Page 1

INDUSTRIAL SEWING MACHINE

MODEL

PLK-G-PAL

TECHNICAL MANUAL

Operation Panel

A180E606P12

Page 2

Page 3

Contents

[1] For safe use ____________________________________________ [1]-1

[2] Precautions for use ______________________________________ [2]-1

[3] Explanations of basic screen, icons and operation ____________[3]-1

1.Screen configuration.........................................................................................[3]-1

2.Explanations of Standard screen 1...................................................................[3]-2

3.Explanations of Standard screen 2...................................................................[3]-3

4.The Up Counter screen is explained below ...................................................... [3]-3

5.The Bobbin Winding screen is explained below................................................ [3]-4

6.Explanations of basic icons............................................................................... [3]-4

7.Explanation of operations.................................................................................. [3]-5

8.Adjusting the Liquid Crystal Contrast................................................................ [3]-6

[4] Sewing Data Compatibility ________________________________ [4]-1

[5] Reading, writing and erasing data __________________________ [5]-1

1.USB...................................................................................................................[5]-1

2.Reading............................................................................................................. [5]-2

3.Writing............................................................................................................... [5]-5

4.Erasing.............................................................................................................. [5]-6

5.Reading data with shortcut icons (Reading from internal memory) .................. [5]-7

6.Rename the data number ................................................................................. [5]-8

[6] Creating stitching data ___________________________________ [6]-1

1.Flow of data creation......................................................................................... [6]-1

2.Description of arrow input screen...................................................................... [6]-4

3.Description of menu.......................................................................................... [6]-5

4.Skip jogging....................................................................................................... [6]-6

[7] Methods of creating sewing data ___________________________ [7]-1

1.Linear input ....................................................................................................... [7]-1

2.Arc input............................................................................................................ [7]-4

3.Circle input........................................................................................................ [7]-8

4.Curve input........................................................................................................[7]-11

5.Broken line input ............................................................................................... [7]-15

6.Point input......................................................................................................... [7]-18

7.Code data input................................................................................................. [7]-20

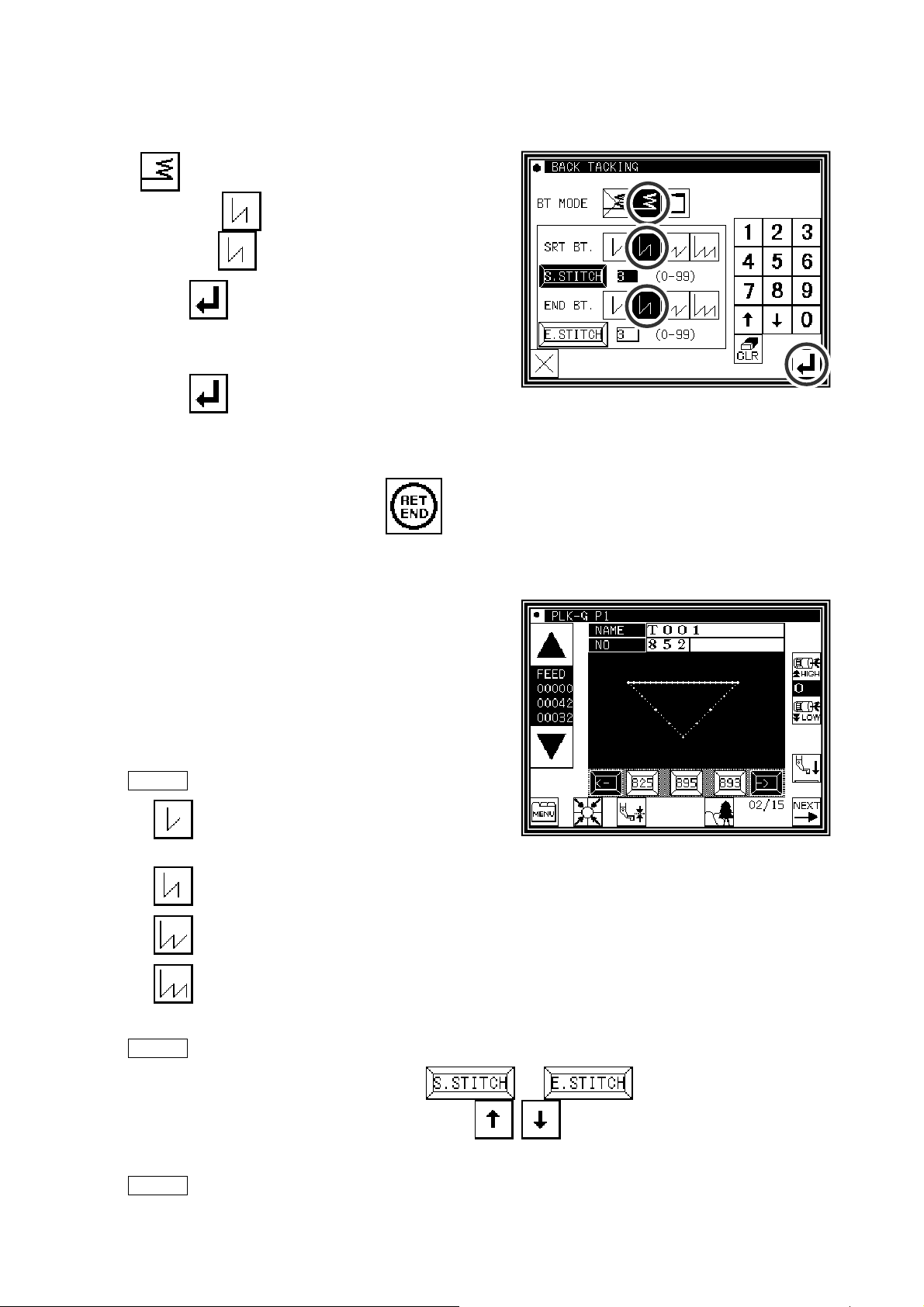

8.Back tacking (start/end back tacking) ............................................................... [7]-25

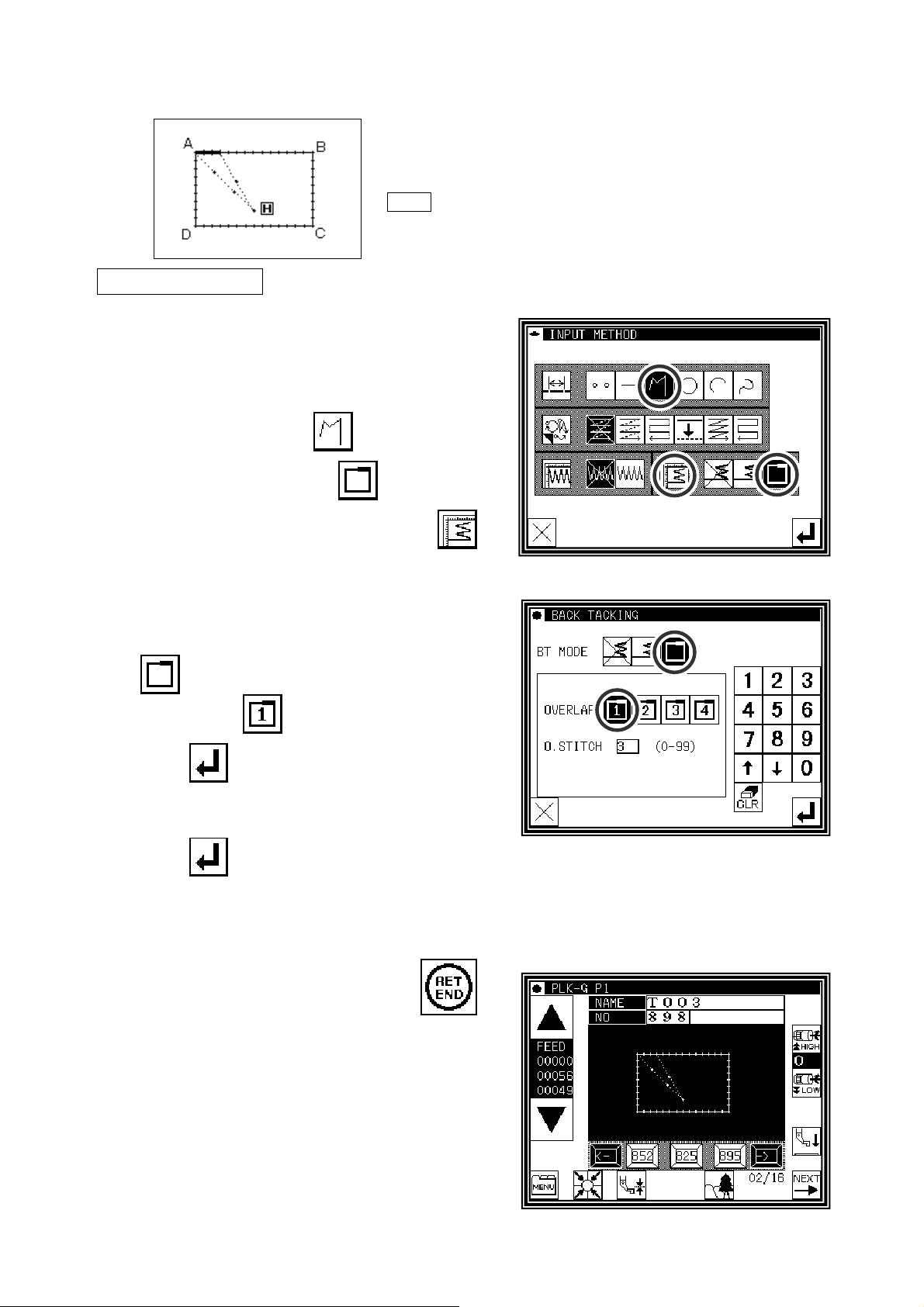

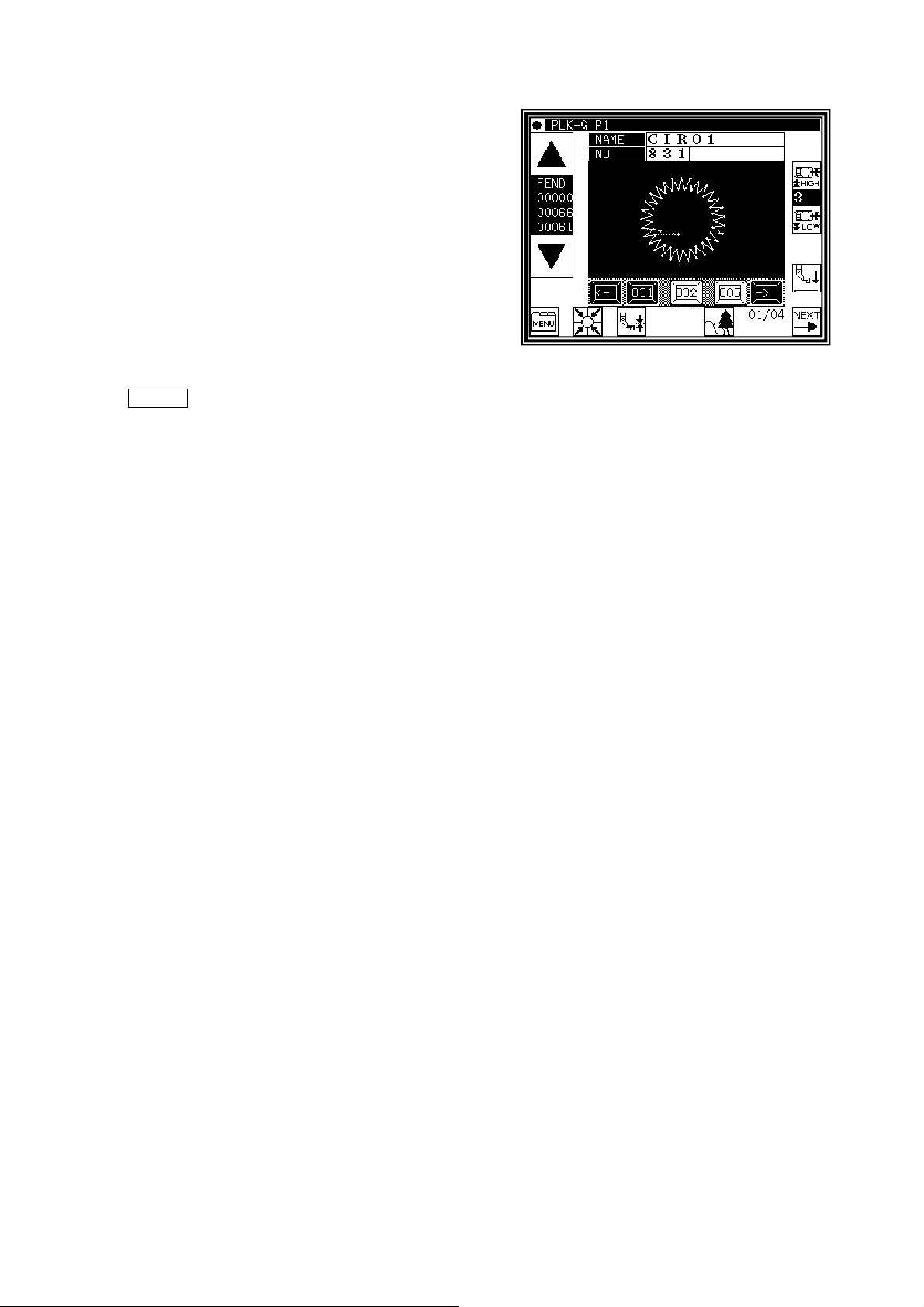

9.Back tacking (overlap back tacking).................................................................. [7]-27

10.Multiple stitching.............................................................................................. [7]-29

11.Offset stitching (with overlap back tacking)..................................................... [7]-32

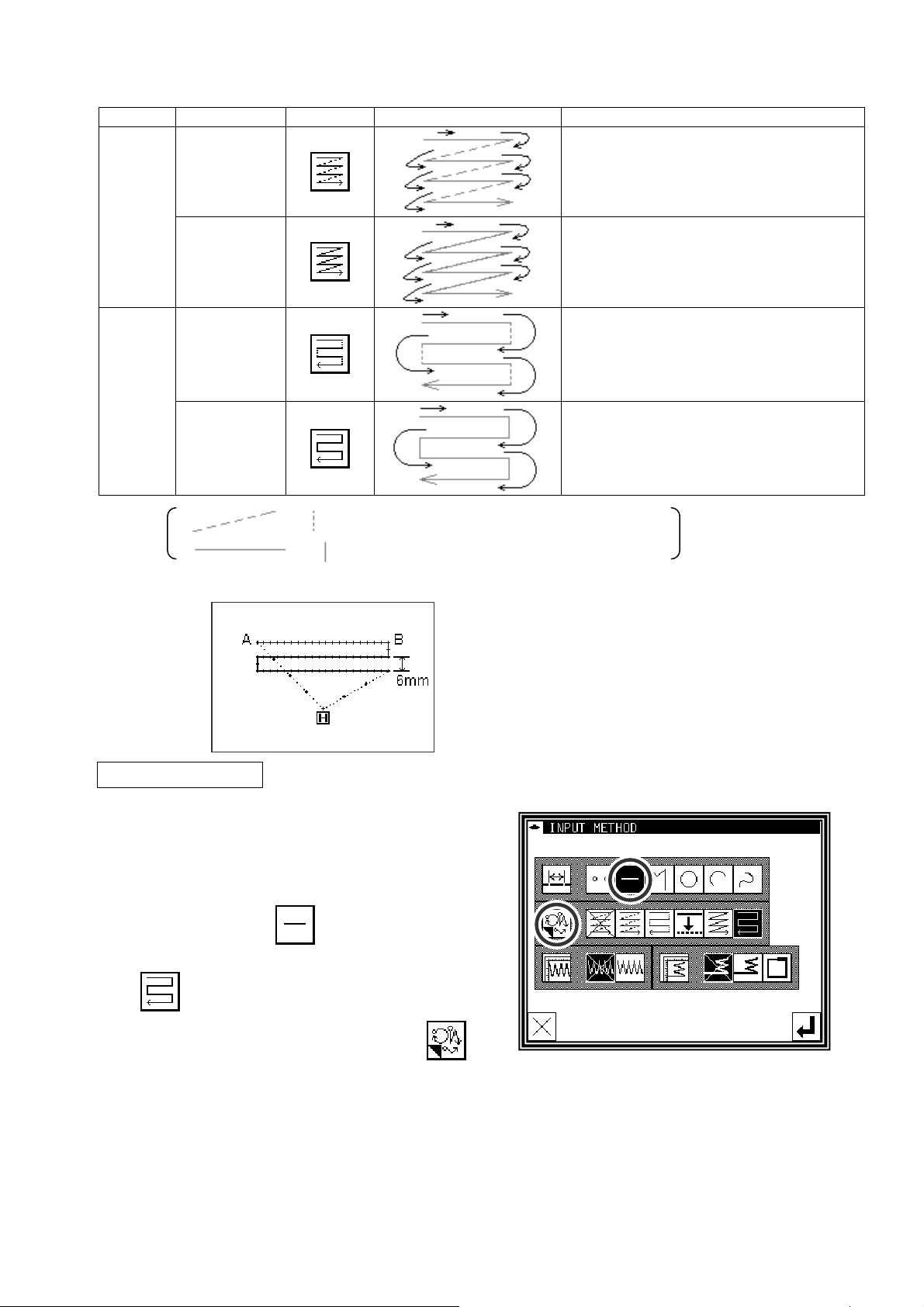

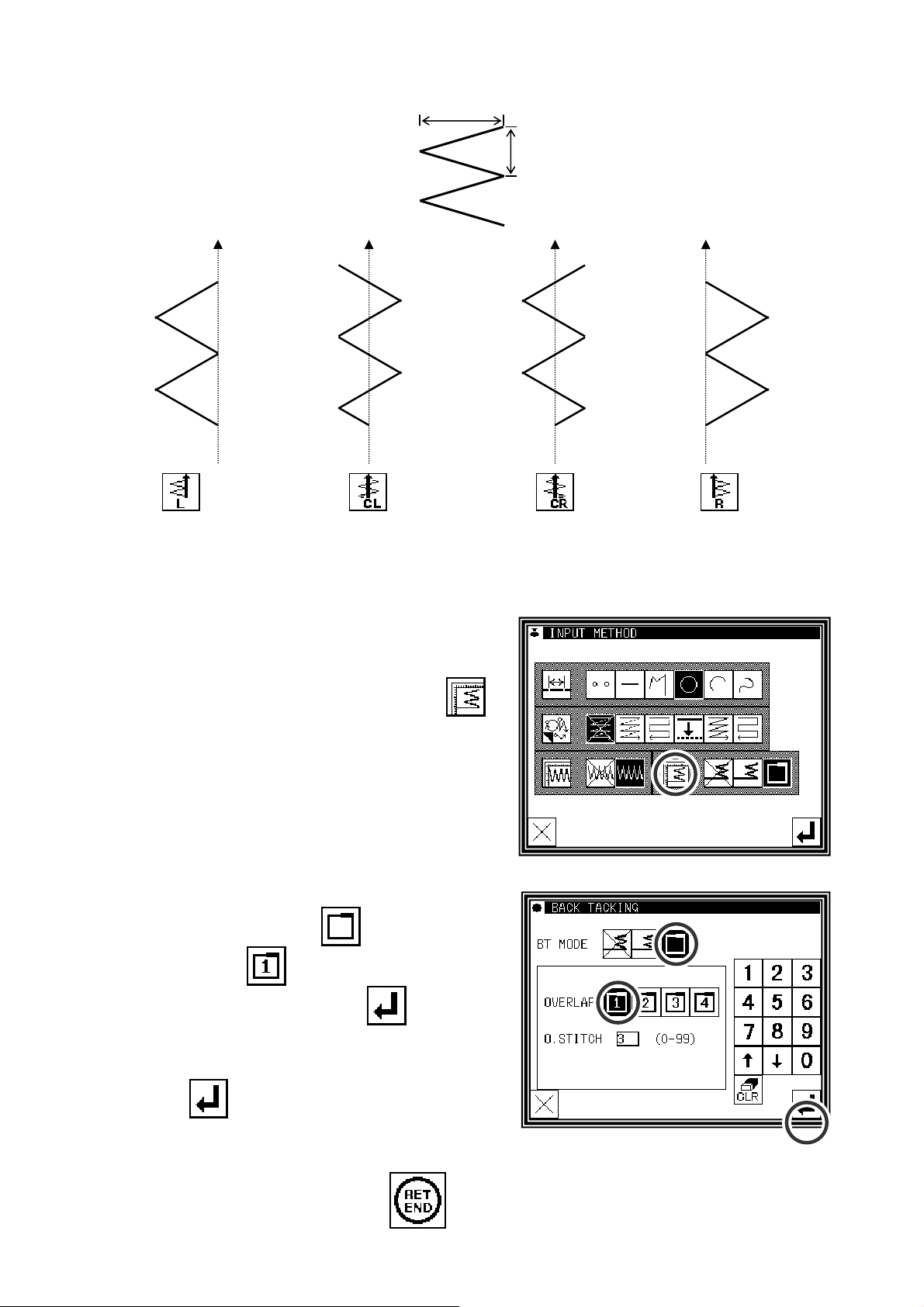

12.Zigzag stitching (with overlap back tacking).................................................... [7]-34

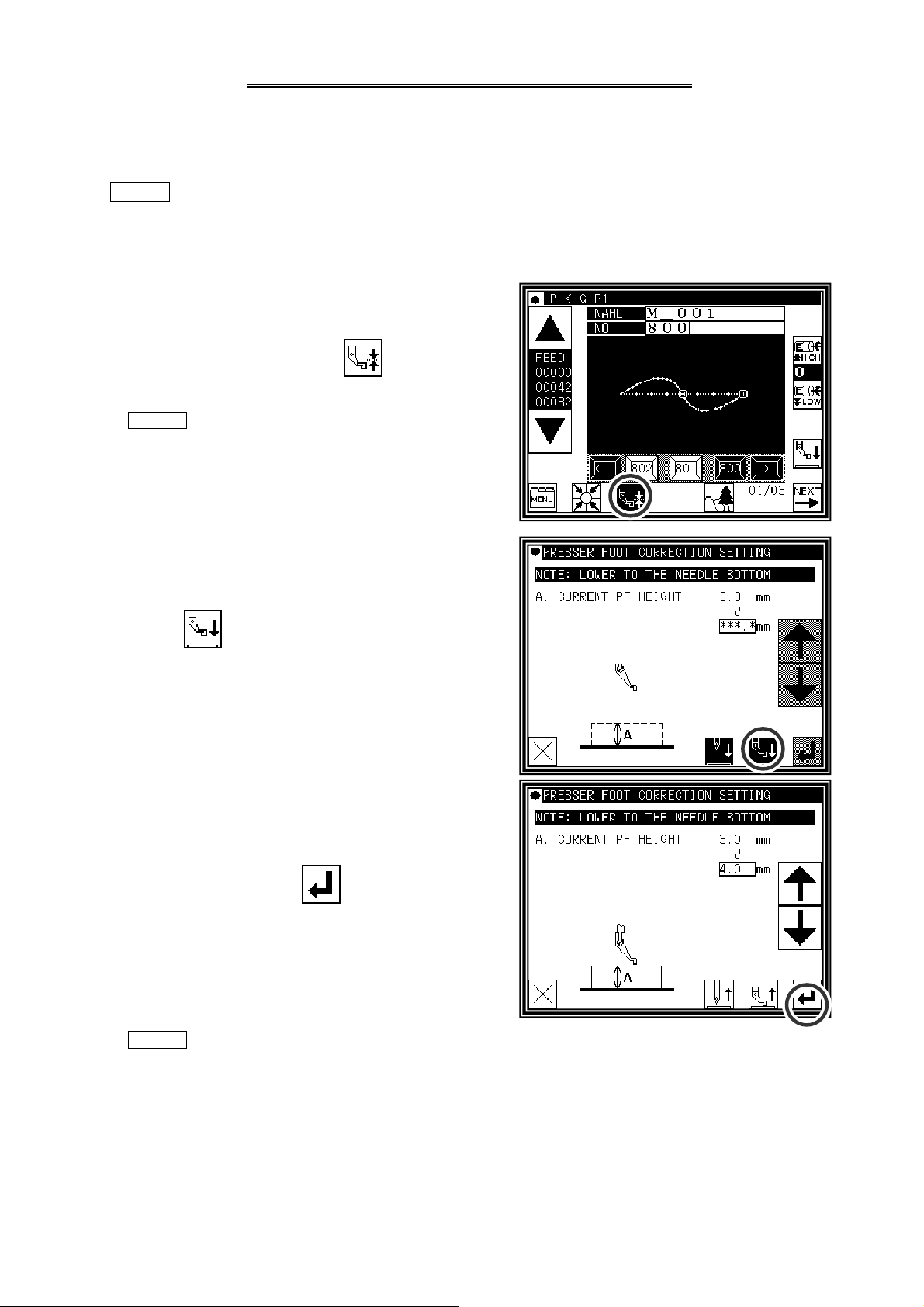

[8] Controlling the Presser Foot_______________________________ [8]-1

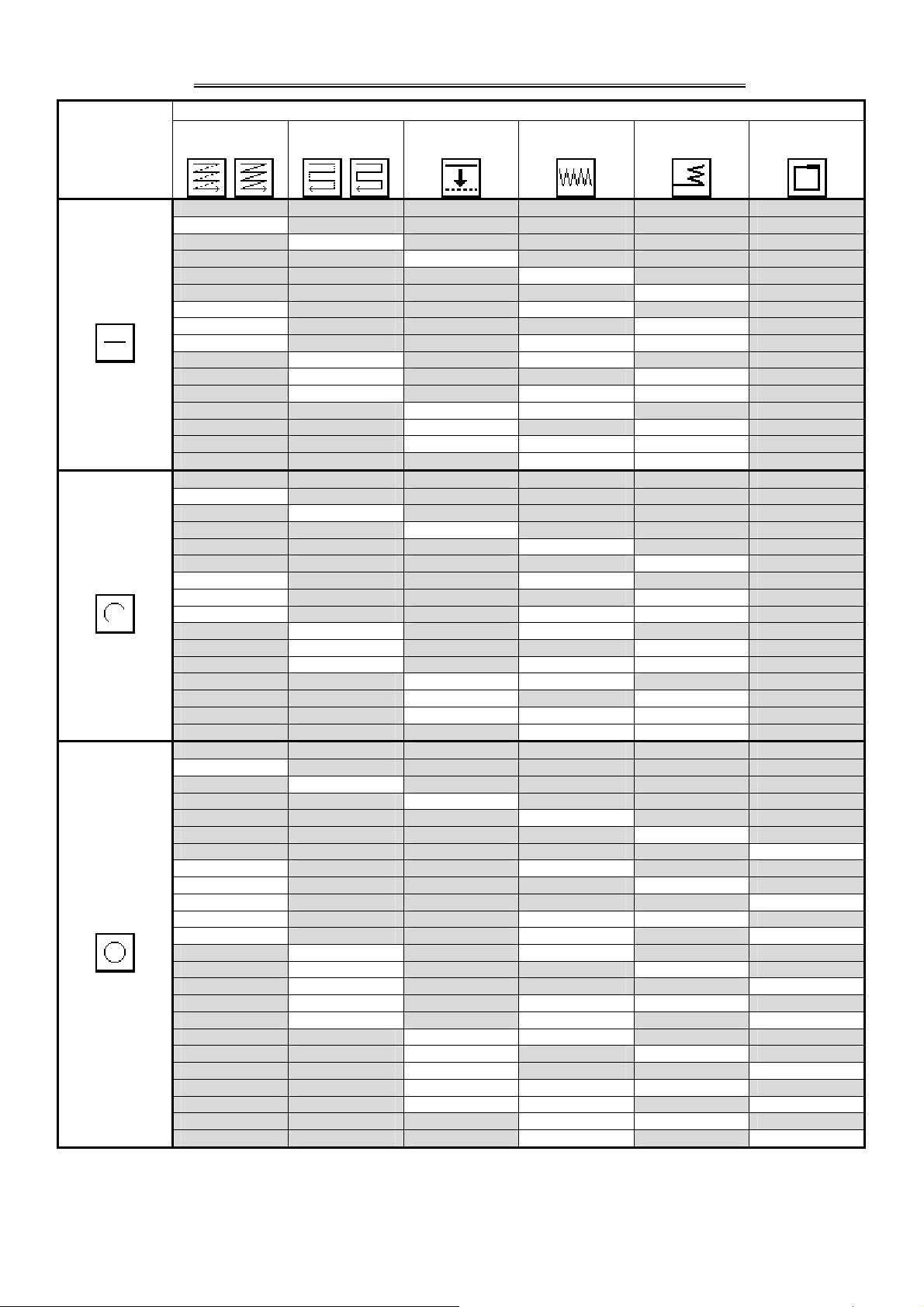

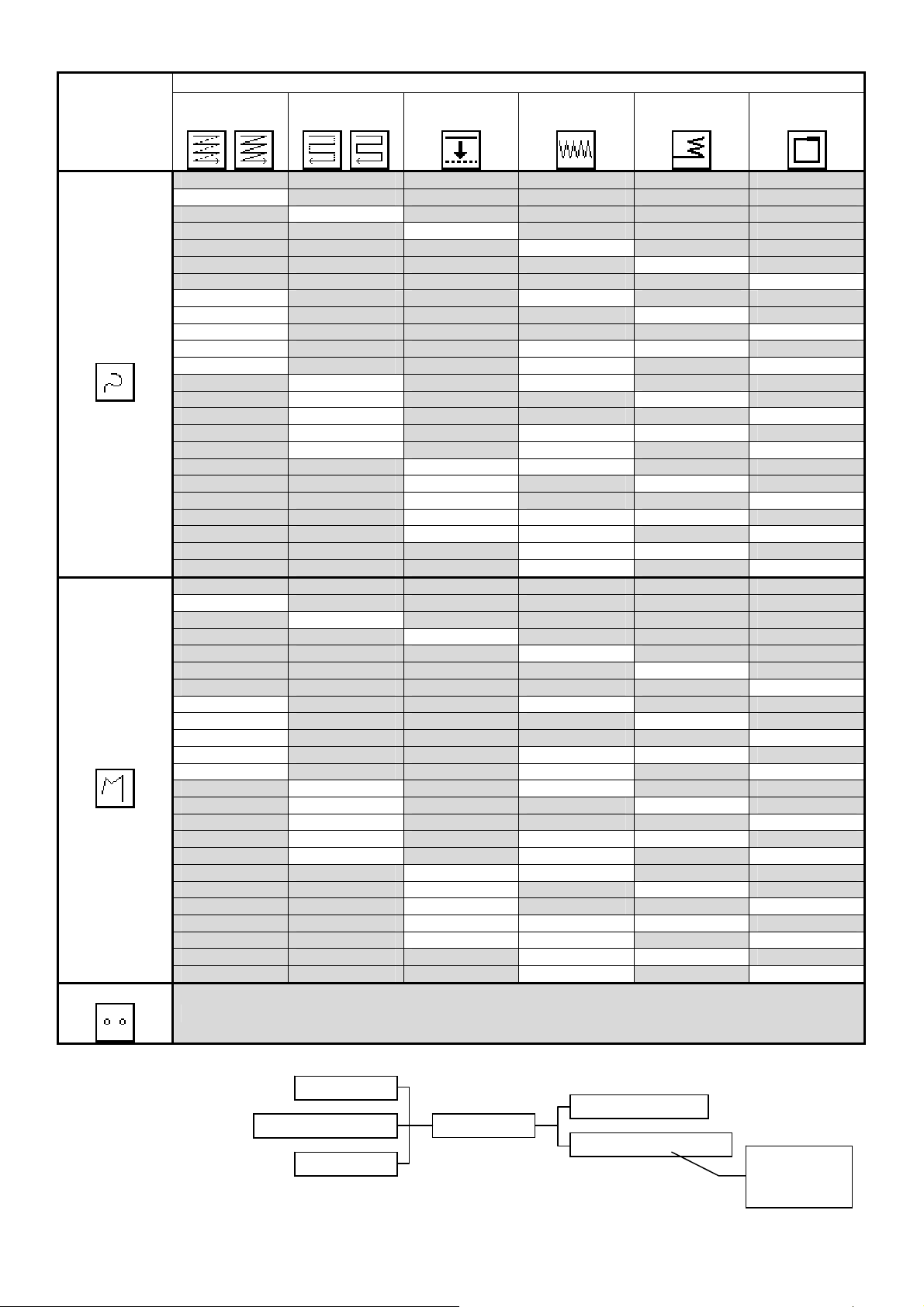

[9] Table of stitching type combinations________________________ [9]-1

[10] Call-up function ________________________________________ [10]-1

- 1 -

Page 4

[11] Modification mode ______________________________________ [11]-1

1.Main modification mode functions.....................................................................[11]-1

2.Entering the modification mode......................................................................... [11]-1

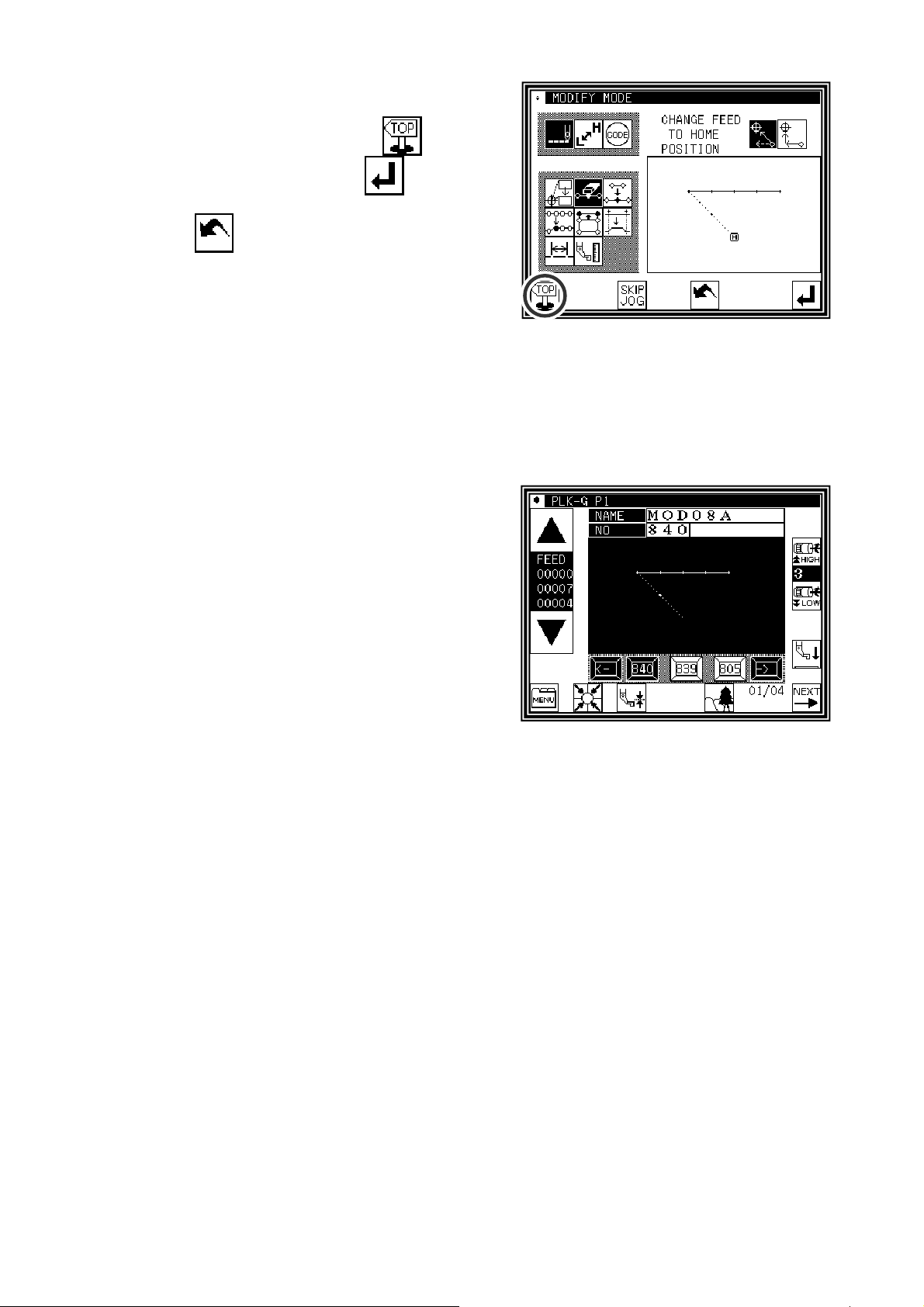

3.Quitting the modification mode.......................................................................... [11]-2

