Mitsubishi MCF-13NV-E4, MCF-18NV-E3, MCF-24NV-E3, MUCF-13NV-E4, MUCF-18NV-E3 Service Manual

...Page 1

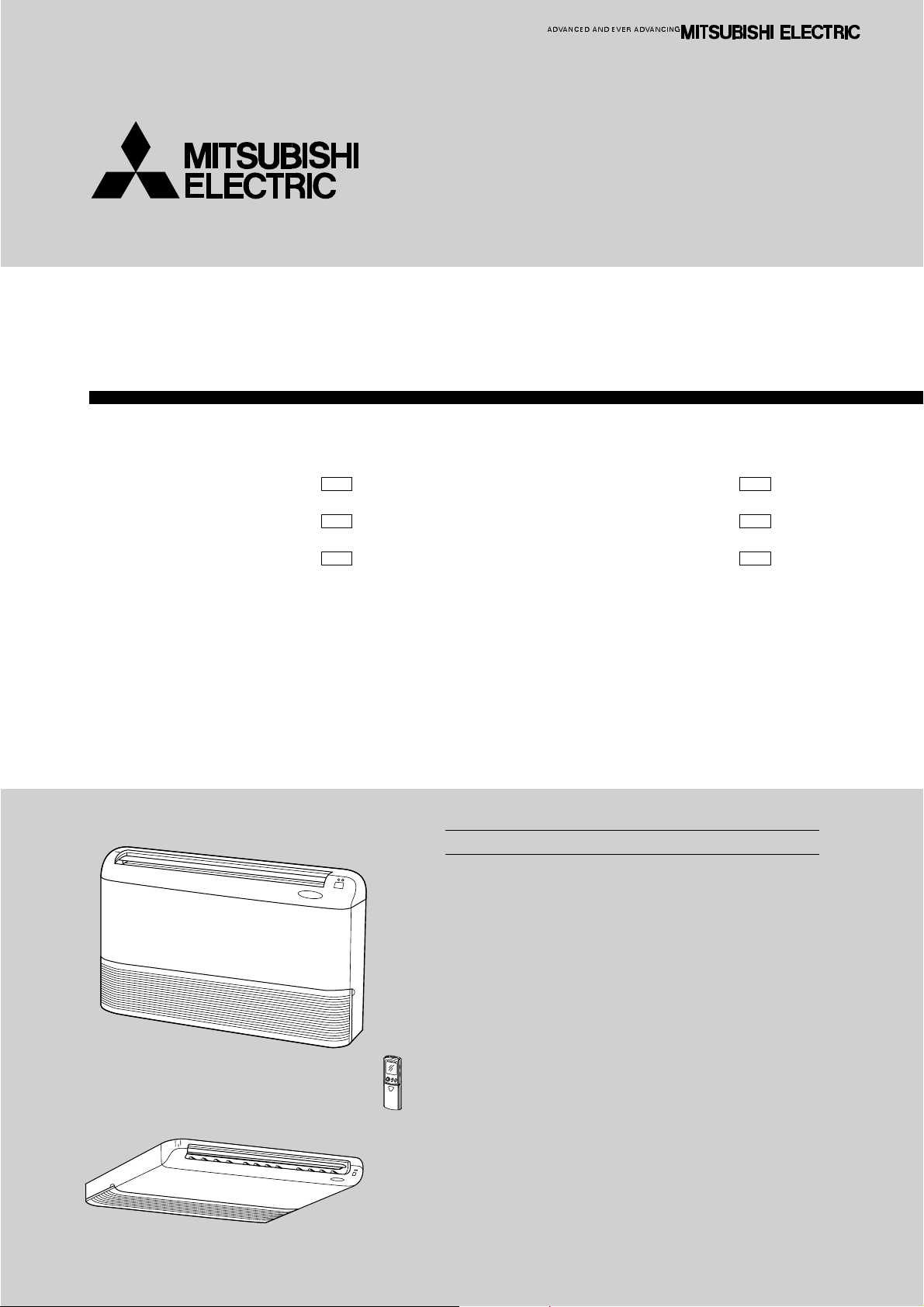

FLOOR AND CEILING TYPE AIR CONDITIONERS

(When installed on the ceiling)

(When installed on the floor)

SERVICE MANUAL

Wireless type

Models

No. OB270

MCF-13NVMCF-18NVMCF-24NV-

(WH)

(WH)

(WH)

·MUCF-13NV-

·MUCF-18NV-

·MUCF-24NV-

CONTENTS

1. TECHNICAL CHANGES ····································2

2. PART NAMES AND FUNCTIONS······················2

3. SPECIFICATION·················································4

4. NOISE CRITERIA CURVES·······························5

5. OUTLINES AND DIMENSIONS·························7

6. WIRING DIAGRAM ············································9

7. REFRIGERANT SYSTEM DIAGRAM··············12

8. PERFORMANCE CURVES······························14

9. MICROPROCESSOR CONTROL ····················28

10. SERVICE FUNCTIONS·····································34

11. TROUBLESHOOTING ······································35

12. DISASSEMBLY INSTRUCTIONS·····················41

13. PARTS LIST······················································47

14. OPTIONAL PARTS ······················BACK COVER

W As for parts lists, all sub number’s series are included.

E4E4

E3E3

E3E3

Page 2

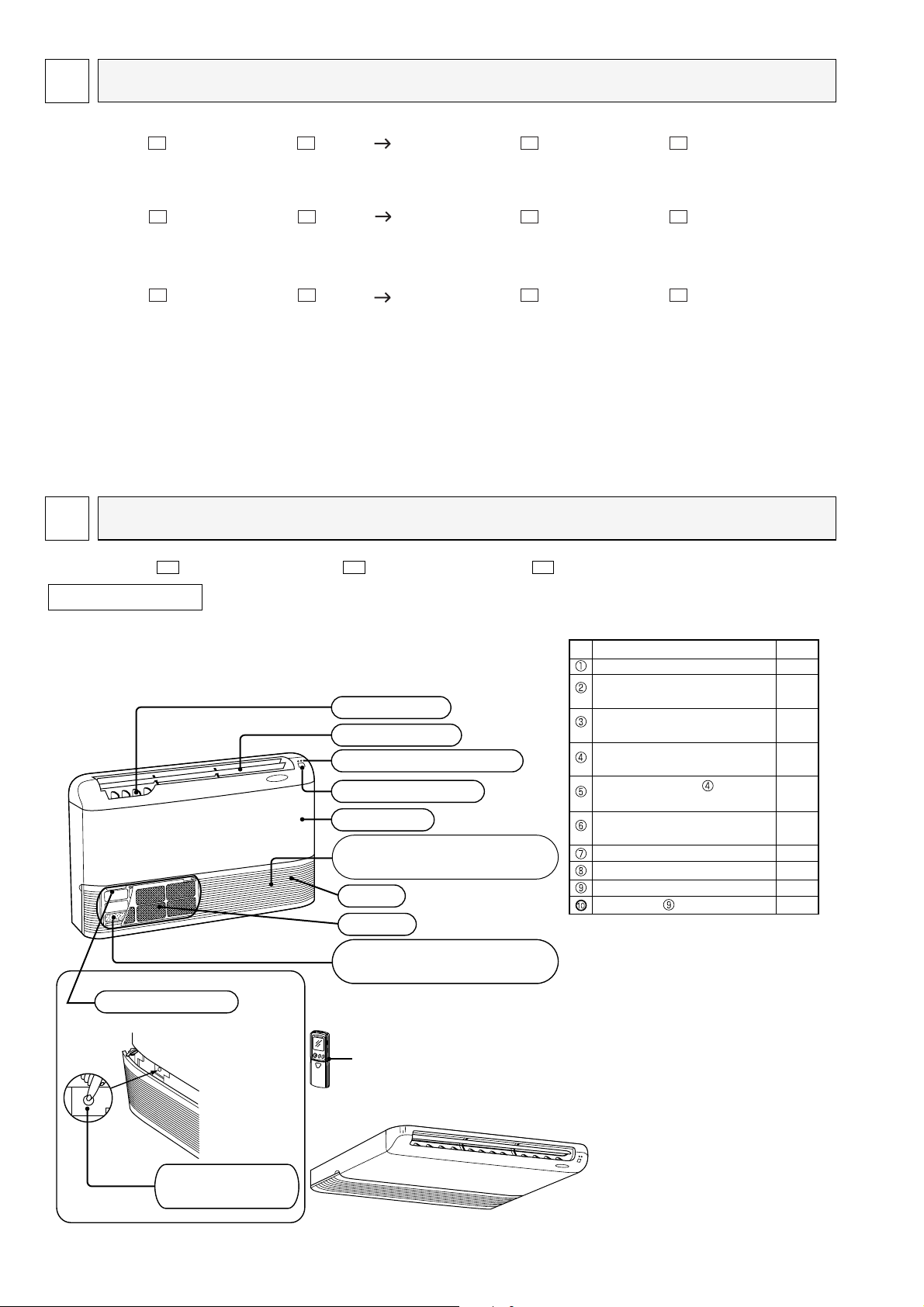

1

(When installed on the floor)

(When the air inlet grille is opened.)

Deodorizing filter

(gray sponge type)(option)

Air filter

Remote controller

Air inlet

Operation section

Air cleaning filter

(white bellows type)(option)

Front panel

Receiving section

Operation indicator lamp

Horizontal vane

Vertical vanes

Emergency

operation switch

(When installed on the ceiling)

ACCESSORIES

Item

Installation plate

Unit fixing screw

5 o 12mm

Wireless remote

controller

Remote controller

mounting hardware

Fixing screw for

3.5 o 16mm (Black)

Battery (AAA) for

remote controller

Drain hose

Drain pipe cover

Knockout cover

Screw for 4 o 10mm

2

2

1

1

2

2

1

1

1

2

Q'ty

TECHNICAL CHANGES

MCF-13NV- · MUCF-13NV- MCF-13NV- · MUCF-13NV-

1. Remote controller has changed.

SWING button is removed, but SWING MODE function is available by VANE CONTROL button.

MCF-18NV- · MUCF-18NV- MCF-18NV- · MUCF-18NV-

1. Remote controller has changed.

SWING button is removed, but SWING MODE function is available by VANE CONTROL button.

MCF-24NV- · MUCF-24NV- MCF-24NV- · MUCF-24NV-

1. Remote controller has changed.

SWING button is removed, but SWING MODE function is available by VANE CONTROL button.

2

MCF-13NV - MCF-18NV - MCF-24NV -

PART NAMES AND FUNCTIONS

E3E3E4

E4E4E3E3

E3E3E2E2

E3E3E2E2

INDOOR UNIT

2

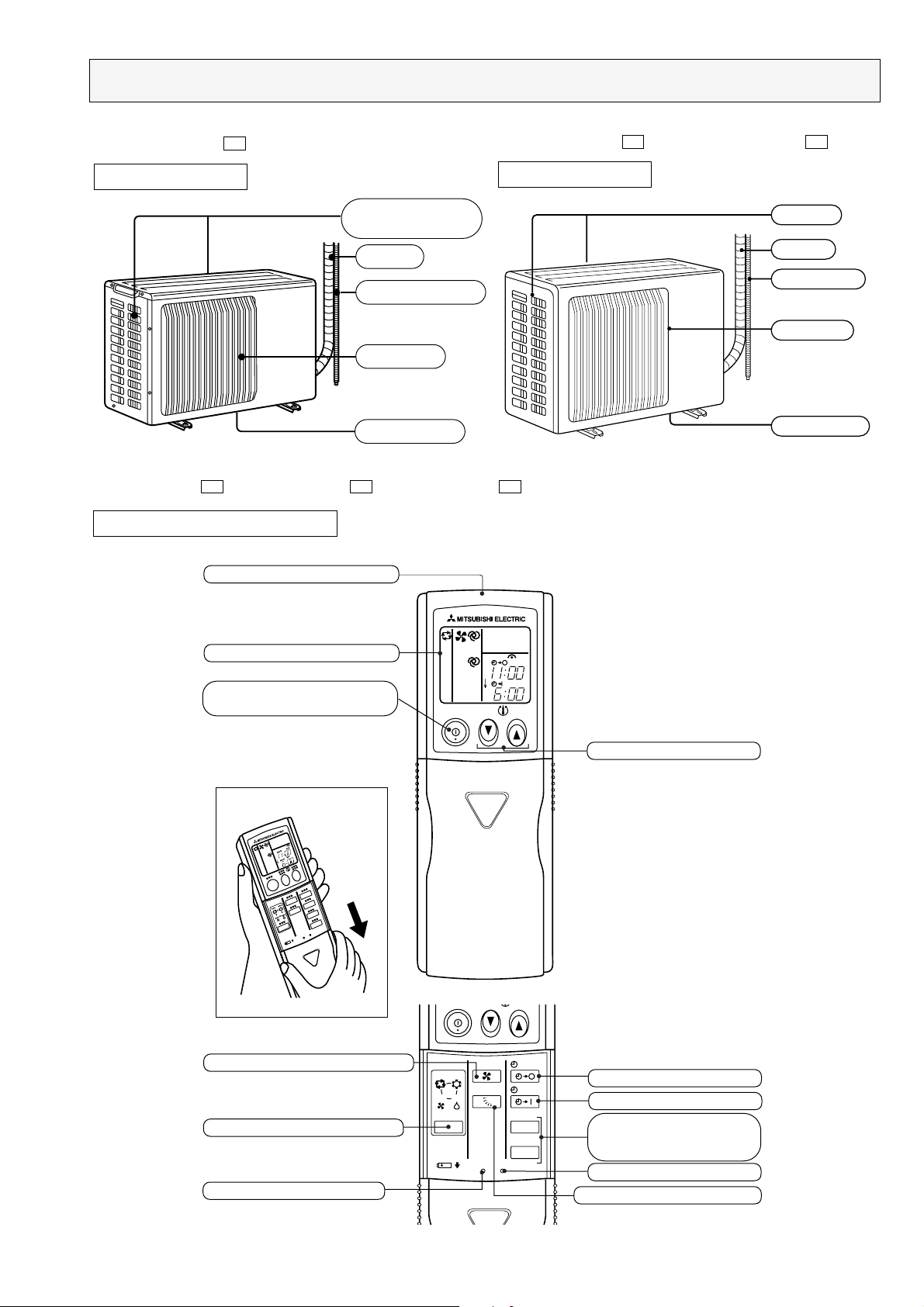

Page 3

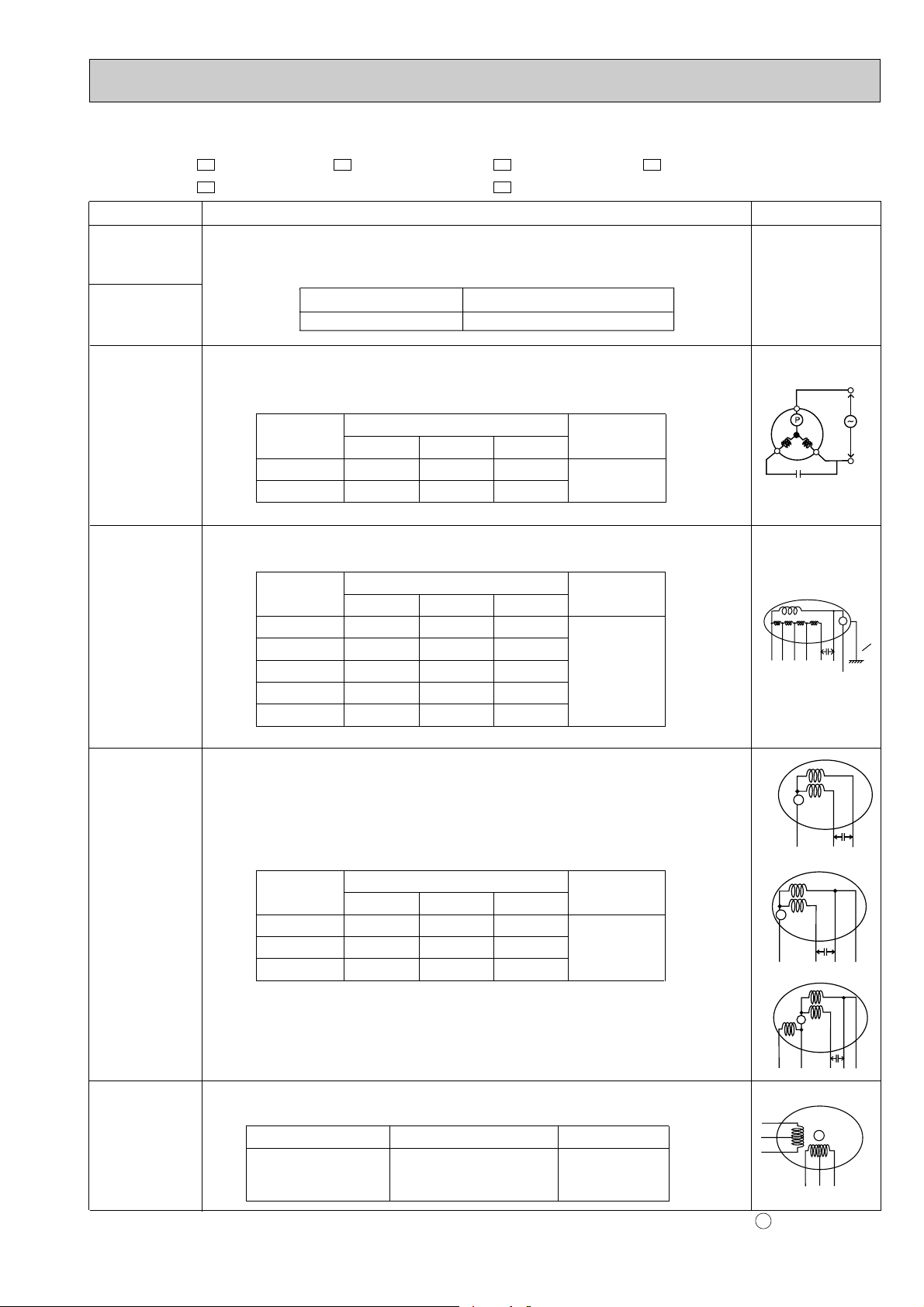

MUCF-13NV -

WARM COOL

Open the front lid.

E4

MUCF-18NV - MUCF-24NV -

E3E3

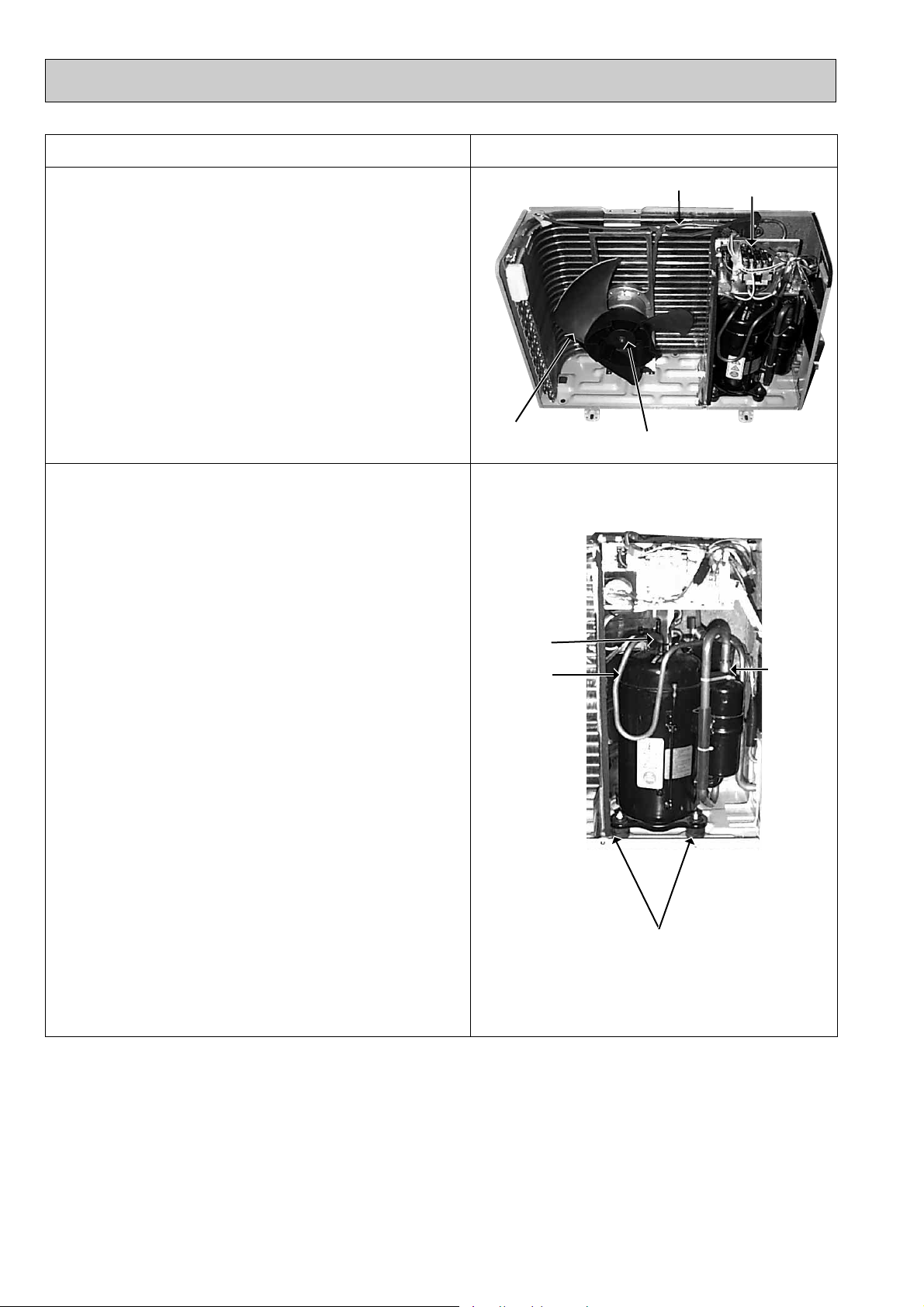

OUTDOOR UNIT

Air inlet

(back and side)

Piping

Drain hose

Air outlet

Drain outlet

MCF-13NV - MCF-18NV - MCF-24NV -

REMOTE CONTROLLER

Signal transmitting section

OUTDOOR UNIT

Air inlet

Piping

Drain hose

Air outlet

Drain outlet

E3E3E4

Operation display section

OPERATE /STOP

(ON /OFF)button

Open the front lid.

FAN SPEED CONTROL button

FAN SPEED CONTROL button

OPERATION SELECT button

OPERATION SELECT button

RESET button

RESET button

ON/OFF

ON/OFF

I FEEL

FAN

MODE

I FEEL

FAN

MODE

COOL

DRY

COOL

DRY

TOO

WARM

TOO

WARM

FAN

VANE

FAN

VANE

RESET

RESET

3

CLOCK

CLOCK

CLOCK

PM

AM

TOO

COOL

PM

AM

TOO

COOL

STOP

START

STOP

HR.

START

MIN.

HR.

MIN.

