Page 1

«v.«E0«0Evefl.0VA«:«0

MITSUBISHI

ELECTRIC

MITSUBISHI

Mitsubishi

INSTRUCTION

Limiservo

MANUAL

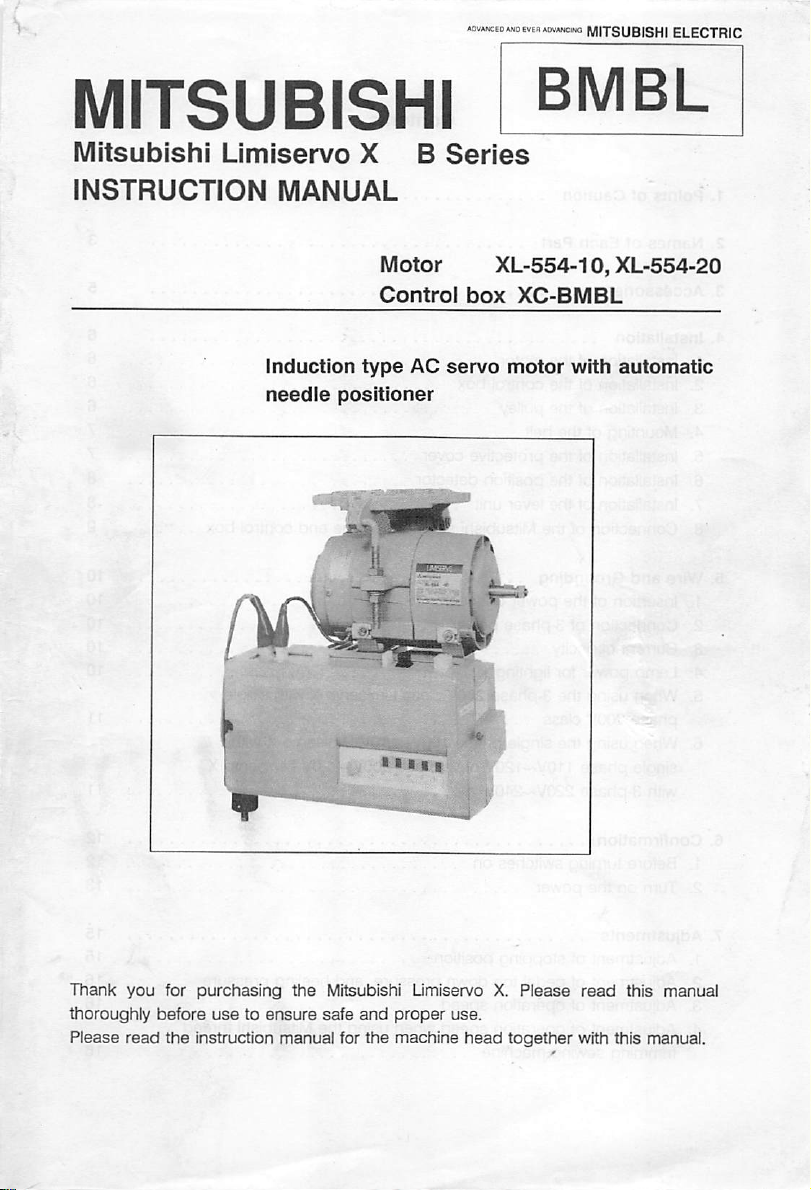

Induction

needle

X B

Motor

Control

type

positioner

AC

Series

box

servo

BMBL

XL-554-10,

XC-BMBL

motor

with

XL-554-20

automatic

Thank you for

thoroughly

Please

read

before

the

purchasing

usetoensure

instruction

the Mitsubishi Limiservo X.

safe

and

proper

use.

manual

for

the

machine

head

Please

together

read

this manual

with this manual.

Page 2

Contents

1.

PointsofCaution

2.

NamesofEach

3.

Accessories

4.

Installation

1.

installationofthe

2.

Installationofthe

Part

motor

control

box

3. Installationof the pulley 6

4. Mounting of the belt 7

5. Installation of

the

protective cover 7

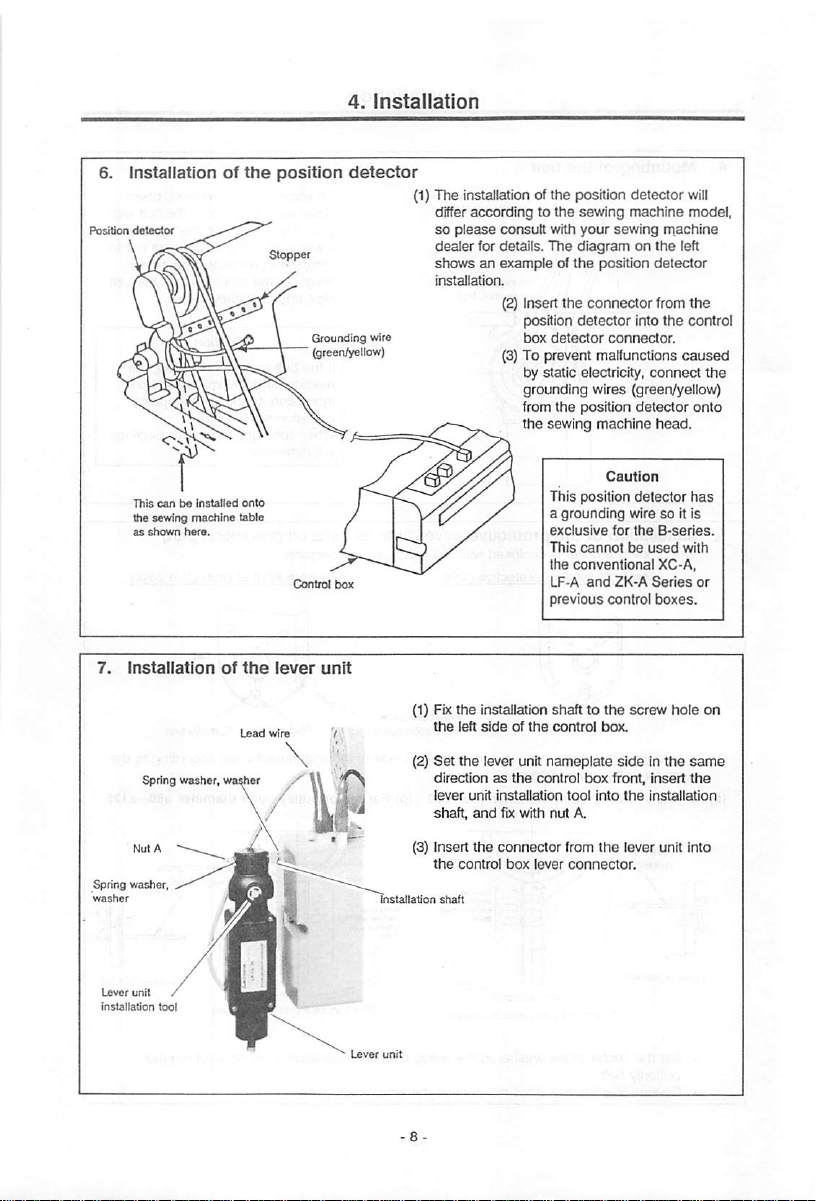

6. Installation of the position detector 8

7.

Installationofthe

8. Connection of the Mitsubishi sewing machine

lever

unit

and

control box 9

1

3

5

6

6

6

8

5. Wire

and

Grounding

1. Insertion of the power connector 10

2. Connection of

3-phase

power 10

3. Current capacity 10

4. Lamp power for lighting 10

5. When using the

phase

200V

6. When using the single

single

phase

with

3-phase

6.

Confirmation

3-phase

200V

class

Limiservo X with single

class

phase

100V~110V Limiservo Xwith

110V~120V or 3-phase 200V'-220V Limiservo X

220V~240V 11

1. Before turning switches on 12

2. Turn on the power 13

7.

Adjustments

1. Adjustment of

2. Adjustment of pedal

3. Adjustment of operation

4. Adjustment of operation

stopping

toe

position 15

down pressure,

and

heeling

pressure

speed

speed

when using the Mitsubishi thread

trimming sewing machine 16

10

11

12

15

16

16

Page 3

8.

Pedal

Operation

9.

Operationofthe

Operation

1. Displays during normal

2.

Selectionofeach

3.

Howtouse

No.1 To

No.2 To

No.3 To

No.4 To

the

change

change

start

sewing with a siow start 23

useasa

(to

use

an external switch) 23

No.5 To apply a

4. Displays

and

functions of

5. Before operating

6. How to

No.1 To

7. How to

No.1 To

use

the

set

the no. of stitches for the start/end V tacking

start

tacking

tacking

retract

use

the

change

(Ex. to

changeto4500 rotations) 30

No.2Tochange

No.3 To

No.4 To

No.5

change

(Ex. to

change

change

(Ex.tochangeto1200

To

change

(Ex.tochangeto1500

No.6

To

change

(Ex.tochangeto300

No.7 To

No.8

No.9

change

(Ex.tochangetothree

To

carry

out

switch

To

stitch

SOH

with

Panel

Keys

mode

and

functions of

mode

normal

mode

the

rotation direction 22

the

needle position during

standing

weak

the

tacking

work

type

sewing machine

brake during stopping 24

each

key in

the

keys for the program

mode

each

stop

tacking

mode

key 18

mode

and

retractto4

program

the

maximum

the

low

the

needle

stitches,

mode

speed

speed

(Ex.tochangeto200

lifting

speed

and3stitches

for

the

end

rotations)[p..

to 180 rotations) 32

the

start

tacking

speed

rotations) 33

the

end

tacking

the

slow

the

numberofstitchesinslow

low

speed

+

SO

one

needle

speed

rotations)

start

speed

rotations) S

stitches) SLN

operation

with

the

[v]

with

external

start

external

switch

SOH

+ SO .

17

18

19

22

22

25

23

28

28

30

31

34

35

36

37

38

Page 4

No.10Toconfirm

the position where the needle passed through

the fabric and to raise the penetration strength of the first

+

stitch

with

the

external

switch

SOH

No.11 To stop tacking withexternal switch

SO

SOH

+ SO

No.12 To bring the one shot function outside and use as the

manual/automatic sewing selection switch for test stitching,

etc.

SOH

SHM

No.13 To carry out automatic operation

(one shot operation) SH + SHM

No.14Toset

No.15 To

No.

16 To delayset

No.17 To execute emergency

No.18 To continue presser foot

No.19 To continue presser foot

No.20

No.21 To not

No.22Toprotect

No.23

No.24 To

No.25

No.26

the

numberofstitchestothe

after detecting the fabric

(Ex. to

set

to 10 stitches) UES + PSU

set

the

numberofstitchestothe

after

the

fabric

endisdetected

(Ex.

set

to 10 stitches) PS + PSD

position

sensor,

operates

etc.,

PS

and

+

detection

restart

PSN

end

even

stop

lifting

lifted

FUM

lifting

and to lowerthe presser foot after the time

has passed

To stop presser foot

heeling,

foot

lifting

To make a

lift

FUM|

+ |FU| 48

lifting

needle

lift

signal

use

automatic

with light heeding) S3L

when

half-stitch

the

needle

the

with

presser

thread

with

the

after

(S2)|FL

trimming

the backstitchswitch| S7 | 52

backstitch switch

needleUPposition

with an optical sensor, etc.

DOWN position

with

the

optical

sensor,

(DOWN

when optical

stop)

with

sensor,

optical

etc.,

during sewing UES

after the needle is

after the needle is

lifting

needle

lifted,

set

on the timer

with

the

[

foot

lifting

(to

stop

presser

knife

does not

S7

When the tip of the needle is stuck in the thick fabric after

thread

Tooperate the backstitch solenoidsimultaneously

trimming

ITBI 55

with

39

40

41

42

stop

43

stop

etc.

44

45

46

47

full

49

return|6TL|51

trimming

RU

thread

50

53

54

Page 5

No.27 To

No.28 To set for a different manufacturer's thread

No.29

No.30

No.31 To

No.32 To

8. How to

No.1

No.2 To

use

a sewing machine that

thread trimming S2R

(Ex.

to set to

Brother

Model

To reverse runto the settingangle

with

full

heeling

and needle

-i-nn

does

8716)|TR

from

lift

signal

not have automatic

trimming

sewing machine

| 57

the

DOWN

position

(S2)|TR

| 58

To drivethe backstitchsolenoid duringstopping IS7 59

stop

start

tacking with the external switch

stop

end

tacking with the external switch PS 61

use

the program mode 62

To adjust the pedal toe down amount

to

sew

high

change

speed

quickly at a high

the time for the sewing machine to reach the

(Ex.

to set to

speed)

100ms

ROC 62

with

simple

LIES

(Ex.

to set value 55

setting

[h])

No.3 To change the timefor the sewing machineto stop

(Ex.to

set

to 230ms withsimple setting

No.4 When using a sewing machine

with

[L].)

a large

DC

inertia

GA 65

No.5 To operate the sewing machine withoutthe detector when the

detectorisbroken

9. How to

No.1

No.2 To

use

the program mode 67

To change the presser foot holdingstrength

(Ex. to

set

to 33% duty [LO]) FUD

set

the needle position stop angle just before the fabric

looking from the UP position (Ex.to

10. How to

No.1

No.2 To

11. How to

No.1

use

the

program

To output a needle cooler output to the sewing machine

connectorLoutput

fix

the operation panel settings during normal mode

and

tacking

use

the

mode

program

To accurately align tacking (To

tacking

corner

No.2 To carry out continuous tack stitch (To

reverse

to 10

No.3 To aligntacking when start/end tacking

1000

rpm BM

NOS

setto[70°].)

mode

0

NCL 69

PSW

mode

set

the stop time at each

to 100

milliseconds)[D1

| + jCT|

set

stitches)

D2

B

M

speed

08

the W tacking forward and

is less than

[AC

56

60

63

64

66

67

68

69

70

71

71

72

74

Page 6

No.4

Tocorrectthe no. of

No.5

To correctthe no. of reversestitches duringstart tacking|

No.6

To correct the no. of reverse stitches during end tacking|

No.7

To correct the no. of

12. How to

No.1

Howtoview

No.2 To

operation

No.3 To

use

check

check

the

program

the

the

signal

the

forward

forward

mode

error

code

pedal

operation

| Si |,| S2 |,| S3 |,|

motor

and

encoder

stitches

during

stitches during end tacking |

history

pT],

signal or external

PD

signals

No.4 To check the positiondetector signal| UP|, |

No.5

Tocheck each

No.6 To check the presser foot

and

thread

13. How to

No.1 To return ail

14.

Howtouse

No.1 To

15.

Tableofprogram

* Mitsubishi

motor

use

the

the

set

the

machine in

180B

thread

pulley

signal

release

program

settingstothe

program

functions for

one

mode

trimming

diameters

output

mode

mode

the

step

(For example, to

functions

machines

|

6TL

1.1S71.1VR

lifter,

thread trimmer,wiper, backstitch

FUO

TO,WO.

R

factory

settings

[T]

Mitsubishi

simple setting values

start

tacking|BT1

[2],

EGA

Ieca

M.1DN

DN

[T]

.

.

EGB

PG

|

BO

. LO

RESET

thread

trimming

set

for the LSI-1180-BIT)

and

BT2

BT3

BT4

sewing

75

76

77

|

78

79

79

80

81

82

83

84

85

85

86

86

88

107

10. HowtoUse

1. Connector layout 108

2. Description of input/output signals 109

3. List of input signal functions

4. To

11. Error Display

12.

Specifications

Table

of digital

the

Option

Connector

useasa standing work type sewing machine 112

display

108

Ill

113

115

116

Page 7

1.

Points

1.

Please

when

of

remove

turning

Caution

your

the

power

foot from

ON.

the

1.

Points

pedal

of

Caution

2. Alwaysturn

the

machine.

the

power OFF

when

leaving

3. Do not

5. Always

7. A high

inspect

the

tester.

The

semiconductor

when

the

tester's

ground

The

S-phase

(green). Always

control circuit with a

parts

voltageIsapplied.

tfie machine.

motor

hasagrounding

ground

voltageIsapplied

machine,sowait10minutes

the

power switch OFF before

cover.

