Mitsubishi PMFY-P06NBMU-E1, PMFY-P08NBMU-E, PMFY-P06NBMU-ER5, PMFY-P06NBMU-E#2, PMFY-P06NBMU-ER3 Technical & Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Indoor unit

[Model names] [Service Ref.]

PMFY-P06NBMU-E

PMFY-P08NBMU-E

PMFY-P06NBMU-E PMFY-P06NBMU-E

PMFY-P06NBMU-E#2 PMFY-P06NBMU-ER3

PMFY-P06NBMU-ER4 PMFY-P06NBMU-ER5

PMFY-P08NBMU-E PMFY-P08NBMU-E

April 2012

No. OC341

REVISED EDITION-F

R410A / R22

1

1

Revision:

• PMFY-P06/08/12/15NBMUER5 have been added in

REVISED EDITION-F.

• Some descriptions have

been modified.

PMFY-P12NBMU-E

PMFY-P15NBMU-E

PMFY-P08NBMU-E#2 PMFY-P08NBMU-ER3

PMFY-P08NBMU-ER4 PMFY-P08NBMU-ER5

PMFY-P12NBMU-E PMFY-P12NBMU-E

1

PMFY-P12NBMU-E#2 PMFY-P12NBMU-ER3

PMFY-P12NBMU-ER4 PMFY-P12NBMU-ER5

PMFY-P15NBMU-E PMFY-P15NBMU-E

1

PMFY-P15NBMU-E#2 PMFY-P15NBMU-ER3

PMFY-P15NBMU-ER4 PMFY-P15NBMU-ER5

CONTENTS

1. TECHNICAL CHANGES

2. FEATURES

3. PART NAMES AND FUNCTIONS

4. SPECIFICATION

5. OUTLINES AND DIMENSIONS

6. WIRING DIAGRAM

7.

REFRIGERANT SYSTEM DIAGRAM

8. MICROPROCESSOR CONTROL

9. TROUBLESHOOTING

10. DISASSEMBLY PROCEDURE

11. RoHS PARTS LIST

...........................................

• Please void OC341

REVISED EDITION-E.

NOTE:

• This manual describes

only service data of the

indoor units.

• RoHS compliant products

have <G> mark on the

spec name plate.

• For servicing RoHS compliant products, refer to the

RoHS PARTS LIST.

.......................

........

...................................

............

.............................

........................

...........

.............................

....

.......

10

14

15

22

31

35

2

3

3

5

9

INDOOR UNIT

Use the specifi ed refrigerant only

OC341F

Never use any refrigerant other than that specifi ed.

Doing so may cause a burst, an explosion, or fi re when the unit is being used, serviced, or disposed of.

Correct refrigerant is specifi ed in the manuals and on the spec labels provided with our products.

We will not be held responsible for mechanical failure, system malfunction, unit breakdown or accidents caused

by failure to follow the instructions.

1

PMFY-P06NBMU-ER4 → PMFY-P06NBMU-ER5

PMFY-P08NBMU-ER4 → PMFY-P08NBMU-ER5

PMFY-P12NBMU-ER4 → PMFY-P12NBMU-ER5

PMFY-P15NBMU-ER4 → PMFY-P15NBMU-ER5

• INDOOR CONTROLLER BOARD (I.B) has been changed. (S/W version up)

PMFY-P06NBMU-ER3 → PMFY-P06NBMU-ER4

PMFY-P08NBMU-ER3 → PMFY-P08NBMU-ER4

PMFY-P12NBMU-ER3 → PMFY-P12NBMU-ER4

PMFY-P15NBMU-ER3 → PMFY-P15NBMU-ER4

1. DRAIN PIPE has been changed.

2. JOINT SOCKET (FOR DRAIN PIPE) has been added.

PMFY-P06NBMU-E#2 → PMFY-P06NBMU-ER3

PMFY-P08NBMU-E#2 → PMFY-P08NBMU-ER3

PMFY-P12NBMU-E#2 → PMFY-P12NBMU-ER3

PMFY-P15NBMU-E#2 → PMFY-P15NBMU-ER3

• CONTROLLER BOARD (I.B) has been changed. (It is possible to extract a signal for an external heater.)

TECHNICAL CHANGES

PMFY-P06NBMU-E1 → PMFY-P06NBMU-E#2

PMFY-P08NBMU-E1 → PMFY-P08NBMU-E#2

PMFY-P12NBMU-E1 → PMFY-P12NBMU-E#2

PMFY-P15NBMU-E1 → PMFY-P15NBMU-E#2

1. CONTROLLER BOARD (I.B) has been changed.

2. PANEL has been changed.

PMP-16BMU → PMP-16BMUW

(White : 0.98Y 8.99/0.63) (Pure white : 6.4Y 8.9/0.4)

3. FAN MOTOR (MF) has been changed.

4. THERMISTORs (TH22, TH23) have been changed.

PMFY-P06NBMU-E → PMFY-P06NBMU-E1

PMFY-P08NBMU-E → PMFY-P08NBMU-E1

PMFY-P12NBMU-E → PMFY-P12NBMU-E1

PMFY-P15NBMU-E → PMFY-P15NBMU-E1

1. FAN MOTOR (MF) has been changed.

2. CONTROLLER BOARD (I.B) has been changed.

2

2

OC341F

Models Cooling capacity / Heating capacity

PMFY-P06NBMU-E 6,000 / 6,700 Btu/h

PMFY-P08NBMU-E 8,000 / 9,000 Btu/h

PMFY-P12NBMU-E 12,000 / 13,500 Btu/h

PMFY-P15NBMU-E 15,000 / 17,000 Btu/h

FEATURES

Indoor Unit

1. Fresh Air Intake

Air recycled indefinitely can become stale and stagnant with air quality suffering significantly. Fresh air is the

answer and it is for this reason that the PMFY- series takes in air directly from outdoors. This fresh air intake

allows you to enjoy the comfort of crisp, refreshing air in the confines of your living or working space.

2. Light and Compact

The main unit weighs only 31 lb. and the panel merely 7 lb. This makes the PMFY- series one of the light-

est in the industry. The unit size is also quite small, having been standardized to a strikingly compact 33-5/8

inch. All of this make the chore of installation and maintenance that much simpler and easier.

3

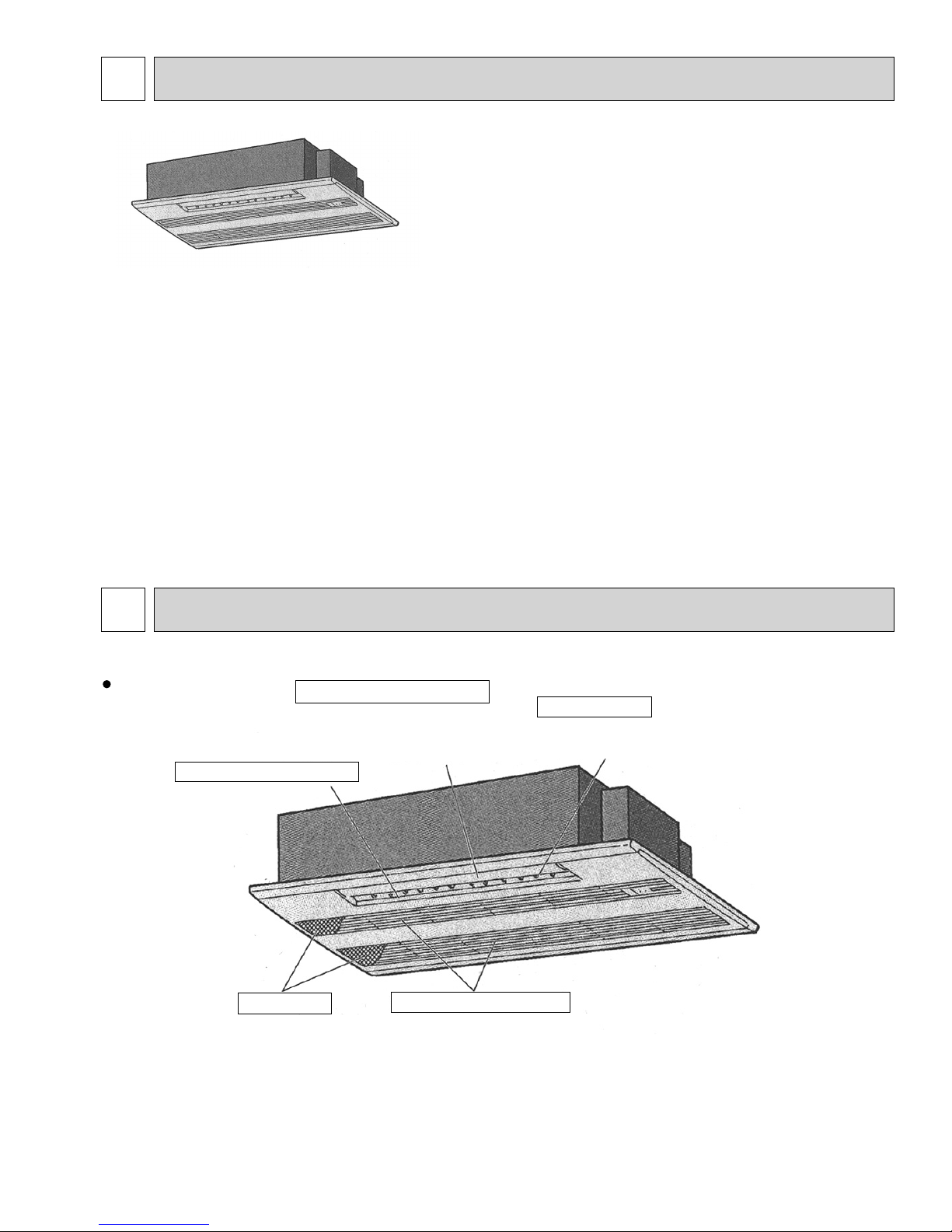

PART NAMES AND FUNCTIONS

Indoor Unit

Horizontal Air Outlet

Filters

Remove dust and pollutants

from return air.

