Air-Conditioners

PKA-A·FA

PKA-A·FAL

English

INSTALLATION MANUAL

For safe and correct use, read this manual and the outdoor unit installation manual thoroughly before installing

the air-conditioner unit.

FOR INSTALLER

Español

MANUAL DE INSTALACIÓN

Para un uso correcto y seguro, lea detalladamente este manual y el manual de instalación de la unidad exterior

antes de instalar la unidad de aire acondicionado.

PARA EL INSTALADOR

2

s Before installing the unit, make sure you read all the “Safety precau-

tions”.

s Please report to your supply authority or obtain their consent before

connecting this equipment to the power supply system.

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that must be observed to prevent damage to the unit.

1.2. Before installation or relocation

Caution:

• Be extremely careful when transporting the units. Two or more persons are

needed to handle the unit, as it weighs 20 kg, 44 lbs or more. Do not grasp

the packaging bands. Wear protective gloves as you can injure your hands

on the fins or other parts.

• Be sure to safely dispose of the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause stabs or other

injuries.

Contents

Warning:

• Ask a dealer or an authorized technician to install the unit.

• For installation work, follow the instructions in the Installation Manual and

use tools and pipe components specifically made for use with refrigerant

specified in the outdoor unit installation manual.

• The unit must be installed according to the instructions in order to minimize

the risk of damage from earthquakes, typhoons, or strong winds. An incorrectly installed unit may fall down and cause damage or injuries.

• The unit must be securely installed on a structure that can sustain its weight.

• If the air conditioner is installed in a small room, measures must be taken to

prevent the refrigerant concentration in the room from exceeding the safety

limit in the event of refrigerant leakage. Should the refrigerant leak and cause

the concentration limit to be exceeded, hazards due to lack of oxygen in the

room may result.

• Ventilate the room if refrigerant leaks during operation. If refrigerant comes

into contact with a flame, poisonous gases will be released.

• All electric work must be performed by a qualified technician according to

local regulations and the instructions given in this manual.

• Use only specified cables for wiring.

• The terminal block cover panel of the unit must be firmly attached.

• Use only accessories authorized by Mitsubishi Electric and ask a dealer or

an authorized technician to install them.

• The user should never attempt to repair the unit or transfer it to another location.

• After installation has been completed, check for refrigerant leaks. If refrigerant leaks into the room and comes into contact with the flame of a heater or

portable cooking range, poisonous gases will be released.

1.1. Before installation (Environment)

Caution:

• Do not use the unit in an unusual environment. If the air conditioner is installed in areas exposed to steam, volatile oil (including machine oil), or sulfuric

gas, areas exposed to high salt content such as the seaside, the performance

can be significantly reduced and the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced, flow,

or accumulate. If combustible gas accumulates around the unit, fire or explosion may result.

• Do not keep food, plants, caged pets, artwork, or precision instruments in the

direct airflow of the indoor unit or too close to the unit, as these items can be

damaged by temperature changes or dripping water.

• When the room humidity exceeds 80% or when the drainpipe is clogged, water may drip from the indoor unit. Do not install the indoor unit where such

dripping can cause damage.

• When installing the unit in a hospital or communications office, be prepared

for noise and electronic interference. Inverters, home appliances, high-frequency medical equipment, and radio communications equipment can cause

the air conditioner to malfunction or breakdown. The air conditioner may also

affect medical equipment, disturbing medical care, and communications equipment, harming the screen display quality.

• Thermal insulation of the refrigerant pipe is necessary to prevent condensation. If the refrigerant pipe is not properly insulated, condensation will be formed.

• Place thermal insulation on the pipes to prevent condensation. If the drainpipe is installed incorrectly, water leakage and damage to the ceiling, floor,

furniture, or other possessions may result.

• Do not clean the air conditioner unit with water. Electric shock may result.

• Tighten all flare nuts to specification using a torque wrench. If tightened too

much, the flare nut can break after an extended period.

1.3. Before electric work

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

• For the power lines, use standard cables of sufficient capacity. Otherwise, a

short circuit, overheating, or fire may result.