TEMPERATURE buttons

OFF-TIMER button

ON-TIMER button

HR. button

OFF-TIMER button

MIN. button

ON-TIMER button

(TIME SET button)

HR. button

CLOCK SET button

VANE CONTROL button

MIN. button

(TIME SET button)

CLOCK SET button

VANE CONTROL button

Page 4

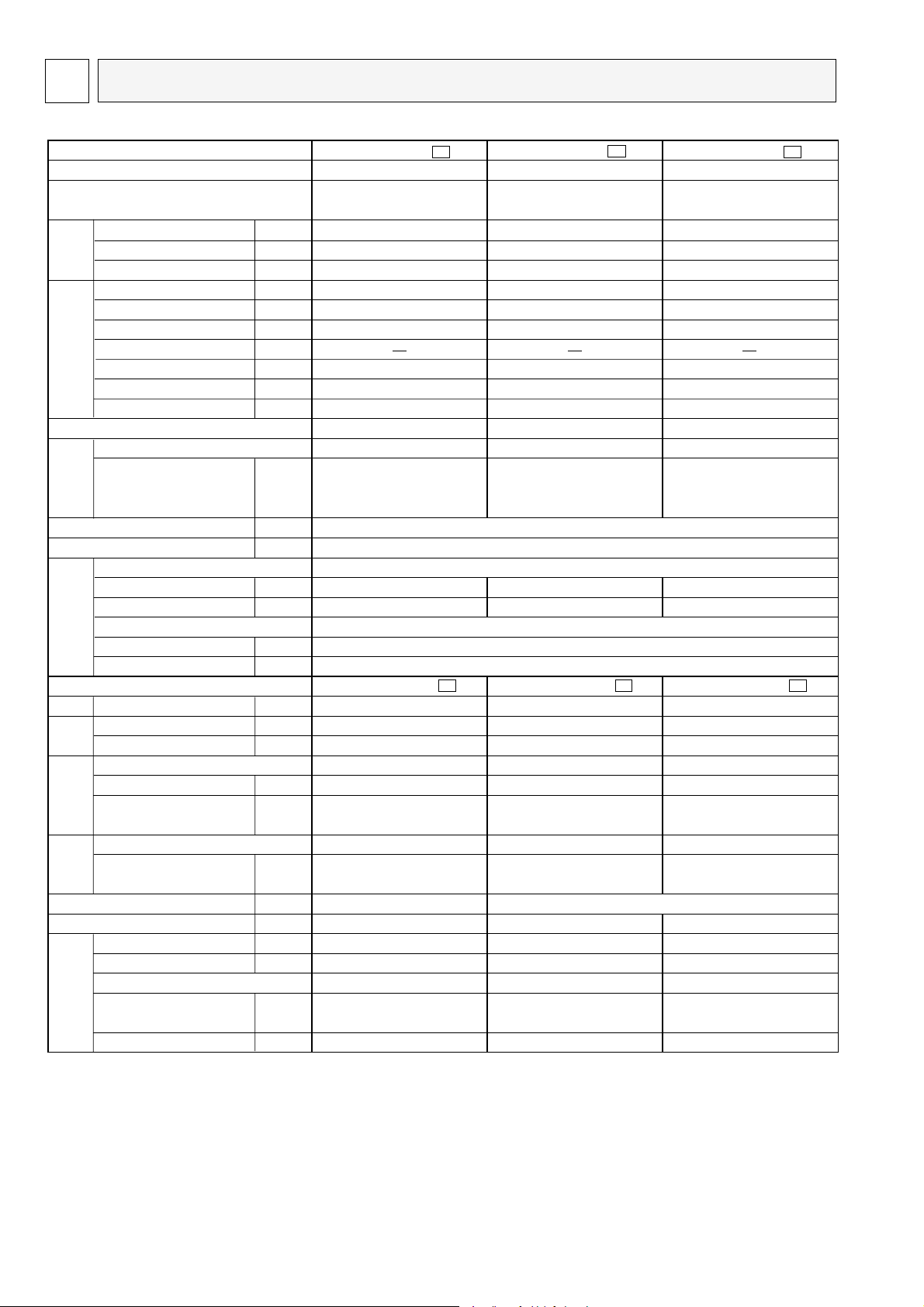

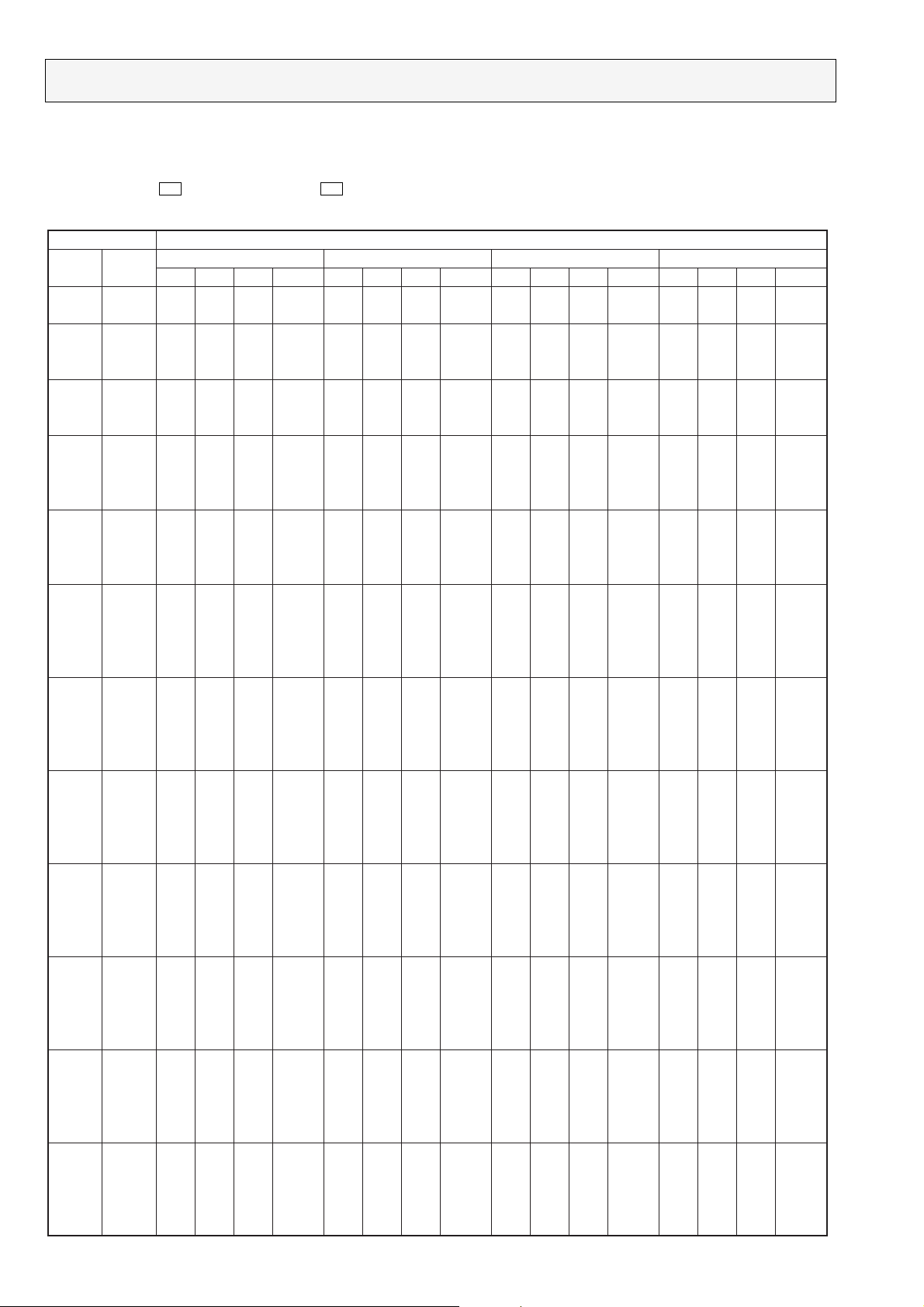

3

Indoor model

Function

Power supply

Capacity

Dehumidification

Air flow(High)

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Fan motor current

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Air direction

Sound level (High)

Fan speed (High)

Fan speed regulator

Thermistor RT11(at25:)

Thermistor RT12(at25:)

Outdoor model

Air flow (High)

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at20:)

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Sound level (High)

Fan speed (High)

Fan speed regulator

Refrigerant filling

capacity(R22)

Refrigerating oil (Model)

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

"

mm

kg

dB

rpm

k"

k"

K /h

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

MCF-18NV -

E3

Cooling

Single phase

240V, 50Hz

5.0

2.4

780

15

8.9-8.8

1,920-2,010

98-95

51-55

0.69-0.69

2.60-2.49

RB4V25-AB

WHT-BLK 182.2 BLK-YLW 68.9

YLW-BLU 47.5 BLU-BRN 31.5

BRN-RED 22.9

1,100O650O180

26

5

46-47

1,220-1,260

3

10

10

MUCF-18NV -

E3

2,190-2,286

8.21-8.11

0.39

NH-33VMDT

1,500

C-R 1.20

C-S 2.70

RA6V50-OG

WHT-BLK 116

BLK-RED 111

55

52

810-845

1

1.50

1,200 (MS32N1)

MCF-24NV -

E3

Cooling

Single phase

240V, 50Hz

6.4

3.4

840

25

13.3-12.9

2,870-2,970

98-96

59-59

0.91-0.91

2.23-2.15

RB4V36-AB

WHT-BLK 82.9 BLK-YLW 65.6

YLW-BLU 36.0 BLU-BRN 27.0

BRN-RED 13.7

48-48

1,310-1,330

MUCF-24NV -

E3

2,286-2,358

12.39-11.99

0.55

NH-47VMDT

2,200

C-R 0.96

C-S 2.07

RA6V60-AC

WHT-BLK 81 BLK-YLW 92

BLK-RED 102

61

53

860-886

2

2.15

1200 (MS32N1)

Electrical

data

Fan

motor

Special

remarks

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance(C.O.P)

Capacity

MCF-13NV -

E4

Cooling

Single phase

220-240V, 50Hz

3.7

1.6

678

10

6.3-6.3

1,310-1,380

95-91

35-38

0.56-0.58

2.82-2.68

RB4V19-AB

WHT-BLK 203.2 BLK-YLW 45.9

YLW-BLU 32.7 BLU-BRN 44.4

BRN-RED 23.3

43-44

1,080-1,130

MUCF-13NV -

E4

1,848-1,980

5.74-5.72

0.30

RH-231VHAT

1,100

C-R 2.11

C-S 3.97

RA6V33-CB

WHT-BLK 176

BLK-RED 413

780o540o255

34

49

700-750

1

0.85

520 (MS56)

850o605o290

SPECIFICATION

NOTE:Test conditions are based on ISO 5151

Cooling : Indoor DB27°C WB19°C

Outdoor DB35°C WB(24°C)

4

Page 5

4

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB 27: WB 19:\

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

High (240V)

SPEED

47

High (220V)

46

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB 27: WB 19:\

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

High

SPEED

43-44

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB 35: WB (24:)

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

High

SPEED

48

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

Test conditions,

Cooling : DB 35: WB (24:

High

SPEED

52

SPL(dB

(A)) LINE

NOISE CRITERIA CURVES

NOISE CRITERIA CURVES

MCF-13NV -

E4

MUCF-13NV -

E4

MCF-18NV -

E3

MUCF-18NV -

5

E3

Page 6

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB 27: WB 19:\

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

High

SPEED

48

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

Test conditions,

Cooling : DB 35: WB (24:)

High

SPEED

53

SPL(dB

(A)) LINE

MCF-24NV -

E3

MUCF-24NV -

E3

6

Page 7

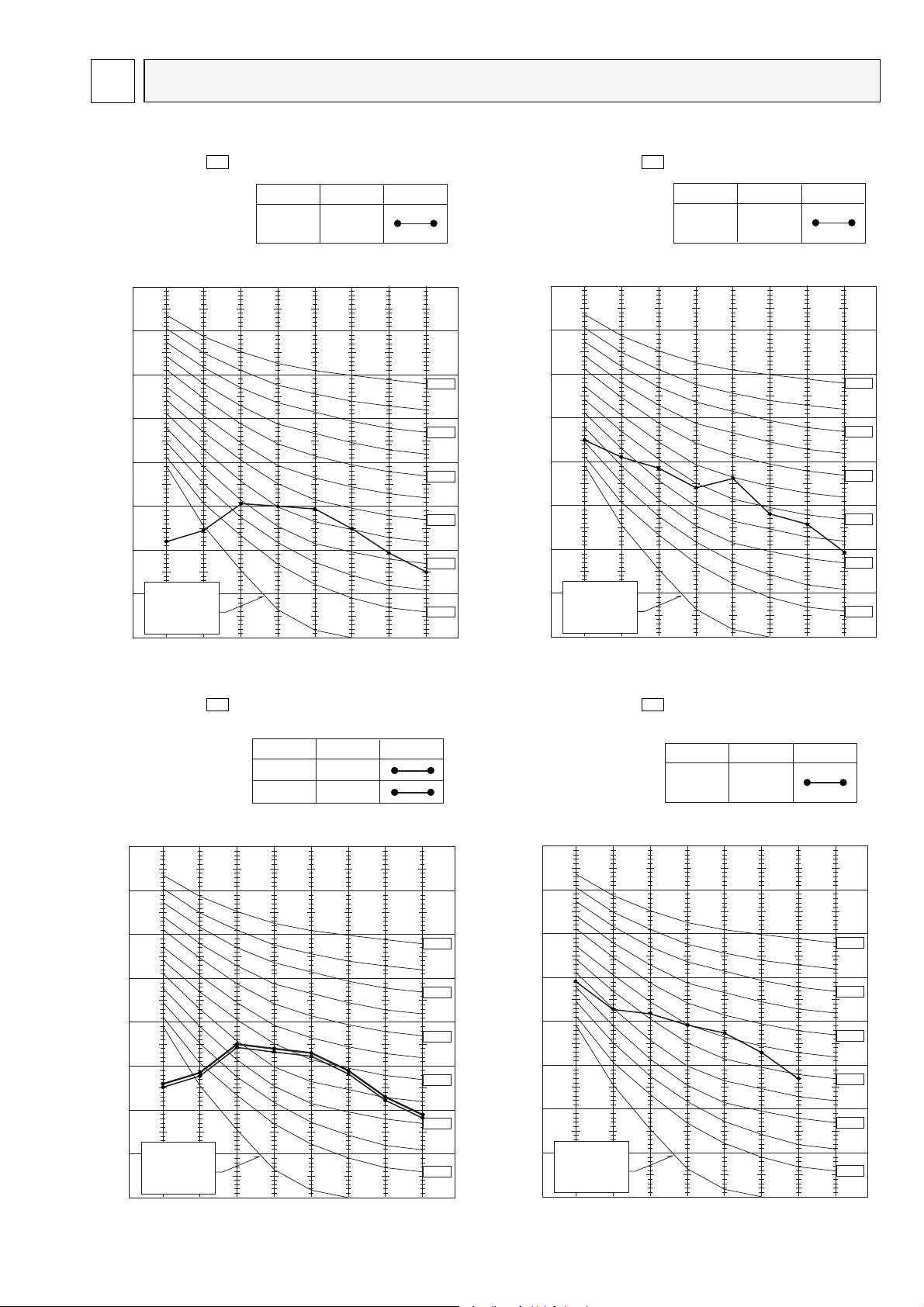

5

(When installed on the floor)

(When installed on the ceiling)

50cm or more

50cm or more

50cm or more

50cm or more

100cm or more

650

616.5

80.8 906 112.8

114

16

1100

93

77

113

143

180

17042.5

[

12.7 (MCF-13)

[

15.88 (MCF-18/24)

Gas line

[

6.35 (MCF-13/18)

[

9.52 (MCF-24)

Liquid line

Wireless remote controller

162

19

58

OUTLINES AND DIMENSIONS

MCF-13NV - MCF-18NV MCF-24NV -

E3

INDOOR UNIT

E3E4

Unit: mm

MUCF-13NV -

OUTDOOR UNIT

121

109

540

260

10

40

E4

320

122

15

REQUIRED SPACE

100mm or more

255

285

320

25

155

90

500

780

74

400mm or more

Service panel

43-

104

100mm or more

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) [6.35

35-

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) [12.7

100mm or more

350mm or more

7

Page 8

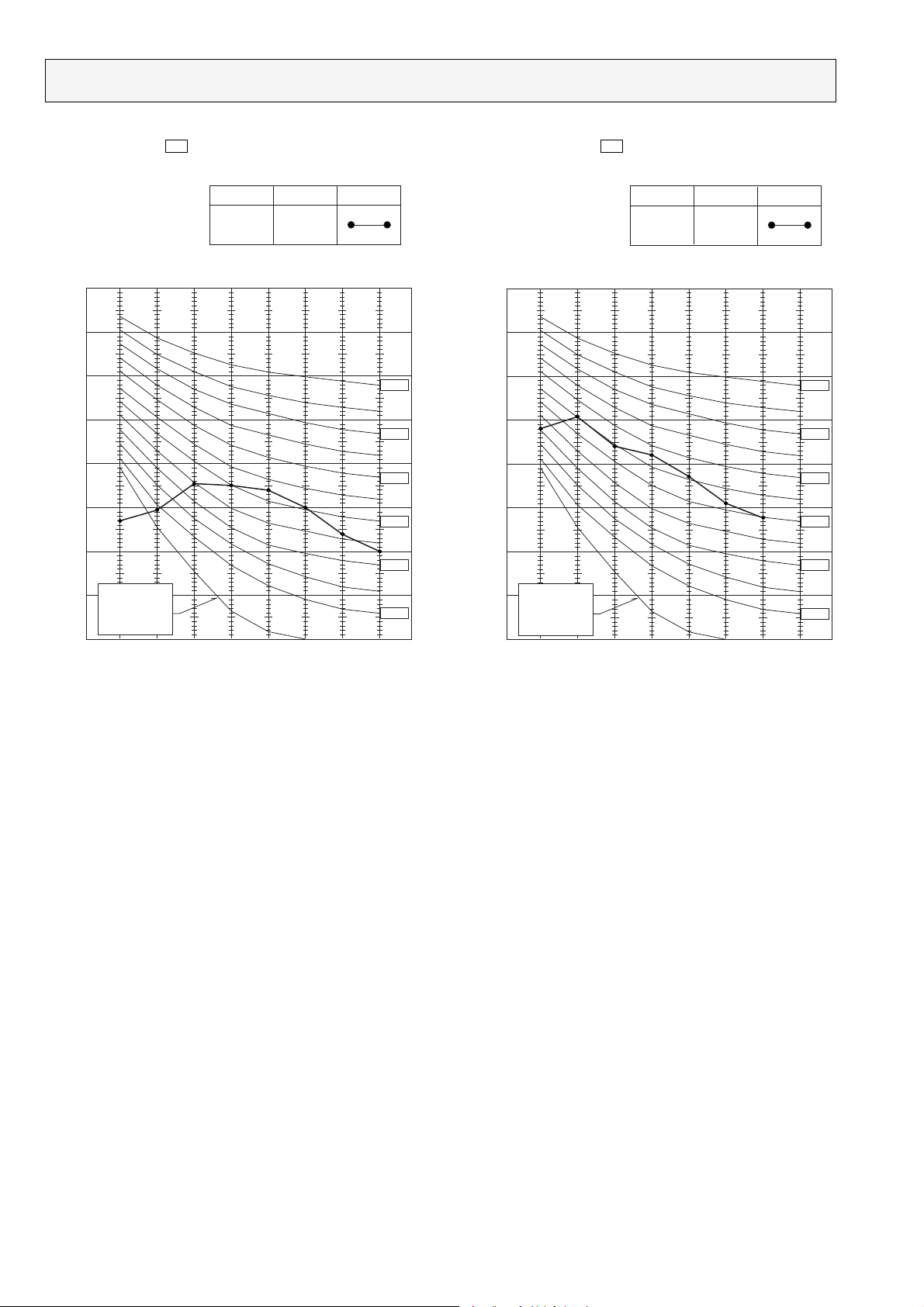

OUTDOOR UNIT

350

Drainage

3holes [33

35

248

20

290

310

345

100mm or more

100mm or more

100mm or more

500mm or more

350mm or more

MUCF-18NV - MUCF-24NV -

E3E3

Unit: mm

30

605

29220

50

133

500

850

74

157

100

30

35

161

Service panel

Liquid refrigerant

Refrigerant pipe

Gas refrigerant

Refrigerant pipe

pipe joint

(flared)

[

6.35(MUCF-18)

[

9.52(MUCF-24)

pipe joint

(flared)

[

15.88

8

Page 9

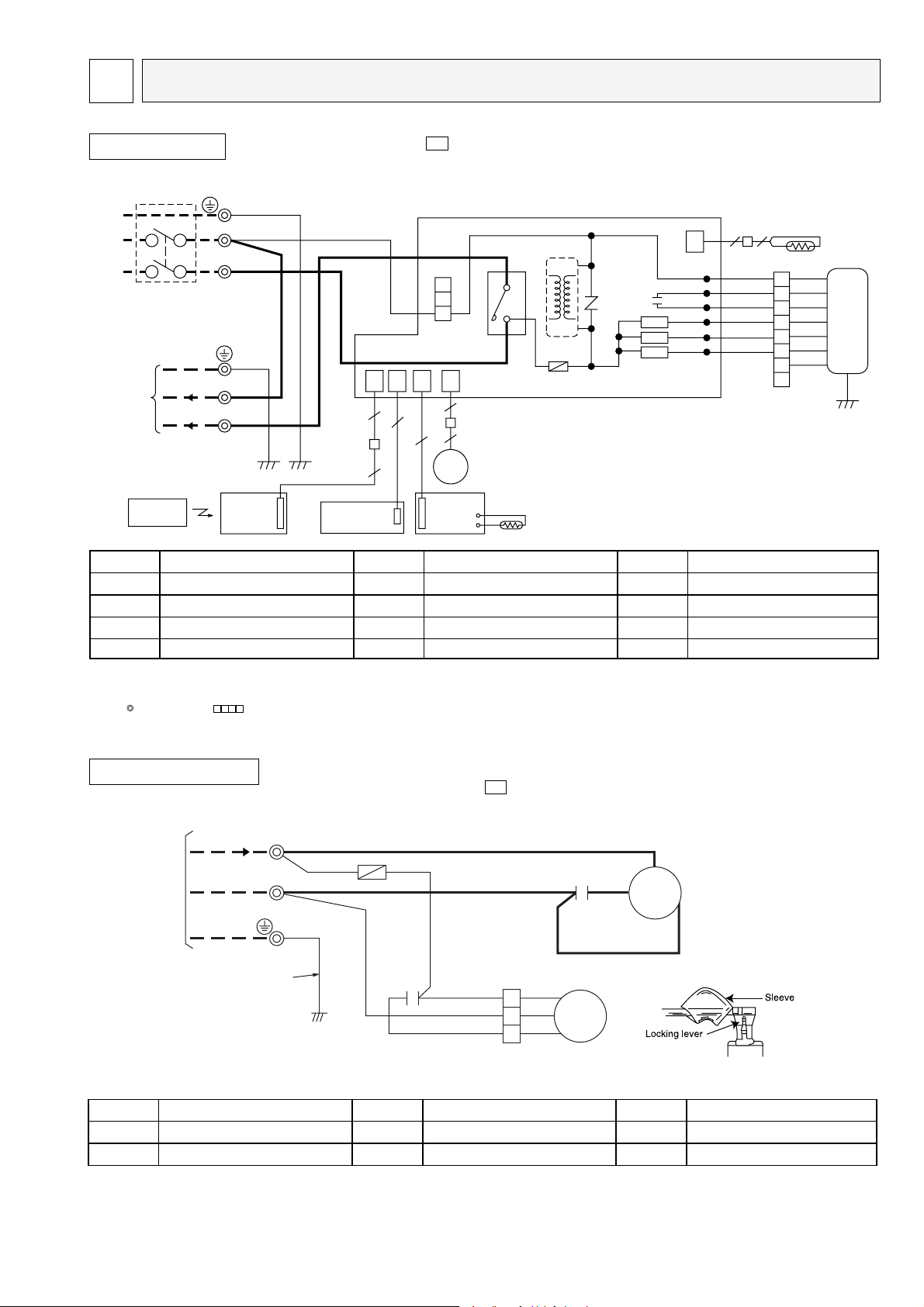

WIRING DIAGRAM6

104

E4

22

CN

SR144

SR143

SR142

112

LDCOM

LDC11

LDC12

LDFH

LDFM

LDFL

WHT

ORN

RED

BLK

YLW

BLU

1

2

3

4

5

6

7

8

HIC1

HIC1

3

2

1

CN201

CN

CN

CN

151

113

6

5

6

4

4

52C

3

TRANS

F11

ELECTRONIC CONTROL P.C BOARD

C11

NR11

MV

SW/THERMO

P.C.BOARD

RT11

INDOOR UNIT

CIRCUIT BREAKER

POWER SUPPLY

~/N 220-240V

50Hz

TO OUTDOOR

UNIT

CONNECTING

220-240V~

REMOTE

CONTROLLER

MODEL MCF-13NV-

TB

GRN/YLW

PE

N

BLU

L

BRN

GRN/YLW

N

BLU

2

WHT

DISP/

RECEIVER

P.C.BOARD

AUTO RESTART

ASSY

101

CN

5

5

SYMBOL SYMBOL SYMBOLNAME NAME NAME

C11

F11

HIC1

MF

NOTE:1. About the outdoor side electric wiring, refer to the outdoor unit electric wiring diagram for servicing.