Auto Air Swing Vane

Disperses airflow up and

down and adjusts the angle

of airflow direction.

Air intake

Returns air from room.

Guide vane

Air flow can be changed to horizontal

by moving the guide vane to the left or right.

3

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Temperature setting buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

cover

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

T o return operation

number

Ventilation button

( Operation button)

To go to next operation

number

Built-in temperature sensor

Wired remote controller

OC341F

Once the controllers are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

Note:

The phrase "Wired remote controller" in this manual refers only to the PAR-21MAA.

If you need any information for the other remote controller, please refer to either the installation manual or initial setting manual which are included in

remote controller's box.

Display Section

For the purposes of this explanation,

all parts of the display are shown.

During actual operation, only

the relevant items will be lit.

Identifies the current operation

Shows the operating mode, etc.

*Multilanguage display is available.

“Centrally Controlled” indicator

Indicates that operation from the

remote controller has been prohibited by a master controller.

“Timer is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, the time to be

switched off is shown.

Up/Down Air Direction indicator

Shows the direction of the

outcoming airflow.

“One Hour Only” indicator

Displays if the airflow is set to

low or downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off in one hour,

when the airflow direction also

changes.

°F°C

TIME SUN MON TUE WED THU FRI SAT

TIMER

AFTER

ONLY1Hr.

ERROR CODE

°F°C

Hr

AFTER

Room Temperature display

Shows the room temperature. The room

temperature display range is 46~102°F.

The display blinks if the temperature

is less than

Louver display

Indicates the action of the swing louver.

Does not appear if the louver is not

running.

(Power On indicator)

Indicates that the power is on.

4

ON

OFF

FUNCTION

FILTER

WEEKLY

SIMPLE

AUTO OFF

46°F or 102°F

or more.

“Sensor” indication

Displays when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

To be displayed on when it is time to

clean the filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

4

OC341F

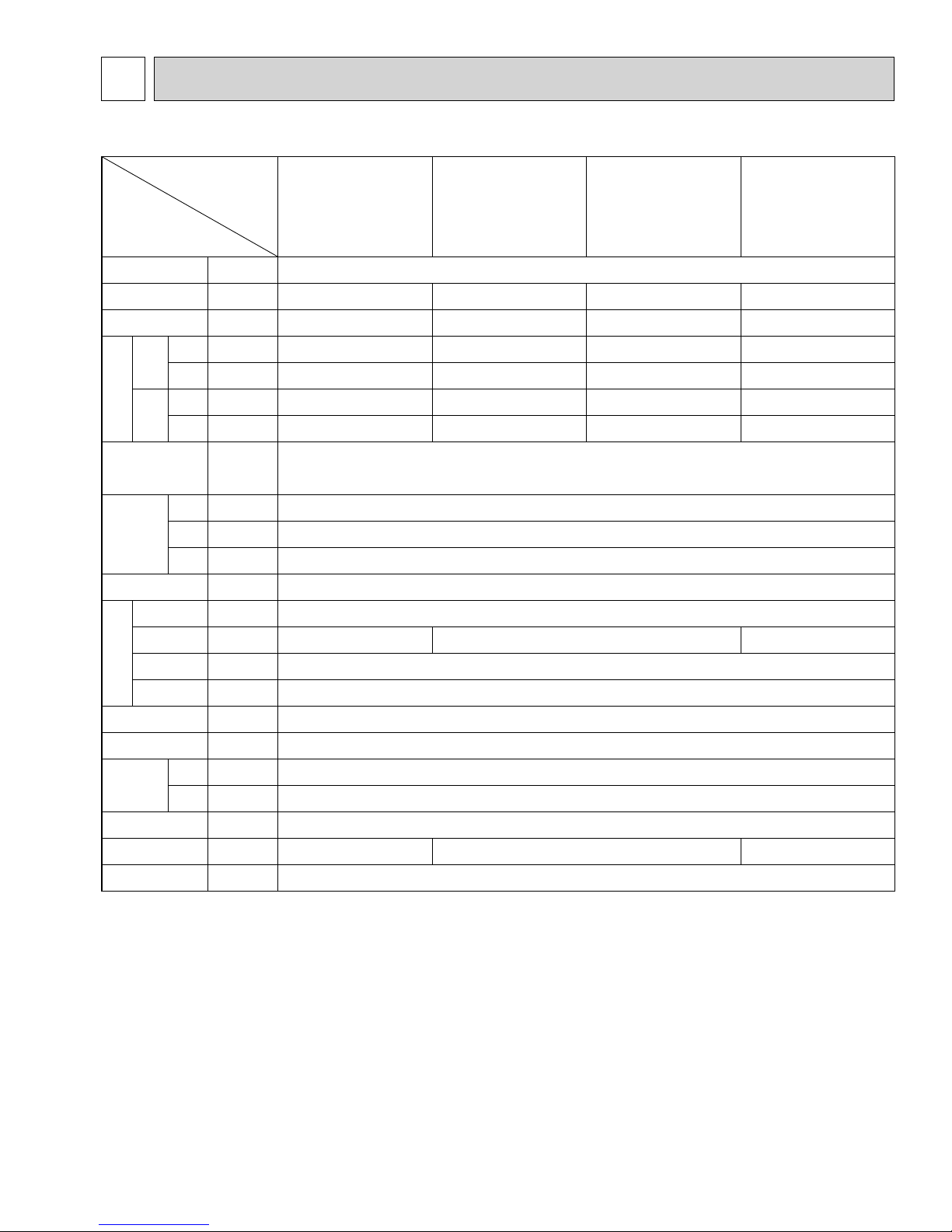

SPECIFICATION

4-1. SPECIFICATIONS

Service ref.

PMFY-P06NBMU-E

PMFY-P06NBMU-E#2

PMFY-P06NBMU-E

Item

PMFY-P06NBMU-ER3

PMFY-P06NBMU-ER4

PMFY-P06NBMU-ER5

Power V · H

Cooling

capacity Btu/h 6,000 8,000 12,000 15,000

Z

PMFY-P08NBMU-E

PMFY-P08NBMU-E

1

PMFY-P08NBMU-E#2

PMFY-P08NBMU-ER3

PMFY-P08NBMU-ER4

PMFY-P08NBMU-ER5

Single phase 208-230V 60Hz

PMFY-P12NBMU-E

PMFY-P12NBMU-E

1

PMFY-P12NBMU-E#2

PMFY-P12NBMU-ER3

PMFY-P12NBMU-ER4

PMFY-P12NBMU-ER5

1

PMFY-P15NBMU-E

PMFY-P15NBMU-E

1

PMFY-P15NBMU-E#2

PMFY-P15NBMU-ER3

PMFY-P15NBMU-ER4

PMFY-P15NBMU-ER5

Heating capacity

Cooling

Btu/h 6,700 9,000 13,500 17,000

kW 0.042 0.042 0.044 0.054

Input

Heating

Cooling

kW 0.042 0.042 0.044 0.054

A 0.20 0.20 0.21 0.26

Current

Electric characteristic

Heating

Exterior

(munsell symbol)

Height

Dimensions

Width

Depth

A 0.20 0.20 0.21 0.26

—

Munsell <0.98Y 8.99/0.63> (PMFY-P·NBMU-E

Unit : Galvanized sheets · Standard grilles : ABS resin acrylic coating

(1)

) / <6.4Y 8.9/0.4> (PMFY-P·NBMU-E#2/ER3/ER4/ER5)

in. 9-1/16<1-3/16>

in. 31-15/16<39-3/8>

in. 15-9/16<18-1/2>

Heat exchanger — Cross fi n

Fan × No — Line fl ow fan × 1

Air fl ow W3 CFM 230-250-280-300 250-280-300-320 270-300-340-370

External

static pressure

Fan

Fan motor

output

in W.G. 0

kW 0.028

Insulator — Polyethylene sheet

Air fi lter — PP honey comb fabric

Pipe

dimensions

Gas

side

Liquid

side

Field drain pipe size

[in. 1/2

[in. 1/4

[

in. 1 O.D. (PVC pipe VP-20 connectable)

Noise level W3 dB 27-30-33-35 32-34-36-37 33-35-37-39

Product weight Ib. 31<7>

Note 1. Rating conditions

Cooling: Indoor: D.B. 80°F W.B. 67°F

outdoor: D.B. 95°F W.B. 75°F

Heating: Indoor: D.B. 70°F

outdoor: D.B. 47°F W.B. 43°F

Note 2. The number indicated in < > is for the grille.