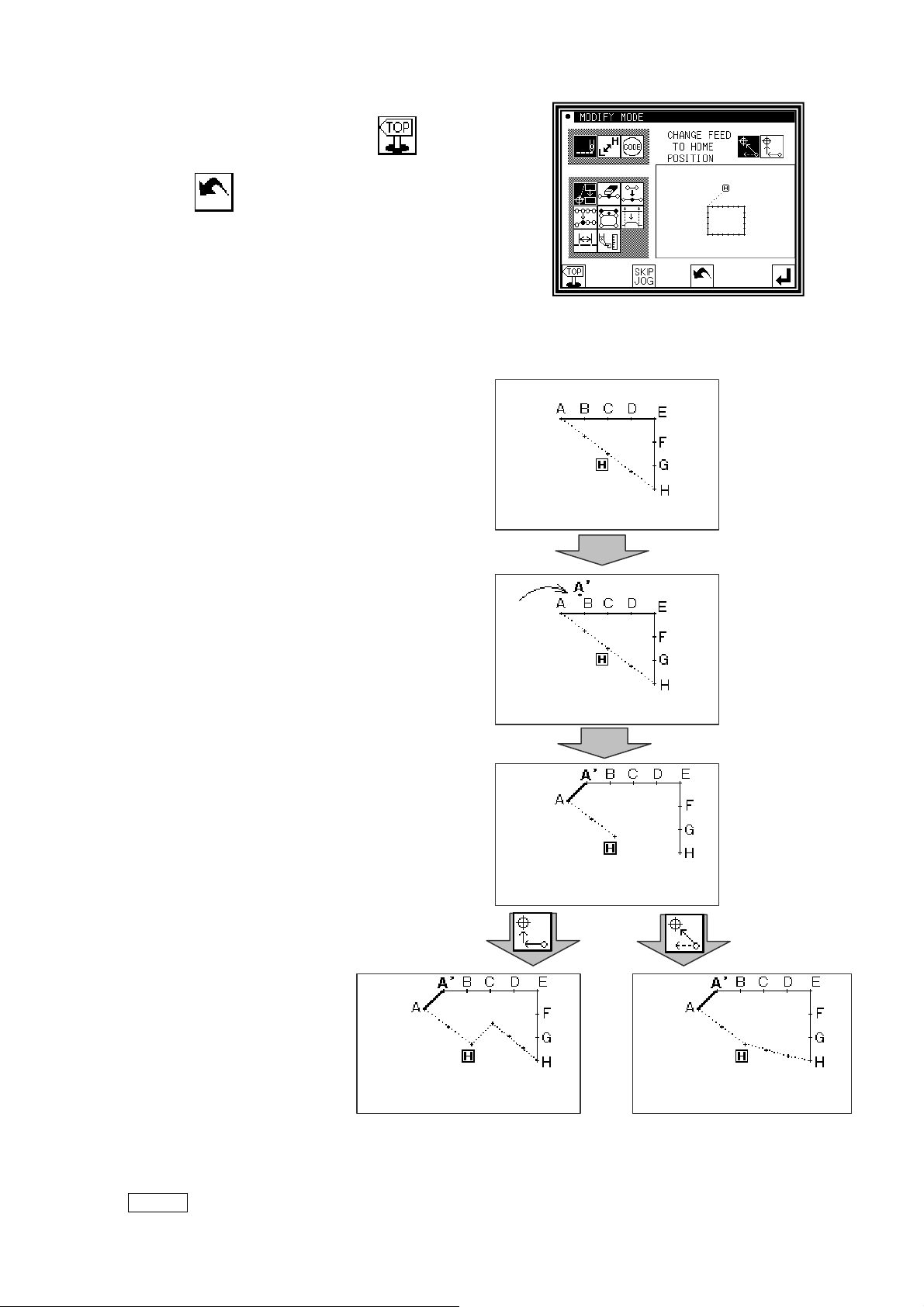

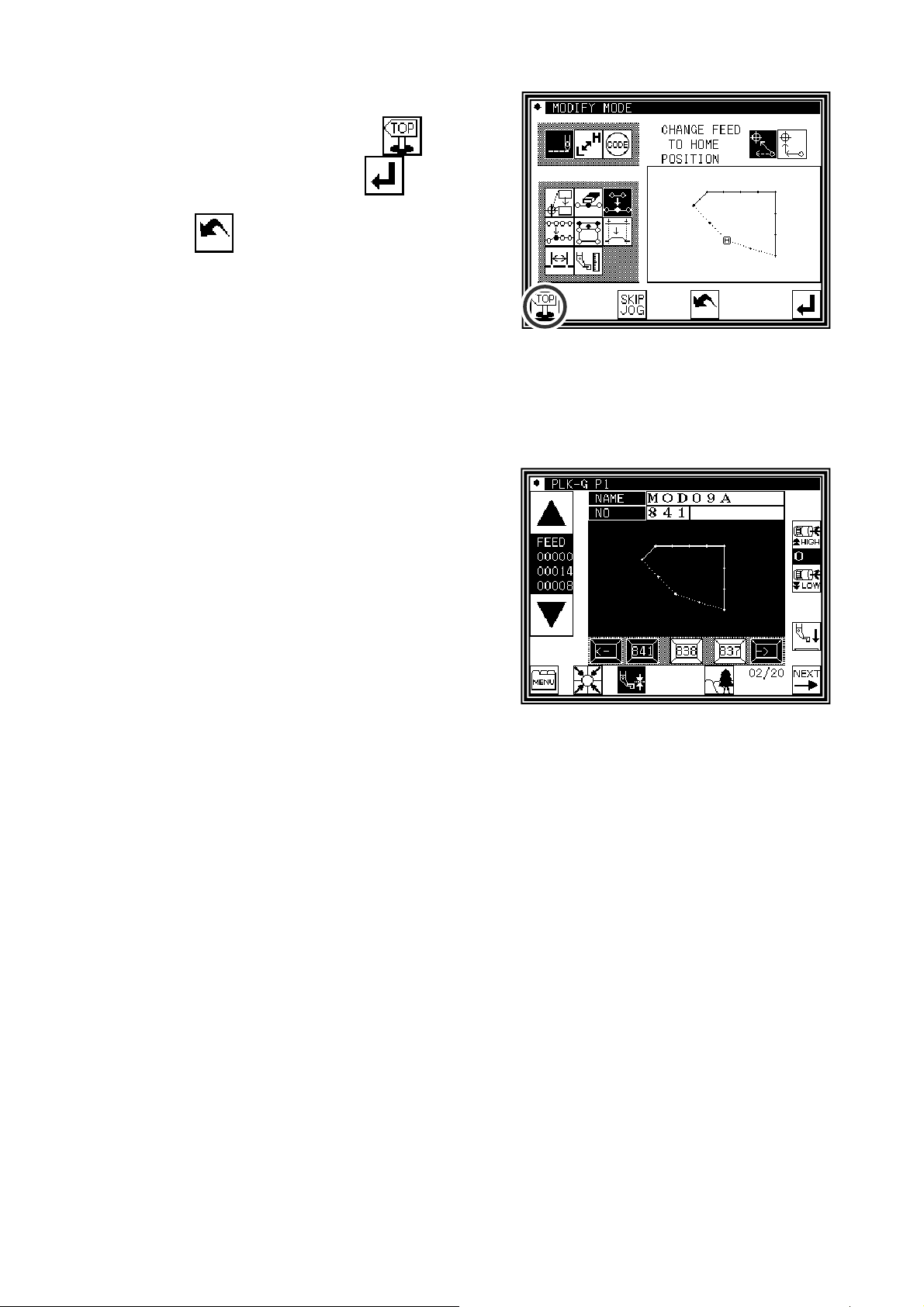

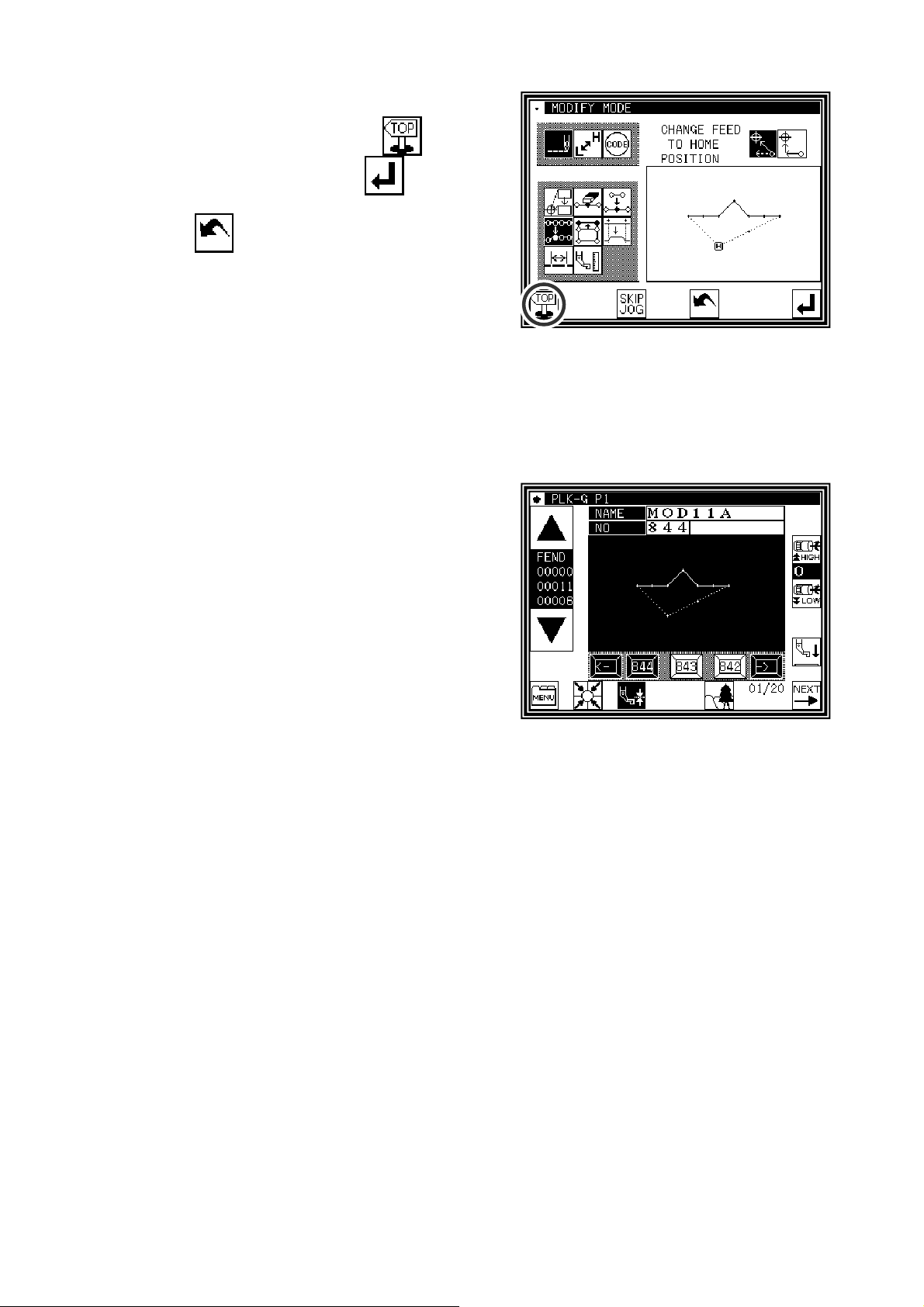

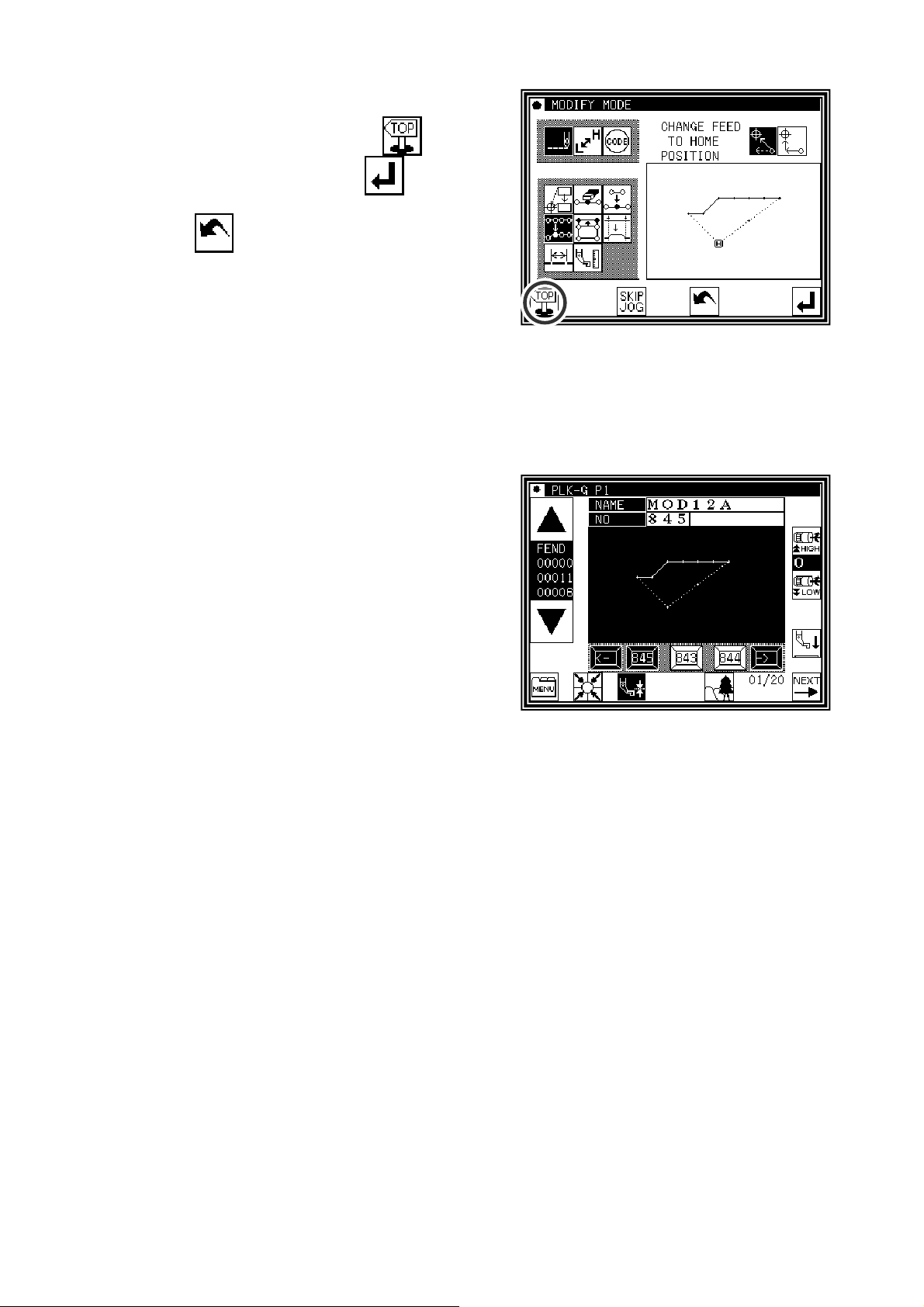

4.Changing the feed data to home position ......................................................... [11]-2

5.Confirming on the image screen....................................................................... [11]-3

6.Modifying the stitching start position................................................................. [11]-5

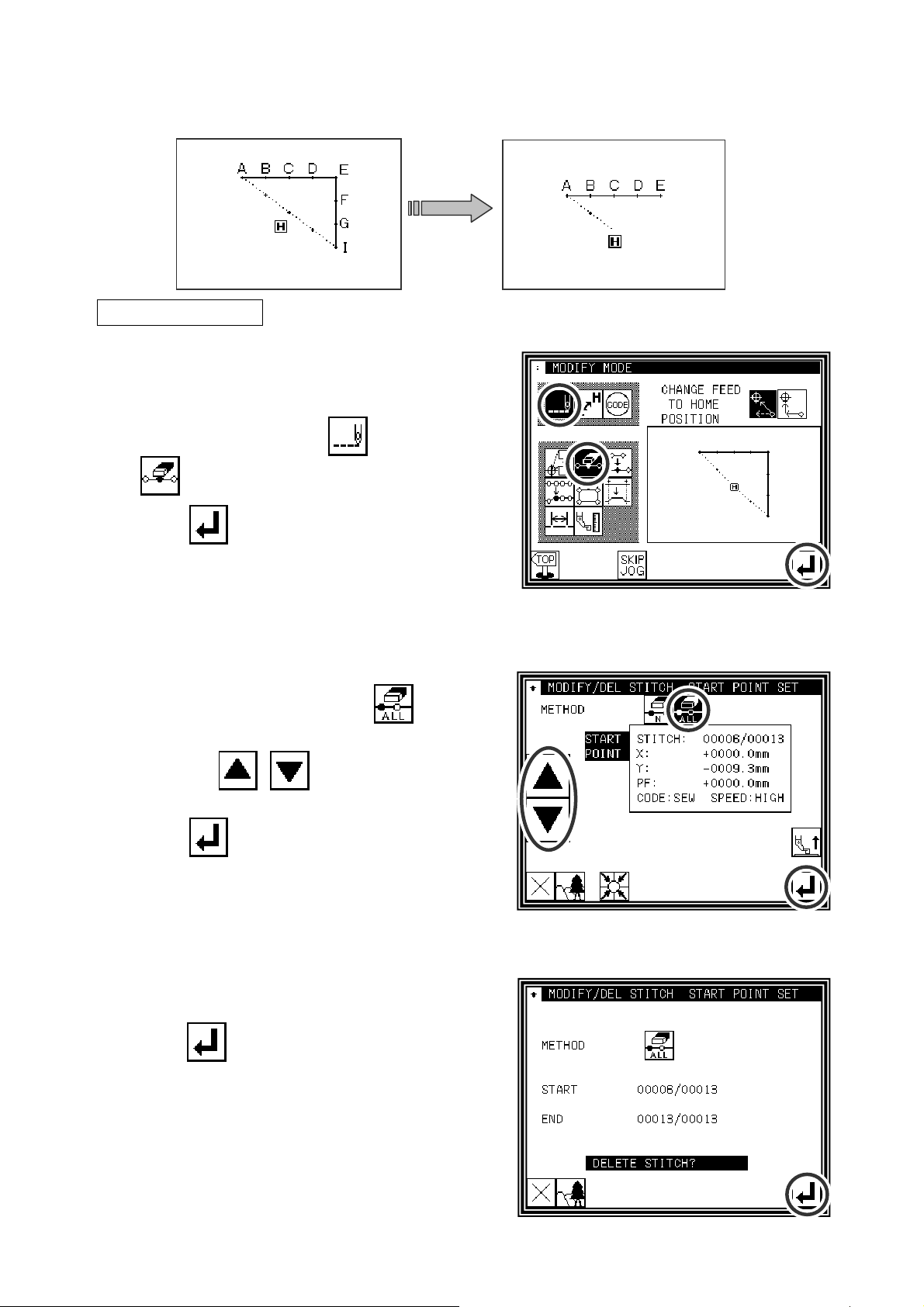

7.Deleting a stitch (Deleting the designated No. of stitches)................................ [11]-7

8.Deleting a stitch (Deleting all stitches after the designated position)................ [11]-9

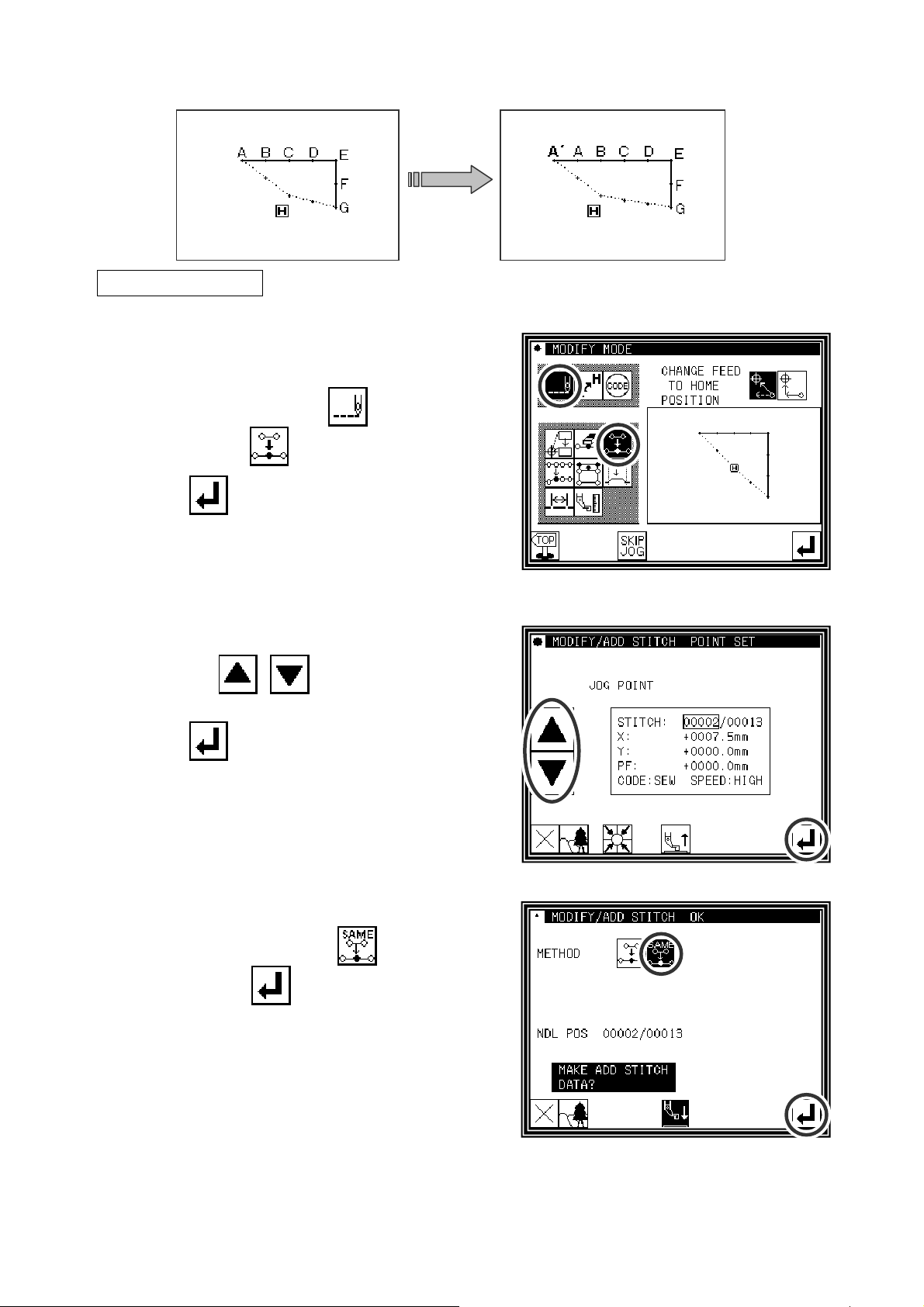

9.Adding a stitch (Adding one stitch).................................................................... [11]-11

10.Adding a stitch (Adding the same stitch)......................................................... [11]-13

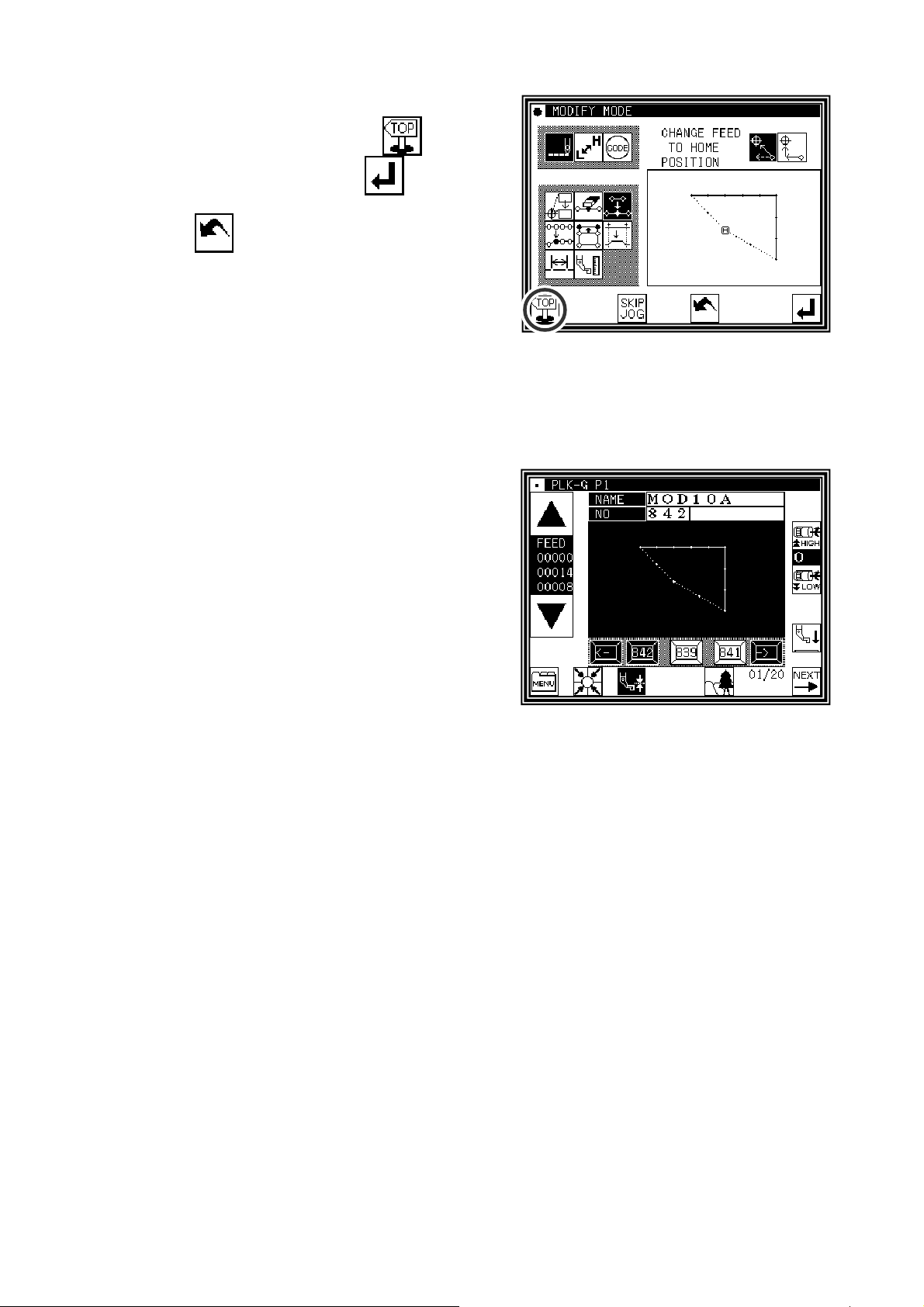

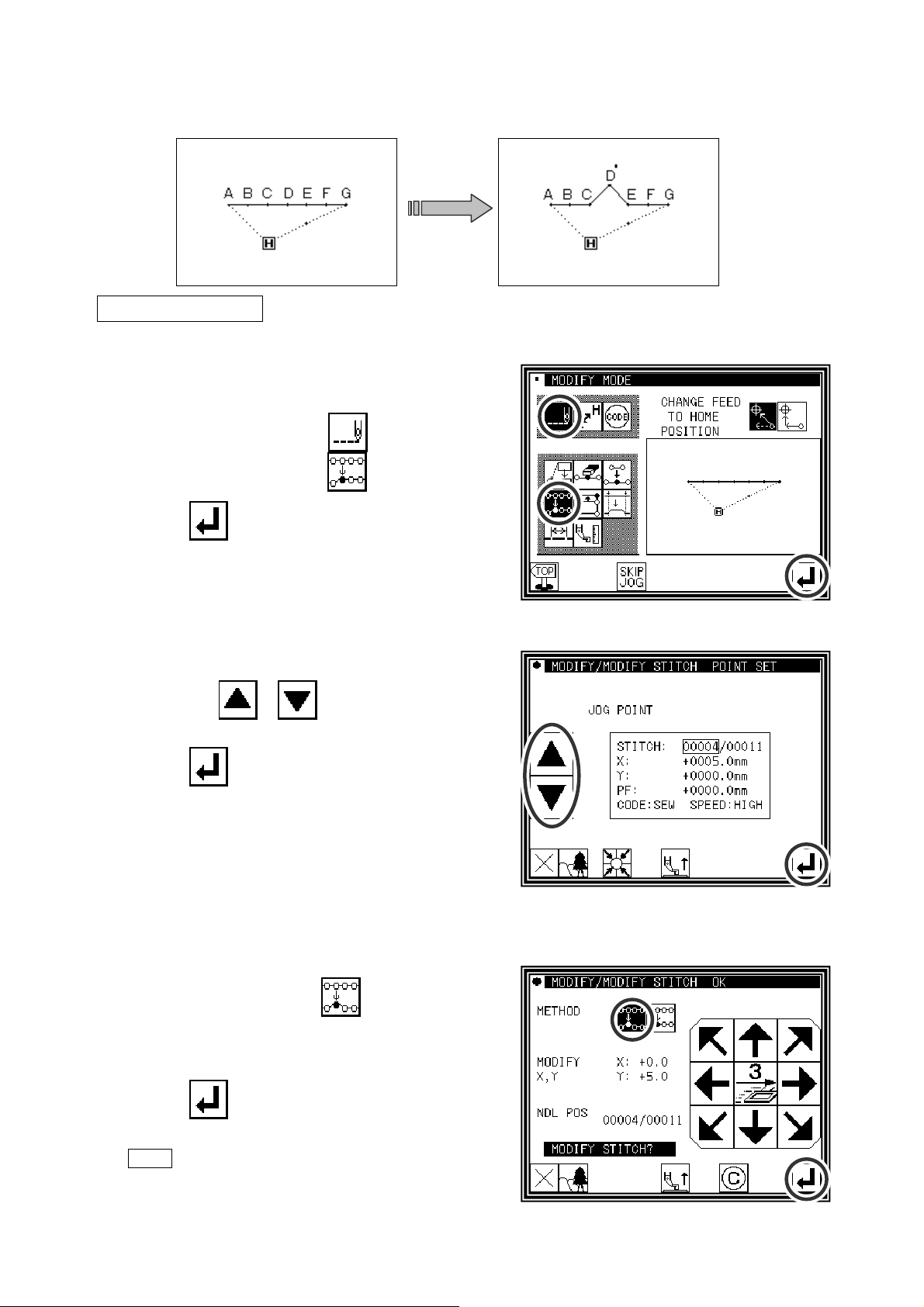

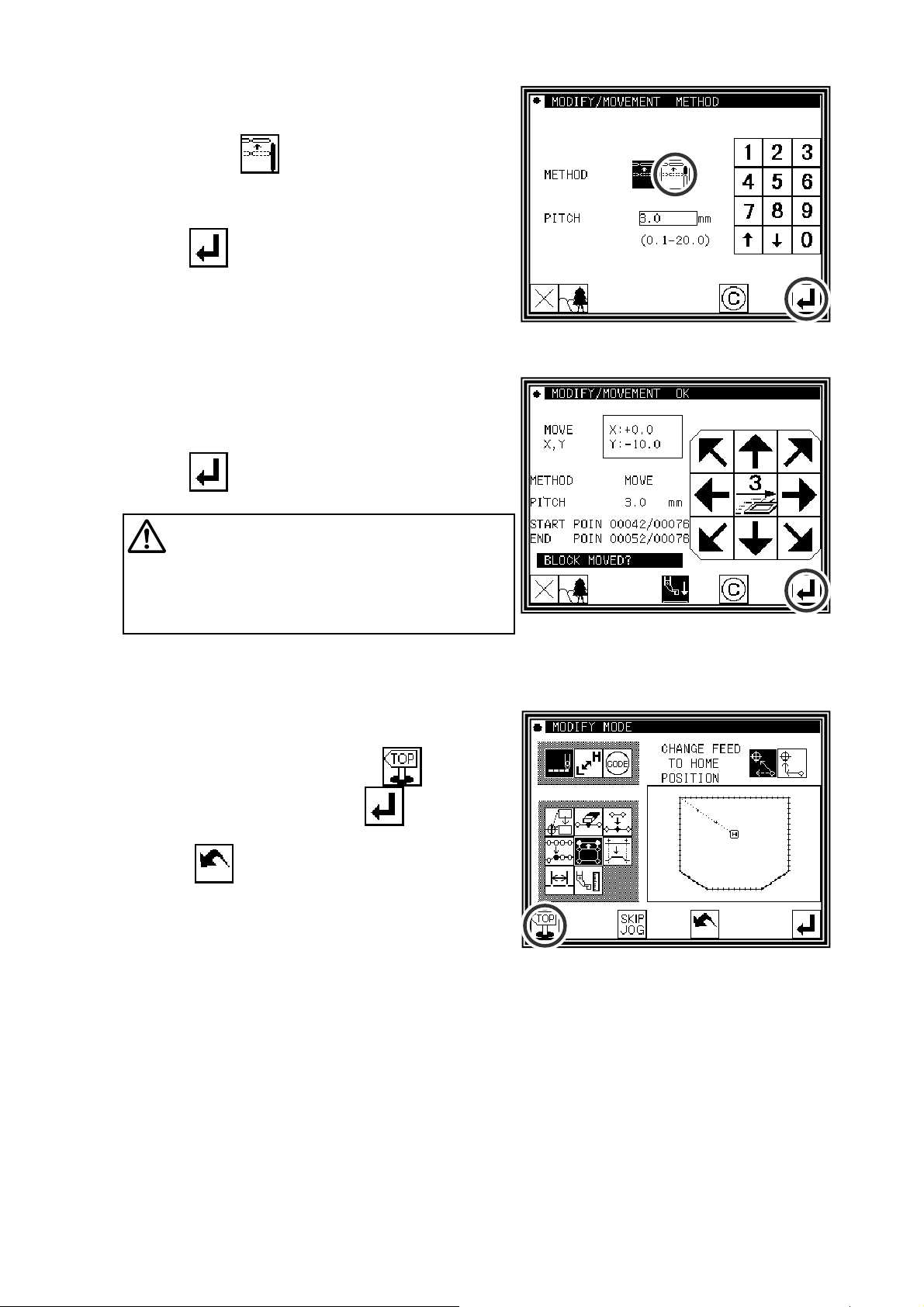

11.Modifying the stitch position (Position of subsequent data fixed).................... [11]-15

12.Modifying the stitch position (Subsequent data position moved).................... [11]-17

13.Moving a block (Changing the prior/subsequent data).................................... [11]-19

14.Moving a block (Adding new data to the prior/subsequent data).................... [11]-21

