Mitsubishi Electric MU-GA20VB-E1, MU-GA25VB-E1, MU-GA20VB-E2, MU-GA25VB-E2, MU-GA35VB-E1 Service Manual

Page 1

HFC

utilized

R410A

SPLIT-TYPE, AIR CONDITIONERS

OUTDOOR UNIT

SERVICE MANUAL

Wireless type

Models

Revision B:

● MU-GA20VB- and MU-GA25VB -

have been added.

Please void OB386 REVISED EDITION-A.

No. OB386

REVISED EDITION-B

E2E2

MU-GA20VBMU-GA20VBMU-GA25VBMU-GA25VBMU-GA35VB-

MU-GA20VB

MU-GA25VB

MU-GA35VB

E1

E2

E1

E2

E1

Indoor unit service manual

MSC-GA• VB Series (OB385)

MSC-CA• VB Series (OB393)

CONTENTS

1. TECHNICAL CHANGES ····································2

2. PART NAMES AND FUNCTIONS······················3

3. SPECIFICATION·················································3

4. NOISE CRITERIA CURVES·······························5

5. OUTLINES AND DIMENSIONS·························6

6. WIRING DIAGRAM ············································6

7. REFRIGERANT SYSTEM DIAGRAM················7

8. PERFORMANCE CURVES································8

9. TROUBLESHOOTING······································17

10. DISASSEMBLY INSTRUCTIONS·····················20

11. PARTS LIST······················································22

12. RoHS PARTS LIST···········································24

NOTE:

• This service manual describes technical data of outdoor units.

• RoHS compliant products have <G> mark on the spec name plate.

For servicing of RoHS compliant products, refer to the RoHS Parts List.

Page 2

Revision A:

• 11-1. PARTS LIST has been modified. (The parts No. of BACK PANEL has been changed.)

Revision B:

• MU-GA20VB- and MU-GA25VB- have been added.

1

TECHNICAL CHANGES

MU-A07YV- ➔MU-GA20VB-

1. Indication of capacity has been changed.(BTU base ➔ kW base)

2. Unit size has been changed. (W780mm x H540mm x D255mm ➔ W800mm x H550mm x D285mm)

3. Outdoor fan motor has been changed. (RC6V20-AC ➔ RA6V21-AC)

4. Stop valve cover has been added.

5. Outdoor fan capacitor has been changed.

6. Compressor capacitor has been changed.

MU-A09YV- ➔MU-GA25VB-

1. Indication of capacity has been changed.(BTU base ➔ kW base)

2. Unit size has been changed. (W780mm x H540mm x D255mm ➔ W800mm x H550mm x D285mm)

3. Outdoor fan motor has been changed. (RC6V20-AC ➔ RA6V21-AC)

4. Stop valve cover has been added.

5. Outdoor fan capacitor has been changed.

6. Compressor capacitor has been changed.

7. Compressor has been changed. (RN099VHSHT ➔ RN092VHSHT)

MU-A12YV- ➔MU-GA35VB-

1. Indication of capacity has been changed.(BTU base ➔ kW base)

2. Unit size has been changed. (W780mm x H540mm x D255mm ➔ W800mm x H550mm x D285mm)

3. Outdoor fan motor has been changed. (RC6V33-AC ➔ RA6V33-KA)

4. Stop valve cover has been added.

5. Outdoor fan capacitor has been changed.

6. Compressor capacitor has been changed.

7. Compressor has been changed. (RN135VHSHT ➔ 5PS132DAH01)

8. Stop valve (Gas) has been changed from [12.7 to [9.52.

9. Fuse for compressor protection has been added.

E2E2

E1E1

E1E1

E1E1

MU-GA20VB- ➔MU-GA20VBMU-GA25VB- ➔MU-GA25VB-

1. Compressor has been changed. (RN092VHST ➔ KN092VDMHC)

2. Compressor capacitor has been changed.

3. Capillary tube has been changed. ([3.0x[1.4x700 ➔ [3.0x[1.4x900)

E2E1

E2E1

2

Page 3

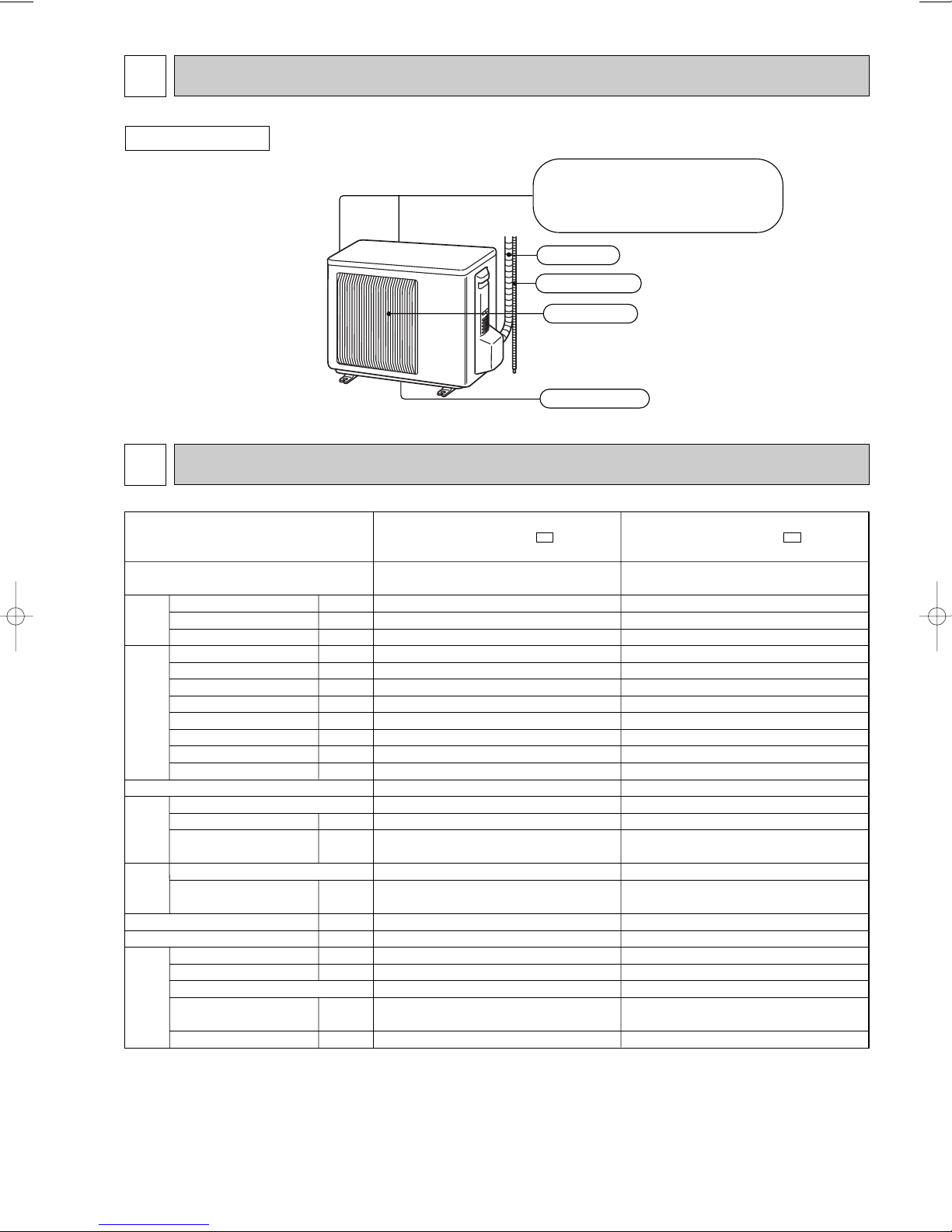

2

Air outlet

Drain outlet

Piping

Drain hose

( )

Air inlet

back : MU-GA20VB

MU-GA25VB

back and side : MU-GA35VB

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at 20:)

Model

Winding

resistance(at 20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity (R410A)

Refrigeration oil (Model)

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

MU-GA20VB -

E1

Single phase

230V,50Hz

2.3

0.9

1,800

10

3.17

715

–

98

21

2.76

0.245

3.22

RN092VHSHT

600

C-R 3.87

C-S 6.14

RA6V21-AC

WHT-BLK 366

BLK-RED 274

800o550o285

31

45

745

1

0.60

350 (NEO22 )

MU-GA20VB -

E2

Single phase

230V,50Hz

2.3

0.9

1,800

10

3.17

715

–

98

15.5

2.76

0.245

3.22

KN092VDMHC

650

C-R 3.62

C-S 5.40

RA6V21-AC

WHT-BLK 366

BLK-RED 274

800o550o285

27

45

745

1

0.60

350 (NEO22 )

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance(C.O.P)

Outdoor unit power supply

Outdoor model

PART NAMES AND FUNCTIONS

OUTDOOR UNIT

MU-GA20VB

MU-GA25VB

MU-GA35VB

3

NOTE: Test conditions are based on ISO 5151.

SPECIFICATION

Cooling : Indoor DB27°C WB19°C

Indoor-Outdoor piping length : 5m

Outdoor DB35°C WB24°C

3

Page 4

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at 20:)

Model

Winding

resistance(at 20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity (R410A)

Refrigeration oil (Model)

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

MU-GA25VB -

E2

Single phase

230V,50Hz

10

KN092VDMHC

650

C-R 3.62

C-S 5.40

RA6V21-AC

WHT-BLK 366

BLK-RED 274

800o550o285

27

45

745

1

0.60

350 (NEO22 )

2.5

1.1

1,800

3.40

775

–

99

15.5

2.99

0.245

3.23

MU-GA25VB -

E1

Single phase

230V,50Hz

10

RN092VHSHT

600

C-R 3.87

C-S 6.14

RA6V21-AC

WHT-BLK 366

BLK-RED 274

800o550o285

31

45

745

1

0.60

350 (NEO22 )

2.5

1.1

1,800

3.40

775

–

99

21

2.99

0.245

3.23

MU-GA35VB -

E1

Single phase

230V,50Hz

1.7

10

5PS132DAH01

900

C-R 2.80

C-S 5.43

RA6V33-KA

WHT-BLK 215

BLK-RED 307

800o550o285

30

49

855

1

0.70

350 (RB68A)

3.45

1,902

5.02

1,120

–

97

21

4.50

0.33

3.08

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance(C.O.P)