INDOOR FAN MOTOR CAPACITOR

FUSE (3.15A)

DC/DC CONVERTER

FAN MOTOR(INNER PROTECTOR)

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate;

: Terminal block, : Connector

MV

NR11

RT11

RT12

VANE MOTOR

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

SR142~SR144

TB

52C

SOLID STATE RELAY

TERMINAL BLOCK

COMPRESSOR CONTACTOR

RT12

WHT

ORN

RED

BLK

MF

YLW

BLU

BRN

GRN/YLW

VG79B036H01

OUTDOOR UNIT

MODEL MUCF-13NV-

E3

TB

220-240V~

TO

INDOOR UNIT

CONNECTING

2 W

N

WHT WHT

W

F

BLU

WHT

C1

RED

C

MC

S

R

BLK

GRN/YLW

C2

WHT

BLU

RED

1

2

3

WHT

BLK

RED

MF

1Slide the sleeve.

2Pull the wire while pushing the locking lever.

SYMBOL SYMBOL SYMBOLNAME NAME NAME

C1 COMPRESSOR CAPACITOR

C2

NOTE:1. Use copper conductors only (For field wiring).

OUTDOOR FAN MOTOR CAPACITOR

2. “W” shows the terminals with a lock mechanism, so they cannnot be removed when you pull the lead wire.

Be sure yo pull the lead wire by pushing the locking lever (projected part) of the terminal with a finger.

MC TB TERMINAL BLOCK

FUSE 2AF

COMPRESSOR (INNER PROTECTOR)

MF

OUTDOOR FAN MOTOR (INNER PROTECTOR)

SG79B458H01

9

Page 10

TO INDOOR UNIT

CONNECTING

220-240V~

GRN/YLW

TB

2

N

WHT

MF

MC

RED

ORN

WHT

BLK

RED

BLU

WHT

ORN

WHT

BLU

1

C2

RED

BLK

S

R

C

C1

F

2

3

4

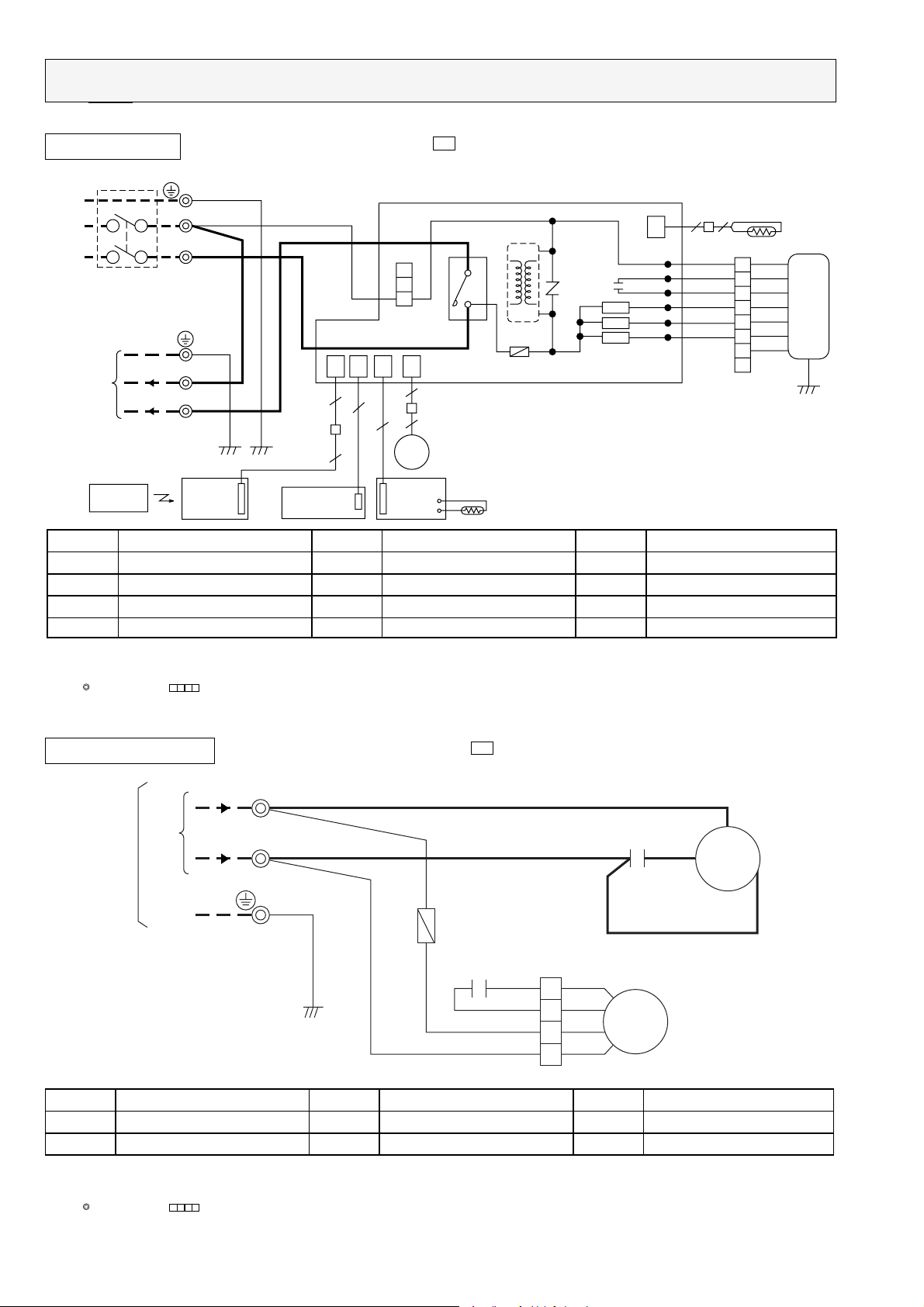

INDOOR UNIT

MODEL MCF-18NV-

E3

N

L

TB

PE

GRN/YLW

N

2

DISP/

RECEIVER

P.C.BOARD

GRN/YLW

BLU

BRN

BLU

WHT

CN

101

AUTO RESTART

ASSY

22

CN

SR144

SR143

SR142

112

LDCOM

LDC11

LDC12

LDFH

LDFM

LDFL

WHT

ORN

RED

BLK

YLW

BLU

1

2

3

4

5

6

7

8

HIC1

HIC1

3

2

1

CN201

CN

113

5

CN

151

6

6

4

MV

SW/THERMO

P.C.BOARD

CN

104

5

5

4

52C

3

TRANS

F11

ELECTRONIC CONTROL P.C BOARD

RT11

C11

NR11

CIRCUIT BREAKER

POWER SUPPLY

~/N 220-240V

50Hz

TO OUTDOOR

UNIT

CONNECTING

REMOTE

CONTROLLER

220-240V~

SYMBOL SYMBOL SYMBOLNAME NAME NAME

C11

F11

HIC1

MF

NOTE:1. About the outdoor side electric wiring, refer to the outdoor unit electric wiring diagram for servicing.

INDOOR FAN MOTOR CAPACITOR

FUSE (3.15A)

DC/DC CONVERTER

FAN MOTOR (INNER PROTECTOR)

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate;

: Terminal block, : Connector

MV

NR11

RT11

RT12

VANE MOTOR

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

SR142~SR144

TB

52C

SOLID STATE RELAY

TERMINAL BLOCK

COMPRESSOR CONTACTOR

RT12

WHT

ORN

RED

BLK

MF

YLW

BLU

BRN

GRN/YLW

VG79B032H01

OUTDOOR UNIT

MODEL MUCF-18NV-

E3

SYMBOL SYMBOL SYMBOLNAME NAME NAME

C1 COMPRESSOR CAPACITOR

C2

NOTE:1. About the outdoor side electric wiring, refer to the outdoor unit electric wiring diagram for servicing.

OUTDOOR FAN MOTOR CAPACITOR

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate;

: Terminal block, : Connector

MC

FUSE 2AF

COMPRESSOR (INNER PROTECTOR)

10

MF

TB TERMINAL BLOCK

OUTDOOR FAN MOTOR (INNER PROTECTOR)

SG79J002H01

Page 11

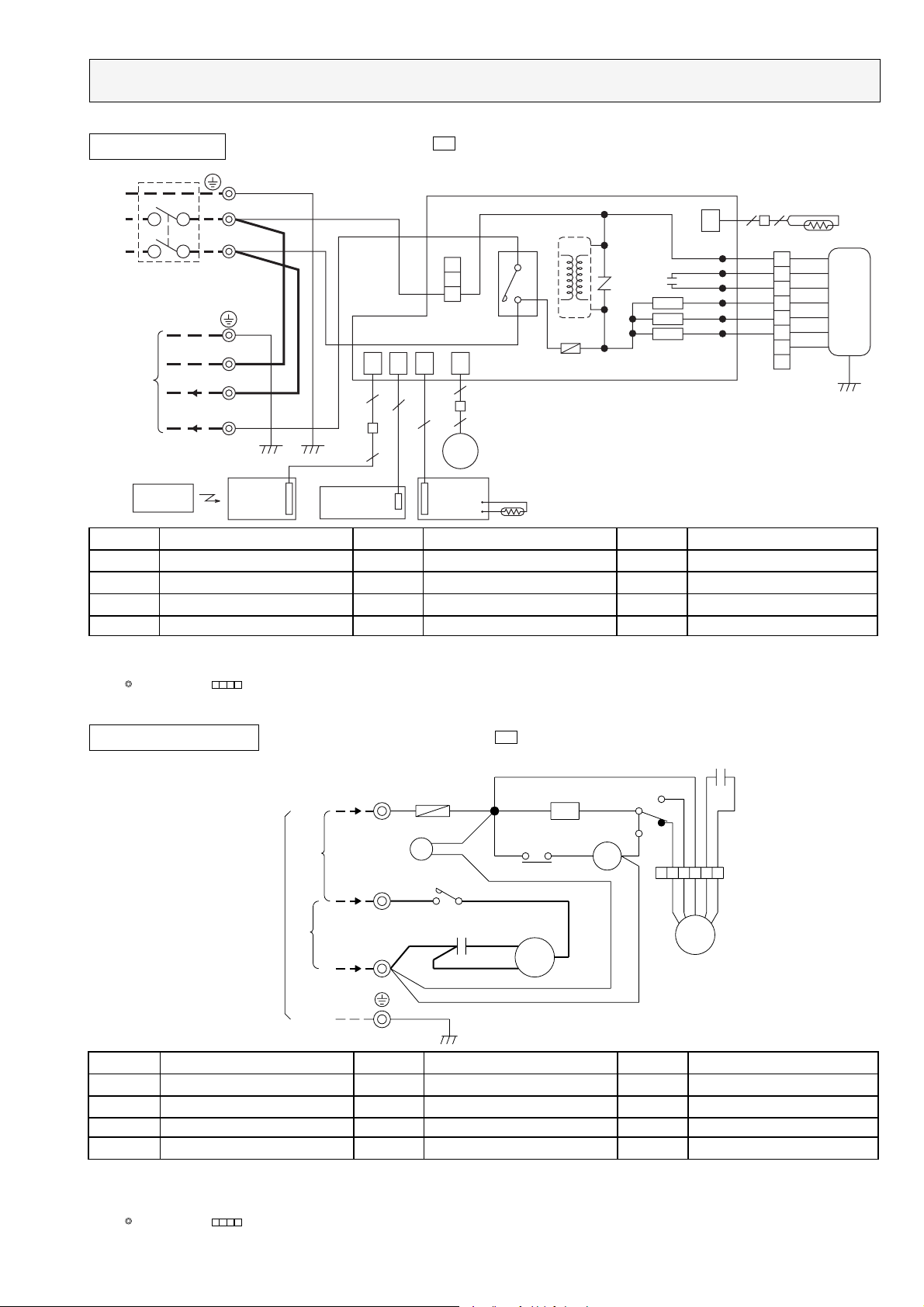

INDOOR UNIT

CIRCUIT BREAKER

POWER SUPPLY

~/N 220-240V

50Hz

TO OUTDOOR

UNIT

CONNECTING

220-240V~

220-240V~

MODEL MCF-24NV-

TB

PE

GRN/YLW

N

L

GRN/YLW

N

2

WHT

3

RED

BLU

BRN

BLU

101

E3

WHT

ORN

RED

BLK

YLW

BLU

22

1

2

3

4

5

6

7

8

WHT

ORN

RED

BLK

YLW

BLU

BRN

GRN/YLW

RT12

MF

CN

HIC1

HIC1

3

2

1

CN201

CN

CN

CN

104

5

5

CN

113

151

6

6

4

4

52C

3

TRANS

F11

ELECTRONIC CONTROL P.C BOARD

C11

NR11

SR144

SR143

SR142

112

LDCOM

LDC11

LDC12

LDFH

LDFM

LDFL

MV

SW/THERMO

P.C.BOARD

RT11

REMOTE

CONTROLLER

DISP/

RECEIVER

P.C.BOARD

5

AUTO RESTART

ASSY

SYMBOL SYMBOL SYMBOLNAME NAME NAME

C11

F11

HIC1

MF

NOTE:1. About the outdoor side electric wiring, refer to the outdoor unit electric wiring diagram for servicing.

OUTDOOR UNIT

INDOOR FAN MOTOR CAPACITOR

FUSE (3.15A)

DC/DC CONVERTER

FAN MOTOR (INNER PROTECTOR)

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate;

: Terminal block, : Connector

MODEL MUCF-24NV-

MV

NR11

RT11

RT12

TB

3

2

VANE MOTOR

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

E3

TB2

RED

WHT

F

A1/a

52C

A2/b

WHT

52C

RED

12

1

BLU

RED

WHT

CR

REDRED

26F1

GRY

X1

SR142~SR144

TB

52C

X1

5

6

87

BLU

SOLID STATE RELAY

TERMINAL BLOCK

CONTACTOR

C2

3

1

BLU

YLW

BLK

RED

WHT

ORN

654321

BLK

YLW

RED

WHT

ORN

VG79B033H01

C1

BLU

N

RED

BLK

S

MC

C

MF

R

TO INDOOR UNIT CONNECTING

GRN/YLW

SYMBOL SYMBOL SYMBOLNAME NAME NAME

C1 COMPRESSOR CAPACITOR

C2

CR

OUTDOOR FAN MOTOR CAPACITOR

SURGE ABSORBER

FUSE 2AF

NOTE:1. About the outdoor side electric wiring, refer to the outdoor unit electric wiring diagram for servicing.

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate;

: Terminal block, : Connector

MC

MF

TB

COMPRESSOR (INNER PROTECTOR)

OUTDOOR FAN MOTOR (INNER PROTECTOR)

TERMINAL BLOCK

TERMINAL BLOCKTB2

26F1

52C

FAN MOTOR RELAYX1

THERMOSTAT (AIRFLOW CONTROL)

COMPRESSOR CONTACTOR

11

SG79J078H01

Page 12

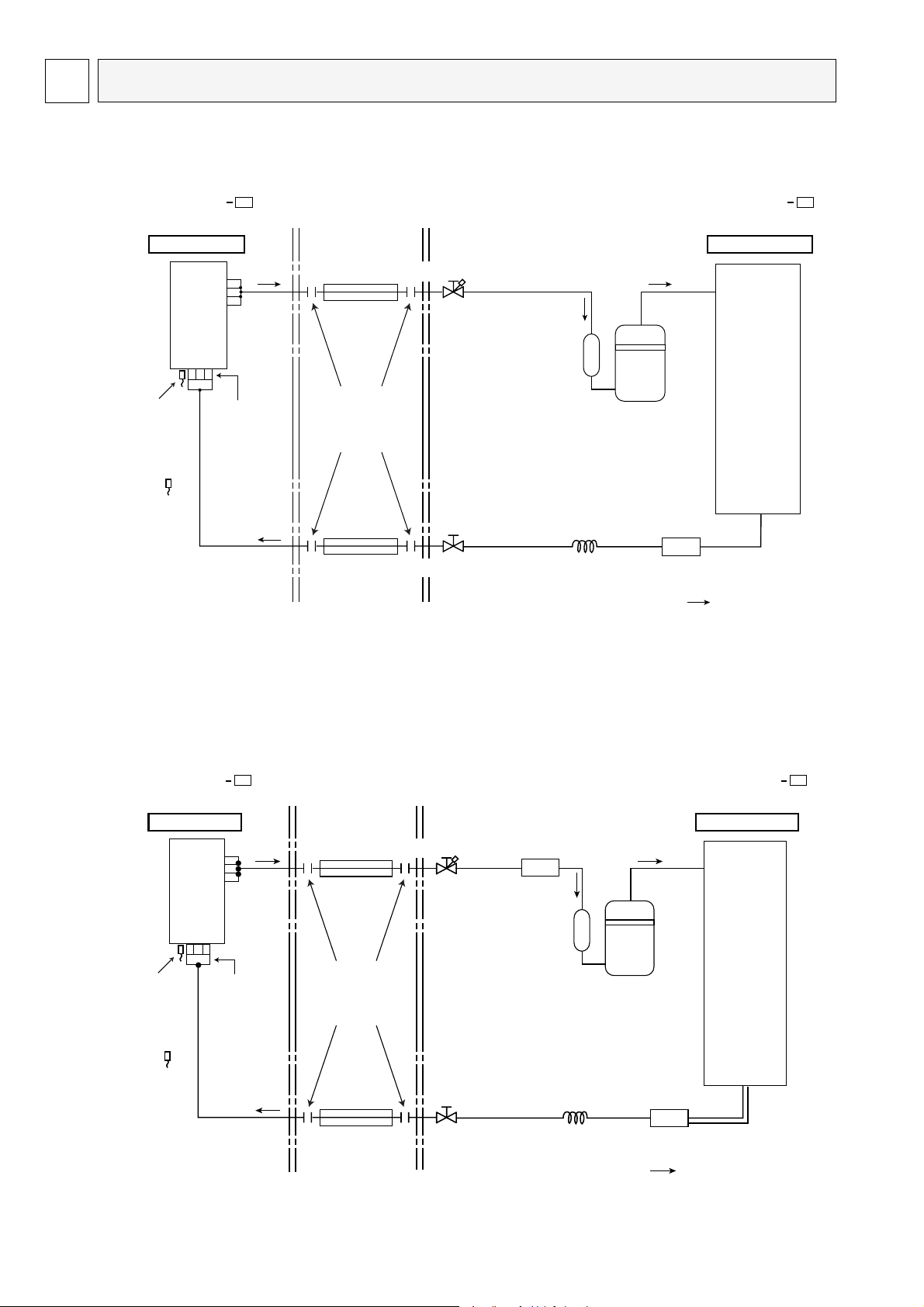

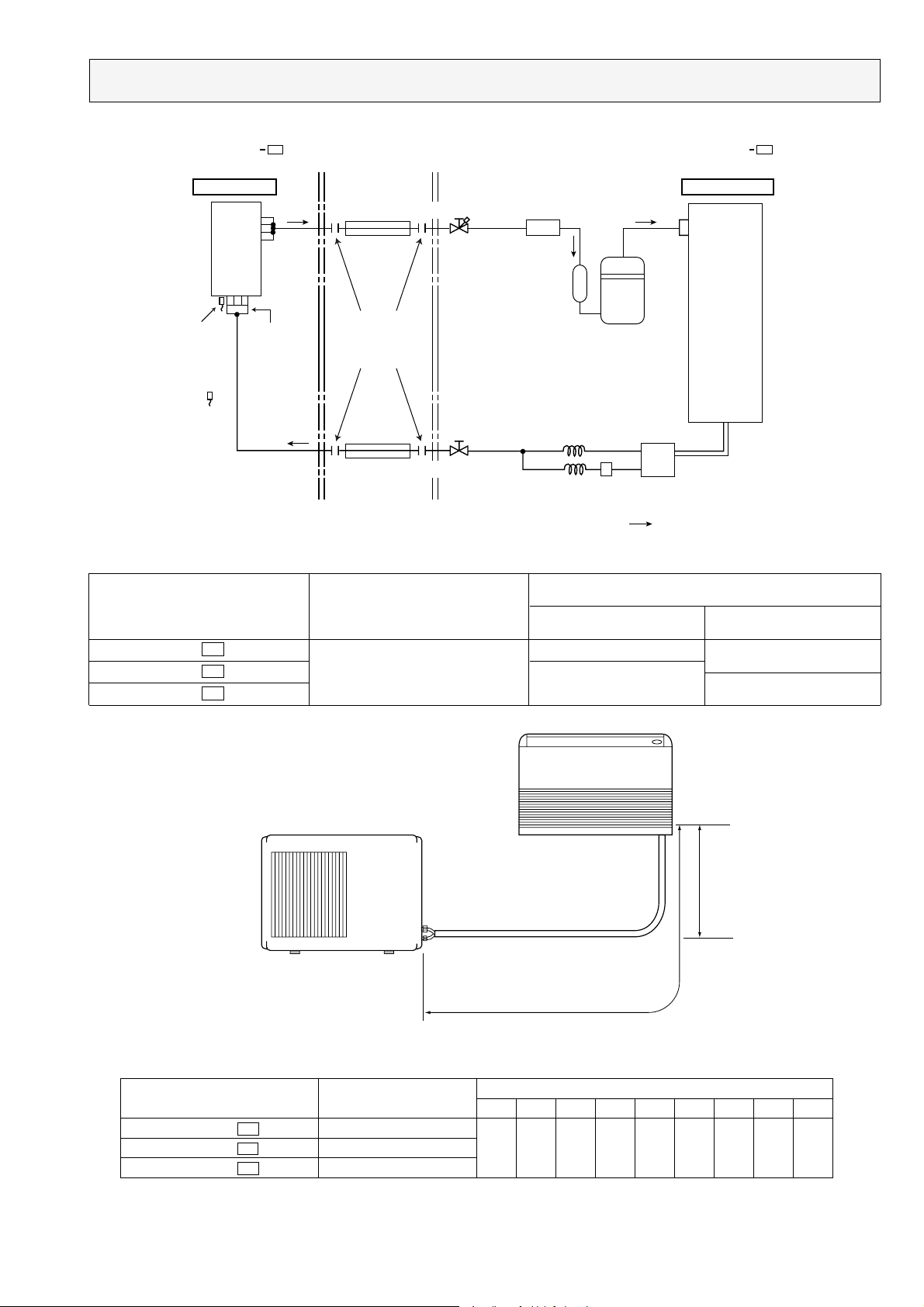

REFRIGERANT SYSTEM DIAGRAM7

INDOOR UNIT OUTDOOR UNIT

Indoor

heat

exchanger

Indoor coil

thermistor

RT12

Room

temperature

thermistor

RT11

(With heat insulation)

Refrigerant pipe

{15.88

(With heat insulation)

Refrigerant pipe

{6.35

Flared

connection

Stop valve

(with service port)

Stop valve

Compressor

Strainer

Capillary tube

{3.0

✕{2.0✕ 700

Outdoor

heat

exchanger

MCF-18NV

E3

MUCF-18NV

E3

Accumulator

Distributor

Refrigerant flow

INDOOR UNIT OUTDOOR UNIT

Indoor

heat

exchanger

Indoor coil

thermistor

RT12

Distributor

Room

temperature

thermistor

RT11

(With heat insulation)

Refrigerant pipe

[12.7

(With heat insulation)

Refrigerant pipe

[6.35

Flared

connection

Stop valve

(with service port)

Stop valve

Compressor

Strainer

Refrigerant flow

Capillary tube

[3.0✕[1.6✕ 300

Outdoor

heat

exchanger

MCF-13NV

E4

MUCF-13NV

E4

Unit:mm

12

Page 13

INDOOR UNIT OUTDOOR UNIT

Indoor

heat

exchanger

Indoor coil

thermistor

RT12

Distributor

Room

temperature

thermistor

RT11

(With heat insulation)

Refrigerant pipe

{15.88

(With heat insulation)

Refrigerant pipe

{9.52

Flared

connection

Stop valve

(with service port)

Stop valve

Compressor

Strainer

Capillary tube

{

3.0✕{2.0✕ 700

Capillary tube

Discharge

pressure

regulator

{

3.0✕{1.6✕ 350

Outdoor

heat

exchanger

MCF-24NV

E3

MUCF-24NV

E3

Accumulator

Refrigerant flow

If pipe length exceeds 7m, additional refrigerant (R22) charge is required.

