Mitsubishi PLH-3AAK, PLH-5AAKH, PLH-6AAKH, PLH-4AAK, PLH-6AAK Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

ON/OFF TEMP

ON/OFF

TEMP.

TECHNICAL & SERVICE MANUAL

February 2006

No. OC360

Indoor unit

[Model names] [Service Ref.]

PLH-3AAK

PLH-4AAK

PLH-5AAK

PLH-6AAK

PLH-3AAKH

PLH-4AAKH

PLH-5AAKH

PLH-6AAKH

PLH-3AAK

PLH-4AAK

PLH-5AAK

PLH-6AAK

PLH-3AAKH

PLH-4AAKH

PLH-5AAKH

PLH-6AAKH

NOTE:

• This manual does not

cover outdoor units.

When servicing outdoor

units, please refer to the

outdoor unit`s service

manual together with this

manual.

CONTENTS

Model name

indication

INDOOR UNIT

WIRELESS REMOTE

CONTROLLER

1. REFERENCE MANUAL······································2

2. PART NAMES AND FUNCTIONS ···················3

3. SPECIFICATIONS············································6

4. DATA ······························································14

5. OUTLINES AND DIMENSIONS·····················28

6. WIRING DIAGRAM ········································31

7. REFRIGERANT SYSTEM DIAGRAM············32

8. TROUBLESHOOTING ···································34

9. FUNCTION SETTING·····································50

10. 4-WAY AIR FLOW SYSTEM ··························57

11. SYSTEM CONTROL ······································62

12. DISASSEMBLY PROCEDURE ······················76

13. PARTS LIST···················································79

14. OPTIONAL PARTS ········································84

WIRED REMOTE

CONTROLLER

1

REFERENCE MANUAL

1-1. OUTDOOR UNIT’S SERVICE MANUAL

Service Ref. Service Manual No.

PUH-3VKA2.TH-A

PUH-3YKA1.TH-A

PUH-4YKSA1.TH-A

PUH-5/6YKSA3.TH-A

PUH-3VKA.TH

PUH-3YKA.TH

PUH-4/5/6YKSA.TH

PUH-3NKA.TH

PUH-4/5/6TKSA.TH

OC156

OC325

OC354

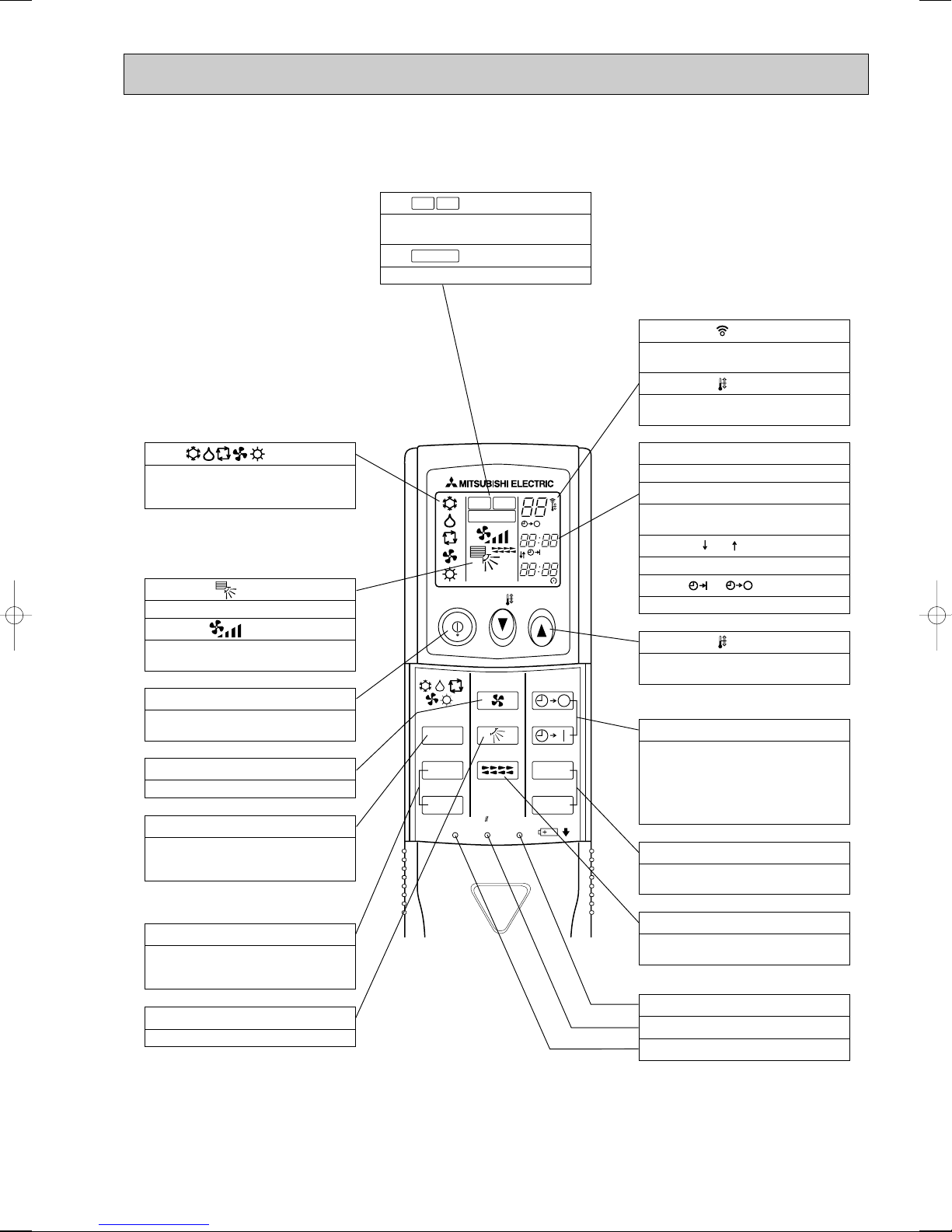

2

2

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door.

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

To preceding operation

number.

Ventilation button

(

Operation button)

To next operation number.

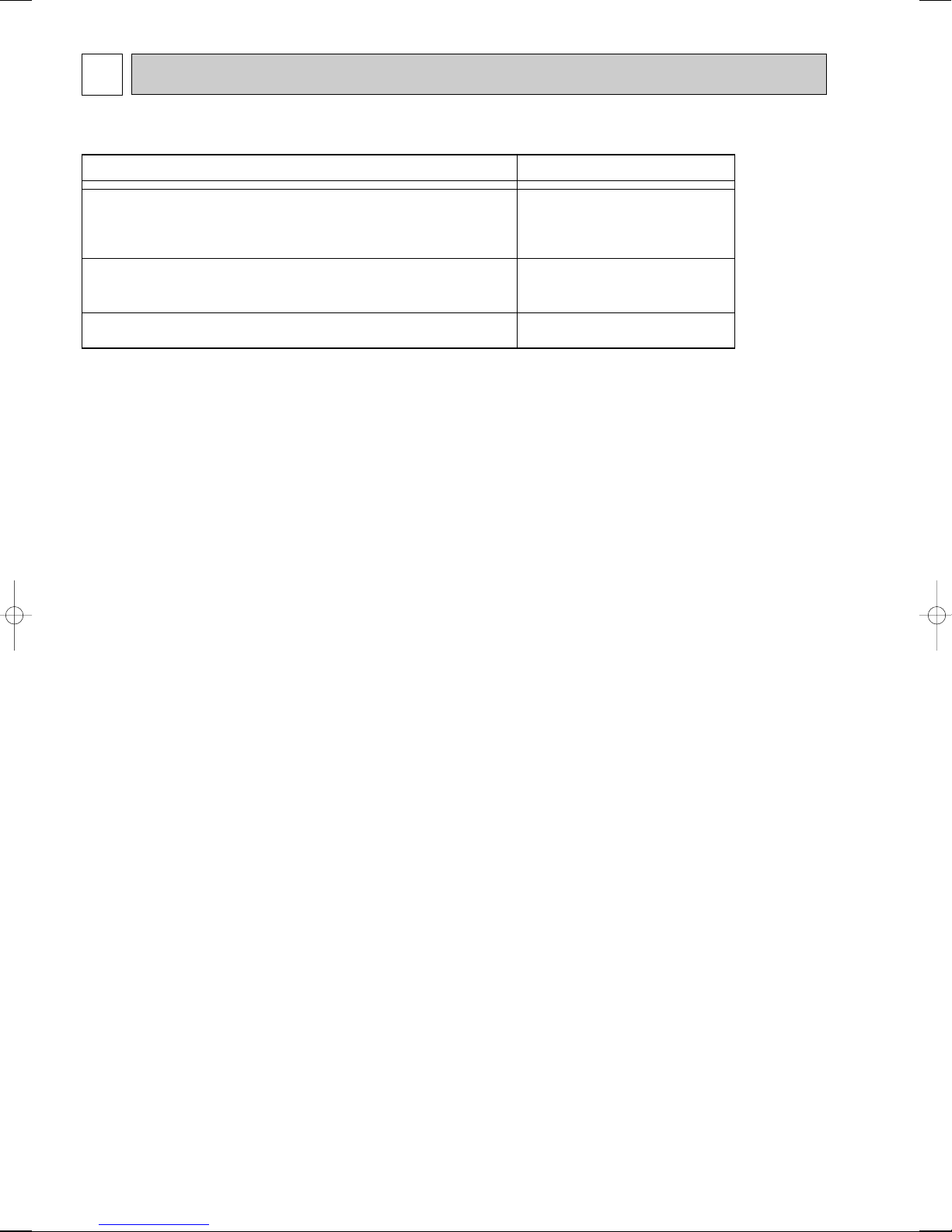

Auto Air Swing Vane

Disperses airflow up and

down and adjusts the angle

of airflow direction.

Grille

Filter

Removes dust and pollutants

from intake air

Horizontal Air Outlet

Sets airflow of horizontal automatically

during cooling or dehumidifying.

Air Intake

Intakes air from room.

PART NAMES AND FUNCTIONS

● Indoor Unit

● Wired remote controller

On the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

3

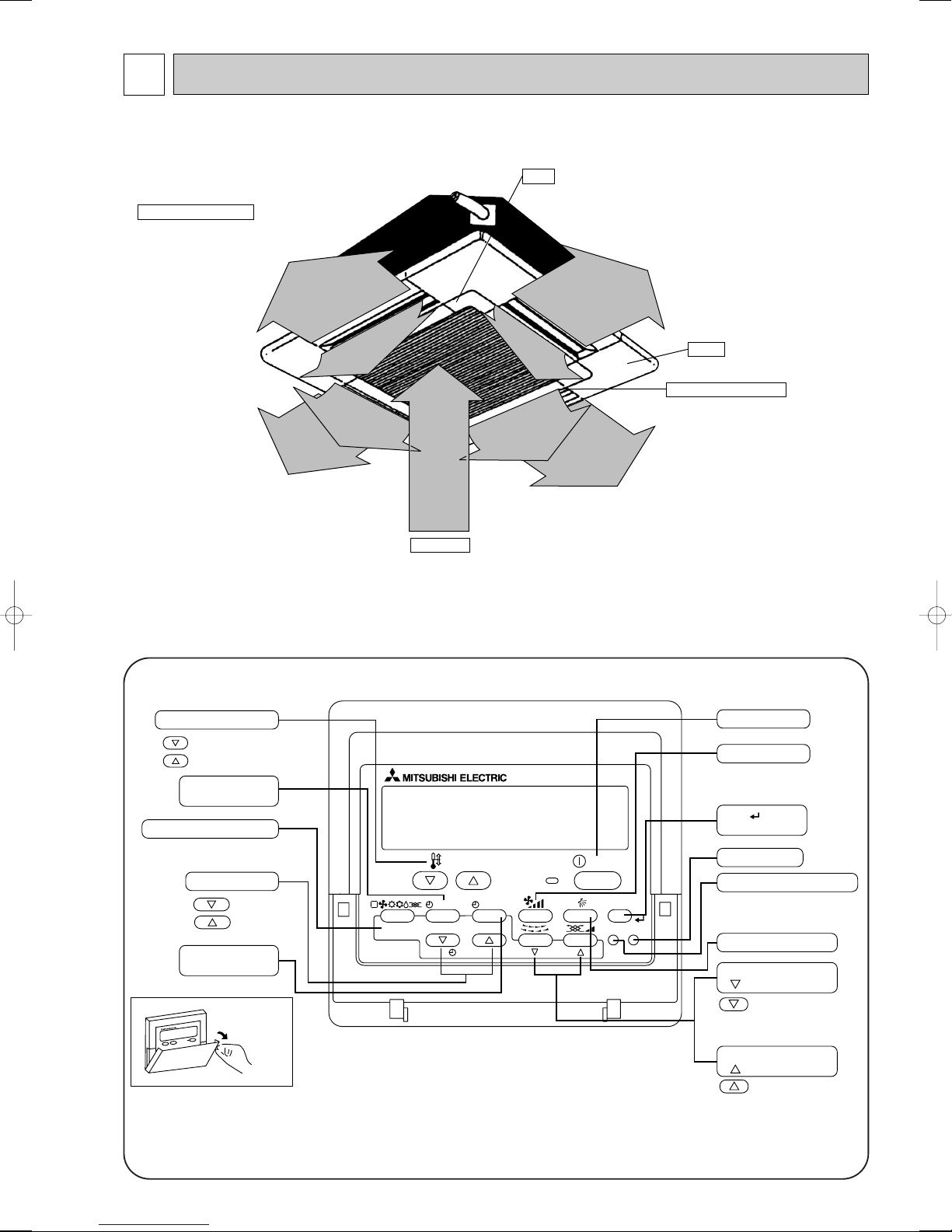

● Display

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

weak and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Caution

● Only the Power on indicator lights when the unit is stopped and power supplied to the unit.

● If you press a button for a feature that is not installed at the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to drive multiple indoor units, this message will appear only if he feature is not

present at the parent unit.

● When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indication (For max. 2minutes). Please wait until this “PLEASE WAIT” indication disappear then start the operation.

4

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL SELECT

NOT AVAILABLE

CHECK

TEST RUN

˚C

AMPM

AMPM

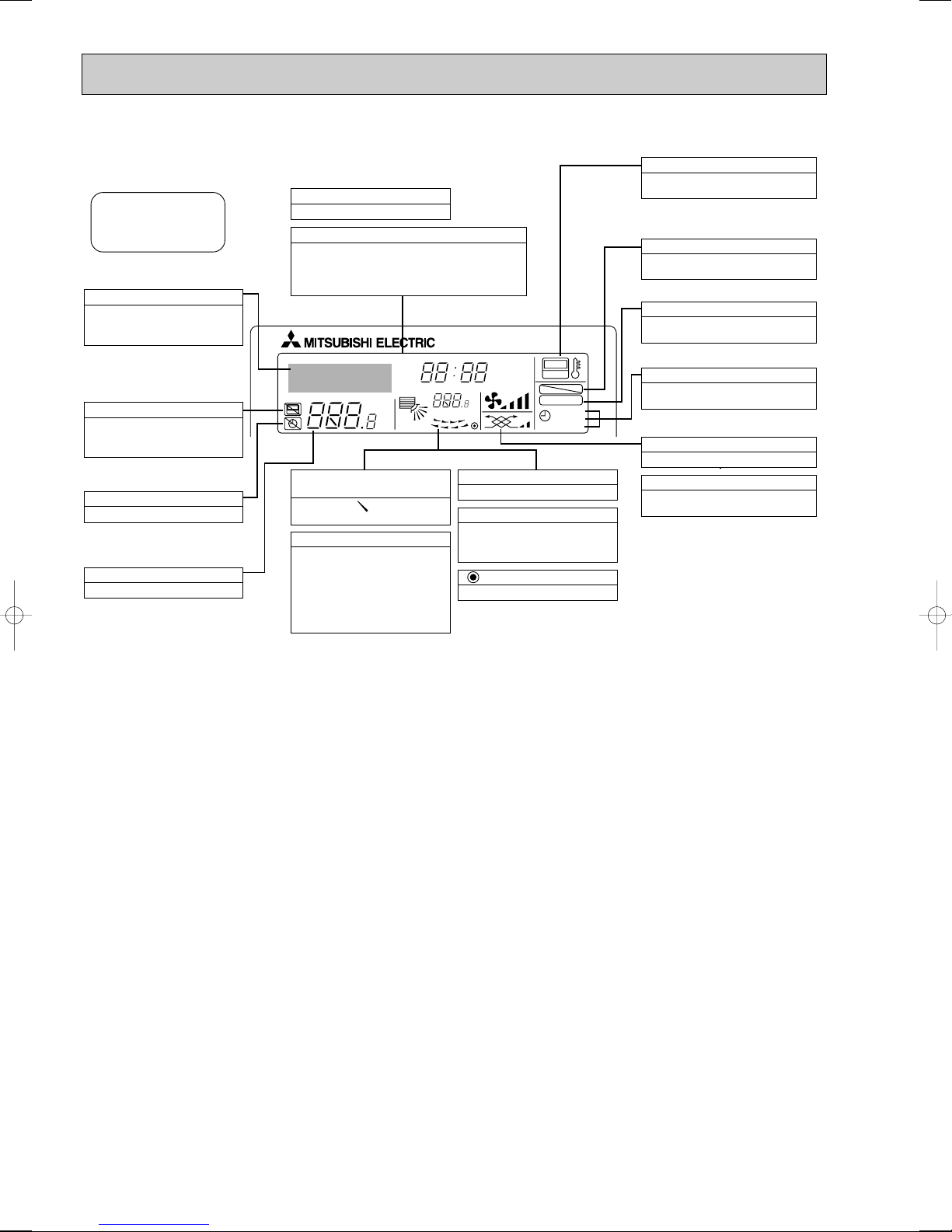

VANE CONTROL button

Used to change the air flow direction.

