Mitsubishi PLY-E7203, PLY-E7200, PLY-E7100, PLY-E7194, PLY-E7191 Instruction Manual

AUTOMAT

I C

POCKTT \l/E

LT I NG

MACH

I NE

PLY-E72OO

PLY_E71OO

(rXS

TRTJCTIoN

SERIES

SERIES

MANU,qr

))

No.

303036

We wish

to express

you

AUTOMATIC POCKET

read this instruction

this machine

will be

manual

geat

sincere thanls

our

WELTING

carefully

potential factor

your

for

MACHINE.

before starting

production.

your

in

CONTENTS

purchase of

should be thanktul

We

operation and

the

our

MITSUBISFtr

you

would

if

hope that

we do

1.

2.

3.

4.

CONSTRUCTION

SPECIFICATION

PREPARATION

OPERATIONPANEL

5. OPERATION

6.

7

OPERATION

SELECTION

"

7-1 SET

7-2 SET

ADruSTMENT

7-3

I.'P FOR

I.'P IN DIP

8. COTJNTER

9.

IO.

11.

12.

13.

T4.

15.

16.

ADruSTMENT

PROCESS

LIST OF OPERATION

ADruSTMENT

INSTRUCTION

EXCHANGE

CONNECTION

MARKING

LAMP

INDICATION

IGI)TNDICATION

I6.2)INDICATION

16-3)CONFIRMATION

AND INSTRUCTION

BEF'ORE

AND

STARTING

MEMORY FOR EACH

BEFORE

MACHINE

OPERATION

SWITCH

OF TIMER

OF TAB KNIFE

OF DOUBLE AND

SINGLE

FOR MACHINE HEAD

OF GAUGE PARTS

TO AIR

FOR TROUBLE

TROUBLE POINTS

FOR

FOR OPERATION POINTS

OF SWITCH CONDMON

OPERATION

FUNCTION

WELT

(SEr

OF THE MACHINE

UP)

(l)

1

COhISTR.IJCTIOI\I

)

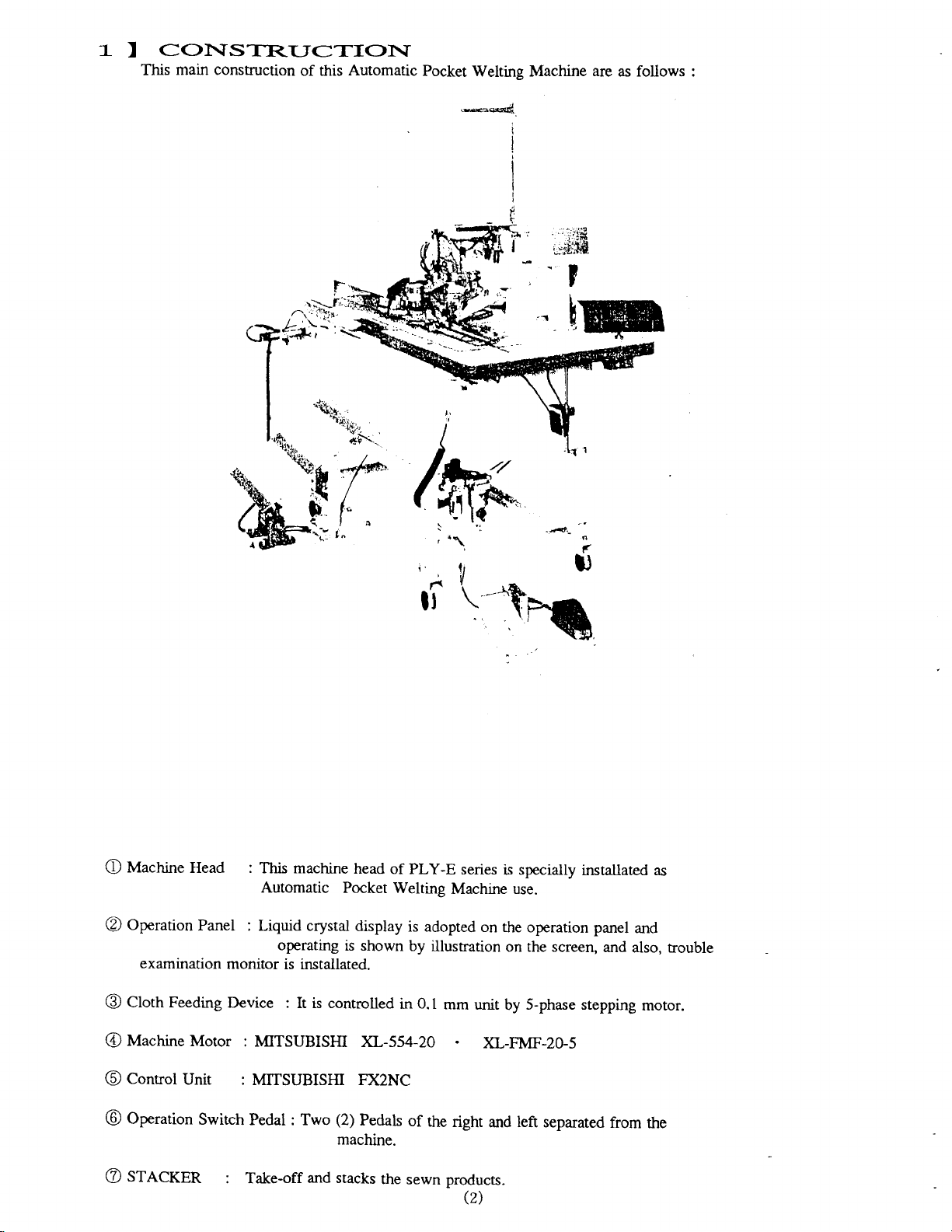

main construction

This

of this Automatic

Pocket

Welting Machine

are

as follows :

Machine

O

operation

@

examination

Head :

Panel

monitor

This machine

Automatic

: Liquid crysral

operating

is installated.

Pocket

is shown

head

of

Welting

display

6

(

lt

\

PLY-E

is adopted

by

series

Machine use.

illustration

-*g,

\h(h

is specially

on rhe

operarion

on the screen,

(

Ufilw

instaliated as

panel

and

and

also, trouble

clottr Feeding

@

Machine

@

Control

@

operation

@

SfeCfgn

@

Motor

Unit

swirch

Device :

: MITSUBISHI

: MITSUBISHI FX2NC

Pedal : Two

: Take-off

Ir is conrrolled

){J--554-20

(2)

Pedals

machine.

and stacks

0.1

in

mm

of

the

rhe

sewn products.

unir

right

Q)

S-phase stepping

by

)CL-FMF-2G5

and left separared

from

motor.

the

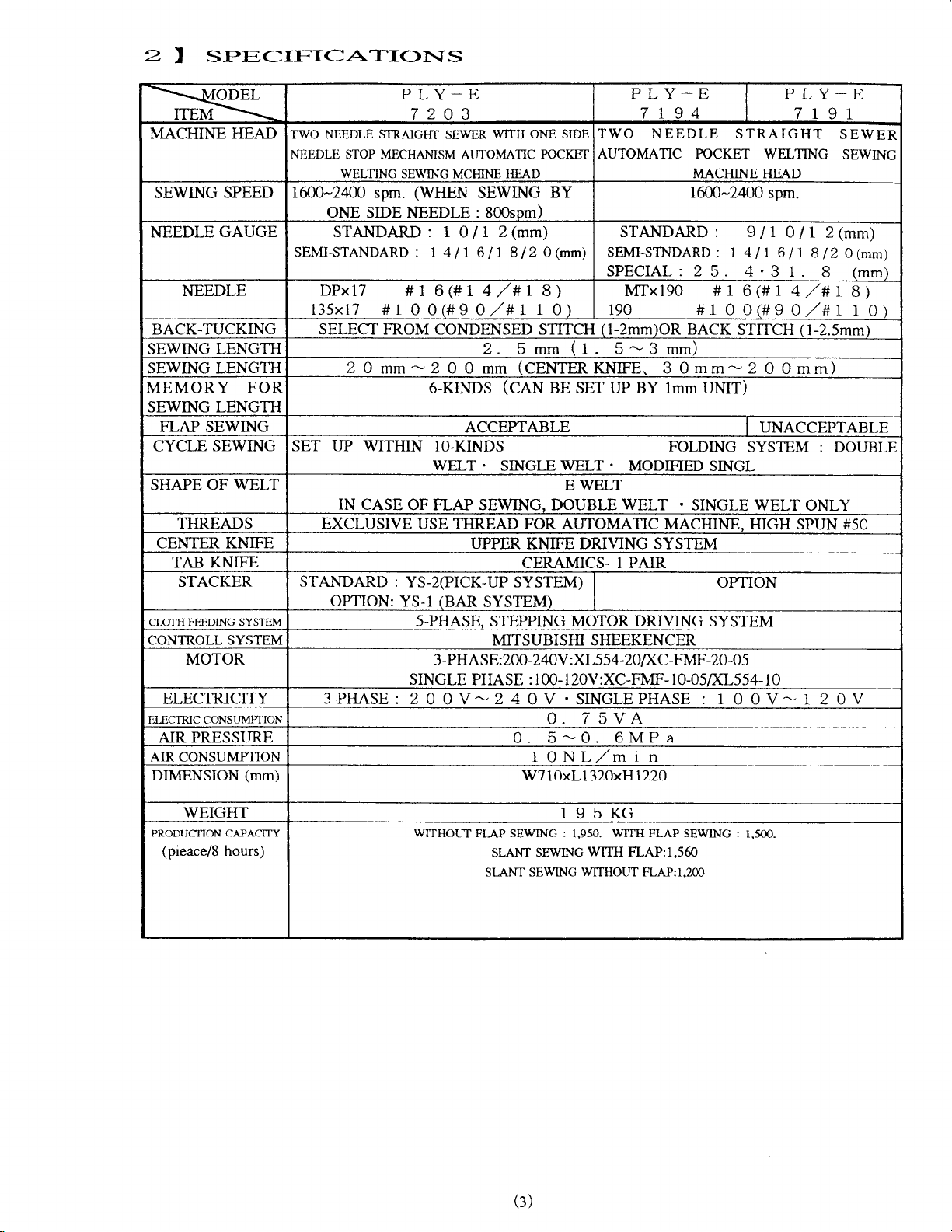

2

seeCIFI<]ATIohTS

I

PLY-E

R

MACHINE HEAD TWO NEEDLE

NEEDLE STOP MECHAMSM

WELTING

SEWING

NEEDLE

SPEED rffi-z4m spm.

