Page 1

Air-Conditioners For Building Application

HEAT SOURCE UNIT

PQHY-P-Y(S)HM-A (-BS)

For use with R410A

PQRY-P-Y(S)HM-A (-BS)

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

EΓXEIPI∆IO O∆HΓIΩN EΓKATAΣTAΣHΣ

°И· ·ЫК¿ПВИ· О·И ЫˆЫЩ‹ ¯Ъ‹ЫЛ, ·Ъ·О·ПВ›ЫЩВ ‰И·‚¿ЫВЩВ ЪФЫВ¯ЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ ВБО·Щ¿ЫЩ·ЫЛ˜ ЪИУ ·Ъ¯›ЫВЩВ ЩЛУ

ВБО·Щ¿ЫЩ·ЫЛ ЩЛ˜ МФУ¿‰·˜ ОПИМ·ЩИЫМФ‡.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по

установке до выполнения установки кондиционера.

MONTAJ ELKMONTAJ ELK

MONTAJ ELK

MONTAJ ELKMONTAJ ELK

Emniyetli ve doqru biçimde naswl kullanwlacaqwnw öqrenmek için lütfen klima cihazwnw monte etmeden önce bu elkitabwnw dikkatle okuyunuz.

WW

TABITABI

W

TABI

WW

TABITABI

GB

D

F

E

I

NL

P

GR

RU

TR

INSTALLATIONSHANDBOK

Läs den här installationshandboken noga innan luftkonditioneringsenheten installeras, för säker och korrekt användning.

РЪКОВОДСТВО ЗА МОНТАЖ

За безопасна и правилна употреба, моля, прочетете внимателно това ръководство преди монтажа на климатизатора.

CZ

SV

HG

PO

SL

SW

HR

BG

RO

Page 2

6

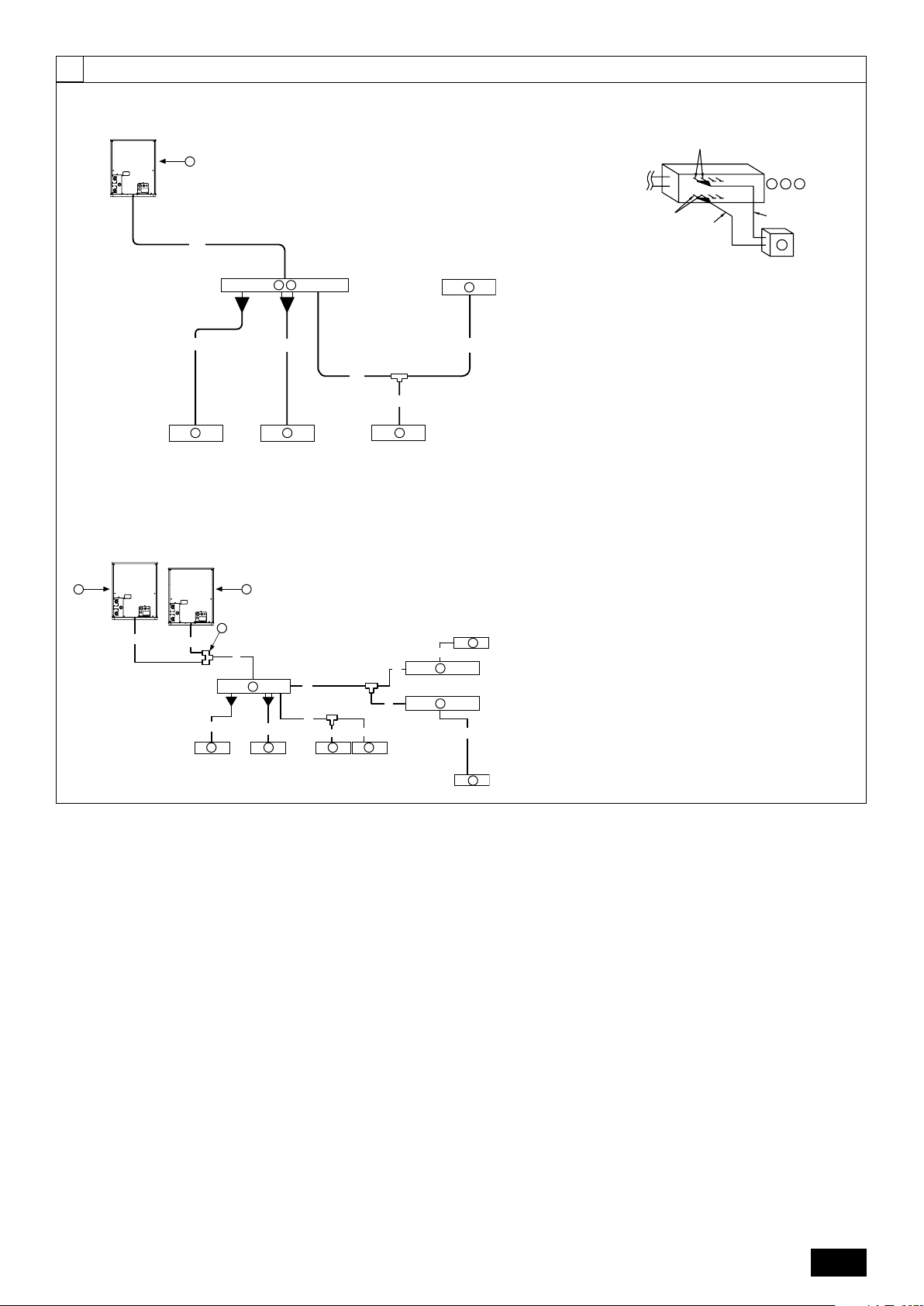

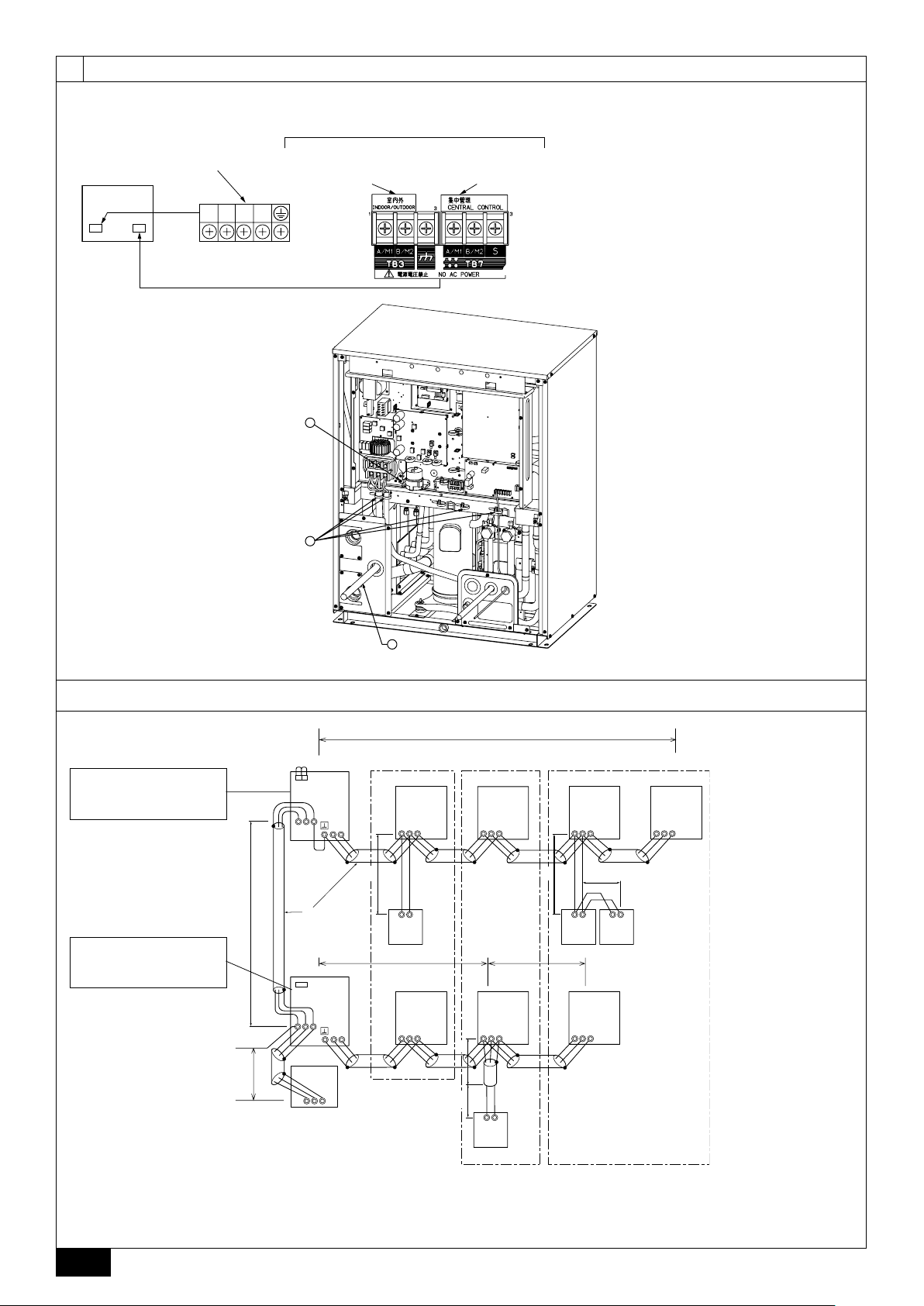

[Fig. 6.0.1]

1 P200 ~ P300

8m

8m

7

[Fig. 7.1.1]

<A> Without detachable leg

25mm or less

AA

CC

<B> With detachable leg

25mm or less

25mm or less

25mm or less

7.1

B

AA

D

AA

A : M10 anchor bolt procured at the site.

B : Check that the corner of the installation leg is securely

supported to prevent the leg from bending.

C : Check that the corner of the installation leg is securely

supported.

D : Detachable leg

D

2

B

[Fig. 7.1.2]

A

A : Screws

Page 3

7

[Fig. 7.2.1]

7.2

A : Space for removing the control box

B : Heat source unit

B

C : Service space (front side)

8

[Fig. 8.1.1]

A

C

450

600

A

8.1

F

C

A

B

E

G

D

H

J

Heat source unit sample installation Heat source unit sample installation (high water pressure model)

F

C

B

E

I

H

A : Main circulating water pipe B : Shutoff valve C : Shutoff valve

D :Water outlet (lower) E : Refrigerant pipes F :Y-type strainer

G :Water inlet (upper) H :Drain pipe I :Water outlet flange (lower)

J :Water inlet flange (upper)

8

8.4

[Fig. 8.4.1]

TB8

3

4

A

63PW

A : Short-circuit wire (Connected before delivery from manufacturer)

B : Pump interlock circuit connection

B

[Fig. 8.4.2]

LN

~ / N 240/230/220V

MCB

52P

A : Heat source unit

B : Site control panel

C :To next unit

A

A

TB8

TB8

B

1

2

3

4

1

2

3

4

TM1

TM2

52P

TM1

TM2

MP

C

3

Page 4

8

8.4

Te r minal No.

Output

Operation

TB8-1, 2

Relay contacts output Rated voltage: L1-N: 220 ~ 240V

• When Dip switch 2-7 is OFF.

The relay closes during compressor operation.

• When DIP switch 2-7 is ON.

The relay closes during reception of cooling or the heating operation signal from the controller.

(Note: It is output even if the thermostat is OFF (when the compressor is stopped).)

9

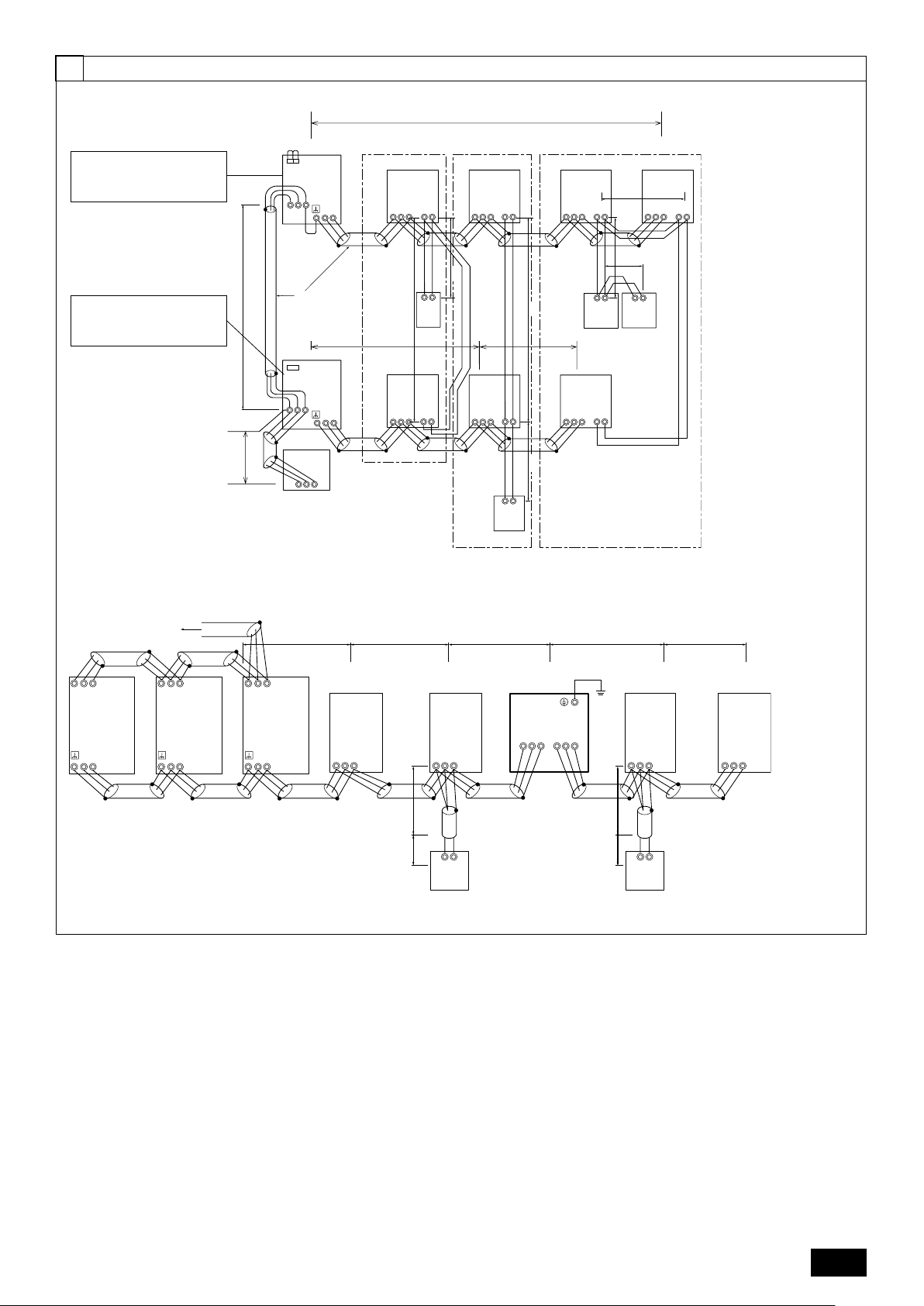

[Fig. 9.2.1]

