Page 1

MITSUBISHI

Mitsubishi

TECHNiCAL

Limiservo

X E

iNSTRUCTION

Series

MANUAL

Induction

and

needle

Motor XL-554-10, XL-554-20

XL-754-20

Control

control

box

type

box

XC-EN,

AC

with

XC-EMF=Y

servo

automatic

motor

positioner

Thank

Please read

Please read the instruction manual forthe machine head together

Save

you for purchasing

this

manual

this

manual

for

future

the

Mitsubishi Limiservo X.

thoroughly

reference.

before

use toensure safe and properuse.

with

this manual.

IB(NA)67331-C(9709)

Page 2

Before

use

"EMFY"

control

box!

This control box

can

be used

with

either

the

lockstitch

thread

trimming sewing

machine or chain stitch thread trimming sewing machine. The factory setting is for the

lock stitch

To

use

function

Program

When

always

this

for

mode

using

thread

control

trimming sewing machine.

box

with

the

the

corresponding

121"onpaces

chain

sewing

31to57.

stitch

machine

thread

with

trimming

the

the controlboxfor the lockstitchthread trimming

performthe reset operationson page90or setthe

sewing

stepsin"Howtouse

sewing

machine,

sewing

machine again,

machine with the

set

the

the

steps in "How to use the program mode [1]" on pages 24.

(Always

running

confirm

the

sewing

the

machine.)

rotation

direction

display

with

the

procedure

on

pace

22

before

Note; When using on XC-EMFYCE type, pleaseread the SAFETYTECHNICAL

MANUAL <XC-EMFYCE> thoroughly before use safe

and

proper

use.

/ I

Page 3

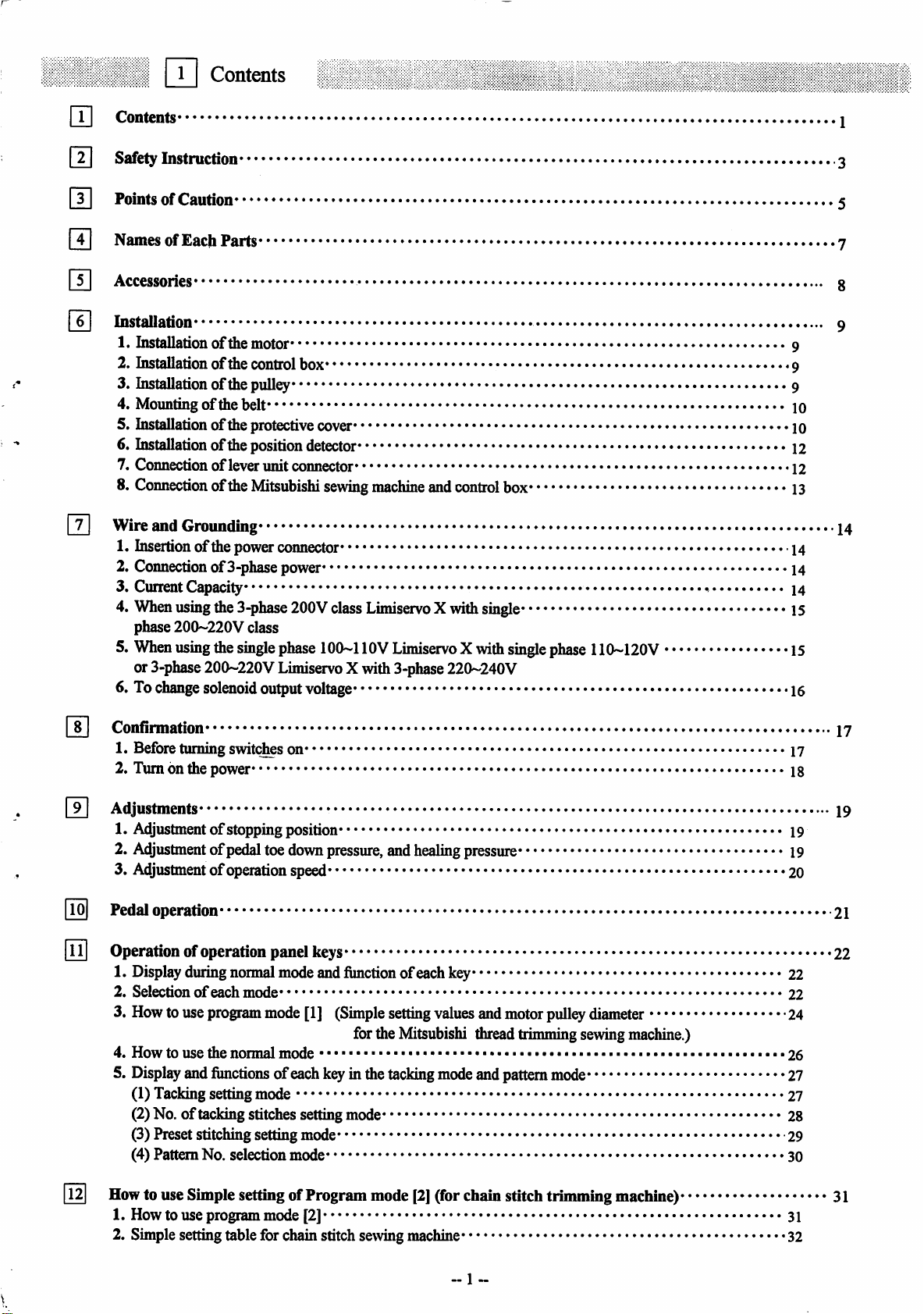

nn

Contents

fT]

Safety

[Tl

PointsofCaution'

0

NamesofEach

0

Accessories'

Installation

1.

Installationofthe

2.

Installationofthe

3. Installationofthe

4. Mountingofthe belt

5. Installationoftheprotectivecover

6. Installationoftheposition detector

7.

Connectionoflever

8.

Connection

Wire and Grounding

0

1. Insertionofthepowerconnector

2. Connection

3. CurrentCapacity

4.

When

phase 200~220V class

5.

When

or3-phase200~220VLimiservo Xwith 3-phase220~240V

6. To

Contents

Instruction

ofthe

of

using

die

using

die

change

solenoid outputvoltage

Parts•

motor

control

pull^

unit

connector

Mitsubishi

3-phasepower

3-phase

single

200V

phase

box

sewing

class

100~1

machine

Limiservo

lOV

LimiservoXwith

and

control

Xwidi

box*

single

single

phase

110~'120V

9

•9

9

10

10

12

•12

13

14

14

14

14

15

15

16

0

Confirmation

1. Beforeturningswitc^s

2. Tum on the power

Adjustments

0

1. Adjustment of stoppingposition

2.

Adjustment

ofpedaltoe

3. Adjustmentofoperationspeed

0

Pedal

operation*

Operation ofoperation panel keys

0

1. Display duringnormalmodeand

2.

Selectionofeach

3. Howtouse

4.

Howtouse

5.

Display

and

program

the

normal

functions

(1) Tacking setting mode

(2) No.

of

tacking stitches settingmode

(3) Presetstitchingsetting mode

(4) PattemNo. selection mode

mode

on*

down

mode

mode

ofeach

[1]

key

pressure,

(Simple

function

and

healing

ofeachkey

setting

values

forthe Mitsubishi thread

inthe

tacking

mode

pressure*

andmotor

andpattem

pull^

trimming

mode

diameter

sewing

17

17

18

19

19

19

20

21

22

22

22

•24

machine.)

26

27

27

28

29

30

12

Howto useSimple setting of Program mode

[2]

(forchain stitch trimming machine)*

1. Howto use program mode [2]

2. Simple settingtablefor chain stitchsewingmachine

-1

31

31

'32

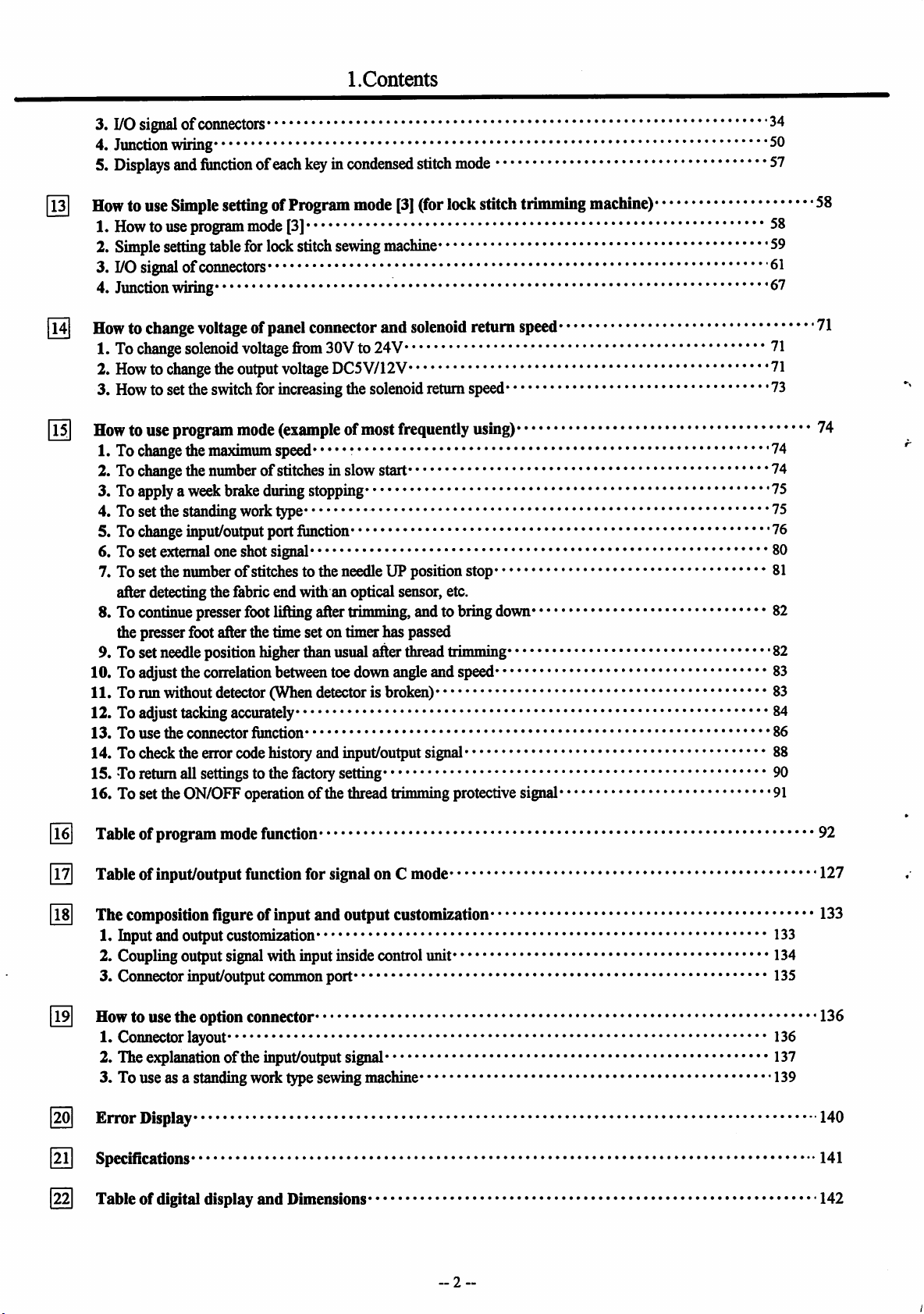

Page 4

1.Contents

3. I/O

signalofconnectors

4. Junction wiring 50

5.

Displays

13

How

1. Howtouse

2.

Simple

3. I/O

4. Junction wiring 67

14

Howtochange

1. To

2. Howto

3. How to set the switchfor increasingthe solenoidreturn speed 73

15]

Howtouse

1. To changethemaximumspeed 74

2. To changethe number

3. To applya weekbrakeduringstopping 75

4. To set the standing worktype 75

5. To changeinput/outputport function 76

6. To set external one shot signal 80

7. To set the numberofstitches to the needle UP position stop 81

after detectingthefabric end with an optical sensor, etc.

8. To continuepresserfootlifting aftertrimming,andto bring down 82

the presserfootafterdie time set on timerhas passed

9. Toset

10. To adjustthe correlation betweentoe downangleandspeed 83

11.

To run without detector (When detector is broken) 83

12. To adjust tacking accurately 84

13.

To

14. To checkthe error codehistory and input/output signal 88

15. To retum all settings to the factorysetting 90

16. To set the ON/OFF operationofthe thread trimming protectivesignal 91

and

function

touse

Simple

setting

signalofconnectors

setting

program

tableforlockstitch

voltage

change

solenoid voltagefrom30Vto 24V

change

theoutputvoltageDC5V/12V

program

needle

position

use

the

connector

ofeachkeyin

ofProgram

mode

[3] 58

ofpanel

mode

(exampleofmost

of

stitchesin slow start 74

higher

function

condensed

sewing

connector

than

usual

mode

ai^

stitch

[3]

(for

machine

and

solenoid

frequently

diread

mode

lock

stitch

return

using)

trimming

trimming

speed

machine)

34

57

58

59

61

71

71

71

74

82

86

16 Table ofprogram modefunction 92

17 Table of input/outputfunction for signal on C mode 127

18]

Thecomposition figureofinput and output customization

1. Input and output customization 133

2. Coupling output signal with input inside control unit 134

3. Connector input/output common port 135

19]

Howto usethe option connector 136

1. Connector layout 136

2. The explanation

3. To use as a standing work type sewing machine 139

20

Error

Display 140

21 Specifications 141

22]

Table of digital display and Dimensions 142

of

the input/output signal 137

-2

133

Page 5

0

Safety

Instructions

1.Toensure

•

Always

machine

1.1Beforestarting

-

Read

and

sewingmachine.

1.2Application andpurpose

-

Tbis

applicationsorpurposes.Donot

measures for the installedsewingmachinehavebeentaken.

1.3

Work

-

Use

which

-

Avoid

(1) Power voltage

(2) Electromagnetic noise

(3)

(4) Atmosphere

(5) Altitude

(6) Storage

(7) Vibration

safe

use

observe

drive

all

follow

drive

envirorunent

this

process

using

-

Place

- Placewhere

-

Place

-

Place

large-output

Temperature

-

Place

- Placesubjecttodirectsunlightor outdoors.

-

Nearaheat

-

Place

-

Atmosphere

-

Atmosphere

- Placewhereat altitudes

- Place

-

If

excessive vibration occurs when the control

sewing

the

unit

(motor

instruction

the

technical

following

manual

itemstoensure

and

control

thoroughly

manuals.

box).

Alsoreadtheinstruction

imitisdesignedtodriveasewing

use

this

drive

unitindry

dry

this

control

where

voltage

frequency

where

the

where

strong

high

and

where

atmospheric

source

where

relative

withdustor

with

where

storage temperature is

machine,

and

well-kept

sewing

material.

unitinthe

fluctuation

fluctuation

specified

power

electricormagnetic

fi-equency

humidity

temperatureis40°Corhigher

suchasa

humidity

corrosive

combustible

exceeds

install it

separately.

following

exceeds

exceeds

capacity

oscillatororhigh

heater.

is 30%orlessand95%or

gases.

gasesorexplosive

1,000mabovemeansealevel.

55®C

before

drive

clean

±10%ofthe

fields

orhigherand

safe

useofthe

starting

machine

unit

locations,

typesofenvironments.

±1%of50/60Hz.

carmotbesecured.

are

fi^quency

box

industrial

useofdiis

manuals

and

must

sewing

drive

unit,

forthe installed

notbe

used

for

untilitcanbeconfirmed

e.g.inthe

rated

generated

atmosphere.

-25®Corlower.

is installed on the

clothing

voltage.

suchasneara

welding

and

machine.

5°Corlower.

more,orwhere

industry,

other

that

safety

dew

condensation

and

occurs.

2.

Installation

2.1

Motor

and

control

-

Correctly

2.2

Accessories

-

Always

anyaccessories listedin the

and

2.3

Cable

(1)

use, and do not excessivelybendthe cable.

(2)Cablesnear

distanceof25mm.

disconnect

remove

Arrange

install

theplug

the

box

according

this

control

fi^om

connection

moving

parts

to theattached technical

unit

fi-om

the

main

technical

theoutlet

cable

(e.g.,

manual.

Qjower

sothat

pulleyor V-belt) mustbewiredat a

(TurnthemainswitchOFF,

supply

excessive

power

line).)

force

-3

manuals.

supply

isnot

~

when

applied

installing

during

minimum

Page 6

(3)

Confinn

control

box

nameplates

designated

ON/OFF

2.4 Grounding

(1)

Correcdy

2.5

Accompanying

(1)

Electric

safetylow voltage.

2.6

Removal

(1)

Turn

the

line)

before

(2)Donot

(3)

There

isa

at least10

fixim

the

that

the

power

meets

the

specifications

before

connecting

placestosupply

switch

turned

connect

die

appliances

accompanying

main

switch

removing

pullonthe

high

minutes

oudet

cord

voltage

after

(power

2.Safety Instructions

voltageofthe

itto

the

power.

OFF.

control

diemotoror

box

and

accessories

appliances

OFF

and

when

removing

applied

running

supply

remove

inside

line)before

power

cable

ondie

motor

the

power

line.

Perform

this

groundingtothe

and

accessories

the

plug

control

die

the

the

power

box.

plug.

control

switch

opening

for

supplyingtothe

and

control

Connect

power

must

fi"om

Always

itto

step

with

supply

onlybeconnected

the

oudet

hold

box,soalways

OFFand

the

control

box

rating

die

the

power

grounding.

(power

the

plug

wait

remove

box

to

supply

itself.

theplug

panel.

3. Maintenance,inspection and repairs

- Follow the technical manuals for maintenance and inspection

of

this

control

-

Repairs

- Donotrunthis

filterblockedorcloggedwithdust,loosecloth,etc.

-

Always

before

replacing

-

Always

4. Other safety measures

Keep

fingers

V-belt, etc.).

- Donotdropthis

- Donot

-If

-Theuser

5. Hazarddisplay, warning display

(1)

operate

any

damageisobserved

properly

unit.

Operate

made by qualified personnel.

Observe

Risks

are

marked

unit.

and

maintenance

control

turn

the

power

die

sewing

use

orif

must

all

that

original

safety

replacement

away

fixim

control

without

operatorisuncertain

the

drive

avoid

making

guidelinesifmodificationsorchanges

may

cause

with

tiiis

mustbedone

withtheventilation

switch

OFF

machine

all

moving

unitor

required

onthis

only

after

modificationsorchanges

person^

symbolinthe

and

and

remove

needle

parts

for

parts

insert

any

protective

control

about

adjustments,

injuiyorrisktothe

instruction

approvedbyspecially

openings

orbobbin,

repairsormaintenance.

(especially

object

devices.

unit,

operation,donot

the

plug

intoany

ifthe

repairs

ofthe

etc.

near

drive

and

basedonuser's

machine

manual.

trained

motor's

firom

sewing

opening.

does

operate

approvals

mustbemade.

the

oudet

machine

notrun

dust-proof

the

personnel.

(power

needle,

drive

have

been

judgment.

iT

supply

line

)

(2)This

Save

symbol

these

indicates electrical risksand

technical

manuals

for

future

warnings.

reference.

