Page 1

UGD-0344A

5.25

INCH FLEXIBLE DISK

TECHNICAL MANUAL

MF504A-3

DRIVE

AMITSUBISHI

ELECTRIC

CORPORATION

Page 2

CHAPTER 1

1.1

1.2

CHAPTER 2

2.1

2.2

2.3

2.4

CHAPTER 3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

CONTENTS

LINE

OUT

Composition of Mechanism by Function

Composition of Electronic Circuitry

MECHANISM

DESCRIPTION

Rotation

Disk

Magnetic H,ad-Positioning

Magnetic Head/Carriage Mechanism . . . . . . . . . . . . . . . . . . .

(Index,

Sensors

DESCRIPTION

Inter.ace and Drive Select Circuits

Power-On Reset and Power

Panel Indicator Circuit .

Sensor

Index

Motor

Step

00

Track

Select

Side

Write/Erase Circuits

Write-Protect Circuit

Circuit

Read

Write Current Switch Circuit . . .

Motor

Spindle

Drive

Write

and

Drive Circuit

Detection

Circuit

............

Drive Circuit

OF

Clamp Mechanism

and

Drive

Protect,

ELECTRONIC

OF

Save

_

...

Ready Circuits

........................

.........................

Circuit

.

.....

..

.

....

.................................

Track

...

Function

by

OPERATION

..............

Mechanism

........................

................................

00)

CIRCUIT

....

Circuits.

............................

..................................

.

OPERATION

.

.

...........

.

2

2

2

3

4

11

12

13

13

14

1.4

15

5

6

9

9

.

.

.

.

.

16

19

19

22

.

23

-1-

Page 3

1.

This section deals

flexible

compatible

However,

signal

switched

In

addition,

only

1.1

Composition

The mechani-sm

(1}

(2) Disk

{3)

{4)

(5) Sensors

1.2

Composition

The

The

motor.

( 1)

(21

(3~

(4)

(5)

(6)

(7)

(8}

(9)

(10)

(11)

disk

unit

with

normal

for

360/JOOrpm

at

the

it

is

the

READ/WRITE

of

Lever

mechanism

rotation

Magnetic

Magnetic

{index,

of

electronic

spindle

motor

Signal

interface

Power-on

Panel

indicator

Index

pulse

Step

motor

Track

00

Side select

Write/erase

Write-protect

Read

circuit

Spindle

motor

CHAPTER 1 OUT LINE

with

the

mechanical parts

with

high

density

48TPI

medium

high

and

to

set

the

is

switched.

by

Function

by

funciton as follows:

door

sw

mechanism

mechanism

mechanism

protect,

Circuitry

installed

constitutes

and

drive select

circuit

circuit

circuit

medium

normal

unit

mechanism

track

by

Function

an

two

and

ready

a 8 inch flexible disk allowing

density

for

same

time.

also posible

circuit

mechanitm

can

be

divided

and

and

clamp

head

positioning

head/carriage

write

Electronic

circuits

are

drive

circuit

circuit

reset

circuit

drive

generator

drive

circuit

detection

circuit

circuit

circuit

circuit

drive

and

control

for

the

reading

be

read.

respectively.

circuits

more

can

density

allows

only

for normal density so

00)

printed-circuit

an

independent

circuit

circuit

of

the

than

lMB

and

writing

The

rotational

The

READ/WRITE

that

the

boards

and

printed-circuit

MF504A-3

flexible

formatted

memory

of

previously used normal

speed

can

be

switched

circuitry

disk

rotational speed remains

can

be

classified

which

is

by

built

board

drive.

capacity.

is

also

at

function

integrally

M

F504A-3

It

is

format

density

disks.

by

an

external

automatically

360rpm

as follows:

