Page 1

SPLIT-TYPE, COOLING AIR CONDITIONERS

ON/OFF

TEMP.

TECHNICAL & SERVICE MANUAL

This manual does not cover the

outdoor units. When servicing

Indoor unit

[

Model names]

[Service Ref.]

them, please refer to the service

manual

OC361 and this manual in a set.

May 2006

No. OC373

No.OC152,OC206,OC353,

PC-2GAK

PC-2.5GAK

PC-3GAK

PC-4GAK

PC-5GAK

PC-6GAK

INDOOR UNIT

PC-2GAK

PC-2.5GAK

PC-3GAK

PC-4GAK

PC-5GAK

PC-6GAK

CONTENTS

10. DISASSEMBLY PROCEDURE···········58

11. PARTS LIST········································63

12. OPTIONAL PARTS·····························71

1. PART NAMES AND FUNCTIONS········2

2. SPECIFICATIONS ·································4

3. DATA·····················································9

4. OUTLINES AND DIMENSIONS··········17

5. WIRING DIAGRAM ·····························22

6.

REFRIGERANT SYSTEM DIAGRAM

7. TROUBLE SHOOTING ·······················24

8. FUNCTION SETTING ·························38

9. SYSTEM CONTROL···························44

······23

REMOTE CONTROLLER

Page 2

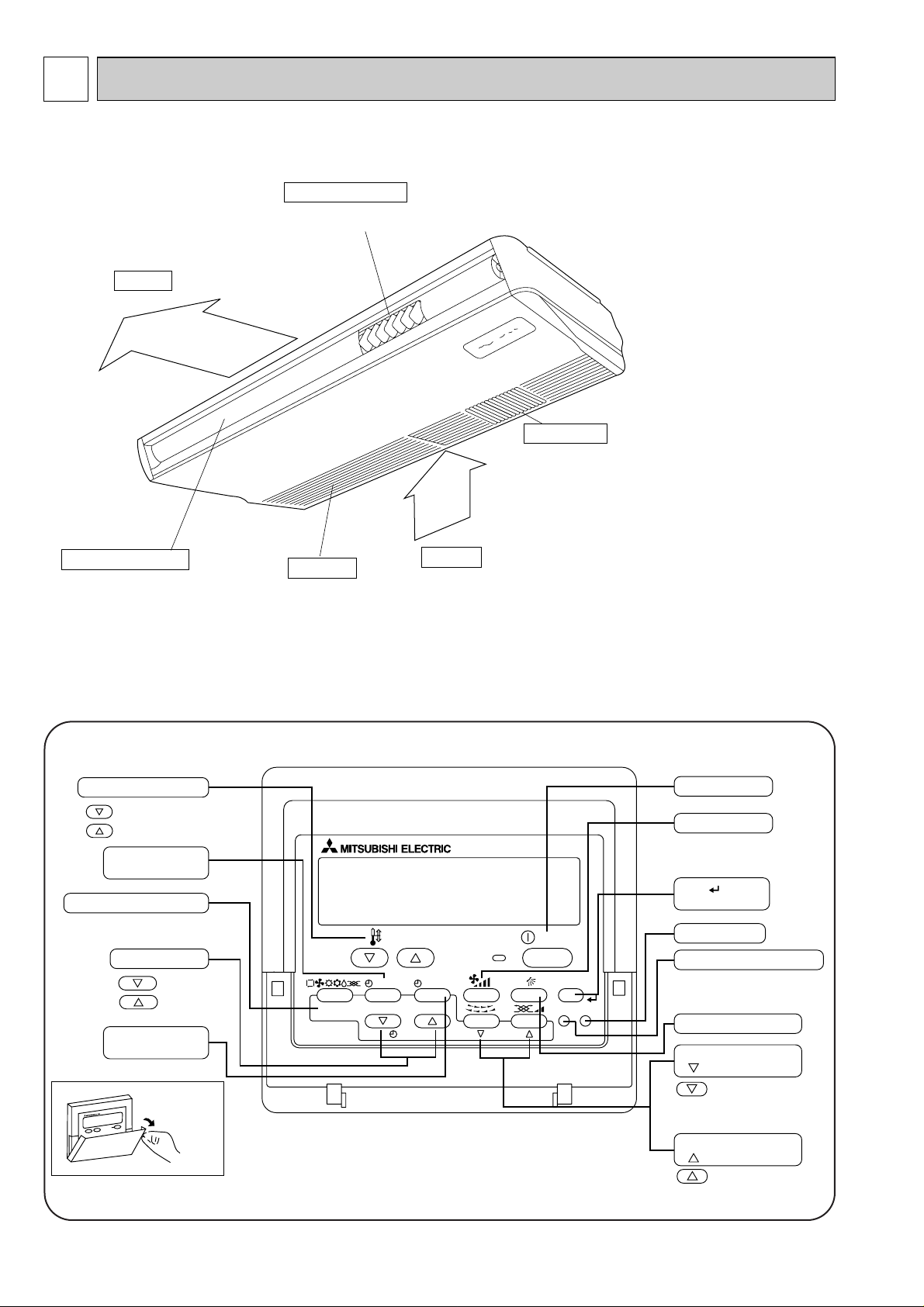

1

Air outlet

Intake grille

Air intake

Left/right guide vanes

Change the direction of airflow

from the horizontal blower.

Long-life filter

Removes dust and foreign matter from air coming in

through the grille (Recommended cleaning interval :

Approx, every 2,500 operating hours)

Up/down guide vanes

Change the direction of airflow from the

vertical blower.

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set Temperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door.

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

To preceding operation

number.

Ventilation button

(

Operation button)

To next operation number.

PART NAMES AND FUNCTIONS

● Indoor Unit

● Remote controller

Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

2

Page 3

● Display

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

˚F˚C

˚F˚C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

weak and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Caution

● Only the Power on indicator lights when the unit is stopped and power supplied to the unit.

● If you press a button for a feature that is not installed at the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to drive multiple indoor units, this message will appear only if he feature is not

present at the parent unit.

● When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indication (For max. 2minutes). Please wait until this “PLEASE WAIT” indication disappear then start the operation.

3

Page 4

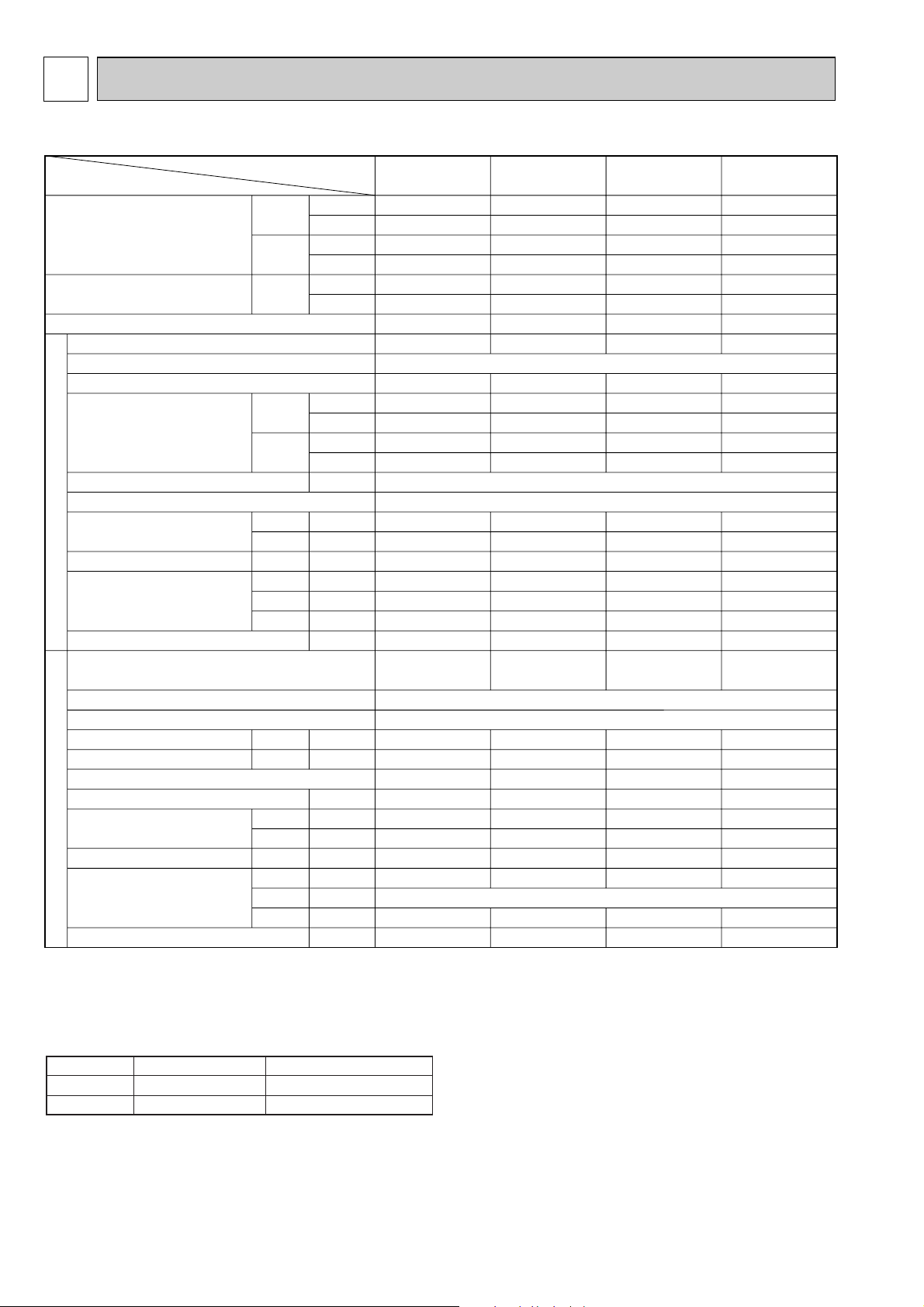

2

Service Ref.