-4-.

ifSlk

Page 7

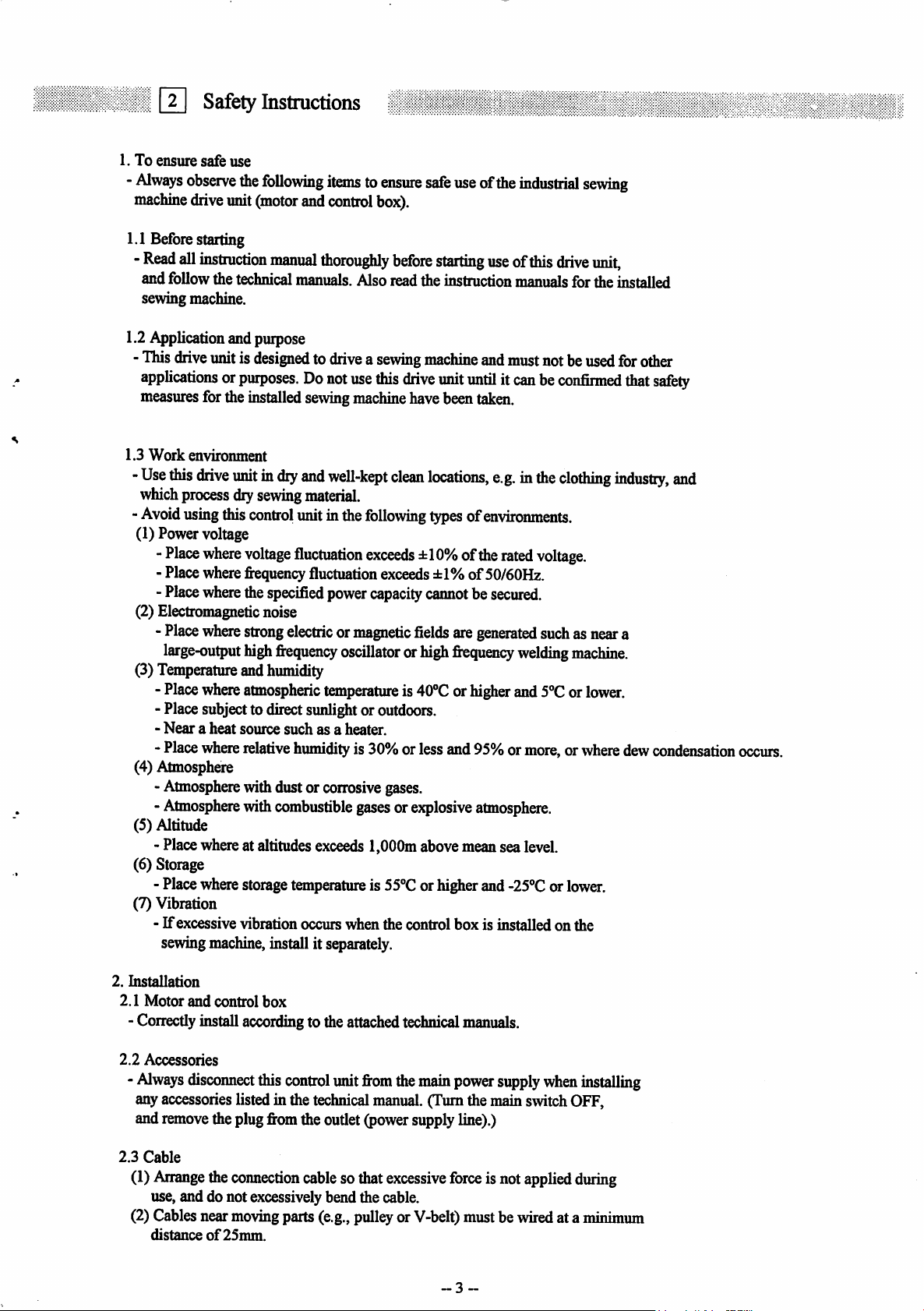

1.

Q

Please

Mdien

PointsofCaution

remove

turning the powerON.

your

foot

from

the

pedal

2.

Always

the

turnthe

machine.

power

OFFwhen

leaving

OFF

1 I

I

3. Do not inspect the control circuit with a tester.

OFF

ON

M"

1 r

4.

Always

turnthepower

the sewingmachinehead,replacing theneedle,

or threading the needle.

switch

OFF

before

Sewing machine

f

tilting

Control

The semiconductor partsmaybedamagedwhen

the tester'svoltageis applied.

5. Always ground the machine.

OFF

ON

circuit

GreenA''ellow

(Green)

Power

Needle

6. Do not use branchedwiringwhen using

the single-phasemotor.

The 3-phasemotor has a groimding wire

(green) (green/yellow).Always ground this.

Page 8

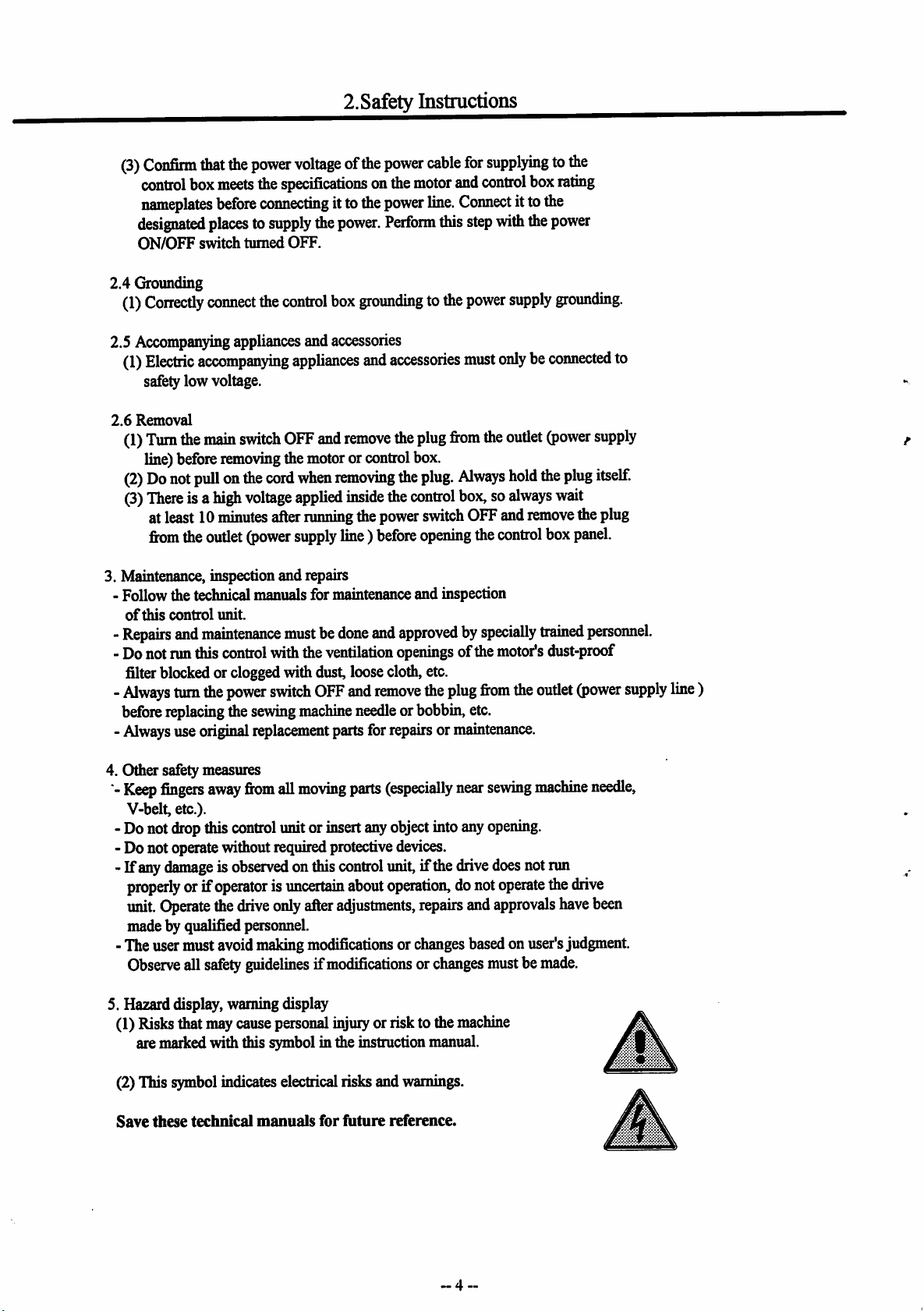

3.Points

of

Caution

7. A highvoltage is appliedinsidethemachine, sowait

10minutesafterturningthe power switch OFF before

opening the cover.

8. Usethemachineawayfromsourcesofstrongnoise

such as a high frequencywelder.

Noise

Lrf

High voltage danger

9.The

brakes

may

not

function

sewingmachineoperation.

10. Match the connector shape and direction, and insert securely.

11.An

optical

method

detection

platevdien

and do not scratchthe plate.Takecarenotto let oilsenterbetweenthedetectordiscs.

12.

When

theposition

the motorwillbe automaticallyturned OFFafter a settimeto preventdamagetothe motor.

(Themotormaynot turnOFF ifthe lockingis not complete.)Aftertheproblemhasbeenresolved, turn the power

OFFand ONand normaloperationwillbe possible. The sameoperationshouldbe taken

wires

are

broken.

isusedforthe

removing

detector

when

the

detector's

the

cover

connector

poweristurned

detection

for

adjustment,

orthebelthas

OFFor

when

there

element

sotakecarenottoletdustoroilsgetonthe

etc.Ifthesedogetonthe

come

offor whenthe

isa

power

failure

plate,

sewing

machineiscompletely

during

wipeoffwitha softcloth

wfren

the detectoror

izzr

locked,

13.

Remove

dust-proof filter once every two to three weeks.

If

the

the filter is clogged,

the motor may overheat

and

affect

14. When coimecting the external switch to the option

coimector, etc., keep the signal wire as short as

possible.Ifit is long, malfunctions may occur.

the

dust

Dust-proof filter

motorisrun

the

vhile

motor

that

life.

has

adheredonthe

motor's

¥

15. Ifthe fuse blows, remove the cause, and replace the

blown fuse with one having the same capacity.

200V

Two

fuses

lOOV

One

Two 20A Fuses (XC-EN, EMFY)

fiises

Two

ISA

Fuses(XC-EMFYCE)

000&

(Frontview

^ Theabovefusesis forprotectionof thecontrol

box power supply section.

•

•B

c

with

cover removed.)

D

•••

_ o

•

SAFuse

Box

(View from backofcover.)

^ The

above

8Afuseisforprotection of the solenoid

output power supply (24V) section.

Use a shield cable for the signal

wire

when

possible.

Wait 10 minutes after turning the power

switch OFF before opening the cover

Page 9

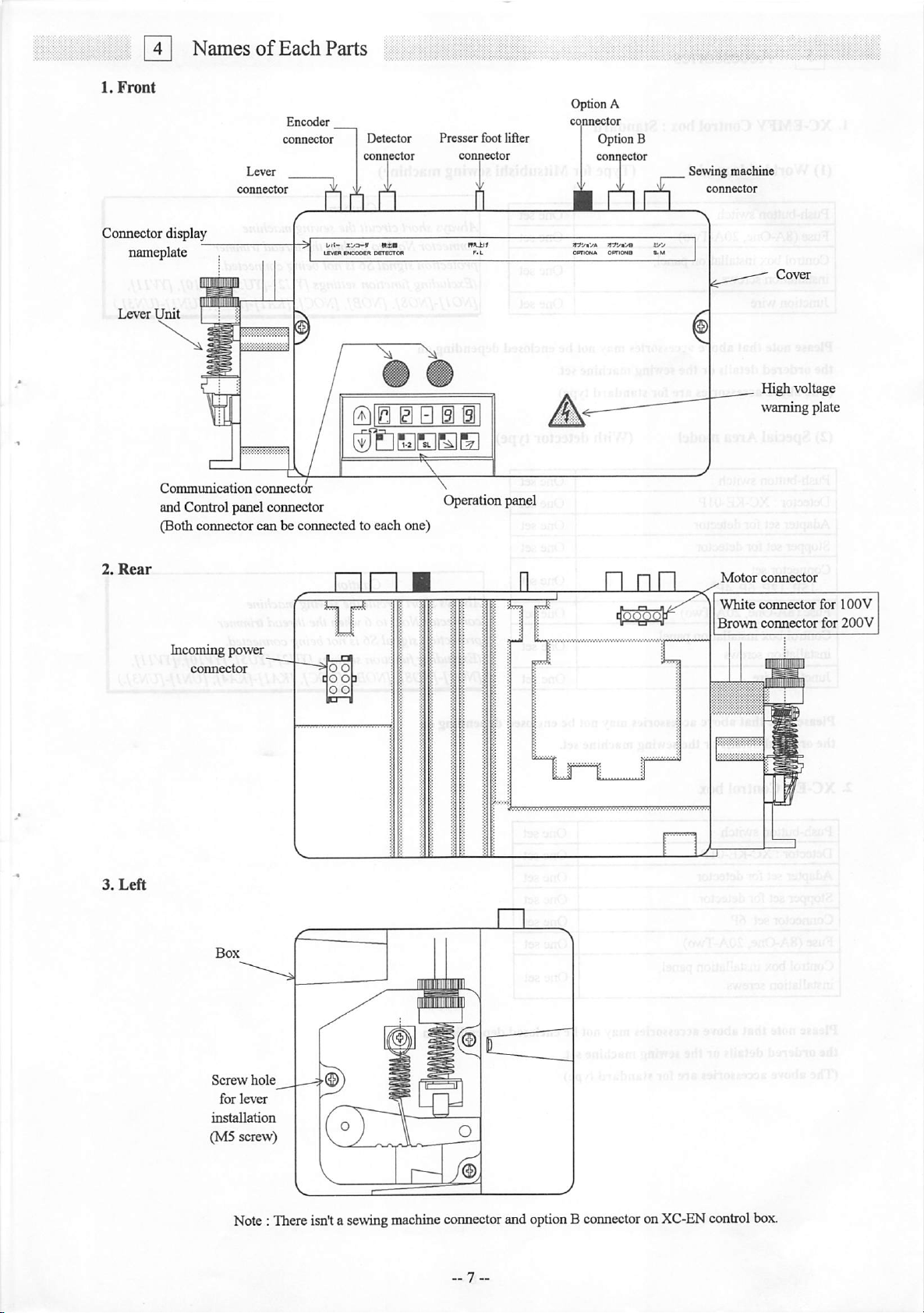

0 0 B a ®

White

Brown

connector

connector

m

voltage

ig plate

for

for

lOOV

200V

Page 10

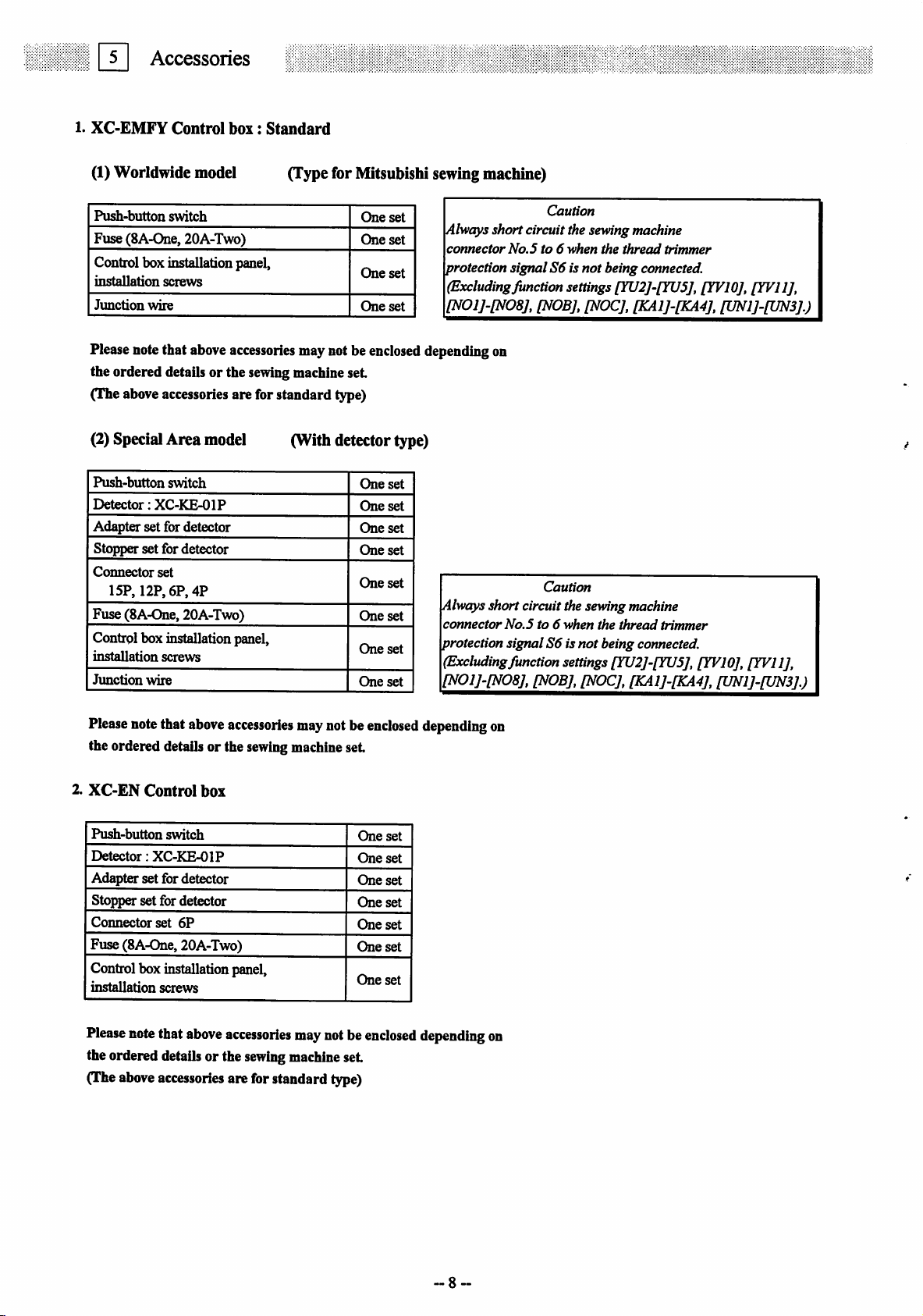

Q

1.

XC-EMFY

(1)

Worldwide

Accessories

Control

box:

model

Standard

(Type for Mitsubishi sewing machine)

Push-button

Fuse (8A-0ne, 20A-Two)

Control box installation panel,

installation

Junction

Pleasenotethat above

the ordered details or the sewingmachine

wire

switch

screws

accessories

maynot be

set

One

set

One

set

One

set

One

set

enclosed

(The aboveaccessories are for standard type)

(2)SpecialArea model (With detectortype)

Push-button

Detector:

Adapter set for detector

Stopper set for detector

Connector

15P, 12P, 6P,

Fuse (8A-One,20A-Two)

Controlbox installationpanel,

installation

Junction

switch

XC-KE-OIP

set

screws

wire

4P

One

One

One

One

One

One

One

One

set

set

set

set

set

set

set

set

Caution

Always

short circuitthesewingmachine

connector

No.5to6when

the

thread

protection signalS6is not being connected.

(ExcludingJunction settings

[N01J-[N08J,

[NOB],

[YU2]-[YU5],

[NOG],

[KA1J-[KA4],

dependingon

Caution

Alwaysshort circuit thesewingmachine

connector

protection signalS6is

(Excludingfunction settings

[N01]-[N08],

No.5to6when

not

[NOB],

the

thread

being connected.

[YU2]-[YU5],

[NOC],

[KAl]-[KA4],

trimmer

trimmer

[YVIO],

[YVllJ,

[UN1J-[UN3J.)

[YVIO],

[YVll],

[UN1]-[UN3].)

Please

notethat

above

accessories

maynotbe

the ordered details or the sewingmachine

2.

