Page 1

MITSUBISHI ELECTRIC

2003

Service

Manual

PLASMA DISPLAY PANEL

PD-5030

CAUTION:

Before servicing this chassis, it is important that the service person read the "SERVICE SAFETY" section in this

manual.

SPECIFICATIONS

• Power : AC 120V, 50/60Hz

480W (Typical)

6.4A (Maximum)

• Signals

Sync Range : Horiz : 15.5 to 110kHz

(Automatic : step scan)

: Vert : 50.0 to 120 Hz

(Automatic : step scan)

Input Signals : RGB, HD*1,

DVD*1, DTV*

• Input Terminals

RGB : Visual 1 (Analog) : Mini D-sub 15-pin

Visual 2 (Analog) : BNC (R,G,B,H/CS,V)*

Visual 3 (M-LINK) : MONITORLINK

Video : Visual 1 : BNC

Visual 2 : RCA-pin

Visual 3 : S-Video: DIN 4-pin

DVD/HD/DTV : Visual 1 RCA-pin (Y,PB[CB},PR{CR])*

Visual 2 BNC (Y,PB[CB},PR{CR])*1*

Audio : Stereo RCA x 3 (Selectable)

External Control : D-sub 9-pin (RS232C)

1

TM

(DVI)

1

• Sound Output : 9W+9W at 6 ohms

• Dimensions : (W)48.1" (H)30" (D)3.8"

(W)1222 (H)736 (D)96 mm

• Weight : 98 lbs / 44.5 kg

*1

HD/DVD/DTV Input Signals supported:

480P (60Hz) 480I (60Hz)

2

525P (60Hz) 525I (60Hz)

576P (50Hz) 576I (50Hz)

625P (50Hz) 625I (50Hz)

720P (60Hz) 1035I (60Hz)

1080I (50Hz) 1080I (60Hz)

*2

The 5-BNC connectors are used as

RGB/PC2 and HD/DVD2 input.

Select one of them under "BNC SELECT".

• Weight and dimensions shown are approximate.

• Design specifications are subject to change without notice.

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2004 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

CONTENTS

SERVICE SAFETY ............................................................................................................................................ 2-1

TROUBLESHOOTING ....................................................................................................................................... 3-1

METHOD OF ADJUSTMENTS .......................................................................................................................... 4-1

METHOD OF DISASSEMBLY ........................................................................................................................... 5-1

PART LIST ......................................................................................................................................................... 6-1

CONNECTION DIAGRAMS............................................................................................................................... 7-1

BLOCK DIAGRAMS ........................................................................................................................................... 8-1

1-1

Page 3

SERVICE SAFETY

■ Safety cautions

The matters to be observed without fail are explained below. These matters are indispensable for the prevention

of an accident during the maintenance servicing, the “security of products” after the completion of servicing

work, and the “prevention of the repeated occurrence of similar fault.”

(1) The degree of danger and material damage, caused as a result of wrong use by disregarding the contents

of the display” is distinguished and explained in the table below.

If this display is disregarded and equipment is handled wrongly,

WARNING

CAUTION

(2) Kinds of the matters to be observed are classified and explained in the icons shown below.

This icon indicates a dangerous place where an electric shock is anticipated.

This icon indicates the contents of “caution” that must be borne in mind, without fail.

this can be a cause of physical injury and a fire, thus leading a

person to death or serious injury.

If this display is disregarded and equipment is handled wrongly,

this may lead to personal injury or material damage.

This icon indicates the contents of “caution” that must be practiced, without fail.

WARNING

• Observe the caution matter, without fail.

• In the place where a particular caution is needed during maintenance servicing, such a

caution note is displayed with a label or a stamp that is given to the cabinet, chassis, PWB,

etc. These caution notes and also the caution matters of

instruction manuals, etc., must be observed, without fail.

• Be careful of an electric shock or a burn.

• The power block or the PDP module involves the sections where high voltage or high temperature is prevalent. When equipment is energized, use working gloves in order to prevent

an electric shock or a burn. At the time of transportation, disassembly, reassembly, and the

replacement of parts, such a servicing job must be done after pulling out the power plug.

• Modification of equipment is absolutely prohibited. Use the specified parts at all times.

• If any modification is performed, the validity of the manufacturer’s warranty is lost at that

moment. The personnel who did this modification is responsible for the physical injury or

the like, if it should occur as a result of the modification. The parts used are given the

safety-based characteristics, such as non-flammability or sufficient withstand voltage. The

parts to be replaced shall be those which are specified in the list of replacement

parts.(Example: The lithium battery (circuit symbol BA9501 in the MAIN PWB) will give

rise to explosion if its polarity is wrongly treated.

WARNING

given in the

• The replaced parts and wiring must be arranged in the original conditions.

• For safety reasons, insulation materials like tubes and tapes may be used or some parts

may be mounted clear of the PWB. The internal wiring and the fastening with the clampers

for separation from high-heat and high-voltage parts shall be returned to their original

conditions, without fail.

2-1

Page 4

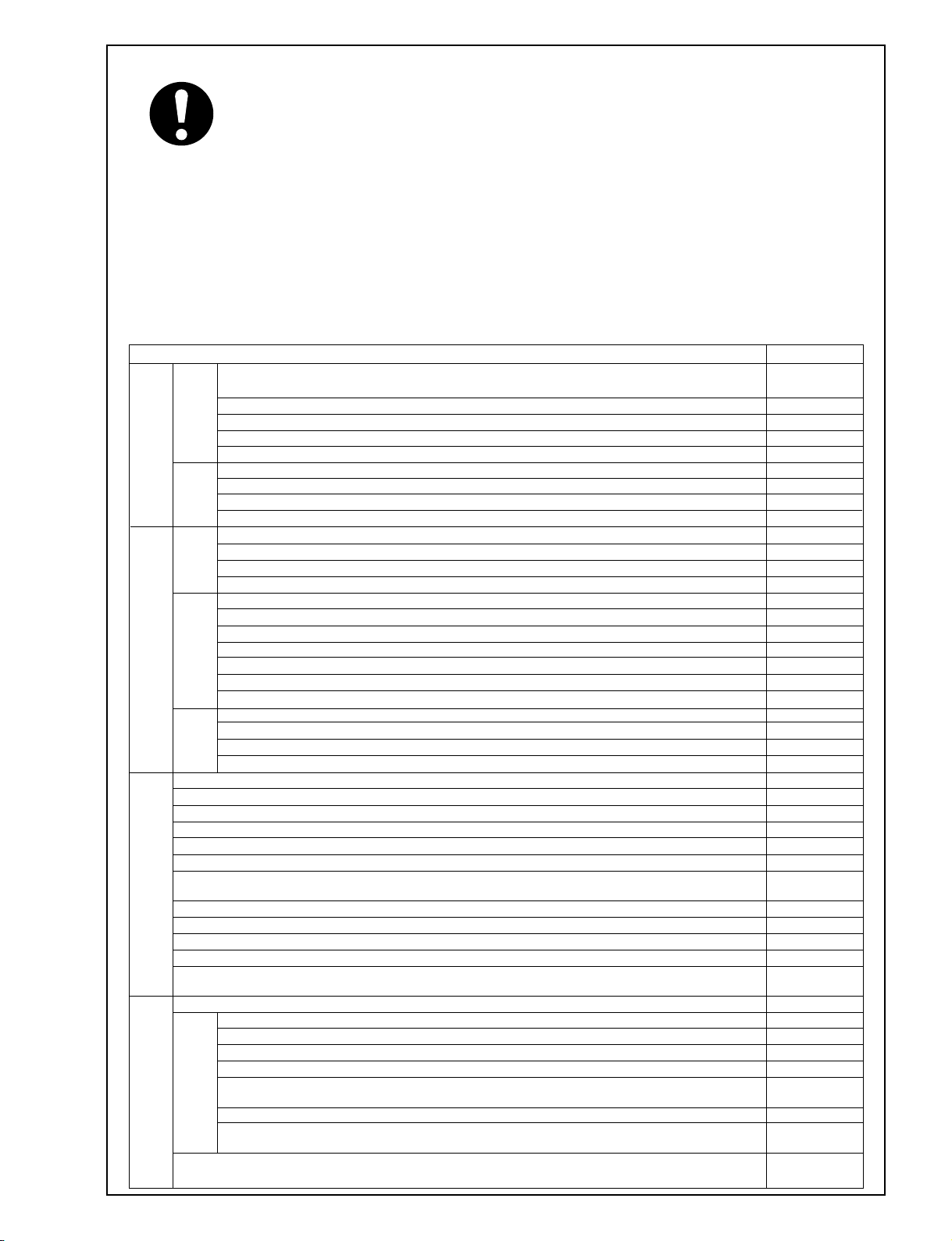

• For the maintenance servicing, safety inspection is needed in accordance with the check list.

• Inspection should be carried out according to the check list shown below, in regard to

safety inspection before and after repairing, authentic repair, and explanation to the user.

(Method of insulation check)

Mount a PDP module on the product to complete it. After the completion of aging and

others, pull out the power plug from the wall outlet, remove the cable, and turn on the

power switch. Use a 500V megger (Note 1) and confirm that the insulation resistance is

500MΩ or more between each terminal (except for the 3-core earth terminal) of the power

plug (Note 2) and the external exposed metallic parts (Note 3). If the insulation resistance

is found to be below the specified value, recover the faulty section and make another

insulation check again.

(Note 1) If a 500V megger is not available at that time, use a circuit tester or the like.

(Note 2) In the case of a 3-core terminal, the earth resistance shall be 1Ω or less between the earth

terminal and the earth side of each input terminal.

(Note 3) Head phone jack, speaker terminals, remote control terminals, each I/O terminals, control termi-

nals, screws, etc.

Check item Check column

Is there any influence by high temperatures (due to direct sunlight, etc.), moisture (steam, etc.), oil

fume, dust, and dew condensation?

Is the condition of ventilation acceptable (distance to the wall, ventilation holes, etc.)?

Is the condition of the antenna acceptable (reach to the wire, bend, tilt, etc.)?

conditions

Is the condition of power supply acceptable (regular outlet, adequate earthing, concentrated wiring, etc.)?

Installation

repairing

Safety inspection before

Authentic repair

Safety inspection after repairing

Explanation to the user

Is the condition of installation acceptable (unstability, height, tilt, falling preventive materials, etc.)?

Are the power plug and the power cord free from damage or the attachment of dust?

Is the product free from unusual sound, unusual odor, or unusually high temperature?

Are the knobs, handles, and back cabinet free from abnormality (rattling, drop off, etc)?

Product

Is equipment free from any abnormality in daily use?

main body

Is the symptom examined according to the user’s statement?

Is the product disassembled to the grade where troubleshooting is possible?

Is the symptom reproduced, the faulty part located as a result of fault diagnosis, and replaced?

Trouble-

shooting

Is the normal condition confirmed after aging?

Is the part, specified in the list of parts, used for the power unit?

Is the part, specified in the list of parts, used for the insulation material (material, thickness, etc)?

Is the part, specified in the list of parts, used for the power plug and the power cord?

Is the part, specified in the list of parts, used for the internal cabling and the high voltage lead wires?

Is the part, specified in the list of parts, used for the PDP module?

Specified parts

Are the rest of replaced parts those specified in the list of parts?

Is the part version correct?

Are the part mounting position, fixing method, and the distance the same as those of original?

Is the wiring layout the same as the original (connector, clamper, distance from a heat generating part, etc)?

Is the soldering condition acceptable (whisker, too much solder, tunnel, failure in winding, etc)?

Wires

mounted

Is the insulation material the same as the original (tubes, tapes, fiber, etc.)?

Are the repaired section and its peripheral parts free from abnormality?

Is there any intrusion of foreign substances (solder chips, wire chips, screw chips, screws, etc.)?

Is everything free from danger due to deterioration (discoloration, damage, leakage, etc.)?

Is the safety protection circuit in normal operation?

Are contamination and dust removed after final finish?

Is there any failure in mounting and tightening (back cabinet, falling preventive materials, etc.)?

Is there any influence by high temperatures (direct sunlight, stove, etc.), moisture (steam, etc.), oil fume,

dust, and dew condensation?

Is the condition of ventilation acceptable (distance to the wall, ventilation holes, etc.)?

Is the condition of the antenna acceptable (reach to the wire, bend, tilt, etc.)?

Is the condition of power supply acceptable (regular outlet, adequate earthing, concentrated wiring, etc.)?

Is the condition of installation acceptable (unstability, height, tilt, falling preventive materials, etc.)?

Is the insulation check finished with a circuit tester or the like? (Refer to the above description, “Method of

insulation check.”)

Are the contents and actual treatment of repairing and safety inspection services duly explained?

To use equipment after reading through the instruction manual.

Not to dislodge the back cabinet.

Not to insert anything in ventilation holes and clearances.

To pull out the power plug if the product is not used for a long time.

To ask an NEC’s authorized maintenance service company for the cleaning of the product interior

for the removal of dust.

To turn off the power switch when cleaning the panel surface and the cabinet.

Explanation of use

To turn off the power switch of the main unit for the product provided with a remote control, in case

of going out or sleeping.

Are explanations given to pull out the power plug in case of abnormality and to contact the dealer or an

NEC’s authorized maintenance service company.

2-2

Page 5

CAUTION

• Observe the caution matter, without fail

• The caution matters of CAUTION given in the instruction manuals, etc., must be

observed, without fail.

• Do not give shocks and vibration.

• The panel surface (display plane) of the filter and the PDP module is made of glass. If any

shocks or vibration is applied, it may be broken and the scattered glass chips will be a

cause of injury.

• Do not put anything.

• Do not put anything on the product. Otherwise, this can be a cause of injury as a result of

falling down or dropping caused by imbalance.

• Transportation must be done by enough personnel.

• The product is heavy. In the case of transportation, unpacking, or packing, more than two

persons should do it (four persons for a product of 50-inch or larger) by supporting the top

and the bottom of the product.

■ Miscellaneous caution matters

(1) This product uses highly integrated semiconductor parts. Since these parts are fragile to electrostatic

charges, earth bands should be used for handling. The product should be handled where measures have

been taken against electrostatic charges.

(2) For this product, the PDP modules and the PWBs are repaired by replacement in a unit. Therefore, the

units of the PDP modules and the PWBs must not be repaired or disassembled. Otherwise, the validity of

warranty will be lost.

