Page 1

FLOW TEMP. CONTROLLER 2

(Cased)

PAC-IF031B-E

INSTALLATION MANUAL

For safe and correct use, read this manual thoroughly before installing the FTC2 unit.

OPERATION MANUAL

For safe and correct use, please read this operation manual thoroughly before operating the air-conditioner unit.

FOR INSTALLER

FOR USER

English

Page 2

Contents

1. Safety precautions .....................................................................................2

2. Installing the FTC2 unit .............................................................................3

3. System ......................................................................................................4

4. Electrical work ...........................................................................................7

5. Switch setting of FTC2 ............................................................................ 12

6. Operation setting .....................................................................................14

7. Before test run .........................................................................................21

8. Remote controller operation ....................................................................22

9. Initial setting by remote controller ............................................................ 31

10. Defi nition of analog signal by remote controller ......................................33

11. Troubleshooting ......................................................................................34

Local application factors ................................................................................35

“FTC2” is the abbreviation of “Flow Temperature Controller 2”, which is described as “FTC2” in this manual.

1. Safety precautions

Before installing the FTC2 unit, make sure you read all the “Safety precautions”.

Please report to your supply authority or obtain their consent before

connecting this equipment to the power supply system.

Warning:

Precautions that must be observed to prevent injuries or death.

Caution:

Precautions that must be observed to prevent damages to the unit.

Warning:

• The unit must not be installed by the user. Ask an installer or an authorized

technician to install the unit. If the unit is installed improperly, electric

shock, or fi re may be caused.

• For installation work, follow the instructions in the Installation Manual and

use tools and pipe components specifi cally made for use with refrigerant

specifi ed in the outdoor unit installation manual.

• The unit must be installed according to the instructions in order to minimize the risk of damages by earthquakes, typhoons, or strong winds.

Improperly installed unit may fall down and cause damages or injuries.

The unit must be securely installed on a structure that can sustain its weight.

•

If the unit is mounted on an unstable structure, it may fall down and cause

damages or injuries.

• All electric work must be performed by a qualifi ed technician according to

local regulations and the instructions given in this manual. The unit must

be powered by dedicated power lines and the correct voltage and circuit

breakers must be used. Power lines with insuffi cient capacity or incorrect

electrical work may result in electric shock or fi re.

After installation, perform the test run to ensure normal operation. Then explain

your customer the “Safety Precautions,” use, and maintenance of the unit based on

the information in the Operation Manual provided by local application manufacture.

Both the Installation Manual and the Operation Manual must be given to the user.

These manuals must always be kept by the actual users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels attached to the unit.

• Only the specified cables can be used for wiring. Connections must be

made securely without tension on the terminals. If cables are connected or

installed improperly, It may result in overheating or fi re.

• Terminal block cover panel of the unit must be fi rmly fi xed. If the cover

panel is mounted improperly, dust and moisture may enter the unit, and it

may cause electric shock or fi re.

• Make sure to use accessories authorized by Mitsubishi Electric and ask

an installer or an authorized technician to install them. If accessories are

improperly installed, it may cause electric shock, or fi re.

• Do not remodel the unit. Consult an installer for repairs. If alterations or

repairs are not performed correctly, it may cause electric shock or fi re.

• The user should never attempt to repair the unit or transfer it to another

location. If the unit is installed improperly, it may cause electric shock or

fi re. If the FTC2 unit needs to be repaired or moved, ask an installer or an

authorized technician.

1.1. Before installation (Environment)

Caution:

• Do not install the FTC2 unit in outdoor location as it is designed for indoor

installation only. Otherwise electric shock or breakdown may be caused by

water drop, wind or dust.

Do not use the unit in an unusual environment. If the FTC2 unit is installed or

•

exposed to steam, volatile oil (including machine oil), or sulfuric gas, or exposed to briny air, the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced,

fl ow, or accumulate. If combustible gas accumulates around the unit, it may

cause fi re or explosion.

1.2. Before installation or relocation

Caution:

• Be fully careful when moving the units. Do not hold the packaging bands.

Wear protective gloves to unpack and to move it, in order to avoid your

hands be injured by parts.

1.3. Before electric work

Caution:

• Be sure to install a circuit breaker. If it is not installed, there may be a risk

to get an electric shock.

• For the power lines, use standard cables of suffi cient capacity. Otherwise,

it may cause a short circuit, overheating, or fi re.

• When installing the power lines, do not apply tension to the cables. The

cables may be cut or overheated resulting in a fi re.

1.4. Before starting the test run

Caution:

• Turn on the main power switch of the outdoor unit more than 12 hours

before starting operation. Starting operation immediately after turning on

the power switch can severely damage the internal parts. Keep the main

power switch turned on during the operation period.

• When installing the unit in a hospital or in a building where communications equipment are installed, you may need to take measure to noise and

electronic interference. Inverters, home appliances, high-frequency medical

equipment, and radio communications equipment can cause the FTC2 unit

to malfunction or to breakdown. At the same time, the noise and electric interference from the FTC2 unit may disturb the proper operation of medical

equipment, and communications equipment.

• Be sure to safely dispose of the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause injuries.

• Do not wash the FTC2 unit. You may receive an electric shock.

• Make sure to ground the unit. Do not connect the ground wire to gas or

water pipes, lightning rods, or telephone grounding lines. If the unit is not

properly grounded, there may be a risk to get an electric shock.

• Make sure to use circuit breakers (ground fault interrupter, isolating switch

(+B fuse), and molded case circuit breaker) with the specifi ed capacity. If

the circuit breaker capacity is larger than the specified capacity, breakdown or fi re may result.

• Before starting operation, check that all protective parts are correctly in-

stalled. Make sure not to get injured by touching high voltage parts.

• Do not touch any switch with wet hands. There may be a risk to get an

electric shock.

• After stopping operation, make sure to wait at least 5 minutes before turn-

ing off the main power. Otherwise, it may cause breakdown.

1.5. Electric booster and Immersion heaters

Warning:

• FTC2 has signal outputs for booster heaters however it can not isolate

power to them in the event of overheating. All electrical heaters used on

the water circuit must have

2

a) Self cut-out mechanism to prevent overheating OR

b) A thermostat to prevent overheating

Page 3

2. Installing the FTC2 unit

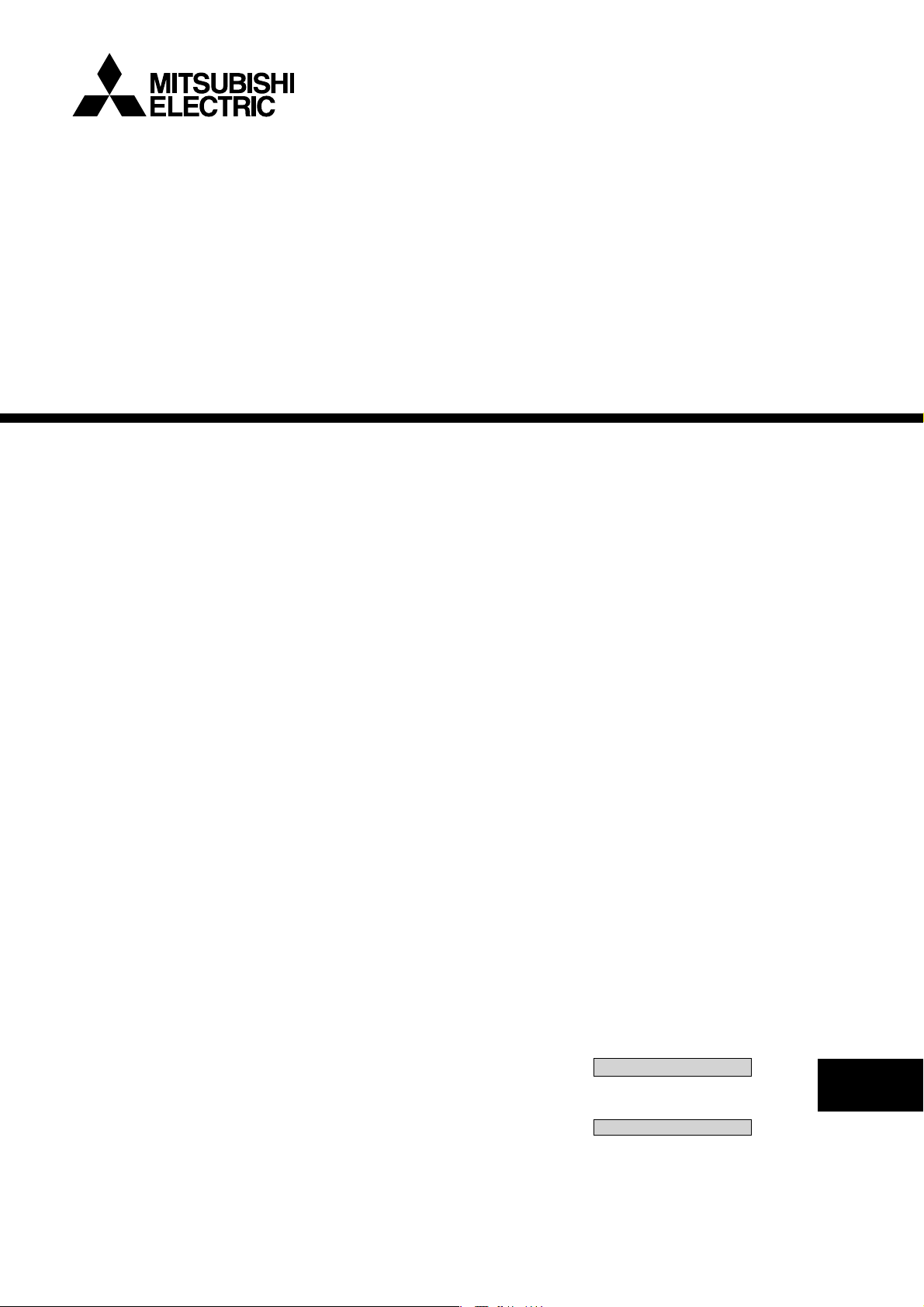

2.1. Check the parts (Fig. 2-1)

The FTC2 unit should be supplied with the following parts.

Part Name Q'ty

FTC2 unit 1

1

Thermistor 3

2

Remote controller cable (5m) 1

3

Remote controller 1

4

TEMP.

Fig. 2-1

ON/OFF

2.2. Choosing the FTC2 unit installation location

• Do not install the FTC2 unit in outdoor location as it is designed for

indoor installation only. (The FTC2 circuit board and casing are not

waterproof.)

• Avoid locations where the unit is exposed to direct sunlight or other

sources of heat.

• Select a location where easy wiring access to the power source is

available.

• Avoid locations where combustible gases may leak, be produced,

fl ow, or accumulate.

• Select a level location that can bear the weight and vibration of the

unit.

• Avoid locations where the unit is exposed to oil, steam, or sulfuric gas.

• Do not install in location that is hot or humid for long periods of time.

