Mitsubishi Electric PQHY-P200-900Y(S)LM-A, PQRY-P200-900Y(S)LM-A Service Manual

PQHY-P200-900Y(S)LM-A

PQRY-P200-900Y(S)LM-A

MODEL

CITY MULTI

MEE15K036

Databook

HEAT SOURCE UNITS

GENERAL LINE-UP

WY SERIES ............................................................................................................................................ 1

WR2 SERIES.......................................................................................................................................... 83

SYSTEM DESIGN

SYSTEM DESIGN WY SERIES ............................................................................................................. 165

SYSTEM DESIGN WR2 SERIES ........................................................................................................... 203

GENERAL LINE-UP

HEAT SOURCE

MEE15K036

I.GENERAL LINE-UP

Heat Pump WY Series

16, 18, 20, 22, 24HP

28, 30, 32, 34, 36HP

PQHY-P250YLM-APQHY-P200YLM-A

PQHY-P300YLM-A

PQHY-P400YLM-A

PQHY-P500YLM-A

PQHY-P600YLM-A

PQHY-P350YLM-A

PQHY-P450YLM-A

PQHY-P550YLM-A

PQHY-P450YSLM-A

PQHY-P550YSLM-A

PQHY-P400YSLM-A

PQHY-P500YSLM-A

PQHY-P600YSLM-A

8, 10, 12HP 14, 16, 18, 20, 22, 24HP

PQHY-P750YSLM-A

PQHY-P850YSLM-A

PQHY-P700YSLM-A

PQHY-P800YSLM-A

PQHY-P900YSLM-A

PQRY-P250YLM-APQRY-P200YLM-A

PQRY-P300YLM-A

PQRY-P400YLM-A

PQRY-P500YLM-A

PQRY-P600YLM-A

PQRY-P350YLM-A

PQRY-P450YLM-A

PQRY-P550YLM-A

PQRY-P450YSLM-A

PQRY-P550YSLM-A

PQRY-P400YSLM-A

PQRY-P500YSLM-A

PQRY-P600YSLM-A

PQRY-P750YSLM-A

PQRY-P850YSLM-A

PQRY-P700YSLM-A

PQRY-P800YSLM-A

PQRY-P900YSLM-A

Heat Recovery WR2 Series

16, 18, 20, 22, 24HP

28, 30, 32, 34, 36HP

8, 10, 12HP 14, 16, 18, 20, 22, 24HP

1

WY SERIES

HEAT SOURCE

HEAT SOURCE UNITS

MEE15K036

I.WY SERIES

1. SPECIFICATIONS........................................................................................................................................... 2