ONE

GAUGE STANDARD: 1

SEMI-STANDARD : 1 4lr

NEEDLE

DPx17

l35xr7 #l

7203

STRAIGIIT

SEWING

SEWER

AUTOMATIC

MCHINE

(WHEN

SIDE

NEEDLE : 800som)

0/1

#1 6(#14,/#tB)

0 0(#9 0

WTIH

ONE

POCKET

I{EAD

SEWING

2(mm)

617 812

/#t

O

1o)

STDE

BY

(mm)

BACK.TUCKING SELECT mOM CONDENSED STITCH

SEWING LENGTH 2.

SEWING LENGTH

MEMORY

FOR

20mm-2O

6-KINDS

0mm

5mm

(CENTERKNIFE.

(CAN

(1

BE SET IJP BY lmm UMT)

SEWING LENGTH

FLAP SEWING

CYCLE

SHAPE OF

SEWING SET UP WITHIN

WELT

THREADS

CENTER KNIFE

TAB KNIFE

STACKER

CI.OTTI

FEEDING

CONTROLL SYSTEM

MOTOR

ELEC1RICITY

EI-ECTRIC

AIR PRESSIIRE

AIR CONSUMPTION

DIMENSION

SYSI-EM

CONST'IVIPI]ON

(mm)

IN CASE

EXCLUSTVE

STANDARD

OPTION:

3-PHASE

OF FLAP SEWING. DOUBLE

:

YS-2(PICK-UP SYSTEM)

YS-l

s-PHASE. STEPPTNG MOTOR DRIVING SYSTEM

SINGLE

: 2

ACCEPTABLE UNACCEPTABLE

IO.KINDS FOLDING

WELT

USE

.

SINGLE

WELT

WELT

E

TIIREAD FOR AI.ITOMATTC MACHINE. HIGH SPUN #50

UPPER

KNIFE DRIVING

CERAMICS- I PAIR

(BAR

SYSTEM)

MITSUBISHI SHEEKENCER

3-PHA SE: 200-240V : XL5

PHASE : 1 00- 1 20V : XC-FMF- 1 0-05/XL5 54- 1 0

O OV-24 0V . SINGLEPHASE

0. 75VA

0. 5-0.

1ONL/min

W7

10xl-l 32OxHl22O

PLY-E

7194

TWO NEEDLE STRAIGHT

AUTOMATIC

POCKET WELTING

MACHINE HEAD

1600-2400

PLY_E

7r91

spm.

STANDARD: 9/1O11

SEMI-STNDARD : I 4 | t

SPECIAL : 2

5.

4

6

.

3 1 .

11 8 12

8

MTxl9O #16(#14,/#18)

190 #r00ft90,/#1

(l-2mm)OR

5-3

BACK

mm)

30mm-2

.

MODIFIM SINGL

WELT

.

STITCH

SYSTEM

SINGLE WELT

(l-2.5mm)

00mm)

: DOUBLE

ONLY

SYSTEM

OPTION

54-20lXC-FNf'-20-05

: I

0 0V- 1 2 0

6MPa

SEWER

SEWING

2(mm)

O(mm)

(mm)

l0)

V

WEIGHT

PRODI'CTION CAPACTTY

(pieace/8

hours)

WITHOLIT

FLAP SEWING

SEWING

SLANT

SI,A.NT SEWING

(3)

195KG

:

WTIH

1,950.

WTIH

WTIHOLIT

FLAP:1,560

FLAP SEWNG

FLAP:1.200

: 1,5OO.

3I

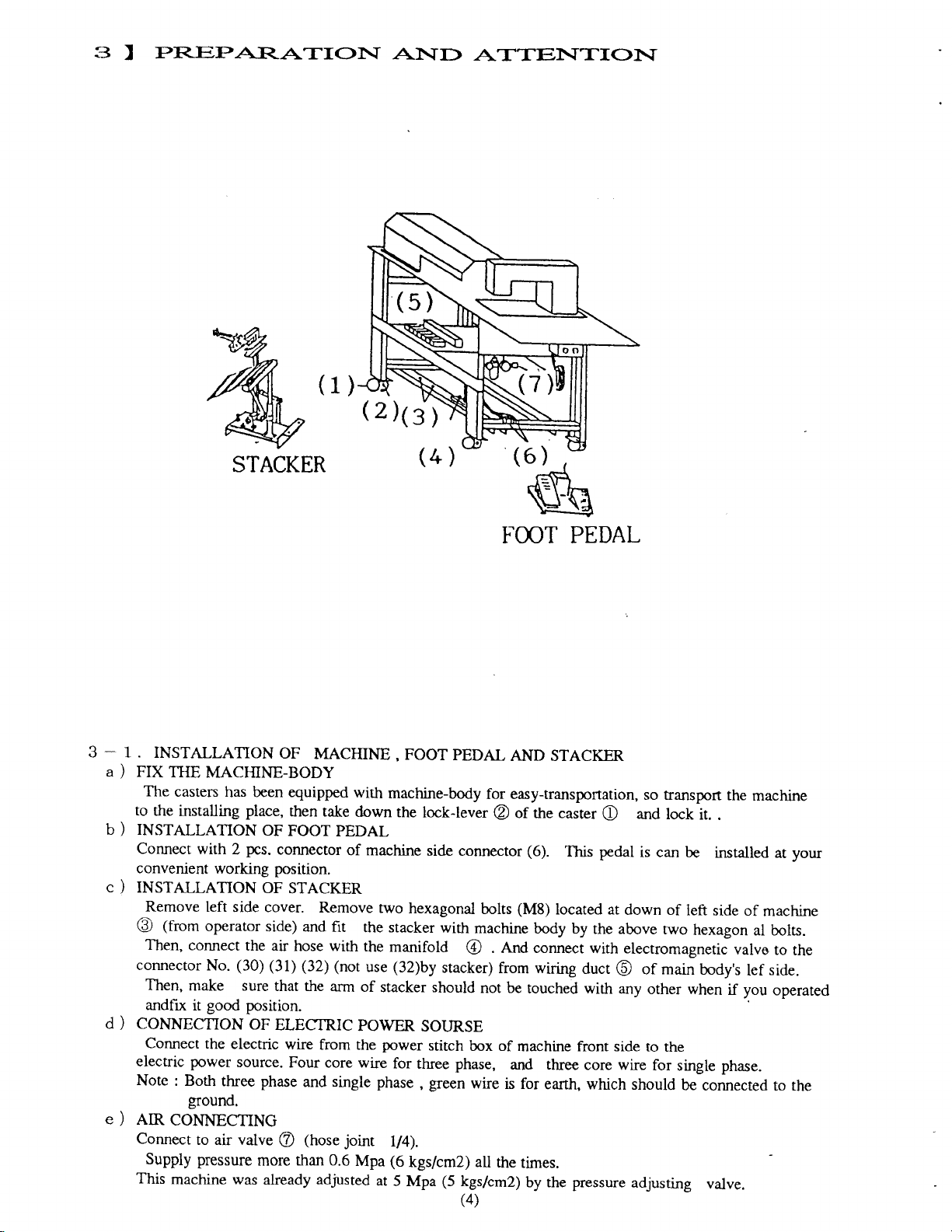

PREPARATIOI\T

STACKER

(1)

(2)13y

AI\ID

AT:TENT:rIOI\T

3-1

a)

b)

c,l

d)

e)

.

INSTALLATION

FIX

TT{E

MACHINE-BODY

The

casters has been

to

the

installing

INSTALLATION

Connect

convenient

INSTALLATION

Remove

@

Then,

connector

Then,

andfix

CONNECTION

Connect

electric

Note

AIR

Connect

Supply

This

with

2

working

left

side cover.

(from

operator

connect

No.

make sure

good position.

it

the electric

power

: Both

three phase

$ound.

CONNECTING

to air valve

pressure

machine was already adjusted

OF

place,

OF

pcs.

connector

position.

OF

side) and

the ah

(30)

(31) (32)

that the

OF

ELECTRIC

source.

@

more rhan

equipped

then take

FOOT

STACKER

hose with

wire

Four core wire

MACHINE,

with

down

PEDAL

of

Remove

fit

the stacker

the

(not

arm

of

POWER

from the

single phase

and

joint

those

0.6

Mpa

FOOT

machine-body

the

lock-lever

machine

rwo

use

at

side connector

hexagonal

with

manifold

(32)by

stacker should

power

for

lt4).

(6

5 Mpa

stacker)

SOI.'RSE

stitch

three phase,

green

,

kgs/cm2) all

(5

FOOT PEDAL

PEDAL

kgs/cm2)

(4\

AND STACKER

for easy-transportation,

of the caster

@

(6).

This pedal

(M8)

bolts

machine

. ena connect

@

from wiring

not be

box of

wire

is for

the

located at

body by

touched with

machine front side

and three

earth, which

times.

pressure

by the

so transport

and

lock

O

is can be

down of

the above

with electromagnetic

duct

core wire

of main

@

any

other when

to the

for

should

adjusting

it.

installed

left

side of

rwo

hexagon

body's

single phase.

be

connected

valve.

the

.

if

machine

machine

al bolts.

vaive

lef

you

your

ar

to

the

side.