W 3. Air flow and the noise level are indicated as Low - Medium2 - Medium1 - High.

5

4-2. ELECTRICAL PARTS SPECIFICATIONS

OC341F

Service Ref.

Parts name

Room temperature

thermistor

Liquid pipe thermistor

Gas pipe thermistor

Fuse

(Indoor controller board)

Fan motor

Vane motor

Symbol

TH21

TH22

TH23

FUSE

MF

MV

PMFY-P06NBMU-E

PMFY-P06NBMU-E

PMFY-P06NBMU-E#2

PMFY-P06NBMU-ER3

PMFY-P06NBMU-ER4

PMFY-P06NBMU-ER5

Resistance 30°F/15.8k, 50°F/9.6k, 70°F/6.0k, 80°F/4.8k, 90°F/3.9k, 100°F/3.2k

Resistance 30°F/15.8k, 50°F/9.6k, 70°F/6.0k, 80°F/4.8k, 90°F/3.9k, 100°F/3.2k

Resistance 30°F/15.8k, 50°F/9.6k, 70°F/6.0k, 80°F/4.8k, 90°F/3.9k, 100°F/3.2k

PMFY-P08NBMU-E

1

PMFY-P08NBMU-E

PMFY-P08NBMU-E#2

PMFY-P08NBMU-ER3

PMFY-P08NBMU-ER4

PMFY-P08NBMU-ER5

250V 6A (PMFY-P·NBMU-E

250V 6.3A (PMFY-P·NBMU-E#2/ER3/ER4/ER5)

DC Brushless Motor

8-pole OUTPUT 28W

PMFY-P12NBMU-E

1

PMFY-P12NBMU-E

PMFY-P12NBMU-E#2

PMFY-P12NBMU-ER3

PMFY-P12NBMU-ER4

PMFY-P12NBMU-ER5

PN0H28-MB

MSFJC 20M23

12V/380

(1))

PMFY-P15NBMU-E

PMFY-P15NBMU-E

1

PMFY-P15NBMU-E#2

PMFY-P15NBMU-ER3

PMFY-P15NBMU-ER4

PMFY-P15NBMU-ER5

1

Drain pump

Drain sensor

Linear expansion valve

Power supply

terminal block

Transmission

terminal block

MA-remote controller

terminal block

DP

DS

LEV

TB2

TB5

TB15

PJV-1063

208-240V 50/60Hz

Thermistor resistance 30"F/6.3k, 50"F/3.9k, 70"F/2.5k, 80"F/2.0k, 90"F/1.6k, 100"F/1.3k

DC12V Stepping motor drive

port dimension :

(L1, L2, GR) Rated to 330V 30A

(M1, M2, S) Rated to 250V 20A

(1,2) Rated to 250V 10A

Note : Refer to WIRING DIAGRAM for the supplied voltage.

+

3.2

EDM-40YGME

(0~2000pulse)

+

+

+

6

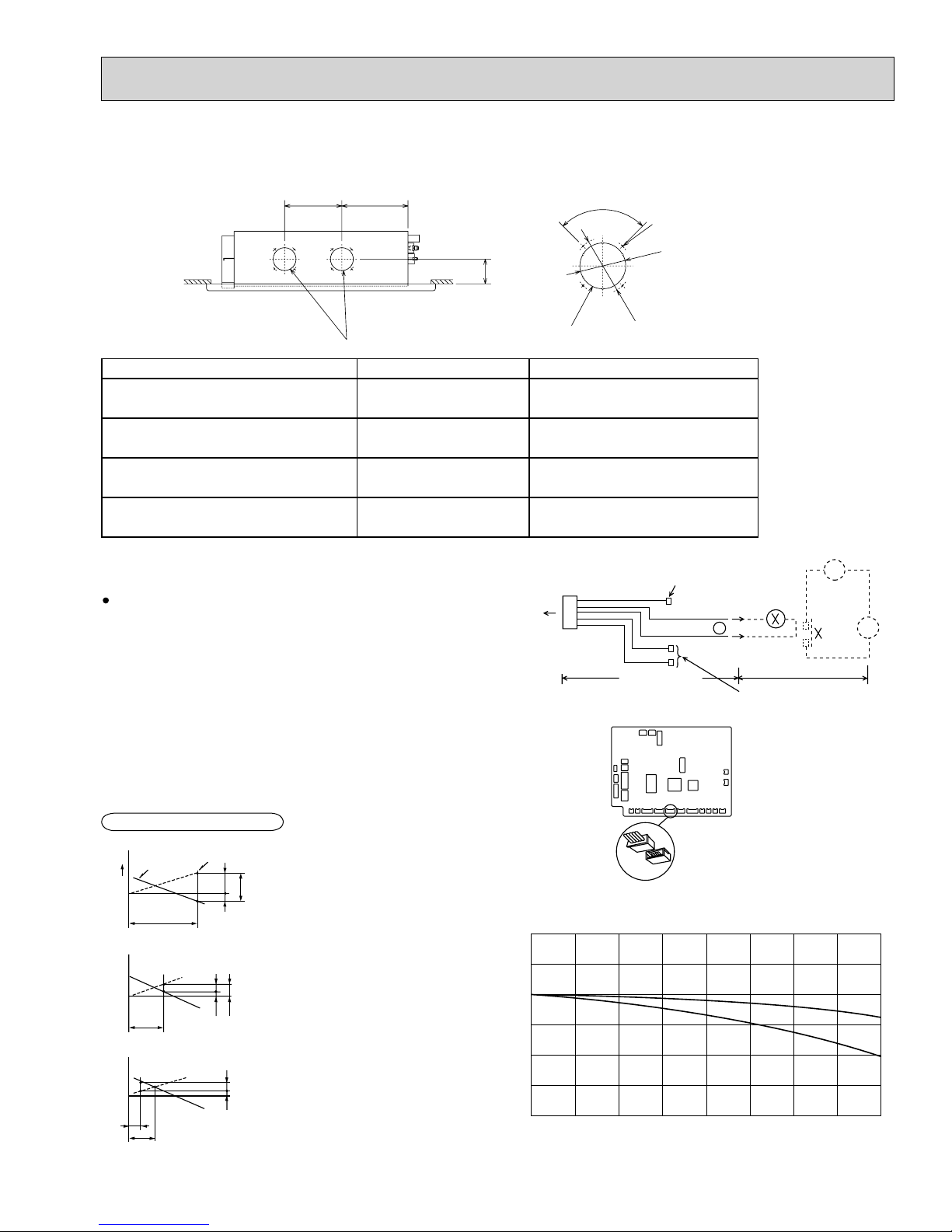

4-3. AIR CAPACITY TAKEN FROM OUTSIDE

OC341F

PMFY-P·NBMU-E series are capable of taking air from outside. When taking air from outside, the duct fan is used.

The air capacity should be 20% or less of the airflow SPEC (Hi).

9-13/16 11-3/8

90

4-Ø1/8

3-15/16

Ø

Fresh air intake hole

(Knockout)

Service Ref. Air fl ow (Hi) Air capacity taken from outside

PMFY-P06NBMU-E/E1/E#2/ER3/ER4/ER5

PMFY-P08NBMU-E/E1/E#2/ER3/ER4/ER5

PMFY-P12NBMU-E/E1/E#2/ER3/ER4/ER5

PMFY-P15NBMU-E/E1/E#2/ER3/ER4/ER5

300 CFM 60CFM

320 CFM 64CFM

320CFM 64CFM

370CFM 74CFM

Operation in conjunction with duct fan (Booster fan)

Whenever the indoor unit is operating, the duct fan

operates.

(1) Connect the optional multiple remote controller

adaptor (PAC-SA88HA-E) to the connector CN51

on the indoor controller board.

(2) Drive the relay after connecting the 12V DC relay

between the Yellow and Orange connector lines.

(w)Use a relay of 1W or smaller.

MB: Electromagnetic switch power relay for duct fan.

X: Auxiliary relay (12V DC LY-1F)

4-1/4

Fresh air intake hole

(Knockout)

CN51

on

indoor unit

board

5

1

Connector (5P)

Indoor unit side

Ø4-

13/16

(Unit: inch)

Be sure to secure insulation

Green

material by tape, etc.

Yellow

Orange

Red

Brown

Multiple remote

controller adapter

PAC-SA88HA-E

Indoor controller board

+

Installation at site

Be sure to secure insulation

material by tape, etc.

Distance between indoor

controller board and relay

must be within 33 feet.

~

MB

How to read curves

Q

Duct characteristics

at site

A

C

B

A

EC

AD

Q…Designed amount of fresh air

intake <CFM>

A…Static pressure loss of fresh air

intake duct system with air flow

amount Q <in. W.G>

B…Forced static pressure at air condi-

tioner inlet with air flow amount Q

C…Static pressure of booster fan with

air flow amount Q <in. W.G>

D…Static pressure loss increase

amount of fresh air intake duct

system for air flow amount Q

E…Static pressure of indoor unit with

air flow amount Q <in. W.G>

Qa…Estimated amount of fresh air

intake without D <CFM>

Curve in the

right graphs

0

Q

Q

Qa

<in. W.G>

<in. W.G>

Multiple remote

controller adapter

PAC-SA88HA-E

CN51

Characteristic diagram of air capacity taken from outside of PMFY-P·NBMU-E

0.2

0.1

0

-0.1

-0.2

Static pressure (in.W.G.)