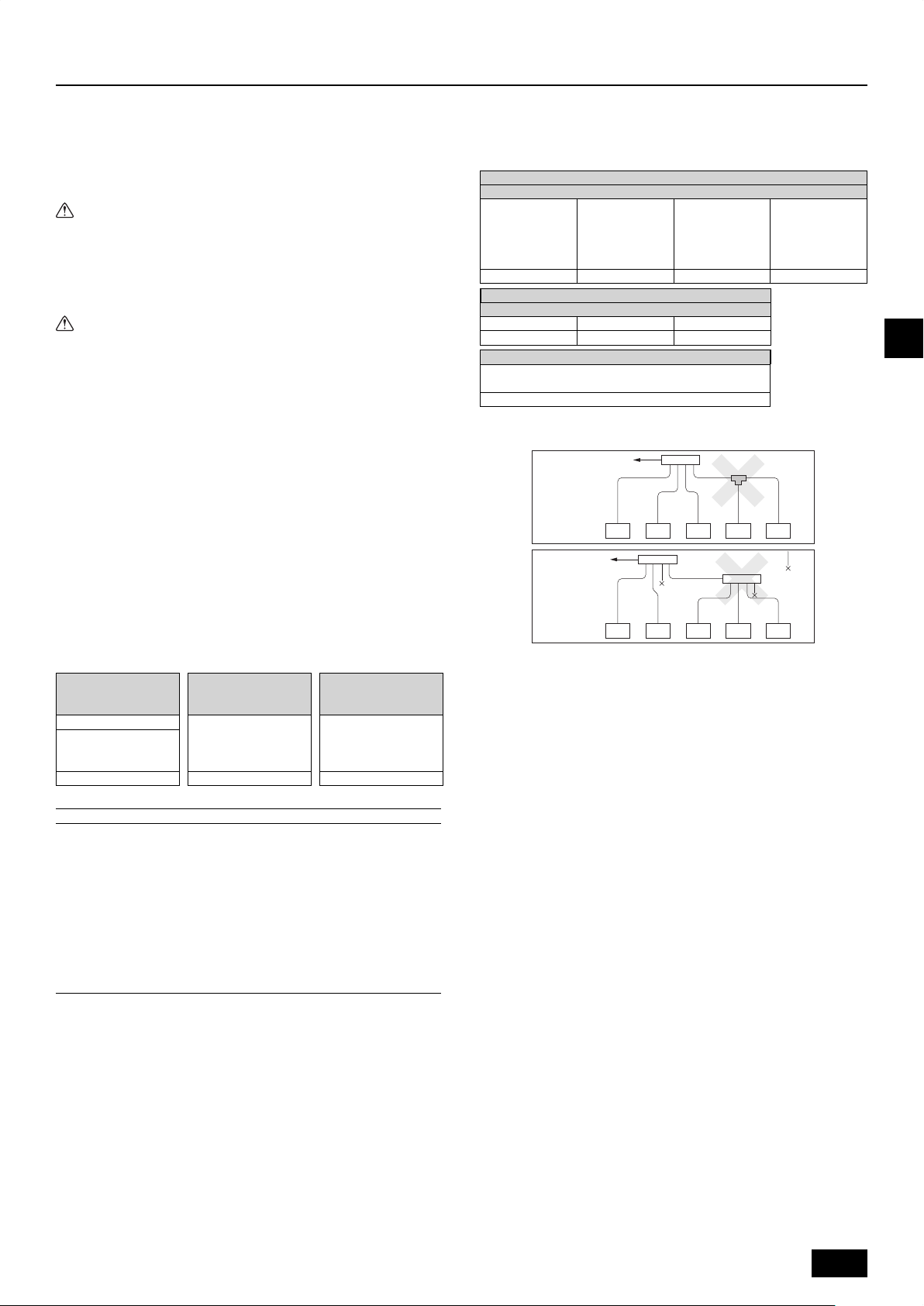

[PQHY-P200/250/300 YHM-A]

A

A

BCD

abcd

B

C

C C C

[PQHY-P400/450/500/550/600 YSHM-A]

unit1 unit2

Rated load: 1A

9.2

A

A

B

e

a

bcd

C C

C

unit1 unit2

C C C

D

e

A

A

1

A

2

E

A

AB

a

B

bcd

C

C C C

C D

e

C

A

A

A1 A2

A

B

E

a

bcde

C C

C C C

D

4

Page 5

9

[Fig. 9.2.2]

[PQRY-P200/250/300 YHM-A]

9.2

(*NOTE 1)

A

h

B C D

A

a

[PQRY-P400/450/500/550/600 YSHM-A]

unit1

A

A

unit2

A

1

G

A

2

A

C

a

E EF E

NOTE1

*

j

i

C

B

b

E

d

g

E

B

c

EFE

A : Heat source unit

B : BC controller (standard)

C : BC controller (main)

E

e

D

D

C

B

E

b

d

c

D

f

E

D : BC controller (sub)

E : Indoor unit (15 ~ 80)

F : Indoor unit (100 ~ 250)

G: Heat source twinning kit

5

Page 6

9

PQHY-P·Y(S)HM-A

A [Standard] (mm)

Å Heat source model

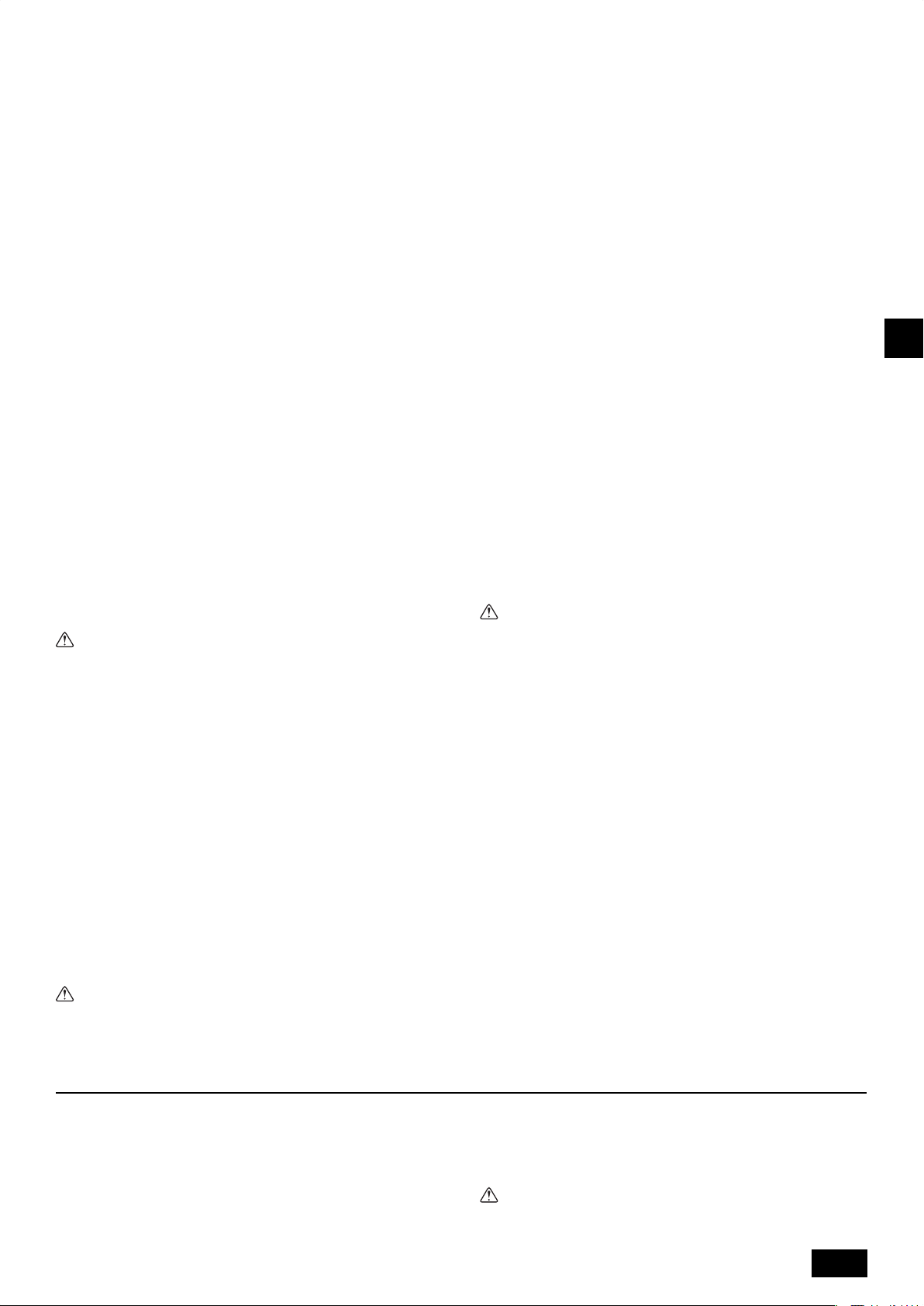

P200 - - ø9.52 ø19.05 - - - P250 - - *1 ø9.52 ø22.2 - - - P300 - - *2 ø9.52 ø22.2 - - - P400 P200 P200 ø12.7 ø28.58 ø9.52 ø19.05 ø9.52 ø19.05

P450 P250 P200 ø15.88 ø28.58 ø9.52 ø22.2 ø9.52 ø19.05

P500 P250 P250 ø15.88 ø28.58 ø9.52 ø22.2 ø9.52 ø22.2

P550 P300 P250 ø15.88 ø28.58 ø12.7 ø22.2 ø9.52 ø22.2

P600 P300 P300 ø15.88 ø28.58 ø12.7 ø22.2 ø12.7 ø22.2

PQRY-P·Y(S)HM-A

A [Standard] (mm)

Å Heat source model

P200 - - ø15.88 ø19.05 - - - P250 - - ø19.05 ø22.2 - - - P300 - - ø19.05 ø22.2 - - - P400 P200 P200 ø22.2 ø28.58 ø15.88 ø19.05 ø15.88 ø19.05

P450 P250 P200 ø22.2 ø28.58 ø19.05 ø22.2 ø15.88 ø19.05

P500 P250 P250 ø22.2 ø28.58 ø19.05 ø22.2 ø19.05 ø22.2

P550 P300 P250 ø28.58 ø28.58 ø19.05 ø22.2 ø19.05 ø22.2

P600 P300 P300 ø28.58 ø28.58 ø19.05 ø22.2 ø19.05 ø22.2

*1 ø12.7 for over 90m

*2 ø12.7 for over 40m

*3 The pipe sizes listed in columns A1 to A3 in this table correspond to the sized for the models listed in the unit 1, 2, and 3 columns. When the order of the models for

unit 1, 2, and 3 change, make sure to use the appropriate pipe size.

Unit combination A A1 *1 A2 *1

unit 1 unit 2 ı Liquid Side Ç Gas Side ı Liquid Side Ç Gas Side ı Liquid Side Ç Gas Side

Unit combination A A1 *1 A2 *1

unit 1 unit 2 Î High press.Side‰

9.2

Low press.SideÎ

High press.Side‰

Low press.SideÎ

High press.Side‰

Low press.Side

PQHY-P·Y(S)HM-A

B, C, D (mm)

Ï Total capacity of indoor units

a, b, c, d, e (mm)

È Model number

20,25,32,40,50

63,71,80,100,125,140

Ô Downstream unit model total

The 1st branch of P450 ~ P650

ˆ 4-Branching header

(Downstream unit

model total

CMY-Y104-G

~ 140

141 ~ 200

201 ~ 300

301 ~ 400

401 ~ 650

651 ~

200

250

~ 200

201 ~ 400

401 ~ 650

651 ~

Å Heat source model

P400 ~ P600

Ø 8-Branching header

<

=

200)

Ì Liquid pipe

ø9.52

ø9.52

ø9.52

ø12.7

ø15.88

ø19.05

ı Liquid pipe

ø6.35

ø9.52

ø9.52

ø9.52

Œ

(Downstream unit

model total

<

=

CMY-Y108-G

400)

CMY-Y102S-G2

CMY-Y102L-G2

CMY-Y202-G2

CMY-Y302-G2

Heat source twinning kit

CMY-Y100VBK2

Ó Gas pipe

ø15.88

ø19.05

ø22.2

ø28.58

ø28.58

ø34.93

Ç Gas pipe

ø12.7

ø15.88

ø19.05

ø22.2

˜ Joint

∏

10-Branching header

(Downstream unit

model total

CMY-Y1010-G

<

=

650)

PQRY-P·Y(S)HM-A

B (mm)

Ï Total capacity of indoor units

C, D (mm)

Ô Downstream

unit model total

201 ~ 300

301 ~ 350

351 ~ 400

401 ~ 450

g, h, i, j (mm)

È Model number

Å

Heat source model

P400 ~ P600

a, b, c, d, e, f (mm)

È Model number

15,20,25,32,40,50

63,71,80,100,125,140

~ 200

100

125

140

200

250

200

250

~ 80

Â

High-pressure

gas pipe

ø15.88

ø19.05

ø19.05

ø22.2

ø22.2

Ì Liquid pipe Ó Gas pipe

g

ø9.52

ø9.52

ø9.52

ø9.52

ø9.52

ΠHeat source twinning kit

CMY-Q100VBK

Ì Liquid pipe

ø9.52

ø9.52

ø9.52

ø9.52

ø9.52

ø6.35

ø9.52

ø9.52

ø9.52

Ì Liquid pipe

ø9.52

Í

Low-pressure

gas pipe

ø19.05

ø22.2

ø28.58

ø28.58

ø28.58

h

i

ø15.88

ø15.88

ø15.88

ø19.05

ø22.2

Ó Gas pipe

ø15.88

Ì Liquid pipe

ø9.52

ø9.52

ø12.7

ø12.7

ø15.88

j

ø15.88

ø15.88

ø15.88

ø15.88

ø15.88

Ó Gas pipe

ø12.7

ø15.88

ø19.05

ø22.2

6

Page 7

D

9

9.2

[Fig. 9.2.3]

2m

B

C

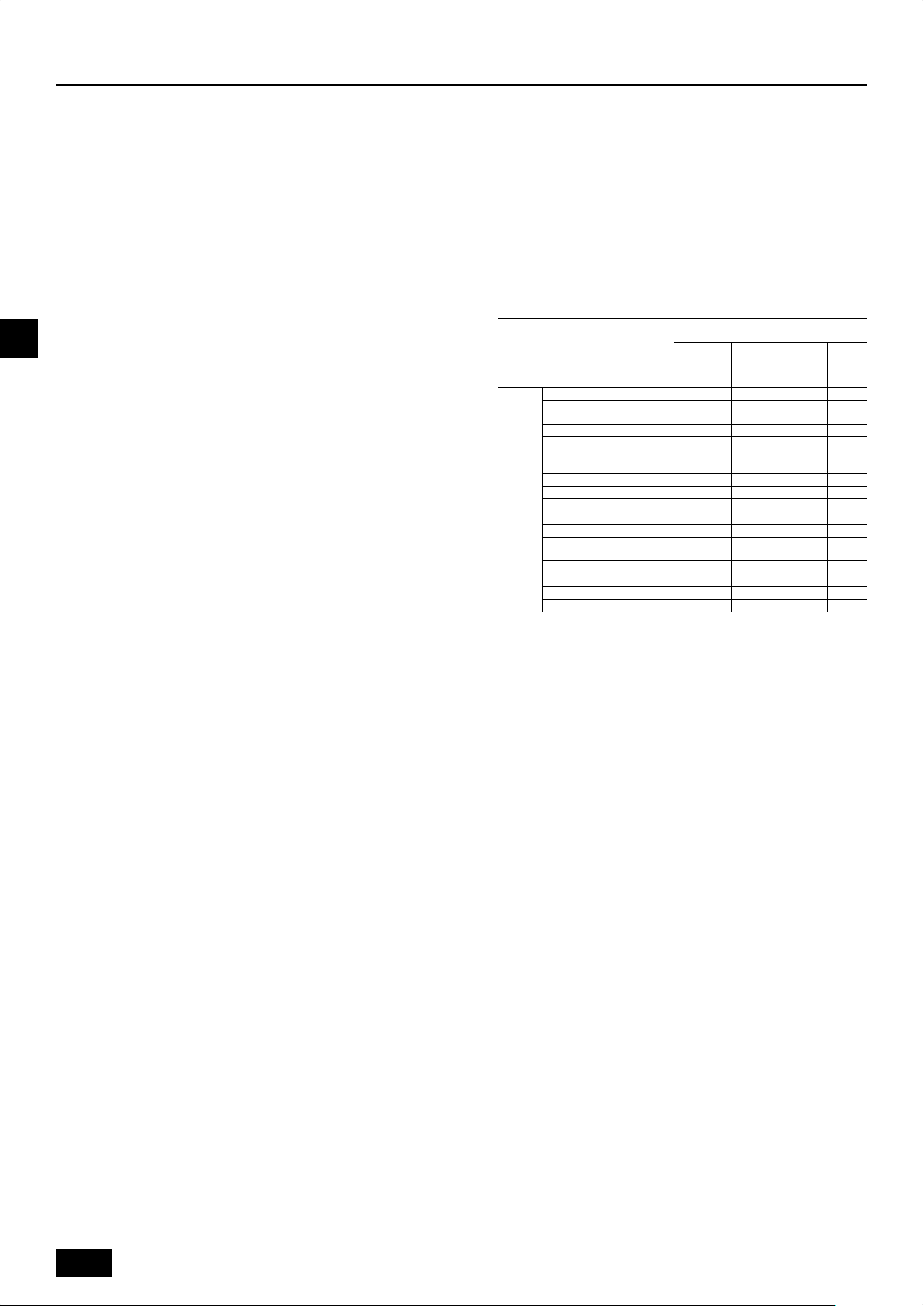

<A> When the piping on the heat source unit side (from the twinning

pipe) exceeds 2 m, ensure a trap (gas pipe only) within 2 m. Make

sure the height of the trap is 200 mm or more.

