Page 1

Page 2

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or registered trademarks of the respective

companies.

Page 3

Page 4

Introduction

CAUTION

This is a setup manual for MITSUBISHI CNC M700VS Series.

This manual is written on the assumption that with all of the MITSUBISHI CNC M700VS Series functions are added,

but the actually delivered NC may not have all optional functions.

Refer to the specifications issued by machine tool builder to confirm the functions available for your NC before

proceeding to operation.

Notes on Reading This Manual

(1) This manual explains general parameters as viewed from the NC.

For information about each machine tool, refer to manuals issued from the machine tool builder.

If the descriptions relating to "restrictions" and "allowable conditions" conflict between this manual and the

machine tool builder's instruction manual, the later has priority over the former.

(2) This manual is intended to contain as much descriptions as possible even about special operations.

The operations to which no reference is made in this manual should be considered "impossible".

(3) The "special display unit" explained in this manual is the display unit incorporated by the machine tool builder,

and is not the MITSUBISHI standard display unit.

(4) This manual is for the machine tool builders who set up the NC system.

If the descriptions relating to the "restrictions" and "allow a ble conditions" conflict between this manual

and the machine tool builder’s instruction manual, the latter has priority over the former.

The operations to which no reference is made in this manual should be considered "impossible".

This manual is complied on the assum ption that your machine is provided with all optional functions. Refer

to the specifications issued by machine tool builder to confirm the functions available for yo ur NC before

proceeding to operation.

In some NC system versions, there may be cases that different pictures appear on the screen, the machine

operates in a different way or some function is not activated.

Page 5

Page 6

Precautions for Safety

DANGER

WARNING

CAUTION

DANGER

WARNING

Always read the specifications issued by the machine tool builder, this manual, related manuals and attached

documents before installation, operation, programming, maintenance or inspection to ensure correct use.

Understand this numerical controlle r, s af et y ite ms an d cau ti o ns be fo re usi n g th e unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

When the user may be subject to imminent fatalities or major injuries if handling is

mistaken.

When the user may be subject to fatalities or major injuries if handling is mistaken.

When the user may be subject to injuries or when physical damage may occur if handling

is mistaken.

Note that even items ranked as " CAUTION", may lead to major results depending on the situation. In any case,

important information that must always be observed is described.

The following sings indicate prohibition and compulsory.

This sign indicates prohibited behavior (mu st not do ).

For example, indicates "Keep fire away".

This sign indicated a thing that is pompously (must do).

For example, indicates "it must be grounded".

The meaning of each pictorial sing is as follows.

CAUTION

Prohibited

Not applicable in this manual.

CAUTION rotated

Disassembly is

prohibited

object

CAUTION HOT

KEEP FIRE AWAY General instruction

Danger Electric shock

risk

Danger explosive

Earth ground

Do not cancel the emergency stop before confirming the basic operation.

Page 7

1. Items related to product and manual

CAUTION

If the descriptions relating to the "restrictions" and "allowable conditions" conflict between this manual

and the machine tool builder's instruction manual. the latter has priority over the former.

The operations to which no reference is made in this manual should be considered "impossible".

This manual is complied on the assumption that your machine is provided with all optional function s.

Confirm the functions available for your machine before proceeding to operation by referring to the

specification issued by the machine tool builder.

In some NC system versions. there may be cases that different pictures appear on the screen, the machine

operates in a different way on some function is not activated.

2. Items related to faults and abnormalities

If the battery low warning is issued, save the machinin g programs, tool data and parameters in an input/

output device, and then replace the battery. When the battery alarm is issued, the machining programs, tool

data and parameters may have been destroyed. Replace the battery and then reload the data.

3. Items related to setup

Always set the stroke end and stroke limit. Failure to set this could result in collision with the machine end.

Do not adjust the spindle when possible risks associated with adjustment proc edures are not thoroughly

taken into consideration.

Be careful when touching spindle's rotating section, or yo ur hand may be caught in or cut.

The analog output R registers are allocated in ascending order of channels and station numbers

automatically. Therefore, the analog output destination may change depending on the added option.

[Continued to next page]

Page 8

4. Items related to maintenance

Do not replace the battery while the power is ON.

Do not short-circuit, charge, overheat, incinerate or disassemble the battery.

Dispose the spent battery according to the local laws.

Do not connect or disconnect the cables between units while the power is ON.

Do not pull the cables when connecting/disconnecting them.

Do not replace the backlight while the power is ON.

Dispose the spent backlight according to the local laws.

Do not touch the backlight while the power is ON. Failure to observe this could result in electric shocks due

to high voltage.

Do not touch the backlight while the LCD panel is in use. Failure to observe this could result in burns.

Do not apply impact or pressure on the LCD panel or backlight. Failure to obser ve this could result in

breakage as they are made of glass.

Incorrect connections could cause devices to damage. Connect the cables to designated connectors.

Do not replace the control unit while the power is ON.

CAUTION

[Continued]

Do not replace the display unit while the power is ON.

Do not replace the keyboard unit while the power is ON.

Do not replace the operation panel I/O unit while the power is ON.

5. Items related to servo parameters and spindle parameters

Do not adjust or change the parameter settings greatly as operation could become unstable.

In the explanation on bits, set all bits not used, including blank bits, to "0".

Page 9

Page 10

Disposal

(Note) This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/EC Article 20 Information for end-users and

Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and components

which can be recycled and/or reused.

This symbol means that batteries and accumulators, at their end-of-life, should be disposed of separately from your

household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the battery or

accumulator contains a heavy metal at a certain concentration. This will be indicated as follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly at your local community waste collection/recycling centre.

Please, help us to conserve the environment we live in!

Page 11

Page 12

本製品の取扱いについて

( 日本語 /Japanese)

本製品は工業用 ( クラス A) 電磁環境適合機器です。販売者あるいは使用者はこの点に注意し、住商業環境以外で

の使用をお願いいたします。

Handling of our product

(English)

This is a class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

본 제품의 취급에 대해서

( 한국어 /Korean)

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또는 사용자는 이 점을 주의하시기 바라며 가정외의 지역에

서 사용하는 것을 목적으로 합니다 .

Page 13

Page 14

CONTENTS

1 Setup Outline. ... ....................................... ... .... ... ....................................... ... ... .............................................. 1

1.1 Device Configuration..............................................................................................................................................2

1.2 Hardware Configuration.........................................................................................................................................3

1.3 Flow of Initial Setup................................................................................................................................................4

2 Connecting and Setting the Hardware............ ... ... ..................................................................................... 5

2.1 Connecting and Setting the Drive Unit.................................................................................................................6

2.1.1 Connecting with Servo Drive Unit ................................................................................................................6

2.1.1.1 Connecting with MDS-D/DH Series......................................................................................................7

2.1.1.2 Connecting with MDS-DM Series.......................................................................................................10

2.1.1.3 Connecting with MDS-SVJ3/SPJ3 Series..........................................................................................15

2.1.2 Setting up without Connecting to the Motor/ Drive unit...........................................................................15

2.2 Setting the Rotary and DIP Switches.................................... ..............................................................................16

2.2.1 MDS-D/DH Series...................................................... ........................................ ............................................16

2.2.2 MDS-DM Series........................................... ... ....................................... ........................................................18

2.2.3 MDS-D-SVJ3/SPJ3 Series................................... ... ......................................................................................20

2.3 Connecting the Batteries......................................................................................................................................21

2.3.1 Control Unit Battery.....................................................................................................................................21

2.3.2 Servo Drive Unit Battery..............................................................................................................................22

2.4 Connecting and Setting the Remote I/O Unit.....................................................................................................24

2.4.1 Outline of the Remote I/O Unit....................................................................................................................24

2.4.2 Connection and Station No. Setting on Remote I/O Unit..........................................................................26

2.4.3 Station No. Setting when Using Multiple Remote I/O Units......................................................................28

2.4.4 Device No. Assignment ...................................... ... ....................................... ...............................................32

2.5 Initializing the NC Internal Data (SRAM).............................................................................................................34

3 Setting Up with M70/M700 SETUP INSTALLER....................................................................................... 35

3.1 Compatible Data and Folder Configuration in the CF Card..............................................................................37

3.2 Operation Procedure ............................................................................................................................................39

3.2.1 Starting Up M70/M700 SETUP INSTALLER................................................................................................39

3.2.2 Installing Language Data........................................................................... ..................................................39

3.2.3 Installing Custom Data .................................... ... ... ......................................................................................41

3.2.4 Uninstalling Custom Data............................................................................................................................42

3.2.5 Installing Custom Startup Screen..................................................... .. ........................................................ 43

3.2.6 Uninstalling Custom Startup Screen..........................................................................................................44

3.3 List of Error Messages .........................................................................................................................................45

4 Setting the Parameters and Date/Time .................................................................................................... 47

4.1 Selecting the NC System Type ............................................................................................................................48

4.2 Setting on the System Setup Screen..................................................................................................................49

4.3 Setting the Parameters for the Machine Specifications....................................................................................53

4.4 Setting Date and Time..........................................................................................................................................55

5 PLC Program Writing................................................................................................................................. 57

5.1 Setting the Ethernet Communication..................................................................................................................58

5.2 Connecting the Control Unit and a Personal Computer....................................................................................59

5.3 Setting the Communication with GX Developer.................................................................................................60

5.4 Setting the Parameters on GX Developer...........................................................................................................62

5.5 Writing a PLC Program with GX Developer........................................................................................................64

