Page 1

2013

DEHUMIDIFIER

SERVICE MANUAL

Model MJ-E14EG-S1-IT

No.MJW-E-13020

Sold from 2014

CONTENTS

1. Precautions 2

2. Names and Functions of Parts 4

3. Specifications 5

4. Outer Dimensions 5

5. Wiring Diagram 6

6. Function 7

7. Technical Points 8

8. Precautions for failure diagnosis 9

9. Troubleshooting Procedure 10

10. Troubleshooting 18

11. Maintenance 20

12. Service Checklist 21

13. Precautions for Disassembly and Reassembly 22

14. Disassembly and Reassembly Hints 24

15. Parts Catalog 34

Page 2

2

1. Precautions

2

Note) This page is extracted from the instruction manual.

Page 3

33

Note) This page is extracted from the instruction manual.

Page 4

4

2. Names and Functions of Parts

Note) This page is extracted from the instruction manual.

Page 5

5

3. Specifi cations

4. Outer Dimensions

Note) This page is extracted from the instruction manual.

238

160

80

210

360

534

Page 6

6

P1

P3

P6

P12P13

HUM.S

P9 P11 P20 P21

P100 P101

P7

P30 P50

P15

VDD GND

P40

P2

CRS

Operation control

board

Control boardPower supply board

5. Wiring Diagram

1) Wiring Diagram

2) Board Diagram

[Operation control board]

[Power supply board]

[Control board]

Com-

pressor

Capacitor for

compressor

Fan

Solenoid

Valve

White

Red

Gray

Gray

Black

Yellow

Blue

Blue

Yellow/Green

Blue

Brown

Power plug

Humidity

sensor

Room

temperature

sensor

Thermopile

(Move Eye)

Ambient

tempera-

ture

Object

tempera-

ture

Float switch

Gray

Blue

White

White

White

Gray

Tube

temperature

thermistor

Stepping

motor

(left/right)

Stepping

motor

(up/down)

Page 7

7

6. Function

Function List

Operation Off

Operating mode

Laundry

Mildew guard

Low

High

Auto

Defrosting

detection

Tank full

detection

(Dehumidify)

Tank full

detection

(Move Eye)

Tank full

protection

Drying inside

ON timer setup

in progress

ON timer setup

complete

Blower fan OFF ON ON ON ON

ON/OFF

ON ON ON OFF

ON/OFF

OFF OFF

Compressor OFF ON ON ON ON

ON/OFF

OFF OFF OFF OFF OFF OFF OFF

Up-down louvre

CLOSE

ON ON *1 *1 *1*3 *1*4 *1 ON OFF

Top

centre

CLOSE CLOSE

Left-right louvre Centre ON ON *2 *2 *2*3 *2*4 *2 ON OFF Centre Centre Centre

LED indicator

POWER

Flashing

FULL

DRYING INSIDE

LCD indicator

7-segment

Current humidity display (3-second display of set humidity only when SELECTION is selected)

Operation mode Selected operating mode lamp lit

Flashing

Lit

MOVE EYE

*4 *4 *4

TIMER Set OFF timer time display

ON timer time display

Up-down swing area

*1 *1, *5 *1 *1 *1

Up-down swing monitor

*1

Left-right swing area

*2 *2, *5 *2 *2 *2

Left-right swing monitor

*2

CHILD LOOK Lit when child lock is ON

Switch

POWER

MOVE EYE *6 *6

DEHUMIDIFY *6 *6

SWING

*5 *5 *5

SWING

*5 *5 *5

DRYING INSIDE

TIMER *7

CHILD LOCK

*1: Operates when ON is selected for the up-down louvre. Stops when OFF is selected.

*2: Operates when ON is selected for the left-right louvre. Stops when OFF is selected.

*3: Operates when the blower fan is running

*4: Can only operate when using MOVE EYE (LAUNDRY, MILDEW GUARD) mode.

*5: Can only operate when using DEHUMIDIFY (LOW, HIGH, AUTO) mode.

*6: Operation mode moves to “tank full protection” when the switch is pressed.

*7: Can operate as the ON timer setting

: Lit/Can operate

: Unlit/Stopped/Cannot operate

When MOVE EYE is to be turned OFF (MOVE EYE operating mode only)

If MOVE EYE is to be turned OFF when it is in MOVE EYE operating mode, turn the power OFF and press

the MOVE EYE switch for at least 3 seconds.

Follow the same procedure to turn operations ON.

MOVE EYE is ON at the time of factory shipment.

This dehumidifi er remembers whether MOVE EYE is ON or OFF.

Even if the power plug is pulled out or power is turned OFF, operations start with the same setting that

was previously set.

Page 8

8

7. Technical Points

Note) This page is extracted from the instruction manual.

Page 9

9

8. Precautions for failure diagnosis

The following precautions should be observed in order to perform troubleshooting safely and correctly.

The following diagrams indicate circumstances where danger can result from mishandling the unit.

WARNING

Mishandling may result in fatal or serious injury, or fi re.

CAUTION

Mishandling may result in injuries or damage to your home or property, etc.

Forbidden

Always follow the

instructions

Alert

Meanings of graphic symbols are explained below.

Remove the power plug

from the socket.

Failure to do so may cause electric shock or injuries.

When performing work with

the power on, be careful not

to touch the live part.

This may cause electric shock.

Do not touch a rotating object

until it completely stops.

The rotating object may catch your hand etc,

and result in injuries.

Do not work with wet hands.

This may cause electric shock.

Check the wiring diagram

before wiring processing.

Failure to do so may cause combustion,

generation of smoke, and/or malfunction.

After the work,

lay the wire out as it was before.

Failure to do so may cause combustion,

generation of smoke, and/or malfunction.

Unplug

Electric shock

Don't touch No wet hands

Check Return to

as it was

WARNING

Wear protective gloves.

Failure to do so may result in injuries

by the edge of metal, electric shock,

and/or burns caused by contact with hot section.

Keep children away.

Failure to do so may result in

electric shock and/or injuries when moving

the unit or using a measuring device.

