Page 1

MELSEC-L I/O Module

User's Manual

-LX10

-LX28

-LX40C6

-LX41C4

-LX42C4

-LY10R2

-LY18R2A

-LY20S6

-LY40NT5P

-LY28S1A

-LY41NT1P

-LY42NT1P

-LY40PT5P

-LY41PT1P

-LY42PT1P

-LH42C4NT1P

-LH42C4PT1P

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the

programmable controller system, refer to the user's manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

1

Page 4

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

Also, all outputs may be turned on if an error occurs in a part, such as an I/O control part, where

the CPU module cannot detect any error. To ensure safety operation in such a case, provide a

safety mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe

circuit example, refer to the "GENERAL SAFETY REQUIREMENTS" chapter in the Safety

Guidelines included with the CPU module or head module.

(3) Outputs may remain on or off due to a failure of a component such as a transistor in an output

circuit. Configure an external circuit for monitoring output signals that could cause a serious

accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to relevant manuals for

each network. Failure to do so may result in an accident due to an incorrect output or malfunction.

● When changing data from a peripheral device connected to the CPU module to the running

programmable controller, configure an interlock circuit in the program to ensure that the entire system

will always operate safely. For other forms of control (such as program modification or operating

status change) of a running programmable controller, read the relevant manuals carefully and ensure

that the operation is safe before proceeding. Especially, when a remote programmable controller is

controlled by an external device, immediate action cannot be taken if a problem occurs in the

programmable controller due to a communication failure. To prevent this, configure an interlock circuit

in the program, and determine corrective actions to be taken between the external device and CPU

module in case of a communication failure.

2

Page 5

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines provided with the CPU module or head module. Failure to do so may result in electric

shock, fire, malfunction, or damage to or deterioration of the product.

● To interconnect modules, engage the respective connectors and securely lock the module joint levers

until they click. Incorrect interconnection may cause malfunction, failure, or drop of the module.

● Do not directly touch any conductive parts and electronic components of the module. Doing so can

cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before wiring. Failure to do so may

result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

3

Page 6

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when a terminal block screw comes

loose, resulting in failure.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● Tighten the terminal block screws within the specified torque range. Undertightening can cause short

circuit, fire, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Mitsubishi programmable controllers must be installed in control panels. Connect the main power

supply to the power supply module in the control panel through a relay terminal block.

Wiring and replacement of a power supply module must be performed by qualified maintenance

personnel with knowledge of protection against electric shock.

For wiring methods, refer to the MELSEC-L CPU Module User's Manual (Hardware Design,

Maintenance and Inspection).

4

Page 7

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock.

Doing so will cause the battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws or connector screws. Failure to do so may result in electric

shock.

[Startup and Maintenance Precautions]

CAUTION

● Before performing online operations (especially, program modification, forced output, and operating

status change) for the running CPU module from the peripheral device connected, read relevant

manuals carefully and ensure the safety. Improper operation may damage machines or cause

accidents.

● Do not disassemble or modify the module. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the terminal block screws or connector screws within the specified torque range.

Undertightening can cause drop of the component or wire, short circuit, or malfunction. Overtightening

can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● After the first use of the product (module, display unit, and terminal block), do not connect/disconnect

the product more than 50 times (in accordance with IEC 61131-2). Exceeding the limit may cause

malfunction.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

5

Page 8

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

6

Page 9

INTRODUCTION

Remark

Thank you for purchasing the Mitsubishi MELSEC-L series programmable controllers.

This manual describes safety precautions, specifications, and functions.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC-L series programmable controller to handle the product correctly.

Operating procedures are explained using GX Works2.

When using GX Developer, refer to the following.

Page 90, Appendix 4

7

Page 10

COMPLIANCE WITH EMC AND LOW VOLTAGE

DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated

into other machinery or equipment, certain measures may be necessary. Please refer to one of the following

manuals.

• MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

• MELSEC-L CC-Link IE Field Network Head Module User's Manual

• Safety Guidelines (This manual is included with the CPU module or head module.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage

Directives.

(2) Additional measures

No additional measures are necessary for the compliance of this product with EMC and Low Voltage Directives.

8

Page 11

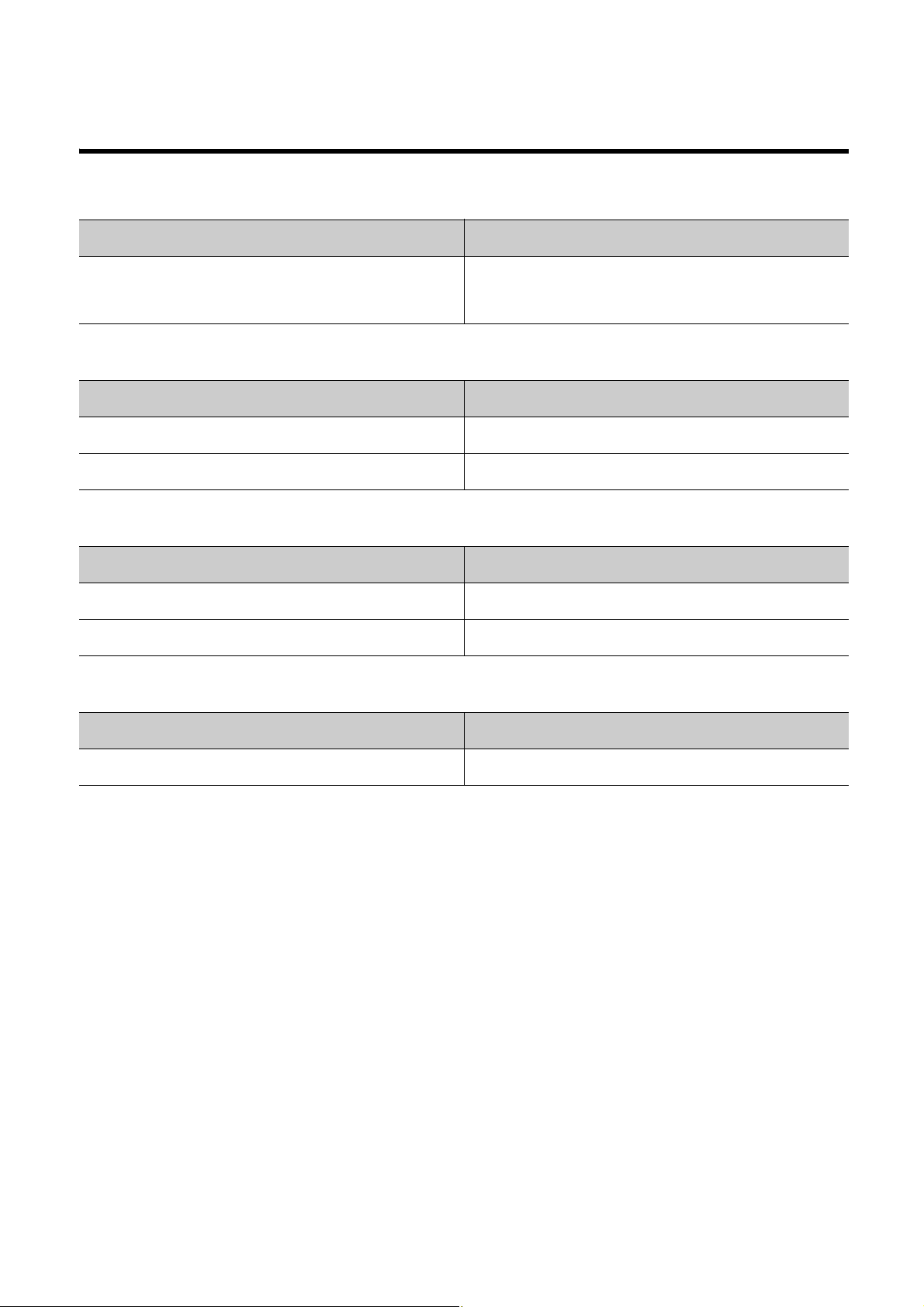

RELEVANT MANUALS

(1) CPU module user's manual

Manual name

manual number (model code)

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and

Inspection)

SH-080890ENG, 13JZ36

(2) Head module User's Manual

Manual name

manual number (model code)

MELSEC-L CC-Link IE Field Network Head Module User's Manual

SH-080919ENG, 13JZ48

MELSEC-L SSCNET III/H Head Module User's Manual

SH-081152ENG, 13JZ78

(3) Operating manual

Manual name

manual number (model code)

GX Works2 Version 1 Operating Manual (Common)

SH-080779ENG, 13JU63

GX Developer Version 8 Operating Manual

SH-080373E, 13JU41

Description

Specifications of the CPU modules, power supply modules, display unit,

branch module, extension module, SD memory cards, and batteries,

information on how to establish a system, maintenance and inspection, and

troubleshooting

Description

Specifications, procedures before operation, system configuration, installation,

wiring, settings, and troubleshooting of the head module

Specifications, procedures before operation, system configuration, installation,

wiring, settings, and troubleshooting of the head module

Description

System configuration, parameter settings, and online operations of GX

Works2, which are common to Simple projects and Structured projects

Operating methods of GX Developer, such as programming, printing,

monitoring, and debugging

(4) User's manual for optional items

Manual name

manual number (model code)

