Page 1

MITSUBISHI ELECTRIC

2004

Service

Manual

PLASMA DISPLAY PANEL

PD-4225S

CAUTION:

Before servicing this chassis, it is important that the service person read the "PRODUCT SAFETY GUIDELINES"

contained in this manual.

SPECIFICATIONS

•Power

•Display

Sc reen Size : 42" Diagonal, V iewable Ex ternal Speaker : 2 x 5 W atts into 8 ohms

As pect Ratio : 16:9

Pix el Array : 480 x 852

Pix el Pitch : 1.08mm x 1.08mm Video : NTSC, 480i, 480p, 720p, 1080i

Horiz Sync Range : 15.5kHz - 68.7kHz PC Monitor (4:3) : VGA, SVGA, XGA, SXGA

Vert S ync Range : 56Hz - 120Hz PC Monitor (16:9) : W -XGA

• Inputs • Dime nsions

Analog : (2) Composite, (1) S-Video, w/ speakers & base : (W)49-5/8" (H)27-5/8" (D)10-7/8"

PC M onitor : (1) Mini D-Sub 15 & stereo audio

MonitorLink™ : DVI, RS-232C, & stereo audio

RF : NTSC VHF 2-13, UHF 14-69, w/ speakers & base : 81.7 lbs

: AC 100-240V, 50/60Hz

350W Typical, 400W Maximum Analog : (1) Composite & stereo audio

(1) Component & stereo audio wo/ speakers & base : (W)40-3/4" (H)26" (D)4-3/8"

CATV 1-125 wo/ speakers & base : 65.2 lbs

• Outputs

PC Monitor : (1) Mini D-Sub 15

•Formats

•Weight

• Weight and dimensions shown are approximate.

• Design specifications are subject to change without notice.

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2004 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

Page 3

MODEL: PD-4225S

CONTENTS

PRODUCT SAFETY GUIDELINES ...................................................................................................... 4

DISASSEMBLY PROCEDURES .......................................................................................................... 5

ELECTRICAL ADJUSTMENTS ............................................................................................................ 6

REPLACEMENT PARTS......................................................................................................................10

BLOCK DIAGRAMS .......................................................................................................................... 12