• When installing the power lines, do not apply tension to the cables.

• Be sure to ground the unit. If the unit is not properly grounded, electric shock

may result.

• Use circuit breakers (ground fault interrupter, isolating switch (+B fuse), and

molded case circuit breaker) with the specified capacity. If the circuit breaker

capacity is larger than the specified capacity, breakdown or fire may result.

1. Safety precautions ................................................................................... 2

2. Installation location .................................................................................. 3

3. Installing the indoor unit ........................................................................... 3

4. Installing the refrigerant piping ................................................................. 5

5. Drainage piping work (Fig. 5-1)................................................................ 6

6. Electrical work .......................................................................................... 7

7. Test run .................................................................................................. 12

8. Easy maintenance function (Option) ...................................................... 15

1. Safety precautions

After installation work has been completed, explain the “Safety Precautions,” use,

and maintenance of the unit to the customer according to the information in the Operation Manual and perform the test run to ensure normal operation. Both the Installation Manual and Operation Manual must be given to the user for keeping. These

manuals must be passed on to subsequent users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affixed to the main unit.

1.4. Before starting the test run

Caution:

• Turn on the main power switch more than 12 hours before starting operation.

Starting operation just after turning on the power switch can severely damage the internal parts.

• Before starting operation, check that all panels, guards and other protective

parts are correctly installed. Rotating, hot, or high voltage parts can cause

injuries.

• Do not operate the air conditioner without the air filter set in place. If the air

filter is not installed, dust may accumulate and breakdown may result.

• Do not touch any switch with wet hands. Electric shock may result.

• Do not touch the refrigerant pipes with bare hands during operation.

• After stopping operation, be sure to wait at least five minutes before turning off

the main power switch. Otherwise, water leakage or breakdown may result.

