Mitsubishi MS-07NV - E2 (WH), MS-12NV - E1 (WH), MS-09NV - E2 (WH), MS-12NV - E2 (WH), MS-18NV - E2 (WH) Service Manual

...Page 1

This Servise Manual OB206 deals with MS-07/09/12/18/24NV-E1,

MU-07/09/12/18/24NV-E1, MS-18NV-E2, and MU-18NV-E2 in

OB175 THIRD EDITION issued in June in 1997.

Therfore, please refer to OB206, not to OB175 THIRD EDITION,

for the above models.

SPLIT-TYPE,HEAT PUMP AIR CONDITIONERS

SERVICE MANUAL

Wireless type

Models

No. OB206

MS-07NV MS-09NV MS-12NV MS-18NV MS-24NV MS-07NV MS-09NV MS-12NV MS-18NV MS-24NV MS-18NV -

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

· MU-07NV -

· MU-09NV -

· MU-12NV -

· MU-18NV -

· MU-24NV -

· MU-07NV -

· MU-09NV -

· MU-12NV -

· MU-18NV -

· MU-24NV -

· MU-18NV -

CONTENTS

E1E1

E1E1

E1E1

E1E1

E1E1

E2E2

E2E2

E2E2

E2E2

E2E2

E3E3

MS-18NV MS-24NV MS-18NV MS-24NV MS-18NV -

E1

E1

E2

E2

E3

1. TECHNICAL CHANGES····································2

2. PART NAMES AND FUNCTIONS······················3

3. SPECIFICATION·················································6

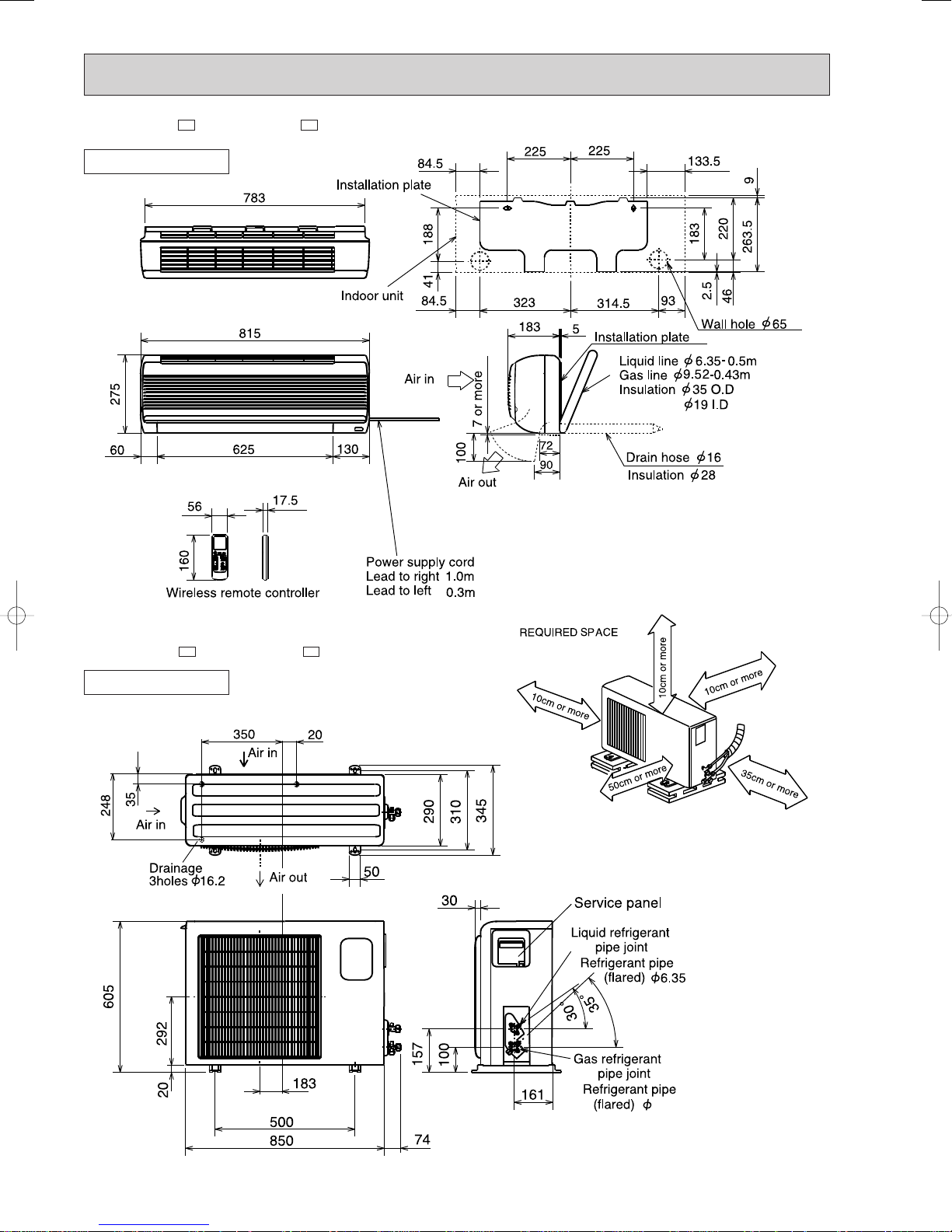

4. OUTLINES AND DIMENSIONS·························9

5. WIRING DIAGRAM ··········································12

6. REFRIGERANT SYSTEM DIAGRAM··············20

7. PERFORMANCE CURVES······························24

8. MICROPROCESSOR CONTROL ····················27

9. SERVICE FUNCTIONS ····································34

10. TROUBLESHOOTING······································37

11. DISASSEMBLY INSTRUCTIONS·····················45

12. PARTS LIST······················································53

13. OPTIONAL PARTS···········································61

Page 2

1

TECHNICAL CHANGES

MS-07NV - ➔MS-07NV -

1. Indoor electronic control P.C. board has changed.

However, it is compatible between and models.

2. Auto restart function is added.

MS-09NV - ➔MS-09NV -

1. Indoor electronic control P.C. board has changed.

However, it is compatible between and models.

2. Auto restart function is added.

3. Refrigerant filling capacity (R-22) has changed. (900g ➔850g)

MS-12NV - ➔MS-12NV -

1. Indoor electronic control P.C. board has changed.

However, it is compatible between and models.

Auto restart function is added.

MS-18NV - ➔MS-18NV -

1. Indoor electronic control P.C. board has changed.

However, it is compatible between and models.

2. Auto restart function is added.

MS-24NV - ➔MS-24NV -

1. Indoor electronic control P.C. board has changed.

However, it is compatible between and models.

2. Auto restart function is added.

E2E1

E2E1

E2E1

E2E1

E2E1

E2E1

E3E2

E3E2

E2E1

E2E1

2

Page 3

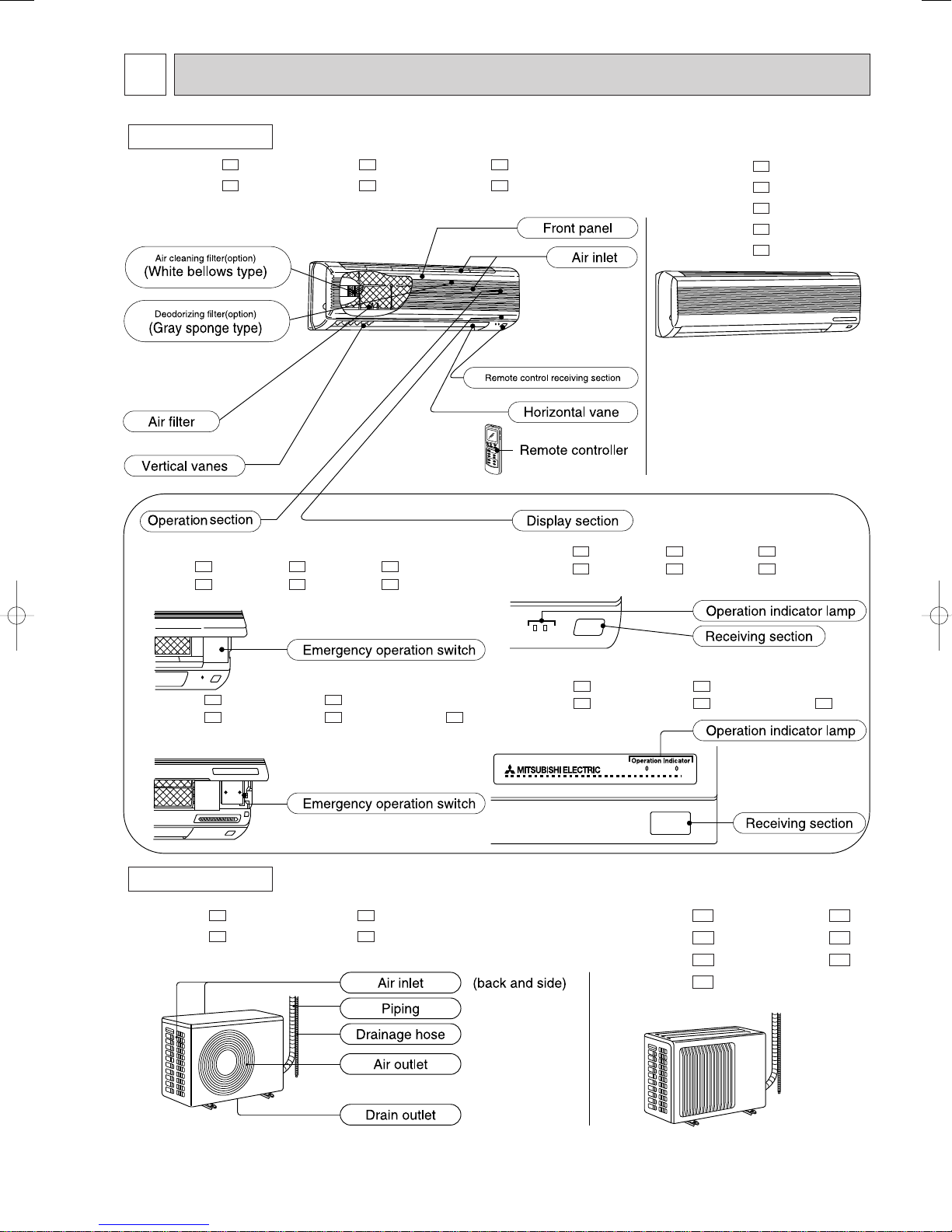

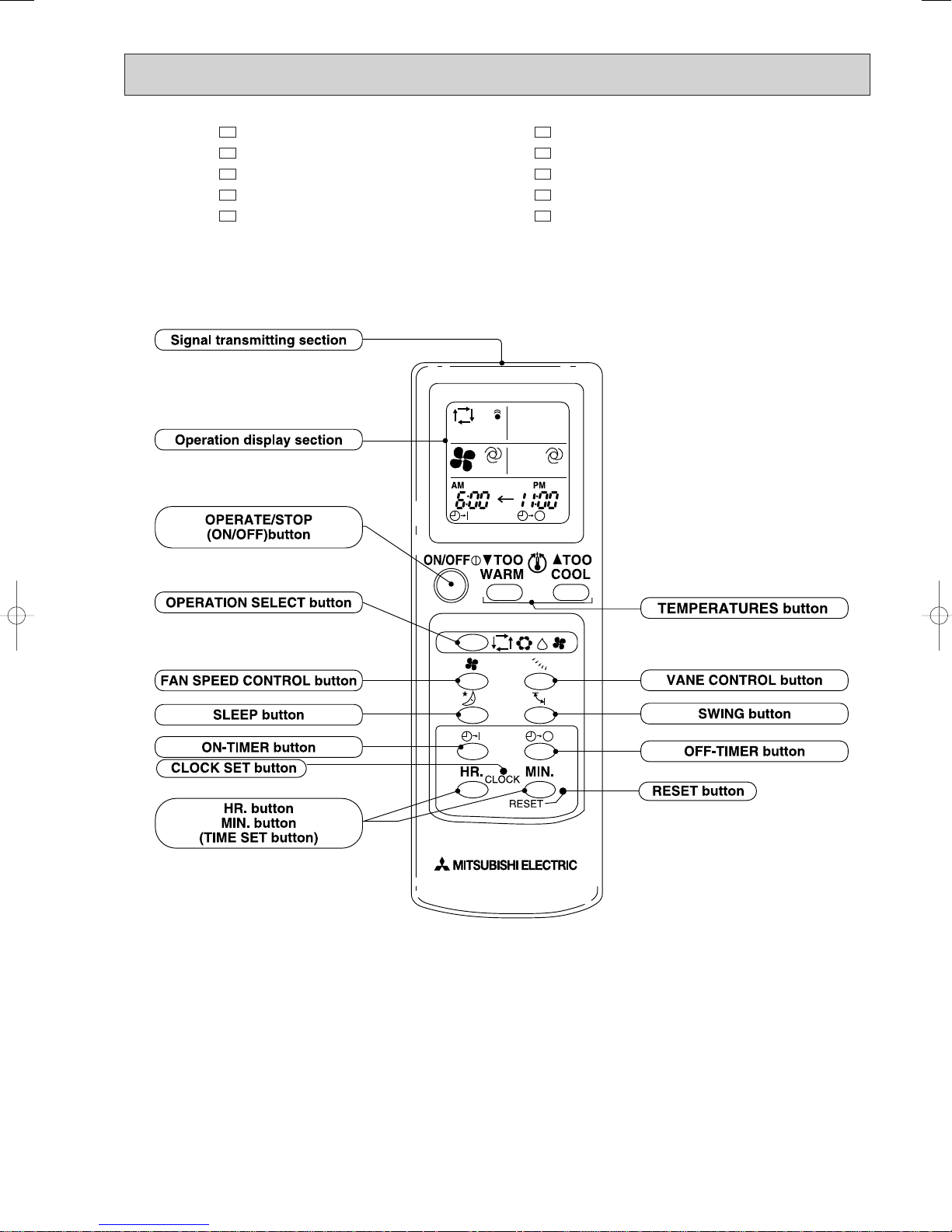

2

PART NAMES AND FUNCTIONS

INDOOR UNIT

MS-07NV - MS-09NV - MS-12NV MS-07NV - MS-09NV - MS-12NV -

E1E1E1

E2E2E2

MS-18NV MS-24NV MS-18NV MS-24NV MS-18NV -

E1

E1

E2

E2

E3

(When the front panel is open)