If there is no trap, oil can accumulate inside the pipe, causing a

shortage of oil and may damage the compressor.

(for PQHY-P·YSHM-A)

[Fig. 9.2.4]

D

A

D

A

<A> The piping from the heat source units to twinning pipe must be made to

slope downwards the twinning pipe. (both the liquid and the gas side for

PQHY-P·YSHM-A, the high-pressure side only for PQRY-P·YSHM-A)

<B> Slope of twinning pipes (for PQHY-P·YSHM-A)

Make sure the slope of the twinning pipes are at an angle within ±15° to the

horizontal plane.

If the slope exceeds the specifi ed angle, the unit may be damaged.

A

D

B

D

C

C

<B> Pipe connection example (for PQHY-P·Y(S)HM-A)

E

F

G

E

A : Indoor unit

B :Trap (gas pipe only)

C : Within 2 m

D :Twinning pipe

E : Pipes on site

F :Twinning kit

G : Straight run of pipe that is 500 mm or more

±15°

E

<C> Pipe connection example (for PQRY-P·YSHM-A)

F

H

G

A :Downward slope

B : Upward slope

C : BC controller (standard or main)

D :Twinning pipe

E :

Slope of the

F :Twinning pipe (low-pressure side)

G :Twinning pipe (high-pressure side)

H : On-site piping (low-pressure connecting pipe: between heat source units)

I : On-site piping (low-pressure main pipe: to BC controller)

J : On-site piping (high-pressure main pipe: to BC controller)

twinning

pipe is at an angle within ±15° to the gro

I

J

und

7

Page 8

10

G

H

I

F

<C>

<B>

10.2

[Fig. 10.2.1]

<A> Refrigerant service valve

(Liquid side/brazed type for

PQHY-P·Y(S)HM-A)

(High-pressure side/brazed type for

PQRY-P·Y(S)HM-A)

C

A

D

[Fig. 10.2.2]

No.

A Shape

PQHY-P200YHM-A

PQHY-P250YHM-A

PQHY-P300YHM-A

PQRY-P200YHM-A

PQRY-P250YHM-A

PQRY-P300YHM-A

<B> Refrigerant service valve

(Gas side/brazed type for

PQHY-P·Y(S)HM-A)

(Low-pressure side/brazed type for

PQRY-P·Y(S)HM-A)

B

A : Shaft

B : Service port

C : Cap

D : Pinched connecting pipe severing portion

E : Pinched connecting pipe brazing portion

E

12 3 4

ID15.88

ID19.05

-

-

-

1 <C> High-pressure side

-

-

ID19.05

ID25.4

1 <B> Gas side

-

-

1 <B> Low-pressure side

-

-

ID22.2

ID25.4

1 <B> Gas side

1 <B> Gas side

-

1 <B> Low-pressure side

1 <B> Low-pressure side

OD25.4

ID19.05

1 <B> Gas side

-

-

1 <C> High-pressure side

1 <C> High-pressure side

<A> Front pipe routing

B When not attaching a low-pressure twinning pipe

<C>

F

<A> Front pipe routing <B>

<D> Severing portion referral figure

A Shape B When not attaching a low-pressure twinning pipe C When attaching a low-pressure twinning pipe (PQRY-P·YSHM-A ONLY)

D Refrigerant service valve piping E On-site piping (low-pressure connecting pipe) F On-site piping (high-pressure connecting pipe)

G Twinning kit (sold separately)

H On-site piping (low-pressure connecting pipe: to BC controller)

I On-site piping (low-pressure connecting pipe: to heat source unit)

J 75 mm (reference measurement) K ID ø25.4 side L Severing portion

*1 For the attachment of the Twinning pipe (sold separately), refer to the instructions included in the kit.

*2 Connection pipe is not used when the Twinning kit is attached.

*3 Use a pipe cutter to sever.

<B>

<D> Severing portion

D

A

B

E

Low-pressure side PQRY-P·Y(S)HM-A (Gas side PQHY-P·Y(S)HM-A)

referral figure

J

L

K

*3

C When attaching a low-pressure twinning pipe (PQRY-P·YSHM-A ONLY) *1,*2

<C>

High-pressure side PQRY-P·Y(S)HM-A (Liquid side PQHY-P·Y(S)HM-A)

8

Page 9

F

D

10.3

[Fig. 10.3.1]

A

C

[Fig. 10.3.3]

A : Nitrogen gas

B

B

C

LOW

D

B In case of the R410A cylinder having no syphon pipe.

HI

E

G

H

I

J

B :To indoor unit

C : System analyzer

D :Low knob

E : Hi knob

F :Valve

G :Low-pressure pipe

H : High-pressure pipe

I : Heat source unit

J : Service port

[Fig. 10.3.2]

LOW

B

10.4

M

A : System analyzer

B :Low knob

C : Hi knob

D :Valve

E :Low-pressure pipe

F : High-pressure pipe

G : Service port

H : Three-way joint

I :Valve

J :Valve

K : R410A cylinder

L : Scale

M :Vacuum pump

N :To indoor unit

O : Heat source unit

EN

N

A

HI

C

H

F

O

G

I

K

J

L

A

A : Syphon pipe

[Fig. 10.4.1]

B

A

D

A : Steel wire B : Piping

C : Asphaltic oily mastic or asphalt

D : Heat insulation material A

E : Outer covering B

C

E

[Fig. 10.4.4]

<A> Inner wall (concealed) <B> Outer wall

D

A B

<E> Roof pipe shaft <F> Penetrating portion on fire

G

C

limit and boundary wall

A B

I

D

B

H

F

A

1m1m

A

B

[Fig. 10.4.3][Fig. 10.4.2]

C

D

E

E

B

E

A

D

A : High-pressure pipe B :Low-pressure pipe

C : Electric wire D : Finishing tape

E : Insulator

<D> Floor (waterproofing)<C> Outer wall (exposed)

E

B

A

D

F

G

B

A : Sleeve B : Heat insulating material

C : Lagging D : Caulking material

J

E : Band F :Waterproofing layer

G : Sleeve with edge H : Lagging material

I : Mortar or other incombustible caulking

J : Incombustible heat insulation material

9

Page 10

B

11

[Fig. 11.2.1]

A

Power supply terminal block

Control box

[Fig. 11.2.2]

A : Cable strap

B :Power source cable

C : Ground terminal for connection to field wiring

(TB1)

L1 L2 L3 N

Terminal block for indoor –

outdoor transmission line

(TB3)

C

C

11.2

Terminal block for

centralized control

(TB7)

A :Power source

B :Transmission line

C : Earth screw

[Fig. 11.3.1]

<A> Change the jumper connec-

tor from CN41 to CN40 *1

<B> SW2-1:ON *2

( ) Address

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

A

B

11.3

L

1

OC

CN40

(51)

TB3

M1M2

M1M2

S

TB7

2

L

D

L

OC

CN40

(52)

TB3

M1M2

M1M2

S

TB7

6

L

System

controller

ABS

A BC

IC

(01)

TB5

M1 M2 S

1

r

AB AB AB

(101)

RC

3

IC

(02)

TB5

M1 M2 S

IC

(04)

TB5

M1 M2 S

L

4

IC

(03)

TB5

M1 M2 S

5

L

4

r

B

A

(103)

RC

IC

(05)

TB5

M1 M2 S

2

r

(105)

RC

TB5

M1 M2 S

3

(155)

E

IC

(07)

r

M1 M2 S

RC

IC

(06)

TB5

*1: When the power supply unit is not connected to the transmission line for centralized control, disconnect the male power supply

connector (CN41) from ONE heat source unit in the system and connect it to CN40.

*2: If a system controller is used, set SW2-1 on all of the heat source units to ON.

10

Page 11

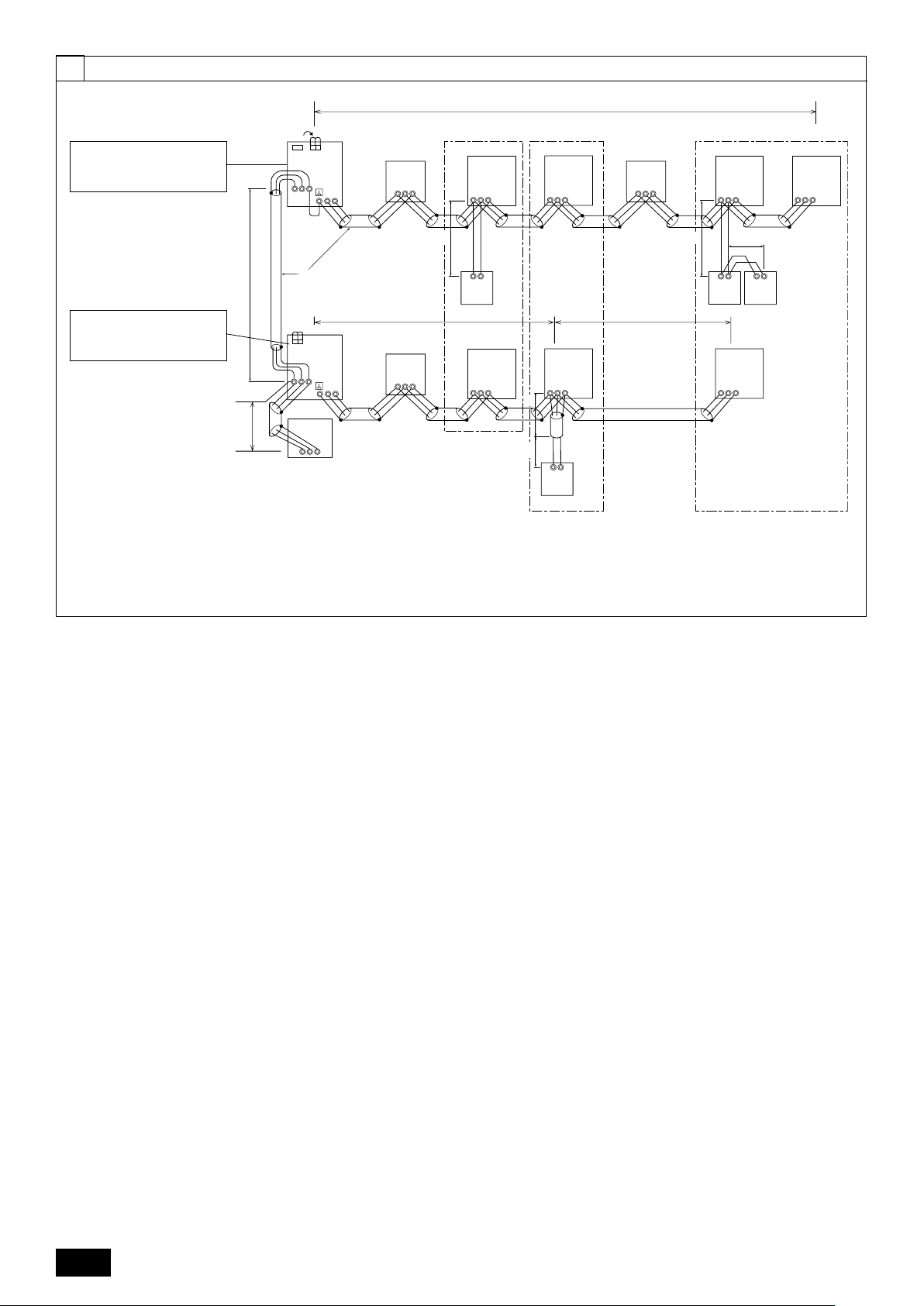

11

11.3

[Fig. 11.3.2]

<A> Change the jumper connec-

tor from CN41 to CN40 *1

<B> SW2-1:ON *2

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

A : Group 1

B : Group 3

C : Group 5

D : Shielded wire

E : Sub remote

controller

( ) Address

L

1

OC

CN40

(51)

TB3

M1 M2

M1M2

S

TB7

2

L

D

L

A BC

IC

(01)

TB5

TB15

M1 M2 1 2S

2

c

3

MA

IC

(04)

TB5

M1 M2 S

1

c

L

4

IC

(05)

c

TB5

M1 M2 S

2

c

E

2

TB15

12

1

c

c

4

ABABAB

MAMAMA

TB5

M1 M2 S

(06)

IC

TB15

12

3

c

OC

(02)

TB5

M1 M2 S

IC

TB15

12

CN40

(52)

TB3

M1 M2

M1M2

S

TB7

6

L

System

controller

B

A

S

TB5

M1 M2 S

(03)

IC

IC

(07)

TB 15

12

AB

1

c

TB5

M1 M2 S

TB15

12

[Fig. 11.3.3]

M1M2 S

TB7

TB3

M1M2

( ) Address

To another

refrigerant system

OS2

(53)

M1M2 S

TB7

TB3

M1M2

OS1

(52)

M1M2 S

TB7

TB3

M1M2

OC

(51)

L

L

L

L

L

1

2

3

5

6

Ground

TB5

M1M2 S

IC

IC

TB5

M1M2 S

4

L

1

r

RC

TB2

AB

RP

S

TB3

ABS

7

L

1

r

TB5

M1M2 S

ABAB

IC

RC

TB5

M1M2 S

IC

11

Page 12

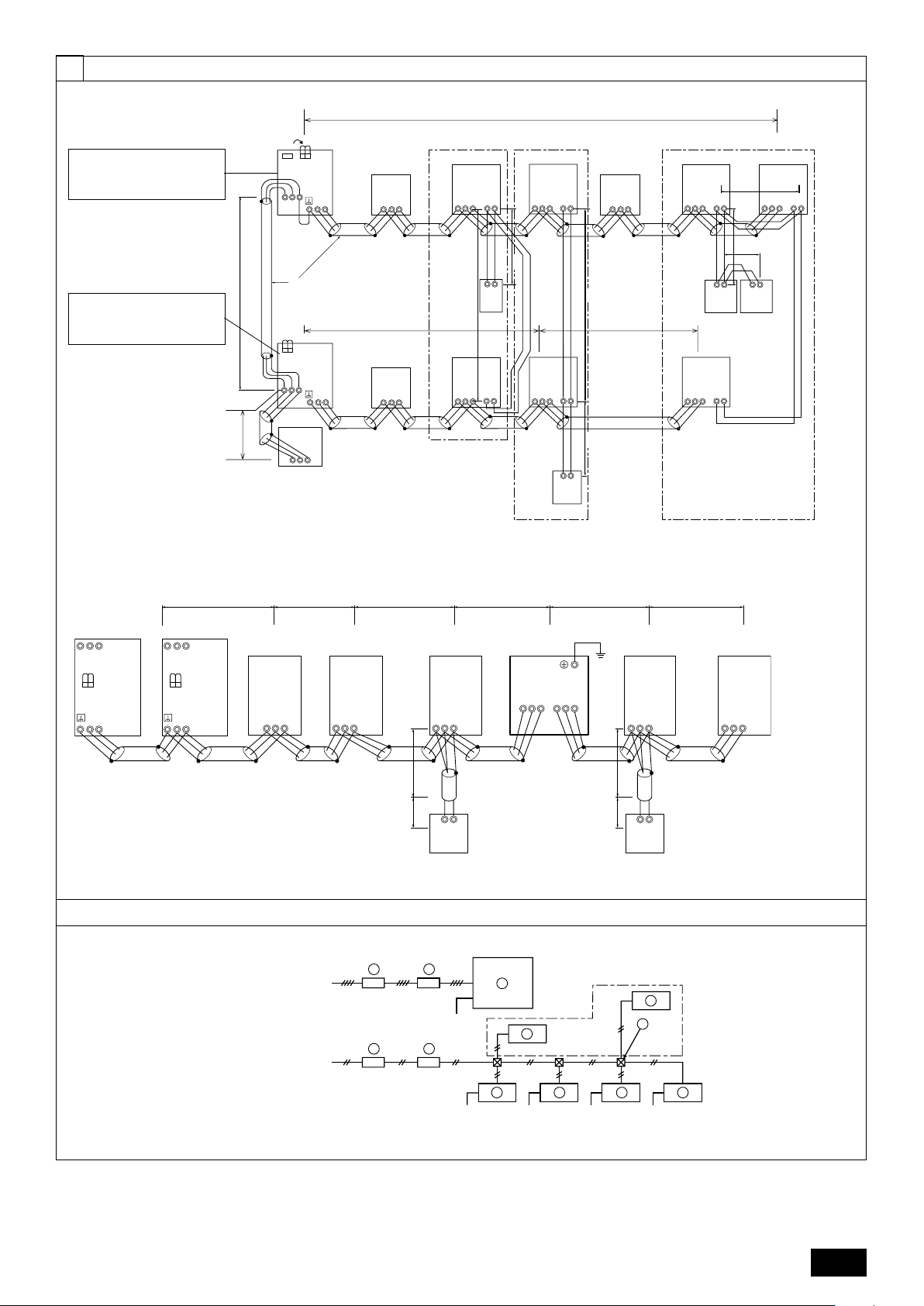

11

11.3

[Fig. 11.3.4]

<A> Change the jumper connec-

tor from CN41 to CN40 *1

<B> SW2-1:ON *2

( ) Address

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

L

1

OC

CN40

CN41

(51)

TB3

M1M2

M1M2

S

TB7

2

L

D

BC

(52)

TB02

M1 M2 S

L

3

A BC

TB5

M1 M2 S

(04)

IC

BS

(55)

TB02

M1 M2 S

2

r

(105)

L

4

IC

(01)

TB5

M1 M2 S

1

r

AB AB AB

(101)

RC

TB5

M1 M2 S

RC

(05)

IC

r

3

(155)

RC

E

TB5

M1 M2 S

IC

(06)

OC

TB5

M1 M2 S

IC

(02)

CN41

CN41

(53)

TB3

M1M2

M1M2

S

TB7

6

L

System

controller

ABS

BC

(54)

TB02

M1 M2 S

IC

(03)

TB5

M1 M2 S

5

L

4

r

B

A

(103)

TB5

M1 M2 S

IC

(07)

RC

*1: When the power supply unit is not connected to the transmission line for centralized control, disconnect the male power supply

connector (CN41) from ONE heat source unit in the system and connect it to CN40.