(3) If this product is used for the fixed character display or the like as in the case of a character display board,

a phenomenon of burning (not warranted) will occur. Burning is a phenomenon that the unevenness in the

brightness is caused in the display. In such a case, the brightness in the section where the integrated

display time is longer becomes lower than the brightness in another section where the integrated display

time is shorter. This phenomenon is in proportion to the integrated display time and the brightness. For this

reason, to relieve this difficulty during servicing, do not use any still picture, but use a display by motion

pictures of a video or the like. In addition, use “FULL” for the screen mode and avoid using any display by

“NORMAL”, “TRUE”, or MULTI SCREEN like side by side etc. If it is necessary to use only a still picture for

unavoidable reasons, use a burning relief function such as “PLE LOCK”, “ORBITER”, “SCREEN WIPER”,

etc.

(4) When a PDP module is operated after a long time of storage, it may encounter a difficulty like a failure in

displaying a screen or unstability according to the condition of storage. In such a case, the PDP module

should be incorporated in the product and aging treatment should be carried out for about two hours (all

screen display).

(5) Sulfides will deteriorate the PDP module and this is a cause of malfunction. Therefore, it is absolutely

prohibited to put any vulcanized rubber or a material containing sulfur in the vicinity of the PDP module.

(6) When taking out a PDP module from the maintenance package box, do it slowly so that the panel surface

2-3

Page 6

does not get any shock or stress.

(7) If one touches the connector of the flexible cable exposed to the rear side of the PDP module, there is

danger of causing a poor contact. As such, it must be handled with utmost care. In addition, the flexible

cable is very weak in mechanical strength. Therefore, this cable must not be touched during handling.

(8) The panel surface of the filter and the PDP module is easy to be hurt. These components should be

handled very carefully not to press or rub them with a hard thing. Never put them on a hard thing with the

panel surface faced downwards.

(9) When the panel surface of the PDP module is contaminated, gently wipe off the contaminant with a piece

of soft dry cloth. Liquid-state contamination can be removed by lightly pressing it, without rubbing it. If it is

difficult to remove the contamination, use a piece of cloth soaked with a neutral detergent. The cloth for

wiping off should be clean. Never use the same cloth repeatedly. If a cleansing detergent or water drops

should enter the module interior or be attached to the module surface other than the display plane at the

time of cleaning, this will give rise to the destruction of the product when the product is energized.

(10) Refer to the “Instruction Manual” in regard to contamination in the filter and the cabinet.

(11) When transporting this product, use the packing materials specified in the list of parts. Once used, such

packing materials should not be used again.

(12) This product is composed of a variety of parts, such as those made of materials like glass, metal, plastics,

etc., and those like a lithium battery (circuit symbol of the MAIN PWB: BA9501), etc. Therefore, when

abandoning this product, this should be done in accordance with the relevant law of the nation or an

autonomous body.

2-4

Page 7

TROUBLESHOOTING

• Problems in the power supply, such as “Failure in Power ON” or “LED flashing or lighting (alarm display)”

→ 1. Go to Power failure (P3-2).

• Problems in the images, such as “No pictures available”

→ 2. Go to Image errors (P3-8).

• “No output from the video loop out”

→ Fault in the MAIN PWB

• Problems in the audio system, such as “No audio output”

→ 3. Go to Audio errors (P3-15).

• “Remote control not effective”

→ 4. Go to Remote control not effective (P3-15).

3-1

Page 8

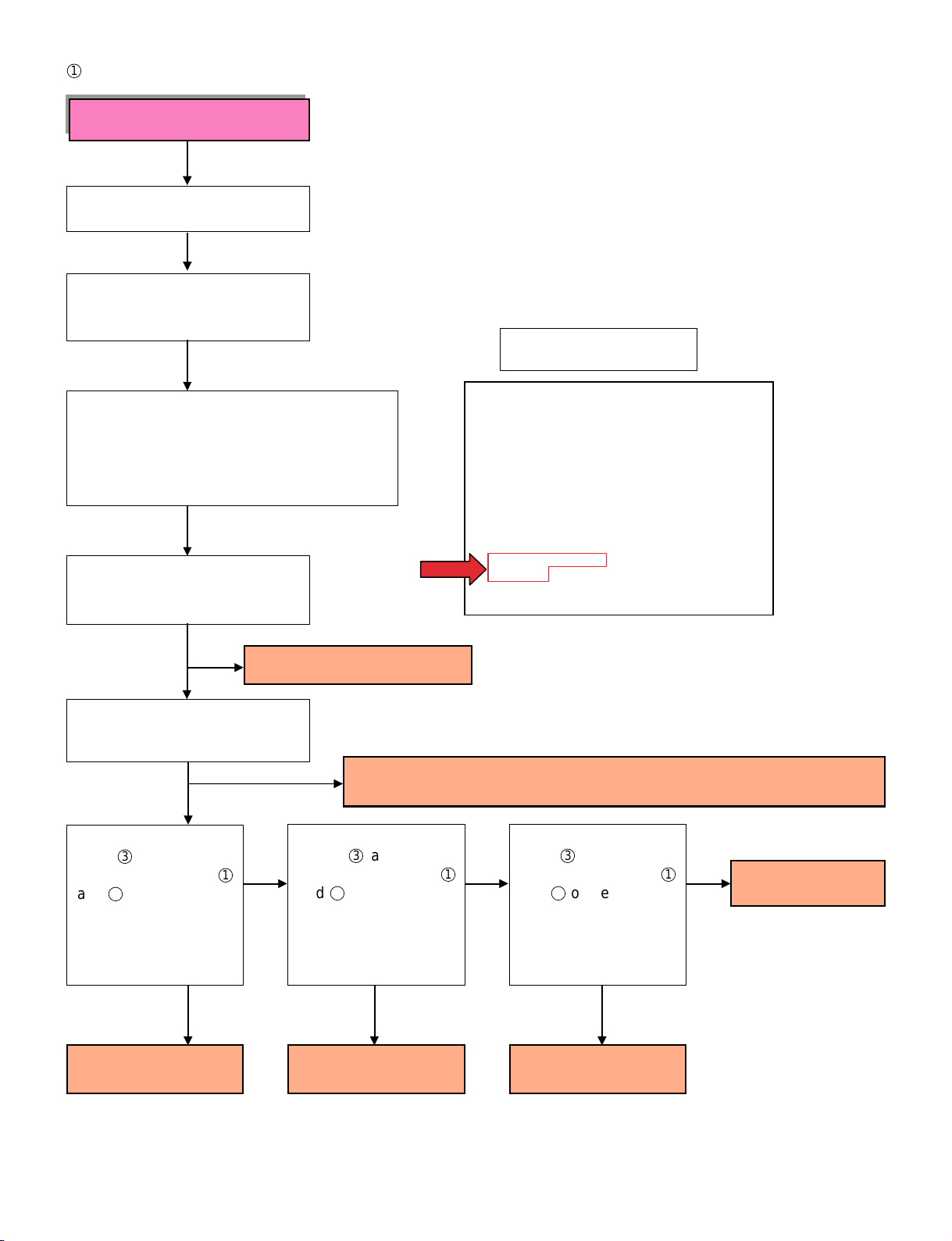

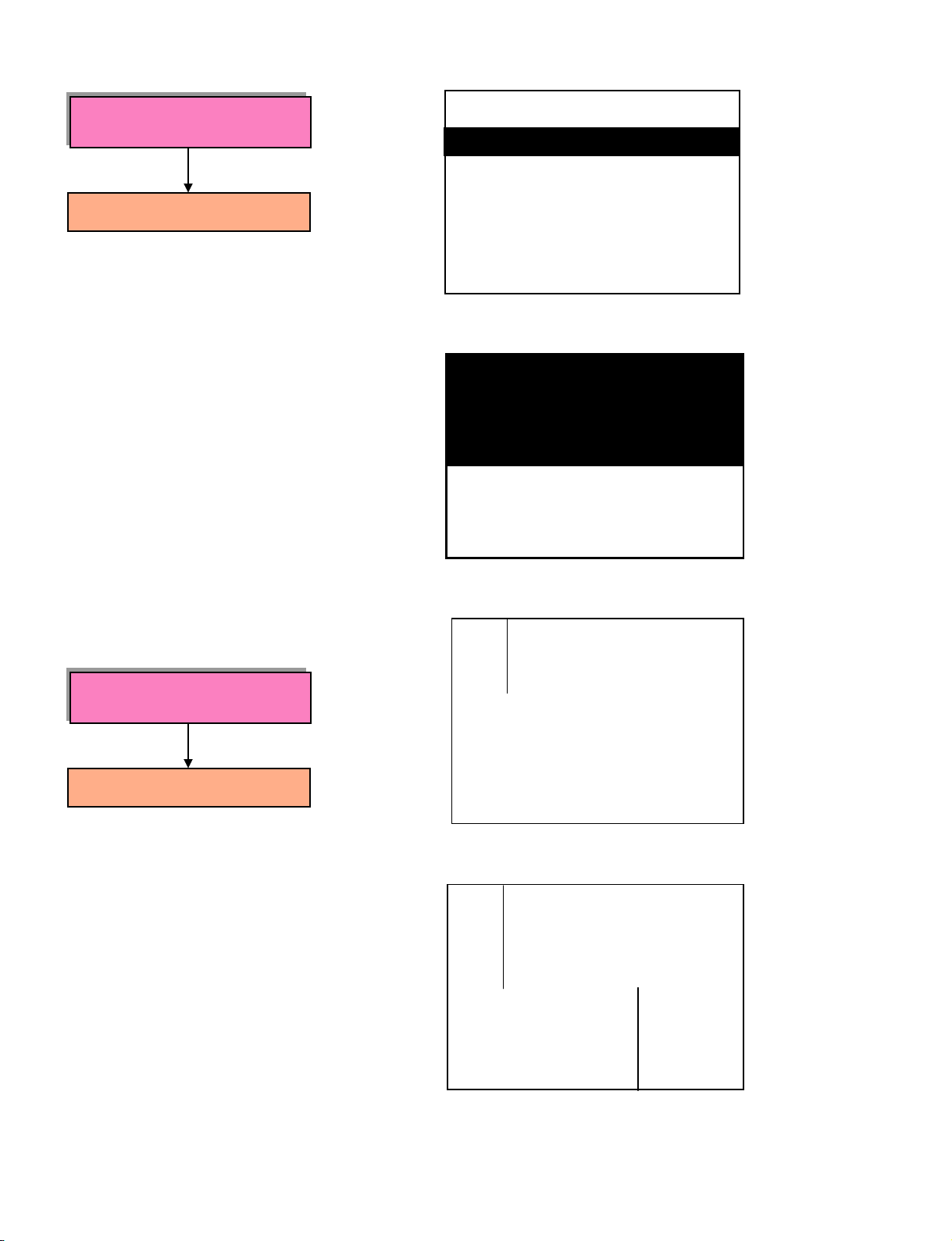

1. Power failure

(1) The power supply is not turned on.

Move the main power setting for

OFF→ ON.

Is the POWER/STANDBY lamp lit?

YES

(2) Flashing in green (Alarm of

temperature sensor error or fan

error) Go to (P4-3).

(3) Flashing in red (Alarm of tem-

perature error) Go to (P4-5).

(4) Reciprocal flashing in red and

green (Alarm of panel error) Go

to (P4-6).

(5) Lighting in green, and then in

red (Alarm of power line error)

Go to (P4-8).

NO

(Caution)If any abnormality is sensed in such a manner that the

LED flashes or lights, all the power lines other than those

of 7Vdc (M+7V) and 5Vdc (M+5V) are automatically

turned off in about 10 seconds. When checking the power

lines other than those of M+7V and M+5V, a circuit tester

or the like should have been connected in advance.

Is the AC power output

available at the AC connector (power cord)?

YES

Is a 6.8Vdc output available

at Pin 1 of the PM connector?

YES

Is a 6.8Vdc output available

at Pin 1 of the PW connector?

NO

NO

NO

The power cord is defective.

Is a 6.8Vdc output available in

the state that the LD connector is disconnected and the

main power is turned ON?

YES

NO

Is a 6.8Vdc output available in

the state that the PW connector is disconnected and the

main power is turned ON?

The LD connector or the

LED PWB is

fault.

Is a 5Vdc output available in the state

that the LD connector is disconnected

and the main power is turned ON?

YES

NO

Is a 5Vdc output available in the state

that the RS connector is disconnected

and the main power is turned ON?

YES

NO

The PW connector, PWR PWB or the

MAIN PWB is fault.

The LD connector or the

LED PWB is

fault.

The RS connector or the

232C PWB is

fault.

The PW con-

YES

Is a 6.8Vdc output available

at Pin 6 of the PM connector?

NO

YES

Is a 4.9Vdc output available

at Pin 3 of the PM connector?

NO

Is a 5Vdc output available

at Pin 4 of the PW connector?

NO

YES

nector or the

PWR PWB is

fault.

The PM connector or the

MAIN PWB is

fault.

YES

YES

NO

Is a 6.8Vdc output available in

the state that the PM connector is disconnected and the

main power is turned ON?

NO

The power unit is fault.

YES

The PW connector or the

PWR PWB is

fault.

The PM connector or the

MAIN PWB is

fault.

The MAIN PWB is fault.

