Page 1

SERVICE MANUAL

• This manual describes only

service data of the indoor

units.

[Model names]

PEA-RP200GA

PEA-RP250GA

PEA-RP400GA

PEA-RP500GA

CONTENTS

1.

TYPES OF CONNECTED OUTDOOR UNITS

····2

2. SAFETY PRECAUTION···································3

3. PART NAMES AND FUNCTIONS····················8

4. SPECIFICATIONS··········································10

5. DATA ·······························································11

6. OUTLINES AND DIMENSIONS·····················13

7. WIRING DIAGRAM ········································16

8. REFRIGERANT SYSTEM DIAGRAM············18

9. TROUBLESHOOTING ···································19

10. SERVICE DATA (PARTS NAME)···················30

Indoor unit

Remote controller

SPLIT-TYPE, HEAT PUMP

AIR CONDITIONERS

2007

Page 2

2

1 TYPES OF CONNECTED OUTDOOR UNITS

Indoor Unit List

Indoor unit Outdoor unit

PEA - RP200GA

PEA - RP250GA

PEA - RP400GA

PEA - RP500GA

PUHZ-BP200YHA

PUHZ-BP250YHA

PUHZ-BP200YHA x 2

PUHZ-BP250YHA x 2

Standard Model

Steel fan

PEA-RP200GA

PEA-RP250GA

PEA-RP400GA

PEA-RP500GA

PEA-RP200GA.TH-AF

PEA-RP250GA.TH-AF

PEA-RP400GA.TH-AF

PEA-RP500GA.TH-AF

PEA-RP200GA.TH-AFMF

PEA-RP250GA.TH-AFMF

-

-

Model name

Specification

Page 3

3

SAFETY PRECAUTION

2

Cautions for units utilising refrigerant R410A

CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

Make sure that the inside and outside of refrige-

rant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

In case of using the existing pipes for R22, be careful with

the followings.

á Be sure to perform replacement operation

before test run.

á Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrige-

rant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of com-

pressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigera-

nt will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterio-

ration of refrigerant oil etc.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of com-

pressor.

If large amount of mineral oil enter, that can cause deterio-

ration of refrigerant oil etc.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

Page 4

4

[2] Storage of Piping Material

(1) Storage location

Store the pipes to be used indoors. (Warehouse at site or ownerÕs warehouse)

Storing them outdoors may cause dirt, waste, or water to infiltrate.

(2) Pipe sealing before storage

Both ends of the pipes should be sealed until immediately before brazing.

Wrap elbows and TÕs in plastic bags for storage.

* The new refrigerator oil is 10 times more hygroscopic than the conventional refrigerator oil (such as Suniso). Water

infiltration in the refrigerant circuit may deteriorate the oil or cause a compressor failure. Piping materials must be stored

with more care than with the conventional refrigerant pipes.

OK

OK

NG

NG

Page 5

5

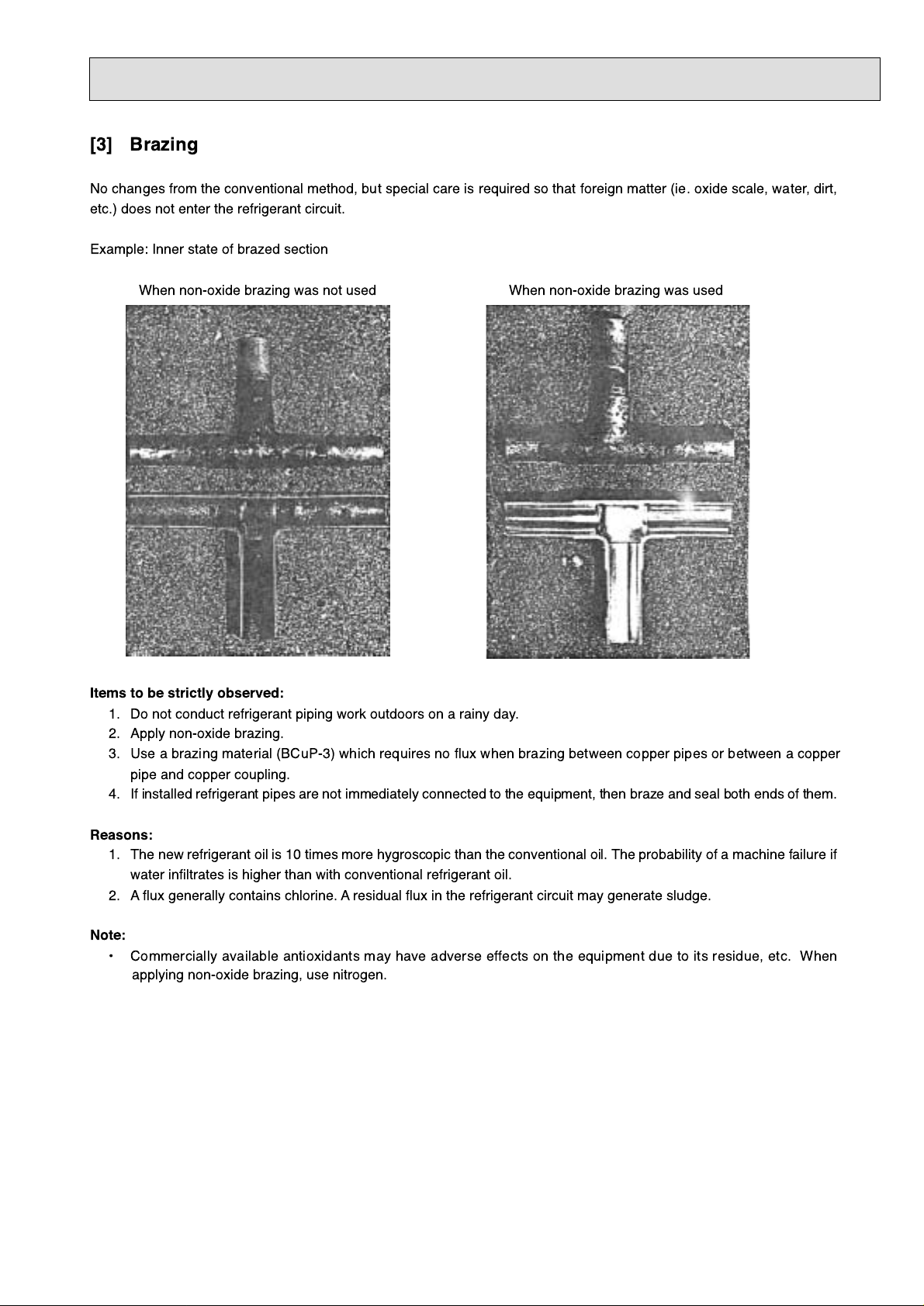

[3] Brazing

No changes from the conventional method, but special care is required so that foreign matter (ie. oxide scale, water, dirt,

etc.) does not enter the refrigerant circuit.

Example: Inner state of brazed section

When non-oxide brazing was not used When non-oxide brazing was used

Items to be strictly observed:

1. Do not conduct refrigerant piping work outdoors on a rainy day.

2. Apply non-oxide brazing.

3. Use a brazing material (BCuP-3) which requires no flux when brazing between copper pipes or between a copper

pipe and copper coupling.

4. If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends of them.

Reasons:

1. The new refrigerant oil is 10 times more hygroscopic than the conventional oil. The probability of a machine failure if

water infiltrates is higher than with conventional refrigerant oil.

2. A flux generally contains chlorine. A residual flux in the refrigerant circuit may generate sludge.

Note:

¥ Commercially available antioxidants may have adverse effects on the equipment due to its residue, etc. When

applying non-oxide brazing, use nitrogen.

Page 6

6

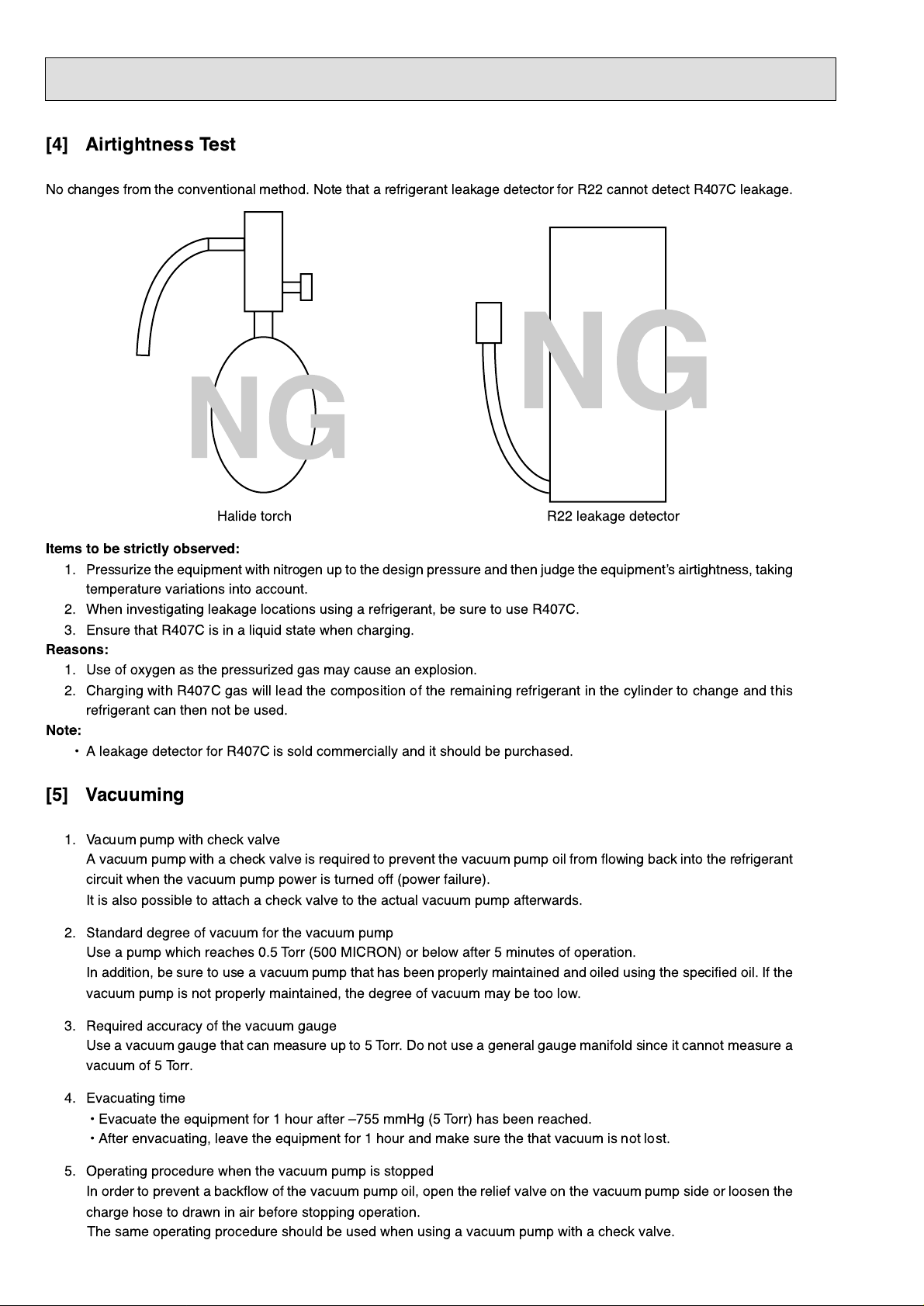

[4] Airtightness Test

No changes from the conventional method. Note that a refrigerant leakage detector for R22 cannot detect R407C leakage.

