Page 1

MITSUBISHI

Industrial Sewing Machine

TECHNICAL MANUAL

MECHANICAL VERSION

Electronic Pattern Sewing Machine

Model PLK-B 1 008H

A

180E463P01

Page 2

2.

SPECIFICATION

(1)

Specification

Sewing area X-Direction(lefl/right)

'

of

mechanism

Y-

Direction (fore/backward)

Maximum sewing speed

Sewing speed

Stitch length

Stitch type

Class of needle

Needle bar stroke

Threaj

Stepping foot lift

Work holder lift

Thickness of material

Hook

Bobbin

Thread trimmer system

take

up

lever

stroke

100mm

700spm

1 o steps variable from 200

0.1

to

12.7 mm

(Adjustable from

Single needle lock stitch

Schmitz 794

56.6

mm

94mm

16mm

20mm (25max.)

Max

10mm

Barrel shuttle hook

Large size

Electric heat cut system

Steel bobbin

#230

0.1

mm

to

80mm

to

700 stitch/min

12.7mm by

0.1

mm

resolution.)

Amount of heating time

Voltage

Pre heating

Thread

Lubrication system

Lubrication

X-Y drive system

Machine dimension

Weight

Type of controller

(2)

Specification of main motor

Type of motor : XL-554-20

oil

available by using Function Code 4

#8~#00

Manual oiling

White machining oil

Stepping motor and timing belt drive

Intermittent or continuous feeding

HEAD

HEAD 92Kg TOTAL 172Kg

PLK-B-CU-20

(Synthetic)

41

OW x 780L

IN:

AC 210/230V

is

selectable by selecting setting table

OUT:

x 540H TOTAL 1200W x 780L x 1320L

AC 1V

Page 3

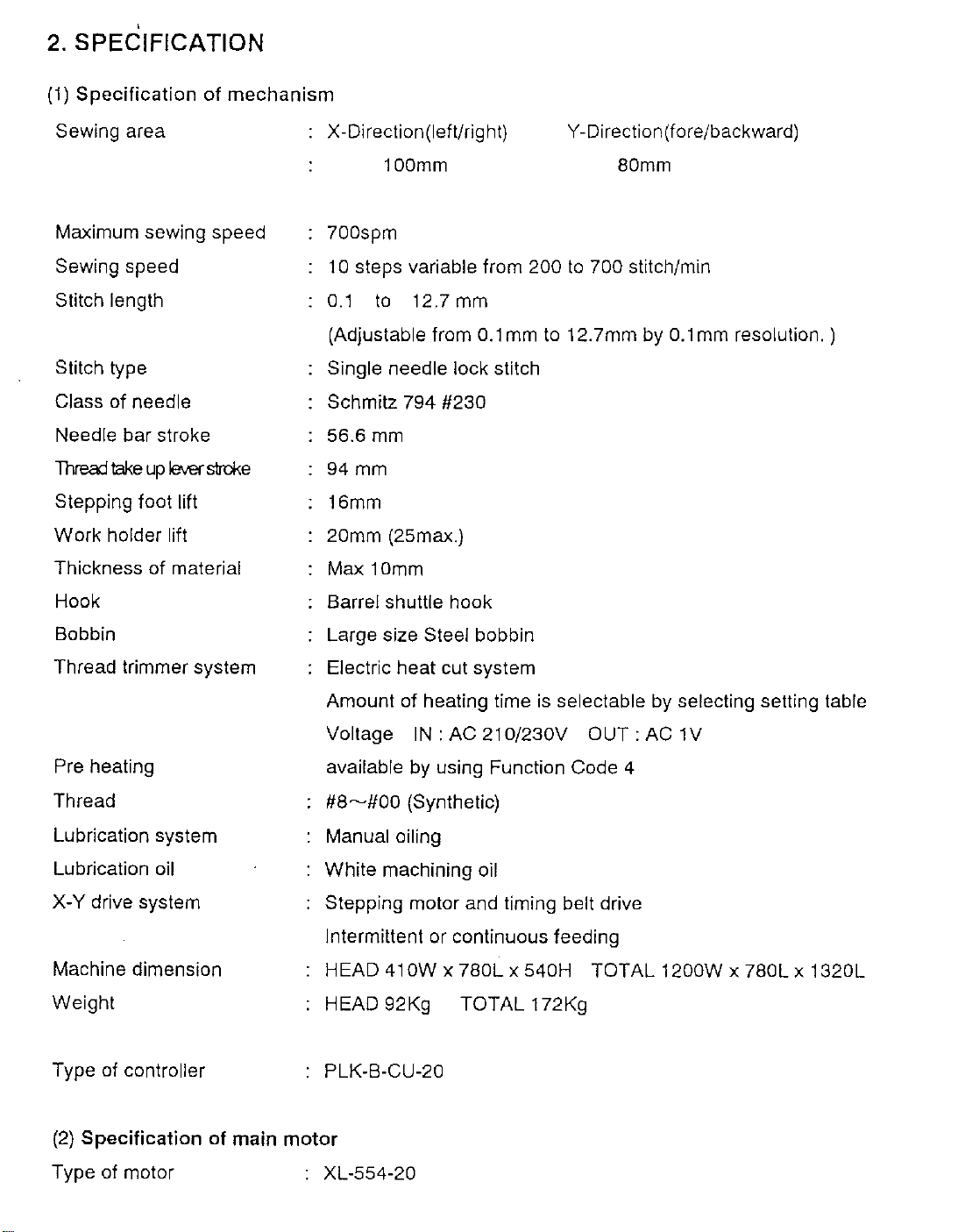

3-6

Installation

of

the

power

switch

If the power switch

with the

1}

(

(2}

(3}

(4}

(5}

(6}

(7}

For

following procedure.

fvlount

Fix the electric cords with the staples (NO.®) underneath the table.

Hook

Hook

Connect the terminal (NO.O}

Two terminal has been prepared on this transformer (for

informed

Connect the other terminal

Detail

These terminal adapter are located inside

Attach the power plug

necessary parts are

detail description, please refer to APPENDIX 1 and 2 Wiring diagram.

the

power

up

the

up

the connector (NO.O) of the cable (NO.®)

in

of wiring are informed

is

purchased without assembling

switch

oonnector

APPENDIX on this manual.

(NO.<D)

(NO.O)

enclosed

with

of

(N0.0)

(N0.0)

the

wood

the

power

to

the terminal adapter

to

in

APPENDIX

to

the another end of the power switch cord (NO.®). All the

in

the accessory box.

to

the table, the power switch has

screw

(NO.@}

switch

(NO.<D)

the terminal adapter PORT No.5 of the relay socket (NO.®).

on

this manual.

of

the motor cover of machine head.

underneath

to

the

to

the

on

oonnector

connector

the transformer (NO.®).

21

OV

the

table

as

shown

(N0.6)

of

and for

of

the control box (NO.®).

230V).

on

the

cable

Detail of wiring are

to

be attached

the

figure.

(NO.®}.

