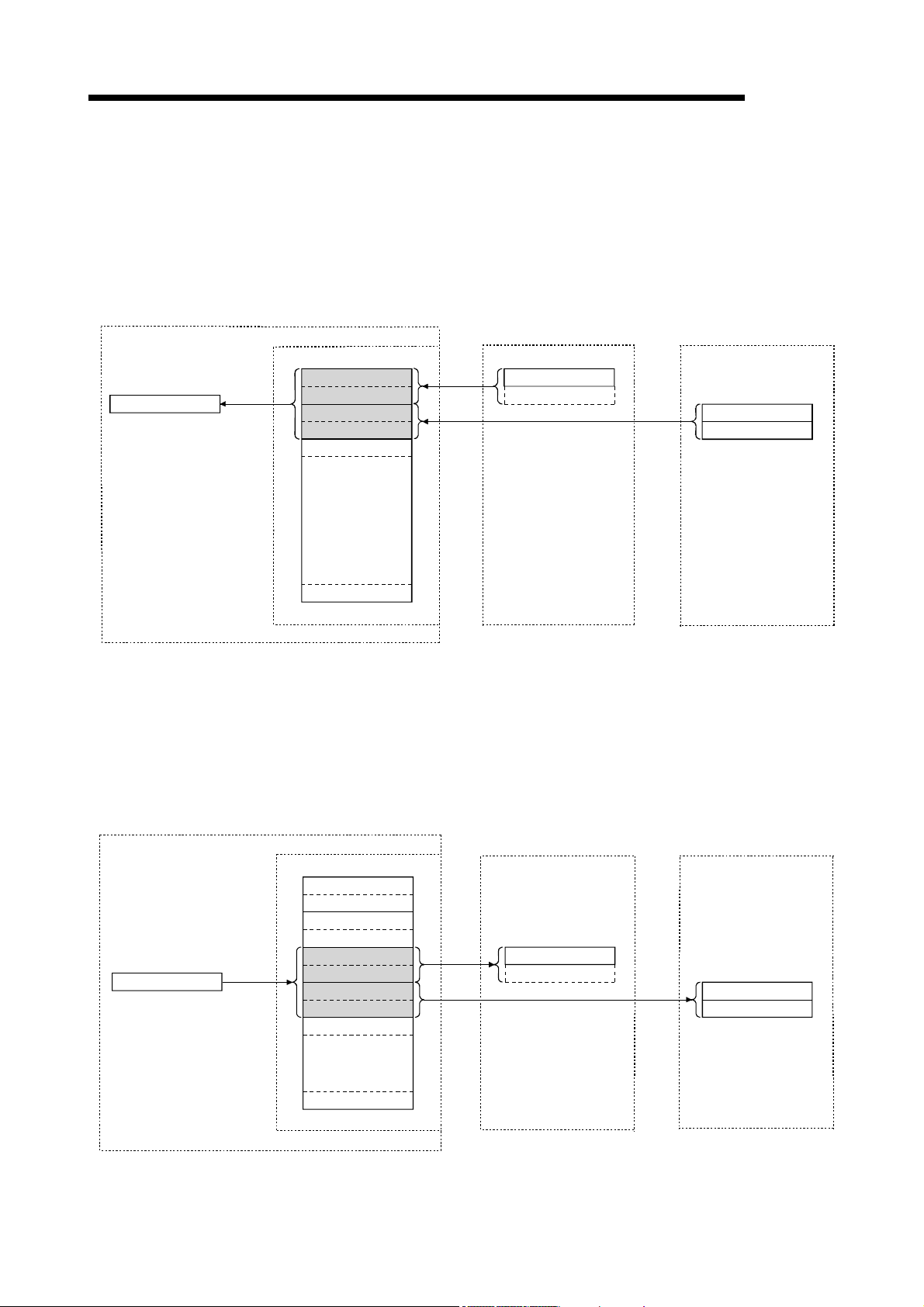

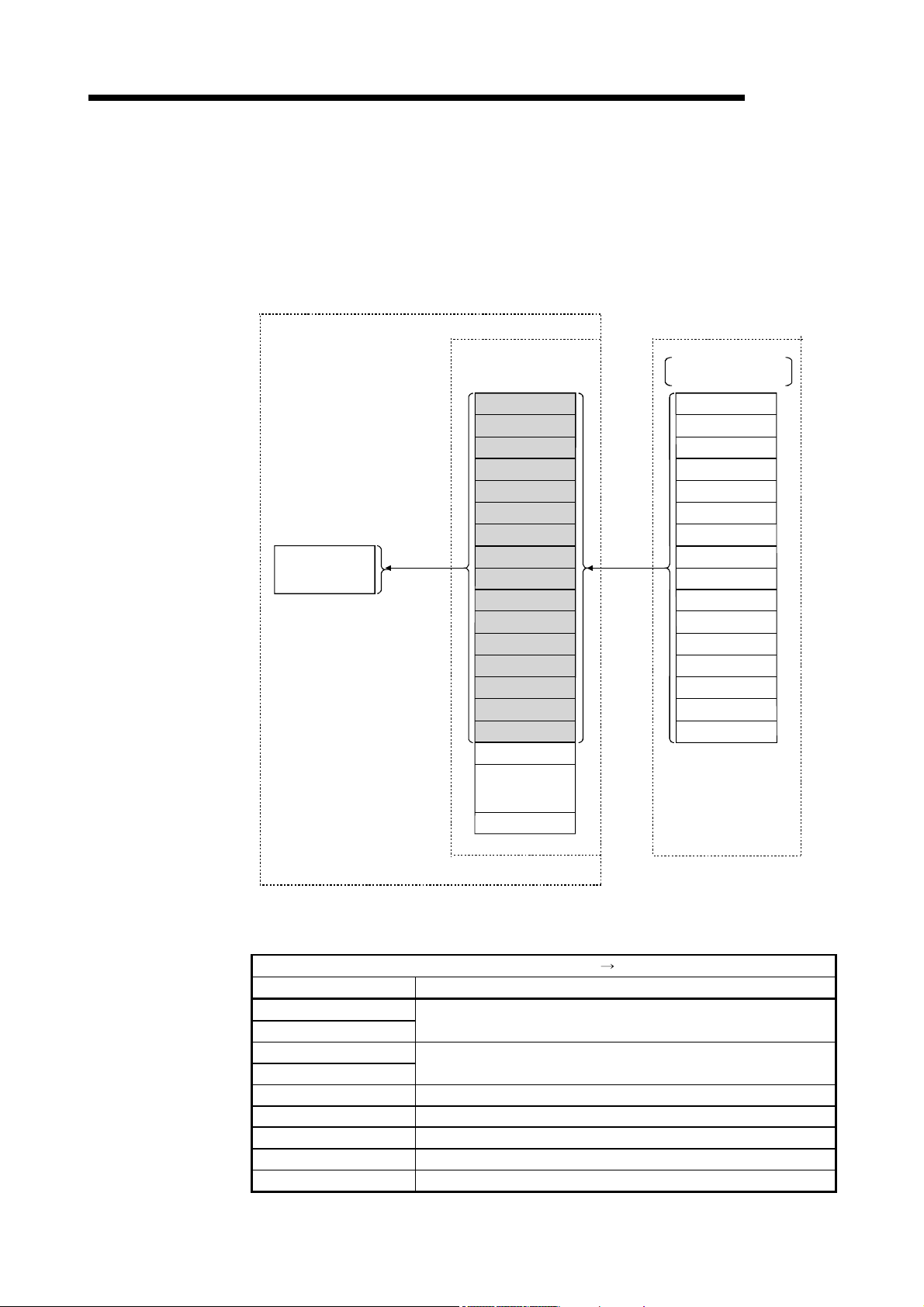

(1) Remote I/O station communication

The on/off status of a switch or indicator lamp is communicated using the remote

input RX and remote output RY.