operated

rhe

to

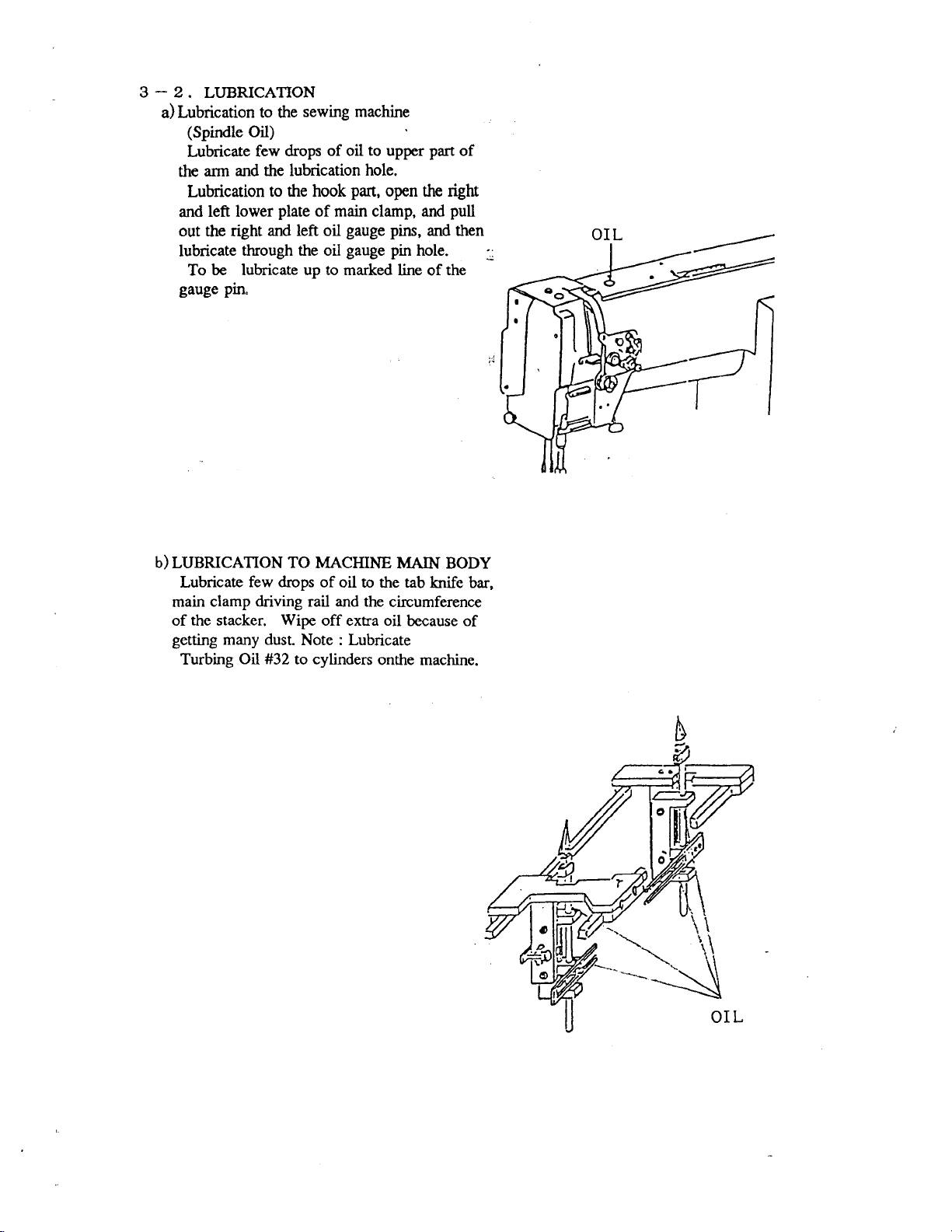

3 _ 2.

LUBRICATION

a)Lubrication

(Spintle

Lubricate

arm

the

Lub,rication

and

out the right

lubricate

To

gauge pin"

sewing machine

to

the

Oil)

of oil to upper part of

drops

few

and the lubrication

the

to

hook

plate

Ieft lower

through the oil

be lubricate up to marked

of main clamp, and

and left oil

hole.

part,

gauge pins,

gauge

open the rigttt

pull

and then

pin

hole.

line of

the

:

b)

LUBRTCATION TO MACHINE

Lubricate

main

the

of

gening

Turbing

few drops

clamp driving rail and the

stacker.

many dust.

Oil #32

of oil to the tab

Wipe

off extra oil

Note : Lubricate

to cylinders

MAIN BODY

knife bar,

circumference

because of

onthe

machine.

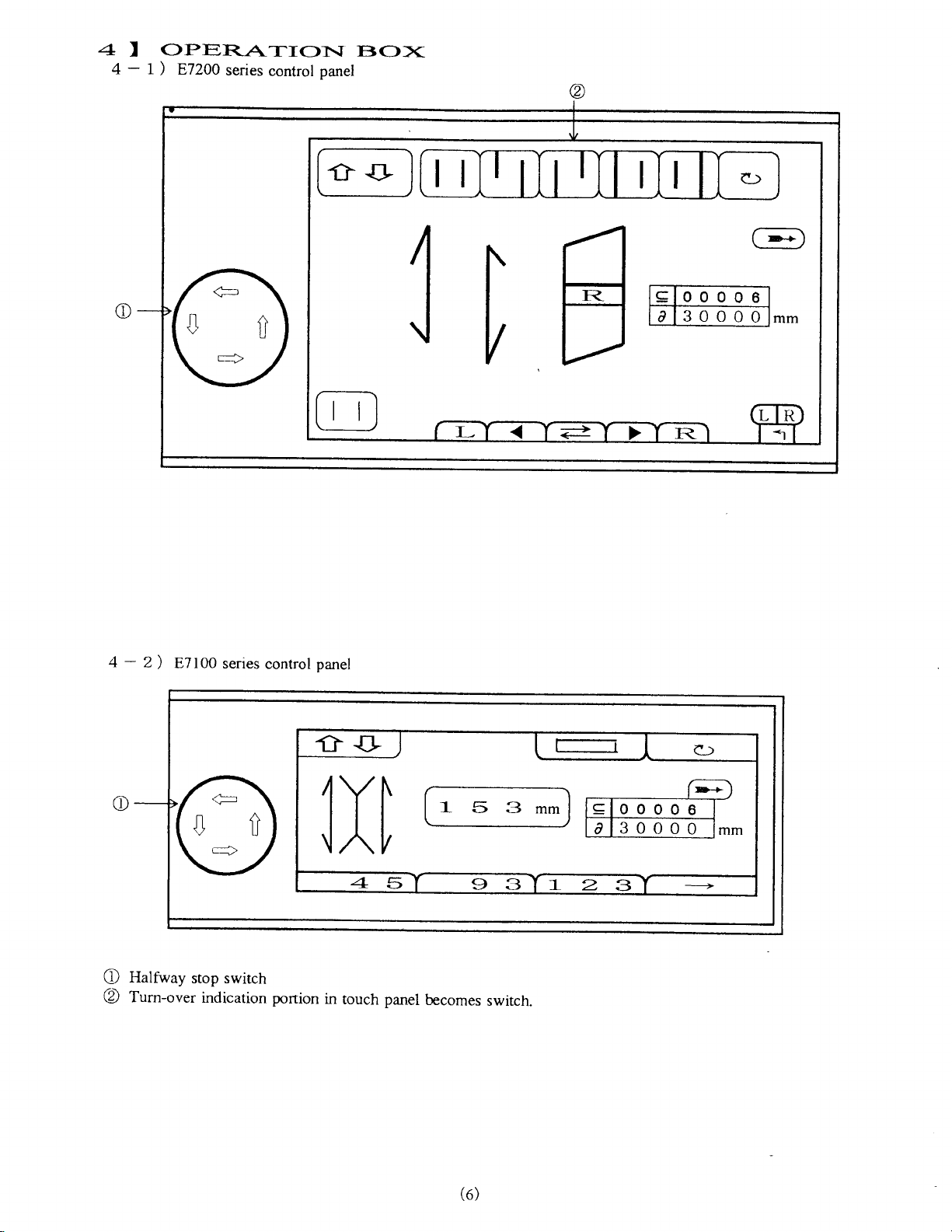

4I

4-

OPER.ATIOhI

|

E7200

)

series

control

ETO><

panel

tl

l;

ll

g

00006

30000

a

c)

-

4

c

Halfway

\t

Turn-over

@

2

87100

)

series

stop switch

indication

control

portion

panel

r'--;=;

]n

in

I

5

touch panel

becomes

switch.

00008

_c

I

30000

3I0

o

I0I

lD-+ I

L-------J

8l

0

0_l.-

F

m

(e)

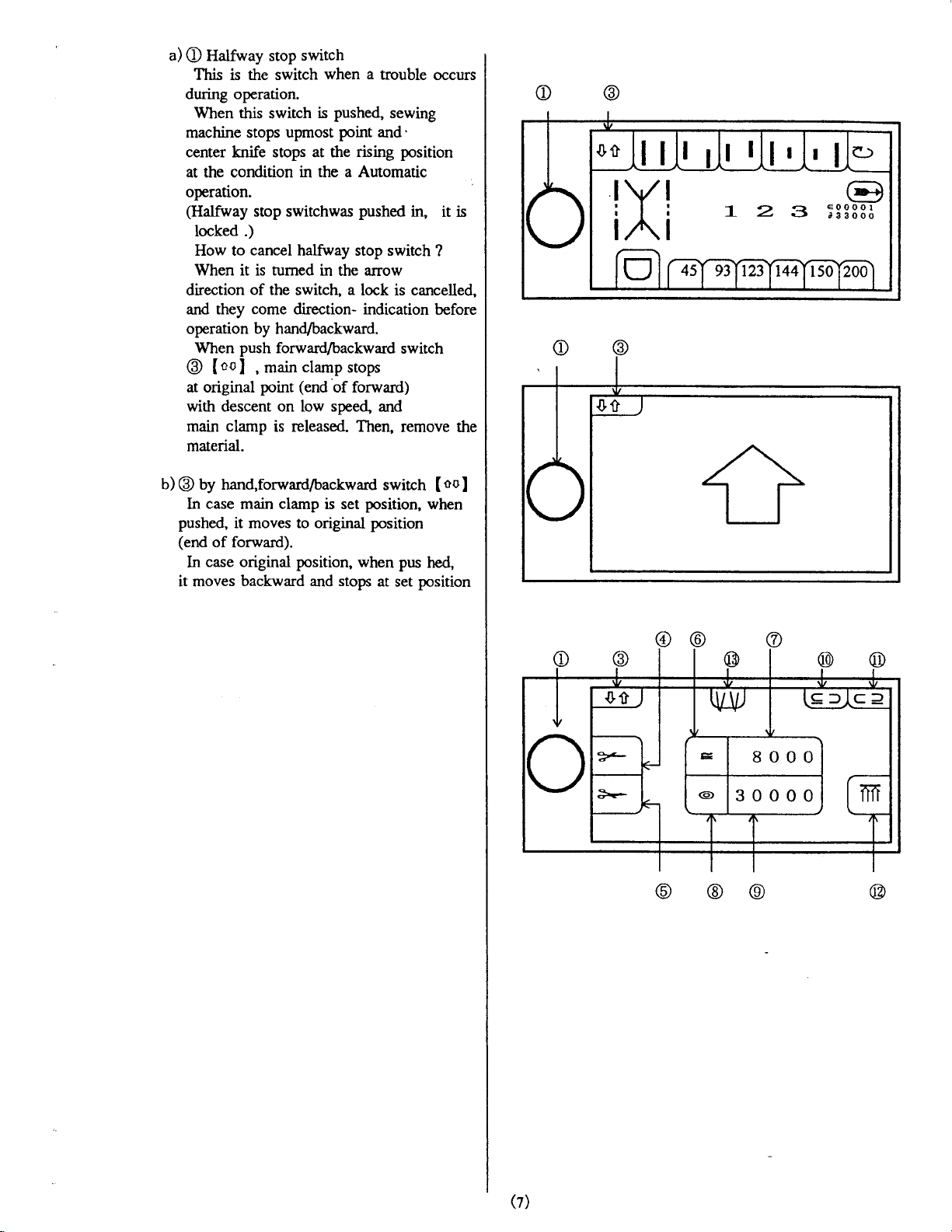

a)

Hafway stop

O

This is the switch

during

machine stops

center knife stops at the

at the condition

operation.

