Page 1

MITSUBISHI

Industrial Sewing Machine

TECHNICAL MANUAL

MECHANICAL VERSION

Electronic Pattern Sewing Machine

Model PLK-E1010

A180E494P01

Page 2

FOR YOUR SAFETY !

If you operate the sewing machine first time, please make sure to read the following

instructions for your safet y and proper oper ation.

In this technical manual, the notice CAUTION is mentioned at some paragraph to attract your

attention for the safety. Please keep it in mind whenever you work with the sewing machine.

CAUTION is used as the notice to warn a possible danger to cause a wound.

This technical manual explains the instructions how to operate and maintain the

sewing machine.

All information in this technical manual ar e subj ect to change without notice.

MITSUBISHI ELECTRIC CORPORATION

Reprinting the parts or all of this technical manual is not allowed without permission.

has all the copy rights on this technical manual.

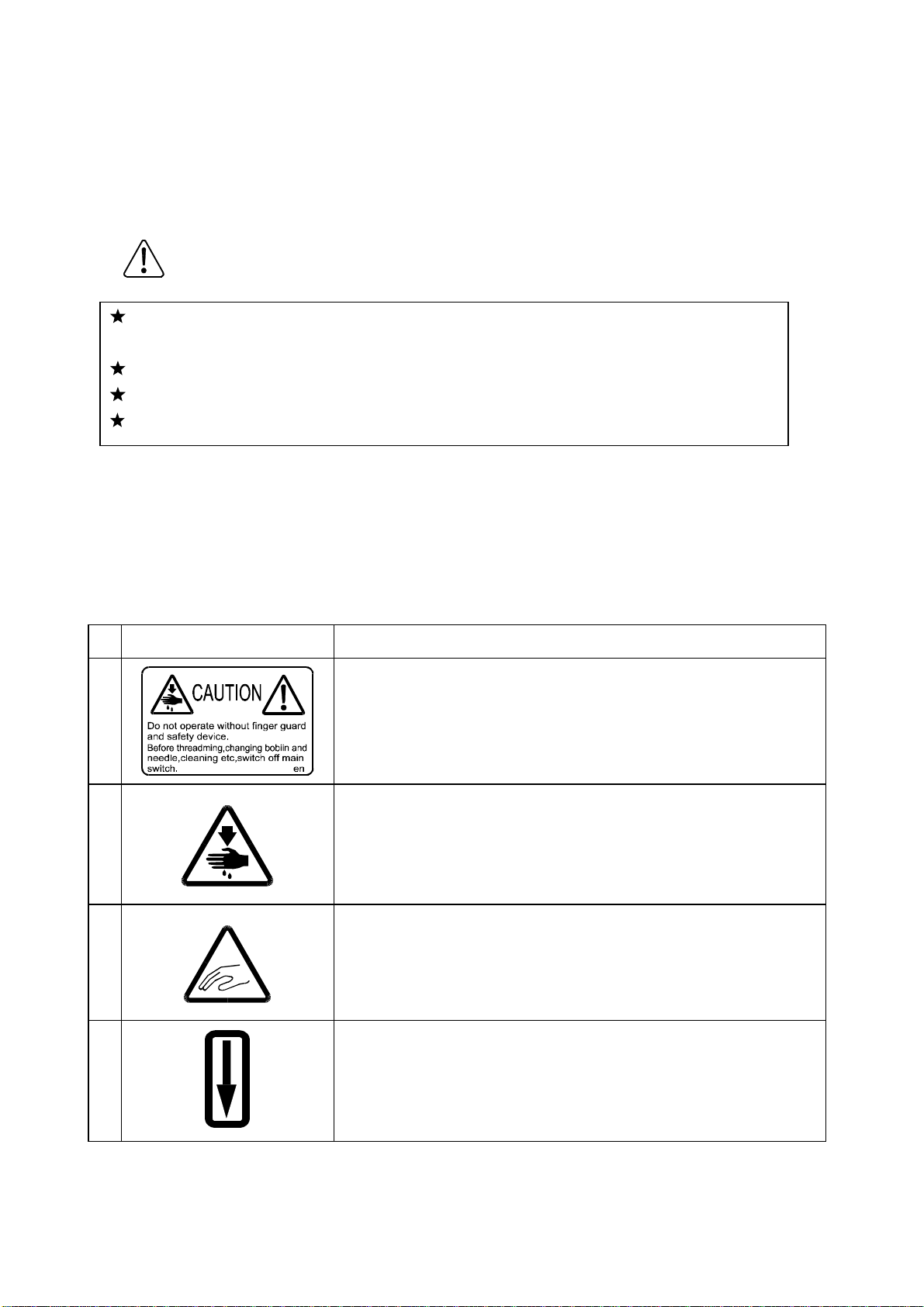

Explanations for the wa r ni ng signs

No Warning sign

1

Caution for sewing machine operation:

Warning to operate the sewing machine without safety

guards and to prohibit doing any operation except sewing

while the power is turned ON.

Meanings of warning sign

2

3

4

Caution for a wound on the fingers:

Warning to a possible danger to cause a wound on the

fingers under the specif ied oper at ion.

Caution for the fing er s to be caught in the machine:

Warning to a possible danger to be caught the fingers in the

machine under the specified operation.

Direction of pulley rotation:

Indicating the proper rotating direction of the sewing

machine pulley.

Page 3

ENVIRONMENT STANDARD

For avoiding the sewing machine from the troubles, please do not operate the sewing

machine under the following conditions.

Caution

(1)

(a) During operating : The atmosphere temperature should not exceeded more 35ºC

(b) During transportation : The atmosphere temperature should not exceeded more

(2)

(a) In the atmosphere filled with dust or cor r osive g as.

(b) In the atmosphere filled with f lam mable or explosive gas.

(3)

(a) In the place where the power fluctuation exceeds more or less 10 % of the fixed

(b) In the place where the power source can not supply enough voltage to keep the

(4)

Temperature and humidity

(95ºF) or less 5ºC(41ºF).

55ºC (131ºF) or less -10ºC (18ºF) .

The relative humidity in the atmosphere should not exceeded more 85% or less 45%.

Atmosphere for the machine oper at ion

Power source voltage

power voltage.

motor running.

Power source voltage

(a) In the place where the power fluctuation exceeds more or less 10 % of the fixed

power voltage.

(b) In the place where the power source can not supply enough voltage to keep the

motor running.

(5)

Noise

(a) In the place near a high frequency tr ansm it t er or a high frequency welder.

(b) In the place filled with strong electrom agnetic radiation or magnetic field.

Page 4

·

·

·

·

·

CONTENTS

1. STRUCTURE OF THE MACHINE ······································································

2. SPECIFICATION ··································································································

3. INSTALLATION ···································································································

1

2

3

3-1. Preparation of the table ··················································································

3-2. Preparation for the steel stand ········································································ 3

3-3. Installation of the motor ··················································································

3-4. Installation of the control box ·········································································· 3

3-5. Connection of the operation panel ·································································· 3

3-6. Installation of the power switch ······································································· 4

3-7. Connection of the foot switch ········································································· 4

3-8. Installation of the oil pan ················································································· 5

3-9. Installation of the sewing machine head ·························································

3-10. Putting across the V-belt ··············································································· 6

3-11. Connection of the electric cables ··································································

3-12. Installation of the belt cover ········································································· 8

3-13. Installation of the thread stand ······································································ 9

3-14. Functioning the work holder pedal ································································ 9

4. LUBRICATION ····································································································

3

3

5

7

10

5. PROPER OPERATION ······················································································

5-1. Loading the system software to the control box ············································· 11

5-2. Installation of the needle ················································································· 11

5-3 Threading the upper thread ············································································· 12

5-4. Winding the bobbin thread ············································································· 12

5-5. Setting the bobbin ··························································································· 14

5-6. Setting the bobbin case ·················································································· 14

6. PROPER SEWING ·······························································································

6-1. Operation of the halt switch ············································································

6-2. The sewing operation ····················································································· 16

6-3. Adjustment of the thread tension ···································································· 17

11

15

15

Page 5

·

·

·

·

·

·

·

·

·

7. ST ANDARD ADJUSTMENT ···············································································

7-1. Adjustment of the needle bar position ····························································· 19

7-2. Adjustment of the position between the needle and the shuttle hook ·············· 20

7-3. Adjustment of the clearance between the shuttle hook and the needle ··········

7-4. Adjustment of the clearance between the driver and the needle ····················· 21

7-5. Adjustment of the thread guide ······································································· 22

7-6. Adjustment of the presser foot ········································································ 22

7-6-1. Adjustment of the presser foot position ················································

7-6-2. Adjustment of the presser foot lift during the sewing ····························

7-6-3. Adjustment of the presser foot timing ··················································· 25

7-7. Adjustment of the wiper ·················································································· 26

7-8. Adjustment of the bobbin winder ····································································· 27

7-9. Adjustment of the work holder ········································································

7-10. Adjustment of the trimmer cam follower ························································ 28

7-11. Adjustment of the position for movable knife point ········································ 28

7-12. Adjustment of the fixed knife position ···························································

7-13. Adjustment of the thread take up spring stroke ············································

7-14. Adjustment of the thread take up spring tension ··········································· 29

7-15. Adjustment of the thread tail after the trimming ············································

7-16. Cancellation of the trimming function ···························································· 30

7-17. Adjustment of the upper thread tension ························································ 30

7-18. Adjustment of the synchronizer ····································································· 31

7-19. Adjustment of the mechanical home position ················································ 32

7-19-1. Shifting the mechanical home position X direction ······························ 32

7-19-2. Shifting the mechanical home position Y direction ······························ 33

7-20. Adjustment of the X-Y contact pressure ······················································· 34

19

21

22

25

27

29

29

30

7-21. Adjustment of the X-Y timing belt tension ····················································· 34

7-21-1. Adjustment of the X timing belt tension ··············································· 34

7-21-1. Adjustment of the Y timing belt tension ··············································· 35

7-22. Adjustment of the V belt tension ··································································· 35

8. MAINTENANCE ·································································································

8-1. Cleaning ·········································································································

8-2. Disposing of oil waste ····················································································· 36

9. BAD SEWING CONDITION & ITS CAUSE AND REMEDY ···························

APPENDIX ··················································································································

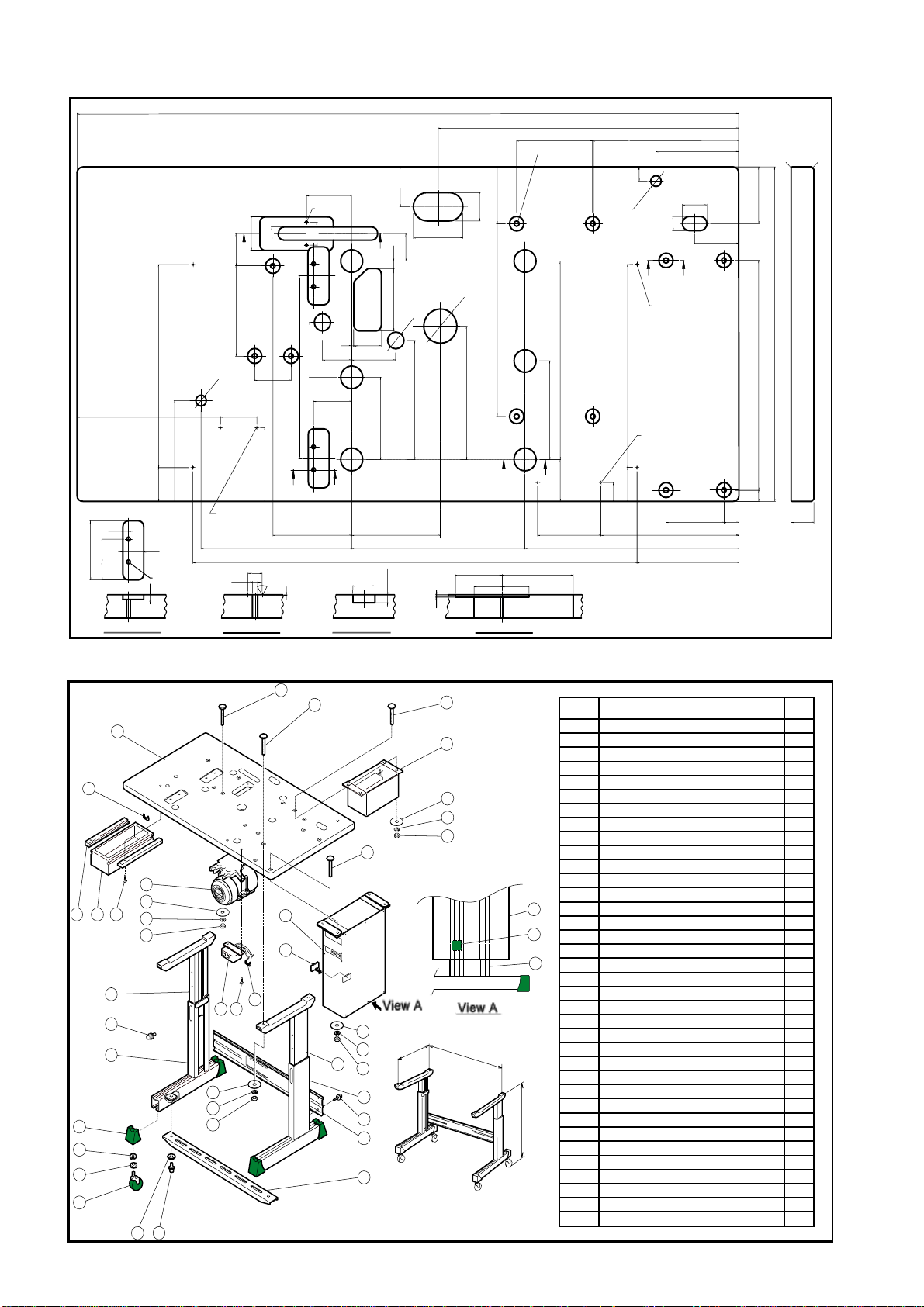

Ref.1. Table cut out drawin g ···················································································· 41

Ref.2. Table & stand assembly ················································································ 41

Ref.3. St and components drawin gs ········································································