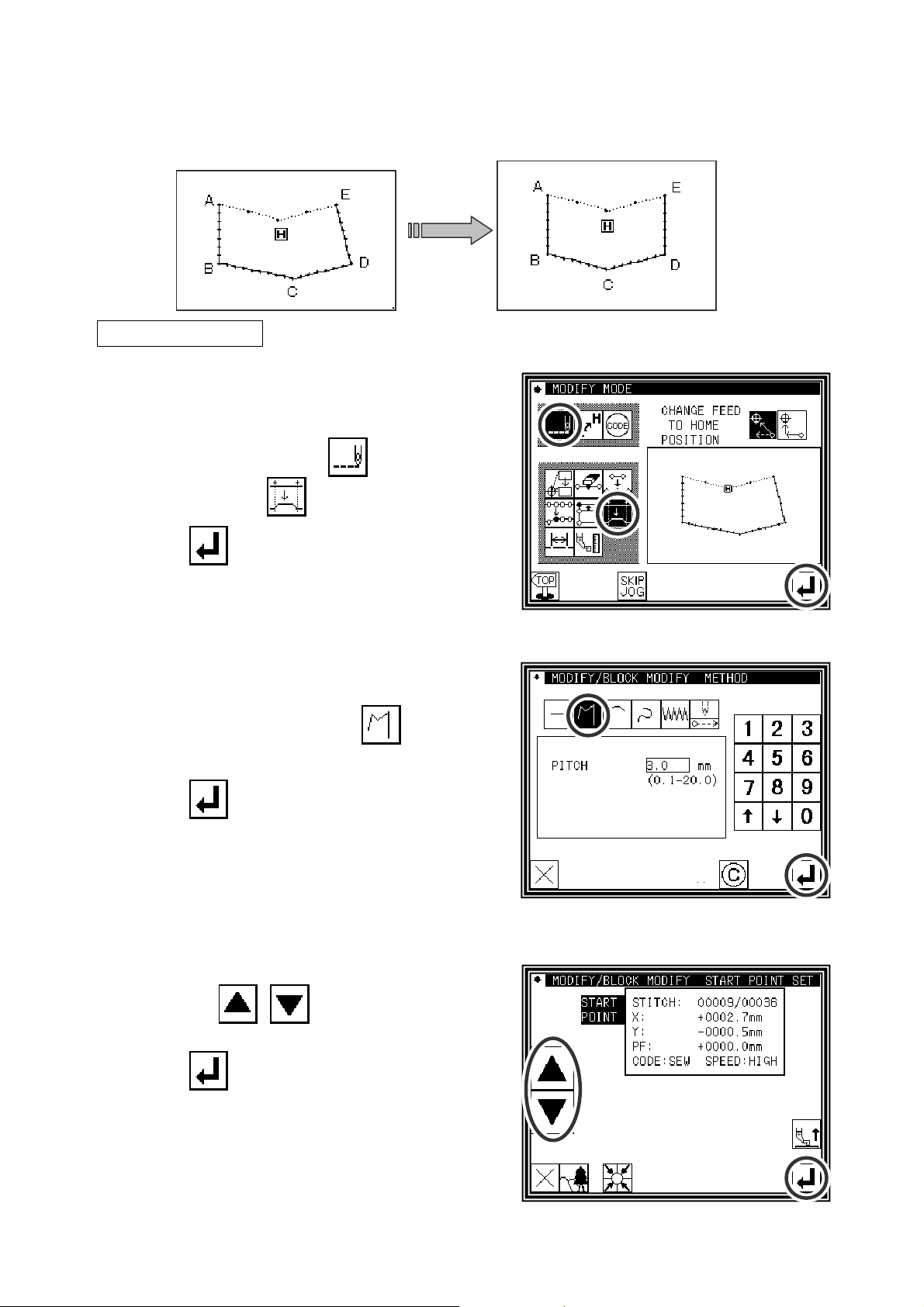

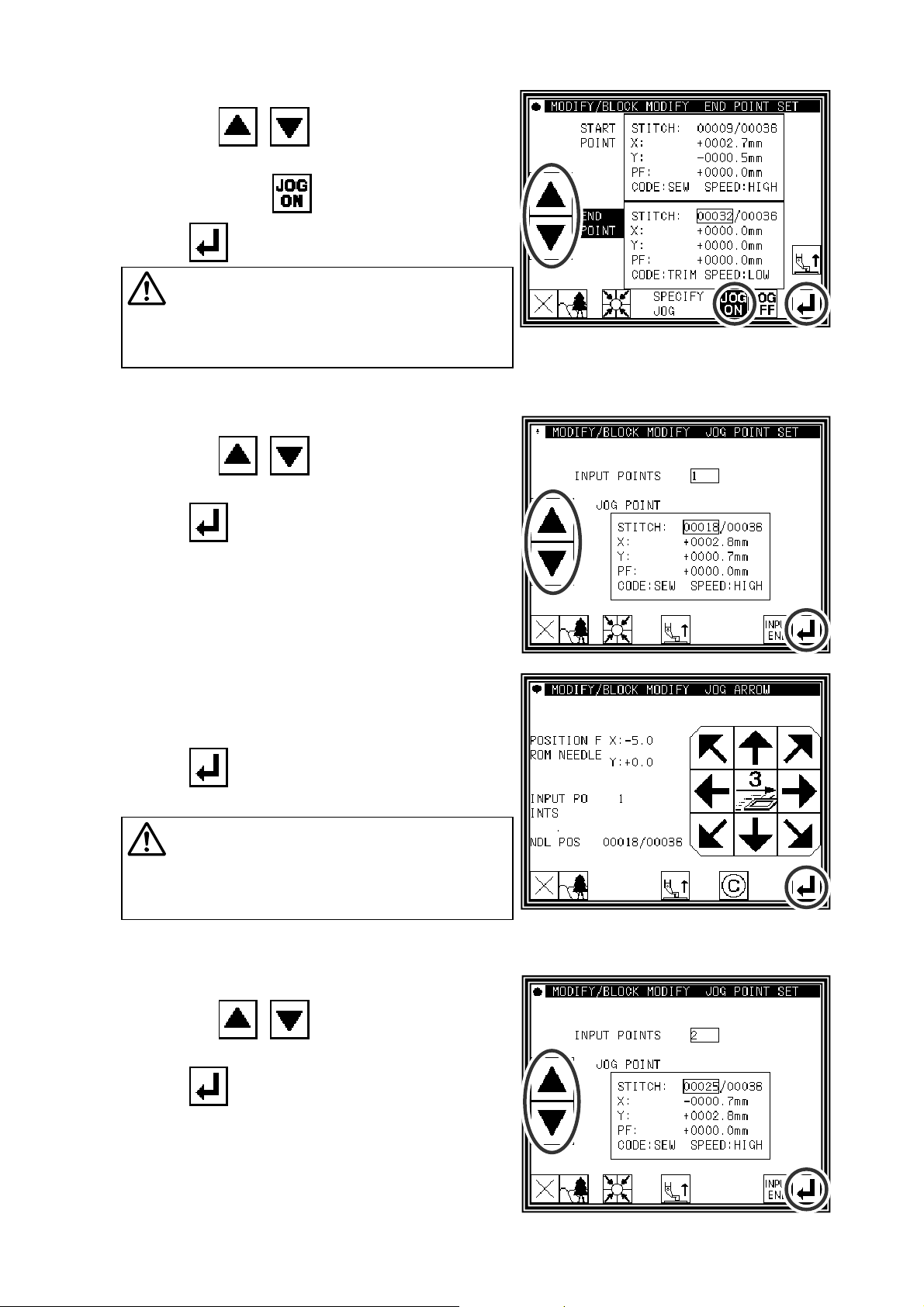

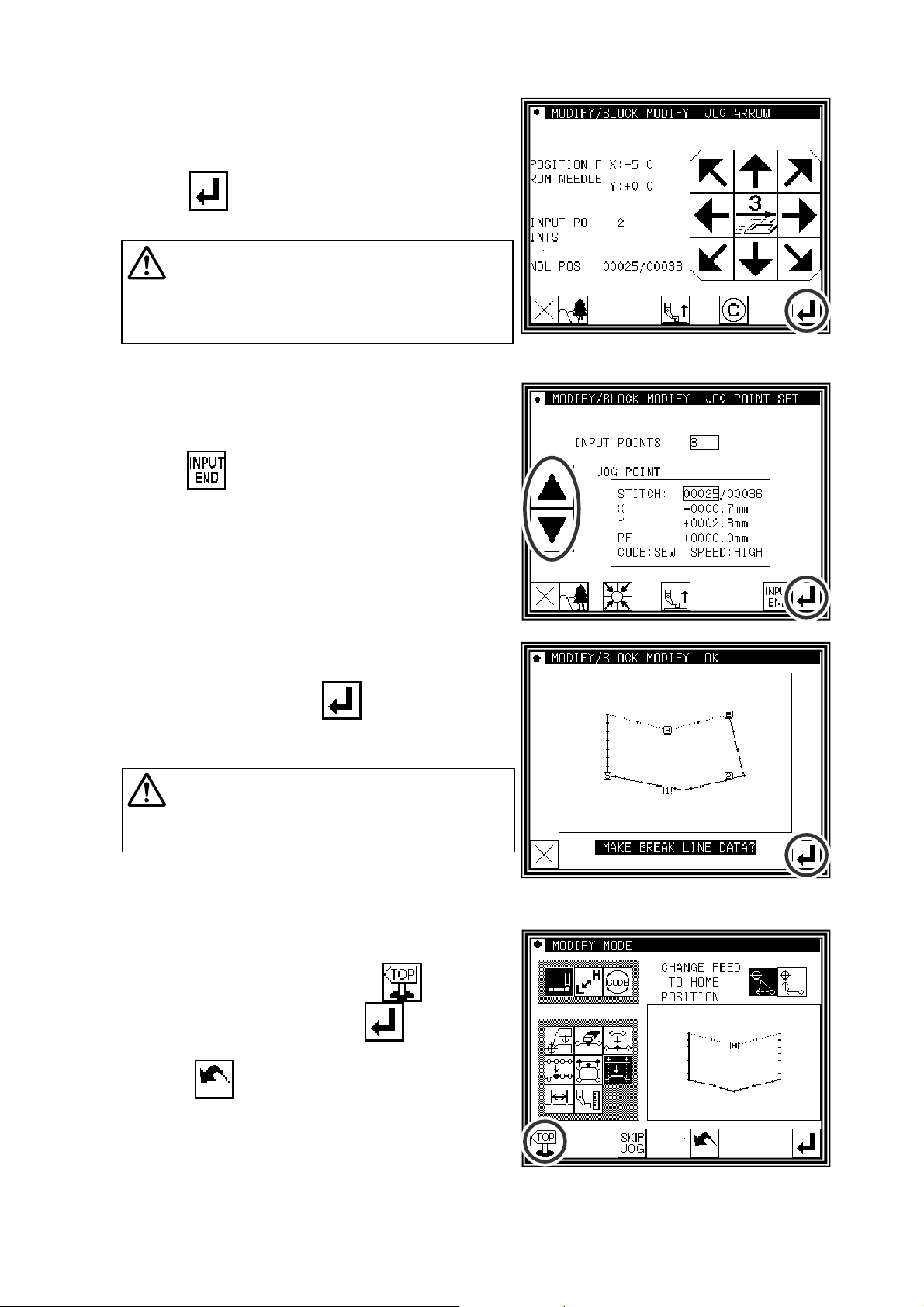

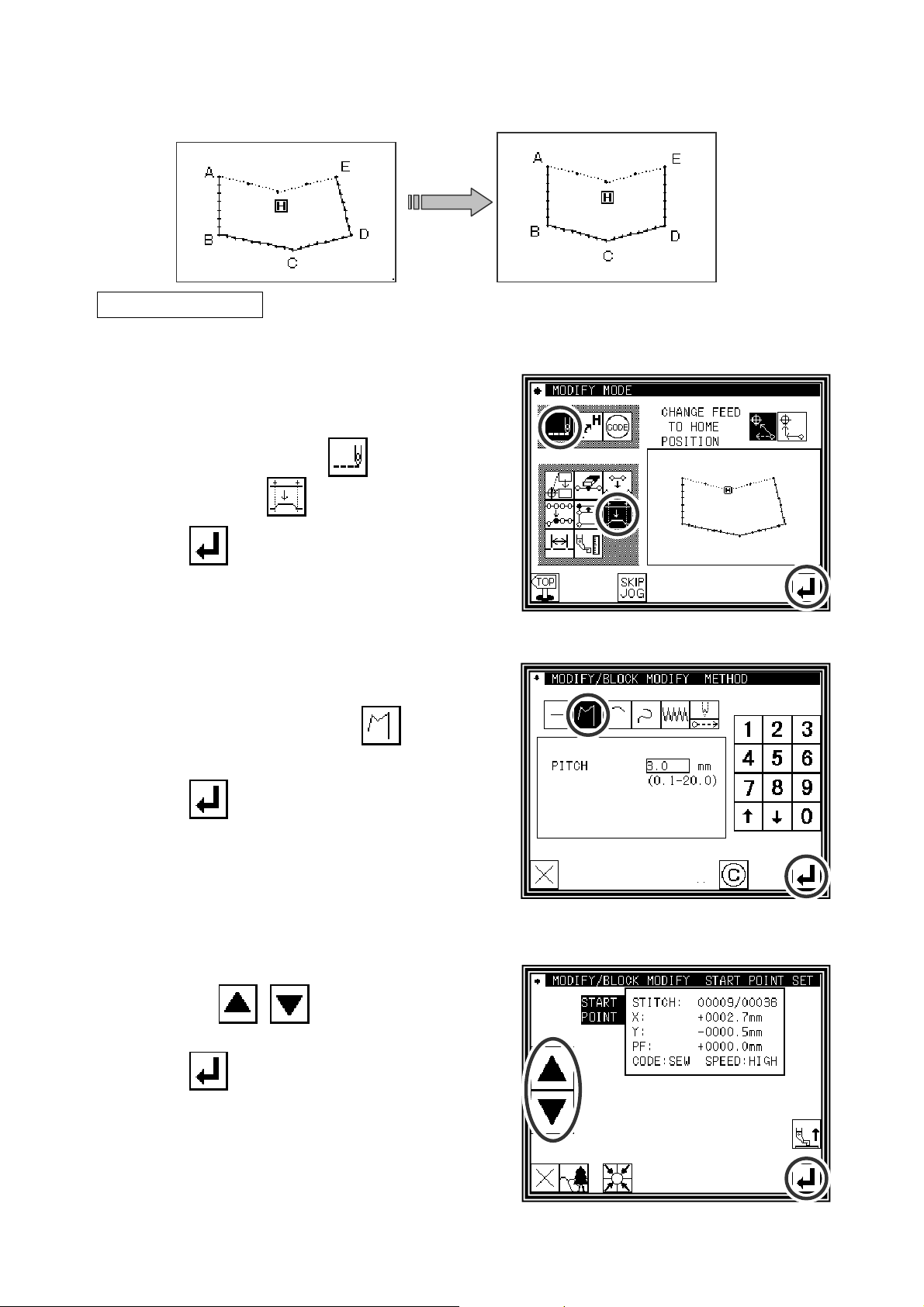

15.Modifying a block 1 (Linear input)................................................................... [11]-23

16.Modifying a block 2 (Broken line, arc, curve input) ......................................... [11]-26

17.Modifying a block 3 (Zigzag input) .................................................................. [11]-32

18.Modifying a block 4 (Changing the feed data)................................................. [11]-34

19.Modifying stitch length (Designated distance modification) ............................ [11]-39

20.Modifying stitch length (All After designated stitch)......................................... [11]-41

21.Modifying material step................................................................................... [11]-43

22.Modifying the stitching speed (All sections after designated position)............ [11]-46

23.Modifying the stitching speed (N stitches after designated position) .............. [11]-48

24.Modifying code data (Adding code data)......................................................... [11]-50

25.Modifying code data (Deleting code data)....................................................... [11]-52

[12] Data conversion mode___________________________________ [12]-1

1.Main data conversion mode functions............................................................... [12]-1

2.Entering the conversion mode .......................................................................... [12]-1

3.Quitting the conversion mode ........................................................................... [12]-2

4.Confirming on the image screen (for the conversion mode)............................. [12]-2

5.Back tacking(Start/end back tacking)................................................................ [12]-3

6.Back tacking(Overlap back tacking).................................................................. [12]-5

7.Zigzag stitching................................................................................................. [12]-7

8.Scaling .............................................................................................................. [12]-9

9.Symmetrical ...................................................................................................... [12]-12

10.Rotation........................................................................................................... [12]-13

11.Multiple............................................................................................................ [12]-15

12.Offset............................................................................................................... [12]-18

[13] Function mode _________________________________________ [13]-1

1.Outline............................................................................................................... [13]-1

2.Explanation of each function mode................................................................... [13]-2

[14] Input/Output setting mode _______________________________ [14]-1

1.Outline............................................................................................................... [14]-1

2.Explanation of input/output setting mode.......................................................... [14]-2

3.Input signal setting table ................................................................................... [14]-6

4.Output signal setting table................................................................................. [14]-9

[15] Program mode _________________________________________ [15]-1

1.Setting methods................................................................................................ [15]-1

2."System, setting file write" and "Setting file read"............................................. [15]-4

- 2 -

Page 5

[16] Program mode list ______________________________________ [16]-1

1.Wiper................................................................................................................. [16]-1

2.Slow start .......................................................................................................... [16]-1

3.Clamp................................................................................................................[16]-1

4.Area limit........................................................................................................... [16]-4

5.Needle position ................................................................................................. [16]-5

6.Thread breaking sensor.................................................................................... [16]-5

7.Home position................................................................................................... [16]-5

8.Halt.................................................................................................................... [16]-7

9.Counter ............................................................................................................. [16]-7

10.Brake............................................................................................................... [16]-9

11.Presser foot..................................................................................................... [16]-9

12.Bobbin winding................................................................................................ [16]-10

13.Feed method................................................................................................... [16]-10

14.Speed.............................................................................................................. [16]-11

15.Thread trimming/Thread release.....................................................................[16]-12

16.Step................................................................................................................. [16]-13

17.Jog .................................................................................................................. [16]-13

18.Feed angle...................................................................................................... [16]-14

19.Other............................................................................................................... [16]-15

20.Pattern............................................................................................................. [16]-16

[17] Error / Message display _________________________________ [17]-1

1.[E-***] Error code............................................................................................... [17]-1

2.[M-***] Message code ....................................................................................... [17]-4

Thank you for purchasing the Mitsubishi industrial sewing machine PLK-G Series.

Please read this technical manual before starting to ensure correct and long-term

use.

* The contents of this manual may not be reproduced in part or whole.

* The contents of this manual are subject to change without notice.

* An utmost effort has been made to cover all points of operation in this manual.

Contact Mitsubishi if you have any questions regarding the contents.

COPYRIGHT(C)2011-2013 MITSUBISHI ELECTRIC CORPORATION

- 3 -

Page 6

[1] For safe use

■ For safe use

Always observe the following matters to safely use the Mitsubishi industrial electronic sewing machine PLK-G

Series.

Before starting

Before using this control unit, read all of the technical manuals carefully, and correctly use the unit

following the manual. Also read the "Mitsubishi Industrial Sewing Machine Technical Manual <Sewing

Machine Head>" for details on the general configuration and sewing machine head.

Application and purpose

This control unit is designed to drive and control the Mitsubishi industrial electronic sewing machine

PLK-G Series. Do not use this control unit for other applications or purposes. Do not use this control unit

until it has been confirmed that safety measures have been accurately taken for the installed electronic

sewing machine head section.

Working environment

Please use this control unit in the industrial setting only. And do not use this control unit in the following

type of environment.

(1) Power voltage

* Where the voltage fluctuation exceeds ±10% of the rated voltage.

* Where the specified power capacity (refer to technical manual [Control unit] page [4]-2 “5. Power

capacity”) cannot be ensured.

(2) Magnetic noise

* Where strong fields or magnetic fields are generated, such as near a high-output high frequency

oscillating machine or high frequency welder.

(3) Temperature and humidity

* Where the ambient temperature is 35°C or more and 5°C or less.

* Where the unit will be subject to direct sunlight, or outdoors.

* Near sources of heat, such as heating appliances.

* Where the relative humidity is 45% or less, or 85% or more, and where dew may condense.

(4) Atmosphere

* In an atmosphere containing dust or corrosive gases, etc.

* In a flammable gas or explosive environment.

(5) Vibration

* If excessive vibration could occur when installed on the sewing machine, separately install the

control box.

■ Installation

Control box

Correctly install the control box according to this manual.

Accessories

Always disconnect the control unit from the main power supply before installing the accessories listed in

this manual. (Turn the power switch OFF, and disconnect the plug from the socket (power supply line).)

Cable

(1) Lay the connection cables so that excessive force will not be applied during operation. Do not

excessively bend the cables.

(2) Cables laid near operating machine sections must be separated by at least 25mm.

(3) Before connecting the power cable to the control box, confirm that the power voltage matches the

specifications given on the control box's rating nameplate and factory shipment voltage nameplate.

Connect the cable to the indicated positions, and then supply the power. When using a power unit,

connect the cable to the power unit and supply the power. In addition, when using a power unit,

confirm that the power voltage matches the specifications given on the power unit's rating nameplate.

Turn the power switch OFF before making any connections.

Grounding

Always ground the power cord's grounding wire.

Enclosed units and accessories

Connect the electrical enclosed units and accessories only to the positions indicated in the manual.

[1] - 1

Page 7

Removal

(1) Always turn the power switch OFF and disconnect the plug from the socket (power supply line) before

removing the control box.

(2) Do not pull out the cord when disconnecting the plug. Always hold the plug receptacle when

disconnecting the plug.

(3) Note that a high voltage is applied inside the control panel, so always turn the power OFF and wait

at least ten minutes before opening the control box cover.

■ NOTICE CONCERNING MARKING

(1) Electronic sewing machine PLK-G series are applied to CE conformity marking by installing the

exclusive device [PLK-G-CE].

When the products are used in the EU region, these devices are necessary to be installed.

(2) Electronic sewing machine should be use limited to the industrial areas even though above-mentioned

countermeasure is done.

[Warning] Use in residential areas may cause interference.

■ Maintenance, inspection and repairs

(1) Follow this manual when carrying out maintenance or inspections related to this control unit.

(2) This unit must be repaired, serviced and inspected only by a worker that has received special training.

(3) Always turn the power OFF before replacing the needle or bobbin, etc., on the head.

(4) Use genuine replacement parts for repairs and maintenance.

■ Other safety measures

(1) Keep fingers away from all moving machine parts (especially around the sewing machine needle,

etc.).

(2) Never drop the control unit, or place objects in the clearances.

(3) Do not operate the sewing machine without the protective parts such as the cover, or protection

devices such as the safety breaker.

(4) If any damage is observed in the control unit, if the unit does not operate correctly, or if the operation

is suspicious, always suspend operation. Only operate the machine after the supervisor has adjusted,

repaired or inspected the machine.

(5) The user must not make improvements or changes without instruction from Mitsubishi.

■ Caution displays and danger displays

(1)In this manual, the dangers and danger levels that arise with incorrect handling are classified using the

following displays.

The warning display shows that incorrect handling can lead to

Warning

Caution

(2)The meanings of these symbols are as follows.

This symbol indicates that the

instructions must be followed.

This symbol indicates hot

temperature requiring caution.

This symbol indicates a

prohibited action.

death or serious injuries.

The caution display shows that incorrect handling can lead to

injuries or damages to your house, household goods, and

others.

This symbol indicates an

electrical hazard or caution

(electric shock caution).

This symbol indicates that

ground wire connection is

required.

* Always deliver this manual to the end user.

* Store this manual nearby where it can be referred to when necessary.

[1] - 2

Page 8

[2] Precautions for use

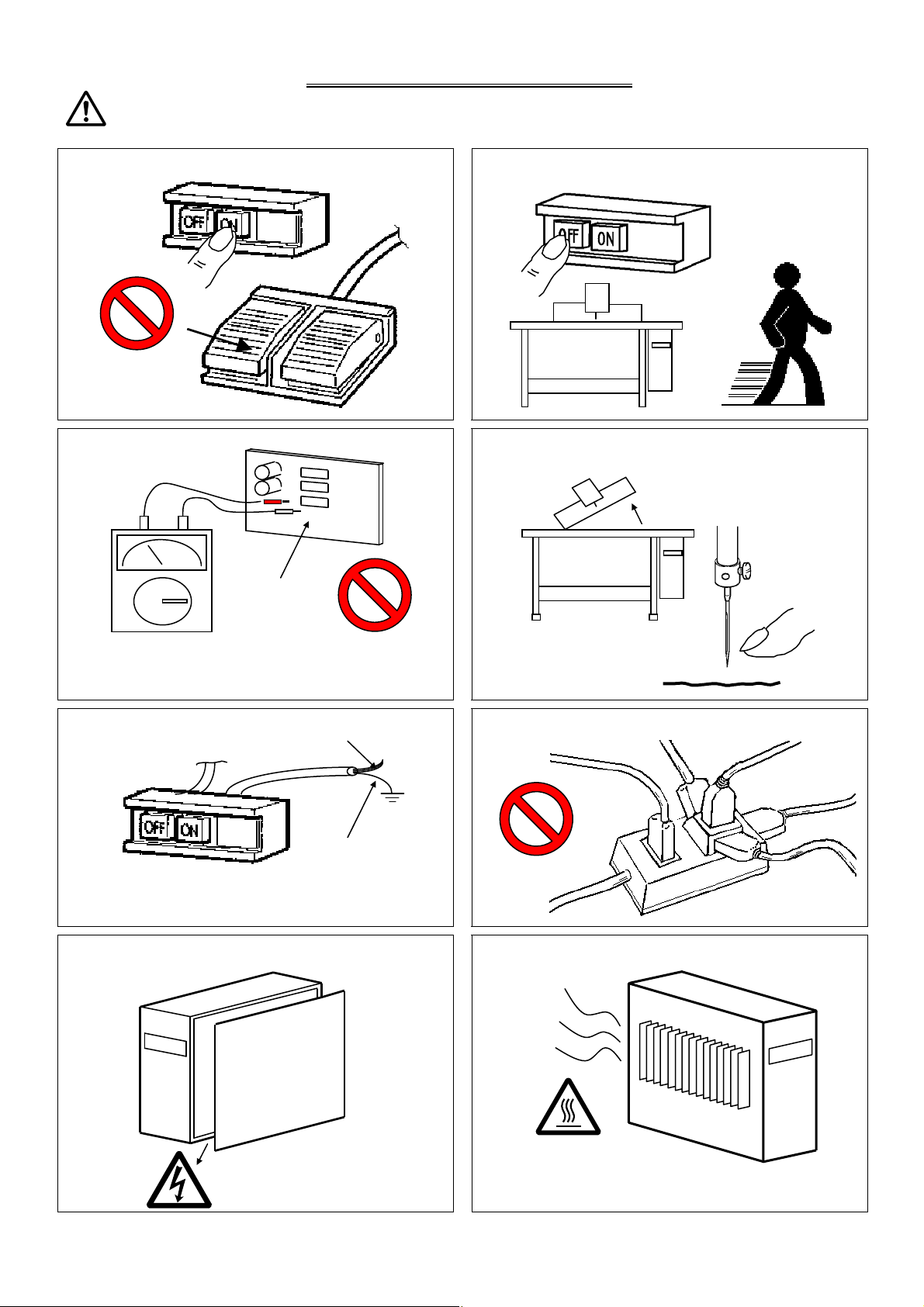

Warning

1. Do not place foot on the foot switch when turning the power ON.

3. Do not inspect the control circuit with a tester.

Control circuit

The tester voltage could be applied on the semiconductor

parts, and cause damage.

5. Always ground the grounding wire.

Power supply

Green

(Green/yellow)

Always ground the provided grounding wire

(green(green/yellow)).

7. A high voltage is applied inside creating a hazardous state, so

always turn the power OFF and wait ten minutes before opening

the cover.

High voltage risk

2. Always turn the power OFF when leaving the sewing machine.

4. Always turn the power switch OFF before tilting the sewing

machine head, replacing the needle, or passing thread through the

needle.

6. Do not use excessive wiring.

8. Radiation fins and other parts may be hot. Do not touch the parts.

[2] - 1

Page 9

)

)20A

)20A

)15A

9. The sewing machine will coast to a stop when the power is turned OFF or a power failure occurs during sewing machine operation.

10. Always align the connector shape and direction, and securely insert the connector.

11. If the position detector's connector dislocates, or the sewing machine is completely locked, the motor will be turned OFF automatically for a

set time to prevent burning. (Note that the motor may not turn OFF if there is incomplete locking or an overload.) When the fault has been

recovered, turn the power OFF and ON once to resume normal operation. The same type of operation will take place if a detector fault or

disconnection occurs.

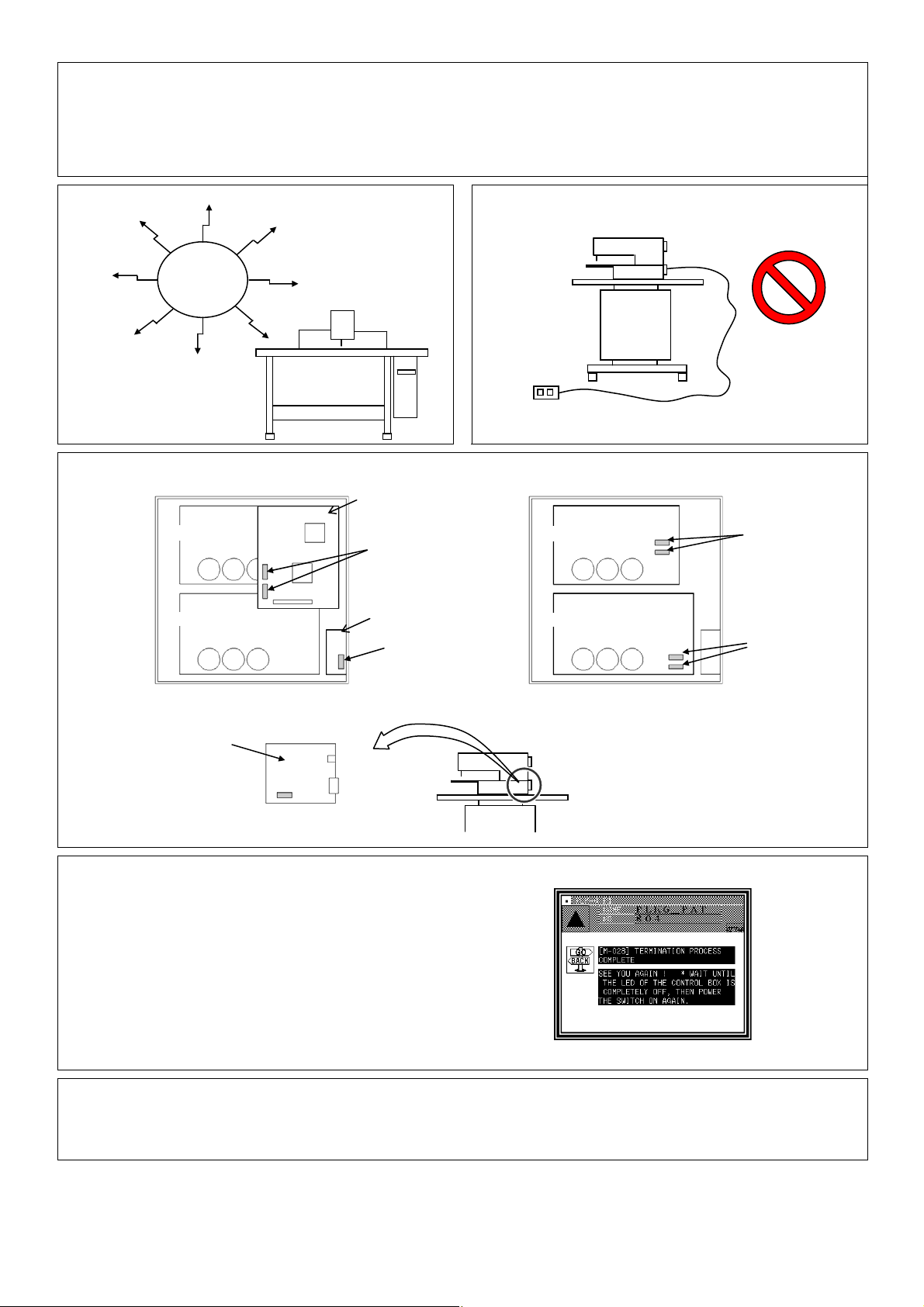

12.Use the machine away from strong noise sources such as high

frequency welders.

14. If the fuse blows, remove the cause, and replace the blown fuse with one having the same capacity.

Noise

PLK-G3-CPU

13. When connecting the external switch to an optional connector,

etc., keep the signal wire as short as possible. A long wire could

cause malfunctions.

Use a shielded wire for the signal wire when possible.

XC-G2-2B-PLK

PLK-G2-PMD

(View from the front with cover removed) (View from the front

15. Attention when power supply is turned on again

Please make sure not to turn on the power supply switch until after

the LED on the front panel of the control box has completely turned off.

(Please do not turn on the power supply again while displaying

the screen of the operation panel.)

* Please note that if power supply is turned on again while LED still turns on,

clamp outputs (O4, O5 port) may go down.

16. When the value of the sewing area limit is changed or the limit setting is deactivated, note the collision and

with the cover and CPU removed)

fuse(one fuse)

Solenoid board located

on back of machine head

2.5Afuse(two fuses

PLK-G2-PMM

8Afuse(one fuse

XC-G2-2B-PLK

PLK-G2-PMD

fuse(two fuses

fuse(two fuses

take care safely.

Also when using it outside the range where the mechanism can be operated, it can not assume the responsibility for

all problems caused by it.

[2] - 2

Page 10

[3] Explanations of basic screen, icons and operation

A

Note When power supply is turned on, if there is not sewing pattern data in the internal memory, the

message of [PATTERN DATA DOES NOT EXIST] is displayed. Press , then the standard screen

is displayed.

Note When you adjust the contrast to make the operation panel screen easier to view, refer to Chapter 8,

“Adjusting the Liquid Crystal Contrast.”(Page[3]-6)

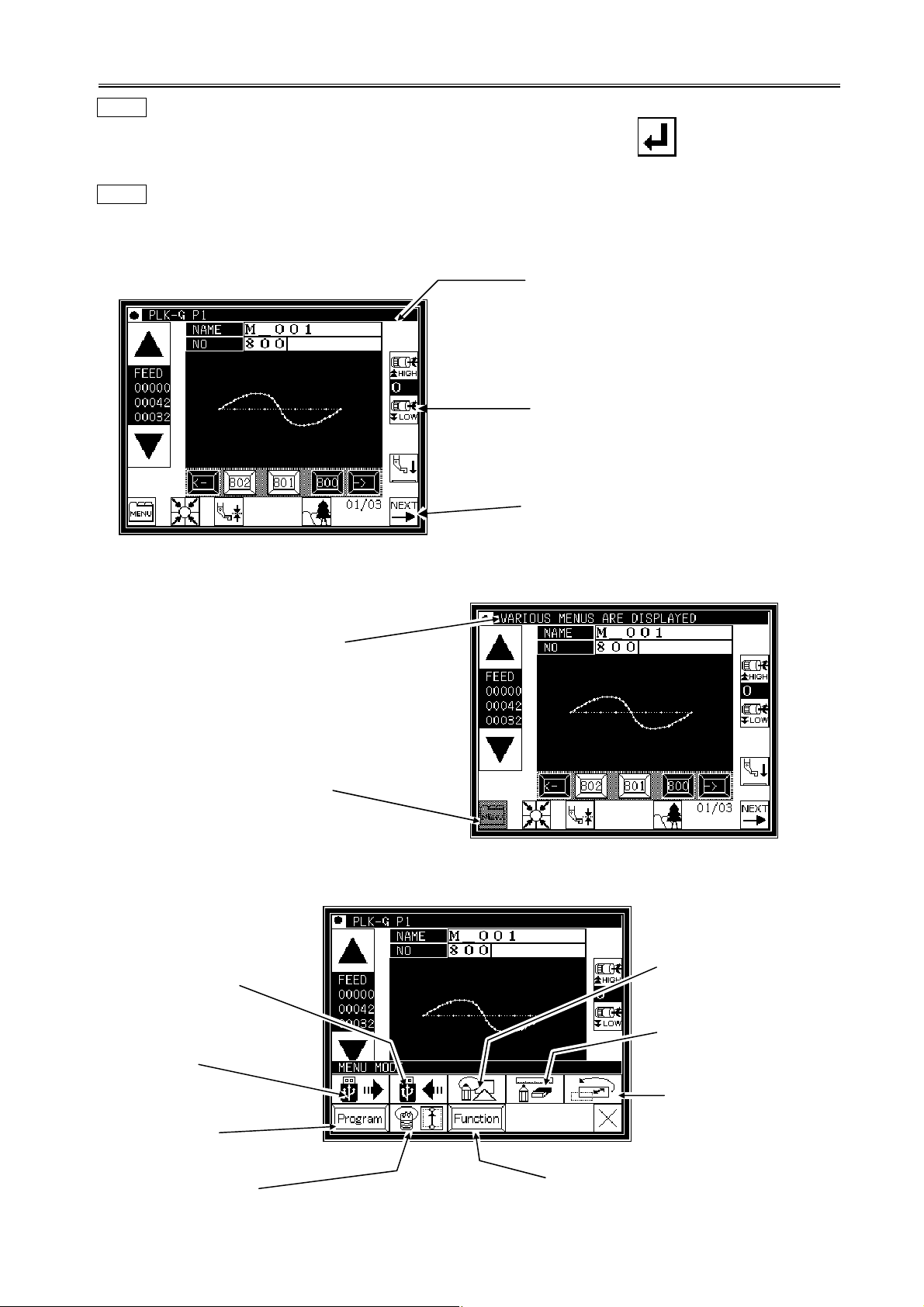

1. Screen configuration

(1)Sample screen 1 (Standard screen 1)

[Line at top of screen]

Normal: Index

(simple explanation of screen)

When any icon is pressed:

The explanation for that icon will

appear. (Refer to sample screen 2.)