MS-07NV - MS-09NV - MS-12NV MS-07NV - MS-09NV - MS-12NV -

MS-18NV - MS-24NV -

E1E1

E1E1E1

E2E2E2

MS-18NV - MS-24NV - MS-18NV -

OUTDOOR UNIT

MU-07NV- MU-09NV MU-07NV- MU-09NV -

E1E1

E2E2

MS-07NV - MS-09NV - MS-12NV MS-07NV - MS-09NV - MS-12NV -

MS-18NV - MS-24NV MS-18NV - MS-24NV - MS-18NV -

E3E2E2

E1E1

MU-12NV - MU-18NV MU-24NV - MU-12NV MU-18NV - MU-24NV MU-18NV -

E3

E1E1E1

E2E2E2

E3E2E2

E1E1

E2E1

E2E2

3

Page 4

MS-07NV - MS-09NV - MS-12NV MS-18NV - MS-24NV - MS-18NV -

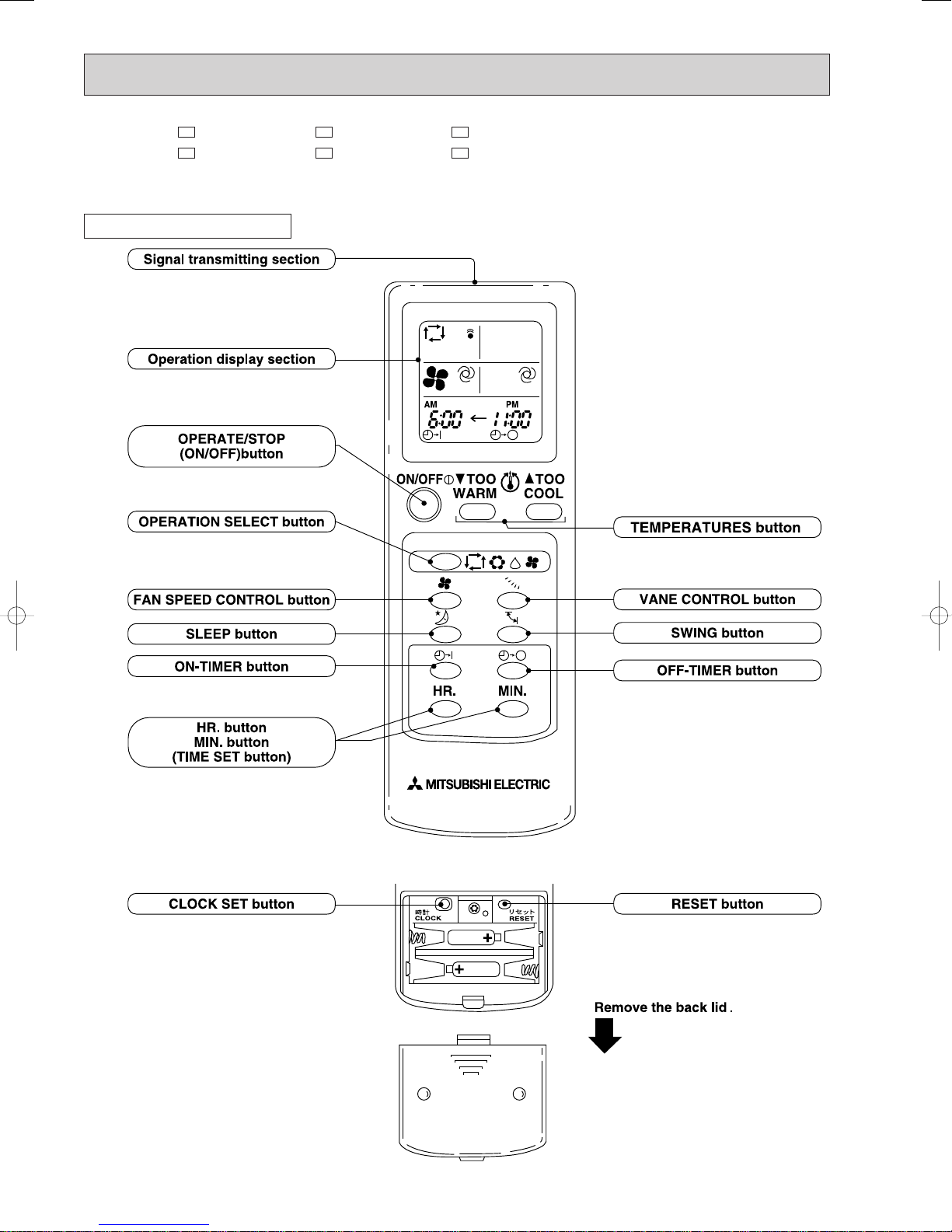

REMOTE CONTROLLER

E1E1E1

E2E1E1

4

Page 5

MS-07NV - (Product number 7000001T~) MS-09NV - (Product number 7000001T~)

MS-12NV - (Product number 7000001T~) MS-24NV - (Product number 7000001T~)

MS-07NV - MS-09NV MS-12NV - MS-18NV - (Product number 7000001T~)

MS-24NV - MS-18NV -

E1E1

E1E1

E2E2

E2E2

E3E2

5

Page 6

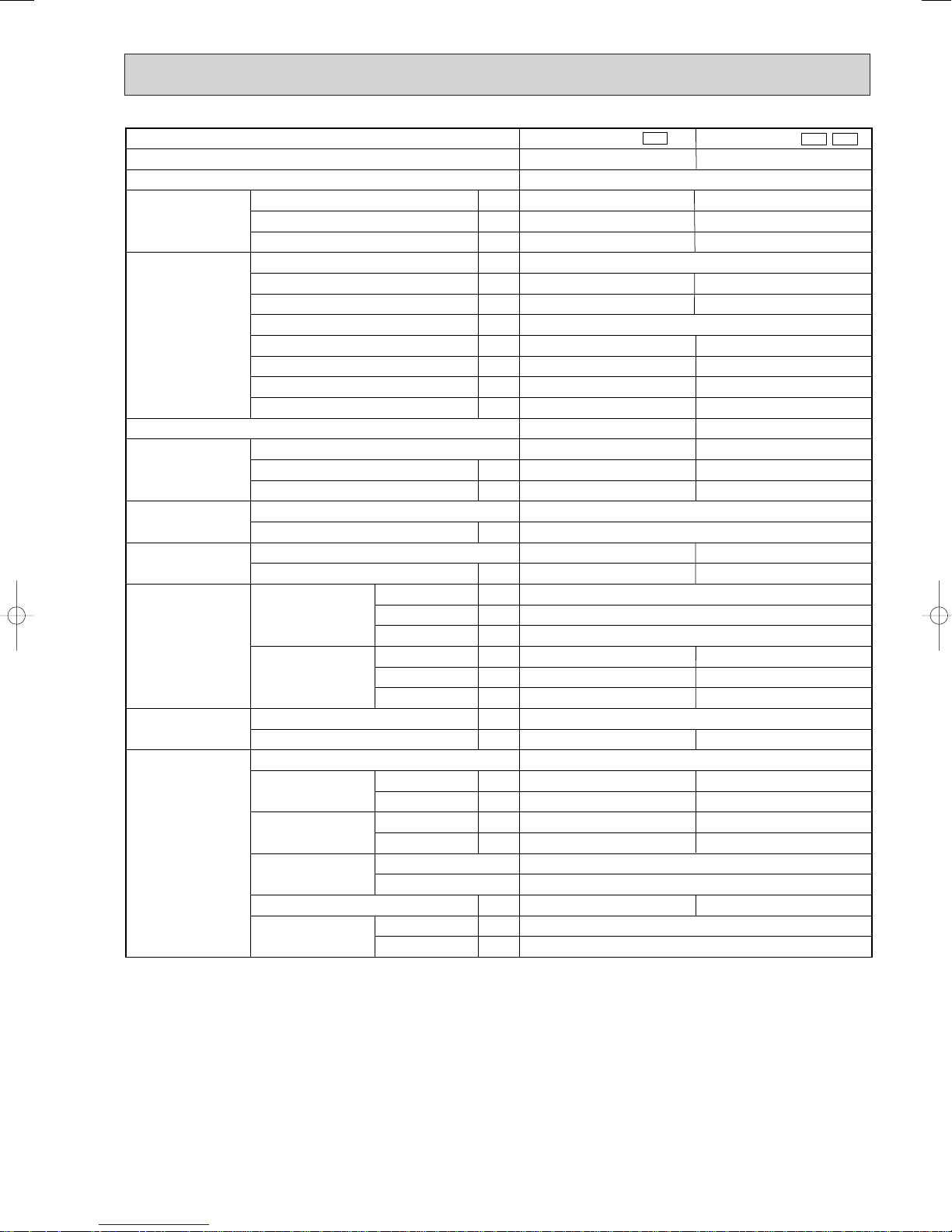

Capacity

Electrical data

Compressor

Indoor

fan motor

Outdoor

fan motor

Dimensions

Weight

Special remarks

Model

Function

Power supply

Coefficient of performance(C.O.P)

Capacity

Dehumidification

Air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding resistance(at20:)

Model

Winding resistance(at20:)

Model

Winding resistance(at20:)

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Air direction

Sound level

(Hi)

Fan speed

(Hi)

Fan speed

regulator

Refrigerant filling capacity(R-22)

Thermistor

Width

Height

Depth

Width

Height

Depth

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

RT11(at25:)

RT12(at25:)

kW

r/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

"

mm

mm

mm

mm

mm

mm

kg

kg

dB

dB

rpm

rpm

kg

k"

k"

MS-07NV -

E1

E2

Cooling

2.2

0.8

3.15-3.05

680-710

98-97

2.69-2.59

3.24-3.10

RH-135VGHT

650

C-R 4.17 C-S 5.75

0.65

MS-09NV - E1

Cooling

2.5

1.1

3.60-3.45

780-810

98-98

3.15-2.99

3.21-3.09

RH-145VGHT

700

C-R 4.04 C-S 5.96

0.9

815

275

183

780

540

255

8

32

5

37

44-45

1,100

740-770

4

1

10

10

Single phase,220-240V,50Hz

INDOOR 492 OUTDOOR 1620

10

—

25

INDOOR 0.17 OUTDOOR 0.29

RC4V19-AA

WHT-BLK292.4 BLK-RED324.6

RA6V23-AB

WHT-BLK268.4 BLK-RED390.8

3

NOTE:Test conditions

6

SPECIFICATION

Cooling : Indoor DB27: / WB19:

Outdoor DB35: / WB24:

Page 7

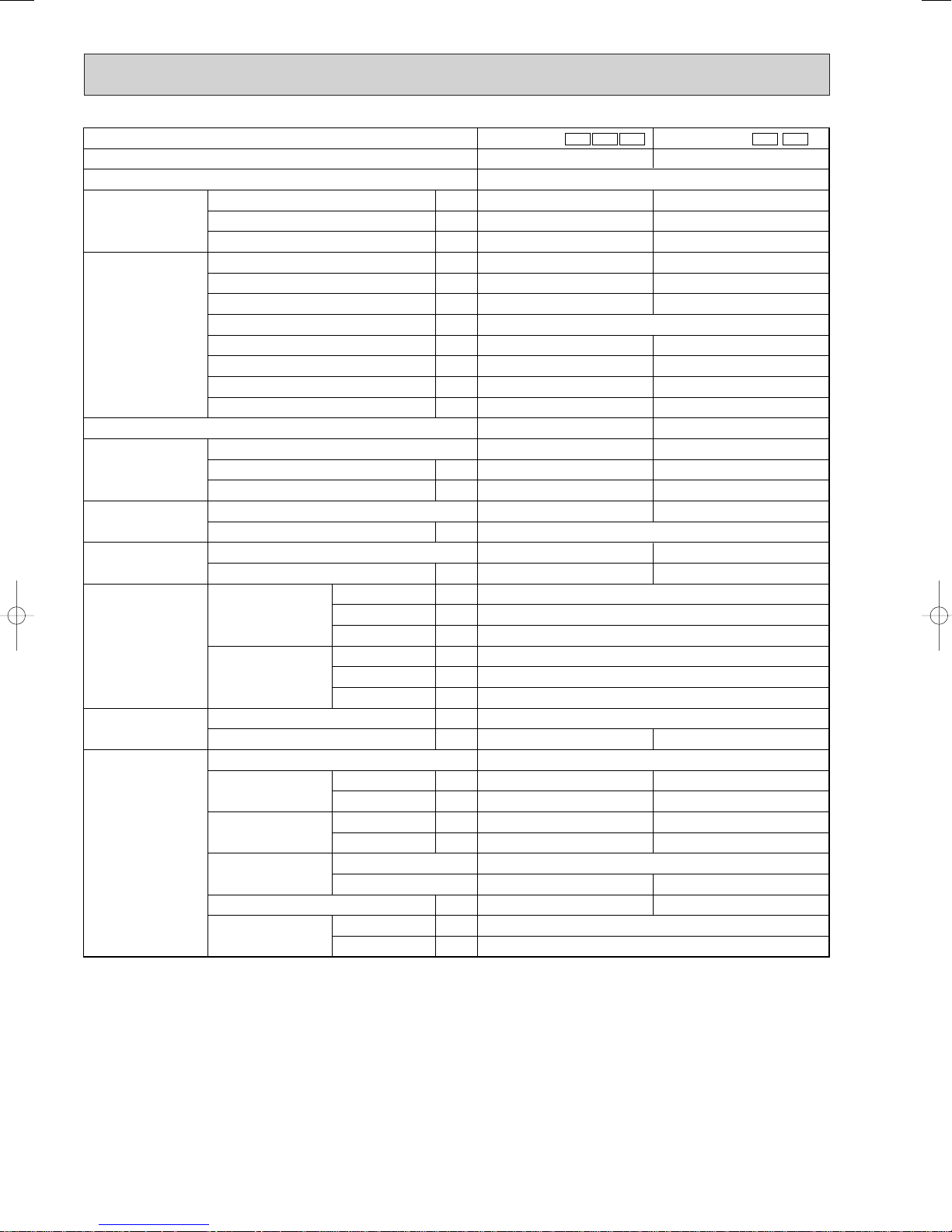

Model

Function

Power supply

Capacity

Capacity

Dehumidification

Air flow

Power outlet

Running current

Power input

Auxiliary heater

Electrical data

Power factor

Starting current

Compressor motor current

Fan motor current

Coefficient of performance(C.O.P)

Model

Compressor

Output

Winding resistance(at20:)

Indoor

fan motor

Outdoor

fan motor

Model

Winding resistance(at20:)

Model

Winding resistance(at20:)

Indoor unit

Dimensions

Outdoor unit

Weight

Indoor unit

Outdoor unit

Air direction

Sound level

(Hi)

Fan speed

Special remarks

(Hi)

Fan speed

regulator

Refrigerant filling capacity(R-22)

Thermistor

NOTE:Test conditions

Cooling : Indoor DB27: / WB19:

Outdoor DB35: / WB24:

Width

Height

Depth

Width

Height

Depth

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

RT11(at25:)

RT12(at25:)

MS-09NV - E2

Cooling

Single phase,220-240V,50Hz

kW

r/h

INDOOR 492 OUTDOOR 1620

K /h

2.5

1.1

A

A

W

3.60-3.45

780-810

A(kW)

%

A

A

INDOOR 0.17 OUTDOOR 0.29

A

98-98

25

3.15-2.99

3.21-3.09

RH-145VGHT

W

"

"

WHT-BLK268.4 BLK-RED390.8

"

700

C-R 4.04 C-S 5.96

WHT-BLK292.4 BLK-RED324.6

RA6V23-AB

mm

mm

mm

mm

mm

mm

780

540

255

kg

kg

dB

dB

rpm

rpm

kg

32

37

44-45

1,100

740-770

0.65

k"

k"

MS-12NV -

Cooling

3.5

1.6

INDOOR 558 OUTDOOR 2190-2304

10

6.20-6.35

1310-1390

—

96-91

35

5.66-5.81

INDOOR 0.17 OUTDOOR 0.37

2.67-2.52

RH-231VHAT

1,100

C-R 2.11 C-S 3.97

RC4V19-AA

RA6V40-EC or EE

WHT-BLK130.4 BLK-RED134.6

815

275

183

850

605

290

8

38

5

42

50

1,230

780-820

4

1

0.8

10

10

E1

E2

7

Page 8

Capacity

Electrical data

Compressor

Indoor

fan motor

Outdoor

fan motor

Dimensions

Weight

Special remarks

Model

Function

Power supply

Coefficient of performance(C.O.P)

Capacity

Dehumidification

Air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding resistance(at20:)

Model

Winding resistance(at20:)

Model

Winding resistance(at20:)

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Air direction

Sound level

(Hi)

Fan speed

(Hi)

Fan speed

regulator

Refrigerant filling capacity(R-22)

Thermistor

Width

Height

Depth

Width

Height

Depth

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

RT11(at25:)

RT12(at25:)

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

"

mm

mm

mm

mm

mm

mm

kg

kg

dB

dB

rpm

rpm

kg

k"

k"

MS-18NV -

E1 E2 E3

MS-24NV -

E1 E2

Single phase,220-240V,50Hz

—

WHT-BLK183.8 BLK-RED250.5

1,015

320

190

850

605

290

14

5

4

10

10

Cooling

6.4

3.4

INDOOR 816 OUTDOOR 2286

25

12.9-12.6

2,780-2,900

98-96

59

12.06-11.76

INDOOR 0.29 OUTDOOR 0.55

2.30-2.21

NH-47VMDT

2,200

C-R0.96 C-S 2.07

RA4V27-EC

RA6V60-AA or AB

WHT-BLK81.1 BLK-RED102.2 BLK-YLW 92.2

61

45

53

1,260

860-886

2

2.15

Cooling

5.1

2.5

INDOOR 756 OUTDOOR 2190

15

9.1

1,910-2,010

95-92

51-55

8.46

INDOOR 0.25 OUTDOOR 0.39

2.67-2.54

NH-33VMDT

1,500

C-R1.2 C-S 2.7

RA4V27-EA

RA6V50-OD or OF

WHT-BLK116.4 BLK-RED111

55

42

52

1,180

810-845

1

1.65

NOTE:Test conditions

Cooling : Indoor DB27: / WB19:

