Page 1

INDUSTRIAL SEWING MACHINE

MODEL

PLK-G-CU-20

TECHNICAL MANUAL

Control Unit

A180E604P09

Page 2

Page 3

Contents

[1] For safe use _______________________________________________ [1]-1

[2] Precautions for use _________________________________________ [2]-1

[3] Installation ________________________________________________ [3]-1

[4] Names of each part, wiring and grounding______________________ [4]-1

[5] Confirmation_______________________________________________ [5]-1

[6] Initial Settings of System Software (Model/Language Settings)_____ [6]-1

[7] Timing chart _______________________________________________ [7]-1

[8] Customized input/output ____________________________________ [8]-1

[9] Input/Output signal _________________________________________ [9]-1

[10] What happened? Could it be an error? ________________________ [10]-1

[11] Several power supply ______________________________________ [11]-1

[12] Unit wiring diagram ________________________________________ [12]-1

[13] Connectors layout _________________________________________ [13]-1

[14] Pin number of connectors __________________________________ [14]-1

[15] Wiring diagram inside control box____________________________

[16] Specifications_____________________________________________ [16]-1

[15]-1

- 1 -

Page 4

Thank you for purchasing the Mitsubishi industrial sewing machine PLK-G Series.

Please read this technical manual before starting to ensure correct and long-term

use.

* The contents of this manual may not be reproduced in part or whole.

* The contents of this manual are subject to change without notice.

* An utmost effort has been made to cover all points of operation in this manual.

Contact Mitsubishi if you have any questions regarding the contents.

COPYRIGHT(C)2012 MITSUBISHI ELECTRIC CORPORATION

- 2 -

Page 5

[1] For safe use

■ For safe use

Always observe the following matters to safely use the Mitsubishi industrial electronic sewing machine PLK-G

Series.

Before starting

Before using this control unit, read all of the technical manuals carefully, and correctly use the unit

following the manual. Also read the "Mitsubishi Industrial Sewing Machine Technical Manual <Sewing

Machine Head>" for details on the general configuration and sewing machine head.

Application and purpose

This control unit is designed to drive and control the Mitsubishi industrial electronic sewing machine

PLK-G Series. Do not use this control unit for other applications or purposes. Do not use this control unit

until it has been confirmed that safety measures have been accurately taken for the installed electronic

sewing machine head section.

Working environment

Please use this control unit in the industrial setting only. And do not use this control unit in the following

type of environment.

(1) Power voltage

* Where the voltage fluctuation exceeds ±10% of the rated voltage.

* Where the specified power capacity (refer to technical manual [Control unit] page [4]-2 “5. Power

capacity”) cannot be ensured.

(2) Magnetic noise

* Where strong fields or magnetic fields are generated, such as near a high-output high frequency

oscillating machine or high frequency welder.

(3) Temperature and humidity

* Where the ambient temperature is 35°C or more and 5°C or less.

* Where the unit will be subject to direct sunlight, or outdoors.

* Near sources of heat, such as heating appliances.

* Where the relative humidity is 45% or less, or 85% or more, and where dew may condense.

(4) Atmosphere

* In an atmosphere containing dust or corrosive gases, etc.

* In a flammable gas or explosive environment.

(5) Vibration

* If excessive vibration could occur when installed on the sewing machine, separately install the

control box.

■ Installation

Control box

Correctly install the control box according to this manual.

Accessories

Always disconnect the control unit from the main power supply before installing the accessories listed in

this manual. (Turn the power switch OFF, and disconnect the plug from the socket (power supply line).)

Cable

(1) Lay the connection cables so that excessive force will not be applied during operation. Do not

excessively bend the cables.

(2) Cables laid near operating machine sections must be separated by at least 25mm.

(3) Before connecting the power cable to the control box, confirm that the power voltage matches the

specifications given on the control box's rating nameplate and factory shipment voltage nameplate.

Connect the cable to the indicated positions, and then supply the power. When using a power unit,

connect the cable to the power unit and supply the power. In addition, when using a power unit,

confirm that the power voltage matches the specifications given on the power unit's rating nameplate.

Turn the power switch OFF before making any connections.

Grounding

Always ground the power cord's grounding wire.

Enclosed units and accessories

Connect the electrical enclosed units and accessories only to the positions indicated in the manual.

[1] - 1

Page 6

Removal

(1) Always turn the power switch OFF and disconnect the plug from the socket (power supply line) before

removing the control box.

(2) Do not pull out the cord when disconnecting the plug. Always hold the plug receptacle when

disconnecting the plug.

(3) Note that a high voltage is applied inside the control panel, so always turn the power OFF and wait

at least ten minutes before opening the control box cover.

■ NOTICE CONCERNING MARKING

(1) Electronic sewing machine PLK-G series are applied to CE conformity marking by installing the

exclusive device [PLK-G-CE].

When the products are used in the EU region, these devices are necessary to be installed.

(2) Electronic sewing machine should be use limited to the industrial areas even though above-mentioned

countermeasure is done.

[Warning] Use in residential areas may cause interference.

■ Maintenance, inspection and repairs

(1) Follow this manual when carrying out maintenance or inspections related to this control unit.

(2) This unit must be repaired, serviced and inspected only by a worker that has received special training.

(3) Always turn the power OFF before replacing the needle or bobbin, etc., on the head.

(4) Use genuine replacement parts for repairs and maintenance.

■ Other safety measures

(1) Keep fingers away from all moving machine parts (especially around the sewing machine needle,

etc.).

(2) Never drop the control unit, or place objects in the clearances.

(3) Do not operate the sewing machine without the protective parts such as the cover, or protection

devices such as the safety breaker.

(4) If any damage is observed in the control unit, if the unit does not operate correctly, or if the operation

is suspicious, always suspend operation. Only operate the machine after the supervisor has adjusted,

repaired or inspected the machine.

(5) The user must not make improvements or changes without instruction from Mitsubishi.

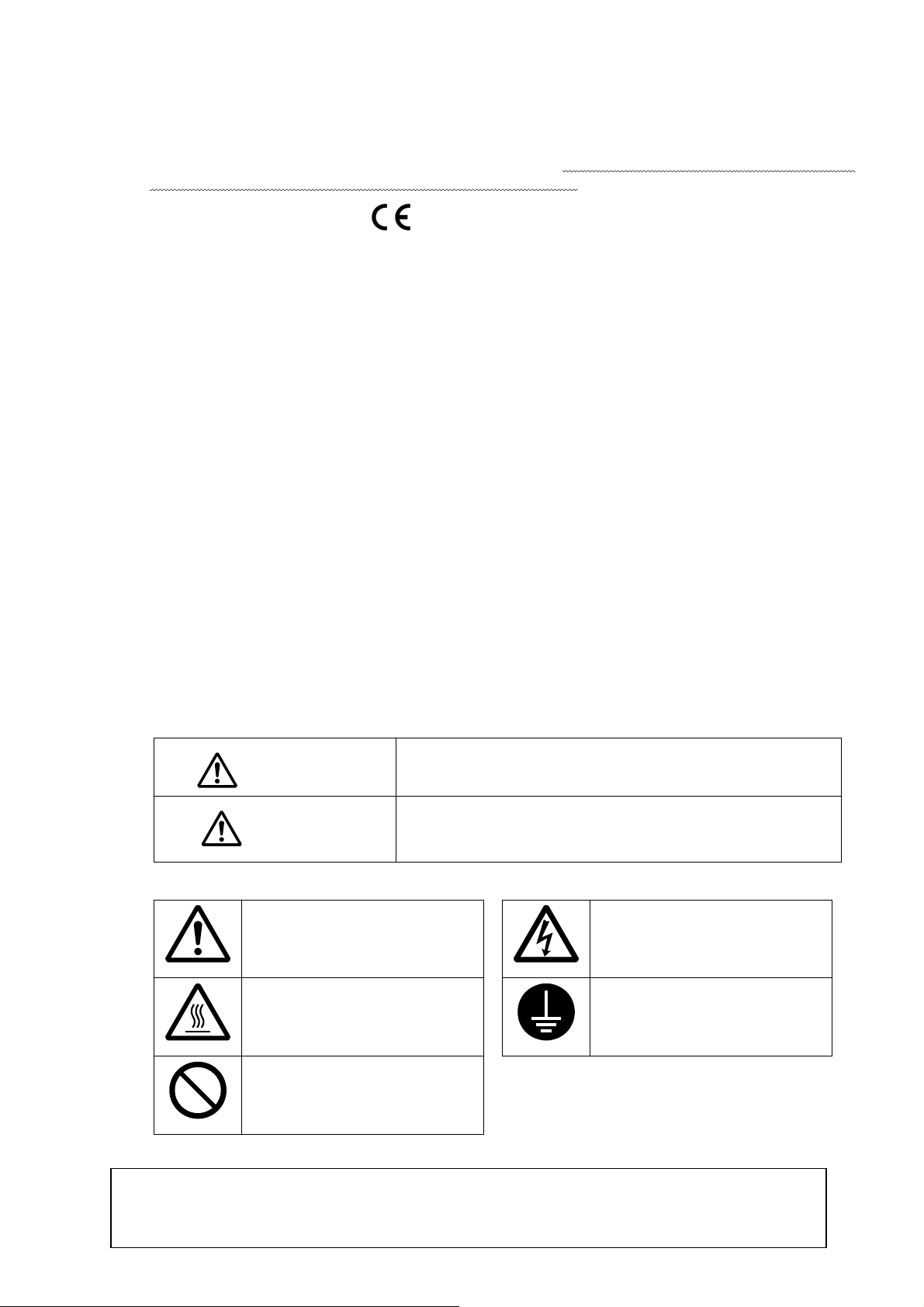

■ Caution displays and danger displays

(1)In this manual, the dangers and danger levels that arise with incorrect handling are classified using the

following displays.

The warning display shows that incorrect handling can lead to

Warning

Caution

(2)The meanings of these symbols are as follows.

This symbol indicates that the

instructions must be followed.

This symbol indicates hot

temperature requiring caution.

This symbol indicates a

prohibited action.

death or serious injuries.

The caution display shows that incorrect handling can lead to

injuries or damages to your house, household goods, and

others.

This symbol indicates an

electrical hazard or caution

(electric shock caution).

This symbol indicates that

ground wire connection is

required.

* Always deliver this manual to the end user.

* Store this manual nearby where it can be referred to when necessary.