(Halfway

direction

and

operation by hand/backward.

@

at original

with descent on low speed

main clamp is released Then,

material.

b)@

ln

pushed,

(end

ln

it moves

operation.

When this

stop switchwas

locked

How to

When it is tumed

When

.)

cancel

of the

they come direction- indication

push

[ool

by hand,forward/backward

case

main clamp is set

it moves to original

of

forward).

case original position,

backward and stops

switch

when a

pushed,

swirch

main

,

point

is

upmost

in the a Automatic

halfivay stop switch

in the

switch, a lock is cancelled,

forward/backward

clamp

(end

of forward)

trouble

sewing

point

and'

rising position

pushed

arrow

switch

stops

and

remove the

swirch

position,

position

when pus

at

set

occurs

in, it is

?

before

Iool

when

hed,

position

!

I

(z)

F\

\?/

@

/61

5

OPER-A:TTOI\T

I

BEFOR.E

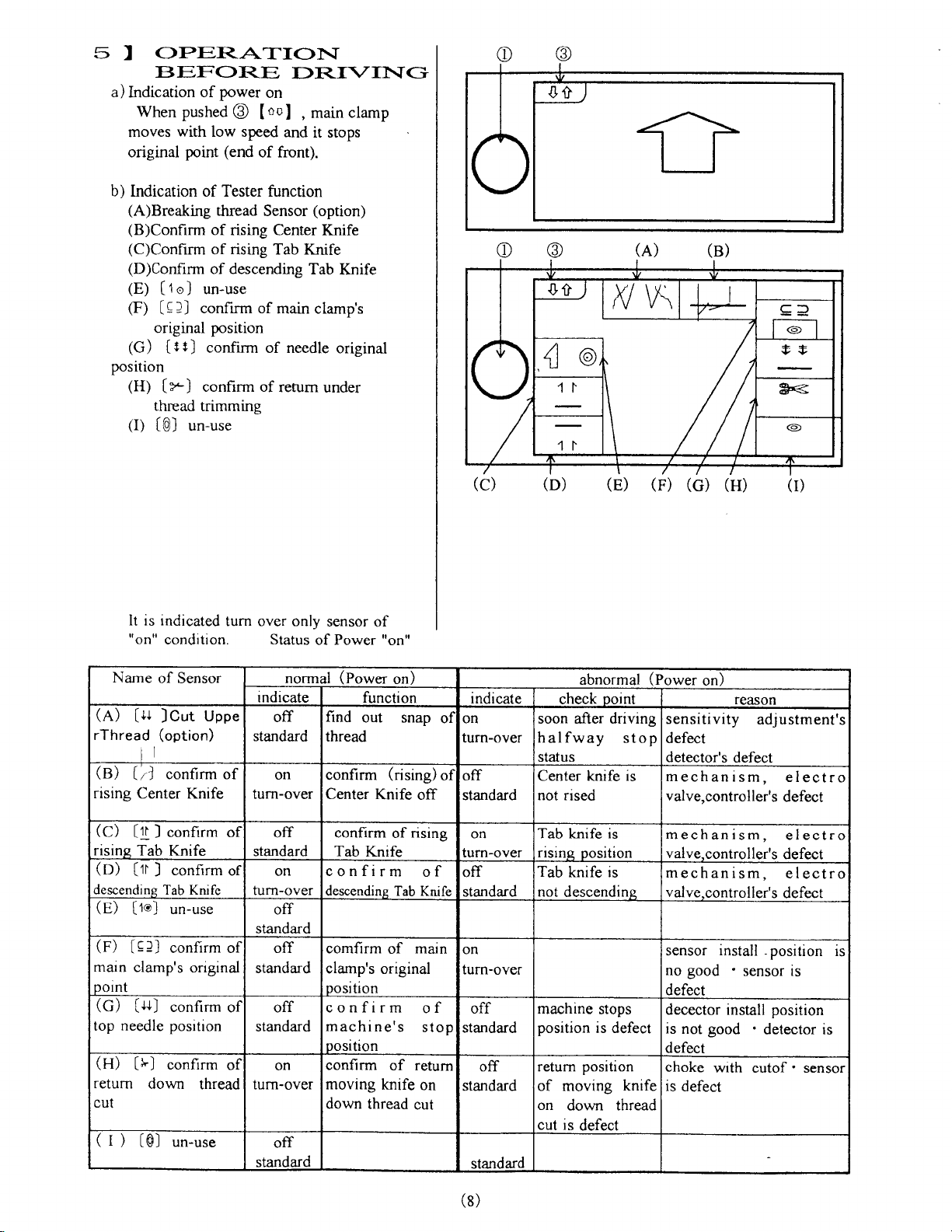

a)

Indication

When pushed

moves

original

b)

Indication of Tester function

(A)Breaking

(B)Confirm

(C)Confirm

(D)Confirm

(E)

[1o]

(F)

tqll

original

(G)

[rtJ

power

of

@

with low speed

(end

point

thread

of

rising Center Knife

rising

of

of descending

un-use

confirm of

position

confirm of needle

position

(H)

thread

O)

[r)

tOl

conhrm of

trimming

un-use

DR.I\

on

,

and

main

it stops

tool

of front).

Sensor

(option)

Tab Knife

Tab

main clamp's

refum

under

T

clamp

Knife

original

TG

It is indicated

turn

"on" condition.

Name

(A)

rThread

(B)

rising

(C)

risinq Tab

(D)

descending

(e)

/-\ r--t

tl.i LeJj conllrm of

main

potnt

(G)

top needle

(H)

return

nr rt

(l)

of Sensor normal

[u Jcut

[r-]

Center Knife

['1f

]

[1] J

[1o]

clamp's

[$]

[tsJ

down

tOl

uppe

(option)

confirm of

confirm of

Knife

confirm

Tab Knitc

un-use

original

confirm

position

confirm

thread

un-use

or

of

of

over only

Status

rndicate

off

standard

on

turn-over

off

standard

on

turn-over

off

standard

off

standard

off

standard

on

turn-over

off

standard

sensor

of

Power

(Power

of

"on"

on)

function

find

out

snap

thread

confirm

Center

confirm

Tab

c o n f ir

descending Tab Knife

comfirm

clamp's

(rising)

Knife

of

Knife

m

of main

original

rising

position

confirm

machine's

oosition

confirm

moving

down

of retum

knife

thread

cut

off

o f

of

stop

on

(c) (D)

indicate

ol

on

turn-over

ol

off

standard

on

turn-over

off

standard

on

turn-oYer

off

standard

off

standard

standard

(E) (F)

abnormal

point

check

soon after driving

halfway

status

Center knife is

not rised

Tab knife

risins

Tab

knife is

not

descendins.

machine

position

return posrtlon

of moving knife

on

down

cut is

5

IOn

oosi

stops

is defect

defect

stop

thread

(c) (H)

(Power

on)

reason

sensitivity

defect

detector's

mechanism,

valve,controller's

mechanism,

valve.controller's

mechanism,

valve,contro

sensor

good

no

defect

install

'

defect

decector install

is

not good

defect

choke

is

with cutof ' sensor

defect

adjustment's

electro

defect

electro

defect

electro

ll

er's defect

position is

sensor

is

position

'

detector is

(8)

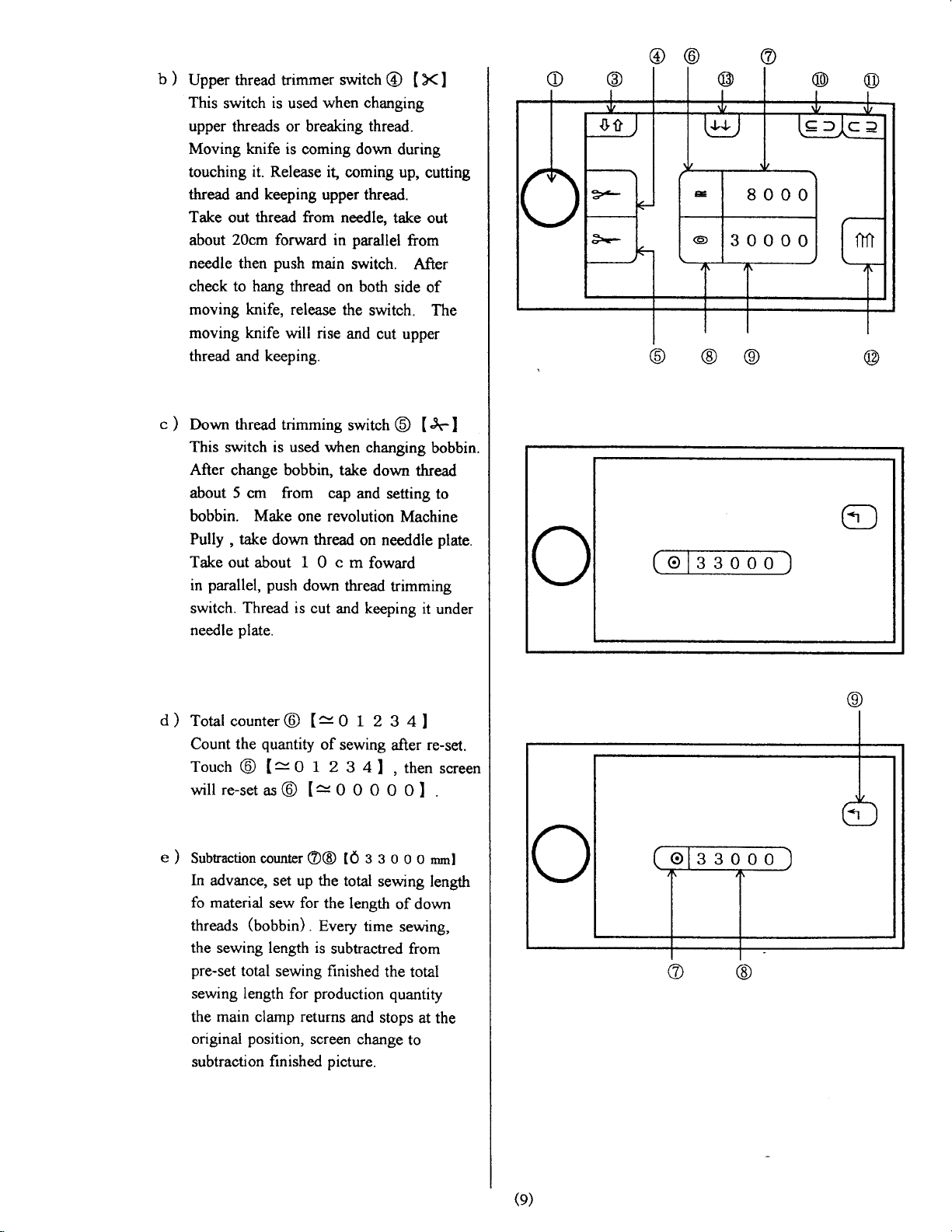

b)

Upper

This

touching

thread

Take

c)

thread trimmer

switch

upper

Moving knife

about

needle then

check to hang thread

moving knife, release

moving knife

thread and keeping.