Outdoor DB35: / WB24:

8

Page 9

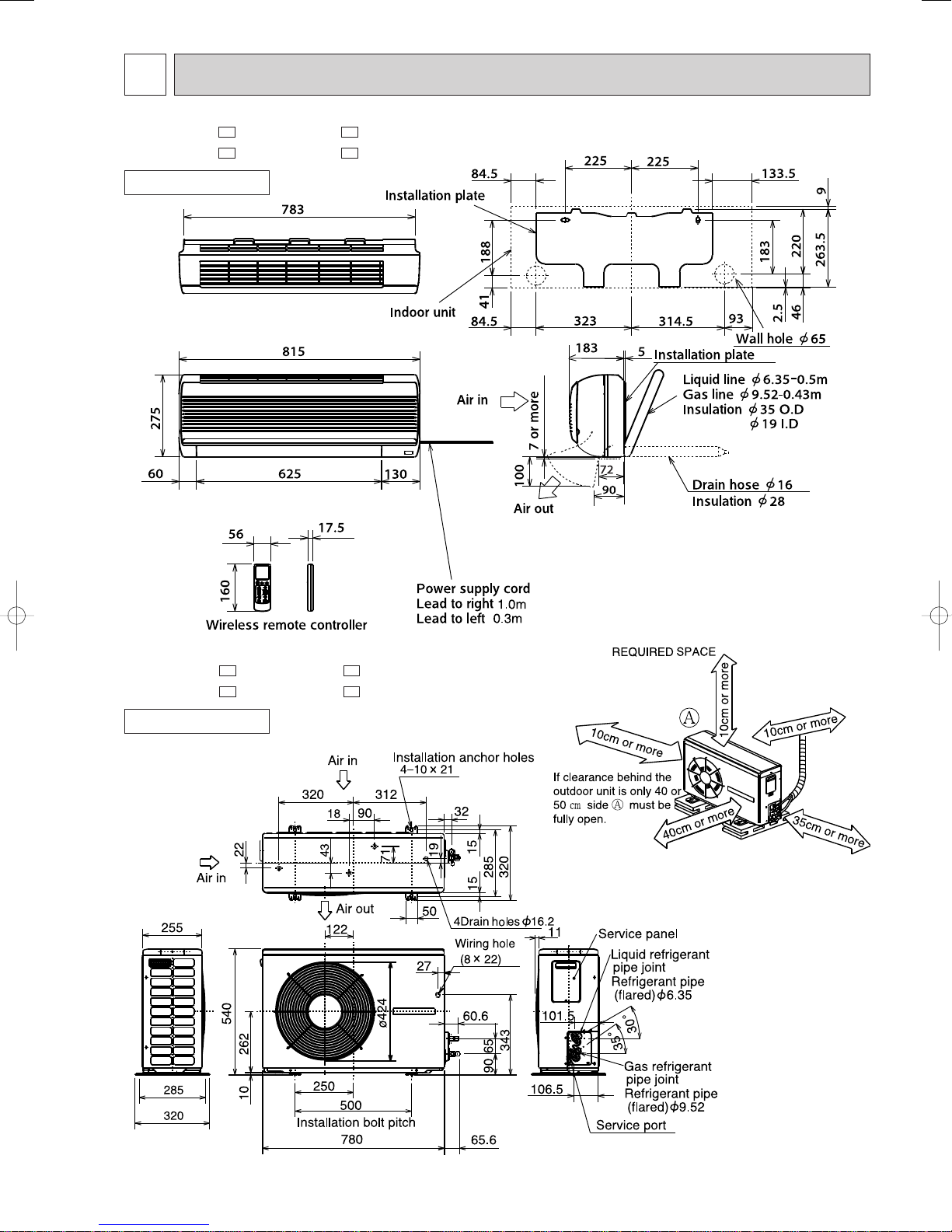

4

OUTLINES AND DIMENSIONS

MS-07NV - MS-09NV MS-07NV - MS-09NV -

INDOOR UNIT

E1E1

E2E2

Unit : mm

MU-07NV - MU-09NV MU-07NV - MU-09NV -

OUTDOOR UNIT

E1E1

E2E2

9

Page 10

MS-12NV - MS-12NV -

INDOOR UNIT

E2E1

Unit : mm

{

MU-12NV - MU-12NV -

OUTDOOR UNIT

E2E1

If the right/left sides or

back side is vacant,the

front has only to be 50cm

unobstructed.

If the front or right/left sides

are vacant, the top has only

to be 10cm unobstructed.

10

12.7

Page 11

MS-18NV - MS-24NV -

E1E1

MS-18NV - MS-24NV - MS-18NV -

INDOOR UNIT

995995

6060

E3E2E2

4040

4holes 14holes 111✕✕2020

150150 648648 217217

Unit : mm

Indoor unitIndoor unit

2020

10151015

320320

1901907757755050

Power supply cordPower supply cord

Lead to right 2mLead to right 2m

Lead to left 1mLead to left 1m

5656

17.517.5

160160

Wireless remote controllerWireless remote controller

MU-18NV - MU-24NV -

E1E1

MU-18NV - MU-24NV - MU-18NV -

OUTDOOR UNIT

Installation plateInstallation plate

Air inAir in

Air outAir out

E3E2E2

450450

450450

352352438438

55190190

Installation plateInstallation plate

Liquid line Liquid line [[8-0.5m8-0.5m

Gas line Gas line [[12-0.43m12-0.43m

{

Insulation Insulation [[50 O.D50 O.D

[ [28 I.D28 I.D

Drain hose Drain hose [[1616

Insulation Insulation [[2828

254254

33 297297

WWall hole all hole [[7575

If the front or right/left sides

are vacant, the top has only

to be 10cm unobstructed.

If the right/left sides or

back side is vacant,the

front has only to be 50cm

unobstructed.

11

Page 12

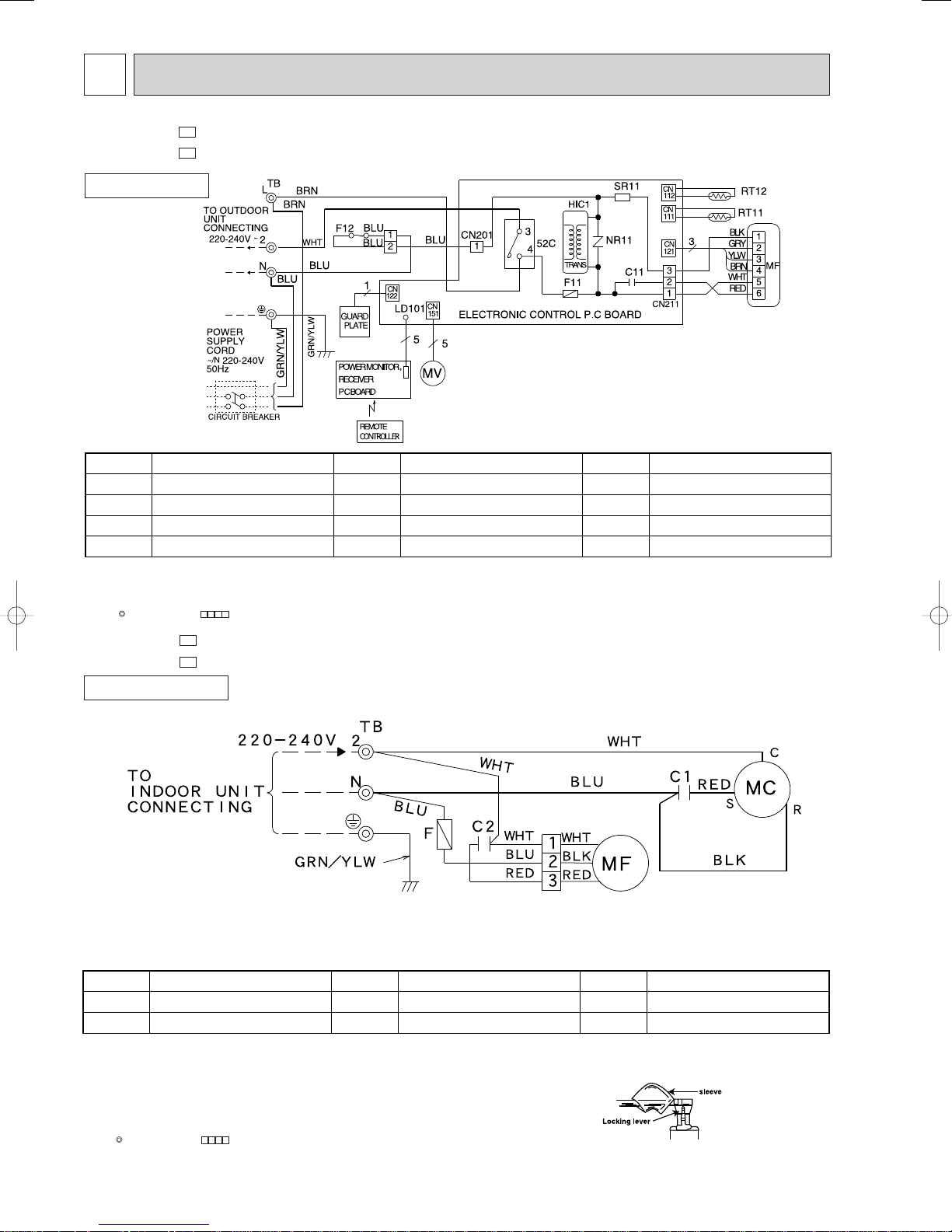

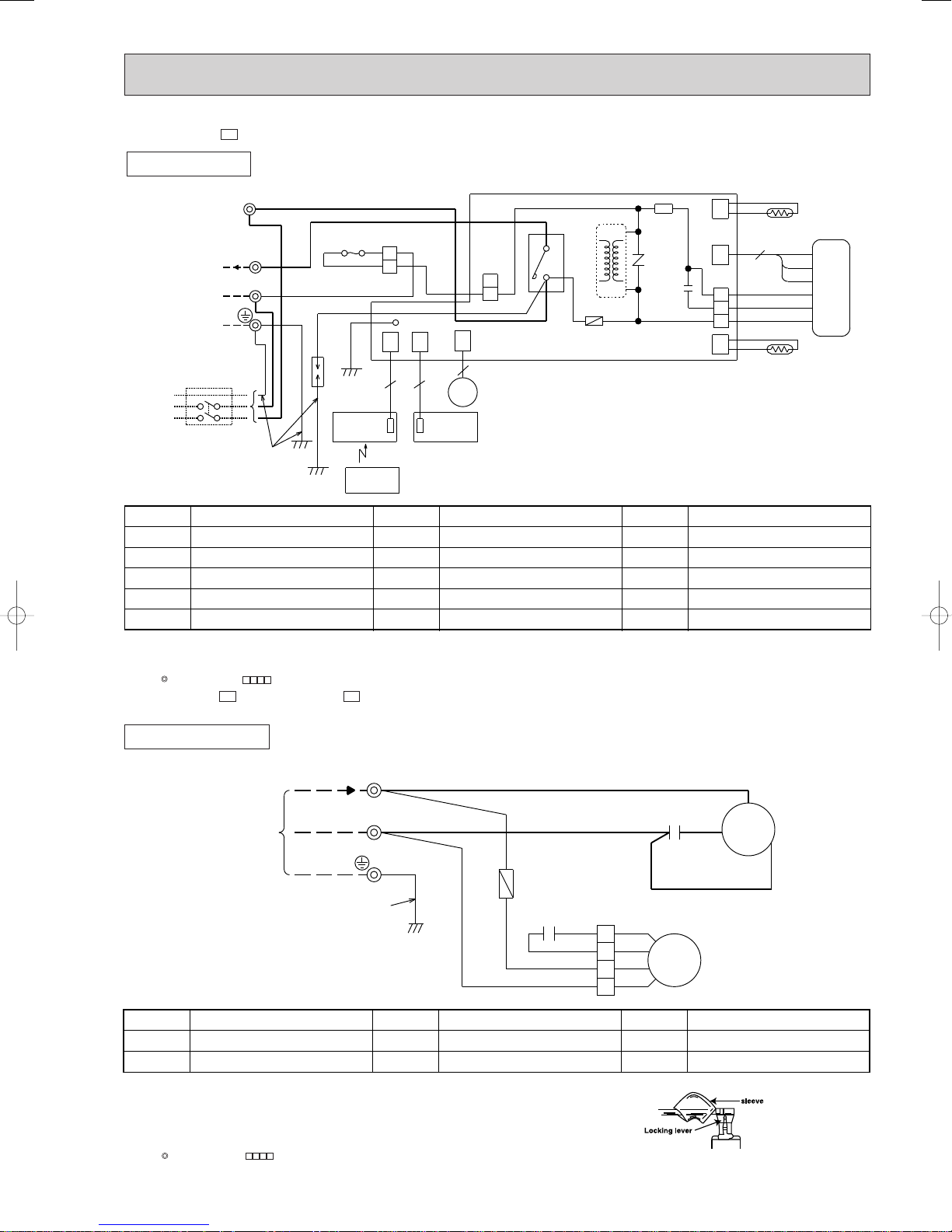

5

WIRING DIAGRAM

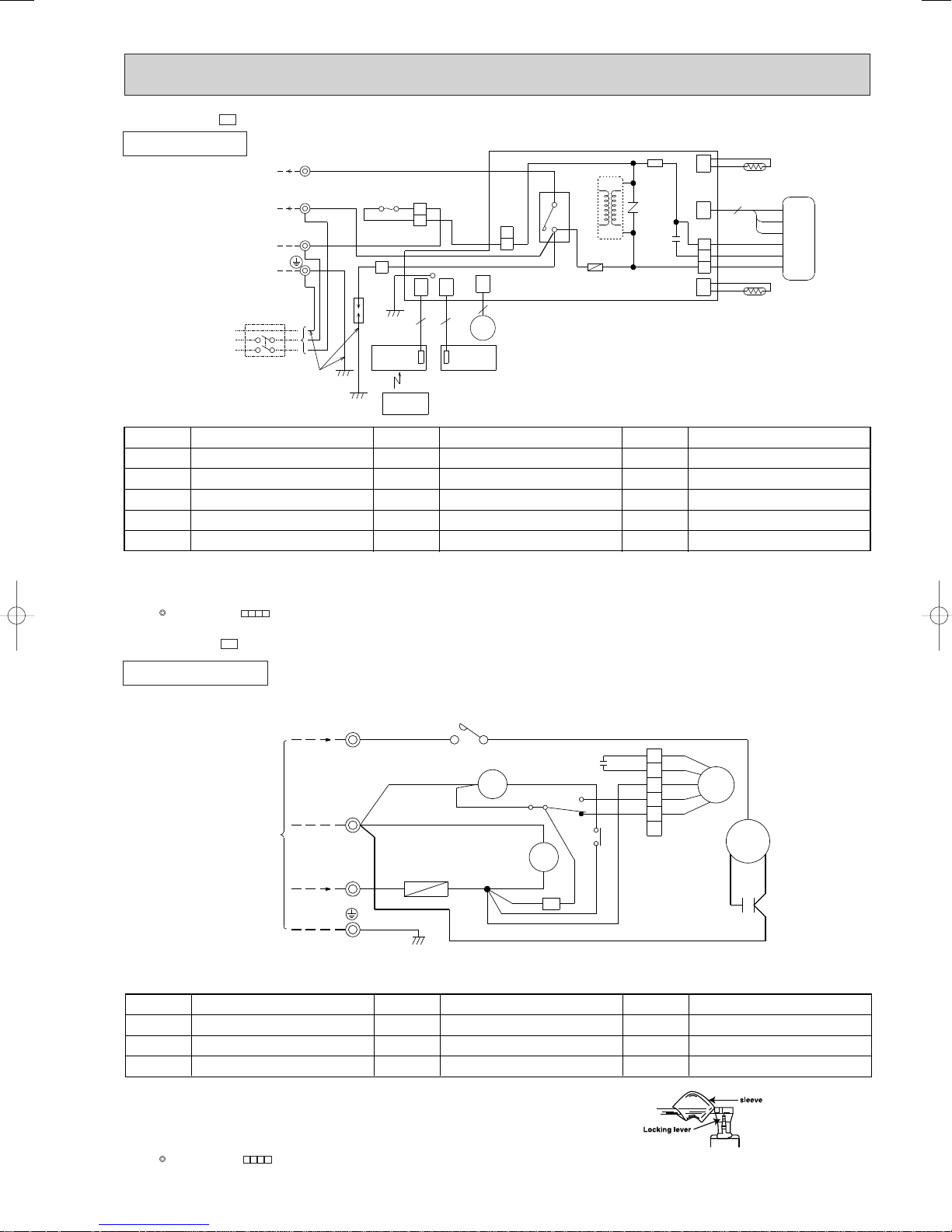

MS-07NV MS-09NV -

INDOOR UNIT

SYMBOL

C11

F12

F11

MF

NOTE:1. For the outdoor electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate.