External finish

Fan motor output

Airflow Lo-Hi

External static pressure

Operation control & Thermostat

Noise level Low-High

Cond. drain connector

Dimensions

Weight

Service Ref.

External finish

Refrigerant (R-22) control

Crankcase Heater w3

Compressor output

Protection devices

Fan motor output

Airflow

Noise level

Dimensions

Weight

W

Btu/h

W

Btu/h

W

Btu/h

K

/min

CFM

K

/min

CFM

Pa(mmAq)

dB

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

W

kW

kW

K/min(CFM)

K/min(CFM)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

50Hz

60Hz

60Hz

50Hz

60Hz

50Hz

60Hz

O.D.

W

D

H

50/60Hz

50/60Hz

50Hz

60Hz

50/60Hz

W

D

H

Munsell 0.70Y 8.59/0.97

0 (Direct blow)

Remote control & Built-in

Munsell 3.0Y 7.8/1.1

Capillary tube

295+24 (11-5/8 add 1)

9,800

33,400

10,800

36,800

9,300

31,700

3.49/4.47

PC-4GAK

0.09

20-25

706-883

20-25

706-883

40-45

40-45

26 (1)

1310 (51-9/16)

680 (26-3/4)

270 (10-5/8)

37 (82)

w10 PU-4JSA-type

32/38

2.7/2.7

w7(V)/w6(Y,T)

0.065+0.065

95 (3352)

95 (3352)

54/55

870 (34-1/4)

1258 (49-1/2)

94 (207)

Cooling capacity w1

Cooling capacity w4

Total input (50/60Hz) w2

Item

Service Ref.

PC-4GAK

7,600

25,900

7,800

26,600

6,500

22,200

3.30/3.60

PC-3GAK

0.07

14-18

494-635

14-18

494-635

37-43

37-43

26 (1)

1310 (51-9/16)

680 (26-3/4)

210 (8-1/4)

34 (75)

w9 PU-3J-type

32/38

2.2/2.2

w5

0.085

50 (1765)

50 (1765)

52/53

870 (34-1/4)

850 (33-7/16)

73 (161)

PC-3GAK

6,500

22,200

7,000

23,900

6,200

21,200

2.58/3.07

PC-2.5GAK

0.07

14-18

494-635

14-18

494-635

37-43

37-43

26 (1)

1310 (51-9/16)

680 (26-3/4)

210 (8-1/4)

34 (75)

PU-2.5VJA

1.TH,

PU-2.5NJA.TH

32/-

2.0/1.7

w5

0.085

50 (1765)

50 (1765)

52/53

870 (34-1/4)

850 (33-7/16)

71 (157)

PC-2.5GAK

5,600

19,100

5,400

18,400

4,300

14,700

2.54/2.60

PC-2GAK

0.054

10-13

353-459

10-13

353-459

37-42

37-42

26 (1)

1000 (39-3/8)

680 (26-3/4)

210 (8-1/4)

27 (60)

PU-2VJA

1.TH,

PU-2NJA.TH

32/-

2.0/1.5

w5

0.065

45 (1588)

45 (1588)

49/50

870 (34-1/4)

650 (25-5/8)

60 (132)

PC-2GAK

Indoor unitOutdoor unit

SPECIFICATIONS

2-1. STANDARD SPECIFICATIONS

Notes : w1. Rating condition (JISB8616)

Models PC-2,2.5,3 PC-4,5,6

50Hz 1ph220V / 1ph220V 1ph220V / 3ph380V

60Hz 1ph220V / 1ph220V

Indoor : D.B 27

Outdoor : D.B 35OC (95OF) , W.B. 24OC (75OF)

Refrigerant piping length (one way) : 5m (16ft)

w2. Total input based indicated voltage (In/Out)

w3. The capacity of crankcase heater (W) shows the

case of 220V.

O

C (80OF) , W.B. 19OC (66OF)

1ph220V / 3ph220V

w4. Rating condition (SSA385, 386)

Indoor : D.B 29OC (84OF) , W.B. 19OC (66OF)

Outdoor : D.B 46OC (115OF), W.B. 24OC (75OF)

Refrigerant piping length (one way ) : 5m (16ft)

w5. Inner thermostat, HP switch, LP switch

w6. Thermal switch, Reversed-phase protector, HP switch, LP

switch

Thermal relay

w7. Thermal switch, HP switch, LP switch,

Inner thermostat

w8. Thermal switch, HP switch,Inner thermostat

w9. PU-3J

w10.PU-4JSA

4

-type···PU-3VJC1.TH, PU-3YJC.TH, PU-3NJA.TH

-type···PU-4VLJSA2.TH, PU-4YJSA1.TH,

PU-4TJSA.TH

Page 5

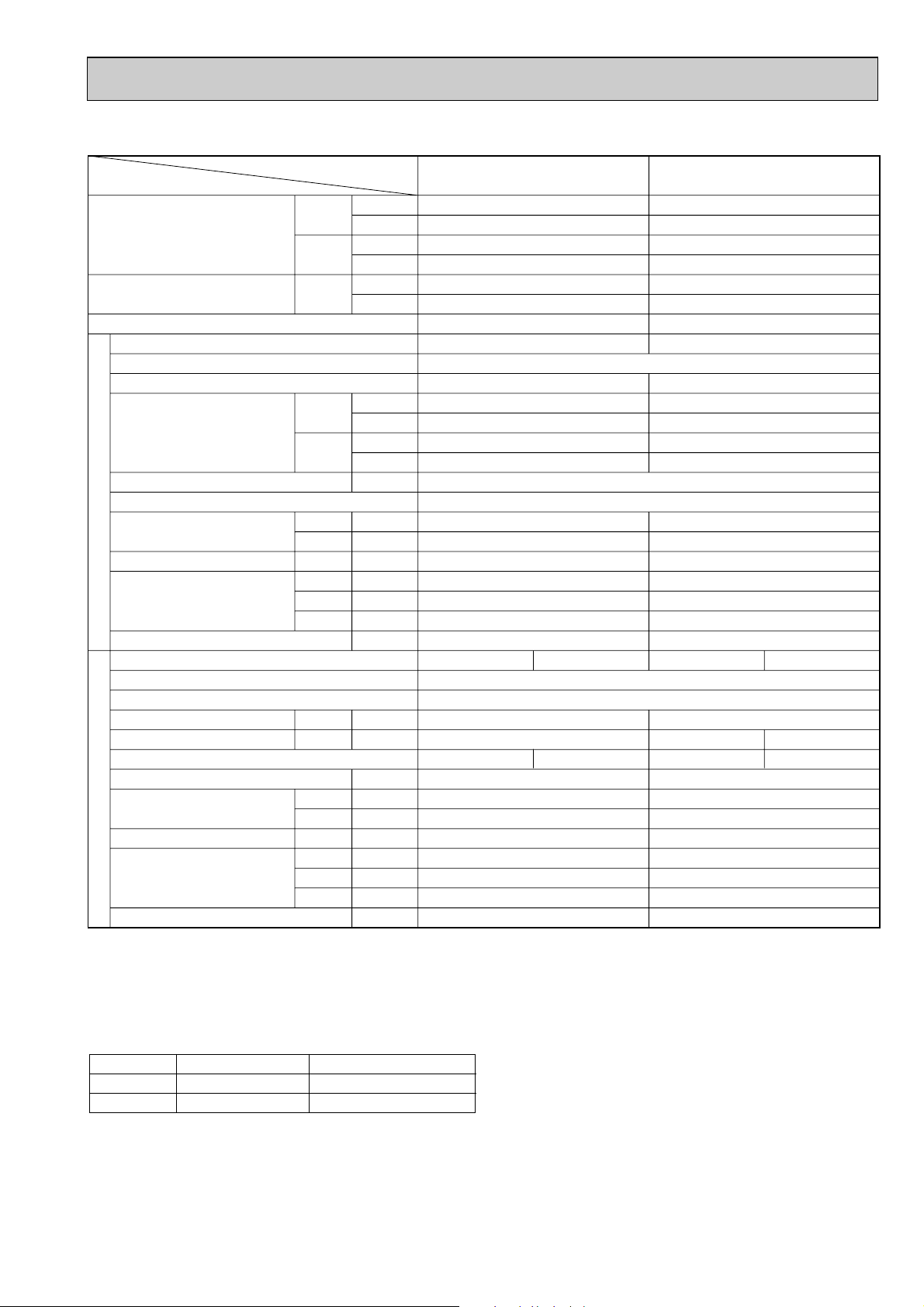

Item

Cooling capacity w1

Cooling capacity w4

Total input (50/60Hz) w2

Service Ref.

External finish

Fan motor output

Airflow Lo-Hi

External static pressure

Operation control & Thermostat

Indoor unitOutdoor unit

Noise level Low-High

Cond. drain connector

Dimensions

Weight

Service Ref.

External finish

Refrigerant (R-22) control

Crankcase Heater w3

Compressor output

Protection devices

Fan motor output

Airflow

Noise level

Dimensions

Weight

Service Ref.

50Hz

60Hz

60Hz

50Hz

60Hz

50Hz

60Hz

O.D.

