Page 1

Air-Conditioners OUTDOOR UNIT

MXZ-8B140,160VA

MXZ-8B140,160YA

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner

unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimaanlage das Installationshandbuch gründlich

durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous

assurer d’une utilisation correcte.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner

installeert.

HFC

utilized

R410A

FOR INSTALLER

English

FÜR INSTALLATEURE

Deutsch

POUR L’INSTALLATEUR

Français

VOOR DE INSTALLATEUR

Nederlands

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de

aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore

d’aria.

EΓXEIPIΔIO OΔHΓIΩN EΓKATAΣTAΣHΣ

Για ασφάλεια και σωστή χρήση, παρακαλείστε διαβάσετε προσεχτικά αυτό το εγχειρίδιο εγκατάστασησ πριν

αρχίσετε την εγκατάσταση τησ μονάδασ κλιματισμού.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade

de ar condicionado.

INSTALLATIONSMANUAL

Læs venligst denne installationsmanual grundigt, før De installerer airconditionanlægget, af hensyn til sikker og

korrekt anvendelse.

INSTALLATIONSMANUAL

Läs denna installationsmanual noga för säkert och korrekt bruk innan luftkonditioneringen installeras.

MONTAJ ELKİTABI

Emniyetli ve doğru biçimde nasıl kullanılacağını öğrenmek için lütfen klima cihazını monte etmeden önce bu

elkitabını dikkatle okuyunuz.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным

руководством по установке до выполнения установки кондиционера.

PARA EL INSTALADOR

PER L’INSTALLATORE

ΓΙΑ ΑΥΤΟΝ ΠΟΥ ΚΑΝΕΙ ΤΗΝ ΕΓΚΑΤΑΣΤΑΣΗ

PARA O INSTALADOR

TIL INSTALLATØREN

FÖR INSTALLATÖREN

MONTÖR İÇİN

ДЛЯ УСТАНОВИТЕЛЯ

Español

Italiano

Ελληνικά

Português

Dansk

Svenska

Türkçe

Русский

Page 2

Contents

1. Safety precautions .....................................................................................2

2. Installation diagram & parts ....................................................................... 3

3. Installation location .................................................................................... 4

4. Installing the outdoor unit .......................................................................... 6

5. Installing the refrigerant piping .................................................................. 6

Note: This symbol mark is for EU countries only.

This symbol mark is according to the directive 2002/96/EC Article 10 Information for users and Annex IV.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and components which can be recycled and reused.

This symbol means that electrical and electronic equipment, at their end-of-life, should be disposed of separately from your household waste.

Please, dispose of this equipment at your local community waste collection/recycling centre.

In the European Union there are separate collection systems for used electrical and electronic product.

Please, help us to conserve the environment we live in!

Caution:

• Do not vent R410A into the Atmosphere.

• R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol, with a Global Warming Potential (GWP)=1975.

6. Drainage piping work ...............................................................................10

7. Electrical work .........................................................................................10

8. Test run ....................................................................................................14

9. Special Functions ....................................................................................15

1. Safety precautions

► Before installing the unit, make sure you read all the “Safety precautions”.

► Please report to or take consent by the supply authority before connec-

tion to the system.

► Equipment complying with IEC/EN 61000-3-12

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that must be observed to prevent damage to the unit.

Warning:

• The unit must not be installed by the user. Ask a dealer or an authorized

technician to install the unit. If the unit is installed incorrectly, water leakage,

electric shock, or fire may result.

• For installation work, follow the instructions in the Installation Manual and use

tools and pipe components specifically made for use with R410A refrigerant.

The R410A refrigerant in the HFC system is pressurized 1.6 times the pressure

of usual refrigerants. If pipe components not designed for R410A refrigerant are

used and the unit is not installed correctly, the pipes may burst and cause damage or injuries. In addition, water leakage, electric shock, or fire may result.

• The unit must be installed according to the instructions in order to minimize

the risk of damage from earthquakes, typhoons, or strong winds. An incor

rectly installed unit may fall down and cause damage or injuries.

• The unit must be securely installed on a structure that can sustain its weight.

If the unit is mounted on an unstable structure, it may fall down and cause

damage or injuries.

• If the air conditioner is installed in a small room, measures must be taken to

prevent the refrigerant concentration in the room from exceeding the safety

limit in the event of refrigerant leakage. Consult a dealer regarding the appro

priate measures to prevent the allowable concentration from being exceeded.

Should the refrigerant leak and cause the concentration limit to be exceeded,

hazards due to lack of oxygen in the room may result.

• Ventilate the room if refrigerant leaks during operation. If refrigerant comes

into contact with a flame, poisonous gases will be released.

• All electric work must be performed by a qualified technician according to

local regulations and the instructions given in this manual. The units must be

powered by dedicated power lines and the correct voltage and circuit breakers

must be used. Power lines with insufficient capacity or incorrect electrical

work may result in electric shock or fire.

• Be sure to connect the power supply cords and the connecting wires for

the indoor units, outdoor units, and branch boxes directly to the units (no

intermediate connections).

Intermediate connections can lead to communication errors if water enters

the cords or wires and causes insufficient insulation to ground or a poor

electrical contact at the intermediate connection point.

After installation work has been completed, explain the “Safety Precautions,” use, and

maintenance of the unit to the customer according to the information in the Operation

Manual and perform the test run to ensure normal operation. Both the Installation

Manual and Operation Manual must be given to the user for keeping. These manuals

must be passed on to subsequent users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affixed to the main unit.

(If an intermediate connection is necessary, be sure to take measures to

prevent water from entering the cords and wires.)

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. If the pipes are not connected correctly, the

unit will not be properly grounded and electric shock may result.

• Use only specified cables for wiring. The connections must be made securely

without tension on the terminals. If the cables are connected or installed

incorrectly, overheating or fire may result.

• The terminal block cover panel of the outdoor unit must be firmly attached. If

the cover panel is mounted incorrectly and dust and moisture enter the unit,

electric shock or fire may result.

-

• When installing or relocating, or servicing the air conditioner, use only the

specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it with

any other refrigerant and do not allow air to remain in the lines.

If air is mixed with the refrigerant, then it can be the cause of abnormal high

pressure in the refrigerant line, and may result in an explosion and other

hazards.

The use of any refrigerant other than that specified for the system will cause

mechanical failure or system malfunction or unit breakdown. In the worst

case, this could lead to a serious impediment to securing product safety.

• Use only accessories authorized by Mitsubishi Electric and ask a dealer or an

authorized technician to install them. If accessories are incorrectly installed,

water leakage, electric shock, or fire may result.

• Do not alter the unit. Consult a dealer for repairs. If alterations or repairs are

not performed correctly, water leakage, electric shock, or fire may result.

• The user should never attempt to repair the unit or transfer it to another location. If the unit is installed incorrectly, water leakage, electric shock, or fire

may result. If the air conditioner must be repaired or moved, ask a dealer or

an authorized technician.

• After installation has been completed, check for refrigerant leaks. If refriger

ant leaks into the room and comes into contact with the flame of a heater or

portable cooking range, poisonous gases will be released.

• Refrigerant leakage may cause suffocation. Provide ventilation in accordance

with EN378-1.

-

1.1. Before installation

Caution:

• Do not use the unit in an unusual environment. If the air conditioner is installed

in areas exposed to steam, volatile oil (including machine oil), or sulfuric gas,

areas exposed to high salt content such as the seaside, or areas where the

unit will be covered by snow, the performance can be significantly reduced

and the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced, flow,

or accumulate. If combustible gas accumulates around the unit, fire or explosion may result.

• The outdoor unit produces condensation during the heating operation. Make

1.2. Before installation (relocation)

Caution:

• Be extremely careful when transporting the units. Two or more persons are

needed to handle the unit, as it weighs 20 kg or more. Do not grasp the pack

aging bands. Wear protective gloves to remove the unit from the packaging

and to move it, as you can injure your hands on the fins or other parts.

• Be sure to safely dispose of the packaging materials. Packaging materials, such

as nails and other metal or wooden parts may cause stabs or other injuries.

2

sure to provide drainage around the outdoor unit if such condensation is likely

to cause damage.

• When installing the unit in a hospital or communications office, be prepared for

noise and electronic interference. Inverters, home appliances, high-frequency

medical equipment, and radio communications equipment can cause the air

conditioner to malfunction or breakdown. The air conditioner may also affect

medical equipment, disturbing medical care, and communications equipment,

harming the screen display quality.

• The base and attachments of the outdoor unit must be periodically checked

-

for looseness, cracks or other damage. If such defects are left uncorrected,

the unit may fall down and cause damage or injuries.

• Do not clean the air conditioner unit with water. Electric shock may result.

• Tighten all flare nuts to specification using a torque wrench. If tightened too

much, the flare nut can break after an extended period and refrigerant can

leak out.

Page 3

1. Safety precautions

1.3. Before electric work

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

IMPORTANT

Make sure that the current leakage breaker is one compatible with higher

harmonics.

Always use a current leakage breaker that is compatible with higher harmonics as this unit is equipped with an inverter.

The use of an inadequate breaker can cause the incorrect operation of

inverter.

• For the power lines, use standard cables of sufficient capacity. Otherwise, a

short circuit, overheating, or fire may result.

1.4. Before starting the test run

Caution:

• Turn on the main power switch more than 12 hours before starting operation.

Starting operation just after turning on the power switch can severely damage

the internal parts. Keep the main power switch turned on during the operation

season.

• Before starting operation, check that all panels, guards and other protective

parts are correctly installed. Rotating, hot, or high voltage parts can cause

injuries.

1.5. Using R410A refrigerant air conditioners

Caution:

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Make sure the insides of the pipes are clean

and do not contain any harmful contaminants such as sulfuric compounds,

oxidants, debris, or dust. Use pipes with the specified thickness. (Refer to

page 6) Note the following if reusing existing pipes that carried R22 refrigerant.

- Replace the existing flare nuts and flare the flared sections again.

- Do not use thin pipes. (Refer to page 6)

• Store the pipes to be used during installation indoors and keep both ends of

the pipes sealed until just before brazing. (Leave elbow joints, etc. in their

packaging.) If dust, debris, or moisture enters the refrigerant lines, oil dete

rioration or compressor breakdown may result.

• Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration

oil applied to the flared sections. If mineral oil is mixed in the refrigeration

oil, oil deterioration may result.

• When installing the power lines, do not apply tension to the cables. If the

connections are loosened, the cables can snap or break and overheating or

fire may result.

• Be sure to ground the unit. Do not connect the ground wire to gas or water

pipes, lighting rods, or telephone grounding lines. If the unit is not properly

grounded, electric shock may result.

• Use circuit breakers (ground fault interrupter, isolating switch (+B fuse), and

molded case circuit breaker) with the specified capacity. If the circuit breaker

capacity is larger than the specified capacity, breakdown or fire may result.

• Do not touch any switch with wet hands. Electric shock may result.

• Do not touch the refrigerant pipes with bare hands during operation. The

refrigerant pipes are hot or cold depending on the condition of the flowing

refrigerant. If you touch the pipes, burns or frostbite may result.

• After stopping operation, be sure to wait at least five minutes before turning off

the main power switch. Otherwise, water leakage or breakdown may result.

• Do not use refrigerant other than R410A refrigerant. If another refrigerant is

used, the chlorine will cause the oil to deteriorate.

• Use the following tools specifically designed for use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant. Contact your

nearest dealer for any questions.

Gauge manifold Flare tool

Charge hose Size adjustment gauge

Gas leak detector Vacuum pump adapter

-

• Be sure to use the correct tools. If dust, debris, or moisture enters the refrigerant lines, refrigeration oil deterioration may result.

• Do not use a charging cylinder. If a charging cylinder is used, the composition

of the refrigerant will change and the efficiency will be lowered.