Some icons will continue execution while

the icon is held down.

Most icons will execute the operation

when the finger is released.

(2)Sample screen 2 (While menu icon on Standard screen 1 is held down)

n explanation of the icon and

the screen will appear.

This icon (menu icon) is

pressed, so the icon will

be highlighted.

(3)Sample screen 3 (When menu is opened on Standard screen 1)

Writing data

Reading data

Program mode

Input/output setting

mode

Function mode

Methods of creating

stitching data

Modification mode

Data conversion

mode

[3] - 1

Page 11

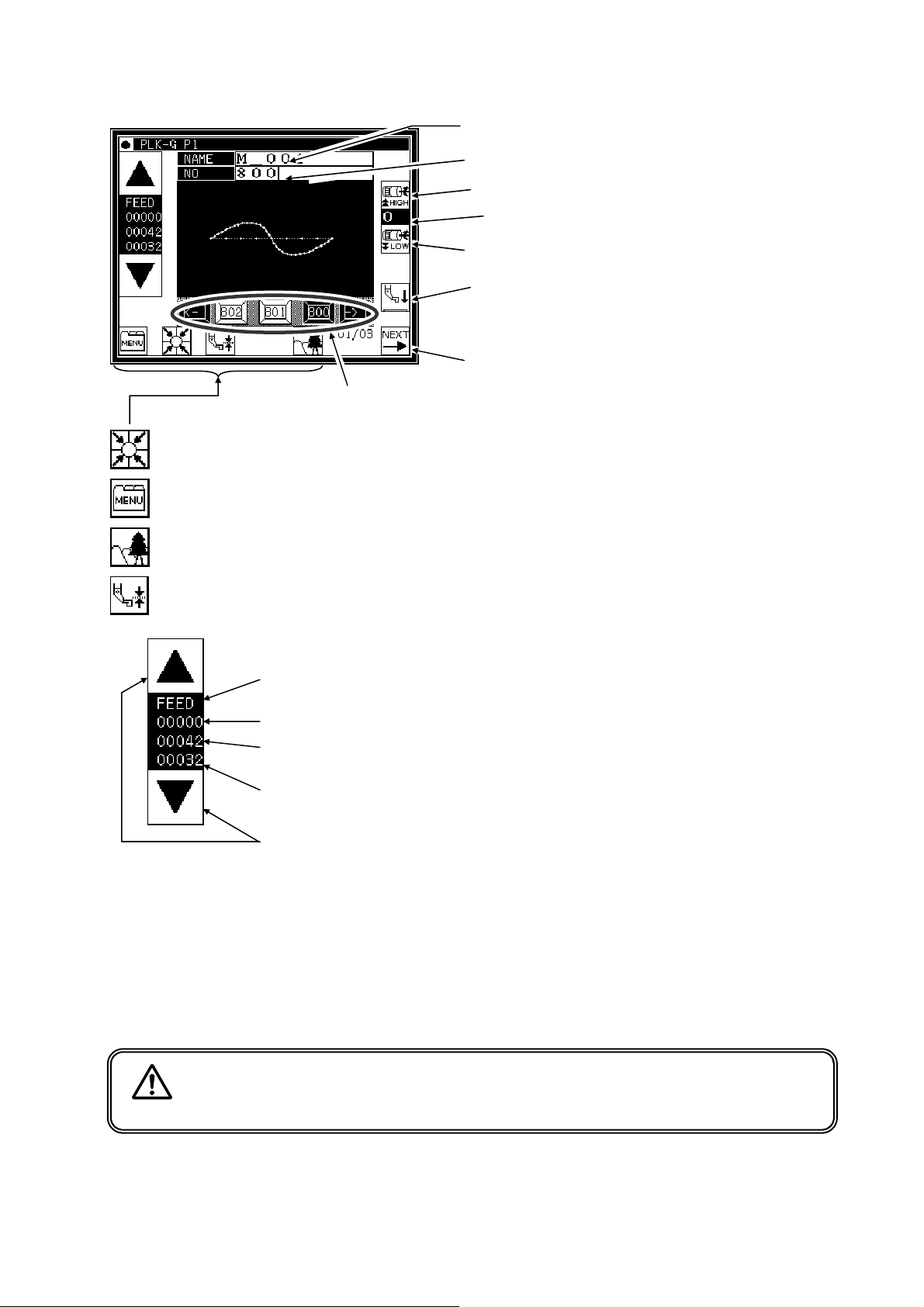

2. Explanations of Standard screen 1

The Standard screen 1 is explained in detail below.

… Home position return will be executed.

… The menu window will open

… The Image screen will open.

The stitching data is changed.

(Data in internal memory)

The pattern name is displayed. (Max : eight characters)

The pattern No. is displayed.

The sewing machine stitching speed is increased.

The current stitching speed setting value is

displayed. (0~9)

The sewing machine stitching speed is decreased.

The presser foot is moved up/down. (*1)

(The direction of the arrow (up/down) will change

according to the current state.)

Standard screen 2 opens.

The screen of setting for material thickness will open.

…

(*1) Presser bar lifting :

The stitching data type for the current work holder position is displayed.

(FEED, SEW, TRIM, etc.)

The current number of stitches is displayed.

The total number of stitches (including the feed data, thread cutting code, end code, and code

data) will be displayed.

The total number of actual stitches (excluding the feed data, thread cutting code, end code, and

code data) will be displayed.

The operation is confirmed (Jogging in forward/reverse direction)

(1) If the work holder is lowered after home position return and the forward jogging direction (upward arrow)

is pressed, the XY table (work holder) will move according to the stitching data. When the icon is

released, the operation will stop at that position. When the jog minus direction (downward arrow) is

pressed, the XY table (work holder) will move in the direction that the stitching data returns. When the

icon is released, the operation will stop at that position.

(2) Check pattern data is correct by jogging buttons, before press start pedal.

(3) During operation, the presser bar lifting will lower at stitching sections in the stitching data, and will rise

at the feed data sections.

Lowering the presser bar lifting when threading the needle is handy.

Caution

Turn the power OFF before threading the needle.

[3] - 2

Page 12

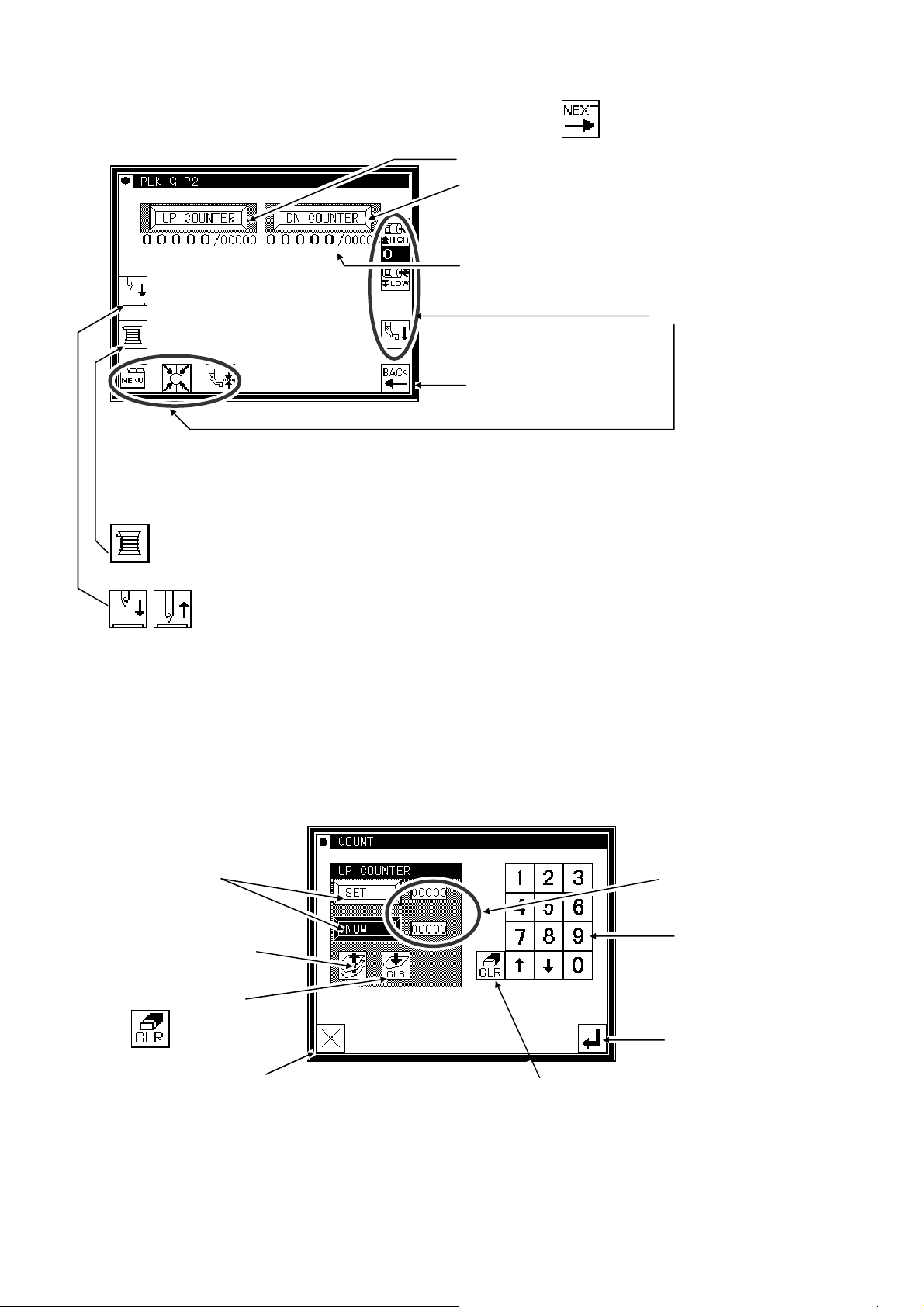

3. Explanations of Standard screen 2

Displays the Standard screen 2 from the Standard screen 1, by pressing .

The Standard screen 2 is explained in detail below.

... Bobbin winding mode (The presser bar lifting will lower, and the Bobbin Winding Setting screen will

open.) (The details are explained on the next page.)

The Up Counter screen is displayed.

The Down Counter screen is displayed.

The counter value is displayed.

(Current value/setting value)

Returns to Standard screen 1.

Same as Standard screen 1.

... Moves the needle up/down.

4. The Up Counter screen is explained below

(The Down Counter screen is the same, except for the valid/invalid icon design.)

* The methods of counting with the up counter (down counter) and clearing the counter are determined by the program

(Page[16]-7)

Displays the setting value

and current value.

Use to change the setting

value and current value.

Determines the

A set value or the selected value is cleared.

settings.(Returns to

Standard screen 2.)

mode setting.

Changes the setting value

or current value.

Changes the validity of

the up counter.

Clears the current value.

(Press to clear the

setting value.)

Returns to the previous

screen.

●When this screen is displayed, sewing cannot be performed.

[3] - 3

Page 13

5. The Bobbin Winding screen is explained below

This screen is used to wind thread on the bobbin. (The presser bar lifting will lower when the bobbin winding

icon is pressed on the Standard screen 2.)

When the work holder switch is turned ON and the start switch is turned ON, the sewing machine will start

rotating at the set speed. The XY table will not move at this time. The sewing machine will stop at the needle

UP position when the start switch is turned OFF.

* The bobbin winding operation is determined by the program mode setting. (Page[16]-10)

Displays the current

setting value.

Exits the bobbin

winding mode.

*When exit winding mod, presser foot is raised.

6. Explanations of basic icons

The basic icons used commonly on several screens are explained in this section.

… Executes home position return.

… Enter : determines the settings, etc.

… Returns to the previous screen.

… Exits the current mode.

… Cancel : undo the previous operation.

… Opens the menu window.

… Displays the previous/next list when lists are displayed (pattern data list, mode list, etc.)

… Turns skip jogging ON/OFF, and opens the operation setting screens.

[3] - 4

Page 14

7. Explanation of operations

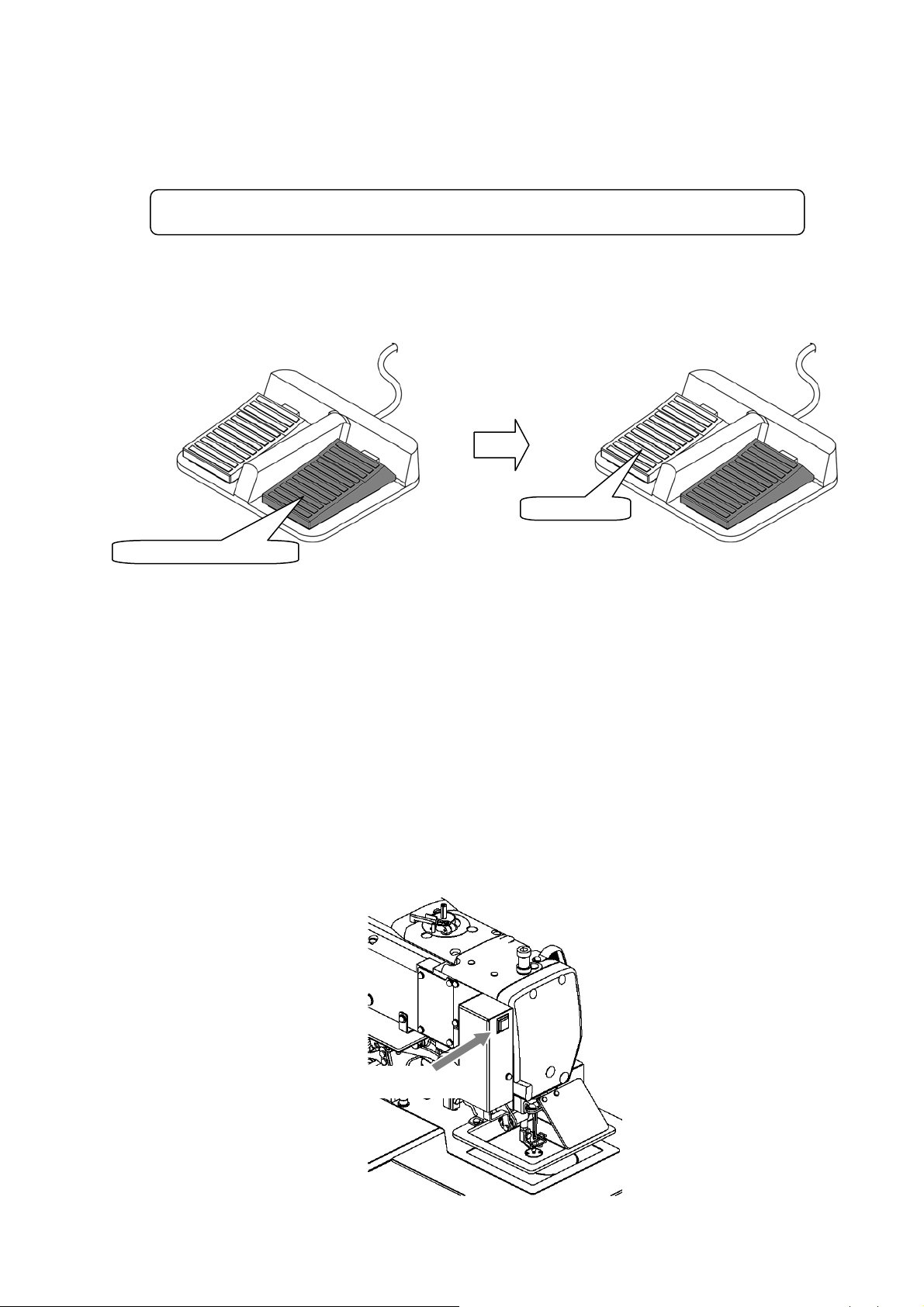

(1)Stitching operations

[1] Reconfirm the stitching data before starting. Take special care to the set stitching speed.

[2] The stitching speed is determined according to the set speed and stitch length. The maximum stitching speed is

determined by the speed setting, and the stitch length limits the stitching speed.

[Caution] Do not change the sewing machine stitching speed during operation except in emergencies.

(Changing the speed can cause fault such as thread catching faults.)

[3] Set the material to be stitched, and turn the work holder switch ON. Next, when the start switch is turned ON, the

sewing machine will start rotating and stitching. Once started, stitching will continue even the operator's foot is

released from the start switch. When the stitching is completed, and the work holder returns to the home position,

the sewing machine will stop and the work holder will automatically rise.

Start stitching

Take down the work holder

(2)Halting

To stop during the stitching, press the HALT switch (installed on sewing machine head; refer to following drawing).

The sewing machine will stop at the needle UP position. (Standard default setting.)

To cancel the halted state, press the HALT switch again. The following operations will be possible when the halted

state is canceled.

[1] Restart of stitching by pressing start switch. (gray pedal)

[2] Movement to stitching start position with forward jog/reverse jog icons.

[3] Lifting of work holder by pressing work holder switch. (black pedal)

[4] Change of stitching speed by setting stitching speed.

[5] Lifting/lowering of presser bar lifting.

[Note] The needle position during the halted state can be set with the program mode .

[Sewing machine head]

HALT switch

[3] - 5

Page 15

(3)Restitching methods

Restitching can be carried out using the previously explained halt function.

If the operation is halted due to needle thread breakage, etc., set the needle at the UP position, and then using the

forward jog/reverse jog icons, move to the position where the thread broke. Tie the needle thread, etc., and restart

stitching by pressing the start switch.

Caution

If the needle must be thread while the power is ON, do not turn

on the start switch while threading. Doing so initiates machine rotation, resulting in an

extremely dangerous situation. To ensure that the start switch is not turned on during

threading, take measures such as moving the start switch away from your feet.

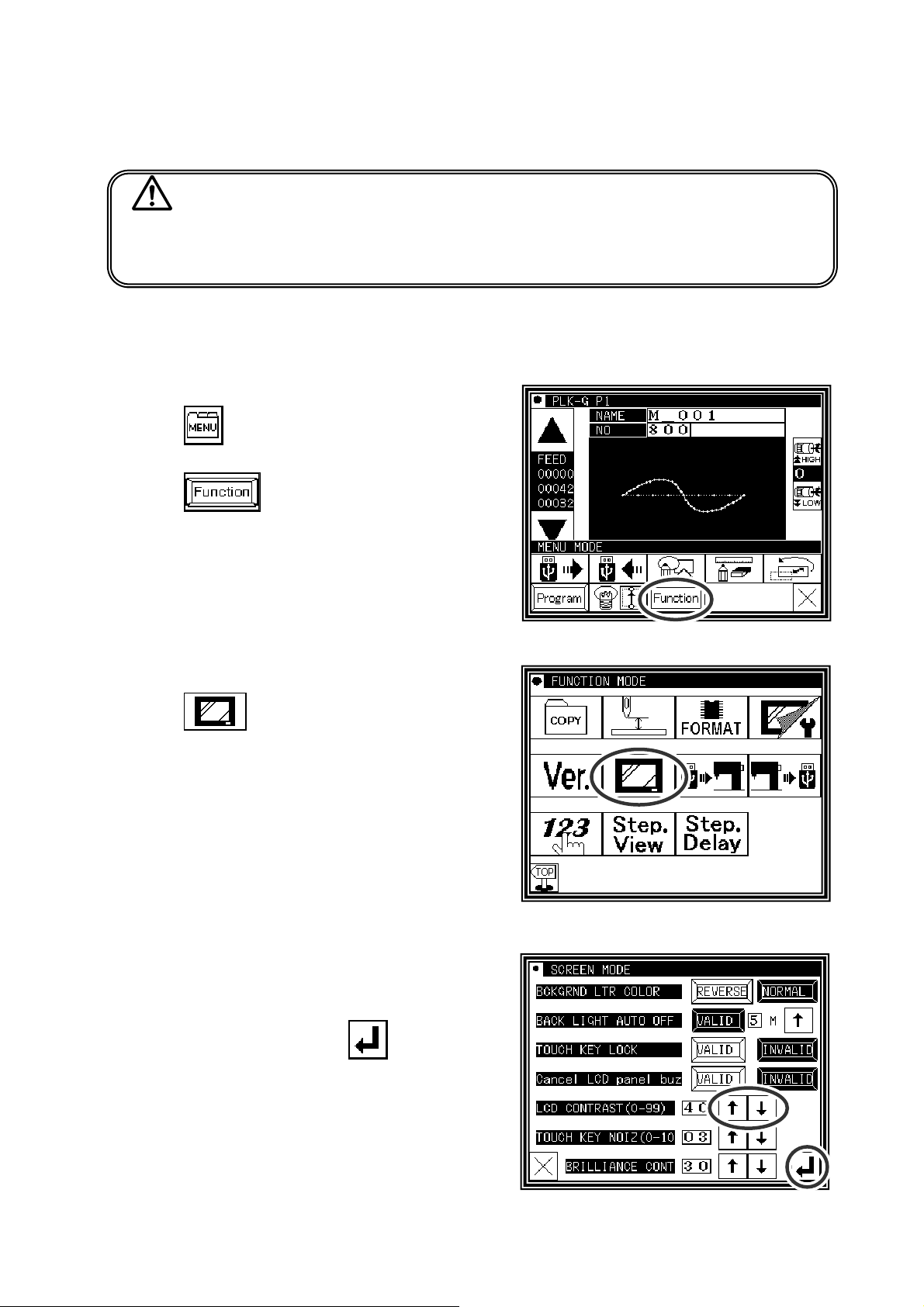

8.Adjusting the Liquid Crystal Contrast

(1)Entering the function mode

►Press

menu mode.

►Press

on the standard screen, and open the

(2)Entering the screen mode

►Press on the function mode menu, and open the

screen mode.

(3)Adjustment of LCD contrast

►Set the liquid crystal contrast value using the up and down

arrow icons.

►After setting the value, press the

apply the value.

►Back to Standard screen, then contrast setting is completed.

[Enter] icon to

[3] - 6

Page 16

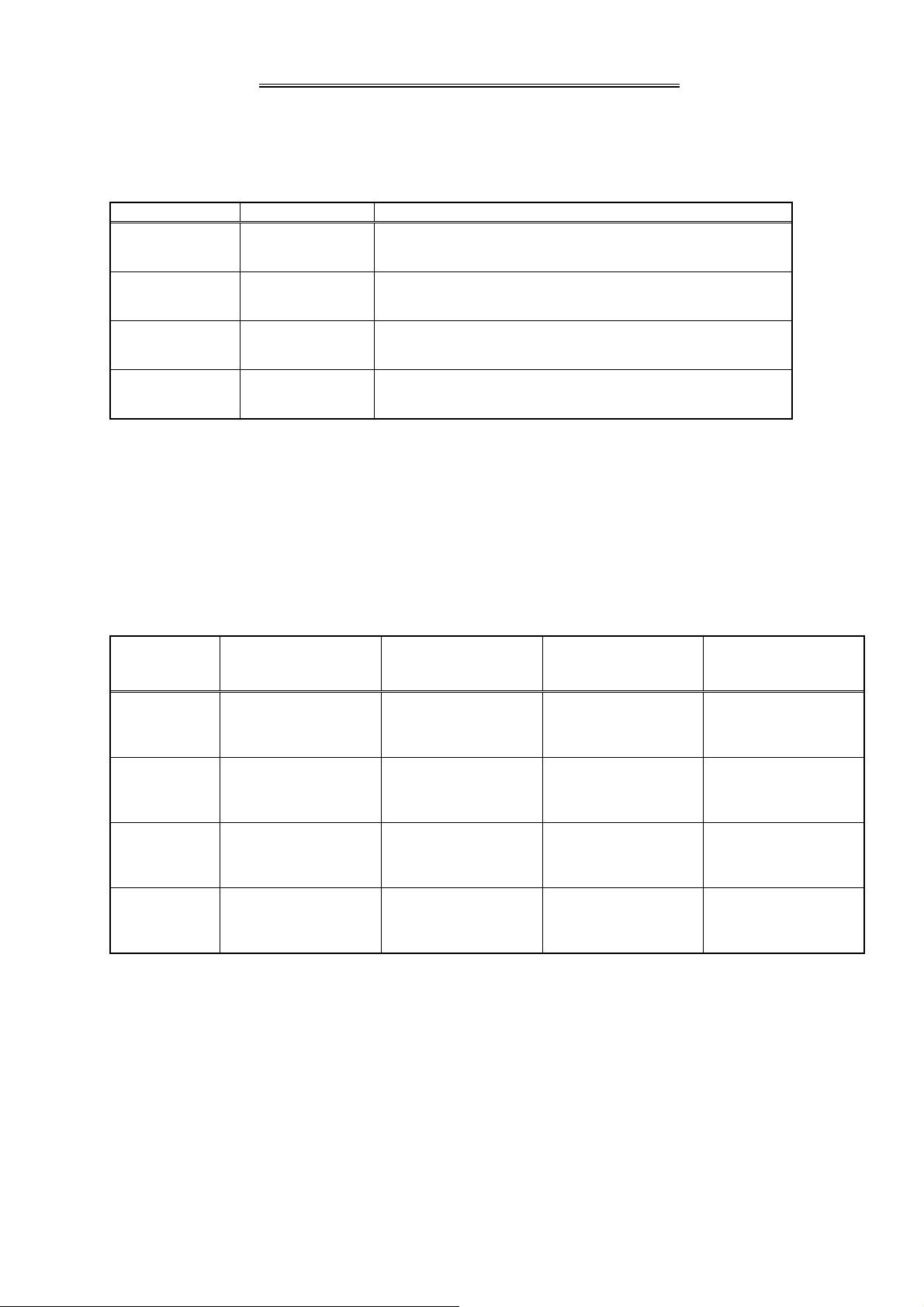

[4] Sewing Data Compatibility

1.Number and type of Sewing Data

Number Type Explanation

100 ~ 999

(*1)

100 ~ 399 A data

400 ~ 499 BA data

600 ~ 799 B data

(*1) :Pattern data which made in G series can be registered up to 900 (No.100-999) but number of the

pattern is changed by a size of each pattern.

G data

This is data created with the PLK-G series.

(The maximum number of stitches is 20,000 stitches.)

This is data created with the PLK-A series

(old model).

This is data created with the PLK-B series and E series

(old model). (For embroidery data)

This is data created with the PLK-B series and E series

(old model).

2.Sewing Data Compatibility

The following table shows the handling capabilities of the sewing machine (PLK-G series) with respect to

four types of sewing data.

Continuous input,

Type Reading Stitching

Modification and

Conversion

Writing

A data

BA data

B data

G data Available Available Available Available

(*1) : The sewing data can be read after converting to G data.

(*2) : It is written as G data.

Available

(*1)

Available

(*1)

Available

(*1)

Available Available

Available Available

Available Available

Available

(*2)

Available

(*2)

Available

(*2)

[4] - 1

Page 17

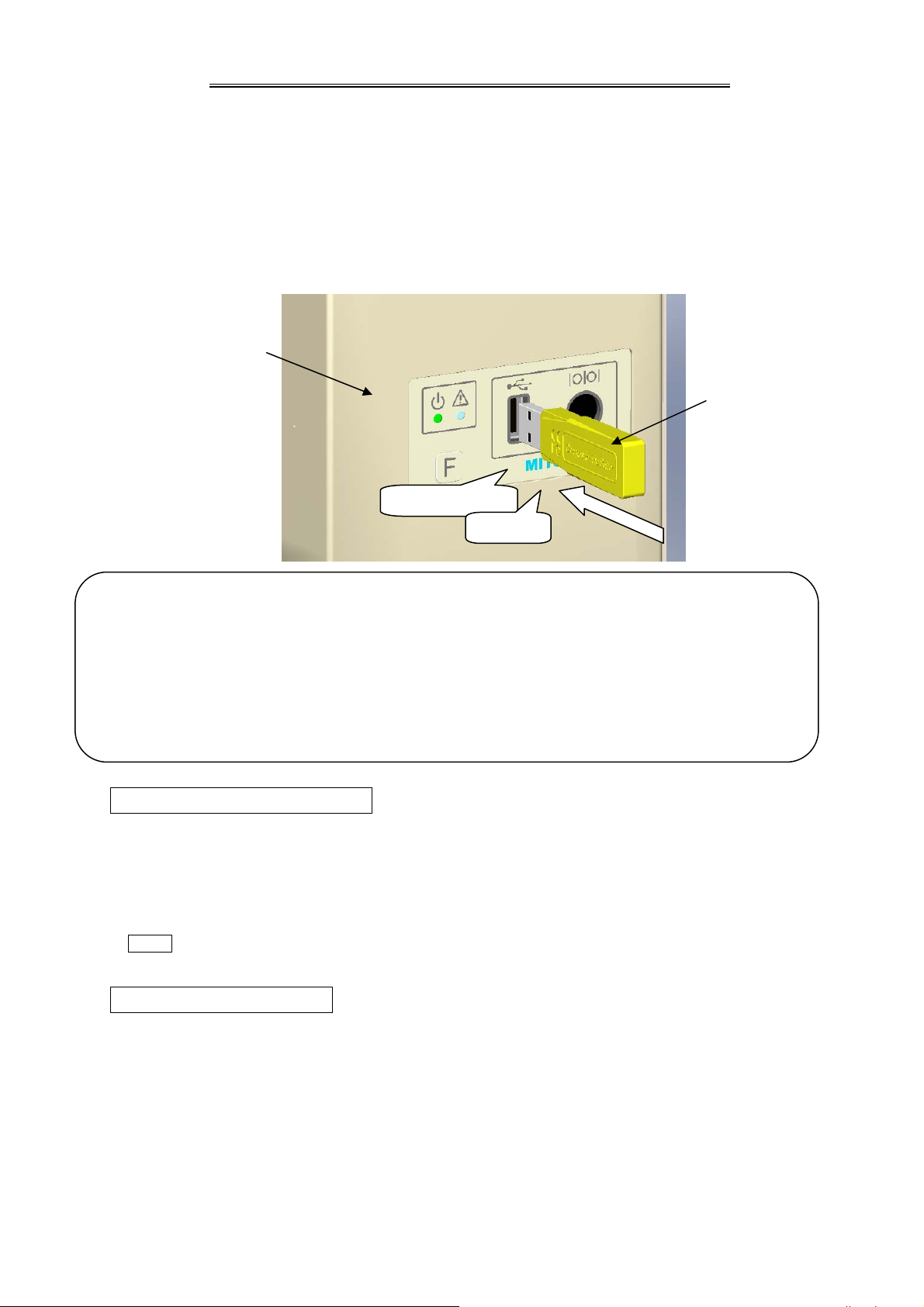

[5] Reading, writing and erasing data

1. USB

To perform actions such as storing (reading/writing) sewing data on a device other than the internal memory

or reinstalling the system, a USB device is used. The device is connected to the USB connector on the front

side of the control box.

When using a USB device, be sure to fully insert the device into the USB connector. (Refer to the figure

below.)

Front panel

USB memory

straightforward

Certainly

[Caution]

■ Connect the USB device during use only. After use, remove and store the device in an appropriate

location. When USB device is not connected, insert protection cap to the USB connector.

(Protection cap must be inserted correctly according to the shape of the USB connector)

■ Sewing cannot be performed with the USB device inserted.

■ Do not insert the USB device during sewing.

■ Be careful that nothing bumps into the inserted USB device.

Conditions of Application

▪ USB1.1 or USB2.0 compatible USB memory and USB floppy disk drive (Note, however, formatting cannot

be performed with a floppy disk drive connected to the machine.)

▪ Required power supply: USB compatible, 500mA or less

Note The write-protector might not be able to recognized according to the kind of USB device.

Please make sure to release the write-protection before writing data to the USB memory.

Inapplicable Devices ■Never connect the following devices.

(Doing so causes malfunctions.)

▪ USB device requiring an external power supply (including Computer devices)

▪ USB hard disk drive, keyboard, mouse

▪ USB memory with fingerprint authentication function or with security function

▪ USB memory with hub function

▪ Media reader

▪ USB device without data storage function

[5] - 1

Page 18

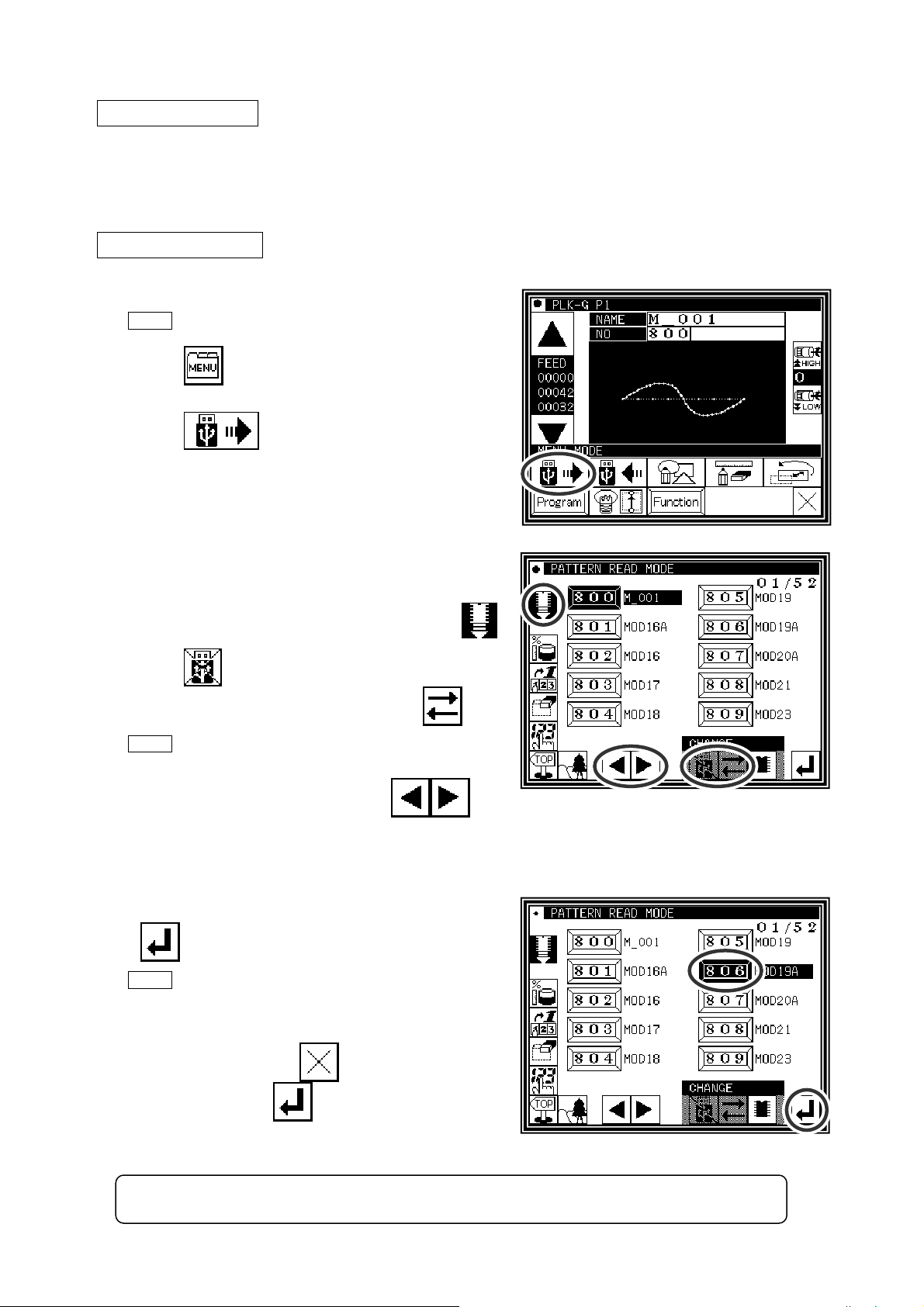

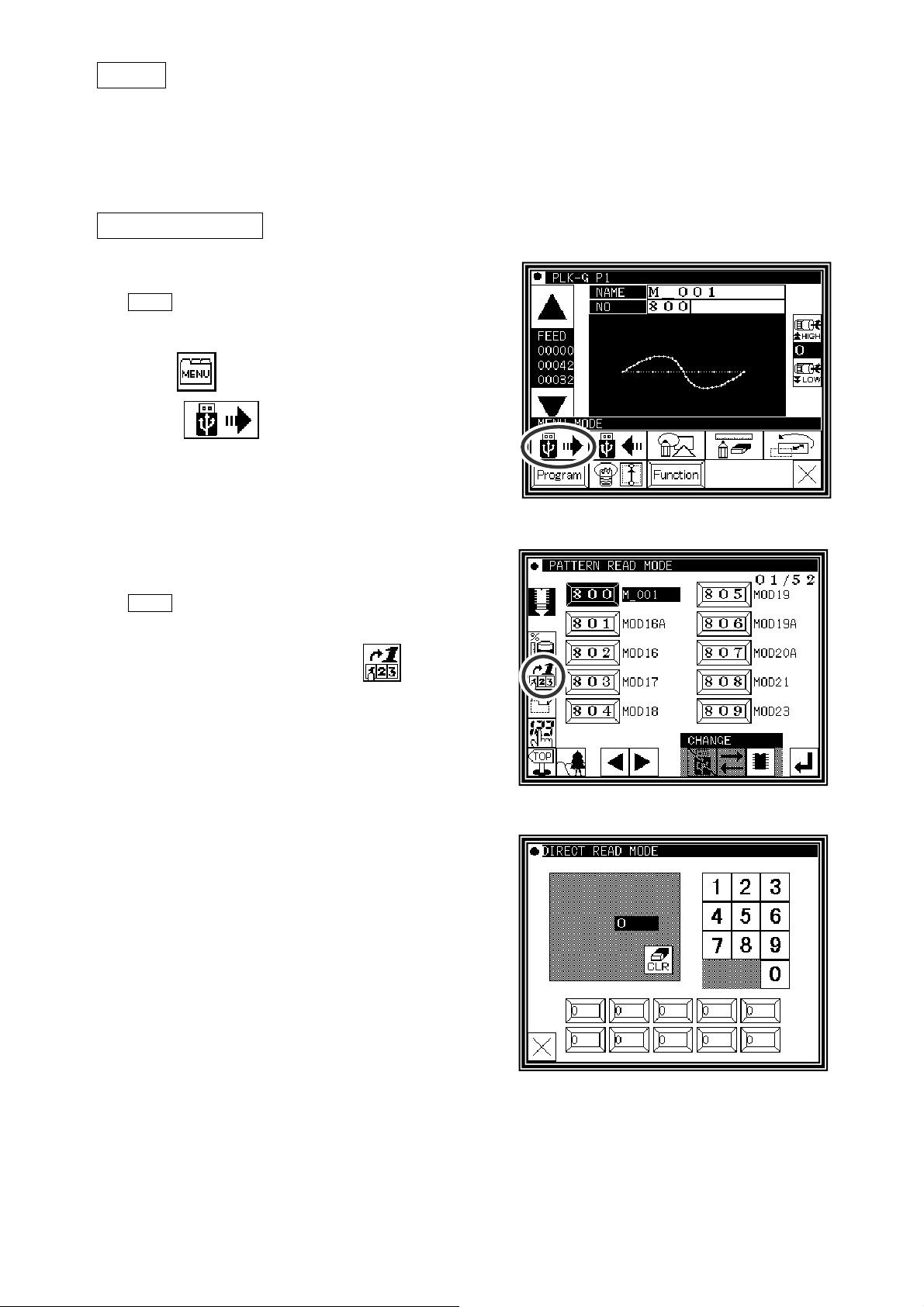

2.Reading

Operation points

·Select “Read mode” from the menu.

