Page 1

Mitsubishi Electric Building

Air Conditioning Control System

MJ-310E

Operation Manual (Management)

1. Safety Precautions ································································································································ 1

2. Precautions Before Starting Use ············································································································ 2

3. Names and Functions of Each Part ······································································································ 3

3.1 Screen Configuration ···················································································································· 3

3.2 Operations ···································································································································· 3

3.3 Functions Table ···························································································································· 4

4. Screen Basic Operation ························································································································ 5

4.1 Button Selection Method ·············································································································· 5

4.2 Operation Contents and Function Select Buttons and Display Unit Buttons ······························ 5

4.3 Display Unit Buttons Operation ···································································································· 6

4.4 Screen Saver Display ·················································································································· 7

5. Initialization Before Use ·························································································································· 8

5.1 Schedule Setting ·························································································································· 8

5.2 Air-conditioning Charge Setting ···································································································· 8

5.2.1 Charge setting ················································································································ 8

5.2.2 Settlement-date designation setting ················································································ 9

6. Normal Operation ·································································································································· 10

6.0 Monitor/Operation·························································································································· 10

6.1 On/Off Operation ·························································································································· 11

6.2 Operation Status Monitor ············································································································ 11

6.3 Operation Details ·························································································································· 12

7. Schedule Setting ···································································································································· 15

7.1 Week Schedule Setting ················································································································ 15

7.2 Year Schedule Setting ·················································································································· 17

7.3 Schedule Setting in Group Units ·································································································· 19

8. Maintenance Operation ·························································································································· 21

8.1 Abnormality History and Operation History ·················································································· 21

8.2 Cumulative Time Monitor ·············································································································· 23

8.3 Filter Reset Operation ·················································································································· 24

8.4 Abnormality Occurrence ·············································································································· 24

8.4.1 Abnormality Display ········································································································ 24

8.4.2 Abnormality Reset Operation ·························································································· 25

8.4.3 Corrective Action When Watt Hour Meter Abnormal ······················································ 25

8.5 Fire Alarm Stop ···························································································································· 26

9. Air-Conditioning Energy Monitor ············································································································ 27

9.1 Charge Display Function ·············································································································· 27

9.2 Block and Watt Hour Meter Air-conditioning Energy Monitor Display ·········································· 28

9.3 Air-conditioning Charge Output ···································································································· 28

9.4 Under Stop Charge ······················································································································ 31

9.5 Air-conditioning Charge Basic Setting ·························································································· 32

9.6 Recalculate the Air-conditioning Charge ······················································································ 32

10. System Display ······································································································································ 33

10.1 System configuration display ········································································································ 33

10.2 Charge system display ················································································································ 36

11. Help ························································································································································ 39

11.1 Version Information ······················································································································ 39

11.2 Contents ······································································································································ 39

12. Error code list ········································································································································ 40

13. System Operation Precautions ·············································································································· 43

13.1 Usage Right ·································································································································· 43

13.2 Operation and Setting Precautions ······························································································ 43

13.3 Air-conditioning Charge Precautions ···························································································· 43

13.4 Others ·········································································································································· 44

14. Maintenance and Service ······················································································································ 45

Please read this manual before using the unit.

Please keep this manual for future use.

Page 2

In this manual, MicrosoftRWindows NTRVersion 4.0 is called Windows NT or Windows NT4.0.

Microcrosoft

R

WindowsR 2000 Professional is called Windows 2000. MicrosoftR Excel 2000 is called MS-Excel 2000.

Trademarks

MS, Microsoft, Microsoft logo, and Windows are registered trademarks and trade names of Microsoft Corporation.

Each company may use as registered trademarks and trade names the product names used in this manual.

Page 3

1

1. Safety Precautions

• Please read the Safety Precautions section very carefully before using the unit.

• The safety cautions provided here are very important for your safety. Please observe them at all times.

• The degree of danger involved with incorrect operation of the unit are indicated in this manual using the following symbols.

WARNING

Incorrect operation could result in death or severe injury.

CAUTION

Incorrect operation could result in injury or damage to property.

WARNING

CAUTION

The customer must not do any wiring or electrical

work.

Have the dealer or a specialist do any wiring or electrical

work. Do not do it yourself. Doing the work yourself may

result in improper installation which may cause electric

shock or fire.

Do not make any improvements or repairs for any

reason.

Making improper improvements or repairs may cause

electric shock or fire. For repairs, consult the company

from which the unit was purchased.

Stop operation immediately if an error message

appears on the computer and the unit stops or is not

operating properly.

Failing to do so may result in fire or damage to the unit.

Immediately contact the company from which the unit

was purchased.

Do not relocate the unit yourself.

Relocating the unit yourself may result in incorrect installation which may cause electric shock or fire.

To relocate the unit, consult the company from which the

unit was purchased.

Read the installation manuals and operation manuals for the computer, peripherals and other

machines.

Improper operation could result in fire or damage to the

computer or peripherals.

Read the installation manual and operation manual

for the air conditioner controller.

Improper operation could result in fire or damage to the

air conditioner controller.

Do not use the unit for any other purpose.

This product is for use with the Mitsubishi Electric

Building Air Conditioning Control System. Do not use it

with any other air conditioning control system or for any

other application. Doing so may cause the unit to malfunction.

Keep children away from the unit.

Inspections and maintenance can be dangerous. Do not

let children near the unit during these times.

Warning to all users (User Agreement)

This document is a contract between the customer and Mitsubishi Electric Corporation. By using this application, you agree

to the following conditions and are considered a user.

- Mitsubishi Electric and associated suppliers are not responsible for any collateral, secondary, or special damages, even

if notified by the distributor of the possibility of a certain type of damage. Mitsubishi Electric is not responsible for any

rights claimed by a third-party.

• After reading this information, please keep this manual together with the operation manual (Field adjustment manual) in a location where the operator can see it. Also, when changing operators give both of these manuals to the new operator.

Note:

- Please observe the safety precautions detailed in the installation manuals and operation manuals of the other machines

such as computers, peripherals, and air conditioners.

Page 4

2

2. Precautions Before Starting Use

Before using the MJ-310E, thoroughly read the following precautions:

❈ Also read Chapter 13 System Operation Precautions.

(1) Installation conditions check

Check the wiring, connection, initial settings etc of the personal computer and peripheral devices. Verify that each device is

installed in accordance with its installation and instruction manuals.

(2) Site adjustment check

Before using this system, check if the initial settings described in the separate Site adjustment manual are complete.

(3) Power supply processing

After installation and adjustment, do not turn off the power to the system devices and air conditioner except when a failure

occurs, or when servicing the equipment.

If the system devices or air conditioner power is turned off, a failure may be displayed. When the power is turned back on,

the display will automatically return to normal.

(4) Screen processing

If the keyboard or mouse is not touched for a certain length of time, a screen saver starts to prevent burning of the screen.

If the mouse or keyboard is touched while the screen saver is running, the display will return to its original state.

(The screen saver function is described in section 4.4.)

(5) Printer processing

When this system is used with a printer, leave the printer power on and check that there is paper in the printer.