Control

etfcuit

maybedamaged

this.

inside

tfte

after

turning

opening

wire

the

4. Alwaystum

tilting

the

the

needle,orthreading

I]

6. Do not

8. Use

the

single-phase

the

strong

welder.

use

noise

machine away from

the

power switch OFF before

sewing machine

the

Sewing

machine

branched

wiring

motor.

suchasa high

head,

needie.

when

sources

frequency

replacing

using

of

High

voltage

Notso

danger

1 -

Page 8

1.

Points

of

Caution

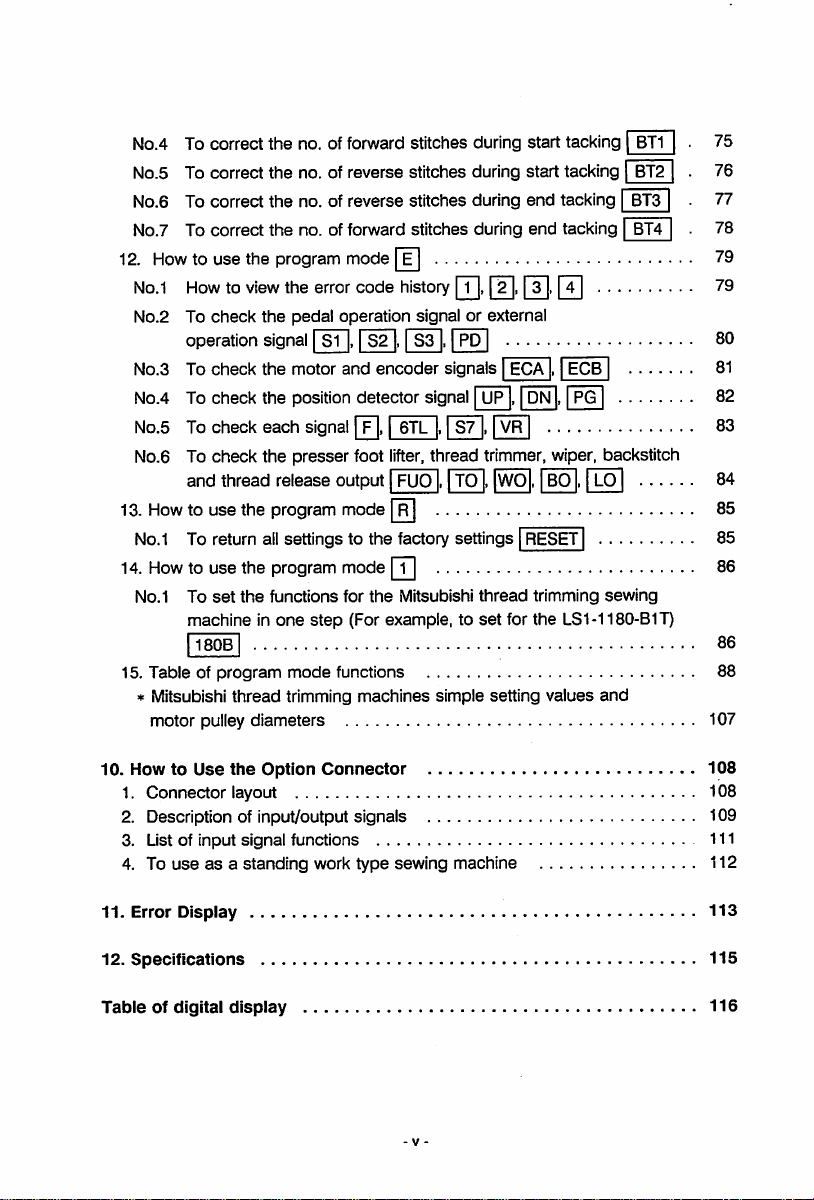

The brakes may not functionwhen the power is turned OFF or when there is a power failure

during

sewing

machine

10.

Match

the

An optical method is

11.

or oils

get

connector

on the detection plate when removing

operation.

shape

used

and

for the

direction,

detector's

and

insert securely.

detection element so

the

cover for adjustment, etc. If

take

care

not to let

on the plate, wipe offwitha soft cloth and do not scratch the plate. Take care not to let oils

enter

between

the

detector

When

12.

the

is completely locked,

position detector connector or

the

discs.

motor

the

belt

has

come

will

be automatically turned OFF after a

off or

when

the

sewing machine

set

time to prevent

damage to the motor. (The motor may not turn OFF ifthe locking is not complete.) Afterthe

problem

has

been

13.

possible.

Remove

the

twotothree

If

clogged,

affect

The

same

the

dust

motor's

dust-proof

weeks.

Dust-proof —N.

filler

the

motorisrun

the

motor may

the

motor

resolved, turn the power OFF

operation should be taken when

that

has

adhered

once

filter

on

every

is

and

life.

while

filter

the

overheat

andONand

the

If

the

15.

replace

the

normal operation will

detector

or wires

fuse

blows,

the

blown

same

capacity.

|20ARjse|

ooo

are

remove

fuse

200V

100V

broken.

the

with

TWofuses

One

these

be

cause,

one

fuse

dust

do get

and

having

14.

When

the

option

signal

long, malfunctions

Useashield

when

connecting

the

connector,

external

etc.,

keep

wireasshortaspossible.

may

occur.

cable

for

the

signal

possible.

switch to

the

Ifit is

wire

(Front view with

n

(View from

back

cover

n_rui

P8AFuse

of cover)

removed.)

I

Page 9

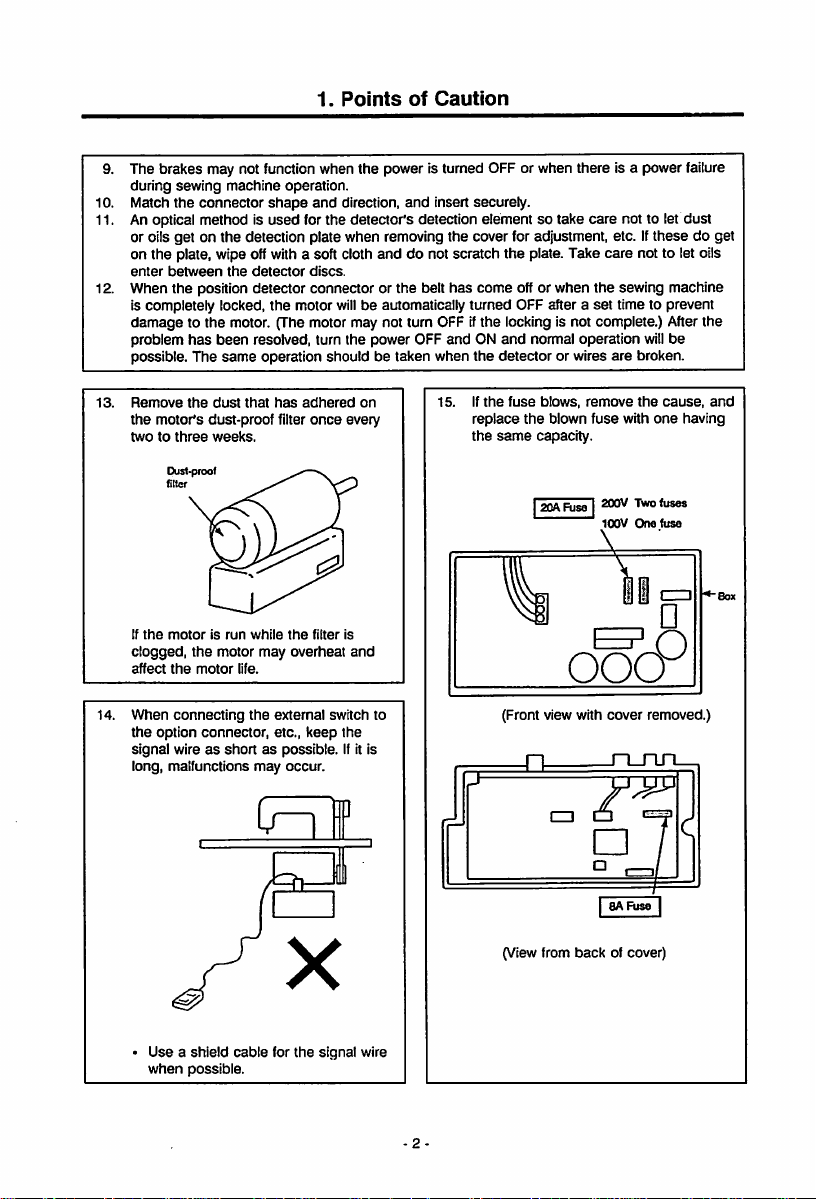

2.

1.

Names

Front

Lever

of

connector

A

Each

Encodcf

Part

connector

2.

Names

of

Each

Part

Connector tor options

(the ccnnecior willrfiffer

according to the model.)

"ID• 0 O

D

Cover Kgh voltaoe warningplate

2.

Left

I 31

Screw

holefor

l"'

installation

o

lever

(M8screw)

41

OperaSoopand

3.

Rear

t5

The

boxed

numerals

refer to

the

reference

pages.

-3-

D1

Motor

connector

WhKe

Brown

I r

»-i

Lamp namepiate

connector

connector

La

I-—'connector

t^0|

(or 100V

(or 200V

Rectory

preset

namepiate

bioocningpower

Lamp

connector

<6 V20W)

voitage

Page 10

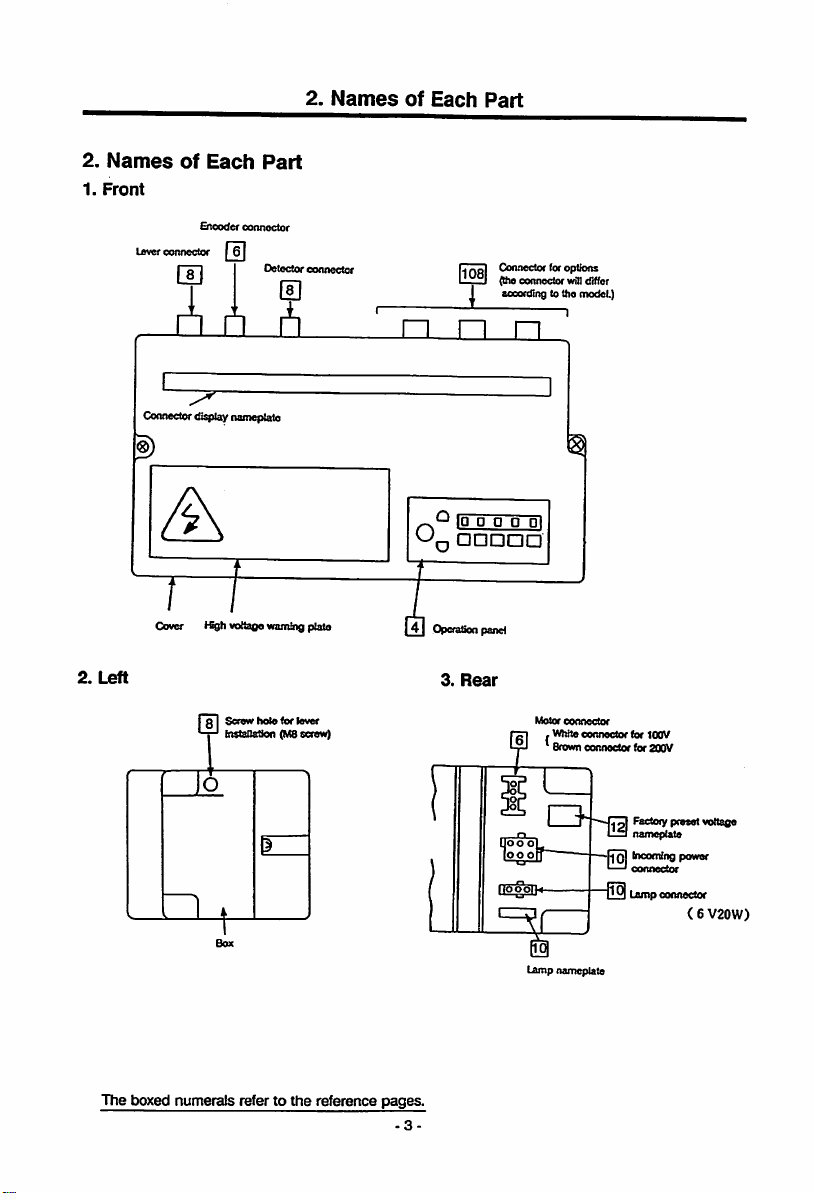

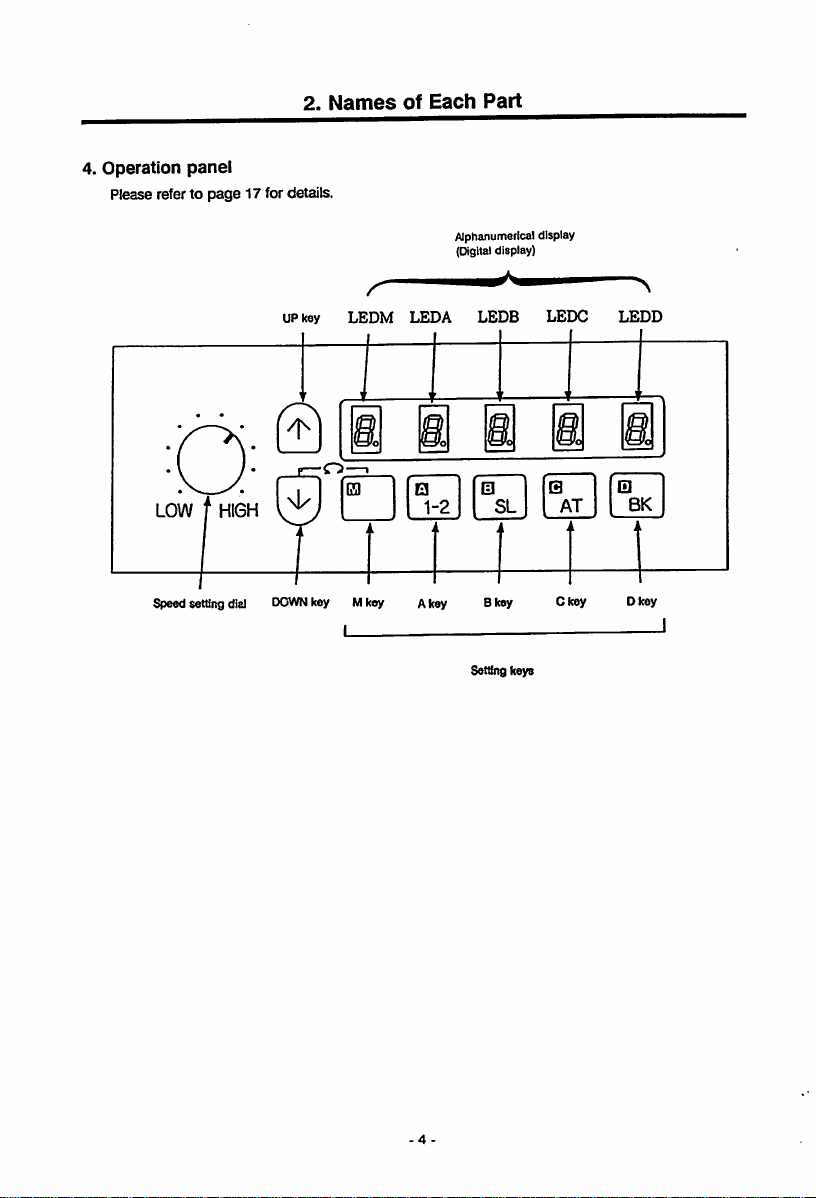

4.

Operation

Please refer to

panel

page

2.

17 for details.

