Page 1

TECHNICAL & SERVICE MANUAL

CONTENTS

1.

TYPES OF CONNECTED OUTDOOR UNITS

····2

2. SAFETY FOR USE··········································3

3. PART NAMES AND FUNCTIONS ··················5

4. DATA ·······························································6

5. OUTLINES AND DIMENSIONS······················7

6. WIRING DIAGRAM·········································8

7. REFRIGERANT SYSTEM DIAGRAM·············9

8. TROUBLE SHOOTING·································10

9. SERVICE DATA (PARTS NAME)··················11

10. OPTIONAL PARTS ·······································14

[Model names]

PU-8YAKD

PU-10YAKD

PU-12YAKD

SPLIT-TYPE, AIR CONDITIONERS

2007

Page 2

2

1 TYPES OF CONNECTED OUTDOOR UNITS

Service manual No.

HWE07060

HWE07060

HWE07060

Model name

Outdoor unit

Indoor unit

PU - 8YAKD

PU - 10YAKD

PU - 12YAKD

PE - 8GAK(T)

PE - 16GAK(T)

PE - 10GAK(T)

PE - 20GAK(T)

PE - 12GAK(T)

PU-8YAKD.TH-BS

PU-10YAKD.TH-BS

PU-12YAKD.TH-BS

PU-8YAKD.TH

PU-10YAKD.TH

PU-12YAKD.TH

Standard Model Salt tolerant

Salt tolerant

Outdoor Unit List

PU-8YAKD

PU-10YAKD

PU-12YAKD

Model name

Specification

PU-8YAKD.TH-BS-T

PU-10YAKD.TH-BS-T

PU-12YAKD.TH-BS-T

PU-8YAKD.TH-T

PU-10YAKD.TH-T

PU-12YAKD.TH-T

Standard Model

PU-8YAKD

PU-10YAKD

PU-12YAKD

Model name

Specification

Page 3

3

2 SAFETY FOR USE

Before conducting installation work, please read this ''SAFETY FOR USE'' carefully

for

correct installation.

Since the caution items shown here contain important description relative to safety, please

observe them without fail.

After reading, please keep it with you together the Instruction Manual, and read it again at the

movement of the unit.

The unit should not be installed by the user.

If the unit is installed improperly, explosion, water

leakage, electric shock or fire may be result.

Consult your dealer or specialist subcontractor for

repair and movement.

For installation, conduct the work correctly by

following the Installation Manual.

Improper installation may cause a fire, electrical shock

or water leakage.

Install the unit on a spot sufficiently durable against

the unit weight.

Insufficient durability can cause an injury by the falling

down of unit.

All electric work must be performed by licensed

technician, according to local regulations and the

instructions given in this manual.

The units should be powered by dedicated power lines.

Power lines with insufficient capacity or improper

electrical work may result in electric shock or fire.

Use only the specified cables for wiring. The

connections must be made secured without

tension the terminals.

Improper connection or fastening can cause a fire or

electrical shock.

The unit should be installed according to the

instructions in order to minimize the risk of damage

from earthquakes, typhoons or strong winds.

Improper installation work can cause an injury by the

falling down of the unit.

The outdoor unit must be installed on stable, level

surface, in a place where there is no accumulation

of snow , leaves or rubbish.

The outdoor unit should be installed in a location

where air and noise emitted by the unit will not

disturb the neighbors. The indoor unit should be

securely installed.

When installing or relocating the unit, make sure that

no substance other than the specified refrigerant

enters the refrigerant circuit.

Any presence of foreign substance such as air can

cause abnormal pressure rise or explosion.

If the unit is loosely mounted, it may fall, and cause injury.

Never repair the unit, remodel or transfer it to

another site by yourself.

If they are performed improperly, water leakage, electric

shock or fire may result. If you need to have the unit

repaired or moved, consult your dealer.

Use only the specified refrigerant (R-22) to charge

the refrigerant circuit.

Do not mix it with any other refrigerant and do not

allow air to remain in the circuit.

Air enclosed in the circuit can cause high pressure resulting

in a rupture and other hazards.

Ventilate the room if refrigerant leaks during

Installation.

The refrigerant heated generates poisonous gas by

decomposition which can cause poisoning.

After completing installation work, make sure that

refrigerant gas has not leaked.