Down thread trimming

This switch is

After change bobbin, take

about 5 cm from

bobbin.

Pully , take

Take

parallel, push

in

switch"

needle

is

used

threads or breaking

is coming down

it.

Release it,

keeping

and

thread from

out

20cm

forward in

push

will

used when changing

Make

one revolution

down

out about 1 0 c m

Thread

plate.

is cut

switch

when changing

thread.

coming up,

upper thread.

needle,

parallel

main

switch. After

on both

the

switch. The

rise

and

cut upper

switch

down

cap

and setting

thread

on needdle

foward

down

thread

and keeping it

@

t X I

during

cutting

take out

from

side

of

@ tJ.l

thread

Machine

trimming

bobbin.

to

plate.

under

o

@

\q/

A

LS/

@

@

O

d)

Total

counter@

Count the

Touch

will

e)

Subtraction counter

ln

advance, set up

fo material

threads

the sewing length is

pre-set

sewing

the main clamp returns

original

subtraction

quantity

@ [=

re-setas@

sew for

(UoUUln).

total

sewing

length for

position,

finished

O L 2

[=

of

sewing

O I 2

3 4

O O

[=0

O@ tO

production

screen change

3 3 0

the total

the length

Every time

subtractred from

finished

and

picture.

3 4l

after re-set.

then

I,

0 OI

0 o

mml

sewing

stops

length

of down

sewing,

the total

quantity

at the

to

screen

.

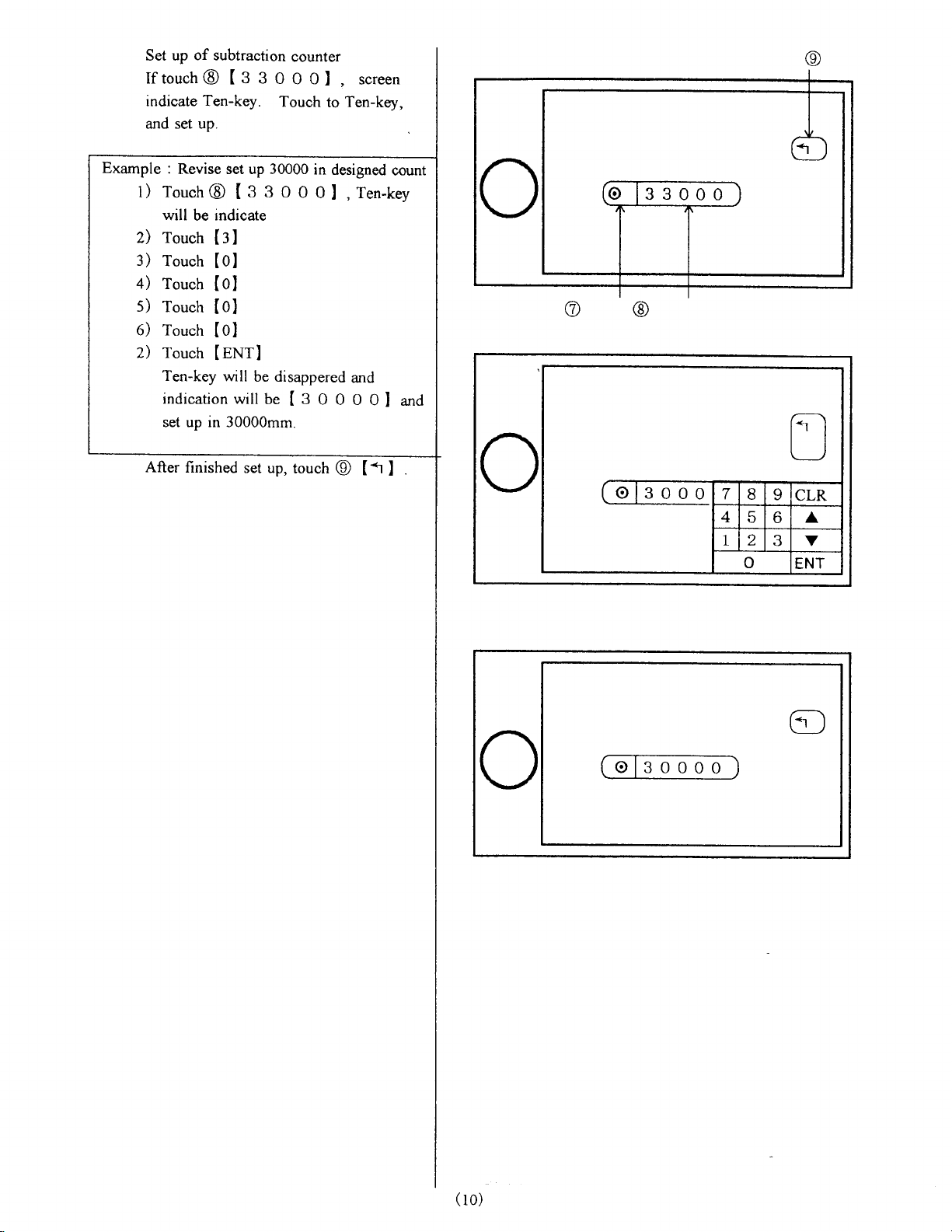

(e)

Set up

If

indicate Ten-key.

and

of

touch

set up.

subtraction

g

@ t

3

counter

0

0 0

Touch

screen

I,

to Ten-key,

Example

1) Touch@

z)

:)

+)

s)

6) Touch

2) Touch

After finished

:

Revise set up 30000

g

3 0

I

will

touch

rouch

touch

Touch

Ten-key

indicationwill

set up rn 30000mm.

indicate

be

[31

[01

[ol

lol

[01

lgNrl

will

be disappered

be

set up,

IgOOO0l and

in

0

0

touch

designed

l

.Ten-key

and

@ [1

I

count

o

o

@IersCD

(

ro)

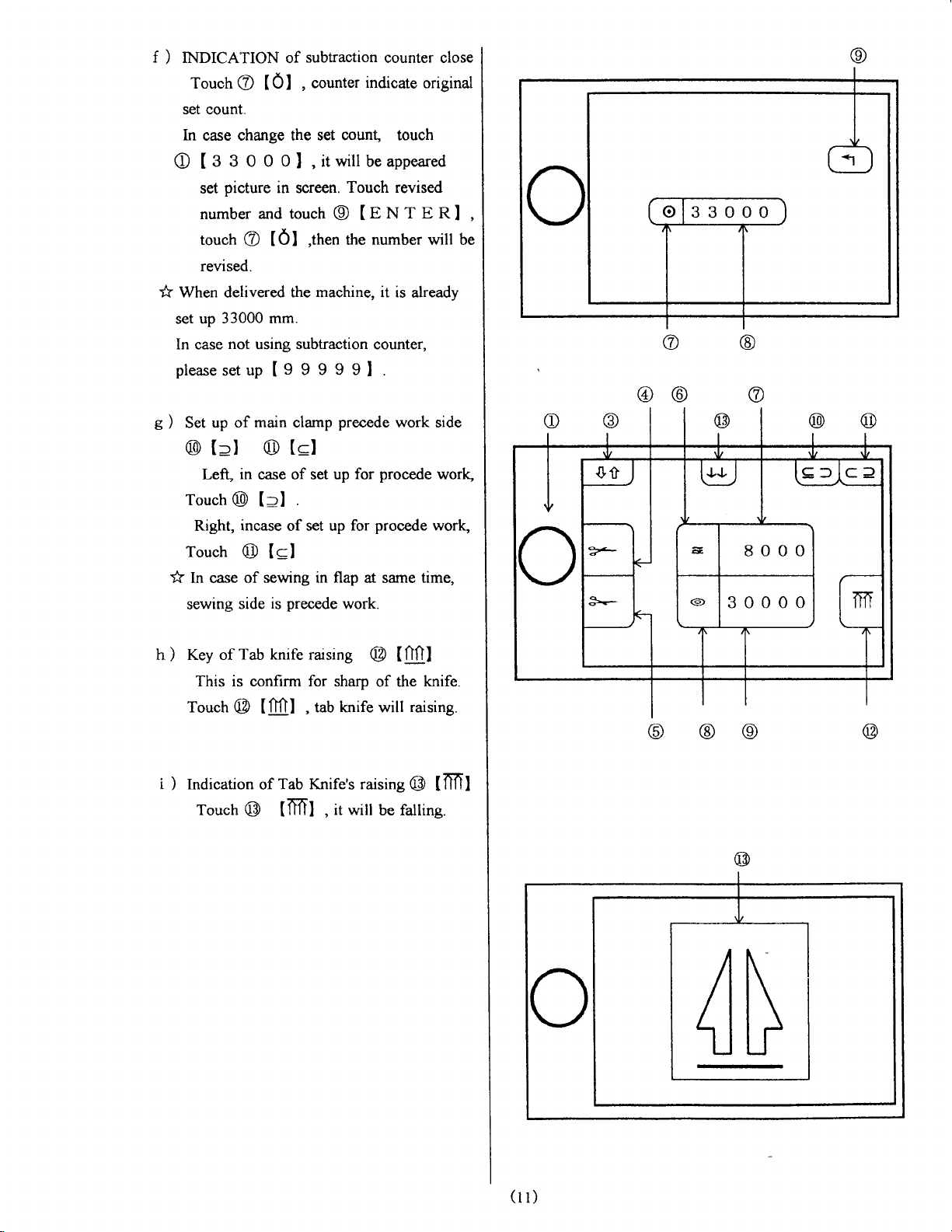

f

INDICATION

)

Touch@

(01

of

,

subtraction

counter

set count.

ln

O

* When delivered

set up

In case

pleasesetup[999991.

