Mitsubishi PKFY-P18NFMU-E, PKFY-P08NAMU-E, PKFY-P06NAMU-E, PKFY-P12NGMU-E, PKFY-P15NGMU-E Technical & Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

May 2009

No. OC342

REVISED EDITION-C

[Models]

PKFY-P06NAMU-E

PKFY-P08NAMU-E

PKFY-P12NGMU-E

PKFY-P15NGMU-E

PKFY-P18NFMU-E

PKFY-P24NFMU-E

PKFY-P30NFMU-E

PKFY-P12NGMU-E

R410A

/

R22

Revision:

•

"12. RoHS PARTS LIST" has

been modified.

• Please void OC342

REVISED EDITION-B.

NOTE:

• This manual describes only

service data of the indoor

units.

• RoHS compliant products have

<G> mark on the spec name

plate.

• For servicing of RoHS compli-

ant products, refer to the RoHS

PARTS LIST.

CONTENTS

1. DIFFERENCES

2. FEATURES

3. PART NAMES AND FUNCTIONS

4. SPECIFICATION

5. OUTLINES AND DIMENSIONS

6. WIRING DIAGRAM

7.

REFRIGERANT SYSTEM DIAGRAM

8. MICROPROCESSOR CONTROL

9. TROUBLESHOOTING

10. DISASSEMBLY PROCEDURE

11. PARTS LIST

12. RoHS PARTS LIST

.....................................

............................................

...................................

.............................

........................

........................................

.............................

........

..........

....

.......

...........

16

20

22

23

30

39

48

56

2

3

6

9

Revision :

"12. RoHS PARTS LIST" has been modifi ed on page 61.

Page Revise point Service Ref.

1

61

All parts

No. 1~9

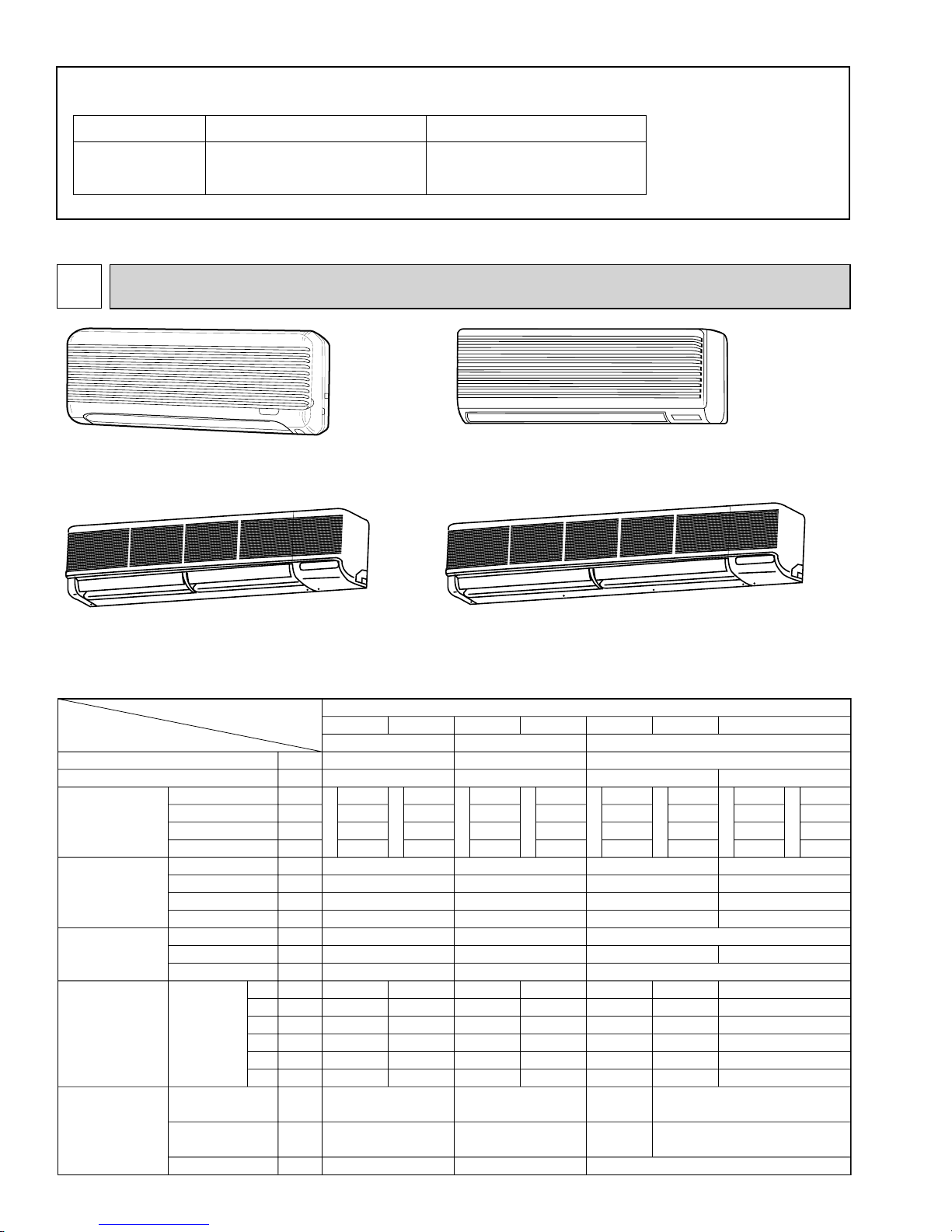

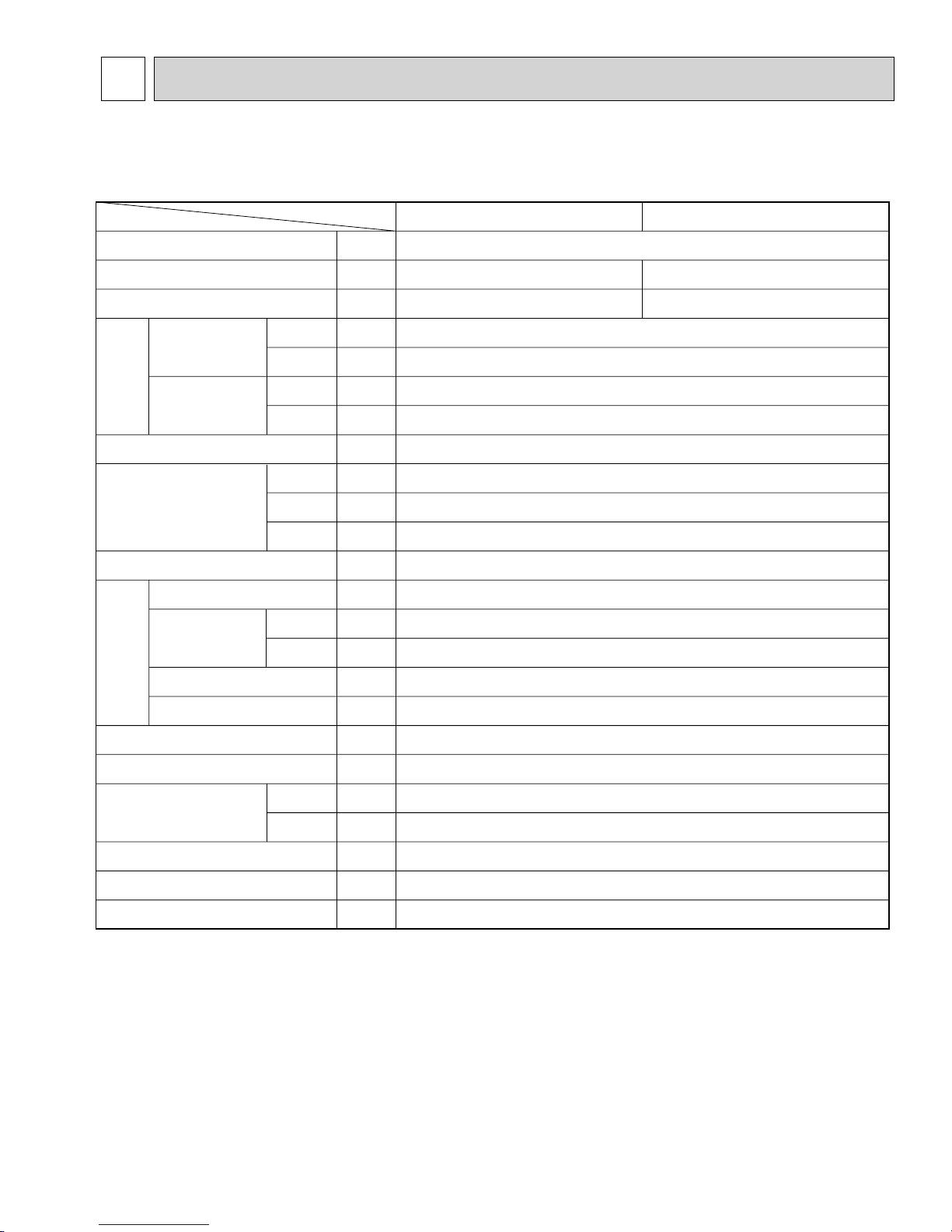

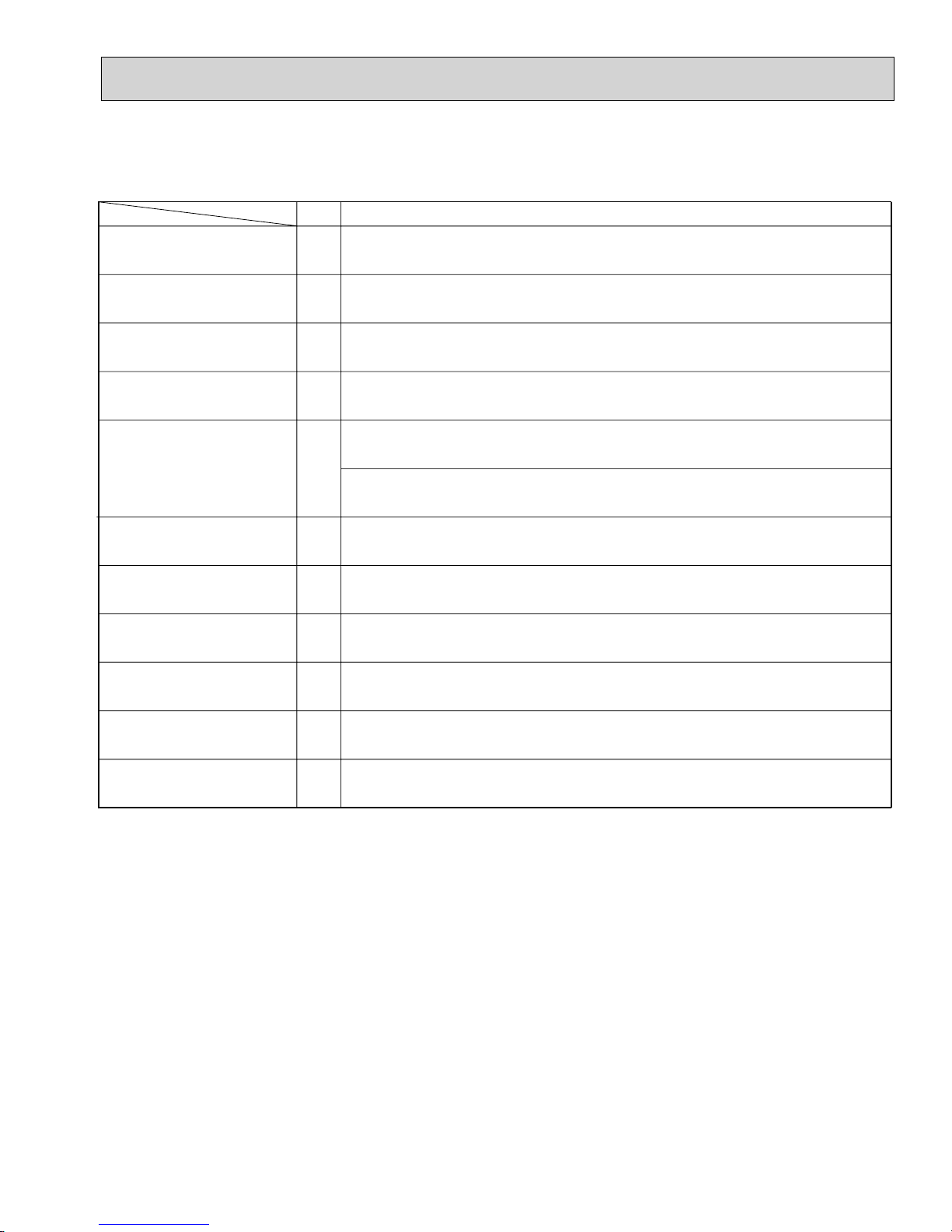

DIFFERENCES

PKFY-P06NAMU-E

PKFY-P08NAMU-E

Indoor Unit

PKFY-P18/24/30NFMU-E

PKFY-P12NGMU-E

PKFY-P15NGMU-E

Indoor Unit

PKFY-P18NFMU-E

PKFY-P24NFMU-E

Indoor Unit

Differences among the models of PKFY series.