5.6 Writing a PLC Program to ROM with GX Developer..................................... ... ..................................................65

5.7 Setting the PLC Parameters.................................................................................................................................67

6 Confirming the Basic Operation............................................................................................................... 69

6.1 Checking Inputs/Outputs and Alarms.................................................................................................................70

6.2 Confirming Manual Operation..............................................................................................................................71

6.2.1 Using the Manual Pulse Generator.............................................................................................................71

6.2.2 Using JOG Feed ...........................................................................................................................................71

6.2.3 Servo Simplified Adjustment ................................................................. ... ..................................................72

6.2.3.1 First Measure Against Vibration.........................................................................................................72

6.2.3.2 Outline of MS Configurator.................................................................................................................73

Page 15

7 Setting the Position Detection System .................................................................................................... 75

7.1 Adjusting the Absolute Position Detection System..........................................................................................76

7.1.1 Marked Aligment Method I .......................................................................................................................... 77

7.1.2 Marked Point Alignment Method II.............................................................................................................78

7.1.3 Other Setting Method................................................................................................................................... 79

7.1.3.1 Machine End Stopper Method: Automatic Initialization..................................................................79

7.1.3.2 Machine End Stopper Method: Manual Initialization........................................................................ 82

7.1.3.3 Dog-type........................................... ... ....................................... .......................................................... 83

7.1.4 Precautions................................................................................................................................................... 84

7.1.4.1 Precautions common for the initilization operation.........................................................................84

7.1.4.2 Precautions common for the dogless-type absolute position detector......................................... 84

7.2 Adjustment of Reference Position Return in Relative Posi tio n Detectio n S ystem........................................86

7.2.1 Dog-type Reference Position Return ................................................................ ... ...................................... 86

7.2.1.1 Dog-type Reference Position Return Operation ..............................................................................86

7.2.1.2 Dog-type Reference Position Return Adjustment Procedures .......................................................87

8 Setting the Tool Entry Prohibited Range ............................................................................................... 93

8.1 Stroke End (H/W OT) ............................................................................................................................................94

8.2 Stored stroke limit (S/W OT)................................................................................................................................ 95

8.2.1 Outline........................................................................................................................................................... 95

8.2.2 Detailed Explanation....................................................................................................................................97

8.2.2.1 Stored Stroke Limit I...........................................................................................................................98

8.2.2.2 Stored Stroke Limit II..........................................................................................................................99

8.2.2.3 Stored Stroke Limit IB.......................................................................................................................101

8.2.2.4 Stored Stroke Limit IC.......................................................................................................................102

8.2.2.5 Movable Range during Inclined Axis Control.................................................................................103

8.2.2.6 Stored Stroke Limit for Rotation Axis.............................................................................................104

8.2.2.7 Precautions......................................... ... .. ..........................................................................................104

9 Confirming the Spindle Operation.......................................................................................................... 105

9.1 In Manual Operation (with Manual Numerical Command) .............................................................................. 106

9.2 In MDI Operation.................................................................................................................................................107

9.3 Confirming the Rotation Speed......................................................................................................................... 107

10 Setting the Deceleration Check ............................................................................................................ 109

10.1 Function.............................................................................................................................................................110

10.2 Deceleration Check Method.............................................................................................................................111

10.3 Deceleration Check for Opposite Direction Movement Reversal............................................................... ..113

10.4 Parameter .......................................................................................................................................................... 114

10.5 Precautions....................................................................................................................................................... 116

11 Data Backup and Restoration............................................................................................................... 117

11.1 All Backup......................................................................................................................................................... 118

11.2 All Restoration.................................................................................................................................................. 121

12 Hardware Replacement Methods........................................................................ .................................. 123

12.1 Durable Parts ....................................................................................................................................................124

12.1.1 Control Unit Battery.................................................................................................................................124

12.1.2 Display Unit Cooling Fan..................................... ....................................................................................126

12.1.3 Backlight................................................................................................................................................... 127

12.1.4 Fuse........................................................................................................................................................... 129

12.1.4.1 Control Unit Protection Fuse ............................. ... ... ...................................................................... 129

12.1.4.2 Operation Panel I/O Unit Protection Fuse..................................................................................... 129

12.1.5 Front Memory Interface Card............................................................................................ ...................... 130

12.1.6 Touch Panel Protective Sheet.................................................................................................................131

12.1.7 Key Sheet..................................................................................................................................................132

12.2 Control Unit....................................................................................................................................................... 133

12.2.1 Installation on FCU7-DU120-11 (8.4-type)..............................................................................................135

12.2.2 Installation on FCU7-DU140-11/31 (10.4-type)....................................................................................... 136

12.2.3 Installation on FCU7-DU140-31 (10.4-type touch panel)....................................................................... 137

12.2.4 Calibration Setting and Confirmation.................................................................................................... 138

12.3 Display Unit....................................................................................................................................................... 141

12.4 Keyboard Unit................................................................................................................................................... 142

12.5 Operation Panel I/O Unit .................................................................................................................................. 143

12.6 CompactFlash (CF) Card..................................................................................................................................144

Page 16

12.7 USB Memory......................................................................................................................................................145

13 Cables .......................................... .... ... ... ....................................... ... ... .... ................................................ 147

13.1 Precautions when Connecting/Disconnecting Cables..................................................................................148

13.2 Precautions for Using Optical Communication Cable...................................................................................151

13.2.1 Optical Communication Cable Outline and Parts..................................................................................151

13.2.2 Precautions for Handling Optical Communication Cable.....................................................................151

13.2.3 Precautions for Laying Optical Communication Cable........................................................................152

Appendix 1 Explanation of Parameters .................................................................................................... 153

Appendix 1.1 User Parameters................................................................................................................................154

Appendix 1.2 Base Specifications Parameters ......................................................................................................220

Appendix 1.3 Axis Specifications Parameters.......................................................................................................289

Appendix 1.4 Servo Parameters..............................................................................................................................319

Appendix 1.5 Spindle Parameters...........................................................................................................................352

Appendix 1.6 Rotary Axis Configuration Parameters............................................................................................408

Appendix 1.7 Machine Error Compensation Parameters......................................................................................415

Appendix 1.8 PLC Constants...................................................................................................................................417

Appendix 1.9 Macro List...........................................................................................................................................420

Appendix 1.10 Position Switches............................................................................................................................430

Appendix 1.11 Open Parameters.............................................................................................................................444

Appendix 1.12 Device Open Parameters ................................................................................................................445

Appendix 1.13 SRAM Open Parameters .................................................................................................................446

Appendix 1.14 CC-Link Parameters ........................................................................................................................447

Appendix 1.15 Anshin-net Parameters 2/ MTB-net Parameters 2 ................................... .....................................459

Appendix 1.16 PLC Axis Indexing Parameters.......................................................................................................472

Appendix 1.17 Screen Transition Chart..................................................................................................................483

Appendix 1.18 Unit....................................................................................................................................................484

Appendix 1.19 Inputting the Machine Parameters.................................................................................................484

Appendix 1.20 Machine Error Compensation (Function Details) .......................................................................485

Appendix 1.20.1 Outline.............................................................................................. ........................................485

Appendix 1.20.2 Setting Compensation Data......................................................... .. ........................... .............488

Appendix 1.20.3 Example in Using a Linear Axis as Base Axis......................................................................489

Appendix 1.20.4 Example in Using a Rotary Axis as Base Axis.....................................................................493

Appendix 1.21 Position Switch (Function Details) ................................................................................................494

Appendix 1.21.1 Outline.............................................................................................. ........................................494

Appendix 1.21.2 Setting and Operation Examples of dog1 and dog2............................................................494

Appendix 1.21.3 Canceling the Position Switch...............................................................................................496

Appendix 1.22 Bit Selection Parameters #6449 to #6496......................................................................................497

Appendix 2 Explanation of Alarms............................................................................................................ 499

Appendix 2.1 Operation Errors (M)..........................................................................................................................500

Appendix 2.2 Stop Codes (T)...................................................................................................................................516

Appendix 2.3 Servo/Spindle Alarms (S)..................................................................................................................522

Appendix 2.3.1 Servo Errors (S01/S03/S04)........................................... ...........................................................522

Appendix 2.3.2 Initial Parameter Errors (S02) ..................................................................................................536

Appendix 2.3.3 Parameter Erro rs ( S 51).............................................................................................................538

Appendix 2.3.4 Servo Warnings (S52)...............................................................................................................539

Appendix 2.4 MCP Alarms (Y)..................................................................................................................................542

Appendix 2.5 System Alarms (Z).............................................................................................................................553

Appendix 2.6 Absolute Position Detection System Alarms (Z7*).........................................................................561

Appendix 2.7 Distance-coded Reference Scale Errors (Z8*) ................................................................................565

Appendix 2.8 Emergency Stop Alarms (EMG)........................................................................................................566

Appendix 2.9 Computer Link Errors (L)..................................................................................................................569

Appendix 2.10 User PLC Alarms (U) .......................................................................................................................570

Appendix 2.11 Network Service Errors (N).............................................................................................................573

Appendix 2.12 Program Errors (P) ..........................................................................................................................575

Appendix 2.13 Troubleshooting..............................................................................................................................606

Appendix 2.13.1 Troubleshooting for NC.................................... .. ... .................................................................606

Appendix 2.13.2 Troubleshooting for drive system.........................................................................................607

Appendix 2.13.2.1 Troubleshooting at power ON.......................................................................................607

Appendix 2.13.2.2 Troubleshooti ng for e ac h al a rm No..............................................................................608