Relay Terminal Module User's Manual (Hardware) A6TE2-16SRN

IB-66833, 13JL53

Description

Specifications and part names of the A6TE2-16SRN

9

Page 12

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MANUAL PAGE ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CHAPTER 1 PRODUCT LINEUP 15

1.1 Product Lineup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2 How to Read the Model Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CHAPTER 2 PART NAMES 18

CHAPTER 3 BEFORE USING I/O MODULE 20

3.1 Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 I/O Combined Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CHAPTER 4 SPECIFICATIONS 28

4.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2 Input Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.1 LX10 AC input module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.2.2 LX28 AC input module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4.2.3 LX40C6 DC input module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.2.4 LX41C4 DC input module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.2.5 LX42C4 DC input module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.3 Output Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3.1 LY10R2 contact output module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.3.2 LY18R2A contact output module (All points independent). . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4.3.3 LY20S6 triac output module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4.3.4 LY28S1A triac output module (All points independent) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4.3.5 LY40NT5P transistor output module (Sink type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.3.6 LY41NT1P transistor output module (Sink type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

4.3.7 LY42NT1P transistor output module (Sink type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.3.8 LY40PT5P transistor output module (Source type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.3.9 LY41PT1P transistor output module (Source type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

4.3.10 LY42PT1P transistor output module (Source type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.4 I/O Combined Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.1 LH42C4NT1P DC input/transistor output combined module (Sink type) . . . . . . . . . . . . . . . . .54

4.4.2 LH42C4PT1P DC input/transistor output combined module (Source type) . . . . . . . . . . . . . . .56

CHAPTER 5 SYSTEM CONFIGURATION 58

10

Page 13

CHAPTER 6 INSTALLATION AND WIRING 61

6.1 Installation Environment and Installation Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2.1 For the 18-point screw terminal block module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

6.2.2 For the 40-pin connector type module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.3 Input Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

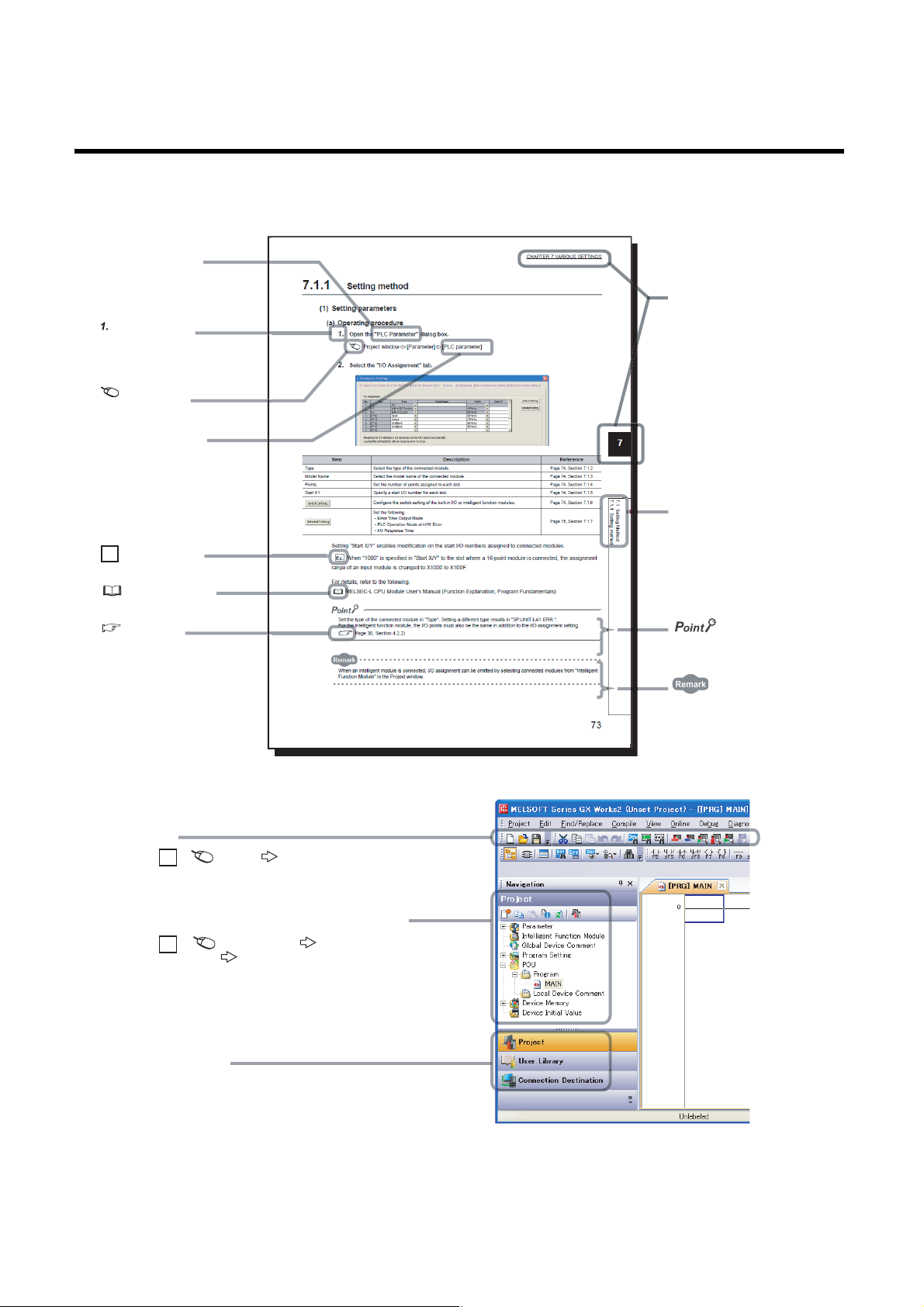

CHAPTER 7 VARIOUS SETTINGS 68

7.1 Input Response Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

7.2 Error Time Output Mode Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

CHAPTER 8 TROUBLESHOOTING 71

8.1 Troubleshooting for Input Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2 Troubleshooting for Output Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

APPENDICES 81

Appendix 1 Optional Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Appendix 1.1 Connector/terminal block converter modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Appendix 1.2 Relay terminal module (A6TE2-16SRN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Appendix 1.3 Dedicated cables with connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Appendix 1.4 Converter modules and interface modules (FA goods) . . . . . . . . . . . . . . . . . . . . . . . .87

Appendix 2 Checking Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Appendix 3 Compatibility of L series and Q series I/O module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Appendix 4 When Using GX Developer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Appendix 5 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Appendix 5.1 I/O modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Appendix 5.2 Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Appendix 5.3 Connector/terminal block converter modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Appendix 5.4 Cable for connector/terminal block converter module . . . . . . . . . . . . . . . . . . . . . . . . .95