Page 4

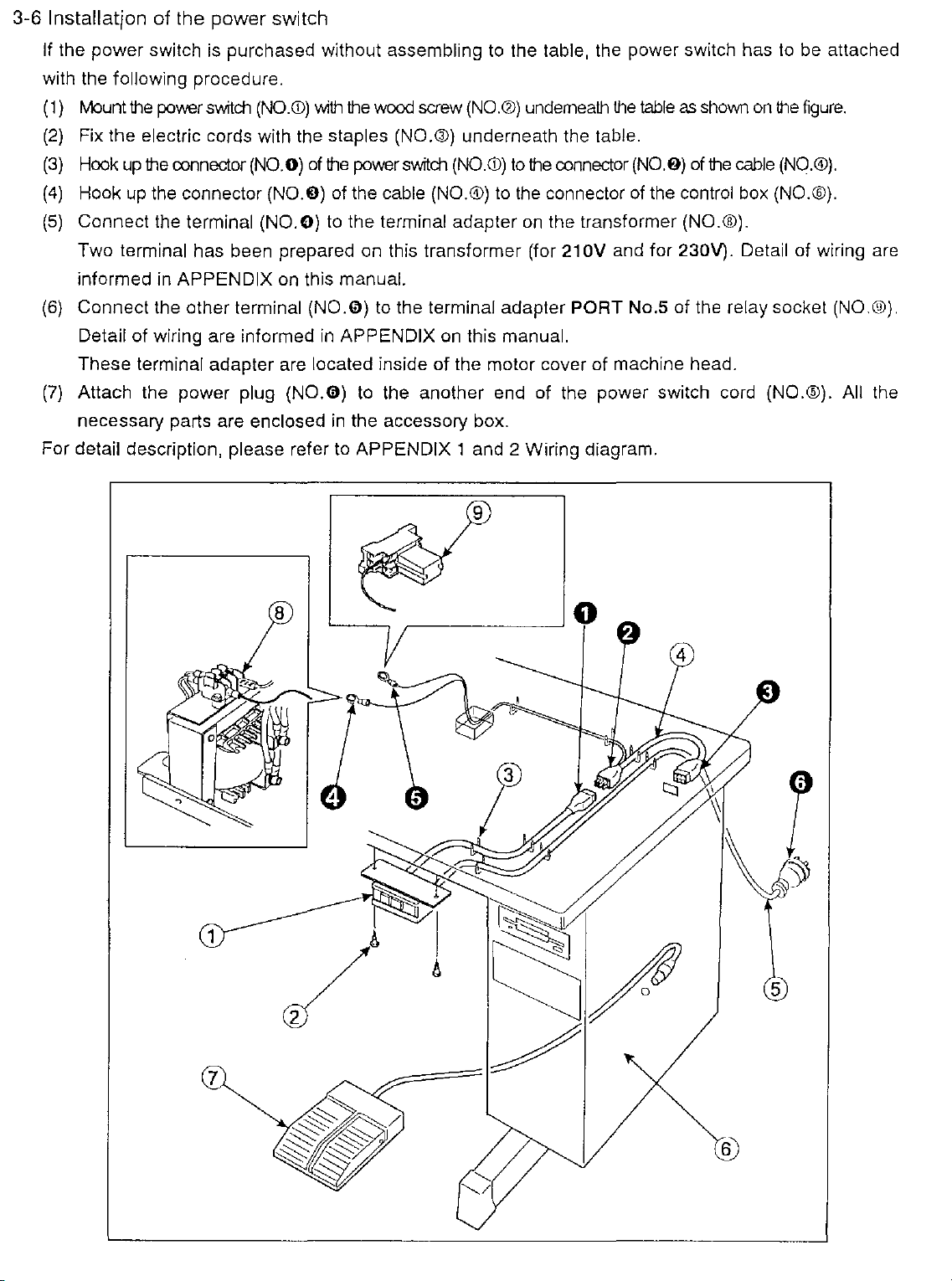

4. LUBRICATION

,----&Caution

* Please make sure

to

turn power switch OFF before oiling.

* Please make sure to put some oil before starting the operation of the brand new machine or

is

when the sewing machine

I

NOTE!

Put

Please use high quality white machining oil.

some oil to red marked

resumed the operation after along interval.

oil

holes and other part as described below arrow sign.

0

=

I

Lubrication position

1 .

Presser foot mechanism

5.

Thread take up shaft

8.

Arm shaft bushing middle

11. Hook shaft bushing left

13. Hook driver

2.

Rock shaft bushing 3. Crank rod

6.

Arm shaft bushing left

9.

Connecting rod 10. Arm shaft bushing right

12. hook shaft bushing right, Rock shaft bushing

7.

Foot lifting eccentric

4.

Thread take up cam

Page 5

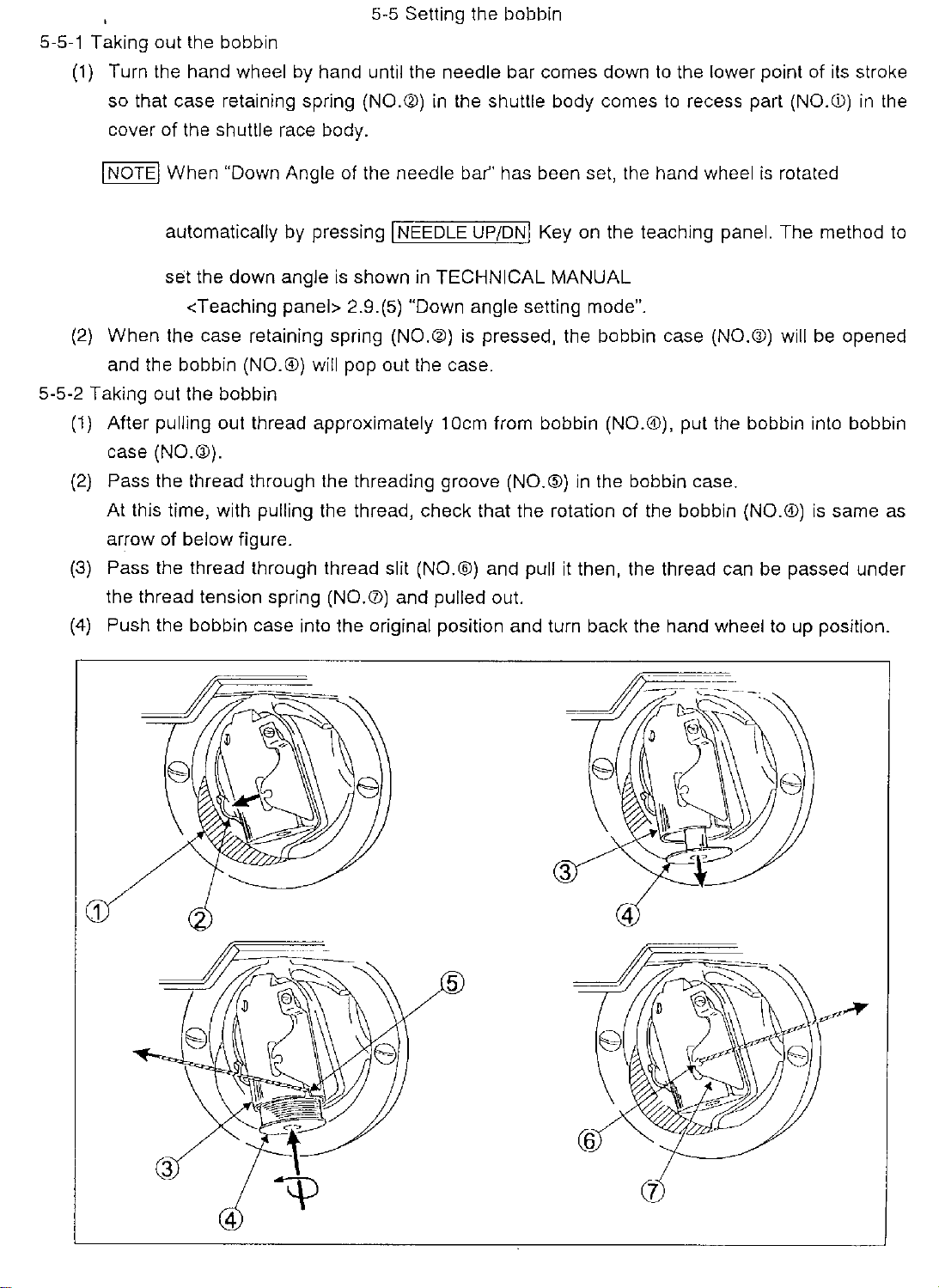

5-5-1 Taking out the bobbin

(1)

Turn the hand wheel by hand until the needle bar comes down

so that case retaining spring

cover of the

shuttle race body.

5-5 Setting the bobbin

(NO.®)

in

the shuttle body comes

to

the lower point of its stroke

to

recess part

(NO.CD)

in

the

I NOTE I When "Down Angle of the needle bar" has been set, the hand wheel

automatically by pressing I NEEDLE UP/DNI Key on the teaching panel. The method

set the down angle

<Teaching

(2)

When

and the bobbin

5-5-2 Taking out the bobbin

(1)

After pulling out thread approximately

case

(2)

Pass the thread through the threading groove (NO.®) in the bobbin case.

At

arrow of

(3)

Pass the thread through thread slit (NO.®) and pull

the thread tension spring

(4)

Push the bobbin case into the original position and turn back the hand wheel

the case retaining spring (NO.®)

(NO.®) will pop out the case.