Appendix 2.13.2.3 Troubleshooti ng for e ac h wa rni ng No. ........................................................................635

Appendix 2.13.2.4 Parameter numbers during initial parameter error .....................................................638

Appendix 2.13.2.5 Troubleshooting the spindle system when there is no alarm or warning................639

Page 17

Page 18

1

1

Setup Outline

Page 19

1 Setup Outline

MITSUBISHI CNC

1.1 Device Configuration

Display unit

Control unit

Remote I/O

unit

Manual pulse

Synchronous feed

encoder

generator

Keyboard unit

Operation panel

I/O unit

Servo/Spindle drive units

MDS-D/DH Series

MDS-D-SVJ3/SPJ3 Series

MDS-DM Series

Remote I/O

unit

Manual pulse

generator

Motors

2

Page 20

M700VS Series Setup Manual

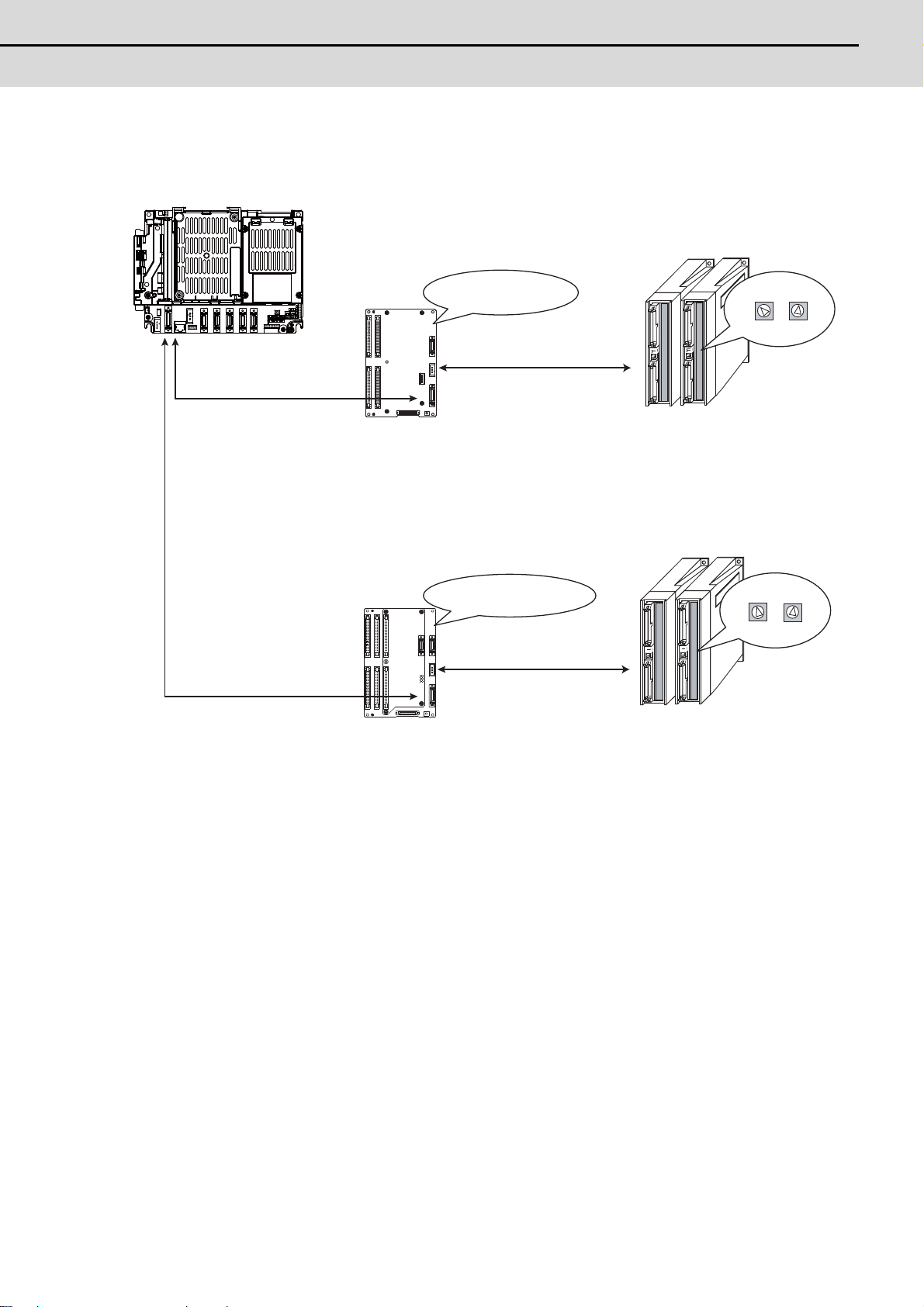

1.2 Hardware Configuration

1.2 Hardware Configuration

(A)

(B)

(C)

The following shows the hardware names used in this manual.

(A) (B) (C) (D)

(A) Cancel key

(B) Menu changeover key

(C) CF card interface on front of display unit

(D) INPUT key

(A) Rotary switch 1

(B) Rotary switch 2

(C) 7-segment LED

3

Page 21

1 Setup Outline

MITSUBISHI CNC

1.3 Flow of Initial Setup

WARNING

The following flow chart shows the procedures of the initial setup.

(Note) When setting up with backup files, refer to the section of "Data Backup and Restoration".

Do not cancel the emergency stop before confirming the basic operation.

Start

Confirming the connection between

control unit and peripheral devices

Points

Is the power supply within a specified range?

Is the power supply polarity correct?

Is the connection of the motor power cable and the detector cable correct?

Is the grounding correct?

Connecting and setting the hardware

Carry out the connecting and setting of drive units, batteries and remote I/O units.

Initialize the NC Internal data (SRAM).

Refer to section 2

Setting Up with

M70/M700 SETUP INSTALLER

Carry out this procedure when installing language data other than Japanese and

English, as well as custom screens.

(Note) If you do not need the installation, go to the next procedure.

Setting Parameters and Date/Time

Set the parameters on the system setup screen and the parameter screen.

Set the date and time on the integrated time screen.

PLC Program Writing

Write the created PLC program to NC's ROM using GX Developer.

Confirming the Basic Operation

Confirm the input/output of signals, the alarm display and the manual operation.

Setting the Position Detection System

Carry out the setting for establishing the reference position (zero point).

Setting the stored stroke limit

Set the tool entry prohibited range.

Confirming the Spindle Operation

Confirm that the spindle operates properly in manual/MDI operation.

Confirm the spindle rotation speed as well.

Inputting the machining program

Refer to section 3

Refer to section 4

Refer to section 5

Refer to section 6

Refer to section 7

Refer to section 8

Refer to section 9

Refer to Instruction Manual

For other settings, refer to the following sections:

- Setting the Deceleration Check

- Data Backup and Restoration

4

End

Page 22

5

2

Connecting and Setting the Hardware

Page 23

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.1 Connecting and Setting the Drive Unit

2.1.1 Connecting with Servo Drive Unit

Connect the optical communication cables from the NC to the each drive unit so that they run in a straight line from the

NC to the drive unit that is a final axis. Up to 16 axes can be connected per system. Note that the number of connected

axes is limited by the NC.

(Note) Refer to "Precautions for Using Optical Communication Cable" when handling and wiring optical

communication cable.

Cable application table

Cable

G396

G395

G380

(Note) Wiring of over 30m can be applied when relaying the optical signal by optical communication repeate r

unit. Refer to the specification manual of the drive unit for the details of the optical communication

repeater unit.

Panel internal wiring Panel external wiring

Under 10m 10 to 30m 10m or less 10 to 30m

○× × ×

○× ○ ×

○○ ○ ○

6

Page 24

M700VS Series Setup Manual

2.1 Connecting and Setting the Drive Unit

2.1.1.1 Connecting with MDS-D/DH Series

CAUTION

POINT

Connected

to the NC

MDS-D/DH-V2

1st/2nd axis

MDS-D/DH-V1

3rd axis

MDS-D/DH-SP

6th axis

(Final axis)

MDS-D/DH-CVMDS-D-SP2

4th/5th axis

Connect the NC and the drive units by the optical communication cables. The distance

between the NC and the final drive unit must be within 30m and the bending radius within

80mm.

Axis Nos. are determined by the rotary switch for setting the axis No. (Refer to the MDS-D/DH

Series Instruction Manual.) The axis No. has no relation to the order for connecting to the NC.

