Mitsubishi PD-5065, PD-4265 Service Manual

20052005

2005

20052005

MITSUBISHI ELECTRIC

SerSer

Ser

SerSer

ManualManual

Manual

ManualManual

PLASMA DISPLA Y P ANEL

vicevice

vice

vicevice

PD-4265

PD-5065

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY INFORMA TION" section in

this manual.

For details, refer to "Important symbols for good services".

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2005 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

Health & Safety Code Section 25249.6 - Proposition 65

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power line

and the set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

service technician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• When the front case is removed, infrared ray is radiated and

may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

2

PD-5065

Insulation Resistance Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

(Case of PD-5065/4265, AC power is always on.)

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.). The resistance shuld be greater than 10MΩ.

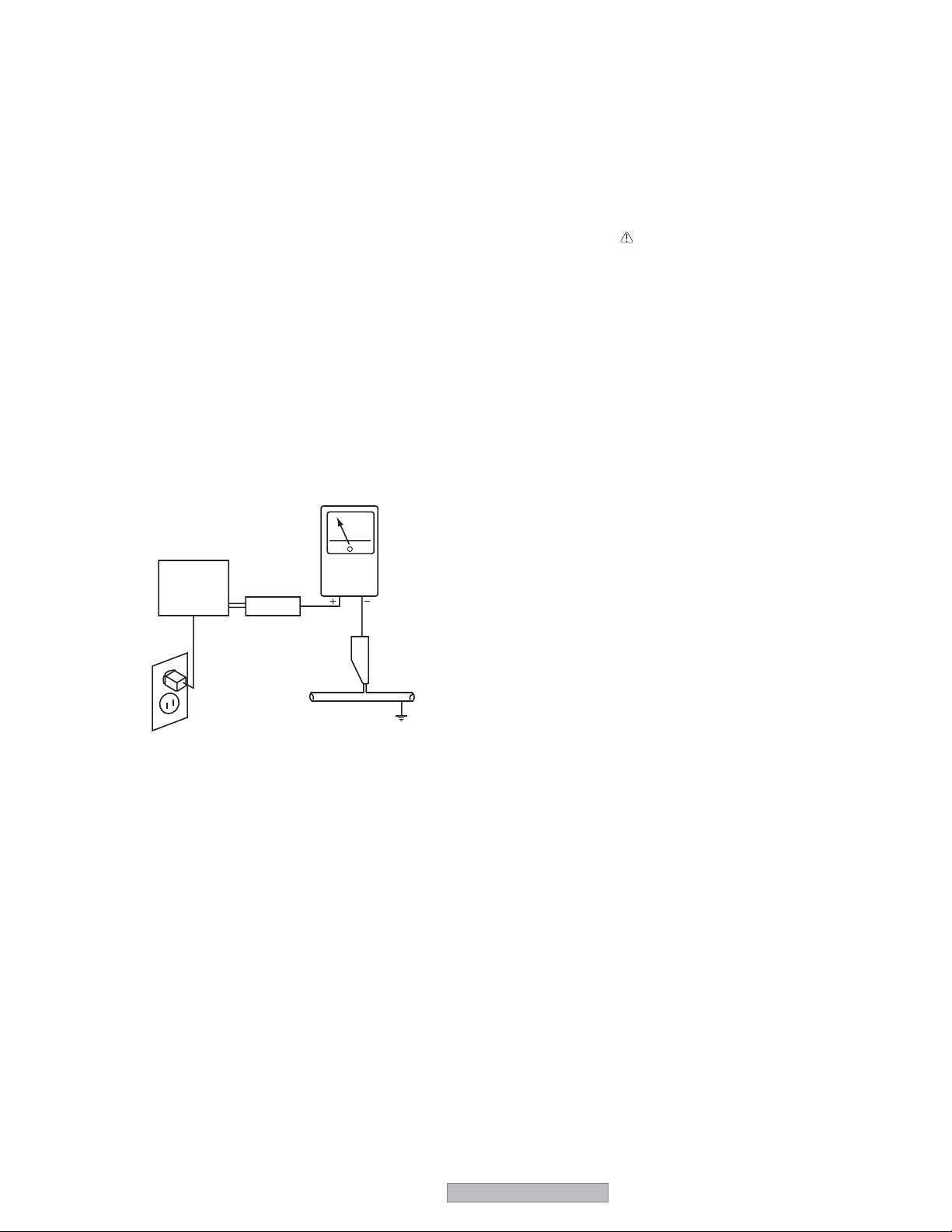

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester", measure for current from all

exposed metal parts of the cabinet (input/output terminals,

screwheads, metal overlays, control shaft, etc.), particularly any

exposed metal part having a return path to the chassis, to a known

earth ground (water pipe, etc.). Any current measured must not

exceed 1.5mA.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

Reading should

not be above

1.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

PD-5065

3

SAFETY SERVICE

7 Safety cautions

The matters to be observed without fail are explained below. These matters are indispensable for the preventi on of an

accident during the maintenance servicing, the [security of products] after the completi on of servicing work, and the

[prevention of the repeated occurrence of similar fault.]

(1) The degree of danger and material damage, caused as a result of wrong use by disregarding the contents of the display”

is distinguished and explained in the table below.

WARNING

CAUTION

(2) Kinds of the matters to be observed are classified and explained in the icons shown below.

This icon indicates a dangerous place where an electric shock is anticipated.

This icon indicates the contents of “caution” that must be borne in mind, without fail.

If this display is disregarded and equipment is handled wrongly, this can be a cause of physical injury and

a fire, thus leading a person to death or serious injury.

If this display is disregarded and equipment is handled wrongly, this may lead to personal injury or

material damage.

This icon indicates the contents of “caution” that must be practiced, without fail.

WARNING

• Observe the caution matter, without fail.

• In the place where a particular caution is needed during maintenance servicing, such a caution note is displayed with a label or a

stamp that is given to the cabinet, chassis, PWB, etc. These caution notes and also the caution matters of given

in the instruction manuals, etc., must be observed, without fail.

• Be careful of an electric shock or a burn.

• The PDP module involves the sections where high voltage and high temperature are prevalent. When equipment is energized,

therefore, use working gloves in order to prevent an electric shock and a burn. At the time of transportation, disassembly,

reassembly, and the replacement of parts, such a servicing job must be done after pulling out all the connector cables that have

been connected with external equipment.

• Modification of equipment is absolutely prohibited. Use the specified parts at all times.

• If any modification is performed, the validity of the manufacturer’s warranty is lost at that moment. The personnel who did this

modification is responsible for the physical injury or the like, if it should occur as a result of the modification. The parts used are

given the safety-based characteristics, such as non-flammability or sufficient

• Danger of explosion.

• The lithium battery will give rise to explosion if its polarity is wrongly treated.

WARNING

4

PD-5065

• Observe the caution matter, without fail

• The caution matters of given in the delivery specifications, etc., must be observed, without fail.

CAUTION

• Do not give shocks and vibration.

• The panel surface (display plane) of the PDP module is made of glass. If any shocks or vibration is applied, it may be broken and

the scattered glass chips will be a cause of injury

• Do not put anything.

• Transportation must be done by enough personnel.

• Do

not put anything on the PDP module. Otherwise, this can be a cause of injury as a result of falling down or dropping caused

by imbalance.

• The PDP module is heavy. In the case of transportation, unpacking, or packing, more than two persons should do it by supporting

the top and the bottom of the product.

7 Miscellaneous caution matters

(1) This PDP module uses highly integrated semiconductor parts. Since these parts are fragile to electrostatic

charges, earth bands should be used for handling. The product should be handled where measures have been

taken against electrostatic charges.

(2) For this product, the PDP modules and the PWBs are repaired by replacement in a unit. Therefore, the units of

the PWBs must not be repaired or disassembled. Otherwise, the validity of warranty will be lost.

(3) If this PDP module is used for the fixed character display or the like as in the case of a character display board,

a phenomenon of burning (not warranted) will occur. Burning is a phenomenon that the unevenness in the

brightness is caused in the display. In such a case, the brightness in the section where the integrated display

time is longer becomes lower than the brightness in another section where the integrated display time is shorter.

This phenomenon is in proportion to the integrated display time and the brightness. For this reason, to relieve

this difficulty during servicing, do not use any still picture, but use a display by motion pictures of a video or the

like. In addition, use “STANDARD” for the screen mode and avoid using any display by “NARROW”, or “TRUE”

etc. If it is necessary to use only a still picture for unavoidable reasons, use a burning

relief function such as “PLE LOCK”, “ORBITER”, etc.

(4) When a PDP module is operated after a long time of storage, it may encounter a difficulty like a failure in

displaying a screen or unstability according to the condition of storage. In such a case, the PDP module should

be incorporated in the product and aging treatment should be carried out for about two hours (all screen display).

(5) Sulfides will deteriorate the PDP module and this is a cause of malfunction. Therefore, it is absolutely prohibited

to put any vulcanized rubber or a material containing sulfur in the vicinity of the PDP module.

(6) When taking out a PDP module from the maintenance package box, do it slowly so that the panel surface

does not get any shock or stress.

(7) If one touches the connector of the flexible cable exposed to the rear side of the PDP module, there is

danger of causing a poor contact. As such, it must be handled with utmost care. In addition, the flexible cable

is very weak in mechanical strength. Therefore, this cable must not be touched during handling.

(8) The panel surface of the PDP module is easy to be hurt and generate cracks. Therefore, it should be handled

very carefully. Never press or rub it with a hard thing. Never put it on a hard thing with the panel surface faced

downwards.

(9) When the panel surface of the PDP module is contaminated, gently wipe off the contaminant with a piece of

soft dry cloth. Liquid-state contamination can be removed by lightly pressing it, without rubbing it. If it is

difficult to remove the contamination, use a piece of cloth soaked with a neutral detergent. The cloth for

wiping off should be clean. Never use the same cloth repeatedly. If a cleansing detergent or water drops

should enter the module interior or be attached to the module surface other than the display plane at the time

of cleaning, this will give rise to the destruction of the product when the product is energized.

(10) When transporting this PDP module, use the packing materials specified in the list of parts. Once used,

such packing materials should not be used again.

(11) The PDP module is composed of a variety of parts, such as those made of materials like glass, metal,

plastics, etc. Therefore, when abandoning the PDP module, this should be done in accordance with the

relevant law of the nation or an autonomous body.

(12) This product is composed of a variety of parts, such as those made of materials like glass, metal,

plastics, etc., and those like a lithium battery , etc. Therefore, when abandoning this product, this

should be done in accordance with the relevant law of the nation or an autonomous body.

CAUTION: Risk of Explosion if Battery is replaced by an Incorrect Type. Dispose of Used Batteries

According to above the Instructions.

*1

,

*1 Only PD-5065 supports "TRUE" mode. "TRUE" mode is available, when "PICTURE SIZE" is set to off in

the "factory adjustment menu".

PD-5065

5

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity.

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

6

PD-5065

CONTENTS

SAFETY INFORMATION......................................................................................................................................2

1. SPECIFICATIONS.............................................................................................................................................8

1.1 SPECIFICATIONS .....................................................................................................................................8

1.2 FRONT PANEL .......................................................................................................................................14

2. DIAGNOSIS ....................................................................................................................................................17

2.1 TROBLESHOOTING.................................................................................................................................17

2.2 DIAGNOSIS..............................................................................................................................................18

3. ADJUSTMENT ................................................................................................................................................33

3.1 ADJUSTING CONDITIONS......................................................................................................................33

3.2 ADJUSTING ITEMS .................................................................................................................................33

4. EXPLODED VIEWS AND PARTS LIST...........................................................................................................63

4.1 PACKING..................................................................................................................................................63

4.2 DISASSEMBLY.........................................................................................................................................69

4.3 PARTS LIST............................................................................................................................................110

5. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ........................................................................................112

5.1 CONECTION DIAGRAM ........................................................................................................................112

5.1.1 OVERALL CONNECTION DIAGRAM ..............................................................................................112

5.1.2 CONNECTOR PIN EXPLANATION..................................................................................................114

5.2 BLOCK DIAGRAM..................................................................................................................................119

5.2.1 OVERALL BLOCK DIAGRAM ..........................................................................................................119

5.2.2 CPU BLOCK.....................................................................................................................................120

6. PCB DIAGAM ................................................................................................................................................122

6.1 MAIN PWB..............................................................................................................................................122

6.2 232C, CLT and LED PWB.......................................................................................................................124

6.3 SENB, SENC, SEND and AUDIO PWB..................................................................................................125

