Page 1

Page 2

Page 3

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or registered

trademarks of the respective companies.

Page 4

Page 5

Introduction

This manual is an instruction manual for NAVI MILL for 700/70 (hereafter NAVI MILL).

This manual explains how to operate NAVI MILL, so read this manual thoroughly before use.

Be sure to study "Precautions for Safety" on the next page and use the system safely.

Details described in this manual

CAUTION

For items described as "Restrictions" or "Usable State" in this manual, the instruction manual

issued by the machine tool builder takes precedence over this manual.

Items not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added. Confirm with the

specifications issued by the machine tool builder before starting to use.

Refer to the Instruction Manual issued by each machine tool builder for details on each

machine tool.

Some screens and functions may differ depending on the NC system (or its version), and

some functions may not be possible. Please confirm the specifications before use.

Refer to the following documents.

MITSUBISHI CNC 700/70 Series Instruction Manual ....................................IB-1500042

MITSUBISHI CNC 700/70 Series Setup Manual ...........................................IB-1500124

MITSUBISHI CNC 700/70 Series Programming Manual (M system) ............IB-1500072

Page 6

Page 7

Precautions for Safety

Always read the specifications issued by the machine tool builder, this manual, related

manuals and attached documents before operation or programming to ensure correct use.

Understand the NAVI MILL, safety items and cautions before using the system.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

When the user may be subject to imminent fatalities or major

injuries if handling is mistaken.

WARN ING

When the user may be subject to fatalities or major injuries if

handling is mistaken.

CAUTION

When the user may be subject to bodily injury or when property

damage may occur if handling is mistaken.

Note that even items ranked as "

CAUTION", may lead to serious consequences depending

on the situation. In any case, important information that must always be observed is described.

DANGER

Not applicable in this manual.

WARNING

1. Items related to operation

If the operation start position is set in a block which is in the middle of the program and

the program is started, the program before the set block is not executed. Please

confirm that G and F modal and coordinate values are appropriate. If there are

coordinate system shift commands or M, S, T and B commands before the block set as

the start position, carry out the required commands using the MDI, etc. If the program is

run from the set block without carrying out these operations, there is a danger of

interference with the machine or of machine operation at an unexpected speed, which

may result in breakage of tools or machine tool or may cause damage to the operators.

Under the constant surface speed control (during G96 modal), if the axis targeted for

the constant surface speed control moves toward the spindle center, the spindle

rotation speed will increase and may exceed the allowable speed of the workpiece or

chuck, etc. In this case, the workpiece, etc. may jump out during machining, which

may result in breakage of tools or machine tool or may cause damage to the

operators.

Page 8

1. Items related to product and manual

For items described as "Restrictions" or "Usable State" in this manual, the instruction

manual issued by the machine tool builder takes precedence over this manual.

Items not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added. Confirm

with the specifications issued by the machine tool builder before starting use.

Refer to the Instruction Manual issued by each machine tool builder for details on

each machine tool.

Some screens and functions may differ depending on the NC system (or its version),

and some functions may not be possible. Please confirm the specifications before

use.

CAUTION

(Continued on next page)

Page 9

2. Items related to installation and assembly

Ground the signal cables to ensure stable system operation. Also ground the NC unit

main frame, power distribution panel and machine to one point, so they all have the

same potential.

3. Items related to preparation before use

Always set the stored stroke limit. Failure to set this could result in collision with the

machine end.

Always turn the power OFF before connecting/disconnecting the I/O device cable.

Failure to do so could damage the I/O device and NC unit.

4. Items related to screen operation

NAVI MILL uses the following variables in order to operate the NC program.

NC program mode Variables used by NAVI MILL

User macro mode #150 to #179

MTB macro mode #450 to #479

When NC program mode is user macro mode, do not use common variables. If those

variables are written over, malfunction will be resulted. If mistakenly written them over,

turn the NC power OFF after securing your safety. When the power is turned ON

again, the system recovers the data.

NC program mode is specified on the Preferences screen.

When either "TOOL REG No." or "HOLE CYCLE" is input in the hole drilling screen,

the feedrate and spindle speed are automatically determined using the data in the tool

file screen and the cutting condition file screen. In the same way, when "TOOL REG

No." is input in the face cutting screen, the contour cutting screen and the pocket

screen, the feedrate and spindle speed are automatically determined. Note that the

feedrate and spindle speed of each process determined once will not be changed by

changing the data in the tool file screen and the cutting condition file screen.

CAUTION

5. Items related to operation

Stay out of the moveable range of the machine during automatic operation. During

rotation, keep hands, feet and face away from the spindle.

Carry out dry operation before actually machining, and confirm the machining program,

tool offset and workpiece coordinate system offset.

If the operation start position is set from a block in the program and the program is

started, the program before the set block is not executed. If there are coordinate

system shift commands or M, S, T, and B commands before the block set as the

starting position, carry out the required commands using the MDI, etc. There is a

danger of interference with the machine if the operation is started from the set starting

position block without carrying out these operations.

Program so the mirror image function is turned ON/OFF at the mirror image center.

The mirror image center will deviate if the function is turned ON/OFF at a position

other than the mirror image center.

(Continued on next page)

Page 10

6. Items related to faults and abnormalities

If the battery low warning is issued, save the machining programs, tool data and

parameters in an input/output device, and then replace the battery. When the battery

alarm is issued, the machining programs, tool data and parameters may be destroyed.

Reload the data after replacing the battery.

If the axis overruns or emits an abnormal noise, immediately press the emergency

stop button and stop the axis movement.

7. Items related to maintenance

Incorrect connections may damage the devices, so connect the cables to the

specified connectors.

Do not apply voltages other than those indicated according to specification on the

connector. Doing so may lead to destruction or damage.

Do not connect or disconnect the connection cables between each unit while the

power is ON.

Do not connect or disconnect the PCBs while the power is ON.

Do not connect the cable by pulling on the cable wire.

Do not short circuit, charge, overheat, incinerate or disassemble the battery.

Dispose the spent battery according to local laws.

Dispose the spent cooling fan according to local laws.

Do not replace the control unit while the power is ON.

Do not replace the operation panel I/O unit while the power is ON.

Do not replace the control section power supply PCB while the power is ON.

Do not replace the expansion PCB while the power is ON.

Do not replace the memory cassette while the power is ON.

Do not replace the cooling fan while the power is ON.

Do not replace the battery while the power is ON.

Be careful that metal cutting chips, etc., do not come into contact with the connector

contacts of the memory cassette.

Do not replace the high-speed program server unit while the power is ON.

CAUTION

Page 11

Disposal

(Note) This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/EC Article 20 Information for endusers and Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and

components which can be recycled and/or reused.

This symbol means that batteries and accumulators, at their end-of-life, should be disposed of

separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the

battery or accumulator contains a heavy metal at a certain concentration. This will be indicated as

follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly at your local community waste collection/

recycling centre.

Please, help us to conserve the environment we live in!

Page 12

Page 13

Contents

1. OUTLINE .....................................................................................................................1

1.1 System Outline............................................................................................................1

1.2 Input Procedures.........................................................................................................2

1.3 Screen Configuration...................................................................................................3

1.4 Starting NAVI MILL......................................................................................................4

1.5 Setting up NAVI MILL..................................................................................................5

2. FUNCTIONS OF DISPLAY AREA...............................................................................7

2.1 LIST VIEW Area..........................................................................................................8

2.2 OPERATION VIEW Area...........................................................................................10

2.3 Setting Area...............................................................................................................11

2.4 Message Area ...........................................................................................................11

2.5 Menu Display Area....................................................................................................11

3. BASIC OPERATIONS................................................................................................12

3.1 Changing Active View................................................................................................12

3.2 Changing Screen.......................................................................................................12

3.3 Setting Data...............................................................................................................14

3.4 Switching Windows....................................................................................................17

3.5 Switching Selection Tags ..........................................................................................17

3.6 Inputting Operations..................................................................................................18

4. SCREEN SPECIFICATIONS.....................................................................................19

4.1 Starting NAVI MILL....................................................................................................19

4.2 Screen Related to the Program.................................................................................20

4.2.1 Program Edit Screen ..................................................................................20

4.3 Screens Related to the Process Edit Functions........................................................24

4.3.1 Process List Screen....................................................................................24

4.3.2 Multiple Parts Screen..................................................................................26

4.3.3 Operating Process......................................................................................30

4.3.4 Process Mode Selection Screen.................................................................36

4.3.5 Initial Condition Setting...............................................................................39

4.3.6 Hole Drilling ................................................................................................43

4.3.7 Face Cutting ...............................................................................................55

4.3.8 Contour Cutting...........................................................................................59

4.3.9 Pocket.........................................................................................................69

4.3.10 EIA Screen................................................................................................78

4.4 Screens Related to File Editing.................................................................................79

4.4.1 Tool File Screen.......................................................................................... 79

4.4.2 Cutting Condition File Screen.....................................................................81

4.5 Screen Related to the Parameters............................................................................83

4.5.1 Parameter Screen.......................................................................................83

4.5.2 PREFERENCE Screen...............................................................................86

4.6 Screen Related to the Version...................................................................................88

4.6.1 Version Screen...........................................................................................88

4.7 Program Checker Screen..........................................................................................89

4.8 Guidance Function ....................................................................................................94

4.8.1 Tool Guidance Screen................................................................................95

Page 14

5. PROGRAM SPECIFICATIONS..................................................................................96

5.1 NC Program...............................................................................................................97

5.1.1 Output Method for NC Program..................................................................97

5.1.2 Restrictions...............................................................................................100

5.2 File Program............................................................................................................101

5.3 Parameter Program.................................................................................................101

5.4 Macro Program........................................................................................................101

6. TOOL FUNCTIONS.................................................................................................102

6.1 Tool Change Command (M6) and T-Command......................................................102

6.2 Editing Tool Number and Next Tool Number...........................................................103

7. RESTRICTIONS FOR CNC FUNCTION SPECIFICATIONS...................................104

8. ALARM MESSAGE..................................................................................................105

8.1 Error Message.........................................................................................................105

8.2 Warning Message....................................................................................................108

8.3 Operation Message.................................................................................................109

APPENDIX 1. VARIABLES USED IN NAVI MILL........................................................110

APPENDIX 2. PROGRAMMING EXAMPLE................................................................112

Appendix 2.1 Machining Drawing ...............................................................................112

Appendix 2.2 Process Table.......................................................................................113

Appendix 2.3 Condition Setting...................................................................................113

Appendix 2.4 Creating Program..................................................................................114

Page 15

1. OUTLINE

1.1 System Outline

1. OUTLINE

1.1 System Outline

This manual is an instruction manual for NAVI MILL for 700/70 (hereafter NAVI MILL).

The part program for the vertical machining center (three axes of X, Y and Z) is created with the NAVI MILL.

(1) The following machining processes can be edited.

• Hole drilling (Drilling, pecking, step, boring, tapping, helical boring)

• Face cutting (Circle, square)

• Contour cutting (Circle, square, free)

• Pocket machining (Circle, square, L pattern, U pattern, track)

• EIA

(2) The tool file and the cutting condition file are provided and the cutting conditions are determined

automatically.

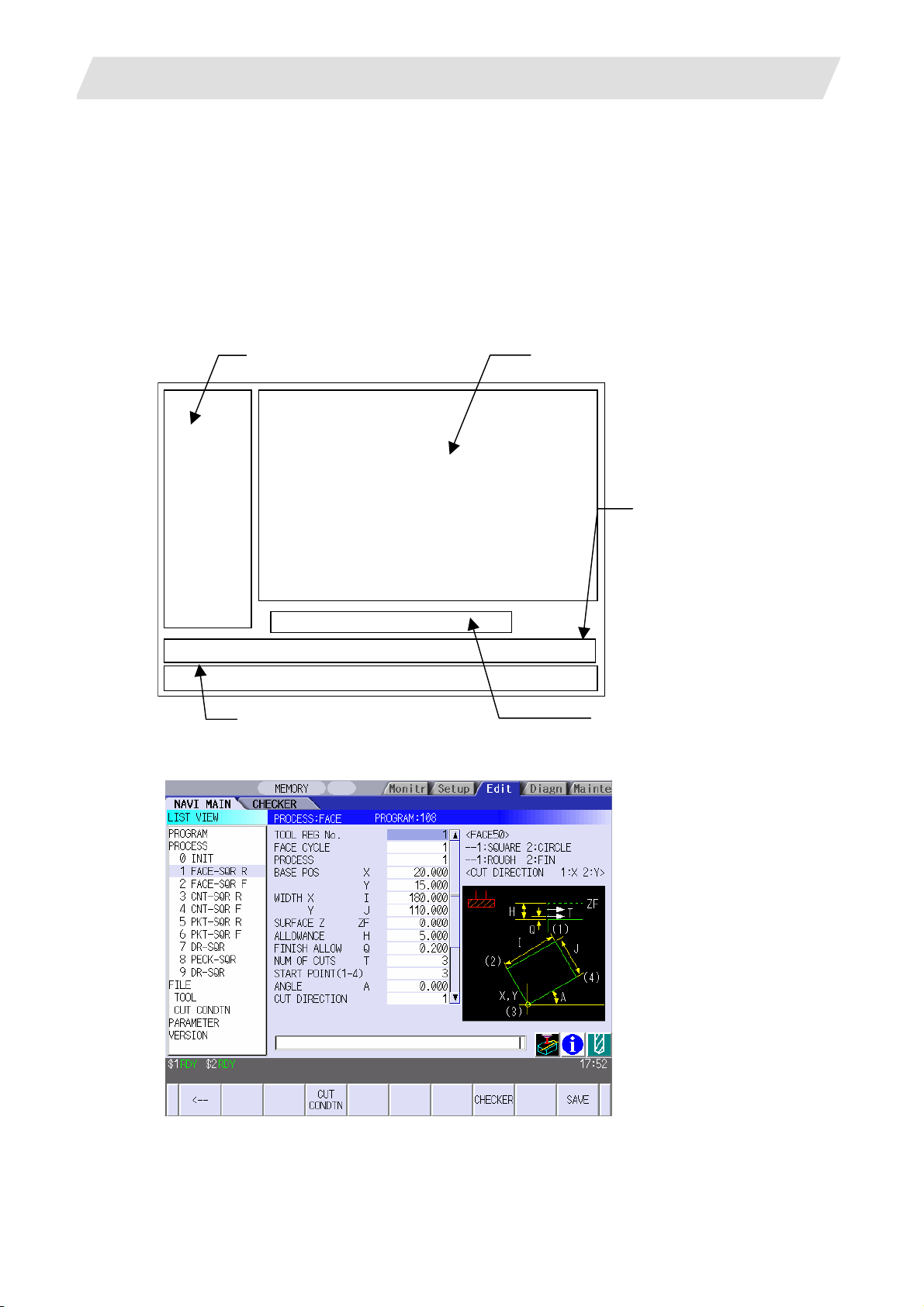

(3) The operation screen consists of the LIST VIEW area and the OPERATION VIEW area. In the LIST VIEW