with

and

the

Page 4

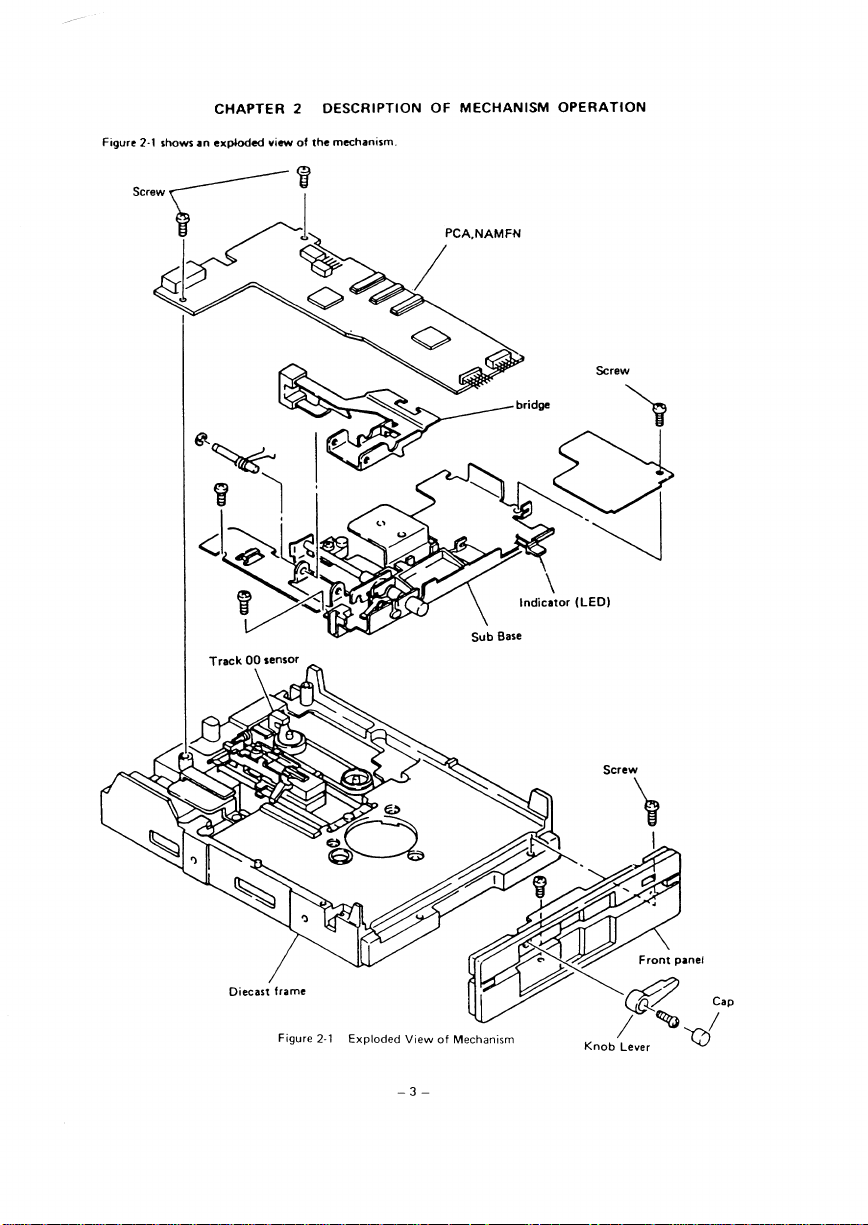

Screw

Sub Base

bridge

l

Qt

\

Indicator (LED)

Screw

\

Diecast

frame

Figure

2-1

Exploded

-3-

v·

iew

Mechanism

of

/~

L

Knob

ever

y-/

V

Cap

Page 5

2.1

Oiik

Rotatton

The disk

rotation

because

it

ts

The

motor

does

spindle directly connected

rotation mechanism

300rpm

and this can be swiched by

The

frequency-genentor

The disk

is

to

clamped

•

position

disk

the disk drives.

The

collet

is

Figure 2-2 shows

The printed-circuit

disk

rotation

signal. And a

Collet assmbly

Spindle

Index sensor

(LEO)

Driff

•nd

Cl•mp

MKh•nism

drive

motor

a b<ushtess

not use

is

type

that

ulft

1

belt, unlike C10nventional C10unt1<pwts,

to

uch

is

completely free

coil detects the spindle

by

the

spindle cone

on

the

inner surfoce

tapered

to

• specific

the

spindle

board

detection,

photo

transistor for receiving its light

•ngl•

motor

tor

the

write protect

cone

1

flit

DC

servo

1

othef. This

the

motor.

H1H

element for coil phase-switching

is

onother feature for p<olonging motor life

of

maintenance.

PCA.

NAMFM signals

motor

on

the

motor

of

the

spindle

to

correct non..,lignment

end

collet.

spindle

motor

-vo

sensor LED

for

is

This motor has as

The

rotational speed

trom

speed

1nd

torms

side

and

by

cone.

This assures compotibility

ot

circuit

hH

an

write

protect

installed

on

another printed-circuit

Jong

1

life

11

1n

ordinary

Mtectton.

but

it

1

direct«iw

of

the

the

main control circuit.

•-YO

the

C10llet

circuit

on

the

spindle

an inserted disk with

type

to

C10ntrol

door.

the

~

tpindle

with

Ind

motor

The

the

ouuring

is

360rpm

it.

CIOllet

diskettes

cone.

AC

rotor

thet

guides

index sensor LED (lifht-emitting diode) for

defection and indicator LED

board

for

(NAMFM).

driving

motor

1nd

the

and

the

end

Figure 2·2 Spindle

-4-

Motor

and Collet

Page 6

Maitnttttc HMd-f'ositioninig

2.2

step

flat

The

step

oppostte

is

distance.