[1] - 2

Page 7

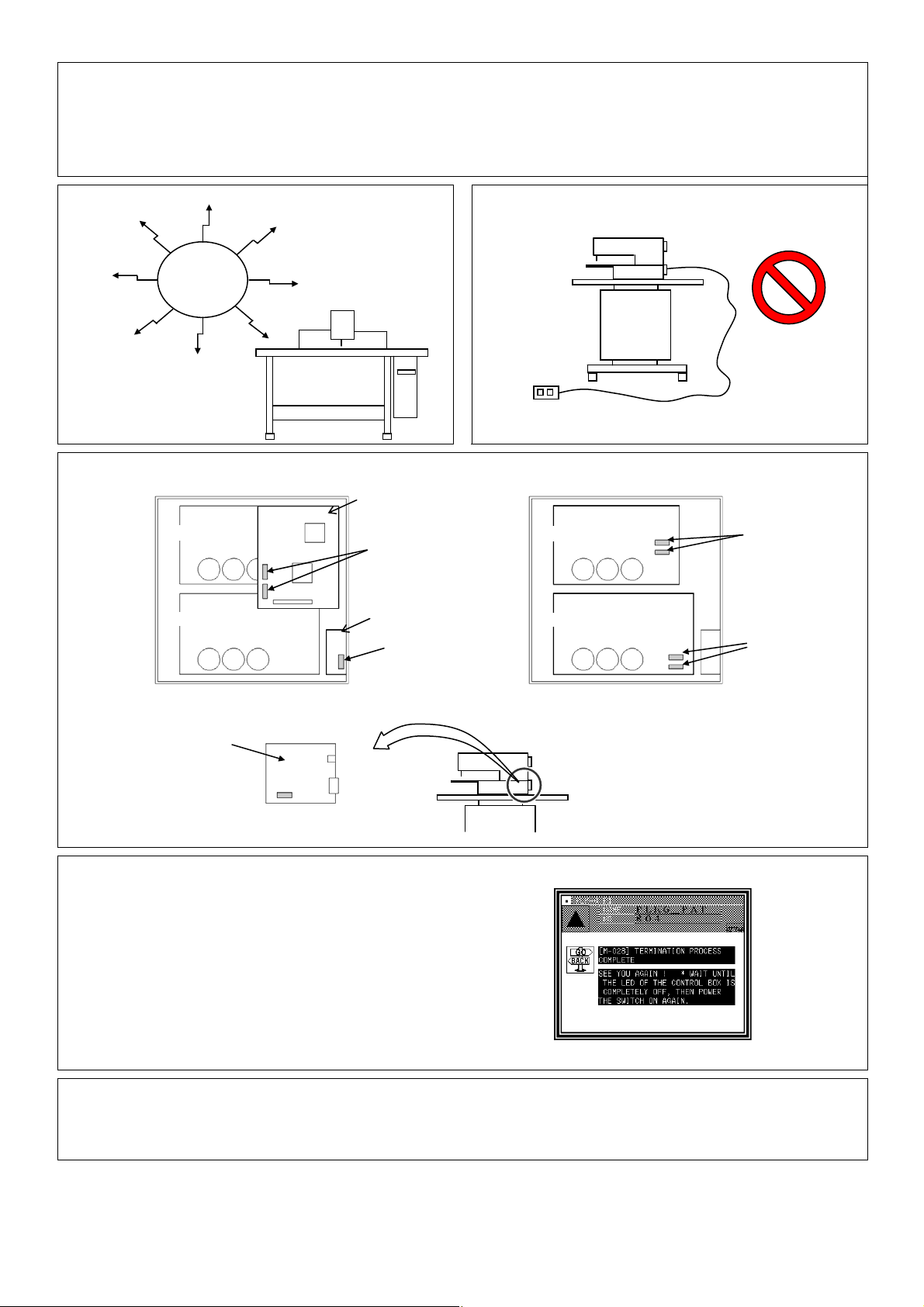

[2] Precautions for use

Warning

1. Do not place foot on the foot switch when turning the power ON.

3. Do not inspect the control circuit with a tester.

Control circuit

The tester voltage could be applied on the semiconductor

parts, and cause damage.

5. Always ground the grounding wire.

Power supply

Green

(Green/yellow)

Always ground the provided grounding wire

(green(green/yellow)).

7. A high voltage is applied inside creating a hazardous state, so

always turn the power OFF and wait ten minutes before opening

the cover.

High voltage risk

2. Always turn the power OFF when leaving the sewing machine.

4. Always turn the power switch OFF before tilting the sewing

machine head, replacing the needle, or passing thread through the

needle.

6. Do not use excessive wiring.

8. Radiation fins and other parts may be hot. Do not touch the parts.

[2] - 1

Page 8

)

)20A

)20A

)15A

9. The sewing machine will coast to a stop when the power is turned OFF or a power failure occurs during sewing machine operation.

10. Always align the connector shape and direction, and securely insert the connector.

11. If the position detector's connector dislocates, or the sewing machine is completely locked, the motor will be turned OFF automatically for a

set time to prevent burning. (Note that the motor may not turn OFF if there is incomplete locking or an overload.) When the fault has been

recovered, turn the power OFF and ON once to resume normal operation. The same type of operation will take place if a detector fault or

disconnection occurs.

12.Use the machine away from strong noise sources such as high

frequency welders.

14. If the fuse blows, remove the cause, and replace the blown fuse with one having the same capacity.

Noise

PLK-G3-CPU

13. When connecting the external switch to an optional connector,

etc., keep the signal wire as short as possible. A long wire could

cause malfunctions.

Use a shielded wire for the signal wire when possible.

XC-G2-2B-PLK

PLK-G2-PMD

(View from the front with cover removed) (View from the front

15. Attention when power supply is turned on again

Please make sure not to turn on the power supply switch until after

the LED on the front panel of the control box has completely turned off.

(Please do not turn on the power supply again while displaying

the screen of the operation panel.)

* Please note that if power supply is turned on again while LED still turns on,

clamp outputs (O4, O5 port) may go down.

16. When the value of the sewing area limit is changed or the limit setting is deactivated, note the collision and

with the cover and CPU removed)

fuse(one fuse)

Solenoid board located

on back of machine head

2.5Afuse(two fuses

PLK-G2-PMM

8Afuse(one fuse

XC-G2-2B-PLK

PLK-G2-PMD

fuse(two fuses

fuse(two fuses

take care safely.

Also when using it outside the range where the mechanism can be operated, it can not assume the responsibility for

all problems caused by it.

[2] - 2

Page 9

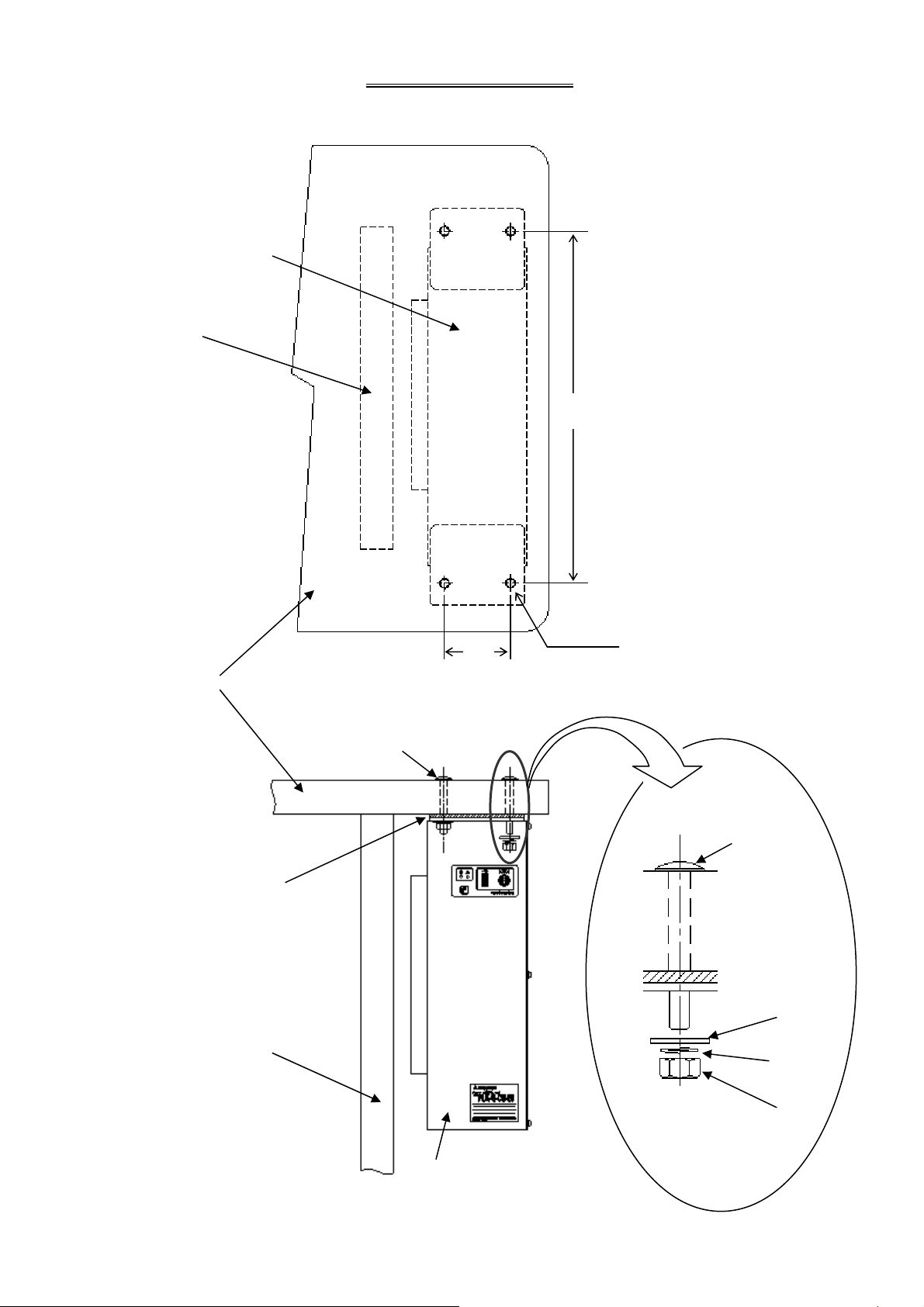

r

1. Installing the control box

control box

Top view of control box

installation area

Front view of control box

installation area

Leg

Top plate

Damper

cushion

Leg

[3] Installation

●Insert the four bolts into the holes

on the top plate and install the

control box.

427

4-Ø9

80

Installation bolt

(Fix at four positions)

Installation bolt

(M8×60)

Washer

Spring

washe

Nuts

control box

[3] - 1

Page 10

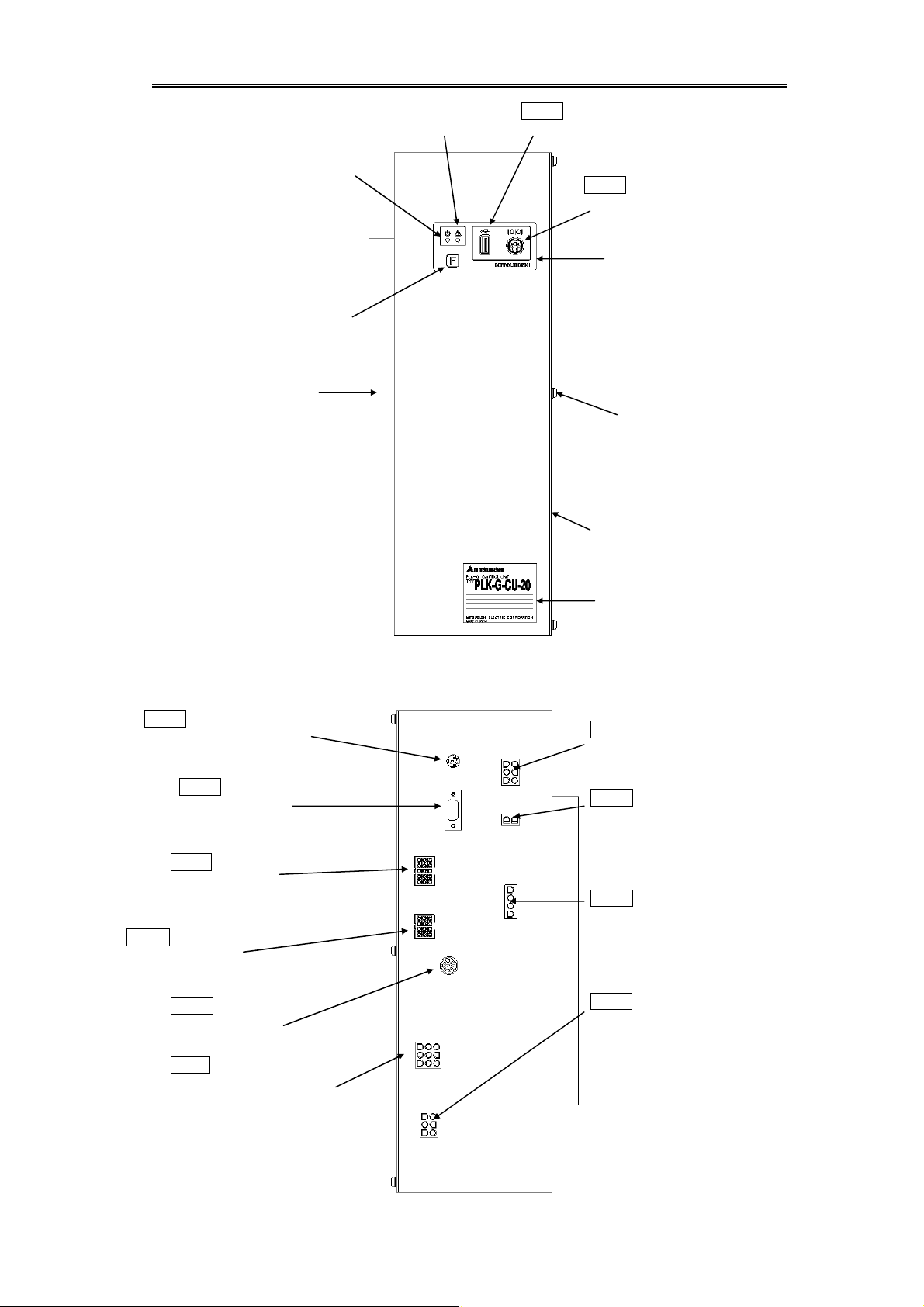

[4] Names of each part, wiring and grounding

p

r

1.Front side

Power

LED(green)