W

D

H

50/60Hz

50/60Hz

50Hz

60Hz

50/60Hz

W

D

H

W

Btu/h

W

Btu/h

W

Btu/h

K/min

CFM

K/min

CFM

Pa(mmAq)

dB

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

W

kW

kW

K/min(CFM)

K/min(CFM)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

PC-5GAK

12,400

42,300

13,500

46,100

11,600

39,600

4.76/5.89

PC-5GAK

0.15

27-34

953-1,200

27-34

953-1,200

41-46

41-46

26(1)

1,620(63-3/4)

680(26-3/4)

270(10-5/8)

43(95)

PU-5YJSA

1.TH PU-5TJSA.TH

—

3.5

w8 w7

0.10+0.10

100(3530)

100(3530)

55

970(38-3/16)

345+24(13-9/16+1)

1,258(49-1/2)

114

Munsell 0.70Y 8.59/0.97

0 (Direct blow)

Remote control & Built-in

PU-6YJSA

Munsell 3.0Y 7.8/1.1

Capillary tube

4.2 4.0

w8 w7

345+24(13-9/16+1)

PC-6GAK

14,600

49,800

15,200

51,900

13,400

45,700

5.31/6.41

PC-6GAK

0.15

27-34

953-1,200

27-34

953-1,200

42-48

42-48

26(1)

1,620(63-3/4)

680(26-3/4)

270(10-5/8)

45(99)

1.TH PU-6TJSA.TH

—

0.10+0.10

100(3530)

100(3530)

56

970(38-3/16)

1,258(49-1/2)

117

Notes : w1. Rating condition (JISB8616)

Indoor : D.B 27

O

C (80OF) , W.B. 19OC (66OF)

Outdoor : D.B 35OC (95OF) , W.B. 24OC (75OF)

Refrigerant piping length (one way) : 5m (16ft)

w2. Total input based indicated voltage (In/Out)

Models PC-2,2.5,3 PC-4,5,6

50Hz 1ph220V / 1ph220V 1ph220V / 3ph380V

60Hz 1ph220V / 1ph220V

1ph220V / 3ph220V

w3. The capacity of crankcase heater (W) shows the

case of 220V.

w4. Rating condition (SSA385, 386)

Indoor : D.B 29

O

C (84OF) , W.B. 19OC (66OF)

Outdoor : D.B 46OC (115OF), W.B. 24OC (75OF)

Refrigerant piping length (one way ) : 5m (16ft)

w5. Inner thermostat, HP switch, LP switch

w6. Thermal switch, Reversed-phase protector, HP switch, LP

switch

Thermal relay

w7. Thermal switch, HP switch, LP switch,

Inner thermostat

w8. Thermal switch, HP switch,Inner thermostat

5

Page 6

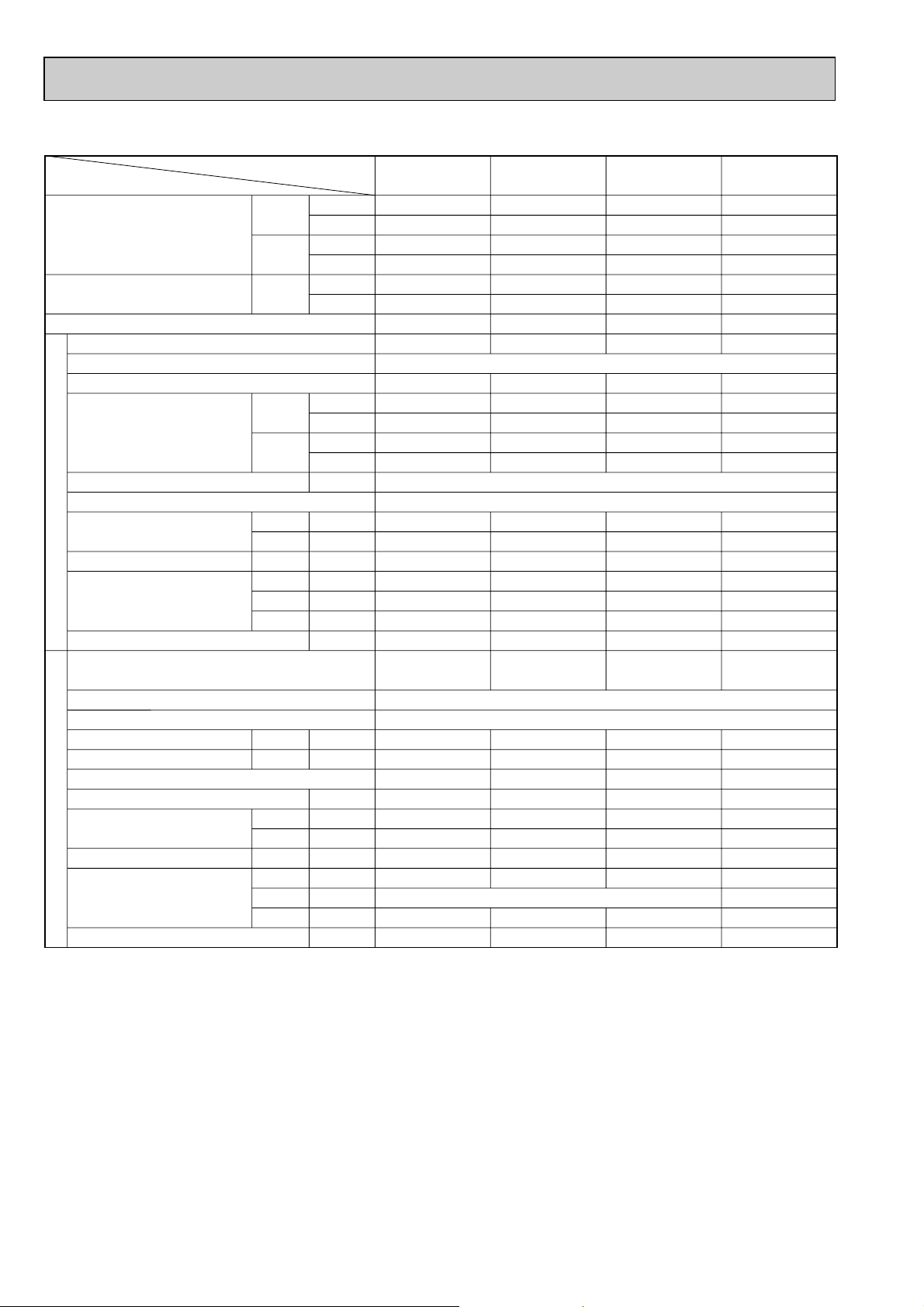

Service Ref.

External finish

Fan motor output

Airflow Lo-Hi

External static pressure

Operation control & Thermostat

Noise level Low-High

Cond. drain connector

Dimensions

Weight

Service Ref.

External finish

Refrigerant (R-22) control

Crankcase Heater

Compressor output

Protection devices

Fan motor output

Airflow

Noise level

Dimensions

Weight

W

Btu/h

W

Btu/h

W

Btu/h

K

/min

CFM

K

/min

CFM

Pa(mmAq)

dB

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

W

kW

kW

K/min(CFM)

K/min(CFM)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

50Hz

60Hz

60Hz

50Hz

60Hz

50Hz

60Hz

O.D.

W

D

H

50/60Hz

50/60Hz

50Hz

60Hz

50/60Hz

W

D

H

Munsell 0.70Y 8.59/0.97

0 (Direct blow)

Remote control & Built-in

Munsell 5Y 7/1

Capillary tube

9,500

32,400

–

–

–

–

3.15

PC-4GAK

0.09

20-25

706-883

–

–

40-45

–

26 (1)

1310 (51-9/16)

680 (26-3/4)

270 (10-5/8)

37 (82)

PU-4YKD-SH

32/-

2.7/w3

0.065+0.065

95 (3352)

–

56/-

970 (38-3/16)

345+24 (13-9/16 add 1)

1258 (49-1/2)

93 (205)

Cooling capacity w1

Cooling capacity

Total input

Item

Service Ref.

PC-4GAK

7,100

24,200

–

–

–

–

2.45

PC-3GAK

0.07

14-18

494-635

–

–

37-43

–

26 (1)

1310 (51-9/16)

680 (26-3/4)

210 (8-1/4)

34 (75)

PU-3VKD-SH

PU-3YKD-SH

32/-

1.9/-

w2(V)/w3(Y)

0.065

50 (1765)

–

53/-

870 (34-1/4)

850 (33-7/16)

V: 75 (165)/Y: 70 (154)

PC-3GAK

6,200

21,200

–

–

–

–

2.18

PC-2.5GAK

0.07

14-18

494-635

–

–

37-43

–

26 (1)

1310 (51-9/16)

680 (26-3/4)

210 (8-1/4)

34 (75)

PU-2.5VKD-SH

25/-

1.6/w2

0.065

50 (1765)

–

53/-

870 (34-1/4)

295+24 (11-5/8 add 1)

850 (33-7/16)

61 (134)

PC-2.5GAK

5,300

18,100

–

–

–

–

1.76

PC-2GAK

0.054

10-13

353-459

–

–

37-42

–

26 (1)

1000 (39-3/8)

680 (26-3/4)

210 (8-1/4)

27 (60)

PU-2VKD-SH

25/-

1.3/w2

0.065

50 (1765)

–

53/-

870 (34-1/4)

850 (33-7/16)

58 (129)

PC-2GAK

Indoor unitOutdoor unit

Notes : w1. Rating condition (JISB8616)

Indoor : D.B 27

Outdoor : D.B 35OC (95OF) , W.B. 24OC (75OF)

Refrigerant piping length (one way) : 5m (16ft)

w2. Inner thermostat

w3. Thermal switch, Thermal relay

O

C (80OF) , W.B. 19OC (66OF)

6

Page 7

Item

220,230,240V

220V

380/220, 400/230, 415/240V

380V/220V

220V

220V

1ph.

3ph.

1ph.

3ph.

50Hz

60Hz

Power supply

Outdoor unit Service Ref.

PC-4GAK

PU-4VLJSA2.TH

—

PU-4YJSA1.TH

PU-4YKD-SH

—

PU-4TJSA.TH

PC-5GAK

—

—

PU-5YJSA1.TH

PU-5YKD-SH

—

PU-5TJSA.TH

PC-6GAK

—

—

PU-6YJSA1.TH

PU-6YKD-SH

—

PU-6TJSA.TH

PC-3GAK

PU-3VJC1.TH

PU-3VKD-SH

PU-3YJC.TH

PU-3YKD-SH

PU-3NJA.TH

—

PC-2.5GAK

P

U-2.5VJA1.TH

PU-2.5VKD-SH

—

—

PU-2.5NJA.TH

—

PC-2GAK

PU-2VJA1.TH

PU-2VKD-SH

—

—

PU-2NJA.TH

—

Indoor unit Service Ref.

