Page 1

DUCTLESS SPLIT-TYPE AIR CONDITIONERS

L

I

S

T

E

D

R

TECHNICAL & SERVICE MANUAL

Wireless type

Models

MS09NW✕2 MS15NN✕1 • MUM30NN

CONTENTS

No.OB204

1. FEATURES·························································2

2. TECHNICAL CHANGES ····································3

3. PART NAMES AND FUNCTIONS······················3

4. SPECIFICATIONS ··············································4

5. DATA ···································································5

6. OUTLINES AND DIMENSIONS·························9

7. WIRING DIAGRAM ··········································10

8. REFRIGERANT SYSTEM DIAGRAM··············11

9. TROUBLESHOOTING······································12

10. DISASSEMBLY INSTRUCTIONS·····················14

11. PARTS LIST······················································17

12. OPTIONAL PARTS ····································BACK

NOTE:For parts list, please refer to the following manuals.

MS09NW ➝ OB192

MS15NN ➝ OB192

The Slim Line.

From Mitsubishi Electric.

Page 2

1 FEATURES

MUM30EN

LCD Wireless

remote controller

MS09NW

MS15NN

MS09NW

This “3 to 1” Multi system (MSM30EN) consists of a single outdoor unit with three compressors that permit up to three

indoor units to be installed separate rooms, each with its own controller.

Cooling Capacity (BTU/h)

Operation

1 Indoor Unit Operation

2 Indoor Unit Operatin

3 Indoor Unit Operation

Indoor unit

MS09NW

8,200

—

—

8,200

8,200

—

8,100

MS09NW

—

8,200

—

8,200

—

8,200

8,100

MS15NN

—

—

12,400

—

12,400

12,400

12,200

1.SPACE-SAVING LAYOUT

Two or three indoor units are served by a single outdoor unit whose installation requires only minimum space. This allows

equipment installed outside the house to be arranged in a neat, space-saving layout.

2.FLEXIBLE INSTALLATION OF INDOOR UNITS

Each indoor unit can be connected to piping up to 65 feet in length, providing plenty of freedom in determining the best locations for installation.

3.AUTO-RESTART FUNCTION

The auto restart function restarts the equipment when power is

restored following an outage automatically. Operation resumes

in the mode in which the equipment was running immediately

before the outage.

HIGH PERFORMANCE ROTARY COMPRESSOR

The advanced design of Mitsubishi Electric’s powerful and energyefficient rotary compressor results in lower operating costs

and longer service life.

2

Page 3

2 TECHNICAL CHANGES

MSM30EW ➔ MSM30NW

1. Indoor unit has been changed.

2. Outdoor unit has been changed.

3. Remote controller has been changed.

(The timer function has been changed to the clock timer function.)

4. Indoor auto vave has been adopted.

5. Fan speed control has changed.

(MF1/MF2 : 1.Lo/Lo➔Stop/Hi 2.Me/Me➔Me/Me 3.Hi/Hi➔Hi/Hi)

