Page 1

MITSUBISHI ELECTRIC

Service

Manual

PLASMA DISPLAY PANEL

PD-5010

20022002

2002

20022002

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

• Power : AC 120V, 50/60Hz

480W (Typical)

5.4A (Maximum)

• Signals

Sync Range : Horiz : 15.5 to 93.8 kHZ

(Automatic : step scan)

: Vert : 50.0 to 120 Hz

(Automatic : step scan)

Input Signals : RGB, HD*

DVD*

• Input Terminals

RGB : Visual 1 (Analog) : Mini D-sub 15-pin

Visual 2 (Analog) : BNC (R,G,B,H/CS,V)*

Visual 3 (M-LINK) : MONITORLINK

Video : Visual 1 : RCA-pin

Visual 2 : BNC

Visual 3 : S-Video: DIN 4-pin

DVD/HD/DTV : Visual 1 RCA-pin (Y,PB[CB},PR{CR])*

Visual 2 BNC (Y,PB[CB},PR{CR])*1*

Audio : Stereo RCA x 3 (Selectable)

External Control : D-sub 9-pin (RS232C)

1

, DTV*

1

,

1

TM

1

• Sound Output : 7W+7W at 6 ohms

• Dimensions : (W)49.5" (H)30.2" (D)4.68"

(W)1257 (H)766 (D)119 mm

• Weight : 98 lbs / 44.5 kg

*1

HD/DVD/DTV Input Signals supported:

480P (60Hz) 480I (60Hz)

2

525P (60Hz) 525I (60Hz)

576P (50Hz) 576I (50Hz)

625P (50Hz) 625I (50Hz)

720P (60Hz) 1035I (60Hz)

1080I (50Hz) 1080I (60Hz)

*2

The 5-BNC connectors are used as

RGB/PC2 and HD/DVD2 input.

Select one of them under "BNC SELECT".

• Weight and dimensions shown are approximate.

• Design specifications are subject to change without notice.

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2002 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

Page 3

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................................. 2-1

TROUBLESHOOTING........................................................................................................................................3-1

METHOD OF ADJUSTMENTS...........................................................................................................................4-1

METHOD OF DISASSEMBLY............................................................................................................................5-1

PACKAGING.......................................................................................................................................................6-1

PART LIST..........................................................................................................................................................7-1

CONNECTION DIAGRAMS................................................................................................................................8-1

BLOCK DIAGRAM..............................................................................................................................................9-1

1-1

Page 4

SAFETY PRECAUTIONS

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT OPEN REAR COVER. NO USER-SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

This symbol warns the user that uninsulated voltage within the unit may have

sufficient magnitude to cause electric

shock. Therefore, it is dangerous to make

any kind of contact with any part inside of

this unit.

This symbol alerts the user that important

literature concerning the operation and

maintenance of this unit has been

included.

Therefore, it should be read carefully in

order to avoid any problems.

ATTENTION

RISQUE D'ELECTROCUTION

NE PAS OUVRIR

ATTENTION: POUR EVITER LES RISQUES D' ELECTROCUTION, NE PAS ENLEVER LE CONVERCLE ARRÈRE. AUCUN DES

ELEMENTS INTERNES NE DOIT ETRE REPARE PAR L'UTILISATEUR. NE CONFIER L' ENTRETIEN QU'A UN

PERSONNEL QUALIFIE.

L'éclair fléché dans un triangle équilatéral est

destiné à avertir l'utilisateur de la présence,

dans l'appareil, d'une zone non-isolée soumise

à une haute tension dont l'intensité est suffisante pour constituer un risque d'électrocution.

Le point d'exclamation dans un triangle équilatéral est destiné à attirer l' attention de l'utilisateur sur la présence d'informations de

founctionnement et d'entretien importantes dans

la brochure accompagnant l'appareil.

WARNING

HEATSINK MAY BE ENERGIZED.

TEST BEFORE TOUCHING.

2-1

Page 5

SAFETY PRECAUTIONS

1. Before returning an instrument to the customer, al-

ways make a safety check of the entire instrument, in-

cluding, but not limited to, the following items.

a. Be sure that no built-in protective devices are

defective and/or have been defeated during

servicing. (1) Protective shields are provided on

this chassis to protect both the technician and

the customer. Correctly replace all missing protective shields, including any removed for servicing convenience. (2) When reinstalling the

chassis and/or other assembly in the cabinet, be

sure to put back in place all protective devices,

including,but not limited to, nonmetallic control

knobs,insulating fishpapers,adjustment and

compartment covers/shields, and isolation resistor/capacitor networks. Do not operate this

instrument or permit it to be operated without all protective devices correctly installed

and functioning.

b. Be sure that there are no cabinet openings

through which an adult or child might be able to

insert their fingers and contact a hazardous voltage. Such opening include,but are not limited to,

(1) spacing between the picture tube and the

cabinet mask, (2) excessively wide cabinet ventilation slots, and (3) an improperly fitted and/or

incorrectly secured cabinet back cover.

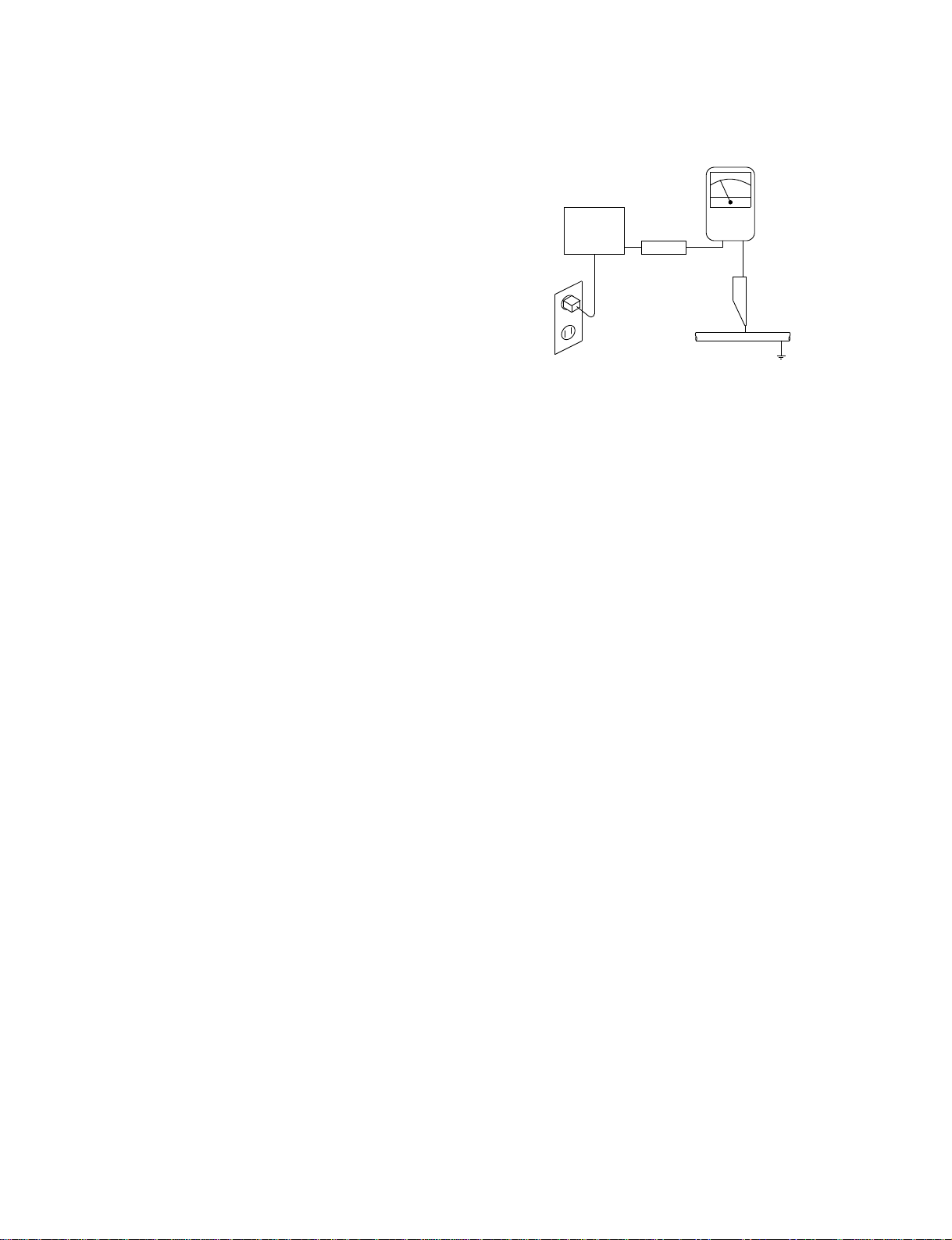

c. Leakage Current Hot Check — With the instru-

ment completely reassembled,plug the AC line

cord directly into a 240V AC outlet. (Do not use

an isolation transformer during this test.) Use a

leakage current tester or a metering system that

complies with American National Standards Institutes (ANSI) C101.1 Leakage Current for Appliances and Underwriters Laboratories(UL)

1950. With the instrument AC switch first in the

ON position and then in the OFF position, measure from a known earth ground (metal

waterpipe, conduit,etc.) to all exposed metal

parts of the instrument(antennas, handle

bracket, metal cabinet, screwheads, metallic

overlays, control shafts,etc.), especially any exposed metal parts that offer an electrical return

path to the chassis. Any current measured must

not exceed 3.5 milliamp. Reverse the instrument power cord plug in the outlet and repeat

test.ANY MEASUREMENTS NOT WITHIN

THE LIMITS SPECIFIED HEREIN INDICATE A

POTENTIAL SHOCK HAZARD THAT MUST

BE ELIMINATED BEFORE RETURNING THE

INSTRUMENT TO THE CUSTOMER.

AC Leakage Test

(READING SHOULD

NOT BE ABOVE

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

3-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

LEAKAGE

CURRENT

TESTER

+–

3.5 mA)

EARTH

GROUND

2. Read and comply with all caution and safety-related

notes on or inside the Monitor cabinet, on the Projection Monitor chassis, or on the picture tube.

3. Design Alteration Warning — Do not alter or add

to the mechanical or electrical design of this unit.

Design alterations and additions, including, but not

limited to, circuit modifications and the addition of

the items such as auxiliary audio and/or video output connections might alter the safety characteristics of this Monitor and create a hazard to the user.

Any design alterations or additions will void the

manufacturer's warranty and will make you,the

servicer,responsible for personal injury or property

damage resulting therefrom.

4. Hot Chassis Warning — a. Some

MultiSync Monitor

chassis are electrically connected directly to one

conductor of the AC power cord and may be safely

serviced without an isolation transformer only if the

AC power plug is inserted so that the chassis is

connected to the ground side of the AC power

source. To confirm that the AC power plug is inserted correctly, with an AC voltmeter measure between the chassis and a known earth ground. If a

voltage reading in excess of 1.0V is obtained, remove and reinsert the AC power plug in the opposite polarity and again measure the voltage potential between the chassis and a known earth ground.

b. Some

Plasma chassis normally have 85V AC

(RMS), between chassis and earth ground regardless of the AC plug polarity. These chassis can be

safely serviced only with an isolation transformer

inserted in the power line between the receiver and

the AC power source, for both personnel and test

equipment protection. c. Some

Plasma chassis

have a secondary ground systems in addition to the

main chassis ground. This secondary ground system is not isolated from the AC power line. The two

ground system are electrically separated by insulating material that must not be defeated or altered.

2-2

Page 6

SAFETY PRECAUTIONS

5. Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

a. near sharp edges, b. near thermally hot parts—

be sure that leads and components do not touch

thermally hot parts, c. the AC supply, d. high voltage, and e. antenna wiring. Always inspect in all

areas for pinched, out-of-place, or frayed wiring. Do

not change spacing between components, and between components and the printed-circuit board.

Check AC power cord for damage.

6. Components,parts, and/or wiring that appear to

have overheated or are otherwise damaged should

be replaced with components, parts, or wiring that

meet original specifications. Additionally,determine

the cause of overheating and/or damage and, if

necessary, take corrective action to remove any

potential safety hazard.

7. PRODUCT SAFETY NOTICE —Many

Monitor

cial safety-related characteristics some of which

are often not evident from visual inspection, nor

can the protection they give necessarily be obtained by replacing them with components rated

for higher voltage, wattage, etc. Parts that have

special safety characteristics are identified in this

service data by shading with a mark on schematics and by shading or a mark in the parts list. Use

of a substitute replacement part that does not have

the same safety characteristics as the recommended replacement part in this service data parts

list might create shock, fire, and/or other hazards.

electrical and mechanical parts have spe-

MultiSync

2-3

Page 7

PRECAUTIONS DE SECURITE

1. Avant de remettre un appareil à un client, faire

toujours d'abord un examen de sécurité de

l'appareil en entier comprenant, mais ne s'y limitant

pas les points cités ci-dessous:

a. Vérifier qu' aucun des dispositifs de protection ne

soit défectueux ou n' ait été endommagé pendant

les travaux.

(1) Les volets protecteurs sur ce châssis ont été

montés pour protéger aussi bien le technicien

que le client. Remplacer correctement tous les

volets protecteurs manquants, aussi bien que

ceux qui ont pu être enlevés pour la commodité

des travaux.

(2) Quand vous remettez le châssis ou d'autres

assemblages ensemble dans le coffret, vérifier

qu' ont été remis à leur place tous les dispositifs

de protection, comprenant mais ne s' y limitant

point, les boutons de contrôle non-métalliques,

les feuilles d'isolation, les couverture/volets de

l'ajustement et du compartiment, et l'isolation des

réseaux résistance/condensateur. Ne pas

travailler sur cet appareil ni permettre qu'y

soit effectué un travail sans que tous les

dispositifs de protection n' y soient

correctement installés fonctionnants.

b. Bien vérifier qu'il n'y ait aucune ouverture sur le

coffret qui ne puisse permettre à un adulte ou à

un enfant d'y faire pénétrer ses doigts et attraper

une décharge électrique.

De telles ouvertures comprendraient sans pour

autant s'y limiter (1) l'espace entre le tube à images et le coffret de l'eppareil, (2) les espaces

excessivement ouverts pour la ventilation et (3) la

couverture arrière du coffret improprement fixée

ou incorrectement protegée.