XC-EN

Push-button

Detector:

Control

switch

XC-KE-OIP

box

Adapterset for detector

StoH)er set for detector

Coimectorset

6P

Fuse (8A-0ne, 20A-Two)

Controlboxinstallation panel,

installation

Please

the ordered detailsor the

(Theabove

note

screws

that

above

accessories

accessories

sewing

maynotbe

machine

are forstandard type)

set

One

One

One

One

One

One

One

set

enclosed

set

set

set

set

set

set

set

enclosed

depending on

depending

on

Page 11

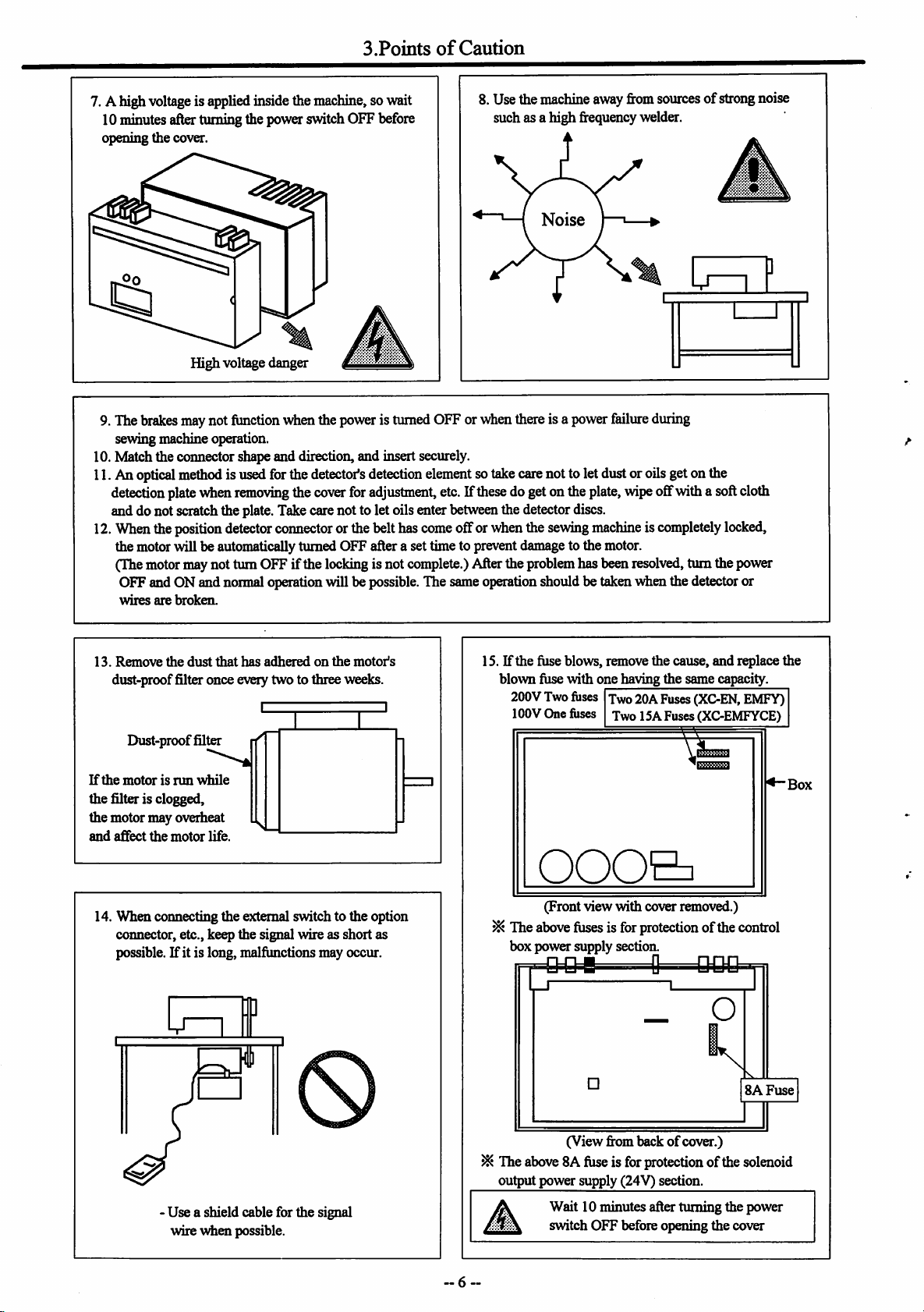

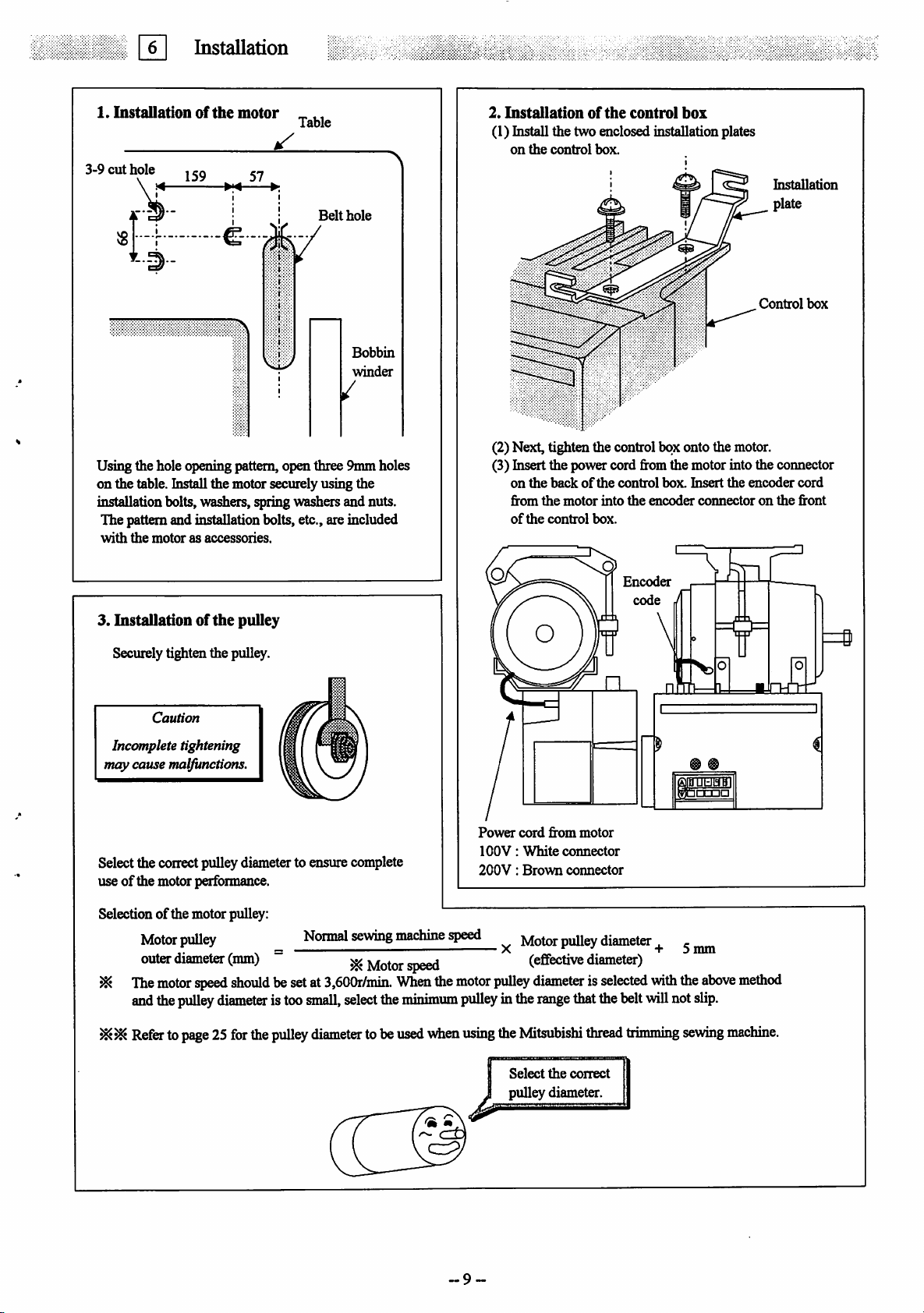

3-9

1.

cut

0

Installation

hole

Installation

of

the

motor

159

57

< •:

Table

Belt

hole

2.

Installation

of

the

control

box

(1) Install the two enclosed installation plates

on

the

control

box.

Installation

plate

Bobbin

winder

/

Using the hole opening pattern, open three 9mm holes

on the table, histall the motor securely using the

installation bolts,washers, spring washers and nuts.

The pattern and installation bolts, etc., are included

with

the

motorasaccessories.

3.

Installationofthe

Securely tighten the pulley.

Caution

Incomplete tightening

may cause malfunctions.

pulley

Control

(2) Next, tighten the control box onto the motor.

box

(3) hisertthe power cord fromthe motor into the connector

on

the

from

of

backofthe

the

the

control

motor

into

box.

control

the

Encoder

code

box.

encoder

J

Insert

the

connectoronthe

oimiiaiiu

encoder

cord

front

Power

cord

from

motor

lOOV:

White

Selectthe correctpulleydiameterto ensure complete

useofthe motor performance.

200V:

Brown

connector

connector

Selection of the motor pulley:

Motm:

outer diameter (mm)

^

The

motor

flnH

the

Refertopage25for

pull^

speed

pulley

should

diameter

the

Noimal

besetat

istoo

pulley

3,600r/min.

small,

select

diameter

sewing

machine

^ Motorspeed

When

the

minimum

tobe

used

vdien

the

speed

motor

pulley

using

Motor

puUev

diameter

X „ . . + 0

(enective diameter)

pulley

diameterisselected

inthe

range

the

Mitsubishi

Select

thatthebelt

the

correct

thread

will

trimming

pulley diameter.

~9

. ,

with

mm

the

not

sewing

above

slip.

method

machine.

Page 12

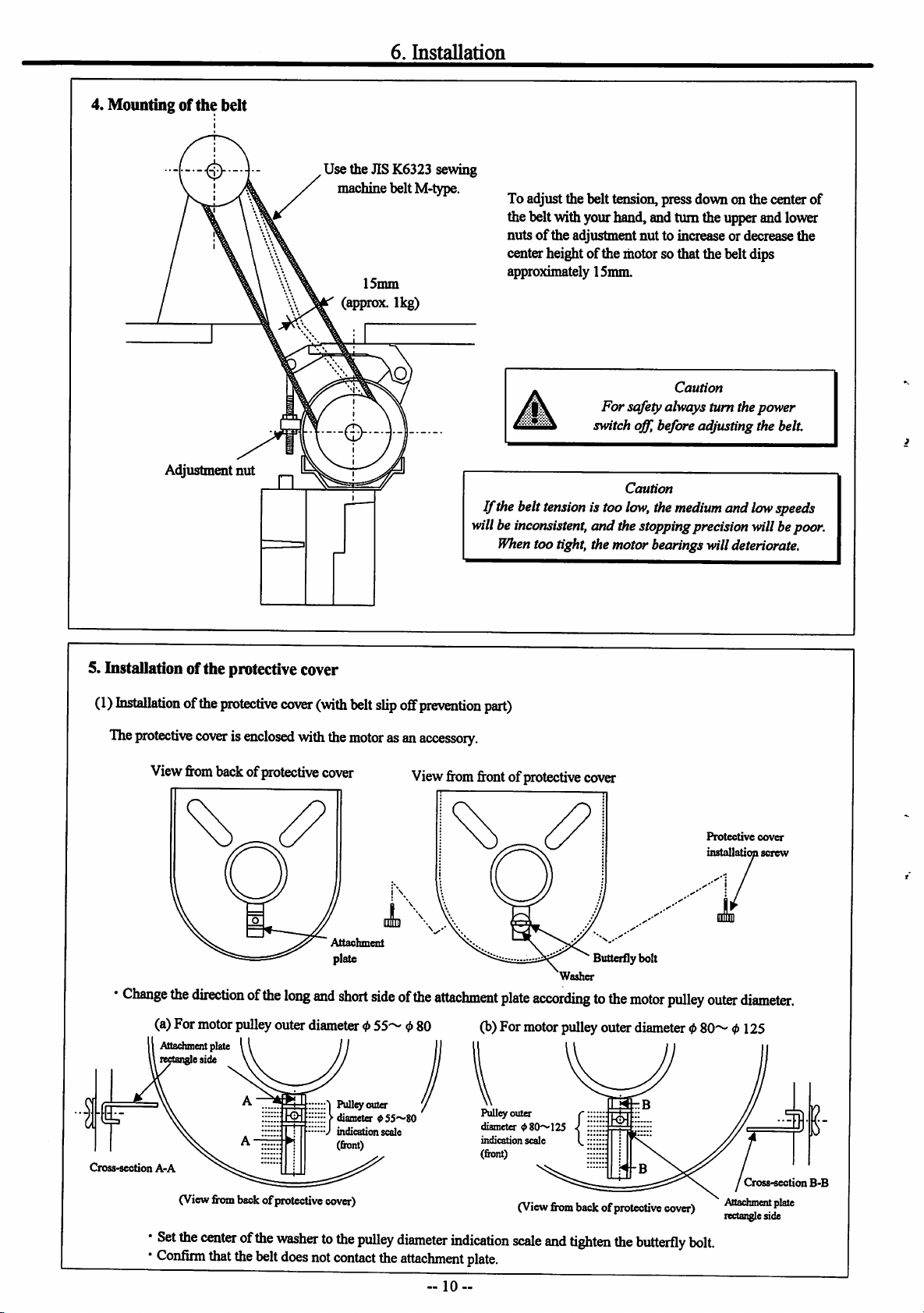

6.

Installation

4. Mounting of

Adjustment nut

the

belt

Use the JIS K6323 sewing

machinebelt M-type.

15mm

(approx. 1kg)

To adjust the belt tension, press down on the center of

the belt withyourhand, andturn the upperandlower

nutsofthe adjustment nut to increase or decrease the

centerheightofthe motorsothat the belt dips

approximately 15mm.

Caution

For

safetyalways turn thepower

switch off, before adjusting the belt.

Caution

If

thebelt

tension

is too

low,

the

willbe

When

medium

inconsistent,

too tight, themotorbearingswilldeteriorate.

and thestoppingprecisionwillbepoor.

and lowspeeds

5. Installation of the protective cover

(1)

histallation

The

protective

Change

ofthe

protective

coverisenclosed

Viewfrombackof protective cover

the

duectionofthe

(a) For motorpulley outer diameter0

Attachmentplate

rectangleside

cover

with

long

(with

and

}

Cross-section

A-A

(View

•

Set

the

•

Confirm

from

backof

centerofthe

that

the

belt

protective

cover)

washertothe

does

not

belt

slip

off

prevention

the

motor

asan

accessory.

Viewfromfrontof protectivecover

Attachment

plate Butterfly bolt

short

sideofthe

55~

Pulley

outer

diameter 055'<-'8O

indication

scale

(front)

pulley

contact

the

attachment

0 80

diameter

attachment

part)

Washer

plate

accordingtothe

(b)For motorpulleyouter diameter 0

Pulley outer

diameter

08O~125

indication

scale

(front)

(View

from

backofprotective

indication

scale

and

tighten

the

plate.

motor

pulley

cover)

butterfly

Protective

installation

outer

80~

bolt.

cover

screw

diameter.

0 125

1

Cross-section

Attachrncnt

rectangleside

plate

B-B

-10--

Page 13

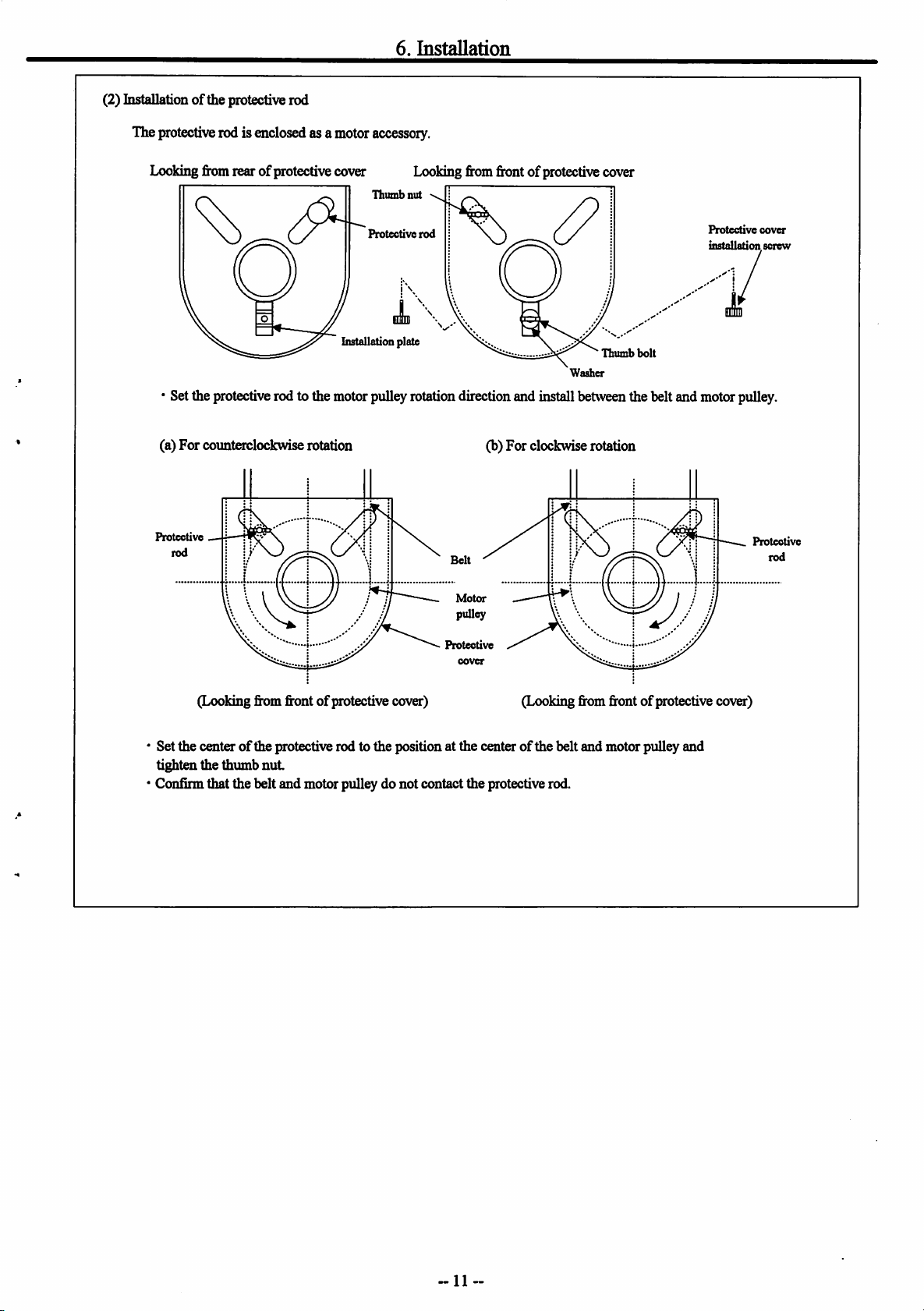

(2) L[istallation of the protective rod

The protectiverod is enclosedas a motoraccessory.

6.

Installation

Looking

fromrearofprotective cover

Installation

Thumb

Protective

Looking

nut

rod

fromfrontof

plate ^ ^ ^ ^

protective

Washer

cover

Protective

installation,

"Thumbbolt

*Settheprotectiverod to the motorpulleyrotationdirectionandinstallbetweenthebelt and motorpulley.

(a)

For

counterclockwiserotation

Protective

rod

(b) For clockwise rotation

Motor

pulley

cover

screw

Protective

rod

Protective

cover

(Looking from frontofprotective cover) (Looking from front

of

protective cover)

Set the centerofthe protective rod to the position at the centerofthe belt and motor pulley and

tighten the thumb

nut

Confirm that the belt and motor pulley do not contact the protective rod.

-11

Page 14

6.