36

36

37

40

42

Page 6

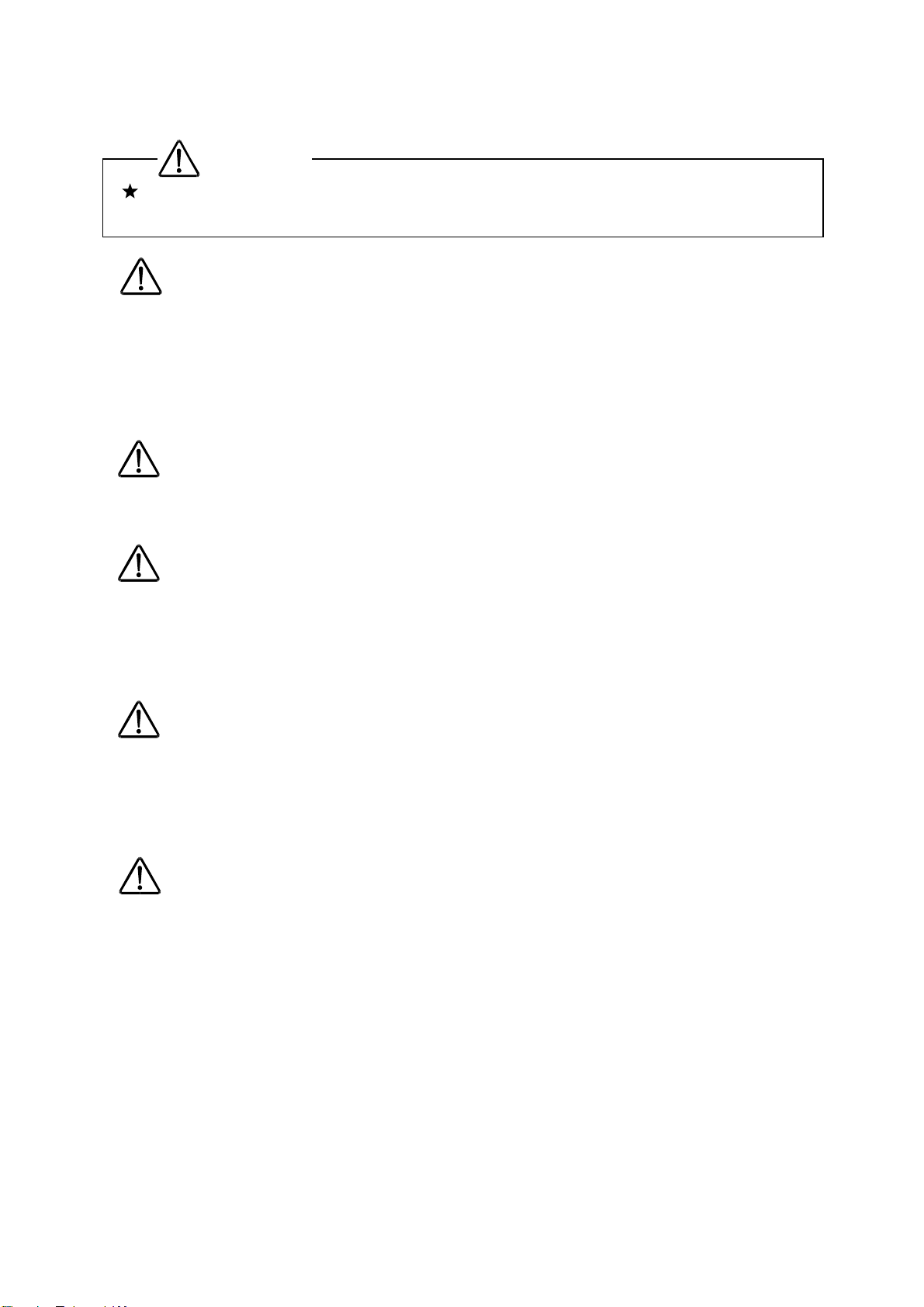

1. STRUCTURE OF THE SEWING MACHINE

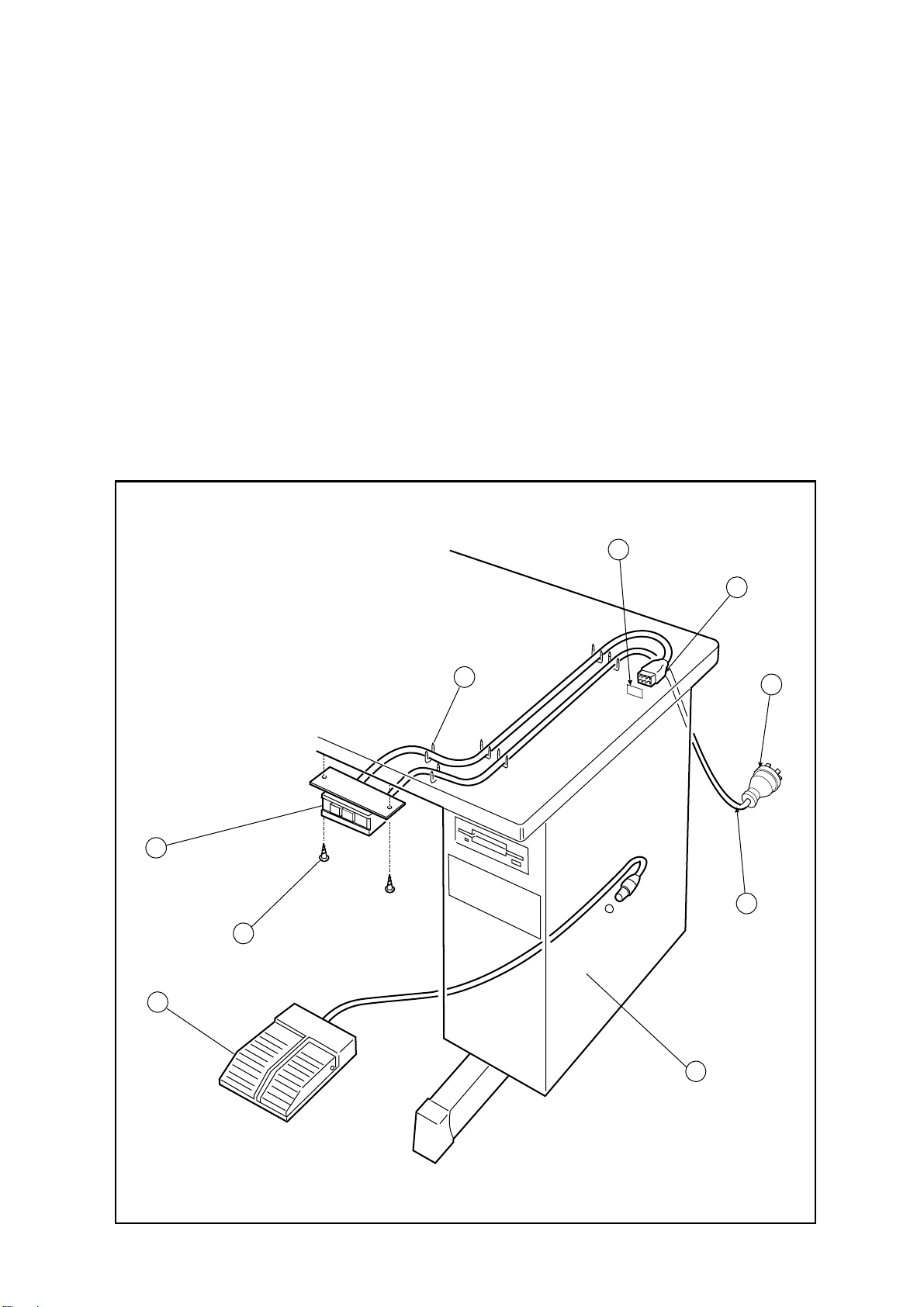

PLK-E1010 electronic pattern sewing machine is constructed with the following main parts.

1

5

2

3

4

9

8

7

6

1

Sewing machine head 2Thread stand

6

Work holder foot switch 7 Start foot switch

*Limi-servo motor

3Operation Panel

8Work holder pedal 9Steel stand

1

4Control Unit

5Halt switch

Page 7

2. SPECIFICATION

(1) Specification of mechanism

Sewing area : X-Direction (left/ right) Y-Direction (fore/backward)

: 100mm 100mm

Maximum sewing speed : 2500 rpm

Sewing speed : 10 steps variable from 200 to 2500 rpm

Stitch length : 0.1 to 12.7 mm

(Adjustable from 0.1mm to 12.7mm by 0.1mm resolution)

Stitch type : Single needle lock stitch

Needle bar stroke : 41.2 mm

Thread take up lever stroke : 68 mm

Class of needle : DP X 17 # 16 (the standard specification)

Wiper system : Back to forward wiping system (the standard specification)

Left to right wiping system (t he optional specification)

*1

Presser foot lift

Presser foot stroke

Work holder lift

: 15 mm (18mm max.)

*2

: Variable from 4mm to 10mm ( 4m m is standard)

*2

: 25 mm

Hook : Large size shuttle hook

Bobbin case : With non racing spring

Bobbin : Large size aluminum bobbin

Thread trimmer system Horizontal engagement with fixed knife and movable knife

Lubrication system :

Manual oiling and replenishment with the oil braids from the oil

tanks

Lubrication oil : White machining oil

X-Y drive system : Stepping motor and timing belt drive

Intermittent or continuous feeding

Machine dimension : 1,200mm(W) x 565mm(L) x 1,220mm(H)

Weight : TOTAL 143Kg

Type of controller : PLK-E-CU-20

Steel stand : T-shape steel stand for the standing or the sitting operation

(2) Specification of main motor

Type of motor : XL- 554- 20

2

Page 8

Cautio

3. INSTALLATION

The machine should be installed by the specialists who have enough experience for the

sewing machine installations.

All the necessary electric wiring should be done by electric engineers who are qualified for the

electric wiring.

If any damage or fault is found on the machine at the installation, please do not operate until it

is repaired.

Please do not operate the sewing machine with excessive modifications from the standard

specification

3-1 Preparation of the table

If the table is not MITSUBISHI original, the thickness of the table is required to have 40mm

more.

And please refer to the cut out t able dr awing for your own preparation.

The cut out drawing is shown on the last page of this technical manual as APPENDIX drawing.

3-2 Preparation for the steel stand

If the steel stand is not MITSUBISHI original, please refer to the assembling drawing for your

own preparation.

The assembling drawing is shown on the last page of t his t echnical manual as Ref.1 to Ref.3.

If the steel stand is MITSUBISHI original, please assemble the steel stand with the assembling

instructions enclosed in the packing.

3-3 Installation of the motor

If the motor is purchased without assembling to the table, the motor has to be installed

underneath the table.

Please install the motor with the instructions explained in the paragraph [Installation of the

Motor] on the other [CONTROL UNI T] technical manual.

3-4 Installation of the control box

If the control box is purchased without assembling to the table, the control box has to be

installed underneath the table.

Please install the control box with the instruction in the paragraph [Installation of the control

n

box] on the other

CONTROL UNIT technical manual.

3-5 Connection of the operation panel

Please connect the operation panel with the instructions of Operation Panel manual enclosed in

the packing.

3

Page 9

3-6 Installation of the power switch

If the power switch is purchased without assembling to the table, the power switch has to be

attached with the following procedure.

(1) Mount the power switch (NO.1) with the wood screw (NO.2) underneath the table as shown

on the figure.

(2) Fix the electric cords with the staples (NO.3) underneath the table.

(3) Hook up the connector (NO.4) of the power switch (NO.1) to the connector (NO.5) of the

control box (NO.9).

(4) Attach the power plug (NO.7) to another end of the power switch cord (NO.6).

3-7 Connection of the foot switch

Connect the foot switch (NO.8) t o t he cont rol box (NO.9)

The foot switch is enclosed in the accessory box.

5

4

3

1

2

7

6

8

4

9

Page 10

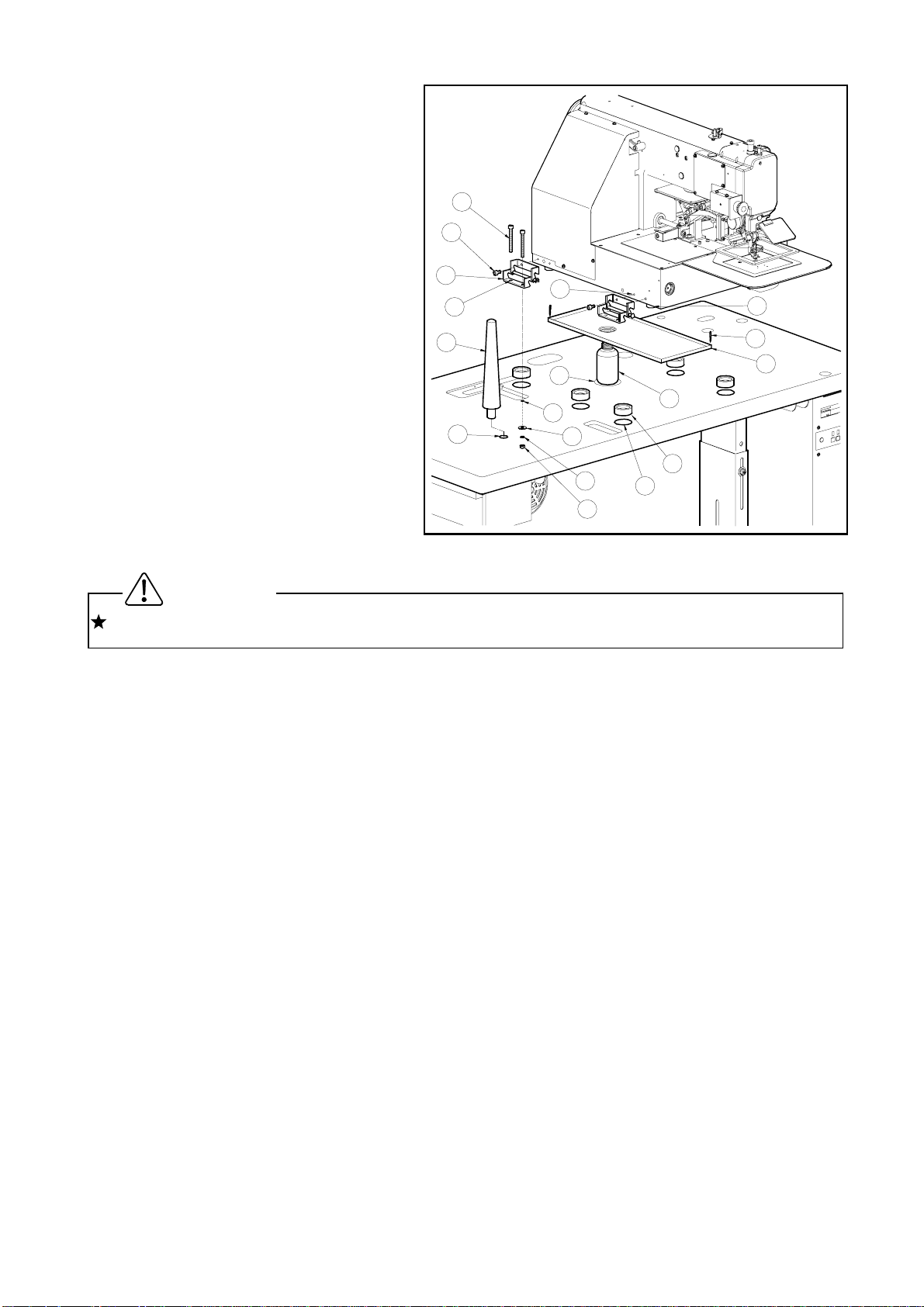

3-8 Installation of the oil pan

(1) Assemble the oil pan (NO.1) and

oil bottle (NO.2), which are

enclosed in the accessory box.

(2) I nsert the oil bottle (NO.2) into the

tabletop cut-out hole (NO.3), which

14

11

has much shorter distance from

the bottle center to the fr ont.