Wear gloves Keep away

CAUTION

Page 10

10

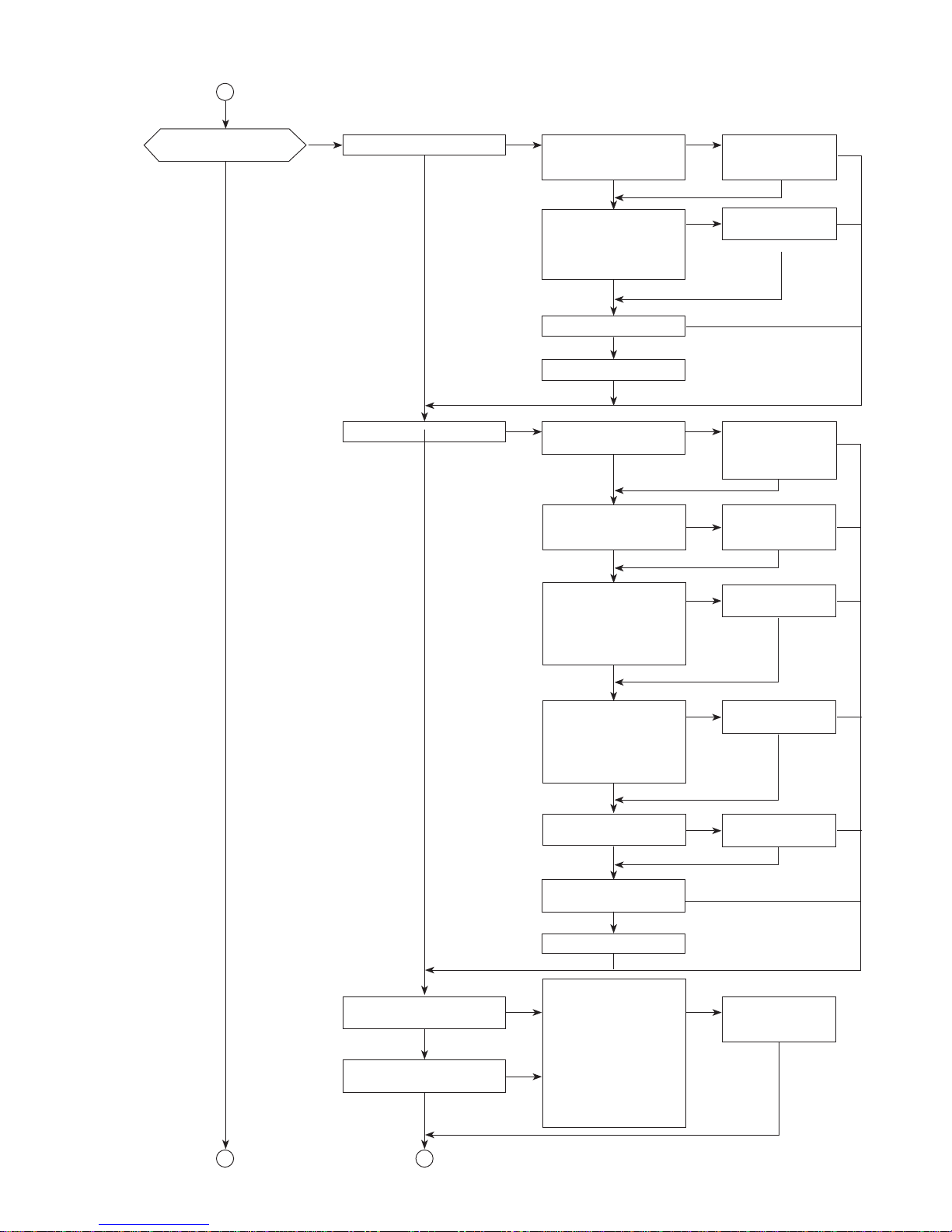

9. Troubleshooting procedure

1) Failure diagnosis fl owchart

Do any of the following

errors appear on the

humidity indicator?

“E0” “E1” “E2” “E3” “E4”

“E5” “E7” “E8” “A1” “A2”

“A6” “A8” “P4”

Perform the recommended

actions described in “Error

Indications and Corrective

Actions” on page 16.

Check the continuity of current

fuse on the power supply board

FUSE1 : 10A FUSE2/3 : 2A

CHILD LOCK indicator

turns on

When the POWER switch is

turned ON, does the operating

mode lamp turn on?

Deactivate the child lock

Check the power cord conduction

Replace the power cord

Replace the power

supply board

Does the detection buzzer

beep when the POWER

switch is turned ON?

Check if the lamps on the

control panel turn on.

* How to turn on all of the

lamps (See “LED and

Monitor indicators” on

page 17)

* Check whether any of the

LEDs on the operation

control board have fallen

off (repair if an LED has

fallen off)

Check that the power

supply board, control

board and operation

control board connectors

are fi rmly connected

(carefully check whether

any of the connector pins

have been pulled out,

etc.).

Firmly insert the

connectors or

connector pins in

the trouble spots

Replace the operation

control board

Replace the control

board

Replace the power

supply board

Is the FULL lamp lit?

Is the tank full?

Drain the water from the tank

Float check:

• Is the fl oat switch disconnected

or installed reversely?

• Is the fl oat operation smooth?

• Is there a magnet attached

to the fl oat?

Repair the fl oat problem

Check the fl oat switch

• Check the control board

P12 connector insertion

and the connector pins

• Check the continuity

between the P12

connector terminals when

the water tank is installed

Normal . . . When tank is

full: shorted

When tank is empty: open

Replace the fl oat switch

Replace the control board

Replace the power

supply board

A

YES

YES

NO

NO

YES YES OK

NG

NG

OK

OK

OK

NG NG

NG

NG

NG

OK

OK

NGNO

OK

OK

NG

NG

NG

OK

NG

NG OK

OK

OK

OK

YES

YES

NO

NO

YES

YES

NO

Page 11

11

Check the power supply

board P7 connector insertion

and the connector pins

Is dehumidifi cation

taking place?

Is the blower fan motor rotating?

A

Firmly insert the

connectors or

connector pins

Check the resistance values

for the blower fan motor.

Normal:Between yellow and blue 217-236Ω

Between black and blue 219-237Ω

Abnormal:Open or shorted

Replace the blower fan motor

Replace the control board

Replace the power

supply board

NO

YES

NO NG

NG

NG

NG

OK

OK

NG

OK

OK

YES

B

Does the compressor operate?

Check the power supply board P2

and P3 (run capacitors) connector

insertions and connector pins

Raise the humidity in the

usage environment and check.

(Compressor stopped due to

abnormally low temperatures)

Firmly insert the

connectors or

connector pins

Check the motor protector

continuity

Normal: shorted

Abnormal: open

* Check it at normal temperature

with the power OFF.

Is the operating environment low

temperature (below 3.2°C)?

Check the resistance

values for the compressor

Normal: 24 to 27 Ω

between C-R

40 to 45 Ω

between C-S

Abnormal: Open or shorted

Is there an overcurrent?

(Surface is hot)

Replace the power supply

board

Replace the control board

Replace the motor

protector

Replace the

compressor

Replace the

compressor

NO

YES

YES

NO

OK

OK

OK

OK

NG

NG

OK

NG

OK

NG

NG

NG

NG

NG

OK

OKYES

OK

OK

NG

NO

Is the heat exchanger

(evaporator) cold?

Are the power consumption

and current normal?

Check the refrigerant

circuit (Leaks or blockages)

• The part of the cooler

near the tube temperature

sensor should be at least

10°C lower than room

temperature when normal.