Page 5

3

3. Names and Functions of Each Part

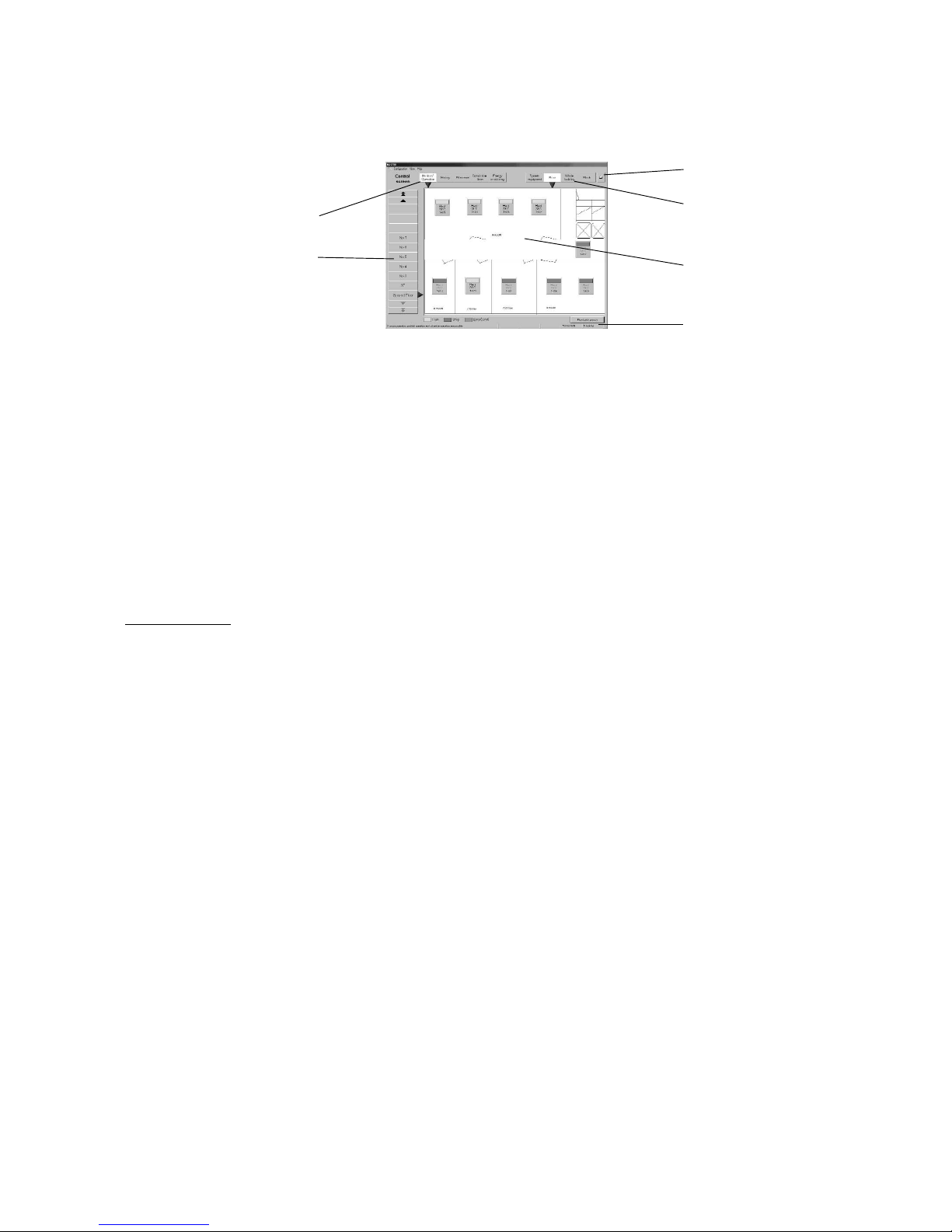

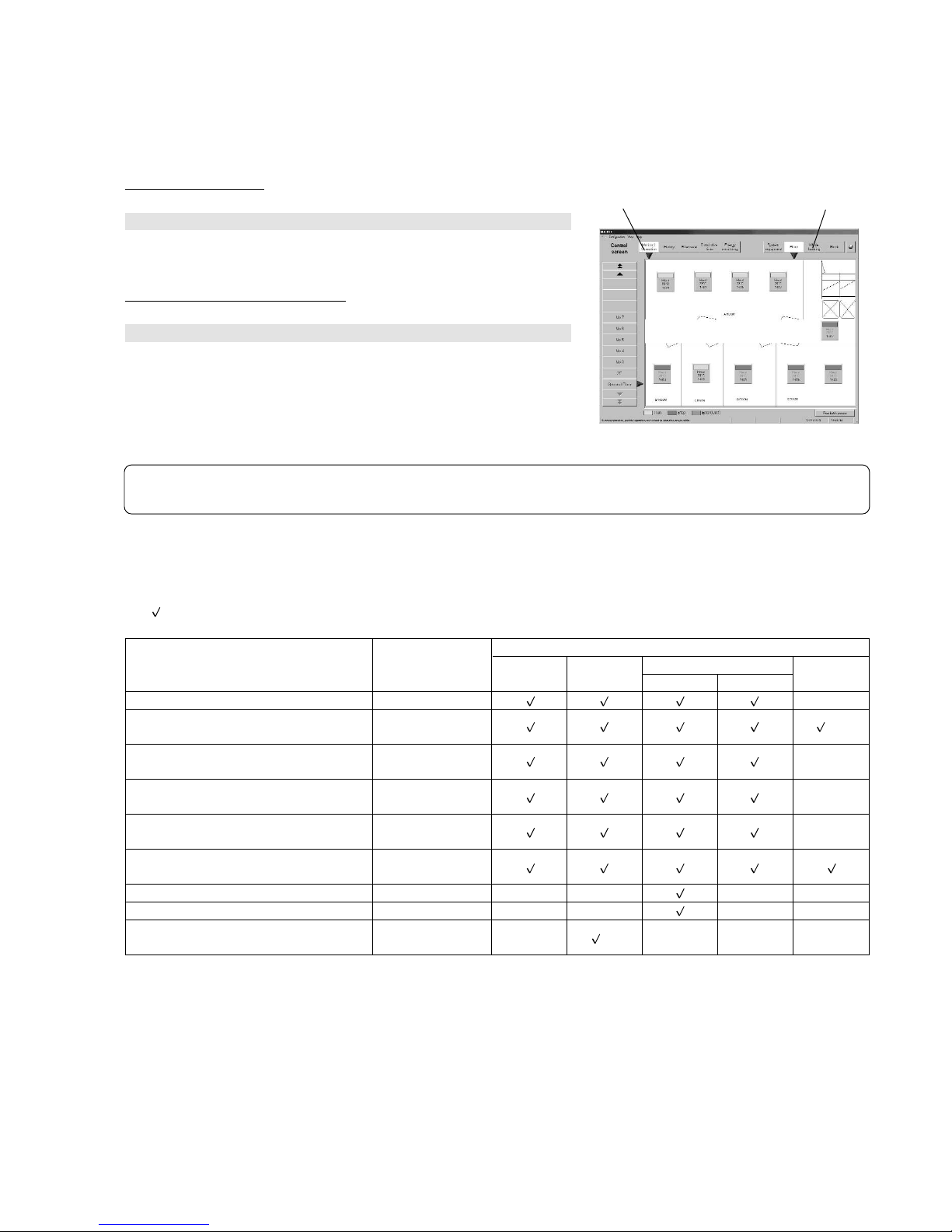

3.1 Screen Configuration

The Management screen consists of the following parts:

Management screen

Display & operation section: Displays and operates the function selected at the function select buttons

Function select buttons: Select the function

Display unit buttons: Select the display unit for each function

Floor switching buttons: Switches the floor

Hard copy button: Prints the currently displayed screen. Printing can be performed while a function is operating

Message bar: Displays operation commands, current time, and system status

There are two system statuses: Serious failure and Minor failure

Serious failure · · · · · · · · Abnormality at IFU, G/W. Indicates that part of the system is not operating normally.

Slight failure · · · · · · · · · · Abnormality in Air conditioning unit. Indicates that part of the system is not operating normally.

3.2 Operations

Mouse operation

The following description assumes that a mouse is used as the pointing device. When using another pointing device, read the

description for that device.

Operation on the screen is the same.

The keyboard can also be used to input characters and numerics.

Move the mouse while viewing the arrow (mouse pointer) on the screen.

Use the left mouse button only.

The following describes the operations:

Click: Pressing and releasing the mouse button once is called “click”.

This operation is used when selecting a button.

Double click: Pressing and releasing the mouse button twice in rapid succession is called “double click”.

Drag: The mouse pointer is moved to an icon and the left mouse button is held down. When the mouse is moved in

this state, the icon moves as if it were being dragged. This operation is called “drag”. The icon can be left at the

new position by releasing the left mouse button.

Keyboard: Primarily used when entering password, characters, or numerics.

Function select buttons

Hard Copy button

Floor switching buttons

Display unit buttons

Display & operation section

Message bar

Page 6

4

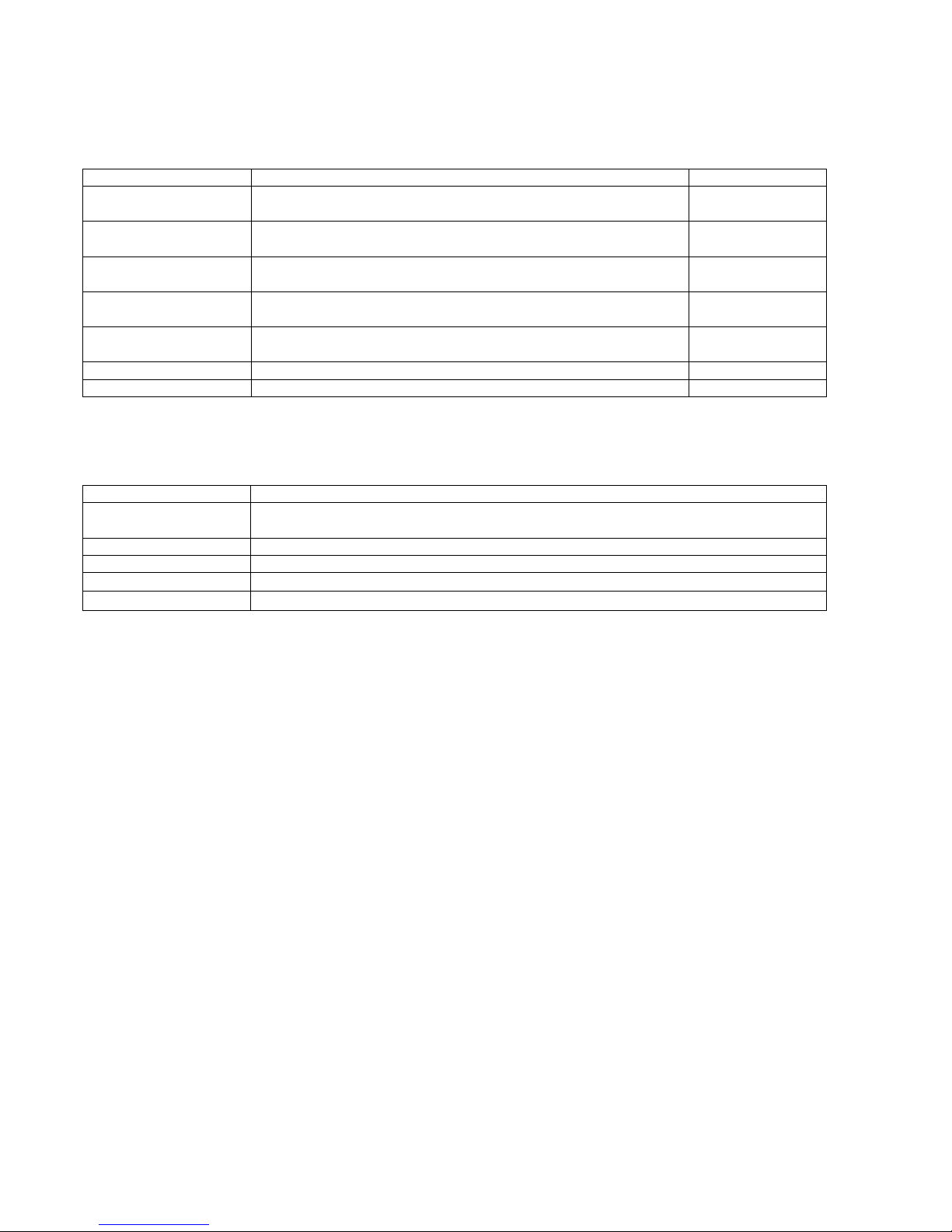

3.3 Functions Table

The MJ-310E has two major functions.