Function button

Heat sink

Warning

LED(red)

CONR

USB(TYPE A)

with Protective cap

CONS

RS-232C(MINI DIN)

with Protective cap

anel

Front

Cover installation screw

(M4 screw)

2.Back side

CONA

Operation panel

(Connect to Operation panel)

CONG

XY axis encoder

(Connect to XY axis stepping motor)

CONE

Various solenoids

(Connect to sewing machine

head section)

CONF

Spindle encoder

(Connect to spindle servo

motor)

Cove

Rating plate

CONB

Power supply

(Connect to power switch box)

CONC

DC power for solenoid

(Connect to sewing machine head

section)

COND

Spindle servo motor

(Connect to spindle servo motor)

CONH

Foot switch

(Connect to foot switch)

CONJ

XY axis stepping motor

(Connect to sewing machine

head stepping motor)

[4] - 1

CONK

PF axis stepping motor

(Connect to sewing machine head

PF axis stepping motor)

Caution: Be sure to connect all connectors

before turning ON the power.

Connect each connector fully to

ensure sufficient contact. Refer to

“[12] Unit Wiring Diagram.”

Page 11

3. Connecting the power connector

p

r

Control box

4. Connecting the 3-phase power supply

3-phase power supply R-phase S-phase T-phase

Push-button switch cord

Red(black)

White(brown)

Black(blue)

Green(green/yellow)

Control box

Power connector (6-pole)

Caution1: Always confirm the connector shape and insertion

Caution2: Please do not bundle the power cable and other

Top plate

owe

orientation and completely insert the power connector

into the control box. Always turn the power OFF before

connecting the connector.

cables together. It may cause of malfunction by the

influence of the power supply noise etc.

Warning

Always connect the green wire to the grounding terminal.

Consult with your electrician for details on the grounding wire.

5. Power capacity

Use a fuse or safety breaker on the power supply.

Power supply Recommended current capacity value

3-phase 200V

10A

6. Using the 3-phase 200V control box with single-phase 200 to 220V

Connect power supply to the "red" and "white" lead wires for the push-button switch.

The black wire is not used, so insulate it by wrapping insulation tape, etc., around it.

Always ground the green grounding wire.

Connect to ground

Connection connector to control box Push-button switch

OFF ON

Do not connect

(Accurately insulate

with tape.)

Green

Red

White

Black

Connect these lead

wires to the power

supply.

[4] - 2

Page 12

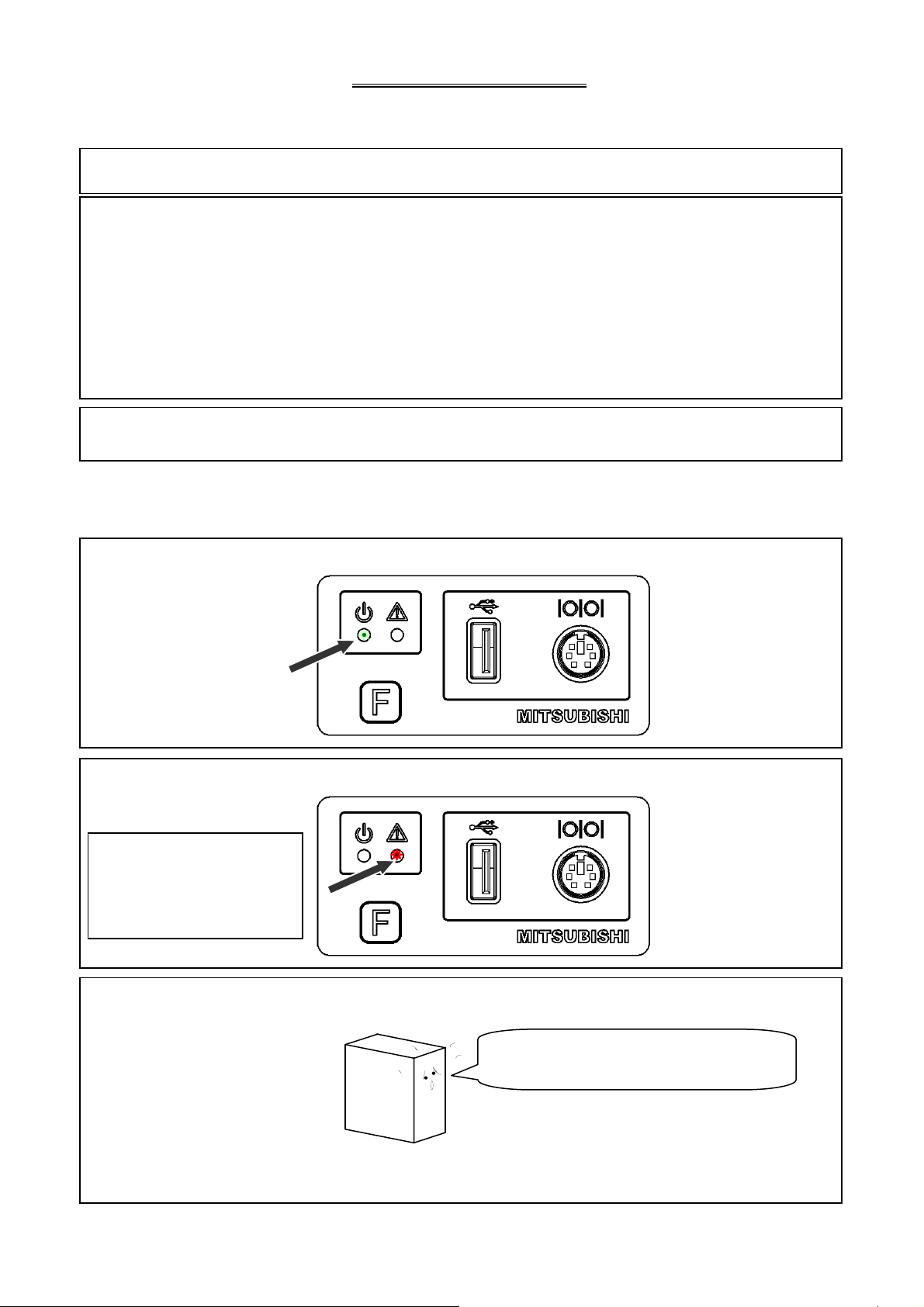

[5] Confirmation

1. Before turning the switch ON

(1)Are the power and capacity correct?

(2)Are the connectors correctly inserted? (

* Power connector from push-button switch

* Connector for connection with sewing machine

* Motor connector

* Motor encoder connector

* Foot switch connector

* Other connectors (solenoid, etc.)

(3)Does the hand pulley turn easily?

2. After turning the switch ON

(1)Is the front panel power LED (green) on?

Refer to “[12] Unit Wiring Diagram.”)

(2)Is the front panel warning LED (red) on or flickering?

For actions to be taken

when the warning LED (red)

is on or flickering, refer to

“[10] What Happened?

Could it Be an Error?”

(3)Is there any heating, odors or abnormal noise from the motor or control box?

● When you turn ON the power, a click noise comes from inside the control box. This noises are not

abnormal.

Turn the sewing machine OFF and contact your

dealer if there is any heating, odors or abnormal

noise.

[5] - 1

Page 13

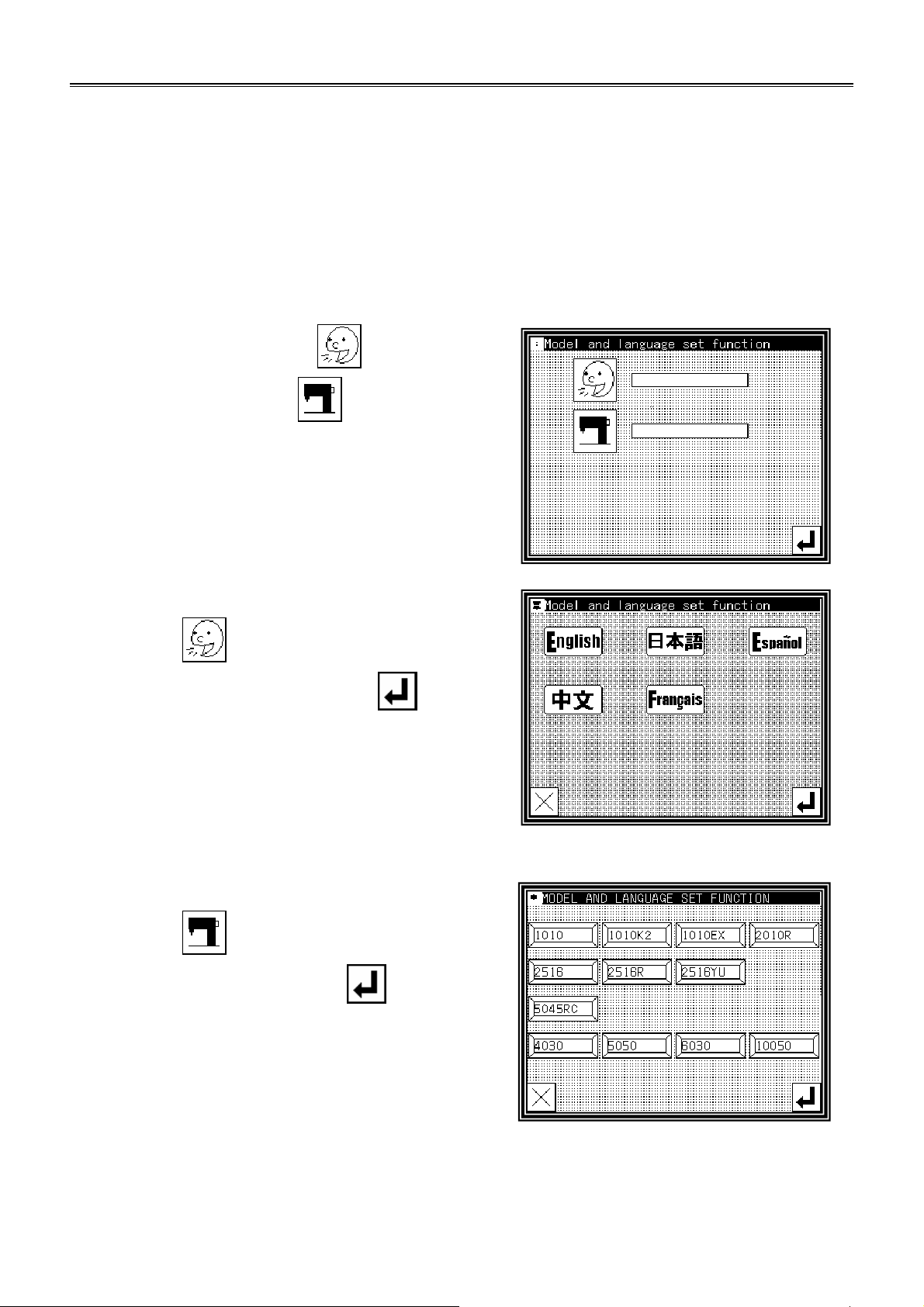

[6] Initial Settings of System Software (Model/Language Settings)

1. Model/Language Settings

The model to be used and the language to be displayed need to be set. When you turn on the machine

power with the system in an initial state, the “Model/Language Setting” screen appears. Perform the

procedures below.