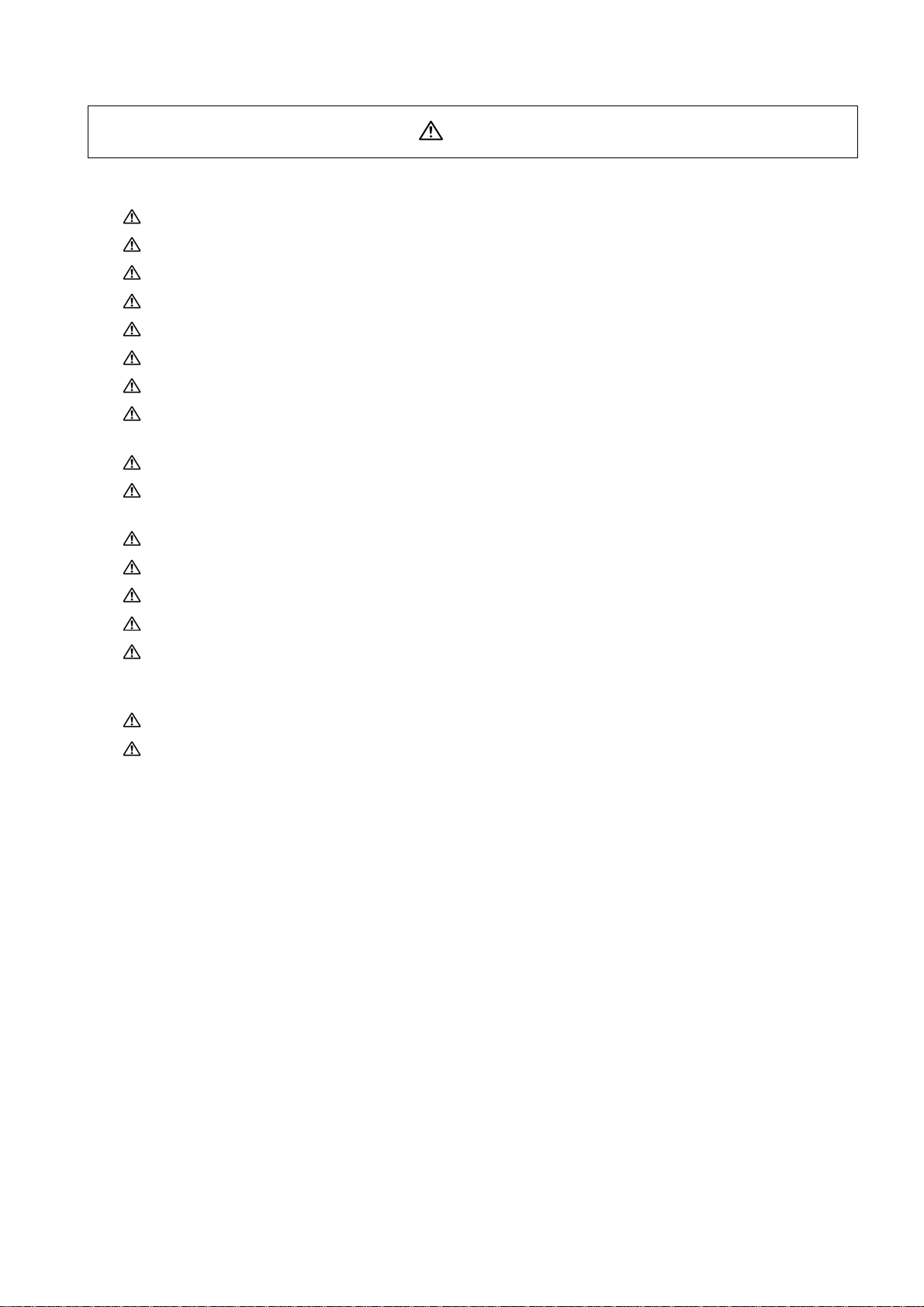

(1) When using one power supply unit

Connect the largest-capacity spindle drive unit to the final axis of the NC communication bus in order to control the

power supply unit. The spindle drive unit must be installed adjacent to the power supply unit. In the system with

servo only, a servo drive unit for controlling unbalance axis must be installed in the same manner in the same way.

<Connection>

CN1A: CN1B connector on NC or previous stage's drive unit

CN1B: CN1A connector on next stage's drive unit

CN4: Connector for communication between power supply unit (master side) and drive unit

Optical

communication

cable

CN4

CN4

The optical communication cables from the NC to the

final drive unit must be within 30m.

Connection when using one power supply unit

7

Page 25

2 Connecting and Setting the Hardware

MITSUBISHI CNC

(2) When using two or more power supply units within a single NC communication bus system

Connected to the NC

MDS-D/DH-SP

8thaxis

(CV control axis)

MDS-D/DH-CV

[2]

MDS-D-SP2

6th/7th axis

MDS-D/DH-V2

1st/2nd axis

MDS-D/DH-V2

3rd/4th axis

(CV control axis)

MDS-D/DH-CV

[1]

MDS-D/DH-V1

5th axis

CAUTION

Two or more power supply units may be required within a single NC communication bus system if the spindle drive

unit capacity is large. The drive unit receiving power (L+, L-) from each power supply unit must always have NC

communication cable connection at the NC side of each power supply unit. In the NC communication bus

connection example below, power supply [1] cannot supply power (L+, L-) to the 5th axis servo drive unit.

For basic connection information, refer to the MDS-D/DH Series Instruction Manual.

Optical

communication

cable

CN4

CN4

Power

cannot be

supplied

CN4

CN4

Connections when using two or more power supply units within a single NC communication bus system

1. The drive unit receiving power (L+, L-) from each power supply unit must always have NC

communication bus connection at the NC side of each power supply unit.

2. If two or more power supply units are connected in the drive system, confirm that the units

are not connected with each other through the L+ and L- lines before turning ON the power.

Also make sure that the total capacity of the drive units connected to the same power

supply unit meets the unit's selected capacity.

8

Page 26

M700VS Series Setup Manual

2.1 Connecting and Setting the Drive Unit

(3) When using one power supply shared unit by two NC communication bus systems

(

MDS-D/DH-V2

1st/2nd axis

MDS- D/DH -V2

3rd/4th axis

(

)

CAUTION

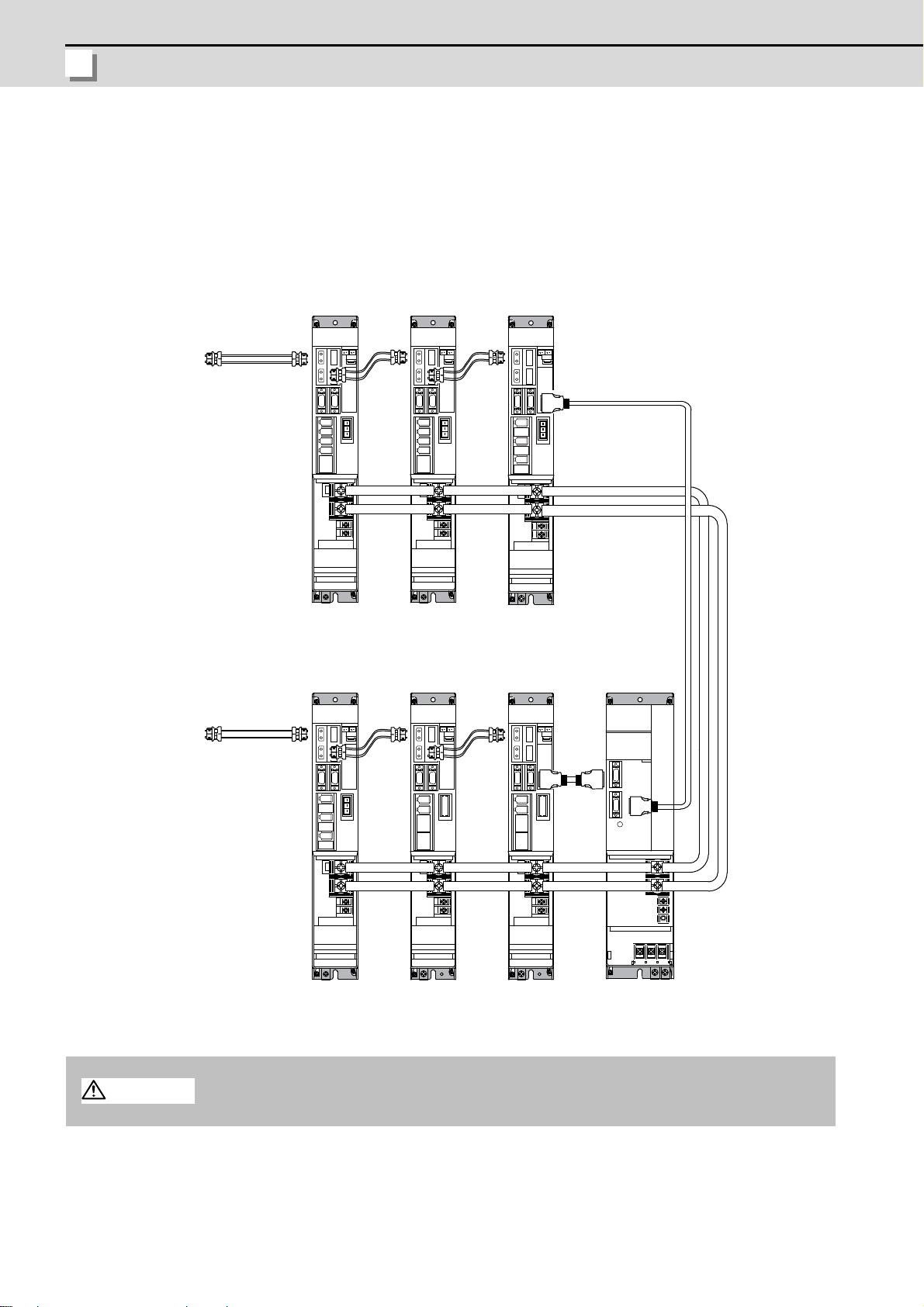

In systems employing a number of small-capacity drive units, a single power supply unit can be shared by two NC

communication bus systems. In this case, a power supply control axis must be set for each axis of each NC

communication bus.

For basic connection information, refer to the MDS-D/DH Series Instruction Manual.