Torque wrench Electronic refrigerant charging scale

Tools (for R410A)

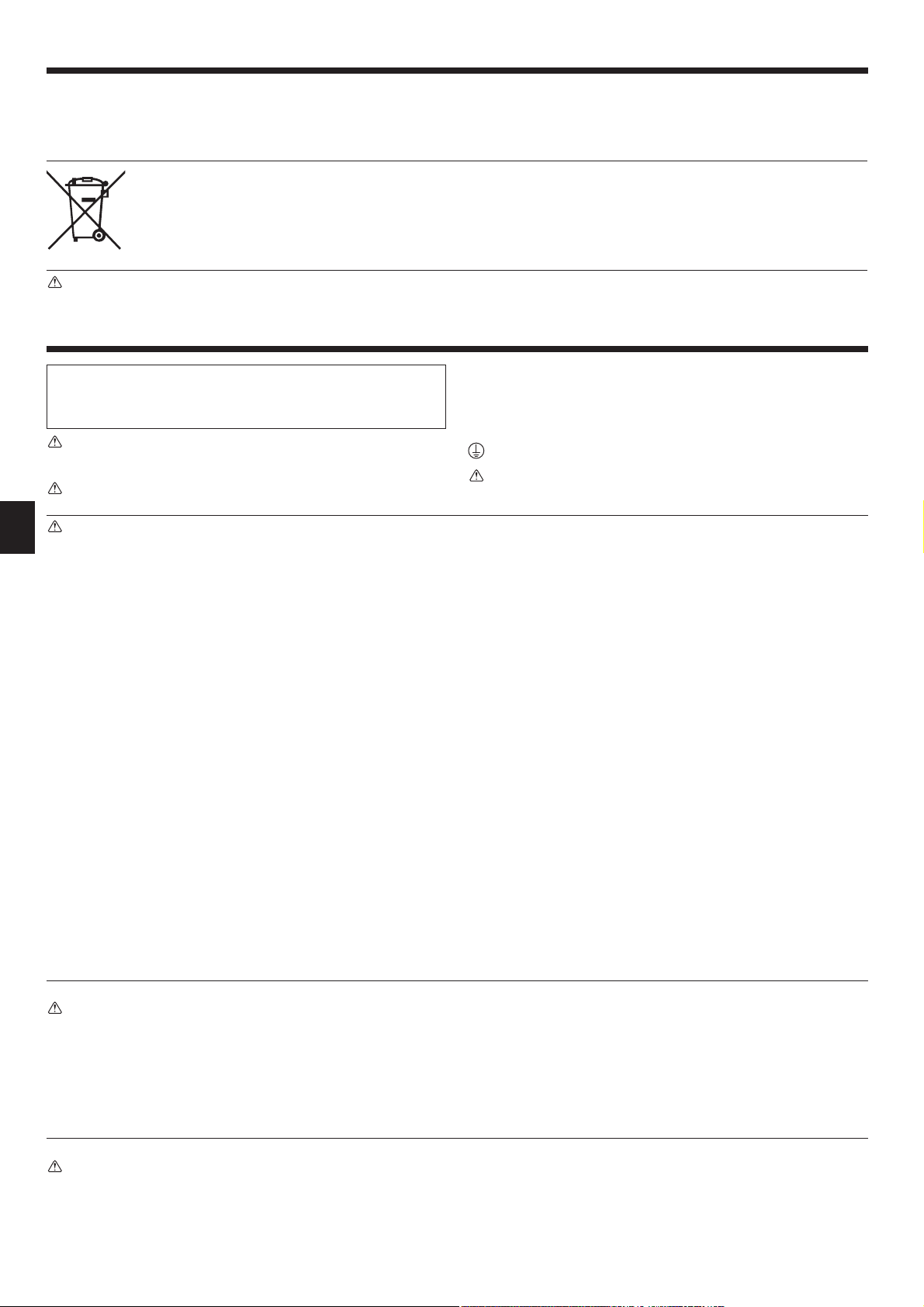

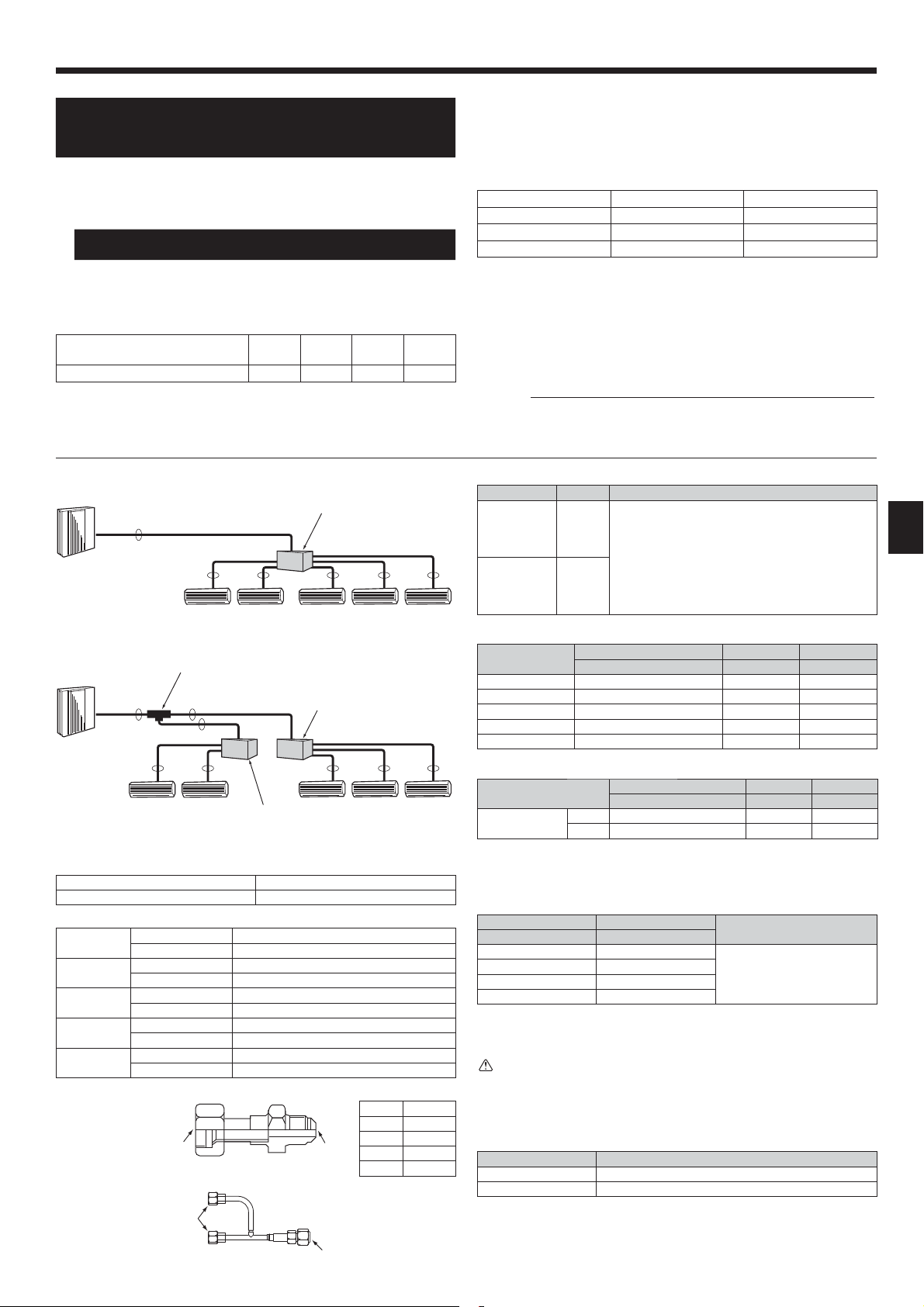

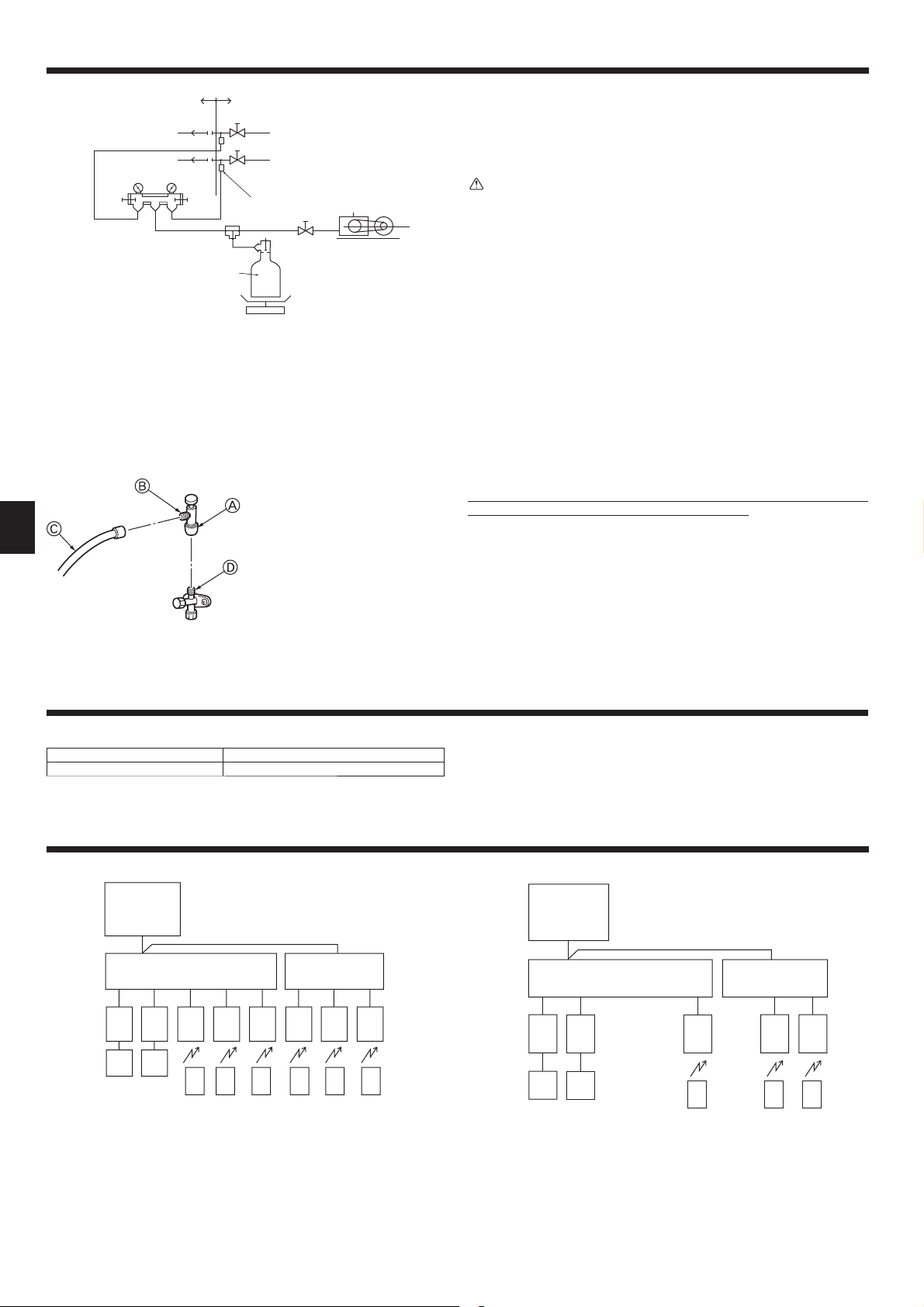

2. Installation diagram & parts

[D]

[H]

[G]

Outdoor unit

[E]

[F]

[B]

[A]

[K]

[I]

Fig. 2-1

Branch box

5-branches type

[C]

3-branches type

2.1. Before installation (Fig. 2-1)

This installation manual is only for the outdoor unit installation. In installing

the indoor units and branch box, refer to the installation manual attached

to each unit.

Any structural alterations necessary for the installation must comply with the local

building code requirements.

This diagram is intended to show the configuration of accessories.

For actual installation, the outdoor unit is to be turned 180°.