area, the whole part program can be always viewed. In the OPERATION VIEW area, there are the guide

drawings related to the input items, and the data can be easily input by using these guide drawings.

[LIST VIEW area]

The object of the NAVI MILL is

selected.

[OPERATION VIEW area]

The screen is displayed

corresponding to the object selected

in the LIST VIEW.

[Cutting conditions automatically

determined]

Upon tool registration No. entry, the

cutting conditions for each process

are automatically determined based

on the tool file and cutting condition

file.

[Help]

[Guide drawing]

[Menu keys]

(Note) The operation screen size is fixed to 800(width) x 600(lengt h).

(4) Program Checker enables the tool paths of a part program to be graphically traced. With this function,

errors in input data can be detected at an earlier stage.

(5) Guidance function provides an operator with error recovery information.

(6) Part program is a macro-program-based NC program. Commands can be added between processes from

the edit screen of the standard MELDAS 700/70 Series.

(7) The macro program mentioned above can be customized by the machine tool builder.

- 1 -

Page 16

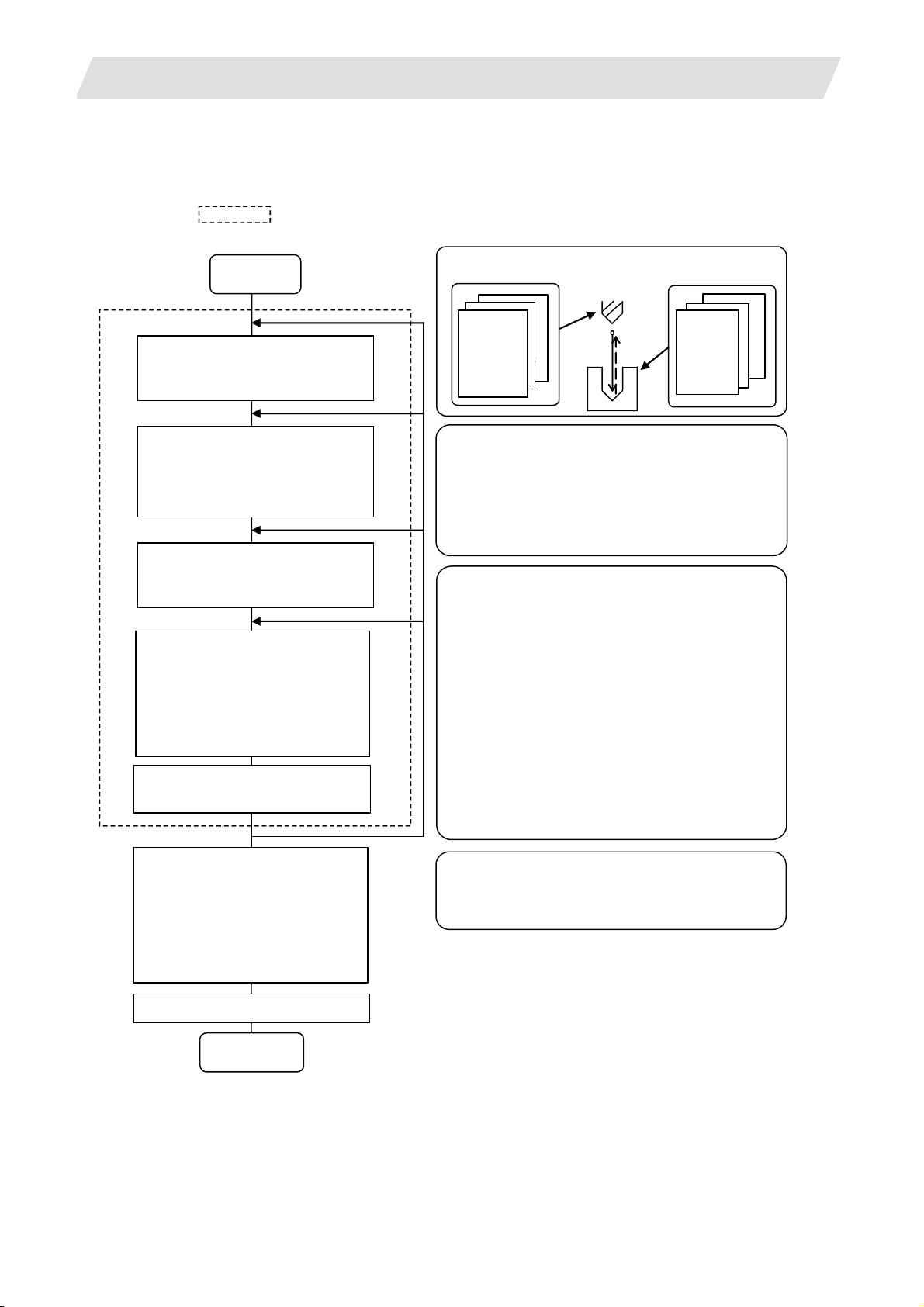

1. OUTLINE

1.2 Input Procedures

The input procedure for the NAVI MILL is shown below.

The part is operated on

the NAVI MILL’s screen.

Supplements

1.2 Input Procedures

Start

File edition

Tool file

Cutting condition file

Parameter setting

Parameter file

(The parameter setting is valid

even if the parameter is set after

editing the NC program)

NC program selection

Newly create

Read out

Process editing:

Initial conditions

Process mode selection

Process data input

Hole drilling / Face cutting /

Contour cutting / Pocket

machining / EIA, etc.

Tool file

(Tool registration No. 1 to 99)

No.

No.

direction

99

1

No.

No.

No.

direction

Tool leng. offset

Tool leng. offset

Tool leng. offset

Tool diam. offset

Tool diam. offset

Spindle rotation

Spindle rotation

:

Cut condition file

(Work registration No.1 to 8)

8

Material

1

Tool applicable

Material

:

rotation rate

Tool applicable

:

rotation rate

:

Parameter setting

• M0 output • M6 output • M19 output •Next tool preparation, etc.

• Common parameters for hole drilling process (Z clearance, tap

selection)

• Common parameters for face cutting process (XYZ clearance, Z

approach G code)

• Common parameters for contour cutting / pocket machining

process

Process editing

Program check

Program Checker is used.

Program check

(Note) Set the tool

compensation amount and

workpiece coordinate system

The NC program, tool file, cutting condition file and

parameter file transferred to the CNC can be edited on

Magicpro-NAVI MILL for 60S.

offset to perform Program

Check. This function is realized

by using the 700/70 Series

graphic check functio n .

NC program operation

END

- 2 -

Page 17

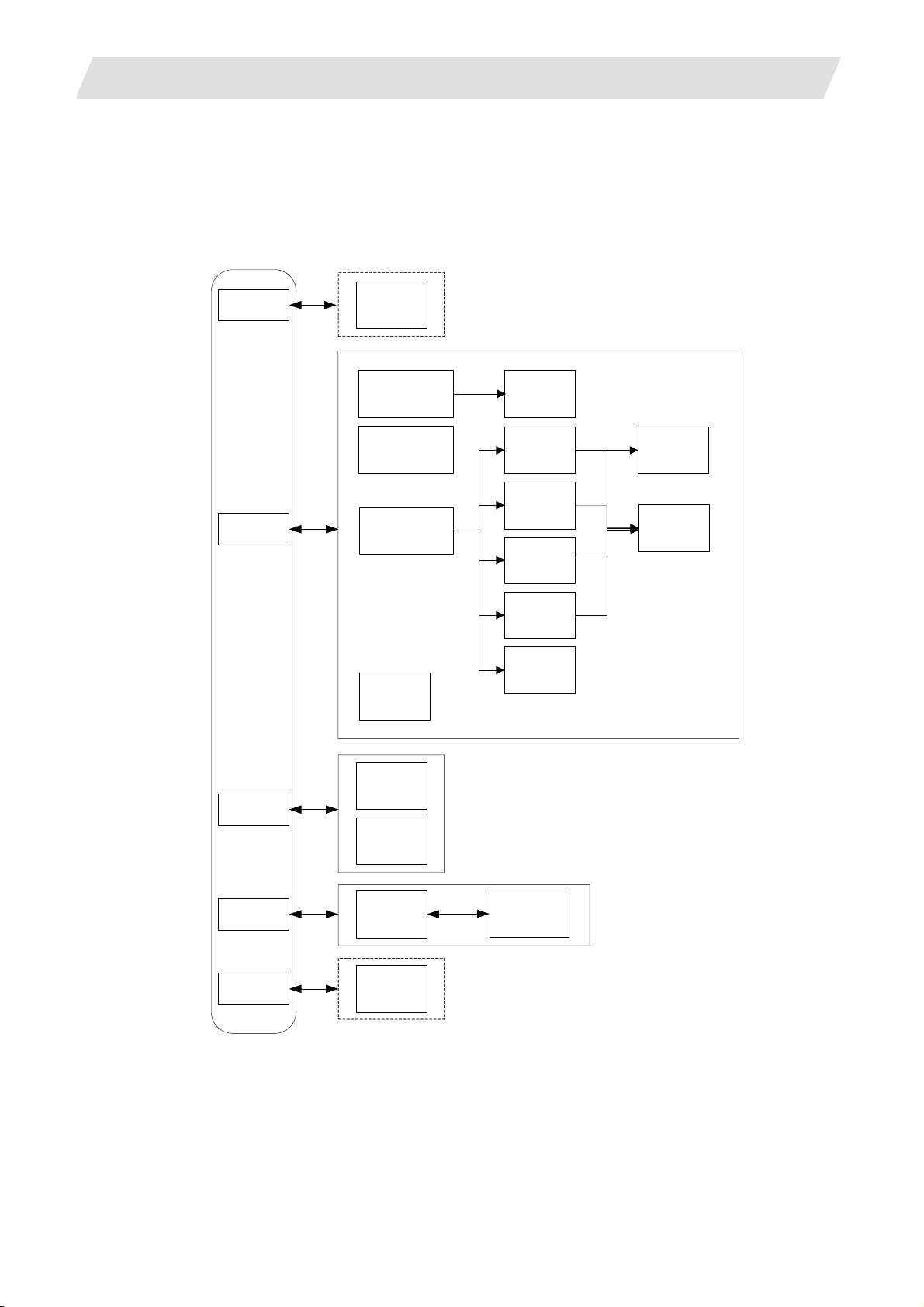

1. OUTLINE

1.3 Screen Configuration

The screen configuration for the MILL NAVI is shown below.

Program

Program

edit

screen

1.3 Screen Configuration

Process

File

Process list

screen

Initial

condition

setting screen

Process

mode select

screen

(For a new process,

select the process

form the process

mode.)