(3) Install the oil pan (NO.1) parallel

with the table front edge.

(4) Fix the oil pan (NO.1) at its four

corners on the table top with four

staples (NO.4) en-closed in the

accessory box.

18

9

13

19

12

10

8

4

3

2

15

6

16

17

7

1

3-9 Installation of the sewing machine head

For the safety, please make sure t o carry the sewing machine head by more than two people.

(1) Make sure to hold the machine table with the caster stopper.

(2) Fit t he rubber cushion pads (NO.6) into the each hole (NO.7) on the tabletop. The rubber

Caution

cushion pads (NO.6) are enclosed in the accessory box.

(3) Put the sewing machine head on the table top and set the each leg (NO.8) to the each

rubber cushion pad (NO.6)

(4) Att ach two hinges (NO.9) temporarily, make the setting screw (NO.11) fastening with the

thread holes (NO.10) light, on the left side surface of the machine bed with the hexagonal

socket head set screws (NO.11).

(5) At this time, take notice that the E-shaped snap ring on the front side hinge must be come

to the backside, and E-shaped snap ring on the backside hinge must be come to the front.

(6) These parts are all enclosed in the accessory box.

(7) Fit the screw holes (NO.13) of the hinges (NO.9) to the bolt setting holes (NO.12) on the

table top then, pass the bolt (NO.14) through these holes and fasten the bolt (NO.14) to fix

the hinges (NO.9) with the flat washers (NO.15), the spring washers (NO.16) and the nuts

(NO.17).

(8) Fasten firmly hexagonal socket head set screws (NO.11), which set the hinges (NO.9)

temporarily at above procedure (4) then, fix the hinges (NO.9) perfect ly.

(9) Insert the headrest (NO.18) into t he hole ( NO .19) on the tabletop.

5

Page 11

Cautio

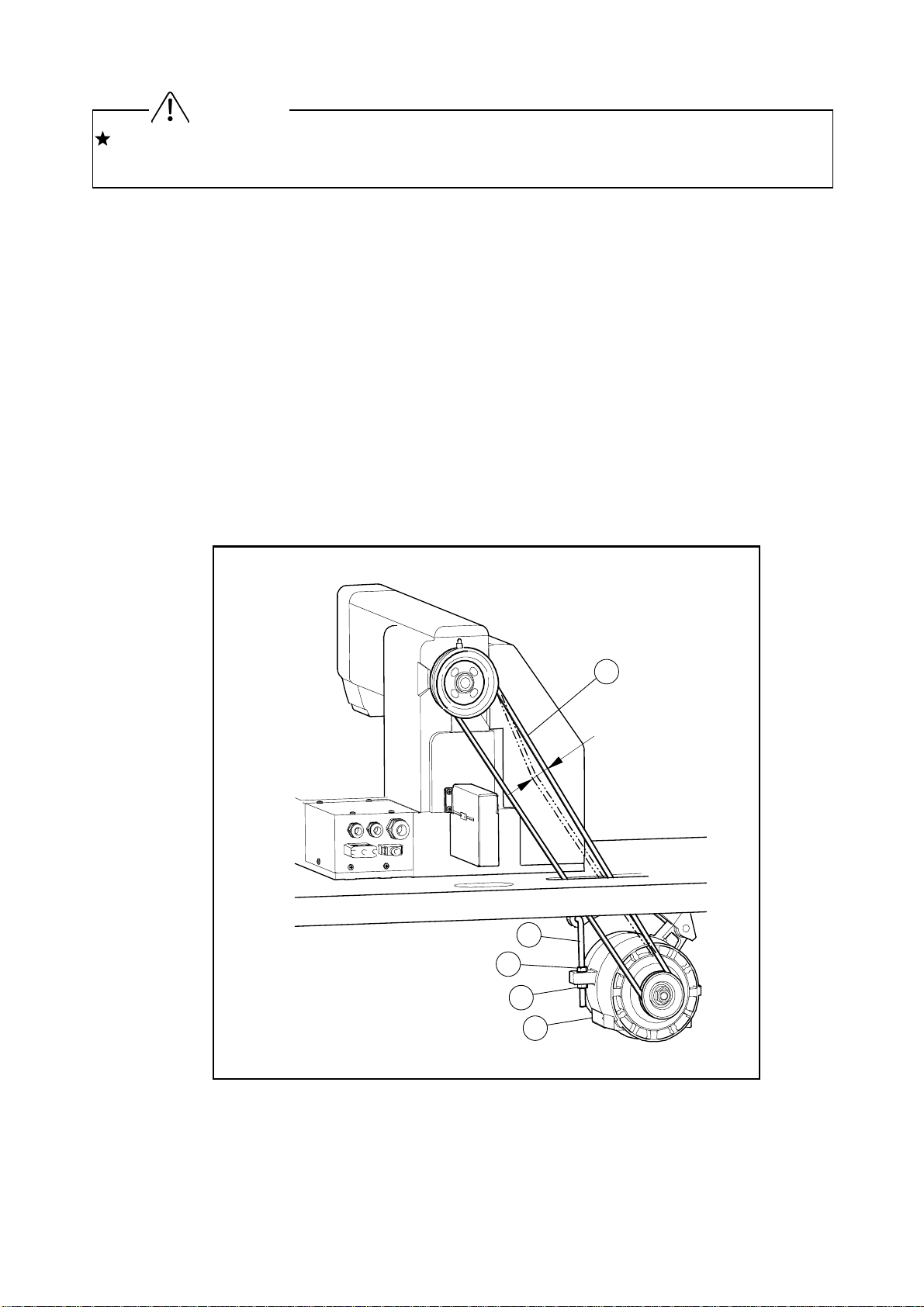

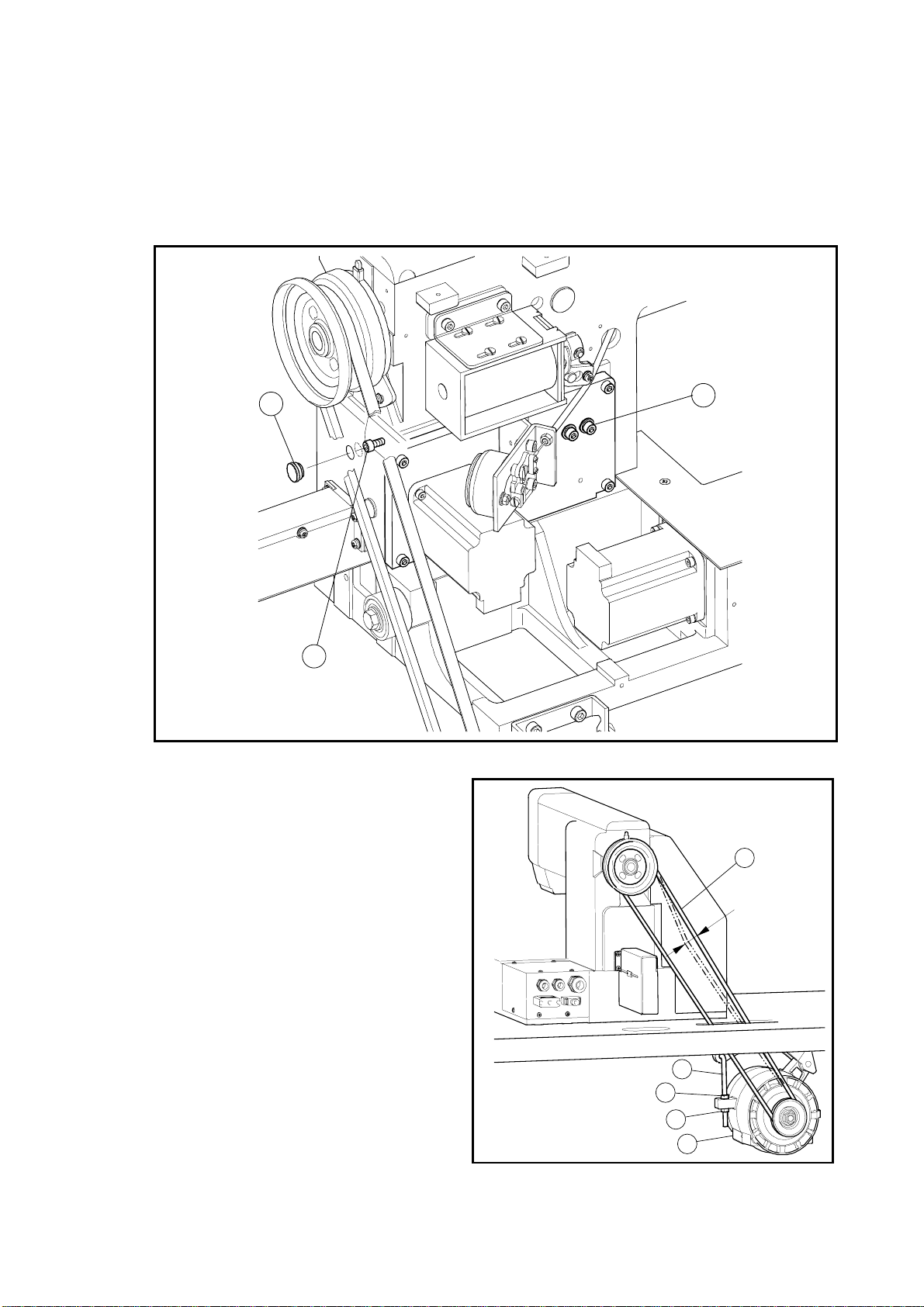

3-10 Putting across the V-belt

For the safety, when tilt or raise the sewing machine head, please make sure to hold the

sewing machine head with both hands by two people at least.

(1) Tilt the sewing machine head to the left, and hold it with the head r est.

(2) Put the V-belt (NO.4) across the sewing machine pulley and the motor pulley with passing it

through the slit on the tabletop.

(3) Raise the tilted sewing machine head to the original position.

(4) Push the center portion of V-belt by the f inger with the presser of about 1Kg.

If the V-belt tension is proper , it should be yielded about 10 mm.

If the V-belt tension is not pr oper, please adjust it as follows.

(5) Loosen two nut (No.2) on the motor .position adjust bolt (No.1).

(6) Fix the motor (No.5) position with putting the tension to the V belt by its weight and firstly,

tighten the upper nut (No.2) t hen secondly, t ighten the lower nut (No.2).

Please make sure to fasten t he nut s ( NO . 5) firmly after the adjust m ent .

(7) Put the motor pulley cover on the motor with the set screws.

n

10

4

mm

1

2

6

3

5

Page 12

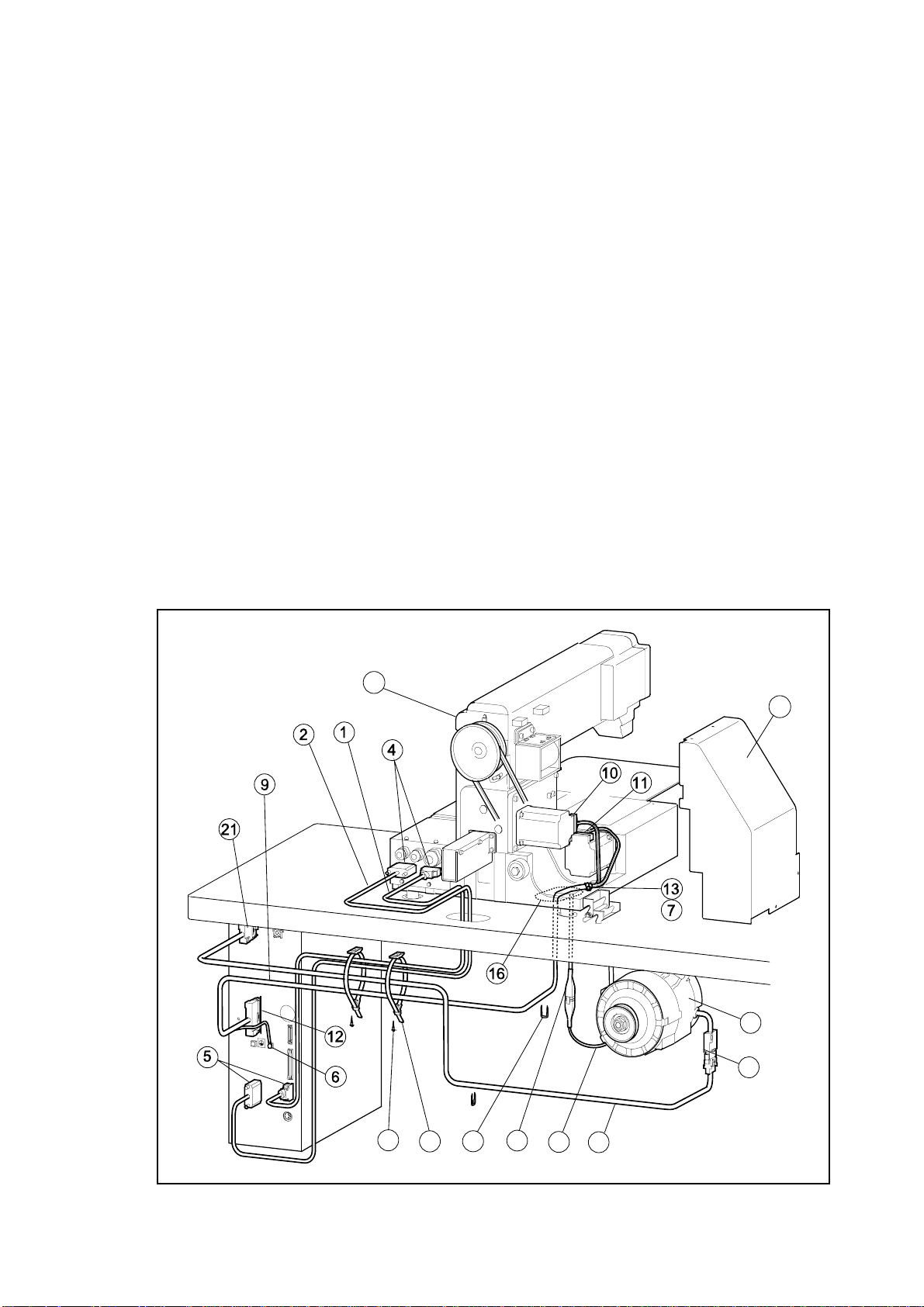

3-11 Connection of the electric cables

(1) Connect t he white color cable (NO.1) and the black color cable (NO.2) across the printed

circuit board unit connectors (NO.4) on the sewing machine head (NO.3) rear face and the

connectors (NO.5) on the control box. T hese cables ar e enclosed in t he accessor y box.

(2) Remove the stepping motor cover (NO.8) f r om sewing machine head ( NO . 3).

(3) Pass upward the cable (NO.9) which is attached the two connectors at the end, through the

cut-out hole (NO.16) on the table top then, connect it to the X-stepping motor connector

(No.11) and to the Y-stepping motor connector (No.10). At this time, fix this cable with the

nylon clip (NO.13) and setscrew (No.7) which are provided on the sewing machine head.

