Page 1

DATA BOOK

AIR CONDITIONERS

MODEL

PQHY-P Y(S)HM-A

PQRY-P Y(S)HM-A

- For ground source application

Page 2

Preface

DATABOOK describes the technical specifications of MITSUBISHI ELECTRIC Corp.'s CITYMULTI air conditioning

system products.

In this DATABOOK for ground source application, information on water-cooled heat source unit PQHY-P Y(S)HM-A/

PQRY-P Y(S)HM-A, with the connection of standard CITY MULTI indoor unit series, Air to Water series, and Close

Control PFD series are specified.

We recommend DATABOOK users to read carefully and take advantage of all the contents inside to design the CITY

MULTI air conditioning system and/or to prepare documents for promotions.

Along with the DATABOOK, MITSUBISHI ELECTRIC provides a Design-Tool software to ensure the users to design

the system correctly and simplify the calculations. Please contact your local distributor for this software.

Please be notified that specifications are subject to change without notice due to continual improvements of the product.

For any inquiries, please contact your local distributor.

i

Page 3

Contents

I Brine information

1. Brine freezing temperature ........................................................................................................ 1

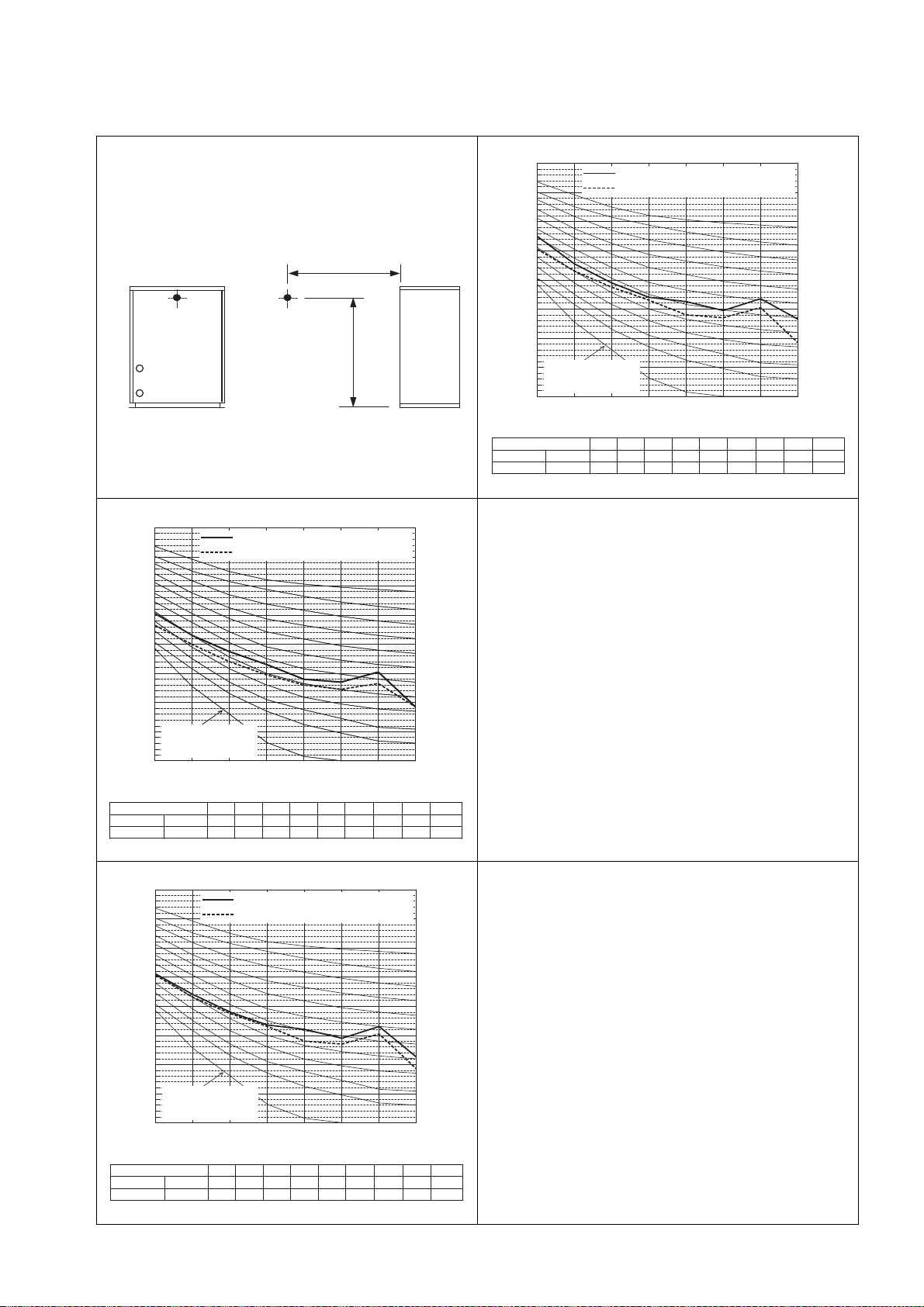

2. Capacity correction by brine concentration (For heat source unit) ...................................... 2

3. Pressure drop correction by brine concentration (For heat source unit) ............................. 3

II Heat source unit information

1. General lineup of water-cooled heat source unit .................................................................... 4

2. PQHY-P-Y(S)HM-A ...................................................................................................................... 5

(1)Specification .............................................................................................................................................. 5

(1)-1 Heat source units specification for standard combination

(Standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU) .................................................. 5

(1)-2 System specification for closed control system (PFD-P250/500VM-E) ....................................... 19

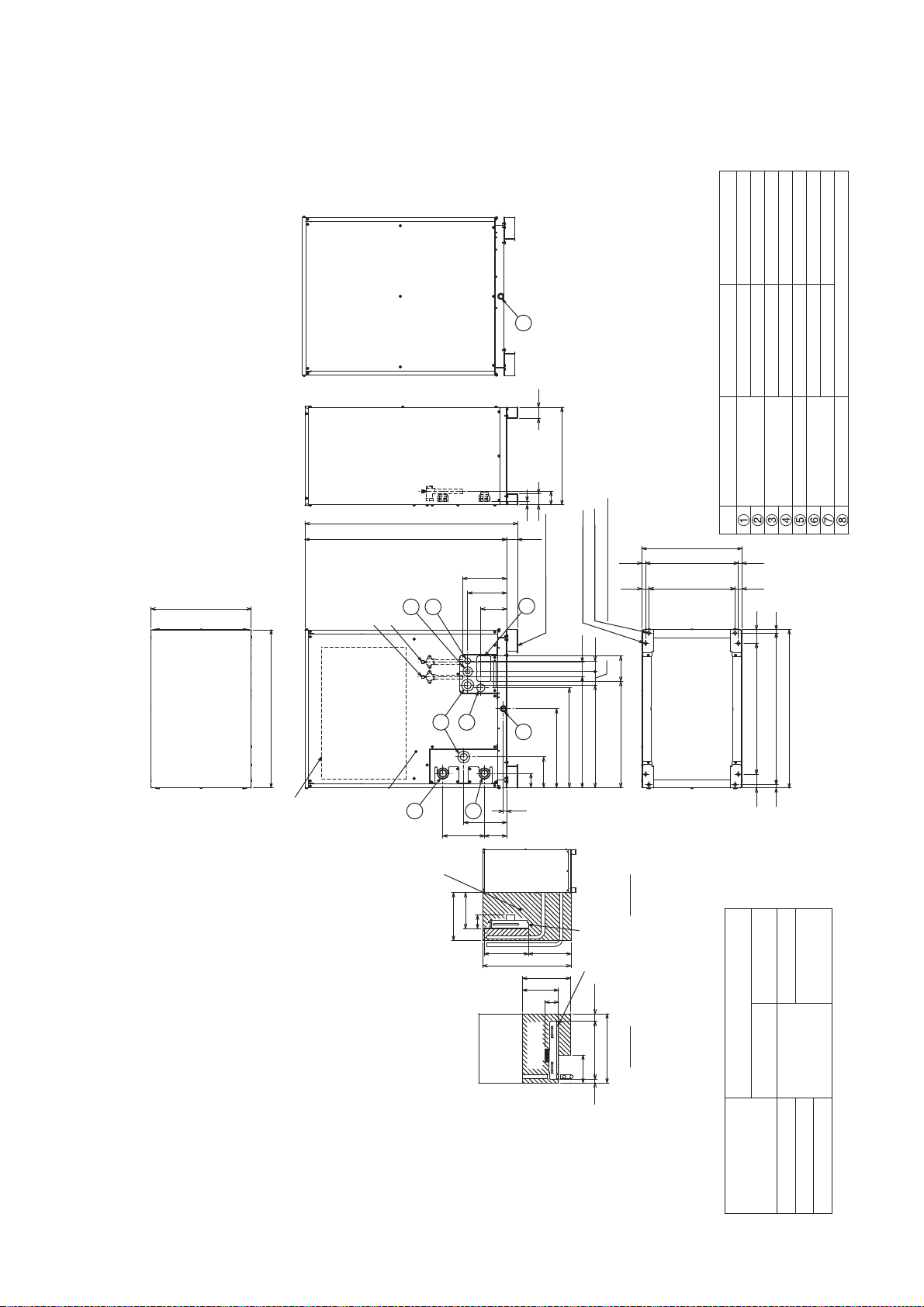

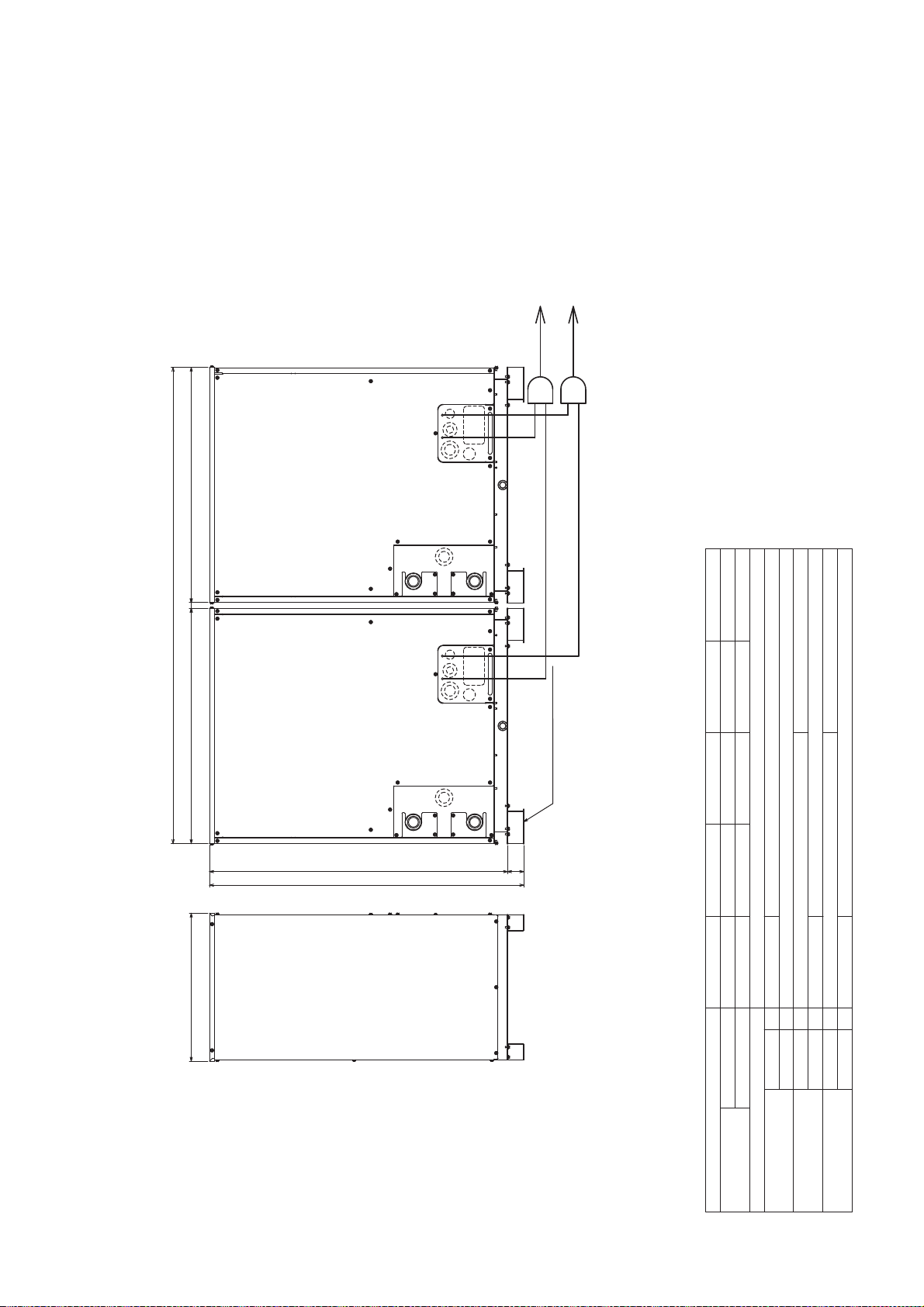

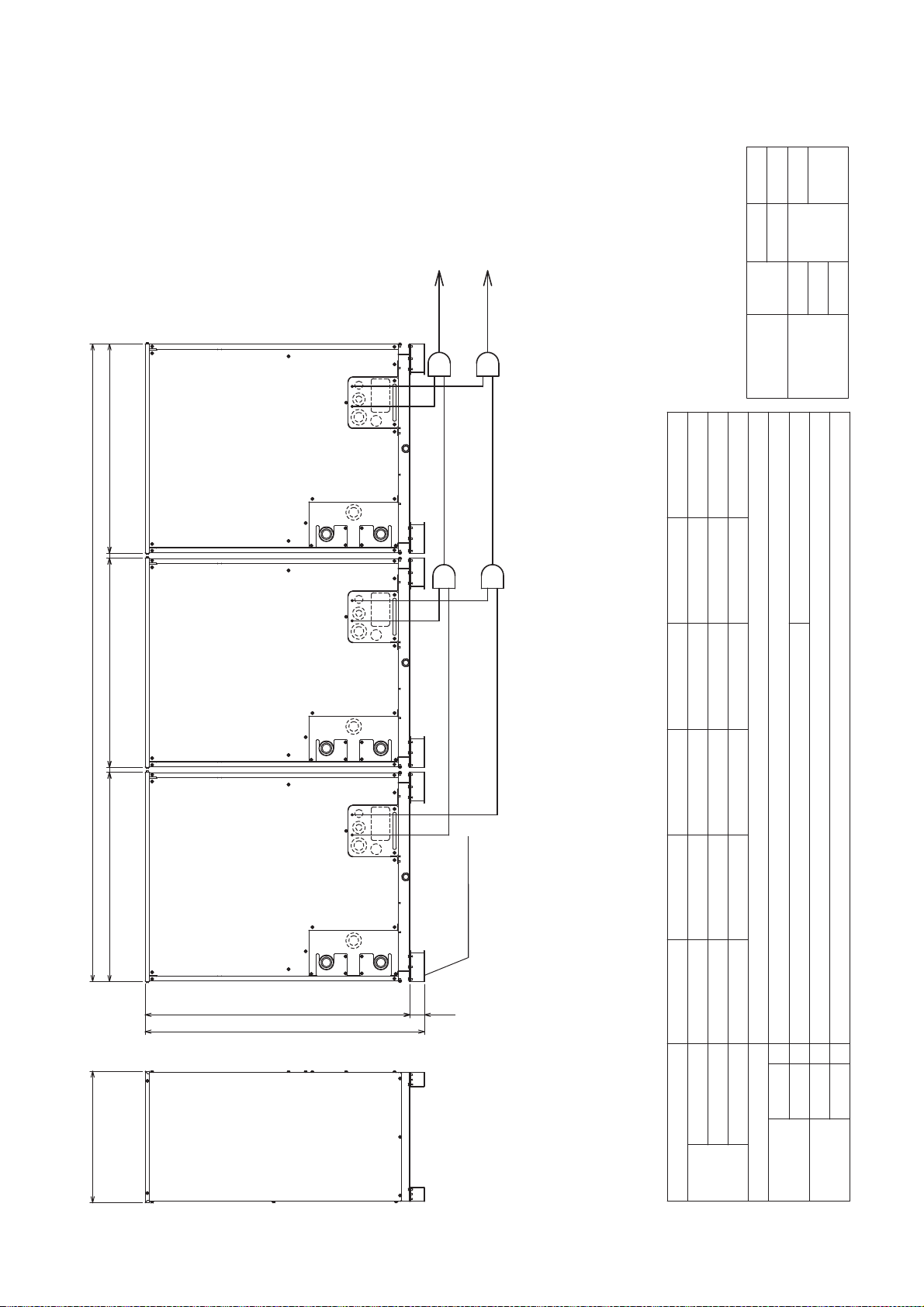

(2)External dimension ..................................................................................................................................21

