Mitsubishi PKFY-P12NHMU-E2, PKFY-P15NHMU-E, PKFY-P18NHMU-E2, PKFY-P15NHMU-E2, PKFY-P18NHMU-E Technical & Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

R22R410A

April 2009

No. OCH460

Indoor unit

[Model names] [Service Ref.]

PKFY-P12NHMU-E

PKFY-P12NHMU-E

PKFY-P15NHMU-E

PKFY-P15NHMU-E

PKFY-P18NHMU-E

PKFY-P18NHMU-E

INDOOR UNIT

Note:

• This manual describes

only service data of the

indoor units.

• RoHS compliant products

have <G> mark on the

spec name plate.

CONTENTS

1. PART NAMES AND FUNCTIONS

2. SPECIFICATION

3. OUTLINES AND DIMENSIONS

4. WIRING DIAGRAM

5. REFRIGERANT SYSTEM DIAGRAM

6. MICROPROCESSOR CONTROL

7. TROUBLESHOOTING

8. DISASSEMBLY PROCEDURE

.....................................

.................................

..........................

.............

..........

..............

..........

...........

2

4

6

7

8

9

14

21

PARTS CATALOG (OCB460)

1

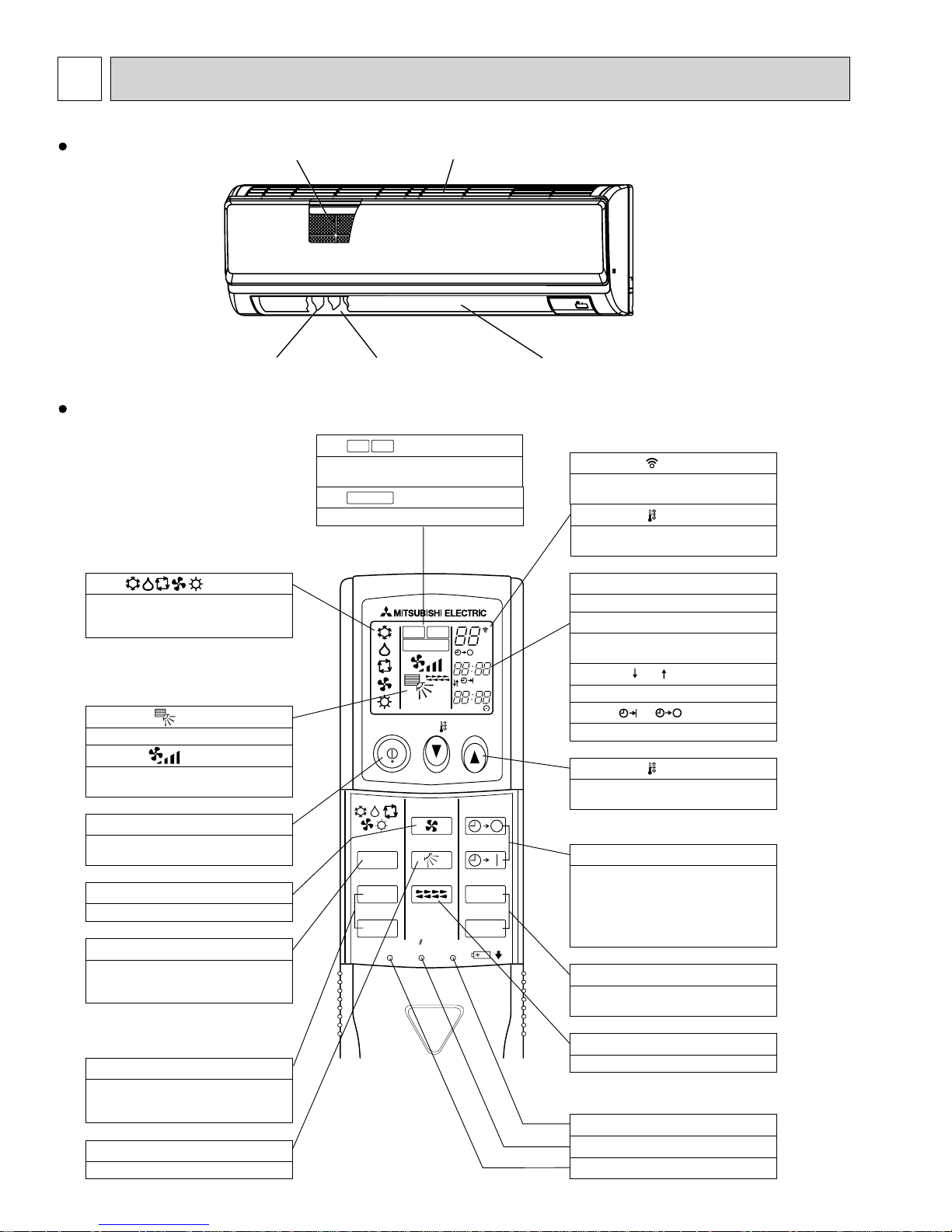

PART NAMES AND FUNCTIONS

Indoor unit

Filter

Louver

Wireless remote controller

display

OPERATION MODE display

Operation mode display indicates which

operation mode is in effect.

display

The vertical direction of air flow is indicated.

display

FAN SPEED display indicates which fan

speed has been selected.

ON/OFF button

The unit is turned ON and OFF alternately

each time the button is pressed.

FAN SPEED SELECT button

Used to change the fan speed.

MODE SELECT button

Used to switch the operation mode between

cooling, drying, fan, heating and auto mode.

+ In case the outdoor unit is cool only type,

the heating and auto mode are not

available.

CHECK-TEST RUN button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

VANE CONTROL button

Used to change the air flow

Air intake

Air outlet

CHECK

TEST RUN

display

CHECK and TEST RUN display indicate that

the unit is being checked or test-run.

