Page 1

MITSUBISHI

ADVANCED

AND EVER

ADVANCINGI

NinSUBiSHl

ELECTRIC

Industrial

Sewing

INSTRUCTION MANUAL <

Electronic

Pattern

Sewing

PLK-A2016F

PLK-A2016FL

Machine

Sewing

Machine

Machine

>

A180E257P01

Page 2

Introduction

Thank

machine

you

please

keep

These

the

instructions

inclusive

sewing

how

to

Instruction

^Mitsubishi

<Control

for

from

read

through

unit

of

Mitsubishi.

the

machine.

prepare

Manual

Industrial

Unit>:

purchasing

these

in

the

best

describe

machine

For

details

the

sewing

below.

A180E243P01

this

industrial-use

Before

attempting

instructions

possible

the

head,

working

operations

of

this

on how

patterns,

Sewing Machine

since

industrial-use

to

operate

reference

Instruction

electronic

to

operate

they

order.

of

the

the

should

the

will

mechanical

help

electronic

control

be

Manual

sewing

unit,

you

unit

made

to

parts,

to

and

the

*

No

part

written

*

The

notice.

*

Every

are

inconsistencies

your

*

COPYRIGHT

MITSUBISHI

of

permission

contents

effort

correct

comments.

this

of

was made

and

(C)

ELECTRIC

manual

from

this

accurate.

or

other

1992

may

be

Mitsubishi

manual

to

CORPORATION

are

ensure

However,

points

copied

subject

that

should

or

transcribed

Electric

to

the

if

any

be

Corporation.

change

contents

errors,

noted,

without

without

of

please

this

manual

send

us

Page 3

Contents

1.

CONSTRUCTION

2.

FEATURES

3.

SPECIFICATIONS 4

3^

^^ 2

3.1

3.2

4.

INSTALLATION

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

5.

6.

PREPARING

CHECKPOINTS

General

Replacement

Installing

Assembling

Connecting

Connecting

Installing

Power

Connecting

Changing

specifications

cord

the

TO

OPERATE

FOR

parts

the

the

the

the

the

for

the

direction

for

table

machine

air

tubes

leads

control

work

power

lamp 16

AND

PRECAUTIONS

OPERATION

light

head

box

cable

of

the

and

motor

heavy

rotation

fabrics

4

8

9

9

10

13

14

15

17

17

19

20

7.

HANDLING

7.1

7.2

7.3

7.4

Threading

Winding

7.5

7.6

7.7

Installing

Removing

THE

SEWING

Lubrication

Installing

the

Installing

the

the

the

needle

bobbin

the

the

inner

MACHINE

HEAD

needle

thread

thread

bobbin

bobbin

case

hook 28

23

24

25

26

26

27

27

Page 4

7.8

Thread

tension

28

7.9

7.10

7.11

7.12

7.13

8.

OPERATION

9.

ADJUSTMENT

^

9.1

9.2

9.3

9.4

9.5

9.6

Adjusting

Adjusting

Replacing

Lubrication

Air

piping

foot

AND MAINTENANCE

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

the

the

the

to

the

the

the

the

the

the

work

presser

lower

with

cylinders

bobbin

height

driver

thread

presser

wiper

holder

clamp

silicone

drive

foot

for

winder

of

the

and

hook

guide

foot

frame

oil

work

holder,

needle

(above

mechanism

bar

hook)

29

31

32

32

presser

33

34

34

34

35

35

37

39

41

^

9.7

9.8

9.9

9.10

9.11

9.12

9.13

9.14

9.15

Adjusting

Maintaining

Adjusting

Adjusting

Adjusting

Adjusting

the

the

the

the

the

home

and

X-Y

position

inspecting

table

synchronizer

thread

trimmer

trimmer

thread

belt

Adjusting the thread release

Adjusting

Adjusting

the

stroke

the

LIMI-STOP Z

of

the

motor

the

tension

tail

take-up

X-Y

belt

table

length

spring

tension

43

47

49

51

53

55

56

57

58

Page 5

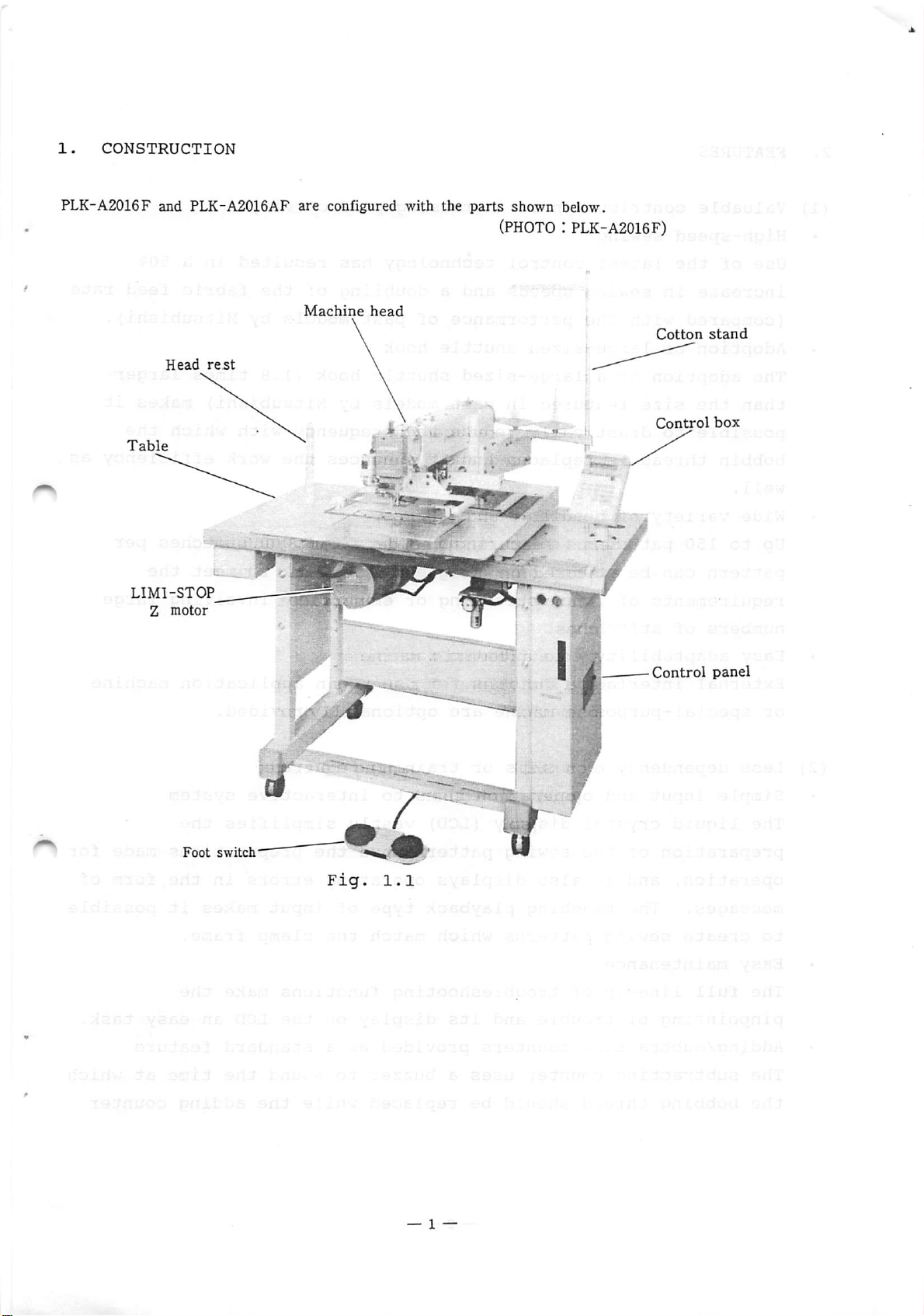

L.

CONSTRUCTION

PLK-A2016F

Table

LIMl-STOP

and

PLK-A2016AF

Head

Z

motor

rest

are

Machine

configured

head

with

the

parts

shown

below.

(PHOTO:PLK-A2016F)

Cotton

Control

stand

box

Foot

switch"

Fig.

1.1

Page 6

2.

(1)

•

FEATURES

Valuable

High-speed

Use

of

contribution

sewing

the

latest

control

to

increasing

technology

productivity

has

resulted

in

a 50%

increase

(compared

Adoption

The

adoption

than

the

possible

bobbin

well.

Wide

Up

pattern

to

thread

variety

150

requirements

numbers

Easy

External

or

adaptability

special-purpose

in

with

of

size

to

patterns

can

of

stitches.

interface

sewing

the

large-sized

of

a

large-sized

featured

drastically

is

replaced

of

needles

be

stored

of

fancy

to

speeds

and

performance

shuttle

in

past

reduce

and

and

featuring

on

a

single

stitching

automatic

functions

machine

are

a

doubling

of

hook

shuttle

models

the

it

patterns

the

or

machine

for

optionally

past

hook

by

frequency

enhances

data

for

floppy

embroidery

use

as

of

the

models

(1.8

Mitsubishi)

the

8,000

disk

an

application

provided.

fabric

by

Mitsubishi).

times

with

work

stitches

to

meet

involving

larger

makes

which

efficiency

the

feed

it

the

per

large

machine

rate

as

^

(2)

Less

Simple

The

liquid

preparation

operation,

messages.

to

create

Easy

The

full

pinpointing

Adding/subtracting

The

subtracting

the

bobbing

dependency

input

crystal

of

and

The

sewing

maintenance

line-up

and

the

it

teaching

of

trouble

thread

on

skills

operation

display

sewing

also

patterns

of

troubleshooting

counters

counter

should

or

thanks

(LCD)

patterns

displays

playback

which

and

its

uses

be

training

vastly

operating

match

display

provided

a

buzzer

replaced

to

and

type

required

interactive

simplifies

the

of

input

the

functions

on

as

a

to

sound

while

system

preparations

errors

clamp

the

standard

the

makes

frame.

make

LCD

the

adding

in

an

the

the

it

the

easy

feature

time

made

form

possible

task.

at

which

counter

for

of

^

— 2 —

Page 7

makes

(3)

Esthetically

it

possible

pleasing

to

verify

seams

the

and

output.

stitching

^ •

Stable

The

uses

feed

fabric

races

intermittent

and

stitches.

Resolution

By

bringing

accurately

both

Maximum

The

where

smoothly

variable

a

large-pitch

system

feed

and

in

the

down

stitch

delicate

sewing

mechanism

backlash-free

feed

0.1

resolution

to

and

length

drive

mm

a

precisely.

stitch

touch

of

units

0.1

of

length

is

such

features

timing

and

makes

of

the

mm

pitch,

12.7

mm

accommodates

required

articles

both

belts.

for

fabric

it

such

as

a

travel

clear,

feed

is

now

everything

as

container

system

It

enables

well-defined

mechanism

possible

in

embroidery

bags.