: Terminal block, : Connector

MU-07NV MU-09NV -

E1

E1

MODELS WIRING DIAGRAM

❈

❈

❈

NAME

INDOOR FAN CAPACITOR

FUSE(93:)

FUSE(3.15A)

INDOOR FAN MOTOR

E1

E1

MODELS WIRING DIAGRAM

SYMBOL

NR11

RT11

RT12

HIC1

❈

❈

NAME NAME

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

DC/DC CONVERTER

SYMBOL

TB

MV

SR11

52C

TERMINAL BLOCK

VANE MOTOR

SOLID STATE RELAY

CONTACTOR

OUTDOOR UNIT

❈

❈

SYMBOL

COMPRESSOR CAPACITOR

C1

OUTDOOR FAN CAPACITOR

C2

NOTE:1. Use copper conductors only.(For field wiring)

2. “❈”show the terminals with a lock mechanism, so they cannot be removed when you pull

the lead wire.

Be sure to pull the wire by pushing the locking lever(projected part) of the terminal with a finger.

3. Symbols below indicate.

: Terminal block, : Connector

NAME

SYMBOL

MF

MC

OUTDOOR FAN MOTOR

COMPRESSOR (INNER THERMOSTAT)

NAME NAME

SYMBOL

TB

F

TERMINAL BLOCK

FUSE (2A)

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

12

Page 13

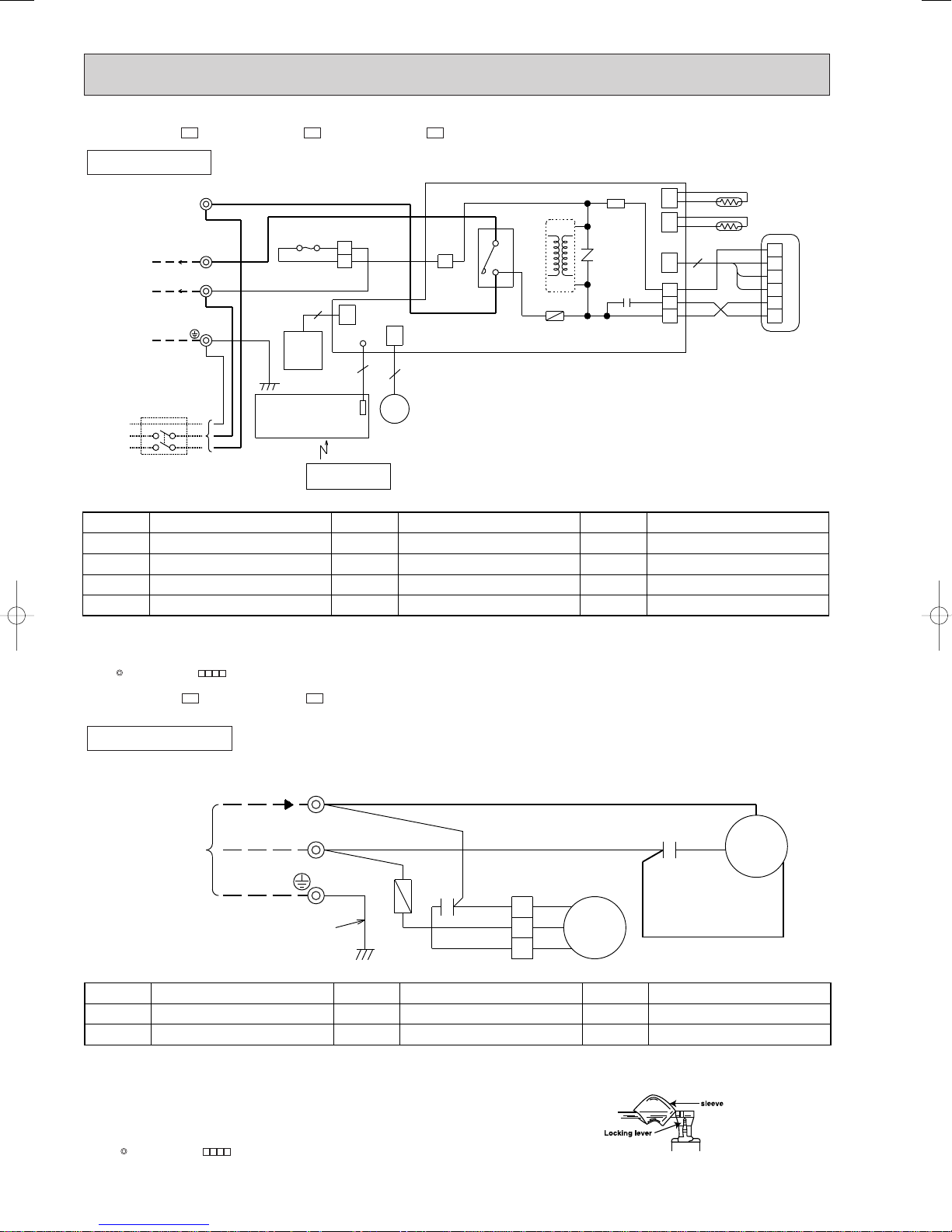

MS-12NV -

E1

MODEL WIRING DIAGRAM

NAME

❈

❈

❈

❈

SYMBOL

NR11

RT11

RT12

HIC1

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

DC/DC CONVERTER

❈

NAME NAME

INDOOR UNIT

SYMBOL

C11

F12

F11

MF

NOTE:1. For the outdoor electric wiring refer to the outdoor unit electric wiring diagram for servicing.

INDOOR FAN CAPACITOR

FUSE(93:)

FUSE(3.15A)

INDOOR FAN MOTOR

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate.

: Terminal block, : Connector

SYMBOL

TB

MV

SR11

52C

TERMINAL BLOCK

VANE MOTOR

SOLID STATE RELAY

CONTACTOR

MU-12NV -

E1

MODEL WIRING DIAGRAM

OUTDOOR UNIT

❈

❈

SYMBOL

COMPRESSOR CAPACITOR

C1

OUTDOOR FAN CAPACITOR

C2

NOTE:1. Use copper conductors only.(For field wiring)

2. “❈”show the terminals with a lock mechanism, so they cannot be removed when you pull

the lead wire.

Be sure to pull the wire by pushing the locking lever(projected part) of the terminal with a finger.

3. Symbols below indicate.

: Terminal block, : Connector

NAME

SYMBOL

MF

MC

OUTDOOR FAN MOTOR

COMPRESSOR (INNER THERMOSTAT)

NAME NAME

SYMBOL

TB

F

TERMINAL BLOCK

FUSE(2A)

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

13

Page 14

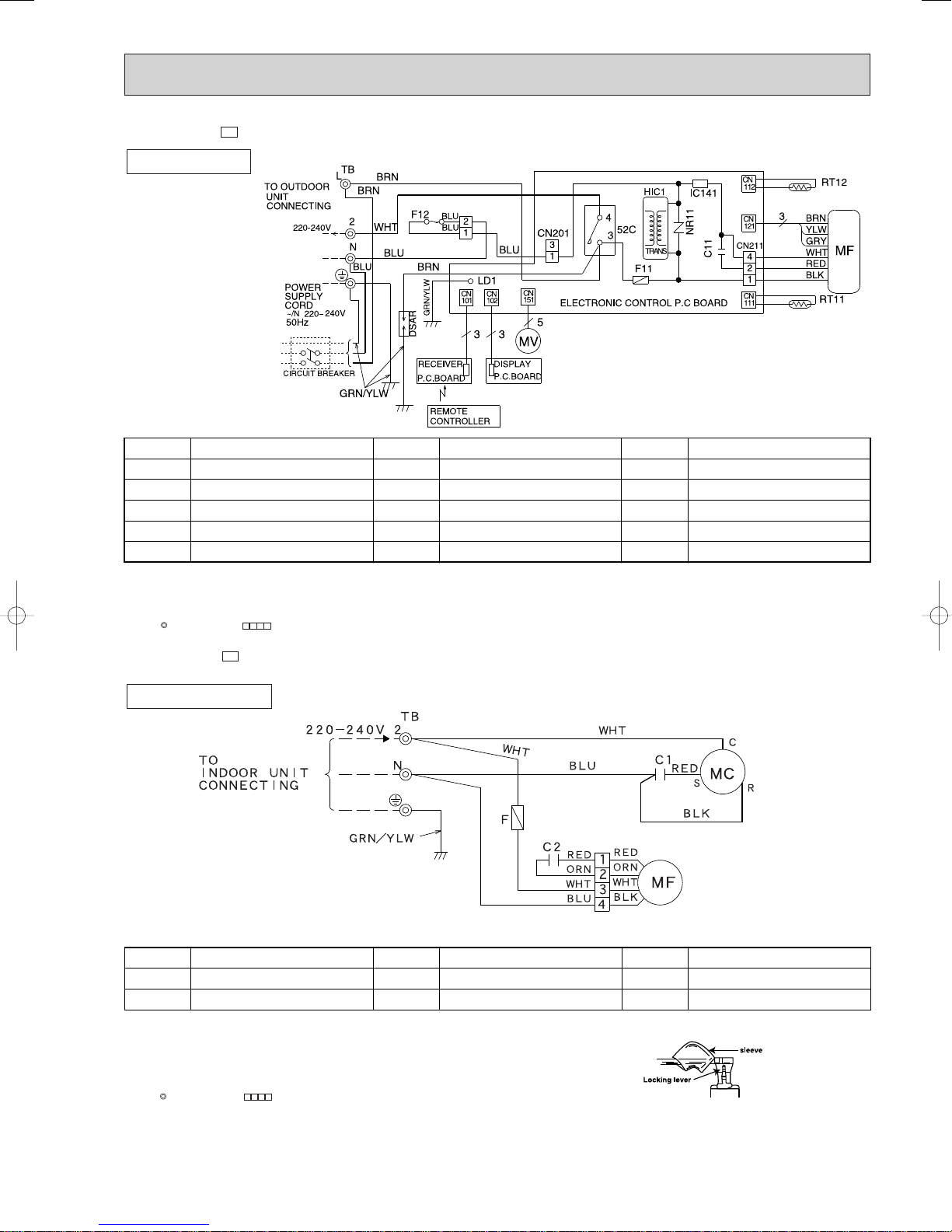

MS-18NV -

E1

INDOOR UNIT

TO OUTDOOR

UNIT

CONNECTING

POWER

SUPPLY

CORD

1~

220-240V

50Hz

MODEL WIRING DIAGRAM

TB

L

❈

BRN

BRN

❈

2

❈

N

❈

BLU

GRN/YLW

WHT

BLK

F12

BRN

DSAR

RECEIVER

P.C.BOARD

BLK

BLK

101CN102

GRN/YLW

REMOTE

CONTROLLER

2

1

LD1

3 3

BLK

CN

DISPLAY

P.C.BOARD

❈

4

CN201

3

1

CN

151

ELECTRONIC CONTROL P.C BOARD

5

MV

52C

❈

3

F11

IC141

NR11

CN

112

3

CN

121

CN211

C11

4

2

1

CN

111

BRN

YLW

GRY

WHT

RED

BLK

RT12

MF

RT11

SYMBOL

C11

F12

F11

MF

MV

NOTE:1. For the outdoor electric wiring refer to the outdoor unit electric wiring diagram for servicing.

INDOOR FAN CAPACITOR

FUSE(93:)

FUSE(3.15A)

INDOOR FAN MOTOR

VANE MOTOR

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate.

: Terminal block, : Connector

MU-18NV -

OUTDOOR UNIT

NAME

E1

TO INDOOR UNIT

CONNECTING

MODEL WIRING DIAGRAM

TB

2

N

SYMBOL

NR11

RT11

RT12

IC141

GRN / YLW

❈

❈

52C

NAME NAME

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

HYBRID IC

CONTACTOR

WHT

BLK

C1

C2

RED

BLK

BLK

WHT

ORN

RED

SYMBOL

MC

S

4

3

2

1

TB

DSAR

C

BLK

WHT

ORN

RED

TERMINAL BLOCK

SURGE ABSORBER

R

MF

SYMBOL

COMPRESSOR CAPACITOR

C1

OUTDOOR FAN CAPACITOR

C2

NOTE:1. Use copper conductors only.(For field wiring)

2. “❈”show the terminals with a lock mechanism, so they cannot be removed when you pull

the lead wire.

Be sure to pull the wire by pushing the locking lever(projected part) of the terminal with a finger.

3. Symbols below indicate.

: Terminal block, : Connector

NAME

14

SYMBOL

MF

MC

NAME NAME

OUTDOOR FAN MOTOR

COMPRESSOR (INNER THERMOSTAT)

SYMBOL

TB

F

TERMINAL BLOCK

FUSE (2A)

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

Page 15

MS-24NV -

SYMBOL

TB

DSAR

HIC1

SYMBOL

NR11

RT11

RT12

IC141

52C

SYMBOL

C11

F12

F11

MF

MV

NAME

NAME NAME

INDOOR FAN CAPACITOR

FUSE(93¡C)

FUSE(3.15A)

INDOOR FAN MOTOR

VANE MOTOR

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

HYBRID IC

CONTACTOR

TERMINAL BLOCK

SURGE ABSORBER

DC / DC CONVERTER

6

5

4

3

2

1

78

RED

X1

BLU

F

1

TB2

RED

BLU

BLU

GRY

WHT

TO INDOOR

UNIT

CONNECTING

REDRED

a

b

TB

2

WHT

52C

1

2

R

C

S

BLK

RED

C1

MC

YLW YLW

BLK

WHT

RED

ORN

WHT

BLK

ORN

RED

C2

MF

RED

CR

52C

N

RED

GRN/YLW

3

6

26F1

X1

BLU

5

1

3

220-240V

220-240V

SYMBOL

C1

C2

X1

SYMBOL

MF

MC

52C

SYMBOL

TB

CR

F

NAME

NAME NAME

COMPRESSOR CAPACITOR

OUTDOOR FAN CAPACITOR

FAN MOTOR RELAY

OUTDOOR FAN MOTOR

COMPRESSOR (INNER THERMOSTAT)

COMPRESSOR CONTACTOR

TERMINAL BLOCK

SURGE ABSORBER

FUSE(2A)

E1

INDOOR UNIT

TO OUTDOOR

UNIT

CONNECTING

POWER

SUPPLY

CORD

~/N 220-240V

50Hz

CIRCUIT BREAKER

MODEL WIRING DIAGRAM

220-240V~

220-240V~

TB

❈

3

2

❈

BRN

N

❈

BLU

GRN/YLW

RED

WHT

BLU

F12

WHT

1

GRN/YLW

DSAR

RECEIVER

P.C.BOARD

REMOTE

CONTROLLER

BLU

BLU

2

1

WHT

101CN102

3 3

LD1

CN

BLU

CN

151

MV

DISPLAY

P.C.BOARD

CN201

5

HIC1

❈

4

52C

❈

3

3

1

ELECTRONIC CONTROL P.C BOARD

TRANS

F11

IC141

NR11

CN

112

CN

121

CN211

C11

4

2

1

CN

111

RT12

3

BRN

YLW

GRY

MF

WHT

RED

BLK

RT11

NOTE:1. For the outdoor electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate.