Program

checker

Tool file

screen

Cutting

condition

file screen

Multiple

parts

screen

Hole

drilling

screen

Face

cutting

screen

Contour

cutting

screen

Pocket

screen

EIA

screen

Machining

pattem

screen

Cutting

condition

screen

Parameter

Version

Parameter

screen

Version

screen

Preference

screen

- 3 -

Page 18

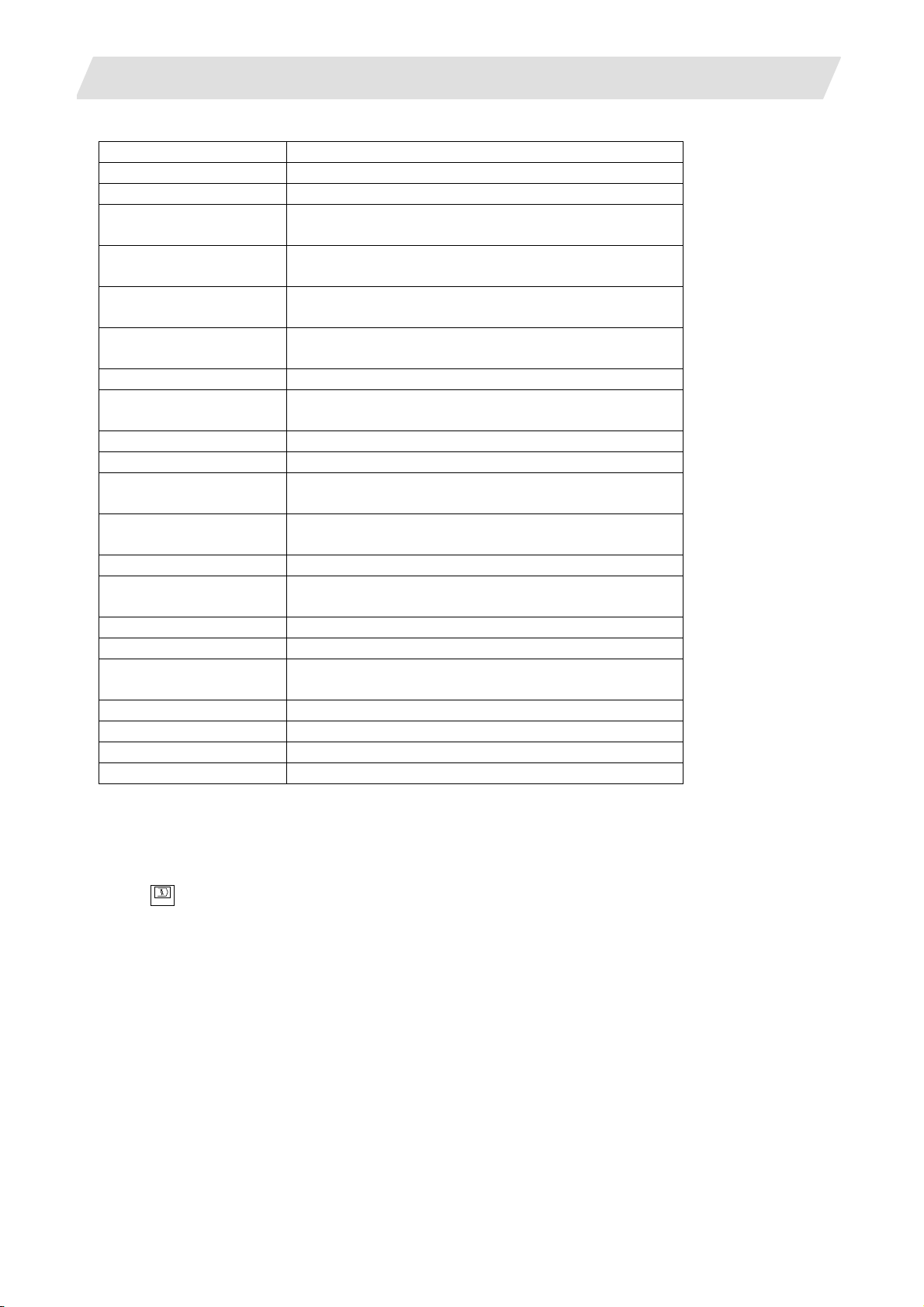

1. OUTLINE

Screen name Details

Title screen This screen is displayed when the power is turned ON.

Program edit screen The process program is read out and saved, etc.

Process list screen Tool information and cutting conditions for each

process of a machining program are listed.

Multiple parts screen A NC program for the multiple parts machining is

generated.

Process mode select

The process mode (hole drilling, etc.) is selected.

screen

Initial conditions setting

The initial conditions for the process program are set.

screen

Hole drilling screen The parameters for the hole drilling process are input.

Hole drilling machining

pattern screen

The parameters related to the machining pattern of the

hole drilling process are input.

Cutting condition screen The cutting conditions by the process are input.

Face cutting screen The parameters for the face cutting process are input.

Contour cutting screen The parameters for the contour cutting process are

input.

Contour cutting pattern

screen

The parameters related to the machining pattern of the

contour cutting process are input.

Pocket screen The parameters of the pocket process are input.

Pocket pattern screen The parameters related to the machining pattern of the

pocket process are input.

EIA screen The EIA process is input.

Tool file screen The tool data by each tool is registered.

Cutting condition file

screen

The cutting conditions (speed rate) by each process are

input.

Parameter screen The tool code and miscellaneous parameter are set.

Preference screen The system is set up.

Version screen The version data of the NAVI MILL is displayed.

Program checker The tool paths of a NC program is graphically traced.

1.4 Starting NAVI MILL

1.3 Screen Configuration

Select

function, then [NAVI] menu to display NAVI MILL screen.

EDIT

Program edit screen is displayed once when the power is turned ON. Then, whatever the screen previously

selected with NAVI MILL is displayed thereafter.

- 4 -

Page 19

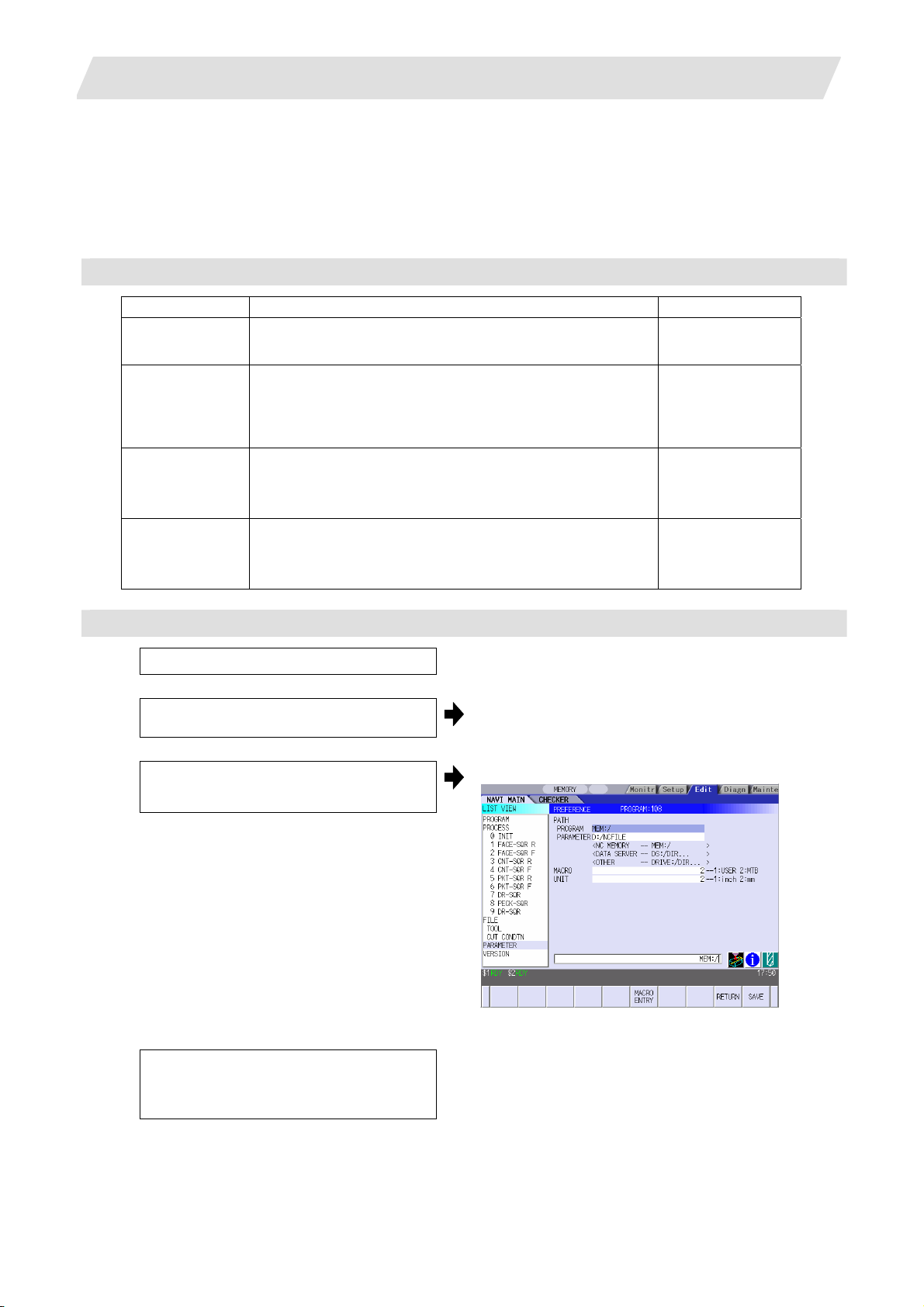

1. OUTLINE

1.5 Setting up NAVI MILL

1.5 Setting up NAVI MILL

Part program output from NAVI MILL is a macro-program-based NC program. Thus, macro programs have to

be registered in the NC system in advance. Also, the destinations where NC programs or NAVI MILL's

reference files are saved, as well as the unit for data input, have to be specified prior to NAVI MILL

operations.

NAVI MILL setup items

Item Details Standard value

PATH

PROGRAM

PATH

PARAMETER

MACRO Macro program mode

UNIT Unit for data input

NAVI MILL setup procedures

(1)

Open PARAMETER screen.

(2) Set "999 MAINTE" to 1. [PREFERENCE] menu is displayed.

(3) Press [PREFERENCE] menu.

Path to the folder in which NC program is saved. MEM:/

Path to the folder in which tool file, cutting condition file

and parameter file are saved.

In 700 Series:

D:/NCFILE/NAVI

In 70 Series:

MEM:/

1 (User Macro)

1: User macro mode

2: MTB macro mode

2 (mm)

1: inch

2: mm

PREFERENCE screen is displayed.

(4) Select the macro type.

(1:Uer macro 2:MTB macro)

- 5 -

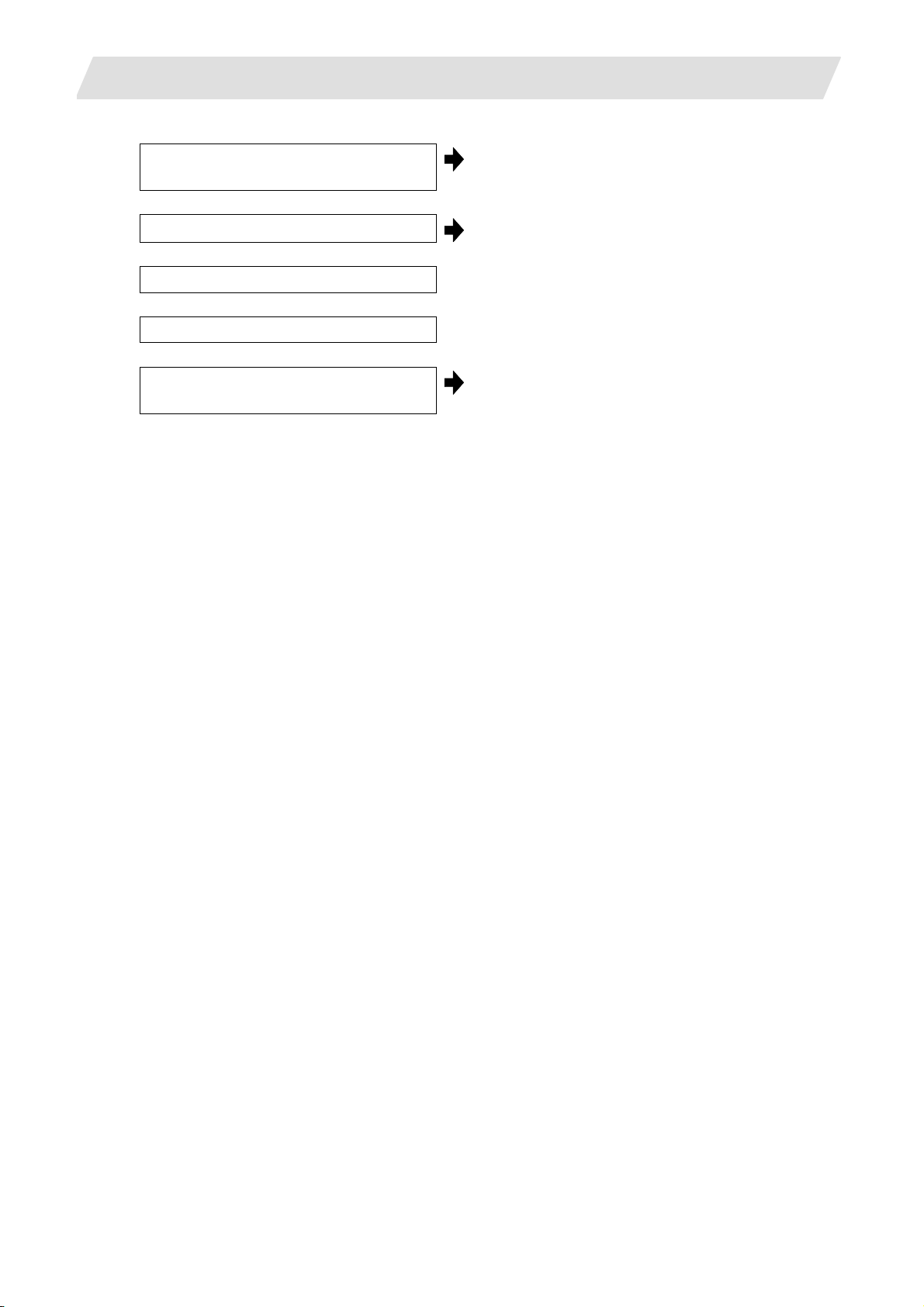

Page 20

1. OUTLINE

1.5 Setting up NAVI MILL

(5)

Press [MACRO ENTRY] menu.