MODEL SELECT

Blinks when model is selected.

display

CHECK

TEST RUN

MODEL SELECT

NOT AVAILABLE

ON/OFF TEMP

FAN

MODE

CHECK

VAN E

LOUVER

TEST RUN

RESETSET CLOCK

°F

°C

AMPM

AMPM

AUTO STOP

AUTO START

h

min

Vane

display

Lights up while the signal is transmitted to

the indoor unit when the button is pressed.

display

SET TEMP. display indicates the set desired

temperature.

CLOCK display

Displays the current time.

TIMER display

Displays when in timer operation or when

setting timer.

“ ” “ ” display

Displays the order of timer operation.

“ ” “ ” display

Displays whether timer is on or off.

button

SET TEMPERATURE button sets any desired

room temperature.

TIMER CONTROL buttons

AUTO STOP (OFF timer): when this switch is

set, the air conditioner will be automatically

stopped at the preset time.

AUTO START (ON timer): when this switch is

set, the air conditioner will be automatically

started at the preset time.

h and min buttons

Buttons used to set the “hour and minute” of

the current time and timer settings.

LOUVER button

Changes left/right airflow direction.

(Not available for this model.)

CLOCK button

RESET button

SET button

2

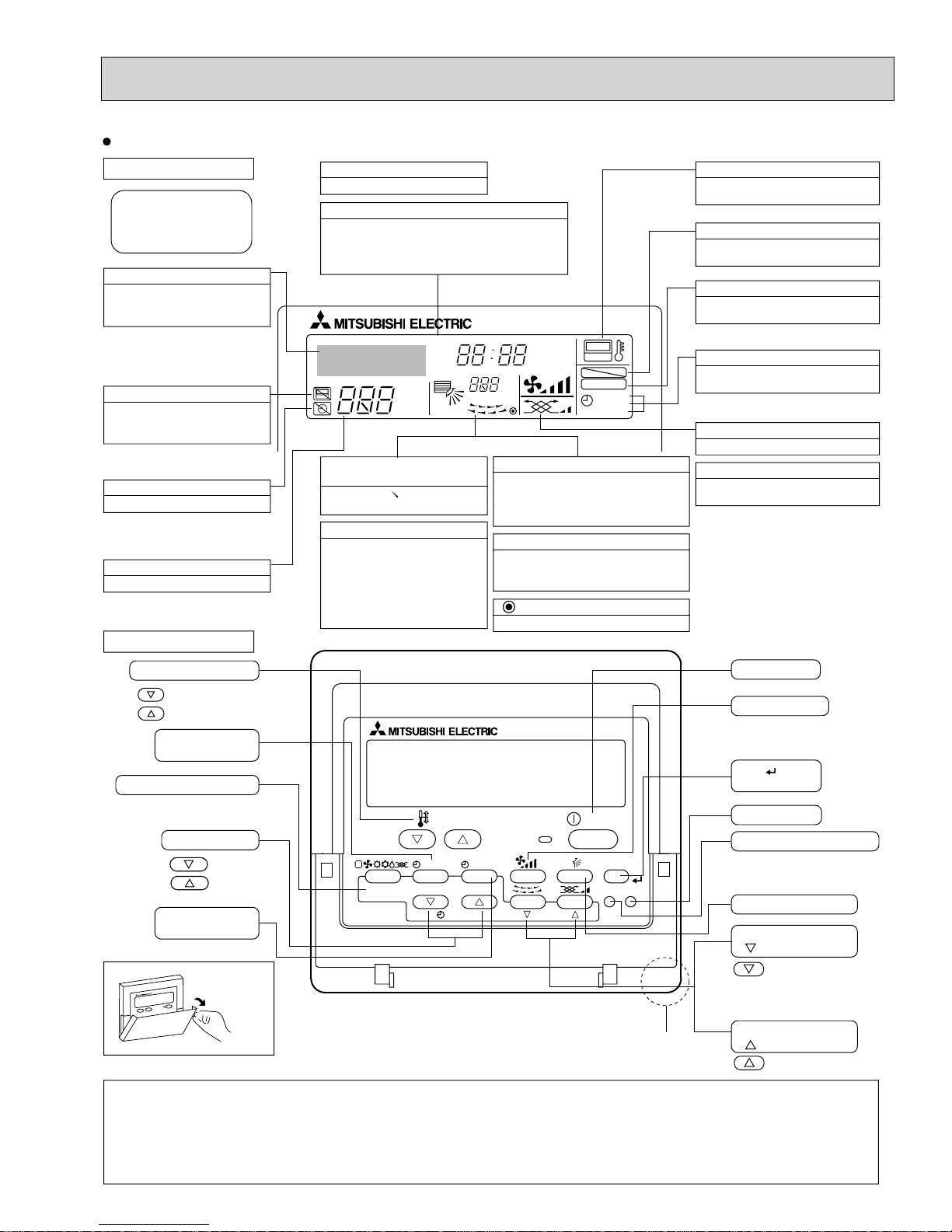

Wired remote controller

Display Section

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

Identifies the current operation

Shows the operating mode, etc.

*Multilanguage display is available.

“Centrally Controlled” indicator

Indicates that operation from the

remote controller has been prohibited by a master controller.

“Timer is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Operation Section

Temperature setting buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, the time to be

switched off is shown.

TIME SUN MON TUE WED THU FRI SAT

TIMER

AFTER

ERROR CODE

°F°C

Hr

AFTER

°F°C

ONLY1Hr.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

Low or downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off in one hour,

at which time the airflow direction

also changes.

Room Temperature display

Shows the room temperature. The room

temperature display range is 46–102°F.

The display blinks if the temperature

is less than 46°F or 102°F or more.

Louver display

Indicates the action of the swing louver.

Does not appear if the louver is not

running.

(Power On indicator)

Indicates that the power is on.

ON

OFF

FUNCTION

FILTER

WEEKLY

SIMPLE

AUTO OFF

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

To be displayed on when it is time to

clean the filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

lid

Note:

“PLEASE WAIT” message

This message is displayed for approximately 3 minutes when power is supplied to the indoor unit or when the unit is recovering from a power failure.