1) Function which monitors the operation status of the air conditioner and controls and sets the air conditioner.

2) Operation function and system initialization and maintenance function.

This section mainly describes function 1).

Function 1) consists of the items shown below. The screen that displays this function is called the “Management screen”.

The following items are necessary when the system configuration was changed, but are not covered in this manual.

Change operation requires a knowledge of system set-up. For the detailed contents and operating instructions, refer to the separate “Site Adjustment manual”.

Name

Air conditioner on/stop

Air conditioner control

Priority specification

History

Cumulative time

Schedule setting

Air-conditioning charge

Function

On/stop operation can be performed in group, floor, block, or whole air

conditioner units. The operating status can also be monitored

Operation (heat/fan/cool/dry) can be switched and the room temperature

can be adjusted in group, floor, block, or whole air conditioner units

Operation can be permitted and prohibited from the local remote

controller in group, floor, block, or whole air conditioner units

The history of abnormalities and operation can be referenced in group,

floor, block, or whole air conditioner units

The air conditioner cumulative operation time can be referenced for each

group

Air conditioner operation can be scheduled for each group

The air-conditioning charge can be monitored for each watt hour meter

Reference

6.1 6.2

6.3

6.3

8.1

8.2

7

9

Name

System configuration set

Charge system set

Charge data maintenance

Operation data monitoring

Remedial apportioning

Function

Performs connected devices, refrigerant system connection, group, operation mode and other

functions settings and block and other settings

Performs various settings for air-conditioning charge calculation

Past charge data can be referenced

Monitors operation data backed-up at IFU

Remedies charge apportioning at WHM failure, etc.

Page 7

5

4. Screen Basic Operation

The function is selected with the function select buttons (top left-hand side of screen) and the operation object is displayed on

the display & operation screen with the display unit buttons (top right of screen).

4.1 Button Selection Method

(1) Select the function

[Procedure]

1) Select the function

Select the function by clicking the function select button of the function to

be displayed and performed.

(2) Select the object to be operated

[Procedure]

1) Select the display unit

Select the display unit by clicking the button of the object unit you want to

display.

4.2 Operation Contents and Function Select Buttons and Display Unit Buttons

This table shows which function display buttons and display unit buttons should be selected when performing an operation.

The symbol indicates that the operation can be performed and the – symbol indicates that the operation cannot be performed.

Note:

- For a detailed description of basic operation, see chapter “6. Normal Operation”.

Control screen

Function select buttons

Display unit buttons

❈1: Other equipment includes IFU, Gateway, system controller, and local remote controller.

❈2: Normal/abnormal display only.

❈3: When Energy monitoring is selected, the air-conditioning charge is displayed even if a display unit button is not selected.

The air-conditioning charge can be displayed in block or watt hour meter units.

Operation

On/off (Run/stop) switching

Operation status (run/stop/abnormality)

check

Detailed setting of operation mode,

temperature, etc.

Operation prohibition setting from local

remote controller

Year schedule and week schedule

setting

Abnormality history and operation

history check

Cumulative time check

Filter sign reset

Energy monitoring

Floor

Display unit buttons (display object)

Function select

button

Monitor/operation

Monitor/operation

Monitor/operation

Monitor/operation

Monitor/operation

History

Cumulative time

Filter reset

Energy

monitoring

Block

—

—

❈3

Group

—

Floor

—

—

—

System

equipment

❈1

—

❈2

—

—

—

—

—

—

Whole

building

—

—

—

Page 8

6

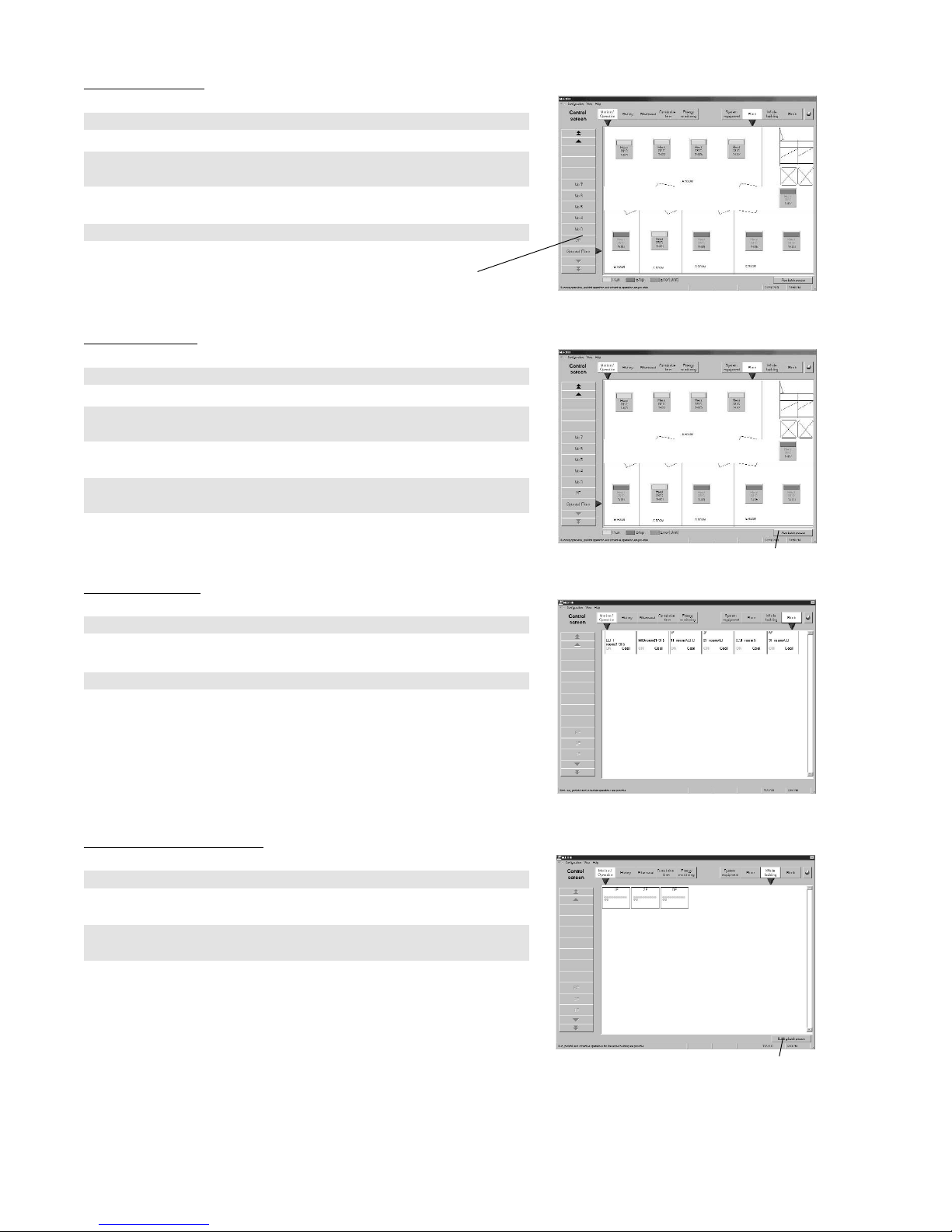

4.3 Display Unit Buttons Operation

(1) Group selection

[Procedure]

1) Click the Floor display unit button

2) Select the object group from the floor switching buttons (left-hand side of

screen)

The selected floor is exhibited on the display & operation screen.

3) Click the object group icon on the displayed floor

(2) Floor selection

[Procedure]

1) Click the Floor display unit button

2) Select the object floor from the floor switching buttons (left-hand side of

screen)

The object floor is exhibited on the display & operation screen

3) Click the Floor batch process button at the bottom right-hand corner of

the screen

(3) Block selection

[Procedure]

1) Click the Block display unit button

All the blocks are exhibited on the display & operation screen.

2) Select the object block from the display & operation screen

(4) Whole building selection

[Procedure]

1) Click the Whole building display unit button

The whole floor is exhibited on the display & operation screen.

2) Click the Building batch process button (bottom right-hand corner

of screen)

Floor screen

Block screen

Whole building screen

Floor batch process button

Building batch process button

Floor screen

Floor switching buttons

Page 9

7

(5) System equipment, IFU, Gateway (G/W) selection

[Procedure]

1) Click the System equipment display unit button

IFU and G/W are exhibited on the display & operation screen.

2) Select G/W of the object system equipment with the G/W switching

button

The system equipment of the selected G/W is displayed on the display &

operation screen

3) Select the object system equipment from the display & operation screen

4.4 Screen Saver Display

When the mouse and keyboard are not touched for a certain length of time, the screen saver starts. (To prevent burning of the

personal computer screen.) The following messages flow across the screen saver screen.

System equipment screen

Maintenance Tip

- Do not set the screen saver at other than the Marquee Display. If set at other than the Marquee Display, the screen saver

will not display the message contents.

Note:

- The “Watt hour meter failure” message is displayed when a message box indicating that a watt hour meter monitor abnormality was detected is displayed. When this message box is not displayed, the screen saver will not display the “Watt

hour meter failure” message.

Gateway switching button

Message contents

MJ-310E

Watt hour meter failure

Serious failure

Serious failure + watt hour meter failure

Slight failure

Slight failure + watt hour meter failure

Contents

No abnormalities in system equipment and air conditioner (When normal)

Abnormality detected at watt hour meter monitor

Abnormality detected at IFU or G/W

Abnormality occurred at IFU or G/W and detected at watt hour meter monitor

Abnormality in air conditioner

Abnormality occurred at air conditioner and detected at watt hour meter monitor

Page 10

8

5. Initialization Before Use

5.1 Schedule Setting

For a description of the schedule setting method, see chapter 7. Schedule Setting.