(6)

Press [Y] key.

(7)

Enter the program path.

(8)

Enter the parameter path.

(9)

Select the unit.

(1:inch, 2:mm)

"OK?(Y/N)" message is displayed.

Macro program is registered in NC system.

When the unit is changed, turn the power OFF

and ON again.

(Addendum)

• Always carry out a macro program registration when setting up NAVI MILL or switching "MACRO" types.

• Change "PROGRAM PATH" and "PARAMETER PATH" when necessary.

• When "UNIT" is changed, turn the power OFF and ON again.

• If the tool file, cutting condition file and parameter file do not exist in "PARAMETER PATH" folder when the

power is turned ON, those files are created by the system.

- 6 -

Page 21

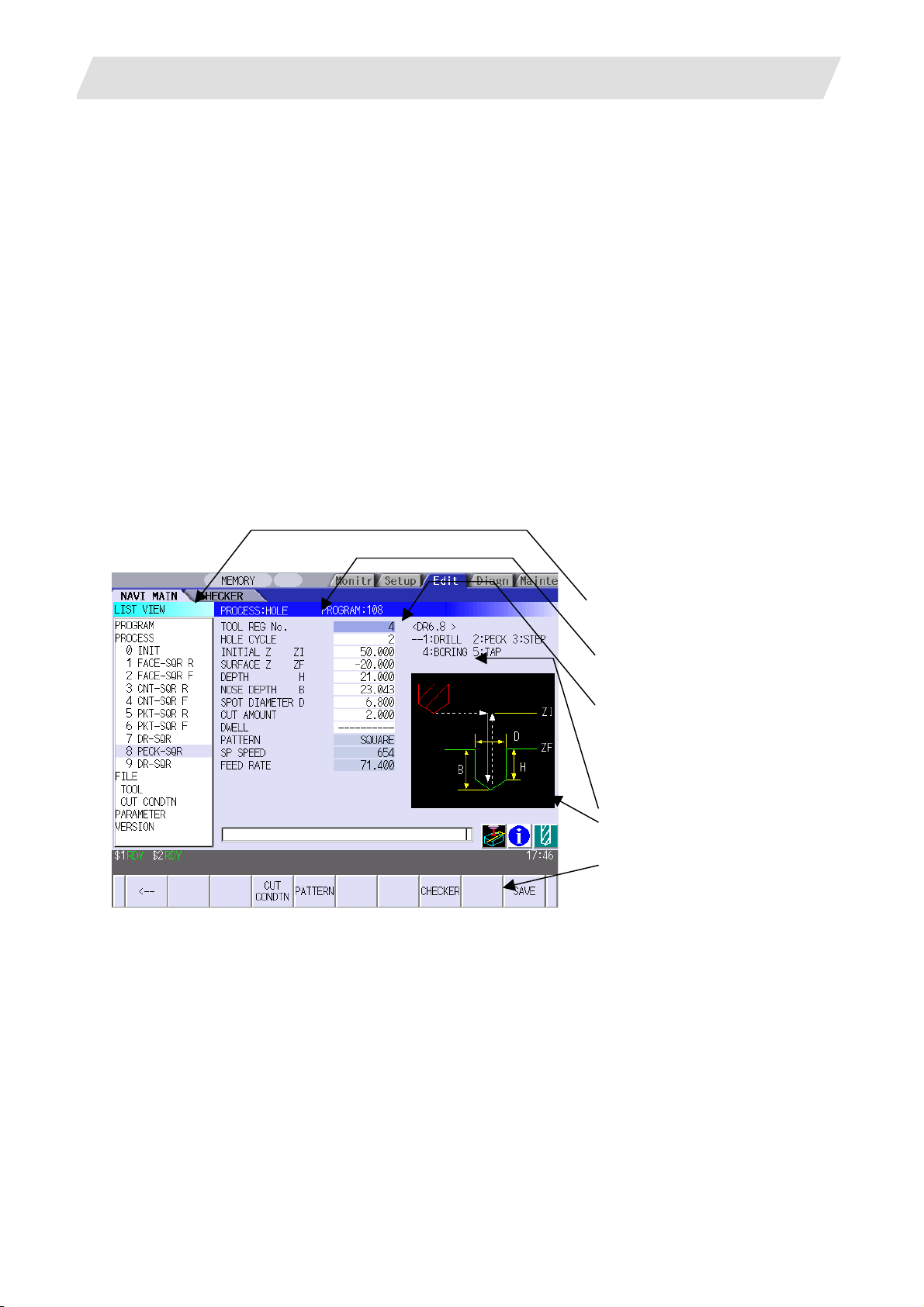

2. FUNCTIONS OF DISPLAY AREA

2. FUNCTIONS OF DISPLAY AREA

The screen of the NAVI MILL is divided into the following five areas.

(1) LIST VIEW area (Refer to "2.1 LIST VIEW Area")

(2) OPERATION VIEW area (Refer to "2.2 OPERATION VIEW Area")

(3) Setting area (Refer to "2.3 Setting Area")

(4) Message area (Refer to "2.4 Message Area")

(5) Menu display area (Refer to "2.5 Menu Display Area")

(1) LIST VIEW area

(2) OPERATION VIEW area

(4) Message area

<Screen example>

(5) Menu display area

(3) Setting area

- 7 -

Page 22

2. FUNCTIONS OF DISPLAY AREA

2.1 LIST VIEW Area

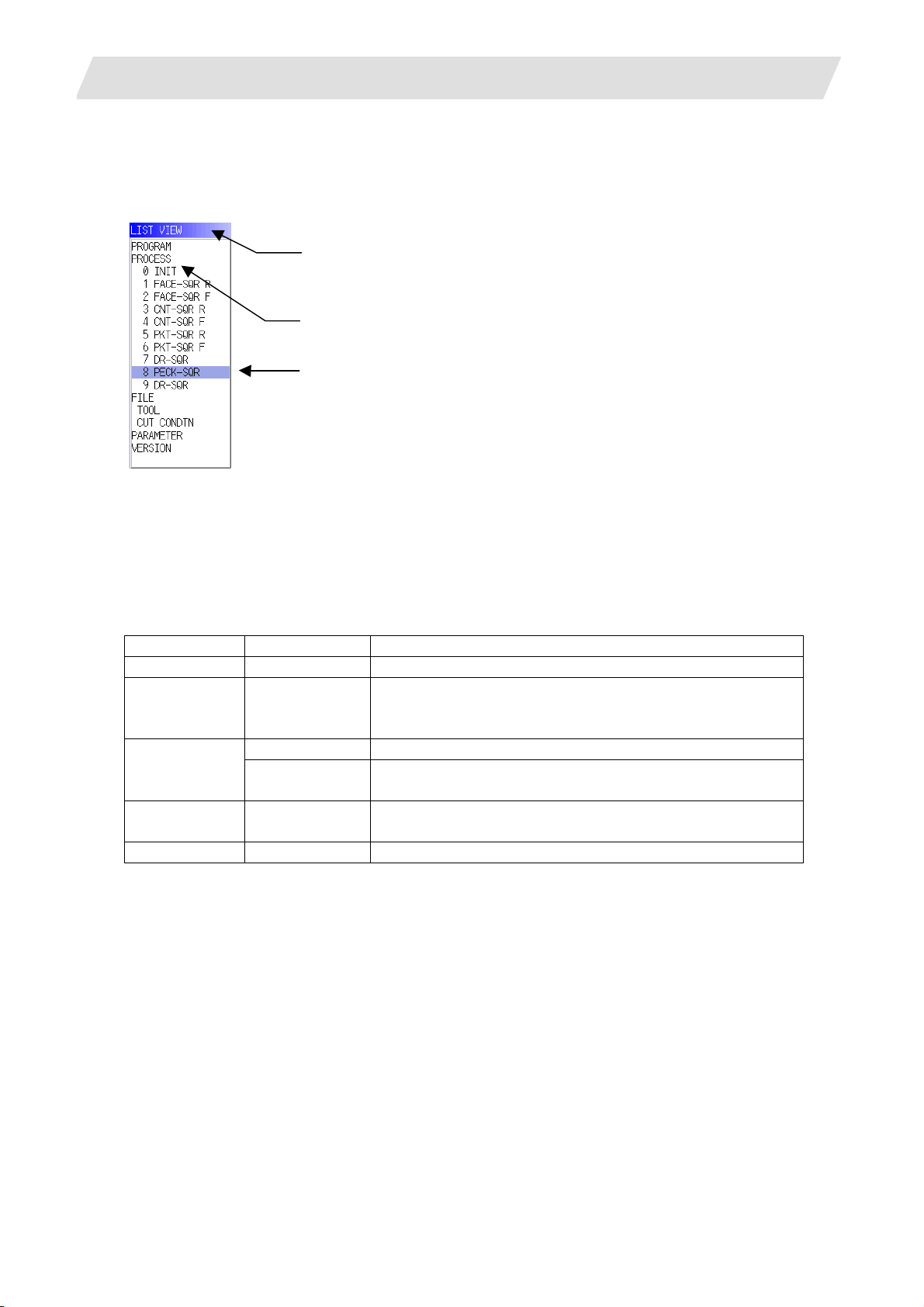

The object of the NAVI MILL is selected in this area.

(1) Area bar

(2) Object

(3) Cursor

2.1 LIST VIEW Area

(1) Area bar

When the LIST VIEW area is active, the area bar is highlighted.

(2) Objects

The list of objects that can be selected are displayed. The object is composed of the main object and the

sub object that the main object is detailed. The details of each object are as follows.

Main object Sub object Details

PROGRAM - Newly creates, reads out, and deletes, etc. the NC program.

PROCESS 0 INIT

1 DR-LINE

:

TOOL Displays and changes the tool file. FILE

CUT CONDTN Displays and changes the cutting conditions for each process

PARAMETER - Displays the tool option and the miscellaneous parameter to

VERSION - Displays the version data of the NAVI MILL.

(Note) If too many processes are registered and all the objects cannot be displayed, a scroll bar will be

displayed. In this case, change display of the list by pressing cursor key or page key down, or by

clicking on the scroll bar.

Displays the currently edited process list.

The settings of the selected process can be displayed and

changed.

per workpiece material.

be used in each process. Those can be changed.

- 8 -

Page 23

2. FUNCTIONS OF DISPLAY AREA

2.1 LIST VIEW Area

(3) Cursors

When the LIST VIEW area is active and the object is selected with the cursor, the display in the

OPERATION VIEW area and the menu display area will be changed.

<Cursor Movement>

The cursor is moved using the cursor keys or a pointing device.

Key type Operation of cursor

[↑] Cursor key Moves the cursor one field up regardless of the main object or sub object.

Note that if the ↑ cursor is pressed when the cursor is at the top, the cursor

does not move.

[↓] Cursor key Moves the cursor one field down regardless of the main object or sub object.

Note that if the ↓ cursor is pressed when the cursor is at the bottom, the cursor

does not move.

[←] Cursor key When the cursor is at the sub object, moves the cursor to the previous main

object.

[→] Cursor key When the cursor is at the sub object, moves the cursor to the next main object.

[Page Up] key Moves the displayed data toward the top.

[Page Down]

key

Pointing device Cursor jumps to the spot where clicked with a pointing device. If an object not

Moves the displayed data toward the bottom.

selectable is clicked, cursor does not jump.

- 9 -

Page 24

2. FUNCTIONS OF DISPLAY AREA

2.2 OPERATION VIEW Area

2.2 OPERATION VIEW Area

The various data are displayed in this area. Selecting the object in the LIST VIEW area changes the contents

displayed in the OPERATION VIEW area.

(1) Area bar

(2) Help

(3) Guide drawing

(4) Sub cursor

(1) Area bar

When the OPERATION VIEW area is active, the area bar is highlighted.

The name of the currently edited program is displayed.

(2) Help

Quick reference on the setting items is displayed.

(3) Guide drawing

When the process is edited, a guide drawing according to the currently edited machining mode is

displayed.

(4) Sub cursor

Key type Operation of cursor

[↑] Cursor key Moves the cursor one field up.

Note that if the ↑ cursor is pressed when the cursor is at the top, the cursor

does not move.

[↓] Cursor key Moves the cursor one field down.

Note that if the ↓ cursor is pressed when the cursor is at the bottom, the cursor

does not move.

[Page Up] key Moves the displayed data toward the top.

[Page Down]

key

Moves the displayed data toward the bottom.