• If the amount of

refrigerant is low due to

a slow leak, white frost

appears on the bottom

of the heat exchanger

Replace the parts

responsible for the

leaks or blockages

NO

NO

NG

OK

YES

C

YES

Page 12

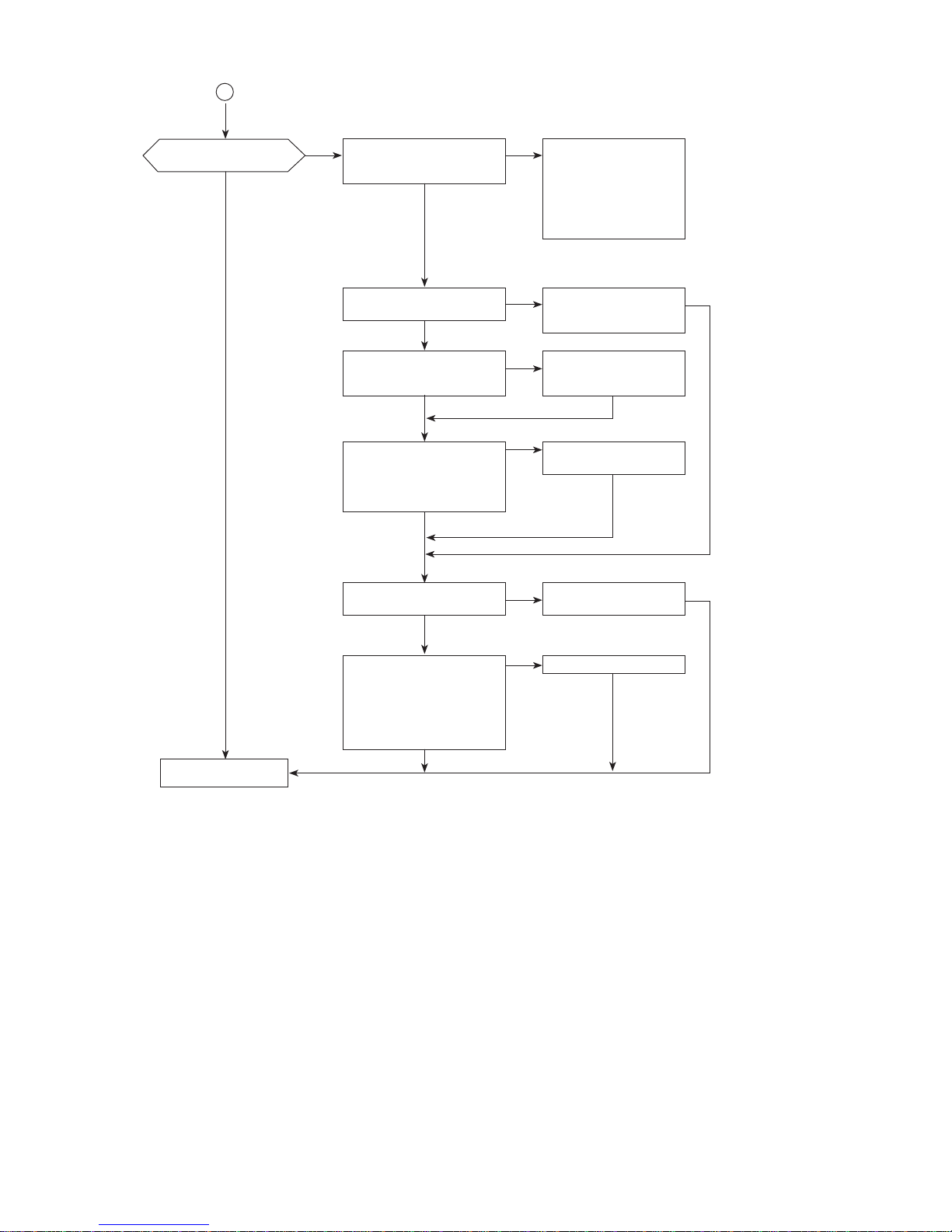

12

B

D

The unit stops working

in the middle of operation

Check the resistance values

for the tube temperature.

Normal: 8.0KΩ to 20.8KΩ

(Between P15 pins)

Abnormal: Open or shorted

Check the resistance values

for the solenoid valve.

Normal: 2.0KΩ to 2.2KΩ

(Between the pin1 and pin2)

Abnormal: Open or shorted

Replace the tube

temperature thermistor

Replace the solenoid valve

The louvre does not

swing

C

Is the fi lter blocked due to dust, etc.?

Is the operating environment low

humidity or low temperature?

The main unit is operating

normally.

Check the operating environment

again, and then operate again.

Is the operation being

performed with the unit set to

automatic operating mode?

(LAUNDRY/MILDEW

GUARD/AUTO/OFF TIMER)

① LAUNDRY: A minimum of about 84 minutes to a maximum of about 12 hours

② MILDEW GUARD: A minimum of about 4 hours to a maximum of about 12 hours

③ AUTO: If the current humidity goes lower than the set humidity, operation stops.

④ OFF TIMER: Has the timer stopped operating? Operation stops at the set time.

⑤ Is the OFF timer being used at the same time as timer OFF for all operating modes?

Operation stops at the set time as timer operation is given priority.

The main unit is operating normally if ① through ⑤ are true.

Is the up-down swing louvre

OFF?

Check the connector connection

between the control board P11

connection and the stepping motor

connector and connector pins.

Check the resistance values

between the stepping motor

connector pins.

Normal

Terminals 1-2

Terminals 1-3

342Ω to 418Ω

Terminals 1-4

Terminals 1-5

Abnormal

Open or shorted

E

Replace the control board

Replace the control board

Replace the power supply board

Replace the power supply board

Clean fi lter

Normal. Dehumidifi cation

may not be possible in low

humidity and low temperature

environments.

Explain the performance curve

on page 8.

Is the dehumidifi er installed

in a low humidity, low

temperature environment?

Does the up-down swing

louvre change to Wide,

Frontward, and Upward?

Firmly insert the

connectors or connector

pins in the trouble spots

Replace the stepping motor

Dehumidifi cation

may not be possible

in a low humidity,

low temperature

environment. Explain

the performance

curve on page 8.

Normal

Replace the control

board

Replace the power

supply board

OK

OK

OK

OK

NG

NG

YES

OK

OK

NO

YES

NO

OK

NG

NG

NG

NG

NG

YESYES

YES

NO

YES YES YES

NO

NO

NO

OK

OK

NG

NG NG OK

OK

NO

OK

OK

NG

Page 13

13

D

F

MOVE EYE operation

is abnormal

Is the left-right swing louvre

stopped?

Normal

E

YES

NO

Does the left-right swing

change to Wide and Stop

swing operation?

Check the connection

between the control board

P9 connector and the

stepping motor as well as the

connector pins.

Firmly insert the

connectors or connector

pins in the trouble spots

Check the resistance values

between the stepping motor

connector pins.

Normal

Terminals 1-2

Terminals 1-3

342Ω to 418Ω

Terminals 1-4

Terminals 1-5

Abnormal

Open or shorted

Replace the stepping

motor

Replace the control

board

Replace the power

supply board

Is the operating mode the

MOVE EYE operating mode?

Is the MOVE EYE monitor on

the control panel lit?

Check the control board P40

connector insertion and the

connector pins

See “LED and Monitor indicators” on page 17 of the Troubleshooting

procedure. Press the MOVE EYE switch and the DEHUMIDIFY

switch 4 times at the same time when the POWER switch is OFF,

and then set the POWER switch to ON within 2 seconds.

After it starts up, select the mode with the TIMER switch. Press the

TIMER switch 6 times to select the mode 6. (the selected mode

number is displayed in the timer display)

Check method: Cover the MOVE EYE sensor with the palm of the

hand, and check whether the humidity display shows approximately 35.

Replace the move eye

How to check the MOVE EYE and louvre operations: Hang a wet

towel on a wall with no window or heat source.

Run with the dehumidifi er operating mode set to LAUNDRY

operating mode. Check that the MOVE EYE monitor is lit. MOVE

EYE and louvre operation is normal if 3 minutes after it starts up,

the area where air blows out from the main unit gradually narrows

and the air hits the centre of the towel being dried.

MOVE EYE is OFF. Turn the POWER switch

OFF and press the MOVE EYE switch for about 3

seconds. When the detector beeps and the MOVE

EYE operating mode is set to LAUNDRY or MILDEW

GUARD, does the MOVE EYE monitor turn on?