PD-5065

7

1. SPECIFICATIONS

1.1 SPECIFICATIONS

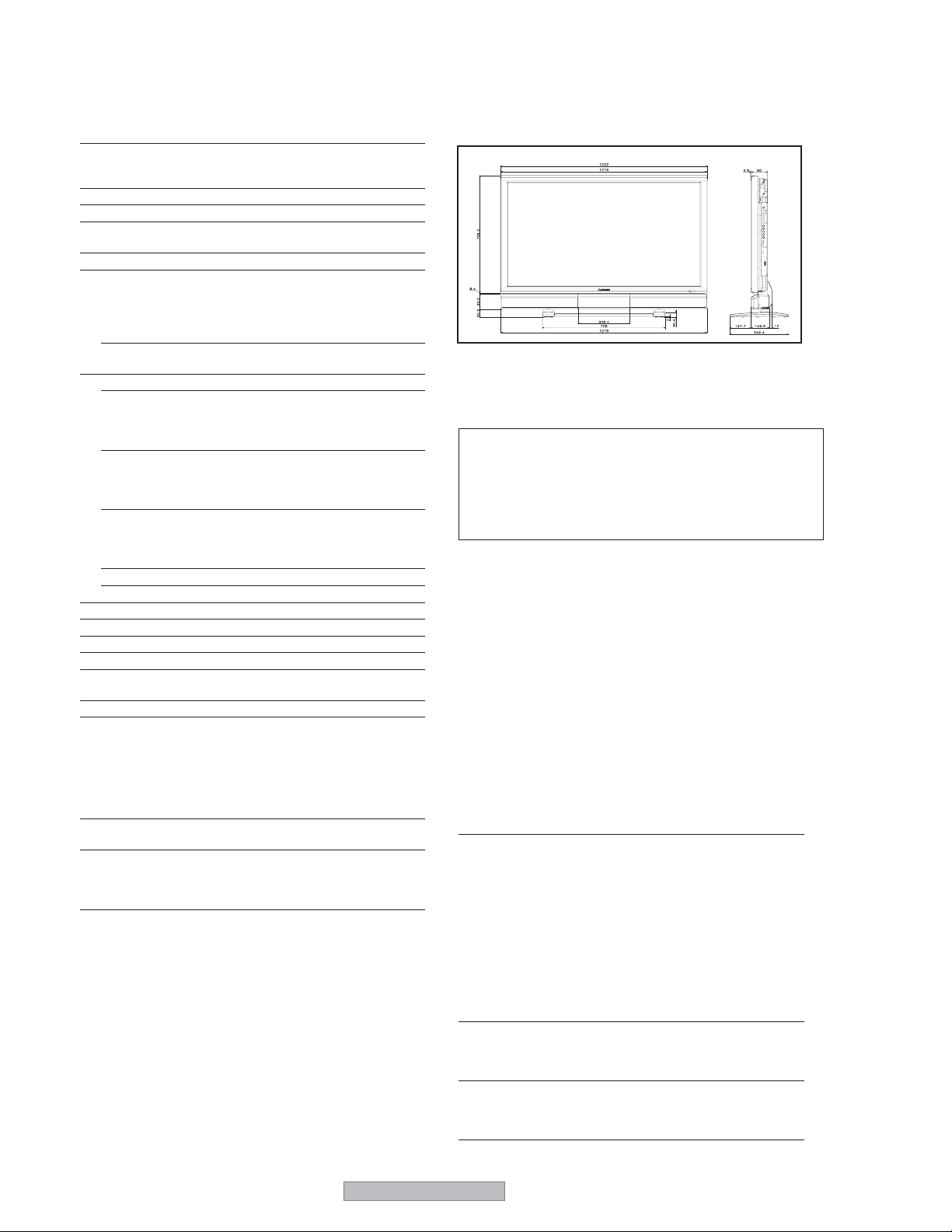

• PD-5065 Specifications

Screen Size 43.5"(H) x 24.5"(V) inches

Aspect Ratio 16 : 9

Resolution 1365(H) x 768(V) pixels

Pixel Pitch 0.032"(H) x 0.032"(V) inches

Color Processing 4,096 steps, 68.7 billion colors

Signals

Synchronization Range Horizontal : 15.5 to 110 kHz

Input Signals RGB, NTSC (3.58/4.43), PAL (B,G,M,N),

Input Terminals

RGB

RGB 1 (Analog) mini D-sub 15-pin 1

RGB 2 (Analog) BNC (R, G, B, H/CS, V) 1*

MONLINK (Digital) HDMI

Video

INPUT 1 BNC 1

INPUT 2 RCA-pin 1

INPUT 3 S-Video: DIN 4-pin 1

DVD/HD/DTV

COMP 1 RCA-pin (Y, PB[CB], PR[CR]) 1*

COMP 2 BNC (Y, PB[CB], PR[CR]) 1*

MONLINK HDMI

Audio Stereo RCA 3 (Selectable)

External Control D-sub 9-pin 1 (RS-232C)

Sound output 9W+9W at 6 ohm

Power Supply AC100-240V 50/60Hz

Current Rating 7.6A (maximum)

Power Consumption 435W (typical), 1.5W (stand-by)

Dimensions 48.1 (W) x 35 (H) x 13.8 (D) inches

Weight 127 lbs / 57.6 kg(Net), 148 lbs / 67.4 kg(Gross)

Environmental Considerations

Operating Temperature 0°C to 40°C / 32°F to 104°F

Humidity 20 to 80% (no condensation)

Altitude 0 to 9180 feet / 0 to 2800 m

Storage Temperature -10°C to 50°C / 14°F to 122°F

Humidity 10 to 90% (no condensation)

Altitude 0 to 9840 feet / 0 to 3000 m

Front Panel User Controls

Remote Control Functions Power on/off, Input source select, Menu/

OSM Functions PICTURE(PICTURE MEMORY/CONTRAST/

1106(H) x 622(V) mm

diagonal 50"

0.81(H) x 0.81(V) mm

(automatic : step scan)

Vertical : 50.0 to 120 Hz

(automatic : step scan)

1

PAL60, SECAM, HD*

1222 (W) x 889 (H) x 350(D) mm

Input Source Select

Volume up/down/OSM Control

Exit,Volume up/down, Adjust (UP,

DOWN,LEFT, RIGHT), Zoom up/down,

Picture control buttons

BRIGHTNESS/SHARPNESS/COLOR/TINT/NR/

COLOR TEMP./WHITE BALANCE/GAMMA/

LOW TONE/SET UP LEVEL/COLOR ADJUST/

FILMMODE/PICTURE MODE), AUDIO (BASS/

TREBLE/BALANCE/AUDIO INPUT1/AUDIO

INPUT2/AUDIO INPUT3/MONITORLINK),

IMAGE ADJUST (ASPECT MODE/V-POSITION/

H-POSITION/V-HEIGHT/H-WIDTH/AUTO

PICTURE/FINE PICTURE/PICTURE ADJ.),

SETUP (LANGUAGE*/BNC INPUT/HD

SELECT/RGB SELECT/HDMI SET UP/COLOR

SYSTEM/BACK GROUND/GRAY LEVEL/S1/

S2/DISPLAY MENU/MENU ADJUST/ALL

RESET), FUNCTION (POWER MGT./INPUT

SKIP/LONG LIFE [PEAK BRIGHT / ORBITER /

INVERSE WHITE / SOFT FOCUS / ORBITER

MENU / MENU CONTRAST]), SIGNAL INFO.

, DVD*1 , DTV*

1

1

2

1

2

'

*

Bezel color is black.

The features and specifications may be subject to change

without notice.

*1HD/DVD/DTV input signals supported on this system

480P (60 Hz) 480I (60 Hz) 525P (60 Hz)

525I (60 Hz) 576P (50 Hz) 576I (50 Hz)

625P (50 Hz) 625I (50 Hz) 720P (60 Hz)

1035I (60 Hz) 1080I (50 Hz) 1080I (60 Hz)

2

The 5-BNC connectors are used as RGB/PC2 and COMP2 input.

*

Select one of them under “BNC INPUT”.

Other Features Motion compensated 3D Scan Converter (NTSC,

Accessories Remote control with two AAA batteries, Power

Regulations UL Approved (UL 60065 and CAN/CSA-C22.2

*English, German, French, Italian, Spanish, Swedish, Chinese, Russian

PAL, 480I, 576I, 525I, 625I, 1035I, 1080I), 2-3

pull down Converter (NTSC, 480I, 525I, 1035I,

1080I (60Hz)), 2-2 pull down Converter (PAL,

576I, 625I, NTSC, 480I, 525I), Digital Zoom

Function (100-900% Selectable), Self Diagnosis,

Image Burn reduction tools (PEAK BRIGHT,

INVERSE WHITE, ORBITER), Color

Temperature select (high/medium/mid low/low,

user has 4 memories), Auto Picture, Input Skip,

Color Adjust, Low Tone (3 mode), Gamma

Correction (4 mode), Plug and play (DDC1,

DDC2b, RGB3: DDC2b only),

cord, Owner’s Guide, Safety metal fittings, Ferrite

cores, Cable clamps, Registration Card, BNCRCA Adapters

No. 60065-03

Meets ICES–003 Class B requirements

Meets FCC Class B requirements

8

PD-5065

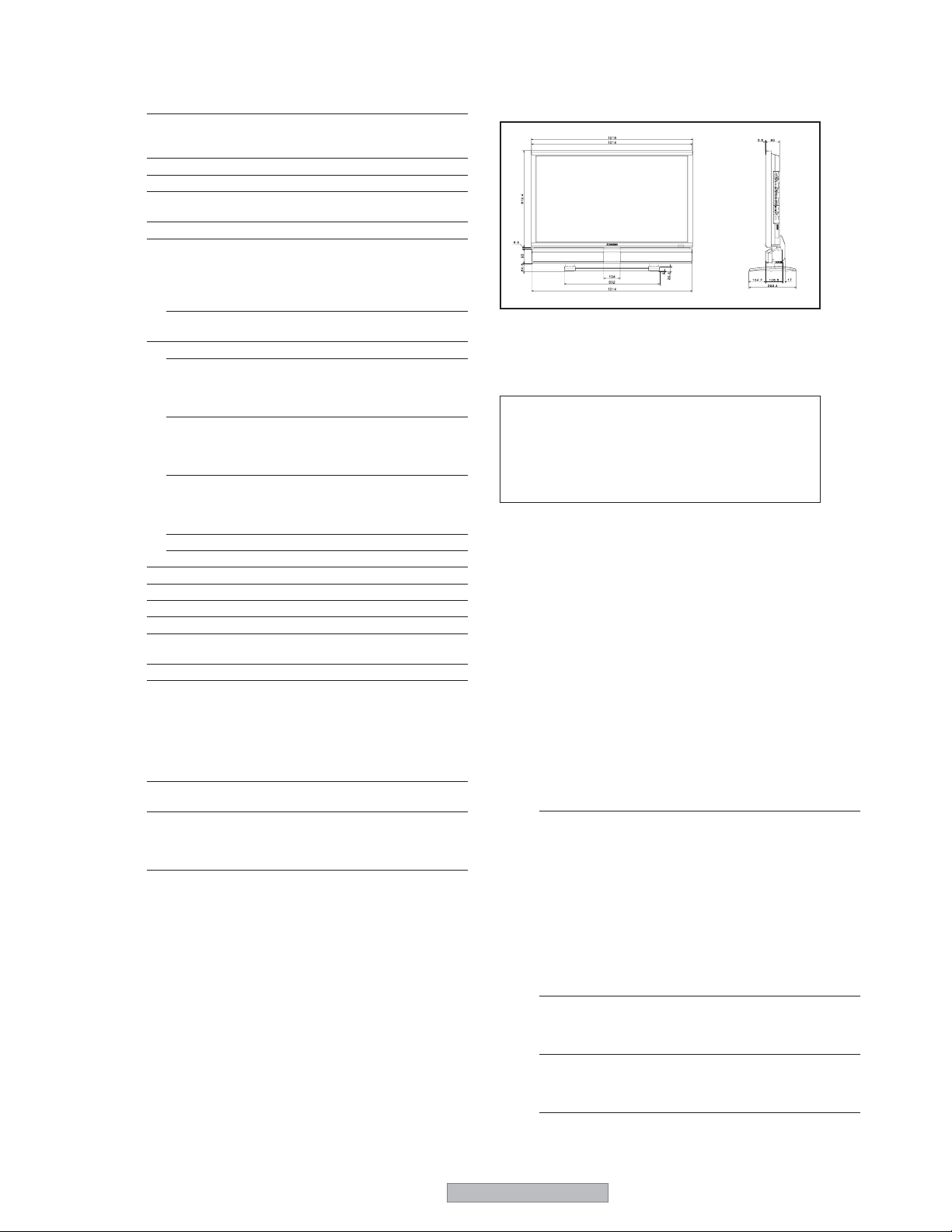

• PD-4265 Specifications

Screen Size 36.1"(H) x 20.4"(V) inches

918(H) x 518(V) mm

diagonal 42"

Aspect Ratio 16 : 9

Resolution 1024(H) x 768(V) pixels

Pixel Pitch 0.036"(H) x 0.027"(V) inches

0.897(H) x 0.675(V) mm

Color Processing 4,096 steps, 68.7 billion colors

Signals

Synchronization Range Horizontal : 15.5 to 110 kHz

(automatic : step scan)

Vertical : 50.0 to 120.0 Hz

(automatic : step scan)

Input Signals RGB, NTSC (3.58/4.43), PAL (B,G,M,N),

PAL60, SECAM, HD

1

*

, DVD*1 , DTV*

1

Input Terminals

RGB

RGB 1 (Analog)mini D-sub 15-pin 1

RGB 2 (Analog)BNC (R, G, B, H/CS, V) 1

2

*

MONLINK (Digital)HDMI

Video

INPUT1 BNC 1

INPUT 2 RCA-pin 1

INPUT 3 S-Video: DIN 4-pin 1

DVD/HD/DTV

COMP 1 RCA-pin (Y, PB[CB], PR[CR]) 1

COMP 2 BNC (Y, PB[CB], PR[CR]) 1*

1

*

1,

2

*

MONLINK HDMI

Audio Stereo RCA 3(Selectable)

External Control D-sub 9-pin 1(RS-232C)

Sound output 8W+8W at 6 ohm

Power Supply AC100-240V 50/60Hz

Current Rating 5.2A (maximum)

Power Consumption 305W (typical), 1.5W(stand-by)

Dimensions 40 (W) x 30 (H) x 11.8 (D) inches

1018 (W) x 763 (H) x 300(D) mm

Weight 95 lbs / 43 kg(Net), 113 lbs / 51.0 kg(Gross)

Environmental Considerations

OperatingTemperature 0°C to 40°C / 32°F to 104°F

Humidity 20 to 80% (no condensation)

Altitude 0 to 9180 feet / 0 to 2800m

StorageTemperature -10°C to 50°C / 14°F to 122°F

Humidity

10 to 90% (no condensation)

Altitude 0 to 9840 feet / 0 to 3000 m

Front Panel User Controls Input source select,

Volume up/down, OSM Control

RemoteControl Functions

Power on/off, Input source select, Menu/

Exit,Volume up/down, Adjust (UP,

DOWN,LEFT, RIGHT), Zoom up/down,

Picture control buttons

OSM Functions PICTURE(PICTURE MEMORY/CONTRAST/

BRIGHTNESS/SHARPNESS/COLOR/TINT/

NR/COLOR TEMP./WHITE BALANCE/

GAMMA/LOW TONE/SET UP LEVEL/

COLORADJUST/FILM MODE/PICTURE

MODE), AUDIO (BASS/TREBLE/BALANCE/

AUDIO INPUT1/AUDIO INPUT2/AUDIO

INPUT3/MONITORLINK), IMAGE ADJUST

(ASPECT MODE/V-POSITION/H-POSITION/

V-HEIGHT/H-WIDTH/AUTO PICTURE/FINE

PICTURE/PICTURE ADJ.),

SETUP (LANGUAGE*/BNC INPUT/HD

SELECT/RGB SELECT/HDMI SET UP/

COLOR SYSTEM/BACK GROUND/GRAY

LEVEL/S1/S2/DISPLAY MENU/MENU

ADJUST/ALL RESET), FUNCTION (POWER

MGT./INPUT SKIP/LONG LIFE [PEAK

BRIGHT/ ORBITER / INVERSE WHITE /

SOFT FOCUS / ORBITER MENU/MENU

CONTRAST]), SIGNAL INFO.