CLOCK button

RESET button

SET button

ON/OFF button

The unit is turned ON and OFF alternately

each time the button is pressed.

LOUVER button

This switch the horizontal fan motion ON

and OFF.

(Not available for this model.)

MODE SELECT button

Used to switch the operation mode between

cooling, drying, blowing, heating and auto

mode.

CHECK-TEST RUN button

Only press this button to perform an inspection check or test operation.

Do not use it for normal operation.

FAN SPEED SELECT button

Used to change the fan speed.

TIMER display

Displays when in timer operation or when

setting timer.

button

SET TEMPERATURE button sets any desired

room temperature.

CLOCK display

Displays the current time.

“ ” “ ” display

Displays the order of timer operation.

“ ” “ ” display

Displays whether timer is on or off.

w In case the outdoor unit is cool only type,

the heating mode is not available.

Buttons used to set the “hour and minute” of

the current time and timer settings.

h and min buttons

display

SET TEMP. display indicates desired temperature set.

display

FAN SPEED display indicates which fan

speed has been selected.

display

The vertical direction of air flow is indicated.

display

Blinks when model is selected.

display

Lights up while transmission to the indoor

unit is mode using switches.

display

CHECK&TEST RUN display indicates that

the unit is being checked or test-run.

display

OPERATION MODE display

Operation mode display indicates which operation mode is in effect.

TIMER CONTROL buttons

AUTO STOP (OFF timer): when this switch

is set, the air conditioner will be automatically stopped at the preset time.

AUTO START (ON timer): when this switch

is set, the air conditioner will be automatically started at the preset time.

MODEL SELECT

CHECK

TEST RUN

● Wireless remote controller

5

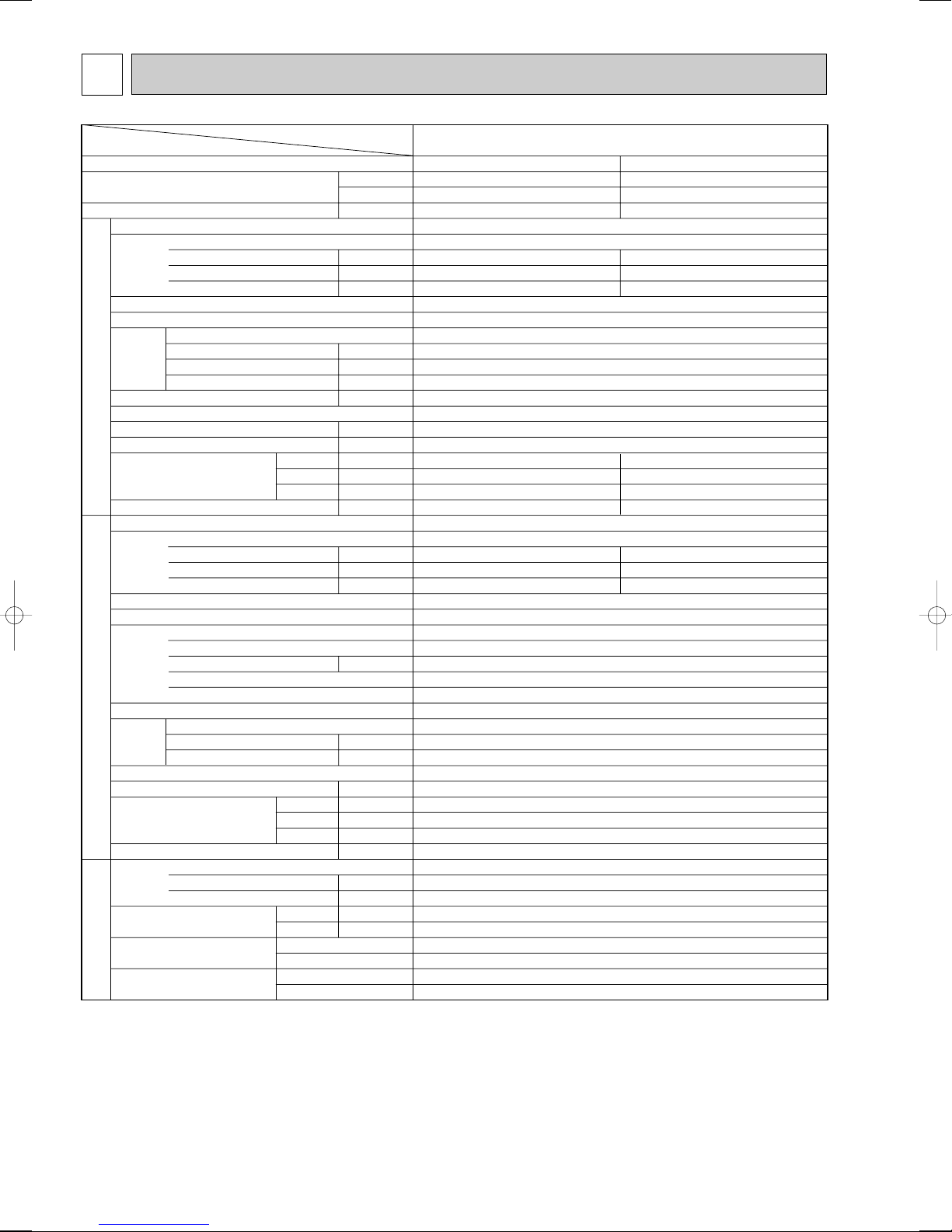

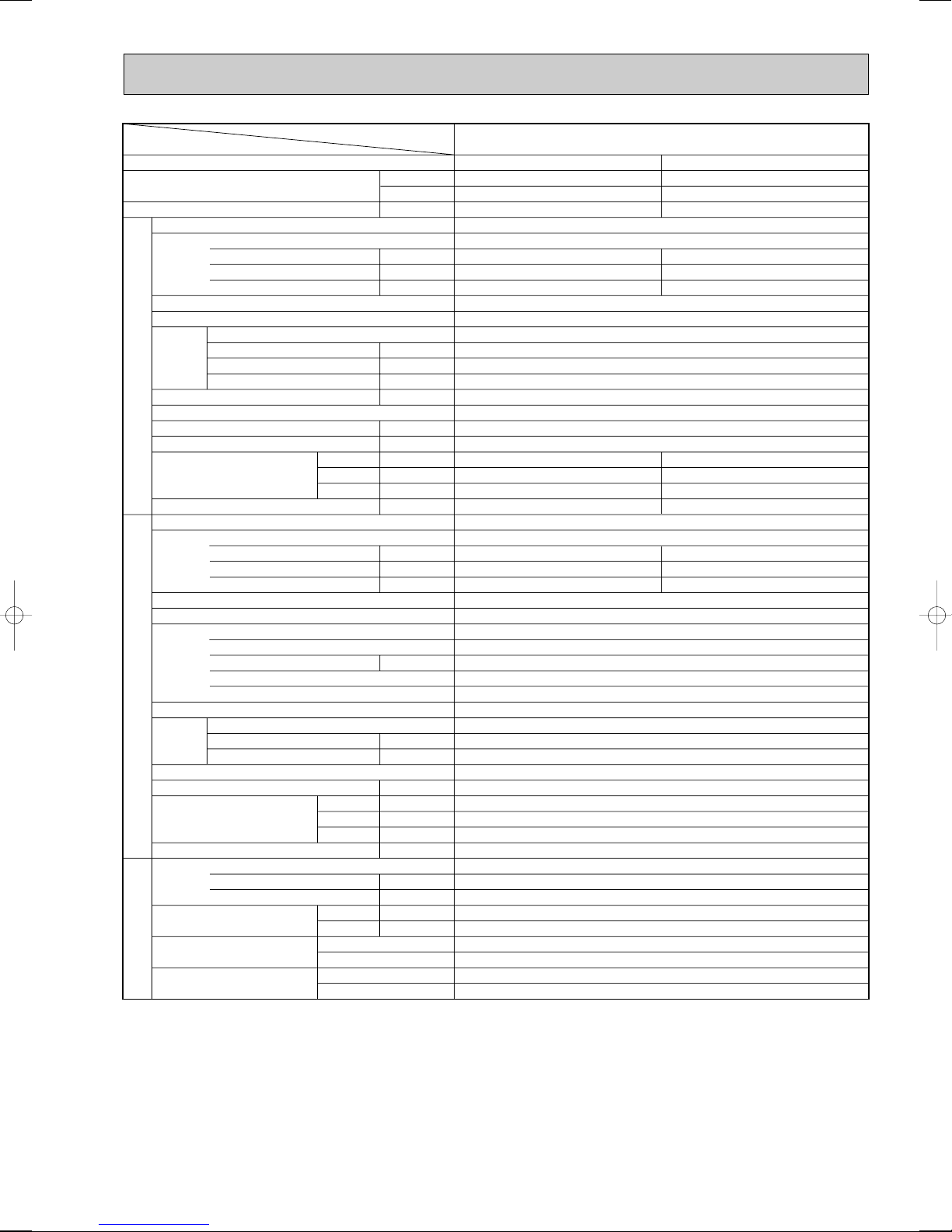

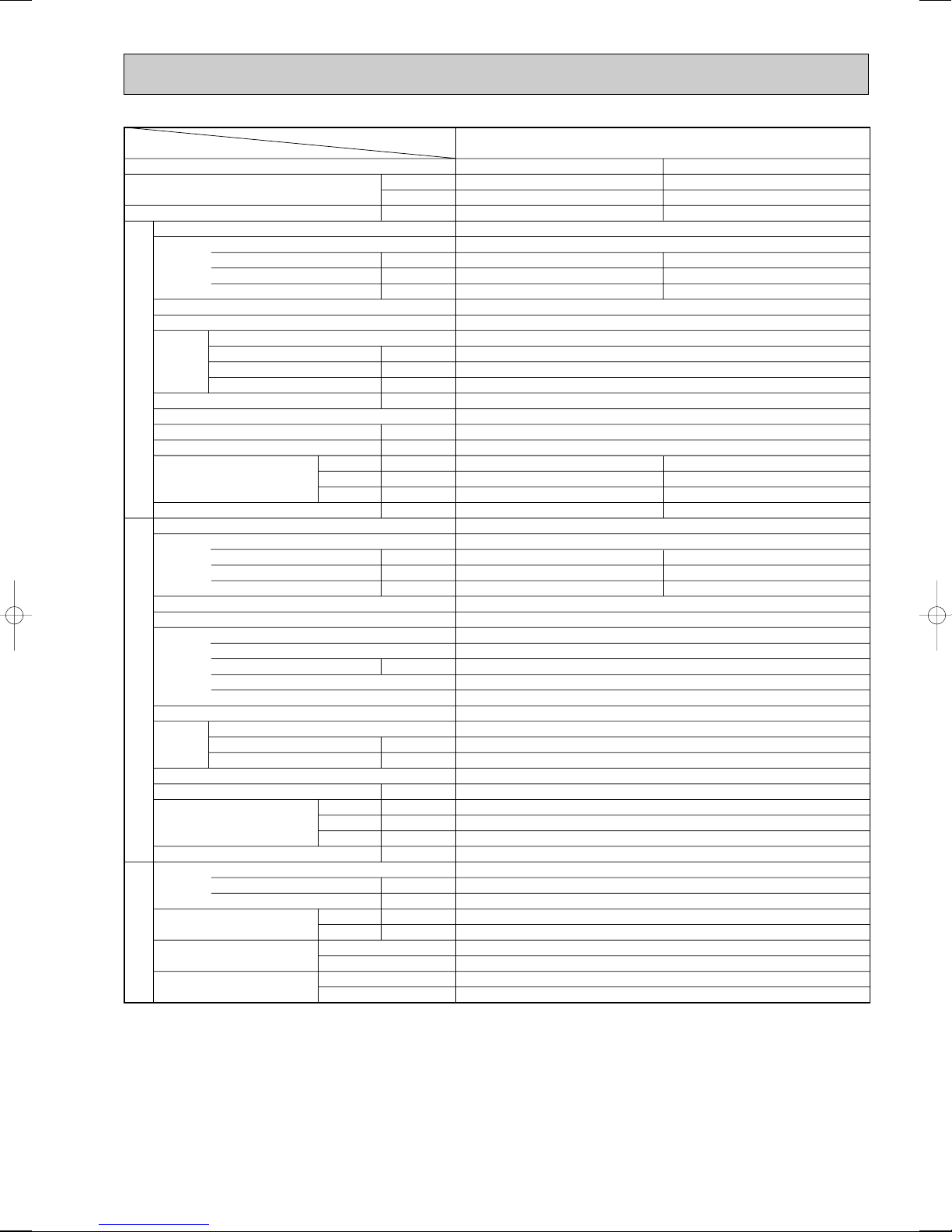

3

PLH-3AAK(H)

Cooling

26,300

7,700

3.32

0.17

0.81

1.00

UNIT : 840(33-1/6)

UNIT : 840(33-1/6)

UNIT : 258(10-1/8)

UNIT : 24(53) [26(57)]

3.15

13.82/5.16

58/37

Heating

28,700[35,800]

8,400[10,500]

3.11[5.21]

0.17[2.27]

0.81[9.47]

1.00[9.7]

PANEL : 950(37-3/8)

PANEL : 950(37-3/8)

PANEL : 30(1-3/16)

PANEL : 5(11)

2.94

12.89/4.81

58/37

PLH-3AAK(H)

Single, 50Hz, 220-240V

Grille : Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) x 1

0.07

15-20(530-705)

0(direct blow)

[2.1]

Remote controller & built-in

28-34

32(1-1/4)

PUH-3VKA.TH, PUH-3VKA

2.TH-A/PUH-3YKA.TH, PUH-3YKA1.TH-A

Single, 50Hz, 220-240V/3, 50Hz, 380-415V(4wires)

Munsell 5Y 7/1

Capillary tube

Hermetic

NH52VNHT/NH52YDAT

2.2/2.4

Line start

w1

Plate fin coil

Propeller (direct) x1

0.085

50(1764)

Reverse cycle

52

870(34-1/4)

295+24 (11-5/8 add 1)

850(33-1/4)

75(165)

R-22

3.2(7.1)

1.6<MS-32>

9.52 (3/8)

15.88(5/8)

Flared

Flared

Max. 50m

Max. 50m

Service Ref.

Power supply(phase, cycle,voltage)

External finish

Heat exchanger

Fan

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor units

Input

Running current

Starting current

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive) x No.

Fan motor output

Airflow

Charge

Oil<Model>

W

D

H

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Function

Capacity

Total input

INDOOR UNITOUTDOOR UNIT

REFRIGERANT

PIPING

Item

Service Ref.