·Select the target (internal memory/USB memory).

·Select the data, and execute reading.

Operation details

(1)Selecting data read

Note Data reading excluding the start position cannot be

executed. Read pattern data after home returning.

►Press

on the standard screen, and open the

menu mode.

►Press

.

(2)·Select the target (internal memory/USB memory).

►When the screen first opens, the mode to read from the

internal memory is selected.

(The mode display at the upper left of the screen is

►Press

(The mode can also be changed by pressing

Note If the USB memory is not inserted into the USB

connector, USB memory icon can not be selected.

►If there is a large amount of data, press

to change to reading from the USB memory.

)

to

)

change the screen.

(3)Selecting and setting the data

►Press the number of the data to be read, and then press

.

Note

►The read data will be displayed.

[ Caution ] When the target is the USB memory, do not remove the USB memory during reading.

When you read data from the USB memory and

select a data number that already exists in the

internal memory, a message confirming that you

overwrite the data appears. If you do not overwrite

the data, press the

data, press the

(Doing so may result in data damage.)

icon. If you overwrite the

icon.

[5] - 2

Page 19

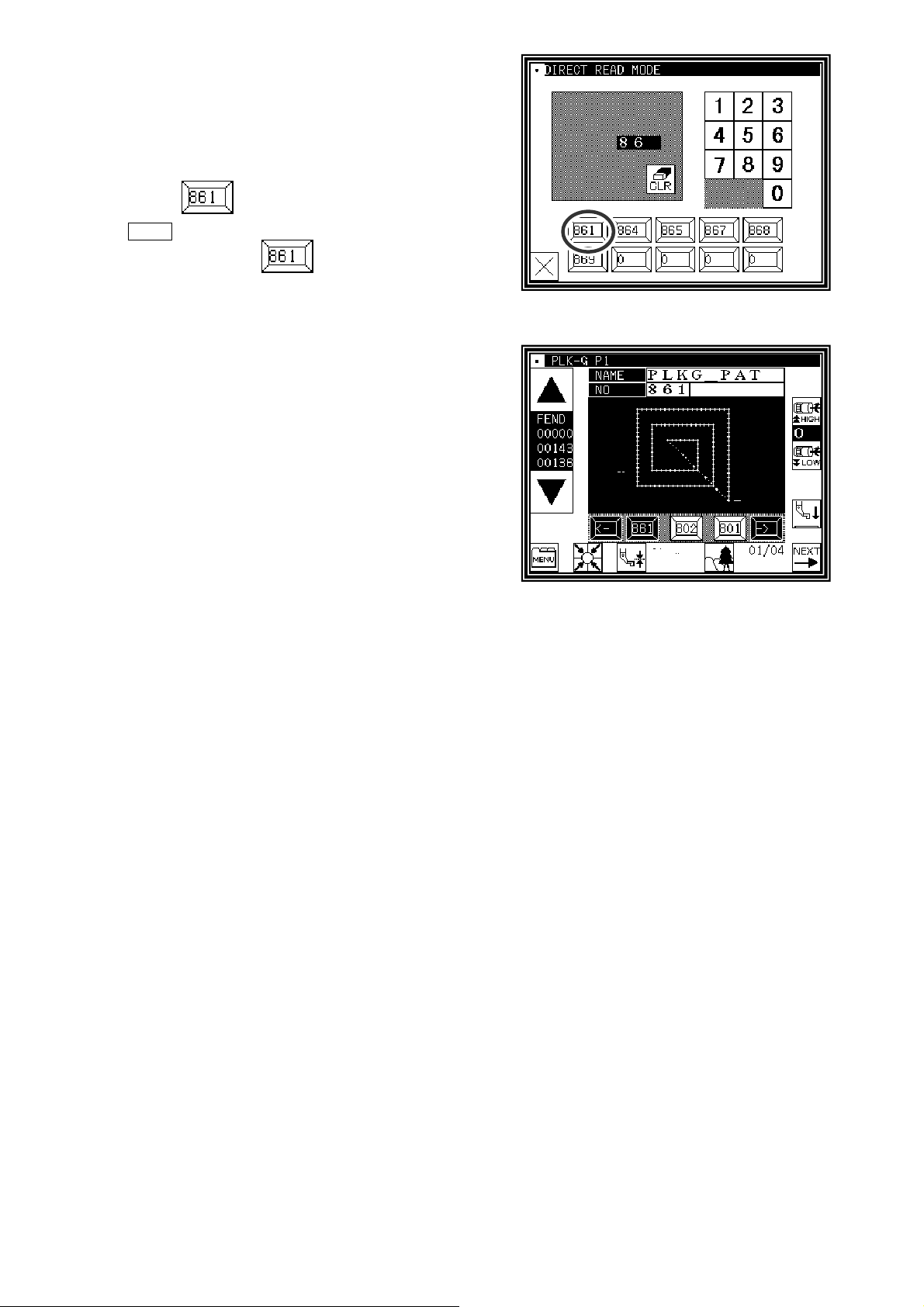

Note When the pattern data number is already known, it is possible to read by specifying the

number directly by the following operations.

(Following operation is limited to reading from an internal memory. )

Reading [Direct reading mode]

Operation details

(1) Selects pattern data read button

Note Data reading excluding the start position cannot be

executed. Read pattern data after home returning.

►Press

►Press

, then menu screen is displayed.

.

(2)Selects direct pattern number selection

Note Direct pattern number selection is possible only to the

data stored into the internal memory.

►Press direct pattern number button

.

(3) Specifies pattern data number 1

(example.Case of reading number [861]. )

► Press number button [8].

► Then 10 of pattern datas which number start from 8 are

displayed.

[5] - 3

Page 20

(4) Specifies pattern data number 2

►Next press number button [6].

► Then all pattern data which number starts from 86 is

displayed.

►At this time, desired pattern number [861] is displayed, then

press .

Note It is also available, if inputs 3 digits in the column as

[861] and push button.

(5)Data read complete

►Standard screen with the figure of pattern number [861] is

displayed.

[5] - 4

Page 21

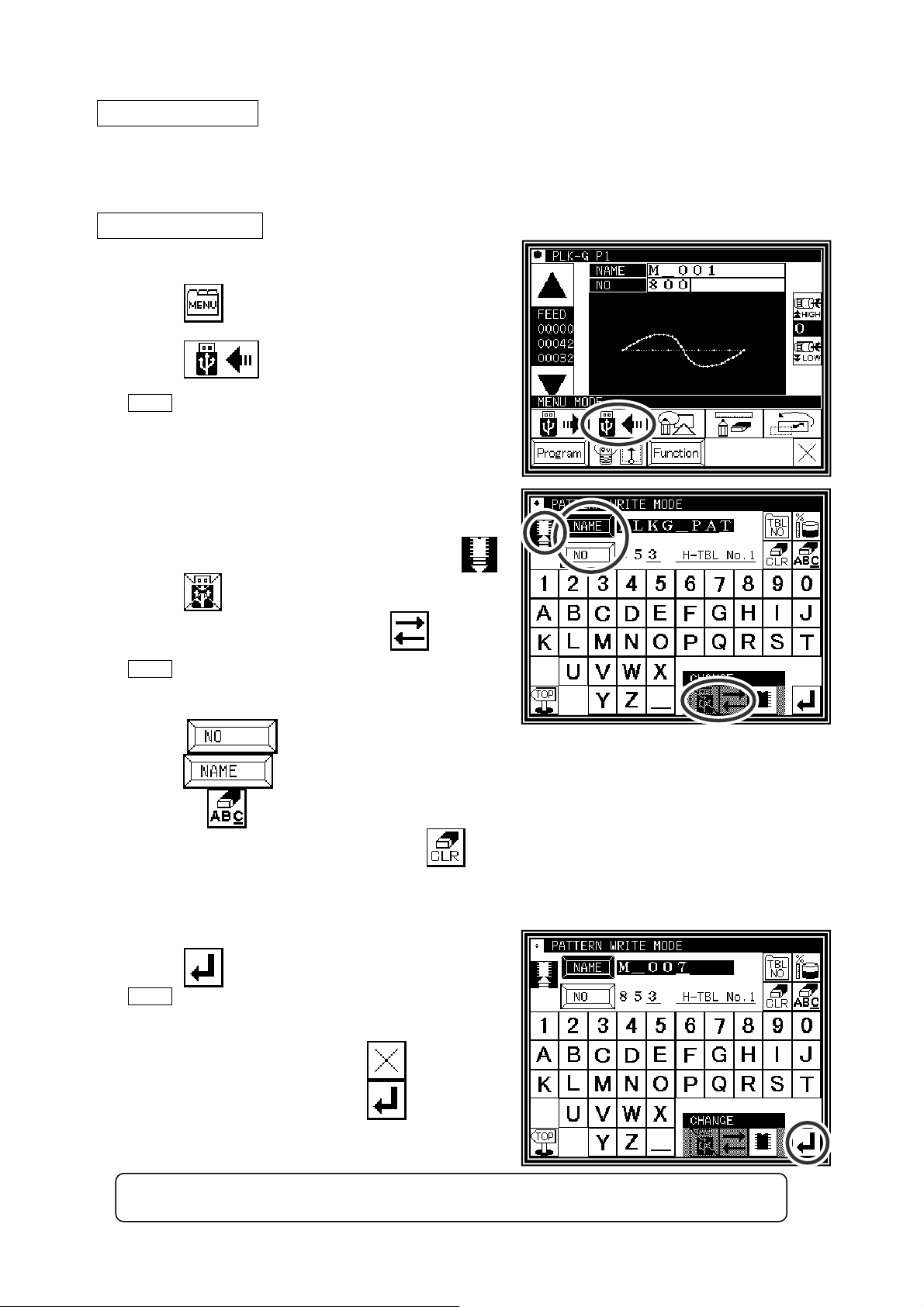

3.Writing

Operation points

·Select “Write mode” from the menu.

·Select the target (internal memory/USB memory).

·Set the pattern name and number, and execute writing.

Operation details

(1)Selecting data write

►Press

on the standard screen, and open the

menu mode.

►Press .

Note Data writing excluding the start position cannot be

executed. Write pattern data after home returning.

(2)Setting the pattern number and name

►When the screen first opens, the mode to write to the

internal memory is selected.

(The mode display at the upper left of the screen is

►Press to change to writing to the USB memory. (The

mode can also be changed by pressing

Note If the USB memory is not inserted into the USB

connector, USB memory icon can not be selected.

►Set the pattern number and name.

P

ress , and to change the name

)

)

ress

p

When the

the pattern number or name. If press the

(

The pattern name can have up to eight characters.

. Highlight the icon, and then change the setting.

icon is pressed, one of the alphanumeric characters from the right can be deleted from

icon, all character is deleted.

Specify the pattern number within the range of “800” to “999”.)

(3)Starting writing

►Press

Note

exists for the write target, a message confirming

that you overwrite the data appears. If you do not

overwrite the data, press the

overwrite the data, press the

►The standard screen will reappears.

[ Caution ] When the target is the USB memory, do not remove the USB memory during writing.

.

If you try to write a data number that already

icon. If you

icon.

(Doing so may result in data damage.)

[5] - 5

Page 22

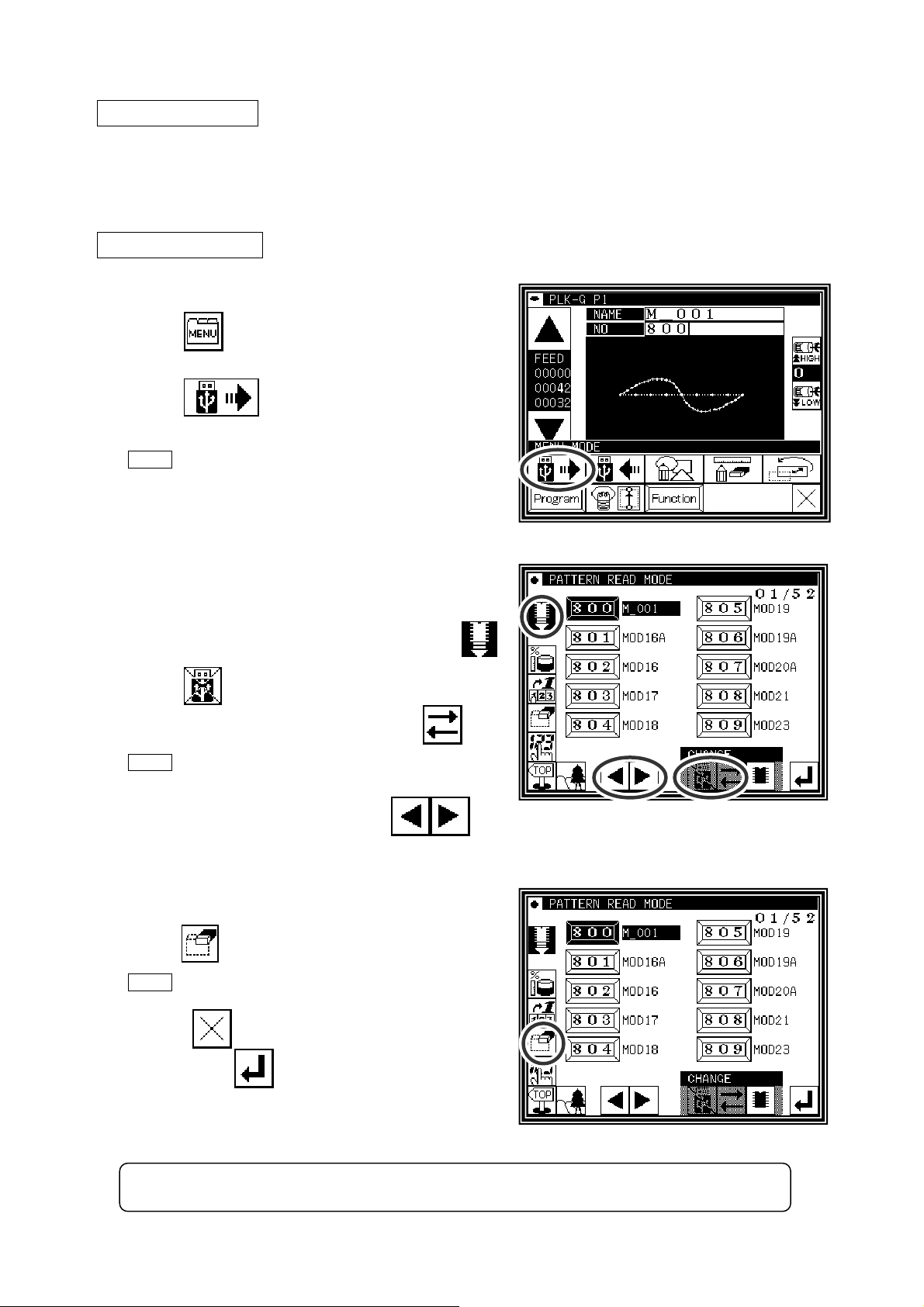

4.Erasing

Operation points

·Select “Read mode” from the menu.

·Select the target (internal memory/USB memory).

·Select the data, and execute erasing.

Operation details

(1)Selecting data erase

►Press

on the standard screen, and open the

menu mode.

►Press

Note Data erasing excluding the start position cannot be

executed. Erase pattern data after home returning.

.

(2)Select the target (internal memory/USB memory).

►When the screen first opens, the mode to erase from the

internal memory is selected.

(The mode display at the upper left of the screen is

►Press

(The mode can also be changed by pressing

Note If the USB memory is not inserted into the USB

connector, USB memory icon can not be selected.

to change to erasing from the USB memory.

)

)

►If there is a large amount of data, press

change the screen.

(3)Selecting and erasing the data

►Press (Select) the number of the data to be erased, and

press

Note

appears. If you cancel the erase operation, press

the

press the

erasing is in progress appears, and then the

Standard screen reappears.

[ Caution ] When the target is the USB memory, do not remove the USB memory during erasing.

.

A message confirming that you erase the data

icon. If you execute the erase operation,

icon. A message indicating that

(Doing so may result in data damage.)

to

[5] - 6

Page 23

5.Reading data with shortcut icons

(Reading from internal memory)

Memo Data can be read out with easy operations.

Operation details

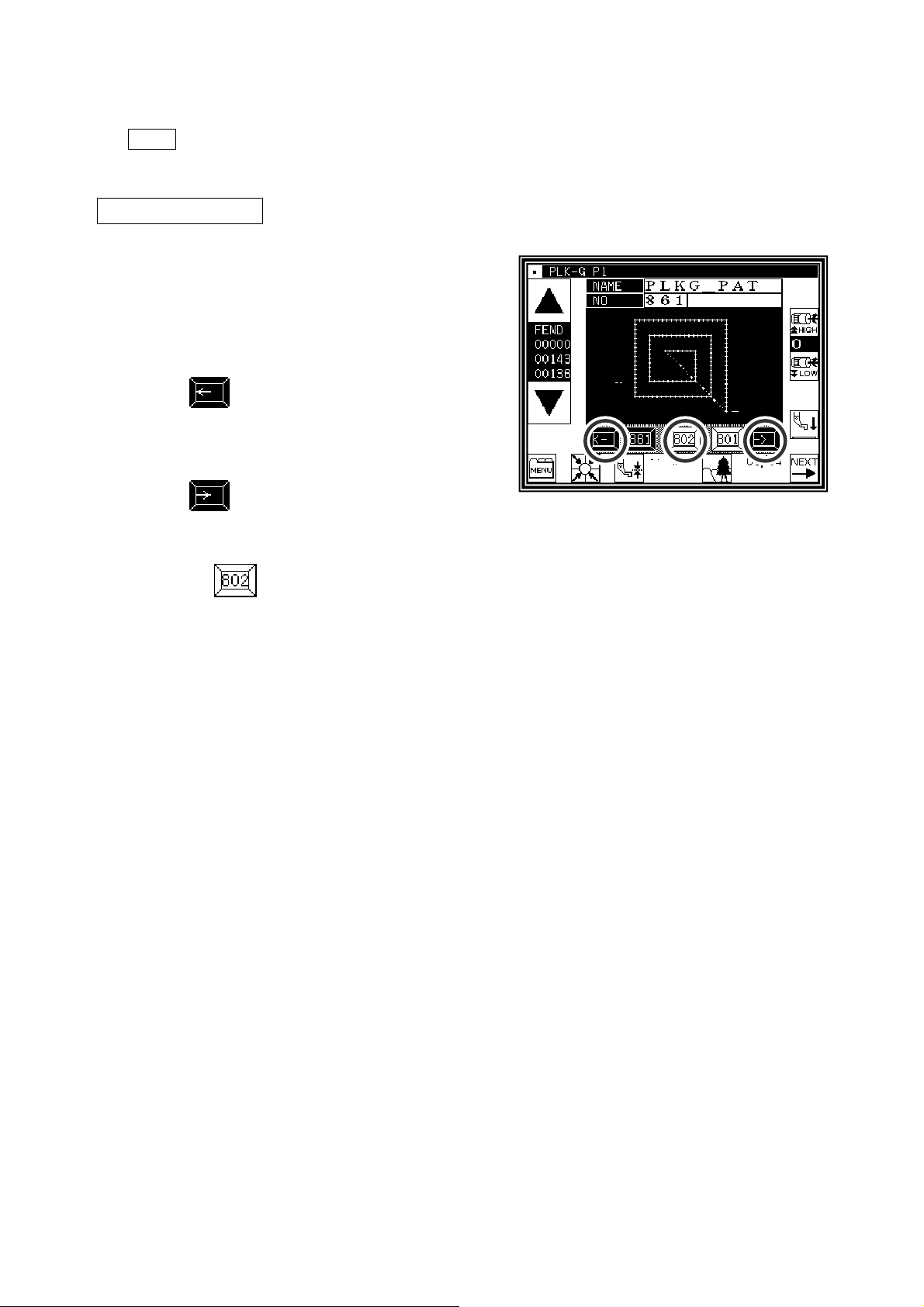

(1)Reading data

►

Use the icon under the image area of the standard

screen for call-up operation.

(No. 802 is used as an example here.)

►

Press to sequentially display the No. icon for

the data written in the internal memory from left to

right.(*1)

►

Press to sequentially display the No. icon for

the data written in the internal memory from right to left.(*1)

►

Press the (No. icon). The data written in the internal memory will be called out. (The data having

the number indicated on the icon will be called out.)

(*1) 20 data recently used are stored.

[5] - 7

Page 24

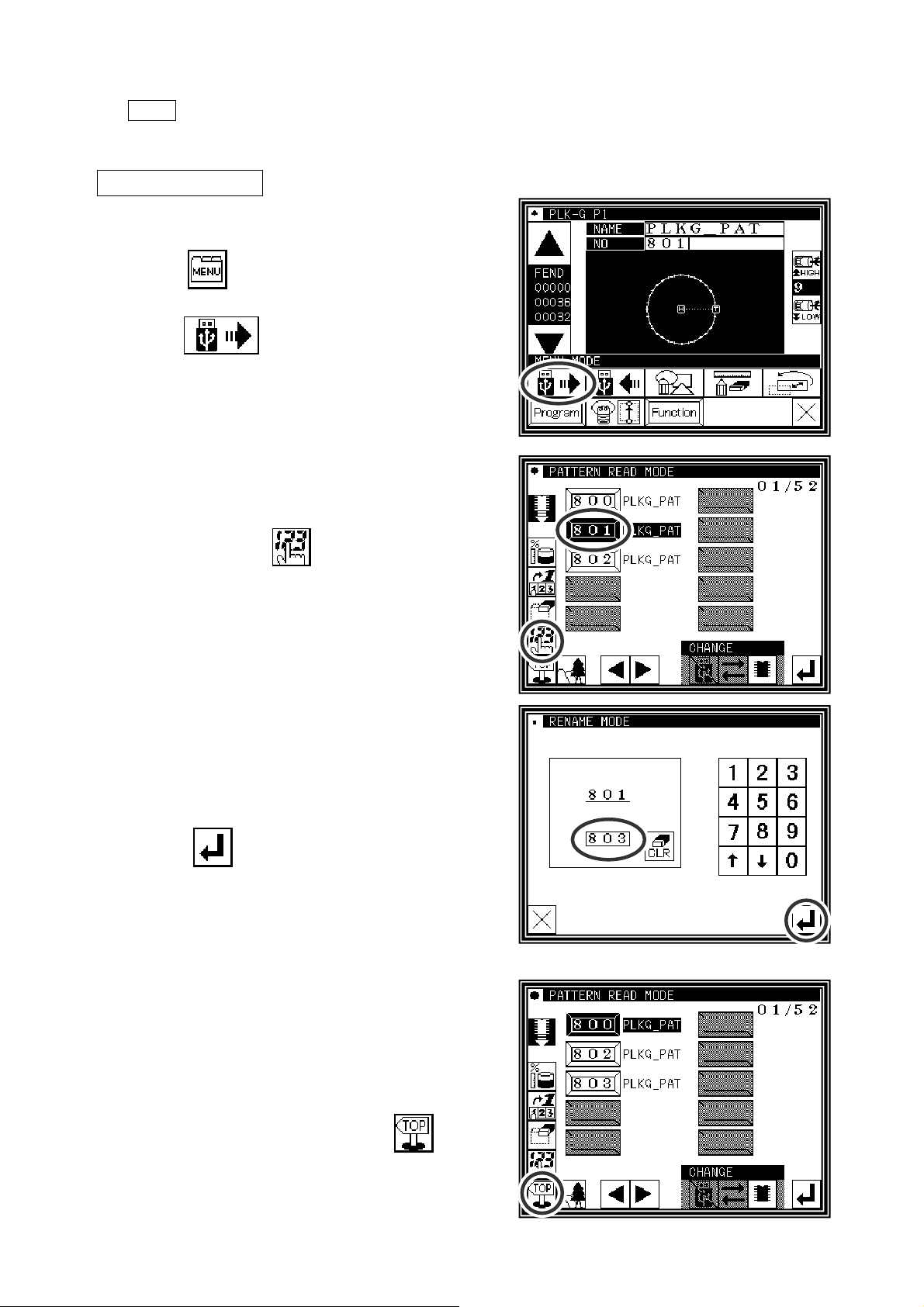

6. Rename the data number

Memo The number of the data that was saved in an internal memory can be changed.

Operation details

(1) Selecting data read

► Press

menu mode.

►Press

(2) Selecting the data

►

Selecting the number of the data that wants to

change and press

on the standard screen, and open the

.

.

(3) Specifies number

► Specifies the number that wants to change using the

numeric key.

►

Press after specifying.

(4) Completing change

► The number of “801” was changed to “803” in this example.

► To return to the standard screen, press

.

[5] - 8

Page 25

[6] Creating stitching data

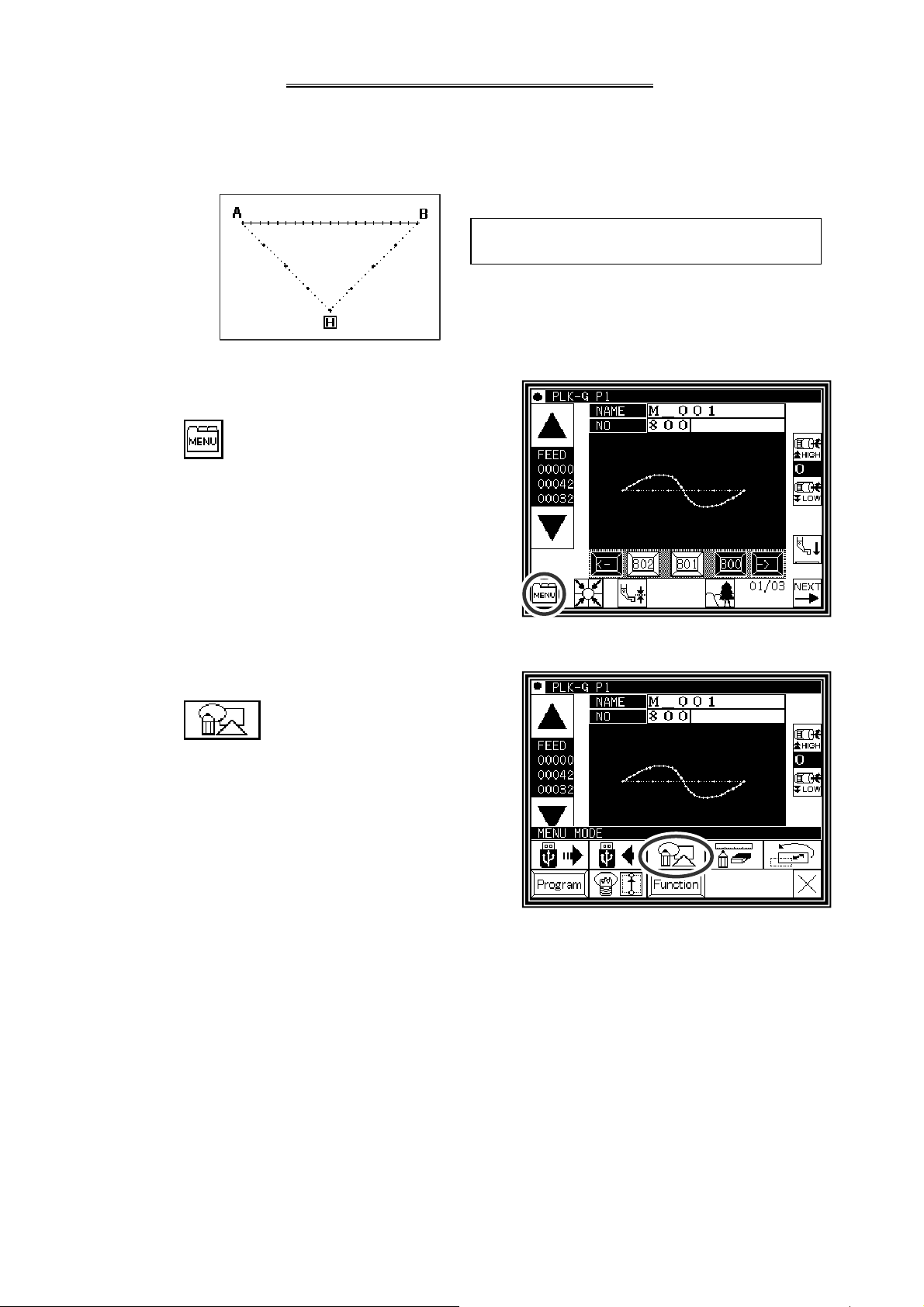

1.Flow of data creation

The flow of creating simple stitching data, as shown below, is explained in this section.

[Sample Fig.1]

(1)Start from the standard screen

The flow of operations for creating data and the

transition of screen displays are explained here.

►Press

.

(2)The menu mode will open.

►Press

.

[6] - 1

Page 26

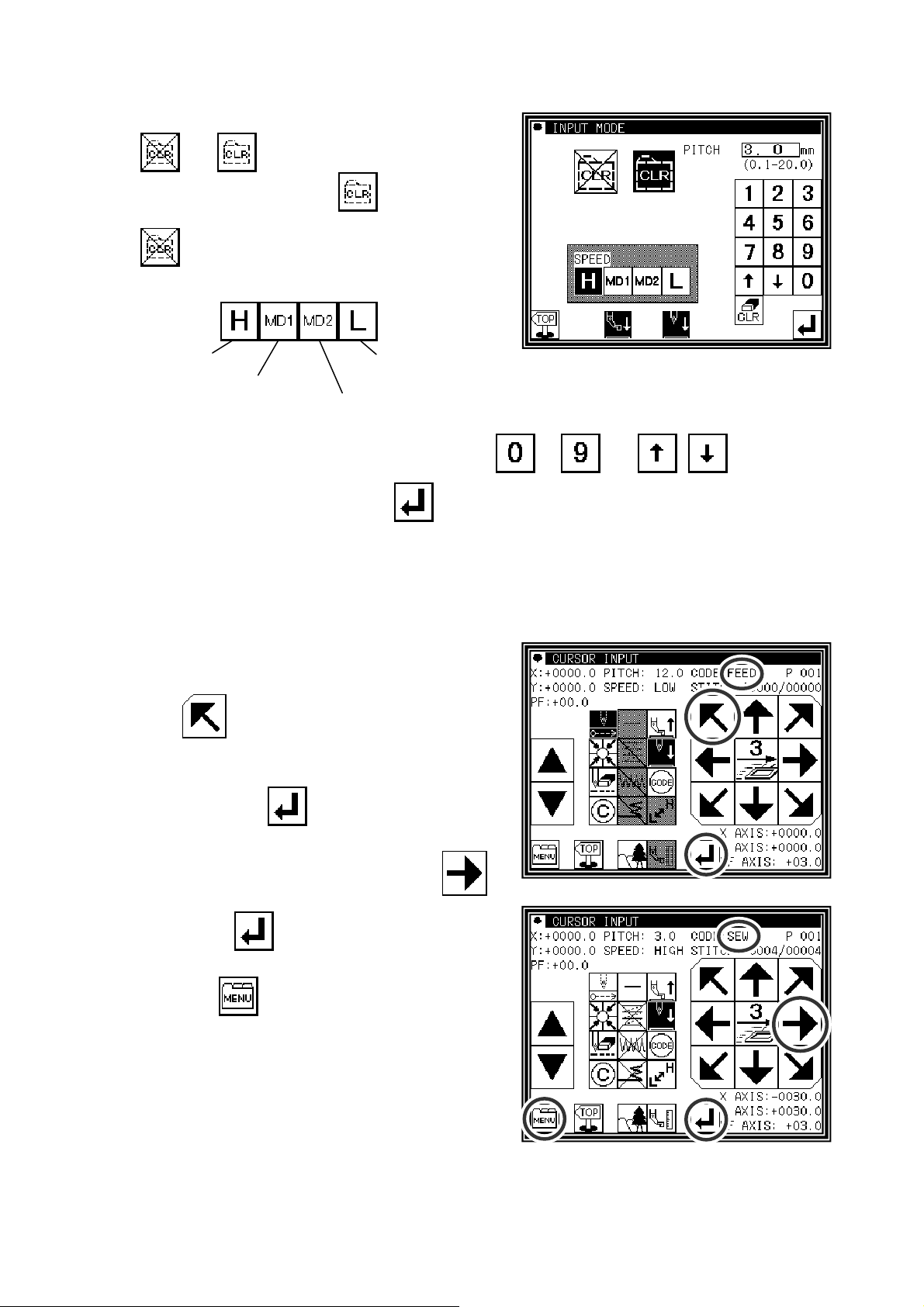

(3)The “INPUT MODE” screen will open.

►If the data has not been input on the standard screen, the

and icons will not appear. To clear the input

data and input new data, press

To continuously input after the data already input, press

.

►Set the speed.

.

High speed Low speed

Medium-1 speed

Medium-2 speed

►Set the stitch length

Set in the range of 1 (0.1mm) to 200 (20.0mm) using the

►When completed setting the data, press .

to and , icons.