Connected to the NC

(1st part system)

Optical

communication

cable

Connected to the NC

2nd part system

MDS-D/DH-V2

8th/9th axis

MDS-D/DH-V1

10th axis

MDS-D/DH-V2

5th/6th axis

MDS-D-SP2

11th/12th axis

MDS-D/DH-V1

7th axis

(CV control axis)

CN4

MDS-D/DH-SP

13th axis

CV control axis)

MDS-D/DH-CV

(Shared)

Optical

communication

cable

CN4

CN4

CN9

Connections when using one power supply shared by two NC communication bus systems

If the two NC communication bus systems include a spindle drive unit, connect the power

supply unit's CN4 connector to the CN4 connector of the largest capacity spindle drive unit. If

there is no spindle drive unit, connect to the unbalance-axis servo drive unit.

9

Page 27

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.1.1.2 Connecting with MDS-DM Series

CAUTION

POINT

Connect the NC and the drive units by the optical communication cables. The distance

between the NC and the final drive unit must be within 30m and the bending radius within

80mm.

Axis Nos. are determined by the rotary switch for setting the axis No. (Refer to the MDS-DM

Series Instruction Manual.) The axis No. has no relation to the order for connecting to the NC.

(1) Connecting the MDS-DM-V3

(a) When using one power supply unit

Connect the largest-capacity spindle drive unit to the final axis of the NC communication bus in order to control

the power supply unit. The spindle drive unit must be installed adjacent to the power supply unit. In the system

with servo only, a servo drive uni t for controlling unbalance axis must be installed in the same manner in the

same way.

< Connection >

CN1A : CN1B connector on NC or previous stage's drive unit

CN1B : CN1A connector on next stage's drive unit

CN4 : Connector for communication between power supply unit (master side) and drive unit

Connected

to the NC

Optical

communication

cable

MDS-D-V2

1st/2nd axis

MDS-DM-V3

3rd/4th/5th axis

MDS-D-SP

6th axis

(Final axis)

CN4

CN4

MDS-D-CV

The optical communication cables from the NC to the

final drive unit must be within 30m.

Connection when using one power supply unit

10

Page 28

M700VS Series Setup Manual

2.1 Connecting and Setting the Drive Unit

(b) When using two or more power supply units within a single NC communication bus system

[2][1]

MDS-DM-V3

MDS-D-V2

MDS-D-CV MDS-D-V1 MDS-D-SP

MDS-D-CV

7th axis

(CV control axis)

6th axis

1st/2nd axis

(CV control axis)

3rd/4th/5th axis

CAUTION

Two or more power supply units may be required within a single NC communication bus system if the spindle

drive unit capacity is large. The drive unit receiving power (L+, L-) from each power supply unit must always

have NC communication cable connection at the NC side of each power supply unit. In the NC communication

bus connection example below, power supply [1] cannot supply power (L+, L-) to the 6th axis servo drive unit.

For basic connection information, refer to the MDS-DM Series Instruction Manual.

Connected to the NC

Optical

communication

cable

CN4

CN4

Power

cannot be

supplied

CN4

CN4

Connections when using two power supply units within a single NC communication bus system

1. The drive unit receiving power (L+, L-) from each power supply unit must always have NC

communication bus connection at the NC side of each power supply unit.

2. If two or more power supply units are connected in the drive system, confirm that the units

are not connected with each other through the L+ and L- lines before turning ON the power.

Also make sure that the total capacity of the drive units connected to the same power

supply unit meets the unit's selected capacity.

11

Page 29

2 Connecting and Setting the Hardware

MITSUBISHI CNC

(c) When using one power supply shared unit by two NC communication bus systems

(

)

CAUTION

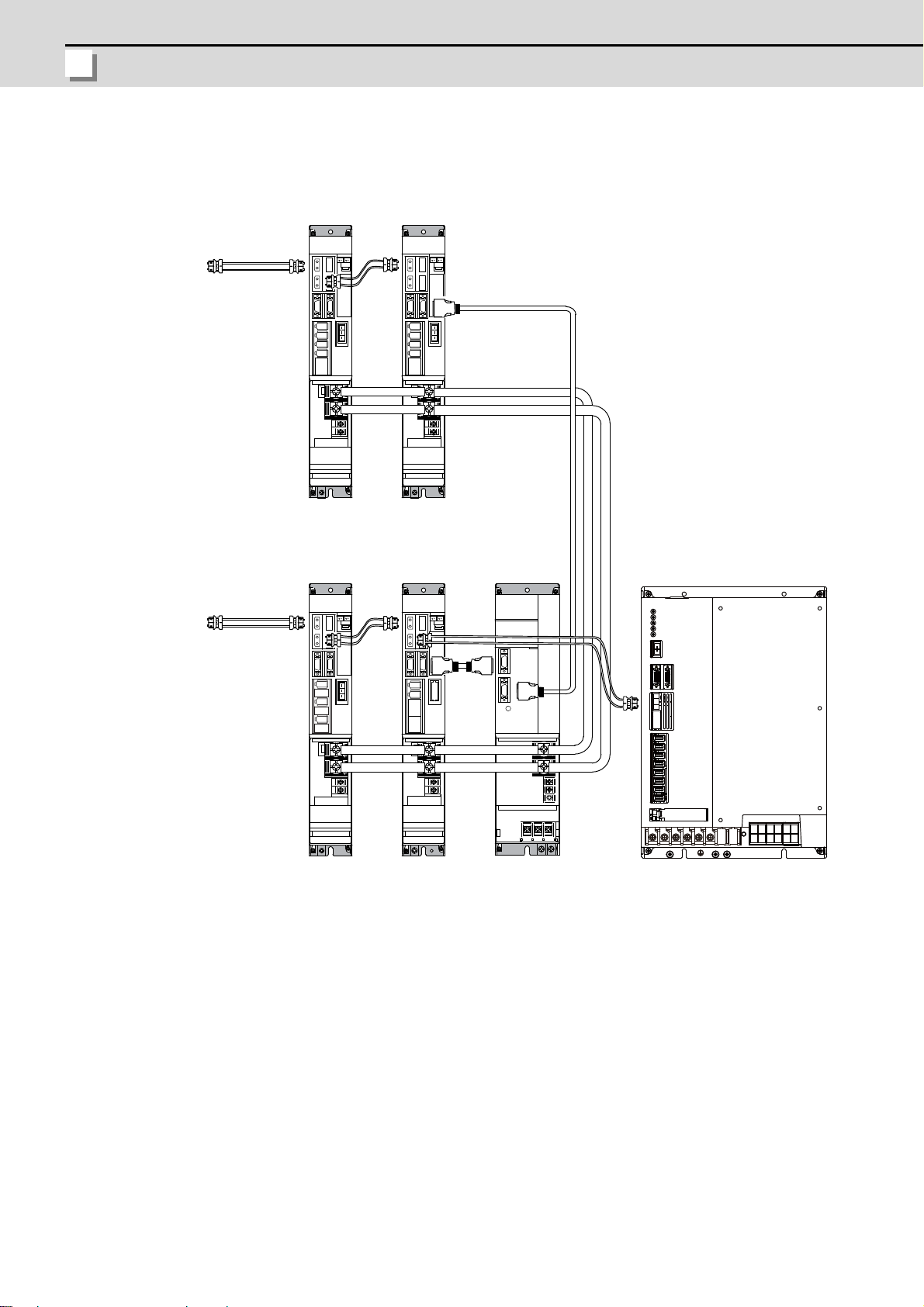

In systems employing a number of small-capacity drive units, a single power supply unit can be shared by two

NC communication bus systems. In this case, a power supply control axis must be set for each axis of each

NC communication bus.

For basic connection information, refer to the MDS-DM Series Instruction Manual.

Connected to the NC

(1st part system)

Optical

communication

cable

Connected to the NC

2nd part system

MDS-D-V2 MDS-D-V2

1st/2nd axis th axis3rd/4

MDS-DM-V3

8th/9th/10th axis

MDS-D-SP

MDS-DM-V3

5th/6th/7th axis

(CV control axis)

MDS-D-SP MDS-D-CV

12th axis

(CV control axis)

CN4

(Shared)11th axis

Optical

communication

cable

CN4

CN4

CN9

Connections when using one power supply shared by two NC communication bus systems

If the two NC communication bus systems include a spindle drive unit, connect the power

supply unit's CN4 connector to the CN4 connector of the largest capacity spindle drive unit. If

there is no spindle drive unit, connect to the unbalance-axis servo drive unit.

12

Page 30

M700VS Series Setup Manual

2.1 Connecting and Setting the Drive Unit

(2) Connecting the MDS-DM-SPV Series

MDS-DM-SPV3F

Spindle:1st axis

Servo:2nd/3rd/4th axis

to the NC

Connected

communication

Optical

cable

MDS-D-V2

MDS-D-SP

MDS-DM-SPV3F

MDS-D-CV

5th/6th axis 7th axis

(Final axis)

Servo:2nd/3rd/4th axis

Spindle:1st axis

(a) When using only MDS-DM-SPV Series

(b) When using the MDS-D unit together

Connected

to the NC

Optical

communication

cable

The optical communication cables from the NC to the

final drive unit must be within 30m.