Outdoor unit power supply

Outdoor model

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C WB19°C

Outdoor DB35°C WB24°C

Indoor-Outdoor piping length : 5m

4

Page 5

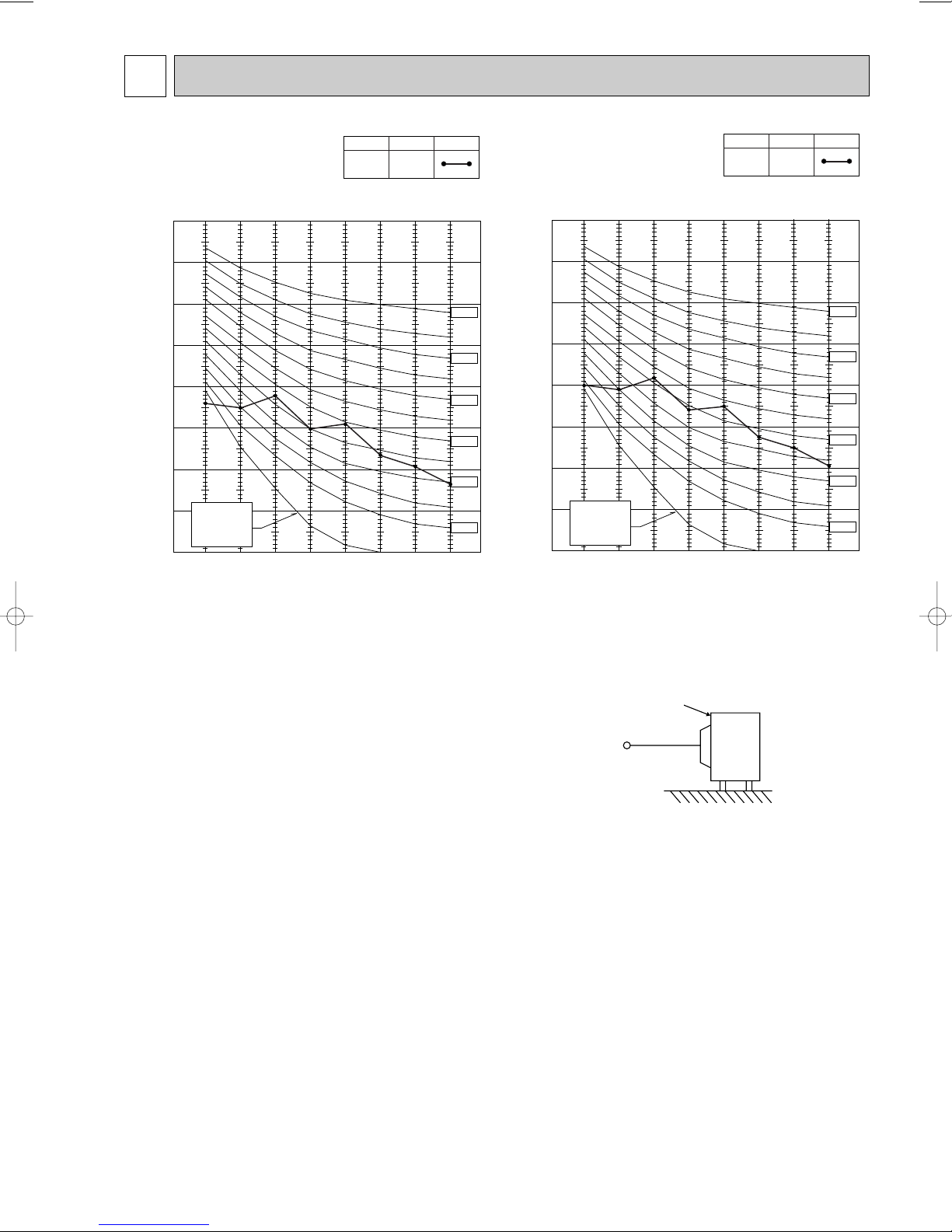

4

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling :DB35: WB24:

MU-GA35VB

COOL

FUNCTION

49

SPL(dB(A)) LINE

OUTDOOR UNIT

MICROPHONE

1m

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB27: WB19:

MU-GA20VB

MU-GA25VB

COOL

FUNCTION

45

SPL(dB(A)) LINE

NOISE CRITERIA CURVES

5

Page 6

5

C2

C1

WHT

POWER SUPPLY

~/N 230V 50Hz

CIRCUIT

BREAKER

BLU

BRN

WHT

RED

BLU

WHT

BLK

RED

12V

TO INDOOR

UNIT

CONNECTING

WHT

BLK

DSAR

52C

TB2

2

1

C

R

S

GRN/YLW

PE

N

L

BRN

TB1

COM

52C

NO

MC

1

3

2

BLK

RED

WHT

MF

SYMBOL

TB2

52C

SYMBOL

MC

MF

TB1

SYMBOL

C1

C2

DSAR

NAME

NAME NAME

COMPRESSOR CAPACITOR

OUTDOOR FAN CAPACITOR

SURGE ABSORBER

COMPRESSOR(INNER PROTECTOR)

TERMINAL BLOCK

COMPRESSOR CONTACTOR

OUTDOOR FAN MOTOR(INNER FUSE)

TERMINAL BLOCK

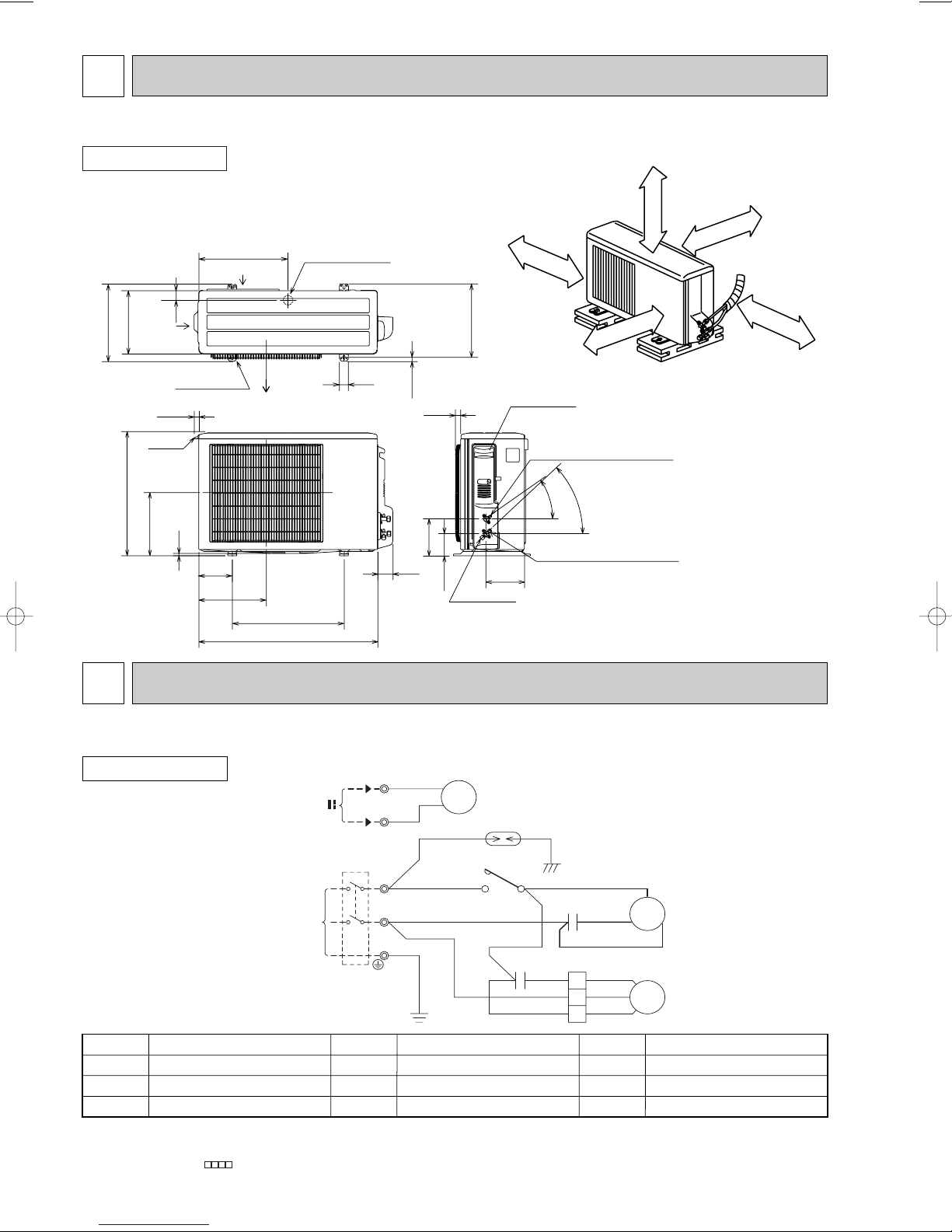

OUTLINES AND DIMENSIONS

MU-GA20VB MU-GA25VB MU-GA35VB

OUTDOOR UNIT

344.5

285

550

44

Air in

(MU-GA35VB)

2 holes 10X21

22.3

Handle

280

10

400

Air in

Air out

150

302.5

500 Bolt pitch for installation

Drain hole [42

40

17.5

164.5

69

800

installation

Bolt pitch for

23

99.5

Service port

REQUIRED SPACE

100mm or more

304~325

Service panel

Liquid refrigerant pipe joint

Refrigerant pipe (flared) [6.35

35-

Gas refrigerant pipe joint

Refrigerant pipe (flared) [9.52

170.5

ore

or m

m

200m

Open two sides of left,

right, or rear side.

43-

Unit: mm

Basically open 100mm or more

without any obstruction in front

and on both sides of the unit.

100mm or more

350m

m

or m

ore

6

WIRING DIAGRAM

MU-GA20VB MU-GA25VB

OUTDOOR UNIT

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

6

Page 7

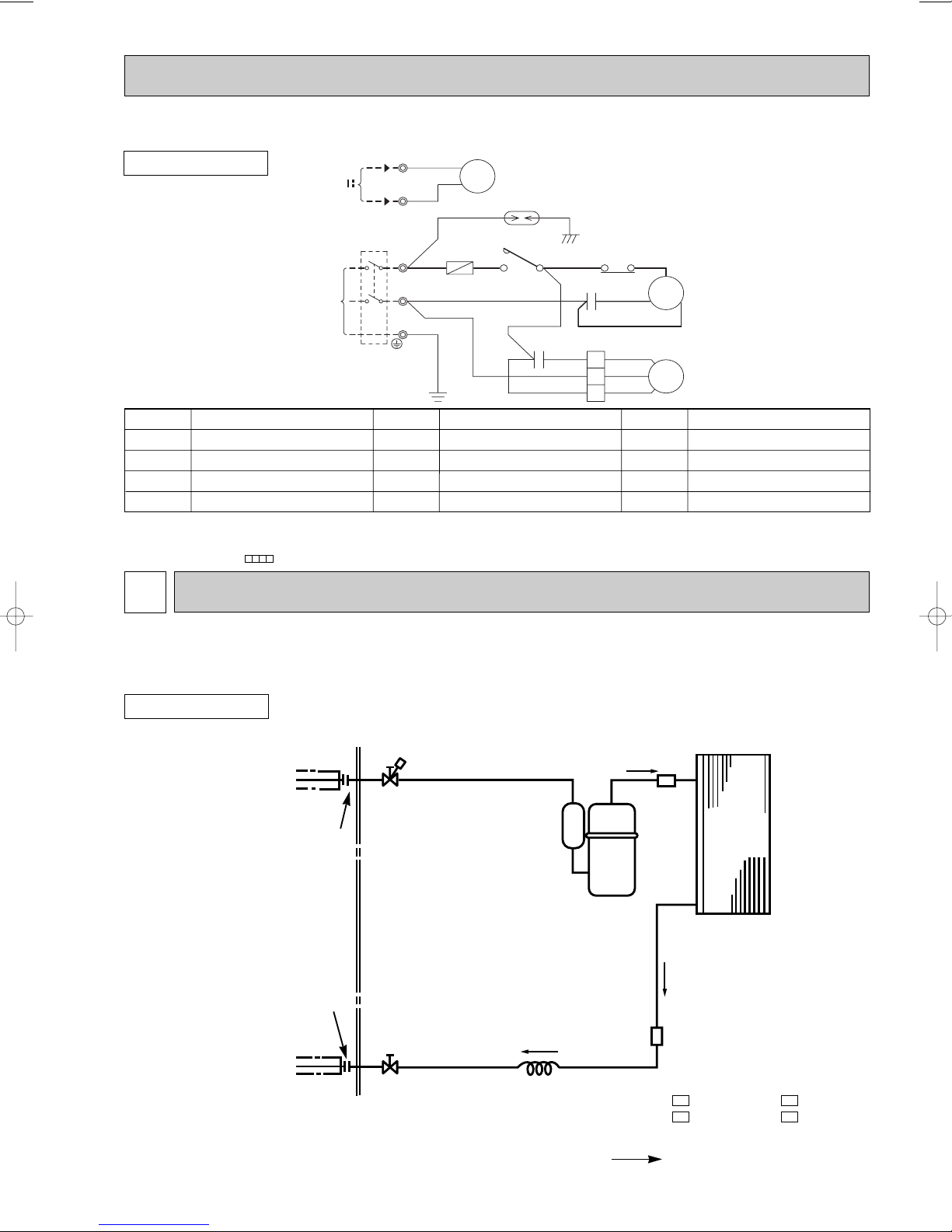

MU-GA35VB

PE

N

L

TB1

1

2

TB2

C1

C2

WHT

CIRCUIT

BREAKER

WHT

51C

41

BRN

F

BLU

BRN

WHT

RED

BLU

WHT

BLK

RED

POWER SUPPLY

~/N 230V 50Hz

12V

TO INDOOR

UNIT

CONNECTING

WHT

BLK

DSAR

52C

C

R

S

GRN/YLW

BRN

COM

52C

NO

MC

1

3

2

BLK

RED

WHT

MF

OUTDOOR UNIT

SYMBOL

COMPRESSOR CAPACITOR

C1

OUTDOOR FAN CAPACITOR

C2

DSAR

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

7

SURGE ABSORBER

F

FUSE (T20AL250V)