Units should be installed by licensed contractor according to local code requirement.

Note:

The dimensions given along the arrows above are required to guarantee the

air conditioner’s performance. Install the unit in as wide a place as possible

for later service or repairs.

Parts to be locally procured

Branch box/outdoor unit connecting wire

[A]

(3-core, Refer to 7.3. External wiring procedure)

[B] Extension pipe 1

[C] Wall hole sleeve 1

[D] Wall hole cover 1

Pipe fixing band

[E]

(The quantity depends on the pipe length.)

Fixing screw for [E] 4 × 20 mm

[F]

(The quantity depends on the pipe length.)

[G] Piping tape 1

[H] Putty 1

[I] Drain hose (hard PVC pipe VP16) 1

[J] Refrigeration oil 1

Power supply cord

[K]

(2-core, Refer to 7.3. External wiring procedure)

1

2 to 7

2 to 7

1

3

Page 4

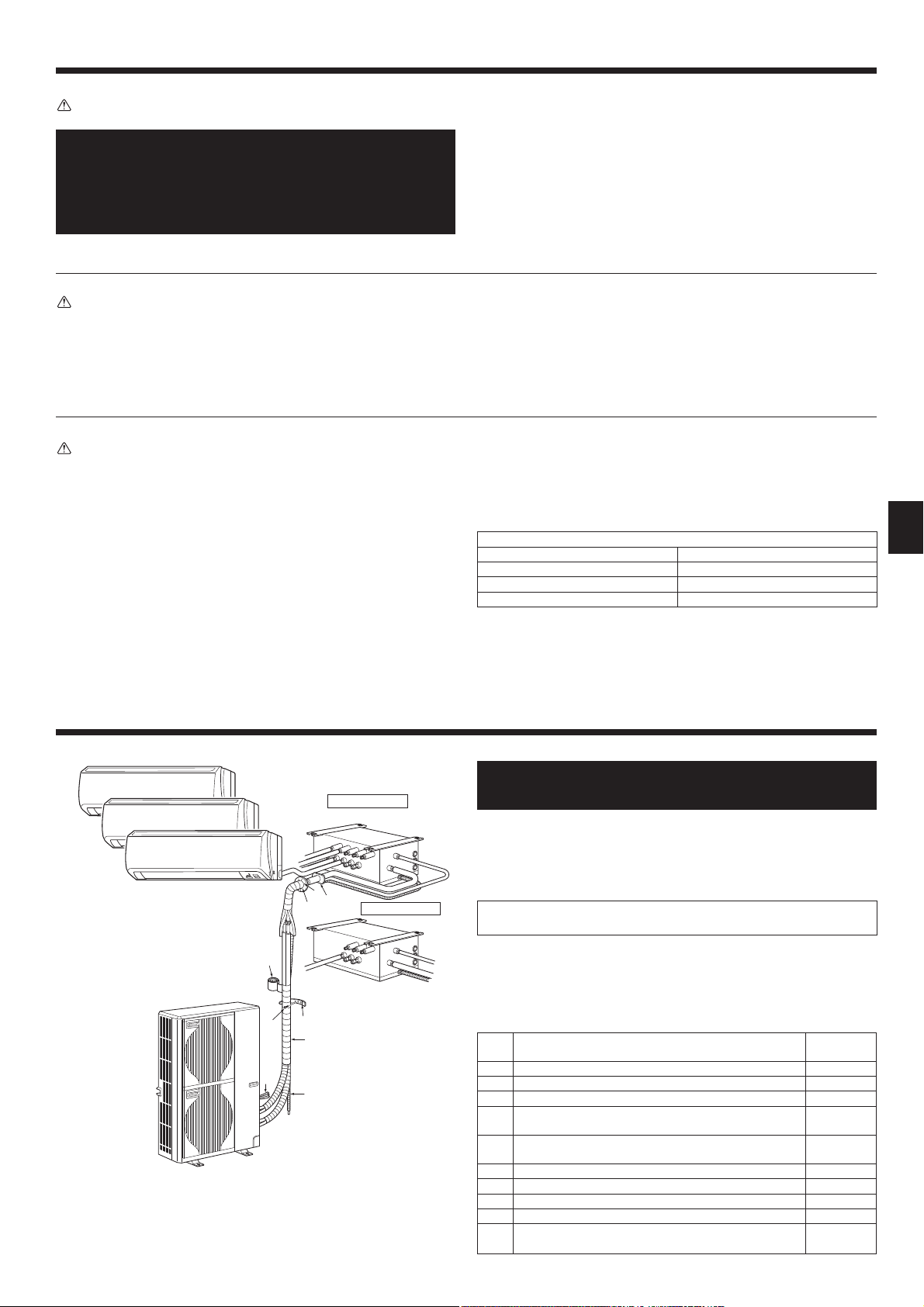

3. Installation location

330+30

1350

950

(mm)

3.1. Refrigerant pipe

Refer to 5.2. Pipe length and height difference.

3.2. Choosing the outdoor unit installation location

• Avoid locations exposed to direct sunlight or other sources of heat.

• Select a location from which noise emitted by the unit will not inconvenience neighbors.

• Select a location permitting easy wiring and pipe access to the power source and

indoor unit.

• Avoid locations where combustible gases may leak, be produced, flow, or accumu

late.

• Note that water may drain from the unit during operation.

• Select a level location that can bear the weight and vibration of the unit.

• Avoid locations where the unit can be covered by snow. In areas where heavy snow

fall is anticipated, special precautions such as raising the installation location or

installing a hood on the air intake must be taken to prevent the snow from block

ing the air intake or blowing directly against it. This can reduce the airflow and a

malfunction may result.

• Avoid locations exposed to oil, steam, or sulfuric gas.

• Use the transportation handles of the outdoor unit to transport the unit. If the unit

is carried from the bottom, hands or fingers may be pinched.

3.3. Outline dimensions (Outdoor unit) (Fig. 3-1)

Constraints on indoor unit installation

You should note that indoor units that can be connected to this outdoor unit are the

following models.

• Indoor units with model numbers 15, 20, 22, 25, 35, 42, 50, 60, 71, 80, 100 can be

connected. Refer to the table below for possible 2-8 room, indoor unit combina

tions.

Verification

The rated capacity should be determined by observing the table below. The unit’s

quantities are limited in 2 to 8 units. For the next step, make sure that the total rated

capacity selected will stay in a range as shown below.

-

-

-

175

Fig. 3-2

600

Fig. 3-1

370

Fig. 3-3

• MXZ-8B140 3.0~18.5kw

• MXZ-8B160 3.0~20.2kw

Example: MXZ-8B140

MSZ-60 = 6.0

+

SEZ-35 = 3.5

+

SLZ-35 = 3.5

+

SEZ-25 = 2.5

+

SLZ-25 = 2.5

Indoor unit type 15 20 22 25 35 42 50 60 71 80

Rated capacity

(Cooling) (kW)

Combinations in which the total capacity of indoor units exceeds the capacity of the

outdoor unit will reduce the cooling capacity of each indoor unit below their rated

cooling capacity. Thus, combine indoor units with an outdoor unit within the outdoor

unit’s capacity, if possible.

*1 When connecting the indoor unit with the model number 100, use the PAC-AK52BC branch box.

Along with this, the PAC-AK52YP-E Y-shape connection pipe is required.

The capacity of outdoor unit

• MXZ-8B140 14.0kw

• MXZ-8B160 15.5kw

1.5 2.0 2.2 2.5 3.5 4.2 5.0 6.0 7.1 8.0 10.0

Total rated capacity

18.018.5 kW

100

*1

3.4. Ventilation and service space

3.4.1. Windy location installation

When installing the outdoor unit on a rooftop or other location unprotected from the

wind, situate the air outlet of the unit so that it is not directly exposed to strong winds.

Strong wind entering the air outlet may impede the normal airflow and a malfunction

may result.

The following shows three examples of precautions against strong winds.

Face the air outlet towards the nearest available wall about 50 cm away from the

wall. (Fig. 3-2)

Install an optional air guide if the unit is installed in a location where strong winds

from a typhoon, etc. may directly enter the air outlet. (Fig. 3-3)

Air guide

Position the unit so that the air outlet blows perpendicularly to the seasonal wind

direction, if possible. (Fig. 3-4)

Wind direction

Fig. 3-4

4

Page 5

3. Installation location

Max. 500

1000

200

Fig. 3-9

1500

150

1000

Max. 300

Fig. 3-12

150

500

1500

Fig. 3-6

250

300

Max. 500

250

Fig. 3-10

Fig. 3-13

1500

200

1500

500

300

1000

Fig. 3-8Fig. 3-7Fig. 3-5

300

Fig. 3-11

500

1500

Fig. 3-14

150

2000

600

1000

1500

Fig. 3-15 Fig. 3-16 Fig. 3-17

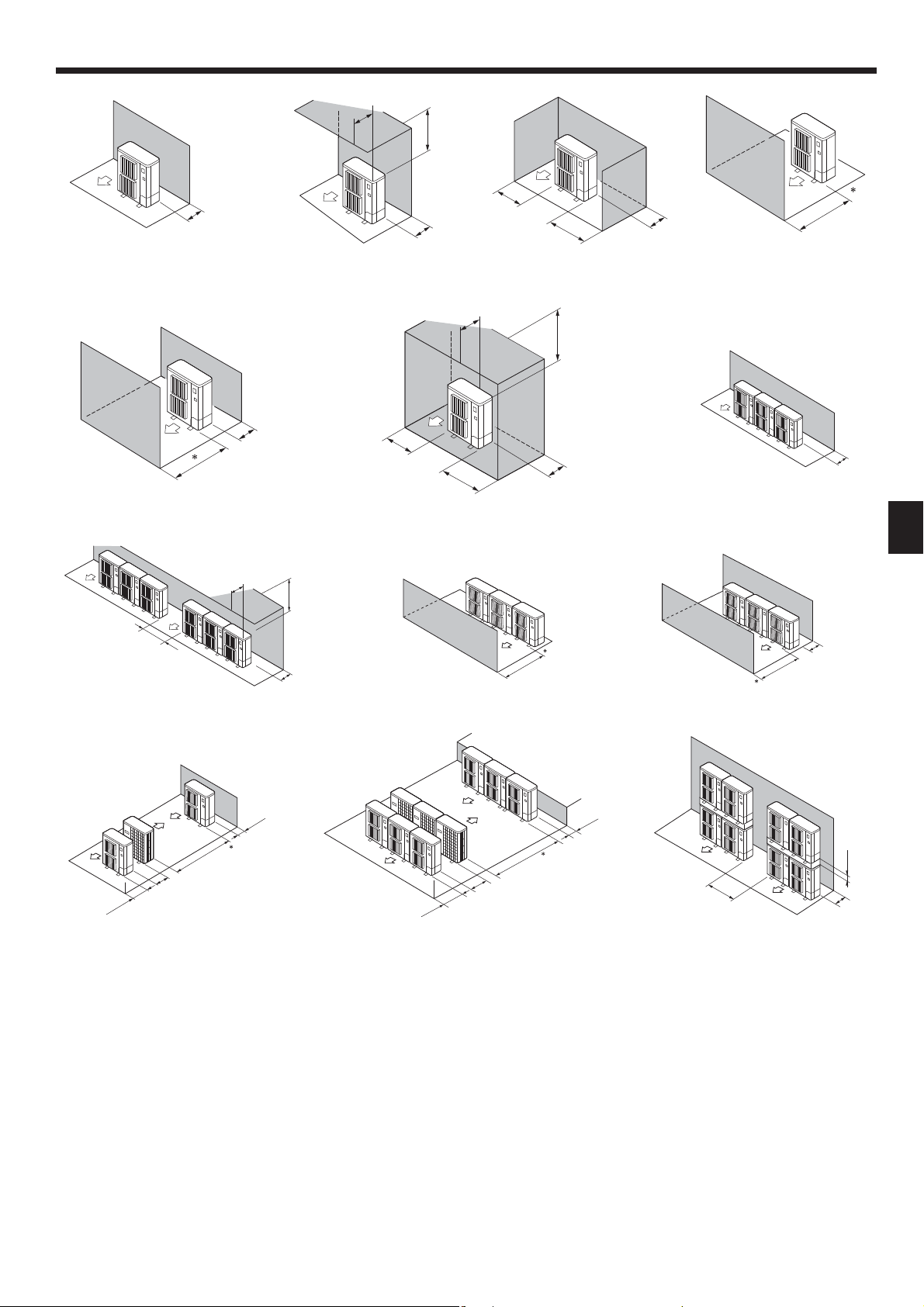

3.4.2. When installing a single outdoor unit

Minimum dimensions are as follows, except for Max., meaning Maximum dimensions, indicated.