- 10 -

Page 25

2. FUNCTIONS OF DISPLAY AREA

2.3 Setting Area

The value to be set to data is input.

2.4 Message Area

An error message or operation message, etc. during operation is displayed.

2.5 Menu Display Area

The screen operation is selected, and the screen is changed.

The different menus are displayed in each screen. (Refer to the chapter 4.)

2.3 Setting Area

- 11 -

Page 26

3. BASIC OPERATIONS

3.1 Changing Active View

3. BASIC OPERATIONS

3.1 Changing Active View

To operate NAVI MILL, activate either LIST VIEW area or OPERATION VIEW area. When the VIEW is active,

the area bar is highlighted and data can be input. Use menu keys [←] and [→] or a pointing device to change

one of the VIEWs to be activated.

3.2 Changing Screen

When the object is selected in the LIST VIEW area, the screen (contents in the OPERATION VIEW area)

changes. (Refer to the section 2.1 LIST VIEW Area.)

Note that the screen cannot be changed while the OPERATION VIEW area is active.

In such a case, press the [←] menu key or click "LIST VIEW" with a pointing device to turn the LIST VIEW

area active.

Operation example

(1) Open the program edit screen.

The OPERATION VIEW area is active.

(2)

Press the [←] menu key.

The LIST VIEW area will turn active.

- 12 -

Page 27

3. BASIC OPERATIONS

(3) Select the object with the cursor key.

3.2 Changing Screen

The OPERATION VIEW area will change

into the screen corresponding to the

selected object.

(4) Press the [MODIFY] menu key.

The OPERATION VIEW area will turn

active.

- 13 -

Page 28

3. BASIC OPERATIONS

3.3 Setting Data

3.3 Setting Data

After moving the sub cursor, input the data into the setting area and then press the [INPUT] key, and the data

will be set. (The sub cursor is displayed only when the OPERATION VIEW area is active.)

Sub-cursor

Setting area

- 14 -

Page 29

3. BASIC OPERATIONS

Operation method

An example for setting the data on the hole drilling screen is shown below.

(1) Screen selection

Select the object to be changed from the

LIST VIEW and press [MODIFY] menu

key.

(2) Setting item selection

Move the sub cursor with cursor keys.

The OPERATION VIEW area will turn

active.

(Refer to the section 3.2 "Changing

screen".)

This is an example of the sub cursor

movement on the hole drilling screen.

3.3 Setting Data

(3) Data key input

Set data with the numeral keys or

alphabet keys, etc.

[1] [2] [3] [.] [4] [5] [6]

(4) [Input] key input

Press the [input] key.

The data is set in the data setting area.

18.000

Data for the selected setting item is set.

The sub cursor moves to the next position.

(Note 1) The contents in the data setting area are only displayed when [INPUT] key is not pressed and will

be invalidated if the screen is changed at this time. Data for the currently selected setting item

will be set when [INPUT] key is pressed.

(Note 2) If illegal data is set, an error occurs when [Input] is pressed. Set the correct data again.

- 15 -

Page 30

3. BASIC OPERATIONS

3.3 Setting Data

Operations in the data setting area

The key is input at the position where the cursor is displayed. If a cursor is not displayed, the key input is

invalid.

When a key is input, the data appears at the cursor position, and the cursor moves one character sp ace to

the right.

[→] / [←] keys: Moves the cursor one character to the left or right.

(1)

The cursor is at the position shown on

the right.

(2)

Press the [→] key.

[DETETE] key: Deletes the character in front of the cursor.

(1)

Move the cursor to the position where

the data is to be deleted.

(2)

Press the [DETETE] key.

1 2 3 7 7 7 | 4 5 6

The cursor moves one character space to

the right.

1 2 3 7 7 7 4 | 5 6

The cursor moves in the data setting area.

1 2 3 4 | 5 6

The character in front of the cursor is

deleted.

1 2 3 | 5 6

- 16 -

Page 31

3. BASIC OPERATIONS

3.4 Switching Windows

When a shortcut button on the keyboard is pressed, its corresponding window is displayed.

Button Application

LIST

?

Displays the tool guidance window.

Displays the message guidance window.

Displays the checker window.

3.5 Switching Selection Tags

3.4 Switching Windows

Menu tag

When a tag button on the keyboard is pressed, the main window and checker window can be switched over.

Button Application

Selects the tag on the left.

Selects the tag on the right.

(Note 1) Depending on the keyboard specifications, tag button may not be available.

- 17 -

Page 32

3. BASIC OPERATIONS

3.6 Inputting Operations

3.6 Inputting Operations

In addition to the method of directly inputting numeric data for specific data settings, a method to input the

operation results using four rules operators and function symbols can be used.

Input method

Numeric values, function symbols, operators and parentheses ( ) are combined and set in the data

setting area.

The operation results appear when the [INPUT] key is pressed. Da ta for the currently selected sett ing item

will be set when [INPUT] key is pressed again.

The contents in the data setting area are erased.

Examples of operator settings,

Operation

Addition =100+50 150.000

Subtraction

Multiplication

Division =100/3 33.333 Cosine COS =COS (15) 0.966

Function

Circle ratio PAI =PAI*10 31.415

Inch INCH =INCH/10 2.54

Operation examples

(1)

(2)

and results

Setting

example

=100−50

=12.3∗4

=1.2∗

(2.5+SQRT(4))

Operation

results

50.000 Square root SQRT =SQRT (3) 1.732

49.200 Sine SIN =SIN (30) 0.5

5.4

Tangent TAN =TAN (45) 1

Arc tangent ATAN =ATAN (1.3) 52.431

Set as shown below, and press the

[Input] key.

=12∗20 [Input]

Press the [Input] key again.

Function symbols, setting examples

and results

Function

Absolute

value

Function

symbol

ABS

Setting

example

=ABS (50−60)

The operation results appear in the data

setting area.

240 |

Data for the selected setting item is set.

The cursor moves to the next position.

Operation

results

10

Notes for using operators and functions

Division : Zero division causes an error.

Square root : If the value in the parentheses is negative, an error occurs.

Triangle function : The unit of angle θ is degree (°).

Arc tangent : −90 < operation results < 90.

Restrictions

• Always use "=" for the first character.

• Do not use the following characters as the second character or last character.

Invalid as second character: ∗, /, )

Invalid as last character: ∗, /, (, +, -

• Make sure that the left parentheses and right parentheses are balanced.

• The 360° limit does not apply on the angle. SIN (500) is interpreted as SIN (140).

- 18 -

Page 33

4. SCREEN SPECIFICATIONS

4. SCREEN SPECIFICATIONS

4.1 Starting NAVI MILL

When NAVI MILL is started, the program edit screen will be displayed.

Screen layout

4.1 Starting NAVI MILL

At the initial start up of NAVI MILL, the cursor is displayed at the position of [PROGRAM] in the LIST VIEW

area, and the program edit screen is displayed in the OPERATION VIEW area.

The LIST VIEW area is active.

The process program is not selected.

- 19 -

Page 34

4. SCREEN SPECIFICATIONS

4.2 Screen Related to the Program

4.2 Screen Related to the Program

4.2.1 Program Edit Screen

The NC program is newly created and read out, etc. on this screen. When [PROGRAM] is selected in the

LIST VIEW area, this screen is displayed.

Screen layout

The process list of the currently selected program is displayed in the LIST VIEW area.

- 20 -

Page 35

4. SCREEN SPECIFICATIONS

< Process displays >

Process name

Hole drilling Drilling DR-****

Pecking PECK-****

Step STEP-****

Boring BORE-****

Tapping (TAP-****)

Helical boring HLX-BORE ? The symbol which indicates the machining

Face cutting Square FACE-SQR ?

Circle FACE-CIR ?

Contour

cutting

Pocket Square PKT-SQR ?

Circle PKT-CIR ?

L pattern PKT-LPT ?

U pattern PKT-UPT ?

Track PKT-TRK ?

EIA EIA (EIA)

Square CNT-SQR ?

Circle CNT-CIR ?

Free CNT-FREE ?

Display

character

4.2 Screen Related to the Program

Remarks

The symbol (abbrev.) which indicates the

machining pattern is applied to the "****" part.

● Random : RNDM

● Linear : LINE

● Arc : ARC

● Circle : CIR

● Square : SQR

● Grid : GRID

type (rough / finishing) is applied to the "?"

part.

● Rough : R

● Finishing : F

The symbol which indicates the machining

type (rough / finishing) is applied to the "?"

part.

● Rough : R

● Finishing : F

Screen display item

No. Display item Details Setting range

1 PROGRAM LIST Displays the program number and comment of the

-

NC program that can be currently read out.

- 21 -

Page 36

4. SCREEN SPECIFICATIONS

r

Menus

No. Menu Details

1 ← Turns the LIST VIEW area active.

2 NEW Newly create s the NC program. (Note 1)

3 OPEN Reads out the existing NC program. (Note 1) (Note 2)

4.2 Screen Related to the Program

< Display in the setting area when pressing the menu >

O( ) COMMENT( )

< Display in the setting area when pressing the menu >

O( )

When this menu is pressed, the cursor appears at the program list's

name section. When the setting area is empty, select a program with

the cursor and press the [INPUT] key to read the program.

Curso

4 COPY Copies the existing NC program to another program. (Note 1)

< Display in the setting area when pressing the menu >

O( ) → O( )

5 COMMENT Edits the comment in the NC program. (Note 1)

< Display in the setting area when pressing the menu >

O( ) COMMENT( )

6 RENAME Renames the existing NC program. (Note 1)

< Display in the setting area when pressing the menu >

O( ) → O( )

7 DELETE Deletes the NC program.

< Display in the setting area when pressing the menu >

O( ) to O( )

8 LIST UPDATE Updates the list display.

(Note 1) 1 to 7999 or 10000 to 99999999 can be set for the O No, and up to 18 alphanumeric characters

can be set for the comment.

(Note 2) NC program mode includes user macro mode and MTB mode. (This i s sp ecified in the

preferences screen.) When user macro mode is active and an NC program created with MTB

mode is opened, the NC program is converted into user macro mode. When MTB mode is active

and an NC program created with user macro mode is opened, the NC program is converted into

MTB mode.

- 22 -

Page 37

4. SCREEN SPECIFICATIONS

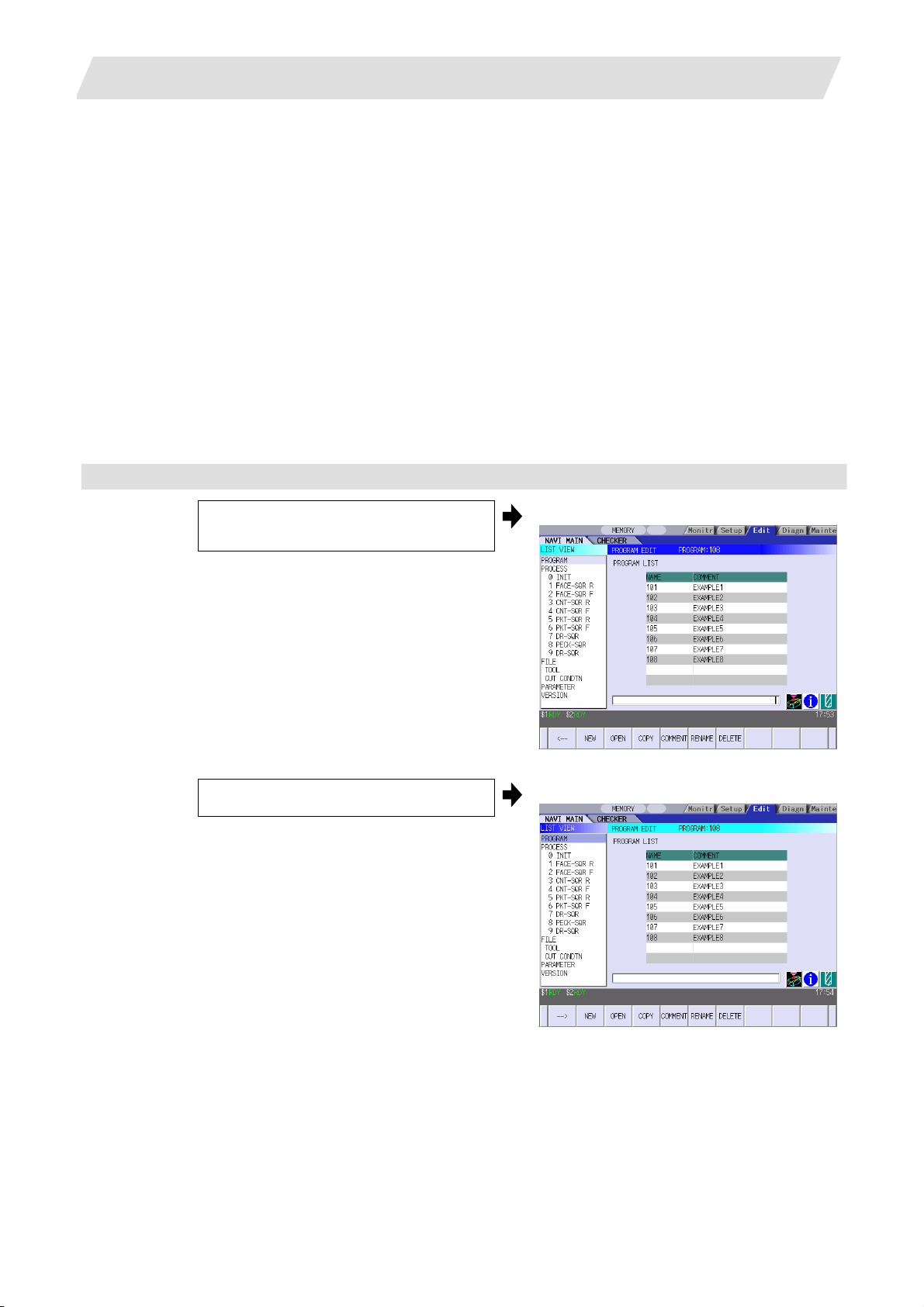

Operation example (Opening the existing NC program)

Select the [PROGRAM] in the LIST

(1)

VIEW area.