Bezel color is black.

Thefeatures and specifications may be subject to change without

notice.

*1HD/DVD/DTV input signals supported on this system

480P (60 Hz) 480I (60 Hz) 525P (60 Hz)

525I (60 Hz) 576P (50 Hz) 576I (50 Hz)

625P (50 Hz) 625I (50 Hz) 720P (60 Hz)

1035I (60 Hz) 1080I (50 Hz) 1080I (60 Hz)

2

The 5-BNC connectors are used as RGB/PC2 and COMP2 input.

*

Select one of them under “BNC INPUT”

Other Features Motion compensated 3D Scan Converter (NTSC,

PAL, 480I, 576I, 525I, 625I, 1035I, 1080I), 2-3

pull down Converter (NTSC, 480I, 525I, 1035I,

1080I (60Hz)), 2-2 pull down Converter (PAL,

576I, 625I, NTSC, 480I, 525I), Digital Zoom

Function (100-900% Selectable), Self Diagnosis,

Image Burn reduction tools (PEAK BRIGHT,

INVERSE WHITE, ORBITER), Color

Temperature select (high/middle/middle low/low,

user has 4 memories), Auto Picture, Input Skip,

Color Adjust, Low Tone (3 mode), Gamma

Correction (4 mode), Plug and play (DDC1,

DDC2b, RGB3: DDC2b only)

Accessories Remote control with two AAA batteries, Power

cord, Owner’s Guide, Safety metal fittings, Ferrite

cores, Cable clamps, Registration Card, BNCRCA Adapters

Regulations UL Approved (UL60065,and CAN/CSA– C22.2)

No.60065-03

Meets ICES-003 Class B requirements

Meets FCC Class B requirements

*English, German, French, Italian, Spanish, Swedish, Chinese, Russian

PD-5065

9

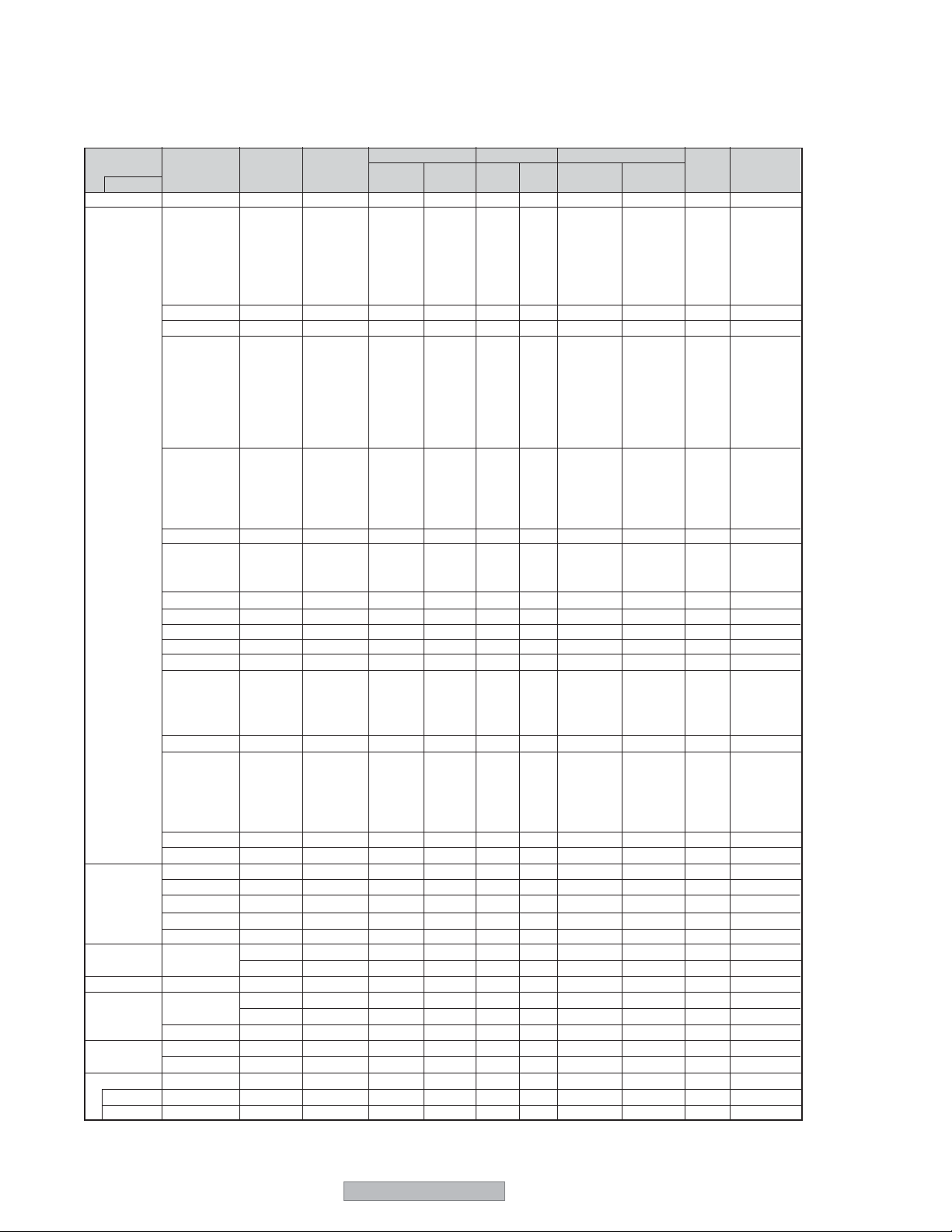

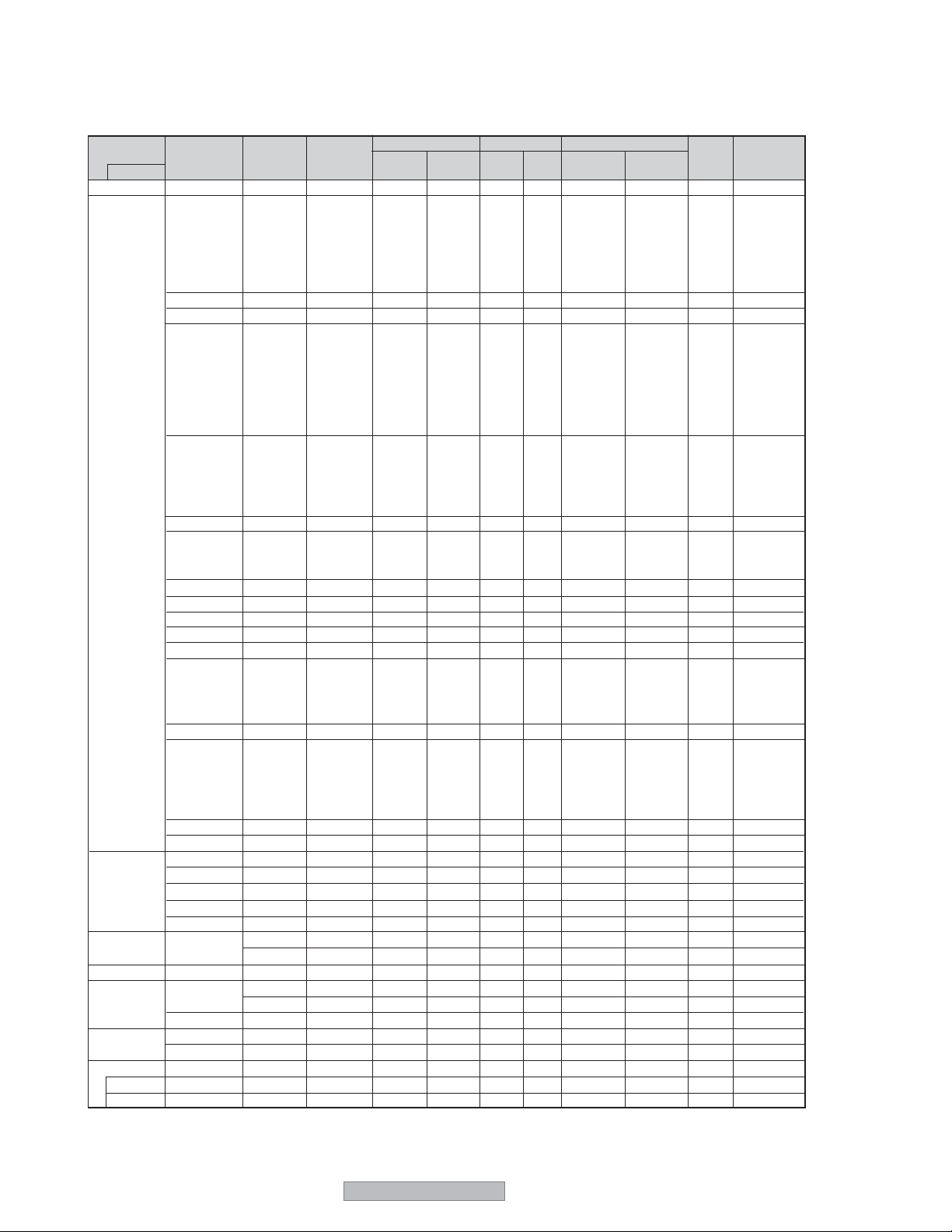

TABLE OF SIGNAL SUPPORTED

Supported resolution (PD-5065)

• When the screen mode is NARROW, each signal is converted to a 1024 dots 768 lines signal. (Except for *

• When the screen mode is STANDARD, each signal is converted to a 1365 dots 768 lines signal. (Except for *

Computer input signals supported by this system

Model

Signal Type

IBM PC/AT*

7

compatible

computers

Apple

Macintosh*

Work Station

(EWS4800)

Work Station(HP)

Work Station

(SUN)

5*7

7

*

7

*

7

*

Work Station

(SGI)

IDC-3000G

PAL625P

NTSC525P

Dots x lines

640 x 400

640 x 480

848 x 480

852 x 480*

800 x 600

1024 x 768

1152 x 864

1280 x 768

1280 x 768*

1280 x 800*

1280 x 854*

1360 x 765

1360 x 768

1376 x 768

1280 x 1024

1680 x 1050*

1600 x 1200

1920 x 1200*

1920 x 1200RB

640 x 480

832 x 624

1024 x 768

1152 x 870

1440 x 900*

1280 x 1024

1280 x 1024

1152 x 900

1280 x 1024

1024 x 768

1280 x 1024

768 x 576

640 x 480

Vertical

frequency

(Hz)

1

8

8

8

8

8

8

*

8

70.1

59.9

72.8

75.0

85.0

100.4

120.4

60.0

60.0

56.3

60.3

72.2

75.0

85.1

99.8

120.0

60.0

70.1

75.0

85.0

100.6

75.0

56.2

59.8

69.8

60.0

60.0

60.0

60.0

59.9

60.0

75.0

85.0

100.1

60.0

60.0

65.0

70.0

75.0

85.0

60.0

60.0

66.7

74.6

74.9

75.1

60.0

60.0

71.2

72.0

66.0

76.0

76.1

60.0

60.0

50.0

59.9

Horizontal

frequency

(kHz)

31.5

31.5

37.9

37.5

43.3

51.1

61.3

31.0

31.7

35.2

37.9

48.1

46.9

53.7

63.0

75.7

48.4

56.5

60.0

68.7

80.5

67.5

45.1

48.0

56.0

49.7

53.1

47.7

47.7

48.3

64.0

80.0

91.1

108.5

65.3

75.0

81.3

87.5

93.8

106.3

74.6

74.0

35.0

49.7

60.2

68.7

56.0

64.6

75.1

78.1

61.8

71.7

81.1

49.7

63.9

31.4

31.5

Sync Polarity Presence

Horizontal

Sync on G

Sync on G

Sync on G

Sync on G

C Sync

C Sync

C Sync

NEG

NEG

NEG

NEG

NEG

NEG

NEG

POS

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

NEG

POS

POS

NEG

POS

POS

POS

NEG

NEG

NEG

POS

POS

NEG

POS

POS

POS

POS

NEG

POS

POS

POS

POS

POS

NEG

NEG

NEG

NEG

NEG

– –

– –

– –

NEG

NEG

Vertical

NEG

NEG

NEG

NEG

NEG

NEG

NEG

POS

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

NEG

POS

POS

NEG

POS

POS

NEG

POS

NEG

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

POS

POS

POS

POS

POS

NEG

NEG

Sync on G

Sync on G

Sync on G

Sync on G

NEG

NEG

NEG

– –

C Sync

C Sync

C Sync

– –

– –

NEG

NEG

Horizontal

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

YES

YES

YES

– –

– –

– –

– –

– –

– –

YES

YES

Vertical

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

YES

YES

YES

– –

– –

– –

– –

– –

– –

YES

YES

2, *3

)

2

)

Screen mode

NARROW

(4:3)

– –

YES

YES

YES

YES

YES

YES

– –

– –

YES

YES

YES

YES

YES

YES

YES

2

YES*

2

YES*

2

YES*

2

YES*

2

YES*

YES

– –

– –

– –

– –

– –

– –

– –

– –

3

YES*

3

YES*

3

YES*

3

YES*

– –

YES

YES

YES

YES

YES

– –

– –

YES

YES

2

YES*

YES

– –

3

YES*

3

YES*

3

YES*

YES

YES

3

YES*

2

YES*

3

YES*

6

YES*

6

YES*

STANDARD

(16:9)

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

2

YES*

2

YES*

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

6

YES*

RGB

select*

YES

STILL

– –

STILL

– –

– –

– –

WIDE2

WIDE1

STILL

STILL

– –

– –

– –

– –

NO

STILL

– –

STILL

– –

– –

STILL

WIDE1

WIDE3

WIDE1

WIDE1

WIDE2

WIDE1

WIDE1

WIDE2

STILL

– –

– –

– –

WIDE4

– –

– –

– –

– –

– –

WIDE2

WIDE3

– –

– –

WIDE1

WIDE1

– –

– –

– –

– –

– –

– –

– –

– –

– –

– –

MOTION

4

Memory

4

5

7

8

9

41

42

19

17

11

12

13

14

15

43

44

24

25

26

27

45

51

52

80

66

21

37

22

22

53

29

30

40

47

38

54

55

56

57

58

81

88

6

16

28

39

89

29

48

59

60

61

30

62

29

31

32

10

PD-5065

*1 Only when using a graphic accelerator board that is capable of displaying 852 x 480.