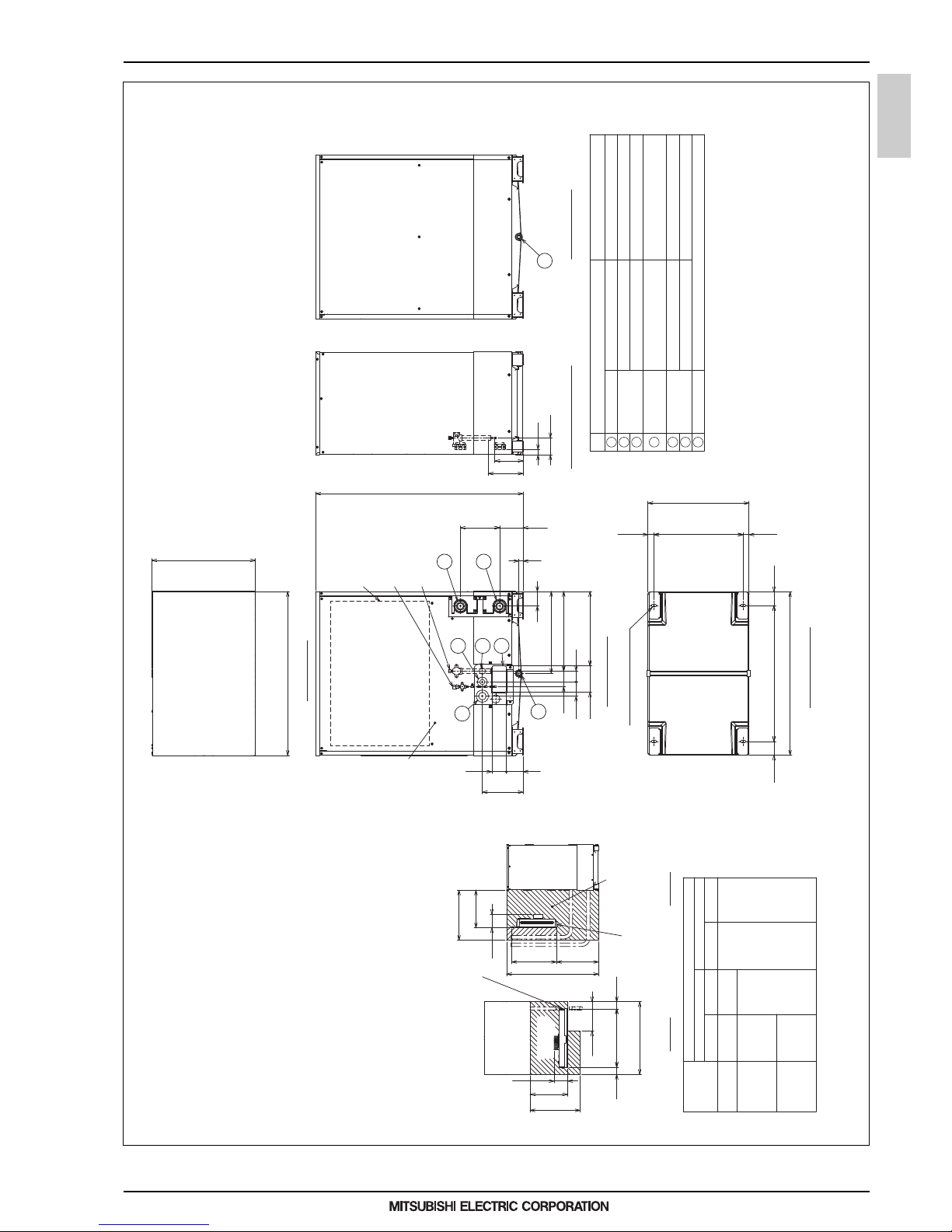

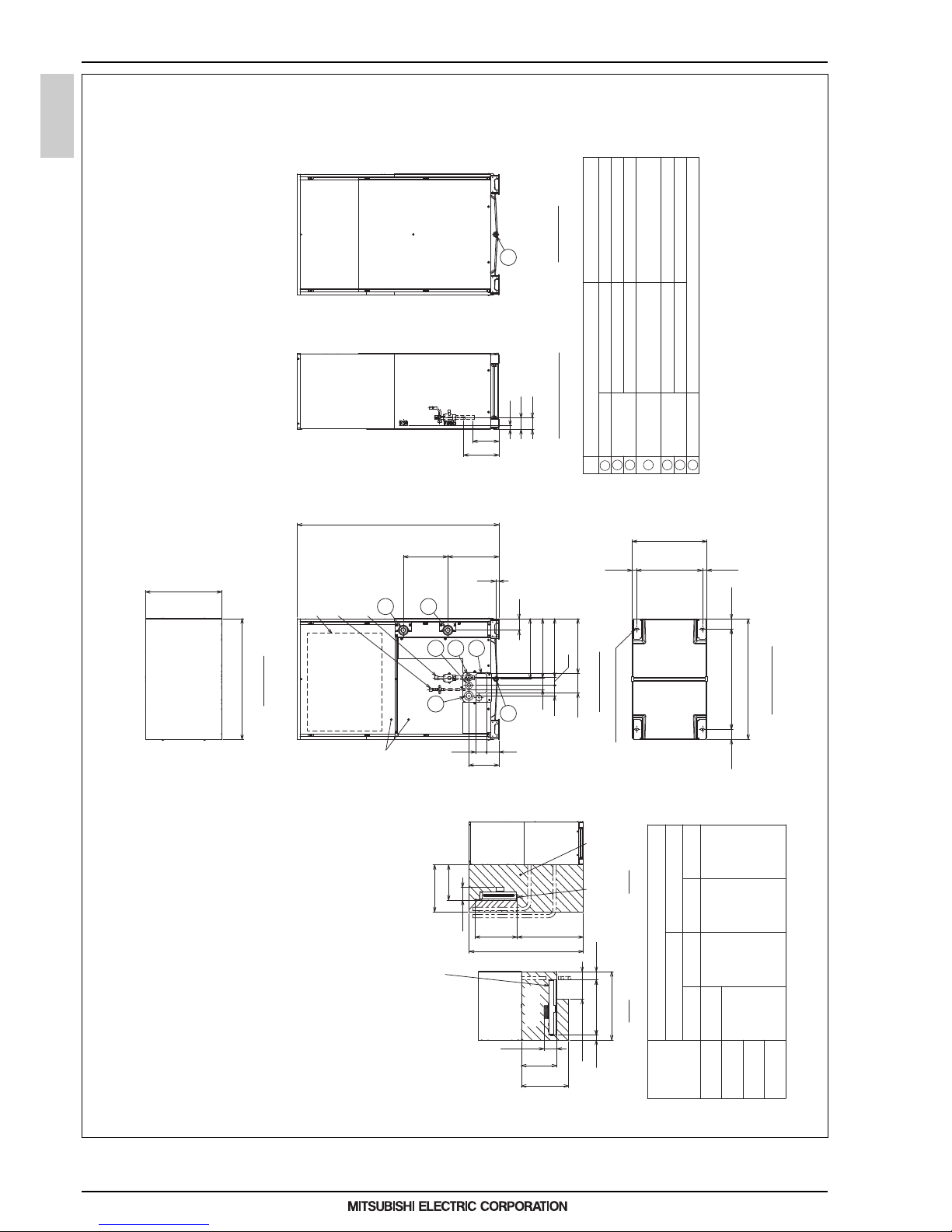

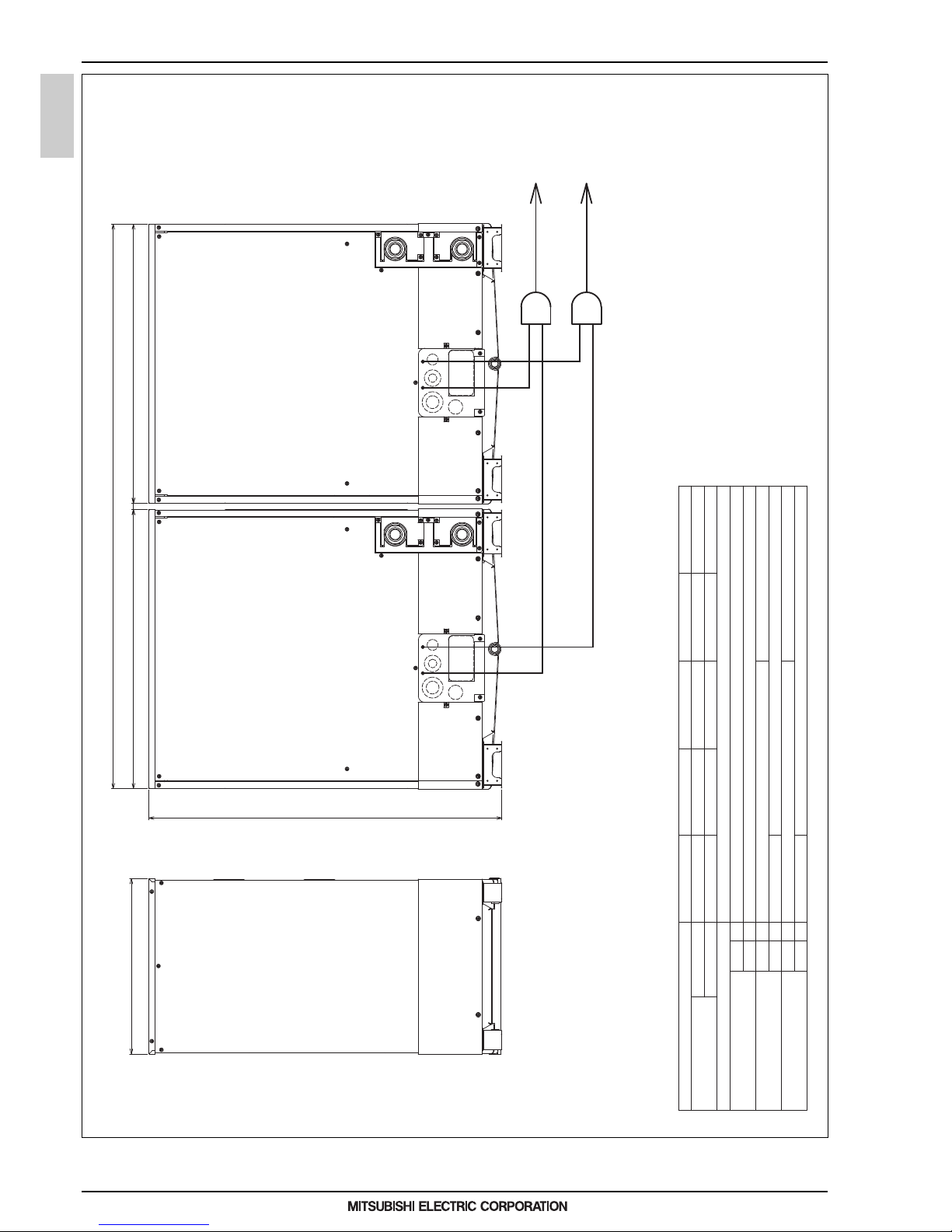

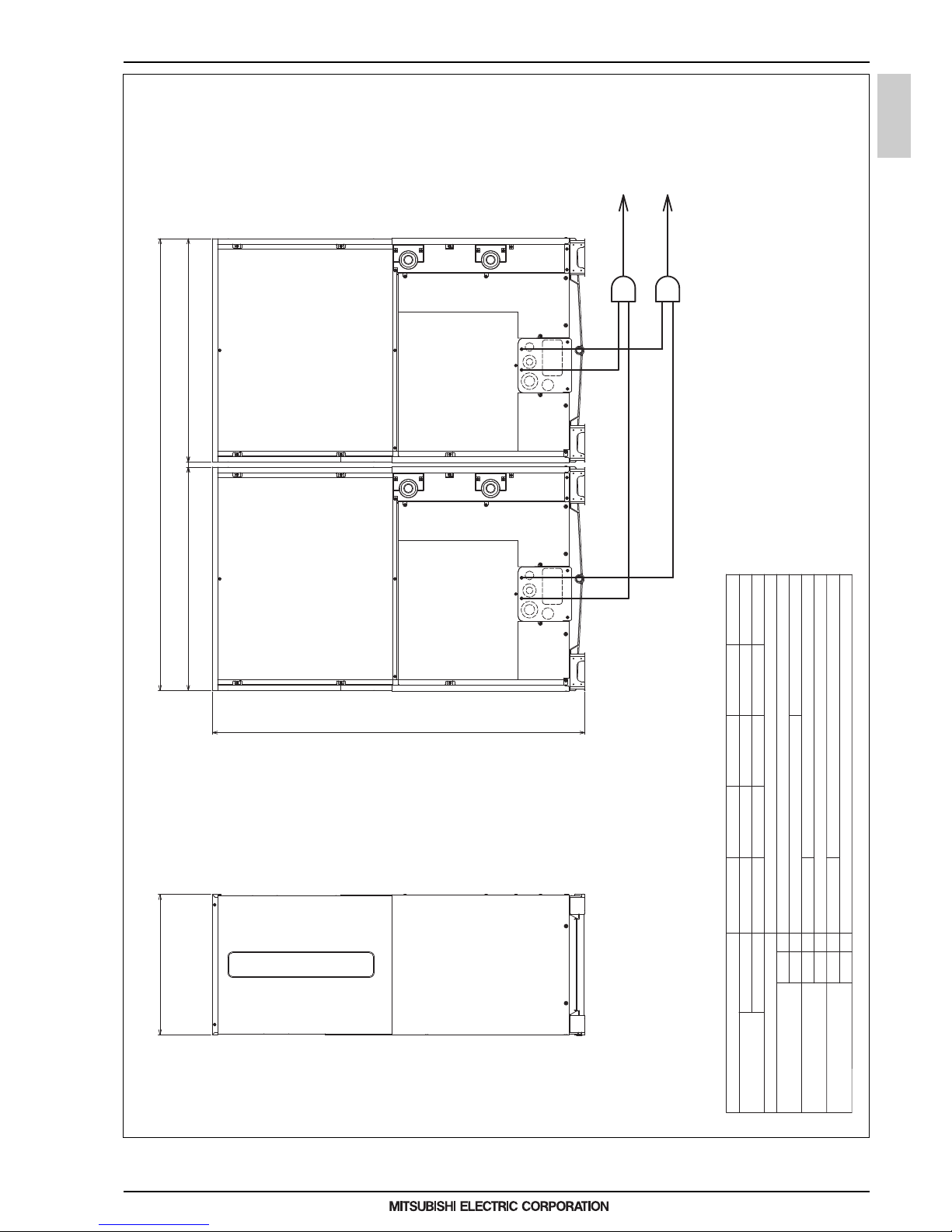

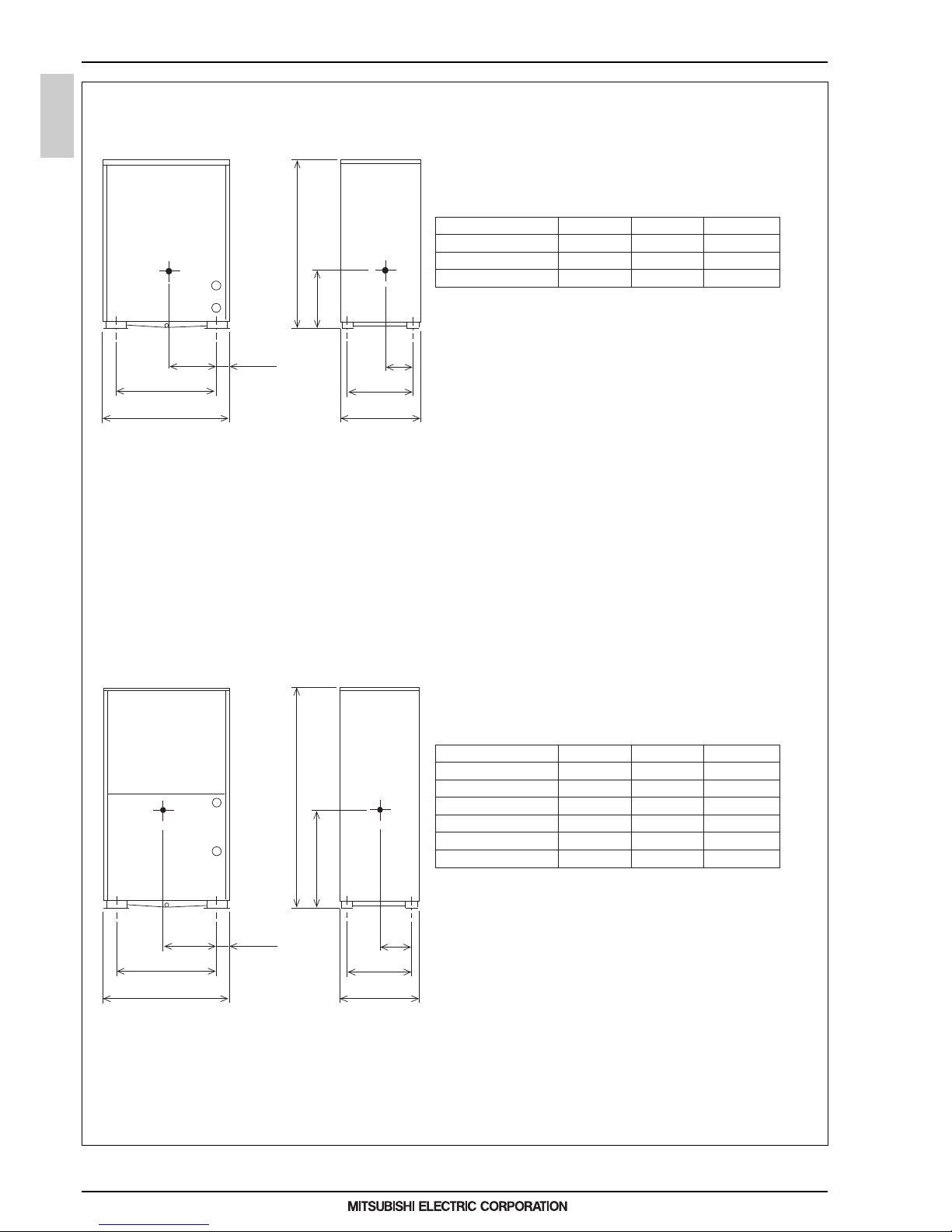

2. EXTERNAL DIMENSIONS .............................................................................................................................. 21

3. CENTER OF GRAVITY ................................................................................................................................... 26

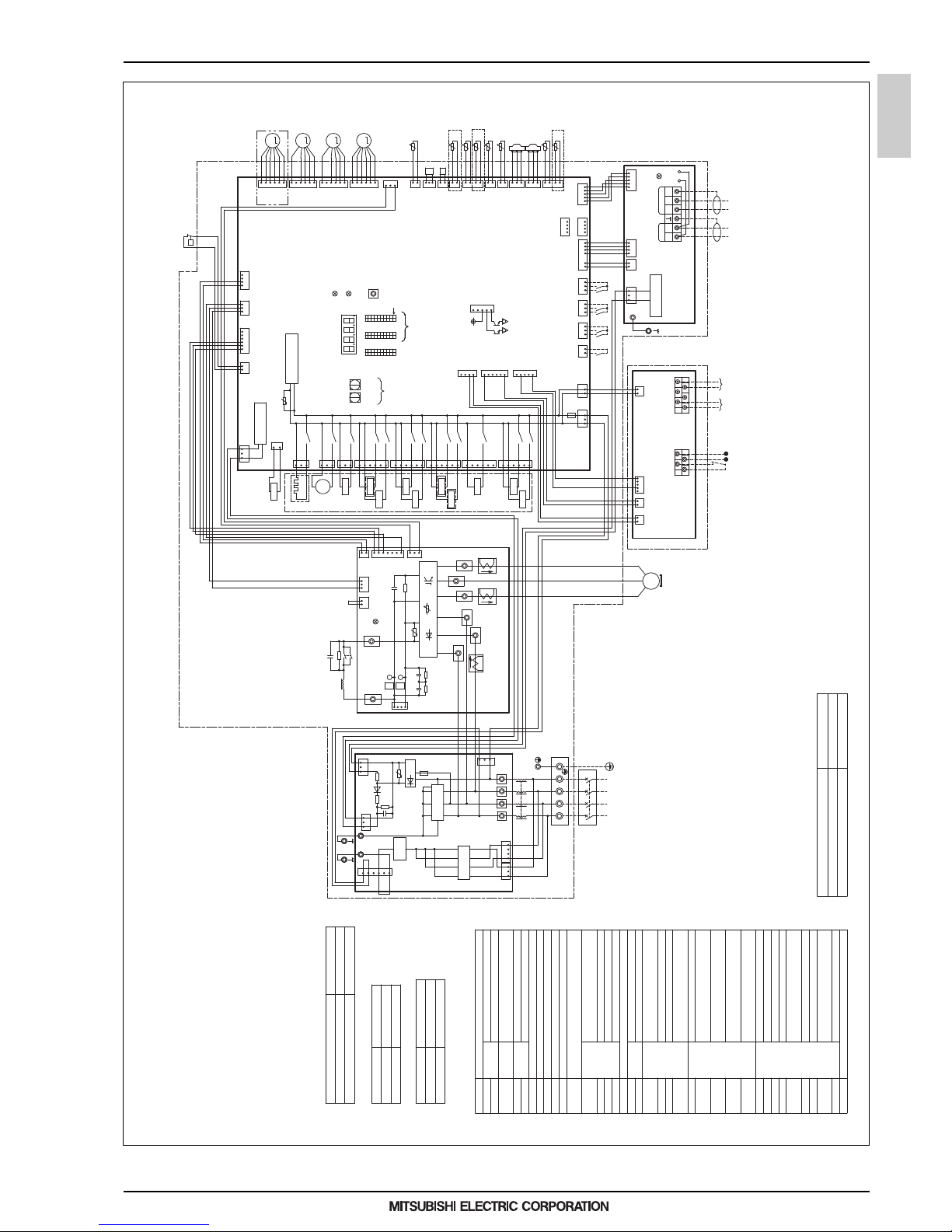

4. ELECTRICAL WIRING DIAGRAMS................................................................................................................ 27

5. SOUND LEVELS ............................................................................................................................................. 28

6. OPERATION TEMPERATURE RANGE.......................................................................................................... 33

7. CAPACITY TABLES........................................................................................................................................ 34

7-1. Correction by temperature....................................................................................................................... 34

7-2. Correction by total indoor......................................................................................................................... 53

7-3. Correction by refrigerant piping length..................................................................................................... 60

8. SYSTEM DESIGN GUIDE............................................................................................................................... 64

8-1. Designing of water circuit system ............................................................................................................ 64

8-2. Water piping work .................................................................................................................................... 76

9. OPTIONAL PARTS.......................................................................................................................................... 80

9-1. JOINT ...................................................................................................................................................... 80

9-2. HEADER.................................................................................................................................................. 81

9-3. OUTDOOR TWINNING KIT..................................................................................................................... 82

