Mitsubishi MXZ-4C36NAHZ-U1, MXZ-8C48NAHZ-U1, MXZ-5C42NAHZ-U1, MXZ-8C48NAHZ, MXZ-8C48NA Technical & Service Manual

...Page 1

TECHNICAL & SERVICE MANUAL

CONTENTS

TECHNICAL CHANGES

.........................................

2

1. SAFETY PRECAUTION

....................................

3

2. OVERVIEW OF UNITS

......................................

6

3. SPECIFICATIONS

............................................

10

4. DATA

................................................................

14

5. OUTLINES AND DIMENSIONS

......................

36

6. WIRING DIAGRAM

.........................................

40

7.

NECESSARY CONDITIONS FOR SYSTEM CONSTRUCTION

....

47

8. TROUBLESHOOTING

....................................

52

9.

PRECAUTIONS AGAINST REFRIGERANT LEAKAGE

....

140

10. DISASSEMBLY PROCEDURE

......................

141

No. OCH573

REVISED EDITION-C

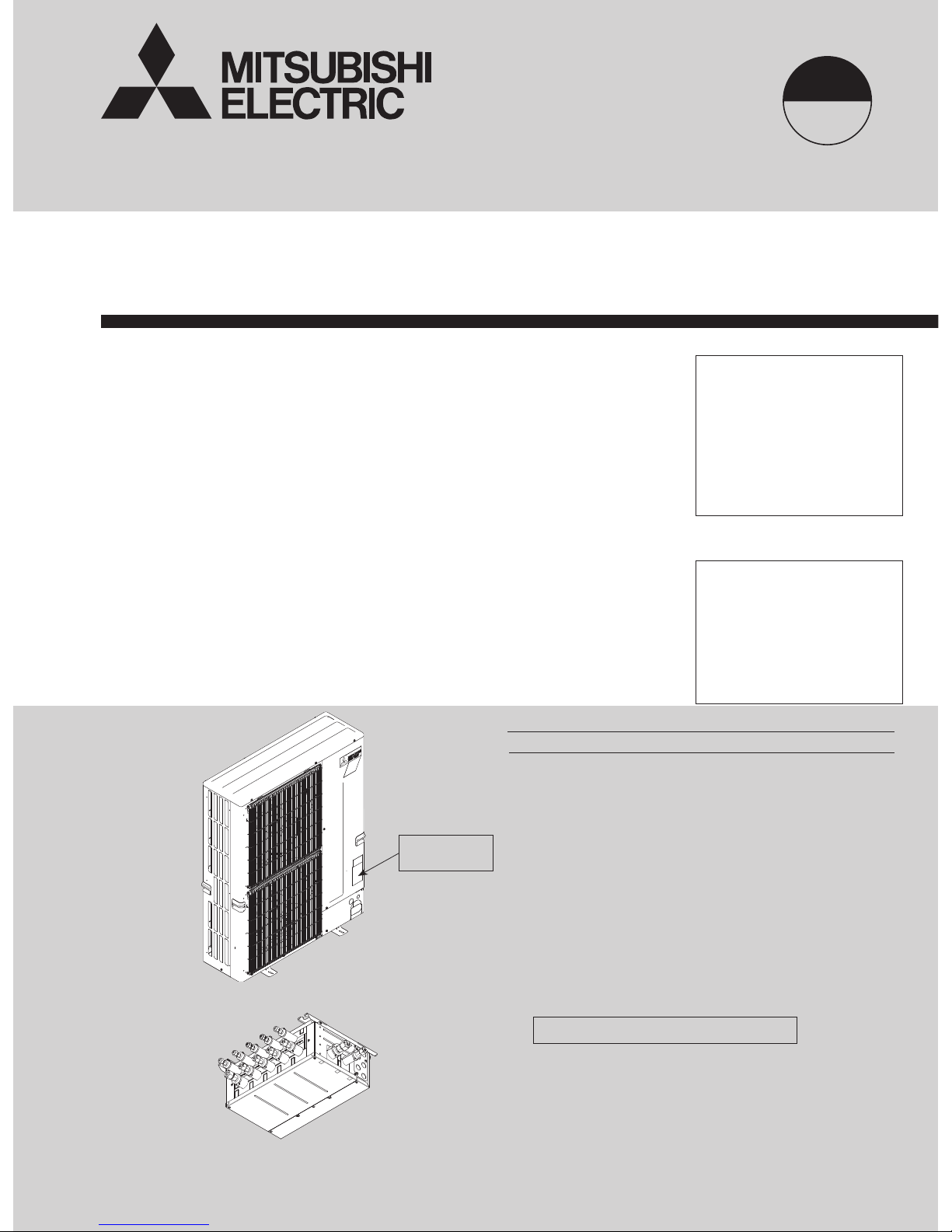

MXZ-4C36NAHZ MXZ-4C36NAHZ-U1

MXZ-5C42NAHZ MXZ-5C42NAHZ-U1

MXZ-8C48NAHZ MXZ-8C48NAHZ-U1

MXZ-8C48NA MXZ-8C48NA-U1

MXZ-8C60NA-U1

PAC-MKA50BC

PAC-MKA30BC

PAC-MKA51BC

PAC-MKA31BC

HFC

utilized

R410A

October 2016

Notes:

• This service manual

describes technical data of

outdoor unit and branch box.

As for indoor units, refer to

its service manual.

• RoHS compliant products

have <G> mark on the spec

name plate.

[Model Name]

<Outdoor unit>

MXZ-4C36NAHZ

MXZ-5C42NAHZ

MXZ-8C48NAHZ

MXZ-8C48NA

MXZ-8C60NA

<Branch box>

PAC-MKA50BC

PAC-MKA30BC

PAC-MKA51BC

PAC-MKA31BC

PARTS CATALOG (OCB573)

[Service Ref.]

OUTDOOR UNIT: MXZ-4C36NAHZ

BRANCH BOX: PAC-MKA51BC

Model name

indication

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

Revision:

• Added PAC-MKA51BC,

PAC-MKA31BC,

MXZ-4C36NAHZ-U1,

MXZ-5C42NAHZ-U1,

MXZ-8C48NAHZ-U1,

MXZ-8C48NA-U1, and

MXZ-8C60NA-U1 in REVISED

EDITION-C.

• Some descriptions have been

modified.

OCH573 REVISED EDITION-B

is void.

Page 2

2

TECHNICAL CHANGES

MXZ-4C36NAHZ MXZ-4C36NAHZ-U1

MXZ-5C42NAHZ MXZ-5C42NAHZ-U1

MXZ-8C48NAHZ MXZ-8C48NAHZ-U1

MXZ-8C48NA MXZ-8C48NA-U1

Service ref. have been changed as follows.

• The shape of piping around a stop valve (T7W E04 410) has been changed.

• The shape of valve bed has been changed.

OCH573C

Page 3

3

Cautions for units utilizing refrigerant R410A

1-1. ALWAYS OBSERVE FOR SAFETY

Use new refrigerant pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22, etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil, etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil, etc.

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil, etc.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil, etc.

Make sure that the inside and outside of refrigerant piping is clean and it has no contaminants

such as sulfur, oxides, dirt, shaving particles, etc,

which are hazard to refrigerant cycle.

In addition, use pipes with specified thickness.

The refrigerant oil applied to flare and flange

connections must be ester oil, ether oil or

alkylbenzene oil in a small amount.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the

unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the

spec labels provided with our products.

We will not be held responsible for mechanical failure,

system malfunction, unit breakdown or accidents caused

by failure to follow the instructions.

Use the specified refrigerant only.

Store the piping indoors, and both ends of the

piping sealed until just before brazing.

(Leave elbow joints, etc. in their packaging.)

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

1-2. CAUTIONS RELATED TO NEW REFRIGERANT

Before obtaining access to terminal, all supply

circuit must be disconnected.

1 SAFETY PRECAUTION

OCH573C

Page 4

4

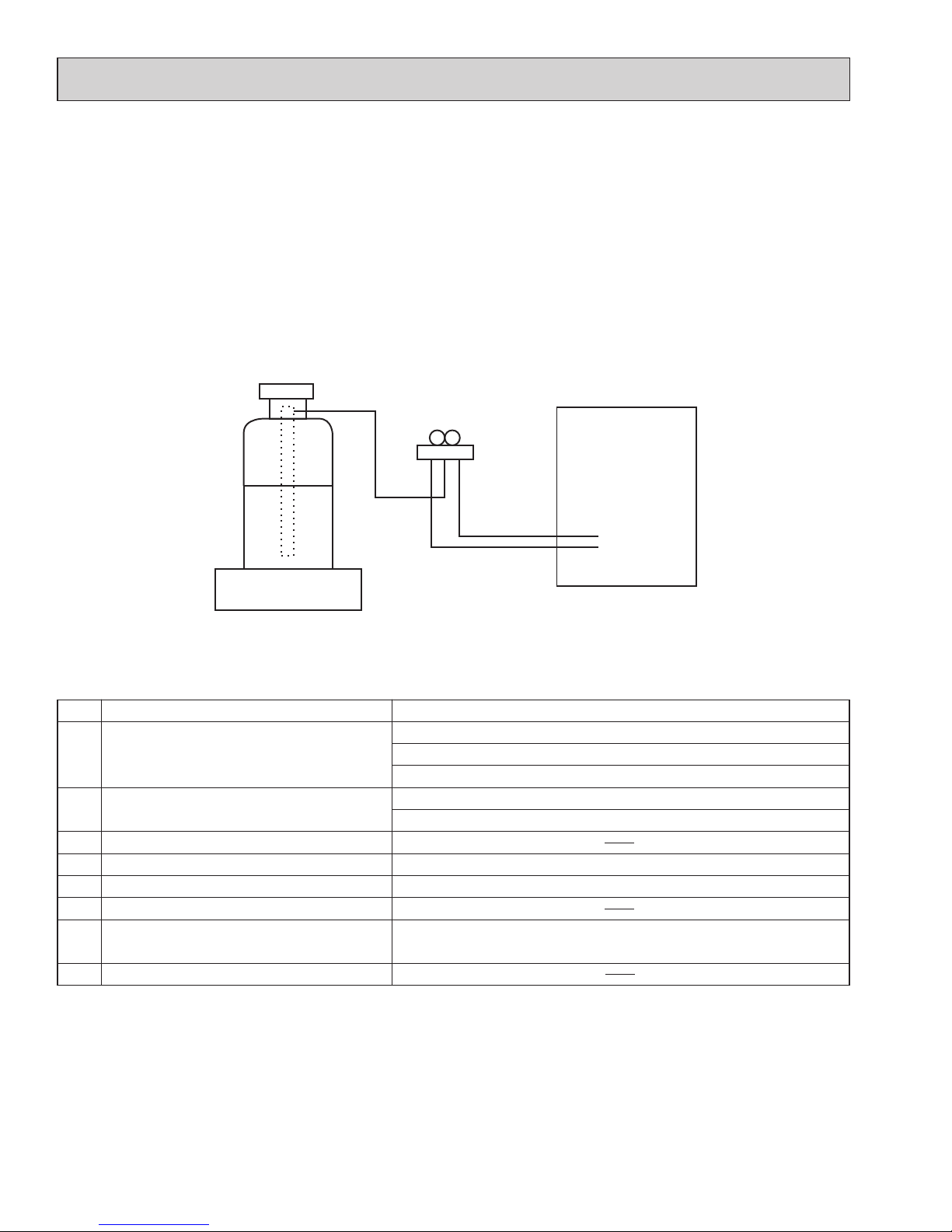

Unit

Electronic weighing scale

[3] Service tools

(1) Use the below service tools as exclusive tools for R410A refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

specifications

. (UNF1/2)

·

Use high-tension side pressure of 768.7 PSIG [5.3 MPaG] or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 738.2 PSIG [5.09MPaG] or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A ·Top of cylinder (Pink)

·Cylinder with syphon

8 Refrigerant recovery equipment

[2] Additional refrigerant charge

When charging directly from cylinder

(1) Check that cylinder for R410A on the market is a syphon type.

(2) Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

[1] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) If moisture or foreign matter might have entered the refrigerant piping during service, ensure to remove them.

OCH573C

Page 5

5

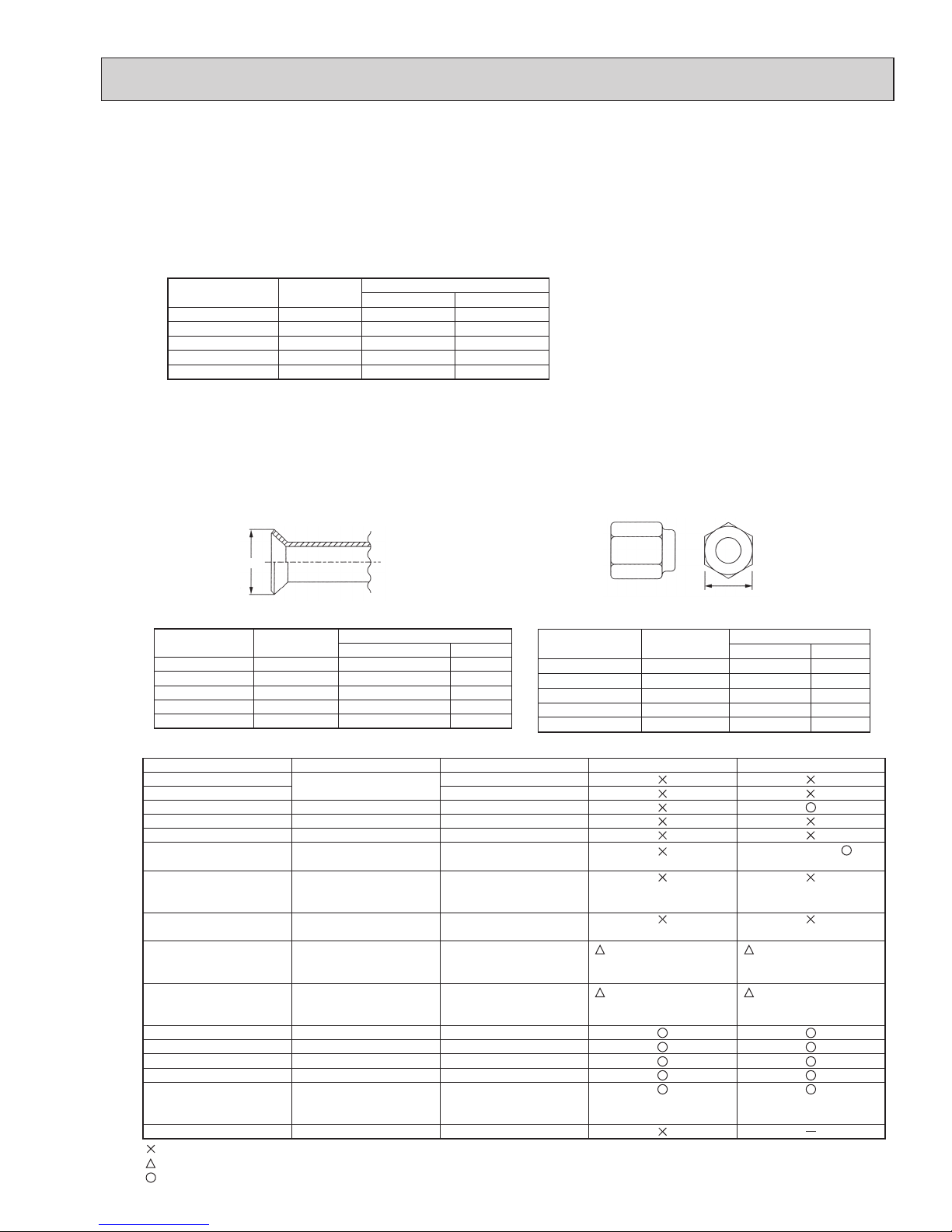

1-3. Cautions for refrigerant piping work

New refrigerant R410A is adopted for replacement inverter series. Although the refrigerant piping work for R410A is

same as for R22, exclusive tools are necessary so as not to mix with different kind of refrigerant. Furthermore as the

working pressure of R410A is 1.6 times higher than that of R22, their sizes of flared sections and flare nuts are different.

1 Thickness of pipes

Because the working pressure of R410A is higher compared to R22, be sure to use refrigerant piping with thickness

shown below. (Never use pipes of 7/256 in [0.7 mm] or below.)

2 Dimensions of flare cutting and flare nut

The component molecules in HFC refrigerant are smaller compared to conventional refrigerants. In addition to that,

R410A is a refrigerant, which has higher risk of leakage because its working pressure is higher than that of other

refrigerants. Therefore, to enhance airtightness and strength, flare cutting dimension of copper pipe for R410A has

been specified separately from the dimensions for other refrigerants as shown below. The dimension B of flare nut for

R410A also has partly been changed to increase strength as shown below. Set copper pipe correctly referring to copper pipe flaring dimensions for R410A below. For 1/2 and 5/8 inch pipes, the dimension B changes.

Use torque wrench corresponding to each dimension.

3 Tools for R410A (The following table shows whether conventional tools can be used or not.)

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

1/32 [0.8]

1/32 [0.8]

1/32 [0.8]

5/128 [1.0]

—

1/32 [0.8]

1/32 [0.8]

1/32 [0.8]

5/128 [1.0]

5/128 [1.0]

Nominal

dimensions

(in)

Diagram below: Piping diameter and thickness

Outside

diameter

(mm)

Thickness

: in [mm]

R410A R22

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

11/32-23/64 [ 9.1]

1/2-33/64 [13.2]

41/64-21/32 [16.6]

49/64-25/32 [19.7]

—

9.0

13.0

16.2

19.4

23.3

Nominal

dimensions (in)

Flare cutting dimensions

Outside

diameter (mm)

Dimension A

( )

+0

-0.4

Unit : in [mm]

R410A R22

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

43/64 [17.0]

7/8 [22.0]

1-3/64 [26.0]

1-9/64 [29.0]

17.0

22.0

24.0

27.0

36.0

Nominal

dimensions (in)

Flare nut dimensions

Outside

diameter (mm)

Dimension B

Unit: in [mm]

R410A R22

—

Gauge manifold

Charge hose

Gas leak detector

Refrigerant recovery equipment

Refrigerant cylinder

Applied oil

Safety charger

Charge valve

Vacuum pump

Flare tool

Bender

Pipe cutter

Welder and nitrogen gas cylinder

Refrigerant charging scale

Vacuum gauge or thermistor vacuum gauge and

vacuum valve

Charging cylinder

Air purge, refrigerant charge

and operation check

Gas leak check

Refrigerant recovery

Refrigerant charge

Apply to flared section

Prevent compressor malfunction

when charging refrigerant by

spraying liquid refrigerant

Prevent gas from blowing out

when detaching charge hose

Vacuum drying and air

purge

Flaring work of piping

Bend the pipes

Cut the pipes

Weld the pipes

Refrigerant charge

Check the degree of vacuum. (Vacuum

valve prevents back flow of oil and refrigerant to thermistor vacuum gauge)

Refrigerant charge

Tool exclusive for R410A

Tool exclusive for R410A

Tool for HFC refrigerant

Tool exclusive for R410A

Tool exclusive for R410A

Ester oil, ether oil and

alkylbenzene oil (minimum amount)

Tool exclusive for R410A

Tool exclusive for R410A

Tools for other refrigerants can

be used if equipped with adopter for reverse flow check

Tools for other refrigerants

can be used by adjusting

flaring dimension

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants can be used

Tools for other refrigerants

can be used

Tool exclusive for R410A

Tools and materials Use R410A tools Can R22 tools be used?

(Usable if equipped

with adopter for rever se flow)

(Usable by adjusting

flaring dimension)

Can R407C tools be used?

Ester oil, ether oil:

Alkylbenzene oil: minimum amount

(Usable if equipped

with adopter for rever se flow)

(Usable by adjusting

flaring dimension)

: Prepare a new tool. (Use the new tool as the tool exclusive for R410A.)

: Tools for other refrigerants can be used under certain conditions.

: Tools for other refrigerants can be used.