3-2

Page 9

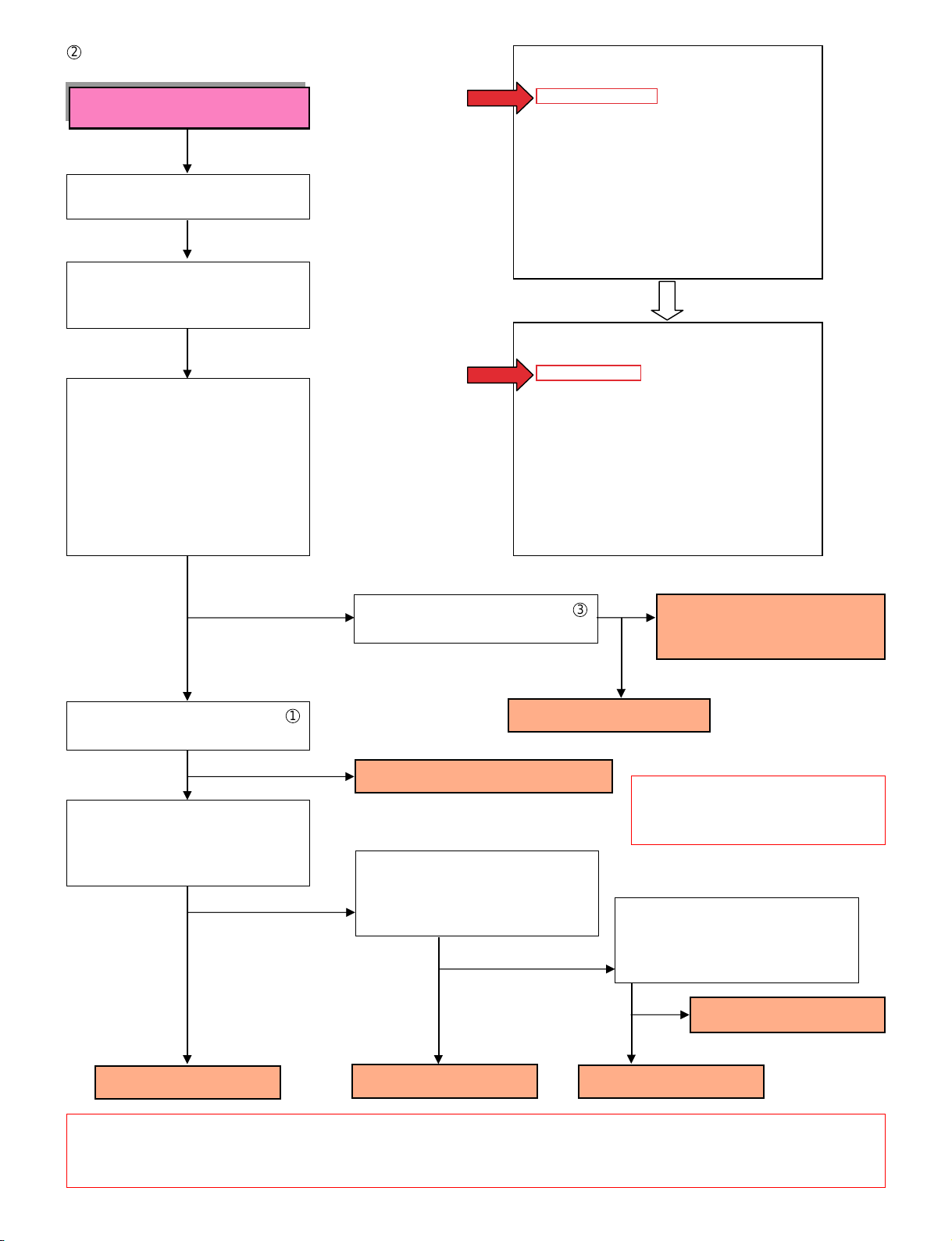

(2) Blinking in green

1

Alarm of temperature sensor error

Blinking in green (intervals of 2

seconds)

Turn off the main power supply.

Pressing the [MENU] key of the

product, turn on the main power

supply to cancel alarming.

FAN SET

Press the remote control keys in the sequential order of [MENU] [MUTE] [EXIT] [SLEEP]

[EXIT] and enter the diagnostics

menu. Press the [MENU/ENTER] key to

display the FAN SET menu (P8/10).

Is there a display of numerals (almost room temperatures) at the

right side of [T1, T2, T3]?

YES

The MAIN PWB is fault.

NO

Is there a display of [-] for all the

numerals at the right side of [T1,

T2, T3]?

NO

When a [-] display is presented, the PWB with the symbol shown below is

fault. T1: SEND PWB, T2: SENB PWB, T3: SENC PWB

YES

Are there a 5Vdc output

at Pin 3 and a clock signal (5Vpp) at Pins

1

and 2 of the TS in the

state that the TS connector is disconnected

and the main power

supply is turned on?

NO

Are there a 5Vdc output

at Pin 3 and a clock

signal (5Vpp) at Pins

and 2 of the TR in the

state that the TR connector is disconnected

and the main power

supply is turned on?

1

FAN SET

FAN MODE H CONT ENA

FAN OFF/L CONT UP

FAN L/M CONT TIME

FAN M/H UP STEP

SF SAVE

PLE SAVE 070 READ TIME

T ALM 095

RET TME

PLE TIME

T1T3030

030

IC ERROR

[MENU/ENTER] NEXT [EXIT] PREV 8/10

T2

T4

–

–

–

075

DOWN STEP

TEMP LEVEL

030

001

025

–

–

MODE 2

Are there a 5Vdc output

NO

at Pin 3 and a clock signal (5Vpp) at Pins

and 2 of the TM in the

state that the TM connector is disconnected

and the main power

supply is turned on?

1

–

–

–

2

2

60

1

NO

The MAIN PWB is

fault.

YES

The TS connector or the

SENC PWB is fault.

YES

The TR connector or the

SEND PWB is fault.

YES

The TM connector or

the SENB PWB is fault.

3-3

Page 10

2

Alarm of fan error

Blinking in green (intervals of 0.5

seconds)

Turn off the main power supply.

Pressing the [MENU] key of the

product, turn on the main power

supply to cancel alarming.

Is the fan running?

(Caution) When alarming is can-

celed, [FAN MODE] of

FAN SET (P8/10) in the

factory adjustment

menu automatically

moves from [ENA] to

[H], thus causing the

fan to run.

FAN SET

FAN MODE ENA CONT ENA

FAN OFF/L CONT UP

FAN L/M CONT TIME

FAN M/H UP STEP

FAN SAVE 075 DOWN STEP

PLE SAVE 070 READ TIME

T ALM 095 TEMP LEVEL

RET TME 030

PLE TIME 001

T1 030 T2

T3 030 MODE 2

IC ERROR

[MENU/ENTER] NEXT [EXIT] PREV 8/10

FAN MODE H

FAN OFF/L

FAN L/M

FAN M/H

FAN SAVE 075

PLE SAVE 070

T ALM 095

RET TME 030

PLE TIME 001

T1 030 T2

T3 030 MODE 2

IC ERROR

[MENU/ENTER] NEXT [EXIT] PREV 8/10

T4

T4

–

–

–

025

–

–

FAN SET

–

–

–

025

–

–

CONT ENA

CONT UP

CONT TIME

UP STEP

DOWN STEP

READ TIME

TEMP LEVEL

–

–

–

2

2

60

1

–

–

–

2

2

60

1

YES

NO

Is there a 9.3Vdc output at Pin

1

of the FA and FB, FC connectors?

YES

NO

Is there a 9.3Vdc output in the

state that the FA connector is disconnected and the main power

supply is turned on?

YES

NO

Is there a 5Vdc output at Pin

3

of the FA and FB, FC connectors?

The MAIN PWB is fault.

The FAN-A/FAN-B/FAN-C is fault.

Is there a 9.3Vdc output in the

state that the FB connector is disconnected and the main power

supply is turned on?

NO

YES

YES

YES

The fan is out of order on the

side where a 5Vdc output is

generated.

NO

(Caution)The FAN-C and FC con-

nectors are used only for

the 61XM2 Series.

Is there a 9.3Vdc output in the

state that the FC connector is disconnected and the main power

supply is turned on?

NO

The MAIN PWB is fault.

The FAN-A is fault.

The FAN-B is fault.

The FAN-C is fault.

(Caution)When repairing is finished, press the [s] key of POSITION/CONTROL at the remote control to return [H] of

FAN MODE to [ENA], without fail. When the main power supply is moved from OFF to ON, [ENA] is automatically recovered.

3-4

Page 11

(3) Blinking in red (Alarm of temperature error)

Since the internal temperature is too high in the product, the temperature protector has been actuated. In such a

case, the following actions should be taken immediately:

1. Turn off the main power supply and pull out the power cord from the wall outlet.

2. Wait for about 60 minutes until the temperature in the main unit lowers.

3. Check whether the heat discharge port is covered with dust or the like. If yes, remove the clogging substance.

4. If the unit is used where the ambient temperature is high, it should be moved to an adequate place (air temperature

ranging from 5°C to 35°C).

3-5

Page 12

(4) Alternation blinking in red and green (Alarm of PDP error)

(Caution)How to reset the alarming condition

Pressing the [Input Select] key of the product, turn on the main power supply of the main unit. In this state,

keep pressing the [Input Select] key for more than 2 seconds until alarming is canceled. Make confirmation

by the method specified below.

1

For the PD-5030

Blinking in red and green

Move the main power setting for

OFF → ON.

NO

Is there alternation blinking in red

and green?

YES

Normal

Turn OFF the main power supply.

With the [Menu] key of the product kept pressed, turn on the main

power supply to assume the [Voltage Check Mode].

Is there a 3.3Vdc output at Pin

94 of IC9501 in the MAIN PWB?

(See the PWB Layout Diagram

on P4-20.)

YES

Turn ON the main power supply

in the state that the AD, PD, and

PH connectors are disconnected.

In this state, are there the outputs

of Vs (170Vdc), Vd (60Vdc), and

5Vdc at the PD/PH connectors as

specified in the table at right? In

this case, however, no images are

generated.

(Caution)When the main power supply is turned on with the [Menu]

key of the product kept pressed, it takes 30 seconds more

to assume the state of [blinking in red and green]. In this

time period, the following voltage checks should be carried

out.

If the state of [blinking in red and green] is assumed during

this checking, take actions of [Alarm Canceling] and [Voltage Check Mode Setup] again.

NO

The MAIN PWB is fault.

NO

The Power unit is fault.

(Caution)The voltage values of Vd and Vs and also the connector

pin numbers can differ according to the PDP. The method

of checking these voltage values is obtainable from [2.

Adjustment of the power unit] in the method of adjustment

plus the table specified below.

YES

The PDP is fault.

Vs Vd GND 5Vdc GND

PD-5030 PD-9pin PD-7pin PD-5pin PH-1pin PH-3pin

3-6

Page 13

(5) Lighting in green, and then in red (Alarm of power voltage error)

Unlike [lighting in red] in the STANDBY mode, [lighting in green] continues for about 30 seconds without any output of

images and audio signals. Since then, the mode turns into [lighting in red].

Lighting in red

Make an OFF → ON setting twice

for the main power supply in order to reset the alarming condition.

NO

Is the LED lit in red after it has been

lit in green for about 30 seconds?

YES

When the main power supply is turned on in the state

that the AD, PD, and PH connectors are disconnected, are there the Vs (170Vdc) and Vd (60Vdc)

outputs at Pins 6-7 to Pins 9-0 of the PD connector and a 5Vdc output at Pins 1-2 of the PH

connector? In this case, is the LED not turned in red

after it has been lit in green for about 30 seconds?

At that time, however, no images are generated.

(Caution)How to reset the alarming condition

The alarming condition can be reset when an OFF→

ON setting is repeated twice for the main power

supply in the state that the LED is lit in red. The

interval between the first and second settings is not

particularly specified.

Normal

YES

The PDP is fault.

(Caution)The voltage values of Vd and Vs can

differ according to the PDP. The method

of checking these voltage values is obtainable from [2. Adjustment of the

power unit] in the method of adjustment.

NO

When the main power supply is turned on in the

state that the PA and PV connectors are disconnected from one after another, is there a 12Vdc

output at Pins 1-3 of the PA connector or the

12Vdc and 6Vdc outputs at Pins 1 and 3-4of

the PV connector? In this case, is the LED not turned

in red after it has been lit in green for about 30 seconds?

NO

When the main power supply is turned on in the

state that the PA and PV connectors are returned

to their original conditions, are there a 3.3Vdc output at Pins 1-3 and a 2.5Vdc output at Pins 7-

9

of the PN connector?

YES

Is there a 3.3Vdc output at Pin 96 of IC9501 in the

MAIN PWB? (Refer to the PWB layout diagram on

Page P4-19 or 20.)

YES

The MAIN PWB or the AUDIO

PWB is fault.

NO

The Power unit or the PN connector is fault.

NO

The MAIN PWB is fault.

YES

The Power unit is fault.