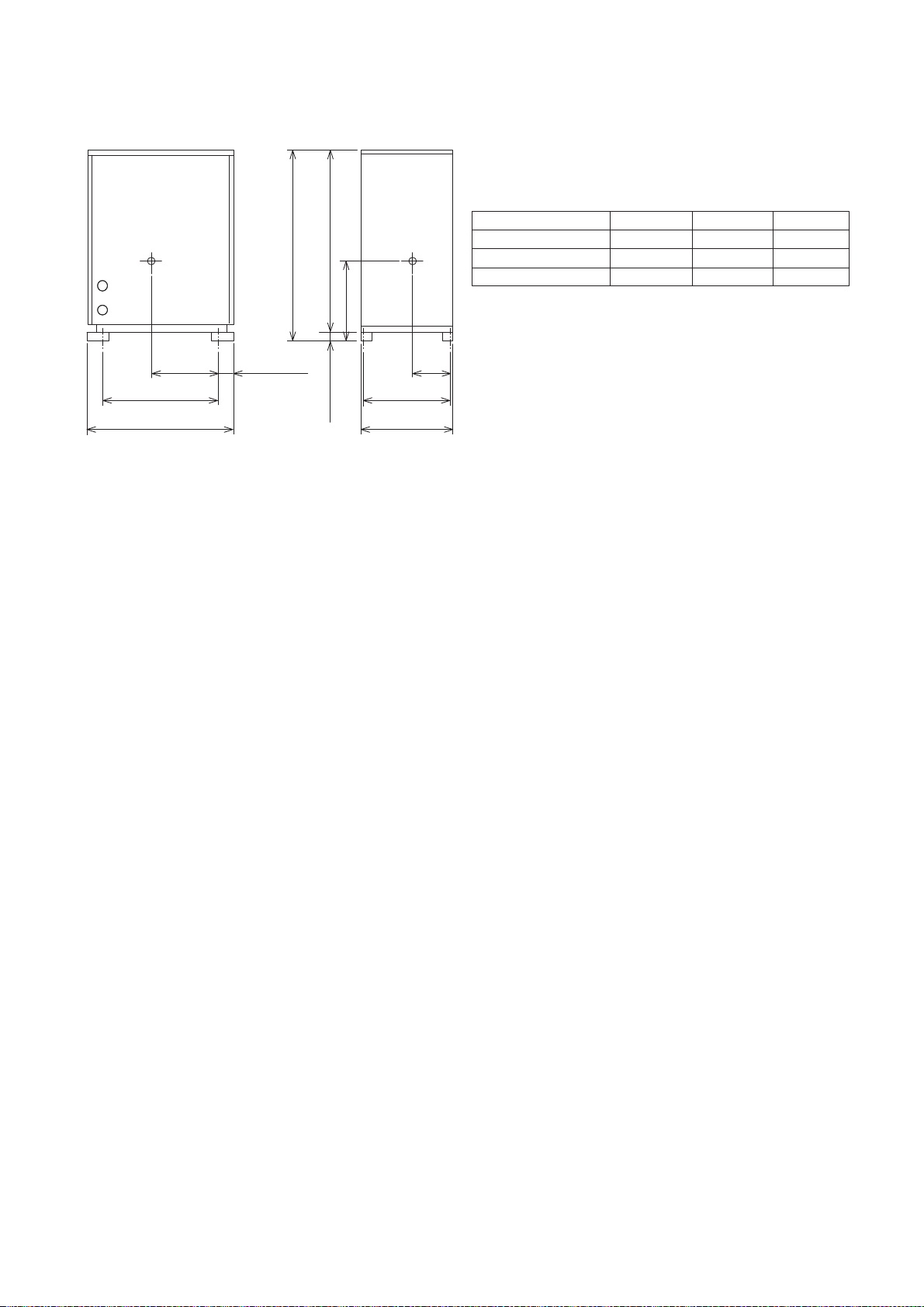

(3)Center of gravity ......................................................................................................................................24

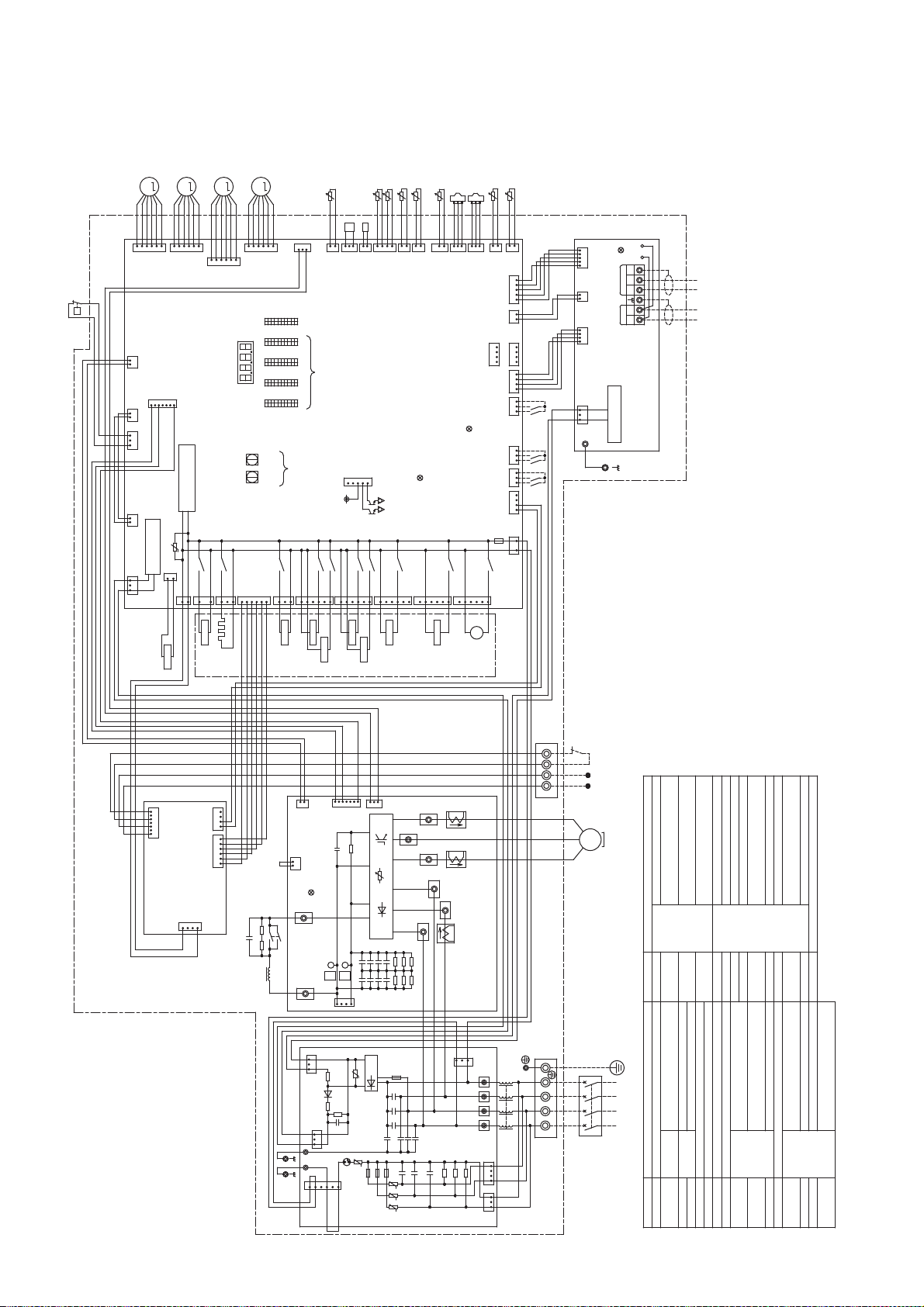

(4)Electrical wiring diagram .......................................................................................................................... 25

(5)Sound levels ............................................................................................................................................ 26

(6)Capacity tables with indoor units .............................................................................................................30

(6)-1 Cooling capacity with standard indoor units .................................................................................30

(6)-2 Heating capacity with standard indoor units ................................................................................. 43

(7)Correction by total indoor .........................................................................................................................44

(8)Correction by refrigerant piping length ..................................................................................................... 46

(9)Correction by water temperature (For heat source unit) .......................................................................... 49

(9)-1 Connection with standard CITY MULTI indoor units .................................................................... 49

(9)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ...............................................................49

(9)-3 Connection with PFD-P250/500VM-E .......................................................................................... 50

(10)Correction by water flow rate (For heat source unit) ..............................................................................51

(10)-1 Connection with standard CITY MULTI indoor units .................................................................... 51

(10)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... 51

(10)-3 Connection with PFD-P250/500VM-E .......................................................................................... 51

(11)Correction by indoor temperature .......................................................................................................... 52

(11)-1 Connection with standard CITY MULTI indoor units .................................................................... 52

(11)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... 52

(11)-3 Connection with PFD-P250/500VM-E .......................................................................................... 52

(12)Correction by water flow rate (For PWFY-P100/200VM-E-AU (HEX unit)) ............................................ 53

(12)-1 Connection with PWFY-P100VM-E-AU (HEX unit) ...................................................................... 53

(12)-2 Connection with PWFY-P200VM-E-AU (HEX unit) ...................................................................... 53

(13)Water pressure drop correction by water volume ................................................................................. 54

(13)-1 Heat source unit correction

(Connection with Standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU,

PFD-P250/500VM-E) ................................................................................................................... 54

(13)-2 HEX unit correction (Connection with PWFY-P100/200VM-E-AU) .............................................. 54

(13)-3 Water pressure drop of strainer only (accessory for PWFY-P100/200VM-E-AU) ........................ 54

(14)Operation temperature range ................................................................................................................ 55

(14)-1 Connection with standard CITY MULTI indoor units .................................................................... 55

(14)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... 55

(14)-3 Connection with PFD-P250/500VM-E .......................................................................................... 56

(15)Piping design ......................................................................................................................................... 57

(15)-1 R410A Piping material .................................................................................................................. 57

(15)-2 PQHY-P200-300YHM Piping

(Connection with standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU) ...................... 58

(15)-3 PQHY-P400-600YSHM Piping

(Connection with standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU) ...................... 59

(15)-4 PQHY-P650-900YSHM Piping

(Connection with standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU) ...................... 60

(15)-5 PQHY-P250/P250+P250YHM

(Connection with PFD indoor unit) ............................................................................................... 61

(15)-6 Refrigerant charging calculation ................................................................................................... 62

Page 4

3. PQRY-P-Y(S)HM-A .................................................................................................................... 63

(1)Specification ............................................................................................................................................ 63

(1)-1 Heat source units specification for standard combination

(Standard CITY MULTI indoor units, PWFY-P100VM-E-BU, PWFY-P100/200VM-E-AU) .......... 63

(2)External dimension ..................................................................................................................................71

(3)Center of gravity ......................................................................................................................................73

(4)Electrical wiring diagram .......................................................................................................................... 74

(5)Sound levels ............................................................................................................................................ 75

(6)Capacity tables with indoor units .............................................................................................................77

(6)-1 Cooling capacity with standard indoor units .................................................................................77

(6)-2 Heating capacity with standard indoor units ................................................................................. 90

(7)Correction by total indoor .........................................................................................................................91

(8)Correction by refrigerant piping length ..................................................................................................... 92

(9)Correction by port counts of the BC controller ........................................................................................93

(10)Correction by water temperature (For heat source unit) ........................................................................94

(10)-1 Connection with standard CITY MULTI indoor units .................................................................... 94

(10)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ................................................................ 94

(10)-3 Connection with PWFY-P100VM-E-BU (Booster unit) ................................................................. 95

(10)-4 Connection with PWFY-P100VM-E-BU (Booster unit) + WCB Energy saving mode* ................. 96

(11)Correction by water flow rate (For heat source unit) ..............................................................................97

(11)-1 Connection with standard CITY MULTI indoor units .................................................................... 97

(11)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... 97

(11)-3 Connection with PWFY-P100VM-E-BU (Booster unit) ................................................................. 97

(12)Correction by indoor temperature ..........................................................................................

(12)-1 Connection with standard CITY MULTI indoor units .................................................................... 98

(12)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... 98

(12)-3 Connection with PWFY-P100VM-E-BU (Booster unit) ................................................................. 98

(13)Correction by water flow rate

(For PWFY-P100/200VM-E-AU (HEX unit) and PWFY-P100VM-E-BU (Booster unit) ........................... 98

(13)-1 Connection with PWFY-P100VM-E-AU (HEX unit) ..................................................................... 98

(13)-2 Connection with PWFY-P200VM-E-AU (HEX unit) ...................................................................... 99

(13)-3 Connection with PWFY-P100VM-E-BU (Booster unit) ................................................................. 99

(14)Water pressure drop correction by water volume ............................................................................... 100

(14)-1 Heat source unit correction

(Connection with Standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU,

PWFY-P100VM-E-BU) ............................................................................................................... 100

(14)-2 Booster unit correction (Connection with PWFY-P100VM-E-BU) ..............................................100

(14)-3 HEX unit correction (Connection with PWFY-P100/200VM-E-AU) ............................................ 100

(14)-4 Water pressure drop of strainer only

(accessory for PWFY-P100VM-E-BU and PWFY-P100/200VM-E-AU) ..................................... 101

(15)Operation temperature range .............................................................................................................. 102

(15)-1 Connection with standard CITY MULTI indoor units .................................................................. 102

(15)-2 Connection with PWFY-P100VM-E-BU (Booster unit) ............................................................... 102

(15)-3 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................. 103

(16)Piping design ....................................................................................................................................... 104

(16)-1 R410A Piping material ................................................................................................................ 104

(16)-2 PQRY-P200-300YHM Piping

IF 16 ports or less are in use, i.e., if only one BC controller is in use with no sub BC controller

(Connection with standard CITY MULTI indoor units, PWFY-P100VM-E-BU,

PWFY-P100/200VM-E-AU) ........................................................................................................105

(16)-3 PQRY-P200-300YHM Piping

IF more than 16 ports are in use, or if there is more than one BC controller in use for

one Heat source unit

(Connection with standard CITY MULTI indoor units, PWFY-P100VM-E-BU,

PWFY-P100/200VM-E-AU) ........................................................................................................106

(16)-4 PQRY-P400YHM Piping

IF more than 16 ports are in use, or if there is more than one BC controller in use for

two heat source units

(Connection with standard CITY MULTI indoor units, PWFY-P100VM-E-BU,

PWFY-P100/200VM-E-AU) ........................................................................................................107

(16)-5 Total piping length restrictions .................................................................................................... 108

(16)-6 Refrigerant charging calculation ................................................................................................. 109