Normal

Repair the control board

P40 connector

Replace the control board

Replace the power supply

board

YES YES

NG

NO

OK

NO

OK

OK

NG

NG

OK

OK

OK

NG

NO YES

YES

NO NO

YES

YES

OKNG

NO

OK

OK

NG

OK

OK

NG

NG

Page 14

14

F

Amount of

dehumidifi cation is low

Is there dust or dirt on the

room temperature sensor?

YES

NO

Replace the room

temperature sensor

Remove the dust or

dirt from the room

temperature sensor

Check the control board P13

connector insertion and the

connector pins

Firmly insert the

connectors or connector

pins in the trouble spots

Check the resistance values for

the room temperature sensor

Connector pins (between 3-4)

Normal: 8 to 20.8KΩ

Abnormal: Open or shorted

Is there dust or dirt on the

humidity sensor?

Remove the dust or dirt

from the humidity sensor

Replace the control board

Check the humidity sensor

operation

(Hold a steaming towel or hot

air from a dryer close to the

humidity sensor for 1 minute.

If the humidity indicator rises,

it is OK.)

Normal

YES

YES

NG

NG

YES

NG

NO

NO

OK

OK

NO

OK

OK

OK

Is the dehumidifi er installed

in a low humidity, low

temperature environment?

The unit is normal.

Dehumidifi cation may

not be possible in a

low humidity and low

temperature environment.

Explain the performance

curve on page 8.

OK

OK

OK

Page 15

15

2) Simple Check Table for Main Parts

Part name Test criteria

Tube temperature

detection thermistor

Disconnect the connector and measure the resistance values with a tester (Part temperature

10°C to 30°C).

Normal Abnormal

8.0KΩ to 20.8KΩ Open or shorted

Room temperature

sensor

Disconnect the connector and measure the resistance values with a tester (Part temperature

10°C to 30°C).

Normal .............8.0 to 20.8KΩ (between pins 3-4)

Abnormal .........Open or shorted

Compressor

Disconnect the connector and measure the resistance values across terminals with a tester

(Coil temperature 10°C to 30°C).

Normal Abnormal

C-R side 24Ω to 27Ω

Open or shorted

C-S side 40Ω to 45Ω

Blower fan motor

Measure the resistance values across terminals with a tester (Part temperature: 10°C to

30°C).

Normal Abormal

Yellow-Blue 217Ω to 236Ω

Open or shorted

Black-Blue 219Ω to 237Ω

* Be careful of injury or shock

Solenoid valve coil

Measure the resistance values across terminals with a tester (Part temperature: 10°C to

30°C).

Normal Abnormal

2.0KΩ to 2.2KΩ Open or shorted

Stepping motor

Measure the resistance values across terminals with a tester (Part temperature: approx

25°C).

Normal Abnormal

Terminals 1-2

342Ω to 418Ω Open or shorted

Terminals 1-3

Terminals 1-4

Terminals 1-5

Page 16

16

3) Error Indications and Corrective Actions

Indicator

(current humidity

display)

Error (failure) Corrective action

A1

Microprocessor failure

RAM error

Replace the control board

A2 Frequency determination error

Check the outlet, 220V power

(Try to replace the power supply and control

boards)

A6

Watchdog error

(Main stop/Interrupt)

Replace the control board

A8

E

2

PROM failure

Replace the control board

E0

Room temperature sensor

disconnected

Check the P13 connector connection

Check the room temperature sensor board

E1 Room temperature sensor short

E2

Move eye thermopile

OBJ High temperature abnormal

(object temperature)

Check the connectors

Replace the move eye thermopile

E3

Move eye thermopile

OBJ Low temperature abnormal

(object temperature)

Check the connectors and the disconnection

Replace the move eye thermopile

E4

Move eye thermopile

AMB High temperature

abnormal (ambient temperature)

Check the connectors

Replace the move eye thermopile

E5

Move eye thermopile

AMB Low temperature abnormal

(ambient temperature)

Check the connectors and the disconnection

Replace the move eye thermopile

E7

Tube temperature thermistor

disconnected

Check the connectors

Check the P15 tube temperature thermistor

connection

E8

Tube temperature thermistor

short

P4 Compressor failure

Check the air fl ow

Check the tube temperature thermistor

Check the compressor operating noise

4) Self Diagnostic Test Program

(1) Deactivate 3-minute restart prevention

Start . . . . . . . . . .Press the MOVE EYE and DEHUMIDIFY switches together 3 times when

the power is off. Press the POWER switch within 2 seconds.

Functions . . . . . . .① Deactivates 3-minute restart (immediate operation)

② Sets the operating mode to LAUNDRY

③ When E2PROM error is detected, FULL LED and CHILD LOCK monitor

are lit.

④ Turns the solenoid valve ON for 3 seconds when the power is off, and

then after 3 seconds, turns the solenoid valve OFF.

⑤ When the operating mode changes, it fi xes the fan rank and unlocks the

E2PROM error display.

Finish . . . . . . . . .Turn the power OFF.

Page 17

17

Microprocessor

version display

Current

humidity

indicator

Room

temperature

indicator

(1°C increments)

Room temperature

indicator

(0.2°C increments)

Tube temperature

indicator

(1°C increments)

Tube temperature

indicator

(0.2°C

increments)

Move eye

thermopile

OBJ indicator

(1°C

increments)

Move eye

thermopile

OBJ indicator

(0.2°C

increments)

MOVE EYE

AMB indicator

Fan rank

indicator

Blower fan

operation

cumulative time

(Top 8 bits)

Blower fan

operation

cumulative time

(Bottom 8 bits)

Current

sensitivity

table

7 seg + All

LEDs lit

(2) LED and Monitor indicators

Start . . . . . . . . . .Press the MOVE EYE and DEHUMIDIFY switches together 4 times when

the power is off. Press the POWER switch within 2 seconds.

Mode selection . . . .Use the TIMER switch to change the diagnostic mode (0 to 13). The selected

mode number is displayed in the timer display.

Finish . . . . . . . . .Turn the power OFF.

How to display the humidity

indicator by diagnostic mode

In decimal : 0, 1, 2, 4, 6, 8, 9, 10, 13

In hexadecimal : 3, 5, 7, 11, 12

(3) Demo mode

Start . . . . . . . . . .Hold the MOVE EYE and DEHUMIDIFY switches together when the power

is off and press the POWER switch.

Operations . . . . . .① Demo mode continues until the microprocessor is reset

② All of the switches are disabled

③ Operates the same way as when in LAUNDRY mode except for the

compressor and the blower fan.

Finish . . . . . . . . .Turn the power OFF.

(4) Error history check mode

Start . . . . . . . . . .Press the MOVE EYE and DEHUMIDIFY switches together 5 times when

the power is off. Press the POWER switch within 2 seconds.

Mode selection . . . .Use the TIMER switch to change the diagnostic mode (0 to 7).

Operations . . . . . .① Mode 0: Newest error history display

② Mode 7: Oldest error history display

Finish . . . . . . . . .Turn the power OFF.

Page 18

18

Note) This page is extracted from the instruction manual.

10. T roubleshooting

Page 19

19

Note) This page is extracted from the instruction manual.

Page 20

20

11. Maintenance

Note) This page is extracted from the instruction manual.

Page 21

21

12. Service Checklist

(1) Points to be checked after completing repairing

After completing repairing, check the all items below to prevent re-repair.

Check items Check

At installation

Was the proper tool used?