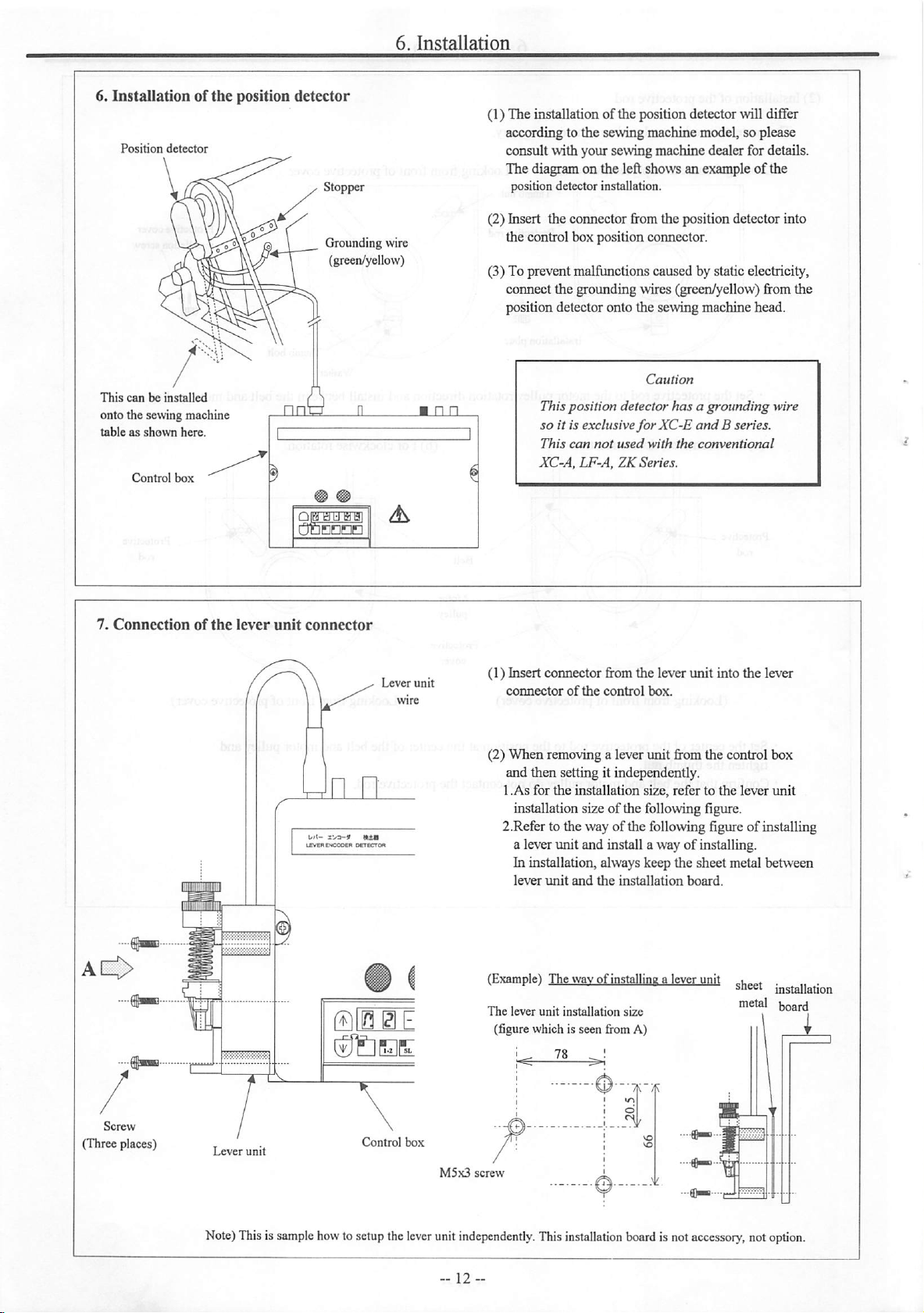

Installationofthe

Position

This

detector

canbeinstalled

onto the sewing machine

tableasshown

Control

here.

box

position

detector

Stopper

Grounding wire

(green/yellow)

(1) The installation of the position detector will differ

according to the sewing machine model, so please

consult with your sewingmachine dealerfor details.

The diagram on the left shows an example of the

position detector installation.

(2) Insert the connector from the position detector into

the control box position connector.

(3) To prevent malfunctions caused by static electricity,

connect the grounding wires (green/yellow) from the

position detector onto the sewing machine head.

Caution

Thisposition detector

so it is exclusive

This

can

not

used

XC-A.LF-A.ZK

has

forXC-E

with

the

Series.

a grounding wire

and

B series.

conventional

7.

Connection

of

the

11

lever

unit

connector

Lever

unit

(1) Insert connector from the lever

connectorofthe

(2)

When

removing a lever

control

unit

into the lever

box.

unit

from the control box

and then setting it independently.

1.As for

the

installation size, refer to

the

lever

unit

installation size of the following figure.

2.Refer to the way of the following figure of installing

a lever unit and install a way of installing.

In installation, always keep the sheet metal between

lever

unit

and

the

installation

(Example) The wav of installing a lever unit „ .

Ti,-

The

u,,-,.

lever

unit

installation

c.;,^

size

(figure which is seen fromA)

board.

sneer

mstallatioo

board

Control

Lever

Note)

unit

Thisissample

how

tosetupthe

box

lever

M5x3

screw

unit

independently.

This

installation

board

is not

accessory,

not

option.

Page 15

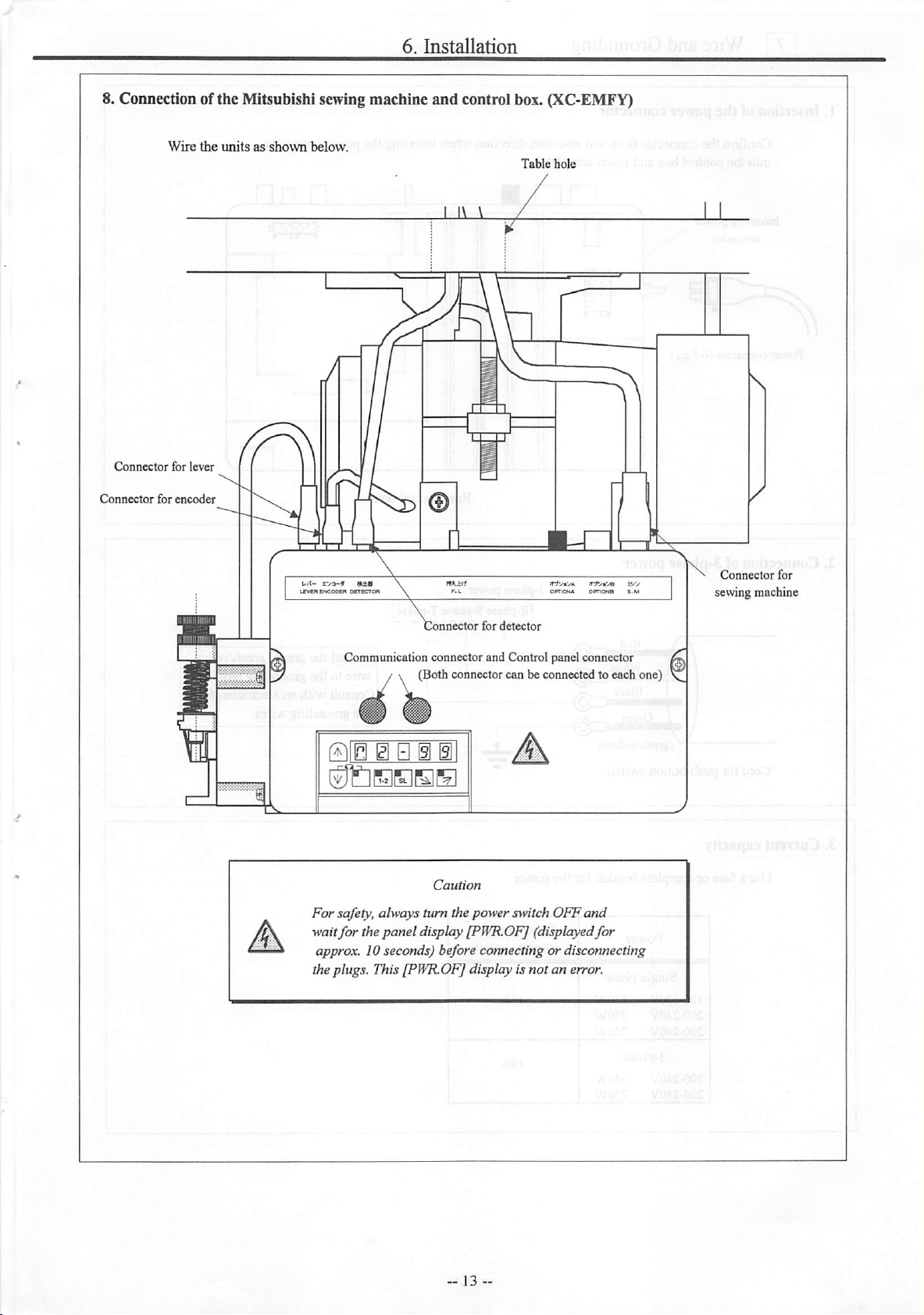

8. Connection ofthe Mitsubishi sewingmachine and control box. (XC-EMFY)

Wire

the

unitsasshown

below.

Table

hole

Connector

Connector

for

for

lever

encoder

Connector

Communication connector and Control panel connector

for

detector

/ \ (Both connectorcan be connected to each one)

WIB @ B i Bl

SJ&SBOE

Caution

For

safety, always turn the powerswitch

wait

for

the

panel

display[PWR.OF] (displayedfor

approx. 10 seconds) before connecting or disconnecting

theplugs. This [PWR.OF] display is not

OFF

an

and

error.

Connector

sewing machine

for

Page 16

pri

Wire

and

Grounding

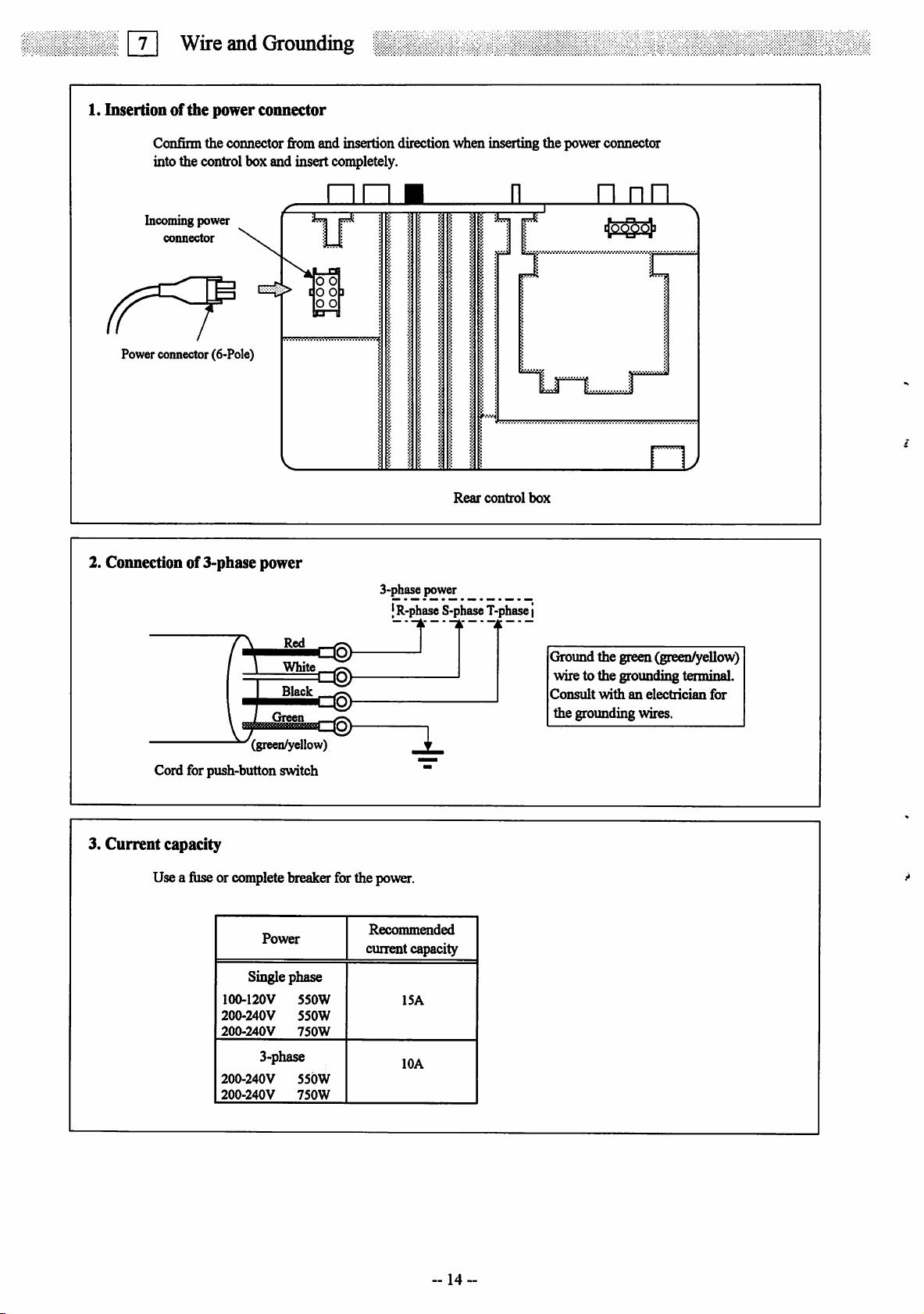

1. Insertion of

the

power

connector

Confinn the connector from and insertion directionwhen inserting the power connector

into the control box and insert completely.

Incomingpower

connector

%

Power connector (6-Pole)

2. Connection of 3-phase power

kr

O O

o o

o o

3-phase power

I

R-phase

S-phase

Rear

JL

control

T-phase

box

j

n

nn

3.

Current

White

Black

Green

'(green/yellow)

Cord for push-button switch

capacity

Usea fuse or completebreakerforthe power.

Power

Single phase

100-120V

200-240V

200-240V

3-phase

200-240V

200-240V

550W

550W

750W

55bW

750W

Recommended

current capacity

15A

lOA

Ground the green (green^ellow)

wire to the grounding terminal.

Consult

withanelectrician

for

the grounding wires.

--14

-

Page 17

7.Wire

and

Groundin

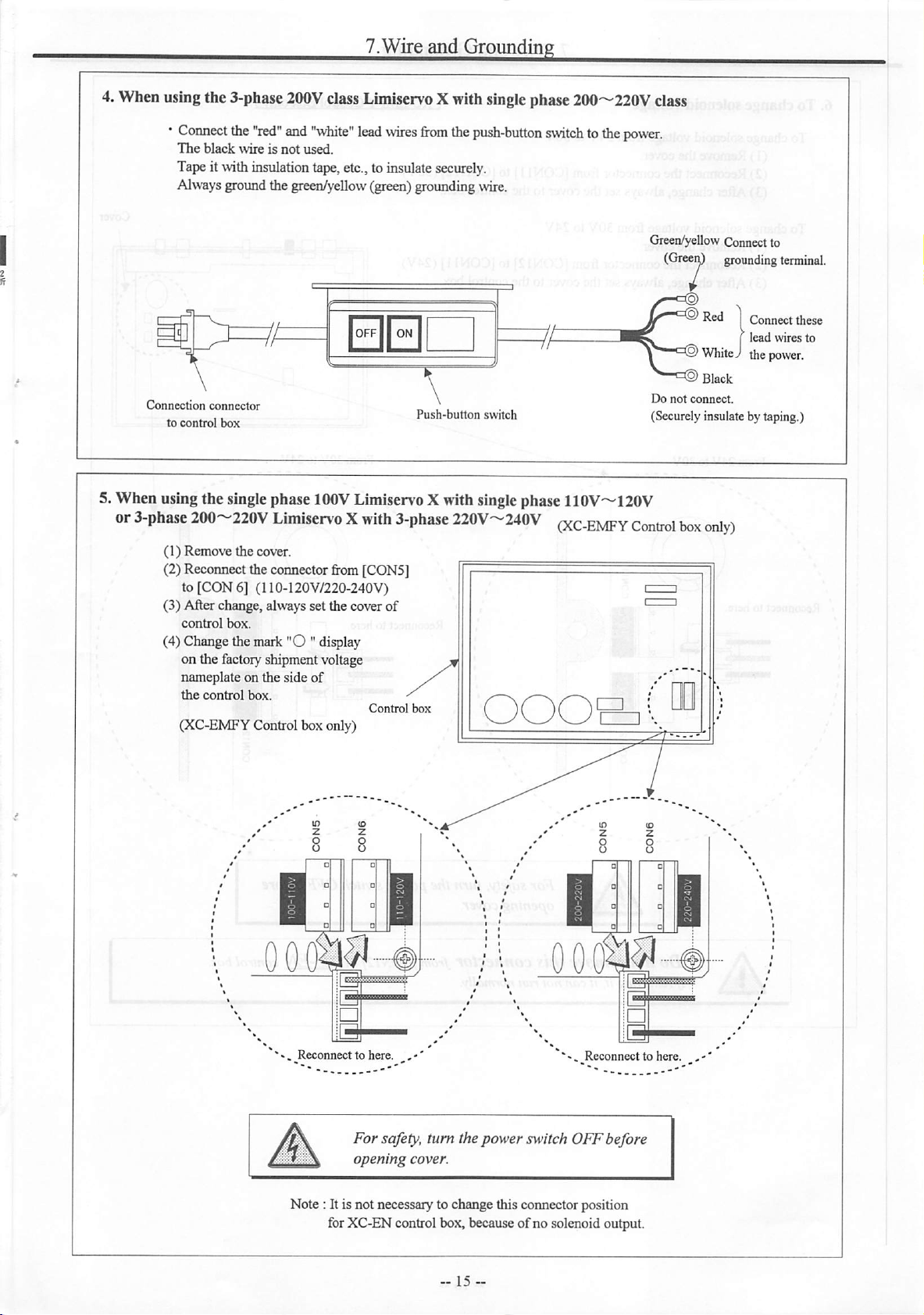

4.When usingthe3-phase

*

Connect

The

Tapeitwith

Alwaysgroundthe green/yellow (green)groundingwire.

black

the

"red"

wireisnot

insulation

200V

classLimiservo Xwith

and

"white"

lead

wires

used.

tape,

etc.,to

insulate

from

securely.

single

the

push-button

phase200'^220Vclass

switch

tothe

power.

Green/yellow Connect to

(GreeiO

*-©

Do

not

(Securelyinsulate by taping.)

grounding

Red1Connect

j

lead

Whitejthe

Black

connect.

terminal.

these

wires

to

power.

Page 18

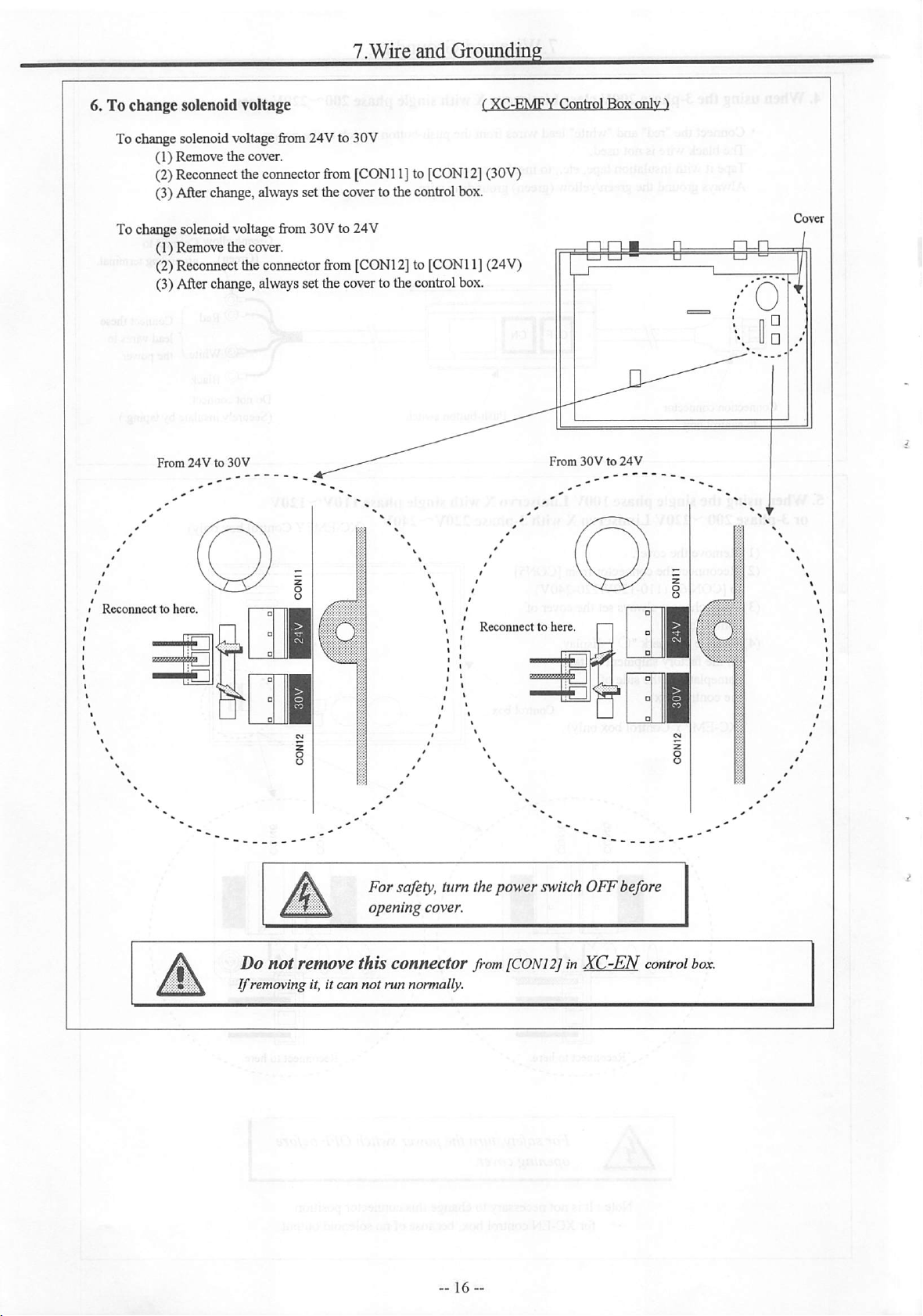

6. To change solenoid voltage

To change solenoid voltage from 24V to 30V

(1) Remove the cover.

