Page 1

SPLIT-TYPE,HEAT PUMP AIR CONDITIONERS

MITSUBISHI ELECTRIC

-CENTRALLY CONTROLLED STAND BY

DEFROST

ON

CHECK DRY

COOL

HEAT

CHECK

SET TEMP

TIMER OFF

AUTO STOP

AUTO START

F

HR

F

LOW HIGH

AUTO RETURN

CHECK TEST RUN

POWER

ON/OFF

HEAT

SET

TEMPERATURE

AUTO COOL/DRY

COOLERWARMER

TIMER MODE HOURS

FAN SPEED LOW/HIOGH

AIR

DISCHARGE

UP/DOWN

SWING

STOP

CHECK TEST RUN

L

I

S

T

E

D

R

A

I

R

S

T

A

N

D

A

R

D

2

1

0

•

M

A

N

U

F

A

C

T

U

R

E

R

C

E

R

T

I

F

I

E

D

T

O

A

R

I

A

S

C

O

M

P

L

Y

I

N

G

W

I

T

H

•

C

E

R

T

I

F

I

C

A

T

I

O

N

S

E

C

T

I

O

N

S

O

F

E

Q

U

I

P

M

E

N

T

A

I

R

-

C

O

N

D

I

T

I

O

N

I

N

G

U

N

I

T

A

R

Y

TECHNICAL & SERVICE MANUAL

No. OC120

Series PKH

<Indoor unit>

Models

PKH18FK / PUH18EK

PKH24FK / PUH24EK

PKH30FK / PUH30EK

PKH36FK / PUH36EK

Wall Mounted

Indoor unit

CONTENTS

1. FEATURES ···········································2

2. SPECIFICATIONS·································5

3. DATA·····················································6

4. OUTLINES AND DIMENSIONS··········16

5. WIRING DIAGRAM ·····························22

6.

REFRIGERANT SYSTEM DIAGRAM

7. OPERATION FLOW-CHART··············26

8. MICROPROCESSOR CONTROL·······30

9. TROUBLESHOOTING························51

10. SYSTEM CONTROL···························59

11. DISASSEMBLY INSTRUCTIONS ·······64

12. PARTS LIST········································71

13. OPTIONAL PARTS·····························83

······25

REMOTE CONTROLLER

The Slim Line.

From Mitsubishi Electric.

Page 2

1

MITSUBISHI ELECTRIC

-CENTRALLY CONTROLLED STAND BY

DEFROST

ON

CHECK DRY

COOL

HEAT

CHECK

SET TEMP

TIMER OFF

AUTO STOP

AUTO START

F

HR

F

LOW HIGH

AUTO RETURN

CHECK TEST RUN

POWER

ON/OFF

HEAT

SET

TEMPERATURE

AUTO COOL/DRY

COOLERWARMER

TIMER MODE HOURS

FAN SPEED LOW/HIOGH

AIR

DISCHARGE

UP/DOWN

SWING

STOP

CHECK TEST RUN

FEATURES

Indoor unit

Remote controller

PUH24EK

Outdoor unit

Models Cooling capacity / Heating capacity SEER

PKH18FK 18,000 / 18,600 [25,100] Btu/h 11.1

PKH24FK 24,000 / 25,000 [31,500] Btu/h 10.2

PKH30FK 30,000 / 33,000 [40,500] Btu/h 10.6

PKH36FK 34,200 / 38,000 [45,500] Btu/h 10.5

1. COMPACT DESIGN

The PK series models have been downsized and now require such minimal wall space that they can even be installed

above windows. For the PKH18/24FK, 13in of wall space between the ceiling and the window allows “above window”

installation (14.5in for the PKH30/36FK)

2. A FURTHER REFINEMENT OF COMFORT WITH NOISE SUPPRESSION

Remarkably low-noise operation has been achieved through the development of a “near-silent” fan and a design which

minimizes airflow resistance.

3. AUTO FLAP SHUTTER

With a simple flick of the OFF switch the air outlet can be closed off with a shutter. The shutter also functions as a flap

during operation to adjust the air flow angle, with “Auto Angle 1” securing a comfortable air flow.

4. INSTALLATION : FAST AND ENDLESSLY ADAPTABLE

(1) External piping

An external piping connection of 24in and a very light body promote trouble-free installation for PKH18FK.

(2) Multi-directional piping

Multi directional drain and refrigerant piping rodically improves flexibility in selecting installation layouts. PKH18FK drain

piping can be installed in 5 directions, while PKH30/36FK models boast refrigerant piping in 4 directions and drain piping

in 2 directions.

(3) Back plate installation guide

The back plate installation guide gives clear instructions on installation positions. The enlarged back plate secures the

unit firmly to the wall, while the support piece which lifts the unit makes left side piping work much easier.

(4) Front power supply box

The front power supply box allows electrical wiring work to be performed easily even after the indoor unit has been fully

installed. All the screws for the indoor unit can be tightened from the front side thus ensuring smooth installation.

(only for PKH18/24FK)

(5) Easily removable filter

The presence of thumbscrews on the filters means that the filters can be quickly and smoothly removed.

(only for PKH30/36FK)

2

Page 3

5. ADVANCED MICROPROCESSOR

Indoor unit Outdoor unit

Indoor

heat

exchanger

4•way

valve

Accumulator

Compressor

Outdoor

heat

exchanger

Capillary tubes

for heating

Capillary

tubes for

cooling

Liquid section

of piping

HIgh-pressure

liquid

retrigerant

Restrictor

valve

Restrictor valve

Indoor unit Outdoor unit

Indoor

heat

exchanger

4•way

valve

Accumulator

Compressor

Outdoor

heat

exchanger

Capillary tubes

for cooling

Capillary

tubes for

heating

Liquid section

of piping

Low-pressure

two-phase

retrigerant

Restrictor

valve

Restrictor valve

MITSUBISHI ELECTRIC

-CENTRALLY CONTROLLED STAND BY

DEFROST

ON

CHECK DRY

COOL

HEAT

CHECK

SET TEMP

TIMER OFF

AUTO STOP

AUTO START

F

HR

F

LOW HIGH

AUTO RETURN

CHECK TEST RUN

POWER

ON/OFF

HEAT

SET

TEMPERATURE

AUTO COOL/DRY

COOLERWARMER

TIMER MODE HOURS

FAN SPEED LOW/HIOGH

AIR

DISCHARGE

UP/DOWN

SWING

STOP

CHECK TEST RUN

(1) Easy to Use Microprocessor

1) Ultra-Thin Remote Controller

The streamlined, square controller is designed to

blend with any kind of interior and the adoption of

a sophisticated microprocessor allows you to

carry out a wide range of operations easily.

2) Ultra-Thin Remote Controller

Units operation mode, set temperature, room tem-

perature, timer setting, fan speed, louver operation, and air flow direction are displayed on the

remote controller with the easily understood visual

Liquid Crystal Display (LCD).

3) Convenient 24-Hour ON-OFF Timer

The timer allows Mr.SLIM to be switched on or

off automatically at the time is shown on the LCD.

4) Self-Diagnostic Feature Indicates Instantly

In the rare case when a problem occurs, the unit stops operating and the set temperature indicator changes to the

self-diagnostic indicator, indicating the location of the fault.

If the check switch is pressed twice, the unit stops operating and the check mode is initiated. The cause of the most

recent problem stored in the memory is displayed on the LCD. This is extremely useful for maintenance purposes.

5) Useful Memory Feature for Storing Instructions

The previous set value is memorized so that constant temperature control can be obtained. This is convenient when,

for example, a power failure occurs.

(2) Non-polar Two-Wire Remote Controller Cables

The non-polar, two-wire type remote controller cable is slim, installation is simple and troublefree. Remote controller

wire can be extended up to 550 yards.

(3) Automatic Cooling / Heating Changeover Operation

An automatic cooling and heating changeover operation system is provided to ensure easy control and year-round air

conditioning.

Once the desired temperature is set, unit operation is switched automatically between cooling and heating, in

accordance with the room temperatures as low as 23

o

F.

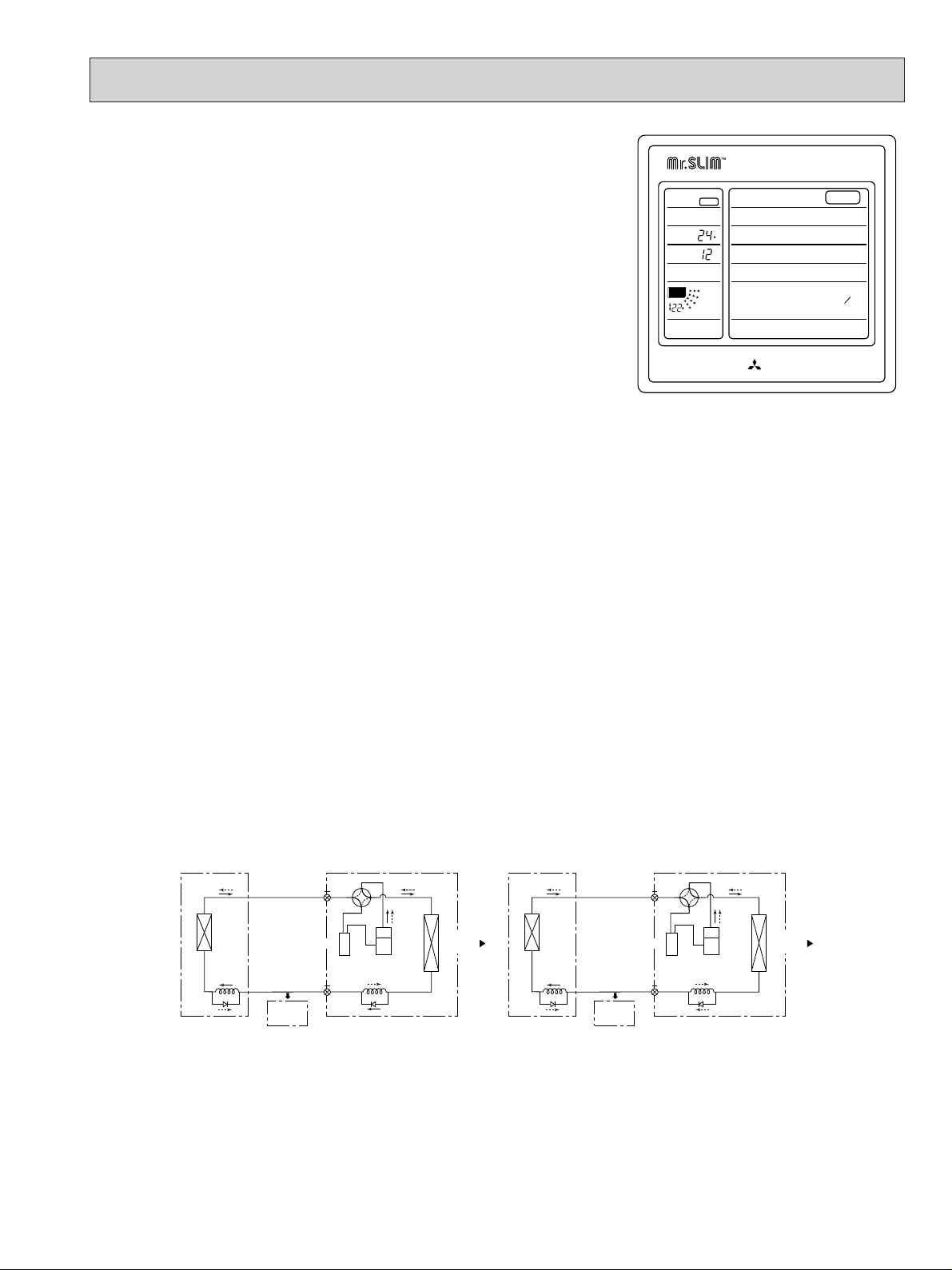

6. REDI-CHARGED REFRIGERANT SYSTEM

PRE-CHARGE REFRIGERANT REQUIRED FOR MAXIMUM PIPING LENGTH AT

SHIPMENT. PREVENTING TROUBLES DUE TO SHORTAGE OF REFRIGERANT.

The unique refrigerant circuit and a large accumulator always controls the refrigerant to its optimum condition regardless of

the length of 164ft maximum or 25ft minimum. The additional refrigerant charging work at the field which often caused

uncertain problems heretofore is completely eliminated. This unique system serves to improve the quality of work and

reliability, and also helps to speed up the installation work.

With normal circulation systems, a high-pressure refrigerant, condensed for cooling by the outdoor heat exacanger, is

reduced in pressure by capillary tubes in the indoor unit after passing through the restrictor valve in the outdoor unit (see

Figure 1). With the new circulation system, the direction of the restrictor valve is reversed as shown in Figure 2, and the

condensed high pressure refrigerant is reduced in pressure by the capacity tubes in the outdoor unit. This results in a “twophase refrigerant” of reduced pressure in the liquid section of the piping, The density of this two-phase refrigerant is 1/3~

1/2 of that of the high pressure liquid refrigerant, and thus is required in smaller amounts (see Figures 1 and 2). As a result,

the length of the piping can be extended further, and the effects of height differences are reduced. These new circulation

system are also equipped with a large accumulator which allows the refrigerant required for the 100ft piping length to be

enclosed in the outdoor unit. The result is an air conditioner that requires no charging unless piping is extended beyond

100ft.

3

Page 4

7. HIGH RELIABILITY AND EASY SERVICING

Red

Right

Base

Front

In addition to the self-diagnostic function, units are also equipped with a 3-minute time delay mechanism (cooling), an auto

restart function, an emergency operation function, a test run switch, etc., to assure high reliability and easy servicing.

8. FOUR-WAY PIPING ACCESS MAKES

INSTALLATION LAYOUT EASY

Piping on the outdoor unit may be connected from either of

four directions: front, rear, side or beneath the base.

This easy-access design makes it possible to install a

number of units in a compact arrangement at a single site.

The outdoor unit allows for unheard-of flexibility in

detemining a piping layout, thus greatly simplifying

installation.

9. FRONT-ACCESS FACILITATES

MAINTENANCE

The outdoor unit has been designed with a frontaccess

service panel that allows easy access to all maintenance

point, regardless of the installation layout. What’s more, this

front panel may be removed by loosening only two screws.

It all adds up to greatly simplified maintenance work.

10

. NITROGEN GAS IS CHARGED TO

INDOOR UNIT

Indoor unit and refrigerant pipes are charged with nitrogen

gas (N2) instead of R-22 before shipment from the

factory.

4

Page 5

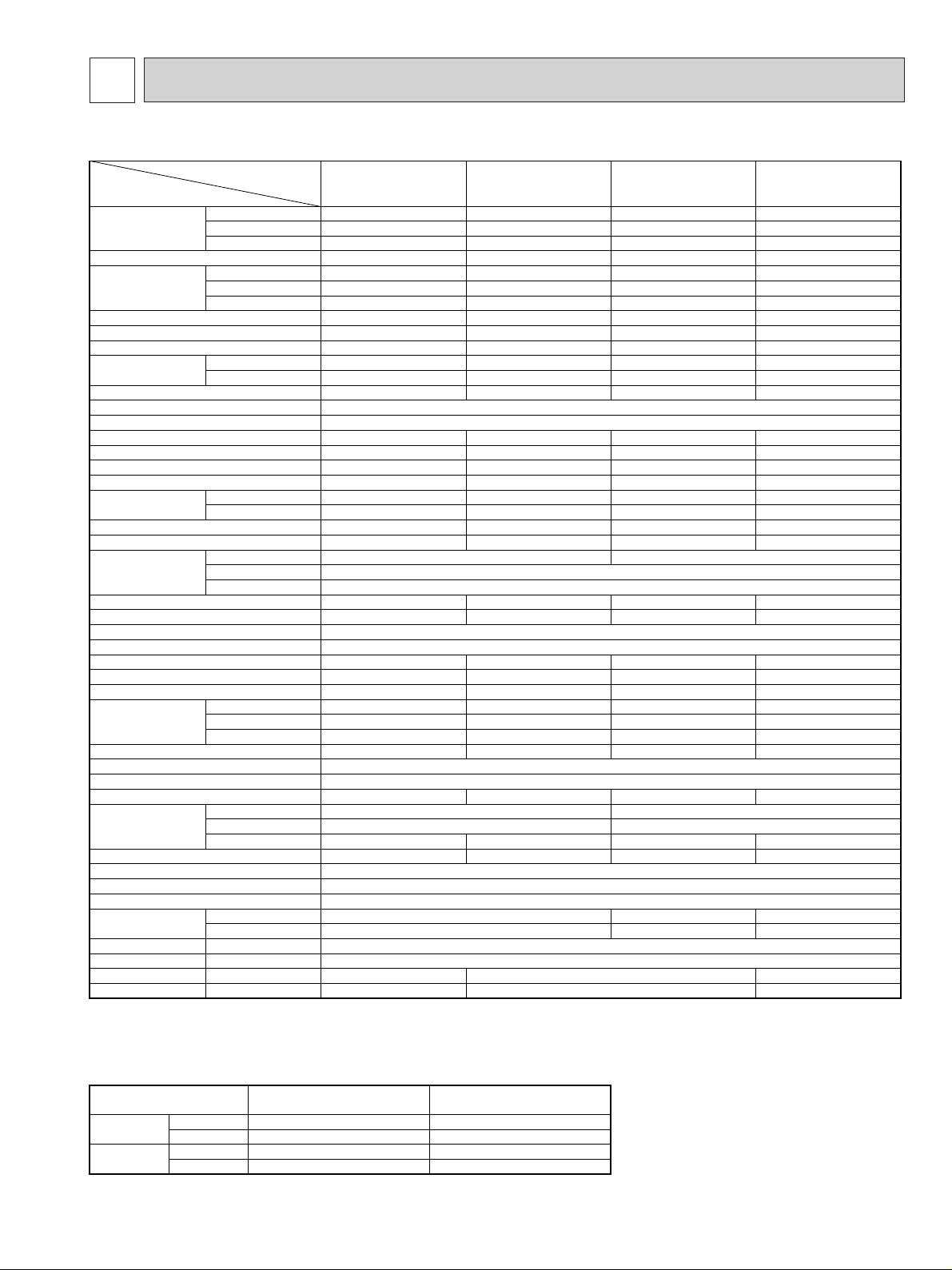

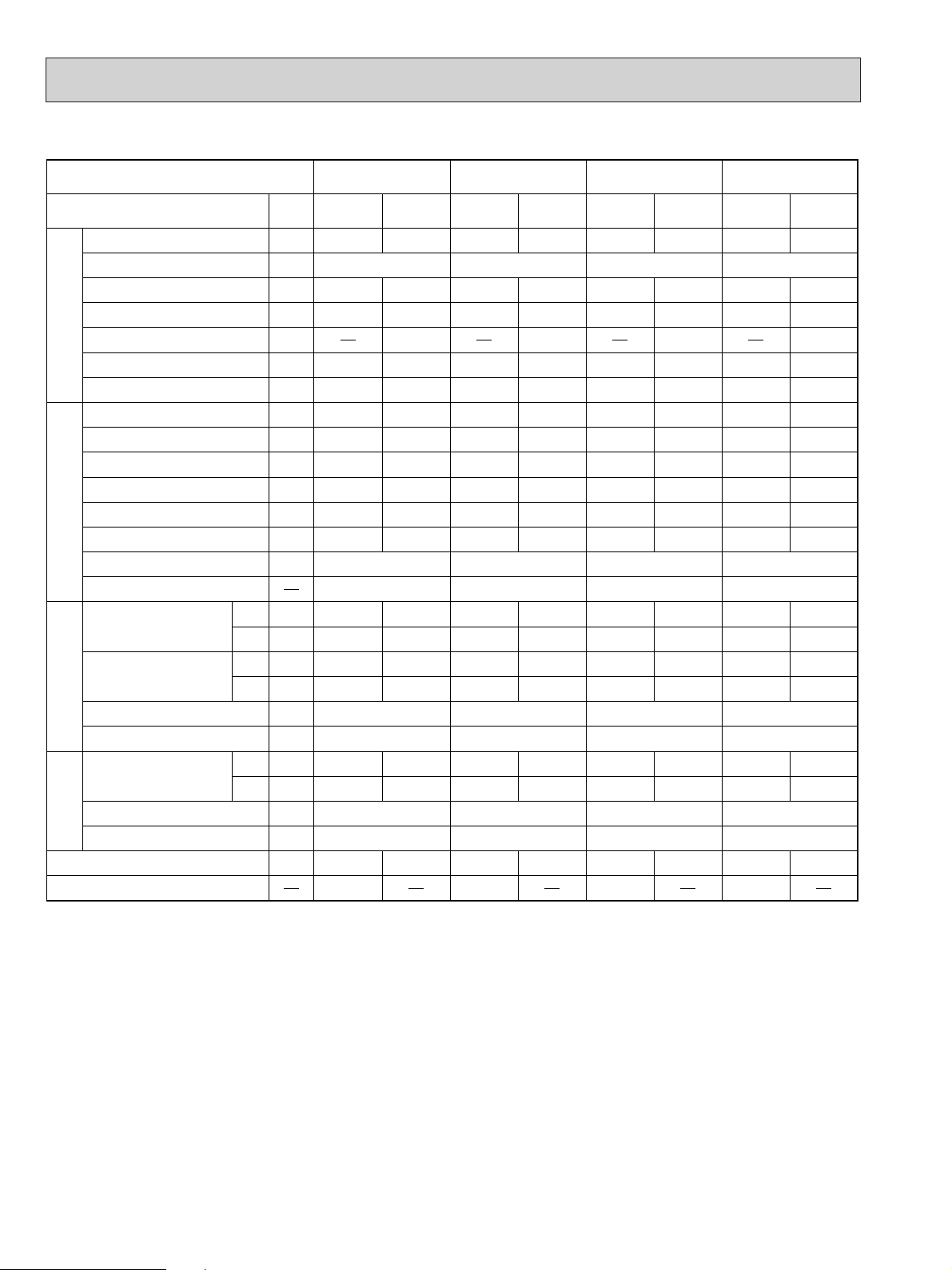

SPECIFICATIONS2

MODELS : PKH18/24/30/36FK

Model

Item

Capacity

Moisture removal

Power

Consomption

EER

SEER

HSPF

COP

INDOOR UNIT MODELS

External finish

Power supply

Max.fuse size (time dalay)