*2 The picture is displayed in the original resolution.

*3 The aspect ratio is 5:4. This signal is converted to a 960 dots x 768 lines signal.

*4 Normally the RGB select mode suite for the input signals is set automatically. If the picture is not displayed

properly, set the RGB mode prepared for the input signals listed in the table above.

*5 To connect the display to Macintosh computer, use a monitor adapter (NOT INCLUDED).

*6 Other screen modes (EXPAND and STRETCH) are available as well.

*7 When viewing a moving picture at a vertical frequency greater than 65Hz, the picture may sometimes be unstable

y). If this occurs, please set the refresh rate of the external equipment to 60Hz.

(jump

To view 480I@60Hz (480 interlaced lines, 60Hz refresh rate) or 576I@50Hz (567 interlaced lines, 50Hz

refresh rate) when sync polarity is “Sync on Green”, set “RGB SELECT” to “MOTION”.

*8 CVT standard compliant.

NOTE:

•

While the input signals comply with the resolution listed in the table above, you may have to adjust the position and

size of the picture or the fine picture because of errors in synchronization of your computer.

•

When a 1280 dots x 1024 lines signal or 1600 dots x 1200 lines signal is input to the monitor, the picture will be

compressed.

•

This display has a resolution of 1365 dots x 768 lines. It is recommended that the input signal should be XGA, wide

XGA, or equivalent.

•

With digital input some signals are not accepted.

•

The sync may be disturbed when a nonstandard signal other than the aforementioned is input.

•

If you are connecting a composite sync signal, use the HD terminal.

• “IBM PC/AT” and “XGA” are registered trademarks of International Business Machines, Inc. of the United

States.

• “Apple Macintosh” is a registered trademark of Apple Computer, Inc. of the United States.

PD-5065

11

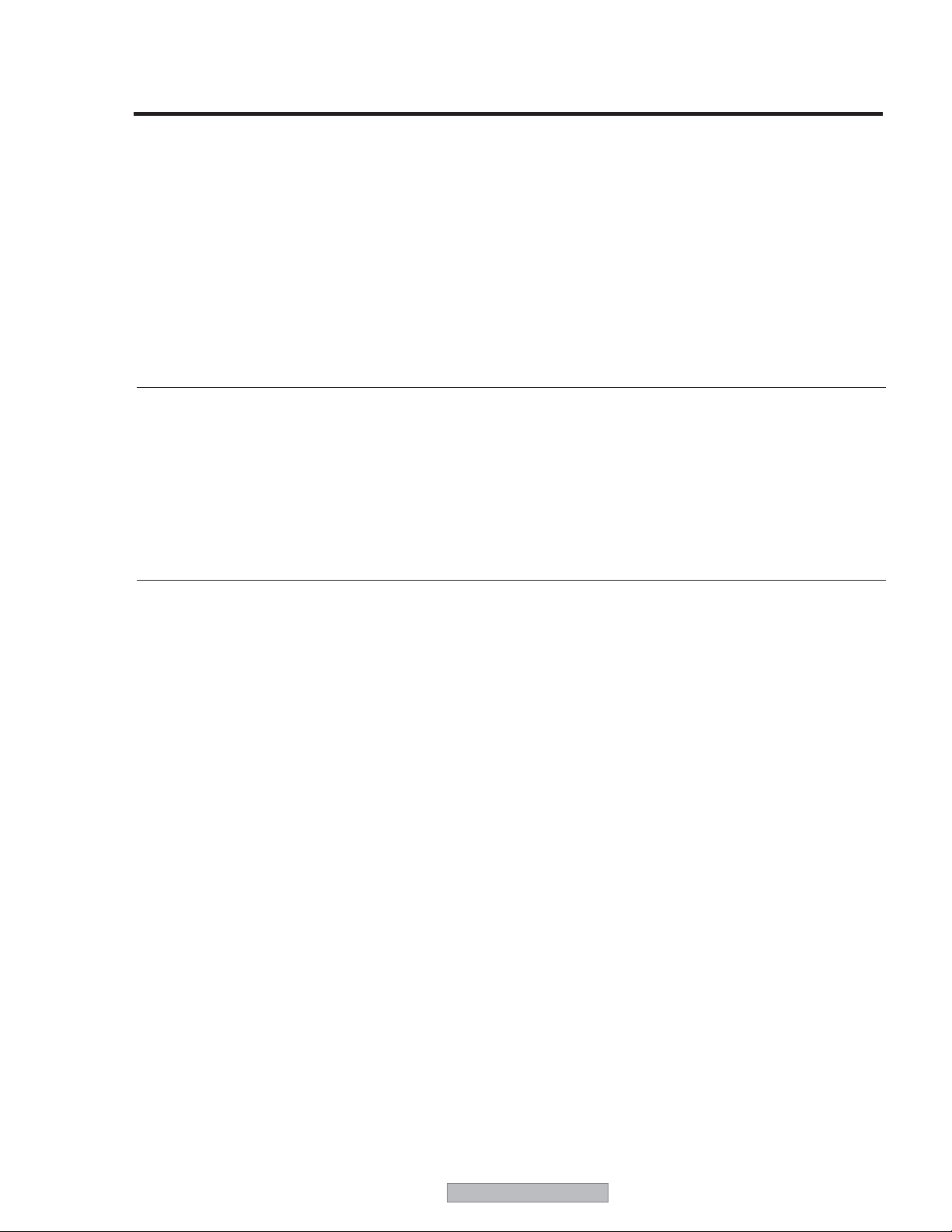

Supported resolution (PD-4265)

• When the screen mode is NARROW, each signal is converted to a 768 dots 768 lines signal. (Except for *3)

• When the screen mode is STANDARD, each signal is converted to a 1024 dots 768 lines signal.

Computer input signals supported by this system

Model

Signal Type

IBM PC/AT*

7

compatible

computers

Apple

Macintosh*

Work Station

(EWS4800)

Work Station(HP)

Work Station

(SUN)

5 *7

7

*

*

7

*

Work Station

(SGI)

IDC-3000G

PAL625P

NTSC525P

Dots x lines

640 x 400

640 x 480

848 x 480

852 x 480*

800 x 600

1024 x 768

1152 x 864

1280 x 768

1280 x 768*

1280 x 800*

1280 x 854*

1360 x 765

1360 x 768

1376 x 768

1280 x 1024

1680 x 1050*

1600 x 1200

1920 x 1200*

1920 x 1200RB

640 x 480

832 x 624

1024 x 768

1152 x 870

1440 x 900*

1280 x 1024

7

1280 x 1024

1152 x 900

1280 x 1024

1024 x 768

1280 x 1024

768 x 576

640 x 480

Vertical

frequency

(Hz)

1

8

8

8

8

8

8

*

8

70.1

59.9

72.8

75.0

85.0

100.4

120.4

60.0

60.0

56.3

60.3

72.2

75.0

85.1

99.8

120.0

60.0

70.1

75.0

85.0

100.6

75.0

56.2

59.8

69.8

60.0

60.0

60.0

60.0

59.9

60.0

75.0

85.0

100.1

60.0

60.0

65.0

70.0

75.0

85.0

60.0

60.0

66.7

74.6

74.9

75.1

60.0

60.0

71.2

72.0

66.0

76.0

76.1

60.0

60.0

50.0

59.9

Horizontal

frequency

(kHz)

31.5

31.5

37.9

37.5

43.3

51.1

61.3

31.0

31.7

35.2

37.9

48.1

46.9

53.7

63.0

75.7

48.4

56.5

60.0

68.7

80.5

67.5

45.1

48.0

56.0

49.7

53.1

47.7

47.7

48.3

64.0

80.0

91.1

108.5

65.3

75.0

81.3

87.5

93.8

106.3

74.6

74.0

35.0

49.7

60.2

68.7

56.0

64.6

75.1

78.1

61.8

71.7

81.1

49.7

63.9

31.4

31.5

Sync Polarity Presence

Horizontal

NEG

NEG

NEG

NEG

NEG

NEG

NEG

POS

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

NEG

POS

POS

NEG

POS

POS

POS

NEG

NEG

NEG

POS

POS

NEG

POS

POS

POS

POS

NEG

POS

POS

POS

POS

POS

NEG

NEG

Sync on G

Sync on G

Sync on G

Sync on G

NEG

NEG

NEG

C Sync

C Sync

C Sync

NEG

NEG

– –

– –

– –

Vertical

NEG

NEG

NEG

NEG

NEG

NEG

NEG

POS

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

NEG

POS

POS

NEG

POS

POS

NEG

POS

NEG

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

POS

POS

POS

POS

POS

NEG

NEG

Sync on G

Sync on G

Sync on G

Sync on G

NEG

NEG

NEG

– –

C Sync

C Sync

C Sync

– –

– –

NEG

NEG

Horizontal

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

YES

YES

YES

– –

– –

– –

– –

– –

– –

YES

YES

Vertical

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

YES

YES

YES

– –

– –

– –

– –

– –

– –

YES

YES

NARROW

Screen mode

(4:3)

– –

YES

YES

YES

YES

YES

YES

– –

– –

YES

YES

YES

YES

YES

YES

YES

2

YES*

2

YES*

2

YES*

2

YES*

2

YES*

YES

– –

– –

– –

– –

– –

– –

– –

– –

3

YES*

3

YES*

3

YES*

3

YES*

– –

YES

YES

YES

YES

YES

– –

– –

YES

YES

2

YES*

YES

– –

3

YES*

3

YES*

3

YES*

YES

YES

3

YES*

2

YES*

3

YES*

6

YES*

6

YES*

STANDARD

(16:9)

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

2

YES*

2

YES*

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

6

YES*

RGB

select*

YES

STILL

– –

STILL

– –

– –

– –

WIDE2

WIDE1

STILL

STILL

– –

– –

– –

– –

NO

STILL

– –

STILL

– –

– –

STILL

WIDE1

WIDE3

WIDE1

WIDE1

WIDE2

WIDE1

WIDE1

WIDE2

STILL

– –

– –

– –

WIDE4

– –

– –

– –

– –

– –

WIDE2

WIDE3

– –

– –

WIDE1

WIDE1

– –

– –

– –

– –

– –

– –

– –

– –

– –

– –

MOTION

4

Memory

4

5

7

8

9

41

42

19

17

11

12

13

14

15

43

44

24

25

26

27

45

51

52

80

66

21

37

22

22

53

29

30

40

47

38

54

55

56

57

58

81

88

6

16

28

39

89

29

48

59

60

61

30

62

29

31

32

12

PD-5065

*1 Only when using a graphic accelerator board that is capable of displaying 852 x 480.

*2 The picture is displayed in the original resolution. The picture will be compressed for other signals.

*3 The aspect ratio is 5:4. This signal is converted to a 720 dots x 768 lines signal.

*4 Normally the RGB select mode suite for the input signals is set automatically. If the picture is not displayed

properly, set the RGB mode prepared for the input signals listed in the table above.

*5 To connect the monitor to Macintosh computer, use the monitor adapter (D-Sub 15-pin) to your computer’s

video port.

*6 Other screen modes (EXPAND and STRETCH) are available as well.

*7 When viewing a moving picture at a vertical frequency greater than 65Hz, the picture may sometimes be

unstable (jumpy). If this occurs, please set the refresh rate of the external equipment to 60Hz.

To view 480I@60Hz (480 interlaced lines, 60Hz refresh rate) or 576I@50Hz (567 interlaced lines, 50Hz

refresh rate) when sync polarity is “Sync on Green”, set “RGB SELECT” to “MOTION”.

*8 CVT standard compliant.

NOTE:

•

While the input signals comply with the resolution listed in the table above, you may have to adjust the position and

size of the picture or the fine picture because of errors in synchronization of your computer.

•

This monitor has a resolution of 1024 dots x 768 lines. It is recommended that the input signal should be XGA, wide

XGA, or equivalent.

•

With digital input some signals are not accepted.

•

The sync may be disturbed when a nonstandard signal other than the aforementioned is input.

•

If you are connecting a composite sync signal, use the HD terminal.

•“IBM PC/AT” and “XGA” are registered trademarks of International Business Machines, Inc. of the United States.

• “Apple Macintosh” is a registered trademark of Apple Computer, Inc. of the United States.