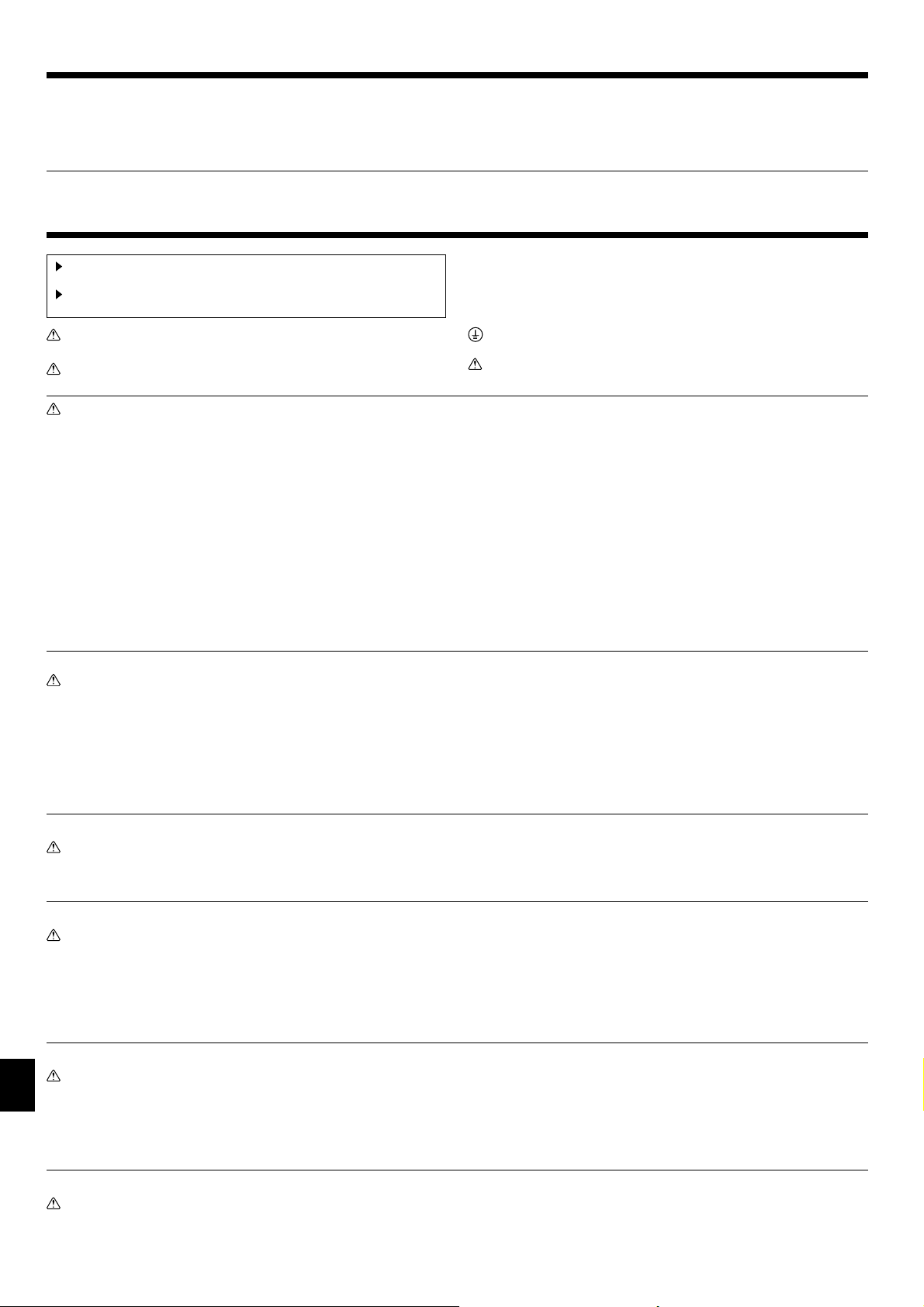

2.3. Installing the FTC2 unit (Fig. 2-2, Photo. 2-1)

1. Remove 2 screws from FTC2 unit and remove the cover.

2. Install the 4 screws (locally supplied) in 4 holes.

Screw B Cover

A

Hole for installation

C

BA

11. 5

TB61 TB62

3-ELECTRIC WIRE INLET

When installed on a wall: Lower side

Photo. 2-1

336

313

TB141TB142

Fig. 2-2

TB6

Unit:mm

(11.5)

:5

:12

22

10

200

278

69

3

Page 4

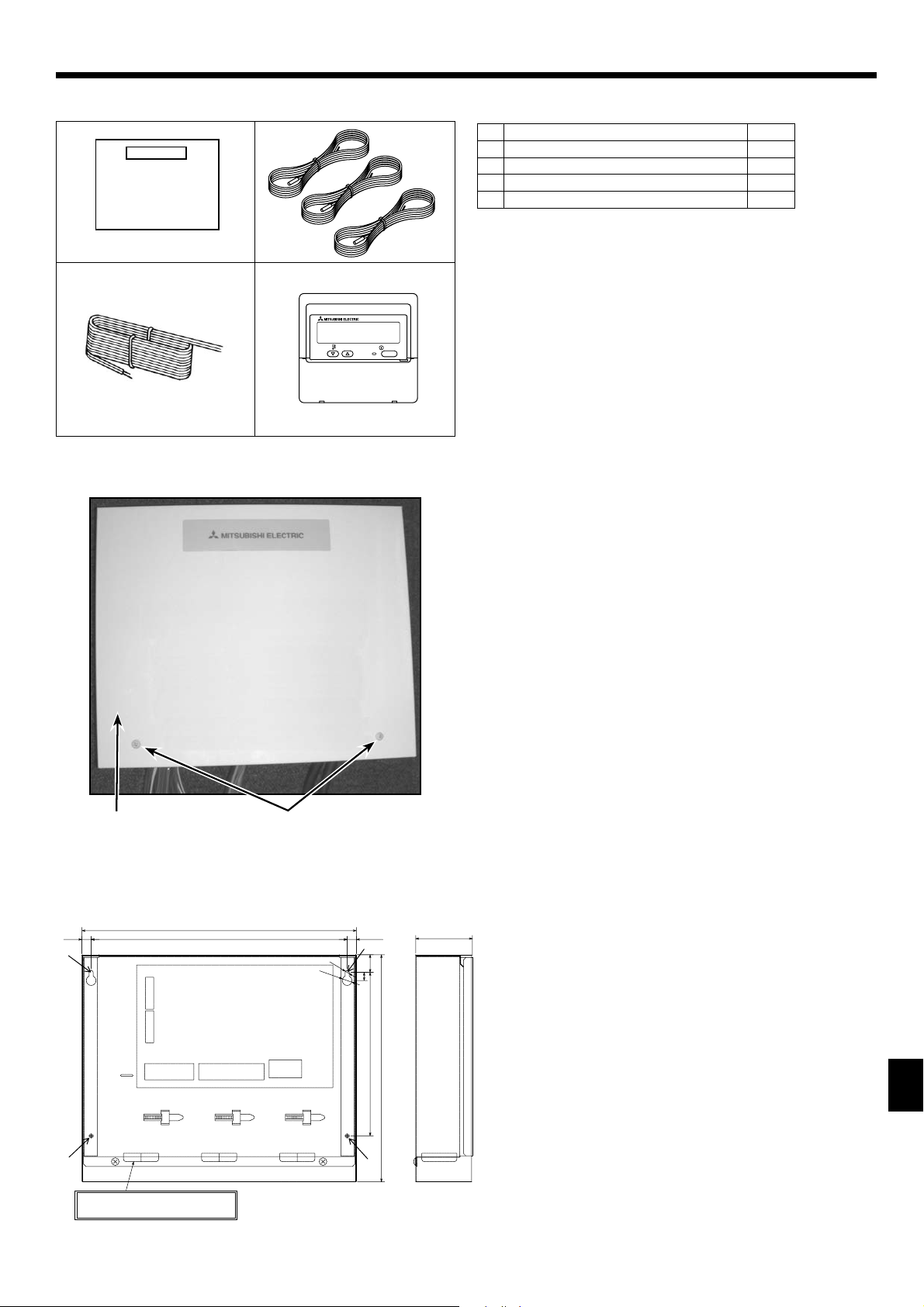

3. System

The FTC2 is designed for use with a number of heat pump systems. Please refer to the following table to fi nd the relevant installation information

for your system.

First step (Electrical work)

Power supplies (Outdoor only)

Remote controller or external input

Mode select

Temp. setting

(PAR-W21MAA) (PAR-W21MAA)

System diagram

FTC2

Remote controller

(PAR-W21MAA)

Outdoor unit

Power supplies

Outdoor unit onlyRemote controllerRemote controller

4.1

4.1.1

Operation mode

input

Remote controller

only

4.2

(External input) (PAR-W21MAA)

(External input)

FTC2

Local controller

(ON/OFF,MODE)

FTC2

Local controller

(ON/OFF,MODE,Temp.)

Remote controller

(PAR-W21MAA)

Outdoor unit

Outdoor unit

Outdoor unit onlyRemote controllerLocal controller

4.1

4.1.1

Outdoor unit onlyAnalog inputLocal controller

4.1

4.1.1

Remote controller

and external input

4.2

4.3

4.3.1

External input and

analog input

4.3

4.3.1

4.3.2

4

Page 5

3. System

Second step (thermistor setting)

Outdoor type (SPLIT type / PACKAGED type)

Domestic Hot Water (DHW) tank

Outdoor unit type DHW tank System diagram

SPLIT type

(Present)

Outdoor unit

TH2

Heat exchanger

FTC2

TH1

DHW tank

TH5

Thermistor

(TH1,TH2,TH5)

TH1: actual flow water temp.

TH2: refrigerant pipe temp.

TH5: actual DHW tank temp.

4.4

Radiator etc.

PACKAGED type

(Absent)

(Present)

(Absent)

Outdoo r uni t

Outdoor unit

Heat e xchanger

Outdoo r unit

FTC2

TH2

Heat exchanger

FTC2

FTC2

TH1

TH1

TH1

DHW tank

TH5

Radiator etc.

Radiator etc.

Radiator etc.

TH1: actual flow water temp.

TH2: refrigerant pipe temp.

TH5:

4.4

TH1: actual flow water temp.

TH2:

TH5: actual DHW tank temp.

4.4

TH1: actual flow water temp.

TH2:

TH5:

4.4

Heat exchanger

5

Page 6

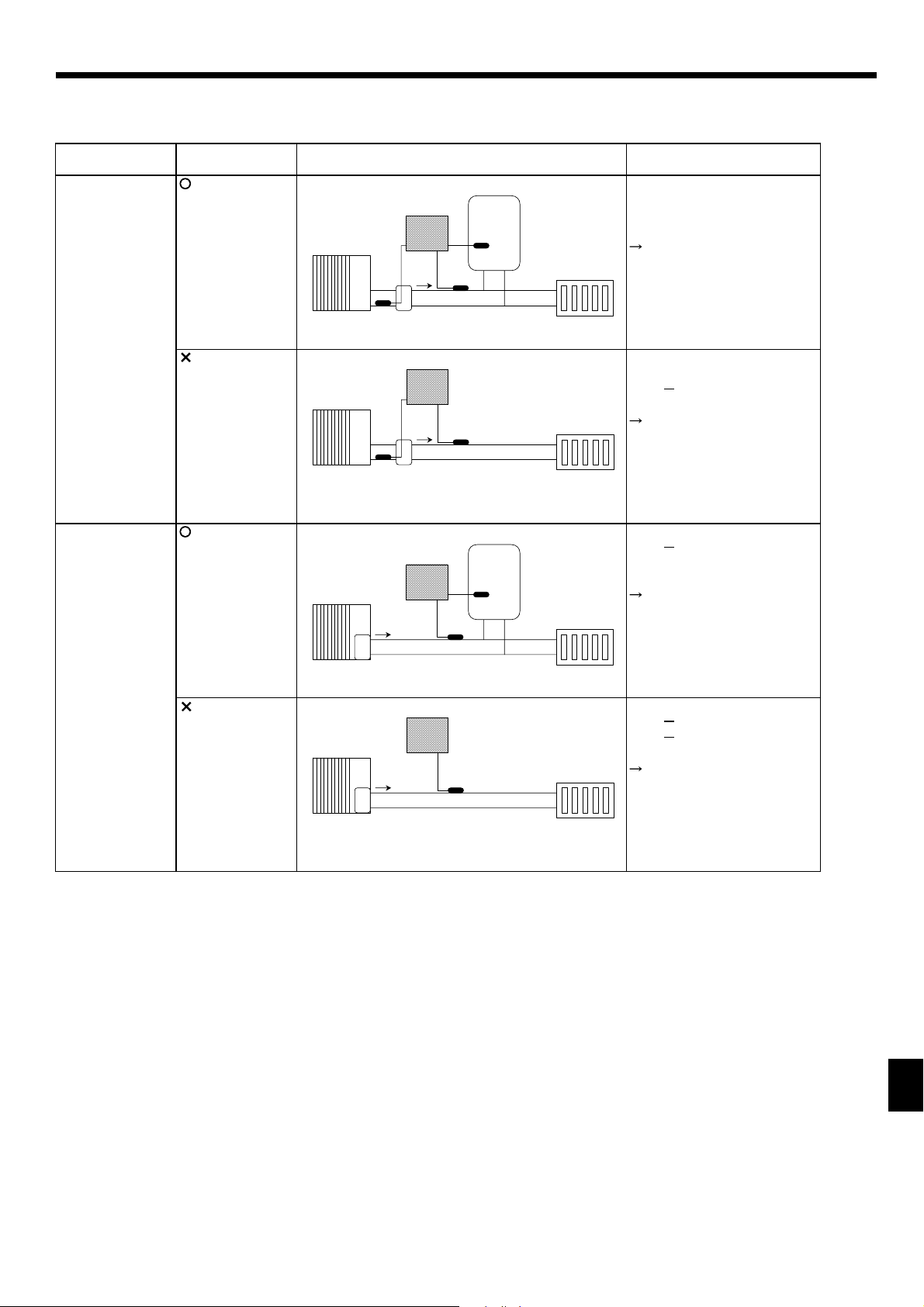

3. System

Third step (Heater setting)

Immersion heater

Booster heater position

Immersion heater

(Absent)

Booster heater

position

both DHW

and Heating

System diagram

FTC2

Sanitary tank

Output signal

Booster heater

only

4.5

(Present)

(Absent)

(Present)

both DHW

and Heating

Heating only

Heating only

Booster

heater

FTC2

Booster

heater

FTC2

Booster

heater

FTC2

Sanitary tank

Immersion

heater

Sanitary tank

Sanitary tank

Immersion

heater

Radiator etc.