Dimension A

Dimension B

OCH573C

Page 6

6

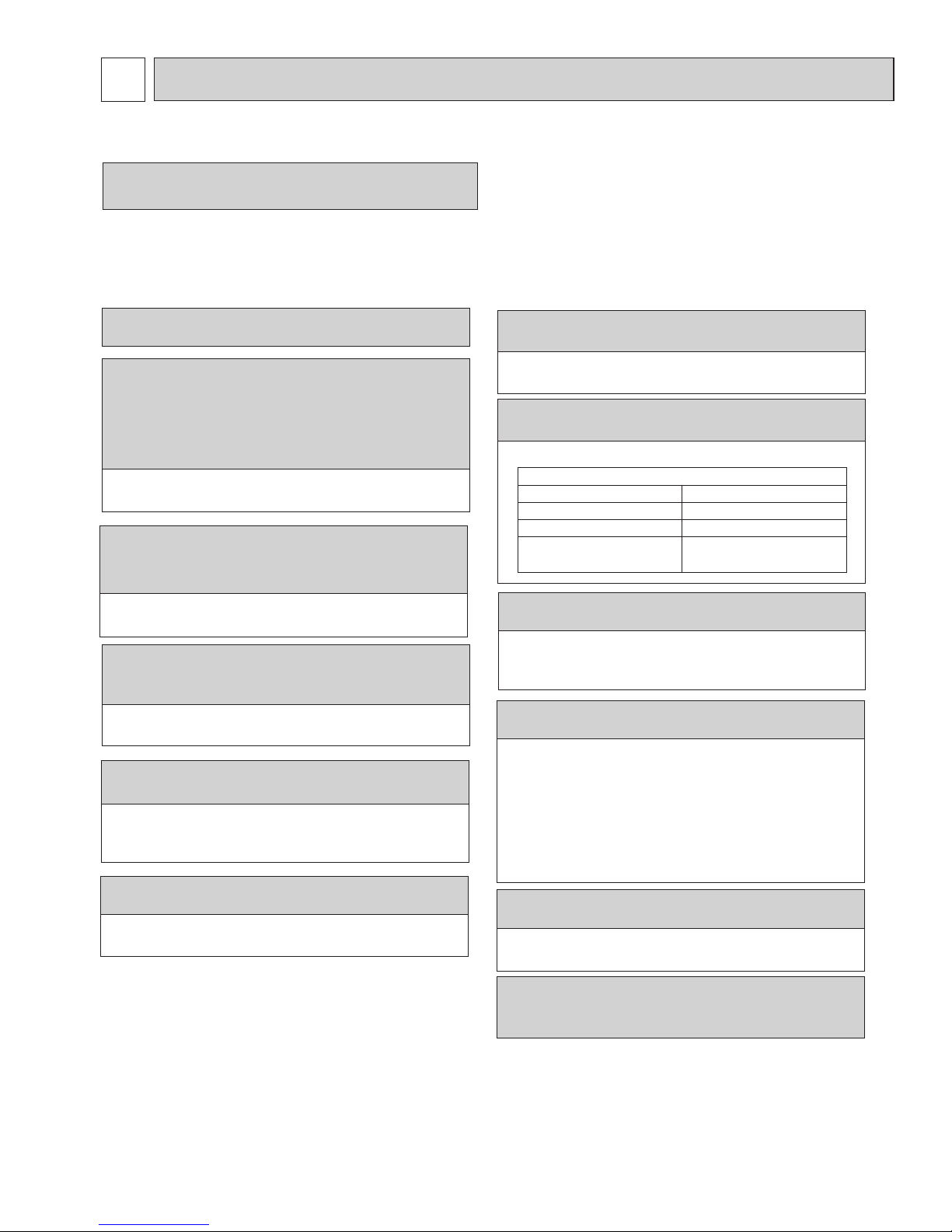

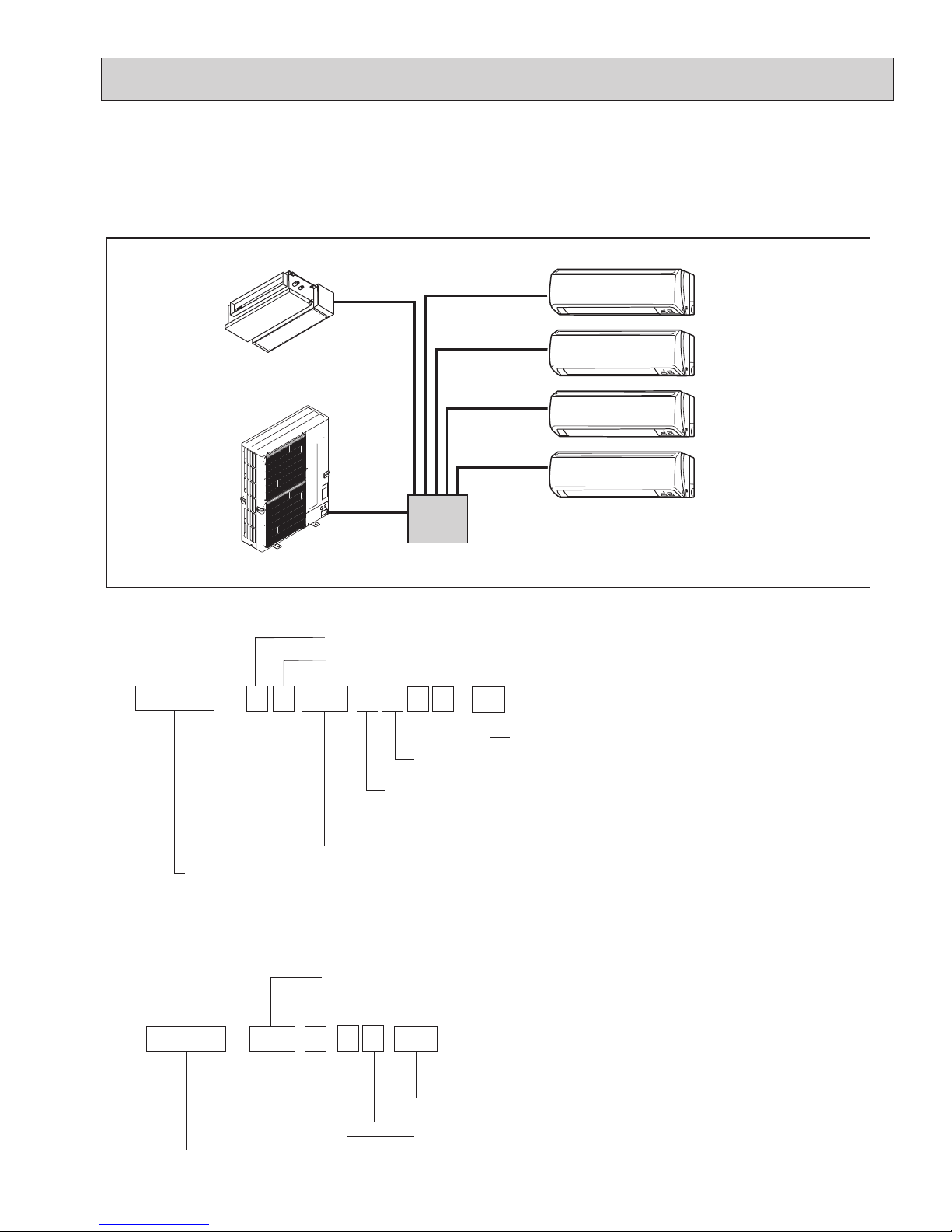

2 OVERVIEW OF UNITS

2-1. CONSTRUCTION OF SYSTEM

Outdoor unit

MXZ-4C36NAHZ(-U1) MXZ-5C42NAHZ(-U1)

MXZ-8C48NAHZ(-U1)

MXZ-8C48NA(-U1)

MXZ-8C60NA-U1

4HP 4.5HP 5HP 7HP

Rated capacity

(kBTU/h)

Cooling 36 42 48 60

Heating 45 48 54 66

Refrigerant R410A

Connectable

indoor unit

Capacity Type 06 to Type 36

Caution: The indoor unit which rated capacity exceeds

36 kBTU/ h (Type 36) can NOT be connected.

Number of units 2(*

1

) to 4 units 2(*1) to 5 units 2(*1) to 8 units 2(*1) to 8 units

Total system wide capacity 33 to 130% of outdoor

unit capacity

(12 to 46.8 kBTU/h)

29 to 130% of outdoor

unit capacity

(12 to 54.6 kBTU/h)

25 to 130% of outdoor

unit capacity

(12 to 62.4 kBTU/h)

20 to 130% of outdoor

unit capacity

(12 to 78 kBTU/h)

Connectable

branch box

Number of units

1 or 2 units

Connectable indoor unit lineups (Heat pump inverter type)

Model type Model name Capacity class [kBTU/h]

06 09 12 15 18 24 30 36

Wall

mounted

Deluxe

MSZ-FE09/12/18NA

MSZ-FH06/09/12/15NA, 18NA2

Designer

MSZ-EF09/12/15/18NA(W/B/S)

Standard

MSZ-GE06/09/12/15/18/24NA

MSZ-GL06/09/12/15/18/24NA

Ceiling

concealed

Low static pressure*

3

SEZ-KD09/12/15/18NA

Middle static pressure*

3

PEAD-A24/30/36AA5

4-way ceiling

cassette

2 by 2 type

SLZ-KA09/12/15NA

Standard

PLA-A12/18/24/30/36BA6

PLA-A12/18/24/30/36EA7*

4

Floor standing

MFZ-KA09/12/18NA

MFZ-KJ09/12/15/18NA

Multi-position*

2

MVZ-A12/18/24/30/36AA4

● Models other than MXZ-8C60NA

Number of connecting

multi-position unit

Constraints

2

Any indoor units other than multi-position models

are not connectable.

1

None

(Only the ordinal constraints apply.)

Option Optional accessories for indoor units and outdoor units are available.

2- branch pipe (joint): Optional parts

In case of using 1- branch box No need

In case of using 2- branch boxes

Model name Connection method

MSDD-50AR-E are

MSDD-50BR-E brazing

Branch box PAC-MKA50BC PAC-MKA51BC PAC-MKA30BC PAC-MKA31BC

Number of branches

(Indoor unit that can be connected)

5 branches

(MAX. 5 units)

3 branches

(MAX. 3 units)

Note: A maximum of 2 branch boxes can be connected to 1 outdoor unit.

● MXZ-8C60NA

(For each connected branch box)

Number of connecting

multi-position unit

Constraints

2

Any indoor units other than multi-position

models are not connectable.

1

·

The total system wide capacity should be 100%

or below including the MVZ-series unit.

· Only 1 SEZ or 1 PEAD can be included in the

connection.

*3 For MXZ-8C60NA; When connecting the SEZ and PEAD-series units, the total system wide capacity per 1 branch box should be 100% or

below including the SEZ and PEAD-series units. (Only if connecting to PAC-MKA50/51BC)

*4 When the system includes even 1 unit of PLA-A·EA7, the number of the maximum connectable indoor units is decreased as follows:

3 for MXZ-4C36NAHZ-U1, 4 for MXZ-5C42NAHZ-U1, and 6 for MXZ-8C48NA(HZ)-U1 and MXZ-8C60NA-U1

*

1

1 for MVZ model.

Single unit connection is possible with MVZ-series unit.

*2 When connecting a multi-position unit(s), set additional constraints as follows. For connections other than those specied below, consult your dealer.

Select a model according to the

connection method.

OCH573C

Page 7

7

Indoor unit (Ceiling concealed type)

Indoor unit

(Wall mounted type)

Outdoor unit

Branch box

2-2. SYSTEM OUTLINE

The additional connection of the branch box together with employment of the compact trunk-looking outdoor unit can successfully realize a long distance piping for large houses. Equipped with a microcomputer, the branch box can translate the

transmission signal of indoor units to achieve the optimum control.

2-2-1. System example

2-2-2. Method for identifying

■ Outdoor unit

Development No. : A, B, ···,etc.

Power supply

N: Single phase 208/230 V 60Hz

Multi type heat pump

inverter outdoor unit

Indicates equivalent to rated cooling capacity.

(kBTU/h)

Number of connectable indoor units (MAX.)

Control and refrigerant

A : New A control and R410A

Model type

M X Z

-

4 88 C N A

P A

C

-

MK

A

5 1 B C

H Z

-

U1

Sub-number

(Indispensable)

Optional parts

Model type

Branch box (Controller)

Number of branches

5 : 5 branches

3 : 3 branches

Marketable area

A: America, Canada

■ Branch box

OCH573C

Page 8

8

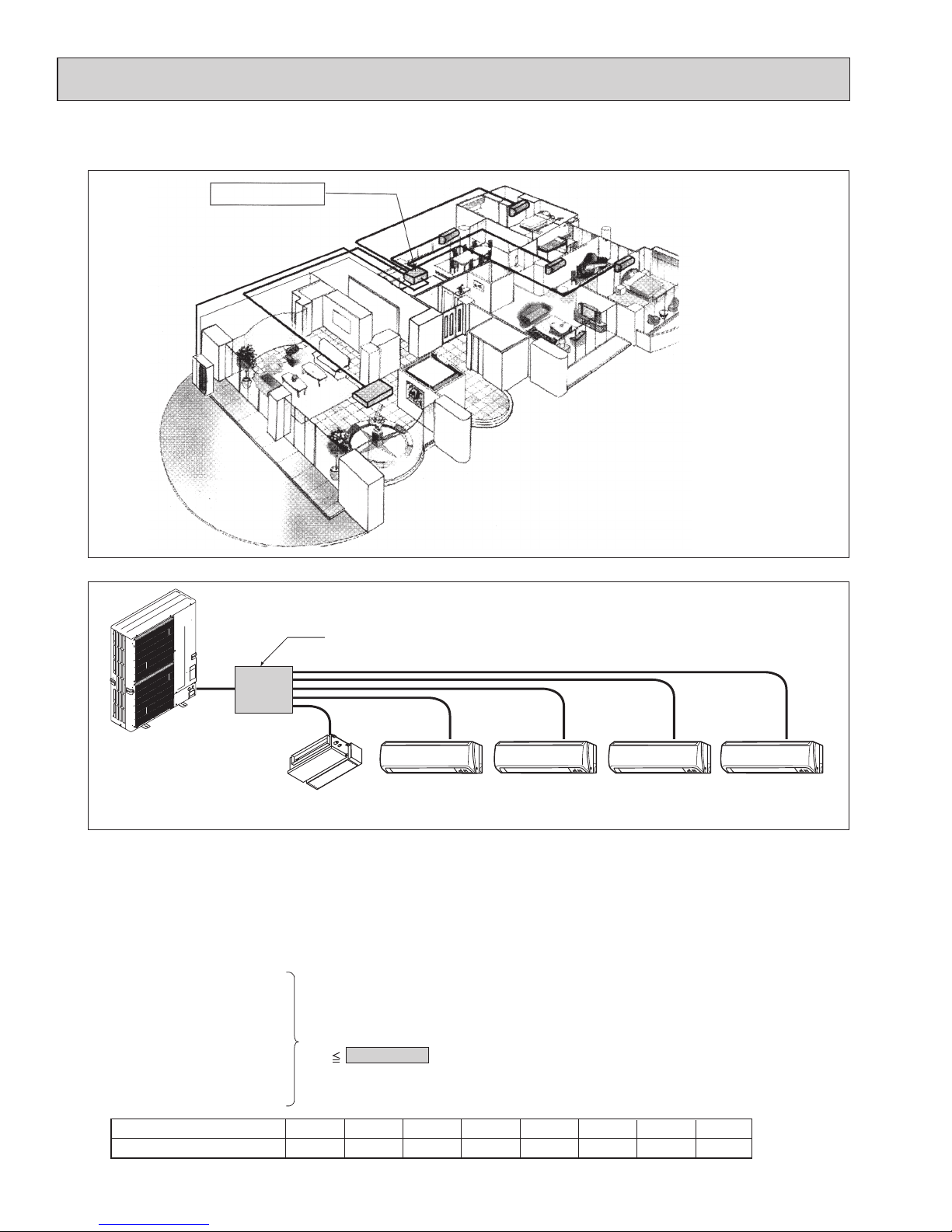

2-3. TYPICAL COMBINATION EXAMPLE

Branch box is located INSIDE of condominium

Branch box

(Inside)

Installing branch box indoors

Only 1 piping is required between the outdoor and

indoor offering a fine external view.

Branch box (5-branches type)

Outdoor unit

SEZ-18 MSZ-12 MSZ-12 MSZ-09 MSZ-09

Living

Dining Bedroom (1) Bedroom (2)

Master

bedroom

Indoor unit type (capacity class)

Rated capacity (cooling) (kBTU/h)066

09

9

12

12

15

15

24

24

18

18

30

30

36

36

■ System example of 5 indoor units

■ Verification (In case of MXZ-8C48NAHZ)

The rated capacity should be determined by observing the table below. The unit’s quantities are limited to 1(*) to 8

units. For the next step, make sure that the selected total rated capacity is in a range of 12 to 62.4 kBTU/h.

The total indoor unit capacity should be within the outdoor units. (= 48.0 kBTU/h is preferred).

Combination of excessive indoor units and an outdoor unit may reduce the capacity of each indoor unit.

The rated indoor capacity is as the table below.

*Single unit connection is possible only with MVZ model. Connect 2 or more units for models other than MVZ.

Example:

Total rated capacity

60 62.4 kBTU/h

MSZ-09 = 9

+

+

+

+

SEZ-18 = 18

MSZ-12 = 12

MSZ-12 = 12

MSZ-09 = 9

OCH573C

Page 9

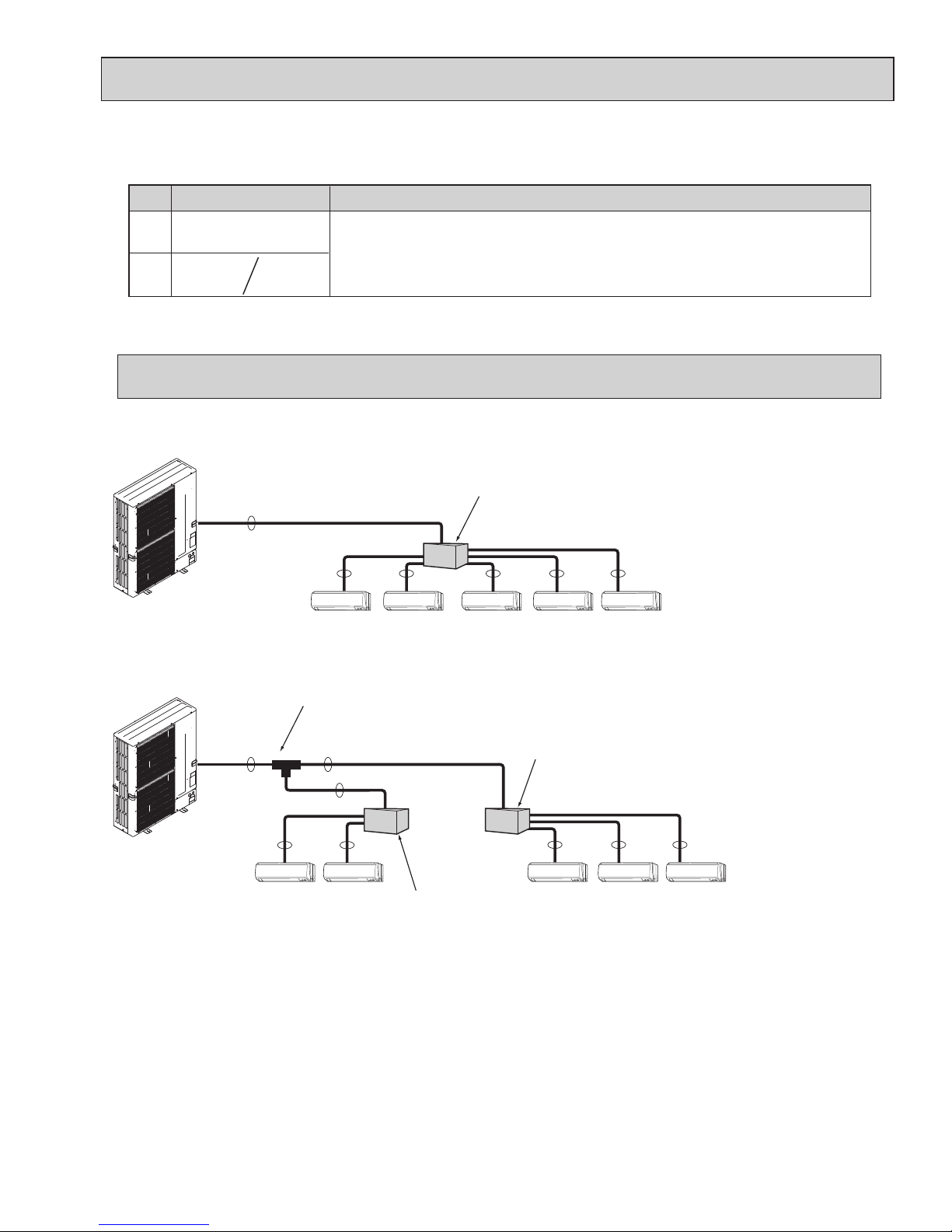

2-4. SIMPLIFIED PIPING SYSTEM

Piping connection size

Liquid

Gas

{3/8 inch

[9.52 mm]

{5/8 inch

[15.88 mm]

The piping connection size differs according to the type and capacity of indoor units.

