Mitsubishi PMFY-P20VBM-A, PMFY-P20VBM-A1, PMFY-P25VBM-A, PMFY-P25VBM-A1, PMFY-P32VBM-A Service Manual

...Page 1

SPLIT-TYPE,HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

2001

No. OC248

REVISED EDITION-A

Series PMFY

Indoor unit

[Model names] [Service Ref.]

PMFY-P20VBM-A PMFY-P20VBM-A

Ceiling Cassettes

R407C

PMFY-P20VBM-A

PMFY-P25VBM-A PMFY-P25VBM-A

PMFY-P25VBM-A

PMFY-P32VBM-A PMFY-P32VBM-A

PMFY-P32VBM-A

PMFY-P40VBM-A PMFY-P40VBM-A

PMFY-P40VBM-A

CONTENTS

R22

1

1

1

1

• PMFY-P20VBM-A1,

PMFY-P25VBM-A1,

PMFY-P32VBM-A1,

PMFY-P40VBM-A1

are added in

Revised Edition-A.

• Please destroy OC248.

INDOOR UNIT

1. TECHNICAL CHANGE·························2

2. SAFETY PRECAUTION ·······················2

3. PART NAMES AND FUNCTIONS········4

4. SPECIFICATION···································6

5. OUTLINES AND DIMENSIONS··········10

6. WIRING DIAGRAM·····························11

7.

REFRIGERANT SYSTEM DIAGRAM

8. TROUBLE SHOOTING ·······················13

9. DISASSEMBLY PROCEDURE ···········19

10. PARTS LIST········································22

···12

Page 2

1

TECHNICAL CHANGES

PMFY-P20VBM-A PMFY-P20VBM-A1

PMFY-P25VBM-A PMFY-P25VBM-A1

PMFY-P32VBM-A PMFY-P32VBM-A1

PMFY-P40VBM-A PMFY-P40VBM-A1

● INDOOR CONTROLLER BOARD(I.B) has changed.

● DRAIN PAN has changed.

2

SAFETY PRECAUTION

Cautions for using with the outdoor unit which adopts R407C refrigerant.

· Do not use the existing refrigerant piping.

-The old refrigerant and lubricant in the existing piping contains a large amount of chlorine which may cause the lubricant

deterioration of the new unit.

· Use “low residual oil piping”.

-If there is a large amount of residual oil (hydraulic oil, etc.) inside the piping and joints, deterioration of the lubricant will result.

· Store the piping to be used during installation indoors with keep both ends sealed until just before brazing.

(Store elbows and other joints in a plastic bag.)

-If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

· Use ESTR , ETHER or HAB as the lubricant to coat flares and flange connection parts.

Use liquid refrigerant to seal the system.

-If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change and performance

may drop.

· Do not use a refrigerant other than R407C.

-If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the lubricant deterioration.

· Use a vacuum pump with a reverse flow check valve.

-The vacuum pump oil may flow back into the refrigerant cycle and cause the lubricant deterioration.

2

Page 3

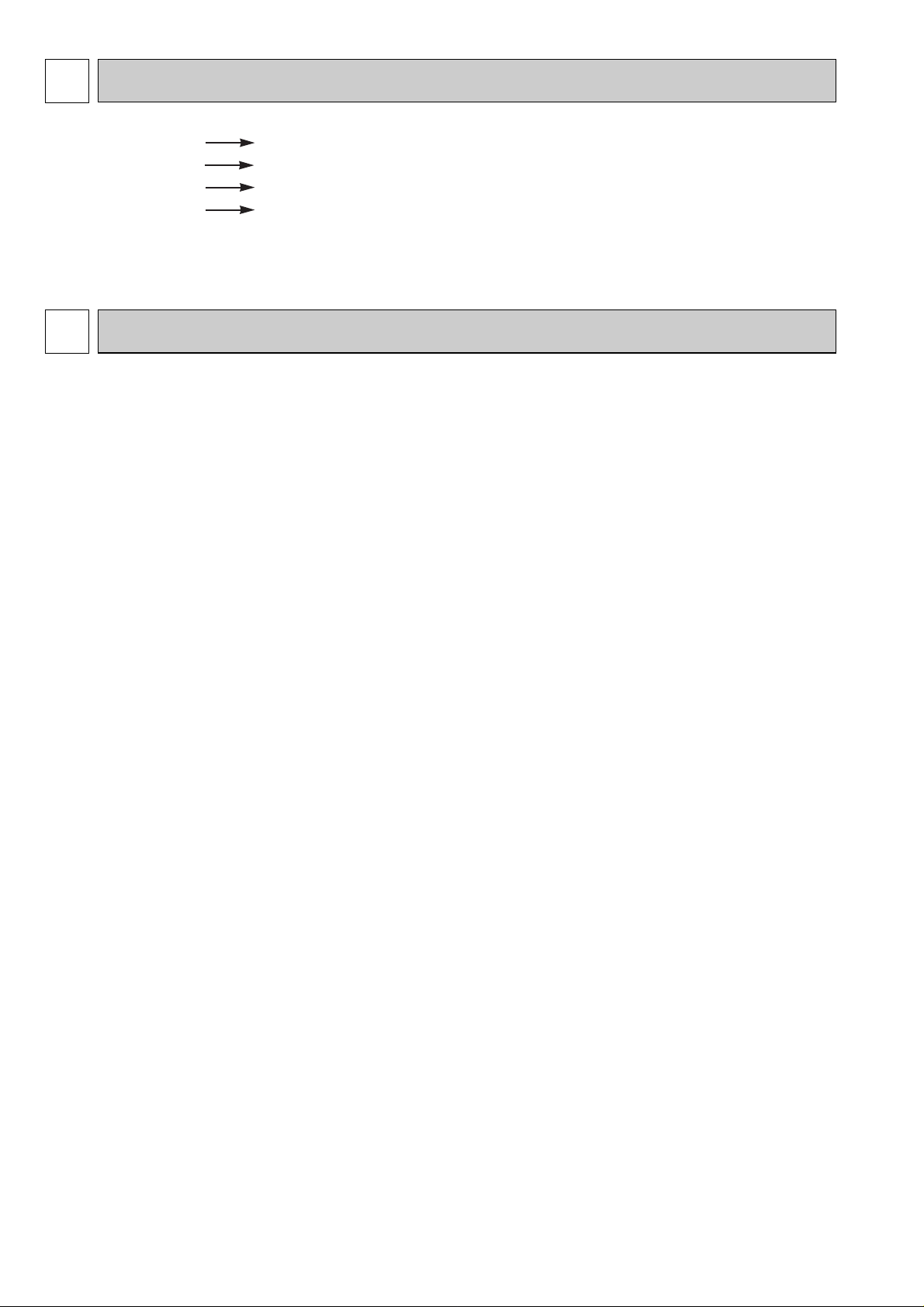

[1] Service tools

Gravimeter

Unit

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a or R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

[2] Notice on repair service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[3] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge by liquid refrigerant

.