Set

)

e

@ [:l @

Touch

Touch

* [n case of

sewing

change the set

case

g

3 o 0 o

t

picture

set

number

touch

revised.

33000 mm.

not

up of main clamp

in screen.

and touch

@ [0]

the machine, it is

using subtraction counter,

(ql

Left, in

Right,

@ [:l

incase

@ Isl

side

of set up for

case

of set up

sewing in flap

precede

is

count, touch

itwill beappeared

I,

Touch revised

@

the

,ttten

precede

.

for

work.

counter close

indicate

Ie

number

procede

at same time,

original

NT E RL

will be

already

work side

procede

work,

@@

work,

h) Key

of

Tab

knife rarsing

This is confirm for sharp

Touch

i

Indication of

)

Touch

tfifll

@

Tab Knife's raising

@ [nfrl

@

of the

tab knife will

,

it will

,

be falling.

t00t

knife

raising.

@ tml

\0/

fol

.9

@

/ih

\atl

I

4N

(n)

6

6

a

b

OPER.ATIO5I

f

-

f

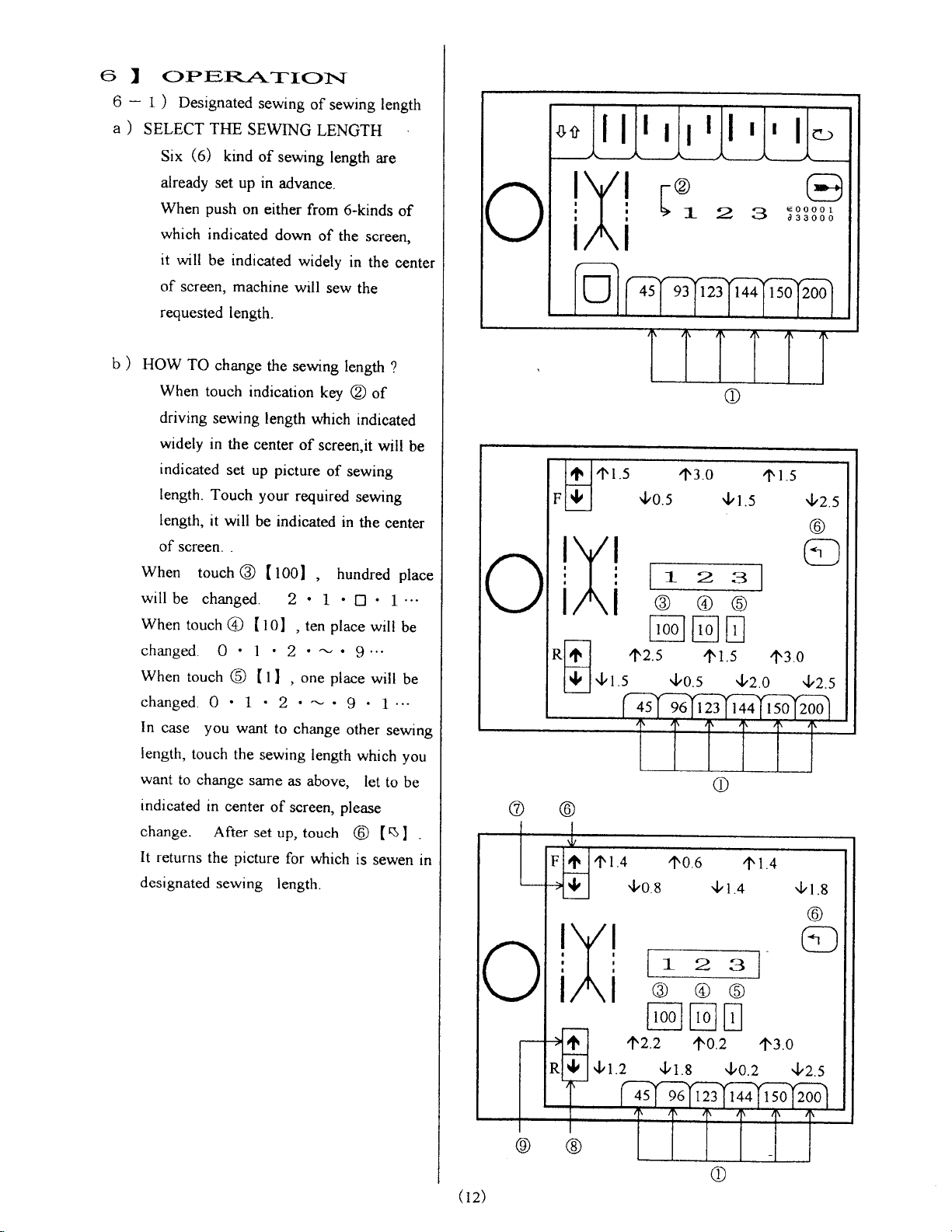

Designated

)

seLgCT

)

Six

already set

When push

which

it

will

of screen, machine

requested

HOW

)

When

driving

wrdely

indicated

length.

length,

of

screen. .

When

will

be changed.

When

changed.

Whentouch@

changed.0

In

case

length,

want

to

indicated

change.

It

returns

designated

sewing

TFm

SEwING

(6)

kind

of

up in

on either

indicated

be indicated

TO

change

touch

sewing

in

set up picture

Touch your

it

will

touch

touch

@ I

0 l.).*.9.'.

you

touch

change

in

center

After

the picture

sewing

down

length.

the sewing

indication

length

the

center

be indicated

toOI

@

[

tOI

ttl

1.2.-.9

want

to

the

sewing

sarne

of screen, please

set up, touch

of

sewing

LENGTH

sewing

advance.

length.

length

are

from

6-kinds

of the

screen,

widely

will

of

required

2,

,

,on"placewill

change

as

for

in

sew

the

length

key

@

which

indicated

screen.it

of

sewing

sewing

in

the

hundred

,

.

L

D

ten place

other

length

which you

above,

which

let

@

is

the

of

will

.

will

sewen

length

of

center

?

be

cenrer

place

1...

be

be

1...

sewing

to be

$

t

I

.

rn

@

I

RI

/F\

a,

Ol.5

ll^2.s

Ot.s

ffi

Ol.4

9oa

,f3.0

Oo.s

a

@

Or.s

2

@@

ujE[qiu

fls 430

.l,o.s

c

,106

{t.+

3

{z.o

41.4

,ttl5

tz.s

@

6]

,lrz.s

.l,t.s

Q2)

,lrt.Z

l-

+2.2

Ot.g

2

lo.Z

3

'13.0

'l'O.Z

@

,lrZ.S

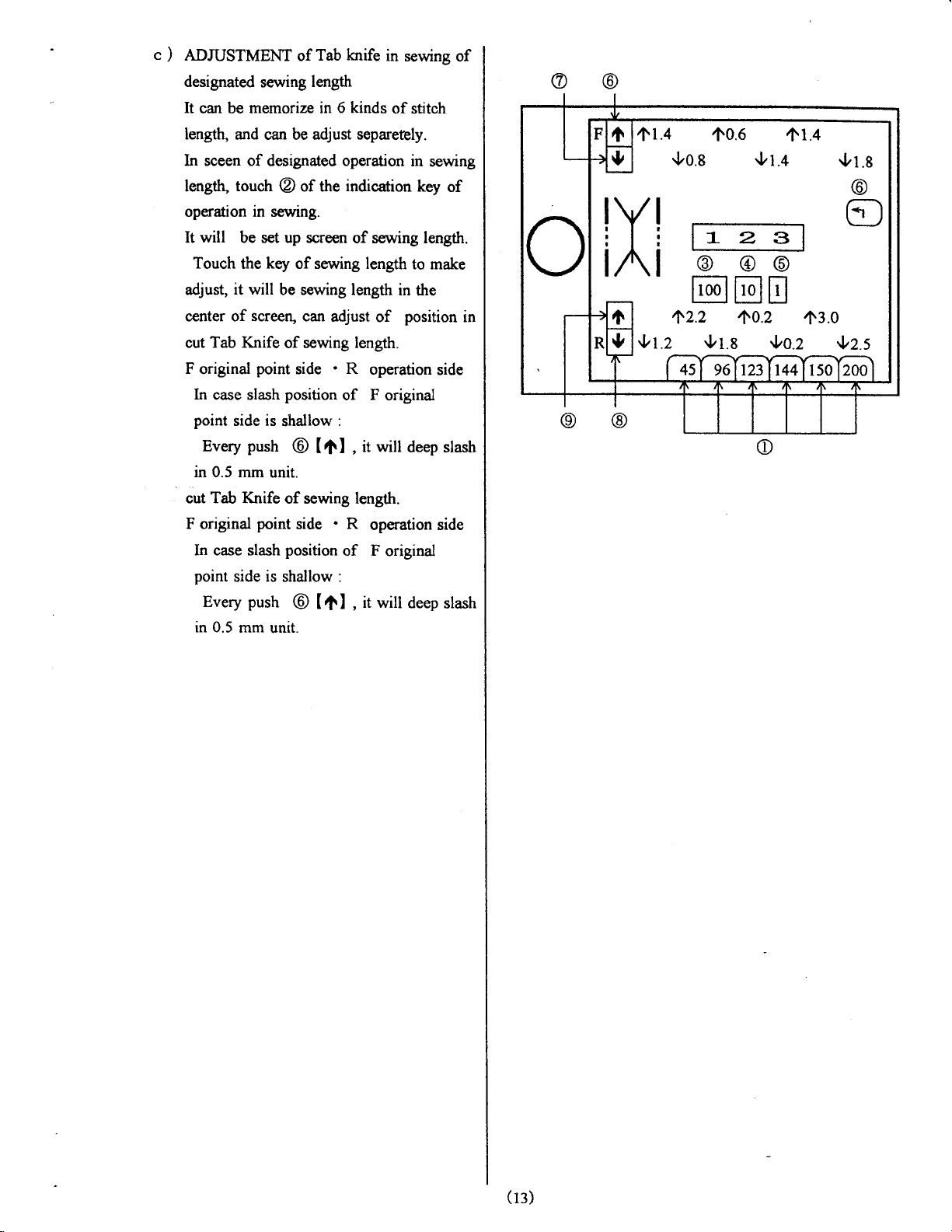

c)

ADruSTMENT

designated

It

can

length,

ln sceen of

lengttr,

operation in sewing.

will

It

Touch

adjust,

center of screeq can

cut Tab

F

original

ln

point

Every

in 0.5 mm

cut

F original

In case slash

point

in 0.5

memorize in

be

and can be adjust separetbly.

touch

be set up screen

the

it will

Knife

point

case slash

side is

push

Tab Knife

point

side is shallow :

push

Every

mm unit.

knife

Tab

of

sewing

length

6 kinds

designated operation in

of the

@

key

of sewing length

be sewing length

adjust

sewing length.

of

side . R

position

shallow

@ tOI

unit.

of sewing length.