1

2

3

4

5

6

Model

—

—

CFM

CFM

CFM

CFM

dB

dB

dB

dB

in.

in.

in.

—

—

—

—

—

—

in.

in.

in.

Item

Fan

Fan speed

Air flow

Noise level

Out dimension

Controller board

Pipe dimension

High

Medium 1

Medium 2

Low

High

Medium 1

Medium 2

Low

Height

Width

Depth

SW2

Gas side

Liquid side

Drain(unit side)

P06

NAMU-E

Lineflow fan × 1

4 speeds type

210

D

R

Y

OFF

OFF

OFF

200

180

170

11- 5/8

32-1/8

6-1/4

ON

—

—

O.D. 5/8"

W

E

T

36

35

33

32

1/2"

1/4"

P08

190

180

170

160

ON

OFF

ON

OFF

—

—

P12

NGMU-E

Lineflow fan × 1

4 speeds type

410

D

R

Y

OFF

OFF

OFF

OFF

W

370

E

340

T

280

42

40

36

32

13-3/8

39

9-1/4

ON

ON

1/2"

1/4"

O.D. 13/16"

2

PKFY-P30NFMU-E

Indoor Unit

PKFY-

P15

370

330

300

250

OFF

OFF

OFF

ON

OFF

OFF

P18

2 speeds type

640

D

—

R

—

Y

490

55-1/8

OFF

ON

OFF

ON

OFF

OFF

1/2" / 5/8"

(Compatible)

1/4" / 3/8"

(Compatible)

P24

NFMU-E

Lineflow fan × 2

570

W

—

E

—

T

440

45

—

—

39

13-3/8

9-1/4

ON

OFF

ON

ON

OFF

OFF

O.D. 13/16"

P30

2 speeds type

990

D

—

R

—

Y

780

66-1/8

OFF

OFF

OFF

OFF

ON

OFF

5/8"

3/8"

49

—

—

46

W

890

—

E

—

T

700

2

FEATURES

PKFY-P06NAMU-E

PKFY-P08NAMU-E

Indoor Unit

Model Cooling capacity / Heating capacity

PKFY-P06NAMU-E 6,000 / 6,700 Btu/h

PKFY-P08NAMU-E 8,000 / 9,000 Btu/h

1. Compact Design

• Compact 11-5/8 inch (29.5cm) high body fits snugly in even limited spaces.

• Light weight 19lbs (8.5kg) unit easy to transport and install.

2. Auto-flap shutter enhances good looks

With a simple flick of the OFF switch, the air outlet can be closed off with a shutter. The shutter also functions as a flap

during operation to adjust the air flow angle, with “Auto Angle” securing a comfortable air flow.

3. Quiet operation

4. The intake grille filter can be completely removed allowing easy cleaning

3

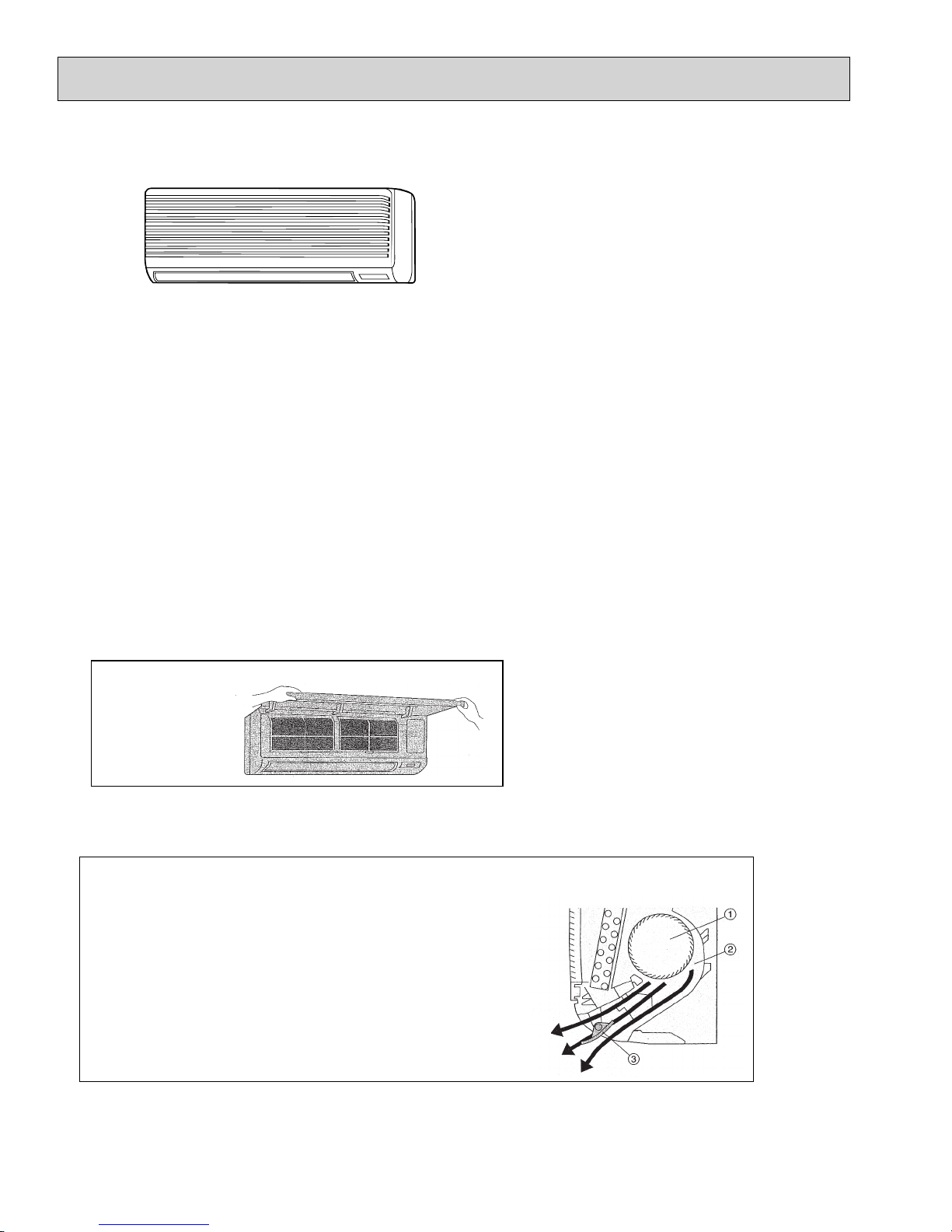

PKFY-P12NGMU-E

PKFY-P15NGMU-E

Indoor Unit

Model Cooling capacity / Heating capacity

PKFY-P12NGMU-E 12,000 / 13,500 Btu/h

PKFY-P15NGMU-E 15,000 / 17,000 Btu/h

1. Compact Design

Units have now been downsized to require minimal wall space.

A 20% reduction in width 39 inch (990mm) compared to previous models means that installation is possible in very narrow

spaces.

2. Auto-flap shutter enhances good looks

With a simple flick of the OFF switch, the air outlet can be closed off with a shutter. The shutter also functions as a flap

during operation to adjust the air flow angle, with “Auto Angle” securing a comfortable air flow.

3. The intake grille filter can be completely removed allowing easy cleaning

(Can be washed in water)

• Front grille

opens out

4. Quiet operation

• Airflow passage configuration that assures quiet operation

By changing fan intervals, quiet operation is achieved

without reduction in airflow. Optimal design of the

airflow passage gives a shortened fan diameter

and allows a highly compact installation.

2 Thanks to a highly practical casing configuration,

airflow generated by the fan is distributed uniformly.

3 Due to careful positioning of the vertical vane axis,

air is blown evenly from the outlet. This prevents mixing

with secondary air and also suppresses condensation.

1 The unit incorporates a random pitch cycling fan.

4

PKFY-P18NFMU-E

PKFY-P24NFMU-E

PKFY-P30NFMU-E

PKFY-P30NFMU-E

Indoor Unit

Models Cooling capacity / Heating capacity

PKFY-P18NFMU-E 18,000 / 20,000 Btu/h

PKFY-P24NFMU-E 24,000 / 27,000 Btu/h

PKFY-P30NFMU-E 30,000 / 34,000 Btu/h

1. A further refinement of comfort with noise suppression

Remarkably low-noise operation has been achieved through the development of a “near -silent” fan and the design

which minimizes air flow resistance.

2. Auto flap shutter

With a simple flick of the OFF switch, the air outlet can be closed off with a shutter. The shutter also functions as a flap

during operation to adjust the air flow angle, with “Auto Angle” securing a comfortable air flow.

3. Easily removable filter

The presence of thumbscrews on the filters means that the filters can be quickly and smoothly removed.