Min.ampacity

Fan motor

Booster heater

Airflow Hi-Lo

Sound level Hi-Lo

Cond. drain connection OD

Dimensions

Weight

OUTDOOR UNIT MODELS

External finish

Power supply

Max.fuse size (time dalay)

Min.ampacity

Fan motor

Compressor

Crankcase heater

Refrigerant control

Defrost method

Sound level

Dimensions

Weight

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT PIPING

Pipe size

Connection

method

Between the indoor

& outdoor units

NOTES : *1.Rating conditions (cooling)-indoor : 80˚FDB,67˚FWB outdoor : 95˚FDB,75˚FWB.

(heating)-indoor : 70˚FDB,60˚FWB outdoor : 47˚FDB,43˚FWB.

*2.Rating conditions (heating)-indoor : 70˚FDB,60˚FWB outdoor : 17˚FDB,15˚FWB.

*3.Heating capacity and power consumption in [ ] includes heater operation at 208/230V.

Operating range

Cooling

Heating

Cooling *1

Heating *1

Heating *2

Cooling *1

Heating *1

Heating *2

*1

*1

*2

Dry

Wet

W

D

H

Model (type)

W

D

H

Liquid

Gas

Indoors

Outdoors

Height difference

Piping length

Maximum

Minimum

Maximum

Minimum

Btu/h

Btu/h

Btu/h

Pints/h

kW

kW

kW

V,phase,Hz

V,phase,Hz

A

A

F.L.A.

)

A(kW

CFM

CFM

)

dB(A

in.

in.

in.

in.

lb

A

A

F.L.A.

R.L.A.

L.R.A.

)

A(W

)

dB(A

in.

in.

in.

lb

in.

in.

ft

ft

Indoor intake air temperature

95˚FDB,71˚FWB

67˚FDB,57˚FWB

80˚FDB,67˚FWB

70˚FDB,68˚FWB

PKH18FK

18,000

18,600[24,100/25,100

10,700[16,200/17,200

5.3

1.79

1.56[3.16/3.46

1.34[2.94/3.24

10.1

11.1

7.2

3.5

2.3

PKH18FK

15

12

0.5

7.6/8.4[1.6/1.9

710-530

640-480

43-35

1

57

PUH18EK

20

16

0.75

RH247NAB

12

37

0.11/0.12[23/28

53

33-1/2

131

Indoor unit-remote controller:DC12V. Indoor unit-outdoor unit:DC12V

130

130

]

]

]

]

]

55-1/8 66-5/32

]

34-1/4

11-5/8

3/8

5/8

Outdoor intake air temperature

PKH24FK

24,000

25,000[30,500/31,500

14,700[20,200/21,200

7.0

2.36

2.37[3.97/4.27

1.92[3.52/3.82

10.2

10.2

6.8

3.1

2.2

PKH24FK

Munsell 3.4Y 7.7/0.8

208/230,1,60

15

12

0.5

7.6/8.4[1.6/1.9

710-530

640-480

43-35

1

57

PUH24EK

Munsell 5Y 7/1

208/230,1,60

20

16

0.65+0.65

NH33NBD

11.5

54

0.16/0.17[33/39

Capillary tube

Reverse cycle

55

49-9/16

202

With indoor unit

Not supplied(optional parts)

Flared

Flared

115˚FDB

0˚FDB

75˚FDB,65˚FWB

17˚FDB,15˚FWB

PKH30FK

]

]

]

]

]

9-1/4

13-3/8

]

164

164

30,000

33,000[39,100/40,500

19,000[25,100/26,500

9.1

3.12

3.02[4.82/5.22

2.48[4.28/4.68

9.6

10.6

7.1

3.2

2.2

PKH30FK

15

13

0.6

8.7/9.6[1.8/2.2

990-780

890-700

46-41

1

66

PHU30EK

30

20

0.75+0.75

NH41NAD

14.0

73

0.16/0.17[33/39

55

38-3/16

13-9/16

49-9/16

245

1/2

3/4

]

]

]

]

]

]

PKH36FK

34,200

38,000[44,100/45,500

19,600[25,700/27,100

10.5

3.44

3.54[5.34/5.74

2.65[4.45/4.85

PKH36FK

8.7/9.6[1.8/2.2

990-780

890-700

46-41

PUH36EK

0.75+0.75

NH47ND

0.16/0.17[33/39

38-3/16

13-9/16

49-9/16

]

]

9.9

10.5

6.9

3.1

2.2

13

0.6

]

1

66

30

22

17.5

87

]

246

1/2

3/4

164

164

]

]

5

Page 6

Models

Models Outdoor intake air DB temperature(˚F

)

PKH18FK

71

67

63

62.5

60

59

71

67

63

62.5

60

59

71

67

63

62.5

60

59

71

67

63

62.5

60

59

TC

21.0

19.5

18.2

18.1

17.2

16.8

27.9

26.1

24.3

24.1

23.0

22.5

34.9

32.6

30.4

30.2

28.8

28.2

39.8

37.1

34.7

34.4

32.8

32.2

SHC

14.4

16.0

17.4

15.5

15.1

14.5

16.1

18.5

20.5

18.0

17.6

17.0

21.5

24.5

26.9

23.8

23.2

22.4

23.0

26.3

29.3

25.8

25.1

24.3

TPC

1.56

1.52

1.49

1.49

1.47

1.46

2.05

2.01

1.97

1.96

1.94

1.93

2.72

2.66

2.60

2.59

2.57

2.56

3.00

2.93

2.87

2.86

2.82

2.81

TC

20.2

18.8

17.5

17.4

16.6

16.2

26.9

25.1

23.4

23.2

22.1

21.7

33.7

31.4

29.2

29.0

27.6

27.0

38.4

35.7

33.3

33.1

31.5

30.8

SHC

13.9

15.4

16.7

14.9

14.5

14.0

15.5

17.8

19.7

17.4

16.9

16.4

20.8

23.6

25.8

22.9

22.2

21.5

22.1

25.3

28.1

24.8

24.1

23.2

TPC

1.69

1.65

1.61

1.61

1.58

1.57

2.23

2.18

2.12

2.12

2.09

2.07

2.95

2.88

2.81

2.80

2.77

2.76

3.25

3.17

3.10

3.09

3.04

3.03

TC

19.4

18.0

16.8

16.6

15.8

15.5

25.8

24.0

22.4

22.2

21.1

20.7

32.3

30.0

27.9

27.7

26.3

25.7

36.8

34.2

31.9

31.6

30.1

29.5

SHC

13.3

14.8

16.0

14.3

13.8

13.4

14.9

17.0

18.9

16.6

16.2

15.6

19.9

22.5

24.6

21.9

21.2

20.4

21.2

24.3

26.9

23.7

23.0

22.3

TPC

1.84

1.79

1.74

1.74

1.70

1.69

2.43

2.36

2.30

2.29

2.25

2.24

3.21

3.12

3.04

3.03

2.99

2.98

3.54

3.44

3.35

3.34

3.28

3.26

TC

18.5

17.1

15.9

15.8

15.0

14.6

24.6

22.9

21.3

21.1

20.1

19.7

30.8

28.6

26.6

26.3

24.9

24.4

35.1

32.6

30.3

30.0

28.5

27.9

SHC

12.7

14.0

15.2

13.6

13.1

12.6

14.2

16.3

18.0

15.8

15.4

14.9

19.0

21.5

23.5

20.7

20.1

19.4

20.2

23.1

25.6

22.5

21.8

21.0

TPC

1.99

1.93

1.88

1.87

1.84

1.83

2.63

2.55

2.47

2.47

2.41

2.39

3.48

3.37

3.27

3.26

3.21

3.19

3.83

3.71

3.61

3.59

3.52

3.50

TC

17.6

16.3

15.1

15.0

14.2

13.9

23.4

21.7

20.1

19.9

18.9

18.5

29.3

27.1

25.1

24.9

23.5

22.9

33.4

30.9

28.7

28.4

26.9

26.4

SHC

12.1

13.4

14.4

12.9

12.4

12.0

13.5

15.4

17.0

14.9

14.5

14.0

18.1

20.3

22.2

19.6

18.9

18.2

19.3

21.9

24.2

21.3

20.6

19.9

TPC

2.15

2.07

2.01

2.00

1.96

1.94

2.84

2.73

2.65

2.64

2.58

2.56

3.75

3.61

3.50

3.49

3.43

3.41

4.13

3.98

3.86

3.85

3.76

3.73

IWB

(˚F)

DB 75¡F (50%RH)

DB 72¡F (50%RH)

DB 70¡F (50%RH)

DB 75¡F (50%RH)

DB 72¡F (50%RH)

DB 70¡F (50%RH)

DB 75¡F (50%RH)

DB 72¡F (50%RH)

DB 70¡F (50%RH)

DB 75¡F (50%RH)

DB 72¡F (50%RH)

DB 70¡F (50%RH)

75 85 95 105 115

710

0.16

Airflow

(

CFM

)

B.F

PKH24FK

710

0.16

PKH30FK

990

0.15

PKH36FK

990

0.14

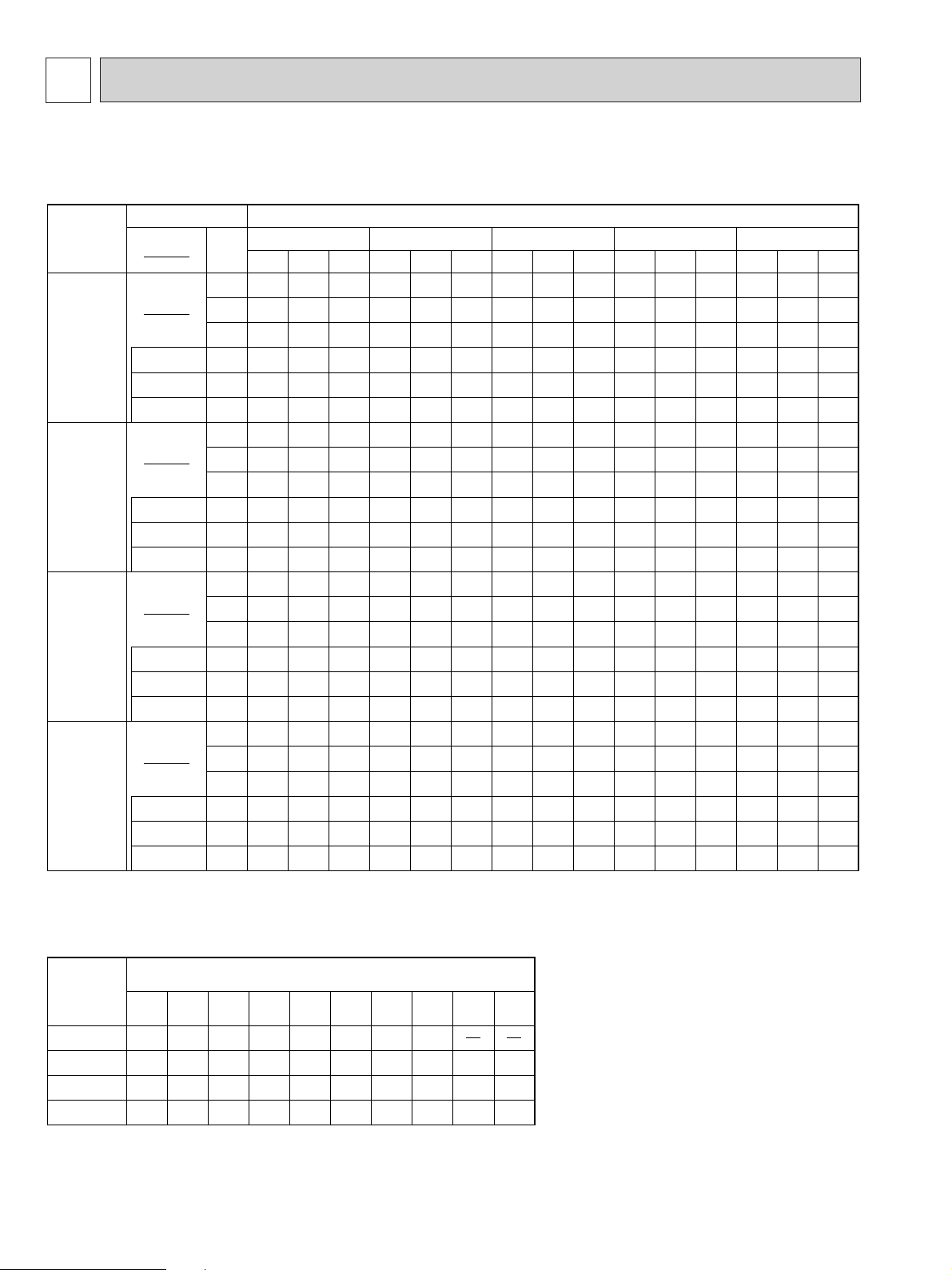

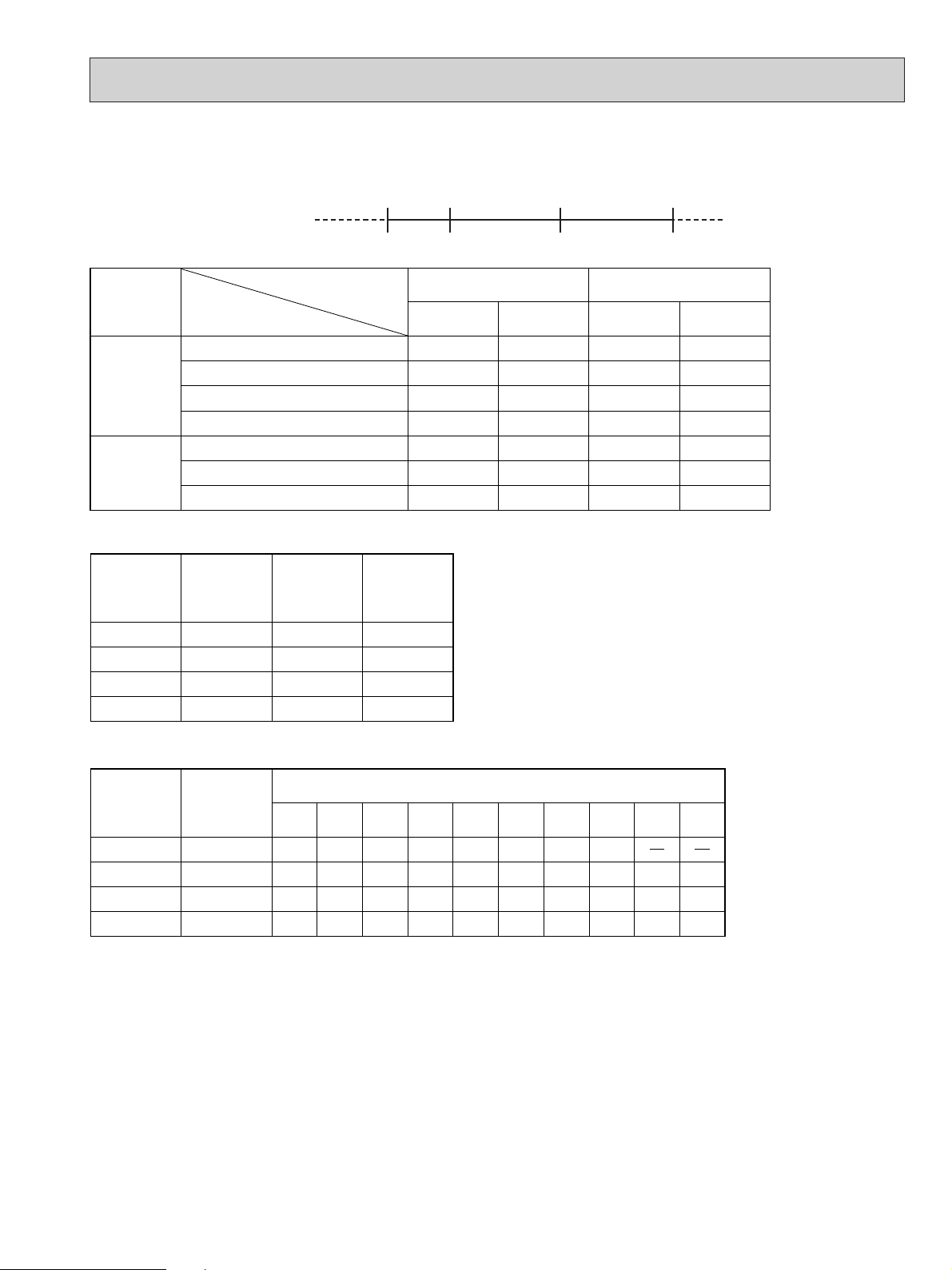

Notes 1. B.F. : Bypass Factor, IWB : Intake air wet-bulb temperature

TC : Total Capacity (x10

3

Btu/h), SHC : Sensible Heat Capacity (x10

3

Btu/h)

TPC : Total Power Consumption (kW)

2. SHC is based on 80˚FDB of indoor intake air temperature.

3. Cooling capacity correction factors and Refrigerant piping length (one way) range.

MODEL

Refrigerant piping length (one way)