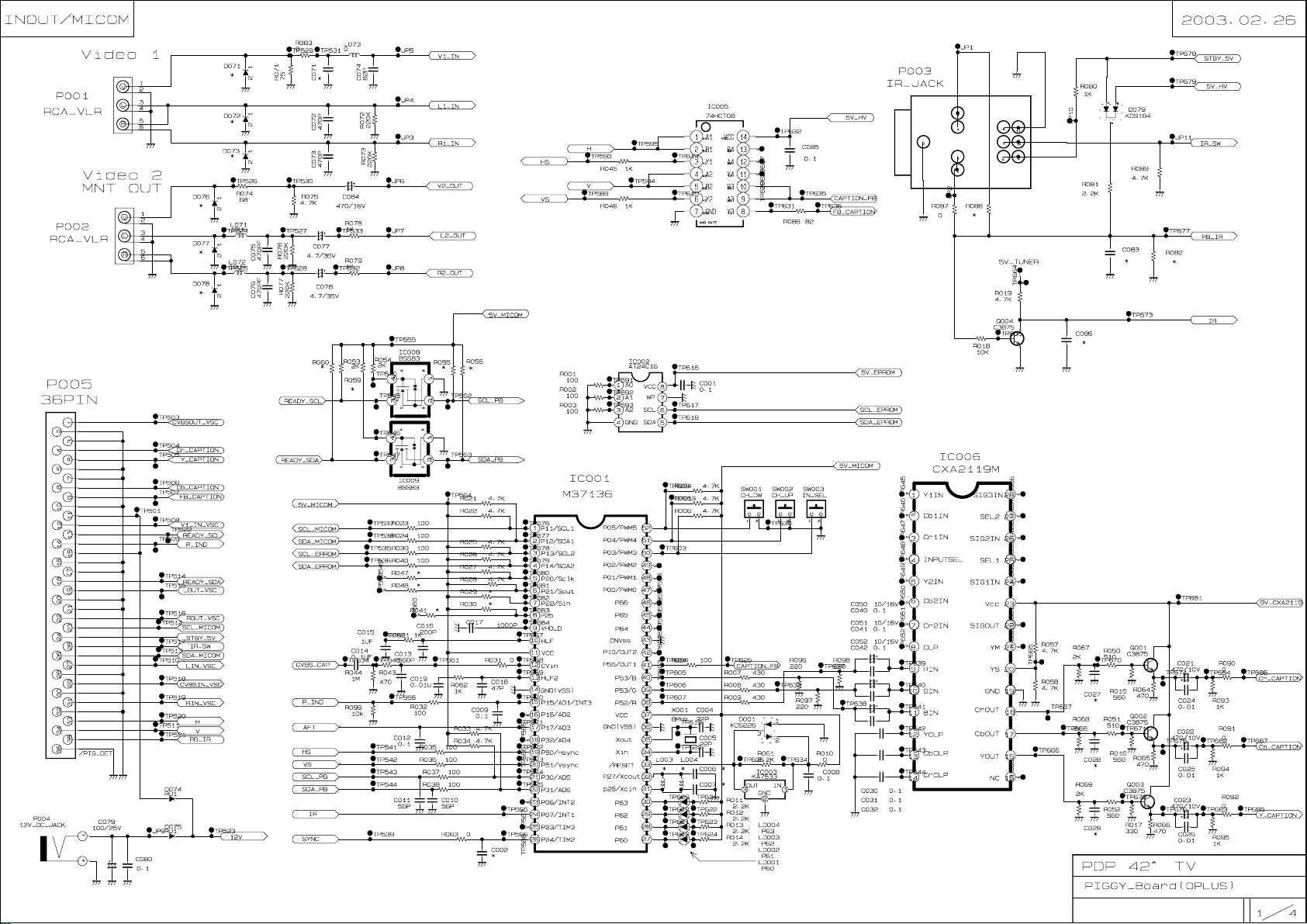

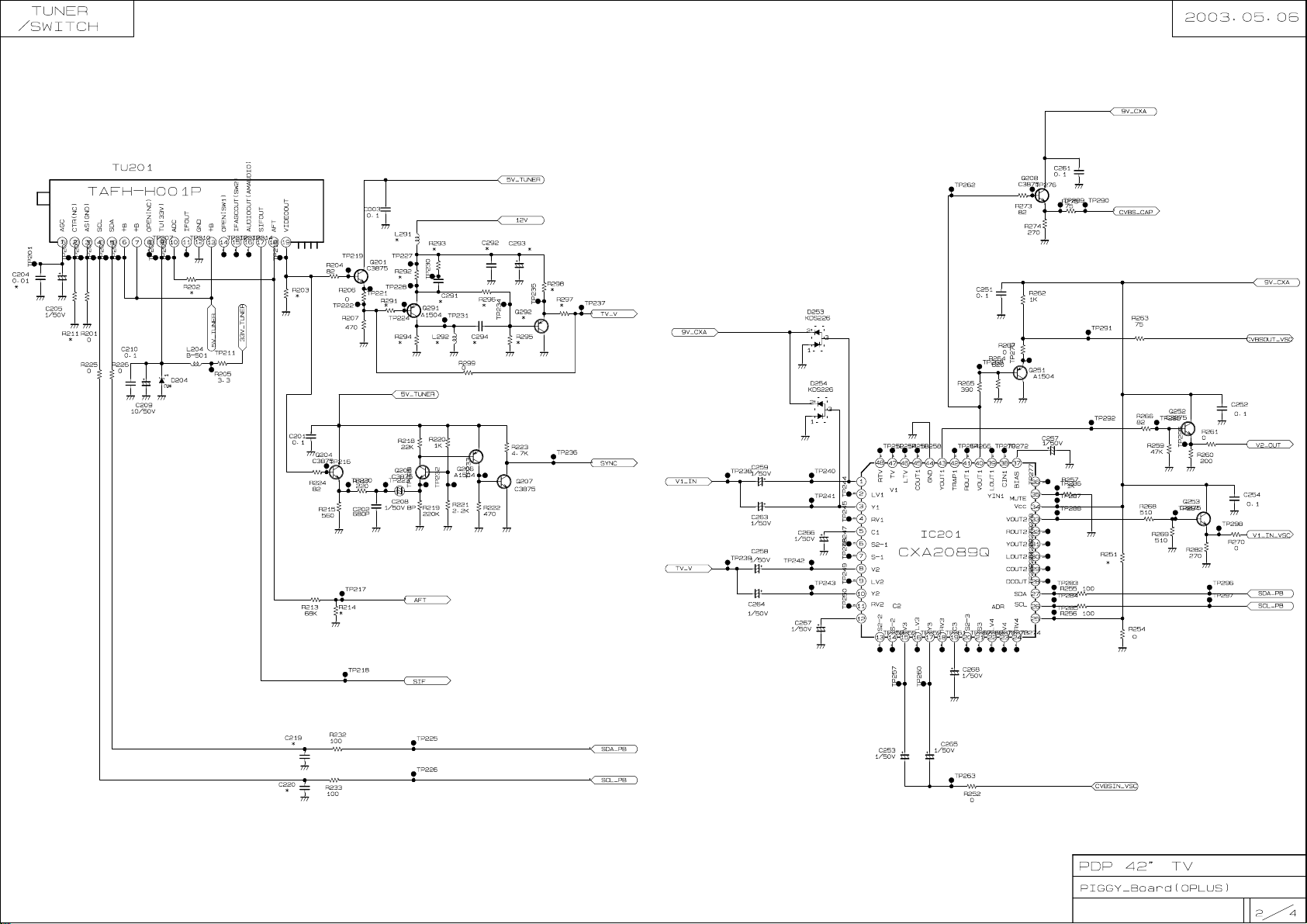

SCHEMATIC DIAGRAMS

PCB MAIN DIAGRAMS

PCB TUNER DIAGRAMS

PCB FRONT DIAGRAMS

PCB LAYOUT DIAGRAMS

Page 3

Page 4

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-visual service

technicians.