: Terminal block, : Connector

MU-24NV -

E1

MODEL WIRING DIAGRAM

OUTDOOR UNIT

NOTE:1. Use copper conductors only.(For field wiring)

2. “❈”show the terminals with a lock mechanism, so they cannot be removed when you pull

the lead wire.

Be sure to pull the wire by pushing the locking lever(projected part) of the terminal with a finger.

3. Symbols below indicate.

: Terminal block, : Connector

❈

❈

❈

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

15

Page 16

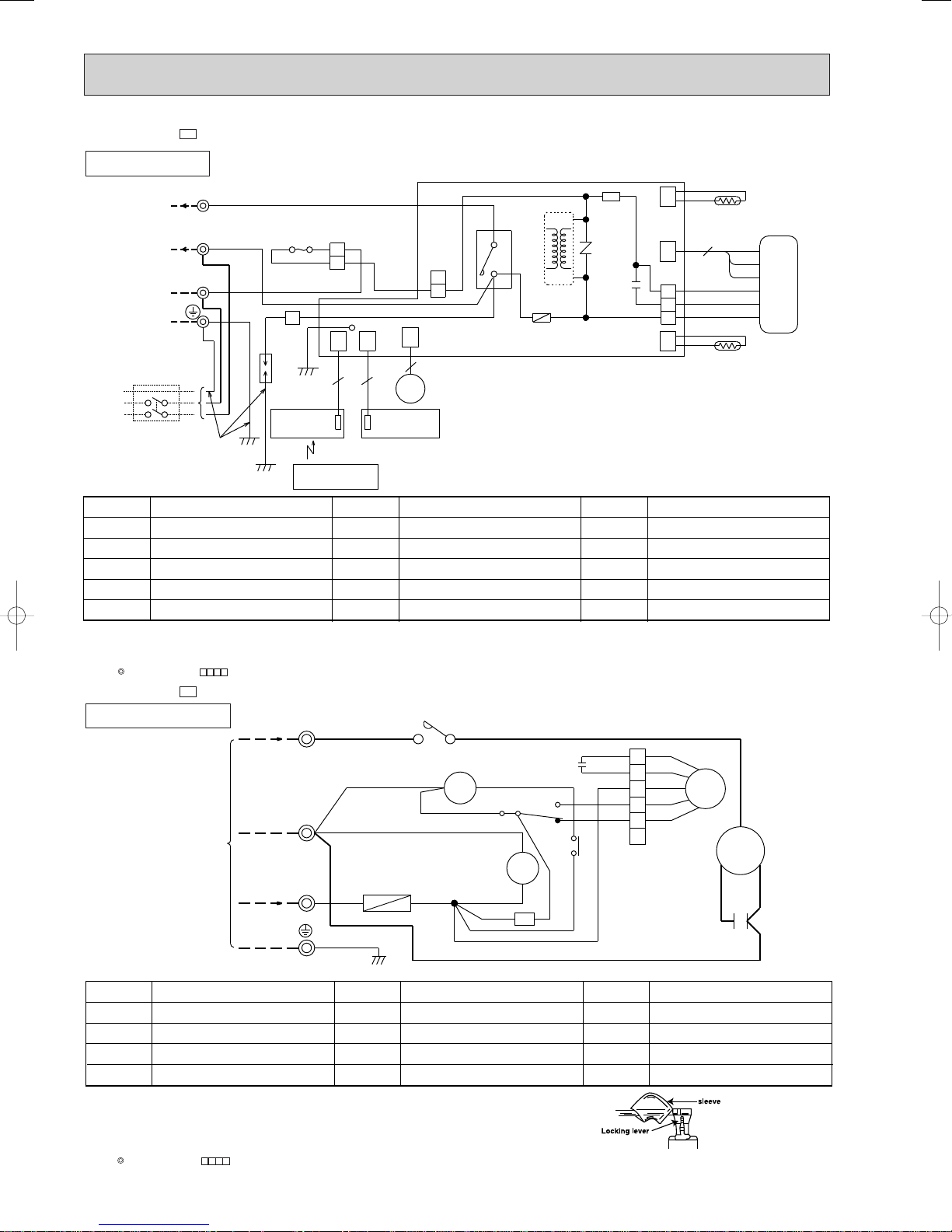

MS-07NV - MS-09NV - MS-12NV -

INDOOR UNIT

TO OUTDOOR

UNIT

CONNECTING

220-240V~

POWER

SUPPLY

CORD

~/N 220-240V

50Hz

MODELS WIRING DIAGRAM

TB

L

❈

BRN

BRN

F12

BLU

1

BLU

122

1

2

CN

LD101

5

2

❈

WHT

❈

N

BLU

BLU

GRN/YLW

GUARD

PLATE

GRN/YLW

POWER MONITOR,

RECEIVER

P.C.BOARD

BLU

CN

151

MV

5

E2E2E2

HIC1

❈

CN201

1

ELECTRONIC CONTROL P.C BOARD

3

52C

4

❈

TRANS

F11

NR11

SR11

C11

CN

112

CN

111

CN

121

3

2

1

CN211

RT12

RT11

BLK

GRY

YLW

BRN

WHT

RED

1

2

3

MF

4

5

6

3

CIRCUIT BREAKER

SYMBOL

C11

F12

F11

MF

NOTE:1. For the outdoor electric wiring refer to the outdoor unit electric wiring diagram for servicing.

INDOOR FAN CAPACITOR

FUSE(93:)

FUSE(3.15A)

INDOOR FAN MOTOR

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate.

: Terminal block, : Connector

NAME

MU-07NV - MU-09NV -

OUTDOOR UNIT

TO

INDOOR UNIT

CONNECTING

MODELS WIRING DIAGRAM

220-240V~

REMOTE

CONTROLLER

E2E2

TB

2

N

GRN/YLW

SYMBOL

NR11

RT11

RT12

HIC1

❈❈❈

❈

BLU

NAME NAME

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

DC/DC CONVERTER

WHT

F

C2

WHT

BLU

RED

1

2

3

BLU

WHT

BLK

RED

SYMBOL

TB

MV

SR11

52C

WHT

MF

TERMINAL BLOCK

VANE MOTOR

SOLID STATE RELAY

CONTACTOR

C

C1

RED

BLK

MC

S

R

SYMBOL

COMPRESSOR CAPACITOR

C1

OUTDOOR FAN CAPACITOR

C2

NOTE:1. Use copper conductors only.(For field wiring)

2. “❈”show the terminals with a lock mechanism, so they cannot be removed when you pull

the lead wire.

Be sure to pull the wire by pushing the locking lever(projected part) of the terminal with a finger.

3. Symbols below indicate.

: Terminal block, : Connector

NAME

16

SYMBOL

MF

MC

NAME NAME

OUTDOOR FAN MOTOR

COMPRESSOR (INNER THERMOSTAT)

SYMBOL

TB

F

TERMINAL BLOCK

FUSE (2A)

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

Page 17

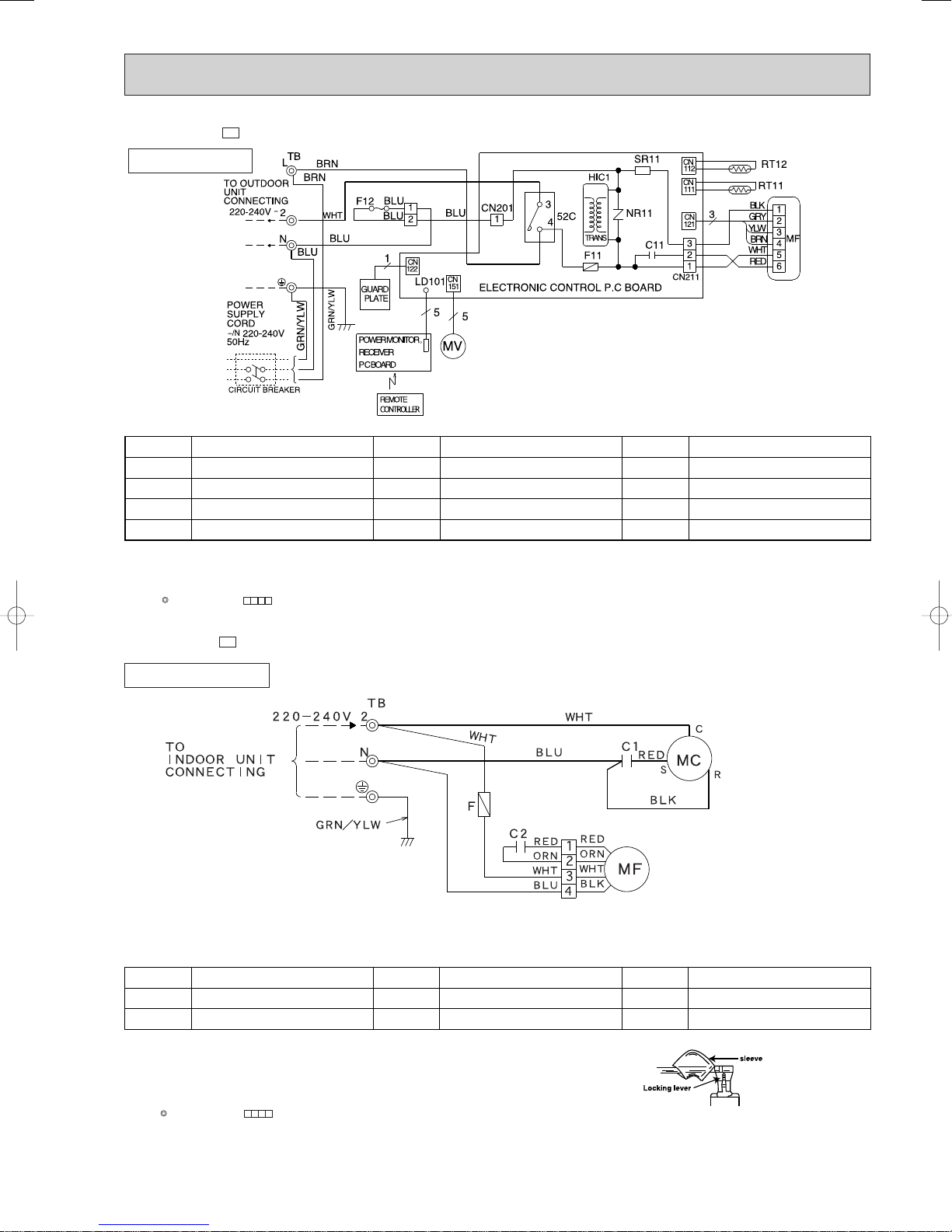

MS-18NV -

E2

MODEL WIRING DIAGRAM

INDOOR UNIT

❈

~

❈

❈

SYMBOL

C11

F12

F11

MF

MV

NOTE:1. For the outdoor electric wiring refer to the outdoor unit electric wiring diagram for servicing.

INDOOR FAN CAPACITOR

FUSE(93¡C)

FUSE(3.15A)

INDOOR FAN MOTOR

VANE MOTOR

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate.

: Terminal block, : Connector

NAME

SYMBOL

NR11

RT11

RT12

IC141

52C

NAME NAME

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

HYBRID IC

CONTACTOR

❈

❈

SYMBOL

TB

DSAR

HIC1

TERMINAL BLOCK

SURGE ABSORBER

DC / DC CONVERTER

MU-18NV -

E2

MODEL WIRING DIAGRAM

OUTDOOR UNIT

❈

❈

SYMBOL

COMPRESSOR CAPACITOR

C1

OUTDOOR FAN CAPACITOR

C2

NOTE:1. Use copper conductors only.(For field wiring)

2. “❈”show the terminals with a lock mechanism, so they cannot be removed when you pull

the lead wire.

Be sure to pull the wire by pushing the locking lever(projected part) of the terminal with a finger.

3. Symbols below indicate.

: Terminal block, : Connector

NAME

SYMBOL

MF

MC

OUTDOOR FAN MOTOR

COMPRESSOR (INNER THERMOSTAT)

NAME NAME

SYMBOL

TB

F

TERMINAL BLOCK

FUSE(2A)

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

17

Page 18

MS-24NV -

E2

INDOOR UNIT

220-240V~ `

MODEL WIRING DIAGRAM

TB

3

❈

RED

HIC1

IC141

112

CN

RT12

220-240V~

TO OUTDOOR

UNIT

CONNECTING

POWER

SUPPLY

CORD

~/N 220-240V

50Hz

CIRCUIT BREAKER

2

GRN/YLW

SYMBOL

C11

F12

F11

MF

MV

NOTE:1. For the outdoor electric wiring refer to the outdoor unit electric wiring diagram for servicing.

MU-24NV -

INDOOR FAN CAPACITOR

FUSE(93¡C)

FUSE(3.15A)

INDOOR FAN MOTOR

VANE MOTOR

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate.

: Terminal block, : Connector

E2

OUTDOOR UNIT

TO INDOOR

WHT

BLU

WHT

F12

BLU

BLU

1

GRN/YLW

DSAR

RECEIVER

P.C.BOARD

REMOTE

CONTROLLER

2

1

WHT

LD1

CN

CN

102

101

3 3

SYMBOL

N

BLU

❈

BRN

❈

NAME

NR11

RT11

RT12

IC141

52C

MODEL WIRING DIAGRAM

TB

220-240 ~

UNIT

CONNECTING

220-240 ~

2

❈

N

❈

3

❈

GRN/YLW

WHT

RED

CN201

BLU

DISPLAY

P.C.BOARD

3

1

CN

ELECTRONIC CONTROL P.C BOARD

151

5

MV

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

HYBRID IC

CONTACTOR

52C

2

BLU

BLU

BLU

RED

TB2

1

F

❈

4

52C

3

❈

NAME NAME

1

RED

78

X1

5

6

A2/b

52C

A1/a

RED

RED

CR

F11

X1

TRANS

C2

3

1

GRY

SYMBOL

DSAR

WHT

26F1

RED

NR11

CN211

C11

TB

TERMINAL BLOCK

SURGE ABSORBER

HIC1

RED

ORN

WHT

BLK

YLW YLW

DC / DC CONVERTER

RED

1

ORN

2

WHT

3

BLK

4

5

6

BLU

CN

121

CN

111

3

BRN

YLW

GRY

MF

MF

S

RED

WHT

RED

BLK

RT11

C

MC

R

BLK

C1

4

2

1

SYMBOL

COMPRESSOR CAPACITOR

C1

OUTDOOR FAN CAPACITOR

C2

FAN MOTOR RELAY

X1

TB2

NOTE:1. Use copper conductors only.(For field wiring)

TERMINAL BLOCK

2. “❈”show the terminals with a lock mechanism, so they cannot be removed when you pull

the lead wire.

Be sure to pull the wire by pushing the locking lever(projected part) of the terminal with a finger.