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

11

Page 14

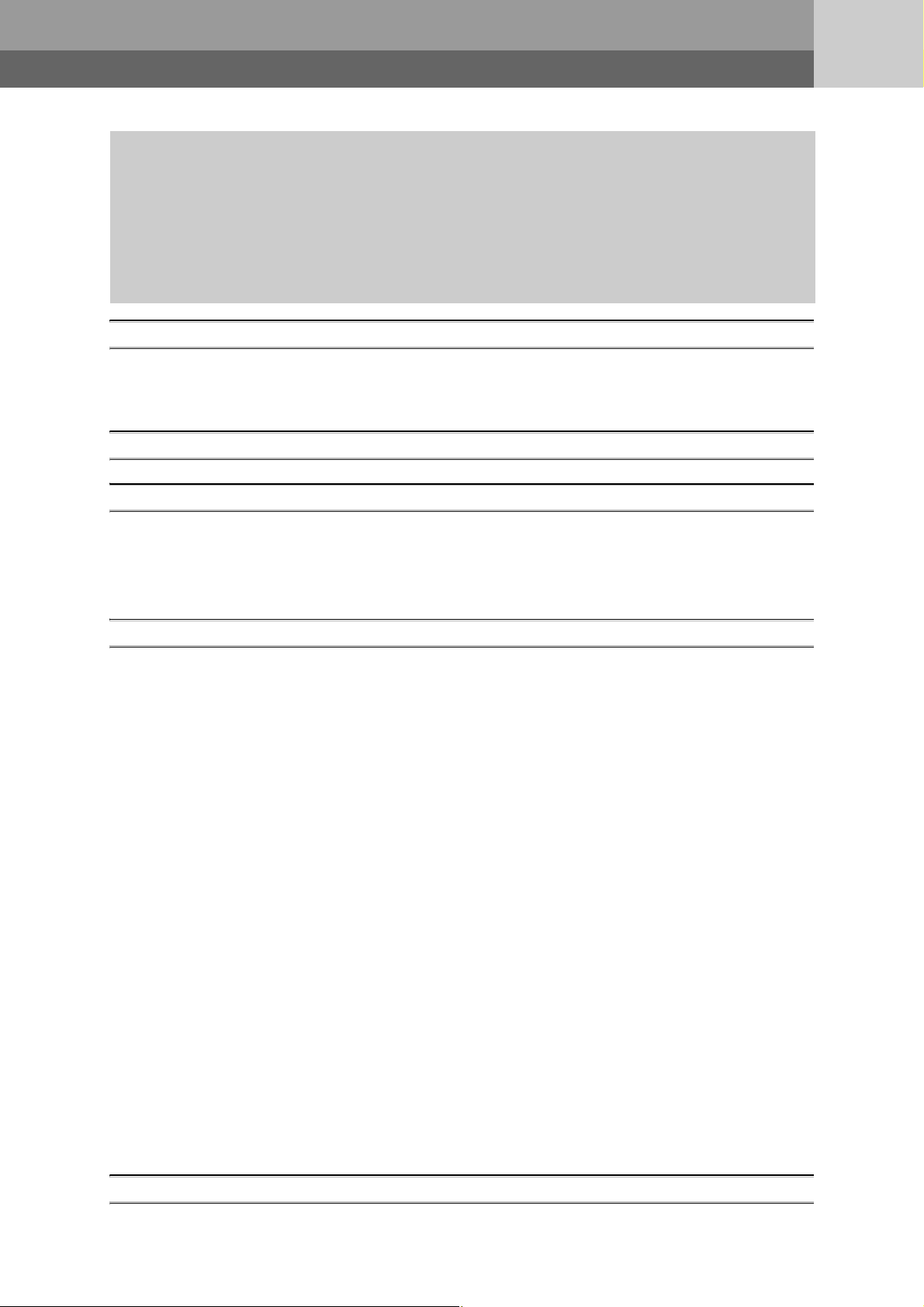

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

screen names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

A window selected in the view selection area is displayed.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[Parameter]

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

Menu bar

Ex.

Ex.

In the Project window, expand [Parameter] and

select [PLC Parameter].

In this manual, pages are organized and the symbols are used as shown below.

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

*1 The mouse operation example is provided below. (For GX Works2)

12

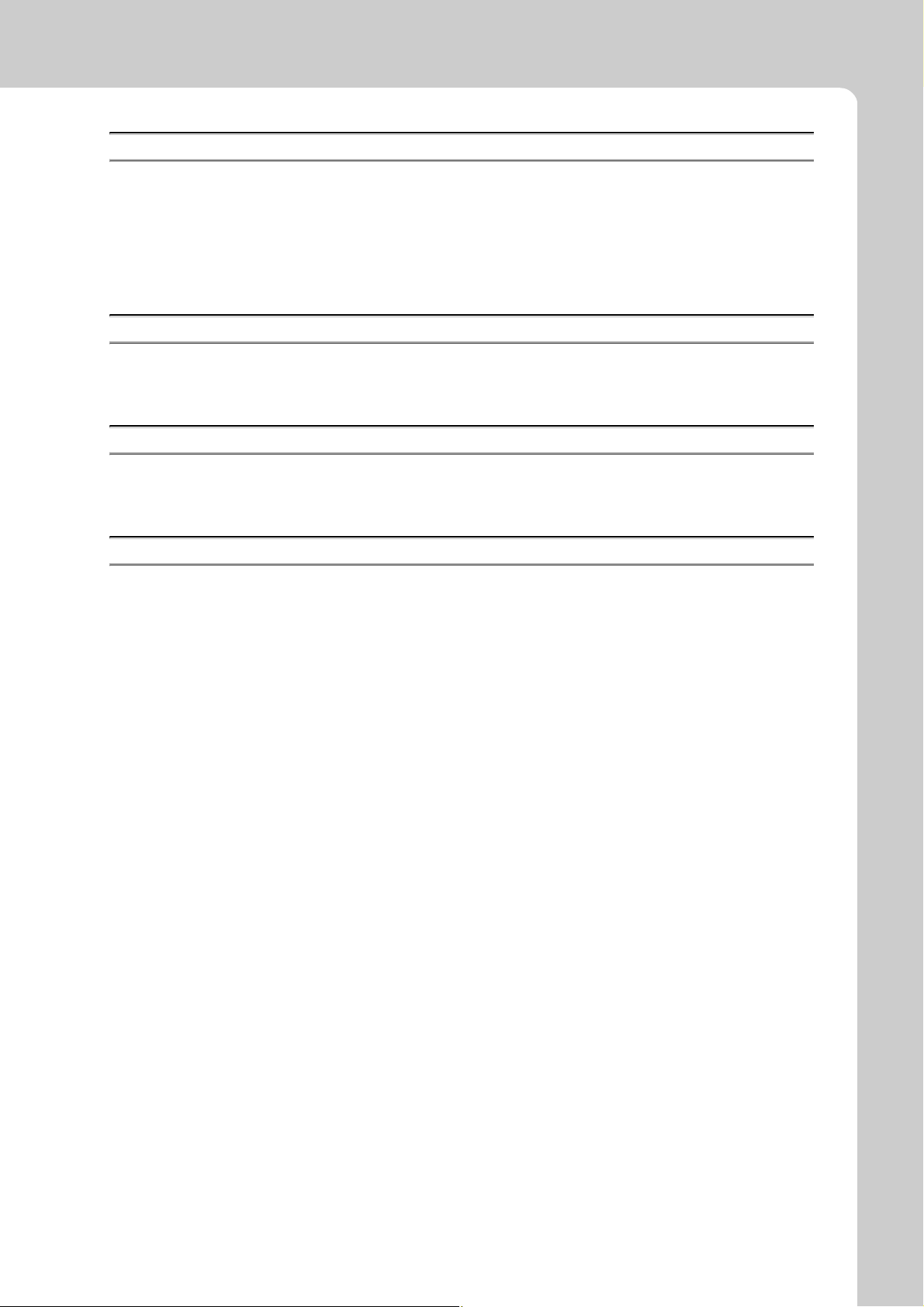

Page 15

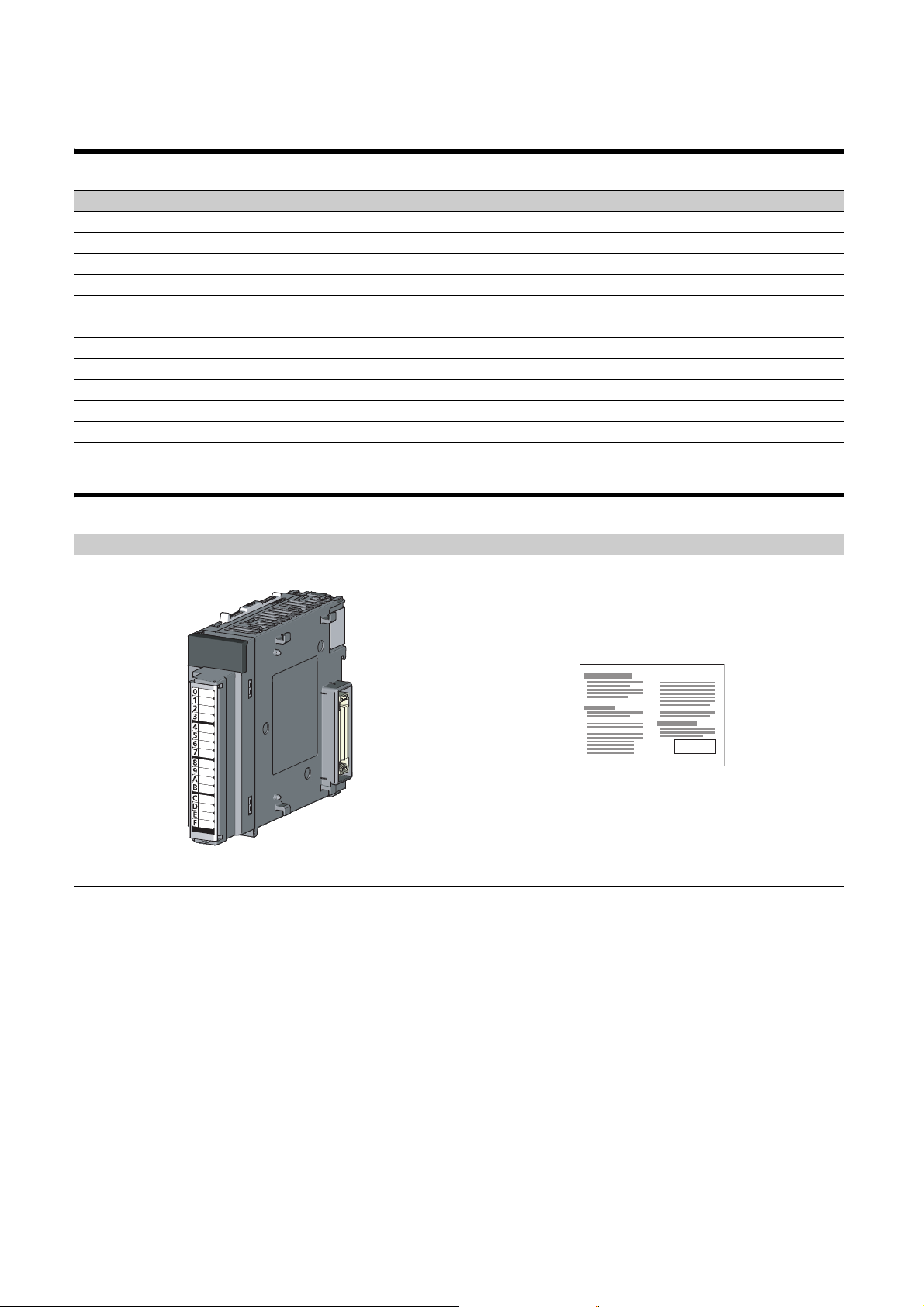

Pages describing specifications are organized as shown below.