.

side

position

trt l

@

in

of stitch

indic*ion

of sewing length.

in

of

operation

of F

original

:

it will

,

R

operation side

of F original

it will

,

sewing

position

deep slash

deep

of

sewing

key

of

to make

the

side

slash

in

@@

Ol.4

ltt0.6

go.s

,t

Or.+

1.4

Or.e

@

f-23

@

@@

@tr8

{t.z

+2.2

gr.s

+0.2

{oz

,13.0

{z.s

(t:)

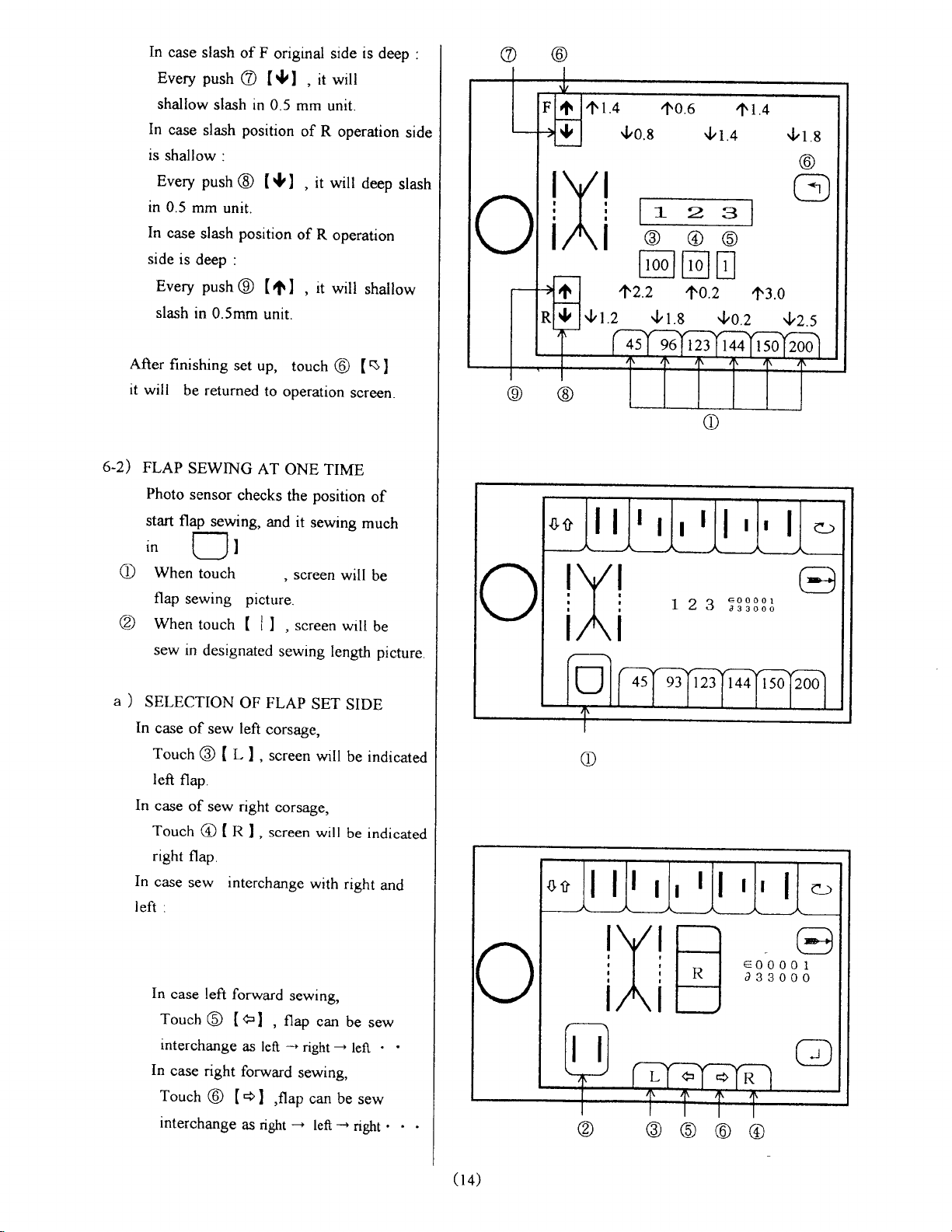

6-2)

C

@

In

case

Every

shallow

In

case

is

shallow

Every

in 0.5

In

case

side

Every push

slash

After

finishing

it

will

FLAP

Photo

start

.

rn

When

flap

When

sew

slash

of F

push

@ I*l

slash in 0.5

position

slash

:

push@

mm

unit.

position

slash

is

deep :

@

in

0.5mm

set

be returned

SEWING

sensor

flap

sewing

in

checks

sewing,

l-] ,

r

(_J

touch

picture.

touch

(

designated

origural side

it witt

,

mm

of R

I9l

( rt

unit.

up,

to

AT

and it

I

it will

,

of R

it

l

,

touch

operation

ONE TIME

position

the

sewing

screen

,

screen

L

sewing

is

deep

unit.

operation

deep

operation

will

shallow

s

@ [

screen.

of

much

will

be

will

be

length

picture.

I

:

side

slash

(

\!/

A

\g/

f

1.4

Oo.e

+2.2

,f0.6

12

@

@@

[00J

[gJ u

10.2

Or.s

2 3

,t

Or.+

3

{oz

53333;

t.+

13.0

gz.s

A

SELECTION

)

In

case

Touch

left

In

case

Touch

right

In

case

left

:

In

Touch@

interchange

ln

Touch

interchange

OF FLAP

of

flap.

of

flap.

sew interchange

case left

case

left

sew

t-

@ t

sew right

n

@ t

forward

(el

as left

right

forward

@

[+l

as right

corsage,

screen

I

,

t..".n

I,

,

,flup

SET

wrll

corsage,

will

with

sewing,

flap

can be

*

right

sewing,

can

-

left

SIDE

be indicated

be indicated

right

and

sew

-

left

be sew

-

riglrt

.

a)

!Y!

tn.t

F

tl

(

l4)

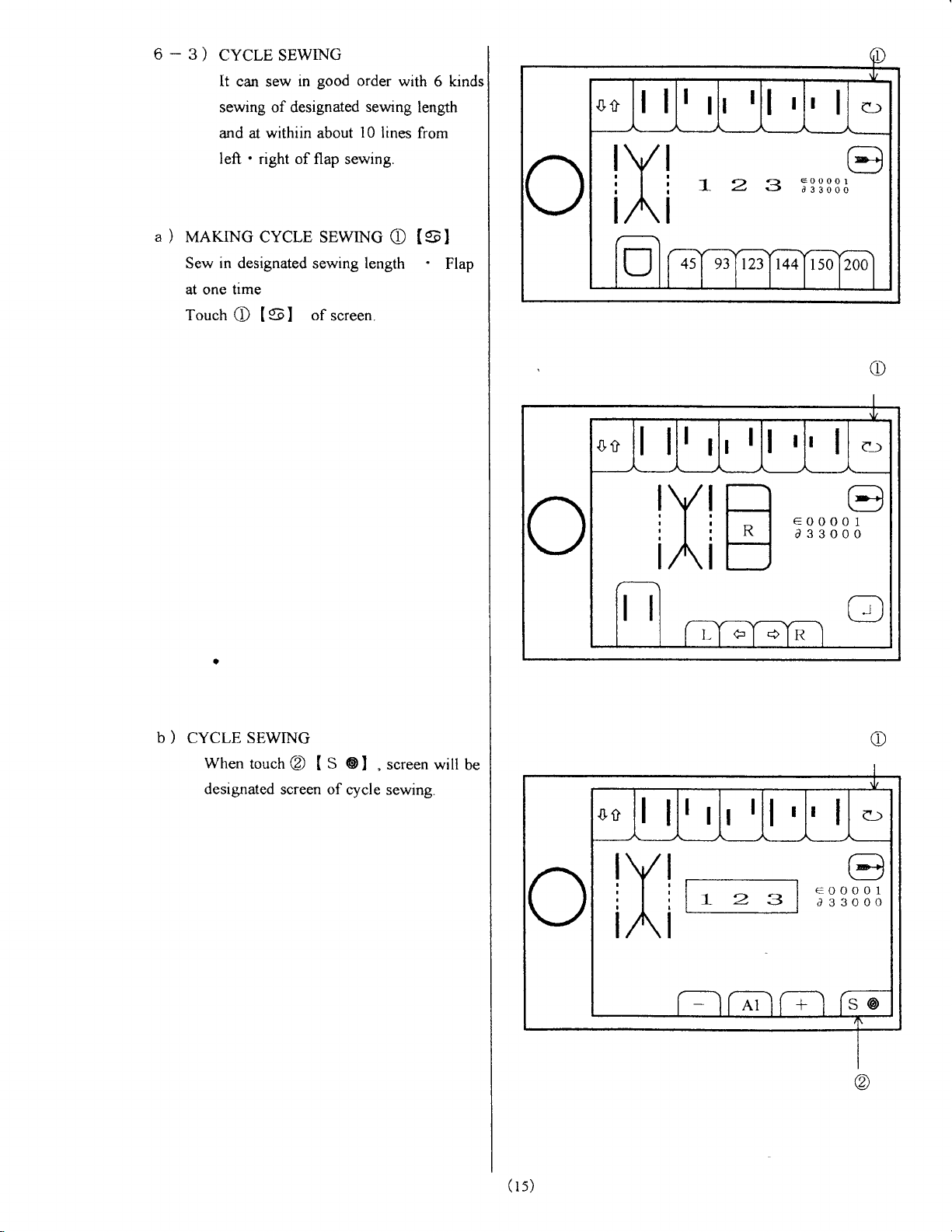

6-3)

a

uernvc

)

Sew

at one time

Touch

CycresEwrNG

good

lt

can sew

sewing of designated

and at

left . right of flap

in

withiin about

order

sewrng

10

sewing.

cYcLE sEwrNG

in

designated sewing length

of

C I5l

screen.

with

lines

C tsl

6 kinds

length

from

Flap

c

b)

CYCLE SEWING

Whentouch@

designated

tS

screen of

@l

.screenwillbe

cycle sewing.