Figure

motor

fastened

2-3

shaft

the

to

shows

motor

steel

the

drives

hm

band

steel

positioning

the

Ori-.ie

magnetic

the

thin~oop

1

m.intain

to

that

so

band

Medt•niMn

head

~nd,

steel

specific

a

turn

a

mechanism.

drive

to

which

of

each

tension.

step

the

track

is

pulled

The

motor

(cylinder)

spring attached

the

by

head/carriage

one

by

succession.

m

assembly,

angle

step

The

1upported

moves

to

the

upstan

idler pulley

the

head

mounted

by

by

two

single

1

guide

the

on

located

rods,

track

Figure 2-3 Magnetic-Head

Step

Positioning

assy

motor

Mechanism

Head/carriage

assembly

-5-

Page 7

(Index.

Sant0n

2.4

sensor

Index

( 1)

index

The

transistor

photo

motor(Figuro

Index sensor timing (position) can

index sensor.

Figure 2-6 shows where

(2) Writ&-p<Otect sensor

writ&-protect senso<

The

This sensor

with

Disks

sensor.

protect

sub-base,

the

00

Track

(31

track

The

track

The

assembly.

screw.

track

The

Protect.

Writ•

sensor

2-2).

protects

diskette's

the

Remember

disk~

the

this

sensor

sensor

00

sensor

00

sensor

The

sensor

00

Trod< 00)

rotation.

disk

detects

light·recei..,ing side.

the

on

photo

the

ind

photo-transistor for

the

the

detects

information

that

The

stored

covered

notch

or

vinyl

write-protect sensor

will transmit signals

that

detects

the

detects

screwed

is

head/carriage assembly are

and

This sensor consists of

The

mounted

is

tronsistor

adjusted

be

write-protect notch

diskette's

read-only disks from

on

tape

with

to

head

position

the

to

is

PCA.]

is

of

STM.

tape

mounted

on

the

cellophane

the

mounted

ts

LED

the main control

on

the

loosening

by

index: sensor

the

that

,..,

1

or

a high percentage

has

that

sub-base ash shown

on

00

track

light-shielding plate

holder

shown

and

in Figure

can

LED

an

the

on

screws

mounted.

is

inhibits

and

destruction

not

does

that

adjusted in

be

2-7.

hght-emitting

the

on

circuit PCA for

serYO

PCA (NAMFM).

circuit

index

the

on

write

operM:ion

by

litht

transmit

light transmission wilt

of

Figure 2-6.

in

projects

position

seonSOf'

operation.

errors.

protected

1re

the

from

by

and

side

spindle

the

removing

and

by

[Attached

head/carriage

loosening

this

not

to

the

a

Write-protect

Figure 2-6 Index

sensor Disket survey lever

Sensor

Write-protect

and

sensor

-7-

Page 8

Head/carriage assembly

Figure 2-7 Track

Track

Sensor and Head/Carriage Assembly

00

00

sensor

-8-

Page 9

3·

ftgure

spindte

TM

integraUy

p.ts

The

CHAPTER

shows

1

motor

with

within

the

the

motor_

the

electrontc

circuit

drive

lines

chain

DESCRIPTION

3

circuits

within

belong

and signal

the

the

to

OF

connections

lines

dotted

mechanism

ELECTRONIC

these circuits.

among

constitutes

the

in

described

CIRCUIT

sepaute

the

previous pages.

OPERATION

printed-circuit

board

that

built

is

-9-

Page 10

-READ

-WAITE

DATA

DATA

-------------

I

RIW

IC

M5101

BAP

Read

circuit

Write

ci.-cuit

Er•e

circuit

or

MC2870P

--,

-SIDE·!

-WRITE

-WRITE

-DIRECTION

-NORMAL

-TRACK

-MOTOR

-ORIVE

-ORIVE

-ORIVE

-DRIVE

SELECT

PROTECT

GATE

-INDEX

-READY

IN

SEL

-STEP

DENSITY

00

ON

-IN

USE

SELO

SEL

SEL2

SEL3

Side

select

ci.-cult

Power

on

ruet

circuit

Wri~e

protect

detection

circuit

Write99te

circuit

Erase

gate

circuit

Index

/ready

circuit

Step

motor

drive

ci.-cuit

Track

counter

Track

00

detection

circuit

Head

load

solenoid

drive

circuit

1---1'---4

P•nel

indicator

drive

circuit

Power

1

circuit

511ve

-----------

r,--s:n:.~~;-

~

I

I

I

I

-~

.

I I

~1

~-~,~~c~t--~

Figure

3-1

MF504A-3

-10-

Electronic

Circuit

Page 11

3-1

lnterf•ce

•nd

11 ~ Receive circuit

AU

the

ohms.

capacity

In

connecting

cabte

(2) Transmit circuit

The

disk

controller

All

input

connected

controller.