MCF-13NV -

E4

MCF-18NV -

E3

MCF-24NV -

E3

850

1,500

2,150

7m

0

8m

15

9m

30

10m

45

11m

60

12m

75

13m

90

14m

105

15m

120

Refrigerant piping length (one way)

Outdoor unit

precharged

Models

REFRIGERANT PIPING MAX. LENGTH & MAX. HEIGHT DIFFERENCE

Unit:mm

Refrigerant piping

Models

MCF-13NV MCF-18NV MCF-24NV -

E4

E3

E3

Outdoor unit

Max. length : m

A

15

Gas Liquid

{12.7

{15.88

Indoor unit

*Height difference should be within

5m regardless of which unit,

indoor or outdoor position is high.

A: Refrigerant piping

Max. length

15m

ADDITIONAL REFRIGERANT CHARGE (R22 : g)

Piping size O.D. : mm

Max. Height

difference *

{6.35

{9.52

5m

Calculation : ✕g=15g/m✕(Refrigerant piping length (m)-7)

13

Page 14

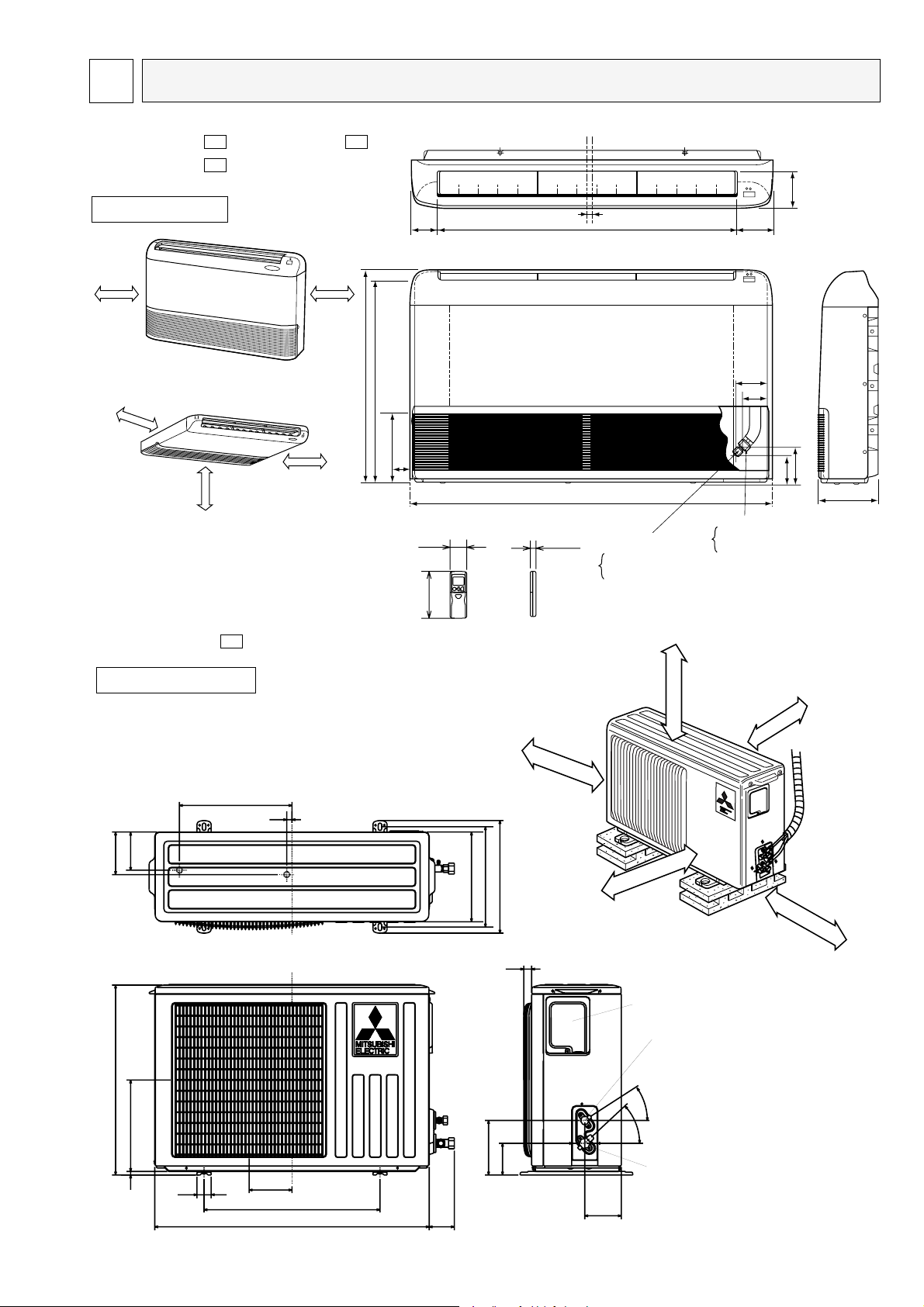

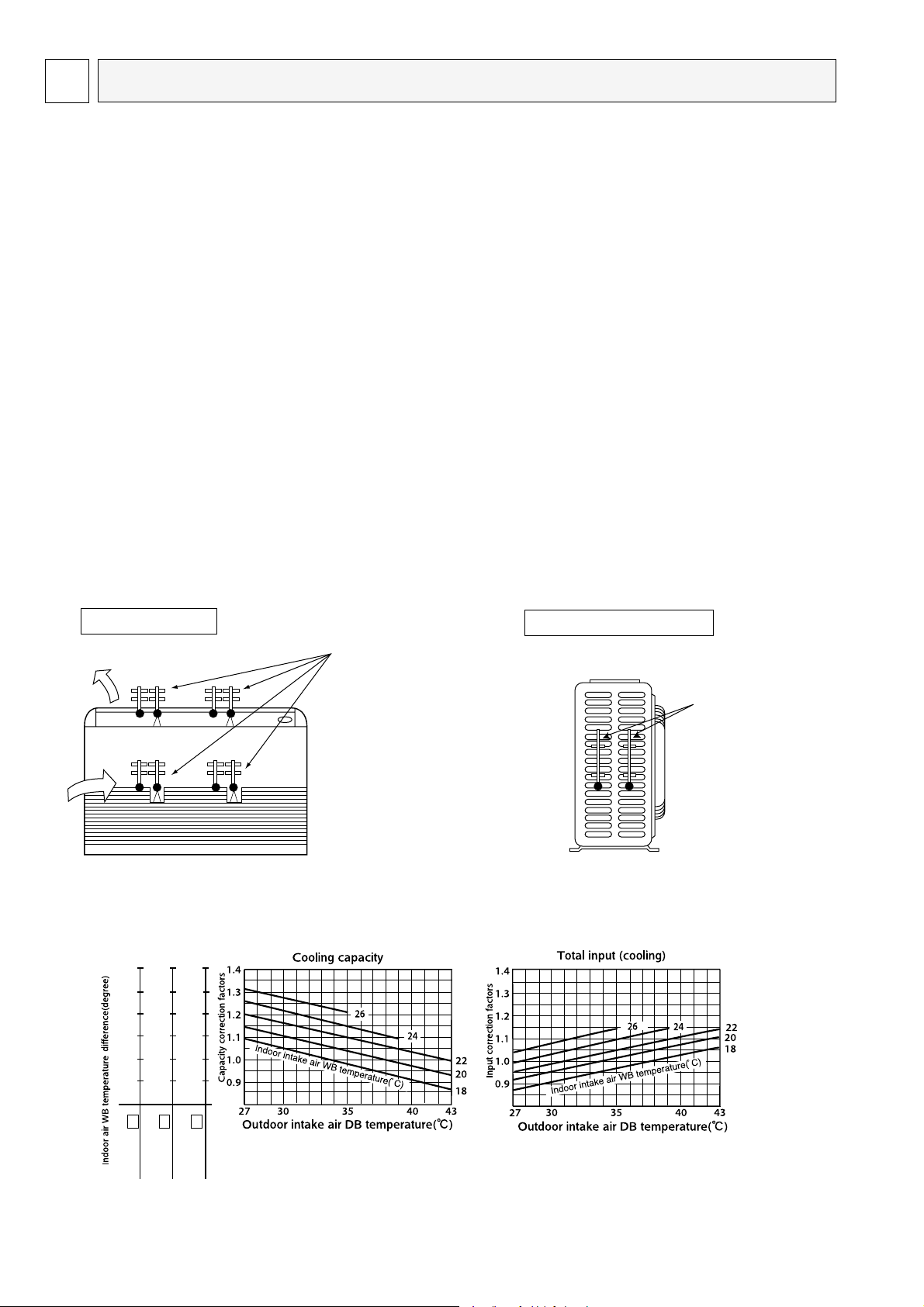

8

Air in

Air out

Wet-and dry-bulb

thermometers

FRONT VIEW

Dry-bulb

thermometers

SIDE VIEW

PERFORMANCE CURVES

The standard data contained in these specifications apply only to the operation of the air conditioner under normal condition.

Operating conditions vary according to the areas where these units are installed. The following information has been provided

to clarify the operating characteristics of the air conditioner under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

198~264V, 50Hz

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature : ˚C WB

(2) Indoor outlet air wet-bulb temperature : ˚C WB

(3) Outdoor intake air dry-bulb temperature : ˚C DB

(4) Total input : W

The table of Indoor air wet-bulb temperature difference at the bottom left on page 15 shows the difference between the

indoor intake air wet-bulb temperature and the indoor outlet air wet-bulb temperature for your reference at service.

How to measure the indoor air wet-bulb temperature difference

1. Attach at least 2. sets of wet-and-dry-bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet-and-dry-bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of dry-bulb thermometers to the outdoor air intake.

Cover the thermometers to avoid direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of the room.

5. Press the EMERGENCY OPERATION switch to start the EMERGENCY operation.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

INDOOR UNIT

10.4

9.5

8.7

7.8

7.0

6.2

13.1

11.9

10.8

9.7

8.7

7.7

15.7

14.2

12.8

11.5

10.3

9.0

OUTDOOR UNIT

MCF-13NV- E4

MCF-18NV- E3

MCF-24NV- E3

14

Page 15

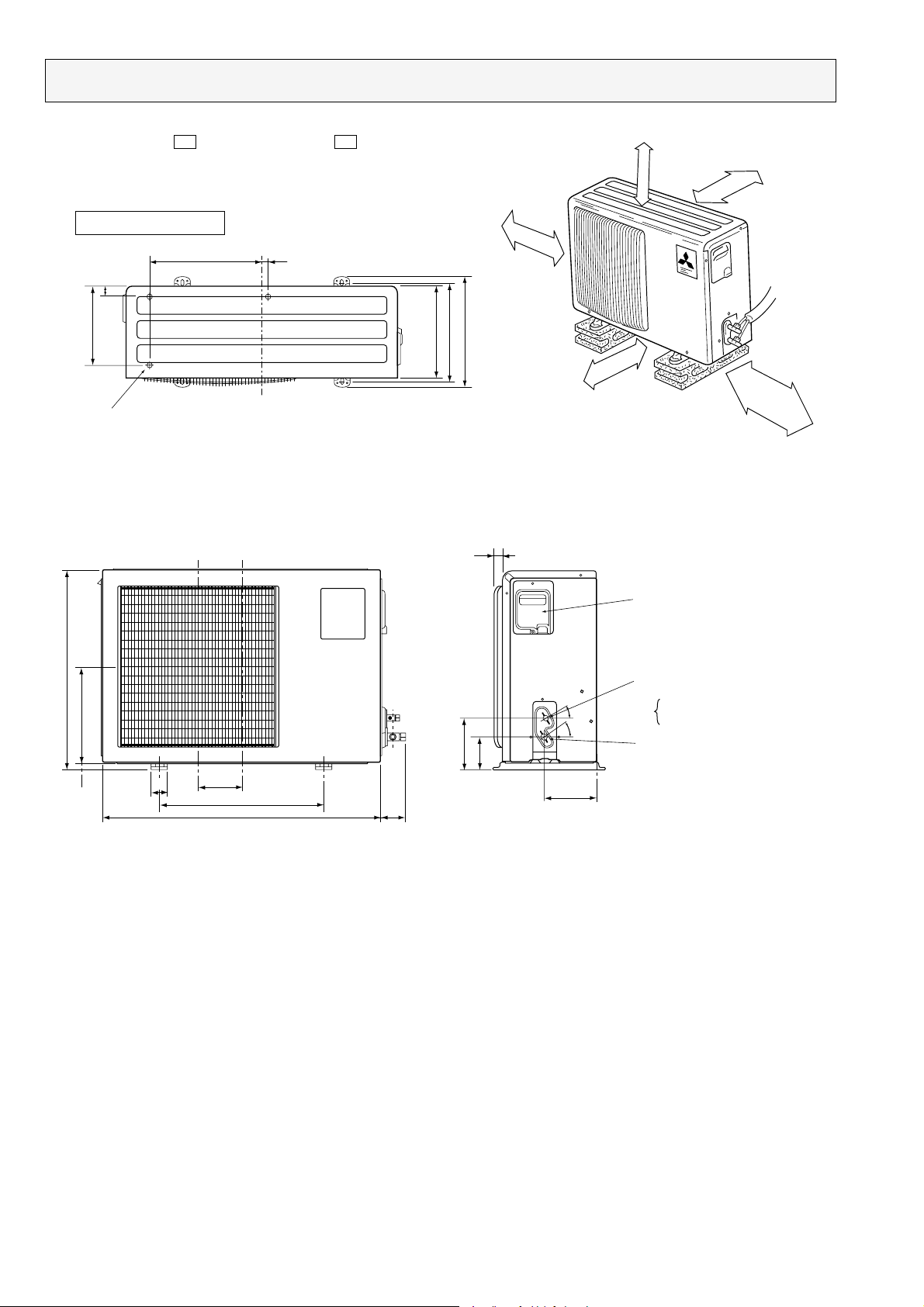

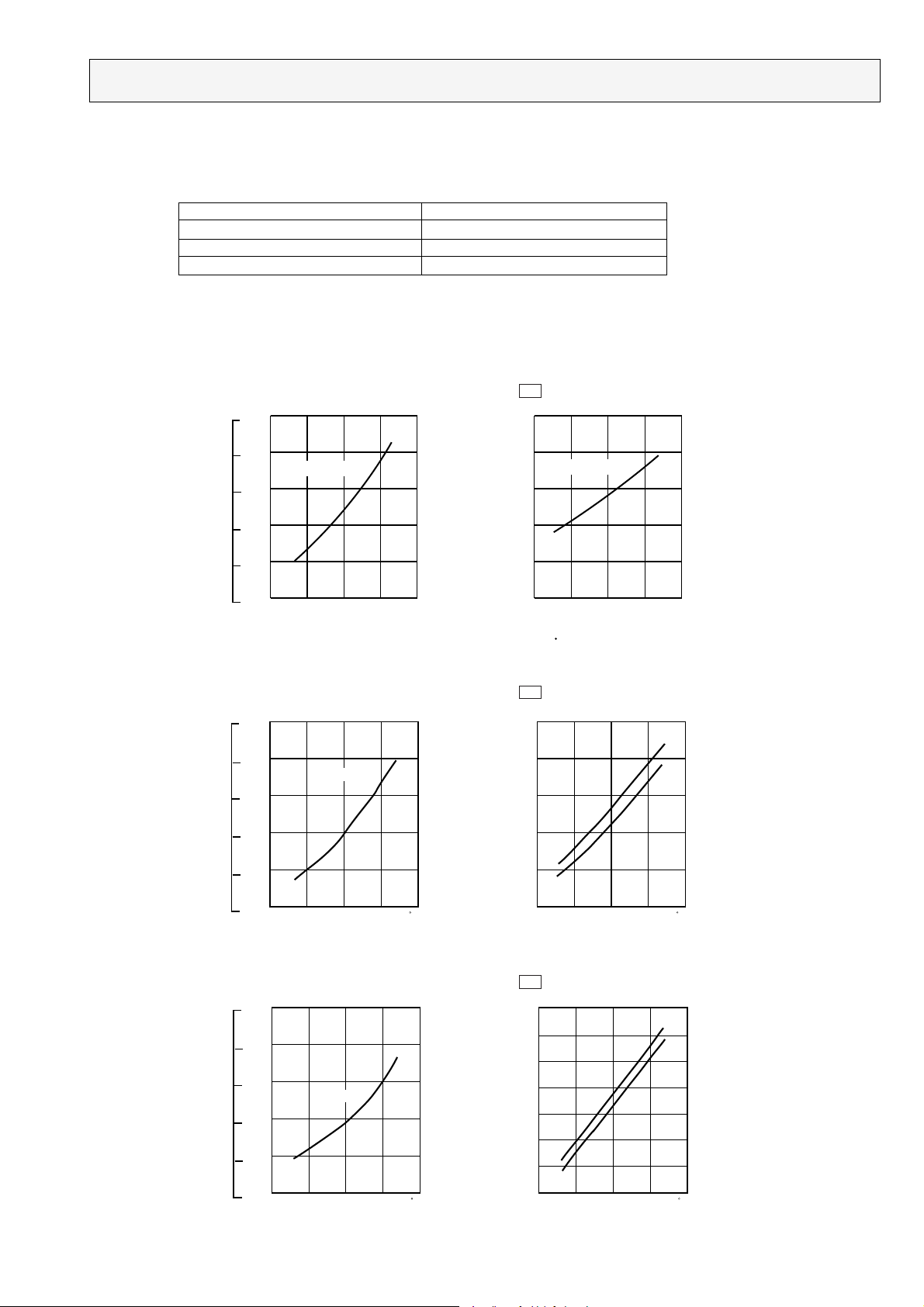

OUTDOOR LOW PRESSURE AND OUTDOOR UNIT CURRENT

220V

240V

220-240V

Ambient temperature (°C)

Ambient humidity(%)

Ambient temperature (°C)

Ambient humidity(%)

18

0.3

0.4

0.5

0.6

0.7

0.8

20 25 30

50 60 70

32

( C)

(%)

Outdoor low pressure

18

5

6

7

8

9

10

20 25 30

50 60 70

32

( C)

(%)

Outdoor unit current (A)

7

6

5

4

3

8

(kgf/F•G)(MPa•G)

220-240V

220V

240V

Ambient temperature (°C)

Ambient humidity(%)

Ambient temperature (°C)

Ambient humidity(%)

18

0.2

0.3

0.4

0.5

0.6

0.7

20 25 30

50 60 70

32

( C)

(%)

Outdoor low pressure

18

7

8

9

10

11

12

13

14

20 25 30

50 60 70

32

( C)

(%)

Outdoor unit current (A)

6

5

4

3

2

7

(kgf/F•G)(MPa•G)

20 25 30

0.3

0.4

0.5

0.6

0.7

0.8

20 25 30

3

4

5

6

7

8

Ambient temperature (:)

Ambient humidity(%)

18

50 60 70

32

(:)

(%)

Ambient temperature (:)

Ambient humidity(%)

18

50 60 70

32

(%)

Outdoor unit current (A)

Outdoor low pressure

7

6

5

4

3

8

(kgf/F•G)(MPa•G)

(:)

220-240V

220-240V

COOL operation

1 Both indoor and outdoor units are under the same temperature/humidity condition.

Dry Bulb temperature (˚C)

20

25

30

Relative humidity (%)

50

60

70

2 Air flow should be set at MAX..

3 The unit of pressure has been changed to MPa on the international system of units(SI unit system).

The converted score against the traditional unit system can be gotten according to the formula below.

1(MPa [Gauge]) =10.2(kgf/ff• [Gauge])