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

3

Page 4

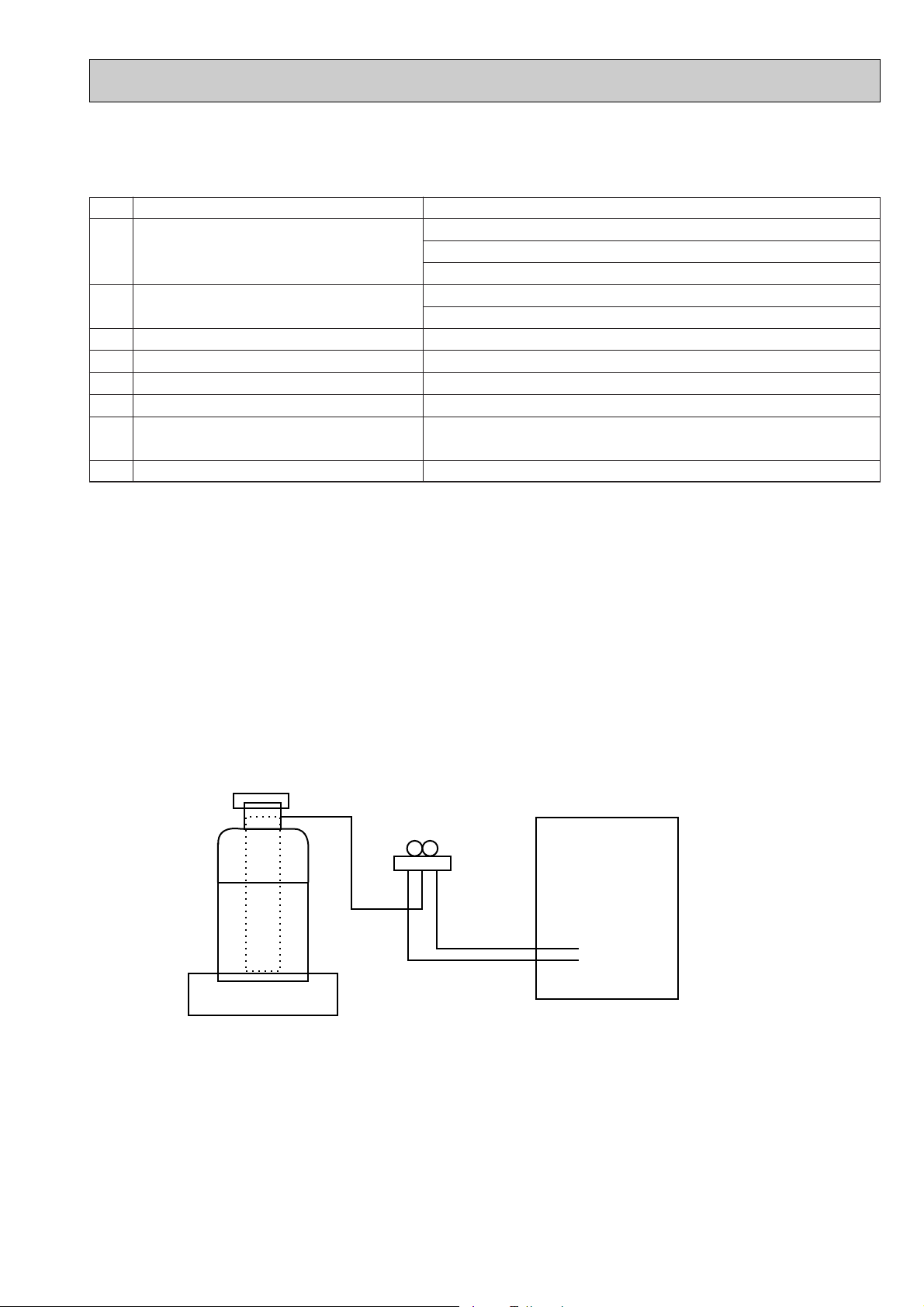

3

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

Press this button to switch the cooler,

electronic dry (dehumidify), automatic

and heater modes.

OPERATION SWITCH button

This sets the room temperature. The

temperature setting can be performed

in 1: units

Setting range

Cooler 19: to 30:

Heater 17: to 28:

TEMP. ADJUSTMENT button

This switches between continuous

operation and the timer operation.

TIMER button

This switches between the operation

and stop modes each time it is pressed.

The lamp on this button lights during

operation.

ON/OFF button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

CHECK-TEST RUN button

This switch the horizontal fan motion

ON and OFF.

(Not available for this model.)

LOUVER button

This adjusts the vertical angle of the

ventilation.

AIR DIRECTION button

This resets the filter service indication

display

FILTER button

This sets the current time, start time

and stop time.

TIME SETTING button

This sets the ventilation fan speed.

AIR SPEED button

PART NAMES AND FUNCTIONS

● Indoor (Main) Unit

Horizontal Air Outlet

Auto Air Swing Vane

Disperses airflow up and

down and adjusts the angle

of airflow direction.

Guide vane

Air flow can be changed to horizontally

by moving the Guide vane to the left or right.

Filters

Remove dust and pollutants

from return air.

● Remote controller

● Operation buttons

Air intake

Returns air from room.

[PAR-20MAA]

● Once the controls are set, the same operation mode can

be repeated by simply pressing the ON/OFF button.

4

Page 5

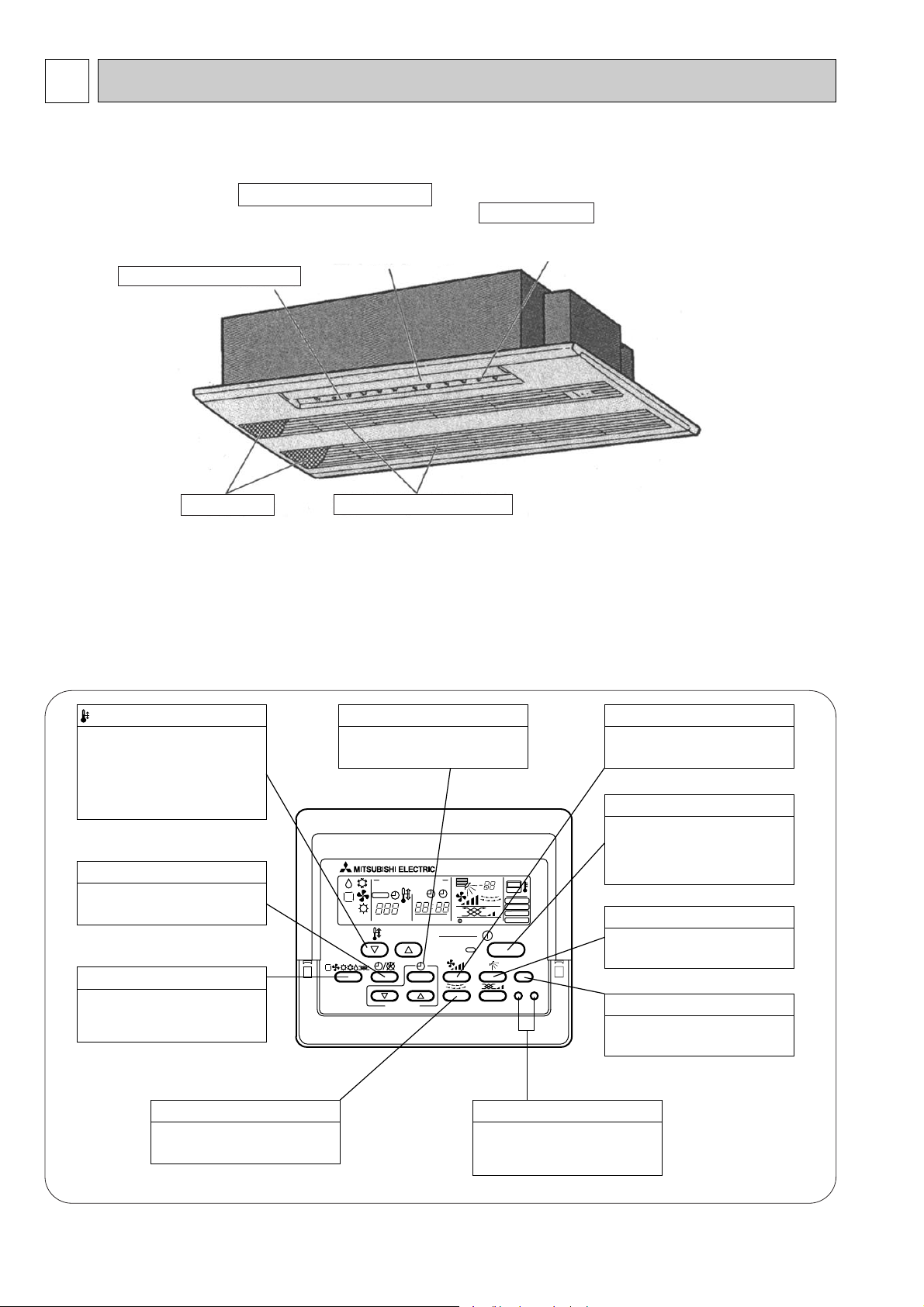

● Display

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

CENTRALLY

CONTROLLED display

This indicates when the unit is con-

trolled by optional features such as

central control type remote controller.

TIMER display

This indicates when the continuous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

The [STANDBY] symbol is only

displayed from the time the heating

operation starts unit the heated air

begins to blow.

DEFROST display

This indicates when the defrost oper-

ation is performed.

CLOCK display

The current time , start time and stop

time can be displayed in ten second

intervals by pressing the time switch

button. The start time or stop time is

always displayed during the timer

operation.

In this display example on the bottom left, a condition where all display lamps light is shown for explanation purposes although this differs

from actual operation.

AIR DIRECTION display

This displays the air direction.

AIR SPEED display

The selected fan speed is displayed.