(2)Reconnecttheconnector

(3)After change,alwayssetthe coverto thecontrolbox.

To change solenoid voltagefrom 30V to 24V

(1) Remove the cover.

(2)

Reconnect

the

connector

(3)After change,alwayssetthecoverto thecontrolbox.

7.Wire

from

[CONl1] to [CONl2](30V)

from

[CONl2]to [CONl1](24V)

and

Groundin

From

Reconnecttohere.

24Vto30V

^ t

. I

Reconnecttohere.

For

safety, turn thepower switch

opening

cover.

From30Vto24V

OFF

before

Do

not

remove

If

removing it, it can

this

connector

not

run normally.

from

[CONl

2]in

control

box.

Page 19

liiiii

H

Confirmation

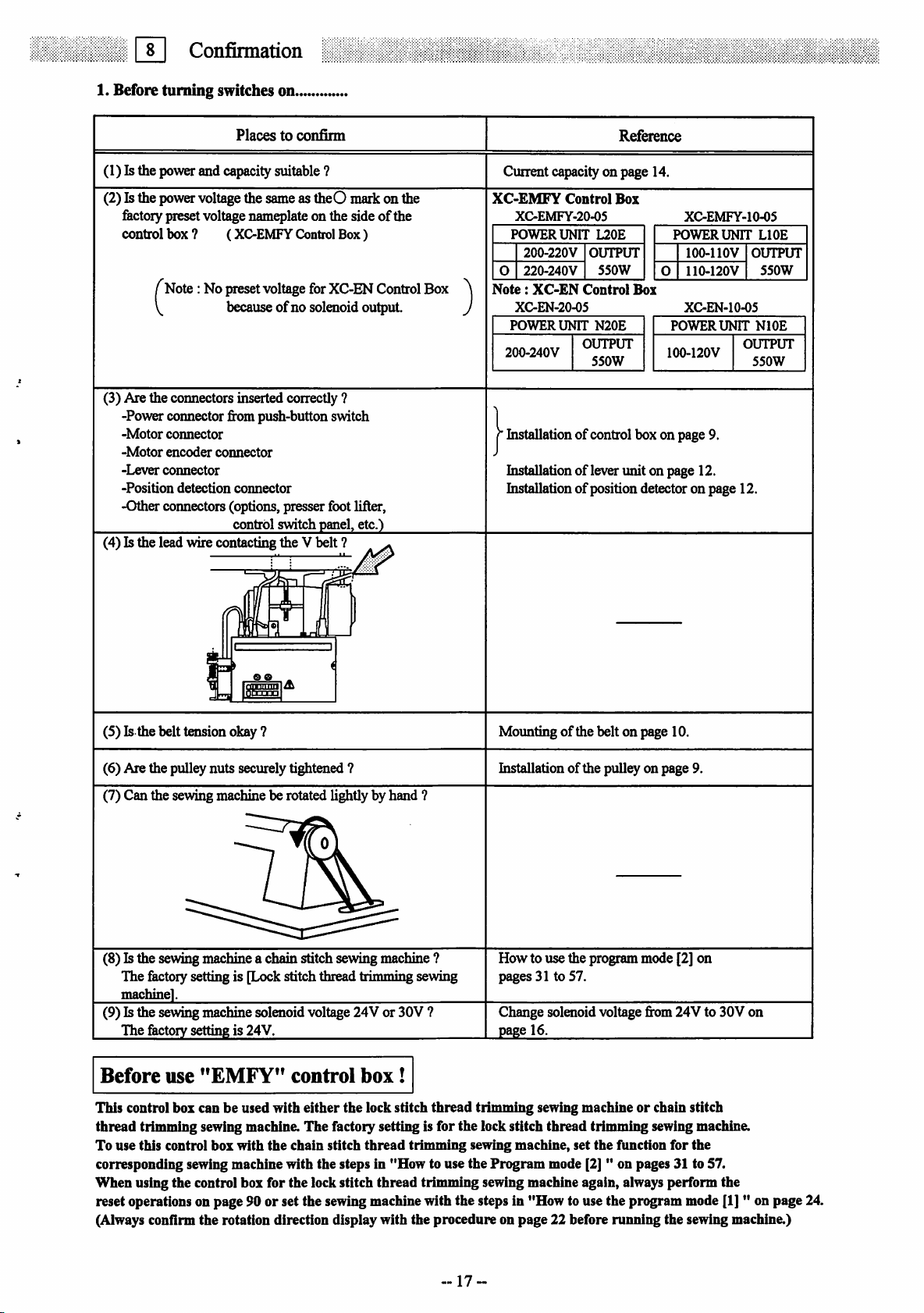

1. Before turningswitches on...

Placestoconfirm

(1) Is the power and capacity suitable ?

(2)Isthe

power

voltage

thesameas theO markonthe

fectorypresetvoltage nameplateon the sideofthe

control box ? (XC-EMFY Control

f

Note:No

preset

voltage

for

XC-EN

Box)

becauseofno solenoid output.

(3) Are the connectors inserted correctly ?

-Power connector from push-button switch

-Motor

connector

-Motor

-Lever

-Position

encoder

connector

detection

connector

connector

-Other connectors (options, presser foot lifter,

control

switchpanel,etc.)

(4) Is the lead wire contacting the V belt ?

Control

Box

Reference

Current capacityon page 14.

XC-EMFY

XC-EMFY-20-05

POWER

0

Note:

XC-EN-20-05

POWER

200-240V

200-220V

220-240V

XC-EN

Control

UNIT

UNIT

L20E

OUTPUT

550W

Control

N20E

OUTPUT

550W

Box

Box

XC-EMFY-10-05

POWER

lOO-llOV

0

110-120V

XC-EN-10-05

POWER

100-120V

histallation of control box on page 9.

histallation of lever unit on page 12.

Installation of position detector on page 12.

UNIT

UNIT

LIOE

OUTPUT

550W

NlOE

OUTPUT

550W

(5) Is the belt tension okay ?

(6) Are the pulley nuts securely tightened 7

Mounting of the belt on page 10.

Installation of the pulley on page 9.

(7) Can the sewing machine be rotated lightly by hand ?

(8) Is the sewing machine a chain stitch sewing machine ?

The factory setting is [Lock stitch thread trimming sewing

How to use the program mode [2] on

pages 31 to 57.

machine].

(9) Is the sewing machine solenoid voltage 24V or 30V ?

The

factory

settingis 24V.

Before

This control box can be used with

thread

To use this control box with

use

"EMFY"

control

either

box!

the lock stitch

thread

trimming sewing machine. The factory settingis for the lock stitch thread trimming sewing machine.

the

chain stitch

thread

trimming

corresponding sewing machine with the steps in "How to use the Program mode [2] " on pages 31 to 57.

When using the control box for the lock stitch thread trimming sewing machine again, always perform the

Change solenoid voltage from 24V to 30V on

page16.

trimming sewing machineorchain stitch

sewing machine, set

the

function

for

the

reset operations on page 90 or set the sewing machine with the steps in "How to use the program mode [1] " on page 24.

(Always confirm

the

rotation direction displaywith the

procedureonpage

22 before

running

the sewing machine.)

17

Page 20

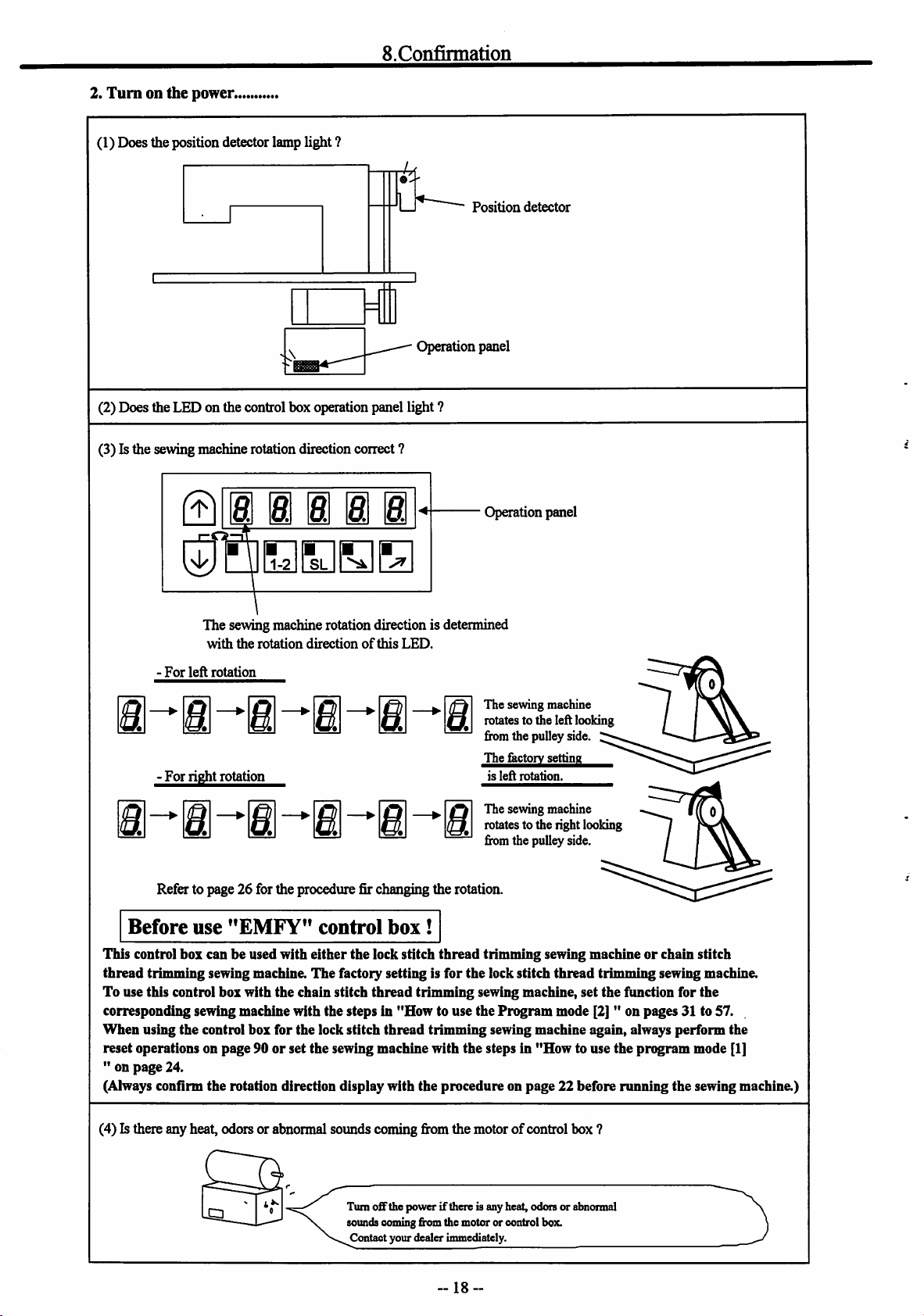

2.

Turnonthe

(1) Does the position detector lamp light ?

power.

S.Confirmation

4

U

Operation panel

(2) Does the LED on the control box operation panel light ?

(3) Is the sewing machine rotation direction correct ?

01

The sewing machine rotation direction is determined

with

i i i i

the

rotation

directionofthis

LED.

Position

detector

Operation panel

-

For

left

rotation

The sewing machine

rotates to the left looking

fromthe pulleyside.

^^fector^ettin^

is

left

For

right

rotation

Refer to page 26 for the procedure fir changing the rotation.

Before

This control box can be used with either the lock stitch

thread

To use this control box with

corresponding sewing machine with the steps in

When

using the control box for the lock stitch

reset operations on

" on

page

(Always confirm the rotation direction displaywith the procedure on page 22 before running the sewing machine.)

use

"EMFY"

trimming sewing machine.

the

page90or

24.

set

control

The

factory settingis for the lock stitch

chain stitch

the

sewing machine with

box

thread

"How

thread

!

thread

trimming

to use

trimming sewing machine again, always perform the

the

rotation.

The sewing machine

rotates to the right looking

ftom the pulley side.

trimming sewing machineorchain stitch

thread

trimming sewing machine.

sewing machine,

the

Program

steps in

set

the

function for

mode [2] " on pages 31 to 57.

"How

to use

the

pn^ram

the

mode [1]

(4) Is there any heat, odors or abnormal sounds coming fi'omthe motor of control box ?

Turnoffthe power ifthere is any heat, odors or abnormal

soundscomingfromthe motor or control box.

Contact your dealer immediately.

18-

Page 21

Q

Adjustments

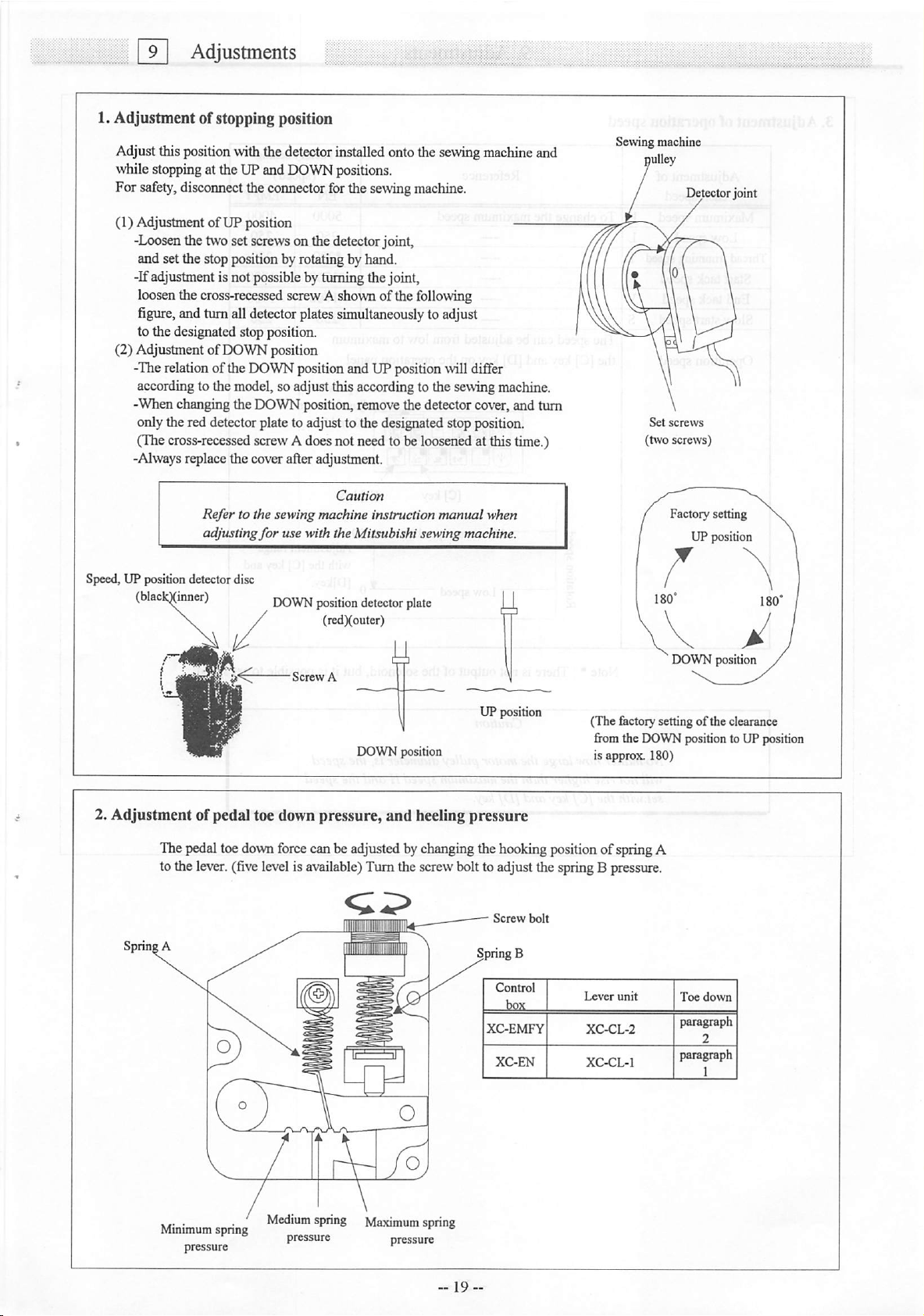

1. Adjustment of stopping position

Adjust this positionwiththe detectorinstalledontothe sewingmachineand

^\1lile

stopping at the UPand DOWNpositions.

For safety,disconnect the connector forthe sewing machine.

(1) AdjustmentofUP position

-Loosen the two set screws on the detector joint,

and set the stop position by rotating by hand.

-Ifadjustmentis notpossiblebyturningthejoint,

loosen the cross-recessed screw A shown of the following

figure,andturn alldetectorplatessimultaneously toadjust

to the designated stop position.

(2) Adjustment of DOWN position

-Therelationofthe DOWNpositionand UP position\villdiffer

according to the model, so adjust this according to the sewing machine.

-When changing the DOWN position, remove the detector cover, and turn

only the red detector plate to adjust to the designated stop position.

(The cross-recessed screwAdoesnot need to be loosenedat this time.)

-Alwaysreplace the cover afteradjustment.