3-7

Page 14

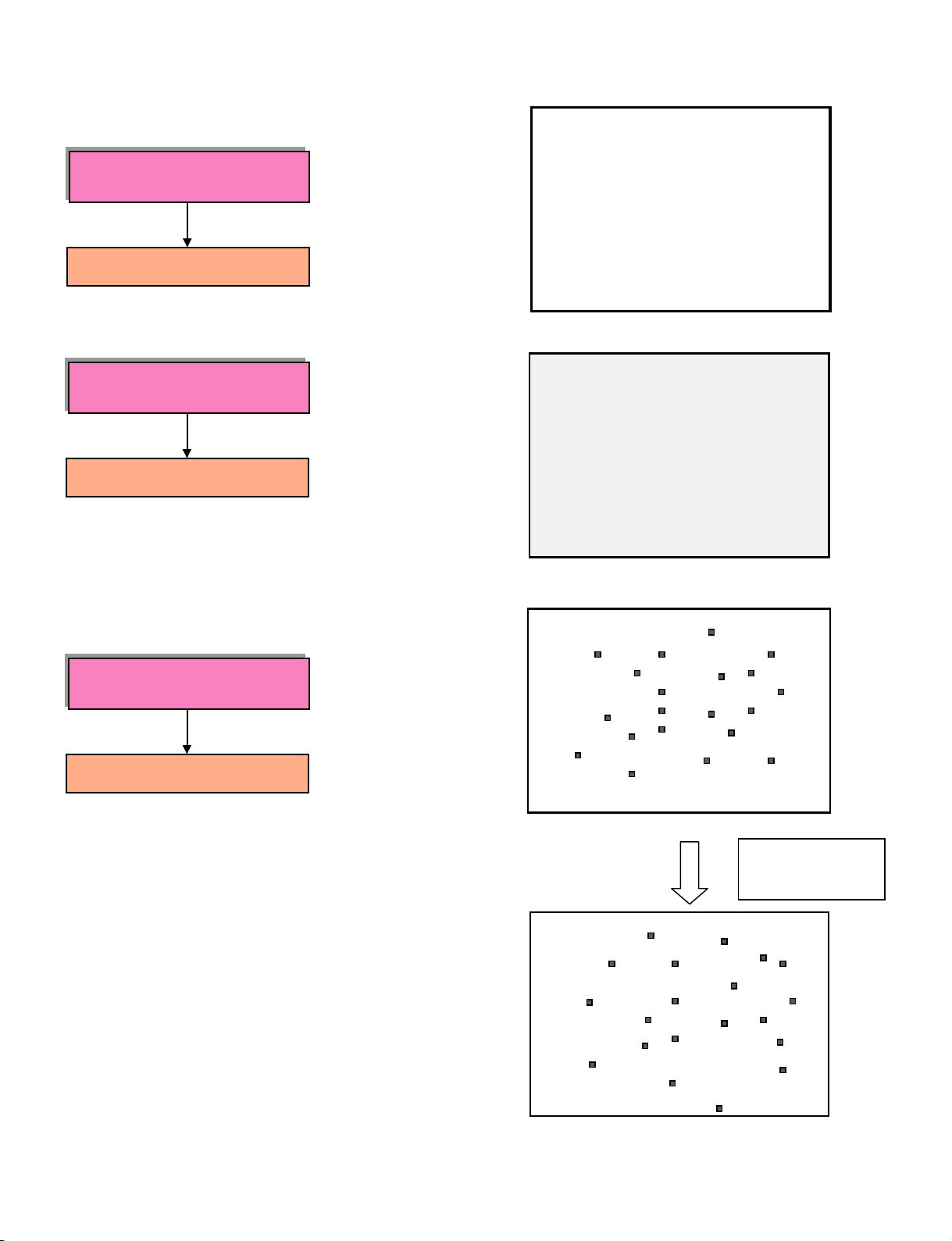

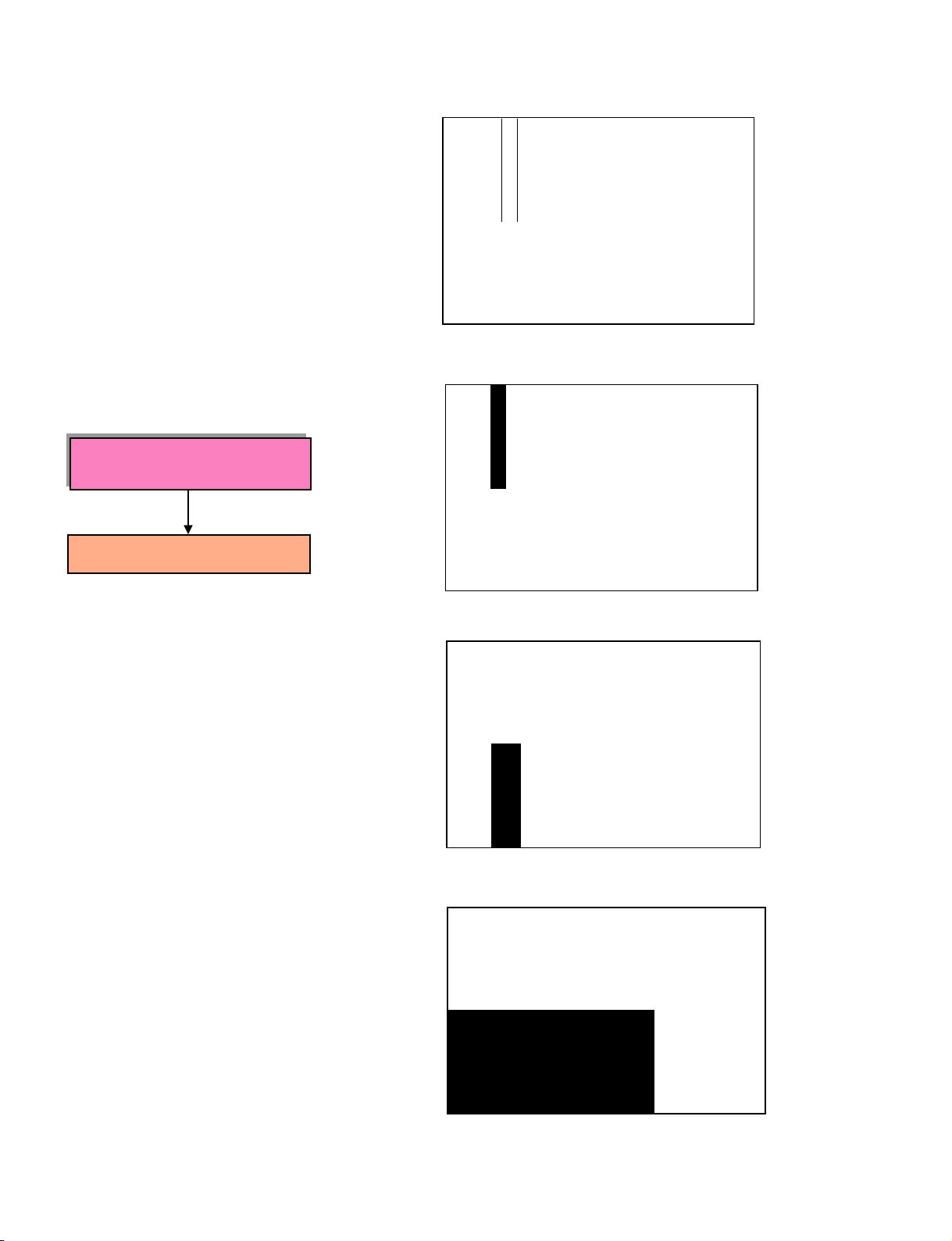

2. Image errors

A

Dot errors change

with no continuity.

All-white signal

All-white signal

All-white signal

No signal

(Caution) Typical abnormal images are shown below. All errors do not always fall on these error samples.

(1) Image burn and deterioration in brightness

Residual images are seen without signal entry.

This is not a fault.

Deterioration in brightness

This is not a fault.

(2) Failure in writing

Failure in writing

The PDP is fault.

3-8

Page 15

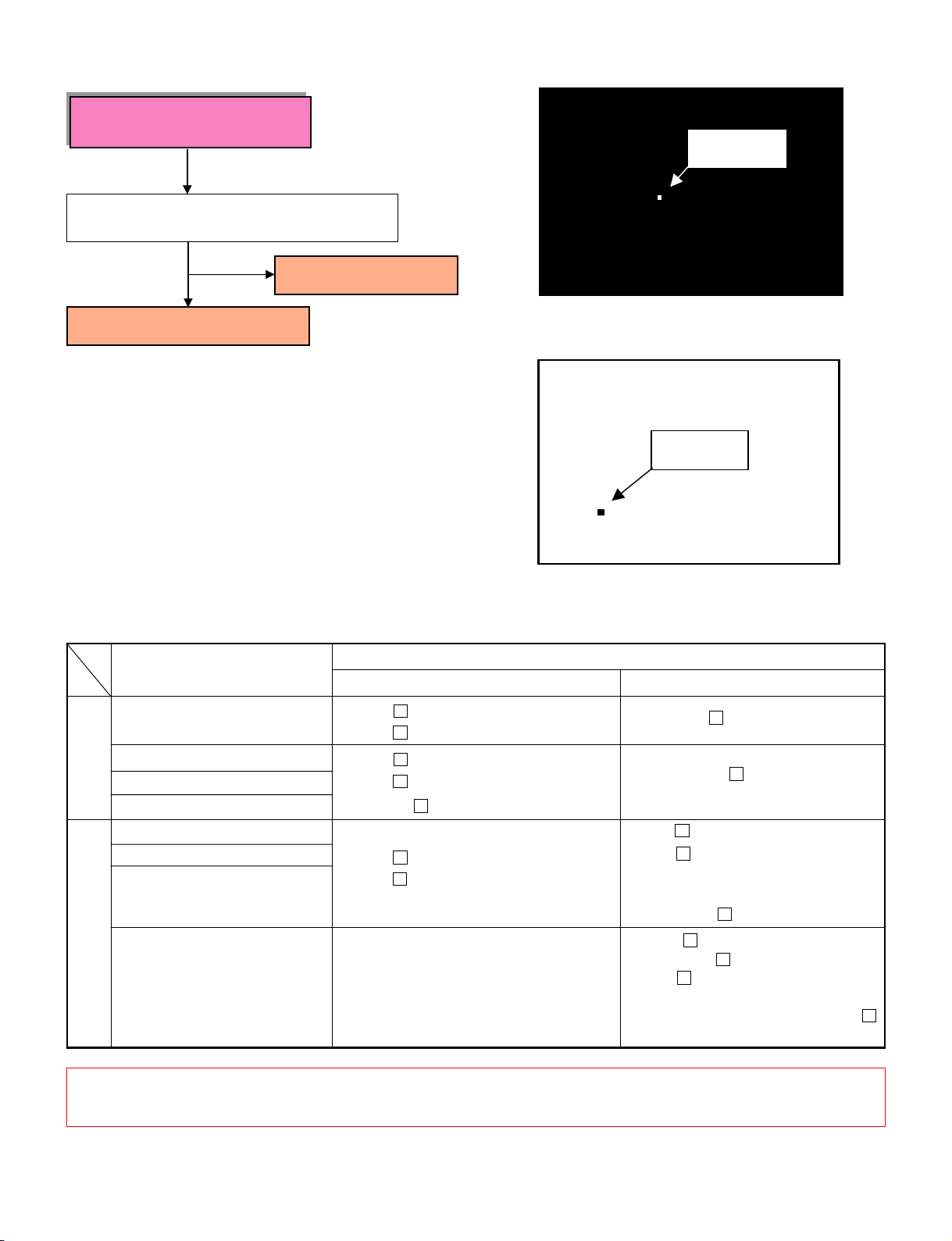

(3) Pixel defect

Pixel defect

Are there many defective pixels exceeding the

pixel defect standard?

Bright defect

N

Y

The PDP is fault.

[Pixel defect standard for reference]

Displayed image

Black all over the screen

(Fig. 1)

Red level 100% over the screen

Green level 100% over the screen

Bright defect

Blue level 100% over the screen Each zone: dots or less for each uni-color

Red level 100% over the screen Zone A: dots or less vertically continuous

Green level 100% over the screen Zone B: dots or less continuous

Blue level 100% over the screen

White all over the screen

Dark defect

(Fig. 2)

This is not a problem.

Pixel defect standard

Non-continuous Continuous

Zone A: dots or less in all for each color

Zone B: dots or less in all for each color

Zone A: dots or less in all for each color

Zone B: dots or less in all for each color

Zone A: dots or less in all for each color

Zone B: dots or less in all for each color

–

(Fig. 1) All-Black Signal

Dark defect

(Fig. 2) All-White Signal

Continuous dots or less

Defective when dots or less are continuously horizontal and seen white.

Except for the continuous portions,

however, the distance between dark

dots shall be cm or more.

Zone A: dots continuous in one

portion or less ( dots for vertical continuity)

Zone B: dots or less continuous

Except for the continuous portions, however,

the distance between dark dots shall be

cm or more.

3-9

Page 16

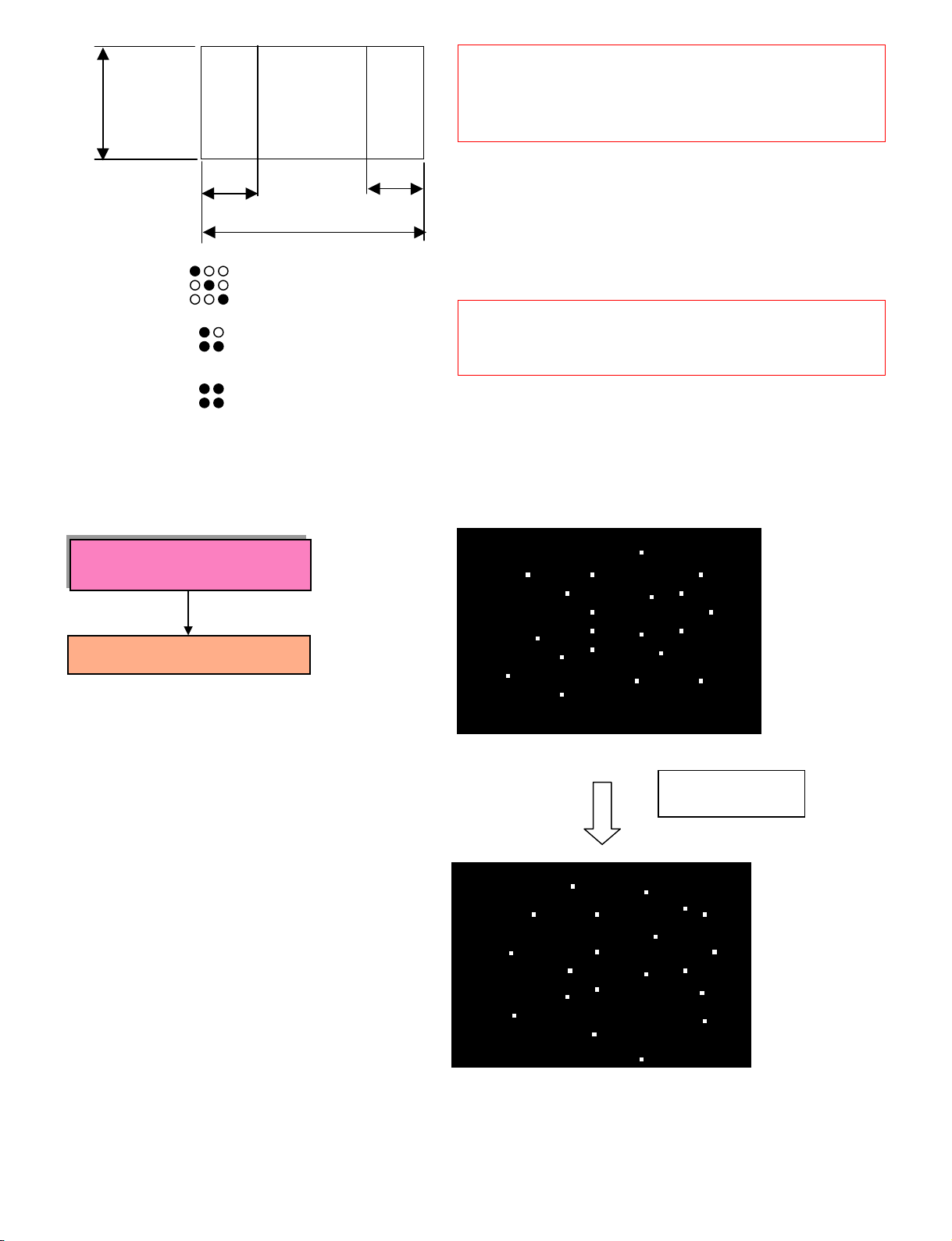

(Caution1) Zone A: Central part (the area surrounded by

the right and left sides by 1/4H) with

V

Zone B Zone B

ZoneA

the area that is 1/2 of the whole

Zone B: Area other than A above

(4) Wrong lighting

Wrong lighting

1/4H

H

3 dots continuous

→

3 dots continuous

→

4 dots continuous

→

1/4H

(Caution2) The continuous dots appearing in the slantwise

direction or in a cluster state shall be defined

as follows:

The PDP is fault.

All-black signal

Dot errors change

with no continuity.