*2: If a system controller is used, set SW2-1 on all of the heat source units to ON.

12

Page 13

11

11.3

[Fig. 11.3.5]

<A> Change the jumper connec-

tor from CN41 to CN40 *1

<B> SW2-1:ON *2

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

A : Group 1

B : Group 3

C : Group 5

D : Shielded wire

E : Sub remote

controller

( ) Address

L1

A BC

IC

(01)

TB5 TB15

M1 M2 1 2S

TB5

M1 M2 S

(04)

TB5

M1 M2 S

(05)

IC

TB15

12

IC

TB15

12

BS

(55)

TB02

M1 M2 S

c1

c2

c4

TB5

M1 M2 S

(06)

IC

TB15

12

CN41

M1M2

OC

CN40

(51)

TB3

M1 M2

S

TB7

BC

(52)

TB02

M1 M2 S

c1

L2

L6

D

CN41

(53)

M1M2

S

TB7

System

controller

A

OC

B

TB5

M1 M2 S

ABABAB

MAMAMA

E

IC

(07)

TB15

12

c3

c2

(02)

TB5

M1 M2 S

MA

IC

(03)

TB15

12

TB5

M1 M2 S

L3

BC

(54)

TB3

M1 M2

S

TB02

M1 M2 S

c2

L4

IC

TB15

12

c1

AB

[Fig. 11.3.6]

L

OS

M1M2 S

(52)

TB7

CN41 CN41

TB3

M1M2

M1M2 S

TB7

M1M2

11

OC

(51)

TB3

M1M2

TB02

L

12

ICBC

TB5

S

M1M2 S

• ( ) Address

• Daisy-chain terminals (TB3) on heat source units in the same refriger-

ant system together.

• Leave the power jumper connector on CN41 as it is. When connecting a

system controller to the transmission line (TB7) for centralized control,

refer to [Fig. 11.3.1], [Fig. 11.3.2], or DATA BOOK.

[Fig. 11.4.1]

A : Switch (Breakers for wir-

ing and current

leakage)

B :Breakers for current

leakage

C : Heat source unit

D : Pull box

E : Indoor unit

F : BC controller

(standard or main)

(for PQRY-P·Y(S)HM-A)

F':BC controller (sub)

(for PQRY-P·Y(S)HM-A)

3N~ (L1, L2, L3, N)

380-415V

~ (L, N)

220-240V

L

13

15

L

1

r

B A

B A

TB5

M1M2 S

RC

L

14

Ground

IC

TB2

AB

RP

S

TB3

ABS

11.4

C

PE

PE

F

E E E E

PE PE PE

L

L

16

IC

TB5

M1M2 S

18

L

1

r

ABAB

RC

17

IC

TB5

M1M2 S

F '

D

13

Page 14

Contents

1. Safety precautions ..................................................................................... 14

1.1. Before installation and electric work .......................................... 14

1.2. Precautions for devices that use R410A refrigerant .................. 14

1.3. Before installation ...................................................................... 15

1.4. Before installation (relocation) - electrical work ......................... 15

1.5. Before starting the test run ........................................................ 15

2. About the product ....................................................................................... 15

3. Combination of heat source units .............................................................. 16

4. Specifi cations ............................................................................................. 16

5. Confi rmation of parts attached ................................................................... 17

6. Lifting method ............................................................................................ 17

7. Installation of unit ....................................................................................... 17

7.1. Installation ................................................................................. 17

7.2. Service space ............................................................................ 17

8. Water pipe installation ................................................................................ 18

8.1. Precautions during installation .................................................. 18

8.2. Insulation installation ................................................................. 18

GB

8.3. Water processing and water quality control ..............................18

8.4. Pump interlock .......................................................................... 18

1. Safety precautions

1.1. Before installation and electric work

X Before installing the unit, make sure you read all the

“Safety precautions”.

X The “Safety precautions” provide very important points

regarding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. (This symbol is displayed on the main unit

label.) <Color: yellow>

Warning:

Carefully read the labels affi xed to the main unit.

HIGH VOLTAGE WARNING:

•

Control box houses high-voltage parts.

•

When opening or closing the front panel of the control box, do not let it

come into contact with any of the internal components.

•

Before inspecting the inside of the control box, turn off the power,

keep the unit off for at least 10 minutes, and confi rm that the voltage

between FT-P and FT-N on INV Board has dropped to DC20V or less.

(It takes about 10 minutes to discharge electricity after the power

supply is turned off.)

Warning:

•

The water circuit should be a closed circuit.

•

Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric

shock, or fi re.

•

Install the unit at a place that can withstand its weight.

- Failure to do so may cause the unit to fall down, resulting in injuries and

damage to the unit.

Use the specifi ed cables for wiring. Make the connections securely so

•

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fi re.

Prepare for strong winds and earthquakes and install the unit at the

•

specifi ed place.

- Improper installation may cause the unit to topple and result in injury and

damage to the unit.

•

Always use fi lters and other accessories specifi ed by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper

installation by the user may result in water leakage, electric shock, or fi re.

Never repair the unit. If the air conditioner must be repaired, consult

•

the dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fi re may

result.

14

9. Refrigerant piping installation ..................................................................... 19

9.1. Caution ...................................................................................... 19

9.2. Refrigerant piping system ........................................................ 20

10. Additional refrigerant charge ...................................................................... 21

10.1. Calculation of additional refrigerant charge ............................... 21

10.2. Precautions concerning piping connection and valve

operation ................................................................................... 22

10.3. Airtight test, evacuation, and refrigerant charging ..................... 23

10.4. Thermal insulation of refrigerant piping ..................................... 24

11. Wiring (For details, refer to the installation manual of each unit and

controller.) .................................................................................................. 24

11.1. Caution ...................................................................................... 24

11.2. Control box and connecting position of wiring ........................... 24

11.3. Wiring transmission cables ....................................................... 25

11.4. Wiring of main power supply and equipment capacity .............. 27

12. Test run ...................................................................................................... 28

12.1. The following phenomena do not represent faults. ................... 28

13. Information on rating plate .........................................................................28

Do not touch the fan and heat exchanger fi ns.

•

If refrigerant gas leaks during installation work, ventilate the room.

•

- If the refrigerant gas comes into contact with a fl ame, poisonous gases will

be released.

Install the air conditioner according to this Installation Manual.

•

- If the unit is installed improperly, water leakage, electric shock, or fi re may

result.

Have all electric work done by a licensed electrician according

•

to “Electric Facility Engineering Standard” and “Interior Wire

Regulations” and the instructions given in this manual and always use

a dedicated power supply.

- If the power source capacity is inadequate or electric work is performed

improperly, electric shock and fi re may result.

Keep the electric parts away from water (washing water etc.).

•

- It might result in electric shock, catching fi re or smoke.

Securely install the heat source unit terminal cover (panel).

•

- If the terminal cover (panel) is not installed properly, dust or water may

enter the heat source unit and fi re or electric shock may result.

When installing and moving the air conditioner to another site, do not

•

charge it with a refrigerant different from the refrigerant specifi ed on

the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the

refrigerant cycle may malfunction and the unit may be damaged.

If the air conditioner is installed in a small room, measures must be

•

taken to prevent the refrigerant concentration from exceeding the

safety limit if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the

safety limit from being exceeded. Should the refrigerant leak and cause

the safety limit to be exceeded, hazards due to lack of oxygen in the room

could result.

When moving and reinstalling the air conditioner, consult the dealer or

•

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock,

or fi re may result.

After completing installation work, make sure that refrigerant gas is not

•

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

Do not reconstruct or change the settings of the protection devices.

•

- If the pressure switch, thermal switch, or other protection device is shorted

or operated forcibly, or parts other than those specifi ed by Mitsubishi

Electric are used, fi re or explosion may result.

To dispose of this product, consult your dealer.

•

The installer and system specialist shall secure safety against leakage

•

according to local regulation or standards.

- Choose the appropriate wire size and the switch capacities for the main

power supply described in this manual if local regulations are not available.

Pay special attention to the place of installation, such as a basement,

•

etc. where refrigeration gas can accumulate, since refrigerant is

heavier than the air.

1.2. Precautions for devices that use

R410A refrigerant

Caution:

Do not use existing refrigerant piping.

•

- The old refrigerant and refrigerant oil in the existing piping contains a large

amount of chlorine which may cause the refrigerant oil of the new unit to

deteriorate.

- R410A is a high-pressure refrigerant and can cause the existing piping to

burst.

Page 15

•

Use refrigerant piping made of phosphorus deoxidized copper and

copper alloy seamless pipes and tubes. In addition, be sure that the

inner and outer surfaces of the pipes are clean and free of hazardous

sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other

contaminant.

- Contaminants on the inside of the refrigerant piping may cause the

refrigerant oil to deteriorate.

•

Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor failure may result.

•

Apply a small amount of ester oil, ether oil, or alkyl benzene to fl ares.

(for indoor unit)

- Infi ltration of a large amount of mineral oil may cause the refrigerant oil to

deteriorate.

•

Use liquid refrigerant to fi ll the system.

- If gas refrigerant is used to fi ll the system, the composition of the

refrigerant in the cylinder will change and performance may drop.

•

Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is mixed with R410A, the chlorine in the

refrigerant may cause the refrigerant oil to deteriorate.

•

Use a vacuum pump with a reverse fl ow check valve.

- The vacuum pump oil may fl ow back into the refrigerant cycle and cause

the refrigerant oil to deteriorate.

•

Do not use the following tools that are used with conventional

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse fl ow check

valve, refrigerant charge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerant oil are mixed in the R410A,

the refrigerant may deteriorate.

- If water is mixed in the R410A, the refrigerant oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for

conventional refrigerants will not react to it.

•

Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

•

Be especially careful when managing the tools.

- If dust, dirt, or water gets into the refrigerant cycle, the refrigerant may

deteriorate.

1.3. Before installation

Caution:

•

Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

•

Do not use the air conditioner where food, pets, plants, precision

instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

•

Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can signifi cantly reduce the performance of

the air conditioner or damage its parts.

•

When installing the unit in a hospital, communication station, or similar

place, provide suffi cient protection against noise.

- Inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air

conditioner to operate erroneously, or fail to operate. On the other hand,

the air conditioner may affect such equipment by creating noise that

disturbs medical treatment or image broadcasting.

•

Do not install the unit on or over things that are subject to water

damage.

- When the room humidity exceeds 80% or when the drain pipe is clogged,

condensation may drip from the indoor unit. Perform collective drainage

work together with the heat source unit, as required.

Never connect in reverse phases.

•

Never connect the Power Line L1, L2, and L3 to Terminal N.

- If the unit is miss wired, when power is supplied, some electrical parts will

be damaged.

Install the power cable so that tension is not applied to the cable.

•

- Tension may cause the cable to break and generate heat and cause a fi re.

Install a leak circuit breaker, as required.

•

- If a leak circuit breaker is not installed, electric shock may result.

Use power line cables of suffi cient current carrying capacity and rating.

•

- Cables that are too small may leak, generate heat, and cause a fi re.

Use only a circuit breaker and fuse of the specifi ed capacity.

•

- A fuse or circuit breaker of a larger capacity, or the use of a substitute

simple steel or copper wire may result in a general unit failure or fi re.

Do not wash the air conditioner units.

•

- Washing them may cause an electric shock.

•

Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal

injury or property damage.

•

Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture

and other possessions.

•

Be very careful about transporting the product.

- One person should not carry the product. Its weight is in excess of 20kg.

- Some products use PP bands for packaging. Do not use any PP bands as

a means of transportation. It is dangerous.

- Do not touch the heat exchanger fi ns. Doing so may cut your fi ngers.

- When transporting the heat source unit, support it at the specifi ed positions

on the unit base. Also support the heat source unit at four points so that it

cannot slip sideways.

•

Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may

cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which has not been torn

apart, they face the risk of suffocation.

1.5. Before starting the test run

Caution:

Turn on the power at least 12 hours before starting operation.

•

- Starting operation immediately after turning on the main power switch

can result in irreversible damage to internal parts. Keep the power switch

turned on during the operational season. Make sure of the phase order of

power supply and voltage between each phase.

Do not touch the switches with wet fi ngers.

•

- Touching a switch with wet fi ngers can result in an electric shock.

Do not touch the refrigerant pipes during and immediately after

•

operation.

- During and immediately after operation, the refrigerant pipes may be hot

or cold, depending on the condition of the refrigerant fl owing through the

refrigerant piping, compressor, and other refrigerant cycle parts. Your

hands may suffer burns or frostbite if you touch the refrigerant pipes.

Do not operate the air conditioner with the panels and guards removed.

•

- Rotating, hot, or high-voltage parts can cause injuries.

Do not turn off the power immediately after stopping operation.

•

- Always wait at least 5 minutes before turning off the power. Otherwise,

drainage water leakage or mechanical failure of sensitive parts may occur.

•

Do not touch the surface of the compressor during servicing.

- If unit is connected to a supply and not running, the crank case heater

located at the base of the compressor may still be operating.

GB

1.4. Before installation (relocation) electrical work

Caution:

Ground the unit.

•

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

2. About the product

This unit uses R410A-type refrigerant.

•

Piping for systems using R410A may be different from that for systems using

•

conventional refrigerant because the design pressure in systems using

R410A is higher. Refer to the Data Book for more information.

Some of the tools and equipment used for installation with systems that use

•

other types of refrigerant cannot be used with the systems using R410A.

Refer to the Data Book for more information.

•

Do not use the existing piping, as it contains chlorine, which is found in

conventional refrigerating machine oil and refrigerant. This chlorine will

deteriorate the refrigerant machine oil in the new equipment. The existing

piping must not be used as the design pressure in systems using R410A

is higher than that in the systems using other types of refrigerant and the

existing pipes may burst.

Caution:

Do not vent R410A into the atmosphere.

•

R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol

•

with a Global Warming Potential (GWP) = 1975.