(

r s)

1_

2

3

C

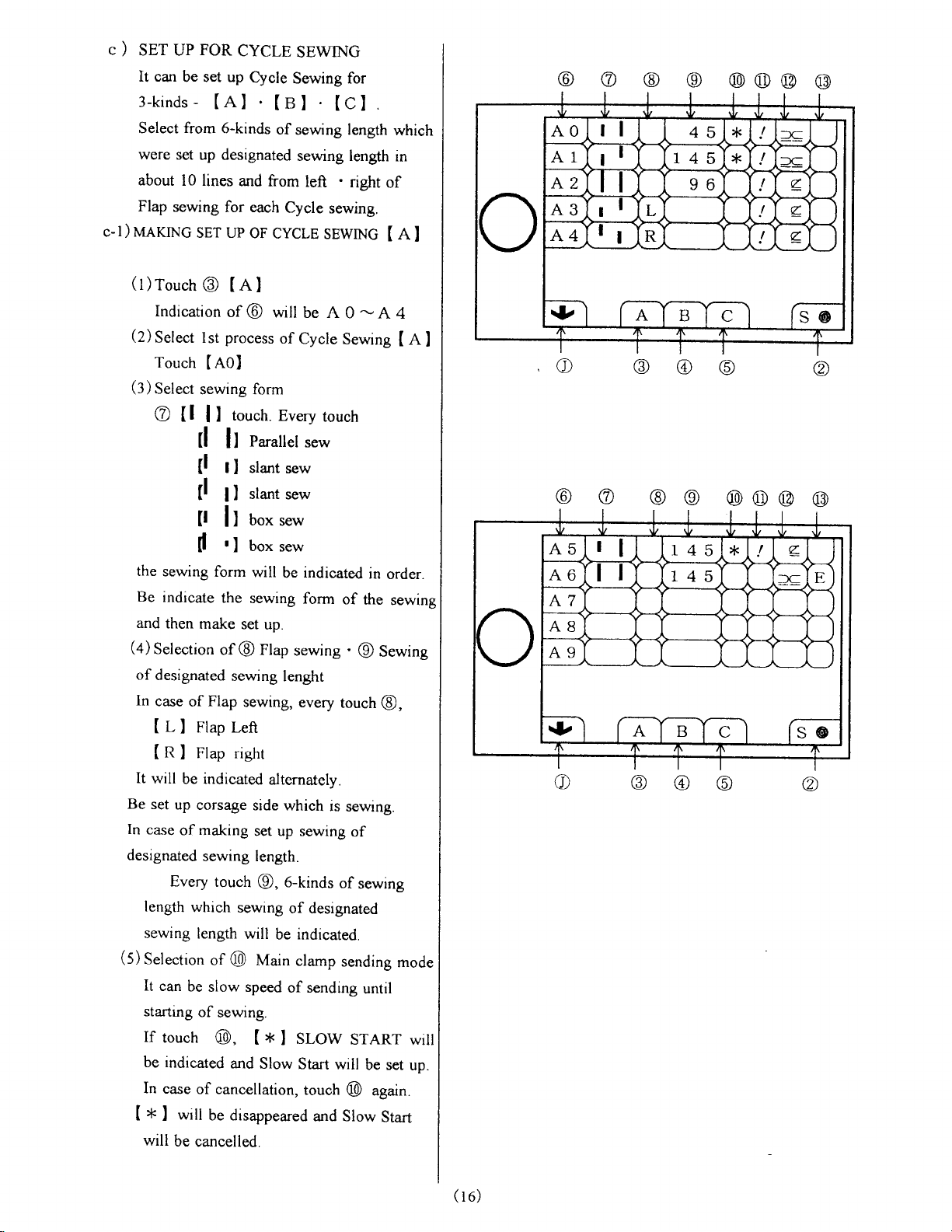

SET

)

UP

It can

be set up

3-kinds-

from

Select

were

set

about

l0 lines

Flap

sewing

c-l) MAKTNG

sET up

FOR

CYCLE

Cycle

Sewing for

.te)

(al

6-kinds

up designated

for each

and

oF

of

from

Cycle

cycl,E

SEWING

.(CI

sewing length

sewing length

left

sewing.

sEwrNG

-

right

.

of

which

in

A

I

,/a\

\,@

I

@

6l

@

@

@

@

(l)Touch

Indication

(2)

Select lst

Touch

(3)Select

@

tl I I

the

sewing

Be

indicate

and

then

(4)

Selection

of

designated

In

case

of

ILl

[RI

It

will

be

Be

set

up

In

case

of making

designated

Every

length

sewing

(5)

Selection

It

can

be

starting

If

touch

be indicated

In

case

*

will

[

I

will

be

@ tAl

of

will

@

process

Ao)

I

sewing form

touch.

d

ll

ll slantsew

tl

I

[l

ll

tl

ll

'l

il

form

the

make

of

sewrng

Flap

of

Every

Parallel

slantsew

bo*r"*

bo*

r"*

will

be

sewing

set

up.

nlap

@

lenght

sewing,

sewing

FlapI-eft

Plap rignt

indicated

corsage

sewing length.

touch

which

length

of @ Main

slow speed

of

sewing.

@,

of cancellation,

be disappeared

cancelled.

alternately.

side

set up

@,

sewing

will

(

*

and

Slow

which

O-kinds

of designated

be

of sending

I

be A

O

Cycle

Sewine

touch

sew

indicated

form

of

.

every

touch

is

sewing.

sewing

indicated.

clamp

St

Start

touch

of

of

sending

Ow

START

wilt

@

and Slow

-

A 4

in

order.

the

sewing

Sewing

@

@,

sewing

mode

until

be set

again.

Start

I

A

will

up.

I

to_/

@

fo\

v@

@@

@

@

(r6)

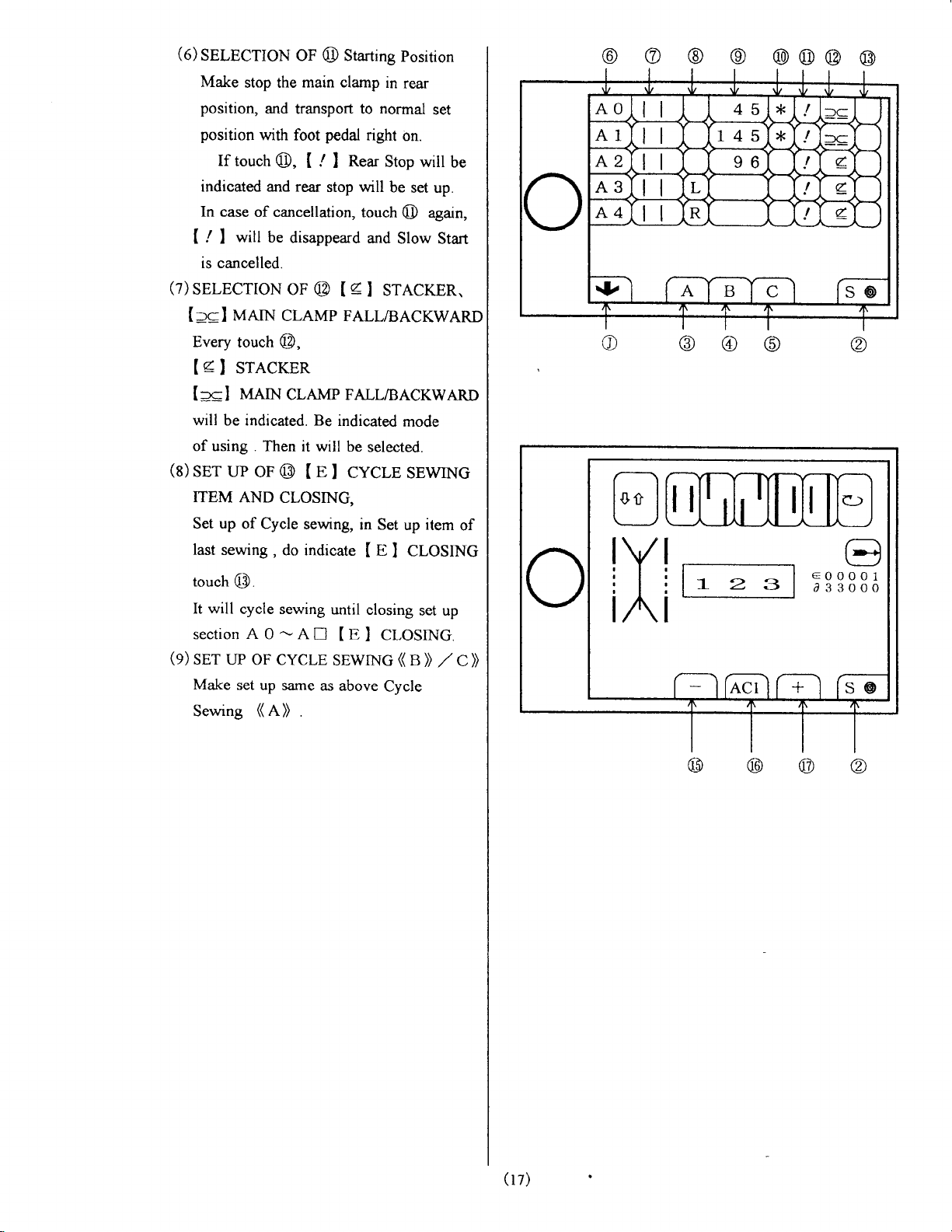

(o)

SelPCuoN

Make

stop the

position,

position

If

touch

indicated and rear

In

case ofcancellation,

will be

[ / I

is cancelled.

(7)SELECTTON

uerN

[:cl

Every

touch

(

4

srecrun

I

[::cl

will

of using .

(s)

ser uP

ITEM

Set

last

Mnnl

be indicated. Be

AND

up

of Cycle

sewing,

OF @ Starting

main clamp

and

transport to

with

foot

@, [

disappeard

OF

cLAMp

@,

cLAMP FALLTBACKwARD

Then it will

oF

@ t

CLOSING,

seu'ing,

do indicate

position

in

rear

normal

pedal

right

on.

Reat

./

I

stop will

@ Ie

Stop will

be

touch

@

and

Slow

SreCrrn.

I

set up.

again,

FALL/BAcKwARD

indicated

be

e

cycle

I

mode

selected.

sEwrNG

in Set

up

e

CLOSINC

I

I

item

set

be

Start

of

@

@@

ll

@

'r

rrl

@

@

@

@

e)

touch

It will

section A 0

(9)

SET

Make

Sewing

@

cycle sewing

-An

UP oF CYCLE

set

up same

(

A)

as

.

until

closing

(

E

CLOSTNG.

I

SEWING

above

Cycle

set up

KB))

./

C>,

r_

2

3

(rz)

Loading...

Loading...