Names

of

Each

Part

LOW HIGH

settSng

dial

Alphanumerical

pgltal

UP

key

LEDM

DOWN

key Mkey Akey Bkey Ckey Dkey

LEDA

•

1-2

LEDB

Setting keys

display)

m

SL

display

LEDC

Q

AT

LEDD

BK

-4

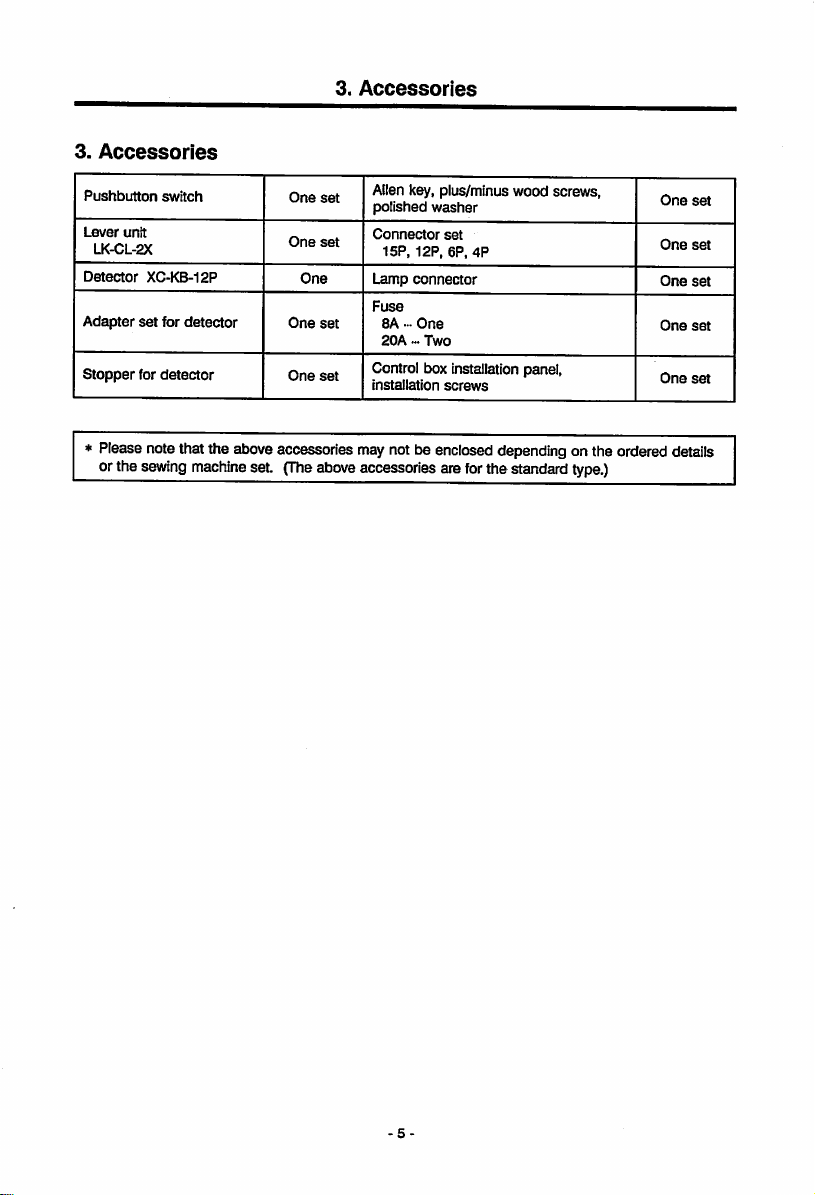

Page 11

3.

Accessories

3.

Accessories

Pushbutton

Lever

unit

LK-CL-2X

Detector

Adapter

Stopper

switch

XC-KB-12P

set

for

for

detector

detector

One

One

One

One

One

Allen key, plus/minus

set

polished

washer

Connector

set

set

set

15P,

12P,

Lamp

connector

Fuse

8A-One

20A

•••

Two

Control box installation panel,

installation

set

6P,

screws

wood

screws,

4P

* Please notethat the above accessories may notbe enclosed dependingon the ordered

orthe

sewing

machine

set.

(The

aboveaccessoriesareforthestandard

type.)

One

One

One

One

One

dptajlg

set

set

set

set

set

Page 12

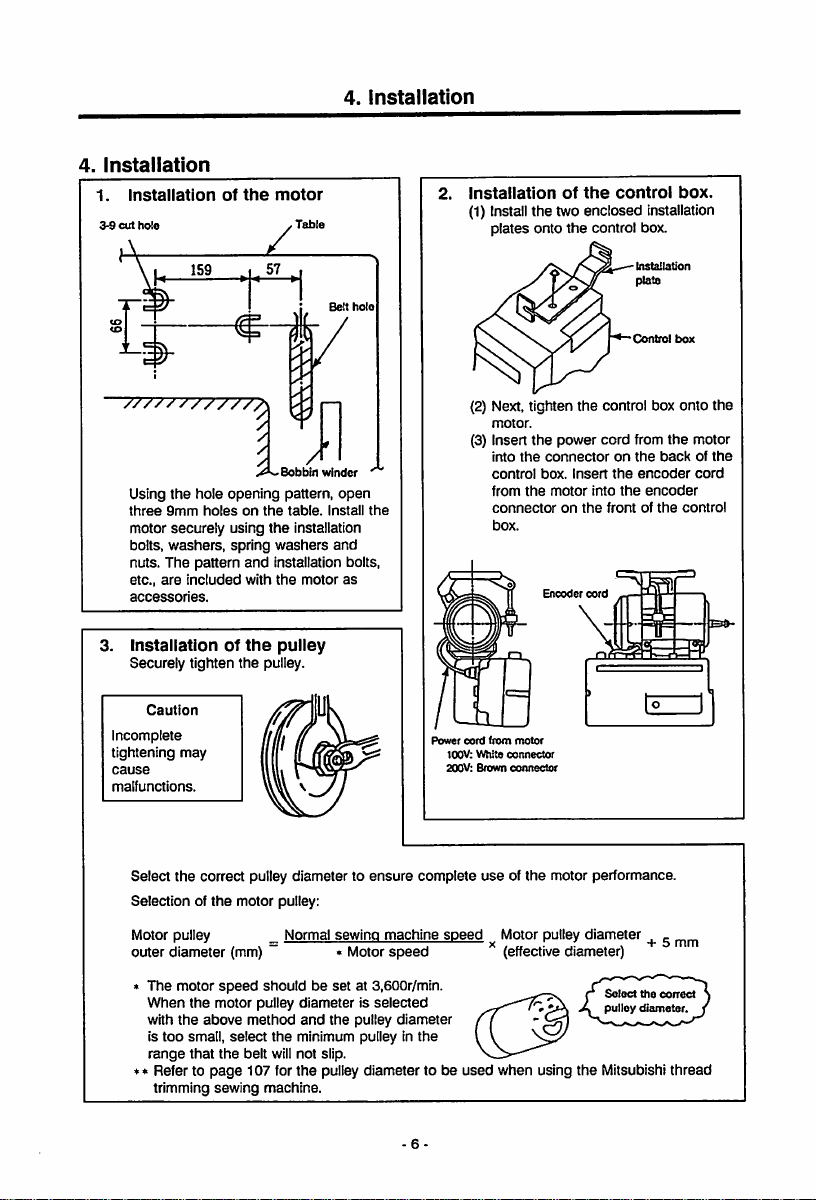

4.

Installation

1.

3-9

Installation

cut

hole

4.

Installation

of

the

motor

Table

Belt

hole

instaiiation

(1) Install the two enclosed installation

plates

onto

of

the

the

controi

control box.

Corttrol

box.

box

Bobbin

winder

Using

the

hole

opening

pattern,

three

9mm

motor securely using

bolts,

washers,

nuts.

The

etc.,

are

included

accessories.

3.

Installationofthe

Securely tighten

Caution

holesonthe

spring

pattern

and

with

the

the

washers

installation bolts,

the

puiiey

pulley.

table.

Install

installation

motor

open

and

as

Incomplete

tightening

cause

malfunctions.

may

Select

the

Selection of

correct pulley diameter to

the

motor pulley:

k/lotorpulley _ Normal sewing machine

outer diameter (mm) ~ • Motor

The

motor

speed

When

with

the

is

too

range

* Refer to

trimming

the

above

small,

that

page

sewing

shouldbeset

motor

pulley

method

select

the

the

belt will not slip.

107 for

machine.

at 3,600r/min.

diameterisselected

and

the

pulley

minimum puiiey in

the

pulley diameter to be

the

ensure

speed

Power

complete

diameter

the

(2) Next, tighten

motor.

(3) Insert

into

control

from

connector

box.

cord

from

100V:

White

Brown

connector

connector

200V:

useofthe

speed

Motor pulley diameter

(effectivediameter)

used

when

the

the

power cord from

the

connectoronthe

box.

Insert

the

motor

on

the

Encoder

motor

motor performance.

using

the

control box

the

into

the

frontofthe

cord

Select

pulley

Mitsubishi

the

backofthe

encoder

encoder

+ 5

the

correct

diameter

onto

motor

cord

control

mm

thread

the

6-

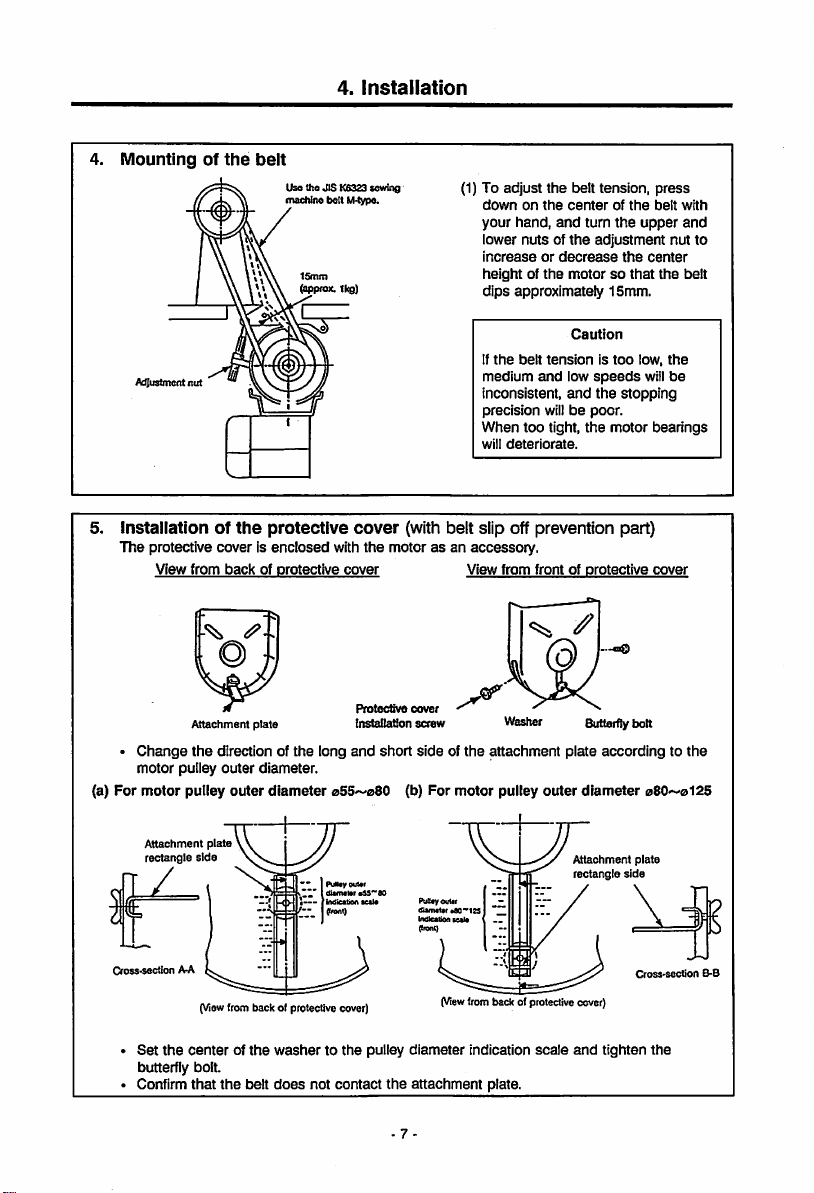

Page 13

4.

Mountingofthe

Adjustment

4.

Installation

belt

Use the JIS K6323 sewing

ntacMne lielt M-type.

ISmm

^pfox.

1kg)

nut

(1) To adjust

downonthe

your

hand,

lower

nutsofthe

increaseordecrease

heightofthe

dips

approximately

If

the

belt

medium

and

inconsistent,

precision

When

too

will

deteriorate.

the

belt tension,

centerofthe

and

turn

the

adjustment

motorsothat

1Smm.

Caution

tensionistoo

low

speeds

and

the

willbepoor.

tight,

the

motor

press

belt

upper

the

center

the

low,

will

stopping

bearings

with

and

nut to

belt

the

be

5. Installation of

The protective cover is

View

from

Attachment

•

Change

the

motor

pulley

(a)

For

motor

pulley

Attachment

rectangle

Cross^section AA

Set

butterfly bolt.

Confirm

plate

side

(Viewfrom back of protective cover)

the

centerofthe

that

the

protective

enclosed

backofprotective

plate

direction of

outer

outer

the

diameter.

diameter

washertothe

the

belt

does

cover

with

the

motorasan accessory.

cover

Protective

tnstallafion

long

and

short

055~08O (b) For

PuNay

outer

diameler

•SS'^60

irrdiettioA

•e«l«

(Irertt)

pulley

not

contact

the

(with belt slip off prevention part)

View

from

frontofprotective

—caQ

cover

screw

sideofthe

PuBeyOuter

tfARMter

Indlcetioo

^ronl)

(View

diameter

attachment

motor

eflO^ISS

tcele

trom

indication

Vlfesher

attachment

pulley

outer

l>ackofprotective

scale

plate.

Butterfly bolt

plate

accordingtothe

diameter

Attachment

rectangle

cover)

and

tighten

plate

side

Cross-secUon

cover

08O~0l25

B-B

the

-7

Page 14

7.

Installation

spring

Spring washer,

washer

Lever

unit

Installation

tool

wssher,

/

of

washer

the

lever

unit

•

(1) Fix

the

(2)

Set

directionasthe

lever

shaft,

(3) insert the

the

7nstallation shaft

the

Installation shaft to

left

sideofthe

the

lever unit

unit

installation

and

fix

with

connector

control

box

This position

a

grounding

exclusive

This

cannotbeused

the

conventional

LF-A

and

previous control

the

control

box.

n^eplate

control

t>ox

tool

into

nut

A.

from

lever

the

connector.

Caution

detector

wiresoit is

for

the

B-series.

XC-A,

ZK-A

Series

boxes.

screw

sideInthe

front,

insert

the

installation

lever unit into

hole

has

with

or

on

same

the

Page 15

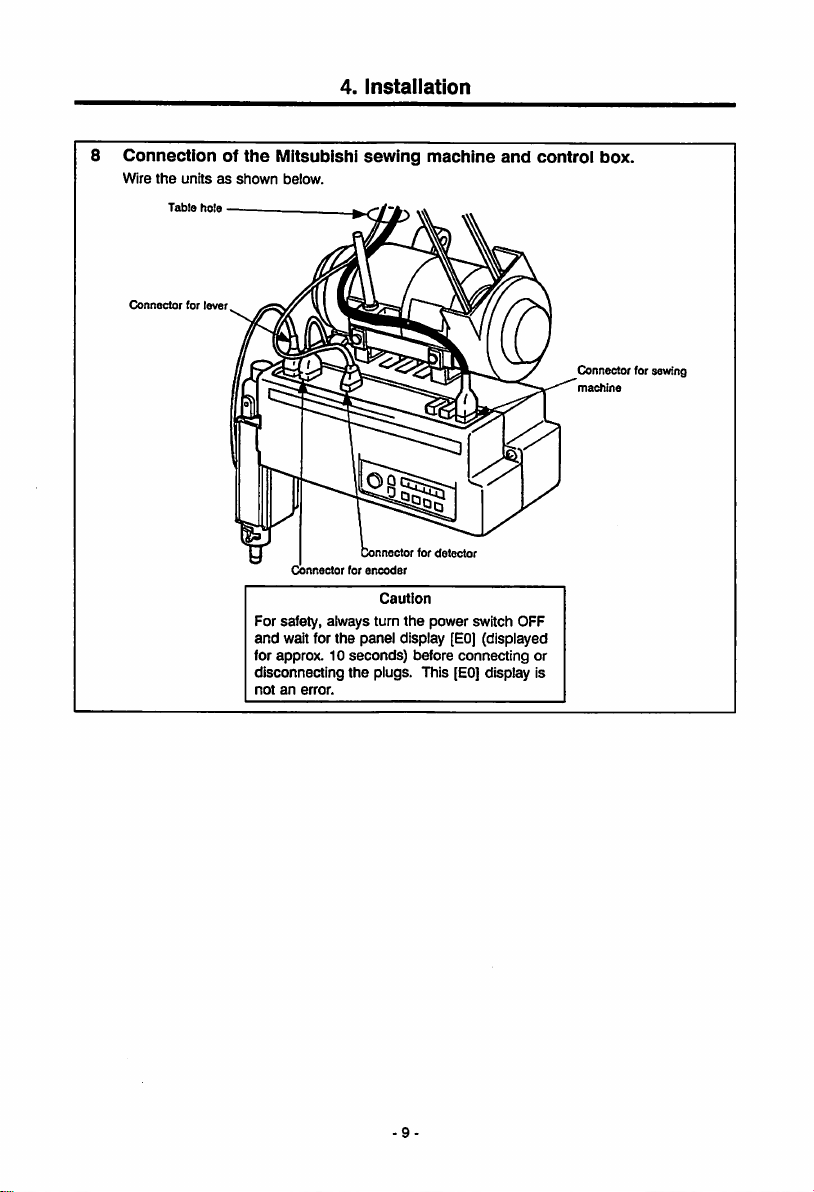

8

Connectionofthe

Wire

the

unitsasshown

Table

Connector

for

hole

lever

For safety, always turn

and

for approx. 10

disconnecting

notanerror.