Btu/h

W

kW

kW

A

A

kW

K/ min (CFM)

Pa

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kW

A

A

kW

kW

K/ min (CFM)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

SPECIFICATIONS

w1 V …Internal Thermostat, HP switch

Y…Anti-phase protector, thermal relay, thermal switch, HP switch

Notes: Rating condition (ISO T1<JIS B8616>)

Cooling: Indoor : D.B. 27°C, W.B. 19°C

Outdoor : D.B. 35°C, W.B. 24°C

Heating: Indoor : D.B. 20°C

Outdoor : D.B. 7°C, W.B. 6°C

Refrigerant piping length(one way):5m(16ft)

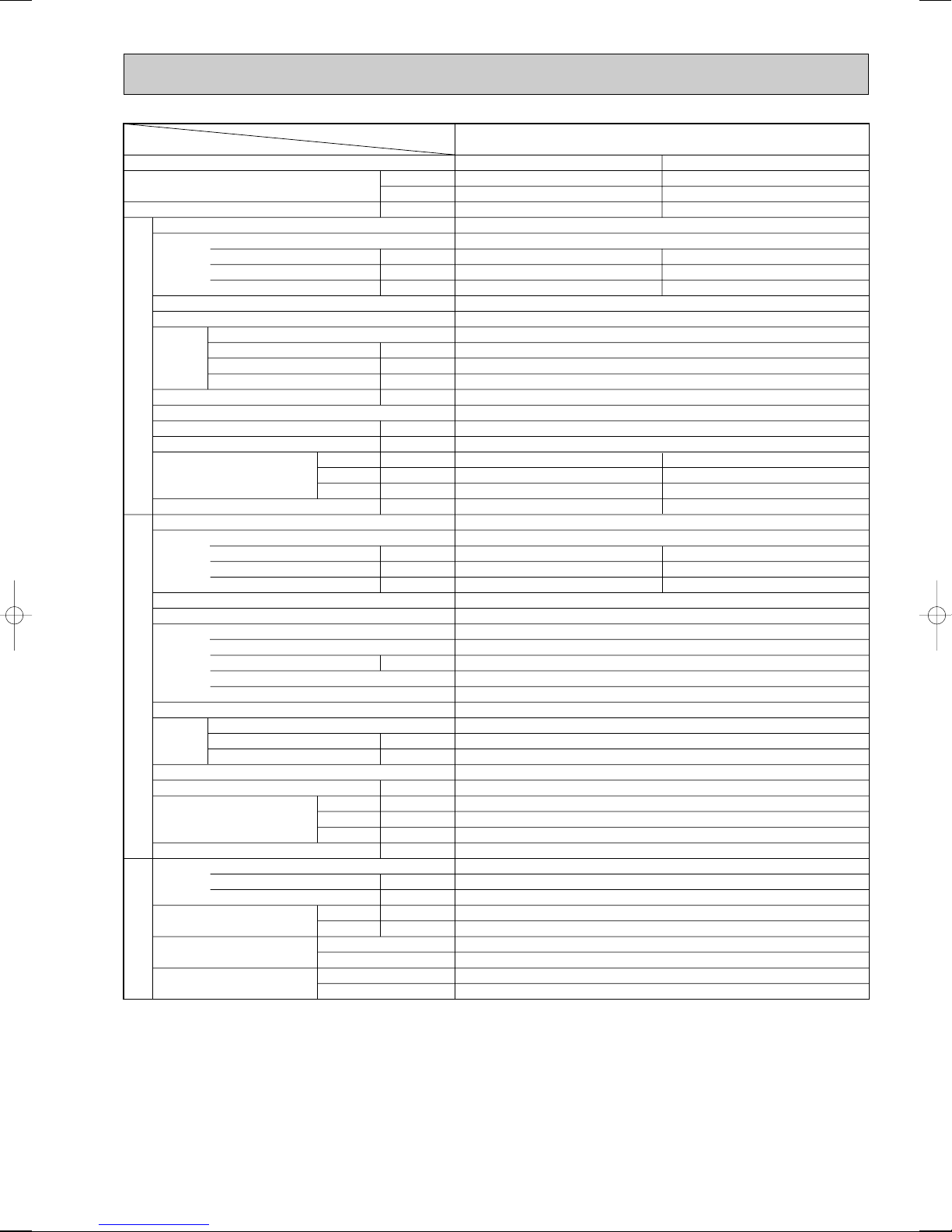

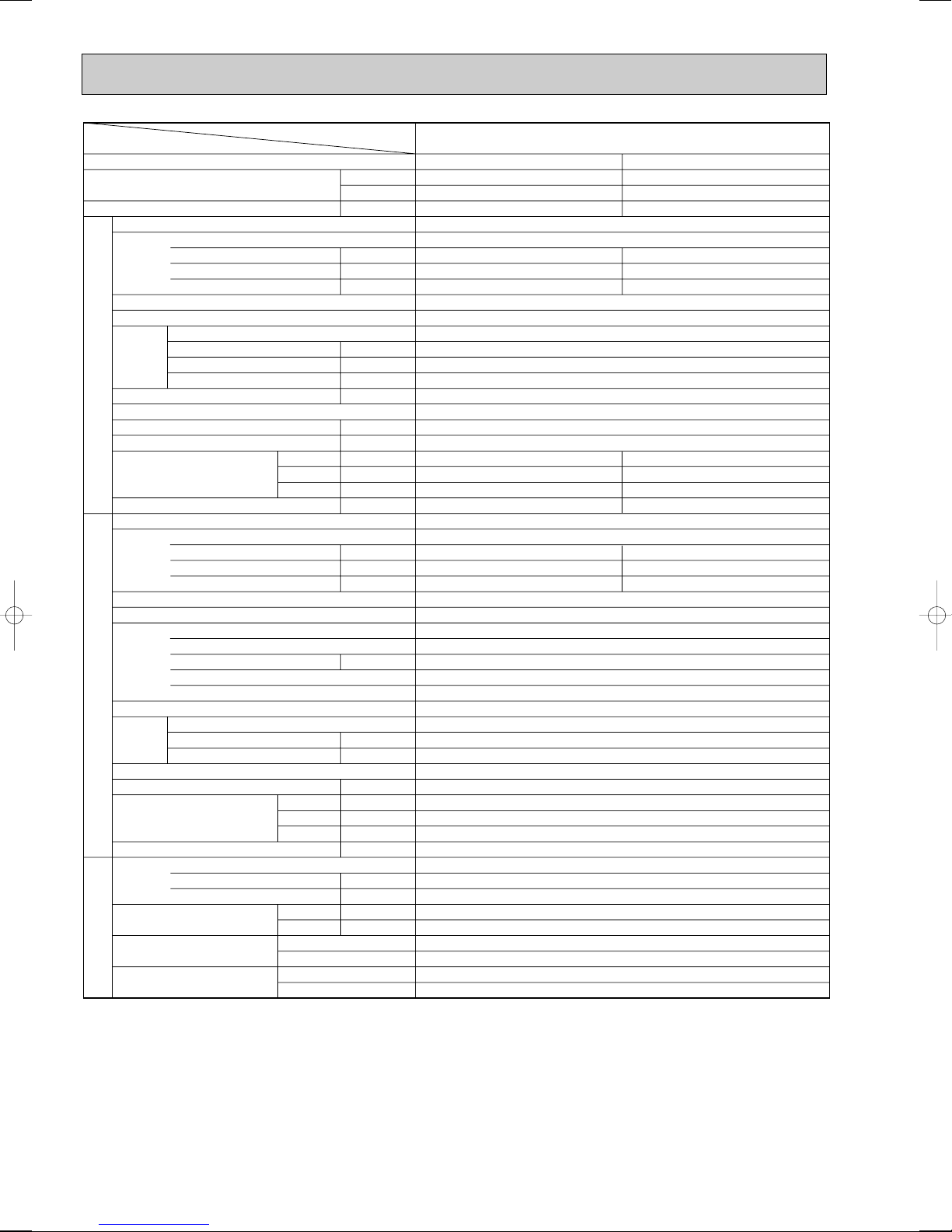

6

Item

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle,voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan

Booster heater

INDOOR UNITOUTDOOR UNIT

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

PIPING

Connection method

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive) x No.

Fan motor output

Airflow

Charge

Oil<Model>

REFRIGERANT

Between the indoor & outdoor units

Notes : w1.Rating condition (SSA 385)

Cooling: Indoor : D.B. 29°C, W.B. 19°C

Outdoor: D.B. 46°C, W.B. 24°C

Heating: Indoor : D.B. 21°C

Outdoor: D.B. 7°C, W.B. 6°C

w2.Rating condition (ISO T1<JIS 8616>)

Cooling: Indoor : D.B. 27°C, W.B. 19°C

Outdoor: D.B. 35°C, W.B. 24°C

Refrigerant piping length(one way):5m(16ft)

Service Ref.

K/ min (CFM)

W

D

H

K/ min (CFM)

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Btu/h

W

kW

kW

A

A

kW

Pa

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kW

A

A

kW

kW

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Cooling w1/w2

23,200/27,300

6,800/8,000

4.29/3.68

0.16

0.77

1.00

Grille : Munsell 0.70Y 8.59/0.97

UNIT : 840(33-1/6)

UNIT : 840(33-1/6)

UNIT : 258(10-1/8)

UNIT : 24(53)

4.13/3.52

18.77/16.49

80

Internal thermostat, HP switch

PLH-3AAK

Heating w1

31,700

9,300

3.49

PLH-3AAK

Single, 60Hz, 220V

0.16

0.77

1.00

Plate fin coil

Turbo fan (direct) x 1

0.07

15-20(530-705)

0(direct blow)

—

Remote controller & built-in

28-34

32(1-1/4)

PANEL : 950(37-3/8)

PANEL : 950(37-3/8)

PANEL : 30(1-3/16)

PANEL : 5(11)

PUH-3NKA.TH

Single, 60Hz, 220V

3.33

15.6

80

Munsell 5Y 7/1

Capillary tube

Hermetic

NHJ47NADT

2.2

Line start

Plate fin coil

Propeller (direct) x1

0.085

50(1764)

Reverse cycle

52

870(34-1/4)

295+24 (11-5/8 add 1)

850(33-1/4)

78(172)

R-22

3.2(7.1)

1.6<MS-32>

9.52 (3/8)

15.88(5/8)

Flared

Flared

Max. 50m

Max. 50m

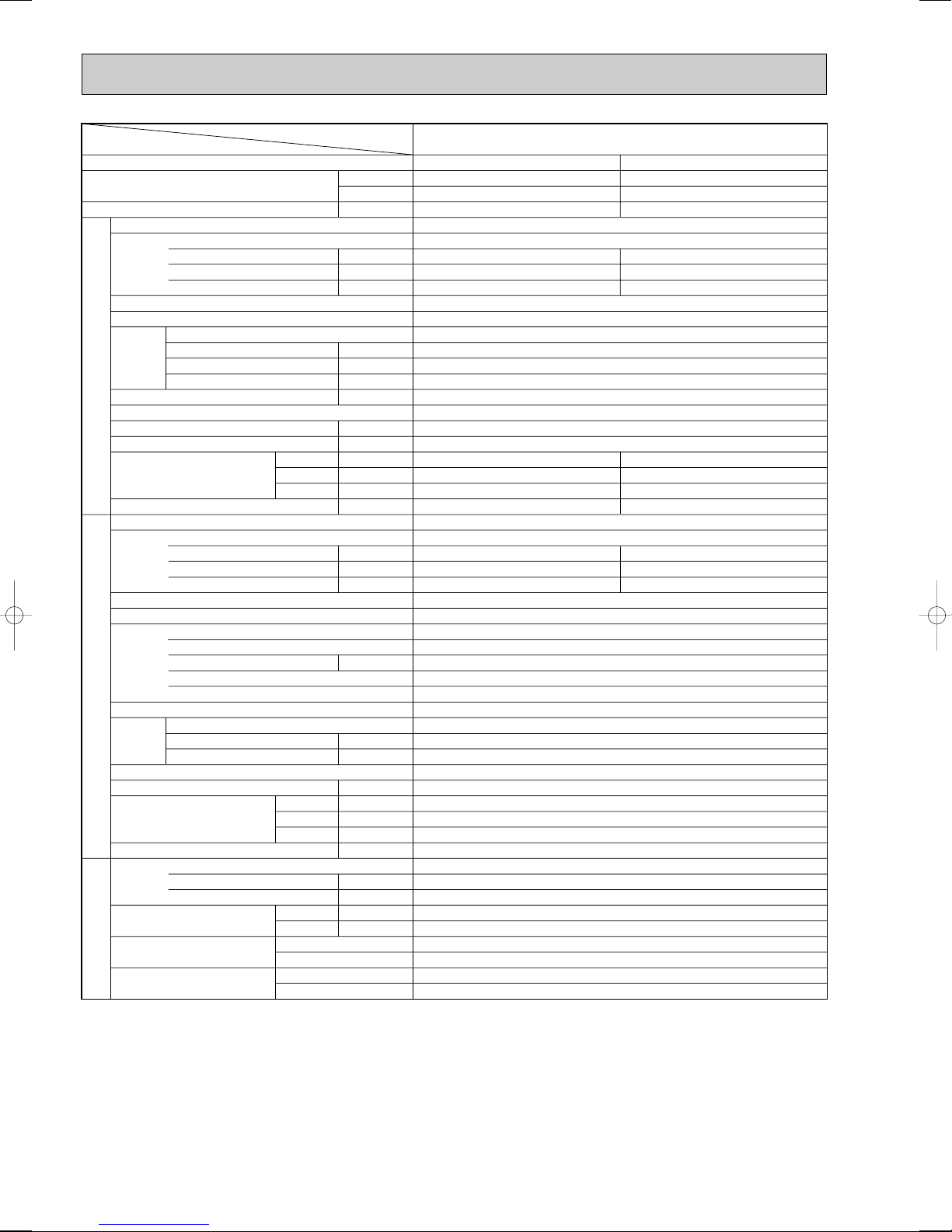

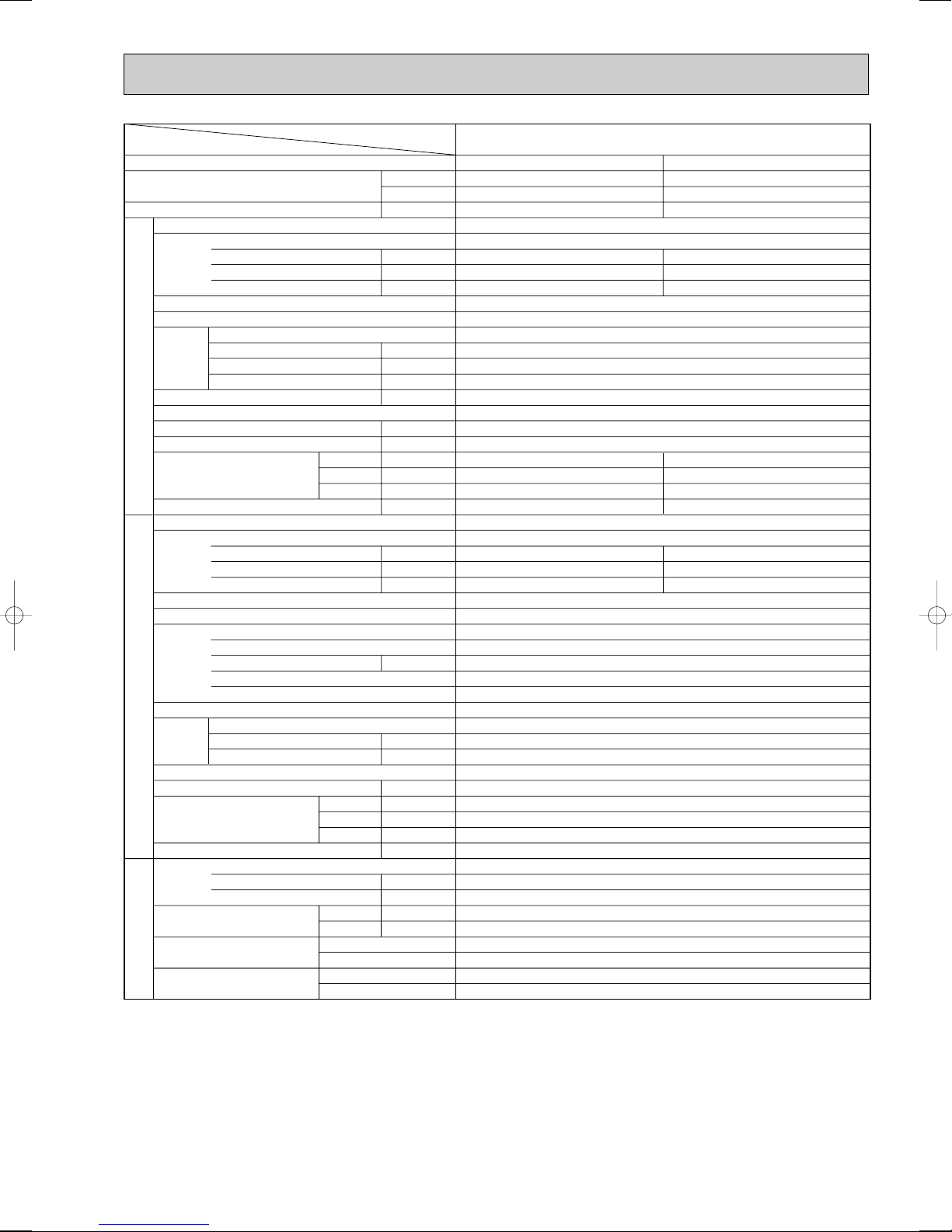

7

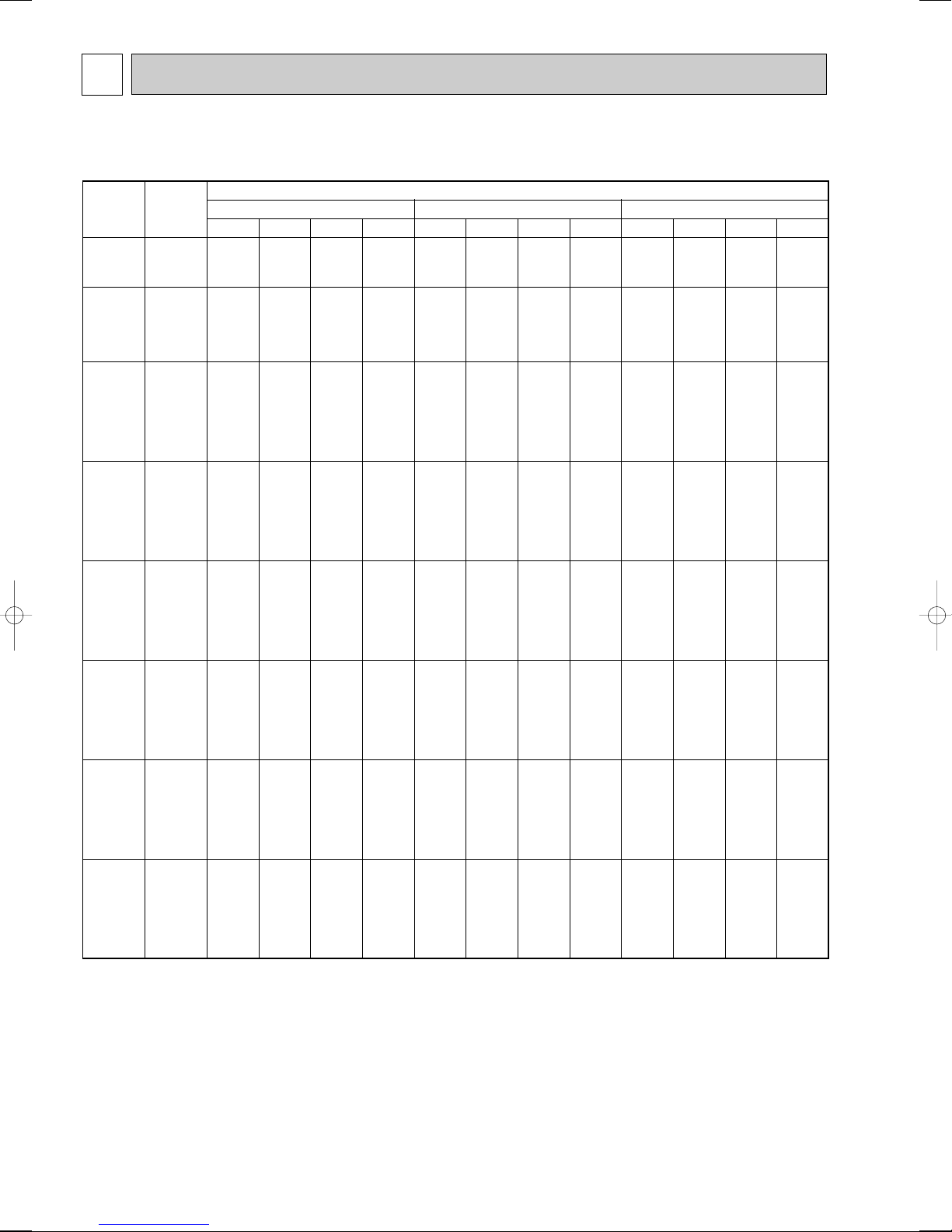

Cooling

33,100

9,700

3.46

0.26

1.25

2.0

UNIT : 840(33-1/6)

UNIT : 840(33-1/6)

UNIT : 298(11-3/4)

UNIT : 30(66)[32(71)]

3.20

5.24

40

Heating

35,500[44,400]

10,400[13,000]

3.45[6.05]

0.26[2.86]

1.25[11.93]

2.0[12.7]

PANEL : 950(37-3/8)

PANEL : 950(37-3/8)

PANEL : 30(1-3/16)

PANEL : 5(11)

3.19

5.22

40

Service Ref.