MUCF-13NV-

E4

MUCF-18NV-

MUCF-24NV-

E3

E3

15

Page 16

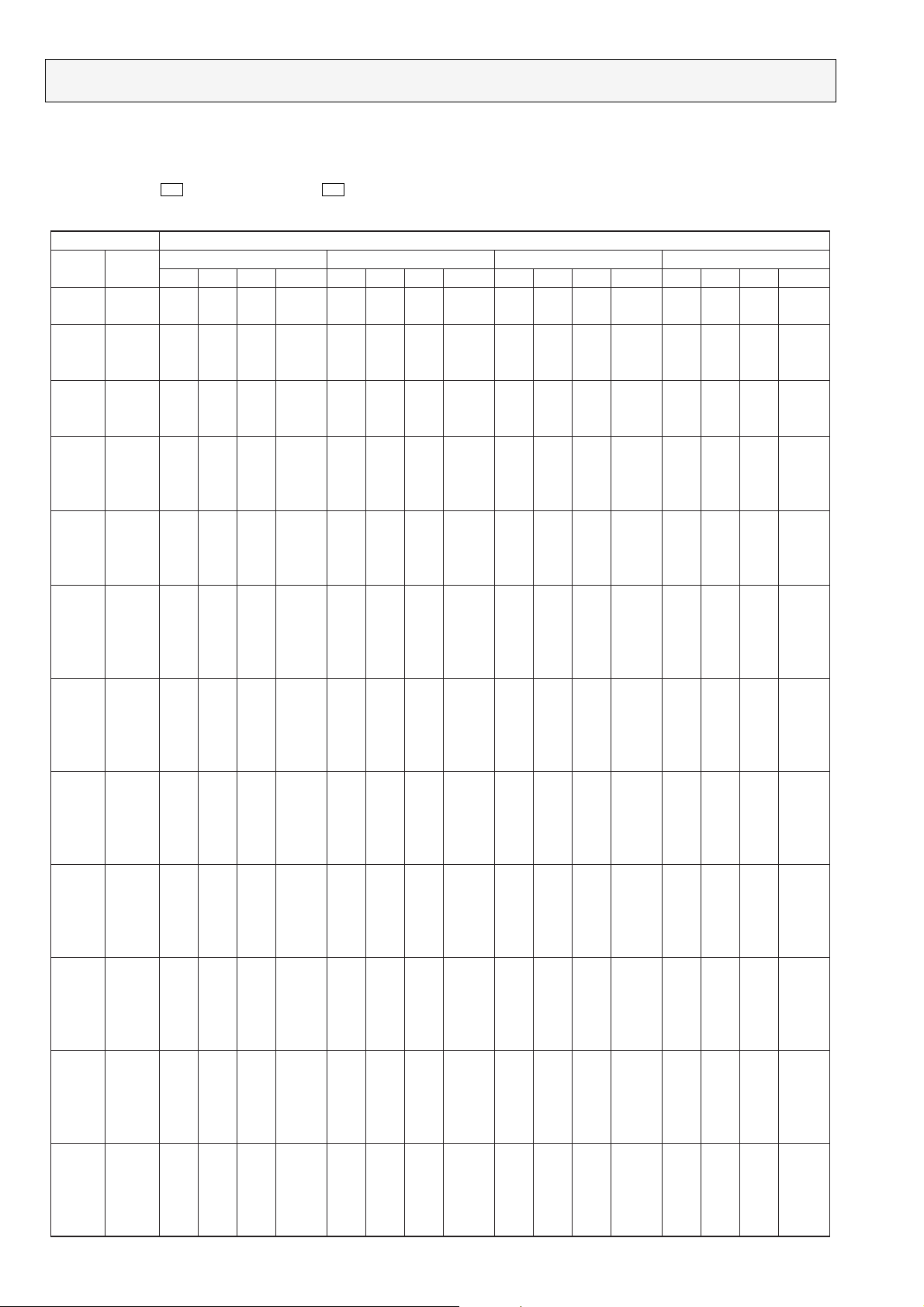

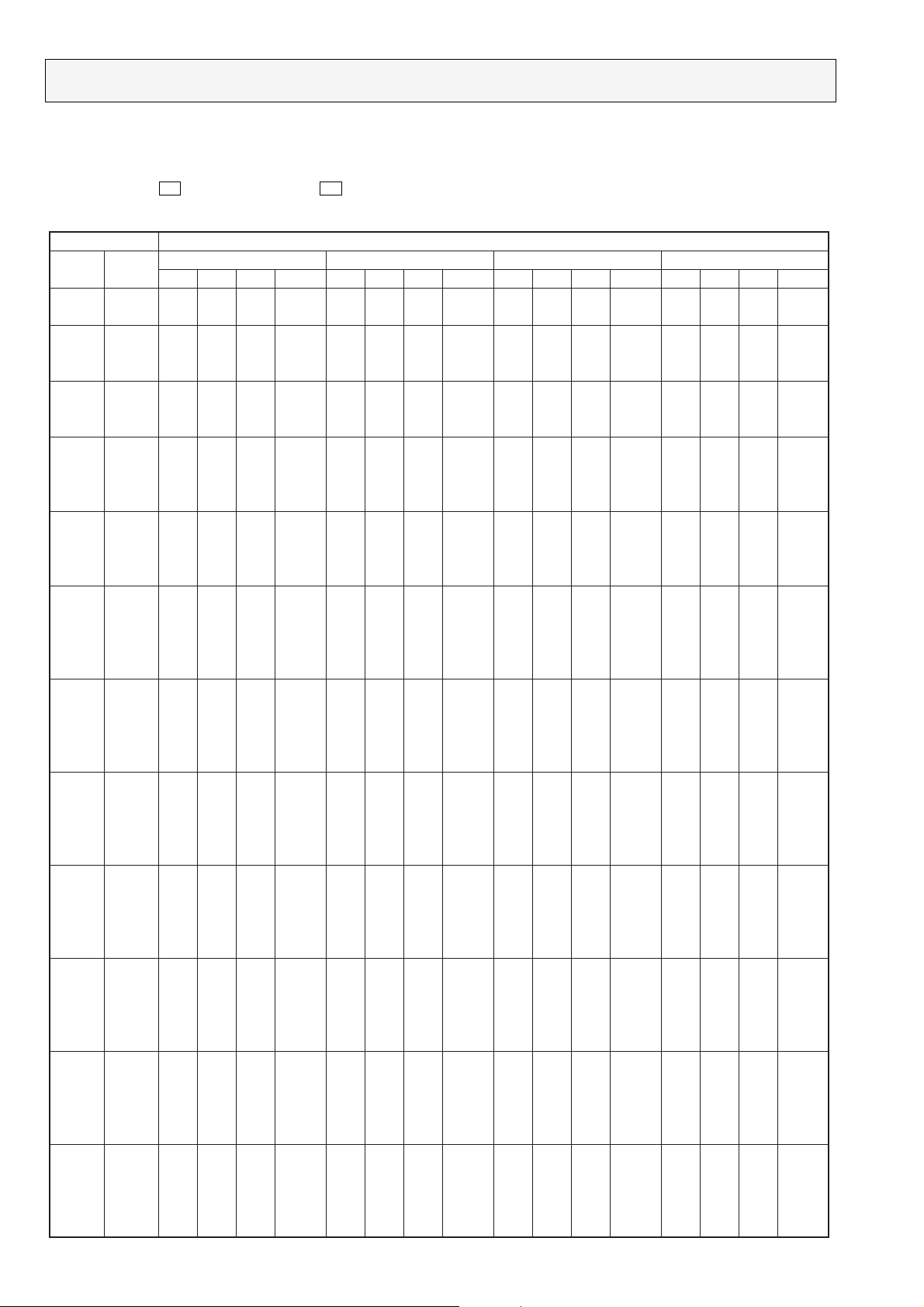

PERFORMANCE DATA

COOL operation(220V)

MCF-13NV - :MUCF-13NV -

CAPACITY : 3.7(kW) SHF : 0.70 INPUT : 1310(W)

INDOOR INDOOR

DB(;) WB(;)

21 18 4.35 2.26 0.52 1048 4.16 2.16 0.52 1100 4.00 2.08 0.52 1153 3.85 2.00 0.52 1205

21 20 4.53 1.81 0.40 1100 4.35 1.74 0.40 1166 4.22 1.69 0.40 1192 4.07 1.63 0.40 1245

22 18 4.35 2.43 0.56 1048 4.16 2.33 0.56 1100 4.00 2.24 0.56 1153 3.85 2.15 0.56 1205

22 20 4.53 1.99 0.44 1100 4.35 1.91 0.44 1166 4.22 1.86 0.44 1192 4.07 1.79 0.44 1245

22 22 4.72 1.51 0.32 1140 4.55 1.46 0.32 1212 4.44 1.42 0.32 1245 4.26 1.36 0.32 1297

23 18 4.35 2.61 0.60 1048 4.16 2.50 0.60 1100 4.00 2.40 0.60 1153 3.85 2.31 0.60 1205

23 20 4.53 2.18 0.48 1100 4.35 2.09 0.48 1166 4.22 2.02 0.48 1192 4.07 1.95 0.48 1245

23 22 4.72 1.70 0.36 1140 4.55 1.64 0.36 1212 4.44 1.60 0.36 1245 4.26 1.53 0.36 1297

24 18 4.35 2.78 0.64 1048 4.16 2.66 0.64 1100 4.00 2.56 0.64 1153 3.85 2.46 0.64 1205

24 20 4.53 2.36 0.52 1100 4.35 2.26 0.52 1166 4.22 2.19 0.52 1192 4.07 2.12 0.52 1245

24 22 4.72 1.89 0.40 1140 4.55 1.82 0.40 1212 4.44 1.78 0.40 1245 4.26 1.70 0.40 1297

24 24 4.96 1.39 0.28 1192 4.77 1.34 0.28 1258 4.66 1.31 0.28 1297 4.51 1.26 0.28 1362

25 18 4.35 2.96 0.68 1048 4.16 2.83 0.68 1100 4.00 2.72 0.68 1153 3.85 2.62 0.68 1205

25 20 4.53 2.54 0.56 1100 4.35 2.43 0.56 1166 4.22 2.36 0.56 1192 4.07 2.28 0.56 1245

25 22 4.72 2.08 0.44 1140 4.55 2.00 0.44 1212 4.44 1.95 0.44 1245 4.26 1.87 0.44 1297

25 24 4.96 1.59 0.32 1192 4.77 1.53 0.32 1258 4.66 1.49 0.32 1297 4.51 1.44 0.32 1362

26 18 4.35 3.13 0.72 1048 4.16 3.00 0.72 1100 4.00 2.88 0.72 1153 3.85 2.77 0.72 1205

26 20 4.53 2.72 0.60 1100 4.35 2.61 0.60 1166 4.22 2.53 0.60 1192 4.07 2.44 0.60 1245

26 22 4.72 2.26 0.48 1140 4.55 2.18 0.48 1212 4.44 2.13 0.48 1245 4.26 2.04 0.48 1297

26 24 4.96 1.78 0.36 1192 4.77 1.72 0.36 1258 4.66 1.68 0.36 1297 4.51 1.63 0.36 1362

26 26 5.11 1.23 0.24 1258 4.96 1.19 0.24 1323 4.88 1.17 0.24 1362 4.74 1.14 0.24 1402

27 18 4.35 3.30 0.76 1048 4.16 3.16 0.76 1100 4.00 3.04 0.76 1153 3.85 2.92 0.76 1205

27 20 4.53 2.90 0.64 1100 4.35 2.78 0.64 1166 4.22 2.70 0.64 1192 4.07 2.60 0.64 1245

27 22 4.72 2.45 0.52 1140 4.55 2.37 0.52 1212 4.44 2.31 0.52 1245 4.26 2.21 0.52 1297

27 24 4.96 1.98 0.40 1192 4.77 1.91 0.40 1258 4.66 1.86 0.40 1297 4.51 1.81 0.40 1362

27 26 5.11 1.43 0.28 1258 4.96 1.39 0.28 1323 4.88 1.37 0.28 1362 4.74 1.33 0.28 1402

28 18 4.35 3.48 0.80 1048 4.16 3.33 0.80 1100 4.00 3.20 0.80 1153 3.85 3.08 0.80 1205

28 20 4.53 3.08 0.68 1100 4.35 2.96 0.68 1166 4.22 2.87 0.68 1192 4.07 2.77 0.68 1245

28 22 4.72 2.64 0.56 1140 4.55 2.55 0.56 1212 4.44 2.49 0.56 1245 4.26 2.38 0.56 1297

28 24 4.96 2.18 0.44 1192 4.77 2.10 0.44 1258 4.66 2.05 0.44 1297 4.51 1.99 0.44 1362

28 26 5.11 1.63 0.32 1258 4.96 1.59 0.32 1323 4.88 1.56 0.32 1362 4.74 1.52 0.32 1402

29 18 4.35 3.65 0.84 1048 4.16 3.50 0.84 1100 4.00 3.36 0.84 1153 3.85 3.23 0.84 1205

29 20 4.53 3.26 0.72 1100 4.35 3.13 0.72 1166 4.22 3.04 0.72 1192 4.07 2.93 0.72 1245

29 22 4.72 2.83 0.60 1140 4.55 2.73 0.60 1212 4.44 2.66 0.60 1245 4.26 2.55 0.60 1297

29 24 4.96 2.38 0.48 1192 4.77 2.29 0.48 1258 4.66 2.24 0.48 1297 4.51 2.17 0.48 1362

29 26 5.11 1.84 0.36 1258 4.96 1.78 0.36 1323 4.88 1.76 0.36 1362 4.74 1.70 0.36 1402

30 18 4.35 3.83 0.88 1048 4.16 3.66 0.88 1100 4.00 3.52 0.88 1153 3.85 3.39 0.88 1205

30 20 4.53 3.44 0.76 1100 4.35 3.30 0.76 1166 4.22 3.21 0.76 1192 4.07 3.09 0.76 1245

30 22 4.72 3.02 0.64 1140 4.55 2.91 0.64 1212 4.44 2.84 0.64 1245 4.26 2.72 0.64 1297

30 24 4.96 2.58 0.52 1192 4.77 2.48 0.52 1258 4.66 2.42 0.52 1297 4.51 2.35 0.52 1362

30 26 5.11 2.04 0.40 1258 4.96 1.98 0.40 1323 4.88 1.95 0.40 1362 4.74 1.89 0.40 1402

31 18 4.35 4.00 0.92 1048 4.16 3.83 0.92 1100 4.00 3.68 0.92 1153 3.85 3.54 0.92 1205

31 20 4.53 3.63 0.80 1100 4.35 3.48 0.80 1166 4.22 3.37 0.80 1192 4.07 3.26 0.80 1245

31 22 4.72 3.21 0.68 1140 4.55 3.09 0.68 1212 4.44 3.02 0.68 1245 4.26 2.89 0.68 1297

31 24 4.96 2.78 0.56 1192 4.77 2.67 0.56 1258 4.66 2.61 0.56 1297 4.51 2.53 0.56 1362

31 26 5.11 2.25 0.44 1258 4.96 2.18 0.44 1323 4.88 2.15 0.44 1362 4.74 2.08 0.44 1402

32 18 4.35 4.17 0.96 1048 4.16 4.00 0.96 1100 4.00 3.84 0.96 1153 3.85 3.69 0.96 1205

32 20 4.53 3.81 0.84 1100 4.35 3.65 0.84 1166 4.22 3.54 0.84 1192 4.07 3.42 0.84 1245

32 22 4.72 3.40 0.72 1140 4.55 3.28 0.72 1212 4.44 3.20 0.72 1245 4.26 3.06 0.72 1297

32 24 4.96 2.97 0.60 1192 4.77 2.86 0.60 1258 4.66 2.80 0.60 1297 4.51 2.71 0.60 1362

32 26 5.11 2.45 0.48 1258 4.96 2.38 0.48 1323 4.88 2.34 0.48 1362 4.74 2.27 0.48 1402

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21 25 27 30

E4E4

OUTDOOR DB(;)

16

Page 17

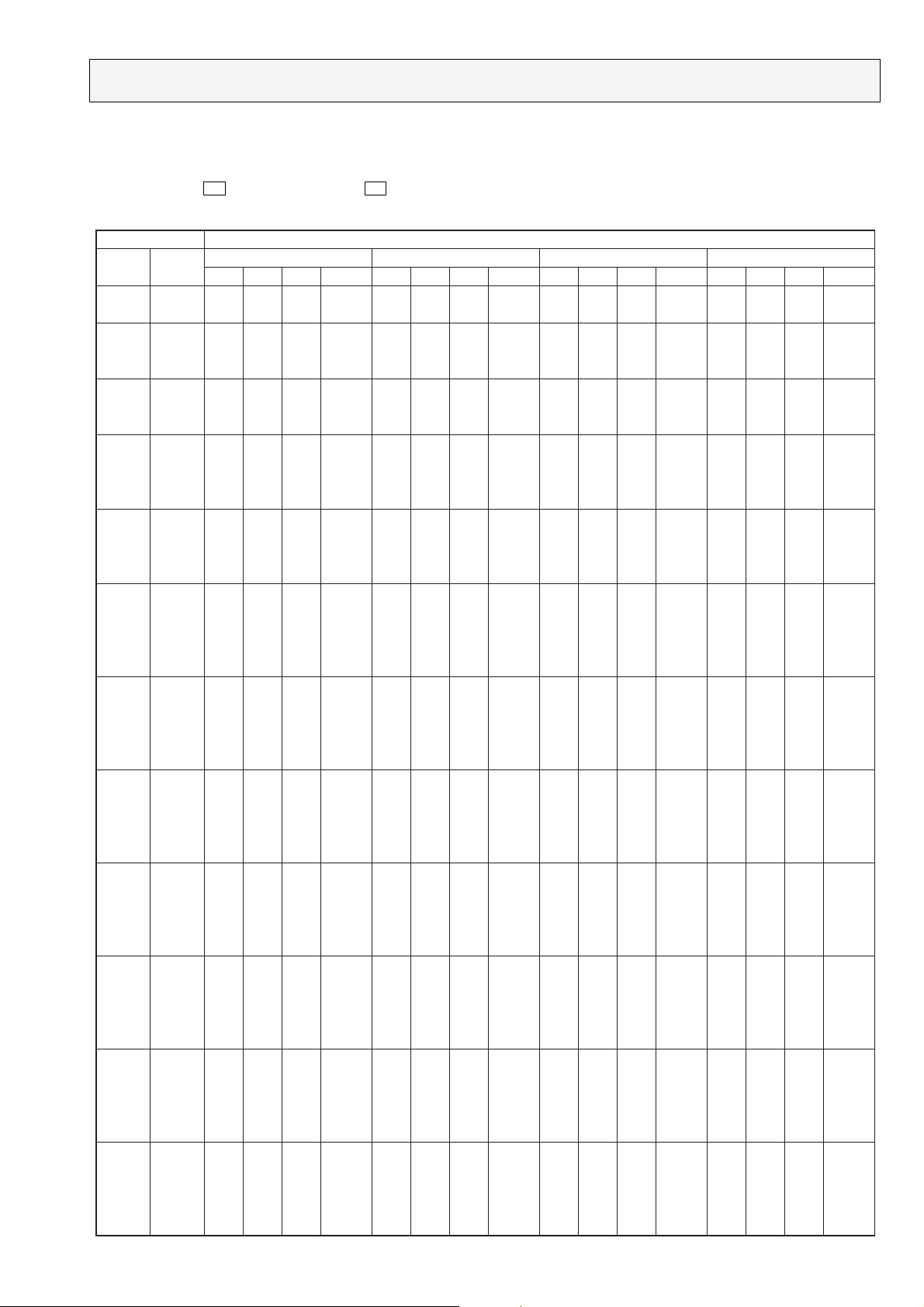

PERFORMANCE DATA

COOL operation(220V)

MCF-13NV - :MUCF-13NV -

CAPACITY : 3.7(kW) SHF : 0.70 INPUT : 1310(W)

INDOOR INDOOR

DB(;) WB(;)

21 18 3.63 1.89 0.52 1284 3.33 1.73 0.52 1362 3.20 1.66 0.52 1389 3.07 1.60 0.52 1415

21 20 3.81 1.52 0.40 1336 3.55 1.42 0.40 1402 3.42 1.37 0.40 1441 3.29 1.32 0.40 1480

22 18 3.63 2.03 0.56 1284 3.33 1.86 0.56 1362 3.20 1.79 0.56 1389 3.07 1.72 0.56 1415

22 20 3.81 1.68 0.44 1336 3.55 1.56 0.44 1402 3.42 1.51 0.44 1441 3.29 1.45 0.44 1480

22 22 4.03 1.29 0.32 1389 3.77 1.21 0.32 1467 3.64 1.17 0.32 1493 3.52 1.12 0.32 1520

23 18 3.63 2.18 0.60 1284 3.33 2.00 0.60 1362 3.20 1.92 0.60 1389 3.07 1.84 0.60 1415

23 20 3.81 1.83 0.48 1336 3.55 1.70 0.48 1402 3.42 1.64 0.48 1441 3.29 1.58 0.48 1480

23 22 4.03 1.45 0.36 1389 3.77 1.36 0.36 1467 3.64 1.31 0.36 1493 3.52 1.27 0.36 1520

24 18 3.63 2.32 0.64 1284 3.33 2.13 0.64 1362 3.20 2.05 0.64 1389 3.07 1.97 0.64 1415

24 20 3.81 1.98 0.52 1336 3.55 1.85 0.52 1402 3.42 1.78 0.52 1441 3.29 1.71 0.52 1480

24 22 4.03 1.61 0.40 1389 3.77 1.51 0.40 1467 3.64 1.46 0.40 1493 3.52 1.41 0.40 1520

24 24 4.26 1.19 0.28 1441 4.00 1.12 0.28 1507 3.89 1.09 0.28 1539 3.77 1.06 0.28 1572

25 18 3.63 2.47 0.68 1284 3.33 2.26 0.68 1362 3.20 2.18 0.68 1389 3.07 2.09 0.68 1415

25 20 3.81 2.13 0.56 1336 3.55 1.99 0.56 1402 3.42 1.92 0.56 1441 3.29 1.84 0.56 1480

25 22 4.03 1.77 0.44 1389 3.77 1.66 0.44 1467 3.64 1.60 0.44 1493 3.52 1.55 0.44 1520

25 24 4.26 1.36 0.32 1441 4.00 1.28 0.32 1507 3.89 1.24 0.32 1539 3.77 1.21 0.32 1572

26 18 3.63 2.61 0.72 1284 3.33 2.40 0.72 1362 3.20 2.30 0.72 1389 3.07 2.21 0.72 1415

26 20 3.81 2.29 0.60 1336 3.55 2.13 0.60 1402 3.42 2.05 0.60 1441 3.29 1.98 0.60 1480

26 22 4.03 1.94 0.48 1389 3.77 1.81 0.48 1467 3.64 1.75 0.48 1493 3.52 1.69 0.48 1520

26 24 4.26 1.53 0.36 1441 4.00 1.44 0.36 1507 3.89 1.40 0.36 1539 3.77 1.36 0.36 1572

26 26 4.48 1.07 0.24 1493 4.22 1.01 0.24 1559 4.09 0.98 0.24 1592 3.96 0.95 0.24 1624

27 18 3.63 2.76 0.76 1284 3.33 2.53 0.76 1362 3.20 2.43 0.76 1389 3.07 2.33 0.76 1415

27 20 3.81 2.44 0.64 1336 3.55 2.27 0.64 1402 3.42 2.19 0.64 1441 3.29 2.11 0.64 1480

27 22 4.03 2.10 0.52 1389 3.77 1.96 0.52 1467 3.64 1.90 0.52 1493 3.52 1.83 0.52 1520

27 24 4.26 1.70 0.40 1441 4.00 1.60 0.40 1507 3.89 1.55 0.40 1539 3.77 1.51 0.40 1572

27 26 4.48 1.25 0.28 1493 4.22 1.18 0.28 1559 4.09 1.14 0.28 1592 3.96 1.11 0.28 1624

28 18 3.63 2.90 0.80 1284 3.33 2.66 0.80 1362 3.20 2.56 0.80 1389 3.07 2.46 0.80 1415

28 20 3.81 2.59 0.68 1336 3.55 2.42 0.68 1402 3.42 2.33 0.68 1441 3.29 2.24 0.68 1480

28 22 4.03 2.26 0.56 1389 3.77 2.11 0.56 1467 3.64 2.04 0.56 1493 3.52 1.97 0.56 1520

28 24 4.26 1.87 0.44 1441 4.00 1.76 0.44 1507 3.89 1.71 0.44 1539 3.77 1.66 0.44 1572

28 26 4.48 1.43 0.32 1493 4.22 1.35 0.32 1559 4.09 1.31 0.32 1592 3.96 1.27 0.32 1624

29 18 3.63 3.05 0.84 1284 3.33 2.80 0.84 1362 3.20 2.69 0.84 1389 3.07 2.58 0.84 1415

29 20 3.81 2.74 0.72 1336 3.55 2.56 0.72 1402 3.42 2.46 0.72 1441 3.29 2.37 0.72 1480

29 22 4.03 2.42 0.60 1389 3.77 2.26 0.60 1467 3.64 2.19 0.60 1493 3.52 2.11 0.60 1520

29 24 4.26 2.04 0.48 1441 4.00 1.92 0.48 1507 3.89 1.86 0.48 1539 3.77 1.81 0.48 1572

29 26 4.48 1.61 0.36 1493 4.22 1.52 0.36 1559 4.09 1.47 0.36 1592 3.96 1.43 0.36 1624

30 18 3.63 3.19 0.88 1284 3.33 2.93 0.88 1362 3.20 2.82 0.88 1389 3.07 2.70 0.88 1415

30 20 3.81 2.90 0.76 1336 3.55 2.70 0.76 1402 3.42 2.60 0.76 1441 3.29 2.50 0.76 1480

30 22 4.03 2.58 0.64 1389 3.77 2.42 0.64 1467 3.64 2.33 0.64 1493 3.52 2.25 0.64 1520

30 24 4.26 2.21 0.52 1441 4.00 2.08 0.52 1507 3.89 2.02 0.52 1539 3.77 1.96 0.52 1572

30 26 4.48 1.79 0.40 1493 4.22 1.69 0.40 1559 4.09 1.64 0.40 1592 3.96 1.58 0.40 1624

31 18 3.63 3.34 0.92 1284 3.33 3.06 0.92 1362 3.20 2.94 0.92 1389 3.07 2.83 0.92 1415

31 20 3.81 3.05 0.80 1336 3.55 2.84 0.80 1402 3.42 2.74 0.80 1441 3.29 2.63 0.80 1480

31 22 4.03 2.74 0.68 1389 3.77 2.57 0.68 1467 3.64 2.48 0.68 1493 3.52 2.39 0.68 1520

31 24 4.26 2.38 0.56 1441 4.00 2.24 0.56 1507 3.89 2.18 0.56 1539 3.77 2.11 0.56 1572

31 26 4.48 1.97 0.44 1493 4.22 1.86 0.44 1559 4.09 1.80 0.44 1592 3.96 1.74 0.44 1624

32 18 3.63 3.48 0.96 1284 3.33 3.20 0.96 1362 3.20 3.07 0.96 1389 3.07 2.95 0.96 1415

32 20 3.81 3.20 0.84 1336 3.55 2.98 0.84 1402 3.42 2.87 0.84 1441 3.29 2.77 0.84 1480

32 22 4.03 2.90 0.72 1389 3.77 2.72 0.72 1467 3.64 2.62 0.72 1493 3.52 2.53 0.72 1520

32 24 4.26 2.55 0.60 1441 4.00 2.40 0.60 1507 3.89 2.33 0.60 1539 3.77 2.26 0.60 1572

32 26 4.48 2.15 0.48 1493 4.22 2.02 0.48 1559 4.09 1.96 0.48 1592 3.96 1.90 0.48 1624

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

35 40 43 46

E4E4

OUTDOOR DB(;)