Cooling capacity w1

Cooling capacity

Total input

Service Ref.

External finish

Fan motor output

Airflow Lo-Hi

External static pressure

Operation control & Thermostat

Indoor unitOutdoor unit

Noise level Low-High

Cond. drain connector

Dimensions

Weight

Service Ref.

External finish

Refrigerant (R-22) control

Crankcase Heater

Compressor output

Protection devices

Fan motor output

Airflow

Noise level

Dimensions

Weight

Service Ref.

50Hz

60Hz

60Hz

50Hz

60Hz

50Hz

60Hz

O.D.

W

D

H

50/60Hz

50/60Hz

50Hz

60Hz

50/60Hz

W

D

H

W

Btu/h

W

Btu/h

W

Btu/h

K/min

CFM

K/min

CFM

Pa(mmAq)

dB

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

W

kW

kW

K/min(CFM)

K/min(CFM)

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs.)

PC-5GAK

12,400

42,300

–

–

–

–

4.40

PC-5GAK

Munsell 0.70Y 8.59/0.97

0.15

27-34

953-1,200

–

–

Remote control & Built-in

41-46

–

26(1)

1,620(63-3/4)

680(26-3/4)

270(10-5/8)

43(95)

PU-5YKD-SH

32/–

3.5

Internal thermostat, Thermal switch

0.065+0.065

95(3353)

–

56/–

970(38-3/16)

345+24(13-9/16+1)

1,258(49-1/2)

93(205)

PC-6GAK

14,400

49,100

–

–

–

–

5.31

PC-6GAK

0.15

27-34

953-1,200

–

–

0 (Direct blow)

42-48

–

26(1)

1,620(63-3/4)

680(26-3/4)

270(10-5/8)

45(99)

PU-6YKD-SH

Munsell 5Y 7/1

Capillary tube

32/-

4.2

0.065+0.065

95(3353)

–

56/–

970(38-3/16)

345+24(13-9/16+1)

1,258(49-1/2)

98(216)

Notes : w1. Rating condition (JISB8616) Indoor: D.B 27OC (80OF), W.B. 19OC (66OF) Outdoor: D.B 35OC (95OF), W.B. 24OC (75OF)

2-2. POWER SUPPLY & MODEL NAMES

Notes : 1. Power supply key N : 1ph, 220V/60Hz T : 3ph, 220V/60Hz

Refrigerant piping length (one way) : 5m (16ft)

2. Primary power supplies for all indoor units are single-phase.

V(L) : 1ph, 220, 230, 240V/50Hz Y : 3ph, 380/220, 400/230, 415/240V, 50Hz, 4wires

7

Page 8

2-3. ELECTRICAL SPECIFICATIONS

A

kW

A

V : 220V , 50Hz

PC-4GAK

0.68

0.14

1.36

PU-4

Power supply (1 Phase)

Service Ref.

Current

Input

Starting current

Outdoor unit to be connected

PC-3GAK

0.51

0.12

1.17

PU-3

PC-2.5GAK

0.51

0.12

1.17

PU-2.5

PC-2GAK

0.38

0.10

1.10

PU-2

PC-6GAK

0.96

0.20

2.00

PU-6

PC-5GAK

0.96

0.20

2.00

PU-5

A

kW

A

V : 230V , 50Hz

PC-4GAK

0.69

0.15

1.42

PU-4

Power supply (1 Phase)

Service Ref.

Current

Input

Starting current

Outdoor unit to be connected

PC-3GAK

0.53

0.13

1.22

PU-3

PC-2.5GAK

0.53

0.13

1.22

PU-2.5

PC-2GAK

0.41

0.12

1.15

PU-2

PC-6GAK

1.01

0.22

2.10

PU-6

PC-5GAK

1.01

0.22

2.10

PU-5

A

kW

A

V : 240V , 50Hz

PC-4GAK

0.70

0.16

1.48

PU-4

Power supply (1 Phase)

Service Ref.

Current

Input

Starting current

Outdoor unit to be connected

PC-3GAK

0.55

0.15

1.27

PU-3

PC-2.5GAK

0.55

0.15

1.27

PU-2.5

PC-2GAK

0.43

0.14

1.20

PU-2

PC-6GAK

1.06

0.25

2.20

PU-6

PC-5GAK

1.06

0.25

2.20

PU-5

A

kW

A

N : 220V , 60Hz

PC-4GAK

0.95

0.20

1.27

PU-4

Power supply (1 Phase)

Service Ref.

Current

Input

Starting current

Outdoor unit to be connected

PC-3GAK

0.70

0.16

1.11

PU-3

PC-2.5GAK

0.70

0.16

1.11

PU-2.5

PC-2GAK

0.61

0.15

1.03

PU-2

PC-6GAK

1.20

0.26

1.91

PU-6

PC-5GAK

1.20

0.26

1.91

PU-5

A

kW

A

N : 220V , 60Hz

PC-4GAK

0.95

0.20

1.27

PU-4

PC-5GAK

1.20

0.26

1.91

PU-5

PC-6GAK

1.20

0.26

1.91

PU-6

Power supply (1 Phase)

Service Ref.

Current

Input

Starting current

Outdoor unit to be connected

PC-3GAK

0.70

0.16

1.11

PU-3

PC-2.5GAK

0.70

0.16

1.11

PU-2.5

PC-2GAK

0.61

0.15

1.03

PU-2

Rating conditions — JIS B8616 Indoor : D.B. 27°C (80°F) , W.B. 19°C (66°F)

Outdoor : D.B. 35°C (95°F) , W.B. 24°C (75°F)

Series PC Indoor unit (Single phase)

Rating conditions — SSA385, 386

Indoor : D.B. 29°C (84°F) , W.B. 19°C (66°F)

Outdoor : D.B. 46°C (115°F) , W.B. 24°C (75°F)

8

Page 9

3

DATA

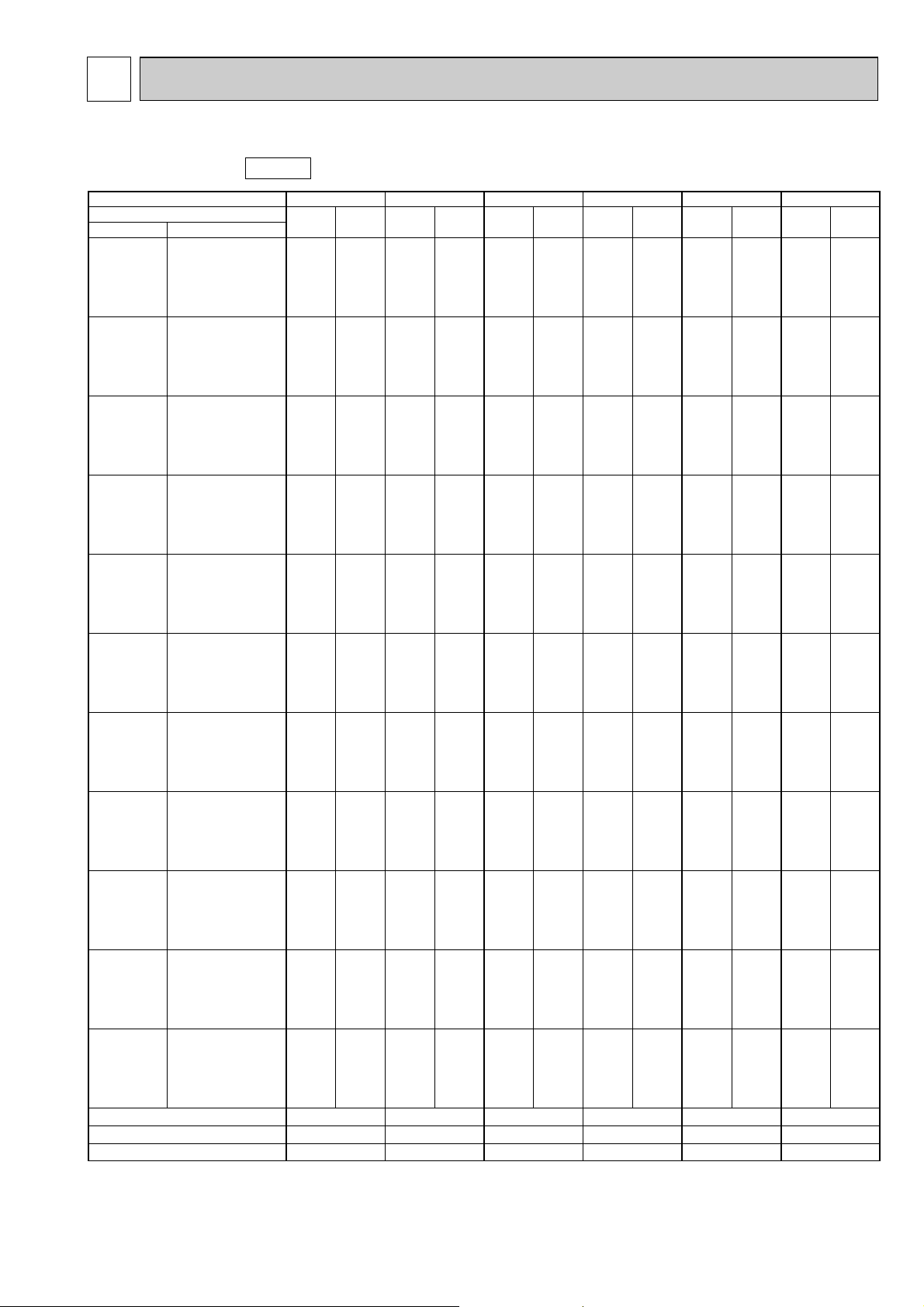

3-1. PERFORMANCE DATA

Cooling capacity

Service Ref.

Temperature

Outdoor D.B.