Press the [OPEN] menu key, and input

(2)

the NC program No. to be read out.

4.2 Screen Related to the Program

The program edit screen will be displayed.

The list of the NC program that can be read

out will be displayed.

The [OPEN] menu will be highlighted, and

the setting area will be displayed.

Press the [INPUT] key.

(3)

The highlight of the [OPEN] menu will turn

OFF, and the setting area will disappear.

The process of the NC program read out

will be displayed in the LIST VIEW area.

The NC program No. read out will be

displayed on the area bar of the

OPERATION VIEW area.

- 23 -

Page 38

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

4.3 Screens Related to the Process Edit Functions

4.3.1 Process List Screen

The tool information and cutting conditions for each process are displayed on this screen. When [PROCESS]

is selected in the LIST VIEW area, this screen is displayed.

When the NC program is not selected, this screen is not displayed.

Screen layout

- 24 -

Page 39

4. SCREEN SPECIFICATIONS

Screen display items

No. Display item Details Setting range

1 PCS The process name is displayed.

2 T NAME The name of tool to be used is displayed. 3 T Specify the No. of tool to be used. 0 to 9999

4 NT Specify the No. of tool to be used in the next

5 H

6 D

7 S Input the spindle rotation speed. 1 to 99999 rev/min

8 F

Menus

No. Menu Details

1 ← Turns the LIST VIEW area active.

2 NEXT T PRESET Sets the next tool No. automatically. For the next tool No., the tool No.

3 MULTI PT

4 SAVE Saves changes in the process list.

4.3 Screens Related to the Process Edit Functions

-

(Note) This name is same as the name displayed

in the LIST VIEW area.

0 to 9999

process. According to the specified tool No., the

tool is determined after the tool change.

(Note) When "1" is set in the parameter "103

NEXT TOOL PREP", this data is valid.

Specify the tool length offset No.

The maximum value for the H is changed

1 to number of tool

sets

according to the specifications.

Specify tool diameter offset No.

The maximum value for the D is changed

1 to number of tool

sets

according to the specifications.

Input the feedrate.

When the hole cycle type is "TAP", input the pitch

(mm/rev).

0.001 to

60000.000 mm/min

0.001 to

999.999 mm/rev

of the next process is set.

Multiple Parts screen is displayed.

When using the Multiple Parts function, press “MULTI PT”.

- 25 -

Page 40

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

4.3.2 Multiple Parts Screen

Multiple Parts function enables you to generate a NC program that allows one designated machining process

to be completed at once for multiple workpieces. This NC program can be generated based on the NC

programs generated for a single part machining with the appropriate arrangement of the multiple workpieces.

When working on multiple workpieces, there are two options available to specify their positions:

• by identifying the values of the work-coordinate system per each workpiece.

• by determining each offset amount from one specific work coordi nate.

As for machining pattern, there are two options available:

• to have one machining process completed for all workpieces on the table before moving on to the next

machining process (the number of times to execute tool-changes can be reduced by choosin g this option).

• to have entire machining processes completed per each workpi ece.

(Note 1) The NC program generated with the Multiple Parts function is differed from its original NC program.

(Note 2) The NC program generated with the Multiple Parts function cannot be edited with NAVI MILL. If

editing is attempted, the operation message “No init process, Create OK? (Y/N)” appears.

<Drawing>

200

90 90

160

70

35

35

50

30

0

1

R

8

9-M8 P=1.25 Depth8

Prepared hole Φ6.8 Depth12

Program for multiple parts

70

50

6-Φ6.8 Hole Depth17

35

90

50

35

4-Φ6.8 Penetration

10

15

20

<NAVI MILL base function>

50

130

50

5

Program for single part

<Layout of workpieces>

Program generater

for multi ple parts

- 26 -

Page 41

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

To view the “Multiple Parts Screen”, go to the “Process List Screen” and press [MULTI PT] menu.

Screen Layout

- 27 -

Page 42

4. SCREEN SPECIFICATIONS

Screen Details

No. Display item Details Setting range

PROGRAM O Program No. and comments are input.

1

NUM OF PARTS Number of parts is input. 2 to 8

2

MACHINING Machining pattern is selected.

3

4.3 Screens Related to the Process Edit Functions

Avoid using the same program No. for the Multiple

Parts NC program and the currently editing program. If

a duplicated program No. is used for both programs, an

error message occurs.

1: A pattern that has one machining process

completed for all workpieces before moving on

to the next machining process

-

1 to 2

2: A pattern that has entire machining processes

completed per one workpiece before moving

on to the next workpiece

- 28 -

Page 43

4. SCREEN SPECIFICATIONS

No. Display item Details Setting range

COORDINATE The method to specify the position of multiple

4

4.3 Screens Related to the Process Edit Functions

workpieces is selected.

1: A method that identifies the values of the

work-coordinate system per each workpiece

2: A method that determines each offset amount

from

one specific work coordinate

1 to 2

5

X

Y

The value of each workpiece position is input

depending on the offset amount from one specific work

coordinate.

This is valid when selecting "2" in the COORDINATE

screen.

WC The value of the work-coordinate system per each

workpiece is input.

This is valid when selecting "1" in the COORDINATE

screen.

(Note) Program No. can be selected from 1 to 7999 or 10000 to 99999999.

Comment section allows up to 18 characters/numbers.

Menu

No. Menu Details

1 GEN PRGM Generate a NC program for the Multiple Parts machining.

2 RETURN Return to the Process List Screen.

-99999.999 to

99999.999mm

54 to 59

P1 to P48

- 29 -

Page 44

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

4.3.3 Operating Process

When the cursor is moved to the sub-object of PROCESS in the LIST VIEW area, a menu for editing the

process is displayed, and the process can be operated.

Screen layout

Menus

No. Menu Details

1 MODIFY The OPERATION VIEW area turns active, and the process parameters

can be changed.

2 NEW Adds a new process.

The process will be inserted into the cursor position.

3 MOVE Changes the process position.

4 DELETE Deletes the process at the cursor position.

When performing the deletion, the process under the deleted process

will be moved up.

5 COPY Copies the process at the cursor position.

The copied process will be inserted under the cursor position.

- 30 -

Page 45

4. SCREEN SPECIFICATIONS

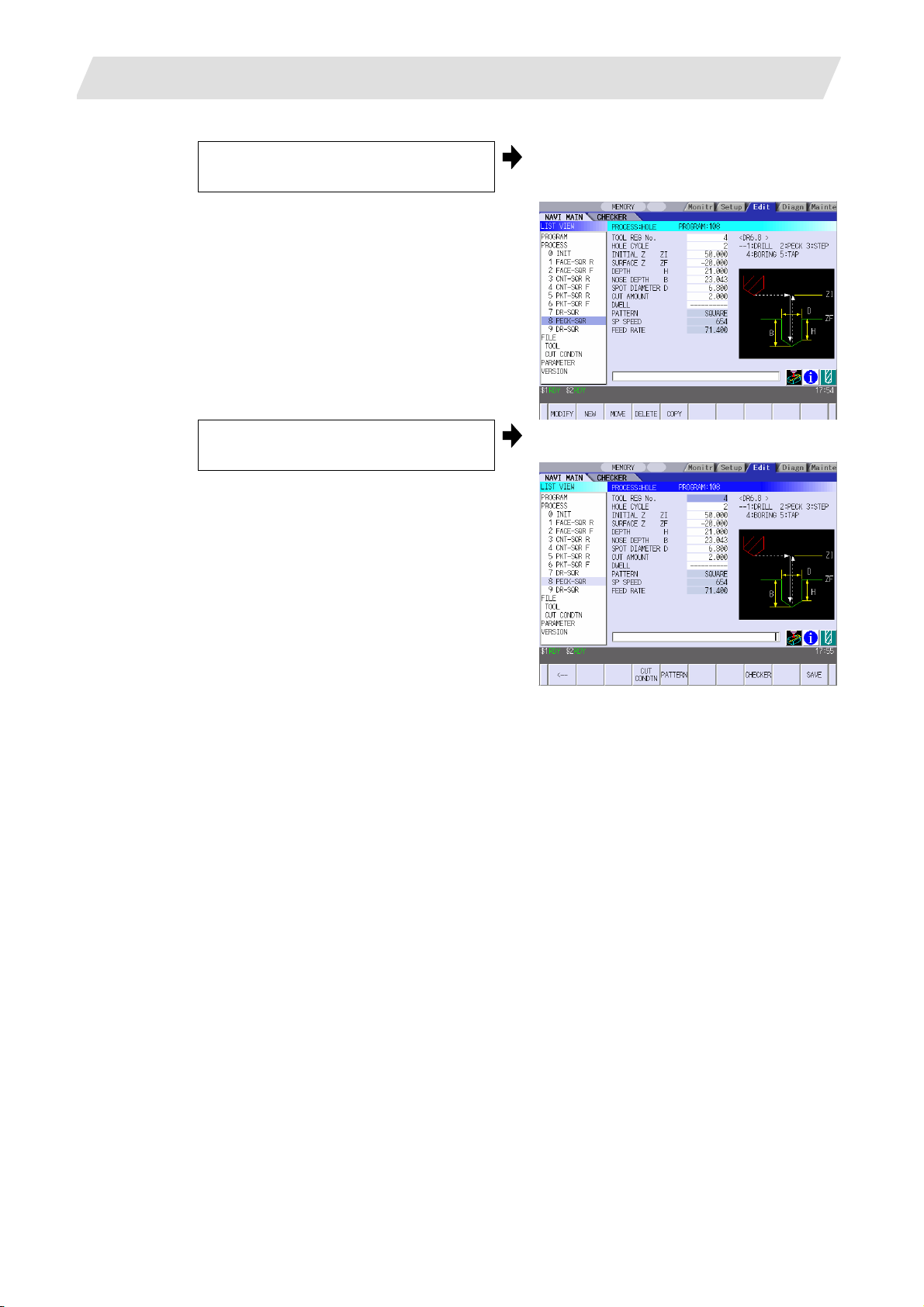

Operation example (Selecting the process)

Validate the LIST VIEW area and select

(1)

the process with the cursor key.

4.3 Screens Related to the Process Edit Functions

The contents of the OPERATION VIEW

area will change to those of the selected

process.

Press the [MODIFY] menu key. (2)

The OPERATION VIEW area will turn

active.

- 31 -

Page 46

4. SCREEN SPECIFICATIONS

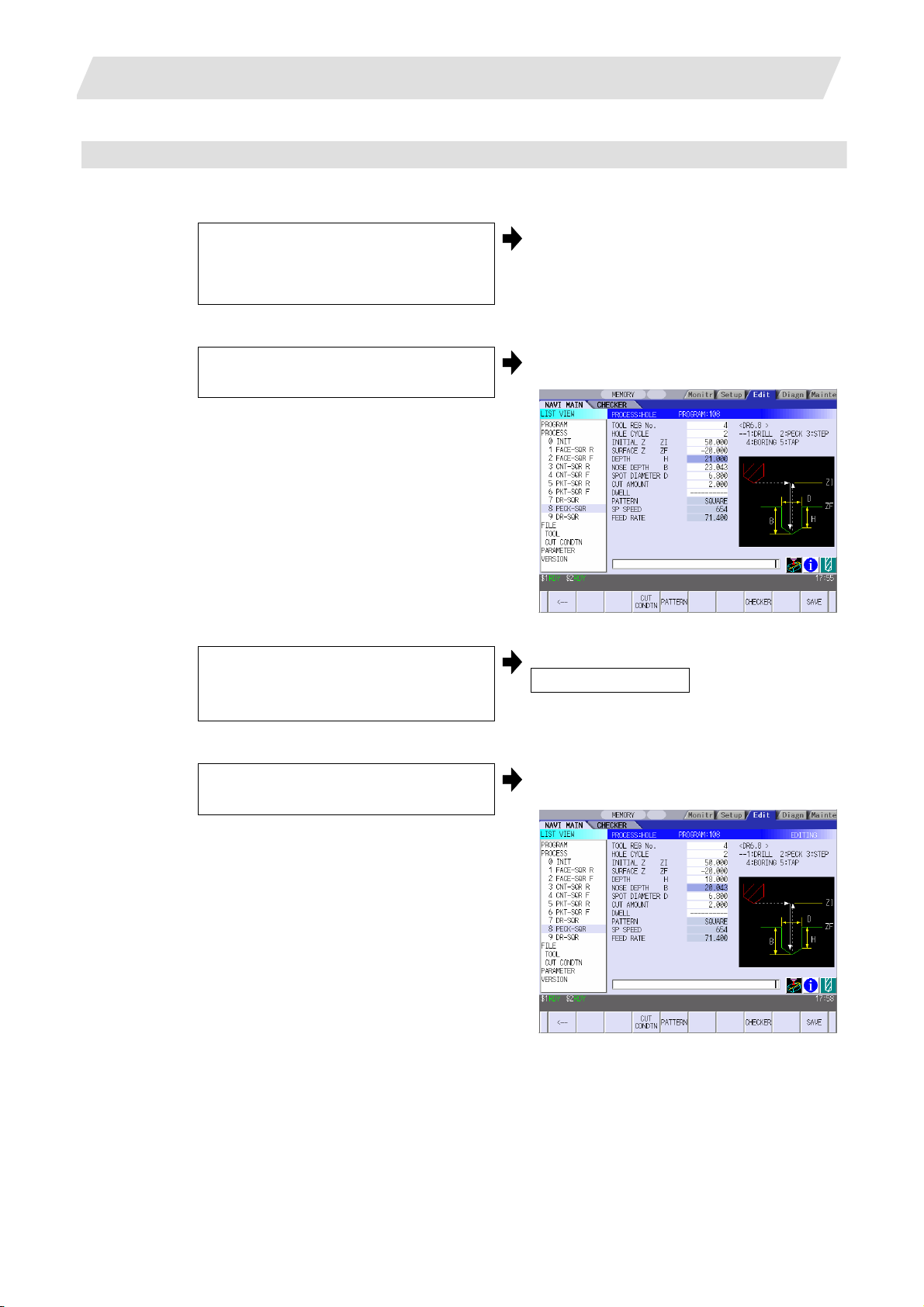

Operation example (Deleting the process)