................98

Page 5

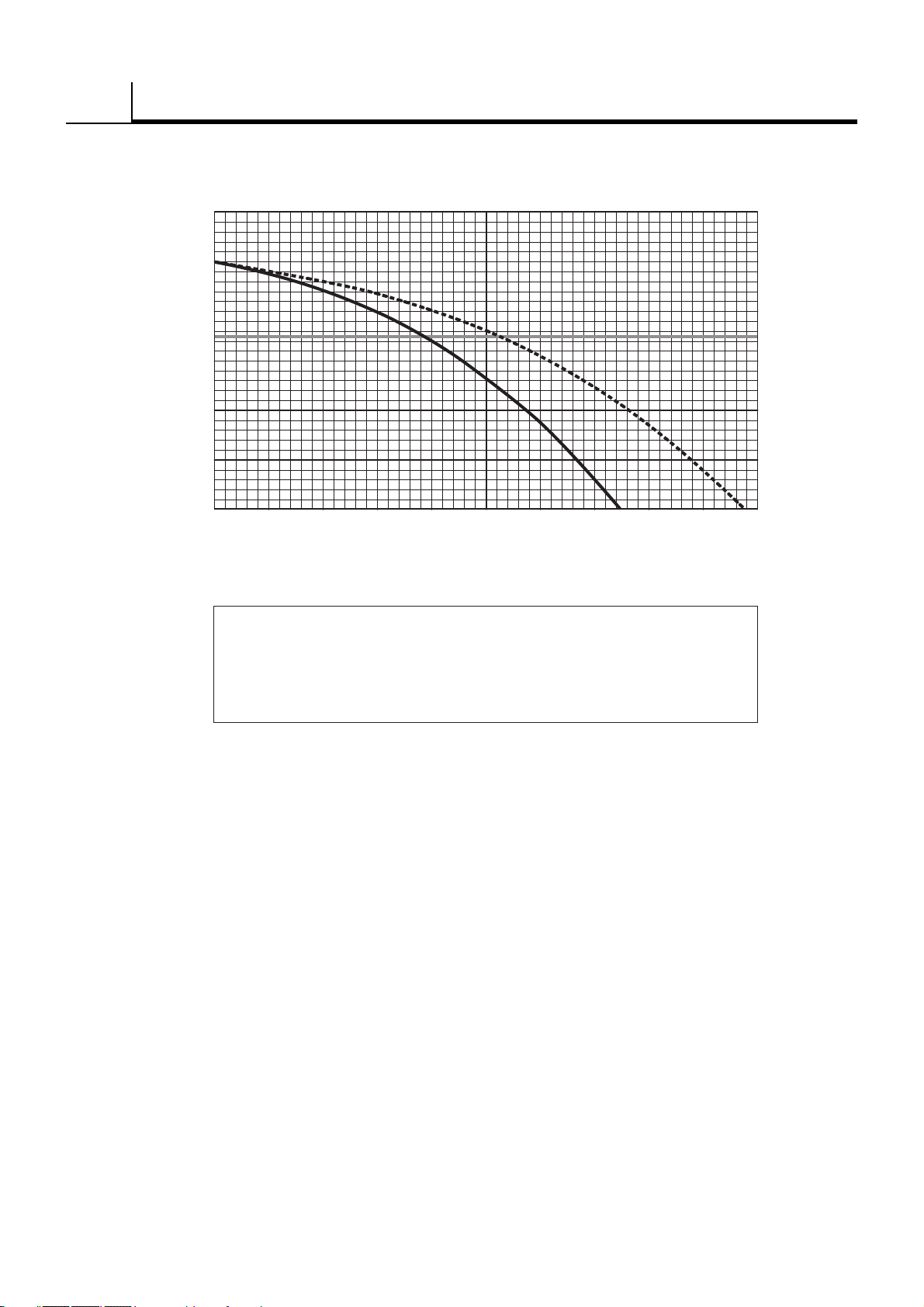

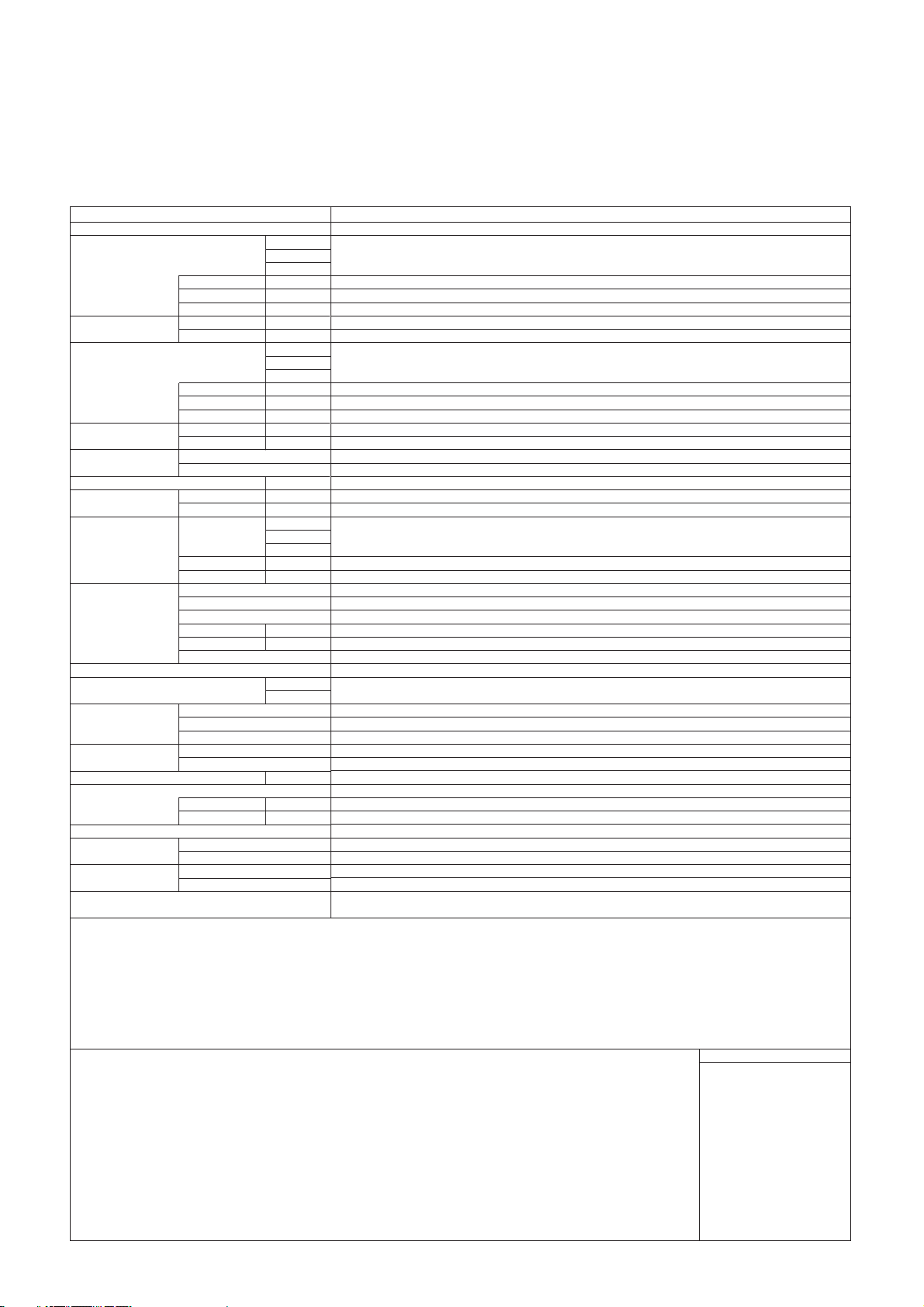

I Brine information

0 10 20 30 40 50 60 70 80 90 100

10

0

-10

-20

-30

-40

-50

Brine concentration [wt%]

Freezing Temperature [deg°C]

Propylene Glycol

Ethylene Glycol

Propylene Glycol

Ethylene Glycol

Note;

The graph was referred from chemical company data.

But Freezing Temperature condition will be slightly different based on each company.

Please confirm detail data to the chemical company directly.

It is recommended to set the brine concentration to a percentage that will keep the freezing

temperature at -15deg

°C or less.

1.Brine freezing temperature

Brine concentration is decided by the freezing temperature. First, it is necessary to decide the freezing temperature and find

out brine concentration which will correspond to the freezing temperature.

- 1 -

Page 6

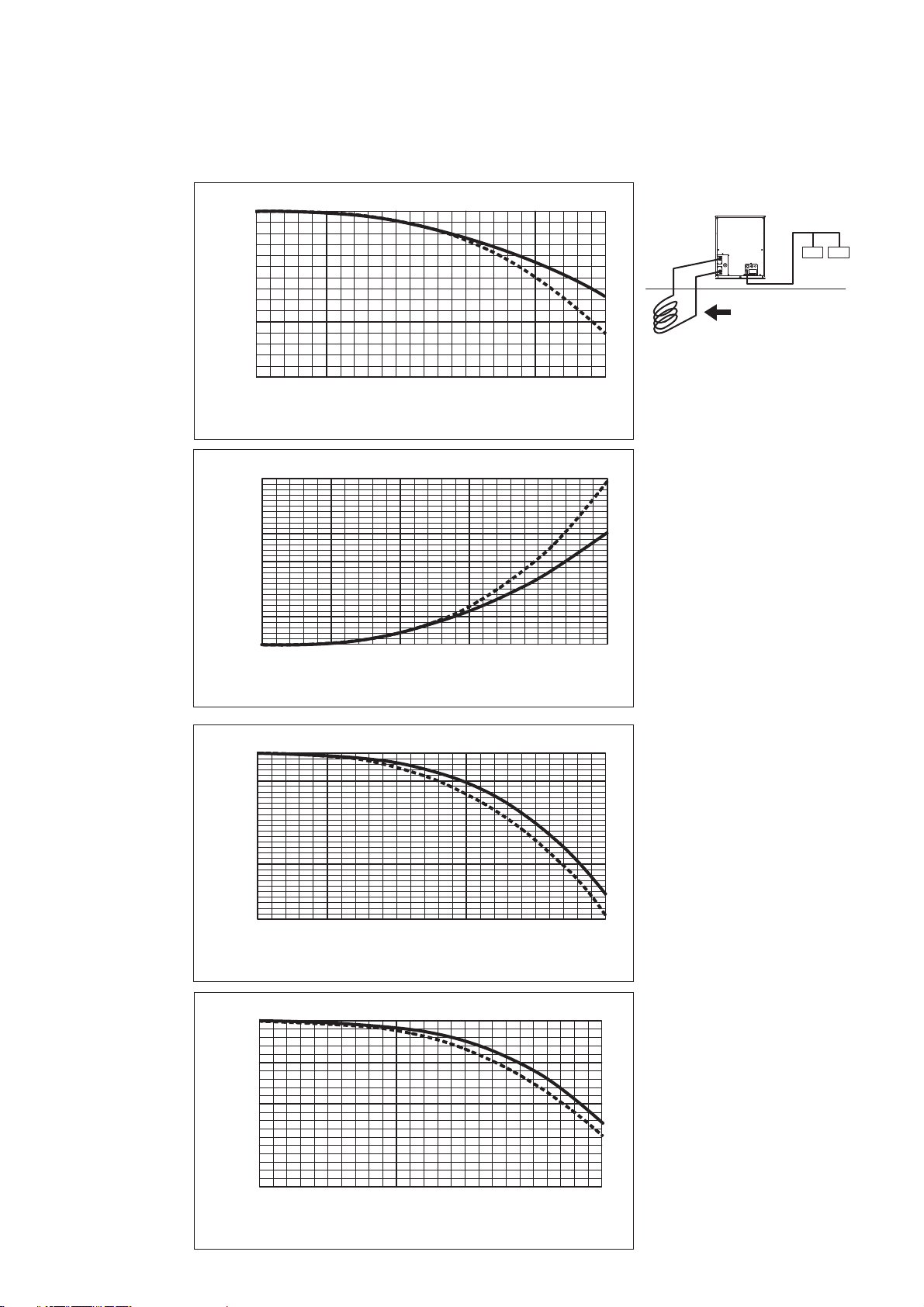

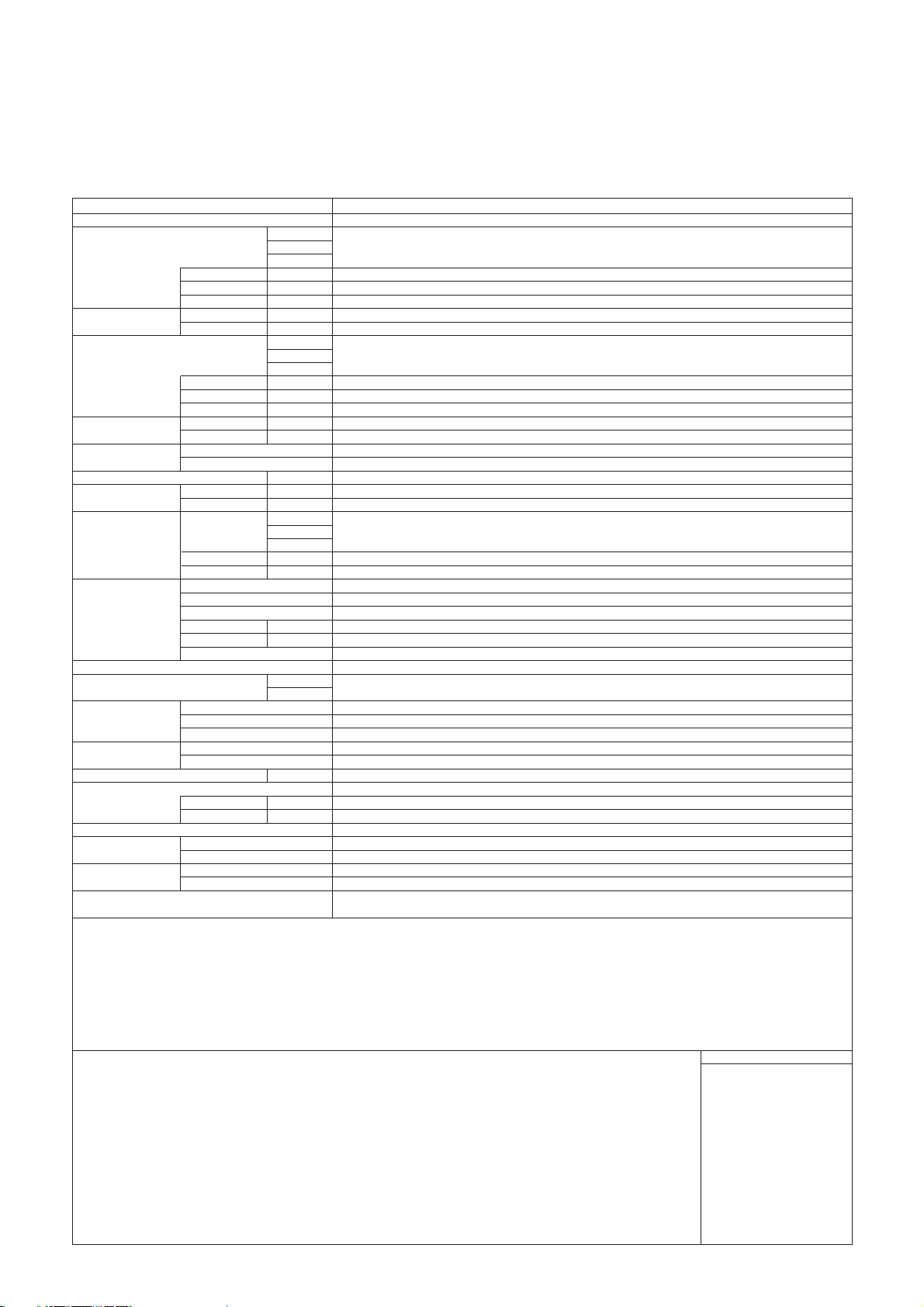

2.Capacity correction by brine concentration (For heat source unit)

Brine concentration [wt%]

Propylene Glycol

Ethylene Glycol

Propylene Glycol

Ethylene Glycol

Ratio of cooling capacity

1

0.95

0.9

0.85

0% 20% 40% 60% 80% 100%

Brine concentration [wt%]

Propylene Glycol

Ethylene Glycol

Propylene Glycol

Ethylene Glycol

Ratio of cooling input

1.30

1.25

1.20

1.15

1.10

1.05

1.00

0% 20% 40% 60% 80% 100%

Brine concentration [wt%]

Propylene Glycol

Ethylene Glycol

Propylene Glycol

Ethylene Glycol

Ratio of heating capacity

1.00

0.95

0.90

0.85

0.80

0.75

0.70

0% 20% 40% 60% 80% 100%

Brine concentration [wt%]

Propylene Glycol

Ethylene Glycol

Propylene Glycol

Ethylene Glycol

Ratio of heating input

1

0.95

0.9

0.85

0.8

0% 20% 40% 60% 80% 100%

PQHY

PQRY

IU IU

Cooling

Heating

Depending on the freezing temperature and brine concentration, the ratio of unit capacity will change.

As shown in the line diagram, higher the brine concentration, the lower the ratio of capacity becomes.

- 2 -

Page 7

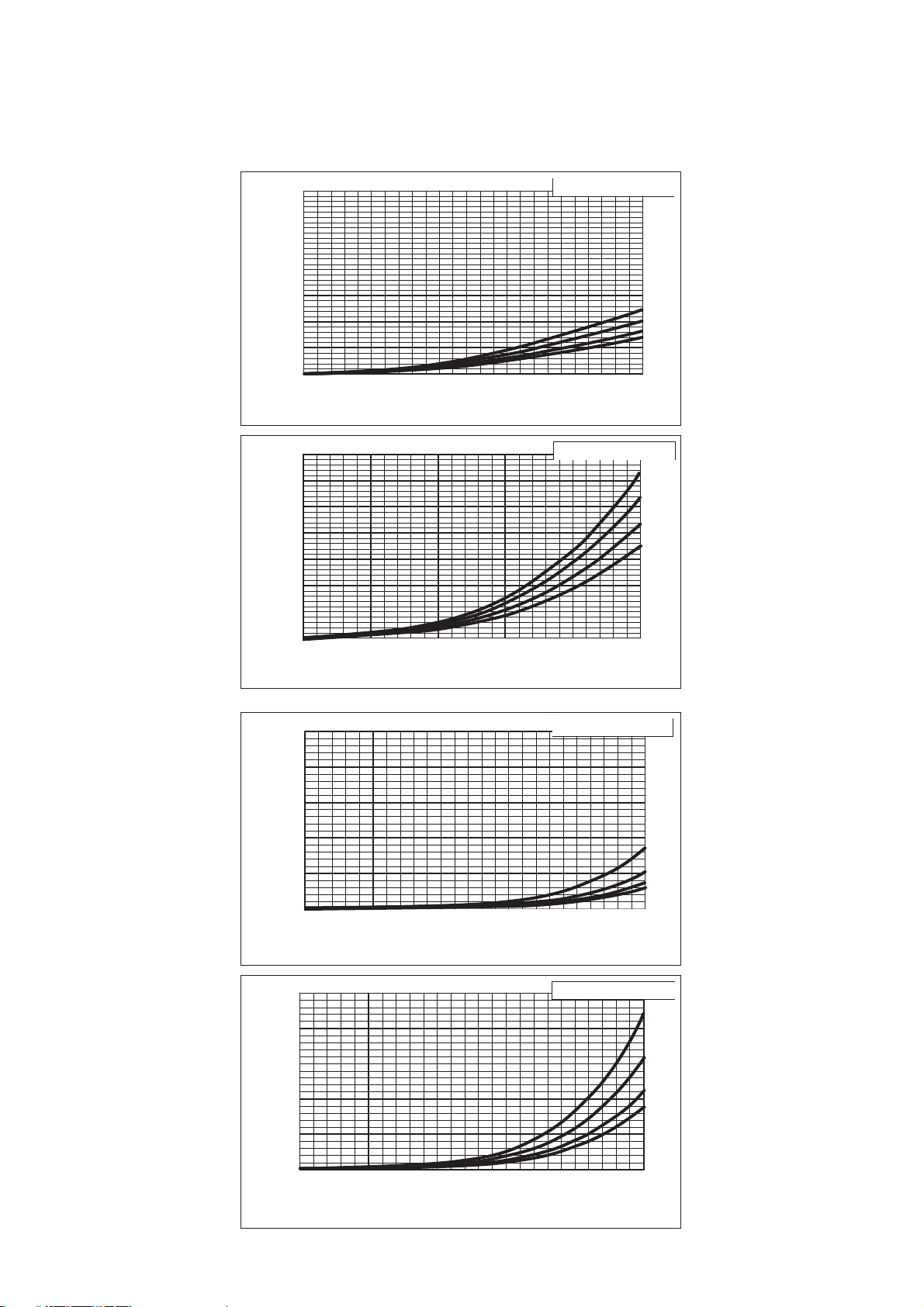

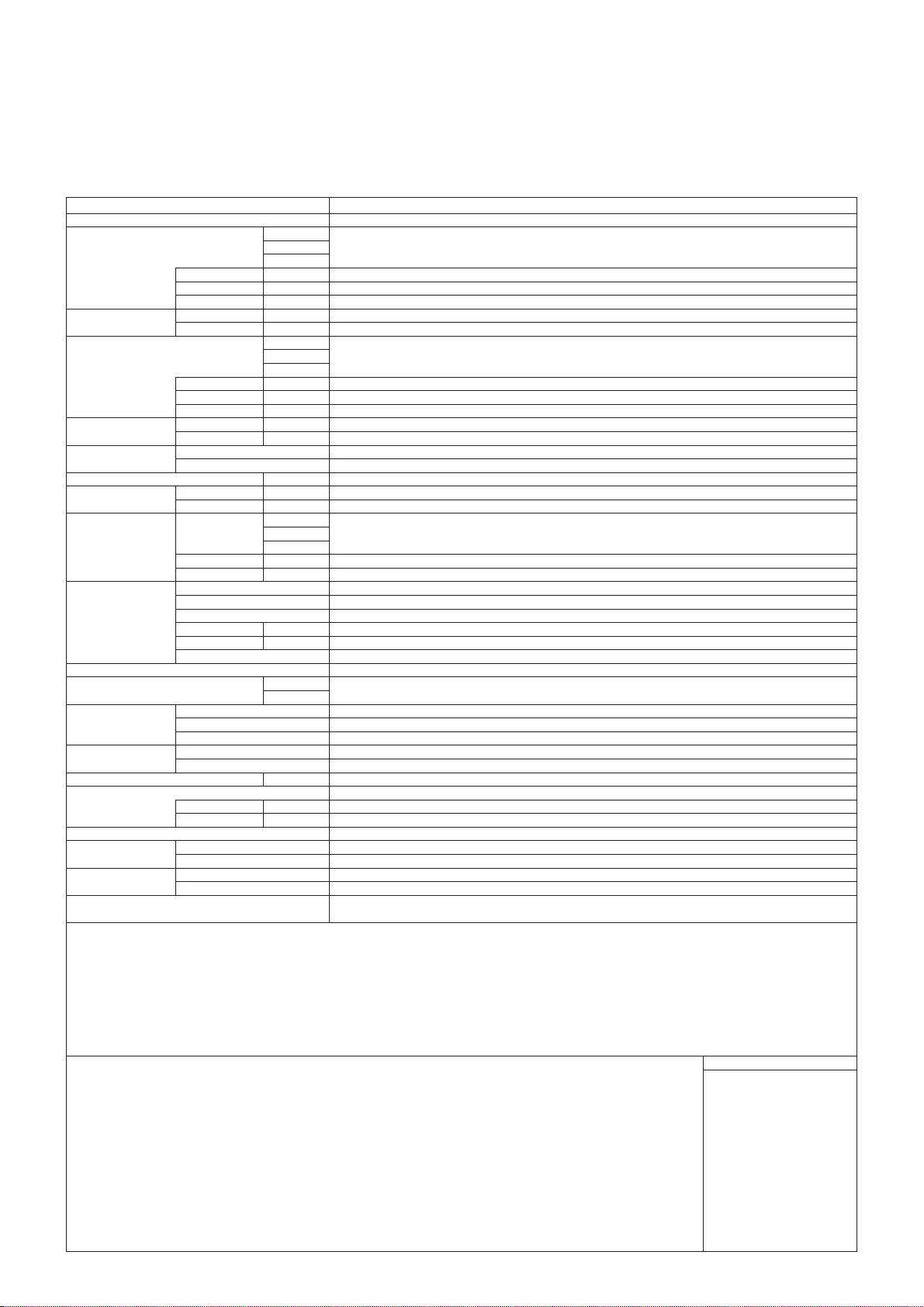

3.Pressure drop correction by brine concentration (For heat source unit)

Cooling

Heating

Brine concentration [wt%]

Inlet-water temp. [°C]

Ratio of pressure drop

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

-5°C

0°C

5°C

10°C

0% 20% 40% 60% 80% 100%

Brine concentration [wt%]

Inlet-water temp. [°C]

Ratio of pressure drop

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

-5°C

0°C

5°C

10°C

0% 20% 40% 60% 80% 100%

Brine concentration [wt%]

Inlet-water temp. [°C]

Ethylene Glycol (heating)Ethylene Glycol (heating)

Ratio of pressure drop

26.0

21.0

16.0

11. 0

6.0

1.0

-5°C

0°C

5°C

10°C

0% 20% 40% 60% 80% 100%

Brine concentration [wt%]

* Please supply strainer on site.