All-black signal

3-10

Page 17

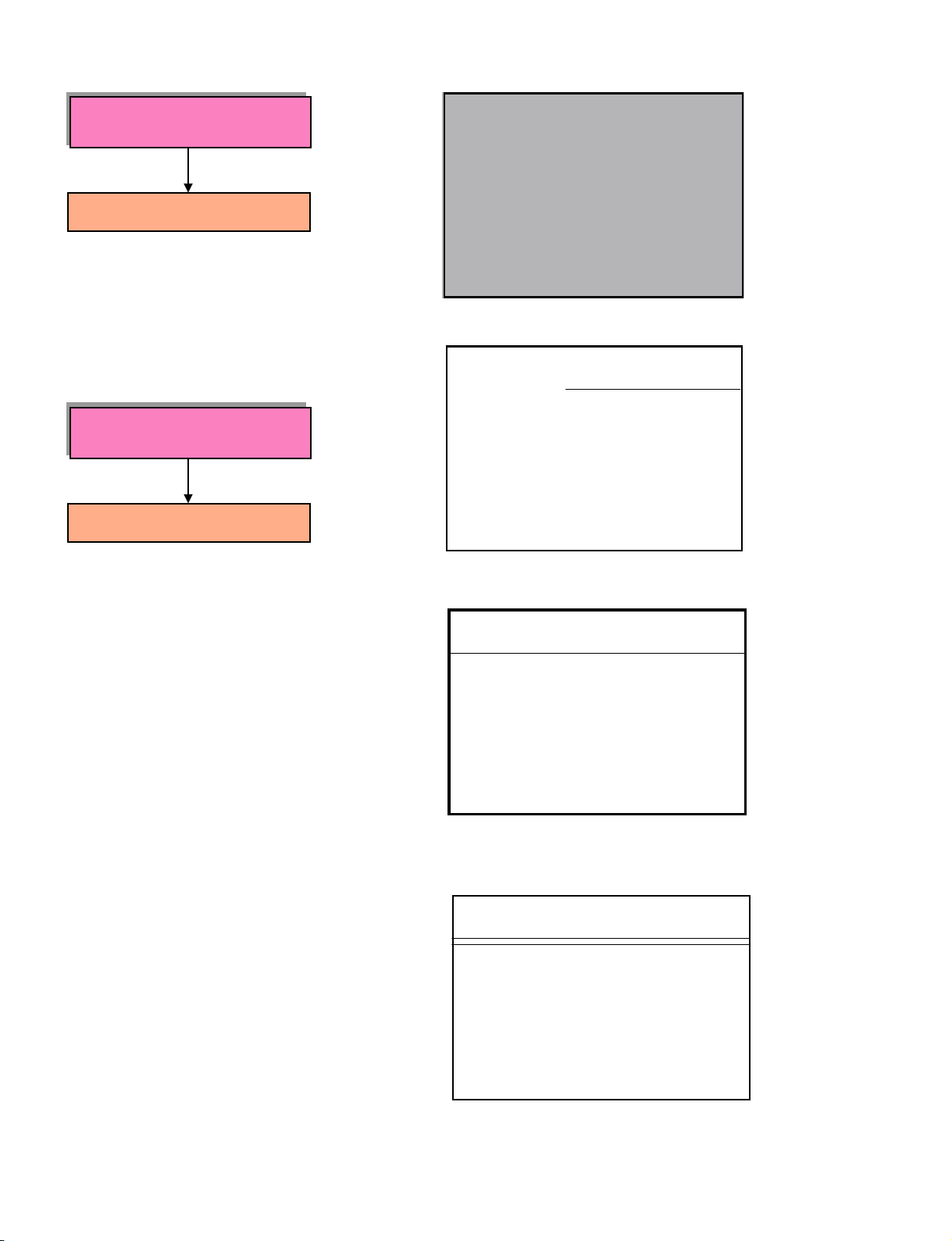

(5) Dark images [Other than the deterioration in brightness as per (1) above]

The images are dark even with

an all-white input signal.

The PDP is fault.

All-white signal

(6) Defect in horizontal lines

Line defect

The PDP is fault.

All-white signal

All-white signal

3-11

All-white signal

Page 18

Defect in the block unit

The PDP is fault.

All-white signal

(7) Defect in vertical lines

Defect in vertical lines

The PDP is fault.

All-white signal

All-white signal

3-12

All-white signal

Page 19

Block defect

The PDP is fault.

All-white signal

All-white signal

3-13

All-white signal

All-white signal

Page 20

(8) No pictures [(Caution) The voltage outputs of Vs = 170V and Vd = 64V, 5Vdc are always generated, but the LED is

not flashing or lighting for alarming. However, the voltage values can differ according to the PDP.]

No picture is displayed.

Make the setting of OFF→ ON for

the main power supply.

Does the priming glimpse?

NO

YES

When the AD connector is disconnected, is the LVDS signal

normally output to each pin of the

AD connector? (For more details

of the signal, refer to the descriptions about the connector pins.)

YES

The AD connector or the PDP is

fault.

The PDP is fault.

NO

The MAIN PWB is fault.

3-14

Page 21

3. Audio errors

(Caution)In regard to the method of audio input setting, refer to the specifications and the instruction manual to

confirm that all the setting is free from errors. Since then, troubleshooting can be carried out. It must be

noted that the protector functions and no audio output is available if the opposing electrodes of the speaker

output or the speaker output and the ground (GND) are short-circuited. In such a case, turn off the main

power supply and make the connections correctly. The protector is reset when the main power supply is

turned on after that.

Audio errors

YES

In the state that the speaker cable is disconnected, is the audio signal output available at

the speaker terminal?

NO

NO

Is the voltage output specified below available

at each pin of the PA connector in the AUDIO

PWB?

The speaker or the speaker

cable is fault.

The power unit or the PA connector is fault.

Pin No. Name Voltage

1 S+12 12Vdc

2 S+12 12Vdc

3 S+12 12Vdc

4 GND GND

5 GND GND

6 GND GND

YES

Is the waveform specified below output to the

AU connector of the AUDIO PWB?

Pin 6

Pin 7

Pin 5

5Vpp

5Vpp

3.5Vdc

NO

The MAIN PWB or the AU connector is fault.

Pin 1,3 • • • Audio signal waveform

YES

The AUDIO PWB is fault.

3-15

Page 22

4. Remote control not effective

(1) The wired remote control is not effective.

1

When a single item is used

The wired remote control is not effective.

(Caution)The wired remote control is not effective if the setting of

[PLE LINK], [Repeat TIMER], or [IR REMOTE] is ON, or

if the setting of [ID NUMBER] has been made. Therefore, such a setting should be turned off, without fail. Since

then, troubleshooting can be carried out.

Is there a signal output specified below at Pin 7 of the RS connector?

5Vpp

NO

Is there a signal output specified below

at Pin 3 of the M2003? (Refer to the

PWB layout diagram on Page P4-22.)

5Vpp

YES

When the RS connector is disconnected, is there a signal output specified below at the RS connector of the

MAIN PWB?

Pin No. Pin Name Voltage

1 M+7V 6.8Vdc

5 M+5V 5Vdc

YES

NO

NO

The RS connector or the

MAIN PWB is fault.

Is there a 3.3Vdc output at

Pin 2 of the M2003? (Refer

to the PWB layout diagram

on Page P4-22.)

YES

NO

The RS232C PWB is fault.

The RS connector or the

MAIN PWB is fault.

The remote control or the remote

control cable is fault.

YES

The 232C PWB is fault.

2

When a daisy chain (including the video wall) is used

The wired remote control is not effective.

Are the 0Vdc and 5Vdc outputs respectively available at Pins 9 and 10

of the RS connector in the standard

product of 232C PWB?

NO

The MAIN PWB is fault.

YES

Is there a clock signal output at Pin 3 of the M2004?

(Refer to the PWB layout

diagram on Page P4-22.)

NO

The 232C PWB is fault.

3-16

YES

Check the products of second and thereafter according to “1 When a single item

is used.”

Page 23

(2) The wireless remote control is not effective.

(Caution)Since the detection of “wired” or “wireless” is conducted for the remote control through the remote terminal,

it is necessary to pull out the remote control cable from the remote terminal, without fail. Troubleshooting

should be carried out after confirming that “IR REMOTE” is set at ON and that “ID NUMBER” is at ALL

according to the user’s menu.

The wireless remote control is not

effective.

NO

Is there a 0Vdc output at Pin 12 of the RS connector?

YES

Is there a signal output specified below at Pin

6 of the PW connector?

5Vp-p

YES

NO

When the RS connector is disconnected, is

there a 0Vdc output at Pin 12 of the RS connector in the MAIN PWB?

YES

The 232C PWB or the RS con-

NO

The MAIN PWB is fault.

nector is fault.

Is there a signal output specified below at Pin

1 of the LD connector?

5Vp-p

YES

The LED connector or the LED PWB is fault.

YES

The PW connector or the PWR

PWB is fault.

3-17

3-19

Page 24

MAIN PWB(HDCP)

IC9501

3-18

Page 25

AUDIO PWB

3-19

Page 26

232C PWB

CTL PWB

PWR PWB

LED PWB

SENB PWB

SENC PWB

SEND PWB

M2003 pin 2

M2004 pin 3

M2003 pin 3

3-20

Page 27

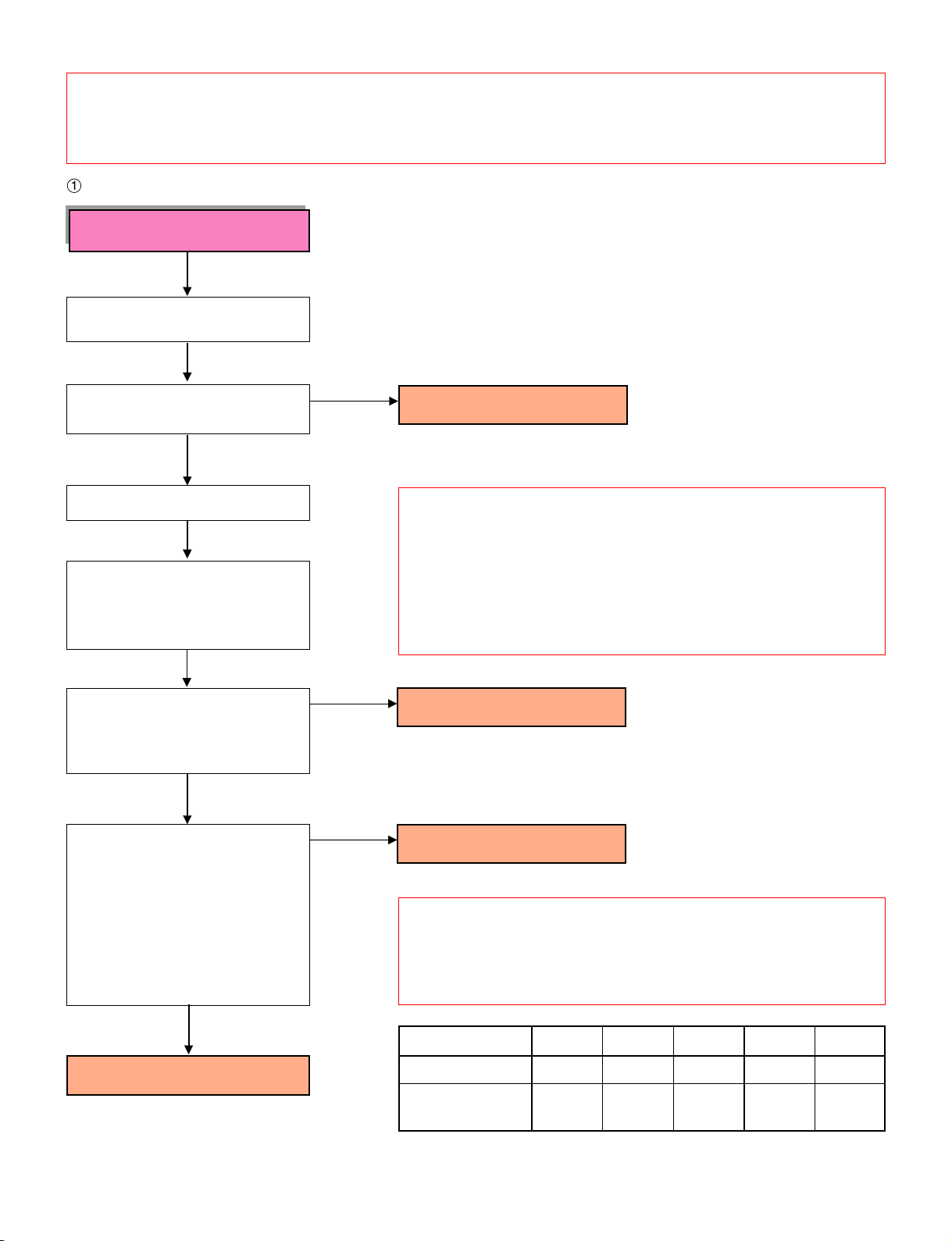

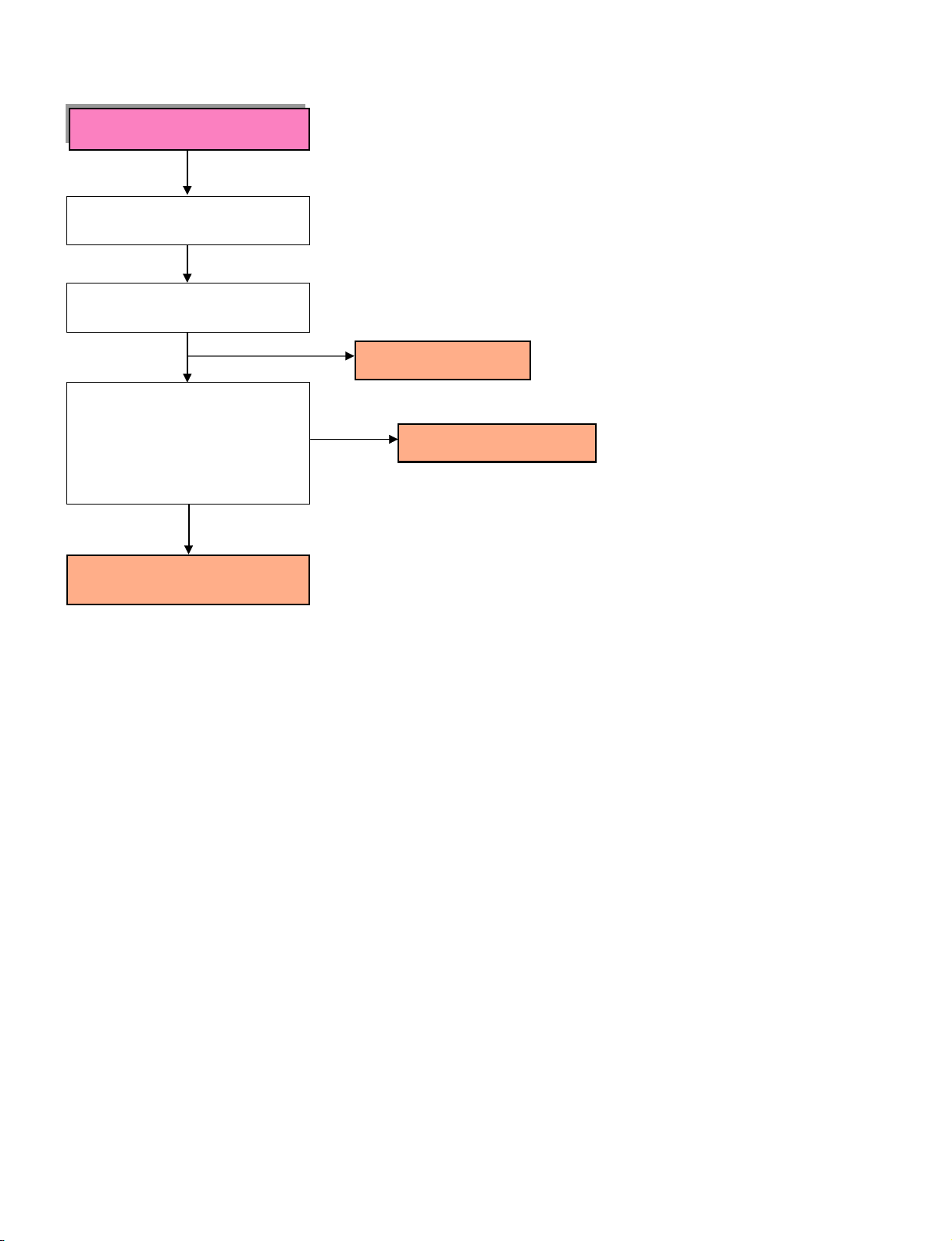

METHOD OF ADJUSTMENTS

■ Adjusting conditions

Adjustments should be carried out in the procedures of A to B specified below. However, any adjustments other than

the items A to B below are not required.