3. Symbols below indicate.

: Terminal block, : Connector

NAME

18

SYMBOL

MF

MC

52C

26F1

NAME NAME

OUTDOOR FAN MOTOR

COMPRESSOR (INNER THERMOSTAT)

COMPRESSOR CONTACTOR

THERMAL READ SWITCH

SYMBOL

TB

CR

F

TERMINAL BLOCK

SURGE ABSORBER

FUSE(2A)

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

Page 19

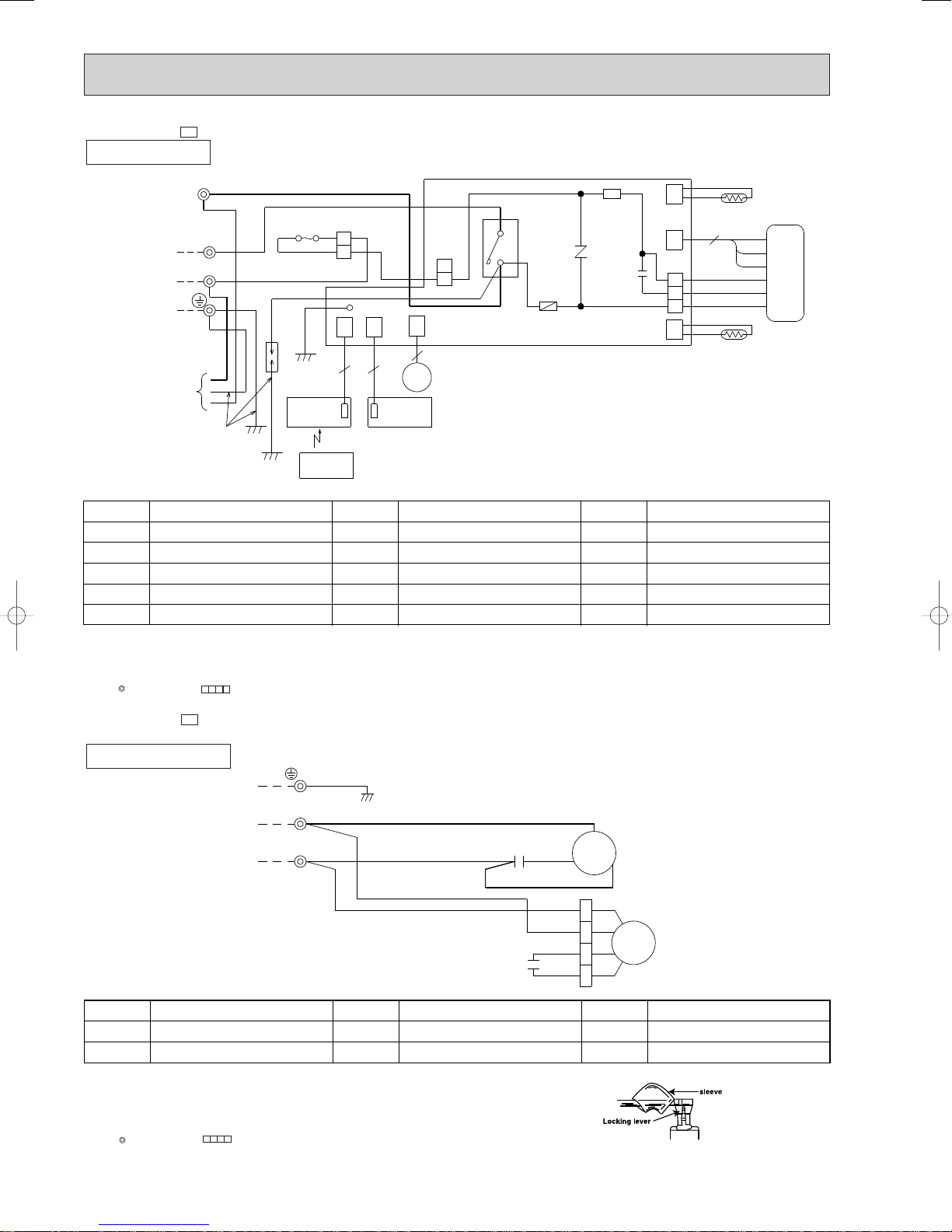

MS-18NV -

E3

INDOOR UNIT

O OUTDOOR

T

UNIT

CONNECTING

220-240V~

POWER

SUPPLY

CORD

~/N 220-240V

50Hz

CIRCUITBREAKER

MODEL WIRING DIAGRAM

TB

L

GRN/YLW

❈

BRN

❈

2

❈

N

❈

BLU

BRN

WHT

BLU

F12

BRN

DSAR

RECEIVER

P.C.BOARD

BLU

BLU

101

GRN/YLW

REMOTE

CONTROLLER

2

1

LD1

CN

3 3

BLU

CN

102

DISPLAY

P.C.BOARD

HIC1

❈

4

CN201

3

1

CN

151

ELECTRONIC CONTROL P.C BOARD

5

MV

52C

❈

3

TRANS

F11

IC141

NR11

CN

112

CN

121

CN211

4

C11

2

1

CN

111

RT12

3

BRN

YLW

GRY

WHT

MF

RED

BLK

RT11

SYMBOL

C11

F12

F11

MF

MV

NOTE:1. For the outdoor electric wiring refer to the outdoor unit electric wiring diagram for servicing.

INDOOR FAN CAPACITOR

FUSE(93¡C)

FUSE(3.15A)

INDOOR FAN MOTOR

VANE MOTOR

2. Use copper conductors only.(For field wiring)

3. Symbols below indicate.

: Terminal block, : Connector

MU-12NV - MU-18NV -

OUTDOOR UNIT

TO

INDOOR UNIT

CONNECTING

NAME

E3E2

SYMBOL

NR11

RT11

RT12

IC141

52C

VARISTOR

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

HYBRID IC

CONTACTOR

MODELS WIRING DIAGRAM

220-240V~

TB

2

N

GRN/YLW

❈

❈

NAME NAME

WHT

F

C2

BLU

RED

ORN

WHT

BLU

WHT

1

2

3

4

RED

ORN

WHT

BLK

SYMBOL

TB

DSAR

HIC1

C1

MF

TERMINAL BLOCK

SURGE ABSORBER

DC / DC CONVERTER

C

RED

MC

S

BLK

R

SYMBOL

COMPRESSOR CAPACITOR

C1

OUTDOOR FAN CAPACITOR

C2

NOTE:1. Use copper conductors only.(For field wiring)

2. “❈”show the terminals with a lock mechanism, so they cannot be removed when you pull

the lead wire.

Be sure to pull the wire by pushing the locking lever(projected part) of the terminal with a finger.

3. Symbols below indicate.

: Terminal block, : Connector

NAME

SYMBOL

MF

MC

NAME NAME

OUTDOOR FAN MOTOR

COMPRESSOR (INNER THERMOSTAT)

SYMBOL

TB

F

TERMINAL BLOCK

FUSE(2A)

1.Slide the sleeve.

2.Pull the wire while

pushing the locking

lever.

19

Page 20

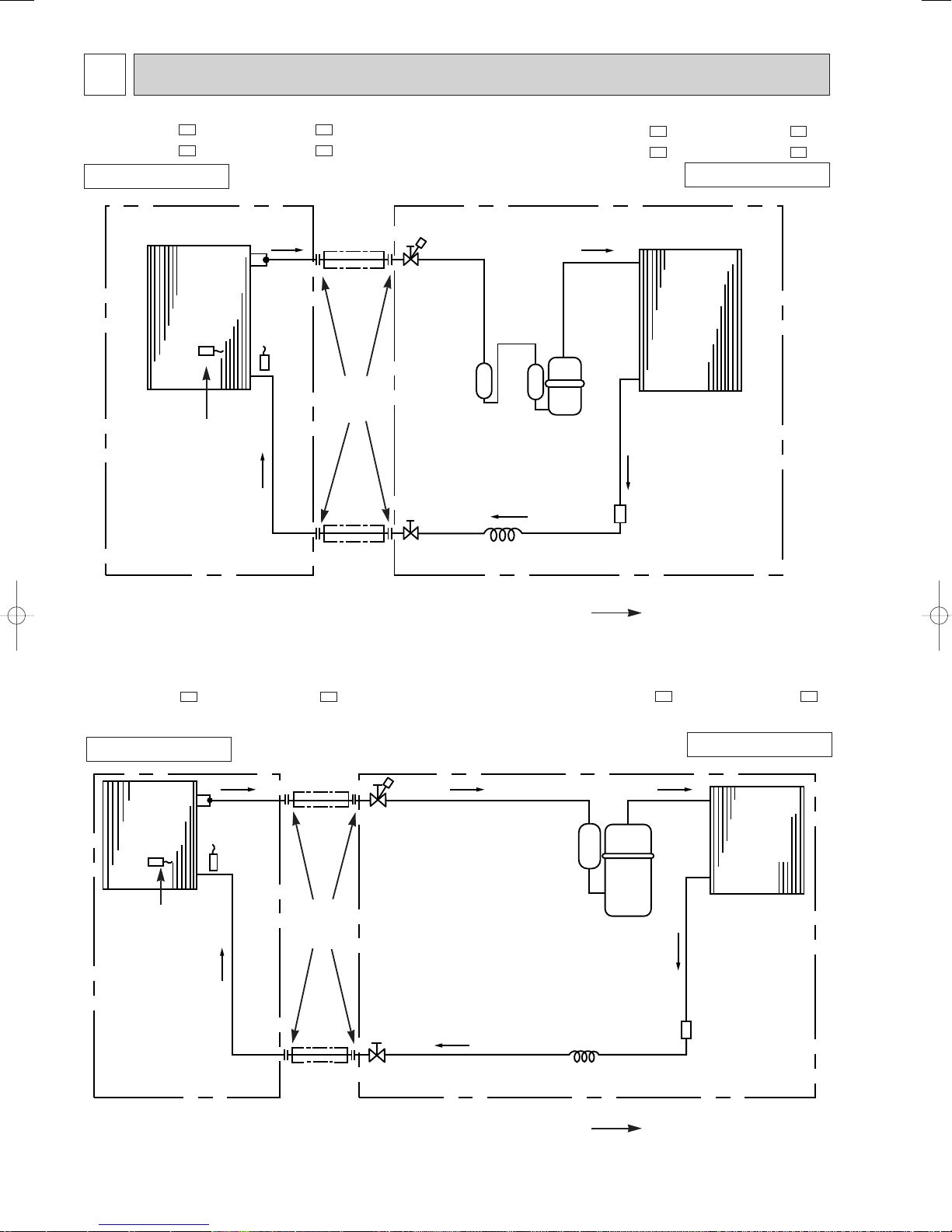

6

REFRIGERANT SYSTEM DIAGRAM

MS-07NV - MS-09NV MS-07NV - MS-09NV -

INDOOR UNIT

Refrigerant pipe [9.52

(Option)

(with heat insulator)

Unit:mm

E1E1

E2E2

MU-07NV - MU-09NV MU-07NV - MU-09NV -

E1E1

E2E2

OUTDOOR UNIT

Stop valve

(with service port)

Indoor

heat

exchanger

Room temperature

thermistor

RT11

Indoor coil

thermistor

RT12

Refrigerant pipe

[6.35

(Option)

(with heat insulator)

MS-12NV - MS-12NV -

Refrigerant pipe [12.7

(Optional)

INDOOR UNIT

(with heat insulator)

Flared

connection

E2E1

Accumulator

Capillary tube

[1.6x1200

Outdoor

heat

exchanger

Compressor

Strainer

Refrigerant flow in cooling

MU-12NV - MU-12NV -

OUTDOOR UNIT

Unit:mm

E2E1

Indoor

heat

exchanger

Room temperature

thermistor

RT11

20

Indoor coil

thermistor

RT12

Flared

connection

Refrigerant pipe

[6.35

(Option)

(with heat insulator)

Stop valve

(with service port)

Stop valve

Compressor

Capillary tube

[1.8x800

Outdoor

heat

exchanger

Strainer

Refrigerant flow in cooling

Page 21

MS-18NV - MS-18NV MS-18NV -

E3

E2E1

MU-18NV - MU-18NV MU-18NV -

E3

E2E1

Unit:mm

INDOOR UNIT

Indoor

heat

exchanger

Distributor

Room temperature

thermistor

RT11

Indoor coil

thermistor

RT12

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Stop valve

(with service port)

Flared

connection

Stop valve

Refrigerant pipe

[6.35

(Option)

(with heat insulator)

Accumulator

Capillary tube

[2.0X700

Compressor

Refrigerant flow in cooling

OUTDOOR UNIT

Outdoor

heat

Strainer

exchanger

MS-24NV - MS-24NV INDOOR UNIT

Indoor

heat

exchanger

Distributor

Room temperature

thermistor

RT11

Indoor coil

thermistor

Refrigerant pipe [15.88 (Option)

(with heat insulator)

RT12

Flared

connection

Refrigerant pipe

[9.52

(Option)

(with heat insulator)

E2E1

Stop valve

(with service port)

Stop valve

MU-24NV - MU-24NV -

Accumulator

Capillary tube

[1.6X350

Capillary tube [2.0X700

Unit:mm

E2E1

OUTDOOR UNIT

Outdoor

heat

exchanger

Compressor

Discharge

Pressure

Regulator

Strainer

Refrigerant flow in cooling

21

Page 22

Model

Outdoor unit precharged

(up to 7m)

650

900

850

800

1650

2150

Refrigerant piping length (one way)

15m

120

7m

0

10m

45

MS-07NV - E1

MS-07NV - E2

MS-09NV - E1

MS-09NV -

E2

MS-12NV -

E1

MS-12NV -

E2

MS-18NV -

E1

MS-18NV - E2

MS-18NV - E3

MS-24NV - E1

MS-24NV - E2

Model

Refrigerant piping

Max. length : m

A

10

15

Piping size O.D : mm

Length of connecting pipe : m

Indoor unit

0.43

Gas

9.52

12.7

15.88

Liquid

6.35

9.52

Outdoor unit

0

MS-07NV - E1

MS-07NV - E2

MS-09NV - E1

MS-09NV -

E2

MS-12NV -

E1

MS-12NV -

E2

MS-18NV -

E1

MS-18NV - E2

MS-18NV - E3

MS-24NV -

E1

MS-24NV -

E2

MAX. REFRIGERANT PIPING LENGTH

MAX. HEIGHT DIFFERENCE

ADDITIONAL REFRIGERANT CHARGE(R-22 : g)

Calculation : Xg=15g/m✕(A-7)m

22

Page 23

EVACUATION PROCEDURES(AIR PURGE)

Connect the refrigerant pipes (both the liquid and gas pipes)

between the indoor and the outdoor units.

Remove the service port cap of the stop valve on the side of the outdoor unit gas pipe (The stop valve will not

work in its initial state fresh out of the factory (totally closed with cap on)).

When vacuuming

Connect the gage manifold valve and the vacuum pump to

the service port of the stop valve on the liquid pipe side of the

outdoor unit.

Run the vacuum pump for more than 15 minutes and at this

time confirm that the pressure gage indicates 0.1 Mpa.

Check the vacuum with the gage manifold valve, then close

the gage manifold valve, and stop the vacuum pump.

Leave it as is for one or two minutes. Make sure the pointer

of the gage manifold valve remains in the same position.

Remove the gage manifold valve quickly from the service port of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves on gas and liquid pipe sides

Operating without fully opening lowers the performance and causes trouble.

Pipe length :

7m maximum

No gas charge

is needed.

Tighten the cap to the service port to obtain the initial status.

Retighten the cap.

Leak test

Pipe length

exceeding 7m

Charge the prescribed

amount of gas.

23

Page 24

7

The standard data contained in these specifications apply only to the operation of the air conditioner under normal conditions.

Since operating conditions vary according to the areas where these units are installed. The following information has been

provided to clarify the operating characteristics of the air conditioner under the conditions indicated by the performance curve.

PERFORMANCE CURVES

(1) GUARANTEED VOLTAGE

Rated voltage : ±10% (198 ~ 264V

),50Hz

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature :°CWB

(2) Indoor outlet air wet-bulb temperature :°CWB

(3) Outdoor intake air dry-bulb temperature :°CDB

(4) Total input :W

Indoor air wet-bulb temperature difference on the left side of the chart on next page shows the difference between the

indoor intake air wet-bulb temperature and the indoor outlet air wet-bulb temperature for your reference at service.

How to measure the indoor air wet-bulb temperature difference

1. Attach at least 2 sets of wet-and dry-bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet-and dry-bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of dry-bulb thermometers to the outdoor air inlet.

Cover the thermometers to prevent direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of room.

5. Press the EMERGENCY OPERATION switch to start the EMERGENCYoperation.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

Cooling

}

24

INDOOR UNIT

OUTDOOR UNIT

Page 25

8

7

6

5

4

3

E3

OUTDOOR LOW PRESSURE AND OUTDOOR UNIT CURRENT

COOL operation

① Both indoor and outdoor unit are under the same temperature/humidity condition.