5

3

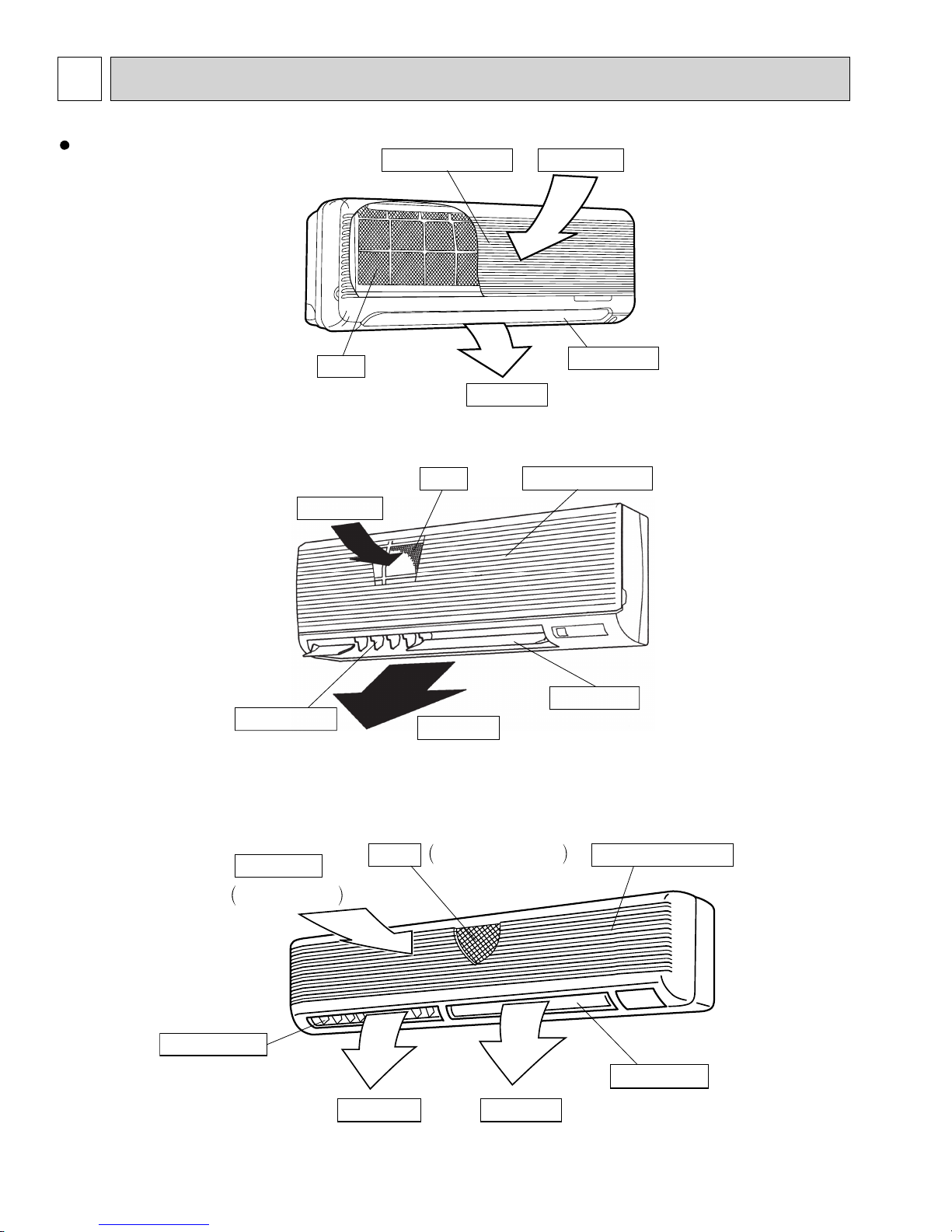

PART NAMES AND FUNCTIONS

Indoor Unit

PKFY-P06NAMU-E

PKFY-P08NAMU-E

PKFY-P12NGMU-E

PKFY-P15NGMU-E

Filter

Air intake

Air intake grille Air intake

Auto vane

Air outlet

Filter

Air intake grille

PKFY-P18NFMU-E

PKFY-P24NFMU-E

PKFY-P30NFMU-E

Guide vane

Air flow can be changed to

horizontally by moving the

Guide vane to the left or right.

Guide vane

Air intake

Room air is

suctioned in here.

Auto vane

Air outlet

Filter Air intake grilles

Removes dust and dirt

from the intake air.

Auto vane

Air outletAir outlet

6

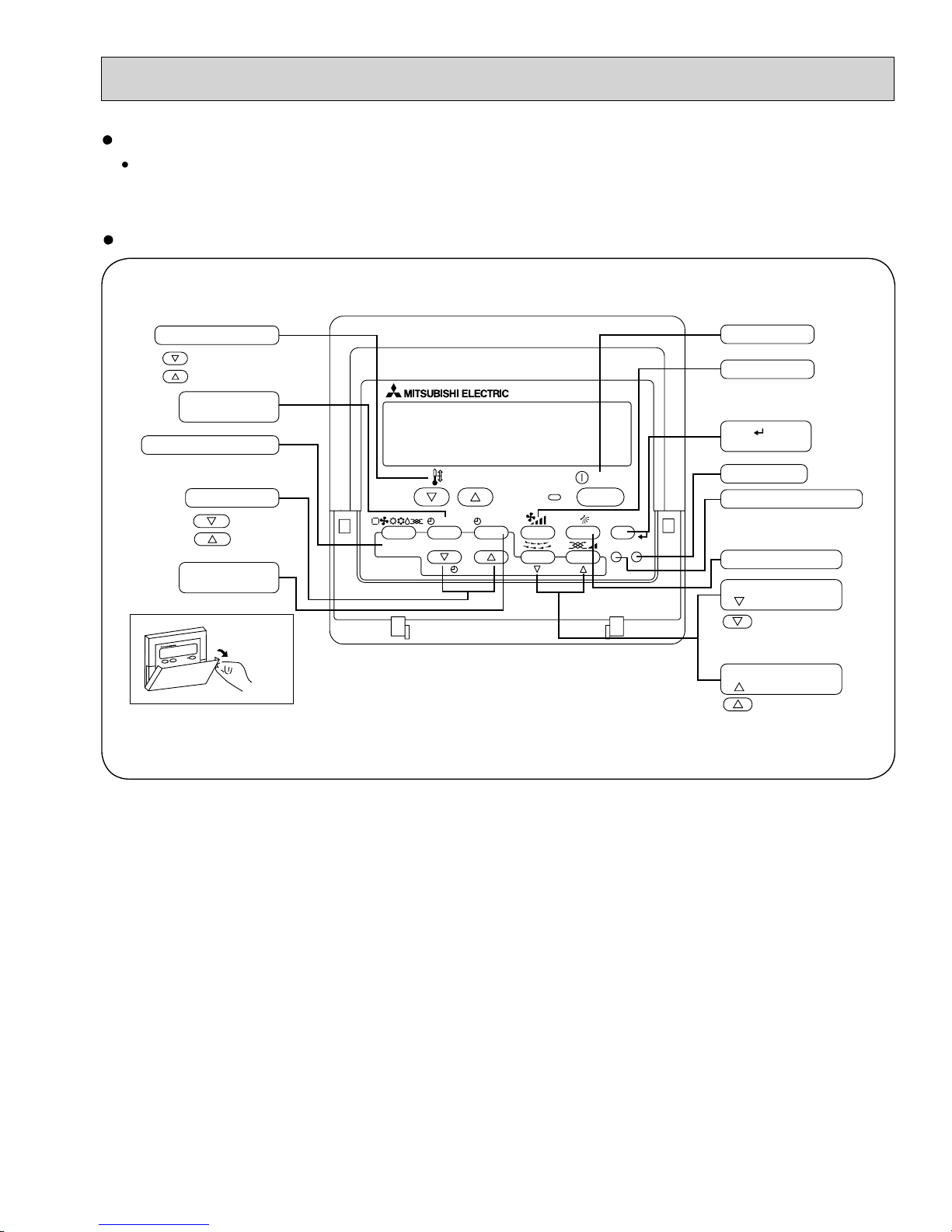

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

To preceding operation

number

Ventilation button

(

Operation button)

To next operation number

Remote controller

Once the operation of the unit is set, subsequent operations can only be performed by pressing the ON/OFF button

repeatedly.

Operation buttons

7

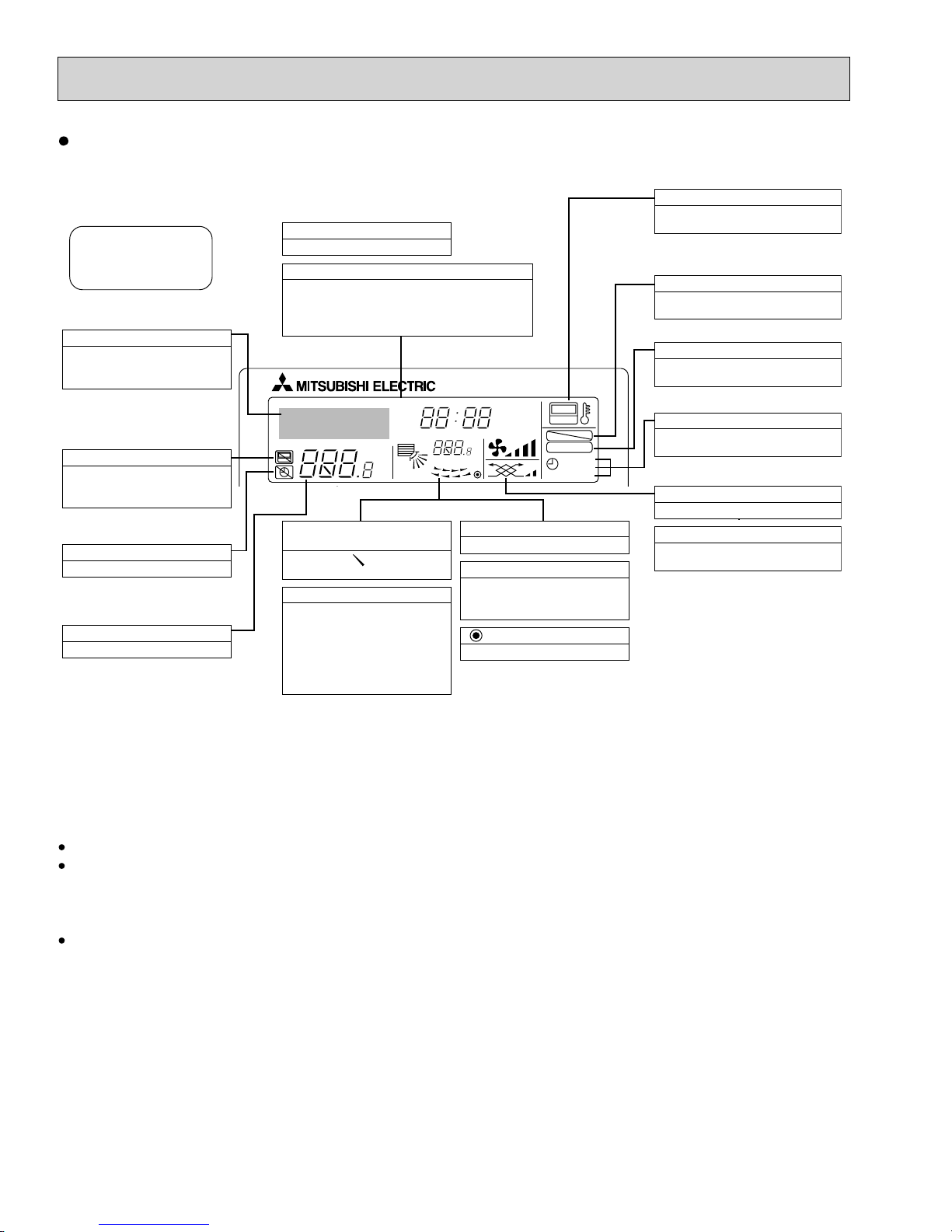

Display

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

TIME SUN MON TUE WED THU FRI SAT

TIMER

AFTER

ERROR CODE

°F°C

Hr

AFTER

°F°C

ONLY1Hr.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

low and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

ON

OFF

FUNCTION

FILTER

WEEKLY

SIMPLE

AUTO OFF

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Caution

Only the Power on indicator lights when the unit is stopped and power supplied to the unit.

If you press a button for a feature that is not installed in the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to operate multiple indoor units, this message will appear only if the feature is not

present at every unit connected.

When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indication

(For max. 2minutes). Please wait until this “PLEASE WAIT” indication disappears then start the operation.