4.

Installation

Mitsubishi

below.

Connector

sewing

for

encoder

onnector

Caution

the

wait for the panel display

seconds)

the

before connecting or

plugs. This

machine

for

detector

and

power switch OFF

[EO]

(displayed

[EO]

display is

controi

Connector for sewing

machine

box.

-9

Page 16

5. Wiring

and

Grounding

5. Wire

and

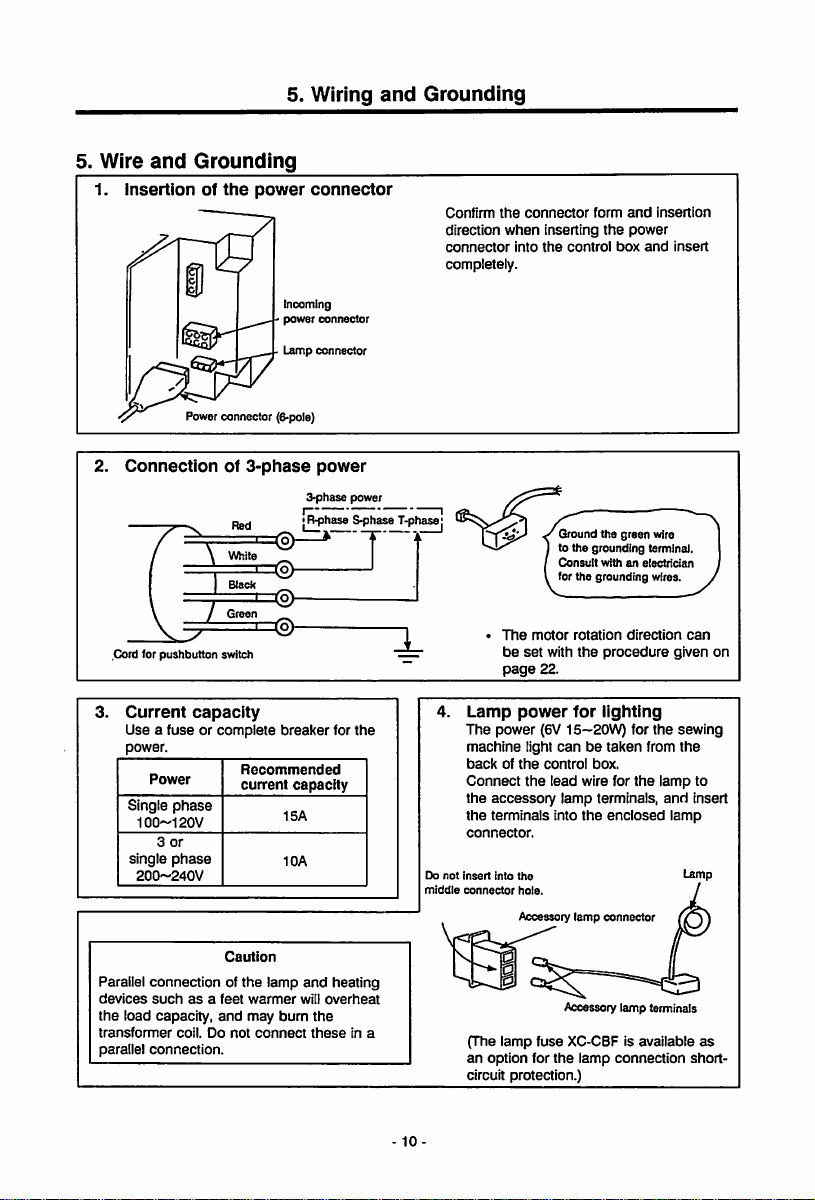

1.

Insertionofthe

Power connector (6*pole)

2.

Connectionof3-phase

.Cord for

pushbutton

3.

Current

Useafuseorcompiete

power.

Power

Single

phase

1G0~120V

3

or

single

phase

2G0~240V

Grounding

power

rted

White

Green

switch

capacity

Recommended

current

connector

Incoming

power

Lamp

Sybase

jR-phase

breaker

capacity

ISA

1GA

connector

connector

power

for

power

Sybase

the

T-phase;

X

Confirm

direction

connector

completeiy.

[3o

not

middle

the

when

The

be

page

Lamp

The

power

machine

backofthe

Connect

the

accessory

the

terminals

connector.

insert

Into

connector

connector

inserting

into

the

control

Ground the green wire

to the grounding terminaJ.

Consult

for the grounding wires.

motor

rotation

set

with

the

22.

power

for

(ev

15—20W) for

light

canbetaken

controi

the

lead wire for

lamp terminals,

into

the

the

hole.

Accessory

lamp

form

and

insertion

the

power

box

and

withanelectrician

direction

procedure

iighting

the

from

box.

the

iamp to

enclosed

connector

insert

given

and

iamp

can

on

sewing

the

insert

Lamp

Parailei

devices

the

load

transformer

parallel

Caution

connectionofthe

suchasa

capacity,

feet

and

coil.Donot

connection.

lamp

warmer

may

connect

burn

and

will

overheat

the

these

heating

in a

-10-

Accessory lamp terminals

(The

lamp

option

fuse

for

the

an

circuit protection.)

XC-CBF is available

iamp

connection

as

short-

Page 17

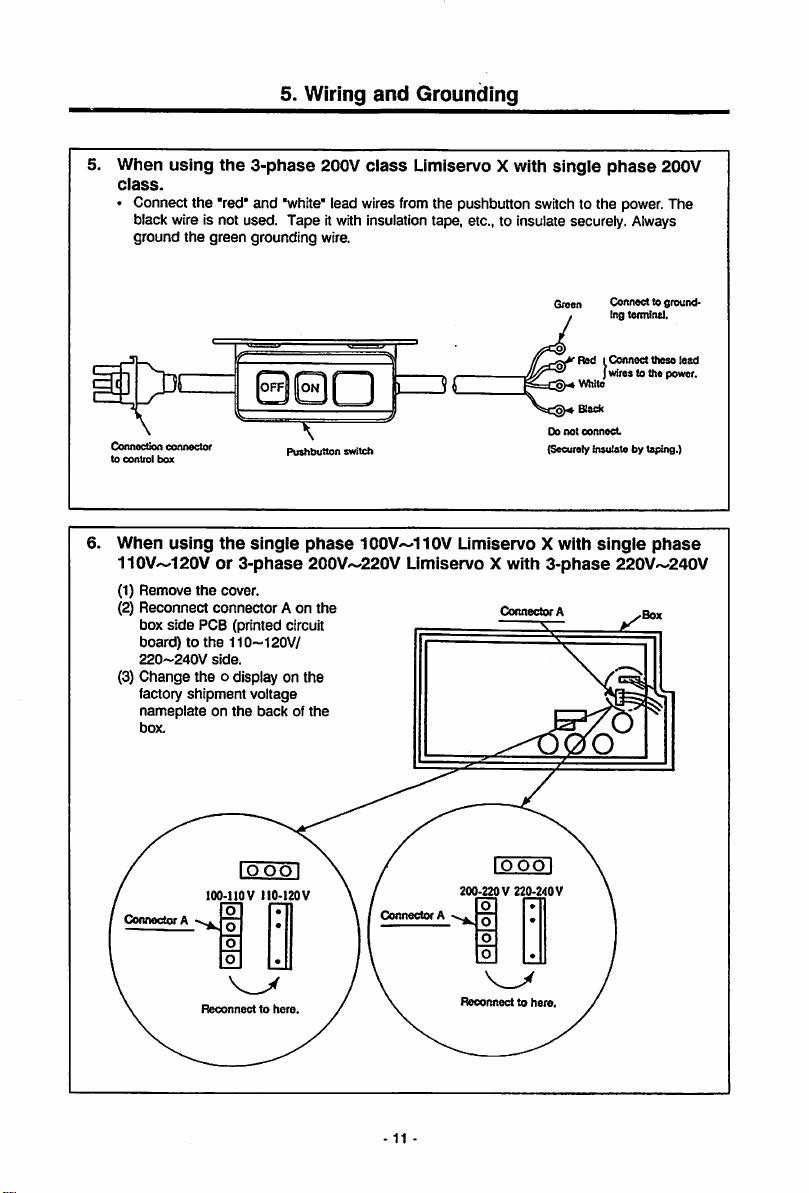

5.

When

using

class.

• Connect the "red*and

the

5. Wiring

3-phase

"white"

and

Grounding

200V

class

LImlservo X with

single

lead wires from the pushbutton switch to the power. The

black wire is not used. Tape itwith insulation tape, etc., to insulate securely. Always

ground

the

green

grounding wire.

phase

200V

Connect to ground-

Ing temtlncl.

Connection

comwctor

to

control

liox

6.

When

using

the

110V'-'120Vor3-phase

(1)

Remove

the

(2)

Reconnect

box

board)tothe

220~240V

(3) Change the o display on the

factory shipment voltage

nameplateonthe

box.

cover.

connector

side

PCB (printed circuit

110—120V/

side.

lOOOi

lOO-UOV

o

\

Pushbutton

switch

single

phase

100V~110V Limiservo X with

200V~220V Limiservo X with

A on the

backofthe

110-120

V

Connector

RedIConnect

Whte

Do

not

oonnecL

(Securely Insulate by taping.)

3-phase

these

(wirestothe

single

phase

220V~240V

lead

power.

Reconnecttohere

Reconnecttohere

11

-

Page 18

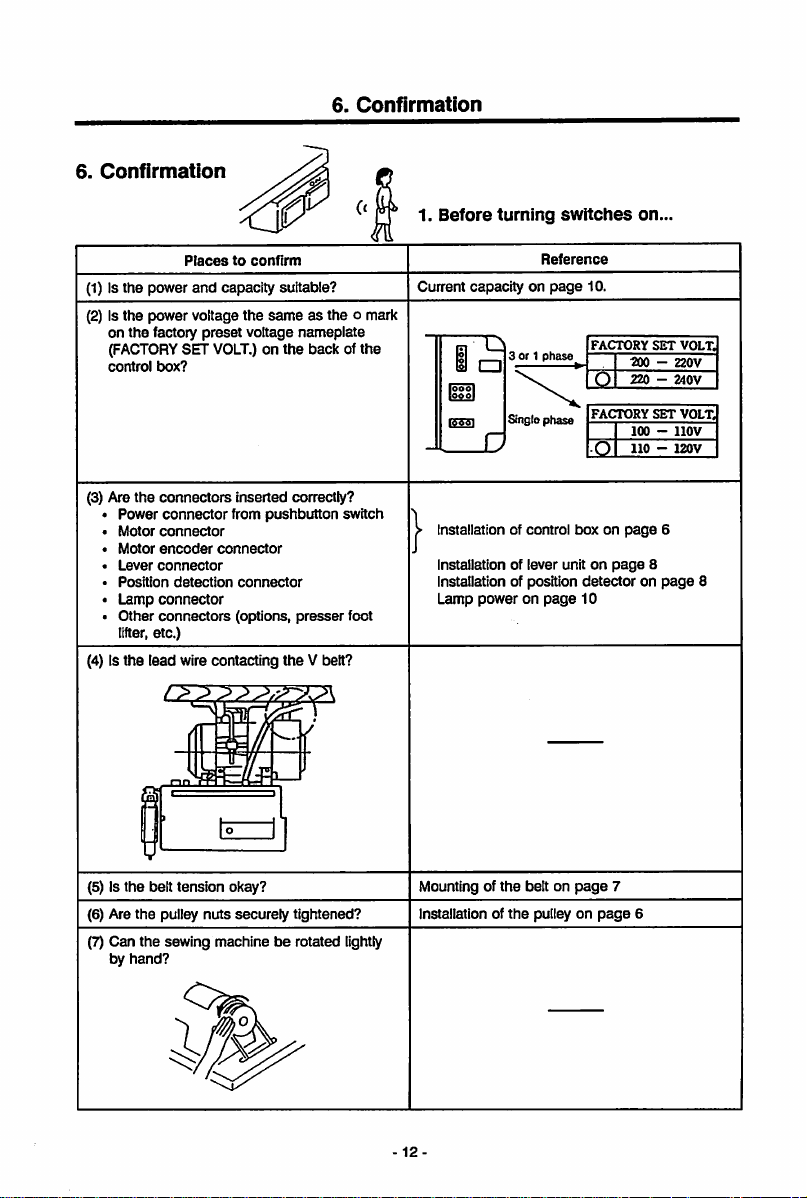

6.

Confirmation

6.

Confirmation

1.

Before

turning

switches

on.

Placestoconfirm

(1) Is the power

(2) Is the power voltage

on

the

(FACTORY

control

(3) Are

• Power

•

Motor

•

Motor

•

Lever

•

Position

•

Lamp

•

Other

lifter,

and

capacity suitable?

the

factory

preset

SET

box?

the

connectors inserted correctly?

connector

connector

encoder

connector

detection

connector

connectors

etc.)

voltage nameplate

VOLT.)onthe

from

connector

connector

(options,

(4) Is the lead wire contacting

sameasthe o mark

back of the

pushbutton

presser

the

switch

foot

V belt?

Current

capacityonpage

lOOOl

n

Installation of

}

Installation of

Installation of position

poweronpage

Lamp

Reference

3 or 1

phase

Single phase

control

lever

10.

FACTORY

700-220V

220-240V

0

FACTORY

100-llOV

110-120V

0

boxonpage

unitonpage

detectoronpage

10

SET

SET

8

VOLT.

VOLT.

6

8

(5) Is the belt tension okay?

(6) Are

the

pulley

nuts

securely

(7) Can

the

sewing machineberotated lightly

by

hand?

tightened?

Mounting of

Installation of

-12-

the

the

belt on

pulley on

page

7

page

6

Page 19

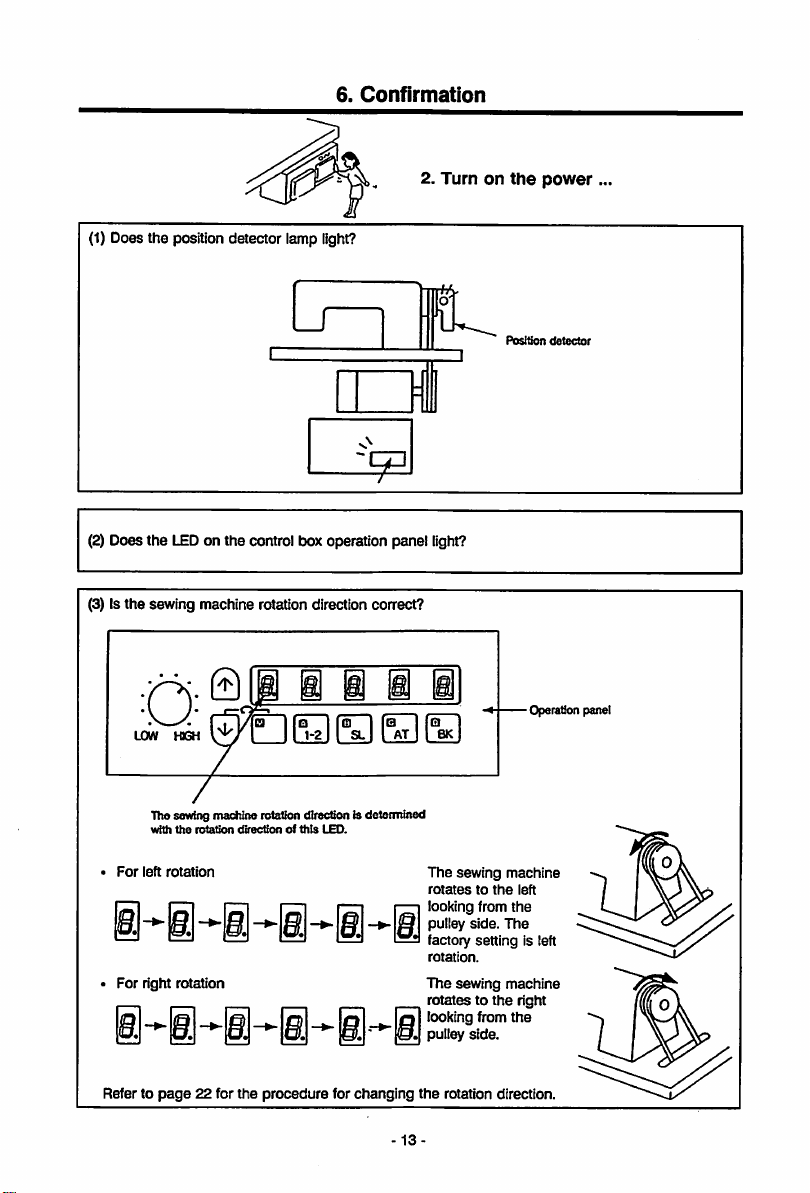

6.