Match the piping connection size of branch box with indoor unit.

If the piping connection size of branch box does not match the piping connection size of

indoor unit, use optional different-diameter (deformed) joints to the branch box side.

(Connect deformed joint directly to the branch box side.)

A B

{3/4 inch*

[19.05 mm]

* MXZ-8C60NA only

Flare connection employed. (No brazing!)

A

B B B B B

Branch box

■ In case of using 1-branch box

Flare connection employed (No brazing)

A

A

A

B B

B B B

2 branches pipe (joint)

: optional parts

Branch box #1

Branch box #2

■ In case of using 2-branch boxes

■ Installation procedure (2 branches pipe (joint))

Refer to the installation manuals of MSDD-50AR-E and MSDD-50BR-E.

9

OCH573C

Page 10

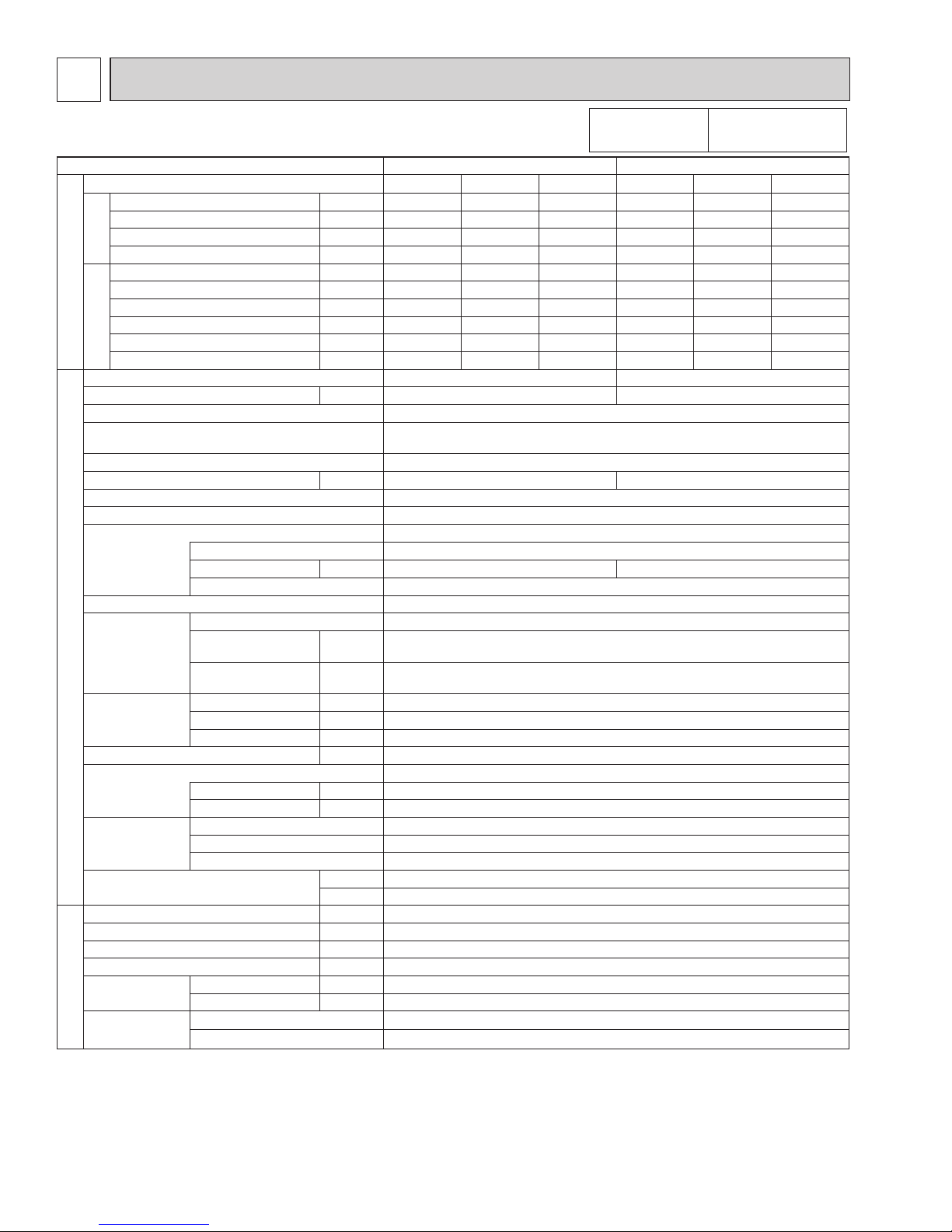

3 SPECIFICATIONS

3-1.

OUTDOOR UNIT

:

MXZ-4C36/5C42/8C48NAHZ(-U1), MXZ-8C48NA(-U1), MXZ-8C60NA-U1

Conversion formula:

kcal/h = kW o 860

BTU/h = kW o 3412

CFM = m

3

/min o 35.31

10

Service Ref. MXZ-4C36NAHZ(-U1) MXZ-5C42NAHZ(-U1)

Standard performance

Indoor type

Non-Ducted

Mix Ducted

Non-Ducted

Mix Ducted

Cooling

Capacity Rated*

1

BTU/h 36,000 36,000 36,000 42,000 42,000 42,000

Rated power consumption*

1

W 2,570 2,845 3,180 3,130 3,470 3,890

EER BTU/Wh 14.00 12.65 11.30 13.40 12.10 10.80

SEER BTU/Wh 19.1 17.5 15.8 19.0 17.0 15.0

Heating

Capacity Rated 47°F

*

1

BTU/h 45,000 45,000 45,000 48,000 48,000 48,000

Capacity Max. 17°F

*

2

BTU/h 45,000 45,000 45,000 48,000 48,000 48,000

Capacity Max. 5°F BTU/h 45,000 45,000 45,000 48,000 48,000 48,000

Rated power consumption 47°F

*

1

W 3,340 3,795 4,250 3,430 3,890 4,350

COP 47°F

*1 BTU/Wh 3.95 3.48 3.10 4.10 3.62 3.23

HSPF 4/

5

BTU/Wh 11.3/9.2 10.7/8.9 10.1/8.5 11.0/9.1 10.6/9.0 10.1/8.8

OUTDOOR UNIT

Connectable indoor units (Max.) 4 5

Max. Connectable Capacity BTU/h 46,000 54,000

Power supply 1 Phase 208/230 V, 60 Hz

Breaker Size/Max. fuse size 50 A/52 A

50 A/50 A (for the models with U1)

Min. circuit ampacity 42 A

Sound level (Cool/Heat) dB 49/ 53 50/ 54

External nish Munsell 3Y 7.8/ 1.1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Model ANB33FJSMT

Motor output kW 2.8 3.0

Starting method Inverter

Heat exchanger Plate n coil

Fan Fan (drive) × No. Propeller fan × 2

Fan motor output kW 0.06 + 0.06

0.074 + 0.074 (for the models with U1)

Airow m³/min

(CFM)

110 (3885)

Dimensions

(H × W × D)

W

in (mm)

41-11/32 (1050)

D

in (mm)

13+1 (330+25)

H

in (mm)

52-11/16 (1338)

Weight lb (kg) 276 (125)

Refrigerant R410A

Charge lb (kg) 10 lbs. 9 oz.(4.8)

Oil/Model oz (L) 73 (2.3)/Ethereal oil (FV50S)

Protection devices

High pressure protection HP switch

Compressor protection

Compressor thermo, Overcurrent detection

Fan motor protection Overheating/Voltage protection

Guaranteed operation range (cool) D.B 23 to 115°F [ D.B.−5 to 46°C ]

*

3

(heat) D.B. −13 to 70°F [D.B. −25 to 21°C ]

REFRIGERANT PIPING

Total Piping length (Max.) ft (m) 492 (150)

Farthest ft (m) 262 (80)

Max. Height difference ft (m) 164 (50)

*

4

Chargeless length ft (m) 0

Piping diameter Liquid

[inch (mm)

[3/8 (9.52)

Gas

[inch (mm)

[5/8 (15.88)

Connection

method

Indoor side Flared

Outdoor side Flared

*1

Rating conditions Cooling Indoor : D.B. 80°F/W.B. 67 °F [D.B.26.7°C/W.B. 19.4°C]

Outdoor : D.B. 95°F [D.B. 35.0°C]

Heating Indoor : D.B. 70°F [D.B. 21.1°C]

Outdoor : D.B. 47°F/W.B. 43°F [D.B. 8.3°C/W.B. 6.1°C]

*

2

Conditions Heating Indoor : D.B. 70°F [D.B. 21.1°C]

Outdoor : D.B. 17°F/W.B. 15°F [D.B. −8.3°C/W.B. −9.4°C]

*

3

D.B. 5 to 115°F [D.B. −15 to 46°C], when an optional Air Outlet Guide is installed.

*

4

131 ft [40 m], in case of installing outdoor unit lower than indoor unit.

Note: Refer to the indoor unit's service manual for the indoor units specications.

OCH573C

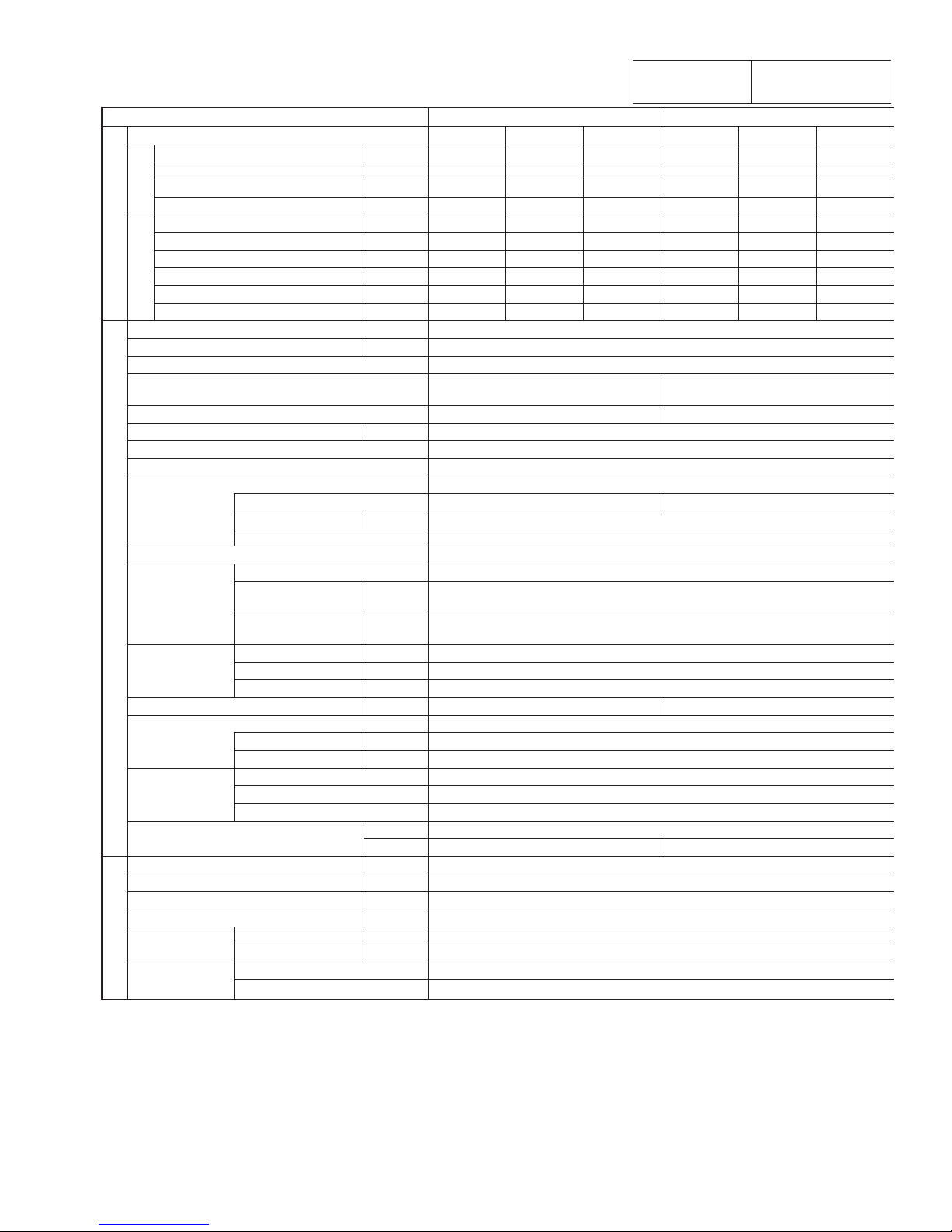

Page 11

11

Service Ref. MXZ-8C48NAHZ(-U1) MXZ-8C48NA(-U1)

Standard performance

Indoor type

Non-Ducted

Mix Ducted

Non-Ducted

Mix Ducted

Cooling

Capacity Rated*

1

BTU/h 48,000 48,000 48,000 48,000 48,000 48,000

Rated power consumption*1

W 4,000 4,465 5,050 4,000 4,465 5,050

EER BTU/Wh 12.00 10.75 9.50 12.00 10.75 9.50

SEER BTU/Wh 18.9 16.8 14.7 18.9 16.8 14.7

Heating

Capacity Rated 47°F

*

1

BTU/h 54,000 54,000 54,000 54,000 54,000 54,000

Capacity 17°F

*

2

BTU/h 54,000 54,000 54,000 36,600 36,600 36,600

Capacity 5°F BTU/h 54,000 54,000 54,000 32,400 32,400 32,400

Rated power consumption 47°F*1

W 4,220 4,605 4,990 4,220 4,605 4,990

COP 47°F

*

1

BTU/Wh 3.75 3.44 3.17 3.75 3.44 3.17

HSPF 4/

5

BTU/Wh 11.0/9.2 10.5/9.2 10.0/9.2 11.4/8.7 10.8/8.6 10.1/8.4

OUTDOOR UNIT

Connectable indoor units (Max.) 8

Max. Connectable Capacity BTU/h 62,000

Power supply 1 Phase 208/230 V, 60 Hz

Breaker Size / Max. fuse size 50 A/ 52 A

50 A/50 A (for the models with U1)

40 A/52 A

40 A/50 A (for the models with U1)

Min. circuit ampacity 42 A 37 A

Sound level (Cool/Heat) dB 51/ 54

External nish Munsell 3Y 7.8 / 1.1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Model ANB33FJSMT ANB33FNHMT

Motor output kW 3.4

Starting method Inverter

Heat exchanger Plate n coil

Fan Fan (drive) × No. Propeller fan × 2

Fan motor output kW 0.06 + 0.06

0.074 + 0.074 (for the models with U1)

Airow m³/min

(CFM)

110 (3885)

Dimensions

(H × W × D)

W inch (mm) 41-11/32 (1050)

D inch (mm) 13+1 (330+25)

H inch (mm) 52-11/16 (1338)

Weight lb (kg) 276 (125) 269 (122)

Refrigerant R410A

Charge lb (kg) 10 lbs. 9 oz. (4.8 )

Oil / Model oz (L) 73 (2.3) / Ethereal oil (FV50S)

Protection

devices

High pressure protection HP switch

Compressor protection

Compressor thermo, Over current detection

Fan motor protection Overheating/Voltage protection

Guaranteed operation range (cool) D.B. 23 to 115°F [ D.B. −5 to 46°C]

*3

(heat) D.B. −13 to 70°F [D.B. −25 to 21°C] D.B. −4 to 70°F [D.B. −20 to 21°C]

REFRIGERANT PIPING

Total Piping length (Max.) ft (m) 492 (150)

Farthest ft (m) 262 (80)

Max. Height difference ft (m) 164 (50)

*4

Chargeless length ft (m) 0

Piping diameter Liquid

[inch (mm)

[3/8 (9.52)

Gas

[inch (mm)

[ 5/8 (15.88)

Connection

method

Indoor side Flared

Outdoor side Flared

*

1

Rating conditions Cooling Indoor : D.B. 80°F/W.B. 67°F [D.B. 26.7°C/W.B. 19.4°C]

Outdoor : D.B. 95°F [D.B. 35.0°C]

Heating Indoor : D.B. 70°F [D.B. 21.1°C]

Outdoor : D.B. 47°F/W.B. 43°F [D.B. 8.3°C/W.B. 6.1°C]

*

2

Conditions Heating Indoor : D.B. 70°F [D.B. 21.1°C]

Outdoor : D.B. 17°F/W.B. 15°F [D.B. −8.3°C/W.B. −9.4°C]

*

3

D.B. 5 to 115°F [D.B. −15 to 46°C], when an optional Air Outlet Guide is installed.

*

4

131 ft [40 m], in case of installing outdoor unit lower than indoor unit.

Note: Refer to the indoor unit's service manual for the indoor units specications.

Conversion formula:

kcal/h = kW o 860

BTU/h = kW o 3412

CFM = m

3

/min o 35.31

OCH573C

Page 12

12

Service Ref. MXZ-8C60NA-U1

Standard performance

Indoor type

Non-Ducted

Mix Ducted

Cooling

Capacity Rated*

1

BTU/h 60,000 60,000 60,000

Rated power consumption*

1

W 4,800 5,525 6,250

EER BTU/Wh 12.50 11.05 9.60

SEER BTU/Wh 17.4 16.3 15.1

Heating

Capacity Rated 47°F

*

1

BTU/h 66,000 66,000 66,000

Capacity Max. 17°F

*

2

BTU/h 65,000 61,500 58,000

Capacity Max. 5°F BTU/h 57,000 49,500 42,000

Rated power consumption 47°F

*

1

W 4,870 4,810 4,750

COP 47°F

*1 BTU/Wh 3.40 3.40 3.40

HSPF 4/

5

BTU/Wh 10.50/8.50 10.25/8.25 10.00/8.00

OUTDOOR UNIT

Connectable indoor units (Max.) 8

Max. Connectable Capacity BTU/h 78,000

Power supply 1 Phase 208/230 V, 60 Hz

Breaker Size/Max. fuse size 50 A/52 A

Min. circuit ampacity 46A

Sound level (Cool/Heat) dB 58/59

External nish Munsell 3Y 7.8/ 1.1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Model ANB66FFZMT

Motor output kW 4.2

Starting method Inverter

Heat exchanger Plate n coil

Fan Fan (drive) × No. Propeller fan × 2

Fan motor output kW 0.2 + 0.2

Airow m³/min

(CFM)

138 (4879)

Dimensions

(H × W × D)

W

in (mm)

41-11/32 (1050)

D

in (mm)

13+1 (330+25)

H

in (mm)

52-11/16 (1338)

Weight lb (kg) 309 (140)

Refrigerant R410A

Charge lb (kg) 11 lbs. 4 oz.(5.1)

Oil/Model oz (L) 73 (2.3)/Ethereal oil (FV50S)

Protection devices

High pressure protection HP switch

Compressor protection

Compressor thermo, Overcurrent detection

Fan motor protection Overheating/Voltage protection

Guaranteed operation range (cool) D.B 23 to 115°F [ D.B.−5 to 46°C ]

*

3

(heat) D.B. −4 to 70°F [D.B. −20 to 21°C ]

REFRIGERANT PIPING

Total Piping length (Max.) ft (m) 492 (150)

Farthest ft (m) 262 (80)

Max. Height difference ft (m) 164 (50)

*

4

Chargeless length ft (m) 0

Piping diameter Liquid

[inch (mm)

[3/8 (9.52)

Gas

[inch (mm)

[3/4 (19.05)

Connection

method

Indoor side Flared

Outdoor side Flared

*1

Rating conditions Cooling Indoor : D.B. 80°F/W.B. 67 °F [D.B.26.7°C/W.B. 19.4°C]

Outdoor : D.B. 95°F [D.B. 35.0°C]

Heating Indoor : D.B. 70°F [D.B. 21.1°C]

Outdoor : D.B. 47°F/W.B. 43°F [D.B. 8.3°C/W.B. 6.1°C]

*

2

Conditions Heating Indoor : D.B. 70°F [D.B. 21.1°C]

Outdoor : D.B. 17°F/W.B. 15°F [D.B. −8.3°C/W.B. −9.4°C]

*

3

D.B. 5 to 115°F [D.B. −15 to 46°C], when an optional Air Outlet Guide is installed.

*

4

131 ft [40 m], in case of installing outdoor unit lower than indoor unit.

Note: Refer to the indoor unit's service manual for the indoor units specications.