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

REFRIGERANT SYSTEM DIAGRAM

NAME

SYMBOL

MC

MF

TB1

TB2

NAME NAME

COMPRESSOR

OUTDOOR FAN MOTOR (INNER FUSE)

TERMINAL BLOCK

TERMINAL BLOCK

MU-GA20VB

MU-GA25VB

MU-GA35VB

OUTDOOR UNIT

Flared connection

Refrigerant pipe [9.52

(with heat insulator)

Stop valve

(with service port)

SYMBOL

51C

52C

Muffler

OVERLOAD RELAY

COMPRESSOR CONTACTOR

Unit:mm

Outdoor

heat

exchanger

Refrigerant pipe [6.35

(with heat insulator)

Flared connection

Stop valve

Capillary tube

[3.0x[1.4x700 (MU-GA20VB

[3.0x[1.4x900 (MU-GA20VB

[3.0x[1.4x450 (MU-GA35VB)

7

Compressor

Strainer

#100

- , MU-GA25VB- )

- , MU-GA25VB- )

E1E1

E2E2

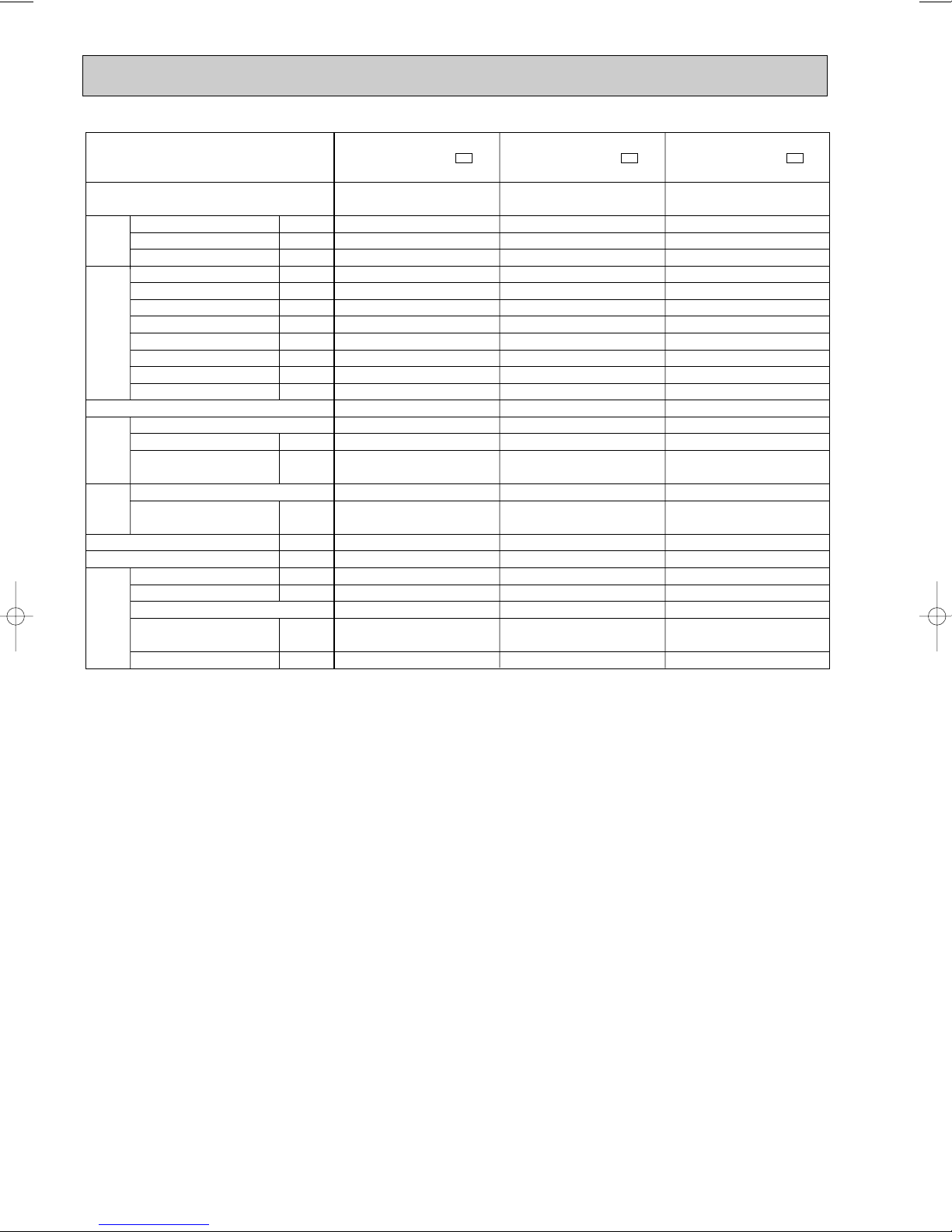

Refrigerant flow in cooling

Page 8

Piping size O.D : mm Length of connecting pipe : m

Model

Refrigerant piping : m

Max. length

A

20

25

Max. height

B

10

Indoor unit

Gas 0.43

Liquid 0.5

Liquid

6.35

Gas

9.52

Outdoor unit

Gas 0

Liquid 0

MU-GA20VB

MU-GA25VB

MU-GA35VB

Indoor

unit

Max. Height

B

Outdoor unit

Refrigerant Piping

Max. length

A

Model

Refrigerant piping length (one way)

Outdoor unit precharged

600

700

25m

360

7m

0

10m

60

15m

160

20m

260

Calculation : Xg=20g/m x(A-7)m

MU-GA20VB

MU-GA25VB

MU-GA35VB

MAX. REFRIGERANT PIPING LENGTH

MAX. HEIGHT DIFFERENCE

ADDITIONAL REFRIGERANT CHARGE(R410A : g)

8

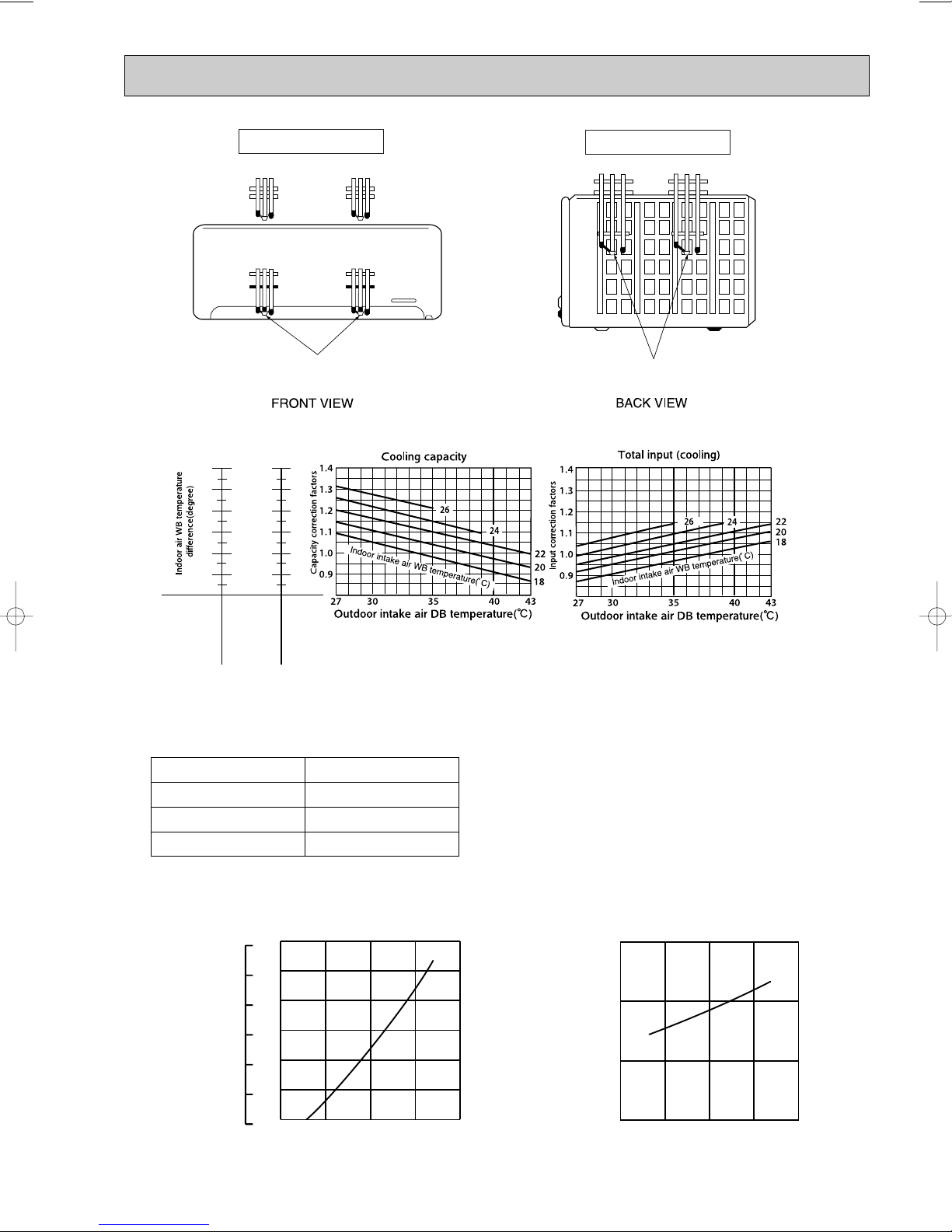

PERFORMANCE CURVES

MU-GA20VB MU-GA25VB MU-A35VB

The standard data contained in these specifications apply only to the operation of the air conditioner under normal conditions,

since operating conditions vary according to the areas where these units are installed. The following information has been provided to clarify the operating characteristics of the air conditioner under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

198~264V

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature : °CWB

(2) Indoor outlet air wet-bulb temperature : °CWB

(3) Outdoor intake air dry-bulb temperature : °CDB

(4) Total input: W

Indoor air wet/dry-bulb temperature difference on the left side of the chart on next page shows the difference between the

indoor intake air wet/dry-bulb temperature and the indoor outlet air wet/dry-bulb temperature for your reference at service.

How to measure the indoor air wet-bulb/dry-bulb temperature difference

1. Attach at least 2 sets of wet-and dry-bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet-and dry-bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of wet-and dry-bulb thermometers to the outdoor air intake.

Cover the thermometers to prevent direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of room.

5. Press the EMERGENCY OPERATION switch once to start the EMERGENCY COOL MODE.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

Cooling

}

8

Page 9

INDOOR UNIT

18 32

230V

15 20

50

25

6030 70

(%)

35(:)

0.7

0.8

0.9

1.0

1.1

1.2

1.3

7

8

9

10

11

12

13

15 20

50

25

60

30

70(%)

35(:)

1

2

4

3

18 32

230V

OUTDOOR UNIT

Wet-and dry-bulb

thermometers

Wet-and dry-bulb

thermometers

8-1.CAPACITY AND THE INPUT CURVES

9.6

8.5

7.8

7.1

6.4

5.8

5.1

MSC-GA20VB

11.0

8.8

10.0

8.0

7.2

6.5

5.7

MU-GA20VB

MU-GA25VB

MSC-GA25VB

9.1

8.2

7.4

6.5

MU-GA35VB

MSC-GA35VB

8-2.OUTDOOR LOW PRESSURE AND OUTDOOR UNIT CURRENT

COOL operation

① Both indoor and outdoor unit are under the same temperature/humidity condition.

Dry-bulb temperature

20

25

30 70

Relative humidity(%)

50

60

➁ Air flow should be set at MAX.

③ The unit of pressure has been changed to MPa on the international system of units(SI unit system).