from

which

reliable

to

sew

stitches

to

seams

— 3 —

Page 8

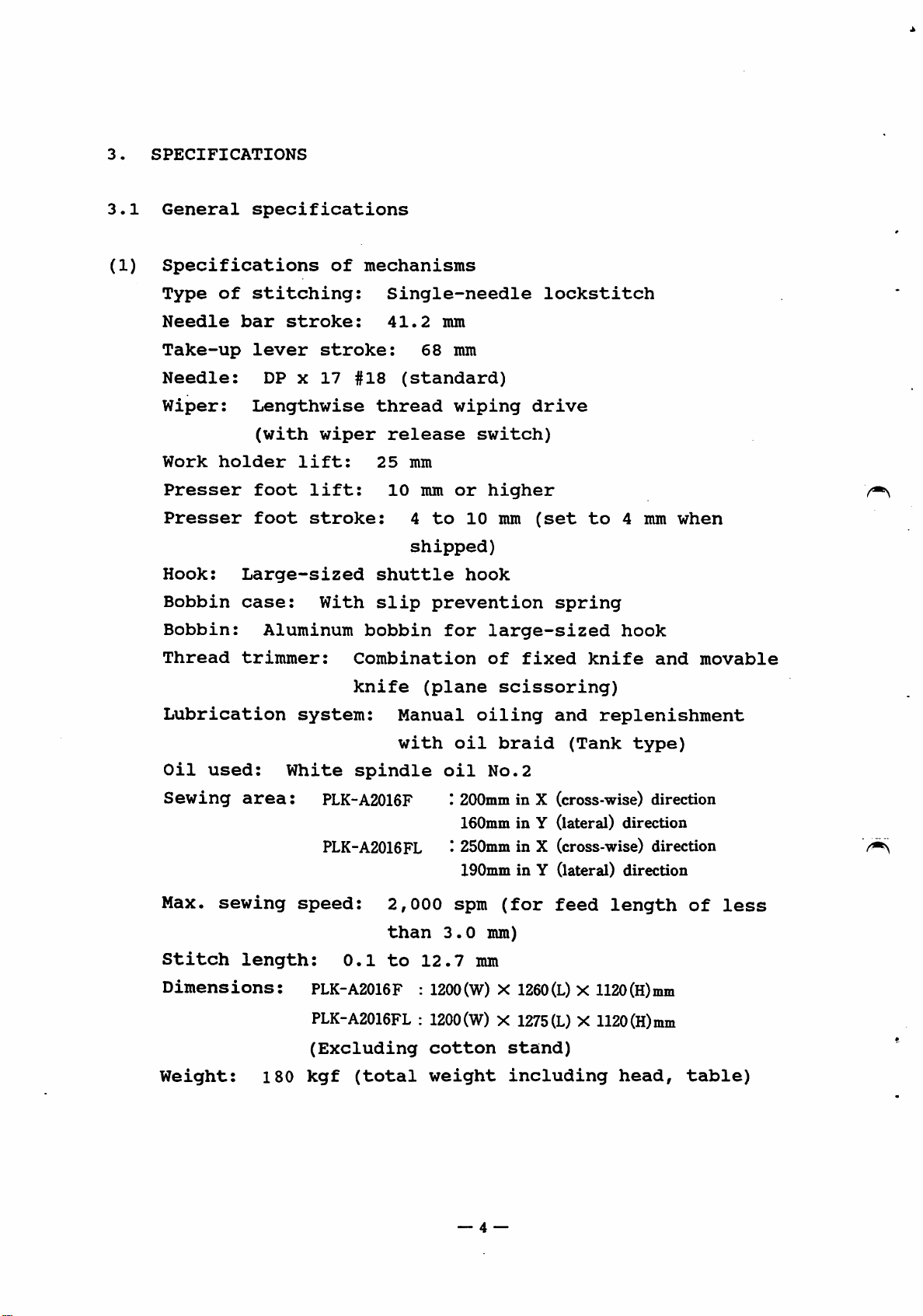

3.

SPECIFICATIONS

3.1

(1)

General

specifications

Specifications

Type

Needle

Take-up

Needle:

Wiper:

Work

Presser

Presser

Hook:

Bobbin

of

stitching:

bar

lever

Lengthwise

(with

holder

foot

foot

Large-sized

case:

Bobbin:

Thread

trimmer:

of

stroke:

stroke:

DP x

17

wiper

lift:

lift:

stroke:

With

Aluminum

mechanisms

Single-needle

41.2

68

#18

(standard)

thread

release

25

mm

10

mm

4

shipped)

shuttle

slip

bobbin

Combination

mm

mm

wiping

switch)

or

higher

to

10

mm

hook

prevention

for

large-sized

of

lockstitch

drive

(set

spring

fixed

to

knife

4

mm

hook

and

^

when

movable

Lubrication

Oil

used:

Sewing

Max.

Stitch

area:

sewing

length:

Dimensions:

Weight:

White

ISO

knife

system:

spindle

(plane

Manual

with

oil

oiling

oil

scissoring)

braid

No.2

and

replenishment

(Tank

type)

PLK-A2016F *200mm in X (cross-wise) direction

160mm in Y (lateral)

PLK-A2016FL 250mm in X (cross-wise) direction

speed:

0.1

2,000

than

to

12.7

190mm in Y

spm

3.0

mm)

mm

(for

(lateral)

feed

direction

direction

length

PLK-A2016F:1200(W)X1260(L)X1120(H)mm

PLK-A2016FL:1200

(Excluding

kgf

(total

(W)X1275

cotton

weight

(L)X1120(H)

stand)

including

mm

head,

of

table)

less

— 4 —

Page 9

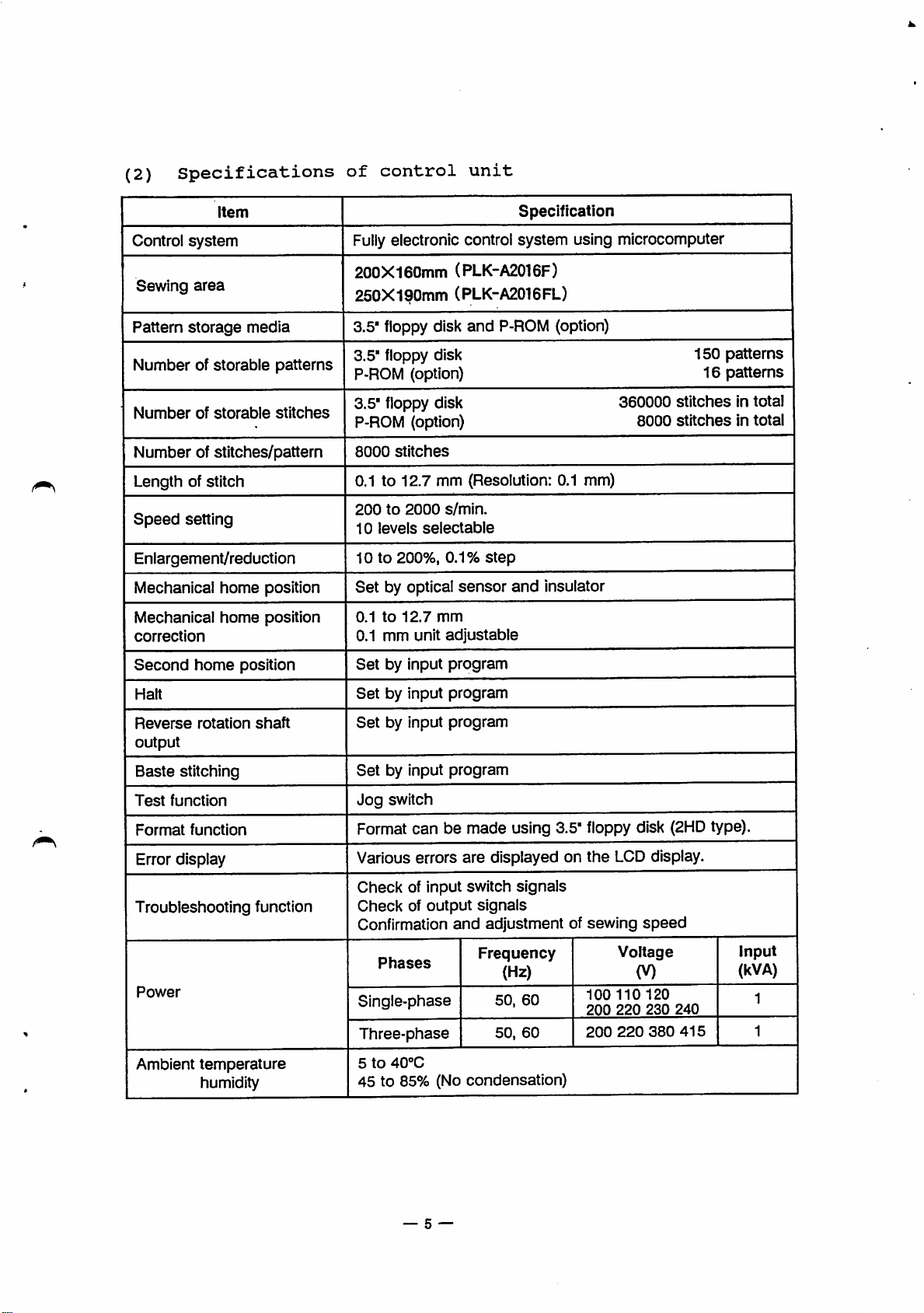

(2)

Specifications

of

control

unit

Item

Control

Sewing

Pattern

Numberofstorable

Number

system

area

storage

of

storable

media

patterns

stitches

Numberofstitches/pattern

Length of stitch

Speed

setting

Enlargement/reduction

Mechanical home position

Mechanical

correction

home

position

Specification

Fullyelectronic control system using microcomputer

200X160mm (PLK-A2016F)

250X190mm

3.5*

floppy disk

3.5" floppy disk

P-ROM

3.5"

floppy

P-ROM

8000

stitches

(PLK-A2016FL)

and

P-ROM

(option)

150

(option) 16 patterns

disk 360000 stitches in total

(option) 8000 stitches in total

0.1 to 12.7 mm (Resolution: 0.1 mm)

200to2000

10

levels

10to200%,

Set

by optical

0.1to12.7

0.1 mm unit

s/min.

selectable

0.1%

sensor

mm

adjustable

step

and

insulator

patterns

Second

Halt

Reverse

output

Baste

Test

Format

home

rotation

stitching

function

function

Error display

Troubleshooting

Power

Ambient

temperature

humidity

position

shaft

function

Set

by input

Setbyinput

Set

by input

Setbyinput

Jog

switch

program

program

program

program

Format can be made using 3.5"floppy disk

Various errors

Check

of input switch

Checkofoutput

Confirmation

Phases

Single-phase

Three-phase

5to40°C

are

displayed on

signals

signals

and

adjustment of sewing

Frequency

(Hz)

50.

60

50,

60

the

LCDdisplay.

Voltage

100 110

200 220

200

220

speed

(V)

120

230

45 to 85% (No condensation)

380

(2HD

240

415

type).

Input

(kVA)

1

1

— 5 —

Page 10

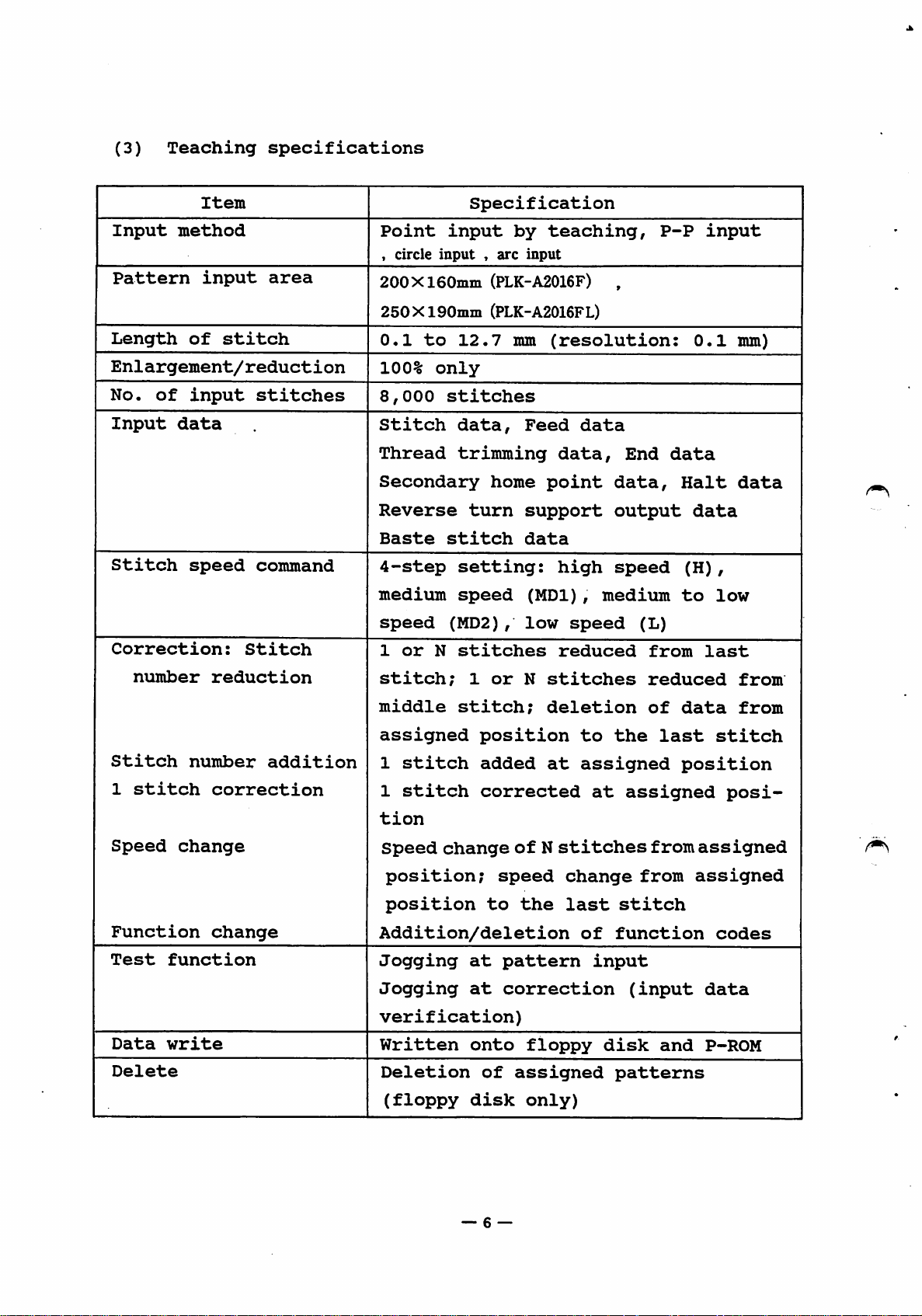

(3)