(NO.GJ).

this time, with pulling the thread, check that the rotation of the bobbin (NO.®)

below figure.

is

shown in TECHNICAL MANUAL

panel> 2.9.(5) "Down angle setting mode".

is

pressed, the bobbin case (NO.®) will

(NO.<V)

1Dcm

and pulled out.

from bobbin (NO.®), put the bobbin into bobbin

it

then, the thread can

is

rotated

be

opened

is

same as

be

passed under

to

up position.

to

5

Page 6

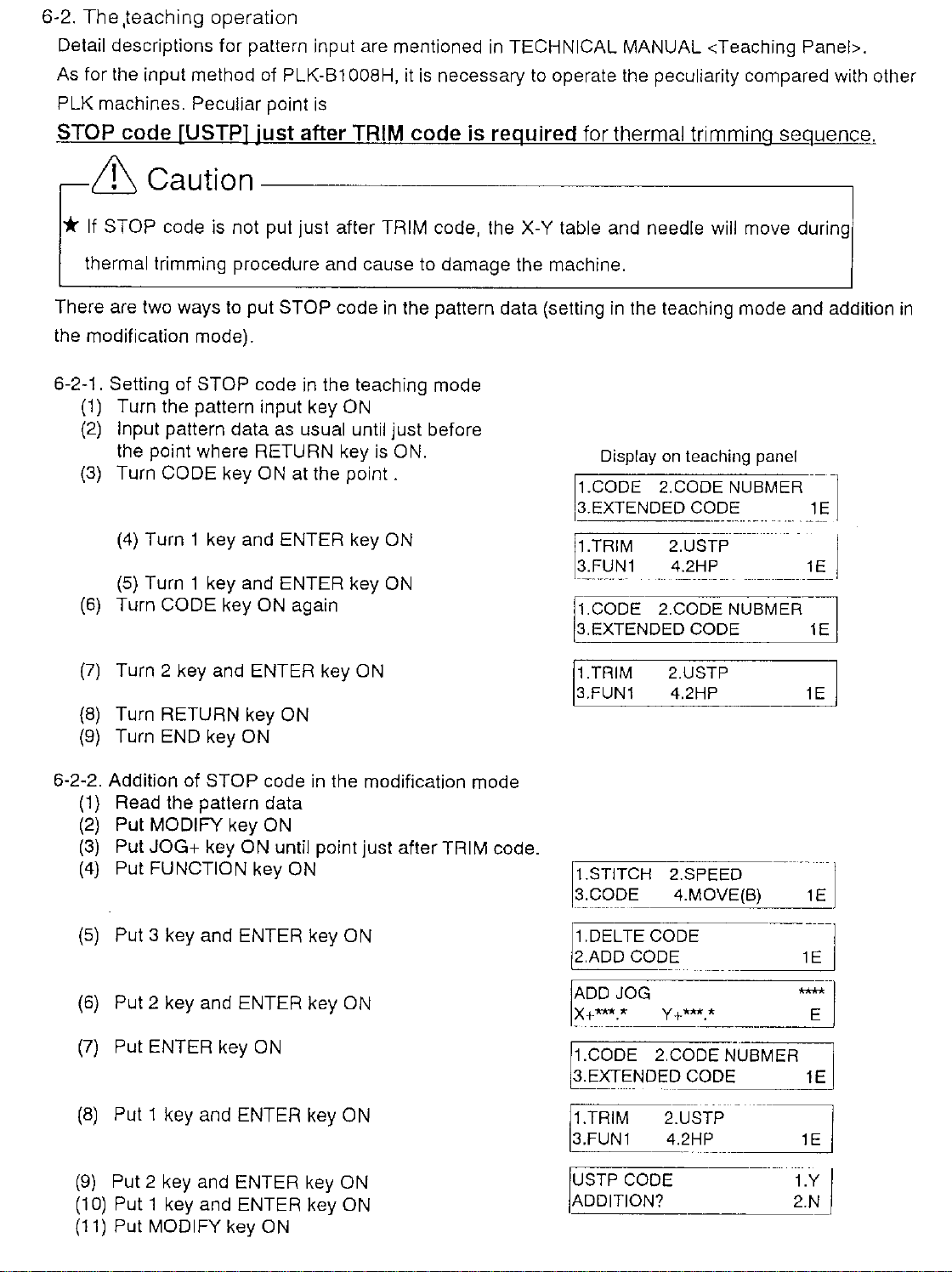

6-2.

The

,teaching

Detail descriptions for pattern input are mentioned

As for the input method of PLK-61 008H, it

PLK machines. Peculiar point

operation

is

is

necessary

in

TECHNICAL MANUAL <Teaching Panel>.

to

operate the peculiarity compared with other

STOP code [USTP] just after TRIM code is required for thermal trimming sequence.

&

* If STOP code

thermal trimming procedure and cause to damage the machine.

There are two ways to put

the modification mode).

6-2-1. Setting of

(1)

(2)

(3) Turn CODE key

(6)

(7)

(8)

(9)

Caution--------------------,

is

not put just after TRIM code, the

STOP code

STOP code

Turn the pattern input key

Input pattern data as usual until just before

the point where RETURN key

(4)

Turn 1 key and ENTER key

(5)

Turn 1 key and ENTER key

Turn CODE key

Turn 2 key and ENTER key

Turn RETURN key

Turn END key ON

ON

ON

in

the teaching mode

at the

again

ON

ON

is

point.

ON

in

the pattern data (setting

ON.

ON

ON

X-

Y table and needle will move during

in

the teaching mode and addition

Display on teaching panel

1.CODE 2.CODE NUBMER

3.EXTENDED CODE 1 E

-

1.TRIM

3.FUN1

1.CODE 2.CODE NUBMER

3.EXTENDED

1.TRIM 2.USTP

3.FUN1 4.2HP

~-----------

2.USTP

4.2HP

CODE 1E

----

--

·-·

.

-----

1 E

in

-~

I

6-2-2. Addition of STOP code

(1)

Read the pattern data

(2)

Put MODIFY key

(3)

Put JOG+ key ON until point just after TRIM code.

(4)

Put FUNCTION key

(5)

Put 3 key and ENTER key ON

(6)

Put 2 key and ENTER key

(7)

Put ENTER key

(8)

Put 1 key and ENTER key 0 N

ON

ON

in

the modification mode

ON

ON

1.STITCH 2.SPEED

3.CODE

1.DEL TE

2.ADD CODE

1.CODE 2.CODE NUBMER

3.EXTENDED

1.TRIM

~=~=:4=.2--HP

(9)

Put 2 key and ENTER key ON

(1

0)

Put 1 key and ENTER key ON

(11)

Put MODIFY key

ON

USTP CODE

ADDITION?

4.MOVE(B)

CODE

-

CODE 1E

2.USTP__

·-~~~

--~

~

2i._YN

I

Page 7

6-3.

Pre-heating

To secure the trimming, it

pattern data. Relationship between FN4 and pre-heating behavior

control

is

available

to

use pre-heating by input Function Code No.4 (FN4)

is

described as below.