Inlet-water temp. [°C]

Ethylene Glycol (cooling)Ethylene Glycol (cooling)

Propylene Glycol (cooling)Propylene Glycol (cooling)

Propylene Glycol (heating)Propylene Glycol (heating)

Ratio of pressure drop

26.0

21.0

16.0

11. 0

6.0

1.0

-5°C

0°C

5°C

10°C

0% 20% 40% 60% 80% 100%

Also, water pump is selected by the ratio of pressure drop of depending on the brine concentration.

- 3 -

Page 8

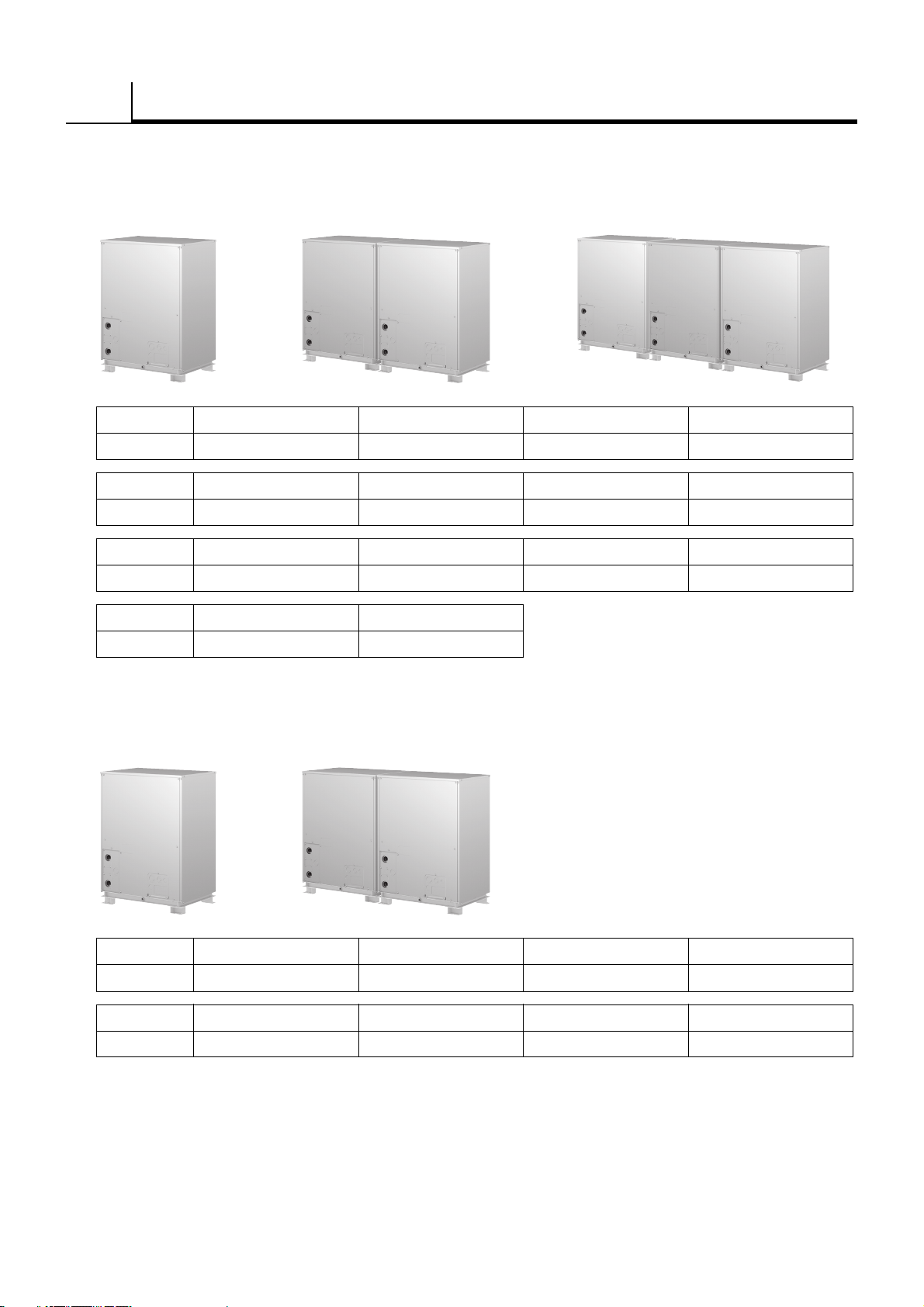

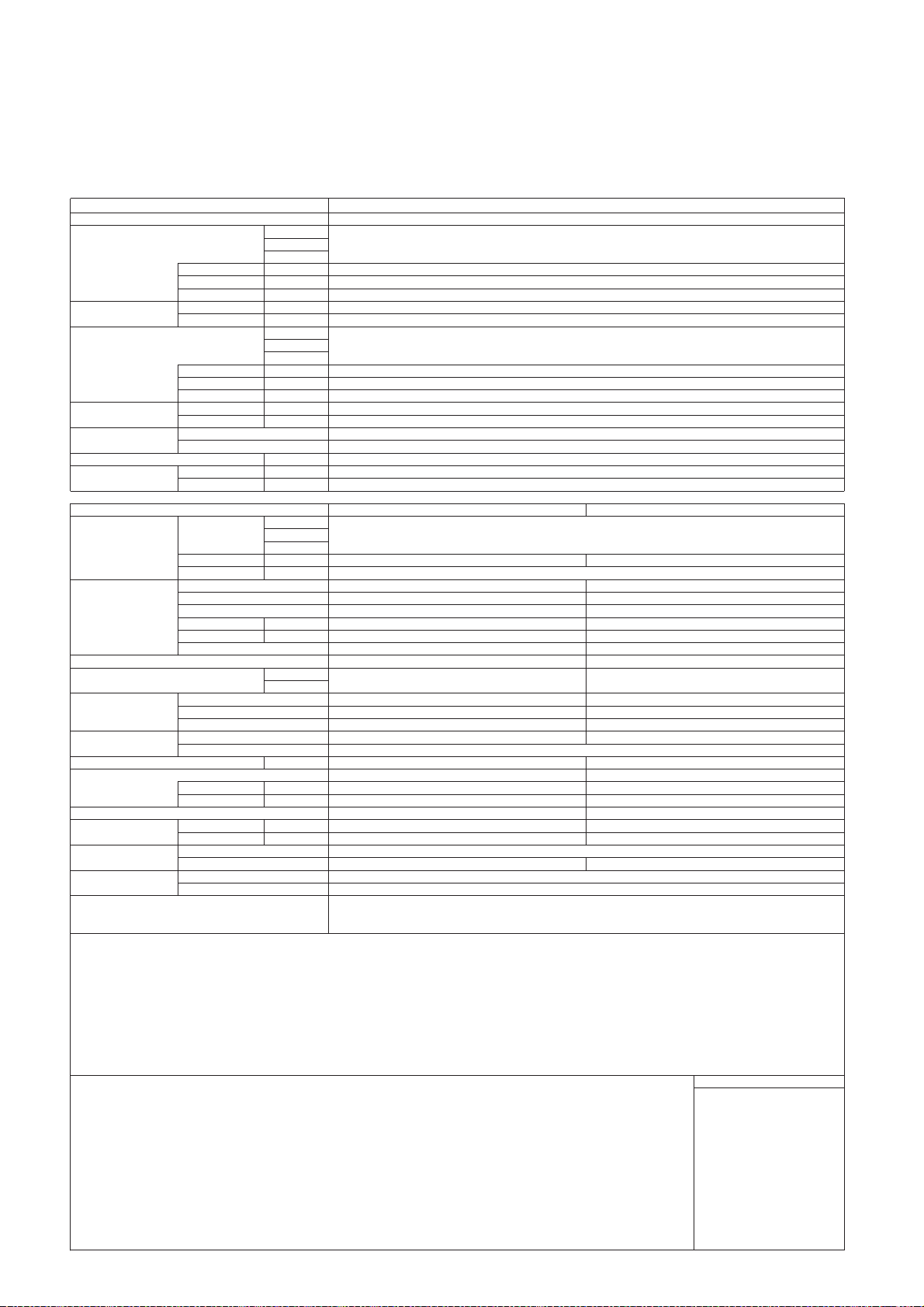

II Heat source unit information

1.General lineup of water-cooled heat source unit

WY (Heat Pump) Series (8HP-36HP)

PQHY-P YHM-A

PQHY-P YSHM-A

Model 8HP 10HP 12HP 16HP

Model Name PQHY-P200YHM-A PQHY-P250YHM-A PQHY-P300YHM-A PQHY-P400YSHM-A

Model 18HP 20HP 22HP 24HP

Model Name PQHY-P450YSHM-A PQHY-P500YSHM-A PQHY-P550YSHM-A PQHY-P600YSHM-A

Model 26HP 28HP 30HP 32HP

Model Name PQHY-P650YSHM-A PQHY-P700YSHM-A PQHY-P750YSHM-A PQHY-P800YSHM-A

Model 34HP 36HP

Model Name PQHY-P850YSHM-A PQHY-P900YSHM-A

WR2 (Heat Recovery) Series (8HP-24HP)