PKH18FK

PKH24FK

PKH30FK

PKH36FK

1.0

1.0

1.0

1.0

25ft

0.992

0.981

0.981

0.981

40ft

0.983

0.968

0.968

0.968

55ft

0.978

0.952

0.952

0.952

70ft

0.966

0.940

0.940

0.940

85ft

0.959

0.925

0.925

0.925

100ft

0.950

0.913

0.913

0.913

115ft

0.945

0.900

0.900

0.900

130ft

0.886

0.886

0.886

150ft

0.874

0.874

0.874

164ft

3

DATA

MODELS : PKH18/24/30/36FK

1. PERFORMANS DATA

1) COOLING CAPACITY

6

Page 7

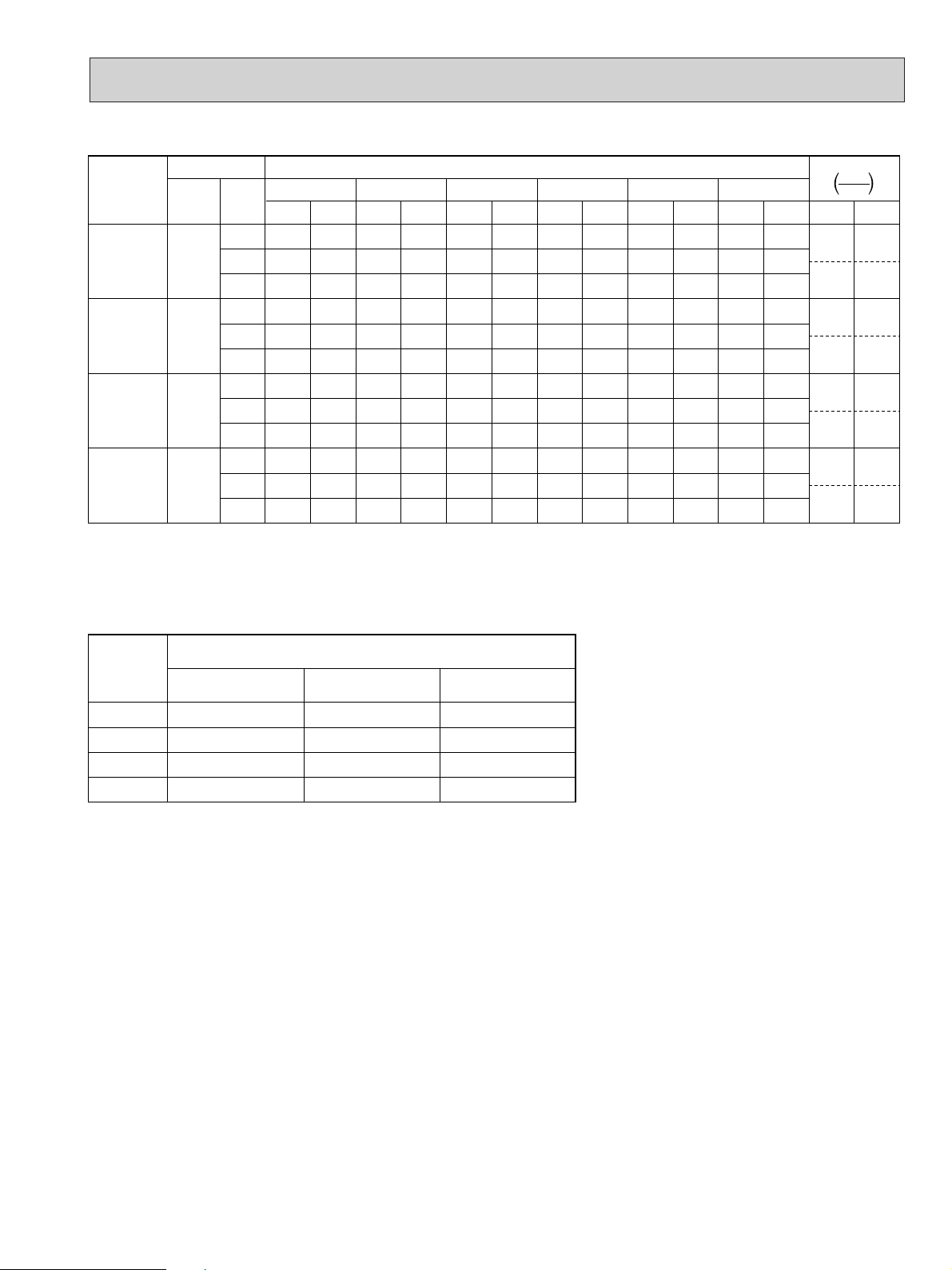

2) HEATING CAPACITY

Models Outdoor intake air WB temperature(˚F

Models

PKH18FK

PKH24FK

PKH30FK

PKH36FK

Notes 1. IDB : Intake air dry-bulb temperature

CA : Capacity (x10

2. When booster heater is "on", total capacity and total power consnmption should be added the figures described in

booster heater colnmn.

•Booster heater ON : When the set temperature is higher than the room temperature by more than 5.4 deg.

•Booster heater OFF : When the set temperature is higher than the room temperature by less than 3.6 deg.

3. Heating capacity correction factors.

Airflow

(CFM)

710

710

990

990

IWB

(˚F)

75

70

65

75

70

65

75

70

65

75

70

65

3

Btu/h), PC : Power Consumption (kW)

15 25 35 45 55 65

CA

PC

CA

PC

CA

PC

CA

PC

CA

12.1

1.20

14.1

1.34

16.3

1.49

18.7

1.65

21.4

12.4

1.16

14.4

1.29

16.7

1.44

19.1

1.59

21.8

12.7

1.11

14.7

1.24

17.0

1.38

19.5

1.53

22.2

16.3

1.82

18.9

2.03

21.9

2.27

25.2

2.51

28.8

16.6

1.76

19.4

1.96

22.4

2.19

25.7

2.42

29.3

17.0

1.69

19.8

1.89

22.9

2.10

26.2

2.32

29.9

21.5

2.32

25.0

2.59

28.9

2.89

33.2

3.20

38.0

21.9

2.24

25.5

2.50

29.6

2.78

33.9

3.08

38.6

22.5

2.15

26.1

2.40

30.2

2.68

34.6

2.96

39.4

24.7

2.71

28.7

3.04

33.3

3.39

38.2

3.75

43.7

25.3

2.62

29.4

2.93

34.1

3.26

39.0

3.61

44.5

25.9

2.53

30.1

2.82

34.8

3.14

39.9

3.47

45.4

)

PC

1.83

1.76

1.69

2.77

2.67

2.56

3.53

3.40

3.26

4.14

3.98

3.83

CA

23.7

24.1

24.5

32.8

33.3

33.9

43.2

43.7

44.6

49.6

50.4

51.3

PC

1.99

1.91

1.83

3.01

2.90

2.78

3.86

3.72

3.56

4.49

4.28

4.14

Auxiliary heater

208V

230V

CA

PC

5.5

1.6

6.5

1.9

5.5

1.6

6.5

1.9

6.1

1.8

7.5

2.2

6.1

1.8

7.5

2.2

Models

PKH18FK

PKH24FK

PKH30FK

PKH36FK

Less than 100ft

1.00

1.00

1.00

1.00

Refrigerant piping length (one way)

100~130ft

0.995

0.995

0.995

0.995

130~164ft

0.990

0.990

0.990

0.990

7

Page 8

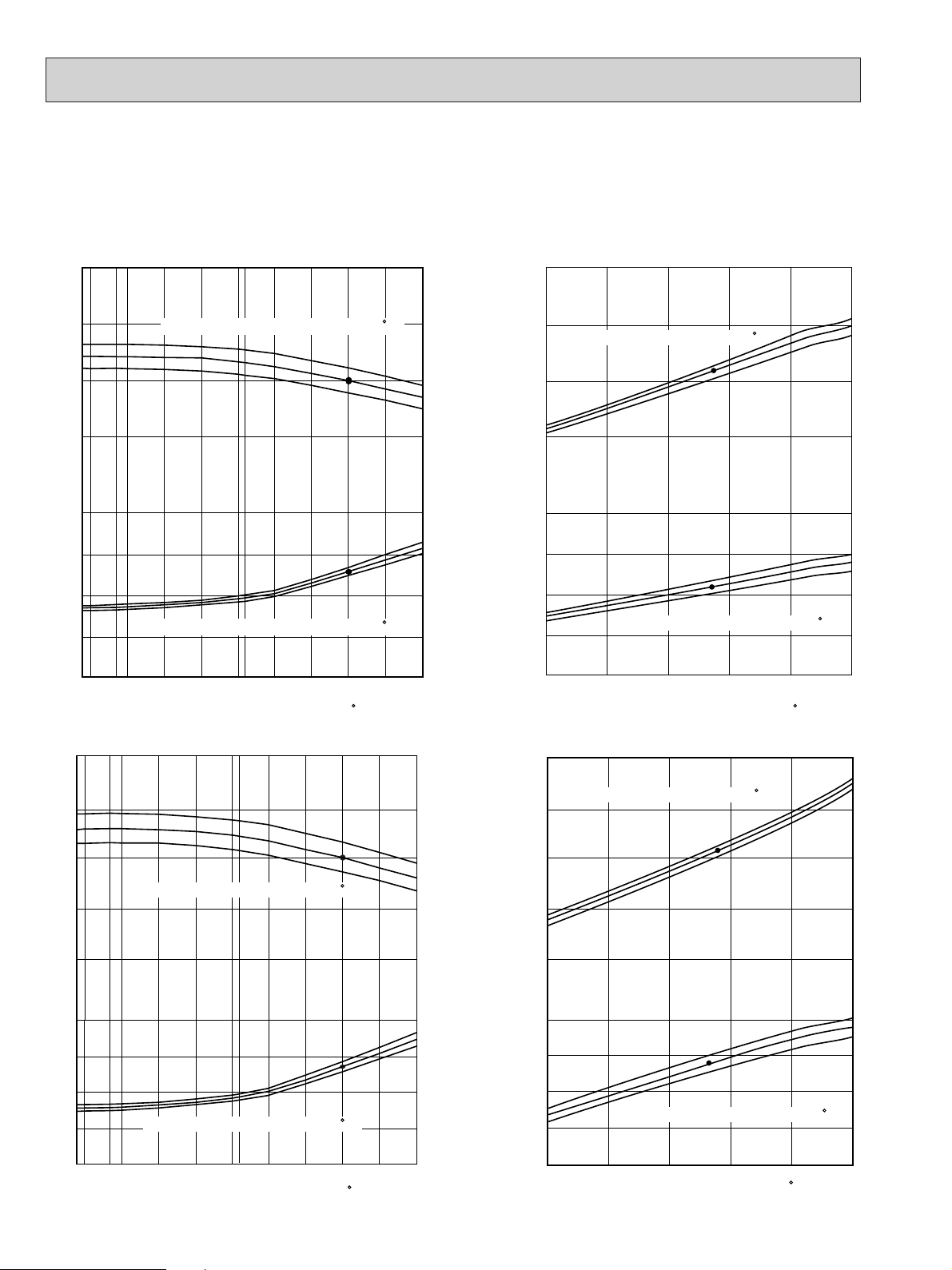

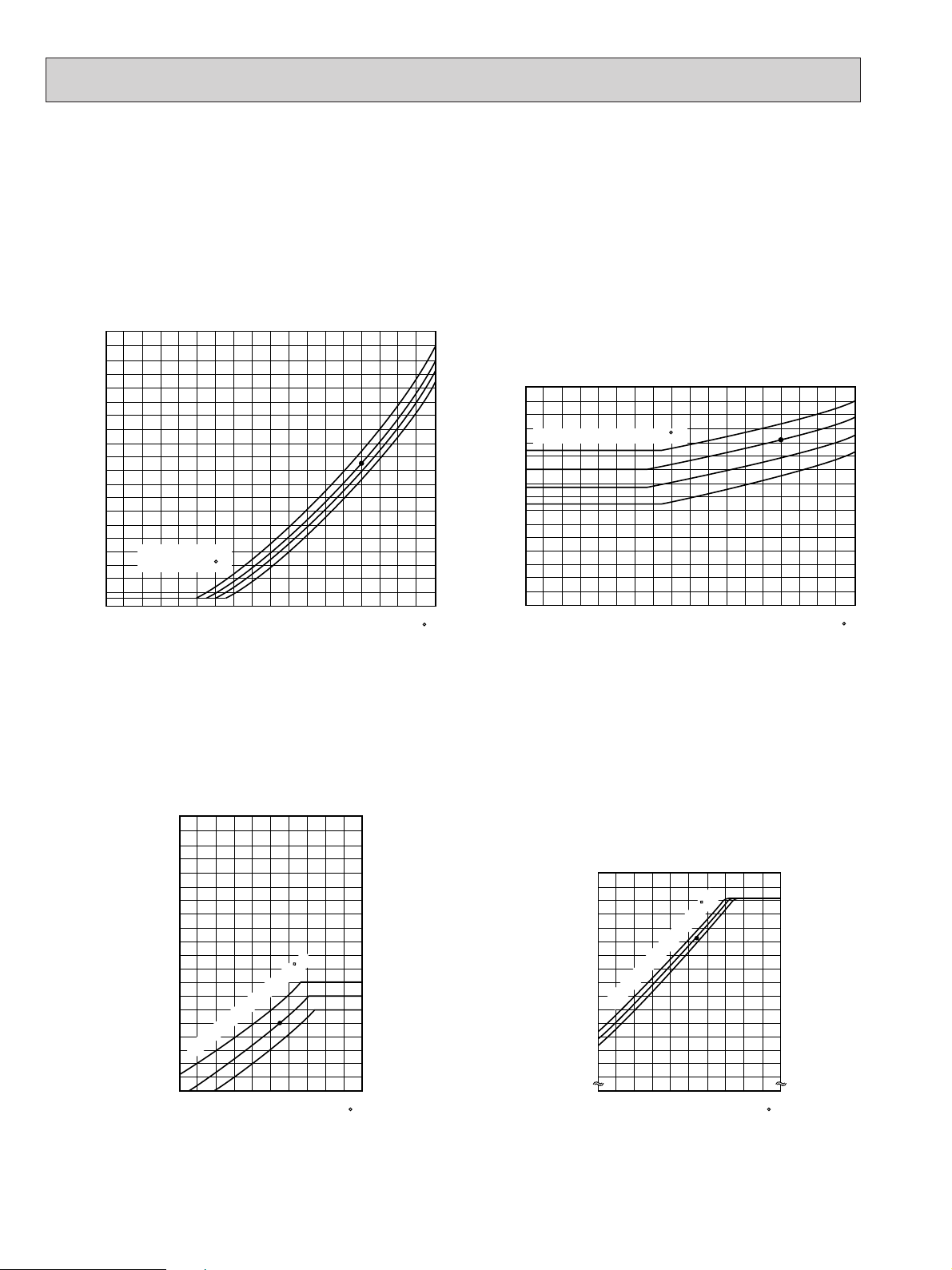

2. PERFORMANCE CURVE

Does not include booster heater (1.9kW)

Total power consumption (kW) Total capacity (x10

3

Btu/h)

30

24

18

12

2.5

2.0

1.5

1.0

15 25 35 45 55 65

Total power consumption (kW) Total capacity (x10

3

Btu/h)

Outdoor intake air DB temperature ( F) Outdoor intake air WB temperature ( F)

Indoor intake air DB temperature ( F)

Indoor intake air DB temperature ( F)

65

65

70

70

75

75

30

24

18

12

2.5

2.0

1.5

1.0

63

67

71

63

67

71

SHF=0.82

PKH18FK COOLING CAPACITY

023 32 35

45 55

65

(67)

75 85 95 105 115

Indoor intake air WB temperature ( F)

Indoor intake air WB temperature ( F)

NOTES : Apoint on the curve shows the reference point.

PKH18FK COOLING CAPACITY PKH18FK HEATING CAPACITY

36

Btu/h)

3

30

24

18

12

3.0

2.5

2.0

1.5

Total power consumption (kW) Total capacity (x10

023 32 35

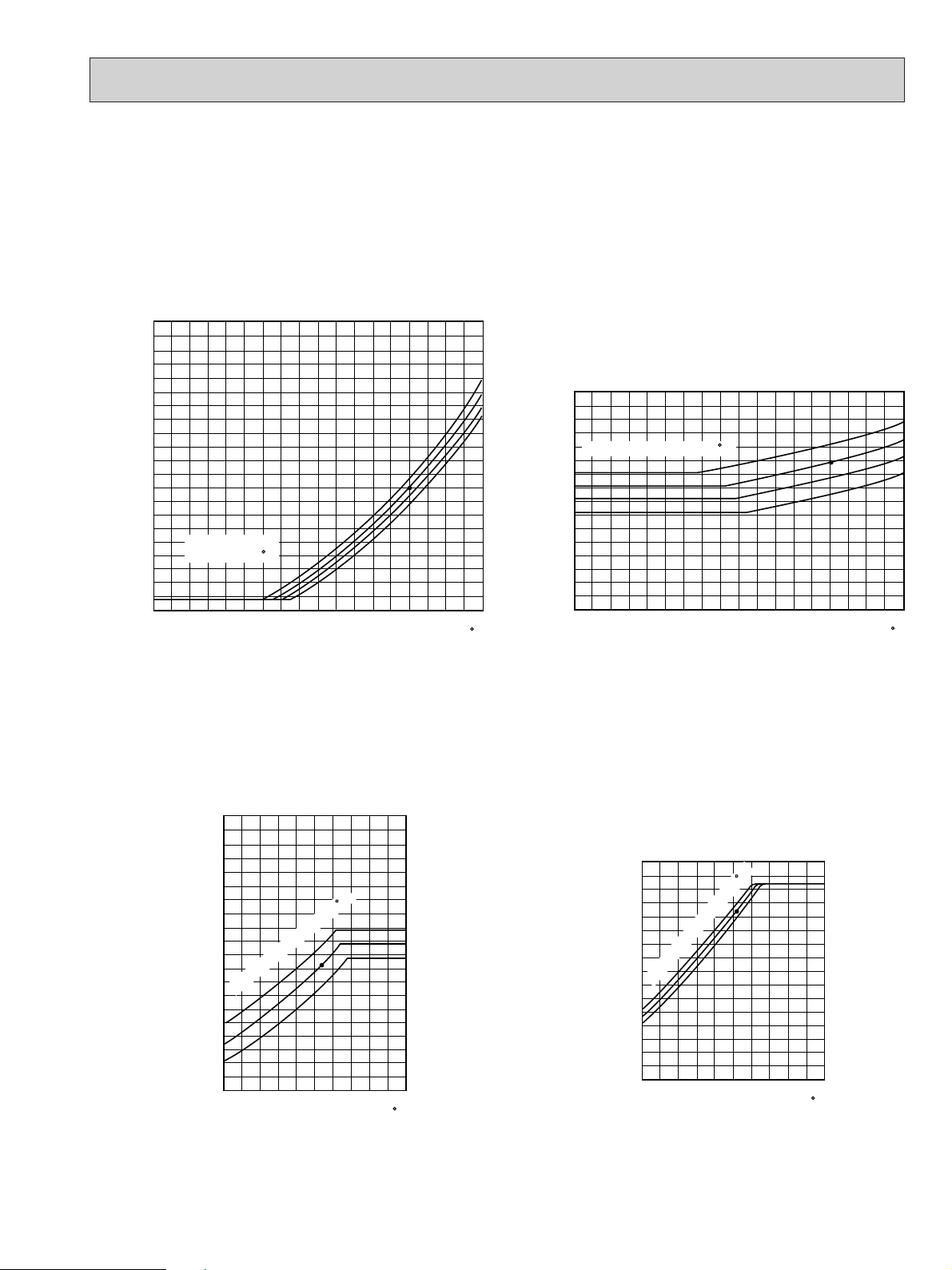

8

PKH24FK COOLING CAPACITY PKH24FK HEATING CAPACITY

SHF=0.71V

Indoor intake air WB temperature ( F)

71

67

63

35

Btu/h)