(1)When the power supply is turned on first time, [Model/Language setting] screen is displayed.

►For language setting, press .

►For model setting, press

.

(2)Language setting

►press .

►Choose Language button, then press .

(3)Model setting

►press .

►Choose Model button, then press .

[6] - 1

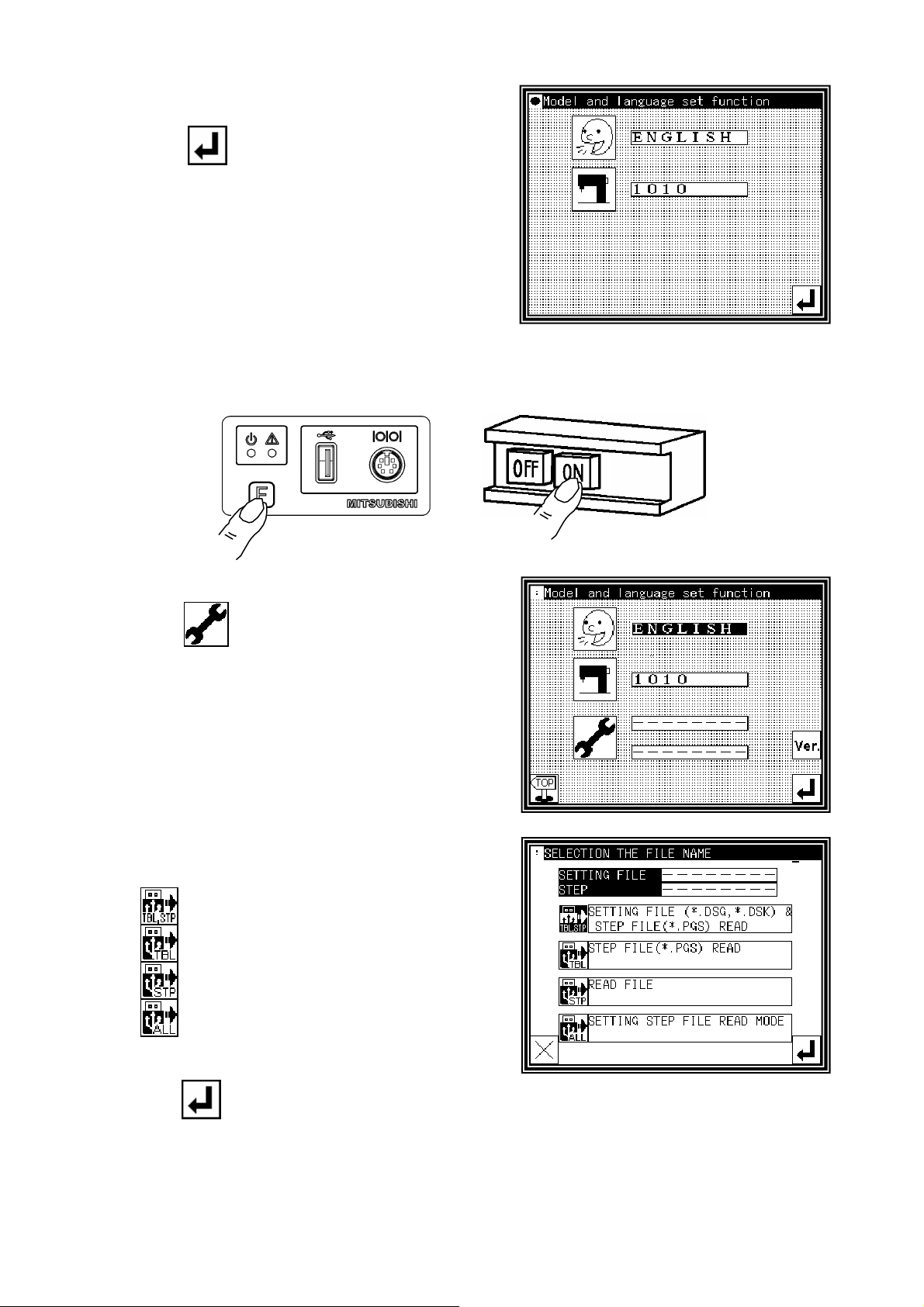

Page 14

(4) Model / Language setting screen is displayed again.

► Press .

(5) Please turn the power off according to the display

of the message.

(6) Setting table / Step file setting (

► While holding down the [F] key on the front panel of the control box, turn the machine power ON. (Keep pushing [F]

key until red LED on the front panel is turned on.)

If setting is not necessary, goto (9).

+

)

(7)Setting table / Step file setting

►Press .

(8)

Setting table / Step file setting mode

►Choose one of following buttons.

Reads Setting table and Step file

Reads Setting table only

Reads Step file only

Reads System file ,Setting table and Step file

►Connect USB memory

to the connector on the front panel of the control box, then,

press

.

, which above data is contained,

[*1]

[6] - 2

Page 15

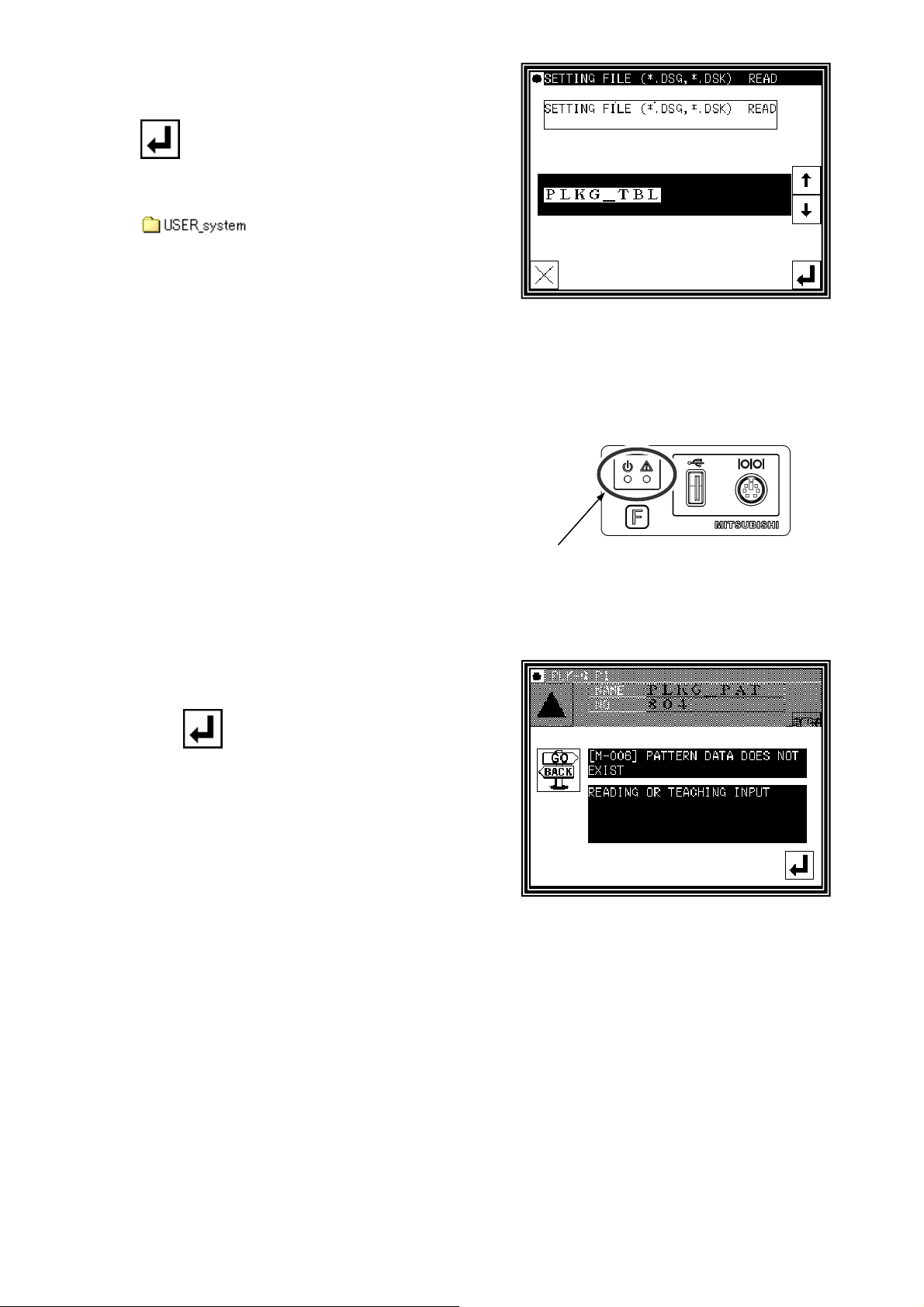

►After file name selection screen is displayed, choose target

filename by using up and down arrow button, then press

.

[*1] Setting table and Step file must be saved in the

[

] folder in the USB memory.

(9)Re-turning on the power supply

► Please turn the power off according to the display of the message.

► After check the LED lamp on the front panel of the control box

Is completely off, turn the power on.

Check the LED lamp is OFF

(10)Initial condition

► At initial condition, the message like a right picture is

displayed.

Press

or read sewing pattern data. ( Refer to technical manual

[ Operation panel ].)

to switch to the Standard screen, then create

[6] - 3

Page 16

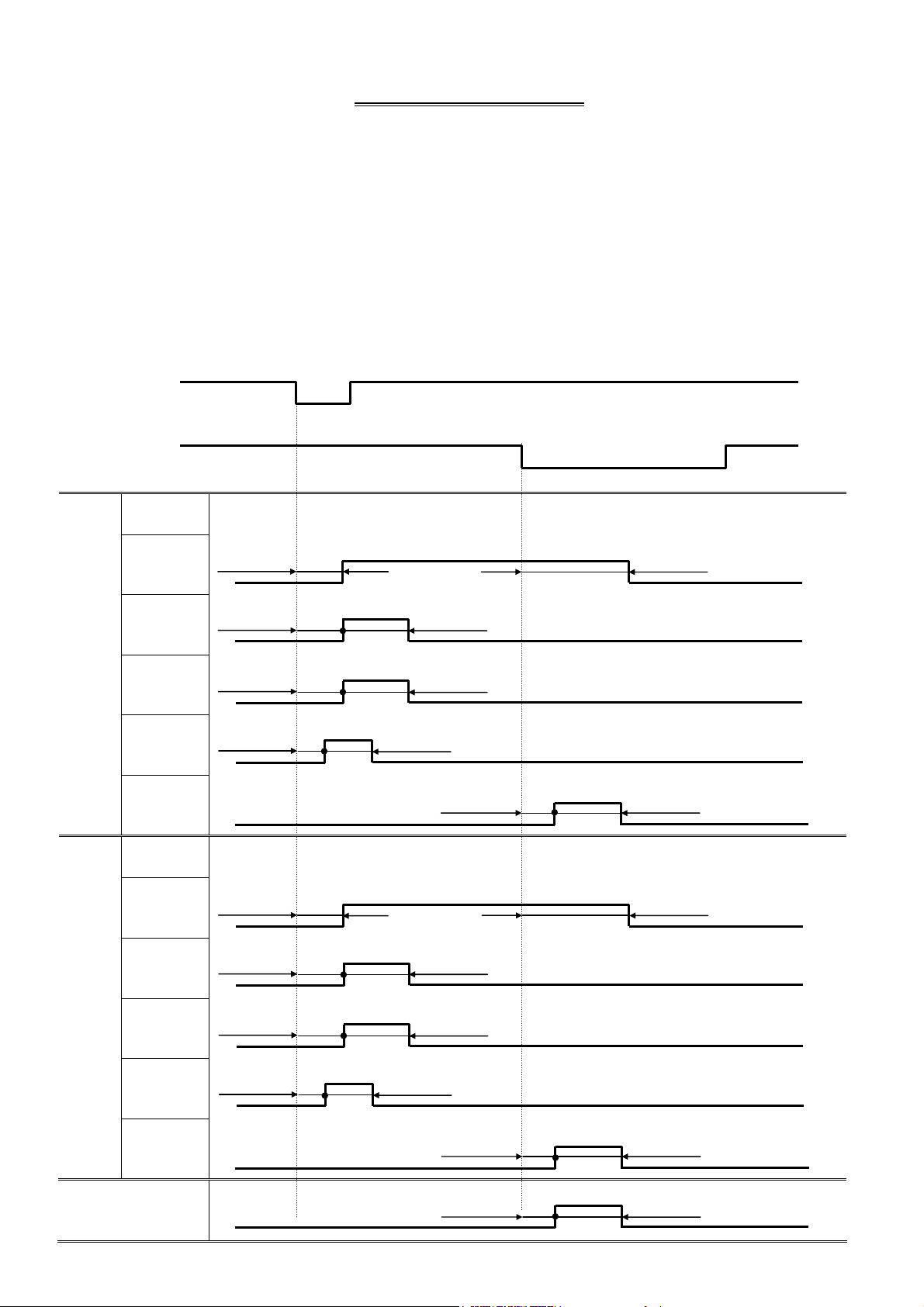

[7] Timing chart

1.Thread trimming timing chart

·Timing for thread trimming output [T] :