(1) Does the positiondetector lamp light?

Confirmation

2.

Turnonthe

power

Lr

m

I

(2) Does the LEDon the control box operation panel light?

(3) Is the sewing machine rotation direction correct?

0

IB

@ B §

B

B

LOW H3GH

The sewing machine rotationdirecdon is determined

with

the

rotadon

For

left

rotation

For right rotation

dfrectionofthis

LEO.

Cl

SL

BK

AT

The sewing machine

rotatestothe

looking from

pulley

factory setting is left

rotation.

The

rotatestothe

looking from

pulley

Position

-Operation panel

left

the

side.

The

sewing machine

right

the

side.

detector

Refer to

page

22 for the

procedure

for

changing

the

rotation direction.

13

Page 20

6.

Confirmation

(4) Is there any heat, odors or abnormal

sounds

coming from the motor of control box?

Turnofftfie powerifttiere is any tieat,odors

or

abnormal

sounds

coming

control box. Contact your dealer Immediately.

from the motor or

14

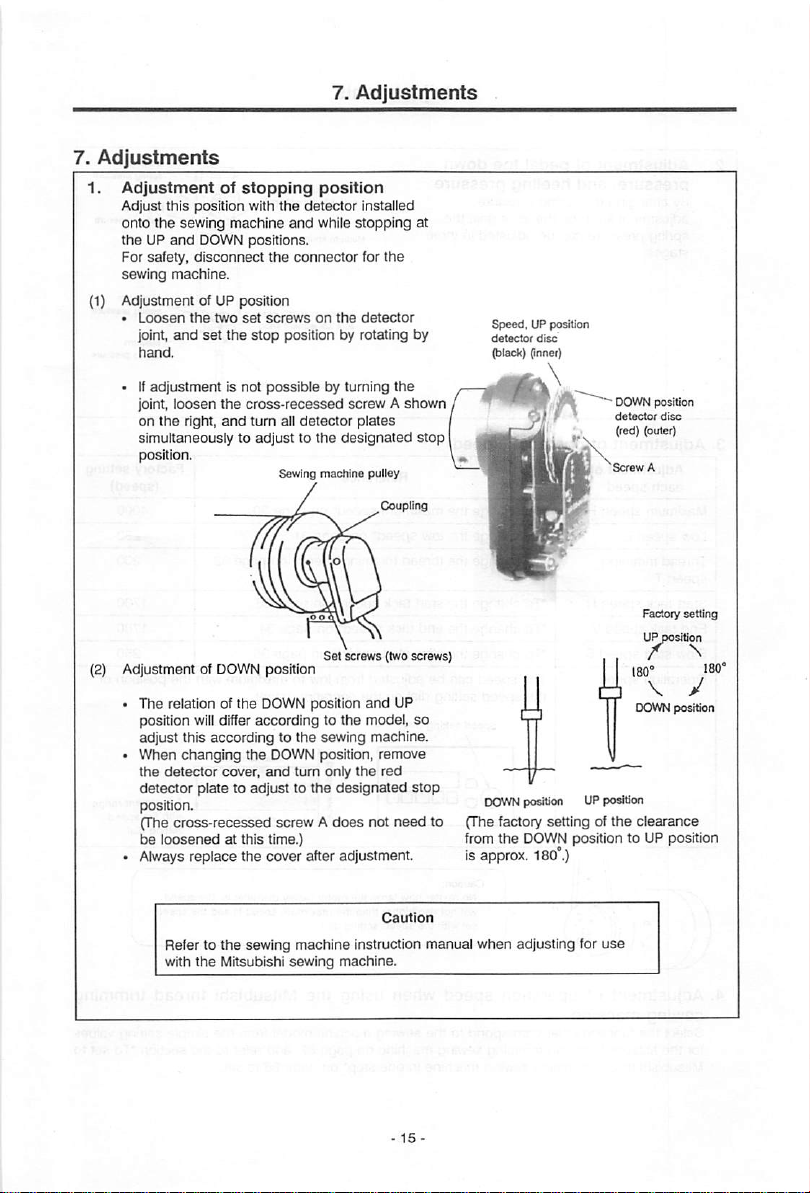

Page 21

7.

Adjustments

1.

Adjustmentofstopping

Adjust this position with

onto

the

sewing

theUPand

For

safety,

machine

DOWN

disconnect

sewing machine.

(1) Adjustment of UP position

•

Loosen

the

two

right,

set

DOWN

set

the

is not

the

and

joint,

and

hand.

• If

adjustment

joint,

loosen

on

the

simultaneouslytoadjusttothe

position.

Adjustment of

•

The

relation of the DOWN position

position willdifferaccording to the model,

adjust

this

changing

detector

plate to

accordingtothe

cover,

•

When

the

detector

position.

(The

cross-recessed

loosened

be

• Always

replace

at this time.)

the

position

the

detector

and

positions.

stop

cross-recessed

turn

the

adjusttothe

while

the

connector

screwsonthe

position by rotating by

possible

by turning the

all

detector

Sewing

machine

Set

position

sewing machine.

DOWN position,

and

turn

only

screwAdoes

cover

after adjustment.

installed

stopping

for

the

detector

screwAshown

plates

designated

pulley

screws

(two

and

UP

remove

the

red

designated

not

need

at

stop

screws]

so

stop

(The factory setting of

to

from

is

approx.

Speed.

UP position

detector

disc

(black) (Inner)

• DOWN position

detector

(red) (outer)

DOWN

position UPposition

the

the

DOWN position to UP position

180°.)

disc

Factory

clearance

setting

Refer to

with

the

the

sewing

Mitsubishi

machine

sewing

instruction

machine.

manual

when

adjusting for

use

Page 22

7.

Adjustments

2.

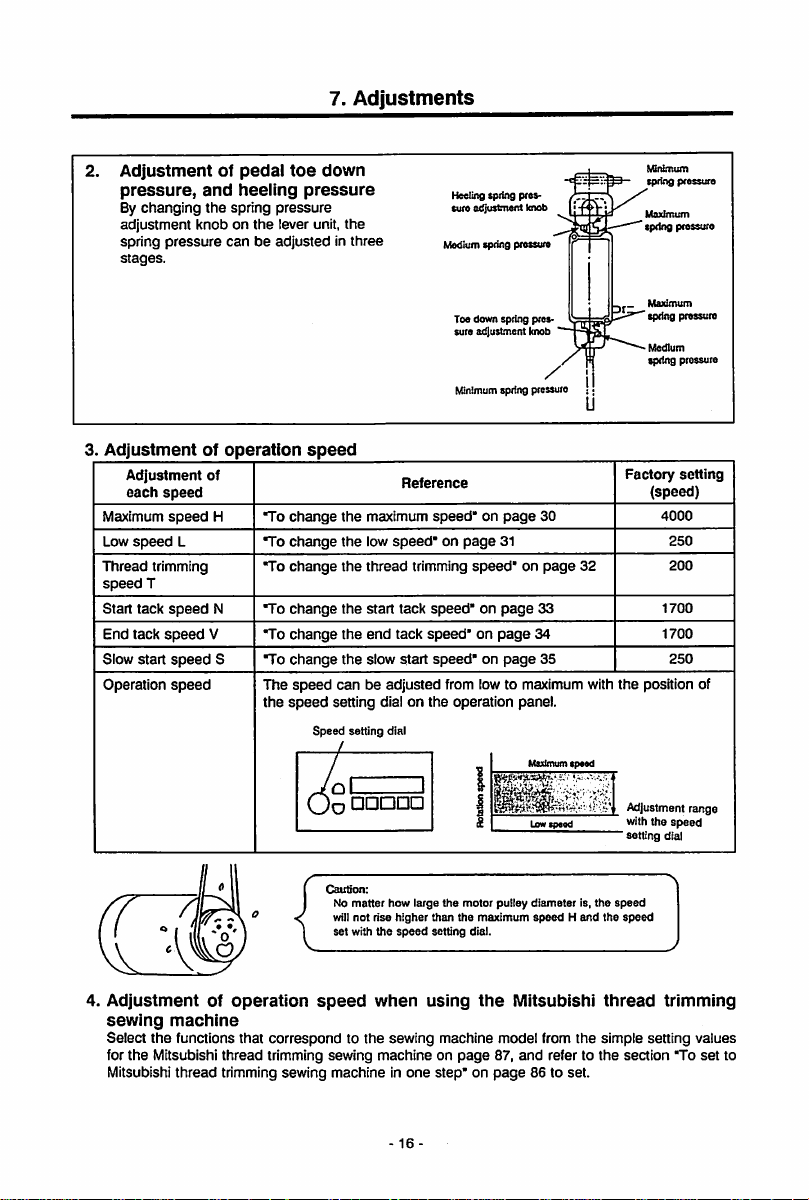

Adjustmentofpedal

pressure,

By

changing

adjustment

spring

stages.

3.

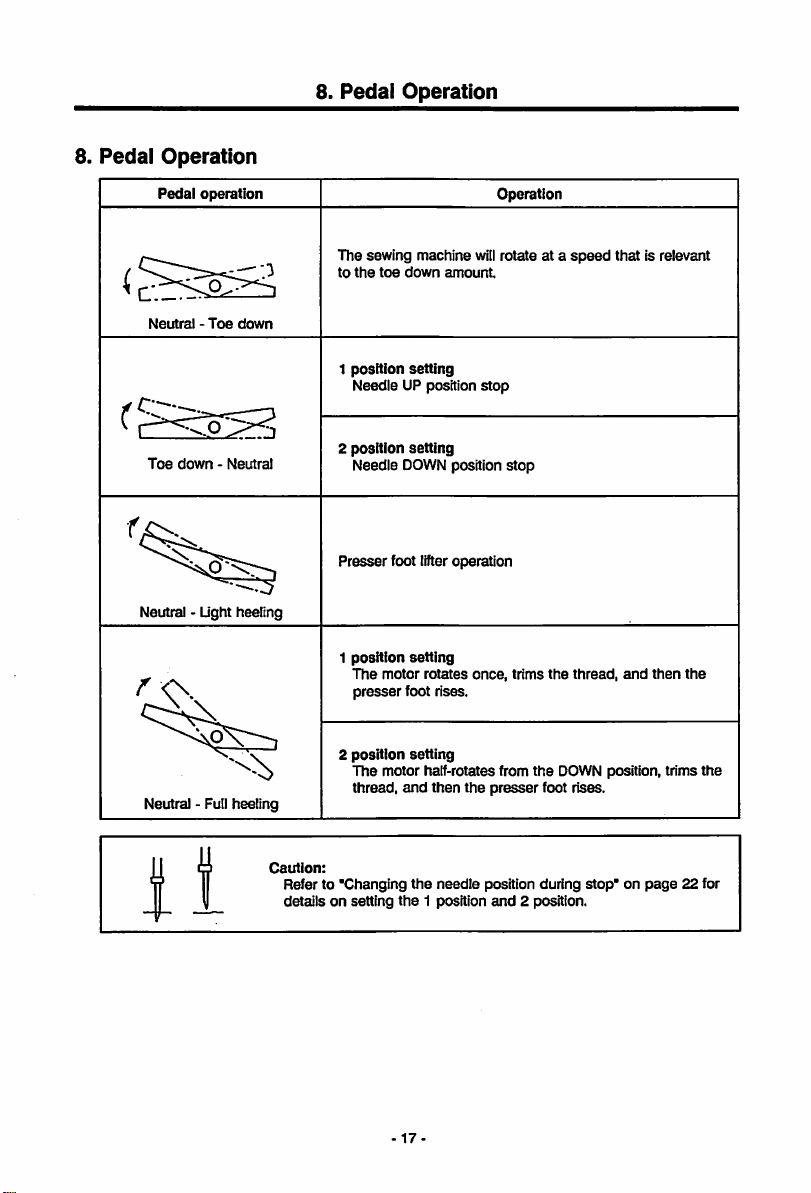

Adjustmentofoperation

Adjustment

each

Maximum

Low

speed

Thread

speed

Start

tack

End

tack

Slow start

Operation

pressure

speed

speed

L

trimming

T

speed

speed

speed

speed

and

heeling

the

spring

knobonthe

canbeadjustedinthree

of

H "To

N

V

S

toe

pressure

lever unit,

change

To

change

To

change

To

change

To

change

To

change

The

the

speed

down

pressure

speed

speed

Speed

Oo

Heeling

tpring

tura

pfes-

ttdjuxtment knob

the

Medium spring

Too down spring pressuto adjustment

Reference

the

maximum

the

low

the

thread

the

start tack

the

end

the slow start

can

be adjusted from low to maximum with the position of

setting dial on

salting dial

/

speed"onpage

speed"onpage

trimming

speed"onpage

tack

speed'onpage

speed'onpage

the

operation panel.

/

pretsjte

Imb

Minimum spring pressure

/

30

31

speed"onpage

33

34

35

Maximum

32

tpeed

I

•••••

1

£

Lowtpeod

Minimum

spring

pressuro

Maximum

tpring prossuro

Maximum

spring pressure

Medium

spring pressure

Factory

setting

(speed)

4000

250

200

1700

1700

250

Adjustmentrange

with the

speed

setting

dial

4.

Adjustmentofoperation

sewing

Select

for

Mitsubishi

machine

the

functions that correspond to the sewing machine model from the simple setting values

the

Mitsubishi thread trimming sewing machine on

thread

trimming sewing machine in

Caution;

No

will not rise

set

speed

matter

with

how large the

higher

the

speed

when

one

16

than

setting

using

step* on

motor

the

dial.

page

pulley

maximum

the

Mitsubishi

87,

page

diameter

speedHand

and

refer to

86 to set.

Is,

the

speed

the

speed

thread

the

section "To

trimming

set

to

Page 23

8.