A. When the “PDP module” is replaced, perform adjustment item 1-1 specified on the following page.

B. When the “POWER UNIT” is replaced, perform adjustment item 1-1 specified on the following page.

4-1

Page 28

1-1. For the PD-5030 Series

1-1-1. Adjustment of the Vs voltage

(1) Enter a color bar input by means of either video signal of VIDEO input, or DVD/HD input, or RGB input, and turn

on the power switch of the main unit.

(2) Turn the volume control (RV6) in the power unit and make adjustments until the voltages of CH2 and CH1 (D,

GND) of the power unit attain the voltage values specified for the PDP (Vs value of the voltage regulation indicator label on below the figure ) ±1V.

1-1-2. Adjustment of the Vd voltage

(1) Enter a color bar input by means of either video signal of VIDEO input, or DVD/HD input, or RGB input, and turn

on the power switch of the main unit.

(2) Confirm that the voltages of CH4 and CH1 (D, GND) of the power unit are maintained at the voltage values

specified for the PDP (Vd value of the voltage regulation indicator label on below the figure) ±1V.

Otherwise, turn the volume control (RV5) until the voltage attains the voltage values specified for the PDP (Vd

value of the voltage regulation indicator label on below the figure) ±1V.

1-1-3. Adjustment of the +5V voltage

(1) Display a color bar by means of either video signal of VIDEO input, or DVD/HD input, or RGB input.

(2) Confirm that the voltages of CH3 and CH1 (D, GND) of the power unit are maintained at “5.15 ± 0.1V”.

Otherwise, turn the volume control (RV2) until the voltage attains “5.15 ± 0.1V”.

SERIAL NO.

********

Vd= **V

Vs=***V

CODE -01

OR

Vs/Vd/100/185/220 V

555/84.2/782/10204 K

347 W/0 /2 P

(Caution) Rear Side View when the Rear Cover is Removed

The label is hidden between the MAIN PWB and

the PDP. It can be checked by peeping into the

gap from above. The position of this label may be

modified without preliminary notice.

4-2

Page 29

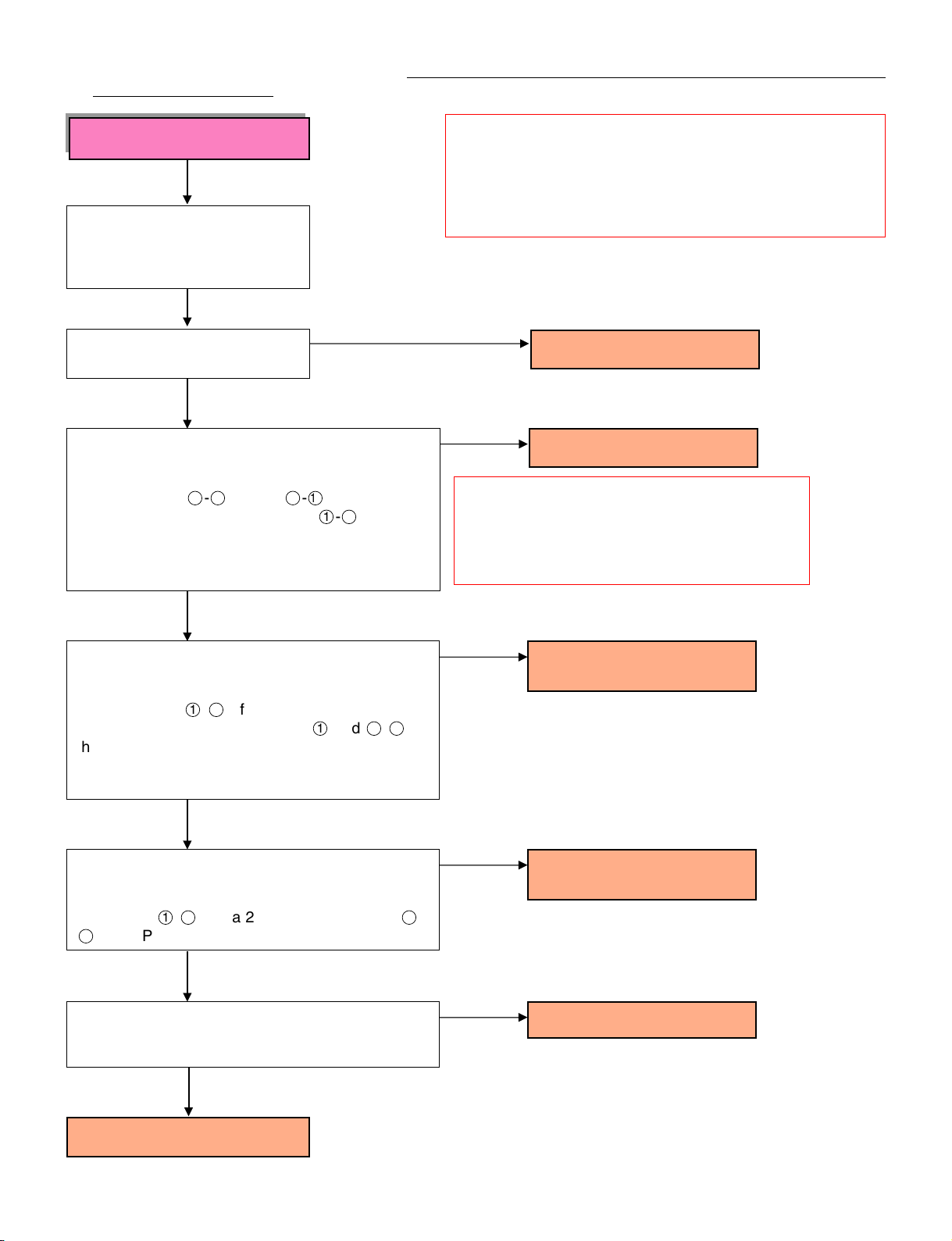

* Top view of the power unit for the PD-5030 Series

P

V

P

M

P

N

P

A

Adjustment

of 5V

RV3

D+3.3 ADJ

CH1

D.GND

RV2

D+5 ADJ

Adjustment of

the Vd voltage

CH3

Vcc

RV5

D+64 ADJ

PH

CH4

Vd

RV6

D+170 ADJ

PD

CH2

Vs

Adjustment of

the Vs voltage

AC

4-3

Page 30

METHOD OF DISASSEMBLY

(Caution)1. Before disassembly, turn power off the main unit and pull out the power plug from the wall outlet.

2. Use a screwdriver with a fitting size. Otherwise, the screw threads may be damaged.

3. Reassembly can be carried out in the reverse order for disassembly. Refer to the disassembly procedures and forward

reassembly in the reverse order.

4. The order for taking out the parts (or components) is indicated by the foregoing numeral that is attached to the name

of each part.

5. The wire connector symbol is indicated by two digits of Marking . Read CN- when examining the table of parts.

6. Class A or Class B in the text is applicable to the models specified below.

CLASS B: Model PD-5030

1. Outlined method of disassembly

The outlined procedures for the disassembly of the major parts are shown below (disassembled in the direction of ).

In regard to the details of disassembly, cautions, etc., refer to the method of replacement for each part [page indicated in ( )].

SET

(with a STAND)

SET

(without a STAND)

* Modification means the removal of screws.

STAND

(P5-2)

Modifications

of a STAND

(P5-11)

BACK COVER

(P5-3~5-4)

Modifications of a

BACK COVER

(P5-12)

BACK COVER

(P5-3)

CHASSIS ASSY

(P5-5)

FRONT PANEL

(P5-10)

BUTTON COVER

(P5-9)

CONTROL BUTTON

(P5-9)

TERMINAL PANEL M SUB ASSY

(P5-13)

TERMINAL PANEL S

(P6-15)

POWER BUTTON COVER

(P5-16)

TERMINAL PANEL B SUB ASSY

(P5-17)

POWER UNIT

(P5-20)

SEND PWB

(P5-21)

SENB PWB

SENCPWB

PDP

(P5-6~5-7)

(P5-21)

(P5-21)

BRACKET FILTER

(P5-8)

SUB FRONT

(P5-9)

LED PWB

CTL PWB

TERMINAL PANEL M

(P5-14)

232C PWB

(P5-15)

POWER BUTTON

(P5-16)

TERMINAL PANEL B

(P5-18~5-19)

FAN

(P5-21)

FILTER

(P5-8)

(P5-8)

(P6-8)

MAIN PWB

(P5-14)

PWR PWB

(P5-16)

AUDIO PWB

(P5-19~5-19)

AC INLET

(P5-19~5-19)

5-1

Page 31

2. STAND

(1)SCREW M6*50 4p

(2)STAND

5-2

Page 32

3. BACK COVER

(4)SRW31 CBIPS*4*12*15KF

*31p

(1)SRW33 CBIPS*5*16*15KF

*4p

M34 GS COVER

(Caution) Replacement is

impossible unless the NAME

PLATE is removed.

M02 SERIAL LABEL

24L44731

M47 NAME PLATE

(Caution) This is not a service part.

(5)BACK COVER ASSY

(2)M14 HANDLE

29F00591 *2p

M48 SPEAKER LABEL

(3)SRW32 PL-CPIMS*3*10*15KF

*9p

M46 AC IN LABEL

5-3

Page 33

(2)M50 BACK COVER

(1)M36 BARRIER PS

*Adhesion should be based on the

position of heat radiator holes.

5-4

Page 34

4. CHASSIS ASSY

(9)CHASSIS ASSY

(4)CONNECTOR

(8)SRW05 PL-CPIMS*5*12*15BF

*6pcs

(6)SRW06 CBIPS*4*12*15KF

24N04471 *10p

*10p

(5)CONNECTOR 2p

(3)SRW18 TP-M3*6*3KF

*5p

5-5

(2)M26 SHIELD MAIN

(1) SRW30 CBIPS*4*12*15KF

*8p

(7)SRW04 PL-CPIMS*4*12*15KF

*3pc

Page 35

5. PDP

(4)CONNECTOR

(1) SCREW

(Caution) This screw is used

to fasten the PWB of the PDP.

(3)M08 LUG(60)

(2)SRW34 TP-M3*6*3KF

*1p

(Caution) The SW cable should

be passed beneath the module.

5-6

(4)PDP PDP-NP50C4MF01AA

3S350005

Page 36

Positioning pin

Positioning pin

(Caution) For use, move the block

in the direction of the arrow.

(Caution) For use, remove these two blocks that

are attached to the maintenance PDP.

5-7

Page 37

6. BRACKET FILTER/FILTER

M37 CUSHION(580*10*T4)

*4p

(1)SRW03 CPIPS*4*8*3KF

*20p

(5)M19 BRACKET FILTER T

5

(Caution) The FRONT PANEL can be taken out

when this screw only has been removed.

However, when you assemble, assemble in the order

within number. Otherwise, the gap between

filters becomes large.

M38 CUSHION(654*10*T4)

(2)M18 BRACKET FILTER L

(8)SRW02 CBIPS*4*12*15KF

*6p

*2p

(6)A06 LED PWB

936Q0SD1

(4)M35 BRACKET FILTER R

(5)A04 CTL PWB

936Q0SB1

(Caution) Insert the CTL PWB in the SUB FRONT

before mounting the BRACKET FILTER B.

(Caution) The SW cable should be

inserted in the clearance toward the rib.

6

(Caution) Hook the upper claw at first.

3

(3)M20 BRACKET FILTER B

4

2

(7)M41 FILTER

CLASS B : 029K00351

(Caution) The FILTER is standardized to be positioned at bottom left.

SHIELDING TAPE (33MM*50M)

1

5-8

Page 38

8. SUB FRONT

(2)M16

CLASS B CONTROL BUTTON :29G00371

(3)M12

CLASS B BUTTON COVER :29F00931

(1)SRW01 CBIPS*3*8*3KF

*2p

(4)M10 SUB FRONT

29D00651

5-9

Page 39

9. FRONT PANEL

(1)M42 INDICATOR

(Caution) For removal, it comes off when it is pressed strongly

from the rear side of the FRONT PANEL. For installation, remove

the separator before adhesion.

(3)M09

CLASS B FRONT PANEL :29D00641

5-10

Page 40

10. STAND (modification)

(1)SCREW M6*50 4p

5-11

Page 41

11. BACK COVER (modification)

(Caution) The illustration below shows a case when the STAND has been removed.

(1)SRW02 CBIPS*4*12*15KF

*6p

(Caution) The FRONT PANEL can be taken out

when this screw only has been removed.

However, when you assemble, assemble in the order

within number. Otherwise, the gap between

filters becomes large.

(2)FRONT PANEL ASSY

5

3

2

1

6

4

5-12

Page 42

12. TERMINAL PANEL M SUB ASSY

(7)SRW20 CBIPS*4*12*15KF

*3p

(9)TERMINAL PANEL M

SUB ASSY

(8)SRW18 TP-M3*6*3KF

*4p

(6)M33 HEAT SINK

(5)SRW19 TP-M3*6*3KF

*2p

(3)SRW18 TP-M3*6*3KF

(Caution) It should be tightened

together with the round terminal

of the AD cable.