Booster heater

and

Immersion heater

4.5

Radiator etc.

Booster heater

only

4.5

Radiator etc.

Booster heater

and

Immersion heater

4.5

Booster

heater

Radiator etc.

6

Page 7

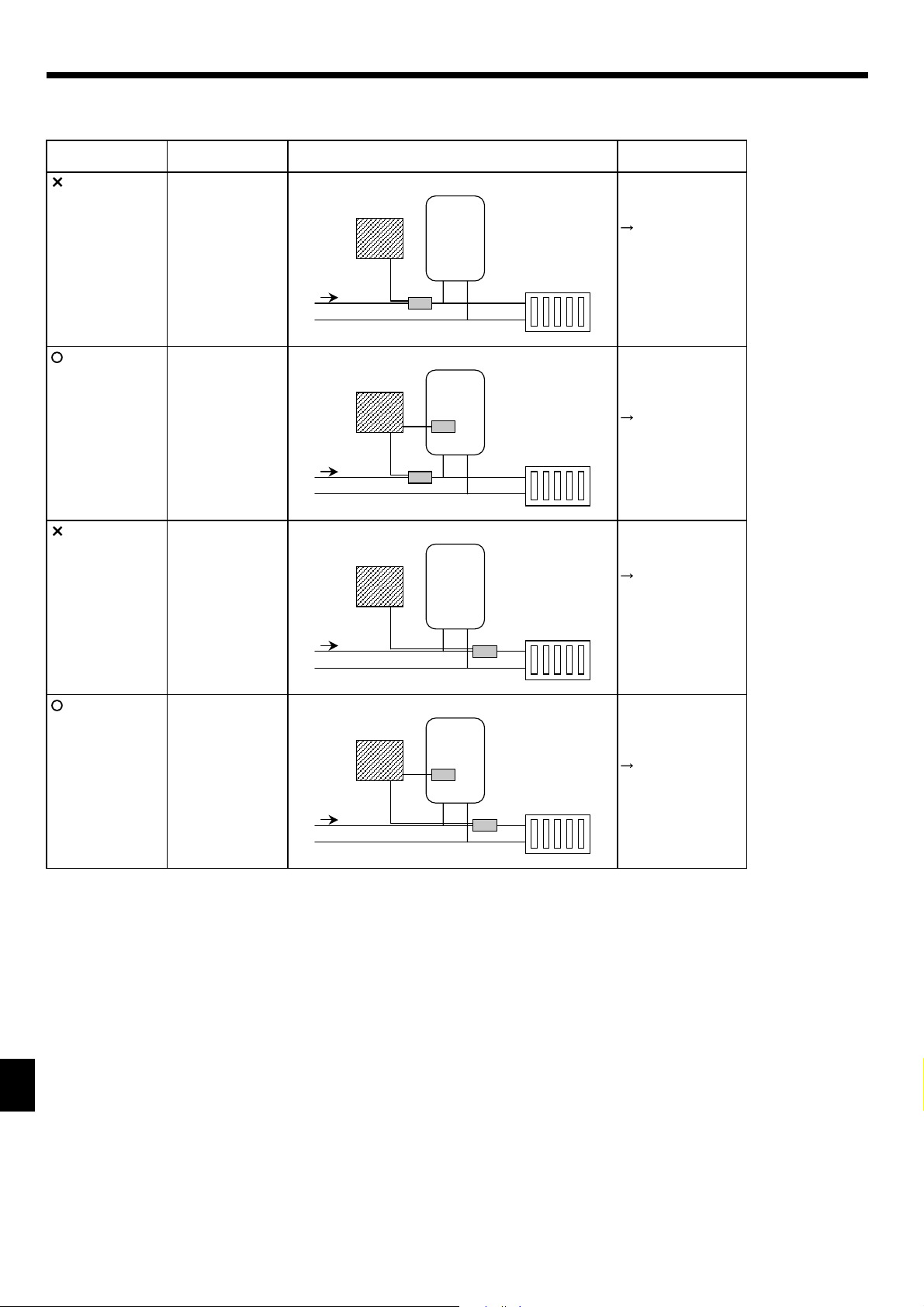

4. Electrical work

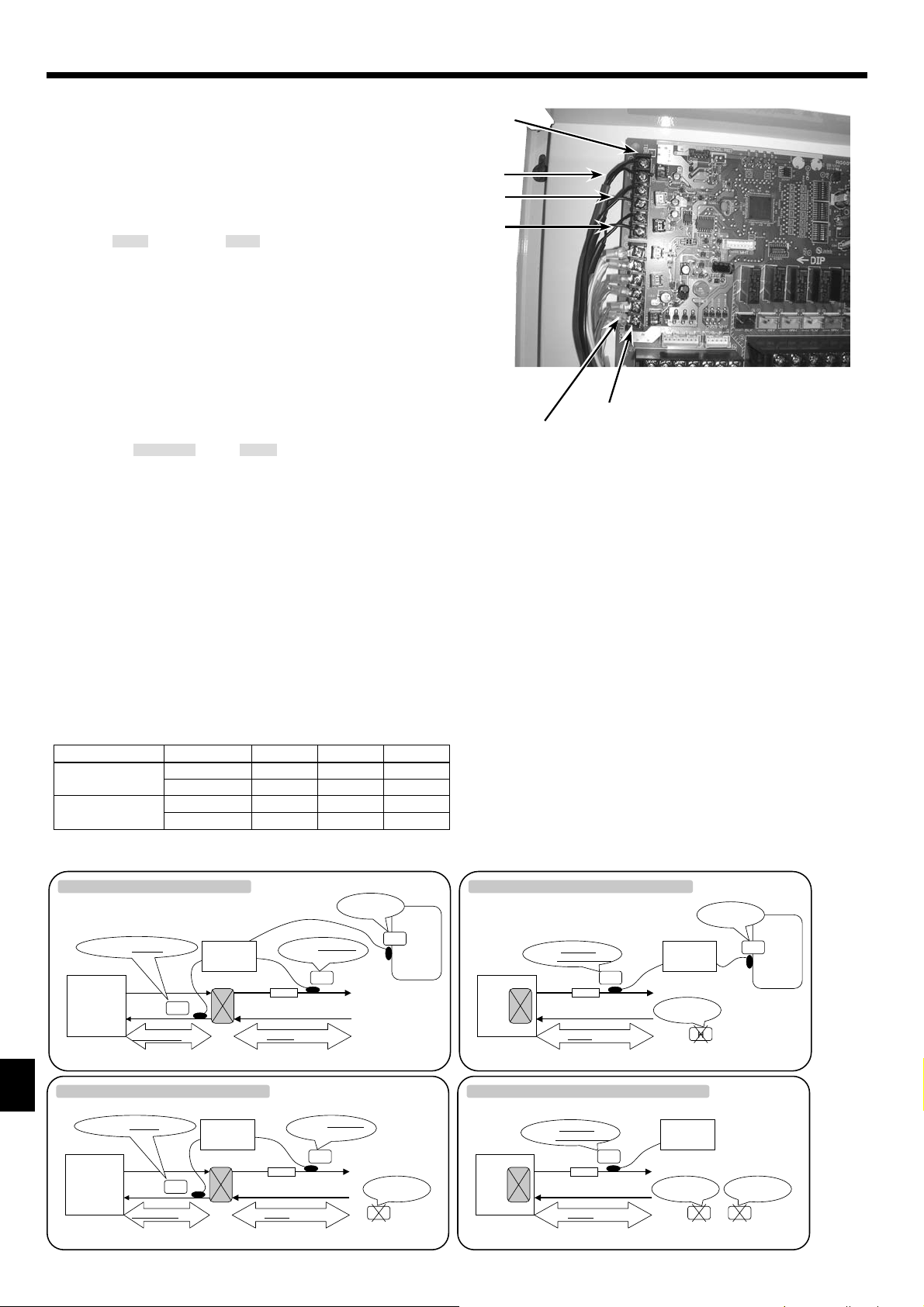

4.1. FTC2 (Photo. 4-1)

1. Remove the cover.

2. Wire the power cable and control cable separately through the

respective wiring inlets given in the photo.

• Make sure to put screws tightly.

Inlet for control cable

A

Inlet for power cable

B

Clamp

C

FTC2 / Outdoor unit connecting terminals

D

Earth terminal

E

D

C

C

Photo. 4-1

A

E

4.1.1. FTC2 unit power supplied from outdoor unit

The outdoor unit must be powered properly. (Details are shown in its installation manual.)

D

L

AB C

N

S1

S2

S3

E

B

F

S1

S2

S3

A Outdoor unit power supply

B Earth leakage breaker

C Wiring circuit breaker or isolating switch

D Outdoor unit

E FTC2 unit/outdoor unit connecting cables

F FTC2 unit

TB6

S2 S3S1

NL

E: FTC2 unit/outdoor unit

connecting cables

Earth cable

Photo. 4-2

FTC2 unit model

FTC2 unit-Outdoor unit

)

2

(mm

Wiring

FTC2 unit-Outdoor unit earth

Wire No. × size

FTC2 unit-Outdoor unit S1-S2

rating

Circuit

FTC2 unit-Outdoor unit S2-S3

*1. Max. 80 m

*2. The fi gures are NOT always against the ground.

S3 terminal has DC 24 V against S2 terminal. However between S3 and S1, these terminals are not electrically insulated by the transformer or other device.

*1

*1

*2

*2

Notes: 1. Wiring size must comply with the applicable local and national codes.

2. Power supply cables and FTC2 unit/outdoor unit connecting cables shall not be lighter than polychloroprene sheathed fl exible

cable. (Design 60245 IEC 57)

3. Install an earth wire longer than other cables.

PAC-IF031B-E

3 × 1.5 (polar)

1× Min.1.5

AC 230 V

DC24 V

7

Page 8

4. Electrical work

30120

46

83.5

Fig. 4-1

B-1. B-2.

TB61

4.2. Connecting the wired remote controller

4.2.1. Connecting the wired remote controller cable to FTC2

Connect the wired remote controller cable to 5 and 6 on the terminal

block (TB62) on the FTC2 controller. (Photo. 4-3)

3030

Wiring wire No. × size (mm

The 5m wire is attached as an accessory. Max. 500 m

Wiring size must comply with the applicable local and national codes.

Circuit rating: DC12V

Circuit rating is NOT always against the ground.

4.2.2. For wired remote controller

1) Installing procedures

(1) Select an installing position for the remote controller. (Fig. 4-1)

► Procure the following parts locally:

2 piece switch box

Thin copper conduit tube

Lock nuts and bushings

[Fig. 4-1]

Remote controller profi le

A

Required clearances surrounding the remote controller

B

Installation pitch

C

(2) Seal the service entrance for the remote controller cable with putty

to prevent possible invasion of dew drops, water, cockroaches or insects. (Fig. 4-2)

Fig. 4-2

For installation in the switch box

A

For direct installation on the wall, select one of the followings:

B

• Prepare a hole through the wall to pass the remote controller cable (in

order to take out the remote controller cable from the back), then seal

the hole with putty.

• Take out the remote controller cable through the cut-out upper case,

then seal the cut-out notch with putty.

BTB

A6

Fig. 4-3

B-1. To lead the remote controller cable from the back of the con-

troller

B-2. To take out the remote controller cable through the upper por-

tion

[Fig. 4-2]

Wall

C

Conduit

D

Lock nut

E

Bushing

F

2) Connecting procedures (Fig. 4-3)

Connect the remote controller cable to the terminal block.