Caution

Refer to the sewingmachine instruction

adjusting

for

use with the Mitsubishi sewing machine.

manual

when

Sewing machine

pulley

Detectorjoint

Set

screws

(two

screws)

Factory setting

UP position

Speed, UP position detector disc

(blackQ^ner)

DOWN

/

•

Screw

position

detector

(redXouter)

A

DOWN position

plate

UP position

DOWN position

(The &ctory setting of the clearance

from the DOWNposition to UP position

isapprox. 180)

Page 22

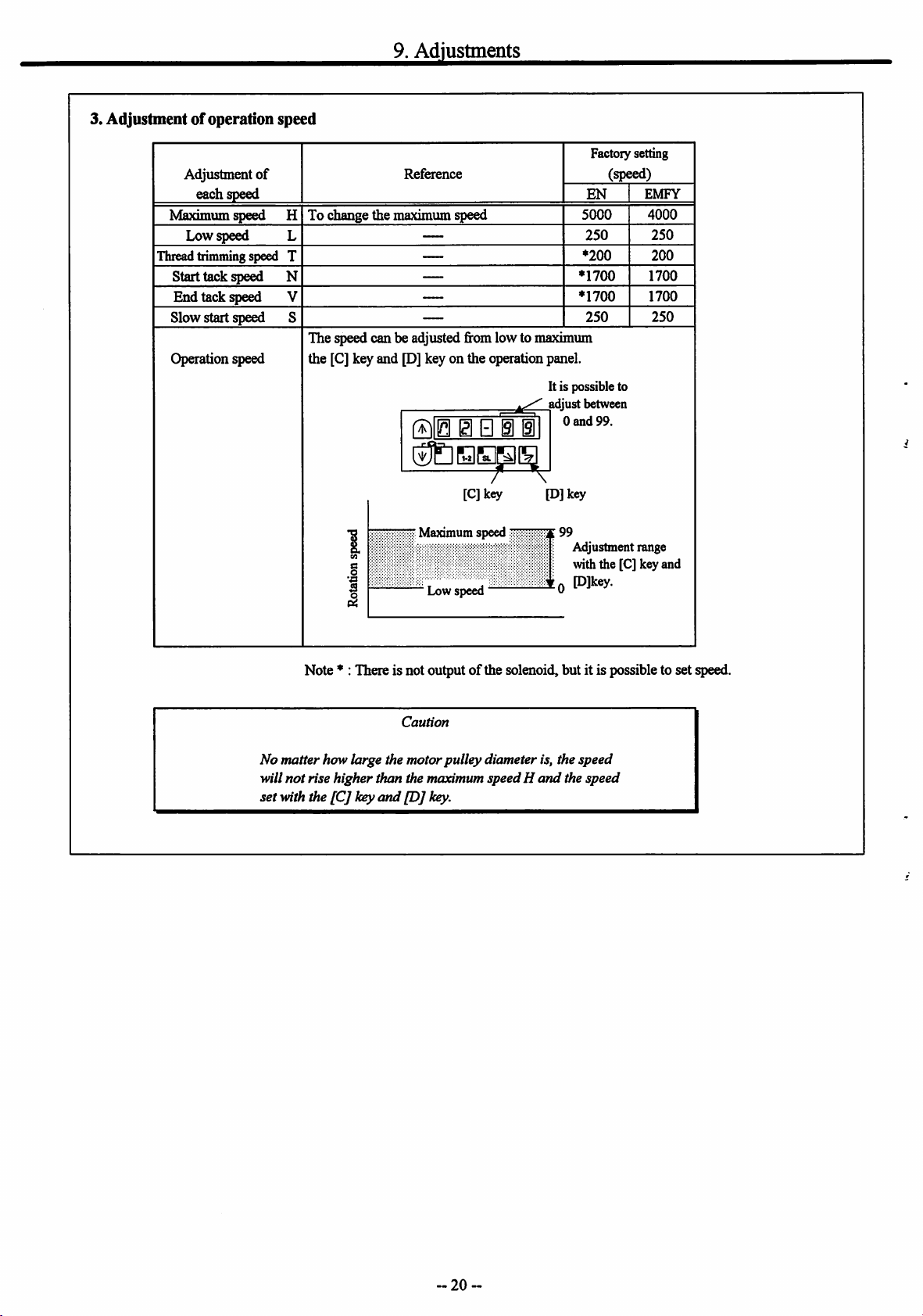

3. Adjustment of operation speed

Adjustment

each

Maximum speed H

Low speed

Thread trimming speed T

Start tack speed N

End tack speed V

Slow start speed 8

Operation speed

of

speed

9.

Adjustments

Reference

To change the maximum speed

The speed can be adjusted fromlow to maximum

the [C] key and [D] key on the operation panel.

It is possible to

adjust between

0

ffllEI gl B i i

and

liULlElBSCS

7^^

[Cjkey

[D] key

Factory setting

(speed)

EN

5000

250

♦200

'1700

♦1700

250

99.

EMFY

4000

250

200

1700

1700

250

:f99

Adjustment range

with the [C] key and

0

Plkey.

1

Maximumspeed

§

Lowspeed

Note♦: There is not outputofthe solenoid, but it is possible to set speed.

Caution

No matter how large the motorpulleydiameter is, the speed

will

not

rise higher than the maximum speedH

set with the

[C]

key

and

[D]

key.

and

the

speed

20

Page 23

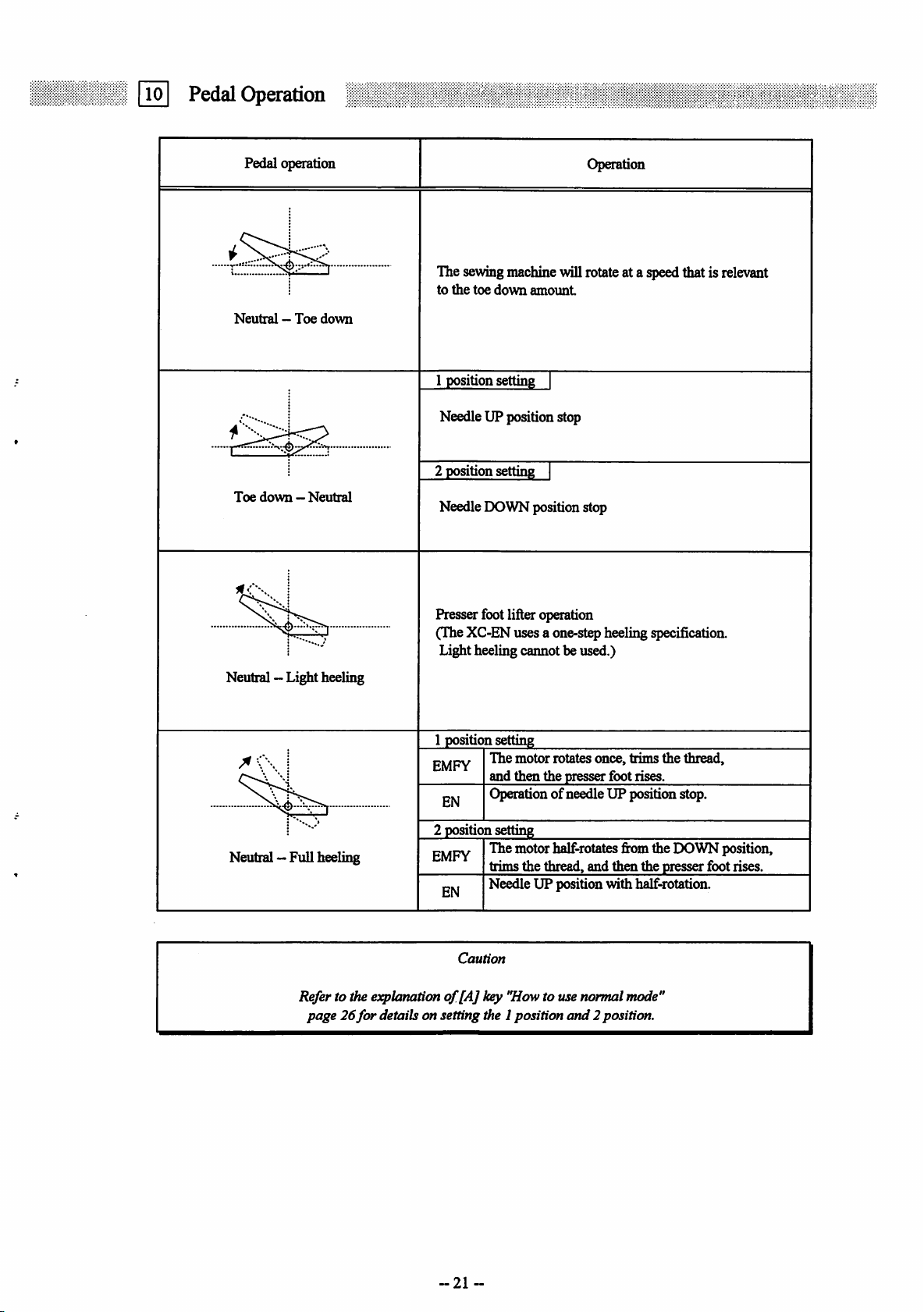

[Tol

Pedal

Operation

Pedal operation

Neutral—Toe

Toe

down-Neutral

down

Operation

The sewingmachinewill rotateat a speedthat isrelevant

to

the

toe

down

amount

1 position setting

NeedleUP positionstop

2

position

setting

Needle DOWN position stop

Presser footlifter operation

(The XC-ENuses a one-stepheeling specification.

Light heeling caimot be used.)

Neutral —Light heeling

Neutral —Fullheeling

Refer to the explanationof[A] key "Howto usenormal mode"

page26for

1 positionsetting

The

EMFY

EN

2 position setting

EMFY

EN

Caution

motor

andthenthe presserfootrises.

Operation of needle UP positicmstop.

The motor half-rotates

trims

the

thread,

Needle UP position with half-rotaticm.

details on setting the 1position

rotates

and

once,

fix>m

and

then

2position.

trims

the

thread,

the DOWN position,

the

presser

foot rises.

21

Page 24

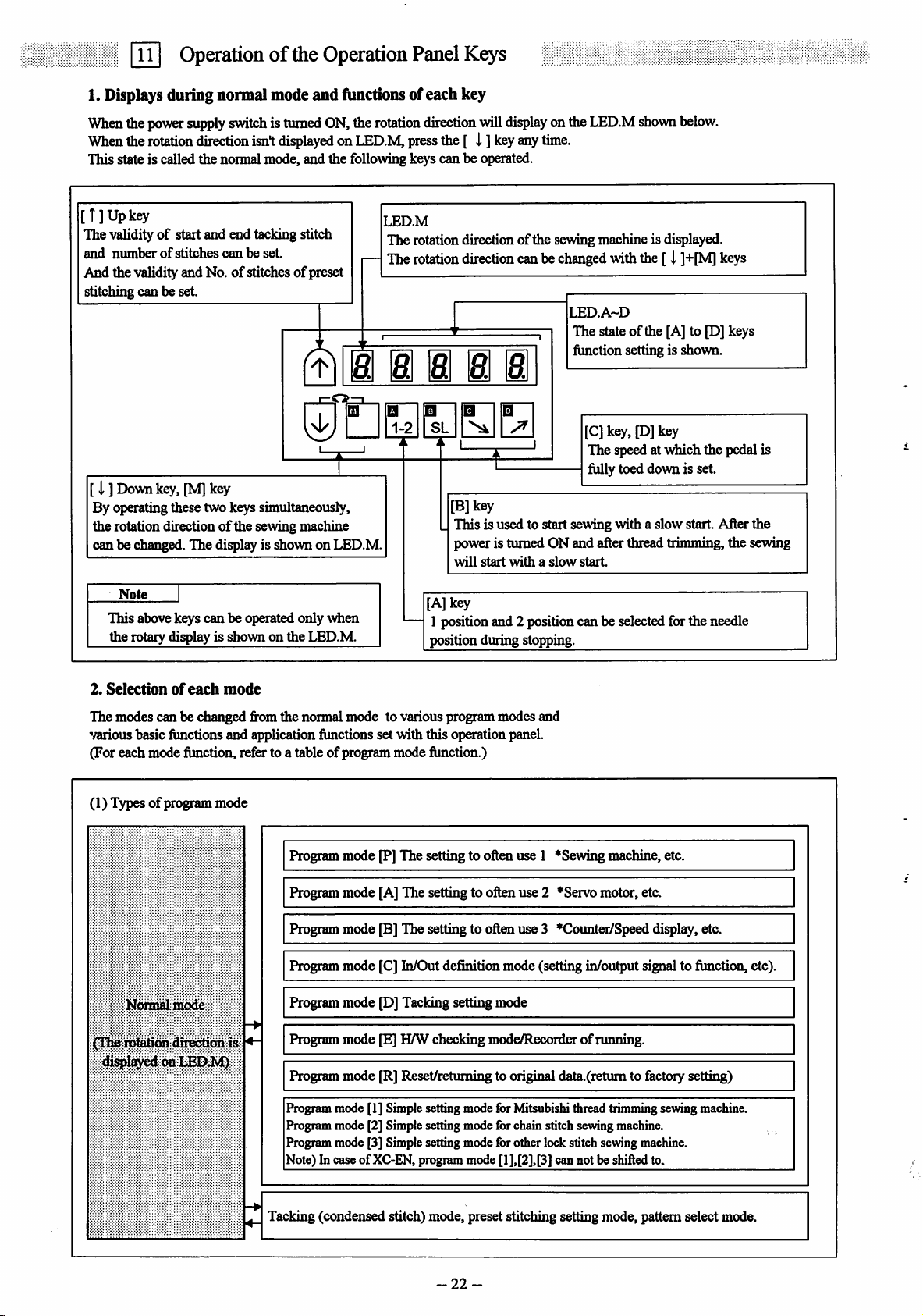

[u]

Operationofthe

Operation

Panel

Keys

1. Displays during normal mode

When

the

power

supply

switchisturned

When

the

rotation

This state is called the normal mode, and the following keys can be operated.

direction

isnt

[T]Upkey

The validityofstart and end tacking stitch

and

numberofstitches

And the validityand No.ofstitches of preset

stitching can be

canbeset.

set

and

fimctions of each key

ON,

the

rotation

displayedonLED.M,

LED.M

The rotation direction of the sewing machine is displayed.

The

direction

press

rotation

will

the[ i ]

direction

display

key

miBi a a a B

r—

0

[I ]

Down

key,

[M]

key

By operating these two keys simultaneously,

the rotation direction

can

be changed.

of

the sewing machine

The

display is shownon LED.M.

Q

1-2

[B]key

This is used to start sewing with a slow start. After the

power is turned ON and after thread trimming, the sewing

will

start

onthe

any

time.

canbe

changed

withaslow

LED.M

LED.A~D

The stateofthe [A] to [D] keys

function setting is shown.

[C] key, [D] key

The speedat which the pedal is

fiillytoed down is set.

start.

with

shown

the[ i

below.

]+[M]

keys

Note

This above keys can be operated only when

the rotary display is shown on the LED.M.

2.

Selectionofeach

The modes can be changed from the normal mode to various program modes and

various basic functions and application functions set with this operation panel.

(For each mode function, refer to a table of program mode function.)

(1) Typesofprogram mode

Normal

(The rotation direction is

mode

dl^layed on

mode

Program mode [P] The setting to often use 1 *Sewing machine,etc.

Program mode [A] The setting to often use 2 *Servo motor, etc.

Program mode [B] The setting to often use 3 •Counter/Speed display, etc.

Program mode [C] In/Out definition mode (setting in/output signal to function, etc).

Program mode [D] Tacking setting mode

Program mode [E] H/W checking

LEDJM)

Program mode [R] Reset/returning to original data.(retum to factory setting)

[A] key

1 position and 2 positioncan be selected forthe needle

positionduring

stopping.

mode^ecorderofrunning.

Program mode [1] Simple setting mode for Mitsubishi thread trimming sewing machine.

Program mode [2] Simplesetting mode forchain stitch sewing machine.

Program mode [3] Simple setting mode for other lock stitch sewing machine.

Note) In caseof XC-EN,programmode[1],[2],[3]can not be shifted to.

Tacking (condensed stitch) mode, preset stitching setting mode, pattern select mode.

22

Page 25

11.Operationofthe Operation Panel Keys

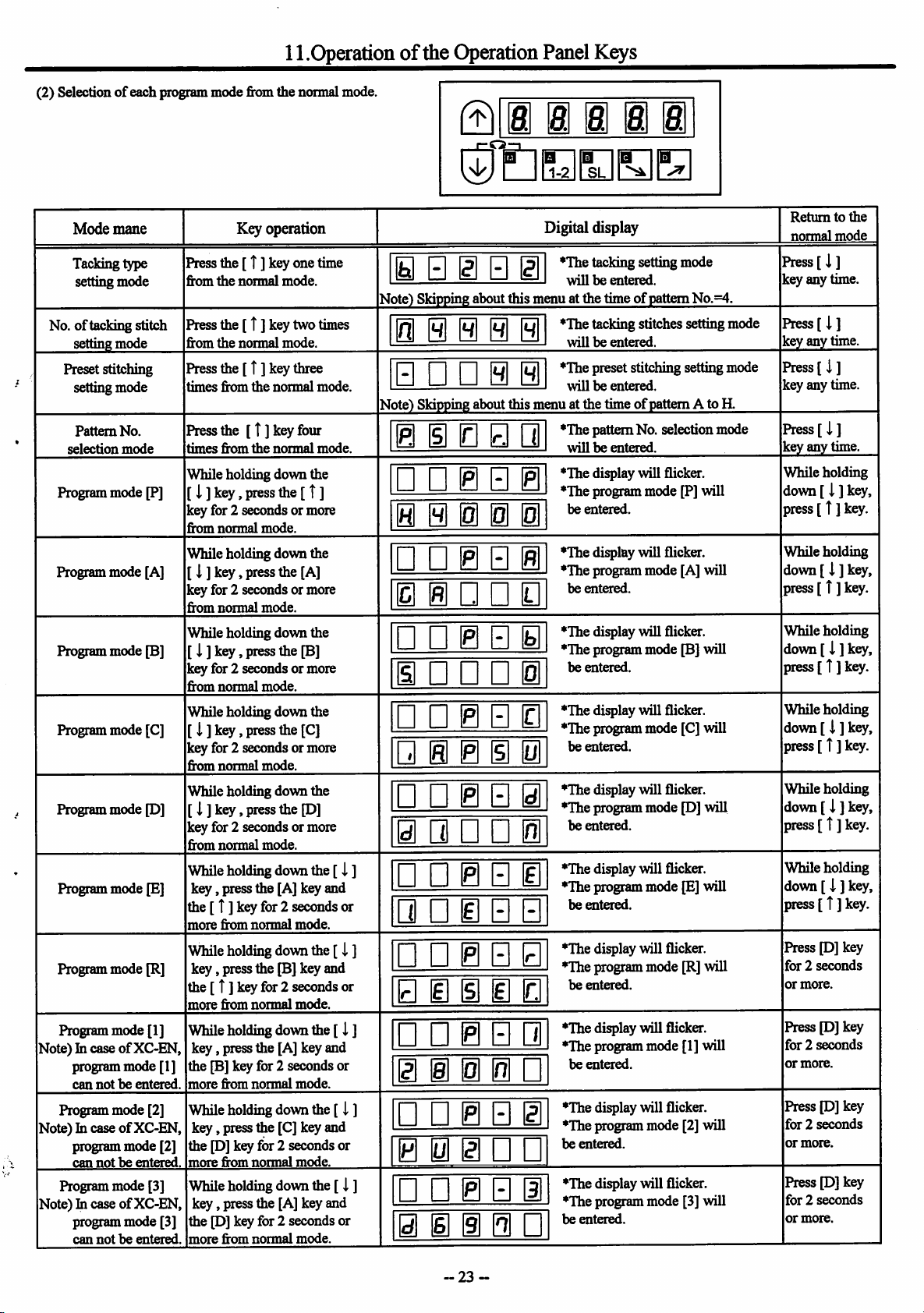

(2) Selectionofeach program mode from the normal mode.

©

8. 8 8 8

i

B

1-2

mSLB a

Mode

mane

Tacking type

setting mode

No.oftacking stitch

setting

mode

Preset stitching

setting mode

Pattern

No.

selection

Program mode [P]

Program mode [A]

Programmode [B]

Program mode [C]

Programmode [D]

Program mode [E]

Program mode [R]

Program mode [1]

Note) In case

programmode [1]

can

Programmode [2]

Note) In caseofXC-EN,

program mode [2]

cannot be

Program mode [3]

Note) In caseofXC-EN,

program mode [3]

can

mode

of

XC-EN,

notheentered.

entei^.

notbeentered.

Keyoperation

Pressthe[ t ]keyone

from

the

normal

Press

the[T] keytwo

from

the

normal

Press

the[ t ] key

times

from

the

Press

the

[t]keyfour

times

from

the

While holding down the

[ i ]key,

key for 2 seconds or more

from

While holding down the

[ i ] key,

key for 2 seconds or more

from

While holding down the

[ i ] key,

key for 2 seconds or more

from

While holdingdown the

[ I ] key,

key for 2 seconds or more

from

While holding down the

[ i ]key,

key for 2 seconds or more

from

While

key,

the[ t ]

more

While

key,

press

normal

mode.

press

normal

mode.

press

normal

mode.

press

normal

mode.

press

normal

mode.

holding

press the [A] key and

key

for2

from

normal

holding

pressthe [B] key and

the[ T] keyfor2

more

from

normal

While

holding

key,

pressthe [A] key and

mode.

mode.

three

normal

normal

the[ t ]

the

[A]

the

[B]

the

[C]

the

[D]

down

seconds

mode.

down

seconds

mode.

down

time

times

mode.

mode.

the[ i ]

the[i ]

the[ i ]

the [B]key for 2 secondsor

more

from

normal

mode.

While

holding

key,

press the [C] key and

down

the[ i ]

thep]keyfor 2 seconds or

more

from

normal

mode.