ROOM TEMPERATURE display

The temperature of the suction air

is displayed during operation. The

display range is 8°C to 39°C. The

display flashes 8°C when the actual

temperature is less than 8°C and

flashes 39°C when the actual temperature is greater than 39°C.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when a malfunction occurs.

This display lights in the check mode

or when a test operation is performed.

CHECK MODE

TEST RUN

display

FILTER display

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

SET TEMPERATURE display

This displays the selected setting

temperature.

Caution

● Only the Power display lights when the unit is stopped and power supplied to the unit.

● When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

● “NOT AVAILABLE” is displayed when the Air speed button are pressed.This indicates that this room unit is not equipped

with the fan direction adjustment function and the louver function.

● When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For max.

2minutes). Please wait until this “H0” indication disappear then start the operation.

POWER display

This lamp lights when electricity is

supplied to the unit.

This lamp lights when the filter need

to be cleaned.

5

Page 6

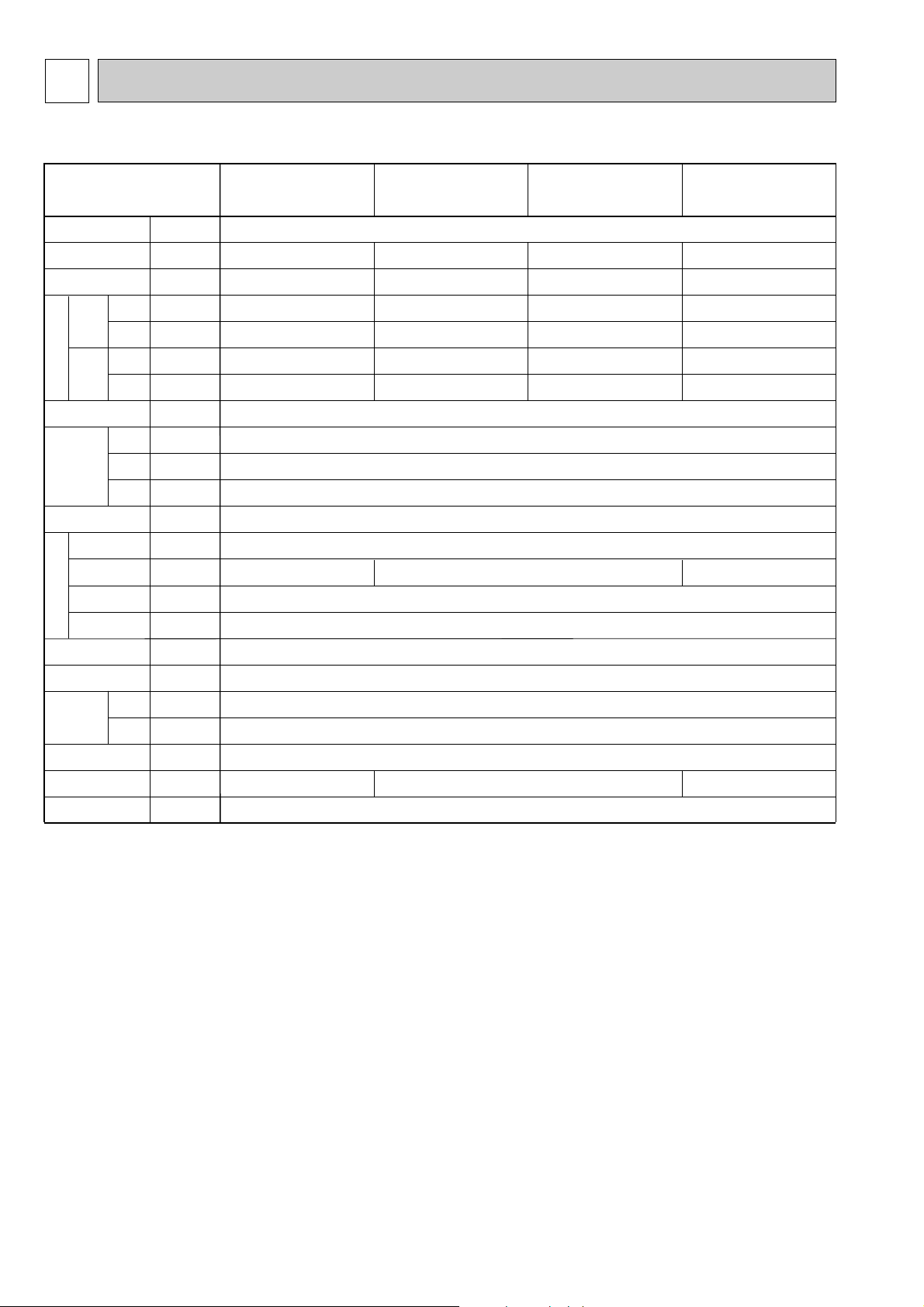

4

Item

V

·Hz

kW

kW

kW

kW

A

A

—

mm

mm

mm

—

—

k/min

Pa

kW

—

—

[mm(in.)

[mm(in.)

[mm

dB

kg

Cooling capacity

Power

Heat exchanger

Insulator

Air filter

Fan ✕ No

Air flow W3

Pipe

dimensions

Unit drain pipe size

Noise level W3

Product weight

Exterior

(munsell symbol)

Fan motor

output

External

static pressure

Liquid

side

Gas

side

Heating capacity

F

a

n

Dimensions

Height

Width

Depth

Electric characteristic

Input

Cooling

Heating

Cooling

Heating

Current

PMFY-P20VBM-A

PMFY-P20VBM-A

1

PMFY-P25VBM-A

PMFY-P25VBM-A

1

PMFY-P32VBM-A

PMFY-P32VBM-A

1

PMFY-P40VBM-A

PMFY-P40VBM-A

1

Single phase 220V-230V-240V 50Hz / 220V 60Hz

2.2

2.5

0.042

0.042

0.20

0.20

2.8

3.2

0.044

0.044

0.21

0.21

3.6

4.0

0.044

0.044

0.21

0.21

4.5

5.0

0.054

0.054

0.26

0.26

9.3-8.6-8.0-7.3

37-36-34-32

8.7-8.0-7.2-6.5

35-33-30-27

10.7-9.7-8.7-7.7

39-37-35-33

Unit : Galvanized sheets · Standard grills : ABS resin acrylic coating Munsell<0.98Y 8.99/0.63>

230<30>

812<1,000>

395<470>

Cross fin

Line flow fan ✕ 1

0

0.028

Polyethylene sheet

PP honey comb fabric

12.7(1/2")

6.35(1/4")

I.D.26 (PVC pipe VP-20 connectable)

14<3.0>

SPECIFICATION

4-1. Specification

Note 1. Rating conditions

Note 2. The number indicated in < > is just for the grille.

W 3. Air flow and the noise level are indicated as High-Middium 1-Middium 2-Low.