When servicing this product, under no circumstances should the original design

be modified or altered without permission from Zenith Electronics Corporation.

All components should be replaced only with types identical to those in the

original circuit and their physical location, wiring and lead dress must conform

to original layout upon completion of repairs.

CAUTION: Do not attempt to modify this product in any way.

Never perform customized installations without manufacturer’s

approval.

Unauthorized modifications will not only void the warranty, but may

lead to property damage or user injury.

Service work should be performed only after you are thoroughly familiar with

these safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended to

alert the service personnel to important safety information in the

service literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence

of noninsulated “dangerous voltage” that may be of sufficient

magnitude to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an

equilateral triangle is intended to convey to the service personnel

the following fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND

RATING AS MARKED NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock.

After the original service problem has been corrected, make a check of the

following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

component shorts. This is especially important on items transported to and

from the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers, shields,

strain reliefs, power supply cords, and other hardware have been reinstalled

per the original design. Be sure that the safety purpose of the polarized line

plug has not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign particles.

4. Check for physical evidence of damage or deterioration to parts and

components, for frayed leads or damaged insulation (including the AC cord),

and replace if necessary.

5. No lead or component should touch a receiving tube or a resistor rated at 1

watt or more. Lead tension around protruding metal surfaces must be avoided.

6. After reassembly of the set, always perform an AC leakage test on all

exposed metallic parts of the cabinet (the channel selector knobs, antenna

terminals, handle and screws) to be sure that set is safe to operate without

danger of electrical shock. DO NOT USE A LINE ISOLATION

TRANSFORMER DURING THIS TEST. Use an AC voltmeter having 5000

ohms per volt or more sensitivity in the following manner: Connect a 1500

ohm, 10 watt resistor, paralleled by a .15 mfd 150V AC type capacitor

between a known good earth ground water pipe, conduit, etc.) and the

exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1500 ohm resistor and

.15 mfd capacitor. Reverse the AC plug by using a non-polarized adaptor

and repeat AC voltage measurements for each exposed metallic part.

Voltage measured must not exceed 0.75 volts RMS. This corresponds to 0.5

milliamp AC. Any value exceeding this limit constitutes a potential shock

hazard and must be corrected immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting

shelf space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where

dew is a factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer

should also avoid the use of decorative scarves or other coverings that might

obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must

follow the factory-approved mounting instructions. A product mounted to a

shelf or platform must retain its original feet (or the equivalent thickness in

spacers) to provide adequate air flow across the bottom. Bolts or screws

used for fasteners must not touch any parts or wiring. Perform leakage tests

on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted

position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters

across thresholds or deep pile carpets.

7. Caution customers against using a cart or stand that has not been listed by

Underwriters Laboratories, Inc. for use with its specific model of television

receiver or generically approved for use with TVs of the same or larger screen

size.

8. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous

consequences to home and family.