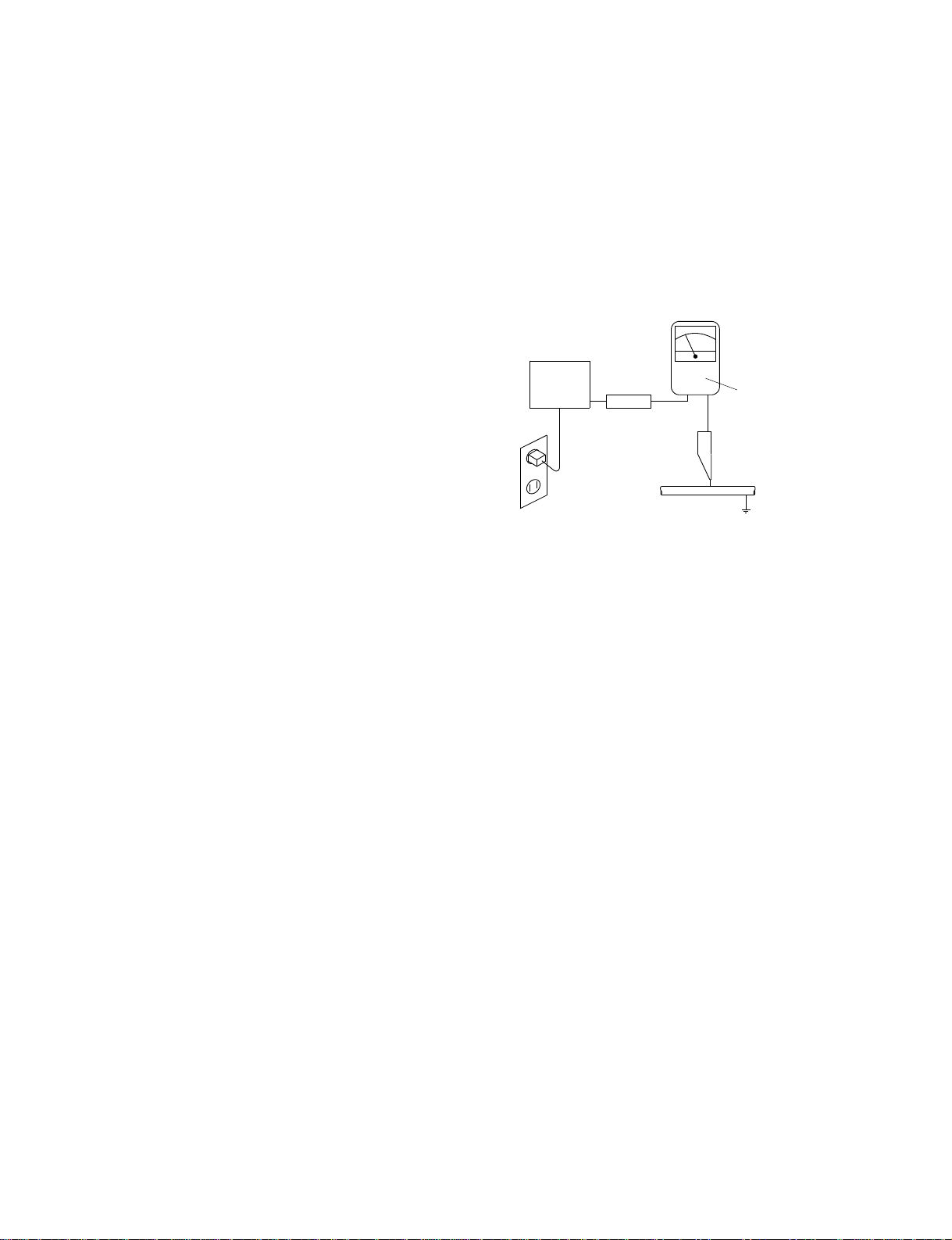

c. Vérification de courant de fuite

L'appareil ayant été complètement réassemblé,

brancher-le à une prise de courant de 240V. (Ne pas se

servir d'un transformateur

d'isolation pendant ce

test). Se servir d'un vérificateur de courant

d'excitation ou d'un système de mesure conforme

aux normes ANSI (American National Standards

Institute) C101.1 Leakage Current for Appliances

et U. L (Underwriters Laboratories) 1950. Le bouton de l'appareil en position "Marche" et ensuite

en position "Arrêt", mesurer à partir d'une prise

de terre (métallique tuyauterie, conduite, etc...) à

toutes les pièces métalliques de l'appareil

exposées (antennes, poignet métalliques, coffren

métallique, tête des vis, surfaces métalliques,

traits de contrôle, etc.) surtout à toutes les pièces

métalliques exposées qui peuvent reconduire le

courant au châssis. En aucun cas, la mesure du

courant ne doit dépasser 3.5 milliamp. Inverser la

fiche de courant de l'appareil dans la prise et

répéter le test. Tout mesurage ne s'arrêtant

pas aux limites spécifiées icicomporte un risque de décharge électrique dangereux, qui

doit être éliminé, avant que l'appareil ne soit

remis au client.

EXAMEN DE COURANT

D'EXCITATION

(LA MESURE DU COURANT

NE DOIT PAS DEPASSER

3.5 MILLIAMP)

DISPOSIT IF

SOUS

L ' EXAMEN

EXAMINER TOUTES

LES PIECES METALLIQUES

DEL' APPAREIL EXPOSEE

3-CORDES DE FIL

EXAMINER AVEC

LA FICHE DE COURANT

INVERSEE

(SE SERVIR DE LA FICHE DE COURANT

DE L' A DAPTATEUR COMME DEMANDEE)

+–

VERIFICATEUR

DE CORANT

DE FUITE

PRISE DE TERRE

2. Lire et respecter toutes les mises en garde et notes

de sécurité à l'intérieur ou à l'extérieur du coffret du

rétro-projecteur, sur le châssis du rétro-projecteur

ou sur le tube à images.

3. Mise en garde contre la modification du dessin

Ne pas modifier ni ajouter à la pièce mécanique ou

électrique du modèle. Des modifications ou additions, comportant, mais ne s'y limitant pas, des

modifications des circuits et l'addition d'éléments

tels que des auxilliairs audio et/ou des

branchements pour la prise de vidéo, pourrait

éprouver la sécurité de ce rétro-projecteur et créer

un risque pour l'utilisateur. Tout changement ou addition accomplie annulera la garantie du fabricant et

va rendre votre service d'entretien, responsable des

dommages corporels ou de biens en résultant.

4. Mise en garde contre le châssis sous tension

a. Certains châssis de rétro-projecteur sont

électriquement reliés à un conducteur du fil de

courant et ainsi peuvent ne comporter aucun risque sans un transformateur d'isolation seulement

si la prise de courant est branchée, de manière

que le châssis est relié à la prise de terre de la

source de courant. Pour s'assurer que la prise de

courant est correctement insérée, relever les

mesures avec un voltmètre de courant entre le

châssis et un point de prise de terre bien connu.

Si le voltage indiqué est supérieur à 1,0V,

débrancher et reinsérer la prise de courant dans

la polarité contraire et une fois de plus remesurer

le voltage potentiel entre le câssis et la prise de

terre.

2-4

Page 8

PRECAUTIONS DE SECURITE

b. Certains châssis de moniteur ont habituellement

85V (RMS) entre le châssis et la prise de terre, en

fonction de la polarité de la prise de courant. Ces

châssis peuvent ne comporter aucun risque

seulement avec un transformateur d'isolation

inséré dans la ligne de puissance située entre de

rétro-projecteur et la source d'électricité, cela

pour la protection aussi bien du personnel que du

matériel de vérfication.

c. Certains châssis de rétro-projecteur ont un

système secondaire de masse en addition avec

le système principal de masse du châssis. Ce

système secondaire de masse n'est pas isolé du

courant électrique. Les deux systèmes sont

électriquement séparés par du matériel

d'isolation qu' on vérifiera bien qu'il ne soit ni

altéré ni défectueux.

5. Vérifier la couverture originale en plomb. Accorder

la plus grande attention à la couverture de plomb

notamment aux endroits ci-dessous indiqués.

a. Près des bords aigus

b. près des parties très chaudes

Vérifier que les composants et les plombs ne

touchent pas les parties très chaudes telles que:

c. l'alimentation du courant

d. la haute tension

e. Ies fils de l'antenne

Pousser l'inspection, à tous les endroits, à la recherche des cordes pincées, déplacées ou effilochées.

Ne pas changer l'écartement entre composants, et

entre composants et le tableau de circuit imprimé.

Vérifier que le fil de conduite électrique est en bon

état.

6. Les composants, parts (pièces) et/ou fils qui ont été

trouvés surchauffés devraient être remplacés avec

les composants, pièces et fils s'y reliant avec d'autre

qui ont les mêmes spécifications que les originales.

De plus, rechercher la cause du surchauffement et/

ou des dommages et si nécessaire, prendre les

mesures propres pour prévenir tout risque potentiel.

7. Note sur sûreté de l'appareil

Beaucoup de pièce de rétro-projecteur, qu'elles

soient électriques ou mécaniques, ont des dispositions de sécurité qui ne sont pas toujours évidentes

d'une simple inspection visuelle et la protection

qu'elles donnent nécessairement ne pourront être

pas obtenues par les remplaçants avec des

composants aux voltages ou watts plus élevés.

Les pièces qui ont des caractéristiques particulières

de sécurité sont identifiées avec un trait marqué

sur les schémas et sont ombragés ou comportent

un trait sur la liste des pièces. L'utilisation d'un

produit substitutif qui n'aurait pas les mêmes

caractéristiques comme il est recommandé dans

ces données d'entretien pourrait provoquer une

décharge électrique, un feu, et/ou d'autres dangers.

2-5

Page 9

SAFETY PRECAUTIONS

1 . Cautions for disassembly

(1) For the wall-hang type

During handling, try to support the set

at its frame. Never touch the filter

or glass surface. Assistant personnel on the

front side should apply hands to the lower part

of the casing. [If the casing receives an impact,

the unseen side area of the module panel glass

may be broken even though the module itself does not

seem to have been broken. Therefore, support the

frame by hand in order not to drop it.]

2. The least minimum cautions for product disassembly

Secure a working space, arranged as wide as possible.

Prior to disassembling the set, protect the acrylic

surface with an air mat or the like.

To prevent the thread ridges from being damaged,

use an adequate screwdriver.

Many screws are actually used. Therefore, use

two or three containers where these screws can

be kept . Never disassemble the inner parts of the

module (pipes, etc.).

When lifting the module from the set, two persons

should stand on both sides of the module to hold

the stable parts of the junction while they lift the

module upright. (If dust or such foreign substance

enters in between the module and the filter, moir*

or similar problems can arise. In addition, once it

enters, it is necessary to take careful measures

not to damage the contamination area while removing

contaminants.) [Please understand that the

replacement of the module may call for an air-blast

treatment (air brush) in a clean room.]

Complementary caution) In particular, if a conductive

foreign matter (such as a metallic chip) is attached

to the flexible cable of the module, there

can be danger of the occurrence of a phenomenon

like wire breakage that is caused by partition

breakdown in the module. For this reason, it

is necessary to bear in mind that the flow of air

blast should be directed only in the predetermined

direction at all times.

2-6

Page 10

SAFETY PRECAUTIONS

(Notes)

The component by the name of “module” used in

this product is defined as a section that is provided with a digital circuit board (including highvoltage parts) used to emit light in the glass panel

part, excluding the surface acrylic fiIter or the tempered glass fiIter. It must be noted that it does

never mean the glass panel part only.

2-7

Page 11

TROUBLESHOOTING

3-1

Page 12

TROUBLESHOOTING

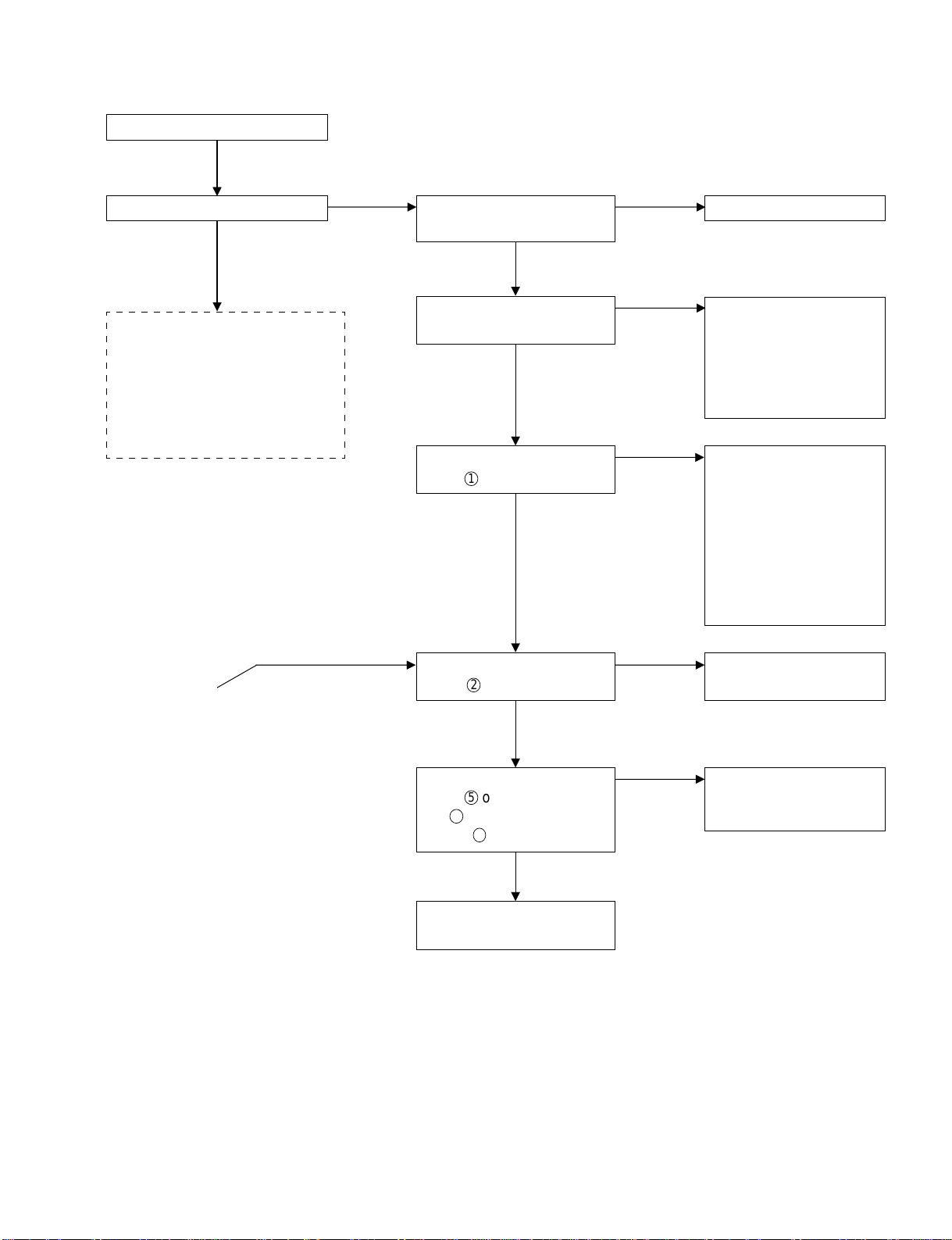

• In the case of abnormality in the POWER system, such as “No power available” or “Alarm (LED flashing)”

Go to → 1. Power failure (P2)

• In the case of abnormality in the VIDEO system, such as “No picture” or “Picture errors”

Go to → 2. No picture displayed, picture errors (P6)

• In the case of no audio output

Go to → 3. No audio output generated (P15)

If set shuts down, reset the microprocessor by pressing the <Power On> and <Input>

keys on the front panel at the same time. Hold for 5 to 6 seconds.