Power supply(phase, cycle,voltage)

External finish

Heat exchanger

Fan

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor units

Input

Running current

Starting current

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive) x No.

Fan motor output

Airflow

Charge

Oil<Model>

W

D

H

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Function

Capacity

Total input

INDOOR UNITOUTDOOR UNIT

REFRIGERANT

PIPING

Item

Service Ref.

Btu/h

W

kW

kW

A

A

kW

K/ min (CFM)

Pa

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kW

A

A

kW

kW

K/ min (CFM)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

PLH-4AAK(H)

PLH-4AAK(H)

Single, 50Hz, 220-240V

Grille : Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) x 1

0.120

20-28(705-990)

0(direct blow)

[2.6]

Remote controller & built-in

33-41

32(1-1/4)

PUH-4YKSA.TH, PUH-4YKSA

1.TH-A

3, 50Hz, 380V-415V(4wire)

Munsell 5Y 7/1

Capillary tube

Hermetic

NH56YDAT

2.7

Line start

Anti-phase protector, Thermal relay, Thermal switch, HP switch

Plate fin coil

Propeller (direct) x2

0.065+0.065

95(3550)

Reverse cycle

54

870(34-1/4)

295+24(11-5/8 add 1)

1258(49-1/2)

94(207)

R-22

4.2(9.2)

1.6<MS-32>

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

Notes: Rating condition (ISO T1<JIS B8616>)

Cooling: Indoor : D.B. 27°C, W.B. 19°C

Heating: Indoor : D.B. 20°C

Refrigerant piping length(one way):5m(16ft)

Outdoor : D.B. 35°C, W.B. 24°C

Outdoor : D.B. 7°C, W.B. 6°C

8

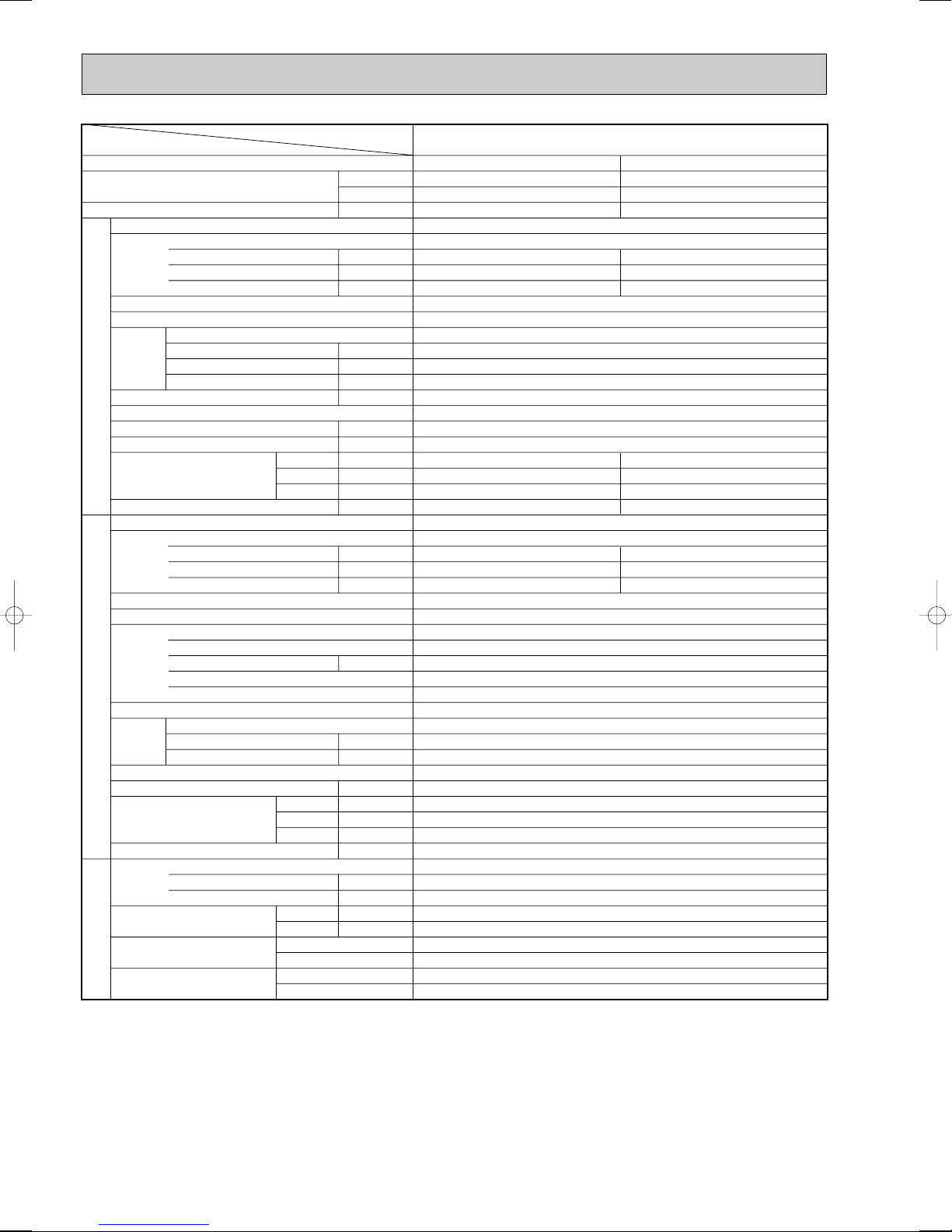

Item

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle,voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan

Booster heater

INDOOR UNITOUTDOOR UNIT

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

PIPING

Connection method

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive) x No.

Fan motor output

Airflow

Charge

Oil<Model>

REFRIGERANT

Between the indoor & outdoor units

Notes: w1.Rating condition (SSA 385)

Cooling: Indoor : D.B. 29°C, W.B. 19°C

Outdoor: D.B. 46°C, W.B. 24°C

Heating: Indoor : D.B. 21°C

Outdoor: D.B. 7°C, W.B. 6°C

w2.Rating condition (ISO T1<JIS 8616>)

Cooling: Indoor : D.B. 27°C, W.B. 19°C

Outdoor: D.B. 35°C, W.B. 24°C

Refrigerant piping length(one way):5m(16ft)

Service Ref.

K/ min (CFM)

W

D

H

K/ min (CFM)

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Btu/h

W

kW

kW

A

A

kW

Pa

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kW

A

A

kW

kW

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

PLH-4AAK

Cooling w1/w2

33,800/37,400

9,900/10,950

5.26/4.93

PLH-4AAK

Single, 60Hz, 220V

0.25

1.19

2.0

Grille : Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) x 1

0.120

20-28(705-990)

0(direct blow)

—

Remote controller & built-in

33-41

32(1-1/4)

UNIT : 840(33-1/6)

UNIT : 840(33-1/6)

UNIT : 298(11-3/4)

UNIT : 30(66)

PUH-4TKSA.TH

3, 60Hz, 220V

5.01/4.14

14.14/11.81

69

Munsell 5Y 7/1

Capillary tube

Hermetic

NHJ56TKAT

2.7

Line start

Anti-phase protector, Thermal relay, Thermal switch, HP switch

Plate fin coil

Propeller (direct) x2

0.065+0.065

95(3550)

Reverse cycle

55

870(34-1/4)

295+24(11-5/8 add 1)

1258(49-1/2)

94(207)

R-22

4.7(10.4)

1.6<MS-32>

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

Heating w1

41,300

12,100

4.21

0.25

1.19

2.0

PANEL : 950(37-3/8)

PANEL : 950(37-3/8)

PANEL : 30(1-3/16)

PANEL : 5(11)

3.96

11.3

69

9

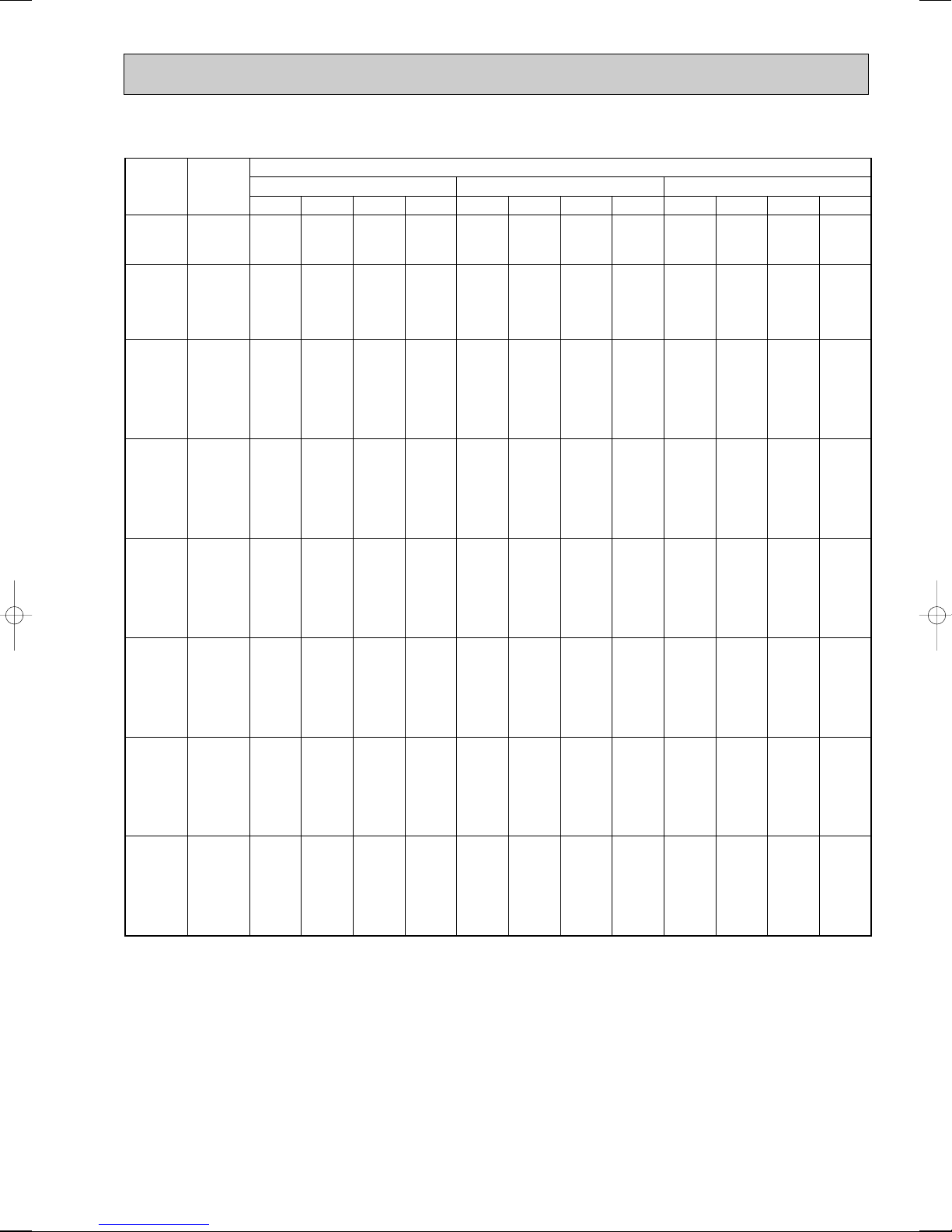

Cooling

42,300

12,400

4.51

0.30

1.43

2.0

UNIT : 840(33-1/16)

UNIT : 840(33-1/16)

UNIT : 298(11-3/4)

UNIT : 30(66) [32(71)]

4.21

6.89

53

Heating

47,800[58,000]

14,000[17,000]

4.46[7.46]

0.30[3.30]

1.43[13.77]

2.0[14.3]

PANEL : 950(37-3/8)

PANEL : 950(37-3/8)

PANEL : 30(1-3/16)

PANEL : 5(11)

4.16

6.81

53

Service Ref.

Power supply(phase, cycle,voltage)

External finish

Heat exchanger

Fan

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor units

Input

Running current

Starting current

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive) x No.

Fan motor output

Airflow

Charge

Oil<Model>

W

D

H

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Function

Capacity

Total input

INDOOR UNITOUTDOOR UNIT

REFRIGERANT

PIPING

Item

Service Ref.

Btu/h

W

kW

kW

A

A

kW

K/ min (CFM)

Pa

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kW

A

A

kW

kW

K/ min (CFM)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

PLH-5AAK(H)

PLH-5AAK(H)

Single, 50Hz, 220-240V

Grille : Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) x 1

0.120

22-30(775-1,060)

0(direct blow)

[3.0]

Remote controller & built-in

35-43

32(1-1/4)

PUH-5YKSA.TH, PUH-5YKSA

3.TH-A

3, 50Hz, 380-415V(4wire)

Munsell 5Y 7/1

Capillary tube

Hermetic

ZR61KC-TFD

3.5

Line start

Internal thermostat, Anti-phase protector, Thermal switch, HP switch

Plate fin coil

Propeller (direct) x2

0.085+0.085

95(3550)

Reverse cycle

55

970(38-3/16)

345+24(13-9/16 add 1)

1258(49-1/2)

114(251)

R-22

5.4(11.9)

2.130<SONTEX-200LT>

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

Notes: Rating condition (ISO T1<JIS B8616>)

Cooling: Indoor : D.B. 27°C, W.B. 19°C

Outdoor : D.B. 35°C, W.B. 24°C

Heating: Indoor : D.B. 20°C

Outdoor : D.B. 7°C, W.B. 6°C

Refrigerant piping length(one way):5m(16ft)

10

Item

Function

Capacity

Total input

Service Ref.

Power supply(phase, cycle,voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan

Booster heater

INDOOR UNITOUTDOOR UNIT

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

PIPING

Connection method

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive) x No.

Fan motor output

Airflow

Charge

Oil<Model>

REFRIGERANT

Between the indoor & outdoor units

Notes: w1.Rating condition (SSA 385)

Cooling: Indoor : D.B. 29°C, W.B. 19°C

Outdoor: D.B. 46°C, W.B. 24°C

Heating: Indoor : D.B. 21°C

Outdoor: D.B. 7°C, W.B. 6°C

w2.Rating condition (ISO T1<JIS 8616>)

Cooling: Indoor : D.B. 27°C, W.B. 19°C

Outdoor: D.B. 35°C, W.B. 24°C

Refrigerant piping length(one way):5m(16ft)

Service Ref.