2

WY

MEE15K036

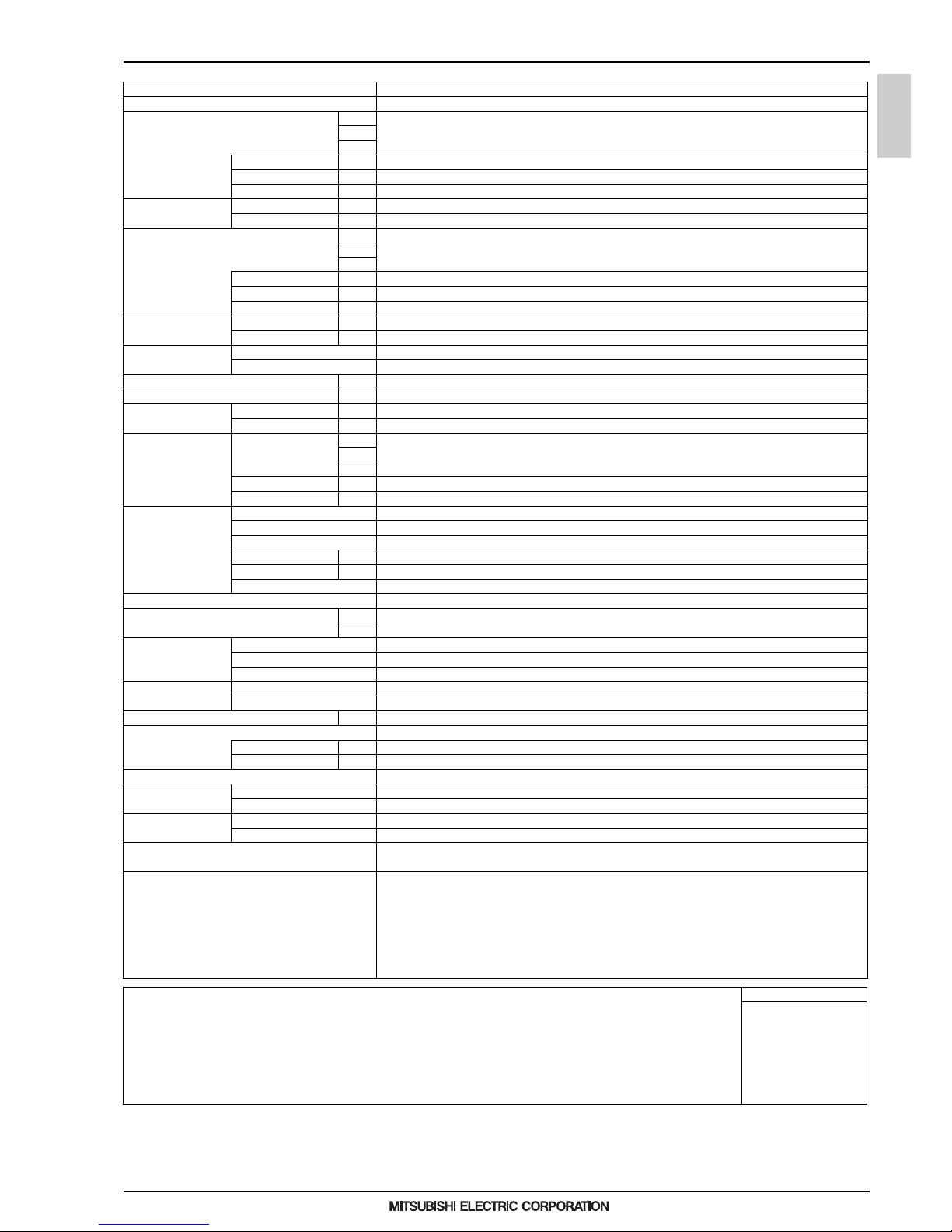

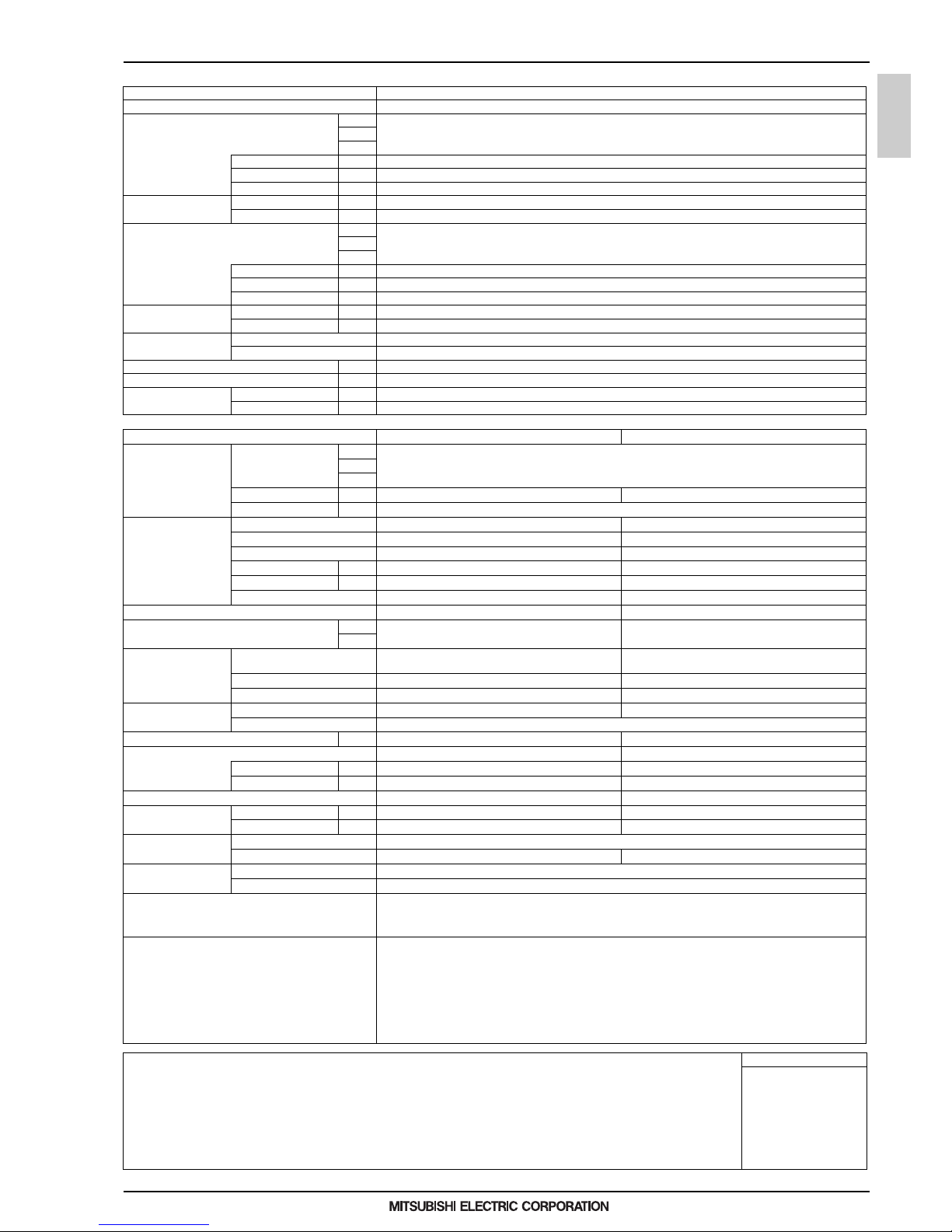

1. SPECIFICATIONS

HEAT SOURCE

I.WY SERIES1. SPECIFICATIONS

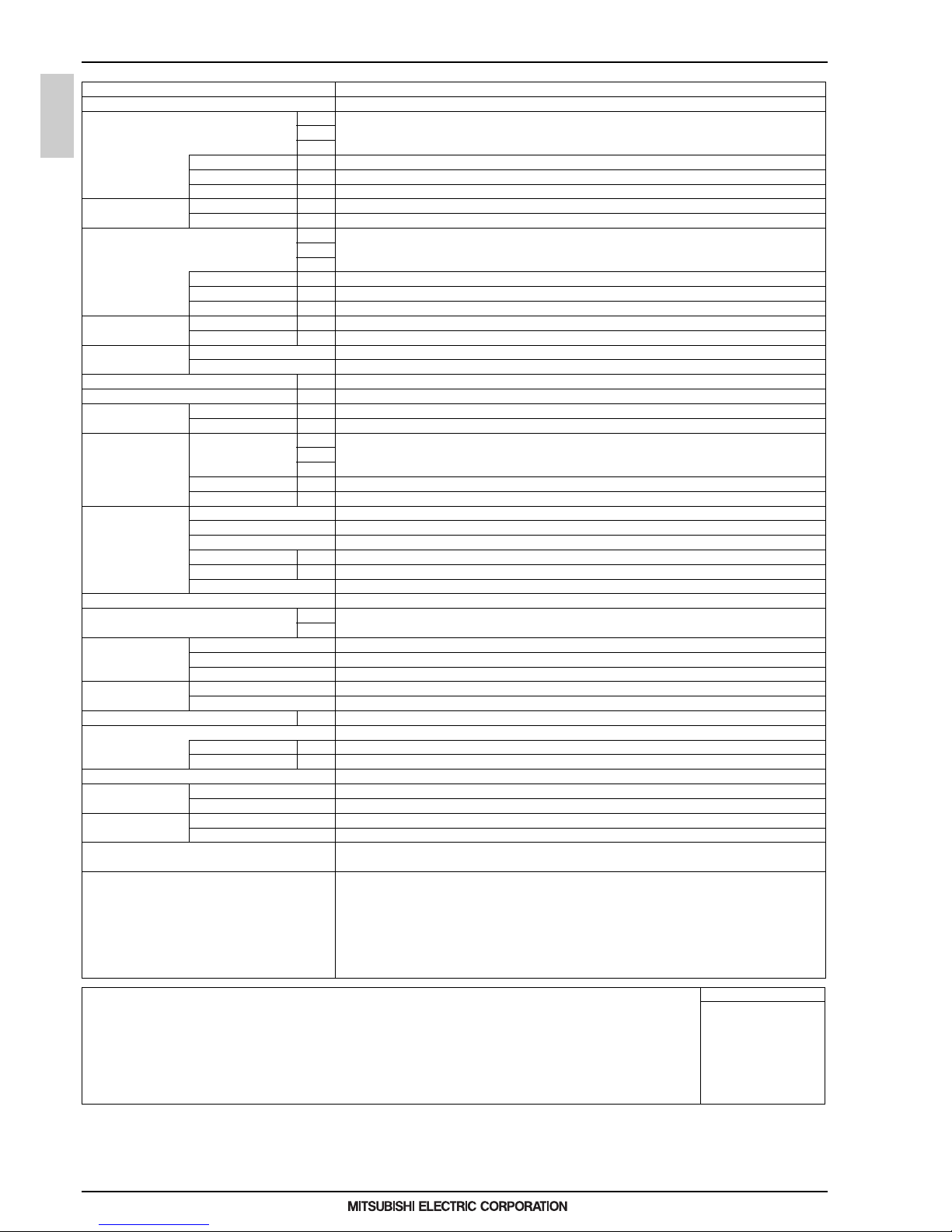

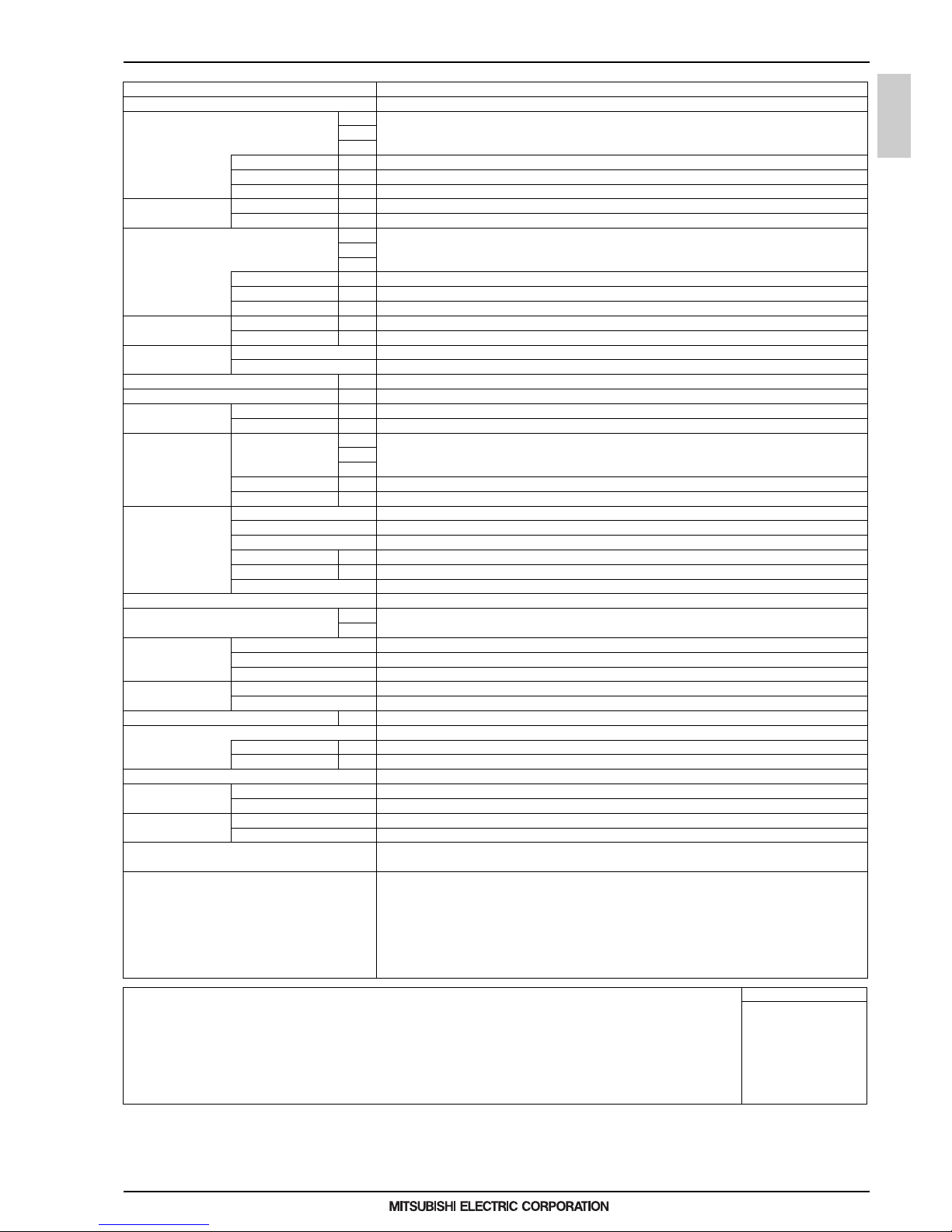

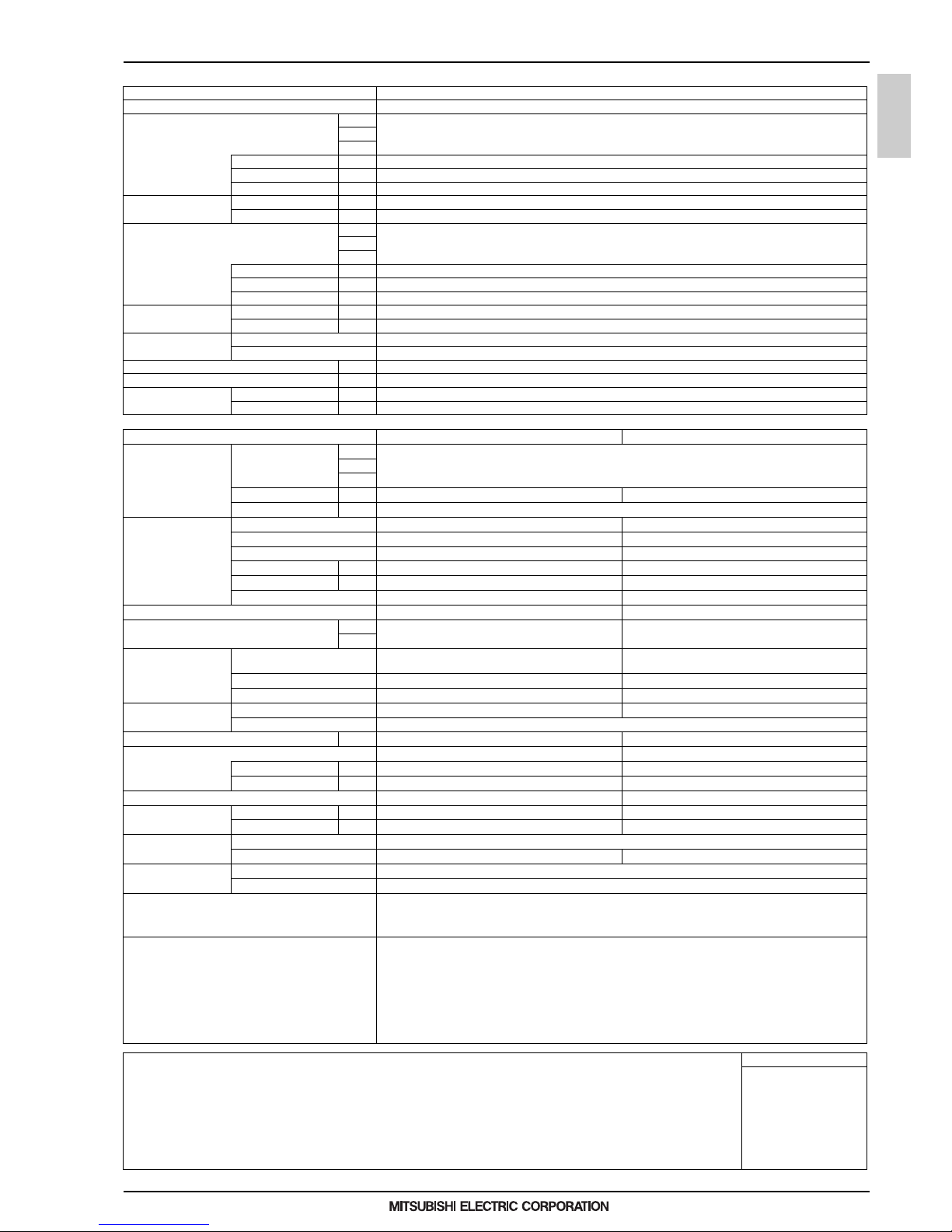

Model PQHY-P200YLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 22.4

(Nominal) kcal/h 20,000

*1 BTU/h 76,400

Power input kW 3.71

Current input A 6.2-5.9-5.7

EER kW/kW 6.03

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 25.0

(Nominal) kcal/h 21,500

*2 BTU/h 85,300

Power input kW 3.97

Current input A 6.7-6.3-6.1

COP kW/kW 6.29

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~17

Sound pressure level (measured in anechoic room) dB <A> 46

Sound power level (measured in anechoic room) dB <A> 60

Refrigerant Liquid pipe mm (in.) 9.52 (3/8) Brazed

piping diameter Gas pipe mm (in.) 19.05 (3/4) Brazed

Circulating water Water flow rate m3/h 5.76

L/min 96

cfm 3.4

Pressure drop kPa 24

Operating volume range m3/h 3.0 ~ 7.2

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 4.8

Case heater kW -

Lubricant MEL32

External finish Galvanized steel sheets

External dimension H x W x D mm 1,100 x 880 x 550

in. 43-5/16 x 34-11/16 x 21-11/16

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection

Compressor Over-heat protection

Refrigerant Type x original charge R410A x 5.0 kg (12 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 174 (384)

Heat exchanger plate type

Water volume in plate I 5.0

Water pressure Max. MPa 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure

Drawing External WKS94C746

Wiring WKE94G131

Standard attachment Do cument Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Joint: CMY-Y102SS/LS-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (sub ject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