3

2. Installation location

3. Installing the indoor unit

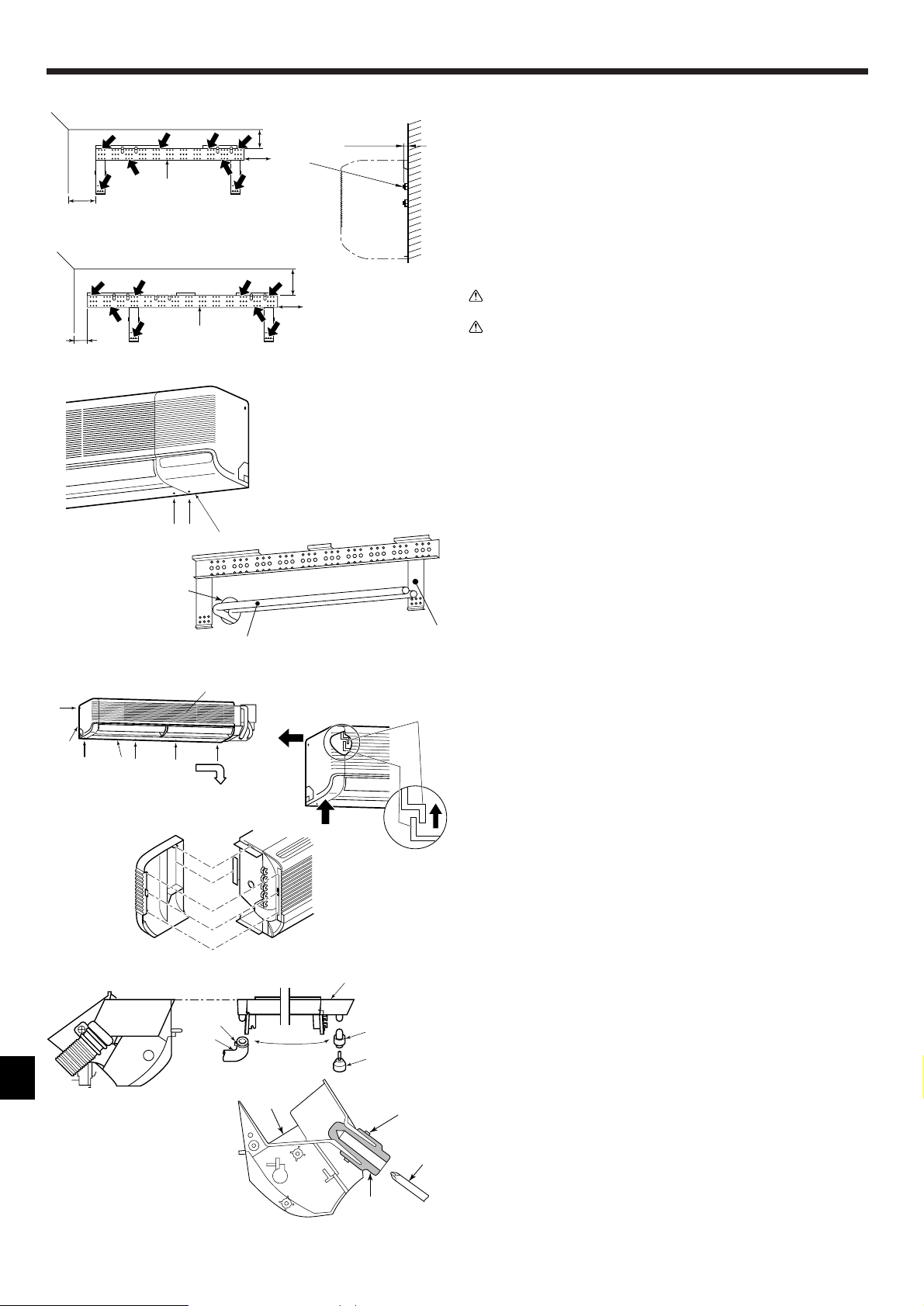

Fig. 2-1

3.1. Check the indoor unit accessories (Fig. 3-1)

The indoor unit should be supplied with the following accessories.

PARTNUMBER

ACCESSORY QUANTITY

LOCATION OF SETTING

1 Wall-fixing bracket 1

Fix at the back of the unit

2 Tapping screw 4 × 35 12

3 Insulation material 2

4 Band

4 (large) + 5 (small)

5 Felt tape 3

6 Drain socket 1 Set inside the unit

7 Wireless remote controller 1

8 Remote controller holder 1

9 Alkali batteries 2

0 Wired remote controller 1 for PKA-A·FA

q Drain adaptor 1

2.1. Outline dimensions (Indoor unit) (Fig. 2-1)

Select a proper position allowing the following clearances for installation and maintenance.

(inch)

Models W D H A B C E F

A24, A30

1400 235 340 Min. 150 Min. 50 Min. 30 Max. 250 Max. 150

55-1/8 9-1/4 13-3/8

Min. 5-15/16

Min. 2

Min. 1-3/16

Max. 10

Min. 5-15/16

A36

1680 235 340 Min. 150 Min. 50 Min. 30 Max. 250 Max. 150

66-5/32 9-1/4 13-3/8

Min. 5-15/16

Min. 2

Min. 1-3/16

Max. 10

Min. 5-15/16

Warning:

Mount the indoor unit on a ceiling strong enough to withstand the weight of the

unit.

2.2. Outline dimensions (Outdoor unit)

Refer to the outdoor unit installation manual.

1

2

3

4

5

6

7

8

9

Fig. 3-1

Fig. 3-3

3.2. Installing the wall mounting fixture (Fig. 3-2)

1) Setting the wall mounting fixture and piping positions

s Using the wall mounting fixture, determine the unit’s installation position

and the locations of the piping holes to be drilled.

Warning:

Before drilling a hole in the wall, you must consult the building contractor.

A Indoor unit center line

B Left drain range

C Right drain range

D Hole for tapping screw

E Bolt hole

F Hole for tapping screw

G Contour of the unit

H Knockout hole for left rear piping

I Rear piping access hole (90-100 mm, 3-9/16 to 4 inch dia.)