1

To TB62 No.5 and 6 on the FTC2 unit

A

TB6 (No polarity)

B

2

) : 2×0.3 (Non-polar)

Switch box

G

Remote controller cable

H

Seal with putty

I

Wood screw

J

TH1

TH2

TH5

TB62

Wired remote controller cable

Photo.4-3

8

Page 9

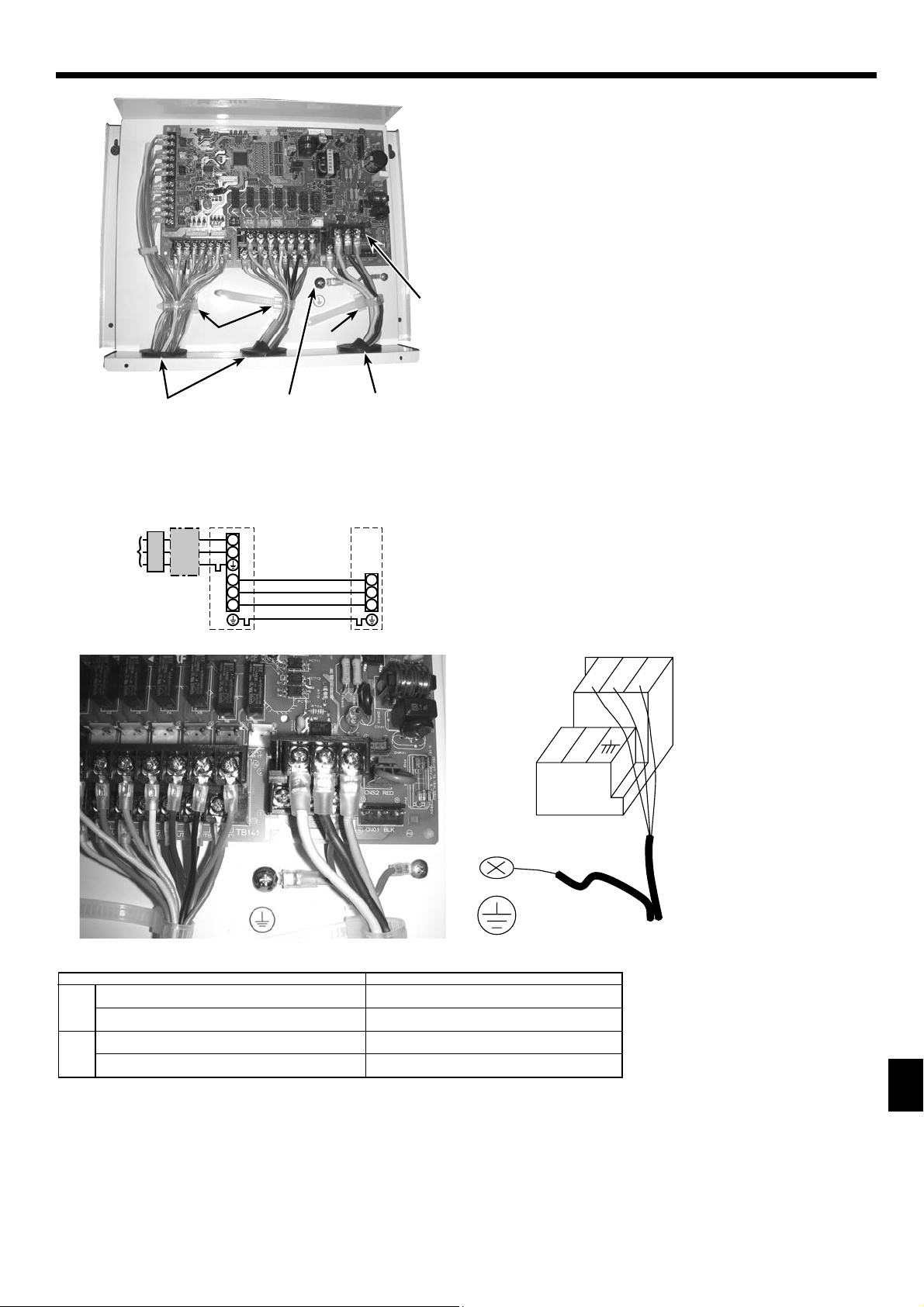

4. Electrical work

4.3. Connecting external input

FTC2 can be operated by following external input.

4.3.1. EXTERNAL INPUT ( Contact signal )

Terminal block OFF (Open) ON (Short) Remark

TB142 1-2 (IN1) OFF Emergency

TB142 3-4 (IN2) OFF

TB142 5-6 (IN3) Normal Comp. OFF SW3-6 = OFF

Comp. OFF Normal SW3-6 = ON

TB142 7-8 (IN4) OFF Cooling

TB142 10-11 (COM-IN5) OFF Heating

TB142 10-12 (COM-IN6) OFF Heating ECO *1

TB142 10-13 (COM-IN7) OFF Hot Water *4

TB142 10-14 (COM-IN8) OFF Anti-Freeze

TB62 1-2 (Ana. IN1) Normal operation Comp. OFF *2 SW3-4 = OFF

Comp. OFF *2 Normal operation SW3-4 = ON

*1 Heating ECO mode sets the set temperature depending on the outdoor temperature.

*2 In case of Cooling, Heating, Heating ECO and Anti-Freeze.

*3 Input signal: Pulse

Pulse specifi cations: ON (short)

OFF (open)

*4 When SW1-1 and SW1-2 are OFF, the mode is switched into Auto hot water.

Input signal: Pulse

Pulse specifi cations: ON (short)

OFF (open)

When SW1-1 or SW1-2, or both are ON, the mode is switched into Hot water.

Legionella prevention *3

200ms or more

200ms or more

TB142

3 5 7 9 11 131

Emergency

Legionella prevention

Forced Comp. OFF →

Cooling

Heating →

HeatingECO →

Hot Water →

Anti-Freeze →

4268101214

At site

→

→

→

FTC2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

TB142

4.3.2. EXTERNAL INPUT ( analog signal ) 4-20mA / 1-5V / 0-10V

Connect the transmission cables to No. 3 and 4 on the terminal block (TB62).

No. 3 on the terminal block (TB62) : Plus side

No. 4 on the terminal block (TB62) : Minus side (Reference side)

Thermostat

4-20mA/1-5V/0-10V

Wired remote controller

FTC2At site

1

(

2

3

4

5

6

TB62

+

(

(

4-20mA / 1-5V / 0-10V setting

FLOW TEMP.

No.2 Temp.

No.1 Temp.

Stop

4-20mA

1-5V

0-10V

Refer to the section 10 for details about No1, 2 Temp.

0mA -- 4mA --------------- 20mA

0V-------1V------------------- 5V

0V------------------10V

ANALOG

SIGNAL

TB141

Photo.4-4

Caution:

The external input signals are separated by basic insulation from power supply for the unit.

The external input signals should be separated by supplementary insulation from where user may touch in case that it is installed where

user may touch.

Connect the terminals by using the ring terminals and also insulate the cables of adjoining terminals when wiring to terminal block.

4.3.3. Wiring specifi cation of External input

Locally supplied parts

Item Name Model and specifi cations

External input

function

External input signal

wire

Use sheathed vinyl coated cord or cable.

Max. 10m

Wire type :CV, CVS or equivalent

Wire size : Stranded wire 0.5mm

Solid wire : {0.65mm to {1.2mm

Switch Non-voltage "a" contact signals

Remote switch : minimum applicable load DC 12V, 1mA

2

to 1.25mm

2

9

Page 10

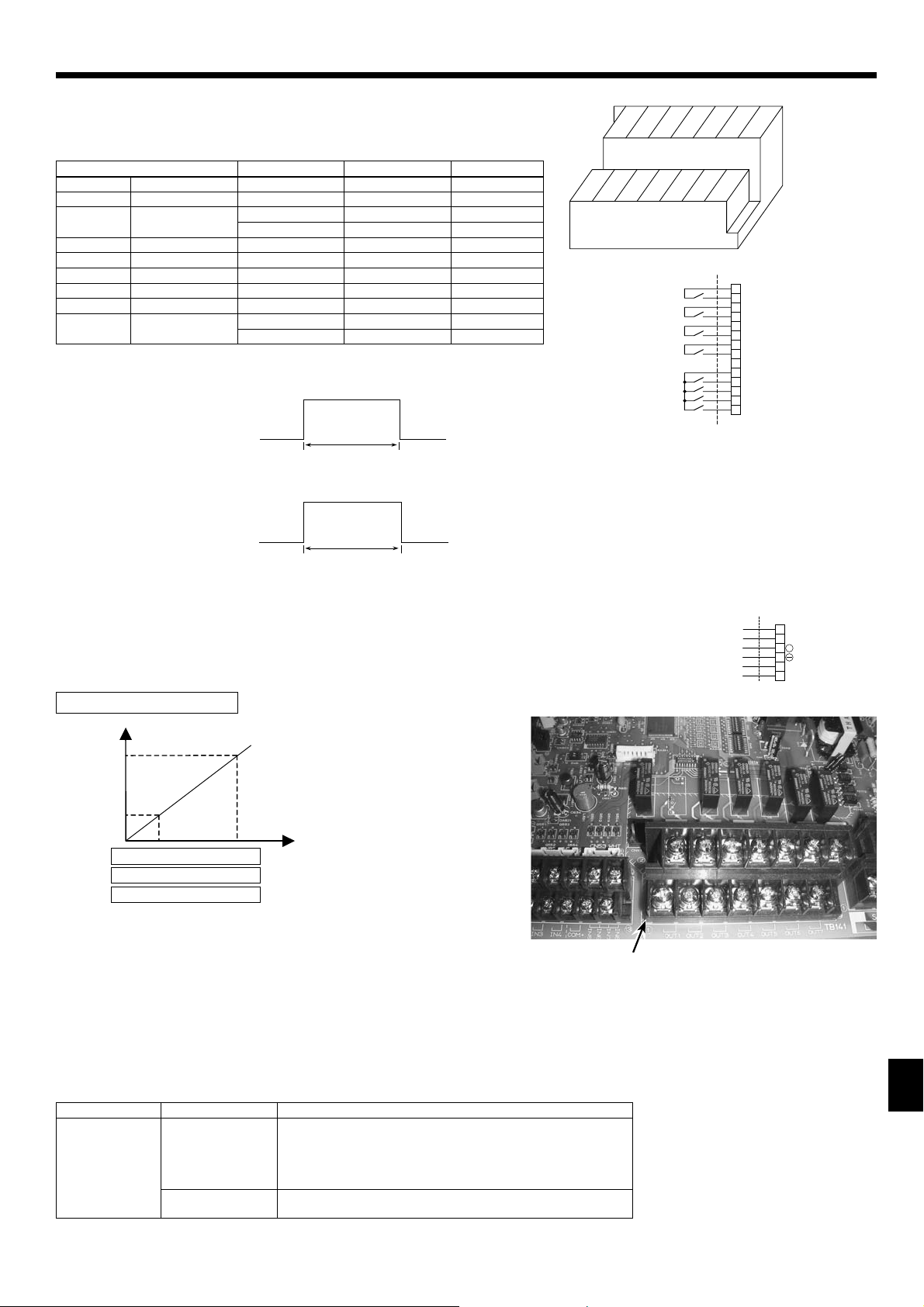

4. Electrical work

4.4. Connecting thermistor cable

Connect the thermistor 2 for the FTC2 controller.

4.4.1. Connecting the actual fl ow water temp. thermistor (TH1)

Connect the thermistor for the actual fl ow water temp. to 1 and 2 on the

terminal block (TB61) on the FTC2 controller.

When the thermistor cables are too long, cut them at the appropriate

length.

Do not bind them in the FTC2 unit.

<Thermistor position>

Put TH1 on

water piping (water outlet side) after booster heater.

Note: Be sure to attach the TH1 where it detects Flow temp.(Water

oulet side) correctly.

4.4.2. Connecting the pipe temp. thermistor (TH2)

Connect the thermistor for the refrigerant pipe temp. to 3 and 4 on the

terminal block (TB61) on the FTC2 controller.

For packaged Outdoor unit : It is NOT necessary to connect TH2.

For split Outdoor unit : Connect TH2.

When the thermistor cables supplied with FTC2 are too long, cut them to

the appropriate length.

Do not bind them in the FTC2 unit.

<Thermistor position>

Put the TH2 on refrigerant piping (Liquid side).

It is better to protect the thermistor with heat insulating materials not to be affected by the ambient temperature.

Note: Be sure to attach the TH2 where it detects Refrigerant piping temp. (Liquid side) correctly.

TB61

TH1

TH2

TH5

Photo.4-3

TB62

Wired remote controller cable

4.4.3. Connecting the actual DHW tank thermistor (TH5)

Connect the thermistor for the actual DHW tank temp. to 5 and 6 on the terminal block (TB61) on the FTC2 controller.

When the thermistor cables supplied with the FTC2 are too long, cut them to the appropriate length.

Do not bind them in the FTC2 unit.

<Thermistor position>

Put the TH5 on the DHW tank. It should be positioned directly onto the lower half of the external surface of the tank.

Caution:

Do not route the thermistor cables together with power cables.

The sensor part of the thermistor should be installed where user must not touch.