And also, connect the other end of the cable (NO.9) to the connector (NO.12) on the control

box. The cable (NO.9) is enclosed in the accessory box.

(4) Pass downward the another cable (NO.15) which is extended from the sewing machine

head through the cut-out hole (NO.16) on the table top then, connect it to the cable (NO.18)

extended from the motor (NO . 17)

(5) Connect the last cable (NO. 19) to the other extended cable (NO.20) from the motor then,

hook up the other end of the cable ( NO.19) to the connector (NO.21) on the control box.

(6) Attach the tow binder (NO.22) underneath the table with the wood screws (NO.23) then,

bundle and fix all the connected cables with the binders (NO.22) and the staples (NO.23).

The binders (NO.22), the wood screws (NO.23) and the stables (NO.24) are enclosed in

the accessory box.

3

8

17

20

23

15

2422

18

19

7

Page 13

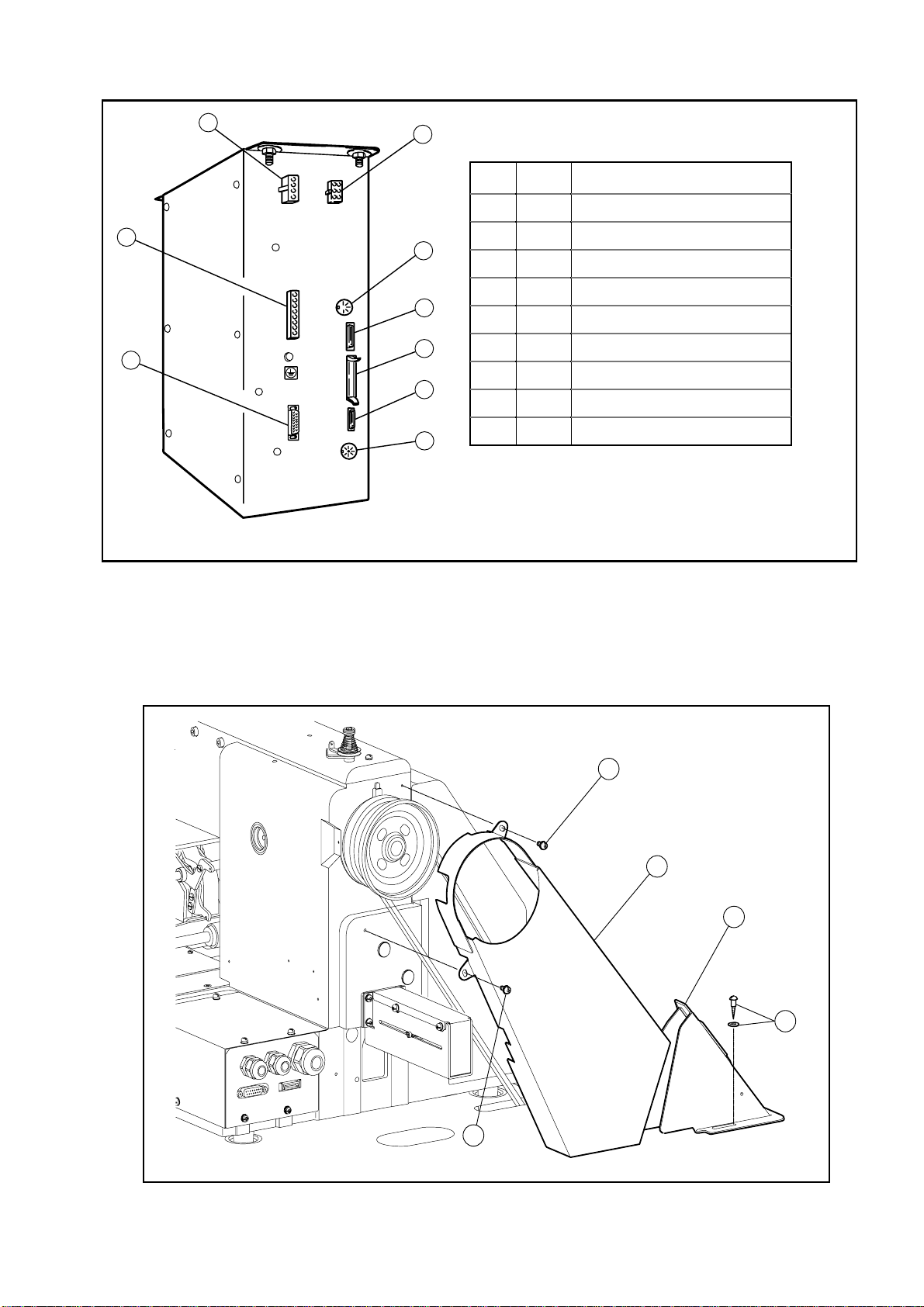

< Back side view of the Control box >

3

4

1

2

Fig Con Connect with

1 A Main motor cable

2 B Power supply cable

5

6

7

8

9

3 C Stepping motor cable

4 D Solenoid output cable

5 E RS-232C (optional use)

6 F O per at ion panel cable

7 G Extension I/O cable

8 H Input signal cable

9 I Foot switch cable

3-12 Installation of the belt cover

Put the large belt cover (NO.2) on t he sewing machine head with the set scr ews (NO. 1 & 4)

and small belt cover (NO.3) on the table top with the set screws (NO. 5)

All the necessary parts are enclosed in the accessory box.

4

2

3

5

1

8

Page 14

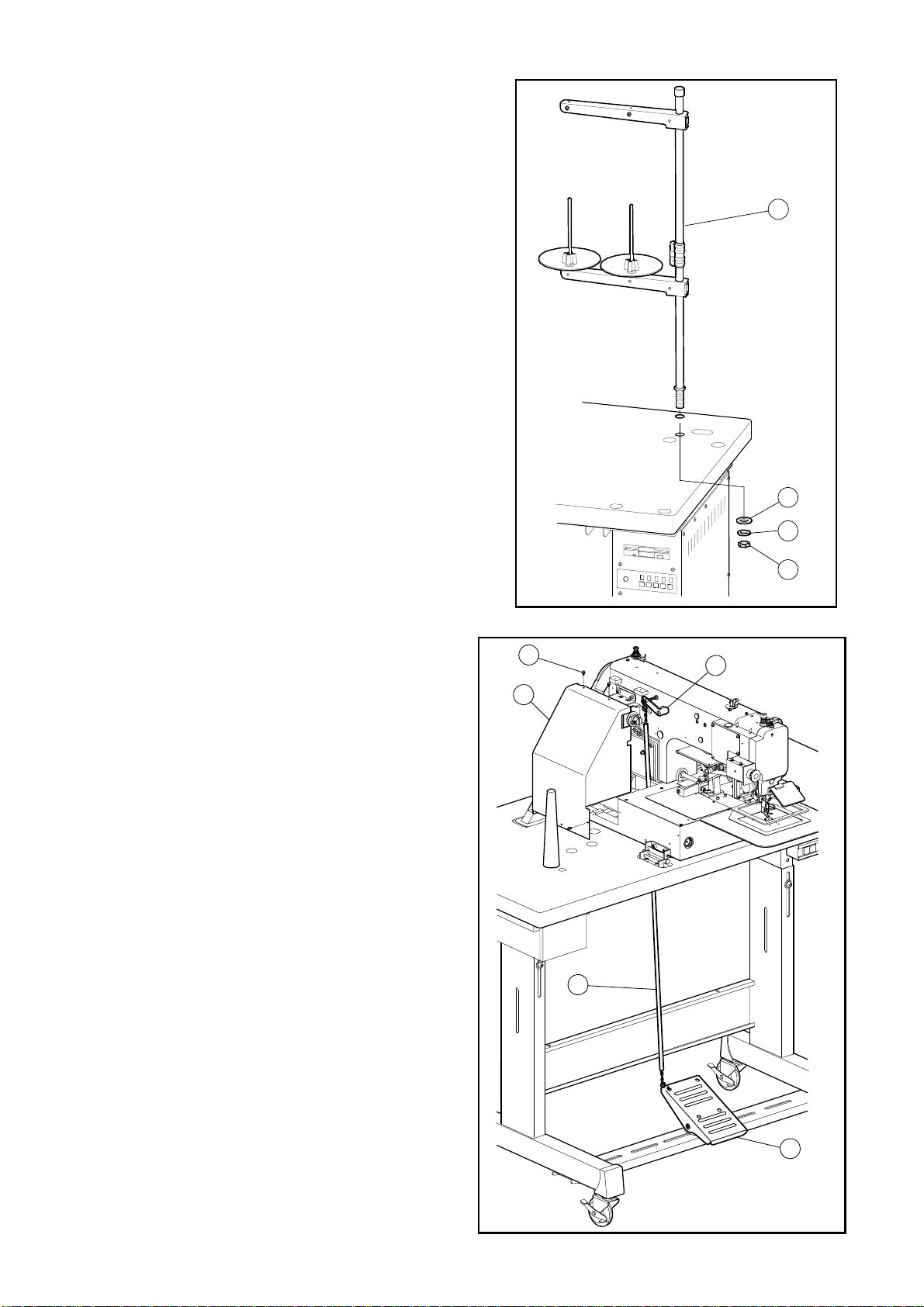

3-13 Installation of the thread stand

(1) Assemble the thread stand with the

instructions enclosed in the packing.

(2) Fit the thread stand (NO.1) in the thread

stand hole on the tabletop.

(3) Fix the thread stand (NO.1) firmly from the

rear side of the table with tightening the nut

(NO.4) and the washers (NO.2, 3).

1

2

3

4

3-14 Functioning the work holder pedal

(1) Connect the chain (NO.1) across the

lever (NO.2) located at the left side of the

sewing machine head and the work

holder pedal mounted on the steel stand

bottom beam. The chain (NO.1) is

enclosed in the accessory box.

(2) Put the stepping motor cover (NO.4) back

on the sewing machine head with the

screw (NO.5) after the chain (NO.1)

connection.