15

Page 16

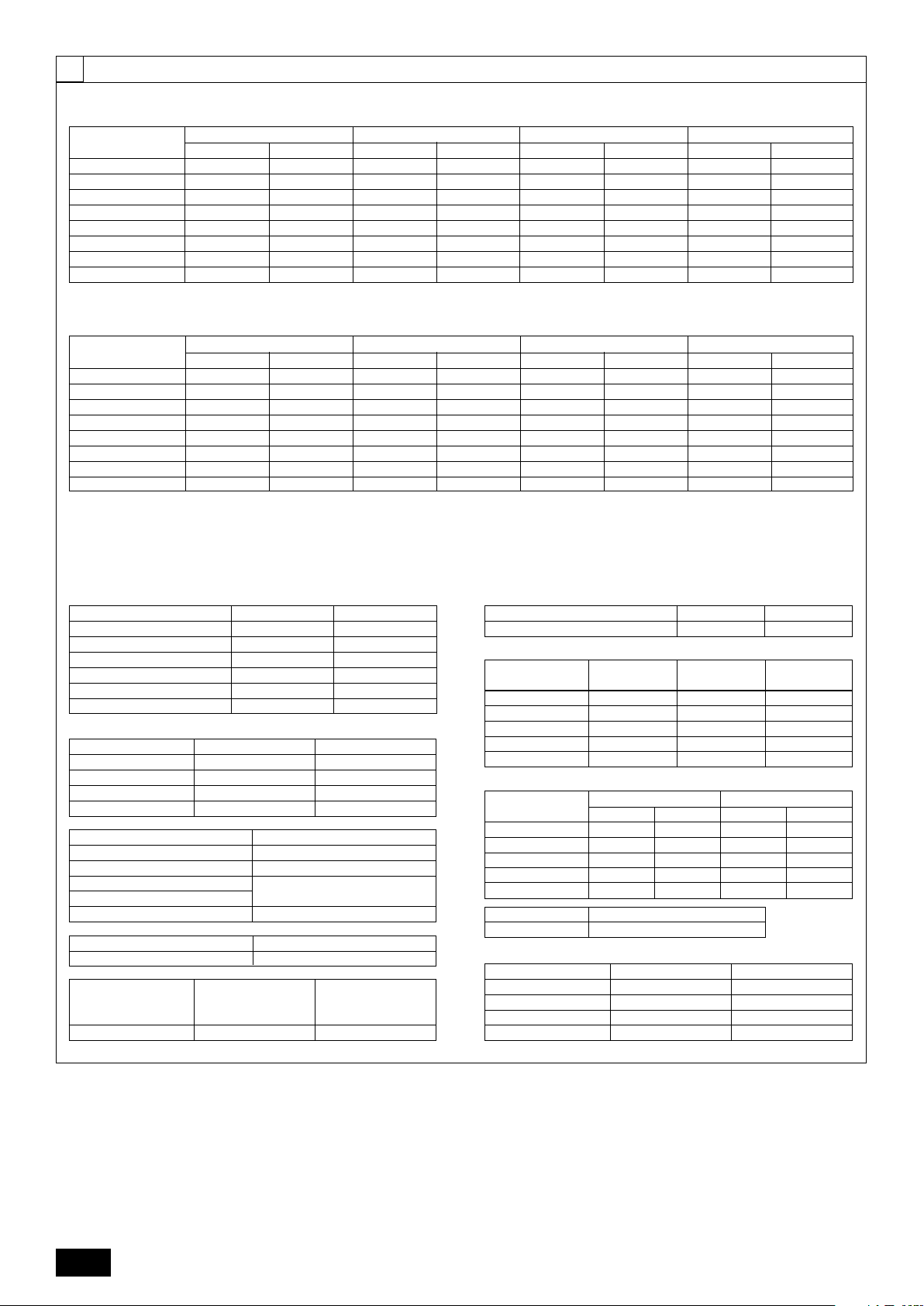

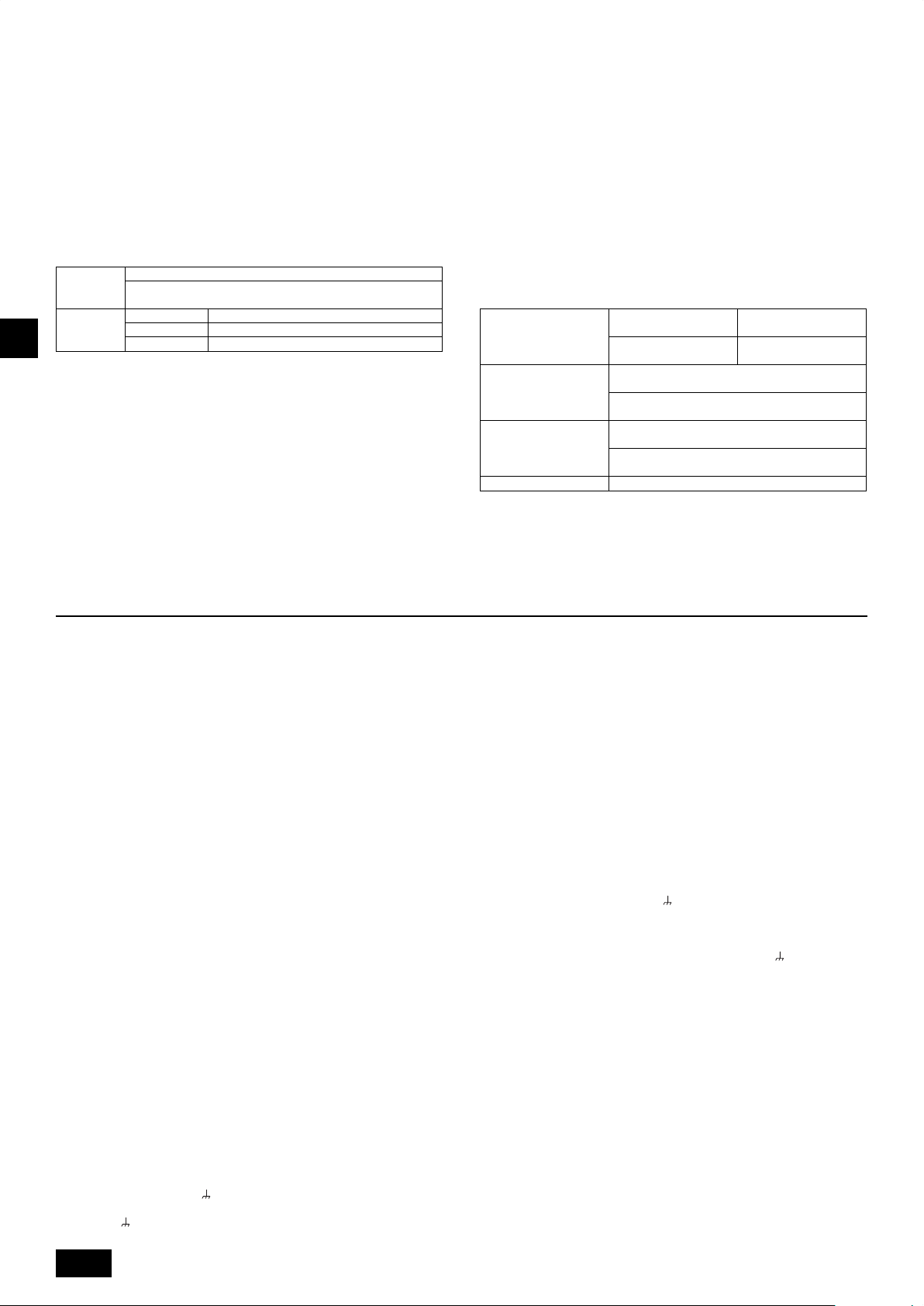

3. Combination of heat source units

Component units of PQHY-P200 to P900 are listed below.

Heat source unit model Component unit model

PQHY-P200YHM-A(-BS) - PQHY-P250YHM-A(-BS) - PQHY-P300YHM-A(-BS) - PQHY-P400YSHM-A(-BS) PQHY-P200YHM-A(-BS) PQHY-P200YHM-A(-BS)

PQHY-P450YSHM-A(-BS) PQHY-P250YHM-A(-BS) PQHY-P200YHM-A(-BS)

PQHY-P500YSHM-A(-BS) PQHY-P250YHM-A(-BS) PQHY-P250YHM-A(-BS)

PQHY-P550YSHM-A(-BS) PQHY-P300YHM-A(-BS) PQHY-P250YHM-A(-BS)

PQHY-P600YSHM-A(-BS) PQHY-P300YHM-A(-BS) PQHY-P300YHM-A(-BS)

Component units of PQRY-P200 to P600 are listed below.

Heat source unit model Component unit model

PQRY-P200YHM-A(-BS) - PQRY-P250YHM-A(-BS) - PQRY-P300YHM-A(-BS) - PQRY-P400YSHM-A(-BS) PQRY-P200YHM-A(-BS) PQRY-P200YHM-A(-BS)

PQRY-P450YSHM-A(-BS) PQRY-P250YHM-A(-BS) PQRY-P200YHM-A(-BS)

GB

PQRY-P500YSHM-A(-BS) PQRY-P250YHM-A(-BS) PQRY-P250YHM-A(-BS)

PQRY-P550YSHM-A(-BS) PQRY-P300YHM-A(-BS) PQRY-P250YHM-A(-BS)

PQRY-P600YSHM-A(-BS) PQRY-P300YHM-A(-BS) PQRY-P300YHM-A(-BS)

4. Specifi cations

PQHY-P·YHM-A

Model PQHY-P200YHM-A(-BS) PQHY-P250YHM-A(-BS) PQHY-P300YHM-A(-BS) PQHY-P400YSHM-A(-BS)

Noise level 47dB<A> 49dB<A> 50dB<A> 50dB<A>

Net weight 195 kg 195 kg 195 kg 195 kg + 195 kg

Allowable pressure HP:4.15 MPa, LP:2.21MPa

Refrigerant R410A: 5.0 kg R410A: 5.0 kg R410A: 5.0 kg R410A: 5.0 kg + 5.0 kg

Indoor units

Operation temperature Water temperature: 10

Total capacity 50 ~ 130%

Model 15 ~ 250

Quantity 1 ~ 17 1 ~ 21 1 ~ 26 1 ~ 34

*1

°C ~ 45°C

Model PQHY-P450YSHM-A(-BS) PQHY-P500YSHM-A(-BS) PQHY-P550YSHM-A(-BS) PQHY-P600YSHM-A(-BS)

Noise level 51dB<A> 52dB<A> 52.5dB<A> 53dB<A>

Net weight 195 kg + 195 kg 195 kg + 195 kg 195 kg + 195 kg 195 kg + 195 kg

Allowable pressure HP:4.15 MPa, LP:2.21MPa

Refrigerant R410A: 5.0 kg + 5.0 kg R410A: 5.0 kg + 5.0 kg R410A: 5.0 kg + 5.0 kg R410A: 5.0 kg + 5.0 kg

Indoor units

Operation temperature Water temperature: 10

*1: The total indoor capacity of units run simultaneously is 130% or less.

PQRY-P·YHM-A

Model PQRY-P200YHM-A(-BS) PQRY-P250YHM-A(-BS) PQRY-P300YHM-A(-BS) PQRY-P400YSHM-A(-BS)

Noise level 47dB<A> 49dB<A> 50dB<A> 50dB<A>

Net weight 181 kg 181 kg 181 kg 181 kg + 181 kg

Allowable pressure HP:4.15 MPa, LP:2.21MPa

Refrigerant R410A: 5.0 kg R410A: 5.0 kg R410A: 5.0 kg R410A: 5.0 kg + 5.0 kg

Indoor units

Operation temperature Water temperature: 10

Model PQRY-P450YSHM-A(-BS) PQRY-P500YSHM-A(-BS) PQRY-P550YSHM-A(-BS) PQRY-P600YSHM-A(-BS)

Noise level 51dB<A> 52dB<A> 52.5dB<A> 53dB<A>

Net weight 181 kg + 181 kg 181 kg + 181 kg 181 kg + 181 kg 181 kg + 181 kg

Allowable pressure HP:4.15 MPa, LP:2.21MPa

Refrigerant R410A: 5.0 kg + 5.0 kg R410A: 5.0 kg + 5.0 kg R410A: 5.0 kg + 5.0 kg R410A: 5.0 kg + 5.0 kg

Indoor units

Operation temperature Water temperature: 10°C ~ 45°C

*1: The total indoor capacity of units run simultaneously is 150% or less.

*2: Connectable branch pipe number is max.48.

Total capacity 50 ~ 130%

Model 15 ~ 250

Quantity 1 ~ 39 1 ~ 43 2 ~ 47 2 ~ 50

Total capacity 50 ~ 150%

Model 15 ~ 250

Quantity 1 ~ 20 1 ~ 25 1 ~ 30 1 ~ 40

Total capacity 50 ~ 150%

Model 15 ~ 250

Quantity 1 ~ 45 1 ~ 50

*2

*1

°C ~ 45°C

*1

°C ~ 45°C

*1

2 ~ 50

*2

2 ~ 50

*2

16

Page 17

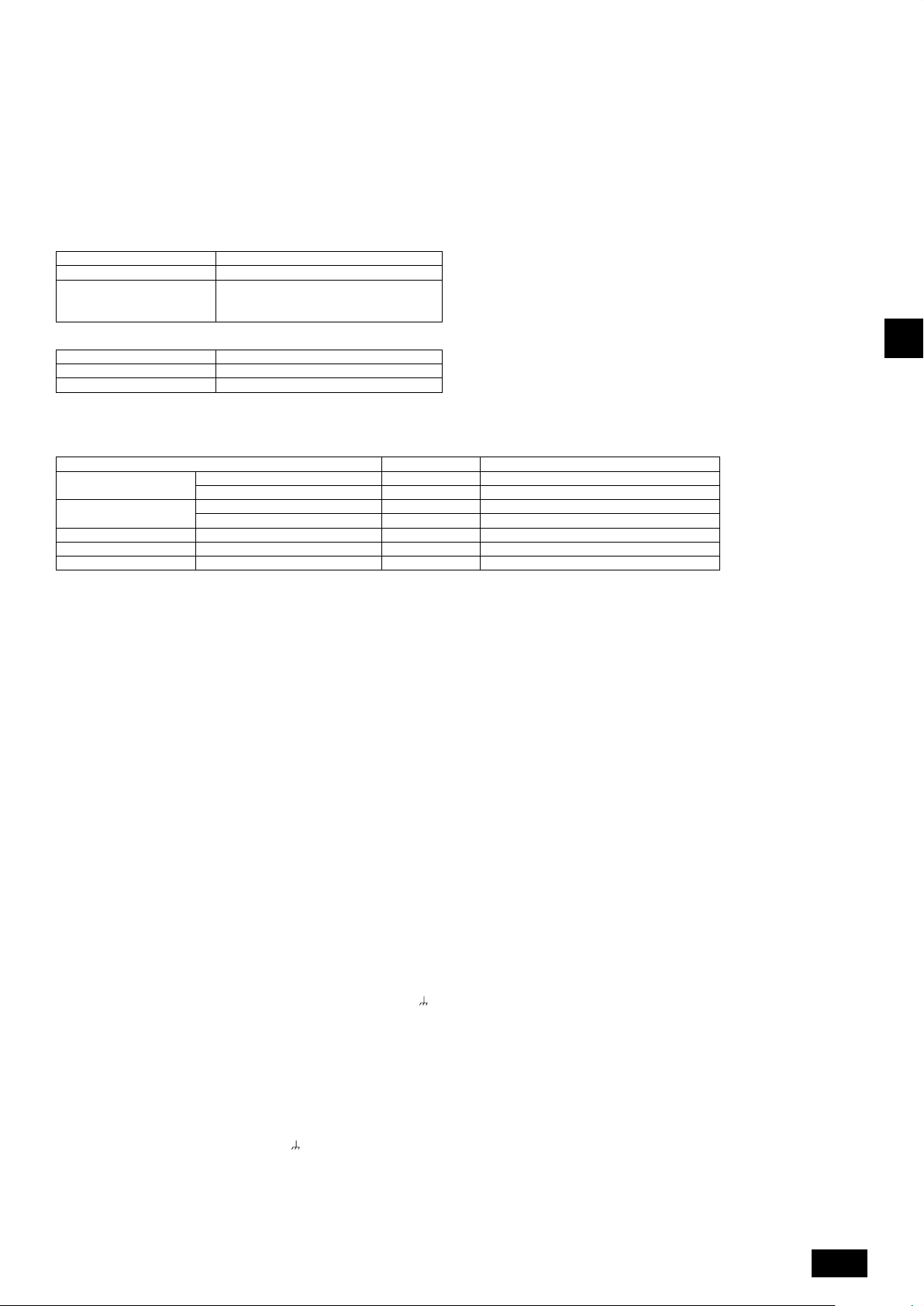

5. Confi rmation of parts attached

This unit includes the following parts. Please check.

