GASOLINE WATER PUMP

IMPORTANT – Please make certain that

persons who are to use this equipment

thoroughly read and understand these

instructions and any additional instructions

provided prior to operation.

NOTE:

No refund or exchange once gasoline is placed

into the fuel tank.Warranty registration must be

complete within 30 days of purchase with proof

of purchase.

MBP15G

MBP20G

MBP30G

MBP40G

MBP20H

MBP30T

Operator’s Manual

TABLE OF CONTENTS

SAFTEY INSTRUCTIONS

● Warning Labels

2-3

3

FEATURES, ASSEMBLY AND ACCESSORIES 4

BEFORE OPERATION 5

OPERATING THE WATER PUMP 6

MAINTENANCE 7-8

STORAGE 8

TROUBLE SHOOTING 9

SPECIFICATIONS 10

PERFORMANCE CURVE 11

LIMITED WARRANTY 13

DANGER WARNING CAUTION

DANGER indicates a potenally

hazardous situaon which, if not

avoided, WILL result in death or

serious injury.

SAFETY INSTRUCTIONS

WARNING indicates a potenally

hazardous situaon which, if not

avoided, could result in death or

serious injury.

CAUTION indicates a potenally

hazardous situaon which, if not

avoided, may result in minor or

moderate personal injury, or

property damage.

WARNING

To reduce the risk of serious injury or even death,

read the following safety precauons and operang

instrucons before operang.

DANGER

Using a water pump indoors WILL KILL YOU IN MINUTES

Engine exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

NEVER use inside a home or garage, even IF doors

and windows are open; only use OUTSIDE and far

away from windows, doors and vents.

DANGER

FUEL IS HIGHLY FLAMMABLE AND EXPLOSIVE

Always turn off the engine before adding fuel. Hot

engine parts, sparks or cigarees can ignite

gasoline. Store fuel away from water pump.

Never refuel while smoking or in the vicinity of an

open flame.

Take care not to spill any fuel on the engine or

muffler when refueling.

Before transporng the water pump in a vehicle,

drain all fuel to prevent leakage that may occur.

Store the water pump in a well venlated area

with the fuel tank empty.

WARNING

Starter and other rotang parts can entangle hands,

hair, clothing, or accessories.

Do not wear loose clothing, jewelry, or anything

that may be caught in the starter or other

rotang parts.

Tie up long hair when operang the water pump.

WARNING

KEEP CHILDREN AND PETS AWAY

Keep bystanders, especially children and pets, at

least 50 feet (15m) from the water pump. Do not let

15m

children touch the water pump. When not in use,

the water pump should be stored in a dry, locked

locaon, out of reach of children.

CAUTION

HEAVY LOAD

Use proper liing techniques when transporng the

water pump from site to site. Improper liing

techniques may result in personal injury.

WARNING

ENGINE AND MUFFLER MAY BE HOT

Contact with muffler area can result in serious burns.

Exhaust heat/gases can ignite combusbles,

structures or damage fuel tank causing a fire.

DO NOT touch hot parts and AVOID hot exhaust

gases. Allow equipment to cool before touching.

- 2 -

CAUTION

Improper treatment can damage the unit and shorten its life

Be sure pump chamber is filled with water before starng the

engine. NEVER run pump without priming.

• Use a non-collapsible hose on the sucon side of the pump.

• Use water pump only for intended uses.

• Not suitable for pumping sea water, beverages, acids, chemical

soluons, or any other liquid, other than clean water.

• DO NOT obstruct the sucon or discharge hose in any way.

• NEVER operate pump without strainer basket connected to end

of sucon hose.

• DO NOT exceed sucon head (see Specificaon). Use shortest

sucon head possible.

• NEVER allow vehicles to drive over hoses. If a hose must be

posioned across a roadway, use planking on each

side of hose to allow vehicles to pass over without obstrucng or

collapsing hose.

• Posion pump to avoid “walking” or equipment movement,

especially if located near a ditch or edge of open ravine. The

equipment could fall in.

• Keep equipment away from edge of river or lake where it could

cause the bank to collapse.

• DO NOT insert any objects through cooling slots.

NOTICE

Engine oil is hazardous to the environment

Be very careful when changing the oil to prevent spilling onto the

ground. Even if it is washed away, it will not mix with water and

will pollute the watershed—having a negave impact on the

plants and animals that it comes in contact with.