5

2

4

1

9

3

Page 15

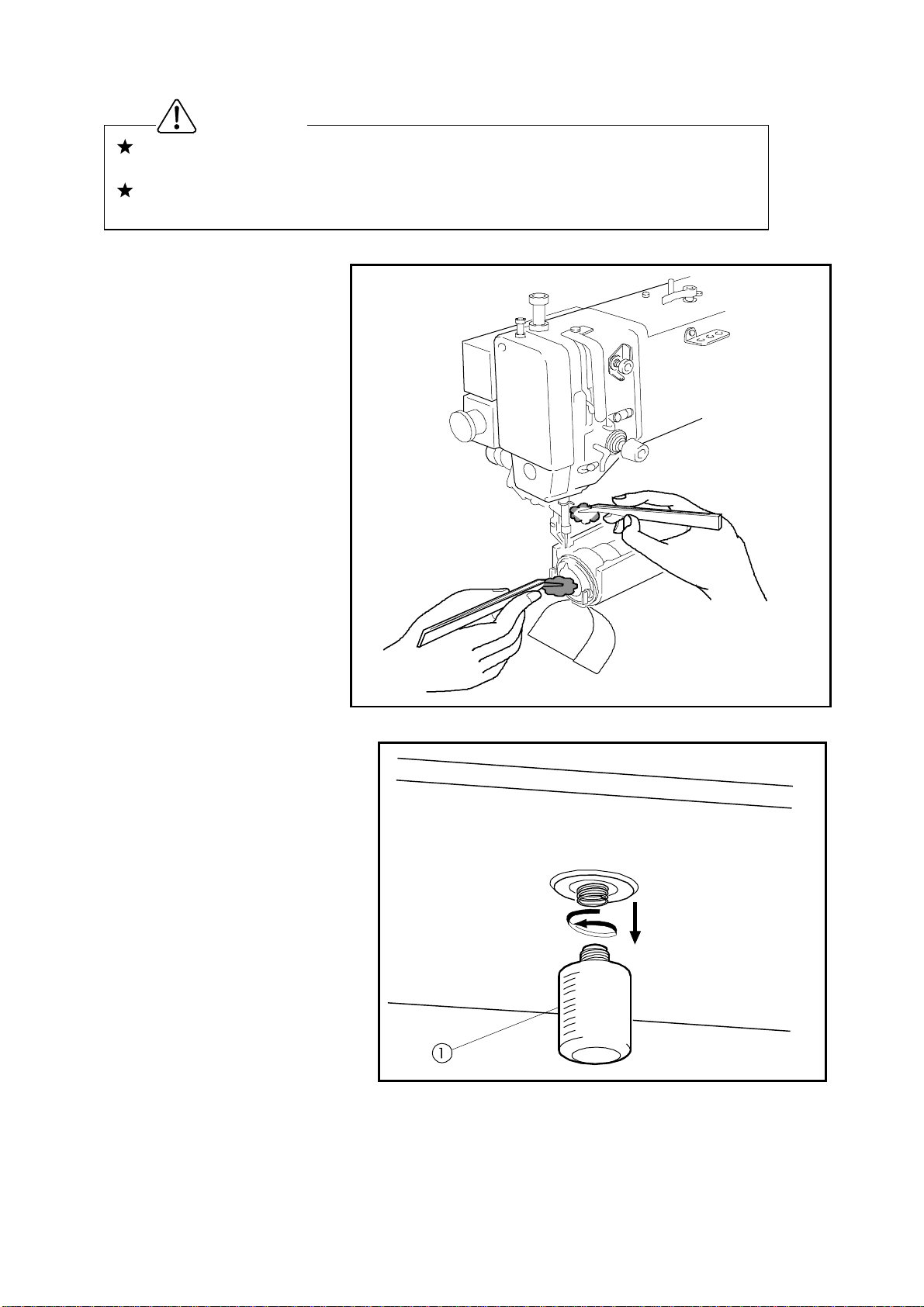

Cautio

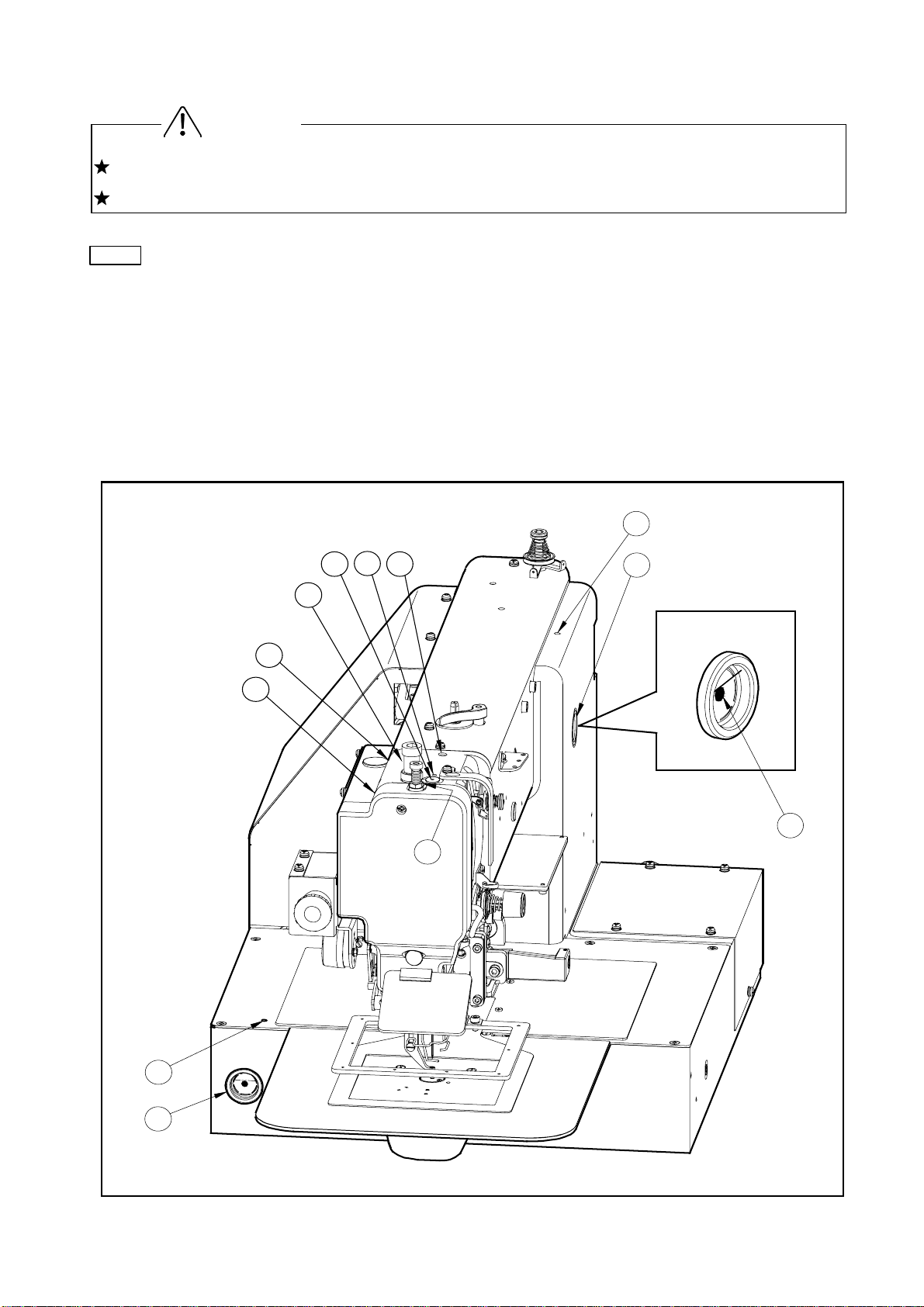

4. LUBRICATION

Please make sure to turn power switch OFF befor e oiling.

Please make sure to put some oil before starting the operation of the brand new machine or

NOTE Please use high quality white machining oil.

4-1 Filling the oil tank

Pour the oil through the oil hole (NO.1) to the oil tank (NO.2) on the machine arm. Move the

work holder by hand to the right end then, machine bed. Please fill with the oil over level mark

(NO.6) of the oil tank.

4-2 Oiling

Put some oil to red marked oil holes (NO . 7 ~ 13).

n

8

9

10

11

12

7

13

1

2

6

4

5

10

Page 16

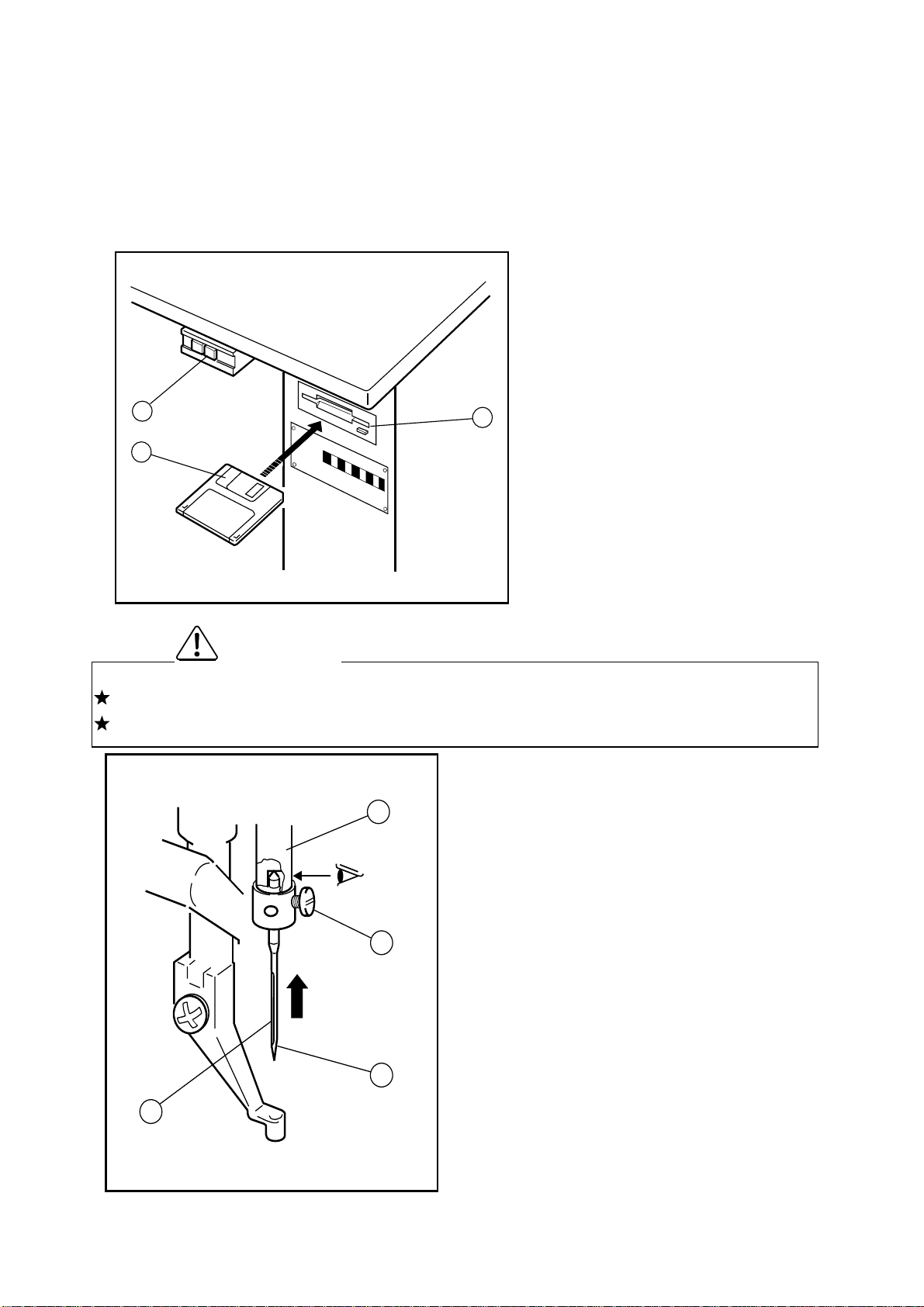

5. PROPER OPERATION

5-1 Loading the system software to the control box.

When the brand new machine is operated first time or when the control box is adjusted for the

repairing, the system software has to be loaded t o the control box.

For this loading, please take the following procedure.

(1) Insert the system floppy disc printed

[ F1 ] (NO.2) into the disc drive (NO.3)

of the control box.

O

F

F

O

N

(2) The system floppy discs are enclosed

in the accessory box.

1

(3) Turn the power switch (NO.1) ON.

3

(4) Load the system software with

2

5-2 Installation of the needle

Please make sure to turn the power switch OFF bef or e installing or replacing the needle.

Please pay attention for the fingers not to be wounded by the needlepoint.

Caution

(1) Loosen the needle set screw (NO.1) then,

insert the new needle (NO.2) until the

3

needle head is reached the end of the

following the instructions [Loading the

system software] on the technical

manual [

(5)

After loading the system software,

CONTROL UNIT].

keep the system floppy disks with in

care.

hole of the needle bar (NO.3).

(2) Fasten the setting screw (NO.1) with

facing the needle groove (NO.4) to the

1

front.

2

4

11

Page 17

5-3 Threading the upper thread

Please make sure to turn the power switch OFF before threading the upper thread.

Please thread the upper thread with referr ing to the below figures.

Caution

5-4 Winding the bobbin thread

Please make sure to pull the upper thread out of the needle before winding the bobbin

(1) Turn the power switch ON.

(2) Press the key on the operation panel

Caution

to enter the second operation window.

(3) Pass through the thread from the thread

stand (NO.3) as shown on the below figure

then, wind the thread to the empty bobbin

(NO.4) in the arrow mark “a” direction couple

times and insert the bobbin (NO.4) into the

bobbin winder (NO.5).

(4) Push the adjust lever (NO.6) in the arrow

mark “b” direction.

(5) Step on the black color foot switch (NO.7)

then work holder goes down.

12

Page 18

(6) Press the key, then work holder

moves to home position.

(7) Press key on the operation panel.

Then presser foot goes down automatically,

and wind mode window will be appeared.

(8) Step on the black color foot switch (NO.7)

again to make work holder down.

(9) Step on the gray color start foot switch

(NO.9). The thread is kept winding to the

bobbin (NO.5) while the gray color start

switch is stepping on.

(10) When the bobbin becomes full of the thread,

the adjust lever (NO.6) is returned to the

original position.

(11) Stop to step the gray foot switch and press

the key to exit winding mode, and

press the key, to back to the standard

operation windows will be appeared.

(12) To wind the bobbin thread during the sewing operation, carry out above (3) and (4)

procedure then, the bobbin winding is perform ed automatically.

(13) Regarding the adjustment for the bobbin thread winding volume, please refer to the

instructions in the paragraph 7-11 Adj ustment of the bobbin winder in the following page.

4

a

5

b

6

9

7

13

3

Page 19

5-5. Settling the bobbin

(1) Set t he bobbin ( NO .2) into the bobbin case (NO.1).

(2) Pull the bobbin thread (NO.3) into the slit (NO.4) and pass the thread through the thread

hole (NO.5).

(3) At this time, pull the bobbin thread (NO.3) then, check with the bobbin (NO.2) if it is rotated

to the arrow direction. If it is not, set the bobbin (NO.2) into the bobbin case (NO.1) over

again to get the proper r ot at ion.

5

3

4

2

1

5-6. Setting the bobbin case

(1) Set the needle bar to its highest position then, open the cylinder cover (NO . 1) .

(2) Open the bobbin case latch lever (NO.2) fully then, f it it securely in the inner hook (NO.3).

[NOTE] Please pull the bobbin thread about 25mm out of the thread hole (NO.4) of the

bobbin case.

3

2

1

14

Page 20

6. PROPER SEWING

6-1. Operation of the halt switch

If an incident such as a thread breakage, needle breakage and any other incidents are

happened during the sewing operation, please hit immediately the halt switch. The sewing

machine running is stopped instantly.

Before start the sewing operation, please make sure the location of the halt switch and

keep it in mind the function and how to use it.

(1) Press the HALT switch (NO.1), All operations will stop, and the sewing machine will stop

at the needle UP state without trimming the thread.

(2) Remove the cause of the abnormality.

(3) To continue sewing, turn the HALT switch to the rig ht .

The switch will be unlocked.

Next, when the start switch (NO.3) (gray foot switch) is pressed again, the operation will

resume from the halted posit ion.

Caution

(4) To cancel sewing, turn the HALT switch (NO.1) to the right, and unlock the switch.

Then, press the key on the operation panel (NO . 2) .

The work holder (NO.4) will return to the home position from th e stopped position and will

stop.

1

2

4

3

15

Page 21

Caution

Depending on the shape of the work

holder, the collision may be happened

with the work holder and the presser foot

while the work holder is on the way back

to the home position. For avoidance of

this accident, before starting the sewing

operation, program the work holder

returning home with the operation panel

of the control box to trace the sewing

pattern.

For this setting, refer to the [Wiper

Setting] in the [PROGRAM MODE] on

the operation panel.

6-2. The sewing operation

Caution

It is very dangerous to operate the sewing machine without the safety guards (Eye guard,

Belt cover, Link cover, Finger guar d et c.).

Please make sure to always operate the sewing machine with the safety guards.

Please do not put unnecessar y art icles except for the sewing operation on the tabletop.

Please keep t he hands and t he face away from the needle.

(1) Turn the power switch (NO.1) ON.

NOTE The collision may be happened with the work holder (No.2) and the presser foot

(No.3) depending on the work holder shape when the work holder is moved to

original position.

In this case, if home positioning method [HPF] is set to ON, home positioning

switch becom es inact ivate during the work holder goes up.

(2) Program or select the requir ed sewing pattern by selecting following icon.

Programming -------- >>

Selecting pattern ---- >>

The sewing pattern programming or selecting can be performed with the operation panel.

For the details, please refer to the instructions on the technical manual [Operation

Panel].

(3) Set the sewing speed by selecting or icon.

(4) Insert the sewing material under the work holder (NO.3) then, step on the black color foot

switch (NO.4). The work holder comes down to press the sewing material.

[NOTE] If the sewing material has to be reset, step the black color foot switch (NO.4)

again then; the work holder goes up t o r elease t he sewing material.

16

Page 22

(6) Step on the gray color start switch (NO.5). T he sewing machine starts the sewing.

(7) After finished the sewing, the work holder is lifted automatically then, the sewing material

is released.

3

5

1

4

6-3. Adjustment of t he t hread tension

The thread tension between the upper and bottom thread should be balanced in the best

condition.

When the upper thread tension is well balanced with the bobbin thread tension, both

threads are interlocked along the centerline of fabric layers as shown on the below

figures.

2

NOTE Nor m ally weaker bobbin thread tension brings better sewing q uality.

So it is prefer to set bobbin thr ead t ension first and then set upper thread t ension.

17

Page 23

○

○ ×

○○

× ×

××

×

××

Well balanced

tension

(1) Bobbin thread tension

Adjust the bobbin thread tension with the thread tension adjusting screw (NO.2) on the

bobbin case (NO.1). The thread tension becomes loose if turn the thread tension adjusting

screw (NO.2) to the counterclockwise, and the thread tension becomes tight if turn it to the

clockwise.

(2) Upper thread tension

Adjust the upper thread tension based on the bobbin thr ead tension.

For this adjustment, turn the thread tension adjusting nut (NO.3). The upper tread tension

becomes tight if turn the thread tension adjusting nut (NO.3) to the clockwise, and the

upper thread tension becomes loose if tur ns it t o the counterclockwise.

The upper thread is tight

or the bobbin thread is loose

The upper thread is loose

or the bobbin thread is tight

1

2

3

18

Page 24

7. STANDARD ADJUSTMENT

Please make sure to turn the power switch OFF befor e adjust the sewing machine.

If the adjust ment is required under t he power switch is ON, keep the start f oot switch

away from the foot.

Be careful not to be wounded by the needle or the inner hook point .

Please make sure to put the safety guards (Eye guard, Belt guard, Link cover and

finger guard etc. ) back on the original location after t he sewing machine adjustment.