3

Indoor intake air DB temperature ( F)

30

24

18

Does not include booster heater (1.9kW)

12

71

67

63

Indoor intake air WB temperature ( F)

45 55

Outdoor intake air DB temperature ( F)

(67)

65

75 85 95 105 115

3.0

2.5

2.0

1.5

Total power consumption (kW) Total capacity (x10

15 25 35 45 55 65

Indoor intake air DB temperature ( F)

Outdoor intake air WB temperature ( F)

65

70

75

75

70

65

Page 9

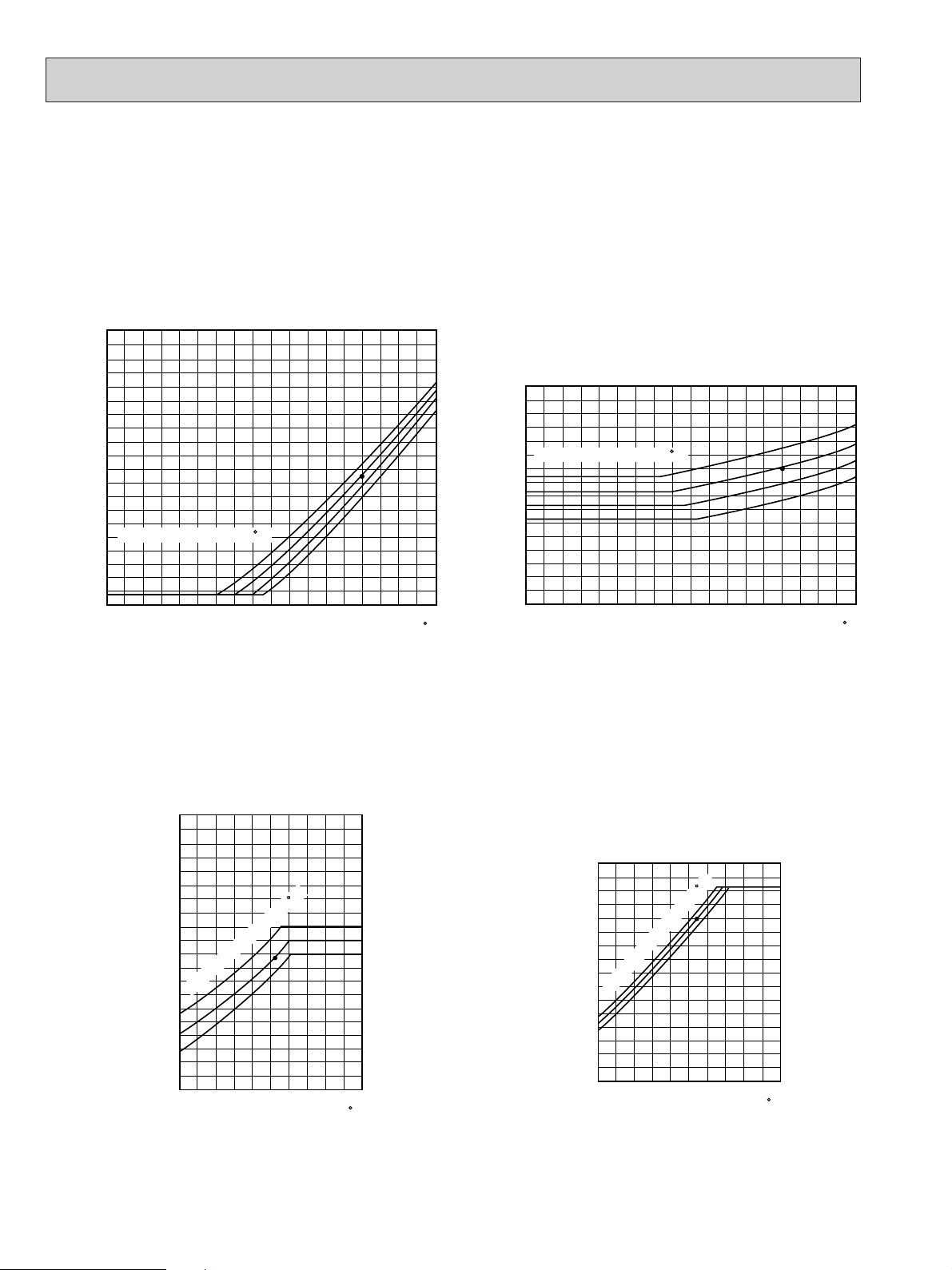

NOTES : Apoint on the curve shows the reference point.

71

67

63

71

67

63

42

36

30

24

4.0

3.5

3.0

2.5

2.0

SHF=0.75

Total capacity(x10 Btu/h)

3

Total power consumption(kW)

Outdoor intake air DB temperature(¡F)

0 23 32 35 45 55 65 (67) 75 85 95 105 115

indoor intake air WB temperature(¡F)

indoor intake air WB temperature(¡F)

48

42

36

30

24

18

4.0

3.5

3.0

2.5

2.0

1.5

15 25 35 45 55 65

Outdoor intake air WB temperature(¡F)

indoor intake air DB temperature(¡F)

indoor intake air DB temperature(¡F)

Does not include booster heater(2.2kW)

65

70

75

75

70

65

Total capacity(x10 Btu/h)

3

Total power consumption(kW)

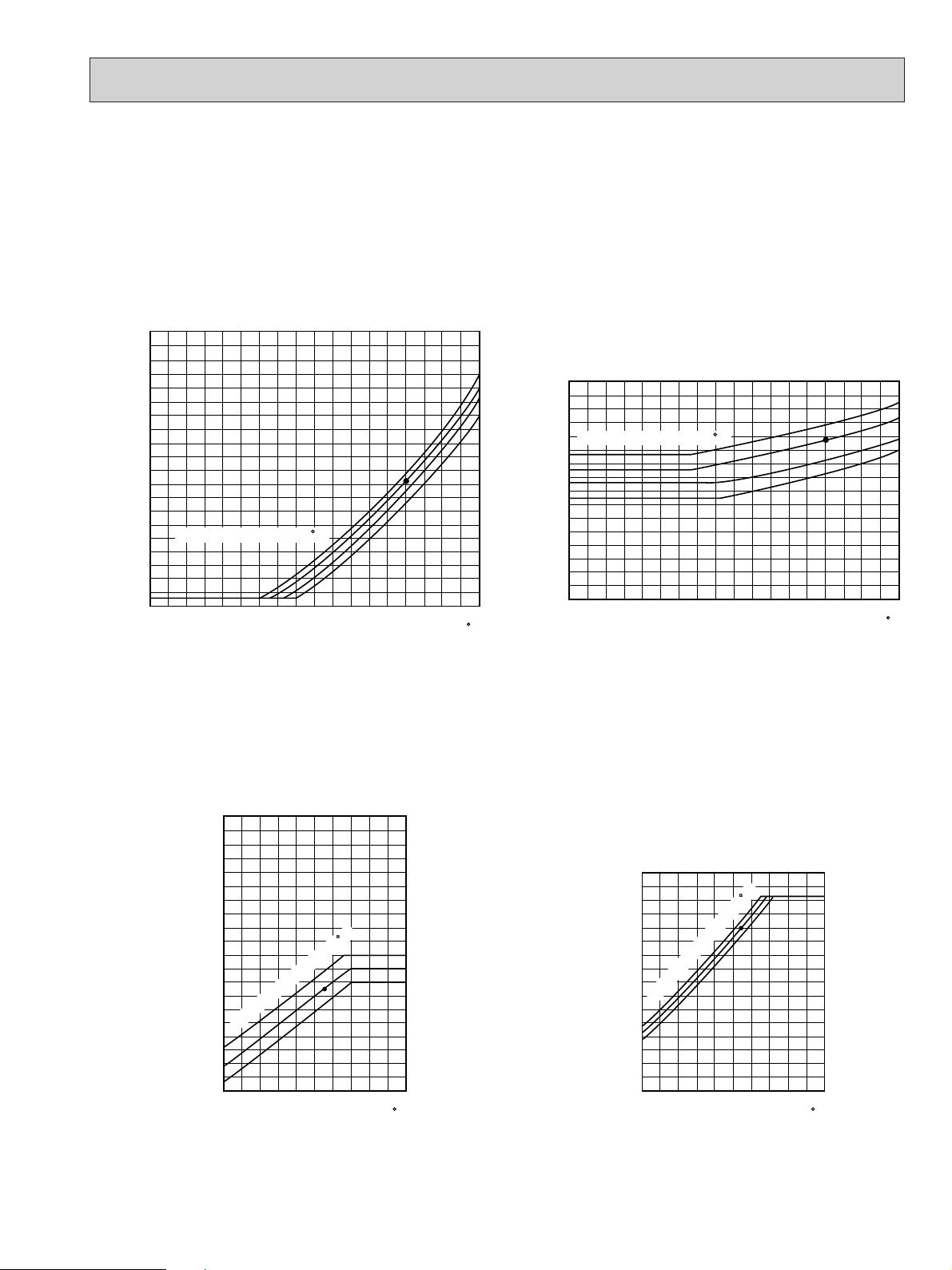

42

36

30

24

4.5

4.0

3.5

3.0

2.5

Total capacity(x10 Btu/h)

3

indoor intake air WB temperature(¡F)

SHF=0.71

Total power consumption(kW)

Outdoor intake air DB temperature(¡F)

indoor intake air WB temperature(¡F)

0 23 32 35 45 55 65 (67) 75 85 95 105 115

71

67

63

71

67

63

54

48

32

36

30

24

4.5

4.0

3.5

3.0

2.5

2.0

15 25 35 45 55 65

Outdoor intake air WB temperature(¡F)

indoor intake air DB temperature(¡F)

indoor intake air DB temperature(¡F)

Does not include booster heater(2.2kW)

65

70

75

75

70

65

Total capacity(x10 Btu/h)

3

Total power consumption(kW)

PKH30FK COOLING CAPACITY PKH30FK HEATING CAPACITY

PKH36FK COOLING CAPACITY PKH36FK HEATING CAPACITY

9

Page 10

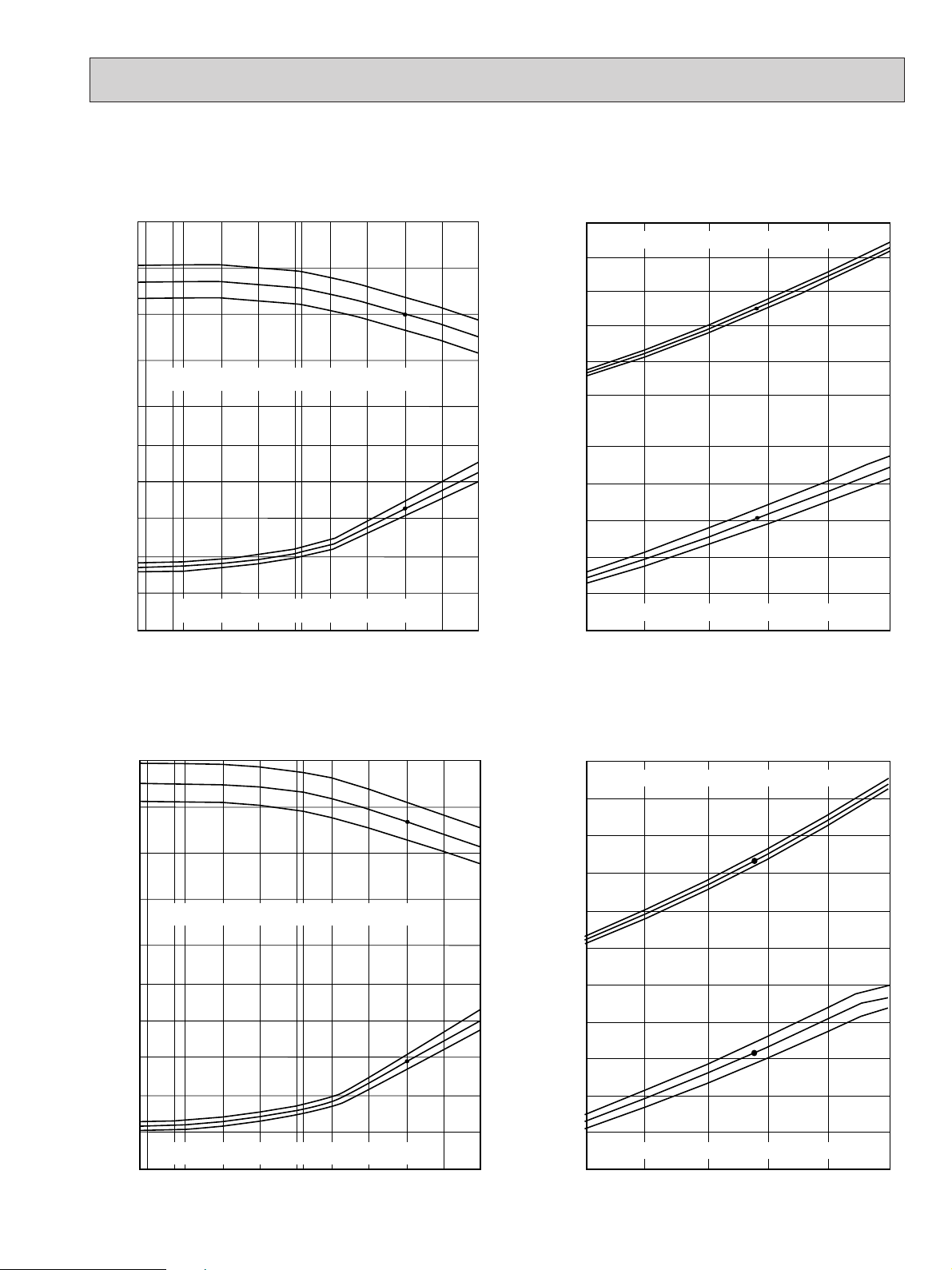

3. CONDENSING PRESSURE AND SUCTION PRESSURE

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

Indoor DB

temperature( F)

86

80

75

70

100

90

80

70

60

50

40

30

20

(psi.G)

Suction pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

Indoor DB temperature( F)

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

80

70

60

50

40

30

20

10

(psi.G)

Suction pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

Data is based on the condition of indoor humidity 50%.

Air flow should be set at HI.

A point on the curve shows the reference point.

<Cooling mode>

PKH18FK PKH18FK

Data is based on the condition of outdoor humidity 75%.

A point on the curve shows the reference point.

<Heating mode>

PKH18FK PKH18FK

10

Page 11

Data is based on the condition of indoor humidity 50%.

360

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

(psi.G)

Condensing pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

Indoor DB

temperature( F)

86

80

75

70

100

90

80

70

60

50

40

30

20

(psi.G)

Suction pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

Indoor DB temperature( F)

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

80

70

60

50

40

30

20

10

(psi.G)

Suction pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

Air flow should be set at HI.

A point on the curve shows the reference point.

<Cooling mode>

PKH24FK PKH24FK

Data is based on the condition of outdoor humidity 75%.

A point on the curve shows the reference point.

<Heating mode>

PKH24FK PKH24FK

11

Page 12

Data is based on the condition of indoor humidity 50%.

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

110

100

90

80

70

60

50

40

30

(psi.G)

Suction pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

Indoor DB temperature( F)

Indoor DB temperature( F)

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

140

(psi.G)

Condensing pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

80

70

60

50

40

30

20

10

(psi.G)

Suction pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

Air flow should be set at HI.

A point on the curve shows the reference point.

<Cooling mode>

PKH30FK PKH30FK

Data is based on the condition of outdoor humidity 75%.

A point on the curve shows the reference point.

<Heating mode>

PKH30FK PKH30FK

12

Page 13

Data is based on the condition of indoor humidity 50%.

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

180

170

160

150

(psi.G)

Condensing pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

90

80

70

60

50

40

30

20

(psi.G)

Suction pressure

30 40 50 60 70 80 90 100 110

Outdoor ambient temperature

DB( F)

86

80

75

70

Indoor DB temperature( F)

Indoor DB temperature( F)

390

380

370

360

350

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

190

(psi.G)

Condensing pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

80

70

60

50

40

30

20

10

(psi.G)

Suction pressure

30 3520 25 45 55 6540 50 60 70

Outdoor ambient temperature

DB( F)

75

70

65

Indoor DB temperature( F)

Air flow should be set at HI.

A point on the curve shows the reference point.

<Cooling mode>

PKH36FK PKH36FK

Data is based on the condition of outdoor humidity 75%.

A point on the curve shows the reference point.

<Heating mode>

PKH36FK PKH36FK

13

Page 14

4. STANDARD OPERATION DATA

Models

Item

Electrical circuitRefrigerant circuitIndoor sideOutdoor side

Voltage

Frequency

Total input

Indoor fan current

Booster heater current

Outdoor fan current

Comp. current

Condensing pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Comp.shell bottom temperature

Ref. pipe length

Refrigerant charge

Fan speed

Airflow (High)

Fan speed upper/lower

Airflow

Unit

V

Hz

kW

A

A

A

A

psi.G

psi.G

˚F

˚F

˚F

˚F

ft

˚F

˚F

˚F

˚F

r.p.m.

CFM

˚F

˚F

r.p.m.

CFM

Btu/h

208/230

1.79

0.5

0.75

7.4/6.9

255

81

182

118

66

171

80

67

61

59

95

75

18,000

0.82

60

Cooling

208/230

1.56

0.5

7.6/8.4

0.75

6.1/5.9

202

61

126

102

34

111

70

60

96

68

47

43

18,600

Heating

PKH18FK

208/230

2.36

0.5

0.65+0.65

9.3/8.7

240

75

158

115

46

141

80

67

58

56

95

75

24,000

0.71

60

Cooling

208/230

2.37

0.5

7.6/8.4

0.65+0.65

9.5/8.7

243

63

149

115

35

126

70

60

105

70

47

43

25,000

Heating

PKH24FK

208/230

3.12

0.5

0.75+0.75

12.6/11.8

245

80

158

115

49

138

80

67

59

58

95

75

30,000

0.75

60

Cooling

208/230

3.02

0.5

7.6/8.4

0.75+0.75

12.2/11.4

236

60

159

113

32

130

70

60

103

70

47

43

33,000

Heating

PKH30FK

208/230

3.44

0.5

0.75+0.75

14.3/13.2

243

74

160

115

45

142

80

67

58

56

95

75

34,100

0.71

60

5 lbs 8 oz

1,490

710

1,490

710

1,490

990

1,490

990

790

1,590

750/750

3,170

760/760

3,350

760/760

3,350

25

9 lbs 15 oz

25

10 lbs 2 oz

25

10 lbs 9 oz

Cooling

208/230

3.54

0.5

8.7/9.6

0.75+0.75

14.7/13.7

263

60

170

120

33

148

70

60

109

71

47

43

38,000

Heating

PKH36FK

Intake

air temperature

Discharge

air temperature

Intake

air temperature

Capacity

SHF

DB

WB

DB

WB

DB

WB

14

Page 15

5. OPERATING RANGE

1) POWER SUPPLY

1 Phase 60Hz 208/230V

Guaranteed voltage range

2) OPERATION

Min. Max.

198V 208V 230V 253V

Function

Cooling

Heating

Air intake temperature

Condition

Standard temperature

Maximum temperature

MInimum temperature

Maximum humidity

Standard temperature

Maximum temperature

MInimum temperature

DB(˚F

80

95

67

80

70

80

70

Indoor

)

6. OUTLET AIR SPEED AND COVERAGE RANGE

Model

PKH18FK

PKH24FK

PKH30FK

PKH36FK

Airflow

(

CFM

710

710

990

990

)

Air speed

(

ft/sec

16.1

16.1

17.7

17.7

)

Coverage

range(ft

41

41

50

50

)

Outdoor

WB(˚F

67

71

57

75

60

67

60

)

DB(˚F

95

115

23

80

47

75

17

)

WB(˚F

75

—

—

75

43

65

15

)

The air coverage range is the value up to the position

where the air speed is 0.8ft/sec. when air is blown out

horizontally from the unit at the High notch position.