-0.3

-0.4

010

20

30 40 50 60 70 80

Air flow (CFM)

7

2 intake

1 intake

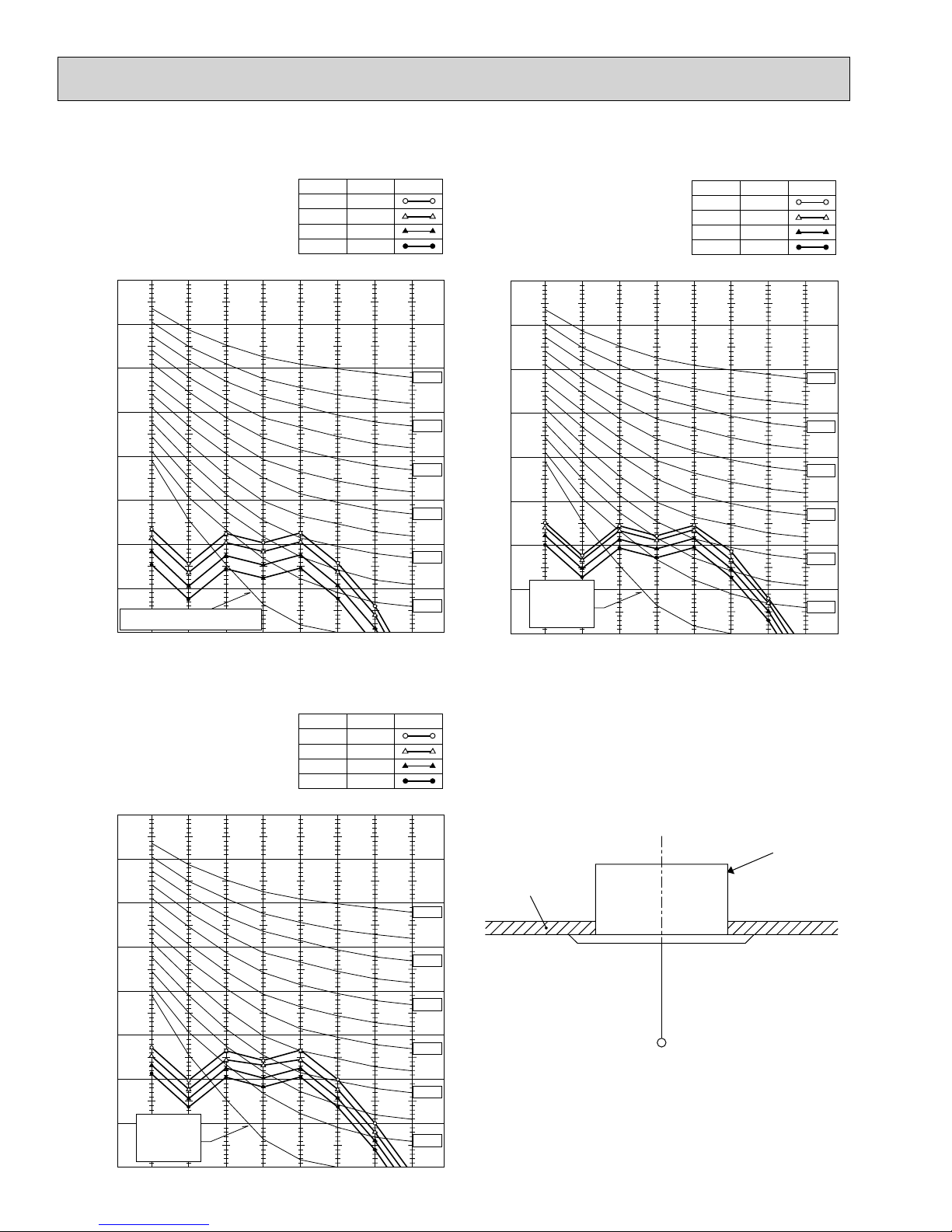

4-4. NOISE CRITERION CURVES

OC341F

PMFY-P06NBMU-E

PMFY-P06NBMU-E

PMFY-P06NBMU-E#2

PMFY-P06NBMU-ER3

PMFY-P06NBMU-ER4

1

NOTCH

High

Medium1

Medium2

Low

PMFY-P06NBMU-ER5

90

SPL(dB)

35

33

30

27

LINE

PMFY-P08/12NBMU-E

PMFY-P08/12NBMU-E

1

PMFY-P08/12NBMU-E#2

PMFY-P08/12NBMU-ER3

PMFY-P08/12NBMU-ER4

PMFY-P08/12NBMU-ER5

90

NOTCH

High

Medium1

Medium2

Low

SPL(dB)

37

36

34

32

LINE

80

70

60

50

40

30

20

APPROXIMATE THRESHOLD OF HEARING

FOR CONTINUOUS NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 μbar)

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

PMFY-P15NBMU-E

PMFY-P15NBMU-E

1

PMFY-P15NBMU-E#2

PMFY-P15NBMU-ER3

PMFY-P15NBMU-ER4

PMFY-P15NBMU-ER5

90

NOTCH

High

Medium1

Medium2

Low

SPL(dB)

39

37

35

33

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

LINE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 μbar)

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 μbar)

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

UNIT

CEILING

5ft

MICROPHONE

8

5

OC341F

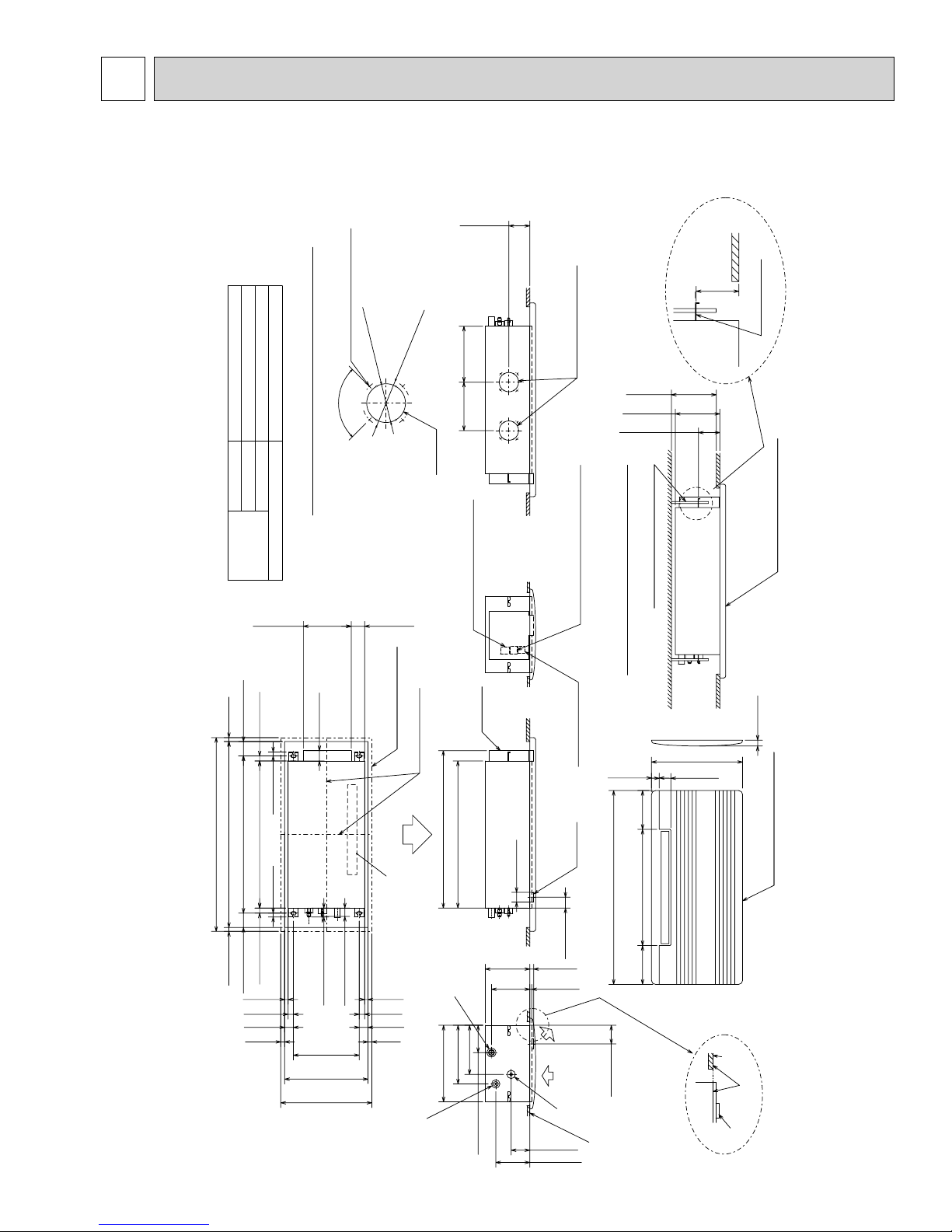

OUTLINES AND DIMENSIONS

PMFY-P06NBMU-E/E1/E#2/ER3/ER4/ER5

PMFY-P08NBMU-E/E

PMFY-P12NBMU-E/E

1/E#2/ER3/ER4/ER5

1/E#2/ER3/ER4/ER5

PMFY-P15NBMU-E/E1/E#2/ER3/ER4/ER5

122)