8

4

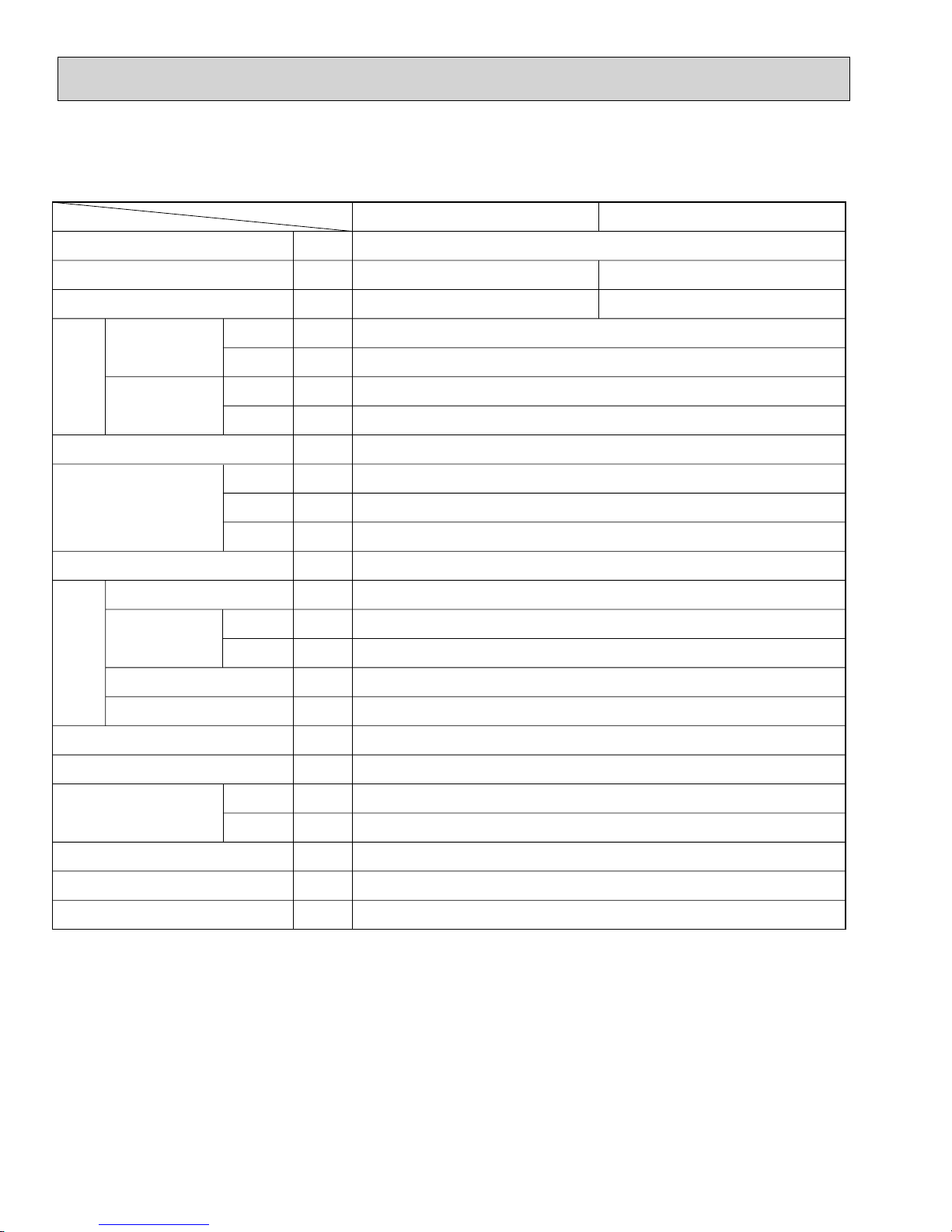

SPECIFICATIONS

4-1. SPECIFICATIONS

PKFY-P06NAMU-E

PKFY-P08NAMU-E

Item

Power source

Cooling capacity

Heating capacity

Power Supply

Electric

Starting Current

characteristic

Exterior <munsell symbol>

Out dimensions

Heat exchanger

Fan × No.

Air flow + 2

Fan

Cooling

Heating

Cooling

Heating

Height

Width

Depth

DRY

WET

Unit

:,V,Hz

Btu/h

Btu/h

kW

kW

A

A

—

in.

in.

in.

—

—

CFM

CFM

PKFY-P06NAMU-E

Single phase, 208/230V, 60Hz

6,000

6,700

0.03

0.03

0.15

0.15

Plastic , white : <2.60Y 8.66/0.69>

11- 5/8

32-1/8

6-1/4

Cross fin (Aluminum plate fin and copper tube)

Lineflow fan × 1

170-180-200-210

160-170-180-190

PKFY-P08NAMU-E

8,000

9,000

External static pressure

Fan motor output

Insulator

Air filter

Gas side

Pipe dimensions

Liquid side

Unit drain pipe size

Noise level + 2

Product weight

Note 1. Rating conditions

Cooling : Indoor D.B. 80˚F W.B. 67˚F

Outdoor D.B. 95˚F W.B. 75˚F

Heating : Indoor D.B. 70˚F

Outdoor D.B. 47˚F W.B. 43˚F

w 2. Air flow and the noise level are indicated as Low - Medium2 - Medium1 - High.

Pa

kW

—

—

in.

in.

in.

dB

lbs

0.017

Polyethylene sheet

PP honey comb

1/2"

1/4"

PVC pipe with O.D. 5/8"

32-33-35-36

0

19

9

PKFY-P12NGMU-E

PKFY-P15NGMU-E

Item

Power source

Cooling capacity

Heating capacity

Input

Electric

Current

characteristic

Exterior <munsell symbol>

Out dimensions

Heat exchanger

Fan × No.

Air flow + 2

Fan

Cooling

Heating

Cooling

Heating

Height

Width

Depth

DRY

WET

Unit

:,V,Hz

Btu/h

Btu/h

kW

kW

A

A

—

in.

in.

in.

—

—

CFM

CFM

PKFY-P12NGMU-E

Single phase, 208/230V, 60Hz

12,000

13,500

0.07

0.07

0.34

0.34

Plastic , white : <0.70Y 8.59/0.97>

13-3/8

39

9-1/4

Cross fin (Aluminum plate fin and copper tube)

Lineflow fan × 1

280-340-370-410

250-300-330-370

PKFY-P15NGMU-E

15,000

17,000

External static pressure

Fan motor output

Insulator

Air filter

Gas side

Pipe dimensions

Liquid side

Unit drain pipe size

Noise level + 2

Product weight

Note 1. Rating conditions

Cooling : Indoor : D.B. 80°F W.B. 67°F

outdoor : D.B. 95°F W.B. 75°F

Heating : Indoor : D.B. 70°F

outdoor : D.B. 47°F W.B. 43°F

W 2. Air flow and the noise level are indicated as Low - Medium2 - Medium1 - High.

Pa

kW

—

—

in.

in.

in.

dB

lbs

0.03

Polyethylene sheet

PP honey comb

1/2"

1/4"

PVC pipe with O.D. 13/16"

32-36-40-42

0

35

10

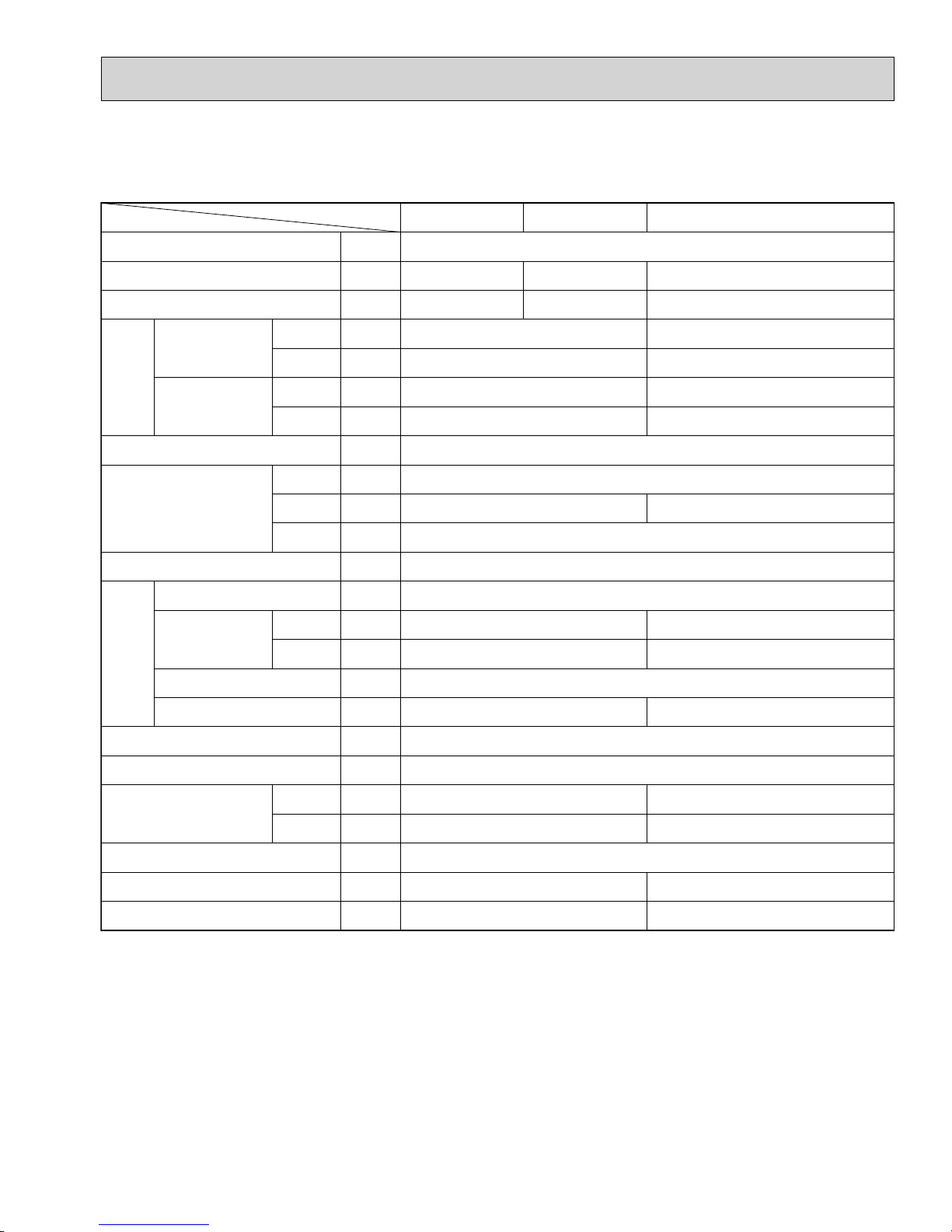

PKFY-P18NFMU-E

PKFY-P24NFMU-E

PKFY-P30NFMU-E

Item

Power source

Cooling capacity

Heating capacity

Input

Electric

Current

characteristic

Exterior <munsell symbol>

Dimensions

Heat exchanger

Type × No.

Air flow

Fan

Low - High

Cooling

Heating

Cooling

Heating

Height

Width

Depth

DRY

WET

Unit

:,V,Hz

Btu/h

Btu/h

kW

kW

A

A

—

in.

in.

in.

—

—

CFM

CFM

PKFY-P18NFMU-E

18,000

20,000

0.09

0.09

0.44

0.44

55-1/8

Cross fin(Aluminum plate fin and copper tube)

490 - 640

440 - 570

PKFY-P24NFMU-E

Single phase, 208V-230V, 60Hz

24,000

27,000

Plastic , white : <3.4Y 7.7/0.8>

13-3/8

9-1/4

Lineflow fan × 2

PKFY-P30NFMU-E

30,000

34,000

0.12

0.12

0.58

0.58

66-1/8

780 - 990

700 - 890

External static pressure

Fan motor output

Insulator

Air filter

Gas side

Pipe dimensions

Liquid side

Unit drain pipe dimension

Noise level Low - High

Product weight

Note 1. Rating conditions

Cooling : Indoor : D.B. 80°F W.B. 67°F

outdoor : D.B. 95°F W.B. 75°F

Heating : Indoor : D.B. 70°F

outdoor : D.B. 47°F W.B. 43°F

Pa

kW

—

—

in.

in.

in.

dB

lbs

0.045

1/2" / 5/8" (compatible)

1/4" / 3/8" (compatible)

39 - 45

53

0

0.070

Polyethylene sheet

PP honey comb

5/8"

3/8"

PVC pipe with O.D. 13/16"