The conversion factor is : 1(MPa[Gauge]) =10.2(kgf/ff[Gauge] )

(kgf/F[Gauge])(MPa[Gauge])

Outdoor low pressure

Ambient temperature(˚C) Ambient humidity(%) Ambient temperature(˚C) Ambient humidity(%)

MU-GA20VB MU-GA20VB

Outdoor unit current (A)

9

Page 10

18 32

230V

15 20

50

256030

70(%)

35(:)

3

4

5

6

18 32

230V

15 20

50

25

6030 70

(%)

35(:)

0.7

0.8

0.9

1.0

1.1

1.2

1.3

7

8

9

10

11

12

13

15 20

50

256030

70(%)

35(:)

1

2

4

3

18 32

230V

18

32

230V

15 20

50

25

6030 70

(%)

35(:)

0.6

0.7

0.8

0.9

1.0

1.1

1.2

6

7

8

9

10

11

12

(kgf/F[Gauge])(MPa[Gauge])

MU-GA25VB

MU-GA25VB

Outdoor low pressure

Ambient temperature(˚C) Ambient humidity(%) Ambient temperature(˚C) Ambient humidity(%)

(kgf/F[Gauge])(MPa[Gauge])

Outdoor low pressure

Ambient temperature(˚C) Ambient humidity(%) Ambient temperature(˚C) Ambient humidity(%)

MU-GA35VB

Outdoor unit current (A)

MU-GA35VB

Outdoor unit current (A)

10

Page 11

PERFORMANCE DATA

21 18 2.70 1.51 0.56 572 2.59 1.45 0.56 601 2.48 1.39 0.56 629 2.39 1.34 0.56 658

21 20 2.82 1.24 0.44 601 2.70 1.19 0.44 636 2.62 1.15 0.44 651 2.53 1.11 0.44 679

22 18 2.70 1.62 0.60 572 2.59 1.55 0.60 601 2.48 1.49 0.60 629 2.39 1.44 0.60 658

22 20 2.82 1.35 0.48 601 2.70 1.30 0.48 636 2.62 1.26 0.48 651 2.53 1.21 0.48 679

22 22 2.93 1.06 0.36 622 2.83 1.02 0.36 661 2.76 0.99 0.36 679 2.65 0.95 0.36 708

23 18 2.70 1.73 0.64 572 2.59 1.66 0.64 601 2.48 1.59 0.64 629 2.39 1.53 0.64 658

23 20 2.82 1.47 0.52 601 2.70 1.41 0.52 636 2.62 1.36 0.52 651 2.53 1.32 0.52 679

23 22 2.93 1.17 0.40 622 2.83 1.13 0.40 661 2.76 1.10 0.40 679 2.65 1.06 0.40 708

24 18 2.70 1.84 0.68 572 2.59 1.76 0.68 601 2.48 1.69 0.68 629 2.39 1.63 0.68 658

24 20 2.82 1.58 0.56 601 2.70 1.51 0.56 636 2.62 1.47 0.56 651 2.53 1.42 0.56 679

24 22 2.93 1.29 0.44 622 2.83 1.24 0.44 661 2.76 1.21 0.44 679 2.65 1.16 0.44 708

24 24 3.08 0.99 0.32 651 2.97 0.95 0.32 686 2.90 0.93 0.32 708 2.81 0.90 0.32 744

25 18 2.70 1.95 0.72 572 2.59 1.86 0.72 601 2.48 1.79 0.72 629 2.39 1.72 0.72 658

25 20 2.82 1.69 0.60 601 2.70 1.62 0.60 636 2.62 1.57 0.60 651 2.53 1.52 0.60 679

25 22 2.93 1.41 0.48 622 2.83 1.36 0.48 661 2.76 1.32 0.48 679 2.65 1.27 0.48 708

25 24 3.08 1.11 0.36 651 2.97 1.07 0.36 686 2.90 1.04 0.36 708 2.81 1.01 0.36 744

26 18 2.70 2.05 0.76 572 2.59 1.97 0.76 601 2.48 1.89 0.76 629 2.39 1.82 0.76 658

26 20 2.82 1.80 0.64 601 2.70 1.73 0.64 636 2.62 1.68 0.64 651 2.53 1.62 0.64 679

26 22 2.93 1.52 0.52 622 2.83 1.47 0.52 661 2.76 1.44 0.52 679 2.65 1.38 0.52 708

26 24 3.08 1.23 0.40 651 2.97 1.19 0.40 686 2.90 1.16 0.40 708 2.81 1.12 0.40 744

26 26 3.17 0.89 0.28 686 3.08 0.86 0.28 722 3.04 0.85 0.28 744 2.94 0.82 0.28 765

27 18 2.70 2.16 0.80 572 2.59 2.07 0.80 601 2.48 1.99 0.80 629 2.39 1.91 0.80 658

27 20 2.82 1.92 0.68 601 2.70 1.84 0.68 636 2.62 1.78 0.68 651 2.53 1.72 0.68 679

27 22 2.93 1.64 0.56 622 2.83 1.58 0.56 661 2.76 1.55 0.56 679 2.65 1.48 0.56 708

27 24 3.08 1.36 0.44 651 2.97 1.31 0.44 686 2.90 1.28 0.44 708 2.81 1.23 0.44 744

27 26 3.17 1.02 0.32 686 3.08 0.99 0.32 722 3.04 0.97 0.32 744 2.94 0.94 0.32 765

28 18 2.70 2.27 0.84 572 2.59 2.17 0.84 601 2.48 2.09 0.84 629 2.39 2.01 0.84 658

28 20 2.82 2.03 0.72 601 2.70 1.95 0.72 636 2.62 1.89 0.72 651 2.53 1.82 0.72 679

28 22 2.93 1.76 0.60 622 2.83 1.70 0.60 661 2.76 1.66 0.60 679 2.65 1.59 0.60 708

28 24 3.08 1.48 0.48 651 2.97 1.42 0.48 686 2.90 1.39 0.48 708 2.81 1.35 0.48 744

28 26 3.17 1.14 0.36 686 3.08 1.11 0.36 722 3.04 1.09 0.36 744 2.94 1.06 0.36 765

29 18 2.70 2.38 0.88 572 2.59 2.28 0.88 601 2.48 2.19 0.88 629 2.39 2.10 0.88 658

29 20 2.82 2.14 0.76 601 2.70 2.05 0.76 636 2.62 1.99 0.76 651 2.53 1.92 0.76 679

29 22 2.93 1.88 0.64 622 2.83 1.81 0.64 661 2.76 1.77 0.64 679 2.65 1.69 0.64 708

29 24 3.08 1.60 0.52 651 2.97 1.54 0.52 686 2.90 1.51 0.52 708 2.81 1.46 0.52 744

29 26 3.17 1.27 0.40 686 3.08 1.23 0.40 722 3.04 1.21 0.40 744 2.94 1.18 0.40 765

30 18 2.70 2.49 0.92 572 2.59 2.38 0.92 601 2.48 2.29 0.92 629 2.39 2.20 0.92 658

30 20 2.82 2.25 0.80 601 2.70 2.16 0.80 636 2.62 2.10 0.80 651 2.53 2.02 0.80 679

30 22 2.93 1.99 0.68 622 2.83 1.92 0.68 661 2.76 1.88 0.68 679 2.65 1.80 0.68 708

30 24 3.08 1.73 0.56 651 2.97 1.66 0.56 686 2.90 1.62 0.56 708 2.81 1.57 0.56 744

30 26 3.17 1.40 0.44 686 3.08 1.36 0.44 722 3.04 1.34 0.44 744 2.94 1.30 0.44 765

31 18 2.70 2.59 0.96 572 2.59 2.48 0.96 601 2.48 2.38 0.96 629 2.39 2.30 0.96 658

31 20 2.82 2.37 0.84 601 2.70 2.27 0.84 636 2.62 2.20 0.84 651 2.53 2.13 0.84 679

31 22 2.93 2.11 0.72 622 2.83 2.04 0.72 661 2.76 1.99 0.72 679 2.65 1.90 0.72 708

31 24 3.08 1.85 0.60 651 2.97 1.78 0.60 686 2.90 1.74 0.60 708 2.81 1.68 0.60 744

31 26 3.17 1.52 0.48 686 3.08 1.48 0.48 722 3.04 1.46 0.48 744 2.94 1.41 0.48 765

32 18 2.70 2.70 1.00 572 2.59 2.59 1.00 601 2.48 2.48 1.00 629 2.39 2.39 1.00 658

32 20 2.82 2.48 0.88 601 2.70 2.38 0.88 636 2.62 2.31 0.88 651 2.53 2.23 0.88 679

32 22 2.93 2.23 0.76 622 2.83 2.15 0.76 661 2.76 2.10 0.76 679 2.65 2.01 0.76 708

32 24 3.08 1.97 0.64 651 2.97 1.90 0.64 686 2.90 1.85 0.64 708 2.81 1.80 0.64 744

32 26 3.17 1.65 0.52 686 3.08 1.60 0.52 722 3.04 1.58 0.52 744 2.94 1.53 0.52 765

INDOOR

DB(:)

INDOOR

WB(:)

OUTDOOR DB(:)

21 2725

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT30Q SHC SHF INPUT

CAPACITY : 2.3(kW) SHF : 0.74 INPUT : 715(W)

COOL operation (230V)

MSC-GA20VB : MU-GA20VB

NOTE Q :Total capacity (kW) SHF :Sensible heat factor DB :Dry-bulb temperature

SHC :Sensible heat capacity (kW) INPUT :Total power input (W) WB :Wet-bulb temperature