17

Page 18

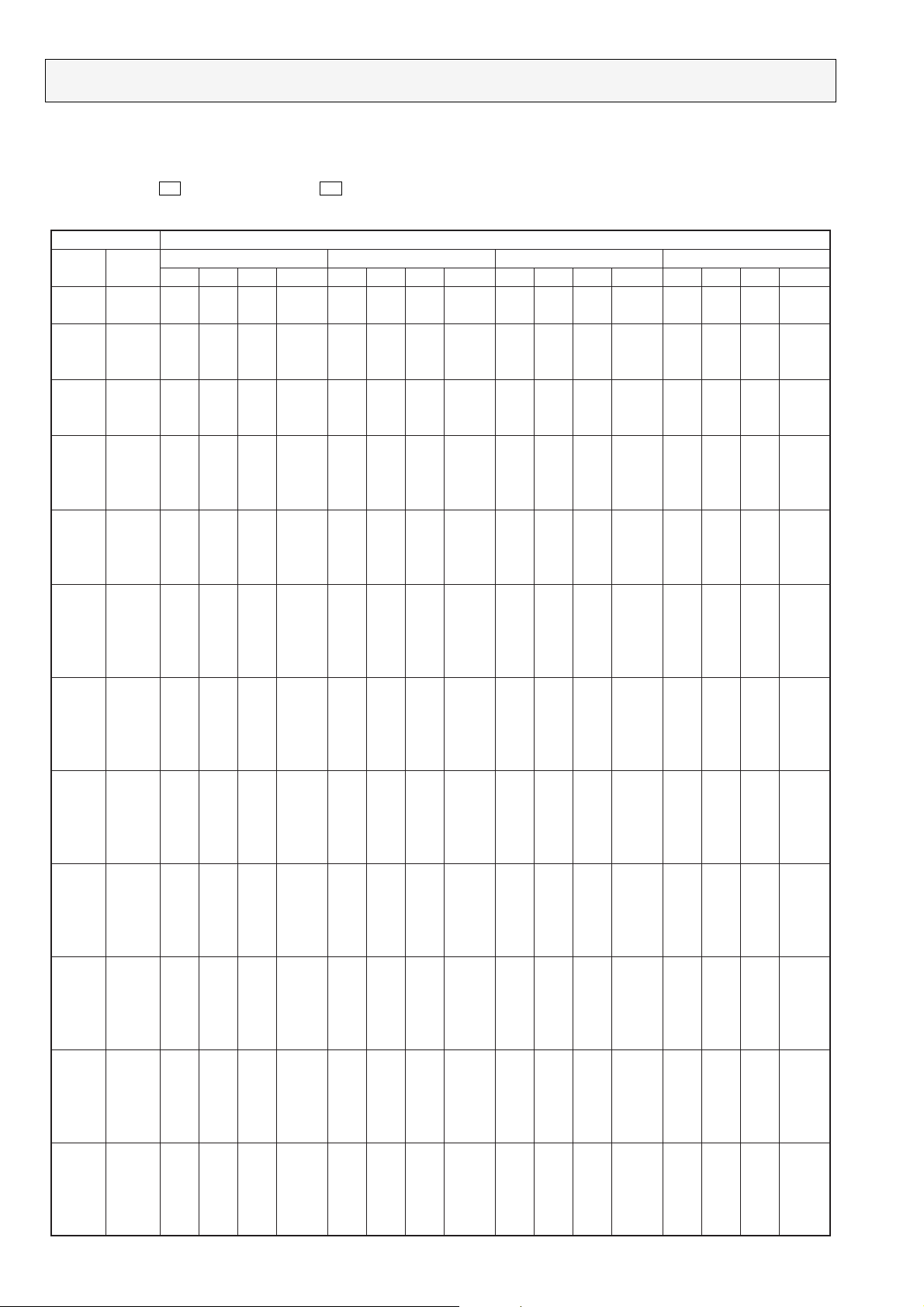

PERFORMANCE DATA

COOL operation(240V)

MCF-13NV - :MUCF-13NV -

CAPACITY : 3.7(kW) SHF : 0.70 INPUT : 1380(W)

INDOOR INDOOR

DB(;) WB(;)

21 18 4.35 2.26 0.52 1104 4.16 2.16 0.52 1159 4.00 2.08 0.52 1214 3.85 2.00 0.52 1270

21 20 4.53 1.81 0.40 1159 4.35 1.74 0.40 1228 4.22 1.69 0.40 1256 4.07 1.63 0.40 1311

22 18 4.35 2.43 0.56 1104 4.16 2.33 0.56 1159 4.00 2.24 0.56 1214 3.85 2.15 0.56 1270

22 20 4.53 1.99 0.44 1159 4.35 1.91 0.44 1228 4.22 1.86 0.44 1256 4.07 1.79 0.44 1311

22 22 4.72 1.51 0.32 1201 4.55 1.46 0.32 1277 4.44 1.42 0.32 1311 4.26 1.36 0.32 1366

23 18 4.35 2.61 0.60 1104 4.16 2.50 0.60 1159 4.00 2.40 0.60 1214 3.85 2.31 0.60 1270

23 20 4.53 2.18 0.48 1159 4.35 2.09 0.48 1228 4.22 2.02 0.48 1256 4.07 1.95 0.48 1311

23 22 4.72 1.70 0.36 1201 4.55 1.64 0.36 1277 4.44 1.60 0.36 1311 4.26 1.53 0.36 1366

24 18 4.35 2.78 0.64 1104 4.16 2.66 0.64 1159 4.00 2.56 0.64 1214 3.85 2.46 0.64 1270

24 20 4.53 2.36 0.52 1159 4.35 2.26 0.52 1228 4.22 2.19 0.52 1256 4.07 2.12 0.52 1311

24 22 4.72 1.89 0.40 1201 4.55 1.82 0.40 1277 4.44 1.78 0.40 1311 4.26 1.70 0.40 1366

24 24 4.96 1.39 0.28 1256 4.77 1.34 0.28 1325 4.66 1.31 0.28 1366 4.51 1.26 0.28 1435

25 18 4.35 2.96 0.68 1104 4.16 2.83 0.68 1159 4.00 2.72 0.68 1214 3.85 2.62 0.68 1270

25 20 4.53 2.54 0.56 1159 4.35 2.43 0.56 1228 4.22 2.36 0.56 1256 4.07 2.28 0.56 1311

25 22 4.72 2.08 0.44 1201 4.55 2.00 0.44 1277 4.44 1.95 0.44 1311 4.26 1.87 0.44 1366

25 24 4.96 1.59 0.32 1256 4.77 1.53 0.32 1325 4.66 1.49 0.32 1366 4.51 1.44 0.32 1435

26 18 4.35 3.13 0.72 1104 4.16 3.00 0.72 1159 4.00 2.88 0.72 1214 3.85 2.77 0.72 1270

26 20 4.53 2.72 0.60 1159 4.35 2.61 0.60 1228 4.22 2.53 0.60 1256 4.07 2.44 0.60 1311

26 22 4.72 2.26 0.48 1201 4.55 2.18 0.48 1277 4.44 2.13 0.48 1311 4.26 2.04 0.48 1366

26 24 4.96 1.78 0.36 1256 4.77 1.72 0.36 1325 4.66 1.68 0.36 1366 4.51 1.63 0.36 1435

26 26 5.11 1.23 0.24 1325 4.96 1.19 0.24 1394 4.88 1.17 0.24 1435 4.74 1.14 0.24 1477

27 18 4.35 3.30 0.76 1104 4.16 3.16 0.76 1159 4.00 3.04 0.76 1214 3.85 2.92 0.76 1270

27 20 4.53 2.90 0.64 1159 4.35 2.78 0.64 1228 4.22 2.70 0.64 1256 4.07 2.60 0.64 1311

27 22 4.72 2.45 0.52 1201 4.55 2.37 0.52 1277 4.44 2.31 0.52 1311 4.26 2.21 0.52 1366

27 24 4.96 1.98 0.40 1256 4.77 1.91 0.40 1325 4.66 1.86 0.40 1366 4.51 1.81 0.40 1435

27 26 5.11 1.43 0.28 1325 4.96 1.39 0.28 1394 4.88 1.37 0.28 1435 4.74 1.33 0.28 1477

28 18 4.35 3.48 0.80 1104 4.16 3.33 0.80 1159 4.00 3.20 0.80 1214 3.85 3.08 0.80 1270

28 20 4.53 3.08 0.68 1159 4.35 2.96 0.68 1228 4.22 2.87 0.68 1256 4.07 2.77 0.68 1311

28 22 4.72 2.64 0.56 1201 4.55 2.55 0.56 1277 4.44 2.49 0.56 1311 4.26 2.38 0.56 1366

28 24 4.96 2.18 0.44 1256 4.77 2.10 0.44 1325 4.66 2.05 0.44 1366 4.51 1.99 0.44 1435

28 26 5.11 1.63 0.32 1325 4.96 1.59 0.32 1394 4.88 1.56 0.32 1435 4.74 1.52 0.32 1477

29 18 4.35 3.65 0.84 1104 4.16 3.50 0.84 1159 4.00 3.36 0.84 1214 3.85 3.23 0.84 1270

29 20 4.53 3.26 0.72 1159 4.35 3.13 0.72 1228 4.22 3.04 0.72 1256 4.07 2.93 0.72 1311

29 22 4.72 2.83 0.60 1201 4.55 2.73 0.60 1277 4.44 2.66 0.60 1311 4.26 2.55 0.60 1366

29 24 4.96 2.38 0.48 1256 4.77 2.29 0.48 1325 4.66 2.24 0.48 1366 4.51 2.17 0.48 1435

29 26 5.11 1.84 0.36 1325 4.96 1.78 0.36 1394 4.88 1.76 0.36 1435 4.74 1.70 0.36 1477

30 18 4.35 3.83 0.88 1104 4.16 3.66 0.88 1159 4.00 3.52 0.88 1214 3.85 3.39 0.88 1270

30 20 4.53 3.44 0.76 1159 4.35 3.30 0.76 1228 4.22 3.21 0.76 1256 4.07 3.09 0.76 1311

30 22 4.72 3.02 0.64 1201 4.55 2.91 0.64 1277 4.44 2.84 0.64 1311 4.26 2.72 0.64 1366

30 24 4.96 2.58 0.52 1256 4.77 2.48 0.52 1325 4.66 2.42 0.52 1366 4.51 2.35 0.52 1435

30 26 5.11 2.04 0.40 1325 4.96 1.98 0.40 1394 4.88 1.95 0.40 1435 4.74 1.89 0.40 1477

31 18 4.35 4.00 0.92 1104 4.16 3.83 0.92 1159 4.00 3.68 0.92 1214 3.85 3.54 0.92 1270

31 20 4.53 3.63 0.80 1159 4.35 3.48 0.80 1228 4.22 3.37 0.80 1256 4.07 3.26 0.80 1311

31 22 4.72 3.21 0.68 1201 4.55 3.09 0.68 1277 4.44 3.02 0.68 1311 4.26 2.89 0.68 1366

31 24 4.96 2.78 0.56 1256 4.77 2.67 0.56 1325 4.66 2.61 0.56 1366 4.51 2.53 0.56 1435

31 26 5.11 2.25 0.44 1325 4.96 2.18 0.44 1394 4.88 2.15 0.44 1435 4.74 2.08 0.44 1477

32 18 4.35 4.17 0.96 1104 4.16 4.00 0.96 1159 4.00 3.84 0.96 1214 3.85 3.69 0.96 1270

32 20 4.53 3.81 0.84 1159 4.35 3.65 0.84 1228 4.22 3.54 0.84 1256 4.07 3.42 0.84 1311

32 22 4.72 3.40 0.72 1201 4.55 3.28 0.72 1277 4.44 3.20 0.72 1311 4.26 3.06 0.72 1366

32 24 4.96 2.97 0.60 1256 4.77 2.86 0.60 1325 4.66 2.80 0.60 1366 4.51 2.71 0.60 1435

32 26 5.11 2.45 0.48 1325 4.96 2.38 0.48 1394 4.88 2.34 0.48 1435 4.74 2.27 0.48 1477

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21 25 27 30

E4E4

OUTDOOR DB(;)

18

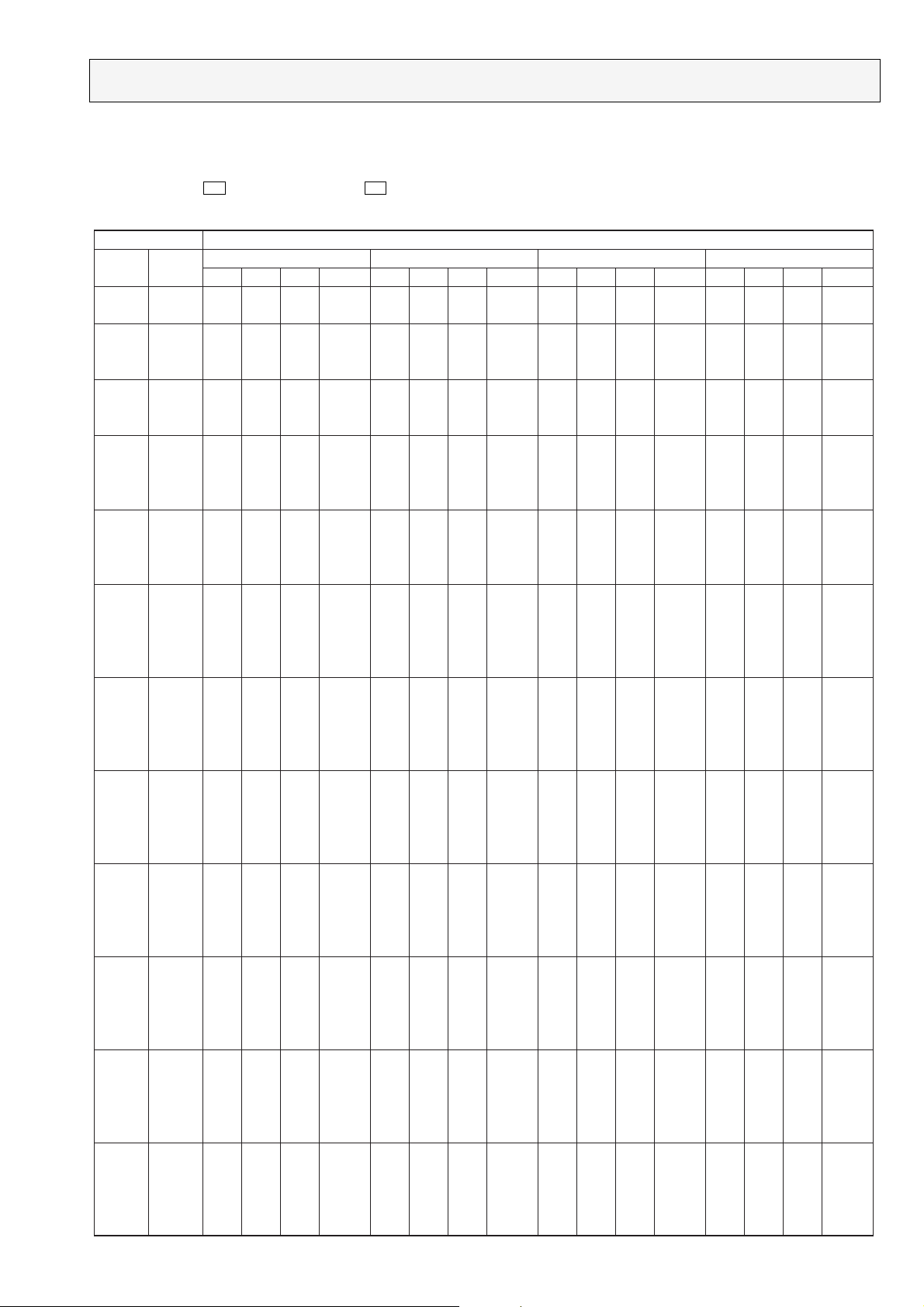

Page 19

PERFORMANCE DATA

COOL operation(240V)

MCF-13NV - :MUCF-13NV -

CAPACITY : 3.7(kW) SHF : 0.70 INPUT : 1380(W)

INDOOR INDOOR

DB(;) WB(;)

21 18 3.63 1.89 0.52 1352 3.33 1.73 0.52 1435 3.20 1.66 0.52 1463 3.07 1.60 0.52 1490

21 20 3.81 1.52 0.40 1408 3.55 1.42 0.40 1477 3.42 1.37 0.40 1518 3.29 1.32 0.40 1559

22 18 3.63 2.03 0.56 1352 3.33 1.86 0.56 1435 3.20 1.79 0.56 1463 3.07 1.72 0.56 1490

22 20 3.81 1.68 0.44 1408 3.55 1.56 0.44 1477 3.42 1.51 0.44 1518 3.29 1.45 0.44 1559

22 22 4.03 1.29 0.32 1463 3.77 1.21 0.32 1546 3.64 1.17 0.32 1573 3.52 1.12 0.32 1601

23 18 3.63 2.18 0.60 1352 3.33 2.00 0.60 1435 3.20 1.92 0.60 1463 3.07 1.84 0.60 1490

23 20 3.81 1.83 0.48 1408 3.55 1.70 0.48 1477 3.42 1.64 0.48 1518 3.29 1.58 0.48 1559

23 22 4.03 1.45 0.36 1463 3.77 1.36 0.36 1546 3.64 1.31 0.36 1573 3.52 1.27 0.36 1601

24 18 3.63 2.32 0.64 1352 3.33 2.13 0.64 1435 3.20 2.05 0.64 1463 3.07 1.97 0.64 1490

24 20 3.81 1.98 0.52 1408 3.55 1.85 0.52 1477 3.42 1.78 0.52 1518 3.29 1.71 0.52 1559

24 22 4.03 1.61 0.40 1463 3.77 1.51 0.40 1546 3.64 1.46 0.40 1573 3.52 1.41 0.40 1601

24 24 4.26 1.19 0.28 1518 4.00 1.12 0.28 1587 3.89 1.09 0.28 1622 3.77 1.06 0.28 1656

25 18 3.63 2.47 0.68 1352 3.33 2.26 0.68 1435 3.20 2.18 0.68 1463 3.07 2.09 0.68 1490

25 20 3.81 2.13 0.56 1408 3.55 1.99 0.56 1477 3.42 1.92 0.56 1518 3.29 1.84 0.56 1559

25 22 4.03 1.77 0.44 1463 3.77 1.66 0.44 1546 3.64 1.60 0.44 1573 3.52 1.55 0.44 1601

25 24 4.26 1.36 0.32 1518 4.00 1.28 0.32 1587 3.89 1.24 0.32 1622 3.77 1.21 0.32 1656

26 18 3.63 2.61 0.72 1352 3.33 2.40 0.72 1435 3.20 2.30 0.72 1463 3.07 2.21 0.72 1490

26 20 3.81 2.29 0.60 1408 3.55 2.13 0.60 1477 3.42 2.05 0.60 1518 3.29 1.98 0.60 1559

26 22 4.03 1.94 0.48 1463 3.77 1.81 0.48 1546 3.64 1.75 0.48 1573 3.52 1.69 0.48 1601

26 24 4.26 1.53 0.36 1518 4.00 1.44 0.36 1587 3.89 1.40 0.36 1622 3.77 1.36 0.36 1656

26 26 4.48 1.07 0.24 1573 4.22 1.01 0.24 1642 4.09 0.98 0.24 1677 3.96 0.95 0.24 1711

27 18 3.63 2.76 0.76 1352 3.33 2.53 0.76 1435 3.20 2.43 0.76 1463 3.07 2.33 0.76 1490

27 20 3.81 2.44 0.64 1408 3.55 2.27 0.64 1477 3.42 2.19 0.64 1518 3.29 2.11 0.64 1559

27 22 4.03 2.10 0.52 1463 3.77 1.96 0.52 1546 3.64 1.90 0.52 1573 3.52 1.83 0.52 1601

27 24 4.26 1.70 0.40 1518 4.00 1.60 0.40 1587 3.89 1.55 0.40 1622 3.77 1.51 0.40 1656

27 26 4.48 1.25 0.28 1573 4.22 1.18 0.28 1642 4.09 1.14 0.28 1677 3.96 1.11 0.28 1711

28 18 3.63 2.90 0.80 1352 3.33 2.66 0.80 1435 3.20 2.56 0.80 1463 3.07 2.46 0.80 1490

28 20 3.81 2.59 0.68 1408 3.55 2.42 0.68 1477 3.42 2.33 0.68 1518 3.29 2.24 0.68 1559

28 22 4.03 2.26 0.56 1463 3.77 2.11 0.56 1546 3.64 2.04 0.56 1573 3.52 1.97 0.56 1601

28 24 4.26 1.87 0.44 1518 4.00 1.76 0.44 1587 3.89 1.71 0.44 1622 3.77 1.66 0.44 1656

28 26 4.48 1.43 0.32 1573 4.22 1.35 0.32 1642 4.09 1.31 0.32 1677 3.96 1.27 0.32 1711

29 18 3.63 3.05 0.84 1352 3.33 2.80 0.84 1435 3.20 2.69 0.84 1463 3.07 2.58 0.84 1490

29 20 3.81 2.74 0.72 1408 3.55 2.56 0.72 1477 3.42 2.46 0.72 1518 3.29 2.37 0.72 1559

29 22 4.03 2.42 0.60 1463 3.77 2.26 0.60 1546 3.64 2.19 0.60 1573 3.52 2.11 0.60 1601

29 24 4.26 2.04 0.48 1518 4.00 1.92 0.48 1587 3.89 1.86 0.48 1622 3.77 1.81 0.48 1656

29 26 4.48 1.61 0.36 1573 4.22 1.52 0.36 1642 4.09 1.47 0.36 1677 3.96 1.43 0.36 1711

30 18 3.63 3.19 0.88 1352 3.33 2.93 0.88 1435 3.20 2.82 0.88 1463 3.07 2.70 0.88 1490

30 20 3.81 2.90 0.76 1408 3.55 2.70 0.76 1477 3.42 2.60 0.76 1518 3.29 2.50 0.76 1559

30 22 4.03 2.58 0.64 1463 3.77 2.42 0.64 1546 3.64 2.33 0.64 1573 3.52 2.25 0.64 1601

30 24 4.26 2.21 0.52 1518 4.00 2.08 0.52 1587 3.89 2.02 0.52 1622 3.77 1.96 0.52 1656

30 26 4.48 1.79 0.40 1573 4.22 1.69 0.40 1642 4.09 1.64 0.40 1677 3.96 1.58 0.40 1711

31 18 3.63 3.34 0.92 1352 3.33 3.06 0.92 1435 3.20 2.94 0.92 1463 3.07 2.83 0.92 1490

31 20 3.81 3.05 0.80 1408 3.55 2.84 0.80 1477 3.42 2.74 0.80 1518 3.29 2.63 0.80 1559

31 22 4.03 2.74 0.68 1463 3.77 2.57 0.68 1546 3.64 2.48 0.68 1573 3.52 2.39 0.68 1601

31 24 4.26 2.38 0.56 1518 4.00 2.24 0.56 1587 3.89 2.18 0.56 1622 3.77 2.11 0.56 1656

31 26 4.48 1.97 0.44 1573 4.22 1.86 0.44 1642 4.09 1.80 0.44 1677 3.96 1.74 0.44 1711

32 18 3.63 3.48 0.96 1352 3.33 3.20 0.96 1435 3.20 3.07 0.96 1463 3.07 2.95 0.96 1490

32 20 3.81 3.20 0.84 1408 3.55 2.98 0.84 1477 3.42 2.87 0.84 1518 3.29 2.77 0.84 1559

32 22 4.03 2.90 0.72 1463 3.77 2.72 0.72 1546 3.64 2.62 0.72 1573 3.52 2.53 0.72 1601

32 24 4.26 2.55 0.60 1518 4.00 2.40 0.60 1587 3.89 2.33 0.60 1622 3.77 2.26 0.60 1656

32 26 4.48 2.15 0.48 1573 4.22 2.02 0.48 1642 4.09 1.96 0.48 1677 3.96 1.90 0.48 1711

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

35 40 43 46

E4E4

OUTDOOR DB(;)

19

Page 20

PERFORMANCE DATA

COOL operation(220V)