46 - 49

62

11

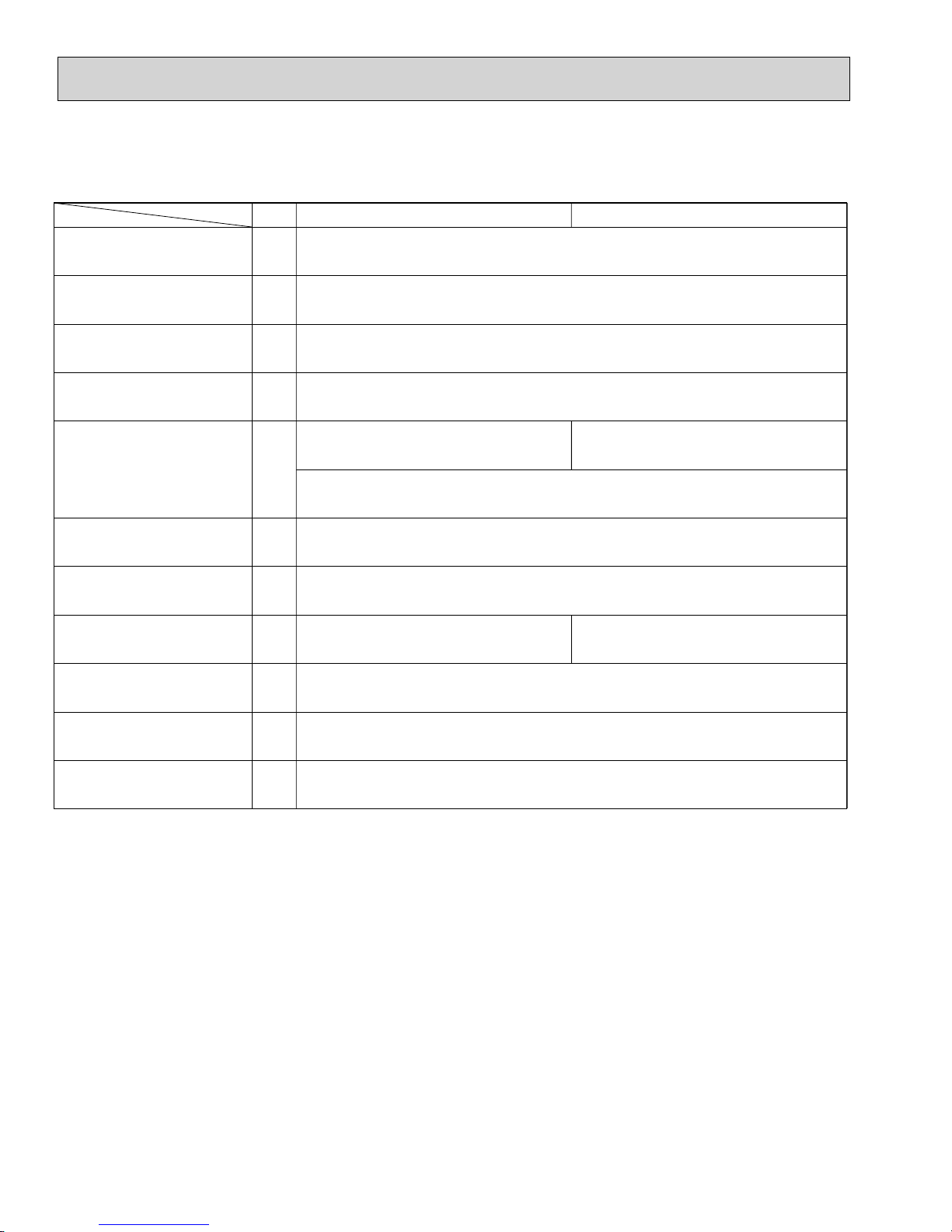

4-2. ELECTRICAL PARTS SPECIFICATIONS

PKFY-P06NAMU-E

PKFY-P08NAMU-E

Model

Symbol

Parts name

Room temperature

thermistor

TH21

Resistance 30°F/15.8k, 50°F/9.6k, 70°F/6.0k, 80°F/4.8k, 90°F/3.9k, 100°F/3.2k

PKFY-P06/P08NAMU-E

Liquid pipe temperature thermistor

Gas pipe temperature thermistor

Fuse

(Indoor power board)

Fan motor

(with thermal fuse)

Fan motor capacitor

Vane motor

(with limit switch)

Linear expansion valve

Power supply terminal

block

Transmission terminal

block

TH22

TH23

FUSE

MF

C

MV

LEV

TB2

TB5

Resistance 30°F/15.8k, 50°F/9.6k, 70°F/6.0k, 80°F/4.8k, 90°F/3.9k, 100°F/3.2k

Resistance 30°F/15.8k, 50°F/9.6k, 70°F/6.0k, 80°F/4.8k, 90°F/3.9k, 100°F/3.2k

250V 6A

4-Pole Output 8W / PS4N8-KA

1.2μF × 440V

MSFBC20A03 DC12V

DC12V Stepping motor drive

Port dimension :3.2 (0~2000pulse) EDM-40YGME

(L1, L2,GR) 250V 20A

(M1, M2) 250V 10A

12

PKFY-P12NGMU-E

PKFY-P15NGMU-E

Parts name

Model

Symbol

PKFY-P12/P15NGMU-E

Room temperature thermistor

Liquid pipe temperature thermistor

Gas pipe temperature thermistor

Fuse

(Indoor controller board)

Fan motor

(with inner-thermostat)

Fan motor capacitor

Vane motor

Linear expansion valve

Power supply terminal block

TH21

TH22

TH23

FUSE

MF

MV

LEV

TB2

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

°

Resistance 30

Resistance 30

Inner-thermostat

C

F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

°

F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

250V 6A

PM4N30-KA 208V/230V 60Hz

4 pole Output 30W

OPEN 25 ± 9 °F

2.0 μF 440V

MP 35 EA DC12V

DC12V Stepping motor drive

Port dimension :3.2 (0 ~ 2000pulse) EDM-40YGME

(L1, L2, GR) 330V 30A

Transmission terminal block

MA remote controller terminal block

TB5

TB15

(M1, M2, S) 250V 20A

(1,2) 250V 10A

13

PKFY-P18NFMU-E

PKFY-P24NFMU-E

PKFY-P30NFMU-E

Parts name

Model

Symbol

PKFY-P18/P24NFMU-E

PKFY-P30NFMU-E

Room temperature thermistor

Liquid pipe temperature thermistor

Gas pipe temperature thermistor

Fuse

(Indoor controller board)

Fan motor

(with inner-thermostat)

Fan motor capacitor

Vane motor

Linear expansion valve

Power supply terminal block

TH21

TH22

TH23

FUSE

MF

C

MV

LEV

TB2

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ

250V 6A

PN4N45-K

208-230V 60Hz

4pole Output 45w

Inner-thermostat

DC12V Stepping motor drive

Port dimension :3.2 (0 ~ 2,000pulse)

EDM-40YGME

OPEN 266 ± 9 °F

2.5440V

MP 35 EA DC12V

(L1, L2, GR) 330V 30A

DC12V Stepping motor drive

Port dimension :5.2 (0 ~ 2,000pulse)

PN4N70-K

208-230V 60Hz

4pole Output 70w

EDM-80YGME

Transmission terminal block

MA remote controller

terminal block

TB5

TB15

(M1, M2, S) 250V 20A

(1,2) 250V 10A

14

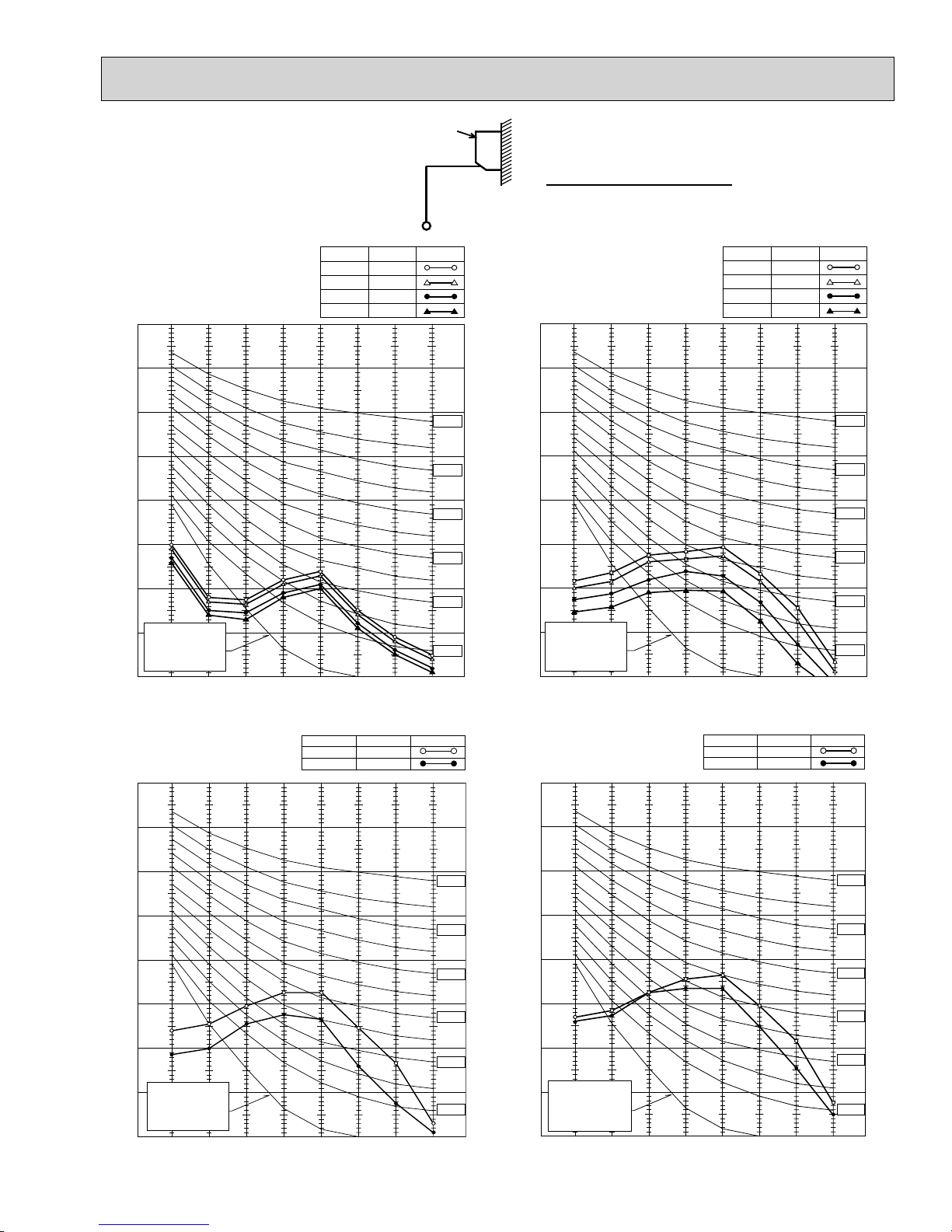

4-3. NOISE CRITERION CURVES

3.3ft

Unit

3.3ft

Wall

Ambient temperature 80°F

High

Low

SPL(dB)

36

35

33

32

PKFY-P06NAMU-E

PKFY-P08NAMU-E

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NOTCH

Medium1

Medium2

LINE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

High

Low

SPL(dB)