(3) Drive select circuit

The

drive select circuit selects

through

The

four

inserted

drives

drives

The

drive select signals also light

In

the

MX

to

Ori••

Select

Circuits

input

terminals

of

the

pulling

them

of

40

mA

or

two

end

four

or

terminating

drive

line driver

to

use a terminating

signals

to

in

the

doisy-chain

interface lines

select lines correspond

to

select

that

will cause errors.

case

maintain

the

are

connected

of

a system requiring no drive selection. insert

a selected condition.

lece1ver

up

to

+5

V.

diik

The

drives

more. Normally.

more

resister and remove

is

an

SN7438N

rnistor

the

line driver are

pattern,

one

of

(OSO

through OS3).

to

the

desired line. Never insert plugs

with

the

same cable; interference between

the

panel indicator LEO.

that

receives

sigNls

from

the

host

con1lloller are

host controlter. therefore. must use driver elements

1n

SN7438N

or

an

equiv•lent

(up

to

fourt

by

the

terminating resistors

or

of

150

ohm1

pted

by

the

signals

the

disk drives Cfour maximum) connected with

jumper

• daisy-chain

equiv1lent open-collector gate. It

or

more.

drive select signals. Thus, if

of

only

one

plugs

on

the

into

open-collector

pattern.

of

the

other

selected disk drive are .transmitted

printedcircuit bOards,

the

same-numbered jacks

the

the

jumper plug for

drive

it

is

necessary

disk drives_

is

necessary for

two

or

more

one

on

output

signals from such disk

the

drive select line

terminated

with

is

recommended.

to

disk drives are

to

the

same cables

of

which should

two

or

a drive

keep

the

the

more

into

at

150

the

host

host

be

disk

the

-11-

Page 12

3.2

Power-On

(

1)

Power·on reset

The

1or preventing

(2) Power save circuit

The power s1ve circuit

operating

temperature

The

of

30 ms.

Timing

- STEP (TP15)

Anet

•nd

Power

S•we

Circuits

circutt

power-on reset circuit. 1 levet-detection

operation

errors of

the

write

controb

current flowing

to

reduce heat

disk drive.

head load solenoid shore

sove circuit

generllion

is

shown in figure 3-2.

step

condition

motor

chan

rise

of

of

and

the

the

po-

type

reset

drcun.

mitiailizes

the

circuit in switching power

to

the

step

motor

by

unnecessary power consumption

the

same timer (rnono-stablemultivibr1torl, which

and

control

on.

off.

head

load solenoid KCOrding

LSI.

ind

and

thus

that"s used

to

their

to

reduce

has

1 range

\

TRl-collector

output

:~2vv_-:::::::~~~~~~~~~

Figure

3·2

Power Save Circuit Timing Chart

......

~~-:~~~-'f"""""""~.._~~~~~~~~-

l

Jo

ms

,

..

-12

-

Page 13

3.3

Panel I ndK::1tor

The

panel

indicator

When

no

in-use signal

If

the

jumper

signal

only.

Regarding

Specifications MF504A-3_

3.4

signals.

The

than

When

the

Figure

Index

Sonsor

The index

ready

300

the

ready

J_J

jumper

s.en10r

circuit

ms and

door

signal is

shows

Circuit

plug for

ind

ReMly

circuit

checks

the

opens

reset.

a

timing

is

plug

next

turned

is

the

ind

on

by a drive select signal

applied

to

drive select

combination

Circuits

detects

the

the

index pulse interva1s

index pulse

the

disk

chart_

the

interface,

circuit

is

and indicator

index

holes

is

generated_

stops

rOtating

the

inserted

conditions,

in

with

and

or

panel

the

the

by

into

disk

a

timer,

motor-on

a

dnve

indicator

the

MX,

refer

with

and

select signal

is

turned

the

panel

to

the

detailed

a

sensor,

becomes

signal

turns

and

in-use signal.

on

by

a

drive

indicator

is

description

and converts

ready

when

off

and

turned

its signals

the

the

select signal

on

by

in

the

intervals

disk

stops

only.

an

in-use

Standard

into

logic

are

rotating

less

DOOR

MOTOR

XINDEX

Timer UCG inside)

READY

CLOSE

OPEN

X. INDEX (ICGl-461

Timer

(ICGl

inside)-------'

READY

(ICG1-34J

ON

(Pl-16)

(ICGl-46)

(ICl

·341

Figure

I

.

3-3 Index

JOO

ms

I

. .

.

DOOR

open/closf·

MOTOR

Sensor

on/oft

and

Ready

Circuit Timing

"'-~~~~~~~~

Li

Chart

-13

-

Page 14

3.5

Step

Motor

Drive

The

step

motor

using

two

These

The

steP

tion

durtng

In

a seek

for

30

Figure 3-4 shows • timing

The

step

seeking

to

prevent

3.6

Track

The

track

assembly, using a sensor. This

signal.

put

is

For a timing

XDSEL flCG1·17J

is

source/sink

four

modes

motor

dritite

times

operation,

ms

or

more, +5 V

mote< drive circuit blocks

during

write

further

00

Detection Circuit

00

detection

The

circuit

on.

chart, refer

Cireutt

a two-phase bipolar

type

drivers.

are

generated

by

circuit

other

outward

will

switches

than

seeking. when

+12 V

is

supplied

is

supplied.

chart.

o-ation.

seek.

circuit detects

not

output

to

figures 3-4.