When disposing of engine oil:

1. While changing the engine oil, place a drip pan under the oil

plug to collect the waste.

2. Soak up any spills with sawdust, kiy lier, or sand. NEVER

dump down the drain or sewer.

3. Take the oil and filter to an oil recycling center.

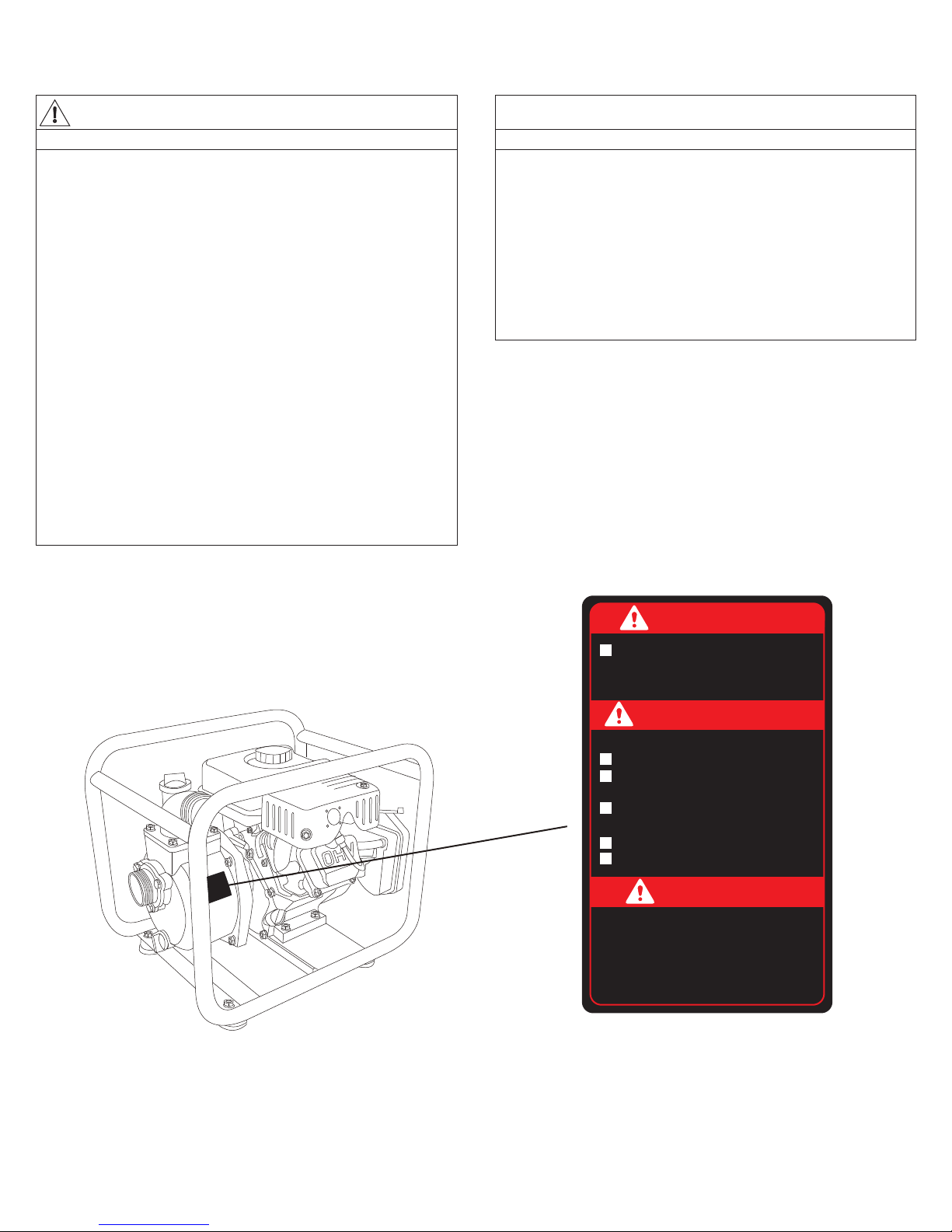

Warning Labels

CAUTION

Fully prime the pump and check all

connections for leakage before starting

this engine.

WARNNING

Fuel is flammable and explosive.

NEVER fuel a running or hot engine.

Ensure there are no fuel leaks before

starting.

Keep sources of sparks and flames

away.

Clean up fuel spills immediately.

Aways keep a fire extinguisher nearby.