CN4

CN4

13

Page 31

2 Connecting and Setting the Hardware

MITSUBISHI CNC

(c) When using one power supply shared unit by two NC communication bus systems

(

)

Connected to the NC

(2nd part system)

Optical

communication

cable

Connected to the NC

1st part system

MDS-D-V2

9th/10th axis

MDS-DM-V3

5th/6th/7th axis

MDS-D-V2

11th/12th axis

(CV control axis)

8th axis

(CV control axis)

CN4

MDS-D-CVMDS-D-SP

(Shared)

MDS-DM-SPV3F

Spindle:1st axis

Servo:2nd/3rd/4th axis

Optical

communication

cable

CN4

CN4

CN9

14

Page 32

M700VS Series Setup Manual

2.1 Connecting and Setting the Drive Unit

2.1.1.3 Connecting with MDS-SVJ3/SPJ3 Series

CAUTION

POINT

Connected

to the NC

Optical

communication

cable

MDS-D-SVJ3

1st axis

MDS-D-SVJ3

2nd axis

MDS-D-SVJ3

3rd axis

MDS-D-SPJ3

4th axis

The optical communication cable up to 5m can be used in G396 series, and up to 20m in G380 series.

Connect the NC and the drive units by the optical communication cables. The bending radius

must be within 50mm.

Axis Nos. are determined by the rotary switch for setting the axis No. (Refer to the MDS-SVJ3/

<Connection>

CN1A: CN1B connector on NC or previous stage's drive unit

CN1B: CN1A connector on next stage's drive unit

SPJ3 Series Instruction Manual.) The axis No. has no relation to the order for connecting to

the NC.

2.1.2 Setting up without Connecting to the Motor/ Drive unit

When connecting the motor or drive unit after setting up the system, set the axis data beforehand to enable the operation

without the motor or drive unit. The following shows the procedures.

Setting up without Connecting to the Motor

The axis detach function can be used for servo axis. The detach function cannot be used for spindle.

(1) Set the drive unit rotary switch and "#1021 mcp_no" for the axis that is not connected to the motor.

(2) Set "1" to the parameter "#1070 axoff" for the axis that is not connected to the motor.

(3) Do (a) or (b).

(a) Set "1" to parameter "#8201 AX. RELEASE" for the axis that is not connected to the motor.

(b) Turn ON the control axis detach signal (Y780) for the axis that is not connected to the motor.

Setting up without Connecting to the Drive unit

Set the following parameters.

(1) Set "#1021 mcp_no" (for the servo axis) or "#3031 smcp_no" (for the spindle axis) to the axis that is not connected

to the drive unit.

(2) Set the following parameters to the axis that is not connected to the drive unit.

For the servo axis: Set "1" to "#2018 no_srv".

For the spindle axis: Set "0" to "#3024 sout".

After connecting to the drive unit, make sure to set "#2018 no_srv" to "0" and "#3024 sout" to "1".

15

Page 33

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.2 Setting the Rotary and DIP Switches

L axis

M axis

1-axis

spindle drive unit

(MDS-D/DH-SP)

2-axis

spindle drive unit

(MDS-D-SP2)

2.2.1 MDS-D/DH Series

(1) Setting the rotary switch

Set the axis number with the rotary switch.

1-axis

Servo drive unit

(MDS-D/DH -V1)

2-axis

Servo drive unit

(MDS-D/DH -V2)

#

$

%

&

'

(

#

$

%

&

'

(

MDS-D/DH-V1/V2/SP/SP2 setting

Rotary switch setting Axis No.

Power supply un it

(MDS-D/DH -CV)

#

$

%

&

'

(

$

%

&

'

(

#

$

%

&

'

(

#

$

%

&

'

(

#

01st axis

1 2nd axis

23rd axis

3 4th axis

4 5th axis

5 6th axis

6 7th axis

7 8th axis

8 9th axis

9 10th axis

A 11th axis

B 12th axis

C 13th axis

D 14th axis

E 15th axis

F 16th axis

$

%

&

#

'

(

MDS-D/DH-CV setting

When not using the external emergency stop: Set SW1 to "0"

When using the external emergency stop: Set SW1 to "4"

*Any other settings are prohibited.

16

Page 34

M700VS Series Setup Manual

2.2 Setting the Rotary and DIP Switches

(2) Setting the DIP switch

(A) (B)

As a standard setting, turn the all DIP switches OFF.

The switches are OFF when facing bottom as illustrated.

Turning these switches ON sets the corresponding axis to the unused axis.

Carry out the unused axis setting when you use the multi-axes drive unit that has any unused axis.

(A) Used to set L axis to an unused axis

(B) Used to set M axis to an unused axis

17

Page 35

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.2.2 MDS-DM Series

<MDS-DM-V3 Series>

(1) Rotary switch settings

Before turning on the power, the axis No. must be set with the rotary switch. The rotary switch settings will be

validated when the drive un i t s are tu rned ON.

3-axis

Servo drive unit

(MDS-DM-V3)

L axis

8

79

6A

5B

4C

3D

2E

1F

0

M axis

8

79

6A

5B

4C

3D

2E

1F

0

Spindle drive unit

S axis

8

79

6A

5B

4C

3D

2E

1F

0

(MDS-D-SP

8

79

6A

5B

4C

3D

2E

1F

0

Rotary switch setting Axis No.

01st axis

1 2nd axis

23rd axis

3 4th axis

4 5th axis

5 6th axis

6 7th axis

7 8th axis

8 9th axis

9 10th axis

A 11th axis

B 12th axis

C 13th axis

D 14th axis

E 15th axis

F 16th axis

18

Page 36

M700VS Series Setup Manual

2.2 Setting the Rotary and DIP Switches

(2) Setting the DIP switch

(A)(B) (C)

As a standard setting, turn the all DIP switches OFF.

The switches are OFF when facing bottom as illustrated.

Turning these switches ON sets the corresponding axis to the unused axis.

Carry out the unused axis setting when you use the multi-axes drive unit that has any unused axis.

(A) Used to set L axis to an unused axis

(B) Used to set M axis to an unused axis

(C) Used to set S axis to an unused axis.

<MDS-DM-SPV2/SPV3 Series>

The setting of the axis number is fixed as follows in the MDS-DM-SPV2/SPV3 Series.

Setting the MDS-DM-SPVx Details

1st axis Spindle axis

2nd axis L-axis

3rd axis M-axis

4th axis S-axis (Only MDS-DM-SPV3)

When using the MDS-DM-SPV2/SPV3, MDS-D and MDS-DM-V3 together, the axis numbers for the MDS-DMSPV2/SPV3 are fixed as above. Set the axis numbers from 4th axis or 5th axis.

19

Page 37

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.2.3 MDS-D-SVJ3/SPJ3 Series

Set the axis number with the rotary switch.

MDS-D-SVJ3 MDS-D-SPJ3

8

79

6A

5B

4C

3D

2E

1F

0

Rotary switch setting Axis No.

01st axis

1 2nd axis

23rd axis

3 4th axis

4 5th axis

5 6th axis

6 7th axis

7 8th axis

8 9th axis

9 10th axis

A 11th axis

B 12th axis

C 13th axis

D 14th axis

E 15th axis

F 16th axis

5B

4C

3D

8

79

6A

2E

1F

0

20

Page 38

M700VS Series Setup Manual

2.3 Connecting the Batteries

2.3 Connecting the Batteries

BAT

Battery

Battery cover

Battery holder

connector

CAUTION

2.3.1 Control Unit Battery

The battery is not connected when the machine is delivered. Be sure to connect the battery before

starting up.

A lithium battery in the control unit battery holder retains parameter settings, machining programs and the like, which

requires to be backed up at the power OFF.

Battery Q6BAT

Battery cumulative data holding time

Battery life Approx. 5 years (from date of battery manufacture)

[Installation method]

(1) Check that the machine power is turned OFF. (If the power is not OFF, turn it OFF.)

(2) Confirm that the control unit LED, 7-segment display, etc., are all OFF.

(3) Open the battery cover of the control unit. Pull the right side of the battery cover toward front.

(4) Fit the new battery into the battery holder.

(5) Insert the connector connected to the new battery into the BAT connector. Pay attention to the connector

orientation: do not insert backwards.

(6) Close the front cover of the control unit. At this time, confirm that the cover is closed by listening for the "click"

sound when the latch catches.

45,000 hours (At 0 to 45°C. The life will be shorter if the temperature is high.)

[Precautions for handling battery]

(1) Do not disassemble the battery.

(2) Do not place the battery in flames or water.

(3) Do not pressurize and deform the battery.

(4) This is a primary battery so do not charge it.

Do not short-circuit, charge, overheat, incinerate or disassemble the battery.

21

Page 39

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.3.2 Servo Drive Unit Battery

BT1

Battery

To battery holder

Battery connector

Battery connector connection part magnified figure

Connector for

connecting cell battery

Connect the cell battery with BT1.

MDS-BTCASE

Battery

Dedicated case

(Note) The battery connection is not necessary unless the drive unit employs absolute position detection. (Spindle

drive unit does not require the battery, because the unit does not employ absolute position detection.)

MDS-D/DH-V1/V2 and MDS-DM-V3

Connect the battery connector to the connector of the drive unit.

BTA

1 2 1

1 2

BTB

(Note) There are different types of battery. Refer to the drive unit's specification manual for details.

Type ER6V-C119B A6BAT(MR-BAT)

Installation typeDrive unit with battery holder type Dedicated case type

Hazard class Not applicable

Number of

connectable

Up to 2 axes

axes

Not applicable

(24 or less)

Up to 8 axes

(When using dedicated

case)

MDS-A-BT- □□

Unit and battery integration

type

Class9

(excluding MDS-A-BT-2)

2 to 8 axes Up to 8 axes

Battery change Possible Possible Not possible Possible

(2)

Appearance

(1)

To the battery

holder

Battery connector

バッテリ

Battery

ER6V-C119B

A6BAT

(MR-BAT)

(3)

MDS-BTBOX-36

Unit and battery integration

type

Not applicable

(4)

22

Page 40

M700VS Series Setup Manual

2.3 Connecting the Batteries

MDS-DM-SPV2/SPV3

BT1

Battery

To battery holder

Battery

connector

Battery connector connection part magnified figure

Connector for

connecting cell battery

Connect the cell battery with BT1.