When

output

type

an

up-down

the

to

the

step

the

the

is

a signal.

the

ANDed with

and

ts

driven

four-court

voltage supplied

the

motor

is

drive

circuit.

pulses

with a write

track

00

sensor

position

of

the

the

therefore,

unless

to a "Step

angle

counter

that

the

motor

if

the

next

gate (except for

turns

the

drive phase is

uses

drive circuit

step pulse

on,

to

still.

but

output

light-shielding plate

step motor drive phase

of

1.8° by feeding four

two

flip-flops.

to

reduce

is

not

the

erase delay time)

the

circuit 1lso blocks

that

projects from

(TKOO)

at

track

00

mode

power

applied

to

the

the

to

generate a track

even if

the

currents,

consump-

the

interface

to

prevent

step

pul-

head/carriage

00

sensor

out-

-DIRECTION

SELECT (TPl-18)

-STEP

(TP151

TKOOIN (TP1)

-WAITE

GATE

(TP6)

STMP1 f!CGl-371

STMP4

llCG1·541

TK

00

iTPl:ll

IN

TO

(INHIBITI

Figure 3-4 Step

TK

I

\J

01

02

I

I

00

I

}TKOO

I

I

I

I

I

I

I

i

I

I

\

' I

\~~

Motor

Drive

Circuit

-14-

02

01

:::i

SENSE\

I

1/

I

When

TKOO

stap

pulses are inhibited

Timing Chart

03

is

enabled,

r-

Step

phase

Same interface

output

outer

moto1

changE>

Page 15

3.7

Side Select Circuit

Side

selection

is

(H1Bl.

system

ONE

SELECT

made

alternately

is

fed

se•ects

if

This

operation

and

an erase current

bias curTents

and

HOB

The

host

same interface line

Figure 3-5 shows a block diagram

SIDE

by

from

from

it is high.

Figure

switchin9

the head center tap

feeds a write

center tap

CT-0 (CT-11

side

1

~

I

current

CT·O {CT-1) to ER-0 (ER-1)

to

HO'A

(HlAI

through

the

interface

of

the

side

select

!'-----

M51018P

I

I

I

I

I

L_

-

3-5

Side Select Circuit Block Diagram

from

circuit.

or

MC2870P

-

from about 0

center

and

HOB

line

if -

Head

select

driver

--

Vat

off

tap

(HlBI

SIDE ONE

to

CT·O

(CT-11

during write operation.

to

induce a voltage

SELECT

about

to

HOA

ERO

is

0

ER1

11

(HlAI

low,

V

at

between

or

on.

In

side

Side 0

Side 1

and

HOB

(HlBI.

read operation

HOA

(H1B)