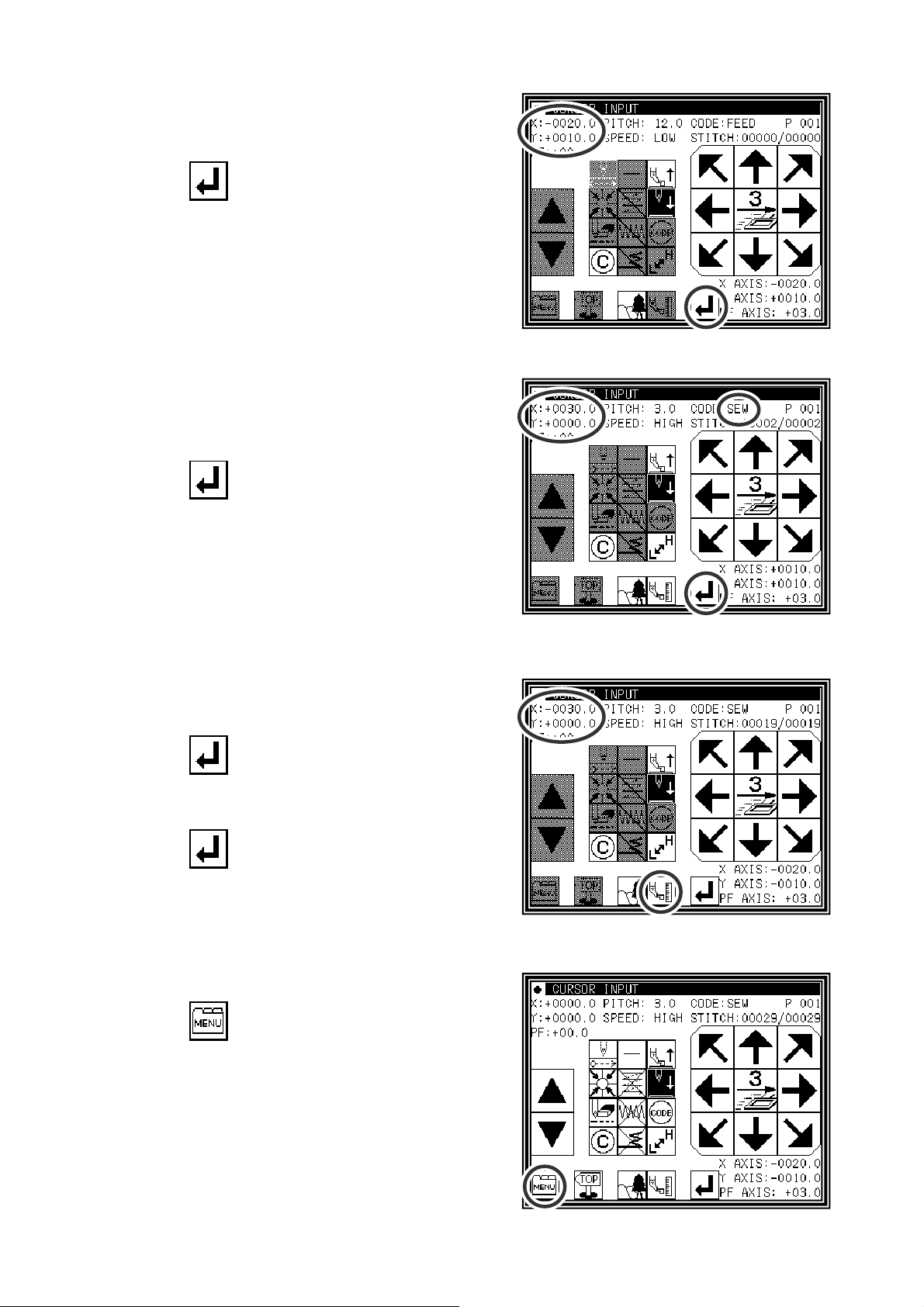

(4)The arrow input screen will open. (Input the sample Fig. 1 data.)

► When this screen is first opened, the code is set to FEED

(feed data).

Press

starting stitching. (Movement using the arrow mark icons

will change the X and Y position values displayed on the

screen.)

After moving, press

(Data on feed data to point A will be created.)

►Next, the code is set to SEW (sewing), so press

and move to the position (B point) for ending stitching. After

moving, press

on straight stitching to point B will be created.)

►Next, press

and move to the position (A point) for

, and set the current position.

, and set the current position. (Data

.

[6] - 2

Page 27

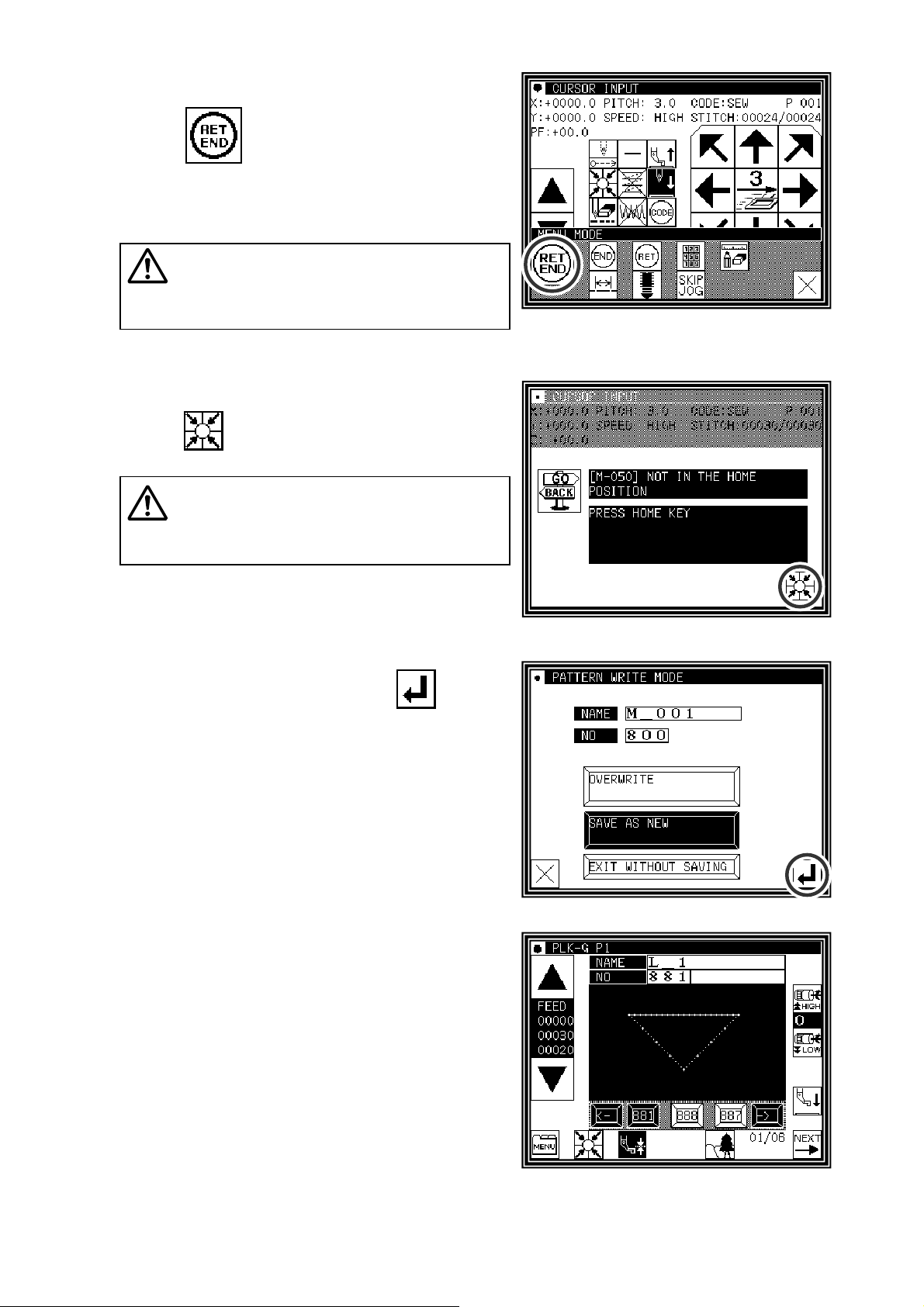

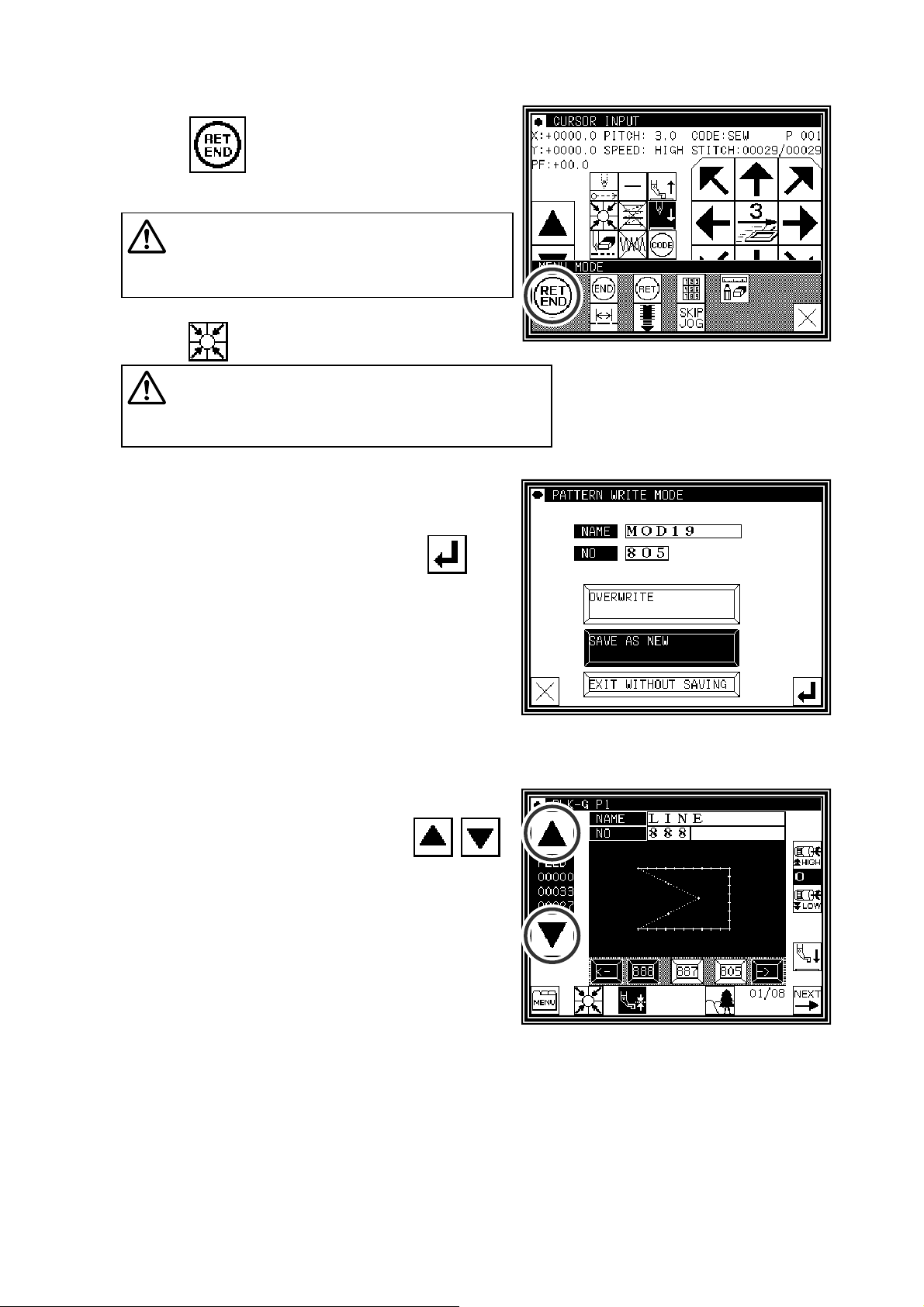

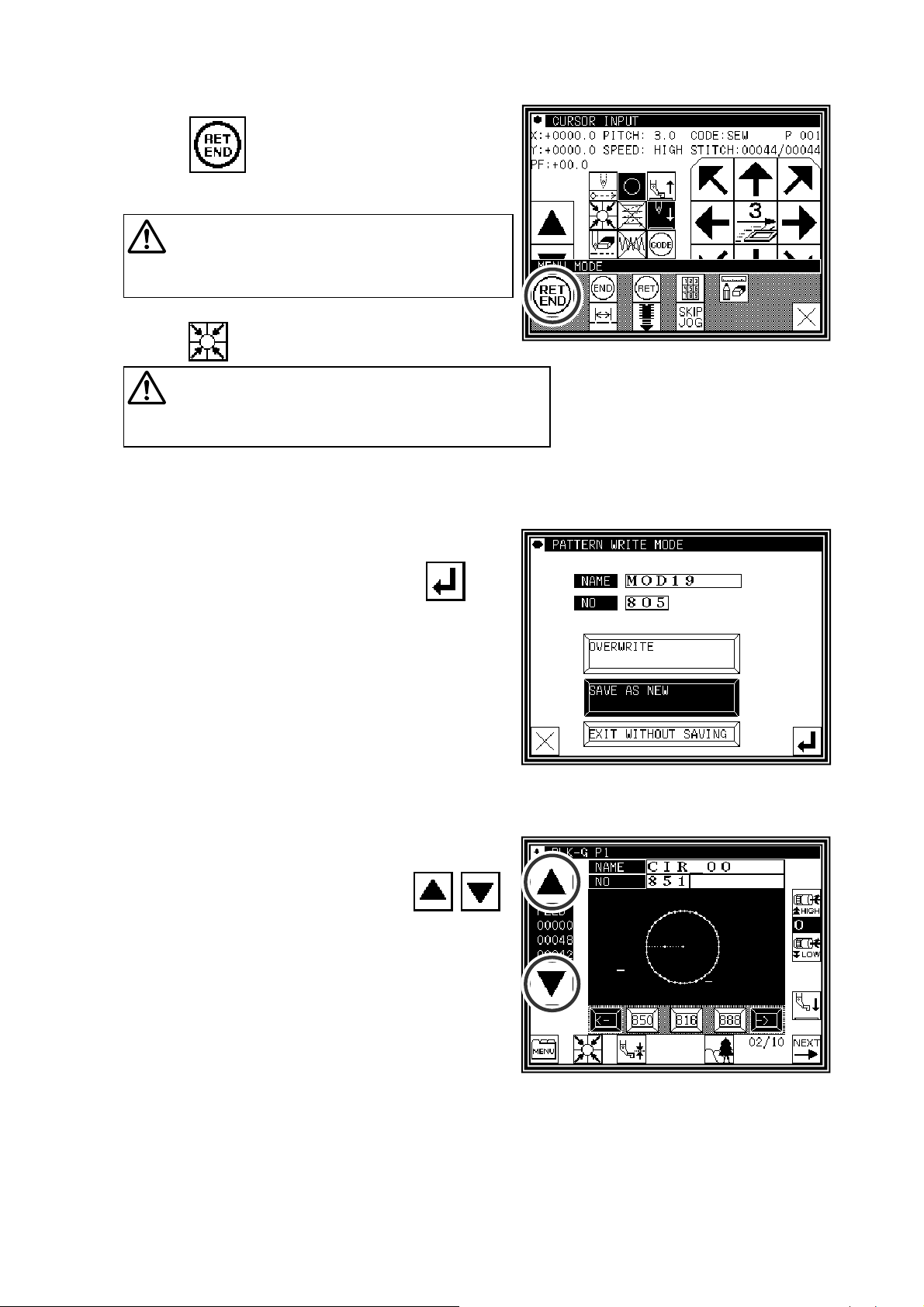

(5)The “INPUT MODE” menu will open.

►When

the home position, and inputting of data will be

completed.(Data on feed data to the home position and the

end code will be created.)

Caution

return to the home position.

Take care when the needle is lowered, etc.

is pressed, the work holder will return to

The work holder will automatically

(6)A prompt for home position return will appear.

►Press

Caution

position. If the needle is not at the UP position, it may

lower once and then return to the UP position.

The needle will rise to the UP

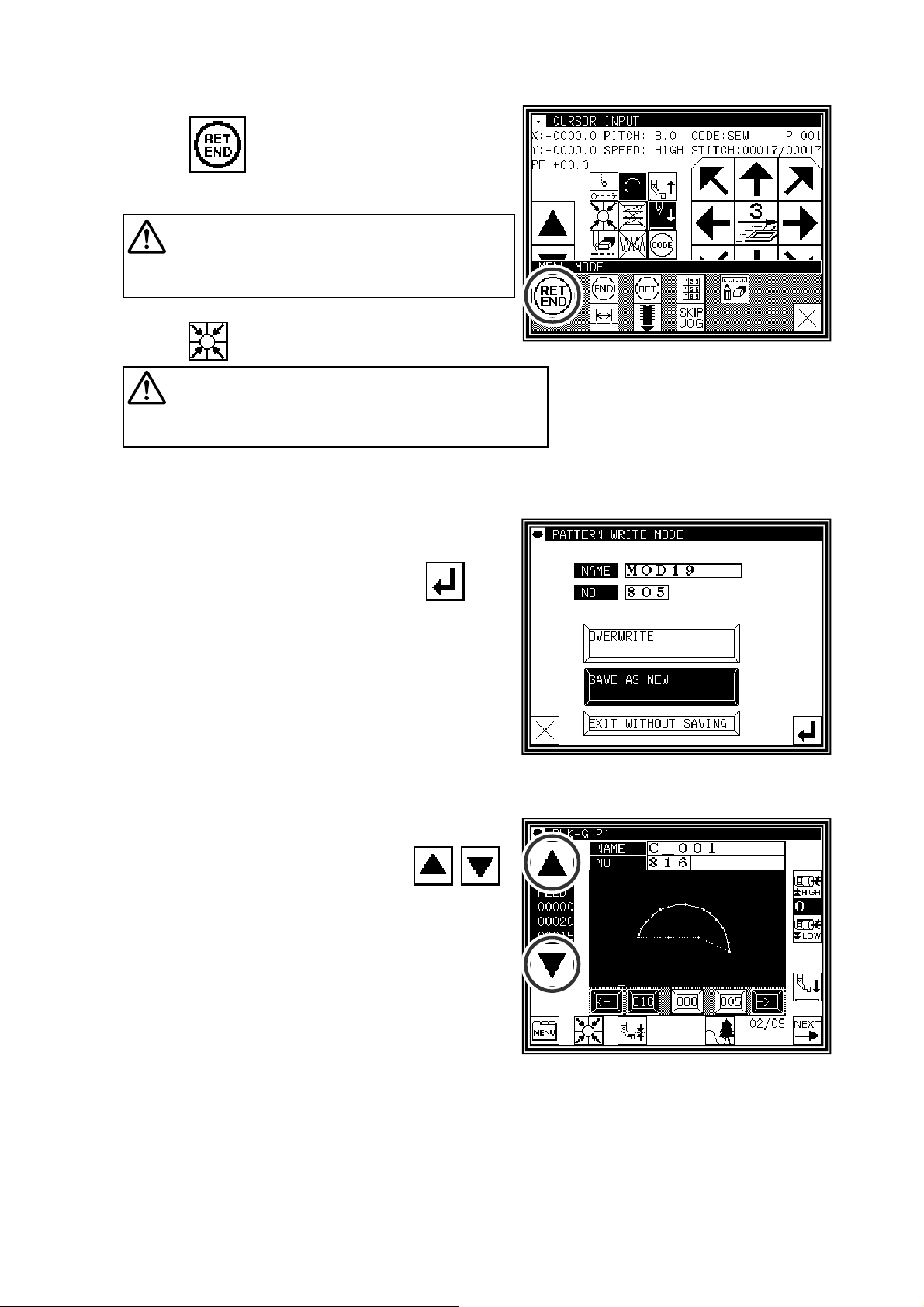

(7)Select a saving method.

►After selecting the saving method, press icon.

(Refer to “[5] Reading, writing and erasing data”)

(8)The Standard screen will open.

►Return to the Standard screen and confirm the input data.

►This completes the input.

[6] - 3

Page 28

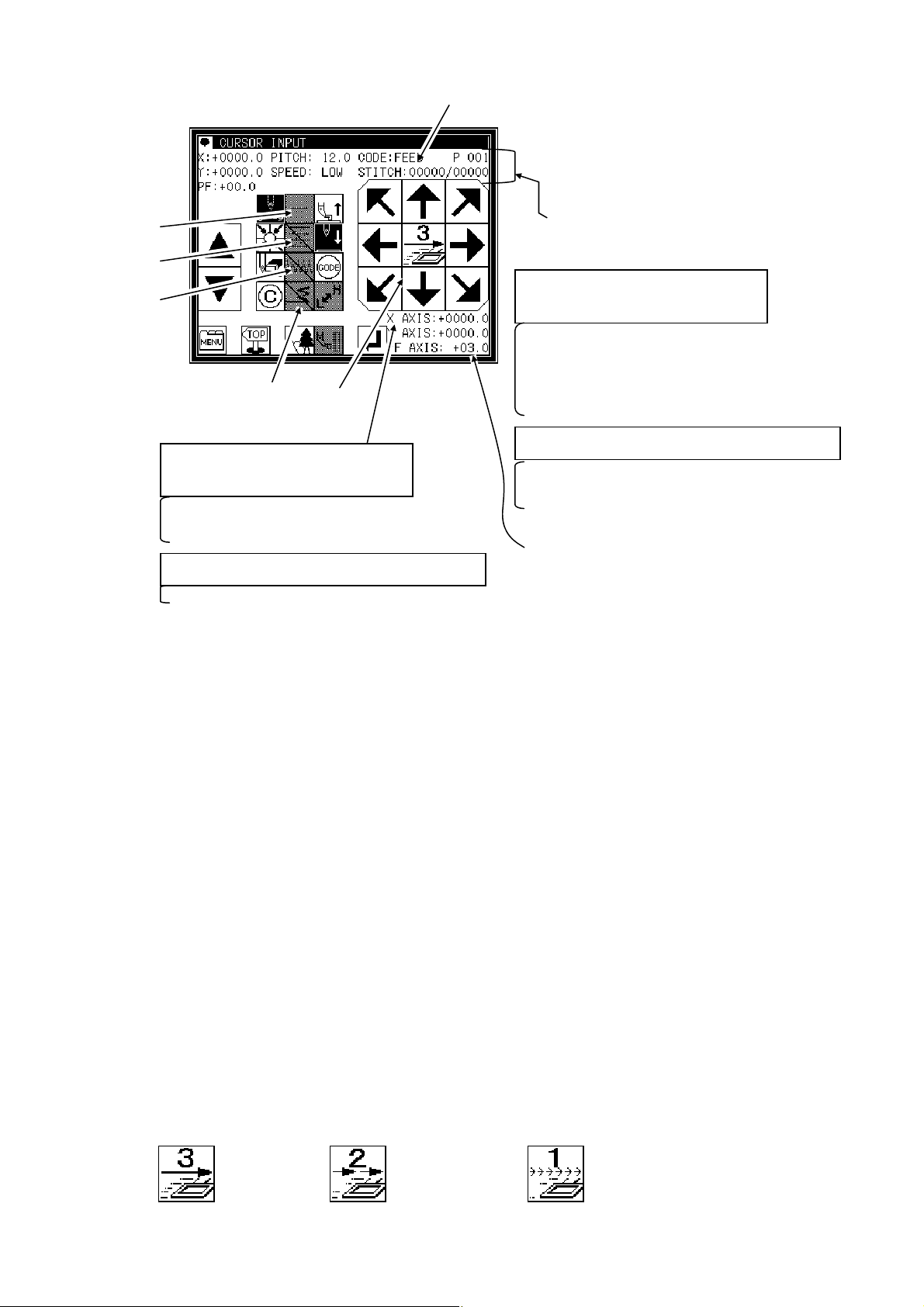

2.Description of arrow input screen

[5]

The arrow input screen is described below.

[1]

[2]

[3]

When the needle is at the final stitch

(current needle position value

= total number of stitches)

Arrow mark icons will appear and data entry will be

possible. To enter the position value, move the

work holder using the arrow mark icons.

During operation in the jog mode

(current needle position < total number of stitches)

The image currently creating will be displayed.

[4]

[6]

The current status will be displayed.

"STITCH": Shows the "current needle position

When the needle is at the final stitch

(current needle position value

= total number of stitches)

"X, Y": Shows the position values entered with the

"Stitch length", "speed", "code"

"P": Shows the number of points entered for an arc,

During operation in the jog mode

(current needle position < total number of stitches)

"X, Y", "Stitch length", "speed", "code"

Displays XY current stitch position

as an absolute value based on the

home position.

value/total number of stitches".

arrow mark icons.

: Shows the currently-set values.

curve, etc.

: Shows the needle data of the specified

position.

[1]”Data entry method setting icon”

The basic data entry method currently set will appear. (Point, straight line, broken line, circle, arc,

curve) Press this icon to display the data entry method setting screen.

[2]”Multi-stitching, reverse multi-stitching, offset data setting icon”

The multi-stitching, reverse multi-stitching, and offset data currently set will appear. (Not set,

multi-stitching (feed data mode), reverse multi-stitching (feed data mode), multi-stitching (sewing

mode), reverse multi-stitching (sewing mode), offset) Press this icon to display the multi-stitching,

reverse multi-stitching, offset data setting screen. Using this screen, you can set detailed data.

[3]”Zigzag setting icon”

The zigzag currently set will be displayed (zigzag or non-zigzag). Press this icon to display the

detailed zigzag data setting screen. Using this screen, you can set the detailed zigzag data.

[4]”Back tack setting icon”

The back tack currently set will appear. (No back tacking, start/end back tacking, overlap back

tacking) Press this icon to display the detailed back tacking data setting screen. Using this screen,

you can set detailed back tacking data.

[5]”Kind of code display”

FEED -----------FEND -----------SEW ------------P ---------------I ----------------O ---------------Z ---------------B ----------------

(Others, the various code data is displayed while JOG is operating.)

[6] [Clamp speed swich icon]

Feed

Feed end cord (Displayed while JOG is operating)

Basic input (Straight line, Arc, Circle, Curve, Broken line, Point)

Multiple sewing

Reverse multiple sewing

Offset sewing

Zigzag sewing

Back tacking sewing

Normal : A little slow : Slower

( Icon is changed whenever icon is pressed for a long period.)

[6] - 4

Page 29

“Cancel”: Cancels the last operation, and returns to the previous data entry point.

(

,

g

Caution The work holder will move. If the needle is lowered, be careful

not to get injured.

“Delete last point”: Deletes the last determined point, and returns to the previous data entry point.

“

Change sewing speed”: Each time you press this icon, the set speed will be changed in the order

The image display screen will be displayed.

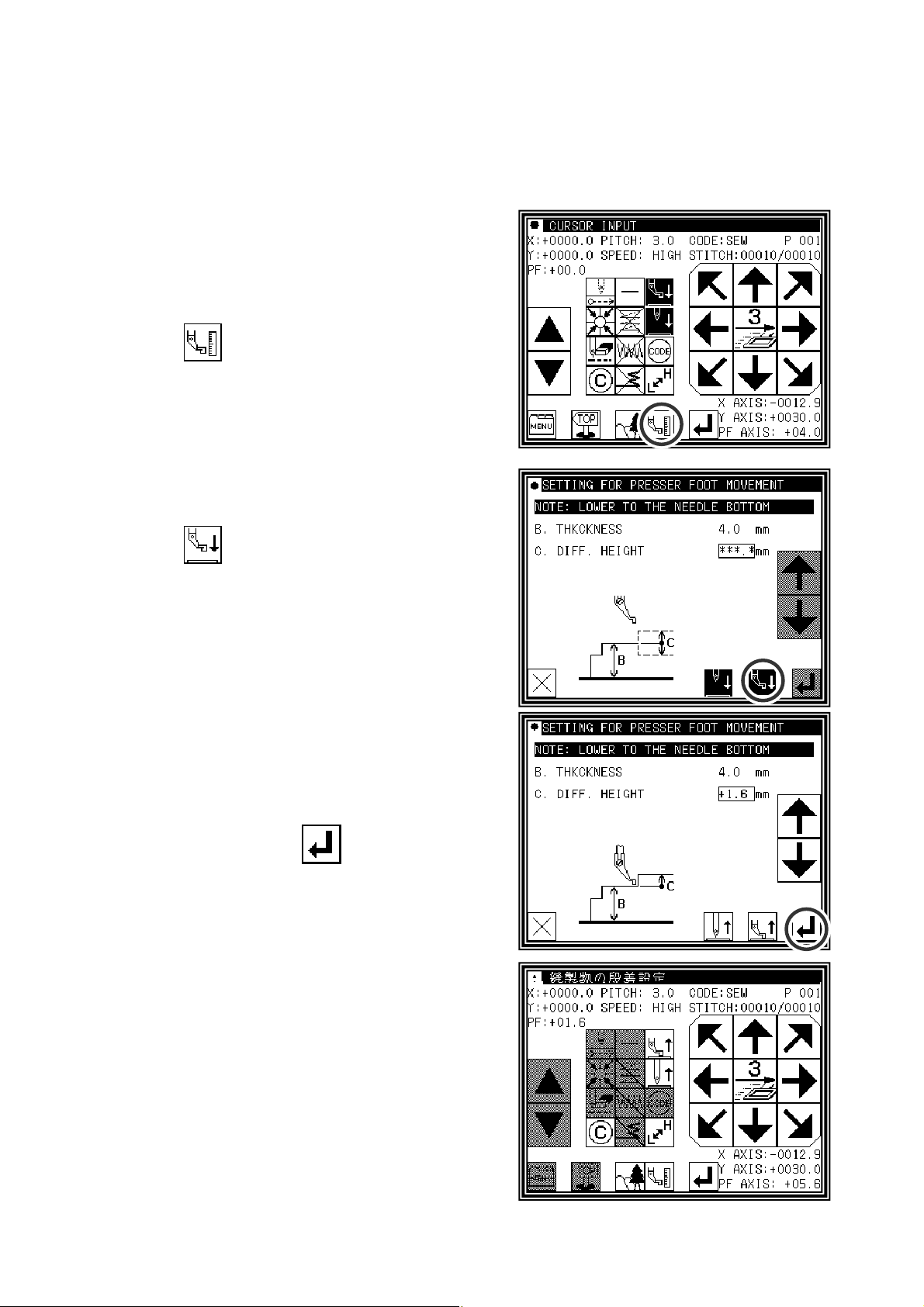

The screen of setting material step will be displayed. (Refer to page [8]-2)

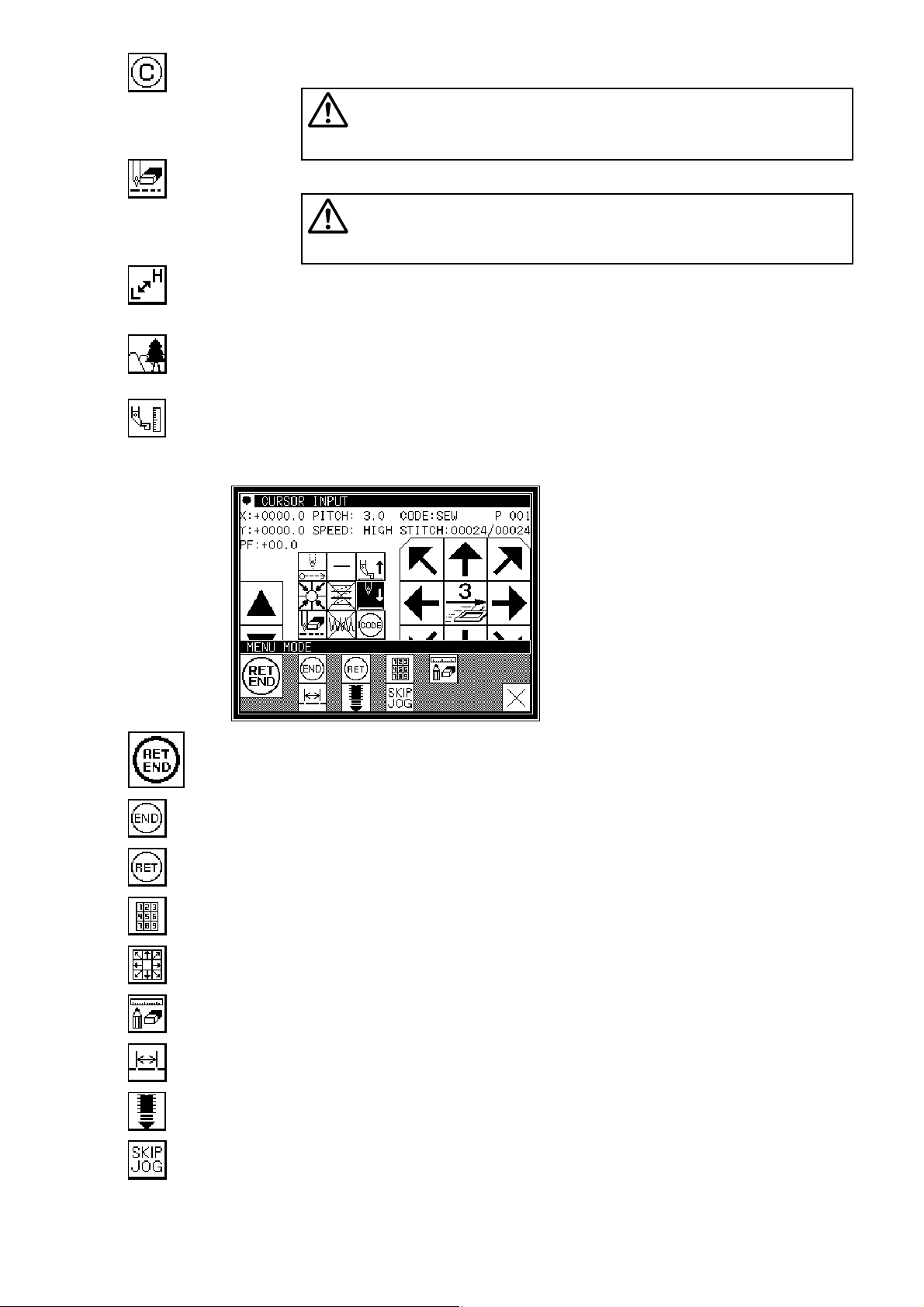

3.Description of menu

Caution The work holder will move. If the needle is lowered, be careful

not to get injured.

of “HIGH → LOW → MD2 → MD1 → HIGH.”

The data on feed data from the current position to the home position and the end code will

be created

The end code will be created, and the system will exit from the input mode.

and the system will exit from the input mode.

The data on feed data from the current position to the home position will be created.

The screen is switched to the data creation screen that enables direct entry of numeric values.

The screen is switched to the input screen that enables data entry using the arrow mark

icons

the arrow mark icons move the work holder).

You can enter the modification mode.

The stitch length change screen will appear.

When inputting data, the stitching data saved in the internal memory is added to the end of

the data bein

input.

The skip jog setting screen will appear. (The details are explained on the next page.)

[6] - 5

Page 30

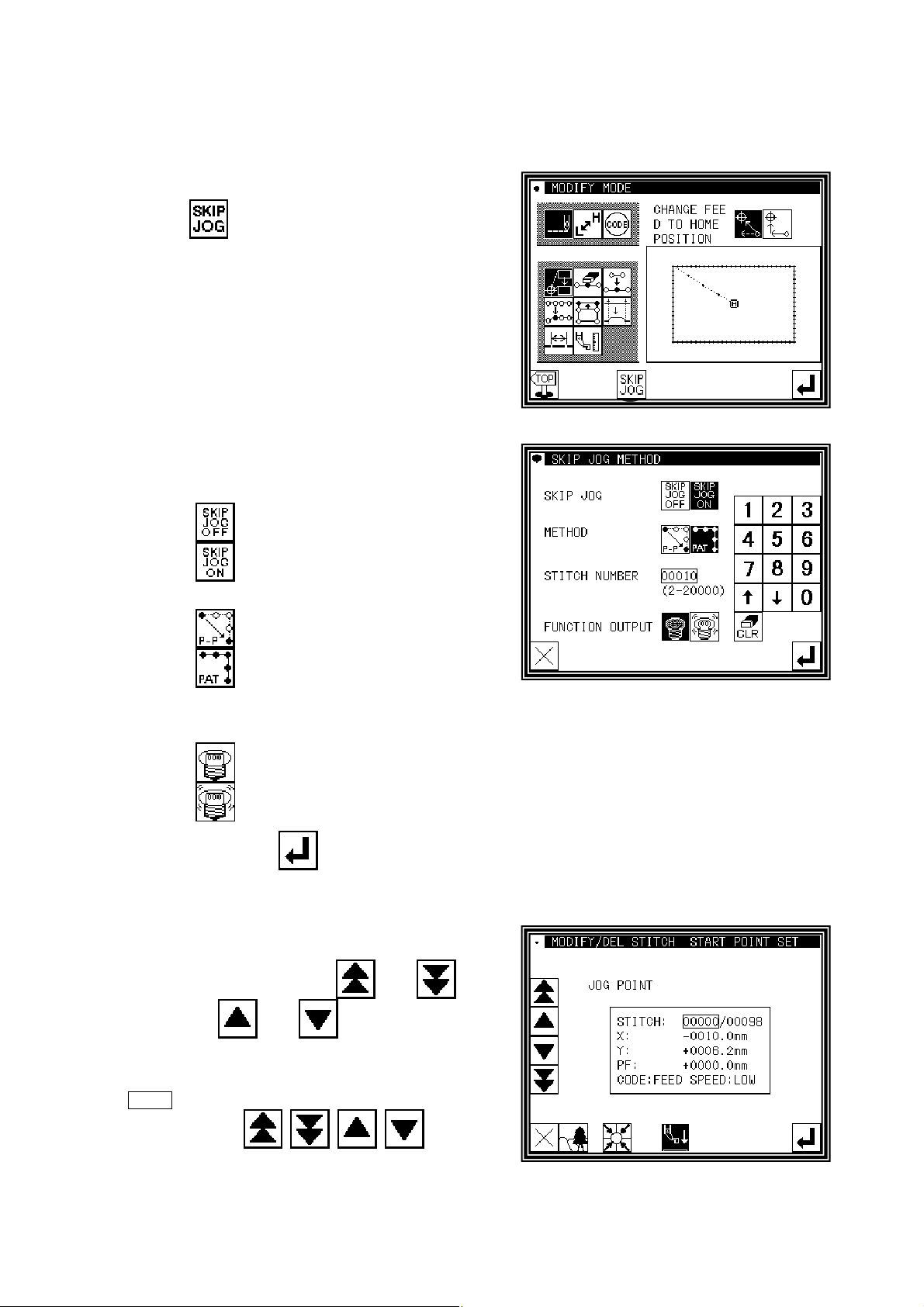

4.Skip jogging

Skip jogging allows movement to the target needle position at a faster speed than normal jogging. Skip

jogging can be used in the input, modification and conversion modes.