3

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

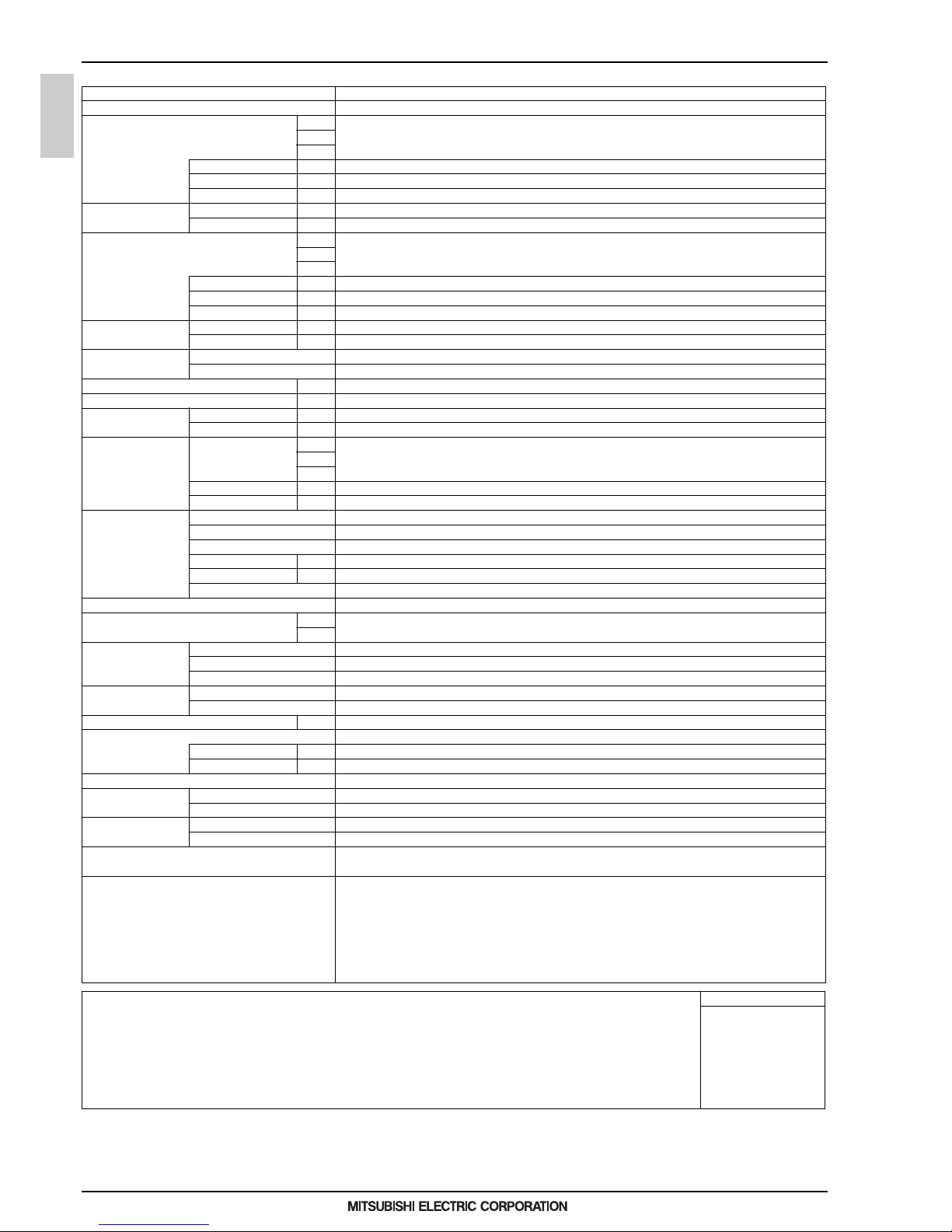

Model PQHY-P250YLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 28.0

(Nominal) kcal/h 25,000

*1 BTU/h 95,500

Power input kW 4.90

Current input A 8.2-7.8-7.5

EER kW/kW 5.71

Temp. range of Indoor W. B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 31.5

(Nominal) kcal/h 27,100

*2 BTU/h 107,500

Power input kW 5.08

Current input A 8.5-8.1-7.8

COP kW/kW 6.20

Temp. range of Indoor D.B . 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~21

Sound pressure level (measured in anechoic room) dB <A> 48

Sound power level (measured in anechoic room) dB <A> 62

Refrigerant Liquid pipe mm (in.) 9.52 (3/8) Brazed (12.7 (1/2) Brazed, farthest length >= 90 m)

piping diameter Gas pipe mm (in.) 22.2 (7/8) Brazed

Circulating water Water flow rate m3/h 5.76

L/min 96

cfm 3.4

Pressure drop kPa 24

Operating volume range m3/h 3.0 ~ 7.2

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 6.2

Case heater kW -

Lubricant MEL32

External finish Galvanized steel sheets

External dimension H x W x D mm 1,100 x 880 x 550

in. 43-5/16 x 34-11/16 x 21 -11/16

Protection devices High pressure protection High pressure sensor, High pressure swit ch at 4.15 MPa (601 psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection

Compressor Over-heat protection

Refrigerant Type x original charge R410A x 5.0 kg (12 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 174 (384)

Heat exchanger plate t ype

Water volume in plate I 5.0

Water pressure Max. MPa 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure

Drawing External WK S94C746

Wiring WKE94G131

Standard attachment Document Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Joint: CMY-Y102SS/LS-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, po wer source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation ma terial to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

4

WY

MEE15K036

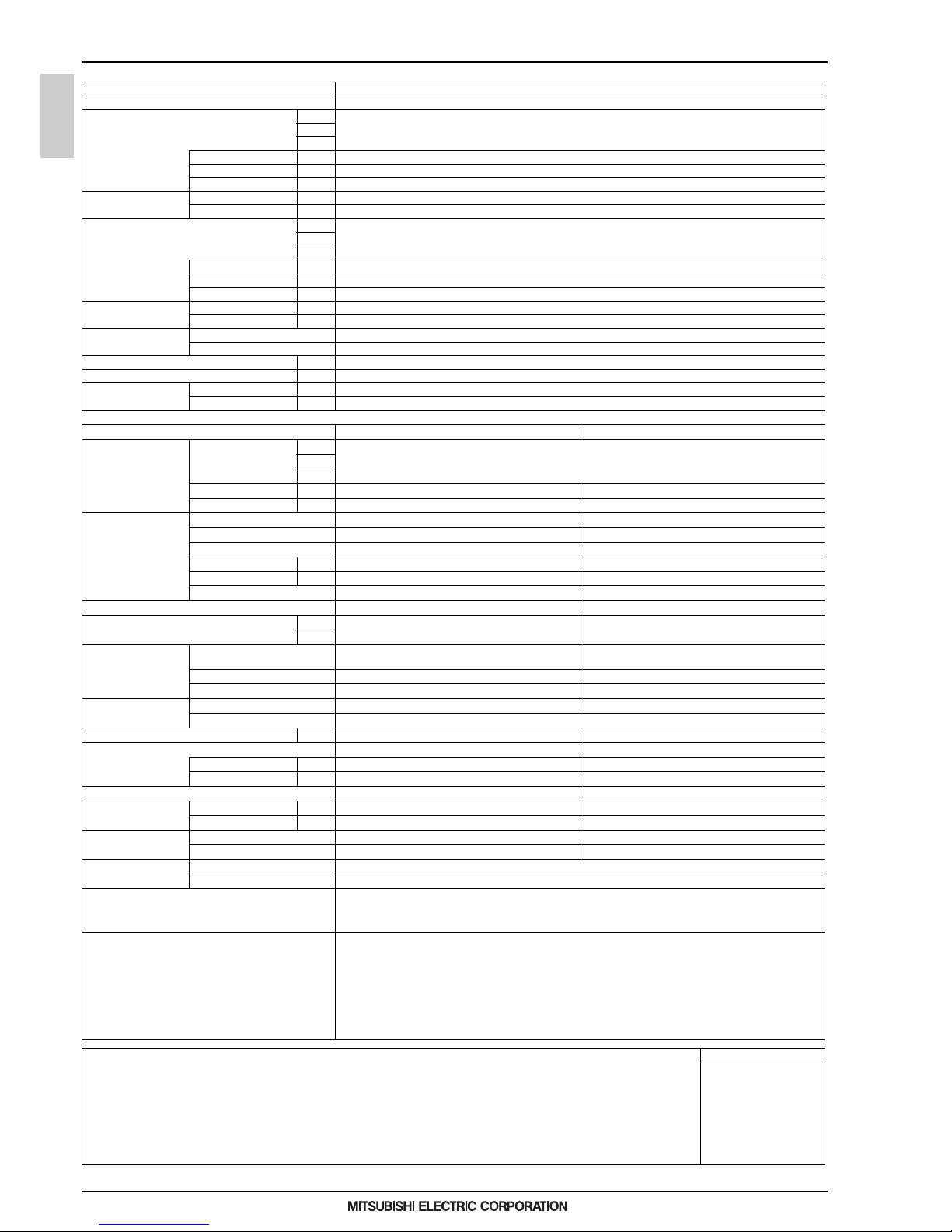

1. SPECIFICATIONS

HEAT SOURCE

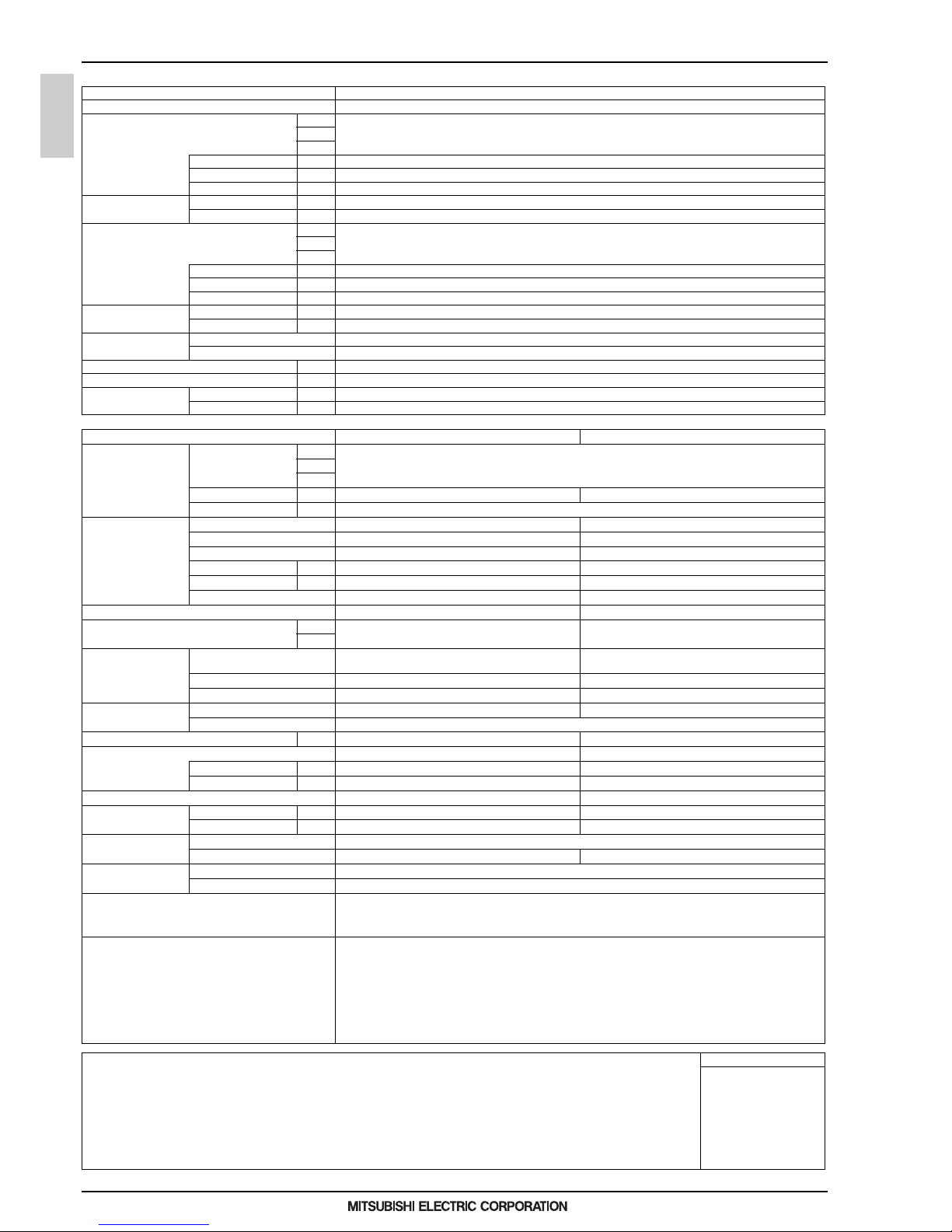

Model PQHY-P300YLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 33.5

(Nominal) kcal/h 30,000

*1 BTU/h 114,300

Power input kW 6.04

Current input A 10.1-9.6-9.3

EER kW/kW 5.54

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 37.5

(Nominal) kcal/h 32,300

*2 BTU/h 128,000

Power input kW 6.25

Current input A 10.5-10.0-9.6

COP kW/kW 6.00

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~26

Sound pressure level (measured in anechoic room) dB <A> 54

Sound power level (measured in anechoic room) dB <A> 68

Refrigerant Liquid pipe mm (in.) 9.52 (3/8) Brazed (12.7 (1/2) Brazed, farthest length >= 40 m)

piping diameter Gas pipe mm (in.) 22.2 (7/8) Brazed

Circulating water Water flow rate m3/h 5.76

L/min 96

cfm 3.4

Pressure drop kPa 24

Operating volume range m3/h 3.0 ~ 7.2

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 7.7

Case heater kW -

Lubricant MEL32

External finish Galvanized steel sheets

External dimension H x W x D mm 1,100 x 880 x 550

in. 43-5/16 x 34-11/16 x 21-11/16

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection

Compressor Over-heat protection

Refrigerant Type x original charge R410A x 5.0 kg (12 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 174 (384)

Heat exchanger plate type

Water volume in plate I 5.0

Water pressure Max. MPa 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure

Drawing External WKS94C746

Wiring WKE94G131

Standard attachment Do cument Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Joint: CMY-Y102SS/LS-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (sub ject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

5

WY

MEE15K036

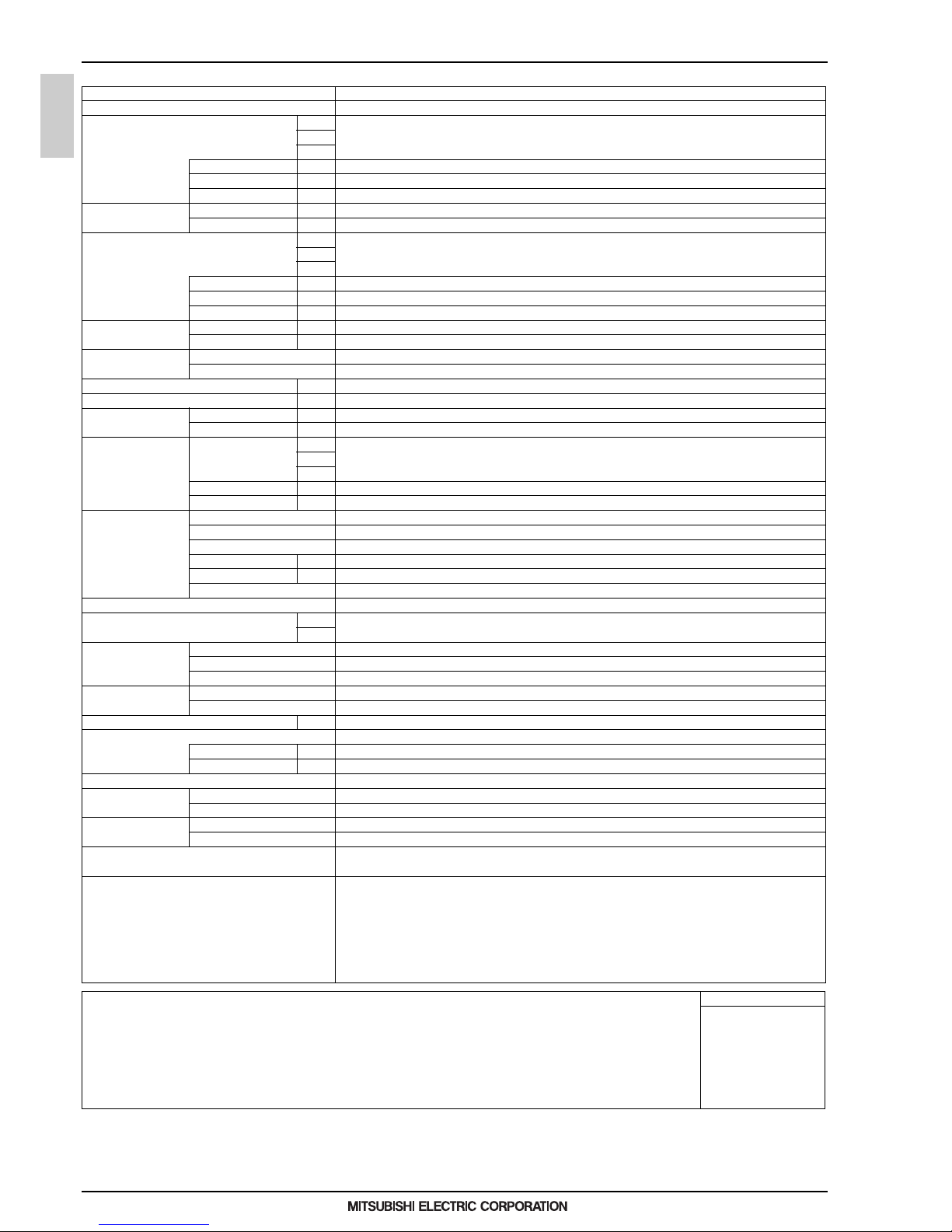

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P350YLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 40.0