6. The relay “X64” has been added to electric circuit.

7. Surge absorber has been added to electric circuit.

3 PART NAMES AND FUNCTIONS

OUTDOOR UNIT

MUM30NN

3

Page 4

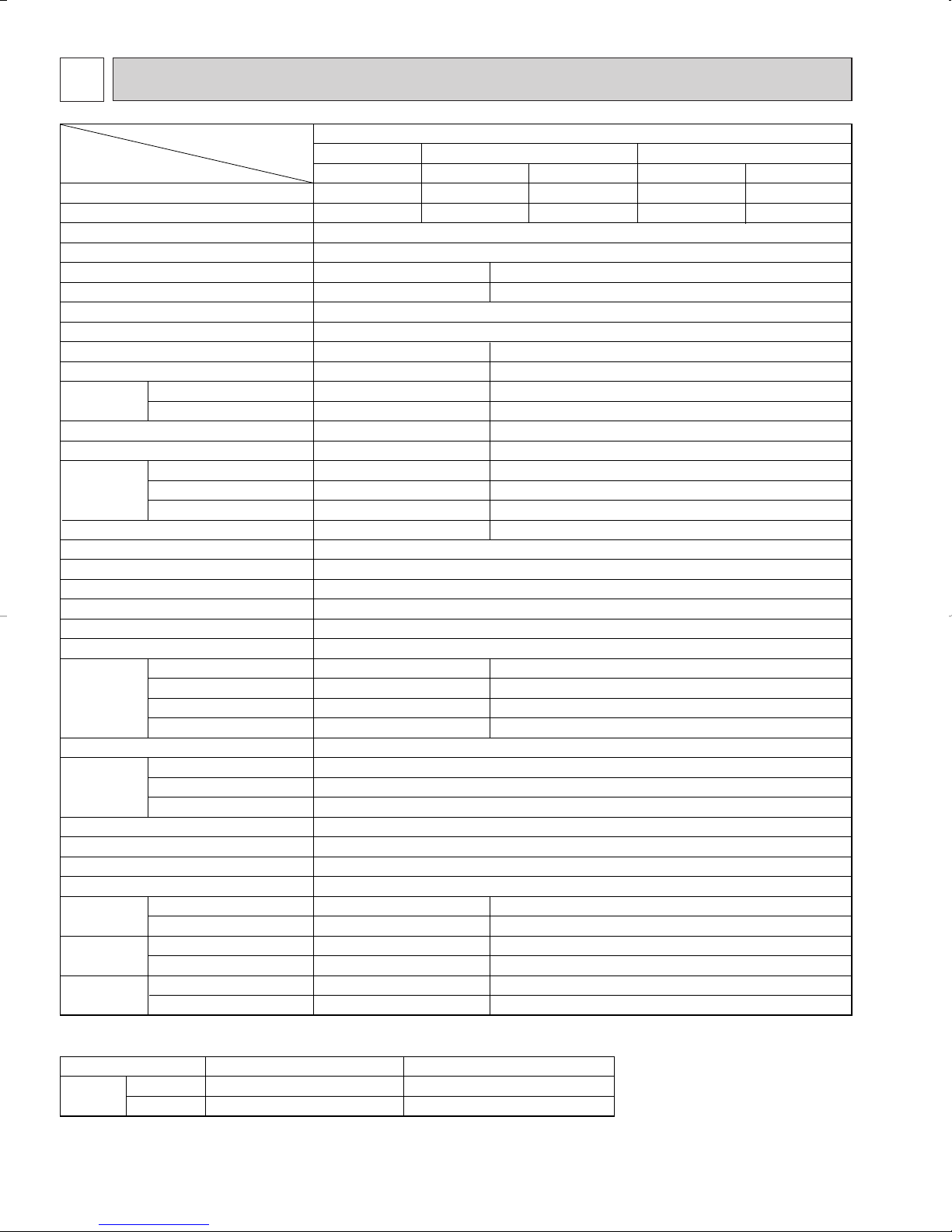

4 SPECIFICATIONS

Model

Cooling capacity w1 BTU/h

w1 WPower consumption

EER (Triple unit operation)

SEER (Triple unit operation)

INDOOR UNIT MODEL

Extenal finish

Power Supply V, Hz, Phase

A

F.L.A

CFM

CFM

(Pints/h)

in.

in.

in.

in.

lbs.

V, Hz, Phase

A

F.L.A

Winding resistance (at 68˚F) "

Model

W

D

H

W

D

H

Dry

Wet

Liquid

Gas

Indoors

Outdoors

Height difference

Piping length

R.L.A

L.R.A

in.

in.

in.

in.

in.

ft

ft

lbs.

Max. fuse size (time delay)

Min. ampacity

Fan motor

Airflow

Lo-Me-Hi

Moisture removal

Cond. drain connection OD

Dimensions

Weight

OUTDOOR UNIT MODEL

External fnish

Power supply

Max. fuse sizu (time delay)

Min. ampacity

Fan motor

Compressor

Refrigerant control

Dimensions

Weight

REMOTE CONTROLLER

Control voltage (be built-in transformer)

REFRIGERANT PIPING

Pipe size

Connection

method

Between the

indoor &

outdoor units

Items

MSM30NN

Triple-Unit

A+B+C

28,400

2,990

DoubIe-Unit

A+B

A+C or B+C

16,400

20,600

1,860

9.9

10.0

2,060

C: MS15NN

White

A & B: MS09NW

White

115,60,1

15.0

0.5 0.6

0.37 0.43

208-265-328 360-395-452

177-226-279 314-342-392

1.0 1.5

5/8 5/8

32-1/16 39-15/16

7-3/16 7-1/2

12-5/8

18 31

MUM30NN

Munsell 5Y 7/1

208/230,60,1(3-wire)