Pedal

Operation

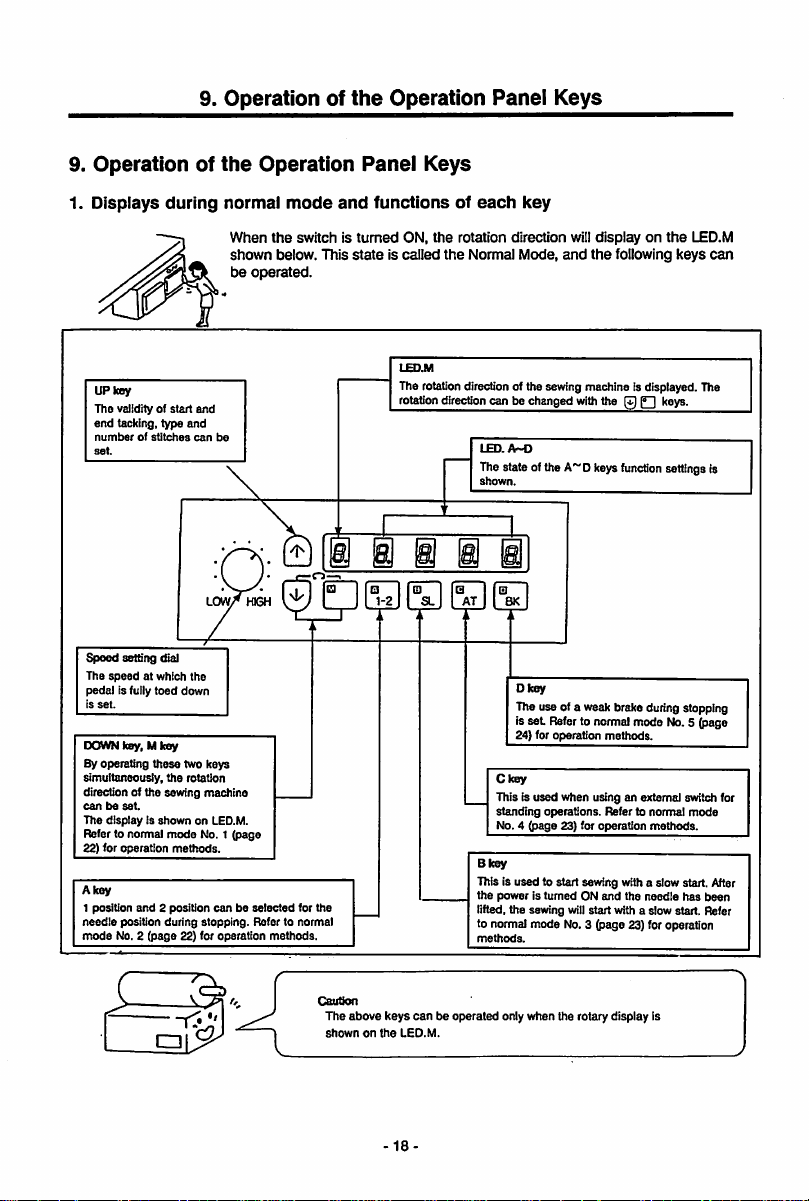

Pedal

operation

8.

Pedal

Operation

Operation

Neutral-Toe

Toe

down-Neutral

Neutral - Light heeling

down

/'O.

Neutral - Full heeling

The sewing machine willrotate at a

to

the toe

down

amount.

1

position

setting

Needle UP position

2 position

setting

Needle DOWN position

Presser

foot lifteroperation

position

1

2

setting

The

motor

presser

foot rises.

position

setting

The

motor half-rotates from

thread,

and

rotates

then

once,

the

stop

presser

stop

trims

the

foot rises.

speed

that is relevant

the

thread,

and

then

DOWN position, trims

the

the

1

1

Caution:

Refer to

'Changing

detailsonsetting

the

-17-

the

needle

1 position

position during stop* on

and

2 position.

page

22 for

Page 24

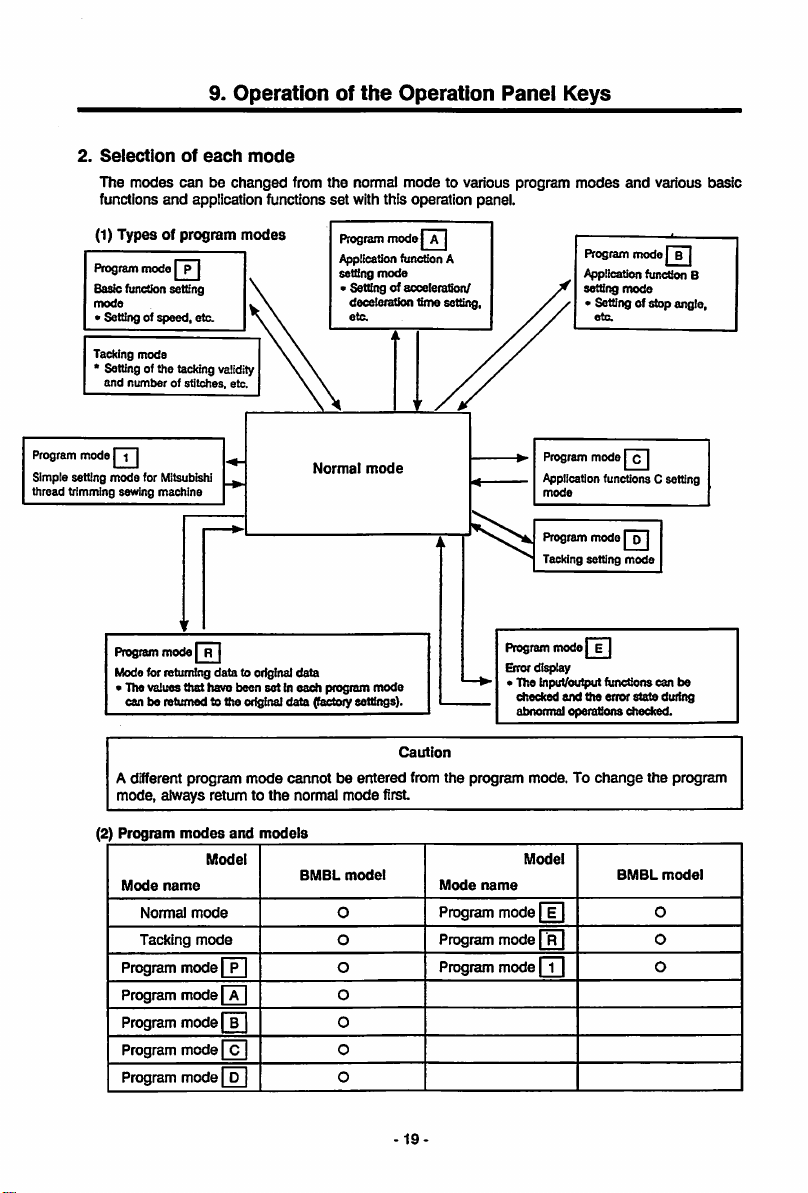

9.

9.

Operationofthe

1.

Displays

UP key

The validity of

end

numberofstitches

Speed

The

pedal

Is

set.

DOWN key, M key

By operating

simultaneously,

direction of the sewing machine

canbeset.

The

Refer to normal

22) for operation

Akey

1 position

needle

mode

during

start

tacking, type

setting dial

speed

is fully

displayisshown

and

position during

No. 2 (page 22) for operation methods.

and

at which the

toed

down

these

two keys

the

rotation

mode

methods.

2 position

and

can

LOWT* HIGH

on LED.M.

No. 1 (page

stopping.

Operationofthe

Operation

normal

be

canbeselected

When

the

shown

be

operated.

Refer to normal

mode

switch is

below. This

•

for the

and

Operation

Panel

turned

state

Keys

functionsofeach

ON,

the

is called

LED.M

The rotationdirection of the sewing machine is displayed. The

rotation

• (D Q

1-2

SL

Panel

Keys

key

rotation direction will

the

Normal Mode,

direction

canbechanged

LED.

A-O

Thestate ofthe A~D keys

shown.

R

AT

BK

Dkey

The use of a weak brake duringstopping

set

is

24) for operation methods.

Ckey

This Is

used

standing

No. 4 (page 23) for operation

Bkey

This is used to start sewing with a slow start. After

the

poweristurnedONand

lifted, the sewing willstart with a slow start. Refer

to normal mode No. 3 (page 23) foroperation

methods.

displayonthe

and

the

with

the0P~|

Referto normalmode No. 5 (page

when using an extemal switch for

operations.

Refer to

following keys

keys.

function

settingsis

normal

methods.

the

needle

has

LED.M

can

mode

been

Cautkm

The

above

shownonthe

keys

canbeoperated

LED.M.

18

only when the rotary display is

Page 25

2.

Selection

The

modes

functions

(1)

Typesofprogram

Program

Basic (unction setting

mode

• Setting of

Tacking

* Settingof the tacking

and

numberofstitches,

Program

mode

| i |

Simple setting

thread trimming sewing

mode

Program

Mode for returning

• The values

can be returned to the ortginaldata (factoiysettings).

of

canbechanged

and

application functions

mode

I p |

speed,

etc.

mode

for Mitsubishi

machine

mode

that

9.

Operationofthe

each

mode

from

modes

validity

etc.

Normal

data

to original

have been set In

data

each

Operation

the

normal

set

Program

Applicationfuncfion A

setting

« Setting of acceleration/

program

mode

with this operation panel.

mode

| A|

mode

deceteration tinne setting

eta

mode

mode

Panei

to various program

Program

Appiication

mode

Program

Tacking setting

Program

mode}

Error display

• The input/output functions can tie

checked

abnormal operationschecked.

Keys

modes

and

Program

mode

Application function B

setting

mode

• Setting of stop angle,

eta

mode

[c |

functions C setting

mode

| p |

mode

E|

and

the

error

state

various

| b j

during

basic

A different program

mode, always return to

(2)

Program

Mode

modes

name

Normal

Tacking

mode

mode

Model

and

mode

the

models

Programmode| P | O

Programmode| A | O

Program

mode| B | O

Program

mode

Program

mode

cannotbeentered

normal mode first

BMBL

model

O

O

O

O

Caution

from

the

program mode. To

Model

Mode

name

Program

mode

fil

Programmode|°R| O

Program

mode

fTl

-19

change

BMBL

the

0

O

program

model

Page 26

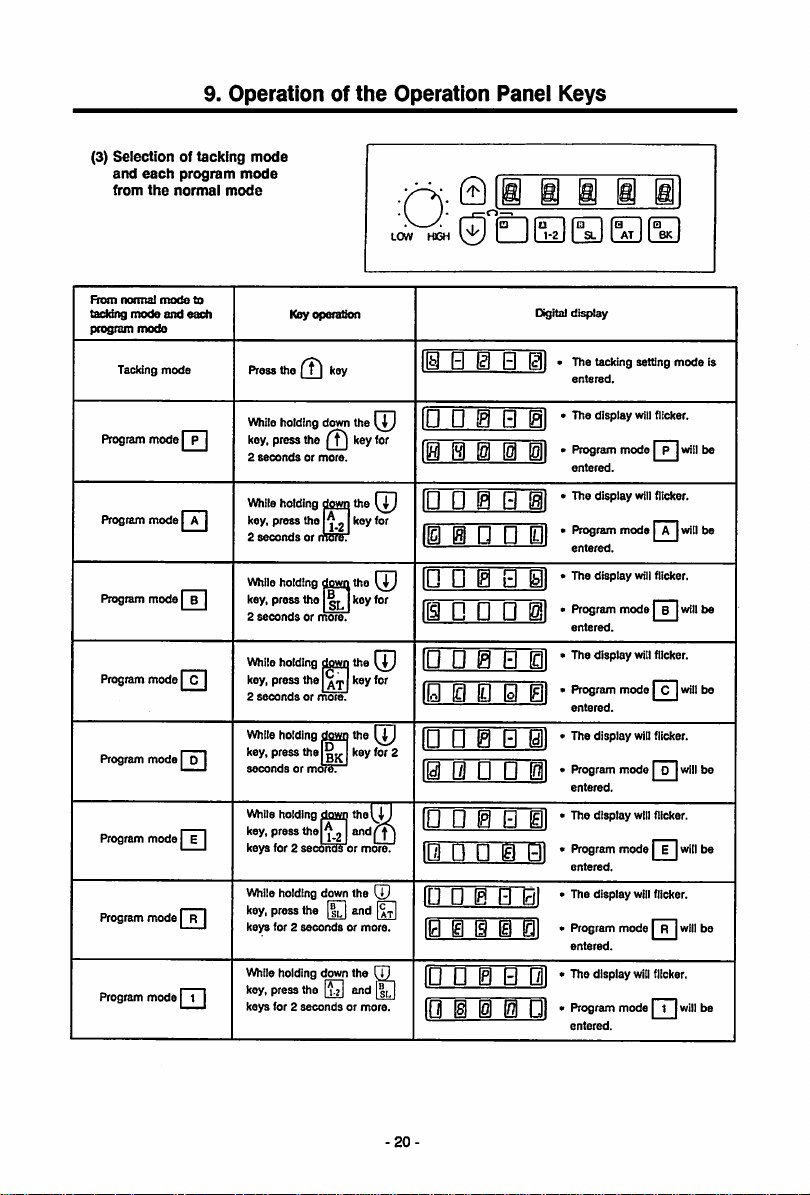

(3)

Selectionoftacking

and

each

notmal

mode

the

mode

normal

modeto

and

mode

program

from

From

taddng

program

Tacking

9.

Operationofthe

mode

mode

mode

each

Press

the key

Key

operation

Operation

011

11^

El

Panei

Q

@1•The

Keys

i

Digital

IBS

ID Q 0

SL AT BK

display

tacking

entered.

setting

mode

is

Program

Program

Program

Program

Program

Program

Program

Program

mode

mode

mode

mode

mode

mode

mode

mode

| p |

[ A|

| B |

| C |

| p [

| E |

[ R |

| i |

While holding down the

key,

press

the key for

2

secondsormore.

Whileholding dowri the

key,

press

f'lo1^j

2

secondsorrmSrST

While

holding

press

the |

holding

press

fitol

press

f>te key for 2

holding

press

the

for 2

secondiormore.

holding

press

the

secondsormore.

holding

press

the

for 2

secondsormore.

dowri

dowij

^tI

down

down

[|2

down

key,

2

secondsormore.

While

key,

2

secondsormore.

While holding dowri the

key,

secondsormof^.

While

key,

keys

While

key,

keys for 2

While

key,

keys

the

Ijrj

key

for

the

the^J

(i)

the

[p

and

[|3

the

Q]

and

l|n

fill

D ® 0

10 0

10 D 0

IIS

0 • n Bl '

' '

IE)

0 @ 0 0] *

@1*tl'spiay

IS

0 01 •

El

0l *

10 0 0 0 0l *

10 0 @ 0 0! *

10 0 0 0

@1•P'«>sram

r0 0 @ 0 0] *

10 0 0 0 01 *

rO 0 0 0 0] *

0 0 0 0

ID 0 E 0 01 *

10 E @HI01 »

0l*Program

r0 0 0 0 Ql *

[Q H 0 0 01 *

Program

mode

entered.

display

Pwgiam

mode

entered.

display

PfogtaAT

mode1B[will

entered.

mode

entered.

display

Program

mode

entered.

'"®P'®y

mode

entered.

display

Program

mode

entered.

display

Program

mode]t[will

entered.

will

will

will

will

^"1

will

will

| p

fT)

| D

| E|

Er~|

flicker.

flicker.

[will

flicker.

will

flicker.

will

flicker.

[will

flicker.

will

flicker.

will

be

be

be

bo

be

be

bo

be

20-

Page 27

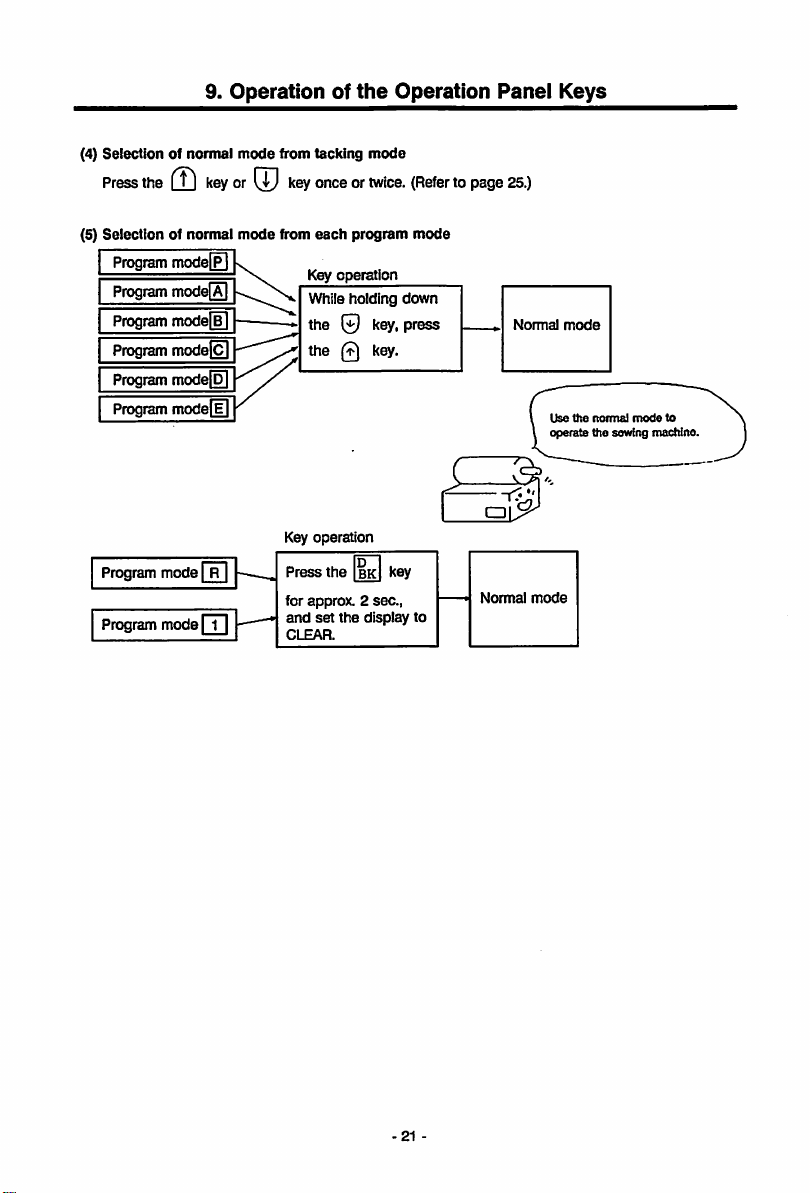

(4)

Selectionofnormal

Press

the

(Tl

(5)

Seiectionofnormal

Program

Program

modeQ

Program

mode[B]

Program model

Program

modefol

Program

Program

mode

Program

mode

9.