Are the parts on the parts catalog used?

Verify that there is no problem in the lead wire (layout and connection) and/or clamp.

Verify that there is no defect, such as lead wire caught in other parts, damage, and/or intermediate connection.

Verify that there is no defect, such as deteriorated or damaged power cord and/or intermediate connection.

Verify that there is no slack and/or damage to power cord.

Are the connectors and metal terminals inserted securely?

Verify that there is no abnormal sound of the motor etc.

If electrical parts are replaced, was the insulation performance checked?

Verify that there is no insuffi cient inserting or gap in the fi tting and/or calking sections.

Is the cushioning attached without fail? Is the parts requires silicon coating surely coated with silicon?

Are the all sorts of specifi ed screws on the parts catalog used?

Are the all sorts of packing, washers, etc. installed without fail?

Are the waterproofi ng and rust prevention performed on the products which require those treatment?

Installation conditions

Is the unit installed at the fl at place?

Is the unit installed at the stable place? (The unit is not easy to fall down?)

Is a fi rm ground selected for the installation place? (Be careful with a hollow fl oor, corrosion, etc.)

Is there enough space around the unit? (Is there no wall, ceiling, curtains, etc. near the unit?)

Verify that the unit is not installed where it is exposed to direct sunlight or near heat- generating devices.

Verify that the unit is not installed in a special environment. (places where chemicals are used or there is a lot of dust.)

Is the product which requires earthing correctly earthed? (Do not connect the earth wire to a water pipe or gas pipe.)

Is the installation criteria described in the instruction or installation manual fulfi lled?

Operation check

Is the power on when you turn it on?

Is the basic operation described in the instruction manual successfully performed?

Verify that there is no problem in operation around the open and close part, rotation part, slide part, etc.

Verify that no abnormal sound or smell is emitted.

Is the power off when you turn it off.

Explanation

after repair

Explain the content of repair, check, and/or adjustment to the customer well.

Tell the customer to read the instruction manual well to use this dehumidifi er.

Tell the customer not to disassemble the product.

Explain to the customer if the installation place is not good or if there is more effi cient way.

Page 22

22

13. Precations for Disassembly and Reassembly

The following precautions should be observed in order to perform disassembly and reassembly safely and correctly.

The following diagrams indicate circumstances where danger can result from mishandling the unit.

WARNING

Mishandling may result in fatal or serious injury, or fi re.

CAUTION

Mishandling may result in injuries or damage to your home or property, etc.

Forbidden

Always follow the

instructions

Alert

Meanings of graphic symbols are explained below.

Remove the power plug

from the socket.

Failure to do so may cause electric shock or injuries.

When replacing parts,

use the specifi ed partslisted

on the parts catalog.

Failure to do so may cause combustion,

moke, and/or malfunction,

Do not touch a rotating object

until it completely stops.

The rotating object may catch your hand etc,

and result in injuries.

Do not work with wet hands.

This may cause electric shock.

Check the wiring diagram

before wiring processing.

Failure to do so may cause combustion,

generation of smoke, and/or malfunction.

After the work,

lay the wire out as it was before.

Failure to do so may cause combustion,

generation of smoke, and/or malfunction.

Do not alter the product.

This may cause fi re, electric shock, and/or injuries.

Comply with the law.

Follow the applicable laws and regulations,

such as "Fire Prevention Ordinance" and

"Electric Equipment Technical Standards."

Failure to do so may cause fi re and electric shock.

Use appropriate tools.

Failure to do so may result in

an accident caused by contact failure or

loose parts.

Earth the product which

requires earthing correctly.

Incomplete earthing or connection to

a gas pipe, water pipe, etc.

may cause an explosion or electric shock.

Do not damage or process

the power cord or lead wire.

This may cause fi re, combustion,

and/or electric shock.

Replace the damaged or

deteriorated power cord or

lead wire.

Failure to do so may cause fi re,

combustion, and/or electric shock.

Unplug

Return to

as it was

Don't touch No wet hands

Check Return to

as it was

No alteration Obey the law

Use proper

tools

Earth

Forbidden

Replace

WARNING

Page 23

23

Wear protective gloves.

Failure to do so may result in injuries

by the edge of metal, electric shock,

and/or burns caused by contact with hot section.

Keep children away.

Failure to do so may result in

electric shock and/or injuries when moving

the unit or using a measuring device.

Do not put the unit

where it may burn.

This may cause fi re,

or combustion.

Check the fi rmness

of installation location.

The product may fall down,

which could cause an accident or injuries.

Perform operation

check after reassembly.

Failure to do so may result

in an accident or malfunction.

Do not wash the unit

with water.

This may result in fi re,

combustion, or malfunction

Wear gloves Keep away

Do not

install unit

Check

Operation

check

No water

CAUTION

1. When the service requires disassembly, be sure to remove the power cord from the outlet.

2. When it is necessary to perform the work with the power on, be careful not to touch the live part.

3. Use appropriate tools for the work.

4. Use the specifi ed parts listed on the "Parts Catalog" of the applicable model.

5. Check the deterioration of the power cord and lead wire at service.

Replace the damaged or deteriorated power cord and lead wire.

6. After the service, perform the operation check.

Verify that the tank full detection works properly and the unit operates without a problem.

Safety precautions for the inspection and service

Page 24

24

(2) Removing the fi lter cover and rear casing assembly

① Remove the water tank. → (See (1)

Removing the water tank)

② Push the tab on the fi lter cover up,

pull it forwards, and remove the fi lter

cover. → (Removing the fi lter cover)

③ Remove the rear casing set screws

(6) and special screws(2). Detach

the catch(1).

④ Remove the rear casing.

<Precautions for Assembly>

When assembling the rear

casing, be careful not to pull out

the lead wires around

the control board.

14. Disassembly and Reassembly Hints

[Precautions for Assembly]

• Firmly connect the lead wire connectors. Firmly tighten the screw connectors in particular.

• If the binding band holding the lead wires is cut, it must be replaced with a new binding band.

• Hold the lead wires that were removed in place with a clamper, etc. and do the wiring.

(1) Removing the water tank

① Pull out the water tank from the side

bottom of the unit. → (Removing the

water tank)

①

Water tank

Main

unit

②

④③

Filter

cover

Rear

casing

Pull it straight out because it is

on rails

Rear casing

set screws (6)

Catch (1)

Ta b

Special

screws (2)

Page 25

25

(4) Removing and replacing the operation control board/louvre assembly

① Remove the front casing. → (See (3)

Removing the front casing)

② Disconnect connectors P9, P11,

P13, P15, P20, P21, and P40 from

the control board on the right side of

the main unit.

③ Remove the louvre assembly.

④ Remove the top cover set screw

(1), and remove the top cover. →

(Removing and replacing the room

temperature thermistor)

⑤ Remove the operation control board

set screws (2) from the louvre

assembly, unlatch the catches (2),

and remove the operation control

board. → (Removing and replacing

the operation control board)

(3) Removing the front casing

① Remove the water tank. → (See (1)

Removing the water tank)

② Remove the rear casing assembly.

→ (See (2) Removing the fi lter cover

and rear casing assembly)

③ Remove the front casing set screw

(1) from the side of the main unit.

④ Release the catch on the bottom of

the front casing, hold both sides,

release the left and right catches (3)

so it opens, pull it forwards, release

the blower fan frame catches (5),

and remove the front casing. →

(Removing the front casing)

<Caution>

The catch on the casing may be

damaged, so push the catch in ④

A on the rear casing to release it to

open the casing.