Conversion formula:

kcal/h = kW o 860

BTU/h = kW o 3412

CFM = m

3

/min o 35.31

OCH573C

Page 13

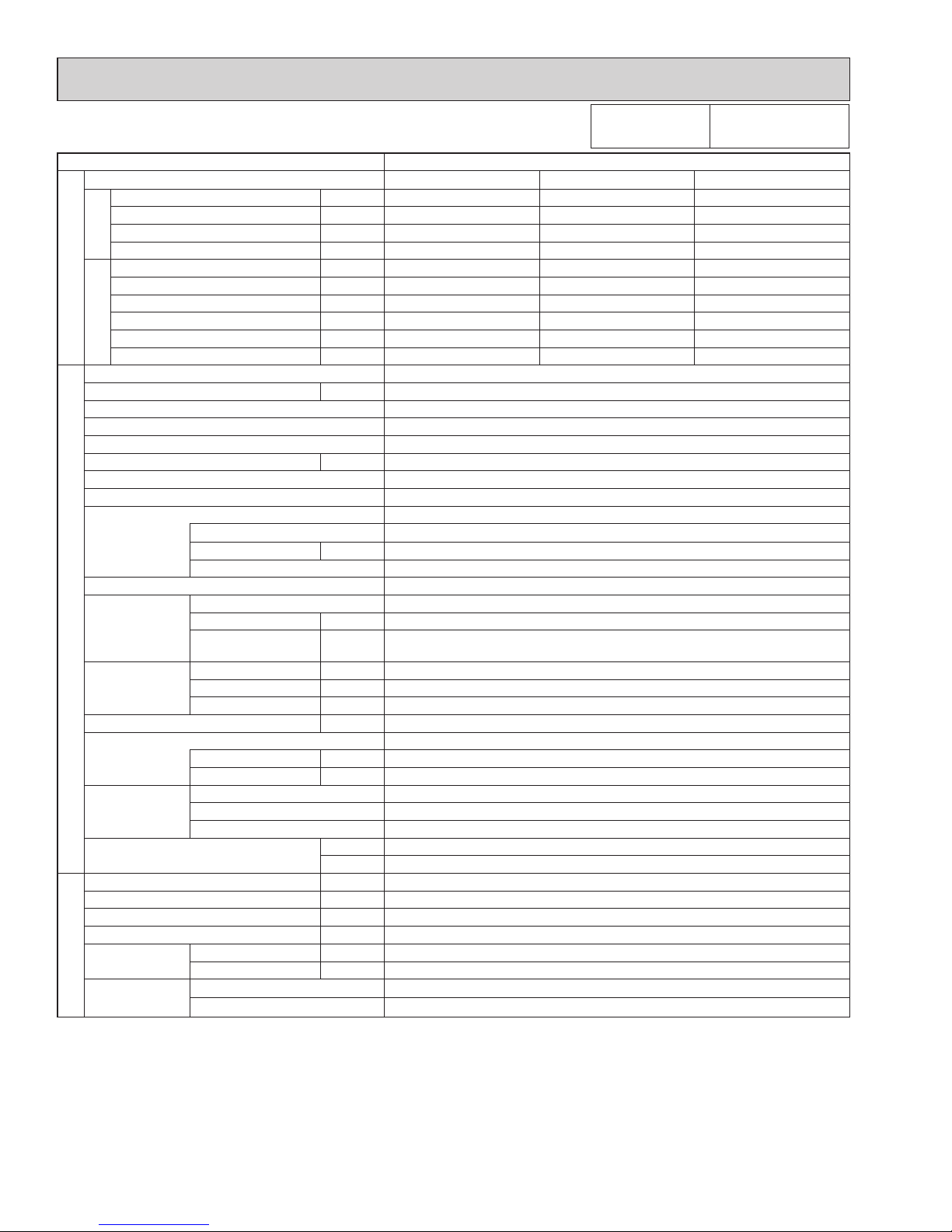

13

kW

A

inch (mm)

inch (mm)

inch (mm)

lb (kg)

inch (mm)

inch (mm)

inch (mm)

inch (mm)

Connectable number of indoor units

Power supply

Input

Running current

External finish

Dimensions

Weight

Piping

connection

(Flare)

Width

Depth

Height

Branch (indoor side)

Main (outdoor side)

Liquid

Gas

Liquid

Gas

Maximum 3

15 (6.7 )

[1/4 (6.35)

× 3 {A,B,C}

[3/8 (9.52) × 3 {A,B,C}

Maximum 5

16 (7.4)

[1/4 (6.35) × 5 {A,B,C,D,E}

[ 3/8 (9.52) × 4 {A,B,C,D},

[ 1/2 (12.7) × 1{E}

PAC-MKA50BC

PAC-MKA51BC

PAC-MKA30BC

PAC-MKA31BC

Single phase, 208/230 V, 60 Hz

0.003

0.05

Galvanized sheets

17-23/32 (450)

11-1/32 (280)

6-11/16 (170)

[3/8 (9.52)

[ 5/8 (15.88)

*

Model name

3-2. BRANCH BOX: PAC-MKA50BC PAC-MKA51BC PAC-MKA30BC PAC-MKA31BC

*The piping connection size differs according to the type and capacity of indoor units. Match the piping connection size for indoor

and branch box. If the piping connection size of branch box does not match the piping connection size of indoor units, use

optional different-diameter (deformed) joints to the branch box side. (Connect deformed joint directly to the branch box side.)

OCH573C

Page 14

14

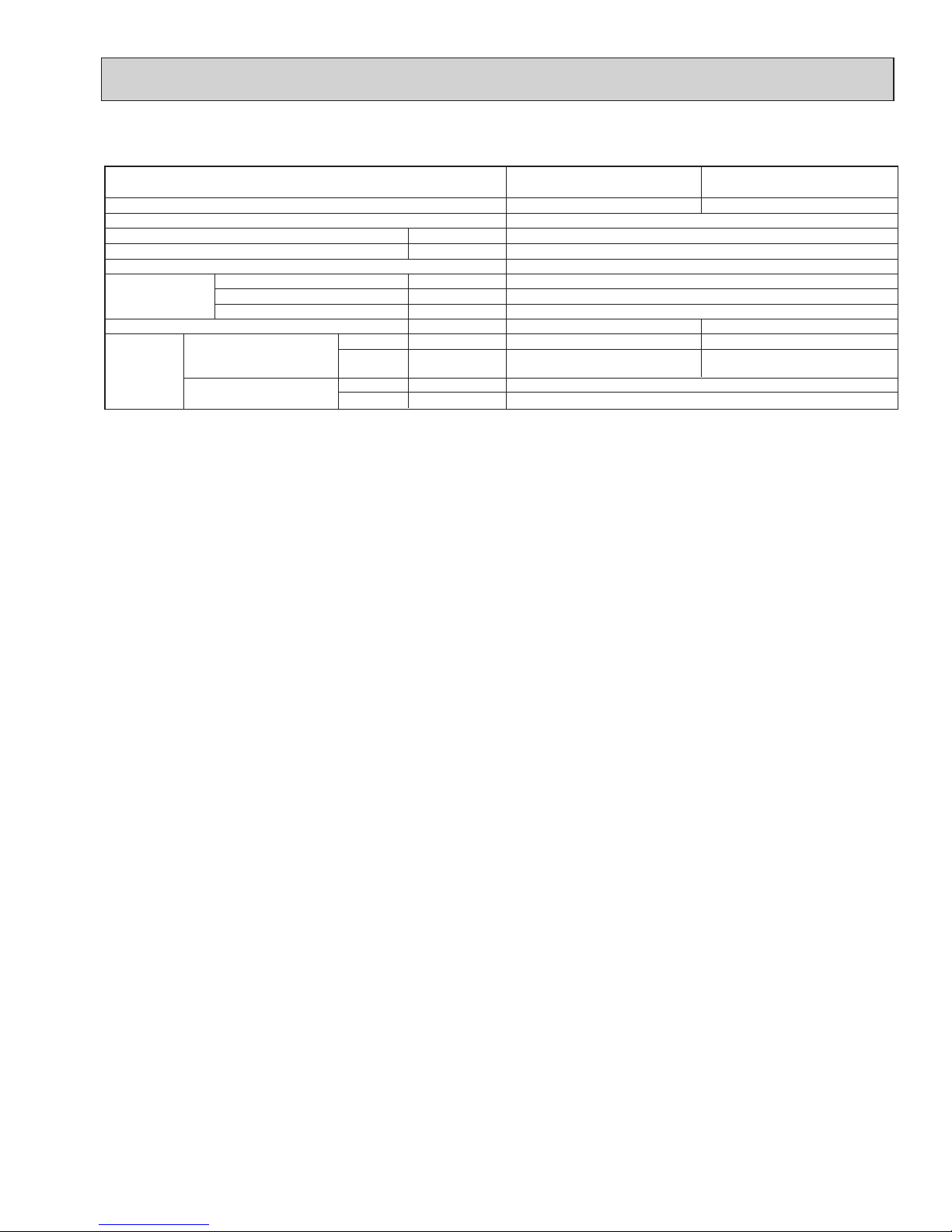

4

4-1. SELECTION OF COOLING/HEATING UNITS

DATA

How to determine the capacity when less than or equal 100% indoor model size units are connected in total:

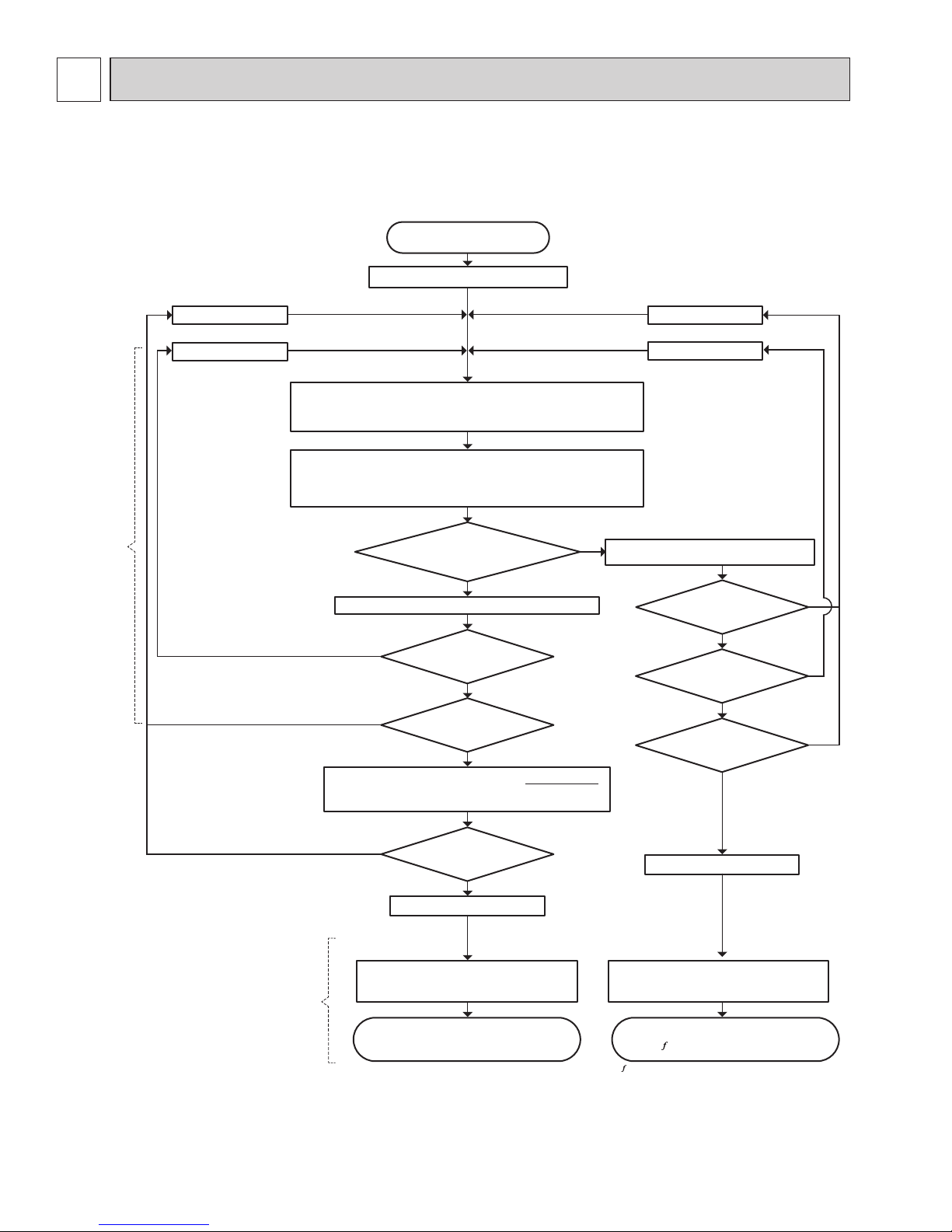

The purpose of this flow chart is to select the indoor and outdoor units. For other purposes, this flow chart is intended only for reference.

No

Yes

Temporarily select the Indoor/Outdoor Units

Reselect the outdoor units

Reselect the indoor units

Reselect the outdoor units

Reselect the indoor units

Indoor Unit

n

Total Indoor Units Capacity (CTi) = ∑ (Individual Rated Indoor Unit Capacity CTik ×

k=1

Individual Indoor Temperature Correction Coef.

α

k

) (Figure 1, 4)

Outdoor Unit

*1

Outdoor Unit Capacity (CTo) = Rated Outdoor Unit Capacity × Outdoor

Temperature Correction Coef. (Figure 2, 5) × Piping Length

Correction Coef. (Figure 3, 6) × Defrost Correction Coef. (in heating operation, Table 1)

Maximum Capacity(CT

max

) = CT

o

Yes

Completed Selecting Units

Want to change to smaller

indoor units?

Does it fulfill the load of

each room?

CT

o

≤ CT

i

L ≤ CT

o

Maximum Capacity(CT

max

) = CT

i

L ≤ CT

i

Need to select smaller

outdoor unit?

Does it fulfill the load of

each room?

Outdoor Unit Input = Rated Outdoor Unit Input ×

c

ave

Determine the load (L) and

the Indoor/Outdoor Temperature

n: Total Number of Indoor Units

k: Indoor Unit Number

Yes

No

No

No

No

Yes

No

No

Yes

Yes

Capacity

Determination

Input

Calculation

Average Indoor temp. power input Coef. (

c

ave

) Average Indoor temp. power input Coef. (

c

ave

)

c

ave

= ∑ {ck × (Mk/ ∑ Mk)}

n

k=1

n

k=1

c

ave

= ∑ {ck × (Mk/ ∑ Mk)}

n

k=1

n

k=1

(If indoor to outdoor connectable

capacity ratio is less than 100%, the

capacity correction is set as 100% )

*ck:

Outdoor unit power input coefficient of k indoor unit room temp. (Refer to 4-2.)

*Mk:

Number part of the k indoor unit model (e.g. P80 → 80)

∑ (CT

im

×

α

m

)

n

m=1

Individual Indoor Unit Capacity: CT'ik= CT

max

×

CTik ×

α

k

Outdoor Unit Input = Rated Outdoor Unit Input ×

c

ave

× (CTi )

Completed Selecting Units

(x) is the approximate correction function when less than or equal

100% model size units are input as connected.

Yes

OCH573C

Page 15

15

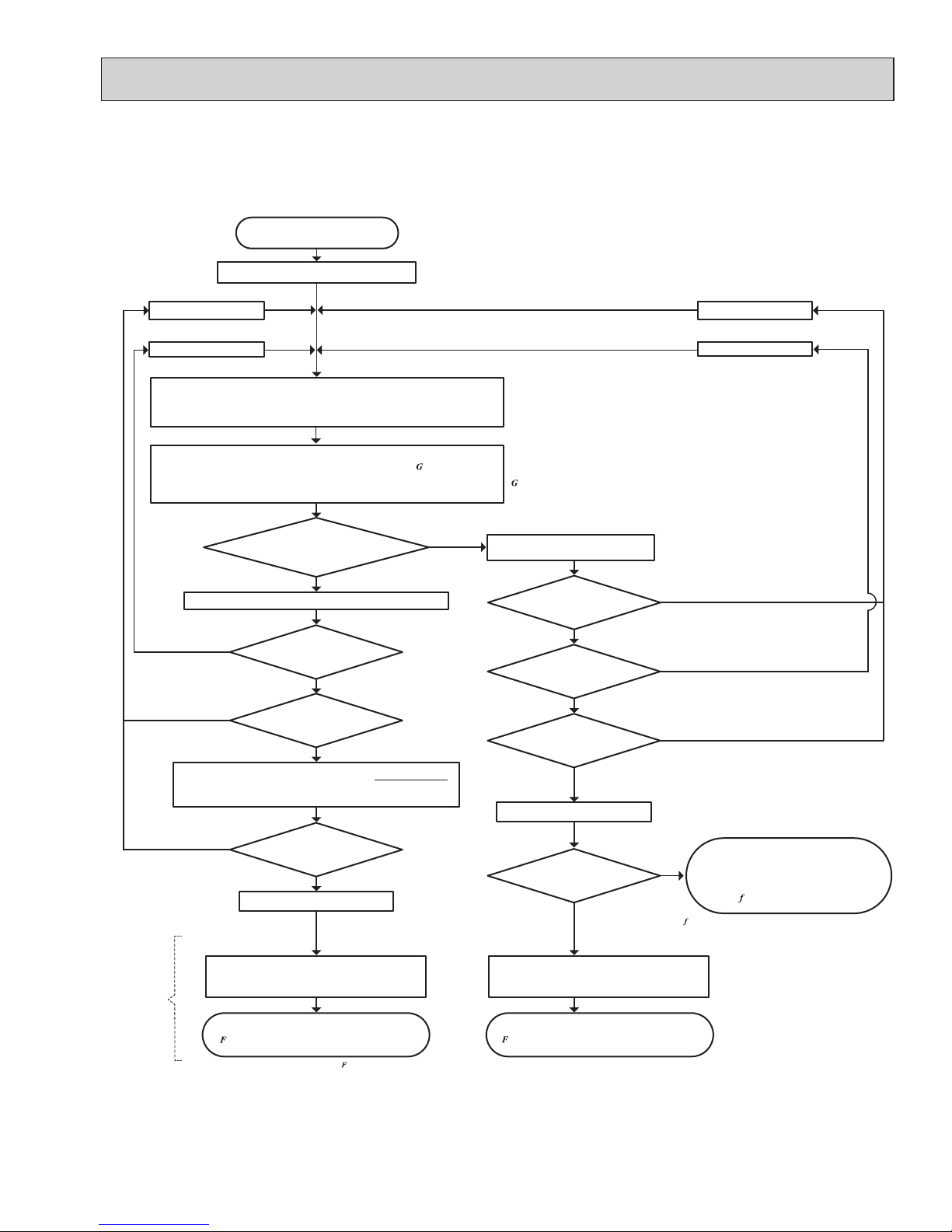

How to determine the capacity when greater than 100% indoor model size units are connected in total:

No

Yes

Temporarily select the indoor/outdoor units

Reselect the outdoor units

Reselect the indoor units

Reselect the outdoor units

Reselect the indoor units

Indoor Unit

n

Total Indoor Units Capacity (CTi) = ∑ (Individual Rated Indoor Unit Capacity CT

ik

×

k=1

Individual Indoor Temperature Correction Coef.

α

k

) (Figure 1, 4)

Outdoor Unit

*1

Maximum Capacity(CT

max

) = CT

o

Yes

Want to change to smaller

indoor units?

Does it fulfill the load of

each room?

CT

o

≤ CT

i

L ≤ CT

o

Maximum Capacity(CT

max

) = CT

i

L ≤ CT

i

Need to select smaller

outdoor unit?

Does it fulfill the load of

each room?

Rated Outdoor Unit Capacity

< Total Indoor Units Capacity

Outdoor Unit Input

= Rated Outdoor Unit Input ×

Outdoor Temperature

Correction

Coef.

× (CT

i

)

Determine the load (L) and

the Indoor/Outdoor Temperature

n: Total Number of Indoor Units

k: Indoor Unit Number

Yes

Yes

No

No

No

No

Yes

No

No

No

Yes

Yes

Yes

Average Indoor temp. power input Coef. (

c

ave

)

= ∑ {c

k

× (Mk/ ∑ Mk)}

n

k=1

n

k=1

The purpose of this flow chart is to select the indoor and outdoor units. For other purposes, this flow chart is intended only for reference.

*ck:

Outdoor unit power input coefficient of k indoor unit room temp. (Refer to 4-2.)

*Mk:

Number part of the k indoor unit model (e.g. P80 → 80)

Average Indoor temp. power input Coef. (

c

ave

)

c

ave

= ∑ {ck × (Mk/ ∑ Mk)}

n

k=1

n

k=1

Outdoor Unit Input =Rated Outdoor Unit Input ×

c

ave

Outdoor Unit Input = Rated Outdoor Unit Input ×

c

ave

× (CTi )

∑ (CT

im

×

α

m

)

n

m=1

Individual Indoor Unit Capacity: CT'ik= CT

max

×

CTik ×

α

k

Completed Selecting Units

Completed Selecting Units

(x) is the approximate correction function when greater

than 100% model size units are connected.