7-1. Adjustment of t he needle bar position

(1)Turn the power switch OFF.

(2)Turn the sewing machine pulley by hand then, stop the needle bar (No.1) at the lowest

position.

(3)Remove the rubber plug (No.2) from the face plate then, loosen the needle bar holder

setscrew (No.3).

(4)Move the needle bar (No.1) to the position where the needle bar timing mark A is matched to

the needle bar bushing bottom line (No.4) t hen, tighten the needle bar holder setscrew (No.3).

[NOTE] If the needle class is DP x 5, match the needle bar timing mark B to the needle bar

Caution

bushing bottom line (No.4).

― 19 ―

Page 25

7-2. Adjustment of t he position between the needle and the shuttle hook

(1) Turn the power switch OFF.

(2) Turn the sewing machine pulley by hand then, move up the needle bar ( No. 1) from the lowest

position and stop it at the position (No.2) where the needle bar timing mark C is m atched to

the needle bar bushing bottom line.

[NOTE] If the needle class is DP x 5, match the needle bar timing mark D to the needle bar

bushing bottom line (No.2).

(3) Open the cylinder cover(No.2).

(4) Remove the bobbin case (No.3).

(5) Turn the hook retainer lever (No.5) then, remove the hook r etainer (No.6).

(6) Loosen the driver setscrew (No.9) then, move the driver (No.10) and adjust the shuttle hook

point (No.7) to be matched with the center line (No. 8) of the needle.

(7) After the adjustment, tighten the driver setscrew (No.9) and put the bobbin case (No.4), the

hook retainer (No.6)and the hook retainer lever (No.5) back to the original location then,

close the cylinder cover (No.3).

2

D

1

6

4

5

C

3

8

10

7

9

― 20 ―

Page 26

7-3. Adjustment of t he clear ance between the shuttle hook and the needle

(1) Please take the same procedur es as above paragraph 7-2. from (1) t o (5).

(2) Loosen the outer hook setscr ew (No.3) and turn the eccentric pin (No.4) so that the clearance

between the shuttle hook point and the needle becomes 0.05~0.1mm.

(3) After the adjustment, securely tighten the outer hook setscrew (No.3) and put the hook

retainer and the bobbin case back to the original location then, close the cylinder cover

(No.5).

1

2

0.05 ~ 0.1mm

5

7-4. Adjustment of t he clear ance between the driver and the needle

(1) Please take the same procedures as above paragraph 7-2. from (1) to (5).

(2) Please make sure the clearance between the shuttle hook point and the needle has been

adjusted 0.05~0.1mm at above procedure 7-3 Adjustment of the clearance between the

shuttle hook and the needle.

(3) Loosen the driver setscrew (No.1) and turn the eccentric pin (No.2) so that the clearance

3

4

between the driver (No.3) and the needle (No.4) can become 0.

(4) After the adjustment, securely tighten the driver setscrew (No.1) and put the hook retainer

and the bobbin case back to the original location t hen, close the cylinder cover(No.5).

― 21 ―

Page 27

7-5. Adjustment of t he thread guide

(1)

Remove the E-shaped snap ring (No.3) which is engaging the movable knife (No.2) and the

link (No.1) then, loosen the setscrews (No.4) and remove the sliding plate (S)(No.5).

(2) Loosen the setscrews (No.10) and move the thread guide (No. 6) to the position where the

needle center line (No.8) divides the needle groove (No.7) evenly and the rear side line

(No.9) of the needle is aligned with the shoulder ( No.9) of the thread guide (No.6) . At this

time, make sure that there is some clearance between the hook retainer and the thread

guide (No.6) at least the upper thread can be passed smoothly through it (standard

clearance is 0.8mm).If this clearance is too wide, it causes the trimming failur e and if this

clearance is too narrow, it causes the sewing condition disturbance, the trimmed upper

thread tail uneven and the locking up the hook with the upper thread.

(3) After the adjustment, engage the link (No.1) of the trimmer mechanism with the movable

knife (No.2) with the E shaped snap ring (No.3) and put the sliding plate (S)(No.5) back on

the original location then, tighten the setscrews (No.4).At this time, set the sliding

plate(S)(No.5) so that the needle (No.11) can come down to the center (No.12) of the

needle hole of the needle plate.

4

6 8

5

1

10

7

0.8mm

1

3

7-6. Adjustment of t he pr esser foot

[NOTE] The presser foot is a very important part to form the fine stitches.

It moves simultaneously with the needle and stabilize the needle penetrating area of t he

sewing material with pressing down it, when the needle sticks into or pulls out the

sewing material and prevent the skip stitch or the over penet ration happening. Please

adjust the presser foot pr oper ly to t he sewing mat er ials with the following instructions.

7-6-1. Adjustment of t he presser foot position

11

13

9

12

[NOTE] Please always adjust the presser foot position when the thick ness of the sewing

material is changed.

― 22 ―

Page 28

(1) Turn the power switch OFF.

(2) Remove the face plate (No.1) and the link cover ( No. 2) .

(3) Turn the sewing machine pulley by hand and stop the needle bar (No.3) at the lowest

position. At this time, make sure the setscrew (No.5) of the eccentric cam (No.4) is

positioned right beside the center line of the upper shaft. This is the standard position of

the eccentric cam (No.4).If the eccentric cam (No.4) is off from this posit ion, set it back to

the standard position with the instructions on the paragraph [7-6-3. Adjustment of the

presser foot timing] in t he following page.

(4) Turn the sewing machine pulley by hand and stop the needle at t he highest position ( this

is also the thread take up lever's highest position).At this time, loosen the set screw (No.9)

of the upper feed lock cr ank shaf t(No. 8) and adjust the cent er line of the bell crank (No.6)

to be parallel with the presser foot bar (No. 7) .

(5) Insert the sewing material (No.10) under the work holder (No.11) and turn the sewing

machine pulley by hand then, stop the presser foot (No.12) at the lowest position.

(6) Loosen the presser f oot bar setscrew (No.14) and move the presser foot bar (No.7) then,

adjust the presser foot ( No.12) position to be become the clearance between the bott om

surface of the presser f oot (No.12) and the surface of the sewing mat erial 0~0.5mm. At

the same time, rotate the presser f oot bar (No.7) for the needle (No.15) to come down to

the center of the needle hole of the presser foot (No.12).

(7) After the adjustment, put the face plate (No.1) and the link cover (No.2) back on the

original location.

[NOTE] The lower position of t he pr esser foot, the more ef fective for the skip stit ches.

However, if the presser foot becomes to press the sewing material, the movement of

the presser foot mechanism g enerates a slight noise. And also, the presser f oot stays

longer to hold the sewing material, so the upper thr ead tension becomes loose or the

sewing pattern forming gets out of shape because the presser foot catches the

surface of the sewing material. For avoiding these troubles, please lower the presser

foot as small as possible.

2

8

6

3

11

― 23 ―

Page 29

[NOTE] If the thick ness of the sewing material chang es very often, it is recommended to tak e

the easy way for the adjustment of the presser foot position with the method that

change only the fixed position of the presser foot after fixed the presser foot bar at

higher position.

For this adjustment, loosen the setscrew (NO.16) then, move the presser foot

(NO.12) up and down.

7-6-2. Adjustment of t he presser foot lift during the sewing

[NOTE] The presser foot lift during the sewing can be adjust ed 0 and 2 ~10mm.

(1) The presser foot lift during the sewing becomes 4~10mm at the condition which the

connection of the link (No.2) and the lever (No.3) with the shoulder screw(No.1) is as

shown on the figure and it becomes 2 to 4 mm if t he connection is m ade with A hole, and it

becomes 0 mm if the connection is made with B hole..

(2) The stepping lift is adjusted 4m m when the sewing machine is shipped from the factory.

(3) For the adjustm ent at the each range of the presser foot lift, rem ove the link cover (No.4)

then, loosen and move the adjust bolt(No.5).

(4) If the link (No.2) connection is changed to A or B hole, the presser foot position is also

changed. So reset the presser f oot position with adjusting the position of the presser foot

bar or the presser foot it self with loosing their setscrews (No.6) or (No.7).

(5) Reg arding the running noise and the vibration, the higher lift effects worse. So adj ust the

presser foot lift dur ing the sewing as small as possible.

(6) After the adjustment, put the link cover (No.4) and the face plate (No.8) back on the

original location.

4

B

A

3

2

8

1

6

7

― 24 ―

5

Page 30

7-6-3. Adjustment of t he pr esser foot timing

[NOTE] The presser foot up and down movement during the sewing synchronizes with the

needle up and down movement.

With changing this synchronized timing to the sewing materials, the skip stitches can

be prevented or the seam tightness can be improved.

For example, the delay of the presser foot timing against the needle movement

prevents the skip stitches especially to the thin materials, and the advance of the

presser foot timing can impr ove the seam t ightness especially to the thick materials.

(1) Remove the link cover(No.1).

(2) Loosen the setscrew "C" of the eccentric cam (No.2).

(3) Turn the sewing machine pulley by hand and stop the needle bar (No.3) at the lowest

position. At this stage, the setscrew "A" of the eccentric cam (No.2) is positioned right

beside the center line of the upper shaft. This is the standard position for the eccentric

cam (No.2).

(4) Loosen the setscrew "A" of the eccentric cam (No.2).

(5) Hold the eccentric cam (No.2) and turn the sewing machine pulley slowly by hand.

If turn the sewing machine pulley to the arrow direction " D", t he presser f oot t iming ag ainst

the needle movement is delayed, and if turn the pulley to the opposite direction, the timing

of the presser foot is advanced.

(6) After the adjustment, tighten the setscrew "A" and "C" in turn with slightly pushing the

eccentric cam (No.2) to the arrow direction "E".

(7) Put the link cover (No.1) back on the original location.

1

3

2

― 25 ―

Page 31

7-7. Adjustment of t he wiper

(1) Loosen the wiper setscrew (No.3) and adjust the wiper (No.1) to be positioned where the

wiper (No.1) passes under the needle point (No.2) with about 2 mm clearances right after

the sewing machine is stopped running at the needle upper position (the thread take up

lever's highest position).

[NOTE] When the presser f oot position or t he presser f oot lif t is changed, the wiper (No.1)

may collide with the presser foot (No.4).

In that case, please do not use the wiper (No.1).

(2) If do not use the wiper (No.1), cancel the wiper funct ion with operation panel as follows.

>> Press button at the normal mode condition, t hen MENU MODE is appeared.

>> Press button. Then below screen will be appeared.

>> Press [Wiper ] but ton.

>> And then press [W I P] and select

[OFF] button.

― 26 ―

Page 32

7-8. Adjustment of t he bobbin winder

(1) Adjustment of the winding volume

Loosen the setscrew (No.2) of the adjusting lever (No.1) and adjust the position of the

adjusting lever (No.1). If move the adjusting lever (No.1) to the arrow direction "a", the

winding volume is reduced, and if move the adjusting lever (No.1) to the arrow direction "b" ,

the winding volume is increased. The winding volume is adjusted 80 % of the full volume

when the sewing machine is shipped from the factory.

(2) Adjustment of the proper posit ion of the bobbin winder

Firstly, loosen the setscrews (No.3) and (No.4) of the bobbin winder and put the empty

bobbin (No.5) on the rotating shaft (No.6) then, push the adjusting lever (No.1) to the

arrow direction "a". Secondary, move the whole bobbin winder to the arrow direction "c" and

stop it at the position where the empty bobbin is rotated t hen, tighten the setscrews ( No.3)

and (No.4) of the bobbin winder. This is the pr oper posit ion of the bobbin winder.

a

b

1

5

3

6

c

4

2

7-9. Adjustment of t he work holder

If the sewing material is thick and t he work holder does not pr ess it strong enough, adjust the

work holder presser as follow.

(1) Insert the sewing material (NO.1) under the work holder ( NO . 2).

(2) Turn the power switch ON and lower the work holder (NO.2) with the work holder foot switch

(black color foot switch).

(3) Loosen the 2 of the setscrews (NO.3) and move adjusting plate (NO.4) until it touches with

the link (NO.5) then, tighten the 2 of the setscrews (NO.3).

2

5

4

1

3

― 27 ―

Page 33

7-10. Adjustment of t he trimmer cam follower

(1) Turn the power switch OFF and remove the top cover.

(2) Under the sewing machine regular stop condition (the needle stop posit ion is upper and the

take up lever stop position is highest), loosen the setscrew (No.5) of the cam f ollower lever

(No.4) and adjust the cam follower (No.2) to be positioned to contact with the shoulder

portion (No.3) of the trimmer cam (No.1) with having about 1mm clearance between the

cam follower (No.2) and the trimmer cam (No.1). After t his adjustment, tighten the set screw

(No.5) of the cam follower lever (No.4).

(3) Push the cam follower lever (No.4) by hand to the

the cam follower (No.2) is engaged into the cam groove (No.3) smoothly.

(4) If the cam follower (No.2) is not engaged smoothly, under confirming with the condition

which the cam follower (No.2) contacts with the shoulder portion (No.3) of the trimmer cam

(No.1), loosen the nut (No.7) and tig hten the stopper screw (No.8) until it touches with the

stopper (NO.9) of the cam follower lever (No.4) then, loosen the st opper screw (No.8) back

about 1/3 turn and fix the nut (No.7) firmly.

arrow direction and make sure that

7-11. Adjustment of the position for the movable knife point

(1) Tilt the sewing machine head to the left to be able to see the bottom component parts.

(2) Open the cylinder cover

(3) Check with the point (No.1) of the movable knife whether it is located at t he position apart

0.5mm from the front face of the hook retainer (No.2).

(4) For the adjustment of the movable knife point (No.1), loosen the adjusting screw (NO.3)

and move the rod end (No.4) right and left then, adjust the position of the movable knife

point.

(5) After the adjustment , tighten the adjusting screw nut (No.3) secur ely.

3

2

1

0.5mm

4

7-12. Adjustment of the fixed knife position

― 28 ―

Page 34

(1) Open the cylinder cover (No.1).

(2) Remove the E-shaped snap ring (No.4), which engages the movable knife (No.2) and t he

link (No.3).

(3) Loosen the setscrews (No.5) then, remove the sliding plate (NO. 6) .

(4) Turn the sliding plate (No.6) upside down and loosen two setscrews (No.9) then, adj ust the

fixed knife (No.10) position t o be positioned f or the blade edg e (No. 7) t o have the clearance

0.5mm from the edge of the needle plate (No.8).

(5) After the adjustment, t ighten the setscrews (No.9) securely.

(6) Put all the parts for this adjustment back to the original locations.

5

6

2

7

9

1

3

8

4

7-13. Adjustment of t he t hr ead take up spring swing stroke

Loosen the setscrew (No.2) and turn the whole thread tension regulator ( No.3) then, adjust t he

thread take up spring swing strok e to be become 9 to 10mm.

After the adjustment , tighten the setscrew (No.2) securely.