30

25

0.8+0.7

KH122WEV<115V>

RH167NAB<208/230V>

C-R 0.97 C-S 4.81

C-R 2.47 C-S 4.62

10 8

37 29

Capillary tube

37-7-16

15-3/8

45-5/16

240

Wireless type

DC12V

Not supplied (optional parts)

1/4 1/4

3/8 5/8

Flared Flared

Flared Flared

Max. 25 Max. 25

Max. 65 Max. 65

Notes w1. Rating conditions (cooling) — Inddor : 80˚FDB, 67˚FWB, Outdoor : 95˚FDB, 75˚FWB

Operating Range

Cooling

Maximum

Maximum

Indoor air intake temperature

90˚FDB,71˚FWB

67˚FDB,57˚FWB

Outdoor air intake temperature

115˚FDB

67˚FDB

Single-Unit

A or B

C

990

8,200

12,400

1,220

10-13/16

4

Page 5

5 DATA

65

0.6

0.8

1.0

1.2

6

8

10

12

75 85 95 105 115

Outdoor intake air DB temperature (-F)

Total power consumption (kW) Total capacity (o 10

3

Btu/h)

Cooling capacity

SHF at rating condition = 0.72

Airflow = 279CFM

Bypass Factor = 0.24

Indoor intake air WB temperature (-F)

Indoor intake air WB temperature (-F)

63

67

71

63

67

71

65

1.0

1.2

1.4

1.6

10

12

14

16

75 85 95 105 115

Outdoor intake air DB temperature (-F)

Total power consumption (kW) Total capacity (o 10

3

Btu/h)

Cooling capacity

SHF at rating condition = 0.71

Airflow = 392CFM

Bypass Factor = 0.19

Indoor intake air WB temperature (-F)

Indoor intake air WB temperature (-F)

63

67

71

63

67

71

MS09NW✕ 2 MS15NN✕1

MUM30NN

1.PERFORMANCE DATA(ONE INDOOR UNIT WITH ONE OUTDOOR UNIT)

1) COOLING CAPACITY

TC

8.20

7.63

7.01

12.40

11.53

10.60

)

SHC

TPC

4.81

1.09

5.49

1.05

5.98

1.01

7.15

1.35

8.19

1.29

8.94

1.24

Indoor air Outdoor intake air DB temperature(˚F

Models

MS09NW

MS15NN

Notes 1. IWB : Intake air wet-bulb temperature

TC : Total Capacity (x10

TPC : Total Power Consumption (kW)

2. SHC is based on 80˚F of indoor intake air DB temperature.

IWB

(˚F)

71

67

63

71

67

63

10.05

15.19

14.38

13.52

3

Btu/h), SHC : Sensible Heat Capacity (x10

75 85 95 105 115

TC

SHC

TPC

5.89

0.88

9.51

6.85

0.83

8.94

7.63

0.79

8.76

1.09

10.21

1.03

11.40

0.98

TC

9.39

8.86

8.28

14.20

13.39

12.52

SHC

5.51

6.38

7.07

8.19

9.51

10.56

3

Btu/h)

TPC

0.97

0.92

0.88

1.19

1.13

1.08

TC

8.82

8.20

7.71

13.33

12.40

11.66

SHC

5.17

5.90

6.58

7.69

8.80

9.83

TPC

1.04

0.99

0.95

1.28

1.22

1.17

2) COOLING CAPACITY CORRECTIONS

Refrigerant piping length (one way)

MODEL

MS-09NW

25ft (std)

1.0

40ft

0.954

49ft

0.927

2.PERFORMANCE CURVE(ONE INDOOR UNIT WITH ONE OUTDOOR UNIT)

NOTE : Apoint on the curve shows the reference point.

MS09NW

MUM30NN

MS15NN

MUM30NN

TC

7.54

7.01

6.40

11.41

10.60

9.67

SHC

4.43

5.05

5.46

6.58

7.53

8.16

TPC

1.14

1.10

1.05

1.40

1.35

1.29

NOTE :

Total capacity = multiply cooling capacity in specifications table on page 4 by capacity correction factor on this page.

Total power consumption = multiply power consumption in specifcations table on page 4 by power correction factor on this

page.