③

Front casing set

screw (1)

②

⑤

④④

③

⑤

Catches

Front

casing

Front casing

bottom catch

Front casing inside

catches (5)

Left/right

catches

(3)

A

Louvre assembly

Top cover

Room

temperature

thermistor

Operation control

board set screws (2)

Top cover set

screw (1)

Operation control board

Catches (2)

④

Right side of main

Right side of main

unit

unit

Control

board

Page 26

26

(5) Removing and replacing the control board

① Remove the front and rear casings.

→ (See (2) Removing the fi lter cover and

rear casing assembly, and (3) Removing the

front casing)

② Disconnect all of the connectors (P9, P11,

P12, P15, P20, P21, P40, and P50) from the

control board, and gently lift and slide the

control board out.

<Precautions for Assembly>

Gently push the casing rib, and at the same

time, insert the board into the groove.

Install the lead wires as shown in ②.

(6) Removing and replacing the power supply board

① Remove the front and rear casings.

→

(See (2) Removing the fi lter cover and rear

casing assembly, and (3) Removing the front casing)

② Remove the board cover T set screw (1), and

pull out the power supply board assembly.

→ (Removing and replacing the power

supply board)

<Precautions for Assembly>

Do not forget the lead wires that are held

together.

Install the lead wires as shown in ②.

③

Remove the board box, and disconnect all of

the connectors (P1, P2, P3, P7, P8, and P30).

④ Remove the power supply board set screw

(1), and remove the board.

→ (Removing and replacing the power

supply board)

<Precautions for Assembly>

Be sure to attach new waterproof tape

(fi lament tape, 19 mm) after peeling off the

old waterproof tape.

②

Press the casing rib with

your fi ngers and pull out

the board

②

④

③

Control board

Slide

Slide

Disconnect all of the connectors

Board cover T

Board box Waterproof tape

Power supply board Capacitor

Power supply

board set

screw (1)

Board cover U

Board cover

T set screw (1)

* Bind the lead wires together

Page 27

27

(7) Removing and replacing the blower net and the blower motor

① Remove the board holder from the board

assembly.

→ (See (6) Removing and replacing the

power supply board)

② Remove the net.

③ Disconnect the P7 connector from the

power supply board.

④ Remove the casing set screws (2), and lift

up the casing to remove it.

⑤ Remove the blower fan stop nut, and

remove the blower fan.

②③

④⑤

Power supply board

Remove connector P7

Net

Casing set screws (2)

Nut

Blower fan

Casing

⑥ Remove the blower motor holding plate set

screws (4), and remove the blower motor.

→ (Removing and replacing the

blower motor)

<Precautions for Assembly>

The motor lead wires must pass through

the casing catch.

(8) Removing and replacing the power plug

① Remove the board holder from the power

supply board assembly. → (See (6)

Removing and replacing the power supply

board)

② Disconnect connector P1 from the power

supply board.

③ Remove the earth wire set screw(1), and

remove the power cord earth wire.

④ Remove the power cord from the main

unit clamper, and remove from the bottom

groove. → (Removing and replacing the

power plug)

<Precautions for Assembly>

When installing the earth wires, give them

some slack.

⑥

Blower motor holding plate set screws(2)

②

③④

Blower motor

holding plate

Blower motor holding plate

set screws(2)

Note:

The motor lead wires must

pass through the casing catch.

Blower motor

Remove connector P1

Power supply board

Power plug

Earth wire set screw (1)

Page 28

28

(10) Removing and replacing the fl oat switch

① Remove the blower fan assembly.

(See (7) Removing and replacing the

blower net and the blower motor)

② Remove the connector P12 on the control

board.

③ Remove the fl oat switch set screw(1) from

the drain pan assembly to remove the fl oat

switch.

→ (Removing and replacing the fl oat

switch)

②

③

Remove the

connector P12

Control board

Float switch

Float switch

set screw(1)

Float

switch

Float

switch

set screw

(9) Removing and replacing the solenoid valve

① Remove the board holder from the power

supply board assembly. → (See (6)

Removing and replacing the power supply

board)

② Disconnect connector P6 from the power

supply board.

③ Remove the solenoid valve set screw(1) to

remove the solenoid valve. → (Removing

and replacing the solenoid valve)

②

③

Remove connector P6

Power supply board

Solenoid valve set screw (1)

Solenoid valve

Page 29

29

(12) Removing and replacing the compressor/heat exchanger

① Remove the drain pan assembly.

→ (See (10) Removing and replacing the

drain pan assembly)

② Place a support under the bottom right of

the heat exchange assembly, and remove

the compressor set screws (3).

③ Remove the compressor and the heat

exchange assembly from the base. →

(Removing and replacing the compressor/

heat exchange assembly)

<Precautions for Assembly>

• When the power supply board earth wire and power cord earth wire are installed, line up the fl at

surfaces of the round terminals as shown in the illustration below.

• Be careful about the installation position for the tube temperature thermistor.

• Install the lead wire for the tube temperature thermistor so that the lead wire does not touch the

heat exchanger.

(11) Removing and replacing the drain pan assembly

① Remove the blower fan assembly.

→ (See (7) Removing and replacing the

blower net and the blower motor)

② Release the drain pan catches (4) from the

base, and remove the drain pan assembly

while holding the heat exchange assembly

away from the main unit. → (Removing

and replacing the drain pan assembly)

<Precautions for Assembly>

• When replacing the drain pan, do not

forget to install the cushions, etc.

In particular, the drain outlet packing is a

countermeasure against water leaking,

so be sure to install it.

②

Drain pan

assembly

②

③

Heat exchange assembly

Compressor

Base

Compressor

set screws(3)

Power supply board earth wire

Power cord earth wire

Power supply board earth wirePower cord earth wire

Gray (R)

White (C)

Red (S)

<Compressor: Wiring diagram>

Support

Page 30

30

(13) Removing and replacing the louvre assembly

① Remove the front casing. → (See (3)

Removing the front casing)

② Remove the operation control board from

the louvre assembly. → (Removing and

replacing the operation control board)

③ Remove the top cover set screws (2) from

the louvre assembly, and remove the top

cover.

④ Remove the gear holder set screws (3),

and remove the gear holder.

⑤ Remove the gear and the stepping motor.

⑥ Remove the sleeve G1 set screws (2), and

remove the sleeve G1.

⑦ Remove the top casing and the louvre

assembly.

If the louvre U assembly is in the way,

push out the shaft louvre with a narrow

rod ( 1 to 3), and remove the louvre U

assembly.

⑧ Gently open both ends of louvre CY-2 and

louvre CY-3, and remove the louvre.

Remove the MOVE EYE set screw (1),

release the left and right CY-1 louvre

catches, and remove the louvre while

pulling out the fi n shaft.

⑨ Remove the louvre CY-N linked fi ns joint,

and remove the linked fi ns.

⑩ Remove the mount MS set screw(1), and

remove the mount MS.

⑪ Remove the stepping motor set screws

(2), and remove the stepping motor.

⑫ Remove the MOVE EYE set screw (1),

and remove the MOVE EYE.