If refrigerant gas has leaked and exposed to fan heater,

stove, oven and so on, it may generate noxious gases.

Take a proper measure to suppress the critical

concentration of refrigerant if leaked when

installing the unit in a small room.

The limit density is made not to be exceeded even if the

refrigerant leaks by any chance.

You are necessary to ventilation measures to prevent

the accident. If the refrigerant leaks, hypoxia accident

may caused.

For the countermeasure to be taken, consult your

dealer.

The terminal block cover of unit must be firmly

attached to prevent entry of dust and moisture.

Improper mounting of the cover cause electric shock or

fire.

Use only optional parts authorised by Mitsubishi

Electric.

If the accessories are installed improperly, water

leakage, electric shock or fire may result.

Ask your dealer or an authorised company to install

them.

Erroneous handling gives a high possibility to induce serious results such as

death or heavy injury.

Erroneous handling may induce serious injury depending on the situation.

Warning

Warning

Caution

Page 4

4

Caution

Never install on the place where a combustible gas

might leak.

The gas may ignite or explode when the gas leaks and

collects in surrounding of the unit.

When the unit is installed at telecommunication

centers or hospitals, take a proper provision

against noise.

The erroneous operation of air conditioner may be

induced by inverter equipment, independent power

device, medical equipment or communication

equipment.

While the erroneous operation of medical equipment or

communication equipment may caused by the air

conditioner.

For special use as for foods, animals/plants,

precision equipment or art objects, the applicability

should be confirmed beforehand.

As the use for the applications other than that

designed originally may result in the deterioration of the

quality. Consult your dealer in this regard.

Do not use the unit under a special atmosphere.

Installing the unit at the following places may cause a

trouble, a place where much machine oil, salt sonnet,

humidity or dust, spa district, a place full of sulfur gas,

volatile gas, or corrosive gas, a place near high

frequency processing machine.

Thermal insulation of the drain pipes is necessary

prevent dew condensation.

If the drain pipes are not properly insulated,

condensation will result and drip on ceiling, floor or other

possessions.

The drain piping must process by surely,and insulate

the drain piping not to be dewy.

When the room humidity exceeds 80% or when the

drain pipe is clogged, water may drip from the indoor

unit. The outdoor unit produces condensation during the

heating operation.

Make sure to provide drainage around the outdoor unit if

such condensation is likely to cause damage.

Install drain piping according to this Installation

Manual to ensure proper drainage.

Place thermal insulation on the pipes to prevent

condensation.

Improper drain piping may cause water leakage and

damage to furniture or other possessions.

The unit must be properly earth connected.

Do not connect the earth wire to gas pipe, city water

pipe, lightning rod or telephone earth wire.

Improper earth connection may cause electrical shock.

When installing at a watery place, provide an

electric leak breaker.

Failure to mount the electric leak breaker may cause

electrical shock.

Use breaker or fuse with proper capacity.

Make sure that there is a main power switch.

Using a wire or a copper wire instead of proper capacity

of fuse can cause fire or trouble.

Other appliances connected to the same line could cause

an overload.

For the power lines, use standard cables of

sufficient current capacity.

Otherwise, current leakage, overheating or fire may

occur.

When installing the power lines, do not apply

tension to the cables.

The tighten or loosen the connections may cause generate

heat and cause fire.

Remote controller is not pushed with the thing

sharpening ahead.

It occasionally causes the electric shock and the

breakdown.

Arrange the configuration of wiring not to bring up

the panel and terminal cover, and fasten the panel

and terminal cover securely.

The poor mounting of the panel or terminal cover may

cause the heat generation of the terminal connection,

a fire or electrical shock.

Do not wash the unit with water.

If washed with water, electrical shock may be caused.

Do not handle the switch with wet hands.

Otherwise electrical shock can be resulted.

Be very careful on handling the unit.

When carrying in outdoor unit, be sure to support it at

four points.

Carrying in and lifting with 3-point support may make

outdoor unit unstable, resulting in a fall of it.

The unit should not be carried by only one person if it is

more than 20kg.

Some units use PP bands for packing.

Do not use any PP band for delivery purpose.

Do not touch the heat exchanger fins with your bear

hands.

Doing so may cut your hands.

Be sure to safely dispose the packaging materials.

Packaging materials, such as catches and other metal

or wooden parts, may cause stabs or other injuries.