Halide torch R22 leakage detector

Items to be strictly observed:

1. Pressurize the equipment with nitrogen up to the design pressure and then judge the equipmentÕs airtightness, taking

temperature variations into account.

2. When investigating leakage locations using a refrigerant, be sure to use R407C.

3. Ensure that R407C is in a liquid state when charging.

Reasons:

1. Use of oxygen as the pressurized gas may cause an explosion.

2. Charging with R407C gas will lead the composition of the remaining refrigerant in the cylinder to change and this

refrigerant can then not be used.

Note:

¥ A leakage detector for R407C is sold commercially and it should be purchased.

[5] Vacuuming

1. Vacuum pump with check valve

A vacuum pump with a check valve is required to prevent the vacuum pump oil from flowing back into the refrigerant

circuit when the vacuum pump power is turned off (power failure).

It is also possible to attach a check valve to the actual vacuum pump afterwards.

2. Standard degree of vacuum for the vacuum pump

Use a pump which reaches 0.5 Torr (500 MICRON) or below after 5 minutes of operation.

In addition, be sure to use a vacuum pump that has been properly maintained and oiled using the specified oil. If the

vacuum pump is not properly maintained, the degree of vacuum may be too low.

3. Required accuracy of the vacuum gauge

Use a vacuum gauge that can measure up to 5 Torr. Do not use a general gauge manifold since it cannot measure a

vacuum of 5 Torr.

4. Evacuating time

¥ Evacuate the equipment for 1 hour after Ð755 mmHg (5 Torr) has been reached.

¥ After envacuating, leave the equipment for 1 hour and make sure the that vacuum is not lost.

5. Operating procedure when the vacuum pump is stopped

In order to prevent a backflow of the vacuum pump oil, open the relief valve on the vacuum pump side or loosen the

charge hose to drawn in air before stopping operation.

The same operating procedure should be used when using a vacuum pump with a check valve.

NG

NG

Page 7

7

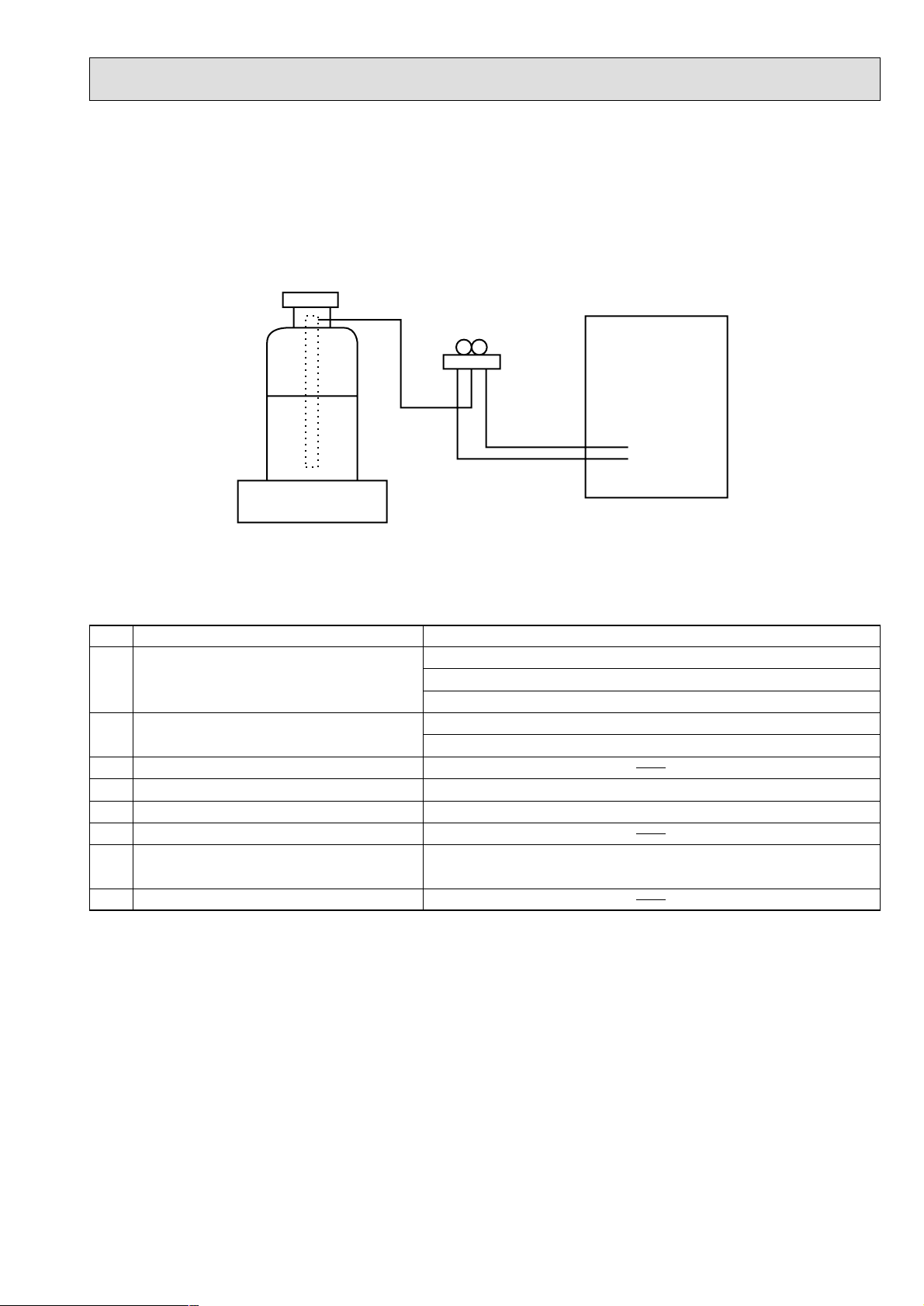

[6] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

[7] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

specifications

. (UNF1/2)

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)