1

Page 13

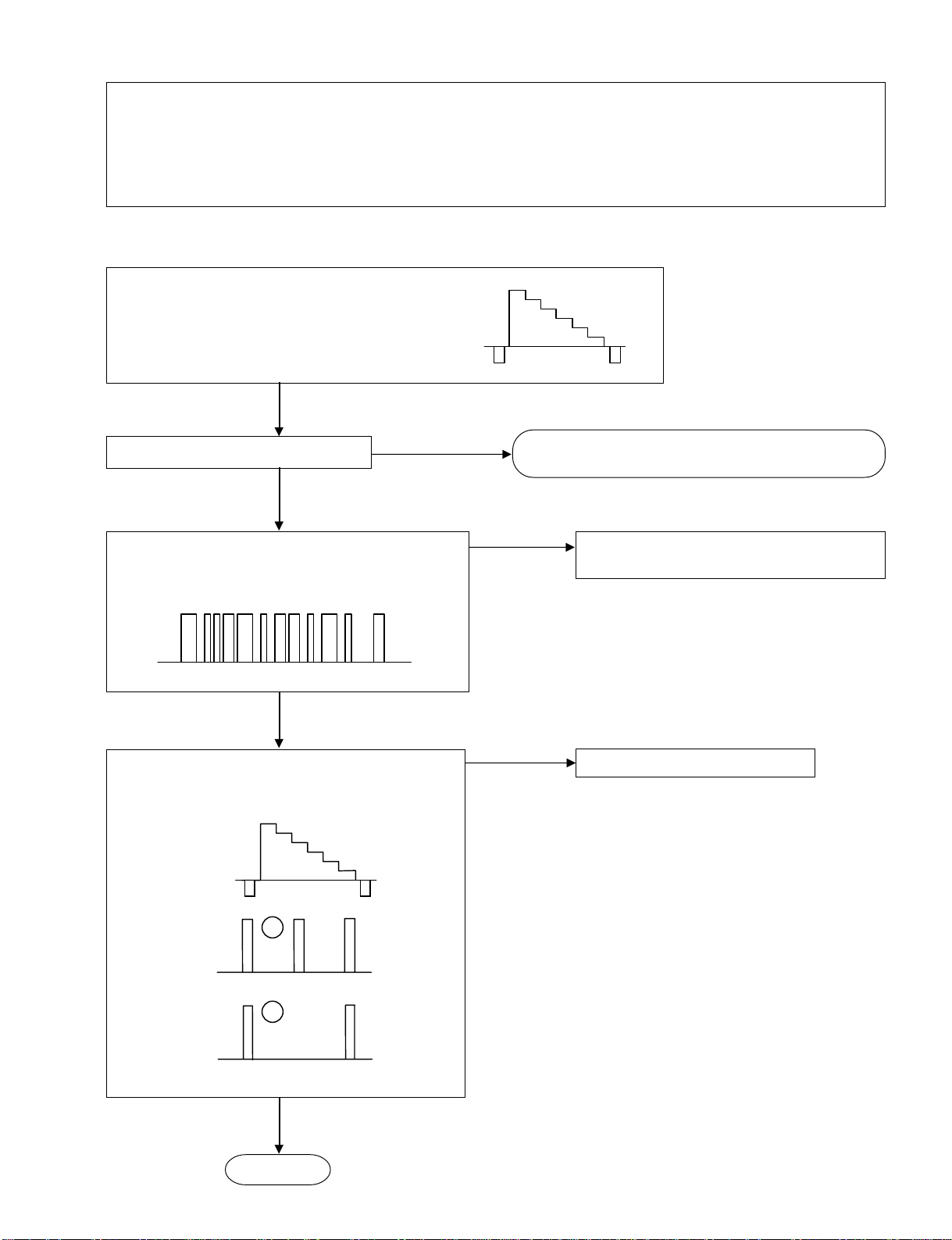

1. Power failure

(1)POWER is turned OFF. Note: To Reset the Microprocessor, Press and hold the <Power On> and <Input>

keys on the front panel at the same time. Hold for 5 to 6 seconds.

Turn on the main power unit.

NO NO

Is the POWER LED lit? Is the power plug connected

to the wall outlet correctly?

YES YES

NO

Is 100V AC available behind Fuses F1 and F2 have blown

• To “Flashing in green” (2) (P3). the fuses F1 and F2? out.

(FAN error detection) If the fuses are replaced

• To “Flashing in red” (3) (P4) and they blow out again,

(Temperature error detection) the POWER unit is out of

• To “Flashing in green and red” order.

(4) (P5). YES

(Panel crack detection) NO

Is the M+7V output available

at Pin 1 of the PM connector?

YES

NO

Is the M+5V output available

at Pin 2 (MAIN) of IC7005?

From (4): Flashing in green

and red (Panel crack detection)

(P4) YES

NO

Is the M+5V output available The +5V line is out of order

at Pin 5 of the LD connector,

Pin 4 of the PW connector, PWR, PWB, or 232C PWB.

and Pin 5 of the RS connector?

Poor power plug connection

If the PW and RS connectors

are disconnected from one

after another and an output

of M+7V is generated, this

is a problem in a circuit

beyond the connectora.

If no output is generated at

t

hat time, then the POWER

unit is out of order.

S2601 (PWR) and associated circuits are out of order.

toward the LED PWB,

YES

IC7001 and peripheral circuits are out of order.

2

Page 14

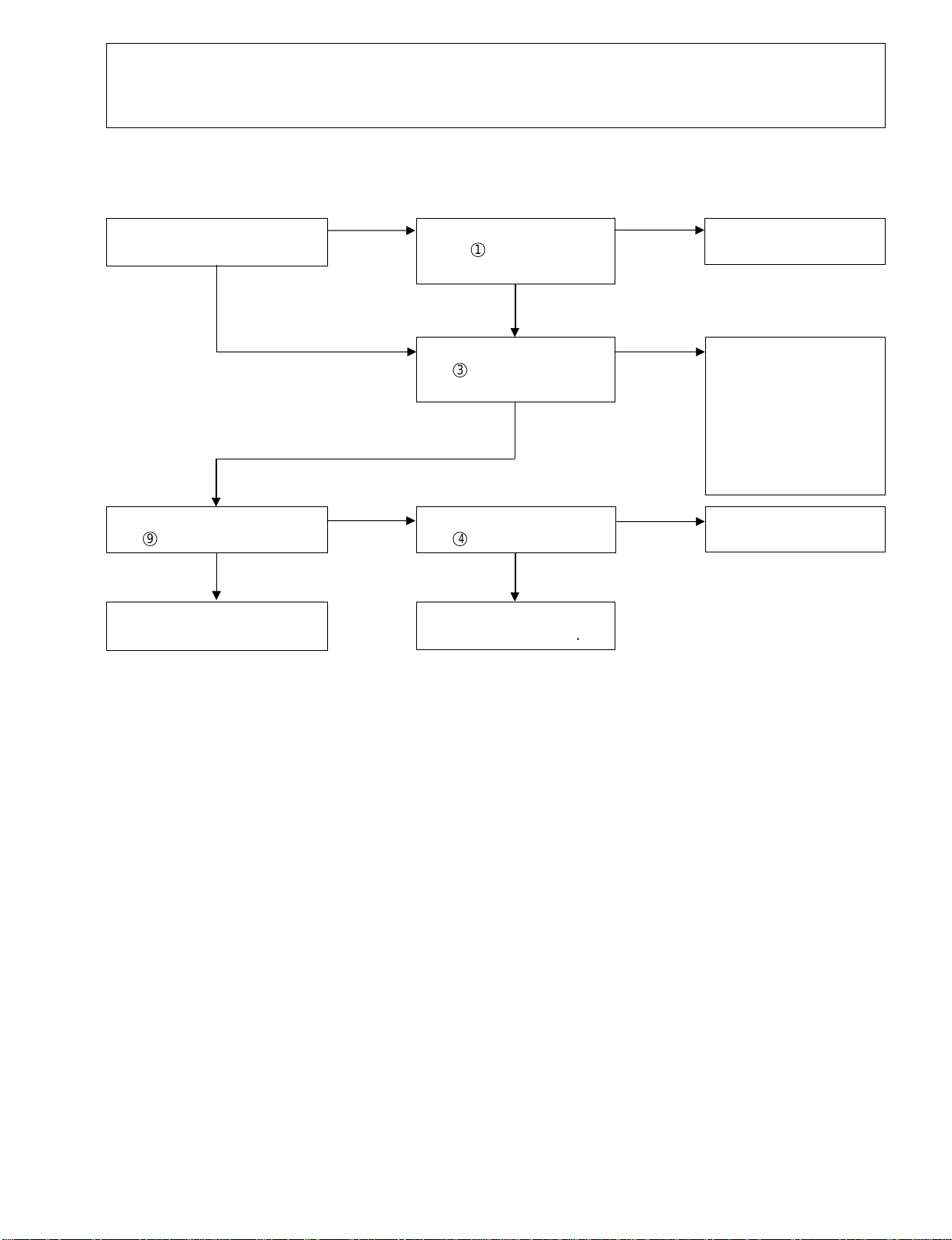

(Caution) When the LED is flashing (protector in operation), all power lines other than M+7 are automatically

turned off. When checking the power lines other than the M+7V system, a circuit tester or the like

should be connected to the measuring point in advance, for confirmation.

(2) Flashing in green (FAN error detection)

NO NO

Does the fan run when the main Is the power supply available IC8802 and peripheral

power supply is turned ON? at Pin 1 of the POF1 and circuits are out of order.

POF2? (7 to 12V)

YES YES

YES

Is Potential 5V available at The fan is out of order,

Pin 3 of the POF1 and where Potential 5V is

POF2? available. This voltage

becomes 0V when the

power supply is turned off.

NO Therefore, a circuit tester

should be connected in

advance before inspection.

NO NO

Is Potential 5V available at Is Potential 5V available at VDDM5 and peripheral

Pin 9 of IC8804? Pin $ of IC8804? circuits are out of order.

YES YES

Check IC8804, and also R8807 IC8804 and peripheral

and R8806. circuit are out of order.

3

Page 15

(3) Flashing in red (Temperature error detection)

NO NO

In the cold-start mode, does it Is Potential 0V maintained IC7001 and peripheral

take less than 15 seconds after at Pin 29 (MAIN) of IC7001? circuits are out of order.

the main power circuit is turned

ON and until it is turned OFF?

YES YES

TH1 in the POWER unit and

Disconnect the PD, PH, and peripheral circuits are out of

AD connectors and turn ON order.

the main power circuit. Does

the power supply work normally NO

in this state? (Are normal out- The POWER unit is out of

puts of D+170V, D+64V, and order.

D+5V available? Is Pin 3 of

the PM connector maintained at

the [H] level? However, no pictures are displayed.)

YES

The MODULE and peripheral

circuits are out of order.

4

Page 16

(4) Flashing in green and red (Panel crack detection)

NO

Is Potential 0V maintained at IC7001 and peripheral

Pin 100 (MAIN) of IC7001? circuits are out of order.

YES

NO YES

Is Potential 0V maintained at Is Potential 5V applied to IC7002 and peripheral

Pin 2 (MAIN) of IC7002? Pin $ of IC7002? circuits are out of order.

YES NO

Disconnect the PD, PH, and Skip to “ (1) Power is turned

AD connectors and turn ON OFF.” (P2).

the main power circuit. Does

the power supply work normally NO

in this state? (Are normal outputs The POWER unit is out of

of D+170V, D+64V, and D+5V order.

available? Is Pin 3 of the PM

connector maintained at the

[H] level? However, no pictures

are displayed.)

YES

The MODULE and peripheral

circuits are out of order.

(Caution) How to cancel the alarm condition:

• While flashing in green and red occurs, the power supply cannot be

reset by ON/OFF operation at the main power switch, remote control,

and wall outlet.

• For alarm resetting, keep pressing the input selector key at the main

unit of the set and move the mains power switch to [ON] at the main

unit. In this state, it is necessary to keep pressing the input selector

key of the main unit for more than 2 seconds.