(It is separated by the supplementary insulation from where user may touch.)

4.4.4. Thermistor position and necessity

For packaged type Outdoor unit: It is NOT necessary to connect TH2.

For split type Outdoor unit: Connect TH2

<Thermistor position and necessity>

Outdoor Type DHW tank TH1 TH2 TH5

PACKAGED type

SPLIT type

Present ΟХΟ

Absent ΟХХ

Present O O O

Absent ΟΟХ

Ο: Necessary. Connect the thermistor.

Х: Not necessary. The thermistor is not required, do not connect.

SPLIT type outdoor unit with DHW tank

Refrigerant LIQUID side

Outdoor unit

TH2

SPLIT type

(without a refrigerant-water HEX inside)

Refrigerant piping

FTC2

*1

*1 Refrigerant-water HEX

Water OUTLET

Booster heater

Water piping

TH1

side

DHW tank

temperature

TH5

PACKAGED type outdoor unit with DHW tank

Water OUTLET side

after Booster heater

Outdoor unit

*1

PACKAGED type

(with a refrigerant-water HEX inside)

TH1

Booster heater

Water piping

TH2:

not necessary

*1 Refrigerant-water HEX

FTC2

DHW tank

temperature

TH2

TH5

SPLIT type outdoor unit without DHW tank

Refrigerant LIQUID side

Outdoor unit

TH2

Refrigerant piping

SPLIT type

(without a refrigerant-water HEX inside)

FTC2

*1

*1 Refrigerant-water HEX

10

Water OUTLET

Booster heater

Water piping

TH1

side

TH5:

not necessary

TH5

PACKAGED type outdoor unit without DHW tank

Water OUTLET side

after Booster heater

Outdoor unit

*1

PACKAGED type

(with a refrigerant-water HEX inside)

TH1

Booster heater

Water piping

FTC2

TH2:

not necessary

TH2 TH5

*1 Refrigerant-water HEX

TH5:

not necessary

Page 11

4. Electrical work

4.5. Connecting external output signal

All outputs has AC 230V signal

Output Use Signal Max. current

OUT1 Water circulation pump AC 230A signal for relay drive 0.5 A

OUT2 Booster heater 1 AC 230A signal for relay drive 0.5 A

OUT3 Booster heater 2 AC 230A signal for relay drive 0.5 A

OUT4 Immersion heater AC 230A signal for relay drive 0.5 A

OUT5 3-port valve AC 230A signal for relay drive 0.5 A

OUT6 Defrost AC 230A signal for direct use 0.5 A

OUT7 Error output AC 230A signal for direct use 0.5 A

*FTC2 has terminal beds for AC 230V output signal. (Relays are NOT available on FTC2)

Caution :

Do not drive directly the pump, heater and valve by these output signals.

Connect the surge absorber according to the load at site.

Wiring specifi cation of External output

Locally supplied parts

Item Name Model and specifi cations

External output

function

External output signal

wire

Relay, etc. AC 230V signal 0.5 A or less

Use sheathed vinyl coated cord or cable.

Max. 50m

Wire type : CV, CVS or equivalent

Wire size : Stranded wire 0.5mm² to 1.25mm²

Solid wire: {0.65mm to {1.2mm

*Connect the surge absorber according to the load at site.

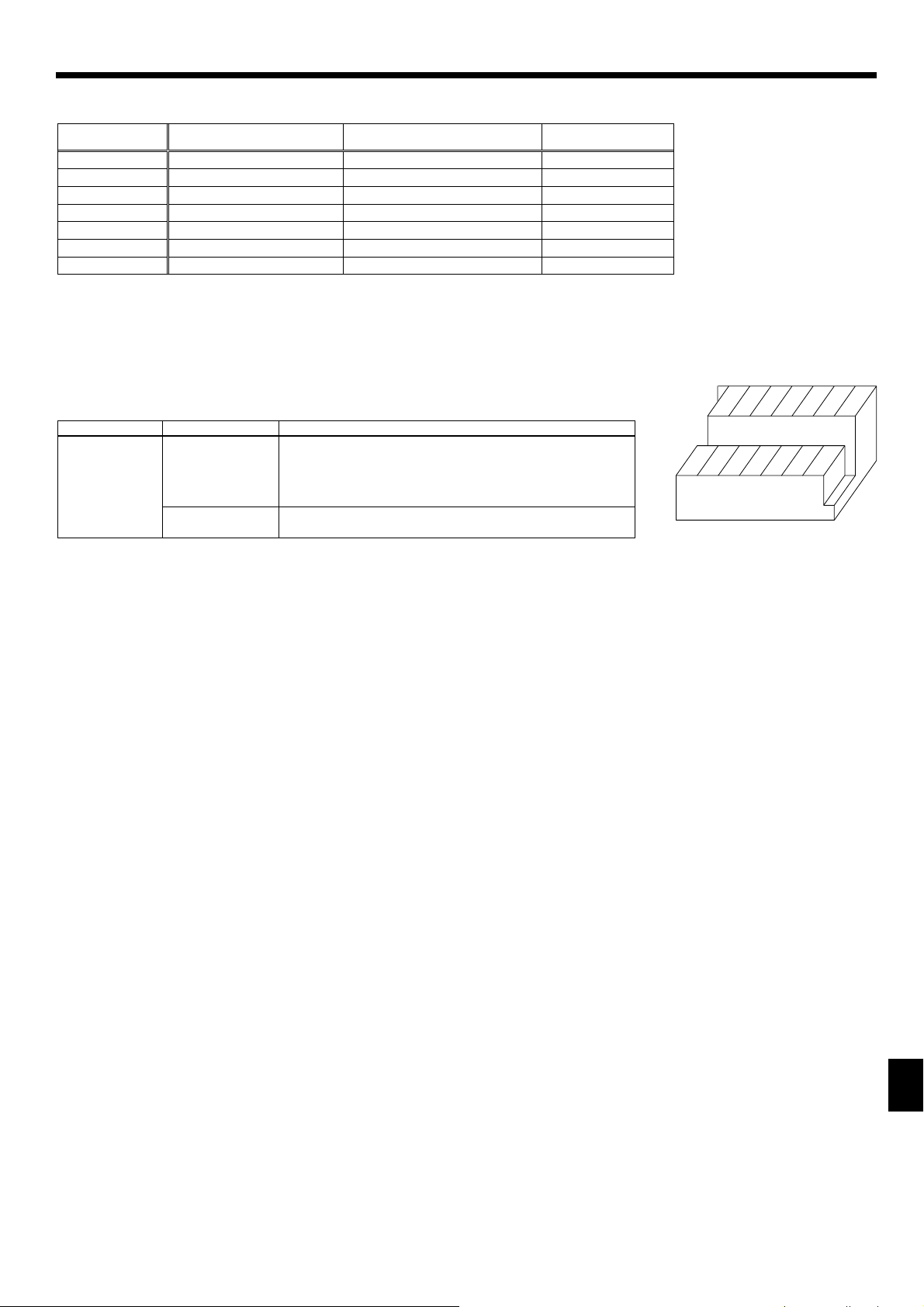

TB141

42

6 8 10 12 14

357911131

11

Page 12

5. Switch setting of FTC2

The functionality of the heat pump is determined by the setting of the Dip switches from SW1 to SW3, and SW6 found on the

FTC2 controller. (Photo. 5-1)

SW1

SW2

SW3

SW6

Photo. 5-1

5.1 Operation mode input method

Input method can be selected with Dip SW 1-1 / 1-2

ON/OFF Input Change mode Input Change TEMP. Input SW1-1 SW1-2 SW6-1 SW6-2

Wired remote controller

(PAR-W21MAA)

External input

(non-voltage contact)

Analog input (1-5V) *1

Analog input (4-20mA) *2

External input

(non-voltage contact)

*1. 4-20mA OFF: 0 ~ 2mA

*2. 1-5V

OFF: 0 ~ 0.5V

Wired remote controller

(PAR-W21MAA)

or External input

External input

(non-voltage contact)

External input

(non-voltage contact)

External input

(non-voltage contact)

External input

(non-voltage contact)

Flow

switch

TH1

TH2

TH5

Wired remote controller

(PAR-W21MAA)

Wired remote controller

(PAR-W21MAA)

Analog input (1-5V) OFF

Analog input (4-20mA) OFF

Analog input (0-10V)

OFF OFF OFF OFF

OFF OFF OFF

ON

ON

ON ON ON

ON ON

Local system controller

External input

IN1 IN2 IN3 IN4 IN5 IN6 IN7 IN8

Emergency

TH1

TH2

TH5

OUT1 OUT2 OUT3 OUT4 OUT5 OUT6 OUT7

Legionella

prevention

Comp

OFF

Heating Hot

Cooling

FTC2

Heating

ECO

Water

OFF

OFF OFF

Anti

freeze

Ana.IN1

ON

Analog input

Non-voltage

contact

Thermostat

Water

circulation

pump

Booster

heater 1

Booster

heater 2

5.2. Thermistor setting

Set Dip SW 1-3 according to whether the system has a DHW tank.

SW 1-3 Setting Notes

OFF With DHW tank Necessary to connect TH5

ON Without DHW tank NOT necessary to connect TH5

When Dip SW 1-3 is ON, DHW mode is NOT available.

Set Dip SW 1-6 according to the connected Heat pump unit type.

SW 1-6 Setting Notes

OFF SPLIT type Necessary to connect TH2

ON PACKAGED type NOT necessary to connect TH2

12

Immersion

heater

3-port

valve

Defrost

Error

PAR-W21MAA

Page 13

5. Switch setting of FTC2

5.3. Heater setting

Set Dip SW 1-4 according to whether the system has an Immersion heater.

SW 1-4 Setting

OFF Without Immersion heater

ON With Immersion heater

Set Dip SW 1-5 according to the location of Booster heater.

SW 1-5 Setting

OFF For both Domestic Hot Water (DHW) and Heating

ON For Heating only or without Booster heater

< Summary: Heater setting >

SW 1-4

Immersion heater

OFF

(Without Immersion heater)

ON

(With Immersion heater)

SW 1-5

Booster heater position

OFF

(For both DHW and Heating)

OFF

(For both DHW and Heating)

Figure

Booster heater

TH1

Booster heater

Sanitary tank

TH5

TH1

Sanitary tank

TH5

Radiator

Immersion heater

Radiator

OFF

(Without Immersion heater)

ON

(With Immersion heater)

ON

(For Heating only)

ON

(For Heating only)

5.4. Other setting

Set Dip SW 1-7 according to the Cooling mode usage.

SW 1-7 Setting

OFF Not in use (Operation mode: Heating/Heating ECO/Hot Water/Anti-freeze)

ON

When Dip SW 1-7 is OFF, Cooling mode is NOT available.

Dip SW 3-4: External input (Ana. IN1) logic change

Exteranl input (Ana. IN1) is for the connection of thermostat.

SW 3-4 Ana. IN1 (TB62 No.1, 2) input Item

OFF

ON

*1 In case of Cooling, Heating, Heating Eco, Anti-freeze.

In use (Operation mode: Heating/Heating ECO/Hot Water/Anti-freeze/Cooling)

OFF (open) Normal operation

ON (short) Heat pump unit OFF *1

OFF (open) Heat pump unit OFF *1

ON (short) Normal operation

TH5

TH5

Sanitary tank

Booster heater

Sanitary tank

Booster heater

Radiator

TH1

Immersion heater

Radiator

TH1

Dip SW 3-6: External input (IN1) logic change

SW 3-6 IN1 (TB142 No.5, 6) input Item

OFF

ON

OFF (open) Normal operation

ON (short) Heat pump unit OFF

OFF (open) Heat pump unit OFF

ON (short) Normal operation

Dip SW 3-5, 3-8: Not in use. Set to OFF. (Initial setting)

13

Page 14

6. Operation setting

6.1. Automatic change over mode

When a system includes a Domestic Hot Water (DHW) tank and a space heating requirement Automatic change over mode should be selected.

Selection is made with Dip SW1-8.

If the system does NOT include a DHW tank Dip SW 1-3 is ON and Automatic change over mode is invalid.

SW 1-8 Operation

OFF With Automatic change over mode (the system has a DHW tank).

ON

Without

OR

Operations on each mode with Automatic change over mode.