“NOT AVAILABLE” message

This message is displayed if an invalid button is pressed (to operate a function that the indoor unit does not have).

If a single remote controller is used to operate multiple indoor units simultaneously that are different types, this message will not be displayed as

far as any of the indoor units is equipped with the function.

TEMP.

MENU

BACK DAY

MONITOR/SET

PAR-21MAA

CLOCK

ON/OFF

33

ON/OFF

FILTER

CHECK

OPERATION

Built-in temperature sensor

CLEAR

TEST

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

To return operation

number

Ventilation button

( Operation button)

To go to next operation

number

2

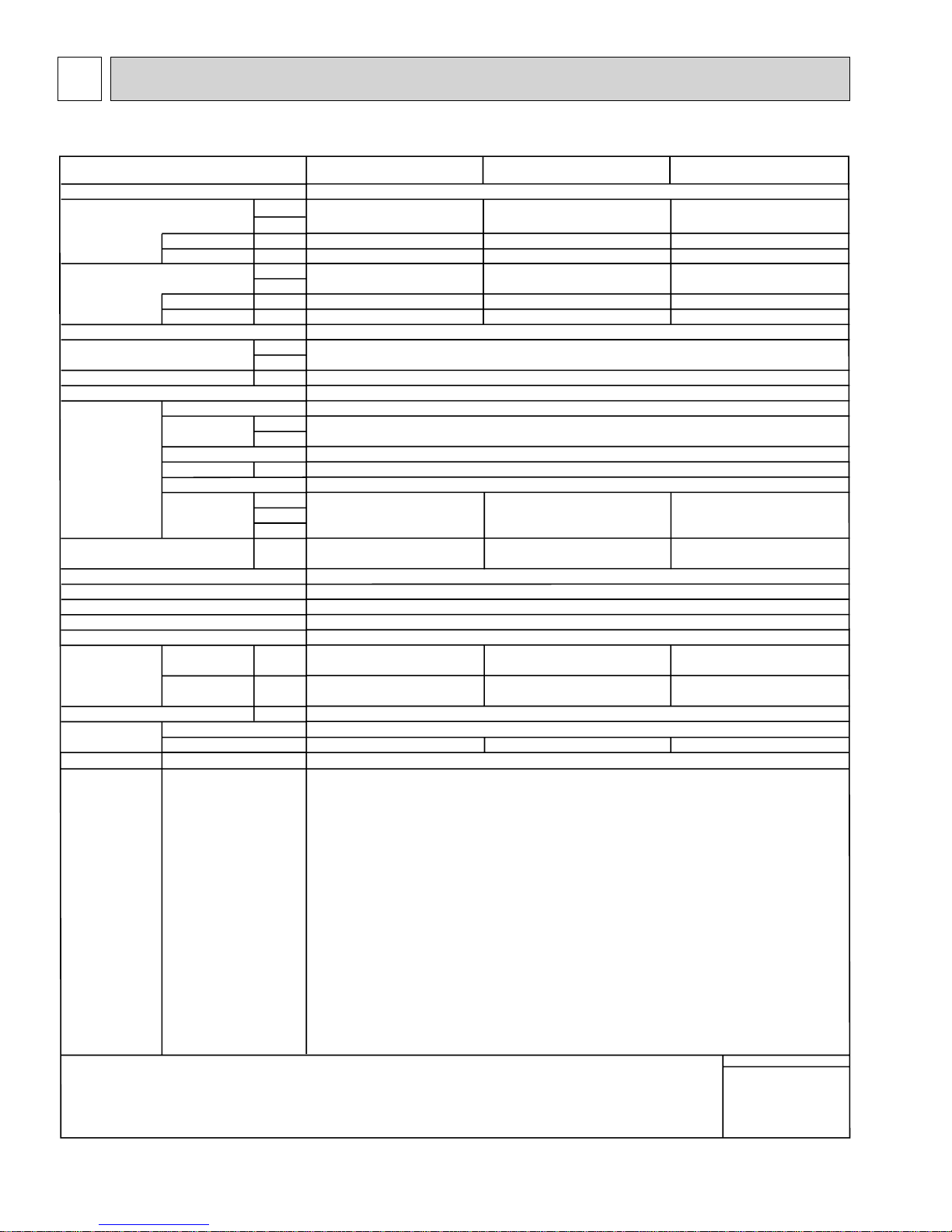

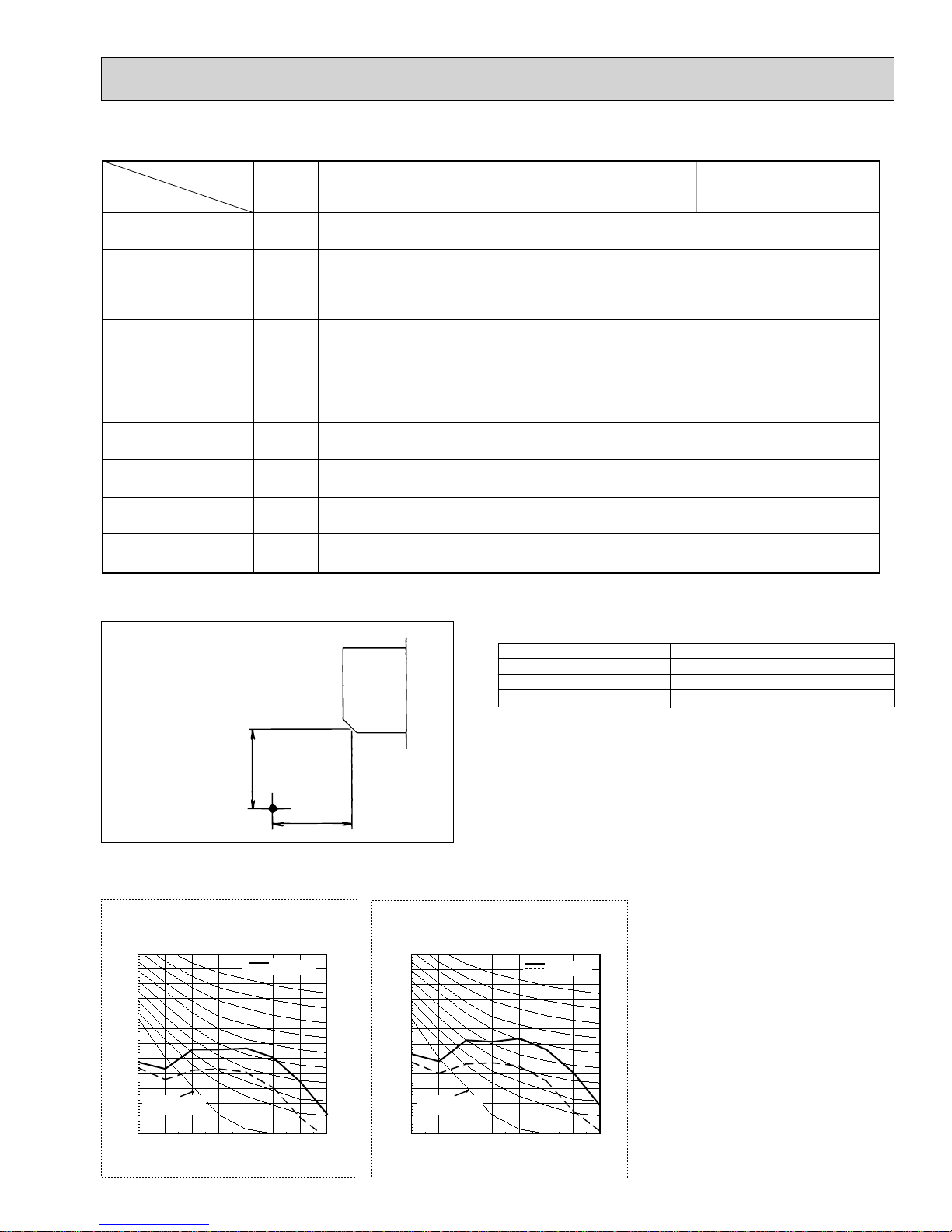

SPECIFICATION

2-1. Specifi cations

Service Ref.

Power source

Cooling capacity

(Nominal)

Power input

Heating capacity

(Nominal )

External finish

External dimension H × W × D

Net weight

Heat exchanger

Fan

Noise level (Low-Mid-High)

(measured in anechoic room)

Insulation material

Air filter

Protection device

Refrigerant control device

Connectable outdoor unit

Diameter of

refrigerant pipe

Field drain pipe size

Standard

attachment

Optional parts

Remarks

Current input

Power input

Current input

Type × Quantity

External

static press.

Motor type

Motor output

Driving mechanism

Airflow rate

(Low-Mid-High)

Liquid

Gas

Document

Accessory

External heater adapter

Installation

*1

*1

*2

*2

(R410A)

(R22)

(R410A)

(R22)

kW

Btu/h

kW

A

kW

Btu/h

kW

A

mm

in.

kg (lb)

Pa

mmH

2

kW

3

/min

m

L/s

cfm

dB <A>

mm (in.)

mm (in.)

mm (in.)

PKFY-P12NHMU-E

PKFY-P15NHMU-E

PKFY-P18NHMU-E

1-phase 208-230V 60Hz

3.5

12,000

0.03