5

Page 17

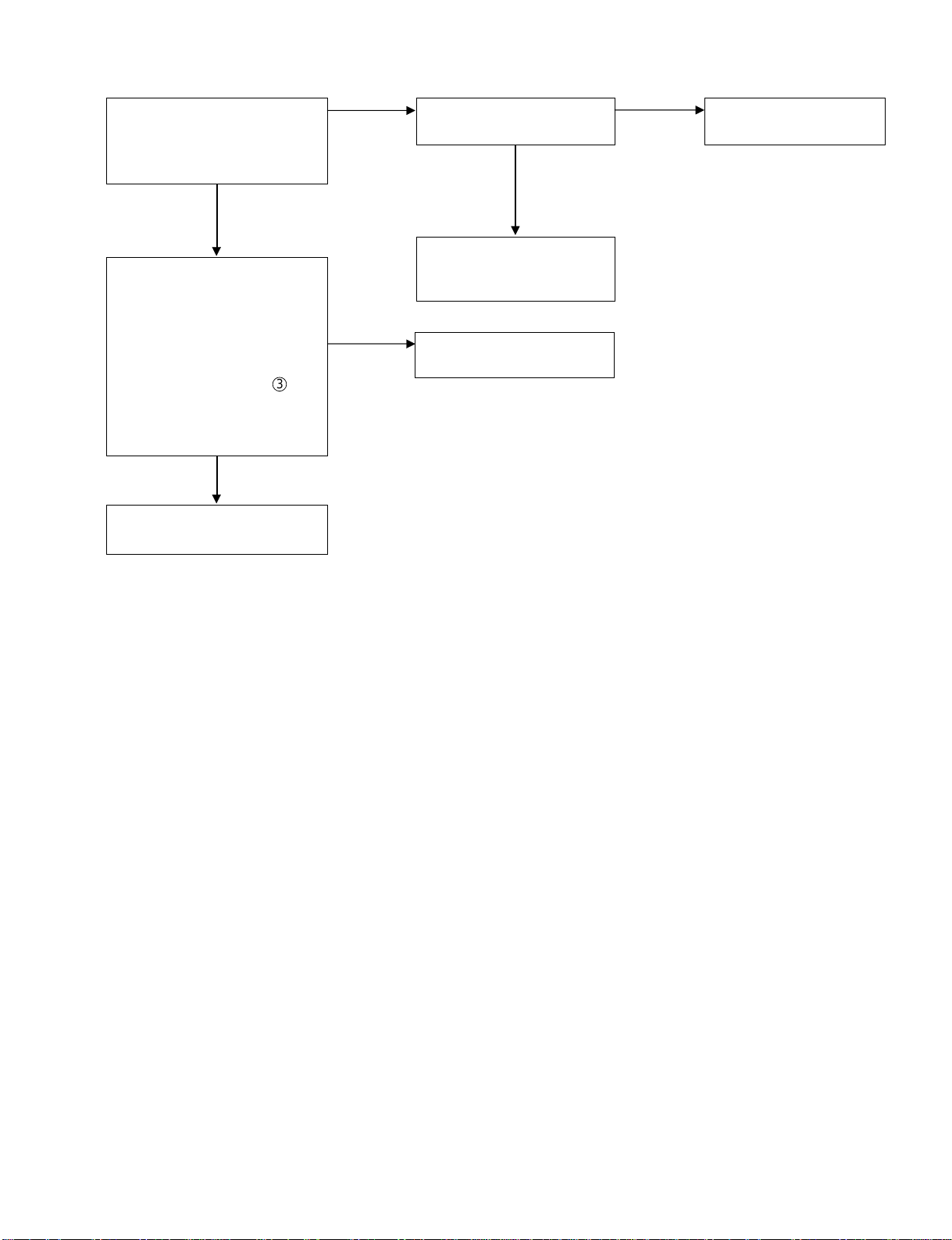

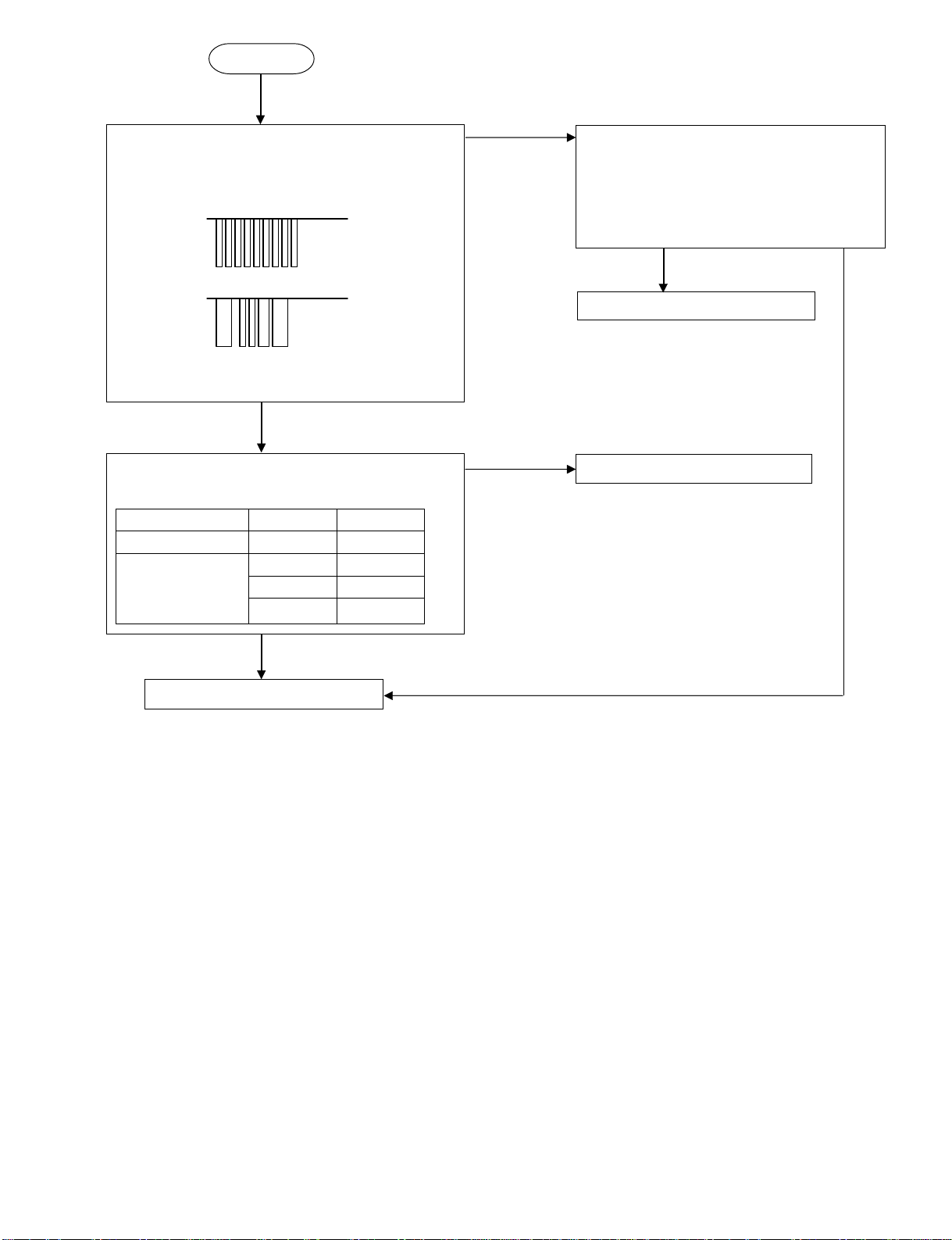

2. No picture displayed and picture errors

(Caution) IPXXXX is installed in the MAIN PWB and the VIDEO PWB. These components are inserted in the

power line. If there is any error occurring in the circuit, these components function to prevent the

evolution of this problem to other areas. Accordingly, check whether the same voltage is generated at

both ends of each component. (In normal state, the component is internally short-circuited.) If the

same voltage is not generated, this means that the MAIN PWB is out of order. The same check is

needed also for the DSP PWB.

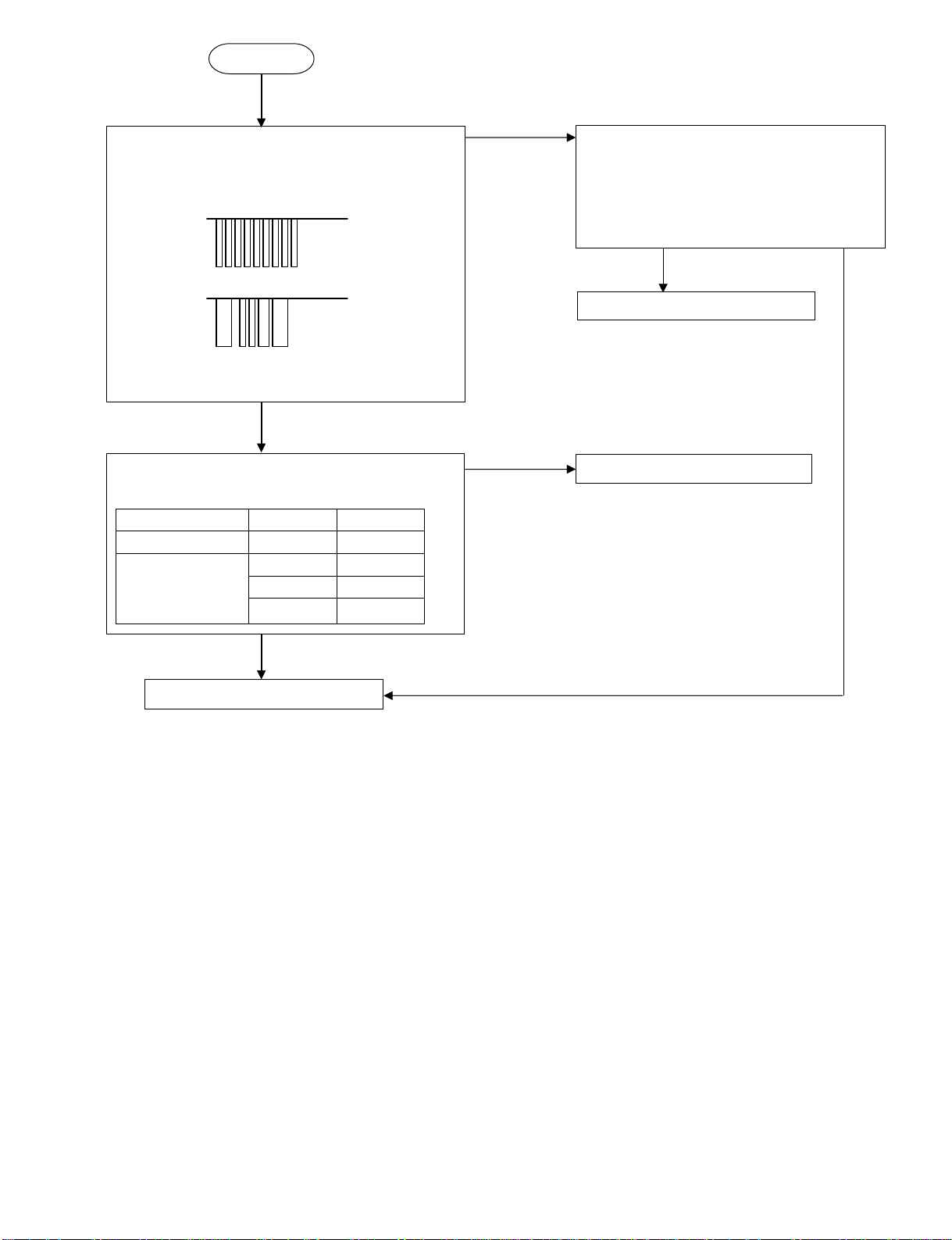

(1) No picture display of the PC signal only or both the VIDEO and PC signals

Enter an input of XGA69H gray scale in the input

circuit of PC1, and select PC INPUT 1.

NO

Is ON-screen display available?

To “No presentation of pictures and ON-screen

display” (P11)

YES

YES

Is a signal of 3Vp-p available at at the signal input The MAIN PWB of the AD connector is out

pins of IC8701 and IC8702? (Signale names: REV_ of order.

LVDS, RODD_LVDS, ets.)

• • • • • •

NO

YES

Is a signal of 0.7Vp-p available at Pins 1, 3, 5 of The MAIN PWB is out of order.

the PC connector and a sync signal of 5Vp-p

available at Pins 7, 9, 10, 12?

1, 3, 5

7, 10

45kHz

H

9, 12

60Hz

V

NO

(1)-1 (P7)

6

Page 18

(1)-1 (P6)

YES

Are the signals below available at Pins 2, 5, 8, 3, Are the specified voltages available at the

6, and 9 of the BU connector? PV connector?

Pin 1 14Vdc

Pin 3 5Vdc

2, 5, 8

Pin 5 6Vdc

Pin 7 7Vdc

5Vp-p

YES

3, 6, 9

NO

The VIDEO PWB is out of order.

5Vp-p

NO

YES

Are the specified voltages available at the The MAIN PWB is out of order.

connectors below? (Power source check)

Connector name Pin No. Voltage

PN 1 3.3Vdc

1 7Vdc

PM 7 5Vdc

9 14Vdc

NO

The POWER unit is out of order.

7

Page 19

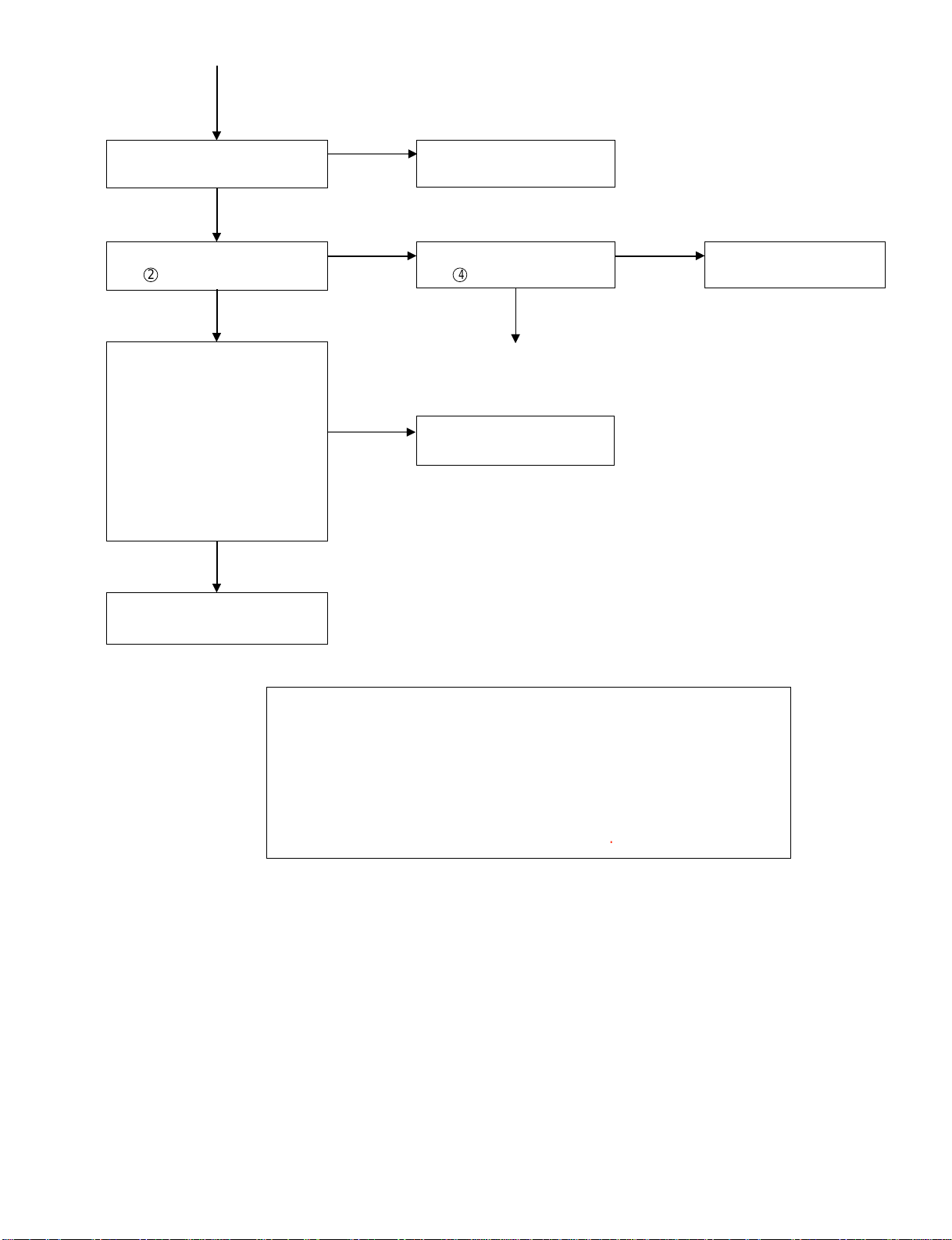

(2) No picture display of the VIDEO signal only

Enter an input of gray scale in the input circuit of VIDEO1,

and select VIDEO1.

YES

Is a signal of about 3Vp-p available at any of The MAIN PWB is out of order.

Pins 21 to 79 of the AM connector in the DSP PWB

(GND terminal excluded)?

• • • • • •

NO

NO

Is a signal of about 3Vp-p available at any of The MAIN PWB is out of order.

Pins 101 to 159 of the AM connector in the DSP

PWB (GND terminal excluded)?

• • • • • •

YES

(2)-1 (P9)

8

Page 20

(2)-1 (P8)

YES

Are the signals below available at Pins 14 to 17, The DSP PWB is out of order.

19, 98, 96, 95, and Pin 3 (IP8001) of the AM

connector in the DSP PWB?

14

5Vp-p

15

5Vp-p

16

3Vp-p

17

5Vdc

19

10MHz, 3Vp-p

98

27MHz, 3Vp-p

96

95

3

H

15KHz, 3Vp-p

V

60Hz, 3Vp-p

3Vdc

NO

YES

Is a signal of 1Vp-p available at Pin 1 of the YU The MAIN PWB is out of order.

connector, and a sync signal of 5Vp-p available at

Pins 7, 9, 10, and 12?

1

7, 10

* 15kHz

H

* In case of an NTSC input.

9, 12

* 60Hz

V

NO

(2)-2 (P10)

9

Page 21

(2)-2 (P9)

YES

Are the signals below available at Pins 2, 5, 8, 3, Are the specified voltages available at the

6, and 9 of the BU connector? PV connector?

Pin 1 14Vdc

Pin 3 5Vdc

2, 5, 8

Pin 5 6Vdc

Pin 7 7Vdc

5Vp-p

YES

3, 6, 9

NO

The VIDEO PWB is out of order.

5Vp-p

NO

YES

Are the specified voltages available at the The MAIN PWB is out of order.

connectors below? (Power source check)

Connector name Pin No. Voltage

PN 1 3.3Vdc

1 7Vdc

PM 7 5Vdc

9 14Vdc

NO

The POWER unit is out of order.

10

Page 22

No presentation of pictures and

ON-screen display (P6)

Are pulses of 3Vp-p available at Pins 38, 39, and

40 of the AD connector?

YES

Are the horizontal/vertical sync signals of 3Vp-p

available at Pins 27/28 of IC8701, and a clock

signal at Pin 31?

50KHz 60Hz 40MHz

YES

Are the signals of 3Vp-p (signal name: REV_L VDS,

RODD_LVDS, etc.) available at the signal input

pin of IC8701?

NO

NO

NO

YES

YES

Is normal display available when the AD, PD, or Each cable is defective.

PH cable is replaced?

NO

YES

Is normal display available when the MAIN PWB The MAIN PWB is out of order.

is replaced?

NO

NO

Are 170V, 64V, and D+5V of the POWER unit See “Power cannot be ON.”

normally output?

YES

The plasma display module is out of order.

YES

Are the specified voltages available at the The MAIN PWB is out of order.

connectors below? (Power source check)

Connector name Pin No. Voltage

PN 1 3.3Vdc

1 7Vdc

PM 7 5Vdc

9 14Vdc

NO

The POWER unit is out of order.

11

Page 23

(3) Picture errors

Display a picture in error mode. However, the video signal

level shall be maintained above 0.7Vp-p.

0.7Vp-p or above

YES

NO

Are pulses of 3Vp-p available at Pins 38, 39, and

40 of the AD connector?

YES

NO

Are the horizontal/vertical sync signals of 3Vp-p

available at Pins 27/28 of IC8701, and a clock

signal at Pin 31?

50KHz 60Hz 40MHz

YES

YES

Is a picture error caused by PC input? Are the specified voltages available at the

connectors below?