(4)CONNECTOR 12p

5-13

(2)M26 SHIELD MAIN

(1) SRW30 CBIPS*4*12*15KF

3

*8p

Page 43

13. TERMINAL PANEL M/MAIN PWB

(Caution) Please note that no DS connector is furnished even though the MAIN PWB is ordered.

(5)M17 SHIELD PLATE MAIN

(Caution) After sticking the TERMINAL SHEET to

the TERMINAL PANEL, push the peripheral area

of the screw hole to strengthen the adhesion.

(In 3 positions)

(6)A01 MAIN PWB

936U1M02

Rear side

* Positioning hole

During the main unit assembling, this

part is combined with the embossed

part of the main unit side.

(3)M43 TERMINAL SHEET MW

(2)SRW15 CBIPS*3*8*3KF

*7p

5-14

(1)SRW16 SCREW(UNC4-40/4-40)

*4p

(Caution) Use a hexagon head driver

(opposite side distance 5mm).

(4)M27 TERMINAL PANEL M

Page 44

14. TERMINAL PANEL S/232C PWB

(4)A03 232C PWB

936Q0SA1

(3)SRW17 SCREW(UNC4-40/4-40)

*2p

(Caution) Use a hexagon head driver

(opposite side distance 5mm).

(1)SRW21 TP-M3*6*3KF

24N04581 *2p

*2p

(2)SRW22 CBIPS*4*12*15KF

Rear side

(Caution) After sticking the TERMINAL SHEET to the TERMINAL PANEL,

push the peripheral area of the screw hole to strengthen the adhesion.

(5)M53 TERMINAL SHEET SW

(6)M29 TERMINAL PANEL S

29H03191

* Positioning hole

During the main unit assembling, this

part is combined with the embossed

part of the main unit side.

5-15

Page 45

15. POWER BUTTON COVER/POWER BUTTON/PWR PWB

(1)SRW23 TP-M3*6*3KF

*2p

Rear side

(Caution) Positioning pin

Use it in the case of reassembly.

(3)M15 POWER BUTTON

29G00281

(2)M13 POWER BUTTON COVER

29F00561

(4)A05 PWR PWB ASSY

936Q0SC1

5-16

Page 46

16. TERMINAL PANEL B SUB ASSY

(1)CONNECTOR 3p

(3) SRW26 TP-M3*6*3KF

*2p

(5)TERMINAL PANEL B

I

SUB ASSY

(4)SRW27 TP-M3*6*3KF

*3p

(2)SRW28 ET-CBIMS*4*8*3KF

5-17

Page 47

17-A. TERMINAL PANEL B/AC INLET

(6)CN-PI CABLE 2P L265 ESD-R-19

(7)CN-FG(GND) CABLE 1P L360

7S530015

(8)E02 AC INLET 10DKDG3S(Y1)

(Caution) For installation, the label

should be made to face upwards.

C

7S530035

(5)M51 BARRIER(AC INLET)

29J00871

(Caution) The bent part shall be

positioned top side.

Rear side

GSK05 SHIELDING SHEET(300*4)

(Caution) The heat radiator holes

must not be hindered.

M29 TERMINAL PANEL B

29H03191

(Caution) Positioning hole

During the main unit assembling, this part

is combined with the embossed part of the

main unit side.

5-18

Page 48

17-B. AUDIO PWB

(2)A02 AUDIO PWB

936R4AA2

(3)SRW24

CPIMS*NO.6-32UNC*8*3GF

*2p

(1)SRW25 CBIPS*3*8*3KF

)

*2p

M29 TERMINAL PANEL B

29H03191

M45 TERMINAL SHEET B(50XM3)

5-19

(4)M52 INLET COLLER

(Caution) Insert it in between the screw

and the TERMINAL SHEET B.

Page 49

18. POWER UNIT

(2)PSU POWER UNIT

3S110171

(1)SRW14 PL-CPIMS*4*12*15KF

*6p

5-20

Page 50

19. SENB PWB/SENCPWB/SEND PWB/FAN

(2)A07 SENB PWB

936Q0SE1

(1)SRW29 CBIPS*4*12*15KF

(7)E01 FAN MOTOR 9G1212M4D03

(7)E01 FAN MOTOR 9G1212M4D03

3S170014 *2

3S170014 *2

(Caution) For assembly, hook the upper claw first and push it in while

the name plate stays in the direction of rightward turning by 90°.

Confirm, without fail, that it is pulled and caught by the claw.

(4)A09 SEND PWB

(3)SRW29 CBIPS*4*12*15KF

E

936Q0SG1

1

5-21

(6)A08 SENC PWB

936Q0SF1

(5)SRW29 CBIPS*4*12*15KF

Page 51

20. BRACKET/SHIELD

(Caution) The mechanical component is provided with an engraved marking of the arrow ( ). Remove the screw where this arrow mark is located.

(2)M21 PWB BASE MAIN

M

Positioning pin

(1)SRW13 CBIPS*4*12*15KF

*2p

Positioning pin

Positioning pin

(3)M39 WASHER(6-10)

*2p

(13)M25 SHIELD CENTER

(13)M25 SHIELD

29H02531

(11)M23 PS BRACKET

(10)SRW10 CBIPS*4*12*15KF

*8p

(7)M40 SILICONE SHEET(AUDIO)

(Caution) Peel off the clear sheets

that are stuck to both sides.

(8)M08 LUG(60)

) (

A )

Positioning pin

(5)M22 PWB BASE SUB(50XM3)

(4)SRW12 CBIPS*4*12*15KF

*2p

(12)SRW09 CBIPS*4*12*15KF

*1p

(6)SRW11 CBIPS*4*12*15KF

)

*9p

5-22

Positioning pin

(9)M24 SHIELD BOTTOM

)

Positioning pin

Page 52

21. FRAME

(2)SRW05 PL-CPIMS*5*12*15BF

*4p

(1)SRW04 PL-CPIMS*4*12*15KF

S

*3

(11)M11 FRAME

A

29D00572

(3)SRW06 CBIPS*4*12*15KF

*10p

(4)SRW08 CBIPS*4*12*15KF

W

*8p

(5)M32 STAND BRKT(50XM3)

(9)M30 PLANE R

(8)SRW07 CBIPS*4*12*15KF

*11p

(7)SRW05 PL-CPIMS*5*12*15BF

*2p

5-23

(6)M32 STAND BRKT

(10)M31 PLANE L

A(

Page 53

22. WIRE CLAMP

M06 CLAMP(MWC-2S)

*19p

CLAMP(WS-2W-V0)

P -

*16p

5-24

Page 54

23. GASKET(CLASS B)

GSK03 SHIELDING SHEET(114*8)

*3p

GSK01 GASKET(L140*13*T1.5)

*4p

GSK04 SHIELDING SHEET(114*8)

*1p

GSK02 SHIELDING SHEET(200*8)

*2p

(Caution) Adhesion should be done in the state

that the notch part is positioned upwards.

5-25

Page 55

24. WIRING

1

5

6 Pass RS.

4

1

Pass AD.

Fix the AD with

Wound Lug

(Caution) “Turns” in the illustration below denotes the number of cable turns to be wound around the ferrite core.

(Example) 3 turns 3 turns of a cable wound around.

x2

3

Pass PH and PD.

x2

7

Pass PH/

PD.

PH PD

4

TR

TS

Pass TS and FAN.

4

x2

Pass TR and FAN.

3 Pass GND, AC and SW.

7 Pass GND and AC.

x5

4

Pass TS.

Fix the surplus

part of SW.

TS

Fix the surplus part of Fan together with TM and TR.

2

Pass TM, FA and FB.

3

Pass AU and PV.

Pass AU and PV.

Pass TM, FA and FB.

1

1 Pass PM and PN.

AD

1 Pass SW and AD.

PW

RS

AU PV

Lable side

Pass PV only.

6

4 Pass PV and AU.

FB

FA

TM

PM

PN

AD

AD

RS

SW

1 Pass RS and PW.

Pass 2 turns of TM.

6

x2

Pass PV and AU.

3

PV

PM

PN

PA

3

7 Pass PM and PN only.

3

Pass 2 turns of SW only.

6

3 Pass PA and AU.

6

5

AC

TM

TR

Pass TM, TR

4

and FAN.

Pass PA.

Pass PM, PN and AU.

x2

Pass 2 turns of PA only.

Fix the AC (blue, brown)

with Wound Lug.

8

Pass RS.

Fix the surplus part of LD.

4

Pass LD.

6

EDGING SADDLE(EDS-1208U)

1

LEAD CLAMPER (D11.5)

2

CLAMP(WS-2W-V0)

3

CLAMP(MWC-2S)

4

x3

LD

PW

LD

Pass PW.

4

Pass RS and PW.

3

Pass PA, AU and SW.

Pass PW.

6

Pass AU.

3

4

PA

Pass AU. 3

AU

4

Pass the SW through

the groove.

6 Pass 2 turns

of AU.

Names of parts Quantity Names of parts Quantity

5

LUG(L60)

1 9

16

19

5

6

FERRITE CORE (ZCAT2032-930)

7

FERRITE CORE (SFT-72SN-026K) 3

8

FERRITE CORE (ZCAT1518-730)

2

1

5-26

x6

Pass SW.

SW

Page 56

PARTS LIST

Ref. Part Number Description

A01 936U1M02 PWB-MAIN

A02 936R4AA2 PWB-AUDIO ASSY

A03 936Q0SA1 PWB-232C

A04 936Q0SB1 PWB-CTL

A05 936Q0SC1 PWB-PWR SWITCH

A06 936Q0SD1 PWB-PWR LED

A07 936Q0SE1 PWB-SENB

A08 936Q0SF1 PWB-SENC

A09 936Q0SG1 PWB-SEND

CN-AD 7S530030 CABLE- 31P L320

CN-PI 7S530035 CABLE- 2P L265 ESD-R-19

E01 3S170014 FAN-MOTOR (9G1212M4D03)

CN-FG 7S530015 CABLE- 1P L360

M09 29D00641 PANEL-FRONT

M10 29D00651 PANEL-FRONT SUB

M11 29D00572 FRAME (50XM3)

M12 29F00931 BUTTON-COVER

M13 29F00561 BUTTON-POWER COVER

M14 29F00591 HANDLE

M15 29G00281 BUTTON-POWER

M16 29G00371 BUTTON-CONTROL

M29 29H03191 PANEL-TERMINAL

M36 29J00871 BARRIER (AC INLET)

M41 029K00351 SCREEN SHIELD (FILTER)

PDP 3S350005 PDP-NP50C4MF01AA (T/A REQ)

PSU 3S110171 PWB-POWER UNIT

7S580006 CABLE-D-SUB 15P L1800

7S580010 CABLE-STEREO MINI L3M

7S552001 CORD-POWER AC

I/B PD5030 OWNERS GUIDE

3S120171 REMOTE

6-1

Page 57

CONNECTION DIAGRAMS

TEMP-SENSOR3

SENC PWB

PCB-5032F

SCL5

SDA5

VDD+5V

GND

DS

123

GND

GND

HDSTP

TEMP-SENSOR2

SEND PWB

1

2

3

4

TS

1

2

3

4

AU

1234567

GND

AU-L

AU-R

1,3,5,6,7pin:shield

1

SCL5

SDA5

VDD+5V

GND

SCL5

SDA5

VDD+5V

GND

2

3

4

AU:SHIELD-WIRE

1234567

GND

SCL7

MUTE

SDA7

A+12

TEMP-SENSOR1

SENB PWB

PCB-5032EPCB-5032G

TR

PV

A+6

A+6

A.GND

A.GND

1

SCL5

2

SDA5

3

VDD+5V

4

GND

TM

8

NC

NC

A.GND

P4 series

XM2 series

PD-5030 series

SCL5

SDA5

123

123

SCL5

SDA5

VDD+5V

GND

4

FA FB

4

GND

VDD+5V

FAN-A

FAN-CTL

123

123

GND

F-ALM1

FAN-CTL

GND

FAN-B

F-ALM1

123

GND

FAN-CTL

FAN-A FAN-B

XX

FAN-CTL

GND

F-ALM1

123

F-ALM2

FC

123

GND

F-ALM3

FAN-CTL

M+7V

D.GND

POWER

D.GND

POMUTE

SW7

NC

D+3.3

D+3.3

D+3.3

D.GND

D.GND

D.GND

D+2.5

D+2.5

D+2.5

D.GND

D.GND

D.GND

10

11

12

PDP

D+5

D+5

D.GND

D.GND

ALARM

D.GND

D.GND

D.GND

D.GND

D+60

D+60NCD+170

D+170

123..

.

293031

123

123456789

4

10

AD

PH

123

4

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

PM

PN

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

10

11

12

M+7V

D.GND

POWER

D.GND

POMUTE

SW7

NC

D+3.3

D+3.3

D+3.3

D.GND

D.GND

D.GND

D+2.5

D+2.5

D+2.5

D.GND

D.GND

D.GND

D+5

D+5

D.GND

D.GND

POWER SUPPLY

PD

123456789

NC

D+60

D.GND

D.GND

D+60

L

N

D.GND

ALARM

D.GND

10

D+170

D+170

1

2

AC

PWR PWB

PCB-5032C

REMIN1

LEDCTL1

LEDCTL2

GND

12345

LD

12345

GND

REMIN1

LEDCTL1

LEDCTL2

LED PWB

PCB-5032D

M+5V

M+5V

SW7

POIN

GND

M+5V

M+7V

REMIN1

LEDCTL1

LEDCTL2

A+12

1

A.GND

1 GND

PLE_CTL

TXD1

GND

101112

2 GND

3 ALARM

4 GND

5 PS+

6 PS 7 MSEL

8 GND

9 RH+

10 RH11 RG+

12 RG13 RF+

14 RF15 GND

16 RE+

17 RE18 RD+

19 RD20 RCLK+

REM

MAIN PWB

PCB-5031

M+7V

TXD

GND

RXD

M+5V

GND

REMIN2/RXD1

SW7

POIN

GND

M+5V

M+7V

REMIN1

LEDCTL1

M+7V

TXD

GND

RXD

M+5V

GND

TXD1

GND

REM

LEDCTL2

8

1

2

3

4

5

RS

6

7

8

9

10

11

12

123456789

RS

1

2

3

4

PW

5

6

7

8

1234567

232C PWB

PCB-5032A

REMIN2/RXD1

RESET SW

PLE_CTL

RESET SW

21 RCLK22 GND

23 RC+

24 RC25 RB+

26 RB27 RA+

28 RA29 GND

30 GND

31 GND

CTL1

123

SW

CTL2

GND

29

30

31

1

2

3

.