K/ min (CFM)

W

D

H

K/ min (CFM)

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Btu/h

W

kW

kW

A

A

kW

Pa

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kW

A

A

kW

kW

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

PLH-5AAK

Cooling w1/w2

37,500/44,400

11,000/13,000

6.78/5.58

PLH-5AAK

Single, 60Hz, 220V

0.26

1.24

2.0

Grille : Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) x 1

0.120

22-30(775-1,060)

0(direct blow)

—

Remote controller & built-in

35-43

32(1-1/4)

UNIT : 840(33-1/16)

UNIT : 840(33-1/16)

UNIT : 298(11-3/4)

UNIT : 30(66)

PUH-5TKSA.TH

3, 60Hz, 220V

6.52/5.32

19.23/16.23

135

Munsell 5Y 7/1

Capillary tube

Hermetic

ZR61KC-TF5

3.5

Line start

Internal thermostat, Anti-phase protector, Thermal switch, HP switch

Plate fin coil

Propeller (direct) x2

0.100+0.100

100(3500)

Reverse cycle

55

970(38-3/16)

345+24(13-9/16 add 1)

1258(49-1/2)

114(251)

R-22

5.4(11.9)

2.13<SONTEX-200LT>

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

Heating w1

56,300

16,500

6.02

0.26

1.24

2.0

PANEL : 950(37-3/8)

PANEL : 950(37-3/8)

PANEL : 30(1-3/16)

PANEL :5(11)

5.76

17.38

135

11

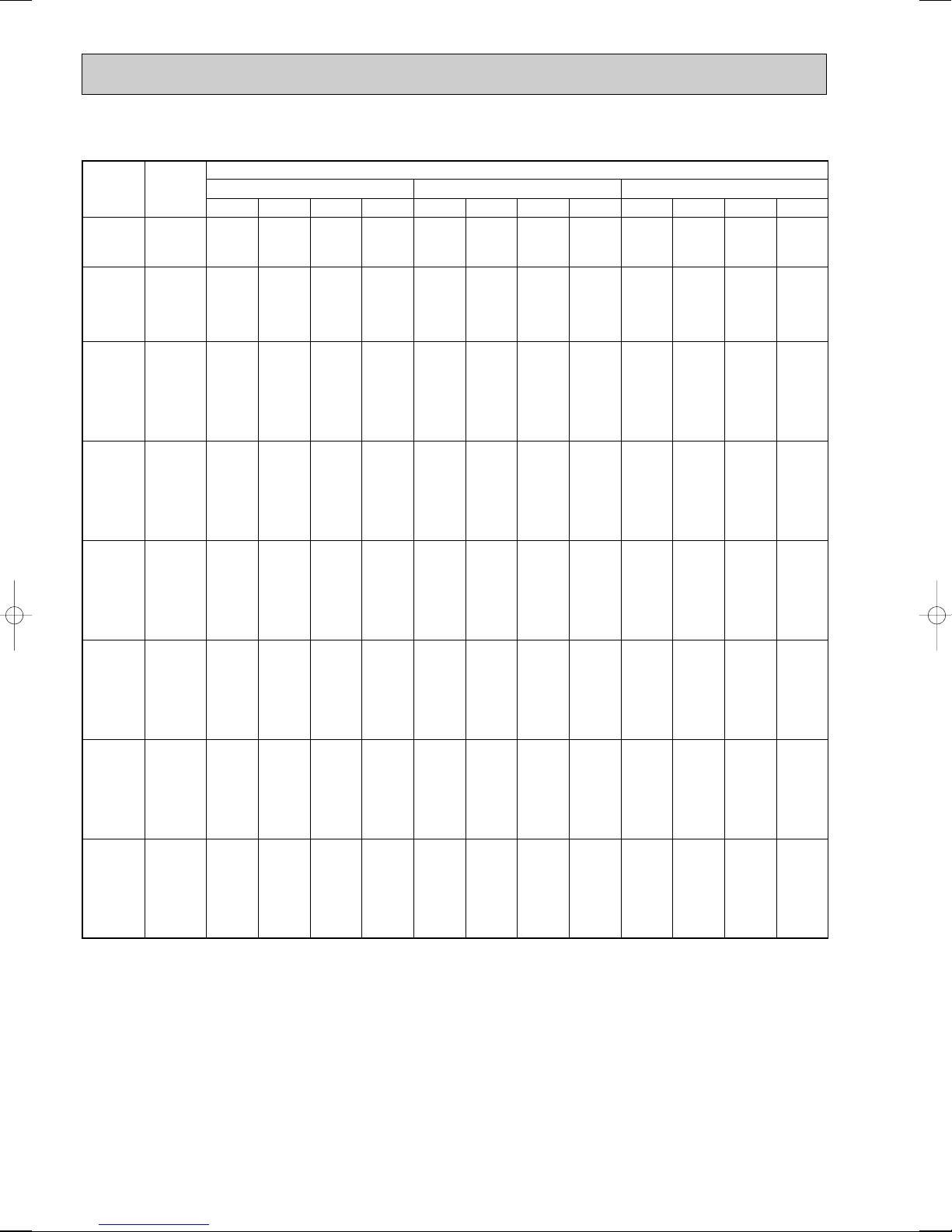

PLH-6AAK(H)

Cooling

47,800

14,000

5.07

0.34

1.64

2.0

UNIT : 840(33-1/16)

UNIT : 840(33-1/16)

UNIT : 298(11-3/4)

UNIT : 32(71)[34(75)]

4.73

7.74

74

Heating

54,900[65,200]

16,100[19,100]

4.92[7.92]

0.34[3.34]

1.64[13.94]

2.0[14.3]

PANEL : 950(37-3/8)

PANEL : 950(37-3/8)

PANEL : 30(1-3/16)

PANEL : 5(11)

4.58

7.50

74

Service Ref.

Power supply(phase, cycle,voltage)

External finish

Heat exchanger

Fan

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor units

Input

Running current

Starting current

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive) x No.

Fan motor output

Airflow

Charge

Oil<Model>

W

D

H

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Function

Capacity

Total input

INDOOR UNITOUTDOOR UNIT

REFRIGERANT

PIPING

Item

Service Ref.

Btu/h

W

kW

kW

A

A

kW

K/ min (CFM)

Pa

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kW

A

A

kW

kW

K/ min (CFM)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

PLH-6AAK(H)

Single, 50Hz, 220-240V

Grille : Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) x 1

0.120

22-30(775-1,060)

0(direct blow)

[3.0]

Remote controller & built-in

37-45

32(1-1/4)

PUH-6YKSA.TH, PUH-6YKSA

3.TH-A

3, 50Hz, 380-415V(4wire)

Munsell 5Y 7/1

Capillary tube

Hermetic

ZR68KC-TFD

4.0

Line start

Internal thermostat, Anti-phase protector, Thermal switch, HP switch

Plate fin coil

Propeller (direct) x2

0.10+0.10

100(3530)

Reverse cycle

56

970(38-3/16)

345+24(13-9/16 add 1)

1258(49-1/2)

117(258)

R-22

5.0(11.0)

1.774<SONTEX-200LT>

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

Notes: Rating condition (ISO T1<JIS B8616>)

Cooling: Indoor : D.B. 27°C, W.B. 19°C

Outdoor : D.B. 35°C, W.B. 24°C

Heating: Indoor : D.B. 20°C

Outdoor : D.B. 7°C, W.B. 6°C

Refrigerant piping length(one way):5m(16ft)

12

PLH-6AAK

Cooling w1/w2

45,700/51,900

13,400/15,200

7.32/6.15

0.28

1.34

2.0

UNIT : 840(33-1/16)

UNIT : 840(33-1/16)

UNIT : 298(11-3/4)

UNIT : 32(71)

7.04/5.87

20.3/17.31

140

Heating w1

59,700

17,500

6.7

0.28

1.34

2.0

PANEL : 950(37-3/8)

PANEL : 950(37-3/8)

PANEL : 30(1-3/16)

PANEL :5(11)

6.42

18.51

140

Service Ref.

Power supply(phase, cycle,voltage)

External finish

Heat exchanger

Fan

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Fan

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor units

Input

Running current

Starting current

Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Fan(drive) x No.

Fan motor output

Airflow

Charge

Oil<Model>

W

D

H

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Function

Capacity

Total input

INDOOR UNITOUTDOOR UNIT

REFRIGERANT

PIPING

Item

Service Ref.

Btu/h

W

kW

kW

A

A

kW

K/ min (CFM)

Pa

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kW

A

A

kW

kW

K/ min (CFM)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

PLH-6AAK

Single, 60Hz, 220V

Grille : Munsell 0.70Y 8.59/0.97

Plate fin coil

Turbo fan (direct) x 1

0.120

22-30(775-1,060)

0(direct blow)

—

Remote controller & built-in

37-45

32(1-1/4)

PUH-6TKSA.TH

3, 60Hz, 220V

Munsell 5Y 7/1

Capillary tube

Hermetic

ZR68KC-TF5

4.0

Line start

Internal thermostat, Anti-phase protector, Thermal switch, HP switch

Plate fin coil

Propeller (direct) x2

0.10+0.10

100(3530)

Reverse cycle

56

970(38-3/16)

345+24(13-9/16 add 1)

1258(49-1/2)

117(258)

R-22

5.0(11.0)

1.774<SONTEX-200LT>

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

Notes: w1.Rating condition (SSA 385)

Cooling: Indoor : D.B. 29°C, W.B. 19°C

Outdoor: D.B. 46°C, W.B. 24°C

Heating: Indoor : D.B. 21°C

Outdoor: D.B. 7°C, W.B. 6°C

w2.Rating condition (ISO T1<JIS 8616>)

Cooling: Indoor : D.B. 27°C, W.B. 19°C

Outdoor: D.B. 35°C, W.B. 24°C

Refrigerant piping length(one way):5m(16ft)

13

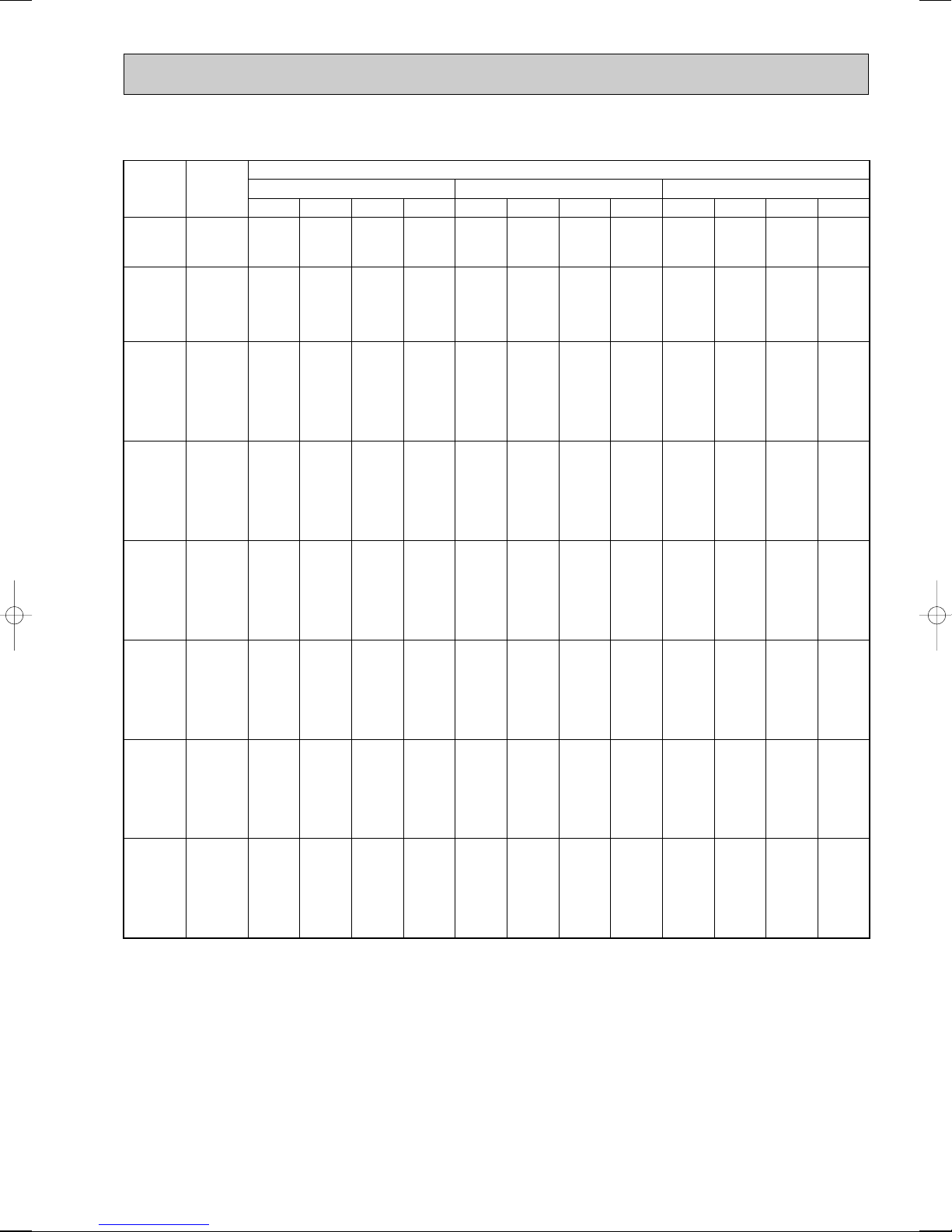

4

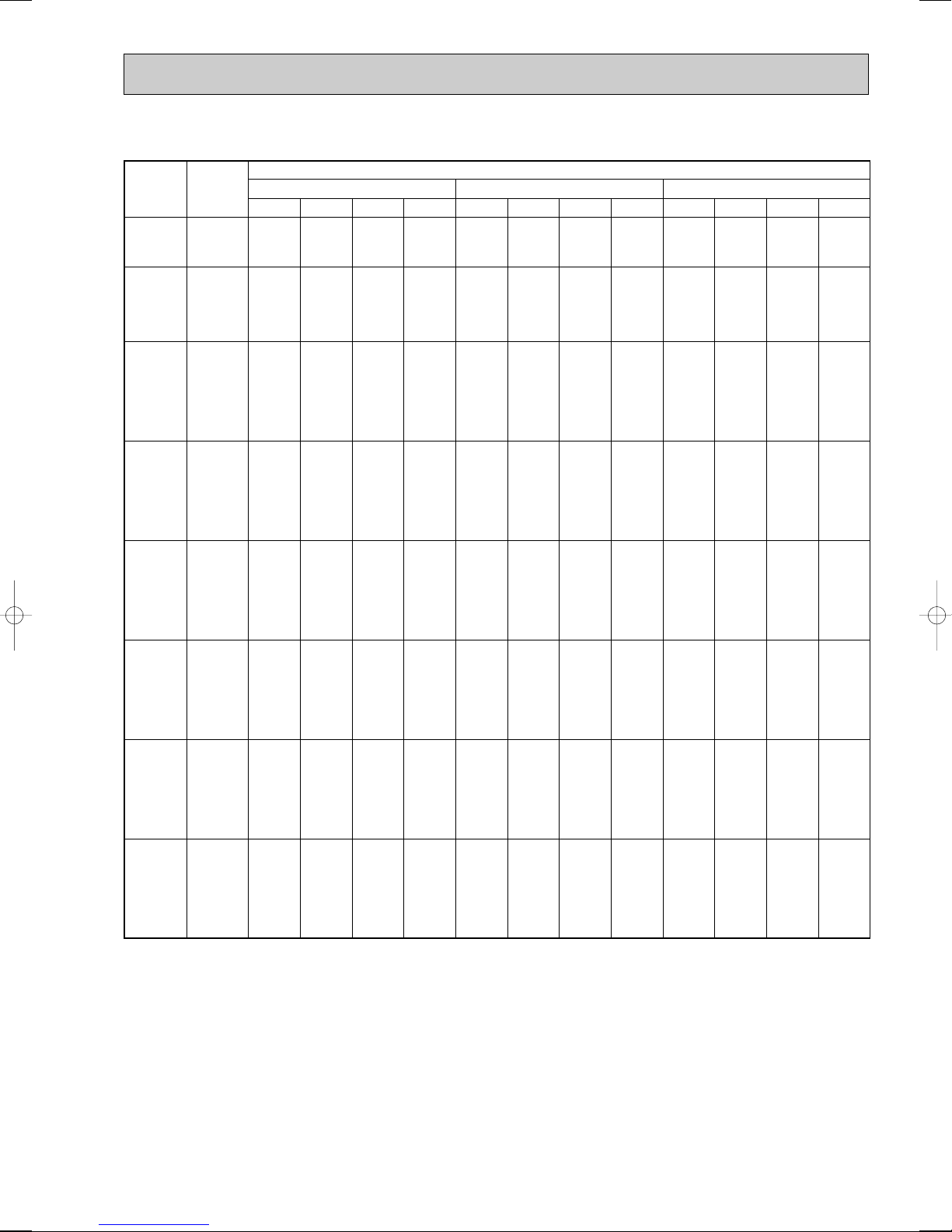

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

16

18

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

7768

8271

7768

8271

8779

7768

8271

8779

9293

7768

8271

8779

9293

7768

8271

8779

9293

7768

8271

8779

9293

7768

8271

8779

9293

7768

8271

8779

9293

CA SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

4972

4301

5593

4963

4214

6214

5624

4916

4089

6836

6286

5619

4832

7147

6617

5970

5204

7457

6948

6321

5576

7768

7609

7023

6319

7768

8271

7726

7063

0.64

0.52

0.72

0.60

0.48

0.80

0.68

0.56

0.44

0.88

0.76

0.64

0.52

0.92

0.80

0.68

0.56

0.96

0.84

0.72

0.60

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

0.64

0.52

0.72

0.60

0.48

0.80

0.68

0.56

0.44

0.88

0.76

0.64

0.52

0.92

0.80

0.68

0.56

0.96

0.84

0.72

0.60

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

0.64

0.52

0.72

0.60

0.48

0.80

0.68

0.56

0.44

0.88

0.76

0.64

0.52

0.92

0.80

0.64

0.52

0.96

0.84

0.72

0.60

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

2.66

2.71

2.66

2.71

2.77

2.66

2.71

2.77

2.82

2.66

2.71

2.77

2.82

2.66

2.71

2.77

2.82

2.66

2.71

2.77

2.82

2.66

2.71

2.77

2.82

2.66

2.71

2.77

2.82

7555

8053

7555

8053

8573

7555

8053

8573

9115

7555

8053

8573

9115

7555

8053

8573

9115

7555

8053

8573

9115

7555

8053

8573

9115

7555

8053

8573

9115

4835

4188

5440

4832

4115

6044

5476

4801

4011

6649

6120

5487

4740

6951

6443

5830

5104

7253

6765

6173

5469

7555

7409

6858

6198

7555

8053

7544

6927

2.77

2.83

2.77

2.83

2.89

2.77

2.83

2.89

2.94

2.77

2.83

2.89

2.94

2.77

2.83

2.89

2.94

2.77

2.83

2.89

2.94

2.77

2.83

2.89

2.94

2.77

2.83

2.89

2.94

7278

7760

7278

7760

8267

7278

7760

8267

8799

7278

7760

8267

8799

7278

7760

8267

8799

7278

7760

8267

8799

7278

7760

8267

8799

7278

7760

8267

8799

4658

4035

5240

4656

3968

5822

5277

4630

3872

6404

5898

5291

4576

6696

6208

5622

4928

6987

6518

5952

5279

7278

7139

6614

5983

7278

7760

7275

6687

2.99

3.06

2.99

3.06

3.12

2.99

3.06

3.12

3.19

2.99

3.06

3.12

3.19

2.99

3.06

3.12

3.19

2.99

3.06

3.12

3.19

2.99

3.06

3.12

3.19

2.99

3.06

3.12

3.19

DATA

1. PERFORMANCE DATA [50Hz]

1) COOLING CAPACITY(1)