21°C

(69.8°F)

25°C

(77°F)

30°C

(86°F)

32.2°C

(90°F)

35°C

(95°F)

40°C

(104°F)

40.6°C

(105°F)

45°C

(113°F)

46°C

(115°F)

50°C

(69.8°F)

52°C

(125.5°F)

Evaporator air flow (k/x )

Bypass factors

S.H.F. at rating conditions

Notes : 1. T.C. : Total capacity (kW) ... (kcal/h) = (kW) ✕ 860, (Btu/h) = 4 ✕ (kW) ✕ 860

2. (°F) = 32 + 9 / 5 (°C)

3. Guaranteed operation range (cooling) :

Indoor W .B.

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

C.F. (T.I.) : Correction factors of Total input (Indoor unit input + Outdoor unit input)

Lower limit ... Indoor : D.B. 21°C (70°F), W.B. 15.5°C (60°F), Outdoor : D.B. 21°C (70°F).

Upper limit ... Indoor : D.B. 35°C (95°F), W.B. 22.5°C (72.5°F), Outdoor : D.B. 52°C (125.5°F). w

50Hz

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(Outdoor unit : PU-J type)

PC-2GAK

T .C. C.F .

5.6

6.0

6.2

6.2

6.4

6.7

5.5

5.9

6.0

6.1

6.2

6.6

5.3

5.6

5.8

5.9

6.0

6.4

5.2

5.5

5.7

5.8

5.9

6.3

5.1

5.4

5.6

5.7

5.8

6.2

4.8

5.2

5.4

5.4

5.5

5.9

4.8

5.2

5.3

5.4

5.5

5.9

4.6

4.9

5.1

5.2

5.3

5.7

4.6

4.9

5.1

5.1

5.2

5.6

4.4

4.7

4.9

4.9

5.0

5.4

4.3

4.6

4.7

4.8

4.9

5.3

C.F .

(T.I.)

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

13

0.07

0.72

PC-2.5GAK

T .C. C.F .

(T.I.)

0.81

6.5

0.82

6.9

0.83

7.2

0.83

7.3

0.84

7.4

0.86

7.8

0.84

6.4

0.85

6.8

0.86

7.0

0.86

7.1

0.87

7.2

0.89

7.7

0.90

6.1

0.92

6.6

0.93

6.8

0.93

6.9

0.94

7.0

0.96

7.4

0.93

6.0

0.95

6.4

0.96

6.6

0.97

6.7

0.97

6.9

0.99

7.3

0.96

5.9

0.99

6.3

1.00

6.5

1.00

6.6

1.01

6.7

1.04

7.2

1.03

5.6

1.06

6.0

1.07

6.2

1.08

6.3

1.08

6.4

1.11

6.9

1.04

5.6

1.06

6.0

1.08

6.2

1.08

6.3

1.09

6.4

1.12

6.8

1.10

5.4

1.12

5.7

1.14

5.9

1.15

6.0

1.16

6.1

1.20

6.6

1.11

5.3

1.14

5.7

1.15

5.9

1.16

6.0

1.17

6.1

1.21

6.5

1.16

5.1

1.19

5.4

1.21

5.6

1.22

5.7

1.23

5.8

1.28

6.3

1.19

4.9

1.22

5.3

1.24

5.5

1.25

5.6

1.26

5.7

1.31

6.1

18

0.08

0.78

PC-3GAK

T .C. C.F.

7.6

8.1

8.4

8.5

8.6

9.1

7.5

7.9

8.2

8.3

8.5

9.0

7.2

7.7

7.9

8.0

8.2

8.7

7.1

7.5

7.8

7.9

8.0

8.5

6.9

7.4

7.6

7.7

7.8

8.4

6.6

7.0

7.3

7.4

7.5

8.0

6.5

7.0

7.2

7.3

7.5

8.0

6.3

6.7

6.9

7.0

7.2

7.7

6.2

6.6

6.9

7.0

7.1

7.6

5.9

6.4

6.6

6.7

6.8

7.3

5.8

6.2

6.4

6.5

6.7

7.2

wVL . Outdoor : D.B. 46°C (115°F).

9

18

0.08

0.73

(T.I.)

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

PC-4GAK PC-5GAK

T .C. C.F .

10.5

10.8

10.9

11.1

11.8

10.2

10.6

10.7

10.9

11.6

10.2

10.3

10.5

11.2

10.0

10.2

10.3

11.0

10.1

10.8

10.3

10.3

9.8

9.6

9.3

9.9

9.1

9.7

8.9

9.5

9.8

9.9

8.5

9.1

9.4

9.5

9.7

8.4

9.0

9.3

9.5

9.6

8.1

8.6

8.9

9.1

9.3

9.9

8.0

8.6

8.9

9.0

9.2

9.8

7.6

8.2

8.5

8.6

8.8

9.4

7.4

8.0

8.3

8.4

8.6

9.2

(T.I.)

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

25

0.08

0.73

T .C. C.F.

12.4

13.3

13.7

13.8

14.1

14.9

12.2

13.0

13.4

13.6

13.8

14.7

11.7

12.5

12.9

13.1

13.3

14.2

11.5

12.3

12.7

12.8

13.1

13.9

11.2

12.0

12.4

12.6

12.8

13.6

10.7

11.5

11.9

12.0

12.3

13.1

10.7

11.4

11.8

12.0

12.2

13.0

10.2

10.9

11.3

11.5

11.7

12.5

10.1

10.8

11.2

11.3

11.5

12.4

10.2

10.3

10.5

10.9

9.1

9.8

8.1

8.7

9.0

9.1

9.3

9.7

(T.I.)

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

34

0.08

0.75

PC-6GAK

T.C.

14.7

15.6

16.1

16.3

16.6

17.6

14.3

15.3

15.8

16.0

16.3

17.3

13.8

14.7

15.2

15.4

15.7

16.7

13.6

14.5

14.9

15.1

15.4

16.4

13.2

14.1

14.6

14.8

15.1

16.1

12.6

13.5

14.0

14.2

14.4

15.4

12.6

13.4

13.9

14.1

14.4

15.3

12.0

12.9

13.3

13.5

13.8

14.7

11.9

12.7

13.1

13.3

13.5

14.6

10.7

11.5

12.0

12.1

12.4

12.8

9.5

10.2

10.6

10.7

11.0

11.4

34

0.03

0.72

(T.I.)

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

Page 10

Cooling capacity

5.4

5.8

6.0

6.0

6.1

6.5

5.3

5.6

5.8

5.9

6.0

6.4

5.1

5.4

5.6

5.7

5.8

6.2

5.0

5.3

5.5

5.6

5.7

6.1

4.9

5.2

5.4

5.5

5.6

5.9

4.7

5.0

5.2

5.2

5.3

5.7

4.7

5.0

5.1

5.2

5.3

5.7

4.4

4.8

4.9

5.0

5.1

5.5

4.4

4.7

4.9

4.9

5.0

5.4

4.2

4.5

4.7

4.7

4.8

5.2

4.1

4.4

4.6

4.6

4.7

5.1

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

7.0

7.5

7.7

7.8

7.9

8.4

6.9

7.3

7.6

7.7

7.8

8.3

6.6

7.1

7.3

7.4

7.5

8.0

6.5

6.9

7.1

7.2

7.4

7.8

6.3

6.8

7.0

7.1

7.2

7.7

6.1

6.5

6.7

6.8

6.9

7.4

6.0

6.4

6.7

6.8

6.9

7.4

5.8

6.2

6.4

6.5

6.6

7.1

5.7

6.1

6.4

6.4

6.5

7.0

5.4

5.9

6.1

6.2

6.2

6.8

5.3

5.7

5.9

6.0

6.2

6.6

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

7.8

8.3

8.6

8.7

8.9

9.4

7.7

8.2

8.4

8.5

8.7

9.2

7.4

7.9

8.1

8.2

8.4

8.9

7.2

7.7

8.0

8.1

8.2

8.8

7.1

7.5

7.8

7.9

8.1

8.6

6.8

7.2

7.5

7.6

7.7

8.2

6.7

7.2

7.4

7.5

7.7

8.2

6.4

6.9

7.1

7.2

7.4

7.9

6.4

6.8

7.1

7.1

7.3

7.8

6.1

6.5

6.8

6.9

7.0

7.5

5.9

6.4

6.6

6.7

6.9

7.3

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

10.8

11.5

11.9

12.0

12.3

13.0

10.6

11.3

11.7

11.8

12.0

12.8

10.2

10.9

11.2

11.4

11.6

12.3

10.0

10.7

11.0

11.2

11.4

12.1

9.8

10.5

10.8

10.8

11.1

11.9

9.4

10.0

10.3

10.5

10.7

11.4

9.3

9.9

10.3

10.4

10.6

11.3

8.9

9.5

9.9

10.0

10.2

10.9

8.8

9.4

9.8

9.9

10.

10.8

8.4

9.0

9.4

9.5

9.7

10.4

8.2

8.8

9.2

9.3

9.5

10.2

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

13.6

14.4

14.9

15.1

15.3

16.2

13.2

14.1

14.6

14.8

15.0

16.0

12.8

13.6

14.0

14.2

14.5

15.4

12.5

13.4

13.8

14.0

14.3

15.2

12.2

13.1

13.5

13.7

13.9

14.9

11.7

12.5

12.9

13.1

13.4

14.3

11.6

12.4

12.9

13.0

13.3

14.2

11.1

11.9

12.3

12.5

12.7

13.6

11.0

11.8

12.1

12.3

12.5

13.5

9.9

10.7

11.1

11.2

11.4

11.8

8.8

9.4

9.8

9.9

10.1

10.5

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

15.3

16.2

16.8

17.0

17.3

18.3

14.9

15.9

16.4

16.6

16.9

18.0

14.4

15.3

15.8

16.0

16.3

17.4

14.1

15.1

15.5

15.7

16.0

17.1

13.8

14.7

15.2

15.4

15.7

16.7

13.2

14.1

14.6

14.7

15.0

16.0

13.1

14.0

14.5

14.7

15.0

16.0

12.5

13.4

13.9

14.1

14.4

15.3

12.4

13.3

13.7

13.8

14.1

15.2

11.2

12.0

12.4

12.6

12.9

13.3

9.9

10.6

11.0

11.2

11.4

11.8

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

1.16

1.19

1.21

1.22

1.23

1.28

1.19

1.22

1.24

1.25

1.26

1.31

C.F .