<SW1-1 OFF / SW1-2 OFF>

Mode System operation

Heating Heating and DHW (Automatic change over mode)

Heating ECO Heating with Weather compensation and DHW (Automatic change over mode)

Hot Water Domestic Hot Water only

Anti-freeze Prevents pipe work freezing during periods of inactivity

<SW1-1 ON / SW1-2 OFF or SW1-1 OFF / SW1-2 ON or SW1-1 ON / SW1-2 ON>

Mode System operation

Heating Heating only *

Heating ECO Heating only with Weather compensation *

Hot Water Domestic Hot Water only *

Anti-freeze Prevents pipe work freezing during periods of inactivity

*1 Automatic change over mode is available only when SW1-1/1-2 is set ON/OFF and the FTC2 receives

external signals for Heating (or Heating ECO) and DHW at the same time from the local controller.

Automatic change over mode is NOT available when SW1-1/1-2 are set OFF/ON or ON/ON.

Automatic change over mode (the system does NOT have a DHW tank).

The end user would like to control the switch over between DHW and space heating.

1

1

1

Operations on each mode without Automatic change over mode.

Mode System operation

Heating Heating only

Heating ECO Heating only with Weather compensation

Hot Water Domestic Hot Water only

Anti-freeze Prevents pipe work freezing during periods of inactivity

When automatic change over mode is selected DHW always has priority over space heating.

System examples

Example 1:

Only our Remote controller (PAR-W21MAA) is used for system control.

NO local system controller exists.

Target temperature for each mode and Heating or Heating ECO mode are set

with PAR-W21MAA. Automatic change over mode is selected (SW 1-8 must

be switched to OFF). The system will automatically change from Heating or

Heating ECO to DHW mode and back dependent on the DHW tank temperature (TH5).

Example 2:

A local timer and our Remote controller (PAR-W21MAA) are used

for system control.

Target temperature for each mode and Heating or Heating ECO mode are set

with PAR-W21MAA.

A local timer is used rather than automatic change over mode (SW1-8 must

be switched to ON). The system runs in Heating or Heating ECO until a signal

is received from the local timer (the signal received from local timer must

be longer than 200 ms). The system then switches to DHW mode.

Once DHW mode is satisfied the system automatically reverts to Heating or

Heating ECO.

SW 1-1 OFF / SW 1-2 OFF / SW 1-8 OFF

Flow

switch

TH1

TH2

TH5

SW 1-1 OFF / SW 1-2 OFF / SW 1-8 ON

Flow

switch

TH1

TH2

TH5

IN1 IN2 IN 3 IN4 IN5 IN6 IN7 IN8

Emergency

TH1

TH2

TH5

OUT1 OUT2 OUT3 OUT4 OUT5 OUT6 OUT7

Water

circulation

pump

Legionella

prevention

Booster

heater 1

Comp

OFF

Booster

heater 2

Heating Hot

Cooling

FTC2

Immersion

heater

Heating

ECO

3-port

valve

Water

Defrost

Local timer

External input

IN1 IN2 IN3 IN4 IN5 IN6 I N7 IN8

Emergency

TH1

TH2

TH5

OUT1 OUT2 OUT3 OUT4 OUT5 OUT6 OUT7

Water

circulation

pump

Legionella

prevention

Booster

heater 1

Comp

OFF

Booster

heater 2

Heating Hot

Cooling

FTC2

Immersion

heater

Heating

ECO

3-port

valve

Water

Defrost

Anti

freeze

Error

Anti

freeze

Error

PAR-W21MAA

PAR-W21MAA

14

Page 15

6. Operation setting

System examples

Example 3:

A Local controller and our Remote controller (PAR-W21MAA) are used

for system control.

Target temperatures for each mode are set with PAR-W21MAA.

A local controller is used to select the running mode rather than Automatic

change over mode (SW 1-8 is switched to ON).

Automatic change over mode is available when SW1-8 is OFF and the FTC2

receives external signals for Heating (or Heating ECO) and DHW at the same

time from the local controller.

<IMPORTANT NOTE>

In this system, the operation mode must be switched by a local controller

which can output separate signals for each operation mode.

(This can be realised by using a schedule timer and relays.)

Example 4:

ONLY a Local controller is used for system control.

The system operates in the same way as Example 3 except that the target

temperatures for each mode must also be inputted via the analogue signal

from the local controller. (SW1-8 must be switched to ON)

<IMPORTANT NOTE>

In this system, the operation mode must be switched by a local controller

which can output separate signals for each operation mode. In addition,

the target temperature in each operation mode must be sent by ANALOG

signal from the local controller.

SW 1-1 ON / SW 1-2 OFF / SW 1-8 ON

or SW 1-1 ON / SW 1-2 OFF / SW 1-8 OFF

Local system controller

Heating Hot

Cooling

FTC2

Immersion

heater

External input

Heating

ECO

3-port

valve

Defrost

Water

Anti

freeze

Error

Error

PAR-W21MAA

Flow

switch

TH1

TH2

TH5

IN1 IN2 IN3 IN4 IN5 IN6 I N7 IN8

Emergency

TH1

TH2

TH5

OUT1 OUT2 OUT3 OU T4 OU T5 OUT6 OUT7

Water

circulation

pump

Legionella

prevention

Booster

heater 1

Comp

OFF

Booster

heater 2

SW 1-1 OFF / SW 1-2 ON / SW 1-8 ON

or SW 1-1 ON / SW 1-2 ON / SW 1-8 ON

Local system controller

Heating Hot

Cooling

FTC2

External input

Heating

ECO

Water

Anti

freeze

Flow

switch

TH1

TH2

TH5

IN1 IN2 IN3 IN4 IN5 IN6 IN7 IN8

Emergency

TH1

TH2

TH5

OUT1 OUT2 OUT3 O UT4 OUT5 OUT6 OUT7

Legionella

prevention

Comp

OFF

Analog input

Water

circulation

pump

Booster

heater 1

Booster

heater 2

Immersion

heater

3-port

valve

Defrost

Error

Error

6.2. DHW OFF conditions

DHW can be selected in 2 ways

Pattern 1.

An external input or remote controller is used to switch to DHW mode.

DHW pattern 1 will turn off when the DHW tank reaches set temperature consecutively for 1 minute.

Then the heat pump will turn OFF

Pattern 2.

Automatic change over mode or an external input (e.g. Local timer – signal received must last > 5secs) is used to switch to DHW mode.

DHW pattern 2 will switch off under the following conditions;

a) The DHW tank reaches set temperature T

b) The system has been in DHW mode consecutively for H

(This allows the system to switch back to Heating or Heating ECO mode should the system fail to reach the set temperature for any reason)

System operation status at start-up H

First power-on

First starting up after Initial filling up

TH5 < 25 deg C (Tank temperature is low.)

Others

* As shown in the table, H

time

becomes longer when the water temperature in the tank is low. This is to delay the operation switchover to Heating mode.

Then the heat pump will revert to Heating or Heating ECO mode.

HW consecutively for 1 minute.

time (minutes)

time (minutes)

300

180

15

Page 16

6. Operation setting

6.3. DHW Heating Procedure

The heating of DHW tank is done in 2 stages, firstly the "Heat pump phase" followed by the "Electric heater phase".

6.3.1. Heat Pump Phase

The Heat pump phase for DHW mode, is used when the temperature difference between tank set temperature and

TH5iseither10degCor20degC(∆T

∆T

H is selected using Dip SW2-1

SW 2-1 Operation

OFF ∆T

ON

H =10degC

∆T

H =20degC

The heat pump will turn off or revert to heating when:

Tank temperature (TH5) > DHW set temperature consecutively for 1 minute.

Heat Pump Operation

The heat pump will be controlled directly by the FTC2 while in DHW mode. The operation characteristics can be selected using Dip SW2-2.

Option 1 – COP priority mode

In this mode the heat pump will heat the water over a slightly longer period of time with a controlled frequency, improving the coefficient of

performance. The result of this will be a more economical DHW heat up.

Option 2 – Speed priority mode

In this mode the heat pump will run at maximum frequency during DHW heat up. The result of this will be a reduced time to heat the tank but also

areductioninCOPandsoanincreaseinenergyconsumption.

SW 2-2 Operation

OFF

ON

COP priority mode

(Operation frequency is controlled to have higher COP.)

Speed priority mode

(Heat pump unit runs at the maximum frequency to reduce operation time.)

There is a 30 sec. delay in the Heat pump unit start to ensure the water circulation pump starts running before the Heat pump unit.

H)

Other factors in the Heat pump phase

Heat pump status

Water circulation

pump status

3-port valve

status

ON for DHW ON ON

OFF for DHW OFF OFF

Booster heater 1

status

Booster heater 2

status

Electric heaters are not used in the Heat pump

phase

Immersion

heater status

6.3.2. Electric Heater Phase

Electric heater phase for DHW, is used when tank temperature (TH5) is less than DHW set temperature and the temperature increase is in

10 minutes is smaller than 1 deg C.

Electric heater phase will switch off when:

Tank temperature TH5 > DHW set temperature consecutively for 1 minute.

Electric Heater Phase Operation

The electric heater phase will vary dependent on the position of the heater within the heating circuit.

Electric heater phase TYPE B

Immersion

ON

heater

TH5

Sanitary tank

Immersion heater

Booster

Booster

heater

heater OFF

Radiator

TH1

Heat

Booster

heater

Electric heater phase TYPE A

Immersion

ON

heater

Sanitary tank

TH5

ON

TH1

Booster

heater

Immersion heater

Radiator

Heat

pump

unit

OFF

pump

unit

ON

Pump

ON

Keep to

DHW circuit

Pump

ON

Switch to

Heating circuit

The Dip switch settings for this operation are given in the following table.

SW 1-4 SW1-5

(Immersion heater) (Booster heater)

OFF

without

(

ON

with

(

IH)

OFF

without

(

ON

(with IH)

IH)

IH)

OFF

(BH for both DHW and Heating)

OFF

(BH for both DHW and Heating)

ON

(BH for Heating only)

ON

(BH for Heating only)

(Immersion heater used)

No heater in DHW circuit No heater in DHW circuit

OFF

TYPE A TYPE A

TYPE A TYPE A

TYPE B No heater in DHW circuit

* BH : Booster heater IH : Immersion heater

16

SW 2-7

ON

(Immersion heater not

used or only for Legionella)

Page 17

6. Operation setting

System Characteristics

System type

A (SW1-5 OFF)

B (SW1-4 ON,

SW1-5 ON,

SW2-7 OFF)

Heat pump

status

ON ON ON ON ON ON

OFF ON OFF OFF OFF

Water circulation

pump status

3-port valve

status

Booster heater

1 status

Booster heater

2 status

Immersion

heater status

ON

Heater operation at Electric heater phase in Domestic Hot Water mode

SW 2-7

SW 1-4 SW1-5

(Immersion heater) (Booster heater)

OFF

without

(

ON

with

(

OFF

without

(

ON

with

(

IH)

IH)

IH)

IH)

OFF

(BH for both DHW and Heating)

OFF

(BH for both DHW and Heating)

ON

(BH for Heating only)

ON

(BH for Heating only)

(Immersion heater used)

OFF

BH1,2 : ON

IH : OFF

ON

BH1,2 :

ON

IH :

(Immersion heater not

used or only for Legionella)

BH1,2 : ON

IH : OFF

BH1,2 :

IH : OFF

No heater in DHW circuit No heater in DHW circuit

BH1,2 : OFF

ON

IH :

No heater in DHW circuit

ON

ON

* BH : Booster heater IH : Immersion heater

6.4. Legionella Prevention mode

It is recommended that sanitary hot water stored in t

In Legionella prevention mode, the system runs to let the temperature in the DHW tank (TH5) reach TLP deg C. The temperature TLP

can be set using Dip SW 2-6.

SW 2-6 Setting temperature

OFF T

ON T

LP=60 deg C

LP=65 deg C

The 65 deg C setting can NOT be selected when the there is no heater in the DHW circuit, Dip SW settings is as follows;

SW 1-4 OFF and SW1-5 ON

anks is heated periodically to 60 deg C or above for the prevention of Legionella.

6.4.1. Start Condition and Finish Conditions

How often the Legionella prevention operation is activated is selected using Dip SW 2-4 and 2-5.

SW 2-4 SW 2-5 Operation

OFF OFF Activate every DHW operation.

ON OFF Activate every "15 times" DHW operations.

OFF ON Activate every "150 times" DHW operations.

ON ON Activate by external input signal (IN2)

Legionella prevention mode is satisfied when TH5> T

LP deg C consecutively for 1 minute

The Legionella prevention mode is satisfied in 2 stages, firstly the heat pump phase followed by the electric heater phase.

Electric heater phase is required if tank temperature (TH5) does not increase for some reason or once TH5 reaches the set temperature T

HW.