PLH-3AAK(H)

CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW) SHF : Sensible heat factor

14

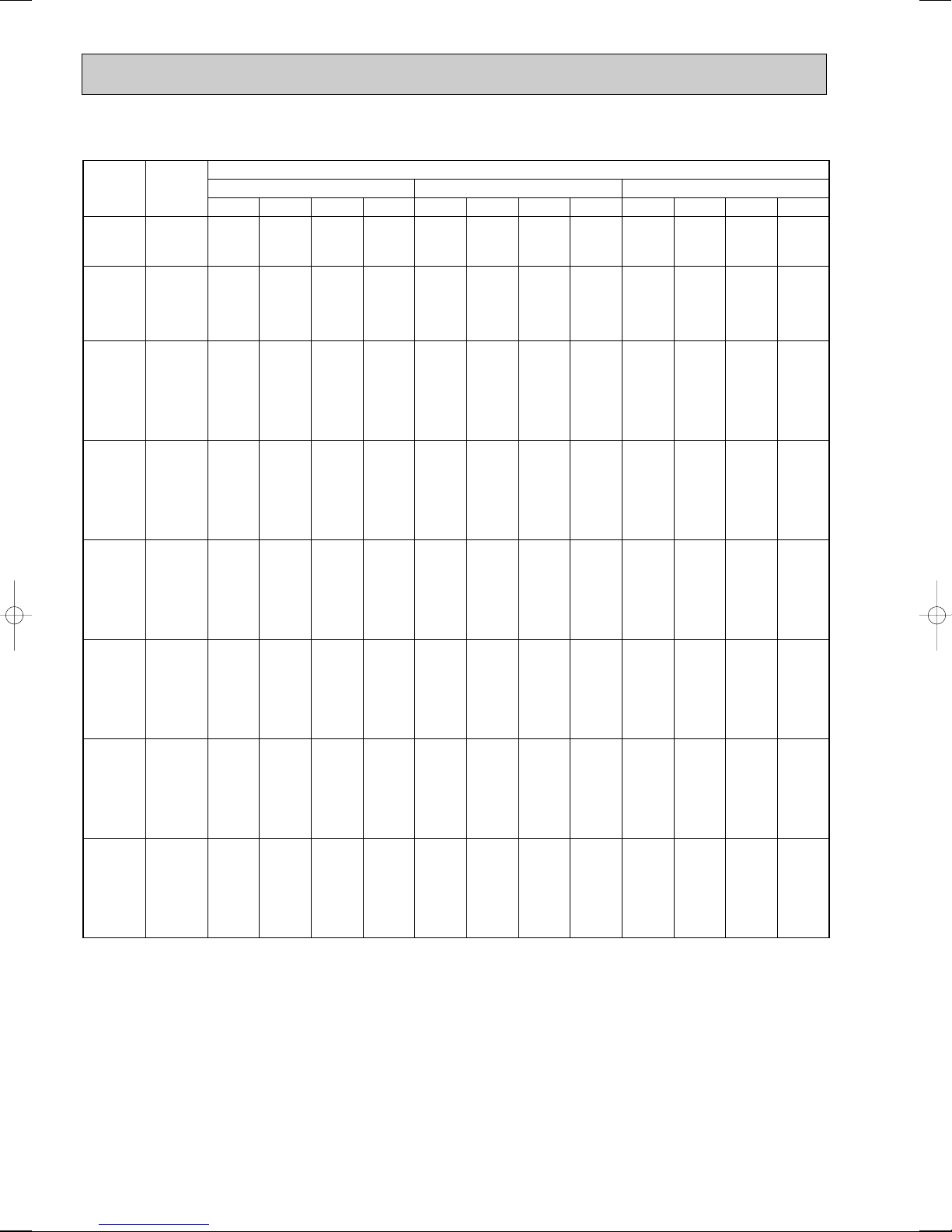

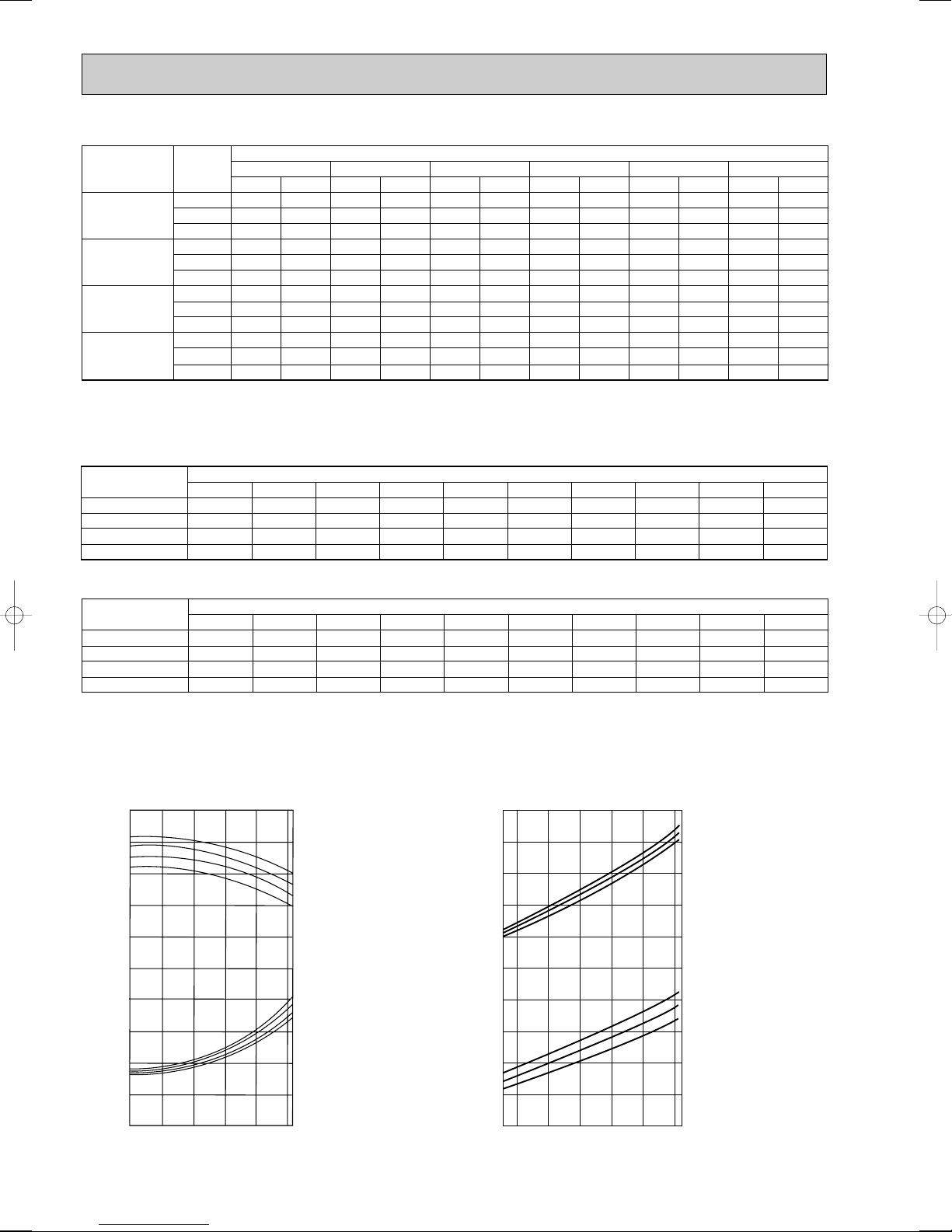

COOLING CAPACITY(2)

Outdoor intake air D.B.(°C)

35 40 45

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

16

18

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

6983

7452

6983

7452

7948

6983

7452

7948

8470

6983

7452

7948

8470

6983

7452

7948

8470

6983

7452

7948

8470

6983

7452

7948

8470

6983

7452

7948

8470

CA SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

4469

3875

5028

4471

3815

5586

5067

4451

3727

6145

5664

5087

4405

6424

5962

5405

4743

6704

6260

5722

5082

6983

6856

6358

5760

6983

7452

6994

6437

0.64

0.52

0.72

0.60

0.48

0.80

0.68

0.56

0.44

0.88

0.76

0.64

0.52

0.92

0.80

0.68

0.56

0.96

0.84

0.72

0.60

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

0.64

0.52

0.72

0.60

0.48

0.80

0.68

0.56

0.44

0.88

0.76

0.64

0.52

0.92

0.80

0.68

0.56

0.96

0.84

0.72

0.60

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

0.64

0.52

0.72

0.60

0.48

0.80

0.68

0.56

0.44

0.88

0.76

0.64

0.52

0.92

0.80

0.64

0.52

0.96

0.84

0.72

0.60

1.00

0.92

0.80

0.68

1.00

1.00

0.88

0.76

3.20

3.28

3.20

3.28

3.36

3.20

3.28

3.36

3.44

3.20

3.28

3.36

3.44

3.20

3.28

3.36

3.44

3.20

3.28

3.36

3.44

3.20

3.28

3.36

3.44

3.20

3.28

3.36

3.44

6671

7130

6671

7130

7616

6671

7130

7616

8128

6671

7130

7616

8128

6671

7130

7616

8128

6671

7130

7616

8128

6671

7130

7616

8128

6671

7130

7616

8128

4269

3708

4803

4278

3656

5337

4848

4265

3576

5870

5419

4874

4227

6137

5704

5179

4552

6404

5989

5483

4877

6671

6559

6093

5527

6671

7130

6702

6178

3.42

3.51

3.42

3.51

3.60

3.42

3.51

3.60

3.70

3.42

3.51

3.60

3.70

3.42

3.51

3.60

3.70

3.42

3.51

3.60

3.70

3.42

3.51

3.60

3.70

3.42

3.51

3.60

3.70

6342

6793

6342

6793

7270

6342

6793

7270

7773

6342

6793

7270

7773

6342

6793

7270

7773

6342

6793

7270

7773

6342

6793

7270

7773

6342

6793

7270

7773

4059

3532

4566

4076

3490

5073

4619

4071

3420

5581

5163

4653

4042

5834

5434

4944

4353

6088

5706

5235

4664

6342

6250

5816

5286

6342

6793

6398

5908

3.64

3.73

3.64

3.73

3.84

3.64

3.73

3.84

3.97

3.64

3.73

3.84

3.97

3.64

3.73

3.84

3.97

3.64

3.73

3.84

3.97

3.64

3.73

3.84

3.97

3.64

3.73

3.84

3.97

PLH-3AAK(H)

CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW) SHF : Sensible heat factor

15

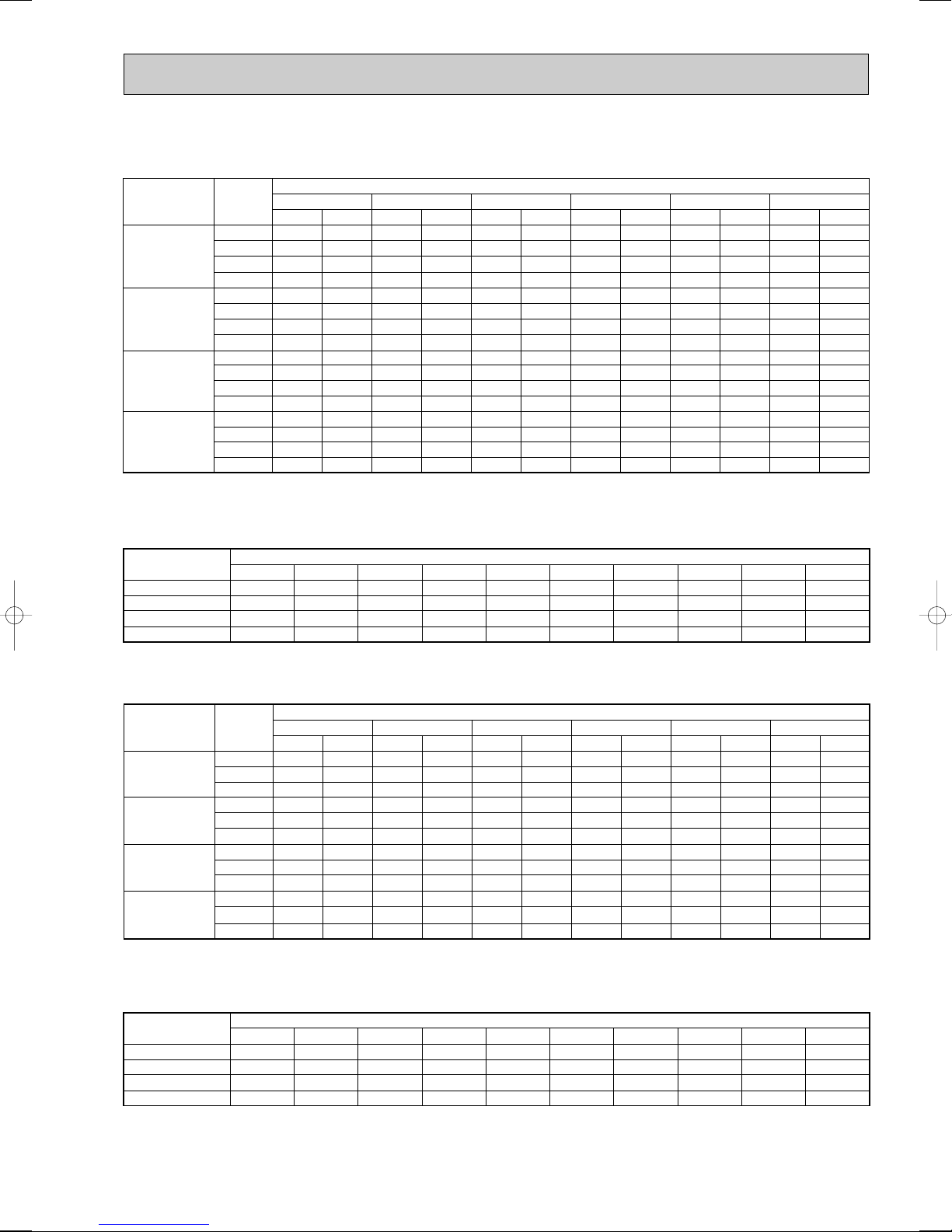

COOLING CAPACITY(3)

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

16

18

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

9786

10419

9786

10419

11060

9786

10419

11060

11707

9786

10419

11060

11707

9786

10419

11060

11707

9786

10419

11060

11707

9786

10419

11060

11707

9786

10419

11060

11707

CA SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

6752

5939

7535

6773

5862

8318

7606

6746

5736

9101

8440

7631

6673

9492

8856

8073

7141

9786

9273

8516

7609

9786

10107

9401

8546

9786

10419

10285

9483

0.69

0.57

0.77

0.65

0.53

0.85

0.73

0.61

0.49

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

0.69

0.57

0.77

0.65

0.53

0.85

0.73

0.61

0.49

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

0.69

0.57

0.77

0.65

0.53

0.85

0.73

0.61

0.49

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

2.77

2.83

2.77

2.83

2.88

2.77

2.83

2.88

2.94

2.77

2.83

2.88

2.94

2.77

2.83

2.88

2.94

2.77

2.83

2.88

2.94

2.77

2.83

2.88

2.94

2.77

2.83

2.88

2.94

9518

10145

9518

10145

10800

9518

10145

10800

11482

9518

10145

10800

11482

9518

10145

10800

11482

9518

10145

10800

11482

9518

10145

10800

11482

9518

10145

10800

11482

6567

5783

7329

6594

5724

8090

7406

6588

5626

8852

8217

7452

6545

9232

8623

7884

7004

9518

9029

8316

7464

9518

9841

9180

8382

9518

10145

10044

9301

2.89

2.95

2.89

2.95

3.01

2.89

2.95

3.01

3.07

2.89

2.95

3.01

3.07

2.89

2.95

3.01

3.07

2.89

2.95

3.01

3.07

2.89

2.95

3.01

3.07

2.89

2.95

3.01

3.07

9168

9775

9168

9775

10414

9168

9775

10414

11085

9168

9775

10414

11085

9168

9775

10414

11085

9168

9775

10414

11085

9168

9775

10414

11085

9168

9775

10414

11085

6326

5572

7059

6354

5520

7793

7136

6353

5431

8526

7918

7186

6318

8893

8309

7602

6762

9168

8700

8019

7205

.9168

9482

8852

8092

9168

9775

9685

8979

3.11

3.18

3.11

3.18

3.25

3.11

3.18

3.25

3.32

3.11

3.18

3.25

3.32

3.11

3.18

3.25

3.32

3.11

3.18

3.25

3.32

3.11

3.18

3.25

3.32

3.11

3.18

3.25

3.32

PLH-4AAK(H)

CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW) SHF : Sensible heat factor

16

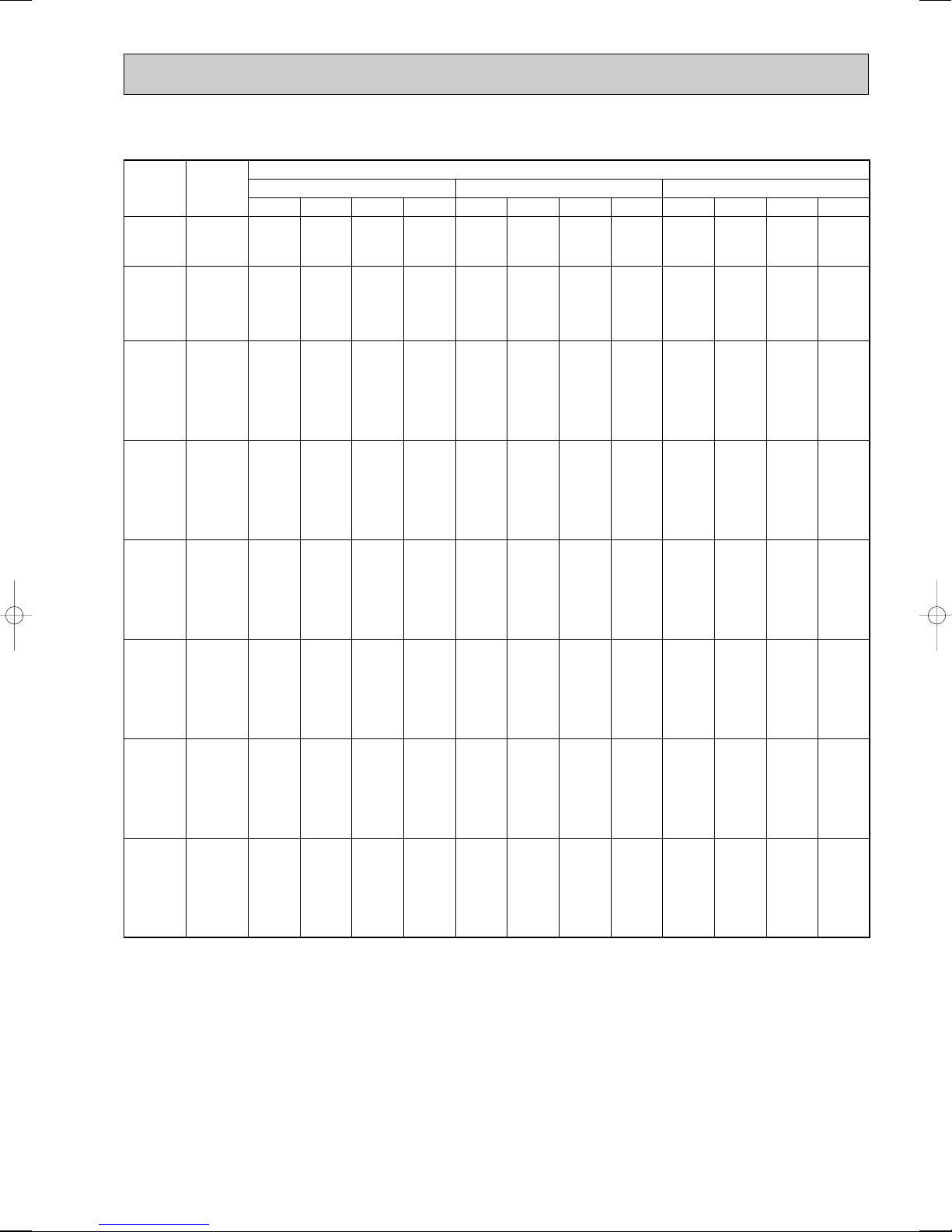

COOLING CAPACITY(4)

Outdoor intake air D.B.(°C)

35 40 45

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

16

18

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

CA SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

6070

5351

6773

6102

5307

7477

6853

6107

5228

8181

7604

6908

6082

8533

7980

7309

6509

8797

8355

7709

6936

8797

9106

8510

7789

8797

9388

9311

8643

0.69

0.57

0.77

0.65

0.53

0.85

0.73

0.61

0.49

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

0.69

0.57

0.77

0.65

0.53

0.85

0.73

0.61

0.49

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

0.69

0.57

0.77

0.65

0.53

0.85

0.73

0.61

0.49

0.93

0.81

0.69

0.57

0.97

0.85

0.73

0.61

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

1.00

1.00

0.93

0.81

3.34

3.42

3.34

3.42

3.50

3.34

3.42

3.50

3.59

3.34

3.42

3.50

3.59

3.34

3.42

3.50

3.59

3.34

3.42

3.50

3.59

3.34

3.42

3.50

3.59

3.34

3.42

3.50

3.59

8404

8982

8404

8982

9594

8404

8982

9594

10240

8404

8982

9594

10240

8404

8982

9594

10240

8404

8982

9594

10240

8404

8982

9594

10240

8404

8982

9594

10240

8797

9388

8797

9388

10012

8797

9388

10012

10670

8797

9388

10012

10670

8797

9388

10012

10670

8797

9388

10012

10670

8797

9388

10012

10670

8797

9388

10012

10670

5798

5120

6471

5838

5085

7143

6557

5852

5017

7815

7275

6620

5837

8151

7634

7003

6246

8404

7994

7387

6656

8404

8712

8155

7475

8404

8982

8922

8294

3.56

3.65

3.56

3.65

3.75

3.56

3.65

3.75

3.86

3.56

3.65

3.75

3.86

3.56

3.65

3.75

3.86

3.56

3.65

3.75

3.86

3.56

3.65

3.75

3.86

3.56

3.65

3.75

3.86

7989

8558

7989

8558

9159

7989

8558

9159

9792

7989

8558

9159

9792

7989

8558

9159

9792

7989

8558

9159

9792

7989

8558

9159

9792

7989

8558

9159

9792

5512

4878

6151

5562

4854

6790

6247

5587

4798

7430

6932

6320

5582

7749

7274

6686

5973

7989

7616

7052

6365

7989

8301

7785

7148

7989

8558

8518

7932

3.79

3.89

3.79

3.89

4.00

3.79

3.89

4.00

4.14

3.79

3.89

4.00

4.14

3.79

3.89

4.00

4.14

3.79

3.89

4.00

4.14

3.79

3.89

4.00

4.14

3.79

3.89

4.00

4.14

PLH-4AAK(H)

CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW) SHF : Sensible heat factor

17

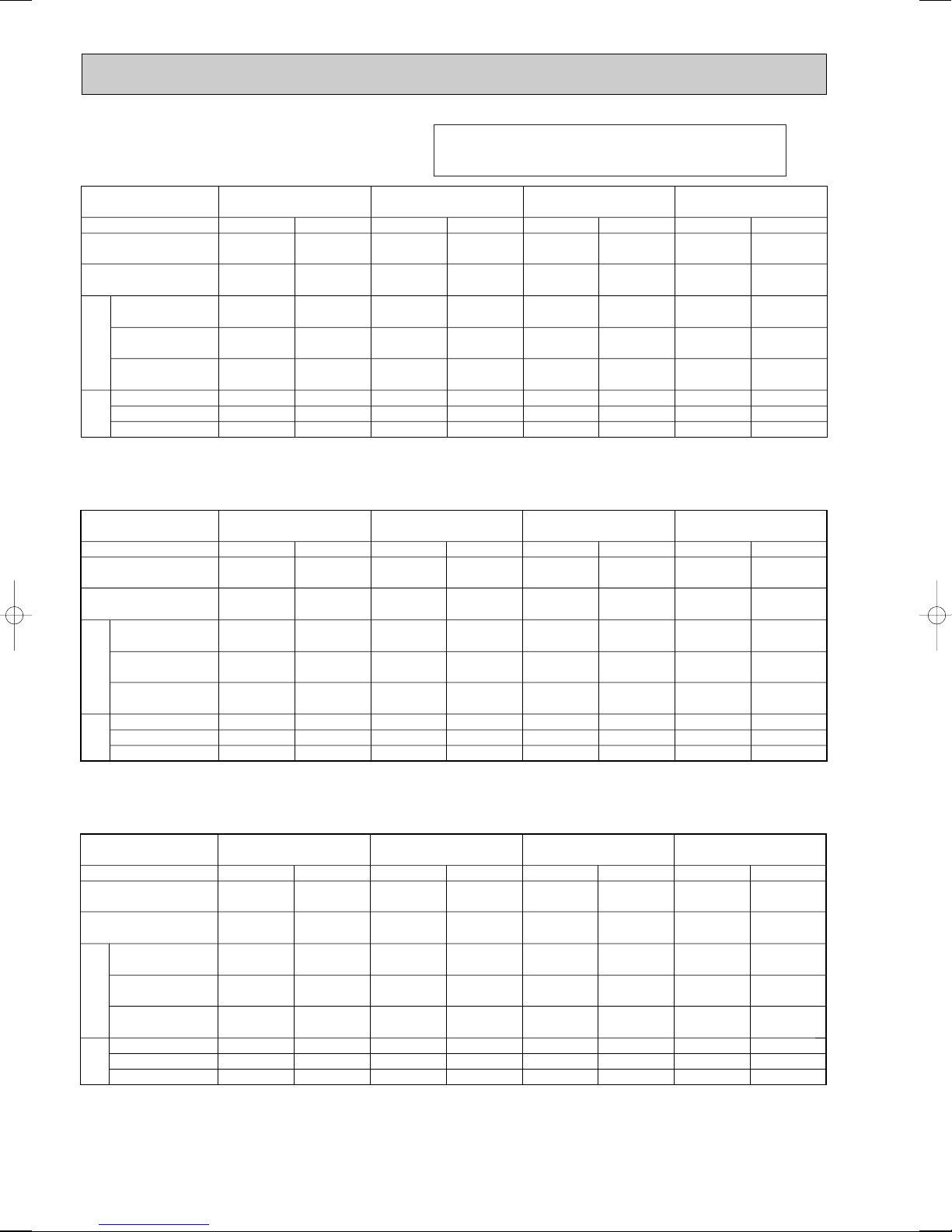

COOLING CAPACITY(5)

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

16

18

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

12510

13319

12510

13319

14138

12510

13319

14138

14965

12510

13319

14138

14965

12510

13319

14138

14965

12510

13319

14138

14965

12510

13319

14138

14965

12510

13319

14138

14965

CA SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

7881

6793

8882

7858

6645

9883

8924

7776

6435

10883

9990

8907

7632

11384

10522

9472

8231

11884

11055

10038

8830

12510

12121

11169

10027

12510

13186

12300

11224

0.63

0.51

0.71

0.59

0.47

0.79

0.67

0.55

0.43

0.87

0.75

0.63

0.51

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.99

0.87

0.75

0.63

0.51

0.71

0.59

0.47

0.79

0.67

0.55

0.43

0.87

0.75

0.63

0.51

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.99

0.87

0.75

0.63

0.51

0.71

0.59

0.47

0.79

0.67

0.55

0.43

0.87

0.75

0.63

0.51

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.99

0.87

0.75

3.61

3.69

3.61

3.69

3.76

3.61

3.69

3.76

3.83

3.61

3.69

3.76

3.83

3.61

3.69

3.76

3.83

3.61

3.69

3.76

3.83

3.61

3.69

3.76

3.83

3.61

3.69

3.76

3.83

12167

12969

12167

12969

13806

12167

12969

13806

14679

12167

12969

13806

14679

12167

12969

13806

14679

12167

12969

13806

14679

12167

12969

13806

14679

12167

12969

13806

14679

7665

6614

8639

7652

6489

9612

8689

7593

6312

10585

9727

8698

7486

11072

10245

9250

8073

11559

10764

9802

8660

12167

11802

10907

9835

12167

12839

12011

11009

3.77

3.85

3.77

3.85

3.92

3.77

3.85

3.92

4.00

3.77

3.85

3.92

4.00

3.77

3.85

3.92

4.00

3.77

3.85

3.92

4.00

3.77

3.85

3.92

4.00

3.77

3.85

3.92

4.00

11720

12496

11720

12496

13313

11720

12496

13313

14170

11720

12496

13313

14170

11720

12496

13313

14170

11720

12496

13313

14170

11720

12496

13313

14170

11720

12496

13313

14170

7384

6373

8321

7373

6257

9259

8373

7322

6093

10196

9372

8387

7227

10665

9872

8920

7794

11134

10372

9452

8360

11720

11372

10517

9494

11720

12371

11582

10628

4.06

4.15

4.06

4.15

4.24

4.06

4.15

4.24

4.33

4.06

4.15

4.24

4.33

4.06

4.15

4.24

4.33

4.06

4.15

4.24

4.33

4.06

4.15

4.24

4.33

4.06

4.15

4.24

4.33

PLH-5AAK(H)

CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW) SHF : Sensible heat factor

18

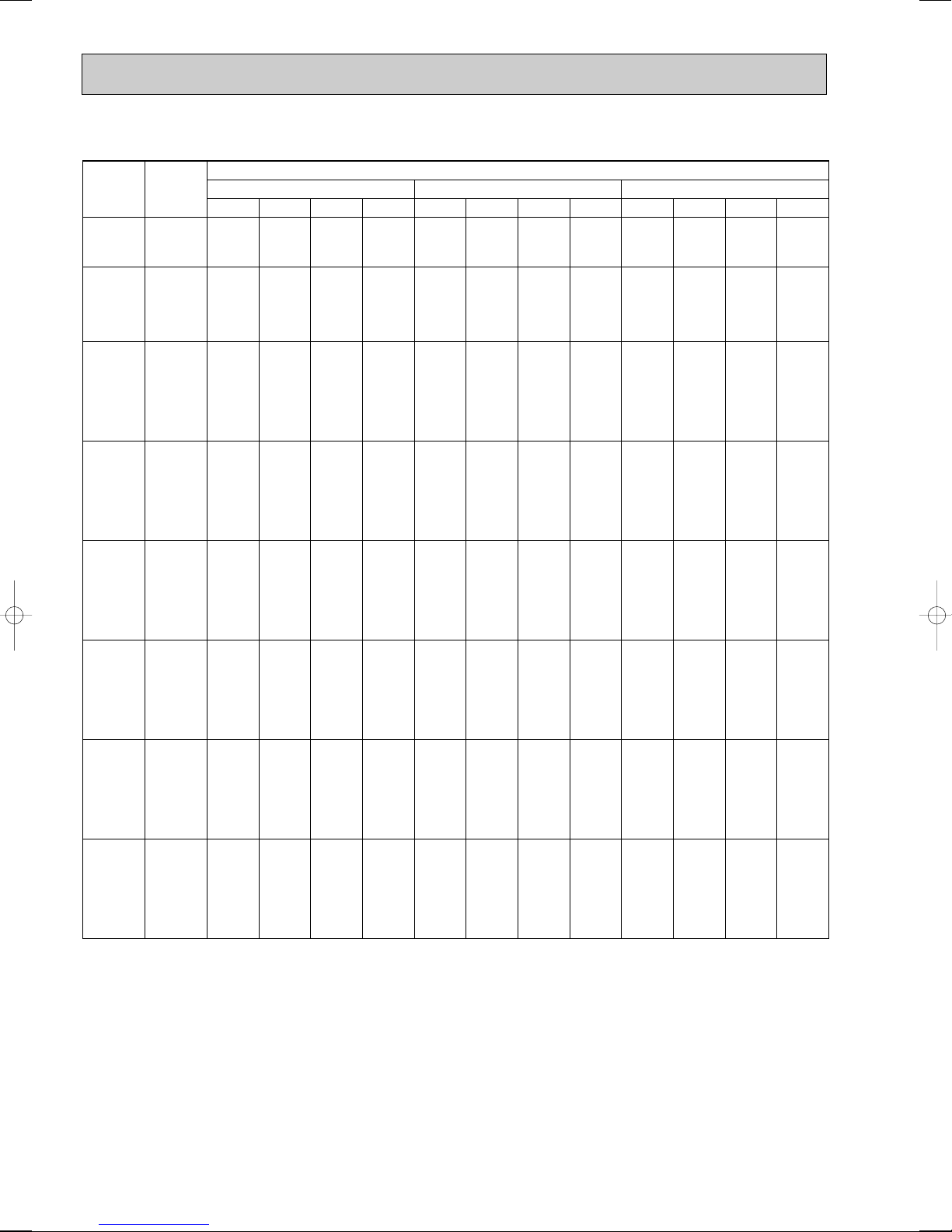

COOLING CAPACITY(6)

Outdoor intake air D.B.(°C)