Tear off and discard plastic packing bags so that

children will not play any of them.

If children play with a plastic bag which was not torn off,

it may cause a risk of suffocation.

Do not leave the mounting base being damaged.

The damaged base may cause the falling down of

the unit which may give injury.

Turn on the main power switch more than 6 hours

before starting operation.

Do not turn the main power switch OFF during seasons

of heavy use, doing so can result in failure.

Do not touch the compressor or refrigerant piping

without wearing glove on your hands.

Touching directly such part can cause a burn or

frostbite as it becomes high or low temperature

according to the refrigerant state.

Do not touch the metal edges inside the unit

without wearing glove on your hands.

Touching directly it may injure your hands.

Do not remove the panel or the fan guard from

the outdoor unit when it is running.

You could be injured if you touch rotating, hot or highvoltage parts.

Do not operate the air conditioner without the air

filter set place.

Dust may accumulate, and cause a failure.

At emergency (if you smell something burning), stop

operation and turn the power source switch off.

Continuing the operation without eliminating the

emergency state may cause a machine trouble, fire, or

electrical shock.

After stopping operation, be sure to wait for five

minutes before turning off the main power switch.

Otherwise, water leakage or unit failure may occur.

Remote controller is not installed for the place

where direct sunshine strikes.

Do not connect the unit in the reverse phase

sequence.

If connected in the reverse phase sequence, the fan

on the outdoor unit will turn in the wrong direction and

makes the compressor rattle, and it will result in compressor

damage.