Module specifications

Model name and

module name

Derating chart

(only for input modules)

External connections

Terminal connections

Appearance

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

13

Page 16

TERMS

Unless otherwise specified, this manual uses the following terms.

Ter m Description

CPU module Abbreviation for the MELSEC-L series CPU module

Power supply module Abbreviation for the MELSEC-L series power supply module

Display unit A liquid crystal display to be attached to the CPU module

LCPU Another term for the MELSEC-L series CPU module

GX Works2

GX Developer

L series I/O module Abbreviation for the MELSEC-L series I/O module

Q series I/O module Abbreviation for the MELSEC-Q series I/O module

I/O module Another term for the MELSEC-L series I/O module

ACTB Abbreviation for the AC05TB, AC10TB, AC20TB, AC30TB, AC50TB, AC80TB, and AC100TB

ACTE Abbreviation for the AC06TE, AC10TE, AC30TE, AC50TE, and AC100TE

The product name of the software package for the MELSEC programmable controllers

PACKING LIST

The following items are included in the package of this product. Before use, check that all the items are included.

I/O module

14

Module Before Using the Product

Page 17

CHAPTER 1 PRODUCT LINEUP

1.1 Product Lineup

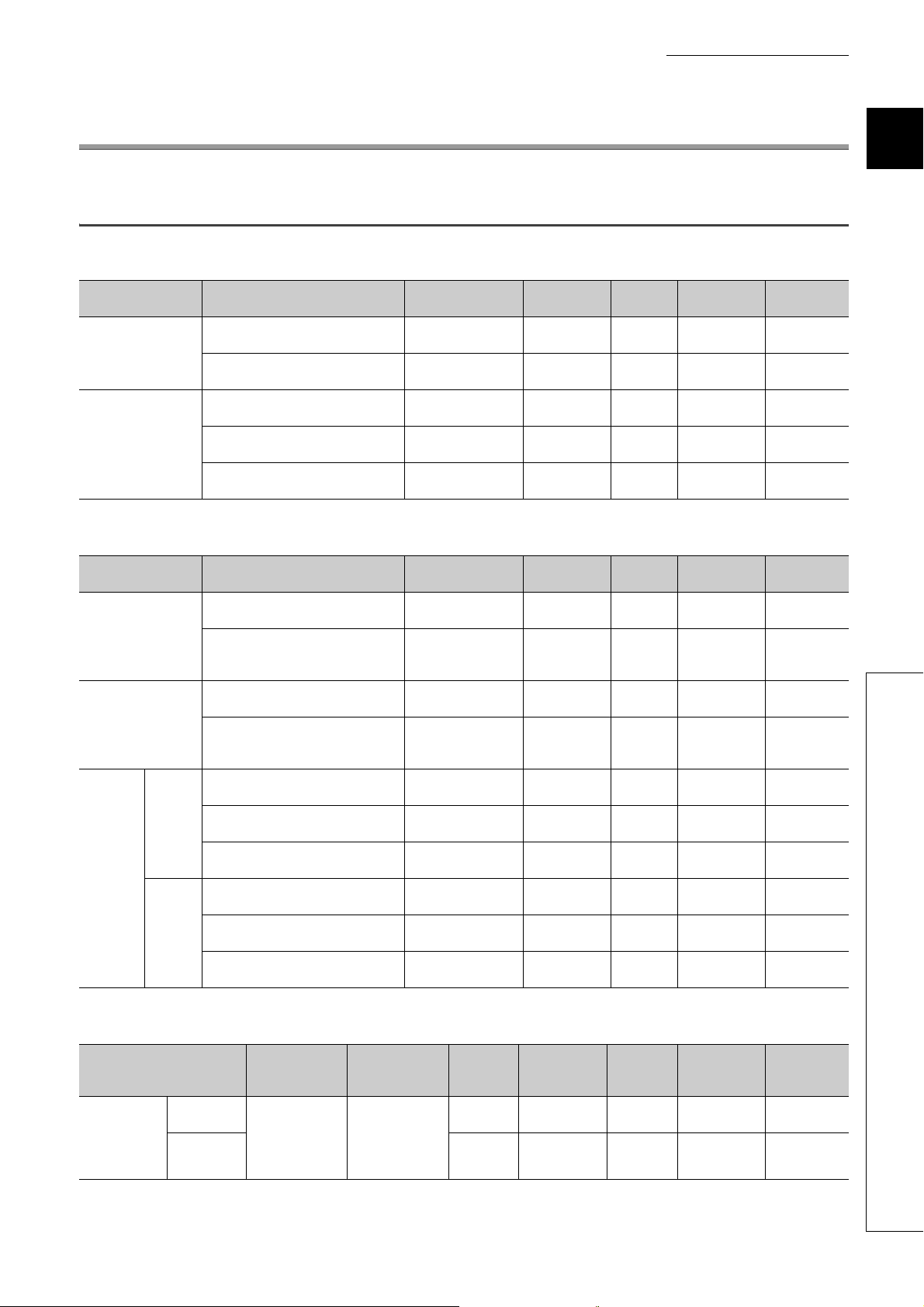

(1) Input module

Module name Input specifications

Terminal block

AC Input module

DC Input module

100 to 120VAC, 16 points

Terminal block

100 to 240VAC, 8 points

Terminal block

24VDC, 16 points

40-pin connector

24VDC, 32 points

40-pin connector (× 2)

24VDC, 64 points

Number of occupied

I/O points

16 points 90mA 0.17kg LX10

16 points 80mA 0.15kg LX28

16 points 90mA 0.15kg LX40C6

32 points 100mA 0.11kg LX41C4

64 points 120mA 0.12kg LX42C4

Current

consumption

CHAPTER 1 PRODUCT LINEUP

1

Weight Model name Reference

Page 29,

Section 4.2.1

Page 31,

Section 4.2.2

Page 32,

Section 4.2.3

Page 34,

Section 4.2.4

Page 36,

Section 4.2.5

(2) Output module

Module name Output specifications

Terminal block

240VAC/24VDC, 2A/1 point, 16 points

Contact output module

Triac output module

Sink type

Transistor

output

module

Source

type

Terminal block

240VAC/24VDC, 2A/1 point, 8 points

All points independent

Terminal block

100 to 240VAC, 0.6A/1 point, 16 points

Terminal block

100 to 240VAC, 1A/1 point, 8 points

All points independent

Terminal block

12 to 24VDC, 0.5A/1 point, 16 points

40-pin connector

12 to 24VDC, 0.1A/1 point, 32 points

40-pin connector (× 2)

12 to 24VDC, 0.1A/1 point, 64 points

Terminal block

12 to 24VDC, 0.5A/1 point, 16 points

40-pin connector

12 to 24VDC, 0.1A/1 point, 32 points

40-pin connector (× 2)