35 40 45

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

16

18

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

11245

12001

11245

12001

12799

11245

12001

12799

13640

11245

12001

12799

13640

11245

12001

12799

13640

11245

12001

12799

13640

11245

12001

12799

13640

11245

12001

12799

13640

CA SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

7085

6120

7984

7080

6016

8884

8041

7040

5865

9783

9001

8064

6957

10233

9481

8575

7502

10683

9961

9087

8048

11245

10921

10111

9139

11245

11881

11135

10230

0.63

0.51

0.71

0.59

0.47

0.79

0.67

0.55

0.43

0.87

0.75

0.63

0.51

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.99

0.87

0.75

0.63

0.51

0.71

0.59

0.47

0.79

0.67

0.55

0.43

0.87

0.75

0.63

0.51

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.99

0.87

0.75

0.63

0.51

0.71

0.59

0.47

0.79

0.67

0.55

0.43

0.87

0.75

0.63

0.51

0.91

0.79

0.67

0.55

0.95

0.83

0.71

0.59

1.00

0.91

0.79

0.67

1.00

0.99

0.87

0.75

4.35

4.46

4.35

4.46

4.56

4.35

4.46

4.56

4.67

4.35

4.46

4.56

4.67

4.35

4.46

4.56

4.67

4.35

4.46

4.56

4.67

4.35

4.46

4.56

4.67

4.35

4.46

4.56

4.67

10743

11482

10743

11482

12264

10743

11482

12264

13090

10743

11482

12264

13090

10743

11482

12264

13090

10743

11482

12264

13090

10743

11482

12264

13090

10743

11482

12264

13090

6768

5856

7627

6774

5764

8487

7693

6745

5629

9346

8611

7726

6676

9776

9071

8217

7199

10206

9530

8708

7723

10743

10448

9689

8770

10743

11367

10670

9817

4.64

4.76

4.64

4.76

4.89

4.64

4.76

4.89

5.03

4.64

4.76

4.89

5.03

4.64

4.76

4.89

5.03

4.64

4.76

4.89

5.03

4.64

4.76

4.89

5.03

4.64

4.76

4.89

5.03

10212

10939

10212

10939

11708

10212

10939

11708

12518

10212

10939

11708

12518

10212

10939

11708

12518

10212

10939

11708

12518

10212

10939

11708

12518

10212

10939

11708

12518

6434

5579

7251

6454

5503

8068

7329

6439

5383

8885

8205

7376

6384

9293

8642

7844

6885

9702

9080

8313

7386

10212

9955

9249

8387

10212

10830

10186

9389

4.94

5.07

4.94

5.07

5.22

4.94

5.07

5.22

5.39

4.94

5.07

5.22

5.39

4.94

5.07

5.22

5.39

4.94

5.07

5.22

5.39

4.94

5.07

5.22

5.39

4.94

5.07

5.22

5.39

PLH-5AAK(H)

CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW) SHF : Sensible heat factor

19

COOLING CAPACITY(7)

Outdoor intake air D.B.(°C)

20 25 30

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

16

18

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

14124

15038

14124

15038

15962

14124

15038

15962

16896

14124

15038

15962

16896

14124

15038

15962

16896

14124

15038

15962

16896

14124

15038

15962

16896

14124

15038

15962

16896

CA SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

8616

7369

9745

8572

7183

10875

9775

8460

6928

12005

10978

9737

8279

12570

11579

10375

8955

13135

12181

11014

9631

14124

13384

12291

10983

14124

14587

13568

12334

0.61

0.49

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

0.61

0.49

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

0.61

0.49

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

4.06

4.15

4.06

4.15

4.22

4.06

4.15

4.22

4.30

4.06

4.15

4.22

4.30

4.06

4.15

4.22

4.30

4.06

4.15

4.22

4.30

4.06

4.15

4.22

4.30

4.06

4.15

4.22

4.30

13737

14642

13737

14642

15587

13737

14642

15587

16573

13737

14642

15587

16573

13737

14642

15587

16573

13737

14642

15587

16573

13737

14642

15587

16573

13737

14642

15587

16573

8380

7175

9479

8346

7014

10578

9517

8261

6795

11677

10689

9508

8121

12226

11274

10132

8783

12776

11860

10755

9446

13737

13031

12002

10772

13737

14203

13249

12098

4.24

4.32

4.24

4.32

4.41

4.24

4.32

4.41

4.50

4.24

4.32

4.41

4.50

4.24

4.32

4.41

4.50

4.24

4.32

4.41

4.50

4.24

4.32

4.41

4.50

4.24

4.32

4.41

4.50

13232

14109

13232

14109

15031

13232

14109

15031

15998

13232

14109

15031

15998

13232

14109

15031

15998

13232

14109

15031

15998

13232

14109

15031

15998

13232

14109

15031

15998

8072

6913

9130

8042

6764

10189

9171

7966

6559

11247

10299

9169

7839

11777

10864

9770

8479

12306

11428

10371

9119

13232

12557

11574

10399

13232

13686

12776

11679

4.56

4.67

4.56

4.67

4.77

4.56

4.67

4.77

4.87

4.56

4.67

4.77

4.87

4.56

4.67

4.77

4.87

4.56

4.67

4.77

4.87

4.56

4.67

4.77

4.87

4.56

4.67

4.77

4.87

PLH-6AAK(H)

CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW) SHF : Sensible heat factor

20

COOLING CAPACITY(8)

Outdoor intake air D.B.(°C)

35 40 45

Indoor

Intake air

D.B.(°C)

Indoor

Intake air

W.B.(°C)

20

20

22

22

22

24

24

24

24

26

26

26

26

27

27

27

27

28

28

28

28

30

30

30

30

32

32

32

32

16

18

16

18

20

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

16

18

20

22

12696

13549

12696

13549

14451

12696

13549

14451

15401

12696

13549

14451

15401

12696

13549

14451

15401

12696

13549

14451

15401

12696

13549

14451

15401

12696

13549

14451

15401

CA SHC SHF P.C. CA SHC SHF P.C. CA SHC SHF P.C.

7745

6639

8760

7723

6503

9776

8807

7659

6314

10792

9891

8815

7546

11300

10433

9393

8162

11808

10975

9971

8778

12696

12059

11127

10010

12696

13143

12283

11242

0.61

0.49

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

0.61

0.49

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

0.61

0.49

0.69

0.57

0.45

0.77

0.65

0.53

0.41

0.85

0.73

0.61

0.49

0.89

0.77

0.65

0.53

0.93

0.81

0.69

0.57

1.00

0.89

0.77

0.65

1.00

0.97

0.85

0.73

4.89

5.01

4.89

5.01

5.13

4.89

5.01

5.13

5.25

4.89

5.01

5.13

5.25

4.89

5.01

5.13

5.25

4.89

5.01

5.13

5.25

4.89

5.01

5.13

5.25

4.89

5.01

5.13

5.25

12129

12963

12129

12963

13847

12129

12963

13847

14779

12129

12963

13847

14779

12129

12963

13847

14779

12129

12963

13847

14779

12129

12963

13847

14779

12129

12963

13847

14779

7399

6352

8369

7389

6231

9339

8426

7339

6059

10310

9463

8446

7242

10795

9982

9000

7833

11280

10500

9554

8424

12129

11537

10662

9606

12129

12574

11770

10789

5.22

5.35

5.22

5.35

5.50

5.22

5.35

5.50

5.65

5.22

5.35

5.50

5.65

5.22

5.35

5.50

5.65

5.22

5.35

5.50

5.65

5.22

5.35

5.50

5.65

5.22

5.35

5.50

5.65

11530

12351

11530

12351

13219

11530

12351

13219

14133

11530

12351

13219

14133

11530

12351

13219

14133

11530

12351

13219

14133

11530

12351

13219

14133

11530

12351

13219

14133

7033

6052

7956

7040

5948

8878

8028

7006

5795

9801

9016

8063

6925

10262

9510

8592

7491

10723

10004

9121

8056

11530

10992

10178

9187

11530

11981

11236

10317

5.55

5.70

5.55

5.70

5.87

5.55

5.70

5.87

6.06

5.55

5.70

5.87

6.06

5.55

5.70

5.87

6.06

5.55

5.70

5.87

6.06

5.55

5.70

5.87

6.06

5.55

5.70

5.87

6.06

PLH-6AAK(H)

CA : Capacity (W) SHC : Sensible heat capacity (W)

P.C. : Power consumption (kW) SHF : Sensible heat factor

21

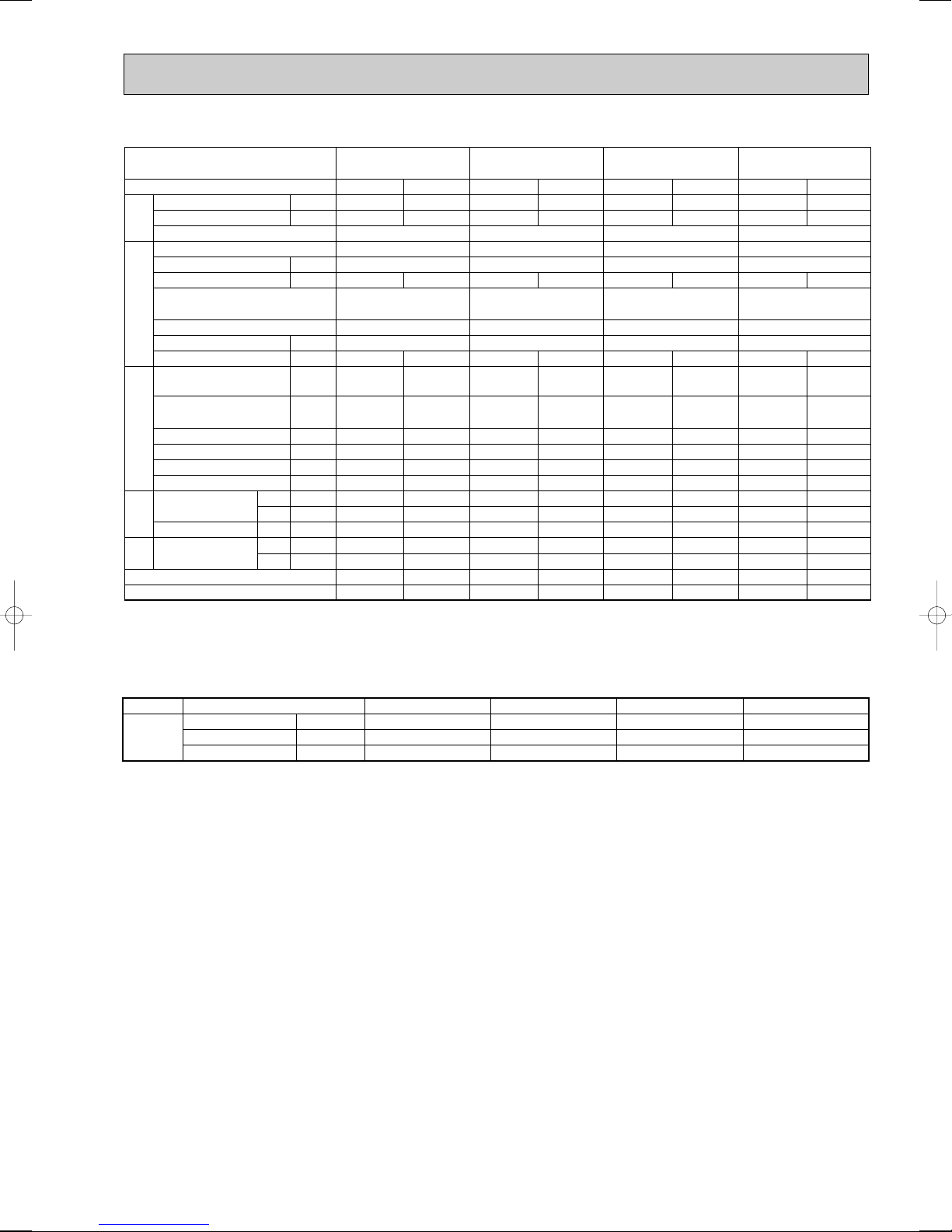

Refrigerant piping length(one way)

5m

1.00

1.00

1.00

1.00

10m

0.981

0.989

0.981

0.975

15m

0.968

0.980

0.968

0.955

20m

0.952

0.970

0.952

0.935

25m

0.940

0.960

0.940

0.918

30m

0.925

0.950

0.925

0.900

35m

0.913

0.940

0.913

0.884

40m

0.900

0.930

0.900

0.869

45m

0.886

0.920

0.886

0.855

50m

0.874

0.910

0.874

0.840

Service Ref.

PLH-3AAK(H)

PLH-4AAK(H)

PLH-5AAK(H)

PLH-6AAK(H)

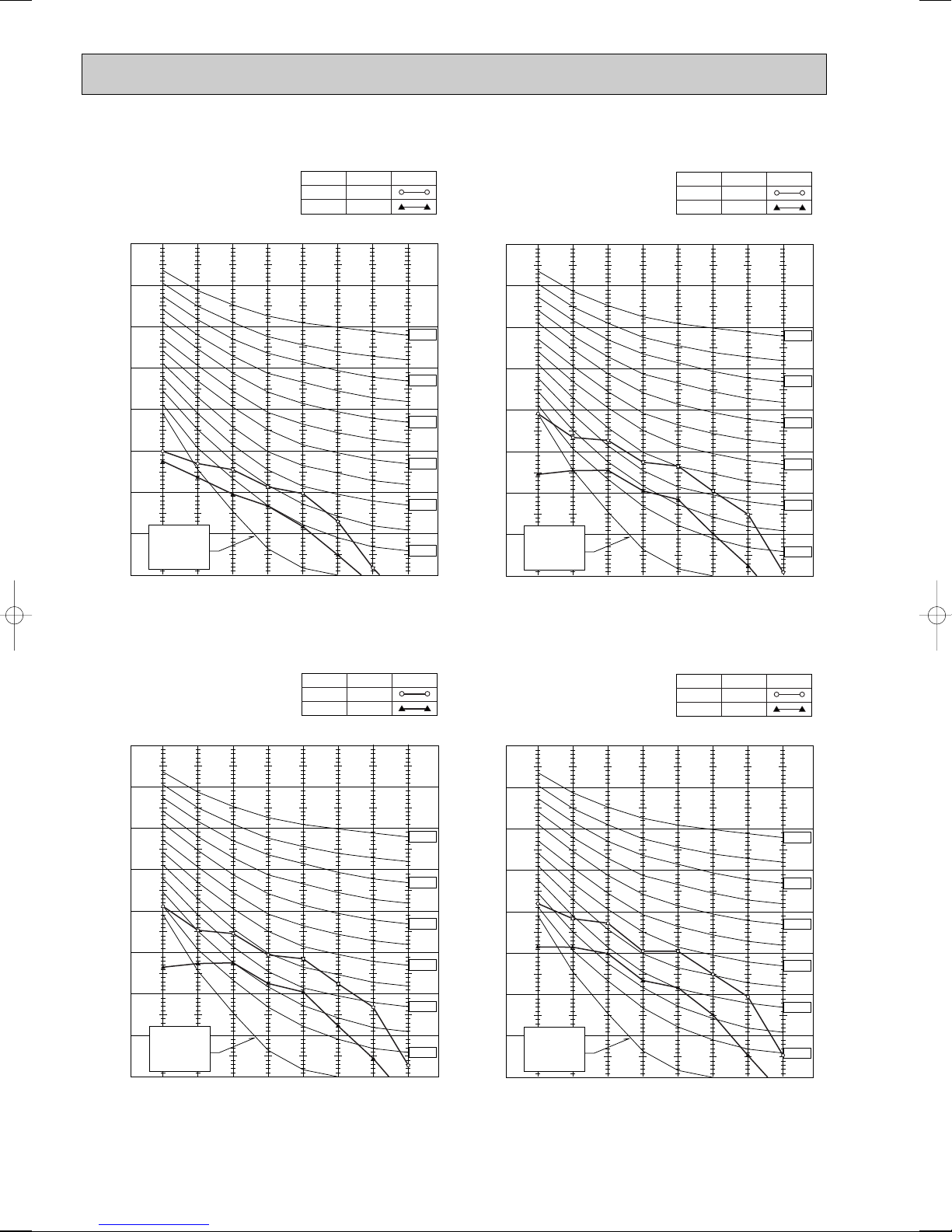

2) HEATING CAPACITY

P.C.

3.38

3.64

3.90

3.75

4.04

4.33

3.75

4.04

4.33

5.35

5.76

6.18

CA

10752

10340

10044

13312

12802

12435

13312

12802

12435

20608

19818

19250

P.C.

3.10

3.34

3.58

3.44

3.70

3.97

3.44

3.70

3.97

4.90

5.28

5.66

CA

9595

9235

8928

11880

11434

11054

11880

11434

11054

18391

17700

17112

P.C.

2.83

3.05

3.27

3.14

3.39

3.63

3.14

3.39

3.63

4.48

4.83

5.17

CA

8516

8198

7895

10543

10150

9774

10543

10150

9774

16322

15713

15131

P.C.

2.58

2.78

2.97

2.86

3.09

3.30

2.86

3.09

3.30

4.09

4.40

4.71

CA

7514

7231

6944

9303

8953

8597

9303

8953

8597

14402

13859

13309

P.C.

2.34

2.53

2.69

2.60

2.80

2.99

2.60

2.80

2.99

3.71

4.00

4.26

CA

6593

6334

6077

8163

7842

7524

10988

10557

10128

12636

12140

11647

P.C.

2.12

2.29

2.43

2.35

2.54

2.69

2.35

2.54

2.69

3.36

3.62

3.84

CA

5752

5508

5293

7122

6820

6554

9587

9180

8822

11026

10557

10146

-10

Outdoor intake air W.B.(°C)

-5 0 5 10 15

Indoor

intake air

D.B.(°C)

15

20

25