Page 5

5

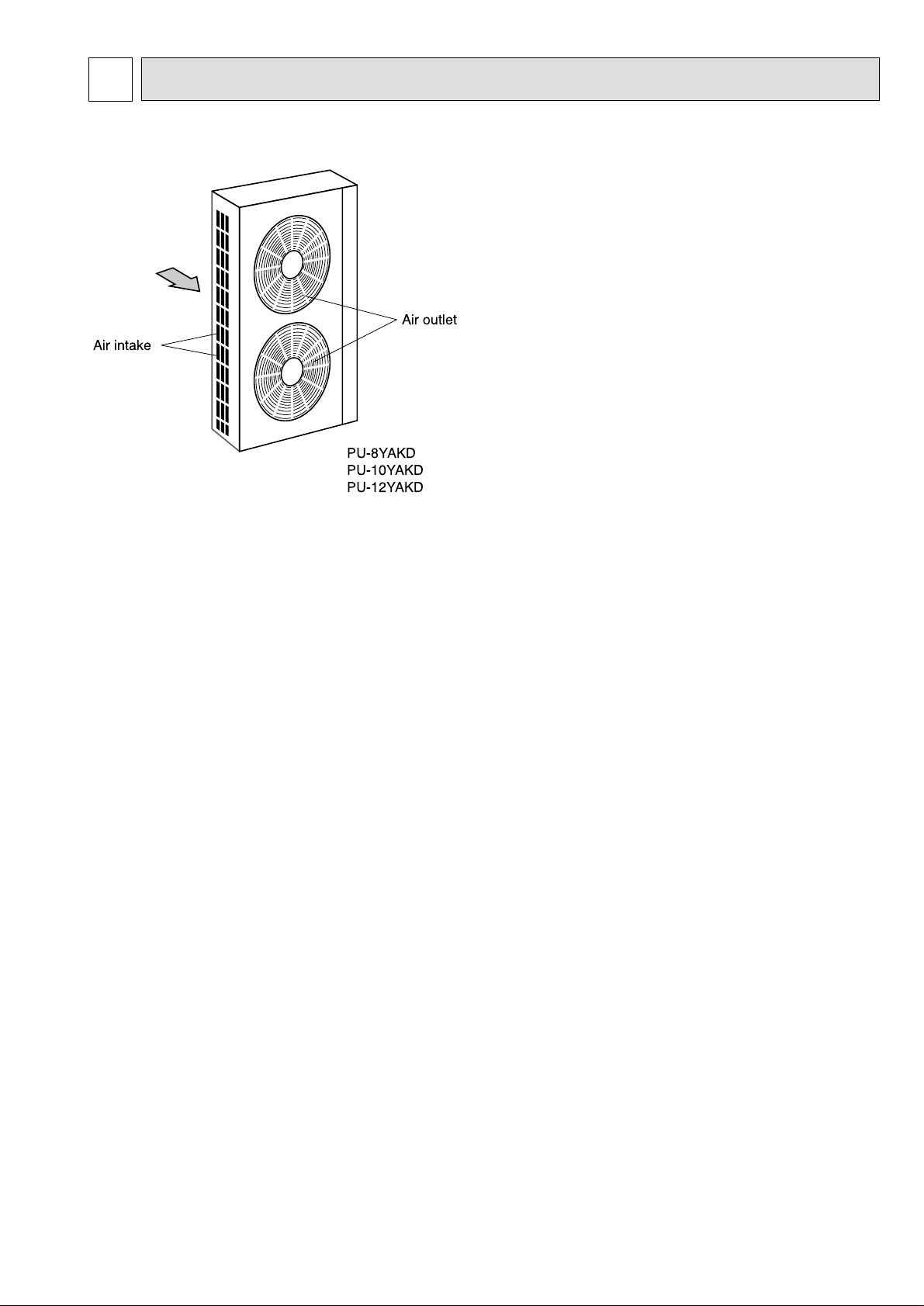

3 PART NAMES AND FUNCTIONS

✻Unit of pressure is based on ISO (International Standardization Organization)

[kgf/cm

2

]➝[MPa] (1MPa=10.2kgf/cm2)

●Outdoor Unit

PU-8YAKD

PU-10YAKD

PU-12YAKD

Air outlet

Air intake

Page 6

6

4-2. COMPRESSOR TECHNICAL DATA

PU-8 PU-10 PU-12

at 25

˚C

Outdoor Unit

Compressor Model

Widing

Resistance

(

Ω)

ZR-94KC-TFD-501

1.59

1.59

1.59

T1-T2

T2-T3

T3-T1

ZR-125KC-TFD-501

1.23

1.23

1.23

ZR-144KC-TFD-501

1.227

1.227

1.227

4 DATA

4-1. ELECTRICAL SPECIFICATIONS

Rating conditions

• JIS B 8616

Indoor : 27˚C(80˚F)D.B.,19˚C(66˚F)W.B.

Outdoor : 35˚C(95˚F)D.B.,24˚C(75˚F)W.B.

PU-8YAKD PU-10YAKD

3N~ 380/400/415V 50Hz

PU-12YAKD

Model name

Power supply

Current

Input

Starting current

A

A

kW

12.4

6.43

95

16.0

9.00

125

17.9

10.32

118

4-3. REFILLING REFRIGERANT CHARGE (R-22 : kg)

4-4. SOUND DATA

Model

7.5m 10m 15m 20m 25m 30m 35m 40m 45m 50m

PU-8

PU-10

PU-12

0.0

0.0

0.0

0.2

0.2

0.2

0.5

0.5

0.5

0.9

0.9

0.9

1.2

1.2

1.2

1.6

1.6

1.6

1.9

1.9

1.9

2.3

2.3

2.3

2.6

2.6

2.6

3.0

3.0

3.0

Piping length (one way) Additional refriferant charge (R22)áááákg

Warning

● If there is an insufficient amount of refrigerant in the system, the unit will behave in one of the following ways: 1) the discharge

temperature of the unit rises abnormally high, which is detected as an error, and the unit comes to a stop; 2) the discharge

temperature of the compressor rises abnormally high, the unit goes into the unload operation, which appears as the P8 error

on the display, and the unit comes to a stop; or 3) the built-in thermostat on the compressor goes off and stops the compressor. In either case, replenish and adjust the refrigerant. Once the unit goes into the unload operation, it will take a long

time until normal operation can be restored.

● It takes at least 3 hours for the compressor to recover after an unload operation.

Outdoor units

Outdoor unit

Position measurement

Measurement

point

Sound Levels

0.75m

1m

SPL

dB(A)

PU-8,10,12

Model

PU-8

PU-10

PU-12

66

66

66

63Hz

72

69

68

125Hz

68

66

65

250Hz

64

64

63

500Hz

64

63

64

1000Hz

62

62

61

2000Hz

58

56

57

4000Hz

53

54

53

8000Hz

44

50

45

OCTAVE BAND FREQ.Hz

Page 7

7

5 OUTLINES AND DIMENSIONS

PU-8,10,12YAKD

Unit : mm

< Accessory >

· Conduit mouting plate

(Painted the same color as the unit body)

a)

ø27 ············································· 1pc.

b)

ø34 ············································· 1pc.