(T.I.)

Service Ref.

Temperature

PC-2GAK

Indoor W .B.

Outdoor D.B.

T .C. C.F .

(T.I.)

PC-2.5GAK

T .C. C.F .

(T.I.)

PC-3GAK

T .C. C.F.

(T.I.)

PC-4GAK PC-5GAK

PC-6GAK

T .C. C.F .

(T.I.)

T .C. C.F.

(T.I.)

T.C.

Evaporator air flow (k/x )

Bypass factors

S.H.F. at rating conditions

13

0.07

0.72

18

0.08

0.75

18

0.08

0.70

25

0.08

0.70

34

0.08

0.73

34

0.03

0.72

21°C

(69.8°F)

25°C

(77°F)

30°C

(86°F)

32.2°C

(90°F)

35°C

(95°F)

40°C

(104°F)

40.6°C

(105°F)

45°C

(113°F)

46°C

(115°F)

50°C

(69.8°F)

52°C

(125.5°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

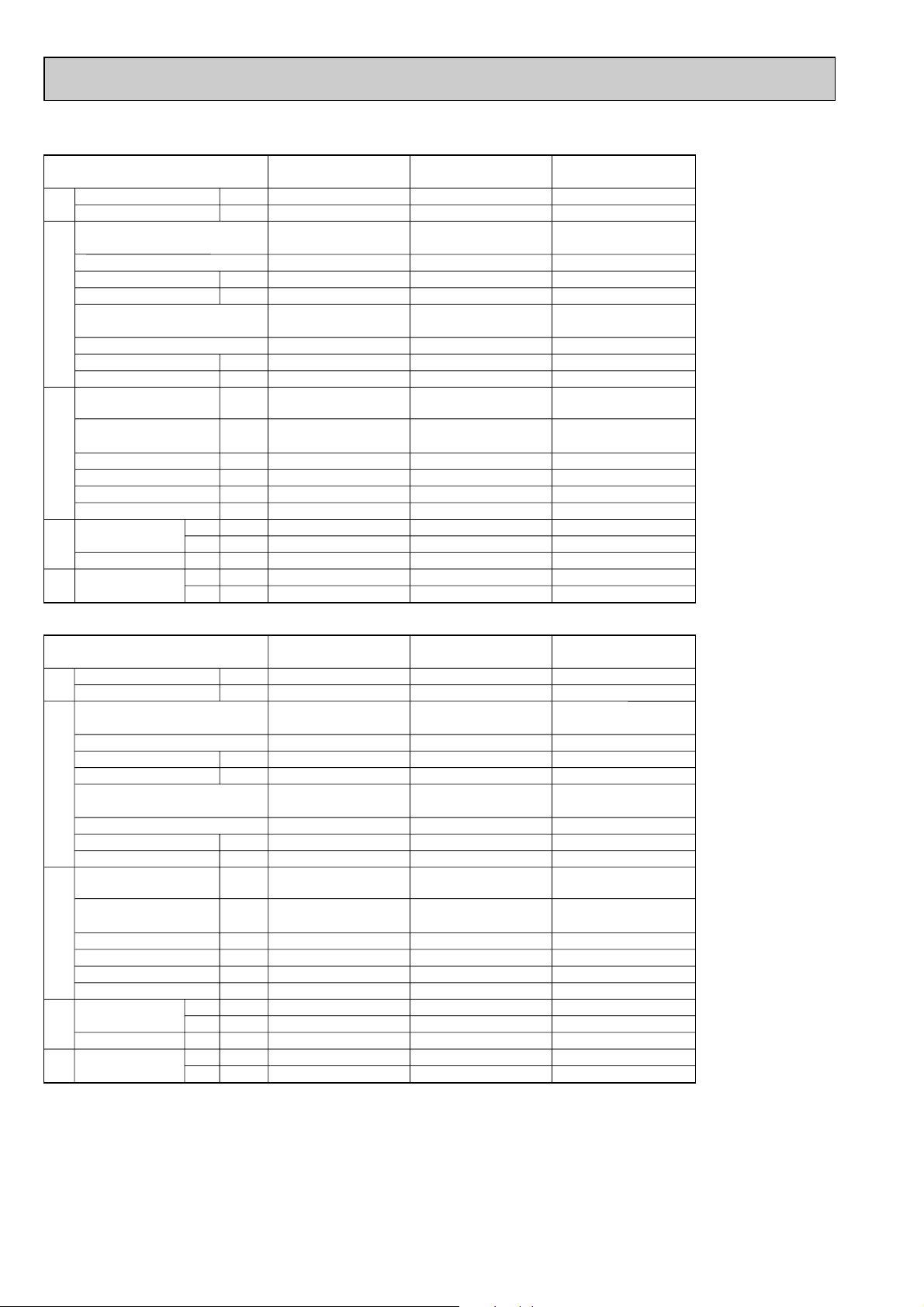

60Hz

Notes:1.T.C. : Total capacity (xkW)

C.F. (T.I.) : Correction factors of Total input (Indoor unit input + Outdoor unit input)

2.(oF)=32+9/5(oC)

3.Guaranteed operating range (cooling):

...

Btu/h=(W)x0.86

Lower limit

{ }

Upper limit

...

Indoor D.B. 21oC (70oF) , W.B. 15.5oC (60oF) , Outdoor D.B. 21oC (70oF)

...

Indoor D.B. 35oC (95oF) , W.B. 22.5oC (72.5oF) , Outdoor D.B. 52oC (125.5oF)

10

Page 11

Cooling capacity

C.F.

(T.I.)

Service Ref.

Temperature

PC-2GAK

Indoor W.B.

Outdoor D.B.

T.C. C.F.

(T.I.)

PC-2.5GAK

T.C. C.F.

(T.I.)

PC-3GAK

T.C. C.F.

(T.I.)

PC-4GAK PC-5GAK

PC-6GAK

T.C. C.F.

(T.I.)

T.C. C.F.

(T.I.)

T.C.

Evaporator air flow (k/x )

Bypass factors

S.H.F. at rating conditions

13

0.07

0.72

18

0.08

0.78

18

0.08

0.73

25

0.08

0.73

34

0.08

0.75

34

0.03

0.72

21°C

(69.8°F)

25°C

(77°F)

30°C

(86°F)

32.2°C

(90°F)

35°C

(95°F)

40°C

(104°F)

40.6°C

(105°F)

45°C

(113°F)

46°C

(115°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

(60.8°F)

(64.4°F)

(66.2°F)

(67°F)

(68°F)

(71.6°F)

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

16°C

18°C

19°C

19.4°

20°C

22°C

16°C

18°C

19°C

19.4°C

20°C

22°C

5.3

5.7

5.8

5.9

6.0

6.4

5.2

5.5

5.7

5.8

5.9

6.3

5.0

5.3

5.5

5.6

5.7

6.1

4.9

5.2

5.4

5.5

5.6

6.0

4.8

5.1

5.3

5.4

5.5

5.8

4.6

4.9

5.1

5.1

5.2

5.6

4.6

4.9

5.0

5.1

5.2

5.6

4.4

4.7

4.8

4.9

5.0

5.4

4.3

4.6

4.8

4.9

5.0

5.3

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

6.2

6.6

6.8

6.9

7.0

7.5

6.1

6.5

6.7

6.8

6.9

7.3

5.9

6.2

6.5

6.5

6.7

7.1

5.8

6.1

6.3

6.4

6.5

7.0

5.6

6.0

6.2

6.3

6.4

6.8

5.4

5.7

5.9

6.0

6.1

6.5

5.3

5.7

5.9

6.0

6.1

6.5

5.1

5.5

5.7

5.7

5.9

6.3

5.1

5.4

5.6

5.7

5.8

6.2

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

7.1

7.6

7.8

7.9

8.1

8.5

7.0

7.4

7.7

7.8

7.9

8.4

6.7

7.2

7.4

7.5

7.6

8.1

6.6

7.0

7.3

7.4

7.5

8.0

6.4

6.9

7.1

7.2

7.3

7.8

6.2

6.6

6.8

6.9

7.0

7.5

6.1

6.5

6.8

6.9

7.0

7.5

5.8

6.3

6.5

6.6

6.7

7.2

5.8

6.2

6.4

6.5

6.6

7.1

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

9.5

10.2

10.5

10.6

10.8

11.4

9.3

9.9

10.3

10.4

10.6

11.2

9.0

9.6

9.9

10.0

10.2

10.9

8.8

9.4

9.7

9.8

10.0

10.7

8.6

9.2

9.5

9.6

9.8

10.5

8.2

8.8

9.1

9.2

9.4

10.0

8.2

8.7

9.0

9.2

9.3

10.0

7.8

8.4

8.7

8.8

9.0

9.6

7.7

8.3

8.6

8.7

8.9

9.5

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

12.4

13.3

13.7

13.8

14.1

14.9

12.2

13.0

13.4

13.6

13.8

14.7

11.7

12.5

12.9

13.1

13.3

14.2

11.5

12.3

12.7

12.8

13.1

13.9

11.2

12.0

12.4

12.6

12.8

13.6

10.7

11.5

11.9

12.0

12.3

13.1

10.7

11.4

11.8

12.0

12.2

13.0

10.2

10.9

11.3

11.5

11.7

12.5

10.1

10.8

11.2

11.4

11.6

12.4

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

14.5

15.4

15.9

16.1

16.3

17.3

14.1

15.1

15.5

15.7

16.0

17.0

13.6

14.5

15.0

15.2

15.5

16.5

13.4

14.3

14.7

14.9

15.2

16.2

13.1

13.9

14.4

14.6

14.9

15.8

12.5

13.3

13.8

14.0

14.2

15.2

12.4

13.3

13.7

13.9

14.2

15.1

11.9

12.7

13.2

13.3

13.6

14.5

11.7

12.6

13.0

13.2

13.5

14.4

0.81

0.82

0.83

0.83

0.84

0.86

0.84

0.85

0.86

0.86

0.87

0.89

0.90

0.92

0.93

0.93

0.94

0.96

0.93

0.95

0.96

0.97

0.97

0.99

0.96

0.99

1.00

1.00

1.01

1.04

1.03

1.06

1.07

1.08

1.08

1.11

1.04

1.06

1.08

1.08

1.09

1.12

1.10

1.12

1.14

1.15

1.16

1.20

1.11

1.14

1.15

1.16

1.17

1.21

13

18

18 25 34

34

0.10

0.09

0.10 0.10 0.07

0.06

0.73 0.79

0.74 0.75 0.78

0.73

50Hz

(Outdoor unit : PU-KD-SH type)

Notes:1.T.C. : Total capacity (xkW)

C.F. (T.I.) : Correction factors of Total input (Indoor unit input + Outdoor unit input)

2.(oF)=32+9/5(oC)

3.Guaranteed operating range (cooling):

...