(Nominal) kcal/h 35,000

*1 BTU/h 136,500

Power input kW 7.14

Current input A 12.0-11.4-11.0

EER kW/kW 5.60

Temp. range of Indoor W. B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 45.0

(Nominal) kcal/h 40,000

*2 BTU/h 153,500

Power input kW 7.53

Current input A 12.7-12.0-11.6

COP kW/kW 5.97

Temp. range of Indoor D.B . 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~30

Sound pressure level (measured in anechoic room) dB <A> 52

Sound power level (measured in anechoic room) dB <A> 66

Refrigerant Liquid pipe mm (in.) 12.7 (1/2) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1-1/8) Brazed

Circulating water Water flow rate m3/h 7.20

L/min 120

cfm 4.2

Pressure drop kPa 44

Operating volume range m3/h 4.5 ~ 11. 6

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 9.5

Case heater kW -

Lubricant MEL32

External finish Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550

in. 57-1 /8 x 34-11/16 x 21-11/16

Protection devices High pressure protection High pressure sensor, High pressure swit ch at 4.15 MPa (601 psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection

Compressor Over-heat protection

Refrigerant Type x original charge R410A x 6.0 kg (14 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 217 (479)

Heat exchanger plate t ype

Water volume in plate I 5.0

Water pressure Max. MPa 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure

Drawing External WK S94C747

Wiring WKE94G131

Standard attachment Document Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, po wer source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation ma terial to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

6

WY

MEE15K036

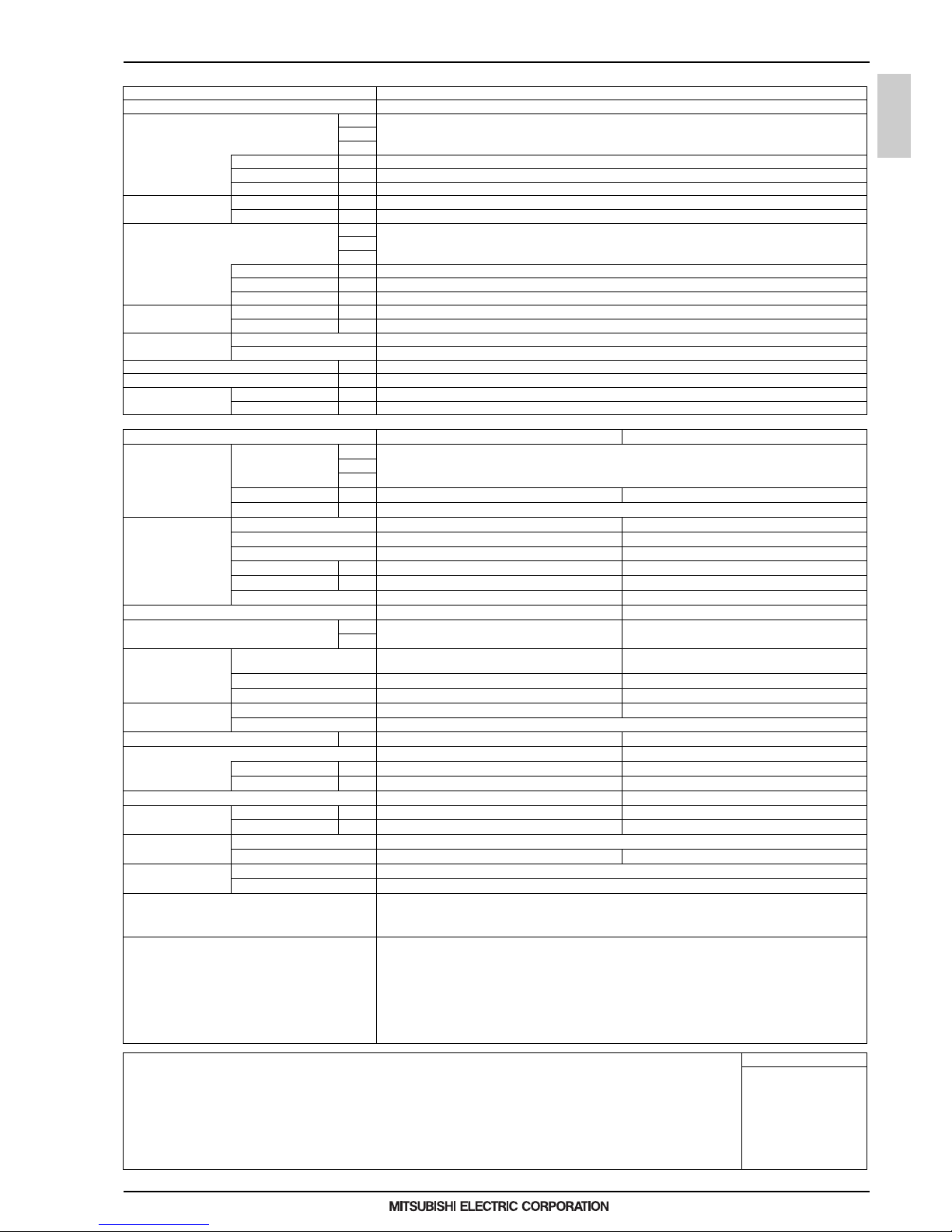

1. SPECIFICATIONS

HEAT SOURCE

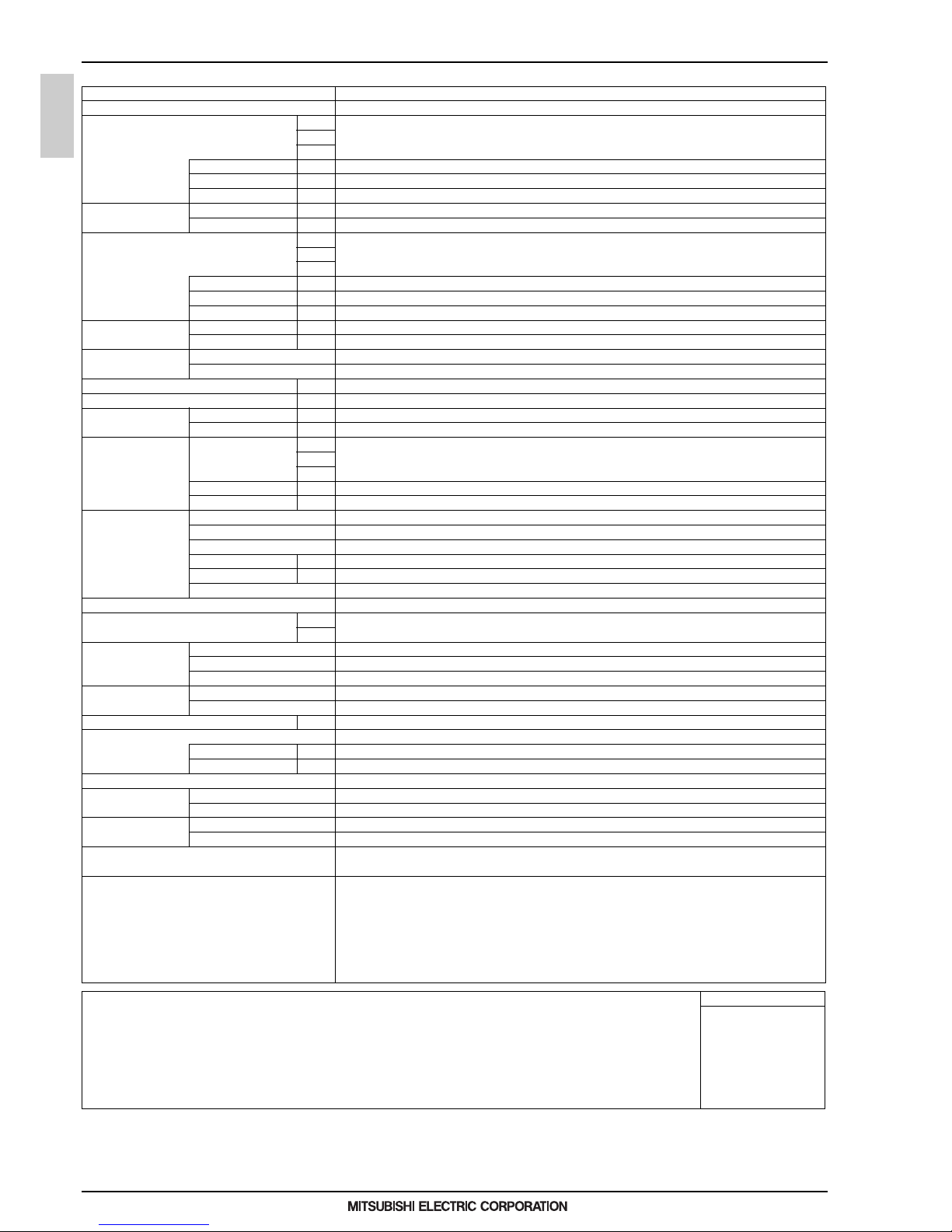

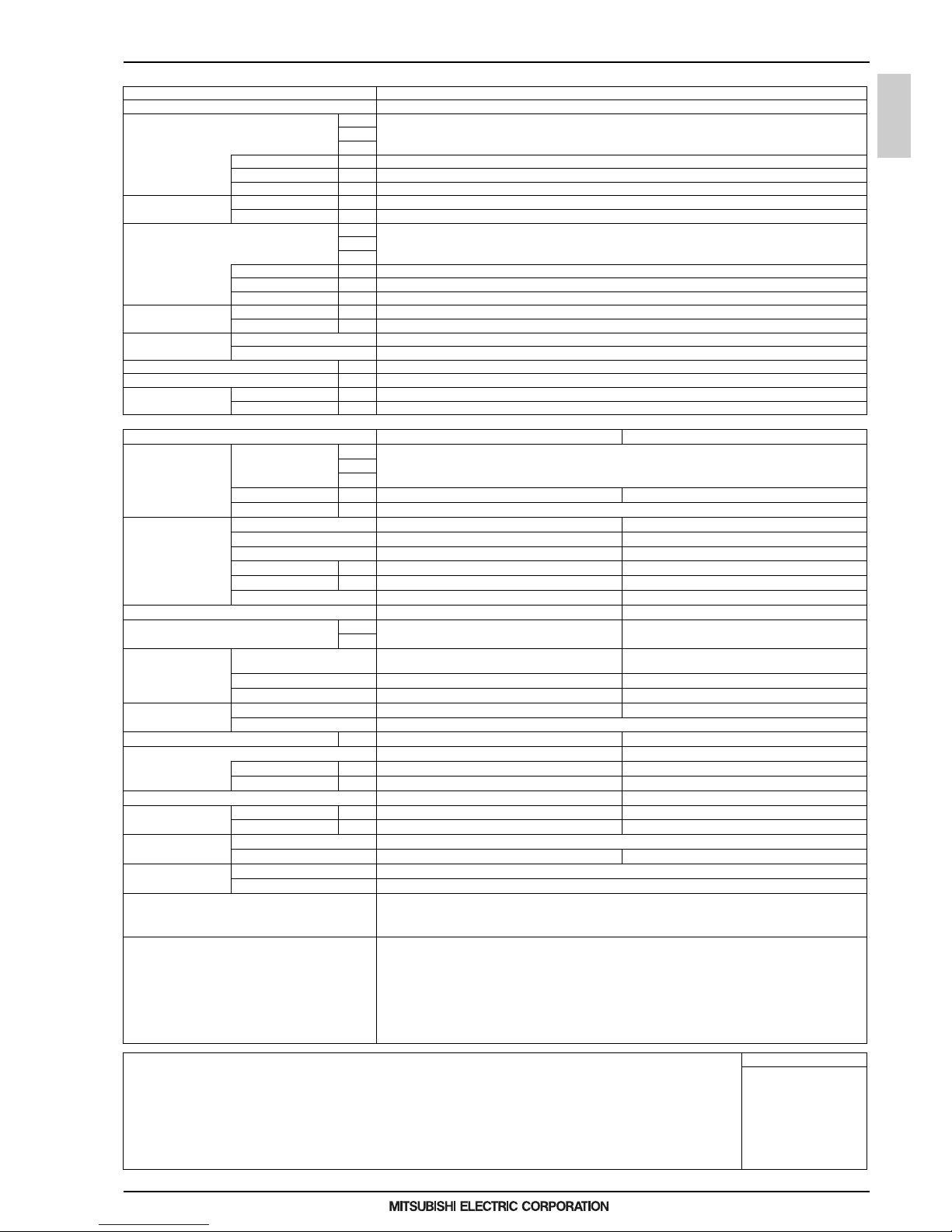

Model PQHY-P400YLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 45.0

(Nominal) kcal/h 40,000

*1 BTU/h 153,500

Power input kW 8.03

Current input A 13.5-12.8-12.4

EER kW/kW 5.60

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 50.0

(Nominal) kcal/h 45,000

*2 BTU/h 170,600

Power input kW 8.37

Current input A 14.1-13.4-12.9

COP kW/kW 5.97

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~34

Sound pressure level (measured in anechoic room) dB <A> 52

Sound power level (measured in anechoic room) dB <A> 66

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1- 1/8) Brazed

Circulating water Water flow rate m3/h 7.20

L/min 120

cfm 4.2

Pressure drop kPa 44

Operating volume range m3/h 4.5 ~ 11.6

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 10.7

Case heater kW -

Lubricant MEL32

External finish Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550

in. 57-1/8 x 34-11/16 x 21-11/16

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection

Compressor Over-heat protection

Refrigerant Type x original charge R410A x 6.0 kg (14 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 217 (479)

Heat exchanger plate type

Water volume in plate I 5.0

Water pressure Max. MPa 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure

Drawing External WKS94C747

Wiring WKE94G131

Standard attachment Do cument Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (sub ject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

7

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P450YLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 50.0

(Nominal) kcal/h 45,000

*1 BTU/h 170,600

Power input kW 9.29

Current input A 15.6-14.8-14.3

EER kW/kW 5.38

Temp. range of Indoor W. B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 56.0

(Nominal) kcal/h 50,000

*2 BTU/h 191,100

Power input kW 9.79

Current input A 16.5-15.7-15.1

COP kW/kW 5.72

Temp. range of Indoor D.B . 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~39