11

Page 12

PERFORMANCE DATA

21 18 2.25 1.26 0.56 701 2.07 1.16 0.56 744 1.99 1.11 0.56 758

21 20 2.37 1.04 0.44 729 2.21 0.97 0.44 765 2.13 0.94 0.44 787

22 18 2.25 1.35 0.60 701 2.07 1.24 0.60 744 1.99 1.19 0.60 758

22 20 2.37 1.14 0.48 729 2.21 1.06 0.48 765 2.13 1.02 0.48 787

22 22 2.51 0.90 0.36 758 2.35 0.84 0.36 801 2.27 0.82 0.36 815

23 18 2.25 1.44 0.64 701 2.07 1.32 0.64 744 1.99 1.27 0.64 758

23 20 2.37 1.23 0.52 729 2.21 1.15 0.52 765 2.13 1.11 0.52 787

23 22 2.51 1.00 0.40 758 2.35 0.94 0.40 801 2.27 0.91 0.40 815

24 18 2.25 1.53 0.68 701 2.07 1.41 0.68 744 1.99 1.35 0.68 758

24 20 2.37 1.33 0.56 729 2.21 1.24 0.56 765 2.13 1.19 0.56 787

24 22 2.51 1.10 0.44 758 2.35 1.03 0.44 801 2.27 1.00 0.44 815

24 24 2.65 0.85 0.32 787 2.48 0.79 0.32 822 2.42 0.77 0.32 840

25 18 2.25 1.62 0.72 701 2.07 1.49 0.72 744 1.99 1.43 0.72 758

25 20 2.37 1.42 0.60 729 2.21 1.32 0.60 765 2.13 1.28 0.60 787

25 22 2.51 1.20 0.48 758 2.35 1.13 0.48 801 2.27 1.09 0.48 815

25 24 2.65 0.95 0.36 787 2.48 0.89 0.36 822 2.42 0.87 0.36 840

26 18 2.25 1.71 0.76 701 2.07 1.57 0.76 744 1.99 1.51 0.76 758

26 20 2.37 1.52 0.64 729 2.21 1.41 0.64 765 2.13 1.36 0.64 787

26 22 2.51 1.30 0.52 758 2.35 1.22 0.52 801 2.27 1.18 0.52 815

26 24 2.65 1.06 0.40 787 2.48 0.99 0.40 822 2.42 0.97 0.40 840

26 26 2.78 0.78 0.28 815 2.62 0.73 0.28 851 2.54 0.71 0.28 869

27 18 2.25 1.80 0.80 701 2.07 1.66 0.80 744 1.99 1.59 0.80 758

27 20 2.37 1.61 0.68 729 2.21 1.50 0.68 765 2.13 1.45 0.68 787

27 22 2.51 1.40 0.56 758 2.35 1.31 0.56 801 2.27 1.27 0.56 815

27 24 2.65 1.16 0.44 787 2.48 1.09 0.44 822 2.42 1.06 0.44 840

27 26 2.78 0.89 0.32 815 2.62 0.84 0.32 851 2.54 0.81 0.32 869

28 18 2.25 1.89 0.84 701 2.07 1.74 0.84 744 1.99 1.67 0.84 758

28 20 2.37 1.71 0.72 729 2.21 1.59 0.72 765 2.13 1.53 0.72 787

28 22 2.51 1.50 0.60 758 2.35 1.41 0.60 801 2.27 1.36 0.60 815

28 24 2.65 1.27 0.48 787 2.48 1.19 0.48 822 2.42 1.16 0.48 840

28 26 2.78 1.00 0.36 815 2.62 0.94 0.36 851 2.54 0.91 0.36 869

29 18 2.25 1.98 0.88 701 2.07 1.82 0.88 744 1.99 1.75 0.88 758

29 20 2.37 1.80 0.76 729 2.21 1.68 0.76 765 2.13 1.62 0.76 787

29 22 2.51 1.60 0.64 758 2.35 1.50 0.64 801 2.27 1.45 0.64 815

29 24 2.65 1.38 0.52 787 2.48 1.29 0.52 822 2.42 1.26 0.52 840

29 26 2.78 1.11 0.40 815 2.62 1.05 0.40 851 2.54 1.02 0.40 869

30 18 2.25 2.07 0.92 701 2.07 1.90 0.92 744 1.99 1.83 0.92 758

30 20 2.37 1.90 0.80 729 2.21 1.77 0.80 765 2.13 1.70 0.80 787

30 22 2.51 1.70 0.68 758 2.35 1.60 0.68 801 2.27 1.54 0.68 815

30 24 2.65 1.48 0.56 787 2.48 1.39 0.56 822 2.42 1.35 0.56 840

30 26 2.78 1.22 0.44 815 2.62 1.15 0.44 851 2.54 1.12 0.44 869

31 18 2.25 2.16 0.96 701 2.07 1.99 0.96 744 1.99 1.91 0.96 758

31 20 2.37 1.99 0.84 729 2.21 1.85 0.84 765 2.13 1.79 0.84 787

31 22 2.51 1.81 0.72 758 2.35 1.69 0.72 801 2.27 1.63 0.72 815

31 24 2.65 1.59 0.60 787 2.48 1.49 0.60 822 2.42 1.45 0.60 840

31 26 2.78 1.34 0.48 815 2.62 1.26 0.48 851 2.54 1.22 0.48 869

32 18 2.25 2.25 1.00 701 2.07 2.07 1.00 744 1.99 1.99 1.00 758

32 20 2.37 2.08 0.88 729 2.21 1.94 0.88 765 2.13 1.87 0.88 787

32 22 2.51 1.91 0.76 758 2.35 1.78 0.76 801 2.27 1.72 0.76 815

32 24 2.65 1.69 0.64 787 2.48 1.59 0.64 822 2.42 1.55 0.64 840

32 26 2.78 1.45 0.52 815 2.62 1.36 0.52 851 2.54 1.32 0.52 869

INDOOR

DB(:)

INDOOR

WB(:)

OUTDOOR DB(:)

35 4340

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 2.3(kW) SHF : 0.74 INPUT : 715(W)

COOL operation (230V)

MSC-GA20VB : MU-GA20VB

NOTE Q :Total capacity (kW) SHF :Sensible heat factor DB :Dry-bulb temperature

SHC :Sensible heat capacity (kW) INPUT :Total power input (W) WB :Wet-bulb temperature

12

Page 13

PERFORMANCE DATA

21 18 2.94 1.53 0.52 620 2.81 1.46 0.52 651 2.70 1.40 0.52 682 2.60 1.35 0.52 713

21 20 3.06 1.23 0.40 651 2.94 1.18 0.40 690 2.85 1.14 0.40 705 2.75 1.10 0.40 736

22 18 2.94 1.65 0.56 620 2.81 1.58 0.56 651 2.70 1.51 0.56 682 2.60 1.46 0.56 713

22 20 3.06 1.35 0.44 651 2.94 1.29 0.44 690 2.85 1.25 0.44 705 2.75 1.21 0.44 736

22 22 3.19 1.02 0.32 674 3.08 0.98 0.32 717 3.00 0.96 0.32 736 2.88 0.92 0.32 767

23 18 2.94 1.76 0.60 620 2.81 1.69 0.60 651 2.70 1.62 0.60 682 2.60 1.56 0.60 713

23 20 3.06 1.47 0.48 651 2.94 1.41 0.48 690 2.85 1.37 0.48 705 2.75 1.32 0.48 736

23 22 3.19 1.15 0.36 674 3.08 1.11 0.36 717 3.00 1.08 0.36 736 2.88 1.04 0.36 767

24 18 2.94 1.88 0.64 620 2.81 1.80 0.64 651 2.70 1.73 0.64 682 2.60 1.66 0.64 713

24 20 3.06 1.59 0.52 651 2.94 1.53 0.52 690 2.85 1.48 0.52 705 2.75 1.43 0.52 736

24 22 3.19 1.28 0.40 674 3.08 1.23 0.40 717 3.00 1.20 0.40 736 2.88 1.15 0.40 767

24 24 3.35 0.94 0.28 705 3.23 0.90 0.28 744 3.15 0.88 0.28 767 3.05 0.85 0.28 806

25 18 2.94 2.00 0.68 620 2.81 1.91 0.68 651 2.70 1.84 0.68 682 2.60 1.77 0.68 713

25 20 3.06 1.72 0.56 651 2.94 1.65 0.56 690 2.85 1.60 0.56 705 2.75 1.54 0.56 736

25 22 3.19 1.40 0.44 674 3.08 1.35 0.44 717 3.00 1.32 0.44 736 2.88 1.27 0.44 767

25 24 3.35 1.07 0.32 705 3.23 1.03 0.32 744 3.15 1.01 0.32 767 3.05 0.98 0.32 806

26 18 2.94 2.12 0.72 620 2.81 2.03 0.72 651 2.70 1.94 0.72 682 2.60 1.87 0.72 713

26 20 3.06 1.84 0.60 651 2.94 1.76 0.60 690 2.85 1.71 0.60 705 2.75 1.65 0.60 736

26 22 3.19 1.53 0.48 674 3.08 1.48 0.48 717 3.00 1.44 0.48 736 2.88 1.38 0.48 767

26 24 3.35 1.21 0.36 705 3.23 1.16 0.36 744 3.15 1.13 0.36 767 3.05 1.10 0.36 806

26 26 3.45 0.83 0.24 744 3.35 0.80 0.24 783 3.30 0.79 0.24 806 3.20 0.77 0.24 829

27 18 2.94 2.23 0.76 620 2.81 2.14 0.76 651 2.70 2.05 0.76 682 2.60 1.98 0.76 713

27 20 3.06 1.96 0.64 651 2.94 1.88 0.64 690 2.85 1.82 0.64 705 2.75 1.76 0.64 736

27 22 3.19 1.66 0.52 674 3.08 1.60 0.52 717 3.00 1.56 0.52 736 2.88 1.50 0.52 767

27 24 3.35 1.34 0.40 705 3.23 1.29 0.40 744 3.15 1.26 0.40 767 3.05 1.22 0.40 806

27 26 3.45 0.97 0.28 744 3.35 0.94 0.28 783 3.30 0.92 0.28 806 3.20 0.90 0.28 829

28 18 2.94 2.35 0.80 620 2.81 2.25 0.80 651 2.70 2.16 0.80 682 2.60 2.08 0.80 713

28 20 3.06 2.08 0.68 651 2.94 2.00 0.68 690 2.85 1.94 0.68 705 2.75 1.87 0.68 736

28 22 3.19 1.79 0.56 674 3.08 1.72 0.56 717 3.00 1.68 0.56 736 2.88 1.61 0.56 767

28 24 3.35 1.47 0.44 705 3.23 1.42 0.44 744 3.15 1.39 0.44 767 3.05 1.34 0.44 806

28 26 3.45 1.10 0.32 744 3.35 1.07 0.32 783 3.30 1.06 0.32 806 3.20 1.02 0.32 829

29 18 2.94 2.47 0.84 620 2.81 2.36 0.84 651 2.70 2.27 0.84 682 2.60 2.18 0.84 713

29 20 3.06 2.21 0.72 651 2.94 2.12 0.72 690 2.85 2.05 0.72 705 2.75 1.98 0.72 736

29 22 3.19 1.91 0.60 674 3.08 1.85 0.60 717 3.00 1.80 0.60 736 2.88 1.73 0.60 767

29 24 3.35 1.61 0.48 705 3.23 1.55 0.48 744 3.15 1.51 0.48 767 3.05 1.46 0.48 806

29 26 3.45 1.24 0.36 744 3.35 1.21 0.36 783 3.30 1.19 0.36 806 3.20 1.15 0.36 829

30 18 2.94 2.59 0.88 620 2.81 2.48 0.88 651 2.70 2.38 0.88 682 2.60 2.29 0.88 713

30 20 3.06 2.33 0.76 651 2.94 2.23 0.76 690 2.85 2.17 0.76 705 2.75 2.09 0.76 736

30 22 3.19 2.04 0.64 674 3.08 1.97 0.64 717 3.00 1.92 0.64 736 2.88 1.84 0.64 767

30 24 3.35 1.74 0.52 705 3.23 1.68 0.52 744 3.15 1.64 0.52 767 3.05 1.59 0.52 806

30 26 3.45 1.38 0.40 744 3.35 1.34 0.40 783 3.30 1.32 0.40 806 3.20 1.28 0.40 829

31 18 2.94 2.70 0.92 620 2.81 2.59 0.92 651 2.70 2.48 0.92 682 2.60 2.39 0.92 713

31 20 3.06 2.45 0.80 651 2.94 2.35 0.80 690 2.85 2.28 0.80 705 2.75 2.20 0.80 736

31 22 3.19 2.17 0.68 674 3.08 2.09 0.68 717 3.00 2.04 0.68 736 2.88 1.96 0.68 767

31 24 3.35 1.88 0.56 705 3.23 1.81 0.56 744 3.15 1.76 0.56 767 3.05 1.71 0.56 806

31 26 3.45 1.52 0.44 744 3.35 1.47 0.44 783 3.30 1.45 0.44 806 3.20 1.41 0.44 829

32 18 2.94 2.82 0.96 620 2.81 2.70 0.96 651 2.70 2.59 0.96 682 2.60 2.50 0.96 713

32 20 3.06 2.57 0.84 651 2.94 2.47 0.84 690 2.85 2.39 0.84 705 2.75 2.31 0.84 736

32 22 3.19 2.30 0.72 674 3.08 2.21 0.72 717 3.00 2.16 0.72 736 2.88 2.07 0.72 767

32 24 3.35 2.01 0.60 705 3.23 1.94 0.60 744 3.15 1.89 0.60 767 3.05 1.83 0.60 806

32 26 3.45 1.66 0.48 744 3.35 1.61 0.48 783 3.30 1.58 0.48 806 3.20 1.54 0.48 829

INDOOR

DB(:)

INDOOR

WB(:)

OUTDOOR DB(:)

21 2725

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT30Q SHC SHF INPUT

CAPACITY : 2.5(kW) SHF : 0.70 INPUT : 775(W)

COOL operation (230V)

MSC-GA25VB : MU-GA25VB

NOTE Q :Total capacity (kW) SHF :Sensible heat factor DB :Dry-bulb temperature

SHC :Sensible heat capacity (kW) INPUT :Total power input (W) WB :Wet-bulb temperature