Validate the LIST VIEW area, select the

(1)

process to be deleted with the cursor

key.

4.3 Screens Related to the Process Edit Functions

The contents of the OPERATION VIEW

area will change to those of the selected

process.

Press the [DELETE] menu key. (2)

Press the [Y] key. (3)

When not deleting the process, press the

[N] key

The [DELETE] menu will be highlighted,

and a massage confirming the deletion will

appear.

The highlight of the [DELETE] menu will

turn OFF, and the process at the cursor

position will be deleted.

The process under the deleted process will

be moved up one.

The contents in the OPERATION VIEW

area will change to those of the process at

the cursor position.

- 32 -

Page 47

4. SCREEN SPECIFICATIONS

Operation example (Copying the process)

Validate the LIST VIEW area, select the

(1)

process of the copy source with the

cursor key.

4.3 Screens Related to the Process Edit Functions

The contents of the OPERATION VIEW

area will change to those of the selected

process.

Press the [COPY] menu key. (2)

The copied process will be inserted under

the cursor position.

- 33 -

Page 48

4. SCREEN SPECIFICATIONS

Operation example (Moving the process)

Validate the LIST VIEW area, select the

(1)

process to be moved with the cursor key.

4.3 Screens Related to the Process Edit Functions

The contents of the OPERATION VIEW

area will change to those of the selected

process.

Press the [MOVE] menu key. (2)

Select the position of the movement

(3)

destination with the cursor key.

The [MOVE] menu will be highlighted.

The mark "M" will be displayed beside the

process to be moved.

- 34 -

Page 49

4. SCREEN SPECIFICATIONS

Press the [INPUT] key.

(4)

If the [MOVE] menu key is pressed again

during the movement operation, the

movement operation will be canceled.

4.3 Screens Related to the Process Edit Functions

The message to confirm a movement is

displayed.

Press the [Y] key. (5)

When not moving the process, press the

[N] key.

(Note) For the [NEW] menu, refer to the next section.

The process of the movement source will

be moved to the cursor position.

The highlight of the [MOVE] menu will turn

OFF.

- 35 -

Page 50

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

4.3.4 Process Mode Selection Screen

When a new process is added, the process mode is selected on this screen.

Screen layout

Screen display item

No. Display item Details Setting range

1 Process mode Displays the process mode that can be selected.

Menu

No. Menu Details

1 ← Cancels adding a new process.

1 to 5

Select the process mode by moving the sub-cursor

or inputting numerical values.

The LIST VIEW area will turn active after cancel.

- 36 -

Page 51

4. SCREEN SPECIFICATIONS

Operation example(Adding a new process)

Validate the LIST VIEW area, and select

(1)

the position where the process is added

with the cursor key.

4.3 Screens Related to the Process Edit Functions

Press the [NEW] menu key. (2)

Select the process mode with the cursor

(3)

or the numerical value input.

A blank process will be inserted into the

cursor position.

The process mode selection screen will be

displayed in the OPERATION VIEW area,

and the OPERATION VIEW area will turn

active.

- 37 -

Page 52

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

Press the [INPUT] key.

(4)

(Note) If the [←] menu key is pressed during adding the process, the screen will return to the state before

pressing the [NEW] menu key (state of the 1).

The contents in the OPERATION VIEW

area will change into those of the selected

process mode.

The selected process mode will be

displayed at the cursor position in the LIST

VIEW area.

- 38 -

Page 53

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

4.3.5 Initial Condition Setting

(1) Initial Condition Setting Screen

The initial conditions for the program are set on this screen. When the [INIT] is selected in the LIST VIEW

area, this screen is displayed.

Screen layout

Screen display items

No. Display item Details Setting range

WORK REG No. Input the registration No. of the workpiece

1

INITIAL POS Z Input the initial position Z.

2

material to be cut. Specify it with the No.

registered in the cutting condition file.

(The list of material names set on the cutting

condition file screen will be displayed. Input the

corresponding No. based on the list.)

In the workpiece coordinate system, input the Z

axis position where the workpiece or jig does not

interfere with the tool even if the table is moved.

1 to 8

-99999.999 to

99999.999mm

(Continued to the next page)

- 39 -

Page 54

4. SCREEN SPECIFICATIONS

(Continued from the previous page)

No. Display item Details Setting range

WORK

3

COORDINATE

4 ATC PATTERN X

ATC PATTERN Y

5 ATC POSITION X

ATC POSITION Y

6 END TOOL No. At the program end, input the tool No. that you

7 END PATTERN X

END PATTERN Y

8 END POSITION X

END POSITION Y

9 END M CODE At the program end, select the M command to be

4.3 Screens Related to the Process Edit Functions

Specify the workpiece coordinate system to be

used.

54 : G54

:

59 : G59

P1 : G54.1 P1

:

P48 : G54.1 P48

Select the table position at the tool change (ATC)

with the following No.’s.

1 : No specification (The table is not moved.)

2 : 1st zero point

3 : 2nd zero point

4 : Specified position (The table is moved to the

specified ATC position.)

In the machine coordinate system, input the table

position at the tool change.

This is valid when "4" is set in the "ACT

PATTERN".

want to call.

If 0 is input, the tool used at the machining end

will be stopped with that attached to the spindle.

If the tool No. is input, the tool will be changed at

the machining end and then stopped.

Select the table position at the program end with

the following No.'s.

1 : No specification (The table is not moved.)

2 : 1st zero point

3 : 2nd zero point

4 : Specified position

(The table is moved to the specified end

position.)

In the machine coordinate system, input the table

position at the program end.

This is valid when "4" is set in the "END

PATTERN".

output.

1 : M30

2 : M02

3 : M99

54 to 59

P1 to P48

1 to 4

-99999.999 to

99999.999mm

0 to 9999

1 to 4

-99999.999 to

99999.999mm

1 to 3

- 40 -

Page 55

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

Menus

No. Menu Details

1 ← Turns the LIST VIEW area active.

2 WORK SHAPE Workpiece Size Setting screen is displayed.

3 SAVE Saves the changes in the initial conditions.

(2) Workpiece Size Setting Screen

The size of workpiece is set on this screen. Parameters on this screen are used to display the size of the

workpiece and the tool paths during Program Checker.

Screen layout

Screen display items

No. Display item Details Setting range

1 WORK SHAPE Input the shape of workpiece.

1 : SQUARE 2 : CIRCLE

(Note) Display items No.2 and later differ according to each shape of workpiece.

1, 2

- 41 -

Page 56

4. SCREEN SPECIFICATIONS

• Parameters for SQUARE

No. Display item Details Setting range

2 +X Input +X position based on the work coordinate

3 -X Input –X position based on the work coordinate

4 +Y Input +Y position based on the work coordinate

5 -Y Input –Y position based on the work coordinate

6 +Z Input +Z position based on the work coordinate

7 -Z Input –Z position based on the work coordinate

• Parameters for CIRCLE

zero point.

zero point.

zero point.

zero point.

zero point.

zero point.

4.3 Screens Related to the Process Edit Functions

-99999.999 to

99999.999mm

-99999.999 to

99999.999mm

-99999.999 to

99999.999mm

-99999.999 to

99999.999mm

-99999.999 to

99999.999mm

-99999.999 to

99999.999mm

Menu

No. Display item Details Setting range

2 CENTER X Input the center of the circle. (X) -99999.999 to

99999.999mm

3 CENTER Y Input the center of the circle. (Y) -99999.999 to

99999.999mm

4 RADIUS R Input the radius of the circle. 0.001 to

99999.999mm

5 +Z Input –Y position based on the work coordinate

zero point.

6 -Z Input +Z position based on the work coordinate

zero point.

-99999.999 to

99999.999mm

-99999.999 to

99999.999mm

No. Menu Details

1 RETURN Returns to the initial condition setting screen.

- 42 -

Page 57

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

4.3.6 Hole Drilling

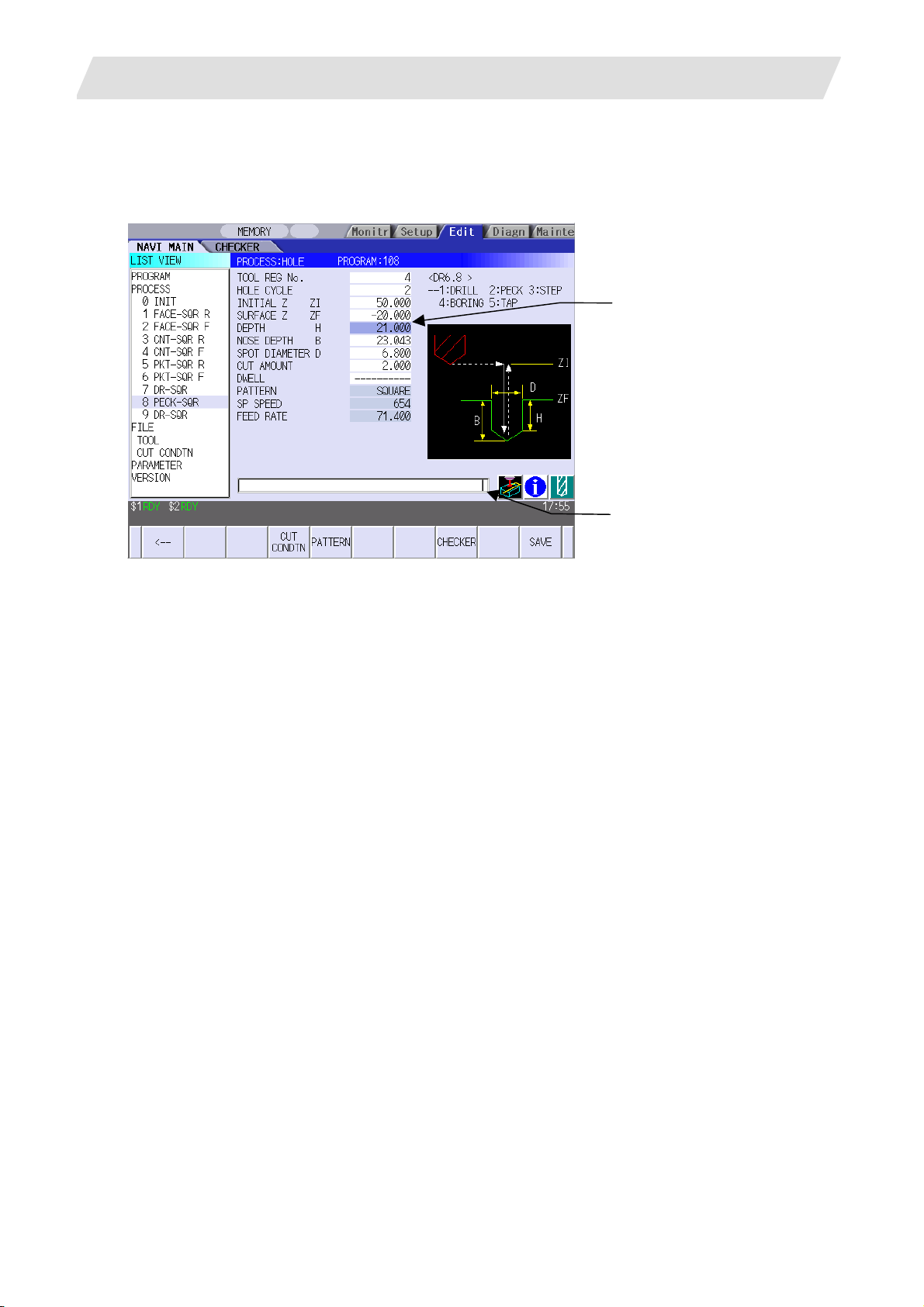

(1) Hole Drilling Screen

The parameters for the hole drilling process are input on this screen.