Dry-bulb temperature

Relative humidity(%)

20

25

30 70

➁ Air flow should be set at MAX.

(kgf/F•G)(MPa•G)

MU-07NV -

220/240V

Outdoor low pressure

Ambient temperature(˚C)Ambient humidity(%)

MU-07NV -

50

60

E2E1

(kgf/F•G)(MPa•G)

8

7

6

MU-09NV -

E2E1

220/240V

5

4

Outdoor low pressure

3

Ambient temperature(˚C)Ambient humidity(%)

E2E1

MU-09NV -

E2E1

220V

Outdoor unit current(A)

Ambient temperature(˚C)Ambient humidity(%)

240V

220V

240V

Outdoor unit current(A)

Ambient temperature(˚C)Ambient humidity(%)

25

Page 26

7

6

5

4

3

2

8

7

6

5

4

3

7

6

5

4

3

2

(kgf/F•G)(MPa•G)

MU-12NV -

E2E1

220/240V

(kgf/F•G)(MPa•G)

MU-18NV -

E3E2E1

220/240V

Outdoor low pressure

Ambient temperature(˚C)Ambient humidity(%)

MU-12NV -

Outdoor unit current(A)

Ambient temperature(˚C)Ambient humidity(%)

(kgf/F•G)(MPa•G)

MU-24NV -

E2E1

220V

240V

E2E1

Outdoor low pressure

Ambient temperature(˚C)Ambient humidity(%)

MU-18NV -

E3E2E1

220/240V

Outdoor unit current(A)

Ambient temperature(˚C)Ambient humidity(%)

Outdoor low pressure

Ambient temperature(˚C)Ambient humidity(%)

MU-24NV -

26

Outdoor unit current(A)

Ambient temperature(˚C)Ambient humidity(%)

220/240V

E2E1

220V

240V

Page 27

8

.

MICROPROCESSOR CONTROL

Wireless remote controller

MS-07NV - MS-09NV - MS-12NV MS-18NV - MS-24NV - MS-07NV MS-09NV - MS-12NV - MS-18NV MS-24NV - MS-18NV -

Once the controls are set, the same operation mode can be

repeated by simply turning the OPERATE/STOP button ON.

Indoor unit receives the signal with a beep tone.

When the system turns off, 3-minute time delay will operate to

protect system from overload and compressor will not restart

for 3 minutes.

1. “I FEEL CONTROL” ( ) OPERATION

(1) Press OPERATE/STOP button on the remote con-

troller. OPERATION INDICATOR LAMP of the

indoor unit will turn on with a beep tone.

(2) Press OPERATION SELECT button to set “I FEEL

CONTROL”( ) .Then a beep tone is heard.

(3) The operation mode is determined by the initial

room temperature at start-up of the operation.

Initial room temperature

more than 25:

13: to 25:

E3E2

mode

COOL mode of

“I FEEL CONTROL“

DRY mode of

“I FEEL CONTROL”

E1E1E1

E2E1E1

E2E2E2

INDOOR UNIT DISPLAY SECTION

● Once the mode is fixed, the mode will not change

by room temperature afterwards.

● Under the ON-TIMER ( ) operation, the mode is

determined according to the room temperature as the

operation starts.

● When the system is stopped with the

OPERATE/STOP button on the remote controller,

and restarted within 2 hours in “I FEEL CONTROL”

( ) mode, the system operates in previous mode

automatically regardless of the room temperature.

Example

Previous operation

COOL mode of

“I FEEL CONTROL” or

COOL mode

● When the system is restarted after 2 hours, the operation

mode is determined by the initial room temperature at

start-up of the operation.

Example

Previous operation

COOL mode of

“I FEEL CONTROL”

or COOL mode

Restart

COOL mode of

“I FEEL CONTROL”

Restart

COOL or DRY mode of

“I FEEL CONTROL” that

determined by initial

room temperature at

start-up of the operation.

27

Page 28

Model

COOL mode of

"I FEEL CONTROL"

DRY mode of

"I FEEL CONTROL"

Initial room temperature Initial set temperature

26: or more

26: or less

13: or 25:

24:

Initial room temperature

minus 2:

Initial room temperature

minus 2:

❈1

(4) The initial set temperature is decided by the initial room temperature.

❈1 After the system restarts by the remote controller, the system operates with the previous set temperature regardless of

the initial set temperature.

The set temperature is calculated by the previous set temperature.

(5) TEMPERATURES buttons

In “I FEEL CONTROL” ( ) mode, set temperature is decided by the microprocessor based on the room temperature.

In addition, set temperature is controlled by TOO WARM or TOO COOL buttons when you feel too cool or too warm.

Each time the TOO WARM or TOO COOL button is pressed, the indoor unit receives the signal and emits a beep tone.

● Fuzzy control

When the TOO COOL or TOO WARM button is pressed, the microprocessor changes the set temperature, considering

the room temperature, the frequency of pressing TOO COOL or TOO WARM button and the user’s preference to heat or

cool. So this is called “Fuzzy control”, and works only in “I FEEL CONTROL” mode.

In DRY mode of “I FEEL CONTROL”, the set temperature doesn’t change.

▲ TOO

COOL… To raise the set temperature 1~2 degrees(°C)

▼ TOO

WARM … To lower the set temperature 1~2 degrees(°C)

28

Page 29

— COOL mode of “I FEEL CONTROL” —

ON

Compressor and

OFF

ON

OFF

outdoor fan motor

Indoor fan motor

ON

Run continuously in cooling mode

NOTE : Coil frost prevention during COOL mode of “I FEEL CONTROL”

There are two types of controls in coil frost prevention.

① Temperature control

<MS-/0709/12> When the indoor coil thermistor RT12 reads 4°C or below for 5 minutes, the coil frost prevention mode

starts.

<MS-18/24> When the indoor coil thermistor RT12 reads -1°C or below, the coil frost prevention mode starts immediately.

However, the coil frost prevention only works after 5 minutes from the compressor starts.

The compressor stops and the indoor fan operates at the set speed for 5 minutes.

After that, if RT12still reads below 4°C (MS-07/09/12) or below -1°C (MS-18/24) this mode prolonged until the RT12 reads

over 4°C (MS-07/09/12) or -1°C (MS-18/24).

② Time control

When the three conditions below have been satisfied for 1 hour and 45 minutes, compressor stops for 3 minutes.

a. Compressor has been continuously operating.

b. Indoor fan speed is Lo or Me.

c. Room temperature is below 26°C.

When compressor stops, the accumulated time is cancelled and when compressor restarts, time counting starts

from the beginning.

Time counting also stops temporarily when the indoor fan speed becomes Hi or the room temperature exceeds

26°C. However, when two of the above conditions (b.and c.) are satisfied again.Time accumulation is resumed.

● Indoor fan operates at the set speed by FAN SPEED CONTROL button.

Followings are the fan speed in AUTO.

Initial temperature difference

Room temperature minus set temperature : 2 degrees or more············································Hi

Room temperature minus set temperature : 1 degree or more and less than 2 degrees·····Me

Room temperature minus set temperature : less than 1 degree···········································Lo

—DRY mode of “I FEEL CONTROL”—

The system for dry operation uses the same refrigerant circuit as the cooling circuit.

The compressor and the indoor fan are controlled by the temperature and the microprocessor.

By such controls, indoor flow amounts will be reduced in order to lower humidity without much room temperature

decrease.

The operation of the compressor and indoor fan is as follows.

1. When the room temperature is 23°C or over:

Compressor operates by temperature control and time control.

① Set temperature is controlled to fall 2°C as initial set temperature.

② When the thermostat is ON, the compressor repeats 8 minutes ON and 3 minutes OFF.

When the thermostat is OFF, the compressor repeats 4 minutes OFF and 1 minute ON.

Indoor fan and outdoor fan operate in the same cycle as the compressor.

Fan speed

1 deg.

2 deg.

1.66 deg.

4 deg.

2. When the room temperature is under 23°C.

When the thermostat is ON, the compressor repeats 2 minutes ON and 3 minutes OFF.

When the thermostat is OFF, the compressor repeats 4 minutes OFF and 1 minute ON.

29

Page 30

Operation time chart

Example

Thermostat

1st ON

ON

OFF

ON

Indoor fan

ON

Outdoor fan

compressor

NOTE ● Coil frost prevention during DRY mode of “I FEEL CONTROL”

The operation is same as coil frost prevention during COOL mode of “I FEEL CONTROL” excepting the

indoor fan is OFF.

● During coil frost prevention the outdoor fan speed becomes Lo and the indoor fan is OFF.

(Because the coil frost prevention is priority.)

8 min.

ON

OFF

ON

OFF

3 min.

ON

OFF

ON

OFF

1 min.

2. COOL ( ) OPERATION

(1) Press OPERATE/STOP button.

OPERATION INDICATOR of the indoor unit

turns on with a beep tone.

(2) Select COOL mode.

(3) Set the TEMPERATURES button.

(TOO WARM or TOO COOL button)

The setting range is 16 ~ 31°C

✻ Indoor fan continues to operate regardless

of thermostat’s OFF-ON

✻ Coil frost prevention is as same as COOL

mode of “I FEEL CONTROL”

3. DRY ( ) OPERATION

(1) Press OPERATE/STOP button.

OPERATION INDICATOR of the indoor unit

turns on with a beep tone.

(2) Select DRY mode.

(3) The microprocessor reads the room temper-

ature and determines the set temperature.

Set temperature is as shown on the right

chart.

Thermostat (SET TEMP.)does not work.

The other operations are same as DRY

mode of “I FEEL CONTROL”.

(4) DRY operation will not function when the

room temperature is 13°C or below.

(5) When DRY operation functions, the fan

speed is lower than cool operation.

30

Page 31

SLEEP

4.FAN( d )OPERATION

(1)Press POWER ON/OFF button.

(2)Select FAN mode with the OPERATION SELECT button.

(3)Select the desired fan speed.When AUTO,it becomes Lo.

Only indoor fan operates.Outdoor unit does not operate.

5. FAN MOTOR CONTROL

(1) Rotational frequency feedback control

The indoor fan motor is equipped with a rotational frequency sensor, and outputs signal to the microprocessor to feedback

the rotational frequency. Comparing the current rotational frequency with the target rotational frequency (Hi,Me,Lo,SLEEP),

the microprocessor controls SR11 (MS-07/09/12), IC141 (MS-18/24) and adjusts fan motor electric current to make the current rotational frequency close to the target rotational frequency. With this control, when the fan speed is switched, the

rotational frequency changes smoothly.

(2) Fan motor lock-up protection

When the rotational frequency feedback signal has not output for 12 seconds, (or when the microprocessor cannot detect

the signal for 12 seconds) the fan motor is regarded locked-up. Then the electric current to the fan motor is shut off. 3 minutes later, the electric current is applied to the fan motor again. During the fan motor lock-up, the OPERATION INDICATOR

lamp flashes on and off to show the fan motor abnormality. (See page 38.)

6. AUTO VANE OPERATION

(1) Vane motor drive

MS(D)-N series is equipped with a stepping motor for the vane. The rotating direction, speed, and angle of the motor are

controlled by pulse signals (approx. 12V) transmitted from indoor microprocessor.

(2) The auto vane angle changes as follows by pressing the VANE CONTROL ( ) button.

31

Page 32

(3) Positioning

The vane is once pressed to the vane stopper below to confirm the standard position and then set to the desired angle.

The positioning is decided as follows.

(a) When the OPERATE/STOP button is pressed. (POWER ON/OFF)

(b) When the vane control is changed from AUTO to MANUAL.

(c) When the SWING is finished.

(d) When the test run starts.

(e) When the power supply turns ON.

(4) VANE AUTO ( ) mode

In VANE AUTO mode, the microprocessor automatically determines the vane angle and operation to make the optimum

room-temperature distribution.

① In COOL and DRY operation

Vane angle is fixed to Angle 1.

➁ In FAN operation

Vane angle is fixed to Angle 4.

(5) Dew prevention

During COOL or DRY operation at Vane Angle 4 or 5 when the compressor cumulative operation time exceeds 1 hour, the

vane angle automatically changes to Angle 1 for dew prevention.

(6) SWING MODE ( )

By pressing the SWING button ( ) vane swings vertically. The remote controller displays “ ”. SWING mode is cancelled when the SWING button or VANE CONTROL button ( ) is pressed or the operation stops or changes to other

mode.

7. SLEEP MODE ( )

• When the SLEEP button ( ) is pressed, the indoor fan speed drops and the air flow sound from the

indoor unit is decreased.

• The indications of the remote controller are “ ” and “ ”.

• When the FAN SPEED CONTROLbutton ( ) is pressed during the SLEEP mode , the SLEEP

mode is released.

32

Page 33

8. TIMER OPERATION

1. How to set the timer

(1) Press OPERATE/STOP button to start the air conditioner.

(2) Check that the current time is set correctly.

NOTE : Timer operation will not work without setting the current time. Initially “AM0:00” blinks at the current time display

of TIMER MONITOR so set the current time, correctly with CLOCK SET button.

(3) Press TIMER CONTROL button to select the operation.

“ ” button... AUTO START operation (ON timer)

“ ” button... AUTO STOP operation (OFF timer)

(4) Press HR. and MIN. button to set the timer. Time setting is 10-minute units.

HR. and MIN. button will work when “ ” or “ ” mark is flashing.

These marks disappear in 1 minute.

When setting the ON timer, check that OPERATION INDICATOR of the indoor unit lights.

NOTE1 : Be sure to place the remote controller at the position where its signal can reach the air conditioner even during

TIMER operation, or the set time may deviate within the range of about 10 minutes.

NOTE2 : Reset the timer in the following cases, or the set time may deviate and other malfunctions may occur.

● A power failure occurs.

● The circuit breaker functions.

2. CANCEL

Timer setting can be cancelled with the TIMER CONTROLbuttons. (“ ” or “ ”)

To cancel the ON timer, press the “ ” button.

To cancel the OFF timer, press the “ ” button.

Timer is cancelled and the display of set time disappears.

PROGRAM TIMER

● The OFF timer and ON timer can be used in combination.

● “ ”and “ ” display shows the order of the OFF timer and ON timer operation.

(Example 1) The current time is 8:00 PM.

The unit turns off at 11:00 PM, and on at 6:00 AM.

(Example 2) The current time is 11:00 AM.

The unit turns on at 5:00 PM, and off at 9:00 PM.

NOTE : TIMER setting will be cancelled by power failure or breaker functioning.

33

Page 34

9. EMERGENCY-TEST OPERATION

Emergency operation

switch

No. 1 unit

No. 2 unit

No. 3 unit

No. 4 unit

1 unit operation

No modification

–

–

–

2 units operation

Same as at left

Replace J10 with J 11

–

–

3 units operation

Same as at left

Same as at left

Replace J20 with J 21

–

4 units operation

Same as at left

Same as at left

Same as at left

Replase J10 with J11

Replase J20 with J21

When the remote controller is missing, or has failed, or when the batteries run down, press the EMERGENCY OPERATION

switch on the front of the indoor unit. The unit will start and the OPERATION INDICATOR lamp will light.

The first 30 minutes of operation will be the test run operation. This operation is for servicing. The indoor fan runs at high

speed and the system is in continuous operation. The thermostat is ON and the timer is reset to normal.

After 30 minutes of test run operation the system shifts to EMERGENCY COOL MODE with a set temperature of 24°C.

The fan shifts to Me speed.

This operation continues until the EMERGENCY OPERATION switch is pressed again or any button on the remote controller is pressed, and after that normal operation will start.

The coil frost prevention circuit operates in this operation.

In the test run or Emergency operation, the horizontal vane operates in AUTO mode with a set temperature of 24°C.

NOTE : Do not press the EMERGENCY OPERATION switch during normal operation.

Press once

<Cool>

Press again

<Stop>

9

SERVICE FUNCTIONS

1. TIMER SHORT MODE

For service, set time can be shortened by short circuit of JPG and JPS on the electronics control P.C. board.