AV

PRODUCT SAFETY GUIDELINES

MODEL: PD-4225S

Page 4

Page 5

MODEL: PD-4225S

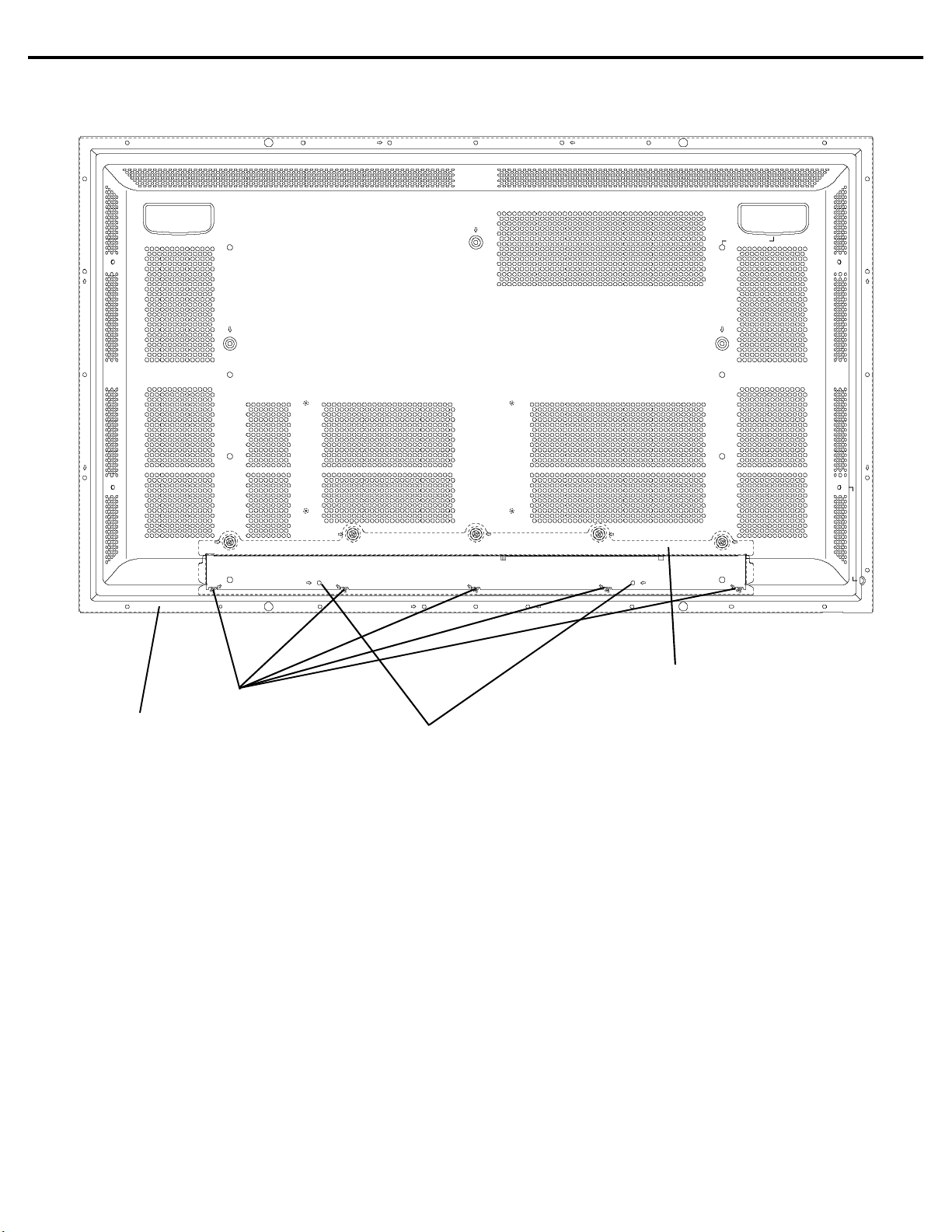

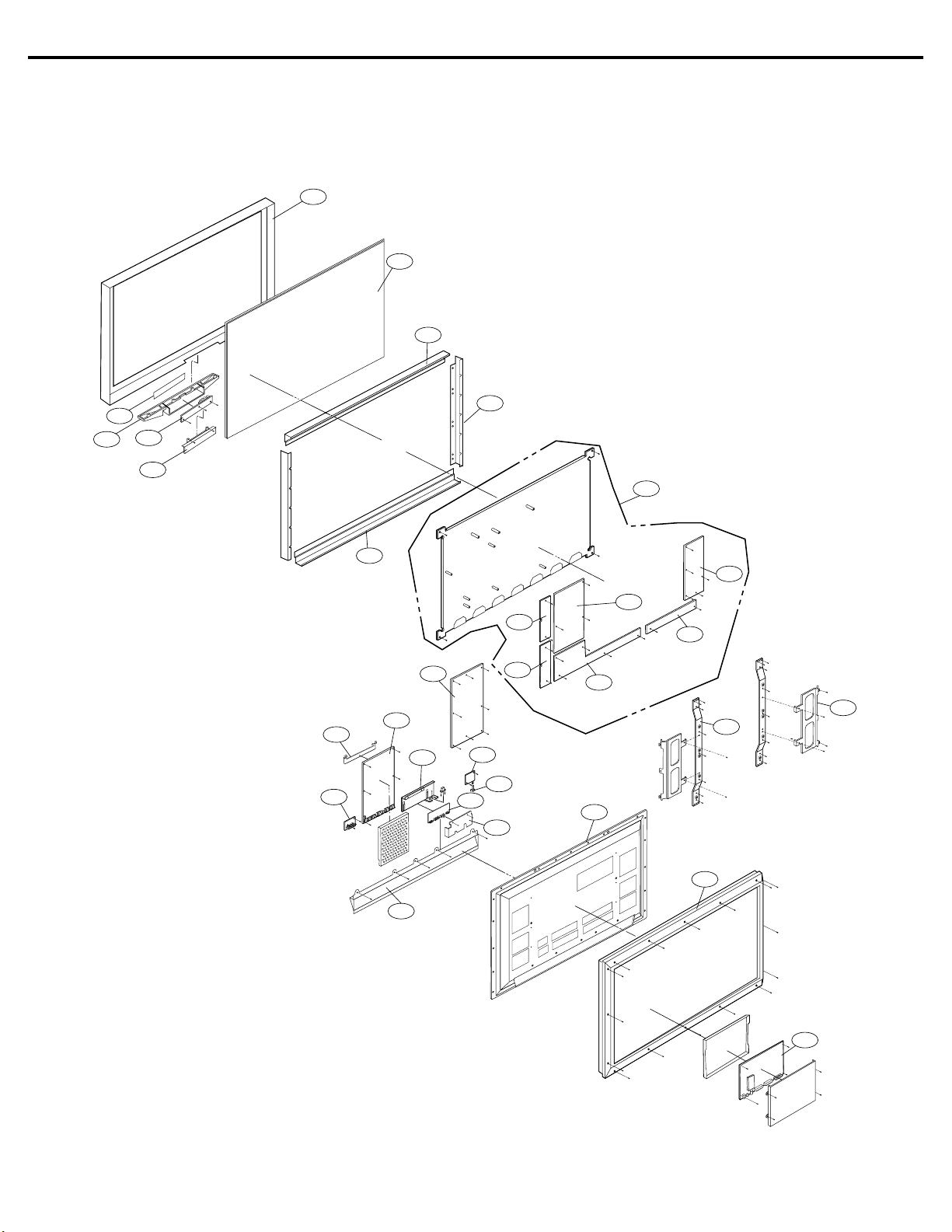

DISASSEMBLY

(b)