Cylinder with syphon

8 Refrigerant recovery equipment

Gravimeter

Unit

Page 8

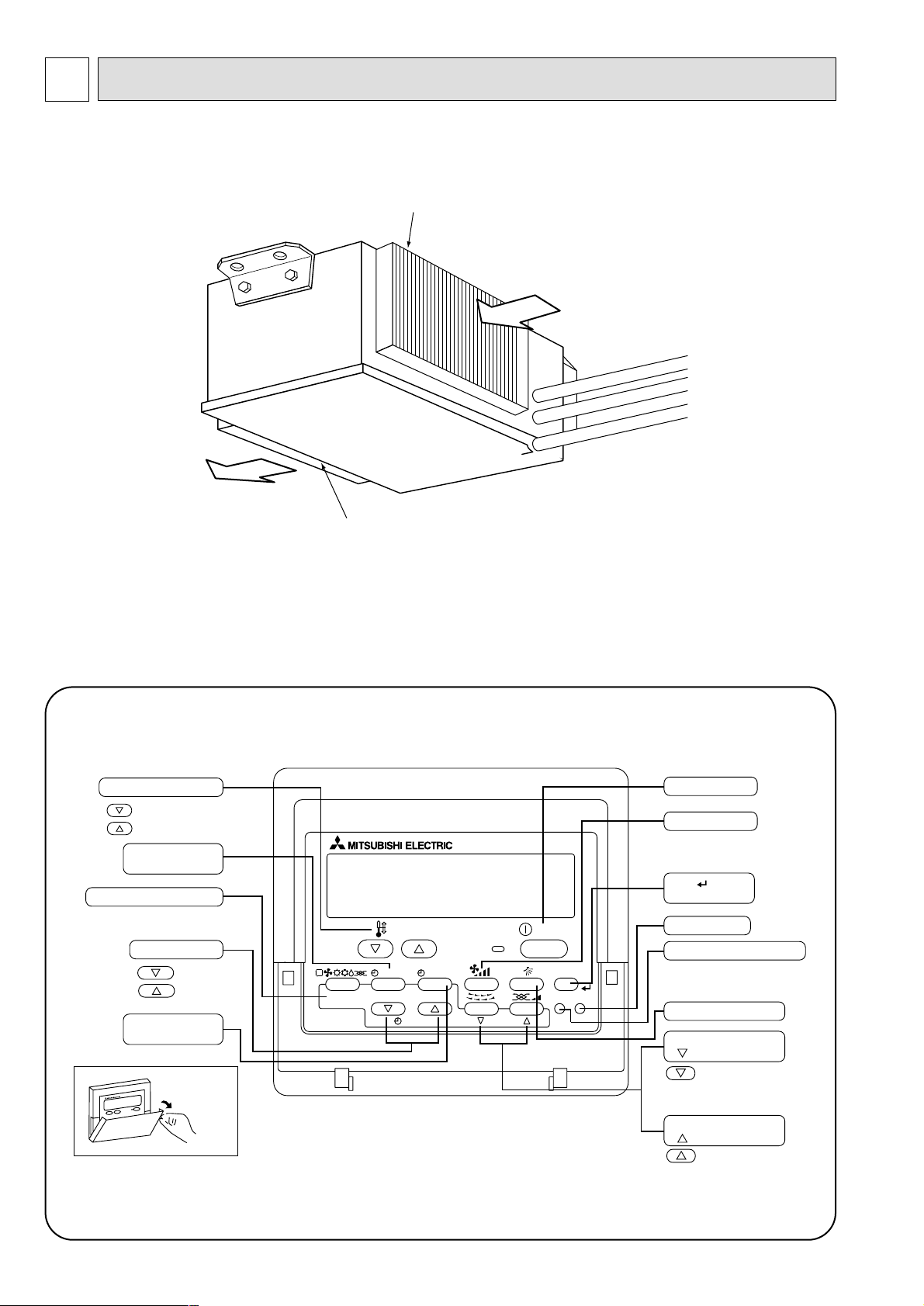

8

3

PART NAMES AND FUNCTIONS

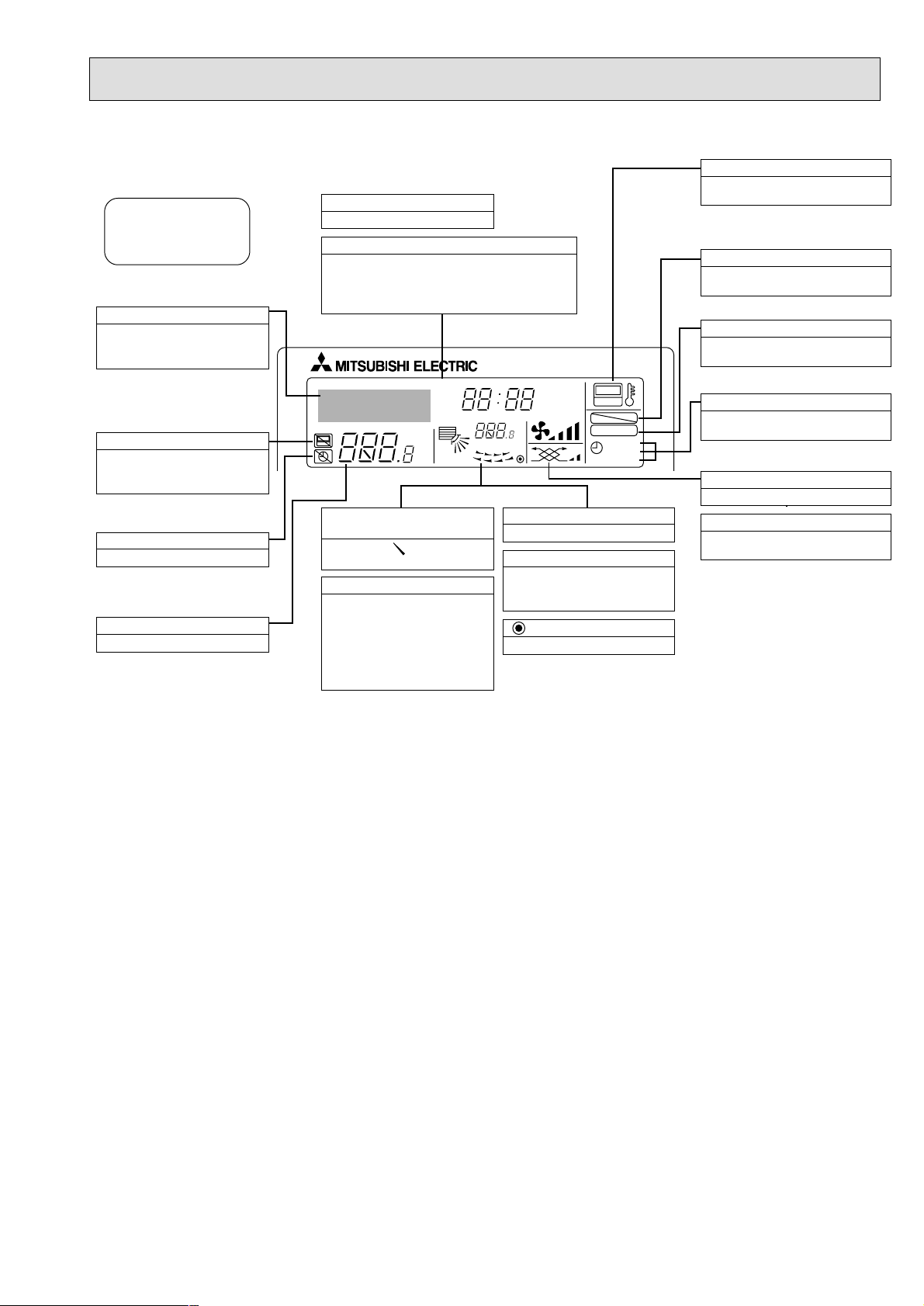

● Remote controller

Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

● Indoor Unit

PEA-RP200GA

PEA-RP250GA

PEA-RP400GA

PEA-RP500GA

Air intake duct flange

Air outlet duct flange

Air outlet

Air intake

(sucks the air inside the room into the unit)

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door.

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

(

Operation button)

To preceding operation

number.

Ventilation button

(

Operation button)

To next operation number.

Page 9

9

● Display

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

weak and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Caution

● Only the Power on indicator lights when the unit is stopped and power supplied to the unit.

● If you press a button for a feature that is not installed at the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to drive multiple indoor units, this message will appear only if he feature is not

present at the parent unit.

● When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indica-

tion (For max. 2minutes). Please wait until this “PLEASE WAIT” indication disappear then start the operation.

Page 10

10

4

SPECIFICATIONS

Model name

Cooling

1.00

1.8

Heating

1.00

1.8

H

W

D

Hi

Lo

kW

A

CMM

L/s

CMM

L/s

Pa

mmAq

dB(A)

dB(A)

mm

mm

mm

kg

lbs

PEA-RP200GA PEA-RP250GA

3PH 4W 50Hz 380-415V

Galvanized steel

Cross fin coil

Centrifugal (direct) o2

0.77

65

1083

52

867

150

15

Remote control & built in

51

48

R1

400

1400

634

70

154

Cooling

1.10

2.1

Heating

1.10

2.1

3PH 4W 50Hz 380-415V

Galvanized steel

Cross fin coil

Centrifugal (direct) o2

0.77

80

1333

64

1067

150

15

Remote control & built in

52

49

R1

400

1600

634

77

169

Power supply (phase, cycle,voltage)

Input

Running current

External finish

Heat exchanger

Operation control & Thermostat

Sound level

Drain connection

Dimensions

Weight

Mode

Fan (drive) o No.

Fan motor output

Airflow

External static pressure

Hi

Lo

Model name

Cooling

1.55

3.8

Heating

1.55

3.8

H

W

D

kW

A

CMM

L/s

Pa

mmAq

dB(A)

mm

mm

mm

kg

lbs

PEA-RP400GA PEA-RP500GA

3PH 4W 50Hz 380-415V

Galvanized steel

Cross fin coil

Centrifugal (direct) o2

1.3

120

2,000

150

15

Remote control & built in

52

R1

595

1947

764

130

286

Cooling

2.84

5.4

Heating

2.84

5.4

3PH 4W 50Hz 380-415V

Galvanized steel

Cross fin coil

Centrifugal (direct) o2

1.8

160

2,667

150

15

Remote control & built in

53

R1

595

1947

764

133

293

Power supply (phase, cycle,voltage)

Input

Running current

External finish

Heat exchanger

Operation control & Thermostat

Sound level

Drain connection

Dimensions

Weight

Mode

Fan (drive) o No.

Fan motor output

Airflow

External static pressure

Fan

Fan

Page 11

11

DATA5

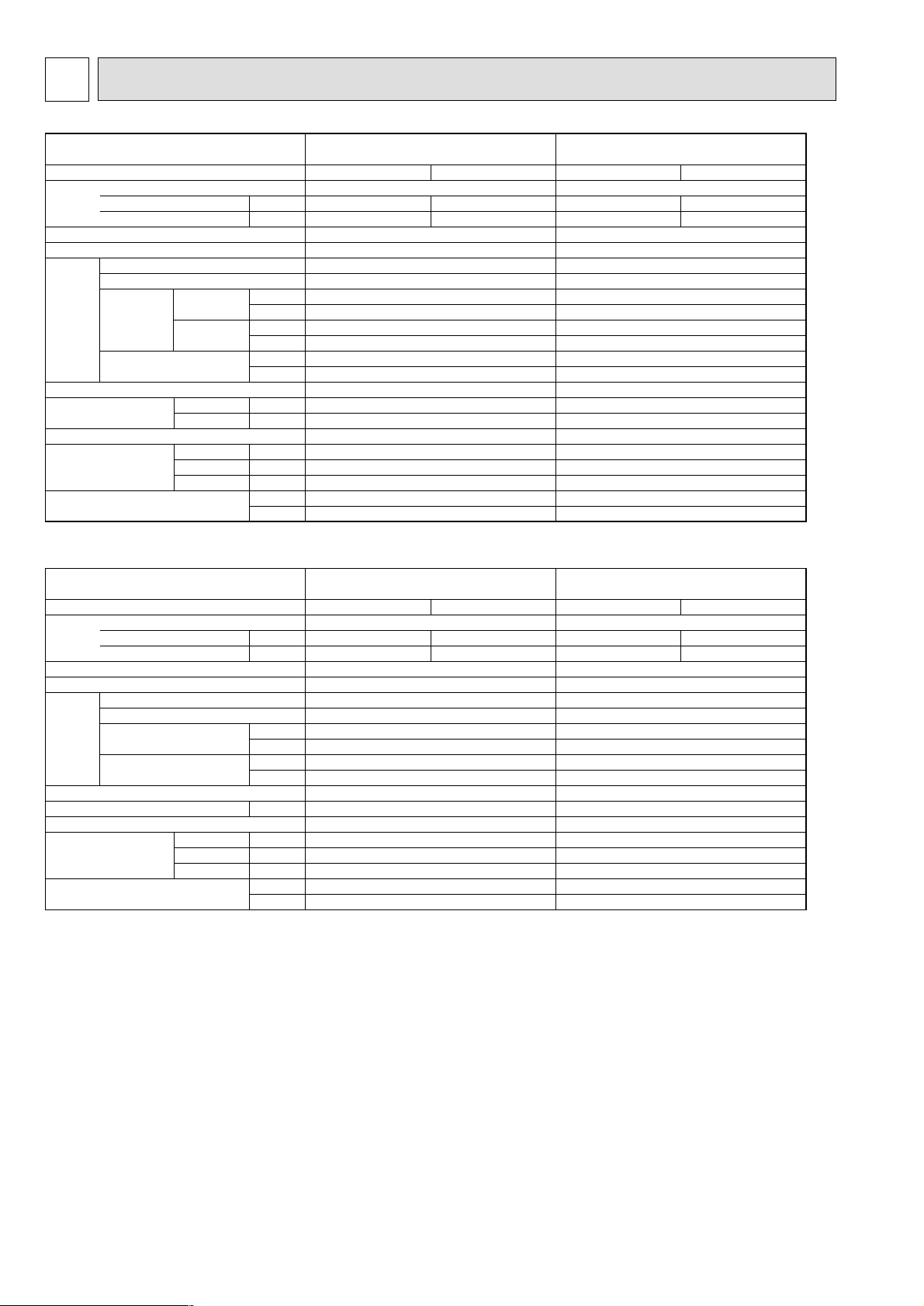

5-1. Sound Data

Indoor units

Indoor unit

Position measurement

Measurement point

Inlet

Outlet

1.5m

2m

1m

PEA-RP200,250: Upper High/Lower Low

SPL

dB(A) 63Hz 125Hz 250Hz 500Hz 1000Hz 2000Hz 4000Hz 8000Hz

51 55 54 51 49 47 43 33 27

48 50 50 47 46 44 40 29 21

52 56 55 52 50 48 44 34 28

49 51 51 48 47 45 41 30 22

53 55 54 51 50 48 44 40 31

52 53 51 52 50 46 44 39 30

PEA-RP200GA

PEA-RP250GA

PEA-RP500GA

PEA-RP400GA

Model

OCTAVE BAND FREQ.Hz

Page 12

12

5-2. Fan Performance Curve

Indoor units

PEA-RP200GA

Fan Performance Curve 50Hz

PEA-RP250GA

Fan Performance Curve 50Hz

PEA-RP400GA

Fan Performance Curve 50Hz

PEA-RP500GA

Fan Performance Curve 50Hz

70.0 80.0 100.0 110.0 120.0 130.090.0

(Pa)