Screen layout

- 43 -

Page 58

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

Screen display items

No. Display item Details Setting range

1 TOOL REG No. Input the tool registration No. to be used.

Specify it with the No. registered in the tool file.

2 HOLE CYCLE Input the type of the hole machining cycle.

<1: DRILL> (G81, G82)

The machining is performed as far as the hole

bottom at a stretch, and the tool is lifted up after

the hole bottom dwell has been executed.

<2: PECK> (G83)

The machining is performed as far as the middle

of the hole, and the tool is returned to the higher

position than the hole top each time. The

machining is performed as far as the hole bottom

with such operation repeatedly executed.

<3: STEP> (G73)

The machining is performed as far as the middle

of the hole, and the tool is returned each time by

the G73 return amount. The machining is

performed as far as the hole bottom with such

operations repeatedly executed.

<4: BORE> (G85, G89)

The machining is performed as far as the hole

bottom at a stretch, and the tool is lifted up with

the cutting feedrate after the hole bottom dwell

has been executed.

<5: TAP> (G84,G74)

The tap machining is performed as far as the hole

bottom, and the tool is lifted up with the reversed

rotation after the hole bottom dwell has been

executed.

<6: HELIX>

The machining is performed with helical

interpolation as far as the hole bottom, and then

the tool is lifted up.

(Note) Display items No.3 and later differ according to each type of hole machini ng cycle.

1 to 99

1 to 5

- 44 -

Page 59

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

• When HOLE CYCLE is set from the types between 1 to 5 (DRILL, PECK, STEP, BORE or TAP)

INITIAL Z (ZI) Input the initial position.

3

The tool is returned to the initial position after the

machining has been finished.

SURFACE Z (ZF) Input the workpiece top surface. -99999.999 to

4

DEPTH (H) Input the hole depth from the workpiece top surface

5

with an addition input method.

When the hole depth is changed, tool nose depth

will be automatically updated.

If the calculated NOSE DEPTH is 0 or below, the

data range over will occur.

NOSE DEPTH (B) Input the tool nose depth from the workpiece top

6

surface with an addition input method.

When the tool nose depth is changed, the hole

depth will be automatically updated.

SPOT DIAMETER

7

(D)

Input the tool radius of the workpiece face.

When the tool radius of the workpiece face is input,

DEPTH and NOSE DEPTH will be automatically

updated.

CUT AMOUNT When the hole cycle type C=2 (PECK) or C=3

8

(STEP) is selected, input the cutting amount for one

time. If a value other than 0.000 is input when

selecting the hole cycle type C=5 (TAP), the

pecking tap process will be applied.

9 DWELL When the hole cycle type C=1 (Drilling), C=3 (Step),

C=4 (Boring), C=5 (Tap) is selected, input the dwell.

10 PATTERN

The machining pattern is displayed.

RANDOM LINE

ARC CIRCLE

SQUARE GRID

Perform changing the machining pattern on the

machining pattern screen.

11 SP SPEED The spindle rotation speed is displayed.

Perform changing the spindle rotation speed on the

cutting condition screen.

12 FEED RATE The feedrate is displayed.

When the hole cycle type is "TAP", the pitch is

displayed.

Perform changing the feedrate on the cutting

condition screen.

-99999.999 to

99999.999mm

99999.999mm

-99999.999 to

99999.999mm

0.001 to

99999.999mm

0.001 to

Tool diameter

0.000 to

99999.999mm

0.000 to

99999.999sec

1 to

99999rev/min

0.001 to

60000.000

mm/min

0.001 to

999.999 mm/rev

-

- 45 -

Page 60

4. SCREEN SPECIFICATIONS

A

4.3 Screens Related to the Process Edit Functions

• When HOLE CYCLE is set to 6 (HELIX)

No. Display item Details Setting range

PROCESS

3

Input the machining type.

<1: ROUGH >

The rough machining is performed and the finishing

allowance remains.

<2: FIN>

The finishing machining is performed to the

machining surface.

Helical interpolation

llowance

XY

Approach

Finishing

allowance XY

1,2

INITIAL Z

4

SURFACE Z

5

POS X

6

POS Y

7

HOLE

8

DIAMETER

DEPTH

9

ALLOWANCE

10

XY

FIN ALLOW XY

11

Depth

Hole diameter

Side surface

finishing machining

Escape

Input the initial position.

After machining, the tool returns to the initial position.

-99999.999mm to

99999.999mm

Input the workpiece top surface position. -99999.99 9mm to

99999.999mm

Input the hole position (X). -99999.999mm to

99999.999mm

Input the hole position (Y). -99999.999mm to

99999.999mm

Input the hole diameter. 0.001mm to

99999.999mm

Input the hole depth from the workpiece top surface

with an addition input method.

Input the allowance of the side surface.

This data is valid for the rough machining only.

Input the finishing allowance of the side surface.

The rough machining leaves the finishing allowance in

0.001mm to

99999.999mm

0.001mm to

99999.999mm

0.000mm to

99999.999mm

respect to the side surface.

This data is valid for the rough machining only.

- 46 -

Page 61

4. SCREEN SPECIFICATIONS

A

g

4.3 Screens Related to the Process Edit Functions

No. Display item Details Setting range

CUT AMOUNT

12

Z

Input the cutting amount in Z-direction.

The remainder, if left after "DEPTH + CLEARANCE Z

/ CUT AMOUNT" has been applied, will be the last

cutting amount.

Clearance Z

Start XY

Cutting amount Z

Surface Z

0.001mm to

99999.999mm

Menus

0.001mm to

99999.999mm

CUT AMOUNT

13

XY

Remainder

Cutting amount XY

Finishing allowance XY

Hole depth

Input the cutting amount in XY-direction.

This data is valid for the rough machining only.

Finishin

llowance XY

First machining

allowance XY

Cutting amount XY

Last machining

Hole position X,Y

Remainder

Hole diameter

14

CUT TYPE

Input the cutting type (up-cutting, down-cutting).

1,2

1: DOWN

2: UP

When the HOLE CYCLE is set to 6 (HELIX), the

cutting type is set to 1 (DOWN) as a default value.

15

SP SPEED

The spindle rotation speed is displayed.

1 to 99999 (r/min)

The spindle rotation speed is changed on the setting

screen for cutting conditions.

FEED RATE F

16

The feedrate is displayed. The feedrate is changed on

the setting screen for cutting conditions.

0.001 to 60000.000 mm/min

0.01 to 999.99 mm/rev

No. Menu Details

1

Turns the LIST VIEW area active.

←

2 CUT CONDTN Displays the setting screen for the cutting conditions.

3 PATTERN Displays the selection screen for the machining pattern.

This menu is not displayed when HOLE CYCLE is set to 6 (HELIX).

4 CHECKER Displays the checker screen. Selects this to check the set data.

5 SAVE Saves the changes in the process.

If an illegal parameter exists when saving, an error message will appear. If

the input parameter is illegal, the cursor moves to the illegal parameter

position. If the input parameters for the pattern input screen or cutting

condition screen are illegal, the screen name and error message will be

displayed.

- 47 -

Page 62

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

(2) Hole Drilling Machining Pattern Screen

The parameters for the hole drilling machining pattern are input on t his screen. When the [PATTERN] menu is

pressed on the hole drilling screen, this screen is displayed. This screen is not available when HOLE CYCLE

is set to 6 (HELIX).

Screen layout

Screen display items

No. Display item Details Setting range

1 PATTERN Input the type of the hole machining pattern.

<1: RANDOM>

The machining points are randomly arranged.

<2: LINE>

The machining points are equally spaced on a line.

<3: ARC>

The machining points are equally spaced on an

arc.

<4: CIRCLE>

The machining points are equally spaced on a

circle.

<5: SQUARE>

The machining points are squarely arranged.

<6: GRID>

The machining points are arranged in grid.

(Note) Display items No.2 and later differ according to each pattern.

1 to 6

- 48 -

Page 63

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

• Parameters for RANDOM

No. Displayed item Details Setting range

2 RETURN POINT Specify the return point when the hole drilling is

3 No. Input the hole No. 1 to 50

4 POS X

POS Y

• Parameters for LINE

completed.

1: Initial point level return (G98)

2: R point level return (G99)

Input the hole position. -99999.999mm to

1,2

99999.999mm

No. Display item Details Setting range

2 ANGLE (A) Input the angle formed with the machining direction

and the positive direction of the X-axis.

3 PITCH (K) Input the space from the machining point to the next

machining point.

4 NUM OF HOLES Input the number of holes. 2 to 999

5 BASE POS X Input the 1st hole position (X). -99999.999 to

6 BASE POS Y Input the 1st hole position (Y). -99999.999 to

7 RETURN POINT Specify the return point that is applied after the hole

machining.

1: Initial point level return (G98)

2: R point level return (G99)

-359.999 to

360.000°

0.000 to

99999.999mm

99999.999mm

99999.999mm

1, 2

- 49 -

Page 64

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

• Parameters for ARC

No. Display item Details Setting range

2 RADIUS (R) Input the arc radius. 0.001 to

99999.999mm

3 START ANGLE

(A)

4 PITCH (K) Input the angle from the previous machining point to

5 NUM OF HOLES Input the number of holes. 2 to 999

6 BASE POS X Input the arc center position (X). -99999.999 to

7 BASE POS Y Input the arc center position (Y). -99999.999 to

8 RETURN POINT Specify the return point that is applied after the hole

• Parameters for CIRCLE

Input the angle formed with the first machining point

and the X-axis direction.

the next machining point.

machining.

1: Initial point level return (G98)

2: R point level return (G99)

-359.999 to

360.000°

-359.999 to

360.000°

99999.999mm

99999.999mm

1, 2

No. Display item Details Setting range

2 DIAMETER (D) Input the circular diameter. 0.001 to

99999.999mm

3 START ANGLE

(A)

4 NUM OF HOLES Input the number of holes. 1 to 999

5 BASE POS X Input the circular center position (X). -99999.999 to

6 BASE POS Y Input the circular center position (Y). -99999.999 to

7 RETURN POINT Specify the return point that is applied after the hole

Input the angle formed with the first machining point

and the positive direction of the X-axis.

machining.

1: Initial point level return (G98)

2: R point level return (G99)

- 50 -

-359.999 to

360.000°

99999.999mm

99999.999mm

1, 2

Page 65

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

• Parameters for SQUARE

No. Display item Details Setting range

2 X WIDTH (I) Input the width of the machining point in the X-axis

direction.

3 X NUM OF

HOLES

4 Y WIDTH (J) Input the width of the machining point in the Y-axis

5 Y NUM OF

HOLES

6 BASE POS X Input the position (X) of the machining start point. -99999.999 to

7 BASE POS Y Input the position (Y) of the machining start point. -99999.999 to

8 RETURN POINT Specify the return point that is applied after the hole

9 ANGLE (A) Input the workpiece’s inclination angle between the

10 ANGLE (B) Input the interior angle.

11 OMIT 1 to 4 Specify the hole No. to be omitted (deleted).

Input the number of machining points in the X-axis

direction.

direction.

Input the number of machining points in the

Y-direction.

machining.

1: Initial point level return (G98)

2: R point level return (G99)

machining start direction and the X axis.

Default value is 90°.

Maximum hole No. that can be specified is 127.

-99999.999 to

99999.999mm

2 to 999

-99999.999 to

99999.999mm

2 to 999

99999.999mm

99999.999mm

1, 2

-359.999° to

360.000°

0.001° to

179.999°

1 to number of

holes

- 51 -

Page 66

4. SCREEN SPECIFICATIONS

4.3 Screens Related to the Process Edit Functions

• Parameters for GRID

No. Display item Details Setting range

2 X WIDTH (I) Input the width of the machining point in the X-axis

direction.

3 X NUM OF

HOLES (J)

Input the number of machining points in the X-axis

direction.

4 Y WIDTH Input the width of the machining point in the Y-axis

direction.

5 Y NUM OF

HOLES

Input the number of machining points in the

Y-direction.

6 BASE POS X Input the position (X) of the machining start point. -99999.999 to

7 BASE POS Y Input the position (Y) of the machining start point. -99999.999 to

8 RETURN POINT Specify the return point that is applied after the hole

machining.

1: Initial point level return (G98)

2: R point level return (G99)

9 ANGLE (A) Input the workpiece’s inclination angle between the

machining start direction and the X axis.

10 ANGLE (B) Input the interior angle.

Default value is 90°.

11 OMIT 1 to 4 Specify the hole No. to be omitted (deleted).

Maximum hole No. that can be specified is 127.

Menus

No. Menu Details

1 RETURN Returns to the hole drilling screen.

2 LINE INSERT Inserts the hole position in front of the cursor position.

This is available for the RANDOM pattern only.

3 LINE DELETE Deletes the hole position at the cursor position.

This is available for the RANDOM pattern only.