BACK COVER INNER

(a)

PLATE A/V

1. Screws marked (a) hold the Plate Assembly in place (Plate A/V).

2. Screws marked (b) connect Plate Assembly with Back Cover Assembly.

3. Screws marked with an arrow on the back of the PDP connect the Back Cover Assembly & Outer

Assembly to the Main Frame.

NOTE: All three Assemblies should be removed in disassembly.

Page 5

Page 6

MODEL: PD-4225S

ELECTRICAL ADJUSTMENTS

Test Equipment

• DMM

• Signal Generator: RGB (VGA) - 1024x768, 60Hz, COMPONENT (YPbPr) - 1280x720p, 60Hz

Notes

• Do not attempt an adjustment if proper equipment is not available.

• Because this is not a Hot chassis, no isolation transformer is required. However, the use of an isolation transformer

will help protect test instruments.

• Perform only the adjustments required, in the correct order.

• Adjustment conditions… Temperature: 68°-86°F. Humidity: 55%-75%. Line Voltage: 100-240V, 50/60 Hz.

• Prior to adjustment, the PDP must be operated for at least 15 minutes while receiving a 100% white pattern.

• CAUTION: If a stationary pattern (i.e. Cross Hatch or digital generator) is displayed for more than 20 minutes, an

after image (image burn) can occur.