0.5mm

7-14. Adjustment of t he t hr ead take up spring tension

Insert the screw driver (No.5) into the slit (No.4) of the thread tension regulator (No.3) and

adjust the thread take up spring (No.1) tension. If turn the screw driver to the clockwise, the

thread take up spring tension becomes tight, and if turn the screw driver to the counter

clockwise, the thread take up spring t ension becom es loose.

― 29 ―

Page 35

7-15. Adjustment of the thread tail after the t rimming

Adjust the thread tail (No.3) from the

needle after the trimm ing with turning the

nut (No.2) of the pre-t ension ( No. 1) .

If turn the nut (No.2) to the clockwise, t he

thread tail becomes shorter and if turn the

nut (No.2) to the counter-clockwise, the

tread tail becomes longer.

7-16 Cancellation of the trimm ing function

If the automatic trimming is not required during the sewing operation, cancel the trimming

function with the setting panel of the control box. For t he detail of this instr uctions, please refer

to the paragraph [4.Program 4 mode display] on

manual

7-17. Adjustment of t he upper thread tension release

[NOTE]

CONTROL UNIT

(a) The upper thread tension release works when the upper thread is trimmed

automatically or the presser foot is lifted during the work holder feeding.

(b) If the upper thread tension release does not work properly when the upper

thread is trimmed automatically, the thread tail from the needle becomes

shorter then, it induces the skip st itch happening or pulling the thread tail out

of the needle at the start of the sewing.

(c) During the sewing operation, the discs (No.1) of the thread tension regulator

is closed while the presser foot is moving up and down.

If the discs (No.1) of the thread tension regulator is not closed, the upper thread

tension becomes loose and the proper stitch condition can not be obt ained.

(d) When the upper thread tension release is activated, the discs (No.1) the

upper thread tension regulator opens 0.8~1.0mm.This is the norm al condition

of the discs (No.1) opening. For this adjust m ent, take the following procedure.

.

9

Basic mode operation of the technical

(1) Remove the top motor cover.

― 30 ―

Page 36

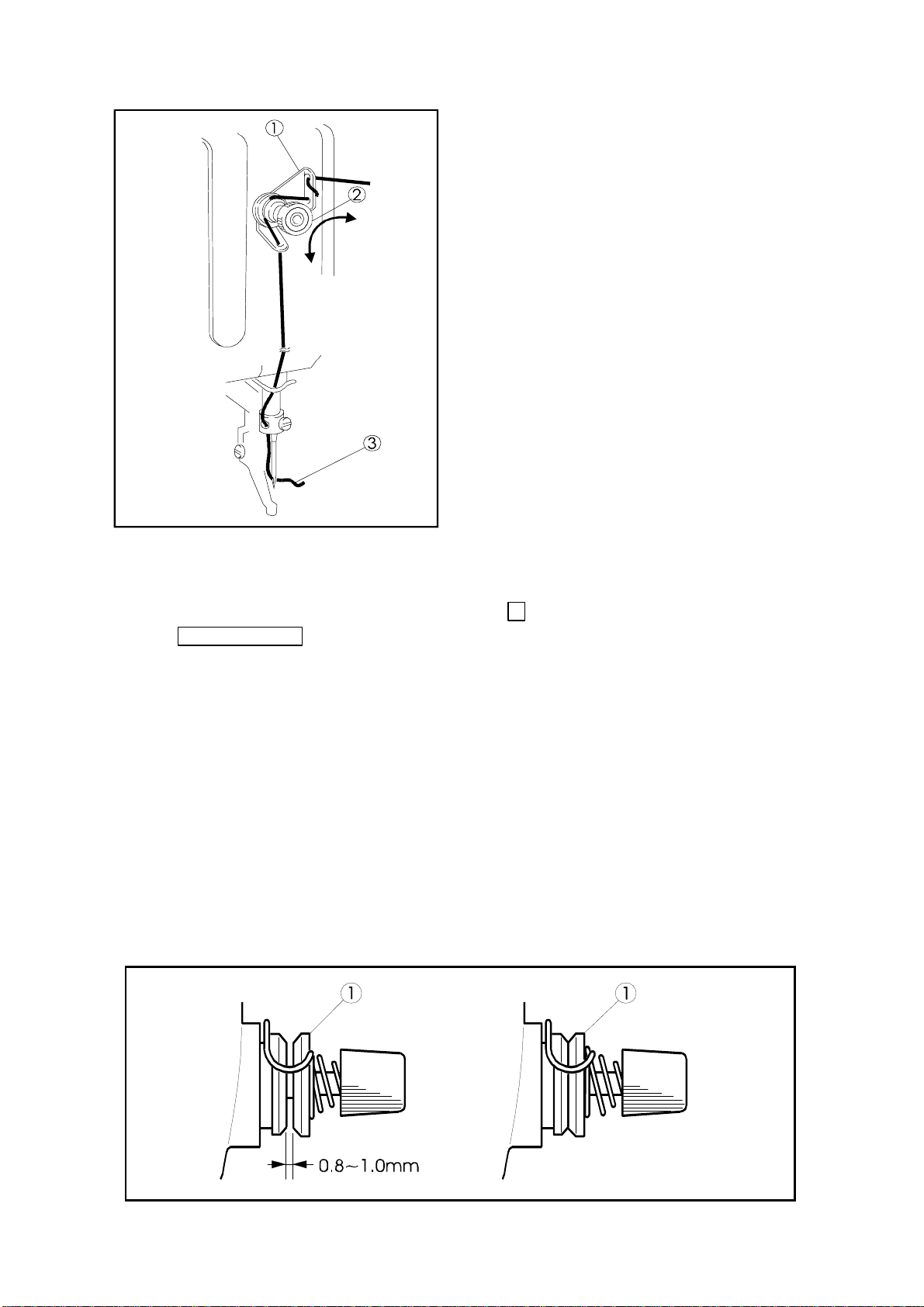

A

(2) Fully turn t he crank (No.3) of the rotary solenoid (No.2) in the arrow direction. At this time,

adjust the upper thread tension release for the discs to be opened 0. 8 t o 1. 0mm.

A

(3) For this adjustment, loosen the nut

becomes wider and if loosen the nut

(4) If the normal opening of the discs can not be obtained with the nut adj ustment, loosen the

wire fix screws (No.5) and adjust the tension of the wire (No.6).

(5) The wire (No.6) may be got longer over a long period machine oper ation. At t hat t ime, adjust

the upper thread tension release again.

then, if tighten the nut B , the discs opening

B

, it becomes narrower.

1

0.8~1.0mm

3

5

6

2

A

B

7-18. Adjustment of t he synchronizer

A

[NOTE]

(a) W hen the sewing is finished, the arm timing mark

B

mark

are matched with each other then, the sewing machine is stopped

and the pulley timing

the running. This is the norm al condit ion.

A

(b) If theses timing mark

and B get out of the matching more than 3mm,

adjust the timing mark m atching.

Hold the sewing machine pulley (No.1) by hand and insert the angle adjuster (No.2) into the

C

hole

the pulley timing mark

mark

then, turn the angle adjust er (No.2).I f turn t he angle adjuster ( No.2) to the clock wise,

B

goes up and if turn it to the counter clockwise, the pulley timing

B

comes down. The angle adjuster (No.2) is enclosed in t he accessor y box.

B

― 31 ―

1

2

C

Page 37

7-19. Adjustment of the mechanical home position

[NOTE] The mechanical home position is fixed at the cent er of the sewing area when the

sewing machine is shipped from the fact ory. However, it can be moved within the

area covered with diagonal lines.

[

Rear side

[

Front side

(1) Turn the power switch ON and cancel the

sewing area limit with the operation panel.

For this cancellation, press key at

the normal mode condition, then MENU

MODE is appeared. Press

]

2

]

50

10

100

1

50

100

(1) Original home position

(2) Adj usta ble

key. And press [Area limit] butt on.

Please select [Area limit control (ALC) ] .

If you select ALC=ON, area limit control is

canceled.

[NOTE] If do not cancel t he sewing area

limit, shifting the mechanical

home position make the

effective sewing area narrower

than the original.

(2) After the cancellation of the sewing area

limit, once, turn the power switch OFF.

7-19-1. Shifting the mechanical home

position to the X direction

(1) Remove the X-Y cover (right), (left) and X cover.

(2) Loosen the detector plate fix screws (2 pieces) (No.1). If move the detector plate

(No.2) to the right, the mechanical home position is shifted to the left and if it is

moved to the left, the mechanical home position is shifted to the right.

― 32 ―

Page 38

(3) After the mechanical home position setting, tighten the detector plate fix screws

(No.1) securely.

(4) If the shift amount of home position by using this method enough. Please adjust

by following procedure.

(5) Remove the detector adaptor fix screws (No.3).

(6) Replace the detector adaptor (No.4) to other position. In this case if move the

detector adaptor (No.4) to the right, the mechanical home position is moved to

the right and if it is moved to the left, the mechanical home position is moved to

the left.

(7) After setting, tighten the detector adaptor fix screws (No.3) securely.

[NOTE] When the original mechanical home position is shifted. Please check the

clearance between the X detector plate and the X det ect or .

This clearance should be set within the range of 1.0 ~ 1.5 mm.

7-19-2. Shifting t he m echanical hom e position to the Y direction

(1) Loosen the Y-detector setscrew (No.1).

(2) If move the Y-detector (No.2) to the front , the mechanical home position is shifted t o the

backward. If it is moved to the backward , t he mechanical home position is shifted to the

front.

(3) After the mechanical home position setting, tighten the screw (No.1) securely.

1

2

4

3

2

1

7-20 Adjustment of the X -Y contact pressure

― 33 ―

Page 39

[NOTE]

When take the X-Y table apart or the X-Y table became weak in the joints,

adjust the X-Y table contact pr essure. The adjustment should be made t he X-Y

table movement as smooth as possible without having play. If the X-Y table

contact pressure is too tight, the over pressure induces the out of control on t he

X-Y table movement.

(1) Remove the right and left X-Y covers and the rig ht X cover plate.

(2) Loosen the setscrew (2 pieces) (No.2) so that the X fixed race (No.1) can be m oved slig ht ly.

(3) If tighten the both right and left contact presser adjusting screws (No.3), the X table contact

pressure is increased.

(4) Loosen the setscrews (2 pieces) (No.5) so that the Y fixed race (No.4) can be moved slig ht ly.

(5) If tighten the contact pressure adjusting screws (No.6), the Y table contact pressure is

increased.

(6) After adjustment, tighten the setscrews (No.2) and (No.5) securely.

7-21 Adjustment of the X-Y timing belt tension

[NOTE]

The proper condition of the X -Y timing belt tension is standing that they will not

be got any yield even it is slightly pushed by hand.

7-21-1 Adjustment of t he X timing belt tension

(1) Remove the right X cover and the right X cover plate.

(2) Loosen the nut (No.8) and the setscrew (No.9) of the br acket (No.7).

(3) If the tighten the tension adjust screw (No.10), the X timing belt (No.11) tension will be

increased.

(4) After adjustment, tighten the nut (No.8) and the setscrew (No.9).

4

5

6

7

3

2

1

8

9

7-21-2. Adjustment of the Y timing belt tension

― 34 ―

11

10

Page 40

(1) Remove stepping motor cover and V belt cover.

(2) Loosen the bracket setscrews (No.1).

(3) Remove the rubber plug (No.3) and tighten the tension adj ust screw (No.2). The Y timing

belt tension will be increased.

(4) After adjustment, tighten the bracket set screws (No.1) securely and put the rubber plug

(No.3), the stepping mot or cover and t he V belt cover to the original position.

3

2

7-22. Adjustment of t he V belt tension

[NOTE]

After operated the sewing machine

for a long period, the V belt tension

becomes loose. Adjust the V belt

tension periodically. The proper V

belt tension is standing that it is bent

about 10 mm with the hand pressure

of 1.0Kg as it shown on the fig ur e.

1

10

4

mm

(1) Turn the power switch OFF.

(2) Remove the V belt covers.

(3) Loosen two nut (No.2) on the motor

position adjust bolt (No.1)

(4) Fix the motor (No.5) position with putting

the tension to the V belt by its weight and

firstly, tighten the upper nut (No.2) then

secondly, tighten the lower nut (No.2).

― 35 ―

1

2

3

5

Page 41

8. MAINTENANCE

Please make sure to turn the power switch always OFF when clean up the sewing

machine.

Before or after the sewing operation, clean up t he sewing machine and check the

oil level in the oil tank.

8-1. Cleaning

(1) Turn the power switch

OFF.

(2) Remove the dust and the

thread waste sticking

around the threading

parts or the shuttle hook

area.

(3) Check the oil level in the

oil tank. If t he oil is under

the red mark level supply

the oil to be over the red

mark level.

Caution

8-2. Disposing of oil waste

(1)If the waste oil is full f illed in

the oil bottle (No.1), remove

the oil bottle (No.1) then,

dispose of the waste oil.

(2)For cleaning the oil pan,

remove the screw(No.2) and

take off the oil bottle

adapter(No.3).

Next remove the screw

(No.4) and pull out the oil

pan(No.5).

― 36 ―

Page 42

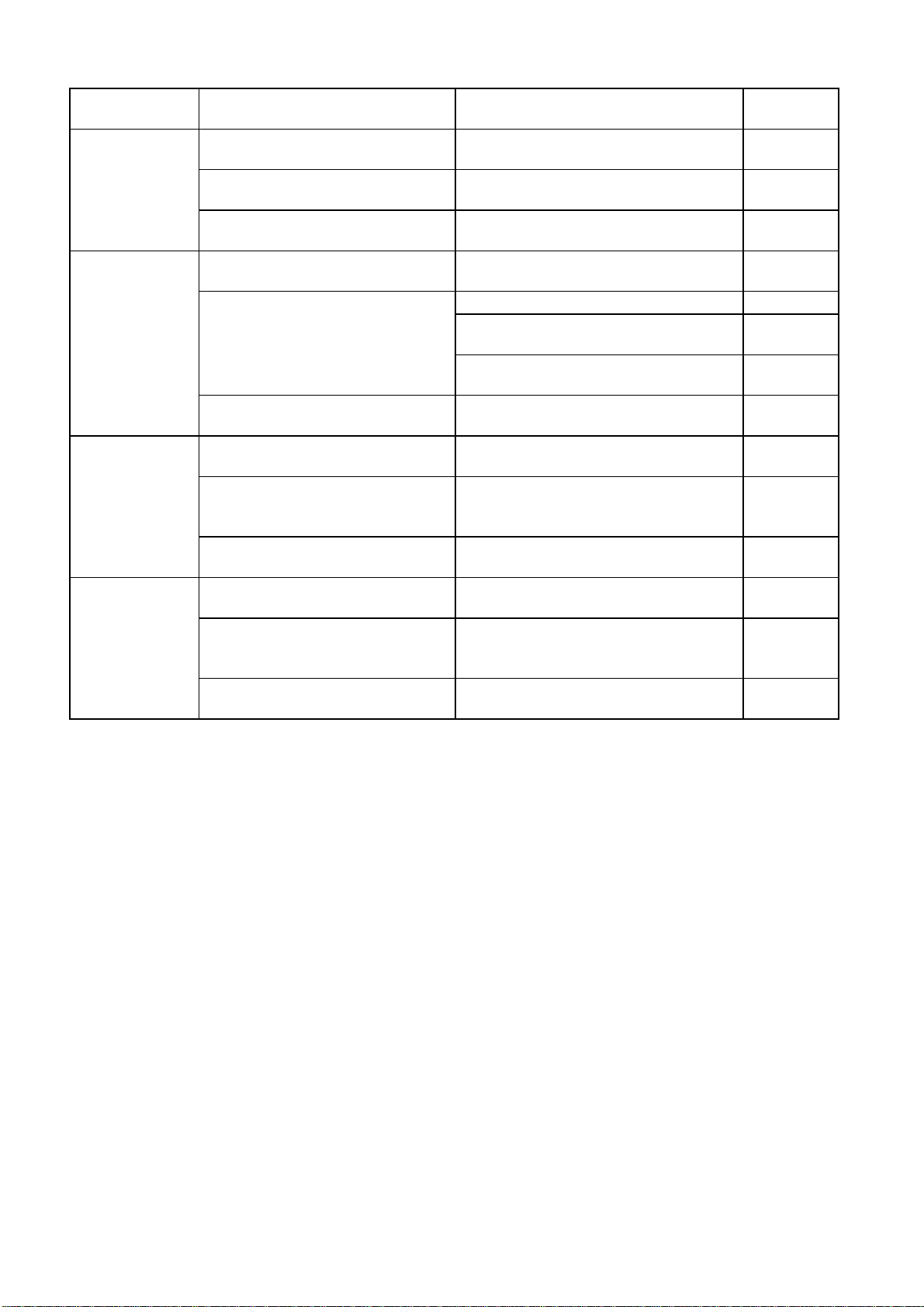

9. BAD SEWING CONDITION & ITS CAUSE AND REMEDY

[NOTE]

Bad condition Cause Remedy

Upper thread

breakage

often happens

Upper thread

is pulled out

from needle

Skip stitch

happens at

start sewing

Please fix the troubles during the sewing machine operation with referring to the

following instructions.