While

holding

key,

press the [A] key and

p]

the

more

from

down

the[J.]

keyfor 2 seconds or

normal

mode.

or

or

0 S g S gl

N

ote)

N

10

•

ote)

Skipping

Skipping

about

0 0 0

••00

about

0 0 0 • •

• • 0 E 0

0 0 0 0 1

•

•0Si

0 i • • D

• • 0 E 0

0 • E • 1

• • 0 E 0

•

0000

• • 0 E 0

0 • • • 1

• • 0 E 0

•

•0EE

•

•0EB

E 0 0 0 0

• • 0 E 0

0 i

11

• • 0 E 0

0 0 0 • •

• • 0 E 0

0 0 0 0 •

Digital display

jnuatthe

this

m(

muatthe

this

m(

•

*Thetacking setting mode

willbeentered,

timeofpattern

*Thetacking stitches setting mode

willbeentered.

*Thepreset stitching setting mode

willbeentered,

timeofpattern

♦The

pattern No. selection mode

willbeentered.

♦The

display will flicker.

♦The

program mode [P] will

be

entered.

♦The

display will flicker.

♦The

program mode [A] will

be

entered.

♦The

display will flicker.

♦The

program modeP]will

be

entered.

♦The

display will flicker.

♦The

programmode [C] will

be

entered.

♦The

display will flicker.

♦The

program modep]will

be

entered.

♦The

display will flicker.

♦The

programmodep]will

be

entered.

♦The

display will flicker.

♦The

programmode[R] will

be

entered.

♦The

display will flicker.

♦The

programmode[I] will

be

entered.

♦The

display will flicker.

♦The

programmode [2] will

be

entered.

♦The

display will flicker.

♦The

programmode [3] will

be

entered.

No.=4.

A to H.

Returntothe

normal

mode

Press[J,

key any time.

]

Press[ i ]

key

any

time.

Press[

i]

key any time.

Press[i]

key

any

time.

While holding

down

[ i ]

key,

press

[ T]

key.

While holding

down[ i ] key,

press[ T]

While holding

down

press[ T]

Whileholding

down

press

While holding

down[ \ ]

press

Whileholding

down[i ]

press

Pressp]key

for2seconds

or

Pressp]key

for2seconds

or

PressP]key

for2seconds

or

PressP]key

for2seconds

or

more.

more.

more.

more.

[ i ]

[ i ]

[ t ]

[ T]

[ T]

key.

key,

key.

key,

key.

key,

key.

key,

key.

-23

Page 26

11.Operationofthe Operation Panel Keys

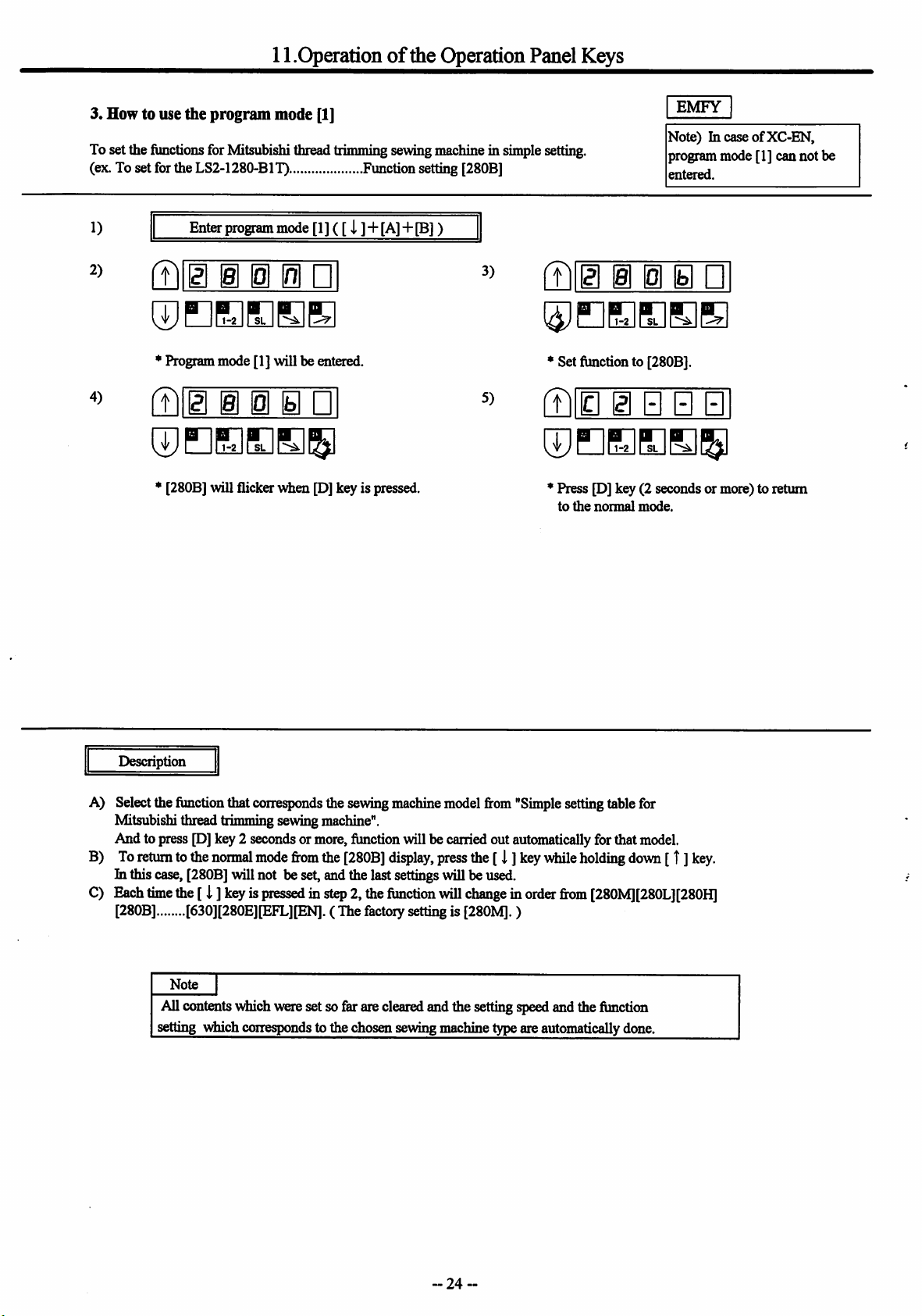

3. How to use the

Toset the functions forMitsubishithreadtrimmingsewingmachinein simplesetting,

(ex.To setfortheLS2-1280-BIT) Functionsetting[280B]

1)

2)

4)

ftllB i i

* Program mode [1] will be entered.

fB

program

Enter

program

i 0 •

mode [1]

mode

[1]([i ]+ [A]+[B])

ED

fBig i i 0 •

♦

Set function to [280B].

[Bib 0 • • 0

©EBEE^

♦

[280B] will flicker

wdien

[D]key is pressed.

* Press [D] key (2 seconds or more) to return

to

the

normal

EMFY

Note) hi caseofXC-EN,

program mode [1] can not be

entered.

mode.

Description

A) Selectthe function thatcorresponds the sewing

Mitsubishithread trimming sewingmachine".

And topress[D]key2 secondsormore,functionwillbecarriedout automatically forthatmodel.

B)

To

return

tothe

normal

mode

from

the

[280B]

In

this

case,

[280B]

will

notbeset,

C)

Each

time

the

[i ]

keyispressedinstep2,the

[280B] [630][280E][EFL][EN]. ( The factorysettingis [280M]. )

Note

Allcontentswhichweresetsofarareclearedand the settingspeedand thefunction

setting

which

corresponds

and

to thechosen

the

machine

display,

last

settings

function

sewing

modelfrom

press

the[I ]

willbeu^.

will

changeinorder

machine

"Simple

key

typeare

settingtablefor

Mhile

holding

from

[280M][280L][280H]

automatically

down

done.

[t ]

key.

24

~

Page 27

♦5

Function

name

280M

280H

280B

210M

230M

230L

^

230B

2S0M

2S0A

2S0B

3370

359

3310

3750

410B

430B

4710

4730

630

280E

EFL

EN

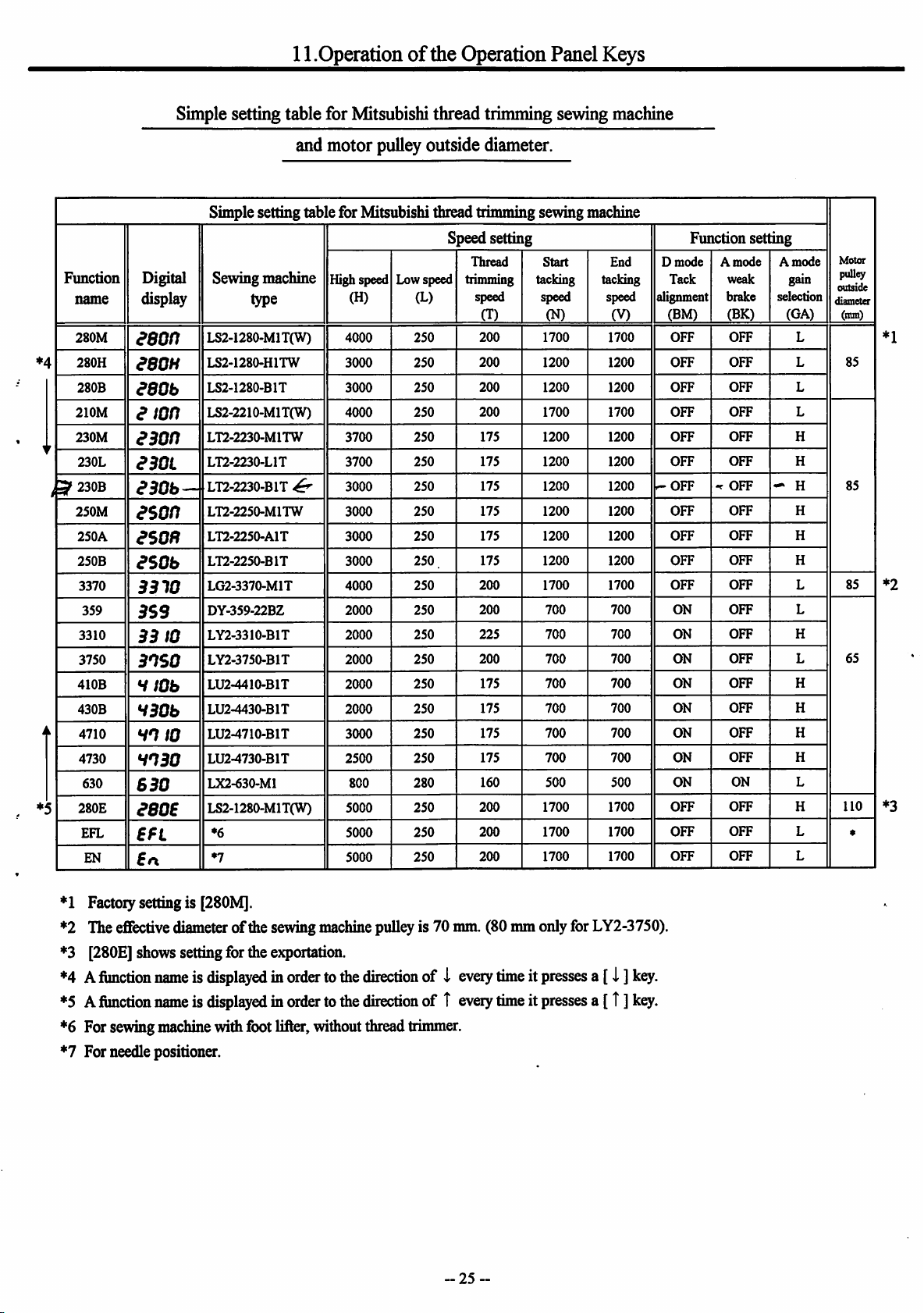

11.Operationofthe Operation Panel Keys

Simplesetting table for Mitsubishithread trimming sewingmachine

and motor pulleyoutside diameter.

Simplesetting table for Mitsubishi thread trimming sewingmachine

peedsetting Function setting

s

Digital

display

aeon

eeoH

asob

a

ton

aaon

asoL

ason

ason

asob

B310

BSS

BB

Bnso

HtOb

HBOb

HO

HOBO

6B0

aeoe

£n

£n

Sewingmachine

LS2-1280-M1T(W)

LS2-1280-H1TW

LS2-1280.B1T

LS2-2210-M1T(W)

LT2-2230-M1TW

LT2-2230-L1T

LT2-2230-B1T

LT2-2250-M1TW

LT2-2250-A1T

LT2-2250-B1T

LG2-3370-M1T

DY-359-22BZ

LY2-3310-B1T

to

LY2-3750-B1T

LU2-4410-B1T

LU2-4430-B1T

LU2^710-B1T

to

LU2-4730-B1T

LX2-630-M1

LS2-1280-M1T(W)

•6

•7

type

^

High speed

(H)

4000

3000

3000

4000

3700

3700

3000

3000

3000

3000

4000

2000

2000

2000

2000

2000

3000

2500

800

5000

5000

5000

Lowspeed

(L)

250

250

250 200

250 200

250

250

250

250

250

250

250

250

250

250

250

250

250

250

280

250

250

250

Thread

trimming

speed

(T)

200

200

175

175

175

175

175

175

200

200

225

200

175

175

175

175

160

200

200

200

Start

tacking

speed

(N)

1700

1200

1200

1700

1200

1200

1200

1200

1200

1200

1700

700

700

700

700

700

700

700

500 500

1700

1700

1700

End

tacking

speed

(V)

1700

1200

1200

1700

1200

1200

1200

1200

1200

1200

1700

700

700

700

700

700

700

700

1700

1700

1700

D

mode

Tack

alignment

(BM)

OFF

OFF

OFF

OFF

OFF

OFF

^OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

•r

A

brake

mode

weak

(BK)

OFF

OFF

OFF

OFF

OFF

OFF

Off

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

A

mode

gain

selection

(GA)

L

L

L

L

H

H

H

H

H

H

L

L

H

L

H

H

H

H

L

H

L

L

Motor

puU^

outside

diameter

(mm)

85

85

85

65

110

*

*1

*2

*3

*1 Factoiy setting is [280M].

*2 Theeffective diameterofthesewing

machine

pulleyis 70mm. (80mm onlyforLY2-3750).

"'3 [280E]showssettingfortheexportation.

'''4Afunction

*5Afunction

*6 For sewing

nameisdisplayedinordertothe

nameisdisplayedinordertothe

machine

withfootlifter, widiout thread

direction

direction

trimmer.

of i

of T

eveiy

timeitpresses

every

timeitpresses

a[i ]

a [T]

key.

key.

*7 For needlepositioner.

25

Page 28

11.Operationofthe Operation Panel Keys

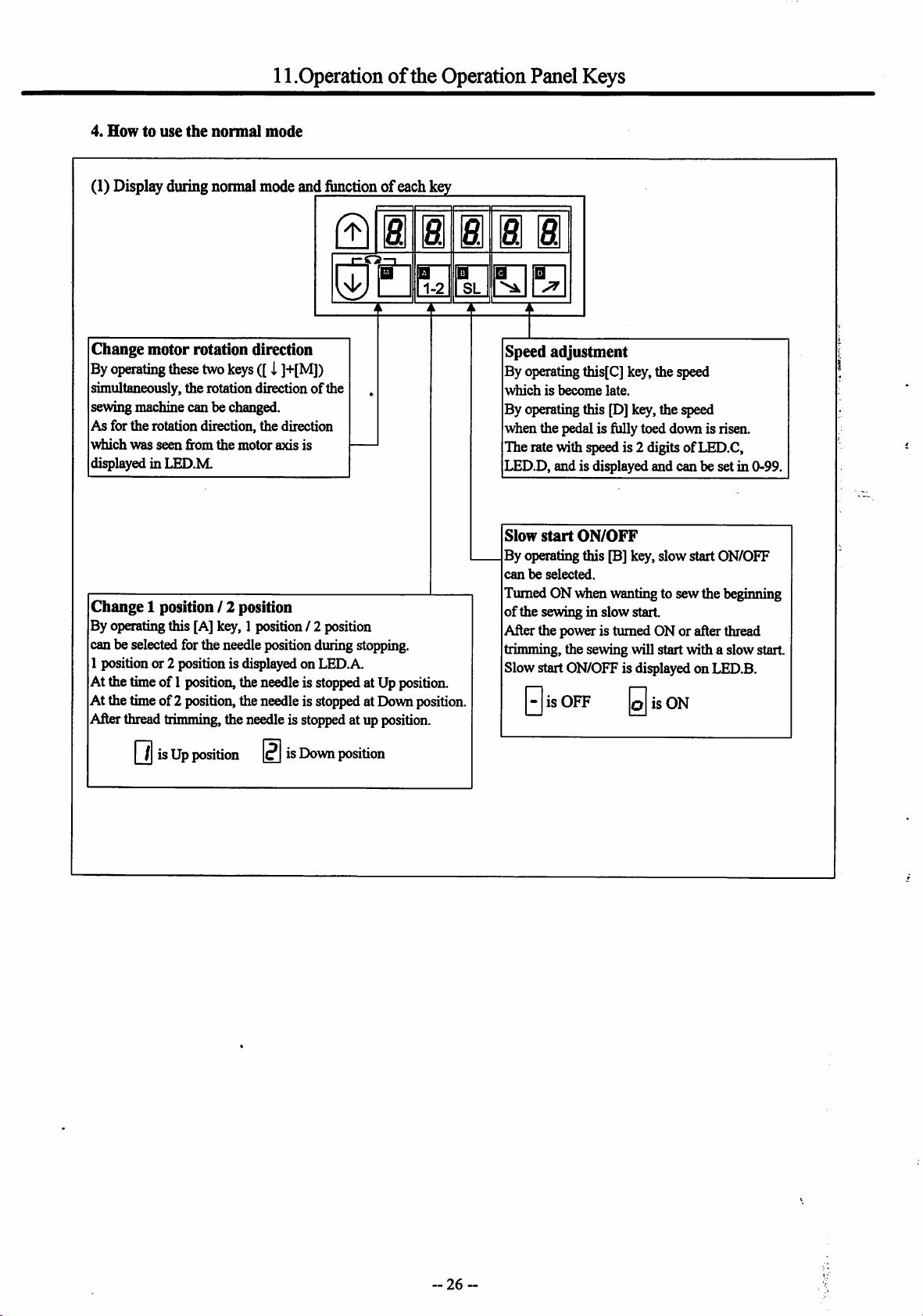

4.

Howtouse

(1) Display during normal mode and functionofeach key

the

normal

mode

la|

e. a a

j*"!

Change motorrotation direction

By

operating

simultaneously,the rotation directionofthe

sewingmachinecan be changed.

As for the rotation direction, the direction

which

displayed in

Change

By operatingthis [A] key, 1 position / 2 position

can be selectedfor the needle positionduring stopping.

1 position or 2 position is displayedon LED.A.

At the timeof 1position,theneedleis stoppedat Up position.

At thetimeof 2 position,the needle is stoppedatDownposition.

Afterthreadtrimming, the needleis stopped at upposition.

these

two

keys

was

seen

from

the

motor

LED.M

1 position / 2 position

([i

]+[M])

axis

is

|Q3|

•

B B

SL

Speed

adjustment

By operatingthis[C] key, the speed

whichisbecome

By operatingthis [D] key, the speed

when the pedal is fully toed down is risen.

The rate with speed is 2 digits ofLED.C,

LED.D, and is displayed and can be set in 0-99.

Slow

start

By operating this [B] key, slow start ON/OFF

canbeselected.

Tumed ON when wantingto sew the beginning

of

the sewing in slow start.

After the power is tumed ON or after thread

trimming, the sewing will start with a slow start.

Slow start ON/OFF is displayed on LED.B.