•

For usage methods, refer to item 10.2.

•

PQHY-P·YHM-A

1 Connecting pipe

ID ø19.05, OD ø19.05

(ID ø3/4'', OD ø3/4'')

<Gas side>

Model PQHY-P200YHM-A 1 pc. – 1 pc. – 1 pc. – –

PQHY-P250YHM-A – 1 pc. – 1 pc. 1 pc. 1 pc. –

PQHY-P300YHM-A – 1 pc. – 1 pc. 1 pc. 1 pc. –

High water pressure ––––––1 pc.

2 Connecting pipe

IDø25.4, ODø25.4

(IDø1'', ODø1'')

<Gas side>

3 Connecting pipe

ODø19.05, IDø25.4

(ODø3/4'', IDø1'')

<Gas side>

4 Connecting pipe

ODø22.2, IDø25.4

(ODø7/8'', IDø1'')

<Gas side>

5 Connecting pipe

IDø9.52, Odø9.52

(ODø3/8'', IDø3/8'')

<Liquid side>

6 Connecting pipe

IDø9.52, IDø12.7

(ODø3/8'', IDø1/2'')

<Liquid side>

7 Packing

(inside ø49,

outside ø89)

PQRY-P·YHM-A

1 Connecting pipe

IDø15.88, IDø19.05

(IDø5/8'', IDø3/4'')

<High-pressure side>

Model PQHY-P200YHM-A 1 pc. 1 pc. – – –

PQHY-P250YHM-A – – 1 pc. 1 pc. –

PQHY-P300YHM-A – – 1 pc. 1 pc. –

High water pressure – – – 1 pc. 1 pc.

2 Connecting pipe

IDø19.05, IDø25.4

(IDø3/4'', ODø1'')

<High-pressure side>

<Low-pressure side>

3 Connecting pipe

IDø22.2, IDø25.4

(IDø7/8'', IDø1'')

<Low-pressure side>

4 Connecting pipe

IDø19.05, ODø19.05

(IDø3/4'', ODø3/4'')

<High-pressure side>

5 Packing

(inside ø49,

outside ø89)

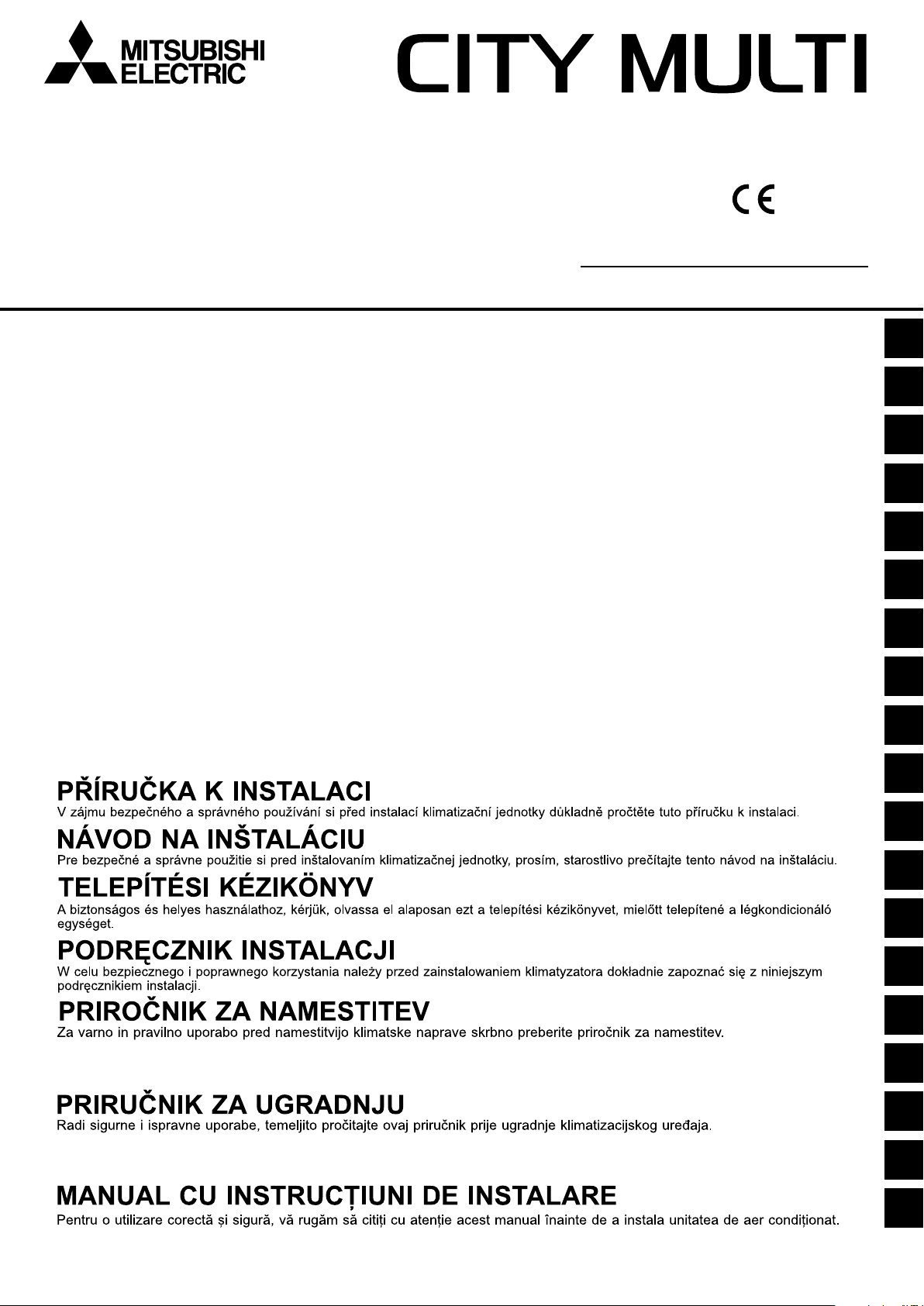

6. Lifting method

[Fig. 6.0.1] (P.2)

Use suspension ropes that will withstand the weight of the unit.

•

When moving the unit, use a 4-point suspension, and avoid giving impacts

•

to the unit (Do not use 2-point suspension).

Place protective pads on the unit where it comes in contact with the ropes to

•

protect the unit from being scratched.

Set the angle of roping at 40° or less.

•

Use 2 ropes that are each longer than 8 meters.

•

Place protective padding at the corners of the product to protect the product

•

from scratches or dents that might be caused by the rope.

Caution:

Be very careful when carrying/moving the product.

- When installing the heat source unit, suspend the unit at the specifi ed location

of the unit base. Stabilize as necessary so that it does not move to the side

and support it at 4 points. If the unit is installed or suspended with 3-point

support, the unit may become unstable and fall.

GB

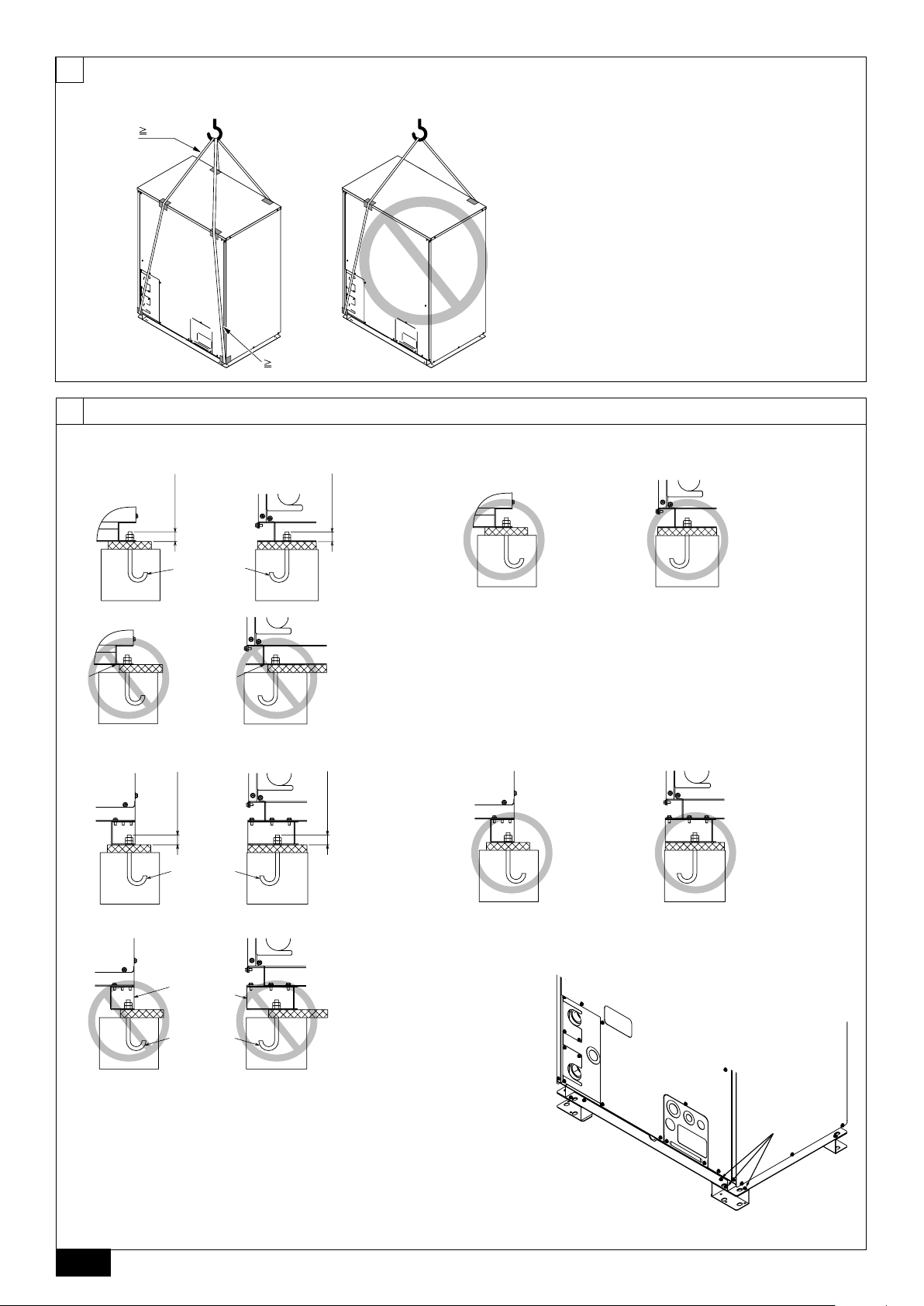

7. Installation of unit

7.1. Installation

[Fig. 7.1.1] (P.2)

<A> Without detachable leg <B> With detachable leg

M10 anchor bolt procured at the

A

site.

Check that the corner of the

C

installation leg is securely supported.

Fix unit tightly with bolts so that unit will not fall down due to earthquakes or

•

strong winds.

Use concrete or an angle bracket for the foundation of unit.

•

Vibration may be transmitted to the installation section and noise and

•

vibration may be generated from the fl oor and walls, depending on the

installation conditions. Therefore, provide ample vibrationproofi ng (cushion

pads, cushion frame, etc.).

Be sure that the corners are fi rmly seated. If the corners are not fi rmly

•

seated, the installation feet may be bent.

When using cushion pads, be sure that the full width of the unit is covered.

•

The projecting length of the anchor bolt should be less than 25 mm.

•

[Fig. 7.1.2] (P.2)

Screws

A

The detachable leg can be removed at the site.

•

Detaching the detachable leg

•

Loosen the three screws to detach the detachable leg (Two each in the front

and back).

If the base leg fi nish is damaged when detaching, be sure to repair at the

site.

Check that the corner of the

B

installation leg is securely supported

to prevent the leg from bending.

Detachable leg

D

Warning:

Be sure to install unit in a place strong enough to withstand its weight.

•

Any lack of strength may cause unit to fall down, resulting in a

personal injury.

•

Have installation work in order to protect against strong winds and

earthquakes.

Any installation defi ciency may cause unit to fall down, resulting in a

personal injury.

When building the foundation, give full attention to the fl oor strength, drain water

disposal <during operation, drain water fl ows out of the unit>, and piping and

wiring routes.

Precautions when routing the pipes and wires below the unit (Without

detachable leg)

When routing the pipes and wires below the unit, be sure that the foundation and

base work do not block the base through-holes. Also make sure the foundation

is at least 100 mm high so that the piping can pass under the unit.

7.2. Service space

•

Please allow for the following service spaces after installation.

•

In case of single installation, 600 mm or more of back space as front space

makes easier access when servicing the unit from rear side.

[Fig. 7.2.1] (P.3)

Space for removing the control box

A

Service space (front side)

C

Heat source unit

B

17

Page 18

8. Water pipe installation

City Multi WY/WR2 Series pipes are similar to other air-conditioning pipes,

however, please observe the following precautions during installation.

8.1. Precautions during installation

The water pressure resistance of the water pipes in the heat source unit is

•

1.0MPa. (2.0MPa for the high water pressure models)

•

Use the reverse-return method to insure proper pipe resistance to each unit.

•

Provide some joints and bulbs around inlet/outlet of each unit for easy

maintenance, checkup, and replacement.

•

In order to protect the heat source unit, install a strainer on the circulating

water inlet pipe within 1.5 m from the heat source unit.

•

Install a suitable air vent on the water pipe. After sending water through the

pipe, be sure to vent the excess air.

•

Compressed water may form in the low-temperature sections of heat source

unit. Use a drainage pipe connected to the drain valve at the base of the unit

to drain the water.

GB

•

Install a back fl ow-prevention valve on the pump and a fl exible joint to

prevent excess vibration.

•

Use a sleeve to protect the pipes where they go through a wall.

•

Use metal fi ttings to secure the pipes, and install them so that they have

maximum protection against breakage and bending.

•

Do not confuse the water intake and outlet valves.

•

This unit doesn’t have any heater to prevent freezing within tubes. When the

water fl ow is stopped on low ambient, take out the water from tubes.

•

The unused knockout holes should be closed and the opening of refrigerant

pipes, water pipes, power source and transmission wires should be fi lled

with putty and so on to prevent from rain. (fi eld construction)

•

The drain plug is installed on the unit rear at factory shipment for fi eld-

connection of the drain pipes on the front of the unit. Relocate the plug to the

unit front to connect the drain pipes on the back of the unit. Check that there

are no leaks from pipe connections.