PQRY-P YHM-A

PQRY-P YSHM-A

Model 8HP 10HP 12HP 16HP

Model Name PQRY-P200YHM-A PQHRY-P250YHM-A PQRY-P300YHM-A PQRY-P400YSHM-A

Model 18HP 20HP 22HP 24HP

Model Name PQRY-P450YSHM-A PQRY-P500YSHM-A PQRY-P550YSHM-A PQRY-P600YSHM-A

- 4 -

Page 9

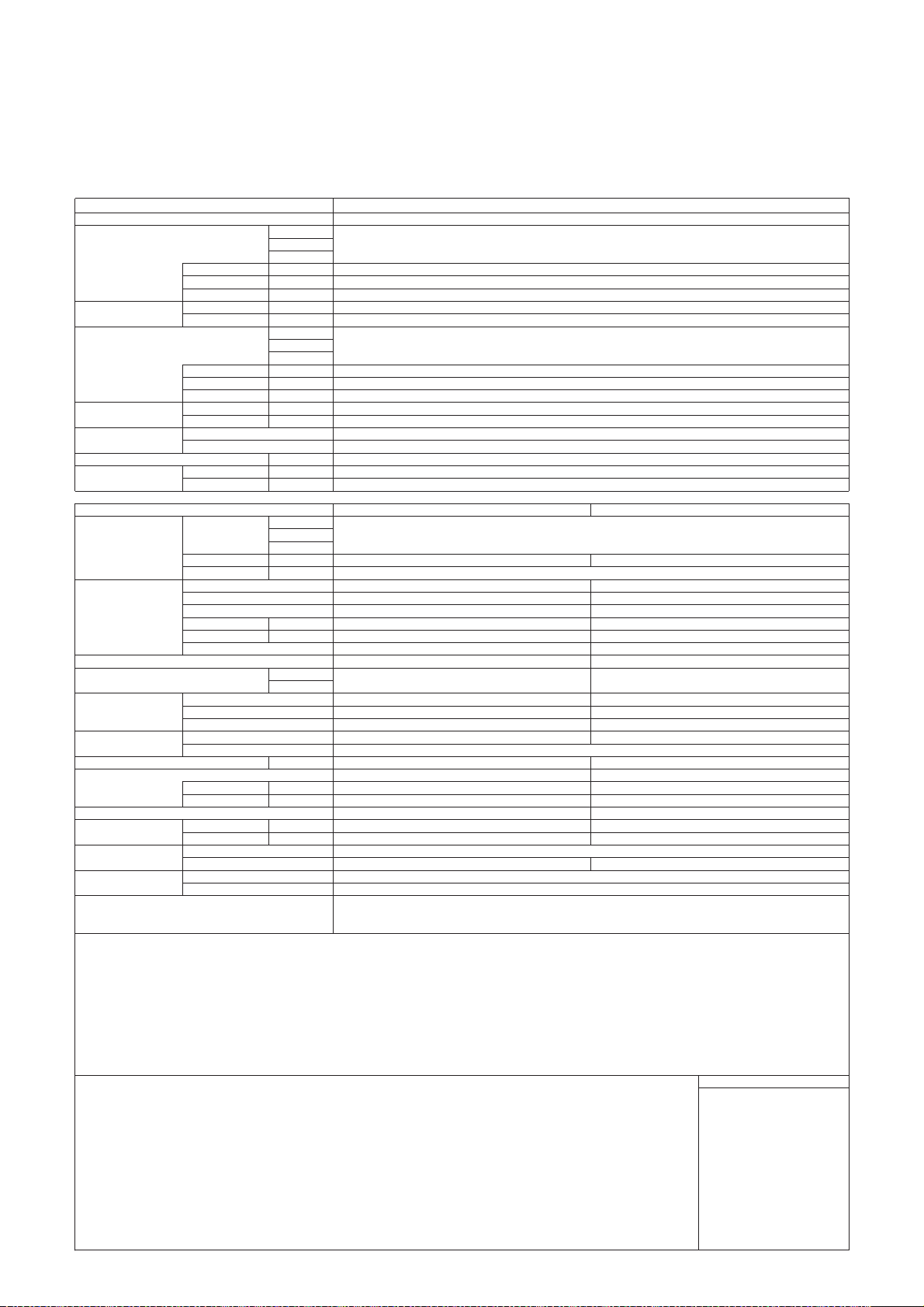

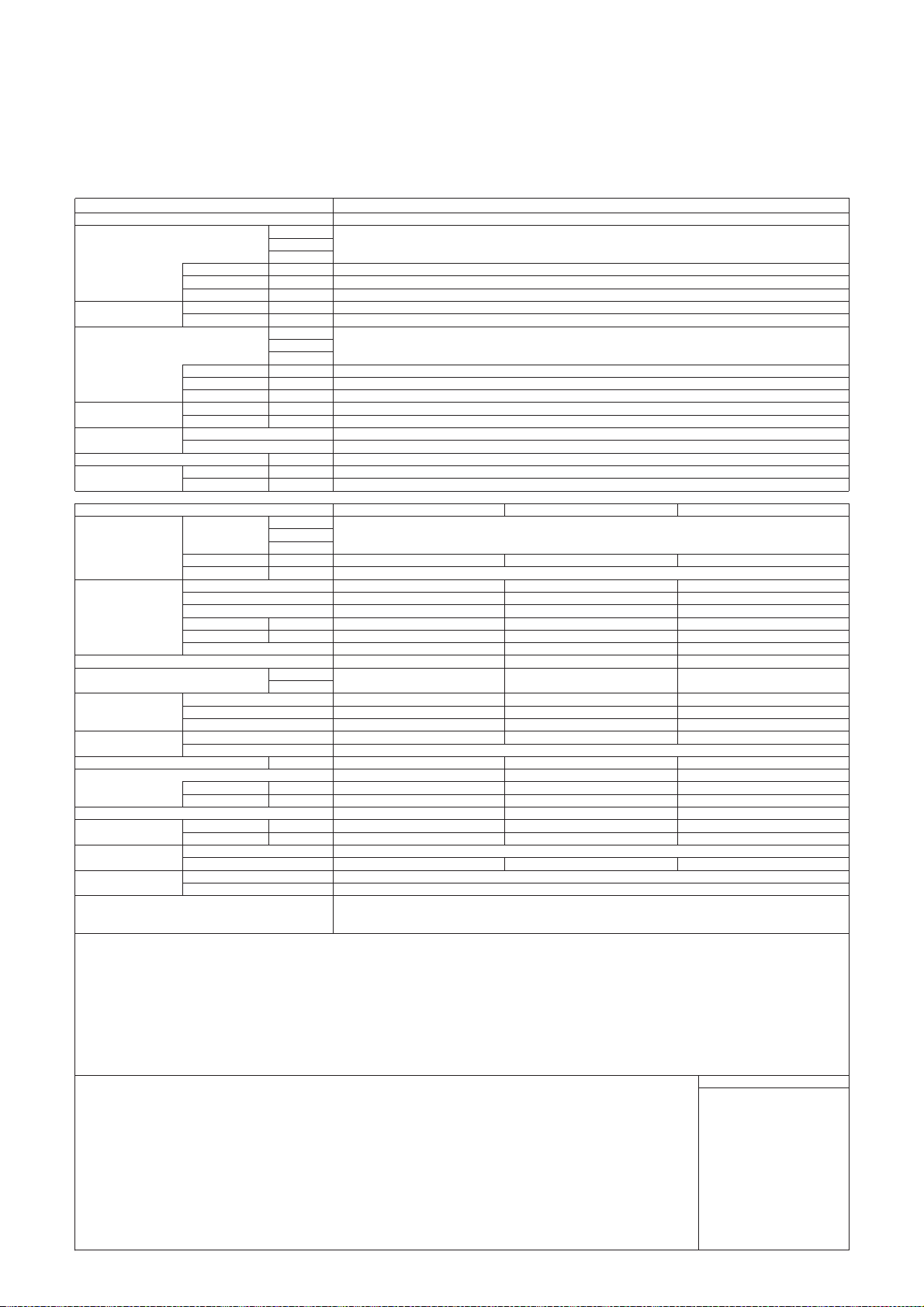

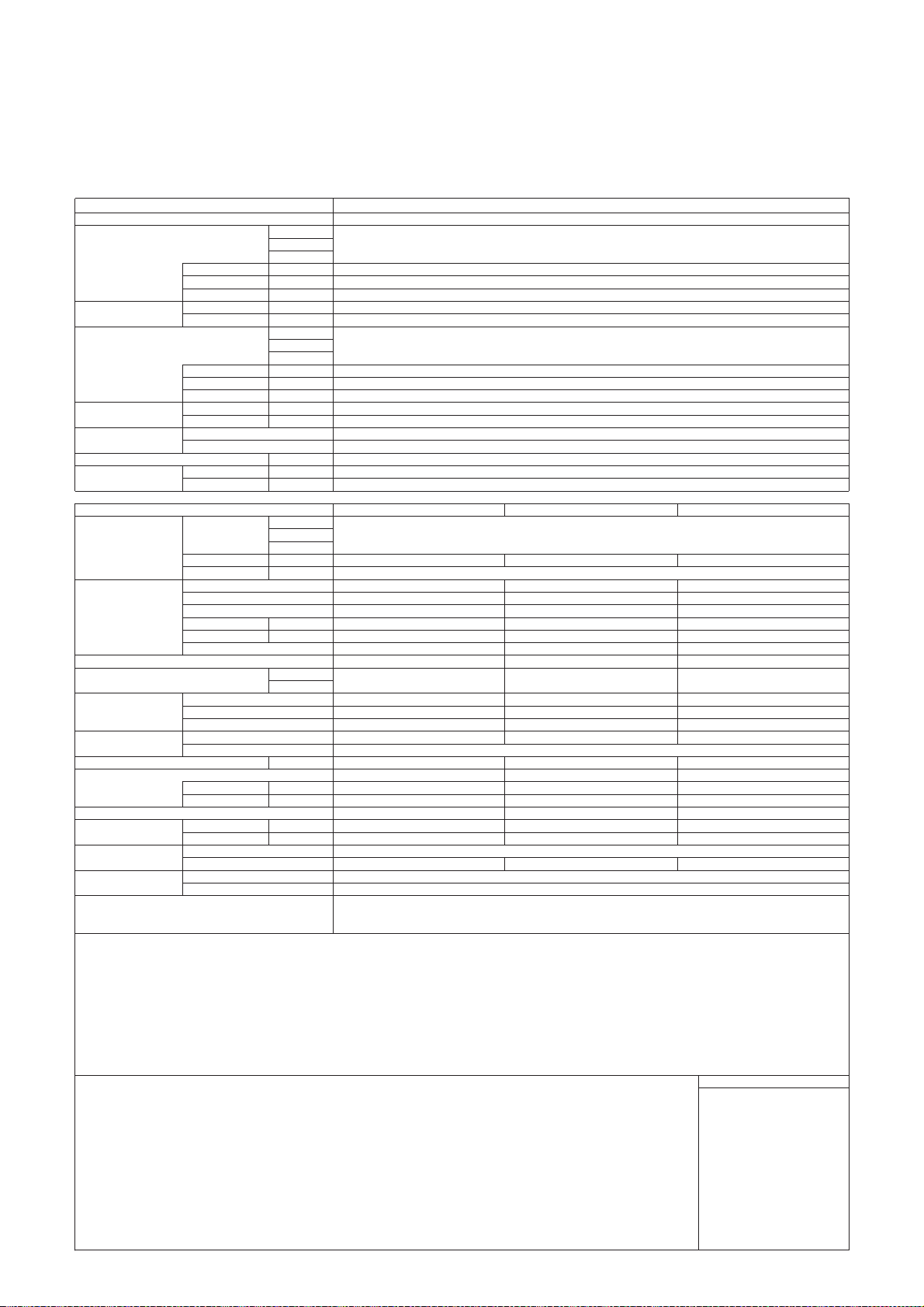

2.PQHY-P-Y(S)HM-A

*1

*2

Optional parts

Refrigerant

A

Current inputkWA

kW

60.6POC kW / kW

6.9-6.6-6.3

kW

kcal / h

*2 BTU / h

Power input

kW / kW

W.B.

5.71

-5.0~45.0°C(23~113°F)

Sound pressure level (measured in anechoic room)

dB <A>

25.0

15.0~24.0°C(59~75°F)

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

cooling

Circulating water

Heating capacity

Cooling capacity

47

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 1~17

-5.0~45.0°C(23~113°F)

85,300

4.12

1.0

KB94T222

5.0

195(430)

External dimension HxWxD

Motor output

kW

Lubricant

Case heater

kW

9.52(3/8) Brazed

19.05(3/4) Brazed

Inverter scroll hermetic compressor

4.5 ~ 7.2

4.6

Indoor LEV and BC controller

0.035(240 V)

High pressure sensor, High pressure switch at 4.15MPa (601 psi) Protection

noitcetorp tnerruc-revO ,noitcetorp taeh-revO).PMOC( tiucric retrevnIseci

ved

Unit converter

KE94C317

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

*The specification data is

subject to rounding variation.

Wiring

Notes:

Standard attachment

Document

Operating volume range

m3 / h

Inverter

AC&R Works, MITSUBISHI ELECTRIC CORPORATION

17

Joint: CMY-Y102S-G2

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

Drawing External

Accessory

Water flow rate

m

3

/ h

L/min

Pressure drop kPa

mm

Compressor

in.

MPa

kg(lbs)

High pressure protection

Net weight

HIC circuit (HIC: Heat Inter-Changer)

Water volume in plate

Water pressure Max.

Compressor

wate

r

Circulating

cfm

96

3.4

MEL32

1,160(1,100 without legs) x 880 x 550

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

Installation Manual

Power source

kW

h / lack)lanimoN(*1

6.6-6.2-6.0

PQHY-P200YHM-A(For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

19,300

22.4

3.92

76,400*1 BTU / h

Indoor unit

Temp. range of

Starting method

Type x Quantit

y

Manufacture

Power input

).ni(mmtnaregirfeR

mm(in.)

Liquid pipe

Gas pipe

Current input

(Nominal)

D.B.

*2

COP

°C

Indoor

Temp. range of Indoor

Model

External finish

Total capacity

piping diameter

Circulating water

°C

connectable

Model / Quantity

heating

21,500

5.76

Type x original charge

Control

l

Acrylic painted steel plate

Over-heat protection

R410A x 5.0kg (12lbs)

Heat exchanger plate type

-

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

(1)

Specification

(1)-1 Heat source units specification for standard combination

(Standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU)

- 5 -

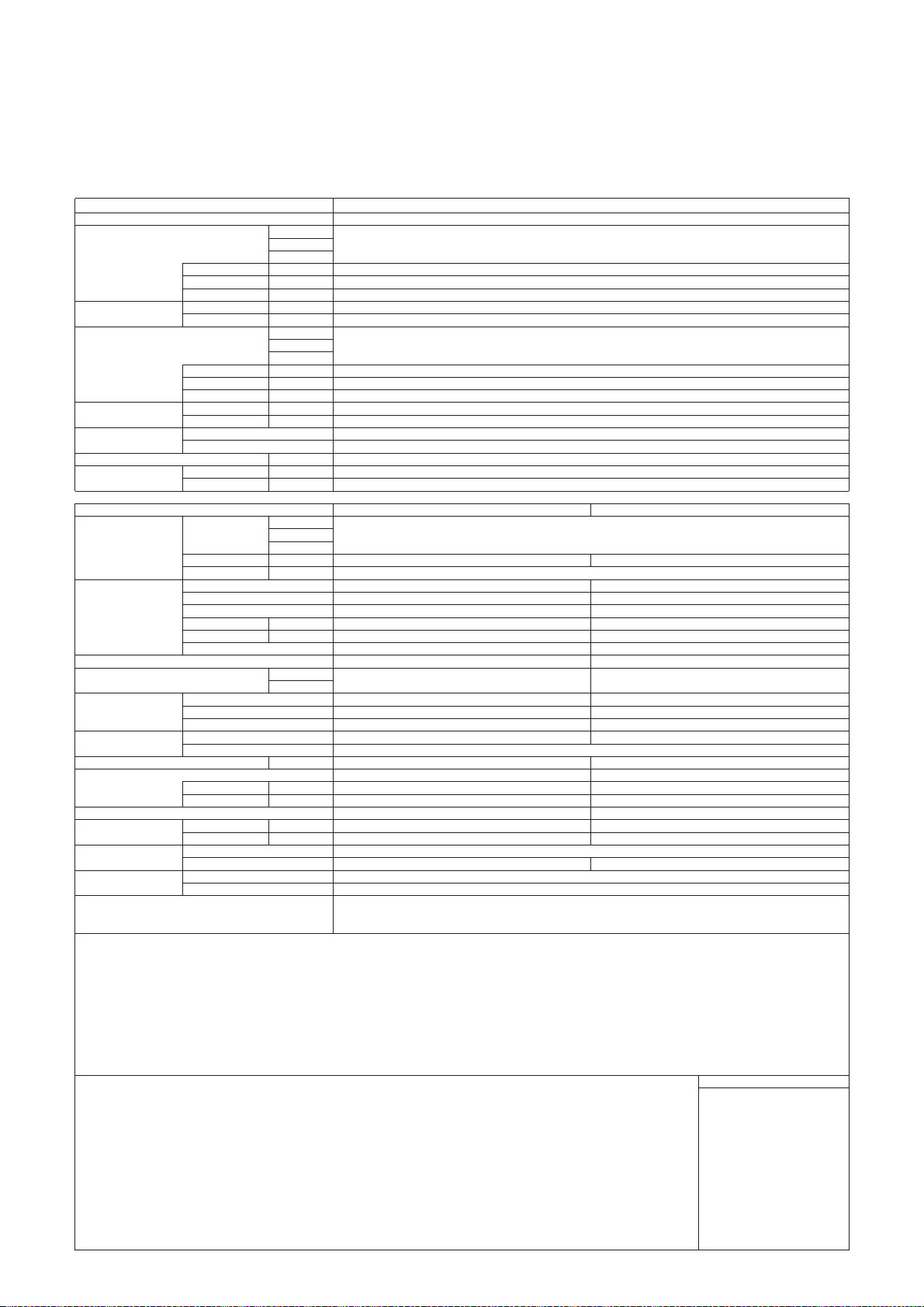

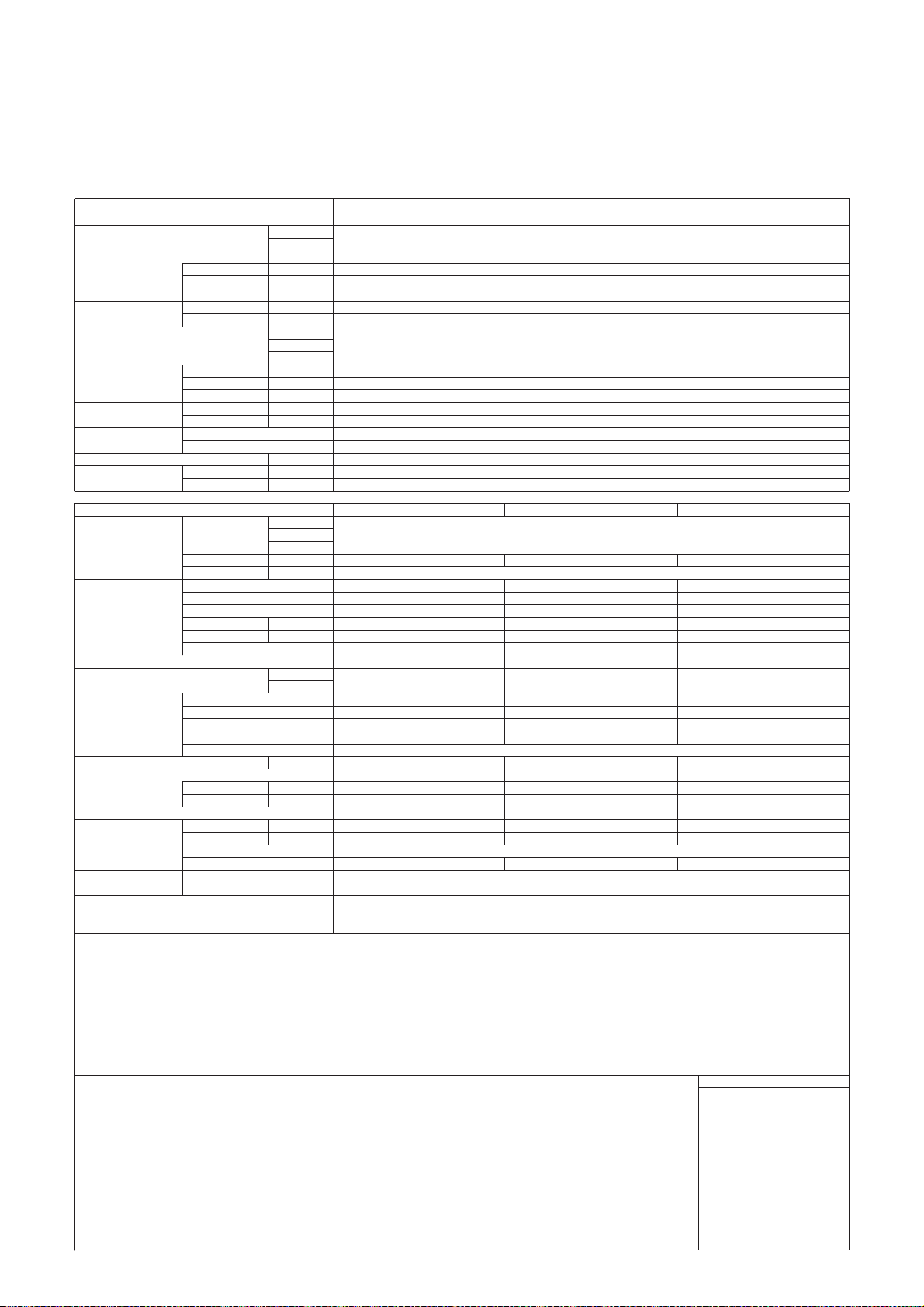

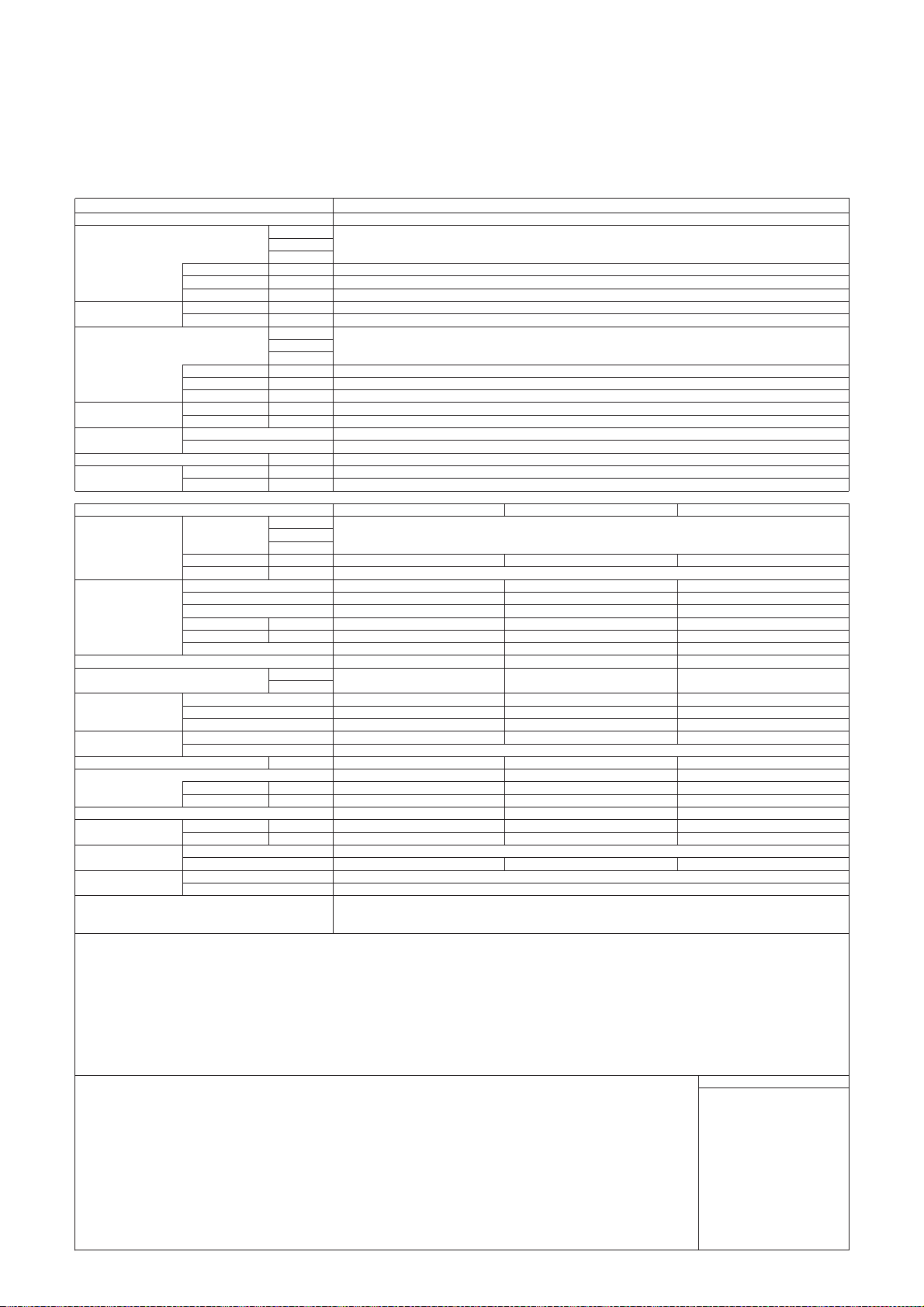

Page 10

*1

*2

-

plate type Heat exchanger

Over-heat protection

Acrylic painted steel plate

l

Type x original charge

Control

5.76

27,100

Circulating water

°C

connectable

Model / Quantity

heating

Model

External finish

Total capacity

piping diameter

D.B.