100)

:

:

1/2F(:12.7)

1/4F(:6.35)

OD:1-11/16(:43)

Gas pipe

Liquid pipe

pipe cover

piping

Refrigerant

4-:1/8(:2.8) Burring hole

90°

PVC pipe:VP-20[OD:31/32(:25)

Details of fresh air intake hole

Drainage piping

4-13/16(

:

3-15/16(

:

Knockout

11-3/8

(288.5)

(250)

9-13/16

4-4/16(108)

Flesh air intake hole

around indoor unit

or more

9-1/2(235)

9-1/16(230)

4-5/16(110)

Unit : inch (mm)

(110)

4-5/16

Mounting plate

Panel(grille):PMP-16BMU(W)

2-15/18(74.5)

1-1/32(26)

13/16(20)13/16(20)

Suspension bolt pitch

Ceiling opening

Outer side of grille

29-7/8(759)

37-13/16(960)

31-15/18(811)

39-3/8(1000)

1-1/32(26)

2-15/18(74.5)

Top

9-3/8(247)

13/16(20)

13/16(20)

11/16(17.5)

1-1/8(28)

1-25/32(45)

13/16(20)

2-1/16(53)

1-13/18(46)

1-11/16(43)

13-3/8(340)

16-15/16(430)

8-1/2(470)

2-11/16(69)

Outer line of grille

Center of unit

Air outlet(lower)

11/16(17.5)

1-1/8(28)

1-25/32(45)

13/16(20)

Suspension bolt pitch

Ceiling opening

Outer side of grille

Refrigirant pipe(gas)

31-15/16(812)

25)]

:

31/32(

:

PVC pipe:

VP-20

Drainage pipe

ޓޓޓ[OD

11-7/8(302)

15-9/16(395)

12.7)

:

1/2(

:

OD

Right side

Terminal block for power supply

Elect box

10(254)

5-9/16(140)

50)

:

1-31/32(

:

(230)

9-1/16

(198)

7-13/16

29-7/8(759)

Suspension bolt(M10 or W3/8)

Terminal block for transmission

Installation space required

remote-controller

Terminal block for

1-9/16(40)

7-7/8

Drain pan

Outer side of grille

23-5/8(600)

39-3/8(1000)

Front

(2-3/16(56))

13/16(20)

(13/32(10))

6.35)

:

1/4(

:

OD

pipe(liquid)

Refrigirant

3-3/8(96)

6-15/16(176)

7-7/8

(3-3/8(96))

Ceiling panel

Left side

(200) (200)

2-3/8(60)

1-3/16(30)

outer side of grille

18-1/2(470)

Panel(grille):PMP-16BMU(W)

Lower view

panel

Ceiling

Same line

Drain pan

9

6

OC341F

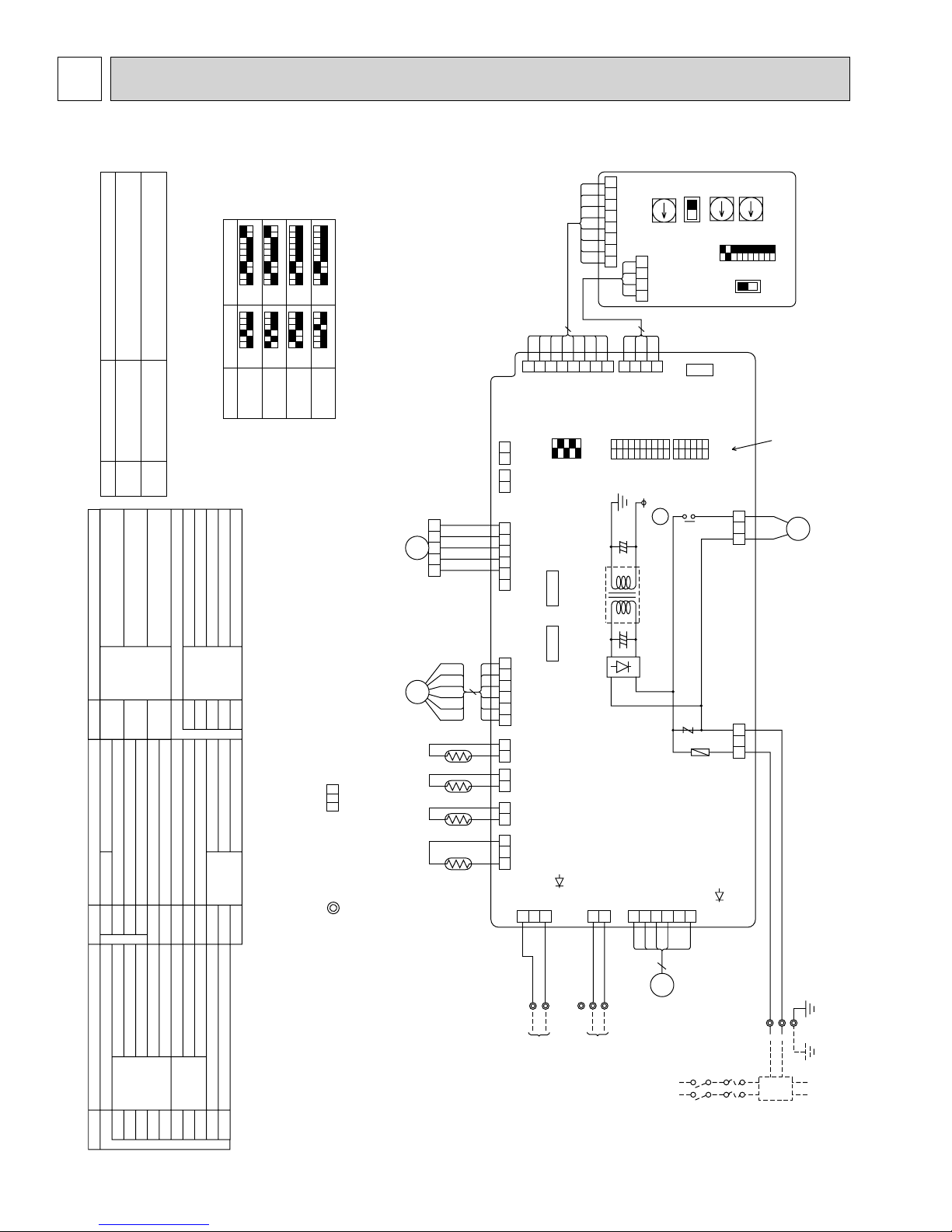

WIRING DIAGRAM

PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E

SW3

ON

Main power supply (Indoor unit:208-230V)

Power on Lamp is lit.

Power supply for MA-Remote controller

on Lamp is lit.

SW2

ON

Models

<fig. +1>

Power supply for

MA-Remote controller

Main power supply

Mark Meaning Function

LED1

LED on indoor board for service

Thermistor Room temp. detection

Symbol Name

TH21

LED2

/5.4k)

/5.4k)

F

/15k, 77˚

F

(32˚

F

/5.4k)

F

/15k, 77˚

1/15k, 77˚

F

F

Pipe temp. detection / Liquid

(32˚

Pipe temp. detection / Gas

(32˚

Mode selection

Switch

SW1

TH22

A.B Address board

TH23Fan motor (with inner thermo)

Voltage selection

Address setting 1s digit

Address setting 10ths digit

SW5

SW11

SW12

SW14 Branch No.

10

9

8

1234567

OFF

123456

OFF

P06

ON

OFF

ON

OFF

P08

10

9

8

1234567

ON

OFF

123456

ON

OFF

P12

10

10

9

9

8

8

7

7

123456

123456

ON

OFF

123456

123456

ON

OFF

P15

(+2) Use copper supply wire.

MV

LEV

TH21

No.