12 to 24VDC, 0.1A/1 point, 64 points

Number of occupied

I/O points

16 points 460mA 0.21kg LY10R2

16 points 260mA 0.14kg LY18R2A

16 points 300mA 0.22kg LY20S6

16 points 200mA 0.15kg LY28S1A

16 points 100mA 0.15kg LY40NT5P

32 points 140mA 0.11kg LY41NT1P

64 points 190mA 0.12kg LY42NT1P

16 points 100mA 0.15kg LY40PT5P

32 points 140mA 0.11kg LY41PT1P

64 points 190mA 0.12kg LY42PT1P

Current

consumption

Weight Model name Reference

Page 39,

Section 4.3.1

Page 40,

Section 4.3.2

Page 41,

Section 4.3.3

Page 42,

Section 4.3.4

Page 44,

Section 4.3.5

Page 45,

Section 4.3.6

Page 47,

Section 4.3.7

Page 49,

Section 4.3.8

Page 50,

Section 4.3.9

Page 52,

Section 4.3.10

1.1 Product Lineup

(3) I/O combined module

Module name

DC

input/transistor

output

combined

module

Sink type

Source type 32 points 150mA 0.12kg LH42C4PT1P

40-pin connector

24VDC, 32 points

Input

specifications

Output

specifications

40-pin connector

12 to 24VDC,

0.1A/1 point, 32

points

Number of

occupied

I/O points

32 points 160mA 0.12kg LH42C4NT1P

Current

consumption

Weight Model name Reference

Page 54,

Section 4.4.1

Page 56,

Section 4.4.2

15

Page 18

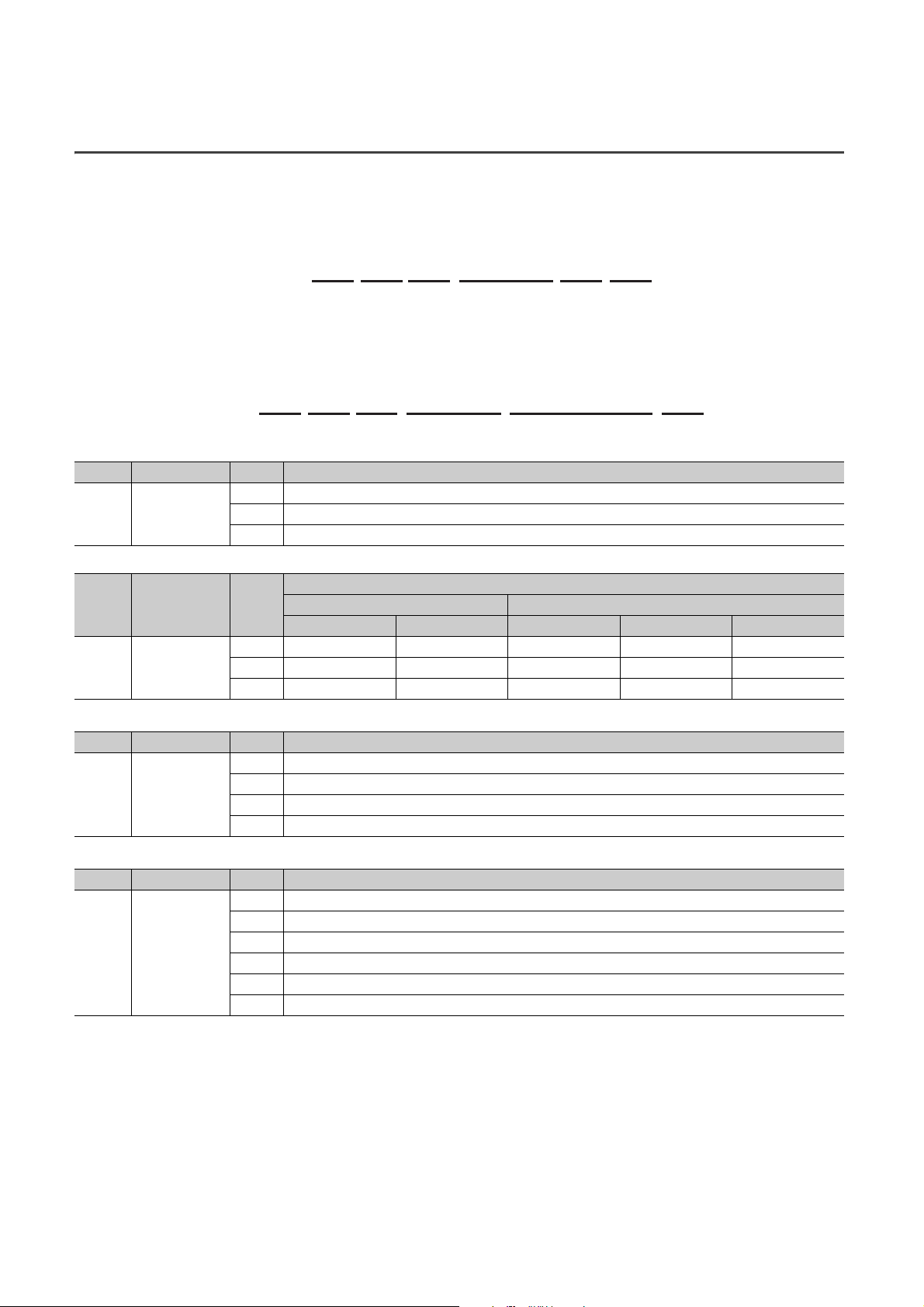

1.2 How to Read the Model Name

L Y 4 0 N T 5 P

1) 2) 3) 4) 5) 6)

L H 4 2 C 4 N T 1 P

1) 2) 3) Input type Output type

5)4) 4)5)

6)

• For input module or output module

• For I/O combined module

No. Item Symbol Specifications

X Input

1) Module type

YOutput

H I/O combined

Specifications

No. Item Symbol

2)

3)

4) I/O type

Voltage

specification

No. Item Symbol Specifications

Number of I/O

points

No. Item Symbol Specifications

1 100 to 120VAC - 24VDC/240VAC - -

2 100 to 240VAC - - 100 to 240VAC -

4 - 24VDC - - 12 to 24VDC

016 points

132 points

264 points

8 8 points

Blank AC input

C DC input (positive/negative common available)

NT Transistor output (sink type)

PT Transistor output (source type)

R Contact output

S Triac output

Input module Output module

AC input DC input Contact output Triac output Transistor output

16

Page 19

CHAPTER 1 PRODUCT LINEUP

Specifications

No. Item Symbol

1 - - - 1A 0.1A

5)

6)

Current

specifications

No. Item Symbol Specifications

Extended

specification

2--2A--

4- 4mA - - -

5----0.5A

6 - 6mA - 0.6A -

P With protection function

A Independent common

Input module Output module

AC input DC input Contact output Triac output Transistor output

1

1.2 How to Read the Model Name

17

Page 20

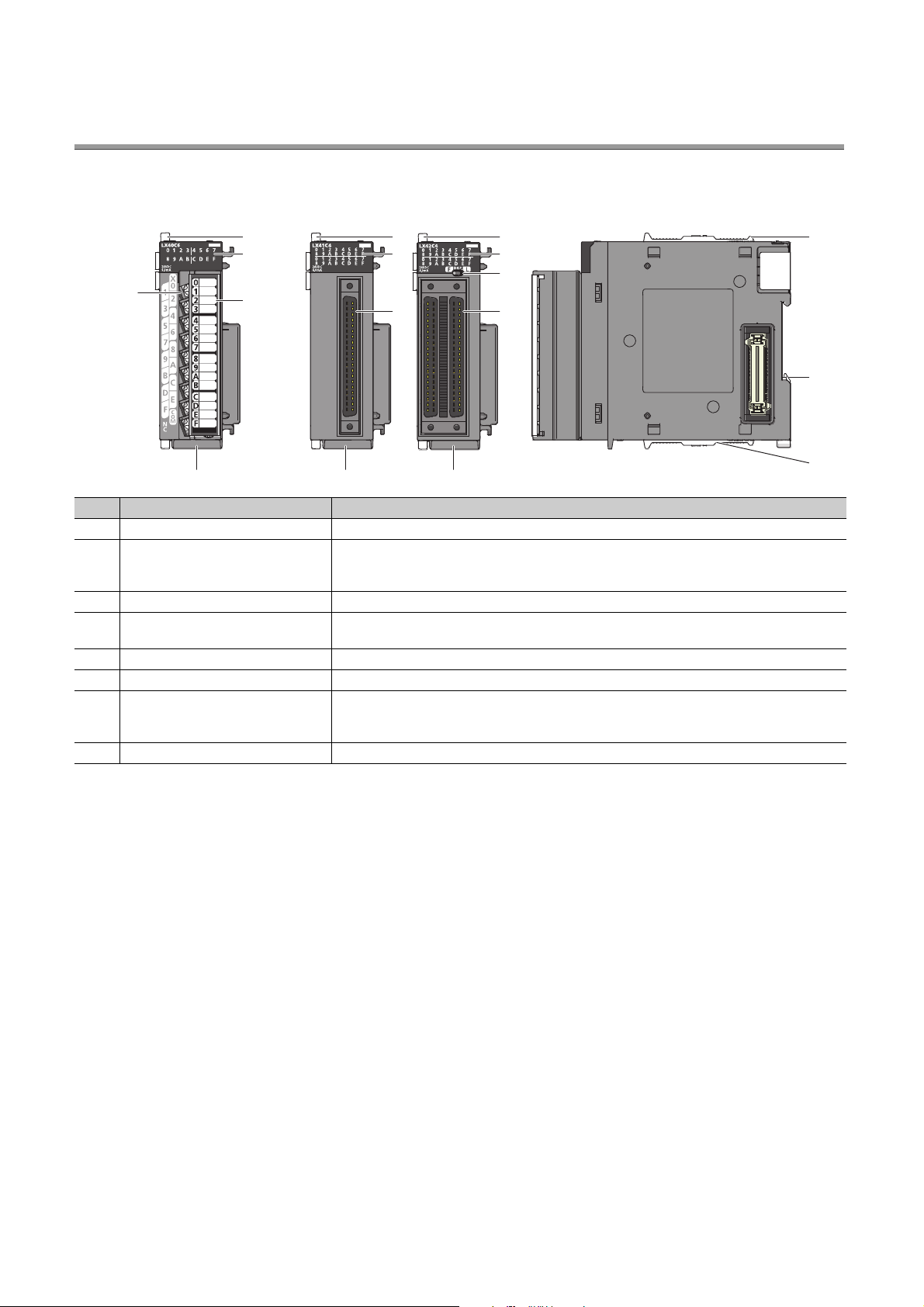

CHAPTER 2 PART NAMES

1)1)

2) 2)

1)

7)

6)

3)

4)

5)

1)

8)

2)

1)

6)

8)

8)

40-pin connector type18-point screw terminal block type

No. Name Description

1) Module joint levers Levers for connecting two modules

2) I/O operation status indicator LEDs

3) Terminal block A 18-point terminal block for connecting I/O signal cables to external devices

4) Terminal cover

5) DIN rail hook A hook used to mount the module to a DIN rail

6) Connectors for external devices (40 pins) A connector for connecting I/O signal cables to external devices.