· Tapping screw 4X12 ·························· 4pcs.

· Connection pipe ································· 1pc.

· Packing ·············································· 1pc.

Note 1. It is possible to change to

ø27 or ø34 by

selecting the conduit mounting plate a,b.

4-10X20 Holes

Refrigerant pipe

PU-8YAKD

:ø25.4 (1 flange)

PU-10,12YAKD

:

ø28.6 (1-1/8 flange)

Knock out hole

Pressure gauge

(For option)

Refrigerant pipe

ø15.88(5/8 flare)

<For the indoor unit

connection wiring>

ø27 Hole

Note 1

<For the power

supply wiring>

ø40 Hole

<For mounting

anchor bolt M8>

[Field supply]

Air outlet

Air

inlet

Air inlet

Top view

Right side view

Front view

Left side view

Connection pipe

(Accessory)

615

3454734

585 1515

1480

1047

108.5 830 108.5

15

62

97

152 55

65

115 100

Page 8

8

6 WIRING DIAGRAM

PU-8,10,12YAKD

3

1

C13

OUTDOOR UNIT

CZ

2

TB2

1

52C30Z

CZ

30Z

51C

C17

63L

1

2

2

1

C14

63H

CH

52C

51C

52C

3

2

1

3

2

C21

1

C11

MF3

MF2

MC

F03

N

L3

L2

POWER SUPPLY

3N~PE

380/400/415V

50HZ

TB1

L1

RED

WHITE

BLACK

BLUE

GREEN/YELLOW

L2

L1

L3

N

L1

1

2

3

4

5

6

78

GRAY

VIOLET

VIOLET

ORANGE

ORANGE

BLUE

INDOOR UNIT

(*1)

(*1)

PE

CIRCUIT BREAKER

(FIELD SUPPLY)

PU-8YAKD : 30A

PU-10YAKD : 40A

PU-12YAKD : 60A

PE

OUTDOOR UNIT

Note:1.The dotted lines show field wiring.

2.Color of earth wire is yellow and green twisting.

3.Specification subject to change without notice.

4.This motor(*1) includes auto reset type internal thermostat.

AUXILIARY RELAY

5. mark is connector. mark is terminal.

FUSE (3.15A 250VAC)

CRANK CASE HEATER (COMPRESSOR)CH

PRESSURE SWITCH (HIGH PRESSURE)

PRESSURE SWITCH (LOW PRESSURE)

63H

63L

TERMINAL BLOCKTB1,2

30Z,CZ

F03

OVER CURRENT RELAY (COMPRESSOR)51C

MAGNETIC CONTACTOR (COMPRESSOR,FAN MOTOR)52C

SYMBOL NAME

MC

MF2,3

COMPRESSOR MOTOR

FAN MOTOR (OUTDOOR)

Caution,

1.To protect compressor from abnormal current,over current relays is installed.

Therefore, do not change factory set value of over current relays.

Page 9

9

7 REFRIGERANT SYSTEM DIAGRAM

PU-8YAKD

PU-10YAKD

Indoor heat

exchanger

Outdoor heat

exchanger

Indoor coil

thermistor

TH2

Brazing

Flange

connection

Refrigerant pipe ø15.88

(With heat insulator)

Flow of refrigerant

Flow of refrigerant

Compressor

Accumulator

Ball Valve

Low pressure

switch

High pressure

switch

Ball Valve

Capillary tube

8HP : O.D. 6.0 X I.D. 4.0X L1000

10HP : O.D. 6.0 X I.D. 7.0 X L700

Strainer

Refrigerant pipe

8HP: ø25.4

10HP:ø28.6

(With heat insulator)

Serviceport

(With service port and strainer)

Serviceport

( )

Indoor heat

exchanger

Outdoor heat

exchanger

Indoor coil

thermistor

TH2

Brazing

Flange

connection

Refrigerant pipe ø15.88

(With heat insulator)

Compressor

Accumulator

Ball Valve

Low pressure

switch

High pressure

switch

Ball Valve

Capillary tube

Capillary tube

(O.D. 6.0 X I.D. 7.0 X L700)

(O.D. 6.0 X I.D. 4.0 X L800)

Capillary tube

(O.D. 6.0 X I.D. 4.0 X L700)

Strainer

Refrigerant pipe

ø28.6

(With heat insulator)

Serviceport Serviceport

(With service port and strainer)

Flared

connection

Flared

connection

PU-12YAKD

Page 10

10

8

TROUBLE SHOOTING

8-1. SELF-DIAGNOSTIC FUNCTION

8-2. HOW TO CHECK THE PARTS

8-2-1. Simple parts check method

Check

code

Diagnosis of malfunction Cause Check points

(P4) Abnormality of drain sensor 1) Bad contact of transmission

wire

2) Damaged thermistor

1) Check the connector.