BRANCH

0

SW14SWC

CN82

(RED)

ADDRESS

8 7 6 5 4 3 2 1

CN43

(RED)

4321

4

4

332

(RED)

ADDRESS

1

CN42

ADDRESS

12345678910

SW3

X1

T

1

A.B

8

87654

2 1

CN27

CN25

GRN

YLW

ORN

RED

BRN

1 2 3 4 5

VANE

(GRN)

CN6V

6 5 4 3 2 1 2 1

WHT

RED

6

YLW

ORN

BRN

BLU

LEV

CN60

(WHT)

6 5 4 3 2 1

2 1

CN20

(RED)

INTAKE

2 1

CN21

(WHT)

LIQUID

OFF

ON

(RED)

15

15

3

CN81

ADDRESS

12345

SW4

CN52

(GRN)

REMOTE

INDICATION

CN51

(WHT)

CONTROL

CENTRALLY

2

1

(WHT)

REMOTE

SW2

X1

FUSE

DIGIT

1s

0

SW11

230V208V

CN32

SWITCH

123456

OFF

ON

6A

250V

CNP

(WHT)

3212 13

CND

(RED)

DIGIT

10ths

0

SW12

12345678910

OFF

ON

SW1

SW5

See fig. +1

DP

Drain pump

Vane motor

X1 Aux.relay

LED1 Power supply (I.B)

LED2 Power supply (I.B)

T Transformer

Symbol Name

Symbol Name

I.B Indoor controller board

[Legend]

Damper

Remote switch

Connector Humidifier

CN25

CN27

CN32

MF

MV

Centrally control

Remote Indication

CN51

CN52

Power supply

Drain sensor

Drain pump

Ter minal

block

DS

DP

TB2

TB5 Transmission

LEV Linear expansion valve

Capacity code

Mode selection

Model selection

Switch

SW2

SW3

SW4

ZNR Varistor

FUSE Fuse (6A / 250V)

TB15 MA-Remote Controller

Note

1. At servicing for outdoor unit, always follow the wiring diagram of outdoor unit.

2. In case of using MA-Remote controller, please connect to TB15. (Remote controller wire is non-polar.)

3. In case of using M-NET, please connect to TB5. (Transmission wire is non-polar.)

DS TH23 TH22

4. Symbol [S] of TB5 is the shield wire connection.

5. Symbols used in wiring diagram above are, : terminal block, :connecter.

6. The setting of the SW2, SW3 dip switches differs in the capacity. For the detail, refer to fig. +1.

7.Please set the switch SW5 according to the power supply voltage.

10

I.B

2 1

GAS

(BLK)

CN29

CN31

(WHT)

DRAIN

3 2 1

(BLU)

CN3A

231

ORN

TB15

1

TO MA-REMOTE

LED2

ORN

TB5

2

SHIELD)

(

S

CONTROLLER

DC8.7-13V

TO OUTDOOR UNIT

(BLU)

CN2M

(M-NET)

2

1

BLU

BLU

M2

M1

BC CONTROLLER

REMOTE CONTROLLER

DC24-30V

)

WHT

FAN

(

1234556

MF

POWER SUPPLY

~ / N 208—230V 60Hz

BREAKER

(15A)

LED1

FUSE(15A)

<+2>

TB2

RED

L1

BLU

GRN / YLW

L2

GR

PULL BOX

TO NEXT INDOOR UNIT

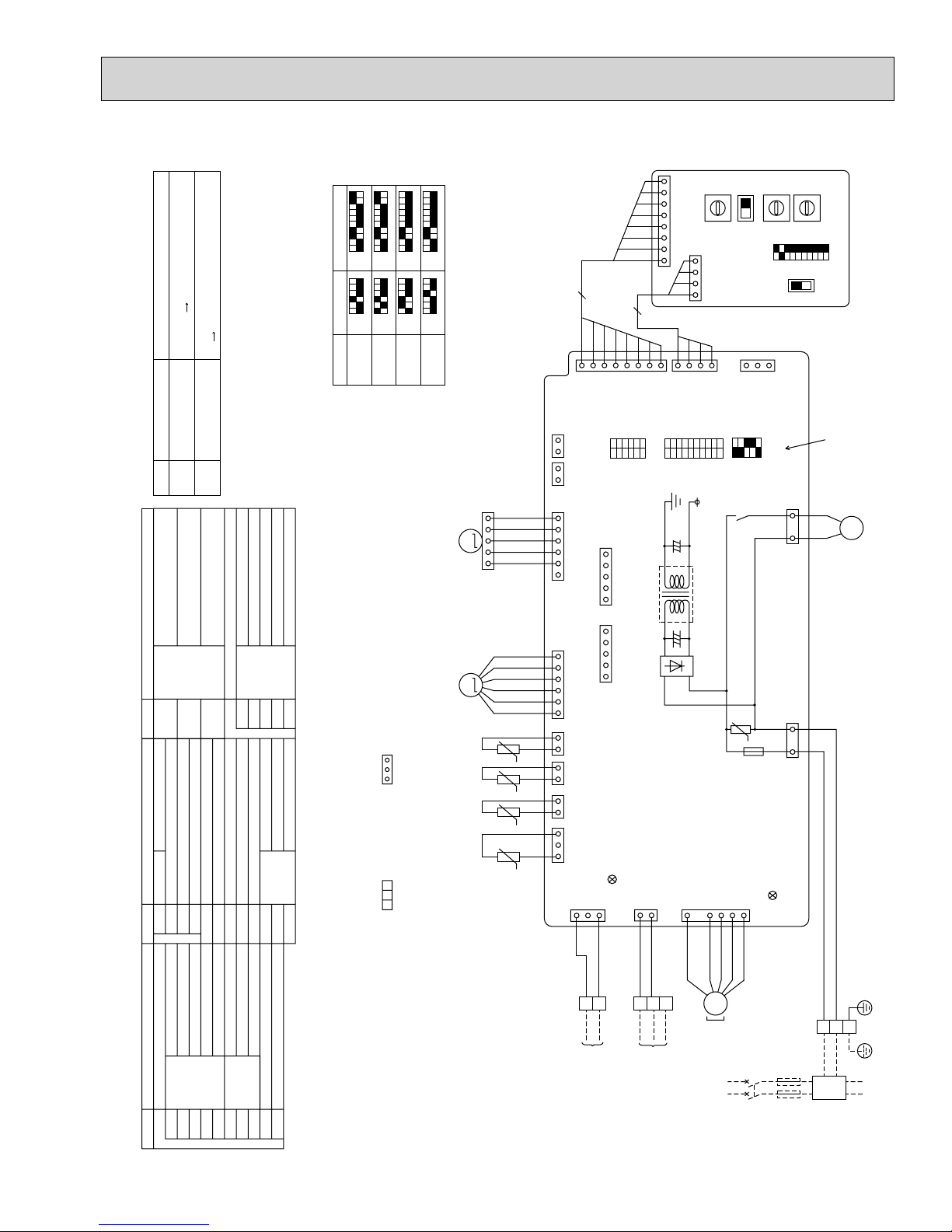

PMFY-P06NBMU-E1 PMFY-P08NBMU-E1 PMFY-P12NBMU-E1 PMFY-P15NBMU-E1

OC341F

Main power supply (Indoor unit:208-230V)

Power on Lamp is lit.

Power supply for MA-Remote controller

on Lamp is lit.

Power supply for

MA-Remote controller

Main power supply

Mark Meaning Function

LED1

LED on indoor board for service

Thermistor Room temp. detection

Symbol Name

TH21

LED2

)

)

)

77˚F/5.4k

77˚F/5.4k

,

(32˚F/15k

77˚F/5.4k

,

,

Pipe temp. detection / Liquid

(32˚F/15k

Pipe temp. detection / Gas

(32˚F/15k

Mode selection

Switch

SW1

TH22

A.B Address board

TH23Fan motor

Voltage selection

Address setting 1s digit

Address setting 10ths digit

SW5

SW11

SW12

SW14 Branch No.

<fig. +1>

SW3

ON

OFF

SW2

ON

OFF

P06

Models

10

9

8

1234567

ON

OFF

123456

ON

OFF

P08

10

9

8

1234567

ON

OFF

123456

123456

ON

OFF

P12

10

10

9

9

8

8

7

7

123456

123456

ON

OFF

123456

ON

OFF

P15

<+2>Use Copper Supply Wire.

MV

15

MM

LEV

TH21

8

8

21

CN27

2121212131

CN25

GRN

YLW

ORN

RED

BRN

WHT

YLW

ORN

BLU

RED

BRN

CN6V

(GRN)VANE

6161

CN60

(WHT)LEV

(RED)

INTAKE

(WHT)

LIQUID

OFF

ON

CN20

CN21

4

CN81

(RED)

ADDRESS

15

(GRN)

15

(WHT)

No.

BRANCH

9

8

A

7

B

6

C

5

D

4

3

E

2

F

1

0

SW14SWC

CN82

(RED) ADDRESS

81

A.B

(RED)

41

ADDRESS

411

CN42

(RED)

ADDRESS

123456

SW2

CN52

REMOTE

INDICATION

CN51

CONTROL

CENTRALLY

12345678910

SW3

T

CN43

1

(WHT)

REMOTE

SW4

X1

U

FUSE

12345

DIGIT

1s

5

6

4

4

7

3

3

8

2

2

9

1

0

SW11

230V208V

3

CN32

SWITCH

OFF

ON

CNP

(WHT)

31

31

CND

(RED)

DIGIT

10ths

5

6

7

8

9

1

0

SW12

12345678910

OFF

ON

SW1

SW5

See fig. +1

M

1~

DP

Drain pump

Vane motor

X1 Aux.relay

LED1 Power supply(I.B)

LED2 Power supply(I.B)

T Transformer

Symbol Name

Symbol Name

I.B Indoor controller board

[Legend]

Damper

Remote switch

Connector Humidifier

CN25

CN27

CN32

MF

MV

Centrally control

Remote Indication

CN51

CN52

Power supply

Drain sensor

Drain pump

Terminal

block

DS

DP

TB2

TB5 Transmission

LEV Linear expansion valve

Capacity code

Mode selection

Model selection

Switch

SW2

SW3

SW4

ZNR Varistor

FUSE Fuse (6A / 250V)

TB15 MA-Remote Controller

Note

GAS

(BLK)