Refer to the figures for each case.

Obstacles at rear only (Fig. 3-5)

Obstacles at rear and above only (Fig. 3-6)

Obstacles at rear and sides only (Fig. 3-7)

Obstacles at front only (Fig. 3-8)

∗ When using an optional air outlet guide, the clearance is 500 mm or more.

Obstacles at front and rear only (Fig. 3-9)

∗ When using an optional air outlet guide, the clearance is 500 mm or more.

Obstacles at rear, sides, and above only (Fig. 3-10)

• Do not install the optional air outlet guides for upward airflow.

500

3000

600

1500

3.4.3. When installing multiple outdoor units

Leave 10 mm space or more between the units.

Obstacles at rear only (Fig. 3-11)

Obstacles at rear and above only (Fig. 3-12)

• No more than three units must be installed side by side. In addition, leave space as shown.

• Do not install the optional air outlet guides for upward airflow.

Obstacles at front only (Fig. 3-13)

∗ When using an optional air outlet guide, the clearance is 1000 mm or more.

Obstacles at front and rear only (Fig. 3-14)

∗ When using an optional air outlet guide, the clearance is 1000 mm or more.

Single parallel unit arrangement (Fig. 3-15)

∗ When using an optional air outlet guide installed for upward airflow, the clearance is 1000

mm or more.

Multiple parallel unit arrangement (Fig. 3-16)

∗ When using an optional air outlet guide installed for upward airflow, the clearance is 1500

mm or more.

Stacked unit arrangement (Fig. 3-17)

• The units can be stacked up to two units high.

• No more than two stacked units must be installed side by side. In addition, leave space as shown.

150

800

5

Page 6

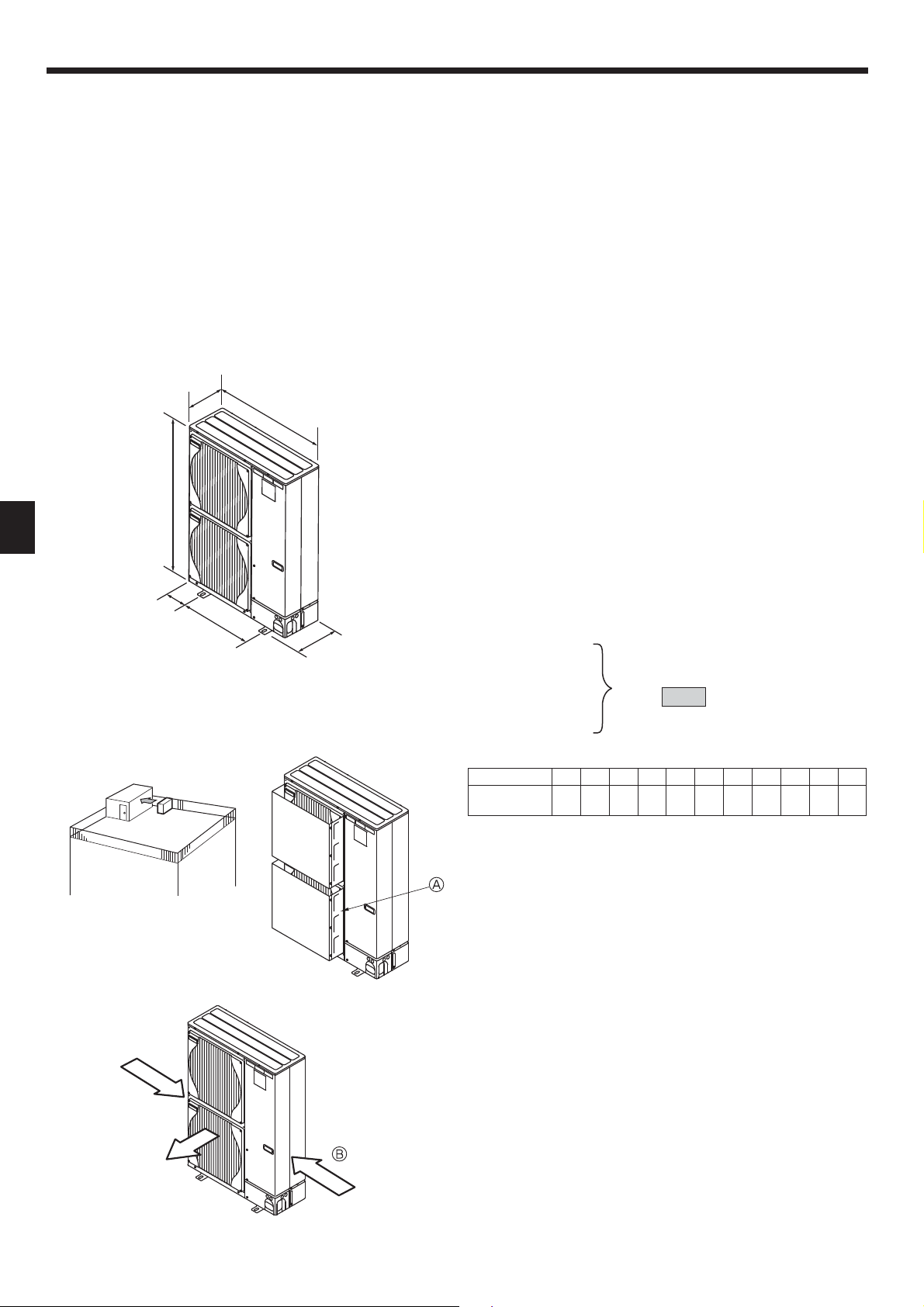

4. Installing the outdoor unit

Max. 30

M10 (3/8”) bolt

Base

As long as possible.

Vent

600 Min. 360 600

175 175

Min. 10

Fig. 4-1

950

330

25

D

370

(mm)

• Be sure to install the unit in a sturdy, level surface to prevent rattling noises during

operation. (Fig. 4-1)

<Foundation specifications>

Foundation bolt M10 (3/8”)

Thickness of concrete 120 mm

Length of bolt 70 mm

Weight-bearing capacity 320 kg

• Make sure that the length of the foundation bolt is within 30 mm of the bottom

surface of the base.

• Secure the base of the unit firmly with four-M10 foundation bolts in sturdy locations.

Installing the outdoor unit

• Do not block the vent. If the vent is blocked, operation will be hindered and break

down may result.

• In addition to the unit base, use the installation holes on the back of the unit to

attach wires, etc., if necessary to install the unit. Use self-tapping screws (ø5

mm or less) and install on site.

Warning:

• The unit must be securely installed on a structure that can sustain its weight.

If the unit is mounted on an unstable structure, it may fall down and cause

damage or injuries.

• The unit must be installed according to the instructions in order to minimize

the risk of damage from earthquakes, typhoons, or strong winds. An incor

rectly installed unit may fall down and cause damage or injuries.

Caution:

• Install the unit on a rigid structure to prevent excessive operation sound or

vibration.

× 15

-

-

5. Installing the refrigerant piping

Outdoor unit

b1

H

h1

a1

h3

*1

h2

a4a3a2

Fig. 5-1

*1 Although two refrigerant pipes are used between the branch box and the Y-shape

connection pipe when connecting the P100 indoor unit, calculate the piping lengths

using only the length of one pipe. (Fig. 5-2)

c1 c2

Fig.5-2

Branch box

Indoor unit

L

b2

I

a6a5

a7 a8

Indoor unit [P100 type]

Y-shape connection pipe

a1 = c1 + c2

5.1. Precautions for devices that use R410A refrigerant

• Refer to page 3 for precautions not included below on using air conditioners

with R410A refrigerant.

• Use ester oil, ether oil, alkylbenzene oil (small amount) as the refrigeration

oil applied to the flared sections.

• Use C1220 copper phosphorus, for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses

specified in the table to the below. Make sure the insides of the pipes are clean

and do not contain any harmful contaminants such as sulfuric compounds,

oxidants, debris, or dust.

Warning:

When installing or relocating, or servicing the air conditioner, use only the

specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it with

any other refrigerant and do not allow air to remain in the lines.

If air is mixed with the refrigerant, then it can be the cause of abnormal high pres

sure in the refrigerant line, and may result in an explosion and other hazards.

The use of any refrigerant other than that specified for the system will cause

mechanical failure or system malfunction or unit breakdown. In the worst case,

this could lead to a serious impediment to securing product safety.

ø6.35, ø9.52, ø12.7 Thickness 0.8 mm

ø15.88 Thickness 1.0 mm

• Do not use pipes thinner than those specified above.

5.2. Pipe length and height difference (Fig. 5-1)

Flared connections

• This unit has flared connections on each indoor unit and branch box and outdoor

unit sides.

• Remove the valve cover of the outdoor unit, then connect the pipe.

• Refrigerant pipes are used to connect the branch box and outdoor unit.

-

Total piping length

Permissible

length

(one-way)

Permissible

height differ

ence

(one-way)

Number of bends

*2 Branch box should be placed within the level between the outdoor unit and indoor units.

Farthest piping length (L)

Piping length between outdoor unit and branch boxes

Farthest piping length after branch box (l)

Total piping length between branch boxes and indoor units

In indoor/outdoor section (H)*2

In branch box/indoor unit section (h1)

In each branch unit (h2)

In each indoor unit (h3)

b1+b2+a1+a2+a3+a4+a5+a6+a7+a8 115 m

b2+a8

b1+b2 55 m

a8 15 m

a1+a2+a3+a4+a5+a6+a7+a8

H 30 m (In case of outdoor unit is set higher than indoor unit)

H 20 m (In case of outdoor unit is set lower than indoor unit)

h1 + h2

h2 15 m

h3 12 m

| b1+a1 |, | b1+a2 |, | b1+a3 |, | b1+a4 |, | b1+a5 |, | b2+a6 |, | b2+a7 |, | b2+a8 | 15

6

70 m (b2 55 m, a8 15 m)

60 m

15 m

Page 7

5. Installing the refrigerant piping

5.3. Addition of refrigerant

• Additional charging is not necessary for this unit if the total pipe length

(b1+b2+a1+a2+a3+a4+a5+a6+a7+a8) does not exceed 40 m.

• If the total pipe length exceeds 40 m, charge the unit with additional R410A

refrigerant according to the permitted pipe lengths in the chart below.

* When the unit is stopped, charge the unit with the additional refrigerant through

the liquid stop valve after the pipe extensions and indoor unit have been vacuumized.

When the unit is operating, add refrigerant to the gas check valve using a safety

charger. Do not add liquid refrigerant directly to the check valve.

After charging the unit with refrigerant, note the added refrigerant amount

on the service label (attached to the unit).

Refer to the “1.5. Using R410A refrigerant air conditioners” for more informa-

tion.

T

able 1

Total piping length

(b1+b2+a1+a2+a3+a4+a5+a6+a7+a8)

Additional refrigerant charging amount 0.6 kg 1.4 kg 2.2 kg 3.2 kg

N In case of using 1-branch box

Flare connection employed. (No. brazing)

A

41 - 50 m 51 - 70 m 71 - 90 m

Branch box

BB B BB

91 - 115 m

If connecting an indoor unit with ø9.52 liquid pipes (model number 71 or more for Mand S-Series and model number 60 or more for P-Series), the additional refrigerant

charging amount in Table 1 must be corrected (add the following

value given in Table 1).