The coverage range should be used only as a general

guideline since it varies according to the size of the

room and furniture installed inside the room.

7. ADDITIONAL REFRIGERANT CHARGE (R-22(oz))

Refrigerant piping length (one way)

55ft

70ft

85ft

0

0

0

0

0

0

0

0

0

0

0

0

100ft

0

0

0

0

Model

PKH18FK

PKH24FK

PKH30FK

PKH36FK

Outdoor unit

precharged

(

up to 100ft

5 lbs 8 oz

9 lbs 15 oz

10 lbs 2 oz

10 lbs 9 oz

)

25ft

40ft

0

0

0

0

0

0

0

0

115ft

2

2

5

5

130ft

4

4

10

10

150ft

7

16

16

164ft

9

20

20

15

Page 16

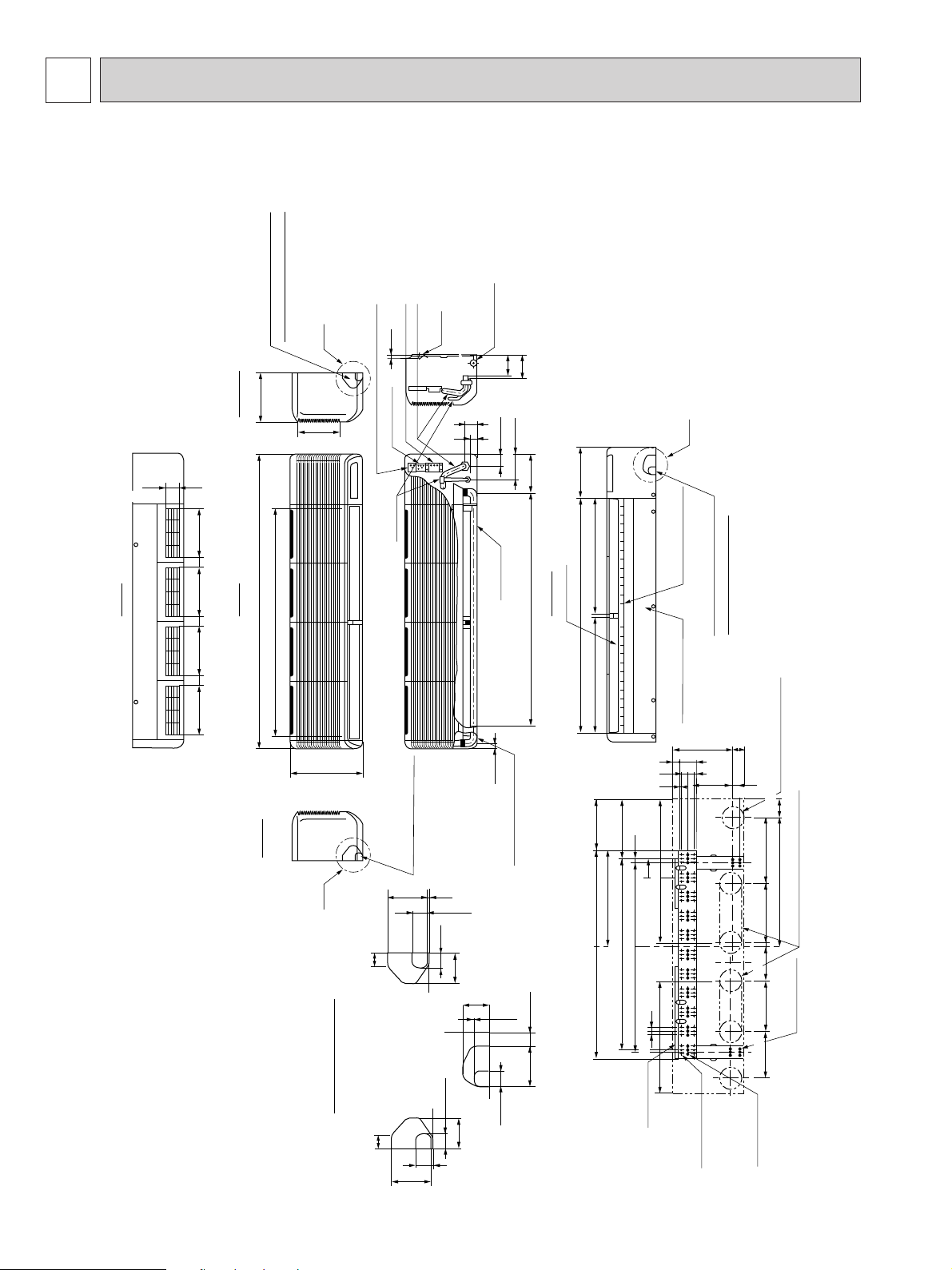

9-1/4

1-25/32

9-1/4

1-25/32

9-1/4 9-1/4

1-25/32

1/2

13-3/8

7-3/4

Top

Front

Right side

Left side

55-1/8

42-15/16

Air intake

9-1/4

C

Knock out hole for right piping

Refrigerant pipe. Drain pipe

Knock out hole for

left piping

Drain hose for

left-hand side piping

Drain hose

Lower side

Auto vane

(Gas pipe)

Drain hose

Bolt

Gas pipe

19/32

Terminal block for power supply

Terminal block for control

Terminal block for remote controller

(Liquid pipe)

Liquid pipe

Gas pipe

Liquid pipe

A

1-3/16

1-15/32

1-17/32

3-27/32 2-9/16

2-29/32

5/32

3-15/16

1-17/32

1-3/16

1-15/32

2-29/32

5/32

1-5/32

11-1/32

1-3/16

7-1/4

1-3/16

3-5/32

1-3/18

2-3/8

13/32

1-17/32

1-15/32

2-9/16

3-15/16

A

B

C

Knock out hole for piping

31/32

43-11/16

7-7/32

9-7/16

B

55-1/8

20-9/16

4-23/32

2-5/32

4-1/32

4-3/8

Air outlet

20-9/16

Air outlet

Change vane (manual)

Under panel

Removable at left-hand

side piping

Knock out hole for under-piping

Refrigerant pipe. Drain pipe

Rear piping opening

Range for left rear piping opening

Hole for

tapping screw

66-{1/4 hole for

tapping screw

Wall fixture

Unit center

32-{15/32

hole for bolt

23/32

3-19/32

35-7/16

38-31/32

17-29/32

11-7/32

9-21/32

3/4

9-7/16 11-1/32 12-3/8

24

Drainage range

on left-hand side

Drainage range

on right-hand side

10x3-19/32=(35-13/16)

7-3/32

2-15/32

8-27/32

7-17/32

23/32

4

OUTLINES AND DIMENSIONS

4.1. Indoor Unit

PKH18/24FK

Unit : mm

16

Page 17

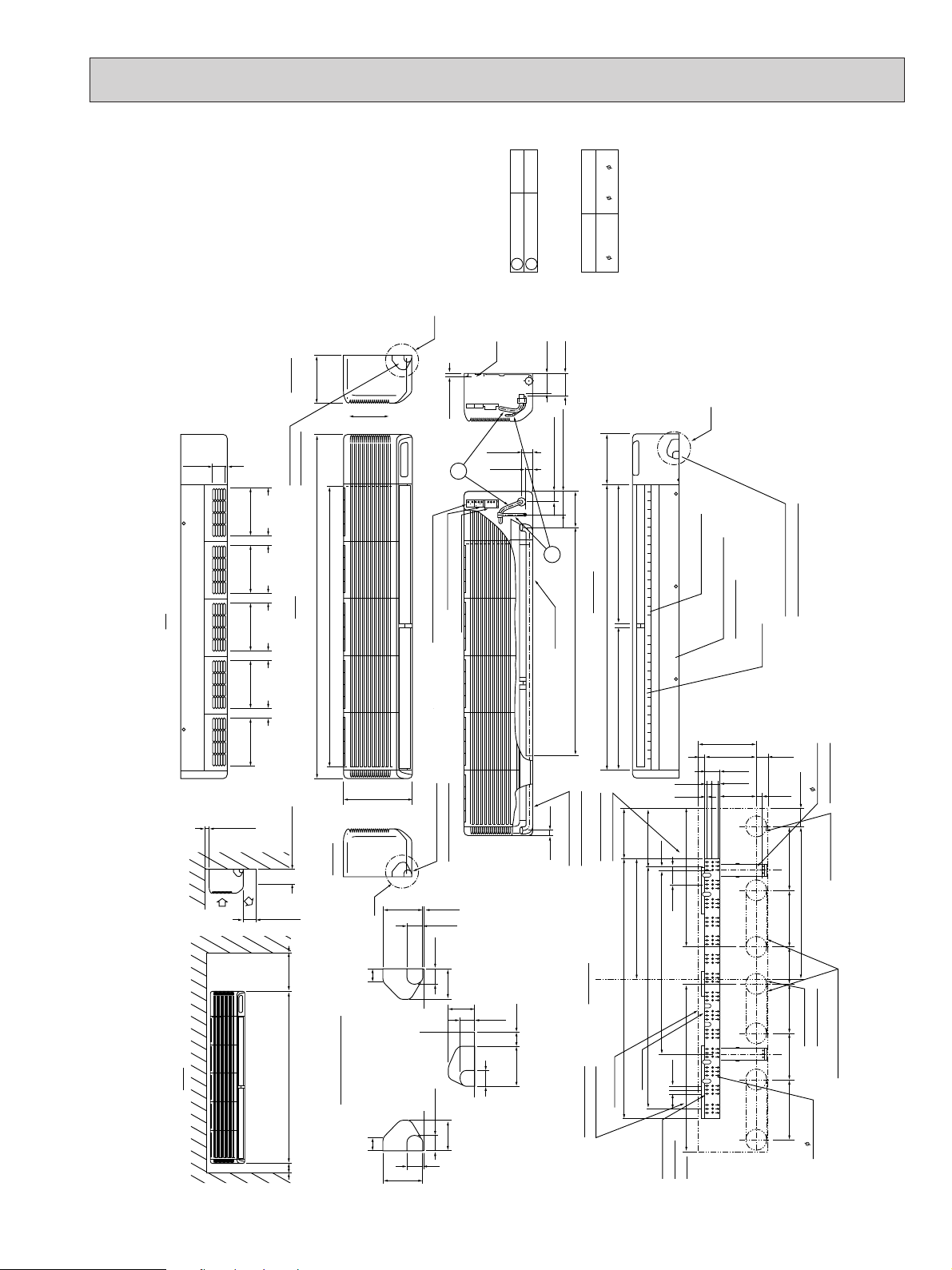

PKH 30/36FK

Unit : mm(inch)

3/4F

Through hole

Liquid pipe 1/2F

Gas pipe

1

2

C

3-1/2 3-1/2~ 4

Sleeve >< 1

>< 1 Sleeves are availaable

on the market.

2-15/32

1/2

9-1/4

1-25/32

9-1/4

Right side

for right piping

Knock out hole

7-3/4

19/32

Bolt

or less

2

2-9/32

1-21/32

4-3/8

4-1/32

2-5/32(Gas pipe)

4-23/32(Liquid pipe)

7-7/32

B

9-7/16

1

9-1/4

1-25/32

Front

66-5/32

Top

9-1/4

1-25/32

9-1/4

1-25/32

9-1/4

53-15/16 Alr Intake

13-3/8

Terminal block for control

Terminal block for powar supply

Terminal block for remote controller

Drain hose

43-11/16 (Drain hose)

Lower side

55-1/8

27-5/16 Air outlet 27-5/16 Air outlet

louvers(manual)

left-hand piping)

Under panel (Removable at

11-1/32

1-5/32

3-5/32

1-3/16

1-3/16

7-1/4 13/32

Knock out hole for under-piping

Refrigerant pipe .Drain pipe

Auto vanes

2-3/8

1-3/16

7-17/32

12- 1/4 hole

for tapping screwRear piping hole

Front

or more

1-3/16

Knock out hole

3-15/16

for left piping

5/32

1-17/32

1-15/32

2-29/32

2-9/16

5-/15/16 or less

Left side

Air

outlet

Air

intake

10 or more

A

C

1-3/161-3/16

1-15/32

2-9/163-27/32

31/32

Drain hose for

B

2 or more 10 or more

Knock out hole for wiring

A

1-17/32

3-15/16

1-15/32

1-17/32

2-29/32

5/32

9-21/32

Drainage range on

right-hand side

left-handside piping

50

Unit center

Unit out line

Drainage range on

Left hand side

23-7/16

13x3-19/32=(7-3/16) 11-7/32

Wall fixture

3/4

3-19/32

35-7/16

23/32

23/32

84- 1/4 hole

for tapping

screw

29-17/32

9-7/16 7-3/328-27/32 11-1/32 12-3/8

Range for left

11-5/8

rear piping hole

41- 15/32 hole

for bolt

Range for left rear piping hole

17

Page 18

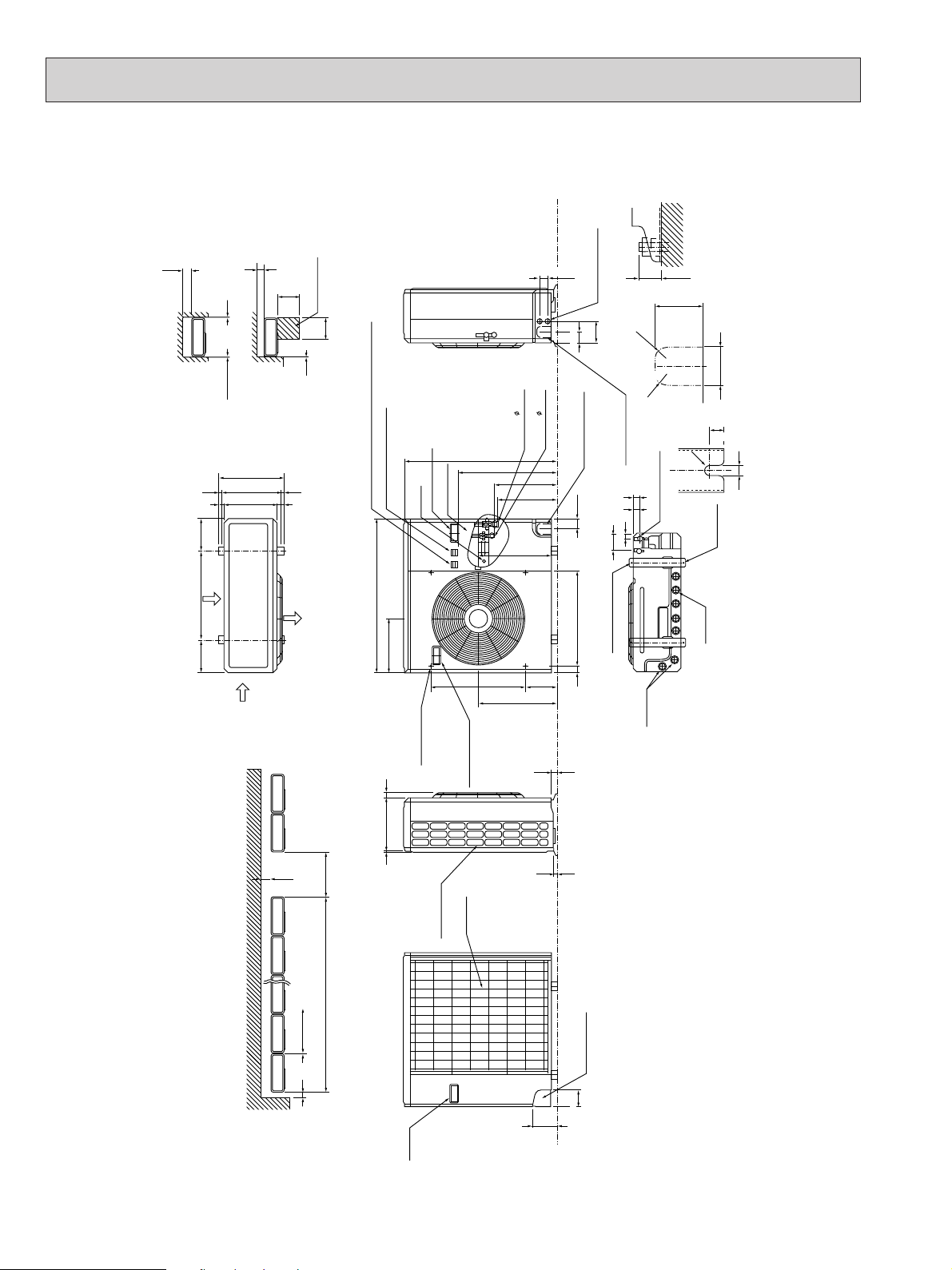

4.2. Outdoor Unit PUH18EK

Terminal block for indoor and outdoor unit connection

Terminal block for power line

Ground

terminal

Handie for moving

Service panel

Refrigerant pipe

(Flared) 5/8

Knock out hole

for front piping

4-3/4

(refrigerant. drainage

and wiring)

4-1/8

Drain hole

Drain hole

2-U-shaped

notched

holes

1-5/8

1-3/4

1/5/16

Bottom piping hole

2-9/16

3-1/8

R13/16

Front right piping holes-

detail figures

Standard bolt length

1 max.

1/2

1/2x7/8 Oval hoies

(standard bolt W3/8(M10)

Knock out hole for

right piping

(refrigerant. drainage

and wiring)

15-7/8

7-1/18 20-5/18

17-3/18

1

2

13-7/4

13-7/8

21-3/4

2-3/820-5/81-9/16

33-9/16

34-1/4

11-7/8

7-9/32 7-9/32

Front opening

Service space

(for N.E.C)

1/2

36

36

4

Note:Allow adequate

upper clearance.

1/2

8

1/2

1-9/161-1/16

13

14-1/4

11/169/16

19-11/16

Refrigerant pipe

(Flared) 3/8

Outlet guide

installation hole

1

40

1/2

Outdoor Unit-Necessary surrouding clearance

(Concentrated installation)

The upper side must be open.