CN29

DS TH23 TH22

t° t° t° t°

I.B

1. At servicing for outdoor unit, always follow the wiring diagram of outdoor unit.

2. In case of using MA-Remote controller, please connect to TB15. (Remote controller wire is non-polar.)

3. In case of using M-NET, please connect to TB5. (Transmission line is non-polar.)

4. Symbol [S] of TB5 is the shield wire connection.

5. Symbols used in wiring diagram above are, : terminal block, :connector.

6. The setting of the SW2, SW3 dip switches differs in the capacity. For the detail, refer to fig. +1.

7. Please set the switch SW5 according to the power supply voltage.

CN31

(WHT)

DRAIN

(BLU)

CN3A

3

1

ORN

ORN

1

2

TB15

TO MA-REMOTE

CONTROLLER

DC8.7-13V

LED2

(BLU)

CN2M

(M-NET)

2

1

BLU

BLU

S

M1

M2

TB5

TO OUTDOOR UNIT

BC CONTROLLER

REMOTE CONTROLLER

1

(SHIELD)

DC24-30V

11

FAN

(WHT)

6

3

3~

MS

MF

POWER SUPPLY

(15A)

~ / N 208-230V 60Hz

BREAKER

LED1

FUSE

(15A)

RED

TB2

<+2>

BLU

GRN / YLW

L1

L2

PULL BOX

GR

TO NEXT INDOOR UNIT

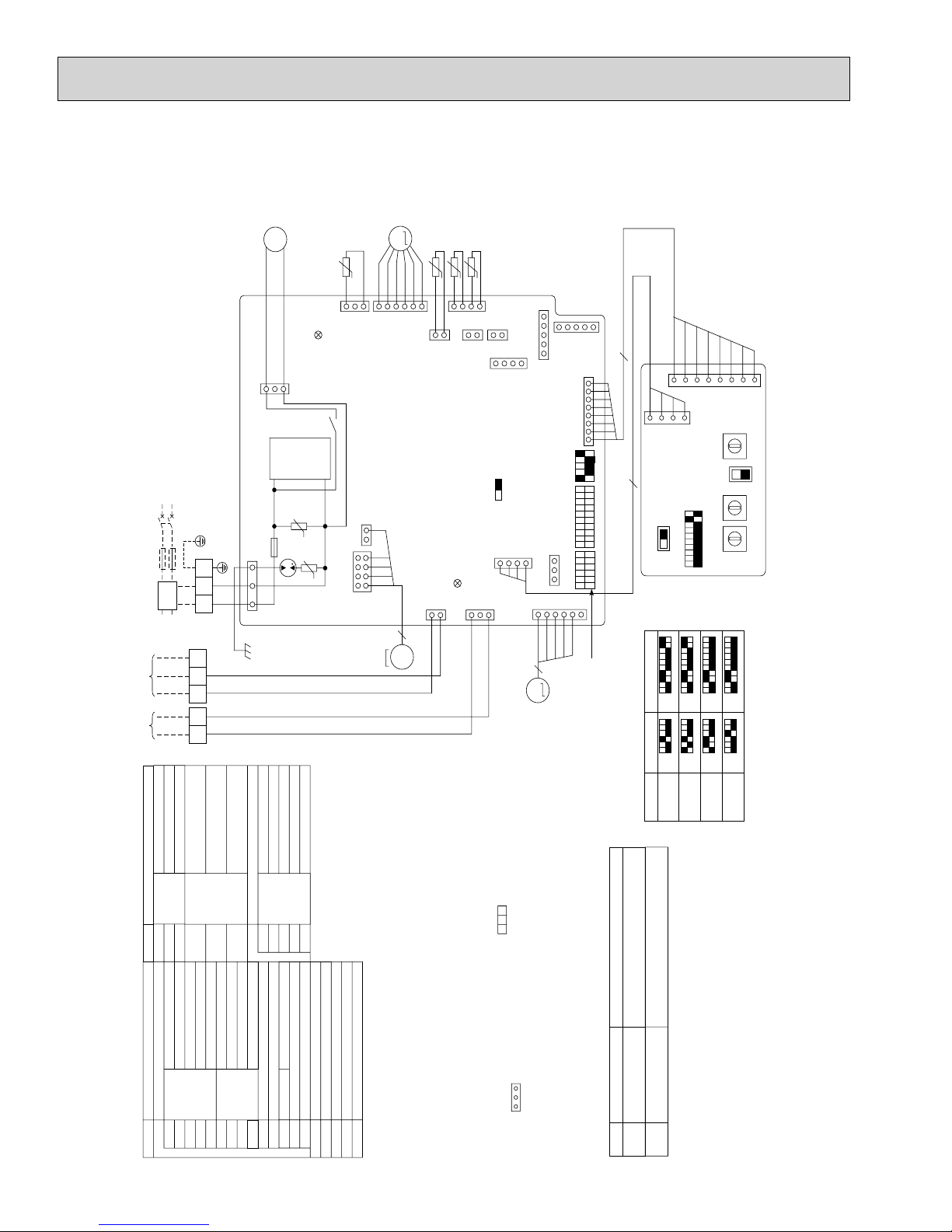

PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2

OC341F

PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3

PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4

POWER SUPPLY

~ / N

208-230V 60Hz

)

(15A

BREAKER

)

(15A

FUSE

PULL BOX

TO NEXT

INDOOR

UNIT

TO OUTDOOR UNIT

BC CONTROLLER

REMOTE CONTROLLER

DC24-30V

REMOTE

TO MA-

CONTROLLER

DC8.7-13V

TB15

TB5

GR

L1 L2

TB2

S

M1 M2

2

1

)

/

YLW

(SHIELD)

)

I.B

GRN

BLU

RED

BLK

1

)

WHT

DRAIN

(

CNMF1

1

2

)

WHT

(

CNMF2

BRN

)

WHT

(

1357

M

LEV

BLU

ORN

YLW

RED

WHT

6

1

)

WHT

LEV

(

CN60

CN2M

5

BLU

3~

MF

MS

TH21

t°t°t°

2

1

)

RED

(

CN20

INTAKE

)

BLU

(

M-NET

2

1

BLU

TH23

4

LED2

CN25

CN3A

1

ORN

TH22

1

1

)

WHT

(

SWE

)

BLU

REMOCON

(

3

ORN

)

WHT

CN44

(

LIQUID/GAS

212

4

)

WHT

(

CN41

ON OFF

CN42

4

CN6V1

)

RED

(

CN27

1

HA

)

RED

(

ADDRESS

1

)

GRN

(

1

5

)

WHT

CENTRALLY

CN51 (

31

1

VANE

RED

BRN

5

M

)

WHT

CN32 (

ORN

5

1

)

GRN

(

CN52

REMOTE

INDICATION

81

)

CONTROL

RED

ADDRESS

CN81 (

SW4

12345

SW3

12345678910

REMOTE SWITCH

SW2

123456

6

YLW

GRN

MV

*See fig. 1

8

8

4

1

RED)

CN43

(

ADDRESS

4

230V208V

SW1

SW5

12345678910

RED)

(

ADDRESS

SW14

SW11

SW12

CN82

3

2

1

0

F

SWC

2

1

0

2

1

0

1

5

4

6

7

8

9

No.

A

B

C

E

D

BRANCH

3

4

5

6

1s

7

9

8

DIGIT

3

4

5

6

7

10ths

9

DIGIT

8

A.B

10

10

10

9

8

1234567

ON

OFF

123456

ON

OFF

P12

10

9

9

8

8

7

7

123456

123456

ON

OFF

123456

123456

ON

OFF

P15

<2> Use Copper Supply Wire.

<fig. 1>

SW3

ON

OFF

SW2

ON

OFF

P06

Models

9

8

1234567

ON

OFF

123456

ON

OFF

P08

M

DP

BLU

1~

BLU

DS

t°

3

LED1

CN31

)

YLW

CNP

(

1

D.U.M

3

X1

~339V

DC311

FUSE

513

DSA

ZNR01

U

ZNR02

U

8642

)

BLK

CND (

)

32°F/15k, 77°F/5.4k

32°F/15k, 77°F/5.4k

Power supply

Terminal

block

Thermistor Room temp. detection

Symbol Name

TB15 MA-Remote Controller

TB2

TB5 Transmission

TH21

Damper

Remote switch

Connector Humidifier

CN25

CN27

CN32

Symbol Name

I.B Indoor controller board

[Legend]

32°F/15k, 77°F/5.4k

(

Pipe temp. detection / Liquid

(

Pipe temp. detection / Gas

(

Mode selection

Switch

TH23

A.B Address board

DRAIN UP MACHINE(TEST MODE)

Capacity code

Mode selection

Model selection

Switch

SW2

SW3

SW4

SWE

SW1

ZNR Varistor

TH22

Centrally control

Remote Indication

CN51

CN52

Voltage selection

Address setting 1s digit

Address setting 10ths digit

SW5

SW11

SW12

SW14 Branch No.

)

)

)

I.B

I.B

Drain pump

(

(

T6.3AL 250V

(

LED1 Power supply

LED2 Power supply

X1 Aux.relay

FUSE Fuse

Fan motor

Vane motor

MF

MV

Drain sensor

Drain pump

LEV Linear expansion valve

DS

DP

Main power supply (Indoor unit:208-230V)

Power on Iamp is lit

Main power supply

Mark Meaning Function

LED1

Note

1. At servicing for outdoor unit, always follow the wiring diagram

of outdoor unit.