0

through

a

the

-15-

Page 16

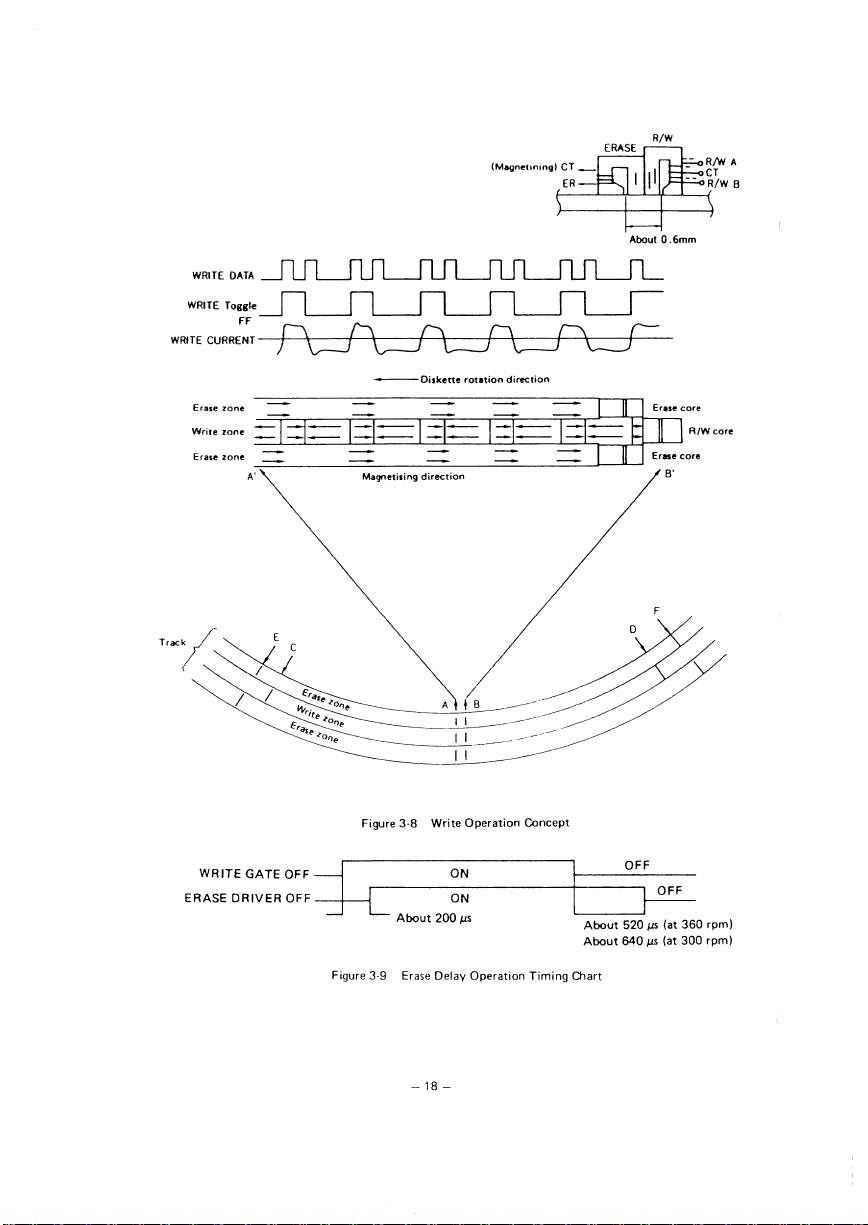

Write/Erase

3.8

write circuit is used for recordi™] dat.a

The

~lected

true

The

data

old

l)fevents

thus

write

The

• Write

• Write driver

• R/W

• Write

1

When

operation.

-ite

changes

This differential signal

write driver

The

current

write

R/W

The

write gate.

a

3-6 shows

Figure

Current

figure, according

the

in

operation

Erase

circumferential

point

a

Therefore,

turning

the

to

for

is

It

360rpm

at

kept

be

erase

The

3-8

Figure

Circuiu

diskette

If

head.

enses

circuit

remaining

from

data

old

consists

circuit

flip-flop

to91Jle

matrix

source

current

write gate

is

Write

synchronously

is

source

feeds a

matrix

the

alternately

is

starts

position

R!W

the

that

delay

the

of

on

purpose

this

(approx.

selected.

function

shows

erases

a

~ite·protect

previous

the

either

on

in

crosstalk

following blocks:

the

of

wrtte

the

input,

counted

is

data

write

the

with

the

switch

a switching

and

erase

fed

to

with

sent

is

current

function

to

the

point

to

to

the

differential

deviation

has passed approx.

gap

core

shown in figure

operation

erase driver

the

erase delay

the

that

300rpm)

at

1000µs

from

data

conceptual

diagram

stltus

dlt•

of

side

reading

toggle flip-flop •

down

data

write driver.

that

ci«"cuit

write driver.

the

head selected

the

figure

and

head

R/W

E befor

R/W

the

of

and

after

disk

the

of

disk.

the

on

detected.

is

both

on

written

written

newty

data.

new

the

....wite

half

one

to

generated.

is

current

feeds a

by

write

3-7. a

two

through

invert its magnetization.

to

signal

write

from

timer

write

core

the

by

start

from

350µs

·9

3

closing

the

provided

is

closing

always

operation

point

is

magnetizing

s.tarts. writing when

It

open1tion

write

no

the

of

sides

due

data

driver and

write

the

by

the

to

ONE SELECT as

SIDE

block

circuit

routes, CT

current

C and ends

core

erase

the

360rpm

at

for

required

write gate

the

of

control

to

write

the

of

figure 3·9,

and

the

performed.

is

DC tfa$Ure.

by

data

devi•tion

slight

1

to

current

write

toggle flip-flop,

head. This

R/W

the

diagram.

R/WA

-+

point

at

0.6

about

is

(approx. 500µs

it

from

time

the

the

to

erase.~triver.

the

head

the

gate.

direction.

one

in

erase

an

V«ite 91te

source

and

current

write

and

after

F

mm,

300rpml

at

the

turning

must

delay

This

had

of

ere

differential

a

is

circuit

CT-+

write

the

and

opening

off

Thus,

remain

operation

opened

is

function

pasition.

enlbled

generated

gate

R/WB

point

end

erase

(near

later

the

of

the

of

approx.

for

the

on

timing

the

for

prevents

and

start

to

that

signal

the

by

opened

is

shown

as

The

0.

reaches

core

321.

TK

gate

write

erase driver.

590µs

and

track

chart.

a

by

-16-

Page 17

NC::;::

...