Beside, if the trouble conditions are not coming under these classification, please

contact the sewing machine dealers nearby.

Poor thread quality Use better quality thread ----

Tight upper thread tension Adjust thread tension 6-3

Adjust thread take up spring

properly

Change needle to suitable size ----

Change them new ones or grind

them with buffing wheel or grind

stone

Change it new one or grind it with

buffing wheel

Move presser foot position 7-6-1(6)

Adjust the timing 7-2

Slow down sewing speed 6-2(4)

Use silicon oil ----

Use needle cooler ----

Adjust thread tension release 7-17

Adjust thread take up spring’s

swing stroke

Adjust fixed knife and needle plate

position

Change needle to suitable size ----

Adjust thread guide position

properly

Adjust the position properly 7-2

Adjust trimmer cam position 7-10

Adjust movable knife position 7-11

Adjust synchronizer position 7-18

Use non racing spring with bobbin ----

Loosen bobbin thread tension

spring

Decrease pre-tension 7-16

Adjust trimmer cam position 7-10

Adjust synchronizer position 7-18

Make thread take up swing stroke

smaller

Advance thread tension release

timing

Adjust thread guide position

properly

1.

2.

3.

Strong thread take up spr ing

Upper thread is thicker than

needle size

Damages on shuttle hook or

driver

Damages inside presser foot

needle hole

Needle touches with presser

foot needle hole

Needle and shuttle hook are

not in proper timing

Thread melts with needle heat

Thread tension discs are not

opened at trimming

Thread take up spring swings

too much

Upper thread is broken befor e

regular trimming

Needle size is bigger than

thread size

Pre-tension is too tight Adjust pre-tension 7-16

Thread guide is in wrong

position

Needle and shuttle hook are in

bad timing

Trimmer timing is not correct

Too short bobbin thread by

bobbin spinning at trimming

Bobbin thread tension is too

tight

Thread tail from needle is very

short after trim m ing

Ref. page

& Item

7-14

----

----

7-14

7-12

7-5

6-3(1)

7-13

Control

unit

7-5

― 37 ―

Page 43

Bad condition Cause Remedy

Pre-tension is too loose Make pre-tension tighter 7-14

4.

Thread tail from

needle is too

long after

trimming

5.

Trimming is

not functioned

6.

Skip stitching

often happens

7.

Stitch forming

is loose

8.

Sewing

machine does

not work even

start switch is

turned ON

9.

Sewing

machine runs

idle at high

speed when

power switch

is turned ON

Trimmer timing is delayed

Upper thread tension release

timing is too fast

Tread guide is in wrong position

Trimmer function is canceled Resume trimmer function

Fixed knife is dull Change it new knife 7-11

Movable Knife is in wrong

position

Skip stitching happens at

trimming

Trimmer timing is wrong

Needle and shuttle hook

clearance is too big

Needle and shuttle hook timing

is not correct

Needle is bent Change it new needle ----

Needle is bent by driver

Needle is in wrong position Amend needle position 7-2

Presser foot position is not

correct

Upper thread tension is not

tight enough

Thread tension regulator’s

discs are opened during sewing

Presser foot position is not

correct

Driver and shuttle hook

clearance is very small

Presser foot up and down

timing is not proper

Cables wiring is disconnected Connect all cables precisely 3

System software is not loaded

Emergency stop switch is kept

ON

Start switch is out of order Change it new start switch ----

Synchronizer cable is

disconnected

Synchronizer is out of order

Adjust trimmer cam position 7- 10

Adjust synchronizer position 7-18

Delay tension release timing

Adjust thread guide position

properly

Adjust movable knife position

properly

Fix skip stitching 7-6

Adjust trimmer cam position 7- 10

Adjust synchronizer position 7-18

Adjust needle and shuttle hook

timing properly

Adjust needle and shuttle hook

timing properly

Adjust needle and diver clearance

properly

Adjust presser foot position

properly

Increase upper thread tension 6-3(2)

Adjust tension regulator posit ion

properly

Adjust upper tension release

position properly

Adjust presser foot position

properly

Change shuttle hook ----

Adjust presser foot timing properly 7- 6- 3

Load system software to control

box

Release emergency stop switch

lock

Connect synchronizer cable

precisely

Change it new synchronizer

Ref. page

& Item

Control

unit

7-5

Control

unit

7-11

7-2

7-2

7-4

7-6

7-17

7-17

7-6-1

5-1

6-1(3)

Control

unit

----

― 38 ―

Page 44

Bad condition Cause Remedy

10.

Work holder

does not work

11.

Sewing pattern

is distorted

12.

Work holder

does not stop

at home

position

13.

Work holder

stops at not

original home

position

Work holder activate cable is

disconnected

Work holder pressure is not

strong enough

Work holder switch is out of

order

Work holder pressure is not

strong enough

Sewing material weight is very

heavy

X-Y timing belts are loose

X-Y detector cabled are

disconnected

X-Y detectors are out o order

(Red pilot lamps do not go on

at home position)

Detector and detector plate

clearance is too big

Detector or detector plate

mounting is loose

Detector and detector plate

clearance is bigger than

standard

Home position correction

function is in working

Connect the cable precisely

Increase work holder pressure 7-9-1

Change it new work holder switch ----

Increase work holder pressure 7-9-1

Slow down sewing speed 6-2(4)

Slow down feeding speed

Select sewing material weight level

at feeding

Adjust X-Y timing belt t ension

properly

Connect X-Y cables precisely ----

Change them new detectors

(Make sure red pilot lamps go on at

home position)

Adjust the clearance properly 7-19

Check setscrews and tighten them

securely

Adjust detector and detector plate

clearance properly

Cancel home position correction

function

Ref. Page

& Item

Control

unit

Control

unit

Control

unit

7-21

----

7-19

7-19

Control

unit

― 39 ―

Page 45

APPENDIX

Tabletop and stand drawings.

Ref.1 ···············Table cut-out for PLK-E1010 machine

Ref.2 ···············Table and stand

Ref.3 ···············Stand components

NOTE Tabletop and stand must be produced refer to below drawings.

Recommendable measurements for original MITSUBISHI tabletop and stand are

shown in the figures.

― 40 ―

Page 46

2

Ref.1 <Table cut-out for PLK-E1010 machine>

C

φ40

70

13

D

48.5

110

φ

50

E

80

C

145

C

161

14

60

23

57

D

A

358

260

178

60

10

104

40

32

Section B

38

2-φ7

8

159

A

9

1

φ

66

For air regulator

installation

φ26

φ9

Section A

66

130

273

60°

82

2-φ4

40

B

E

323

143

4

97

53

69

B

B

A

B

1

Section C

1200

30

210

805

314

545

138

4-φ9

100

50

A

90

C

φ60

340

C

235

A

174

C

C

C

84.5

51

4

48.5

129

A

350

A

74

115

265

25

9

1

φ

A

4-φ2.5depth16

(underneath)

358

For switch installation

60

33

250

388

150

45

25

80

A

A

A

27

105

185

C0.5

C

100

590

405

A

20

41

Section D

Ref.2 <Table and stand>

1

26

24 23 25

20

16

17

18

2

6

27 28

29

3

10

11

12

13

9

8

16

17

18

22

15

15

Fig.No Description Q ty.

1 Table T op 1

21

2Stand (A) 2

3Stand (B) 2

4 S upport fram e (A ) 1

5 S upport fram e (B ) 1

16

17

18

15

Note: Apply rubber plate

to a control box

6Bolt w ith S W - P W (large) M 8x20 6

7Bolt w ith S W - P W (sm a ll) M 8 x 2 0 4

8Bolt w ith S W - P W (m iddle) M 8x20 2

9Wide-rim m ed w asher (large) 8 2

10Pedal 1

11 Shaft 1

12 Shaft housing 2

13Collar 2

14

14

19

14Bolt w ith S W M 8 x 2 0 2

15T nut M8 2

19

16 T op cap 4

17Washer M124

3

18 Spacer 4

19Caster 4

20 W ood screw 5.8x32 4

21 Control box 1

16

17

2

18

3

7

4

8

5

3

805

720

800

22 M ounting bolt M 8 x 6 0 8

23 W ide-rim m ed w asher (large) 8 11

24 W ide-rim m ed w asher 8 11

25 N ut M 8 11

26 R ubber plate 1

27 M otor 1

28 P ow er box 1

~

29 M ounting bolt M 8 x 7 0 13

30 D raw er 1

mm

31 Rail2

32 W ood screw 4.5x38 4

5

33 S taple (L) 1

34 S w itc h ass e m b ly 1

35 W ood screw 4.1x162

36 S taple (S) 5

― 41 ―

Page 47

d

Ref.3 <Stand components>

18

95

9-φ11

120.3±0.5

65 60

182

(472.3)

470

A

A

119 63

H01

H02

No.

Description

Material

Surface Treatment

(40.3)

Caution

1

Stand (A)

H01: SPCC 2.3T

H02: SPCC 2.3T

101: WELD NUT M8

Paint(unti-corrosion)

String chamfer, except as noted

(chamfer slightly)

Trigonometry

2-φ6

(20)

128

358±0.5

270

9-Weld Nut M8

25 25

Section A

101

DIVISION OF DIM

to 100

over 100 to 300

over 300 to 1000

over 1000

LIMIT

±0.4

±0.5

±0.7

±1.0

20

39

2

Support frame (A)

SPCC 2.3T

Paint(unti-corrosion)

String chamfer, except as note

(chamfer slightly)

Trigonometry

4-φ9.5

80

120

115

10

18

DIVISION OF DIM

to 100

over 100 to 300

over 300 to 1000

over 1000

LIMIT

±0.4

±0.5

±0.7

±1.0

No.

Description

Material

Surface Treatment

Caution

18

130

38

805

841

130

10

4-φ9.5

― 42 ―

10

18

38

Page 48

5

30 30

25

(50)

25

+0.3

0

121

(60.5)

60.5

106

120

9

120

80

70

H01

H03

6 points

2-M12

No.

Description

Material

Surface Treatment

Caution

DIVISION OF DIM

to 100

over 100 to 300

over 300 to 1000

over 1000

3

Stand (B)

H01: SPCC 2.3T

H02: SPCC 2.3T

H03: SPCC 2.3T

H04: SPHC 4.5T

101: WELD NUT M8

Paint(unti-corrosion)

String chamfer, except as noted

(chamfer slightly)

Trigonometry

LIMIT

±0.4

±0.5

±0.7

±1.0

(560)

12

120

500

36.5

9

25

2-φ11

H02

101

22.5

60

10

2-φ9.5

10

25

4.5

44

50

LIMIT

17

25

No.

Description

Material

Surface Treatment

Caution

Support frame (B)

SPCC 2.3T

Paint(unti-corrosion)

String chamfer, except as noted

(chamfer slightly)

Trigonometry

17

25

155

(500)

345

DIVISION OF DIM

to 100

over 100 to 300

over 300 to 1000

over 1000

±0.4

±0.5

±0.7

±1.0

R2

R5

74

8585 32 20

10

85108

858520 20 8532

(108)

850

805±0.5

8

R4

48

48

22

R4

― 43 ―

Page 49

d

φ

2

2

M8ネジ

44±0.4

20

M8

No.

Description

Material

Surface Treatment

Caution

44±0.4

No.

Description

Material

Surface Treatment

SPHC 4.5T

6

Bolt with SW-PW (large)

M8 X 20

SS100

Electroplated Coating

Trigonometry

8

Screw plate (A)

Electroplated Coating

String chamfer, except as noted

(chamfer slightly)

Trigonometry

M8

No.

Description

Material

Surface Treatment

0

.

3

Surface Treatment

No.

Description

Material

Caution

φ

1

6

4

.

0

±

8

3

φ

2-φ10

20

φ

9

±

7

Bolt with SW-PW (small)

M8 X 20

SS100

Electroplated Coating

Trigonometry

9

Wide-rimmed washter (large)8

SPCC 2.6T

Electroplated Coating

String chamfer, except as noted

(chamfer slightly)

Trigonometry

120

R13

14.5 14.5

14.5

208

15

5

φ8

5

24

R30

60

85

134

φ12

2-C0.5

DIVISION OF DIM

0.5 to 3

over 3 to 6

over 6 to 30

over 30 to 120

φ9

over 120 to 315

over 315 to 1000

5

φ8

R10

13

R10

LIMIT

±0.1

±0.1

±0.2

±0.3

±0.5

±0.8

13

No.

5

Description

Material

Surface Treatment

Caution

No.

Description

Material

Surface Treatment

Caution

R13

DIVISION OF DIM

to 100

over 100 to 300

15

over 300 to 1000

over 1000

10

Pedal

SPCC 1.2T

Paint (unti-corrosion)

String chamfer, except as note

(chamfer slightly)

Trigonometry

11

Shaft

S15C

Electroplated Coating

String chamfer, except as noted

(chamfer slightly)

Trigonometry

LIMIT

±0.4

±0.5

±0.7

±1.0

― 44 ―

Page 50

d

φ8.5

R

1

No.

Description

Material

(4.5t)