Program mode [Thread trimming/release timing] -- [LTM] T1~T5

Program mode [Thread trimming/release timing] -- [TRS] msec / deg

Program mode [Thread trimming/release timing] -- [TRE] msec / deg

·Timing for thread release output [L] :

Program mode [Thread trimming/release timing] -- [LLM] L1~L5

Program mode [Thread trimming/release timing] -- [LRS] msec / deg

Program mode [Thread trimming/release timing] -- [LRE] msec / deg

·Timing for wiper output [W] :

Program mode [Wiper] -- [W1] msec

Program mode [Wiper] -- [W2] msec

Needle down

position DN

Needle up

position UP

LTM

setting

ON

ON

Thread trimming output [T]

Thread release output [L]

T1

T2

T3

T4

T5

LLM

setting

L1

L2

TRS(deg) TRE(ms)

ON

TRS(deg) TRE(deg)

ON

TRS(deg) TRE(ms)

ON

TRS(ms) TRE(ms)

ON

TRS(ms) TRE(ms)

ON

LRS(deg) LRE(ms)

ON

LRS(deg) LRE(deg)

ON

Wiper [W]

L3

L4

L5

LRS(deg) LRE(ms)

ON

LRS(ms) LRE(ms)

ON

LRS(ms) LRE(ms)

ON

W1(ms) W2(ms)

ON

[7] - 1

Page 17

2.Timing chart for [Clamp of output ON/OFF delay setting]

Clamp input 1~8

IF1~IF8

ON ON

1A~8A 1B~8B

Clamp output 1~8

OF1~OF8

ON

3.Timing chart for [Priority of clamp]

Clamp input 1

IF1

ON

Clamp input 2

IF2

Clamp input 3

IF3

Clamp input 4

IF4

[WHY]=[OFF]

Clamp output 1

OF1

Clamp output 2

OF2

Clamp output 3

OF3

Clamp output 4

OF4

[WHY]=[ON]

Clamp output 1

OF1

ON

ON

ON

ON

ON

ON

ON

ON

ON

Clamp output 2

OF2

Clamp output 3

OF3

Clamp output 4

OF4

ON

ON

ON

Note: [WHY]=[ON]

* The clamp input signal [IF2],[IF3],[IF4] is invalidated when clamp output 1 is not ON.

* The clamp input signal [IF2] is validated when clamp output 1 is ON.

* The clamp input signal [IF3] is validated when clamp output 2 is ON.

* The clamp input signal [IF4] is validated when clamp output 3 is ON.

[7] - 2

Page 18

4.Timing chart for

[Clamp link setting (CF)]=ON, [Valid Number of clamp setting (FN)]=4

Clamp input 1

IF1

Clamp output 1

OF1

ON

1A

ON

ON

1B

Clamp output 2

OF2

Clamp output 3

OF3

Clamp output 4

OF4

Note: Halt switch is validated.

2A

ON

3A

ON

4A

ON

4B

5.Timing chart for

[Selection of pneumatic pressure two-step (AF2)]=ON

Can not use other function in “Work holder” mode.

ON

Pneumatic pressure

two-step clamp

input signal A2F

Start

input signal SRT

ON ON ON ON ON

ON ON

2B

3B

Pneumatic pressure

two-step clamp

low pressure output AFL

Pneumatic pressure

two-step clamp

high pressure output AFH

Pneumatic pressure

two-step clamp

eject pressure output AFE

Movement of

sewing machine

ON ON ON

ON ON ON

ON

ON

1T

ON

[7] - 3

Page 19

6.The divisions of clamp setting [OFB]=2

Setting of [FN],[CF],[F4BN],[F4SN] is invalidated when above setting.

[WHY]=OF,[OFB]=2,[CF1]=ON,[CF2]=OF,[F21N]=4,[F22N]=3

When not using the clamp step input.

Clamp input 1

IF1

ON

ON

Clamp input 2

IF2

Clamp input 3

IF3

Clamp input 4

IF4

Clamp input 5

IF5

Clamp input 6

IF6

Clamp input 7

IF7

Clamp input 8

IF8

Start input signal

SRT

The divisions of clamp 1,

[F21N]=4

Clamp output 1

OF1

Clamp output 2

OF2

1A

ON

2A

ON

ON

ON

ON

ON

ON

ON

ON

2B

2A

ON

Clamp output 3

OF3

Clamp output 4

The divisions of clamp 2,

[F22N]=3

OF4

Clamp output 5

OF5

Clamp output 6

OF6

Clamp output 7

OF7

Clamp output 8

OF8

Movement of

sewing machine

3A

ON

4A

ON

5A

ON

6A

ON

7A

4B

ON

Note 1.When the setting ([CF1]=ON), clamp input 1 is link input.

2.When the setting ([CF2]=ON), clamp input 5 is link input.

3B

3A

ON

4A

ON

ON

[7] - 4

Page 20

7.The divisions of clamp setting [OFB]=2(When using the clamp step input.)

Setting of [FN],[CF],[F4BN],[F4SN] is invalidated when above setting.

[WHY]=OF,[OFB]=2,[CF1]=ON,[CF2]=OF,[F21N]=4,[F22N]=4

When using the clamp step input.

The clamp step

(forward direction)

division 1 FP1

The clamp step

(backward direction)

division 1 FM1

The clamp step

(forward direction)

division 2 FP2

The clamp step

(backward direction)

division 2 FM2

Start input signal

SRT

ON

ON ON

ON

ON

ON

ON

ON ON ON ON

ON

ON

The divisions of clamp 1,

[F21N]=4

Clamp output 1

OF1

Clamp output 2

OF2

Clamp output 3

OF3

Clamp output 4

The divisions of clamp 2,

[F22N]=4

OF4

Clamp output 5

OF5

Clamp output 6

OF6

Clamp output 7

OF7

Clamp output 8

OF8

Movement of

sewing machine

1A

ON

2A

ON

3A

ON

3A

3B

ON

4A

ON

5A

ON

6A

ON

7A

ON

8A

ON

8B

8A

ON

ON

[7] - 5

Page 21

8.The divisions of clamp setting [OFB]=4

Setting of [FN],[CF],[F21N],[F22N],[CF1],[CF2] is invalidated when above setting.

Clamp(O1,O2),(O3,O4),(O5,O6),(O7,O8) is link movement when above setting.

Only in this case, the block division operation is possible by the setting of [F4BN].

[WHY]=OF,[OFB]=4,[F4BN]=4

When not using the clamp step input.

Clamp input 1

IF1

ON

ON

ON

Clamp input 2

Clamp input 3

Clamp input 4

Clamp input 5

Clamp input 6

Clamp input 7

Clamp input 8

Start input signal

Clamp output 1

1

2

Clamp output 2

IF2

IF3

IF4

IF5

IF6

IF7

IF8

SRT

OF1

OF2

1A

ON

2A

ON

ON

2B

ON

ON

ON

ON

ON

1A

1B

2A

ON

2B

ON

2A

ON

Clamp output 3

2

2

OF3

Clamp output 4

OF4

Clamp output 5

3

2

OF5

Clamp output 6

OF6

Clamp output 7

4

2

OF7

Clamp output 8

OF8

←Block number of clamp

←Number of clamps

Movement of

sewing machine

3A

ON

4A

ON

5A

ON

6A

ON

7A

ON

8A

ON

ON

[7] - 6

Page 22

9.The divisions of clamp setting [OFB]=4

Setting of [FN],[CF],[F21N],[F22N],[CF1],[CF2] is invalidated when above setting.

Clamp(O1,O2),(O3,O4),(O5,O6),(O7,O8) is link movement when above setting.

Only in this case, the block division operation is possible by the setting of [F4BN], and block

step operation is possibleby the setting of [F4SN].

[WHY]=OF,[OFB]=4,[F4BN]=4,[F4SN]=4

When not using the clamp step input.

The clamp step

(forward direction)

general input signal SFP

The clamp step

(backward direction)

general input signal SFM

Start input signal

SRT

Clamp output 1

1

2

OF1

Clamp output 2

OF2

Clamp output 3

2

2

OF3

Clamp output 4

OF4

Clamp output 5

3

2

OF5

Clamp output 6

OF6

ON

1A

ON

ON ON ON ON

ON

ON

1A

1B

2A

ON

2B

ON

2A

ON

3A

ON

4A

ON

5A

ON

6A

ON

4

2

←Block number of clamp

←Number of clamps

Clamp output 7

OF7

Clamp output 8

OF8

Movement of

sewing machine

7A

ON

8A

ON

ON

[7] - 7

Page 23

[8] Customized input/output

p

1.Customized input/output configuration diagram

[8] - 1

(Refer to page[8]-3) (Refer to page[8]-2) (Refer to page[8]-2) (Refer to page[8]-3)

A B C D E

(Input port)

·Terminal block

·Connector

Input

control

section

Alternate

Input reversal

Physical

input

I1

I2

I3

I4

I5

:

:

:

Virtual

input

S1

F

Two stage

clamp input

Sewing machine

operation prohibit

Home position

return prohibit

Virtual input 0

Virtual input 1

:

:

:

:

Virtual

out

ut

T

L

W

OF1

PF

Two stage

clamp output

Sewing machine control

Virtual output 0

Virtual output 1

:

:

:

:

Physical

output

O1

O2

O3

O4

O5

:

:

:

Output

control

section

Alternate

output reversal

(Output port)

·Terminal block

·Connector

chopping

ON/OFF delay

WL

[13]-1

Page 24

2.Outline of customized input/output mode

p

(A to E below correspond to A to E on the previous page.)

(1)Customizing the input signal

A.The ON/OFF signal input from the input port passes through the input control section (no operation,

alternate operation, signal reversal), and is then stored in the physical input area corresponding to the

input port.

B.

Each signal stored in the physical input area is connected to a desired position in the sewing machine

control virtual input port.

(Refer to page[8]-3)

(Refer to page[8]-2)

C.The sewing machine carries out control based on the function assigned to the virtual input area.

(2)Customizing the output signal

D.As opposed to the customized input, the virtual output area port, assigned a specific meaning, can be

connected and set to a desired position in the physical output area port.

E.

The signal for each port in the physical output area passes through the output control section

(no operation, delay circuit, alternate, etc.), and is then output to the output port.

3.Customizing the virtual input/output

Input control

section

Alternate

Input reversal

Physical

input

I1

I2

I3

I4

Customized

input

Virtual

input

SRT

F

Virtual

out

ut

T

L

FU

Sewing machine control

Customized

output

(Refer to page[8]-2)

(Refer to page[8]-3)

Output control

Physical

output

O1

O2

O3

O4

section

Alternate

ON/OFF delay

output reversal

chopping

Selection and connection of physical input/output port and virtual input/output port

For example, to connect the physical input port [I1] and virtual input port [SRT] (start) and to connect the

physical output port [O1] and virtual output port [T] as shown in the diagram, set as follows.