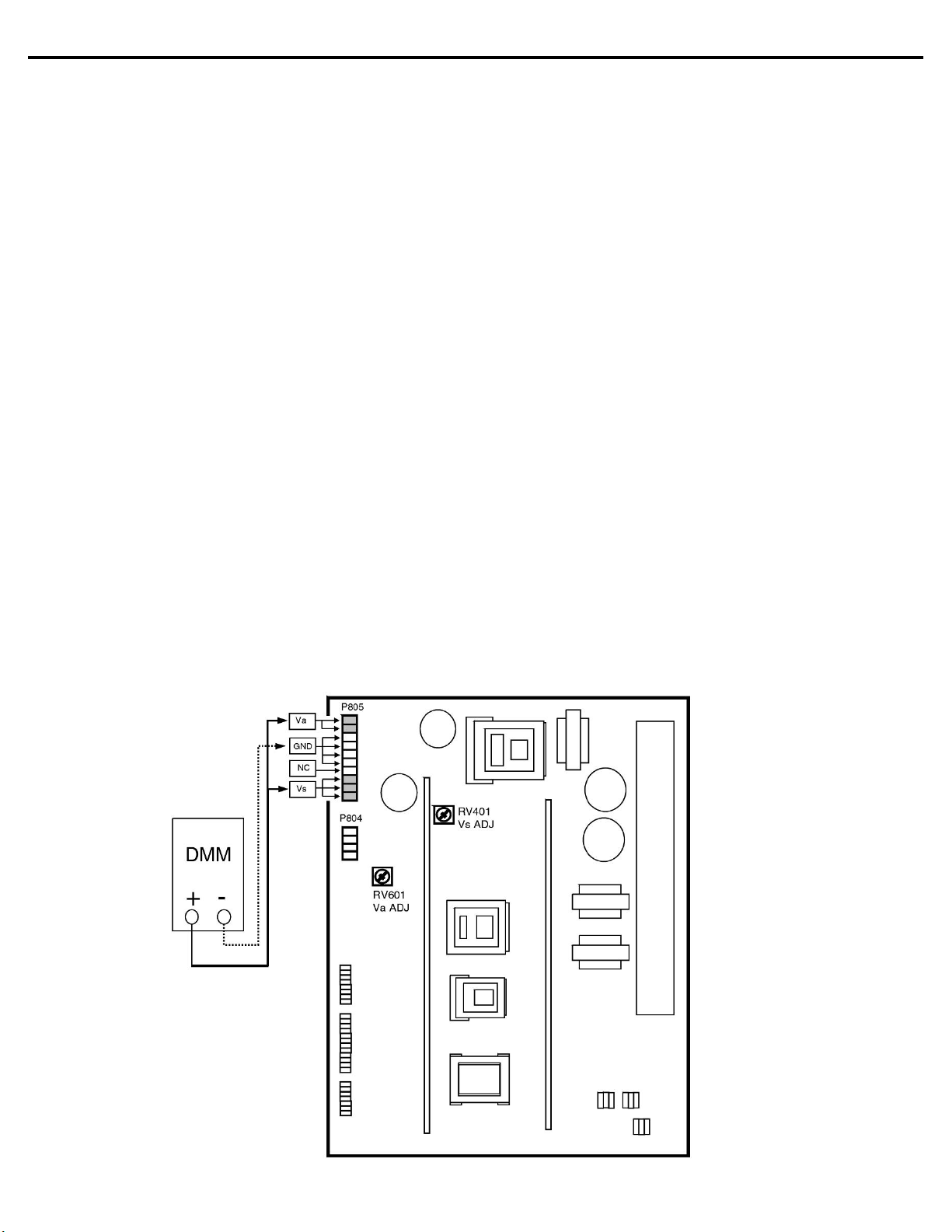

1. PWB Power Assembly Adjustments (Va, Vs Voltage Adjustments)

These adjustments must be performed after the repair or replacement of the PWB Power Assembly, or after replacing

the PDP.

A. Va Adjustment

1. Supply a 100% White pattern.

2. Connect a DMM between the Va and GND pins of P805 on the PWB Power. See Figure 4.

3. Note the Va voltage listed on the label located on the panel, top right side.

4. Adjust RV601 so the voltage is equal to the voltage listed, ± 0.5V.

B. Vs Adjustment

1. Connect the DMM between the Vs and GND pins of P805.

2. Note the Vs voltage listed on the label located on the panel, top right side.

3. Adjust RV401 so the voltage is equal to the voltage listed, ± 0.5V.

Page 6

Page 7

200

203

205

204

206

510

400

410

210

220

300

340

350

570

MODEL: PD-4225S

EXPLODED VIEW

305

301

330

360

560

303

520

551

580

550

540

302

541

490

201

202

401

Page 7

Page 8

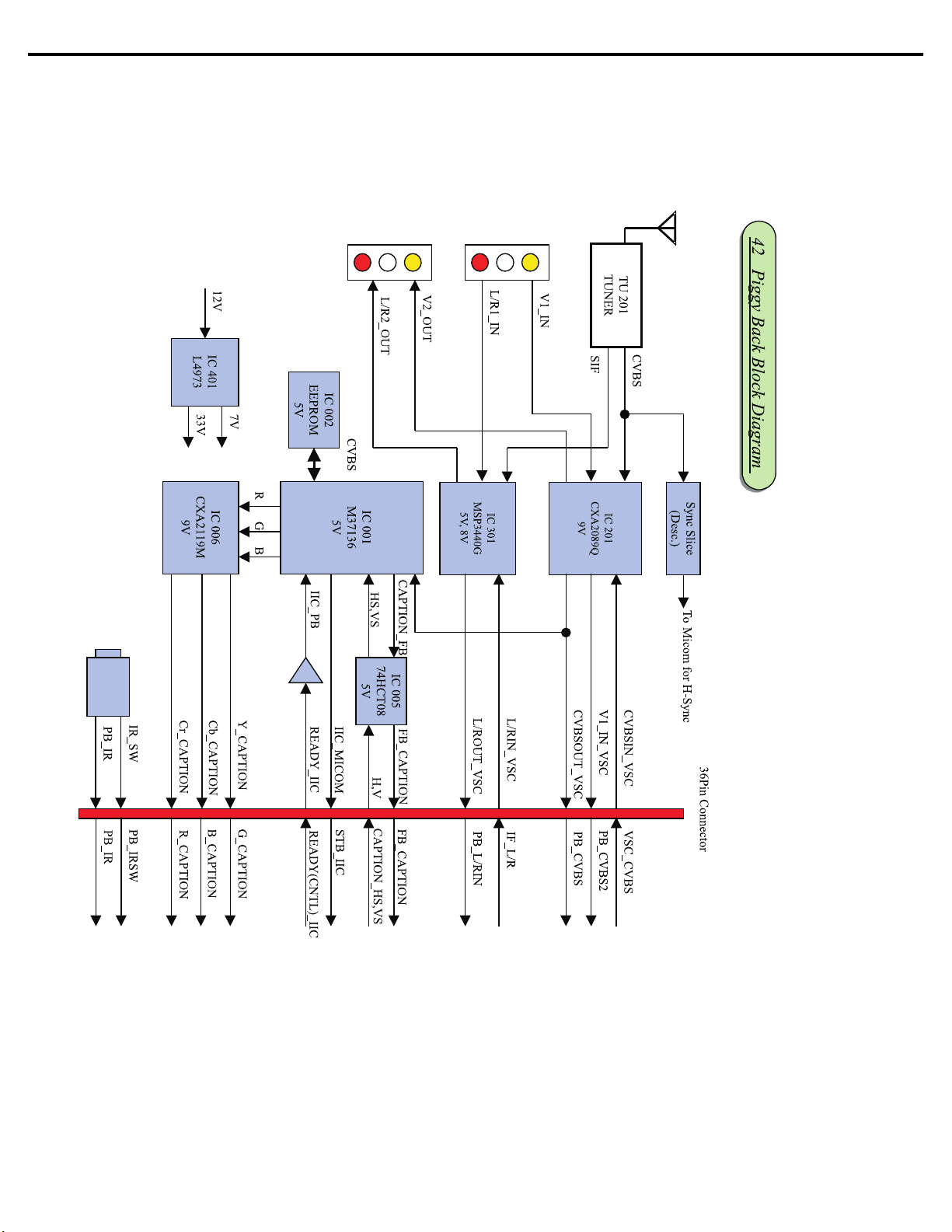

MODEL: PD-4225S

REPLACEMENT PARTS LIST

Ref. No. Part Number Description

200 6348Q-E037T PDP-NP50C2MF01 (T/A REQ)