in

the

ex.1) Pattern data

Heater

ex.2) Pattern data

Heater

When FN4 code

When FN4 code

Usually FN4

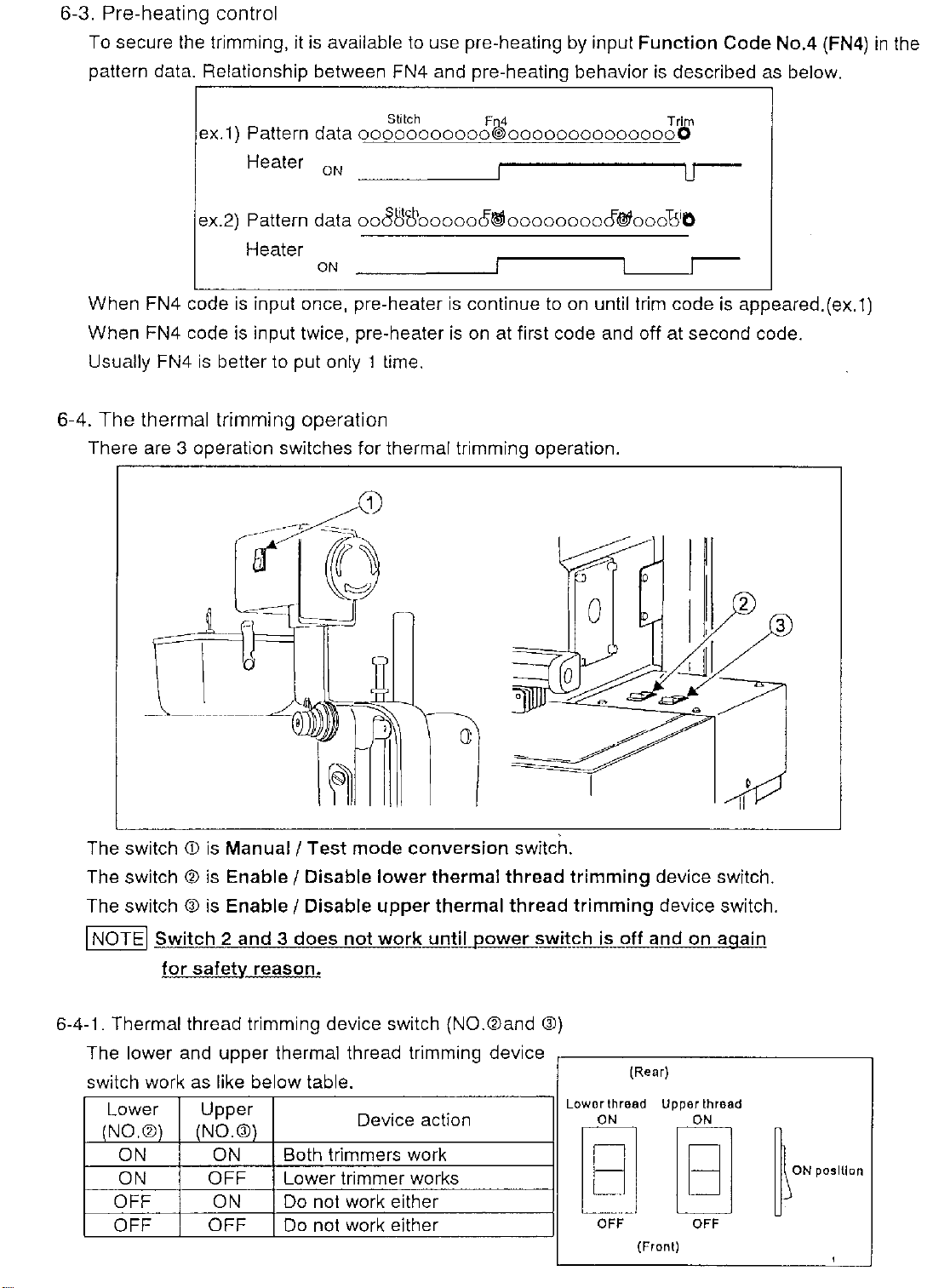

6-4.

The

thermal

There are 3 operation switches for thermal trimming operation.

is

input once, pre-heater

is

input twice, pre-heater

is

better to put only 1 time.

trimming

oN

ON

operation

Stitch

ooooooooooowooooooooooooooo

ooJ1'l't\'oooooo~ooooooooo@iooot5iO

Fu_4

is

continue to

is

on

at first code and off at second code.

on

until trim code

Trjrn

is

appeared.(ex.1)

The switch

The switch

The switch

I NOTEI Switch 2 and 3 does not wqrk

6-4-1.

Thermal thread trimming device switch (NO.®and ®)

Th I d

e ower

switch work as like below table.

Lower Upper

(NO.C?l)

ON ON Both trimmers work

ON OFF Lower trimmer works

OFF ON Do not work either

OFF

<D

is

Manual/

®

is

Enable I Disable lower thermal thread trimming device switch.

@

is

Enable I Disable upper thermal thread trimming device switch.

for safety reason.

an

upper

(NO.®)

OFF

Test mode conversion switch.

th

erma rea

Do not work either

unt[[_J!ower

I th d t . d

Device action

nmm1ng

lLWitg_~_.9lL1!nd

ev1ce

Low

or

thread Upper thread

ON

lgl

OFF OFF

on

{Rear)

ON

IB'

{Front)

again

~~

'"''"",.

'

Page 8

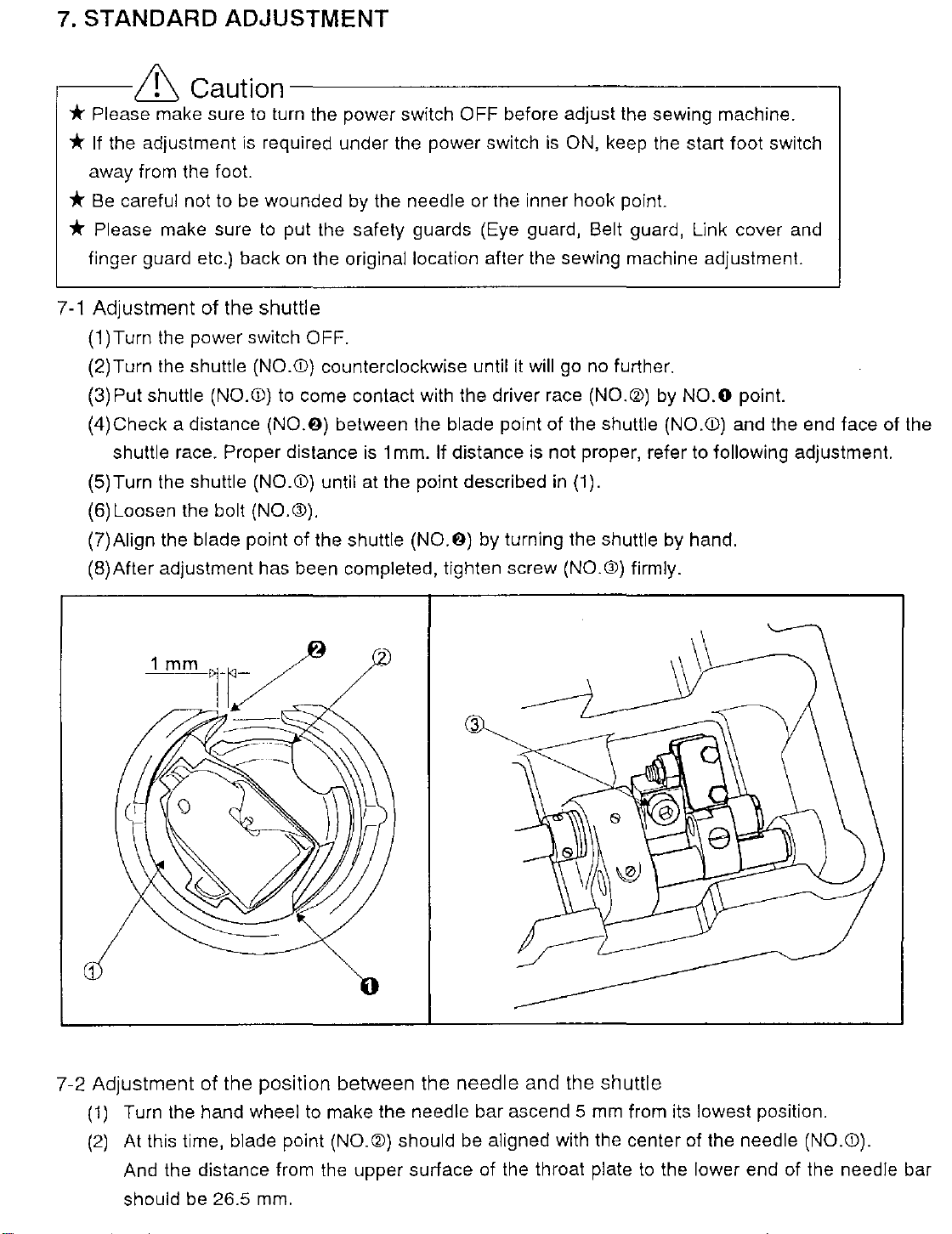

7.

STANDARD ADJUSTMENT

.----&

*Please

*

If

the adjustment

away from the foot.

*

Be

careful not to

*

Please make sure

finger guard etc.) back

Adjustment

7-1

(1

)Turn the power switch OFF.

(2) Turn the shuttle (NO.

Put shuttle (NO.!D) to come contact with the driver race

(3)

(4)Check a distance

shuttle race. Proper distance

(5)Turn the

(6)

Loosen the bolt (NO.®).

(?)Align

(B)

After adjustment has been completed, tighten screw (NO.®) firmly.

Caution--------------------,

make sure

of

shuttle (NO.

the blade point of the shuttle

to

turn the power switch OFF before adjust the sewing machine.

is

required under the power switch

be

wounded by the needle or the inner hook point.

to

put the safety guards (Eye guard, Belt guard, Link cover and

on

the original location after the sewing machine adjustment.

the

shuttle

!D)

counterclockwise until

(N0.6)

between the blade point of the shuttle (NO.!D) and the end face of the

is

1 mm. If distance

!D)

until at the point described in (1).

(N0.6)

by turning the shuttle by hand.

is

ON, keep the start foot switch

it

will go no further.

(NO.a>)

is

not proper, refer to following adjustment.

by

NO.O point.