Outdoor Unit Capacity (CTo) = Rated Outdoor Unit Capacity × ( )

× Outdoor Temperature Correction Coef. (Figure 2, 5)

× Piping Length Correction Coef. (Figure 3, 6) × Defrost Correction Coef. (in heating, Table 1)

(x) is the approximate correction function when greater than 100%

model size units are input as connected.

(x) is the approximate correction function when less than or equal

100% model size units are input as connected.

CT

i

× (CTi )

Input

Calculation

OCH573C

Page 16

16

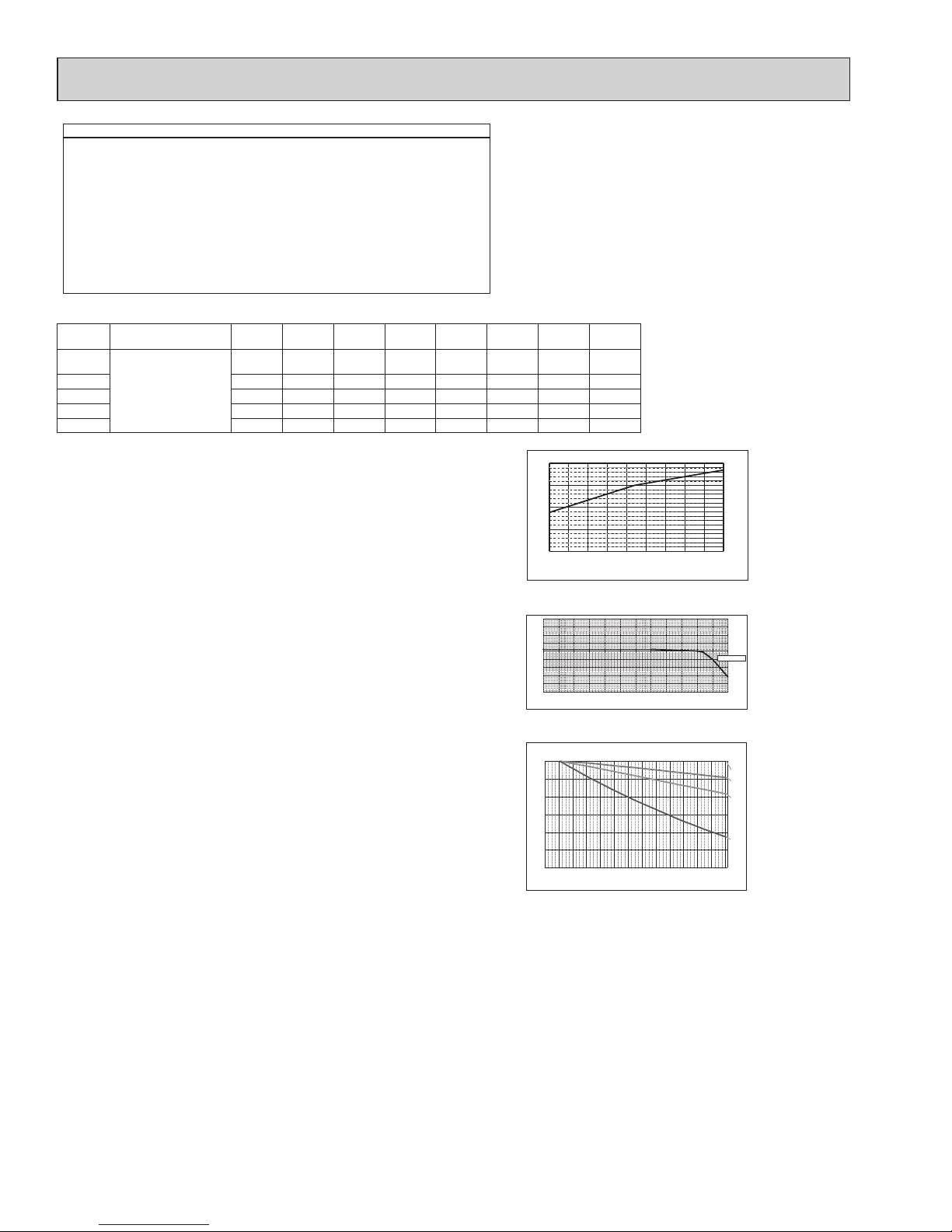

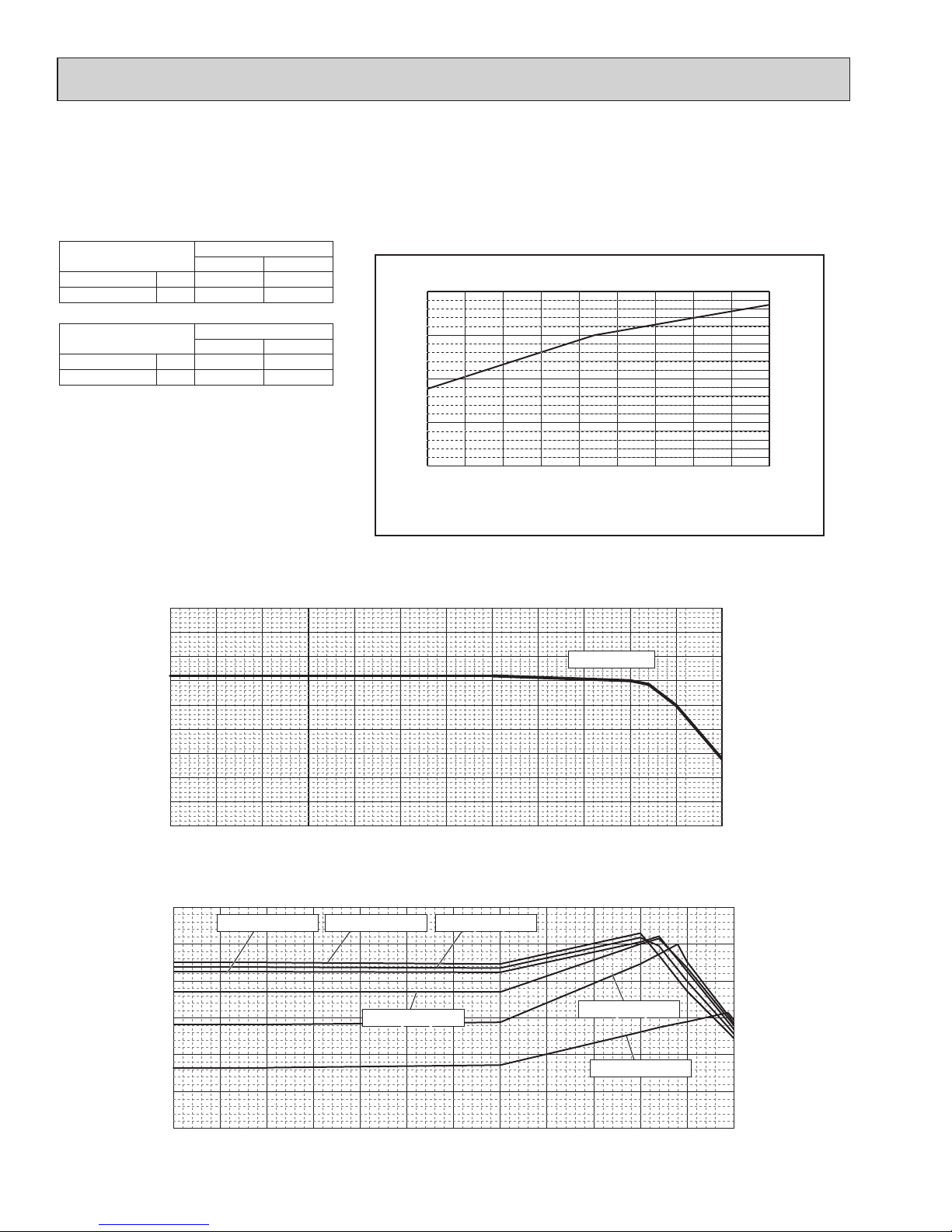

<Cooling>

Design Condition

Outdoor Design Dry Bulb Temperature 98.6ºF (37.0ºC)

Total Cooling Load 29.6 kBTU/h

Room1

Indoor Design Dry Bulb Temperature 80.6ºF (27.0ºC)

Indoor Design Wet Bulb Temperature 68.0ºF (20.0ºC)

Cooling Load 13.6 kBTU/h

Room2

Indoor Design Dry Bulb Temperature 75.2ºF (24.0ºC)

Indoor Design Wet Bulb Temperature 66.2ºF (19.0ºC)

Cooling Load 16.0 kBTU/h

<Other>

Indoor/Outdoor Equivalent Piping Length 250 ft

1. Cooling Calculation

(1) Temporary Selection of Indoor Units

Room1

MSZ-FH15

15.0 kBTU/h (Rated)

Room2

MSZ-FH18

17.2 kBTU/h (Rated)

(2) Total Indoor Units Capacity

15 + 18 = 33

(3) Selection of Outdoor Unit

The P36 outdoor unit is selected as total indoor units capacity is P33

MXZ-4C36

36.0 kBTU/h

(4) Total Indoor Units Capacity Correction Calculation

Room1

Indoor Design Wet Bulb Temperature Correction (68.0ºF)

1.02 (Refer to Figure 1)

Figure 1

Indoor unit temperature correction

To be used to correct indoor unit only

Figure 2 Outdoor unit temperature correction

To be used to correct outdoor unit only

Figure 3

Correction of refrigerant piping length

Room2

Indoor Design Wet Bulb Temperature Correction (66.2ºF)

0.95 (Refer to Figure 1)

CTi = Σ (Indoor Unit Rating × Indoor Design Temperature Correction)

= 15.0 × 1.02 + 17.2 × 0.95

= 31.6 kBTU/h

(5) Outdoor Unit Correction Calculation

Outdoor Design Dry Bulb Temperature Correction (98.6ºF)

0.98 (Refer to Figure 2)

Piping Length Correction (250 ft)

0.93 (Refer to Figure 3)

Total Outdoor Unit Capacity (CTo)

Total Indoor Units Capacity (CTi)

CTo = Outdoor Rating × Outdoor Design Temperature Correction × Piping Length Correction

= 36.0 × 0.98 × 0.93

= 32.8 kBTU/h

(6) Determination of Maximum System Capacity

Comparison of Capacity between Total Indoor Units Capacity (CTi) and Total Outdoor Unit Capacity (CTo)

CTi = 31.6 < CTo = 32.8, thus, select CTi.

CTx = CTi = 31.6 kBTU/h

(7) Comparison with Essential Load

Against the essential load 29.6 kBTU/h, the maximum system capacity is 31.6 kBTU/h: Proper outdoor units have been selected.

(8) Calculation of Maximum Indoor Unit Capacity of Each Room

CTx = CTi, thus, calculate by the calculation below

Room1

Indoor Unit Rating × Indoor Design Temperature Correction

= 15.0 × 1.02

= 15.3 kBTU/h

OK: fulfills the load 13.6 kBTU/h

Room2

Indoor Unit Rating × Indoor Design Temperature Correction

= 17.2 × 0.95

= 16.3 kBTU/h OK: fulfills the load 16.0 kBTU/h

Go on to the heating trial calculation since the selected units fulfill the cooling loads of Room 1, 2.

Indoor

Temperature

Ratio of cooling capacity

Indoor Temperature

[°F W.B.]

[°C W.B.]

-15 -10

-5 0 5 10 15 20 25 30 35 40 45

5 14

23 32 41 50 59 68 77 86 95 104 113

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

Ratio of cooling capacity

Outdoor Temperature

[°C D.B.]

[°F W.B.]

67.0°F(19.4°C) W.B

15 16 17 18 19 20 21 22 23 24

59 60.8 62.6 64.4 66.2 68 69.8 71.6 73.4 75.2

0.4

0.6

0.8

1.0

1.2

0 20 40 60 80 100 120 140 160 180 200 220 240 260

0.70

0.75

0.80

0.85

0.90

0.95

1.00

18 [kBTU/h]

27 [kBTU/h]

36 [kBTU/h]

Capacity ratio

Piping equivalent length (ft)

Total capacity of indoor unit

46.8 [kBTU/h]

Capacity of indoor unit

Model Number for indoor

unit

Model 06Model 09Model 12Model 15Model 18Model 24Model 30Model

36

M series Model Capacity [KBtu/h]

6.0 9.0 12.0

14.0*

1

15.0*

2

17.0*3

17.2*

4

22.5 ─ ─

P series ─ ─ 12.0 ─ 18.0 24.0 30.0 36.0

SEZ ─ 8.1 11.5 14.1 17.2 ─ ─ ─

SLZ ─ 8.4 11.1 15.0 ─ ─ ─ ─

MVZ ─ ─ 12.0 ─ 18.0 24.0 30.0 36.0

*1 For MSZ-GE/GL15NA

*

2

For the models other than

*1 above

*3 For MFZ-KA/KJ18NA

*

4

For the models other than

*3 above

OCH573C

Page 17

17

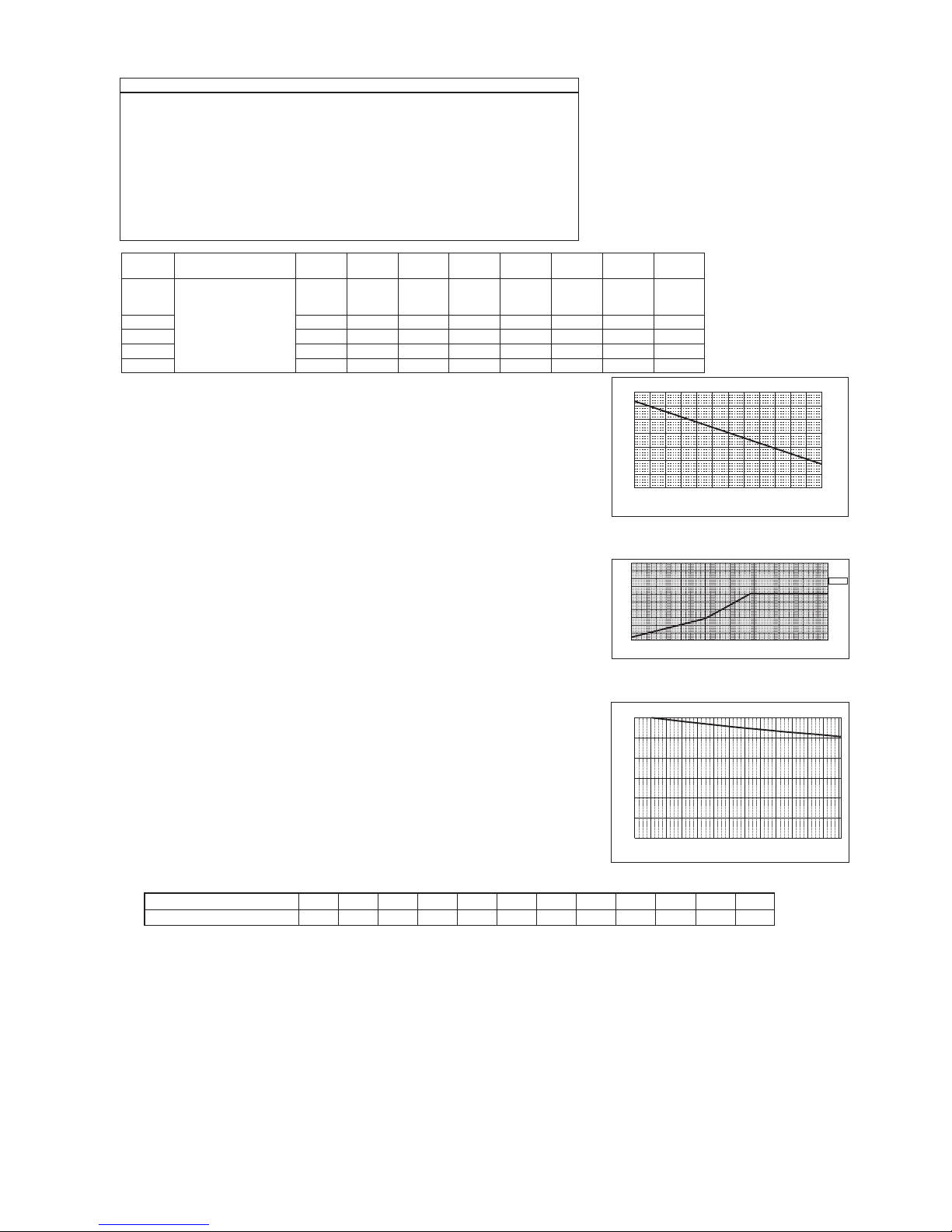

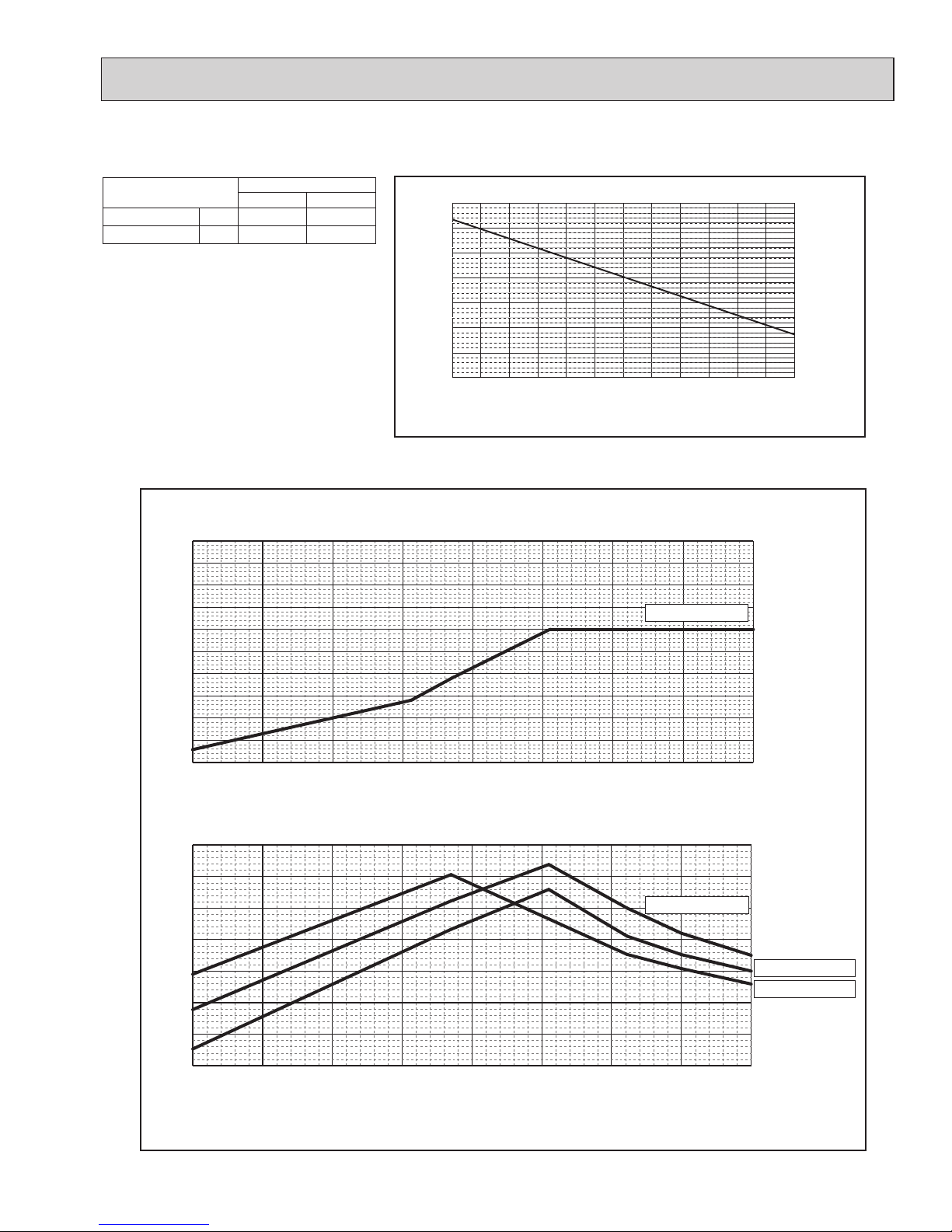

<Hea ting>

Design Condition

Outdoor Design W et Bulb Temperature 35.6ºF (2.0ºC)

Total Heating Load 34.4 kBTU/h

Room1

Indoor Design Dry Bulb Temperature 69.8ºF (21.0ºC)

Heating Load

16.3 kBTU/h

Room2

Indoor Design Dry Bulb Temperature 73.4ºF (23.0ºC)

Heating Load

18.1 kBTU/h

<Other>

Indoor/Outdoor Equivalent Piping Length 230 ft

2. Hea ting Calcula tion

(1) Temporary Selection of Indoor Units

Room1

MSZ-FH15 18.0 kBUT/h (Rated)

20.3 kBUT/h (Rated)

Room2

MSZ-FH18

(2) Total Indoor Units Capacity

15 + 18 = 33

(3) Selection of Outdoor Unit

The P36 outdoor unit is selected as total indoor units capacity is P33

MXZ-4C36 45.0 kBUT/h

(4) Total Indoor Units Capacity Correction Calculation

Room1

Indoor Design Dry Bulb Temperature Correction (69.8ºF)

1.00 (Refer to Figure 4)

Room2

Indoor Design Dry Bulb Temperature Correction (73.4ºF)

0.92 (Refer to Figure 4)

CTi = Σ (Indoor Unit Rating × Indoor Design Temperature Correction)

= 18.0 × 1.00 + 20.3 × 0.92

= 36.7 kBTU/h

(5) Outdoor Unit Correction Calculation

Outdoor Design Wet Bulb Temperature Correction (35.6ºF)

1.0 (Refer to Figure 5)

Piping Length Correction (230 ft)

Defrost Correction

0.96 (Refer to Figure 6)

0.89 (Refer to Table 1)

Total Outdoor Unit Capacity (CTo)

Total Indoor Units Capacity (CTi)

CTo = Outdoor Unit Rating × Outdoor Design Temperature Correction × Piping Length

Correction × Defrost Correction

= 45.0 × 1.0 × 0.96 × 0.89

= 38.4 kBTU/h

(6) Determination of Maximum System Capacity

Comparison of Capacity between Total Indoor Units Capacity (CTi) and Total Outdoor Unit Capacity (CTo)

CTi = 36.7 < CTo = 38.4, thus, select CTi.