Cooling: Indoor: D.B. 27°C W.B. 19.0°C

Heating: Indoor: D.B. 20°C

outdoor: D.B. 35°C

outdoor: D.B. 7°C W.B. 6°C

6

Page 7

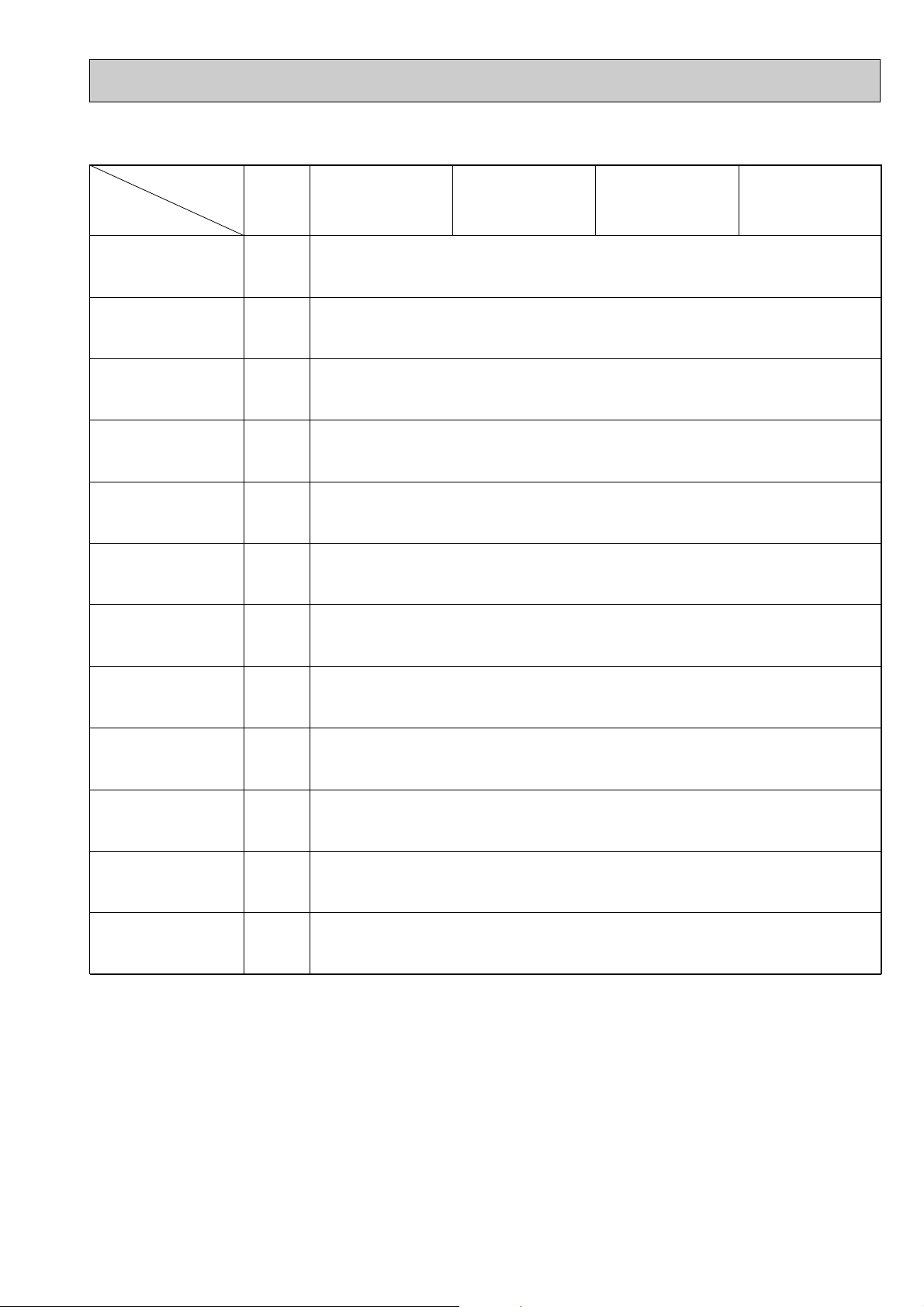

4-2. Electrical parts specifications

Parts name

Model

Symbol

TH21

TH22

TH23

FUSE

MF

MV

DP

DS

LEV

TB2

TB5

TB15

Resistance 0:/15k", 10:/9.6k", 20:/6.3k", 25:/5.2k", 30:/4.3k", 40:/3.0k"

Resistance 0:/15k", 10:/9.6k", 20:/6.3k", 25:/5.2k", 30:/4.3k", 40:/3.0k"

Resistance 0:/15k", 10:/9.6k", 20:/6.3k", 25:/5.2k", 30:/4.3k", 40:/3.0k"

250V 6.3A

Thermistor resistance 0:/6k", 10:/3.9k", 20:/2.6k", 25:/2.2k", 30:/1.8k", 40:/1.3k"

(L, N, ;) 330V 30A

(M1, M2, S) 250V 20A

(1,2) 250V 10A

Liquid pipe thermistor

Gas pipe thermistor

Drain-up mechanism

Drain sensor

Linear expansion valve

PMFY-P20VBM-A

PMFY-P20VBM-A

1

PMFY-P25VBM-A

PMFY-P25VBM-A

1

PMFY-P32VBM-A

PMFY-P32VBM-A

1

PMFY-P40VBM-A

PMFY-P40VBM-A

1

Room temperature

thermistor

Fuse

(Indoor controller board)

Fan motor

Vane motor

Power supply

terminal block

Transmission

terminal block

DC Brushless Motor

8-pole OUTPUT 28W

PN0H28-MA

MSFJC 20M23

12V/380

"

PJV-1046

220-240V 50/60Hz

DC12V Stepping motor drive port

(0~2000pulse)

EDM-402ME

MA-remote controller

terminal block

7

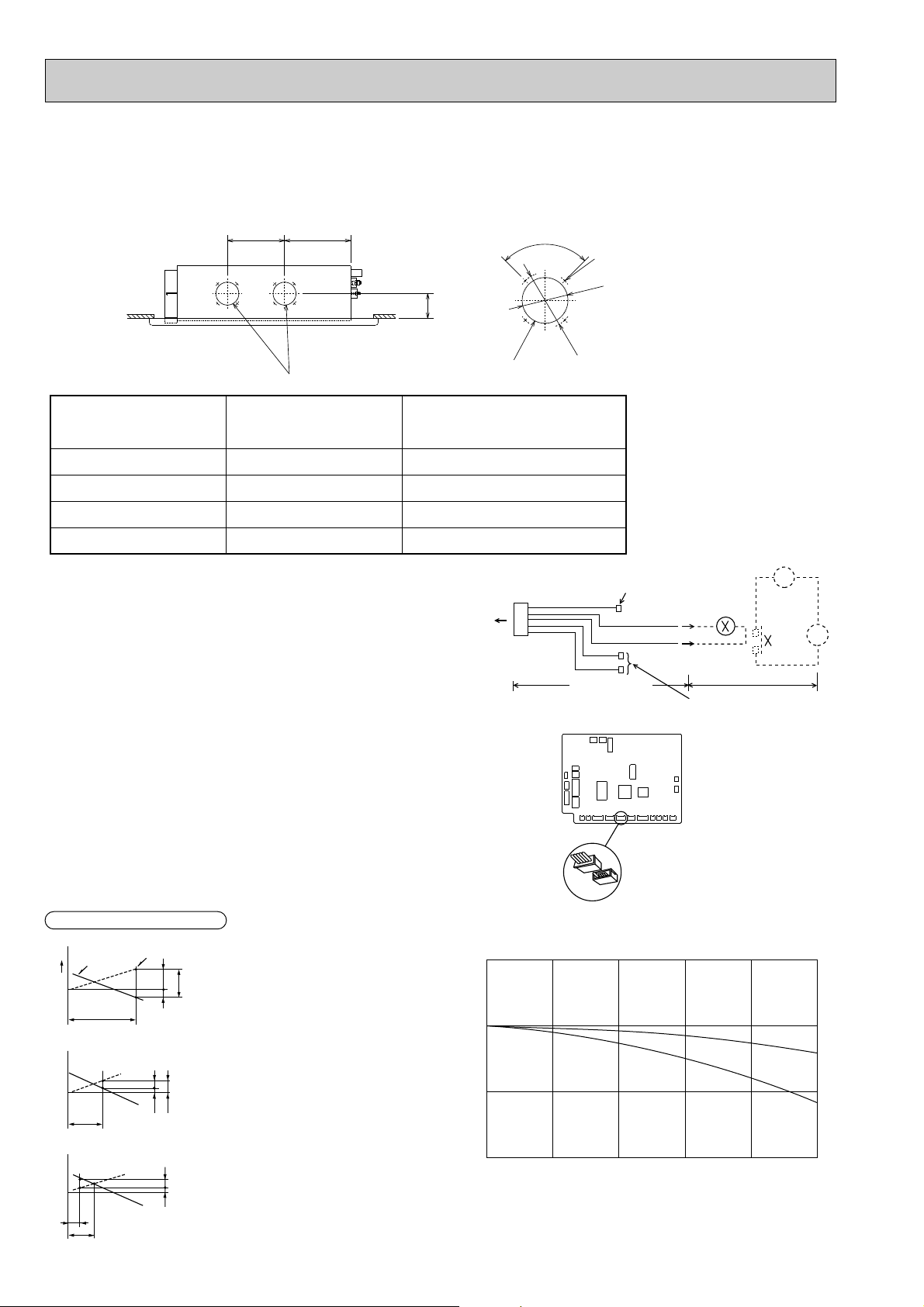

Page 8

4-3. Air capacity taken from outside

50.0

-50.0

-100.0

0.0 0.5 1.0

Air flow (m

3

/min)

2 intakes

1 intake

Characteristic diagram of air capacity taken from outside of PMFY-P·VBM

Static pressure (Pa)

1.5 2.0 2.5

0.0

PMFY-P20VBM-A

PMFY-P20VBM-A

1

PMFY-P25VBM-A

PMFY-P25VBM-A

1

PMFY-P32VBM-A

PMFY-P32VBM-A

1

PMFY-P40VBM-A

PMFY-P40VBM-A

1

8.7m3/min

9.3m3/min

9.3m3/min

10.7m3/min

Max 1.74m3/min

Max 1.86m3/min

Max 1.86m3/min

Max 2.14m3/min

Air flow

(Hi)

Air capacity taken outside

Service Ref.