3

1

7-2

Adjustment

(1)

Turn the hand wheel to make the needle bar ascend 5

(2)

At this time, blade point

And the distance from the upper surface of the throat plate

should be

of

26.5

the

position

mm.

between

(NO.a>)

the

should

needle

be

and

the

shuttle

mm

aligned with the center of the needle (NO.!D).

from its lowest position.

to

the lower end of the needle bar

Page 9

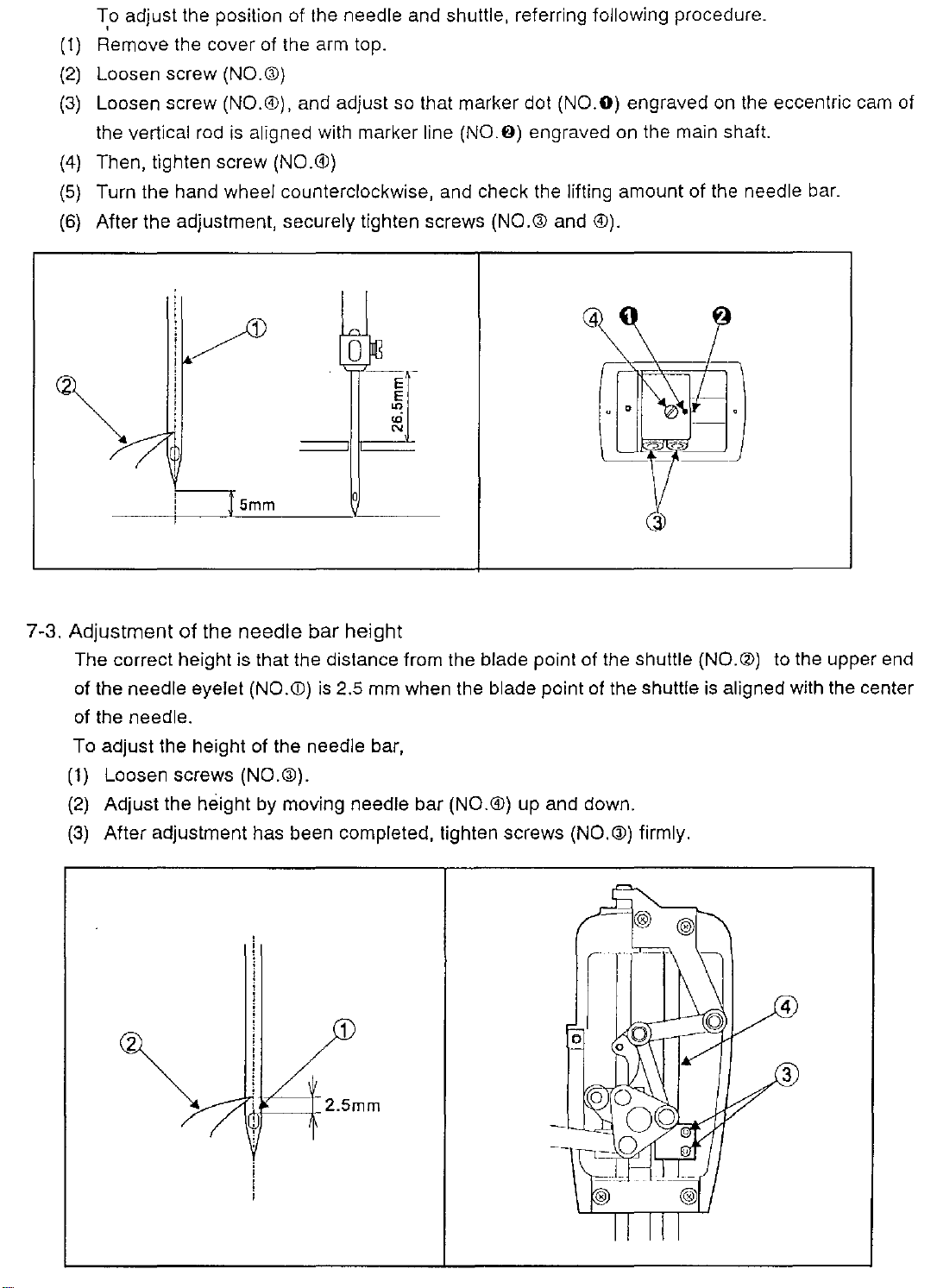

To adjust the position of the needle and shuttle, referring following procedure_

'

(1)

Remove the cover of the arm top.

(2)

Loosen screw (NO.Ql)

(3)

Loosen screw (NO.®). and adjust so that marker dot (NO.O) engraved on the eccentric cam of

the vertical rod

(4)

Then, tighten screw (NO.®)

(5)

Turn the hand wheel counterclockwise, and check the lifting amount of the needle

(6)

After the adjustment, securely tighten screws (NO.

is

aligned with marker line

(N0.6)

engraved on the main shaft.

Gil

and ®).

t\

bar_

/

0

7-4

Adjustment

To adjust the needle-to-shuttle clearance,

(1)

(2)

(3)

of

the

needle-to

Correct clearance between the recess

(NO.@)

is

0.25-

0.35

mm.

shuttle

clearance

in

the needle (NO.

CD)

and the blade point of the shuttle

Loosen screw (NO.®).

Adjust the clearance by moving shuttle driving shaft bushing (NO.®)

After adjustment has been completed, tighten screw (NO.®) firmly.

to

the left and right.

7-5 Adjustment of the needle-to-driver clearance

Correct

range of

clearance between the needle

0 -

0.05

mm.

(NO.CD)

To adjust the needle-to-driver clearance,

(1)

Loosen two screws (NO.®) and Bolt (NO.®).

(2)

Adjust clearance by moving the shuttle driving shaft (NO.®)

(3)

After

adjustment has been completed, secure the shuttle driving shaft thrust collar (NO.®) and

the small pendulum

(N0.0},

making sure there

5

and the needle guard of the driver (NO.@) has the

to

the left and right.

is

no axial play of the shuttle driving shaft.

,

..

0-0.0Smm

--

i

-------~-

Page 11

!The standard for adjusting the clearance between the needle and the blade point of the shuttle!

Use a standard

(1)

Adjust the clearance (NO.O)

to 0.

(2)

Align the needle center with the blade point of shuttle

needle against the driver

{3)

Adjust the clearance NO.O section to a minimum, with the needle

driver

shuttle

By

this adjustment the needle-to-shuttle blade point clearance

Schmelz

(NO.Cil).

(NO.®).

l.lJ

l

jctJ

794-Nm230 needle.

between/he

(NO.

cv).

making sure that the needle

convex section of needle

1.J

l

171

......

o!

V'

~0

IJ

·Lll

(NO.Q))

)V

(NO.Q))

(NO.@)

does not contact the blade point of the

and press the

(NO.Q))

will

be

0.25-0.35

and driver

N0.8

pressed against the

mm.

(NO.CV)

section of the

~

Pl

'

,IV

~

.

7-6

Test

mode

7-6-1. Entrance for the test mode operation

The test mode operation

of mechanical position (height or stroke) for the

thermal thread trimmer equipment and also

for check the position of the sensors of the

cylinders. For entrance this mode,

(1)

(2)

(3)

(4)

(5)

When the check of sensor

(Check input /output signal)

For enter E-mode,

(1)

operation

is

used for adjustment

Turn the power switch ON.

Put

on

the gray foot switch (clamp switch).

Put on the RESET switch on the teaching

panel.

Put on the gray foot switch again.

Reverse the mode conversion switch (NO.) to test mode position.

is

required

Put on the [f] key

in

the setting panel of the control

in

this operation mode, it

box.

NORMAl-MOO

POSITION

TEST-MOOEf

POSITION

is

available to enter the E-mode.

(2)

Put on the Up arrow key and

simultaneously over 3 seconds.

For description of the E-mode

Down

is

described

arrow key

in

the technical manual <CONTROL UNIT>.

on

the setting panel of the control box

Page 12

7-6-2. Key function

In

the test mode, each key on the teaching panel works to operate the thermal thread trimmer

in

the test mode

equipment

Relationship between the key and the

Key NO. Function

10

TENSION

RELEASE

lsroPPE~~

(cylinders or relay) independently.

equipment

1 Push/Pull the

2 Push/Pull the

3 Push/Pull the

4 Push/Pull the

5 Push/Pull the

6 Push/Pull the

7

8 Return the equipment to original position (Reset)

9

On

the Upper and Lower

1

cycle

Push/Pull the

KEY

FUNCTION in

TEST

1

g

LOWER

TRIMER

Tension

Thread

Wiper

Thickness

Lower

Upper

operation

Presser

MODE

5

8

release

puller

cylinder

trimmer

trimmer

detector

heater

foot

cylinder

cylinder

cylinder

cylinder

G;J

6

UPPER

TRIMER

is as below.

cylinder

cylinder

during 2

second

In

the Test mode, Start switch is disabled.

Each key function has

•:•

From

is up.

·:· KEY3 is disabled when Presser

•:•

From

is off.

•:•

KEY9

Presser

some

KEYO

KEY4

foot

to KEY9 is disabled when Clamp

to KEY6 is disabled when

is available when Clamp is down and

is up.

rule like below

foot

is down.

Wiper

[;;;]

0

PRESSEF

FOOT

I

RESET

11

CYCL:I

1

....

After

turning the

to normal-mode,

KETS(RESET) .