Additional refrigerant charging correction amount

ΔR=0.01 [kg/m] × ø9.52 branch pipe (liquid pipe) total length [m]

Example) b1=20 m, b2=25 m

Indoor unit A ø9.52 Liquid pipe a1=12 m

Indoor unit B ø6.35 Liquid pipe a2=11 m

Indoor unit C ø6.35 Liquid pipe a6=14 m

Indoor unit D ø9.52 Liquid pipe a7=13 m

Total piping length : b1+b2+a1+a2+a6+a7=95 m

→ According to Table 1, the additional refrigerant charging amount is 3.2 kg.

Because indoor units with ø9.52 liquid pipes are connected (indoor units A and D in

this example), the additional refrigerant charging amount must be corrected.

Additional refrigerant charging correction amount

ΔR =0.01 [kg/m] × ø9.52 branch pipe (liquid pipe) total length (a1+a7)

=0.01 × (12+13 m)

=0.25 kg

Therefore, the additional refrigerant charging amount is 3.2 kg + 0.25 kg = 3.45 kg.

* Although two ø6.35 liquid pipes are used between the branch box and the Y-shape

connection pipe when connecting the P100 indoor unit, calculate the additional

refrigerant charging amount assuming only one ø9.52 liquid pipe is used.

ΔR value from the

5.4. Selecting pipe size (Fig. 5-3)

A B

The piping connection size differs according to the type

Liquid (mm) ø9.52

Gas (mm)

ø15.88

and capacity of indoor units. Match the piping connection size of branch box with indoor unit.

If the piping connection size of branch box does not

match the piping connection size of indoor unit, use

optional different-diameter (deformed) joints to the

branch box side. (Connect deformed joint directly to

the branch box side.)

N In case of using 2-branch boxes

2 branches pipe (joint)

: optional parts.

A

A

A

BB B BB

Branch box #2

Branch box #1

Fig. 5-3

(1) Valve size for outdoor unit

For liquid ø9.52 mm

For gas ø15.88 mm

(2) Valve size for branch box

UNIT

UNIT

UNIT

UNIT

UNIT

* 3-branch type : only , , unit

Liquid pipe ø6.35 mm

Gas pipe ø9.52 mm

Liquid pipe ø6.35 mm

Gas pipe ø9.52 mm

Liquid pipe ø6.35 mm

Gas pipe ø9.52 mm

Liquid pipe ø6.35 mm

Gas pipe ø9.52 mm

Liquid pipe ø6.35 mm

Gas pipe ø12.7 mm

A

B

Conversion formula

Fig. 5-4

1/4 F ø6.35

3/8 F ø9.52

1/2 F ø12.7

5/8 F ø15.88

3/4 F ø19.05

Different-diameter joint (optional parts) (Fig. 5-4)

Model name

MAC-A454JP ø9.52 → ø12.7 ø9.52 ø12.7

MAC-A455JP ø12.7 → ø9.52 ø12.7 ø9.52

MAC-A456JP ø12.7 → ø15.88 ø12.7 ø15.88

PAC-493PI ø6.35 → ø9.52 ø6.35 ø9.52

PAC-SG76RJ-E ø9.52 → ø15.88 ø9.52 ø15.88

Y-shape connection pipe for 100 type indoor unit (optional parts) (Fig. 5-5)

Model name

PAC-AK52YP-E

N Installation procedure (Y-shape connection pipe)

Refer to the installation manuals of PAC-AK52YP-E.

Piping preparation

Table below shows the specifications of pipes commercially available.

Outside diameter Insulation thickness

mm mm

6.35 8

9.52 8

12.7 8

15.88 8

Ensure that the 2 refrigerant pipes are insulated to prevent condensation.

Refrigerant pipe bending radius must be 100 mm or more.

Caution:

Be sure to use the insulation of specified thickness. Excessive thickness may

cause incorrect installation of the indoor unit and branch box, and lack of

thickness may cause dew drippage.

2-branch pipe (Joint) : Optional parts (According to the connection method,

you can choose the favorite one.)

Model name Connection method

MSDD-50AR-E flare

MSDD-50BR-E brazing

Connected pipes diameter Diameter A Diameter B

mm mm mm

Connected pipe diameter Diameter A Diameter B

mm mm mm

Liquid ø6.35 → ø9.52 ø6.35 ø9.52

Gas ø9.52 → ø15.88 ø9.52 ø15.88

Insulation material

Heat resisting foam plastic

0.045 specific gravity

A

Fig. 5-5

N Installation procedure (2 branches pipe (Joint))

Refer to the installation manuals of MSDD-50AR-E and MSDD-50BR-E.

B

7

Page 8

5. Installing the refrigerant piping

452

øA

90° ± 0.5°

Flare cutting dimensions

Flare nut tightening torque

(Fig. 5-6)

Copper pipe O.D.

(mm)

ø6.35 8.7 - 9.1

ø9.52 12.8 - 13.2

ø12.7 16.2 - 16.6

ø15.88 19.3 - 19.7

(Fig. 5-6)

Copper pipe O.D.

(mm)

ø6.35 17 14 - 18

ø6.35 22 34 - 42

ø9.52 22 34 - 42

ø9.52 26 49 - 61

ø12.7 26 49 - 61

ø12.7 29 68 - 82

ø15.88 29 68 - 82

ø15.88 36 100 - 120

R0.4~R0.8

C

Fig. 5-6

Flare dimensions

øA dimensions (mm)

Flare nut O.D.

(mm)

A

B

Fig. 5-7

B

D

A

Die

Copper pipe

Tightening torque

(N·m)*

* 1 N·m 10 kgf·cm

Refrigerant collection when relocating the indoor and outdoor units

(pump down)

Connect a gauge manifold valve (pressure gauge included) to the service port

near the gas stop valve of the outdoor unit so that the refrigerant pressure

can be measured.

Turn on the power supply (circuit breaker).

Close the liquid stop valve, and then perform the test run for cooling operation

(SW4-1: ON and SW4-2: OFF).

* Be sure to wait at least 3 minutes after turning on the power supply before

setting SW4-1 and SW4-2. If the DIP switches are set before 3 minutes has

elapsed, the test run may not start.

Fully close the gas stop valve when the pressure reading on the gauge drops

to 0.05 - 0.00 MPa* (approximately 0.5 - 0.0 kgf/cm

* If too much refrigerant has been added to the air conditioner system, the pres-

sure may not drop to 0.5 kgf/cm

device to collect all of the refrigerant in the system, and then recharge the

system with the correct amount of refrigerant after the indoor and outdoor

units have been relocated.

Stop the air conditioner operation (SW4-1: OFF and SW4-2: OFF).

Turn off the power supply (circuit breaker).

2

. If this occurs, use a refrigerant collecting

2

).

5.5. Connecting pipes (Fig. 5-6)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C or more,

thickness of 12 mm or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam insula

tion materials (specific gravity of 0.03, thickness of 9 mm or more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening

flare nut.

• Use two wrenches to tighten piping connections.

• Use leak detector or soapy water to check for gas leaks after connections are

• Apply refrigerating machine oil over the entire flare seat surface.

• Use the flare nuts as follows.

N Pipe size (Outdoor unit-Branch box)

Pipe size

(ømm)

N Pipe size (Branch box-Indoor unit) *Case of M series or S series Indoor unit

Indoor

unit type

Pipe size

(ømm)

* When using 60 type indoor unit of MEXZ series, use the flare nut in the

Do not use the flare nut (gas side) attached to the indoor unit. If it is used,

N

Indoor unit

type

Pipe size

(ømm)

*1 When using 35, 50 type indoor unit of P series, use the flare nut attached

Do not use the flare nut in the indoor unit accessory. If it is used, a gas

*2 For details about connecting the pipes for the P100 indoor unit, refer to the

• When bending the pipes, be careful not to break them. Bend radii of 100 mm to 150

•

Pipes must be connected starting from the indoor unit.

Flare nuts must be tightened with a torque wrench.

Flare the liquid pipes and gas pipes and apply a thin layer of refrigeration oil (Ap-

• When usual pipe sealing is used, refer to Table 2 for flaring of R410A refrigerant

The size adjustment gauge can be used to confirm A measurements.

• Be sure to wrap insulation around the piping. Direct contact with the bare

Table 2 (Fig. 5-7)

completed.

Liquid ø9.52

Gas ø15.88

(kW) 15 20 22 25 35 42 50 60 71 80

Liquid

ø6.35 ø6.35 ø6.35 ø6.35 ø6.35 ø6.35 ø6.35 ø6.35 ø9.52 ø9.52

Gas

ø9.52 ø9.52 ø9.52 ø9.52 ø9.52 ø9.52 ø12.7

indoor unit accessory for the gas side connecting of indoor unit.

a gas leakage or even a pipe extraction may occur.

Pipe size (Branch box-Indoor unit) *Case of P series indoor unit

to the indoor unit.

leakage or even a pipe extraction may occur.

installation manual of the Y-shape connection pipe (PAC-AK52YP-E).

mm are sufficient.

Make sure the pipes do not contact the compressor. Abnormal noise or vibration

may result.

plied on site).

pipes.

Caution:

piping may result in burns or frostbite.

Copper pipe O.D.

(mm)

ø6.35 (1/4”) 0 - 0.5 1.0 - 1.5

ø9.52 (3/8”) 0 - 0.5 1.0 - 1.5

ø12.7 (1/2”) 0 - 0.5 1.0 - 1.5

ø15.88 (5/8”) 0 - 0.5 1.0 - 1.5

*1

(kW)

Liquid ø6.35 ø6.35 ø9.52 ø9.52 ø9.52

Gas ø12.7 ø12.7 ø15.88 ø15.88 ø15.88

35

The lineup of a connectable indoor unit

depends on a district/areas/country.

*1

50 60 71

Flare tool for R410A Flare tool for R22·R407C

A (mm)

Clutch type

ø15.88 *ø15.88 ø15.88

*2

100

-

8

Page 9

5. Installing the refrigerant piping

Front piping cover

Piping cover

Stop valve

Service panel

Band radius : 100 mm - 150 mm

Fig. 5-8

B

(2)

B

D

A

E

E

C

F

H

Fig. 5-9

C

I

E

(1)

B

A

K

C

H

Type A Type B

(3)