CTx = CTi = 36.7 kBTU/h

(7) Comparison with Essential Load

Against the essential load 34.4 kBTU/h, the maximum system capacity is 36.7 kBTU/h: Proper outdoor units have been selected.

(8) Calculation of Maximum Indoor Unit Capacity of Each Room

CTx = CTi, thus, calculate by the calculation below

Room1

Maximum Capacity × Room1 Capacity after the Temperature Correction/(Room1,2 Total Capacity after the Temperature Correction

= 36.7 × (18.0 × 1.00) / (18.0 × 1.00 + 20.3 × 0.92)

= 18.0 kBTU/h OK: fulfills the load 16.3 kBTU/h

Room2

Maximum Capacity × Room1 Capacity after the Temperature Correction/(Room1,2 Total Capacity after the Temperature Correction

= 36.7 × (20.3 × 0.92) / (18.0 × 1.00 + 20.3 × 0.92)

= 18.7 kBTU/h OK: fulfills the load 18.1 kBTU/h

Completed selecting units since the selected units fulfill the heating loads of Room 1, 2.

Figure 4 Indoor unit temperature correction

To be used to correct indoor unit only

Figure 5 Outdoor unit temperature correction

To be used to correct outdoor unit only

Figure 6 Correction of refrigerant piping length

-4 5 14 23 32 41 50 59

-25

-20 -15 -10 -5 0 5 10 15

0.4

0.5

0.6

0.7

0.8

0.9

0.8

0.5

0.6

0.7

1.0

1.1

1.2

1.0

1.1

1.3

1.4

Ratio of heating capacity

Outdoor Temperature [°C W.B.]

70.0°F (21.1°C) D.B

15 16 17 18 19 20 21 22 23 24 25 26 27

59 60.8 62.6 64.4 66.2 68 69.8 71.6 73.4 75.2 77 78.8 80.6

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Ratio of heating capacity

Indoor Temperature

[°C D.B.]

[°F W.B.]

[°C D.B.]

[°F W.B.]

Indoor

Temperature

0 20 40 60 80 100 120 140 160 180 200 220 240 260

0.70

0.75

0.80

0.85

0.90

0.95

1.00

Total capacity of indoor unit

Capacity ratio

Piping equivalent length (ft)

Table 1 Table of correction factor at frost and defrost

Outdoor Intake temperature <W.B.°F (°C)>

43(6) 37(4) 36(2) 32(0) 28(−2) 25(−4) 21(−6) 18(−8) 14(−10) 5(−15) −4(−20) −13(−25)

Correction factor

1.0 0.98 0.89 0.88 0.89 0.9 0.95 0.95 0.95 0.95 0.95 0.95

Capacity of indoor unit

Model Number for indoor

unit

Model 06Model 09Model 12Model 15Model 18Model 24Model 30Model

36

M series Model Capacity [KBtu/h]

6.0 10.9

13.6*

1

14.4*

2

13.0*

3

18

20.3*

1

21.6*

2

21.0*

3

27.6 ─ ─

P series ─ ─ 13.5 ─ 18.0 26.0 34.0 40.0

SEZ ─ 10.9 13.6 18.0 17.2 ─ ─ ─

SLZ ─ 10.2 13.7 17.1 ─ ─ ─ ─

MVZ ─ ─ 12.0 ─ 18.0 27.0 34.0 40.0

*1 For MSZ-FH/FE12,18NA

*

2

For MSZ-GE/GL12,18NA

*

3

For the models other than

*1 and

*2 above

OCH573C

Page 18

18

n: Total number of the indoor units

k: Number of the indoor unit

c

k

: Outdoor unit power input coefficient of k indoor unit room temp.

M

k

: Number part of the k indoor unit model (e.g. P80 → 80)

<Cooling>

3. Power input of outdoor unit

Outdoor unit : MXZ-4C36

Indoor unit 1 : MSZ-FH15

Indoor unit 2 : MSZ-FH18

(1) Rated power input of outdoor unit 2.57 kW

1.04 (Refer to “4-2. CORRECTING BY TEMPERATURE”.)

(2) Calculation of the average indoor temperature power input coefficient

Coefficient of the outdoor unit for indoor unit 1 (Outdoor temp. 98.6°F [37.0°C] D.B., Indoor temp. 68.0°F [20.0°C] W.B.)

Maximum System Capacity (CTx) = Total Outdoor unit Capacity (CTo), so use the following formula

Total Indoor units capacity

15 + 18 = 33, thus, (CTi) = 0.9 (Refer to the tables in “4-4.STANDARD CAPACITY DIAGRAM”.)

PIo = Outdoor unit Cooling Rated Power Input × Correction Coefficient of Indoor temperature × (CTi)

= 2.57 × 0.94 × 0.9

= 2.2 kW

0.85 (Refer to “4-2. CORRECTING BY TEMPERATURE”.)

Coefficient of th

e outdoor unit for indoor unit 2 (Outdoor temp. 98.6°F [37.0°C] D.B., Indoor temp. 64.4°F [18.0°C] W.B.)

= 1.04 × 15/(15 + 18) + 0.85 × 18/(15 + 18)

= 0.94

n

k=1

n

k=1

Average indoor temp. power input coefficient (

c

ave

)

= ∑ {ck × (Mk/ ∑ Mk)}

(4) Outdoor power input (PIo)

(3) Coefficient of the partial load (CTi)

OCH573C

Page 19

19

n: Total number of the indoor units

k: Number of the indoor unit

c

k

: Outdoor unit power input coefficient of k indoor unit room temp.

M

k

: Number part of the k indoor unit model (e.g. P80 → 80)

<Heating>

(1) Rated power input of outdoor unit 3.34 kW

1.34 (Refer to “4-2. CORRECTING BY TEMPERATURE”.)

(2) Calculation of the average indoor temperature power input coefficient

Coefficient of the outdoor unit for indoor unit 1 (Outdoor temp. 26.6°F [−3°C] W.B., Indoor temp. 68.0°F [20°C] D.B.)

Maximum System Capacity (CTx) = Total Indoor unit Capacity (CTi), so use the following formula

PIo = Outdoor unit Heating Rated Power Input × Correction Coefficient of Indoor temperature × (CTi)

= 3.34 × 1.20 × 0.9

= 3.61 kW

1.09 (Refer to “4-2. CORRECTING BY TEMPERATURE”.)

Coefficient of the outdoor unit for indoor unit 2 (Outdoor temp. 26.6°F [−3°C] W.B., Indoor temp. 77.0°F [25°C] D.B.)

= 1.34 × 15/(15 + 18) + 1.09 × 18/(15 + 18)

= 1.20

n

k=1

n

k=1

Average indoor temp. power input coefficient (

c

ave

)

= ∑ {ck × (Mk/ ∑ Mk)}

(4) Outdoor power input (PIo)

(3) Coefficient of the partial load (CTi)

Total indoor units capacity

15 + 18 = 33, thus, (CTi) = 0.9 (Refer to the tables in “4-4. STANDARD CAPACITY TEMPERATURE”.)

OCH573C

Page 20

20

4-2. CORRECTING BY TEMPERATURE

15 16 17 18 19 20 21 22 23 24

59 60.8 62.6 64.4 66.2 68 69.8 71.6 73.4 75.2

0.4

0.6

0.8

1.0

1.2

Ratio of cooling capacity

Indoor Temperature

[°CW.B.]

[°FW.B.]

5 14

23 32 41 50 59 68 77 86 95 104 113

-15 -10

-5 0 5 10 15 20 25 30 35 40 45

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Ratio of cooling capacity

Outdoor Temperature

67.0°F (19.4°C) W.B.

[°C W.B.]

[°F W.B.]

-15 -10

-5 0 5 10 15 20 25 30 35 40 45

5 14

23 32 41 50 59 68 77 86 95 104 113

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Ratio of power input

Outdoor Temperature

[°C W.B.]

[°F W.B.]

68.0°F (20.0°C) W.B.68.0°F (20.0°C) W.B. 75.2°F (24.0°C) W.B.75.2°F (24.0°C) W.B.

71.6°F (22.0°C) W.B.71.6°F (22.0°C) W.B.

67.0°F (19.4°C) W.B.67.0°F (19.4°C) W.B.

64.4°F (18.0°C) W.B.64.4°F (18.0°C) W.B.

60.8°F (16.0°C) W.B.60.8°F (16.0°C) W.B.

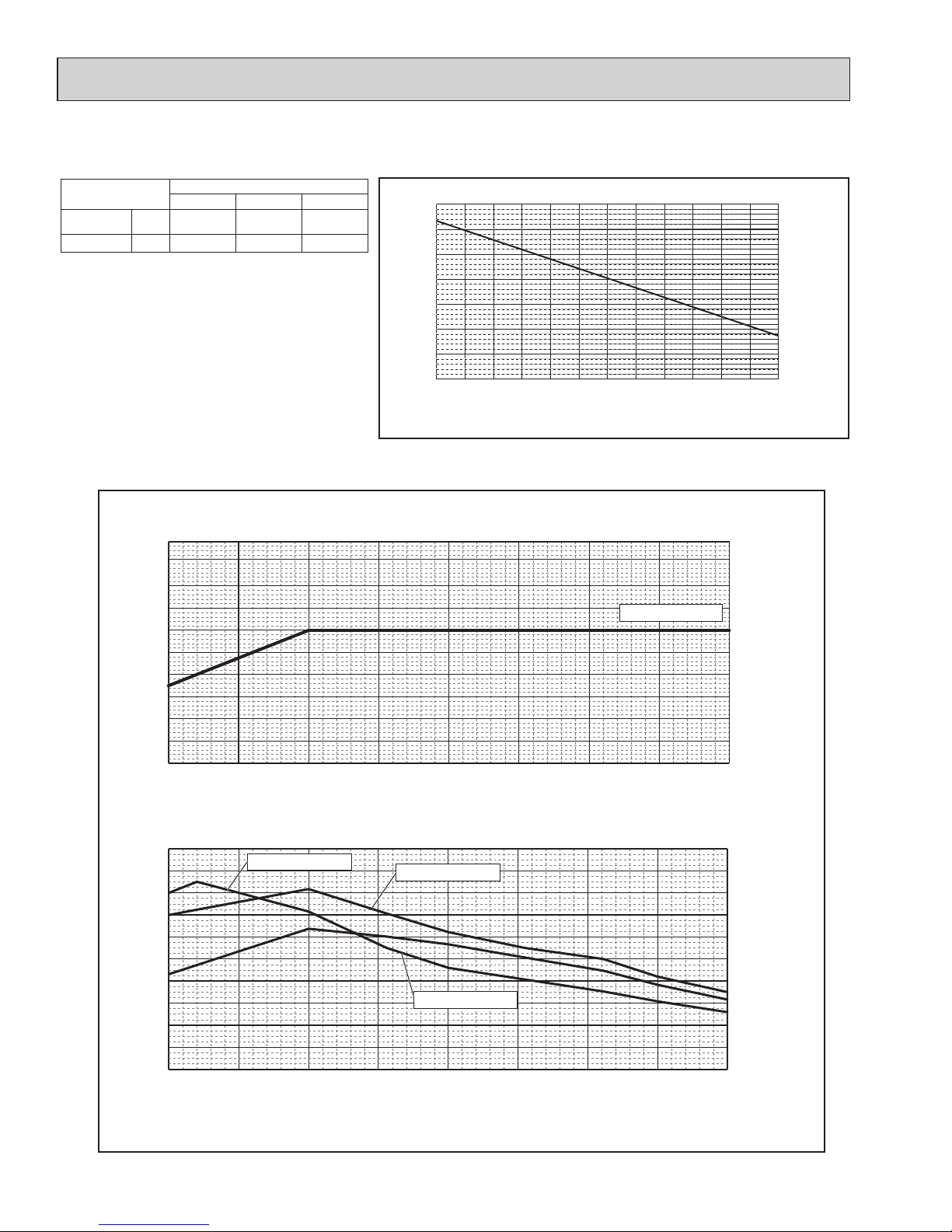

MXZ-4C36/5C42/8C48NA(HZ), 8C60NA could have varied capacity at different designing temperature. Using the nominal

cooling/heating capacity value and the ratio below, the capacity can be observed at various temperature.

MXZ

4C36 5C42

Nominal cooling capacity

BTU/h 36,000 48,000

Input kW 2.57 3.13

Figure 7 Indoor unit temperature correction

To be used to correct indoor unit capacity only

Figure 8 Outdoor unit temperature correction

To be used to correct outdoor unit capacity only

<Cooling>

Indoor Temperature

Indoor Temperature

MXZ

8C48 8C60

Nominal cooling capacity

BTU/h 48,000 60,000

Input kW 4.00 4.80

OCH573C

Page 21

21

<Heating>

15 16 17 18 19 20 21 22 23 24 25 26 27

59 60.8 62.6 64.4 66.2 68 69.8 71.6 73.4 75.2 77 78.8 80.6

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Ratio of heating capacity

Indoor Temperature

[°C W.B.]

[°F W.B.]

-25

-20 -15 -10 -5 0 5 10

15

-13

-4 5 14 23 3 41 50

59

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

Ratio of heating capacity

Outdoor Temperature

[°C W.B.]

[°F W.B.]

70.0°F (21.1°C) D.B.

-25

-20 -15 -10 -5 0 5 10

15

-13

-4 5 14 23 3 41 50

59

0.0

0.2

0.4

1.0

0.6

0.8

1.2

1.4

Ratio of power input

Outdoor Temperature

[°C W.B.]

[°F W.B.]

70.0°F (21.1°C) D.B.

60.8°F (16.0°C) D.B.

78.8°F (26.0°C) D.B.

Figure 9 Indoor unit temperature correction

To be used to correct indoor unit capacity only

Figure 10 Outdoor unit temperature correction

To be used to correct outdoor unit capacity only

MXZ

8C48NA 8C60NA

Nominal heating capacity

BTU/h 54,000 66,000

Input kW

4.22 5.67

Indoor Temperature

Indoor Temperature

OCH573C

Page 22

22

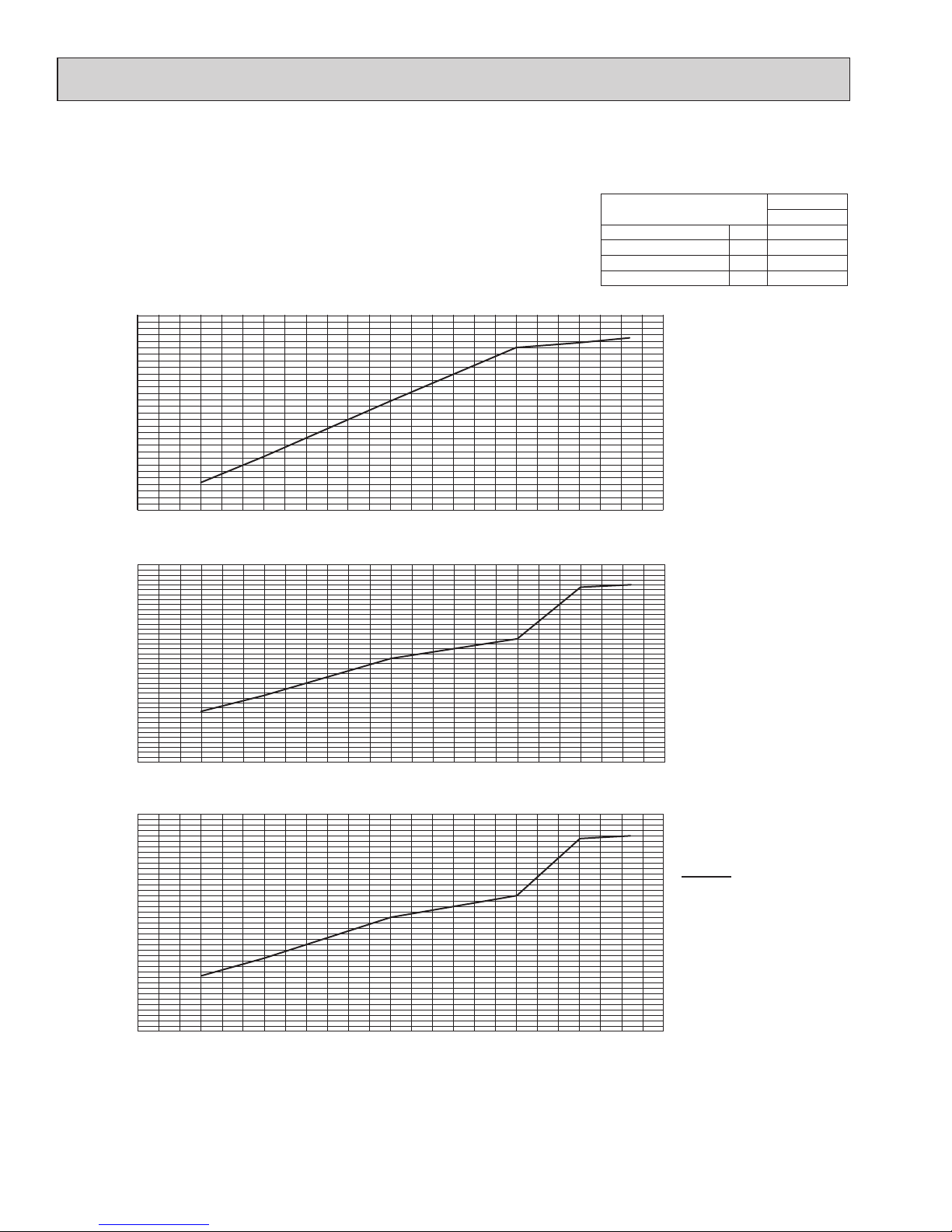

<Heating> (NAHZ)

15 16 17 18 19 20 21 22 23 24 25 26 27

59 60.8 62.6 64.4 66.2 68 69.8 71.6 73.4 75.2 77 78.8 80.6

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Ratio of heating capacity

Indoor Temperature

[°C W.B.]

[°F W.B.]

-25

-20 -15 -10 -5 0 5 10

15

0.4

1.3

-13

-4 5 14 23 3 41 50

59

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.4

Ratio of heating capacity

Outdoor Temperature

[°C W.B.]

[°F W.B.]

70.0°F (21.1°C) D.B.

Ratio of power input

Outdoor intake air dry-bulb temperature

-13 -14 5 14 23 32 41 50 59

-25

-20 -15 -10 -5 0 5 10

15

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

[°C W.B.]

[°F W.B.]

60.8°F (16.0°C) W.B.

69.8°F (21.0°C) W.B.

78.8°F (26.0°C) W.B.