2) Drilling the piping hole (Fig. 3-3)

s Use a core drill to make a hole of 90-100 mm, 3-9/16 to 4 inch diameter in the

wall in the piping direction, at the position shown in the diagram to the left.

s The hole should incline so that the outside opening is lower than the inside

opening.

s Insert a sleeve (with a 90 mm, 3-9/16 inch diameter and purchased locally)

through the hole.

Note:

The purpose of the hole’s inclination is to promote drain flow.

A Sleeve

B Hole

C (Indoors)

D Wall

E (Outdoors)

(mm)

(inch)

■ A24, A30

■ A36

Fig. 3-2

0

}

for PKA-A·FAL

77

77

7 -

99

99

9 are stored in a cut-out section of the packing material (styrofoam).

q

B

W

A

D

H

E

F

C

D

E

D

E

A

38-31/32

13/32×3-19/32= (35-13/16)

35-7/16

23/3223/32

B

7-3/327-3/32

G

1/2×3-19/32=(46-9/16)

23/3223/32

B

11-5/8 8-27/32 9-71/16

F

17-29/32

3-19/32

C

24-1/32

A

50

23-7/16

35-7/16 3/4

C

7-3/32

11-1/32 12-3/8

12-3/811-1/329-7/168-27/32

3/4

29-17/32

9-21/32

11-7/32

G

3-17/32

3-19/32

IHF

13/32

7-1/4

1-3/16

1-3/161-3/16

9-21/32

11-7/32

1-5/32

3-5/323-5/32

3-17/32

11-1/32

2-3/8

13/327-1/4

1-3/16

IHH

1-3/161-3/16

1-5/32

3-5/323-5/32

11-1/32

2-3/82-3/8

A

B

C

E

D

4

3. Installing the indoor unit

3) Installing the wall mounting fixture

s Since the indoor unit weighs near 30 kg, 66 lbs, selection of the mounting

location requires thorough consideration. If the wall does not seem to be

strong enough, reinforce it with boards or beams before installation.

s The mounting fixture must be secured at both ends and at the centre, if

possible. Never fix it at a single spot or in any nonsymetrical way.

(If possible, secure the fixture at all the positions marked with a bold arrow.)

(Fig. 3-4)

s Secure the wall mounting fixture through its middle row of 12-mm, 1/2

inch-dia. holes using locally purchased bolts (through bolts, bolt anchor

and nut anchor) of M10 or W3/8 threading. The bolt tip must not protrude by

more than 15 mm, 9/32 inch from the wall surface. (Fig. 3-5)

Use at least two bolts for a concrete wall, and at least four bolts for a foamed

concrete wall.

A Wall-fixing bracket B Mounting bolt C Wall

Warning:

If possible, secure the fixture at all the positions marked with a bold arrow.

Caution:

The unit body must be mounted horizontally.

3.3. Preparation for piping connection

Remove the vinyl band that holds the drain piping.

• This vinyl band can be used to temporarily attach the pipes to the wall mounting

fixture while connecting the left pipe.

1) Rear, right and lower piping (Fig. 3-6)

1 Remove the right side panel.

2) Left and left rear piping

1 Remove the side panel.

When embedding pipes into the wall (Fig. 3-7)

When the refrigerant pipe, drain pipes, internal/external connection lines, etc., are to

be embedded into the wall in advance, the extruding pipes, etc., may have to be bent

and have their length modified to the unit.

• Make the pipes to be embedded slightly longer than necessary, and install.

A Right side panel C On-site piping

B Through hole D Wall-fixing bracket 1

2 Remove the five screws indicated by the arrows in the diagram. (Fig. 3-8)

3 Remove the left side panel, then the lower panel.

1. While pushing up the front lower portion of the side panel (to disengage the side

panel catch from the unit catch), slide the upper portion of the side panel to the

left.

• When the indoor unit is already mounted, be sure the unit does not fall from the wall

mounting fixture.

• For reassembly, put the catch at the front lower portion of the side panel over the

unit body and push it to the right.