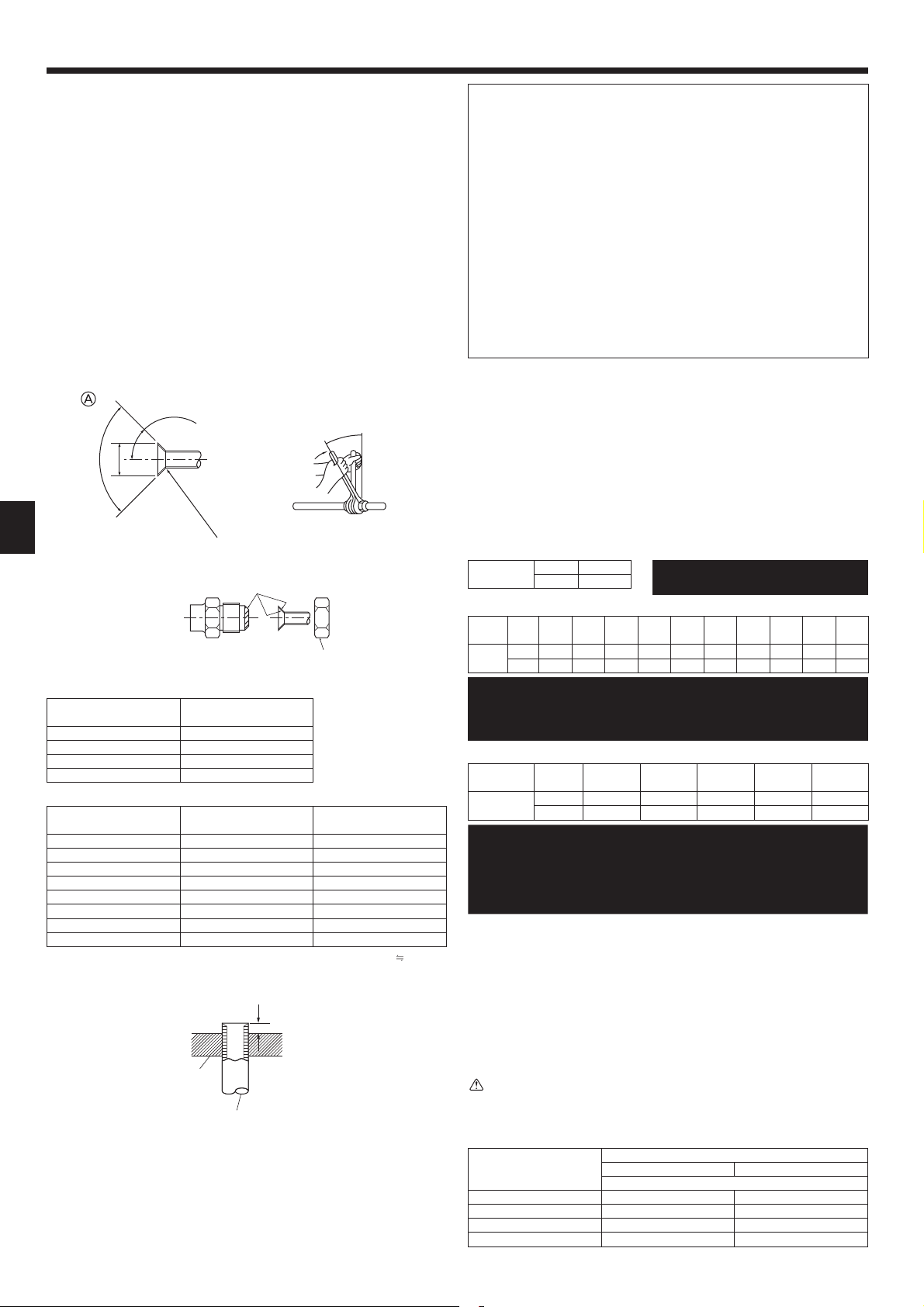

5.6. Refrigerant piping (Fig. 5-8)

Remove the service panel (three screws) and the front piping cover (two screws)

and rear piping cover (two screws).

Refrigerant pipes are protectively wrapped

• The pipes can be protectively wrapped up to a diameter of ø90 before or after con

necting the pipes. Cut out the knockout in the pipe cover following the groove and

wrap the pipes.

Pipe inlet gap

• Use putty or sealant to seal the pipe inlet around the pipes so that no gaps re

main.

(If the gaps are not closed, noise may be emitted or water and dust will enter the

unit and breakdown may result.)

-

-

5.7. Caution for piping connection/valve operation

• Conduct piping connection and valve operation accurately by following the figure

below.

• Apply sealer along the insulator to prevent water entering the insulator covering the

refrigerant pipe joints.

• After evacuation and refrigerant charge, ensure that the handle is fully open. If

operating with the valve closed, abnormal pressure will be imparted to the high- or

low-pressure side of the refrigerant circuit, giving damage to the compressor, etc.

• Determine the amount of additional refrigerant charge (refer “5.3. Addition of refriger-

ant”), and charge refrigerant additionally through the service port after completing

piping connection work.

• After completing work, tighten the service port (12 - 15 N·m) and cap (20 - 25 N·m)

securely to prevent gas leak.

10 kgf·cm

*1 N·m

Method of completely opening the stop valve

The stop valve opening method varies according to the outdoor unit model. Use the

appropriate method to open the stop valves.

(1) Type A (Fig. 5-9)

Remove the cap, then turn one-quarter rotation counter-clockwise with a flat-bladed

screwdriver to complete open.

Check that the valves are fully open, then return the cap to its original state and

tighten it down.

(2) Type B (Fig. 5-9)

Remove the cap, pull the handle toward you and rotate 1/4 turn in a counterclock-

wise direction to open.

G

Make sure that the stop valve is open completely, push in the handle and rotate

the cap back to its original position.

(3) Type C (Fig. 5-10)

Remove the cap and turn the valve rod counterclockwise as far as it will go with

the use of a 4 mm hexagonal wrench. Stop turning when it hits the stopper.

Make sure that the stop valve is open completely and rotate the cap back to its

original position.

Valve

Unit side

Service port

Handle

Cap

Completely closed

Completely open

(On-side installation) Refrigerant

piping side

Direction the refrigerant flows in

Wrench hole

Operation section

A

H

Type C

J

Fig. 5-10

EF

B

LO

HI

CD

Fig. 5-11

G

K

H

I

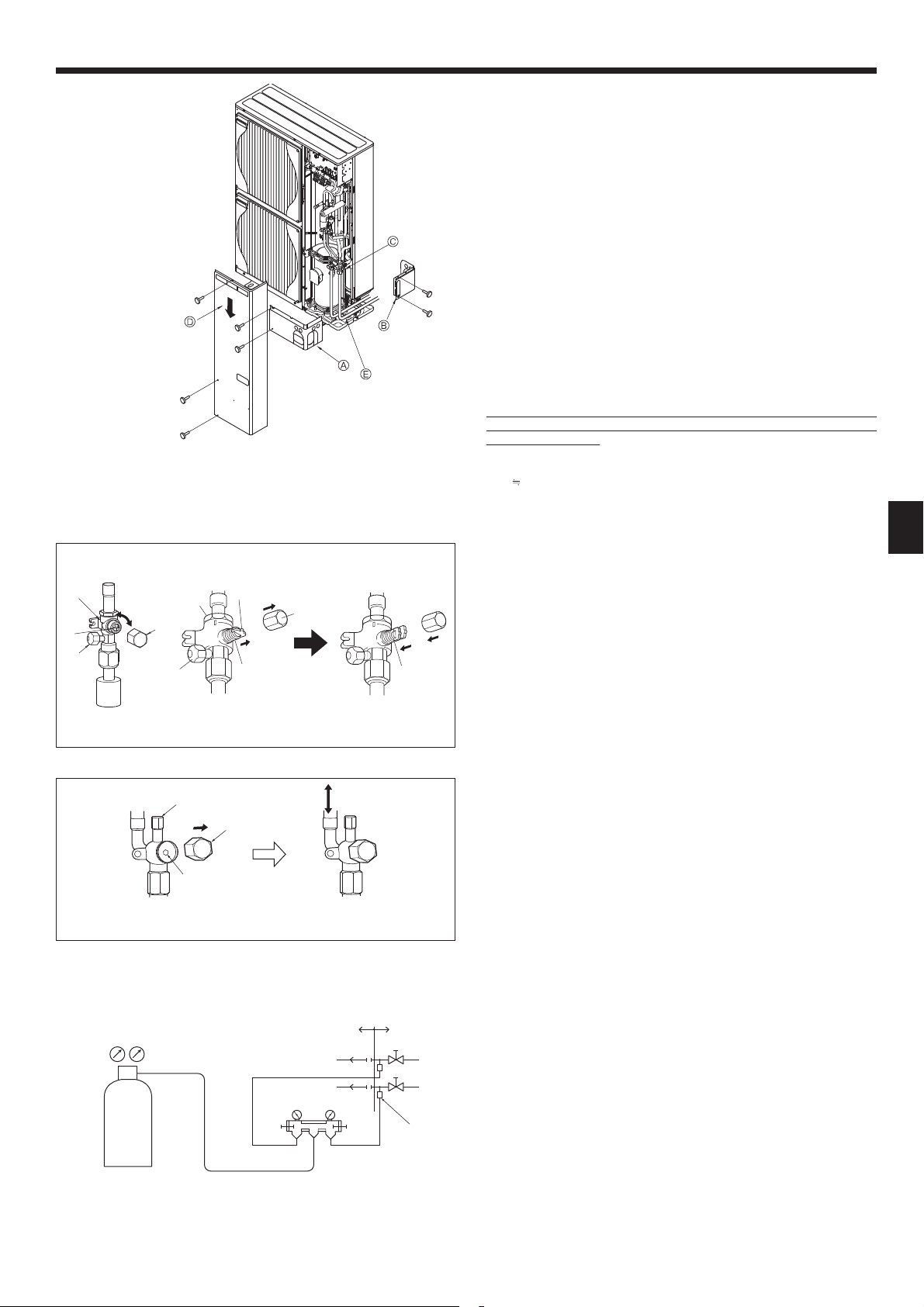

5.8.

Airtight test and evacuation

Airtight test (Fig. 5-11)

Airtight test should be made by pressurizing nitrogen gas. For the test method, refer

to the following figure.

(1) Connecting the testing tool. Make a test with the stop valve closed. Be also sure

to pressurize both liquid or high-pressure pipe and gas or low pressure pipe.

(2) Do not add pressure to the specified pressure all at once; add pressure little by lit

tle.

Pressurize to 0.5 MPa (5 kgf/cm

pressure does not decrease.

Pressurize to 1.5 MPa (15 kgf/cm

pressure does not decrease.

Pressurize to 4.15 MPa (41.5 kgf/cm

perature and refrigerant pressure.

(3) If the specified pressure holds for about one day and does not decrease, the pipes

have passed the test and there are no leaks.

• If the surrounding temperature changes by 1 °C, the pressure will change by

about 0.01 MPa (0.1 kgf/cm

(4) If the pressure decreases in steps (2) or (3), there is a gas leak. Look for the source

of the gas leak.

Nitrogen gas

System analyzer

Lo-knob

Hi-knob

To branch box

Outdoor unit

2

G), wait five minutes, and make sure the

2

G), wait five minutes, and make sure the

2

G) and measure the surrounding tem-

2

G). Make the necessary corrections.

Stop valve

Liquid pipe or high-pressure

pipe

Gas pipe or low-pressure pipe

Service port

9

-

Page 10

5. Installing the refrigerant piping

JI

K

F

LO HI

GH

D

A

Freon cylinder

Scale

Valve

3-way joint

Vacuum pump

System analyzer

Lo-knob

Fig. 5-12

L

M

N

C

C

E

B

Hi-knob

To branch box

Outdoor unit

Stop valve

Liquid pipe or high-pressure pipe

Gas pipe or low-pressure pipe

! Service port

* The figure to the left is an example

only. The stop valve shape, service port position, etc., may vary

according to the model.

* Turn section

(Do not further tighten sections

and together.)

only.

Evacuation (Fig. 5-12)

Evacuation should be made from the service port provided on the outdoor unit’s stop

valve to the vacuum pump commonly used for both liquid or high-pressure pipe and

gas or low-pressure pipe. (Make evacuation from both liquid or high-pressure pipe

and gas or low-pressure pipe with the stop valve closed.)

Remember: Never carry out air purge by refrigerant.

Warning:

When installing or moving a unit to another place, do not mix anything other than

specified refrigerant into the refrigeration cycle. If air is mixed, the refrigeration

cycle may obtain abnormally high pressure, resulting in a burst pipe.

* A high-precision gravimeter measurable up to 0.1 kg should be used. If you are unable

to prepare such a high-precision gravimeter, you may use a charging cylinder.

Note:

• Use a gauge manifold, changing hose, and other parts for the refrigerant

indicated on the unit.

• Use a gravimeter. (One that can measure down to 0.1 kg)

Precautions when using the charge valve (Fig. 5-13)

Do not tighten the service port too much when installing it, otherwise, the valve core

could be deformed and become loose, causing a gas leak.

After positioning section

it.

Do not further tighten sections and together after tightening section .

in the desired direction, turn section only and tighten

Charge hose

Service port

Fig. 5-13

6. Drainage piping work

Outdoor unit drainage pipe connection

When drain piping is necessary, use the drain socket or the drain pan (option).