Sound pressure level (measured in anechoic room) dB <A> 54

Sound power level (measured in anechoic room) dB <A> 70

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1-1/8) Brazed

Circulating water Water flow rate m3/h 7.20

L/min 120

cfm 4.2

Pressure drop kPa 44

Operating volume range m3/h 4.5 ~ 11. 6

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 11.6

Case heater kW -

Lubricant MEL32

External finish Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550

in. 57-1 /8 x 34-11/16 x 21-11/16

Protection devices High pressure protection High pressure sensor, High pressure swit ch at 4.15 MPa (601 psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection

Compressor Over-heat protection

Refrigerant Type x original charge R410A x 6.0 kg (14 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 217 (479)

Heat exchanger plate t ype

Water volume in plate I 5.0

Water pressure Max. MPa 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure

Drawing External WK S94C747

Wiring WKE94G131

Standard attachment Document Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, po wer source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation ma terial to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

8

WY

MEE15K036

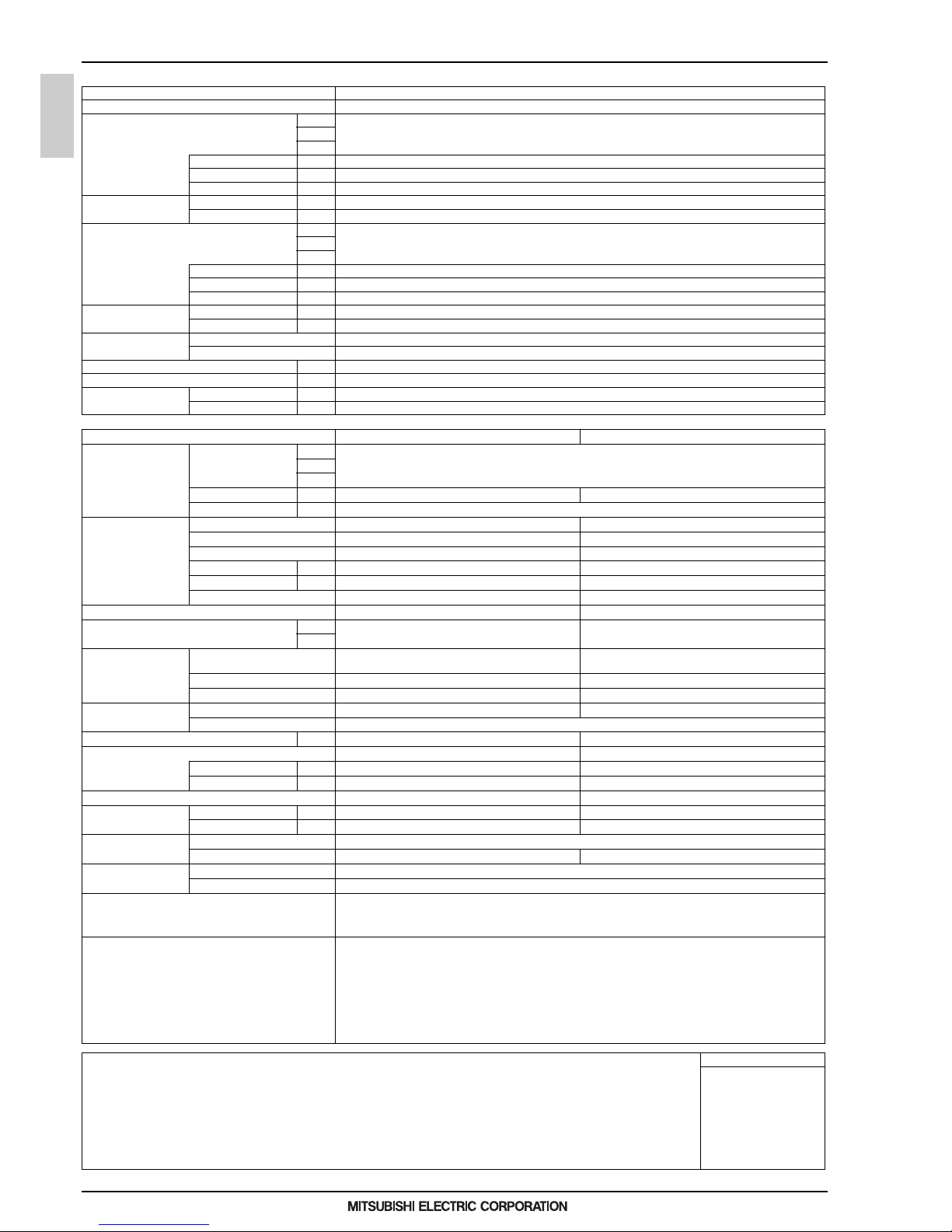

1. SPECIFICATIONS

HEAT SOURCE

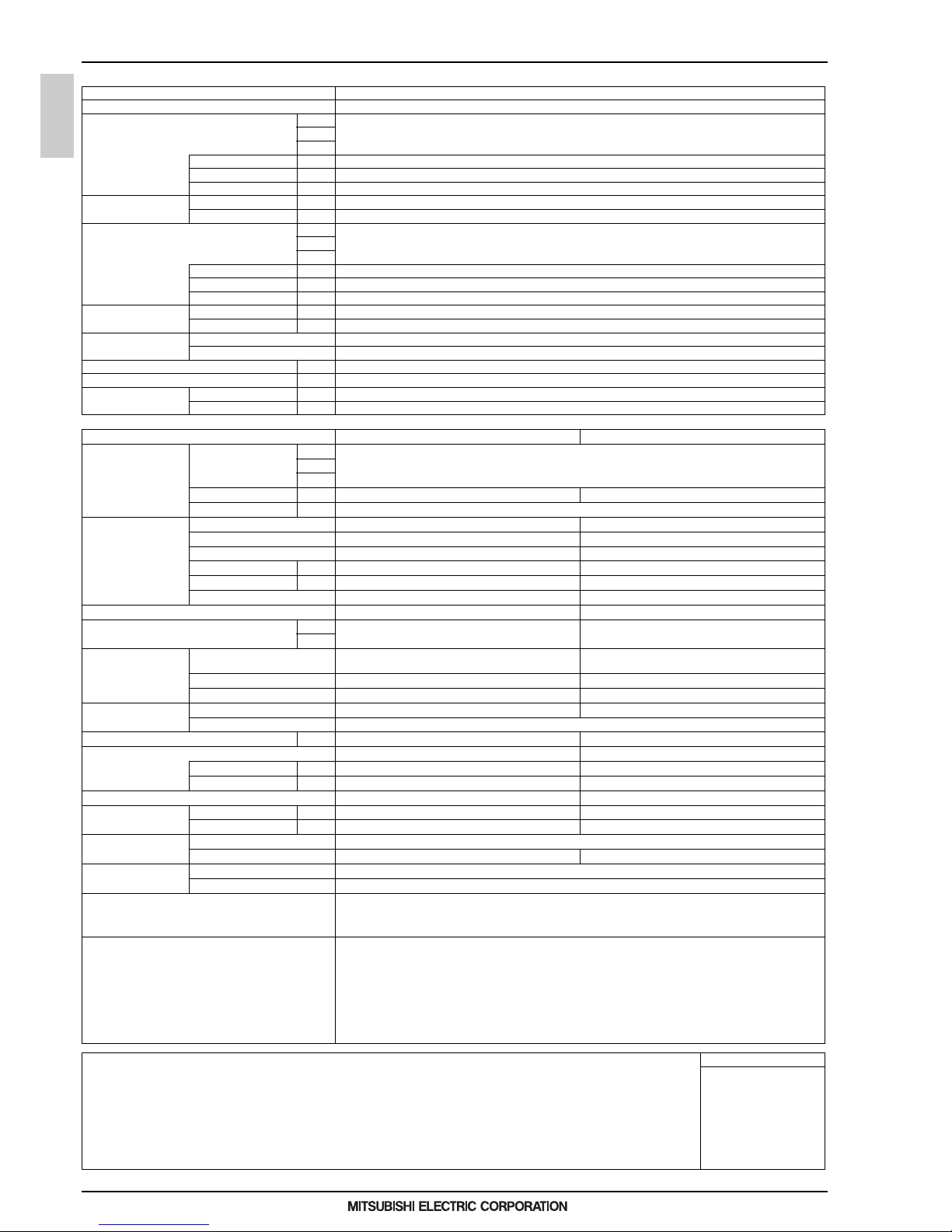

Model PQHY-P500YLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 56.0

(Nominal) kcal/h 50,000

*1 BTU/h 191,100

Power input kW 11.17

Current input A 18.8-17.9-17.2

EER kW/kW 5.01

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 63.0

(Nominal) kcal/h 55,000

*2 BTU/h 215,000

Power input kW 11.43

Current input A 19.2-18.3-17.6

COP kW/kW 5.51

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~43

Sound pressure level (measured in anechoic room) dB <A> 54

Sound power level (measured in anechoic room) dB <A> 70.5

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1- 1/8) Brazed

Circulating water Water flow rate m3/h 7.20

L/min 120

cfm 4.2

Pressure drop kPa 44

Operating volume range m3/h 4.5 ~ 11.6

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 13.0

Case heater kW -

Lubricant MEL32

External finish Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550

in. 57-1/8 x 34-11/16 x 21-11/16

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection

Compressor Over-heat protection

Refrigerant Type x original charge R410A x 6.0 kg (14 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 217 (479)

Heat exchanger plate type

Water volume in plate I 5.0

Water pressure Max. MPa 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure

Drawing External WKS94C747

Wiring WKE94G131

Standard attachment Do cument Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (sub ject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

9

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P550YLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 63.0

(Nominal) kcal/h 55,000

*1 BTU/h 215,000

Power input kW 12.54

Current input A 21.1-20.1-19.3

EER kW/kW 5.02

Temp. range of Indoor W. B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 69.0

(Nominal) kcal/h 60,000

*2 BTU/h 235,400

Power input kW 12.27

Current input A 20.7-19.6-18.9

COP kW/kW 5.62

Temp. range of Indoor D.B . 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/2~47

Sound pressure level (measured in anechoic room) dB <A> 56.5

Sound power level (measured in anechoic room) dB <A> 71.5

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1-1/8) Brazed

Circulating water Water flow rate m3/h 11.52

L/min 192

cfm 6.8

Pressure drop kPa 45

Operating volume range m3/h 6.0 ~ 14. 4

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 15.0

Case heater kW 0.045 (240 V)

Lubricant MEL32

External finish Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550

in. 57-1 /8 x 34-11/16 x 21-11/16

Protection devices High pressure protection High pressure sensor, High pressure swit ch at 4.15 MPa (601 psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection

Compressor Over-heat protection

Refrigerant Type x original charge R410A x 11.7 kg (26 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 246 (543)

Heat exchanger plate t ype

Water volume in plate I 10.0

Water pressure Max. MPa 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure

Drawing External WK S94C748

Wiring WKE94G131

Standard attachment Document Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, po wer source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation ma terial to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

10

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P600YLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 69.0

(Nominal) kcal/h 60,000

*1 BTU/h 235,400

Power input kW 14.49

Current input A 24.4-23.2-22.3

EER kW/kW 4.76

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 76.5

(Nominal) kcal/h 65,800

*2 BTU/h 261,000

Power input kW 14.51

Current input A 24.4-23.2-22.4

COP kW/kW 5.27

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/2~50

Sound pressure level (measured in anechoic room) dB <A> 56.5

Sound power level (measured in anechoic room) dB <A> 73

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1- 1/8) Brazed

Circulating water Water flow rate m3/h 11.52

L/min 192

cfm 6.8

Pressure drop kPa 45

Operating volume range m3/h 6.0 ~ 14.4

Compressor Type Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter

Motor output kW 16.1

Case heater kW 0.045 (240 V)

Lubricant MEL32

External finish Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550

in. 57-1/8 x 34-11/16 x 21-11/16

Protection devices High pressure protection High pressure sensor, High pressure switch at 4.15 MPa (601 psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection

Compressor Over-heat protection

Refrigerant Type x original charge R410A x 11.7 kg (26 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 246 (543)

Heat exchanger plate type

Water volume in plate I 10.0

Water pressure Max. MPa 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure

Drawing External WKS94C748

Wiring WKE94G131

Standard attachment Do cument Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (sub ject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