-is

0

ON/OFF

OFF

late.

is

ON

[7|isUp

position0is

Down

position

-

26

Page 29

11.Operationofthe Operation Panel Keys

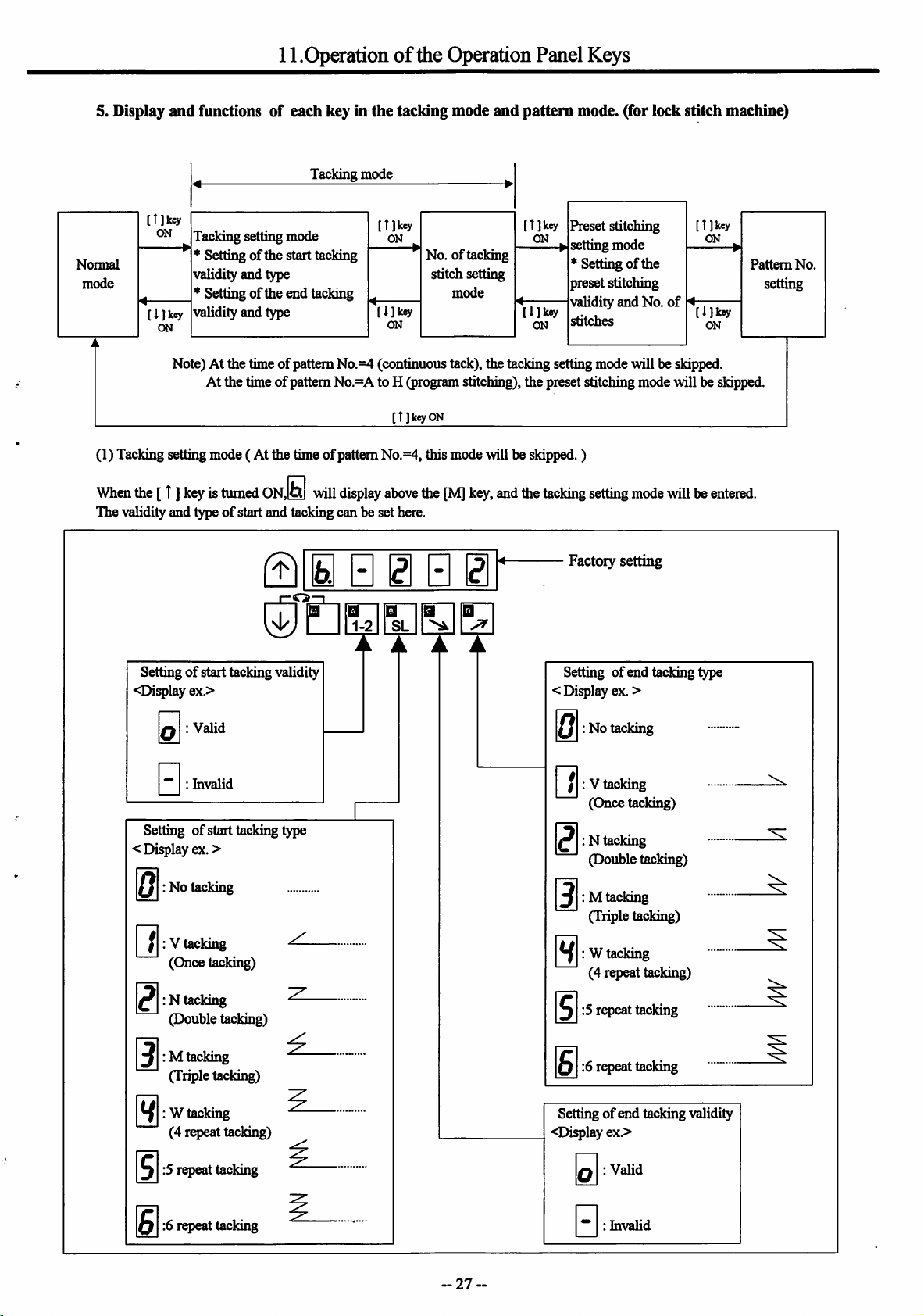

5. Display

Normal

mode

(1) Tackingsettingmode( At the time ofpatternNo.=4, this mode will be skipped.)

When

The validity and typeofstart and tacking can be set here.

and

functions of each key in

Tacking mode

Tacking setting mode

* Settingofthe start tacking

validity and type

* Setting of the end tacking

validity and type

Note) At the timeofpattern No.=4 (continuous tack), the tacking setting mode will be skipped.

At the time ofpattern No.=A to H (programstitching), the preset stitching modewill be skipped.

the

[T]

keyisturned

ON.I^

will

the

[T]keyON

display

above

tacking mode

No. of tacking

stitch setting

mode

the

[M]

key,

and

and

pattern

the

mode, (for lock stitch machine)

Preset stitching

setting mode

* Setting

preset stitching

validity and No. of

stitches

tacking

setting

Factory setting

of

the

mode

[T]key

ON

willbeentered.

Pattern

setting

No.

[3^

Settingofstart tacking validity

<Di^lay

< Display ex. >

0

[~^:Vtacking

ex.>

VaUd

0:

Invalid

0:

Setting of start tacking type

:No tacking

(Once tacking)

:N tacking

(Double tacking)

: M tacking

(Triple tacking)

B

B

SL

^ A A A

Setting of end tacking type

< Display ex. >

: No tacking

0

|~^:Vtacking

(Once tacking)

:N tacking

(Double tacking)

: M tacking

(Triple tacking)

: W tacking

(4 repeat tacking)

:Srepeat tacking

:6 repeat tacking

: W tacking

(4 repeat tacking)

:5 repeat tacking

:6 repeat tacking

27

Setting

of

end tacking validity

<Display ex.>

Valid

0

Invahd

0

Page 30

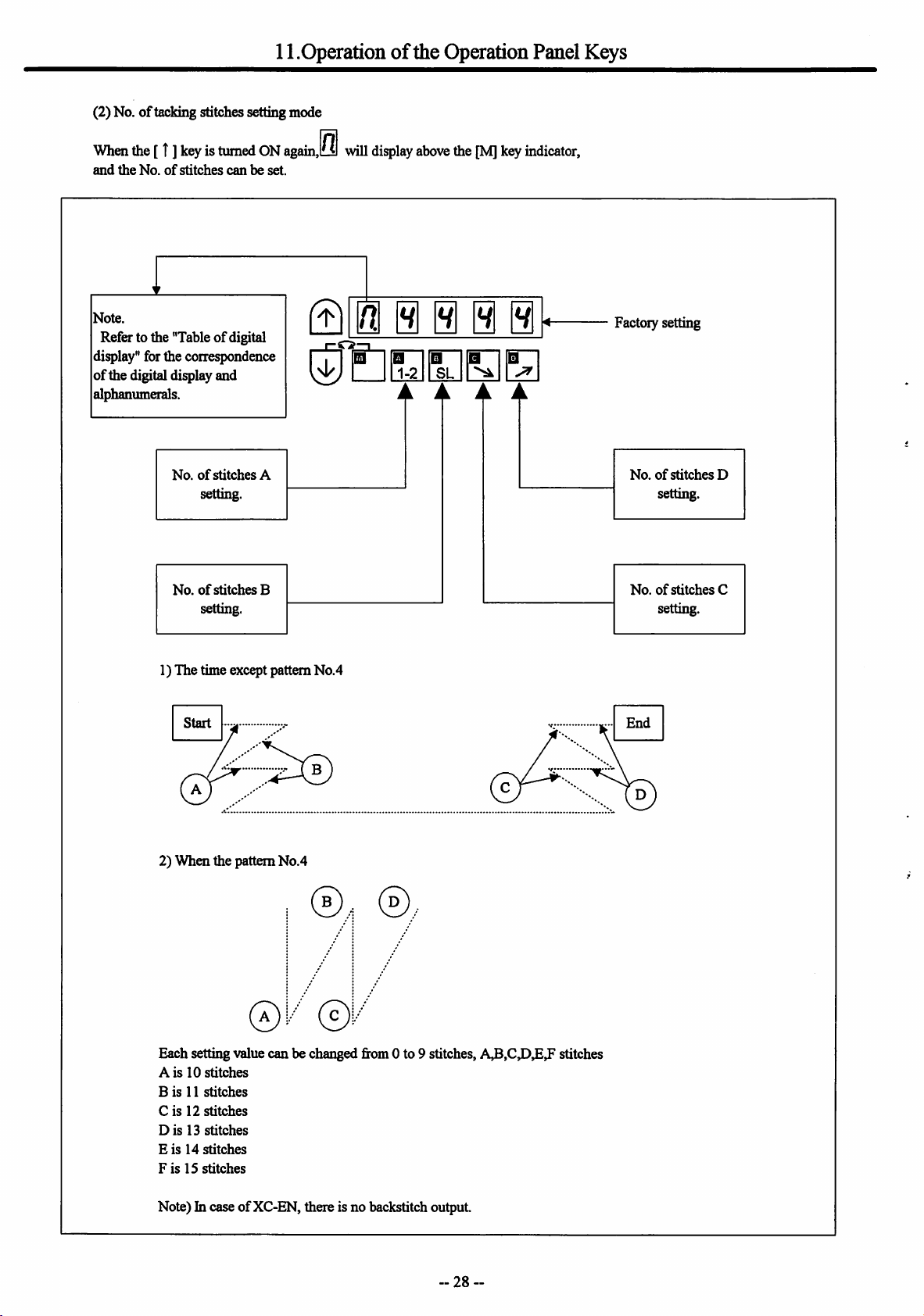

11.Operationofthe Operation Panel Keys

(2) No.oftacking stitches setting mode

When

the

[t]

and

the

No.ofstitches

keyisturned

ON

canbeset.

again,l0l

will

display

above

the

[M]

key

indicator,

Note.

Refer to the "Tableofdigital

display"forthecorrespondence

of

the digital display and

alphanumerals.

No.ofstitches

settmg.

No.ofstitches

settmg

1) The time except pattern No.4

Start

A

B

© i @@@s

B

m

1-2

©

SL

A A A

Factory setting

No.ofstitches

settmg.

No.ofstitches

settmg.

End

D

C

2)

When

the pattern

Each setting value can be changed from 0 to 9 stitches, stitches

Ais10

stitches

Bis11

stitches

Cis12

stitches

Dis13stitches

Eis14

stitches

FisIS

stitches

Note) In case ofXC-EN, there is no backstitch output.

No.4

©,.i

®.

~

28

Page 31

11.Operationofthe Operation Panel Keys

(3) Preset stitching settingmode

1) When the pattern is the time except patternNo.4

Q • • • 0 B

Factory setting

of

0:

0:

preset stitching

VaUd

hivalid

Setting

<Display ex.>

Start tacking

0

End

tacking

2) When the pattern is No.4

|

Start

tacking

that

was

N

End

tacking

thatwasinthe

QEnnnir

1-2MSLN>^I

inthe

an

tacking

tacking

H I

mode

mode

will

will

Setting of No. stitches N

( 0 to 9999 stitches )

start

start

atthe (D

atthe d)

position.

positioiL

-Factory setting

Settingofcontmuons

tack stitching validity

Oisplay

0:

®4

0""

©'"

ex.>

Valid

hivalid

N

@/

In the No. of times(N) setting is N=3, the stitching will be

in the order or

will be in the orderofA3.C3.C.If

orderwill be

(IfN=0, tackingwill continue in the order ABCDCD... while

the pedal is pressed down.)

Note) hi case of XC-EN, there is no backstitch output.

29-

A3

snd C. If the setting is N=5, the stitching

A,B,C3,C3

Setting of No. times N

(0 to 9999 stitches)

the N is 6 or more, the

Page 32

11.Operationofthe Operation Panel Keys

(4) Pattern No. selection mode

When

the[ t ] keyis

Selectingof preset stitching setting, continuous tack stitching, program stitching(pattern No. A to H).

1) Display of preset stitching (Pattern 0 to 3)

turnedONagain,

andthe

pattern

No.

selection

mode

willbe

entered.

Q 0 S 0 0 B

©•BaSB

2) Displayof continuous tack stitching (Pattern 4)

© 0 E i 0 S

1-2MSL

3) Displayofprogram stitching (Pattern A to H)

g)0@0Si

M^ M ^

w

Display of pattern 0.

When pattern 1,2,3, display show 1,2,3.

When control panel is connected,

the pattern 0 disappears.

Display of pattern A

When pattern B, C, D, E, F, G, H display

showB,C,D,E,F,G,H

a.Pattern A throughH can be set on controlpanel "XC-E500Y".

Sov4ien programming will be changed, use control panel "XC-E500Y".

(Referto technicalmanualof controlpanelin detail)

Caution

For

safetypurposes, always turn

whenconnectingor disconnecting the controlpanel.

off

thepowerswitch

-30

~

Page 33

Howto use SimplesettingofProgramMode [2] (for chain stitchtrimmingmachine)

1. How to use

the

program

No.1 Tosetthe functionsforchain stitchsewingmachinein simplesetting

(Ex.to set forthe VC2600class,

1)

2)

4)

mode [2]

"YAMATO")

Enter

program

mode

[2]

([ i ] +

i • • •

Program mode [2] will be entered.

[C]+[D])

Functionsetting

^dicates

3)

ftllB i B • •

5)

ftllB i a • PI

[^•EEB®

[YU2] will flickerwiien [D] is pressed.

6)

[YU2]

keyoperation.Referto Page23.)

CEEBB

Set function to [YU2].

D E B B

[CLEAR]will be displayedwhenthe [D] key is

pressed for approx. two seconds.

[T]ID

[Tj

PressP]to return to the normal mode.

Description

A)

Select

the

function

chainstitch

willbe

carried

B)To

return

tothe

hi thiscase, [YU2]willnot be set, and the lastsettingswillbe used.

C)

Each

time

the

[YU4] [JMH].

D)RefertoFig.1(page34)fortheconnectorinput/output signals.

E) RefertoFig.50

F) Setthesolenoidvoltage to 30V.Refertopage16.(The

G) Set the optionA

H) The thread trimmingprotectionsignal S6will stopthe sewingmachinewhen the switchis turned OFF.

i B

B~EI

BEEEB

that

corresponds

sewing

machine"

out

automatically

normal

[ i

]keyispressedinstep2,the

^age

cormector

onthe page32.

mode

from

50)forthejunction

5/12Vsettingto

tothe

forthat

the

sewing

Display

model.(Refer

[YU2]

display,

function

wiring.

12V.

Refertopage71.(The

machine

[CLEAR]

tothe

press

will

factory

model

for

"Simple

withtheP]key,and

simple

setting

the[ T]

key

while

changeinorder

settingis 24V.)

factory

setting

table

for

holding

from

[YU2], [YU3],

settingis 12V.)

table

for

fimctions

"YAMATO"onpage

down

[ 1].

32.)

31-

Page 34

(/>

§'

•o

Note

Note

Note

Sewing

Function

YU2

YU3

YU4

YU5

YCl

YC2

YC3

YC4

YVIO

lo

YVll

NOl

N02

machine

maker

YAMATO

YAMATO

YAMATO

YAMATO

YAMATO

YAMATO

YAMATO

YAMATO

YAMATO

YAMATO

PEGASUS

PEGASUS

Modelname of sewing machine and device

VC2600, VC2700

trimmer

VC2600, VC2700 class Air-operated under thread triinmer

with air wiper

VC384SP,2845P,2840PclassAir-operated under thread

trimmerwithairwq>er

Solenoid-operated under thread trimmerwithsolenoid wiper

CM3S7, CM400class for manual feed rollerdevice

condensed

CM400

stitch

invalid

CM3S7,

condensed

CM400

stitch

valid

VXseriesThe sewingmaehtnowiththe UT-A device

VXseriesThesewingmachinewith the UT-A/ST-Adevice Fig.3

W500,600,700

threadtrimmerwithsolenoidwqier withouttop coverthread

trimmer

WSOO,

thread trimmerwith solenoid wq>erandtop cover thread

trimmer

clan

Solenoid-opoiated under thread

stitch

invalid

class

for

automatic

feed

roller

CM400

class for manual feed

stitch

valid

class

for

automatic

feed

roller

/ UT207,171434 Solenoid-operatedunder

600,700

/ Ur207, UT434 Solenoid-operated under

device

roller

device

condensed

device

condensed

I/O signals

of

connectors

Fig.1

Fig.1 Fig.50

Fig.1

Fig.1

Fig.2

Fig.2

Fig.2

Fig.2

Fig.3

Fig.4

Fig.4

Jimction

wiring

Fig.50

Fig.50

Fig.50

Fig.51

Fig.51

Fig.51

Fig.51

—

_

Fig.52

Fig.52

Note

solenoid

voltage

30V

30V

30V

30V

30V

30V

30V

30V

30V

30V

24V

24V

1

2

DCSVor

12V setting

In option A

connector

12V

12V

12V

12V

5V

5V

5V

5V

5V

5V

5V

5V

3

Lo^coftiiread

trimniing

protection

signal S6

Sewingroaehine

stops \riien

switcfaropen

Sewingmachine

stops when

switch»hort

4

Settingofswitch

to

increase

solentrid

return

speed

•Noted

1/2 pos

2

2

2

2

1

1

1

1

1

1

2

2

High

speed

H

6000

6000

6000

6000

2000

2000

2000

2000

4200

4200

6000

6000

Low

speed

L

200

200

200

200

200

200

200

200

200

200

200

200

Trimniing

speed

T

200

200

200

200

200

200

200

200 200

200

200

200

200

•Start

condensed

speed

N

1400

1400

1400

1400

200

200

200

1400

1400 1400

1400

1400

End

condensed

speed

V

1400

1400

1400

1400

200

200

200

200

1400

1400

1400

n

U)

f5

m

g

n

•t

n

er

A

I

CA

ts)

ffi

i

S"

g

(D

00

cT

CO

n>

i.

ere

5

g*

S*

rt

OQ

I—I

o

s

a

o

K)

S*

•1

&

N03

N04

N05

N06

N07

PEGASUS

PEGASUS

PEGASUS

PEGASUS

PEGASUS

WSOO,600,700/Uri03,104,109,

under thread trimmerwith solenoid wiperwithout top cover

thread

trimmer

UT335 Super tack solenoid-operated under thread trimmer

with air wqier

WS62-82Ur Angledstitch Fig.5 Fig.52

W600 / UT/ MS Solenoid-i^rerated under thread trimmer

with solenoid wqier and condensed stitdi, without top cover

thread

trimmer

111 Solenoid-operated

—

Fig.4

Fig.52

Fig.4 Fig.53

Fig.5

Fig.6

—

Fig.52

24V

24V

24V

24V

24V

5V

5V

5V

5V

5V

W600 / UT/ MS Solenoid-operated under thread trimmer

N08

PEGASUS

withsolenoidwiperand condensedstitchand tq>cover

thread

trimmer

Fig.6

—

24V

5V

Sewingmachine

stops sriien

switdropcn

4500

2

4000

2

6000

2

6000

2

200

200

200

200

200

200

200

200

1400

1400

1400

1400

1400

1400

1400

1400

I

OQ

B

6000

2

6000

2

200

200

200

200

1400

1400

1400

o

1400

Page 35

Function

NOB

NOC

KAl

KA2

KA3

KA4

UNI

UN2

UN3

U345

Sewing

machine

maker

PEGASUS

PEGASUS

KANSAI

KANSAI

KANSAI

KANSAI

UNION

SPECIAL

UNION

SPECIAL

UNION

SPECIAL

Model nameofsewing machine and device

—

—

MRXsciies

D series Automatic thread trimmerwith airwqier

Fseries

DX series Air-operated under threadtrimmerwithairwqier

33700,34500class Solenoid-cperatcd under thread trimmer

34800s]»c class Solenoid-operated under thread trimmer

34700 class Push and Pull air-operated under thread trimmer

with air wqrer

AuttHiiatic

Air-(q)erBtod

threadtrimmerwithsolenoid

wrqier

under thread trimmer with air wq>er

I/O signals

connectors

Junction

of

Fig.7

Fig.8

Fig.9 Fig.54

Fig.9 Fig.54

Fig.10

Fig.9

Fig.ll

Fig.12 Fig.55

Fig.12

wiring

—

_

Fig.54

Fig.54

Fig.55

Fig.56

Note

solenoid

voltage

24V

24V

24V

24V

24V

24V

30V

30V

30V

1

Do

Note

2

DCSVor

12V setting

In option A

connector

5V

5V

I2V

12V

12V

12V

12V

12V

12V

not

use

Note

Logicofthread

trimrmng

protection

signalS6

Sowingmachme

stops triten

switchopen

I!

3

Note

4

Settingofswitdt

toinciease

solenoid

ictum

speed

"Noted

Alwaysset

n

:SLOW

15:

FAST

18:

SLOW

1/2 pos

2

2

2

2

2

2

2

2

2

High

speed

H

8000

4000

6000

6000

6000

6000

4000

5500

4000

Low

Trimming

speed

200

200

250 250

250

250

250

200

200

200

speed

L

200

200

250

250

250

200

200

200

♦Start

condensed

T

speed

N

End

condensed

speed

V

K)

X

i

1400