42

40

36

32

PKFY-P12NGMU-E

PKFY-P15NGMU-E

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NOTCH

Medium1

Medium2

LINE

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

High

Low

SPL(dB)39LINE

45

PKFY-P18NFMU-E

NOTCH

PKFY-P24NFMU-E

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

High

Low

SPL(dB)46LINE

49

PKFY-P30NFMU-E

90

80

70

60

50

40

30

APPROXIMATE

20

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NOTCH

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

15

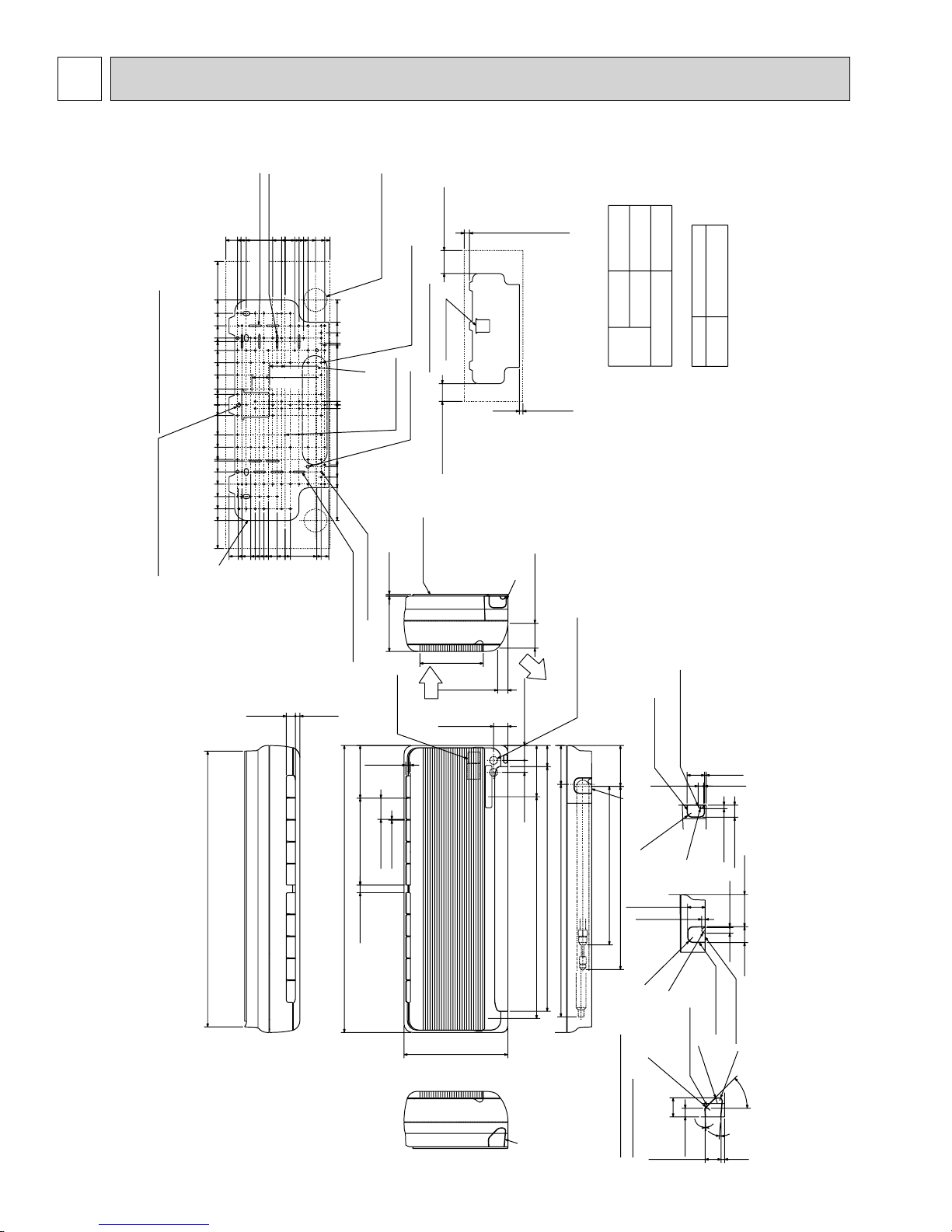

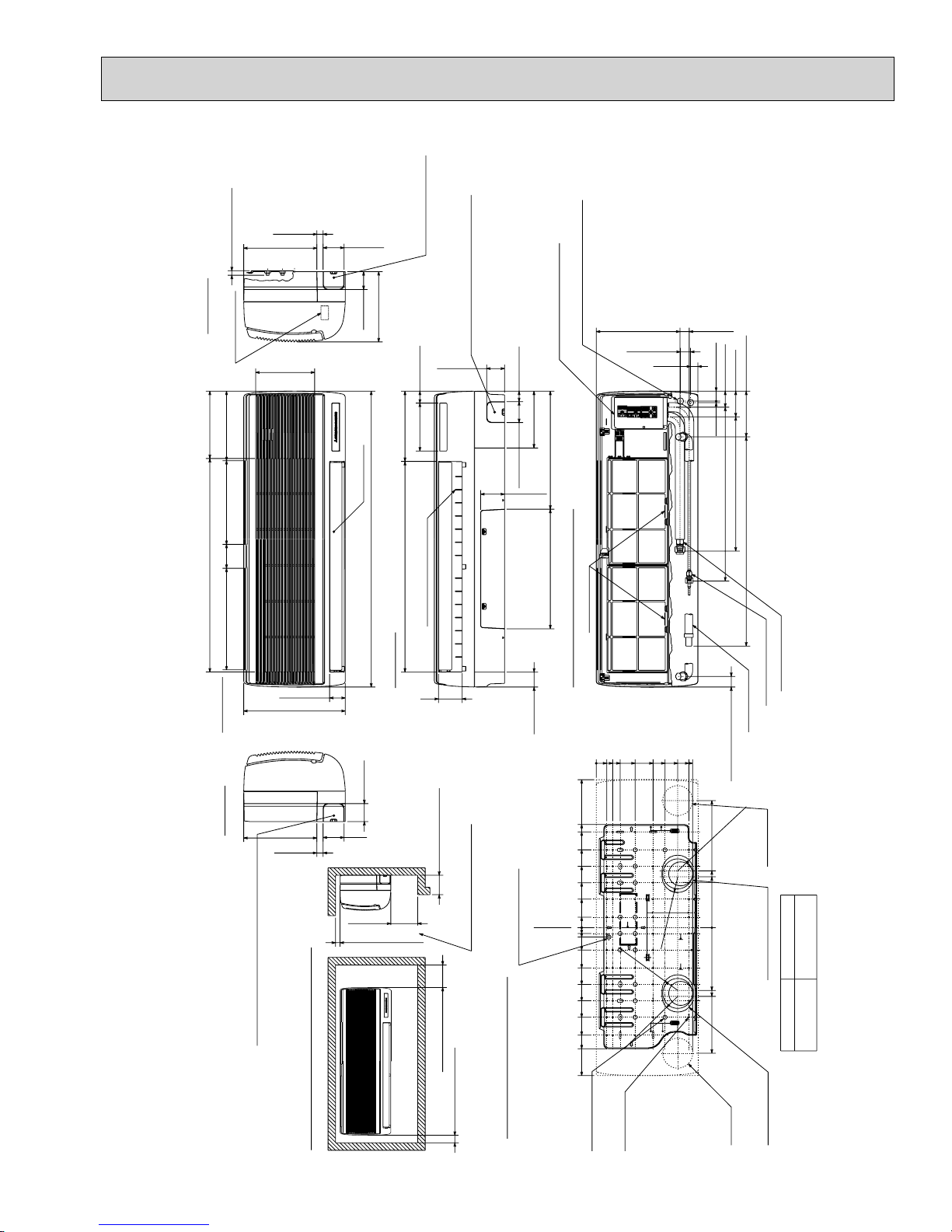

5

OUTLINES AND DIMENSIONS

PKFY-P06NAMU-E

PKFY-P08NAMU-E

Details of installation plate

Installat plate balance point hole

30-13/16(783)

6-5/8(168)

5-5/16(135)

4-11/32(110)

4-29/32(125)

1-3/8(35)013/32(10)

16-1/32(407.5)

11-23/32(298)

10-1/4(260)

8-27/32(225)

7-15/32(190)

7-3/32(180)

6-3/32(155)

4-23/32(120)

3-11/32(85)

1-3/4(45)

1-3/16(30)

0

0

0

0

1-3/16(30)

3-11/32(85)

4-23/32(120)

6-3/32(155)

6-1/4(159)

7-15/32(190)

8-27/32(225)

10-1/4(260)

11-5/8(295)

12-29/32(328)

16-1/32(407.5)

Installation plate

3/16x1-9/16 (4.5x40) 4 holes

3/16x1-15/32 (4.5x37) 4 holes

2-3/8(60)

5-1/4(133)

6-1/4(159)

1-7/8(47.5)

3-11/32(85)

3-27/32(97.5)

2-27/32(72.5)

4-13/16(122.5)

0

0

0

1-3/32(27.5)

1-9/16(40)

1-23/32(44)

1-31/32(50)

0

0

0

0

0

19/32(15)

7/8(22.5)

Air intake

4-7/16(113)

3-7/16(87)

5-1/32(128)

2-9/16(65)

2-3/32(53)

0

0

0

4-7/8(124)

3-17/32(90)

4-1/32(102.5)

3/16x1-3/8(4.5x35) 4 holes

1/2(13) 1(25.5)

5-29/32(150)

9-3/4(247.5)

32-3/32(815)

27/32(21.5)

Piping hole:2-9/16(:65)

11-23/32(298)

9-1/4(235)

8-1/16(205)

6-7/8(175)

6-11/16(170)

Knockout hole

13/32(10)

13/32(10)

12-:1/8(:2.8)holes

6-11/16(170)

6-7/8(175)

8-1/16(205)

9-1/4(235)

12-29/32 (328)

3/16(5)

8-:5/32(:4.3) holes

6-7/32(158)

Air intake

3/32(2.5)

2-3/8(60)

5-1/8(130) or more

87-:3/16(:5.1)holes

Installation space

4-:11/32(:9)holes

3-15/16(100) or more

installaion plate

Terminal block

(Direction)

Air intake

1/2(13)

Supporting piece

Air intake

7-3/32(180)

Air outlet

1-15/32(37.4)

1-5/8(40.5)

left-rear piping

leftpiping

J1

2-1/8(54) of more

1 5-1/8(130) or more

25/32(20) or more

A

2-25/32(70.3)

Air outlet

Wiring entrance holes

Air outlet

(Direction)

1-11/16(42.5)

5-3/4 (146)

2-3/8 (60)

4-11/32(110)

1-11/ 32(34)

Air outlet

Air intake

27-3/8(695)

(Drain pipe total 29-29/32(760))

24-13/16(630)

26-31/32(660)

Unit : inch(mm)

1/2F

1/4F

:5/8(:16) I.D

Through-hole

:2-9/16~:2-3/4

Liquid pipe

Gas pipe

(:65~:70)

Drain pipe

Sleeve

:2-9/16

piping

Refrigerart

Notes 1. Use M10 or W3/8 screw for installation plate.

2. Extension piping side.

Knockout hole for

remote control wiring

Knockout hole of

right piping

4-9/16(116)

B

A

Gas pipe

R15/32(R12)

Liquid pipe

17-23/32(450)

20-25/32(520)

1-31/32(50)

13/32(10)

(:65)

3. Sleeves are available on the market.

1-31/32 (50)

5/8 (16)

R5/16(R8)

5/32(4)

13/32(10)

1-11/32(34)

3/32(2.5)

3/32(2.5)

3-19/32 (91.5)

B

5/8(16)

R19/32(R15)

R5/16(R8)

1-25/32 (45)

16

11-5/8(295)

Knockout holt for

under piping

Knockout hole of

remote control wiring

Knockout hole for

left piping

R15)

R5/16(R8)

R19/32(R15)

C

2-1/8(54)

C

Detailed figure dwg (ABC)

(Knockout hole)

31/32(24.4)

R19/32(

45

3

5

1-25/32(45)13/32(10)