11

WY

MEE15K036

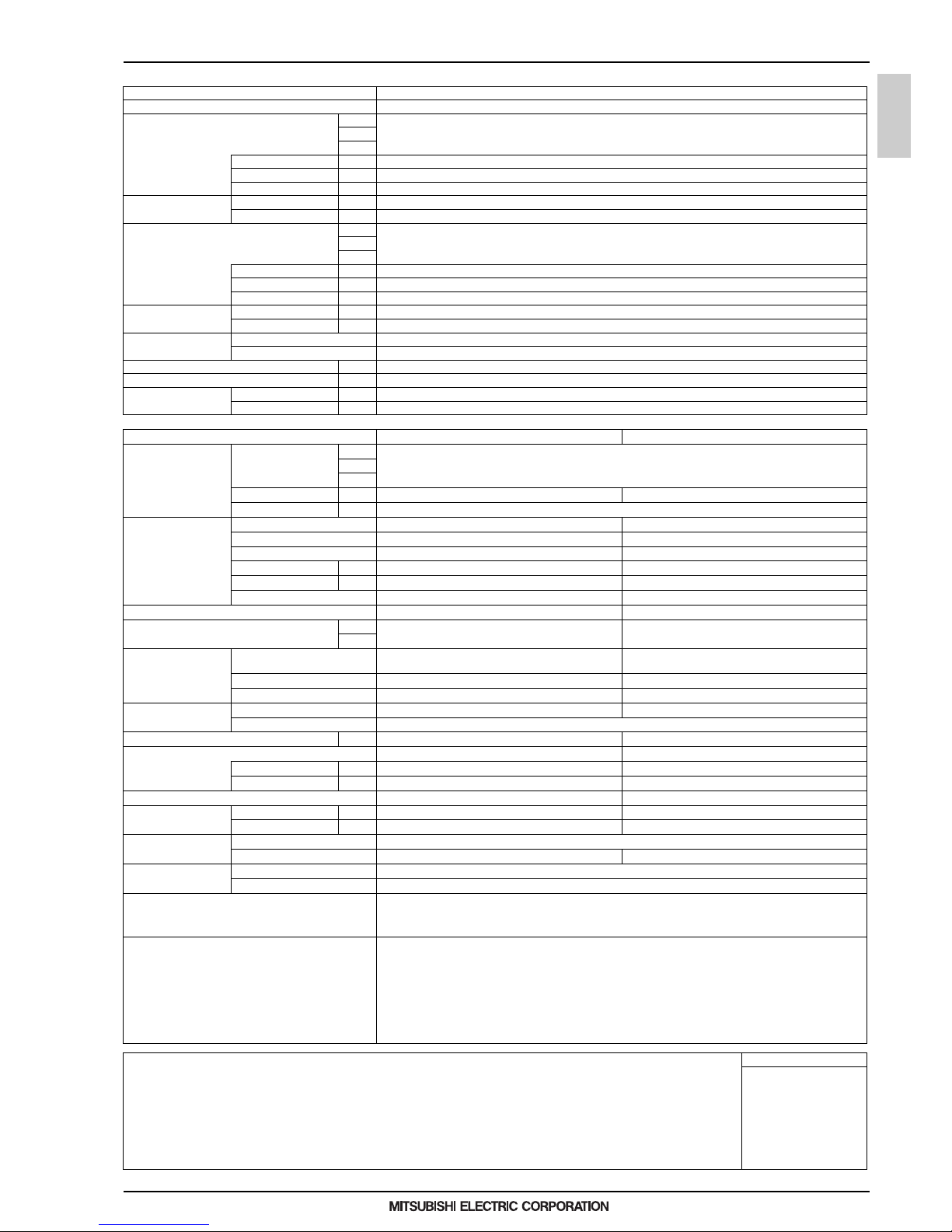

1. SPECIFICATIONS

HEAT SOURCE

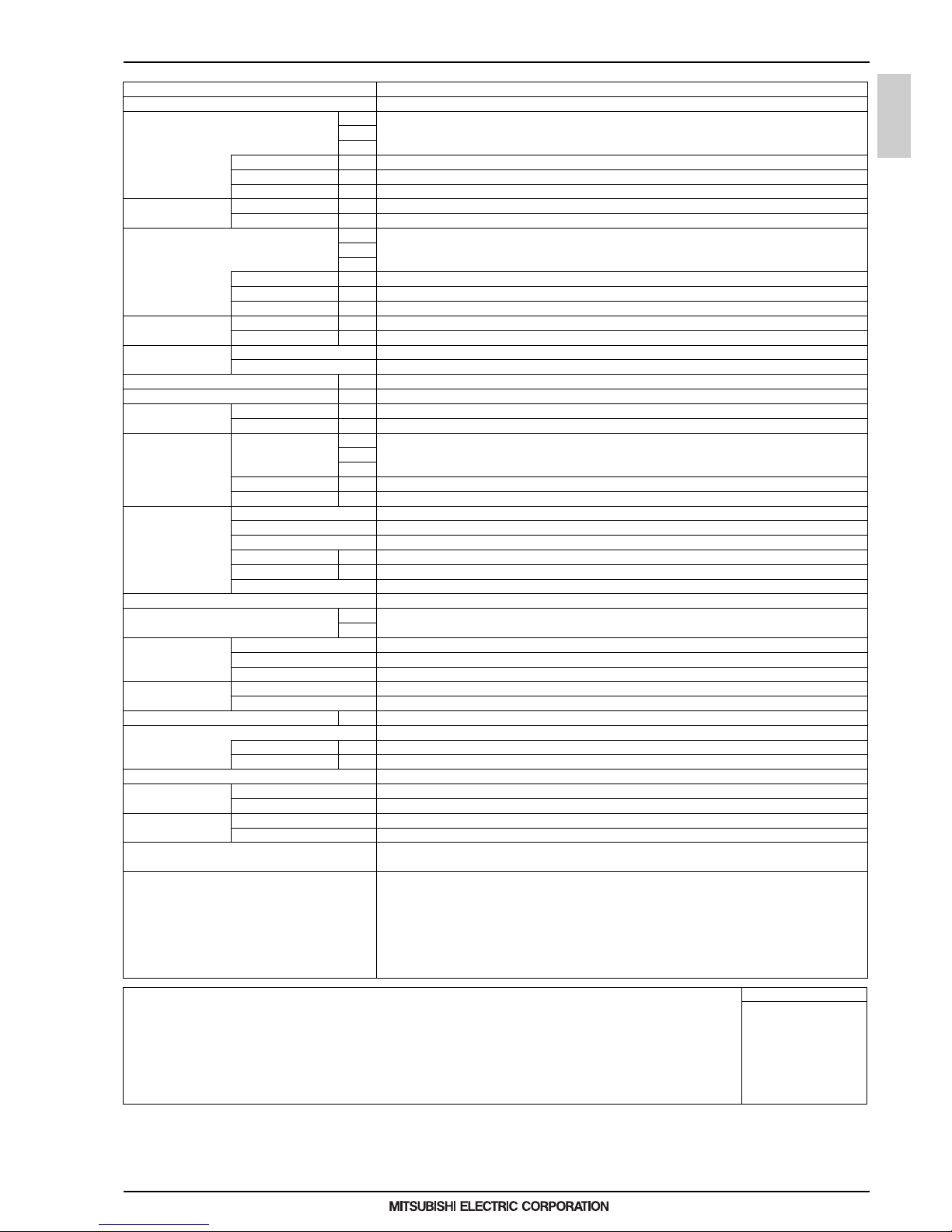

Model PQHY-P400YSLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 45.0

(Nominal) kcal/h 40,000

*1 BTU/h 153,500

Power input kW 7.70

Current input A 12.9-12.3-11.9

EER kW/kW 5.84

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 50.0

(Nominal) kcal/h 45,000

*2 BTU/h 170,600

Power input kW 7.94

Current input A 13.4-12.7-12.2

COP kW/kW 6.29

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~34

Sound pressure level (measured in anechoic room) dB <A> 49

Sound power level (measured in anechoic room) dB <A> 63

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1-1/8) Brazed

Set Model

Model PQHY-P200YLM-A PQHY-P200YLM-A

Circulating water Water flow rate m3/h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop kPa 24 24

Operating volume range m3/h 3.0 + 3.0 ~ 7.2 + 7.2

Compressor Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 4.8 4.8

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D mm 1,100 x 880 x 550 1,100 x 880 x 550

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

Protection devices High pressure protection

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Refrigerant Type x original charge R410A x 5.0 kg (12 lbs) R410A x 5.0 kg (12 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 174 (384) 174 (384)

Heat exchanger plate type plate type

Water volume in plate I 5.0 5.0

Water pressure Max. MPa 2.0 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure Copper pipe, tube-in-tube struct ure

Pipe between unit and Liquid pipe mm (in.) 9.52 (3/8) Brazed 9.52 (3/8) Braze d

distributor Gas pipe mm (in.) 19.05 (3/4) Brazed 19.05 (3/4) Brazed

Drawing External WKS94C751

Wiring WKE94G131 WKE94G131

Standard attachment Document Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Heat Source Twinning kit: CMY-Y100VBK3

Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation ma terial to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

12

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P450YSLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 50.0

(Nominal) kcal/h 45,000

*1 BTU/h 170,600

Power input kW 8.78

Current input A 14.8-14.0-13.5

EER kW/kW 5.69

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water ° C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 56.0

(Nominal) kcal/h 50,000

*2 BTU/h 191,100

Power input kW 8.97

Current input A 15.1-14.3-13.8

COP kW/kW 6.24

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~39

Sound pressure level (measured in anechoic room) dB <A> 50

Sound power level (measured in anechoic room) dB <A> 64

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1-1/8) Brazed

Set Model

Model PQHY-P250YLM-A PQHY-P200YLM-A

Circulating water Water flow rate m3/h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop kPa 24 24

Operating volume range m3/h 3.0 + 3.0 ~ 7.2 + 7.2

Compressor Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 6.2 4.8

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D mm 1,100 x 880 x 550 1,100 x 880 x 550

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

Protection devices High pressure protection

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High press ure switch at 4.15 MPa (601

psi)

Inverter circuit (COMP.) Over-heat protection, Over -current protection Over-h eat protection, Over-current protection

Compressor O ver-heat protection Over-heat pro tection

Refrigerant Type x original charge R410A x 5.0 kg (12 lbs) R410A x 5.0 kg (12 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 174 (384) 174 (384)

Heat exchanger plate type plate type

Water volume in plate I 5.0 5.0

Water pressure Max. MPa 2.0 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure Copper pipe, tube-in-tube structure

Pipe between unit and Liquid pipe mm (in.) 9.52 (3/8) Brazed 9.52 (3/8) Brazed

distributor Gas pipe mm (in.) 22.2 (7/8) Brazed 22.2 (7/ 8) Brazed

Drawing External WKS94C751

Wiring WKE94G131 WKE94G131

Standard attachment Do cument Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Heat Source Twinning kit: CMY-Y100VBK3

Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (sub ject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

13

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P500YSLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 56.0

(Nominal) kcal/h 50,000

*1 BTU/h 191,100

Power input kW 10.12

Current input A 17.0-16.2-15.6

EER kW/kW 5.53

Temp. range of Indoor W. B. 15.0~24.0°C (5 9~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 63.0

(Nominal) kcal/h 55,000

*2 BTU/h 215,000

Power input kW 10.16

Current input A 17.1-16.2-15.7

COP kW/kW 6.20

Temp. range of Indoor D.B . 15.0~27 .0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/1~43

Sound pressure level (measured in anechoic room) dB <A> 51

Sound power level (measured in anechoic room) dB <A> 65

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1-1/8) Brazed

Set Model

Model PQHY-P250YLM-A PQHY-P250YLM-A

Circulating water Water flow rate m3/h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop kPa 24 24

Operating volume range m3/h 3.0 + 3.0 ~ 7.2 + 7 .2

Compressor Type Inverter scroll hermetic compressor Inverte r scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUB ISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 6.2 6.2

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D mm 1,100 x 880 x 550 1,100 x 880 x 550

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

Protection devices High pressure protection

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor O ver-heat protection Over-heat prot ection

Refrigerant Type x original charge R410A x 5.0 kg (12 lbs) R410A x 5.0 kg (12 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 174 (384) 174 (384)

Heat exchanger plate type plate type

Water volume in plate I 5.0 5.0

Water pressure Max. MPa 2.0 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure Copper pipe, tube-in-tube structur e

Pipe between unit and Liquid pipe mm (in. ) 9.52 (3/8) Brazed 9.52 (3/8) Brazed

distributor Gas pipe mm (in.) 22.2 (7/8) Brazed 22.2 (7/8) Brazed

Drawing External WKS94C751

Wiring WKE94G131 WKE94G131

Standard attachment Document Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Heat Source Twinning kit: CMY-Y100VBK3

Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation ma terial to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

14

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P550YSLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 63.0

(Nominal) kcal/h 55,00 0

*1 BTU/h 215,000

Power input kW 11.55

Current input A 19.4-18.5-17.8

EER kW/kW 5.45

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 69.0

(Nominal) kcal/h 60,00 0

*2 BTU/h 235,400

Power input kW 11.31

Current input A 19.0-18.1-17.4

COP kW/kW 6.10

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capaci ty 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/2~47

Sound pressure level (measured in anechoic room) dB <A> 55

Sound power level (measured in anechoic room) dB <A> 69

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1-1/8) Brazed

Set Model

Model PQHY-P300YLM-A PQHY-P250YLM-A

Circulating water Water flow rate m3/h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop kPa 24 24

Operating volume range m3/h 3.0 + 3.0 ~ 7.2 + 7.2

Compressor Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 7.7 6.2

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D mm 1,100 x 880 x 550 1,100 x 880 x 550

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

Protection devices High pressure protection

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Refrigerant Type x original charge R410A x 5.0 kg (12 lbs) R410A x 5.0 kg (12 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 174 (384) 174 (384)

Heat exchanger plate type plate type

Water volume in plate I 5.0 5.0

Water pressure Max. MPa 2.0 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure Copper pipe, tube-in-tube structure

Pipe between unit and Liquid pipe mm (in.) 12.7 (1/2) Brazed 12.7 (1/2) Brazed

distributor Gas pipe mm (in.) 22.2 (7/8) Brazed 22.2 (7/8) Brazed

Drawing External WKS94C751

Wiring WKE94G131 WKE94G131

Standard attachment Do cument Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Heat Source Twinning kit: CMY-Y100VBK3

Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (sub ject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

15

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P600YSLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 69.0

(Nominal) kcal/h 60,000

*1 BTU/h 235,400

Power input kW 12.84

Current input A 21.6-20.5-19.8

EER kW/kW 5.37

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 76.5

(Nominal) kcal/h 65,800

*2 BTU/h 261,000

Power input kW 12.75

Current input A 21.5-20.4-19.7

COP kW/kW 6.00

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/2~50

Sound pressure level (measured in anechoic room) dB <A> 57

Sound power level (measured in anechoic room) dB <A> 71

Refrigerant Liquid pipe mm (in.) 15.88 (5/8) Brazed

piping diameter Gas pipe mm (in.) 28.58 (1-1/8) Brazed

Set Model

Model PQHY-P300YLM-A PQHY-P300YLM-A

Circulating water Water flow rate m3/h 5.76 + 5.76

L/min 96 + 96

cfm 3.4 + 3.4

Pressure drop kPa 24 24

Operating volume range m3/h 3.0 + 3.0 ~ 7.2 + 7.2

Compressor Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Invert er Inverter

Motor output kW 7.7 7.7

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D mm 1,100 x 880 x 550 1,100 x 880 x 550

in. 43-5/16 x 34-11/16 x 21-11/16 43-5/16 x 34-11/16 x 21-11/16

Protection devices High pressure protection

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Refrigerant Type x original charge R4 10A x 5.0 kg (12 lbs) R410A x 5.0 kg (12 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 174 (384) 174 (384)

Heat exchanger plate t ype plate type

Water volume in plate I 5.0 5.0

Water pressure Max. MPa 2 .0 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure Copper pipe, tube-in-tube structure

Pipe between unit and Liquid pipe mm (in. ) 12.7 (1/2) Brazed 12.7 (1/2) Brazed

distributor Gas pipe mm (in.) 22.2 (7/8) Brazed 22.2 (7/8) Brazed

Drawing External WKS94C751

Wiring WKE94G131 WKE94G131

Standard attachment Document Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Heat Source Twinning kit: CMY-Y100VBK3

Joint: CMY-Y102SS/LS-G2, CMY-Y202S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation wo rk, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation ma terial to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