13

Page 14

PERFORMANCE DATA

21 18 2.45 1.27 0.52 760 2.25 1.17 0.52 806 2.16 1.12 0.52 822

21 20 2.58 1.03 0.40 791 2.40 0.96 0.40 829 2.31 0.93 0.40 853

22 18 2.45 1.37 0.56 760 2.25 1.26 0.56 806 2.16 1.21 0.56 822

22 20 2.58 1.13 0.44 791 2.40 1.06 0.44 829 2.31 1.02 0.44 853

22 22 2.73 0.87 0.32 822 2.55 0.82 0.32 868 2.46 0.79 0.32 884

23 18 2.45 1.47 0.60 760 2.25 1.35 0.60 806 2.16 1.30 0.60 822

23 20 2.58 1.24 0.48 791 2.40 1.15 0.48 829 2.31 1.11 0.48 853

23 22 2.73 0.98 0.36 822 2.55 0.92 0.36 868 2.46 0.89 0.36 884

24 18 2.45 1.57 0.64 760 2.25 1.44 0.64 806 2.16 1.38 0.64 822

24 20 2.58 1.34 0.52 791 2.40 1.25 0.52 829 2.31 1.20 0.52 853

24 22 2.73 1.09 0.40 822 2.55 1.02 0.40 868 2.46 0.99 0.40 884

24 24 2.88 0.81 0.28 853 2.70 0.76 0.28 891 2.63 0.74 0.28 911

25 18 2.45 1.67 0.68 760 2.25 1.53 0.68 806 2.16 1.47 0.68 822

25 20 2.58 1.44 0.56 791 2.40 1.34 0.56 829 2.31 1.30 0.56 853

25 22 2.73 1.20 0.44 822 2.55 1.12 0.44 868 2.46 1.08 0.44 884

25 24 2.88 0.92 0.32 853 2.70 0.86 0.32 891 2.63 0.84 0.32 911

26 18 2.45 1.76 0.72 760 2.25 1.62 0.72 806 2.16 1.56 0.72 822

26 20 2.58 1.55 0.60 791 2.40 1.44 0.60 829 2.31 1.39 0.60 853

26 22 2.73 1.31 0.48 822 2.55 1.22 0.48 868 2.46 1.18 0.48 884

26 24 2.88 1.04 0.36 853 2.70 0.97 0.36 891 2.63 0.95 0.36 911

26 26 3.03 0.73 0.24 884 2.85 0.68 0.24 922 2.76 0.66 0.24 942

27 18 2.45 1.86 0.76 760 2.25 1.71 0.76 806 2.16 1.64 0.76 822

27 20 2.58 1.65 0.64 791 2.40 1.54 0.64 829 2.31 1.48 0.64 853

27 22 2.73 1.42 0.52 822 2.55 1.33 0.52 868 2.46 1.28 0.52 884

27 24 2.88 1.15 0.40 853 2.70 1.08 0.40 891 2.63 1.05 0.40 911

27 26 3.03 0.85 0.28 884 2.85 0.80 0.28 922 2.76 0.77 0.28 942

28 18 2.45 1.96 0.80 760 2.25 1.80 0.80 806 2.16 1.73 0.80 822

28 20 2.58 1.75 0.68 791 2.40 1.63 0.68 829 2.31 1.57 0.68 853

28 22 2.73 1.53 0.56 822 2.55 1.43 0.56 868 2.46 1.38 0.56 884

28 24 2.88 1.27 0.44 853 2.70 1.19 0.44 891 2.63 1.16 0.44 911

28 26 3.03 0.97 0.32 884 2.85 0.91 0.32 922 2.76 0.88 0.32 942

29 18 2.45 2.06 0.84 760 2.25 1.89 0.84 806 2.16 1.82 0.84 822

29 20 2.58 1.85 0.72 791 2.40 1.73 0.72 829 2.31 1.67 0.72 853

29 22 2.73 1.64 0.60 822 2.55 1.53 0.60 868 2.46 1.48 0.60 884

29 24 2.88 1.38 0.48 853 2.70 1.30 0.48 891 2.63 1.26 0.48 911

29 26 3.03 1.09 0.36 884 2.85 1.03 0.36 922 2.76 0.99 0.36 942

30 18 2.45 2.16 0.88 760 2.25 1.98 0.88 806 2.16 1.90 0.88 822

30 20 2.58 1.96 0.76 791 2.40 1.82 0.76 829 2.31 1.76 0.76 853

30 22 2.73 1.74 0.64 822 2.55 1.63 0.64 868 2.46 1.58 0.64 884

30 24 2.88 1.50 0.52 853 2.70 1.40 0.52 891 2.63 1.37 0.52 911

30 26 3.03 1.21 0.40 884 2.85 1.14 0.40 922 2.76 1.11 0.40 942

31 18 2.45 2.25 0.92 760 2.25 2.07 0.92 806 2.16 1.99 0.92 822

31 20 2.58 2.06 0.80 791 2.40 1.92 0.80 829 2.31 1.85 0.80 853

31 22 2.73 1.85 0.68 822 2.55 1.73 0.68 868 2.46 1.67 0.68 884

31 24 2.88 1.61 0.56 853 2.70 1.51 0.56 891 2.63 1.47 0.56 911

31 26 3.03 1.33 0.44 884 2.85 1.25 0.44 922 2.76 1.22 0.44 942

32 18 2.45 2.35 0.96 760 2.25 2.16 0.96 806 2.16 2.08 0.96 822

32 20 2.58 2.16 0.84 791 2.40 2.02 0.84 829 2.31 1.94 0.84 853

32 22 2.73 1.96 0.72 822 2.55 1.84 0.72 868 2.46 1.77 0.72 884

32 24 2.88 1.73 0.60 853 2.70 1.62 0.60 891 2.63 1.58 0.60 911

32 26 3.03 1.45 0.48 884 2.85 1.37 0.48 922 2.76 1.33 0.48 942

INDOOR

DB(:)

INDOOR

WB(:)

OUTDOOR DB(:)

35 4340

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 2.5(kW) SHF : 0.70 INPUT : 775(W)

COOL operation (230V)

MSC-GA25VB : MU-GA25VB

NOTE Q :Total capacity (kW) SHF :Sensible heat factor DB :Dry-bulb temperature

SHC :Sensible heat capacity (kW) INPUT :Total power input (W) WB :Wet-bulb temperature

14

Page 15

PERFORMANCE DATA

21 18 4.05 1.95 0.48 896 3.88 1.86 0.48 941 3.73 1.79 0.48 986 3.59 1.72 0.48 1030

21 20 4.23 1.52 0.36 941 4.05 1.46 0.36 997 3.93 1.42 0.36 1019 3.80 1.37 0.36 1064

22 18 4.05 2.11 0.52 896 3.88 2.02 0.52 941 3.73 1.94 0.52 986 3.59 1.87 0.52 1030

22 20 4.23 1.69 0.40 941 4.05 1.62 0.40 997 3.93 1.57 0.40 1019 3.80 1.52 0.40 1064

22 22 4.40 1.23 0.28 974 4.24 1.19 0.28 1036 4.14 1.16 0.28 1064 3.97 1.11 0.28 1109

23 18 4.05 2.27 0.56 896 3.88 2.17 0.56 941 3.73 2.09 0.56 986 3.59 2.01 0.56 1030

23 20 4.23 1.86 0.44 941 4.05 1.78 0.44 997 3.93 1.73 0.44 1019 3.80 1.67 0.44 1064

23 22 4.40 1.41 0.32 974 4.24 1.36 0.32 1036 4.14 1.32 0.32 1064 3.97 1.27 0.32 1109

24 18 4.05 2.43 0.60 896 3.88 2.33 0.60 941 3.73 2.24 0.60 986 3.59 2.15 0.60 1030

24 20 4.23 2.03 0.48 941 4.05 1.95 0.48 997 3.93 1.89 0.48 1019 3.80 1.82 0.48 1064

24 22 4.40 1.58 0.36 974 4.24 1.53 0.36 1036 4.14 1.49 0.36 1064 3.97 1.43 0.36 1109

24 24 4.62 1.11 0.24 1019 4.45 1.07 0.24 1075 4.35 1.04 0.24 1109 4.21 1.01 0.24 1165

25 18 4.05 2.59 0.64 896 3.88 2.48 0.64 941 3.73 2.38 0.64 986 3.59 2.30 0.64 1030

25 20 4.23 2.20 0.52 941 4.05 2.11 0.52 997 3.93 2.05 0.52 1019 3.80 1.97 0.52 1064

25 22 4.40 1.76 0.40 974 4.24 1.70 0.40 1036 4.14 1.66 0.40 1064 3.97 1.59 0.40 1109

25 24 4.62 1.29 0.28 1019 4.45 1.25 0.28 1075 4.35 1.22 0.28 1109 4.21 1.18 0.28 1165

26 18 4.05 2.76 0.68 896 3.88 2.64 0.68 941 3.73 2.53 0.68 986 3.59 2.44 0.68 1030

26 20 4.23 2.37 0.56 941 4.05 2.27 0.56 997 3.93 2.20 0.56 1019 3.80 2.13 0.56 1064

26 22 4.40 1.94 0.44 974 4.24 1.87 0.44 1036 4.14 1.82 0.44 1064 3.97 1.75 0.44 1109

26 24 4.62 1.48 0.32 1019 4.45 1.42 0.32 1075 4.35 1.39 0.32 1109 4.21 1.35 0.32 1165

26 26 4.76 0.95 0.20 1075 4.62 0.92 0.20 1131 4.55 0.91 0.20 1165 4.42 0.88 0.20 1198

27 18 4.05 2.92 0.72 896 3.88 2.79 0.72 941 3.73 2.68 0.72 986 3.59 2.58 0.72 1030

27 20 4.23 2.54 0.60 941 4.05 2.43 0.60 997 3.93 2.36 0.60 1019 3.80 2.28 0.60 1064

27 22 4.40 2.11 0.48 974 4.24 2.04 0.48 1036 4.14 1.99 0.48 1064 3.97 1.90 0.48 1109

27 24 4.62 1.66 0.36 1019 4.45 1.60 0.36 1075 4.35 1.56 0.36 1109 4.21 1.52 0.36 1165

27 26 4.76 1.14 0.24 1075 4.62 1.11 0.24 1131 4.55 1.09 0.24 1165 4.42 1.06 0.24 1198

28 18 4.05 3.08 0.76 896 3.88 2.95 0.76 941 3.73 2.83 0.76 986 3.59 2.73 0.76 1030

28 20 4.23 2.70 0.64 941 4.05 2.59 0.64 997 3.93 2.52 0.64 1019 3.80 2.43 0.64 1064

28 22 4.40 2.29 0.52 974 4.24 2.21 0.52 1036 4.14 2.15 0.52 1064 3.97 2.06 0.52 1109

28 24 4.62 1.85 0.40 1019 4.45 1.78 0.40 1075 4.35 1.74 0.40 1109 4.21 1.68 0.40 1165

28 26 4.76 1.33 0.28 1075 4.62 1.29 0.28 1131 4.55 1.28 0.28 1165 4.42 1.24 0.28 1198

29 18 4.05 3.24 0.80 896 3.88 3.11 0.80 941 3.73 2.98 0.80 986 3.59 2.87 0.80 1030

29 20 4.23 2.87 0.68 941 4.05 2.76 0.68 997 3.93 2.67 0.68 1019 3.80 2.58 0.68 1064

29 22 4.40 2.46 0.56 974 4.24 2.38 0.56 1036 4.14 2.32 0.56 1064 3.97 2.22 0.56 1109

29 24 4.62 2.03 0.44 1019 4.45 1.96 0.44 1075 4.35 1.91 0.44 1109 4.21 1.85 0.44 1165

29 26 4.76 1.52 0.32 1075 4.62 1.48 0.32 1131 4.55 1.46 0.32 1165 4.42 1.41 0.32 1198

30 18 4.05 3.41 0.84 896 3.88 3.26 0.84 941 3.73 3.13 0.84 986 3.59 3.01 0.84 1030

30 20 4.23 3.04 0.72 941 4.05 2.92 0.72 997 3.93 2.83 0.72 1019 3.80 2.73 0.72 1064

30 22 4.40 2.64 0.60 974 4.24 2.55 0.60 1036 4.14 2.48 0.60 1064 3.97 2.38 0.60 1109

30 24 4.62 2.22 0.48 1019 4.45 2.14 0.48 1075 4.35 2.09 0.48 1109 4.21 2.02 0.48 1165

30 26 4.76 1.71 0.36 1075 4.62 1.66 0.36 1131 4.55 1.64 0.36 1165 4.42 1.59 0.36 1198