MCF-18NV - :MUCF-18NV -

CAPACITY : 5.0(kW) SHF : 0.67 INPUT : 1920(W)

INDOOR INDOOR

DB(;) WB(;)

21 18 5.88 2.88 0.49 1536 5.63 2.76 0.49 1613 5.40 2.65 0.49 1690 5.20 2.55 0.49 1766

21 20 6.13 2.27 0.37 1613 5.88 2.17 0.37 1709 5.70 2.11 0.37 1747 5.50 2.04 0.37 1824

22 18 5.88 3.11 0.53 1536 5.63 2.98 0.53 1613 5.40 2.86 0.53 1690 5.20 2.76 0.53 1766

22 20 6.13 2.51 0.41 1613 5.88 2.41 0.41 1709 5.70 2.34 0.41 1747 5.50 2.26 0.41 1824

22 22 6.38 1.85 0.29 1670 6.15 1.78 0.29 1776 6.00 1.74 0.29 1824 5.75 1.67 0.29 1901

23 18 5.88 3.35 0.57 1536 5.63 3.21 0.57 1613 5.40 3.08 0.57 1690 5.20 2.96 0.57 1766

23 20 6.13 2.76 0.45 1613 5.88 2.64 0.45 1709 5.70 2.57 0.45 1747 5.50 2.48 0.45 1824

23 22 6.38 2.10 0.33 1670 6.15 2.03 0.33 1776 6.00 1.98 0.33 1824 5.75 1.90 0.33 1901

24 18 5.88 3.58 0.61 1536 5.63 3.43 0.61 1613 5.40 3.29 0.61 1690 5.20 3.17 0.61 1766

24 20 6.13 3.00 0.49 1613 5.88 2.88 0.49 1709 5.70 2.79 0.49 1747 5.50 2.70 0.49 1824

24 22 6.38 2.36 0.37 1670 6.15 2.28 0.37 1776 6.00 2.22 0.37 1824 5.75 2.13 0.37 1901

24 24 6.70 1.68 0.25 1747 6.45 1.61 0.25 1843 6.30 1.58 0.25 1901 6.10 1.53 0.25 1997

25 18 5.88 3.82 0.65 1536 5.63 3.66 0.65 1613 5.40 3.51 0.65 1690 5.20 3.38 0.65 1766

25 20 6.13 3.25 0.53 1613 5.88 3.11 0.53 1709 5.70 3.02 0.53 1747 5.50 2.92 0.53 1824

25 22 6.38 2.61 0.41 1670 6.15 2.52 0.41 1776 6.00 2.46 0.41 1824 5.75 2.36 0.41 1901

25 24 6.70 1.94 0.29 1747 6.45 1.87 0.29 1843 6.30 1.83 0.29 1901 6.10 1.77 0.29 1997

26 18 5.88 4.05 0.69 1536 5.63 3.88 0.69 1613 5.40 3.73 0.69 1690 5.20 3.59 0.69 1766

26 20 6.13 3.49 0.57 1613 5.88 3.35 0.57 1709 5.70 3.25 0.57 1747 5.50 3.14 0.57 1824

26 22 6.38 2.87 0.45 1670 6.15 2.77 0.45 1776 6.00 2.70 0.45 1824 5.75 2.59 0.45 1901

26 24 6.70 2.21 0.33 1747 6.45 2.13 0.33 1843 6.30 2.08 0.33 1901 6.10 2.01 0.33 1997

26 26 6.90 1.45 0.21 1843 6.70 1.41 0.21 1939 6.60 1.39 0.21 1997 6.40 1.34 0.21 2054

27 18 5.88 4.29 0.73 1536 5.63 4.11 0.73 1613 5.40 3.94 0.73 1690 5.20 3.80 0.73 1766

27 20 6.13 3.74 0.61 1613 5.88 3.58 0.61 1709 5.70 3.48 0.61 1747 5.50 3.36 0.61 1824

27 22 6.38 3.12 0.49 1670 6.15 3.01 0.49 1776 6.00 2.94 0.49 1824 5.75 2.82 0.49 1901

27 24 6.70 2.48 0.37 1747 6.45 2.39 0.37 1843 6.30 2.33 0.37 1901 6.10 2.26 0.37 1997

27 26 6.90 1.73 0.25 1843 6.70 1.68 0.25 1939 6.60 1.65 0.25 1997 6.40 1.60 0.25 2054

28 18 5.88 4.52 0.77 1536 5.63 4.33 0.77 1613 5.40 4.16 0.77 1690 5.20 4.00 0.77 1766

28 20 6.13 3.98 0.65 1613 5.88 3.82 0.65 1709 5.70 3.71 0.65 1747 5.50 3.58 0.65 1824

28 22 6.38 3.38 0.53 1670 6.15 3.26 0.53 1776 6.00 3.18 0.53 1824 5.75 3.05 0.53 1901

28 24 6.70 2.75 0.41 1747 6.45 2.64 0.41 1843 6.30 2.58 0.41 1901 6.10 2.50 0.41 1997

28 26 6.90 2.00 0.29 1843 6.70 1.94 0.29 1939 6.60 1.91 0.29 1997 6.40 1.86 0.29 2054

29 18 5.88 4.76 0.81 1536 5.63 4.56 0.81 1613 5.40 4.37 0.81 1690 5.20 4.21 0.81 1766

29 20 6.13 4.23 0.69 1613 5.88 4.05 0.69 1709 5.70 3.93 0.69 1747 5.50 3.80 0.69 1824

29 22 6.38 3.63 0.57 1670 6.15 3.51 0.57 1776 6.00 3.42 0.57 1824 5.75 3.28 0.57 1901

29 24 6.70 3.02 0.45 1747 6.45 2.90 0.45 1843 6.30 2.84 0.45 1901 6.10 2.75 0.45 1997

29 26 6.90 2.28 0.33 1843 6.70 2.21 0.33 1939 6.60 2.18 0.33 1997 6.40 2.11 0.33 2054

30 18 5.88 4.99 0.85 1536 5.63 4.78 0.85 1613 5.40 4.59 0.85 1690 5.20 4.42 0.85 1766

30 20 6.13 4.47 0.73 1613 5.88 4.29 0.73 1709 5.70 4.16 0.73 1747 5.50 4.02 0.73 1824

30 22 6.38 3.89 0.61 1670 6.15 3.75 0.61 1776 6.00 3.66 0.61 1824 5.75 3.51 0.61 1901

30 24 6.70 3.28 0.49 1747 6.45 3.16 0.49 1843 6.30 3.09 0.49 1901 6.10 2.99 0.49 1997

30 26 6.90 2.55 0.37 1843 6.70 2.48 0.37 1939 6.60 2.44 0.37 1997 6.40 2.37 0.37 2054

31 18 5.88 5.23 0.89 1536 5.63 5.01 0.89 1613 5.40 4.81 0.89 1690 5.20 4.63 0.89 1766

31 20 6.13 4.72 0.77 1613 5.88 4.52 0.77 1709 5.70 4.39 0.77 1747 5.50 4.24 0.77 1824

31 22 6.38 4.14 0.65 1670 6.15 4.00 0.65 1776 6.00 3.90 0.65 1824 5.75 3.74 0.65 1901

31 24 6.70 3.55 0.53 1747 6.45 3.42 0.53 1843 6.30 3.34 0.53 1901 6.10 3.23 0.53 1997

31 26 6.90 2.83 0.41 1843 6.70 2.75 0.41 1939 6.60 2.71 0.41 1997 6.40 2.62 0.41 2054

32 18 5.88 5.46 0.93 1536 5.63 5.23 0.93 1613 5.40 5.02 0.93 1690 5.20 4.84 0.93 1766

32 20 6.13 4.96 0.81 1613 5.88 4.76 0.81 1709 5.70 4.62 0.81 1747 5.50 4.46 0.81 1824

32 22 6.38 4.40 0.69 1670 6.15 4.24 0.69 1776 6.00 4.14 0.69 1824 5.75 3.97 0.69 1901

32 24 6.70 3.82 0.57 1747 6.45 3.68 0.57 1843 6.30 3.59 0.57 1901 6.10 3.48 0.57 1997

32 26 6.90 3.11 0.45 1843 6.70 3.02 0.45 1939 6.60 2.97 0.45 1997 6.40 2.88 0.45 2054

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21 25 27 30

E3E3

OUTDOOR DB(;)

20

Page 21

PERFORMANCE DATA

COOL operation(220V)

MCF-18NV - :MUCF-18NV -

CAPACITY : 5.0(kW) SHF : 0.67 INPUT : 1920(W)

INDOOR INDOOR

DB(;) WB(;)

21 18 4.90 2.40 0.49 1882 4.50 2.21 0.49 1997 4.33 2.12 0.49 2035 4.15 2.03 0.49 2074

21 20 5.15 1.91 0.37 1958 4.80 1.78 0.37 2054 4.63 1.71 0.37 2112 4.45 1.65 0.37 2170

22 18 4.90 2.60 0.53 1882 4.50 2.39 0.53 1997 4.33 2.29 0.53 2035 4.15 2.20 0.53 2074

22 20 5.15 2.11 0.41 1958 4.80 1.97 0.41 2054 4.63 1.90 0.41 2112 4.45 1.82 0.41 2170

22 22 5.45 1.58 0.29 2035 5.10 1.48 0.29 2150 4.93 1.43 0.29 2189 4.75 1.38 0.29 2227

23 18 4.90 2.79 0.57 1882 4.50 2.57 0.57 1997 4.33 2.47 0.57 2035 4.15 2.37 0.57 2074

23 20 5.15 2.32 0.45 1958 4.80 2.16 0.45 2054 4.63 2.08 0.45 2112 4.45 2.00 0.45 2170

23 22 5.45 1.80 0.33 2035 5.10 1.68 0.33 2150 4.93 1.63 0.33 2189 4.75 1.57 0.33 2227

24 18 4.90 2.99 0.61 1882 4.50 2.75 0.61 1997 4.33 2.64 0.61 2035 4.15 2.53 0.61 2074

24 20 5.15 2.52 0.49 1958 4.80 2.35 0.49 2054 4.63 2.27 0.49 2112 4.45 2.18 0.49 2170

24 22 5.45 2.02 0.37 2035 5.10 1.89 0.37 2150 4.93 1.82 0.37 2189 4.75 1.76 0.37 2227

24 24 5.75 1.44 0.25 2112 5.40 1.35 0.25 2208 5.25 1.31 0.25 2256 5.10 1.28 0.25 2304

25 18 4.90 3.19 0.65 1882 4.50 2.93 0.65 1997 4.33 2.81 0.65 2035 4.15 2.70 0.65 2074

25 20 5.15 2.73 0.53 1958 4.80 2.54 0.53 2054 4.63 2.45 0.53 2112 4.45 2.36 0.53 2170

25 22 5.45 2.23 0.41 2035 5.10 2.09 0.41 2150 4.93 2.02 0.41 2189 4.75 1.95 0.41 2227

25 24 5.75 1.67 0.29 2112 5.40 1.57 0.29 2208 5.25 1.52 0.29 2256 5.10 1.48 0.29 2304

26 18 4.90 3.38 0.69 1882 4.50 3.11 0.69 1997 4.33 2.98 0.69 2035 4.15 2.86 0.69 2074

26 20 5.15 2.94 0.57 1958 4.80 2.74 0.57 2054 4.63 2.64 0.57 2112 4.45 2.54 0.57 2170

26 22 5.45 2.45 0.45 2035 5.10 2.30 0.45 2150 4.93 2.22 0.45 2189 4.75 2.14 0.45 2227

26 24 5.75 1.90 0.33 2112 5.40 1.78 0.33 2208 5.25 1.73 0.33 2256 5.10 1.68 0.33 2304

26 26 6.05 1.27 0.21 2189 5.70 1.20 0.21 2285 5.53 1.16 0.21 2333 5.35 1.12 0.21 2381

27 18 4.90 3.58 0.73 1882 4.50 3.29 0.73 1997 4.33 3.16 0.73 2035 4.15 3.03 0.73 2074

27 20 5.15 3.14 0.61 1958 4.80 2.93 0.61 2054 4.63 2.82 0.61 2112 4.45 2.71 0.61 2170

27 22 5.45 2.67 0.49 2035 5.10 2.50 0.49 2150 4.93 2.41 0.49 2189 4.75 2.33 0.49 2227

27 24 5.75 2.13 0.37 2112 5.40 2.00 0.37 2208 5.25 1.94 0.37 2256 5.10 1.89 0.37 2304

27 26 6.05 1.51 0.25 2189 5.70 1.43 0.25 2285 5.53 1.38 0.25 2333 5.35 1.34 0.25 2381

28 18 4.90 3.77 0.77 1882 4.50 3.47 0.77 1997 4.33 3.33 0.77 2035 4.15 3.20 0.77 2074

28 20 5.15 3.35 0.65 1958 4.80 3.12 0.65 2054 4.63 3.01 0.65 2112 4.45 2.89 0.65 2170

28 22 5.45 2.89 0.53 2035 5.10 2.70 0.53 2150 4.93 2.61 0.53 2189 4.75 2.52 0.53 2227

28 24 5.75 2.36 0.41 2112 5.40 2.21 0.41 2208 5.25 2.15 0.41 2256 5.10 2.09 0.41 2304

28 26 6.05 1.75 0.29 2189 5.70 1.65 0.29 2285 5.53 1.60 0.29 2333 5.35 1.55 0.29 2381

29 18 4.90 3.97 0.81 1882 4.50 3.65 0.81 1997 4.33 3.50 0.81 2035 4.15 3.36 0.81 2074

29 20 5.15 3.55 0.69 1958 4.80 3.31 0.69 2054 4.63 3.19 0.69 2112 4.45 3.07 0.69 2170

29 22 5.45 3.11 0.57 2035 5.10 2.91 0.57 2150 4.93 2.81 0.57 2189 4.75 2.71 0.57 2227

29 24 5.75 2.59 0.45 2112 5.40 2.43 0.45 2208 5.25 2.36 0.45 2256 5.10 2.30 0.45 2304

29 26 6.05 2.00 0.33 2189 5.70 1.88 0.33 2285 5.53 1.82 0.33 2333 5.35 1.77 0.33 2381

30 18 4.90 4.17 0.85 1882 4.50 3.83 0.85 1997 4.33 3.68 0.85 2035 4.15 3.53 0.85 2074

30 20 5.15 3.76 0.73 1958 4.80 3.50 0.73 2054 4.63 3.38 0.73 2112 4.45 3.25 0.73 2170

30 22 5.45 3.32 0.61 2035 5.10 3.11 0.61 2150 4.93 3.00 0.61 2189 4.75 2.90 0.61 2227

30 24 5.75 2.82 0.49 2112 5.40 2.65 0.49 2208 5.25 2.57 0.49 2256 5.10 2.50 0.49 2304

30 26 6.05 2.24 0.37 2189 5.70 2.11 0.37 2285 5.53 2.04 0.37 2333 5.35 1.98 0.37 2381

31 18 4.90 4.36 0.89 1882 4.50 4.01 0.89 1997 4.33 3.85 0.89 2035 4.15 3.69 0.89 2074

31 20 5.15 3.97 0.77 1958 4.80 3.70 0.77 2054 4.63 3.56 0.77 2112 4.45 3.43 0.77 2170

31 22 5.45 3.54 0.65 2035 5.10 3.32 0.65 2150 4.93 3.20 0.65 2189 4.75 3.09 0.65 2227

31 24 5.75 3.05 0.53 2112 5.40 2.86 0.53 2208 5.25 2.78 0.53 2256 5.10 2.70 0.53 2304

31 26 6.05 2.48 0.41 2189 5.70 2.34 0.41 2285 5.53 2.27 0.41 2333 5.35 2.19 0.41 2381

32 18 4.90 4.56 0.93 1882 4.50 4.19 0.93 1997 4.33 4.02 0.93 2035 4.15 3.86 0.93 2074

32 20 5.15 4.17 0.81 1958 4.80 3.89 0.81 2054 4.63 3.75 0.81 2112 4.45 3.60 0.81 2170

32 22 5.45 3.76 0.69 2035 5.10 3.52 0.69 2150 4.93 3.40 0.69 2189 4.75 3.28 0.69 2227

32 24 5.75 3.28 0.57 2112 5.40 3.08 0.57 2208 5.25 2.99 0.57 2256 5.10 2.91 0.57 2304

32 26 6.05 2.72 0.45 2189 5.70 2.57 0.45 2285 5.53 2.49 0.45 2333 5.35 2.41 0.45 2381

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

35 40 43 46

E3E3

OUTDOOR DB(;)

21

Page 22

PERFORMANCE DATA

COOL operation(240V)

MCF-18NV - :MUCF-18NV -

CAPACITY : 5.0(kW) SHF : 0.67 INPUT : 2010(W)

INDOOR INDOOR

DB(;) WB(;)

21 18 5.88 2.88 0.49 1608 5.63 2.76 0.49 1688 5.40 2.65 0.49 1769 5.20 2.55 0.49 1849

21 20 6.13 2.27 0.37 1688 5.88 2.17 0.37 1789 5.70 2.11 0.37 1829 5.50 2.04 0.37 1910

22 18 5.88 3.11 0.53 1608 5.63 2.98 0.53 1688 5.40 2.86 0.53 1769 5.20 2.76 0.53 1849

22 20 6.13 2.51 0.41 1688 5.88 2.41 0.41 1789 5.70 2.34 0.41 1829 5.50 2.26 0.41 1910

22 22 6.38 1.85 0.29 1749 6.15 1.78 0.29 1859 6.00 1.74 0.29 1910 5.75 1.67 0.29 1990

23 18 5.88 3.35 0.57 1608 5.63 3.21 0.57 1688 5.40 3.08 0.57 1769 5.20 2.96 0.57 1849

23 20 6.13 2.76 0.45 1688 5.88 2.64 0.45 1789 5.70 2.57 0.45 1829 5.50 2.48 0.45 1910

23 22 6.38 2.10 0.33 1749 6.15 2.03 0.33 1859 6.00 1.98 0.33 1910 5.75 1.90 0.33 1990

24 18 5.88 3.58 0.61 1608 5.63 3.43 0.61 1688 5.40 3.29 0.61 1769 5.20 3.17 0.61 1849

24 20 6.13 3.00 0.49 1688 5.88 2.88 0.49 1789 5.70 2.79 0.49 1829 5.50 2.70 0.49 1910

24 22 6.38 2.36 0.37 1749 6.15 2.28 0.37 1859 6.00 2.22 0.37 1910 5.75 2.13 0.37 1990

24 24 6.70 1.68 0.25 1829 6.45 1.61 0.25 1930 6.30 1.58 0.25 1990 6.10 1.53 0.25 2090

25 18 5.88 3.82 0.65 1608 5.63 3.66 0.65 1688 5.40 3.51 0.65 1769 5.20 3.38 0.65 1849

25 20 6.13 3.25 0.53 1688 5.88 3.11 0.53 1789 5.70 3.02 0.53 1829 5.50 2.92 0.53 1910

25 22 6.38 2.61 0.41 1749 6.15 2.52 0.41 1859 6.00 2.46 0.41 1910 5.75 2.36 0.41 1990

25 24 6.70 1.94 0.29 1829 6.45 1.87 0.29 1930 6.30 1.83 0.29 1990 6.10 1.77 0.29 2090

26 18 5.88 4.05 0.69 1608 5.63 3.88 0.69 1688 5.40 3.73 0.69 1769 5.20 3.59 0.69 1849

26 20 6.13 3.49 0.57 1688 5.88 3.35 0.57 1789 5.70 3.25 0.57 1829 5.50 3.14 0.57 1910

26 22 6.38 2.87 0.45 1749 6.15 2.77 0.45 1859 6.00 2.70 0.45 1910 5.75 2.59 0.45 1990

26 24 6.70 2.21 0.33 1829 6.45 2.13 0.33 1930 6.30 2.08 0.33 1990 6.10 2.01 0.33 2090

26 26 6.90 1.45 0.21 1930 6.70 1.41 0.21 2030 6.60 1.39 0.21 2090 6.40 1.34 0.21 2151

27 18 5.88 4.29 0.73 1608 5.63 4.11 0.73 1688 5.40 3.94 0.73 1769 5.20 3.80 0.73 1849

27 20 6.13 3.74 0.61 1688 5.88 3.58 0.61 1789 5.70 3.48 0.61 1829 5.50 3.36 0.61 1910

27 22 6.38 3.12 0.49 1749 6.15 3.01 0.49 1859 6.00 2.94 0.49 1910 5.75 2.82 0.49 1990

27 24 6.70 2.48 0.37 1829 6.45 2.39 0.37 1930 6.30 2.33 0.37 1990 6.10 2.26 0.37 2090

27 26 6.90 1.73 0.25 1930 6.70 1.68 0.25 2030 6.60 1.65 0.25 2090 6.40 1.60 0.25 2151

28 18 5.88 4.52 0.77 1608 5.63 4.33 0.77 1688 5.40 4.16 0.77 1769 5.20 4.00 0.77 1849

28 20 6.13 3.98 0.65 1688 5.88 3.82 0.65 1789 5.70 3.71 0.65 1829 5.50 3.58 0.65 1910

28 22 6.38 3.38 0.53 1749 6.15 3.26 0.53 1859 6.00 3.18 0.53 1910 5.75 3.05 0.53 1990

28 24 6.70 2.75 0.41 1829 6.45 2.64 0.41 1930 6.30 2.58 0.41 1990 6.10 2.50 0.41 2090

28 26 6.90 2.00 0.29 1930 6.70 1.94 0.29 2030 6.60 1.91 0.29 2090 6.40 1.86 0.29 2151

29 18 5.88 4.76 0.81 1608 5.63 4.56 0.81 1688 5.40 4.37 0.81 1769 5.20 4.21 0.81 1849

29 20 6.13 4.23 0.69 1688 5.88 4.05 0.69 1789 5.70 3.93 0.69 1829 5.50 3.80 0.69 1910

29 22 6.38 3.63 0.57 1749 6.15 3.51 0.57 1859 6.00 3.42 0.57 1910 5.75 3.28 0.57 1990

29 24 6.70 3.02 0.45 1829 6.45 2.90 0.45 1930 6.30 2.84 0.45 1990 6.10 2.75 0.45 2090

29 26 6.90 2.28 0.33 1930 6.70 2.21 0.33 2030 6.60 2.18 0.33 2090 6.40 2.11 0.33 2151

30 18 5.88 4.99 0.85 1608 5.63 4.78 0.85 1688 5.40 4.59 0.85 1769 5.20 4.42 0.85 1849

30 20 6.13 4.47 0.73 1688 5.88 4.29 0.73 1789 5.70 4.16 0.73 1829 5.50 4.02 0.73 1910

30 22 6.38 3.89 0.61 1749 6.15 3.75 0.61 1859 6.00 3.66 0.61 1910 5.75 3.51 0.61 1990

30 24 6.70 3.28 0.49 1829 6.45 3.16 0.49 1930 6.30 3.09 0.49 1990 6.10 2.99 0.49 2090

30 26 6.90 2.55 0.37 1930 6.70 2.48 0.37 2030 6.60 2.44 0.37 2090 6.40 2.37 0.37 2151

31 18 5.88 5.23 0.89 1608 5.63 5.01 0.89 1688 5.40 4.81 0.89 1769 5.20 4.63 0.89 1849

31 20 6.13 4.72 0.77 1688 5.88 4.52 0.77 1789 5.70 4.39 0.77 1829 5.50 4.24 0.77 1910

31 22 6.38 4.14 0.65 1749 6.15 4.00 0.65 1859 6.00 3.90 0.65 1910 5.75 3.74 0.65 1990

31 24 6.70 3.55 0.53 1829 6.45 3.42 0.53 1930 6.30 3.34 0.53 1990 6.10 3.23 0.53 2090

31 26 6.90 2.83 0.41 1930 6.70 2.75 0.41 2030 6.60 2.71 0.41 2090 6.40 2.62 0.41 2151

32 18 5.88 5.46 0.93 1608 5.63 5.23 0.93 1688 5.40 5.02 0.93 1769 5.20 4.84 0.93 1849

32 20 6.13 4.96 0.81 1688 5.88 4.76 0.81 1789 5.70 4.62 0.81 1829 5.50 4.46 0.81 1910