16

WY

MEE15K036

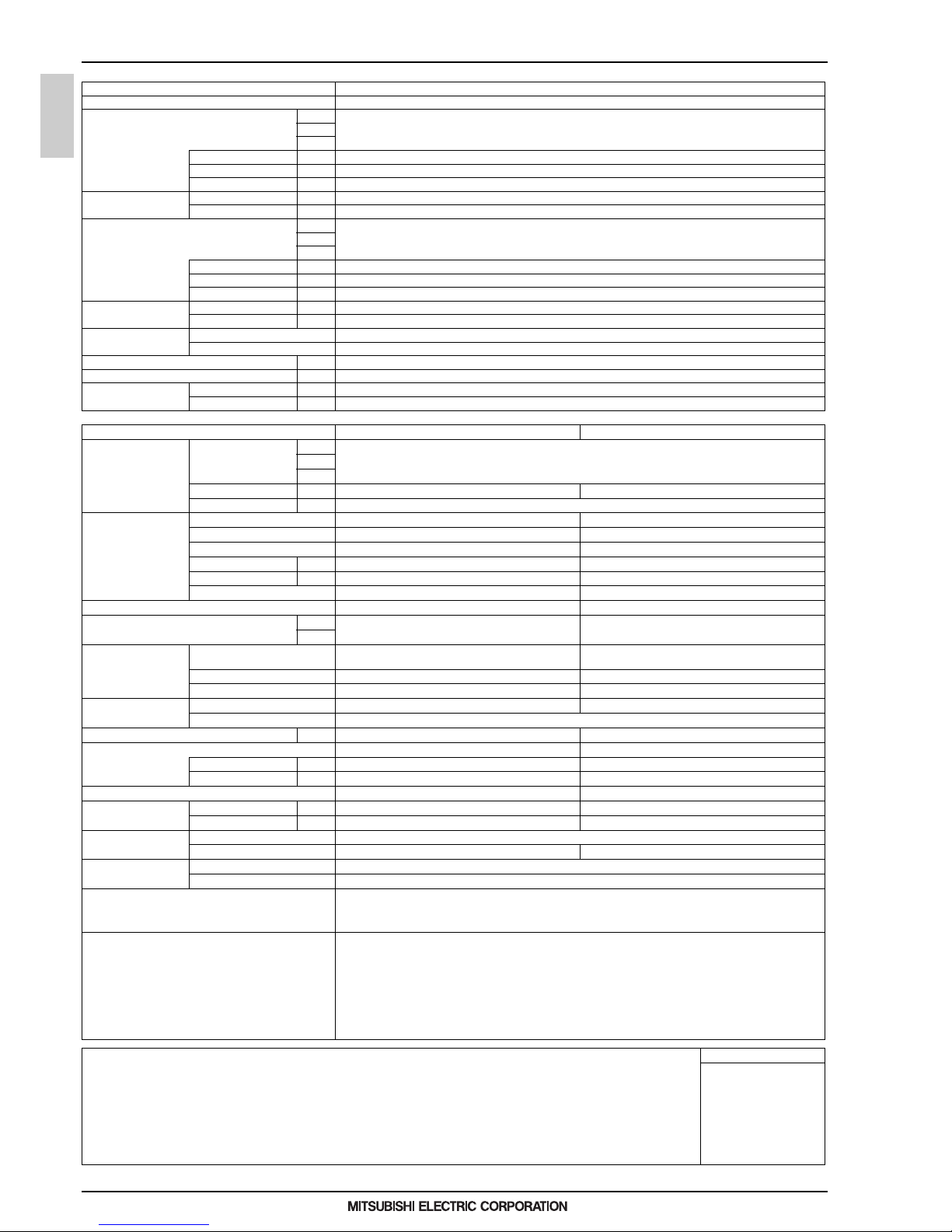

1. SPECIFICATIONS

HEAT SOURCE

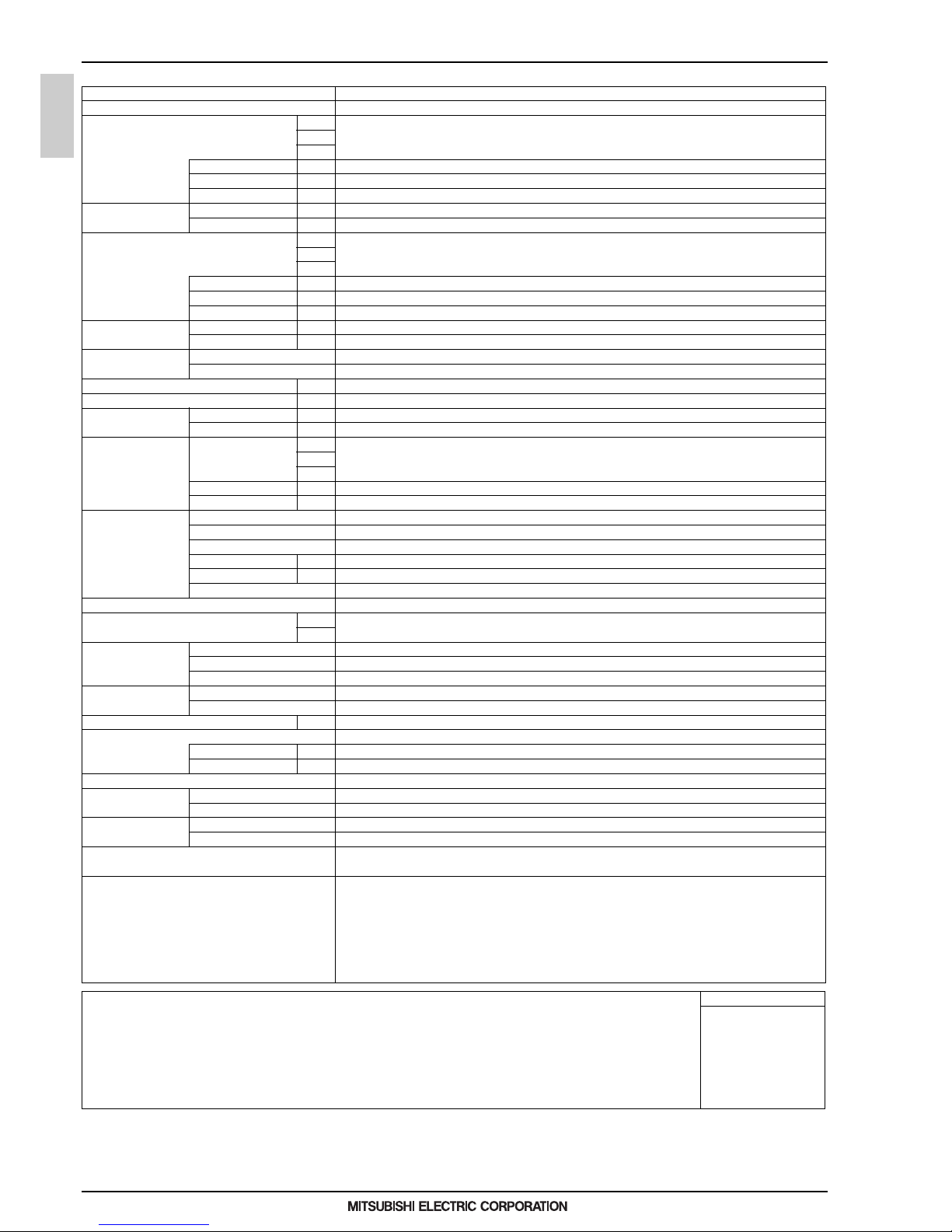

Model PQHY-P700YSLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 80.0

(Nominal) kcal/h 68,800

*1 BTU/h 273,000

Power input kW 14.73

Current input A 24.8-23.6-22.7

EER kW/kW 5.43

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 88.0

(Nominal) kcal/h 75,700

*2 BTU/h 300,300

Power input kW 14.73

Current input A 24.8-23.6-22.7

COP kW/kW 5.97

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/2~50

Sound pressure level (measured in anechoic room) dB <A> 55

Sound power level (measured in anechoic room) dB <A> 69

Refrigerant Liquid pipe mm (in.) 19.05 (3/4) Brazed

piping diameter Gas pipe mm (in.) 34.93 (1-3/8) Brazed

Set Model

Model PQHY-P350YLM-A PQHY-P350YLM-A

Circulating water Water flow rate m3/h 7.20 + 7.20

L/min 120 + 120

cfm 4.2 + 4.2

Pressure drop kPa 44 44

Operating volume range m3/h 4.5 + 4.5 ~ 11.6 + 11.6

Compressor Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 9.5 9.5

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550 1,450 x 880 x 550

in. 57-1/ 8 x 34-11/16 x 21-11/16 57-1/8 x 34-1 1/16 x 21-11/16

Protection devices High pressure protection

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Refrigerant Type x original charge R410A x 6.0 kg (14 lbs) R410A x 6.0 kg (14 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 217 (479) 217 (479)

Heat exchanger plate type plate type

Water volume in plate I 5.0 5.0

Water pressure Max. MPa 2.0 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure Copper pipe, tube-in-tube structure

Pipe between unit and Liquid pipe mm (in.) 12.7 (1/2) Brazed 12.7 (1/2) Brazed

distributor Gas pipe mm (in.) 28.58 (1-1/8) Brazed 28.58 (1 -1/8) Brazed

Drawing External WKS94C752

Wiring WKE94G131 WKE94G131

Standard attachment Do cument Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Heat Source Twinning kit: CMY-Y200VBK2

Joint: CMY-Y102SS/LS-G2, CMY-Y202, 302S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (sub ject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

17

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P750YSLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 85.0

(Nominal) kcal/h 73,100

*1 BTU/h 290,000

Power input kW 15.64

Current input A 26.4-25.0-24.1

EER kW/kW 5.43

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 95.0

(Nominal) kcal/h 81,700

*2 BTU/h 324,100

Power input kW 15.90

Current input A 26.8-25.4-24.5

COP kW/kW 5.97

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/2~50

Sound pressure level (measured in anechoic room) dB <A> 55

Sound power level (measured in anechoic room) dB <A> 69

Refrigerant Liquid pipe mm (in.) 19.05 (3/4) Brazed

piping diameter Gas pipe mm (in.) 34.93 (1-3/8) Brazed

Set Model

Model PQHY-P400YLM-A PQHY-P350YLM-A

Circulating water Water flow rate m3/h 7.20 + 7.20

L/min 120 + 120

cfm 4.2 + 4.2

Pressure drop kPa 44 44

Operating volume range m3/h 4.5 + 4.5 ~ 11.6 + 11.6

Compressor Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Invert er Inverter

Motor output kW 10.7 9.5

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550 1,450 x 880 x 550

in. 57-1/8 x 34-11/16 x 21-11/16 57-1/8 x 34-11/16 x 21-11/16

Protection devices High pressure protection

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Refrigerant Type x original charge R4 10A x 6.0 kg (14 lbs) R410A x 6.0 kg (14 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 217 (479) 217 (479)

Heat exchanger plate t ype plate type

Water volume in plate I 5.0 5.0

Water pressure Max. MPa 2 .0 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure Copper pipe, tube-in-tube structure

Pipe between unit and Liquid pipe mm (in. ) 15.88 (5/8) Brazed 15.88 (5/8) Brazed

distributor Gas pipe mm (in.) 28.58 (1-1/8) Brazed 28.58 (1-1/8 ) Brazed

Drawing External WKS94C752

Wiring WKE94G131 WKE94G131

Standard attachment Document Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Heat Source Twinning kit: CMY-Y200VBK2

Joint: CMY-Y102SS/LS-G2, CMY-Y202, 302S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation wo rk, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation ma terial to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (subject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variation.

18

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P800YSLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 90.0

(Nominal) kcal/h 77,400

*1 BTU/h 307,100

Power input kW 16.57

Current input A 27.9-26.5-25.6

EER kW/kW 5.43

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 100.0

(Nominal) kcal/h 86,000

*2 BTU/h 341,200

Power input kW 16.75

Current input A 28.2-26.8-25.8

COP kW/kW 5.97

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/2~50

Sound pressure level (measured in anechoic room) dB <A> 55

Sound power level (measured in anechoic room) dB <A> 69

Refrigerant Liquid pipe mm (in.) 19.05 (3/4) Brazed

piping diameter Gas pipe mm (in.) 34.93 (1-3/8) Brazed

Set Model

Model PQHY-P400YLM-A PQHY-P400YLM-A

Circulating water Water flow rate m3/h 7.20 + 7.20

L/min 120 + 120

cfm 4.2 + 4.2

Pressure drop kPa 44 44

Operating volume range m3/h 4.5 + 4.5 ~ 11.6 + 11.6

Compressor Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Inverter Inverter

Motor output kW 10.7 10.7

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550 1,450 x 880 x 550

in. 57-1/ 8 x 34-11/16 x 21-11/16 57-1/8 x 34-1 1/16 x 21-11/16

Protection devices High pressure protection

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Refrigerant Type x original charge R410A x 6.0 kg (14 lbs) R410A x 6.0 kg (14 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 217 (479) 217 (479)

Heat exchanger plate type plate type

Water volume in plate I 5.0 5.0

Water pressure Max. MPa 2.0 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure Copper pipe, tube-in-tube structure

Pipe between unit and Liquid pipe mm (in.) 15.88 (5/8) Brazed 15.88 (5/8) Brazed

distributor Gas pipe mm (in.) 28.58 (1-1/8) Brazed 28.58 (1 -1/8) Brazed

Drawing External WKS94C752

Wiring WKE94G131 WKE94G131

Standard attachment Do cument Installation Manual

Accessory Refrigerant conn. pipe

Optional parts Heat Source Twinning kit: CMY-Y200VBK2

Joint: CMY-Y102SS/LS-G2, CMY-Y202, 302S-G2

Header: CMY-Y104, 108, 1010-G

Remarks Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred

to the Installation Manual.

Due to continuing improvement, above specifications may be subject to change without notice.

The ambient temperature of the heat source unit needs to be kept below 40°C D.B.

The ambient relative humidity of the heat source unit needs to be kept below 80%.

The heat source unit should not be installed at outdoor.

Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit.

Be sure to provide interlocking for the unit operation and water circuit.

Install the supplied insulation material to the unused drain-socket.

When installing insulation material around both water and refrigerant piping, follow the installation manual.

Notes: Unit converter

1.Nominal cooling conditions (sub ject to JIS B8615-2)

Indoor: 27°CD.B./19°CW.B. (81°FD.B./66°FW.B.), Water temperature: 30°C (86°F)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

2.Nominal heating conditions (subject to JIS B8615-2)

Indoor: 20°CD.B. (68°FD.B.) ,Water temperature: 20°C (68°FD.B.)

Pipe length: 7.5 m (24-9/16 ft.), Level difference: 0 m (0 ft.)

BTU/h =kW x 3,412

cfm =m3/min x 35.31

lbs =kg/0.4536

*Above specification data is

subject to rounding variatio n.

19

WY

MEE15K036

1. SPECIFICATIONS

HEAT SOURCE

Model PQHY-P850YSLM-A

Power source 3-phase 4-wire 380-400-415 V 50/60 Hz

Cooling capacity *1 kW 96.0

(Nominal) kcal/h 82,600

*1 BTU/h 327,600

Power input kW 18.03

Current input A 30.4-28.9-27.8

EER kW/kW 5.32

Temp. range of Indoor W.B. 15.0~24.0°C (59~75°F)

cooling Circulating water °C 10.0~45.0°C (50~113°F)

Heating capacity *2 kW 108.0

(Nominal) kcal/h 92,900

*2 BTU/h 368,500

Power input kW 18.49

Current input A 31.2-29.6-28.5

COP kW/kW 5.84

Temp. range of Indoor D.B. 15.0~27.0°C (59~81°F)

heating Circulating water °C 10.0~45.0°C (50~113°F)

Indoor unit Total capacity 50~130% of heat source unit capacity

connectable Model/Quantity P15~P250/2~50

Sound pressure level (measured in anechoic room) dB <A> 56

Sound power level (measured in anechoic room) dB <A> 71.5

Refrigerant Liquid pipe mm (in.) 19.05 (3/4) Brazed

piping diameter Gas pipe mm (in.) 41.28 (1-5/8) Brazed

Set Model

Model PQHY-P450YLM-A PQHY-P400YLM-A

Circulating water Water flow rate m3/h 7.20 + 7.20

L/min 120 + 120

cfm 4.2 + 4.2

Pressure drop kPa 44 44

Operating volume range m3/h 4.5 + 4.5 ~ 11.6 + 11.6

Compressor Type Inverter scroll hermetic compressor Inverter scroll hermetic compressor

Manufacture AC&R Works, MITSUBISHI ELECTRIC CORPORATION AC&R Works, MITSUBISHI ELECTRIC CORPORATION

Starting method Invert er Inverter

Motor output kW 11.6 10.7

Case heater kW - -

Lubricant MEL32 MEL32

External finish Galvanized steel sheets Galvanized steel sheets

External dimension H x W x D mm 1,450 x 880 x 550 1,450 x 880 x 550

in. 57-1/8 x 34-11/16 x 21-11/16 57-1/8 x 34-11/16 x 21-11/16

Protection devices High pressure protection

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

High pressure sensor, High pressure switch at 4.15 MPa (601

psi)

Inverter circuit (COMP.) Over-heat protection, Over-current protection Over-heat protection, Over-current protection

Compressor Over-heat protection Over-heat protection

Refrigerant Type x original charge R4 10A x 6.0 kg (14 lbs) R410A x 6.0 kg (14 lbs)

Control LEV and HIC circuit

Net weight kg (lbs) 217 (479) 217 (479)

Heat exchanger plate t ype plate type

Water volume in plate I 5.0 5.0

Water pressure Max. MPa 2 .0 2.0

HIC circuit (HIC: Heat Inter-Changer) Copper pipe, tube-in-tube structure Copper pipe, tube-in-tube structure

Pipe between unit and Liquid pipe mm (in. ) 15.88 (5/8) Brazed 15.88 (5/8) Brazed

distributor Gas pipe mm (in.) 28.58 (1-1/8) Brazed 28.58 (1-1/8 ) Brazed

Drawing External WKS94C752

Wiring WKE94G131 WKE94G131

Standard attachment Document Installation Manual