(1)Turning skip jogging ON/OFF, and displaying the setting screen

►

Press found on the input screen menu, the

modification mode and conversion mode.

(The explanations are made with the Modification

Mode screen.)

(2)Setting skip jogging

►

Determine whether to use (ON) or not use (OFF)

skip jogging.

►

Determine the movement method.

: Do not use. (OFF)

: Use. (ON)

: Move linearly.

: Move along a path.

►

Using the numeric keypad, set the number of movement stitches.

►

Determine the function output method.

: The output signal is invalid.

: The output signal is valid.

►

After setting, press

.

(3)Skip jog operations

►

Skip jogging will start when and are

pressed. (

.

icons

Note

Skip jogging will stop

if one of is pressed.

and are the normal jogging

[6] - 6

Page 31

[7] Methods of creating sewing data

Caution

icon is pressed.

Note that the needle will rise to the UP position when the "Home position Return"

(If the needle is not at the UP position, it may lower once and then return to

the UP position.) By removing the presser bar lifting from sewing machine, data can be input

safety and accurately.

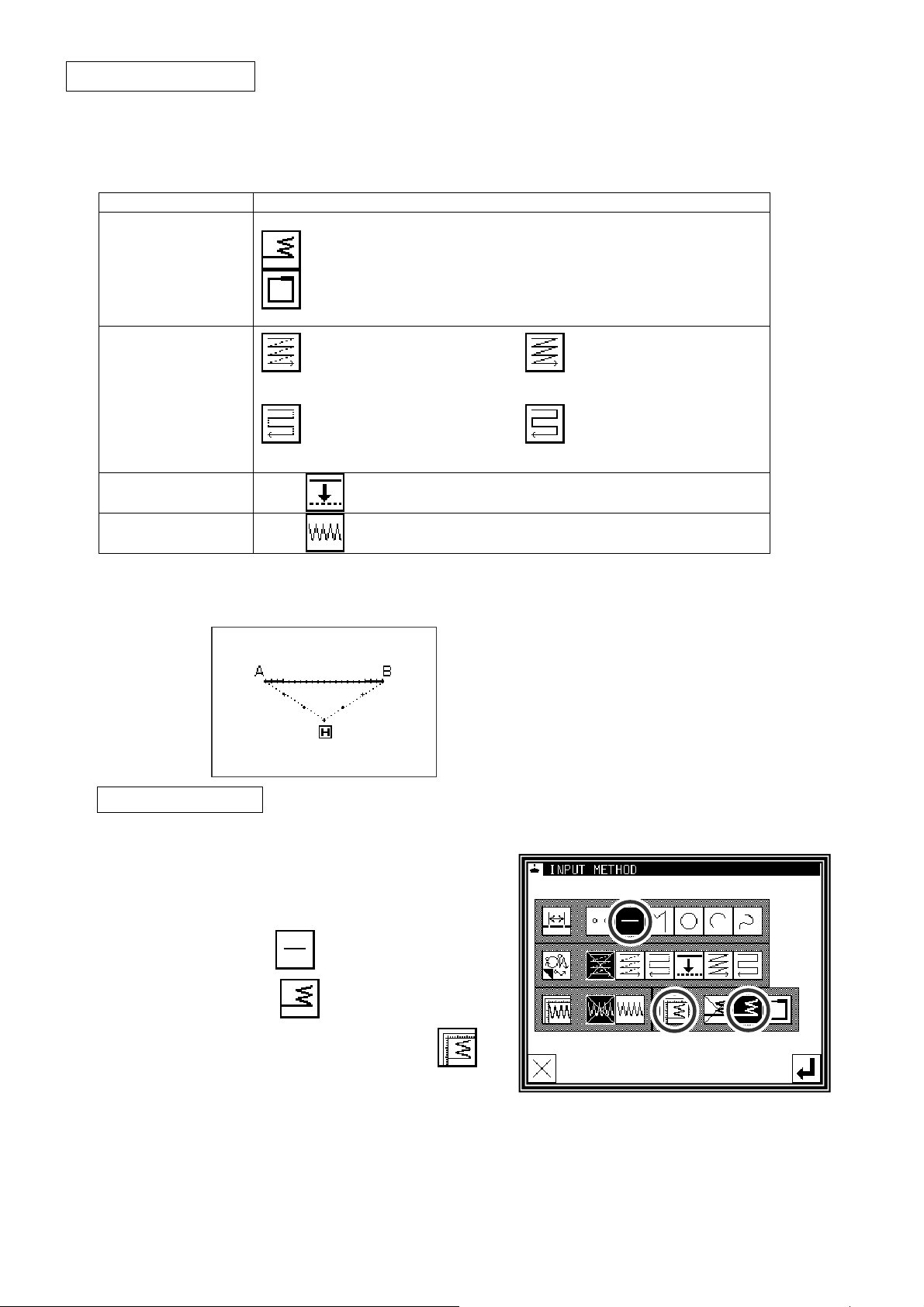

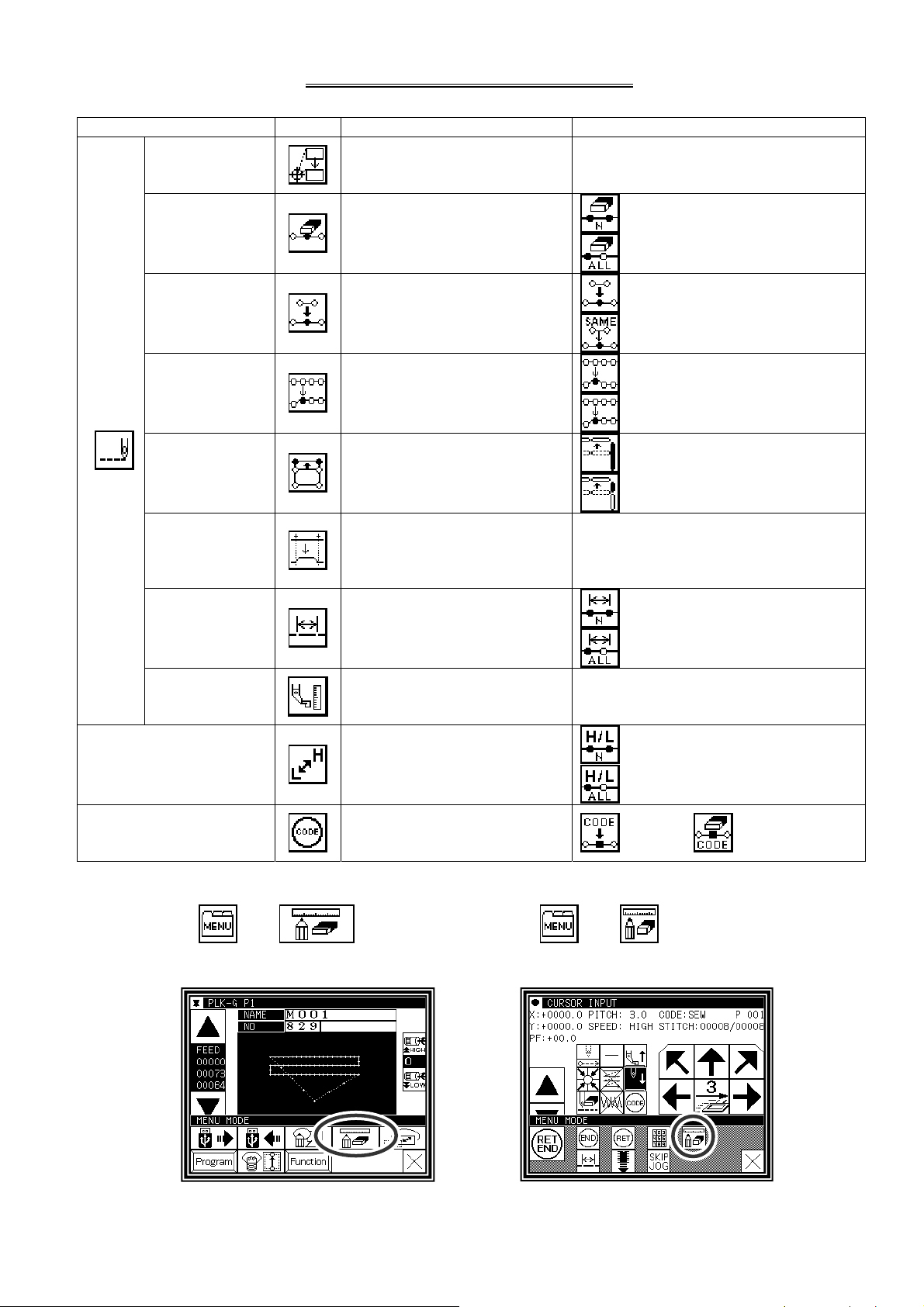

Basic Inputs

Function icon Explanation

Linear

([7]-1)

Arc

([7]-4)

Circle

([7]-8)

Curve

([7]-11)

Broken line

([7]-15)

Point

([7]-18)

Code

([7]-20)

2-point input: A linear line is created between the current position (already input)

and the newly input point.

3-point input: An arc, passing through the current position (already input) and two

newly input points, is created.

3-point input: A circle, passing through the current position (already input) and two

newly input points, is created.

A curve passing through the current position (already input) and the input point

(up to 300 points possible) is created.

A broken line connecting the current position (already input) and the input point

(up to 300 points possible) is created.

The point can be input one stitch at a time.

* The distance between the points must be within 20mm.

The code by which various controls are done can be input.

1.Linear input

Operation points

▪ Designate linear input(

▪ Input two points (A linear line is created between the current position (already input) and the newly

input point.)

[Example] The following type of sewing data will be created.

Operation details

(1)Inputting feed data to A point

►

Press and on the Standard

screen. After making the various settings on the Data

Setting Input screen, the Arrow Input screen will open.

(Refer to Page[6]-2)

)

►

Check that the code is set to FEED. If different code

is set, press

►

Press the arrow icons and move to the A point.

(Feed data to A point.)

and set the code to FEED.

[7] - 1

Page 32

(2)Setting feed data to A point

►

The movement amount can be confirmed.

[Example] X: -20.0, Y: +10.0

►

Press to set the data.

(Data on feed data to point A will be created.)

►

The movement amount will be cleared.

X:+0.0,Y:+0.0

►

The code will change to "SEW".

(3)Inputting stitching to B point

►

Press the arrow icons and move to the B point.

►

Press to set the data.

(

Data on straight stitching to point B will be created.)

(4)Inputting stitching from C point to D point

►

Press the arrow icons and move to the C point.

►

Press to set the data.

(

Data on straight stitching to point C will be created.)

►

Press the arrow icons and move to the D point.

►

Press to set the data.

(

Data on straight stitching to point D will be created.)

(5)Setting stitching to D point

►

Press

.

[7] - 2

Page 33

(6)Inputting the return/end code

►

Press .

(

Data on feed data to the home position and the end

code will be created.)

Caution

The work holder will

automatically return to the home position. Take

care when the needle is lowered, etc.

►

A prompt for home position return will appear.

Press

Caution

.

The needle will rise to the UP position.

If the needle is not at the UP position, it may lower

once and then return to the UP position.

(7)Select a saving method.

►After selecting the saving method, press icon.

(R

efer to section [5]Reading, writing and erasing data.)

►Return to the standard screen.

(8)Confirming the data

►

Confirm the data. Press the jog icons ( )

so the sewing machine movement can be confirmed.

(Even if the data input has not been completed, if the

data input last has been set, the movement can be

confirmed in the same manner.)

►

If the data must be modified, refer to section [11]

Modification mode Modifying the stitching data.

[7] - 3

Page 34

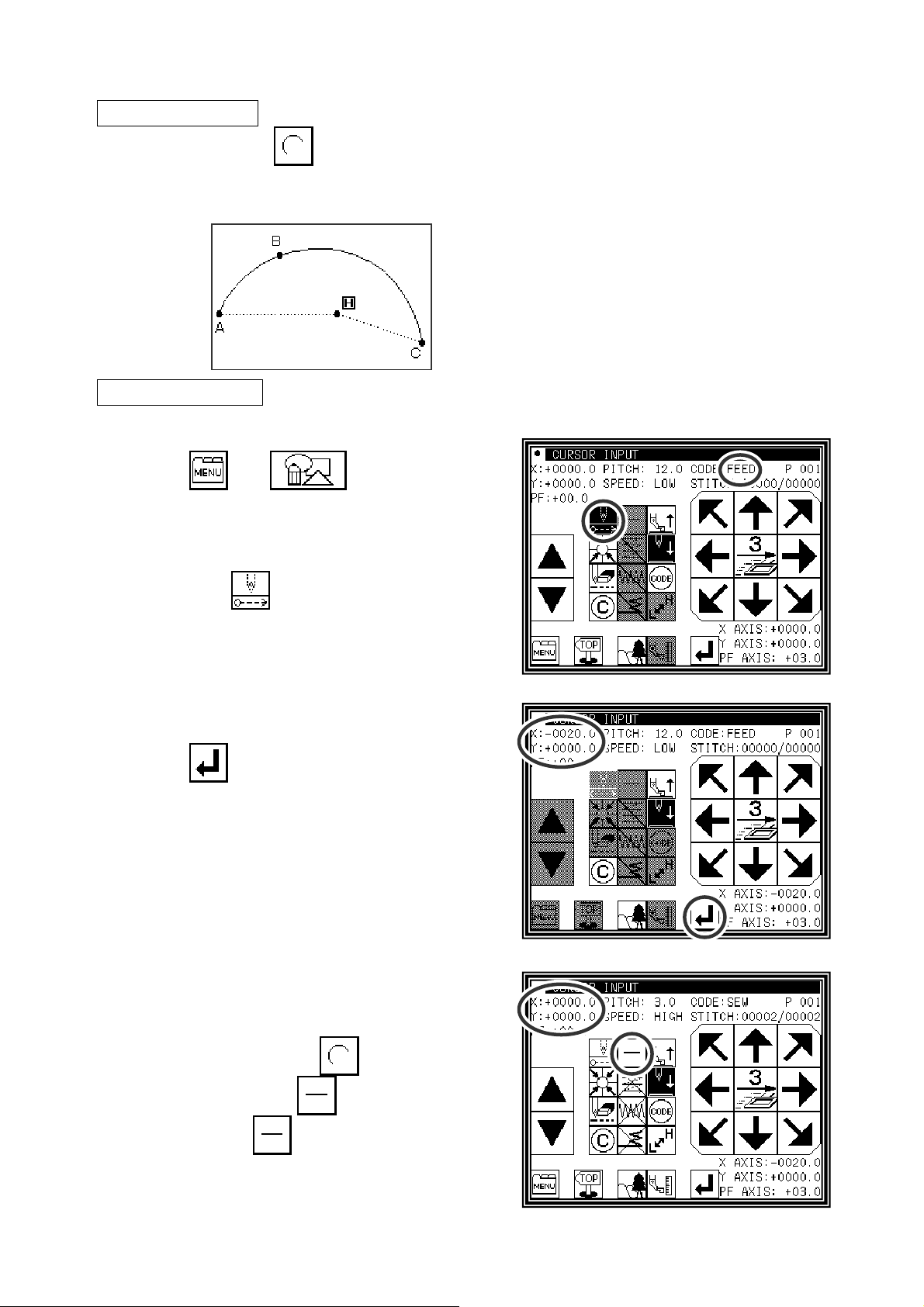

2.Arc input

Operation points

▪ Designate arc input ( )

▪ Input three points (An arc, passing through the current position (already input) and two newly input

points, is created.)

[Example] The following type of sewing data will be created.

Operation details

(1)Inputting feed data to A point

►

Press and on the Standard

screen. After making the various settings on the Data

Setting Input screen, the Arrow Input screen will open.

(Refer to Page[6]-2)

►

Check that the code is set to FEED. If different code

is set, press

►

Press the arrow icons and move to the A point.

(Feed data to A point.)

and set the code to FEED.

(2)Setting feed data to A point

►

The movement amount can be confirmed.

►

Press to set the data. (Data on feed data to

point A will be created.)

(3)Changing the input method

►

The movement amount will be cleared.

►

The code will change to "SEW".

►

If the stitching type is not "ARC

INPUT", (if the type is

INPUT"), press

and change the type.

"LINEAR

(The currently set stitching type will be displayed on

the icon.)

[7] - 4

Page 35

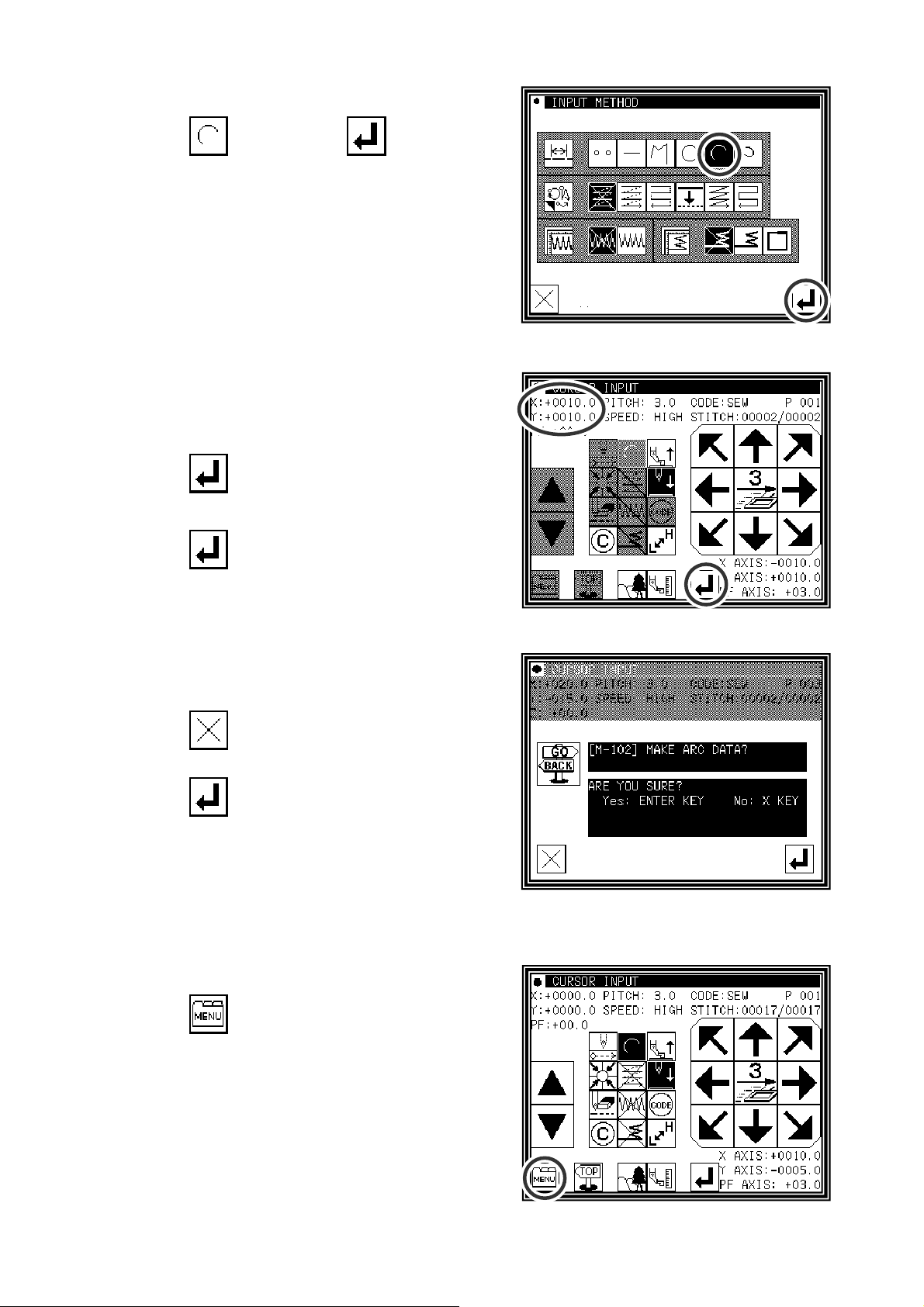

(4)Designating arc input

►

Press and then press .

►

The system will return to the arrow input screen.

(5)Setting B point and C point

►

Press the arrow mark icon to move to point B.

►

The movement amount can be confirmed.

►

Press to determine point B.

►

Press the arrow mark icon to move to point C.

►

Press and set the arc input.

(6)Creating the arc input data

►

The confirmation message "Create arc" will appear.

►

Press to return to the point C data entry

screen.

►

Press and start creation of the arc input data.

(The arc will be created.)

►

A message indicating that the data is being created

will appear.

(7)Completing creation of the arc input data

►

Press .

[7] - 5

Page 36

(8)Inputting the return/end code

►

Press .

(

Data on feed data to the home position and the end

code will be created.)

Caution

The work holder will automatically

return to the home position. Take care when the

needle is lowered, etc.

►

A prompt for home position return will appear.

Press

Caution

.

The needle will rise to the UP position.

If the needle is not at the UP position, it may lower

once and then return to the UP position.

(9)Select a saving method.

►

After selecting the saving method, press icon.

(R

efer to section [5]Reading, writing and erasing data.)

►Return to the standard screen.

(10)Confirming the data

►

Confirm the data. Press the jog icons ( )

so the sewing machine movement can be confirmed.

(Even if the data input has not been completed, if the

data input last has been set, the movement can be

confirmed in the same manner.)

►

If the data must be modified, refer to section [11]

Modification mode Modifying the stitching data.

[7] - 6

Page 37

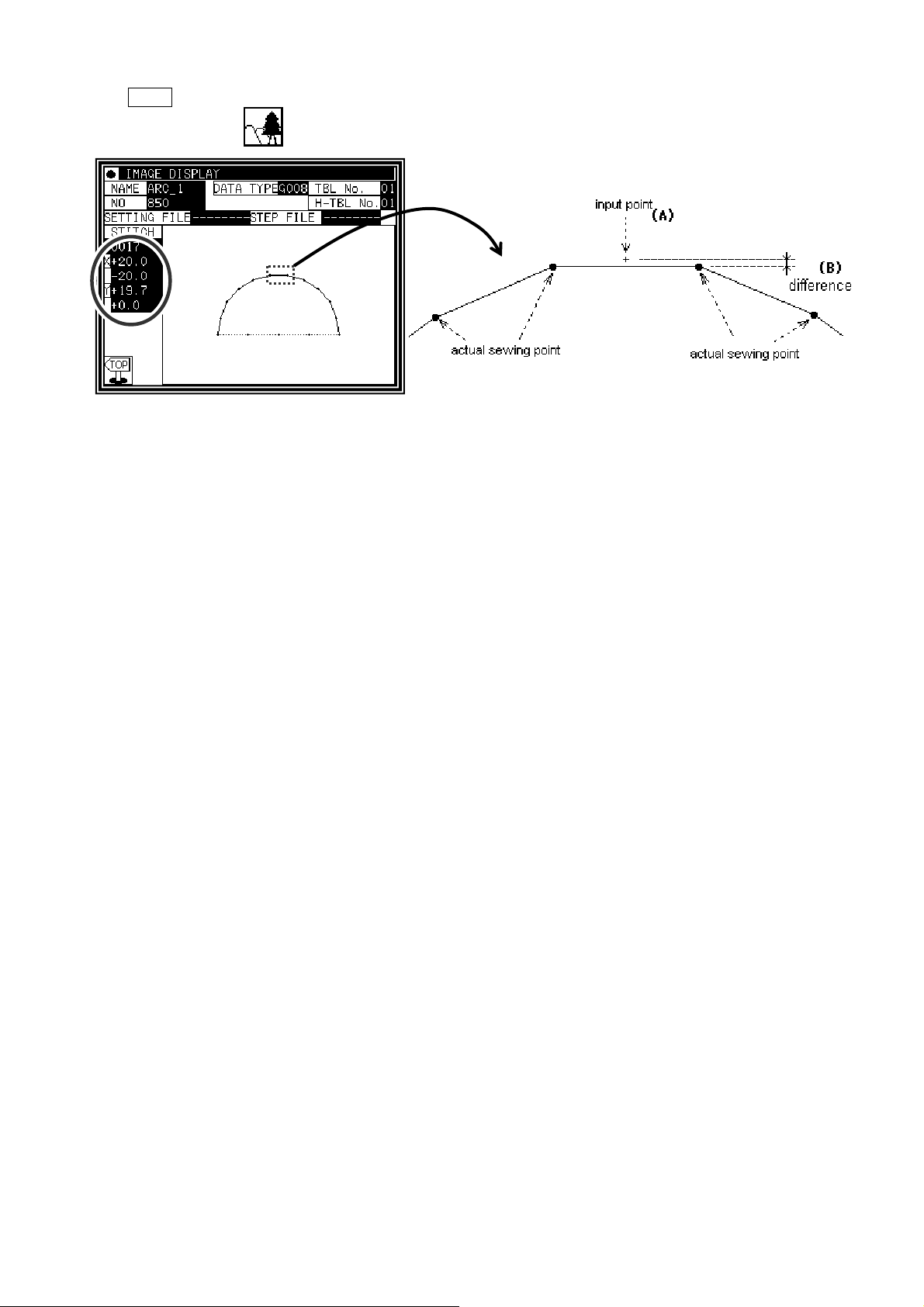

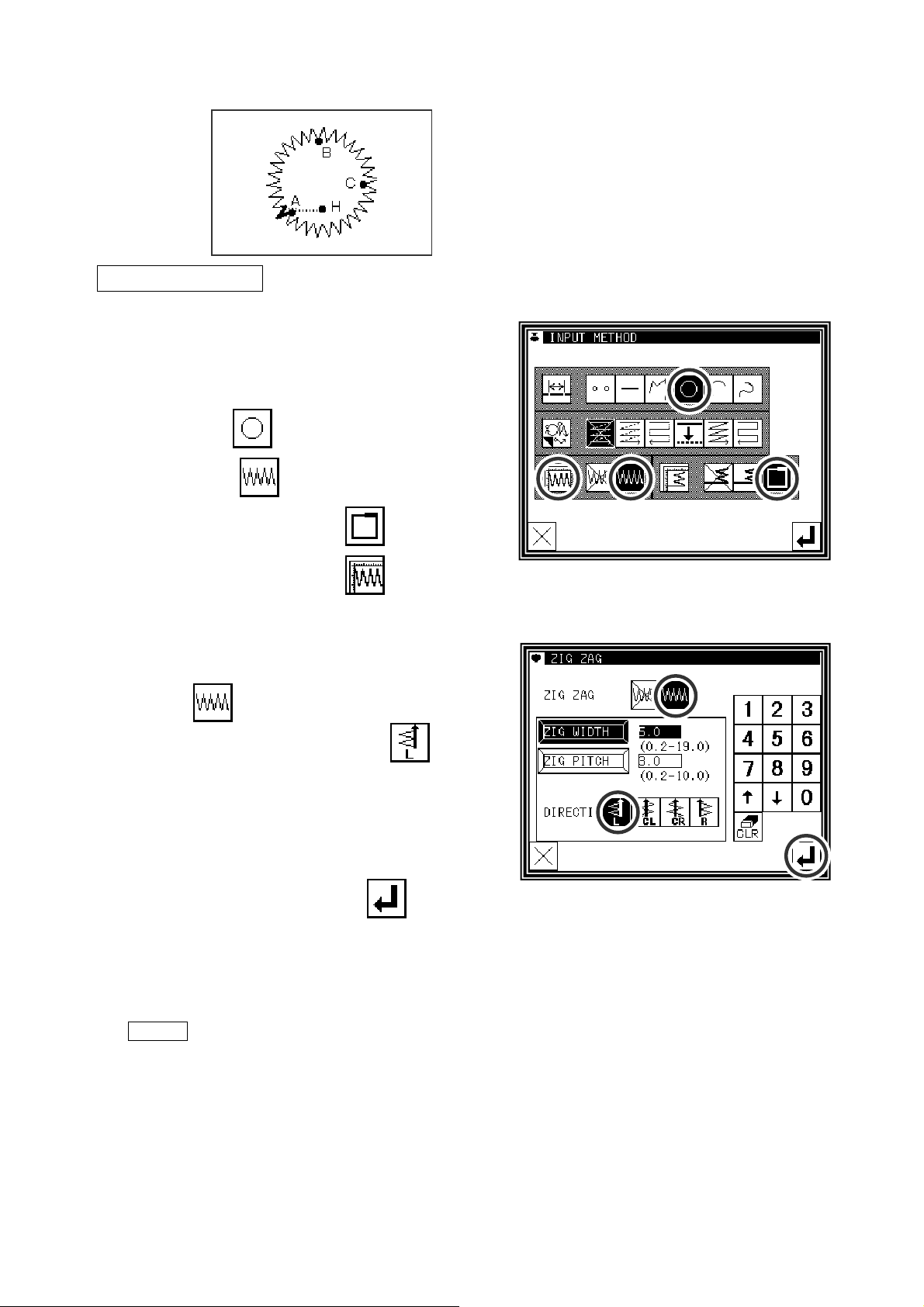

Memo The size display of the pattern data is explained when "The arc" or "The Circle" is made and the

image display is pushed from a standard screen, the image display screen is opened.

For instance, when made the 20mm half circle data but the size display is not [20.0] Y axially, is [19.9] it

like the above figure.

The reason for this is that the displayed value is calculated with an actual sewing point. Tries to make the

circle or the circular arc which passes input point as shown in the figure below, the data is made

according to the specified stitch length, it is not match that sewing point and input point (A). There is

difference (B) of the figure below because the value is calculated with the sewing point.