Start Electric heater phase conditions:

TH5 temperature increase in 10 minutes < 1degC OR

TH5 > DHW set temperature (T

HW)consecutivelyfor1 minute

Finish Electric heater phase condition:

TH5 > T

LP deg C consecutively for 1 minute

6.5. Heating and Heating ECO mode

Choice of either Heating or Heating ECO mode is made using the PAR-W21MAA or local controller. Both modes use the Heat pump to heat the

water to the set point T

if needed.

There is a 1 minute delay before the Heat pump unit starts, so that the Water circulation pump starts running earlier than the Heat pump.

6.5.1. Water Circulation Pump

In Heating or Heating ECO mode the Water circulation pump can be either on continually or turned off 5 minutes after the Heat pump unit stops

operating at which point it will then cycle ON for 1 minute OFF for 3 minutes repeatedly. The setting is selected using Dip SW2-3

SW 2-3 Operation

OFF Always ON (to prevent water circuit from freezing)

ON

OFF 5 minutes after Heat pump unit stops operation. Then the pump will switch ON

for 1 minute OFF for 3 minutes repeatedly until the heat pump starts again.

HE and then allow for the use of Booster heaters if present on the heating circuit to raise the space heating flow temp (TH1)

6.5.2. Booster Heater

If Booster heater is NOT used in Heating mode, Dip SW2-8 must be switched ON.

SW 2-8 Operation

OFF Booster heater used in Heating mode

ON

Booster heater is NOT used in Heating mode (Booster only used in DHW

mode, Legionella prevention mode and Emergency mode)

17

Page 18

6. Operation setting

6.6. Defrost operation

The heat pump process requires regular defrost cycles. The FTC2 operates as follows when the system receives defrost signal and when it

completes defrosting.

6.6.1. When defrost signal is received

3-port valve

In DHW mode the 3-port valve remains ON.

In heating mode the valve can be OFF enabling the Heat pump unit to defrost while keeping the heat in the heating circuit or switched to ON so

system is defrosted using accumulated heat.

Selection is made using Dip SW3-1

SW 3-1 Operation

OFF Remains OFF (defrost while keeping Heating circuit).

ON

Other factors in the Defrost operation

Heat pump status

Defrost operation

6.6.2. When System completes defrost operation

All water circuit parts return to normal settings except for the Heat pump unit.

Heat Pump unit

If the unit was running in Heating or Heating ECO previous to the defrost cycle the system restricts the maximum frequency for 10 minutes from

completion of defrost. In this time it considers the operation it was previously performing.

* The maximum frequency shall be restricted as follows depending on the temperature drop of outlet water during the defrost operation.

Temperature differential at the

beginning of defrost operation

HE Maximum frequency is NOT restricted.

T

HE -TH1<2degC

T

Switch to ON (switch to DHW circuit to defrost. The system defrosts using

accumulated heat for defrosting).

Water circulation

pump status

ON

Booster heater 1

status

Booster heater 2

status

Electric heaters have the same control in each mode

Operation

- TH1 2 deg C

Maximum frequency is restricted for 10 minutes.

Immersion heater

status

6.7. Cooling mode (not available on some models)

Cooling mode works in a similar manner to Heating mode. The heat pump unit is controlled by the FTC2 and has a 1 minute delay in starting to

allow for the Water circulation pump to start before the Heat pump unit.

The operation of the Water circulation pump is selected using Dip SW 2-3 as before

SW 2-3 Operation

OFF Always ON (to prevent water circuit from freezing)

ON

OFF 5 minutes after Heat pump unit stops operation. Then the pump will switch ON

for 1 minute OFF for 3 minutes repeatedly until the heat pump starts again.

The 3-port valve is always OFF in Cooling mode.

The Booster heaters and the Immersion heater are always OFF in Cooling mode.

6.8. Anti-freeze mode

Anti-freeze mode is selected using the PAR-W21MAA or local controller.

Anti-freeze mode characteristics

Anti-freeze mode

Heat pump

status

ON ON ON

OFF OFF ON OFF NOT USED

Water circulation

pump status

Booster heater 1

status

Booster heaters have same control as in

Heating mode

Booster heater 2

status

Immersion

heater status

NOT USED

18

Page 19

6. Operation setting

6.9. Emergency (electric heater only) mode

Emergency mode is available in case of Heat pump unit's failure. In this mode, only electric heater operates as a heat source. Heat pump unit

operation comes first in any operation mode, except in Emergency mode. In the Emergency mode, the heater is switched ON without operating

Heat pump unit.

IMPORTANT: If there are no electric heaters in the circuit "Emergency mode" can not operate.

Emergency mode can activated when the system has external input (IN1) or if Dip SW 3-7 is manually switched to ON.

SW 3-7 Operation

OFF Normal operation

ON

6.9.1. Start condition

Emergency mode shall start when one of the following conditions is fulfilled.

a) The system has external input (IN1).

b) SW 3-7 is ON

6.9.2. Finish condition

Emergency mode shall finish when all of the following conditions are fulfilled.

a) The system does NOT have external input (IN1).

b) SW 3-7 is OFF

Operation mode is selected by local system controller or remote controller settings.

6.9.3. In Domestic Hot Water mode

Heat pump unit is OFF.

Electric heater phase starts immediately.

When the switch setting is for "No heater in DHW circuit", phase can NOT be switched to Electric heater phase.

(System keeps thermo OFF.)

Emergency (electric heater only) mode

.

6.9.4. In Legionella prevention mode

Heat pump unit is OFF.

Electric heater phase starts immediately.

When the switch setting is for "No heater in DHW circuit", phase can NOT be switched to Electric heater phase.

(System finishes Legionella prevention mode.)

6.9.5. In Heating and Anti-freeze mode

Heat pump

status

OFF

Water circulation

pump status

ON

Booster heater 1 status Booster heater 2 status

ON when Heat pump runs

consecutively for 0minuteAND

T

HE -TH1 1deg C

ON when BH1 is ON

consecutively for 10 minutes AND

T

HE -TH1 1degC

Immersion

heater status

NOT USED

6.9.6. Return to Normal operation

When returning from Emergency (electric heater only) mode to Normal operation mode, stop sending the signal of external input (IN1) and switch off

Dip SW 3-7.

Then turn off the power of the outdoor unit and FTC2, and start up the system again.

19

Page 20

6. Operation setting

6.10. SUMMARY of Dip Switch Functions

Dip switch Function OFF ON

Change mode

Input

Remote controller

or External input

SW1-1

SW1-1 SW1-2 ON/OFF Input

OFF OFF Remote controller

Change TEMP.

Input

Remote controller

System select

SW1-2

SW1

ON OFF External input Remote controller

OFF ON

ON ON External input

Analog input

(4-20mA/1-5V)

External input

SW1-3 Domestic Hot Water tank with DHW tank without DHW tank

SW1-4 Immersion heater without Immersion heater with Immersion heater

SW1-5 Booster heater position For both DHW and Heating

For Heating only or without Booster

heater

SW1-6 Connected Heat pump unit type SPLIT type PACKAGED type

SW1-7 Cooling mode usage Not in use In use

SW1-8 Automatic change over mode with Automatic change over mode

without Automatic change over mode

SW2-1 Thermo differential in DHW mode 10 deg C 20 deg C

SW2-2 H/P unit control in DHW mode COP priority mode Speed priority mode

SW2

SW2-3

SW2-4

SW2-5

Water circulation pump control in Heating mode

Legionella prevention mode select

Always ON OFF 5 min. after H/P unit stops

SW2-4 SW2-5 Operation

OFF OFF Activate every DHW operation.

ON OFF

OFF ON

ON ON

Activate every

"15 times" DHW operations.

Activate every

"150 times" DHW operations.

Activate by external input signal

(IN2)

Analog input

(4-20mA/1-5V)

Analog input

(0-10V)

SW2-6

SW2-7

Set temperature in Legionella prevention mode

Immersion heater usage in Domestic Hot

Water mode

60 deg C 65 deg C

In use Not in use

SW2-8 Booster heater usage in Heating mode In use Not in use

SW3-1

3-port valve control during defrost in

Heating mode

OFF (Heating circuit) ON (Domestic Hot Water circuit)

SW3-2 Pump control for Initial fi lling up OFF ON

SW3-3 3-port valve control for Initial fi lling up OFF ON

SW3

SW3-4 External input (Ana. IN1) logic change Comp. OFF at short Comp. OFF at open

SW3-5 - - -

SW3-6 External input (IN3) logic change Comp. OFF at short Comp. OFF at open

SW3-7 Emergency (electric heater only) mode Normal operation

Emergency (electric heater only) mode

SW3-8 - - -

SW6-1 SW6-2 Analog input setting

SW6

SW6-1

Analog input setting

OFF OFF 0-10 V or Analog input is not in use

ON OFF —

OFF ON 1-5 V

SW6-2

ON ON 4-20 mA

20

Page 21

7. Before test run

7.1. Check

After completing installation and the wiring and piping of the local application and outdoor units, check for refrigerant leakage, looseness in the power

supply or control wiring, wrong polarity, and no disconnection of one phase in the supply.

Use a 500-volt megohmmeter to check that the resistance between the power supply terminals and ground is at least 1.0MΩ.

Warning:

Do not use the system if the insulation resistance is less than 1.0MΩ.

Caution:

Do not carry out this test on the control wiring (low voltage circuit) terminals.

7.2. Self-check

Turn on the power.

1

Press [CHECK] button twice.

2

Press [CHECK] button twice to fi nish self-check.

3

CHECK button B IC : FTC2 unit OC : Outdoor unit C Check code

A

Check code Symptom

P1 Flow water (TH1) sensor error

P2 Refrigerant liquid Pipe (TH2) sensor error

P6 Freezing/Overheating protection operation

P9 Actual tank temp. (TH5) sensor error

Fb FTC2 unit control system error (memory error, etc.)

E0~E5 Signal transmission failure between remote controller and FTC2.

E6~EF Signal transmission failure between outdoor unit and FTC2.

– – – – No trouble generated in the past.

FFFF No corresponding unit

U*, F* Outdoor unit failure. Refer to the outdoor unit wiring diagram.

TEMP.

For description of each LED(LED1~5) provided on the FTC2, refer to the following table.

LED 1 (Power for microcomputer) Indicates whether control power is supplied. Make sure that this LED is always lit.

LED 2 (Power for remote controller) Indicates whether power is supplied to the remote controller. This LED lights only in the case of the FTC2 unit

LED 3

(Communication between FTC2 and outdoor unit)

LED 4 for maintenance —

LED 5 for maintenance —

which is connected to the outdoor unit refrigerant address “0“.

Indicates state of communication between the FTC2 and outdoor unit. Make sure that this LED is always blinking.

ERROR CODE

ON/OFF

7.3. Initial filling up

When the system is installed, the whole circuit must be filled with water. At this stage, Water circulation pump and 3-port valve shall be operated

individually.

Water circulation pump operates according to Dip SW 3-2 setting.

SW 3-2 Operation

OFF Water circulation pump is OFF.

ON

3-port valve operates according to Dip SW 3-3 setting.

SW 3-3 Operation

OFF 3-port valve is OFF.

ON

*NOTE

Even if you forget to reset the Dip SW settings above, the normal operation mode can be recovered automatically in 60 minutes.

Water circulation pump is ON.

(It is switched OFF after 60 minutes consecutive operation.)

3-port valve is ON.

(It is switched OFF after 60 minutes consecutive operation.)

21

Page 22

8. Remote controller operation

Note (Marking for

WEEE)

This symbol mark is for EU countries only.

This symbol mark is according to the directive 2002/96/EC Article 10 Information for users and Annex IV.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and components which can be recycled and reused.

This symbol means that electrical and electronic equipment, at their end-of-life, should be disposed of separately from your household waste.

Please, dispose of this equipment at your local community waste collection/recycling centre.

In the European Union there are separate collection systems for used electrical and electronic product.

Please, help us to conserve the environment we live in!

8.1. Safety precautions

► Before installing the unit, make sure you read all the “Safety Precau-

tions”.

► The “Safety Precautions” provide very important points regarding

safety. Make sure you follow them.

► Please report to or take consent by the supply authority before connec-

tion to the system.

Warning:

• For appliances not accessible to the general public.

• The unit must not be installed by the user. Ask the dealer or an authorized

company to install the unit. If the unit is installed improperly, water leakage, electric shock or fi re may result.

• Do not stand on, or place any items on the unit.

• Do not splash water over the unit and do not touch the unit with wet hands.

An electric shock may result.

• Do not spray combustible gas close to the unit. Fire may result.

• Do not place a gas heater or any other open-fl ame appliance where it will

be exposed to the air discharged from the unit. Incomplete combustion

may result.