I NOTE I Reset method against the trouble

When

When

the thread trimmer device is stop by electrical problem (for example signal from sensor

does

program by

not

come), it

under

(1)

Put the

(2)

Change

(3)

Put the RESET key ON.

the thread trimmer device is stop by mechanical problem (for example jam with thread), it

necessary

is

with thread trimmer device.

HALT

mode switch to

to

is

possible to return the device to original position and reset sequence

mentioned method.

switch ON and turning back the

power

TEST

switch OFF. In this case the presser

mode.

I

HALT

switch to OFF.

mode

foot

conversion switch back

make

keep up to avoid interference

sure to put on

Page 13

7-7

Adjustment

7-7-1

(1)

(2)

(3)

(4)

of

the

presser

foot

Adjustment of the driving shaft arm(front) and the presser foot

Turn the power switch OFF

Remove the side cover and the face cover.

Turn the sewing machine pulley by hand and stop the driving shaft arm-rear(NO.lD)

maximum swing position in arrow direction.

Disconnect the presser bar lifting link (NO.®) from the presser lift plate

'

(NO.@)

by removing the

at

its

hinge screw

(5)

Lift up the presser bar (NO.®) and the hand lift link (NO.®).

(6)

Insert the 12.7mm block

(7)

Tighten the screw (NO.®) of the driving shaft arm-front

(NO.®) .

(NO.<Ll)

without the axial clearance of

the driving shaft.

{8)

After the adjustment, connect the presser bar lifting link (NO.®) with the presser lift plate

(NO.@)

by setting the hinge screw (NO.®) and put the face cover and the side

cover

the original location.

(9)

Loosen the screw (NO.®) of the presser foot (NO.®) and then, adjust the presser foot position

to be become the

the sewing

(1

0)

Tighten the screw (NO.®) of the presser foot with to come

material

clearance between the bottom surface of

o~o.5

mm.

down

the

presser foot and the surface of

to

the center of the needle hole

of the presser foot.

[Signal=

I D)

back

on

Page 14

7-7-2 Adjustment of the sensor of the presser foot cylinder

At

normal position, the sensor

At activate position, these sensor will

ID(NO.EJ)

be

is

ON and the sensor IE{NO.O) is OFF.

reversed.

Check the sensors by using

7-8 Adjustment

When tension close (the tension release plate

sensor

When tension open, (tension release plate approach to the tension disc), these sensors will

reversed.

Check the sensor

of

the tension release

IC(NO.®) on the cylinder

IB and

E-MODE (test mode)

(NO.GJ)

is

ON

and the sensor

IC

in

E mode and TEST MODE simultaneously.

leaves from the tension disc(NO.G:l)

IB(NO.GJ)

is

OFF.

),

the

be

7-9 Upper thread heat cut device

7-9-1 Setting thread puller

For a secure sewing at the seam beginning, a certain quantity of drawn-forward needle thread

required. The drawn-forward occurs after completion of seam with the clamps still lowered.

I Function sequence of Upper thread heat-cut procedure!

is

Page 15

-¢>

The sewing pattern

-¢>

The needle stops

-¢>

The presser foot lifted

-¢>

The needle thread tension open.

-¢>

The thread puller pulls the requiredthread quantity forward.

-¢>

The thread puller moves back into its base position.

-¢>

The needle thread tension close again.

-¢>

the thickness detector lowers

-¢>

The thread wiper pulls the drawn-forward needle thread into the

-¢>

heating position.

-¢>

The upper heater lowers.

-¢>

The thread is heated off.

-¢>

The clamp move up.

-¢>

A new sewing sequence can

The thread puller must

beginning

is

assured. If the drawn-forward thread quantity

is

finished.

in

the high-position of thread lever.

in

it's up-position.

!

on

the clamps.

be

started.

be

set so that, depending

on

the material

is

too small, the thread is too taut during

to

be worked, a secure seam

heating, and The thread end doesn't melt together.

To adjust the drawn-forward thread quantity

(1)

Loosen the nut (NO.

(2) Adjust the length

(3) At this time, make sure that sensor IB(NO.®) of the thread puller cylinder (NO.®) functions at

the end of the stroke of the cylinder. The sensor

position and

(4)

If

the sensor doesn't function, adjust the sensor position to correct position.

(5)

Fasten the nut

ON at it's drawn-forward position.

<D).

(A]

of the stopper screw (NO.®).

(NO.<D).

IB(NO.®) should be OFF at it's normal

0

[Signai=IS]

3

4

0

I i

'

I I

Page 16

7-9-2 Setting of the thickness detector

(

1)

Place material of the maximum

allowable thickness

between the upper and

(NO.CD).

(2)

Loosen the setting screw (NO.®)

slightly.

(3)

Pull the thickness detector (NO.®)

downward until it touches the lower

clamp

{4)

Tighten the setting screw (NO.®) .

(5)

At this time, make sure the sensor

(NO.®) of the thickness detector

cylinder (NO.®) functions. At upper

(normal) position the sensor

be ON.

7-9-3 Setting of the thread wiper

(NO.CD).

(1

Omm)

lower clamp

or

spacer

15

should

15

~J

0 0

@

0

1

0

The thread wiper

drawn-forward by the thread pull into the

correct position

The drawn-forward thread quantity must be

enough

Too high a tension

thread during heat-cutting.

To correct the thread wiper stroke

(1)

(2)

(3)

(4)

{5)

(6)

so

that the thread is not under tension.

Remove the rod cover

Loosen the nuts (NO.®).

Set the swing movement of the thread

wiper

up or down.

Tighten the nuts (NO.®) .

Replace the rod cover again.

After adjustment, check the position of the

sensors

wiper

At the initial position of the thread wiper,

the sensor

(NO.®) by rotating the nuts (NO.®)

cylinder (NO.®).

19

must be OFF.

pulls the thread quantity

for

the heat-cut procedure.

leads to

I9(NO.®) and IA(NO.®) of the

lA must

be

(NO.CD).

be

ON

a fraying of the

and the sensor

L_----;:=================:::;

6

The thread wiper should move freely past

under the

To correct the height of the thread wiper

(1)Piace material of the maximum

needle.

Page 17

(1)

allowance thickness

(2)

Swing the thread wiper manually past under the needle and check the thread wiper should not

(1

Omm)

or spacer between upper and lower clamp.

thereby strike against the

(3)

Loosen clamping screw

(4)

Adjust the height of the thread wiper.

(5)

Tighten clamping screw.

7-9-4 Adjustment of the upper thread heater

The upper heater must be

fully extended heater must have a clearance of approx. 1

The

fully extended heater must touch on the thread positioned by the thread wiper with a slight

The

pressure.

To adjust the position of the upper thread heater

(1)

Extend the heater (NO.

(2)

Loosen the screws

(3)

Adjust the heater vertically and horizontally.

needle. If the wiper interfere, adjust

(N0.0).

an

angle of approx.

CD)

manually.

(NO.@)

and the screws

by

following procedure.

90°

to the thread positioned by the thread wiper.

mm

to

the clamped material.

(NO.Cil).

(4)

tighten the screws (NO.@and

(5)

After this adjustment, check the sensor 17(NO.®) of the heater cylinder (NO.®) should

ON

and the sensor 16(NO.®) should be OFF at the normal position.

0 0

(@

0

Cil)and

the screws.

3

[Signal=l7]

0

~I

I

I

I

I

~I

2

be

4

6

1

Page 18

7-10

Adjustment

The lower heater

of

lower

is

thread

in

cut

heater

it's initial position, when the

,---------------

thread puller is outside the area of needle hole. \

(2)

Distance between the

edge of the cylinder and

the joint should be about

34mm so that the left side

of the lower heater

is

in

line with the outer edge of

needle plate bush.

For correction of the lower

heater, loosen nut of the

lower heater cylinder and

adjust the length the

cylinder rod.

Slide plate

2.2mm

L!'!_f!_e_d_le_ho!~

Needle

1

Rlate

~-

\ower

heo."ter

thrl'o.ol

"'

-

~~;:-------------

needl

hole

p<Aller

c

y\lnde-r

senser

--

IG

(3)

Height of the lower

heater

in

the normal

position should not

touched any part.

For correction, bend the

lower heater accordingly.

(4)

Height of the lower

heater

in

the normal

position should

positioned 2.2mm lower

than the slide plate.

For correction, bend the

thread

puller accordingly.

be

be

threo.d

cylinder

puller

cyllnclc>r

sense>r

St:"nser

IF

cylinder

SC'r1S('r

lG

-~-~F=====-.

IF

Page 19

The standard stroke of thread take-up spring

(NO.CD)

To adjust operating range,

(1)

(2)

(3)

is

8 to 15 mm.

Loosen screw

Adjust the operating range

thread the take-up spring adjusting plate

(NO.@)

After adjustment, tighten screw

firmly.

up and down.