5.2 Air-conditioning Charge Setting

When the “Energy monitoring” button at the top left-hand side of the Control screen is clicked, the Air-conditioning energy monitoring screen is opened. Air-conditioning energy monitoring is initialized from this screen.

5.2.1 Charge setting

There are three charge settings: Exchange Unit setting, Air-con Charge setting, and Basic Charge setting.

Open the Charge Set screen

[Procedure]

1) Click the Charge set button

Click the Charge set button on the air-conditioning charge screen. The

Charge set screen opens.

(1) Set the Currency unit

[Procedure]

1) Click the Selection of Currency unit button

Click the button in the Charge Set screen. The currency unit set screen

opens. This screen is also displayed when the currency Set screen is

opened.

2) Select the currency unit to be used

Click the option box of the currency unit to be used.

Otherwise, in Etc. colum, set a currency unit (9 characters) and the number of digits to be displayed after the decimal point (0 to 4).

(2) Set the electric use unit price

Set the electric use unit price. One charge system can be selected from daytime/nighttime, weekend, seasonal charge, etc.

[Procedure]

1) Click the Air-con charge button

When the Air-con charge button is selected from the Charge Set screen,

the electric use unit price screen opens.

2) Select the charge system to be used

Set the charge system by clicking the option button at the charge system

you want to use.

3) Select the unit price and applicable time or applicable day of the week

Select the unit price, applicable time, applicable date, or applicable day of

the week in accordance with the set charge system.

Some of the data can also be input from the keyboard.

Currency unit set screen

Electric use unit price set screen

Charge set

Air-conditioning charge screen

Note:

- When the charge function is not available, Air-con Charge is not displayed.

Page 11

9

(3) Set the standard (fixed) charge

Block units and watt hour meter units standard charge (per month) can be set. However, for standard charge in watt hour meter

units, only the watt hour meter unit charge object (K controller, OAprocessing unit, etc.) can be set.

[Procedure]

1) Select the Standard Charge button

When the “Standard Charge” button on the Charge Set screen is clicked,

the standard charge set screen opens.

2) Set the standard charge

Set the standard charge in watt hour meter or block units. For watt hour

standard charge, only charge in watt hour meter units is the object.

Standard charge can be input from the keyboard by clicking with the cursor.

Clicking the standard charge allows the value to be input from the keyboad.

Ending charge setting

[Procedure]

1) Click the OK or Cancel button

At the end of charge setting, click the OK button.

OK: Accepts the changes and returns to the air-conditioning charge

screen.

Cancel: Ignore the changes and returns to the air-conditioning charge

screen.

5.2.2 Settlement-date designation setting

Set the settlement-date designation day

Since the air-conditioning charge is calculated once a month, set the settlement date.

[Procedure]

1) Select settlement-date designation specification

When the “Settlement-date designation” button at the bottom right-hand

side of the screen is clicked, the Settlement-date designation specification

screen opens.

2) Specify the settlement

T o specify the end of month, click End of month. To specify the actual date,

click Manual and select the date by clicking the ▲/▼ buttons.

(Numerical values can also be input from the keyboard.)

3) Select OK or Cancel

Click OK to end settlement-date designation setting.

OK: Accepts the changes and completes settlement-date designa-

tion setting.

Cancel: Ignore the changes and completes settlement-date designa-

tion setting.

Note:

- When an item which must be set is not set, a caution message is displayed. Reset that item.

Settlement-

date designation

specification screen

Note:

- The 29th, 30th, and 31th cannot be set as the settlement-date designation. (However, they can be set as the end of

month.)

Standard charge set screen

Note:

- When there is no WHM connection the watt-hour standard charge cannot be set.

Page 12

10

6. Normal Operation

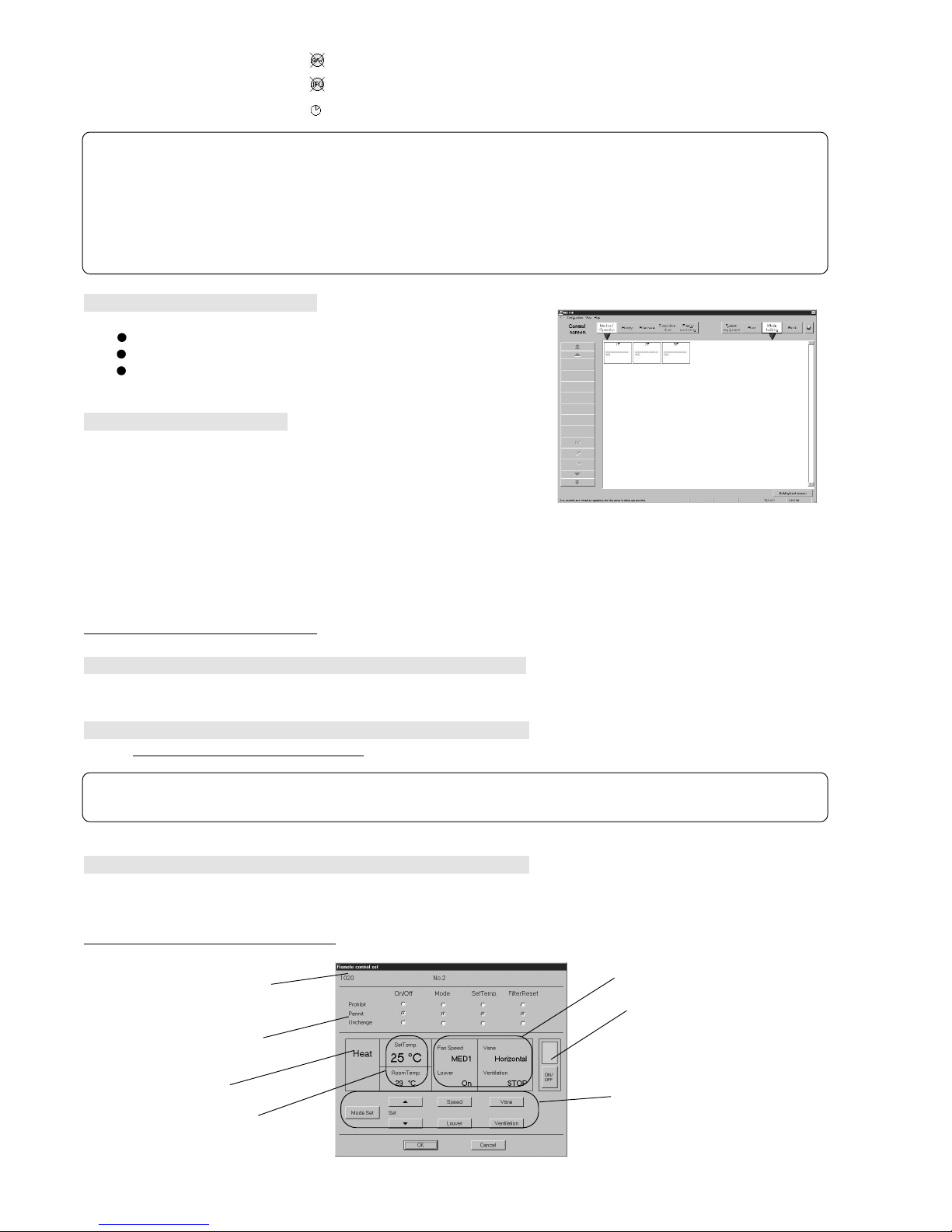

6.0 Monitor/Operation

Perform normal operation from the Management screen.

Display the Management screen by clicking the Monitor/Operation function select button (top left-hand side of screen), then

selecting the operation object from the display unit buttons (top right-hand side of screen). The “Air-conditioning charge display”

is only displayed when there is a charge function.

(1) Select the function

When the Monitor/Operation function select button is clicked, the monitor/

operation screen opens.

(2) Select the operation object

[Procedure]

When group is the object

Click the Floor button in display units.

Select the distribution floor of the object group from the floor switching buttons (left-hand side of screen).

The floor is displayed on the monitor/operation screen.

Click the object group icon on the displayed floor.

When whole floor is the object

Click the Floor button in display units.

Select the object floor from the floor switching buttons (left-hand side of

screen).

The object floor is displayed on the monitor/operation screen.

Click the Floor batch process bottom at the bottom right-hand corner of the

screen.

When block is the object

Click the Block button in display units.

All the blocks are displayed on the monitor/operation screen.

Select the object block from the monitor/operation screen.

When whole building is the object

Click the Whole building button in display units.

Whole building is displayed on the monitor/operation screen.

Click the Building batch process button at the bottom right-hand corner of

the screen.

When system equipment, IFU, or G/W is the object

Click the System equipment button in display units.

IFU, G/W is displayed on the monitor/operation screen.

Select the G/W connected to the object equipment with the G/W select

button (▼).

The system equipment of the selected G/W is displayed in the

monitor/operation screen.

Select the object system equipment from the monitor/operation screen.

Normal operation screen

Function select

- Monitor/Operation

- History

- Filter reset

- Cumulative time

- Energy monitoring

Display units

- System equipment

- Floor

- Whole building

- Block

Display units

Function selection

Page 13

11

6.1 On/Off Operation

Air conditioner On/Off operation is possible.

Block, floor batch, whole building, and other multiple group batch operations are also possible.

Operable objects: Group, floor batch, block, whole building

[Procedure]

1) Select Monitor/Operation

When the Monitor/Operation function select button is clicked, the moni-

tor/operation screen opens.

2) Select the object to be turned on or off

Click the on/of

f object. A menu appears.

3) Select on/stop

If the selected object is currently running, OFF is displayed in the menu

and if the selected object is stopped, ON is displayed in the menu.

When ON or OFF is selected from the menu, operation is switched.