Operationofthe

mode

keyor[5

mode

modeE

modefll

[r^

[T]

from tacking

key

onceortwice.

from

each

Key

operation

While holding

the

0

the

Q

Key

operation

Press

the

for

approx.2sec.,

and

set

the

CLEAR.

mode

program

key,

key.

D

key

BK

display

Operation

(Refertopage

mode

down

press

to

Panel

Normal

25.)

Normal

mode

Keys

mode

Use

the

operate

normal

the

mode

sewfng

to

machine

-21

-

Page 28

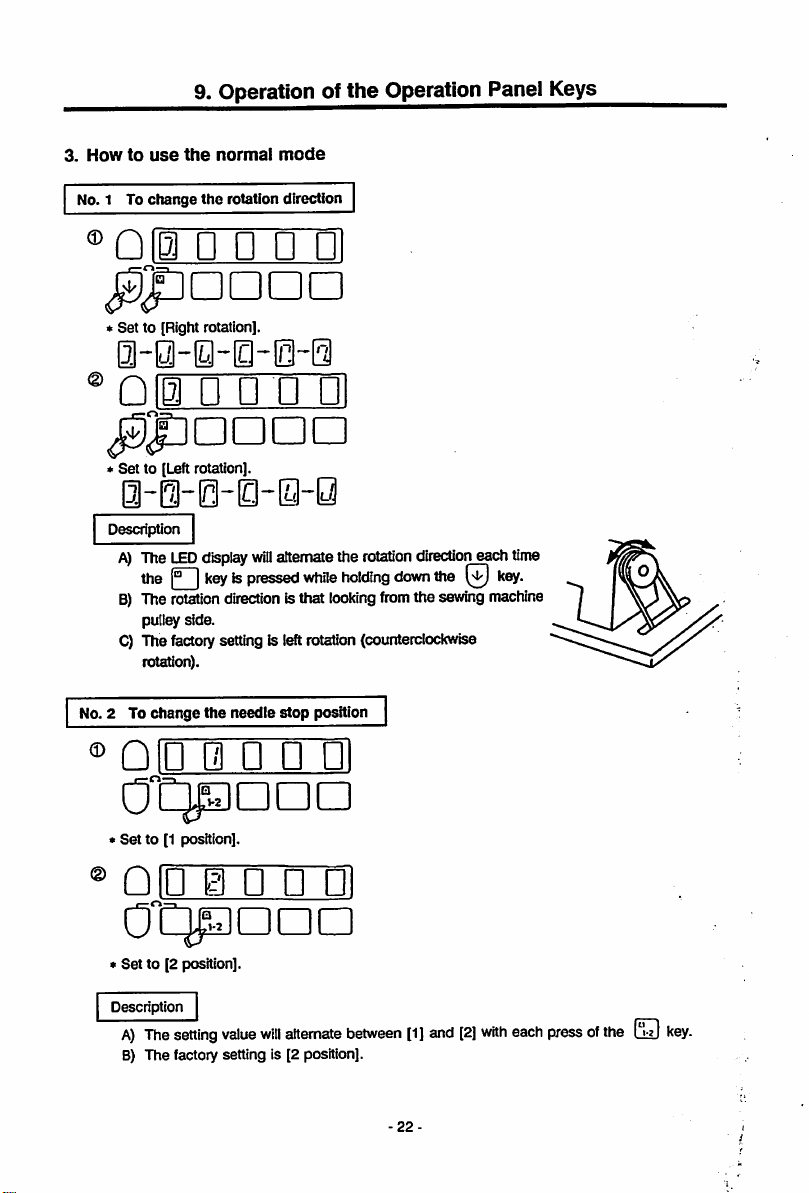

3.

Howtouse

9. Operation of

the

normal

mode

the

Operation Panel Keys

No. 1 To

change

the

OB

•

'Q

Set

0-

Set

D U U 0

to [Right rotation].

3~0~[3 lcl~0

0 • • • •!

to [Leftrotation].

rotation

direction

0-@-0-0-0-y

Description

The

LED

display

wili

alternatethe

the1°I

B)

The

pulley side.

C) Thefactorysetting is leftrotation(counterclockwise

rotation).

No. 2 To

®

Qin

keyispressed

rotation

change

the

0 • • •!

direction

needle

isthat

stop

while

looking

position

rotation

holding

down

from

direction

the

the

sewing

each time

key.

machine

*

Set

to [1 position].

®Qjg 0 • •

0

CjpZI

*

Set

to [2 position].

Description

A)

The

setting

B) The factory setting is [2 position].

Dn

value

will

ni

CD

alternate

between

22-

[1]

and

[2]

with

eachpressofthe

fin

Li±J

key.

Page 29

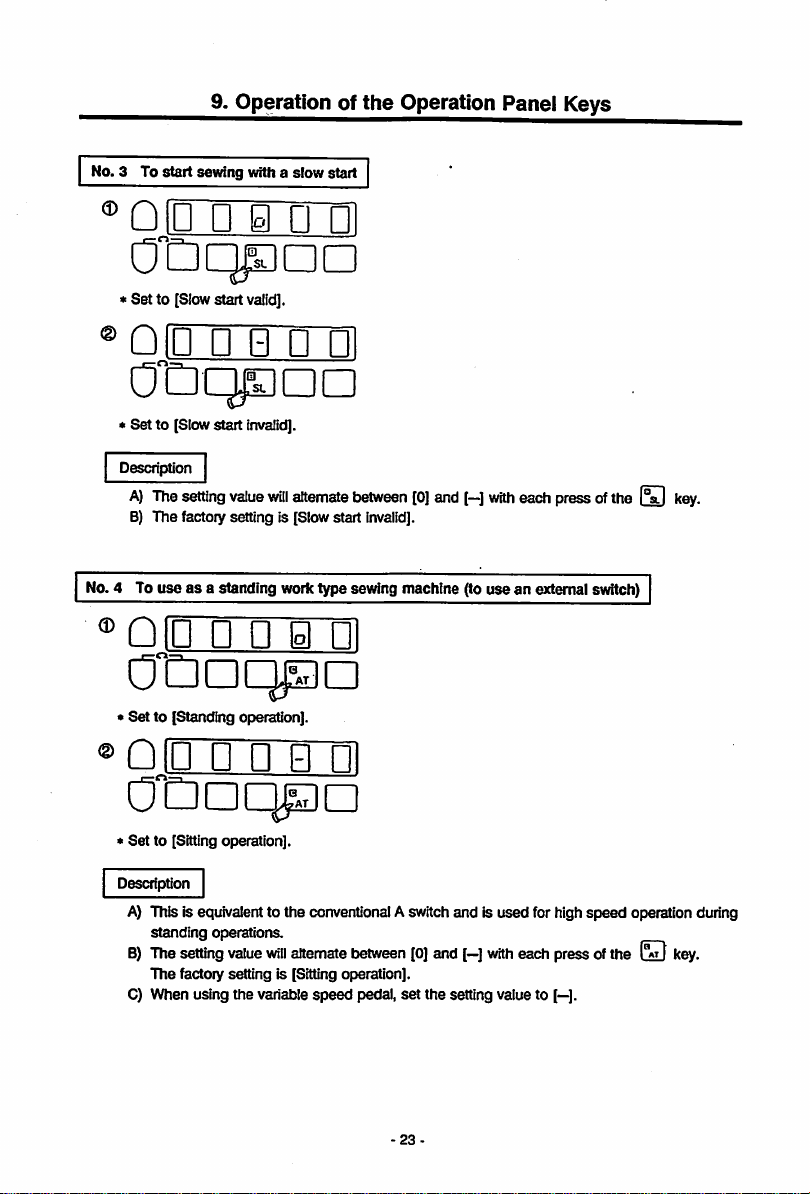

9. Operation of

the

Operation Panel Keys

No. 3 To

start

sewing with a slow start

"^QlU • H n p]

* Set to [Slow start valid].

®QIU • B • PI

OtDqpoD

• Set to [Slowstart invalid).

Description

A)

Thesettingvalue

B) The factory setting is [Slowstart

No.4 To use as a standing worktype sewing machine (to use an externalswitch)

will

alternatebetween[0]and

invalid].

[—]

with

each press ofthe

Q IP P P H PI

OtlDC^D

• Set to [Standing operation].

key.

®

Qip

p p n PI

Otiaqpn

*

Set

to [Sitting operation].

Description

A) This is equivalentto the conventionalAswitch and Is used for high

standing

8)

The

The factory setting is [Sitting operation].

C) When using the variable

operations.

setting

value

vrill

alternate

tjetween

[0]

and

speed

pedal, set the setting valueto

-23

[—]

with

speed

each

pressoftheQkey.

[—].

operation during

Page 30

9. Operation ofthe Operation Panel Keys

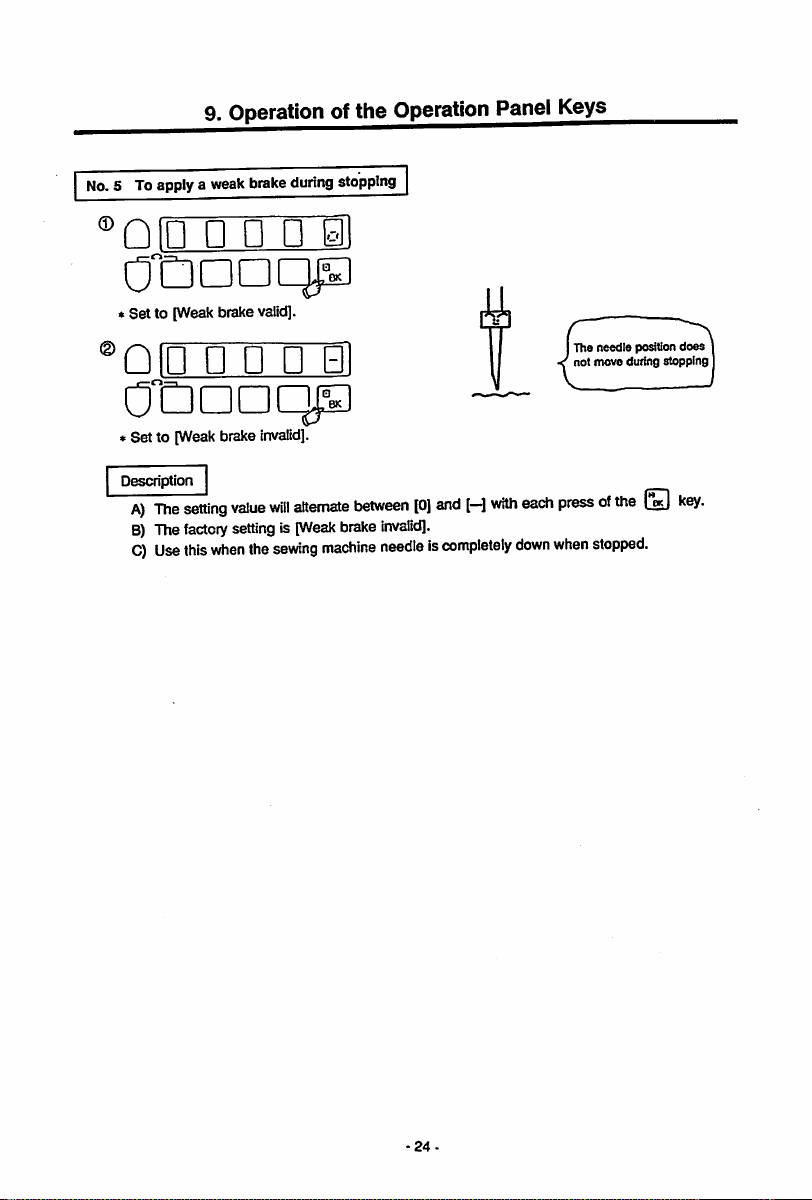

No.5 To applya weakbrakeduringstopping

®nin

«Set to [Weakbrake valid].

®Qin

• Set to [Weak brake

Description

A)

B)

C)

The

The

Use

n • u

n • •

setting

value

factory

settingIs[Weak

this

when

invalid].

will

the

sewing

B1

alternate

between

brake

machine

[0]

and

[—]

with

invalid].

needleiscompletely

down

The needle position

not move during stopping

each

pressofthe

when

does

L®eJ

stopped.

24

Page 31

9. Operation of

the

Operation Panel Keys

4. Displays

(1) Types of tacking modes and key operations

Normal

and

functions of

mode

Qkey

key ON

each

key in

ON

Tacking

setting

• Setting of the start tacking

validity

Setting of the end tacking

validity

t

(2) Tacking

When

the

mode

will

setting

mode

(T)

keyisturned

be entered. The

ON,

validity

and type of start and end tacking can be

Qli

Sstting of ttftft tscldng validity

<0i8ptay

ox,>

0 :

Valid

Q :

Invalid

Setting of start tackingtype

< Display ex. >

: No

tacking

1/]:V

tacking

LU

:

Ntacking

: M

tacking

:

Wtaddng

^

the

tacking

mode

and

type

and

type

will

display

above

B g B B

mode

Tacking

mode

Qkey

ON

No. of tacking stitch setting

mode

• Setting of the no. of

0

key

ON

Qkey

ON

the

jkey,

Factory setting

Setting of end tacking type

< Display

ex.>

: No tacking

:V

tacking

: Ntacking

: Mtacking

: W tacking

Setting ot

validity

< Display ex. >

stitches

tacking.

and

0^

0

the

set

end

for

tacking

startorend

tacking

here.

s

^

^

:

Valid

:

Invalid

setting

-25-

Page 32

9. Operation of

(3) No.Oftacking stitches setting mode

When

the@keyIsturnedONagain,

of

stitches

canbeset

the

Operation Panel Keys

will

displayontheQkey

indicator,

and

the

no.

Caution

Refertothe

display"onpage

the

correspondenceofthe

digital display

alphanumerals.

No.ofstitctres

A

setting

No.ofstitcfies

B

setting

Each setting value

0 to 9

stitches.

Ais10

stitches

8 Is11stitches

CIS12stitches

D is13stitches

Eis14

stitches

Fis15

stitches

_

116

for

and

canbechanged

A, B,0,D, E, F

^

from

stitches

PH

SrSf

•Factory setting

No.ofst

tones

0 setting

No.ofstitctres

C

setting

26

Page 33

9. Operation of

the

Operation

Panel

Keys

5. Before operating

• Following

Program-

* * *

♦

Normal

Description of

A)

Purpose

• This

B)

Set

names

select

function

the

keys for

the

next section,

£

what kind of operation

name

the

program mode

the

following description method

]

k'mction^-

the

sewing machine makes.

will

be used.

@

Purpose

^

Set

function

© Settingorder

Digital display

Display

descnption—

Mode

trartsition

(g)

Outline

description —

—

name

• The •« displayin | )| Isthefunctionname, and the ••display in | ningi|

value in

the

function.