(NO.@)

by

moving

(NO.@)

7-14.

The position detecting disc do not normally need

positions stand in the relationship indicated below.

(1)

(2)

(3)

Adjustment

Draw out the synchronizer cover

The synchronizer comes with 2 position detecting discs. The front disc (red)

down position, and the rear disc (black)

The rear disk (black) has a scale. Align the triangular mark (NO. O)of the front disc (red) at the

degree position on this scale. This setting

&

of

the

position

detecting

(NO.CD)

disc

to

be adjusted but it should

cable and remove

(NO.@)

to detect the up position.

is

used for determine the start timing of X-Y table.

it.

be

checked that their

is

used to detect the

Caution----------------~

* If the setting of discs is changed, accurate movement of X-Y table can not be

performed.

(4)

Adjusting for up position thread take

(5)

Turn the synchronizer bush (NO.®) with holding pulley.

(6)

After adjustment tighten screw

up

(NO.@).

lever

is

in high end), loosen screw (NO.@).

90

3

4

0

Page 20

7-15.

Adjustment

of

the

mechanical

home

position

[NOTE] The mechanical home position

sewing machine

covered with

.....

... ...

is

shipped from the factory. However, it

diagonal lines.

...

0

is

fixed at the center of the sewing area when the

can

be

moved within the area

1

0

..,.

0

""

L_

l

®Original home position 0Adjustable area

(1)

Turn the power switch

box. For this cancellation, at the normal mode condition of the setting panel, push

(No.1) then, press

display !ALCon! is appeared and the sewing area limit

The

---"s~o

ON

QJ

key (No.2) and

~----<

100

and cancel the sewing area limit with the setting panel of the control

[.8]

Key (No.3) at the same time for more than 2 seconds.

w

[[B]

[]

[0

is

canceled.

[QJ

[QJJ

[EJ

key

~

2

Page 21

[NOTE]

If

do not cancel the sewing area limit, shifting the mechanical home position make the effective

sewing area narrower than the

original.

(Example)

If

shift the mechanical home position to the X direction 30mm, the Y direction 20mm

without

invalid and the effective sewing area becomes narrower

the figure.

canceling the sewing area limit, the area cov<lred with diagonal lines becomes

as

a bold rectangle shown

0

-t-."'

100

on

(2)

After the cancellation of the sewing area limit, once, turn the power switch OFF.

7-15-1. Shifting the mechanical home position to the X direction

(1)

Loosen the detector plate fix screws

to the right, the mechanical home position is shifted to the right and if it

the mechanical home position

(2)

After the mechanical home position shifting, tighten the detector plate fix screws(2 pieces)

securely.

is

(2

pieces)

shifted to the left.

(NO.<D).

If move the detector plate

is

moved to the left,

(NO.@)

Page 22

[NOTE]

7-15-2. Shifting the mechanical h me position to the Y direction

(a)

In

the case described above, available amount of adjustment of the home

position

For further adjustment, Loosen set

detector adapter(NO.

(b)

If move the detector adapter(NO.@) to the right, the mechanical home

position

(c)

After adjustment, tighten the set screw(NO.Gl).

(1)

Remove the V-belt cove and cover plate of the machine

{2)

Loosen

front , the mechanical h me position

(3)

After the mechanical ho e position shifting, tighten the

screws(NO.CD)

is

0 to 25mm.

@).

is

shifted to the left.

f the Adjuster plate(NO.@).

screw(NO.@l) and move position of the

is

shifted to the backward.

arm

tail.

If

move the Adjuster plate(NO.@) to

screws(NO.CD)

securely.

0

7-15-3. Fine adjustment of the mechanical home position

[NOTE] When the original mechanical home position

or it

is

required to move a little, a fine adjustment of the mechanical home

position

box. For this fine adjustment, refer to the instructions

display and the function of each key]

operation of the technical manual

in

the

X,

Y direction can be done with the setting panel of the control

I CONTROL UNIT!.

in

the

X,

is

shifted to the another position

in

the paragraph

Y direction

[1.

Program 1 mode

[Q]

Basic mode

Page 23

7-16.

Adjustment

[NOTE] The work holder stop position which

by the

plate is changed, the mechanical home position

aberration is happened, make the following adjustment.

the detector senses the home position, the red pilot light of the detector goes on

each time.

7-16-1 . Adjustment of the X detector clearance

(1)

Remove the X detector cover.

(2)

Check the clearance between the surface of the detector and the detector plate.

of

the X-Y

X-

Y detectors.

detector

If

the clearance between the detector and the detector

clearance

is

the mechanical home position

is

al:;o changed. If such

Plioase keep it

is

detected

in

mind if

If

this clearance

(3)

If

this clearance is out of the normal condition, loosen the set screws

move the detector plate, then adjust the clearance to

(4)

After the adjustment, make the detector surface parallel with the detector plate then,

tighten the

7-16-2 Adjustment of

The clearance between the detector surface andY-drive shaft is set to 1.5mm.

is

There

,----LG

no adjustable space

Caution

set

is

about

1.5~2.5mm,

it

. .

screws

theY

(NO.<D)

detector clearance

securely.

in

this clearance.

________________

is

the normal condition.

be

proper.

* If the detector clearance becomes more than 2.5mm, the work holder stop

position becomes unstable, furthermore, if the clearance becomes far bigger

than 2.5mm the work holder does not stop and becomes out of

control.

(NO.<D)

----,

and

Page 24

7-17

Adjustment

[NOTE] The proper condition of the X-Y timing belt tension is standing that they will not

7-17-1

Adjustment

(1)

Remove the X-bellow (left) and X-Y cover.

(2)

Loosen the set screws

(3)

If tighten the tension adjust screw (NO.Gl), the X timing belt (NO.®) tension will be increased.

(4)

After the adjustment, securely tighten the set screw (NO.®) of the bracket

X-Y cover and X-bellows

of

the

X-Y

timing

be got any yield even it

of

the

X timing

(N0.®)(4

on

belt

tension

is

slightly pushed by hand .

belt

the original locations.

. ·

tension

pieces) of the bracket

(NO

.CD).

(NO.CD)

and put the

Page 25

7-17-2.

(1)

Adjustment

Loosen set

of

theY

screws(NO.CD)

timing belt tension

of

the

brackets. (It's located machine arm taii)Aiso loosen set

screw(

(2)

If

(3)

After the adjustment, tighten

NO.@) of the bracket.

tighten the tension adjust screw

the

(NO.@),

set

screws(NO.CD)

theY

timing belt tension will be increased.

securely.

2

Page 26

APPENDIX

1 CHART OF CONNECTING WIRES

16Z~-02R1(

1'551TL)

CA.BL[J

VCTF

5CXO.J5Q

sa.6(nROO

MLIR)

SQ7{1DISIJN

11f1LIS[)

sru(lOW£R

TO"ER)

SOLZ(CLAUP

LIFT)

lllli~~~~~~~~=========~:::~=====

SOC9{SIU'?I~

roor)

~

Pin No

25

"

'

'

2

4

14

SIC

""

OH

ov

II

ov

IJ

01

''"

CON

CB

-

NO

G

LOW

UP

NOTE

BUZZER

TRI~

TRI~

UP

TRI~

ENil

ENS

ON

OSBL

OSBL

Orf

HALT

X-HOME

DETECTOR

SWITCH

BUZZER

~209-0J[S1051L)

~

VPP[R

n1~fAD

ll!lllLR

Slli(IHU<NESS

51U(ClMP

Slll.l(llf'I'OIIRMIIER)

SOI..S{niRIAIJ

SI:MIB{IHUJ(S'i

S[N'A=p!hu

S[N\,I{UI'I'[R

S£Uii(UI'I'£R

SOf.ll(ntWD PlllfR)

OmCTOO)

RK:!H)

PULIIR)

50lll(lfl0l[

COOUR)

5a.IO(lSlACI:SIIPI'IHC)c

(.,.,!>~not)

[l(l[Cllll)

!ide

3f.:nsor~S·[lii~'B~•jpo·O~•o••••••o•-~~~~g~~~~t~~~-~-~

IRLlU[II)

lRI!MR)

=:~

:

L_l

-----;;;;-~<=3====l

~=T[

0~=

~

c:::=:::::;fl================~

0~~

EXLON

AH-6

10/151N

KURO

'"

'"

'"

0

:-1r<>1::;•::===================================================

CAIJLE

L_

c=0

(Q] PLUG(5006ll)

D

RECEPTAClE(SOO'JTl)

; 5025-02?1 m 5015-0ZRI

151l15-0<PI

I 002S-04RI

IMNUAL/AUTOr-

SWITCII

STEI'PING~OTOR

X-AXIS

5(NI\l.(L0W(A

i!IIOIOI[R)

SIN81(l0W[R

IRII!OI[R)

SITPPINCMOIOR~

Y-MIS

J:l0179-1

C}ijj'

~50779-1

~50760-1

J

•

•

J~760-1

CABLE9

Page 27

7

~

-~

CAULE4

OR-VCTF

KXO.JS

OR-VCTF

vcrr

JCXO.JSQ

4Cm.Jsa

CN3LE5

CAilLE6

i~B_LE_a

__

v_c_rr_,_s_cx_o

__

J_so

__________________________________

,-~

dfi:_

~

=:::::

__J-~1===============~~"@:

L___

l r

~~j

ti~;~

151~5-01

l>n»)

lllU

~:

5195-02-llJ

112151)

5195-02-IJJ

••

'

l1215t)

••

;~~

~m-o~

___

lXI

.1

[5715JL)

'-""

..