Connect the battery connector to the connector of the drive unit.

12

12

BTA

MDS-D-SVJ3

Connect the battery connector to the connector BAT of the drive unit.

BAT

Remove

Install

23

Page 41

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.4 Connecting and Setting the Remote I/O Unit

(A)

(B)

(C)

(D)

DX10* DX11*/12* DX14*

A

2.4.1 Outline of the Remote I/O Unit

There are eight types of remote I/O unit (FCUA-DX***): DX10*, DX11*, DX12* and DX14* (* is "0" or "1"). Specifications

are different as shown below. Each unit has one or two rotary switch(es) for unit No. setting, which links the device Nos.

(with X/Y).

Front

(H)

(A)

(E)

(A)

(B)

(C)

(D)

(A) Left input connector

(B) DIO specification switch

Currently not used. Always set to "OFF".

Front view View from A direction

OFF

(C),(F) Rotary switch

(D) Left output connector

(E) Right input connector

(G) Right output connector

(H) Analog input/output connector

(F)

(G)

(B)

(C)

(D)

(F)

24

Page 42

M700VS Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

Bottom

(A)

(B)

(C)

(A) RIO1 (From controller)

(B) RIO2 (To terminating resister or to next RIO unit)

(C) DCIN (24VDC input)

Unit type

DX10* (FCUA-DX10*)

Machine control signals that can be

handled

Digital input signal (DI) (Photocoupler

insulation)

Left Right Total

32 points - 32 points

Digital output signal (DO) (Non-insulated) 32 points - 32 points

DX11* (FCUA-DX11*)

Digital input signal (DI) (Photocoupler

insulation)

32 points 32 points 64 points

Digital output signal (DO) (Non-insulated) 32 points 16 points 48 points

DX12* (FCUA-DX12*)

Digital input signal (DI) (Photocoupler

insulation)

Digital output signal (DO) (Non-insulated) 32 points 16 points 48 points

32 points 32 points 64 points

Analog output (AO) - 1 point 1 point

DX14* (FCUA-DX14*)

Digital input signal (DI) (Photocoupler

insulation)

Digital output signal (DO) (Non-insulated) 32 points - 32 points

32 points - 32 points

Analog input (AI) - 4 points 4 points

Analog output (AO) - 1 point 1 point

(Note) "*" in the table is "0" when the output is sink type, and is "1" when the output is source type. The input is

changeable.

Number of

occupied

stations

1

2

2

2

25

Page 43

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.4.2 Connection and Station No. Setting on Remote I/O Unit

㨪

㨪

RIO1

CG72

G214

FCUA-R211/SH41

FCU7-MU531/ FCU7-MU541/ FCU7-MA541

FCUA-DX1**

FCUA-DX1**

Station No.1 - 8

Remote I/O unit

Control unit

Station No.1 - 8

Remote I/O 2ch

Max. 8 channels

Max. input: 256 points (X000 to X0FF)

Max. output: 256 points (Y000 to Y0FF)

Max. 8 channels

Max. input: 256 points (X100 to X1FF)

Max. output: 256 points (Y100 to Y1FF)

Remote I/O 1ch

When connecting directly to the control unit

(Note) A remote I/O unit has one or two rotary switch(es) for unit No. setting, which links the device Nos. (with X/

Y). The rotary switch setting is as follows, from "0" to "7".

When using MITSUBISHI CNC Machine operation panel, RIO station No. "4" to "6" will be occupied.

Station

No.

Rotary switch

10

21

32

43

54

65

76

87

26

Page 44

M700VS Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

When connecting to the operation panel I/O unit

㨪

㨪

FCU7-DX710/711

FCUA-R211

FCUA-R211

RIO3

RIO3

FCU7-DX720/721

/730/731

G011

G011

CG71

Control unit

Operation panel I/O unit

Remote I/O 3ch

Max. 4 channels

Max. input: 128 points (X240 to X2BF)

Max. output: 128 points (Y240 to Y2BF)

Max. 3 channels

Max. input: 96 points (X260 to X2BF)

Max. output: 96 points (Y260 to Y2BF)

Remote I/O unit

Station No.3 - 6

Remote I/O 3ch

Max. input: 96 points (X200 to X25F)

Max. output: 96 points (Y200 to Y25F)

Max. input: 64 points (X200 to X23F)

Max. output: 64 points (Y200 to Y23F)

Station No.4 - 6

Occupies

the station No. 1, 2, 7, 8

Occupies

the station No. 1, 2, 3, 7, 8

FCUA-DX1**

FCU7-MU531/ FCU7-MU541/ FCU7-MA541

(Note) Operation panel I/O unit occupies the specified Nos. of stations. (Station No. 7 and 8 are reserved for

manual pulse generator.)

RIO3 can use either four stations (3rd to 6th) or three stations (4th to 6th) which depends on the

operation panel I/O unit type.

27

Page 45

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.4.3 Station No. Setting when Using Multiple Remote I/O Units

0

㧗

FCUA-DX100/101

0

1

2

㧗

㧗

FCUA-DX100/101

FCUA-DX110/111

or

FCUA-DX120/121

Multiple remote I/O units can be used, as long as the total No. of occupied stations connected with serial links is

eight or less. (three/four or less when connected to the operation panel I/O unit).

Unit type Number of occupied stations

FCUA-DX10* 1

FCUA-DX11* 2

FCUA-DX12* 2

FCUA-DX14* 2

When using multiple remote I/O units, a characteristic station No. must be set for each unit. The FCUA-DX10* unit

has one rotary switch, FCUA-DX11*, DX12* and DX14* unit have two. Each of these switches must be set to a

characteristic station No. within a range of 0 to 7 (2 or 3 to 5 when connected to the operation panel I/O unit).

When connecting directly to the control unit

Setting example 1

Total number of occupied stations: 1

Setting example 2

Number of occupied stations: 1 2

Total number of occupied stations: 3

28

Page 46

M700VS Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

Setting example 3

0 1

㧗 㧗 㧗

㧗

2 3

4 5

6 7

FCUA-DX110/111

or

FCUA-DX120/121

Number of occupied stations: 2 2 2 2

Total number of occupied stations: 8 (Maximum configuration)

29

Page 47

2 Connecting and Setting the Hardware

MITSUBISHI CNC

When connecting to the operation panel I/O unit

㧗

2

FCU7-DX710/711

FCUA-DX100/101

+

4

5

+

2

3

FCU7-DX710/711

FCUA-DX110/111

or

FCUA-DX120/121

FCUA-DX110/111

or

FCUA-DX120/121

Station No. 1, 2, 7, 8 (or 1, 2, 3, 7, 8) are occupied by the operation panel I/O unit. (Station No. 7 and 8 are reserved

for manual pulse generator.)

The maximum numbers of stations and I/O points assigned to remote I/O unit(s) via RIO3 are as follows.

Operation panel I/O unit

type

FCU7-DX710 4 stations (No. 3 to 6) 128 points/128 points 2 to 5

FCU7-DX711 4 stations (No. 3 to 6) 128 points/128 points 2 to 5

FCU7-DX720/730 3 stations (No. 4 to 6) 96 points/96 points 3 to 5

FCU7-DX721/731 3 stations (No. 4 to 6) 96 points/96 points 3 to 5

Setting example 1

Max. number of stations

(RIO3 connection)

Max. number of I/O

points (RIO3

connection)

Rotary switch

Setting range

Remote I/O

Number of occupied stations: 1

Total number of occupied stations: 1

Setting example 2

Number of occupied stations: 2 2

Total number of occupied stations: 4 (Maximum configuration)

30

Page 48

M700VS Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

Setting example 3

+

3

+

4

5

FCU7-DX720/721

/730/731

FCUA-DX100/101

FCUA-DX110/111

or

FCUA-DX120/121

Number of occupied stations: 1 2

Total number of occupied stations: 3 (Maximum configuration)