Teaching

specifications

Item

Input

Pattern

Length

method

input

of

stitch

Enlargement/reduction

No.

of

Input

Stitch

Correction:

number

input

data

speed

stitches

command

Stitch

reduction

area

Point

,

circle

input

input*arc

200X160niin

250X190min

0.1

to

12.7

100%

8,000

Stitch

Thread

only

stitches

data.

trimming

Secondary

Reverse

Baste

4-step

medium

speed

1

stitch;

or

stitch

setting:

speed

(MD2),

N

stitches

Specification

by

teaching,

input

(PLK-A2016F) ,

(PLK-A2016FL)

mm

(resolution:

Feed

data.

home

turn

point

support

data

high

(MDl),

low

reduced

1

or

N

stitches

data

speed

End

data.

output

speed

medium

(L)

from

reduced

P-P

data

0.1

Halt

data

(H),

to

input

mm)

data

low

last

from

Stitch

1

stitch

Speed

Function

Test

Data

Delete

number

change

function

write

correction

change

addition

middle

assigned

1

stitch

1

stitch

tion

Speed

position;

position

stitch;

position

added

corrected

change

speed

to

Addition/deletion

Jogging

Jogging

at

at

verification)

Written

Deletion

(floppy

onto

of

disk

deletion

to

at

assigned

ofNstitches

change

the

last

of

pattern

correction

floppy

assigned

only)

the

at

stitch

function

input

disk

patterns

of

data

last

position

assigned

from

from

(input

and

from

stitch

posi

assigned

assigned

codes

data

P-ROM

— 6 —

Page 11

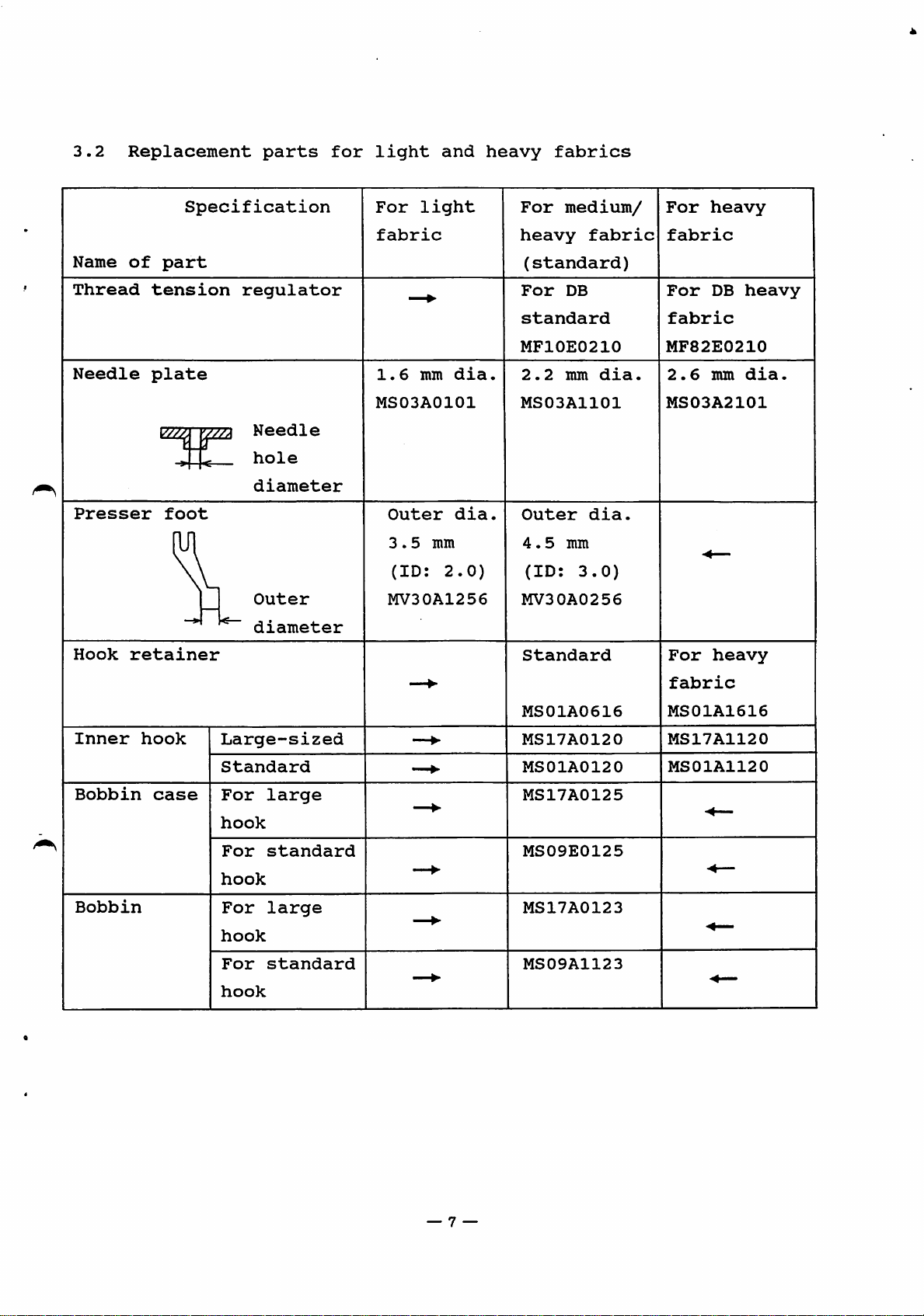

3.2

Replacement

parts

for

light

and

heavy

fabrics

Name

Thread

Needle

Presser

Hook

of

tension

plate

retainer

Specification

part

foot

regulator

Needle

hole

diameter

Outer

diameter

For

light

fabric

1.6

mm

MS03A0101

Outer

3.5

(ID:

MV30A1256

mm

dia

dia,

2.0)

For

medium/

heavy

(standard)

For

DB

standard

MF10E0210

2.2

mm

MS03A1101

Outer

4.5

mm

(ID:

MV30A0256

Standard

fabric

dia

3.0)

dia

For

heavy

fabric

For

DB

fabric

MF82E0210

2.6

mm

MS03A2101

For

heavy

heavy

dia.

Inner

Bobbin

Bobbin

hook

case

Large-sized

Standard

For

large

hook

For

standard

hook

For

large

hook

For

standard

hook

MS01A0616

MS17A0120

MS01A0120

MS17A0125

MS09E0125

MS17A0123

MS09A1123

fabric

MS01A1616

MS17A1120

MS01A1120

— 7 —

Page 12

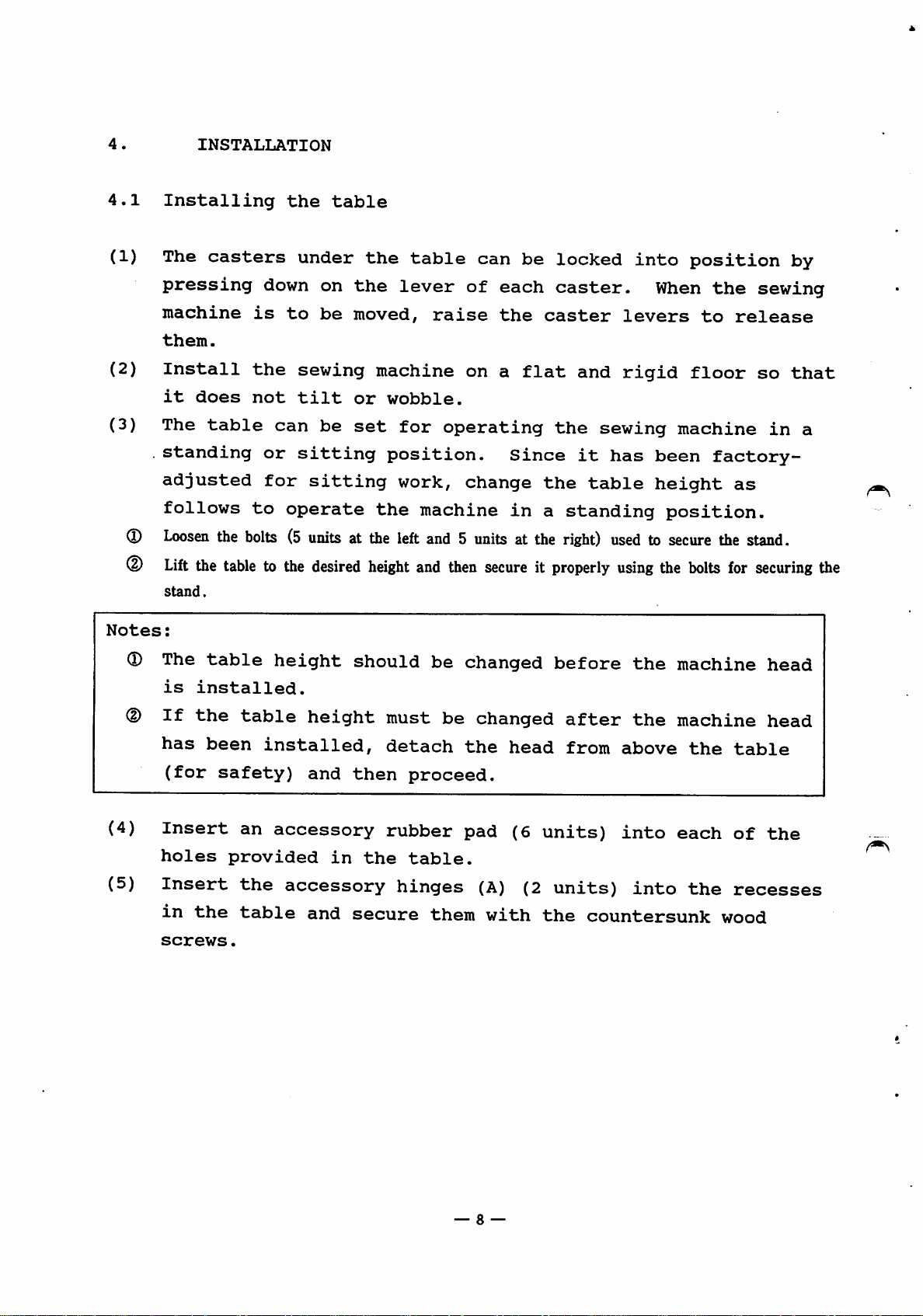

4.