A Grille D Catch

B Left side panel E Side panel

C Lower panel F Unit body

∗ Structure of the side panel and the unit body (Fig. 3-9)

1. Panel catch engages the unit body catch.

2. Panel catch is put in the unit body hole.

3. Panel catch engages the unit body catch.

4. Sheet metal of the unit body enters the panel.

5. Panel catch enters the unit body hole.

4 The drain hose can be connected at two different positions. Use the most conven-

ient position and, if necessary, exchange the position of the drain pan, rubber plug

and the drain hose. (Fig. 3-10)

G Drain pan

H Band

I Plug

J Drain hose

K Screwdriver

1

2

3

∗

Fig. 3-7

Fig. 3-9

Fig. 3-10

Fig. 3-4

Fig. 3-5

Fig. 3-6

Fig. 3-8

¡ A24, A30

™ A36

(inch)

4

Min.2-3/8

Min.19-11/16

A

Min.6-1/2

Min.19-11/16

A

Min.6-1/2

B

A

B

C

A

C

EF

5

4

3

2

1

H

J

B

Min.2-3/8

Max.19/32

G

I

K

D

D

C

D

G

H

K

I

5

3. Installing the indoor unit

4. Installing the refrigerant piping

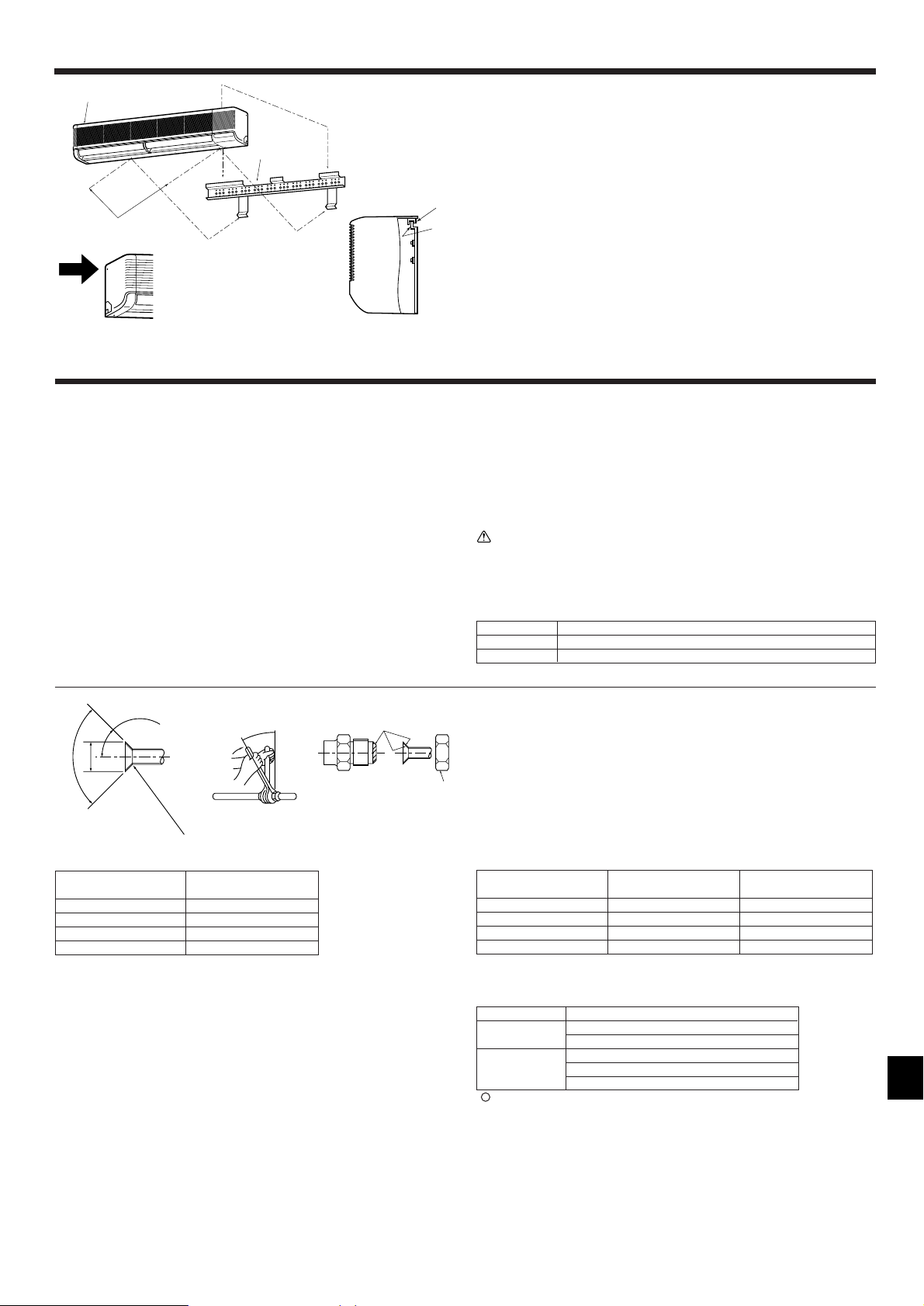

3.4. Mounting the indoor unit (Fig. 3-11)

1 Make sure to hang the metal catches of the indoor unit over the hooks of the wall

mounting fixture.

2 When the piping has been completed, use the securing screws to fix the indoor

unit on the wall mounting fixture.

Note:

Check that the catches of the indoor unit securely fit over the hooks of the wall

mounting fixture.

3 The screw indicated by the bold arrow is used only during transportation and

should be removed. Remove the screw before installation if there is not enough

space at the left side to remove it once the unit has been installed.

A Indoor unit

B Wall fixing bracket 1

C Hook

D Metal catch of the indoor unit

E Securing screws

1

3

2

Fig. 3-11

4.1. Precautions

4.1.1. For devices that use R410A refrigerant

• Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration oil

applied to the flared sections.

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses

specified in the table to the below. Make sure the insides of the pipes are