NO (Power source check)

NO

Are the signals below available at Pins 14 to 17,

19, 98, 96, and 95 of the AM connector and at

Pin 3 (IP8001) in the DSP PWB?

14

5Vp-p

Connector name Pin No. Voltage

PN 1 3.3Vdc

1 7Vdc

PM 7 5Vdc

9 14Vdc

15

16

17

19

98

96

95

YES NO

5Vp-p

The MAIN PWB The POWER unit

is out of order. is out of order.

3Vp-p

5Vdc

10MHz, 3Vp-p

27~37NHz* 3Vp-p

H

15~45KHz * 3Vp-p

V

50~60Hz * 3Vp-p

3

5Vdc

* Changed according to the input signal.

YES

(3)-1 (P13)

12

Page 24

(3)-1 (P12)

NO

Does this phenomenon correspond to “Specific

gradations (brightness) are tinted.”?

YES

YES

Are the signals of 3Vp-p (signal name:REV_ (3)-2 (P14)

LVDS, RODD_LVDS, etc.) available at all the

signal input pin of IC8701 and IC8702?

• • • • • •

NO

YES

Is a signal of about 3Vp-p available at all Pins 21 The MAIN PWB is out of order.

to 79 of the AM connector (GND terminals

excluded) in the DSP PWB?

• • • • • •

NO

YES

Is a signal of about 3Vp-p available at all Pins 101 The DSP PWB is out of order.

to 159 of the AM connector (GND terminal excluded)

in the DSP PWB?

• • • • • •

NO

Are the specified voltages available at the

connectors below? (Power source check)

Connector name Pin No. Voltage

PN 1 3.3Vdc

1 7Vdc

PM 7 5Vdc

9 14Vdc

YES NO

The MAIN PWB is The POWER unit is out

out of order. of order.

13

Page 25

(3)-2 (P13)

YES

Is normal display available when the AD, PD, or Each cable is defective.

PH cable is replaced?

NO

YES

Is normal display available when the MAIN PWB The MAIN PWB is out of order.

is replaced?

NO

NO

Are 170V, 64V, and D+5V of the POWER unit See “Power cannot be ON.”

normally output?

YES

The plasma display module is out of order.

14

Page 26

3. No audio output generated

Note) This model is enabled to set up an audio input terminal for each video input terminal. No audio output is

available unless the input terminal of the displayed pictures (example: VIDEO 1) coincides with that of

audio (example: RGB 3). Therefore, analysis for troubleshooting should be carried out after the displayed

video input terminal (example: VIDEO 1) has been made to coincide with the audio input terminal according to the instruction manual.

Enter a signal input in AUDIO IN.

YES

Is the audio signal present at the speaker OUT? Speaker or cable is defective.

NO

YES

Are the voltages specified below available at the The POWER unit or the cable is out

PA connector of the AUDIO unit? of order.

(Power source check)

Pin Signal name Voltage

1 S+24 +23.5~33Vdc

2 S+24 +23.5~33Vdc

3 S.GND GND

4 S.GND GND

5 A+13 +13Vdc

6 A.GND GND

(Note) When confirming the source volt-

age by disconnecting the PA connector, short-circuit the section between Pins 3 4 of the PA connector and Pin 6 (like short-circuiting between S.GND of the POWER

unit), and then turn on the POWER

unit.

YES

NO

Are the following waveforms observed at the AU The MAIN PWB or the cable is out

connector of the AUDIO unit? of order.

Pin 6

Pin 7

Pin 5

5Vp-p

5Vp-p

4.8Vdc

Pin 1, 2 : Audio signal waveforms

YES

The AUDIO unit is out of order.

15

Page 27

METHOD OF ADJUSTMENTS

4-1

Page 28

Adjusting conditions

Adjustments should be carried out in accordance with the procedures described below. However, any adjustments

other than the items A to C below are not required.

A. When the [PDP module] is replaced, adjust the sections according to the adjusting items [1 to 3] specified below.

(Caution) When the PDP module has been replaced, clear the USAGE TIME to “0” without fail, according to

“how to clear the usage time” shown below.

B. When the [POWER unit] is replaced, adjust the sections according to the adjusting items [1 to 3] specified below.

C. When the [MAIN PWB] is replaced, adjust the sections according to the adjusting item [4 and 5] specified below.

* How to clear the integrated time

Assume the folloing factory mode by the use of the remote control. Press [MENU/ENTER] key six times to

the screen [USAGE TIME]. In this state, the integrated time up to the present time is displayed.

The integrated time is cleared to [0] when the remote control keys are pressed in the order of [MUTE] ®

cursor keys [ ]® cursor keys [V] ® [SLEEP].

* How to enter or withdraw from the factory setting mode:

Press the keys in the sequential order of [SLEEP] [EXIT] [MUTE] [SLEEP].

When a conventional remote control is used:

Press the keys in the sequential order of [OFF TIMER] ® [OK] ® [MUTE] ® [OFF TIMER].

At that time, use the [MENU] key in place of the [PROCEED] key.

V

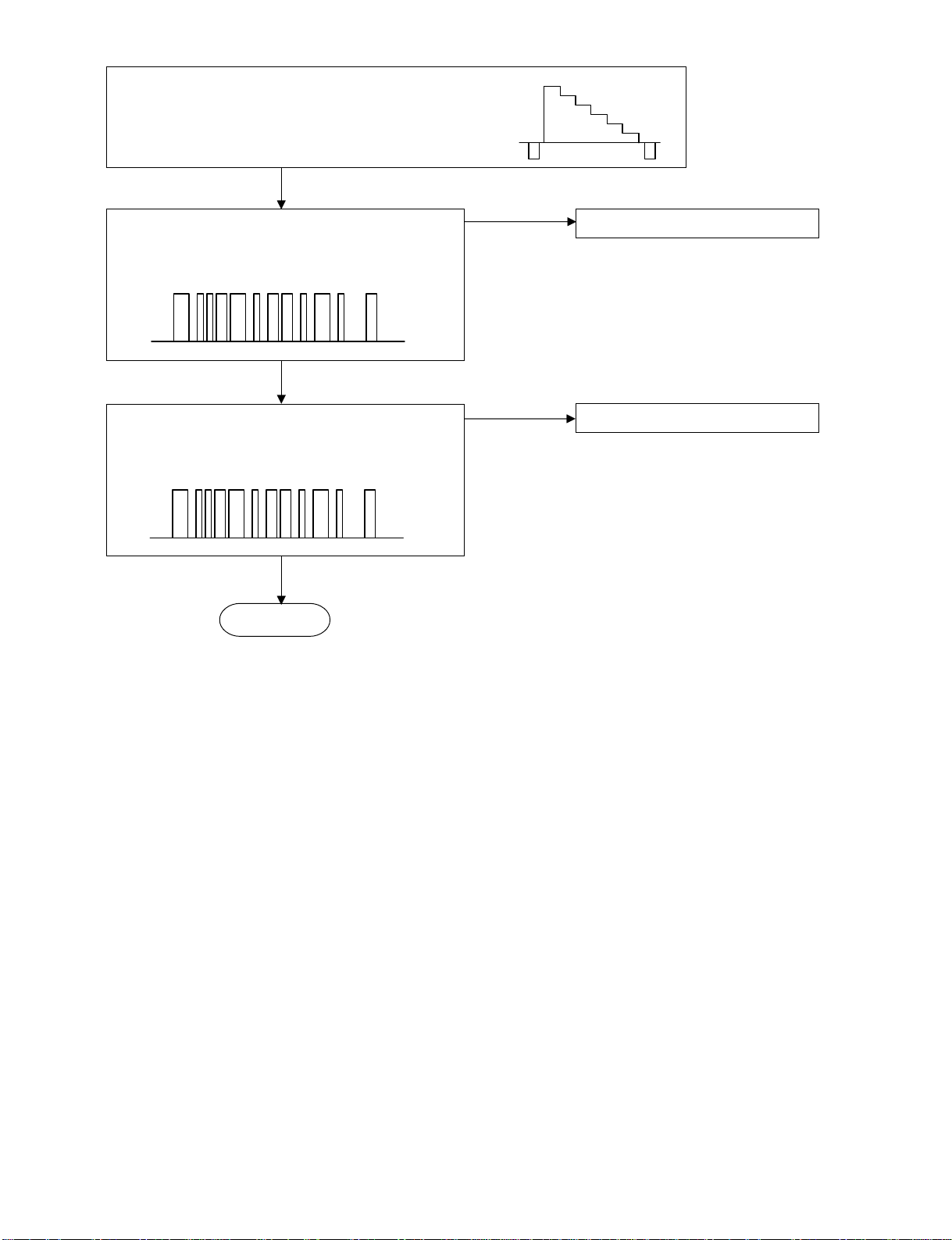

1. Adjustment of +170V

(1) Using any video signal of VIDEO input, DVD/HD input, or RGB input, and display a color bar signal. Turn on

the power switch of the main unit.

(2) Turn the volume control (RV3) in the [D+170V ADJ] section of the power unit, and adjust the voltage value

between TP3 (D+170V output) and TP2 (D.GND) of the power unit so that this voltage settles within the

range of “specified voltage of the PDP module (Value Vs on the label shown below) ± 1V.”

(Caution) The figure below shows a rear side view when the

back cover has been removed.

SERIAL NO.

** ** ** ** *

Vd=**V

Vs=*** V

CODE -01

1

Page 29

2. Adjustment of +64V

(1) Using any video signal of VIDEO input, DVD/HD input, or RGB input, and display a color bar signal. Turn on

the power switch of the main unit.

(2) Confirm that the voltage at TP4 (D+60V output) and TP2 (D.GND) of the power unit is maintained at a

voltage value (Vd value of the label described in Item 1 above) within ± 1V, specified for the PDP module.

If the voltage specified above cannot be secured, turn the volume control (RV4) in the [D+64V ADJ] block

and adjust the voltage until it attains “the voltage specified for the PDP module (Value Vd on the label of the

above-mentioned Item 1) ± 1V.”

3. Adjustment of +5V

(1) Use any video signal of VIDEO input, DVD/HD input, or RGB input, and display a color bar signal.

(2) Confirm that the voltage value between TP1 (+5V output) and TP2 (D.GND) of the power unit is maintained

at “5.10 ± 0.1V.”

If the voltage specified above cannot be secured, turn the volume control (RV2) in the [D+5V ADJ] block

and adjust the voltage until it attains “5.10 ± 0.1V.”

* POWER unit layout

RV3

D+170

ADJ

TP3

D+170

RV2

D+5 ADJ

TP4

D+64

RV4

D+64

ADJ

PH

PD

TP1

D+5

TP2

D.GND

P

M

P

N

P

V

P

A

P

I

2

Page 30

4. Initial setting

(1) Enter the factory setting mode by pressing the keys in the order of [SLEEP] [EXIT] [MUTE] [SLEEP].

(2)Press the MENU/ENTER] key of the remote control 4 times to obtain the [FUNCTION] menu.

(3) Move the cursor to the [SHIP] item by means of the cursor keys [ ] and [V], and select the adequate

alphabets of the destination specified below, using the cursor keys [<] and [>].

J:JAPAN JW: OEM Specifications for Japan

A:NORTH AMERICA AW: MITSUBISHI PD-5010

G:EUROPE GW: OEM Specifications for Europe

FUNCTION

SCART OFF

SI AUTO

SHIP AW

LIMIT-VD OFF

LIMIT-PC ON

REMAKE OFF

V

ENTER NEXTEXIT PREV

(4)Press the [MUTE] key → the cursor key [ ] → the cursor key [V] → the [SLEEP] key in this order to

V

5/8

make factory setting.

When factory setting is executed, red characters of [SET] are displayed for about 7 seconds at the right of

the [destination alphabets]. When the red characters of [SET] go out, this is a sign that the setting has been

finished.

FUNCTION

SCART OFF

SI AUTO

SHIP AW SET

LIMIT-VD OFF

LIMIT-PC ON

REMAKE OFF

ENTER NEXTEXIT PREV

5/8

(5) Withdraw from the factory setting mode by means of the remote control.

3

Page 31

[Initial setting values]

(User setting values)

Mode J, JW Other than J, JW

Remote control standby ON condition ON condition

Sound volume 10 steps 10 steps

Input mode VIDEO1 VIDEO1

Display modeSTRETCHED STRETCHED

AUTO picture OFF (All of RGB1 to 3) OFF (All of RGB1 to 3)

HD select 1080B 1080B

Language Japanese English

Color system AUTO1 AUTO1

(Factory setting values)

Mode J, JW A, AW G, GW

MXT 601 709 709

SUS ORG ORG ORG

SCART OFF OFF ON

SI AUTO AUTO AUTO

LIMIT-VD OFF OFF OFF

LIMIT-PC ON ON ON

FUNCTION

FAN SET

REMAKE OFF OFF OFF

USAGE TIME 00000H 00000H 00000H

FPIC ON ON ON

STF TEMP 1 2 25 25 25

STF TEMP2 3 50 50 50

STF TEMP3 4 55 55 55

STF IME 30 30 30

— ———

— ———

— ———

— ———

4

Page 32

5. Adjustment of VIDEO screen position and phase

5-1. Adjustment of VIDEO screen position

(Caution) Adjustments should be started after returning the [VIDEO] and [SCREEN] setting of the main

menu to the initial setting conditions.

(1)Enter an input of NTSC and PAL monoscopic signals in VIDEO 1 and use the [FORMAT] key of the remote

control to change over the screen size in the sequential order of [STRETCHED → ZOOM → NARROW→

STANDARD]. Confirm in each screen that the screen position is uniformly arranged to the top, bottom, right,

and left. If the screen position is found to be unevenly arranged, make adjustments according to the

“method of screen position adjustment” shown below.

(2)Enter an input of PAL monoscopic signal in VIDEO 1 and use the [MENU/ENTER] key of the remote control

to select [Information] of the main menu. Change over the [color (COLOR SYSTEM)] to [SECAM]. In

addition, change over the screen size in the sequential order of [STRETCHED → ZOOM → NARROW →

STANDARD]. Confirm in each screen that the screen position is uniformly arranged to the top, bottom, right,

and left. If the screen position is found to be unevenly arranged, make adjustments according to the

“method of screen position adjustment” shown below.

[Method of screen position adjustment]

(1) Enter the factory setting mode by means of the remote control.

(2) In the [POSITION] screen ([POSITION] mode for initial setting), make the following setting:

Ver. XXXX

POSITION

NTSC

STRETCHED

H POS 0 H PHA 0

V POS 0 H CLK 0

MHPOS 160 H DS 1080B

MVPOS 10 RGBS AUTO

SUS ORG

CINEMA ON

ENTER NEXTEXIT PREV

1/8

MHPOS : Adjustment of horizontal display range for the display in the PDP module.

MVPOS : Adjustment of vertical raster display range for the display in the PDP module.

H POS : Adjustment of horizontal signal position in the display range.

V POS : Adjustment of vertical signal position in the display range.

(3)Press the FORMAT key of the remote control in order to select the NARROW mode.

(4) When the display range of the PDP module is displaced, press the cursor keys [ ] and [V] of the remote

control to select [MHPOS] and [MVPOS], and make adjustments by pressing the cursor keys [<] and [>].

(5) Press the cursor keys [ ] and [V] to select [H POS].

V

V

(6) Press the cursor keys [<] and [>] to adjust the screen position so that the screen can be arranged evenly

to the right and left.

(7) Press the cursor keys [ ] and [V] to select [V POS].

V

(8) Press the cursor keys [<] and [>] to adjust the screen position so that the screen can be arranged evenly

to the top and bottom.

Confirm that [H PHA] is 0. Otherwise, adjust it to 0 by pressing the cursor keys [<] and [>].

(10) Confirm that [H CLK] is 0. Otherwise, adjust it to 0 by pressing the cursor keys [<] and [>].