INSTALLATION

4.1

Installing

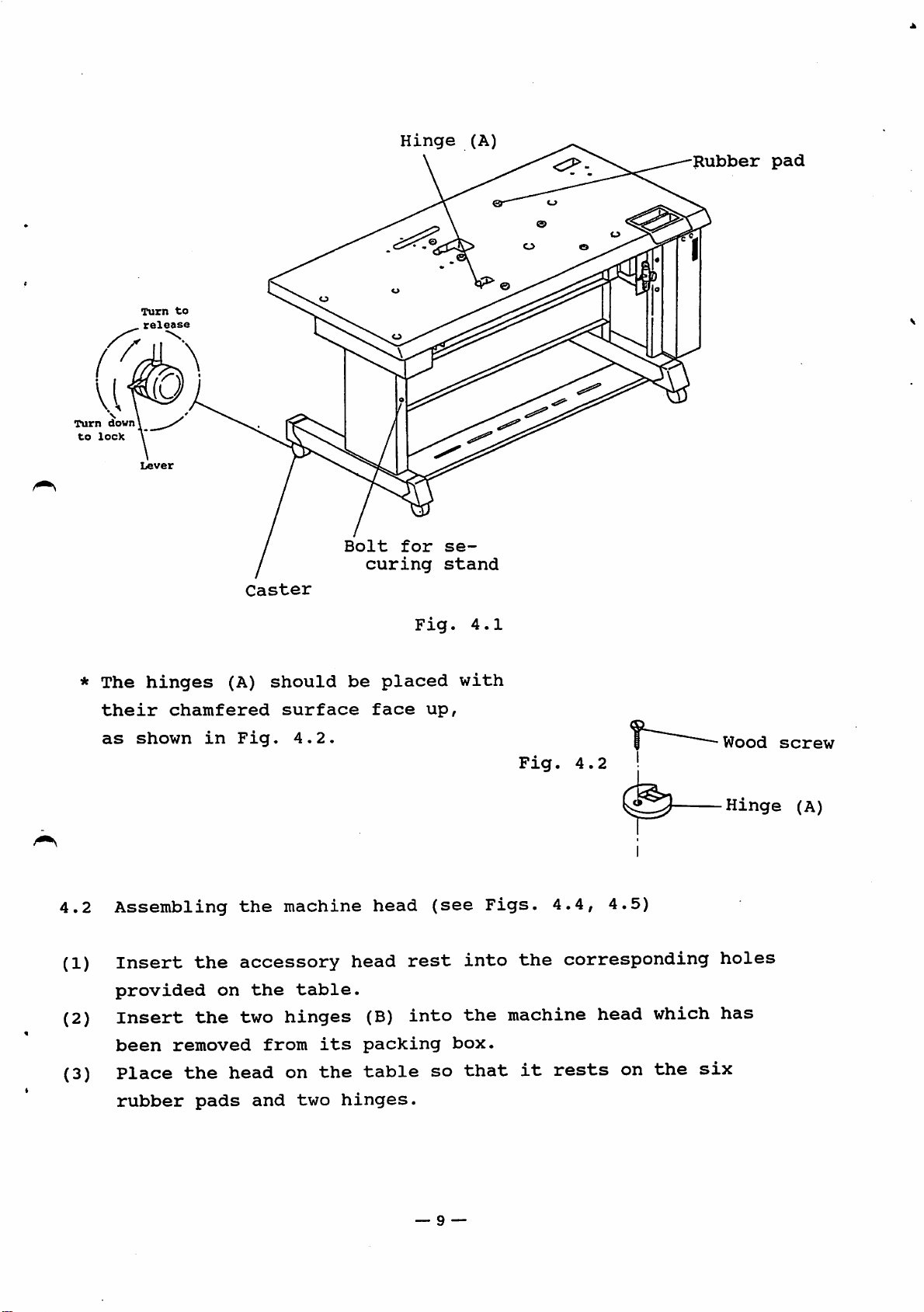

(1) The

pressing

machine

them.

(2)

Install

it

(3) The

standing

adjusted for

follows

(I)

Loosen

d)

Lift

stand.

Notes:

casters

does

table

the

the

tabletothe

the

under

down

is

the

not

or

to

sewing

tilt

can

sitting

on

be

be

sitting

to

operate

bolts(5units

desired

table

the

the

moved,

or

set

at the left

height

table

lever

raise

machine

wobble.

for

position.

work,

the

machine

and5units

and

can

of

each

the

on a

operating

Since

change

in

at the

then

secureitproperly

be

flat

locked

caster.

caster

and

the

it

the

a

standing

right)

into

When

levers

rigid

sewing

has

been

table

height as ^

usedtosecure

using

position

the

to

floor

machine

factory-

position.

the stand,

the

bolts

sewing

release

so

for

securing

in

by

that

a

the

® The

(D

(4)

(5)

is

installed.

If

the

has

(for

Insert

holes

Insert

in

the

screws.

table

been

safety)

provided

height

table

installed,

an

accessory

the

table

should

height

and

then

in

the

accessory

and

secure

be

must

detach

proceed.

rubber

table.

hinges

them

changed

be

changed

the

pad

(A)

head

(6

with

units)

(2

the

before

after

from

units)

countersunk

the

the

above

into

into

machine

machine

the

table

each

the

of

recesses

wood

head

head

the

— 8 —

Page 13

Turn

to

lock

down

Turn

Hinge

to

(A)

Rubber

pad

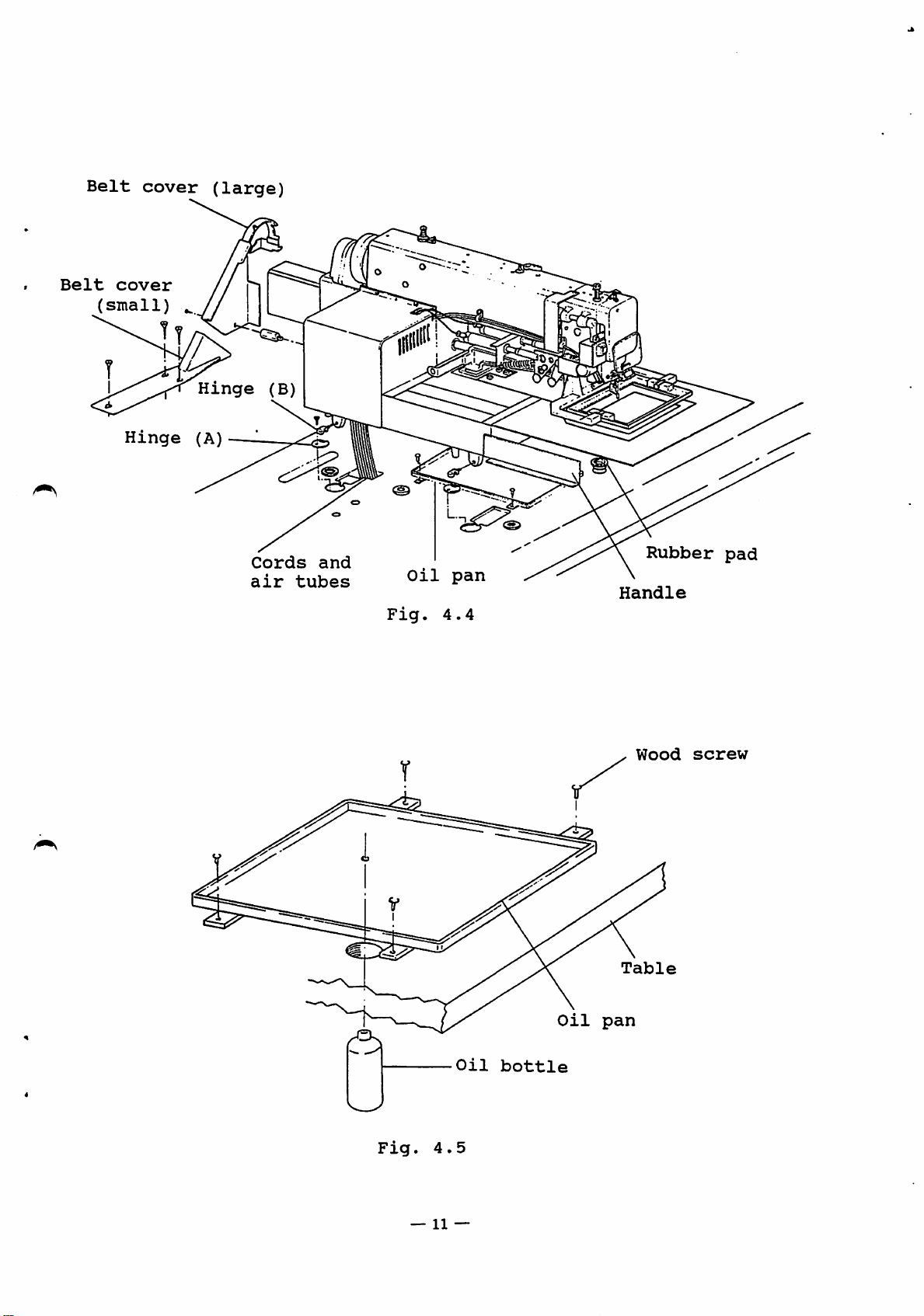

4.2

(1)

*

The

their

as

Assembling

Insert

provided

hinges

chamfered

shown

(A)

in

the

on

Caster

should

surface

Fig.

the

4.2.

machine

accessory

the

table.

Bolt

curing

be

head

for

placed

face

head

Fig.

up,

rest

se

stand

(see

4.1

with

into

Figs.

Fig.

4.2

4.4,

the

corresponding

4.5)

Wood

Hinge

holes

screw

(A)

(2)

(3)

Insert

been

Place

rubber

the

removed

the

pads

two

head

and

hinges

from

on

two

its

the

hinges.

(B)

into

packing

table

so

— 9 —

the

box.

that

machine

it

rests

head

on

which

the

has

six

Page 14

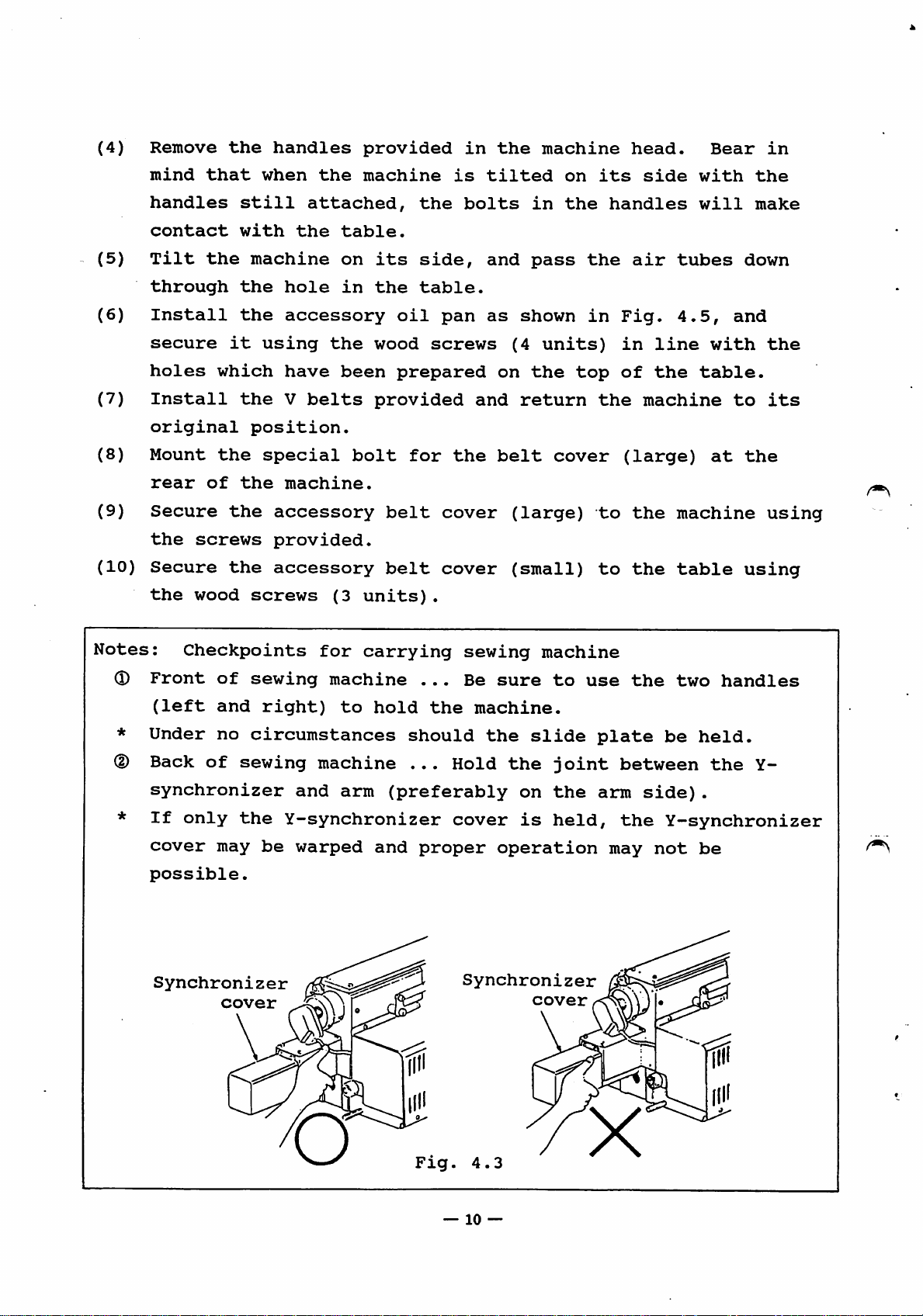

(4)

Remove

the

handles

provided

in

the

machine

head.