31 18 4.05 3.57 0.88 896 3.88 3.42 0.88 941 3.73 3.28 0.88 986 3.59 3.16 0.88 1030

31 20 4.23 3.21 0.76 941 4.05 3.08 0.76 997 3.93 2.99 0.76 1019 3.80 2.88 0.76 1064

31 22 4.40 2.82 0.64 974 4.24 2.72 0.64 1036 4.14 2.65 0.64 1064 3.97 2.54 0.64 1109

31 24 4.62 2.40 0.52 1019 4.45 2.31 0.52 1075 4.35 2.26 0.52 1109 4.21 2.19 0.52 1165

31 26 4.76 1.90 0.40 1075 4.62 1.85 0.40 1131 4.55 1.82 0.40 1165 4.42 1.77 0.40 1198

32 18 4.05 3.73 0.92 896 3.88 3.57 0.92 941 3.73 3.43 0.92 986 3.59 3.30 0.92 1030

32 20 4.23 3.38 0.80 941 4.05 3.24 0.80 997 3.93 3.15 0.80 1019 3.80 3.04 0.80 1064

32 22 4.40 2.99 0.68 974 4.24 2.89 0.68 1036 4.14 2.82 0.68 1064 3.97 2.70 0.68 1109

32 24 4.62 2.59 0.56 1019 4.45 2.49 0.56 1075 4.35 2.43 0.56 1109 4.21 2.36 0.56 1165

32 26 4.76 2.09 0.44 1075 4.62 2.03 0.44 1131 4.55 2.00 0.44 1165 4.42 1.94 0.44 1198

INDOOR

DB(:)

INDOOR

WB(:)

OUTDOOR DB(:)

21 2725

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT30Q SHC SHF INPUT

CAPACITY : 3.45(kW) SHF : 0.66 INPUT : 1120(W)

COOL operation (230V)

MSC-GA35VB : MU-GA35VB

NOTE Q :Total capacity (kW) SHF :Sensible heat factor DB :Dry-bulb temperature

SHC :Sensible heat capacity (kW) INPUT :Total power input (W) WB :Wet-bulb temperature

15

Page 16

PERFORMANCE DATA

21 18 3.38 1.62 0.48 1098 3.11 1.49 0.48 1165 2.98 1.43 0.48 1187

21 20 3.55 1.28 0.36 1142 3.31 1.19 0.36 1198 3.19 1.15 0.36 1232

22 18 3.38 1.76 0.52 1098 3.11 1.61 0.52 1165 2.98 1.55 0.52 1187

22 20 3.55 1.42 0.40 1142 3.31 1.32 0.40 1198 3.19 1.28 0.40 1232

22 22 3.76 1.05 0.28 1187 3.52 0.99 0.28 1254 3.40 0.95 0.28 1277

23 18 3.38 1.89 0.56 1098 3.11 1.74 0.56 1165 2.98 1.67 0.56 1187

23 20 3.55 1.56 0.44 1142 3.31 1.46 0.44 1198 3.19 1.40 0.44 1232

23 22 3.76 1.20 0.32 1187 3.52 1.13 0.32 1254 3.40 1.09 0.32 1277

24 18 3.38 2.03 0.60 1098 3.11 1.86 0.60 1165 2.98 1.79 0.60 1187

24 20 3.55 1.71 0.48 1142 3.31 1.59 0.48 1198 3.19 1.53 0.48 1232

24 22 3.76 1.35 0.36 1187 3.52 1.27 0.36 1254 3.40 1.22 0.36 1277

24 24 3.97 0.95 0.24 1232 3.73 0.89 0.24 1288 3.62 0.87 0.24 1316

25 18 3.38 2.16 0.64 1098 3.11 1.99 0.64 1165 2.98 1.91 0.64 1187

25 20 3.55 1.85 0.52 1142 3.31 1.72 0.52 1198 3.19 1.66 0.52 1232

25 22 3.76 1.50 0.40 1187 3.52 1.41 0.40 1254 3.40 1.36 0.40 1277

25 24 3.97 1.11 0.28 1232 3.73 1.04 0.28 1288 3.62 1.01 0.28 1316

26 18 3.38 2.30 0.68 1098 3.11 2.11 0.68 1165 2.98 2.03 0.68 1187

26 20 3.55 1.99 0.56 1142 3.31 1.85 0.56 1198 3.19 1.79 0.56 1232

26 22 3.76 1.65 0.44 1187 3.52 1.55 0.44 1254 3.40 1.50 0.44 1277

26 24 3.97 1.27 0.32 1232 3.73 1.19 0.32 1288 3.62 1.16 0.32 1316

26 26 4.17 0.83 0.20 1277 3.93 0.79 0.20 1333 3.81 0.76 0.20 1361

27 18 3.38 2.43 0.72 1098 3.11 2.24 0.72 1165 2.98 2.15 0.72 1187

27 20 3.55 2.13 0.60 1142 3.31 1.99 0.60 1198 3.19 1.91 0.60 1232

27 22 3.76 1.81 0.48 1187 3.52 1.69 0.48 1254 3.40 1.63 0.48 1277

27 24 3.97 1.43 0.36 1232 3.73 1.34 0.36 1288 3.62 1.30 0.36 1316

27 26 4.17 1.00 0.24 1277 3.93 0.94 0.24 1333 3.81 0.91 0.24 1361

28 18 3.38 2.57 0.76 1098 3.11 2.36 0.76 1165 2.98 2.27 0.76 1187

28 20 3.55 2.27 0.64 1142 3.31 2.12 0.64 1198 3.19 2.04 0.64 1232

28 22 3.76 1.96 0.52 1187 3.52 1.83 0.52 1254 3.40 1.77 0.52 1277

28 24 3.97 1.59 0.40 1232 3.73 1.49 0.40 1288 3.62 1.45 0.40 1316

28 26 4.17 1.17 0.28 1277 3.93 1.10 0.28 1333 3.81 1.07 0.28 1361

29 18 3.38 2.70 0.80 1098 3.11 2.48 0.80 1165 2.98 2.39 0.80 1187

29 20 3.55 2.42 0.68 1142 3.31 2.25 0.68 1198 3.19 2.17 0.68 1232

29 22 3.76 2.11 0.56 1187 3.52 1.97 0.56 1254 3.40 1.90 0.56 1277

29 24 3.97 1.75 0.44 1232 3.73 1.64 0.44 1288 3.62 1.59 0.44 1316

29 26 4.17 1.34 0.32 1277 3.93 1.26 0.32 1333 3.81 1.22 0.32 1361

30 18 3.38 2.84 0.84 1098 3.11 2.61 0.84 1165 2.98 2.51 0.84 1187

30 20 3.55 2.56 0.72 1142 3.31 2.38 0.72 1198 3.19 2.30 0.72 1232

30 22 3.76 2.26 0.60 1187 3.52 2.11 0.60 1254 3.40 2.04 0.60 1277

30 24 3.97 1.90 0.48 1232 3.73 1.79 0.48 1288 3.62 1.74 0.48 1316

30 26 4.17 1.50 0.36 1277 3.93 1.42 0.36 1333 3.81 1.37 0.36 1361

31 18 3.38 2.98 0.88 1098 3.11 2.73 0.88 1165 2.98 2.63 0.88 1187

31 20 3.55 2.70 0.76 1142 3.31 2.52 0.76 1198 3.19 2.43 0.76 1232

31 22 3.76 2.41 0.64 1187 3.52 2.25 0.64 1254 3.40 2.17 0.64 1277

31 24 3.97 2.06 0.52 1232 3.73 1.94 0.52 1288 3.62 1.88 0.52 1316

31 26 4.17 1.67 0.40 1277 3.93 1.57 0.40 1333 3.81 1.52 0.40 1361

32 18 3.38 3.11 0.92 1098 3.11 2.86 0.92 1165 2.98 2.75 0.92 1187

32 20 3.55 2.84 0.80 1142 3.31 2.65 0.80 1198 3.19 2.55 0.80 1232

32 22 3.76 2.56 0.68 1187 3.52 2.39 0.68 1254 3.40 2.31 0.68 1277

32 24 3.97 2.22 0.56 1232 3.73 2.09 0.56 1288 3.62 2.03 0.56 1316

32 26 4.17 1.84 0.44 1277 3.93 1.73 0.44 1333 3.81 1.68 0.44 1361

INDOOR

DB(:)

INDOOR

WB(:)

OUTDOOR DB(:)

35 4340

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 3.45(kW) SHF : 0.66 INPUT : 1120(W)

COOL operation (230V)

MSC-GA35VB : MU-GA35VB

NOTE Q :Total capacity (kW) SHF :Sensible heat factor DB :Dry-bulb temperature

SHC :Sensible heat capacity (kW) INPUT :Total power input (W) WB :Wet-bulb temperature

16

Page 17

9

Lead wiring

Housing point

TROUBLESHOOTING

MU-GA20VB

MU-GA25VB

MU-GA35VB

9-1. Cautions on troubleshooting

1. Before troubleshooting, check the following:

1) Check the power supply voltage.

2) Check the indoor/outdoor connecting wire for mis-wiring.

2. Take care the following during servicing.

1) Before servicing the air conditioner, be sure to turn off the main unit first with the remote controller, and then after

confirming the horizontal vane is closed, turn off the breaker and/ or disconnect the power plug.

2) Be sure to turn OFF the power supply before removing the front panel, the cabinet, the top panel, and the electronic

control P.C. board.

3) When removing the electronic control P.C. board, hold the edge of the board with care NOT to apply stress on the

components.

4) When connecting or disconnecting the connectors, hold the housing of the connector. DO NOT pull the lead wires.

17

Page 18

9-2. Instruction of troubleshooting

Start

Indoor unit

operates.

Outdoor unit

doesn't

operate.

Indoor unit

doesn't receive

the signal from

remote controller.

Indoor unit

operates.

Outdoor unit

doesn't operate

normally.

OPERATION

INDICATOR

lamp on the

indoor unit is

flashing on

and off.

Outdoor unit

operates in

only Test Run

operation. W

Indoor unit

operates,

when the

EMERGENCY

OPERATION

switch is

pressed.

Indoor unit

doesn't operate,

when the

EMERGENCY

OPERATION

switch is

pressed.

Check room

temperature

thermistor.

Refer to

"Test point

diagram and

voltage" .

Refer to

"Check of

remote

controller

and receiver

P.C. board".

2-time flash

Cause:

Indoor unit

• Trouble of

room temp erature/

indoor coil

thermistor

3-time flash

Cause:

Indoor unit

• Trouble of

indoor fan

motor

Check room

temperature

thermistor

and indoor

coil thermistor.

Refer to

"Test point

diagram and

voltage".

Refer to

"Check of

indoor fan

motor".

1. Check indoor /

outdoor

connecting wire.

2. Refer to

"Check of indoor

electronic control

P.C. board".

Outdoor unit

doesn't

stop even

if indoor unit

stops.

Check of

wiring diagram

of outdoor unit

(Refer to 6.

WIRING

DIAGRAM.)

Flash on and

off at 0.5-second

intervals

Cause:

Wrong setting

of switch (SW2-2)

on the electronic

control P.C. board.

Refer to 9-4. A

"Check of

MU & MUX TYPE /

MUH & MXZ TYPE

SWITCH OVER "

(When

outdoor unit

doesn't operate.).

4-time flash

Cause:

Indoor unit

• Trouble of

indoor unit

control

system

Replace the

indoor

electronic

control

P.C. board.

W "Test run operation"

means the operation

within 30 minutes

after

EMERGENCY

OPERATION

switch is pressed.

Refer to indoor

unit service

manual.

MU-GA20VB

MU-GA25VB

MU-GA35VB

18

Page 19

P

R

C

S

RED

BLK

WHT

MAINAUX.

R

R

C

S

MAINAUX.

WHTRED

BLK

MAIN

AUX.