7)

Indication selector switch

8) Serial number display Displays the serial number printed on the rating plate.

*1 Operate the Indication selector switch with your fingers. Do not use a screwdriver or similar tool as it may damage the

switch.

*1

Indicate the I/O status.

• On (green): I/O signal is on.

• Off: I/O signal is off.

A cover for preventing electric shock

A label on it is used for recording the signal names of devices allocated to terminals.

• For input module or output module: Used to switch the LED indications between the first-half 32 points

and latter-half 32 points of a 64-point module.

• For I/O combined module: Used to switch the LED indications between input and output.

18

Page 21

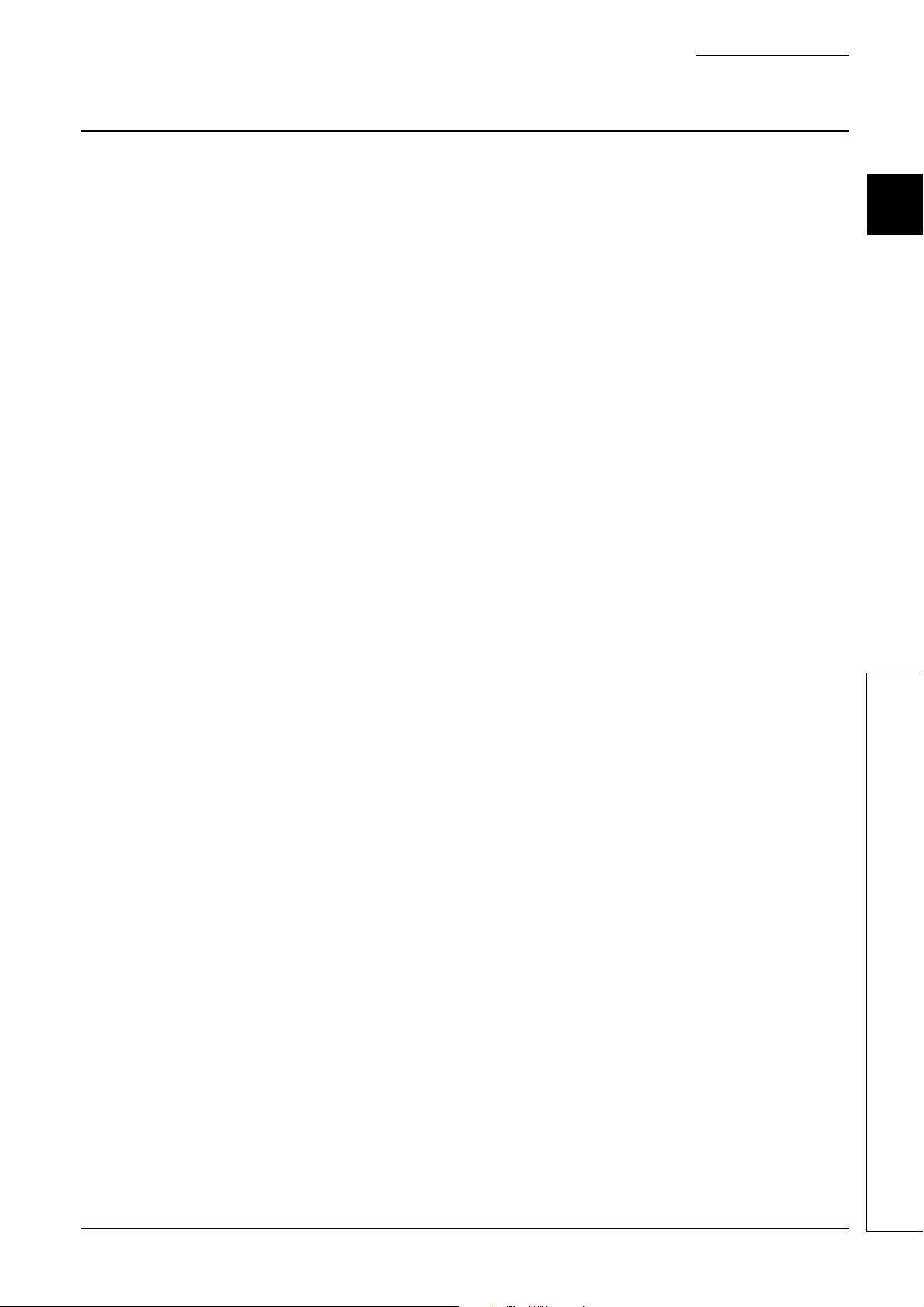

Memo

CHAPTER 2 PART NAMES

2

19

Page 22

CHAPTER 3 BEFORE USING I/O MODULE

3.1 Input Module

(1) Common precautions for all output modules

(a) Simultaneous on points

The number of simultaneous on points of input module depends on the input voltage and ambient temperature.

Refer to the derating chart of the input module specifications. ( Page 28, CHAPTER 4)

(2) Precautions for using the DC input module

(a) Measures against back EMF

When an inductive load is connected, connect a diode in parallel with the load.

Use a diode that meets the following conditions.

• Reverse breakdown voltage is equal to or more than 10 times as large as the circuit voltage.

• Forward current is equal to or more than 2 times as large as the load current.

IN

COM

Inductive

load

Diode

Positive common

IN

COM

Inductive

load

Diode

Negative common

20

Page 23

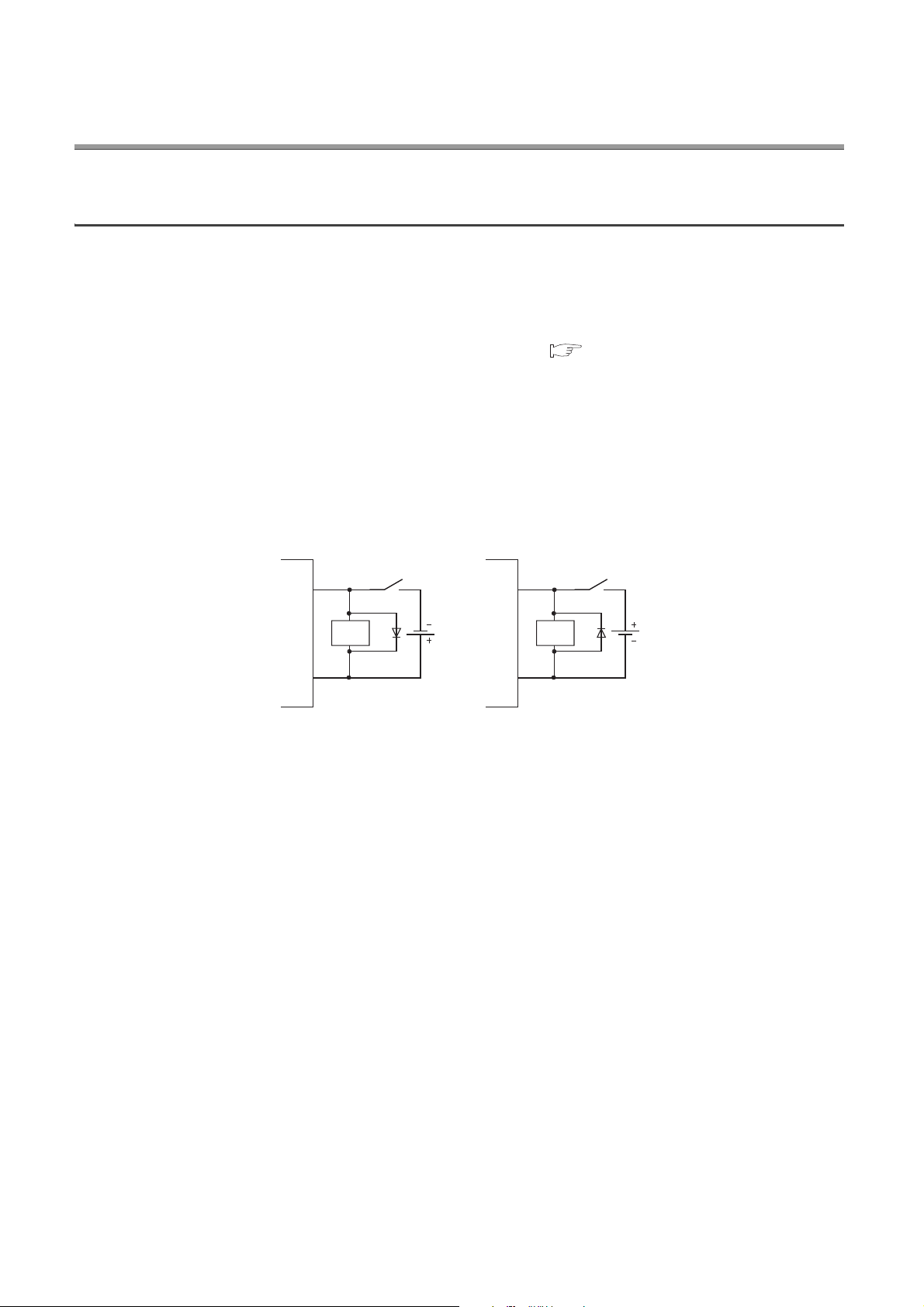

3.2 Output Module

Output

module

Inductor Load

(1) Common precautions for all output modules

(a) Maximum switching frequency when the module drives Inductive load.