(Pa) (Pa)

External static pressure

Air flow

(CMM)

0

50

100

150

200

300

250

110.0100.0 120.0 130.0 140.0 150.0 160.0 170.0

(Pa)

External static pressure

Air flow

(CMM)

0

50

100

150

200

350

300

250

Hi

Lo

45.0 50.0 55.0 60.0 65.0 70.0

Hi

Lo

0

50

100

150

200

250

300

0

50

100

150

200

250

60.0 65.0 70.0 75.0 80.0 85.0 90.0

External static pressure

Air flow Air flow

(CMM)

(CMM)

External static pressure

Page 13

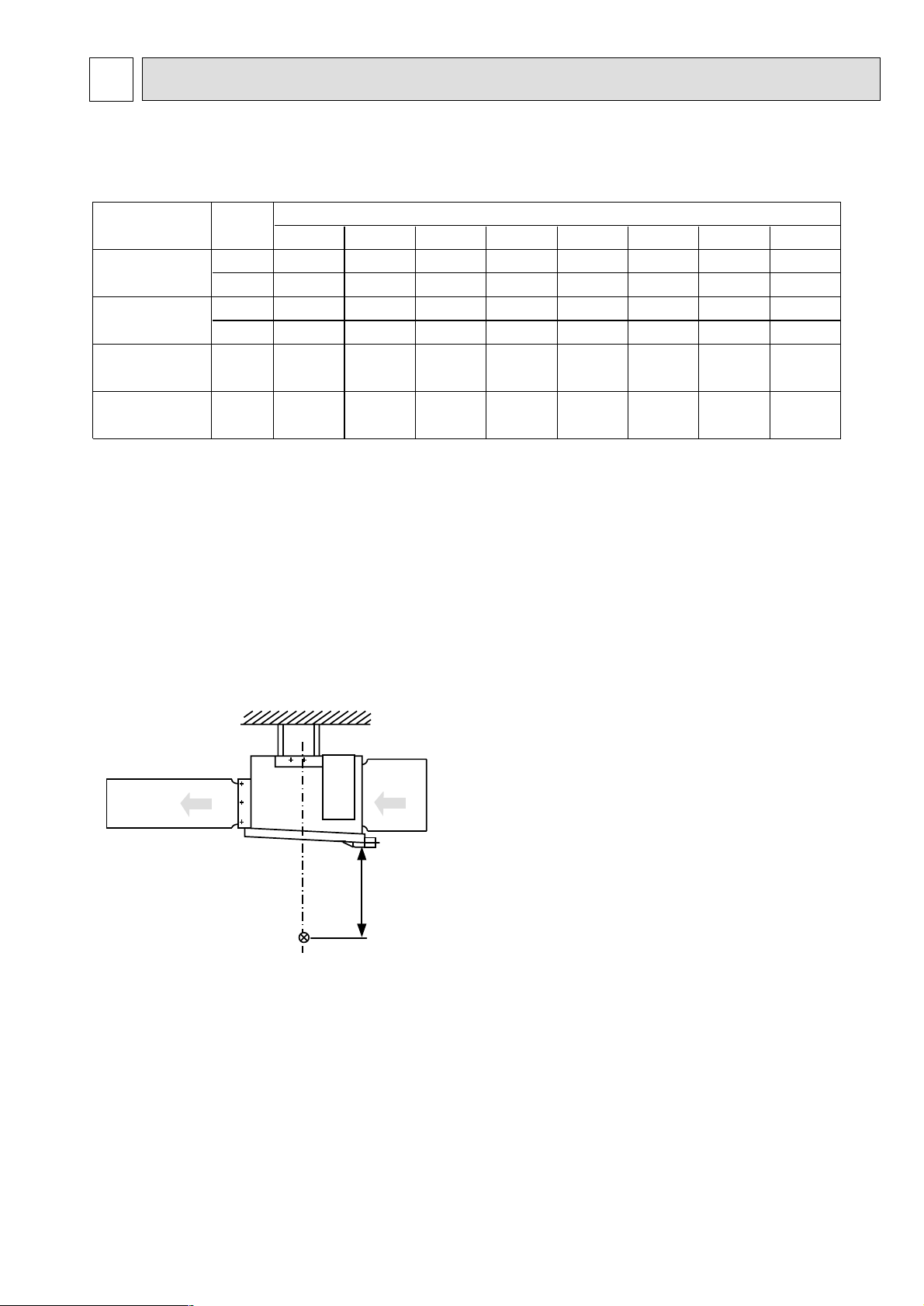

13

OUTLINES AND DIMENSIONS

6

Return air

sensor

A

Rubber bush <Remote

controller wiring>

Rubber bush

<Outdoor unit

connection wiring>

Rubber bush

<Power supply

wiring>

A

4-

ø

12 Holes

Drain R1

Top view

Control box

Return air

duct flange

Supply air

duct flange

<For hanging bolt M10>

[Field supply]

22-

ø

3.1 Holes

24-

ø

3 Holes

Refrigerant pipe

ø

9.52 (3/8 braze)

Refrigerant pipe

ø

25.4 (1 braze)

<Accessory>

2pcs.

·

Pipe cover ··································

(For dew condensation prevention of

local piping and unit connection.)

1pc.

·

Remote controller························

Return air

Left side view

Supply air

Front view

75

55

12970

42

124 34

131

530

50

9525011

7x130(=910)

10

130

130

45

45

31 31

1102

200

10

8x130(=1040)

1300

20

199

100

40

20

462

144

1284

400

155 1000 105

40 1260 40

1340

1400

56539

22330

145

89

35

130

130

35

634

262 73

10

54

10

376

2510010025

Unit : mm

PEA-RP200GA

Page 14

14

Unit : mm

PEA-RP250GA

Rubber bush <Remote

controller wiring>

Rubber bush

<Outdoor unit

connection wiring>

Rubber bush

<Power supply

wiring>

A

A

4-

ø

12 Holes

Drain R1

Top view

Control box

22-

ø

3.1 Holes

<For hanging bolt M10>

[Field supply]

Return air

duct flange

Supply air

duct flange

26-

ø

3 Holes

Left side view

Supply air

Return air

Front view

Return air

sensor

<Accessory>

·Pipe cover ································· 2pcs.

(For dew condensation prevention of

local piping and unit connection.)

·Remote controller ······················ 1pc.

Refrigerant pipe

ø

12.7 (1/2 braze)

Refrigerant pipe

ø

25.4 (1 braze)

42

144145

755570 129

124

131

50 530

34

130

9525011

10

66

1302

1484

7x130(=910)

130

45

45

200

20

100

20

199

40

1500

462

66 9X130(=1170)

10

25 100 100 25

10 10

1540

40146040

255 205

376

1000

1600

73262

400

39 565

54

634

35

130

89

330 22

130

35

Page 15

15

PEA-RP400,500GA

45

Refrigerant pipe

PEA-RP400GA : ø9.52 (3/8 braze)

PEA-RP500GA : ø12.7 (1/2 braze)

[2 places (*2 part)]

*2*1*2

*1

Refrigerant pipe ø25.4 (1 braze)

[2 places (*1 part)]

Return air sensor

(2 places)

Drain R1

24- ø3.1 HOLES

36- ø3 HOLES

Left side view

Front view

Top view

Return air

Supply air

4- ø15 HOLES

<For hanging bolt M12>

[Field supply]

Return air duct flange

Control box

Supply air duct flange

A

Rubber bush

<Remote controller wiring>

Rubber bush

<Power supply wiring>

Rubber bush

<Outdoor unit connection wiring>

A

<Accessory>

·Pipe cover ································· 4pcs.

(For dew condensation prevention of

local piping and unit connection.)

·Remote controller ······················ 1pc.

81

117156117

10

20 1840

10

40

60

60

61

60

4040

1800

1880

50 664

525

22

102

22.5

120

4X120(=480)

22.5

595

1824

50

764

2801125395

340 18822

1947

570

40 130 130 40

10

33

29

130

12X130(=1560)

29

149 1618

100

42.5

130

8X130(=1040)42.5

10

203320141

20

42559

700

39

Unit : mm

Page 16

16

7

WIRING DIAGRAM

PEA-RP200,250GA

OUTDOOR UNIT

CIRCUIT BREAKER

(FIELD SUPPLY)

PEA-RP200,250GA:15A

DSR

DSA

(3P)

(Hi)

C02

(6P)

(Lo)

C01

C01

5

4

TH5

TH2

TH1

INDOOR UNIT

POWER SUPPLY

3N~PE

380/400/415V

50Hz

BLACK

WHITE

RED

N

BLACK

WHITE

RED

TB2

L3

L2

L1

PE

52F

Hi

Lo

321

52F

123

MF1

TB6

LCD

REMOTE CONTROLLER

FB

TB4

S3

S2

S1

X6X5X4

375 1

FAN

ZNR

FUSE

4123

SW2

OFF

ON

5

TAB1

3

1

CNSK

2

1

CN2S

DC

13.1V

CN2D

CN90

CN22

CN2L

CNDK

CND

CN32

CN31

CN51

12345

31

31

3112

DC13.1V

LED1

LED2

LED3

21212

1

213

365

4

987

312

CN3C

CN20

CN21

CN41

CN29

123

4

121

2

2

1

1

2

TB5

Hi

52F

Lo

52F

X1

X1

X1

49F

51F

X6X5X4

12345

SW1

OFF

ON

SWE

OFF

ON

SWITCH (MODEL SELECTION)