5

Page 6

67

40

50

60

70

80

90

100

(PSIG)

70

Outdoor ambient temperature

75 80 85 90 95 100 104-F

Suction pressure

70

86-F

80

75

Indoor DB temperature

67

170

180

200

220

240

260

280

300

(PSIG)

70

Outdoor ambient temperature

75 80 85 90 95 100 104-F

70

75

80

86-F

Condensing pressure

Indoor DB temperature

3.CONDENSING PRESSURE AND SUCTION PRESURE

67

170

180

200

220

240

260

280

300

(PSIG)

70

Outdoor ambient temperature

75 80 85 90 95 100 104-F

70

75

80

86-F

Condensing pressure

Indoor DB temperature

67

40

50

60

70

80

90

100

(PSIG)

70

Outdoor ambient temperature

75 80 85 90 95 100 104-F

Suction pressure

70

86-F

80

75

Indoor DB temperature

(ONE INDOOR UNIT WITH ONE OUTDOOR UNIT)

Data is based on the condition of indoor humidity 50%. Air flow should be set at HI. A point on the corve shows the reference

point.

MS09NW MS15NN

MUM30NN MUM30NN

MS09NW MS15NN

MUM30NN MUM30NN

6

Page 7

2.STANDARD OPERATION DATA

MODEL Triple

A+B+C

Double

A+B A+C or B+C

Single

115,60,1 115,60,1 115,60,1

0.7+0.8 0.65+0.75 0.6+0.7

95 95 95

— — —

850/940 750/840 0/1030

2,720 2,360 1,039

A or B

C

28,400 16,400 20,600 8,200 12,400

0.72 0.72 0.71 0.72

2.99 1.86 2.06 0.99 1.22

2.873 1.79 1.978 0.955 1.173

MSM30NN

CoolingUnit

BTU/h

—

kW

kW

A

kW

A

A

PSIG

PSIG

˚F

˚F

˚F

˚F

ft

—

˚F

˚F

˚F

˚F

DB

WB

DB

WB

R.P.M.

CFM

˚F

˚F

DB

WB

R.P.M.

CFM

Item

Capacity

SHFTotal

Electrical

circuit

Refrigerant

circuit

Indoor

side

Outdoor

side

Input

Indoor unit model

Power supply (V,Hz,{)

Input

Fan current

Outdoor unit model

Power supply (V,Hz,{)

Input

Comp. current

Fan current

Condensing pressure

Suction pressure

Discharge temp.

Condensing temp.

Suction temp.

Comp.shell botton temp.

Ref.pipe length

Refrigerant charge

Entering

air temp.

Discharge

air temp.

Entering

air temp.

Fan speed

Airflow (Hi)

Fan speed

Airflow

MS09NW MS09NW MS15NN MS09NW MS09NW MS09NW MS15NN MS09NW MS15NN

0.035

0.34

0.035

0.34

0.047

0.71

0.41

0.035

0.34

0.035

0.34

MUM30NN

208/230,60,1(3-wire)

0.035

0.34

0.047

0.41

0.035

0.34

0.047

0.41

7.0

273

80

154

122

47

130

25

3 lbs 3 oz

80

67

60

57

1,230

279

264

80

157

118

47

130

25

3 lbs 3 oz

80

67

60

57

1,230

279

243

82

169

111

54

145

25

3 lbs 8 oz

80

67

58

57

1,200

392

262

78

197

118

60

171

25

3 lbs 3 oz

80

67

60

57

1,230

279

263

79

171

116

47

146

25

3 lbs 3 oz

80

67

60

57

1,230

279

269

78

151

118

47

124

25

3 lbs 3 oz

80

67

60

57

1,230

279

240

82

169

110

54

144

25

3 lbs 8 oz

80

67

58

57

1,200

392

267

80

143

121

52

129

25

3 lbs 3 oz

80

67

60

57

1,230

279

267

85

141

118

51

139

25

3 lbs 8 oz

80

67

58

57

1,200

392

7.0 3.8 7.0 7.0 7.0 3.8 7.0 3.8

0.72 0.71

INDOOR UNIT C

INDOOR UNIT B

INDOOR UNIT A

OUTDOOR UNIT

208/230V,60Hz,

1{ 3wire

POWER SUPPLY

115V common

115V 230V

SIGNAL WIRE 2wire 12V DC

115V,60Hz,1{

115V,60Hz,1{

115V,60Hz,1{

7

Page 8

4.OPERATING RANGE

Indoor unit

115V 60Hz 1[

208/230V 60Hz 1[

(3wires)