0.30

4.0

13,500

0.03

0.30

4.4

15,000

0.03

0.30

5.0

17,000

0.03

0.30

5.3

18,000

0.03

0.30

5.9

20,000

0.03

0.30

Plastic, MUNSELL (1.0Y 9.2/0.2)

295 × 898 × 249

11-5/8" × 35-3/8" × 9-13/16"

13 (29)

Cross fin (Aluminum fin and copper tube)

Line flow fan × 1

0

O

0

DC motor

0.030

Direct-drive

9 - 10 - 11

150 - 167 - 183

320 - 355 - 390

34 - 38 - 42

9 - 10.5 - 11.5

150 - 175 - 192

320 - 370 - 405

34 - 38 - 42

9 - 10.5 - 12

150 - 175 - 200

320 - 370 - 425

36 - 41 - 45

Polyethylene sheet

PP honeycomb

Fuse

LEV

R410A, R22 CITY MULTI

ø6.35 (ø1/4")

ø6.35 (ø1/4")

ø12.7 (ø1/2")

ø12.7 (ø1/2")

Flare

Flare

Flare

Flare

ø6.35 (ø1/4")

ø6.35 (ø1/4")

ø12.7 (ø1/2")

ø12.7 (ø1/2")

Flare

Flare

Flare

Flare

ø6.35 (ø1/4")

ø9.52 (ø3/8")

ø12.7 (ø1/2")

ø15.88 (ø5/8")

I.D. 16mm (5/8")

Installation Manual, Instruction Book

—

—

—

PAC-YU25HT

Details on foundation work, insulation work, electrical wiring, power source switch, and other items shall be referred to

the Installation Manual.

Flare

Flare

Flare

Flare

*3

*3

Note :

Pipe length :

Level difference :

* Due to continuing improvement, above specification may be subject to change without notice.

*1 Nominal cooling conditions

Indoor :

Outdoor :

80°FDB/67°FWB (26.7°CDB/19.4°CWB)

95°FDB (

25 ft. (7.6 m)

0 ft (

35°CDB)

0 m)

*2 Nominal heating conditions

70°FDB(21°CDB)

47°FDB/43°FWB (8.3°CDB/6.1°CWB)

25 ft. (7.6 m)

0 ft (0 m)

*3 Connect the joint

(purchased locally) for R22

Unit converter

kcal/h = kW × 860

Btu/h = kW × 3,412

3

cfm = m

lb = kg/0.4536

*Above specification data is

subject to rounding variation.

/min × 35.31

4

2-2. Electrical parts specifi cations

Service Ref.