Drain socket PAC-SG61DS-E

Drain pan PAC-SG64DP-E

7. Electrical work

[1] Basic systems

OC

ABCDEBCABC

(5-branch type)

BC

ICIC IC IC IC

IC

OC: Outdoor unit

BC: Branch box

IC: Indoor unit

RC: Remote controller

(3-branch type)

IC IC

Note:

The indoor units can be connected

to any of the 5 connectors (5-branch

OC

(5-branch type)

BC

type) or 3 connectors (3-branch type)

of the branch box.

(3-branch type)

ABCD EBCABC

ICRCIC IC

IC

IC

RC

RC

RCRCR

* For details about connecting the wires for the P100 indoor unit, refer to the

installation manual of the Branch box (PAC-AK52BC).

C

R

R

C

R

C

C

10

RC

R

C

R

R

C

C

Page 11

7. Electrical work

[2] Standard systems

2-1. Only 3-branch type 2-2. Only 5-branch type 2-3. 2-branch boxes (3-branch type)

OC

(3-branch type) (5-branch type) (3-branch type) (3-branch type)

BC

AB C

IC

IC

IC

R

R

R

C

2-4. 2 branch boxes (5-branch type, maximum 8 indoor units)

C

C

OC

BC

ABCDE

IC

IC

IC

R

R

R

C

C

C

OC

(5-branch type) (5-branch type)

BC

ABCDE

ABCDE

BC

OC

BC

ABC

IC

IC

IC

IC

R

R

C

C

IC

R

R

R

C

C

C

BC

ABC

IC

IC

IC

R

R

R

C

C

C

IC

IC

R

R

C

C

[3] Incorrect systems

3-1. Group operation

by single remote

controller

OC OC OC OC

(3-branch type) (3-branch type) (3-branch type) (3-branch type)

BC

AB C

ICRCIC IC

IC

IC

IC

IC

IC

IC

IC

IC

1. Up to 2 branch boxes can be connected to a single outdoor

unit.

2. Up to 8 indoor units can be connected to the system.

R

R

R

R

R

R

R

C

C

C

C

C

3-2. Group operation between different refrigerant

systems

BC

AB C

IC

C

BC

AB C

IC IC

R

C

C

3-3. Connection of M-NET adapter to outdoor unit

Master controller

(G-50, etc.)

Power supply unit

BC

AB C

IC

IC IC

ADP

001

M-NET

R

C

3-1. Plural indoor units cannot be operated by a single remote controller.

3-2. Different refrigerant systems cannot be connected together.

3-3. A M-NET adapter cannot be connected to an outdoor unit.

RC

R

C

RC RC

R

C

11

Page 12

7. Electrical work

LN

S1 S2 S3

■

8B140,160V

■

8B140,160Y

L1 L2 L3 N

S1 S2 S3

7.1. Outdoor unit (Fig. 7-1)

Remove the service panel.

Wire the cables referring to the Fig. 7-1.

Earth terminal

Terminal block

Clamp

Service panel

Wire the cables so that they do not contact the center of the service panel or the gas

valve.

Fig. 7-1

7.2. Branch box/outdoor wire connection and outdoor power supply cord connection

Warning:

• Be sure to attach the terminal block covers/panel of the outdoor unit securely. If it is not attached correctly, it could result in a fire or an electric shock due to

dust, water, etc.

• Be sure to connect the power supply cords and the connecting wires for the indoor units, outdoor units, and branch boxes directly to the units (no intermediate

connections).

Intermediate connections can lead to communication errors if water enters the cords or wires and causes insufficient insulation to ground or a poor electrical

contact at the intermediate connection point.

(If an intermediate connection is necessary, be sure to take measures to prevent water from entering the cords and wires.)

Caution:

• Be careful not to make mis-wiring.

• Firmly tighten the terminal screws to prevent them from loosening.

• After tightening, pull the wires lightly to confirm that they not move.

• If the connecting wire is incorrectly connected to the terminal block, the unit does not operate normally.

• Be sure to install N-line. Without N-line, it could cause damage to the unit.

Terminal

block

Connection details

• Connect wire from the branch box correctly to the terminal block.

• For future servicing, give extra length to connecting wire.

7.3. External wiring procedure (Fig. 7-2)

The power supply work is needed only to the outdoor unit. The power supply to the branch box or indoor unit is conducted through wiring.

Therefore, the power supply work can be carried out at just one spot of the outdoor unit. It will contribute to simplify the work and save costs.

Power supply

Model

140-160V ~ /N 220/ 230/ 240V 50Hz , ~ /N 220V 60Hz

140-160Y 3N~ 380/ 400/ 415V 50Hz

Max. Permissive System Impedance 0.22(Ω)

Note:

Power supply input: Outdoor unit only.

Connect the lines (C), (D) in accordance with the terminal block names to ensure correct polarity.

Model

140-160V

(A) Main power line (B) Earth line (C) Signal line (D) Signal line Interrupting current

2

6.0 mm

Power supply

Wire diameter Breaker *1

6.0 mm

2

1.5 mm2 *2 1.5 mm

2

40 A

Performance characteristic

for 0.1 sec. or less

Loosen terminal screw.

Lead wire

40A, 30 mA

140-160Y 1.5 mm

When using twisted wire for the wiring, the use of round terminal is required.

*1. A breaker with at least 3 mm contact separation in each pole shall be provided. Use earth leakage breaker (NV).

*2. Max. 45 m (“Outdoor unit - Branch box #1” plus “Branch box #1 - Branch box #2”).

If 2.5 mm2 used, Max. 55 m.

2

1.5 mm

2

1.5 mm2 *2 1.5 mm

2

25 A

25A, 30 mA

for 0.1 sec. or less

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Power supply cords and Indoor unit/branch box/outdoor unit connecting cords shall not be lighter than polychloroprene sheathed flexible cord.

3. Install an earth line longer than power cables.

IMPORTANT

(Design 60245 IEC 57)

Make sure that the current leakage breaker is one compatible with higher harmonics.

Always use a current leakage breaker that is compatible with higher harmonics as this unit is equipped with an inverter.

The use of an inadequate breaker can cause the incorrect operation of inverter.

12

Page 13

S1 S2 S3

7. Electrical work

<Example> (In case of 2-branch boxes)

140-160V

■

Outdoor unit

(A)

Circuit

breaker

(A)

L

N

(C)

S1

(B)

S2

S3

(C)

Branch box*1

(5-branch type)

TB3A

S1

S2

S3

TB3BTB2B

S1

S1

S2

S2

S3

S3

TB3C

S1

S2

S3

TB3D

S1

S2

S3

TB3E

S1

S2

S3

TB3A

S1

S2

S3

TB3B

S1

TB2B

S2

S1

S3

S2

S3

TB3C

S1

S2

S3

(D)

(D)

(D)

(D)

(D)

(D)

(D)

(D)

Indoor unit

S1

S2

S3

S1

S2

S3

S1

S2

S3

S1

S2

S3

S1

S2

S3

Indoor unit

S1

S2

S3

S1

S2

S3

S1

S2

S3

A ROOM

B ROOM

C ROOM

D ROOM

E ROOM

F ROOM

G ROOM

H ROOM

■

140-160Y

Circuit

breaker

(C)

(C)

Branch box*1

(5-branch type)

TB3A

TB3BTB2B

S1

S2

S3

TB3C

TB3D

TB3E

TB3A

TB3B

TB2B

S1

S2

S3

TB3C

Indoor unit

(D)

S1

S2

S3

(D)

S1

S2

S3

(D)

S1

S2

S3

(D)

S1

S2

S3

(D)

S1

S2

S3

(D)

S1

S2

S3

(D)

S1

S2

S3

(D)

S1

S2

S3

S1

S2

S3

S1

S2

S3

S1

S2

S3

S1

S2

S3

S1

S2

S3

Indoor unit

S1

S2

S3

S1

S2

S3

S1

S2

S3

A ROOM

B ROOM

C ROOM

D ROOM

E ROOM

F ROOM

G ROOM

H ROOM

Outdoor unit

(A)

(A)

L1

L2

L3

N

S1

(B)

S2

S3

Branch box*2

(3-branch type)

Warning:

Branch box*2

(3-branch type)

Fig. 7-2

In case of A-control wiring, there is high voltage potential on the S3 terminal caused by electrical circuit design that has no electrical insulation between power

line and communication signal line. Therefore, please turn off the main power supply when servicing. And do not touch the S1, S2, S3 terminals when the power

is energized. If isolator should be used between outdoor unit and branch box/indoor unit and branch box, please use 3-poles type.

Power supply

3 poles isolator (Switch)

S1

S2

S3

Branch

box

S1

S2

S3

S1

S2

S3

“A-control”

Indoor unit

Outdoor unit

Isolator (Switch)

S1

S2

S3

Caution:

After using the isolator, be sure to turn off and on the main power supply to reset the system. Otherwise, the outdoor unit may not be able to detect the branch

box(es) or indoor units.

WIRING SPECIFICATIONS

(OUTDOOR-BRANCH BOX CONNECTING CABLE)

Cross section of cable Wire size (mm2) Number of wires Polarity L (m)*6

Round

Flat

Flat

Round

2.5 3

2.5 3

1.5 4 From left to right : S1-Open-S2-S3

2.5 4

*1 : Power supply cords of appliances shall not be lighter than design 60245 IEC or

227 IEC.

*2 : In case that cable with stripe of yellow and green is available.

*3 : In case of regular polarity connection (S1-S2-S3), wire size is 1.5 mm

*4 : In case of regular polarity connection (S1-S2-S3).

*5 : In the flat cables are connected as this picture, they can be used up to 55 m.

Clockwise : S1-S2-S3

* Pay attention to stripe of yellow and green

Not applicable

(Because centre wire has no cover finish)

Clockwise : S1-S2-S3-Open

*Connect S1 and S3 to the opposite angl

2

.

*6 : Mentioned cable length is just a reference value.

It may be different depending on the condition of installation, Humidity or materials,

(50)

*2

Not applicable

*5

(45)

*3

(55)

*4

(3C Flat cable × 2)

etc.

Be sure to connect the outdoor-branch box/indoor-branch box connecting cables directly to the units (no intermediate connections).

Intermediate connections can lead to communication errors if water enters the cables and causes insufficient insulation to ground or a poor electrical contact at the intermediate connection point.

(If an intermediate connection is necessary, be sure to take measures to prevent water from entering the cables.)

13

Page 14

8. Test run

8.1. Before test run

► After completing installation and the wiring and piping of the indoor and

outdoor units, check for refrigerant leakage, looseness in the power supply

or control wiring, wrong polarity, and no disconnection of one phase in the

supply.

► Use a 500-volt M-ohm tester to check that the resistance between the power

supply terminals and ground is at least 1 MΩ.

► Do not carry out this test on the control wiring (low voltage circuit) termi-

nals.

Warning:

Do not use the air conditioner if the insulation resistance is less than 1 MΩ.

Insulation resistance

After installation or after the power source to the unit has been cut for an extended

period, the insulation resistance will drop below 1 MΩ due to refrigerant accumulating

in the compressor. This is not a malfunction. Perform the following procedures.

1. Remove the wires from the compressor and measure the insulation resistance of

the compressor.

2. If the insulation resistance is below 1 M

ance dropped due the accumulation of refrigerant in the compressor.

8.2. Test run

8.2.1. Using remote controller

Refer to the indoor unit installation manual.

• Be sure to perform the test run for each indoor unit. Make sure each indoor unit

operates properly following the installation manual attached to the unit.

• If you perform the test run for all indoor units at once, you cannot detect any

erroneous connection, if any, of the refrigerant pipes and the connecting wires.

* The compressor operation is not available for 3 minutes at least after the power

is supplied.

• The compressor can emit noise just after turn on the power supply or in case of

low outside air temperature.

About the restart protective mechanism

Once the compressor stops, the restart preventive device operates so the compressor

will not operate for 3 minutes to protect the air conditioner.

8.2.2. Using SW4 in outdoor unit

In case of the test run from outdoor unit, all indoor units operate. Therefore,

you can not detect any erroneous connection of refrigerant pipes and the

connecting wires. If it aims at detection of any erroneous connection, be

sure to carry out the test run from remote controller with reference to “8.2.1.