Min. 198V 208V 230V Max. 253V

Min. 103v—Max. 127V

Outdoor unit

MS09NW

MS15NN

MUM 30NN

Models Rating Guaranteed Voltage

Function

Cooling

Indoor Outdoor

78% –

DB (˚F)

80

95

67

Standard temperature

Maximum temperature

Minimum temperature

Maximum humidity

WB (˚F)

67

71

57

DB (˚F)

95

115

67

WB (˚F)

–

–

–

Intake air

temperature

Condition

Model

Outdoor unit

precharged

(up to 25ft)

Refrigerant piping length (one way)

MUM

MS09NW

MS15NN

3 Ibs 3 oz o2

3 Ibs 8 oz

25ft 30ft 33ft 40ft 45ft 49ft 65ft

0 1 1 2 2 3 5

Indoor unit A

MS09NW

w Max. Height

difference 25ft

Indoor unit B

MS09NW

Outdoor unit

MUM30NN

Indoor unit C

MS15NN

Max. Length

65ft

w Max. Height

difference 25ft

w Max. Height

difference 25ft

Max. Length

65ft

Max. Length

65ft

Model

Additional piping

Max. length : ft

A

Length of connecting pipe : in.

MS09NW

MS15NN

65

Gas Liquid Indoor unit

16-15/16

Piping size O.D. : in.

0

[3/8

[5/8

[1/4

Outdoor unit

(1)

POWER SUPPLY

(2)

OPERATION

5.ADDITIONAL REFRIGERANT CHARGE (R-22(oz))

6.MAX. REFRIGERANT PIPING LENGTH & MAX. HEIGHT DIFFERENCE

MSM30NN

7.PIPING PREPARATION

8

Page 9

6 OUTLINES AND DIMENSIONS

Air intake

Min.4in.

Min.36in.

Min.33in.

Min.4in.

Min.12in.

Space for servicing

wining and piping

3-3/16

2-9/16

Air intake

Drainage

hole

2-{1

18-3/4

Installation anchor hole

1-13/16

4-{7/16

7/16

16-9/16

7/16

5-15/16

5-15/16

2

25-5/8

Air outlet

15-3/8

Earth terminal

Service panel

Electrical box

2-1/16

2-5/32

17-3/8

1

45-5/16

Air outlet

handle for

moving

12-1/4

20-1/2

12-5/8

{1

{1

13-5/8

37-7/16

Drainage hole

1

Air intake

4 wiring holes

{7/8

Refrigerant pipe (Flared) {1/2

Refrigerant pipe (Flared) {1/4

Refrigerant pipe (Flared) {3/8

2-3/8

2-3/8

2-3/8

2-3/8

2-3/8

2-15/16

NOTE : The symbol { indicates the diameter.

MODEL : MUM30NN

OUTDOOR UNIT

Unit : inch

9

Page 10

7 WIRING DIAGRAM

115V115V

RED

POWER

SUPPLY

208/230V

1phase

3wires

60Hz

GROUND

BLU

L2

BLK

N

BLK

RED

L1

TB1

RED

BLU

NO

52C2

COM

WHT

2

51C2

1

1

51C1

2

WHT

COM

52C1

NO

52C3

NO

COM

WHT

2

1

51C3

BLK

MC1

R

C

RED

C1

WHT

BLK

R

MC3

S

RED

C3

C

WHT

BLK

BLK

WHT

BLK

MC2

R

C

S

C2

RED

BLK

ORN

BRN

ORN

BRN

ORN

BRN

BRN

ORN

BRN

ORN

TO INDOOR UNIT(15C)

CONNECTING WIRES

DC12V

TO INDOOR UNIT(09B)

CONNECTING WIRES

DC12V

TB2

2

1

INDOOR

UNIT

(09A)

(09B)

INDOOR

UNIT

TB3

TO INDOOR UNIT(09A)

CONNECTING WIRES

DC12V

1

2

(15C)

INDOOR

UNIT

ORN

TB4

1

2

BRN

52C3

2

52C2

1

2

52C1

1

WHT

BLK

YLW

ORN

RED

1

6

5

4

3

2

ORN

RED

BLU

YLW

BLK

WHT

C62

C61

(52C3) (52C2) (52C1)