• Do not remove the front panel or the fan guard from the outdoor unit when

it is running.

• When you notice exceptionally abnormal noise or vibration, stop operation, turn off the power switch, and contact your dealer.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates a part which must be grounded.

• Never insert fi ngers, sticks etc. into the intakes or outlets.

• If you detect odd smells, stop using the unit, turn off the power switch and

consult your dealer. Otherwise, a breakdown, electric shock or fi re may

result.

• This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

• If the refrigeration gas blows out or leaks, stop the operation of the air

conditioner, thoroughly ventilate the room, and contact your dealer.

• Do not install in location that is hot or humid for long periods of time.

Caution:

• Do not use any sharp object to push the buttons, as this may damage the

remote controller.

• Never block or cover the indoor or outdoor unit’s intakes or outlets.

Disposing of the unit

When you need to dispose of the unit, consult your dealer.

22

Page 23

8. Remote controller operation

8.2. Parts name

■

Wired Remote-Controller

Display Section

For purposes of this explanation,

all parts of the display are shown.

During actual operation, only the

relevant items will be displayed.

Identifi es the current operation

Shows the operating mode, etc.

* Multi language display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited

by a master controller.

“Timer is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Operation Section

Shows the current day of the week.

Time/Timer Display

Day-of-Week

Shows the current time, unless the

simple or Auto Off timer is set.

If the simple or Auto Off timer is set,

shows the time remaining.

TIME SUN MON TUE WED THU FRI SAT

TIMER

AFTER

ERROR CODE

˚F˚C

ON/OFF indicator

Indicates if timer is set ON/OFF.

ON

Hr

OFF

AFTER

˚F˚C

FUNCTION

WEEKLY

“Locked” indicator

Indicates that remote controller buttons have been locked.

Timer indicators

The indicator comes on if the corresponding timer is set.

Error indicator

Comes on when error occurs.

Temperature indicator

Shows the current water temperature.

(Power On indicator)

Indicates that the power is on.

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

ON/OFF button

Setting change button

CIR. WATER button

(<Enter> button)

Not available

TEST run function is not

available with this FTC2

unit.

Self check (Clear) button

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

lid

TEMP.

ON/OFF

Note:

● “PLEASE WAIT” message

This message is displayed for approximately 3 minutes when power is supplied to the FTC2 unit or when the unit is recovering from a power

failure.

● “NOT AVAILABLE” message

This message is displayed if a button is pressed to operate a function that the FTC2 unit does not have, or a function that is not available due to

the setting.

23

Page 24

8. Remote controller operation

Function Selection of remote

controller

Standard Control Screens

OFF ON

Set Day/Time

TIME SUN

˚F˚C

˚C

<Screen confi guration>

For details on setting the language for the remote controller display, refer

to 8.6. Function Selection.

The initial language setting is English.

● Function Selection of remote controller:

● Set Day/Time:

● Standard Control Screens:

Set the functions and ranges available to the remote

controller (timer functions, operating restrictions, etc.)

Set the current day of the week or time.

View and set the air conditioning system’s operating

status

<How to change the screen>

A : Hold down both the Mode button 2 and the Timer On/Off button 9

for 2 seconds.

B : Press either of the Set Time buttons ( or ) 1.

c : Press the Mode button 2.

TEMP.

1

Day of the Week

TIME SUN

˚C

˚C

ON/OFF

& Time display

9

42

8.3. Setting the day of the week and time

1. Press the or Set Time button 1 to show display 2.

2. Press the Timer On/Off (Set Day) button 9 to set the day.

* Each press advances the day shown at 3 :

Sun → Mon → ... → Fri → Sat.

3. Press the appropriate Set Time button 1 as necessary to set the time.

* As you hold the button down, the time (at 4) will increment fi rst in

one-minute intervals, then in ten-minute intervals, and then in 1-hour

intervals.

1

4. After making the appropriate settings at Steps 2 and 3, press the

button 4 to lock in the values.

Note:

Day of the Week Setting

3

2

TIME SUN

Time Setting

4

The day and time will not appear if clock use has been disabled at

Function Selection of remote controller.

8.4. Operation

Available items are different depending on your system.

(Refer to section 3.)

8.4.1. Switching

<To Start Operation>

■ Press the ON/OFF button 1.

• The ON lamp 1 and the display area come on.

Note:

When the unit restarts, the previous settings are recalled as follows.

Remote controller setting

Mode Last operation mode

Temperature setting Last set temperature

TEMP.

˚C

˚C

ON/OFF

1

1

24

<To Stop Operation>

■

Press the ON/OFF button 1 again.

• The ON lamp 1 and the display area go dark.

Note:

Even if you press the ON/OFF button to restart the system while

turning down the operation, the outdoor unit will not start for about

3 minutes.

This is to prevent the internal components from being damaged.

Page 25

8. Remote controller operation

8.4.2. Mode select

Press operation mode ( ) button 2 and select operation mode .

Heating mode (Space heating)

Heating ECO mode (

Space heating with weather compensation *1

)

Hot water mode (Domestic hot water)

Anti freeze mode (

Heating to prevent water pipe from freezing

)

Cooling mode (Space cooling)

*1

Target fl ow temp. varies according to the outdoor temperature. (Refer

to 9. for setting.)

*2 While Automatic change over mode or Legionella prevention mode,

the operation mode is switched in Hot water mode automatically

although during the other operation mode. After fi nishing Automatic

change over mode or Legionella prevention mode, the previous operation mode is recalled.

2

3

˚C

TEMP.

˚C

ON/OFF

3

2

<How to Lock the Buttons>

1. While holding down the CIR. WATER button 4, press and hold down

the ON/OFF button 1 for 2 seconds. The “Locked” indication appears

on the screen (at 1), indicating that the lock is now engaged.

* If locking has been disabled in Function Selection of remote control-

ler, the screen will display the “Not Available” message when you

press the buttons as described above.

˚C

˚C

1

FUNCTION

• If you press a locked button, the “Locked” indication (at 1) will blink

on the display.

˚C

˚C

1

FUNCTION

<How to Unlock the Buttons>

1. While holding down the CIR. WATER button 4, press and hold down

the ON/ OFF button 1 for 2 seconds—so that the “Locked” indication

disappears from the screen (at 1).

8.4.3. Temperature setting

► To decrease the target temperature:

Press

button 3 to set the desired temperature.

The selected temperature is displayed 3.

► To increase the target temperature:

Press button 3 to set the desired temperature.

The selected temperature is displayed 3.

Note: Heating ECO mode sets the set temperature depending on

the outdoor temperature.

While Legionella prevention mode, the set temperature is

switched in 60 °C or 65 °C automatically.

8.5. Other Functions

8.5.1.

Locking the Remote Controller Buttons (Operation function limit)

■ If you wish, you can lock the remote controller buttons. You can use

the Function Selection of remote controller to select which type of lock

to use.

(For information about the lock type, refer to 8.6, item [2].)

Specifi cally, you can use either of the following 2 lock types.

1 Lock All Buttons:

Locks all of the buttons on the remote controller.

2 Lock All Except ON/OFF:

Locks all buttons other than the ON/OFF button.

Note:

The “Locked” indicator appears on the screen to indicate that buttons are currently locked.

Lock Indicator

1

˚C

˚C

1

TEMP.

TIME SUN

FUNCTION

˚C

˚C

ON/OFF

1

4

25

Page 26

8. Remote controller operation

8.5.2. Error Codes indication

ERROR CODE

ON/OFF

ON lamp

(Blinking)

Indoor Unit’s Refrigerant Address

If you have entered contact number to be called in the event of a problem, the screen displays this number.

(You can set this up under Function Selection of remote controller. For information, refer to 8.6.)

●

If the ON lamp and error code are both blinking: This means that the air conditioner is out of order and operation has been stopped (and cannot re-

Error Code Indoor Unit No.

Alternating Display

sume). Take note of the indicated unit number and error code, then switch off the power to the air conditioner and call your dealer or service.

When the Check button is pressed:

ERROR CODE

˚C

●

If only the error code is blinking (while the ON lamp remains lit): Operation is continuing, but there may be a problem with the system. In this case,

˚C

ON/OFF

Error Code

CALL:XXXX

XXX:XXX

ON/OFF

you should note down the error code and then call your dealer or service for advice.

* If you have entered contact number to be called in the event of a problem, push the Check button to display it on the screen. (You can set this up

under Function Selection of remote controller. For information, refer to 8.6.)

8.6. Function Selection

Various remote controller functions are selectable in the remote controller function selection mode. Change setting when needed.

Item 1 Item 2 Item 3

1. Change language

(“CHANGE LAN-

GUAGE”)

2. Function limit

(“FUNCTION SELEC-

TION”)

3. Mode selection

(“MODE SELECTION”)

4. Display change

(“DISP MODE SET-

TING”)

Language setting to display • Some European languages are selectable.

(1) Operation function limit setting (operation lock) (“LOCKING

FUNCTION”)

(2) Use of operation mode setting (“SELECT MODE”) • Setting the use or non-use of operation mode

(3) Temperature range limit setting (“LIMIT TEMP FUNCTION”) • Setting the temperature adjustable range (maximum, minimum)

(1) Remote controller main/sub setting (“CONTROLLER MAIN/

SUB”)

(2) Use of clock setting (“CLOCK”) • To select the use or non-use of clock function

(3) Timer function setting (“TIMER MODE”) • To select the timer type

(4) Contact number setting in case of fault (“CALL.”) • Contact number display in case of error

(5) Temperature offset setting (“TEMP OFFSET FUNCTION”) • To select the use or non-use of the water temperature offset function

(1) Temperature display °C/°F setting (“TEMP MODE °C/°F”) • To select the temperature unit (°C or °F) to display

(2) Water temperature display setting (“WATER TEMP. DISP.

SELECT”)

• To invalidate some functions.

• Selecting main or sub remote controller

* When 2 remote controllers are connected to 1 group, 1 controller

must be set to sub.

• To select the telephone number

• To select the use or non-use of the display of “actual fl ow water tem-

perature”

26

Page 27

8. Remote controller operation

[Function selection flow chart]

Setting language (English)

Normal display

Hold down the () button and press the () button for 2 seconds.

Hold down the () button and press the () button for 2 seconds.

Change

Language

Function

selection

English

Germany Spanish

Swedish French

Russian

Italian

OFF No1

No2

Dot display

OFF … Operation lock setting is not used. (Initial setting)

No1 … Operation lock setting for all buttons except ON/OFF is active.

No2 … Operation lock setting for all button is active.

TEMP.

ON/OFF

Present setting: Select mode = OFF

Select mode = OFF

OFF

Present setting:Select mode=ON

Select mode = ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Select mode = OFF (Initial setting)

• All operation modes are available in

this mode.

Select mode = ON

• Selected mode is skipped.

OFF ···· Skipped

ON ···· Available

Limit TEMP. = OFF (Initial setting)

• Water temp. setting range : standard

Limit TEMP. = ON

• Water temp. setting range : limited

Lower limit ···· sets the lowest water

Upper limit ···· sets the highest water

* “LIMIT TEMP. HOT WATER” mode

( )

temperature.

temperature.

also limits the setting range in the

“Heating” mode.

Limit TEMP. = OFF

OFF

Present setting:Limit TEMP. = ONPresent setting:Limit TEMP. = OFF

Limit TEMP. = ON

Lower limit

Upper limit

Lower limit

Upper limit

Lower limit

Upper limit

Mode

selection

Display mode

setting

MAIN ····The remote controller will be the main controller. (Initial setting)

SUB ···· The remote controller will be the sub controller.

ON

OFF

ON ····The clock function can be used. (Initial setting)

OFF ····The clock function can not be used.

*

TIMER MODE OFF : Timer mode can not used. (Initial setting)

WEEKLY TIMER : Weekly timer can be used.

*

AUTO OFF TIMER : Auto off timer can be used.

SIMPLE TIMER : Simple timer can be used.

* These are timer mode.

*

OFF

ON

OFF ····The set contact numbers are not displayed in case of error.

(Initial setting)

ON ····The set contact numbers are displayed in case of error.

ON

OFF

°C

°F

OFF

ON

ON ····The offset function of the water temperature can be used.

(Initial setting)

OFF ····The offset function of the water temperature can not be used.

°C ···· The temperature unit “°C” is used. (Initial setting)

°F ····The temperature unit “ °F” is used.

OFF ····Water temperature is displayed. (Initial setting)

ON ····Water temperature is not displayed.

27

Page 28

8. Remote controller operation

[Detailed setting]

[4]-1 CHANGE LANGUAGE setting