2. In case of using MA-Remote controller, please connect to

TB15. (Remote controller wire is non-polar.)

3. In case of using M-NET, please connect to TB5.

(Transmission line is non-polar.)

4. Symbol [S] of TB5 is the shield wire connection.

5. Symbols used in wiring diagram above are, : terminal

block, :connector.

6. The setting of the SW2, SW3 dip switches differs in the capacity.

For the detail, refer to fig. 1.

LED on indoor board for service

7. Please set the switch SW5 according to the power supply

voltage.

12

Power supply for MA-Remote controller

on Iamp is lit

Power supply for

MA-Remote controller

LED2

Note

1.At servicing for outdoor unit, always follow the wiring diagram of outdoor unit.

2.In case of using MA-Remote controller, please connect to TB15.

(Remote controller wire is non-polar.)

3.In case of using M-NET, please connect to TB5.

(Transmission line is non-polar.)

4.Symbol [S] of TB5 is the shield wire connection.

5.Symbols used in wiring diagram above are, : terminal block,

:connector.

6.The setting of the SW2, SW3 dip switches differs in the capacity for the detail,

refer to the fig :

1.

7.Please set the switch SW5 according to the power supply voltage.

CN51

CN52

SW2

SW3

SW4

SWE

A.B Address board

SW1

SW5

SW11

SW12

Mode selection

Voltage selection

Address setting 1s digit

Address setting 10ths digit

SW14 Branch No.

Centrally control

Remote Indication

Switch

Switch

Capacity code

Mode selection

Model selection

DRAIN UP MACHINE(TEST MODE)

X1 Aux.relay

Drain pump

FUSE Fuse (T6.3AL 250V)

LED1 Power supply (I.B)

LED2 Power supply (I.B)

TH21

MF

MV

Thermistor Room temp. detection

(32°F/15k, 77°F/5.4k)

Pipe temp. detection / Liquid

(32°F/15k, 77°F/5.4k)

Pipe temp. detection / Gas

(32°F/15k, 77°F/5.4k)

LEV Linear expansion valve

TH22

TH23

Fan motor

Vane motor

TB15 MA-Remote Controller

[Legend]

Symbol Name

I.B Indoor controller board

CN25

CN27

CN32

Connector Humidifier

Damper

Remote switch

Symbol Name

DS

DP

Drain sensor

Drain water lifting-up mech.

TB2

TB5 Transmission

Terminal

block

Power supply

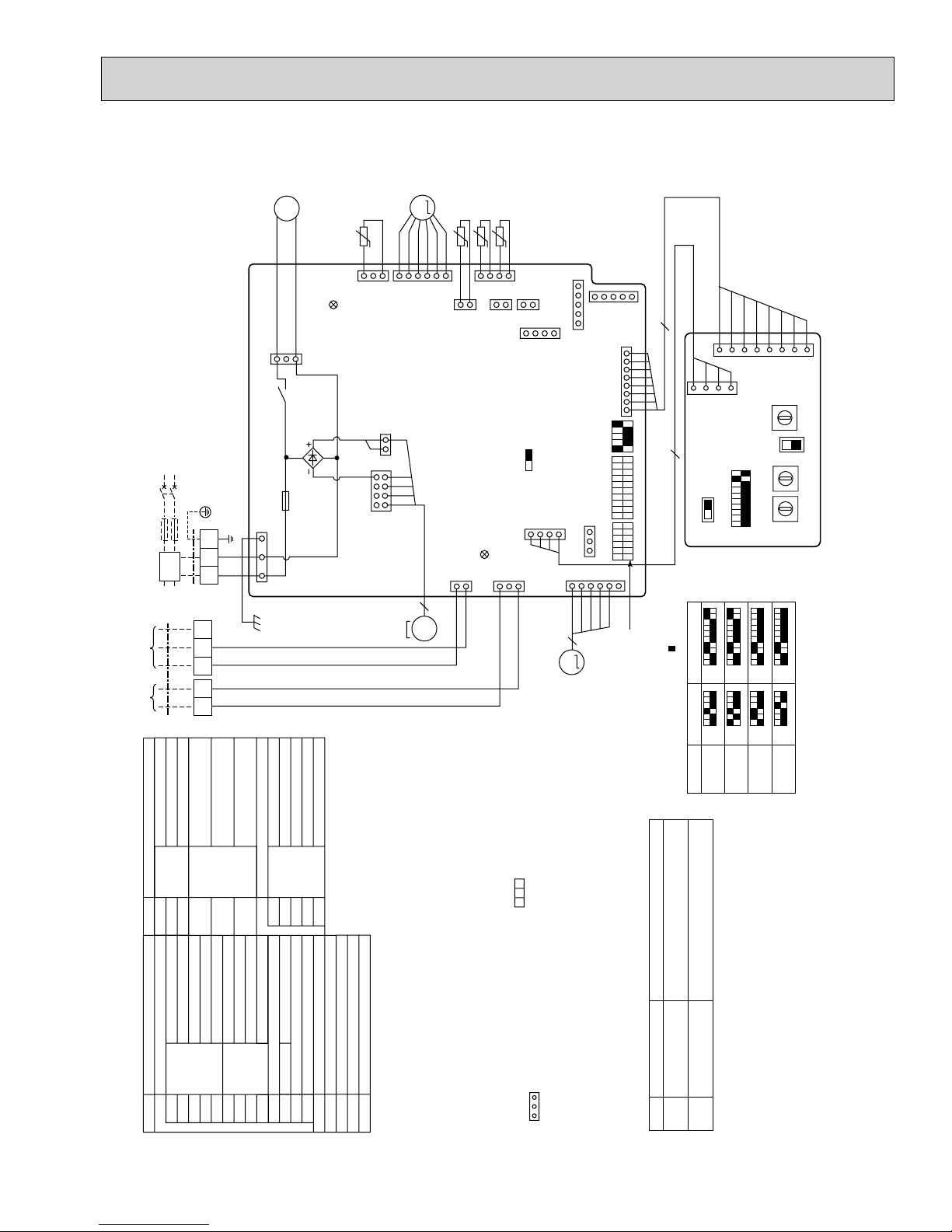

Models

P06

P08

P12

P15

SW2

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

123456

ON

OFF

SW3

1234567

ON

OFF

1234567

ON

OFF

123456

ON

OFF

123456

7

7

8

8

8

8

9

9

9

9

10

10

10

10

ON

OFF

<fig : 1>

Mark Meaning Function

Power supply for

MA-Remote controller

Main power supply (Indoor unit:208-230V)

Power on Iamp is lit

LED on indoor board for service

LED1

Main power supply

Power supply for MA-Remote controller

on Iamp is lit

LED2

<2> Use Copper Supply Wire.

The black square ( ) indicates

a switch position.

SWE

ON OFF

ON

OFF

GR

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

10ths

DIGIT

1s

DIGIT

BRANCH

No.

SW12 SW11

SW14

CN2M

(BLU)

M-NET

CNP

(

YLW)

DUM

CN3A

(BLU)

MA REMOCON

TB5

(SHIELD)

M1 M2

TB2

TB15

1

S

TH23

TH22

CN20

(RED)

INTAKE

CN60

(WHT)

LEV

CN52

(GRN)

REMOTE

INDICATION

CN6V1

(GRN)

VANE

TH21

CNMF2

(WHT)

CNMF1

(WHT)

CN31

(WHT)

DRAIN

CN44

(WHT)

LIQUID

/

GAS

CN25

(WHT)

CN27

(RED)

ADDRESS

CN81

(RED)

CN42

(RED)

ADDRESS

CN32

(WHT)

REMOTE SWITCH

X1

CND

(BLK)

FUSE

CN51

(WHT)

CENTRALLY

CONTROL

CN41

(WHT)

HA

4

8

5

5

LEV

M

DS

DP

t°

t°

t°

t°

2

L1 L2

12345678910

SW3

123456

SW2

12345

SW4

81

5

1

513

6

1

6

1

5

1

4

1

2

1

2

1

2

1

4

1

1

3

3

1

3

1

31

2

1

2

1

1

4

1357

864 2

I.B

M

1~

M

MS

3~

PULL BOX

FUSE

(15A)

BREAKER

(15A)

POWER SUPPLY

~

/ N

208-230V 60Hz

TO NEXT

INDOOR

UNIT

BLU

BRN

ORN

YLW

RED

WHT

SWC

12345678910

SW1

SW5

230V208V

(RED)

ADDRESS

CN82

(RED)

ADDRESS

CN43

A.B

8

1

4

1

TO MA-

REMOTE

CONTROLLER

DC8.7-13V

TO OUTDOOR UNIT

BC CONTROLLER

REMOTE CONTROLLER

DC24-30V

RED

BLU

GRN

/

YLW

MF

MV

ORN

*See fig : 1

ORN

BLU

BLU

BLU

BLU

LED2

LED1

GRN

YLW

ORN

RED

BRN

BLK

PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5

OC341F

13

Loading...

Loading...