FUSE

9-3. Trouble criterion of main parts

MU-GA20VB

MU-GA25VB

MU-GA35VB

Part name

Compressor

(MC)

INNER

PROTECTOR

MU-GA20/

GA25VB-

E1

150i 5°C OPEN

90i10°C CLOSE

MU-GA20/

GA25VB-

E2

160i5°C OPEN

90i10°C CLOSE

OVERLOAD

RELAY

MU-GA35VB

140i 5°C OPEN

75i 5°C CLOSE

Outdoor fan

motor

(MF)

INNER FUSE

145i 2°C

CUT OFF

Measure the resistance between the terminals with a tester.

(Coil wiring temperature –10°C ~ 40°C)

MU-GA20/GA25VB

C-R

C-S

3.41~4.18Ω

5.41~6.63Ω

Measure the resistance between the terminals with a tester.

(Coil wiring temperature –10°C ~ 40°C)

Color of

lead wire

WHT-BLK

BLK-RED

Check method and criterion

Normal

E1

-

MU-GA20/GA25VB

3.19~3.91Ω

4.76~5.83Ω

Normal

MU-GA20/GA25VB

323 ~ 396

241 ~ 296

Ω

Ω

E2

-

MU-GA35VB

189 ~ 233

270 ~ 332

Ω

Ω

MU-GA35VB

2.46~3.01Ω

4.79~5.56Ω

Figure

MU-GA20/GA25VB

MU-GA35VB

9-4. Troubleshooting flow

Indoor unit MSC type

When OPERATION INDICATOR lamp flashes 0.5-second intervals.

Outdoor unit doesn’t operate.

AA

Check of MU & MUX TYPE / MUH & MXZ TYPE SWITCH OVER

Start

Turn OFF the power supply (indoor / outdoor unit).

Set switch (SW2-2) on the indoor electronic

control P.C. board to MU type. w1

Does the unit operate?

No

Refer to the

"Instruction of

troubleshooting."

Yes

w 1 Set the switch (SW2-2) on the indoor electronic control P.C. board to

MU type, when the outdoor unit is MU type.

If the setting is MUH or MXZ type, the unit does not work.

Refer to "MU & MUX TYPE / MUH& MXZ TYPE SWITCH OVER AND

AUTO RESTART FUNCTION" on the indoor unit service manual.

OK

19

P INNER PROTECTOR

R OVERLOAD RELAY

Page 20

10

DISASSEMBLY INSTRUCTIONS

<"Terminal with locking mechanism" Detaching points>

The terminal which has the locking mechanism can be detached as shown below.

There are two types ( Refer to (1) and (2)) of the terminal with locking mechanism.

The terminal without locking mechanism can be detached by pulling it out.

Check the shape of the terminal before detaching.

(1) Slide the sleeve and check if there is a locking lever or not.

Sleeve

1Slide the sleeve.

2Pull the terminal while

Locking lever

pushing the locking

lever.

MU-GA20VB MU-GA25VB MU-GA35VB

OUTDOOR UNIT

OPERATING PROCEDURE

1. Removing the cabinet

(1) Remove the screws of the top panel.

(2) Remove the screw of the service panel.

(3) Remove the screws of the cabinet.

(4) Remove the screws of the front panel and motor support.

(5) Remove the service panel, and remove the screw from

the insides.

(6) Remove the top panel.

(7) Remove the cabinet.

(2) The terminal with this connector has the

locking mechanism.

1Hold the sleeve, and

pull out the terminal

slowly.

Connector

PHOTOS

Photo 1

Screw of the front panel and motor support

Photo 3

Screws of the

top panel

Screw of the cabinet

Screw of the

Service panel

Screws of the cabinet

Photo 2

MU-GA20/GA25VB

Screws of

the top panel

Screws of

the cabinet

20

Page 21

OPERATING PROCEDURE PHOTOS

2. Removing the electrical parts

(1) Remove the service panel and the cabinet.(Refer to 1.)

(2) Remove the following parts.

• Compressor capacitor (C1)

• Outdoor fan capacitor (C2)

• Terminal block (TB1, TB2)

• Surge absorber (DSAR)

• Compressor contactor (52C)

3. Removing the propeller and the outdoor fan motor

(1) Remove the cabinet. (Refer to 1.)

(2) Remove the propeller nut.

(3) Remove the propeller.

NOTE : Loose the propeller in the rotating direction for

removal.

When attaching the propeller, align the mark on the

propeller and the motor shaft cut section.

Set the propeller in position by using the cut on the

shaft and the mark on the propeller.

(4) Remove lead clamps and disconnect the outdoor fan motor

connector.

(5) Remove screws fixing the fan motor.

(6) Remove the outdoor fan motor.

Photo 4

Compressor

capacitor (C1)

Outdoor fan

capacitor (C2)

Photo 5

Screws of the

outdoor fan motor

Propeller

Compressor

contactor (52C)

Surge absorber

(DSAR)

Hook

block(TB2)

Outdoor

fan motor

Terminal

Terminal

block

(TB1)

Outdoor

fan motor

connector

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1.)

(2) Remove the relay panel.

(3) Remove the soundproof felt.

(4) Remove the terminal cover on the compressor.

(5) Disconnect lead wires from the glass terminal of the com-

pressor.

(6) Recover gas from the refrigerant circuit.

NOTE: Recover gas from the pipes until the pressure gauge

shows 0 kg/cm

(7) Disconnect the welded part of the discharge pipe.

(8) Disconnect the welded part of the suction pipe.

(9) Remove nuts fixing the compressor.

)

(

Remove the compressor.

10

2

(0 MPa) .

21

Propeller nut

Screws of the

outdoor fan motor

Photo 6

Glass

terminal

Compressor

Compressor nuts

Discharge

pipe

Suction

pipe

Page 22

11

PARTS LIST (non-RoHS compliant)

MU-GA20VB

MU-GA25VB

MU-GA35VB

11-1.

OUTDOOR UNIT STRUCTURAL PARTS, ELECTRICAL PARTS AND FUNCTIONAL PARTS

20

1

2

3

4

5

19

6

7

18

17

8

15 14

16

13

12

10

9

11

This figure shows MU-GA20/GA25VB.

22

Page 23

No.

Part No.

Part name

Remarks

Symbol

in Wiring

Diagram

Q'ty/unit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

E02 901 630

E02 903 630

E02 899 301

E02 900 301

E02 665 501

E02 899 232

E02 903 232

E02 927 521

E02 899 290

E02 903 290

E02 075 506

E02 781 506

E02 742 900

E02 903 900

E02 901 661

E02 901 662

E02 901 233

E02 927 233

E02 927 245

E02 817 374

E02 832 374

E02 899 351

E02 900 351

E02 742 353

E02 665 353

E02 899 523

E02 838 523

E02 899 515

E02 927 297

E02 899 293

E02 735 382

E02 735 241

E02 466 340

E02 895 383

E02 408 936

E02 637 936

E02 903 330

OUTDOOR HEAT EXCHANGER

OUTDOOR HEAT EXCHANGER

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

PROPELLER

CABINET

CABINET

GRILLE(OUT)

BASE

BASE

COMPRESSOR RUBBER SET

COMPRESSOR RUBBER SET

COMPRESSOR

COMPRESSOR

STOP VALVE(GAS)

STOP VALVE(LIQUID)

BACK PANEL

BACK PANEL

SERVICE PANEL

TERMINAL BLOCK

TERMINAL BLOCK

OUTDOOR FAN CAPACITOR

OUTDOOR FAN CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

CONDENSER NET

CONDENSER NET

MOTOR SUPPORT

TOP PANEL

SEPARATOR

FUSE

FUSE HOLDER

COMPRESSOR CONTACTOR

SURGE ABSORBER

CAPILLARY TUBE

CAPILLARY TUBE

OVERLOAD RELAY

RA6V21RA6V33-

3RUBBERS/SET

3RUBBERS/SET

RN092VHSHT

5PS132DAH01

{9.52

{6.35

3P

2P

1.8µF/440VAC

2.0µF/440VAC

20µF/440VAC

25µF/440VAC

T20AL250V

{3.0x{1.4x700

{3.0x{1.4x450

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MF

MF

MC

MC

TB1

TB2

C2

C2

C1

C1

F

52C

DSAR

51C

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MU-GA20VB-

E1

E1

E1

MU-GA25VB-

MU-GA35VB-

PARTS LIST (non-RoHS compliant)

MU-GA20VB MU-GA25VB MU-GA35VB

11-1.

OUTDOOR UNIT STRUCTURAL PARTS, ELECTRICAL PARTS AND FUNCTIONAL PARTS

Part numbers that are circled are not shown in the illustration.

23

Page 24

12

RoHS PARTS LIST (RoHS compliant)

MU-GA20VB

MU-GA25VB

MU-GA35VB

12-1.

OUTDOOR UNIT STRUCTURAL PARTS, ELECTRICAL PARTS AND FUNCTIONAL PARTS

20

1

2

3

4

5

19

6

7

17

18

9

8

This figure shows MU-GA20/GA25VB.

16

15 14

10

13

12

11

24

Page 25

No.

RoHS

Part No.

Part name

Remarks

Symbol

in Wiring

Diagram

Q'ty/unit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

G

E12 901 630

E12 903 630

E12 899 301

E12 900 301

E12 665 501

E12 899 232

E12 903 232

E12 927 521

E12 899 290

E12 903 290

E12 A89 290

E12 075 506

E12 781 506

E12 065 506

E12 742 900

E12 903 900

E12 B14 900

E12 901 661

E12 901 662

E12 B14 662

E12 901 233

E12 927 233

E12 927 245

E12 817 374

E12 832 374

E12 899 351

E12 900 351

E12 742 353

E12 665 353

E12 899 523

E12 838 523

E12 899 515

E12 927 297

E12 899 293

E12 735 382

E12 735 241

E12 466 340

E12 895 383

E12 408 936

E12 637 936

E12 B14 936

E12 903 330

OUTDOOR HEAT EXCHANGER

OUTDOOR HEAT EXCHANGER

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

PROPELLER

CABINET

CABINET

GRILLE(OUT)

BASE

BASE

BASE

COMPRESSOR RUBBER SET

COMPRESSOR RUBBER SET

COMPRESSOR RUBBER SET

COMPRESSOR

COMPRESSOR

COMPRESSOR

STOP VALVE(GAS)

STOP VALVE(LIQUID)

STOP VALVE(LIQUID)

BACK PANEL

BACK PANEL

SERVICE PANEL

TERMINAL BLOCK

TERMINAL BLOCK

OUTDOOR FAN CAPACITOR

OUTDOOR FAN CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

CONDENSER NET

CONDENSER NET

MOTOR SUPPORT

TOP PANEL

SEPARATOR

FUSE

FUSE HOLDER

COMPRESSOR CONTACTOR

SURGE ABSORBER

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

OVERLOAD RELAY

RA6V21RA6V33-

3RUBBERS/SET

3RUBBERS/SET

3RUBBERS/SET

RN092VHSHT

5PS132DAH01

KN092VDMHC

{9.52

{6.35

{6.35

3P

2P

1.8µF/440VAC

2.0µF/440VAC

20µF/440VAC

25µF/440VAC

T20AL250V

{3.0x{1.4x700

{3.0x{1.4x450

{3.0x{1.4x900

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MF

MF

MC

MC

MC

TB1

TB2

C2

C2

C1

C1

F

52C

DSAR

51C

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MU-

GA20VB-

E1

MU-

GA20VB-

E2

MU-

GA25VB-

E1

MU-

GA35VB-

E1

MU-

GA25VB-

E2

RoHS PARTS LIST (RoHS compliant)

MU-GA20VB MU-GA25VB MU-GA35VB

12-1.

OUTDOOR UNIT STRUCTURAL PARTS, ELECTRICAL PARTS AND FUNCTIONAL PARTS

Part numbers that are circled are not shown in the illustration.

25

Page 26

26

Page 27

27

Page 28

HEAD OFFICE: TOKYO BLDG.,2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO100-8310, JAPAN

CC

Copyright 2005 MITSUBISHI ELECTRIC ENGINEERING CO.,LTD

Distributed in May 2006. No.OB386 REVISED EDITION-B 6

Distributed in Mar. 2005. No.OB386 REVISED EDITION-A 6

Distributed in Jan. 2005. No.OB386 6

Made in Japan

New publication, effective May 2006

Specifications subject to change without notice.

Loading...

Loading...