6.2 Operation Status Monitor

The air conditioner operation status can be monitored.

Operable objects: Floor, block, whole building, system equipment

(1) Display the operation status

[Procedure]

1) Select Monitor/Operation

When the Monitor/Operation function select button is clicked, the moni-

tor/operation screen opens.

2) Select the object whose operation status is to be displayed

When the object whose operation status is to be displayed

is clicked, the

current operation status is displayed.

(2) Description of operation status

Floor display screen

Description of floor icons

Operation status display screen: Displays the operation status.

Green: Running

Red: Stopped

Yellow: Abnormal

×

: Local remote controller operation prohibited

Operation mode display screen: Displays the operation mode.

(Example: Auto, Cool, others)

Set temperature display screen: Displays the set temperature.

Group name display screen: Displays the group name. When selected with the mouse cursor, the long name is dis-

played.

Filter sign: Displays Filter in a yellow frame at the center.

(Displayed only when the Filter reset function select button is selected.)

Operation prohibited state: Shows that the system is in the operation prohibited state. (See Notes.)

Outdoor unit abnormal: “ ” is displayed at the top right corner of the group icon.

Subsidiary outdoor unit abnormal: “ ” is displayed at the top right corner of the group icon.

BC controller abnormal: “ ” is displayed at the top right corner of the group icon.

Note:

- When multiple groups are the operation object, if at least one group is on, OFF operation has precedence.

Note:

- For a description of the underlined part, see par. “6.0 (2) Select the operation object” to be operated.

Group icon

Operation status

Operation mode

Set temperature

Group name

Note:

- For a description of the underlined part, see par. “6.0 (2) Select the operation object” to be operated.

Running prohibition state

Page 14

12

G/W abnormal: “ ” is displayed at the top right corner of the group icon.

IFU abnormal: “ ” is displayed at the top right corner of the group icon.

Schedule set: “ ” is displayed at the top left corner of the group icon.

Block & whole building display screen

Displayed in group units in the block frame and floor frame.

(Green): Running (On)

(Red): Stopped (Off)

(Blue): Only running fan unit on

× (Yellow): Abnormal

System equipment display screen

When an equipment is abnormal, × is displayed at the icon of the abnormal equipment.

6.3 Operation Details

Air conditioner operation mode switching, temperature adjustment, and other functions can be monitored and operated.

Objects which can be monitored and operated: Floor, block, whole building

(1) Display the remote control screen

[Procedure]

1) Select Monitor/Operation

When the Monitor/Operation function select button is clicked, the moni-

tor/operation screen opens.

2) Select the object whose remote control screen is to be displayed

Click the object whose remote control screen

is to be displayed.

3) Select properties

When Properties is selected from the menu, the remote control screen

opens.

(2) Description of remote control screen

Remote control screen

Note:

- For a description of the underlined part, see par. “6.0 (2) Select the operation object” to be operated.

Remote control

operation prohibit setting

ON/OFF SW

Group and floor names

Operation mode

Temperature display

Fan speed/vane/ventilation

equipment display

Operation section

Note:

- Depending on the characters used, the entire 8 characters of the group name may not be displayed on the icon.

- At stop, the operation mode and set temperature displays are hidden. (Gray characters display)

- When the indoor unit is in the operation prohibited state, the operation mode and set temperature background color

changes to red. In the operation prohibited state, the indoor unit operation state remains stopped, the remote controller

continues to display the operation state, and the operation mode flashes. To reset the operation prohibited state,

change the operation mode.

Some models do not have this display.

Whole building screen

Page 15

13

Group and floor names

- Group name: Displays the group name. (Group object only)

- Floor name: Displays the name of the floor on which the group is distributed.

(For whole building, Whole building is displayed.)

Remote control operation prohibit setting: Displays the operation prohibit setting state of the local remote controller.

ON/OFF: Displays the current operation status by color. (Green: On, Red: Off)

Operation mode: Displays the current operation mode.

Temperature display

- Target set temperature: Displays the target set temperature.

- Indoor temperature: Displays the current indoor temperature.

Fan speed/vane/ventilation equipment display

- Fan speed: Displays the current fan speed.

- Vane: Displays the current wind direction.

- Louver: Displays the current louver status.

- Ventilation equipment: Displays the interlocked ventilation unit status.

Operation section: Performs operation mode, target temperature, and wind setting and other operations.

(3) Remote control screen operation

ON/OFF

Perform ON/OFF switching by clicking the ON/OFF button.

ON (green)/OFF (red) are alternately switched each time the button is clicked.

Operation mode change

Switch the operation mode by clicking the Mode Set button at the operation section.

The operation mode is switched in Fan → Cool → Heat → Dry → Auto → Fan · · · order each time the button is clicked.

For ventilation group, the operation mode is switched in Auto → Heat ex. → By-Pass → Auto · · · order.

(The operation modes that can be changed depends on the setting.)

Set temperature change

Change the set temperature by clicking set temp. adjustment ▲/▼ buttons.

(The range of temperatures that can be changed depends on the operation mode.)

Fan Speed change

Change the wind velocity by clicking the Fan Speed button.

Fan Speed is switched in Lo → Mid 1 → Mid 2 → Hi → Lo · · · order.

For ventilation group, Fan Speed is switched in Lo → Hi → Stop → Lo · · · order.

(The changeable Fan Speed depends on the function setting.)

Vane change

Change the vane by clicking the Vane button.

The vane is switched in Horizontal → Down 60% → Down 80% → Down 100% → Swing → Horizontal · · · order.

(Whether or not there is a Swing and screen direction switching function depends on the function setting.)

*Ventilation group does not have this function.

Louver change

Change the louver by clicking the Louver button.

Louver is switched in On → Off → On · · · order.

(Whether or not there is a Louver switching function depends on the function setting.)

*Ventilation group does not have this function.

Note:

- When the setting is different for each group, the following is displayed by operation from floor batch, whole building

batch, and block:

On/Off: White display

Operation mode: – –

Set temperature: – –

Note:

- The newest information is displayed on the remote control screen only when this remote control screen was displayed.

Page 16

14

Interlocked ventilation group operation

Switch ventilation unit operation by clicking the Ventilation button. (Hi/Lo/Stop)

When ventilation group interlock is set, ON/OFF operation also performs ventilation group Hi/Lo/OFF switching.

(Whether or not there is a ventilation group interlock setting depends on the function setting.)

*Ventilation group does not have this function.

Local remote control operation Prohibit/Permit

When Prohibit On/Off is selected, On/Off operation cannot be performed from the local remote controller.

When Prohibit Mode is selected, the mode cannot be changed from the local remote controller.

When Prohibit Set Temp. is selected, the temperature cannot be changed from the local remote controller.

When Prohibit Filter Reset is selected, filter reset cannot be performed from the local remote controller.

When Unchange is selected, Prohibit/Permit remains in the current state.

(For ventilation group, only On/Off and Filter Reset can be prohibited and permitted.)

Select OK or Cancel

At the end of each setting, click the OK button.

OK: Accepts the changes and returns to the monitor/operation screen.

Cancel: Ignore the changes and returns to the monitor/operation screen.

(4) Other functions

The following are displayed on Floor screen of the monitor/operation screen:

- Long name

- Operation block name

- Charge block name

[Procedure]

1) Select Monitor/Operation

When the Monitor/Operation function select button is clicked, the moni-

tor/operation screen opens.

2) Select floor display

When the Floor display unit button is clicked, the floor display screen

opens.

3) Select group

When the group item of the group whose names are to be displayed is

clicked, a menu appears.

4) Select the name to be displayed

When Long name, Operation block name, or Charge block name is select-

ed from the menu, the names are displayed.

5) Select OK

After checking the names, click the OK button.

Note:

- For floor batch, whole building batch, and block setting, wind velocity, vane, louver, and interlock ventilation operations

cannot be performed. Perform these operations for each group.

- The range over which each setting can be changed depends on the contents set by the indoor unit & ventilation function setting of the system configuration settings. For a detailed description of the setting contents, refer to Site

Adjustment manual section 8.5.9 Indoor Unit and Ventilator Function Settings.

❈ The set contents can be checked by System display. (For the detailed operating instructions, see chapter 10.

System Display.)

- When the wind direction is set to downwards, the indoor unit control may automatically change it to another direction.

Note:

- When the setting is different for each group at floor batch, whole building batch, and block processing, the initial value

is Unchange.

- In the case of K control models, if even one of ON/OFF, mode or set temperature is prohibited, the other settings are

also prohibited. Filter reset can not be prohibited.

Page 17

15

7. Schedule Setting

The operation mode, temperature, wind velocity, and On/stop from the specified time can be set with the schedule setting function. There are two schedules: Weekly schedule and Year schedule. Weekly schedule can be set for each day of the week and

Year schedule can be set in day units. For days set by both schedules, Year schedule has precedence.

The minimum unit that can be set is group.

Operable objects: Group, floor, block, whole building

7.1 Week Schedule Setting

Switch from Management screen to schedule set screen

[Procedure]

1) Select Monitor/Operation

When the Monitor/Operation function select button is clicked, the moni-

tor/operation screen opens.

2) Select the object whose schedule is to be set

Click the object whose schedule is to be set.

When the cursor is moved to Schedule in the displayed menu, the schedule menu is displayed.

3) Select week schedule

When Week schedule is selected from the menu, the Week schedule set

screen opens.

Perform the following operations from the Week schedule set screen.

(1) Schedule setting

[Procedure]

1) Select the day of the week to be set

When the button of the day of the week to be set is clicked, a menu

appears.

2) Select Setting

Select Setting from the menu.

The selected day of the week is displayed in the set day of the week field

at the bottom of the screen.

3) Select the Start time or Stop time

When Start Time or Stop Time is clicked, the Start/Stop set screen opens.