SWITCH (CAPACITY CODE)

CONNECTOR (EMERGENCY OPERATION)

SNB

BOARD 1

ZNR5~7 VARISTOR

DSA,DSR ARRESTER

INDOOR UNIT

NAMESYMBOL

COND/EVA TEMP

LIQUID PIPE TEMP

ROOM TEMP

52FHi MAGNETIC CONTACTOR (INDOOR FAN MOTOR<HIGH SPEED>)

SURGE KILLERCR1,2

SW1

TH5

LED (TRANSMISSION<INDOOR

·

OUTDOOR>)LED3

LED (POWER SUPPLY<REMOTE CONTROLLER>)LED2

LED (POWER SUPPLY)LED1

SWE

SW2

X4-6 AUXILIARY RELAY

VARISTORZNR

FUSE (T6.3AL250V)FUSE

THERMISTOR

TERMINAL BLOCK

INTERNAL THERMOSTAT (INDOOR FAN MOTOR)

OVER CURRENT RELAY (INDOOR FAN MOTOR)

FAN MOTOR (INDOOR)

TH2

TH1

TB2,4,5

49F

51F

MF1

52FLo MAGNETIC CONTACTOR (INDOOR FAN MOTOR<LOW SPEED>)

AUXILIARY RELAYX1

FERRITE COREFB

BOARD

CONTROLLER

INDOOR

CN2L

CN31

CN90

CN51

CN41

CN32

CONNECTOR (DRAIN SENSOR)

CONNECTOR (REMOTE SWITCH)

CONNECTOR (HA TERMINAL-A)

CONNECTOR (CENTRALLY CONTROL)

CONNECTOR (WIRELESS REMOTE CONTROLLER)

CONNECTOR (LOSSNAY)

4.Indoor and outdoor connecting wires are made with polarities,make sure

matching wiring and terminal.

5.Emergency operation

If a trouble occurs with either the remote controller or the indoor microcom-

puter and no other trouble exists, emergency operation for cooling or heating

can be performed by changing the setting of connector (SWE) "ON" on the

indoor controller board.

SWE :ON / Indoor fan is running high speed.

TERMINAL BLOCKTB6

SYMBOL

REMOTE CONTROLLER

NAME

SNB BOARD 1

REMOTE

CONTROLLER

BOARD

POWER BOARD

INDOOR

INDOOR

CONTROLLER

BOARD

Note:1.The dotted lines show field wiring.

2.Color of earth wire is yellow and green twisting.

3.Specification subject to change without notice.

51F

Caution,

1.To protect fan motor from abnormal current,over current relays is installed.

Therefore, do not change factory set value of over current relays.

6. mark is connector. mark is terminal.

CR1CR2

ZNR5~7

TO OUTDOOR UNIT

CONNECTING WIRES

(POLAR)

Page 17

17

PEA-RP400,500GA

GREEN/YELLOW

INDOOR UNIT

OUTDOOR UNIT

OUTDOOR UNIT

TAB1

TAB1

FAN

CNDK

31

1573

X4 X5 X6

CN20

CN21

CN41

CN29

123

4

121

2

2

1

CN2D

CN90

CN22

CN2L

CND

CN32

CN31

CN51

12345

FUSE

ZNR

31

3112

DC13.1V

LED1

LED2

LED3

21212

1

213

365

4

987

312

CN3C

3

1

CNSK

2

1

CN2S

DC

13.1V

3

1

CNSK

2

1

CN2S

DC

13.1V

CN2D

CN90

CN22

CN2L

FAN

CNDK

CND

CN32

CN31

CN51

12345

FUSE

ZNR

31

31

3112

DC13.1V

1573

X4 X5 X6

LED1

LED2

LED3

21212

1

213

365

4

987

312

CN3C

CN20

CN21

CN41

CN29

123

4

121

2

2

1

FB11

S1

1

2

REMOTE CONTROLLER

S2

S3

TB5

TB6

LCD

X1

FB21

S1S2S3

X2

TH1-1

TH2-1

TH5-1

TH5-2

TH2-2

TH1-2

TB4-2

TB4-1

FB12

FB22

X4 X5 X6

X4 X5 X6

51F

BLUE

POWER SUPPLY

3N~PE

380/400/415V

50Hz

CIRCUIT BREAKER

(FIELD SUPPLY)

PEA-RP400,500GA:15A

BLACK

WHITE

RED

DSR

DSA

N

BLACK

WHITE

RED

TB2

L3

L2

L1

PE

52F

C01 C02

123

MF1

123

52F

C01

5

4

X01

X02

49F

SWE

OFF

ON

345

SW1

OFF

ON5ON

OFF

34

12

21

SWE

OFF

ON

345

SW1

OFF

ON5ON

OFF

SW2

34

12

21

SW2

AUXILIARY RELAYX4-6

MF1

51F

49F

TB2,4-1,4-2,5

TH1-1,1-2

TH2-1,2-2

FAN MOTOR (INDOOR)

OVER CURRENT RELAY (INDOOR FAN MOTOR)

INTERNAL THERMOSTAT (INDOOR FAN MOTOR)

TERMINAL BLOCK

THERMISTOR

INDOOR UNIT

FUSE FUSE (T6.3AL250V)

ZNR VARISTOR

TH5-1,5-2

CR SURGE KILLER

MAGNETIC CONTACTOR (INDOOR FAN MOTOR)52F

ROOM TEMP

LIQUID PIPE TEMP

COND/EVA TEMP

FERRITE COREFB11,FB12

FB21,FB22

INDOOR

CONTROLLER

BOARD

X1,2 AUXILIARY RELAY

NAMESYMBOL

SNB

BOARD 1

ZNR5~7 VARISTOR

DSA,DSR ARRESTER

SW2

SWE

LED1 LED (POWER SUPPLY)

LED2 LED (POWER SUPPLY<REMOTE CONTROLLER>)

LED3 LED (TRANSMISSION<INDOOR

·

OUTDOOR>)

SWITCH (MODEL SELECTION)SW1

SWITCH (CAPACITY CORD)

CONNECTOR (EMERGENCY OPERATION)

OUTDOOR UNIT

TERMINAL BLOCK

NAMESYMBOL

TB3,TB8

CN2L

CN31

CN90

CN51

CN41

CN32

CONNECTOR (DRAIN SENSOR)

CONNECTOR (REMOTE SWITCH)

CONNECTOR (HA TERMINAL-A)

CONNECTOR (CENTRALLY CONTROL)

CONNECTOR (WIRELESS REMOTE CONTROLLER)

CONNECTOR (LOSSNAY)

REMOTE CONTROLLER

TERMINAL BLOCK

NAMESYMBOL

TB6

4.Indoor and outdoor connecting wires are made with polarities,make sure

matching wiring and terminal.

5.Emergency operation

If a trouble occurs with either the remote controller or the indoor microcom-

puter and no other trouble exists, emergency operation for cooling or heating

can be performed by changing the setting of connector (SWE) "ON" on the

indoor controller board.

SWE :ON / Indoor fan is running high speed.

(No.2)

INDOOR

CONTROLLER

BOARD

(No.1)

REMOTE

CONTROLLER

BOARD

INDOOR

POWER

BOARD

(No.1)

(No.2)

INDOOR

CONTROLLER

BOARD

(No.2)

TO OUTDOOR UNIT

CONNECTING WIRES

(POLAR)

TO OUTDOOR UNIT

CONNECTING WIRES

(POLAR)

SNB BOARD 1

(No.1)

INDOOR

POWER BOARD

Note:1.The dotted lines show field wiring.

2.Color of earth wire is yellow and green twisting.

3.Specification subject to change without notice.

51F

6. mark is connector. mark is terminal.

Caution,

1.To protect fan motor from abnormal current,over current relays is installed.

Therefore, do not change factory set value of over current relays.

CR

ZNR5~7

Page 18

18

PEA-RP200GA PEA-RP250GA

PEA-RP400GA PEA-RP500GA

Unit : mm

Pipe temperature

thermistor/liquid

(TH2)

Distributor

Condenser/evaporator

temperature thermistor

(TH5)

Room temperature

thermistor (TH1)

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer

Strainer

Heat exchanger

Refrigerant GAS pipe connection

Brazing

Refrigerant LIQUID pipe connection

Brazing

8

REFRIGERANT SYSTEM DIAGRAM

Page 19

19

9 TROUBLESHOOTING

<Error code display by self-diagnosis and actions to be taken for service (summary)>

Present and past error codes are logged and displayed on the wired remote controller or controller board of outdoor unit.

Actions to be taken for service and the inferior phenomenon reoccurrence at field are summarized in the table below. Check

the contents below before investigating details.

9-1. TROUBLESHOOTING

Unit conditions at service

Error code

Actions to be taken for service (summary)

The inferior phenomenon is

reoccurring.

Displayed

Not displayed

Judge what is wrong and take a corrective action

according to “SELF-DIAGNOSIS ACTION TABLE” (9-2).

Identify the cause of the inferior phenomenon and take

a corrective action according to “TROUBLESHOOTING

BY INFERIOR PHENOMENA ” (9-3).

The inferior phenomenon is

not reoccurring.

Logged

Not logged

1Consider the temporary defects such as the work of

protection devices in the refrigerant circuit including

compressor, poor connection of wiring, noise and etc.

Re-check the symptom, and check the installation

environment, refrigerant amount, weather when the

inferior phenomenon occurred, and wiring related.

2Reset error code logs and restart the unit after finishing

service.

3There is no abnormality in electrical components,

controller boards, and remote controller.

1Recheck the abnormal symptom.

2Identify the cause of the inferior phenomenon and take

a corrective action according to “TROUBLESHOOTING

BY INFERIOR PHENOMENA ” (9-3).

3Continue to operate unit for the time being if the cause

is not ascertained.

4There is no abnormality in electrical components,

controller boards, remote controller etc.

Page 20

20

9-2. SELF-DIAGNOSIS ACTION TABLE

Note: Refer to the manual of outdoor unit for the details of display

such as F, U, and other E.

Error Code

Meaning of error code and detection method

Cause

Countermeasure

P1

Abnormality of room temperature

thermistor (TH1)

1 The unit is in three-minute resume

prevention mode if short/open of

thermistor is detected. Abnormal if the

unit does not reset normally after three

minutes. (The unit returns to normal

operation, if it has normally reset.)

2 Constantly detected during cooling,

drying, and heating operation.

Short: 90

: or more

Open: -40

: or less

1 Defective thermistor

characteristics.