clean and do not contain any harmful contaminants such as sulfuric compounds, oxidants, debris, or dust.

Warning:

When installing or moving the air conditioner, use only the specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it with any other refrigerant and do not allow air to remain in the lines. Air enclosed in the lines can

cause pressure peaks resulting in a rupture and other hazards.

A24, A30, A36

Liquid pipe ø9.52 mm, 3/8 inch thickness 0.8 mm, 1/32 inch

Gas pipe ø15.88 mm, 5/8 inch thickness 1.0 mm, 3/64 inch

• Do not use pipes thinner than those specified above.

4.2. Connecting pipes (Fig. 4-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C, 212 °F or

more, thickness of 12 mm, 1/2 inch or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam insulation materials (specific gravity of 0.03, thickness of 9 mm, 23/64 inch or more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening

flare nut.

• Use two wrenches to tighten piping connections.

• Use refrigerant piping insulation provided to insulate indoor unit connections. Insulate carefully.

B Flare nut tightening torque

Copper pipe O.D. Flare nut O.D. Tightening torque

(mm, inch) (mm, inch) (N·m, ft·lbs)

ø6.35, 1/4” 17, 43/64 14 - 18, 10-13

ø9.52, 3/8” 22, 7/8 34 - 42, 25-30

ø12.7, 1/2” 26, 1-3/64 49 - 61, 35-44

ø15.88, 5/8” 29, 1-9/64 68 - 82, 49-59

C Apply refrigerating machine oil over the entire flare seat surface.

D Use correct flare nuts meeting the pipe size of the outdoor unit.

Available pipe size

A24, A30, A36

Liquid side

–

ø9.52

–

Gas side ø15.88

–

: Factory flare nut attachment to the heat-exchanger.

A Flare cutting dimensions

Copper pipe O.D. Flare dimensions

(mm, inch) øA dimensions (mm, inch)

ø6.35, 1/4” 8.7 - 9.1, 11/32-23/64

ø9.52, 3/8” 12.8 - 13.2, 1/2-33/64

ø12.7, 1/2” 16.2 - 16.6, 41/64-21/32

ø15.88, 5/8” 19.3 - 19.7, 49/64-25/32

Fig. 4-1

(inch)

A

B

E

D

C

A

45°±2°

øA

90°±0.5°

R1/64 to R 1/32

B

C

D

Loading...

Loading...