Top cover set screws(2)

③④

⑤⑥

⑦⑧

⑩

⑫

⑨

Gear holder

Gear holder set screws(3)

Gear

Stepping motor

Sleeve G1 set screws(2)

Top casing

Louvre

CY-2

Louvre

CY-3

Louvre U

assembly

Louvre assembly

Link fi n

Louvre CY-N

Mount MS set screw(1)

Stepping motor

set screws(2)

MOVE EYE

set screw(1)

⑪

Louvre

CY-1

Louvre

CY-N

Page 31

31

Louvre/gear assembly procedure

① Raise the louvre assembly so that the gear does

not drop.

② Place each of the louvres CY-1, CY-2, and CY-3

in the upward position, and line up the protrusions

with the markings on the top casing.

③ Run the lead wires through gears L3, L2, and L1, and line up the gear notches with the markings .

④ Insert the gear L3, L2, and L1 grooves into the protrusions of respective louvre CY-1, CY-2, and CY-

3.

⑤ Hold the louvre so that gears L3, L2, and L1 do

not turn and at the same time, line up the gear M

notch in the upward direction and attach.

If the gear position shifts even one tooth, the

louvre open/close position shifts.

If gears L3, L2, and L1 are allowed to move in

the direction of the arrows, it is easier for them

to fi t together.

⑥ Install the stepping motor and gear SM.

⑦ Run the lead wires through the gear holder hole,

and tighten the gear holder set screws (3).

③

④

⑤

⑥

Upward

position

Line up the

protrusions

on louvres

CY1, CY2,

and CY3

with the

markings

on the top

casing.

Louvre

protrusions

Gear

notches

Lead

wires

Gear L1

Gear L2

Gear L3

Gear M notch

*Gear runout direction

Stepping

motor

Gear SM

Gear holder set screws(3)

②

⑦

Page 32

32

Operation Checks

① When the side of the move sensor assembly is

held and rotated left and right about 60 degrees

(a total of 120 degrees), the fan must move

smoothly in sync.

② When louvre N is held and rotated by hand, it

must operate smoothly with no unusual noises.

③ At the upward position (until the top casing is

slanted), the louvre CY-N must open.

④ The louvre CY-N top edge must be at the parting

position at the stop position.

⑤ The louvre CY-2 front edge must be at the

difference position at the stop position.

⑥ The louvre CY-3 front edge must be at the

stopper position at the stop position.

⑦ Louvre CY-1, CY-2, and CY-3 must have no

gaps.

<Precautions for Assembly>

• When the move sensor assembly side is held and rotated left and right 60° (a total of 120°), adjust

the length of the sensor lead wires so that they do not become taut, and secure with tape.

① Left and right 60°

② Rotate up and down

Gear holder

⑤ Difference position

⑥ Stopper position

④ Parting position

Louvre CY-N

Give them some slack

Filament tape

MOVE EYE

Rotate left

and right 60°

Page 33

33

Page 34

34

MJ-E14EG-S1-IT Model Structural Disassembly Diagram

[

Casing and Tank Structure

]

109

147

138

136

106

107

108

110

101

105

104

111

112

144

114

113

128

119

103

102

117

118

142

143

127

124

120

121

122

123

129

130

131

140

132

133

135

126

125

139

145

146

134

136

137

107

108

SCW-PL-TBFZR

4×12(1)

SCW-PL-TBFZR

4×12(6)

TBFZR

3×10M(2)

SCW-PL-TBFZR

4×12(2)

SCW-DPFZR-PT(White)

3×10(1)

SCW-TPFZR

3×8N(3)

SCW-DPFZR-PT

3×10(1)

SCW-PL-TBFZR

4×12(2)

SCW-TBFZR

3×10M(1)

SCW-PL-TBFZR

4×12(1)

SCW-PL-TBFZR

4×12(3)

141

116

SCW-MPFZR

M4×14-TORX(2)

115

15. Parts Catalog

Page 35

35

Notes:

1. Circled reference numbers indicate performance parts.

2. New parts and the parts that are used only with these models lack compatibility.

3. Those parts that are marked by and are of critical importance for sustaining safety and performance.

Use specified parts at replacement.

4. When ordering parts without part numbers, use the design number. The order may take a while to process.

*1. If the part is out of production, you may be required to use a common part.

*2. Parts found installed in products may have a different part number from service parts.

However, there should be no difference in performance and can be installed.

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

2

1

1

1

1

1

1

1

1

1

1

7*110*T5

7*170*T5

Badge attached

7*70*T5

L 345

expendable item

E80EX-H

E80EX-H

100EX

100EX

H100CX

10HGX

100EX

100EX

E105EF-TW

100EX

100EX

100EX

E80EX-H

10HGX

E14EG-E1

E14EG-E1

100EX

100EX

100EX

100EX

100EX

100EX

100EX

10HGX

10HGX

E14EG-E1

100GX

100GX

100EX

100EX

H100CX

100EX

E80EX-H

100EX

100EX

E14EG-E1

100EX

10HGX

E80EX-H

100EX

E105EF-TW

E80EX-H

M22 C75 345

M22 C75 345T

M22 B56 320TC

M22 B56 330

M22 B46 340

M22 B70 310R

M22 B56 0553

M22 B56 0556

M22 C81 310

M22 B56 0555

M22 B56 180

M22 B56 321F

M22 C75 310

M22 C95 689

M22 B70 320

M22 C98 555

M22 C95 440

M22 C98 311

M22 B56 261G1

M22 B56 261GW

M22 B56 110L1

M22 B56 110L2

M22 B56 110L3

M22 B56 110M

M22 B56 110

M22 B70 620

M22 B70 260

M22 C98 405

M22 B66 405CY2

M22 B66 405CY3

M22 B56 405CY1

M22 B56 261

M22 B46 620S

M22 B56 110

M22 C75 405CYN

M22 B56 405

M22 B56 405S

M22 C98 150

M22 B56 183

M22 B70 405L

M22 C75 100

M22 B56 370

M22 C81 449

M22 C75 349

M22 C95 450

M22 C75 468

M22 C95 936

TANK*ASSY-EX

TANK*EX

COVER-TANK*EX

LID-TANK*EX

FLOAT*ASSY-CX

CASE-R*E105EF

PACKING-PCA*EX

PACKING-PCA*EX

CASE-F-ASSY-2*E105EF

PACKING-PCA*EX

HANDLE*EX

COVER-FILTER*ASSY-EX

CASE-T-SUB*ASSY-E80X

PCA*MJ-E14EG-S1-IT

COVER-T*GX

THERMISTOR-RT*HGX

ESC-SW*E14EG-IT

CASE-T*EEF

SLEEVE-G1*EX

SLEEVE-GM*EX

GEAR-L1*EX

GEAR-L2*EX

GEAR-L3*EX

GEAR-M*EX

GEAR-SM*EX

STEPPING-MOTOR-2-HX

HOLDER-GEAR*HGX

LOUVER*ASSY-EX

LOUVER-CY-2*GX

LOUVER-CY-3*GX

LOUVER-CY-1*EX

MOUNT-SM*EX

STEPPING-MOTOR*CX

GEAR-SM*EX

LOUVER-CY-N*EX

FIN*EX

FIN-S*EX

SENSOR-TP*ASSY-EX

LINK-FIN*EX

LOUVER-U-ASSY*HGX

SHAFT-LOUVER-SWRM*EX

REINFORCE-PL*EX

CLEAR-PLATE*E80EX

AIR-FILTER*ASSY-E80X

NAME-PL*E14CG-S1-IT

ESCUTCHEON-PL*E80EX

I.B*E14EG-S1-IT

Part NO.