2 Contact failure of connector

(CN20) on the indoor controller

board. (Insert failure)

3 Breaking of wire or contact

failure of thermistor wiring.

4 Defective indoor controller

board.

1~3 Check resistance value of thermistor.

0

: ······15.0k"

10: ····9.6k"

20: ····6.3k"

30: ····4.3k"

40: ····3.0k"

If you put force on (draw or bend) the lead wire

with measuring resistance value of thermistor

breaking of wire or contact failure can be

detected.

2 Check contact failure of connector (CN20) on

the indoor controller board. Refer to 9-6.

Turn the power on again and check restart

after inserting connector again.

4 Check room temperature display on remote

controller.

Replace indoor controller board if there is

abnormal difference with actual room

temperature.

Turn the power off, and on again to operate

after check.

P2

Abnormality of pipe temperature

thermistor/Liquid (TH2)

1 The unit is in three-minute resume

prevention mode if short/open of

thermistor is detected. Abnormal if the

unit does not reset normally after three

minutes. (The unit returns to normal

operation, if it has normally reset.)

2 Constantly detected during cooling,

drying, and heating (except defrosting)

operation.

Short: 90

: or more

Open: -40

: or less

1 Defective thermistor

characteristics.

2 Contact failure of connector

(CN21) on the indoor controller

board. (Insert failure)

3 Breaking of wire or contact

failure of thermistor wiring.

4 Defective refrigerant circuit is

causing thermistor temperature

of 90

: or more or -40: or

less.

5 Defective indoor controller board.

1~3 Check resistance value of thermistor.

For characteristics, refer to (P1) above.

2 Check contact failure of connector (CN21) on

the indoor controller board. Refer to 9-6. Turn

the power on and check restart after inserting

connector again.

4 Check pipe <liquid> temperature with remote

controller in test run mode. If pipe <liquid>

temperature is exclusively low (in cooling

mode) or high (in heating mode), refrigerant

circuit may have defective.

5 Check pipe <liquid> temperature with remote

controller in test run mode. If there is exclusive

difference with actual pipe <liquid> temperature,

replace indoor controller board.

Turn the power off, and on again to operate

after check.

P4

Abnormality of drain sensor (DS)

1 Suspensive abnormality, if short/open of

thermistor is detected for 30 seconds

continuously.

Turn off compressor and indoor fan.

2 Short/open is detected for 30 seconds

continuously during suspensive

abnormality.

(The unit returns to normal operation,

if it has normally reset.)

3 Detect the following condition.

• During cooling and drying operation.

• In case that pipe <liquid> temperature

- room temperature <-10deg

(Except defrosting)

• When pipe <liquid> temperature or

room temperature is short/open

temperature.

• During drain pomp operation.

1 Defective thermistor

characteristics

2 Contact failure of connector

(CN31) on the indoor controller

board. (Insert failure).

3 Breaking of wire or contact

failure of drain sensor wiring.

4 Defective indoor controller board.

1~3 Check resistance value of thermistor.

0

: ······6.0k"

10: ····3.9k"

20: ····2.6k"

30: ····1.8k"

40: ····1.3k"

2 Check contact failure of connector (CN31) on

the indoor controller board. Refer to 9-6. Turn

the power on again and check restart after

inserting connector again.

4 Replace indoor controller board if drain

pump operates with the line of drain sensor

connector CN31-

1 and 2 is short-circuited,

and abnormality reappears.

Turn the power off, and on again to operate

after check.

P5

Malfunction of drain pump (DP)

1 Suspensive abnormality, if thermistor

of drain sensor is let heat itself and

temperature rises slightly. Turn off

compressor and indoor fan.

2 Drain pomp is abnormal if the condition

above is detected during suspensive

abnormality.

3 Constantly detected during drain pomp

operation.

1 Malfunction of drain pump

2 Defective drain

Clogged drain pump

Clogged drain pipe

3 Attached drop of water at the

drain sensor

• Drops of drain trickles from

lead wire.

• Clogged filter is causing

wave of drain.

4 Defective indoor controller board.

1 Check if drain-up machine works.

2 Check drain function.

3 Check the setting of lead wire of drain sensor

and check clogs of the filter.

4 Replace indoor controller board if drain

pump operates with the line of drain sensor

connector CN31-1 and 2 is short-circuited

and abnormality reappears.

Refer to 9-6.

Turn the power off, and on again to operate

after check.

Page 21

21

Error Code

Meaning of error code and detection method

Cause

Countermeasure

P6

Freezing/overheating protection is

working

1 Freezing protection (Cooling mode)

The unit is in six-minute resume prevention

mode if pipe <liquid or condenser/evaporator> temperature stays under

-15: for three minutes, three minutes

after the compressor started. Abnormal

if it stays under -15: for three minutes

again within 16 minutes after six-minute

resume prevention mode.

<Frost prevention mode>

If pipe <liquid or condenser-evaporator>

temperature is 2

: or below when 16

minutes has passed after compressor

starts operating, unit will start operating

in frost prevention mode which stops

compressor operation. After that, when

pipe <liquid or condenser/evaporator>

temperature stays 10: or more for 3

minutes, frost prevention mode will be

released and compressor will restart its

operation.

2 Overheating protection (Heating mode)

The units is in six-minute resume

prevention mode if pipe <condenser /

evaporator> temperature is detected as

over 70: after the compressor started.

Abnormal if the temperature of over

70: is detected again within 10 minutes

after six-minute resume prevention

mode.

P8

1 Slight temperature difference

between indoor room

temperature and pipe <liquid

or condenser / evaporator>

temperature thermistor

• Shortage of refrigerant

• Disconnected holder of pipe

<liquid or condenser /

evaporator> thermistor

• Defective refrigerant circuit

2 Converse connection of

extension pipe (on plural units

connection)

3 Converse wiring of indoor/

outdoor unit connecting wire

(on plural units connection)

4 Defective detection of indoor

room temperature and pipe

<condenser / evaporator>

temperature thermistor

5 Stop valve is not opened

completely.

(Cooling or drying mode)

1 Clogged filter (reduced airflow)

2 Short cycle of air path

3 Low-load (low temperature)

operation beyond the tolerance

range

4 Defective indoor fan motor

• Fan motor is defective.

• Indoor controller board is

defective.

5 Defective outdoor fan control

6 Overcharge of refrigerant

7 Defective refrigerant circuit

(clogs)

(Heating mode)

1 Clogged filter (reduced airflow)

2 Short cycle of air path

3 Over-load (high temperature)

operation beyond the tolerance

range

4 Defective indoor fan motor

• Fan motor is defective.

• Indoor controller board is

defective.

5 Defective outdoor fan control

6 Overcharge of refrigerant

7 Defective refrigerant circuit

(clogs)

8 Bypass circuit of outdoor unit

is defective.

(Cooling or drying mode)

1 Check clogs of the filter.

2 Remove shields.

4 Measure the resistance of fan motor's winding.

Measure the output voltage of fan's connector

(Relay fo r FAN) on the indoor controller

board.

∗The indoor controller board should be

normal when voltage of AC 220~240V is

detected while fan motor is connected.

Refer to 9-6.

5 Check outdoor fan motor.

67 Check operating condition of refrigerant

circuit.

(Heating mode)

1 Check clogs of the filter.

2 Remove shields.

4 Measure the resistance of fan motor's

winding.

Measure the output voltage of fan's connector

(Relay for FAN) on the indoor controller

board.

∗The indoor controller board should be

normal when voltage of AC 220~240V is

detected while fan motor is connected.

Refer to 9-6.

5 Check outdoor fan motor.

6~8Check operating condition of refrigerant

circuit.

Abnormality of pipe temperature

<Cooling mode>

Detected as abnormal when the pipe temperature is not in the cooling range 3 minutes later of compressor start and 6 minutes later of the liquid or condenser/evaporator pipe is out of cooling range.

Note 1) It takes at least 9 min. to detect.

Note 2) Abnormality P8 is not detected in

drying mode.

Cooling range : -3 deg ] (TH-TH1)

TH: Lower temperature between: liquid

pipe temperature (TH2) and condenser/evaporator temperature (TH5)

TH1: Intake temperature

<Heating mode>

When 10 seconds have passed after the

compressor starts operation and the hot

adjustment mode has finished, the unit is

detected as abnormal when

condenser/evaporator pipe temperature is

not in heating range within 20 minutes.

Note 3) It takes at least 27 minutes to

detect abnormality.

Note 4) It excludes the period of defrosting

(Detection restarts when defrosting

mode is over)

Heating range : 3 deg [ (TH5-TH1)

1~4Check pipe <liquid or condenser /

evaporator> temperature with room temperature display on remote controller and

outdoor controller circuit board.

Pipe <liquid or condenser / evaporator>

temperature display is indicated by

setting SW2 of outdoor controller circuit

board as follows.

23Check converse connection of extension

pipe or converse wiring of indoor/outdoor

unit connecting wire.

Conduct temperature check with outdoor

controller circuit board after connecting

‘A-Control Service Tool(PAC-SK52ST)’.

(

)

Page 22

22

Error Code

Meaning of error code and detection method

Cause

Countermeasure

P9

Abnormality of pipe temperature thermistor / Condenser-Evaporator (TH5)

1 The unit is in three-minute resume pro-

tection mode if short/open of thermistor

is detected. Abnormal if the unit does

not get back to normal within three minutes. (The unit returns to normal operation, if it has normally reset.)

2 Constantly detected during cooling, dry-

ing, and heating operation (except

defrosting)

Short: 90: or more

Open: -40: or less

1 Defective thermistor

characteristics

2 Contact failure of connector

(CN29) on the indoor controller

board. (Insert failure)

3 Breaking of wire or contact

failure of thermistor wiring.

4 Temperature of thermistor is

90: or more or -40: or less

caused by defective refrigerant

circuit.

5 Defective indoor controller

board.

1~3 Check resistance value of thermistor.

For characteristics, refer to (P1) above.

2 Check contact failure of connector (CN29)

on the indoor controller board.

Refer to 9-6.

Turn the power on and check restart after

inserting connector again.

4 Operate in test run mode and check pipe

<condenser / evaporator> temperature with

outdoor controller circuit board. If pipe

<condenser / evaporator> temperature is

exclusively low (in cooling mode) or high (in

heating mode), refrigerant circuit may have

defective.

5 Operate in test run mode and check pipe

<condenser / evaporator> temperature with

outdoor control circuit board. If there is

exclusive difference with actual pipe

<condenser / evaporator> temperature

replace indoor controller board.

There is no abnormality if none of above

comes within the unit.

Turn the power off and on again to operate.