4

8

For 10 units or less

11-5/8

Side air intake

Handle for

moving

Rear fresh

air intake

Rear piping hole

Handle for moving

3-3/4

5-7/16

2-3/8

Knock out holes for

power line 1-1/16

1-3/4

2-1/16

Air intake

Air intake

Air outlet

11/16

R1/4

R13/16

Unit : mm

18

Page 19

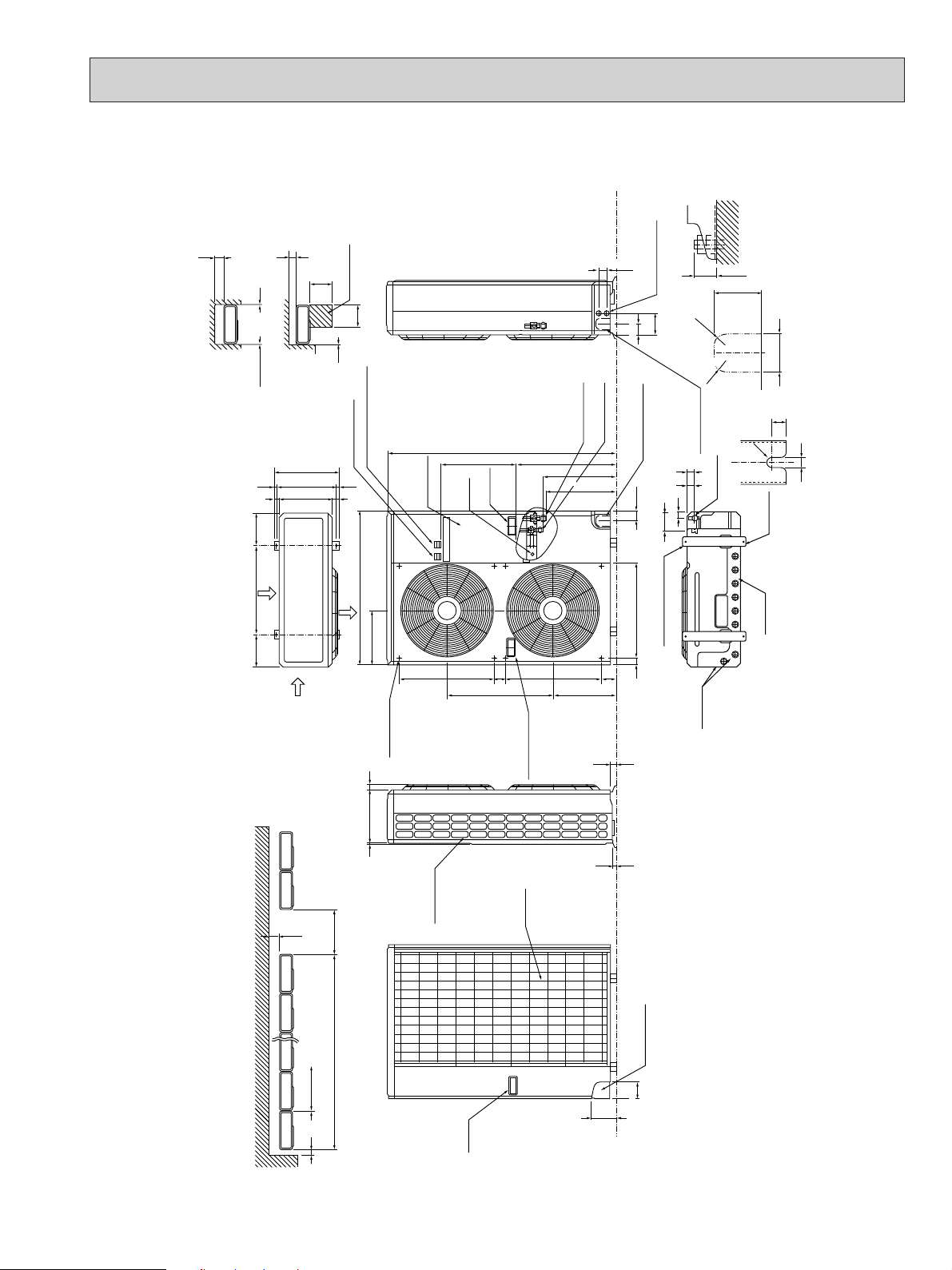

Outdoor Unit PUH24EK

Terminal block for

indoor and outdoor

unit connection

Terminal block for power line

Ground

terminal

Handie

for moving

Service panel

Refrigerant pipe

(Flared) 5/8F

Knock out hole

for front piping

4-3/4

(refrigerant. drainage

and wiring)

4-1/8

Drain hole

Drain hole

2-U-shaped

notched

holes

2-1/16

2-1/4

1/9/16

Bottom

piping hole

2-9/16

3-1/8

R13/16

Front right piping holes-

detail figures

Standard bolt length

1 max.

1/2

2-1/2x7/8 Oval hoies

(standard bolt M10)W3/8(M10)

Knock out hole

for right piping

(refrigerant.

drainage and wiring)

3-1/4

20-5/8 20-5/82-3/8

13-9/16 23-1/16

1

2

15-1/16

37-34

2-3/820-5/81-9/16

49-1/2

34-1/4

11-7/8

7-9/32 7-9/32

Front opening

Service space

(for N.E.C)

3/8

36

36

4

Note:Allow adequate

upper clearance.

Outdoor Unit - necessary surrounding clearance

1/2

12

1/2

1-9/161-1/16

13

14-1/4

11/169/16

19-11/16

Refrigerant pipe

(Flared) 3/8F

Outlet guide

installation hole

1

40

1/2

Outdoor Unit-Necessary surrouding clearance

(Concentrated installation)

The upper side must be open.

6

12

For 10 units or less

11-5/81/4

Side air intake

Handle

formoving

Rear fresh

air intake

Rear piping hole

Handle for moving

3-3/4

5-7/16

2-3/8

Knock out holes for

power line 1-1/16

1-3/4

2-1/16

Air intake

Air intake

Air outlet

11/16

R1/4

R13/16

15-7/8

Unit : mm

19

Page 20

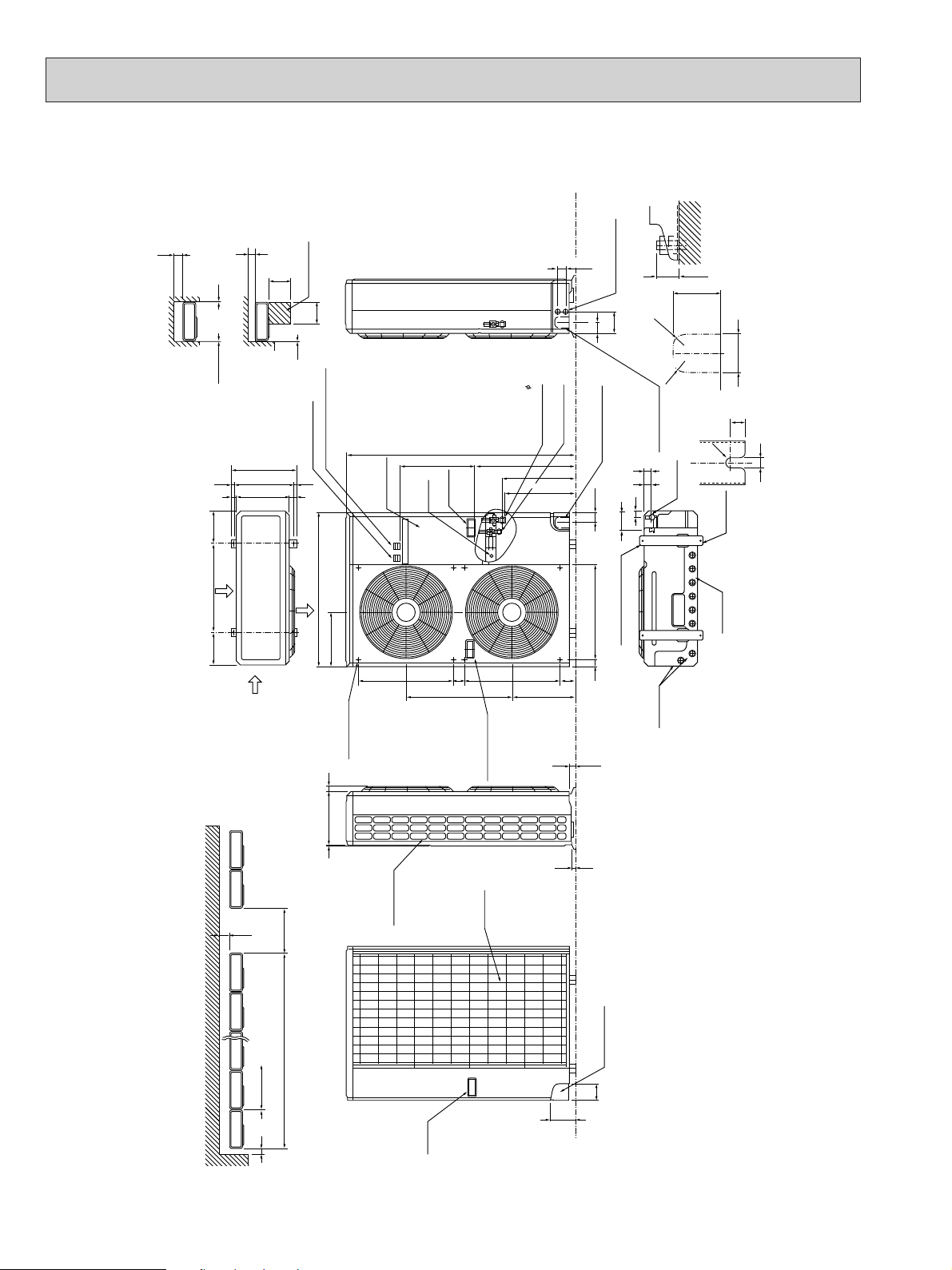

Outdoor Unit PUH30/36EK

Unit : mm

12

Outdoor Unit - necessary surrounding clearance

6

upper clearance.

Note:Allow adequate

1/2

Front opening

1/2

11/169/16

Air intake

23-5/8

7-9/32 7-9/32

36

1/2

Terminal block for

16-1/4

14-31/32

1-9/16 1-1/16

Air intake

Service space

indoor and outdoor

Air outlet

(for N.E.C)

36

unit connection

Terminal block for power line

38-3/16

13-7/8

Service panel

Ground

Handie

terminal

49-1/2

for moving

Refrigerant pipe

(Flared)

(PUH30/36EK) 3/4

(PUH42EK)7/8F

37-3/4

20-5/8 20-5/82-3/8

1-3/4

Refrigerant pipe

(Flared) 3/8F

15-7/8

15-1/16

3-1/4

13-9/16 23-1/16

2-1/16

Knock out holes for

power line 1-1/16

4-3/4

2-3/8

Knock out hole

for front piping

(refrigerant. drainage

and wiring)

2-3/820-5/81-9/16

1/9/16

4-1/8

2-1/2x7/8 Oval hoies

(standard bolt W3/8(M10)

R13/16

Knock out hole

for right piping

(refrigerant.

2-1/4

2-1/16

Bottom

Drain hole

Standard bolt length

1 max.

3-1/8

R13/16

drainage and wiring)

R1/4

piping hole

2-U-shaped

notched

holes

Drain hole

2-9/16

Front right piping holes-

detail figures

11/16

1/2

20

12

40

The upper side must be open.

For 10 units or less

1/2

Outdoor Unit-Necessary surrouding clearance

(Concentrated installation)

6

Outlet guide

installation hole

1

13-9/161/4

Side air intake

Handle

formoving

Handle for moving

Rear fresh

air intake

1-5/16

7/8

Rear piping hole

3-3/4

5-7/16

Page 21

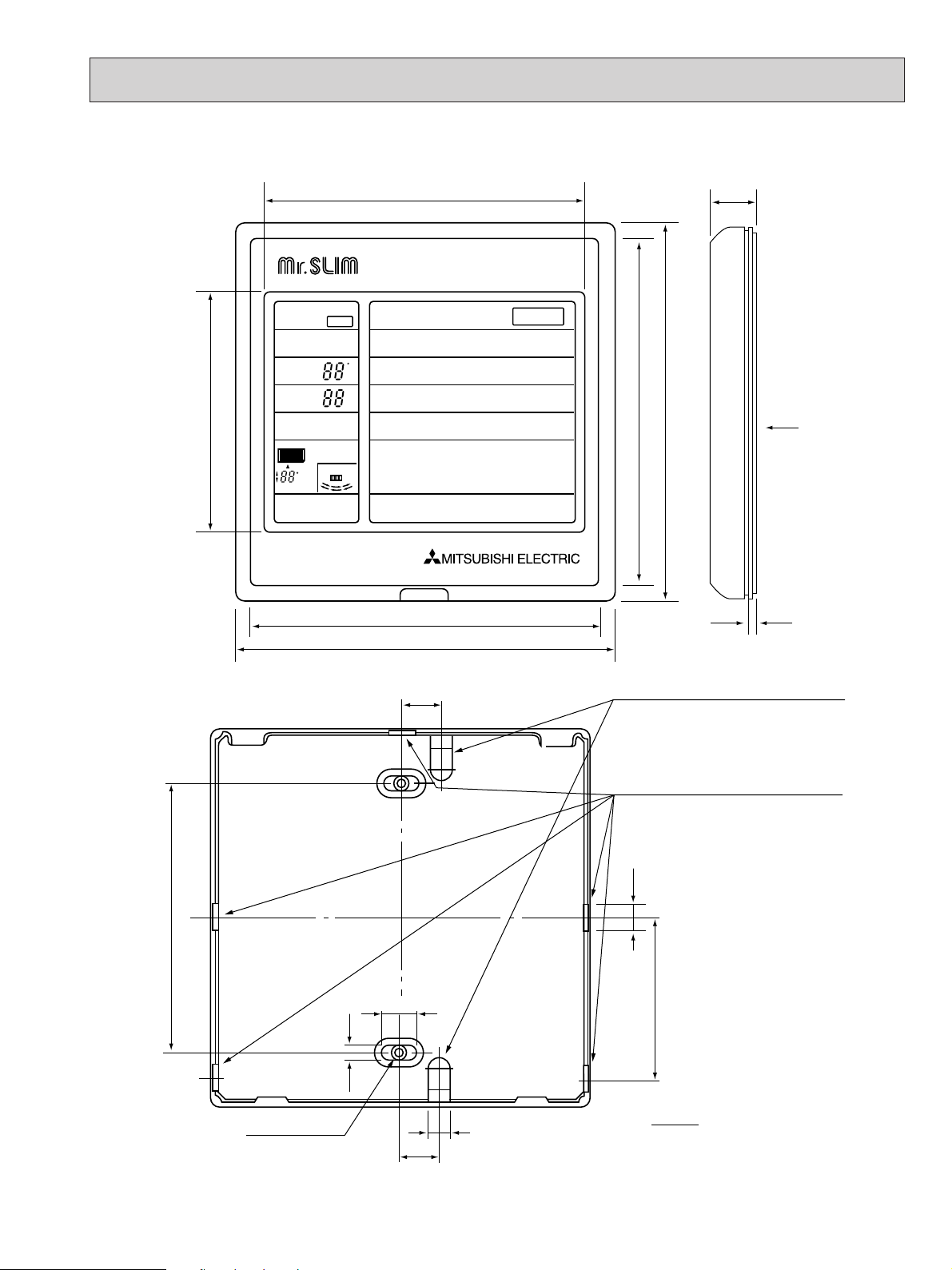

Remote controller (PKH series)

•

2-3/4

CENTRALLY CONTROLLED

STAND BY

DEFROST

AUTO DRY

HEAT COOL

CHECK

SET TEMP

TIMER OFF

AUTO STOP

AUTO START

LOW HIGH

F

ON

AIR SWEEP

•

HEAT AUTO COOL/DR Y

F

SET

TEMPERATURE

TIMER MODE HOURS

HR

FAN SPEED LOW/HIGH

AIR

DISCHARGE

3-5/8 3-5/8 5/8

—

ON/OFFPOWER

WARMER COOLER\

4-3/4

4-1/4

UP/DOWN SWING/STOP

Unit : mm

A

3-9/32

CHECK TEST RUN

CHECK TEST RUN

4-3/4

4-3/4

1/2

5/32

Rear side wiring arrangement opening

Side wiring arrangement opening

5/16

Fixing holes

3/16

3/8

1/2

1/4

2

VIEW A

21

Page 22

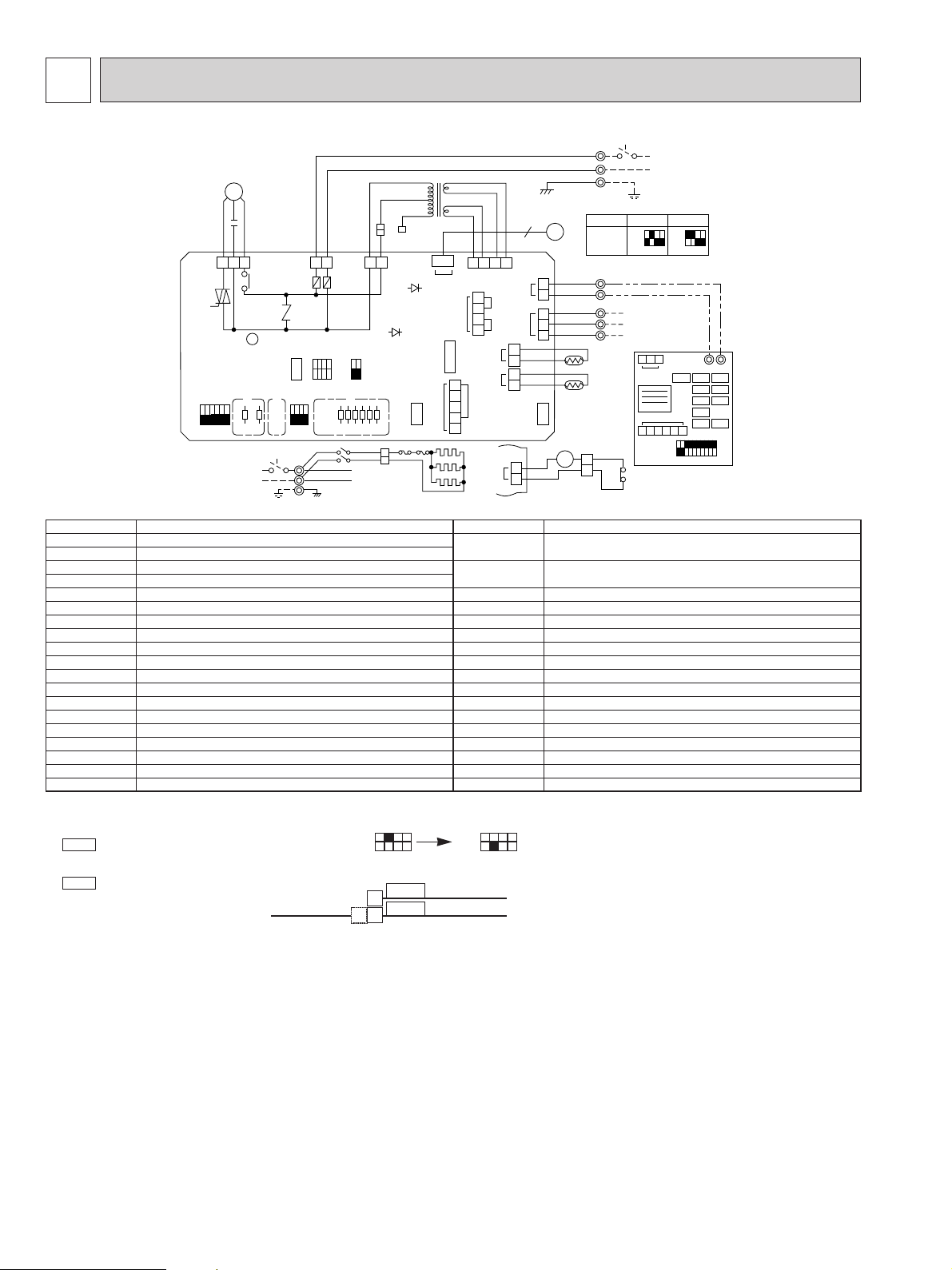

5

WIRING DIAGRAM

MODELS PKH18/24/30/36FK

MF

C

I.B

RED

WHT

BLK

FAN1

X4

X4

SW2

ON

OFF

123456

POWER SUPPLY

~(1 PHASE)

AC208/230V 60Hz

SYMBOL

C

FAN MOTOR CAPACITOR

CN1<R.B> PROGRAM TIMER CONNECTOR

CN2<R.B> REMOTE SWITCH CONNECTOR

CN21<I.B> LOSSNAY CONNECTOR

CN27<I.B> DRAIN LIFT-UP MECHANISM CONNECTOR

CN51<I.B> CENTRALLY CONTROL CONNECTOR

F1,2<I.B> FUSE (6A250V)

FS1,2 THERMAL FUSE <243°F / 18, 24FK : 10A. 30.36FK : 16A>

H HEATER

I.B INDOOR CONTROLLER BOARD

J1 MODE SELECTOR JUMPER RESISTORS

J5 MODE SELECTOR JUMPER RESISTORS

J9 MODE SELECTOR JUMPER RESISTORS

LCD<R.B> LIQUID CRYSTALDISPLAY

LED1<I.B> LED (DC 12V POWER)

LED2<I.B> LED (DC 5V POWER)

MF FAN MOTOR

MV VANE MOTOR

L1

L2

GR

WIRING DIAGRAM

RED

BLE

WHT

F1

SW3SW7

ON

OFF

12

J1J9J5

456789

88H

563

4

YLW YLW

LED1 12V

POWER

REDRED

BLU

ZNR

CN27

D.U.M

CND

POWER

SW6

12342 4

TB2

NAME

F2

1234

RED

BLU

GRN/YLWGROUND

230V

208V

RED

CNT

TRANS

LED2 5V

POWER

HEATER

CN24

L1

POWER SUPPLY

~(1 PHASE)

L2

AC208/230V 60Hz

TB2

MODELS

TB5

BLU 2

BLU 1

TB4

BRN 3

ORN 2

YLW

RT2

RT1

5 6

78

GR

GROUND

18.24FK 30.36FK

ON

SW7

OFF

1234

TRANSMISSON WIRES

DC12V

TO OUTDOOR UNIT

CONNECTING WIRES-POLAR

DC12V

1

R.B

1 2 3

CN2

LCD

CN1

1 2 3 4 5 6

GRY

26H

GRY

ON

OFF

1234

TB6

SW17

09876542321

NAME

1 2

OFF

ON

661

CNGV

VANE

CENTRALLY

CONTROL

DRAIN

CN50

FS2HFS1

T

POWER

CN51

10VAC

14.3VAC

RED

4 3 2 1

4 3 2 1

REMOCON

CN40

5 4 3 2 1

INTAKE

CN24

HEATER

RT1

RT2

RED

BRN

PEMOCON

CN21

PIPE

CN20

SYMBOL

GRN/YLW

MV

BRN

CN4T

TRANS

TO

CN22 CN30

OUTDOOR

3 2 12 1

2 1 2 1

LOSSNAY

CN21

I.B

88H

BWN

YLW

1 2

ROOM TEMP. THERMISTOR

(32°F / 15KΩ, 77°F / 5.4KΩ DETECT)

INDOOR COIL THERMISTOR

(32°F / 15KΩ, 77°F / 5.4KΩ DETECT)

SW2<I.B> ADDRESS SELECTOR

SW3<I.B> EMERGENCY OPERATION

SW6<I.B> MODEL SELECTOR

SW7<I.B> MODEL SELECTOR

SW17<I.B> ADDRESS SELECTOR

T TRANSFORMER

TB2 POWER TERMINAL BLOCK

TB4 INDOOR / OUTDOOR CONNECTING LINE TERMINAL BLOCK

TB5 REMOTE CONTROLLER TERMINAL BLOCK

TB6 TRANSMISSION LINE

X4<I.B> FAN MOTOR RELAY

ZNR VARISTOR

26H HEATER THERMALSWITCH

88H HEATER CONTACTOR

R.B REMOTE CONTROLLER BOARD

NOTES :

1. Since the indoor fan motor (MF) is connected with 230V power, using 208V power will require a setting change of the dip switch (SW7<I.B>) on the indoor controller board as shown in fig :

fig w1

Indoor fan motor (MF) for 208V.