Btu/h=(W)x0.86

{ }

Lower limit

Upper limit

...

...

Indoor D.B. 21oC (70oF) , W.B. 15.5oC (60oF) , Outdoor D.B. 21oC (70oF)

Indoor D.B. 35oC (95oF) , W.B. 22.5oC (72.5oF) , Outdoor D.B. 46oC (115oF)

11

Page 12

Cooling Capacity Correction Factors

Service Ref.

PC-2GAK

PC-2.5GAK

PC-3GAK

PC-4GAK

PC-5GAK

PC-6GAK

5m(16ft) 10m(33ft) 15m(49ft) 20m(66ft) 25m(82ft) 30m(98ft)

1.0

1.0

1.0

1.0

1.0

1.0

0.985

0.983

0.978

0.978

0.978

0.970

0.975

0.972

0.962

0.974

0.962

0.950

0.964

0.961

0.948

0.964

0.948

0.931

50Hz

Refrigerant piping length (one way)

(Outdoor unit : PU-J type)

35m(115ft)

0.954

0.951

0.934

0.954

0.934

0.912

0.944

0.940

0.921

0.944

0.921

0.896

0.935

0.908

0.880

—

—

—

40m(131ft)

—

—

—

0.926

0.896

0.864

45m(148ft)

—

—

—

—

0.884

0.850

50m(164ft)

—

—

—

—

0.875

0.840

Cooling Capacity Correction Factors

Service Ref.

PC-2GAK

PC-2.5GAK

PC-3GAK

PC-4GAK

PC-5GAK

PC-6GAK

5m(16ft) 10m(33ft) 15m(49ft) 20m(66ft) 25m(82ft) 30m(98ft) 35m(115ft) 40m(131ft)

1.0 0.985 0.975 0.964 0.954 0.944 — —

1.0 0.978 0.963 0.948 0.934 0.921 — —

1.0 0.971 0.950 0.931 0.913 0.896 — —

1.0 0.980 0.966 0.952 0.939 0.826 0.914 0.902

1.0

1.0

0.971

0.960

0.950

0.933

Cooling Capacity Correction Factors

Service Ref.

PC-2GAK

PC-2.5GAK

PC-3GAK

PC-4GAK

PC-5GAK

PC-6GAK

5m

1.00

1.00

10m

0.981

0.981

15m

0.968

0.968

60Hz

Refrigerant piping length (one way)

0.931

0.908

20m

0.952

0.952

0.913

0.885

50Hz

Refrigerant piping length(one way)

25m

0.940

0.940

0.896

0.864

(Outdoor unit : PU-KD-SH type)

30m

0.925

0.925

0.880

0.845

35m

0.913

0.913

0.864

0.828

40m

0.900

0.900

45m(148ft) 50m(164ft)

—

—

—

——

0.850 0.840

0.812 0.800

45m

-

0.886

—

—

—

50m

-

0.874

12

Page 13

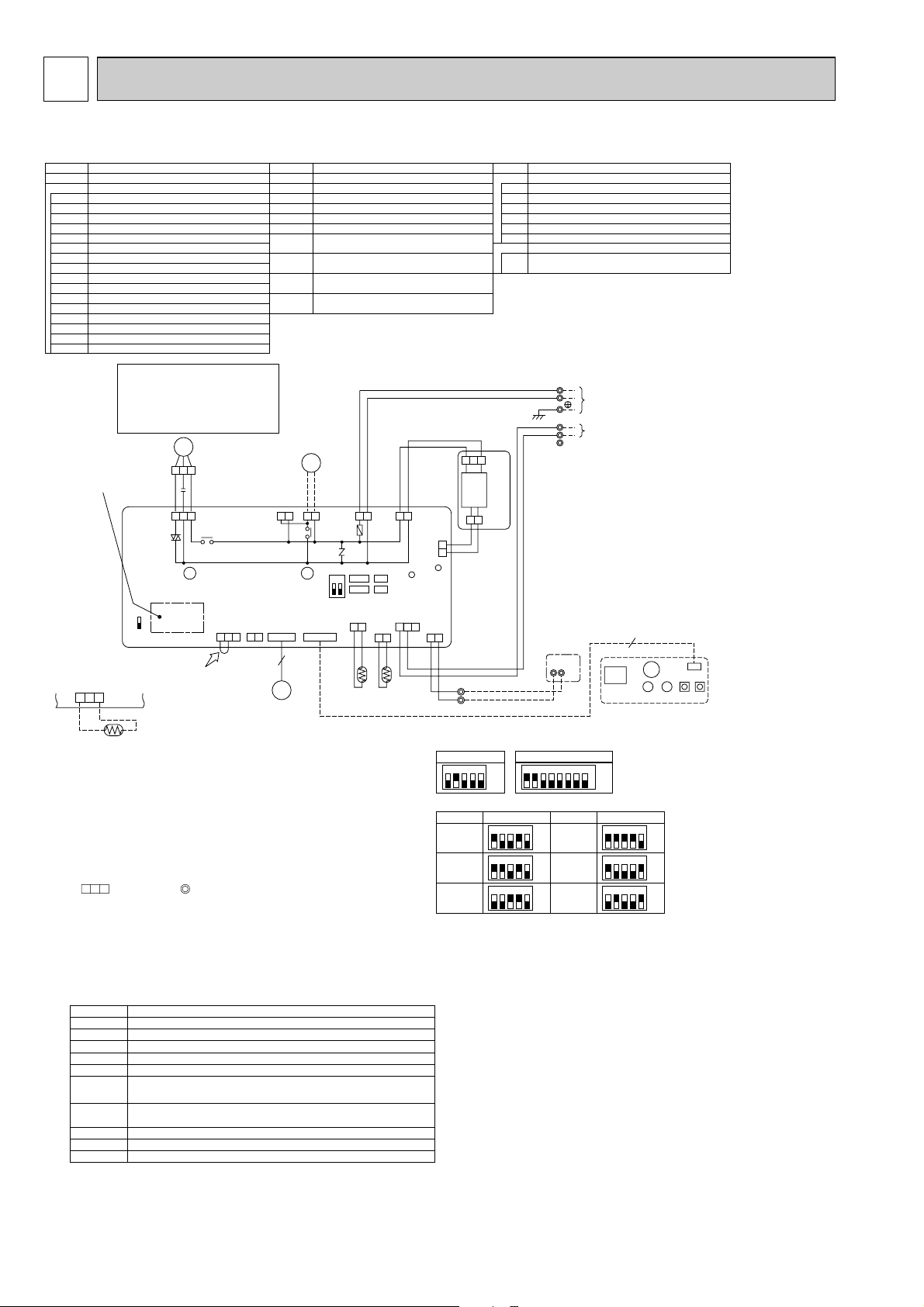

3-2. STANDARD OPERATION DATA

Capacity

Input

Indoor unit Service Ref.

phase, Hz

Volts

Amperes

Outdoor unit Service Ref.

phase, Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air temperature

Discharge air temperature

Intake air temperature

W

kW

V

A

V

A

°C

°C

°C

m

°C

°C

°C

°C

°C

D.B.

W.B.

D.B.

D.B.

W.B.

Service Ref.

Electrical circuit TotalRefrigerant circuit

Indoor side

Outdoor

side

MODE

PC-4GAK PC-5GAK PC-6GAK

PC-4GAK PC-5GAK PC-6GAKPC-3GAK

PC-2.5GAK

PC-2GAK

Cooling

9,300

5.17

1,60

220

0.95

PU-

4TJSA.TH

3,60

220

14.0

2.40

(24.4)

0.51

(5.2)

88.4

54.5

6.0

5

29

19

11.7

46

24

Cooling

12,400

4.76

1,50

220

0.96

PU-

5YJSA1.TH

3,50

380

8.15

1.83

(18.7)

0.46

(4.7)

72.9

48.8

3.1

5

27

19

13.7

35

24

Cooling

11,600

6.94

1,60

220

1.20

PU-

5TJSA.TH

3,60

220

19.61

2.41

(24.6)

0.43

(4.4)

94.8

60.1

1.7

5

29

19

14.9

46

24

Cooling

14,600

5.31

1,50

220

0.96

PU-

6YJSA1.TH

3,50

380

8.63

1.96

(20.0)

0.41

(4.2)

75.4

51.1

2.3

5

27

19

12.2

35

24

Cooling

13,400

7.54

1,60

220

1.20

PU-

6TJSA.TH

3,60

220

21.45

2.41

(24.6)

0.42

(4.3)

94.8

60.3

1.6

5

29

19

12.6

46

24

Cooling

9,800

3.43

1,50

220

0.68

PU-

4YJSA1.TH

3,50

380

5.7

1.80

(18.3)

0.51

(5.2)