5

Page 33

(11)In the same manner, press the FORMAT key and select [NARROW → STANDARD → STRETCHED → ZOOM → U-

SCAN] in this order. Adjust the screen position so that the screen can be arranged evenly to the top,

bottom, right, and left. Confirm that [H PHA] and [H CLK] are 0. Otherwise, press the cursor keys [<] and

[>] to adjust them to 0.

(12) This should be done only if SECAM is adjusted as per (2) above.

Press the [ENTER/MENU] key to display the D-CONTROL menu and adjust the cursor to C-SYSTEM by

means of the cursor keys [ ] and [V]. Select [A1] by means of the cursor keys [<] and [>].

V

D-CONTROL

SECAM

CONT 0 SUB CONT 8

BRIGHT 0 Y LEVEL 41

COLOR 56 C-LEVEL 31

B-Y 4

C-Y 12

C-SYSTEM A1

ENTER NEXTEXIT PREV

2/8

Displayed only for SECAM

(13) Withdraw the factory setting mode.

5-2. Adjustment of DVD/HD screen position

(Caution) Adjustments should be started after returning the [VIDEO] and [SCREEN] setting of the main menu

to the initial setting conditions.

(1)Enter an input of HDTV monoscopic signal in the DVD/HD1 IN terminal. Use the [MENU/ENTER] key of the

remote control to select [HD SELECT] of [OPTION] of the main menu. Make setting at [1035i] by pressing the cursor keys [<] and [>].

(2) Select [HD IN] with the remote control or the main-unit front key. Confirm that the screen position is

uniformly arranged to the top, bottom, right, and left. If the screen position is found to be unevenly

arranged, make adjustments according to the “method of screen position adjustment” shown below. (The

screen size is FULL only.)

(3) Select the NTSC COMPONENT signal (480i) for the input video signal and change over the screen size

in the sequential order of [STRETCHED → ZOOM → NARROW → STANDARD]. Confirm in each screen that

the screen position is uniformly arranged to the top, bottom, right, and left. If the screen position is found to be

unevenly arranged, make adjustments according to the “method of screen position adjustment” shown

below.

(4) Select the PAL COMPONENT signal (5760i) for the input video signal and change over the screen size

in the sequential order of [STRETCHED ZOOM NARROW STANDARD]. Confirm in each screen that the

screen position is uniformly arranged to the top, bottom, right, and left. If the screen position is found to

be unevenly arranged, make adjustments according to the “method of screen position adjustment” shown

below.

(5) Select the DTC 1080i signal for the input video signal. Select [HD SELECT] of the screen. Make setting

at [1035B] by pressing the cursor keys [<] and [>]. Confirm that the screen position is uniformly arranged

to the top, bottom, right, and left.

If the screen position is found to be unevenly arranged, make adjustments according to the “method of

screen position adjustment” shown below. (The screen size is FULL only.)

6

Page 34

(6) Select the DTV 720P signal for the input video signal. Confirm that the screen position is uniformly

arranged to the top, bottom, right, and left.

If the screen position is found to be unevenly arranged, make adjustments according to the “method of

screen position adjustment” shown below. (The screen size is STANDARD only.)

(7) Select the DTV 480P signal for the input video signal and change over the screen size in the sequential

order of [STRETCHED ZOOM NARROW STANDARD]. Confirm in each screen that the screen position is

uniformly arranged to the top, bottom, right, and left. If the screen position is found to be unevenly

arranged, make adjustments according to the “method of screen position adjustment” shown below.

[Method of screen position adjustment]

(1) Enter the factory setting mode by means of the remote control.

(2) In the [POSITION] screen ([POSITION] mode for initial setting), make the following setting:

Ver. DXXX

POSITION

COMP N

STANDARD

H POS 0 H PHA 0

V POS 0 H CLK 0

MHPOS 160 H DS 1080B

MVPOS 10 RGBS AUTO

SUS ORG

CINEMA ON

ENTER NEXT

EXIT PREV

(3)Press the FORMAT key of the remote control in order to select the NARROW mode.

(4) When the display range of the PDP module is displaced, press the cursor keys [ ] and [V] of the remote

control to select [MHPOS] and [MVPOS], and make adjustments by pressing the cursor keys [<] and [>].

(5) Press the cursor keys [ ] and [V] to select [H POS].

V

1/8

V

(6) Press the cursor keys [<] and [>] to adjust the screen position so that the screen can be arranged evenly

to the right and left.

(7) Press the cursor keys [ ] and [V] to select [V POS].

V

(8) Press the cursor keys [<] and [>] to adjust the screen position so that the screen can be arranged evenly

to the top and bottom.

(9) Confirm that [H PHA] is 0. Otherwise, adjust it to 0 by pressing the cursor keys [<] and [>].

(10)Confirm that [H CLK] is 0. Otherwise, adjust it to 0 by pressing the cursor keys [<] and [>].

(11)In the same manner, press the [FORMAT] key to select the screen mode. (According to the signal type, the

screen mode varies as shown below.) In each case, make adjustments so that the screen position is

uniformly arranged to the top, bottom, right, and left. Confirm that both [H PHA] and [H CLK] are set at 0.

Otherwise, press the cursor keys [<] and [>] in order to adjust both to zero.

• 480 i, 576 i, 480P, 576P[NARROW → STANDARD → STRETCHED → ZOOM → U-SCAN]

• 1080 i, 1035 i, 720P[STANDARD → U-SCAN]

(12) Withdraw the factory setting mode.

7

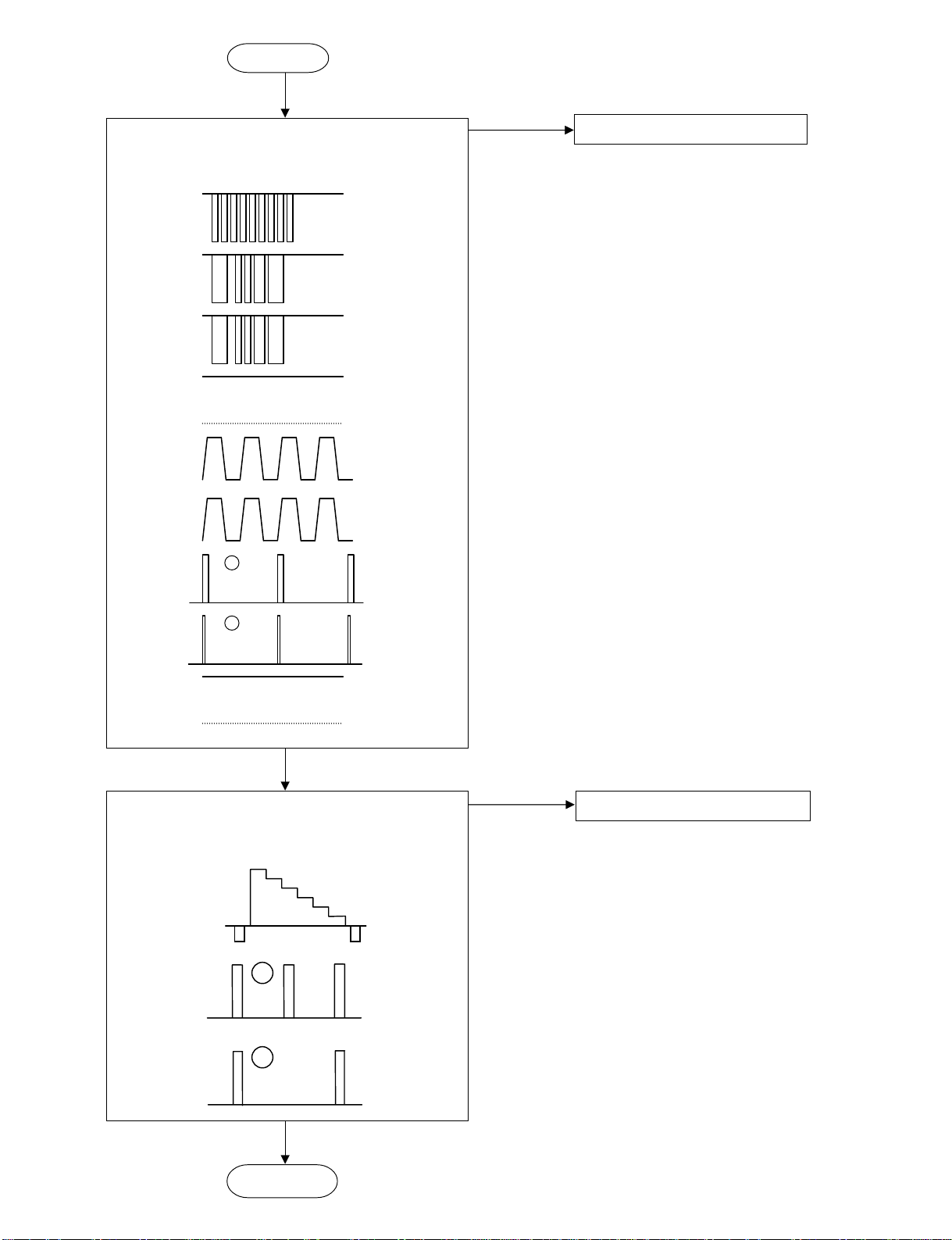

Page 35

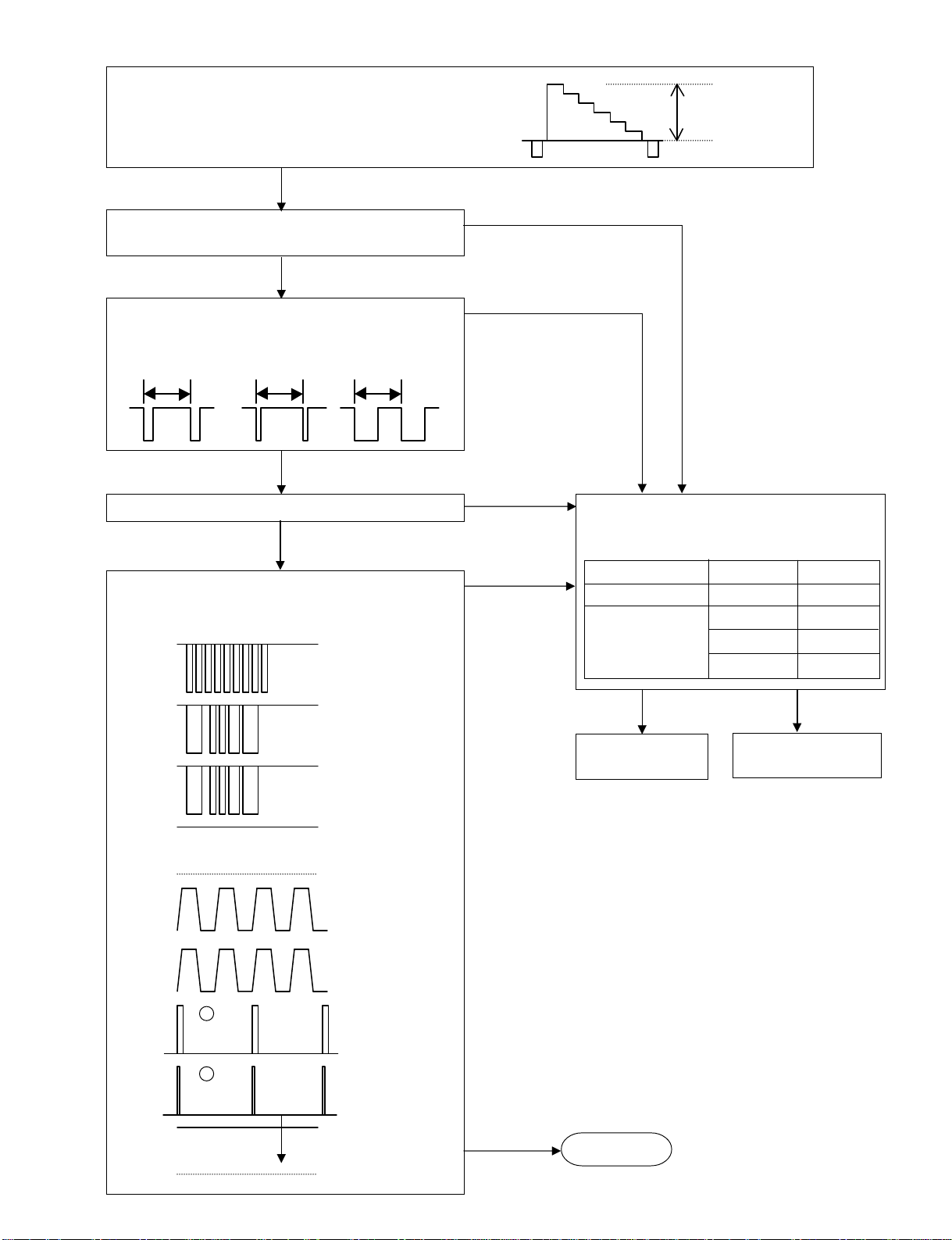

The PWB-SCAN and PWB-COMMON are included together. Replace both PWB's at the same time.

After replacment, perform the Vsw , Vp+, and Vbw adjustments in the order described.

Voltage Label Check

1. Prior to adjustment, note the voltage levels recorded on the Voltage Label as shown.

Vbw Vsw Vp+

Example:

Vbw : 99.9

Vsw : 179.2

Vp+ : 200.8

Vsw Adjustment... PWB-COMMON

Note: Measure voltage between the TP and closest Chassis Ground.

1. Vsw - Adjust VR101 so the voltage at TP4 is set to the level specified for Vsw1 on the Voltage Label +/- 0.5V.

Vsw

TP4 VR101

PWB-COMMON

8

Page 36

Vp+ & Vbw Adjustment s... PWB-SCAN

Note: Measure voltage between the TP and closest Chassis Ground.