Parts name

Room temperature

thermistor

Liquid pipe thermistor

Gas pipe thermistor

Fuse

(Indoor controller board)

Fan motor

Vane motor

(with limit switch)

Linear expansion valve

Power supply terminal

block

Transmission terminal

block

MA remote controller

terminal block

2-3. Sound levels

Symbol

TH21

TH22

TH23

TH24

FUSE

MF

MV

LEV

TB2

TB5

TB15

PKFY-P12NHMU-E PKFY-P15NHMU-E

PKFY-P18NHMU-E

Resistance 30°F/15.8k, 50°F/9.6k, 70°F/6.0k, 80°F/4.8k, 90°F/3.9k, 100°F/3.2k

Resistance 30°F/15.8k, 50°F/9.6k, 70°F/6.0k, 80°F/4.8k, 90°F/3.9k, 100°F/3.2k

Resistance 30°F/15.8k, 50°F/9.6k, 70°F/6.0k, 80°F/4.8k, 90°F/3.9k, 100°F/3.2k

250V 3.15A

8-Pole Output 30W / RCOJ30-CK

MSFBC20 DC12V

DC12V Stepping motor drive

Port :3.2 (0~2000pulse)

(L1, L2, GR) 250V 20A

(M1, M2, S) 250V 20A

(1, 2) 250V 10A

3.3 ft.

(1m)

Measurement location

* Measured in anechoic room.

2-4. NC curves

PKFY-P12, 15NHMU-E

External static pressure : 0Pa

Power source : 208,230V, 60Hz

70.0

MPa

65.0

60.0

55.0

50.0

45.0

40.0

35.0

30.0

25.0

Approximate minimum

20.0

audible limit on

continuous noise

15.0

10.0

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20

63 125 250 500 1k 2k 4k 8k

OCTAVE BAND CENTER FREQUENCIES(Hz)

High speed

Low speed

3.3 ft.

(1m)

PKFY-P18NHMU-E

External static pressure : 0Pa

Power source : 208,230V, 60Hz

70.0

65.0

NC60

NC50

NC40

NC30

NC20

60.0

55.0

50.0

45.0

40.0

35.0

30.0

25.0

Approximate minimum

20.0

audible limit on

continuous noise

15.0

10.0

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20MPa

63 125 250 500 1k 2k 4k 8k

OCTAVE BAND CENTER FREQUENCIES(Hz)

Service Ref.

PKFY-P12NHMU-E

PKFY-P15NHMU-E

PKFY-P18NHMU-E

High speed

Low speed

Sound level at anechoic room : Low-Middle-High

Sound level dB (A)

34-38-42

34-38-42

36-41-45

NC60

NC50

NC40

NC30

NC20

55

3

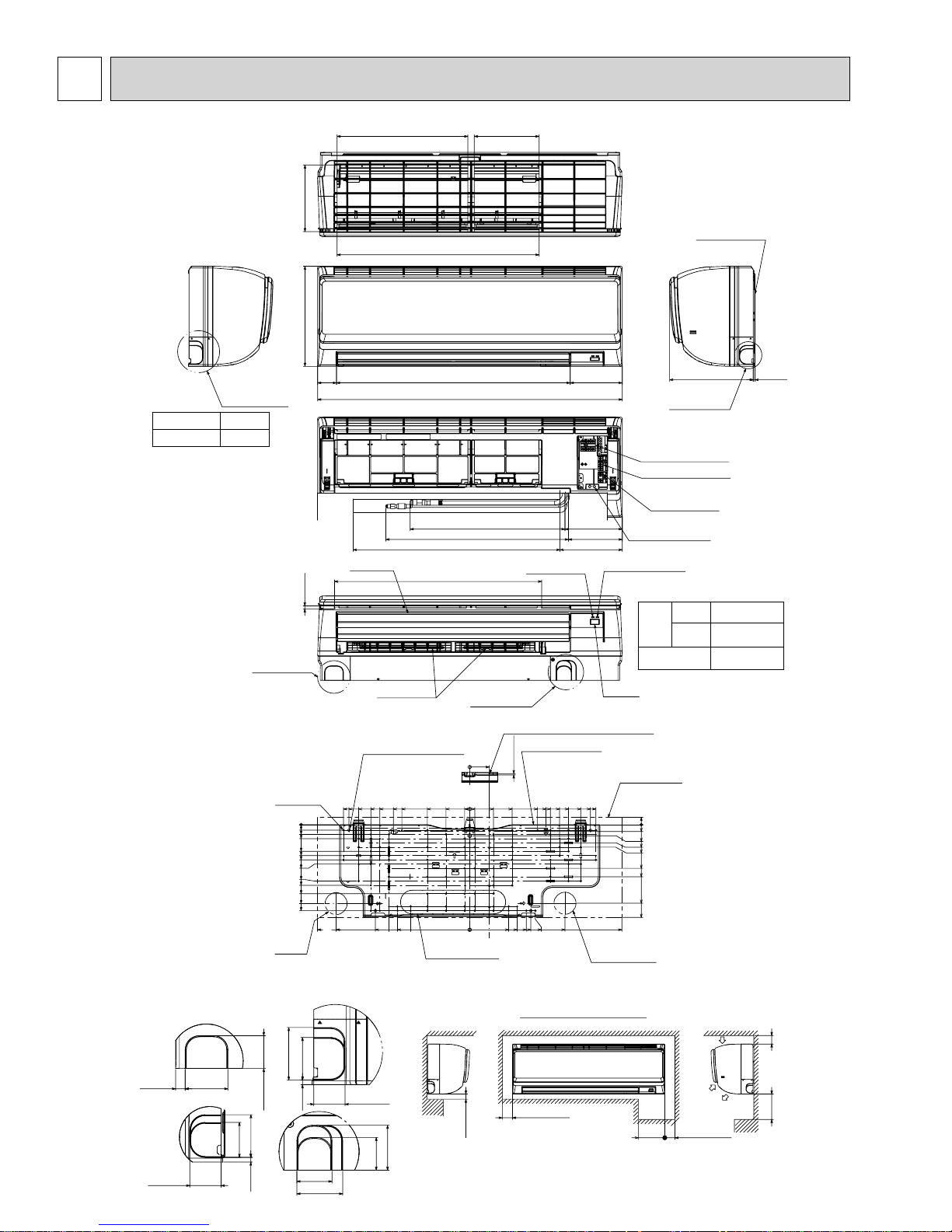

OUTLINES AND DIMENSIONS

PKFY-P12, 15, 18NHMU-E

Left side

D

Knockout hole

for left piping

Sleeve

(purchased locally)