1. Using customized input, select the [I1] input functions, and set SRT.

2. Using customized output, select the [O1] input functions, and set SRT.

With the above settings, [I1] and [SRT], and [O1] and [T] will be connected.

One port from the virtual input ports can be selected for the [I*] port by changing the setting.

One port from the virtual output ports can be selected for the [O*] port by changing the setting.

[8] - 2

Page 25

4.Block diagram (input control section)

Standard Physical input

A

OF

ON

B

Logic changeover Operation changeover

Alternate

NO

AL

C

5.Explanation of operations (input control section)

The input signal passes through the A point, B point and C point of the input port, and finally is connected

to the physical input

A point

B point (1) When the logic setting is set to "normal"(OF), the operation will be the same as the input

Inputs the signal to the input port from an external source.

signal A point.

(2) When the logic setting is set to "reverse"(ON), the operation will be the reverse of the input

signal A point.

C point (1) When the operation selection is set to "normal"(NO), the operation will be the same as the

input signal B point.

(2) When the operation selection is set to "alternate"(AL), the signal will turn ON at the first rising

edge, turn OFF at the second rising edge, and will turn ON at the third rising edge. The signal

waveform will repeatedly turn ON and OFF at the input rising edge.

The C point signal input and controlled in the above manner is input into the physical input port.

Logic

changeove

Logic operation

selection when

logic changeover is

set to "normal"

Logic operation

selection when logic

changeover is set to

"reverse"

Input port A

“Normal” B

"Reverse" B

“Normal” C

"Alternate" C

“Normal” C

"Alternate" C

[8] - 3

Page 26

6.Block diagram (output control section)

y

Physical output

O1

O2

O3

Alternate

OFF delay

NO

D

Setting time

Chopping

Full wave time

Setting value x 100μs

OFF delay

OF

ON

Operation

selection

Full wave time

NO

AL

Dut

A

100% ON

66% ON(8ms ON/4ms OFF)

66% ON(4ms ON/2ms OFF)

50% ON(4ms ON/4ms OFF)

50% ON(2ms ON/2ms OFF)

33% ON(2ms ON/4ms OFF)

17% ON(2ms ON/10ms OFF)

8% ON(2ms ON/22ms OFF)

Manual setting

C

ON delay

OF

ON

ON delay

7.Explanation of operation (output control section)

The operation of the signal output from the physical output is selected and then the signal is connected to

the output port F point.

A point

Logic operation selection

(1)

When "normal"(NO) is selected, the input waveform is connected.

(2)

When "alternate"(AL) is selected, the signal will alternately turn ON and OFF, turning ON at the

first rising edge and OFF at the next rising edge.

Input signal O1

“Normal” A

“Alternate” A

Setting time

E

Logic

changeover

OF

ON

Output port

B

D

[8] - 4

Page 27

B point ON

delay setting

(1)

When "invalid" is selected, the same signal as the A point will be output to the B point.

(2)

When "valid" is selected, the waveform will rise after the {set value x 100μs} time (*1) set with the

A point input waveform. (ON delay)

Input signal A

“Invalid” B

“Valid” B

C point OFF delay setting

(1)

When "invalid" is selected, the same signal as the B point will be output to the C point.

(2)

When "valid" is selected, the ON time will be delayed by the {set value x 100μs} time (*2) set with

the B point input waveform.

Input signal B

“Invalid” C

“Valid” C

D point Logic setting

(1)

When "normal" is selected, the C point signal will be output to the D point without any changes.

(2)

When "reverse" is selected, D point signal will be reversing signal of the C point signal.

Input signal C

Normal D

“Reverse” D

E point Chopping setting

(1) When [100%ON] is set, there is no change, and input signal of D point is output to E point.

(2) When other than [100%ON] is set, outpu of E point is on while {setting time x 100 us}. Afterwards the

output becomes square wave accordning to duty ratio setting.

Input signal D

“

100%ON” E

“

Other than 100%ON” E

Full wave time

*1 Delay time to ON

Duty

100% ON

66% ON(8ms ON/4ms OFF)

66% ON(4ms ON/2ms OFF)

50% ON(4ms ON/4ms OFF)

50% ON(2ms ON/2ms OFF)

33% ON(2ms ON/4ms OFF)

17% ON(2ms ON/10ms OFF)

8% ON(2ms ON/22ms OFF)

Manual setting

*2 Delay time to OFF

[8] - 5

Page 28

[9] Input/Output signal

1.Input signal setting table

Code Function Specifications

FSP

FSM

FP1

FM1

FP2

FM2

IFR

A2F Pneumatic two-step clamp

IF1~IF8 Clamp input signal 1 ~ 8 When IF1 input is on, OF1 output is turned on.

F1C~F8C Clamp output prohibition signal

OFC

WC

TC

S6

HPC

TH2

THS

ARS

IO0~IOF

NO

SRT

HP

PF

JGP

JGM

STP

Clamp all step ON signal Whenever FSP input is on, clamp output [1],[2],[3],[4],[5],[6],[7],[8] turned on

Clamp all step OFF signal Whenever FSM input is on, clamp output [8],[7],[6],[5],[4],[3],[2],[1] turned off

Clamp division1 step ON

signal

Clamp division1 step OFF

signal

Clamp division2 step ON

signal

Clamp division2 step OFF

signal

All clamp output clear signal If IFR signal is on, all clamp outputs are turned off.

switch input signal

1 ~ 8

All clamp output cancel signal When OFC input is on, OF1 to OF8 outputs are prohibited.

Wiper output cancel signal When WC input is on, W output is prohibited.

Trimmer output cancel signal When TC input is on, Thread trimmer sequence output T, L and W is

Thread trimming protection

signal

Home positioning prohibition

signal

Upper thread sensor 2 input

signal

Upper thread sensor input

signal

Less pressure detection signal When ARS input is on, all operation is interrupted, and error [E-025] is

General purpose input 0 ~ F When IO0 input is on, OT0 output is turned on at the same time.

No operation signal Anything does not operate, if NO input is turned on.

Start signal When SRT input is on, sewing operation is started. However, when clamp

Home position returning signal When HP input is on, home position returning operation is executed.

Presser foot signal When PF input is on, The presser foot will return to home position.

JOG plus signal When JGP input is on, XY table is moved in positive direction according to

JOG minus signal When JGP input is on, XY table is moved in negative direction according to

Halt signal When STP input is on, machine is stopped.

one by one. However, when [ Program mode > Clamp output > number of

effective clamp (FN) ] is set to 1, FSP input is ineffective.

one by one. However, when [ Program mode > Clamp output > number of

effective clamp (FN) ] is set to 1, FSM input is ineffective.

Whenever FP1 input is on, clamp output [1],[2],[3],[4] turned on one by one.

Whenever FM1 input is on, clamp output [4],[3],[2],[1] turned off one by one.

However [ Program mode> clamp output block division number setting (OFB)]

is set to no or set to 4, or [ number of valid clamp setting (F21N)] is set to 1,

FM1 input is ineffective.

Whenever FP2 input is on, clamp output [5],[6],[7],[8] turned on one by one.

Whenever FM2 input is on, clamp output [8],[7],[6],[5] turned off one by one.

However [ Program mode> clamp output block division number setting (OFB)]

is set to no or set to 4, or [ number of valid clamp setting (F22N)] is set to 1,

FM2 input is ineffective.

Whenever A2F input is on, following operation (1), (2), (3) is repeated.

This signal is effective when [Program mode > Setting for Pneumatic two-step

clamp(AF2)] is on.

(1)When A2F input is on first time, AFL output is turned on.

(2)When A2F input is on second time, AFH output is turned on.

(3) When A2F input is on third time, AFE output is turned on.

When IF1 input is on again, OF1 output is turned off.

(same from IF2 toIF8)

When F1C input is on, OF1 output is prohibited.

(same from F2C to F8C)

prohibited.

When S6 input is on while machine is driving, the machine is stopped and

when S6 input is off, the machine start driving again.

When S6 input is on while thread trimming operation, machine is stopped

after trimming.

When HPC is ON, home returning operation by the home positioning key or

HP signal is prohibited.

When setting of [ Program mode > Needle thread breaking sensor 2

ON/OFF ] is on, the signal can be used for thread breakage detection input

(channel 2).

When setting of [ Program mode > Needle thread breaking sensor ON/OFF ]

is on, the signal can be used for thread breakage detection input.

displayed. (Returns by power supply re-turning on)

(same from IO1 to IOF)

output is turned off, this signal is invalid.

However, please note there is a timing that becomes invalid, for example

while machine is running.

When PF input is on again, presser foot goes to down position.

the pattern.

the pattern.

[9] - 1

Page 29

< sequel to INPUT SIGNAL >

Code Function Specifications

BC

CCL

SRC

CCU

CCD

UAD

UDC

DAD

DDC

KNK

RNK

WNK

INK

MNK

CNK

PNK

NNK

FNK

SNK

P01

P02

P04

P08

P16

P32

IFA

HES

I_9

I_A

Fixed angel (rotation/reverse

rotation) signal

Counter clear signal When CCL input is on, UP/DOWN counter is cleared.

Start cancel signal When SRC input is on, sewing operation with Stringhalt is prohibited.

Up counter clear signal When CCU input is on, UP counter is cleared.

Down counter clear signal When CCD input is on, DOWN counter is cleared.

Up counter addition signal When UAD input is on, 1 is added to UP counter

Up counter subtraction signal When UDC input is on, 1 is subtracted from UP counter

Down counter addition signal When DAD input is on, 1 is added to DOWN counter

Down counter subtraction

signal

Signal that invalidates MENU

key

Signal that invalidates “pattern

read” key

Signal that invalidates “pattern

write” key

Signal that invalidates

“teaching input” key

Signal that invalidates

“teaching modification” key

Signal that invalidates

“teaching conversion” key

Signal that invalidates

“program mode” key

Signal that invalidates “IN/OUT

setting” key

Signal that invalidates “function

mode” key

Signal that invalidates “speed”

key

Pattern number switch signal

+1

Pattern number switch signal

+2

Pattern number switch signal

+4

Pattern number switch signal

+8

Pattern number switch signal

+16

Pattern number switch signal

+32

DO NOT USE

Machine head tilting detection

signal

DO NOT USE

DO NOT USE

To confirm the needle thrust position, the needle is stopped just before the

sewing material. Whenever BC input is ON, operation of [rotation] → [reverse

rotation] → [rotation] is repeated. When the start switch is on afterwards,

following sewing operation is started. However, if the following data is non

stitch feed, the message [M-020] is appeared, in this case please move the

needle to up position and re-turning on the start switch. Setting value of fixed

angle can be set in the [ Function mode > Needle down angle setting].

When DDC input is on, 1 is subtracted from DOWN counter

When KNK is on, “MENU” key becomes invalid.

When RNK is on, “pattern read” key becomes invalid.

When WNK is on, “pattern write” key becomes invalid.

When INK is on, “teaching input” key becomes invalid.

When MNK is on, “teaching modification” key becomes invalid.

When CNK is on, “teaching conversion” key becomes invalid.

When PNK is on, “program mode” key becomes invalid.

When NNK is on, “IN/OUT setting” key becomes invalid.

When FNK is on, “function mode” key becomes invalid.

When SNK is on, “speed” key becomes invalid.

When P01 is on, pattern data number is switch to 801 (800+1).

When P02 is on, pattern data number is switch to 802 (800+2).

When P04 is on, pattern data number is switch to 804 (800+4).

When P08 is on, pattern data number is switch to 808 (800+8).

When P16 is on, pattern data number is switch to 816 (800+16).

When P32 is on, pattern data number is switch to 832 (800+32).

< When you want to change to other patterned numbers >

ex.1) pattern number to 803

turns on P01 input and P02 input

P01 (+1) + P02 (+2) + 800 = 803

ex.1) pattern number to 811

turns on P01, P02 and P08 input

*Pattern number can be changed within the range from 800 to 863.

*P01,P02,P04,P08,P16,P32 is effective when [Pattern select function by

external signal(APC)] has been set to ON.