CN623 CN622 CN621

LD605

LD606

LD615

LD616

2121 1 2

MF1

X63

X61

X62

4

3

2

1

LD621

LD620

RED

BLU

GRN

F

(AC)

TAB62

T

(2A)

(TRS)

CN64

TAB61

DSAR61

LD61

NR61

LD614

LD613

LD603

LD612

LD602

LD611

LD601

BLU

BLU

BLK

BLK

X63

X62

X61

RED

RED

BLU

BLU

GRY

BLU

GRY

BLU

1

3

CR

7 8

1

2

X64

GRY

BLU

WHT

BLK

YLW

ORN

RED

1

6

5

4

3

2

RED

YLW

BLK

WHT

ORN

6

5

4

3

2

1

GRY

BRN

X64

5

1

3

4

6

2

MF2

ORN

RED

BLU

YLW

BLK

WHT

X64

S

w

w

w

w

w

w

OUTDOOR

MODEL MUM30NN WIRING DIAGRAM

SYMBOL NAME SYMBOL NAME SYMBOL NAME

C1~C3

C61,C62 FAN MOTOR CAPACITOR MF1,2

DSAR61 SURGE ABSORBER NR61 VARISTOR 51C1,2

NOTE:1. Use copper conductors only (For field wiring).

2. Symbols below indicate.

3. “w”shows the terminals with a lock mechanism, so they cannot be removed when you pull

10

COMPRESSOR CAPACITOR

F FUSE (2A) T TRANSFORMER 52C1,2

the lead wire.

Be sure to pull the wire by pushing the locking lever (projected part) of the terminal with a finger.

: Terminal block, : Connector

MC1~MC3

COMPRESSOR(INNER THERMOSTAT)

FAN MOTOR(INNER THERMOSTAT)

TB1~TB4 TERMINAL BLOCK

X61~X63 FAN MOTOR RELAY

OVERCURRENT RELAY

COMPRESSOR CONTACTOR

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

Page 11

8 REFRIGERANT SYSTEM DIAGRAM

Refrigerant pipe [1/4

(Option)

(with heat insulator)

Indoor coil

thermistor

RT12

Room temp

thermistor

RT11

Flared

connection

Flared

connection

Ball valve

with service port

Refrigerant pipe [3/8

(Option)

(with heat insulator)

Ball valve

Service

port

Service

port

Accumulator

Muffler

Fusible

plug

Compressor

Capillary tube

Strainer

MS09NW

Evaporator

Indoor coil

thermistor

RT12

Room temp

thermistor

RT11

Flared

connection

Flared

connection

Refrigerant pipe [1/4

(Option)

(with heat insulator)

Ball valve

with service port

Refrigerant pipe [5/8

(Option)

(with heat insulator)

/2

(Option)

(with heat insulator)

Ball valve

Service

port

Service

port

Accumulator

Muffler

Fusible

plug

Compressor

[0.12o[0.063o15-3/4

Capillary tube

Strainer

MS15NN

Evaporator

Indoor unit Outdoor unit

Indoor coil

thermistor

RT12

Room temp

thermistor

RT11

Flared

connection

Flared

connection

Refrigerant pipe [1/4

(Option)

(with heat insulator)

Ball valve

with service port

Refrigerant pipe [3/8

(Option)

(with heat insulator)

Ball valve

Service

port

Service

port

Accumulator

Muffler

Fusible

plug

Compressor

[0.12o[0.055o33-7/16

Capillary tube

Strainer

MS09NW

Evaporator

Condenser

[0.12o[0.055o33-7/16

MS09NW✕ 2 MS15NN✕1/MUM30NN

Unit : inch

11

Page 12

9 TROUBLESHOOTING

Measure the resistance between the terminals with a tester.

(Coil wiring temperature-10¡C ~ 40¡C)

Measure the resistance between the terminals with a tester.

(Coil wiring temperature-10¡C ~ 40¡C)

Part name

Compressor

Outdoor fan

motor

Check method and criterion Figure

Normal(KH22WEV)

0.8~1.1'

Opened or

short-circuited

C-R

C-S 4.8~5.2'

Abnormal

Normal(Upper)

60~75'

Opened or

short-circuited

WHT-BLK

BLK-YLW

YLW-BLU

15~20'

12~16'

Abnormal

Normal(Lower)

56~61'

14~19'

12~16'

Normal(RH167NAB)

2.1~2.7'

4.0~5.0'

BLU-RED

51~64'

54~67'

BLK

RED

YLW

ORN

WHT

P

BLU

MUM30NN

9-1 Cautions on troubleshooting

9-1-1 Before troubleshooting, check the followings:

1) Check the power supply voltage.