(Wither

Modified

WRITE

(from J20104)

NORMAL

OENSITY

Modified

ERASE

(from J20104)

NORMAL

DENSITY

SIDE

ONE

SELECT

1

remems

~

hod)

3-6 Erase Function

Figure

r-------------

WRITE

I Toggle Write

'

DATA

GATE

GATE

----+--------i

r---J

I

:

>---T----------<tD'>-i

I driver

I

L---------------l

FF

2

V

+l

<>-----------<Power

+svo-~--------i

I

I

I

Dl.c

rotation

R/W

core position durmg readmg

This shaded parl

Driver

driver

Side

select

1s

read.

To

read

amp

,___

__

....,

1--~c--'

R/W

core

:•

position

w•ltlng

Figure 3.7 Write Circuit Block Diagram

-17

-

Page 18

(Magnehningl

WRITE

OATA

WRITE

Tout•

FF

WRITE

CURRENr-7-+-\.-\;::J--+---'l-c=J---.f--+t=::J--l--+c:=:;--+--\.-c::=:J---J--

I\

D 0

I\

CT_

ER

/\

About

c=

R/W

0.6mm

Erase

zone

Write

zone

_=_.__I

Erase zone

WRITEGATEOFF--i

ERASE DRIVER OFF

=l_._==____._I

A'

---Diskette

=__.._l==~l---"=l.__:=___.__I

Magnetising direction

Figure

3-8

_

--::J--{__----0-N------+---~~

About

roution

direction

=_.___l==__._=__.._1-...,..._

/

A I B

11

11

11

Write Operation Concept

ON

200

IJ5

I

1:

d e

....

co

..

-..-1;

9-r-E~r••

~o:~w

1

About

About

OFF

520

640

µs

µs

core

B'

F

(at 360 rpm)

(at 300 rpm)

Figure 3-9

Erase

Delay Operation Timing

-18-

Oiart

Page 19

Write-Protect

3.9

The

Opefation

interface.

RHd

3.10

The

The

previously

This

The

amplifies

The

The

for

Because

peak-detection

The

•

•

•

The

to

analog signal

MFM

Circuit

write-protect

even

Figure

if

3-16

Circuit

diskette

R/N

vohage

core

written

is

is

input

read

is

read Pfeamplifier

input

the

read signal from

pass filter

low

optimum

the

pos4tion

the

peak-detection

differentiator

a zero-crossing

circuit

Differentiator

Comparator

domain

Time

a digital signal.

to

frequency

means

circuit

write

a

shows

when

tr.ck.

a

on

to

data

the

to

PfOVides

a

into

the

constructed

is

frequency

of

to

circuit

filter

differentiating

ts a

point.

detects

gate

the

induce

rad

differential

is

sigrnil

diagram

circuit

a

gate

write

head

a

If

voltage between

1

preemplifier via

gain

1

signal high

notch

the

read preamplifier

that

so

the

of

each

of

magnetization

inverting

a read

generate

consists

The

modulation.

thfee

of

circuit

differentiated

point

The

The

received

and

has

about

data

write-protect

the

of

erase driver are closed.

selected,

been

the

R!W

the

times the level of

200

enough

through a low·pass

fed

is

automatically

is

it

two.

expres~ed

is

pulse.

blocks.

the

detect

to

routed

is

signal

of

change

of

of

frequency

in

(cutout

from

the

interface,

the

core

the

two ends

matrix.

for signal processing.

switched

by

peak

to

this digital signal actually

magnetization

outputs

and

circuit.

tM

reads

R/W

the

of

few millivolts induced in

a

that

filte<

for high/normal

a read signal

the

and

point,

comparator.

the

inversion intervals used

diskette

the

of

jack.et)

' sensor

with

write-protect

a

of

inversions

coil (between

excess high frequencies.

out

cuts

density.

the

peak,

detected

where

becomes

to

magnetization

R/WA

the

is

It

read signal

point

peak

converted

is

it

data

a

are

inhibit

signal

R/WB).

and

head,

matched

thus,

fed

is

converted

is

from

pulse. FM

in figure

write

to

of

the

the

and

to

3-IO

a

an

or

.

T2

~

360rpm

density

High

300rpm

density

Normal

360rpm

density

Normal

I:

Tl

2.0

4.0

3.3

Figure

µs

µs

µs

3-10

Tl

-19-

FM

DATA

T2

MFM

T2

4.0

8.0

7

6.