1. Vp+ - Adjust VR1 so the voltage at TP33 is set to the level specified for Vp+ on the Voltage Label +/- 0.5V.

2. Vbw - Adjust VR2 so the voltage at TP34 is set to the level specified for Vbw on the V olt age Label +/- 0.5V.

Vp+

VR1 TP33

PWB-SCAN

VR2 TP34

Vbw

9

Page 37

[Morgue]

1. Signal Generator

(1) Digital RGB and component signal generator

¥ Equivalent to the Video Generator LT1615 (made by LEADER)

¥ Equivalent to the Panel Adapter LT9217 (made by LEADER)

¥ Equivalent to the Video Encoder LT1606 (made by LEADER)

(2) NTSC signal generator

¥ Equivalent to the NTSC Pattern Generator LCG-403YC (made by LEADER)

(3) PAL signal generator

¥ Equivalent to the Color Bar Pattern Generator PM5518 (made by PHILIPS)

2. VIDEO input

Input: Composite video input or S-terminal input for one system

3. DVD/HD/DTV input

3-1. HD: Y/Pb/Pr component input, tri-sync signal

700

300

300

YPb Pr

100% color bar signal (mVp-p)

3-2. DVD: Y/B-Y/R-Y component input

700 (all white)

300

YCb Cr

75% color bar signal (mVp-p)

350

350

700

10

Page 38

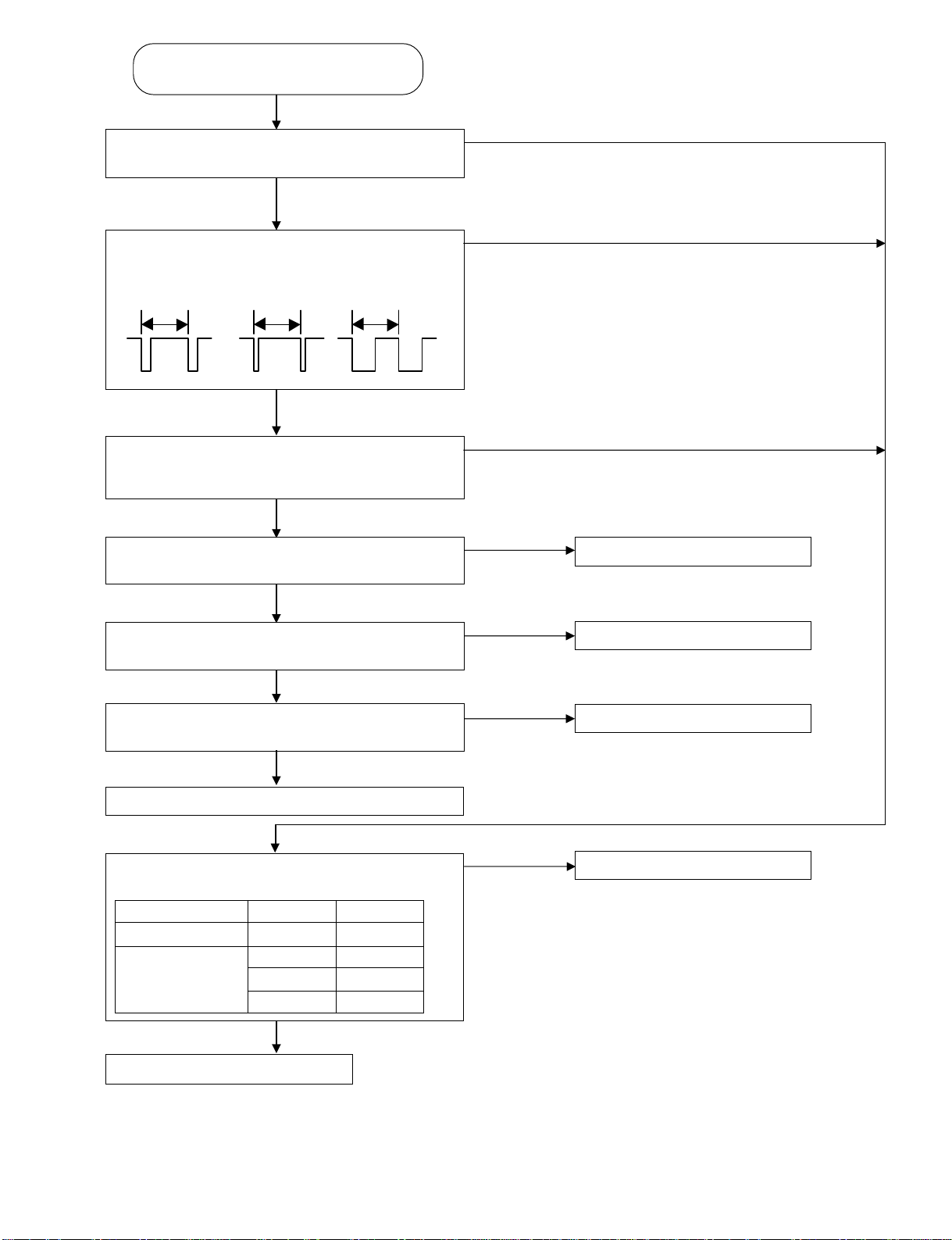

4. RGB/PC input

1) Horizontal sync period

Video signal

0.7Vp-p

Sync signal

TTL level

Positive/negative polarity

(2) Vertical sync period

Video signal

0.7Vp-p

Sync signal

TTL level

Positive/negative polarity

c

b

h

g

de

a

ij

f

* The data a to j above are specified in the next page and thereafter, classified for various inspection signals.

11

Page 39

5. RGB/PC signal timing table

PC mode 1 2 3 4 5

Signal name VU-6010 VU-6010 PC98 IBM PC98

NTSC PAL/SECAM 400@56Hz 400@70Hz 480@60HZ

Definition 640*240 768*288 640*400 640*400 640*480

Dot clock frequency (MHz) 12.214 14.752 21.053 25.175 25.175

H frequency (kHz) 15.734 15.557 24.826 31.469 31.469

V frequency (Hz) 59.94 50.39 56.423 70.086 59.94

H total (uS) 63.534 64.262 40.285 31.778 31.778

(dots) 776 948 848 800 800

H display period (uS) 52.4 52.06 30.4 25.422 25.422

(dots) 640 768 640 640 640

H front porch (uS) 1.146 1.288 2.803 0.675 0.596

(dots) 14 19 59 17 15

H sync pulse width (uS) 8.76 8.677 3.04 2.542 3.813

(dots) 107 128 64 64 96

H back porch (uS) 1.228 2.237 4.037 3.138 1.946

(dots) 15 33 85 79 49

V total (mS) 16.652 20.055 17.723 14.268 16.683

(line) 262 312 440 449 525

V display period (mS) 15.3 18.513 16.112 12.711 15.253

(line) 240 288 400 400 480

V front porch (mS) 0.191 0.321 0.282 0.413 0.191

(line) 3 5 7 13 6

V sync pulse width (mS) 1.144 1.093 0.322 0.064 0.064

(line) 18 17 8 2 2

V back porch (mS) 0.064 0.064 1.007 1.08 1.176

(line) 1 1 25 34 37

H sync polarity Neg Neg Neg Neg Neg

V sync polarity Neg Neg Neg Neg Neg

Scan type Interlaced Interlaced Non Non Non

Interlaced Interlaced Interlaced

12

Page 40

PC mode 6 7 8 9 10

Signal name MAC@13Ó VESA VESA VESA XGA-2

480@72Hz 480@75Hz 480@85Hz 480@75HZ

Definition 640*480 640*480 640*480 640*480 640*480

Dot clock frequency (MHz) 30.24 31.5 31.5 36.0 31.5

H frequency (kHz) 35 37.861 37.5 43.269 39.375

V frequency (Hz) 66.667 72.809 75 85.008 75

H total (uS) 28.571 26.413 26.667 23.111 25.4

(dots) 864 832 840 832 800

H display period (uS) 21.164 20.317 20.317 17.778 20.32

(dots) 640 640 640 640 640

H front porch (uS) 2.116 0.762 0.508 1.556 0.508

(dots) 64 24 16 56 16

H sync pulse width (uS) 2.116 1.27 2.032 1.556 3.048

(dots) 64 40 64 56 96

H back porch (uS) 3.175 4.064 3.81 2.222 1.524

(dots) 96 128 120 80 48

V total (mS) 15 13.735 13.333 11.764 13.333

(line) 525 520 500 509 525

V display period (mS) 13.714 12.678 12.8 11.093 12.19

(line) 480 480 480 480 480

V front porch (mS) 0.086 0.237 0.027 0.023 0.279

(line) 3 9 1 1 11

V sync pulse width (mS) 0.086 0.079 0.08 0.069 0.051

(line) 3 3 3 3 2

V back porch (mS) 1.114 0.739 0.427 0.578 0.813

(line) 39 28 16 25 32

H sync polarity Sync on G Neg Neg Neg Neg

V sync polarity Sync on G Neg Neg Neg Neg

Scan type Non Non Non Non Non

Interlaced Interlaced Interlaced Interlaced Interlaced

13

Page 41

PC mode 11 12 13 14 15

Signal name VESA VESA VESA VESA VESA

600@56Hz 600@60Hz 600@72Hz 600@75Hz 600@85Hz

Definition 800*600 800*600 800*600 800*600 800*600

Dot clock frequency (MHz) 36 40 50 49.5 56.25

H frequency (kHz) 35.156 37.879 48.077 46.875 53.674

V frequency (Hz) 56.25 60.317 72.188 75 85.061

H total (uS) 28.444 26.4 20.8 21.333 18.631

(dots) 1024 1056 1040 1056 1048

H display period (uS) 22.222 20 16 16.162 14.222

(dots) 800 800 800 800 800

H front porch (uS) 0.667 1 1.12 0.323 0.569

(dots) 24 40 56 16 32

H sync pulse width (uS) 2 3.2 2.4 1.616 1.138

(dots) 72 128 120 80 64

H back porch (uS) 3.556 2.2 1.28 3.232 2.702

(dots) 128 88 64 160 152

V total (mS) 17.778 16.579 13.853 13.333 11.756

(line) 625 628 666 625 631

V display period (mS) 17.067 15.84 12.48 12.8 11.179

(line) 600 600 600 600 600

V front porch (mS) 0.028 0.026 0.77 0.021 0.019

(line) 1 1 37 1 1

V sync pulse width (mS) 0.057 0.106 0.125 0.064 0.056

(line) 2 4 6 3 3

V back porch (mS) 0.626 0.607 0.478 0.448 0.503

(line) 22 23 23 21 27

H sync polarity Pos. Pos. Pos. Pos. Pos.

V sync polarity Pos. Pos. Pos. Pos. Pos.

Scan type Non Non Non Non Non

Interlaced Interlaced Interlaced Interlaced Interlaced

14

Page 42

PC mode 16 17 18 19 20

Signal name MAC@16Ó I/O dater CEREB VESA wide VESA wide

wide wide 1 (NEC 1) (NEC 2)

Definition 832*624 852*480 864*480 848*480 1024*576

Dot clock frequency (MHz) 57.2832 34.006 42.526 33.75 47.25

H frequency (kHz) 49.725 31.722 37.5 31.02 35.795

V frequency (Hz) 74.55 59.966 75 60 60.059

H total (uS) 20.111 31.524 26.667 32.237 27.937

(dots) 1152 1072 1134 1088 1320

H display period (uS) 14.524 25.055 20.317 25.126 21.672

(dots) 832 852 864 848 1024

H front porch (uS) 0.559 0.659 0.508 0.474 0.339

(dots) 32 22 22 16 16

H sync pulse width (uS) 1.117 3.764 2.032 3.319 3.048

(dots) 64 128 86 112 144

H back porch (uS) 3.91 2.047 3.81 3.319 2.878

(dots) 224 70 162 112 136

V total (mS) 13.414 16.676 13.333 16.667 16.65

(line) 667 529 500 517 596

V display period (mS) 12.549 15.132 12.8 15.474 16.091

(line) 624 480 480 480 576

V front porch (mS) 0.02 0.378 0.027 0.193 0.056

(line) 1 12 1 6 2

V sync pulse width (mS) 0.06 0.095 0.08 0.258 0.112

(line) 3 3 3 8 4

V back porch (mS) 0.784 1.072 0.427 0.741 0.391

(line) 39 34 16 23 14

H sync polarity Sync on G Neg Pos. Pos. Pos.

V sync polarity Sync on G Neg Neg Pos. Pos.

Scan type Non Non Non Non Non

Interlaced Interlaced Interlaced Interlaced Interlaced

15

Page 43

PC mode 21 22 23 24 25

Signal name VESA wide VESA wide CEREB VESA VESA

(NEC 3) (NEC 4) wide 2 768@60Hz 768@70Hz

Definition 1280*720 1360*768 1024*600 1024*768 1024*768

Dot clock frequency (MHz) 76.5 85.5 51.2 65 75

H frequency (kHz) 45.106 47.712 37.879 48.363 56.476

V frequency (Hz) 60.142 60.015 60.317 60.004 70.069

H total (uS) 22.17 20.959 26.4 20.677 17.707

(dots) 1696 1792 1352 1344 1328

H display period (uS) 16.732 15.906 20 15.754 13.653

(dots) 1280 1360 1024 1024 1024

H front porch (uS) 0.627 0.749 1 0.369 0.32

(dots) 48 64 51 24 24

H sync pulse width (uS) 2.301 1.310 3.2 2.092 1.813

(dots) 176 112 164 136 136

H back porch (uS) 2.51 2.994 2.2 2.462 1.92

(dots) 192 256 113 160 144

V total (mS) 16.627 16.662 15.579 16.666 14.272

(line) 750 795 628 806 806

V display period (mS) 15.962 16.097 15.84 15.88 13.599

(line) 720 768 600 768 768

V front porch (mS) 0.089 0.063 0.026 0.062 0.053

(line) 4 3 1 3 3

V sync pulse width (mS) 0.177 0.126 0.106 0.124 0.106

(line) 8 6 4 6 6

V back porch (mS) 0.399 0.377 0.607 0.6 0.513

(line) 18 18 23 29 29

H sync polarity Pos. Pos. Neg Neg. Neg.

V sync polarity Pos. Pos. Pos. Neg. Neg.

Scan type Non Non Non Non Non

Interlaced Interlaced Interlaced Interlaced Interlaced

16

Page 44

PC mode 26 27 28 29 30

Signal name VESA VESA MAC@19Ó VESA VESA

768@75Hz 768@85Hz 1024@60Hz 1024@75Hz

Definition 1024*768 1024*768 1024*768 1280*1024 1280*1024

Dot clock frequency (MHz) 78.75 94.5 80 108 135

H frequency (kHz) 60.023 68.677 60.24 63.981 79.976

V frequency (Hz) 75.029 84.997 74.93 60.02 75.025

H total (uS) 16.66 14.561 16.600 15.63 12.501

(dots) 1312 1376 1328 1688 1688

H display period (uS) 13 10.836 12.8 11.852 9.481

(dots) 1024 1024 1024 1280 1280

H front porch (uS) 0.203 0.508 0.4 0.444 0.119

(dots) 16 48 32 48 2

H sync pulse width (uS) 1.219 1.016 1.2 1.037 1.067

(dots) 96 96 96 112 144

H back porch (uS) 2.235 2.201 2.2 2.296 1.837

(dots) 176 208 176 248 248

V total (mS) 13.328 11.765 13.347 16.661 13.329

(line) 800 808 804 1066 1066

V display period (mS) 12.795 11.183 12.749 16.005 12.804

(line) 768 768 768 1024 1024

V front porch (mS) 0.017 0.015 0.050 0.016 0.013

(line) 1 1 3 1 1

V sync pulse width (mS) 0.05 0.044 0.050 0.047 0.038

(line) 3 3 3 3 3

V back porch (mS) 0.466 0.524 0.498 0.594 0.475

(line) 28 36 30 38 38

H sync polarity Pos. Pos. Ñ Pos. Pos.

V sync polarity Pos. Pos. Ñ Pos. Pos.