E0

or

E4

Remote controller transmission

error(E0)/signal receiving error(E4)

1 Abnormal if main or sub remote con-

troller can not receive normally any

transmission from indoor unit of refrigerant address “0” for three minutes.

(Error code : E0)

2 Abnormal if sub remote controller could

not receive for any signal for two minutes. (Error code: E0)

1 Abnormal if indoor controller board can

not receive normally any data from

remote controller board or from other

indoor controller board for three minutes.

(Error code: E4)

2 Indoor controller board cannot receive

any signal from remote controller for two

minutes. (Error code: E4)

1 Check disconnection or looseness of indoor

unit or transmission wire of remote controller.

2 Set one of the remote controllers “main”.

If there is no problem with the action above.

3 Check wiring of remote controller.

• Total wiring length: max.500m

(Do not use cablex 3 or more)

• The number of connecting indoor units:

max.16units

• The number of connecting remote controller: max.2units

When it is not the above-mentioned problem of

1~3

4 Diagnose remote controllers.

a) When “RC OK” is displayed,

Remote controllers have no problem.

Put the power off, and on again to check.

If abnormality generates again, replace

indoor controller board.

b) When “RC NG” is displayed,

Replace remote controller.

c) When “RC E3” is displayed,

d) When “ERC 00-06” is displayed,

[ c),d)→Noise may be causing abnormality. ]

∗ If the unit is not normal after replacing

indoor controller board in group control,

indoor controller board of address “0”

may be abnormal.

E3

or

E5

Remote controller transmission

error(E3)/signal receiving error(E5)

1 Abnormal if remote controller could not

find blank of transmission path for six

seconds and could not transmit.

(Error code: E3)

2 Remote controller receives transmitted

data at the same time, compares the

data, and when detecting it, judges

different data to be abnormal 30

continuous times. (Error code: E3)

1 Abnormal if indoor controller board could

not find blank of transmission path.

(Error code: E5)

2 Indoor controller board receives trans-

mitted data at the same time, compares

the data,and when detecting it, judges

different data to be abnormal 30

continuous times. (Error code: E5)

1 Set a remote controller to main, and the

other to sub.

2 Remote controller is connected with only one

indoor unit.

3 The address changes to a separate setting.

4~6 Diagnose remote controller.

a) When “RC OK”is displayed, remote con-

trollers have no problem.

Put the power off,and on again to check.

When becoming abnormal again, replace

indoor controller board.

b)When “RC NG”is displayed, replace

remote controller.

c)When “RC E3”or “ERC 00-66”is displayed,

noise may be causing abnormality.

1 Contact failure at transmission

wire of remote controller

2 All remote controllers are set

as “sub” remote controller. In

this case, E0 is displayed on

remote controller, and E4 is

displayed at LED (LED1, LED2)

on the outdoor controller circuit

board.

3 Mis-wiring of remote controller.

4 Defective transmitting receiving

circuit of remote controller

5 Defective transmitting receiving

circuit of indoor controller board

of refrigerant address “0”.

6 Noise has entered into the

transmission wire of remote

controller.

1 Two remote controller are set

as “main.”

(In case of 2 remote con-

trollers)

2 Remote controller is connected

with two indoor units or more.

3 Repetition of refrigerant

address.

4 Defective transmitting receiving

circuit of remote controller.

5 Defective transmitting receiving

circuit of indoor controller

board.

6 Noise has entered into trans-

mission wire of remote controller.

In case of checking pipe temperature

with outdoor controller circuit board,

be sure to connect A-control service

tool (PAC-SK52ST).

(

)

Page 23

23

PA

(2502)

(2500)

Forced compressor stop

(due to water leakage abnormality)

1 When the intake temperature subtracted

with liquid pipe temperature is less than

-10

:, drain sensor is detected whether

it is soaked in the water or not at the interval

of 90 seconds. (Drain pump will start operating

when the drain sensor is detected to be

soaked in the water.)

2 The unit has a water leakage abnormality

when the following conditions, a and b, are

satisfied while the above-mentioned detection

is performed.

a) The drain sensor is detected to be

soaked in the water 10 times in a row.

b) The intake temperature subtracted with

liquid pipe temperature is detected to be

less than -10

: for a total of 30 minutes.

(When the drain sensor is detected to

be NOT soaked in the water, the detection

record of a and b will be cleared.)

3 The drain sensor detection is performed

in operations other than cooling. (When

the unit stops operating, during heating

or fan operation, when the unit stops

because of some abnormality)

*Once the water leakage abnormality is

detected, abnormality state will not be

released until the main power is reset.

1) Drain pump trouble

2) Drain defective

· Drain pump clogging

· Drain pipe clogging

3) Open circuit of drain sensor

side heater

4) Contact failure of drain sensor

connector

5) Dew condensation on drain

sensor

· Drain water descends along

lead wire.

· Drain water waving due to filter

clogging.

6) Extension piping connection

difference at twin, triple,

quadruple system.

7) Mis-wiring of indoor/ outdoor

connecting at twin, triple,

quadruple system.

8) Room temperature thermistor /

liquid pipe temperature thermistor detection is defective.

Check the drain pump.

Performance

Please confirm whether water can be drained.

Confirm the resistance of the drain sensor side

heater.

Check the connector contact failure.

1 Check the drain sensor leadwire mounted.

2 Check the filter clogging

Check the piping connection.

Check the indoor/ outdoor connecting wires.

Check the room temperature display of remote

controller.

Check the indoor liquid pipe temperature display of outdoor controller board.

E6

1 Contact failure, short circuit or,

mis-wiring (converse wiring) of

indoor/outdoor unit connecting

wire

2 Defective transmitting receiving

circuit of indoor controller board

3 Defective transmitting receiving

circuit of indoor controller board

4 Noise has entered into indoor/

outdoor unit connecting wire.

∗ Check LED display on the outdoor control cir-

cuit board. (Connect A-control service tool,

PAC-SK52ST.)

Refer to EA-EC item if LED displays EA-EC.

1 Check disconnection or looseness of indoor/

outdoor unit connecting wire of indoor unit or

outdoor unit.

Check all the units in case of twin triple

indoor unit system.

2~4 Turn the power off, and on again to

check. If abnormality generates again,

replace indoor controller board or outdoor

controller circuit board.

∗ Other indoor controller board may have

defective in case of twin triple indoor unit

system.

E7

Indoor/outdoor unit communication

error (Transmitting error)

Abnormal if “1” receiving is detected 30

times continuously though indoor controller

board has transmitted “0”.

1 Defective transmitting receiving

circuit of indoor controller board

2 Noise has entered into power

supply.

3 Noise has entered into outdoor

control wire.

1~3 Turn the power off, and on again to

check. If abnormality generates again,

replace indoor controller board.

Indoor/outdoor unit communication

error (Signal receiving error)

1 Abnormal if indoor controller board

cannot receive any signal normally for

six minutes after putting the power on.

2 Abnormal if indoor controller board

cannot receive any signal normally for

three minutes.

3 Consider the unit abnormal under the

following condition: When two or more

indoor units are connected to one

outdoor unit, indoor controller board

cannot receive a signal for three minutes

from outdoor controller circuit board, a

signal which allows outdoor controller

circuit board to transmit signals.

Error Code

Meaning of error code and detection method

Cause

Countermeasure

Fb

Abnormality of indoor controller board

Abnormal if data cannot be normally read

from the nonvolatile memory of the indoor

controller board.

1 Defective indoor controller

board.

1 Replace indoor controller board.

E1

or

E2

Abnormality of remote controller control board

1 Abnormal if data cannot be normally

read from the nonvolatile memory of the

remote controller control board.

(Error code: E1)

2 Abnormal if the clock function of remote

controller cannot be normally operated.

(Error code: E2)

1 Defective remote controller.

1 Replace remote controller.

Page 24

24

(For the separate indoor/outdoor unit power sup-

ply system)

1 Power supply of 220~240V AC is not supplied to

indoor unit.

2 The connectors of the optional replacement kit are

not used.

3 Defective indoor controller board.

4 Defective indoor power board.

9-3. TROUBLESHOOTING BY INFERIOR PHENOMENA

Note: Refer to the manual of outdoor unit for the detail of remote

controller.

Phenomena

Cause

Countermeasure

(1)LED2 on indoor controller board

is off.

• When LED1 on indoor controller board is also off.

1 Power supply of rated voltage is not supplied to out-

door unit.

2 Defective outdoor controller circuit board.

3 Power supply of 220~240V is not supplied to indoor

unit.

4 Defective indoor power board.

5 Defective indoor controller board.

1 Check the voltage of outdoor power

supply terminal block (L, N) or (L3, N).

• When AC 220~240V is not detected.

Check the power wiring to outdoor unit

and the breaker.

• When AC 220~240V is detected.

—Check 2 (below).

2 Check the voltage between outdoor

terminal block S1 and S2.

• When AC 220~240V is not detected.

Check the fuse on outdoor controller

circuit board.

Check the wiring connection.

• When AC 220~240V is detected.

—Check 3 (below).

3 Check the voltage between indoor terminal

block S1 and S2.

• When AC 220~240V is not detected.

Check indoor/outdoor unit connecting

wire for mis-wiring.

• When AC 220~240V is detected.

—Check 4 (below).

4 Check voltage output from CN2S on indoor

power board (DC13.1V). Refer to 9-6-1.

• When no voltage is output.

Check the wiring connection.

• When output voltage is between

DC12.5V and DC13.7V.

—Check 5 (below).

5 Check the wiring connection between

indoor controller board and indoor power

board. Check the fuse on indoor controller

board. If no problems are found, indoor

controller board is defective.

• When LED1 on indoor controller board is lit.

1 Mis-setting of refrigerant address for outdoor unit

(There is no unit corresponding to refrigerant

address “0”.)

1 Reconfirm the setting of refrigerant

address for outdoor unit

Set the refrigerant address to “0”.

(For grouping control system under

which 2 or more outdoor units are

connected, set one of the units to “0”.)

Set refrigerant address using SW1 (3-6)

on outdoor controller circuit board.

1 Check the voltage of indoor power supply

terminal block (S1,S2).

• When AC220~240V is not detected.

Check the power supply wiring.

• When AC220~240V is detected.

-Check 2 (below).

2 Check that there is no problem in the

method of connecting the connectors.

• When there are problems in the method

of connecting the connectors.

Connect the connector correctly refer-

ring to installation manual of an optional

kit.

• When there is no problem in the

method of connecting the connectors.

-Check

3 (below).

3 Check voltage output from CNDK on

indoor controller board.

• When AC220~240V is not detected.