Up to 10 start/stop settings are possible. (Start + Stop <10)

=

4) Set the times, operation prohibit, operation mode, temperature, etc.

Set the times with the ▲/▼ button.

Operation Permit/Prohibit can be set for the local remote controller. ON/OFF

operation, operation mode change, and temperature change can be set.

When a setting does not change, select Unchanging.

Note:

- For a description of the underlined part, see section “6.0 (2) Select the operation object” to be operated.

Note:

- Multiple schedules cannot be set for the same time and a time

between 23:56 and 0:04 cannot be set.

Page 18

The operation mode and temperature can be set by mode and temperature

setting. Switch to a settable operation mode with the Mode button.

The temperature can be changed with the ▲/▼ buttons.

When a setting does not change, select Unchanging.

Use the Delete button to delete a set schedule.

Week schedule can be set up to 10 items/day of the week.

5) Select OK or Cancel

At the end of setting, click the OK button.

The set schedule is displayed at the set day of the week field.

OK: Accepts the changes and returns to the Week schedule set

screen.

Cancel: Ignore the changes and returns to the Week schedule set

screen.

(2) Schedule change

Use this function to change a set schedule.

[Procedure]

1) Select the day of the week to be changed

When the button of the day of the week to be changed is clicked, a menu

appears.

2) Select Setting

Select Setting from the menu.

The selected day of the week is displayed at the set day of the week field.

3) Select the schedule to be changed

When Schedule is clicked, the Start/Stop set screen opens.

For the operating instructions, see (1) Schedule setting.

When only the set time is changed, the change can be made by dragging

Schedule. (10 minutes units)

4) Select OK or Cancel

At the end of setting, click the OK button.

The changed schedule is displayed at the set day of the week field.

OK: Accepts the changes and returns to the week schedule set

screen.

Cancel: Ignore the changes and returns to the week schedule set

screen.

(3) Schedule clearing

[Procedure]

1) Select the day of the week whose schedule is to be cleared

When the button of the day of the week whose schedule is to be cleared is

clicked, a menu appears.

2) Select Clear

Select Clear from the menu.

The clear check screen opens.

3) Select OK or Cancel

After checking the setting, click the OK button.

OK: Clears all the schedules of the selected day of the week and

returns to the Week schedule set screen.

Cancel: Returns to the Week schedule set screen.

16

Note:

- When Unchanging is selected, the temperature and operation mode cannot be changed. Before making any changes,

release Unchanging.

Note:

- When batch schedule setting and schedule check were performed for two or more groups, the setting field of days of the

week with duplicate settings is displayed in cyan.

Note:

- Multiple schedule setting to the same time and a time between 23:56 and 0:04 cannot be set.

Page 19

17

(4) Schedule copy

This function copies the schedule settings of the specified day of the week to another day of the week.

[Procedure]

1) Select the copy from day of the week

When the copy from day of the week button is clicked, a menu appears.

2) Select Copy

Select Copy from the menu.

3) Select the copy to day of the week

When the copy to day of the week is clicked, a menu appears.

4) Select Paste

When Paste is selected from the menu, the schedule of the copy source

day of the week is pasted.

This schedule can also be pasted to other days of the week.

Ending week schedule setting

Select OK or Cancel

At the end of schedule setting and change, click the OK button.

OK: Accepts the changes and returns to the monitor/operation screen.

Cancel: Ignore the changes and returns to the monitor/operation screen.

(When returned to the monitor/operation screen, a schedule mark is displayed at the set group icon.)

7.2 Year Schedule Setting

Switch from Management screen to Schedule set screen

[Procedure]

1) Select the monitor/operation screen

When the Monitor/Operation function select button is clicked, the moni-

tor/operation screen opens.

2) Select the object whose schedule is to be set

Click the object whose schedule is to be set.

When the cursor is moved to Schedule in the displayed menu, a schedule

menu appears.

3) Select Year schedule

When Year schedule is selected from the menu, the Year schedule set

screen opens.

Year schedule is displayed up to 24 months from the current month.

Schedule setting is possible beginning from the current day.

Color of calendar date frame:

White: Not set

Red: Holiday set

Blue: Schedule set

Cyan: Different schedule set for multiple groups

× mark: Past date

Perform the following operations from the Year schedule set screen.

Maintenance Tip

- When only checking the week schedule contents, click Cancel instead of OK at the end of the check.

Note:

- For a description of the underlined part, see par. “6.0 (2) Select the operation object” to be operated.

Page 20

(1) Schedule setting and change

[Procedure]

1) Select the day whose schedule is to be set

When the selected day is clicked, a menu appears.

When Day of the week is clicked, all the days of the week of that month are selected.

2) Select schedule set

Select Setting from the menu.

3) Select the start time or stop time

See pars. 7.1 (1) Schedule setting and 7.1 (2) Schedule change.

4) Select OK or Cancel

At the end of setting, click the OK button.

OK:

Accepts the changes and returns to the Year schedule set screen.

Cancel:

Ignore the changes and returns to the Year schedule set screen.

The set day is displayed in blue on the calendar.

Year schedule can be set up to 20 days/24 months and 10 items/day.

(2) Holiday set/reset

Week schedule for days set as a holiday is invalid.

[Procedure]

1) Select the day to be holiday set/reset

When the day to be holiday set or reset is clicked, a menu appears.

When Day of the week is clicked, all the days of the week of that month

are selected.

2) Select holiday set/reset

Select Holiday set or Holiday reset from the menu.

(3) Schedule clear

When this function is used, all the schedule settings and holiday settings of

the selected day are cleared.

[Procedure]

1) Select the day whose schedule setting and holiday settings are to be cleared

When the day whose schedule and holiday settings are to be cleared is

clicked, a menu appears.

When Day of the week is clicked, the settings for all the days of the week

of that month are cleared.

2) Select schedule clear

Select Clear from the menu.

(4) Schedule copy

This function copies the schedule settings of the specified day to another day.

[Procedure]

1) Select the copy from day

When the copy from day is clicked, a menu appears.

2) Select Copy

Select Copy from the menu.

3) Select the copy to day

When the copy to day is clicked, a menu appears.

4) Select Paste

When Paste is selected from the menu, the schedule of the copy to day is pasted.

This schedule can also be pasted to other days.

18

Note:

- The schedule for today and tomorrow can be set by Year schedule.

- The Year schedule takes priority over the Week schedule.

Page 21

(5) Year schedule check

[Procedure]

1) Select the day to be checked

When the day to be checked is clicked, a menu appears.

2) Select schedule view

When Schedule view is selected from the menu, the Schedule check

screen opens.

The Schedule check screen also has a function that outputs the schedule

to the screen.

Schedule output

[Procedure]

1) Select output

Click the Output button on the Schedule check screen.

(Click Cancel to end the Schedule check screen without outputting the schedule.)

2) Select the output type

Click Printing output or Exporting file.

When Exporting file was selected, input the filename. The save location

can be referenced with the Reference button.

3) Select Output or Cancel

After the contents to be output are set, click the Output button.

Output: Accepts the changes and outputs the schedule and returns to

the preceding screen.

Cancel: Ignore the changes and returns to the preceding screen.

Ending schedule setting

Select OK or Cancel

At the end of schedule setting and change, click the OK button.

OK: Accepts the changes and returns to the monitor/operation screen.

Cancel: Ignore the changes and returns to the monitor/operation screen.

(When returned to the monitor/operation screen, a schedule mark is displayed at the set group icon.)

7.3 Schedule Setting in Group Units

(1) Schedule copy

This function copies the schedule settings of one group to another group.

Operable objects: Floor, block, whole building

[Procedure]

1) Select Monitor/Operation

Click the Monitor/Operation function select button.

2) Click the copy from group

When the cursor is set to Schedule of the menu displayed by clicking the

copy from group, a schedule menu appears.

3) Select Copy

When Copy is selected from the menu, the Copy menu appears.

4) Select the schedule to be copied

Select Week schedule, Year schedule, or Week and Year schedule from the Copy menu.

5) Select the object whose schedule is to be copied

Click the object whose schedule is to be copied.

When the cursor is set to Schedule in the displayed menu, the schedule

menu appears.

19

Note:

- When batch schedule check was performed for two or more groups, [**] is displayed at the days with duplicate settings.

Maintenance Tip

- When only checking the Year schedule, at the end checking, click the Cancel button instead of the OK button.

Page 22

6) Select Paste

When Paste is selected from the menu, the schedule is pasted.

The schedule can also be pasted to other groups, blocks, or floors.

(2) Schedule check

Today’s and yesterday’s schedules of the group can be checked.

Operable objects: Floor, block, whole building

[Procedure]

1) Select Monitor/Operation

When the Monitor/Operation function select button is clicked, the moni-

tor/operation screen opens.

2) Select the object whose schedule is to be checked

Click the object whose schedule is to be checked.

When the cursor is set to Schedule of the displayed menu, a schedule

menu appears.

3) Select Schedule view

When Schedule view is selected from the menu, the schedule check

screen opens.

The schedule check screen also has a function that outputs the schedule to the screen.

Schedule output

[Procedure]

1) Select Output

Click the Output button on the schedule check screen.

(Click the Cancel button to end the schedule check screen without outputting the schedule.)

2) Select the output type

Click Printing output or File exporting.

For File exporting, input the filename. The save location can also be referenced by Reference button.

3) Select Output or Cancel

When the contents to be output are set, click the Output button.

Output: Accepts the changes and outputs the schedule and returns to

the preceding screen.

Cancel: Ignore the changes and returns to the preceding screen.

20

Note:

- For a description of the underlined part, see par. “6.0 (2) Select the operation object” to be operated.

Note:

- For a description of the underlined part, see par. “6.0 (2) Select the opration object” to be operated.

Note:

- When batch schedule check was performed for two or more groups, [**] is displayed at the days with duplicate settings.