PD-5065

13

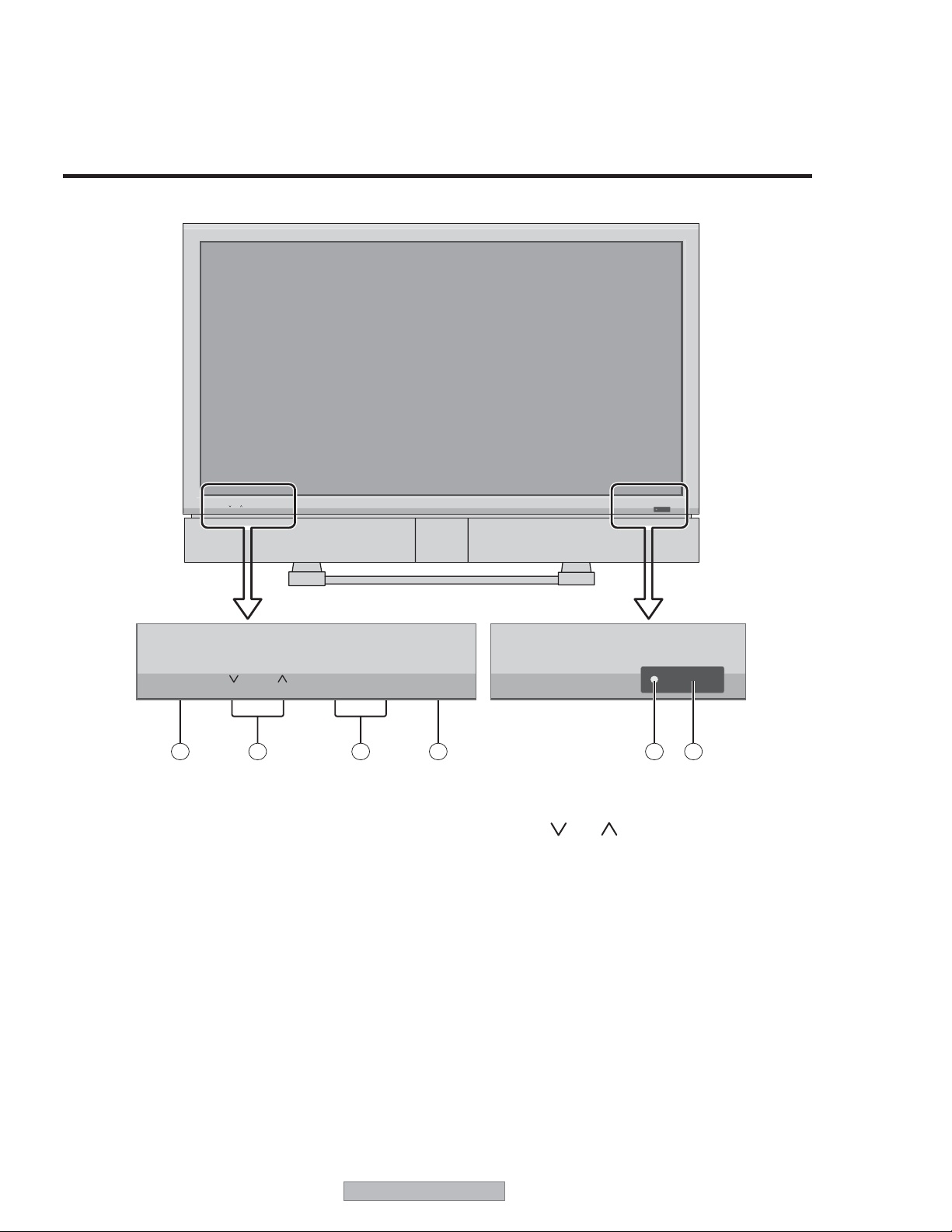

1.2 FRONT PANEL

Part Names and Function

Front View

VOLUME

MENU/ENTER LEFT/-RIGHT/+INPUT/EXIT

MENU/ENTER LEFT/

6

VOLUME

5

-

4

1 REMOTE SENSOR WINDOW

Receives the signals from the remote control.

2 POWER/STANDBY Indicator

When the power is on ............................. Lights green.

When the power is in the standby mode ... Lights red.

3 INPUT / EXIT BUTTON

Switches the input.

The available inputs depend on the setting of “BNC

INPUT”, “RGB SELECT” and “HDMI SET UP”.

Functions as the EXIT buttons in the On-Screen Menu

mode.

RIGHT/+INPUT/EXIT

3

1

2

5 VOLUME

and

Adjusts the volume. Functions as the ADJUST ( /

buttons in the On-Screen Menu mode.

6 MENU/ENTER BUTTON

Display the main menu or select a menu item. The

MENU/ENTER button can also be used to turn the

display on or off.

To turn the display on, press MENU/ENTER button.

To turn the display off, press and hold the MENU/

ENTER button for five seconds.

)

4 LEFT/– and RIGHT/+

Functions as the ADJUST (

Screen Menu mode.

14

) buttons in the On-

/

PD-5065

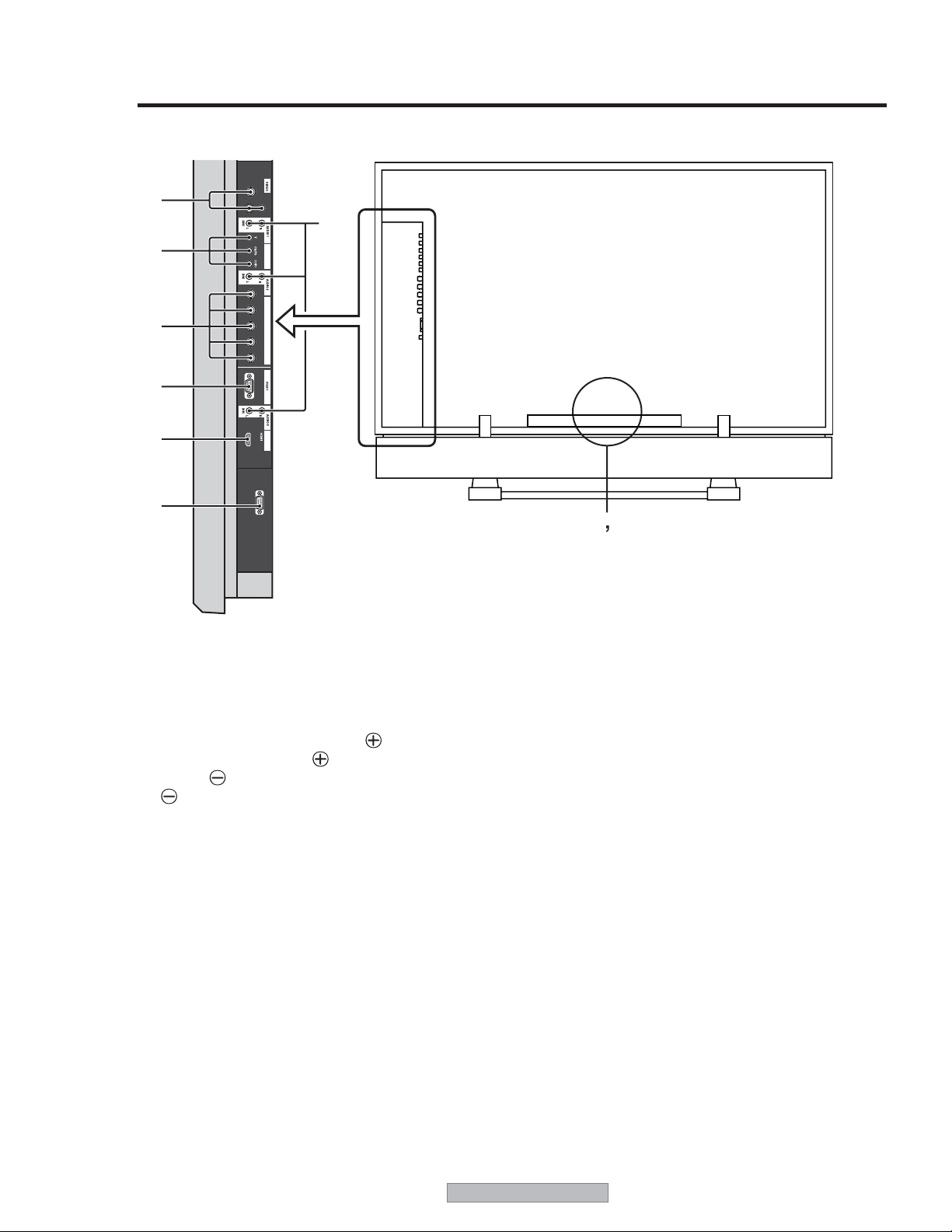

Side View Rear View

INPUT 1

INPUT 2

C

INPUT 3

D

E

COMPONENT 1

R/Cr/Pr G/Y

RGB2/COMPONENT2

B/Cb/Pb H V

F

G

H

MONITOR LINK

MONITORLINK

CONTROL

I

A AC IN

Connect the included power cord here.

B EXT SPEAKER L and R

Maintain the correct polarity. The

wire is connected to the

and the

(negative) speaker wire is connected to the

EXT SPEAKER terminal

EXT SPEAKER terminal on both LEFT and

RIGHT channels.

C INPUT1, 2, 3 (BNC, RCA, S-Video)

Connect VCR s, DVD s or Video Cameras, etc. here.

D AUDIO1, AUDIO2, AUDIO3

These are audio input terminals.

The input is selectable. Select which video input to

assign them to from the audio menu screen.

(positive) speaker

AB

F RGB2 / COMPONENT2

COMP2: You can connect DVDs, High

Definition sources, Cable Boxes, etc.

here.

This input can be set for use with an

RGB or component source.

RGB2: You can connect an analog RGB signal

and the syncronization signal.

G RGB1 (D-Sub)

Connect an analog RGB signal from a computer, etc.

here.

H MONITORLINK/HDMI

Connect a digital signal from a source with a HDMI

output.

E COMPONENT1

Connect DVD s, Cable Boxes or High Definition

sources, etc. here.

I MONITORLINK CONTROL (RS-232C)

This terminal is used when operating and controlling

the display externally (by external control).

PD-5065

15

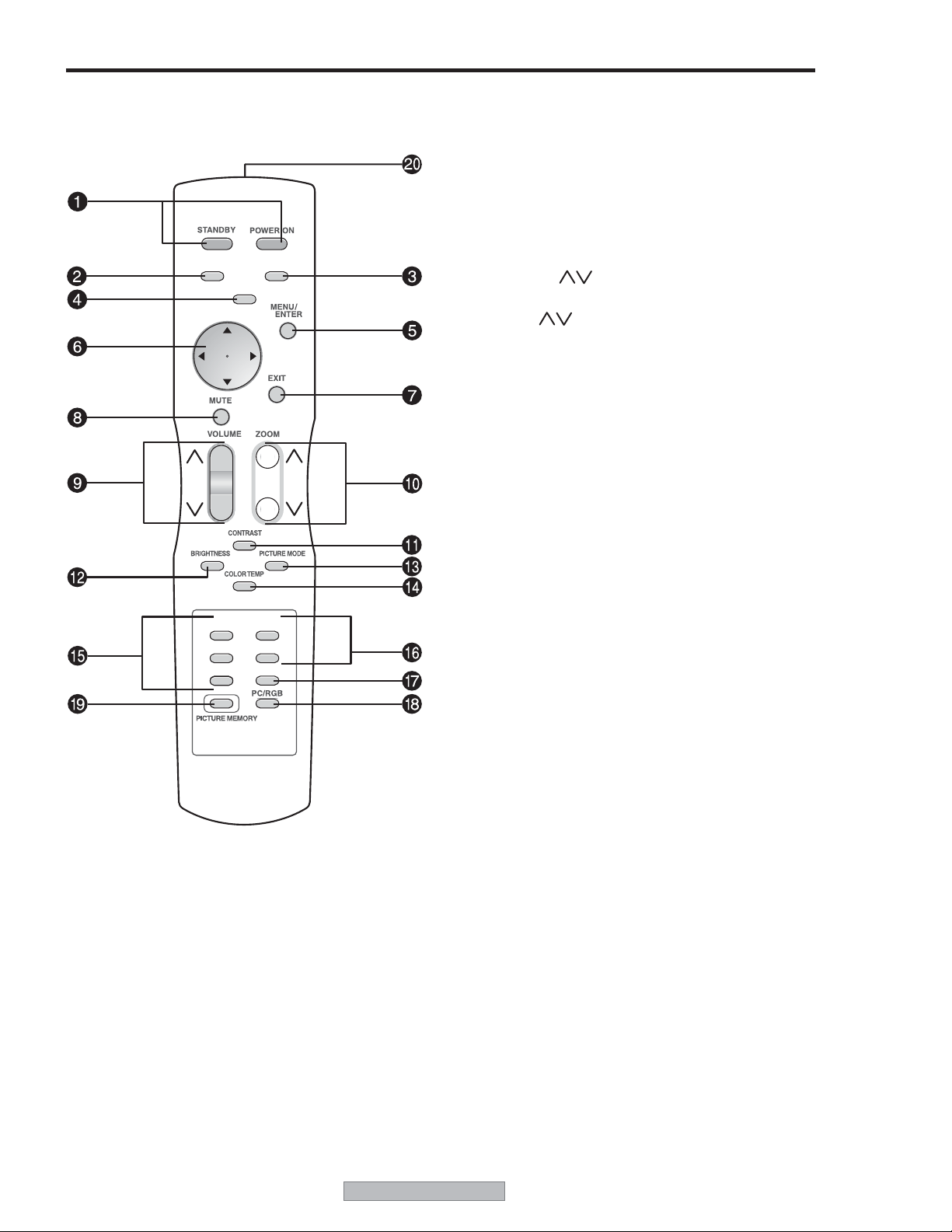

Remote Control

FORMAT

DEVICE

INFO

COMP 1

COMP 2

MONLINK

SLEEP

ADJUST

INPUT 1

INPUT 2

INPUT 3

1 POWER ON/STANDBY

Switches the power to ON or STANDBY mode.

2 SLEEP

Press this button to activate the off timer.

3 INFO

Displays the source settings on the screen.

4 FORMAT

Automatically detects the signal and sets the aspect

ratio. FORMAT button is not active for all signals.

5 MENU/ENTER

Press this button to access the Menu.