Part name

Compatibility Miscellaneous

Safety

Part

Pc/1

unit

New

New

New

New

Model MJ-E14EG-S1-IT Model Parts List

[

Casing and Tank Structure

]

Exploded

View

Matching No.

Page 36

36

MJ-E14EG-S1-IT Model Structural Disassembly Diagram

[

Blower Fan Parts

]

212

201

203

204

219

217

206

202

209

207

208

205

210

213

214

216

218

211

SCW-PL-TBFZR

4×12(1)

SCW-PL-TBFZR

4×12(4)

SCW-TPFZR

4×8M

*After removing the filament tapes,

be sure to attach new ones.

Filament tapes

(width:19)

NUT-LFZR

M6(1)

SCW-PL-TBFZR

4×12(2)

220

215

Page 37

37

Notes:

1. Circled reference numbers indicate performance parts.

2. New parts and the parts that are used only with these models lack compatibility.

3. Those parts that are marked by and are of critical importance for sustaining safety and performance.

Use specified parts at replacement.

4. When ordering parts without part numbers, use the design number. The order may take a while to process.

*1. If the part is out of production, you may be required to use a common part.

*2. Parts found installed in products may have a different part number from service parts.

However, there should be no difference in performance and can be installed.

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

-

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

Gray

440V 6.5UF

7*70*T5

7*70*T5

7*170*T5

E14EG-E1

100EX

E14EG-E1

100EX

E100VX-K

100EX

E14EG-E1

E21CX-S1-IT

100GX

10HGX

10HGX

E14EG-E1

E14EG-E1

100GX

E80EX-H

E14EG-E1

E80EX-H

100EX

100EX

100EX

M22 C98 310

M22 B56 360

M22 C98 689M

M22 B56 321

M22 C60 041

M22 B56 119

M22 C98 260

M22 C73 620

M22 B66 770T

M22 B70 311

M22 B70 311T

M22 C98 320

M22 C98 689

M22 B66 260

M22 C75 546

M22 C98 320T

M22 C75 682

M22 B56 0555

M22 B56 0555

M22 B56 0556

M22 C95 753

CASING*E14EG

NET*EX

PBA-T*MJ-E14EG*M

COVER-HUM*EX

NUT-LFZR M6

FAN*ASSY-EX

HOLDING PLATE-M*NX-R

MOTOR-E22WX

CUSHION-HEX-T-GX

BOX-PCA-U*HX

BOX-PCA-T*HX

COVER-PCA-U*EX

PBA-T*MJ-E14EG*P

HOLDER-CONDENSER*GX

RUN CAPACITOR*E80EX

COVER-PCA-T*EX

LEAD WIRE-R/C*E80EX

PACKING-PCA*EX

PACKING-PCA*EX

PACKING-PCA*EX

P-CASE*E14EG-S1-IT

New

Part NO.

Part name

Compatibility Miscellaneous

Safety

Part

Pc/1

unit

Model MJ-E14EG-S1-IT Model Parts List

[

Blower Fan Part

]

Exploded

View

Matching No.

Page 38

38

A

Figure A

Figure B

313 : tube temperature thermistor

attached part

B

MJ-E14EG-S1-IT Model Structural Disassembly Diagram

[

Heat Exchanger and Compressor Parts

]

SCWBPBN

M4×6(1)

322

343

321

335

332

339

333

324

340

341

334

337

336

317

318

323

306

320

319

SCW-TPFZR

5×35M(3)

SPL-WASHER-R(3)

325

308

305

307

309

327

SCW-DPFZ-SPL

4×12(1)

304

302

303

301

329

331

330

328

326

310

311

313

312

314

315

338

316

342

SCW-DPFZ-SPL

4×12(1)

Page 39

39

Notes:

1. Circled reference numbers indicate performance parts.

2. New parts and the parts that are used only with these models lack compatibility.

3. Those parts that are marked by and are of critical importance for sustaining safety and performance.

Use specified parts at replacement.

4. When ordering parts without part numbers, use the design number. The order may take a while to process.

*1. If the part is out of production, you may be required to use a common part.

*2. Parts found installed in products may have a different part number from service parts.

However, there should be no difference in performance and can be installed.

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

322

323

324

325

326

327

328

329

330

331

332

333

334

335

336

337

338

339

340

341

342

343

1

4

4

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Gray

Clip and H-inter attached

Lead wire attached

220V BSA460CV

Gray

Damper attached

220-240V Tape attached

7*250*T5

7*110*T5

7*110*T5

7*215*T3

7*125*T3

E14EG-E1

100P

10HGX

100GX

E80EX-H

100EX

H100AX

100EX

100GX

E85EF-H

100FX

100EX

H100DX

H100DX

H100DX

E80EX-H

63LGX(W)

180SX

E80EX-H

E14CG-S1-SWE

100FX

E105EF-TW

E14EG-E1

100EX

100EX

100EX

100EX

100EX

100EX

100EX

E92CG-TW

E82CF-H

M22 C98 200

M22 J90 908

M22 B70 100

M22 C95 509

M22 B66 340

M22 C75 501

M22 B56 202

M22 B39 120

M22 B56 128

M22 B66 770

M22 C81 390

M22 B63 390H

M22 B56 555

M22 B51 069

M22 B51 320

M22 B51 368

M22 C75 502

M22 J16 923

M22 B13 511

M22 C75 118

M22 C92 320

M22 B63 420S

M22 C81 420

M22 C98 629

M22 B56 055

M22 B56 0554

M22 B56 0553

M22 B56 320

M22 B56 0553

M22 B56 0551

M22 B56 0552

M22 C91 420

M22 C84 629

BASE*HGX-R

WHEEL*P(X)

SHAFT-B*HX

PLUG CORD*EEG-S1

DRAINPAN-R*GX

SWITCH-LEVEL*EX

STOPPER-PL*EX

STOPPER-S*AX

SPRING-S*EX

CUSHION-HEX-U-100GX

COOLER*E105EF

CONDENSER*FX

THERMISTOR-EVA*EX

CLIP

TERMINA-COV-ASSY-DX2

BUSH-COMP*DX

MOTOR PRO*ASSY-E80EX

PACKING

RUBBER-MOUNT*S(X)

COMPRESSOR*BSA460CV

PIPE COVER*COMP

PIPE SUC*100FX*ASSY

PIPE DIS*EF*ASSY

S/COIL TAPE*ASSY-E

SEAL-SHEET*EX

PACKING-PCA*EX

PACKING-PCA*EX

PIPE-COVER-C*100EX

PACKING-PCA*EX

PACKING-PCA*EX

PACKING-PCA*EX

PIPE-DJ*E14EG

CHARGE-PIPE*E14EG

PIPE-IN-CON*E14EG

PIPE-IN-COOL*E14EG

PIPE-OUT-COOL*E14EG

PIPE-CT*E14EG

PIPE-OUT

-CON*CG

JOINT-E16V(X)

SOLENOID VALVE-R

PIPE-SV-CT*E14EG

LEAD WIRE-C/P*EX

LEAD-WIRE-BOX-EARTH

Part NO.

Part name

Compatibility Miscellaneous

Safety

Part

Pc/1

unit

New

Model MJ-E14EG-S1-IT Model Parts List

[

Heat Exchanger and Compressor Part

]

Exploded

View

Matching No.

Loading...

Loading...