Page 23

21

8. Maintenance Operation

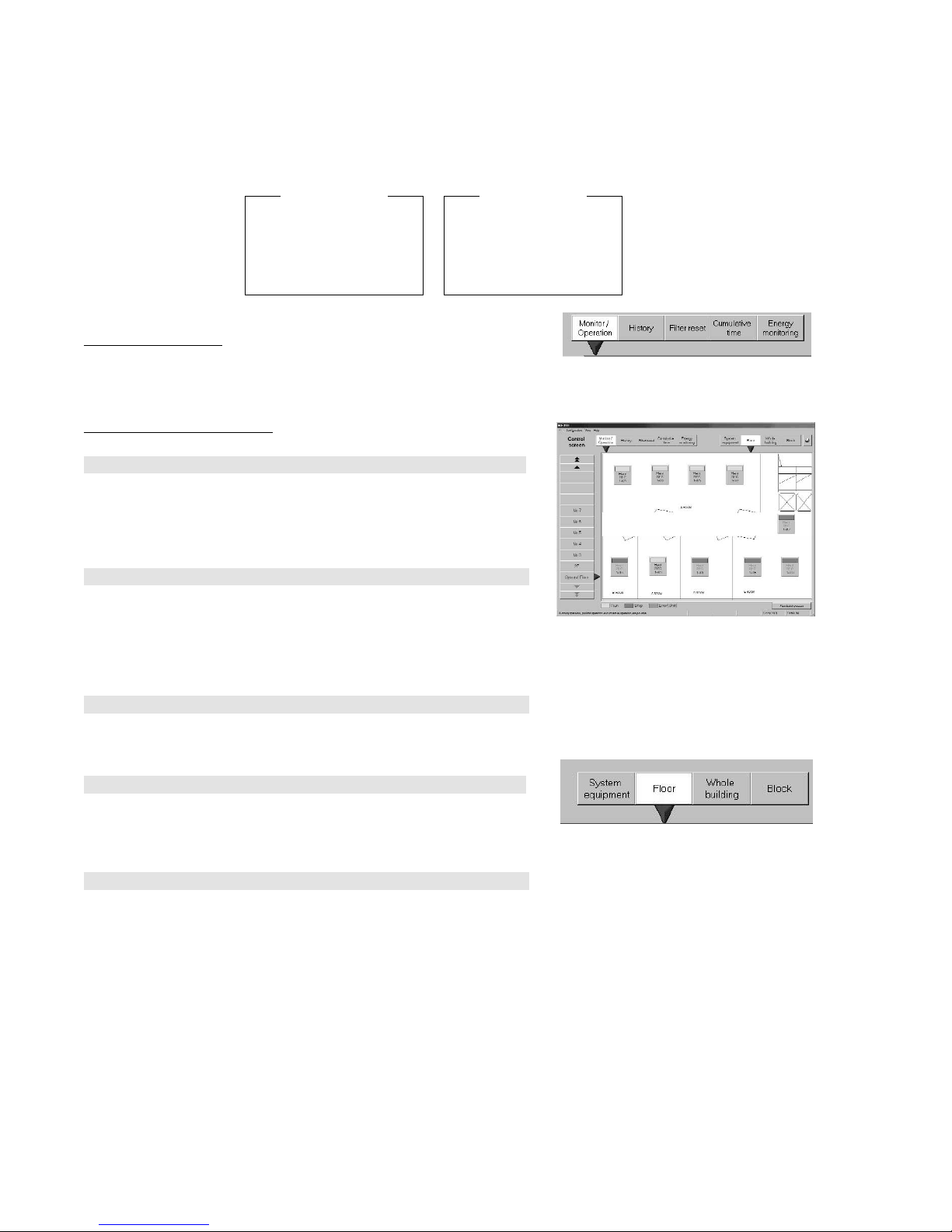

8.1 Abnormality History and Operation History

There are two kinds of history: Abnormality history and Operation history.

- Abnormality history: Displays abnormalities that occurred in the past. (WHM abnormality history is not recorded.

)

- Operation history: Displays the operations (start, stop, etc.) performed in the past.

(1) Switch from Management screen to history screen

[Procedure]

1) Select History

Click the History function select button.

2) Select the object whose history is to be displayed

When the object whose history is to be displayed

is clicked, the History

screen opens.

Perform the following operations from the History screen.

(2) Description of History screens

Abnormality history

The Abnormality History screen displays air conditioner failures, transmission failures, and other abnormalities in the order in which they occurred.

Up to 1000 items can be displayed. When the number of items exceeds

1000, the items are deleted in ascending order.

Occurrence time: Displays the time the abnormality occurred.

Recovery time: Displays the time the abnormality recovered. Blank

indicates that the abnormality is still in effect.

Origin address: Displays the G/W No. and address of the equipment at

which the abnormality occurred.

Occurrence point:Displays the occurrence floor at the left and the group

or equipment name at the right.

Contents: Displays the error code and its description.

Operation history

The Operation history screen displays the operations performed at the air

conditioner. Up to 10,000 items can be displayed. When the number of

items exceeds 10,000, the items are sequentially deleted in ascending

order.

Operation time: Displays the time the operation was performed.

Controller: Displays the equipment that issued the operation com-

mand.

Object address: Displays the controller G/W No. and address.

Operation point: Displays the occurrence floor at the left and the group or

equipment name at the right.

Contents: Displays the contents of the operation that was per-

formed.

(3) History screen operation

The Abnormality History and Operation History screen displays can be

switched and updated.

[Procedure]

History display switching

When the Abnormality history button is clicked, the display switches to the

Abnormality History screen and when the Operation history button is

clicked, the display switches to the Operation History screen.

Display updating

When Update of display button is clicked, the display is updated to the current history. The updated time is displayed at Display Time.

Note:

- For a description of the underlined part, see par. “6.0 (2) Select the operation object” to be operated.

Abnormality History screen

Operation History screen

Page 24

(4) History search

This function searches the histories based on the set conditions.

There are the following search items. The search conditions can be set by combining these items.

Abnormality history search

1) Search from abnormality occurrence date

Specifies the occurrence date.

2) Search from abnormality recovery date

Specifies the recovery date.

3) Search from abnormality occurrence point

Specifies IFU, G/W and unit.

4) Search from error code

Specifies the error code that caused the abnormality.

Operation history search

1) Search from operated date

Specifies the operated date.

2) Search from controller

Specifies the controller.

3) Search from operated group

Specifies G/W and group No.

[Procedure]

1) Select Search

When the Search button is clicked, a search screen opens.

2) Input the search item

Specify the search condition at the search item check box. Specify the

object with the Option button.

Numerics can be input by clicking the ▲/▼ buttons at the right-hand side

of the numeric part or by clicking the numeric part. They can also be input

from the keyboard.

Search conditions can also be combined by selecting multiple items.

3) Select Find or Cancel

After setting the search conditions, click the Find button.

(If there is no history that meets the set conditions, nothing is displayed.)

Find: Displays, on the history screen, histories that meet the search

conditions.

Cancel: Returns to the history screen.

(5) History delete

Deletes the specified range of histories from START to END.

[Procedure]

1) Select Delete

When the Delete button is clicked, the Delete screen opens.

2) Input the delete start date

Set the START date with the ▲/▼ buttons. When the numeric part is

clicked, the date can also be input from the keyboard.

3) Input the delete end date

Set the END date with the ▲/▼ buttons. When the numeric part is

clicked, the date can also be input from the keyboard.

4) Select Delete or Cancel

After setting the range of histories to be deleted, click the Delete button.

Delete: Deletes the histories within the specified range and returns to

the history screen.

Cancel: Returns to the history screen without deleting the histories.

22

Note:

- Once deleted, histories cannot be recovered.

Page 25

(6) History output

Outputs daily or monthly history.

The output type can be selected from printing output and file output (text format). (Search results history cannot be output.)

[Procedure]

1) Select Daily or Monthly

When the Daily or Monthly button is clicked, the Output History screen

opens.

2) Input the date to be printed

Set the date with the ▲/▼ buttons at the right-hand side of the numeric

part.

When the numeric part is clicked, the date can also be input from the keyboard. At the end of input, click the Output button. (Click the Cancel button to stop output.)

3) Select printing output or file output

For printing output, click the Printing output option button and for file out-

put, click the Exporting file option button. For file output, input the filename. The save location can be referenced with the Reference button.

4) Select Output or Cancel

When the Output button is clicked, the histories generated within the input

range are output.

Output: Outputs the histories generated within the specified range and

returns to the history screen.

Cancel: Returns to the history screen without outputting the histories.

8.2 Cumulative Time Monitor

(1) Switch from Management screen to cumulative time monitor

[Procedure]

1) Select Cumulative time

When the Cumulative time function select button is clicked, the cumulative

time monitor screen opens. Select the target floor with the floor switching

buttons.

(2) Description of cumulative time monitor

The cumulative time monitor displays Group Address - Group Name Cumulative Time, from left to right.

The cumulative time unit is “hours”.

(3) Cumulative time monitor operation

[Procedure]

1) Select Update of Display.

When the Update of display button is clicked, the cumulative time is updat-

ed to the current cumulative time. The updated time is displayed next to

Display Time at the right-hand side of the screen.

(4) Cumulative time clear

[Procedure]

1) Select the group whose cumulative time is to be reset

When the group to be clear is clicked on the screen, that group changes

to the selected blue color. When that group is clicked again, it is released.

All the groups can be selected with the All select button.

All selections can be released with the All release button.

2) Select Cleared

When the Clear button is clicked, the cumulative time of the selected

group is cleared.

(5) Cumulative time output

This function outputs the cumulative time screen. The output type can be selected from printing output or file output (text format).

23

Note:

- Once cleared, cumulative time cannot

be recovered.

Page 26

24

[Procedure]

1) Select Output

When the Output button is clicked, the cumulative time output screen

opens.