2) Measure the resistance of the thermistor

4 ~

5.

As for the normal resistance, refer to the case

of P1.

If the resistance is normal, replace the indoor con-

troller board.

(P5) Malfunction of drain pump 1) Malfunction of drain pump

2) Damaged drain sensor

1) Check the drain pump.

2)

● Check the drain sensor.

● Check the drain sensor heater. Normal resis-

tance should be 82Ω.

If the resistance is normal, replace the indoor con-

troller board.

(P6) Coil frost protection is work-

ing.

1) Short cycle of air cycle

2) Dirty air filter

3) Damaged fan

4) Abnormal refrigerant

1) Clear obstructions from the air cycle.

2) Clean the air filter

3) Check the fan.

4) Check the refrigerant temperature.

(P8) Abnormality in outdoor unit 1) Wrong wiring of indoor/outdoor

connecting wire

2) Reversed phase

✻

3) Protection device is working

4) Damaged outdoor coil thermistor

1) Check the indoor/outdoor connecting wire.

2) Change the connection of electric wiring.

3) Check the protection device.

4) Measure the resistance of the outdoor coil thermistor. If the resistance is normal, replace the

outdoor controller board.

(P1)

(P2)

Abnormality of room temperature thermistor (TH1)

Abnormality of indoor coil

thermistor (TH2)

1) Bad contact of thermistor

2) Damaged thermistor

1) Check the thermistor.

2) Measure the resistance of the thermistor.

Normal resistance should be as follows.

0°C···15kΩ 30°C ····4.3kΩ

10°C·····9.6kΩ 40°C·····3.0kΩ

20°C·····6.3kΩ

If the resistance is normal, replace the indoor

controller board.

✻Warning

To avoid damage to the compressor, make certain that all three phases of the power supply voltage are in the proper phase

sequence.The fan on the outdoor unit that is connected in the reverse phase sequence will turn in the wrong direction and

make the compressor rattle.Once the built-in thermostat is triggered, it will take a long time until it returns to its pre-set temperature. Until the built-in thermal switch closes, the compressor cannot be started, even after the phase sequence is corrected.

¥ Outdoor units

Part name

Fan motor

Thermal protector

trip temperature

150±5ûC : ON

90±14ûC: OFF

Judgment instructions

Measure the resistance value across the terminals with a multimeter. (Winding

temperature 20 ûC)

White

Black

Normal

26

Ω

Abnormal

Open or short

Motor lead wire

Between 2 phases

Red

Page 11

11

9

SERVICE DATA (PARTS NAME)

PU-8,10YAKD

Detailed View of Section A

A

Pressure switch

63L

Pressure switch

63H

Crankcase

heater

Compressor

Heat exchanger

Heat exchanger

Accumulator

Capillary tube

Ball valve

Ball valve

Service port

Page 12

12

PU-12YAKD

A

Detailed View of Section A

Pressure switch

63L

Pressure switch

63H

Crankcase

heater

Compressor

Heat exchanger

Heat exchanger

Accumulator

Capillary tube

Capillary tube

for cooling

Ball valve

Service port

Ball valve

Capillary tube

Page 13

13

CONTROL BOX

Power source terminal block

Fuse F03

Magnetic contactor

for compressor (52C)

Relay(30Z)

Relay(CZ)

Terminal block for outdoor / indoor

control wiring connection

Page 14

1

2

14

10 OPTIONAL PARTS

Item Individual order number

Outlet grill PAC-SG208SG-E

Pressure gauge

Remark

2 pcs / pack

1 pcs / packPAC-SK209PG-E

Page 15

15

Page 16

New publication, effective July 2007.

Specifications subject to change without notice.

HWE07070

Printed in Japan

Loading...

Loading...