Check the fuse on indoor controller

board.

Check the wiring connection between

indoor power supply terminal block and

CND on indoor controller board.

• When AC220~240V is detected.

-Check 4 (below).

4 Check voltage output from CN2S on

indoor power board.

• When no voltage output.

Check the wiring connection between

CNDK on indoor controller board and

CNSK on indoor power board.

If no problem are found,indoor power

board is defective.

• When DC12.5~13.7V is detected.

Check the wiring connection between

CN2S on indoor power board and

CN2D on indoor power board.

If no problem are found,indoor con-

troller board is defective.

Page 25

25

Note: Refer to the manual of outdoor unit for the detail of remote

controller.

Phenomena

Cause

Countermeasure

(2)LED2 on indoor controller board

is blinking.

• When LED1 on indoor controller board is also blinking.

Connection failure of indoor/outdoor unit connecting

wire

• When LED1 is lit.

1 Mis-wiring of remote controller wires

Under twin triple indoor unit system, 2 or more indoor

units are wired together.

2 Refrigerant address for outdoor unit is wrong or not

set.

Under grouping control system, there are some units

whose refrigerant address is 0.

3 Short-cut of remote controller wires

4 Defective remote controller

Check indoor/outdoor unit connecting wire

for connection failure.

1 Check the connection of remote con-

troller wires in case of twin triple indoor

unit system. When 2 or more indoor units

are wired in one refrigerant system,

connect remote controller wires to one of

those units.

2 Check the setting of refrigerant address

in case of grouping control system.

If there are some units whose refrigerant

addresses are 0 in one group, set one of

the units to 0 using SW1 (3-6) on outdoor

controller circuit board.

34 Remove remote controller wires and

check LED2 on indoor controller board.

• When LED2 is blinking, check the

short-cut of remote controller wires.

• When LED2 is lit, connect remote

controller wires again and:

if LED2 is blinking, remote controller

is defective; if LED2 is lit, connection

failure of remote controller terminal

block etc. has returned to normal.

9-4.

WHEN WIRED REMOTE CONTROLLER OR INDOOR UNIT MICRO COMPUTER TROUBLES

1. If there is not any other wrong when trouble occurs, emergency operation starts as the indoor controller board switch (SWE)

is set to ON.

During the emergency operation the indoor unit is as follows;

(1) Indoor fan high speed operation (2) Drain-up machine operation

2. When emergency operating for COOL or HEAT, setting of the switch (SWE) on the indoor controller board and outdoor unit

emergency operation are necessary.

3. Check items and notices as the emergency operation

(1) Emergency operation cannot be used as follows;

• When the outdoor unit is something wrong.

• When the indoor fan is something wrong.

• When drain over flow protected operation is detected during self-diagnosis. (Error code : P5)

(2) Emergency operation will be serial operation by the power supply ON/OFF.

ON/OFF or temperature, etc. adjustment is not operated by the remote controller.

(3) Do not operate for a long time as cold air is blown when the outdoor unit starts defrosting operation during heat emer-

gency operation.

(4) Cool emergency operation must be within 10 hours. Other wise, heat exchanger of indoor unit may get frosted.

(5) After completing the emergency operation, return the switch setting, etc. in former state.

(6) Since vane does not work at emergency operation, position the vane slowly by hand.

Page 26

26

9-5. HOW TO CHECK THE PARTS

PEA-RP200GA PEA-RP250GA

PEA-RP400GA PEA-RP500GA

Parts name Check points

Disconnect the connector then measure the resistance using a tester.

(Surrounding temperature 10:~30:)

(Refer to the thermistor)

Room temperature

thermistor (TH1)

Pipe temperature

thermistor/liquid (TH2)

Condenser/evaporator

temperature thermistor

(TH5)

Normal

4.3k"~9.6k

"

Abnormal

Open or short

Thermal protector trip temperature

135±5ûC :open

86±15ûC :close

¥PEA-RP200/250GA

Thermal protector trip temperature

150±5ûC :open

96±15ûC :close

¥PEA-RP400/500GA

THERMO

W

ZY

ab

U

X

V

THERMO

Normal

19.9

Ω

25.1

Ω

PEA-RP

200/250GA

Red-White / White-Blue / Red-Blue

Red-White / White-Blue / Red-Blue

Red-White / White-Blue / Red-Blue

Red-White / White-Blue / Red-Blue

Abnormal

Open or short

Hi

Lo

34.2

Ω

PEA-RP

400GA

25.2

Ω

PEA-RP

500GA

Measure the resistance value across the terminals with a multimeter. (Winding

temperature 20 ûC)

(LO)

(LO)

(HI)

(HI)

U2

U1

V1

V1

W1

W2

(LO)

(HI)

Black marking

Black marking

Black marking

Yellow

Blue

Red

Red

Blue

Yellow

White

White

0

10

20

30

40

50

-20 -10 0 10 20 30 40 50

< Thermistor for lower temperature >

Temperature (:)

Resistance (K")

<Thermistor Characteristic graph>

•Room temperature thermistor(TH1)

•Pipe temperature thermistor/liquid(TH2)

•Condenser/Evaporator temperature

thermistor(TH5)

Thermistor R

0=15k' ±3%

Fixed number of B=3480 ± 2%

Rt=15exp { 3480( ) }

0

: 15k'

10: 9.6k'

20: 6.3k'

25: 5.2k'

30: 4.3k'

40: 3.0k'

Thermistor for

lower temperature

1

273+t

1

273

Page 27

27

9-6. TEST POINT DIAGRAM

9-6-1. Power board

PEA-RP200GA PEA-RP250GA

PEA-RP400GA PEA-RP500GA

CNSK

Connect to the indoor controller board

(CNDK)

Between

11

to 33220-240V AC

CN2S

Connect to the indoor controller board (CN2D)

Between

11

to

33

12.6-13.7V DC (Pin11(+))

Page 28

28

9-6-2. Indoor controller board

PEA-RP200GA PEA-RP250GA

PEA-RP400GA PEA-RP500GA

FAN

Fan motor output

CNP

Drain-pump output

(DP)

(220~240V AC)

CNC

Dew prevention

heater (H2)

(220~240V AC)

CNDK

Connect to the indoor

power board (CNSK)

(220~240V AC)

FUSE

(6.3A 250V)

CND

Power

supply input

(220~240V AC)

SWE

Emergency operation

SW2

Capacity setting

SW1

Model setting

CN2L

Connector

(LOSSNAY)

CN51

Centrally control

CN6V

Vane motor output

(MV)

CN90

Connect to the

wireless remote

controller board

(CNB)

CN31

Drain sensor (DS)

CN29

Condenser/evaporator

temperature thermistor

(TH5)

CN21

Pipe temperature

thermistor/Liquid

(TH2)

CN20

Room temperature

thermistor (TH1)

CN22

Remote controller

connecting wire

(10.4~14.6V DC)

LED3

Transmission

(Indoor/outdoor)

LED2

Power supply

(R.B)

LED1

Power supply

(I.B)

CN2D

Connector to the indoor

power board (CN2S)

(12.5~13.7V DC)

CN3C

Transmission

(Indoor/outdoor)

(0~24V DC)

}

}

Non polarity

+

–

+

–

CN41

Connector

(HA terminal-A)

Page 29

29

9-7. FUNCTIONS OF DIP SWITCH AND JUMPER WIRE

Each function is controlled by the dip switch and the jumper wire on control p.c. board.

(Marks in the table below) Jumper wire ( : Short : Open)

Jumper wire

SW1

SW2

JP1

JP3

Functions

Model

settings

Capacity

settings

Unit type

setting

Indoor

controller

board type

setting

Setting by the dip switch and jumper wire

PEA-RP200/250 PEA-RP400/500

JP3

5432

ON

OFF

1

1

Without TH5

Indoor controller board type

5432

ON

OFF

5432

ON

OFF

Model

With TH5

Factory shipment

Service parts

JP1

1

Remarks

There is no jumper (JP1) because these models

have the cond./eva. temperature thermistor (TH5).

Page 30

30

10 SERVICE DATA (PARTS NAME)

Control box

Drain pan

Drain pipe connection

(R1)

Fan motor

Sirocco fan

Suspension bracket

Special washer

Liquid pipe thermistor

(TH2)

2-phase

pipe

thermistor

(TH5)

Strainer

Strainer

Heat exchanger

Liquid pipe

Gas pipe

Inlet thermistor

(TH1)

Drain pan

PEA-RP200/250GA

Page 31

31

PEA-RP400/500GA

Suspension bracket

Special

washer

Drain pipe connection

(R1)

Control box

Sirocco fan

Fan motor

No.1

Inlet thermistor

(TH1-1)

No.2 Gas pipe

No.2 Liquid pipe

2-phase pipe

thermistor

(TH5-1)

No.1 Gas pipe

No.1 Liquid pipe

Drain pan

No.2

Inlet thermistor

(TH1-2)

2-phase pipe

thermistor

(TH5-2)

No.2 Strainer

Strainer

Drain pan

Liquid pipe thermistor

(TH2-2)

Heat exchanger

No.1 Strainer

Liquid pipe thermistor

(TH2-1)

Strainer

Page 32

32

A

Ferrite core

Power supply board

Control board

I/D

POWER BOARD

I/D

CONTROLLER BOARD

Lo

52F

Hi

52F

51F

X1

FB

view A

L2 NL3L1

TB2

TB4TB5

12 S2S1 S3

Relay

SNB

board

Magnetic contactor

(Fan motor Lo speed)

Magnetic contactor

(Fan motor Hi speed)

Terminal block for

remote controller

Terminal block for

outdoor/indoor control

wiring connection

Power supply

terminal block

PEA-RP200/250GA

Page 33

33

PEA-RP400/500GA

view A

Control board

(No.2 unit)

SNB board

Magnetic

contactor

Control board

(No.1 unit)

A

Relay

Ferrite core Ferrite core

FB11

FB21

I/D

POWER BOARD

(NO.2)

52F

I/D

POWER BOARD

(NO.1)

51F

TB2

X1

X2

Power supply

terminal block

Control board

(No.1 unit)

FB12

I/D

CONTROLLER BOARD

(NO.1)

TB4-1 TB5TB4-2

Terminal block for

outdoor/indoor control

wiring connection

(No.1 unit)

FB22

I/D

CONTROLLER BOARD

(NO.2)

Terminal block for

outdoor/indoor control

wiring connection

(No.2 unit)

Control board

(No.2 unit)

Terminal block for

remote controller

Page 34

New publication, effective July 2007.

Specifications subject to change without notice.

HWE07080

Printed in Japan

Loading...

Loading...