2) Check the indoor/outdoor connecting wire for mis-wiring.

9-1-2 Take care the followings during servicing.

1) Before servicing the air conditioner, be sure to first turn off the remote controller to stop the main unit, and then after

confirming the horizontal vane is closed, disconnect the breaker.

2) When removing the P.C. board, hold the edge of the board with care NOT to apply stress on the components.

3) When connecting or disconnecting the connectors, hold the housing of the connector. DO NOT pull the lead wires.

9-2 Trouble criterion of main parts

12

Page 13

MUM30NN

SYSTEM

Triple

Double

Single

52C CONTACTOR

All three : ON

Two of them : ON

One of them : ON

OPERATION OF 52C1, 52C2, 52C3, X61, X62, X63, x64

NOTE

1 : Compressor is on while 52C is on.

2 : Compressor is off while 52C is off.

3: Relay of X61~X63 can not turn on at the same time.

4: Relay “X64” is turned on only in a single operation.

52C1 52C2 52C3 X61

OFF

OFF

OFF

OFF

OFF

ON

OFF OFF OFF

ON OFF OFF

OFF OFF OFF

X62 X63

OFF

ON

ON

OUTDOOR FAN RELAY

Hi speed / Hi speed

Me speed / Me speed

Stop / Hi speed

X64

OFF

ON

ON

OFF

ON

ON

ON

ON

ON

OFF

OFF

ON

ON

ON OFF ON

OFF OFF OFF

ON OFF ON

OFF OFF ON

ON ON OFF

FAN RELAY / FAN SPEED / APPLIED VOLTAGE

FAN MOTOR RELAY

X61 is ON

X62 is ON

X63 is ON

OUTDOOR FAN SPEED

Hi

Me

Lo

APPLIED VOLTAGE TO FAN

230V AC between WHT and BLK

230V AC between WHT and YLW

230V AC between WHT and BLK(Only MF2)

OFF

ON

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

13

Page 14

10 DISASSEMBLY INSTRUCTIONS

OUTDOOR UNIT MUM30NN

OPERATING PROCEDURE PHOTOS

1. Removing of the cabinet

(1)Remove the set screws of the valve cover to remove

the valve cover as shown in Photo 2.

(2)Remove the set screws of the side panel to remove

the side panel and cabinet.

Screw

Photo 2

Photo 1

Screws

Screws

2. Removing the propeller

(1)Remove the propeller nut.

(2)Loosen the propeller in the rotating direction.

(3)Pull the propeller forward.

Note:

● To set the propeller, fit the cut on the shaft to the

mark on the propeller.

Photo 4

Photo 3

Propeller

Nut

14

Page 15

OPERATING PROCEDURE PHOTOS

3. Removing the outdoor fan motor.

(1) Remove the cabinet. (Refer to 1)

(2) Remove the propeller. (Refer to 2)

(3) Disconnect the connector remove the clamp of out-

door fan

motor lead wire.

(4) Remove the screws fixing the outdoor fan motor.

Photo 5

Set screws of the relay panel

Clamp

Photo 6

Connector

15

Page 16

OPERATING PROCEDURE PHOTOS

4. Removing the compressor

(1)Disconnect the cord connector. (See Phot 5)

(2)Remove the set screws of the relay panel.

(3)Remove the set nuts of the terminal cover.

(4)Pull up the compressor.

(5)Pull out the lead wires from the compressor terminal

to remove overcurrent relay.

(6)Remove set nuts of the compressor base.

(7)Remove the low pressure side welded part and high

pressure side welded part using a burner.

Note:

● Before using a welder, release gas inside the unit and

make sure that the gauge pressure shows 0 kg/

● During welding, open the charge plug because

pressure rises due to expansion by heat

f.

Photo 7

Set nuts of the terminal cover

16

Nuts

Page 17

11 PARTS LIST

No. Parts No. RemarksParts Name

Symbol in

Skeleton

Wiring

Diagram

Q,ty/unit

MUM30NN

1

2

3

4

5

6

R01 539 668

T2W 510 509

R01 539 662

T2W 800 662

T2W E46 297

T2W E46 001

FRONT PANEL See above NOTE.