CABLE2

~

0

- 0

leoNa

IEIDI

IcoN>~

liil

[)

lcoNlO

[j)

!coN7

IeoNI

I

lffl

~

TEZ

Siq

No

t24Y

84

06

A4

07

A5

~HV

85

08

A6

09

A7

fl~V

OA

A8

OB

A9

t14V

"'

oc

AID

+2~1/

88

1E1

A1

"

15

A2

._,

IN

16

A4

A5

"'

17

A6

18

AB

A9

"'

19

A10

lA

84

18

86

IC

88

10

810

TE2

IE

A1

If

AJ

IG

81

IH

83

810

"'

,,

I

'"

04

1

+24V

2

I

t±J

02EI

.)

124V

II

;

l,~ivl

if±l+~~vlOT7_t_~~

J.~;vJ

II

'

J

'

X-t(lld[

""

'

J

I

'1

""

'

4

I

SERVO

ENCODER

Func

HfAlfR

014

OT5

1HICK!'I£SS

-

OF2

Cl.AI.IP

OT7

UPP(R

-

016

11~1!_00

019

NEEDLE

-

OTA

2

-

- -

NO

nlON£SS

-

NO

UPP[R

UPPER

NO

NO

THREAil

WIPER

NO

W\Prn

NO

NO

llNSKlN RUfA5E

101$11,)!4

NO

PRt:Sst:R

NO

NO

P!USSER

NO

LOWER

NO

LO'IIER

NO

IMN~AUTO

--

Fum;

Note

OF1

Cl~Pt[fl

WIP(R

-

1

ll[ISIJN

IPHESSfR_~

Pf

X-I!Ot.lf

I

R!:lillf]

S!:NSOII

"'

T-IKJUfSlli'llH

HOldE

"'

Note

-

OC!ECIQR

RICH!

TJIII!U.IER

-

Putt! R

COOI..IH

-

STACE

~p_~ton!!!l_

omcm~

(lUi

-

TRit.tt.tER"fPUSH:::l

TRI\.MR

(PULL)

Pt..UER

(PULl)

(PUSH)

(1'\Jtl)

(PUS~-

RELEASE

(PLII.l)

roorTrusu)

FOOl

PUl

TR!Mt.I[H

TR~~Q!.(fl,!ill_

t)

(f.u,.Jl

SWHCH

c_

LIYCY

0034608

•8CX0.5SQ

61,05112-1(}50669-1)

'

•

CON

~-

'

'

'

•

'

'

•

C (lor

'.>IEI'PINC

"'"

••

'IHif[

~·

=·

=

..

....

·~

'~

51CML

~

Me

""

'"'

·~

"'

·~

·~

WIOR)

Page 28

(")

"

<!)

;.(!

~ll

0

!-"

CJ

"

L ..... i

n

0

z

<

fTl

z

:::l

0

z

>

;-··

n

>

w

r

i""l

1/1

0

;;u

c

:z.

:::j

[Jl

------

....

----:-

B-

LN

DJ

0

<.::

' !

r··---.

.....

.

..

:/

I

,1..·

__ -...... \ ......

,

---

1

•,

____

.

L

}·----'!

---00~;,-J

L!UuM

~I

jj_

,

..

b.

.

c

~~

'-"

",

i~~,i

I

·";vi: , _..-

" . I

. .

If!

II

i I

--

~~\

:._L

...... , ..

L_,

__

_j

&-16

_____

1

rs~i

I

----,

~

)J

; i i

;

i

.~-

: I

: - I

i !

j

I

':;']""TIl

_J§~~i

_____

i:

_,

~1A

l~

:.

l.Li

··:·l_

I

I

'

~--

_j

I

'

..

...,

0 X

"'"'

or'l

[Till

p·\

()

.... ,

:E

Jl

z

G)

Ol

m

~

m

m

z

:r!

m

"ll

0

:E

m

Jl

(/)

~

(")

I

~

0

Jl

m

s

;;.:

I

'..:U

0

0

(ll

l

0

<

- ....

~\

X.

··.:.::::

I

!

i

i'"

r_J

~

:-~:...:

0

r

.... :

..

··

..

--'

......

L.-

f?l

' '

j i

' .

' .

! i

. '

. '

! :

I I

c·

''

0

m

··;--

o:::-1

X

::u

0

•

L

..

--------··------

!

'

..

-~

_______

J

----

-L

: l

' '

' '

' '

: I

' '

\ i

: i

:

·--~---·

•••.•••••

.L

··················

..........

--~ i

.......

:.

...

-~

.

Page 29

3 PLK-B1008H

l/0

TABLE

TERMINAL

CON

1-2

CON

1-3

CON

H-3

TE1-A2

TE1-A4

TE1-A6

TE1-A8

TE1-A10

TE1B4

TE1-B6

TE1-B8

INPUT

SIGNAL

11

12

14

15

16

17

18

19

lA

IB

START

CLAMP

STOP

THICKNESS DETECTOR UP

UPPER

UPPER

UPPER

WIPER

WIPER

TENSION

IC TENSION

FUNCTION

TRIMMER

ACT

TRIMMER BACK

THREAD

PULL

BACK

ACT

RELEASE

RELEASE

BACK

ACT

ACT

OUTPUT

TERMINAL SIGNAL CUSTOMIZE FUNCTION SOL

CON

CON

CON

CON

CON

TE2-A4

TE2-AS

TE2-A6

TE2-A7

TE2-AB

TE2-A9

D-1

D-S

D-2

D-10

D-3

01

02

03

04

OS

06

07

08

OS

OA

OB

OT2 LOWER TRIMMER

OT1

NO

OF1

WIPER

TENSION RELEASE

CLAMP LEFT

OTA PRESSER FOOT

OT4

OTS

OF2

HEATER

THICKNESS DETECTOR -.

CLAMP RIGHT

OT7 UPPER TRIMMER 4

OTS

DRT NEADLE COOLER

THREAD PULLER

10

No

8

6

7

2

g

-

1

3

5

TE1-B1 0 ID

TE2-A1

TE2-A3

TE2-B1

TE2-B3

CON

G-3

CON

'-----~

G-4

IE

IF

IG

IH

II

IJ

PRESSER

PRESSER

LOWER

LOWER

NORMAL I TEST

LOWER

UPPER

FOOT

FOOT

TRIMMER

DOWN

UP

ACT

TRIMMER BACK

SWITCH

TRIMMER SWITCH

TRIMMER SWITCH

----~-

CON

G-13

OH

OTB

BUZZER -

()1

Page 30

4 TRIMMING TIME CHART

Start

SW

[DSW]

[SRC] ON

[T]

[UP]

[SRT]

[FN4]

ON

_n_

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

sewi~

n

I

lr

Trimming

1

I

process

(

sewing or

I

feed

-

l

-

Presser

Tension release OPEN

Thread

hickness

Lower

Upper

foot

CLOSE

puller PULL

Wiper

Heater

detector

trimmer

trimmer

SWEEP

UP

DOWN

BACK

BACK

ON IJ're

OFF

DOWN

GO

BACK

GO

BACK

UP

I

I

-\l

heatinl[

'---

I;

400ms

350ms

~

l

1500ms(default)

L

\

1-

r'-

'----

'----

-

-

-

-

-

,--

!Heater

[DSW]

[SRC] : Start prohibit inpu signal

[SRT]

[FN4] : Function No.4 output

protection

: Sewing in progress output signal

(by

[T]

:Thread trimming output signal (output

:Up

[UP]

position output signal (by system) '

: Start input signal (output

: In the trimming process, heater is automatically off after 2.5

. trimming process is

:In any time, heater can

by

signal (output by teaching data)

end

or not.

be

off

(by

system)

step sequence)

by

teaching data)

teaching data)

by

pressing the halt switch.

sec

inspite of

Loading...

Loading...