*2

COP

°C

Indoor

Temp. range of Indoor

Current input

(Nominal)

mm(in.)

mm(in.)

Liquid pipe

Gas pipe

Power input

Refrigerant

Starting method

Type x Quantit

y

Manufacture

BTU / h

Indoor unit

Temp. range of

*1

28.0

5.45

95,500

9.2-8.7-8.4

PQHY-P250YHM-A(For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

24,100h / lack)lanimoN(*1

Power source

kW

R410A x 5.0kg (12lbs)

Installation Manual

MEL32

1,160(1,100 without legs) x 880 x 550

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

cfm

96

3.4

Compressor

water

Net weight

HIC circuit (HIC: Heat Inter-Changer)

Water volume in plate

Water pressure Max.

High pressure protection

MPa

kg(lbs)

mm

Compressor

in.

L/min

Pressure drop kPa

Water flow rate

m

3

/ h

Circulating

Accessory

Drawing External

Joint: CMY-Y102S-G2, CMY-Y102L-G2

17

Inverter

AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Operating volume range

m3 / h

Wiring

Standard attachment

Document

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

KE94C317

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

Protection

noitcetorp tnerruc-revO ,noitcetorp taeh-revO).PMOC( tiucric retrevnIsecived

Indoor LEV and BC controller

0.035(240 V)

9.52(3/8) Brazed (12.7(1/2) Brazed,total length >= 90m)

22.2(7/8) Brazed

kW

Inverter scroll hermetic compressor

4.5 ~ 7.2

6.3

External dimension HxWxD

Motor output

kW

Lubricant

Case heater

5.0

195(430)

1.0

KB94T222

107,500

5.80

49

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 1~21

-5.0~45.0°C(23~113°F)

Cooling capacity

cooling

Circulating water

Heating capacity

Sound pressure level (measured in anechoic room)

dB <A>

31.5

15.0~24.0°C(59~75°F)W.B.

5.13

-5.0~45.0°C(23~113°F)

kW / kW

kcal / h

*2 BTU / h

Power input

kW

9.7-9.3-8.9

34.5POC kW / kW

kW

Current inputkWA

A

Optional parts

Refri

gerant

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

Unit converter

*The specification data is

subject to rounding variation.

Notes:

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

- 6 -

Page 11

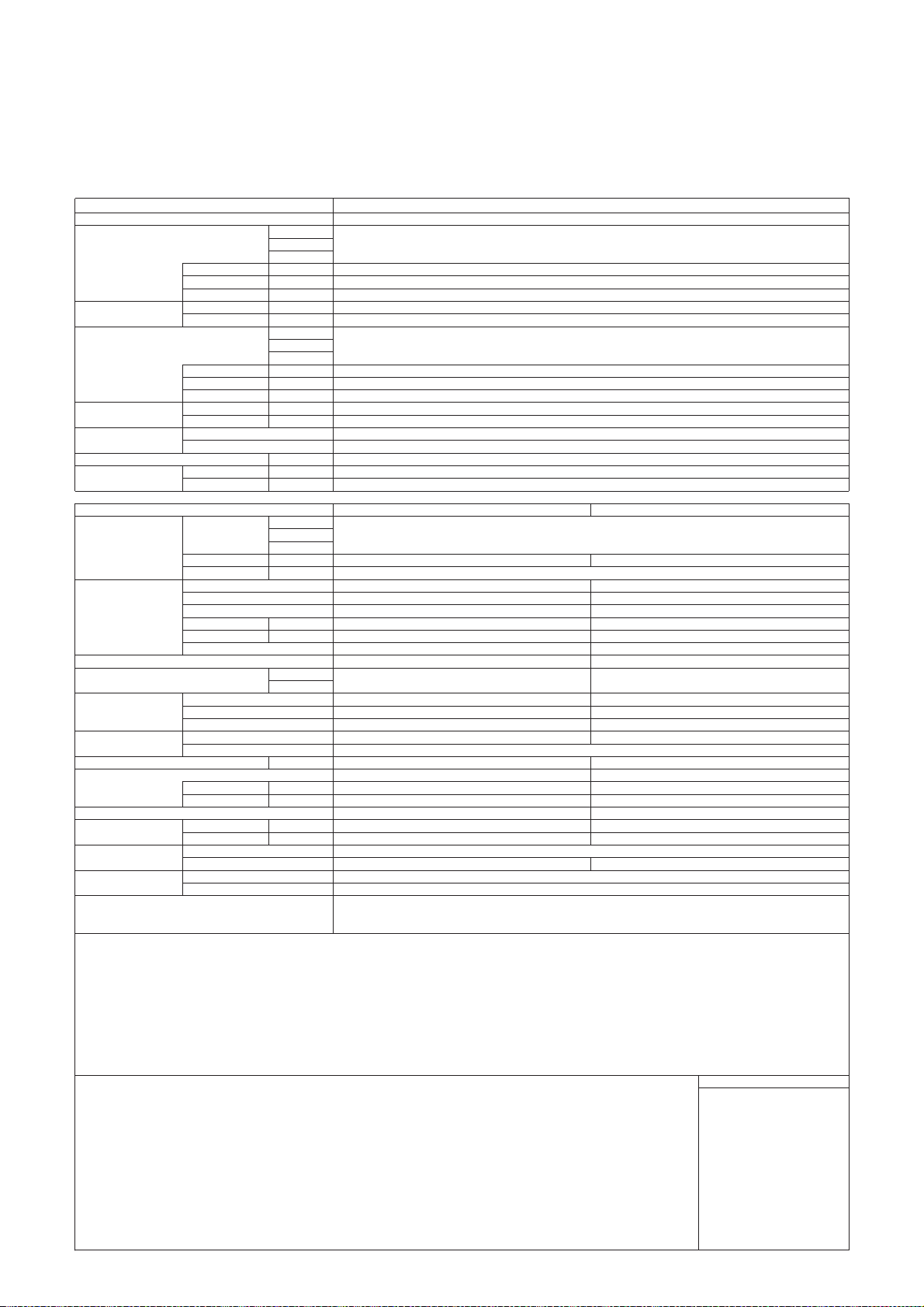

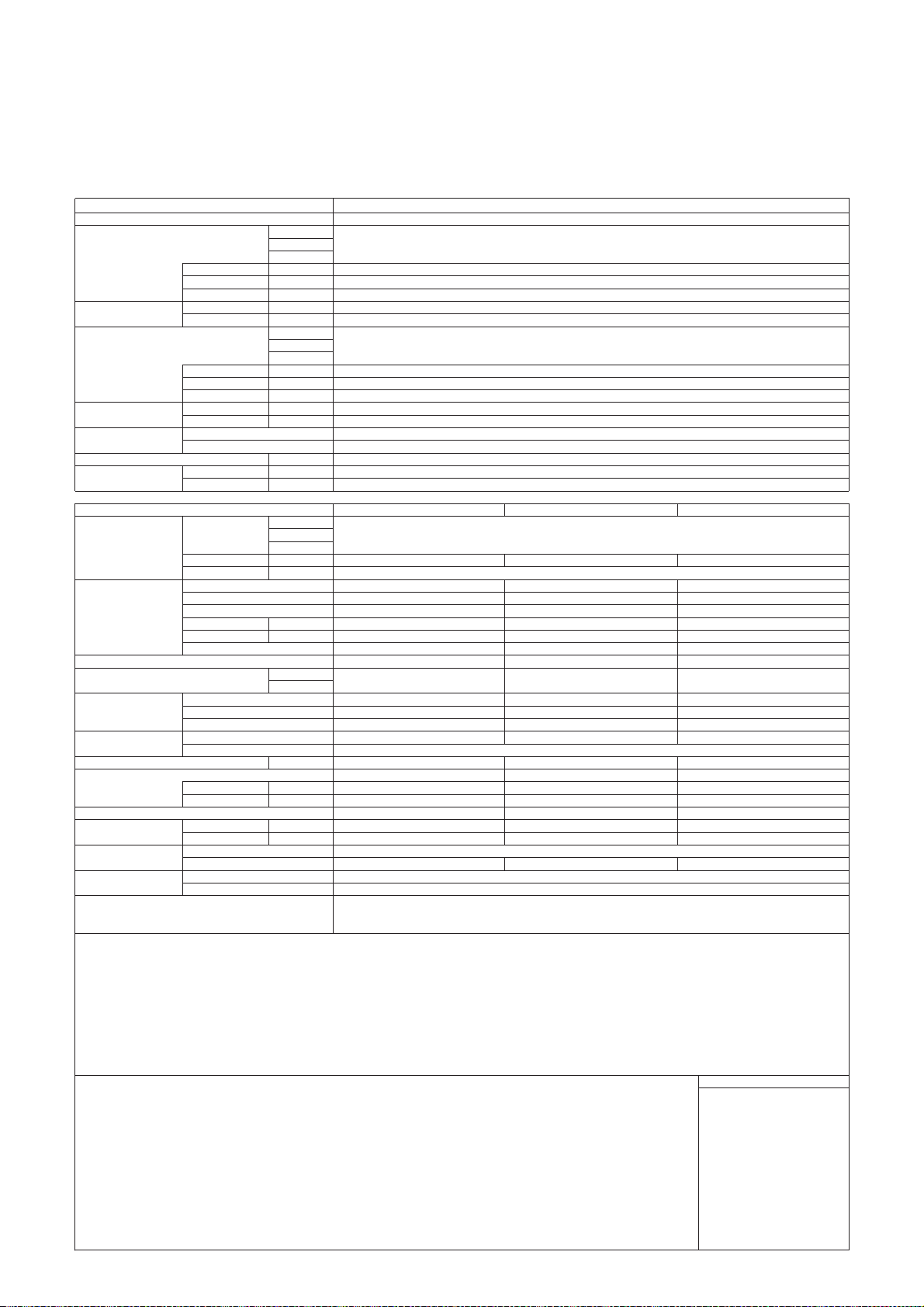

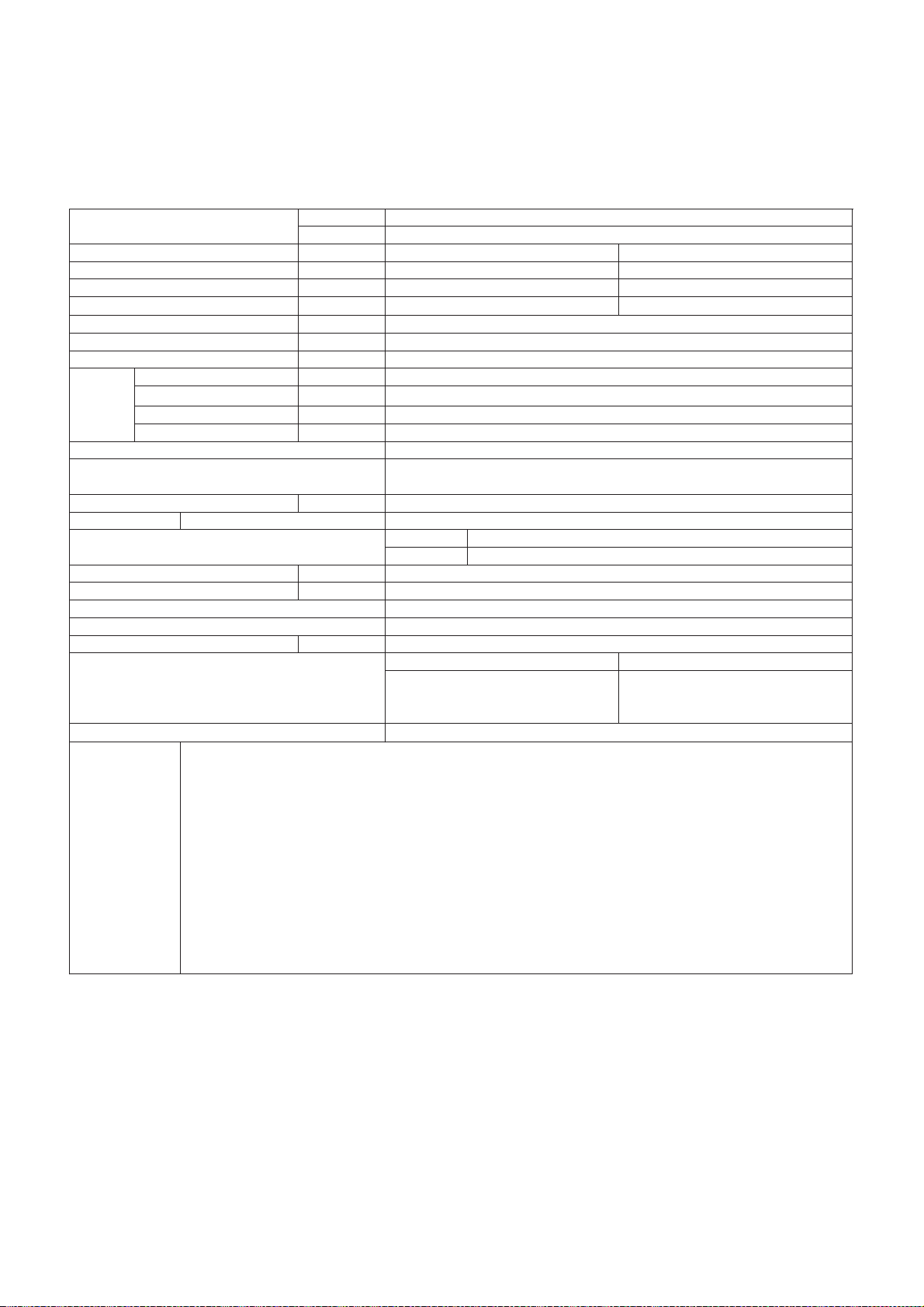

*1

*2

-

plate type

Heat exchanger

Over-heat protection

Acrylic painted steel plate

l

Type x original charge

Control

5.76

32,300

Circulating water

°C

connectable

Model / Quantity

heating

Model

External finish

Total capacity

piping diameter

D.B.

*2

COP

°C

Indoor

Temp. range of Indoor

Current input

(Nominal)

mm(in.)

mm(in.)

Liquid pipe

Gas pipe

Power input

Refrigerant

Starting method

Type x Quantit

y

Manufacture

BTU / h

Indoor unit

Temp. range of

*1

33.5

7.36

114,300

12.4-11.8-11.3

PQHY-P300YHM-A(For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

28,800h / lack)lanimoN(*1

Power source

kW

R410A x 5.0kg (12lbs)

Installation Manual

MEL32

1,160(1,100 without legs) x 880 x 550

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

cfm

96

3.4

Compressor

water

Net weight

HIC circuit (HIC: Heat Inter-Changer)

Water volume in plate

Water pressure Max.

High pressure protection

MPa

kg(lbs)

mm

Compressor

in.

L/min

Pressure drop kPa

Water flow rate

m

3

/ h

Circulating

Accessory

Drawing External

Joint: CMY-Y102S-G2,CMY-Y102L-G2

17

Inverter

AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Operating volume range

m3 / h

Wiring

Standard attachment

Document

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

KE94C317

High pressure sensor, High pressure switch at 4.15MPa (601 psi) Protection

noitcetorp tnerruc-revO ,noitcetorp taeh-revO).PMOC( tiucric retrevnIsecived

Indoor LEV and BC controller

0.035(240 V)

9.52(3/8) Brazed (12.7(1/2) Brazed,total length >= 40m)

22.2(7/8) Brazed

kW

Inverter scroll hermetic compressor

4.5 ~ 7.2

7.4

External dimension HxWxD

Motor output

kW

Lubricant

Case heater

5.0

195(430)

1.0

KB94T222

128,000

8.15

50

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 1~26

-5.0~45.0°C(23~113°F)

Cooling capacity

cooling

Circulating water

Heating capacity

Sound pressure level (measured in anechoic room)

dB <A>

37.5

15.0~24.0°C(59~75°F)W.B.

4.55

-5.0~45.0°C(23~113°F)

kW / kW

kcal / h

*2 BTU / h

Power input

kW

13.7-13.0-12.5

06.4POC

kW / kW

kW

Current inputkWA

A

Optional parts

Refri

gerant

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

Unit converter

*The specification data is

subject to rounding variation.