2. Since the indoor transformer (T) is connected with 230V power if 208V power is used. Change the wiring connection showing fig : w 2.

fig w2

When power supply is

w 1.

230V

SW7

ON

OFF

1

2 3 4

240V

208V

ON

OFF

YELLOW

REDYELLOW

1

2 3 4

3. Since the outdoor side electric wiring may change be sure to check the outdoor unit electric wiring for servicing.

4. Indoor and outdoor connecting wires are made with polarities, make wiring matching terminal numbers.

5. Symbols used in wiring diagram above are,

6. Emergency operation

¤¤ : Connector, / : Terminal block.

If remote controller or microcomputer fails but there is no other trouble, emergency operation is possible by setting dip switch (SW3<I.B>) on the indoor controller board.

[Check items]

(1)Make sure that no other trouble exist the outdoor unit. Trouble with the outdoor unit prevents emergency operation.

(If any trouble exists the outdoor unit error code "P8" will be displayed on the remote controller and the trouble position will be shown on the outdoor controller

board LED. See electric wiring diagram of the outdoor unit for details.)

(2)Make sure that there is no trouble with the indoor fan.

Emergency operation will be continuous operation mode due to power ON/OFF (ON/OFF with the remote controller is not possible).

[Emergency operation procedure]

(1)Set the dip switch (SW3<I.B>) on the indoor controller board to 1 on and 2 off for cooling and 1 - 2 on for heating.

(2)Turn on outdoor unit side circuit breaker, then indoor unit side circuit breaker.

(3)During emergency operation indoor fan runs at high speed but automatic vane remains stopped.

If the air outlet is blocked up with the vane, Open it with your hands.

(4)Thermostat will not function. Cold air blows out for defrosting during heating thus do not operate defrosting for along time.

(5)Emergency cooling should be limited to 10 hours maximum.

(The indoor unit heat exchanger may freeze).

(6)After every operation, switch the fan connector to FAN1, and set all dip switches (SW3<I.B>) to OFF.

22

BG79N687H01

Page 23

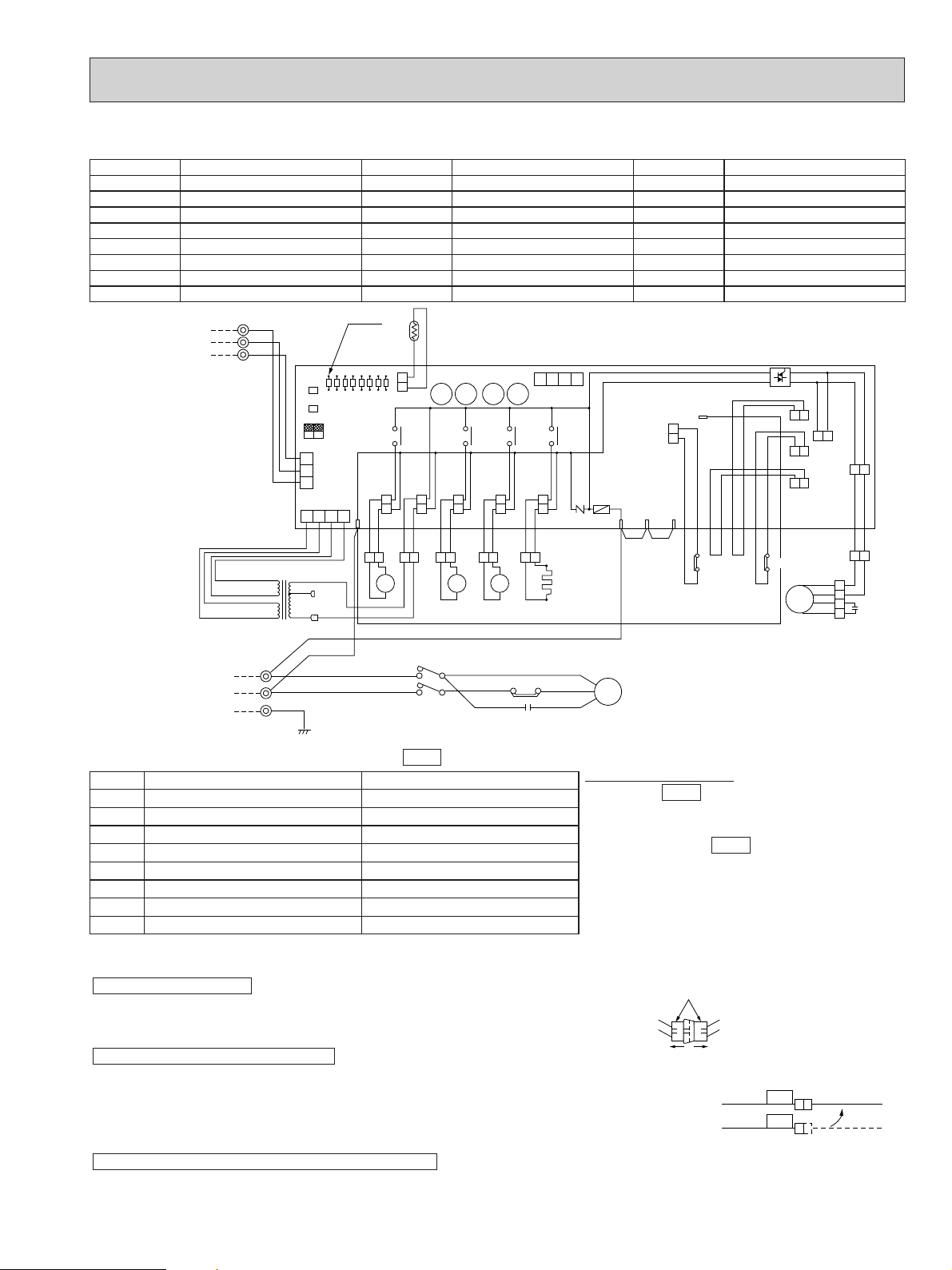

MODELS PUH18EK

LD8

LD7

LD6

LD5

LD4

LD3

LD2

LD1

O.B

SW1

SW2

SW3

OFF

ON

2 1

CN2

RT

LED

1

2

3

TB3

YLW

ORN

BRN

FROM INDOOR UNIT

CONNECTING WIRES

12V DC (polar)

L1

L2

GR

GRN

TB1

POWER SUPPLY

1{ 208/230V

60Hz

3

2

1

CN3

CN4T

4 3 2 1

CN4

4 3 2 1

BRN 12.3V AC

RED 12.3V AC

MF

BLU

BLU

WHT

BLU

WHT

WHT

RED

RED

ORN ORN

C1

MF2

MF1

FC

26C

63H2

63H1

63H1

51CM

5

BRN

BRN

YLW

YLW

YLW

YLW

RED

RED

BLU

63H2

MC

R

C

C

S

2 1

51C

52C

BLU

BLU

WHT

RED

WHT

UR

T W

RED

RED

RED

ORN

BLK

BLK

T

208V

230V

21R

RED

RED

RED

RED

SV

WHT

WHT

TRF

21

S4

BLK

BLK

BLK

BLK

21S4

52C

GRY

GRY

GRY

GRY

52C

WHT

WHT

CH ZNR

R/1

S/2

T/3

BLU BLU

F

HC

WHT

WHT

4

S

A

B

X11X12X13X14

X14

X13 X12 X11

4

3

2

1

C

C1

F<O.B>

FC<O.B>

HC

LD1~LD8

MC

MF

O.B

COMPRESSOR CAPACITOR

FAN CAPACITOR

FUSE<6A>

FAN CONTROLLER

CRANKCASE HEATER

LED<CHECK,SERVICE>

COMPRESSOR

FAN MOTOR<INNER THERMOSTAT>

OUTDOOR CONTROLLER BOARD

WIRING DIAGRAM

RT

SW1•2•3<0.B>

T

TB1,3

X11<O.B>

X12<O.B>

X13<O.B>

OUTDOOR COIL THERMSTOR

<32˚F/15kΩ,77˚F/5.4kΩ>

SELECTOR<CHECK,SERVICE>

TRANSFORMER

TERMINAL BLOCK

CRANKCASE HEATER RELAY

COMPRESSOR RELAY

R.V RELAY

X14<O.B>

ZNR<O.B>

21R

21S4

51C

52C

63H1

63H2

BYPASS VALVE RELAY

VARISTOR

BYPASS VALVE COIL

R.V COIL

OVERCURRENT RELAY

CONTACTOR

CONTROL HIGH PRESSURE SWITCH

PROTECT HIGH PRESSURE SWITCH

SW3

How to use SW1 and 2

● Pressing erases the past check contents

SW1

loaded on the microcomputer.

● The output display (light) remains during operation but pressing displays the past check

SW2

contents in flashing mode. Pressing the switch

again retums to output display (light).

White connector

When Power Supply is 208V

w

RED WHITE

ORANGE

208V

230V

Main function of LED(when both Nos.1 and 2 of are "OFF")

LED NO. Output display (light) Check display (flash)

LD1 Compressor indoor command —

LD2 Heating indoor command —

LD3 63H1 ON RT short/open

LD4 Compressor ON 63H2 funcitons

LD5 Outdoor fan ON —

LD6 R.V.coil ON —

LD7 Bypass valve ON RT overheat protection

LD8 Crankcase heater ON Defective input

NOTES : 1. If the operation stops to function of the protection device, the check display flashes.

CAUTION FOR SERVICING

● The connector marked

The compressor stops by disconnecting the white connector as shown at the right.

CAUTIONS FOR POWER SUPPLY WIRING

2. Symbols used in wiring diagram above are. / :Terminal block, ¤¤¤ :Connector, ¤ :PC board insertion tab.

● Since LD8 lights when normal power is turned "ON", check the power supply with the "ON"

or "OFF" LD8.

w Since the indoor transformer (T) is connected with 230V power, if 208V power is used,

change the wiring connection as shown in the right figure.

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

● Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor

and outdoor units.

s

—¤— is to turn the compressor ON-OFF during servicing.

23

Page 24

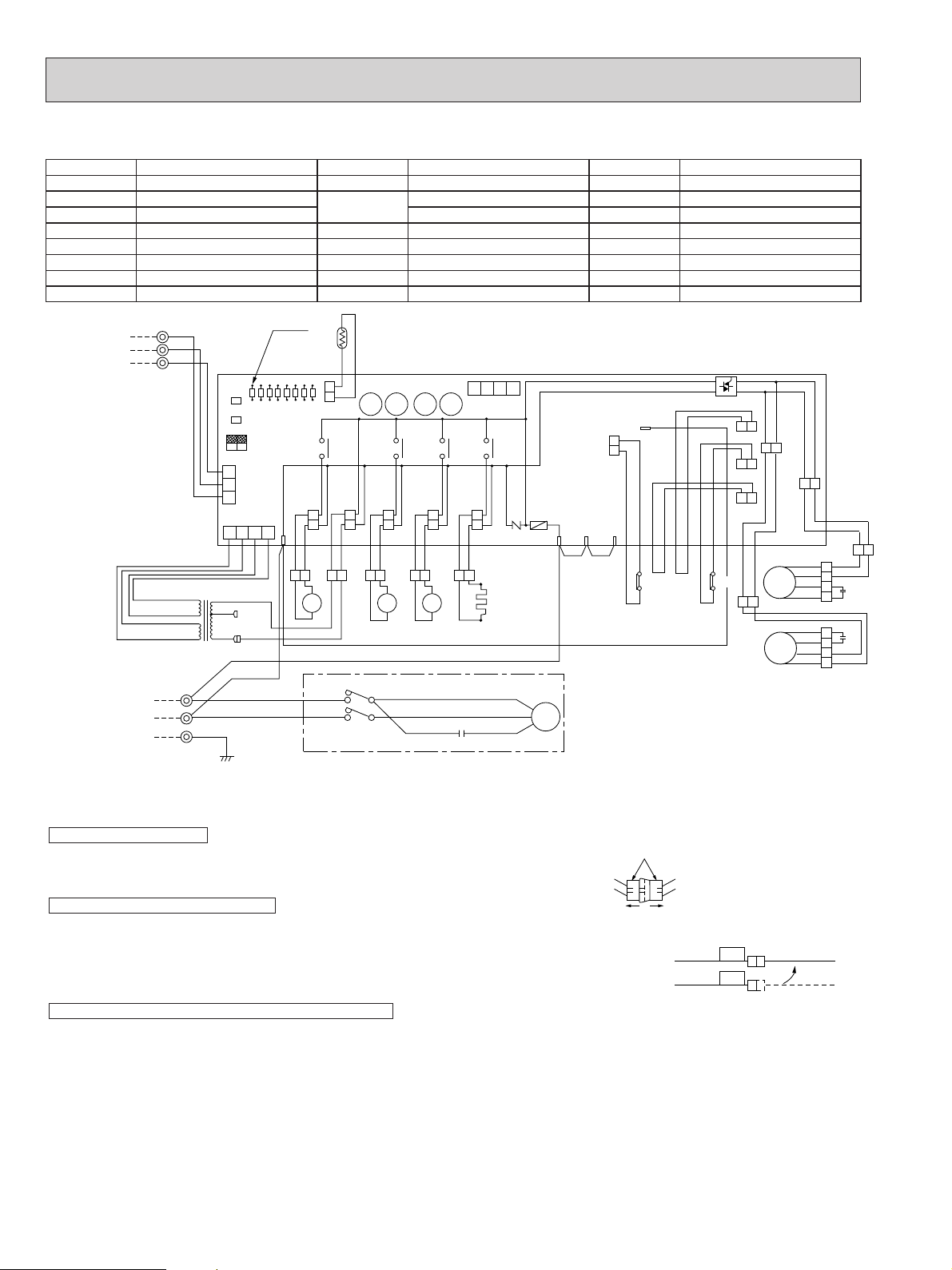

MODELS PUH24/30/36EK

LD8

LD7

LD6

LD5

LD4

LD3

LD2

LD1

O.B

SW1

SW2

SW3

OFF

ON

2 1

CN2

RT

LED

1

2

3

TB3

YLW

ORN

BRN

FROM INDOOR UNIT

CONNECTING WIRES

12V DC (poler)

L1

L2

GR

GRN

TB1

POWER SUPPLY

1[ 208/230V

60Hz

3

2

1

CN3

CN4T

4 3 2 1

CN4

4 3 2 1

BRN 12.3V AC

RED 12.3V AC

MF1

BLU

BLU

WHT

WHT

BLU

WHT

RED

RED

ORN ORN

C1

MF2

YLW YLW

BLU

WHT

BRN

WHT WHT

BRN

BLU BLU

C1

MF2

MF1

FC

26C

63H2

63H1

63H1

51CM

5

BRN

BRN

YLW

YLW

YLW

YLW

RED

RED

BLU

63H2

MC

R

C

C

S

52C

BLU

BLU

WHT

RED

WHT

UR

T W

RED

RED

RED

ORN

BLK

BLK

T

208V

230V

21R

RED

RED

RED

RED

SV

WHT

WHT

TRF

21

S4

BLK

BLK

BLK

BLK

21S4

52C

GRY

GRY

GRY

GRY

52C

WHT

WHT

CH ZNR

R/1

S/2

T/3

BLU BLU

F

HC

WHT

WHT

4

S

A

B

X11X12X13X14

X14

X13 X12 X11

4

3

2

1

1

2

3

4

C

C1,2

C5

F<O.B>

FC<O.B>

HC

LD1~LD8

MC

MF1,2

COMPRESSOR CAPACITOR

FAN CAPACITOR

COMPRESSOR STARTCAPACITOR

FUSE<6A>

FAN CONTROLLER

CRANKCASE HEATER

LED<CHECK,SERVICE>

COMPRESSOR<INNER THERMOSTAT>

FAN MOTOR<INNER THERMOSTAT>

WIRING DIAGRAM

O.B

R

RT

SW1•2•3<O.B>

T

TB1,3

X11<O.B>

X12<O.B>

OUTDOOR CONTROLLER BOARD

RESISTOR

OUTDOOR COIL THERMISTOR

<32˚F/15kΩ, 77˚F/5.4kΩ>

SELECTOR<CHECK,SERVICE>

TRANSFORMER

TERMINAL BLOCK

CRANKCASE HEATER RELAY

COMPRESSOR RELAY

X13<O.B>

X14<O.B>

ZNR<O.B>

19

21R

21S4

52C

63H1

63H2

R.V RELAY

BYPASS VALVE RELAY

VARISTOR

COMPRESSOR STARTRELAY

BYPASS VALVE COIL

R.V COIL

CONTACTOR

CONTROL HIGH PRESSURE SWITCH

PROTECT HIGH PRESSURE SWITCH

NOTES : Symbols used in wiring diagram above are. / :Terminal block, ¤¤¤ :Connector, ¤ :PC board insertion tab.

s

White connector

w

When Power Supply is 208V

RED WHITE

ORANGE

208V

230V

CAUTION FOR SERVICING

● The connector marked

The compressor stops by disconnecting the white connector as shown at the right.