DANGER

Do not use the water pump in an

enclosed area, exhaust fumes can

KILL.

- 3 -

FEATURES, ASSEMBLY AND ACCESSORIES

1. FUEL TANK

2. FUEL TANK CAP

3. DISCHARGE OUTLET

4. PRIMING PLUG

5. CHOKE LEVER

6. FUEL COCK

7. SPEED LEVER

8. RECOIL STARTER

9. STOP SWITCH

10. OIL DRAIN PLUG

11. OIL GAUGE

12. SUCTION INLET

13. WATER DRAIN PLUG

14. SPARK PLUG

15. AIR FILTER

16. MUFFLER

Assembly Main Accessories

Inlet/Outlet O-Ring

Nut (X 4)

Hose Clamp

Strainer

CAUTION: Running water pump without rubber feet will

shorten engine life.

Rubber Feet (X 4)

Bolt (X 4)

- 4 -

Spark Plug Wrench

Screwdriver

BEFORE OPERATION

Check Engine Oil

WARNING

DO NOT aempt to start this engine without filling the crank case

with the proper amount and type of oil. Your water pump has

been shipped from the factory without oil in the crankcase.

Operang the unit without oil can damage the engine.

Use class SE oil or a higher grade according to the table below. SAE

10W-30 or 10W-40 is recommended for general, all temperature

use.

Single

Grade

Oil

Multiple

Grade

Oil

Temperature°°C

F

- Inspect the oil level by using the oil gauge

before starng the engine each me;

- Top off the oil level to the maximum level

mark and/or unl oil flows from the

opening;

10W

20W

20#

10W-40

10W-30

–30 –20 –10 0 10 20 30 40

–22 –4 14 32 50 68 86 104

30#

5W-20

40#

OIL GAUGE

(Not Tightened)

Regular Oil

Level

Fill the tank with clean, fresh unleaded

Fuel Level

automove gasoline

- Check fuel level.

- If fuel level is low, refill with unleaded

automove gasoline.

- Be sure to use the fuel filter screen on the

fuel filter neck.

Check Air Cleaner to Make Sure It Is Clean

If not, please refer to “HOW-TO” MAINTENANCE.

Check Loose and Missing Parts

Before starng the water pump, check for loose or missing parts and

for any damage which may have occurred during shipment.

- Ensure both Oil Gauges are secure.

Lowest Oil Level

NOTICE

Low oil sensor

The unit is equipped with a low oil sensor. If the oil level becomes

lower than required, the sensor will acvate a warning device or

stop the engine.

If water pump shuts off and the oil level is within specificaons,

check to see if water pump is sing at an angle that forces oil to

shi. Place on an even surface to correct this.

If engine fails to start, the oil level may not be sufficient to

deacvate low oil level switch. Make sure the sump is completely

full of oil.

Check Engine Fuel

WARNING

DO NOT refuel while smoking or near open flame or other such

potenal fire hazards. Otherwise a fire accident may occur.

- Do not refill tank while engine is running or hot.

- Close fuel cock before refueling with fuel.

- Be careful not to admit dust, dirt, water or other foreign objects

into fuel.

- Wipe off spilt fuel thoroughly before starng engine.

- Keep open flames away.

- 5 -

OPERATING THE WATER PUMP

Aach Sucon Hose

Use a commercially available hose with hose connector and fixtures.

The sucon hose must be reinforced with a non-collapsible wall or

braided material.

a. Insert O-ring into end of hose fixture.

b. Screw hose fixture assembly onto

pump in clockwise rotaon unl hose

fixture assembly is ghtened securely.

CAUTION

The pump will fail to li water if the sucon process has air leak.

c. Aach Sucon Hose to Strainer

Slide hose clamp over hose. Aach open

end of sucon hose to strainer hose

connector. Tighten hose clamp securely.

Connect Discharge Hose

Use a commercially available hose with hose connector and fixture.

Prime the Water Pump

To enable the pump to prime, the pump

chamber must be full of water.

a. Remove drain plug from top of pump.

b. Fill pump with clean, clear water up to

top of discharge outlet. Make sure that

the drain plug is always replaced aer

filling.

• BE SURE pump chamber is filled with

water before starng the engine.

• DO NOT let pump run dry or damage

to mechanical seals may result.

WARNING

Running water pump without priming will severely damage pump

seal system.