201 6871QDH051A PWB-DSP YDRV ASSY (PD4225)

202 6871QDH052A PWB-DSP YDRV ASSY (PD4225)

203 6871QCH025A PWB-PDP-DRV-CONTROL

204 6871QYH027A PWB-YSUS ASSY (PD4225)

205 6871QRH034A PWB-XRRT ASSY (PD4225)

206 6871QZH030A PWB-ZSUS (PD4225)

210 4980V00460A SUPPORTER,VERTICAL MN-42PZ40

220 4980V00464B SUPPORTER

300 3211V00126B FRAME-ASSY FRONT

305 5230V00016A SCREEN SHIELD (FILTER)

330 3581V00038A DOOR-CONTROL

340 3110V00324B CASE-ASSY

350 4810V00826A COVER-BRACKET

400 3809V00A58E FRAME-COVER REAR

401 3301V00010S PLATE-ASSY

410 3809V00A47N COVER-BACK ASSY

510 6871VSMV64B PWB-FRONT-CONTROL

520 6871VMMP39F PWB-MAIN (PD4225)

540 6871VSMV04A PWB-PSW (PD4225)

541 5020V00666D BUTTON-POWER

550 6871VSMU98B PWB-AV (PD4225)

560 6871VSMU45A PWB-SPK (PD4225)

570 6871VSMX52B PWB-SUB VIDEO ASSY (PD4225)

580 3501V00148A BOARD-ASSY (POWER)

6850J00002A CABLE-DVI

6410VUH005A CORD-POWER AC

6710V00129A REMOTE

SPEAKER-PD4225S SPEAKER ASSEMBLY

BRACKET-SPEAKER BRACKET-SPEAKER (EXTERNAL)