2) Select printing output or file output

For printing output, click the Printing output option button and for file out-

put, click the Exporting file option button. For file output, input the filename. The save location can be referenced with the Reference button.

3) Select Output or Cancel

When the Output button is clicked, all the cumulative times of the dis-

played floor are output.

Output: Outputs the displayed cumulative time screen and returns to

the preceding screen.

Cancel: Returns to the preceding screen without outputting the cumu-

lative time screen.

8.3 Filter Reset Operation

(1) Switch from Management screen to filter reset screen

[Procedure]

1) Select filter reset

When the Filter reset function select button is clicked, the filter reset

screen opens.

Select the target floor with the floor switching buttons.

(2) Description of filter reset screen

The filter sign is displayed in a yellow frame at the center of the group icon.

(3) Filter reset

[Procedure]

1) Select a group displaying the filter sign

When a group displaying the filter sign is clicked, the filter reset screen

opens.

To reset the whole floor, press the Floor batch process button.

2) Select OK or Cancel

When the OK button is clicked, the filter sign is reset.

OK: Resets the filter sign and returns to the filter reset screen.

Cancel: Returns to the filter reset screen.

8.4 Abnormality Occurrence

8.4.1 Abnormality Display

Equipment at which abnormalities can be detected: Indoor unit, ventilation unit, outdoor unit, G/W, IFU, remote controller, group

remote controller, SC

(1) Display when abnormality occurs

Indoor unit abnormality

The color of the group icon status display screen changes to yellow.

For whole building display, × is displayed in yellow at groups. When there

is an abnormal unit in a block, the word “error” appears in orange at the

block status. Also, “Slight failure” is displayed on the message bar at the

bottom of the screen.

Maintenance Tip

- Always perform filter maintenance (cleaning, replacement, etc.) of the actual equipment before using this function to reset

the filter sign.

Filter sign

Page 27

25

Outdoor unit abnormality

× OC is displayed at the group icon of the outdoor unit at which the abnormality occurred and the equipment connected to it. In the system equipment screen, × is displayed at the icon of the outdoor unit at which the

abnormality occurred.

IFU abnormality

× IFU is displayed at the group icon of the equipment (all kinds) connected

to the abnormal IFU. In the system equipment screen, × is displayed at the

IFU icon. Also, Serious failure is displayed on the message bar at the bottom of the screen.

G/W abnormality

× G/W is displayed at the group icon of the equipment connected to the

abnormal G/W. In the system equipment screen, × is displayed at the icon

of the abnormal G/W.

Also, Serious failure is displayed on the message bar at the bottom of the

screen.

8.4.2 Abnormality Reset Operation

The abnormality reset operation can send an abnormality reset command to an abnormal unit.

However, when the unit abnormality is not actually cleared, the abnormality cannot be reset.

Equipment which can be reset: Indoor unit, outdoor unit

(1) Abnormality reset method

[Procedure]

1) Select Monitor/Operation

When the Monitor/Operation function select button is clicked, the moni-

tor/operation screen opens.

2) Select the object to be reset

When the object to be reset

is clicked, the menu screen opens.

3) Click the Error Reset

When the Error reset is clicked, a check screen is displayed.

4) Select OK or Cancel

When the OK button is clicked, the abnormality reset operation is per-

formed.

OK: Performs the abnormality reset operation and returns to the

monitor/operation screen.

Cancel: Returns to the monitor/operation screen without performing the

abnormality reset operation.

8.4.3 Corrective Action When Watt Hour Meter Abnormal

The watt hour meter abnormality function detects connected watt hour meter failure and transmission line breakage at the watt

hour meter monitor.

(Since the abnormality occurs between the previous monitor time and the current monitor time, it is not a real-time abnormality.)

(1) Display method when abnormality detected

When a watt hour meter abnormality is detected, the message box shown at

the right is displayed.

(2) Abnormality reset method

Click OK in the message box and restore operation and inspect and repair the

watt hour meter.

Note:

- IFU, Gateway, remote controller, and system controller abnormalities cannot be reset.

Note:

- For a description of the underlined part, see par. “6.0 (2) Select the

operation object” to be operated.

Note:

- Other operations cannot be performed while this message is being

displayed.

OK button

Page 28

26

8.5 Fire Alarm Stop

(1) Start of fire alarm stop

When the fire alarm stop signal is input, the Fire alarm stop operating

message box is displayed. The system sends stop operation and operation prohibition commands to all the indoor units and disables operation

from the local remote controllers. It also stops the schedule function.

Man-machine operation is also impossible while this message box is displayed. However, when the message box is cleared, operation is enabled.

(2) End of fire alarm stop

When the fire alarm stop signal is reset, the Fire alarm stop operating message box is cleared. An operation prohibition reset

command is sent to all the indoor units and the operation prohibition status returns to its state before the fire alarm stop operation. The schedule function is restarted and schedule operation groups return to the status in which they were before the

fire alarm stop operation.

Note:

- When the personal computer, I/O board, IFU, GateWay, etc. is abnormal or the power is OFF, the fire alarm function may

not operate.

- During fire alarm stop input, Fire Alarm is displayed on the message bar.

Fire alarm stop message

Note:

- The unit operation status does not return to the status before the fire alarm stop operation even if fire alarm stop is

reset. Perform running operation from the local remote controller, by man-machine operation, etc.

Page 29

27

9. Air-Conditioning Energy Monitor

9.1 Charge Display Function

When the Energy monitoring button at the top left-hand side of the Management screen is clicked, this screen opens.

There are two types of monitoring screens: With WHM connection and Without WHM connection.

Functions table

[With WHM connection]

Air-conditioning energy monitoring screen

[Without WHM connection]

Air-conditioning energy monitoring screen

[Description of displays and buttons]

(1) Block names

Displays the block units air-conditioning charges for up to three preceding months.

(2) Watt hour meter

Displays the watt hour units air-conditioning charge for up to three preceding months.

(3) Apportioned electric power

Displays the Apportioned electric power for each unit.

(4) Apportioning charge

Displays the monthly air-conditioning charge: (electric use unit price + standard charge) for each unit.

(5) Apportioning total

Displays the proportional division electric power and proportional division charge.

Individual output

Apportioned electric

power

Block names or

Watt hour meter

Apportioning total

Whole term day specification

Apportioned charge

Recalculation

Note:

- This function cannot be used if the Use charge function is not selected by user setting. (The Energy monitoring button is

not displayed either.)

- Block air-conditioning charge does not include the electric amount of the watt hour meter units K controller, OA processing unit, etc.

- The Without WHM connection air-conditioning charge only covers the refrigerant usage amount of the M-NET indoor unit.

The electric amount and charge are temporarily calculated from the indoor unit capacity and operation amount, and can-

not be used as is. They are also different from the With WHM connection air-conditioning charge.

Calculated charge

display

Percentage accuracy

display

Page 30

28

(6) Individual specification

Specifies an individual object and calculates and outputs the air-conditioning charge.

1) Date specification

Specifies the date and calculates and outputs the air-conditioning charge for the selected block.

2) Individual output

Calculates and outputs the air-conditioning charge for the selected block.

(7) Whole building object

Sets, calculates and outputs the air-conditioning charge for the whole building.

1) Whole term day specification

Specifies the term day and calculates and outputs the air-conditioning charge for all blocks, or all watt hour meters.

2) Whole building output

Specifies the term day and calculates and outputs the air-conditioning charge for all blocks and all watt hour meters.

3) Settlement date designation

Specifies the air-conditioning charge settlement date designation.

4) Electric power under stop

Displays and outputs the electric power under stop.

5) Charge set

Calls the Air-conditioning energy monitoring basic set screen.

(8) Recalculation

Recalculates the air-conditioning charges.

(9) Calculated charge display

Displays and outputs the billing electric amount and calculated air-conditioning charge.

(10) Percentage accuracy display

Displays and outputs the billing electric amount and percentage accuracy.

9.2 Block and Watt Hour Meter Air-conditioning Energy Monitor Display

(1) Select the display object

1) Select the display object.

With WHM connection

Select the display object with the Charge block or Watt hour meter button at the top left-hand side of the screen.

Without WHM connection

Select the display type with the Calculated charge display or Percentage

accuracy display button at the top left-hand side of the screen. The display object is only Block.

(2) Display color

Characters color

Black characters: Normal

Red characters: Abnormal

Blue characters: Maintenance

9.3 Air-conditioning Charge Output

(1) Set the automatic printing function

[Procedure]

1) Select Settlement date designation

When the Settlement data designation button is clicked, the settlement

of date designation screen opens.

2) Specify the settlement date

When specifying the end of month, click End of month.

When specifying other than the end of month, click Manual.

Set the date by clicking the ▲/▼ buttons.

(The date can also be input from the keyboard.)

Note:

- The electric amount, charge, etc. displays are the values with the

undisplayed digits raised to the next higher digit. The total is the

total of the displayed values.

- When the maintenance function was used to change and recalculate the Apportioned electric power, the characters turn to blue.

❈ - For a description of the maintenance function, refer to Field

Adjustment manual section “9.2 Charge Data Maintenance”.

- For a description of the recalculation function, see section 9.6

Recalculate the air-conditioning charge.

Page 31

29

(2) Description of functions

1) Individual air-conditioning charge output

When the Air-conditioning energy monitoring screen is block display, selects and outputs the unit block and when the Air-con-

ditioning energy monitoring screen is watt hour meter display, selects and outputs the unit watt hour meter.

Date specification: Specifies the term day and calculates and outputs the air-conditioning charge.

Individual output: Selects 1 month before, 2 months before, or 3 months before and outputs the air-conditioning charge

in month units.

2) Whole building air-conditioning charge output

Specifies all blocks, all watt hour meters, or all blocks and all watt hour meters and outputs the air-conditioning charge.