(Knock out)

4-{2.8

Fresh air intake hole

(Knock out)

Fresh air intake hole

90-

{

122

{

100

108

250 288.5

Installation at site

1

~

CN51

Multiple remote

controller adapter

PAC-SA88HA-E

Indoor controller board

Distance between indoor

controller board and relay

must be within 10m.

Be sure to secure insulation

material by tape and such

5

Green

Yellow

Orange

Connector (5P)

Package side

Multiple remote

controller adapter

PAC-SA88HA-E

Be sure to secure insulation

material by tape and such

CN51

on

indoor unit

board

Red

Brown

MB

Q

0

B

A

C

1

2

3

Curve in the

rigth graphs.

Duct characteristics

at site

Q

A

E C

Q

Qa

A D

PMFY-P·VBM-A series are possible to be taken air from outside.

When taking air from the outside, the duct fan can be used to.

The air capacity should be 20% or less of the air flow SPEC(Hi).

Interlocking operation method with duct fan

(Booster fan)

●Whenever the indoor unit is operating, the duct fun also

operates.

(1)Connect the optional multiple remote controller

adapter(PAC-SA88HA-E)to the connector CN51 on the

indoor controller board.

(2)Drive the relay after connecting the 12V DC relay

between the Yellow and Orange connector lines.

(w)Use a relay under 1W.

MB: Electromagnetic switch power relay for duct fan.

X: Auxiliary relay (12V DC LY-1F)

How to read curves

Q…Planned amount of fresh air intake

A…Static pressure loss of fresh air

intake duct system with air flow

amount Q

B…Forced static pressure at air condi-

tioner inlet with air flow amount Q

C…Static pressure of booster fan with

air flow amount Q

D…Static pressure loss increase

E…Static pressure of indoor unit with

Qa…Estimated amount of fresh air

amount of fresh air intake dust

system for air flow amount Q

air flow amount Q

intake with out D <m3/min>

3

<m

/min>

<Pa>

<Pa>

<Pa>

<Pa>

<Pa>

8

Page 9

4-4. NOISE CRITERION CURVES

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE THRESHOLD OF HEARING

FOR CONTINUOUS NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

PMFY-P20VBM-A

PMFY-P20VBM-A

1

Hi

NOTCH

Mi1

Mi2

Lo

35

SPL(dB)

33

30

27

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

PMFY-P25VBM-A

PMFY-P25VBM-A

1

PMFY-P32VBM-A

PMFY-P32VBM-A

1

Hi

NOTCH

Mi1

Mi2

Lo

37

SPL(dB)

36

34

32

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

PMFY-P40VBM-A

PMFY-P40VBM-A

1

Hi

NOTCH

Mi1

Mi2

Lo

39

SPL(dB)

37

35

33

LINE

UNIT

1.5m

MICROPHONE

CEILING

Ambient temperature 27:

Test conditions are based on JIS Z8731

9

Page 10

5

Details of fresh air intake hole

Knock out

4-{2.8 Burring hole

Fresh air intake hole

110

230

235 or more

110

suspension bolt(M10 or W 3/8)

Panel(grille):PMP-40BM

Installation space required around indoor unit

mounting plate

176

Panel(grille):PMP-40BM

Lower view

60 40

200600200

Top

Air outlet(lower)

46

43

2828

20

26

20

53

69

247

30

Right side

outer line of grille

center of unit

75926

811 suspension bolt pitch74.5

960 ceiling opening20 20

1000 outer side of grille

17.517.5

45

340 suspension bolt pitch

45

430 ceiling opening

470 outer side of grille

20

20

74.5

Terminal block for power supply

Terminal block for transmission

812

96

Left side

Front

drain pan

elect box

Drainage pipe

PVC pipe:VP-20[I.D.{26]

Refrigerant pipe(gas)

O.D.{12.7

Refrigerant

pipe(liquid)

O.D.{6.35

ceiling panel

drain pan

ceiling

panel

O.D.{12.7(1/2")

PVC pipe:VP-20[I.D.{26(1")]

O.D.{6.35(1/4")

O.D.{43

Drainage piping

Gas pipe

Liquid pipe

pipe cover

Refrigerant

piping

1000 outer side of grille

470 outer side of grille

{50

(56)

230

(96)

(20)

(10)

302

254

198

141 759

395

90-

{

122

{

100

108

250 288.5

same line

Terminal block for

MA remote controller

OUTLINES AND DIMENSIONS

PMFY-P20VBM-A, PMFY-P20VBM-A1

PMFY-P20VBM-A, PMFY-P20VBM-A1

PMFY-P32VBM-A, PMFY-P32VBM-A1

PMFY-P40VBM-A, PMFY-P40VBM-A1

Unit : mm

10

Page 11

6

NAME

NAME

SYMBOL

I.B

SYMBOL

MF

MV

DP

DS

TB2

TB5

TB15

TH21

TH22

TH23

LEV

POWER SUPPLY

TRANSMISSION

MA-REMOTE CONTROLLER

ROOM TEMPERATURE DETECTION

(0:/15k", 25:/5.4k")

PIPE TEMPERATURE DETECTION/LIQUID

(0:/15k", 25:/5.4k")

PIPE TEMPERATURE DETECTION/GAS

(0:/15k", 25:/5.4k")

FAN MOTOR

VANE MOTOR

DRAIN WATER LIFTING-UP MACH.

DRAIN SENSOR

TERMINAL

BLOCK

THERMISTOR

LINEAR EXPANSION VALVE

A.B

CN25

CN27

CN32

CN41

CN51

CN52

SW2

SW3

SW4

ZNR

FUSE

X1

T

LED1

LED2

SW1

SW5

SW11

SW12

SW14

HUMIDIFIER

DAMPER

REMOTE SWITCH

HA TERMINAL-A

CENTRALLY CONTROL

REMOTE INDICATION

CAPACITY CODE

MODE SELECTION

MODEL SELECTION

DRAIN PUMP

MODE SELECTION

VOLTAGE SELECTION

ADDRESS SETTING 1ST DIGIT

ADDRESS SETTING 2ND DIGIT

CONNECTION NO.

INDOOR CONTROLLER BOARD

CONNECTOR

SWITCH

VARISTOR

FUSE(6.3A/250V)

AUX.RELAY

TRANSFORMER

POWER SUPPLY(I.B)

POWER SUPPLY(I.B)

CIRCUIT BOARD

SWITCH

[ LEGEND ]

NOTES:

1.At servicing for outdoor unit, always follow the wiring

diagram of outdoor unit.

2.Symbol [S] of TB5 is the shield wire connection.

3.Symbols used in wiring diagram above are,

:terminal block, :connector.

4.The setting of the SW2 dip switches differs in the capacity for

the detail, see the table <w1>.

5.Please set the switch SW5 according to the power supply voltage.

Set SW5 to 240V side when the power supply is 230 and 240 volts.

When the power supply is 220 volts, set SW5 to 220V side.

O

CN32

I.B

TH23

TH21

CN21

(WHT)

LIQUID

CN29

(BLK)

GAS

CN20

(RED)

INTAKE

TH22

CN31

(WHT)

DRAIN

6

4

DS

(SHIELD)

M1 M2

TB5

TO OUTDOOR UNIT

BC CONTROLLER

DC24-30V

CN2M

(BLU)

M-NET

REMOTE CONTROLLER

5

FUSE

MV

LEV

MF

PULL BOX

1

5

1

5

CN51

(WHT)

CENTRALLY

CONTROL

1

HA

CN41

(WHT)

(RED)

ADDRESS

CN81CN42

ADDRESS

(RED)

(WHT)

REMOTE

3

1

CN27

CN25

0FF

65432 109876543211

10N2345

ZNR

X1

(RED)

CND

(YLW)

CNP

0FF

0N

SW2 SW3 SW4

DP

SWC

(RED)

ADDRESS

CN43

(RED)

ADDRESS

CN82

A.B

CONNECTION

SW14

2ND.

DIGIT

1ST.

DIGIT

3RD.