:2-1/2~:3-1/8

(:65~:80)

Through hole

:2-1/2~:3-1/8

(:65~:80)

Knockout hole

for lower piping

7-3/4(197)

11-5/8(295)

5/16(8)

2-1/8

(55)

15-3/16(387)

23-9/16(599)

7-1/2(192)

Top side

Front side

Unit : inch (mm)

Mount board

Right side

A

1/4F (:6.35)

1/2F (:12.7)

:

5/8 (:16) I.D

3/16(5)9-13/16(249)

Vane(auto)

27-1/16(688)

35-3/8(898)

Front side(Grille open)

17-15/16(457)Gas pipe

21-3/16(539)Liquid pipe

24(610)Drain hose

Under side

24-1/16(612)

Operation lamp

6-1/16(155)

6-5/8(169)

6-3/16(158)

7-3/16(184)

Knockout hole

for right piping

Terminal block for power supply

Terminal block for transmission

Terminal block for

MA-remote controller

Emergency operation switch

(cooling/heating)

DEFROST/STAND BY lamp

Refrigerart

Piping

Liquid pipe

Gas pipe

Drain hose

C

Louver(manual)

Knockout hole

for lower piping

Receiver

B

77-

:

3/16(:5.1)

Tapping

screw hole

0

5/8(16)

1-1/16(28.5)

1-9/16(41)

3-1/16(78.5)

3-9/16(91)

4-1/16(103.5)

4-9/16(116)

6-1/2(166)

7(178.5)

8(203.5)

9-1/8(232.5)

9-15/16(253.5)

Wall hole

for

left rear

piping

Knockout hole for piping

2-11/16(69)

1-11/16(43)

2-3/16(56)

3/16(6)

1-3/4(46)

2-5/16(60)

1-11/16(43)

2-3/16(56)7/16(12.5)

A

C

2-3/16(56)

1-3/4(46)

3/16(6)

14-5/8(372.3)

14(356.3)

15-1/2(394)

17-5/8(449)

1-11/16(43)

4-:5/16(:9) Bolt hole

12-7/8(327.5)

10-3/8(265)

11-7/16(291.5)

7-13/16(200)

8-13/16(225)

8-3/8(213)

9-5/16(238)

6-13/16(174)

10-15/16(278.3)

D

2-5/16(59)

1-11/16(43)

B

0

4-7/8(125)

2-3/4(70)

0

9/16(15)

9/16(15)

0

Knockout hole for

rear piping

2-3/4×12-3/16(70×310)

Min.1/4(7)

6

Center measurement hole :3/32(:2.5)

Mount board

2-1/4(58)

5/32(3.8)

11-7/16(291.5)

10-3/8(265)

9-5/16(238)

8-13/16(225)

7-13/16(200)

2-3/4(70)

4-7/8(125)

4-1/2(115)

5-1/2(140)

6-9/16(167)

11-1/16(281)

7-9/16(193.5)

7-1/16(180.3)

Required space(Indoor unit)

Min.1-31/32(50)

14-5/8(372.3)

14(356.3)

12-7/8(237.5)

Wall hole for

right rear piping

Min.8-5/8

(220)

Indoor unit outline

13/16(21.8)

0

3/4(20)

1-1/4(32.7)

2-1/16(53.5)

2-9/16(66)

5(128.5)

6(153.5)

9-1/16(231.5)

10-3/4(273.2)

17-5/8(449)

Min.5-7/8(150)

Air inlet

Min.1-31/32(50)

Air inlet

Air outlet

Min.9-13/16(250)