Starng the Water Pump

a. Make sure unit is on a flat, level

surface and pump chamber is primed.

b. Turn fuel cock to “On” posion.

pump output, and moving the engine speed lever in the “Slow”

direcon will decrease pump output.

e. Turn the engine stop switch “On” .

f. Pull the starter handle slowly unl

resistance is felt. This is the

“compression” point.

Return the handle to its original posion

and pull swily unl engine starts.

WARNING

To avoid accidently hurng people nearby when pulling the

starter handle, Please keep bystanders, especially children and

pets, away.

CAUTION

Do not allow the starter handle to snap back against the engine.

Return it gently to its starng posion to prevent damage to the

starter or the housing.

g. Aer the engine starts, return the

choke lever gradually to “Open”(Le)

poson and move engine speed lever to

“Fast” (Le) posion.

Note

• Posion the water pump as close as

possible to the water and run the engine

at full speed. Expect to wait for

approximately one minute for the pump

to prime and start pumping. This me

will increase if the pump is further from

the water – parcularly if there is a deep

sucon li.

• If the pump fails to prime, check

TROUBLESHOOTING

Stopping the Water Pump

1. Move engine speed lever to

“Slow” (Right) posion.

2. Push stop switch to “Off”

posion.

3. Turn fuel cock to “Off”

posion.

OPEN

1)

3)

Fast

CHOKE

ON

2)

OFF

c. Set the choke lever to “Choke”

(Right)positon. Not necessary if the

engine is warm.

d. Move engine speed lever to half way

to “Fast” (Le) posion .

Pump output is controlled by adjusng

engine speed. Moving the engine speed

lever in the “Fast” direcon will increase

CHOKE

2)

CHOKE

1)

ON

OFF

CAUTION

Move the engine stop switch to the “OFF” posion to stop engine

directly in an emergency situaon.

Drain the Water Pump

a. Disconnect and sucon and discharge hoses.

b. Remove water drain plug.

c. Replace drain plug aer draining.

- 6 -

1. Maintenance Schedule

MAINTENANCE

(daily)

PRE

INITIAL

EVERY

EVERY

EVERY

ITEM REMARKS

OPERATION

25HR

50HR

100HR

300HR

Check condition adjust gap

Spark Plug

●

and clean. Replace if necessary

Check oil level ●

Engine Oil

replace ● ●

Air Filter Clean, replace if necessary ●

●

Clean and adjust. Replace

Fuel Filter

●

if necessary

Check fuel hose for crack

Fuel Line

●

or damage. Replace if necessary

Check for leakage. Retighten or

●

Exhaust

System

replace gasket if necessary

Check muffler screen.

●

Clean/replace if necessary.

Carburetor check choke operation ●

Cooling

Check fan damage

●

System

Starting

Check recoil starter operation

●

System

Filling/Fast

Check all fittings and

●

eners

fasteners correct if necessary

CAUTION

To prevent accidental starng, always remove the spark plug or

cable from the spark plug before maintaining the water pump or

engine.

- 7 -

2. “How-To” Maintenance

Engine Oil Change

1. Drain oil by removing the drain

plug and the oil gauge while

engine is warm.

2. Reinstall the drain plug and fill

the engine with oil unl it

reaches the upper level on the oil

filler cap.

3. Clean the oil on the panel.

Dispose of used oil in local

authority disposal site.

WARNING

Engine oil may be hot.

Let engine cool at least 2 minutes before removing

fuel cap. Loosen cap slowly to relieve pressure in

tank.

Oil Gauge

Oil Drain Plug

Clean Air Filter

1. Unscrew the air filter cover;

2. Remove filter element and wash

well in solvent;

3. Pour a small amount of oil onto the

filter element and gently squeeze out

any excess oil;

4. Replace the filter element and air

filter cover;

5. Be sure the filter cover seals

properly all around.

Element Holder

Clean Spark Plug

1. If the plug is contaminated

with carbon, remove it using a

plug cleaner and wire brush.

2. Adjust the electrode gap to 0.7

to 0.8 mm.

Engine GT241/400/600 GT1000/GT1300

Manufacturer NGK

Product No. BP6RSH E6RTC BPR5ES W16EPR RN11YC

Bosch

NGK

Denso Champion

Element

Bosch

WR8DC+

Besides draining fuel from fuel tank, the

following procedures should be followed

prior to storage of your water pump for

periods of 3 months or longer.