Bear

in

(5)

(6)

(7)

(8)

(9)

(10)

mind

handles

contact

Tilt

through

Install

secure

holes

Install

original

Mount

rear

Secure

the

screws

Secure

the

wood

that

the

it

which

the

of

the

the

when

still

with

machine

the

the

using

the

position.

special

the

accessory

provided.

accessory

screws

the

attached,

the

table.

on

hole

in

accessory

the

have

V

machine.

been

belts

(3

machine

its

the

wood

provided

bolt

belt

belt

units).

the

side,

table.

oil

pan

screws

prepared

for

the

cover

cover

is

bolts

tilted

and

as

and

shown

(4

on

return

belt

(large)

(small)

in

pass

units)

the

on

the

top

cover

its

the

in

the

to

to

side

handles

air

Fig.

in

line

of

the

machine

(large)

the

the

with

will

tubes

4.5,

and

with

table.

to

at

machine

table

the

make

down

the

its

the

using

using

Notes;

(D

*

(D

Checkpoints

Front

(left

Under

Back

of

of

and

no

sewing

synchronizer

If

only

cover

possible.

Synchronizer

the

may

cover

for

sewing

right)

machine

to

circumstances

machine

and

arm

Y-synchronizer

be

warped

carrying

...

hold

should

...

(preferably

and

proper

sewing

Be

the

machine.

Hold

cover

Synchronizer

sure

the

slide

the

on

is

operation

cover

machine

to

use

joint

the

held,

plate

between

arm

the

may

the

two

be

held.

the

side).

Y-synchronizer

not

be

handles

Y-

Fig.

4.3

—

10

—

X

Page 15

Belt

cover

(large)

Belt

cover

(small)

Hinge

Hinge

(A)

(B)

Cords

air

tubes

and

pi

Fig.

Oil

pan

4.4

Rubber

Handle

pad

Fig.

4.5

Oil

bottle

Oil

pan

Wood

Table

screw

—

11

—

Page 16

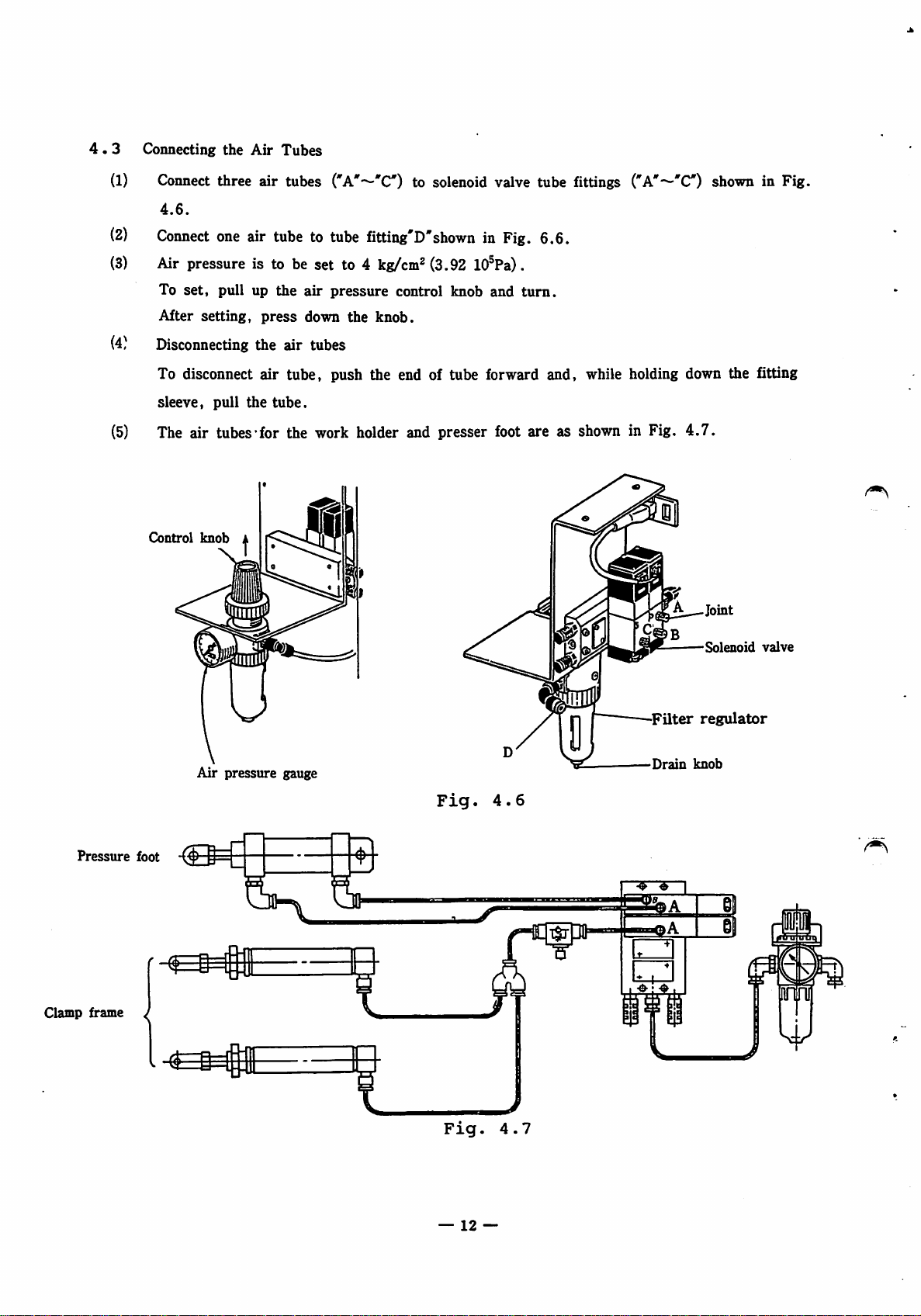

4.3

(1)

(2)

Connecting

Connect

4.6.

Connect

the

Air

Tubes

three air tubes

one

air

tubetotube

('A'—'C)

to solenoid valve tube fittings

fitting'D'shown in Fig. 6.6.

("A'-^'C)

shown in Fig.

(3)

Air pressure is to be set to 4

To

set,

pull up

After

(4)

setting,

Disconnecting

To disconnect

sleeve,

pull

press

the air tubes

air

the

the

air

down

pressure

the

kg/cm^

knob.

(3.92 lO^Pa).

control knob and

turn.

tube, push the end of tube forward and, while holding down the fitting

tube.

(5) The air tubes'for the work holder and presser foot are as shown in Fig.

Control

knob

4.7.

Joint

Solenoid

valve

Pressure

Clamp frame ^

foot

Air

pressure

gauge

Fig.

Fig.

4.6

4.7

T$T

Filter

Drain

regulator

knob

II

—

12

—

Page 17

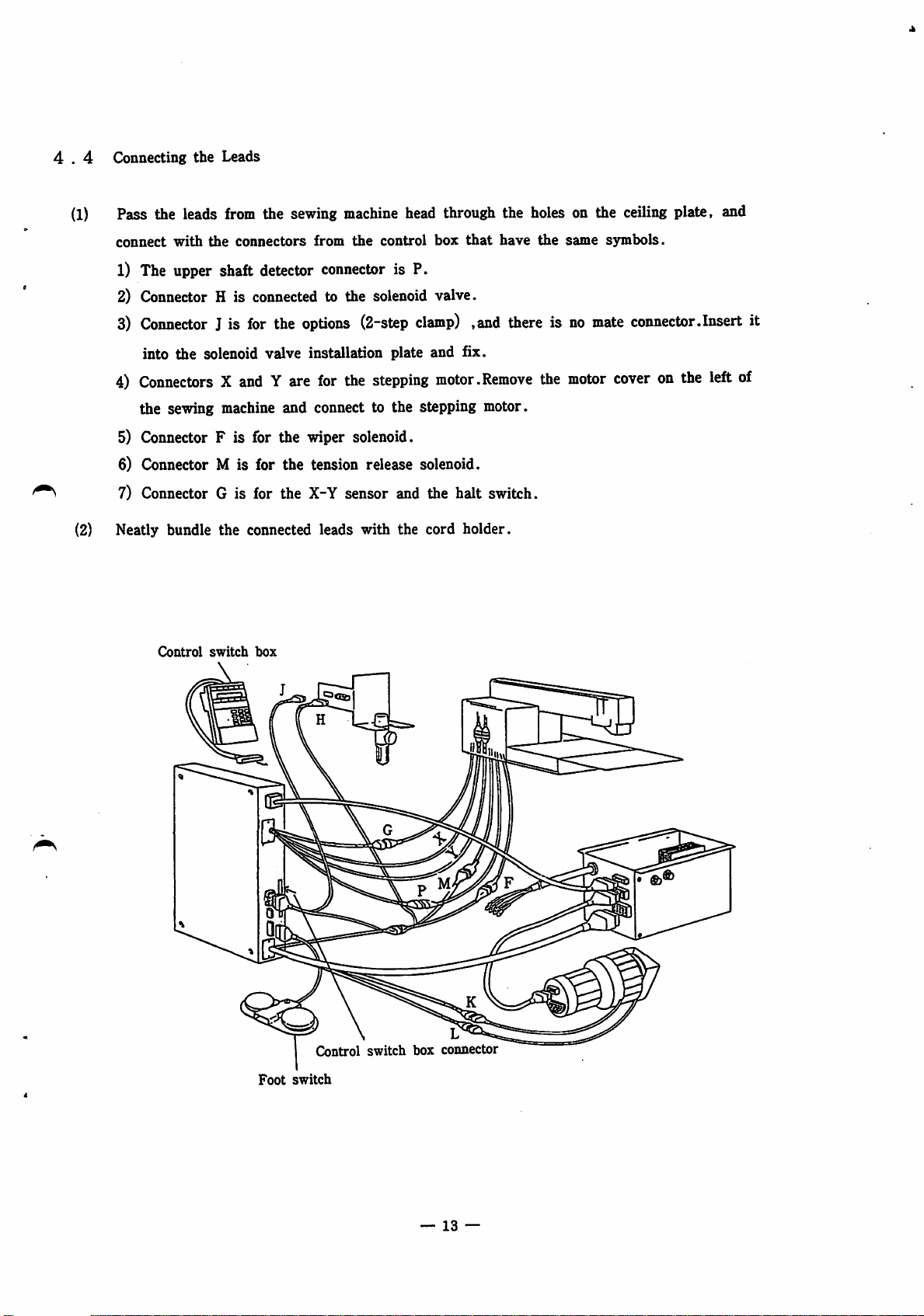

4 . 4 Connecting

(1)

Pass the leads

the

Leads

from

the sewing

machine

head through the holes on the

ceiling

plate, and

connect

with

the

connectors

from

the

control

box

that

have

1) The upper shaft detector connector is P.

2) Connector H is connected to the solenoid valve.

3)

Connector

into

4)

ConnectorsXand

the sewing machine and connect to the stepping motor.

5) Connector F is for the wiper solenoid.

6) Connector M is for the tension release solenoid.

^ 7) Connector G is for the X-Y sensor and the halt switch.

(2) Neatly bundle

Control

J is

for

the

options

the

solenoid valve installation plate and fix.