32 22 6.38 4.40 0.69 1749 6.15 4.24 0.69 1859 6.00 4.14 0.69 1910 5.75 3.97 0.69 1990

32 24 6.70 3.82 0.57 1829 6.45 3.68 0.57 1930 6.30 3.59 0.57 1990 6.10 3.48 0.57 2090

32 26 6.90 3.11 0.45 1930 6.70 3.02 0.45 2030 6.60 2.97 0.45 2090 6.40 2.88 0.45 2151

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21 25 27 30

E3E3

OUTDOOR DB(;)

22

Page 23

PERFORMANCE DATA

COOL operation(240V)

MCF-18NV - :MUCF-18NV -

CAPACITY : 5.0(kW) SHF : 0.67 INPUT : 2010(W)

INDOOR INDOOR

DB(;) WB(;)

21 18 4.90 2.40 0.49 1970 4.50 2.21 0.49 2090 4.33 2.12 0.49 2131 4.15 2.03 0.49 2171

21 20 5.15 1.91 0.37 2050 4.80 1.78 0.37 2151 4.63 1.71 0.37 2211 4.45 1.65 0.37 2271

22 18 4.90 2.60 0.53 1970 4.50 2.39 0.53 2090 4.33 2.29 0.53 2131 4.15 2.20 0.53 2171

22 20 5.15 2.11 0.41 2050 4.80 1.97 0.41 2151 4.63 1.90 0.41 2211 4.45 1.82 0.41 2271

22 22 5.45 1.58 0.29 2131 5.10 1.48 0.29 2251 4.93 1.43 0.29 2291 4.75 1.38 0.29 2332

23 18 4.90 2.79 0.57 1970 4.50 2.57 0.57 2090 4.33 2.47 0.57 2131 4.15 2.37 0.57 2171

23 20 5.15 2.32 0.45 2050 4.80 2.16 0.45 2151 4.63 2.08 0.45 2211 4.45 2.00 0.45 2271

23 22 5.45 1.80 0.33 2131 5.10 1.68 0.33 2251 4.93 1.63 0.33 2291 4.75 1.57 0.33 2332

24 18 4.90 2.99 0.61 1970 4.50 2.75 0.61 2090 4.33 2.64 0.61 2131 4.15 2.53 0.61 2171

24 20 5.15 2.52 0.49 2050 4.80 2.35 0.49 2151 4.63 2.27 0.49 2211 4.45 2.18 0.49 2271

24 22 5.45 2.02 0.37 2131 5.10 1.89 0.37 2251 4.93 1.82 0.37 2291 4.75 1.76 0.37 2332

24 24 5.75 1.44 0.25 2211 5.40 1.35 0.25 2312 5.25 1.31 0.25 2362 5.10 1.28 0.25 2412

25 18 4.90 3.19 0.65 1970 4.50 2.93 0.65 2090 4.33 2.81 0.65 2131 4.15 2.70 0.65 2171

25 20 5.15 2.73 0.53 2050 4.80 2.54 0.53 2151 4.63 2.45 0.53 2211 4.45 2.36 0.53 2271

25 22 5.45 2.23 0.41 2131 5.10 2.09 0.41 2251 4.93 2.02 0.41 2291 4.75 1.95 0.41 2332

25 24 5.75 1.67 0.29 2211 5.40 1.57 0.29 2312 5.25 1.52 0.29 2362 5.10 1.48 0.29 2412

26 18 4.90 3.38 0.69 1970 4.50 3.11 0.69 2090 4.33 2.98 0.69 2131 4.15 2.86 0.69 2171

26 20 5.15 2.94 0.57 2050 4.80 2.74 0.57 2151 4.63 2.64 0.57 2211 4.45 2.54 0.57 2271

26 22 5.45 2.45 0.45 2131 5.10 2.30 0.45 2251 4.93 2.22 0.45 2291 4.75 2.14 0.45 2332

26 24 5.75 1.90 0.33 2211 5.40 1.78 0.33 2312 5.25 1.73 0.33 2362 5.10 1.68 0.33 2412

26 26 6.05 1.27 0.21 2291 5.70 1.20 0.21 2392 5.53 1.16 0.21 2442 5.35 1.12 0.21 2492

27 18 4.90 3.58 0.73 1970 4.50 3.29 0.73 2090 4.33 3.16 0.73 2131 4.15 3.03 0.73 2171

27 20 5.15 3.14 0.61 2050 4.80 2.93 0.61 2151 4.63 2.82 0.61 2211 4.45 2.71 0.61 2271

27 22 5.45 2.67 0.49 2131 5.10 2.50 0.49 2251 4.93 2.41 0.49 2291 4.75 2.33 0.49 2332

27 24 5.75 2.13 0.37 2211 5.40 2.00 0.37 2312 5.25 1.94 0.37 2362 5.10 1.89 0.37 2412

27 26 6.05 1.51 0.25 2291 5.70 1.43 0.25 2392 5.53 1.38 0.25 2442 5.35 1.34 0.25 2492

28 18 4.90 3.77 0.77 1970 4.50 3.47 0.77 2090 4.33 3.33 0.77 2131 4.15 3.20 0.77 2171

28 20 5.15 3.35 0.65 2050 4.80 3.12 0.65 2151 4.63 3.01 0.65 2211 4.45 2.89 0.65 2271

28 22 5.45 2.89 0.53 2131 5.10 2.70 0.53 2251 4.93 2.61 0.53 2291 4.75 2.52 0.53 2332

28 24 5.75 2.36 0.41 2211 5.40 2.21 0.41 2312 5.25 2.15 0.41 2362 5.10 2.09 0.41 2412

28 26 6.05 1.75 0.29 2291 5.70 1.65 0.29 2392 5.53 1.60 0.29 2442 5.35 1.55 0.29 2492

29 18 4.90 3.97 0.81 1970 4.50 3.65 0.81 2090 4.33 3.50 0.81 2131 4.15 3.36 0.81 2171

29 20 5.15 3.55 0.69 2050 4.80 3.31 0.69 2151 4.63 3.19 0.69 2211 4.45 3.07 0.69 2271

29 22 5.45 3.11 0.57 2131 5.10 2.91 0.57 2251 4.93 2.81 0.57 2291 4.75 2.71 0.57 2332

29 24 5.75 2.59 0.45 2211 5.40 2.43 0.45 2312 5.25 2.36 0.45 2362 5.10 2.30 0.45 2412

29 26 6.05 2.00 0.33 2291 5.70 1.88 0.33 2392 5.53 1.82 0.33 2442 5.35 1.77 0.33 2492

30 18 4.90 4.17 0.85 1970 4.50 3.83 0.85 2090 4.33 3.68 0.85 2131 4.15 3.53 0.85 2171

30 20 5.15 3.76 0.73 2050 4.80 3.50 0.73 2151 4.63 3.38 0.73 2211 4.45 3.25 0.73 2271

30 22 5.45 3.32 0.61 2131 5.10 3.11 0.61 2251 4.93 3.00 0.61 2291 4.75 2.90 0.61 2332

30 24 5.75 2.82 0.49 2211 5.40 2.65 0.49 2312 5.25 2.57 0.49 2362 5.10 2.50 0.49 2412

30 26 6.05 2.24 0.37 2291 5.70 2.11 0.37 2392 5.53 2.04 0.37 2442 5.35 1.98 0.37 2492

31 18 4.90 4.36 0.89 1970 4.50 4.01 0.89 2090 4.33 3.85 0.89 2131 4.15 3.69 0.89 2171

31 20 5.15 3.97 0.77 2050 4.80 3.70 0.77 2151 4.63 3.56 0.77 2211 4.45 3.43 0.77 2271

31 22 5.45 3.54 0.65 2131 5.10 3.32 0.65 2251 4.93 3.20 0.65 2291 4.75 3.09 0.65 2332

31 24 5.75 3.05 0.53 2211 5.40 2.86 0.53 2312 5.25 2.78 0.53 2362 5.10 2.70 0.53 2412

31 26 6.05 2.48 0.41 2291 5.70 2.34 0.41 2392 5.53 2.27 0.41 2442 5.35 2.19 0.41 2492

32 18 4.90 4.56 0.93 1970 4.50 4.19 0.93 2090 4.33 4.02 0.93 2131 4.15 3.86 0.93 2171

32 20 5.15 4.17 0.81 2050 4.80 3.89 0.81 2151 4.63 3.75 0.81 2211 4.45 3.60 0.81 2271

32 22 5.45 3.76 0.69 2131 5.10 3.52 0.69 2251 4.93 3.40 0.69 2291 4.75 3.28 0.69 2332

32 24 5.75 3.28 0.57 2211 5.40 3.08 0.57 2312 5.25 2.99 0.57 2362 5.10 2.91 0.57 2412

32 26 6.05 2.72 0.45 2291 5.70 2.57 0.45 2392 5.53 2.49 0.45 2442 5.35 2.41 0.45 2492

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

35 40 43 46

E3E3

OUTDOOR DB(;)

23

Page 24

PERFORMANCE DATA

COOL operation(220V)

MCF-24NV - :MUCF-24NV -

CAPACITY : 6.4(kW) SHF : 0.63 INPUT : 2870(W)

INDOORINDOOR

DB(;) WB(;)

21 18 7.52 3.38 0.45 2296 7.20 3.24 0.45 2411 6.91 3.11 0.45 2526 6.66 3.00 0.45 2640

21 20 7.84 2.59 0.33 2411 7.52 2.48 0.33 2554 7.30 2.41 0.33 2612 7.04 2.32 0.33 2727

22 18 7.52 3.68 0.49 2296 7.20 3.53 0.49 2411 6.91 3.39 0.49 2526 6.66 3.26 0.49 2640

22 20 7.84 2.90 0.37 2411 7.52 2.78 0.37 2554 7.30 2.70 0.37 2612 7.04 2.60 0.37 2727

22 22 8.16 2.04 0.25 2497 7.87 1.97 0.25 2655 7.68 1.92 0.25 2727 7.36 1.84 0.25 2841

23 18 7.52 3.99 0.53 2296 7.20 3.82 0.53 2411 6.91 3.66 0.53 2526 6.66 3.53 0.53 2640

23 20 7.84 3.21 0.41 2411 7.52 3.08 0.41 2554 7.30 2.99 0.41 2612 7.04 2.89 0.41 2727

23 22 8.16 2.37 0.29 2497 7.87 2.28 0.29 2655 7.68 2.23 0.29 2727 7.36 2.13 0.29 2841

24 18 7.52 4.29 0.57 2296 7.20 4.10 0.57 2411 6.91 3.94 0.57 2526 6.66 3.79 0.57 2640

24 20 7.84 3.53 0.45 2411 7.52 3.38 0.45 2554 7.30 3.28 0.45 2612 7.04 3.17 0.45 2727

24 22 8.16 2.69 0.33 2497 7.87 2.60 0.33 2655 7.68 2.53 0.33 2727 7.36 2.43 0.33 2841

24 24 8.58 1.80 0.21 2612 8.26 1.73 0.21 2755 8.06 1.69 0.21 2841 7.81 1.64 0.21 2985

25 18 7.52 4.59 0.61 2296 7.20 4.39 0.61 2411 6.91 4.22 0.61 2526 6.66 4.06 0.61 2640

25 20 7.84 3.84 0.49 2411 7.52 3.68 0.49 2554 7.30 3.58 0.49 2612 7.04 3.45 0.49 2727

25 22 8.16 3.02 0.37 2497 7.87 2.91 0.37 2655 7.68 2.84 0.37 2727 7.36 2.72 0.37 2841

25 24 8.58 2.14 0.25 2612 8.26 2.06 0.25 2755 8.06 2.02 0.25 2841 7.81 1.95 0.25 2985

26 18 7.52 4.89 0.65 2296 7.20 4.68 0.65 2411 6.91 4.49 0.65 2526 6.66 4.33 0.65 2640

26 20 7.84 4.16 0.53 2411 7.52 3.99 0.53 2554 7.30 3.87 0.53 2612 7.04 3.73 0.53 2727

26 22 8.16 3.35 0.41 2497 7.87 3.23 0.41 2655 7.68 3.15 0.41 2727 7.36 3.02 0.41 2841

26 24 8.58 2.49 0.29 2612 8.26 2.39 0.29 2755 8.06 2.34 0.29 2841 7.81 2.26 0.29 2985

26 26 8.83 1.50 0.17 2755 8.58 1.46 0.17 2899 8.45 1.44 0.17 2985 8.19 1.39 0.17 3071

27 18 7.52 5.19 0.69 2296 7.20 4.97 0.69 2411 6.91 4.77 0.69 2526 6.66 4.59 0.69 2640

27 20 7.84 4.47 0.57 2411 7.52 4.29 0.57 2554 7.30 4.16 0.57 2612 7.04 4.01 0.57 2727

27 22 8.16 3.67 0.45 2497 7.87 3.54 0.45 2655 7.68 3.46 0.45 2727 7.36 3.31 0.45 2841

27 24 8.58 2.83 0.33 2612 8.26 2.72 0.33 2755 8.06 2.66 0.33 2841 7.81 2.58 0.33 2985

27 26 8.83 1.85 0.21 2755 8.58 1.80 0.21 2899 8.45 1.77 0.21 2985 8.19 1.72 0.21 3071

28 18 7.52 5.49 0.73 2296 7.20 5.26 0.73 2411 6.91 5.05 0.73 2526 6.66 4.86 0.73 2640

28 20 7.84 4.78 0.61 2411 7.52 4.59 0.61 2554 7.30 4.45 0.61 2612 7.04 4.29 0.61 2727

28 22 8.16 4.00 0.49 2497 7.87 3.86 0.49 2655 7.68 3.76 0.49 2727 7.36 3.61 0.49 2841

28 24 8.58 3.17 0.37 2612 8.26 3.05 0.37 2755 8.06 2.98 0.37 2841 7.81 2.89 0.37 2985

28 26 8.83 2.21 0.25 2755 8.58 2.14 0.25 2899 8.45 2.11 0.25 2985 8.19 2.05 0.25 3071

29 18 7.52 5.79 0.77 2296 7.20 5.54 0.77 2411 6.91 5.32 0.77 2526 6.66 5.13 0.77 2640

29 20 7.84 5.10 0.65 2411 7.52 4.89 0.65 2554 7.30 4.74 0.65 2612 7.04 4.58 0.65 2727

29 22 8.16 4.32 0.53 2497 7.87 4.17 0.53 2655 7.68 4.07 0.53 2727 7.36 3.90 0.53 2841

29 24 8.58 3.52 0.41 2612 8.26 3.38 0.41 2755 8.06 3.31 0.41 2841 7.81 3.20 0.41 2985

29 26 8.83 2.56 0.29 2755 8.58 2.49 0.29 2899 8.45 2.45 0.29 2985 8.19 2.38 0.29 3071

30 18 7.52 6.09 0.81 2296 7.20 5.83 0.81 2411 6.91 5.60 0.81 2526 6.66 5.39 0.81 2640

30 20 7.84 5.41 0.69 2411 7.52 5.19 0.69 2554 7.30 5.03 0.69 2612 7.04 4.86 0.69 2727

30 22 8.16 4.65 0.57 2497 7.87 4.49 0.57 2655 7.68 4.38 0.57 2727 7.36 4.20 0.57 2841

30 24 8.58 3.86 0.45 2612 8.26 3.72 0.45 2755 8.06 3.63 0.45 2841 7.81 3.51 0.45 2985

30 26 8.83 2.91 0.33 2755 8.58 2.83 0.33 2899 8.45 2.79 0.33 2985 8.19 2.70 0.33 3071

31 18 7.52 6.39 0.85 2296 7.20 6.12 0.85 2411 6.91 5.88 0.85 2526 6.66 5.66 0.85 2640

31 20 7.84 5.72 0.73 2411 7.52 5.49 0.73 2554 7.30 5.33 0.73 2612 7.04 5.14 0.73 2727

31 22 8.16 4.98 0.61 2497 7.87 4.80 0.61 2655 7.68 4.68 0.61 2727 7.36 4.49 0.61 2841

31 24 8.58 4.20 0.49 2612 8.26 4.05 0.49 2755 8.06 3.95 0.49 2841 7.81 3.83 0.49 2985

31 26 8.83 3.27 0.37 2755 8.58 3.17 0.37 2899 8.45 3.13 0.37 2985 8.19 3.03 0.37 3071

32 18 7.52 6.69 0.89 2296 7.20 6.41 0.89 2411 6.91 6.15 0.89 2526 6.66 5.92 0.89 2640

32 20 7.84 6.04 0.77 2411 7.52 5.79 0.77 2554 7.30 5.62 0.77 2612 7.04 5.42 0.77 2727

32 22 8.16 5.30 0.65 2497 7.87 5.12 0.65 2655 7.68 4.99 0.65 2727 7.36 4.78 0.65 2841

32 24 8.58 4.55 0.53 2612 8.26 4.38 0.53 2755 8.06 4.27 0.53 2841 7.81 4.14 0.53 2985

32 26 8.83 3.62 0.41 2755 8.58 3.52 0.41 2899 8.45 3.46 0.41 2985 8.19 3.36 0.41 3071

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

21 25 27 30

E3E3

OUTDOOR DB(;)

24

Page 25

PERFORMANCE DATA

COOL operation(220V)

MCF-24NV - :MUCF-24NV -

CAPACITY : 6.4(kW) SHF : 0.63 INPUT : 2870(W)

INDOOR INDOOR

DB(;) WB(;)

21 18 6.27 2.82 0.45 2813 5.76 2.59 0.45 2985 5.54 2.49 0.45 3042 5.31 2.39 0.45 3100

21 20 6.59 2.18 0.33 2927 6.14 2.03 0.33 3071 5.92 1.95 0.33 3157 5.70 1.88 0.33 3243

22 18 6.27 3.07 0.49 2813 5.76 2.82 0.49 2985 5.54 2.71 0.49 3042 5.31 2.60 0.49 3100

22 20 6.59 2.44 0.37 2927 6.14 2.27 0.37 3071 5.92 2.19 0.37 3157 5.70 2.11 0.37 3243

22 22 6.98 1.74 0.25 3042 6.53 1.63 0.25 3214 6.30 1.58 0.25 3272 6.08 1.52 0.25 3329

23 18 6.27 3.32 0.53 2813 5.76 3.05 0.53 2985 5.54 2.93 0.53 3042 5.31 2.82 0.53 3100

23 20 6.59 2.70 0.41 2927 6.14 2.52 0.41 3071 5.92 2.43 0.41 3157 5.70 2.34 0.41 3243

23 22 6.98 2.02 0.29 3042 6.53 1.89 0.29 3214 6.30 1.83 0.29 3272 6.08 1.76 0.29 3329

24 18 6.27 3.58 0.57 2813 5.76 3.28 0.57 2985 5.54 3.16 0.57 3042 5.31 3.03 0.57 3100

24 20 6.59 2.97 0.45 2927 6.14 2.76 0.45 3071 5.92 2.66 0.45 3157 5.70 2.56 0.45 3243

24 22 6.98 2.30 0.33 3042 6.53 2.15 0.33 3214 6.30 2.08 0.33 3272 6.08 2.01 0.33 3329

24 24 7.36 1.55 0.21 3157 6.91 1.45 0.21 3301 6.72 1.41 0.21 3372 6.53 1.37 0.21 3444

25 18 6.27 3.83 0.61 2813 5.76 3.51 0.61 2985 5.54 3.38 0.61 3042 5.31 3.24 0.61 3100

25 20 6.59 3.23 0.49 2927 6.14 3.01 0.49 3071 5.92 2.90 0.49 3157 5.70 2.79 0.49 3243

25 22 6.98 2.58 0.37 3042 6.53 2.42 0.37 3214 6.30 2.33 0.37 3272 6.08 2.25 0.37 3329

25 24 7.36 1.84 0.25 3157 6.91 1.73 0.25 3301 6.72 1.68 0.25 3372 6.53 1.63 0.25 3444

26 18 6.27 4.08 0.65 2813 5.76 3.74 0.65 2985 5.54 3.60 0.65 3042 5.31 3.45 0.65 3100

26 20 6.59 3.49 0.53 2927 6.14 3.26 0.53 3071 5.92 3.14 0.53 3157 5.70 3.02 0.53 3243

26 22 6.98 2.86 0.41 3042 6.53 2.68 0.41 3214 6.30 2.58 0.41 3272 6.08 2.49 0.41 3329

26 24 7.36 2.13 0.29 3157 6.91 2.00 0.29 3301 6.72 1.95 0.29 3372 6.53 1.89 0.29 3444

26 26 7.74 1.32 0.17 3272 7.30 1.24 0.17 3415 7.07 1.20 0.17 3487 6.85 1.16 0.17 3559

27 18 6.27 4.33 0.69 2813 5.76 3.97 0.69 2985 5.54 3.82 0.69 3042 5.31 3.67 0.69 3100

27 20 6.59 3.76 0.57 2927 6.14 3.50 0.57 3071 5.92 3.37 0.57 3157 5.70 3.25 0.57 3243

27 22 6.98 3.14 0.45 3042 6.53 2.94 0.45 3214 6.30 2.84 0.45 3272 6.08 2.74 0.45 3329

27 24 7.36 2.43 0.33 3157 6.91 2.28 0.33 3301 6.72 2.22 0.33 3372 6.53 2.15 0.33 3444

27 26 7.74 1.63 0.21 3272 7.30 1.53 0.21 3415 7.07 1.49 0.21 3487 6.85 1.44 0.21 3559

28 18 6.27 4.58 0.73 2813 5.76 4.20 0.73 2985 5.54 4.04 0.73 3042 5.31 3.88 0.73 3100

28 20 6.59 4.02 0.61 2927 6.14 3.75 0.61 3071 5.92 3.61 0.61 3157 5.70 3.47 0.61 3243

28 22 6.98 3.42 0.49 3042 6.53 3.20 0.49 3214 6.30 3.09 0.49 3272 6.08 2.98 0.49 3329

28 24 7.36 2.72 0.37 3157 6.91 2.56 0.37 3301 6.72 2.49 0.37 3372 6.53 2.42 0.37 3444

28 26 7.74 1.94 0.25 3272 7.30 1.82 0.25 3415 7.07 1.77 0.25 3487 6.85 1.71 0.25 3559

29 18 6.27 4.83 0.77 2813 5.76 4.44 0.77 2985 5.54 4.26 0.77 3042 5.31 4.09 0.77 3100

29 20 6.59 4.28 0.65 2927 6.14 3.99 0.65 3071 5.92 3.85 0.65 3157 5.70 3.70 0.65 3243

29 22 6.98 3.70 0.53 3042 6.53 3.46 0.53 3214 6.30 3.34 0.53 3272 6.08 3.22 0.53 3329

29 24 7.36 3.02 0.41 3157 6.91 2.83 0.41 3301 6.72 2.76 0.41 3372 6.53 2.68 0.41 3444

29 26 7.74 2.25 0.29 3272 7.30 2.12 0.29 3415 7.07 2.05 0.29 3487 6.85 1.99 0.29 3559

30 18 6.27 5.08 0.81 2813 5.76 4.67 0.81 2985 5.54 4.48 0.81 3042 5.31 4.30 0.81 3100

30 20 6.59 4.55 0.69 2927 6.14 4.24 0.69 3071 5.92 4.08 0.69 3157 5.70 3.93 0.69 3243

30 22 6.98 3.98 0.57 3042 6.53 3.72 0.57 3214 6.30 3.59 0.57 3272 6.08 3.47 0.57 3329

30 24 7.36 3.31 0.45 3157 6.91 3.11 0.45 3301 6.72 3.02 0.45 3372 6.53 2.94 0.45 3444

30 26 7.74 2.56 0.33 3272 7.30 2.41 0.33 3415 7.07 2.33 0.33 3487 6.85 2.26 0.33 3559

31 18 6.27 5.33 0.85 2813 5.76 4.90 0.85 2985 5.54 4.71 0.85 3042 5.31 4.52 0.85 3100

31 20 6.59 4.81 0.73 2927 6.14 4.49 0.73 3071 5.92 4.32 0.73 3157 5.70 4.16 0.73 3243