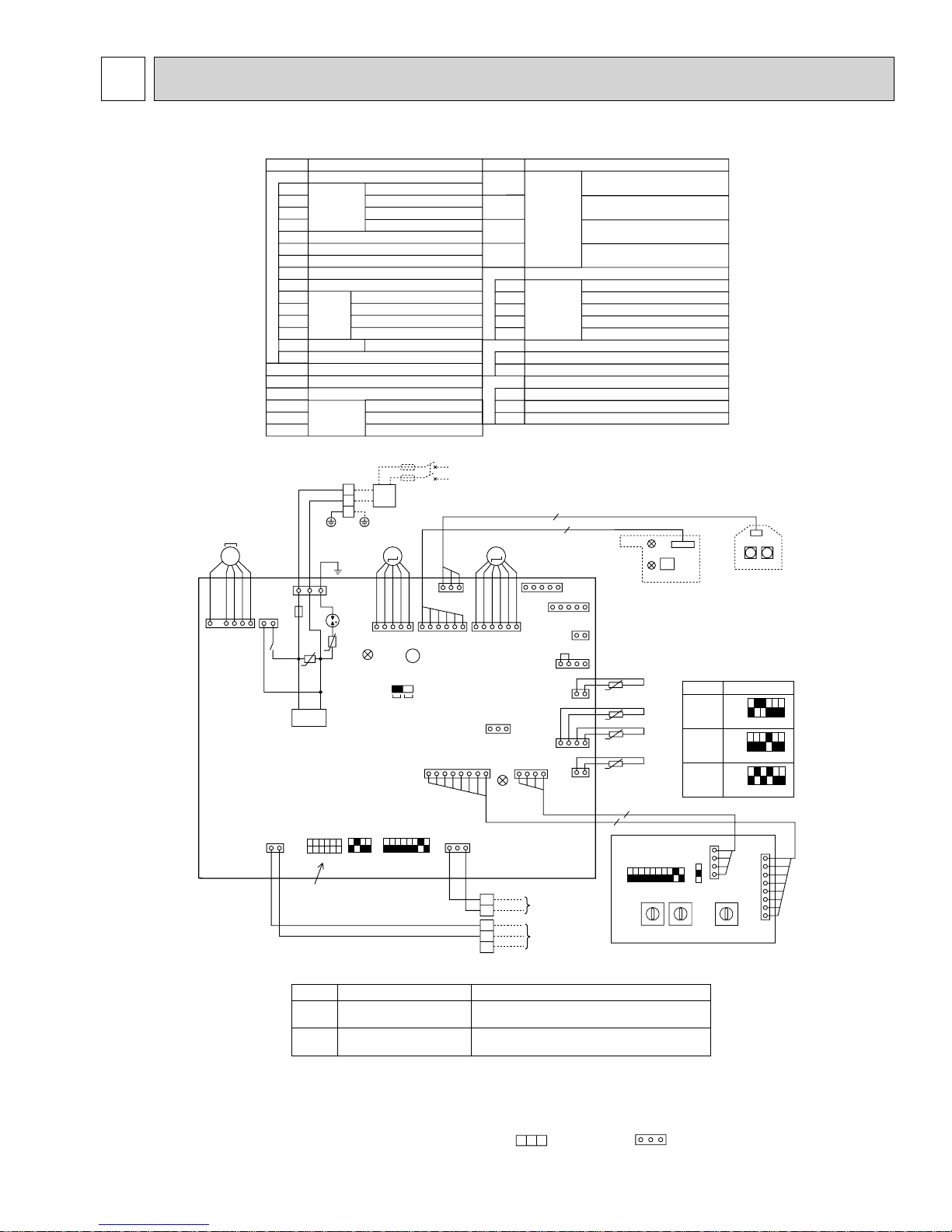

WIRING DIAGRAM4

PKFY-P12, 15, 18NHMU-E

SYMBOL

INDOOR CONTROLLER BOARD

I.B

CN24

CONNECTOR

CN32

CN51

CN52

BZ

BUZZER

DSA SURGE ABSORBER

FUSE FUSE (T3.15AL 250V)

LED1 POWER SUPPLY (I.B)

LED2 POWER SUPPLY (I.B)

SW2

SWITCH

SW3

SW4

SWE

X1 AUX.RELAY

MOV 01.02

VARISTOR

LEV LINEAR EXPANSION VALVE

MF

FAN MOTOR

MV

VANE MOTOR

TB2

TERMINAL

TB5

BLOCK

TB15

NAME

EXTERNAL HEATER

REMOTE SWITCH

CENTRALLY CONTROL

REMOTE INDICATION

CAPACITY CODE

MODE SELECTION

MODEL SELECTOR

DRAIN PUMP (TEST MODE)

DRAIN PUMP (

POWER SUPPLY

TRANSMISSION

MA-REMOTE CONTROLLER

OPTION

SYMBOL

TH21

THERMISTOR

TH22

TH23

TH24

ADDRESS BOARD

A.B

SWA

SWITCH

SW1

SW11

SW12

SW14 BRANCH No.

)

S.B SWITCH BOARD

SWE1

EMERGENCY OPERATION(HEAT)

SWE2

EMERGENCY OPERATION(COOL)

W.B PCB FOR WIRELESS REMOTE CONTROLLER

LED(OPERATION INDICATOR:GREEN)

LED1

LED2

LED(OPERATION FOR HEATING :ORANGE )

RU

RECEIVING UNIT

NAME

ROOM TEMP. DETECTION

32°F/15k,77°F/5.4k)

(

PIPE TEMP. DETECTION / LIQUID

32°F/15k,77°F

(

PIPE TEMP. DETECTION / GAS1

32°F/15k,77°F

(

PIPE TEMP. DETECTION / GAS2

32°F/15k,77°F

(

FAN SPEED SELECTOR

MODE SELECTION

ADDRESS SETTING 1s DIGIT

ADDRESS SETTING 10ths DIGIT

/5.4k)

/5.4k)

/5.4k)

RED

163

MF

MS

3

BLK

FAN

CNMF

(WHT)

~

WHT

BLU

YLW

CN2M(BLU)

POWER SUPPLY

208/230V 60Hz

BREAKER

)

(

16A

)

M

331

LDSWE(A

)

(

BLU

BRN

)

RED

ORN

BLU

BRN

CNRU

(WHT)

ADDRESS

CN81

(RED)

MA-REMOCON

CN3A

(BLU)

1

3

ORN

ORN

6

TB15

TB5

M1

M2

LEV

CN60

(YLW)

CN32

(WHT)

31

LED2

1

2

S

(SHIELD)

61

81

51

51

WHT

YLW

CN24

1

(YLW)

FLOAT SW

CN4F

(WHT)

GAS2

CN2G

(BLK)

LIQUID/GAS1

CN44

(WHT)

ADDRESS

CN42

(RED)

41

INTAKE

CN20

(RED)

TO MA-

REMOTE

CONTROLLER

DC8.7-13V

TO OUTDOOR UNIT

BC CONTROLLER

REMOTE CONTROLLER

DC24-30V

6

I.B

CN52

(GRN)

CN51

(WHT)

21

41

21

41

21

W.B

t

t

t

t

4

8

ON

OFF

11223345678910

A.B

LED2

LED1

TH24

TH23

TH22

TH21

SW1

0

9

8

7

6

5

10ths

DIGIT1sDIGIT

FUSE

CNP

(

BLU

13

X1

M-NET

12

BLU

RED

BLU

GRN/YLW

BLU

RED

BLK

51

)

MOV1

U

U

DC311~339V

RECTIFICATION

SW2

ON

OFF

123456

BLU

See fig:1

CND

(BLK)

<+2>

TB2

GR

DSA

MOV2

L1

L2

SW4

1234

FUSE

PULL

(

16A

BOX

TO NEXT

INDOOR

UNIT

MV LEV

M

RED

YLW

GRN

ORN

51

VANE

CN151

(WHT)

LED1

SWE

OFFBZON

SW3

12345678

LED on indoor board for service

Mark Meaning Function

LED1

LED2

NOTES:

1.At servicing for outdoor unit,always follow the wiring diagram of outdoor unit.