Figure 11 Indoor unit temperature correction

To be used to correct indoor unit capacity only

Figure 12 Outdoor unit temperature correction

To be used to correct outdoor unit capacity only

MXZ

4C36NAHZ 5C42NAHZ 8C48NAHZ

Nominal heating

capacity

BTU/h 45,000 48,000 54,000

Input kW

3.34 3.43 4.22

Indoor Temperature

Indoor Temperature

OCH573C

Page 23

23

Operation

Outdoor unit model

MXZ-4C36NAHZ MXZ-5C42NAHZ

Operating

conditions

Ambient

temperature

Indoor

DB/WB

80°F/67°F 70°F/60°F 80°F/67°F 70°F/60°F

Outdoor 95°F/75°F 47°F/43°F 95°F/75°F 47°F/43°F

Indoor unit

No. of connected units

Unit

4 4

No. of units in operation

4 4

Model — 09 × 4 09 × 2 + 12 ×2

Piping

Main pipe

m

9.84 (3) 9.84 (3)

Branch pipe 14.76 (4.5) 14.76 (4.5)

Total pipe length 68.90 (21) 68.90 (21)

Fan speed — Hi Hi

Amount of refrigerant

lb oz

(kg)

17 lb 7 oz (7.9) 17 lb 7 oz (7.9)

Outdoor unit

Electric current A 14.1 18.7 17.2 19.1

Voltage V 230 230

Compressor frequency Hz 59 74 70 80

LEV

opening

Indoor unit Pulse 112 128 129 128

Pressure High pressure/Low pressure

MPaG 2.57/0.98 2.78/0.64 2.72/0.80 2.80/0.56

PSIG 373/142 403/93 395/116 406/81

Temp. of

each section

Outdoor

unit

Discharge

°F

[°C]

143.8 [62.1] 151.5 [66.4] 148.6 [64.8] 145.8 [63.2]

Heat exchanger outlet 100.8 [38.2] 36.7 [2.6] 101.8 [38.8] 35.6 [2.0]

Accumulator inlet 50.5 [10.3] 36.1 [2.3] 49.5 [9.7] 34.9 [1.6]

Compressor inlet 47.1 [8.4] 34.0 [1.1] 45.3 [7.4] 32.7 [0.4]

Indoor unit

LEV inlet 70.0 [21.1] 103.5 [39.7] 83.7 [28.7] 100.2 [37.9]

Heat exchanger inlet 54.1 [12.3] 138.9 [59.4] 49.6 [9.8] 132.3 [55.7]

4-3. STANDARD OPERATION DATA (REFERENCE DATA)

Operation

Outdoor unit model

MXZ-8C48NA/NAHZ MXZ-8C60NA

Operating

conditions

Ambient

temperature

Indoor

DB/WB

80°F/67°F 70°F/60°F 80°F/67°F 70°F/60°F

Outdoor 95°F/75°F 47°F/43°F 95°F/75°F 47°F/43°F

Indoor unit

No. of connected units

Unit

4 5

No. of units in operation

4 5

Model — 12 × 4 09 × 3 + 15 + 18

Piping

Main pipe

m

9.84 (3) 9.84 (3)

Branch pipe 14.76 (4.5) 14.76 (4.5)

Total pipe length 68.90 (21) 83.79 (25.5)

Fan speed — Hi Hi

Amount of refrigerant

lb oz

(kg)

17 lb 7 oz (7.9) 20 lb (8.9)

Outdoor unit

Electric current A 22.1 21.9 20.4 24.4

Voltage V 230 230

Compressor frequency Hz 86 91 45 51

LEV

opening

Indoor unit Pulse 11 2 132 187 229

Pressure High pressure/Low pressure

MPaG 2.83/0.77 2.82/0.55 2.84/0.92 2.44/0.672

PSIG 410/112 409/80 412/134 354/97.5

Temp. of

each section

Outdoor

unit

Discharge

°F

[°C]

157.6 [69.8] 149.2 [65.1] 167 [75.0] 133.9 [56.6]

Heat exchanger outlet 105.6 [40.9] 34.3 [1.3] 98.8 [37.1] 51.1 [10.2]

Accumulator inlet 47.1 [8.4] 33.4 [0.8] 49.5 [9.7] 32.4 [0.2]

Compressor inlet 42.4 [5.8] 30.6 [−0.8] 72.5 [22.5] 31.6 [−0.2]

Indoor unit

LEV inlet 71.1 [21.7] 98.8 [37.1] 59.7 [15.4] 81.9 [27.7]

Heat exchanger inlet 47.5 [8.6] 134.6 [57.0] 52.5 [11.4] 104.2 [40.1]

OCH573C

Page 24

24

4-4. STANDARD CAPACITY DIAGRAM

Before calculating the sum of total capacity of indoor units, please convert the value into the kW model capacity following the formula on

"4-1. Method for obtaining system cooling and heating capacity".

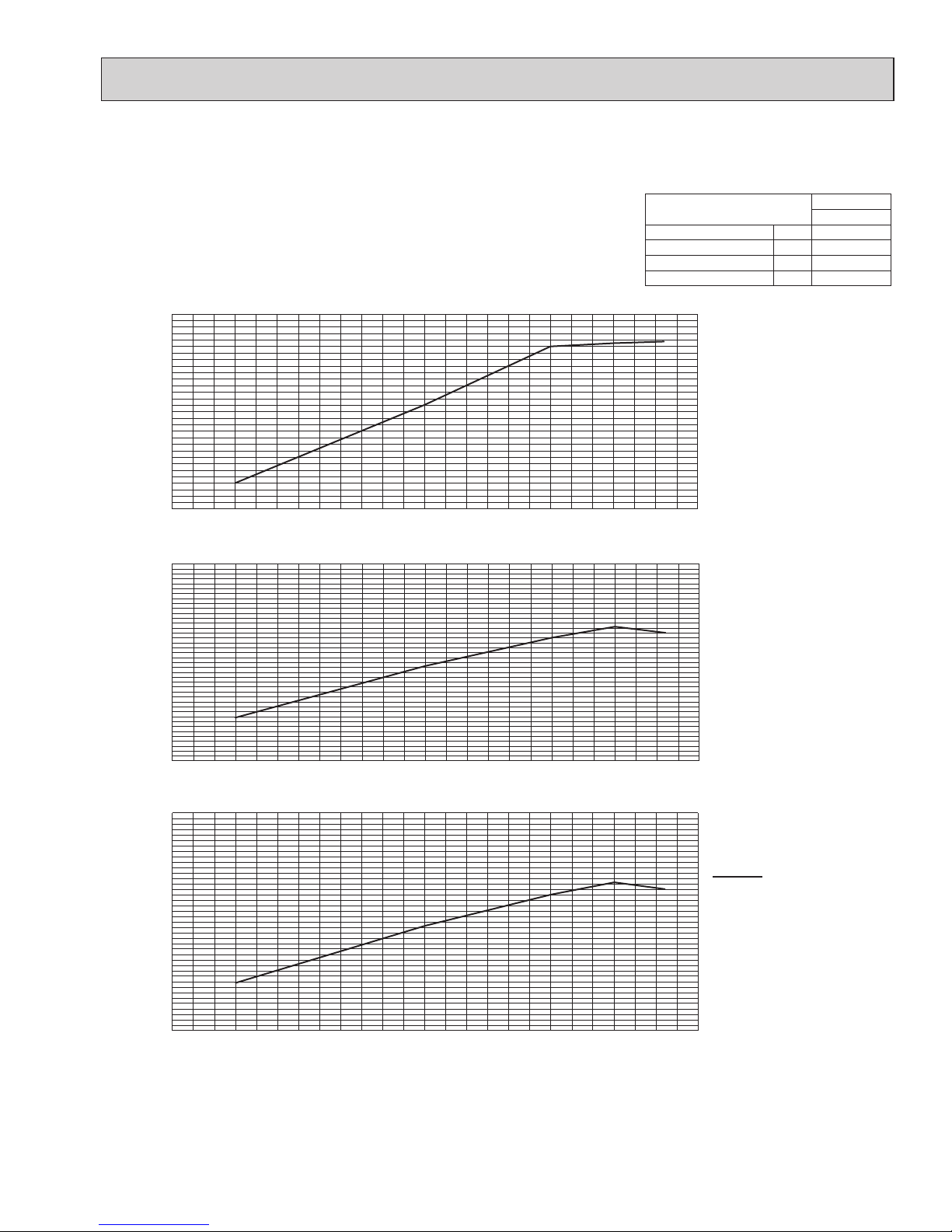

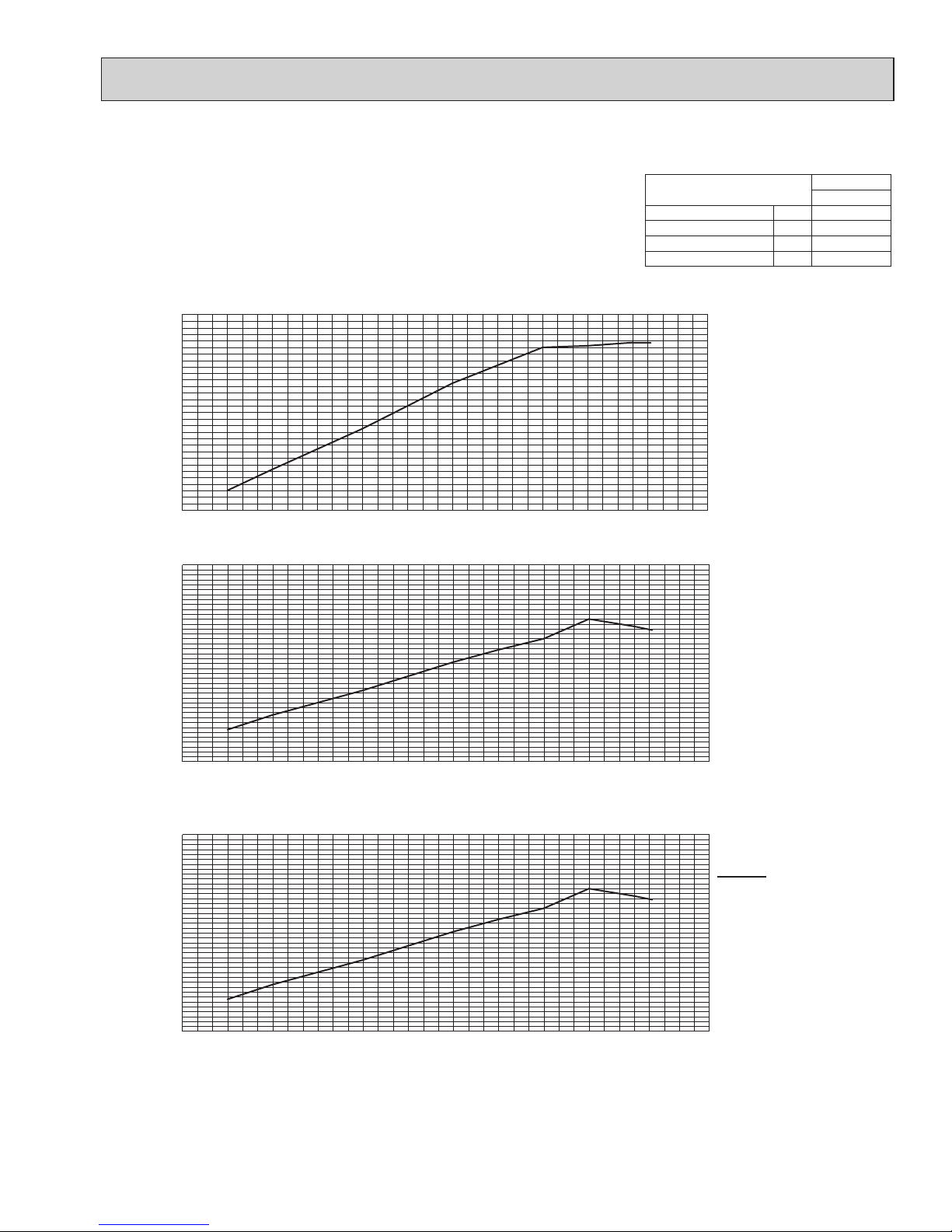

4-4-1. MXZ-4C36NAHZ <cooling>

Ratio of capacity

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

Ratio of power inputRatio of current

Total capacity of indoor units (kBTU/h)