Personal computer

Master station

Remote I/O station

MELSEC

Program

mdReceive

mdSend

Read

Write

CC-Link Ver.2 board

Remote input

RX

Remote output

RY

Link scan

Link scan

Input

Output

(2) Remote device station communication

Handshaking signals with the remote device station (initial request, error

occurred flag, etc.) are communicated using the remote input RX and remote

output RY. The setting data to the remote device station are communicated using

the remote registers RWw and RWr.

Personal computer

Program

mdReceive

mdSend

Read

Write

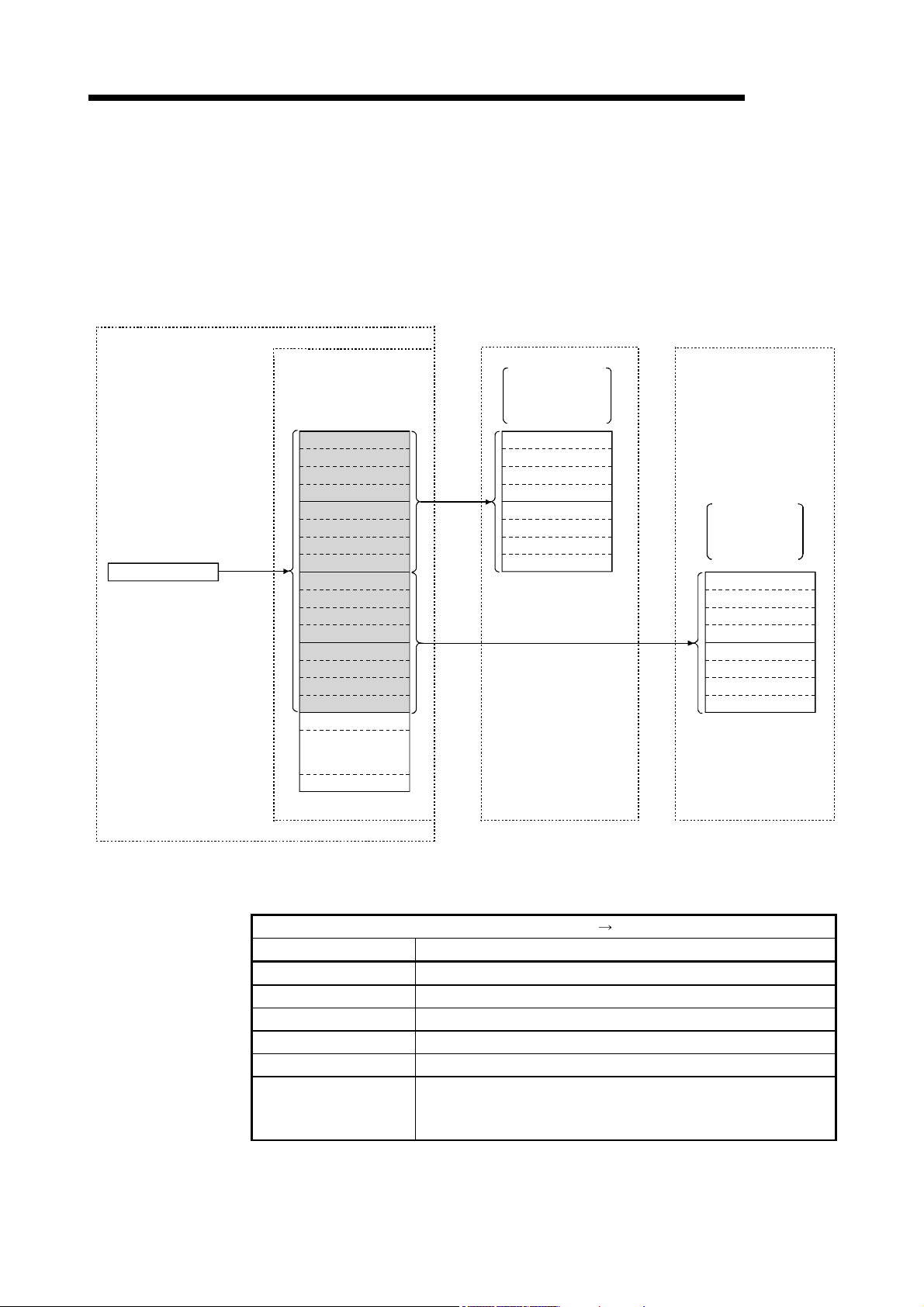

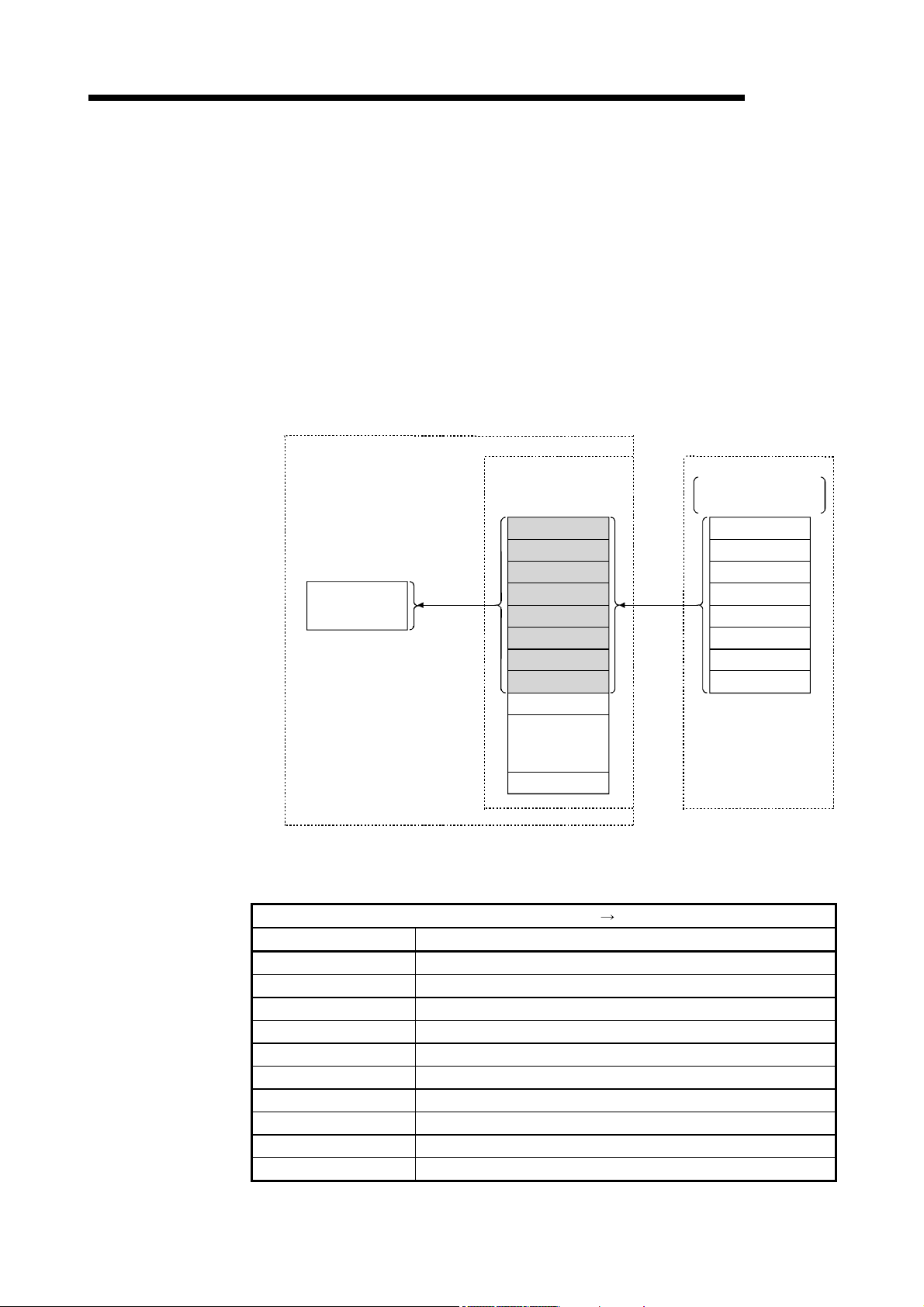

Master station