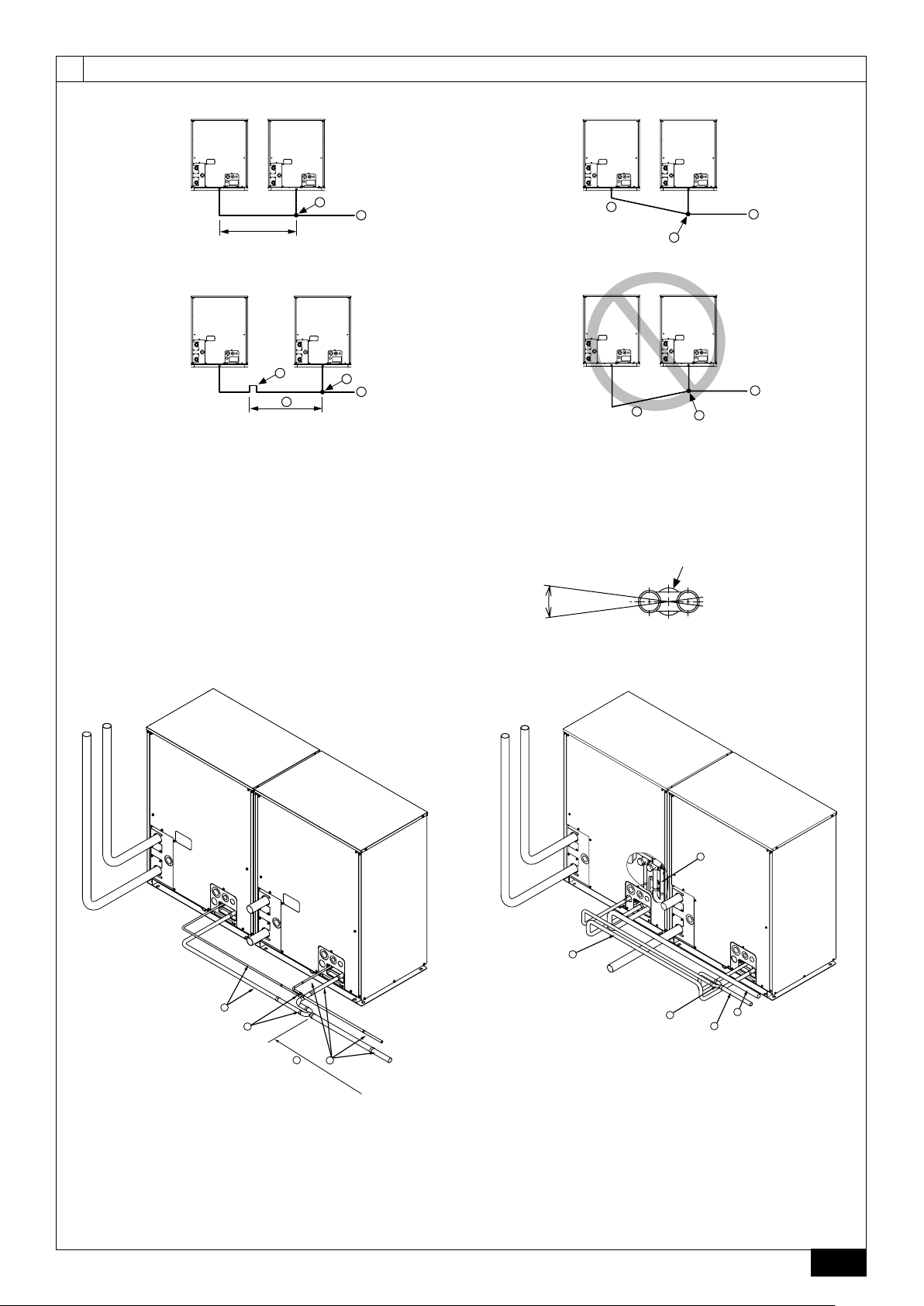

•

For 2-unit combination, install water pipes in parallel to each other so that

the water fl ow rate through both units will be equal.

•

Wrap the sealing tape as follows.

1 Wrap the joint with sealing tape in the direction of the threads

(clockwise), and do not let the tape run over the edge.

2 Overlap the sealing tape by two-thirds to three-fourths of its width on

each turn. Press the tape with your fi ngers so that it is pressed fi rmly

against each thread.

3 Leave the 1.5th through 2nd farthest threads away from the pipe end

unwrapped.

•

Hold the pipe on the unit side in place with a spanner when installing the

pipes or strainer. Tighten screws to a torque of 150 N.m.

Example of heat source unit installation (using left piping)

[Fig. 8.1.1] (P.3)

Main circulating water pipe

A

Shutoff valve

C

Refrigerant pipes

E

Water inlet (upper)

G

Water outlet fl ange (lower)

I

Shutoff valve

B

Water outlet (lower)

D

Y-type strainer

F

Drain pipe

H

Water inlet fl ange (upper)

J

8.2. Insulation installation

With City Multi WY/WR2 Series piping, as long as the temperature range of

the circulating water is kept to average temperatures year-round (30 °C in

the summer, 20 °C in the winter), there is no need to insulate or otherwise

protect indoor piping from exposure. You should use insulation in the following

situations:

•

Any heat source piping.

•

Indoor piping in cold-weather regions where frozen pipes are a problem.

•

When air coming from the outside causes condensation to form on piping.

•

Any drainage piping.

8.3. Water processing and water quality

control

To preserve water quality, use the closed type of cooling tower for WY/WR2.

When the circulating water quality is poor, the water heat exchanger can develop

scales, leading to a reduction in heat-exchange power and possible corrosion of

the hea exchanger. Please pay careful attention to water processing and water

quality control when installing the water circulation system.

Removal of foreign objects or impurities within the pipes.

•

During installation, be careful that foreign objects, such as welding

fragments, sealant particles, or rust, do not enter the pipes.

•

Water Quality Processing

1 Depending on the quality of the cold-temperature water used in the

airconditioner, the copper piping of the heat exchanger may become

corroded.

We recommend regular water quality processing.

Cold water circulation systems using open heat storage tanks are

particularly prone to corrosion.

When using an open-type heat storage tank, install a water-to-water heat

exchanger, and use a closed-loop circuit on the air conditioner side. If a

water supply tank is installed, keep contact with air to a minimum, and

keep the level of dissolved oxygen in the water no higher than 1mg/ℓ.

2 Water quality standard

temperature water system

Items

pH (25°C) [77°F] 7.0 ~ 8.0 7.0 ~ 8.0

Electric conductivity (mS/m) (25°C) [77°F]

(μ s/cm) (25°C) [77°F]

Chloride ion (mg Cl-/ℓ) 50 or less 50 or less

Sulfate ion (mg SO4

Standard

items

Acid consumption (pH4.8)

(mg CaCO

Total hardness (mg CaCO

Calcium hardness (mg CaCO3/ℓ)

Ionic silica (mg SiO

Iron (mg Fe/ℓ) 1.0 or less 0.3 or less

Copper (mg Cu/ℓ) 1.0 or less 0.1 or less

Sulfi de ion (mg S

Reference

Ammonium ion (mg NH

items

Residual chlorine (mg Cl/ℓ) 0.25 or less 0.3 or less

Free carbon dioxide (mg CO2/ℓ)

Ryzner stability index 6.0 ~ 7.0 –

Recirculating

[20<T<60°C]

[68<T<140°F]

[300 or less]

2-

/ℓ) 50 or less 50 or less

3

/ℓ)

3

/ℓ) 70 or less 70 or less

2

/ℓ) 30 or less 30 or less

2-

/ℓ)

+

4

/ℓ) 0.3 or less 0.1 or less

Lower mid-range

water

30 or less

50 or less 50 or less

50 or less 50 or less

not to be

detected

0.4 or less 4.0 or less

Make-up

water

30 or less

[300 or less]

not to be

detected

Tendency

Scale-

Corrosive

forming

cc

cc

c

c

cc

c

c

c

c

c

cc

c

c

c

c

Reference : Guideline of Water Quality for Refrigeration and Air Conditioning

Equipment. (JRA GL02E-1994)

3 Please consult with a water quality control specialist about water quality

control methods and water quality calculations before using anticorrosive solutions for water quality management.

4 When replacing a previously installed air conditioning device (even when

only the heat exchanger is being replaced), fi rst conduct a water quality

analysis and check for possible corrosion.

Corrosion can occur in cold-water systems even if there has been no

prior signs of corrosion.

If the water quality level has dropped, please adjust water quality

suffi ciently before replacing the unit.

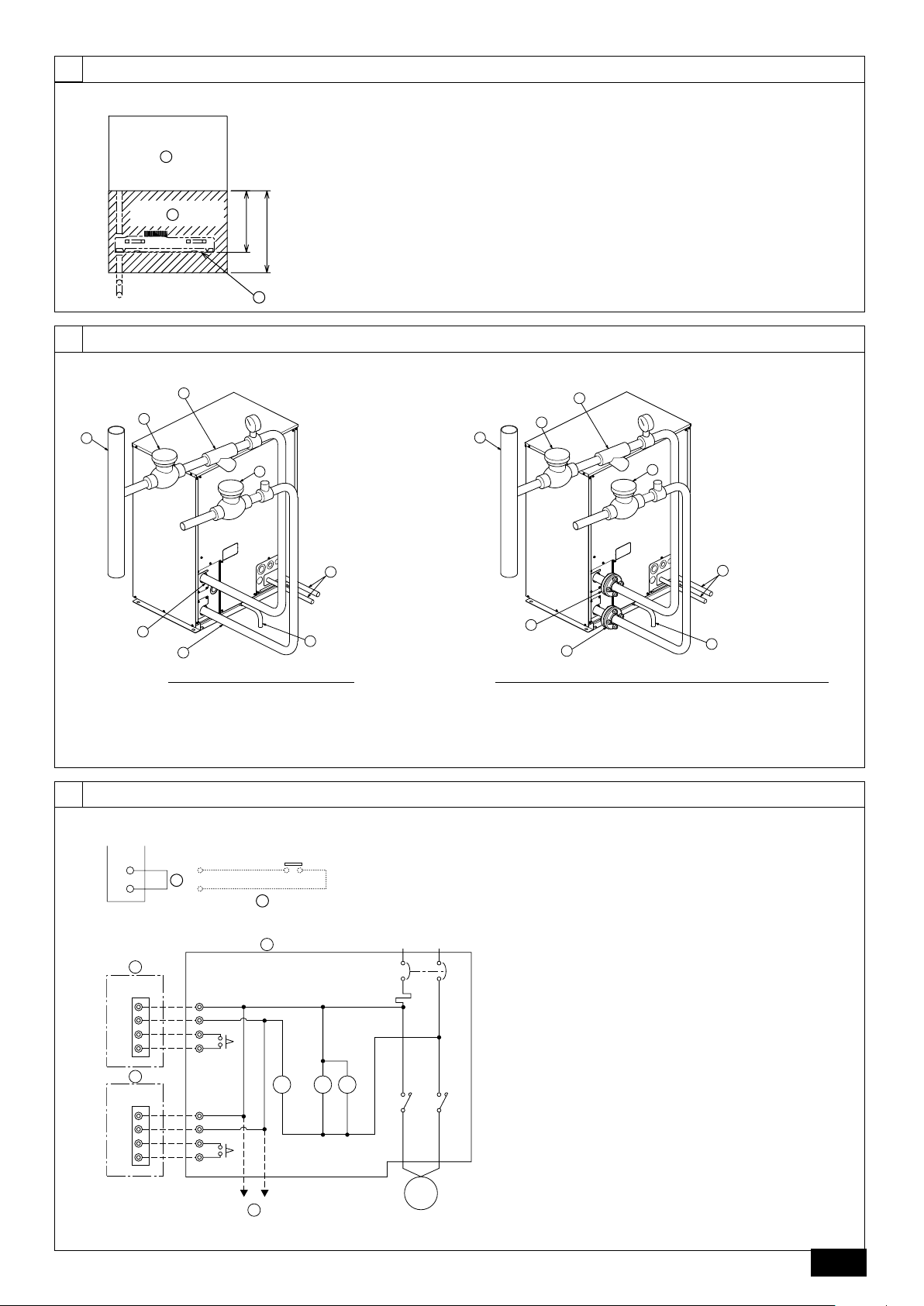

8.4. Pump interlock

The heat source unit may become damaged if it is operated with no water

circulating through the pipes.

Be sure to interlock unit operation and the water-circuit pump. Use the terminal

blocks for interlocking (TB8-1, 2, 3, 4) that can be found on the unit.

In the case of a pump interlock circuit signal connection to the TB8-3, 4, remove

the short-circuit wire. Also, use pressure valve 63PW with a minimum current of

5mA or less to prevent miss detection due to poor connection.

Pump interlock cords of parts of appliances for heat source use shall not be

lighter than polychloroprene sheathed fl exible cord (design 245 IEC 57).

[Fig. 8.4.1] (P.3)

Short-circuit wire (Connected before delivery from manufacturer)

A

Pump interlock circuit connection

B

[Fig. 8.4.2] (P.3)

This circuit is for interlocking of the heat source unit operation and the matercircuit pump.

Heat source unit

A

To next unit

C

TM1, 2 : Timer relay (closes after elapsing the set time when it is

powered, while opens promptly when it is not powered)

52P : Magnetic contactor for water circuit pump

MP : Water circuit pump

MCB : Circuit breaker

* Remove the short circuit wire between 3 and 4 when wiring to TB8.

Site control panel

B

18

Page 19

9. Refrigerant piping installation

The pipe is connected via a terminal-branch type connection in which refrigerant

piping from the heat source unit is branched at the terminal and is connected to

each of the indoor units.

The method of pipe connection is as follows: fl are connection for the indoor units,

Gas (low-pressure for PQRY-P·Y(S)HM-A) pipes and Liquid (high-pressure for

PQRY-P·Y(S)HM-A) pipes for heat source, brazed connection. Note that the

branched sections are brazed.

Warning:

Always use extreme care to prevent the refrigerant gas from leaking while

using fi re or fl ame. If the refrigerant gas comes in to contact with a fl ame

from any source, such as a gas stove, it breaks down and generates

a poisonous gas which can cause gas poisoning. Never weld in an

unventilated room. Always conduct an inspection for gas leakage after

installation of the refrigerant piping has been completed.

Caution:

•

Do not vent R410A into the atmosphere.

•

R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol

with a Global Warming Potential (GWP) = 1975.

9.1. Caution

This unit uses refrigerant R410A. Follow the local regulations on materials and

pipe thickness when selecting pipes. (Refer to the table below.)

1 Use the following materials for refrigeration piping.

•

Material: Use copper alloy seamless pipes made of phosphorus

deoxidized copper. Ensure the inner and outer surfaces of the pipes

are clean and free from hazardous sulfur, oxide, dusts, shaving

particles, oils, and moisture (contamination).

•

Size: Refer to item 9.2. for detailed information on refrigerant piping

system.

2 Commercially available piping often contains dust and other materials.

Always blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from entering the

piping during installation.

4 Reduce the number of bending portions as much as possible, and make

bending radii as big as possible.

5 For indoor and heat source branching and merging section, be sure to use

the following twinning pipe sets and merge pipe sets (sold separately).

Indoor twinning pipe

kit model PQRY-

P·Y(S)HM-A ONLY

Line branch

Lower stream unit

model

Less than 80 in total

CMY-Y102S-G2 CMY-R160-J CMY-Q100VBK

Copper pipe size and radial thickness for R410A CITY MULTI.

Size (mm) Size (inch) Radial thickness (mm) Pipe type

ø6.35 ø1/4 0.8 Type-O

ø9.52 ø3/8 0.8 Type-O

ø12.7 ø1/2 0.8 Type-O

ø15.88 ø5/8 1.0 Type-O

*ø19.05 ø3/4 1.2 Type-O

*ø19.05 ø3/4 1.0 Type-1/2H or H

ø22.2 ø7/8 1.0 Type-1/2H or H

ø25.4 ø1 1.0 Type-1/2H or H

ø28.58 ø1-1/8 1.0 Type-1/2H or H

ø31.75 ø1-1/4 1.1 Type-1/2H or H

ø34.93 ø1-3/8 1.2 Type-1/2H or H

ø41.28 ø1-5/8 1.4 Type-1/2H or H

* Both pipe types can be used for pipe size ø19.05 (3/4 inch) for R410A air

conditioner.

Indoor junction pipe

kit model PQRY-

P·Y(S)HM-A ONLY

Total indoor model

P100 ~ P250

Heat source twinning

kit model PQRY-

P·Y(S)HM-A ONLY

Total heat source

model

P400 ~ P600

6 Use a fi tting if a specifi ed refrigerant pipe has a different diameter from that

of a branching pipe.

7 Always observe the restrictions on the refrigerant piping (such as rated

length, height difference, and piping diameter) to prevent equipment failure

or a decline in heating/cooling performance.

Indoor twinning pipe set model PQHY-P·Y(S)HM-A ONLY

Lower stream unit

model

Less than 200 in

total

CMY-Y102S-G2 CMY-Y102L-G2 CMY-Y202-G2 CMY-Y302-G2

Indoor twinning pipe set model PQHY-P·Y(S)HM-A ONLY

4 branching 8 branching 10 branching

CMY-Y104-G CMY-Y108-G CMY-Y1010-G

Heat source twinning kit model PQHY-P·Y(S)HM-A ONLY

8 Branching cannot be made after header branching (corresponding parts are

marked with X in the diagram below). *PQHY-P·Y(S)HM-A ONLY.

9 Either a lack or an excess of refrigerant causes the unit to make an

emergency stop. Charge the system with an appropriate amount of

refrigerant. When servicing, always check the notes concerning pipe

length and amount of additional refrigerant at both locations, the refrigerant

volume calculation table on the back of the service panel and the additional

refrigerant section on the labels for the combined number of indoor units

(Refer to item 9.2. for detailed information on refrigerant piping system).