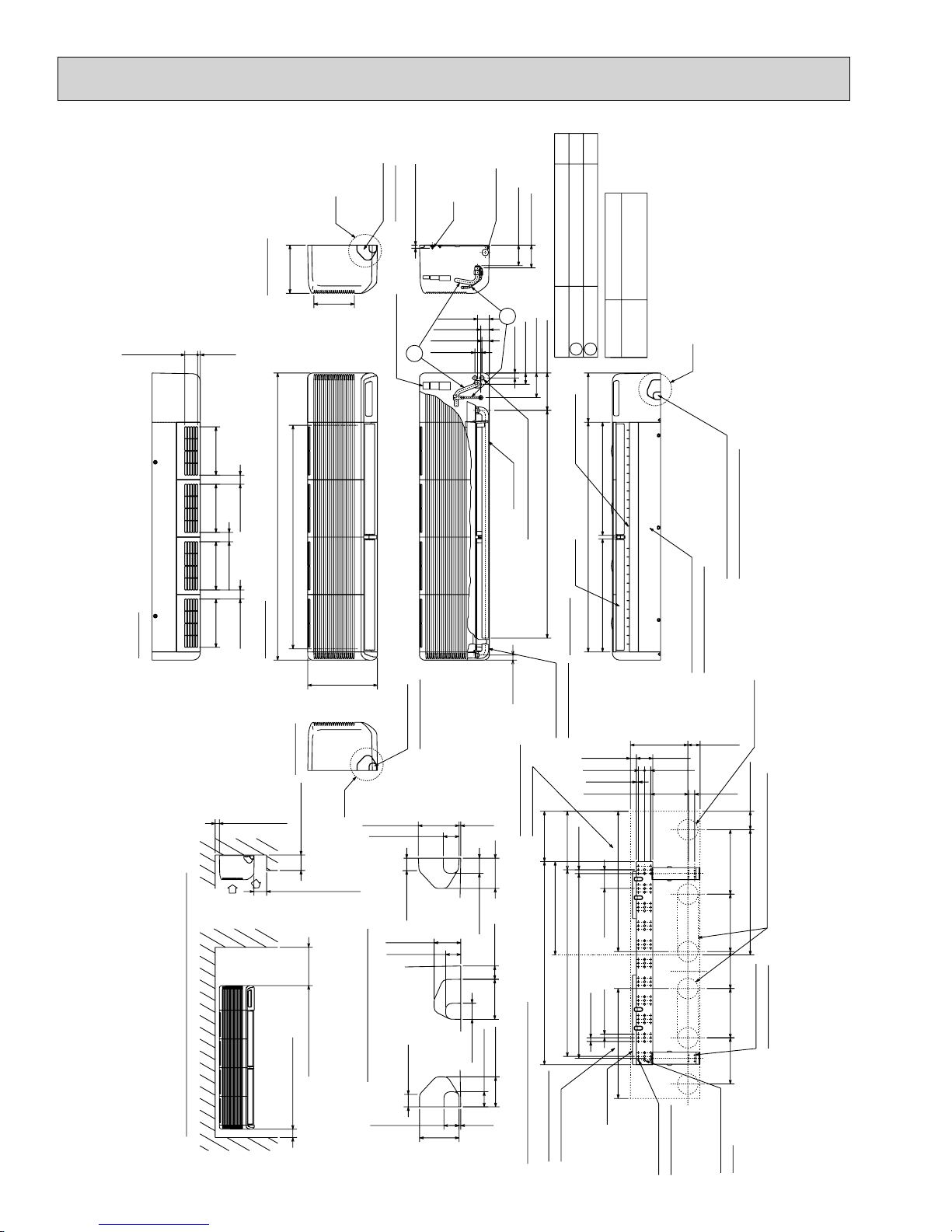

PKFY-P12NGMU-E

PKFY-P15NGMU-E

Unit : inch(mm)

Less than 19/32(15)

Right side

Address board

Air intake

11-1/32(280) 9-3/16(233)

3-5/32(80)

28-5/32(715) Air intake 8-27/32(225)

Air intake

13-3/8(340)

Front view

Left side

Knock out hole for left piping

Refrigerant pipe.Drain pipe.Wiring hole.

13/16(21)

9-21/32(245)

Air intake

7-25/32(198)

2-3/32(53)

13-3/8(340)

9-21/32(245)

13/16(21)

Right side

2-3/4(70)

Knockout hole for right piping

Refrigerant pipe.Drain pipe.

Wiring hole

9-1/4(235)

2-3/8(60)

Knockout hole for under piping

6-5/16(160) 1-9/16(40)

Auto vane

39(990)

27-3/4(705) Air outlet 9-1/4(235)

12—Louvers (manual)

Lower side

2-3/8(60)

2-3/4(70)

Less than 5-1/8(130)

7-3/32(180) or more

1-13/16(30) or more

5-29/32(150) or more

Wiring entrance holes

Refrigerant piping.Drain pipe.

Wiring hole

2-3/8(60)

Service panel

(Power supply access)

7-15/32(190)

15-9/16(395)15-3/4(400)

2-3/4(70) 1-3/8(35)

3-1/8(80)

Front view (top open the grille)

3-1/8(79)

1-31/32(50)

19-1/2(495)

13-19/32(345)

12-19/32(320)

10-1/4(260)

8-1/16(205)

5-29/32(150)

3-3/4(95)

1-3/8(35)

0

25/32(20)

(Necessary clearance for

Unit installation)

Installation plate

balance point hole

Unit center

1-1/4(32)

2-15/16(75)

5-5/16(135)

7-15/32(190)

9-21/32(245)

11-13/16(300)

14-3/16(360)

15-15/16(405)

19-1/2(495)

Filter grip

0

1-3/8(35)

2-5/32(55)

0

3-5/32(80)

5-1/8(130)

R2-1/16(R52.5)

1-11/32(34)

1(25)

7-15/32(190)

9-1/16(230)

10-23/32(272)

16(R52.5)

R2-1/

R2-1/16(R52.5)

1-5/16(33)

3/16(5)

12-11/16(322)+1

12-7/32(310)

(Left side piping

R2-1/16(R52.

0

1-7/32(31) 11-1/32(280)

2-1/8(54)

(Right side piping installation)

3-3/8(86)

17-11/16(449)

22-7/8(581)

27-9/16(700) 6-1/32(153)

(Flexible hose total length 31-1/2(800))

Gas pipe 1/2F

Liquid pipe 1/4F

Drain hose

installation)

1-3/8(35)

16-23/32(425)

5)

Right-rear

piping hole

7-15/32(190)

6-11/16(170)

+1 Sleeves are available on the market.

Through-holeSleeve 1

Knockout hole for

right-rear piping

:2-15/16~:3-5/32

8-9/32(210)

9-1/16(230)

:2-15/16(:75)

16-17/32(420)

+2 This size shows the lower end of through hole.

(:75~:80)

Service space required around indoor unit

1-31/32(50) or more

Details of installation plate

17

14-:9/16(:14)holes

for bolts

for tapping screw

49-:3/16(:5)holes

Left-rear

piping hole

Knockout hole for

left-rear piping

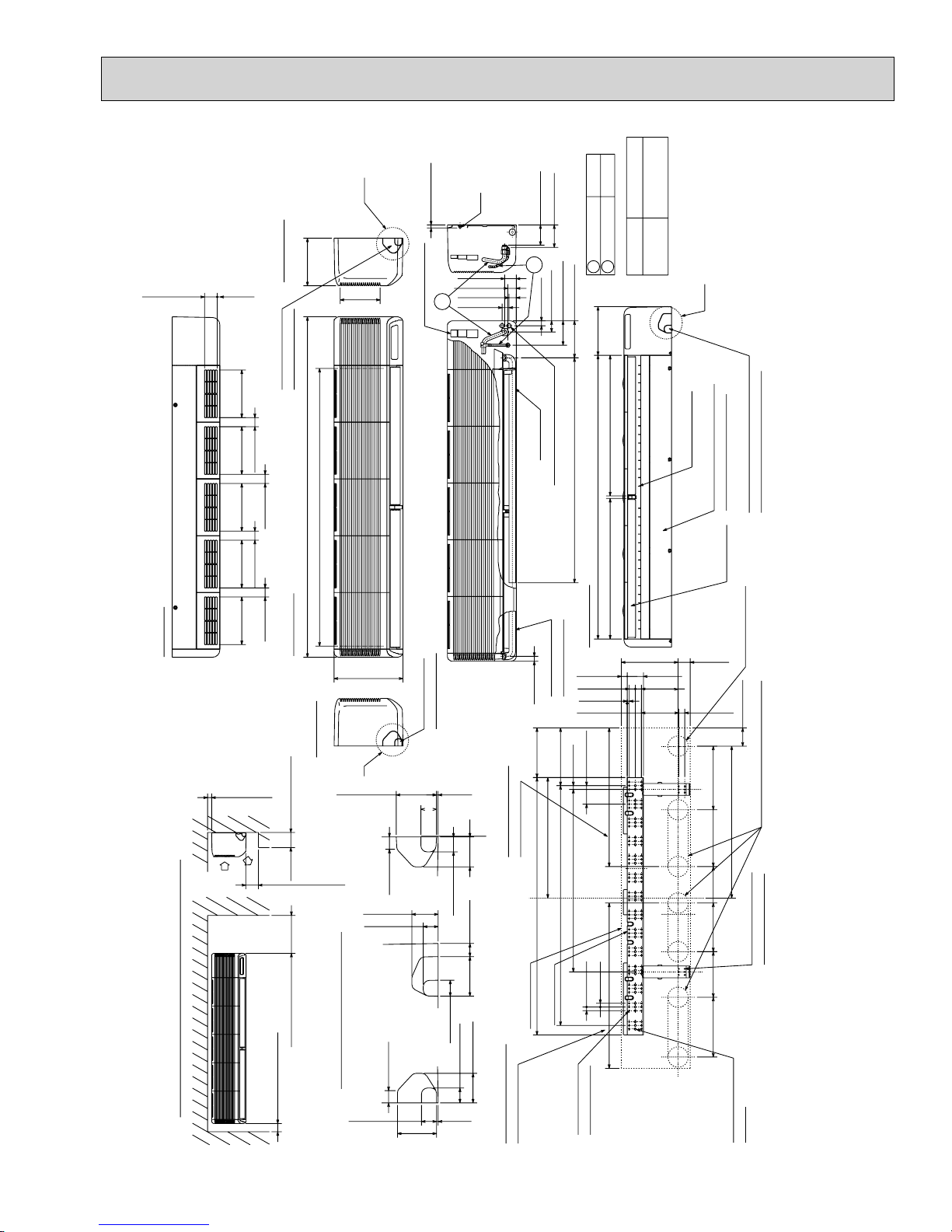

PKFY-P18NFMU-E

PKFY-P24NFMU-E

P24

3/8FLiquid pipe

5/8F

Unit : inch(mm)

Top side

2-15/32(62.5)

9-1/4(235)

9-1/4(235)

9-1/4(235) 9-1/4(235)

1/2(13)

1-25/32(45)

1-25/32(45)

1-25/32(45)

9-1/4(235)

Right side

55-1/8(1400)

42-29/32(1090) Air intake

Front view

C

Knock out hole

7-3/4(197)

13-3/8(340)

for right piping

Less than 19/32(15)

2

Terminal blockTerminal block

Bolt

Drain hose

2-9/32(58)

1-21/32(42)

1-7/16(36)

1-5/16(34)

4-7/32(107)

P18MODEL

4-3/8(111)

1/4F / 3/8F (Compatible)

1

1

2-5/32(55)

15/16(24)

7-7/32(183)

4-23/32(120)

9-7/16(240)

Louvers(Manual)Auto vanes

Drain hose

Wiring entrance holes

44-3/32(1120)

43-11/16(1110) Drain hose

Lower side

31/32(25)

1/2F / 5/8F (Compatible)

:3-17/32~:3-15/16

(:90~:100)

Through-hole

+1

Gas pipe

:3-17/32

21-23/32(552) Air outlet

21-23/32(552) Air outlet

(:90)

Sleeve

+1 Sleeves are available

on the market.