Using remote controller.”

Ω, the compressor is faulty or the resist-

3. After connecting the wires to the compressor, the compressor will start to warm

up after power is supplied. After supplying power for the times indicated below,

measure the insulation resistance again.

• The insulation resistance drops due to accumulation of refrigerant in the com

pressor. The resistance will rise above 1 MΩ after the compressor is warmed

up for two to three hours.

(The time necessary to warm up the compressor varies according to atmospheric

conditions and refrigerant accumulation.)

• To operate the compressor with refrigerant accumulated in the compressor, the

compressor must be warmed up at least 12 hours to prevent breakdown.

4. If the insulation resistance rises above 1 M

Caution:

• The compressor will not operate unless the power supply phase connection

is correct.

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can result

in severe damage to internal parts. Keep the power switch turned on during the

operational season.

► The followings must be checked as well.

• The outdoor unit is not faulty. LED on the control board of the outdoor unit flash

when the outdoor unit is faulty.

• Both the gas and liquid stop valves are completely open.

SW4-1 ON

SW4-2 OFF

SW4-1 ON

SW4-2 ON

* After performing the test run, set SW4-1 to OFF.

• A few seconds after the compressor starts, a clanging noise may be heard from

the inside of the outdoor unit. The noise is coming from the check valve due to the

small difference in pressure in the pipes. The unit is not faulty.

The test run operation mode cannot be changed by DIP switch SW4-2 during

the test run. (To change the test run operation mode during the test run, stop

the test run by DIP switch SW4-1. After changing the test run operation mode,

resume the test run by switch SW4-1.)

When a test run is started by “Using SW4 in outdoor unit”, even if it carries

out stop instructions by remote controller, outdoor unit does not stop (a test

run is not ended). In this case, please set SW4 in outdoor unit to off.

Note:

Be sure to wait at least 3 minutes after turning on the power supply before setting SW4-1 and SW4-2. If the DIP

the test run may not start.

Cooling operation

Heating operation

switches are set before 3 minutes has elapsed,

Ω, the compressor is not faulty.

-

14

Page 15

9. Special Functions

SW2SW1

CN3S

Y

X

BC

H

I

J

D

A

E

2

3

1

GF

YX

A

X

E

SW1

Remote control panel

Relay circuit

External input adapter

(PAC-SC36NA)

Outdoor unit control board

Relay power supply

A

Y

E

SW2

Remote control panel

Relay circuit

External input adapter

(PAC-SC36NA)

Outdoor unit control board

Relay power supply

BC

H

1

2

I

X

J

3

D

CNDM

GF

Procure locally

Max. 10 m

Orange

Brown

Red

Fig. 9-1

BC

H

I

J

Y

CNDM

1

2

3

GF

Procure locally

Max. 10 m

Orange

Brown

Red

Fig. 9-2

9.1. Low noise mode (on-site modification) (Fig. 9-1)

By performing the following modification, operation noise of the outdoor unit can be

reduced by about 3-4 dB.

The low noise mode will be activated when a commercially available timer or the

contact input of an ON/OFF switch is added to the CNDM connector (option) on the

control board of the outdoor unit.

• The capacity may be insufficient according to the outdoor temperature and condi

tions, etc.

Complete the circuit as shown when using the external input adapter (PAC-

SC36NA). (Option)

D

9.2. Demand function (on-site modification) (Fig. 9-2)

• It is possible to reduce electricity consumption within a range from 0 to 100 percent

by performing the following on-site installation.

The demand function can be enabled by adding a commercially available input

contact point ON/OFF switch to the CNDM connector (the contact point demand

input, sold separately).

Incorporate the “Adaptor for external input (PAC-SC36NA)” into the circuit as

shown in the diagram on the left.

By switching SW7-1 on the control circuit board for the outdoor unit, the following

power consumption restrictions (compared to rated power) can be set.

SW7-1 Power consumption when SW2 is on

OFF 0% (Forced compressor stop)

ON 50%

-

A

BC

L1 L2

M

E

X

YX

Y

L

K

F G

L1 : Error display lamp

L2 : Compressor operation lamp

X, Y : Relay (Coil standard of 0.9W or less for DC 12V)

X, Y : Relay (DC1mA)

Fig. 9-3

9.3. Error and compressor operation monitoring func-

D

5

CN51

4

3

tion (CN51)

Remote control panel

Relay circuit

External output adapter (PAC-SA88HA-E)

Outdoor unit control board

Lamp power supply

Procure locally

Max. 10m

Orange

Yellow

Green

9.4. Auto change over - Operation mode locking func-

tion by external signal (CN3S)

Remote control panel

Relay circuit

External input adapter (PAC-SC36NA)

Outdoor unit control board

Relay power supply

Procure locally

Max. 10m

Orange

Brown

Red

Fig. 9-4

SW1 Heating Cooling

ON OFF

SW2 Validity of SW1 Invalidity of SW1

* Any indoor unit that is operating in a mode different from the one specified by the

external signal will enter the standby mode.

* The setting becomes effective when the outdoor unit is under stop.

* The operation mode specified for the test run has priority over the mode specified

using this function.

15

Page 16

Содержание

1. Меры предосторожности.....................................................................156

2. Монтажная схема и детали .................................................................157

3. Место монтажа ....................................................................................158

4. Установка наружного прибора ............................................................160

6. Дренажные трубы ................................................................................ 164

7. Электрические работы ........................................................................ 164

8. Выполнение испытания....................................................................... 168

9. Специальные функции ........................................................................169

5. Прокладка труб хладагента ................................................................ 160

Примечание: Данный символ предназначен только для стран-членов ЕС.

Данный символ используется в соответствии с директивой 2002/96/EC статья 10 Информация для пользователей и Приложением IV.

Изделие MITSUBISHI ELECTRIC разработано и изготовлено с использованием высококачественных материалов и компонентов, которые

подлежат переработке и повторному использованию.

Этим символом обозначается электрическое и электронное оборудование, которое в конце срока службы должно утилизироваться отдельно от бытовых отходов.

Утилизация этого оборудования должна осуществляться местной организацией по вывозу отходов/в центре переработки.

В Европейском Союзе существуют отдельные системы вывоза для использованного электрических или электронных изделий.

Помогите сохранить окружающую среду, в которой мы живем!

Осторожно:

• Не допускайте выброса в атмосферу хладагента R410A.

•

R410A является фторированным парниковым газом, на который распространяется действие Киотского протокола и который обладает потенциалом глобального потепления (GWP)=1975.

1. Меры предосторожности

►

До установки прибора убедитесь, что Вы прочли все “Меры предосторожности”.

► Пожалуйста, проконсультируйтесь с органами электроснабжения до

подключения системы.

► Оборудование соответствует IEC/EN 61000-3-12

Предупреждение:

Описывает меры предосторожности, необходимые для предотвращения

получения травмы или гибели пользователя.

Осторожно:

Описывает меры предосторожности, необходимые для предотвращения повреждения прибора.

Предупреждение:

• Прибор не должен устанавливаться пользователем. Для выполнения установки

прибора обратитесь к дилеру или сертифицированному техническому специа

листу. Неправильная установка аппарата может повлечь за собой протечку воды,

удар электрическим током или возникновение пожара.

• При установочных работах следуйте инструкциям в Руководстве по установке. Ис

пользуйте инструменты и детали трубопроводов, специально предназначенные

для использования с хладагентом марки R410A. Хладагент R410A в HFC-системе

находится под давлением в 1,6 раза большим, чем давление, создаваемое при

использовании обычных хладагентов. Если компоненты трубопроводов не

предназначены для использования с хладагентом R410A, и аппарат установлен

неправильно, трубы могут лопнуть и причинить повреждение или нанести травму.

Кроме того, это может привести к утечке воды, поражению электрическим током

или возникновению пожара.

• Прибор должен быть установлен согласно инструкциям, чтобы свести к минимуму

риск повреждения от землетрясений, тайфунов или сильных порывов ветра.

Неправильно установленный прибор может упасть и причинить повреждение

или нанести травму.

• Прибор должен быть установлен на конструкции, способной выдержать его вес.

Прибор, установленный на неустойчивой конструкции, может упасть и причинить

повреждение или нанести травму.

• Если кондиционер установлен в небольшом помещении, необходимо принять

меры для предотвращения концентрации хладагента свыше безопасных преде

лов в случае утечки хладагента. Проконсультируйтесь у дилера относительно

соответствующих мер, предотвращающих превышение допустимой концентра

ции. В случае утечки хладагента и превышении допустимой его концентрации

из-за нехватки кислорода в помещении может произойти несчастный случай.

• Если во время работы прибора произошла утечка хладагента, проветрите поме

щение. При контакте хладагента с пламенем образуются ядовитые газы.

• Все электроработы должны выполняться квалифицированным техническим

специалистом в соответствии с местными правилами и инструкциями, приве

денными в данном Руководстве. Приборы должны быть подключены к специ

ально выделенным линиям электропитания с соответствующим напряжением

через автоматические выключатели. Использование линий электропитания

недостаточной мощности или неправильно проведенных линий может привести

к поражению электрическим током или возникновению пожара.

• Обязательно подключайте кабели электропитания и соединительные провода

внутренних приборов, наружных приборов и ответвительных коробок непос

редственно к приборам (без промежуточных соединений).

Промежуточные соединения могут привести к ошибкам связи, если вода попадет

в кабели или провода и приведет к недостаточной изоляции заземления или

плохому электрическому контакту в точке промежуточного соединения. (Если

промежуточное соединение необходимо, обязательно предпримите меры по

После окончания установочных работ проинструктируйте пользователя относительно

правил эксплуатации и обслуживания аппарата, а также ознакомьте с разделом “Мера

предосторожности” в соответствии с информацией, приведенной в Руководстве по

использованию аппарата, и выполните тестовый прогон аппарата для того, чтобы убедиться, что он работает нормально. Обязательно передайте пользователю на хранение

экземпляры Руководства по установке и Руководства по эксплуатации. Эти Руководства

должны быть переданы и последующим пользователям данного прибора.

: Указывает, что данная часть должна быть заземлена.

Предупреждение:

Внимательно прочтите текст на этикетках главного прибора.

предотвращению проникновения воды в кабели и провода.)

• Для соединения медных или медносплавных бесшовных труб, предназначенных

для хладагента, используйте медный фосфор C1220. Если трубы соединены

неправильно, прибор не будет должным образом заземлен, что может привести

к поражению электрическим током.

-

• Используйте только указанные кабели для электропроводки. Соединения должны

быть выполнены надежно, без натяжения около клемм. Если кабели подключены

или укреплены неправильно, это может привести к пер егреву или возникнове нию

пожара.

• Крышка наружного прибора должна быть надежно присоединена к прибору. Если

крышка установлена неправильно, в прибор могут попасть пыль и влага, что мо

жет привести к поражению электрическим током или возникновению пожара.

• При установке, перемещении или сервисном обслуживании кондиционера

используйте только указанный хладагент (R410A) для заправки трубопроводов

хладагента. Не допускается его смешивание с другим хладагентом или наличие

воздуха в трубопроводах.

При смешивании воздуха с хладагентом может произойти чрезмерное повышение

давления в трубопроводе хладагента, что способно вызывать взрыв или другие

нештатные ситуации.

Использование любого иного хладагента, кроме указанного для системы, при

ведет к механическому отказу, неисправности системы или поломке прибора. В

худшем случае это может привести к серьезному препятствию для обеспечения

безопасности изделия.

• Используйте только те дополнительные принадлежности, на которые имеется

разрешение от Mitsubishi Electric; для их установки обратитесь к дилеру или

уполномоченному техническому специалисту. Неправильная установка до

полнительных принадлежностей может привести к протечке воды, поражению

электрическим током или возникновению пожара.

• Не изменяйте конструкцию прибора. При необходимости ремонта обратитесь к

дилеру. Если изменения или ремонт выполнены неправильно, это может привести

к протечке воды, удару электрическим током или возникновению пожара.

-