Press this button during the display of the main menu

to go to the sub menu.

6 ADJUST ( / / /

)

Use these buttons to select items or settings and to

adjust settings or switch the display patterns.

7 EXIT

Press this button to exit the MAIN MENU. Press this

button during the display of the sub menu to return to

the previous menu.

8 MUTE

Press this button to mute the audio.

9 VOLUME (

)

Press this button to adjust audio volume.

0 ZOOM (

)

Press this button to enlarge or reduce the image.

- CONTRAST

Press this button to adjust contrast directly.

= BRIGHTNESS

Press this button to adjust brightness directly.

~ PICTURE MODE

Press this button to adjust picture mode directly.

! COLOR TEMP

Press this button to adjust color tone directly.

@ INPUT1, 2, 3

Press one of these buttons to select INPUT1 or INPUT2

or INPUT3 as the source.

INPUT 1-3 can also be selected using the INPUT/EXIT

button on the front panel of the display.

# COMP1, 2

Press one of these buttons to select COMP1 or COMP2

as the source.

COMP 1-2 can also be selected using the INPUT/EXIT

button on the front panel of the display.

$ MONLINK

Press this button to select MONLINK/HDMI as the

source.

% PC/RGB

Press this button to select PC/RGB as the source. PC/

RGB can also be selected using the INPUT SELECT

button on the display.

^ PICTURE MEMORY

Switches sequentially between picture memory settings

1 to 6

& Remote control signal transmitter

Transmits the remote control signal

16

PD-5065

2. DIAGNOSIS

2.1 TROUBLESHOOTING

• Problems in the power supply, such as "Failure in Power ON" or "LED flashing or lighting (alarm display)"

→ 1. Go to Power failure (P18).

• Problems in the images, such as "No pictures available"

→ 2. Go to Image errors (P24).

• No video loop-out signal is generated.

→ The MAIN PWB is faulty.

• "Remote control not effective"

→ 3. Go to Audio errors (P31).

• "Remote control not effective"

→ 4. Go to Remote control is not effective (P32).

PD-5065

17

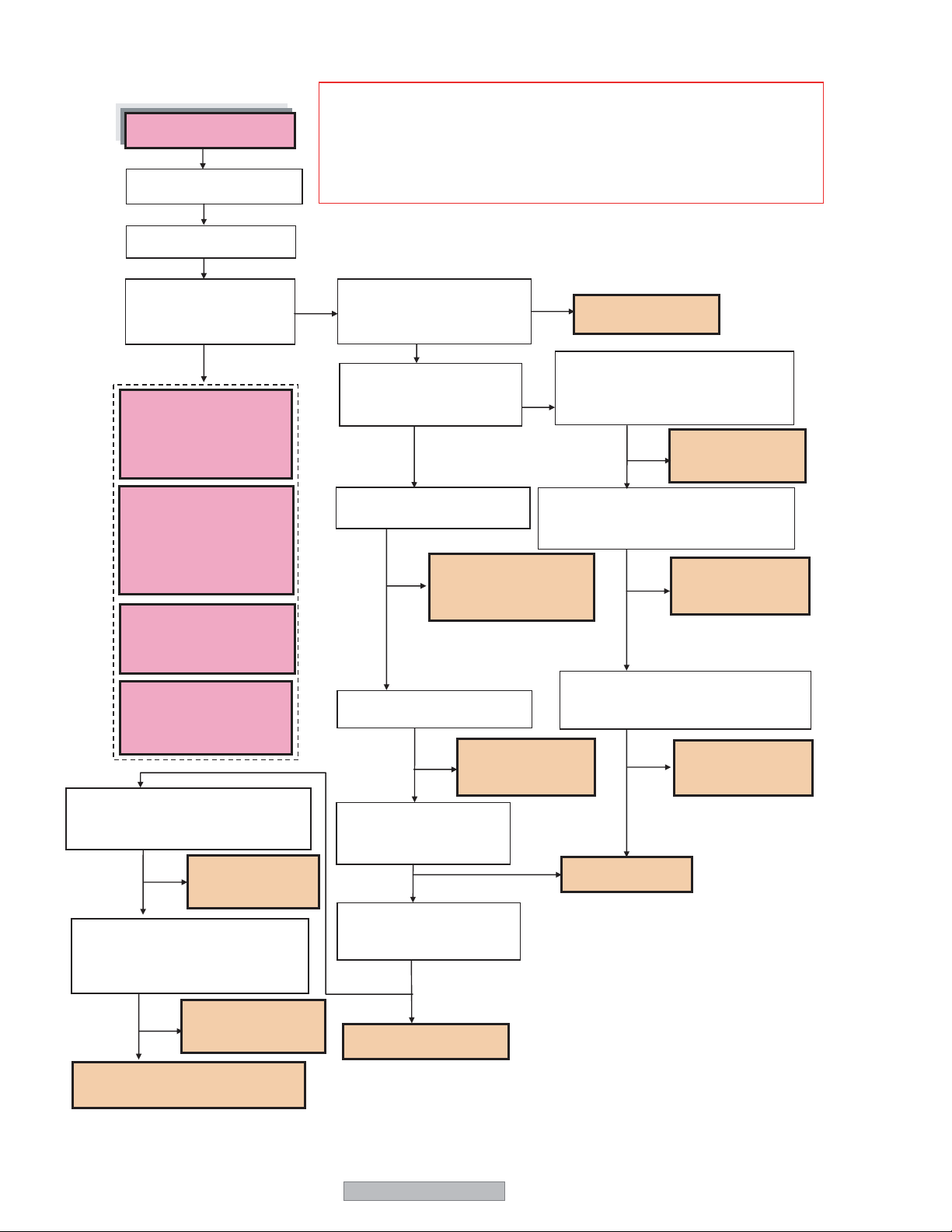

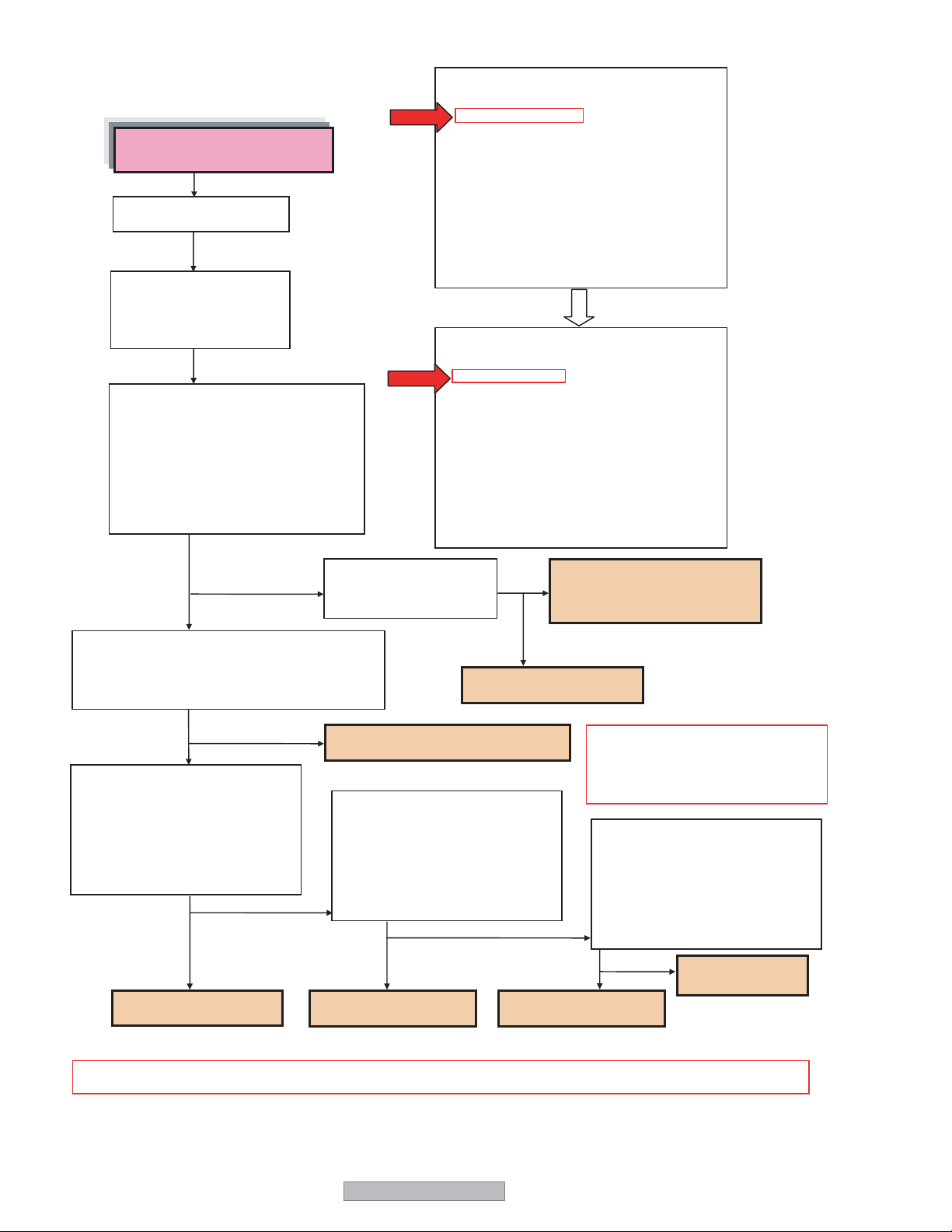

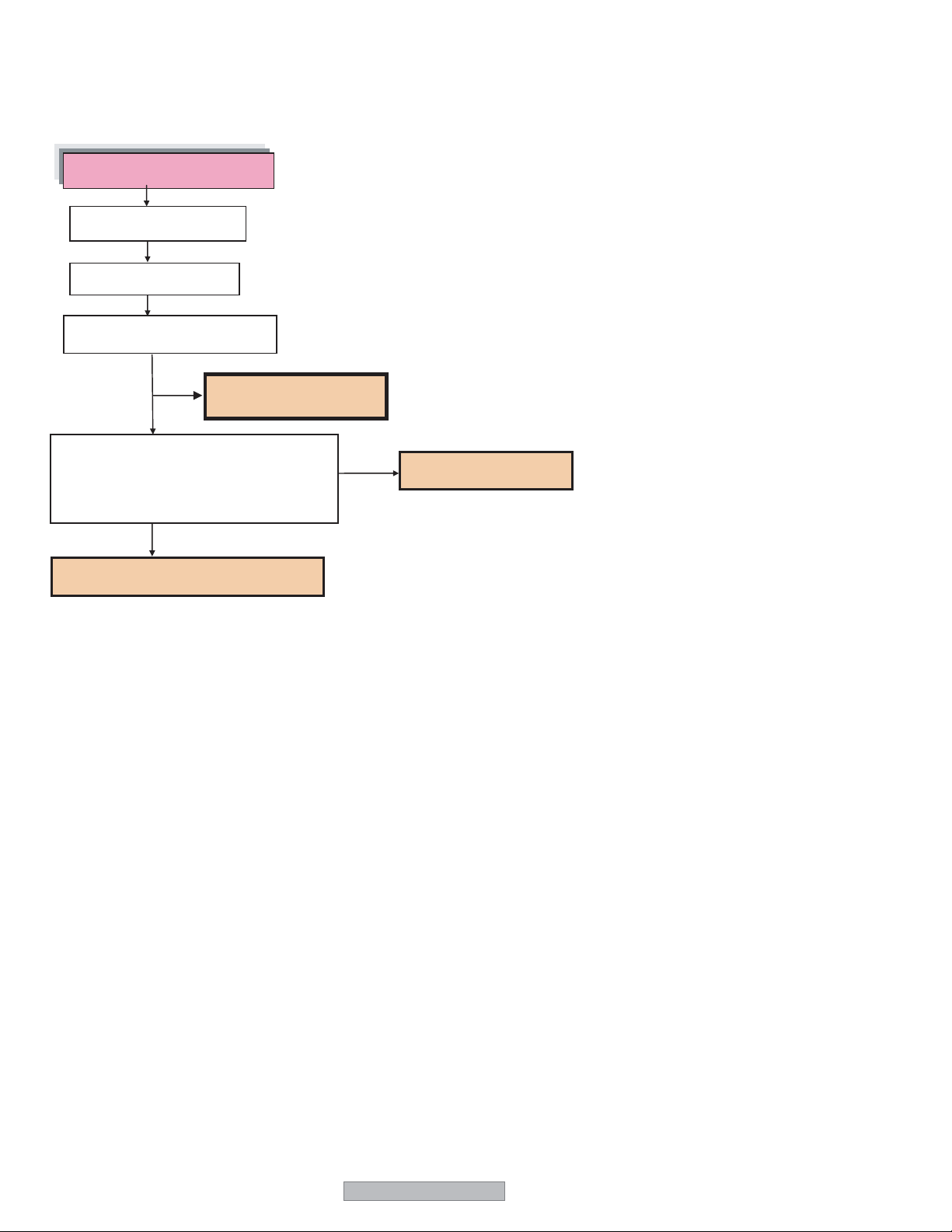

2.2 DIAGNOSIS

1. Power failure

(1) Power failure

(1)The power supply is

not turned on.

Disconnect the power cord.

Connect the power cord.

(Caution) If any abnormality is sensed in such a manner that the LED flashes

or lights, all the power lines other than those of 7Vdc (M+7V) and

5Vdc (M+5V) are automatically turned off in about 10 seconds.

When checking the power lines other than those of M+7V and

M+5V, a circuit tester or the like should have been connected in

advance. Is the AC power output available at the AC connector

Is the POWER/STANDBY

lamp lit?

YES

(2) Blinking in green

(Alarm of temperature

sensor error or fan

error)Go to (P19, P20 )

(3) Blinking in red after

repeating reciprocal flash

in red and green (POWER

ON OFF) 3times (Alarm of

temperature error) Go to

(P21).

(4) Alternation blinking in

red and green (Alarm of

panel error) Go to

(P22).