1

2

1

1

1

1

OUTE NOZZLE

SIDE PANEL (L)

SERVICE PANEL

TOP PANEL

LABEL See above NOTE.

OUTDOOR UNIT PARTS

MUM30NN

Refer to MS09NW,MS15NN for indoor unit.

17

Page 18

No. Parts No. RemarksParts Name

Symbol in

Skeleton

Wiring

Diagram

Q,ty/unit

MUM30NN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

T2W 800 630

T2W 800 631

R01 093 115

T2W 800 301

T2W 800 302

T2W 461 642

M21 B90 641

T92 510 272

T92 650 452

M21 463 936

T2W 460 662

T2W 460 661

R01 L11 410

M21 987 936

T2W 800 523

HEAT EXCHANGER (UPPER)

RA4N80-AC

1

1

2

1MF1

MF2

MC1,MC2

MC3

1

3

6

2

1

2

3

2

1

1

1

HEAT EXCHANGER (UPPER)

PROPELLER

OUTDOOR FAN MOTOR (UPPER)

OUTDOOR FAN MOTOR (LOWER)

FUSIBLE PLUG

CAHRGE PLUG

COMPRESSOR

COMPRESSOR

VALVE (GAS) (for 09A, 09B)

VALVE (LIQUID) (for 09A, 09B)

VALVE (GAS) (for 09A, 09B)

VALVE (GAS)

CAPILLARY TUBE (for 15C)

REAR PANEL

KH-122WEV

RH-167NAB

[0.12o[0.055o25-9/16

(1/4)

(3/8)

(1/2) 15C

[0.12o[0.063o15-3/4

RA4N55-AB

When servicing, cut the tube to the proper length as shownin the REFRIGERANT SYSTEM DIAGRAM see page 11.

18

Page 19

No. Parts No. RemarksParts Name

1

T2W 738 353

2

T2W 500 353

3

T2W 800 451

4

T2W 800 382

5

T2W 800 339

6

T2W 382 342

7

T2W 359 340

8

T2W 800 375

9

T2W E41 374

10

T2W E42 375

11

T2W 464 340

12

T2W 394 330

MC1. MC2. CAPACITOR 35+ 330V

MC3. CAPACITOR

OUTDOOR P. C. BOARD

FUSE

TRANSFORMER

MC1. MC2. CONTACTOR

MC3 CONTACTOR

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

MC1. MC2. THERMAL SWTCH

MC3 THERMAL SWITCH

Symbol in

Skeleton

Wiring

Diagram

C1,C2

C3

F

T

52C1, 52C2

52C3

TB1

TB

TB

51C1, 51C2

51C3

Q,ty/unit

MUM30NN

2

1

1

1

1

2

1

1

1

1

2

1

25+ 370V

2A 250V

G4F-11123T

VF-12HU

UNIT 15C

UNIT 09A.O9B

MRA98881

MRA98921

19

Page 20

L

I

S

T

E

D

R

12 OPTIONAL PARTS

1. REFRIGERANT PIPES

The air conditioner has flared connections its indoor and outdoor sides.

Please use the optional extension pipe as follows.

MS09NW

MS15NN

Part No.Model

MAC - 440PI

MAC - 441PI

MAC - 442PI

MAC - 443PI

MAC - 670PI

MAC - 671PI

MAC - 672PI

MAC - 673PI

MAC - 674PI

Pipe length

10ft

16ft

23ft

33ft

10ft

16ft

23ft

33ft

49ft

Cross-section

Pipe size O.D

A-Gas B-Liquid

3/8

1/4

5/8

Insulation

C 13/16

D 1-1/16

C 1-7/32

D 1-1/16

Additional

refrigerant

charge

R-22(Oz)

0

1

0

1

3

CCopyright 1997 MITSUBISHI ELECTRIC ENGINEERING CO.,LTD.

Issued in Sep. 1997 NO.MEE(MELSHI) No.OB204 111

The Slim Line.

From Mitsubishi Electric.

New publication, effective Sep. 1997.

Specifications subject to change without notice.

Page 21

3400 Lawrenceville Suwanee Road ● Suwanee, Georgia 30024

Toll Free: 800-433-4822 ● Toll Free Fax: 800-889-9904

Specifications are subject to change without notice.

www.mrslim.com

Loading...

Loading...