µs

µs

µs

Timing

3.0

6.0

5.0

T3

T3

. j

frequency

Highest

Tl)

(at

kHz

µs

µs

µs

250

125 kHz

kHz

150

Page 20

Adjacent

m.agnetiim

lengthen,

genented.

provided

filter is

matically

comparator

the

If

for a specific

data

read

The

read

a

3-12,

magnetiution

electronic

an

to

howeve<.

differenti1ted

the

for

for

switched

output

amount

generated

thus

chart.

timing

in11ersion waveforms.

signal. so the•r

imerference

mutual

the

waveform

the

removing

high/normal

maintains

time

the

time,

of

sent

is

intedere

combined

w11vetorm

magnetiz11tion

the

with

decreases. resulting

the

that

pulse.

data

thus,

is

It

to

prior

filter generates

so

set

the

The

for

time

the

single

that

zero-crosses

wrong

density.

level

the

domain

host system. Figure 3-11 shows a read

the

to

f"Nd. If

is

generating

in

wrong

domain

optimum

operation

output

inv«ston

matnetiz•tion

a

pulse

d•t•

is

filter

frequency for

©following

real read

.n

circuit

wa'iefOf'm

shoutdef.

det«ted.

is

constructed

e.::h

the

@.

data

block

conv~ted

inversion intervals

shoulder

When a

of

domain

time

A

is

it

that

so

two.

the

zero crossover

figure

and

diagtam

from

is

auto-

point

-20

-

Page 21

R/W core

Voltage

--

mmgneti-sm

from

-=

Magnetism

Erase zone

Read zone

Erase zone

pre

Read

out

amp

Odlerent1ator

out

unod5ervable)

(

t!N

~

~~-~~-·

converted

=l=I==

TP9

R/W coil

Ai-

I I

I

~

NORMAL

----------

R/W Read

matrik

i

DENSITY

pre-amp

-:

I

I

_____

L

Low

pass

filter

I

I

I

Side

I

select

I

driver

I

L--------1

direcrion

Time

domain

filter

Figure 3·11

---

I

I

I

I

L-----

Circuit Block Diagram

Read

rotation

Diskette

1=1~1=1==1=1==1=1==21~

direction

Magnetis1n9

noise

Shoulder

TPlO

r------------,

I

I :

Ditter-

I

entiator Comparator

I

~--~

J

ME101BP

MC2870P

or

r-----------J

DATA

DENSITY

DD

READ

Erase core

-

1--'----

__

I

I

I

_J

NORMAL

II§

DD

Era~e

A/W

core

I

I

I

I

I

I

I

I

I

I

I

KIA()

DATA

__

Chan

T1m1ng

Read

3·12

Figure

-

-21

Page 22

3.11 Write current switch

switched

is

write

The

switch

current

Write

( 1)

Write

Write

current

current

for

for

high

normal

on

density

density

this

unit

disk.sis

disks

for

set

is

the

when

set

optimum

the

the

when

recording

interface

interface

line

current

is

line

logical

logical "O".

is

for

"1".

both

high

and

normal

density

disks.

-22

-

Page 23

Drive Circuft

Motor

Spindle

3.12

motm

spmdle

The

the

with

It

LED.

This

meter

Spindle

the

The

voltage,

the coil. The rotational speed

Figure

spindle

correct

motor.

the

connected

is

feedback

generator.

rotating

information

speed

which

3-13

motor

speed

signal

shows

drive

a OC,

~s

times_

o1ll

at

main

the

to

servo circuit

speed

for

position

the

to

fed

is

output

compared

is

a spindle

circuit

direct.

This

control

employs

feedback

detected

is

predriver

the

by

with

the

of

motor

waveforms.

molm

brushleu

installed

is

circuit

four

with

circuit

elements

Hall

to

by

to

frequency

reference speed voltage

the

motor

drive circuit

constitute

Hall

the

alternate'y

gener•tor

switched

is

a

elements

block

for which a feedback sefvo

printed-circuit

separate

a

on

position

system

located

driver

to

changing

diagram

+12 V DC, 0

feedback

stabilize

to

symmetrically

driver

and

1

control

back

feed

reference speed

the

f~ure

and

is

signal lines:

for

se<:ondary

switch

for speed

by

a

and

2.

rectified

level

the

3-14

circuit

board

motor-on

V,

frequency

motor

from

and

of

conceptual

a

1

employed

is

that

signal,

generator.

rotation.

rotat~ng

the

integr.ted

current

value.

built

is

be

to

diagram

maintain

to

int~rally

USE

IN

and

tacho·

or

and

spindle.

a speed

into

supplied

the

of

to

- 23 -

Page 24

r-------_----,

I

-

P

I

redriver

I

~~~I-+~

I I

I I

I

Speed voltage

Onver

,...,_~___,~I'--~~~~~~

Position

detected

I

I

I

Hall

elements

Speed

Coil

current

Fig. 3-13 Spindle

HJ---~

H2

FG

Feedback speed voltage

voltage

=========~'\,.======s~""';:=:==~=----1_'.'.v_

controllin'

l11F

A

Fig.

3-14

-A

Spindle

motor

drive

circuit

block diagram

~

Rectified pulse (designated pulse

l

~

motor

-1

l==i

drive

-24

-

cl

current

The

be

LJ

wavefrom

________.--f

differential

nagatively

n

cfl

configuration

width)

of

this

feedback

voltage will

to

the

current

Loading...

Loading...