When HES input is on, message [M-038] is displayed.

P01 (+1) + P02 (+2) + P08 (+8) + 800 = 811

[9] - 2

Page 30

< sequel to INPUT SIGNAL >

Code Function Specifications

SP0~SP9

SPU

SPD

CK1

CK2

Speed dial signal Speed dial value is switched to 0~9.

Speed up signal Speed dial value is increased +1.

Speed down signal Speed dial value is decreased -1.

Cassette jig sensor 1 signal

Cassette jig sensor 2 signal

When CK1 and CK2 inputs is on, OF1 output turn on.

*CK1 and CK2 is effective when [Cassette jig function ON/OFF(CHK)] and

[Cassette jig sensor ON/OFF(CSN)] has been sets to ON.

[9] - 3

Page 31

2.Output signal setting table

Code Function Specifications

OT0~OTF General purpose output 0 ~ F

FN1~FNH Function code output 1 ~ H

OF1~OF8 Clamp output 1 ~ 8 When IF1 is on, OF1 output is reversed (same OF2 to OF8 )

NO

PF

AFL

AFH

AFE

DHP

D2H

RED

DSW

SP

TSE

END

DCS

DST

HPO

ERR

CUE

CDE

DTS

--1

DRT

DN

CB

UP

PWR

PUS

MSG

OP1 Option output 1 General purpose output signal 1

OP2 Option output 2 General purpose output signal 2

SSW

MOV

[NO]output Nothing is done

Trimmer output Trimming operation is done

T

Thread tension release output Thread tension release operation is done

L

Wiper output Wiper operation is done

W

Presser foot output Presser foot operation is done

Pneumatic two-step switch

clamp low pressure output

Pneumatic two-step switch

clamp high pressure output

Pneumatic two-step switch

clamp excess pressure release

output

Home position output When XY table is sopped on the home position, DHP output is turned on.

Second home position output When XY table is sopped on the second home position, DHP output is turned

Preparation ready output When the machine is ready state (when clamp output is on), RED output is

Sewing in progress output When the machine is sewing, DSW output is turned on. When machine is

Sewing machine rotation start

output

Trimming start output When trimming sequence (down position) is started, TSE output is turned on.

Sewing completion output When a sewing pattern operation is finished, END output is turned on.

Halt code output When the halt code data (USTP, DSTP) is read while sewing, DCS output is

Halt in progress output When the machine is on halt state, DST output is turned on. When the

Home returning in progress

output

Error output When the error or message is displayed on the operation panel, ERR output

Count up completion output When the current value of up counter is reached at counter set value, CUE

Countdown completion output When the current value of down counter is reached at 0, CDE output signal is

Halt in progress output after

upper thread sensor detection

DO NOT USE

Sewing machine rotation in

progress output

Down position output When the needle is down position, DN output is turned on.

Buzzer output While the buzzer in the operation panel is on, CB output is turned on.

Up position output When the needle is up position, UP output is turned on.

Power on output While power supply is on, PWR output signal is turned on.

Presser hoot home position

output

Message display output When the message is displayed on the operation panel, ERR output is turned

Halt signal being on output

Sending table's moving output

signal

When IO0 is on, OT0 output at the same time (same from OT1 to OTF )

When FUN1 code is read while sewing operation, FN1 output is reversed.

(same from FN2 to FNH)

When A2F input is on first time, AFL output is turned on.

Setting is effective when [ Program mode > Clamp > Pneumatic two-step

switch clamp ON/OFF (AF2)] is on.

When A2F input is on second time, AFH output is turned on.

Setting is effective when [ Program mode > Clamp > Pneumatic two-step

switch clamp ON/OFF (AF2)] is on.

When A2F input is on third time, AFE output is turned on.

Setting is effective when [ Program mode > Clamp > Pneumatic two-step

switch clamp ON/OFF (AF2)] is on.

on.

turned on. When machine is start sewing, RED is turned off.

stopping on the home position, DSW output is turned off.

After non stitch feed, when the sewing machine start to rotate, SP output is

turned on. When home positioning is executed, SP output is turned off.

When trimming sequence is finished (when all the outputs of T, L and W are

turned off), TSE output is turned off.

When the next sewing is started, END output is turned off.

turned on. When the machine restarts DCS output is turned off.

machine restarts DST output is turned off. However, it is not output while

stopping by the USTP code or the DSTP code.

While the operation of home returning by the home positioning key or HP

signal, HPO output is turned on.

is turned on.

output signal is turned on. When the current value is cleared, CUE output is

turned off.

turned on. When the current value is initialized, CDE output is turned off.

When the machine is on halt state with thread breakage, DTS output is

turned on. When the machine restarts, DTS output is turned off.

While the machine is rotating, DRT output is turned on.

(includes rotation in winding mode)

(including count up/countdown message display)

While presser foot is on the home position, PUS output is turned on.

on.

SSW is turned on during power supply is on. However, input signal STP turns

on SSW is turned on with blinking.

Turn on during XY table is moving. (It does not turn on when automatic

sewing operation)

[9] - 4

Page 32

[10] What happened? Could it be an error?

When an error occurs, the error code and corresponding message appear on the operation panel. Take

a corrective action in accordance with the message. This section describes the errors and others that do

not appear on the operation panel.

[Case1]

Nothing appears on the operation panel when you turn the power switch ON.

(Both the front panel green (power) and red (warning) LEDs are off.)

[Checking Items and Corrective Actions]

Is the power switch definitely turned ON?

▪Check the power supply connection and turn ON the power switch again.

Is the power supply connector fully connected?

▪Check the power supply connector connection, contact state and others,

and then turn ON the power switch again.

Refer to “(12) Unit Wiring Diagram.”

Is there a blown fuse in the control box?

▪Replace the blown fuse with a fuse of identical capacity.

Refer to page. [2]-2

Is a harness inside the control box disconnected?

▪Check the connections of the harnesses inside the control box, and turn

ON the power switch again.

Refer to “(15) Wiring Diagram Inside Control Box”

[10] - 1

Page 33

[Case2]

Nothing appears on the operation panel when you turn the power switch

ON. (The front panel red (warning) LED is on or flickering.)

Pattern1 Blink once

Red (warning) LED flickering pattern

☼ - - - ☼ - - - ☼ - - - ☼ - - - ☼ - - -

Pattern2 Blink twice

Pattern3 Blink 3 times

Pattern4 Blink 4 times

☼ - ☼ - - - ☼ - ☼ - - - ☼ - ☼ - - -

☼ - ☼ - ☼ - - - ☼ - ☼ - ☼ - - -

☼ - ☼ - ☼ - ☼ - - - ☼ - ☼ - ☼ - ☼ - - -

☼ : ON - : OFF

[Checking Items and Corrective Actions]

Is the front panel red (warning) LED on?

▪A system error occurred. Reinstall the system.

Refer to “[Action Method 1] Reinstalling the System” later in this section.

▪If you take a corrective action but no improvement is made, consult with

your local representative.

Is the front panel red (warning) LED showing flickering pattern 1?

(Refer to the above table.)

▪A communication error occurred. Please turn on the power again after

check connection of the operation panel cable.

▪If you take a corrective action but no improvement is made, consult with

your local representative.

Is the front panel red (warning) LED showing flickering pattern 2?

(Refer to the above table.)

Open the control panel lid. Is fuse 2.5A on the PLK-G3-CPU board blown?

▪Replace the blown fuse with a fuse of identical capacity.

Refer to page. [2]-2

Is the front panel red (warning) LED showing flickering pattern 3?

(Refer to the above table.)

▪The backlight of the operation panel may be burnt out. Consult with your

local representative.

Is the front panel red (warning) LED showing flickering pattern 4?

(Refer to the above table.)

▪There is a problem in the control box. Consult with your local

representative.

[10] - 2

Page 34

[Case3]

Though you turn the power switch ON and a screen appears on the

operation panel, the screen display is incorrect.

[Checking Items and Corrective Actions]

Is the problem solved when you switch the screen or turn the power switch OFF and

then ON again?

▪Reinstall the system.

Refer to “[Action Method 1] Reinstalling the System” later in this section.

[Case4]

I press the foot pedal, but the machine does not run.

The message “MACHINE HEAD TILT WAS DETECTED” appears.

[Checking Items and Corrective Actions]

Is the machine tilted?

▪Return the machine back to its proper state and try again.

▪Check if the tilting sensor switch is damaged or disconnected.

Is the signal HES among the input signals changed?

▪Check input customization.

[Case5]

No screen appears on the operation panel when you turn the power switch

ON. (The front panel red (warning) LED is off.)

[Checking Items and Corrective Actions]

The operation panel may be defective.

▪Consult with with your local representative.

[10] - 3

Page 35

[Action Method 1] Reinstalling the System

The sewing machine is normally shipped with the system installed. However, if a reinstallation is

required for some reasons and others, reinstall the system using a USB memory, and follow the

method below.

(1)Save the system data in a USB memory.

(Refer to page[10]-8 [System data save to USB memory])

►Copy the [

memory.

(2)Turn the machine power OFF and insert the USB memory.

folder where the installed system datas are included, into the root directory of USB

]

System

data

(3)While holding down the [F] key on the front panel of the control box, turn the machine power ON.

(Keep pushing [F] key until red LED on the front panel is turned on.)

(4)Installation is started. Please wait for a while.

+

[10] - 4

Page 36

(5) After installation complete, [Machine

type/Language setting] screen on the

operationpanel is appeared.

(6)Pull out USBmemory.

(7)Language setting

►press .

►Choose Language button, then press .

(8)Model setting

►press .

►Choose Model button, then press .

[10] - 5

Page 37

(9)Setting table / Step file setting

►For Setting table/ step file setting, press .

If setting is not necessary, goto (10).

►Choose one of following buttons.

Reads Setting table and Step file

Reads Setting table only

Reads Step file only

Reads System file ,Setting table and Step file

►Connect USB memory

to the connector on the front panel of the control box, then,

press

►After file name selection screen is displayed, choose target

filename by using up and down arrow button,

then press

.

. Goto (12)

, which above data is contained,

[*1]

[*1] Setting table and Step file must be saved in the

[

] folder in the USB memory.

(10) Model / Language setting screen is displayed again.

► press .

[10] - 6

Page 38

(11)Initialize of set value

►To initialize set value, press .

Setting will be returned to the factory setting)

(

To exit without setting, press

.

(12)Re-turning on the power supply

►Turn the power off.

► After check the LED lamp on the front panel of the control box

Is completely off, turn the power on.

►Reinstallation is complete.

Check the LED lamp is OFF

[10] - 7

Page 39

[System data save to USB memory (using copy tool)]

[Outline] Coping system data of the CD-ROM to the USB memory by using copy tool.

[Note] If

(1) Inset the PLK-G Document CD-ROM to your PC.

Insert USB memory to the USB connector on your PC.

Check the CD-ROM drive and USB memory drive.

(ex. CD-ROM drive= “D:” , USB memory drive = “E:”)

(2) Open the CD-ROM root directory by using exploler etc.

Double click “PLKG System Setup.exe”

(3) After open the PLKG System Setup window, select CD-ROM drive and USB memory drive

respectively.

“ ”, “ ”is already exist in the USB memory, they are

over-written.

(Please move necessary data to other folder or memory before using copy tool.)

(4) Click the “SystemCopy” button.

Data copy will be executed.

(5) When copying is complete, the message will be appeared, then click OK button.

Press

button to close the window.

(6) The system data copy to USB memory is completed. Please confirm the content of USB

memory. Please use this USB memory for system installation.

[10] - 8

Page 40

[System data save to USB memory (manual operation)]

[Outline] Copy the [ ] folder where the installed system datas are included, into the

root directory of USB memory.

However, before installation to the sewing machine, please

the data

in the following way.

(1) Insert CD-ROM(PLK-G Document CD)to the CD drive of the computer.

Insert the USB memory that system data will be preserved.

(2) [

]folder exists under “System Folder”. Copy the folder onto the root directory of

USB memory.

change the attribute of

(3) Left-click the [

] with the mouse.