Y are

the

connected leads with the

switch

box

for

(2-step

the

clamp)

stepping

,and there isnomate

motor.Remove

cord

holder.

the

the

same

motor

symbols.

connector.Insert it

cover

on the

left

of

Foot

Control

switch

switch

box

—

connector

13

—

Page 18

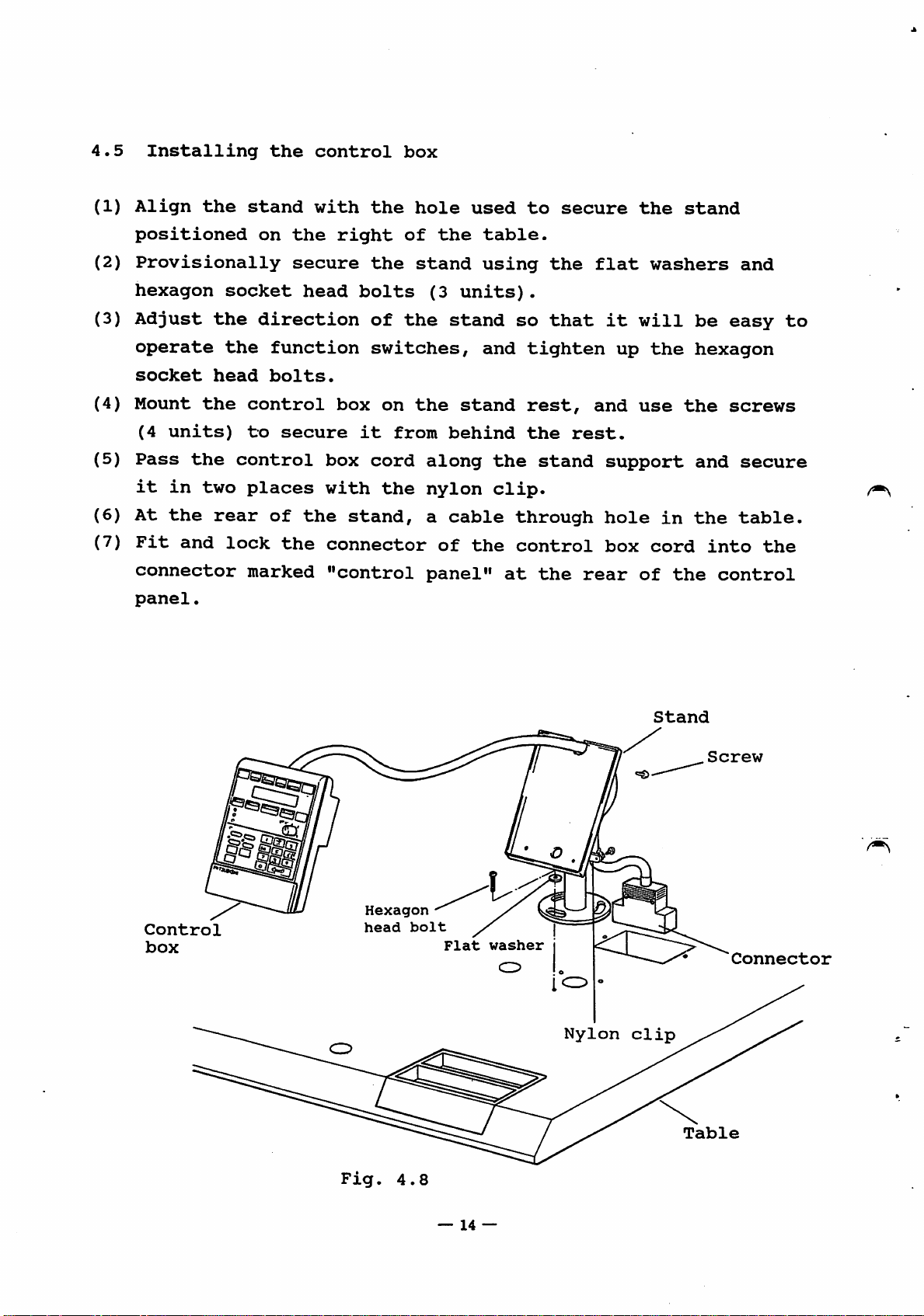

4.5

(1)

Installing

Align

the

the

stand

control

with

the

box

hole

used

to

secure

the

stand

positioned

(2)

Provisionally

hexagon

(3)

Adjust

operate

socket

(4)

Mount

(4

(5)

Pass

it

(6)

At

(7)

Fit

connector

panel.

units)

the

in

the

and

the

head

the

two

rear

on

socket

direction

the

control

to

control

places

lock

marked

the

secure

head

function

bolts.

secure

of

the

the

right

the

bolts

of

switches,

box

on

it

box

cord

with

the

stand,

connector

"control

of

stand

the

the

from

the

(3

units).

stand

stand

behind

along

nylon

a

cable

of

panel"

table.

using

and

the

clip.

the

so

tighten

rest,

the

stand

through

control

at

the

the

that

rest.

rear

flat

it

up

and

support

hole

box

washers

will

the

use

the

in

cord

of

the

and

be

easy

hexagon

screws

and

secure

the

table.

into

control

to

the

Control

box

head

bolt

Flat

washer

Nylon

Stand

Connector

clip

Fig.

4.8

—

14

—

Page 19

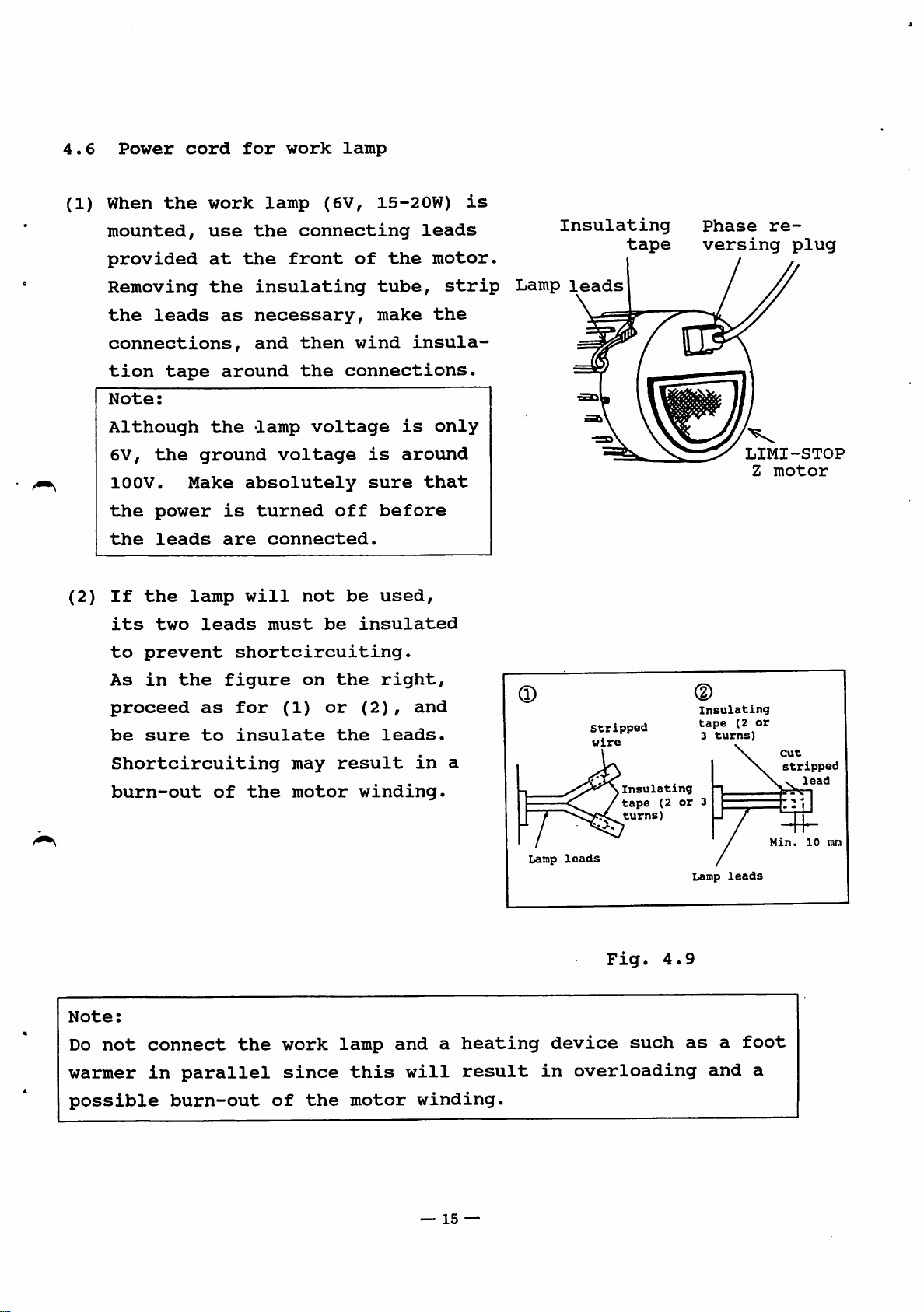

4.6

(1)

Power

When

the

mounted,

provided

cord

work

use

at

for

the

lamp

the

work

(6V,

connecting

front

lamp

of

15-20W)

leads

the

motor.

is

Insulating

tape

Phase

versing

re

plug

Removing

the

connections,

tion

Note:

Although

6V,

10OV.

the

the

(2)

If

its

to

As

proceed

be

Shortcircuiting

burn-out

leads

tape

the

Make

power

leads

the

two

prevent

in

the

sure

the

as

around

the

ground

absolutely

is

are

lamp

will

leads

shortcircuiting.

figure

as

for

to

insulate

of

the

insulating

necessary,

and

then

the

lamp

voltage

voltage

turned

connected.

not

must

on

(1)

may

motor

tube,

make

wind

connections.

is

sure

off

before

be

used,

be

insulated

the

right,

or

(2),

the

leads.

result

winding.

the

insula

is

only

around

that

and

in

strip

a

Lamp

leads

stripped

wire

Insulating

tape

turns)

LIMI-STOP

Z

motor

Insulating

tape

(2

3

(2

or

or

turns)

cut

stripped

lead

Note:

Do

not

warmer

possible

connect

in

parallel

burn-out

the

work

since

of

the

lamp

this

motor

and

will

winding.

—

a

heating

result

15

—

Lamp

in

leads

device

Fig.

such

overloading

4.9

Lamp

as

a

and

leads

foot

a

Min.

10

mm

Page 20

4.7

Use

Connecting

a

power

supply

the

power

with

cable

a

capacity

high

enough

to

accommodate

the

motor

adequate

(1)

When a

correct

white

(2)

Connect

ground

undertake

qualified

This

supply

3

(3)

When a

into

Notes:

rating,

to

grounding

pins

a

and

accommodate

3-phase

phase

lead;

the

terminal.

"W"

green

this

electrician

and

the

with

ground

single-phase

branch

select

motor

sequence:

phase

lead

To

ground

work

accessory

to

socket

a

power

the

power

is

used,

"U"

...

in

ensure

connection.

do

must

2

pins)

motor

but

cable

supply

connect

phase

black

the

3-phase

safety,

this

be

conversion

to

is

for

done

are

used,

a

wall

...

lead.

you.

if

used.

which

is

requirements.

the

red

power

do

not

Be

sure

a

single-phase

plug

do

outlet.

(for

not

more

power

lead;

cable

neglect

to

plug

than

supply

"V"

phase

to

to

have

a

power

conversion

the

power

the

in

its

...

^

from

cord

All

will

<2>

The

<3>

The

connected.

4.8

If

Changing

the

motor

direction,

when

machine

operation

leads

not

plugs

power

reverse

stops

should

come

and

into

connectors

plug

the

direction

of

the

is

started,

operating.

be

bundled

contact

must

be

sewing

rotation

REVERSE

together

with

must

be

disconnected

of

the

motor

machine

is

the

is

first

following

ROTATION

and

the

V-belts.

securely

when

rotation

rotating

identified

display

secured

so

connected.

any

of

the

in

the

automatically

appears,

that

leads

reverse

and

they

are

the

—

16

—

Page 21

When

this

display

has

appeared,

normal

rotation

is

restored

by

turning

Be

sure

4.10)

Since

it

completely

switch

motor

while

rotation

the

on

the

phase-reversing

to

insert

takes

about

after

the

power

will

motor

it

the

is

properly

5

minutes

power

after

remain

running.)

plug

as

for

has

been

it

has

unchanged

through

far

as

a

single-phase

turned

stopped.

if

180°

it

the

will

off,

(The

power

and

go.

remember

direction

inserting

(See

motor

is

turned

Direction

of

Fig.

to

to

of

rotation

it.

stop

the

on

Note:

Phase-

reversing

Be

sure

disconnecting

to

plug

set

the

the

power

power

Fig.

switch

plug.