Page 8

Page 9

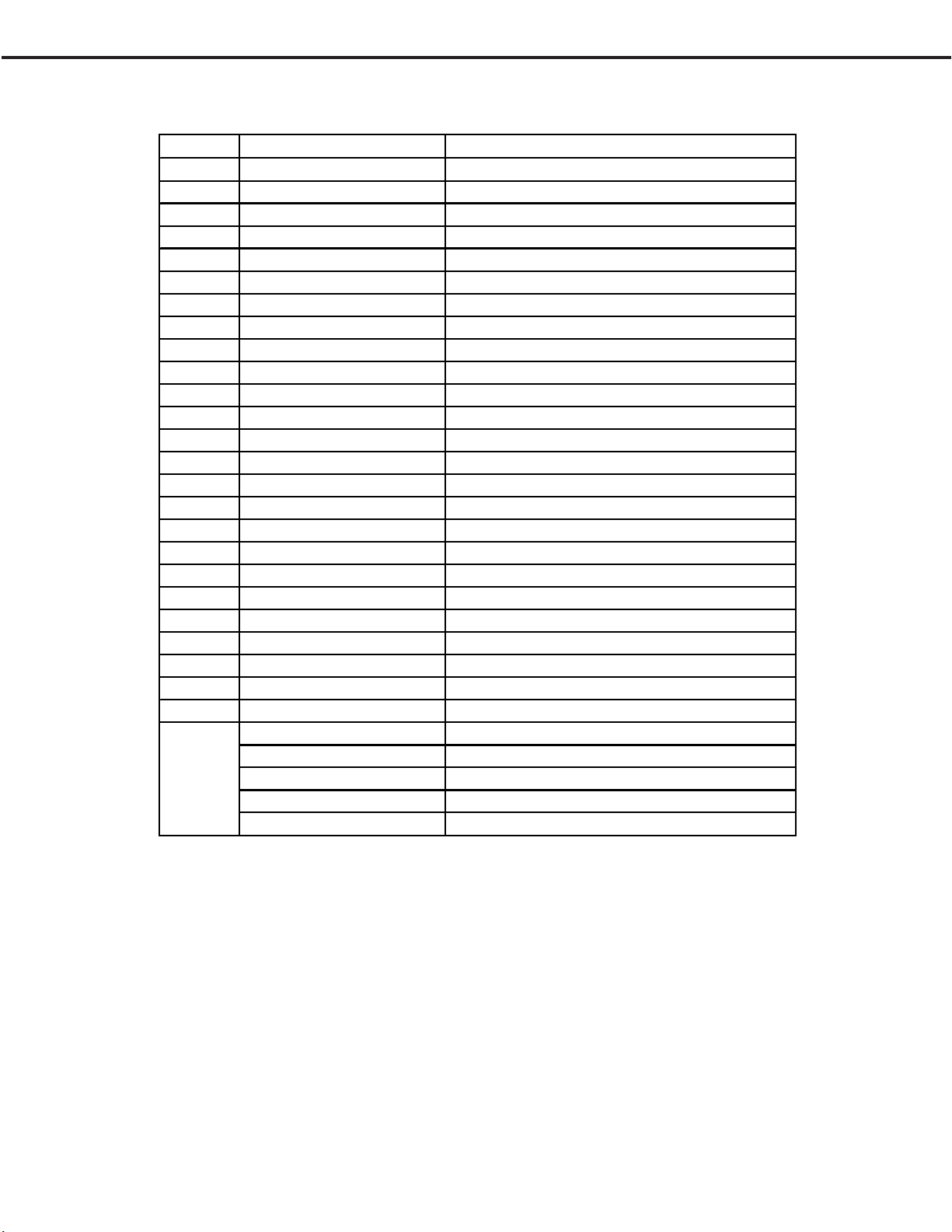

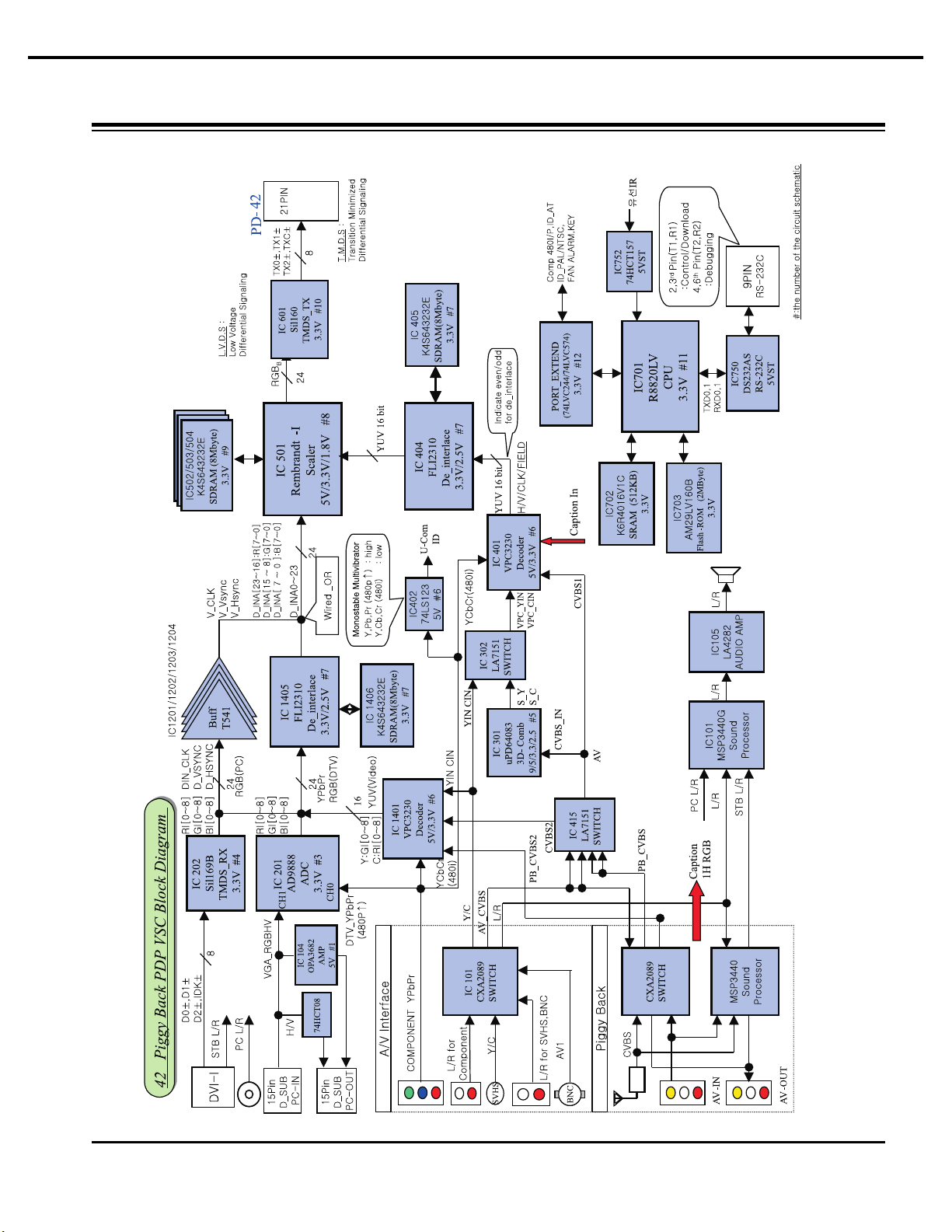

MODEL: PD-4225S

BLOCK DIAGRAMS

Page 9

Page 10

MODEL: PD-4225S

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

PD-4225S POWER PWB

Loading...

Loading...