1. Turn fuel cock to “OPEN” posion.

2. Loosen the drain screw on the side of

the carburetor float chamber, and drain

the fuel completely.

NOTE

1) There are two screws on carburetor.

The vercal one is the screw to hold the

carburetor float chamber; the other one

on the side of the carburetor float

chamber is the drain screw.

2) Tighten the drain screw very carefully

to avoid damaging the fuel cup.

STORAGE

3. Remove the spark plug, pour 2 to 3 cc of

engine oil into the cylinder, and turn the

crank sha several mes.

4. Replace the spark plug and pull starter

Drain screw

handle unl resistance is felt.

5. Store the water pump in a well

venlated, low humidity area.

OIL

- 8 -

TROUBLE SHOOTING

Problem Cause Correcon

1. Pump not primed.

1. Fill pump chamber with water and prime

pump.

No pump output or low

pump output when water

pump is running.

Engine will not start; lacks

power; starts and runs

rough; or "hunts" or falters.

2. Sucon hose restricted, collapsed, damaged,

too long, or diameter too small.

3. Strainer not completely under water.

4. Air leak at sucon hose connector.

5. Strainer clogged.

6. Discharge hose restricted, damaged, too long,

or diameter too small.

7. Excessive or marginal head.

8. Engine speed lever is in “Slow ” posion.

1. Stop switch set to " Off ".

2. Fuel valve is in "Off " posion.

3. Dirty air cleaner.

4. Out of fuel.

5. Stale or contaminated fuel or water in fuel.

6. Spark plug wire not connected to spark plug.

2. Replace sucon hose.

3. Sink the strainer and the end of sucon hose

completely under water.

4. Replace sealing washer if missing or

damaged. Tighten hose connector and clamp.

5. Clean debris from strainer.

6. Replace discharge hose.

7. Relocate pump and/or hoses to reduce head.

8. Move engine speed lever to “ Fast ”

posion.

1. Set switch to "On".

2. Turn fuel valve to "On" posion.

3. Clean or replace air cleaner.

4. Wait two minutes and fill fuel tank.

5. Drain fuel tank and carburetor; fill

with fresh fuel.

6. Connect wire to spark plug.

7. Bad spark plug.

8. Excessive fuel is present in the air/fuel mixture

causing a “flooded” condion.

9. Excessively rich fuel mixture.

10. Intake valve stuck open or closed.

11. Engine has lost compression.

12. Carburetor is running too rich or too lean.

- 9 -

7. Replace spark plug.

8. Wait 5 minutes and re-crank engine.

9. Contact service facility.

10. Contact service facility.

11. Contact service facility.

12. Contact service facility.

SPECIFICATION

MODEL NO. MBP15G MBP20G MBP30G

Brand: MITSUBISHI MITSUBISHI MITSUBISHI

Displacement: 79.6 cc 126 cc 181 cc

Fuel Tank Si ze:

0.423 Gal l on/Unleaded Gas oline 0.66 Gallon/Unleaded Gas oline 1 Gallon/Unleaded Gasoline

0.1 Gallon/Engine oi l SD or Higher 0.16 Gallon/Engi ne oil SD or Hi gher .0.16 Gallon/Engine oil SD or Higher

Max. Flow: 66 GPM 132 GPM 264 GPM

Outlet Diameter: 1.5’’ NPT 2’’ NPT 3" NPT

Self Priming: Yes Yes Yes

Pump Head Material : Aluminum Aluminum Aluminum

Max. Sucon: 23 Feet 23 Feet 23 Feet

Max. Li: 72 Feet 98 Feet 98 Feet

Hose Bands :

Spark Pl ug Driver Ki t

Overview

Engine

Pump

Accessories

Brand: MITSUBISHI MITSUBISHI MITSUBISHI

Engine Model NO.: GT1000 GT600 GT600

Type: OHV, 4 Stroke, Air cooled OHV, 4 Stroke, Air cool ed OHV, 4 Stroke, Air cool ed

Displacement: 296 cc 181 cc 181 cc

0.32 Gallon /Engine oi l SD or Higher 0.16 Gallon/Engine oil SD or Higher 0.16 Gallon/Engine oil SD or Higher

Starng System: Manual Start Ma nua l Start Manual Start

Max. Flow: 352 GPM 122 GPM 198 GPM

Self Priming: Yes Yes Yes

Pump Head Material : Aluminum Al uminum Aluminum

Mechanical Seal Material: Ceramic Carbon Cerami c Carbon Ceramic Carbon

Max. Sucon: 20 Feet 20 Feet 20 Feet

Max. Li: 82 Feet 180.5 Feet 82 Feet

Strainer:

Hose Bands :

Spark Pl ug Driver Ki t

Weight: 110 Lbs. (50 kilogra ms) 72.8 Lbs. (33 kilograms) 105.8 Lbs. (48 kilograms)

Overview

Pump

Accessories

Engine Model NO.: GT241 GT400 GT600

Type: OHV, 4 Stroke, Air cool ed OHV, 4 Stroke, Air cool ed OHV, 4 Stroke, Air cool ed

Lubrica ng oi l :

Starng Sys tem: Manual Start Manual Start Manual Start

Oil Alert: Equipped Equipped Equipped

Inl et Diameter: 1.5’’ NPT 2’’ NPT 3" NPT

Mechanical Seal Material : Ceramic Carbon Ceramic Carbon Ceramic Carbon

Strai ner: Equipped Equipped Equipped

Equipped Equipped Equipped

Equipped Equipped Equipped

Weight: 44 Lbs.(22 kilograms) 62 Lbs. (28 kilograms)s 70.5 Lbs. (32 kilograms)

Dimensions: 17.5"L×14"W×14.6"H 19.7"L×15"W×26.7"H 20.5"L×16.3"W×17.7"H

MODEL NO. MBP40G MBP20H MBP30T

Engine

Fuel Tank Si ze:

1.6 Gallon /Unleaded Gasoline 1 Gallon/Unleaded Gasoline 1 Gallon/Unleaded Gasoline

Lubricang oi l :

Oil Alert:

Equipped Equipped Equipped

Inlet Diameter: 4" NPT 2" NPT 3" NPT

Outlet Diameter: 4" NPTmm 2''/1.5"/1.5'' NPT 3" NPT

Equipped Equipped Equipped

Equipped Equipped Equipped

Equipped Equipped Equipped

Dimensions : 24.2"L×17.5"W×20.5"H 20.5"L×16.3"W×17.7"H 21.7"L×17.3"W×18"H

- 10 -

Li(m)

PERFORMANCE CURVE

30

Li(m)

25

Flow

85

80

75

Li(m)

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

0 5 10 15 20 25 30 35

MBP20H

Flow

20

15

10

10

5

0

0 5 10 15 20 25 30 35 40 45 50

MBP30T

Flow

- 11 -

LIMITED WARRANTY

This Mitsubishi engine product carries a guarantee of 24 months. If

your product develops a fault within this period, DO NOT return to

store, you should, in the first instance contact our customer

service.

We welcome warranty repairs and apologize to you for being

inconvenienced. Any Authorized Service Dealer may perform

To avoid misunderstanding which might occur between the

customer and the dealer, listed below are some of the causes of

engine failure that the warranty does not cover.

Normal wear: Engines, like all mechanical parts, need periodic

parts service and replacement to perform well. Your warranty will

not cover repairs when wear has occurred because of misuse, lack

of a part or an engine. Warranty would not apply if engine damage

is void if the serial number of the engine has been removed or the

engine has been altered or modified.

Improper maintenance: The life of an engine depends upon the

1. Problems caused by parts that are not original parts.

damage, caused by using contaminated or stale fuel.

3. Parts which are scored or broken because an engine was

and change at recommended intervals). OIL GARD may not shut

down running engine. Engine damage may occur if oil level is not

properly maintained.

4. Damage or wear to parts caused by dirt, which entered the

engine because of improper air cleaner maintenance, re-assembly,

or use of a non-original air cleaner element or cartridge. At

recommended intervals, clean and/or replace the filter as stated in

the Operator’s Manual.

grass, debris, or dirt, which plugs or clogs the cooling fins, or

recommended intervals as stated in the Operator’s Manual.

be premature wear. Such wear, when caused by dirt, dust, spark

plug cleaning grit, or other abrasive material that has entered the

engine because of improper maintenance, is not covered by

warranty.

workmanship only, nor does the warranty extend to repairs

required because of:

to find out closest repair center,

or to order replacement parts or accessories.

HOW TO ORDER REPLACEMENT PARTS

valves, valve seats, valve guides, or burned starter, caused by the

use of gasoline formulated with ethanol greater than 10%.

contact

MBG??????-07203

Loading...

Loading...