[7] - 7

Page 38

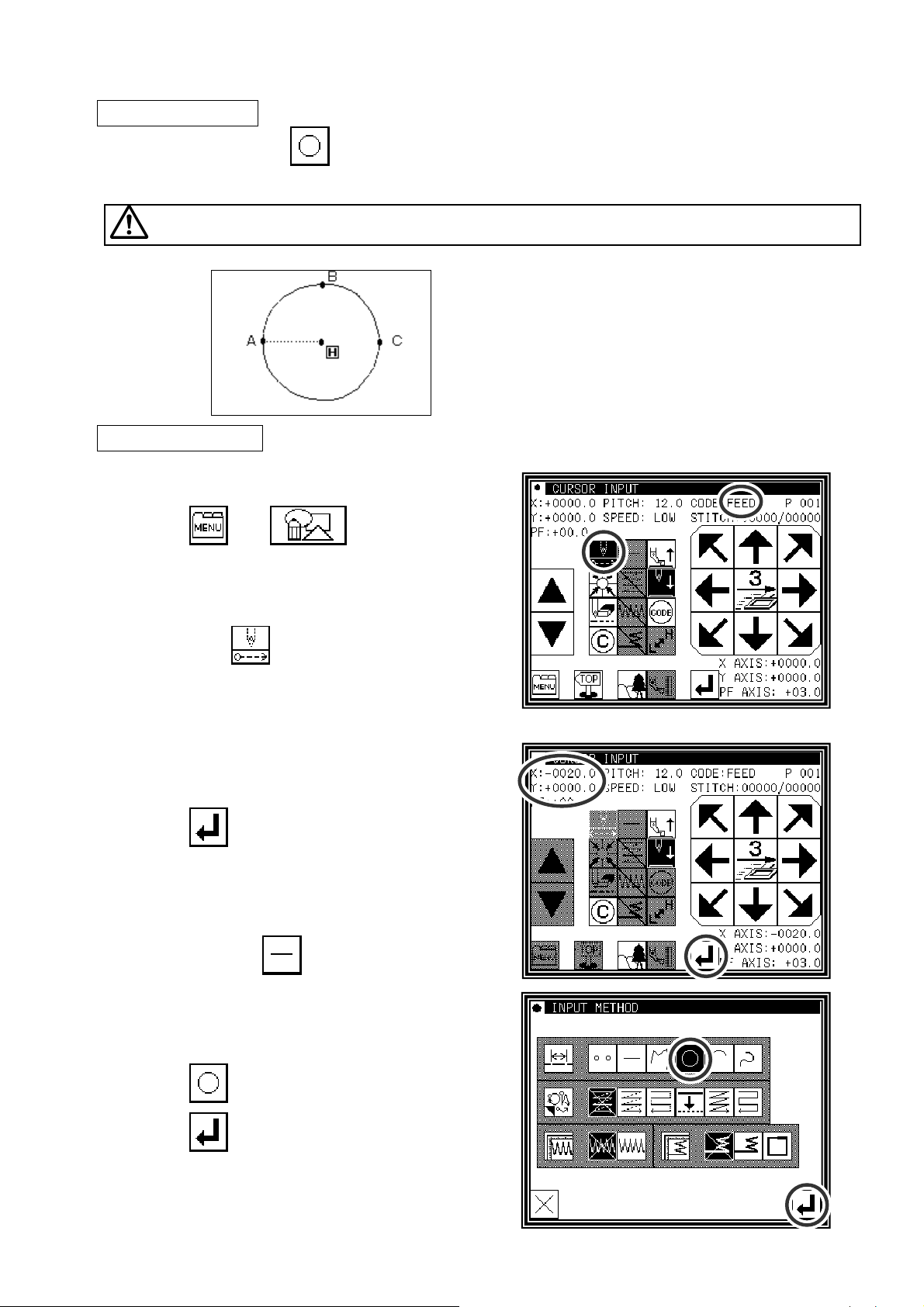

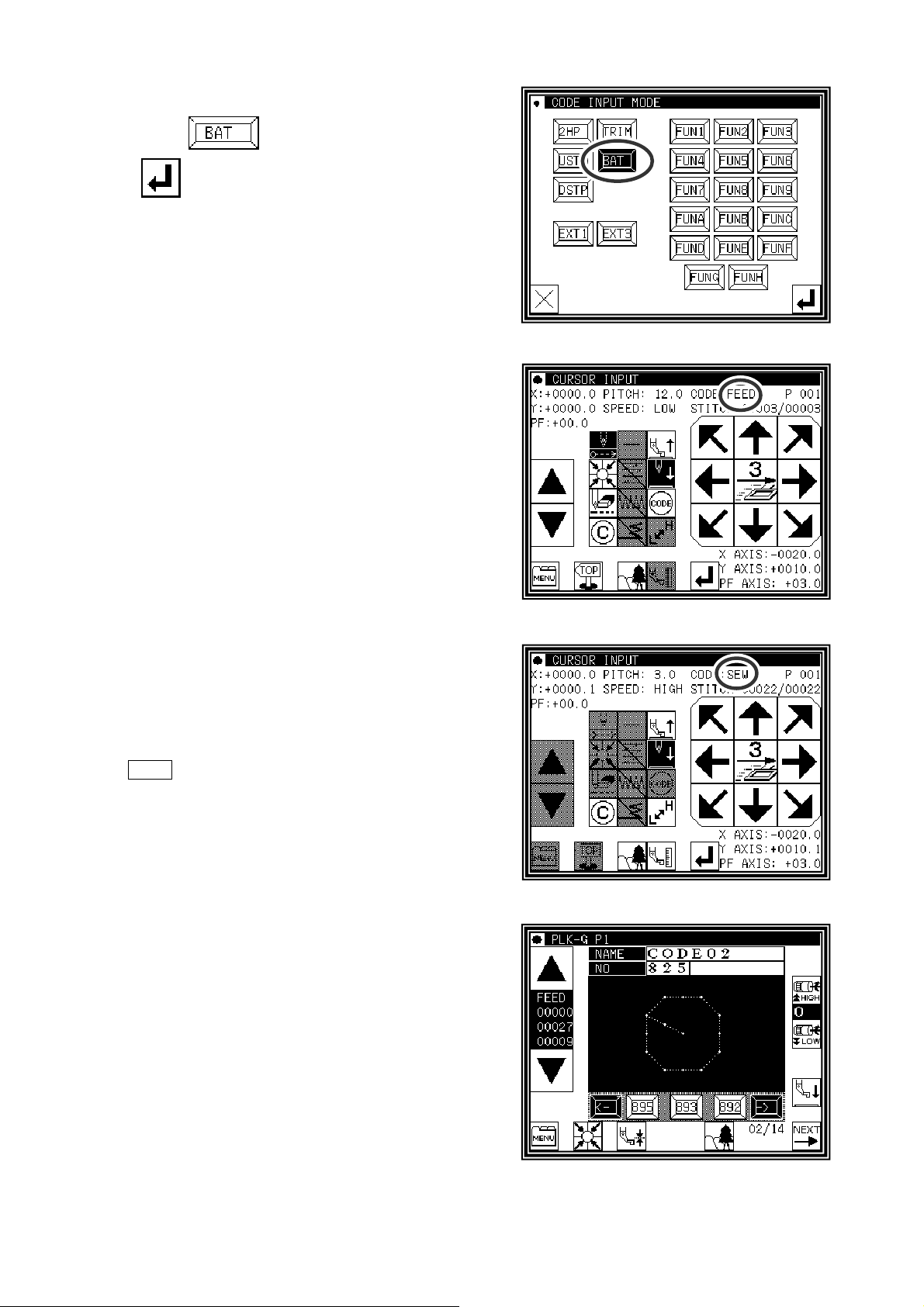

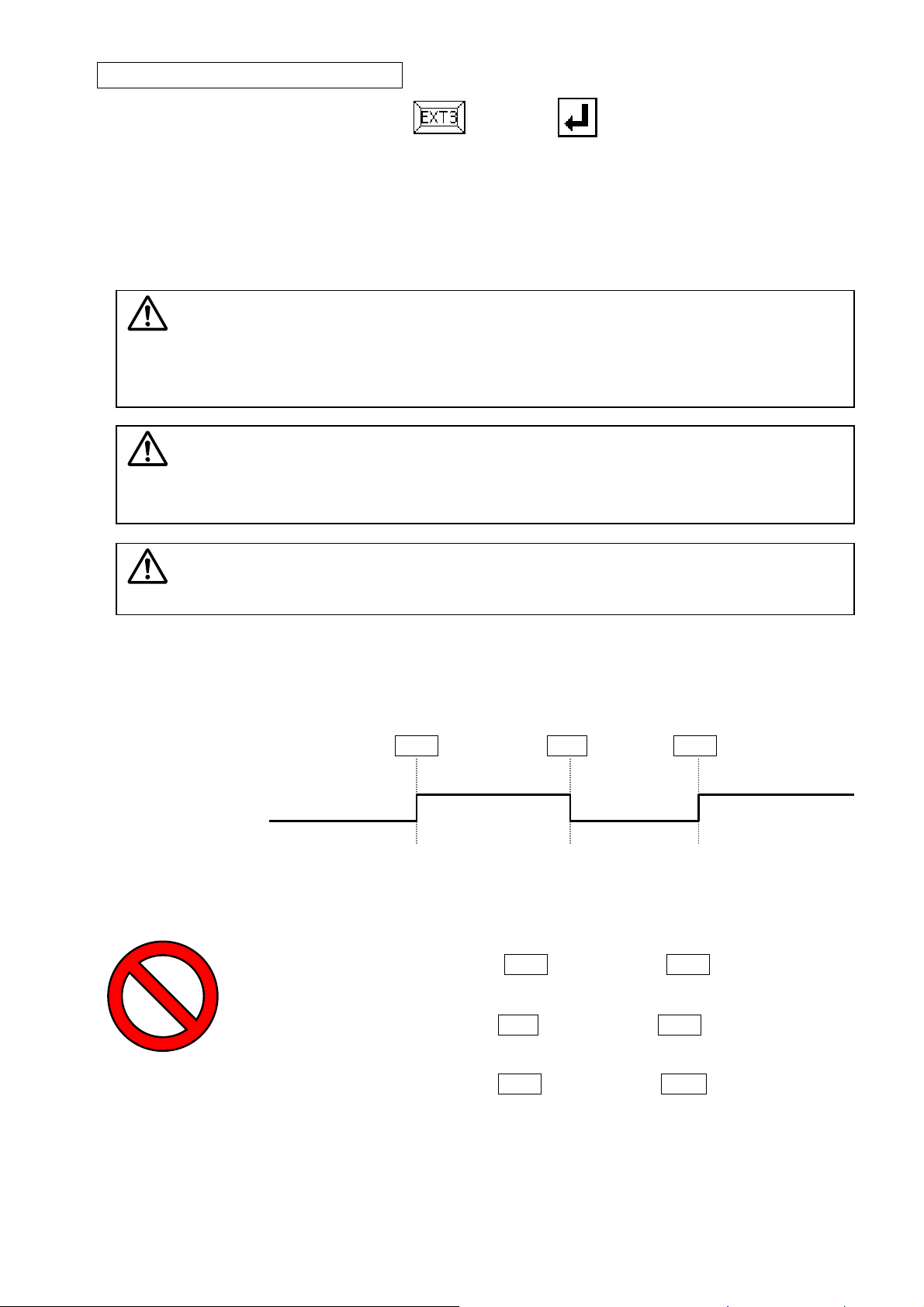

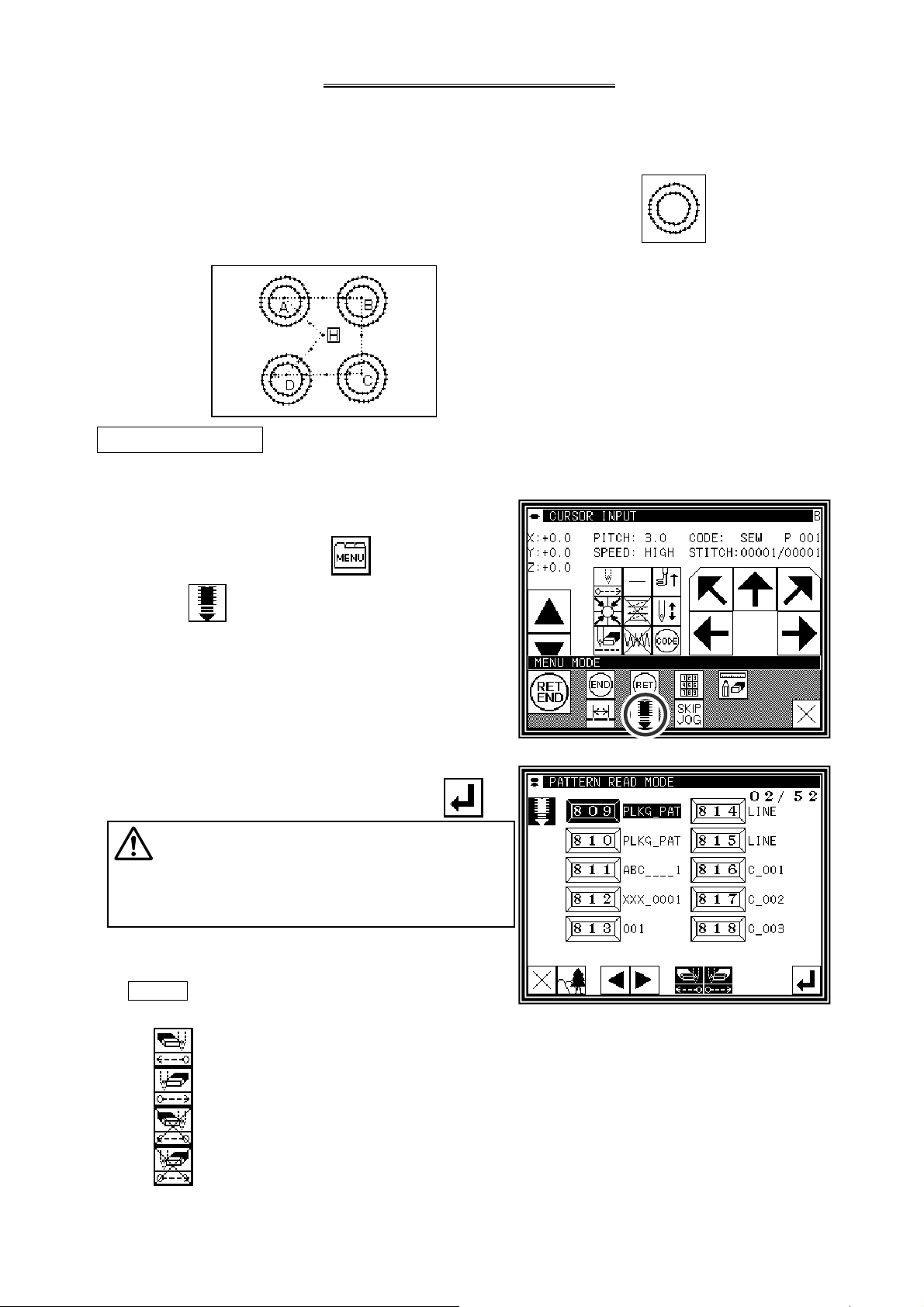

3.Circle input

Operation points

▪ Designate circle input ( )

▪ Input three points (A circle, passing through the current position (already input) and two newly input

points, is created.)

Caution

Note that the work holder will go back to the circle start position after the data is created.

[Example] The following type of sewing data will be created.

Operation details

(1)Inputting feed data to A point

►

Press and on the Standard

screen. After making the various settings on the Data

Setting Input screen, the Arrow Input screen will open.

(Refer to Page[6]-2)

►

Check that the code is set to FEED. If different code

is set, press

and set the code to FEED.

►

Press the arrow icons and move to the A point.

(Feed data to A point.)

(2)Setting feed data to A point

►

The movement amount can be confirmed.

►

Press to set the data.

(Data on feed data to point A will be created.)

►

To change the stitching type to "Circle input", press

the input method setting icon.

(In this case, the

icon.)

(3)Designating circle input

►

Press .

►

Press and set the data.

►

The system will return to the arrow input screen.

[7] - 8

Page 39

(4)Setting B point and C point

►

Using the arrow icons, move to the B point.

►

Press to determine point B.

►

The Arrow Input screen will reappear, so press the

arrow icons and move to the C point.

►

Press to determine point C.

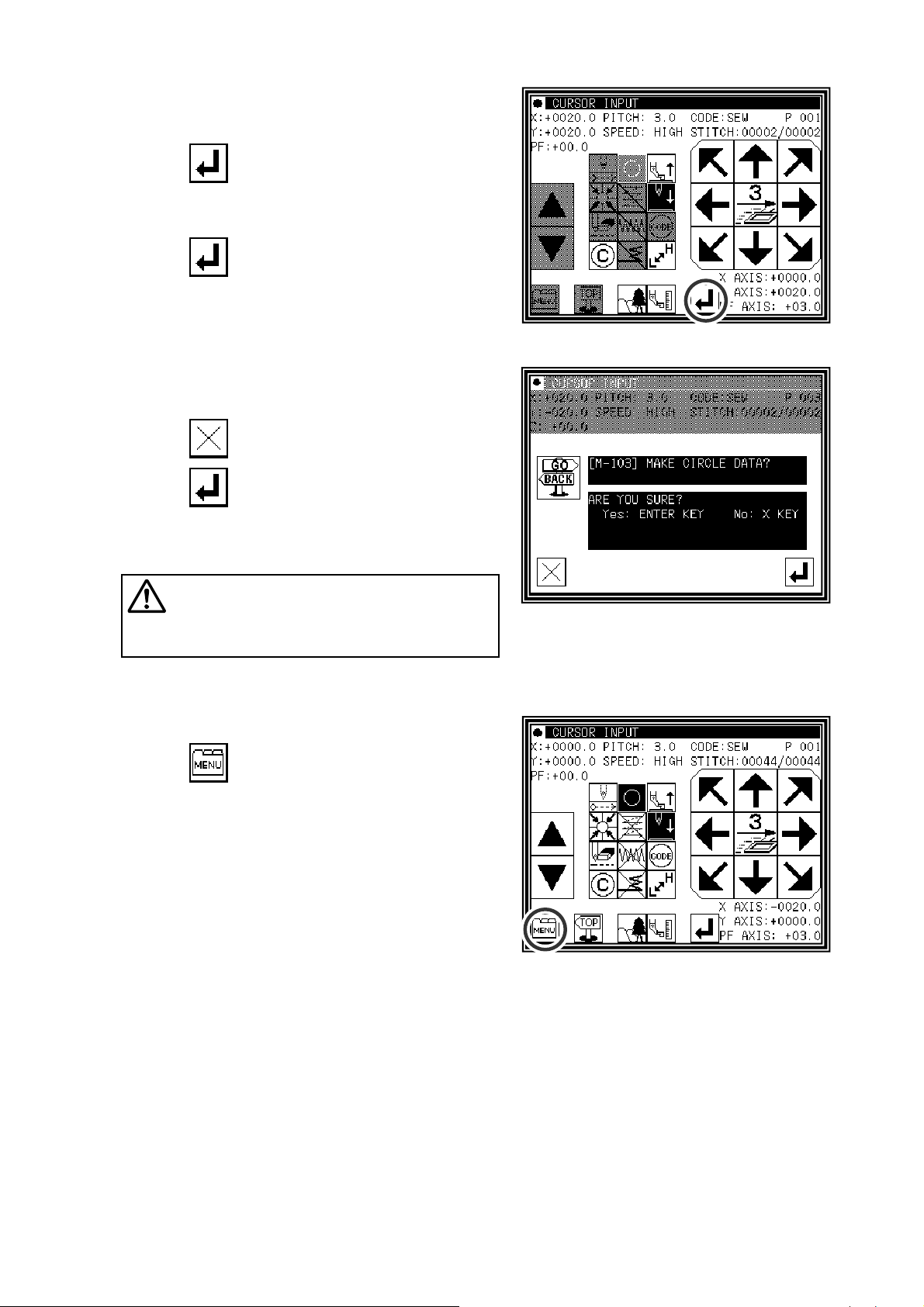

(5)Creating the circle input data

►

The confirmation message "Create circle" will appear.

►

Press to return to the point C data entry panel.

►

Press and start creation of the circle input

data.

►

A message indicating that the data is being created

will appear.

Caution

move to the current position after the data is

created.

Note that the work holder will

(6)Completing circle input

►

Press

.

[7] - 9

Page 40

(7)Inputting the return/end code

►

Press .

(

Data on feed data to the home position and the end

code will be created.)

Caution

The work holder will

automatically return to the home position. Take

care when the needle is lowered, etc.

►

A prompt for home position return will appear.

Press

Caution

.

The needle will rise to the UP position.

If the needle is not at the UP position, it may lower

once and then return to the UP position.

(9)Select a saving method.

►

After selecting the saving method, press icon.

(R

efer to section [5]Reading, writing and erasing data.)

►Return to the standard screen.

(10)Confirming the data

►

Confirm the data. Press the jog icons ( )

so the sewing machine movement can be confirmed.

(Even if the data input has not been completed, if the

data input last has been set, the movement can be

confirmed in the same manner.)

►

If the data must be modified, refer to section [11]

Modification mode Modifying the stitching data.

[7] - 10

Page 41

4.Curve input

Operation points

▪ Designate curve input ( )

▪ Up to 300 points can be input (A curve, passing through the current position and the input points, is

created.)

▪ A delimiter point can be inserted at a pointed corner to continuously input the curve.

[Example] The following type of sewing data will be created.

A delimiter is set at the C point.

[Memo] Set the stitch length between 0.1 to 10.0mm.

Operation details

(1)Inputting feed data to A point

►

Press and on the Standard

screen. After making the various settings on the Data

Setting Input screen, the Arrow Input screen will open.

(Refer to Page[6]-2)

►

Check that the code is set to FEED. If different code

is set, press

►

Press the arrow icons and move to the A point.

(Feed data to A point.)

and set the code to FEED.

(2)Setting feed data to A point

►

The movement amount can be confirmed.

►

Press to set the data.

(Data on feed data to point A will be created.)

►

To change the stitching type to "CURVE INPUT",

press the input method setting icon.

(In this case, the

icon.)

(3)Designating curve input

►

Press .

►

Press and set the data.

►

The system will return to the arrow input screen.

[7] - 11

Page 42

(4)Setting B point

►

Press the arrow mark icon to move to point B.

►

Press to determine point B.

(5)Setting C point

►

Press the arrow mark icon to move to point C.

►

Press to determine point C.

►

Press again to enter the breakpoint.

(6)Inserting a delimiter point

►

The data creation confirmation message "Create

breakpoint data" will appear.

►

Press to return to the point C data entry

screen.

►

Press . The breakpoint will be set here.

(7)Setting the D point, E point and F point, and setting the curve input

►

The Arrow Input screen will reappear.

►

Press the arrow icons, and move to the D point.

►

Press to determine point D.

►

Press the arrow icons again, and move to the E point.

►

Press to determine point E.

►

Press the arrow icons again, and move to the F point.

►

Press to determine point F.

(Up to 300 points can be input.)

►

At the completion of all point data entry, press again to create data.

[7] - 12

Page 43

(8)Creating the curve input

►

The data creation confirmation message "Create

breakpoint data" will appear.

►

Press to return to the last point input screen.

►

Press to start creation of the curve input data.

►

A message indicating that the data is being created

will appear.

(9)Completing curve input creation

►

Press .

(10)Inputting the return/end code

►

Press .

(

Data on feed data to the home position and the end

code will be created.)

Caution

The work holder will automatically

return to the home position. Take care when the

needle is lowered, etc.

►

A prompt for home position return will appear.

Press

Caution

.

The needle will rise to the UP position.

If the needle is not at the UP position, it may lower

once and then return to the UP position.

(9)Select a saving method.

►

After selecting the saving method, press icon.

(R

efer to section [5]Reading, writing and erasing data.)

►Return to the standard screen.

[7] - 13

Page 44

(10)Confirming the data

►

Confirm the data. Press the jog icons ( )

so the sewing machine movement can be confirmed.

(Even if the data input has not been completed, if the

data input last has been set, the movement can be

confirmed in the same manner.)

►

If the data must be modified, refer to section [11]

Modification mode Modifying the stitching data.

Memo If the distance between the curve start point and the end point is less than 0.5 mm, the pattern will

be regarded as the "closed pattern", and the same coordinate value will be automatically set for

both the start point and end point.

Precautions for inputting a curve

►

For shape data as shown below, continuous curve input is possible by selecting a delimiter point where

the corner is pointed (K point).

(This can also be applied for noncontinuous points such as for offset stitching, multiple stitching, and

reverse multiple stitching.)

[7] - 14

Page 45

5.Broken line input

Operation points

▪ Designate broken line input( )

▪ Up to 300 points can be input (A broken line connecting the current position and input points is

created.)

[Example] The following type of sewing data will be created.

Operation details

(1)Inputting feed data to A point

►

Press and on the Standard

screen. After making the various settings on the Data

Setting Input screen, the Arrow Input screen will open.

(Refer to Page[6]-2)

►

Check that the code is set to FEED. If different code

is set, press

►

Press the arrow icons and move to the A point.

(Feed data to A point.)

and set the code to FEED.

(2)Setting feed data to A point

►

The movement amount can be confirmed.

►

Press to set the data.

(Data on feed data to point A will be created.)

►

To change the stitching type to "Broken line input",

press the input method setting icon.

(In this case, the icon.)

(3)Designating broken line input

►

Press .

►

Press and set the data.

►

The system will return to the arrow input screen.

[7] - 15

Page 46

(4)Setting B point , C point , D point , E point

►

Press the arrow mark icon to move to point B.

►

Press to determine point B.

►

Press the arrow mark icon to move to point C.

►

Press to determine point C.

►

Press the arrow mark icon to move to point D.

►

Press to determine point D.

►

Press the arrow mark icon to move to point E.

►

Press to determine point E.

(Up to 300 points can be input.)

►

At the completion of all point data entry, press again to create data.

(5)Creating the broken line input

►

The data creation confirmation message "Create

breakpoint data" will appear.

►

Press to return to the last point input screen.

►

Press to start creation of the broken line input

data.

►

A message indicating that the data is being created

will appear. (The broken line will be created.)

(6)Creating the broken line input

►

Press

.

[7] - 16

Page 47

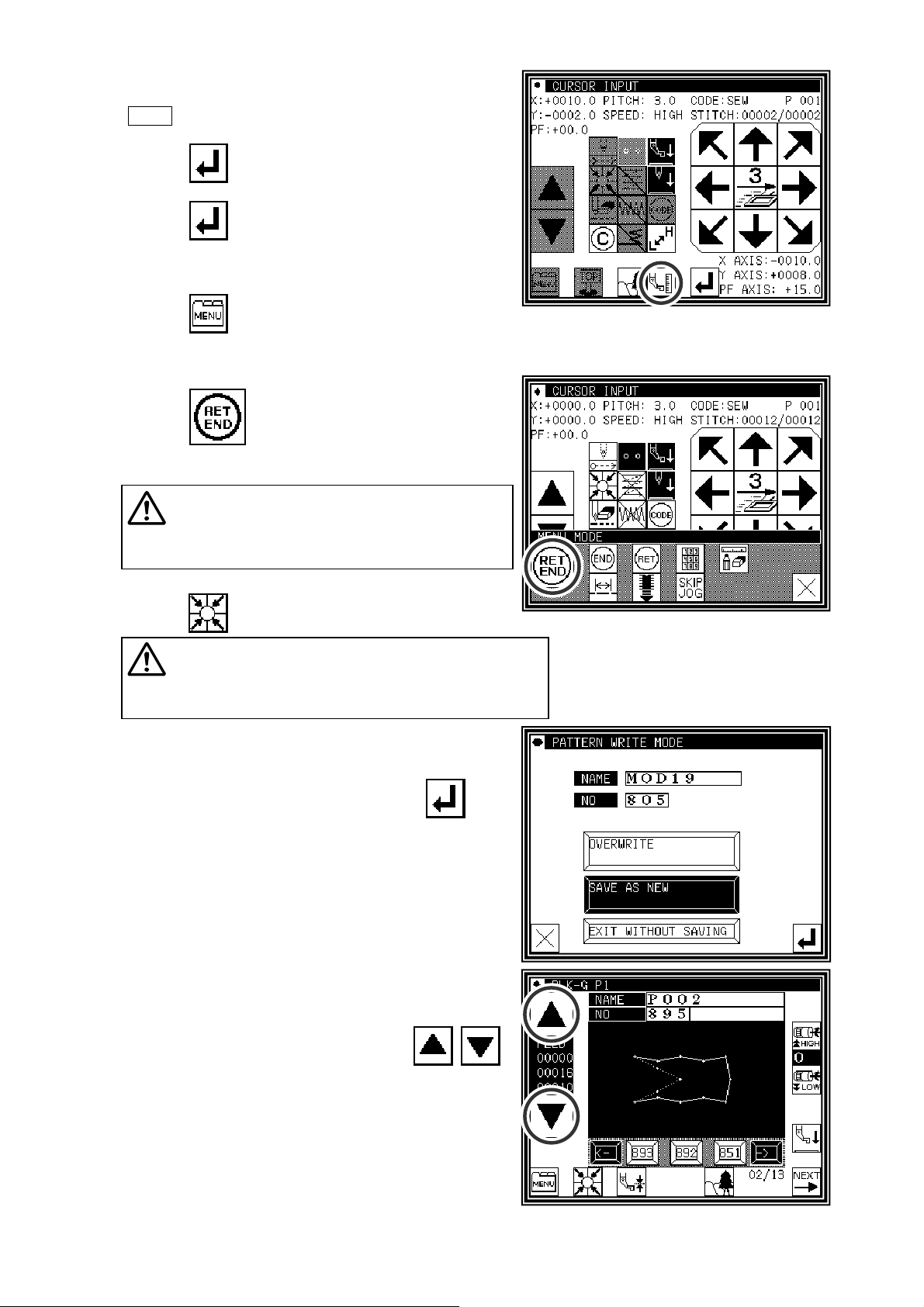

(7)Inputting the return/end code

►

Press .

(

Data on feed data to the home position and the end

code will be created.)

Caution

The work holder will

automatically return to the home position. Take

care when the needle is lowered, etc.

►

A prompt for home position return will appear.

Press

Caution

.

The needle will rise to the UP position.

If the needle is not at the UP position, it may lower

once and then return to the UP position.

(8)Select a saving method.

►

After selecting the saving method, press icon.

(R

efer to section [5]Reading, writing and erasing data.)

►Return to the standard screen.

(9)Confirming the data

►

Confirm the data. Press the jog icons ( )

so the sewing machine movement can be confirmed.

(Even if the data input has not been completed, if the

data input last has been set, the movement can be

confirmed in the same manner.)

►

If the data must be modified, refer to section [11]

Modification mode Modifying the stitching data.

Memo

If the distance between the broken line start point and the end point is less than 0.5 mm, the

pattern will be regarded as the "closed pattern", and the same coordinate value will be

automatically set for both the start point and end point.

[7] - 17

Page 48

6.Point input

Operation points

▪ Designate point input( )

(The distance between the points must be within 20mm)

[Example] The following type of sewing data will be created.

Operation details

(1)Inputting feed data to A point

►

Press and on the Standard

screen. After making the various settings on the Data

Setting Input screen, the Arrow Input screen will open.

(Refer to Page[6]-2)

►

Check that the code is set to FEED. If different code

is set, press

►

Press the arrow icons and move to the A point.

(Feed data to A point.)

and set the code to FEED.

(2)Setting feed data to A point

►

The movement amount can be confirmed.

►

Press to set the data.

(Data on feed data to point A will be created.)

►

To change the stitching type to "POINT INPUT",

press the input method setting icon.

(In this case, the

icon.)

(3)Designating point input

►

Press .

►

Press and set the data.

►

The system will return to the arrow input screen.

[7] - 18

Page 49

(4)Setting B point to K point

►

Press the arrow mark icon to move to point B.

Memo The distance between the points must be within

20mm.

►

Press to determine point B.

►

Press the arrow mark icon to move to point C.

►

Press to determine point C.

►

The Arrow Input screen will reappear, so press the

arrow icons and move to the D point to K point in the

same manner.

►

Press .

(5)Inputting the return/end code

►

Press .

(

Data on feed data to the home position and the end

code will be created.)

Caution

return to the home position. Take care when the

needle is lowered, etc.

►

A prompt for home position return will appear.

The work holder will automatically

Press

Caution

.

The needle will rise to the UP position.

If the needle is not at the UP position, it may lower

once and then return to the UP position.

(6)Select a saving method.

►

After selecting the saving method, press icon.

(R

efer to section [5]Reading, writing and erasing data.)

►Return to the standard screen.

(7)Confirming the data

►

Confirm the data. Press the jog icons ( )

so the sewing machine movement can be confirmed.

(Even if the data input has not been completed, if the

data input last has been set, the movement can be

confirmed in the same manner.)

►

If the data must be modified, refer to section [11]

Modification mode Modifying the stitching data.

[7] - 19

Page 50

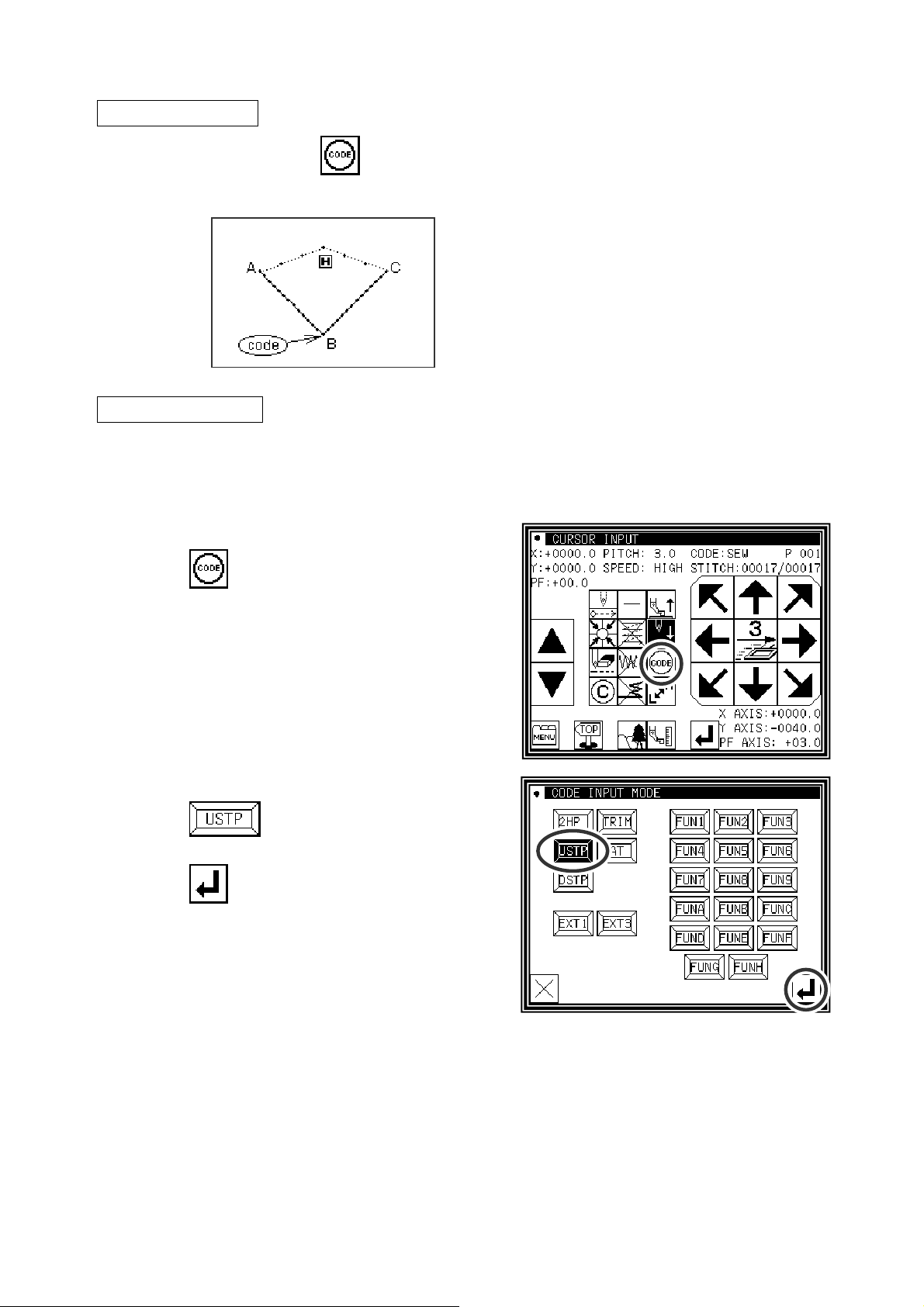

7.Code data input

Operation points

▪ Designate code data input( )

▪ Select and input the code data from the code data list

[Example] The following type of sewing data will be created.

Operation details

(1)Inputting a linear line from A point to B point

Input the "NEEDLE UP HALT" code at the B point

between the A-B point linear line and B-C linear line.

[Memo] Code data cannot be inserted when inputting

with a linear, circle, arc, curve or polygonal

line. To input, add the code data with the

modification mode. (Input between the linear

lines is possible as shown in the example.)

►

Input a linear line from the A point to B point using the linear input procedures.

(2)Inputting the code data (NEEDLE UP HALT)

►

Press .

►

Press .

(Refer to the code list of the next page.)

►

Press to set the code.

(The "NEEDLE UP HALT" code will be created.)

►

The system will return to the arrow input screen.

(3)Inputting a linear line from B point to C point

►

Input a linear line from the B point to C point using the linear input procedures.

(4)Inputting the return end and the data completion

►

The return end is input and it is completion.

[7] - 20

Page 51

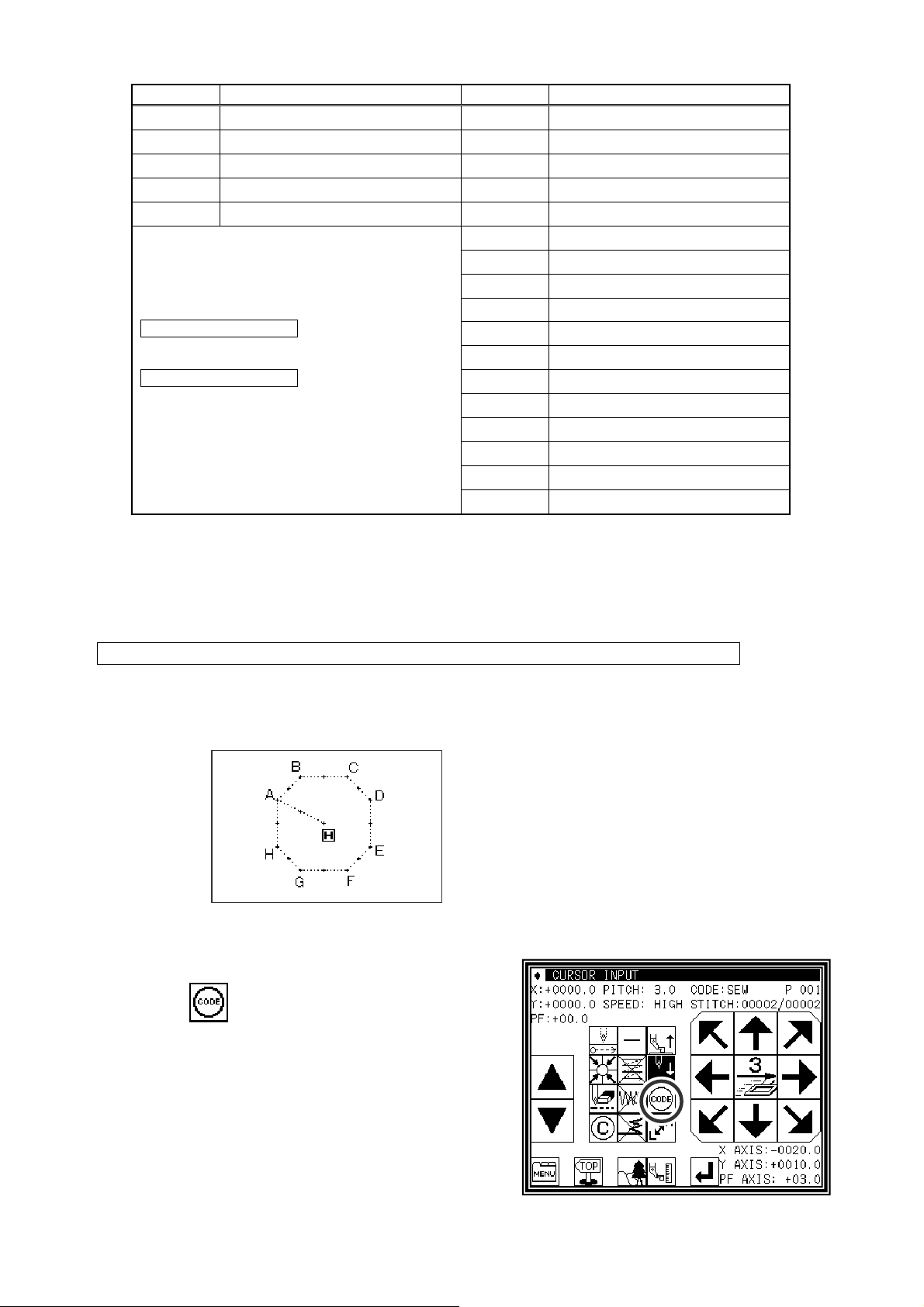

■List of code data

Code Function Code Function

2HP

USTP

DSTP

TRIM

BAT

EXT1 : Extension code

ASRT : Automatic start after stopping

EXT3 : Extension code

F1_H~FH_H : FN (1~H) Output ON

F1_L~FH_L : FN (1~H) Output OFF

2nd home position

Needle UP halt

Needle DOWN halt

Thread trimming

Basting

FUN1

FUN2

FUN3

FUN4