The output must be on for one second or longer and off for one second or longer.

(b) Load for connection

When connecting a counter or timer that has a DC-DC converter as a load, select an output module whose

maximum load current is larger than inrush current of the load.

Selecting an output module by average current of the load may cause a failure of the module because inrush

current flows at a constant frequency at power-on or during operation due to the connected load.

If an output module needs to be selected by average current of the load, take either of the following actions to

reduce an influence from inrush current.

• Connecting a resistor to the load in series

Resistor

CHAPTER 3 BEFORE USING I/O MODULE

3

Load

Output

module

• Connecting an inductor to the load in series

3.2 Output Module

21

Page 24

(2) Precaution for using the transistor output module

OUT1

OUT2

COM

OUT1

OUT2

COM

Diode

Diode

Diode

Diode

Load

Load

Sink type

OUT1

OUT2

COM

OUT1

OUT2

COM

Diode

Diode

Diode

Diode

Load

Load

Source type

OUT

COM

Sink type

Additional circuit

Source type

Diode

OUT

COM

Diode

Additional circuit

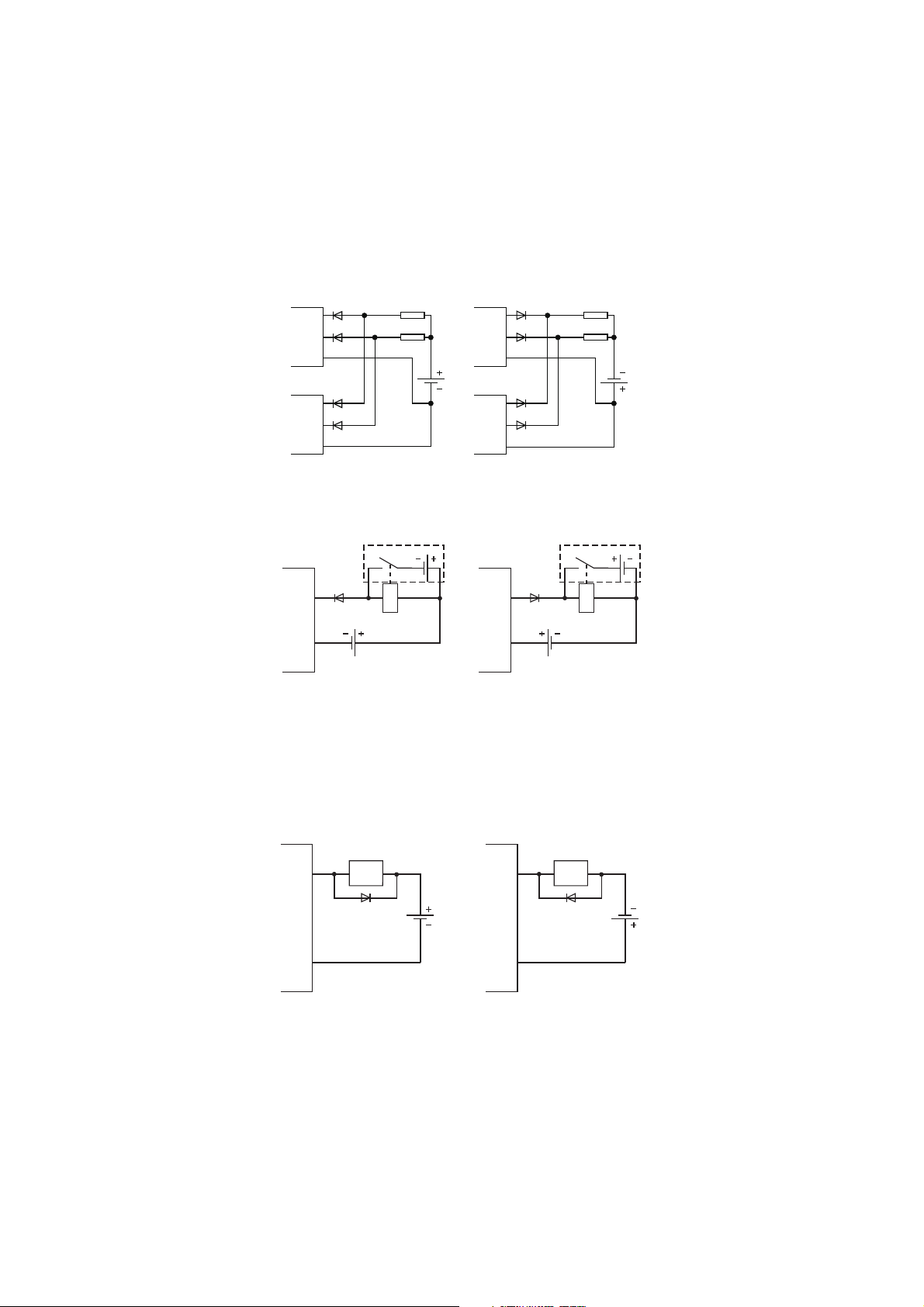

(a) Action against reverse current

If a transistor output module is wired as shown below, reverse current flows in an output element, causing a

failure of the element.

When wiring a transistor output module, connect a diode as shown below.

• When connecting transistor output modules in parallel

• When incorporating an additional circuit parallel to a transistor output module

22

(b) Measures against back EMF

When an inductive load is connected, connect a diode in parallel with the load.

Use a diode that meets the following conditions.

• Reverse breakdown voltage is equal to or more than 10 times as large as the circuit voltage.

• Forward current is equal to or more than 2 times as large as the load current.

OUT

COM

Sink type

Inductive

load

Diode

OUT

COM

Inductive

load

Diode

Source type

Page 25

(3) Precautions for using the contact output module

When using the contact output module, consider the following.

• Relay life (contact switching life)