2.In case of using MA-Remote controller, please connect to TB15.

(Remote controller wire is non-polar.)

3.In case of using M-NET, please connect to TB5. (Transmission line is non-polar.)

4.Symbol [S] of TB5 is the shield wire connection.

5.Symbols used in wiring diagram above are, : terminal block, :connecter.

6.The setting of the SW2 dip switches differs in the capacity. for the detail, refer to the fig:1.

Main power supply

Power supply for

MA-Remote controller

Main power supply (Indoor unit:208-230V)

Power on Iamp is lit

Power supply for MA-Remote controller

on Iamp is lit

<+2>Use copper supply wires.

RU

1

2

3

4

LD101(B)

<fig:1>

Models

ADDRESS

(RED)

0

1

9

2

8

3

7

4

6

5

P12

P15

P18

CN43

SWA

OFF

OFF

OFF

ADDRESS

SW14SW11SW12

0

1

F

E

D

C

B

A

8

9

BRANCH

No.

LD SWE(B)

SWE1

SW2

ON

ON

ON

CN82

(RED)

2

3

4

5

6

7

SWE2

S.B

123456

123456

123456

7

5

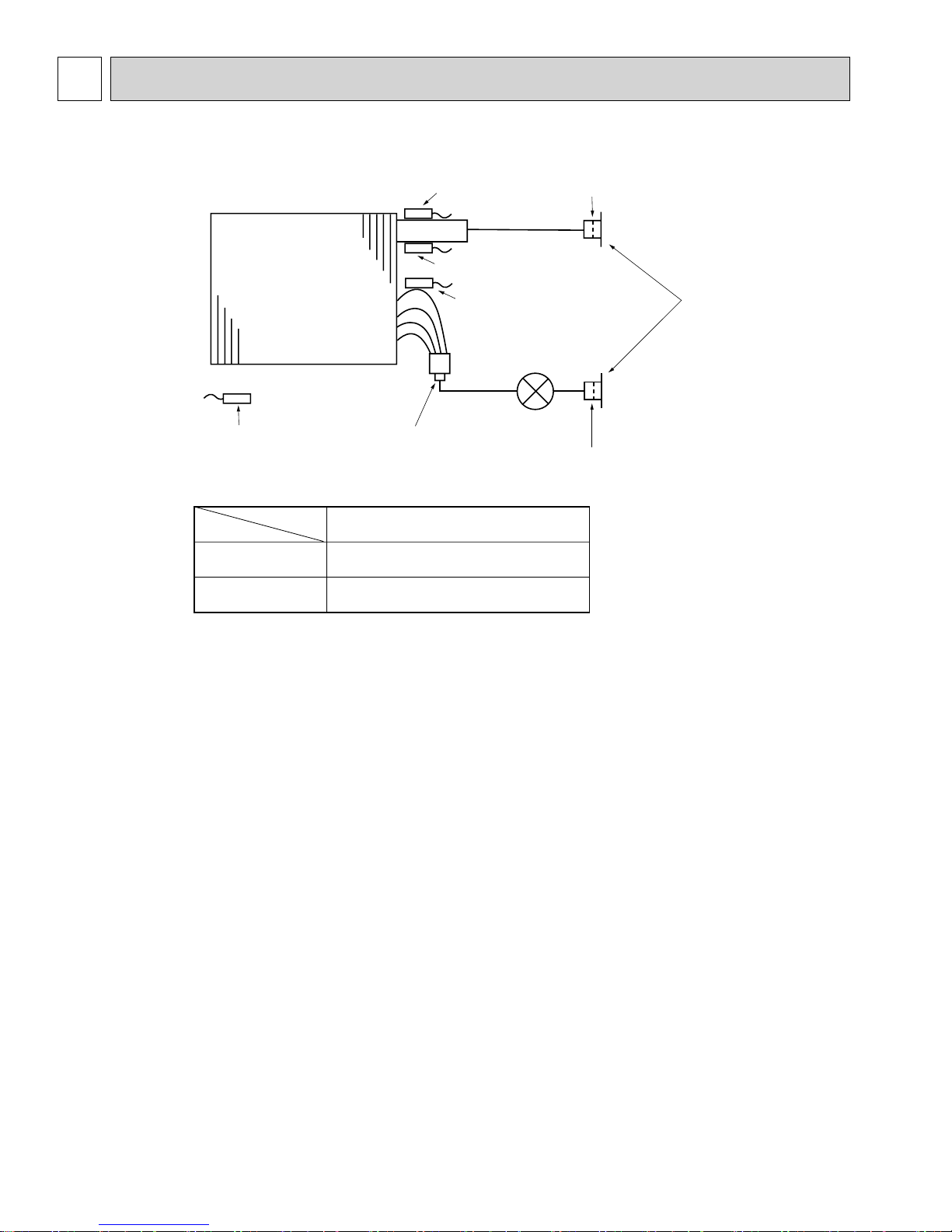

REFRIGERANT SYSTEM DIAGRAM

PKFY-P12, 15, 18NHMU-E

Heat exchanger

Room temparature thermistor TH21

Service Ref.

Item

Gas pipe

Liquid pipe

Gas pipe thermistor TH23

Gas pipe thermistor TH24

Liquid pipe thermistor TH22

Linear expansion valve

Strainer1 (#50mesh)

Strainer2 (#100mesh)

Unit : mm (inch)

PKFY-P12,15,18NHMU-E

:12.7(1/2)

:6.35(1/4)

Strainer (#50mesh)

Gas pipe

Flare connection

Liquid pipe

Strainer (#100mesh)

8

Loading...

Loading...