31

Page 49

2 Connecting and Setting the Hardware

MITSUBISHI CNC

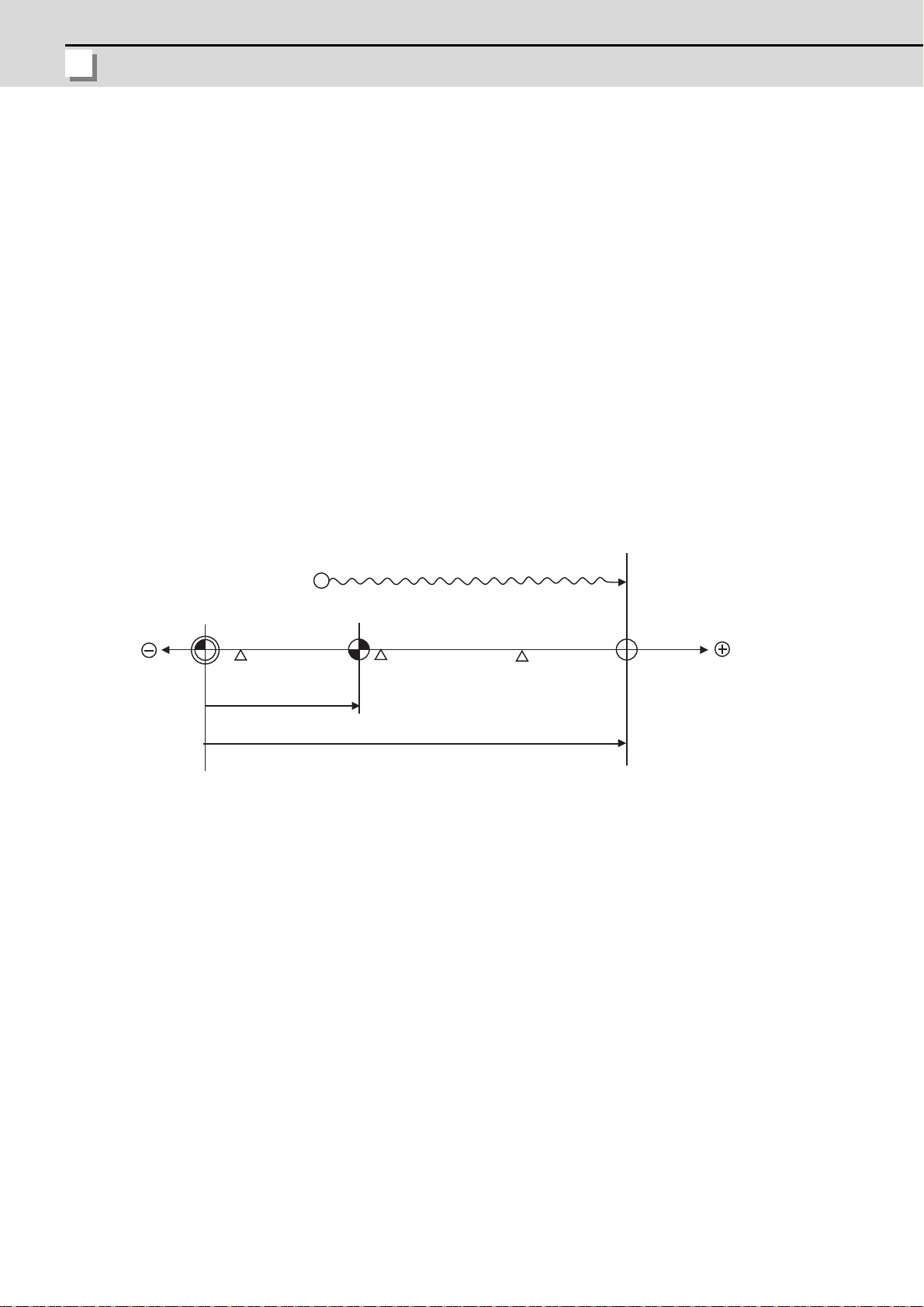

2.4.4 Device No. Assignment

The devices used by the PLC are determined as follows after the station Nos. are set with the rotary switches.

Rotary switch No.

0 X00 to X1F Y00 to Y1F(Y0F)

1 X20 to X3F Y20 to Y3F(Y2F)

2 X40 to X5F Y40 to Y5F(Y4F)

3 X60 to X7F Y60 to Y7F(Y6F)

4 X80 to X9F Y80 to Y9F(Y8F)

5 XA0 to XBF YA0 to YBF(YAF)

6 XC0 to XDF YC0 to YDF(YCF)

7 XE0 to XFF YE0 to YFF(YEF)

Rotary switch No.

0 X100 to X11F Y100 to Y11F(Y10F)

1 X120 to X13F Y120 to Y13F(Y12F)

2 X140 to X15F Y140 to Y15F(Y14F)

3 X160 to X17F Y160 to Y17F(Y16F)

4 X180 to X19F Y180 to Y19F(Y18F)

5 X1A0 to X1BF Y1A0 to Y1BF(Y1AF)

6 X1C0 to X1DF Y1C0 to Y1DF(Y1CF)

7 X1E0 to X1FF Y1E0 to Y1FF(Y1EF)

Device No. read in Output device No. Analog output (AO)

RIO channel 1 RIO channel 1 RIO channel 1

The rotary switches

correspond to the file

registers R200 to R207 in

order of small numbers.

Device No. read in Output device No. Analog output (AO)

RIO channel 2 RIO channel 2 RIO channel 2

Not possible (Neither input

nor output is possible)

Rotary switch No.

0-1-2 X240 to X25F Y240 to Y25F(Y24F)

3 X260 to X27F Y260 to Y27F(Y26F)

4 X280 to X29F Y280 to Y29F(Y28F)

5 X2A0 to X2BF Y2A0 to Y2BF(Y2AF)

6-7--

The values shown in parentheses are the device range of the card mounted to the right side of the unit.

Device No. read in Output device No. Analog output (AO)

RIO channel 3 RIO channel 3 RIO channel 3

Not possible (Neither input

nor output is possible)

32

Page 50

M700VS Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

(Note) When the analog output is equipped to several RIO channels, maximum of four RIO channels will be valid in the

RIO1

RIO3

AO

AO

AO

Controlunit

RIO unit

OperationpanelI/Ounit

Second

station

Fourth

station

Sixth station

following order of priority.

(1) RIO channel 1, (2) RIO channel 2, (3) RIO channel 3

(Ex.) When the analog output is equipped to RIO channel 1 and RIO channel 3.

#3024 sout R register Allocation of AO

2 R200 (AO1) 2nd station of RIO 1

3 R201 (AO2) 4th station of RIO 1

4 R202 (AO3) 6th station of RIO 3

5 R203 (AO4) -

The analog output R registers are allocated in ascending orde r of channels and station

CAUTION

numbers automatically. Therefore, the analog output destination may ch a nge de pe nding on

the added option.

33

Page 51

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.5 Initializing the NC Internal Data (SRAM)

A

A

A

A

The initialization does not affect the settings of the option parameters.

(1) With the NC power OFF, turn the left rotary switch (RSW1) to "0" and the right rotary switch (RSW2) to "C". Then,

turn the power ON.

NCLD1

0

1

F

D

B

7 9

8

NCLD2

0

1

F

2 E

D

3

4 C

B

5

6

2 E

3

4 C

5

6

7 9

8

RSW2 RSW1

(2) The LED display will change to "08." -> "00" -> "01" -> ... "08". The process is completed when "0Y" is displayed.

NCLD2NCLD1

(3) Turn the NC power OFF.

(4) Set the right rotary switch (RSW2) to "0".

(5) Turn the power ON again.

NCLD1

0

1

F

D

B

7 9

8

NCLD2

0

1

F

2 E

D

3

4 C

B

5

6

2 E

3

4 C

5

6

7 9

8

RSW2 RSW1

(Note) The initial screen after the initialization is displayed in English. Refer to "Setting on the System Setup Screen"

for how to set a language to display.

34

Page 52

35

3

Setting Up with M70/M700 SETUP

INSTALLER

Page 53

3 Setting Up with M70/M700 SETUP INSTALLER

MITSUBISHI CNC

(Note) M70/M700 SET UP INST ALLER is used to install language data other than Japanese and English, as well as

custom screens.

If you do not need the installation, go to the next section.

You can install the following data with M70/M700 SETUP INSTALLER.

(1) Language data

(2) Custom data

- Custom screen

- PLC alarm guidance

(3) Custom startup screen

A CF card is used for the installation.

The following products' operations have been guarante ed by MITSUBISHI.

<SanDisk CompactFlash cards>

64MB SDCFB-64-J60 (JAN: 4523052000294)

128MB SDCFB-128-J60 (JAN: 4523052000300)

256MB SDCFB-256-J60 (JAN: 4523052000317)

512MB SDCFB-512-J60 (JAN: 4523052000324)

1.0GB SDCFB-1024-J60 (JAN: 4523052000331)

<Panasonic SD memory cards>

1.0GB SD-CF adapter BN-CSDABP3/P + SD memory card (1GB) RP-SDM01GJ1A

2.0GB SD-CF adapter BN-CSDABP3/P + SD memory card (2GB) RP-SDM02GJ1A

(Note) The adapter BN-CSDABP3/P does not support SDHC memory card.

SD-CF adapter which supports SDHC is required when SDHC memory card is used.

The successful operations of these cards are confirmed under certain conditions. Some cards might not work under

the end-users' system environment. And some cards might have the same type name but different parts inside:

Complete guarantees cannot be given.

Contact the manufacturer or distribu to r be fo re pu rchase: There might be some cards which are not currently

produced.

36

Page 54

M700VS Series Setup Manual

3.1 Compatible Data and Folder Configuration in the CF Card

3.1 Compatible Data and Folder Configuration in the CF Card

(1) M70/M700 SETUP INSTALLER compatible data

Type Data Details Remarks

lang0_xxx.bin Language data (for FROM) Language

identification string is

Language data

Custom data

Custom startup

screen

lang1_xxx.bin

Custom screen

module

config.ini

customdef.ini

customload.txt

PLC alarm guidance

data

startupscreen.bmp

Language data (for expansion

FROM)

Interpreter data and object data

A setting file to register custom

screens

A setting file to register custom

screens on the menus and

function buttons located to the

default screen

A setting file to register a name

and a load order of the object data

HTML/JPEG files to be displayed

in the PLC alarm guidance

A bitmap file to be displayed on

the initial screen when the power

is turned ON

shown instead of xxx.

(ex. jpn: Japanese,

fra: French)

Color: 256 colors

(8 bit) Size:

640 * 440

37

Page 55

3 Setting Up with M70/M700 SETUP INSTALLER

MITSUBISHI CNC

(2) Folder configuration in the CF card

A

A