(4) Click the [File] – [Properties] on the menu bar.

(5) Click "Reading exclusive use" and then, clear

the check box. (make the check box blank).

Then click OK button.

(6) Choose "The change is applied to this

folder, the subfolder, and the file", and

click OK button.

(7) Attribute change complete. Please use this USB memory for system installation.

[10] - 9

Page 41

This page is blank.

[10] - 10

Page 42

1.3Ø AC200V - 240V 50/60Hz

[11] Several power supply

Red

White

Black

Green

ON

OFF

Push button switch assay

K14M47932202

Red

White

Black

Green

1

2

3

4

5

6

To control box

CONB

60-9090-306-108-002

2.1Ø AC200V - 240V 50/60Hz (Except Europe)

[11] - 1

Blue

Brown

Green/

Yellow

Push button switch assay

K14M47932206

OFF

ON

60-9090-306-108-005

Blue

1

Brown

2

3

4

5

Green/

Yellow

6

To control box

CONB

3.3Ø AC380V - 415V 50/60Hz (Except Europe)

60-9090-306-108-002

Black

Black

Brown

Blue

Green/

Yellow

ON

OFF

Push button switch assay

K14M47932203

Brown

Blue

Green

1

2

3

4

5

6

60-9090-306-208-002

Power unit PLK-B-PUC-B40

3-phase transformer 3Ø 800VA

BKO-E3138H02

F1

1

Brown

2

3

4

5

6

Black

Blue

Ground

5A

Black

Brown

Blue

F2

5A

Green/Yellow

Green/Yellow

U

V

W

u

Black

Red

v

w

Blue

60-9090-304-118-006

Black

1

1

Brown

2

2

Blue

3

3

Green/Yellow

4

Green/

Yellow

4

60-9090-304-218-006

60-9090-304-118-006

60-9090-305-108-005

Black

1

1

2

2

Brown

3

3

Blue

4

4

Green/

5

5

Yellow

Black

1

Blue

2

3

4

5

6

Brown

Green/

Yellow

Green/

Yellow

60-9090-306-108-005

To control box

CONB

Page 43

4.1Ø AC100V - 120V 50/60Hz

r

w

White

Black

Green

OFF

Push button switch assay

K14M47932205

60-9090-306-108-005

ON

White

Black

Green

1

1

2

2

3

3

4

4

5

5

6

6

5.1Ø AC200V - 240V 50/60Hz (Europe)

[11] - 2

Blue

1

Blue

Brown

Green/

Yello

Power code

K14M73981530

60-9090-306-208-005

Brown

Green

Green/

Yellow

1

2

2

3

3

4

4

5

5

6

6

Power unit PLK-B-PUC-A10

60-9090-306-108-005 60-9090-304-108-005

Black

Brown

Green/Yellow

Ground

Noise filter unit PLK-G-NU-SET

Ferrite core

Black

Brown

Blue

Green/Yellow

Green/

Yellow

Ground

Single-phase transformer 1Ø 600VA

BKO-E3140H03

100V

Black

F1

20A

Brown

Green/Yellow

0V

60-9090-304-118-00660-9090-306-108-005

1

1

2

2

3

3

4

4

200V

Black

0V

Red

PLK-B1-FIL P.W.B

60-9090-305-208-005

Black

1

1

Brown

2

2

Blue

3

3

Green/Yellow

4

4

60-9090-304-218-006

60-9090-305-208-005

60-9090-305-108-005

Black

Brown

Blue

Green/

Yellow

Black

1

1

Brown

2

2

3

3

Blue

4

4

Green/

5

5

Yellow

60-9090-305-108-005

Black

1

1

2

2

own

B

3

3

Blue

4

4

Green/

5

5

Yellow

Black

1

Blue

2

3

4

5

6

Brown

Green/

Yellow

Green/

Yellow

60-9090-306-108-005

Black

Brown

Blue

Green/

Yellow

Green/

Yellow

60-9090-306-108-005

To control box

CONB

1

2

3

4

5

6

To control box

CONB

Page 44

[12] Unit wiring diagram

■For connector pin details, refer to “[13] Connectors Layout” and “[14] Pin Number of Connectors.”

[12]-1

Page 45

[12]-2

Page 46

[13] Connectors layout

[Back side of machine head]

[Back side of control box] [front panel of the control box]

[13] - 1

Page 47

[14] Pin number of connectors

1.Back side of

control box/sewing machine

CONA (Operation panel)

Signal Pin No.

RXD-IO 1

RXD-PAL 2

TXD-IO 3

GND 4

+12V 5

TXD-PAL 6

CONB (Power supply)

Signal Pin No.

R 1

S 2

T 3

- 4

E 5

FG 6

CONC (DC power supply for various solenoids

(same for CONN))

Signal Pin No.

+24V 1

GND 2

COND (Main axis servo motor)

Signal Pin No.

W 1

U 2

V 3

FG 4

CONE (Various solenoids (same for CONP))

Signal Pin No.

+12V 1

SCL OUT 2

SDA OUT 3

GND 4

+12V 5

SCL IN

SDA IN 7

GND

X HOME 9

Y HOME 10

Z HOME 11

STP

SCL OFF 13

SCL_TE

SDA_TE 15

CONF (Main axis encoder)

Signal Pin No.

GND 1

UP 2

DN 3

+5V 4

FG 5

EA

ERA 7

EB

ERB 9

- 10

EZ 11

ERZ

EU 13

EV

EW 15

6

8

12

14

6

8

12

14

CONG (XY axis encoder)

Signal Pin No.

GND 1

+5V 2

GND 3

FG 4

ENXAN

ENXBN 6

ENYAN

ENYBN 8

ENXAP 9

ENXBP

ENYAP 11

ENYBP 12

5

7

10

CONH (Foot switch)

Signal Initial setting

+12V +12V 1

I1

I2

VC1

GND GND 5

GND GND 6

I3

GND GND 8

[SRT]

Start input

[IF1]

Work holder output 1

ANI1

Analog input

[IF2]

Work holder output 2

Pin

No.

CONJ (XY axis stepping motor)

Signal Pin No.

XA1 1

XA2 2

XB1 3

YA1 4

FG 5

XB2 6

YA2 7

YB1 8

YB2 9

CONK (PF axis stepping motor)

Signal Pin No.

+24V 1

BR 2

B 3

AR 4

A 5

+24V 6

2

3

4

7

[14] - 1

Page 48

CONL (General purpose iutput)

Signal Initial setting

I8 [NO] No operation 1

GND GND 2

I9 [NO] No operation 3

IA [NO] No operation 4

GND GND 5

IB [NO] No operation 6

IC [NO] No operation 7

GND GND 8

ID [NO] No operation 9

IE [NO] No operation 10

GND GND 11

IF [NO] No operation 12

Pin No.

CONM (General purpose output)

(Output for solenoid valve. The solenoid cannot be drived.)

Signal Initial setting Pin No.

O8 [FN1] Function code 1 1

+24V +24V 2

O9 [FN2] Function code 2 3

OA [NO] No operation 4

+24V +24V 5

OB [[NO] No operation 6

+24V +24V 7

+24V +24V 8

+24V +24V 9

OC [NO] No operation 10

+24V +24V 11

OD [NO] No operation 12

OE [NO] No operation 13

+24V +24V 14

OF [NO] No operation 15

*Refer「3. Ratings value of output」P.[14]-3, for the

ratings of solenoid valve

CONR (USB)

Signal Pin No.

VBUS 1

DM 2

DP 3

GND 4

CONS (RS-232C)

Signal Pin No.

RXD1 1

RXD0 2

TXD1 3

GND 4

+12V 5

TXD0 6

2.PLK-G2-SOL

(1)Input

CON3

Printed

character

GND Ground 1

XH

CON4

Printed

character

YH

CON5

Printed

character

ZH

XHOME

+12V DC12V power supply 3

GND Ground 1

GND Ground 2

YHOME

+12V DC12V power supply 4

GND Ground 1

GND Ground 2

GND Ground 3

ZHOME

+12V DC12V power supply 5

Signal Pin No.

X axis home position

detection

Signal Pin No.

Y axis home position

detection

Signal Pin No.

PF axis home position

detection

2

3

4

[14] - 2

CON6

CON7

CON8

CON9

Printed

character

ES

Printed

character

S6

Printed

character

THS

Printed

character

FSW

Signal Pin No.

I4 [STP] Halt switch 1

GND Ground 2

+12V DC12V power supply 3

O6 [SSW] Halt stop output 4

Signal Pin No.

+12V DC12V power supply 1

I5

GND Ground 3

+12V DC12V power supply 1

I6

GND Ground 3

GND Ground 4

GND Ground 5

+12V DC12V power supply 1

I7 [NO] No operation 2

GND Ground 3

[HES] Mahine tilting

detection input

Signal Pin No.

[THS] Thread

breakage detection

input

Signal Pin No.

2

2

Page 49

(2)Output

CON10

Printed

character

CON11

Printed

character

CON12

Printed

character

CON13

Printed

character

FU

CON14

Printed

character

OP2

CON15

Printed

character

OP1

T

W

L

Signal Pin No.

O1 [T] Trim 1

+24V DC24V power supply 2

Signal Pin No.

O2 [W] Wiper 1

- - 2

+24V DC24V power supply 3

Signal Pin No.

O3 [L] Thread release 1

+24V DC24V power supply 2

Signal Pin No.

O4 [OF1] Work holder 1

+24V DC24V power supply 2

Signal Pin No.

O7 [NO] No operation 1

- - 2

+24V DC24V power supply 3

Signal Pin No.

O5P [OF2] Clamp 2 output(-) 1

- - 2

O5N [OF2] Clamp 2 output(+) 3

* When the error occurs, outputs are turned off. However,

"O4" and "O5" outpus do not turned off except

overcurrent error situation.

3. Ratings value of output

(1)Ragings value of the solenoid valve output

Output Name Power Resistance Ratings

O1 T DC24V 6Ω or more Moment

O2 W DC24V 6Ω or more Moment

O3 L DC24V 10Ω or more Moment

O4 FU DC24V 6Ω or more Continuity (Note1)

O5 OP1 DC24V 12Ω or more (Note2) Continuity (Note1)

O7 OP2 DC24V 12Ω or more (Note2) Continuity (Note1)

(Note 1) Continuity ratings is available when chopping duty is set to 33% or lower.

(Note 2) When neither OP1 nor OP2 are output simultaneously, it is possible to use these resistance 6 ohms or

more.

(2)Ratings value for solenoid valve

Output Power Maximum ratings current

O8 ~ OF DC24V Output total 0.5A or less (Note 3)

(Note 3) Total maximum ratings current for solenoids and solenoid valves is 3.0A.

(3) Output for display light or buzzer

Outpu Name Pwer Maximum ratings current

O6 ES DC12V 0.1A or less

[14] - 3

Page 50

[15] - 1

[15] Wiring diagram inside control box

Page 51

Specifications

Power unit

Noise filter unit - -

Model name XL-K756-20

Main

motor

Rated output 750W

Rated speed 3,000rpm

Control

box

Model name PLK-G-CU-20

Rated output DC 24V

Power source 1KVA

Range of rating

Condition

voltage

Ambient

temperature

Ambient humidity 45% ~ 85%

[16] Specifications

Power

source

100~120V

Single phase

50/60Hz

PLK-B-PUC-

A10

200~240V

Single phase

/ 3-phase

50/60Hz

- -

5°C ~ 35°C

200~240V

Single phase

/ 3-phase

(Europe)

50/60Hz

PLK-G-NU-

±10%

SET

380~415V

3-phase

50/60Hz

PLK-B-PUC-

B40

-

[16] - 1

Page 52

MEMO

Page 53

Page 54

FACT ORY AUT OMA TION SYSTEM

TOKYO BLDG. 2-7-3,Marunouchi Chiyoda-ku Tokyo 100-8310,Japan

FAX +81-3-3218-6821

New publication, effective AUGUST.2012.

Specifications subject to change without notice

Loading...

Loading...