Scan type Non Non Non Non Non

Interlaced Interlaced Interlaced Interlaced Interlaced

17

Page 45

PC mode 31 32 33 34 35

Signal name IDC-3000G IDC-3000G HDTV-J DTV (480P) DTV (720P)

PAL 625P NTSC 525P

Definition 768*576 640*480 1920*1034 644*483 1280*720

Dot clock frequency (MHz) 29.687 24.39 74.25 24.37 74.25

H frequency (kHz) 31.389 31.47 33.75 31.469 45.000

V frequency (Hz) 50 59.9 60/60 59.94 60

H total (uS) 31.933 31.775 29.63 31.777 22.222

(dots) 948 775 2200 774 1650

H display period (uS) 25.87 26.24 25.86 26.427 17.239

(dots) 768 640 1920 644 1280

H front porch (uS) 0.269 0.41 0.59 0.75 0.943

(dots) 8 10 44 18 70

H sync pulse width (uS) 2.526 2.46 0.59 2.35 1.077

(dots) 75 60 44 57 80

H back porch (uS) 3.267 2.665 2.59 2.25 2.963

(dots) 97 65 192 55 220

V total (mS) 19.911 16.522 16.652 16.683 16.667

(line) 625 525 562/562 525 750

V display period (mS) 18.35 15.106 15.319 15.348

(line) 576 480 517/517 483 720

V front porch (mS) 0.223 0.252 0.148 0.191 0.111

(line) 7 8 5 6 5

V sync pulse width (mS) 0.223 0.22 0.148 0.191 0.111

(line) 7 7 5 6 5

V back porch (mS) 1.115 0.944 1.037 0.953 0.444

(line) 35 30 35 30 20

H sync polarity Neg Neg Neg Neg Neg

V sync polarity Neg Neg Neg Neg Neg

Scan type Non Non Interlaced Non Non

Interlaced Iinterlaced Interlaced Interlaced

18

Page 46

PC mode 36 37 38 39

Signal name HDTV-W SSPE JSPE MAC@12Ó

Definition 1920*1080 1024*512 852*480 1152*870

Dot clock frequency (MHz) 74.25 40 16 100

H frequency (kHz) 33.75 33.727 15.75 68.681

V frequency (Hz) 60/60 60.012 59.94 75.062

H total (uS) 29.630 29.650 63.750 14.560

(dots) 2200 1186 1020 1456

H display period (uS) 25.859 25.600 53.250 11.520

(dots) 1920 1024 852 1152

H front porch (uS) 0.593 0.600 1.250 0.320

(dots) 44 24 20 32

H sync pulse width (uS) 1.185 1.200 4.750 1.280

(dots) 88 48 76 128

H back porch (uS) 1.993 2.250 4.500 1.440

(dots) 148 90 72 144

V total (mS)

16.652/16.682

(line) 562/563 562 262.5/262.5 915

16.663 16.683 13.322

V display period (mS)

(line) 540/540 511 239/239 870

V front porch (mS) 0.059/0.074 0.178 0.064/0.096 0.044

(line) 2/2.5 6 1/1.5 3

V sync pulse width (mS) 0.148/0.148 0.148 0.191/0.191 0.044

(line) 5/5 5 3/3 3

V back porch (mS) 0.444/0.459 1.186 1.211/1.243 0.568

(line) 15/15.5 40 19/19.5 39

H sync polarity Neg Neg Neg Sync on G

V sync polarity Neg Neg Neg Sync on G

Scan type Interlaced Non Interlaced Non

16.000/16.000

15.15

Interlaced Interlaced

15.236/15.236

12.667

19

Page 47

METHOD OF DISASSEMBLY

(Cautions)

1. Before disassembly, turn power off the main unit and pull out the power plug from the wall outlet.

2. Use a screwdriver with a fitting size. Otherwise, the screw threads may be damaged.

3. Reassembly can be carried out in the reverse order for disassembly. Refer to the disassembly procedures and

forward reassembly in the reverse order.

4. The order for taking out the parts (or components) is indicated by the foregoing numeral that is attached to the

name of each part (or component).

5. The wire connector symbol is indicated by two digits of Marking . Read CN- when examining the table

of parts.

5-1

Page 48

1.LABEL

FILAMENT TAPE(9mm*50m)

NAME PLATE(M53)

LABEL (EARTH) (M65)

SUPPLEMENT SHEET (M62)

SPEAKER LABEL(M54)

SERIAL LABEL(M10)

LABEL A (2001) (M66)

AC IN LABEL(M55)

2.BACK COVER

BACK COVER REAR SIDE

SYMBOL PARTS NAME PARTS NO. Q'TY

1 (GSK03) GASKET (L50*10*T7) 4

2 (GSK04) GASKET (L200*10*T7) 5

5

(1)PL-CPIMS*4*12*15KF(SRW36)

TERMINAL LABEL B (M57)

(3) BACK COVER (M58)

(2)PL-CPIMS*3*6*3KF(SRW35)

3

GASKET L=200

GASKET L=50

1

SCREW(M68)

024N04431 *6

LABEL (OUT) (M64)

STAND REAR SIDE

4

GASKET L=290

5

3

GASKET L=200

4

GASKET L=250

BACK COVER

GASKET L=250

3

GASKET L=250

4

3

GASKET L=200

FELTSHHET(M69)

GASKET L=50

1

GASKET L=200

3 (GSK05) GASKET (L290*10*T7) 1

4 (GSK06) GASKET (L250*10*T7) 4

5 (GSK07) GASKET (L100*10*T7) 1

3.MAIN PWB/DSP PWB/VIDEO PWB

GASKET (L160*9*T4) (M19 (GSK11))

TP-M4*8*3KF(SRW11,12)

*4X2

FAN MOTOR(E01)

*2

SCREW,M3*30*15KF(SRW29)

*2X2

BRACKET (FAN) R (M37)

GASKET(L300*10*T7)(M20(GSK12))

TP-M4*8*3KF(SRW28)

*1X2

(Caution) When mounting a back

cover, stick the filament tape

(30mm*50m) for the

prevention of getting flaws.

In this case, however, the filament

tape shall be removed after

mounting.

BUTTON(PWR)(M07) COVER(POWER SW)(M26)

*2

(1)TP-M4*8*3KF(SRW34)

PWR PWB ASSY(PWC-4419C)(A10)

2

GASKET L=50

1

GASKET L=100

4

BRACKET (FAN) L (M36)

TP-M4*8*3KF(SRW30)

*2

1

GASKET L=250

GASKET L=200

3

GASKET (L150*10*T4) (M20

(GSK13)) *2

GASKET (L200*10*T7) (M12 (GSK04))

*2

(4) SHIELD COVER (MAIN/VIDEO) (M43)

(2) BRACKET (OPTION L) (M42)

(3)TP-M3*6*3KF(SRW33)

*8

COVER(BOTTOM)(M29)

*2

GASKET(L70*10*T1)(M18(GSK10)

*2X2

TP-M4*8*3KF(SRW31)

*4X2

BRACKET STAND(A)(M30)

*2

TP-M4*8*3KF(SRW32)

*2X2

BRACKET STAND(B)(M31)

*2

GASKET L=50

1

Page 49

(Caution) At the time of assembly, it shall

be tightened together with the round

terminal of the connector CN-AD.

EDGE SADDLE(M06)

*3

(5)TP-M4*8*3KF(SRW13)

*6

(6) TERMINAL PANEL (VI) ASSY (M59)

Adhesion of the protective tape

TP-M4*8*3KF(SRW34)

BRACKET (OPTION R) (M44)

*2

PANEL PWB ASSY (PCB-5023B) (A03)

PL-CPIMS*3*6*3KF(SRW15)

*2

TP-M3*6*3KF(SRW20)

*4

232C PWB ASSY (PWC-4419A) (A08)

TP-M3*6*3KF(SRW19)

*2

TERMINAL PANEL (232) ASSY (M60)

SCREW(UNC4-40/4-40)(SRW241)

*2

C/L BUTTON(M08)

PL-CPIMS*3*6*3KF(SRW202)

*2

(Caution) When mounting a back

cover, stick the filament tape

(30mm*50m) for the

prevention of getting flaws.

In this case, however, the filament

tape shall be removed after mounting.

[C]

• TERMINAL PANEL (VI) ASSY

(8) MAIN PWB ASSY (PCB-5022) (A01)

(9) DSP PWB ASSY (PCB-5022) (A06)

(7)TP-M3*6*3KF(SRW16,162)

*9

[C][A]

[D]

[D]

(11) 6SCREW (UNC4-40/4-40) (SRW106)

*2

(12)TP-M3*6*3KF(SRW17)

*5

(13) VIDEO PWB ASSY(PCB-5023A) (A02)

SHIELD PLATE (VIDEO) (M46)

[B]

(10) CBIPS*3*8*3KF (SRW18)

*9

CUSHION RUBBER(M70)

*2

[B]

[A]

2

Page 50

4. AUDIO AMPLIFIER MODULE

LED PWB ASSY (PCB-4419B) (A11)

CBIPS*4*12*3KF (SRW02)

*3

SP PWB ASSY (PWC-4419E) (A12)

TERMINAL PANEL (SP) (M61)

TP-M3*6*3KF(SRW24)

*2

CTL PWB ASSY (PCB-4419B) (A09)

• AC INLET ASSY

CABLE 1P(E02) 07S530015 Green

CABLE 2P (E02)

Blue

CABLE 2P(E02) Brown

MESH (M47)

(2)SCREW,P-CPIMS*3*14*3KF(SRW22)

*2

ET-CBIMS*4*8*3KF(SRW26)

(3)AUDIO AMPLIFIER MODULE(A_UNIT)

TP-M4*8*3KF(SRW37)

*4

(1)TP-M3*6*3KF(SRW21)

*2

CBIPS*3*8*3KF(SRW23)

*2

GASKET (L70*10*T1) (M17 (GSK09))

*2

Rear side of the set

Insulation tube

AC INLET 10GEEG3C(E02)

(Caution) No bending process

Hook

Lock release terminal

COVER (INLET) (M63)

GASKET (L60*10*T2) (M17 (GSK08))

*2

BARRIER (INLET) (M09)

TP-M4*8*3KF(SRW27)

*2

Rear side of the set

Front side of the set

Lock hole button side

(Caution) Insert the cable in the AC inlet until its terminal hook is locked.

After insertion, try to pull the cable to confirm whether or not

it comes out. To disconnect the cable, push the lock release

terminal by a finger in the direction of the arrow, and pull out

the cable in the lengthwise direction. (No unlocking unless the

position of hook's tip is lower than the lock hole bottom side.)

Side view

3

PL-CPIMS*3*10*15KF(SRW25)

*2

Page 51

5. POWER UNIT

TP-M4*8*3KF(SRW39,40)

*2 x 2

SENS PWB ASSY(PCB-5023C)(A04)

PLATE(M48)

*2

SENT PWB ASSY(PCB-5023D)(A05)

(2)BRACKET(POWER)(M41)

(3) TP-M4*8*3KF (SRW09)

*6

(1)TP-M4*8*3KF(SRW10)

*7

(4)POWER UNIT(A13)

PLATE

INSULATORD4.5*T1)(M67)

*6

SENS PWB ASSY

SENT PWB ASSY

6.PDP MODULE

(6)TP-M4*8*3KF(SRW05)

*9

(7)BRACKET(R)(M33)

(3)FRAME(R) (M28)

(11)FRAME(T)(M34)

CN 9P(PH)(CN-PH)

(10)TP-M4*8*3KF(SRW07)

*2

CN 10P(PD) (CN-PD)

(4)TP-M4*8*3KF(SRW04)

*8

(1)PL-CPIMS*4*16*3GF(SRW03)

*4 x 2

(5)BRACKET(L)(M32)

(2)FRAME(L) (M27)

STOP UP SHEET(M71)

*8

FRAME(L) FRAME(R)

STOP UP SHEET

(M71)

*8

(12)TP-M4*8*3KF(SRW06)

*4

(13)FRAME(B)(M35)

(9) FRAME(CENTER)(M45)

(8) TP-M4*8*3KF(SRW08)

*2

4

Page 52

CLAMPER, WIRE (M04)

(8) TP-M3*6*3KF(SRW38)

(Caution)

Make a connection

where no "AD" label

is present.

(14) PDP-NP50C2MF01 (P01)

7.FRONT PANEL ASSY/FILTER

(2) BRACKET FILTER (T) (M38)

(2) CUSHION (10*5*600) (M49)

(3)BRACKET FILTER(S)(M40)

*2

A=10 ± 5mm

TAPE 1150mm*2

(30m)

(1)CBIPS*4*12*3KF(SRW01)

*16

TAPE 680mm x 2

(30m)

(4) BRACKET FILTER (B) (M39)

A

SPACER(FILTER)(M51)

*4

A

(5) FILTER(M52)

(6)FRONT PANEL ASSY(M01)

A

Reference position

5

Page 53

WIRING DIAGEAM

Delete the TR

PD

Add the X2

5

Pass the TM, TR

Allocate each to the upper

and lower sides of the PD

and PH cables.

The cables shall be passed

between the core and the

clamper .

1

X2

5

Pass the LD, PW

6

Pass the PV

5

Wind the TR by one turn

5

Fixed to the vicinity of the sensor PWB

Fix the surplus

3

part of the fan

PD

Fix the fan, TR,

1

PH, and PD twice

Wind the green wire by two turns

8

1

Hook the LE on the LD

Fix the LD, PW

1

Wind the green

5

wire by one turn

1

Fix the AD

1

Fix the PV, PA, LD, PW

2

Fix the green wire

PW

LE

LD

LE

Fix the AC line by

8

means of a winding

lug so that it cannot

come off the chassis

Fix the FAN, PD

Pass the PD, PH

*3

6

Pass the AC

6

line and the

green wire

Fix the PD, PH

1

PH

PD

PN

PV

PA

PM

AC

6

1

Fix the PD, PH

1

Pass the AD

5

F2

AD

TR

F3

TM

PM

PN

LD

PW

RS BU

AQSW

RM LM AU PA

LM RM

Fix the LM, RM

1

Give two turns to the

LM and RM assembled

together

Fix the LD, PW

1

Fix the AD

Fix the PH

1

Wind the TM by one turn

5

TMTR

F1

SY

PL

YU

PC

6

Fix the PV, PA, AQ, SW, RS BU

1

DS

SY

BU

YU

PC

AQ

PV

Wind the PA by one turn

Fixed to the vicinity of the sensor PWB

Fix the surplus part of the fan

4

Pass the AD in the vicinity of

5

the digital PWB of the module

Pass the PN

5

PN, PV, PA, PM

2

Pass the YU

5

1

AU

5

PL

Pass the RS

RS

SW

*2 Fix the AU, PA

1

5

5

BU, AU, PV,

RS, SW

Pass the AQ and fix it

by the use of the harness

band attached

Pass the PC

SYMBOL PARTS NAME PART No.

—

CN-AD CABLE 41P L250

—

CN-AQ CN 4P(AQ) 400W,2791-28

—

CN-AU

—

CN-BU

—

CN-DS

—

CN-LD

—

CN-LE

—

CN-LM

—

CN-PA

—

CN-PC

—

CN-PD

—

CN-PH

—

CN-PL

—

CN-PM

—

CN-PN

—

CN-PV

—

CN-PW

—

CN-RM

—

CN-RS

—

CN-SW

—

CN-SY

—

CN-TM

—

CN-TR

—

CN-YU

CN 7P(AU) 500W,2791-28

CN 14P(BU) 325W,2468-26

CN 3P(DS) 50S, 1007-26

CN 5P(LD) 625W,2468-26

CN 5P(LE) 125,2468-26

CN 3P(LM) 400,2468-26

CN 6P(PA) 700,2468-26

CN 13P(PC) 125W,MIX

CN 10P(PD) 900W, 1007-20

CN 9P(PH) 500W, 1007-20

CABLE, TWINAX 21P L450

CN 11P(PM) 100W,2468-26

CN 10P(PN) 150W,2468-26

CN 8P(PV) 600W,2468-26

CN 6P(PW) 650W,2468-26

CN 2P(RM) 375,2468-26

CN 9P(RS) 475W,2468-26

CN 3P(SW) 625W,2468-26

CN 5P(SY) 175W,1691-28

CN 4P(TM) 525W,2468-26

CN 4P(TR) 525W,2468-26

CN 12P(YU) 125W,MIX

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Q'ty

(Caution) Fix the AC cable by means of a winding lug to

reduce the cable height so that it cannot come

in contact with the back cover.

SYMBOL PARTS NAME PART No. Q'ty

1

M02

CLAMPER,WIRE 15

M03

2

3

4

5

5

5

5

5

5

5

5

5

5

5

5

5

6

6

6

6

7

8

CLAMPER,WIRE (D11.5) 2

M05

CLAMPER,WIRE (D8.3) 1

M21

LEAD CLAMPER (D5.2) 1

FL31 FERRITE CORE ZCAT2032-930(FG)

FERRITE CORE ZCAT2032-930(AD)

FL12 2

FERRITE CORE ZCAT2032-930(TM)

FL35

FERRITE CORE ZCAT2032-930(TR)

FL36 1

FERRITE CORE ZCAT2032-930(PN)

FL5

FERRITE CORE ZCAT2032-930(RS)

FL6 1

FERRITE CORE ZCAT2032-930(PC)

FL8 1

FERRITE CORE ZCAT2032-930(LD/PW)

FL37