Notes:

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

- 7 -

Page 12

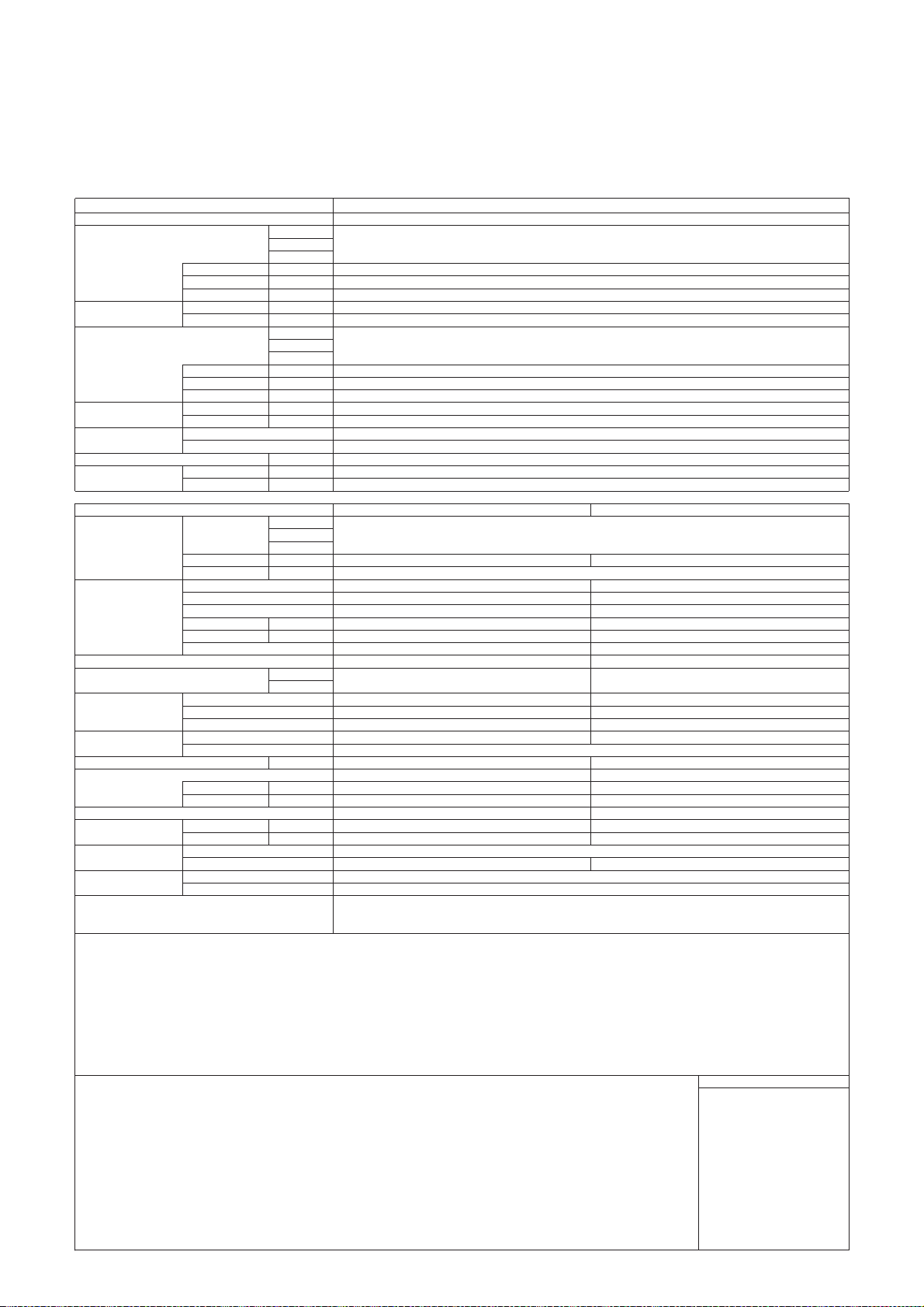

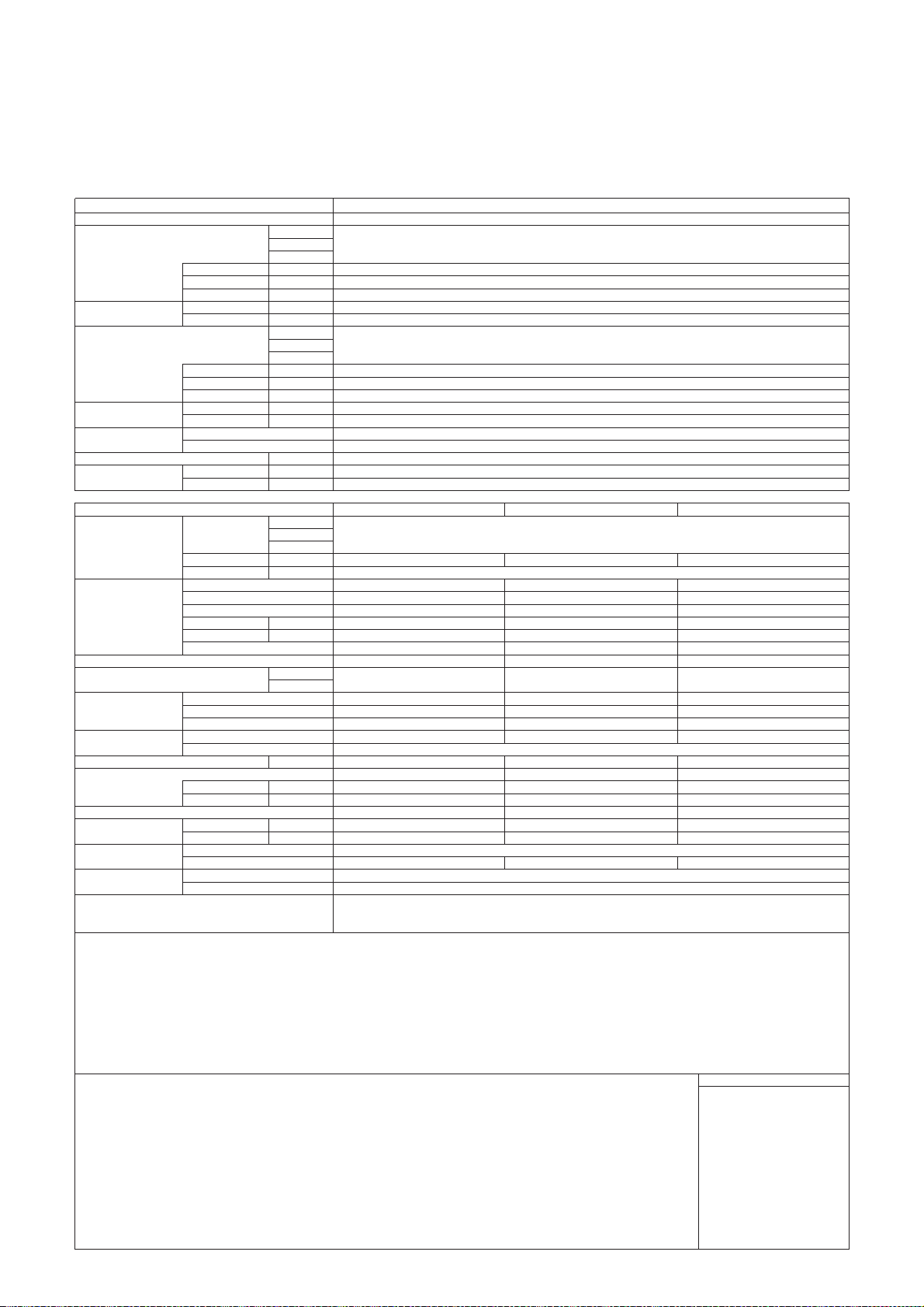

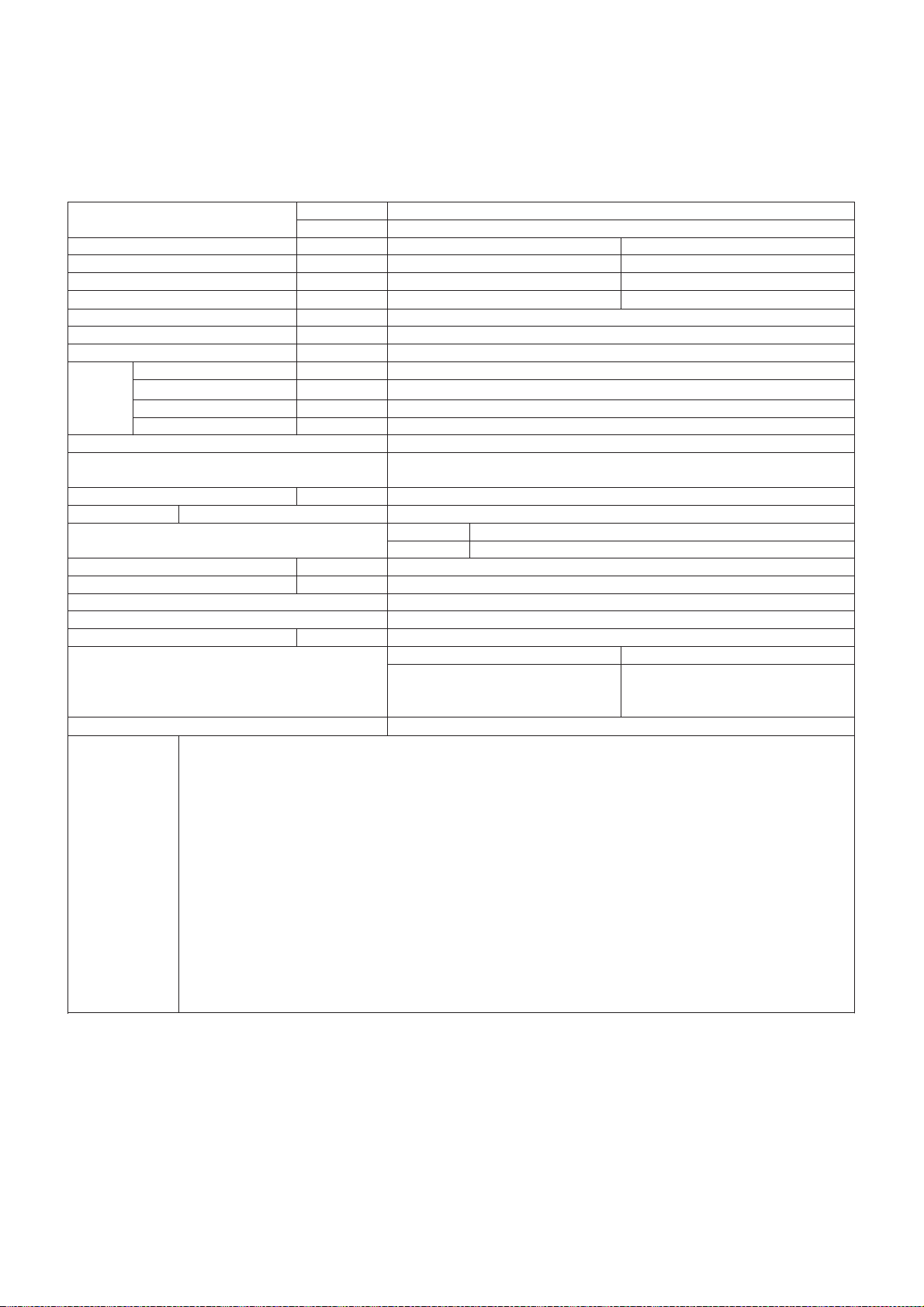

*1

*2

Heat Source Twinning kit: CMY-Y100VBK2

9.52(3/8) Brazed

-

1.0

5.0

1.0

Over-heat protection, Over-current protection Over-heat protection, Over-current protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

Over-heat protection

Acrylic painted steel plate

23LEM23LEM

4.6

)V 042(530.0)V 042(530.0Wkretaeh esaC

6.4Wktuptuo rotoM

Inverter scroll hermetic compressor

Inverter

AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter

Inverter scroll hermetic compressor

in.

Over-heat protection

Control

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

195(430)

5.76 + 5.76

43,000

Circulating water

°C

Set Model

Model

connectable

Model / Quantity

heating

Model

Total capacity

piping diameter

D.B.

*2

COP

°C

Indoor

Temp. range of

Current input

(Nominal)

mm(in.)

mm(in.)

Liquid pipe

Gas pipe

Power input

Refrigerant

BTU / h

Indoor unit

Temp. range of

*1

45.0

8.25

153,500

13.9-13.2-12.7

PQHY-P400YSHM-A (For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

38,700h / lack)lanimoN(*1

Power source

kW

Installation Manual

Acrylic painted steel plate

1,160(1,100 without legs) x 880 x 550

cfm

96 + 96

3.4 + 3.4

l

Water volume in plate

wate r

HIC circuit (HIC: Heat Inter-Changer)

Heat exchanger

Water pressure Max.

Protection

mm

External dimension HxWxD

Type x original charge

)sbl(gkthgiew teN

MPa

High pressure protection

Inverter circuit (COMP.)

Manufacture

Starting method

L/min

Water flow rate

m

3

/ h

Circulating

Compressor

Accessory

Drawing

distributor

KE94C317

Joint: CMY-Y102S-G2, CMY-Y102L-G2, CMY-Y202-G2

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

●Twinning kit is required.

KE94C317

kPaPressure drop

Operating volume range

m3 / h

Notes:

Standard attachment

Document

Wiring

External

*The specification data is

subject to rounding variation.

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

Unit converter

R410A x 5.0kg (12lbs)

Indoor LEV and BC controller

1,160(1,100 without legs) x 880 x 550

PQHY-P200YHM-A(For Ground source)

12.7(1/2) Brazed

28.58(1-1/8) Brazed

epyt etalp epyt etalp

5.0

4.5 + 4.5 ~ 7.2 + 7.2

Lubricant

Type x Quantity

External finish

-

R410A x 5.0kg (12lbs)

195(430)

KB94T223

9.52(3/8) Brazed

170,600

PQHY-P200YHM-A(For Ground source)

8.65

50

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 1~34

-5.0~45.0°C(23~113°F)

7171

Gas pipe mm(in.)

dezarB )4/3(50.91dezarB )4/3(50.91

Cooling capacity

devices

Compressor

cooling

Circulating water

Indoor

Heating capacity

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

Pipe between unit and

Liquid pipe mm(in.)

Sound pressure level (measured in anechoic room)

dB <A>

50.0

15.0~24.0°C(59~75°F)W.B.

5.45

-5.0~45.0°C(23~113°F)

kW / kW

kcal / h

*2 BTU / h

Power input

kW

14.6-13.8-13.3

87.5POC kW / kW

kW

Current inputkWA

A

Optional parts

Refri gerant

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

- 8 -

Page 13

*1

*2

Wkretaeh esaC

Wktuptuo rotoM

in.

Control

Circulating water

°C

Set Model

Model

connectable

Model / Quantity

heating

Model

Total capacity

piping diameter

D.B.

*2

COP

°C

Indoor

Temp. range of

Current input

(Nominal)

mm(in.)

mm(in.)

Liquid pipe

Gas pipe

Power input

Refrigerant

BTU / h

Indoor unit

Temp. range of

*1

h / lack)lanimoN(*1

Power source

kW

cfm

l

Water volume in plate

wate r

HIC circuit (HIC: Heat Inter-Changer)

Heat exchanger

Water pressure Max.

Protection

mm

External dimension HxWxD

Type x original charge

)sbl(gkthgiew teN

MPa

High pressure protection

Inverter circuit (COMP.)

Manufacture

Starting method

L/min

Water flow rate

m

3

/ h

Circulating

Compressor

Accessory

Drawing

distributor

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

●Twinning kit is required.

kPaPressure drop

Operating volume range

m3 / h

Notes:

Standard attachment

Document

Wiring

External

*The specification data is

subject to rounding variation.

Unit converter

Lubricant

Type x Quantity

External finish

Gas pipe mm(in.)

Cooling capacity

devices

Compressor

cooling

Circulating water

Indoor

Heating capacity

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

Pipe between unit and

Liquid pipe mm(in.)

Sound pressure level (measured in anechoic room)

dB <A>

W.B.

kW / kW

kcal / h

*2 BTU / h

Power input

kW

POC kW / kW

kW

Current inputkWA

A

Optional parts

Refri gerant

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

Heat Source Twinning kit: CMY-Y100VBK2

9.52(3/8) Brazed

--

1.0

5.0

1.0

Over-heat protection, Over-current protection Over-heat protection, Over-current protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

Over-heat protection

Acrylic painted steel plate

23LEM23LEM

4.6

)V 042(530.0)V 042(530.0

3.6

Inverter scroll hermetic compressor

Inverter

AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter

Inverter scroll hermetic compressor

Over-heat protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

195(430)

5.76 + 5.76

48,200

50.0

9.84

170,600

16.6-15.7-15.2

PQHY-P450YSHM-A(For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

43,000

Installation Manual

Acrylic painted steel plate

1,160(1,100 without legs) x 880 x 550

96 + 96

3.4 + 3.4

KE94C317

Joint: CMY-Y102S-G2, CMY-Y102L-G2, CMY-Y202-G2

KE94C317

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

R410A x 5.0kg (12lbs)

Indoor LEV and BC controller

1,160(1,100 without legs) x 880 x 550

PQHY-P250YHM-A(For Ground source)

15.88(5/8) Brazed

28.58(1-1/8) Brazed

epyt etalp epyt etalp

5.0

4.5 + 4.5 ~ 7.2 + 7.2

R410A x 5.0kg (12lbs)

195(430)

KB94T223

9.52(3/8) Brazed

191,100

PQHY-P200YHM-A(For Ground source)

10.42

51

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 1~39

-5.0~45.0°C(23~113°F)

7171

dezarB )8/7(2.22dezarB )8/7(2.22

56.0

15.0~24.0°C(59~75°F)

5.08

-5.0~45.0°C(23~113°F)

17.5-16.7-16.1

73.5

- 9 -

Page 14

*1

*2

Wkretaeh esaC

Wktuptuo rotoM

in.

Control

Circulating water

°C

Set Model

Model

connectable

Model / Quantity

heating

Model

Total capacity

piping diameter

D.B.

*2

COP

°C

Indoor

Temp. range of

Current input

(Nominal)

mm(in.)

mm(in.)

Liquid pipe

Gas pipe

Power input

Refrigerant

BTU / h

Indoor unit

Temp. range of

*1

h / lack)lanimoN(*1

Power source

kW

cfm

l

Water volume in plate

wate r

HIC circuit (HIC: Heat Inter-Changer)

Heat exchanger

Water pressure Max.

Protection

mm

External dimension HxWxD

Type x original charge

)sbl(gkthgiew teN

MPa

High pressure protection

Inverter circuit (COMP.)

Manufacture

Starting method

L/min

Water flow rate

m

3

/ h

Circulating

Compressor

Accessory

Drawing

distributor

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

●Twinning kit is required.

kPaPressure drop

Operating volume range

m3 / h

Notes:

Standard attachment

Document

Wiring

External

*The specification data is

subject to rounding variation.