67.5

48.3

7.3

5

27

19

10.5

35

24

Cooling

6,500

4.25

1,60

220

0.70

PU-

3NJA.TH

1,60

220

20.9

2.54

(25.9)

0.44

(4.5)

82.0

61.6

3.6

5

29

19

12.8

46

24

PC-3GAK

Cooling

7,600

3.30

1,50

220

0.51

PU-

3VJC1.TH

1,50

220

15.1

1.96

(20.0)

0.44

(4.5)

87.9

52.3

3.7

5

27

19

12.2

35

24

Cooling

6,200

3.60

1,60

220

0.70

PU-

2.5NJA.TH

1,60

220

15.8

2.68

(27.3)

0.52

(5.3)

94.3

57.6

10.2

5

29

19

15.3

46

24

PC-2.5GAK

Cooling

6,500

2.58

1,50

220

0.51

PU-

2.5VJA1.TH

1,50

220

11.4

1.96

(20.0)

0.5

(5.1)

72.3

52.4

8.6

5

27

19

12.0

35

24

Cooling

4,300

3.12

1,60

220

0.61

PU-

2NJA.TH

1,60

220

13.6

2.49

(25.4)

0.53

(5.4)

77.7

60.5

8.3

5

29

19

13.8

46

24

PC-2GAK

Cooling

5,600

2.54

1,50

220

0.38

PU-

2VJA1.TH

1,50

220

11.3

1.93

(19.7)

0.44

(4.5)

68.6

51.6

3.3

5

27

19

9.7

35

24

MPa

(kgf/F)

MPa

(kgf/F)

The unit of pressure has been changed to MPa based on SI(International System of unit) in accordance with I.S.O.(International

Organization for Standardization).

The conversion factor is : 1(MPa)=10.2(kgf / FF)

13

Page 14

Capacity

Input

Indoor unit Service Ref.

Phase, Hz

Volts

Amperes

Outdoor unit Service Ref.

Phase,Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air

temperature

Discharge air temperature

Intake air

temperature

Total

W

kW

V

A

V

A

MPa

(kgf/F)

MPa

(kgf/F)

°C

°C

°C

m

°C

°C

°C

°C

°C

PC-2GAK PC-2.5GAK PC-3GAK

Service Ref.

5,300

1.76

PC-2GAK

1, 50

220

0.38

PU-2VKD-SH

1, 50

220

7.7

1.75

(17.8)

0.50

(5.1)

73.3

46.8

7.2

5

27

19

12.4

35

24

6,200

2.18

PC-2.5GAK

1, 50

220

0.51

PU-2.5VKD-SH

1, 50

220

9.6

1.98

(20.2)

0.52

(5.3)

84.9

50.1

9.6

5

27

19

12.8

35

24

7,100

2.45

PC-3GAK

1, 50

220

0.51

PU-3VKD-SH

/ PU-3YKD-SH

1 / 3, 50

220 / 380

10.8 / 3.9

1.86

(19.0)

0.48

(4.9)

76.1

49.7

5.6

5

27

19

12.3

35

24

Electrical circuitRefrigerant circuit

Indoor

side

Outdoor

side

D.B.

W.B.

D.B.

D.B.

W.B.

Capacity

Input

Indoor unit Service Ref.

Phase, Hz

Volts

Amperes

Outdoor unit Service Ref.

Phase,Hz

Volts

Amperes

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref. pipe length

Intake air

temperature

Discharge air temperature

Intake air

temperature

Total

W

kW

V

A

V

A

MPa

(kgf/F)

MPa

(kgf/F)

°C

°C

°C

m

°C

°C

°C

°C

°C

PC-4GAK PC-5GAK PC-6GAK

Service Ref.

9,500

3.15

PC-4GAK

1, 50

220

0.68

PU-4YKD-SH

3, 50

380

5.6

1.68

(17.1)

0.49

(5.0)

65.4

45.3

6.1

5

27

19

12.5

35

24

12,400

4.40

PC-5GAK

1, 50

220

0.96

PU-5YKD-SH

3, 50

380

7.8

1.79

(18.3)

0.44

(4.5)

65.0

47.8

3.4

5

27

19

12.4

35

24

14,400

5.31

PC-6GAK

1, 50

220

0.96

PU-6YKD-SH

3, 50

380

9.6

1.89

(19.3)

0.41

(4.2)

77.3

50.1

2.9

5

27

19

11.3

35

24

Electrical circuitRefrigerant circuit

Indoor

side

Outdoor

side

D.B.

W.B.

D.B.

D.B.

W.B.

The unit of pressure has been changed to MPa based on the internaional SI system.

The conversion factor is 1(MPa)=10.2(kgf / FF)

14

Page 15

3-3 . OUTLET AIR SPEED AND COVERAGE RANGE

Airflow

Air speed

Coverage

range

Airflow

Air speed

Coverage

range

m

3

/min

m/sec.

m

ft

m

3

/min

m/sec.

m

ft

Configuration

50Hz

Frequency

60Hz

Service Ref.

PC-4GAK

25

4.1

12.6

41.6

25

4.1

12.6

41.6

PC-5GAK

34

4.38

15.2

50.0

34

4.38

15.2

50.0

PC-6GAK

34

4.38

15.2

50.0

34

4.38

15.2

50.0

PC-3GAK

18

3.8

10.4

34.5

18

3.8

10.4

34.5

PC-2.5GAK

18

3.8

10.4

34.5

18

3.8

10.4

34.5

Ceiling suspended

PC-2GAK

13

3.7

8.8

29

13

3.7

8.8

29

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

PC-2GAK

NOTCH

High

Low

SPL(dB)

42

37

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

PC-2.5GAK

PC-3GAK

NOTCH

High

Low

SPL(dB)

43

37

LINE

The air coverage range is the value up to the position where the air speed is 0.25 m/sec. when air is blown out horizontally from the unit at Hi

notch position.

The coverage range should be used as a general guideline since it varies according to the size of the room and furniture inside the room.

3-4. NOISE CRITERION CURVES

15

Page 16

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

PC-4GAK

NOTCH

High

Low

SPL(dB)

45

40

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

PC-5GAK

NOTCH

High

Low

SPL(dB)

46

41

LINE

1m

1m

unit

about 1.4m

MICROPHONE

ceiling

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

BAND CENTER FREQUENCIES, Hz

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

PC-6GAK

NOTCH

High

Low

SPL(dB)

48

42

LINE

16

Page 17

4

180

210

157

15

85

182 (3/8F) liquid

201 (5/8F) gas

241 (Drainage)

Air intake

918

254

680

Electrical box

226

70

525

928

352

263

171

138

86

46 175 1

131

38

38 79

161

32

179

42

6-7

Celling

Electrical box

When electrical

box is pulled

down

3

2

8

5

1

4

6

2

1

17

150

140

70

320

80

933 (suspension bolt pitch)

983

1000

Air outlet

81

904

76

Gap to ceiling

OUTLINES AND DIMENSIONS

4-1. INDOOR UNIT

PC-2GAK

1 Drainage pipe connection (Unit side: 26mm I.D.) 5

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wiring arrangement

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

Refrigerant pipe will be only upper drain pipe arrangement.

Refrigerant-pipe connection (liquid pipe side/flared connection)

[FRONT VIEW]

Unit : mm

17

Page 18

PC-2.5GAK

1240 (suspension bolt pitch)

140

150

320 80

17

70

6

1290

1214

210

180

81 76

1310

Air outlet

1228

680

254

Air intake

85

182

201

241

15

157

(3/8F liquid)

(5/8F gas)

(Drainage)

3

2

8

5

1

4

Electrical box

When electrical

box is pulled

down

Celling

32

179

161

38

38 79

42

6~7

525

1235

416

263

171

138

86

131

175 1

46

1

2

Electrical

box

70

226

Gap to ceiling

PC-3GAK

1 Drainage pipe connection (Unit side : 26mm I.D.) 5

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wiring arrangement

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

Refrigerant pipe will be only upper drain pipe arrangement.

Refrigerant-pipe connection (liquid pipe side/flared connection)

[FRONT VIEW]

Unit : mm

18

Page 19

PC-4GAK

1 Drainage pipe connection (Unit side : 26mm I.D.)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left drain pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wiring arrangement

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).

Refrigerant pipe will be only upper drain pipe arrangement.

5 Refrigerant-pipe connection (liquid pipe side/flared connection)

3

42 239

When electrical

box is pulled

down

2

6~7

[FRONT VIEW]

Electrical box

93

160

525

1235

Celling

8

687

17

150

38 140

38

5

140

263

138

171

Unit : mm

1

4

Gap to ceiling

1

192

236

86

45

6

70

320 80

Electrical

box

1

1240 (suspension bolt pitch)

70

270

207

81 96

229

2

Air intake

Air outlet

1214

1310

680

254

1228

217

87

16

182

(3/8F liquid)

198

(3/4F gas)

245

(Drainage)

19

Page 20

PC-5GAK

1535

680

254

Air intake

1524

270

207

81 96

1620

Air outlet

1547(suspension bolt pitch)

140

150

320 80

18

70

6

87

182

198

245

16

217

(3/8F liquid)

(3/4F gas)

(Drainage)

3

2

8

5

1

4

Electrical box

When electrical

box is pulled

down

Celling

93

160

38

38 140

42 239

6~7

525

1545

687

263

171

138

86

192

236

1

45

1

2

Electrical

box

70

229

Gap to ceiling

PC-6GAK

1 Drainage pipe connection (Unit side : 26mm I.D.)

2 Drainage pipe connection (for the left arrangement) 6 Knock out hole for upper pipe arrangement

3 Knock out hole for left drain-piping arrangement 7 Knock out hole for left pipe arrangement

4 Refrigerant-pipe connection (gas pipe side/flared connection) 8 Knock out hole for wiring arrangement

NOTES:

1. Use M10 or W3/8 screws for anchor bolt.

2. Please be sure when installing the drain-up machine (option parts).