AD

.

.

PV

AU:SHIELD-WIRE

2

3

4

5

6

7

8

1

2

PA

3

4

5

6

AUDIO PWB

PCB-5033

SPEAKER_OUT

A+6

A+6

A.GND

A.GND

NC

NC

S+12

S+12

S+12

GND

GND

GND

ROUT+

123

ROUT-

LOUT+

LOUT4

12345

S+12

S+12

SW

S+12

1

2

3

PA

GND

CTL1

CTL2

GND

GND

6

GND

AU-L

1

GND

2

AU-R

3

GND

4

MUTE

5

SCL7

6

SDA7

7

CTL PWB

PCB-5032B

AU

7-1

Page 58

CONNECTOR PIN EXPLANATION

(Caution) The operating voltages specified below are used in common irrespective of the presence of signals. In this case, how-

ever, part of the operating voltages (red characters) may change according to the signal conditions when the main

power supply is turned on (POWER button ON).

Status of LED lighting: v for lighting in green, vv for unlighting, and vvv for lighting in red.

Name Pin No. Pin name Function

PN

PM

PV

DS

AU

RS

1 D+3.3

2 D+3.3

3 D+3.3

4D.GNDGND 000000––

5D.GNDGND 000000––

6D.GNDGND 000000––

7 D+2.5

8 D+2.5

9 D+2.5

10D.GNDGND 000000––

11D.GNDGND 000000––

12D.GNDGND 000000––

1 M+7

2D.GNDGND 000000––

3 POWER Power control 0 4.9 4.9 0 0 0 – MAIN→POWER

4D.GNDGND 000000––

5 POMUTE Mute signal for AC power OFF 4.8 4.8 4.8 4.8 4.8 4.8 4.8→ POWER→MAIN

6 SW7 Power start control 0 6.8 6.8 6.8 6.8 0 – POWER→MAIN

7 NC Non-connection terminal – – – – – – – –

1 A+12V

2A.GNDGND 000000––

3 A+6

4 A+6

5A.GNDGND 000000––

6A.GNDGND 000000––

7 NC No-connection terminal – – – – – – – –

8 NC No-connection terminal – – – – – – – –

1 GND GND 0 0 0 0 0 0 – –

2 HDSTP

3 GND GND 0 0 0 0 0 0 – –

1 AU_L Audio signal L CH 0

2 GND GND 0 0 0 0 0 0 – –

3 AU_R Audio signal R CH 0

4 GND GND 0 0 0 0 0 0 – –

5 MUTE Mute signal of audio output 3.5 3.5→0 3.5→0 3.5 3.5→0 3.5 3.5→0 MAIN→AUDIO

6 SCL7 Clock line of the I2C bus 0 Clock signal Clock signal 0 0 0 – MAIN→AUDIO

7 SDA7 Data line of the I2C bus 0 Clock signal Clock signal 0 1 0 – MAIN→AUDI

1 M+7V

2 TXD RS232 driver output 5 5 5 5 5 5 – MAIN→RS232C

3 GND GND 0 0 0 0 0 0 – –

4 RXD RS232 receiver input 0 Clock signal Clock signal Clock signal 0 0 – RS232C→MAIN

5 M+5V

6 GND GND 0 0 0 0 0 0 – –

7

REMIN2/RXD1

3.3V power supply for digital circuits

3.3V power supply for digital circuits

3.3V power supply for digital circuits

2.5V power supply for digital circuits

2.5V power supply for digital circuits

2.5V power supply for digital circuits

7V power supply for microcomputer

12V power supply for analog circuits

6V power supply for analog circuits

6V power supply for analog circuits

Video mute control for chroma signals

7V power supply for microcomputer

5V power supply for microcomputer

Data signal of wired remote control

Basic operation (Numerical unit: Vdc; except for the case when units are individually indicated)

AC power ON

(Power cord

connected to

the wall outlet)

vv

6.8 6.8 6.8 6.8 6.8 6.8 – POWER→MAIN

Main power ON

(POWER button ON)

No signal With signal

0 3.3 3.3 0 0 0 – POWER→MAIN

0 3.3 3.3 0 0 0 – POWER→MAIN

0 3.3 3.3 0 0 0 – POWER→MAIN

0 2.5 2.5 0 0 0 – POWER→MAIN

0 2.5 2.5 0 0 0 – POWER→MAIN

0 2.5 2.5 0 0 0 – POWER→MAIN

0 12 12 0 0 0 – POWER→MAIN

0 6 6 0 0 0 – POWER→MAIN

0 6 6 0 0 0 – POWER→MAIN

0 0V when the 0V when the 0V when the 0V when the 0 – –

DS connector DS connector DS connector DS connector

is connected; is connected; is connected; is connected;

High-Z when High-Z when High-Z when High-Z when

it is not conn- it is not conn- it is not conn- it is not connected ected ected ected

(Video mute) (Video mute) (Video mute) (Video mute)

Selected input Selected input

signals are out- signals are output. put.

Selected input Selected input

signals are out- signals are output. put.

(5Vac) when (5Vac) when

data are rec- data are received; 5Vdc eived; 5Vdc

when no data when no data

are received. are received.

(5Vac) when (5Vac) when

data are rec- data are received; 5Vdc eived; 5Vdc

when no data when no data

are received. are received.

6.8 6.8 6.8 6.8 6.8 6.8 – MAIN→RS232C

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

055550–MAIN→RS232C

0 Clock signal Clock signal Clock signal 0 0 – RS232C→MAIN

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

v

management

Power

vvv

Standby

vvv

0 0 0 – MAIN→AUDIO

0 0 0 – MAIN→AUDIO

Main power

vv

OFF

AC power OFF

(Power cord

pulled out of the

vv

wall outlet)

Ver. 1

Signal direction

7-2

Page 59

Name Pin No. Pin name Function

8 RESET SW NC – – – – – – – –

9 PLE_CTL PLE control 0 Clock signal Clock signal Clock signal 0 0 – MAIN→RS232C

10 TXD1 RS232 driver output 0 Clock signal Clock signal Clock signal 0 0 – MAIN→RS232C

11 GND GND 0 0 0 0 0 0 – –

TM

TR

TS

12 REM

1 SCL5 Clock line of the I2C bus 0 Clock signal Clock signal Clock signal 0 0 – MAIN→SENB

2 SDA5 Data line of the I2C bus 0 Clock signal Clock signal Clock signal 0 0 – MAIN←→SENB

3 VDD+5V

4 GND GND 0 0 0 0 0 0 – –

1 SCL5

2 SDA5

3 VDD+5V

4 GND GND 0 0 0 0 0 0 0 –

1 SCL5

2 SDA5

3 VDD+5V

4 GND GND 0 0 0 0 0 0 0 –

Insertion detection for wired remote control input

5V power supply for analog signals

I2C bus clock for temperature sensors

I2C bus data for temperature sensors

5V power supply for analog signals

I2C bus clock for temperature sensors

I2C bus data for temperature sensors

5V power supply for analog signals

Basic operation (Numerical unit: Vdc; except for the case when units are individually indicated)

AC power ON

(Power cord

connected to

the wall outlet)

vv

Main power ON

(POWER button ON)

No signal With signal

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

0 5V when the 5V when the 5V when the 0 0 – RS232C→MAIN

wired remote wired remote wired remote

control is co- control is co- control is connected; 0V nnected; 0V nnected; 0V

when no wired when no wired when no wired

remote control remote control remote control

is connected. is connected. is connected.

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

0 5 5 0 0 0 – MAIN→SENB

0 Clock signal Clock signal Clock signal 0 0 – SENB←→SEND

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

0 Clock signal Clock signal Clock signal 0 0 – SENB←→SEND

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

0 5 5 0 0 0 – SENB→SEND

0 Clock signal Clock signal Clock signal 0 0 – SEND←→SENC

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

0 Clock signal Clock signal Clock signal 0 0 – SEND←→SENDC

(5Vac) when (5Vac) when (5Vac) when

data are rec- data are rec- data are received; 5Vdc eived; 5Vdc eived; 5Vdc

when no data when no data when no data

are received. are received. are received.

0 5 5 0 0 0 – SEND→SENC

v

management

Power

vvv

Standby

vvv

Main power

OFF

vv

AC power OFF

(Power cord

pulled out of the

vv

wall outlet)

Signal direction

7-3

Page 60

Name Pin No. Pin name Function

FA

FB

1 FAN-CTL

2 GND GND 0 0 0 0 0 0 – –

3 ALARM Fan lock detect

1 FAN-CTL Voltage-controll-

Voltage-controllable

power supply

signal output

able power supply

Basic operation (Numerical unit: Vdc; except for the case when units are individually indicated)

AC power ON

(Power cord

connected to

the wall outlet)

vv

0 0V during nor- 0V during nor- 0 0 0 – FAN→MAIN

mal fan opera- mal fan opera-

Main power ON

(POWER button ON)

No signal With signal

9.3Vdc during 9.3Vdc during

high-speed high-speed

revolution revolution

(Fan mode H); (Fan mode H);

7.6Vdc during 7.6Vdc during

medium- mediumspeed revolu- speed revolution (Fan tion (Fan

mode L); mode L);

5.3Vdc during 5.3Vdc during

low-speed low-speed

revolution revolution

(Fan mode (Fan mode

OFF). OFF).

tion; 5V while tion; 5V while

the fan is sto- the fan is stopped. pped.

v

Power

management

vvv

Standby

vvv

Main power

OFF

vv

AC power OFF

(Power cord

pulled out of the

vv

wall outlet)

Signal direction

FC

(not used)

AD

9.3Vdc during 9.3Vdc during

high-speed high-speed

revolution revolution

(Fan mode H); (Fan mode H);

7.6Vdc during 7.6Vdc during

medium- mediumspeed revolu- speed revolution (Fan tion (Fan

mode L); mode L);

5.3Vdc during 5.3Vdc during

low-speed low-speed

revolution revolution

(Fan mode (Fan mode

2 GND GND 0 0 0 0 0 0 – –

3 ALARM Fan lock detect

1 VCC 0-9V

2 GND GND – – – – – – –0 –

3 ALARM Fan lock detect signal output – – – – – – – FAN→MAIN

1 GND GND 0 0 0 0 0 0 – –

2 GND GND 0 0 0 0 0 0 – –

3 ALARM Module alarm signal 0 5Vdc during 5Vdc during 0 0 0 – PDP→MAIN

4 GND GND 0 0 0 0 0 0 – –

signal output

Voltage-controllable power supply

0 0V during nor- 0V during nor- 0 0 0 – FAN→MAIN

OFF). OFF).

mal fan opera- mal fan opera-

tion; 5V while tion; 5V while

the fan is sto- the fan is stopped. pped.

–––––––MAIN→FAN

normal PDP normal PDP

operation; 0V operation; 0V

when the PDP when the PDP

is out of order. is out of order.

7-4

Page 61

Name Pin No. Pin name Function

5 PS+ PSS input PS+ 0 PSS LVDS PSS LVDS 0 0 0 – PDP→MAIN

6 PS– PSS input PS– 0 PSS LVDS PSS LVDS 0 0 0 – PDP→MAIN

7 MSEL 42V5 compatible interface OFF 0 0 0 0 0 0 – –

8 GND GND 0 0 0 0 0 0 – –

9 RH+ OSD system output H+ 0 OSD LVDS OSD LVDS 0 0 0 – MAIN→PDP

10 RH– OSD system output H– 0 OSD LVDS OSD LVDS 0 0 0 – MAIN→PDP

11 RG+ OSD system output G+ 0 OSD LVDS OSD LVDS 0 0 0 – MAIN→PDP

12 RG– OSD system output G– 0 OSD LVDS OSD LVDS 0 0 0 – MAIN→PDP

13 RF+ Mode system output F+ 0 Video mode Video mode 0 0 0 – MAIN→PDP

14 RF– Mode system output F– 0 Video mode Video mode 0 0 0 – MAIN→PDP

15 GND GND 0 0 0 0 0 0 – –

16 RE+ Video system output E+ 0 Video data Video data 0 0 0 – MAIN→PDP

17 RE– Video system output E– 0 Video data Video data 0 0 0 – MAIN→PDP

18 RD+ Video system output D+ 0 Video data Video data 0 0 0 – MAIN→PDP

19 RD– Video system output D– 0 Video data Video data 0 0 0 – MAIN→PDP

Basic operation (Numerical unit: Vdc; except for the case when units are individually indicated)

AC power ON

(Power cord

connected to

the wall outlet)

vv

Main power ON

(POWER button ON)

No signal With signal

serial differen serial differen

tial PS+ input tial PS+ input

0Vac; Bias 0.3Vac; Bias

1.1Vdc 1.25Vdc

serial differen serial differen

tial PS+ input tial PS+ input

0Vac; Bias 0.3Vac; Bias

1.4Vdc 1.25Vdc

serial differen- serial differential H+ output tial H+ output

0Vac; Bias 0Vac; Bias

1.1Vdc 1.1Vdc

serial differen- serial differential H– output tial H– output

0Vac; Bias 0Vac; Bias

1.41Vdc 1.4Vdc

serial differen- serial differential G+ output tial G+ output

0.3Vac; Bias 0.3Vac; Bias

1.25Vdc 1.25Vdc

serial differen- serial differential G– output tial G– output

0.3Vac; Bias 0.3Vac; Bias

1.25Vdc 1.25Vdc

LVDS serial LVDS serial

differential F+ differential F+

output 0.3Vac; output 0.3Vac;

Bias 1.25Vdc Bias 1.25Vdc

LVDS serial LVDS serial

differential F– differential F–

output 0.3Vac; output 0.3Vac;

Bias 1.25Vdc Bias 1.25Vdc

LVDS serial LVDS serial

differential E+ differential E+

output 0Vac; output 0Vac;

Bias 1.1Vdc Bias 1.1Vdc

LVDS serial LVDS serial

differential E– differential E–

output 0Vac; output 0.3Vac;

Bias 1.4Vdc Bias 1.25Vdc

LVDS serial LVDS serial

differentialD+ differential D+

output 0Vac; output 0.3Vac;

Bias 1.1Vdc Bias 1.25Vdc

LVDS serial LVDS serial

differential D– differential D–

output 0Vac; output 0.3Vac;

Bias 1.4Vdc Bias 1.25Vdc

v

*Only for the

PX-42VP4V

Series, 0.3Vac

and bias 1.25

Vdc in theater

mode when 60Hz

motion pictures

are displayed.