—

17

—

4.10

to

the

OFF

position

when

Page 22

5.

(1)

(2)

PREPARING

Check

of

Check

that

the

that

TO

sewing

OPERATE

the

the

supply

machine

floppy

AND

voltage

being

disk

PRECAUTIONS

conforms

used.

containing

with

the

the

patterns

requirements

has

been

(3)

(4)

•

•

(5)

installed

(When

the

patterns

inside

Check

Section

Check

Move

is

Make

foot.

Position

The

such

that

out

and

always

sure

relationship

that

holder

equivalent

Fig.

5.1.

are

the

7.1.)

position

of

but

properly.

sewing

contained

front

the

machine

the

following

located

that

the

the

work

home

deviates

to

the

machine

cover

the

work

within

needle

holder

between

position

to

allowance

leaves

on

of

parts

points

the

the

the

the

the

holder

is

is

right

for

the

accessory

control

have

before

frame

set

at

work

not

of

the

manufacturing

floppy

panel.)

been

lubricated.

turning

by

hand

of

the

the

center

holder

at

and

the

center

presser

so

work

center

by

foot,

disk

on

that

holder.

of

home

a

dimension

plant,

attached

(See

the

power.

the

the

position

of

the

as

shown

test

needle

presser

is

work

in

holder

Work

(6)

Check

that

kgf/cm» .

Home

needle

PLK-A2016F

the

air

(S.SEXlo'Pa)

Work

is

holder

Effective

sewing

position

hole

being

position)

Fig.

arm

area

Work

holder

(same

as

5.1

supplied

—

18

—

Work

holder

j"'

Effective

sewing

•

i

Home

163

at

148

PLK-A2016FL

a

pressure

needle

position

hole

of

position)

4

area

(same

arm

as

Page 23

6.

(1)

CHECKPOINTS

Safety

FOR

OPERATION

® A

(D

(2)

<D

© Do

®

machine

must

be

remember

work

Make

order

Operating

Do

40®C)

or

or

absolutely

to

not

or

malfunctioning

not

will

such

Take

from

be

as

care

entering

which

taken

to

turn

inspections.

safeguard

environment

operate

low

temperatures

install

exposed

heating

not

is

not

off

sure

the

the

to

appliance.

to

allow

the

operating

to

touch

the

that

against

sewing

may

occur

sewing

direct

machine

power

water

is

any

of

before

the

sewing

noise

machine

(under

in

machine

sunlight

or

head

dangerous

its

and

at

S'C).

the

machine.

in

or

any

other

and

control

and

moving

proceeding

machine

electric

high

temperatures

Otherwise,

a

position

near

liquid

a

unit

so

parts.

is

grounded

shocks.

source

every

with

trouble

where

of

substance

and

to

care

Also,

repair

in

(over

it

heat

keep

(3)

®

(D

(D

(D

(D

metal

sewing

The

sewing

will

be

Avoid

be

exposed

Operation

Do

NOT

the

floppy

drive

lost.

Turn

cassette.

When

off

sewing

perform

waste

machine.

exposed

using

turn

LED

the

a

and

machine

the

to

off

disk

is

lighted).

power

a

test

other

cannot

explosive

sewing

excessive

the

drive

before

new

pattern

operation

conductive

machine

shock

power

is

This

be

used

gases,

or

remove

reading

may

inserting

or

enlarging

and

check

materials

in

or

in

an

dust

a

location

or

vibration.

the

or

writing

cause

or

the

away

atmosphere

oily

vapors.

where

floppy

data

the

data

removing

a

pattern,

relationship

from

disk

stored

the

the

where

it

while

(while

P-ROM

be

between

will

sure

to

it

the

be

to

the

work

holder

and

pattern.

—

19

—

Page 24

®

Remove

your

foot

from

the

start

switch

(pedal

switch)

when

turning

<D

The

turned

that

When

bobbin

®

The

length.

accordance

should

the

presser

manually.

the

the

winder

maximum

be

Stitch

Stitch

0.1

3.1

3.6

4.1

power

foot

wheel

power

sewing

The

with

set

length

to

to

to

to

switch

must

It

can

be

is

ON,

switch

speed

maximum

the

for

each

length

(mm)

3.0

3.5

4.0

4.5

be

is

lowered

rotated

it

to

the

speed

lengths

individual

and

ON

or

lowered

can

be

ON

differs

is

shown

maximum

Maximum

OFF.

when

when

without

the

the

further

lowered

position.

according

automatically

in

the

fabric.

speed

speed

2,000

1,820

1,670

1,430

balance

power

by

table,

limit

limit

adjustment.

setting

to

the

limited

(spm)

is

and

wheel

off

the

stitch

in

it

is

so

(2)

When

®

Burnouts

mechanical

®

Under

fingers

being

start

the

power

stabilizes.

(see

4.6

5.1

6.6

9.1

a

single-phase

operation

has

may

page

24)

no

circumstances

near

operated.

to

to

to

to

—

—

be

parts.

the

5.0

6.5

9.0

12.7

immediately

been

caused

Before

and

check

work

motor

switched

by

the

should

holder

is

being

but

wait

on

until

insufficient

operation,

parts.

the

while

1,250

1,000

800

600

400

200

used,

about

the

be

operator

the

do

not

10

motor

lubrication

sure

to

bring

sewing

perform

seconds

operation

lubricate

his

machine

of

the

or

the

after

her

is

® Do

not

protective

operate

covers

the

sewing-

in

place.

machine

—

20

—

without

the

eye

guard

and

Page 25

(4)

(D

(D

Supply

Use

When

voltage

a

supply

an

instantaneous

voltage

within

power

a

±10%

failure

range

occurs,

of

the

the

rating.

sewing

(5)

machine

operation,

switch

Noise

(D

When

the

the

(D

Similar

operated

high

the

use

(D

Using

noise

broadcast.

or

it

the

stitch

sewing

noise

machine

a

separate

a

interference

place

stops

first

back

power

pattern

machine.

effects

in

levels

radio

the

in

the

as

or

In

radio

the

make

on

again.

line

may

vicinity

(such

far

power

TV

cases

reset

is

may

occur

away

line

set

in

like

or

sure

affected

shift

when

of

as

from

to

near

the

reception

this,

TV

set

or

error

that

a

the

by

surge

or

malfunctioning

the

sewing

any

equipment

high-frequency

such

equipment

supply

the

sewing

use

at

a

distance

mode.

power

power

of

the

a

different

To

is

OFF

voltages

machine

which

welder).

is

to

it.

machine

radio

from

resume

and

may

generates

possible

may

or

power

the

then

(noise),

occur

is

Keep

cause

TV

supply

sewing

in

and

(6)

(7)

machine.

Inspection

(D

Avoid

circuitry

semiconductor

Up-turn

When

of

0

Before

(upper,

to

(D

Remove

sewing

of

using

of

the

thread

turning

see

prevent

beforehand.the

machine

head

as

of

control

a

multimeter

since

sewing

the

parts.

circuitry

voltage

machine

to

head

sewing machine head

trimmer,

Fig.

it

sliding

it

is

up

the

7.1)

motor

raised

etc.,

because

head

with

down

V

belt

higher.

observe

inspect

from

is

(see

the

with

which

the

the

such

turned

following

Fig.

adhesive

its

own

is

belt

internal

may

damage

up

for

6.2),

tape,

weight.

connected

will

control

the

the

cautions.

fix

X-Y

etc.

to

disturb

adjustm.ent

cover

in

order

7

type

the

up—turn

—

21

—

Page 26

(D

Place

a

holder

of

head

on

the

table

(Fig.

6.1).

Since

the

belt

7.

Names

cover

remove

Belt

(large)

HANDLING

of

(small)

beforehand

cover

V

THE

major

Belt

belt

SEWING

parts

interferes

the

cover(small)

/

Head

of

cover

holder

MACHINE

machine

with

by

HEAD

head

the

loosing

head

Up-turn

of

head

when

set

it

screws.

Fig.

is

raised,

6.2

Belt

cover

(small)

Eye

Slide

plate

Halt

guard

Needle

Presser

adjusting

switch

plate

foot

Work

holder

screw

Thread

Clamp

unit

regulator

viium

Feed

plate

tension

X-Y

Bobbin

winder

cover

(top)

X-Y

cover(bottom)

Synchronizer

Y-synchronizer

cover

Oil

gauge

Fig.

—

7.1

22

—

Page 27

7.1

(1)

Lubrication

Supplying

the

lubricant

Before

necessary,

proceeding

parts

J I

with

A

to

operation,

F

indicated

be

by

sure

the

to

arrows

lubricate,

in

Fig.

as

7.2.

Lubricate

after

(Normally,

supply

(2)

Replenishing

Replenish

and

red

may

tilted.

the

tank.)

head

mark

cause

parts

sewing

lubricant

the

oil

side,

in

the

oil

A

to

J

machine

is

oil

tank

through

respectively,

center

to

spill

Fig.

before

has

supplied

supply

of

the

from

7.2

proceeding

been

automatically

ports

until

oil

the

supply

installed.

K

and

the

oil

gauge.

ports

with

L

on

reaches

Excessive

when

a

test

(Fig.

from

the

arm

the

the

run

7.2)

the

side

round

supply

head

oil

is

—

23

—

Page 28

Note;

Oil

Use

tank

white

spindle

oil

#2

for

Oil

lubrication.

tank

7.2

(1)

(2)

(3.)

(4)

Installing

Before

so

that

Insert

go.

With

the

For

that

the

needle

more

the

direction

the

installing

the

sewing

the

needle

needle

set

satisfactory

needle

of

^ D

the

needle

prime

screw

be

arrow

S-

Fig.

or

removing

machine

into

to

installed

2=3

7.3

the

groove

secure

stitching

in

Fig.

the

will

needle

turned

and

M=r

needle,

not

socket

the

results,

turned

7.4

be

to

needle.

Clearance

turn

started

as

the

it

by

off

up

far

front,

is

recommended

about

in

as

tighten

10°

the

it

power

error.

will

in

up

the

o

V

Fig.

—

X X

7.4

24

—

I)

Page 29

7.3

The

Threading

needle

thread

the

needle

should

thread

be

threaded,

as

shown

in

Figs.

7.5

and

7.6,

7.4

(1)

with

Winding

Pass

Fig.

the

the

7.7

thread

the

thread

and

bobbin

coming

wind

end

the

extended

thread

from

end

of

the

the

about

spool

4

thread

cm

Arm

holder

from

thread

guide

around

Fig.

base

the

Top

the

needle.

Thread

thread

7.6

as

bobbin

Take-up

spring

Tension

discs

shown

guide

in

by

several

turns

in

the

direction

Fig.

of

arrow

7.7

"a."

—

25

—

Page 30

(2)

(3)

Push

Lower

the

the

adjust

work

lever

holder

in

using

the

direction

the

work

of

holder

arrow

switch

(b).

(black

(4)

(5)

(6)

7.5

(1)

(2)

pedal

Setting

ON

position

the

sewing

Step

While

will

Upon

winder

Installing

Place

the

bobbin

Put

the

slit

the

eyelet

switch).

the

machine

on

the

the

start

operate

completion

key

again.

the

bobbin

case

thread

(C)

and

(D).

bobbin

(LED

start

at

the

(E)

pass

winder

lights)

to

switch

switch

a

speed

of

the

(This

bobbin

(B)

(A).

into

it

lowers

enter

(red

is

equivalent

thread

turns

inside

the

through

switch

the

pedal

pressed

winding,

on

the

bobbin

the

the

presser

winder

switch).

down,

to

approximately

press

LED

off.)

control

the

panel

foot

mode.

sewing

the

and

machine

600

bobbin

to

allows

spm.

the

7.6

(1)

(2)

(See

Installing

Set

the

position

(See

Open

fully

the

inner

Note;

The

thread

about

in

the

Fig.

Fig.

the

and

2.5

7.8)

needle

and

7.9)

bobbin

hook.

bobbin

fit

cm

end

the

open

from

bar

it

should

case.

bobbin

to

the

case

securely

the

case

its

bottom

latch

be

square

highest

cover

(A)

into

extended

hole

Fig.

Fig.