0 Be sure to charge the system using liquid refrigerant.

a Never use refrigerant to perform an air purge. Always evacuate using a

vacuum pump.

b Always insulate the piping properly. Insuffi cient insulation will result in a

decline in heating/cooling performance, water drops from condensation and

other such problems (Refer to item 10.4 for thermal insulation of refrigerant

piping).

c When connecting the refrigerant piping, make sure the valve of the heat

source unit is completely closed (the factory setting) and do not operate it

until the refrigerant piping for the heat source, indoor units and BC controller

has been connected, a refrigerant leakage test has been performed and the

evacuation process has been completed.

d Braze only with non-oxide brazing material for piping. Failure to do so

may damage the compressor. Be sure to perform the non-oxidation

brazing with a nitrogen purge.

Do not use any commercially available anti-oxidizing agent since it may

cause pipe corrosion and degrading of the refrigerant oil.

Please contact Mitsubishi Electric for more details.

(Refer to item 10.2. for details of the piping connection and valve operation)

e Never perform heat source unit piping connection work when it is

raining.

Lower stream unit

More than 201

and less than 400

Header branch

Total heat source model

P400 ~ P600

CMY-Y100VBK2

To the heat source unit

To the heat source

unit

model

in total

Line branch

Lower stream unit

More than 401

and less than 650

model

in total

Lower stream unit

model

More than 651 in

total

CAP

GB

19

Page 20

Warning:

When installing and moving the unit, do not charge the system with any

other refrigerant other than the refrigerant specifi ed on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to

malfunction and may result in severe damage.

Caution:

Use a vacuum pump with a reverse fl ow check valve.

•

- If the vacuum pump does not have a reverse fl ow check valve, the vacuum

pump oil may fl ow back into the refrigerant cycle and cause deterioration of

the refrigerant oil.

•

Do not use the tools shown below used with conventional refrigerant.

(Gauge manifold, charge hose, gas leak detector, check valve,

refrigerant charge base, vacuum gauge, refrigerant recovery

equipment)

- Mixing of conventional refrigerant and refrigerant oil may cause the

refrigerant oil to deteriorate.

- Mixing of water will cause the refrigerant oil to deteriorate.

- R410A refrigerant does not contain any chlorine. Therefore, gas leak

detectors for conventional refrigerants will not react to it.

•

Manage the tools used for R410A more carefully than normal.

GB

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant oil will

deteriorate.

•

Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerant oil

in the existing piping will cause the new refrigerant to deteriorate.

•

Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will deteriorate

and the compressor may fail.

•

Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

•

Do not use special detergents for washing piping.

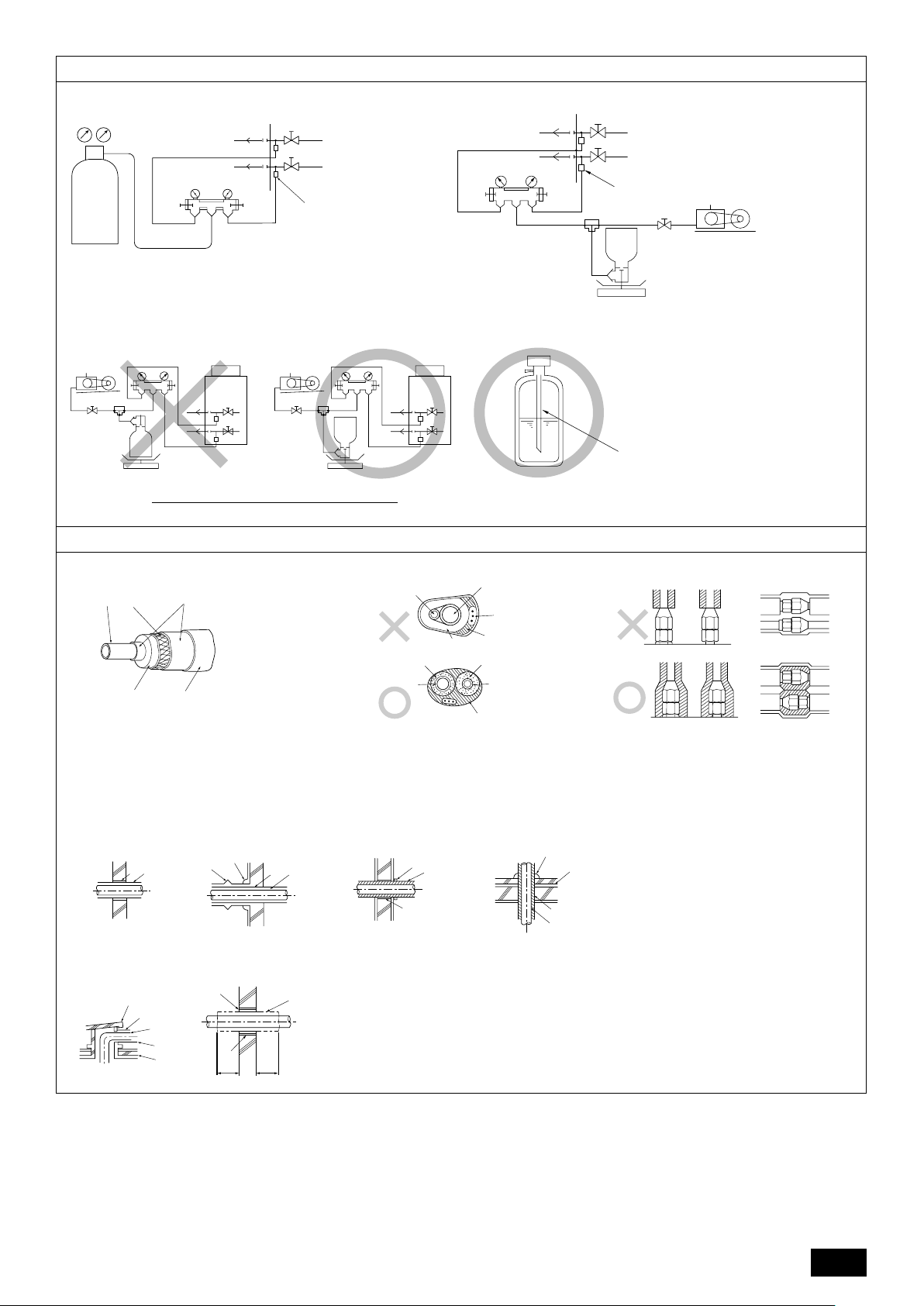

Precautions for heat source unit combinations

Refer to [Fig. 9.2.3] for the positioning of twinning pipes.

[Fig. 9.2.3] (P.7)

<A> When the piping on the heat source unit side (from the twinning pipe)

exceeds 2 m, ensure a trap (gas pipe only) within 2 m. Make sure the height

of the trap is 200 mm or more.

If there is no trap, oil can accumulate inside the pipe, causing a shortage of

oil and may damage the compressor. (for PQHY-P·YSHM-A)

<B> Pipe connection example (for PQHY-P·Y(S)HM-A)

Indoor unit

A

Within 2 m

C

Pipes on site

E

Straight run of pipe that is 500 mm or more

G

Trap (gas pipe only)

B

Twinning pipe

D

Twinning kit

F

Precautions for heat source unit combinations

Refer to [Fig. 9.2.4] for the positioning of twinning pipes.

[Fig. 9.2.4] (P.7)

<A> The piping from the heat source units to twinning pipe must be made to

slope downwards the twinning pipe. (both the liquid and the gas side for

PQHY-P·YSHM-A, the high-pressure side only for PQRY-P·YSHM-A)

<B> Slope of twinning pipes (for PQHY-P·YSHM-A)

Make sure the slope of the twinning pipes are at an angle within ±15° to the

horizontal plane.

If the slope exceeds the specifi ed angle, the unit may be damaged.

<C> Pipe connection example (for PQRY-P·YSHM-A)

Downward slope

A

BC controller (standard or main)

C

Slope of the twinning pipe is at an angle within ±15° to the ground

E

Twinning pipe (low-pressure side)

F

On-site piping (low-pressure connecting pipe: between heat source units)

H

On-site piping (low-pressure main pipe: to BC controller)

I

On-site piping (high-pressure main pipe: to BC controller)

J

Upward slope

B

Twinning pipe

D

Twinning pipe (high-pressure side)

G

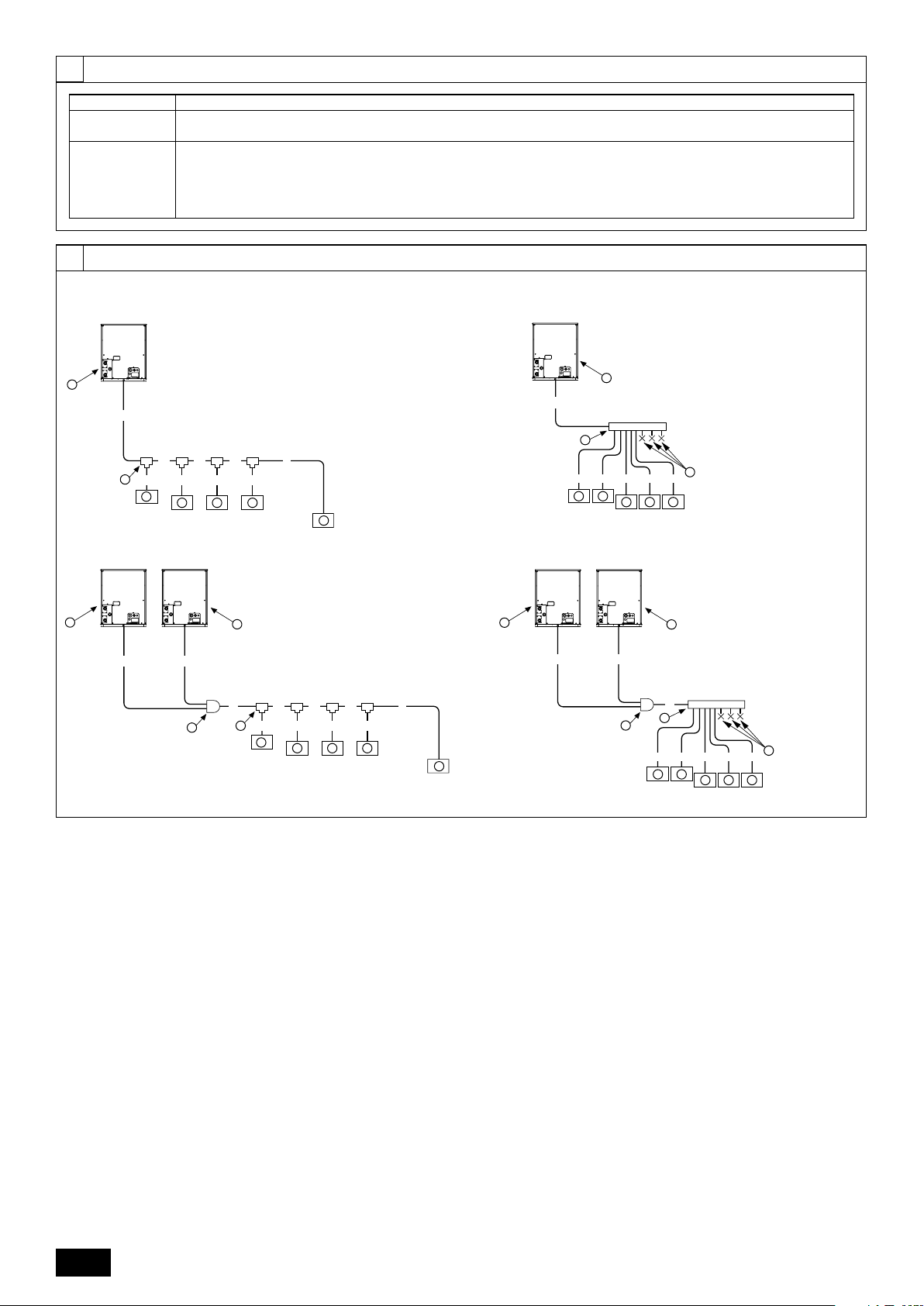

9.2. Refrigerant piping system

Connection example

[Fig. 9.2.1] (P.4)

Heat source model Liquid side

Gas side Total capacity of indoor units

Liquid pipe Gas pipe

Model number Downstream unit model total

The 1st branch of P450 ~ P650

Joint

4-Branching header

8-Branching header (Downstream unit model total <= 400)

10-Branching header (Downstream unit model total <= 650)

Heat source twinning kit

Heat source unit

A

Indoor unit

C

Heat source twinning kit

E

*1 ø12.7 for over 90 m

*2 ø12.7 for over 40 m

*3 The pipe sizes listed in columns A1 to A3 in this table correspond to the sizes

for the models listed in the unit 1, 2, and 3 columns. When the order of the

models for unit 1, 2, and 3 change, make sure to use the appropriate pipe size.

(Downstream unit model total <= 200)

[Fig. 9.2.2] (P.5)

Heat source model High-pressure side

Low-pressure side Total capacity of indoor units

Liquid pipe Gas pipe

Model number Downstream unit model total

Heat source twinning kit High-pressure gas pipe

Low-pressure gas pipe

Heat source unit

A

BC controller (main)

C

Indoor unit (15 ~ 80)

E

Heat source twinning kit

G

*1 The pipe sizes listed in columns A1 to A2 in this table correspond to the sizes

for the models listed in the unit 1 and 2 columns. When the order of unit 1 and

2 is changed, make sure to use the appropriate pipe size for the model.

The 1st branch of P700, P750, P800

First branch

B

Cap

D

BC controller (standard)

B

BC controller (sub)

D

Indoor unit (100 ~ 250)

F

20

Page 21

10. Additional refrigerant charge

At the time of shipping, the heat source unit is charged with refrigerant.

This charge does not include the amount needed for extended piping and

additional charging of each refrigerant line will be required on site. In order that

future servicing may be properly provided, always keep a record of the size and

length of each refrigerant line and the amount of additional charge by writing it in

the space provided on the heat source unit.

For PQHY-P·Y(S)HM-A

<Additional Charge>

Additional

refrigerant charge

Liquid pipe size

Total length of

=

ø19.05 × 0.29

(kg) (m) × 0.29 (kg/m) (m) × 0.2 (kg/m) (m) × 0.12 (kg/m)

Liquid pipe size

Total length of

+

ø9.52 × 0.06

(m) × 0.06 (kg/m) (m) × 0.024 (kg/m)

Liquid pipe size

Total length of

+

ø15.88 × 0.2

Liquid pipe size

Total length of

+

ø6.35 × 0.024

Liquid pipe size

Total length of

+

ø12.7 × 0.12

+

α

<Example>

Indoor 1: 125 A: ø12.7 40 m a: ø9.52 10 m

2: 100 B: ø9.52 10 m b: ø9.52 5 m

3: 40 C: ø9.52 15 m c: ø6.35 10 m

4: 32 D: ø9.52 10 m d: ø6.35 10 m

At the

conditions

below:

5: 63 e: ø9.52 10 m

The total length of each liquid line is as follows:

ø12.7: A = 40 = 40 m

ø9.52: B + C + D + a + b + e = 10 + 15 + 10 + 10 + 5 + 10 = 60 m

ø6.35: c + d = 10 + 10 = 20 m

Therefore,

<Calculation example>

Additional refrigerant charge

= 40 × 0.12 + 60 × 0.06 + 20 × 0.024 + 2.5 = 11.4 kg

Value of α

Total capacity of connecting indoor units

α

Models ~ 80 2.0 kg

Models 81 ~ 160 2.5 kg

Models 161 ~ 330 3.0 kg

Models 331 ~ 390 3.5 kg

Models 391 ~ 480 4.5 kg

Models 481 ~ 630 5.0 kg

Models 631 ~ 710 6.0 kg

Models 711 ~ 8.0 kg

10.1. Calculation of additional refrigerant

charge

Calculate the amount of additional charge based on the length of the piping

•

extension and the size of the refrigerant line.

Use the table below as a guide for calculating the amount of additional

•

charging and then charge the system accordingly.

If the calculation results in a fraction of less than 0.1 kg, round up to the next

•

0.1 kg. For example, if the result of the calculation was 27.73 kg, round the

result up to 27.8 kg.

For PQRY-P·Y(S)HM-A

<Additional charge>

Additional

refrigerant charge

<Example>

Indoor 1: 80 A: ø28.58 40 m a: ø9.52 10 m

The total length of each liquid line is as follows:

ø28.58: A = 40 m

ø22.2: F = 3 m

ø19.05: G = 1 m

ø9.52: C + D + E + a + b + f = 50 m

ø6.35: c + d + e = 20 m