B

2

Under panel(Removable at

Knockout hole for under-piping

Refrigerant pipe /Drain pipe

left-hand side piping)

Left side

1-3/16(30) or more

Less than 9-27/32(250)

Air

intake

Air

outlet

9-27/32(250) or more

1-31/32(50) or more

Service space required around indoor unit

Knockout hole

for left piping

A

3-15/16(100)

1-17/32(39)

9-27/32(250) or more

1-3/16(30)

2-9/16(65)

1-15/32(37)

Knockout hole for wiring

1-3/16(30)

AB C

1-17/32(39)

5/32(4)

2-29/32(74)

1-15/32(37)

1-1/4(32)

3-27/32(98)

1-9/16(39)

2-29/32(74)

1-15/32(37)

5/32(4)

3-15/16(100)

18

Drain hose for

left-hand side piping

1-5/32(29)

1-3/16(30)

13/32(10)

7-1/4(184)

Drainage range on

right-hand side

3/4(19)

9-21/32(245)

17-29/32(455)

Unit center

38-31/32(990)

35-7/16(900)

23/32(18)

13/323-19/32=(35-13/16) (1091=(910)) 11-7/32(285)

3-19/32(91)

23/32(18)

Wall fixture

Drainage range on

left hand side

Details of installation plate

66-:1/4(:6) holes

11-1/32(280)

3-1/8(80)

1-3/16(30)

for tapping screws

2-3/8(60)

1-3/16(30)

11-1/32(280) 12-3/8(314)

7-3/32(180)

9-7/16(240)

8-27/32(225)

32-:15/32(:12) holes

for bolts

Rear piping hole

3-17/32(90)

24-1/32(610)

Range for left rear piping hole

12-1/4(6) holes

for tapping screws

PKFY-P30NFMU-E

Unit : inch(mm)

Top side

2-15/32(62.5)

1/2(13)

9-1/4(235)

1-25/32(45)

9-1/4(235)

9-1/4(235)

9-1/4(235)

1-25/32(45)

9-1/4(235)

9-1/4(235)

Right side

Knock out hole

for right piping

66-1/8(1680)

1-25/32(45)

1-25/32(45)

Front view

53-15/16(1370) Air intake

C

7-3/4(197)

13-3/8(340)

Less than 9/16(15)

2

Terminal block

Knockout hole

for left piping

Bolt

2-9/32(58)

1-21/32(42)

1-7/16(36)

1-5/16(34)

4-3/8(111)

4-1/32(102)

7-7/32(183)

4-23/32(120)

Liquid pipe 3/8F

1

9-7/16(240)

1

2-5/32(55)

15/16(24)

Drain hose

Wiring entrance holes

43-11/16(1110) Drain hose

55-1/8(1400)

Lower side

Drain hose for

left-hand side piping

31/32(25)

5/8F

Gas pipe

2

27-5/16(694) Air outlet

27-5/16(694) Air outlet

1-5/32(29)

1-3/16(30)

13/32(10)

Through-hole

:3-17/32~:3-15/16

(:90~:100)

+1

(:90)

:3-17/32

Sleeve

+1 Sleeves are available

on the market.

Louvers(Manual)

11-1/32(280)

3-5/32(80)

1-3/16(30)

B

Under panel(Removable at

left-hand side piping)

Knockout hole for under-piping

Refrigerant pipe /Drain pipe

Auto vanes

2-3/8(60)

Rear piping hole

1-3/16(30) 7-1/4(184)

3-9/16(90)

Left side

1-3/16(30) or more

Less than 5-29/32(150)

Air

Air

intake

Service space required around indoor unit

outlet

9-27/32(250) or more

1-31/32(50) or more

A

3-15/16(100)

9-27/32(250) or more

1-3/16(30)

2-9/16(65)

1-15/32(37)

ACB

1-3/16(30)

Knockout hole for wiring

5/32(4)

2-29/32(74)

1-15/32(37)

1-1/4(32)

3-27/32(98)

1-17/32(39)

2-29/32(74)

1-15/32(37)

5/32(4) 1-17/32(39)

3-15/16(100)

19

9-21/32(245)

1-17/32(39)

Drainage range on

right-hand side

50(1270)

Unit center

Unit out line

Drainage range on

left hand side

3/4(19)

11-7/32(285)

23-7/16(595)

35-7/16(900)

1/23-19/32=(46-9/16) (1391=(1183))

Wall fixture

84-:1/4(:6) holes

3-19/32(91)

23/32(18)

23/32(18)

for tapping screws

29-17/32(750)

9-7/16(240) 7-3/32(180) 11-1/32(280) 12-3/8(314)

11-5/8(295) 8-27/32(225)

41-:15/32(:12) holes

Range for left rear piping hole

12-:1/4(:6) holes

for tapping screws

for bolts

6

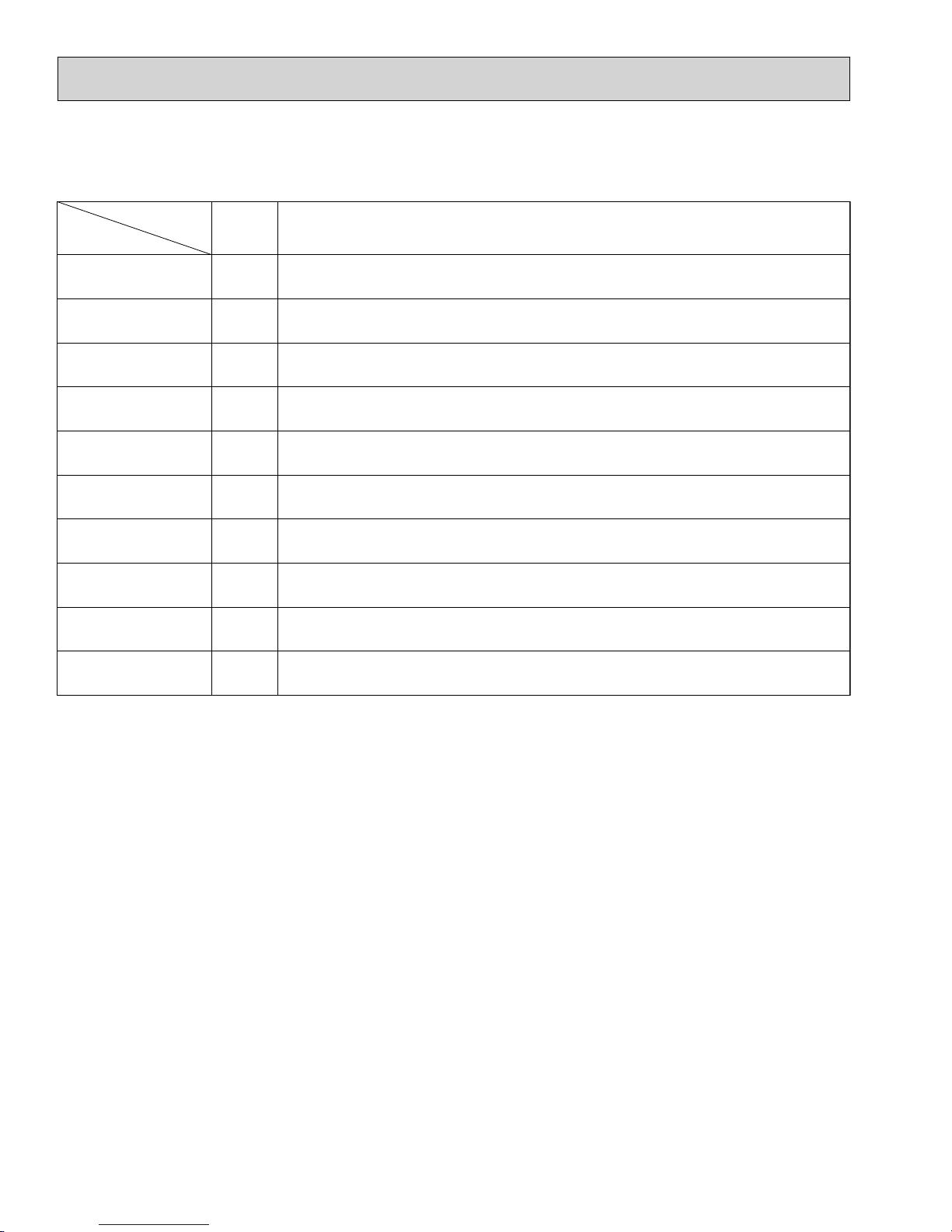

WIRING DIAGRAM

PKFY-P06NAMU-E

PKFY-P08NAMU-E

[ LEGEND ]

SYMBOL NAME NAMESYMBOL SYMBOL

A. B

SWITCH

SW1

SW5

SW11

SW12

SW14

M. B

INDOOR CONTROLLER BOARD

CONNECTOR

CN32

CN51

CN52

SW2

SWITCH

SW3

NAME

MODE SELECTION

VOLTAGE SELECTION

ADDRESS SETTING 1ST DIGIT

ADDRESS SETTING 2ST DIGIT

CONNECTION No.

REMOTE SWITCH

CENTRALLY CONTROL

REMOTE INDICATION

CAPACITY CODE

MODE SELECTION

P. BCIRCUIT BOARD (ADDRESS)

INDOOR POWER BOARD

CAPACITOR (FAN MOTOR)

C

FAN PHASE CONTROL

F.C

FUSE (6A/250V)

FUSE

VARISTOR

ZNR

LEV

MF

MV

TB2

TB5

TH21

TH22

TH23

LINEAR EXPANSION VALVE

FAN MOTOR

VANE MOTOR

TERMINAL

BLOCK

THERMISTOR

POWER SUPPLY

TRANSMISSION

ROOM TEMP. DETECTION

(32°F/15k, 77°F/5.4k)

PIPE TEMP. DETECTION/LIQUID

(32°F/15k, 77°F/5.4k)

PIPE TEMP. DETECTION/GAS

(32°F/15k, 77°F/5.4k)

TH21TH22TH23

A.B

SW5

ON

OFF

12345678910

3RD

DIGIT

230V208V

SW1

SW12 SW14SW11

00

2ND

1ST

DIGIT

DIGIT

5VDC SUPPLY

4

(RED)

3

ADDRESS

2

CN43

1

(RED)

ADDRESS

CN82

0

CONNECTION

NO.

LEV

ORN

WHT

YLW

123456

CN60

LEV

(WHT)

4

8

7

6

5

4

3

2

1

8

OFF

12345678910

1234

12345 12345

CENTRALLY

CONTROL

ON

M.B

6

RED

BLU

CN51

(WHT)

SW3 SW2

BRN

12345

MV

5

YLW

RED

ORN

BLU

CN5V

(

BLU)

CN52

REMOTE

INDICATION

(GRN)

See Fig.1

REMOTE

1234

CN42

ADDRESS

(RED)

LED2

YLW

123 123

CN32

CN34

(GRN

SWITCH

(WHT)

12345678

CN81

ADDRESS

(RED)

POWER BOARD

BRN

GRY

12 12

CN21

CN29

LIQUID

GAS

)

(WHT

(BLK

)

123

CN3A

(BLU)

CN53M

12345

(RED)

CN35M

POWER BOARD

(BLU)

)

INTAKE

123

12

CN20

(RED)

Notes:

1. At servicing for outdoor unit, always follow the wiring diagram of outdoor unit.

2. In case of connecting MA-Remote controller, please connect MA remote controller cable in an accessorie

to the connector . (Remote controller wire is non-polar.)

12

3.In case of using M-NET, please connect to TB5. (Transmission line is non-polar.)

4.Symbols used in wiring diagram above are, : terminal block, : connecter, : direct wire connection.

5.Please set the switch SW5 according to the power supply voltage.

Set SW5 to 230V side when the power supply is 230 volts.

When the power supply is 208 volts, set SW5 to 208V side.

6. The setting of the SW2 dip switches differs in the capacity. For the detail, refer to the Fig.1.

LED on indoor board for service

Mark

LED1

LED2

Meaning Function

Main power supply

Power supply for

MA -Remote controller

Main power supply (Indoor unit:208-230V)

power on © lamp is lit

Power supply for MA -Remote controller

on © lamp is lit

TO MA-REMOTE

CONTROLLER

DC8.7-13V

12

MF

ORN

ORN

YLW

ORN

BRN

123

CN35P

MICON

BOARD

(BLU)

BLK

5

CN53P

YLW

4

MICON

ORN

3

BOARD

RED

2

(RED)

BRN

1

LED1

TO OUTDOOR UNIT

BC CONTROLLER

M-NET REMOTE CONTROLLER

DC24-30V

M2M1

TB5 S(SHIELD)

BLU

BLU

WHT

RED

BLK

12

CN2M

M-NET

(BLU)

F.C

123456 123

(GRN)

FAN

C

ZNR

CND

(RED)

<Fig.1>

MODELS

PKFY-P06NAMU-E

PKFY-P08NAMU-E

<+>Use Copper Supply Wire.

RED

FUSE

250V

6A

TO NEXT

INDOOR UNIT

<+>

TB2

L1

L2

GR

GRN/YLW

BREAKER

BLU

(15A)

POWER SUPPLY

~/N 208-230V 60Hz

P.B

SW2

ON

OFF

1234

ON

OFF

1234

PULL

BOX

FUSE

(15A)

20

Loading...

Loading...