The time will be shortened as follows.

3-minute delay : 3-minute ➔ 3-second.

AUTO START : 1 hour ➔ 1-minutes

AUTO STOP : 1 hour ➔ 1-minutes

Short the connector during the timer mode.

}

2. P.C. BOARD MODIFICATION FOR INDIVIDUAL OPERATION

A maximum of 4 indoor units with wireless remote controllers can be used in a room.

In this case, to operate each indoor unit individually by each remote controller, P.C. boards of remote controller must be

modified according to the number of the indoor unit.

(1) <The reset button can be located on the rear side.>

MS-07NV - MS-09NV - MS-12NV - MS-18NV MS-24NV - MS-18NV -

How to modify the remote controller P.C. board

Remove batteries before modification.

The board has a print as shown below :

The P.C.board has the print “J10” and “J20”.Jumper wires are mounted to each “J10” and “J20”.Replace J20 and J10 with

J21 and J11 according to the number of indoor unit as shown in Table 1.

After modification,push the reset button near the batteries.

E2E1

NOTE : For remodeling, take out the batteries at first.

After finish remodeling, put back the batteries then push the RESET button.

E1E1E1E1

Table.1

Note : When power supply failure or installation time, Indoor unit will delete memory about its remote controller so when power

supply is restoration again, indoor unit recommend its remote controller by receive signal from remote controller at first.

34

Page 35

No. 1 unit

No. 2 unit

No. 3 unit

No. 4 unit

1 unit operation

No modification

–

–

–

2 units operation

Same as at left

Cut J1

–

–

3 units operation

Same as at left

Same as at left

Cut J2

–

4 units operation

Same as at left

Same as at left

Same as at left

Cut both J1 and J2

(2)<The reset button can be located on the front side.>

MS-07NV - (Product number 7000001T~) MS-09NV - (Product number 7000001T~)

MS-12NV - (Product number 7000001T~) MS-24NV - (Product number 7000001T~)

MS-07NV - MS-09NV MS-12NV - MS-18NV - (Product number 7000001T~)

MS-24NV - MS-18NV -

How to modify the remote controller P.C. board

Remove batteries before modification.

The board has a print as shown below :

The P.C.board has the print “J1” and “J2”.Jumper wires are mounted to each “J1” and “J2”.Cut J1 and J2 according to the

number of indoor unit as shown in Table 1.

After modification,push the reset button.

E1E1

E1E1

E2E2

E2E2

E3E2

NOTE : For remodeling, take out the

batteries at first.

After finish remodeling, put

back the batteries then

push the RESET button.

Table.1

Note : At power supply failure or installation. indoor unit deletes the memory about remote controller. When the power supply

is turned on and indoor unit receives the first signals from the remote controller, the remote controller number is designated as the indoor unit number. Therefore at and after the second time indoor unit accepts the remote controller of the

initial setting number.

At setting-error, turn the power supply off to cancel the individual operation, and then turn the power supply on to restart

the setting.

35

Page 36

C11

52C

CN201

CN112

CN121SW

CN111

IC101

CN211

CN151

JR07

JR06

CN102

CN151

CN112 CN111CN121

CN101

BZ

SW

52C

IC101 RA102

IC141

CN211

C11CN201

2. AUTO RESTART FUNCTION

MS-07NV - MS-09NV MS-12NV - MS-24NV MS-18NV -

When the indoor unit is controlled with the remote controller, the operation mode, set temperature, and the fan speed are

memorized by the indoor electronic control P.C.board. The “AUTO RESTART FUNCTION” sets to work the moment power

has restored after power failure.Then, the unit will restart automatically. However if the unit is operated in “I FEEL CONTROL.” mode before power failure, the operation is not memorized. In “I FEEL CONTROL.” mode, the operation is decided

by the initial room temperature.

How to set “AUTO RESTART FUNCTION”

1Turn off the main power for the unit.

2Removed the electronic control P.C. board and the display P.C.board.(See page 45 and 47.)

3Cut the RESISTOR JR07 (MS-07/09/12) or JR06(MS-18/24) on the indoor electronic control P.C.board.

E3

MS-07/09/12

E2E2

E2E2

MS-18/24

Operation

1If the main power (220/240V AC) has been cut, the operation settings remain.

2After the power is restored, the unit restarts automatically according to the memory.(However, it takes at least 3 minutes

for the compressor to start running.)

Note:

36

•The operation settings are memorized when 10 seconds have passed after the indoor unit was operated with the remote

controller.

•If main power is turned off while AUTO START/STOP timer is active, the timer setting is cancelled when auto restart

function works.

•If the unit has been off with the remote controller before power failure, the auto restart function does not works as the

power button of the remote controller is off.

•To prevent breaker off due to the rush of startting current, systematize other home appliance not to turn on at the same

time.

•When more than one air conditioners are connected under the same power system,compressor starting current as large

as that for all the compressors used flows at a time as soon as the units restart automatically.

Therefore, the specific counter-measures are required to prevent main voltage drop or the rush of starting current after

power failure by providing the system to allow the units to start in regular succession.

Page 37

10 TROUBLESHOOTING

MS-07NV - MS-09NV - MS-12NV - MS-18NV MS-24NV - MS-07NV - MS-09NV - MS-12NV MS-18NV - MS-24NV - MS-18NV -

E3E2E2

E1E1E1E1

E2E2E2E1

10-1 Cautions on troubleshooting

10-1-1 Before troubleshooting, check the followings:

1) Check the power supply voltage.

2) Check the indoor/outdoor connecting wire for mis-wiring.

10-1-2 Take care the followings during servicing.

1) Before servicing the air conditioner, be sure to first turn off the remote controller to stop the main unit, and then after

confirming the horizontal vane is closed, turn off the breaker.

2) When removing the electronic control P.C. board, hold the edge of the board with care NOT to apply stress on the

components.

3) When connecting or disconnecting the connectors, hold the housing of the connector. DO NOT pull the lead wires.

10-1-3 Troubleshooting procedure

1) First, check if the OPERATION INDICATOR lamp on the indoor unit is flashing on and off to indicate an abnormality.

To make sure, check the abnormality indication for 2 or 3 times before starting service work.

2) If the electronic control P.C. board is supposed to be defective, check the copper foil pattern for disconnection and

the components for bursting and discoloration.

3) When troubleshooting, refer to the flow chart and the check table on page 38.

10-1-4 How to replace batteries

Weak batteries may cause the remote controller malfunction.

In this case, the remote controller can not be repaired only by the battery replacement. To operate the remote controller normally, discharge the remote controller in the following order.

This remote controller has the reset button. After refilling new batteries, press the reset button with tip end of ball point

pen or the like, and then use the remote controller.

AA

RESET button

There are two kinds of remote controllers. A type has the RESET button at the back, and B type does it on the front.

BB

RESET button

37

Page 38

10-2 Instruction of troubleshooting

Start

Indoor unit operates. Outdoor unit

doesn’t operate.

Outdoor unit

operates in

only Test

Run operation.

Check room

temperature

thermistor.

Outdoor unit

doesn’t operate even in

Test Run

operation.

Refer to

D

“Check of

outdoor unit”

on page 41.

Indoor unit

doesn’t receive

the signal from

remote

controller.

Refer to

B

”Check of

receiver P.C.

board” on page

40.

OPERATION INDICATOR

lamp on the indoor unit is

flashing on and off.

Indoor unit doesn’t

receive the signal from

remote controller.

Also, OPERATION INDICATOR lamp doesn’t

flash, when the EMER-

2-time flash

GENCY OPERATION

switch is pressed.

2.5-second OFF

3-time flash

Refer to “Check of

indoor electronic control

2.5-second OFF

P.C. board” on page 41.

Cause:Indoor unit

2-time-Room temperature/Indoor coil thermistor trouble

3-time-Indoor fan motor trouble

Check indoor coil

thermistor. Refer

to“Test point dia-

Refer to

A

“Check of indoor

fan motor” on

page 40.

Check room temperature

thermistor. Refer to“Test

point diagram and voltage” on page 42~44.

gram and voltage”

on page 42~44.

C

10-2-1 troubleshooting check table

❈ Before taking measures make sure that the symptom reappears, for accurate troubleshooting.

Self check table

Abnormal

NO.

1

2

38

point

Indoor coil

thermistor

Room

temperature thermistor

Indoor fan

motor

2-time flash

2.5-second OFF

3-time flash

Indication

2.5-second OFF

Symptom

Outdoor unit

does not run.

Indoor fan

repeats 12 seconds ON and 3

minutes OFF.

When the indoor

fan breaks, the

fan keeps stopping.

Detect method

Detect Indoor coil/room temperature thermistor short or

open circuit every 2 seconds

during operation.

When rotational frequency

feedback signal is not emit

during 12-second indoor fan

operation

● Check thermistor calibration.

● Reconnect connector.

● Check indoor electronic control P.C.

● Disconnect connector CN211 and then

● Check indoor electronic control P.C.

● Check indoor fan motor.

● Reconnect connector.

Check point

board.

check connector CN121 2 - 3 to make

sure rotational frequency feedback signal

of 1.5V or over exists.

board.

Page 39

10-2-2 Trouble criterion of main parts

P

~

BLK

R

MAIN

AUX

RED

S

C

WHT

MAIN

AUX

FUSE

BLK RED WHT

MAIN

AUX

BLK RED WHTORN

P

MAIN

AUX

BLK RED WHT

P

MAIN

AUX

BLKYLW RED WHTORN

P

MAIN

YLW

RED

BLU

ORN

PNK

ROTOR

INNER PROTECTOR

P

Part name

Room

temperature

thermistor

Indoor coil

thermistor

Measure the resistance with a tester.

(Part temperature 10°C ~ 30°C)

Normal

8kΩ ~ 20kΩ

Measure the resistance between the terminals with a tester.

(Coil wiring temperature –10°C ~ 40°C)

MS-07NV - MS-09NV - MS-12NV - MS-18NV MS-24NV - MS-07NV - MS-09NV - MS-12NV MS-18NV - MS-24NV - MS-18NV -

E3E2E2

Check method and criterion

Abnormal

Opened or short-circuited

E1E1E1E1

E2E2E2E1

Figure

Compressor

Indoor fan

motor

Outdoor fan

motor

Normal

09NV

3.56~4.36Ω

5.25~6.44Ω

12NV 18NV

1.86~2.28Ω

3.50~4.29Ω

1.05~1.30

2.38~2.92Ω

Ω

0.84~1.04Ω

1.82~2.24Ω

24NV

C-R

C-S

07NV

3.67~4.50Ω

5.07~6.21Ω

Measure the resistance between the terminals with a tester.

(Coil wiring temperature10°C ~ 30°C)

Normal

Motor partSensor part

WHT-BLK

BLK-RED

07/09/12NV

280 ~ 303Ω

313 ~ 336Ω

18/24NV

176 ~ 192Ω

240 ~ 261Ω

Measure the voltage Power ON.

BRN-YLW

YLW-GRY

Normal

4.5 ~ 5.5V

(When fan revolved one time)

0V➔5V➔0V

(Approx.)

Abnormal

Remain 0V or 5V

Measure the resistance between the terminals with a tester.

(Coil wiring temperature –10°C ~ 40°C)

Normal

WHT-BLK

BLK-RED

07/09NV

236 ~ 290Ω

344 ~ 422Ω

12NV

115 ~ 141Ω

118 ~ 146Ω

18NV

102 ~ 126Ω

97.9 ~ 120Ω

BLK-YLW

Abnormal

Opened or

short-circuited

Opened or

short-circuited

24NV

71.5 ~ 87.5Ω

90.1 ~ 111Ω

81.3 ~ 99.5Ω

Abnormal

07NV

09NV

12NV

18NV

Abnormal

Opened or

short-circuited

24NV

Vane motor

Measure the resistance between the terminals with a tester.

(Part temperature10°C ~ 30°C)

Normal

07/09/12NV 282 ~ 305Ω

18/24NV 358 ~ 388Ω

Abnormal

Opened or short-circuited

39

Page 40

A

Check of indoor fan motor

Indoor fan does not operate.

Are lead wires connected?

Reconnect the lead

wires.

Disconnect lead wires from connector CN211 on indoor electronic control P.C. board.

Measure resistance between lead wires No.1 and No.4 and then No.1 and No.2(MS-12/18/24)

Check of receiver P.C. board

B

Turn OFF power supply.

Check connector CN211 visually.

YesNo

{

No.1 and No.3 and then No.2 and No.3(MS-07/09)

Is resistance 0 (short circuit) or ∞ (open circuit)?

Yes ( 0 or ∞ )

Repair the indoor fan motor.

Is soldered point normal?

Yes

}

Replace the indoor electronic control P.C.

board.

No

(others)

No

Resolder it.

Indoor unit operates by pressing the EMERGENCY OPERATION switch, but does not operate with the remote controller.

Check the model name of remote

controller.

Is.LCD display on remote con-

troller visible?

Yes

Remove batteries and then set them back.

Check if the unit operates with remote

controller.

Does the unit operate with remote

controller?

Yes

OK

No

(not clear)

No

Replace batteries.(see page 37.)

Turn on a radio to AM and press switch on

remote controller.

Is noise heard from radio?

Yes

Are there any fluorescent lights of

inverter or rapid-start type within

the range of 1m?

No

Turn ON power supply.

Measure the voltage between receiver P.C. board connector No.2

when remote controller button is pressed.

{

indoor electronic control P.C. board connector LD101 No.2 and JPG(MS-07/09)

No

Yes

Replace the remote controller.

● Re-install the unit away from lights.

● Attach a filter on receiving part.

(+)

and No.1(MS-12/18/24)

}

40

Is the voltage approx. 4V DC?

No(5V or 0V DC)

Replace the receiver.

Yes

Replace the indoor electronic control P.C.

board.

Page 41

Check of indoor electronic control P.C. board

C

The unit doesn’t operate with

the remote controller.

Replace the fuse.

Also, the OPERATION INDICATOR lamp doesn’t light up by

pressing the EMERGENCY

OPERATION switch.

Is fuse(F11)blown?

Check both “parts side” and

“pattern side” of indoor

electronic control P.C.board

visually.

Be sure to check

both fuse and varistor in any case.

Yes

No

1.Pull out power supply

cord.

2.Measure voltage

between CN201

1

on electronic control P.C. board and

on the terminal block

with a tester.

Trouble of indoor electronic control P.C. board.

Yes

Is there resistance?

(Approx.0Ω)

N

No

Trouble of fuse(F12)

Is varistor(NR11)burnt?

No

07NV

09NV

Yes

Replace the varistor.

12NV

18NV

24NV

D

Check of outdoor unit

Compressor and outdoor fan do not operate.(Only indoor fan operates.)

MS-07NV

MS-24NV

MS-09NV

MS-12NV

Start

Start

MS-18NV

Yes

Check the outdoor

fan motor and

compressor.

Press EMERGENCY OPERATION

switch.

3-minute time delay works.

Test run operation operates for 30

minutes.

Check voltage to terminal block of

outdoor unit. Is there AC220-240V to

terminal block between 2 - N ?

No

Press EMERGENCY OPERATION

switch.

3-minute time delay works.

Test run operation operates for 30

minutes.

Check voltage to terminal block of

outdoor unit. Is there AC220-240V to

terminal block between 2 - N ?

Yes

CN201

CN201

13

1

2

No

F12

L

Terminal

N

block

F12

L

Terminal

N

block

Check the continuity of

indoor and outdoor unit

connection.

Replace the indoor electronic control P.C.board.

No

Yes

Check the conti-

Check the continu-

nuity of indoor

ity of indoor and

and outdoor unit

outdoor unit con-

connection.

nection.

Check voltage to terminal block of

indoor unit. Is there AC220-240V to

terminal block between 2 - N ?

Replace the indoor electronic control P.C. board.

No

Check voltage to terminal block of

outdoor unit. Is there AC220-240V to

terminal block between 3 - N ?

Yes

Check the outdoor wiring and conductor relay at first, then check the

outdoor fan motor and compressor.

No

Check voltage to terminal block of