0

10

20

30

40 50

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

0 10 20

30

40 50

0.0

0.2

0.4

0.6

0.8

1.0

0 10 20

30

40 50

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

MXZ

4C36NAHZ

Nominal cooling capacity BTU/h 36,000

Input kW 2.57

Current (208V) A 12.8

Current (230V) A 11.6

208, 230 V

OCH573C

Page 25

25

4-4-2. MXZ-4C36NAHZ <heating>

MXZ

4C36NAHZ

Nominal cooling capacity BTU/h 45,000

Input kW 3.34

Current (208V) A 16.4

Current (230V) A 14.8

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

0

10

20

30

40 50

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

0 10 20

30

40 50

0.0

0.2

0.4

0.6

0.8

1.0

0 10 20

30

40 50

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

Ratio of capacity

Ratio of power inputRatio of current

208, 230 V

OCH573C

Page 26

26

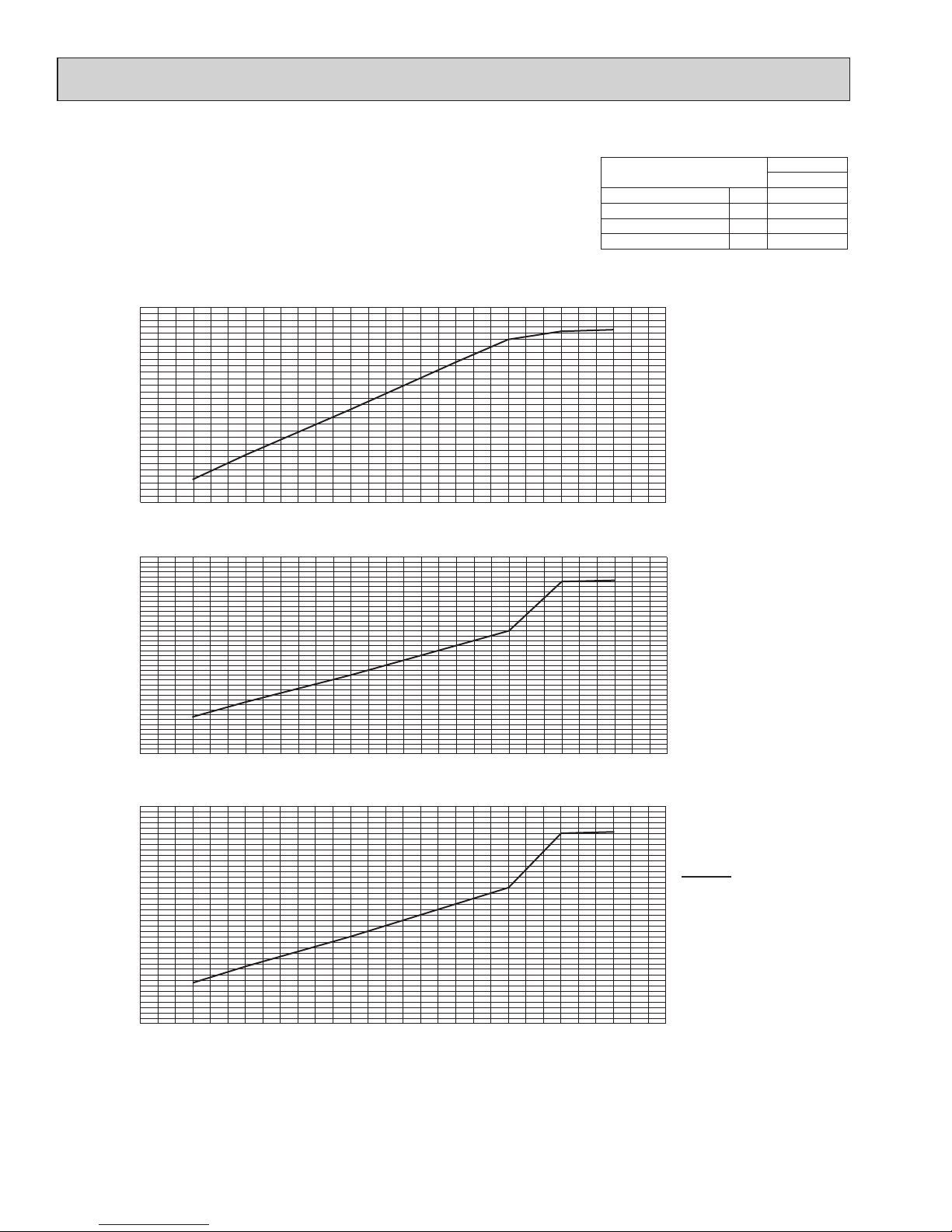

4-4-3. MXZ-5C42NAHZ <cooling>

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

0

10

20

30

40 50

60

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

0 10 20

30

40 50

60

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 10 20

30

40 50

60

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

Ratio of capacity

Ratio of power inputRatio of current

MXZ

5C42NAHZ

Nominal cooling capacity BTU/h 42,000

Input kW 3.13

Current (208V) A 15.4

Current (230V) A 14.0

208, 230 V

OCH573C

Page 27

27

4-4-4. MXZ-5C42NAHZ <heating>

MXZ

5C42NAHZ

Nominal cooling capacity BTU/h 48,000

Input kW 3.43

Current (208V) A 16.8

Current (230V) A 15.2

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

0 10 20

30

40 50

60

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.0 7.5 15.0 22.5

30.0

37.5 45.0 52.5

60.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

0.0 7.5 15.0 22.5

30.0

37.5 45.0 52.5

60.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

Ratio of capacity

Ratio of power inputRatio of current

208, 230 V

OCH573C

Page 28

28

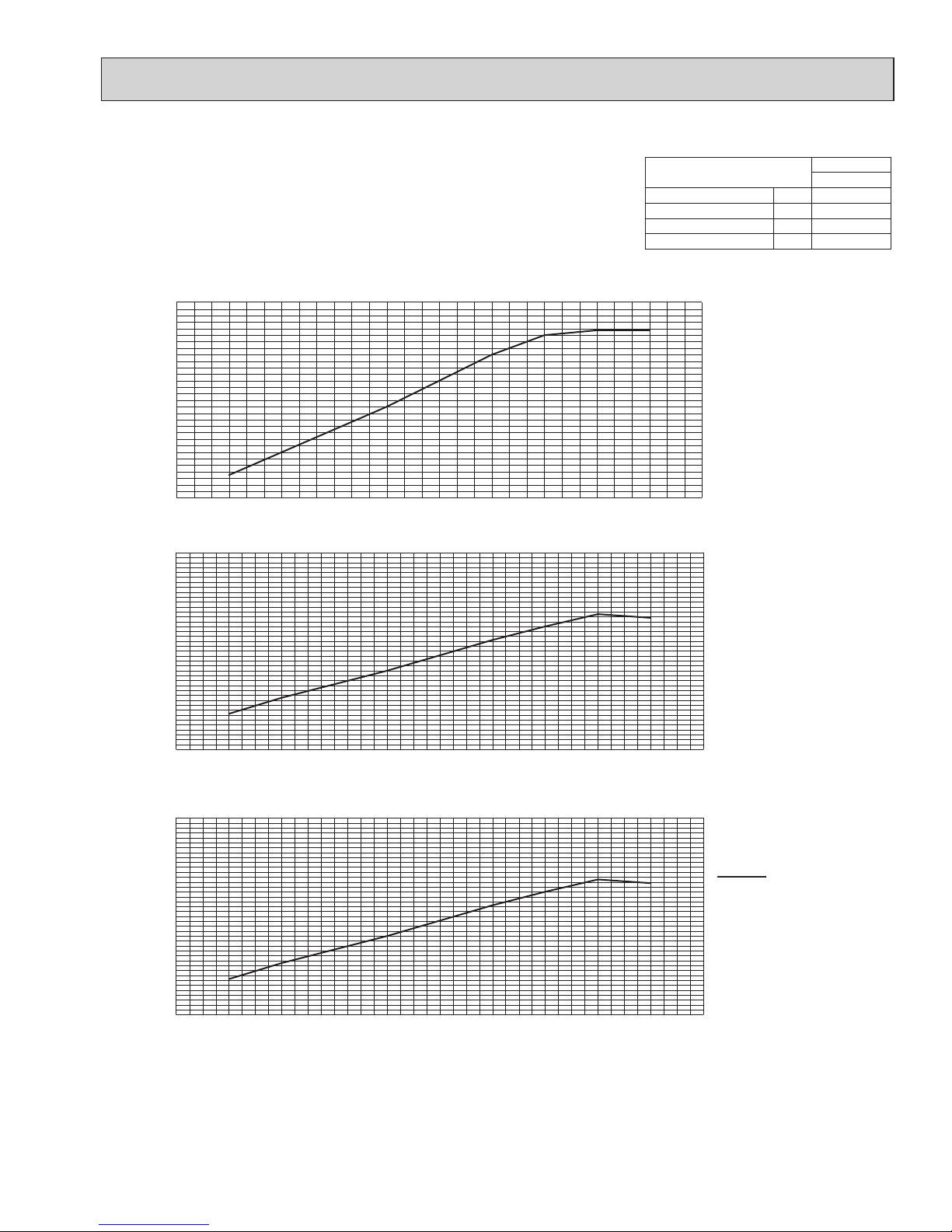

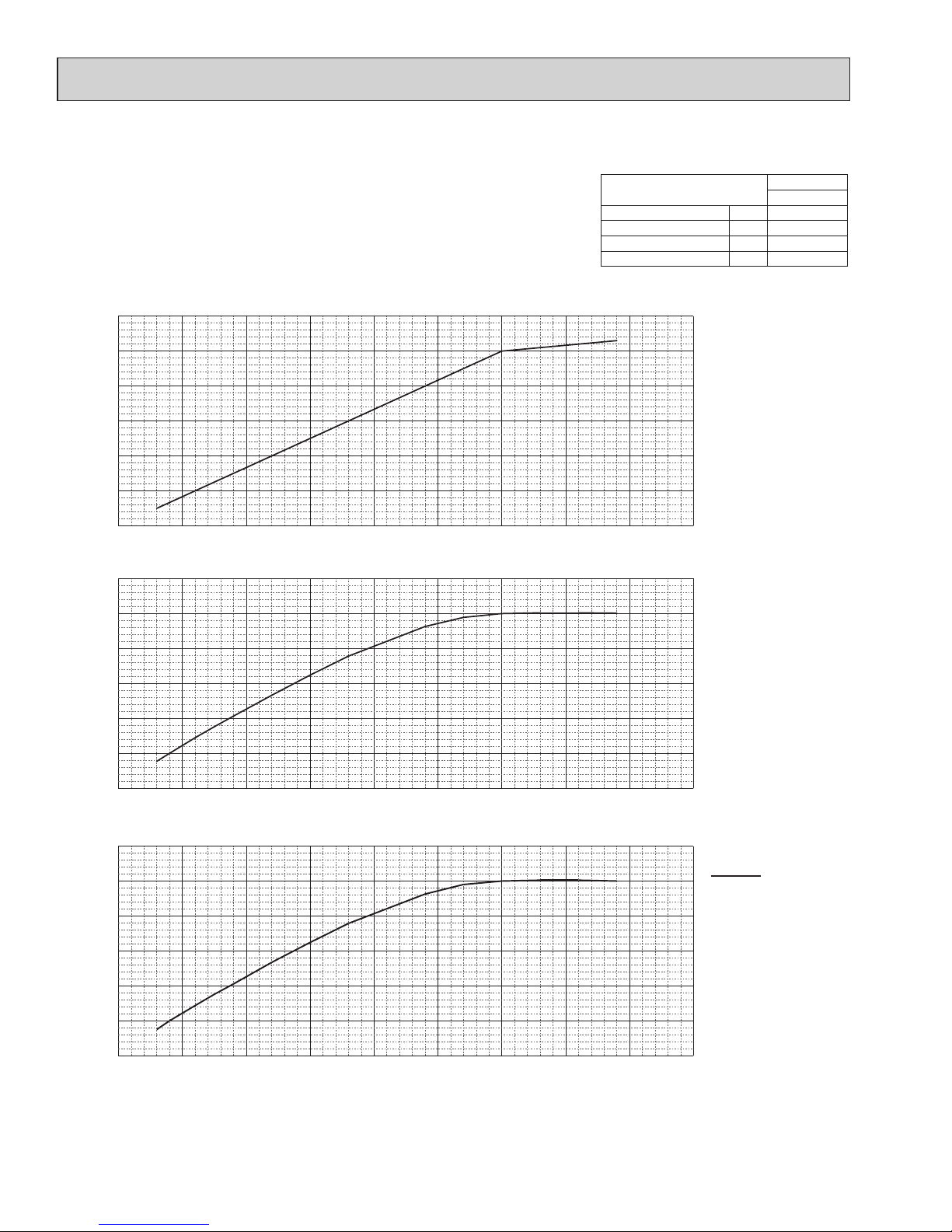

4-4-5. MXZ-8C48NA MXZ-8C48NAHZ <cooling>

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

Ratio of capacity

Ratio of power inputRatio of current

0 10 20

30

40 50

60

70

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 10 20 30 40 50

60

70

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

0 10 20 30 40 50

60

70

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

MXZ

8C48NAHZ

Nominal cooling capacity BTU/h 48,000

Input kW 4.00

Current (208V) A 19.5

Current (230V) A 17.6

208, 230 V

OCH573C

Page 29

29

4-4-6. MXZ-8C48NA MXZ-8C48NAHZ <heating>

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

Total capacity of indoor units (kBTU/h)

Ratio of capacity

Ratio of power inputRatio of current

0 10 20

30

40 50

60

70

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 10 20

30

40 50

60

70

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

0 10 20

30

40 50

60

70

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

MXZ

8C48NA(HZ)

Nominal cooling capacity BTU/h 54,000

Input kW 4.22

Current (208V) A 20.5

Current (230V) A 18.6

208, 230 V

OCH573C

Page 30

30

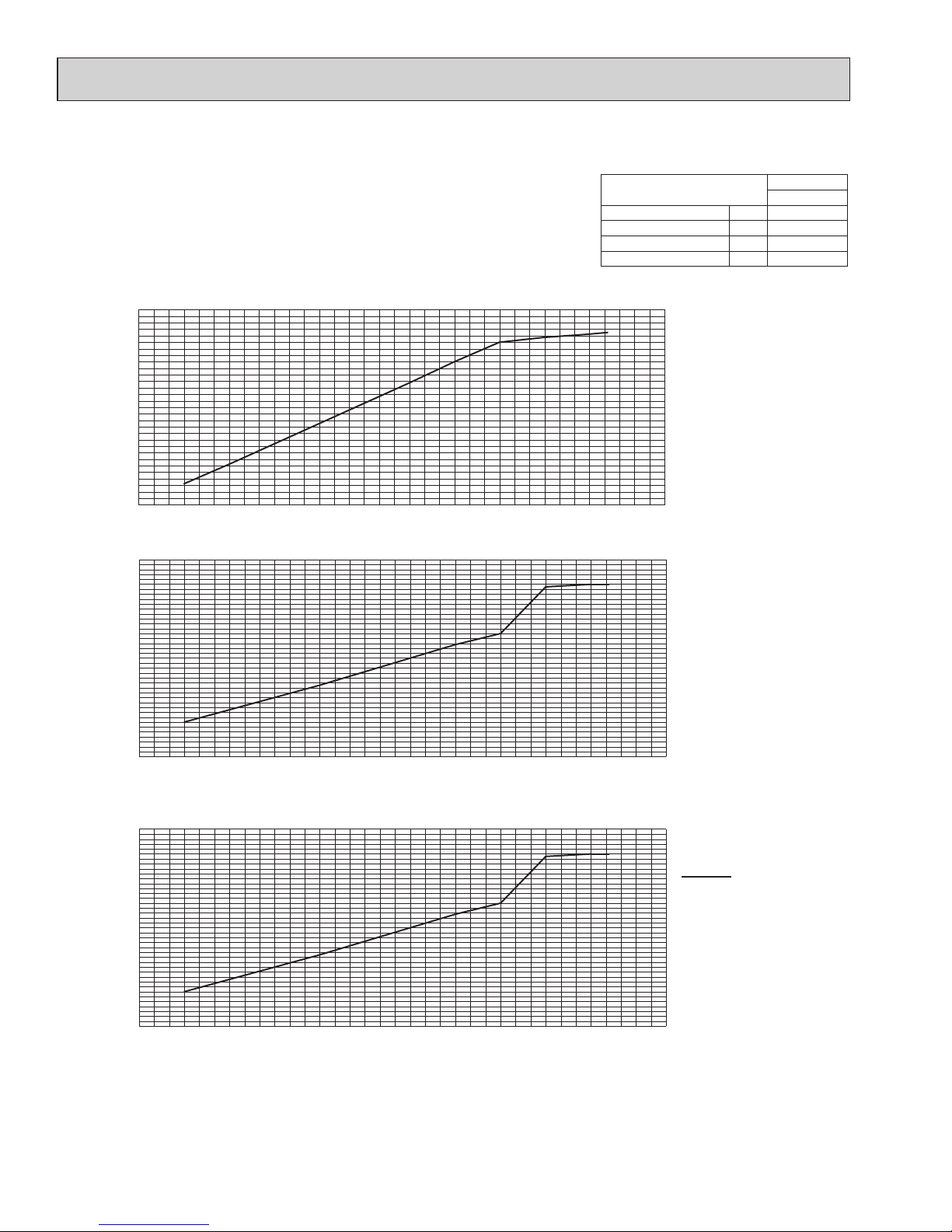

4-4-7. MXZ-8C60NA <cooling>

0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0

0.0

0.2

0.4

0.6

0.8

1.0

0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0

0.0

0.2

0.4

0.6

0.8

1.0

Total capacity of indoor units(kBTU/h)

Total capacity of indoor units(kBTU/h)

Total capacity of indoor units(kBTU/h)

Ratio of capacity

Ratio of power inputRatio of current

MXZ

8C60NA

Nominal cooling capacity BTU/h 60,000

Input kW 4.80

Current (208V) A 24.1

Current (230V) A 21.8

208, 230 V

OCH573C

Page 31

31

4-4-8. MXZ-8C60NA <heating>

0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

208 V, 230 V

Total capacity of indoor units(kBTU/h)

Total capacity of indoor units(kBTU/h)

Total capacity of indoor units(kBTU/h)

Ratio of capacity

Ratio of power inputRatio of current

MXZ

8C60NA

Nominal cooling capacity BTU/h 66,000

Input kW 5.67

Current (208V) A 28.5

Current (230V) A 25.7

208, 230 V

OCH573C

Page 32

32

4-5.

CORRECTING CAPACITY FOR CHANGES IN THE LENGTH OF REFRIGERANT PIPING

(1) During cooling, obtain the ratio (and the equivalent piping length) of the outdoor units rated capacity and the total in-use

indoor capacity, and find the capacity ratio corresponding to the standard piping length from Figure 13 to 18. Then multiply by the cooling capacity from Figure 7 and 8 in "4-2. CORRECTION BY TEMPERATURE" to obtain the actual capacity.

(2) During heating, find the equivalent piping length, and find the capacity ratio corresponding to standard piping length from

Figure 17. Then multiply by the heating capacity from Figure 9 to 12 in "4-2. CORRECTION BY TEMPERATURE" to

obtain the actual capacity.

(1) Capacity Correction Curve

0 20 40 60 80 100 120 140 160 180 200 220 240 260

0.70

0.75

0.80

0.85

0.90

0.95

1.00

0 20 40 60 80 100 120 140 160 180 200 220 240 260

0.70

0.75

0.80

0.85

0.90

0.95

1.00

18 [kBTU/h]

27 [kBTU/h]

36 [kBTU/h]

Capacity ratio

Piping equivalent length (ft)

Total capacity of indoor unit

Total capacity of indoor unit

Capacity ratio

Piping equivalent length (ft)

46.8 [kBTU/h]

21 [kBTU/h]

31.5 [kBTU/h]

42 [kBTU/h]

54.6 [kBTU/h]

Figure 13 MXZ-4C36NAHZ <Cooling>

Figure 14 MXZ-5C42NAHZ <Cooling>

OCH573C

Page 33

33

0 20 40 60 80 100 120 140 160 180 200 220 240 260

0.70

0.75

0.80

0.85

0.90

0.95

1.00

Total capacity of indoor unit

Capacity ratio

Piping equivalent length (ft)

24 [kBTU/h]

36 [kBTU/h]

48 [kBTU/h]

62.4 [kBTU/h]

0 20 40 60 80 100 120 140 160 180 200 220 240 260

0.70

0.75

0.80

0.85

0.90

0.95

1.00

Total capacity of indoor unit

Capacity ratio

Piping equivalent length (ft)

30 [kBTU/h]

45 [kBTU/h]

60 [kBTU/h]

78 [kBTU/h]

Figure 15 MXZ-8C48NA <Cooling>

Figure 16 MXZ-8C60NA <Cooling>

OCH573C

Page 34

34

Figure 17 MXZ-4C36NAHZ/5C42NAHZ/8C48NA <Heating>

Figure 18 MXZ-8C60NA <Heating>

(2) Method for Obtaining the Equivalent Piping Length

Equivalent length for type P60 = (length of piping to farthest indoor unit) + (0.3 o number of bends in the piping) (m)

Length of piping to farthest indoor unit: type P60.....80 m

4-5-1. Correction of Heating Capacity for Frost and Defrosting

If heating capacity has been reduced due to frost formation or defrosting, multiply the capacity by the appropriate correction

factor from the following table to obtain the actual heating capacity.

Correction factor diagram

Outdoor Intake temperature <W.B.°F (°C)>

43(6) 39(4) 36(2) 32(0) 28(−2) 25(−4) 21(−6) 18(−8) 14(−10) 5(−15) −4(−20) −13(−25)

Correction factor

1.0 0.98 0.89 0.88 0.89 0.9 0.95 0.95 0.95 0.95 0.95 0.95

0 20 40 60 80 100 120 140 160 180 200 220 240 260

0.70

0.75

0.80

0.85

0.90

0.95

1.00

Total capacity of indoor unit

Capacity ratio

Piping equivalent length (ft)

0 20 40 60 80 100 120 140 160 180 200 220 240 260

0.70

0.75

0.80

0.85

0.90

0.95

1.00

Total capacity of indoor unit

Capacity ratio

Piping equivalent length (ft)

OCH573C

Page 35

35

4-6. NOISE CRITERION CURVES

5 ft

(1.5 m)

3.3 ft (1 m)

MICROPHONE

UNIT

GROUND

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

MXZ-5C42NAHZ

MXZ-5C42NAHZ-U1

COOLING

MODE

HEATING

50

SPL(dB)

54

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

MXZ-8C48NA

MXZ-8C48NA-U1

MXZ-8C48NAHZ

MXZ-8C48NAHZ-U1

COOLING

MODE

HEATING

51

SPL(dB)

54

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

MXZ-4C36NAHZ

MXZ-4C36NAHZ-U1

COOLING

MODE

HEATING

49

SPL(dB)

53

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

MXZ-8C60NA-U1

COOLING

MODE

HEATING

58

SPL(dB)

59

LINE

OCH573C

Page 36

36

5 OUTLINES AND DIMENSIONS

5-1. OUTDOOR UNIT

MXZ-4C36NAHZ MXZ-5C42NAHZ MXZ-8C48NAHZ MXZ-8C48NA

Air Discharge

Rear Air Intake

Side Air Intake

2-12×36 Oval holes

(Foundation Bolt M10<W3/8>)

2-U Shaped notched holes

(Foundation Bolt M10<W3/8>)

Installation Feet

42<1-21/32>

56<2-7/32>

370 <14-9/16>

25<1>

417 <16-13/32>

70

<2-3/4>

28<1-3/32>

225

<8-27/32>

225

<8-27/32>

330 <13>

600

<23-5/8>

19<3/4>

56<2-7/32>

33.2 <1-5/16>053<2-3/32>

1/2 inch Conduit

attachment

{

22.2<7/8>

{

34.5<1-23/64>

When installing the conduit.

Set the attachment to the

inner side of each panel.

1 inch Conduit

attachment

Scale 1:5

24.7 <31/32>

5<3/16>

60<2-3/8> 24 <15/16>

101.5 <4>

Ground for the

branch box

power supply

For the

power supply

For the

branch box

power supply

For the

transmission line

For concentration

control

Terminal connection

From left to right

Handle for moving

Ground for the transmission line

Ground for concentration control

1

2

Handle for moving

Service panel

Ground for the power supply

("GR"marking position)

632 <24-7/8>

1338 <52-11/16>

26<1-1/32>

1050 <41-11/32>

1067 <42>

426 <16-25/32> *

1

369 <14-17/32>

362 <14-1/4>

510 <20-3/32> *

1

Rear piping cover

Front piping cover

Air intake

Bottom piping hole

(Knockout)

Drain hole

(5-

{

33<1-5/16>)

160

<6-5/16>

110 <4-11/32>

160

<6-5/16>

160

<6-5/16>

136

<5-11/32>

86<3-3/8>

81<3-3/16>

45<1-25/32>

154

<6-1/16>

Right piping hole

(Knockout)

Conduit hole

(

{

24<15/16>Knockout)

Conduit hole

(

{

37<1-15/32>Knockout)

Right trunking hole

(Knockout)

92<3-5/8>

60<2-3/8>

5<3/16>

60<2-3/8>

55<2-3/16>

53<2-3/32>

92

<3-5/8>

26<1-1/32> 27 <1-1/16>

29<1-5/32>

73<2-7/8>

{

92

<3-5/8>

Min. 150mm<5-29/32>Min. 1000mm<39-3/8>

Side Air Intake

Conduit hole

(

{

37<1-15/32>Knockout)

Front trunking hole

(Knockout)

Front piping hole

(Knockout)

Conduit hole

(

{

24<15/16>Knockout)

55<2-3/16>

27<1-1/16>

92<3-5/8>

75<2-15/16>

73<2-7/8>26<1-1/32>

55<2-3/16>

60

<2-3/8>

5

<3/16>

60<2-3/8>

{

92

<3-5/8>

FREE

Min. 15mm<19/32>

Min. 15mm<19/32>

Handle for

moving

Handle for

moving

Rear Air Intake

Conduit hole

(

{

24<15/16>Knockout)

Conduit hole

(

{

37<1-15/32>Knockout)

Rear trunking hole

(Knockout)

Rear piping hole

(Knockout)

75<2-15/16>

60<2-3/8>

92<3-5/8>

73<2-7/8>

26<1-1/32>

27<1-1/16>

55<2-3/16>

55<2-3/16>

5<3/16>

60<2-3/8>

{

92

<3-5/8>

1……

Refrigerant GAS pipe connection (FLARE){15.88 (5/8F)

2……

Refrigerant LIQUID pipe connection (FLARE){9.52 (3/8F)

*

1

.......

Indication of STOP VALVE connection location.

Piping and wiring connections

can be made from 4 directions:

FRONT, Right, Rear and Below.

4 PIPING-WIRING DIRECTIONS

3 FOUNDATION BOLTS

2 SERVICE SPACE

1 FREE SPACE (Around the unit)

Please secure the unit firmly

with 4 foundation (M10<W3/8>) bolts.

(Bolts and washers must be

purchased locally.)

Dimensions of space needed

for service access are

shown in the below diagram.

The diagram below shows a basic example.

Explantion of particular details are

given in the installation manuals etc.

Max.

<Foundation bolt height>

FOUNDATION

Service space

Min.

Min.

Min.

Min.

15<19/32>

500

<19-11/16>

500

<19-11/16>

150

<5-29/32>

30<1-3/16>

Piping Knockout Hole Details

Example of Notes

mm<inch>

Unit: mm <inch>

OCH573C

Page 37

37

MXZ-4C36NAHZ-U1 MXZ-5C42NAHZ-U1 MXZ-8C48NAHZ-U1 MXZ-8C48NA-U1

2-12×36 Oval holes

(Foundation Bolt M10<W3/8>)

2-U Shaped notched holes

(Foundation Bolt M10<W3/8>)

Installation Feet

Air Discharge

Rear Air Intake

Side Air Intake

417 <16-13/32>

70

<2-3/4>

225

<8-27/32>

600

<23-5/8>

225

<8-27/32>

330 <13>25<1>

42

<1-21/32>

60.5

<2-3/8>

28 <1-3/32> 370 <14-9/16> 19 <3/4>

39.5 <1-9/16>

56 <2-7/32>

53 <2-3/32>

0

Drain hole

(5-

{

33<1-5/16>)

Bottom piping hole

(Knock-Out)

154

<6-1/16>

136

<5-11/32>

45

<1-25/32>

110

<4-11/32>

160

<6-5/16>

160

<6-5/16>

160

<6-5/16>

81

<3-3/16>

86 <3-3/8>

Rear piping cover

Front piping cover

Air intake

Ground for the

branch box

power supply

For the

power supply

For the

branch box

power supply

For the

transmission line

For concentration

control

Terminal connection

From left to right

Handle for moving

Ground for the transmission line

Ground for concentration control

1

2

Handle for moving

Service panel

Ground for the power supply

("GR"marking position)

26 <1-1/32>

1050 <41-11/32>

362 <14-1/4>

1338 <52-11/16>

632 <24-7/8>369 <14-17/32>

485 <19-3/32>

426 <16-25/32>

1067 <42>

Side Air Intake

Handle for

moving

Rear Air Intake

Handle for

moving

{15.88 (5/8F)

{9.52(3/8F)

1

2

Example of Notes

Rear piping hole

(Knock-Out)