(5) Lighting in green, and

then in red (Alarm of

power line error) Go to

(P23).

Is a 5Vdc output available in the state

that the LD connector is disconnected

and the main power is turned ON?

The LD connector

YES

or the LED PWB is

NO

Is a 5Vdc output available in the

state thatthe RS connector is

disconnected and the main power is

turned ON?

NO

YES

fault.

The RS connector or

the 232C PWB is

fault.

Is the AC power output

NO

available at the AC connector

(power cord)?

YES

Is a 6.8Vdc output

available at Pin 1 of the

PM connector?

YES

Is a 6.8Vdc output available at

Pin 1 of the PW connector?

The PW connector is

NO

fault.

YES

Is a 6.8Vdc output available at

Pin 6 of the PM connector?

NO

YES

Is a 4.9Vdc output

available at Pin 3 of the

PM connector?

NO

Is a 5Vdc output available at

Pin 4 of the PW connector?

NO

The MAIN PWB is fault.

YES

YES

NO

The power cord is

defective.

Is a 6.8Vdc output available in the

state that the LD connector is

NO

disconnected and the main power is

turned ON?

Is a 6.8Vdc output available in the state

that the PW connector is disconnected

and the main power is turned ON?

Is a 6.8Vdc output available in the state

that the PM connector is disconnected

and the main power is turned ON?

The PM connector or

the MAIN PWB is

fault.

The power unit is

fault.

NO

NO

NO

The LD connector

YES

or the LED PWB is

fault.

The PW connector is

YES

fault.

YES

The PM connector or

the MAIN PWB is

fault.

The PW connector, or the MAIN PWB

is fault.

18

PD-5065

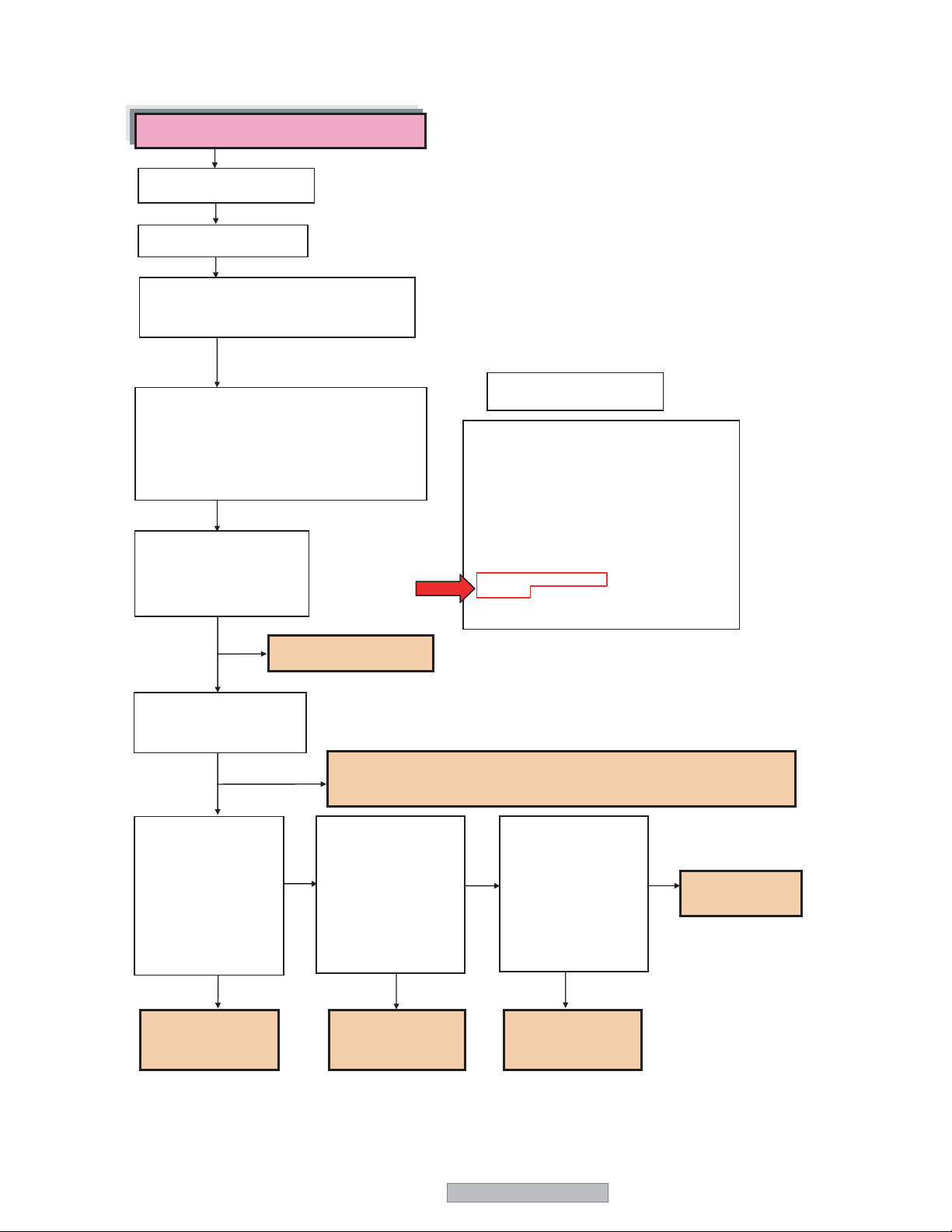

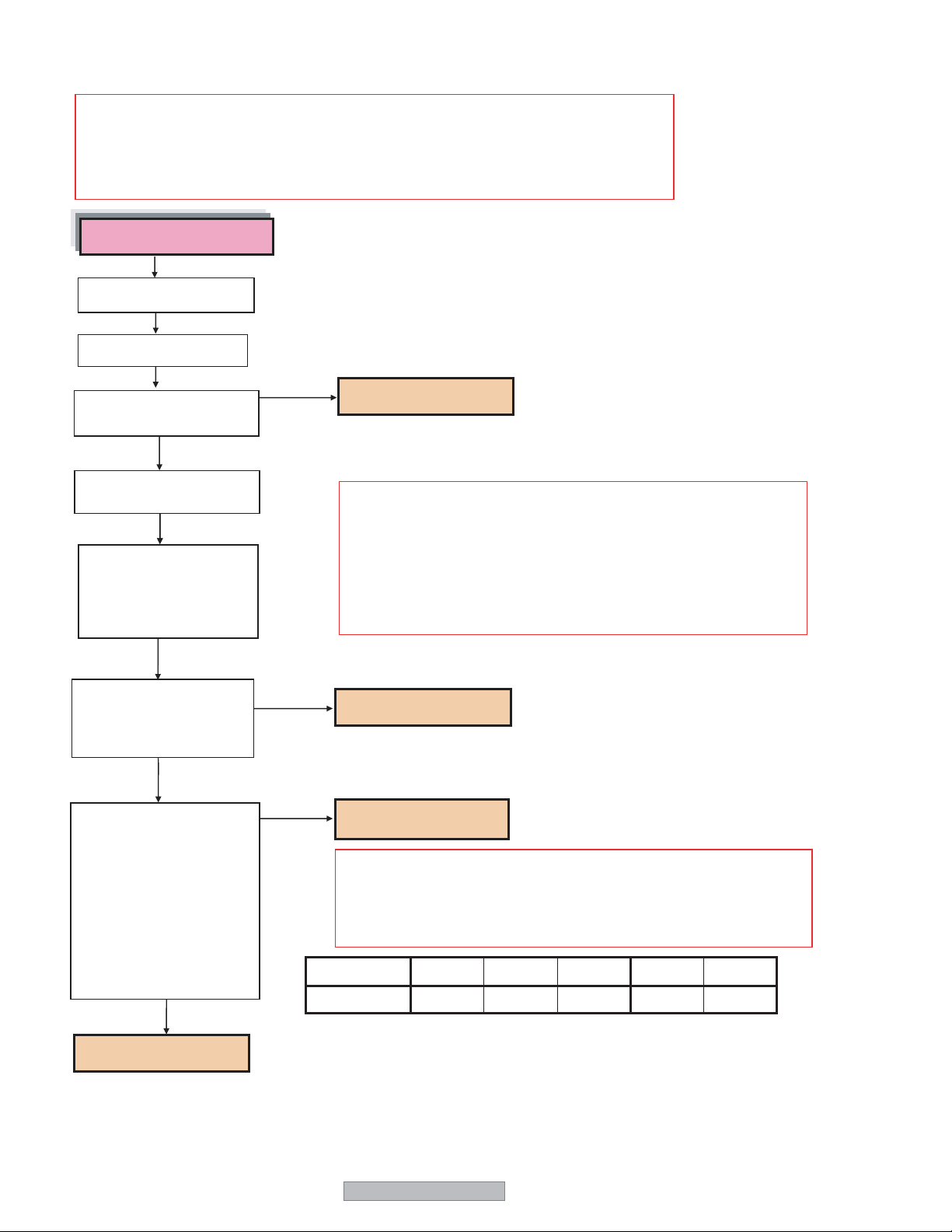

(2) Blinking in green

1 Alarm of temperature sensor error

Blinking in green (intervals of 2 seconds)

Disconnect the power cord.

Connect the power cord.

Pressing the [MENU] key of the product,

turn on the main power supply to cancel

alarming.

Press the remove control keys in the

sequential order of [MENU/ENTER]

→[EXIT]→ [SLEEP]→[EXIT] and

enter the factory adjustment menu.

Press the [MENU/ENTER] key to display

the FAN SET menu (P9/11).

Is there a display of

numerals (almost room

temperatures) at the right

side of [T1, T2, T3]?

YES

The MAIN PWB is fault.

NO

Is there a display of [-] for

all the numerals at the

right side of [T1, T2, T3] ?

NO

YES

Are there a 3.3Vdc

output at Pin 3 and a

clock signal (3.3Vpp) at

Pins 1 and 4 of the

TS in the state that the

TS connector is

disconnected and the

main power supply is

turned on?

NO

→ [MUTE]

When a [-] display is presented, the PWB with the symbol shown below is

fault. T1: SEND PWB, T2: SENB PWB, T3: SENC PWB

Are there a 3.3Vdc

output at Pin 3 and

a clock signal (3.3Vpp)

at Pins 1 and 4 of the

TR in the state that the

TR connector is

disconnected and the

main power supply is

turned on?

FAN SET

FAN MODE H CONT ENA —

FAN OFF/L — CONT UP —

FAN L/M — CONT TIME —

FAN M/H — UP STEP 2

SF SAVE 075 DOWN STEP 2

PLE SAVE 070 READ TIME 60

T ALM 095 TEMP 1

RET TME 030

PLE TIME 001

T1 030 T2 025

T3 030 T4 —MODE 2

IC ERROR —

[MENU/ENTER] NEXT [EXIT] PREV 9/11

Are there a 3.3Vdc

output at Pin 3 and a

NO

clock signal (3.3Vpp)

at Pins 1 and 4 of the

TM in the state that the

TM connector is

disconnected and the

main power supply is

turned on?

FAN SET

NO

The MAIN PWB

is fault.

YES

The TS connector

or the SENC PWB

is fault.

YES

The TR connector

or the SEND PWB

is fault.

YES

The TM connector

or the SENB PWB is

fault.

PD-5065

19

2 Alarm of fan error

Blinking in green (intervals of

0.5 seconds)

Disconnect the power cord.

Pressing the [MENU] key

of the product, Connect the

power cord. to cancel

alarming.

Is the fan running?

(Caution) When alarming is canceled,

[FAN MODE] of FAN SET

(P9/11) in the factory

adjustment menu

automatically moves from

[ENA] to [H], thus causing

the fan to run.

FAN SET

FAN MODE ENA CONT ENA —

FAN OFF/L — CONT UP —

FAN L/M — CONT TIME —

FAN M/H — UP STEP 2

SF SAVE 075 DOWN STEP 2

PLE SAVE 070 READ TIME 60

T ALM 095 TEMP LEVEL 1

RET TME 030

PLE TIME 001

T1 030 T2 025

T3 030 T4 — MODE 2

IC ERROR —

[MENU/ENTER] NEXT [EXIT] PREV 9/11

FAN SET

FAN MODE H CONT ENA —

FAN OFF/L CONT UP —

FAN L/M ——CONT TIME —

FAN M/H — UP STEP 2

SF SAVE 075 DOWN STEP 2

PLE SAVE 070 READ TIME 60

T ALM 095 TEMP LEVEL 1

RET TME 030

PLE TIME 001

T1 030 T2 025

T3 030 T4 — MODE 2

IC ERROR —

[MENU/ENTER] NEXT [EXIT] PREV 9/11

YES

NO

Is there a voltage output of 11.3Vdc for PD-4265,

11.2Vdc for PD-5065 respectively, at Pin 1 of

the FA, FB, and FC connectors?

NO

Is there a voltage output of

11.3Vdc for PD-4265, 11.2Vdc for

PD-5065 respectively, when the FA

connector is disconnected and the

mains power is turned ON?

YES

The FAN-A is fault.

YES

Is there a 3.3Vdc output

at Pin 3 of the FA and

FB, FC connectors?

The FAN-A/FAN-B/FAN-C is fault.

Is there a voltage output of

11.3Vdc for PD-4265,

11.2Vdc for PD-5065

respectively, when the FB connector

is disconnected and the mains

power is turned ON?

NO

YES

The FAN-B is fault.

YES

The MAIN PWB is fault.

The fan is out of order on the

side where a 3.3Vdc output is

generated.

NO

(Caution) The FAN-C and FC

Is there a voltage output of 11.3Vdc

for PD-4265, 11.2Vdc for PD-5065

respectively, when the FC connector

is disconnected and the mains

power is turned ON?

NO

NO

YES

The FAN-C is fault.

connectors are used

only for the 61XM3

Series.

The MAIN PWB

is fault.

(Caution) In the FAN MODE, [ENA] is automatically recovered when the main power is turned OFF→ON.