DIGIT

SW11SW12

TB2

L

CN60

(WHT)

LEV

CN6V

(GRN)

VANE

RED

BLU

BLU

BLU

BLU

BRN

ORN

YLW

RED

WHT

BRN

RED

ORN

YLW

GRN

PMFY-P20/25/32/40VBM-A

1

Only

(WHT)

FAN

POWER

D.U.M

4

8

12 345678910

SW1

*See fig:W1

No.

240V

SW5

220V

CN52

(GRN)

REMOTE

INDICATION

SWITCH

RED

BLU

BLU

BLU

N

GRN/YLW

INDOOR UNIT

TO NEXT

(15A) (15A)

BREAKERFUSE

~/N 220-230-240V 50Hz

220V 60Hz

POWER SUPPLY

0N

0FF

654321

0N

0FF

654321

0N

0FF

654321

123 456

0FF

0N

LED1

LED2

PE

123 456

0FF

0N

123 456

0FF

0N

123 456

0FF

0N

0N

0FF

654321

10987

10987

10987

10987

3

1

1

3

431 2 21 3 4 5 6 7 8

1

2

2

1

5

4

3

2

1

1

2

3

4

5

6

6

5

4

3

2

1

1

2

1

2

1

2

1

2

3

21

21 3 654

1

2

3

4

1

2

3

4

5

6

7

8

<W1>

P20VBM

SW2

MODELS

P25VBM

P32VBM

P40VBM

SW3

X1

T

000

1

2

TB15

CN3A

(BLU)

REMOCON

21

TO MA-REMOTE CONTROLLER

DC8.7-13V

ORN

ORN

0FF

10N2345

SW4

PMFY-P20VBM-A

PMFY-P20VBM-A1

PMFY-P25VBM-A

PMFY-P25VBM-A1

PMFY-P32VBM-A

PMFY-P32VBM-A1

PMFY-P40VBM-A

PMFY-P40VBM-A1

WIRING DIAGRAM

11

Page 12

REFRIGERANT SYSTEM DIAGRAM7

Strainer (#50mesh)

Strainer (#100mesh)

Strainer (#100mesh)

Heat exchanger

Room temperature thermistor TH21

Gas pipe

temperature

thermistor TH23

Liquid pipe

temperature

thermistor TH22

Linear expansion valve

w1 w2

Gas pipe

Liquid pipe

Flare connection

Gas pipe

Liquid pipe

[12.7(1/2")

[6.35(1/4")

Item

Service Ref.

Capillary tube w1

Capillary tube w2

O.D.[4.6 o I.D.[3.4 o R200

O.D.[3.6 o I.D.[2.4 o R200

O.D.[3.6 o I.D.[2.4 o R80

PMFY-P20, P25, P32, P40VBM-A

PMFY-P20, P25, P32, P40VBM-A1

PMFY-P20, P25VBM-A

PMFY-P20, P25VBM-A1

PMFY-P32, P25VBM-A

PMFY-P40, P25VBM-A1

PMFY-P20VBM-A PMFY-P25VBM-A PMFY-P32VBM-A PMFY-P40VBM-A

PMFY-P20VBM-A1 PMFY-P25VBM-A1 PMFY-P32VBM-A1 PMFY-P40VBM-A1

12

Page 13

8

Parts name Check points

Disconnect the connector then measure the resistance using a tester.

(Surrounding temperature 10:~30:)

Disconnect the connector then measure the resistance valve using a tester.

Refer to the next page for a detail.

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20:~30:)

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20:)

Measure the resistance after 3 minutes have passed since the power supply was intercepted.

(Surrounding temperature 0:~60:)

Vane motor

Linear expansion

valve

Drain-up

mechanism

Drain sensor

(Refer to the next page for a detail.)

(Refer to the next page for a detail.)

(Refer to the next

page for a detail.)

Room temperature

thermistor (TH21)

Liquid pipe temperature

thermistor (TH22)

Gas pipe temperature

thermistor (TH23)

1

2

Blue

Blue

1

2

3

Normal

4.3k"~9.6k"

Abnormal

Open or short

Abnormal

Open or short

Normal

0.6k"~6.0k"

Abnormal

Open or short

Normal

150k" i10%

(1)-(5)

White-Red

(2)-(6)

Yellow-Blown

(3)-(5)

Orange-Red

(4)-(6)

Blue-Brown

NormalConnector Abnormal

380" i7% Open or short

Normal Abnormal

400"~480" Open or short

Orange

Red

White

Blue

Brown

Yellow

3

6

1

5

4

2

3

6

1

5

4

2

MV

M

Orange

Red

Brown

Brown — Yellow

Brown — Red

Brown — Orange

Brown — Green

Green

Yellow

31

5

4

2

TROUBLE SHOOTING

8-1. How to check the parts PMFY-P20/25/32/40VBM-A

PMFY-P20/25/32/40VBM-A1

13

Page 14

<Thermistor Characteristic graph>

-20 0 20 40 60 80

< Thermistor for drain sensor >

Temperature (:)

0

1

2

3

4

5

6

7

8

9

10

Resistance (K")

Thermistor for

lower temperature

Room temperature thermistor(TH21)

Liquid pipe temperature thermistor(TH22)

Gas pipe temperature thermistor(TH23)

Thermistor R0=15k' ± 3%

Fixed number of B=3480k' ± 2%

< Thermistor for lower temperature >

50

40

30

Rt=15exp { 3480( ) }

1

273+t

1

273

0: : 15k'

10: : 9.6k'

20: : 6.3k'

25: : 5.2k'

30: : 4.3k'

40: : 3.0k'

Thermistor R0=6.0k' ± 3%

Fixed number of B=3390k' ± 2%

Rt=6exp { 3390( ) }

1

273+t

1

273

0: : 6 k'

10: : 3.9k'

20: : 2.6k'

25: : 2.2k'

30: : 1.8k'

40: : 1.3k'

Resistance (K")

20

10

0

-20 -10 0 10 20 30 40 50

Temperature (:)

Linear expansion valve

① Operation summary of the linear expansion valve.

• Linear expansion valve open/close through stepping motor after receiving the pulse signal from the indoor controller board.

• Valve position can be changed in proportion to the number of pulse signal.

<Connection between the indoor controller board and the linear expansion valve>

Controller board

Relay connector

Linear expansion valve

Blue

4

M

5

1

Red

White

Note : Since the number of the connector at the controller board side and the relay connector are different, follow the color of

the lead wire.

Brown

6

Yellow

2

3

Orange

[4

[3

[2

[1

5

1

3

4

6

Brown

Red

Blue

Orange

Yellow

White

Connector (CN60)

14

DC12V

62

5

4

3

2

1

Drive circuit

[4

[3

[2

[1

Page 15

<Output pulse signal and the valve operation>

D

A

E

B

C

Open

Extra tightning (80~100pulse)

Pulse number

2000 pulse

Opening a valve

all the way

Close

Valve position (capacity)

Thermistor

(Liquid pipe)

Linear

expansion

valve

150

'

10%.

Output

(Phase)

{1

{2

{3

{4

Linear expansion valve operation

➁

1

ON

ON

OFF

OFF

2

OFF

ON

ON

OFF

Output

3

OFF

OFF

ON

ON

4

ON

OFF

OFF

ON

Closing a valve : 1 → 2 → 3 → 4 → 1

Opening a valve : 4 → 3 → 2 → 1 → 4

The output pulse shifts in above order.

❈ 1. When linear expansion valve operation stops, all output phase

become OFF.

2. At phase interruption or when phase does not shift in order,

motor does not rotate smoothly and motor will locks and vibrates.

❈ When the switch is turned on, 2200 pulse closing valve signal

will be send till it goes to

A point in order to define the valve posi-

tion.

When the valve move smoothly, there is no noise or vibration

occurring from the linear expansion valve : however, when the

pulse number moves from E to A or when the valve is locked,

more noise can be heard than normal situation.

❈ Noise can be detected by placing the ear against the screw

driver handle while putting the screw driver to the linear expansion valve.

Trouble shooting

➂

Symptom

Operation circuit fail-

ure of the micro

processor.

Linear expansion

valve mechanism is

locked.

Short or breakage of

the motor coil of the

linear expansion

valve.

Valve doesn't close

completely (thermistor leaking).

Wrong connection of

the connector or

contact failure.

Check points

Disconnect the connector on the controller board, then connect LED for checking.