CAUTION FOR POWER SUPPLY WIRING

● Since LD8 lights when normal power is turned "ON", check the power supply with the "ON"

or "OFF" LD8.

w Since the indoor transformer (T) is connected with 230V power, if 208V power is used,

change the wiring connection as shown in the right figure.

—¤— is to turn the compressor ON-OFF during servicing.

CAUTION FOR INDOOR AND OUTDOOR CONNECTING WIRES

● Since the indoor and outdoor connecting wires has polarity, make sure to connect the same terminal numbers (1,2,3) for indoor

and outdoor units.

24

Page 25

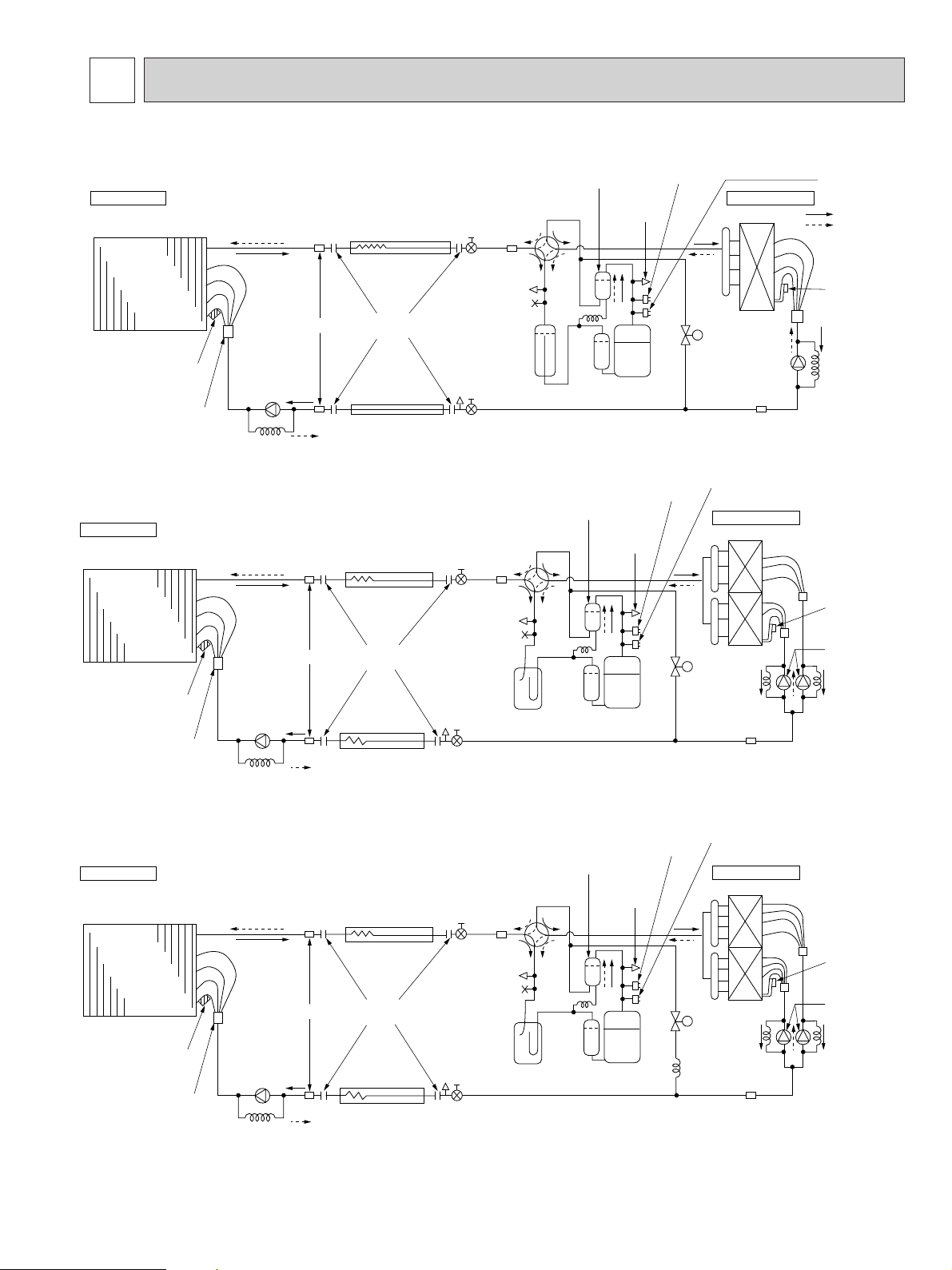

6

Indoor unit Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor coil

thermistor

RT2

Distributor

Restrictor

valve

Capillary

tube

({0.126x{0.071x15.7)

({0.126x{0.071x9.8)

PKH30FK({0.157x{0.079x11.4)

PKH36FK({0.157x{0.079x11.4)

Capillary tubesize:(ODxIDxLength)

The symbol { indicates diameter.

Capillary

tube

({0.157x{0.079

x33.5)

Refrigerant pipe

(option)

{3/8"

(with heat insulator)

Refrigerant pipe

(option)

{5/8"

(with heat insulator)

Ball valve

(with service port)

Ball valve

Strainer

Strainer

Strainer

Flared

connection

Accumulator

Muffler

Flexible tube

Compressor

Service

port

(check)

Service

port

(check)

Fusible

plug

Bypass

valve

Oil separator

4-way valve

Control

high pressure

switch

Protect

high pressure

switch

Outdoor coil

thermistor

RT

Restrictor

valve

Indoor coil

thermistor

RT2

Distributor

Restrictor

valve

Capillary

tube

Capillary

tube

({0.126x{0.063

x17.3)x2

Refrigerant pipe

(option)

{3/8"

(with heat insulator)

Refrigerant pipe

(option)

{5/8"

(with heat insulator)

Ball valve

(with service port)

Ball valve

Strainer

Strainer

Strainer

Flared

connection

Accumulator

Muffler

Flexible tube

Compressor

Service

port

(check)

Service

port

(check)

Fusible

plug

Bypass

valve

Oil separator

4-way valve

Control

high pressure

switch

Protect

high pressure

switch

Outdoor coil

thermistor

RT

Restrictor

valve

Indoor coil

thermistor

RT2

Distributor

Restrictor

valve

Capillary

tube

Capillary tube

PUH30EK

({0.157x{0.079

x23.6)x2

PUH36EK

({0.157x{0.079

x17.7)x2

Capillary tube

Refrigerant pipe

(option)

{1/2"

(with heat insulator)

Refrigerant pipe

(option)

{3/4

(with heat insulator)

Ball valve

(with service port)

Ball valve

Strainer

Strainer

Strainer

Flared

connection

Accumulator

Muffler

Flexible tube

Compressor

Service

port

(check)

Service

port

(check)

Fusible

plug

Bypass

valve

Oil separator

4-way valve

Control

high pressure

switch

Protect

high pressure

switch

Outdoor coil

thermistor

RT

Restrictor

valve

COOL

HEAT

w

PKH18FK

REFRIGERANT SYSTEM DIAGRAM

PKH24FK

PKH-30/36FK

25

Page 26

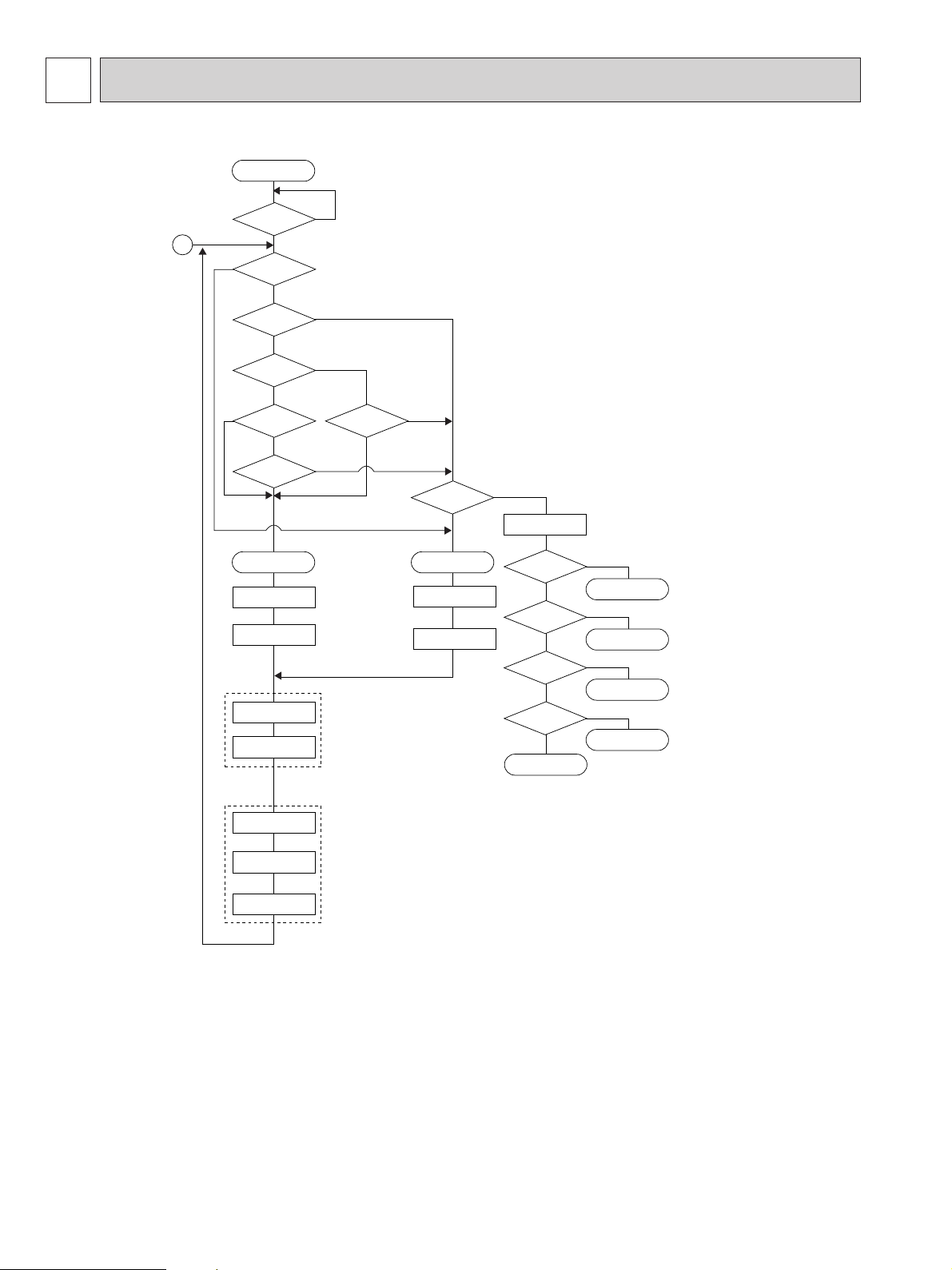

7 OPERATION FLOW-CHART

START

Power circuit

breaker

Check SW

ON twice

Operation SW

ON

“OFF” timer

“ON” timer

STOP

Set time

complete

Set time

complete

1

NO

NO

NO NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

w 1

w 2

w 3

w 4

w 5

w 7

w 6

PROTECTION DEVICE

SELF HOLD RELEASE

Remote controller

indicator lamp OFF

Trouble STOP

Remote controller

operation display

Operating mode

(COOL)

Operating mode

(DRY)

Operating mode

(HEAT)

Operating mode

(FAN)

Auto COOL/HEAT

operation

COOL operation

DRY operation

HEAT operation

FAN operation

Trouble

PROTECTION DEVICE

SELF HOLD

Remote controller

trouble display

Indoor side

Outdoor side

Fan STOP

Auxiliary heater OFF

Compressor OFF

Fan STOP

Four-way valve OFF

MAIN OPERATION

w1 In addition, the centralized and remote control can be operated.

w2 The modes which indicate the sources of trouble are listed below.

● EO=Signal transmitting/receiving error

● P1=Room temperature thermistor malfunction

● P2=Indoor coil thermistor malfanction

● P4=Drain sensor malfunction

● P5=Drain over flow

● P6=Coil frost/overheat protection

● P7=System error

● P8=Outdoor unit trouble

w3 The CHECK swich will show if an error has occurred in the past.

w4 Fan runs on low speed for 1 minute in order to remove overheat air.

w5 The 3-minute (6 minutes … heating mode) time-delay functions after compressor stops.

w6 FAN or AUTO mode is selected by the indoor dipswitch setting.

w7 In FAN mode, fan speed and vane operation depend on the remote controller setting. (Compressor is OFF.)

26

Page 27

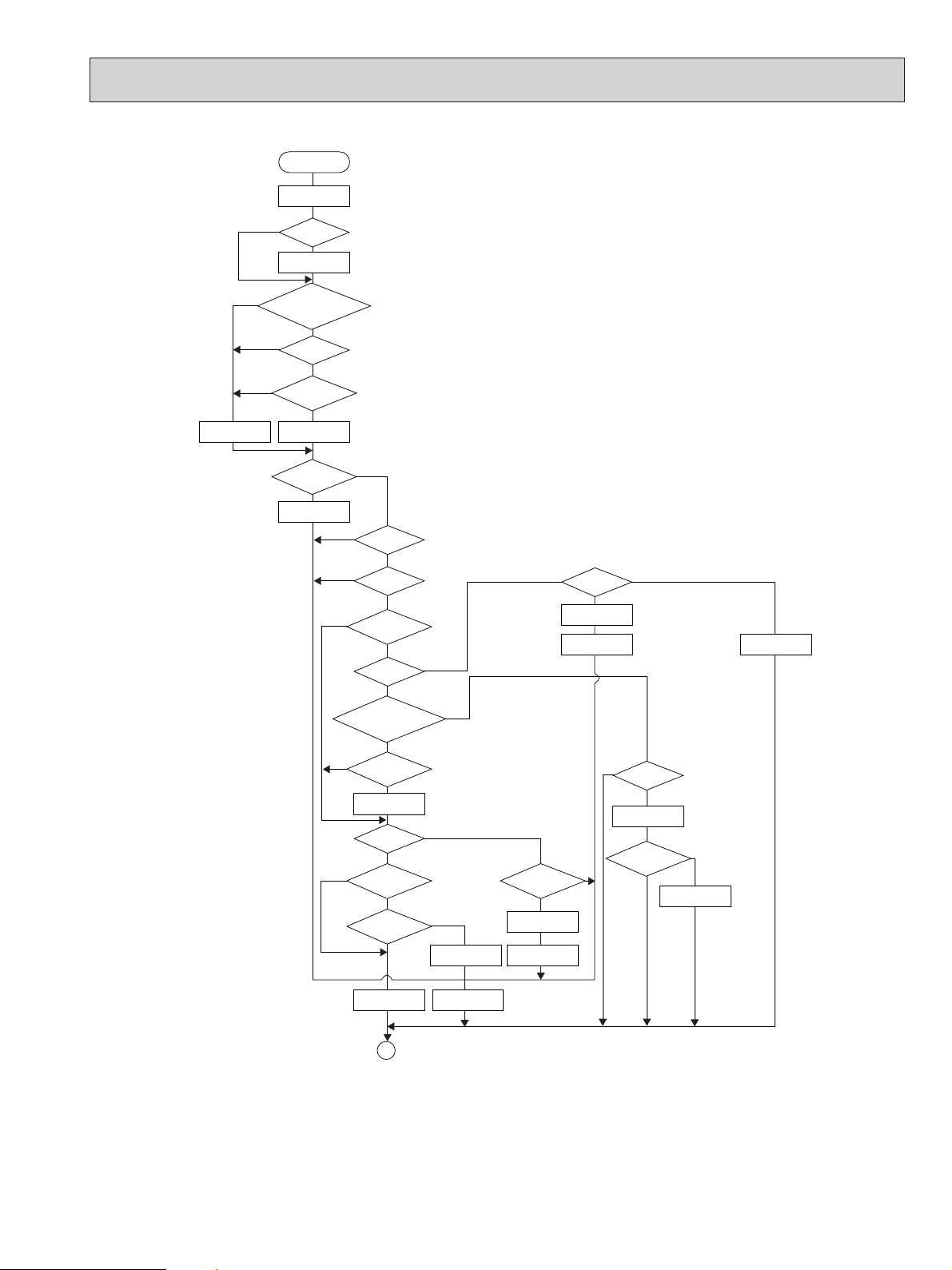

COOLING OPERATION

COOL operation

Four-way valve/OFF

NO

NO

NO

NO

Vane setting notch

Initial

COOLING

w 8

w 9

YES

Vane intial

setting

Vane

60 deg downward angle

70 deg downward angle

YES

Fan speed

LOW

YES

Downward discharge

1 hour

YES

Vane horizontal

airflow

NO

Compressor

thermostat

ON

NO

Allowance

cancel

NO

YES

YES

NO

w 10

w 11

YES

3-minute

time delay

6-minute

time delay

3-minute

compressor opration

Coil frost

prevention

Cooling area

NO

NO

YES

NO

YES

NO

Aliowance

period

NO

6 minute

time delay

Allowance set

YES

Coil frost protection

YES

10-minute

NO

compressor operation

Allowance cancel

NO

compressor operation

Compressor ON

YES

Coil frost

protection

NO

16-minute

YES

Indoor pipe

temperature is

34¡F or lower

NO

1

YES

YES

Coil frost

prevention

Compressor OFF

Indoor coil

tempreature is

50¡F or higher

YES

3-minute

time delay

Coil frost

prevention release

NO

NO

1 min continue

FAN speed

YES

LOW

FAN speed

LOW 5 min

elapse

NO

YES

Outdoor unit

trouble

w8 When operation stops or changes to cooling or dry mode, the auto vane turns to a horizontal angle. IF opera-

tion changes during auto vane SWING, the auto vane will continue to swing.

w9 When operating TEST RUN, the thermostat will be continuously ON.

w10After 3 minute compressor operation, if the indoor coil thermistor reads -59°F or below for 3 minutes, the com-

pressor will stop for 6 minutes.

w11Cooling area : Indoor coil temperature is more than 9 degrees above the room temperature.

Heating area : Indoor coil temperature is more than 9 degrees below the room temperature.

FAN area : Indoor coil temperature is within 9 degrees either way of the room temperature.

27

Page 28

HEATING OPERATION

Heat operation

Intial

HEATING

YES

Vane intial setting

NO

Defrosting

NO

Four-way valve ON

Hor adjust

in process

NO

Compressor ON

NO

Compressor

thermostat ON

Allowance cancel

Indoor piping

-5¡F or lower

YES

Outdoor unit

trouble

FAN SPEED

Very low airflow

Compressor OFF

1

w 15

2

NO

Vane setting notch

w 9

NO

YES

YES

YES

YES

3 min.restart

prevention

YES

6 min. restart

prevention

NO

Hot adjust start

FAN SPEED very low

Compressor ON

NO

Allowance cancel

w 11

FAN STOP

w 11

20 min.elaspe

YES

w 11

Cooling area

Defrost operation

Four-way valve

10-minute

compressor

operation

YES

Heating

area

Ariflow area

Airflow area

Heating area

NO

Airflow area

YES

START

OFF

w 10

w 11

YES

YES

NO

Heating area

NO

Defrost

30 min. elaspe

YES

Outdoor unit trouble

1

A

Outdoor unit

trouble

YES

Defrost release

NO

131¡F or lower

NO

Auxiliary heater

NO

140¡F or higher

YES

Auxiliary heater OFF

Overheat remote

NO

158¡F or higher

Allowance

Overload protect

2

B

Indoor piping

NO

ON

YES

Indoor piping

START

Indoor unit

YES

period

YES

YES

NO

Auxiliary heater ON

NO

6-minute restart

Allowance set

Compressor OFF

Auxiliary heater

thermostat ON

YES

prevention