Unit converter

Lubricant

Type x Quantity

External finish

Gas pipe mm(in.)

Cooling capacity

devices

Compressor

cooling

Circulating water

Indoor

Heating capacity

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

Pipe between unit and

Liquid pipe mm(in.)

Sound pressure level (measured in anechoic room)

dB <A>

W.B.

kW / kW

kcal / h

*2 BTU / h

Power input

kW

POC kW / kW

kW

Current inputkWA

A

Optional parts

Refri gerant

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

Heat Source Twinning kit: CMY-Y100VBK2

9.52(3/8) Brazed

-

1.0

5.0

1.0

Over-heat protection, Over-current protection Over-heat protection, Over-current protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

Over-heat protection

Acrylic painted steel plate

23LEM23LEM

6.3

)V 042(530.0)V 042(530.0

3.6

Inverter scroll hermetic compressor

Inverter

AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter

Inverter scroll hermetic compressor

Over-heat protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

195(430)

5.76 + 5.76

54,200

56.0

11.45

191,100

19.3-18.3-17.6

PQHY-P500YSHM-A(For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

48,200

Installation Manual

Acrylic painted steel plate

1,160(1,100 without legs) x 880 x 550

96 + 96

3.4 + 3.4

KE94C317

Joint: CMY-Y102S-G2, CMY-Y102L-G2, CMY-Y202-G

2

KE94C317

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

R410A x 5.0kg (12lbs)

Indoor LEV and BC controller

1,160(1,100 without legs) x 880 x 550

PQHY-P250YHM-A(For Ground source)

15.88(5/8) Brazed

28.58(1-1/8) Brazed

epyt etalp epyt etalp

5.0

4.5 + 4.5 ~ 7.2 + 7.2

-

R410A x 5.0kg (12lbs)

195(430)

KB94T223

9.52(3/8) Brazed

215,000

PQHY-P250YHM-A(For Ground source)

12.06

52

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 1~43

-5.0~45.0°C(23~113°F)

7171

dezarB )8/7(2.22dezarB )8/7(2.22

63.0

15.0~24.0°C(59~75°F)

4.89

-5.0~45.0°C(23~113°F)

20.3-19.3-18.6

22.5

- 10 -

Page 15

*1

*2

Wkretaeh esaC

Wktuptuo rotoM

in.

Control

Circulating water

°C

Set Model

Model

connectable

Model / Quantity

heating

Model

Total capacity

piping diameter

D.B.

*2

COP

°C

Indoor

Temp. range of

Current input

(Nominal)

mm(in.)

mm(in.)

Liquid pipe

Gas pipe

Power input

Refrigerant

BTU / h

Indoor unit

Temp. range of

*1

h / lack)lanimoN(*1

Power source

kW

cfm

l

Water volume in plate

wate r

HIC circuit (HIC: Heat Inter-Changer)

Heat exchanger

Water pressure Max.

Protection

mm

External dimension HxWxD

Type x original charge

)sbl(gkthgiew teN

MPa

High pressure protection

Inverter circuit (COMP.)

Manufacture

Starting method

L/min

Water flow rate

m

3

/ h

Circulating

Compressor

Accessory

Drawing

distributor

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

●Twinning kit is required.

kPaPressure drop

Operating volume range

m3 / h

Notes:

Standard attachment

Document

Wiring

External

*The specification data is

subject to rounding variation.

Unit converter

Lubricant

Type x Quantity

External finish

Gas pipe mm(in.)

Cooling capacity

devices

Compressor

cooling

Circulating water

Indoor

Heating capacity

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

Pipe between unit and

Liquid pipe mm(in.)

Sound pressure level (measured in anechoic room)

dB <A>

W.B.

kW / kW

kcal / h

*2 BTU / h

Power input

kW

POC kW / kW

kW

Current inputkWA

A

Optional parts

Refri gerant

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

Heat Source Twinning kit: CMY-Y100VBK2

12.7(1/2) Brazed

-

1.0

5.0

1.0

Over-heat protection, Over-current protection Over-heat protection, Over-current protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

Over-heat protection

Acrylic painted steel plate

23LEM23LEM

6.3

)V 042(530.0)V 042(530.0

4.7

Inverter scroll hermetic compressor

Inverter

AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter

Inverter scroll hermetic compressor

Over-heat protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

195(430)

5.76 + 5.76

59,300

63.0

13.46

215,000

22.7-21.5-20.8

PQHY-P550YSHM-A(For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

54,200

Installation Manual

Acrylic painted steel plate

1,160(1,100 without legs) x 880 x 550

96 + 96

3.4 + 3.4

KE94C317

Joint: CMY-Y102S-G2, CMY-Y102L-G2, CMY-Y202-G2,CMY-Y302-G2

KE94C317

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

R410A x 5.0kg (12lbs)

Indoor LEV and BC controller

1,160(1,100 without legs) x 880 x 550

PQHY-P300YHM-A(For Ground source)

15.88(5/8) Brazed

28.58(1-1/8) Brazed

epyt etalp epyt etalp

5.0

4.5 + 4.5 ~ 7.2 + 7.2

-

R410A x 5.0kg (12lbs)

195(430)

KB94T223

12.7(1/2) Brazed

235,400

PQHY-P250YHM-A(For Ground source)

14.65

52.5

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 2~47

-5.0~45.0°C(23~113°F)

7171

22.2(7/8) BrazeddezarB )8/7(2.22

69.0

15.0~24.0°C(59~75°F)

4.68

-5.0~45.0°C(23~113°F)

24.7-23.4-22.6

07.4

- 11 -

Page 16

*1

*2

Wkretaeh esaC

Wktuptuo rotoM

in.

Control

Circulating water

°C

Set Model

Model

connectable

Model / Quantity

heating

Model

Total capacity

piping diameter

D.B.

*2

COP

°C

Indoor

Temp. range of

Current input

(Nominal)

mm(in.)

mm(in.)

Liquid pipe

Gas pipe

Power input

Refrigerant

BTU / h

Indoor unit

Temp. range of

*1

h / lack)lanimoN(*1

Power source

kW

cfm

l

Water volume in plate

wate r

HIC circuit (HIC: Heat Inter-Changer)

Heat exchanger

Water pressure Max.

Protection

mm

External dimension HxWxD

Type x original charge

)sbl(gkthgiew teN

MPa

High pressure protection

Inverter circuit (COMP.)

Manufacture

Starting method

L/min

Water flow rate

m

3

/ h

Circulating

Compressor

Accessory

Drawing

distributor

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

●Twinning kit is required.

kPaPressure drop

Operating volume range

m3 / h

Notes:

Standard attachment

Document

Wiring

External

*The specification data is

subject to rounding variation.

Unit converter

Lubricant

Type x Quantity

External finish

Gas pipe mm(in.)

Cooling capacity

devices

Compressor

cooling

Circulating water

Indoor

Heating capacity

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

Pipe between unit and

Liquid pipe mm(in.)

Sound pressure level (measured in anechoic room)

dB <A>

W.B.

kW / kW

kcal / h

*2 BTU / h

Power input

kW

POC kW / kW

kW

Current inputkWA

A

Optional parts

Refri gerant

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

Heat Source Twinning kit: CMY-Y100VBK2

12.7(1/2) Brazed

-

1.0

5.0

1.0

Over-heat protection, Over-current protection Over-heat protection, Over-current protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

Over-heat protection

Acrylic painted steel plate

23LEM

7.4

)V 042(530.0

23LEM

)V 042(530.0

4.7

Inverter scroll hermetic compressor

Inverter

AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter

Inverter scroll hermetic compressor

Over-heat protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

195(430)

5.76 + 5.76

65,800

69.0

15.48

235,400

26.1-24.8-23.9

PQHY-P600YSHM-A(For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

59,300

Installation Manual

Acrylic painted steel plate

1,160(1,100 without legs) x 880 x 550

96 + 96

3.4 + 3.4

KE94C317

Joint: CMY-Y102S-G2, CMY-Y102L-G2, CMY-Y202-G2,CMY-Y302-G2

KE94C317

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

R410A x 5.0kg (12lbs)

Indoor LEV and BC controller

1,160(1,100 without legs) x 880 x 550

PQHY-P300YHM-A(For Ground source)

15.88(5/8) Brazed

28.58(1-1/8) Brazed

epyt etalpepyt etalp

5.0

4.5 + 4.5 ~ 7.2 + 7.2

-

R410A x 5.0kg (12lbs)

195(430)

KB94T223

12.7(1/2) Brazed

261,000

PQHY-P300YHM-A(For Ground source)

17.12

53

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 2~50

-5.0~45.0°C(23~113°F)

7171

22.2(7/8) Brazed22.2(7/8) Brazed

76.5

15.0~24.0°C(59~75°F)

4.45

-5.0~45.0°C(23~113°F)

28.9-27.4-26.4

64.4

- 12 -

Page 17

*1

*2

Wkretaeh esaC

Wktuptuo rotoM

in.

Control

Circulating water

°C

Set Model

Model

connectable

Model / Quantity

heating

Model

Total capacity

piping diameter

D.B.

*2

COP

°C

Indoor

Temp. range of

Current input

(Nominal)

mm(in.)

mm(in.)

Liquid pipe

Gas pipe

Power input

Refrigerant

BTU / h

Indoor unit

Temp. range of

*1

h / lack)lanimoN(*1

Power source

kW

cfm

l

Water volume in plate

wate r

HIC circuit (HIC: Heat Inter-Changer)

Heat exchanger

Water pressure Max.

Protection

mm

External dimension HxWxD

Type x original charge

)sbl(gkthgiew teN

MPa

High pressure protection

Inverter circuit (COMP.)

Manufacture

Starting method

L/min

Water flow rate

m

3

/ h

Circulating

Compressor

Accessory

Drawing

distributor

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

●Twinning kit is required.

kPaPressure drop

Operating volume range

m3 / h

Notes:

Standard attachment

Document

Wiring

External

*The specification data is

subject to rounding variation.

Unit converter

Lubricant

Type x Quantity

External finish

Gas pipe mm(in.)

Cooling capacity

devices

Compressor

cooling

Circulating water

Indoor

Heating capacity

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

Pipe between unit and

Liquid pipe mm(in.)

Sound pressure level (measured in anechoic room)

dB <A>

W.B.

kW / kW

kcal / h

*2 BTU / h

Power input

kW

POC kW / kW

kW

Current inputkWA

A

Optional parts

Refri gerant

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

25.5

24.8-23.6-22.7

5.22

-5.0~45.0°C(23~113°F)

81.5

15.0~24.0°C(59~75°F)

53

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 2~50

-5.0~45.0°C(23~113°F)

12.7(1/2) Brazed

278,100

14.74

195(430)

KB94T659

Over-heat protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

Over-heat protection, Over-current protectionOver-heat protection, Over-current protectionOver-heat protection, Over-current protection

R410A x 5.0kg (12lbs) R410A x 5.0kg (12lbs)

Over-heat protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

5.0

19.05(3/4) Brazed

34.93(1-3/8) Brazed

4.5 + 4.5 + 4.5 ~ 7.2 + 7.2 + 7.2

LEV and HIC circuit

epyt etalpepyt etalp

5.0

1.0

17

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

Joint: CMY-Y102S-G2,CMY-Y102L-G2,CMY-Y202-G2,CMY-Y302-G2

96 + 96 + 96

3.4 + 3.4 + 3.4

Installation Manual

713C49EK713C49EK713C49EK

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

1,160(1,100 without legs) x 880 x 550 1,160(1,100 without legs) x 880 x 550 1,160(1,100 without legs) x 880 x 550

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

23.5-22.3-21.5

PQHY-P650YSHM-A(For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

62,800

73.0

13.96

249,100

70,100

PQHY-P200YHM-A(For Ground source)

PQHY-P200YHM-A(For Ground source)PQHY-P250YHM-A(For Ground source)

5.76 + 5.76 + 5.76

7171

Inverter scroll hermetic compressor

AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter scroll hermetic compressor Inverter scroll hermetic compressor

AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter

6.3

retrevnIretrevnI

6.46.4

0.035(240 V)

MEL32

0.035(240 V) 0.035(240 V)

23LEM23LEM

Acrylic painted steel plateAcrylic painted steel plate Acrylic painted steel plate

R410A x 5.0kg (12lbs)

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

Over-heat protection

195(430)

epyt etalp

Copper pipe,tube-in-tube structure

1.0

5.0

1.0

Copper pipe,tube-in-tube structure

12.7(1/2) Brazed

22.2(7/8) Brazed

Heat Source Twinning kit: CMY-Y300VBK2

12.7(1/2) Brazed

19.05(3/4) Brazed 19.05(3/4) Brazed

Copper pipe,tube-in-tube structure

195(430)

- 13 -

Page 18

*1

*2

Wkretaeh esaC

Wktuptuo rotoM

in.

Control

Circulating water

°C

Set Model

Model

connectable

Model / Quantity

heating

Model

Total capacity

piping diameter

D.B.

*2

COP

°C

Indoor

Temp. range of

Current input

(Nominal)

mm(in.)

mm(in.)

Liquid pipe

Gas pipe

Power input

Refrigerant

BTU / h

Indoor unit

Temp. range of

*1

h / lack)lanimoN(*1

Power source

kW

cfm

l

Water volume in plate

wate r

HIC circuit (HIC: Heat Inter-Changer)

Heat exchanger

Water pressure Max.

Protection

mm

External dimension HxWxD

Type x original charge

)sbl(gkthgiew teN

MPa

High pressure protection

Inverter circuit (COMP.)

Manufacture

Starting method

L/min

Water flow rate

m

3

/ h

Circulating

Compressor

Accessory

Drawing

distributor

Remarks

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be refer

●Turn DipSW 3-9 ON before power ON.

red to the Installation Manual.

●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40 °C D.B.

●The ambient relative humidity of the heat source unit needs to be kept below 80%.

●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

●Twinning kit is required.

kPaPressure drop

Operating volume range

m3 / h

Notes:

Standard attachment

Document

Wiring

External

*The specification data is

subject to rounding variation.

Unit converter

Lubricant

Type x Quantity

External finish

Gas pipe mm(in.)

Cooling capacity

devices

Compressor

cooling

Circulating water

Indoor

Heating capacity

=kW x 860

=kW x 3,412

=m

3

/min x 35.31

=kg / 0.4536

kcal

BTU/h

cfm

lb

Pipe between unit and

Liquid pipe mm(in.)

Sound pressure level (measured in anechoic room)

dB <A>

W.B.

kW / kW

kcal / h

*2 BTU / h

Power input

kW

POC kW / kW

kW

Current inputkWA

A

Optional parts

Refri gerant

1.<Standard CITY MULTI indoor unit>

Nominal cooling conditions(subject to JIS B8615-1)

Indoor:27°CDB/19°CWB(81°FDB/66°FWB)

Water temperature:30°C(86°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

2.<PWFY-P100/200VM-E-AU>

Nominal cooling conditions

Circulating water Temp. : 30°C (86°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 23°C

Water flow rate : 1.93m

3

/h (P100) / 3.86m3/h (P200)

Brine concentration 0%

Nominal heating conditions(subject to JIS B8615-1)

Indoor:20°CDB(68°FDB)

Water temperature:20°C(68°F)

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.)

Brine concentration 0%

Nominal heating conditions

Circulating water Temp. : 20°C (68°F)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0m (0ft)

Inlet water Temp 30°C

Water flow rate : 2.15m

3

/h (P100) / 4.30m3/h (P200)

Brine concentration 0%

33.5

27.8-26.4-25.5

5.13

-5.0~45.0°C(23~113°F)

88.0

15.0~24.0°C(59~75°F)

53.5

15.0~27.0°C(59~81°F)

50~130 % of heat source unit capacity

P15~P250 / 2~50

-5.0~45.0°C(23~113°F)

12.7(1/2) Brazed

300,300

16.51

195(430)

KB94T659

Over-heat protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

Over-heat protection, Over-current protectionOver-heat protection, Over-current protectionOver-heat protection, Over-current protection

R410A x 5.0kg (12lbs) R410A x 5.0kg (12lbs)

Over-heat protection

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

5.0

19.05(3/4) Brazed

34.93(1-3/8) Brazed

4.5 + 4.5 + 4.5 ~ 7.2 + 7.2 + 7.2

LEV and HIC circuit

epyt etalpepyt etalp

5.0

1.0

17

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

Refrigerant conn. pipe

Header: CMY-Y104/108/1010-G

Joint: CMY-Y102S-G2,CMY-Y102L-G2,CMY-Y202-G2,CMY-Y302-G2

96 + 96 + 96

3.4 + 3.4 + 3.4

Installation Manual

713C49EK713C49EK713C49EK

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

1,160(1,100 without legs) x 880 x 550 1,160(1,100 without legs) x 880 x 550 1,160(1,100 without legs) x 880 x 550

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16

26.3-24.9-24.0

PQHY-P700YSHM-A(For Ground source)

3-phase 4-wire 380-400-415V 50/60Hz

68,800

80.0

15.58

273,000

75,700

PQHY-P200YHM-A(For Ground source)PQHY-P250YHM-A(For Ground source)PQHY-P250YHM-A(For Ground source)

5.76 + 5.76 + 5.76

7171

Inverter scroll hermetic compressor

AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter scroll hermetic compressor

AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter scroll hermetic compressor

AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Inverter

6.3

retrevnIretrevnI

6.43.6

0.035(240 V)

MEL32

0.035(240 V) 0.035(240 V)

23LEM23LEM

Acrylic painted steel plateAcrylic painted steel plate Acrylic painted steel plate

R410A x 5.0kg (12lbs)

High pressure sensor, High pressure switch at 4.15MPa (601 psi)

Over-heat protection

195(430)

epyt etalp

Copper pipe,tube-in-tube structure

1.0

5.0

1.0

Copper pipe,tube-in-tube structure

12.7(1/2) Brazed

22.2(7/8) Brazed

Heat Source Twinning kit: CMY-Y300VBK2

12.7(1/2) Brazed

22.2(7/8) Brazed 19.05(3/4) Brazed

Copper pipe,tube-in-tube structure

195(430)

- 14 -

Page 19

*1

*2

Wkretaeh esaC

Wktuptuo rotoM