Pulse signal will be sent out for 10 seconds as soon as the

main switch is turn on. If there is LED with lights on or lights

off, it means the operation circuit is abnormal.

Motor will idle and make ticking noise when motor is operated

while the linear expansion valve is locked. This ticking sound

is the sign of the abnormality.

Measure the resistance between the each coil (red-white,

red-orange, brown-yellow, brown-blue) using a tester. It is

normal if the resistance is in the range of

To check the linear expansion valve, operate the indoor unit

in fan mode and at the same time operate other indoor units

in cooling mode, then check the pipe temperature <liquid

controller, it means the valve is not closed all the way. It is

not necessary to exchange the linear expansion valve, if the

leakage is small and not making any trouble.

Check the color of lead wire and missing terminal of the connector.

LED1k"

pipe temperature> of the indoor unit by the

outdoor multi controller board operation

monitor. During fan operation, linear

expansion valve is closed completely and if

there are some leaking, detecting temperature of the thermistor will go lower. If the

detected temperature is much lower than

the temperature indicated in the remote

6

5

4

3

2

1

Countermeasures

Exchange the indoor controller board at drive circuit

failure.

Exchange the linear

expansion vale.

Exchange the linear

expansion valve.

If large amount of thermistor is leaked, exchange the

linear expansion valve.

Disconnect the connector

at the controller board,

then check the continuity.

15

Page 16

8-2. TROUBLE SHOOTING

Notes

· High voltage is applied to the connecter (FAN) for the fan motor. Give attention to the service.

· Do not pull out the connector (Fan) for the motor with the power supply on.

(It causes trouble of the control

p.c.board)

Self check

Conditions : The indoor fan cannot turn around.

N0

Wiring contact check

Contact of fan motor connector (FAN)

Contact of power supply cable.

Fan motor check

Measure the resistance between the fan motor connecter 1(+) and 3( ).

(With the connecter is pulled out from the

p.c.board)

Power supply check

Check the voltage in the indoor control

p.c.board

Approx. 310~340V between the connecter (FAN) 1(+) and 3( ).

Approx. 1~3V between the connecter (FAN) 5(+) and 3( ).

The voltage between the 5 and 3 is a value during the fan motor operation.

In the case that the fan motor off, the voltage is 0V.

Fan motor position sensor signal check

Turn around the fan motor more than one revolution slowly, and check

the voltage between the connecter (FAN) 6(+) and 3( ).

Check method of indoor fan motor (fan motor / control p.c.board)

Wiring recovery

Trouble of the fan motor Replacement of the motor

Is the resistance 1M" or more?

Trouble of the indoor

p.c.board

Replacement of the indoor control

p.c.board

Trouble of the fan motor

Replacement of the motor

Dose the voltage repeat DC0V and DC15V?

Replacement of the indoor control

p.c.board

Is the voltage normal?

Was contact caused good?

Yes

1

2

N0

Yes

N0

Yes

N0

Yes

16

Page 17

8-3. FUNCTION OF DIP SWITCH

Switch Function Remarks

<At delivery>

ON

OFF

1 2 3 4 5 6 7 8 9

10

Address board

Operation by switch

ON OFF

(

w1

) Fan operation at Heating

mode.

(

w2

) Heater thermo ON is

operating.

(

w3

) SW 1-7=OFF, SW 1-8=ON

→ Setting air flow.

SW 1-7=OFF, SW 1-8=ON

→ Indoor fan stop.

Pole

Bult-in remote controller

Provided

2,500hr

Effective

Thermostat ON signal indication

Always operated while the heat in ON w1

Low w3

Setting air flow

Effective

Effective

Filter crogging detection

Filter cleaning sign

Fresh air intake

Remote indication switching

Humidifier control

Air flow at

Heat thermostat OFF

Auto restart function

Power source ON/OFF

Indoor unit

Not provided

100hr

Not effective

Fan output indication

Operated depends on the condition w2

Extra low w3

Depends on SW1-7

Not effective

Not effective

Cooling only

Available

Available

Available

Second setting

Horizontal angle

Effective

Not effective

9deg. (5deg.) w6

15deg.

Heat pump / Cool only

Louver

Vane

Vane swing function

Vane horizontal angle

Vane cooling limit angle setting w4

Heating 4deg. up

Target superheat setting w5

Target sub cool setting w5

Heat pump

Not available

Not available

Not available

First setting

Down B, C

Not effective

Effective

6deg. (2deg.) w6

10deg.

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

SW1

Mode

Selection

SW2

Capacity

code

setting

1~6

1~5

SW3

Function

Selection

SW4

Unit

Selection

Indoor linear expansion

valve opening change

Thermistor <intake temperature

detection> position

<At delivery>

ON

OFF

1 2 3 4 5 6 7 8 9

10

Indoor controller board

( w4 ) At cooling mode, each

angle can be used only

1 hour.

(

w6

)

The numerical valve in

the parentheses shows

the case which the R22

outdoor unit is connected.

Indoor controller board

<At delivery>

Set while the unit is off.

Set while the unit is off.

Set while the unit is off.

Set for each capacity.

Indoor controller board

(

w5

) SW 3-9 setting

PMFY-P20, P25VBM

(1)=ON

PMFY-P32, P40VBM

(1)=OFF

SW 3-10 setting

PMFY-P20, P25VBM

(1)=ON

PMFY-P32, P40VBM

(1)=OFF

ON

OFF

1 2 3 4 5

ON

OFF

1 2 3 4 5

ON

OFF

MODELS

PMFY-P20VBM

PMFY-P20VBM

1

PMFY-P25VBM

PMFY-P25VBM

1

PMFY-P32VBM

PMFY-P32VBM

1

PMFY-P40VBM

PMFY-P40VBM

1

SW 2 MODELS SW 2

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF

1 2 3 4 5

ON

OFF

1 2 3 4 5

PMFY-P20/25/32/40VBM PMFY-P20/25/32/40VBM1

PMFY-P20/25/32/40VBM PMFY-P20/25/32/40VBM1

17

Page 18

0

5

9

4

8

3

7

2

6

1

0

5

9

4

8

3

7

2

6

1

0

5

9

4

8

3

7

2

6

1

0

5

9

4

8

3

7

2

6

1

0

8

F

7

E

6

D

5

C

4

B

3

A

2

9

1

0

8

F

7

E

6

D

5

C

4

B

3

A

2

9

1

220V 240V

Rotary switchRotary switch

SW14

Connection

No.

setting

SW5

Voltage

Selection

SW11

1st digit

address

setting

SW12

2nd digit

address

setting

2

Address setting should be done when M-NET

remote controller is being used.

This is the switch to be used when the indoor

unit is operated with R2 series outdoor unit

as a set.

If the unit is used at the 230V or 240V area,

set the voltage to 240V.

If the unit is used at the 220V, set the voltage

to 220V.

Address can be set while the

unit is stopped.

Address board

<At delivery>

Address board

<At delivery>

Address board

SW1210SW11

1

SW12 SW11

SW14

SW14

<At delivery>

220V 240V

Switch Pole RemarksOperation by switch

18

Page 19

9

DISASSEMBLY PROCEDURE

PMFY-P32VBM-A1

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

Be careful on removing heavy parts.

1. Removing the intake grille

Opening the air intake grille

(1) Press the of the air intake grille.(See figure 1)

(2) Put your figure on the both end of nut of the air intake grille

and put it down after the grille clicked.

Removing the air intake grille

(1) Press the of air intake grille, and pull down the both

end of nut with your fingers after the grille clicked.

(See figure 1)

(2) Pull out the handle of air intake grille strong toward you.

(See figure 2)

(3) Draw the string of air intake grille to prevent the grille from

dropping.(see figure 3)

PUSH

PUSH

Photo 1

Air filter

Figure 1

Figure 2

Figure 3

19

Page 20

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

2. Removing the electrical parts box

(1) Remove the panel.

(2) Remove the address board cover.

(3) Remove the electrical parts cover.

(4) Disconnect the connectors of

fan motor, vane motor,

drain pump, room temperature thermistor,

pipe temperature thermistor,

condenser/evaporator temperature thermistor,

and drain sensor on the electrical controller board.

(5) Disconnect the lead wire and earth wire from terminal

block.

(6)Remove the electrical parts box.

3. Removing the nozzle

Note when the nozzle is removed

·The insulation material (white) which prevents water

drop is mounted to the side of vane motor, remove the

insulation material before removing nozzle.