20

PD-5065

(3) Blinking in red (Alarm of temperature error)

Since the internal temperature is too high in the product, the temperature protector has been actuated. In such

a case, the following actions should be taken immediately:

1. Turn off the main power supply and pull out the power cord from the wall outlet.

2. Wait for about 60 minutes until the temperature in the main unit lowers.

3. Check whether the heat discharge port is covered with dust or the like. If yes, remove the clogging substance.

4. If the unit is used where the ambient temperature is high, it should be moved to an adequate place

(air temperature ranging from 5°C to 35°C).

PD-5065

21

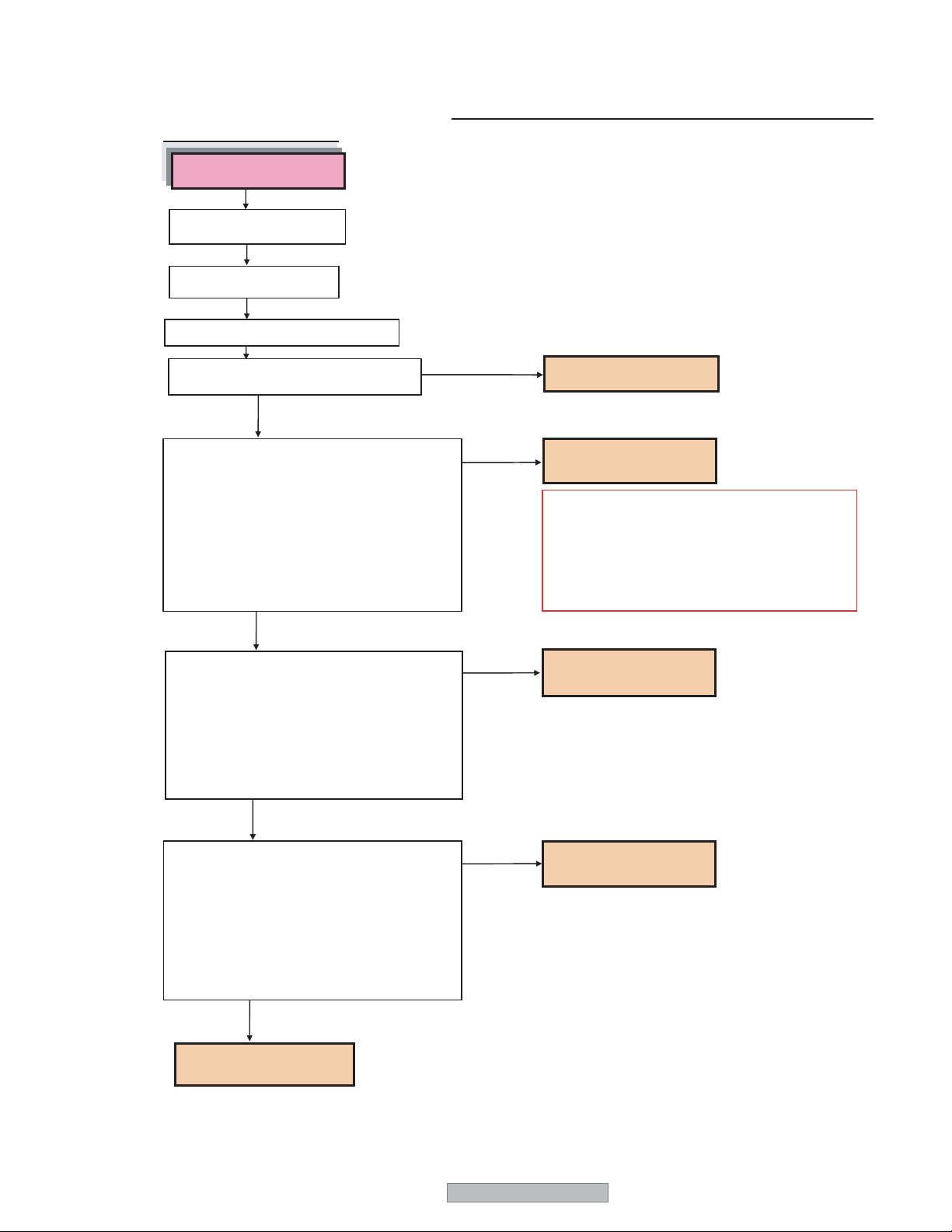

(4) Alternation blinking in red and green (Alarm of PDP error)

(Caution) How to reset the alarming condition.

Pressing the [INPUT/EXIT] key of the product, turn on the main power supply

of the main unit. In this state, keep pressing the [Input Select] key for more

than 2 seconds until alarming is canceled. Make confirmation by the method

specified below.

Blinking in red and green

Disconnect the power cord.

Connect the power cord.

Is there alternation blinking

in red and green?

YES

Turn OFF the main power

supply.

With the [Menu] key of the

product kept pressed, turn

on the main power supply

to assume the

[Voltage Check Mode].

Is there a 3.3Vdc output at

Pin 3 of AD connector in

the MAIN PWB?

NO

Turn ON the main power

supply in the state that the

AD, PD, and PH connectors

are disconnected. In this

state, are there the outputs

of Vs (170Vdc), Vd (60Vdc),

and 5Vdc at the PD/PH

connectors as specified in

the table at right? In this

case, however, no images

are generate.

YES

NO

YES

NO

Normal

(Caution) When the main power supply is turned on with the

[Menu] key of the product kept pressed, it takes 30 seconds

more to assume the state of [blinking in red and green].

In this time period, the following voltage checks should be

carried out. If the state of [blinking in red and green] is

assumed during this checking, take actions of

[Alarm Canceling] and [Voltage Check Mode Setup] again.

The MAIN PWB is fault.

The Power unit is fault.

(Caution) The voltage values of Vd and Vs and also the connector

pin numbers can differ according to the PDP. The method of

checking these voltage values is obtainable from

[2. Adjustment of the power unit] in the method of adjustment

plus the table specified below.

Inch Vs Vd GND 5Vdc GND

42/50 PD-9pin PD-7pin PD-5pin PH-1pin PH-3pin

The PDP is fault.

(To the separate PDP service manual)

22

PD-5065

(5) Lighting in green, and then in red (Alarm of power voltage error)

Unlike [lighting in red] in the STANDBY mode, [lighting in green] continues for about 30 seconds without any output

of images and audio signals. Since then, the mode turns into [lighting in red].

Lighting in red

Disconnect the power cord.

Connect the power cord.

Turn On the power by remotecontrol.

Is the LED lit in red after it has been lit

in green for about 30 seconds?

YES

When the main power supply is turned on in

the state that the AD, PD, and PH connectors

are disconnected, are there the Vs (170Vdc)

and Vd (60Vdc) outputs at Pins 6-7to Pins

9-0 of the PD connector and a 5Vdc output

at Pins 1-2 of the PH connector?

In this case, is the LED not turned in red after

it has been lit in green for about 30 seconds?

At that time, however, no images are

generated.

NO

When the main power supply is turned on in

the state that the PA and PV connectors are

disconnected from one after another, is there a

12Vdc output at Pins 1-3 of the PA connector

or the 12Vdc and 6Vdc outputs at Pins 1 and

3-4 of the PV connector? In this case, is the

LED not turned in red after it has been lit in

green for about 30 seconds?

NO

YES

YES

Normal

(To the separate PDP service manual)

The PDP is fault.

(Caution) The voltage values of Vd and Vs

can differ according to the PDP. The

method of checking these voltage

values is obtainable from

[2. Adjustment of the power unit] in

the method of adjustment.

The MAIN PWB or the

AUDIO PWB is fault.

NO

Is there an output of 3.3Vdc available at Pins

1~3 and 2.5Vdc at Pins 7~9 in the state

that the PA and PV connectors are returned to

the former state, the main power is turned ON,

and the PN connector is disconnected? In this

case, however, this check must be finished in

30 seconds. Otherwise, there will be power

tripping on account of an alarm.

YES

The MAIN PWB is fault.

NO

PD-5065

The Power unit or the

PN connector is fault.

23

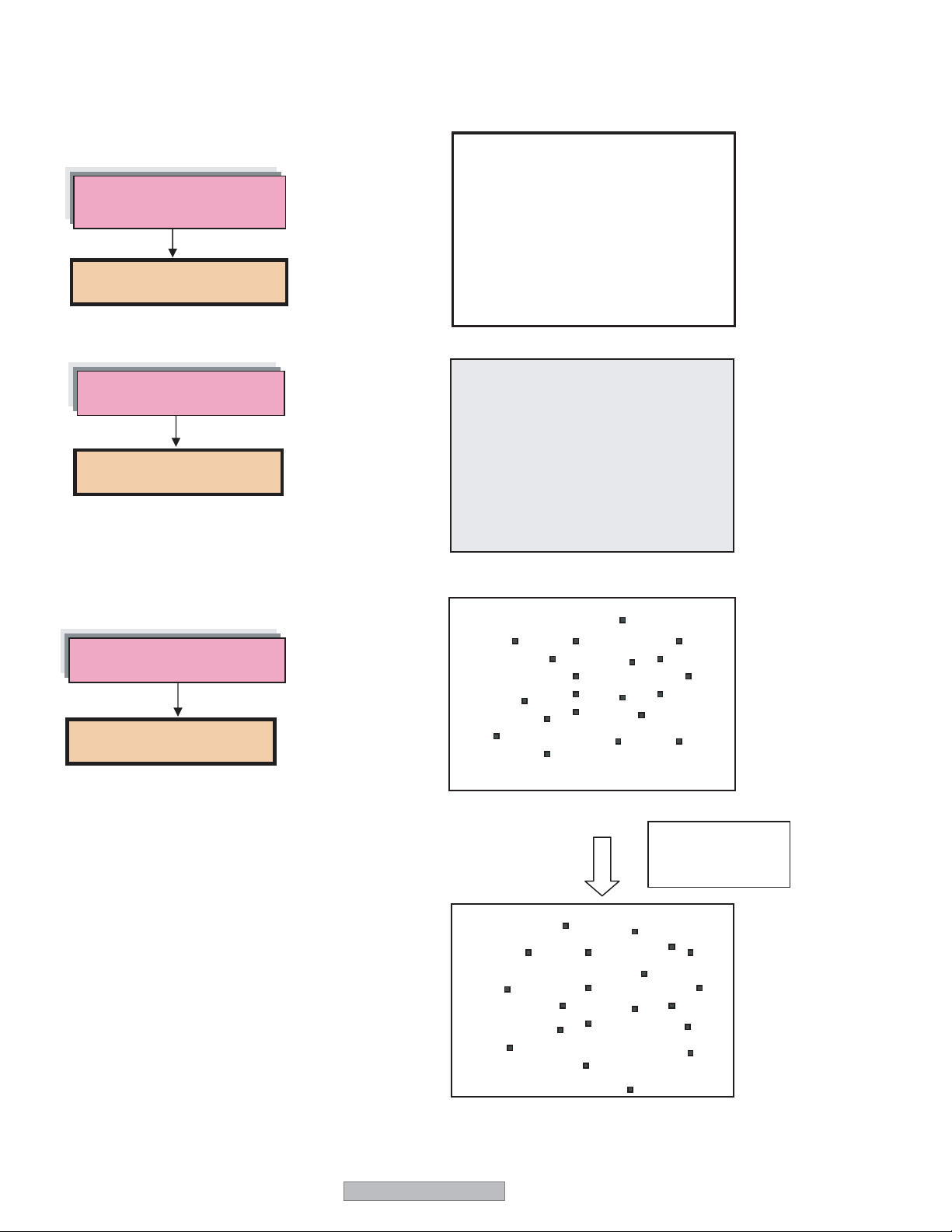

2. Image errors

(Caution) Typical abnormal images are shown below. All errors do not always fall on these error samples.

(1) Image burn and deterioration in brightness

Residual images are seen

without signal entry.

A

This is not a fault.

No signal

Deterioration in brightness

This is not a fault.

(2) Failure in writing

Failure in writing

The PDP is fault.

(To the separate PDP service manual)

All-white signal

All-white signal

Dot errors change

with no continuity.

24

All-white signal

PD-5065

(3) Pixel defect

Pixel defect

Are there many defective pixels exceeding the

pixel defect standard?

Bright defect

NO

This is not a fault.

YES

The PDP is fault.

(To the separate PDP service manual)

(Fig. 1) All-Black Signal

Dark defect

(Fig. 2) All-White Signal

PD-5065

25

(4) Wrong lighting

Wrong lighting

The PDP is fault.

(To the separate PDP service manual)

All-black signal

Dot errors change

with no continuity.

All-black signal

(5) Dark images [Other than the deterioration in brightness as per (1) above]

The images are dark even with

an all-white input

The PDP is fault.

(To the separate PDP service manual)

All-white signal

(6) Defect in horizontal lines

Line defect

The PDP is fault.

(To the separate PDP service manual)

26

All-white signal

PD-5065

All-white signal

Defect in the block unit

The PDP is fault.

(To the separate PDP service manual)

All-white signal

All-white signal

PD-5065

All-white signal

27

(7) Defect in vertical lines

Defect in vertical lines

The PDP is fault.

(To the separate PDP service manual)

All-white signal

All-white signal

Block defect

The PDP is fault.

(To the separate PDP service manual)

28

All-white signal

All-white signal

PD-5065

All-white signal

All-white signal

PD-5065

29

(8) No pictures [(Caution) The voltage outputs of Vs = 170V and Vd = 64V, 5Vdc are always generated, but the LED is

not flashing or lighting for alarming. However, the voltage values can differ according to the MODULE.]

No picture is displayed.

Disconnect the power cord.

Connect the power cord.

Does the priming glimpse?

NO

The PDP is fault.

YES

When the AD connector is disconnected, is

the LVDS signal normally output to each

pin of the AD connector? (For more details

of the signal, refer to the descriptions about

the connector pins.)

YES

The AD connector or the PDP is fault.

(To the separate PDP service manual)

(To the separate PDP service manual)

NO

The MAIN PWB is fault.

30

PD-5065

Loading...

Loading...