7.8

7.9

—

26

—

Page 31

7.7

Removing

the

inner

hook

The hook clamp and

the

hook

arrow

7.8

Attain

as

Thread

a

clamp

far

as

tension

balance

lever

the

inner

(Fig.

horizontal

between

hook

7.10)

the

itself

in

position.

Fig.

needle

can

the

Hook

7.10

thread

be

removed by

direction

clamp

tension

shown by

lever

and

turning

the

bobbin

thread

As shown

the

needle

center

®

Balanced

tension

thread

tension.

in

line

Fig.

thread

of

O

needle

and

tension

the

bobbin

(A),

is

thread

the

interlocked

fabric

optimum

layers.

Tight

or

thread

needle

loose

tension

with

X

bobbin

tension

Fig.

the

tension

7.11

balance

bobbin

is

thread

Loose

tension,

bin

yielded

along

needle

tight

thread

tension

when

the

thread

bob

—

27

—

Page 32

(1)

Bobbin

The

thread

bobbin

tension

thread

tension

can

be

adjusted

by

turning

the

thread

turning

counterclockwise.

(2)

Needle

The

bobbin

regulating

tension

thread

needle

thread

Bobbin

the

Tension

adjusting

screw

tension

thread

tension.

thumb

case

adjusting

clockwise

(Fig.

tension

nut

To

increase

To

reduce

in

screw

screw.

7.12)

is

To

Fig.

and

adjusted

adjust,

7.13.

The

reduced

turn

tension

by

in

reference

the

is

turning

tension

increased

it

to

Tension

ting

thumb

To

To

reduce

by

the

regula

nut

increase

Note:

Excessive

7.9

Adjusting

7.9.1

The

work

system,

regulator

higher

The

standard

Fig.

7.12

tension

Adjusting

holder

and

it

knob.

work

holder

air

may

the

work

the

pressure

can

be

(See

pressure

pressure

result

holder

work

is

adjusted

Fig.

in

holder

generated

4.6)

and

is

4

puckering

pressure

by

turning

Increase

reduce

kgf/cm^.

by

it

Fig.

or

a

the

the

for

7.13

a

broken

pneumatic

air

pressure

air

pressure

a

lower

thread.

(air)

pressure.

for

a

—

28

—

Page 33

7.9.2

(1)

(2)

The

To

arm

To

Replacing

work

remove

pin.

install

holder

it,

the

the

work

can

push

the

replacement

holder

be

replaced

work

holder

work

in

a

down

holder,

single-action

from

the

engage

work

its

operation.

holder

U-groove

with

play

of

the

in

play

work

the

may

holder

direction

cause

a

arm

indicated

shift

pin.

in

the

Then

by

stitches.

check

the

that

arrow.

there

The

is

no

existence

Work

holder

arm

U-groove

Fig.

—

7.14

29

Pin

—

Work

holder

Page 34

7.10

(1)

Adjusting

Check

that

the

the

presser

needle

foot

passes

(2)

(3)

through

presser

Rotate

ually

foot

presser

9.11)

of

the

the

lower

foot

above

presser

position.

The

vertical

presser

adjusted

crease

the

bolt

and

set

and

is

the

the

foot

the

loosen

screw

bar

adjust

presser

end

between

fabric

bar

foot

to

the

in

center

hole.

balance

set

of

is

stroke

is

4 mm.

stroke,

Fig.

the

(Fig.

screw

the

foot

the

0

and

when

at

its

factory-

7.16

of

wheel

presser

7.15)

height

so

presser

of

To

loosen

the

man

(Fig.

that

0.5

the

lowest

the

in

and

or

mm

move

Bolt

Presser

adjusting

Fabric

Fig.

foot

Approx.

30

screw

mm

Presser

foot

Presser

O^O-Omm

7.15

set

foot

screw

Auxiliary

adjusting

screw

Approx.

20

Thumb

mm

nut

it

up.

can

be

(4)

To

adjust

presser

nut

presser

The

screw

counterclockwise.

Normally,

to

be

Note:

The

thickness

The

increased

foot,

in

Fig.

foot

pressure

is

touched.

height

the

turned

there

of

of

vertical

pressure

loosen

7.16

adjusting

increases

the

the

up

to

and

clockwise

The

is

no

presser

fabric

stroke

10

of

the

turn

screw.

when

figure

need

mm.

the

thumb

the

and

foot

is

the

reduced

shows

for

the

must

changed.

when

the

auxiliary

also

Fig.

it

standard

be

changed

7.16

is

turned

adjustment.

adjusting

when

screw

the

—

30

—

Page 35

7.11

(1)

(2)

Replacing

To

replace

replace.

The

guide

the

the

plate

lower

lower

is

clamp

clamp

provided

frame

frame,

for

(Fig.

remove

positioning

7.17)

screws

(For PLK-A2016-F)

(A)

and

the

lower

clamp

7.12

frame.

holder,

Lower

Lubrication

If

the

loosen

clamp

lower

screws

plate

with

clamp

(A)

silicone

frame

and

oil

(B),

is

not

and

Fig.

aligned

adjust.

Screw

7.17

with

Screw

Guide

A

the

B

plate

Work

arm

work

holder

When

guide

as

applying

with

shown

in

the

Fig.

Face

silicone

felt

7.18,

plate

area

oil

and

Fig.

onto

to

the

the

supply

7.18

Thread

—

31

needle

bottom

the

Needle

oil

thread,

part

to

thread

guide

of

the

with

mount

the

felt

felt

face

area.

the

thread

plate,

area

Page 36

8.

OPERATION

Refer

9.

9.1

(1)

to

the

ADJUSTMENT

Adjusting

Adjusting

To

reduce

the

adjust

volume,

The

adjust

of

arrow

on

the

separate

the

the

move

"a"

bobbin.

AND

the

winding

winding

lever

it

lever

with

control

MAINTENANCE

bobbin

winder

volume

volume,

toward

in

the

is

set

the

thread

unit

the

bobbin;

opposite

so

that

manual

first

direction.

it

wound

Shaft

loosen

conversely,

will

up

to

Bobbin

return

80%

screw

of

to

in

its

(A)

increase

the

full

and

move

direction

volume

the

(2)

Adjusting

Loosen

onto

the

wound,

Next,

"c"

in

tighten

operation.

screws

and

move

the

up

the

shaft

push

the

center

screws

turning

(C)

a

bobbin

the

bobbin

and

of

(C)

of

(D)

adjust

winder

the

and

the

of

on

figure.

(D)

Adjust

Fig.

bobbin

the

which

lever

complete

—

32

to

9.1

winder

thread

in

Once

finalize

—

lever

the

bobbin

has

direction

in

the

resistance

the

complete,

been

direction

positioning

mount

appropriately

of

arrow

of

is

felt,

"b."

arrow

Page 37

9.2

(1)

(2)

(3)

Adjusting

First,

Turn

Remove

the

switch

pulley

the

the

off

rubber

height

the

and

plug

set

of

the

power.

the

from

needle

needle

the

face

bar

bar

to

plate

its

and

lowest

loosen

position.

the

set

(4)

•

screw

Move

bar

this

(Set

of

needle

There

with

of

the

against

position

mark

are

the

the

needle

the

(B)

is

4

timing

type

needle

bar

bottom

using

against

used.)

of

bar

up

the

marks,

needle

and

end

the

clamp.

down

of

needle

bottom

one

used.

Face

the

bar

of

to

set

metal,

connecting

of

which

plate

the

timing

and

metal

is

selected

mark

lock

stud

when

the

)

For

}For

(A)

on

bar

set

screw.

the

DPx5

to

correspond

DPx5

DPX17

the

at

type

Needle

connecting

stud

screw

9.3

(1)

set

Adjusting

Use

an

insert

bar

Allen

the

Fig.

the

wrench

wrench

9.2

driver

to

is

Needle

Timing

on

needle

and

hook

loosen

provided

mark

—

bar

bar

the

under

33

—

metal

driver

the

Fig.

set

screw.

cylinder

9.3

head.)

(A

hole

to

Page 38

(2)

Adjust

the

driver

so

that

the

head

of

the

inner

hook

is

aligned

(3)

with

mark

bar

Now

of

and

first

the

(C)

metal.

Head

adjust

0

to

needle.

loosening

needle

(or

of

the

0.05

(D))

(See

inner

mm

(See

center

is

Fig.

position

is

created

Fig.

its

when

pointing

9.4)

hook

9.6)

set

of

the

between

screw

the

Fig.

The

pulley

to

the

9.4

rotating

rotating

and

Needle

the

then

is

bottom

hook

head

turning

turned

end

center

of

hook

so

of

that

the

can

the

and

the

inner

be

eccentric

when

needle

a

clearance

moved

timing

hook

by

pin

(4)

using

In

driver

is

screw.

a

this

so

reduced

slot-head

condition,

that

to

screwdriver.

i

Rotating

the

zero

hook

screw

set

adjust

clearance

millimeters,

the

between

Eccentric

Fig.

9.5

longitudinal

and

then

the

pin

position

driver

lock

0.05—O.lmm

Fig.

and

the

driver

9.6

of

and

5

the

needle

set

—

34

—

Page 39

3.2inni

9.4

(1)

*

Driver

Lateral

As

a

also

the

head

of

the

Adjusting

Adjust

Riinn

Fig.

adjustment

general

be

adjusted

hook

the

of

set

9.7

guideline

the

has

the

thread

screw

by

hook

been

thread

of

creating

guide

driver

and

and

left

retracted

guide

above

as

a

(above

shown

clearance

side

to

its

the

hook

Fig.

in

of

hook)

9.8

Fig.

of

the

needle

leftmost

(Fig.

so

that

9.8,

about

Hook

lever

the

3.2

when

position.

9.9)

its

left

retainer

timing

mm

the

and

can

between

head

(2)

right

A

shift

shoulders

failure

out

Adjust

between

permit

thread

conversely,

length

the

hook

in

of

the

thread

the

hook

the

needle

trimming

if

of

the

may

are

thread

alignment.

guide

retainer

thread

may

it

is

trimmed

result.

aligned

trimming

so

to

result

too

small,

needle

that

and

if

with

may

pass

thread

the

result

a

thread

through

this

improper

side

clearance

guide

clearance

or

jamming

surface

if

easily.

thread

this

(standard:

is

created

is

of

of

position

A

failure

too

great;

tension,

the

the

0.8

which

thread

needle.

should

mm)

will

in

uneven

in

—

35

—

Page 40

(3)

Check

carefully

that

the

surface

condition

is

smooth

since

the

condition

comes

trimming

Thread

of

into

contact

performance.

guide

0.8mm

the

//

thread

greatly

set

Thread

screw

/

Fig.

guide

guide

surfaces

affects

Shoulders

9.9

the

Thread

0

Needle

with

thread

Hook

which

guide

tension

set

retainer

the

thread

and

screw

thread

—

36

—

Page 41

9.5

Adjusting

the

presser

foot

9.5.1

To

on

(1)

(2)

(3)

(4)

^

(5)

(6)

Adjusting

adjust

the

back

Loosen

Turn

lowest

positioned

Loosen

Secure

position

The

timing

direction

turned

After

the

direction

and

the

the

the

(C)

vertical

of

the

the

eccentric

pulley

position.

at

the

eccentric

the

eccentric

ring

is

(of

in

the

adjustment,

in

that

the

timing

arm,

and

the

(B).

increased

arrow

other

of

the

order.

motion

and

ring

stop

The

front

ring

ring

(D));

direction.

arrow

of

the

of

make

set

it

eccentric

(standard

set

(B),

when

conversely,

press

while

the

the

screw

when

screw

the

down

presser

presser

adjustment

the

ring

position).

and

turn

pulley

on

tightening

(C).

needle

set

(A).

it

the

foot

foot,

screw

the

is

turned

is

eccentric

motion

remove

through

bar

reaches

(A)

pulley

reduced

up

set

the

will

slowly

in

when

ring

screws

the

the

cover

window.

its

be

to

forward

it

(B)

in

(A)

is

(7.)

Position

clamping

crank

lever

is

is

and

screw

made

at

secure

parallel

its

Window

so

highest

that

the

upper

the

vertical

to

the

position.

(g)

Upper

vertical

presser

vertical

center

foot

feed

crank

line

bar

crank

of

when

using

the

the

its

bell

take-up

Crank

rod

Fig.

—

37

—

9.10

Page 42

9.5.2

(1)