(See figure 4)

·After completing the service, re-mount the insulation

material as before as shown in right figure.

·After service, mount the double layer insulation

without fail.

The hard material side should be faced to the nozzle.

(See figure 4)

(1) Remove the panel.

(2) Remove the room temperature thermistor.

(3) Unhook the claw in the middle of nozzle and remove the

drain pan. (5 screws) (See photo 2)

(4) Remove the nozzle side of the heat exchanger.(2 screws)

(5) Remove the address board cover.

(6) Remove the electrical parts cover.

(7) Disconnect the connector of vane motor.

(8) Remove the insulation material (white) on the right side of

nozzle.

(9)Remove the nozzle. (6 screws)

Photo 2

Drain pan

Photo 3

Photo 4

Nozzle

Room temperature thermistor

Figure 4

Hard side of insulation

Nozzle

Vane motor

Claw in middle

of nozzle

Insulation material

Nozzle

Heat exchanger

Soft side of insulation

Electrical parts

Electrical parts

cover

Address board

cover

Vane motor

4. Removing the vane motor

(1) Remove the nozzle. Refer to above-mentioned (3)

Removing the nozzle.

(2) Remove the vane motor.

20

Photo 5

Vane motor

Page 21

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

5. Removing the drain pump

(1) Remove the panel.

(2) Unhook the claw in the middle of nozzle and remove the

drain pan.

(3) Remove the address board cover.

(4) Remove the electrical parts cover.

(5) Disconnect the connector of drain pump.

(6) Remove the drain hose.

(7) Remove the drain pump.(2 screws)

6. Removing the fan motor and line flow fan

(1) Remove the panel.

(2) Unhook the claw in the middle of nozzle and remove the

drain pan.

(3) Unscrew 2 screws at the nozzle side of the heat exchanger.

(4) Remove the address board cover.

(5) Remove the electrical parts cover.

(6) Disconnect the connector of vane motor,fan motor and

drain pump.

(7) Remove the nozzle side of the heat exchanger.(2 screws)

(8) Remove the nozzle.

(9) Remove the drain pump.

(10) Unscrew 2 screws in the motor support.

(11) Remove the fan motor and line flow fan (The fan motor

and line flow fan can be removed without removing the

heat exchanger.)

Photo 6

Photo 7

Drain sensor

Line flow fan

Drain pump

Fan motor

Fan motor

7. Removing the thermistor<Intake temperature detector>

(1) Remove the panel.

(2) Remove the address board cover.

(3) Remove the electrical parts cover.

(4) Remove the thermistor <intake temperature detector>

(5) Disconnect the lead wire from the cord clamp (5 points)

(6) Disconnect the connector (CN20) on the indoor controller

board.

8. Removing the thermistor<Liquid pipe temperature detector>

<Gas pipe temperature detector>

(1) Remove the panel.

(2) Remove the address board cover.

(3) Remove the electrical parts cover.

(4) Remove the drain pan.

(5) Remove the thermistor <Gas pipe temperature detector>

/<Liquid pipe temperature detector>.

(6) Disconnect the lead wire from the cord clamp

(7) Disconnect the connector (CN21)/(CN29) on the indoor

controller board.

21

Page 22

PARTS LIST10

1

2

3

4

5

6

7

8

9

10

11

12

13

T7W E11 003

R01 E00 055

—

R01 E00 099

RO1 E01 054

RO1 E01 500

R01 E02 500

TW7 E01 691

R01 E00 054

R01 E00 648

R01 E00 044

R01 E00 096

—

1

2

2

2

2

1

1

1

2

1

2

1

1

(DT88D360H03)

AIR OUTLET GRILLE

LATCH

HANGER

PANEL HOOK

GRILLE CATCH

L.L.FILTER

L.L.FILTER

INTAKE GRILLE

GRILLE CATCH

RECEIVER COVER

MAGNET

SCREW CAP

REMOTE CONTROLLER

No. Part No. Part Name Specification

Q'ty/set

Price

Unit

Amount

Remarks

(Drawing No.)

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

PMFY-P20/P25

P32/P40

VBM-A

VBM-A

1

PAR-20MAA R.B

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECKTEST

TEMP.

TIMER SET

PANEL PARTS

PMFY-P20VBM-A

PMFY-P20VBM-A1

PMFY-P25VBM-A

PMFY-P25VBM-A1

PMFY-P32VBM-A

PMFY-P32VBM-A1

PMFY-P40VBM-A

PMFY-P40VBM-A1

11

12

1

11

2

3

4

5

2

3

4

10

5

6

9

7

8

13

22

Page 23

FUNCTIONAL PARTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

PMFY-P · VBM-A

PMFY-P · VBM-A

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

TH21

TH22

LEV

TH23

MV

DS

DP

MF

(DT00A478G64)

(RG02L277H02)

(RG00L311G07)

CABINET

ADDRESS BOARD COVER

BEARING MOUNT

SLEEVE BEARING

LINE FLOW FAN

STABILIZER ASSY

VANE SLEEVE

HEAT EXCHANGER

HEAT EXCHANGER

DRAIN PAN

DRAIN PAN

THERMISTOR

GUIDE VANE

THERMISTOR

LINEAR EXPANSION VALVE

THERMISTOR

VANE

VANE MOTOR

CASING

SENSOR HOLDER

DRAIN SENSOR

DRAIN PUMP

MOTOR SUPPORT

FAN MOTOR

MOTOR MOUNT

DRAIN PIPE

CONTROL BOX COVER

SCREW ASSY

ROOM

LIQUID

GAS

No.

Part No. Part Name Specification

Q'ty/set Price

Unit

Amount

Remarks

(Drawing No.)

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

20/25 32/40 20/25 32/40

—

—

R01 22A 102

R01 005 103

R01 E02 114

R01 E00 079

R01 E00 092

T7W E39 480

T7W E40 480

R01 E04 529

R01 E10 529

R01 E00 202

R01 E00 038

R01 E01 202

R01 E00 401

R01 E03 202

R01 E01 002

R01 E01 223

R01 E00 110

R01 31K 241

R01 E01 266

T7W E02 355

R01 E00 130

R01 E03 220

R01 E01 105

R01 E00 527

—

R01 E01 673

PMFY-P20VBM-A

PMFY-P20VBM-A1

PMFY-P25VBM-A

PMFY-P25VBM-A1

PMFY-P32VBM-A

PMFY-P32VBM-A1

PMFY-P40VBM-A

PMFY-P40VBM-A1

25

24

1

2

23

19

3

4

22

21

18

20

5

6

7

8

9

10

Part number that is circled is not shown in the figure.

17

16

15

14

13

12

11

23

Page 24

ELECTRICAL PARTS

1

2

3

4

5

6

7

8

1

1

1

1

1

1

1

1

(RG02B337G10)

TB2

TB5

TB15

A.B

FUSE

I.B

I.B

CONTROL BOX

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

ADDRESS BOARD

CABLE ASSY

FUSE

INDOOR CONTROLLER BOARD

INDOOR CONTROLLER BOARD

3P (L,N,;)

3P (M1,M2,S)

2P(1,2)

250V 6.3A

with POWER BOARD

with POWER BOARD

No. Part No. Part Name

Specification

Q'ty/set

Price

Unit

Amount

Remarks

(Drawing No.)

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

PMFY-P20/P25

P32/P40

VBM-A1

1

1

1

1

1

1

1

1

VBM-A

—

T7W A14 716

T7W E00 716

T7W 515 716

T7W B01 294

R01 E00 304

T7W 520 239

T7W E11 310

T7W E16 310

CNP

FAN

CN60

CN6V

RG79L094H01

PMFY-P20VBM-A

PMFY-P20VBM-A1

PMFY-P25VBM-A

PMFY-P25VBM-A1

PMFY-P32VBM-A

PMFY-P32VBM-A1

PMFY-P40VBM-A

PMFY-P40VBM-A1

8

1

7

2

3

4

cCopyright 2001 MITSUBISHI ELECTRIC ENGINEERING CO., LTD.

Distributed in Jun. 2001. No. OC248 REVISED EDITION-A PDF 1070

Reprinted in Apr. 2001. No. OC248 10

Reprinted in Mar. 2001. No. OC248 25

Distributed in Feb. 2001. No. OC248 PDF 685

Made in Japan

HEAD OFFICE : MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO100-8310, JAPAN

5

6

New publication, effective Jun. 2001

Specifications subject to change without notice

Loading...

Loading...