The

function

name

and

set

value

are

separated

(Whenone functionis used | ( )| , when twoare used | ( Ij+1 (

C) Mode transition

• This Is

D) Setting

•

E) Digitaldisplay

• Press

• The function

• When setting the functionsetting withthe

• When settingtwo or more functions (purposes) in the

•

F) Display description

• This is a description of

G) Outline description

• This is an outline

the

LED d'splay

entered.

order

Setintfie

displayedonthe

mark.

be

orderofnumtiers.

the

key marked with

set

are

name

the

same,

and

LED.

and

setting value will

the

display description displayed first when

the

key

does

mark until

not

the

change

-^key,

needtobe

function

with

ifthe

pressed

(purpose)can be set consecutivelyaftersettingthe first

for

consecutive

The

function

setting.

will

advance

guideofeach

with

each

press

ofthe(J)

the

LEDdisplay contents of the functions set with

condition

when

setting

name

or setting value to t)e

each

pressofthe

LED

displayand the functionsetting to

(reset).

same

program mode,

function

(purpose).Press the key

key

and

will

return

the

functions.

—

Name

with a period (.).

1|

each

program mode is

key marked with

the

second

with

the

the

-e

istheset

.)

used

the

function

key.

mark key.

is

27-

Page 34

6.

Howtouse

9. Operation of the Operation Panel Keys

the

tacking

mode

No.1 To

set

the

tacking retract to 4 stRches, and 3 stRches forthe end tacking

retract

no.ofstRches

Function

iStartl4stitches

for

the

start/endVtacking

setting|blOIOIII+1 M I

3

stitches

•11-

"(Thisindicates the key operation. Referto

QIB

QIB

Enter

the

tacking

B H B Bl

mode

((D)-

OtDDDDa

*

Set

•The tacking

QIB

mode

• B • 01

OtDqpan

*

Set

the

start

[Vtacking].

QIB

Otiaaa^

*

Set

[Vtacking].

tacking seRing to

B B B Bl

the

end

tacking seUing to

willbeentered.

to [Start

Q IB B B H Bl

01

.

Set

to [End tacking valid].

QIB

OtiDDnD

* Complete

and

start

043011

lEndl

B B •

tacking

II

II

B a H Bl

the

tacking setting.

•!

valid].

^

page

20.)

^10

El ElBlEll

CCDDDDD

*

The

no. of tacking

willbeentered.

QjBB H B

*

Set

the

no. of

stitches

start

to [4].

stitches

Bl

tacking

setting

retract

QIB

H B B Bl

cTQpaaD

*

Set

the

no. of start tacking

0

QIB

B B i Bl

*

Set

the

no. of

-28-

end

tacking

advance

advance

stRches to [0].

stRches

to [0].

Page 35

9. Operation of

the

Operation Panel Keys

0 ©

QID • • •

Otianap

»Setthe no.ofend

stitches to [3]. completed.

il

tacking

retract

QlioliigHIil

cJDdddd

»Theno.of

tacking

stitches

setting

has been

©

Description

A)

B) In the tacking setting mode, the

C) Inthe no. oftacking stitches setting mode, the

Return

to the

normal

mode.

( (T))-

Refer

to section

•

Selectionofstart

•

Selectionofend

The setting value

Co];

[-]:

(Both keys are set to [-]:

•

The

The

For both keys: (o): No tacking

(Both keys are

Selection

Selectionofthe

Selectionofthe

Selection

Wheneach ofthe four keys are pressed, the setting value

B,C, D, E, F stitches. A refers to 10 stitches, Bto 11 stitches, C to 12 stitches, Dto 13 stitches, E

to 14 stitches, and F to 15 stitches. (Theno. of all stitches isset to [4] at shipment.)

"Displays

tacking

Start

tackingorend

Start

tacking

patterntostart

patterntoend

ofthe

no.ofstart

no.ofstart

no.ofend

ofthe

no.ofend

and

functions

tacking

validity

validity

will

alternatebetween[0] and (-)

tacking

orend

tacking

invalid

tackingisselected

tackingisselected

(1): V tacking

UK N tacking

C3]:M tacking

(4): W tacking

set

to (Ntacking] at shipment.)

tacking

tacking

tacking

tacking

ofeach keyinthe

following

will

with

I".;!

withEDkey.

valid

invalid

at shipment.)

with

with

forward

reverse

reverse

forward

-(This indicates the key operation. Refer to

page

21.)

tacking

mode"

on pages 25 and 26.

occur.

key.

with

each press of the

the j

the |

following

stitches

stitches

stitches

stitches

with

with

with

with

key.

key.

occur.

the |°.g|

the

the

the

key.

["a.Ikey.

)

key.

[*%;|key.

will

change between 0 to 9 stitches, A.

key.

-29

Page 36

9. Operation of

the

Operation

Panel

Keys

7. Howtouse

No.1 To change the maximum speed (Ex. to change to 4500 rotations)

Enter

the

program

program

mode

mode

Function

( (J) + 0 )-

(Refer

totheTableof

88 to 96.)

setting [ h I

•

(This

Program

4500

fl

indicatesthe keyoperation. Refertopage 20.)

•>

oezzb

OtDDDDO

♦

Program mode | P |

QiD

n

Bi

n 01

OtDqpan

•

Set

to [5].

QID

0 • n

CDaacp)

>

Set

to [0].

Return

tothe

will

be entered. • Set to [4].

ffll

normal

mode.

( + 0 )

qjli

OQpDDD

QID

OtDoqpo

»Set

to [0].

QiB

OtDanoD

• The [H] function setting

completed.

t

(This

indicates

the

key

operation.

Refer to

page

mu u ui

• • @ PI

H a

21.)

a~ii

(The

functions

f

Mode

has

page

Functions

been

Page

88

for

referenceinthe

tableisshown.)

on pages

Description

A) The

setting

B) By pressing

(However,

C)

The

factory

rangeofthe

eachofthe

the

key is only

settingis(4000

maximum

rotations).

speed

between

is 0 ~ 8999 rotations.

keys,

the

setting value will

1 ~ 8.)

30

change

between 0 ~ 9.

Page 37

9.

Operationofthe

Operation

Panel

Keys

No.2 To

®

Description

A)

B) By pressing each of the keys, the setting value

C) The factoiy setting Is [250 s/min].

change

the

low

Enter

program

mode

QiM

H 0 a 01

Ot:nann

Program

mode

Qiu

• H n ni

ODc

>

Set

to [2].

Qin

(1 n

nioii

0

Qooci^^

•

Set

to [0].

Returntothe

The settingrange ofthe

(However,

nomial

the

speed

(Ex. to

change

to 200 s/mln)

Function

(®

setting

+

ffl)

Qia

jStDDDOa

will

be entered. *

Set

QliJ

Ollinqpa

*

Set

QEnm

OtDDDan

>Complete

mod&(CD+(T))

maximum

key is only between 0 ~ 4.)

speed is 0 ~ 499

I L I

200

• n n

function to (L].

• •

to [0].

the

rotations.

H

[L]function setting.

151

ni

ni

Page

win

change between 0 ~ 9.

88

-31

Page 38

9. Operation of

the

Operation Panel Keys

No.3 Tochange the thread trimmingspeed (Ex.to change to 180 rotations)

Enter program

Qi

mode

ElH01

OtiaaDa

♦

Programmode

D ®

Qi'u •

PI

n m

OtDqpna

*

Set

to [1].

D

Qiu

• n

nil

*

Set

to [0].

®

Returntothe

Description

A) The setting range of

B)

Bypressing each ofthe keys,the settingvalue

(However,

C)

The

factory

normal

the (°a.|

setting

Function

(

ai

wiil

be entered. *Set

mode.(CD

the

thread trimming

keyisonly

is [200 s/min].

between0~4.)

setting

It I

IBoTI

QiH

• • n (1

jStDaODD

function

to [T].

oru

• n

O'dnqpa

*

Set

to [8].

QJEOm

ODDDDa

Complete the (I] fitnction setting.

+ 0 )

speed

is 0 ~ 499 rotations.

Bi

ni

(Refertothe Table of

display* on

alphanumerals.)

Page

will

digital

page

116

for

88

change between0 ~ 9.

-32

Page 39

9. Operation of

No.4 Tochange the start tacking speed (Ex.to change to 1200 rotations)

Enter

program

mode (CD+ (T))

Qli

B i i Bl

the

Operation Panel Keys

Function setting n 11200

Qiy

• n n a

OtDDDDO

* Program

QID B • n PI

0 (HID

♦

Set

to (1].

mode

willbeentered.

•

Set

function to [N].

i)

QID

• a n PI

OtiqpDD

•

Set

to [2].

D

QIU

• • i

CT

0"C3DqpD

Set

to [1].

QIB

Q ^ i

ODDDDG

:The [N] function setting

completed.

Description

A) The setting range of the start tacking

B)Bypressing

(However,

C) The factory setting is [1700 rotations],

D) This is effective

eachofthe

the

(D

when

il

has

been

(DOIDIS

keyisonly

aligning

the

§)

Q!•D • D

0

•

Set

speed

is 0 ~ 2999 rotations.

between0~2.)

start tacking.

i1

CDDDIHJi^]

to [2].

Return

tothe

normal

keys,

the

setting

value

moda(

Page

will

change

CD

^ )

88

between0~9.

-33-

Page 40

9. Operation of

the

Operation

Panel

Keys

No.5 To change the end tacking speed (Ex.to change to 1500 rotations)

Enter

program

niH

mode

B i i

ii

(

(J?

Function

+ (2 )

setting

v

nia

11500

• • • PI

•"••••a

♦

Program mode

D @

QJD

H• •

01lIi|3DnD

•

Set

to [1].

QID

• n

will

be entered. * Set function to

ni

»

IS!

PI

[V].

Qin

n gi •

OtiQPDD

Set

to [5],

•

!••••

ni

a

OtDDcpa

*

Set

*

Set

to [0].

nin

Rig]loi

0"Daaaa

m

to [0].

Return

tothe

normal

moda( (J) +

(T)

)

* The [V]function setting

completed.

Description

A) The setting

B)Bypressing

(However,

C) The factory setting is [1700 rotations].

D) This is effective

rangeofthe

eachofthe

the01keyisonly

when

has

end

aligning

been

tacking

(3

the

speed

is 0 ~ 2999 rotations.

S 0

betweeno~2.)

end

tacking.

-34

the

setting

value

will

Page

88

change

between0~9.

Page 41

9.

Operationofthe

Operation

Panel

Keys

No.6 To

Enter

Qii

Program

nn

change

program

a i i

mode

n a

OtDc^aa

*

Set

to [3].

QID

• • •

OtDDDQP

*

Set

to [0].

®

Returntothe

the

slow start

mode

fpl(CD

willbeentered.

rrpi

normal

speed

........

Function

ii

il

mode.(CD

(Ex. to

setting

+ )

change

to 300 rotations)

300

QIH

U • • PI

*

Set

function to [S].

Q iu u n p ni

OTzudd^d

•

Set

to [0].

QiB

• a 0 11

OtDDDDD

* The [S] function setting

completed.

+ (B )

has

been

Page

88

Description

A)

Thisisvalid

B) The setting range of

0)Bypressing

(However,

D)

The

when

eachofthe

the

factory setting is [250 rotations].

the

FsTl

the

speed

(31

keyisonlyo~2.)

keyinthe

normal

is 0 ~ 2999 rotations.

(5i]

(3

-35-

modeisturned

keys,

the

setting

ON.

value

will

change

between0^9.

Page 42

9.

Operationofthe

No.7 To change the number of stitches in siow start (Ex.to change to three stitches)

Enter

program

niH

mode

w isi a HI

(

(XI

+ (2) )

OtDDDDD

*

Program

Qin

mode| P |

n n n H

will

be entered. *Set

O'Daaqp

«

Set

to [3].

Returntothe

Description

A)

Thisisvalid

B) The setting

C)Bypressing

D) The factory setting is [2 stitches].

normai

mode.(CD+(T)

when

theOkeyinthe

range

of the number of stitches is 1 ~ 5 stitches.

PbkI

key,

the

setting

Function

normal

value

will

Operation

setting[SLN

Qiia

gi H n •!

C]eno imiiij

functionto[SLN].

QiB

OtnoDDp

»

The

[SLN] function setting

compieted.

) |

modeisturned

change

between

Panel

1"^]

H n

1~ 5

ON.

Keys

ii

stitches.

has

been

Page

88

36-

Page 43

9.

Operationofthe

Operation

Panel

Keys

No.8Tocarry

Function

Enter

program

niH

pa

OtDDDDD

♦

Program mode

QID

• •

*

Set

to [SO].

QiB

a • • PI

^tDDoaa

*

Press

the[pkey

function to [SO].

QIB

a • •

OtDDDDn

out

low

speed

setting|SOH

mode| P | (CD+

i i

ii

will

be entered. • Set function to

Bl

il

once,

and

il

operation

set

with

["S^+l

(T)

)

the

external

switch

SO

I Oil

Q

IBI

i 0 •

^tlDDOD

[SOH].

Qli

a HB)El

OtlDDDD

* Complete

•!••••

OtDoaq^

*

Set

to [0].

Return

the

tothe

[SOH]

function setting.

ai

normal

mode.(CD

+ 0 )

• The

[SO]

completed.

Description

A)

Set

B) The low

the

C)

Each

t}etween

D)

Each

Inorderof [0],[1],

Note) When using this function, always return to the normal mode before starting operations.

function setting has

both

the

[SOH]

speed

No. 6 pin in

time

the IVI

[SO]

and

time

the

and

operation

the

option 2 connector.

keyIspressedInstep3, theset

[SH].

I°bkIkeyispressedInstep6,the

[RND],

been

[SO]functions.

will

be valid withthe switch

(Thefactorysetting Is

[SO],

[SCR],

[USR],

37

[SO].)

set

[UO],

[SO]

connected to

value

will

alternate

value

will

change

[BTL].

(Thefactoiysetting Is

Page

88

Option 2

[0].)

Page 44

9.

Operationofthe

Operation

Panel

Keys

No.9Tostitch

with

one

Function

Enterprogrammode | P | (

QIH

a B i Bl

OtDanoa

Program

mode

Qlu

• n H

OCdddc^^]

*

Set

to [SO].

Qia

B n n

^tDDDDO

*

Press

the

key

function to [SO].

Qia

B n n m

OtDDDaa

needle

with

the

setting|SOHISO

willbe entered. »

loll

ni

once,

and

set

the

external

switch

il+l

SO

I 1

QiB

^tDDDna

Set

function to [SOH].

@

QiB

♦

Complete

Qin

OtDoaqp

♦

Set

to [1].

Return

11

H a n

H a

the

• • n Bl

tothe

ni

isi

il

[SOH]function setting.

normal

mode.

( © + © )

•The

[SO]

completed.

Description

A) Set both the

B) The one needle stitching

to

0) Each time the key is pressed in

between

D)

Each

order of [0], [1],

Note)

function setting has been

[SOH]

and

[SO]

functions.

will

be valid with the switch

the

No. 6 pin in

[SO]

time

Whenusingthis

the

option 2

and [SH]. (The factory setting is

the(3keyIspressedInstep6,the

[RND],

[BC],

[BCR],

function,

alwaysretumto the

connector.

step

[USR], [UO],

3, the

-38

set

[SO].)

set

Page

[SO]

connected

value

will

alternate

value

will

change

in

[BTL].

(The factory setting is [0].)

normal

mode beforestarting operations.

88

Options

Page 45

9. Operation of

the

Operation Panel Keys

No.10 To confirm

penetration

Enter

program

QtFWHSl

the

position where the needle

strength

ofthe

first

stitch

mode (CD+ (U )

passed

with

the

Function

QjEnnini

through

extemai

switch

setting|SOH

OtDaODD

Program

QID

OtDDoq^

*

Set

QIB

mode

• • B M

to [SO].

a • • •!

willbeentered. *

Set

function to [SOH].

Q|g|

a w B

OtDaDDD

* Complete

i)

QID

the

• B B Bl

[SOH]

OtDDOq^

«

Press

theCDkey

function to [SO].

QID

i B B Bl

O^DDDDD

The

[SO]function setting

completed.

Description

A)

Set

both

B) This is

C)

D) Each time

Note) When using this function, always return to

the

usedtoincrease