• Effects to relay life due to connected load

• Measures against back EMF

CHAPTER 3 BEFORE USING I/O MODULE

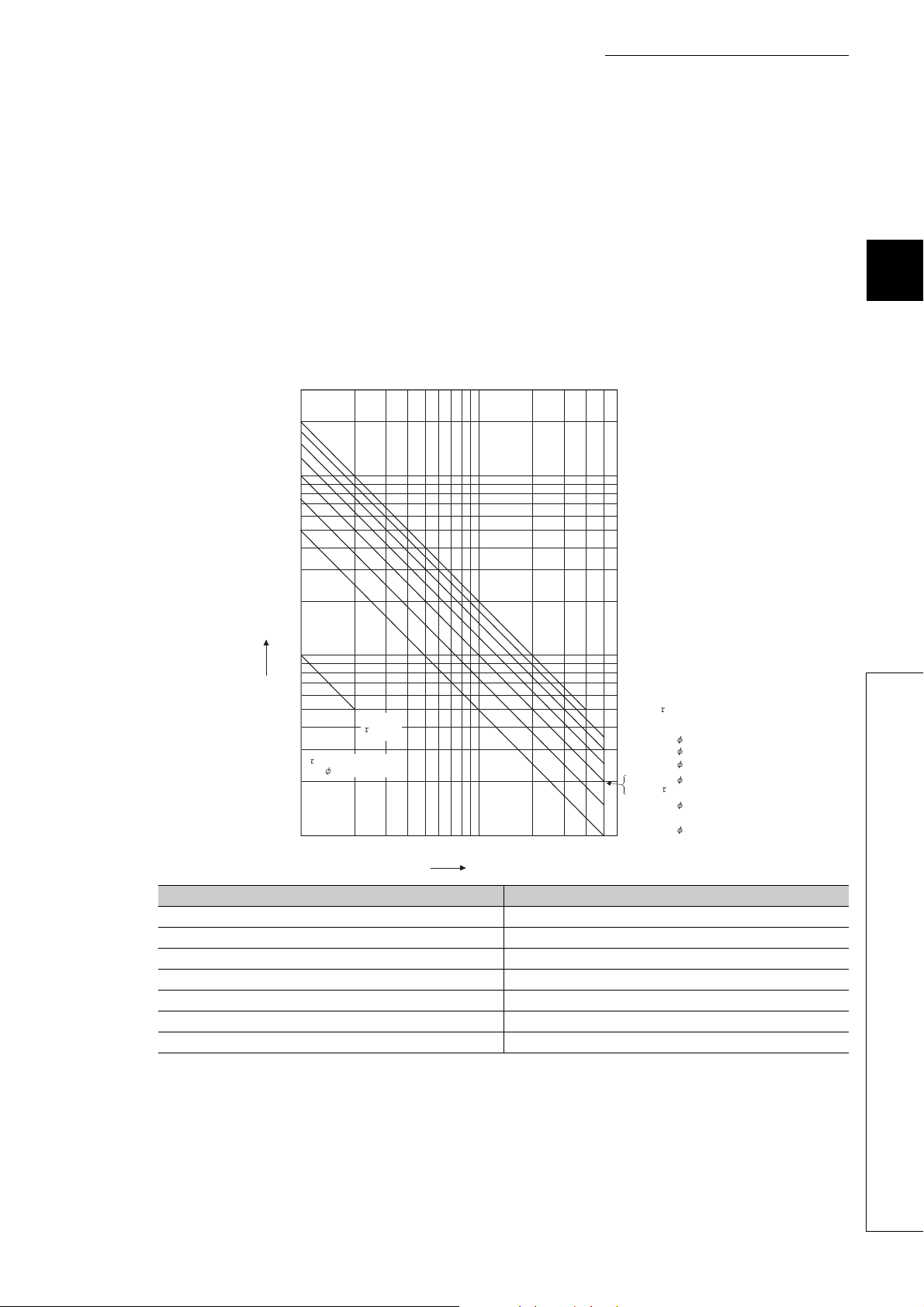

(a) Relay life (contact switching life)

Applicable module LY10R2, LY18R2A

The relay life depends on the operating environment. Select a module according to the operating environment.

The relay lives shown below are the actual service values, not the guaranteed values. Replace the module well

in advance since the actual switching life may be shorter than the one shown below.

200

100

70

50

30

20

Switching life

(10,000 times)

10

7

5

3

(L/R) : Time constant

cos

2

1

0.1 0.2 0.3 0.5 0.7 1 2 3 5

100VDC

=ms7

: Power factor

Switching current (A)

30VDC =0ms

100VAC cos =0.7

200VAC cos =0.7

100VAC cos =0.35

200VAC cos =0.35

24VDC =7ms

120VAC cos =0.2

240VAC cos =0.2

3

3.2 Output Module

Operating environment Switching life

Rated switching voltage/current, rated load 100 thousand times

200VAC 1.5A, 240VAC 1A (COS = 0.7) 100 thousand times

200VAC 0.4A, 240VAC 0.3A (COS = 0.7) 300 thousand times

200VAC 1A, 240VAC 0.5A (COS = 0.35) 100 thousand times

200VAC 0.3A, 240VAC 0.15A (COS = 0.35) 300 thousand times

24VDC 1A, 100VDC 0.1A (L/R = 7ms) 100 thousand times

24VDC 0.3A, 100VDC 0.03A (L/R = 7ms) 300 thousand times

23

Page 26

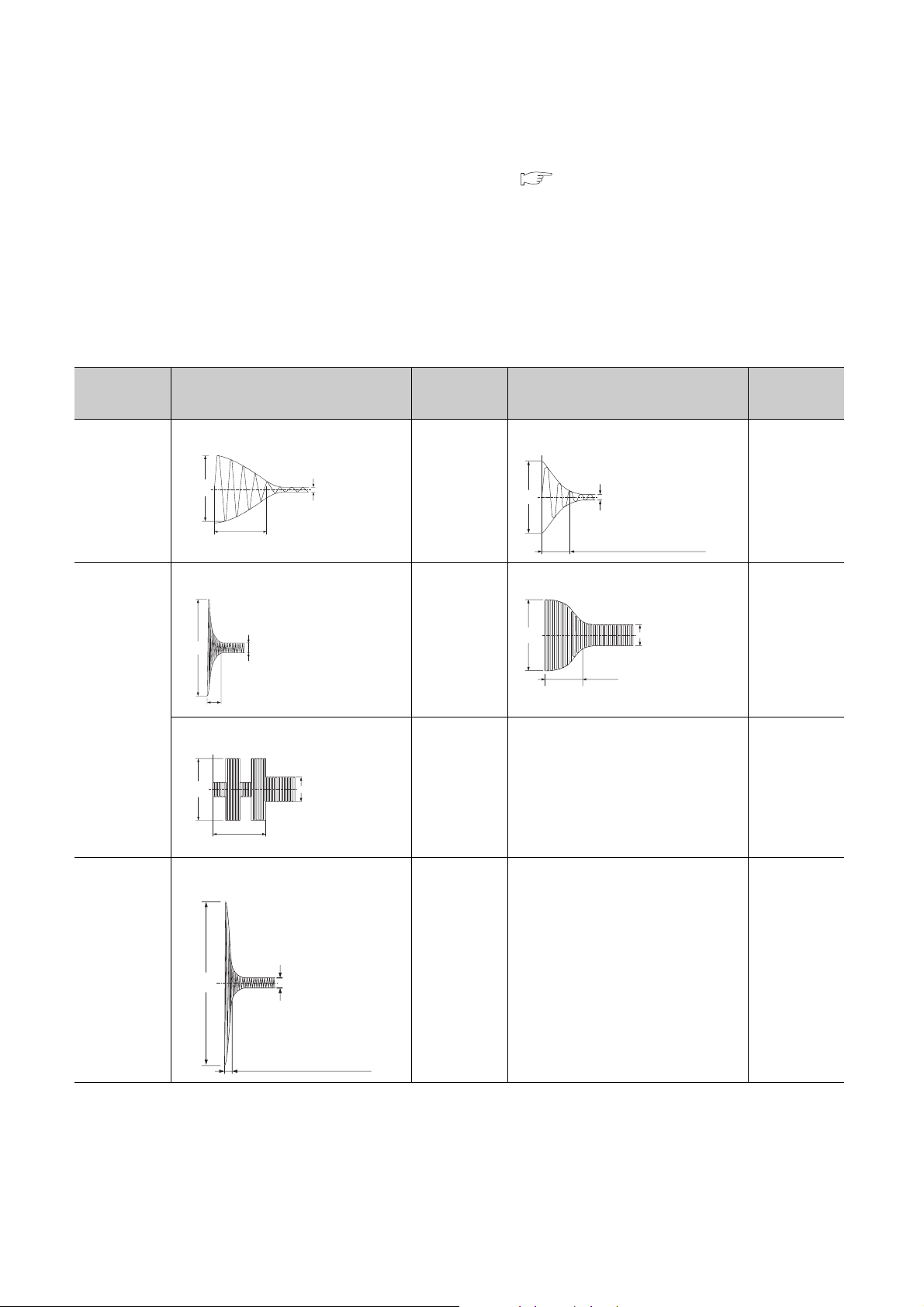

(b) Effects to relay life due to connected load

i

i

o

0.07 to 0.1 seconds

Load of a solenoid

i: Inrush current

i

o: Rated current

i: Inrush current

i

o

: Rated current

i

o

Load of an incandescent bulb

i

Approx. 0.33 seconds

Load of a mercury lamp

i

i

o

180 to 300 seconds

(3 to 5 minutes)

i: Inrush current

i

o: Rated current

i: Inrush current

i

o: Rated current

Load of a fluorescent

i

o

Within 10 seconds

i

The actual relay life may be significantly shortened compared to the relay life curve, depending on the type of a

load connected and the characteristics of inrush current. ( Page 23, Section 3.2 (3) (a)) Also, the inrush

current may cause the module contact welding.

Take the following measures to prevent shortening of the relay life and the contact welding.

• Select a load so that the inrush current will be within the rated current of the module.

• Connect an external relay that can withstand the inrush current.

The following table shows the relation between the road and the inrush current.

Select a load so that the inrush current (i) and the rated current (io) will be within the rated switching current

specified for the output module used.

The inrush current may flow for a longer time depending on the load.

Load type Signal waveform diagram

Inrush current

(i)/rated current

(io)

Signal waveform diagram

Load of an electromagnetic contactor

Inrush current

(i)/rated current

(io)

Inductive load

Lamp load

Capacitive load

Approx. 10 to 20

times

i

i: Inrush current

i

o

: Rated current

o

i

Approx. 3 to 10

times

0.017 to 0.033 seconds

(1 to 2 cycles)

Approx. 3 to 10

times

Approx. 5 to 10

times

2

*

Approx. 3 times

*1

Capacitive load

24

Approx. 20 to 40

i

o

i

times

i: Inrush current

i

o

: Rated current

0.008 to 0.33 seconds

(0.5 to 2 cycles)

*1 Typical electric-discharge lamp circuit includes discharge tubes, transformers, choke coils, and capacitors. Therefore,

note that the inrush current may flow 20 to 40 times as large as the rated current in the case of high power factor and low

power impedance.

*2 When the wiring of the circuit is long, take care of the wire capacity.

Page 27

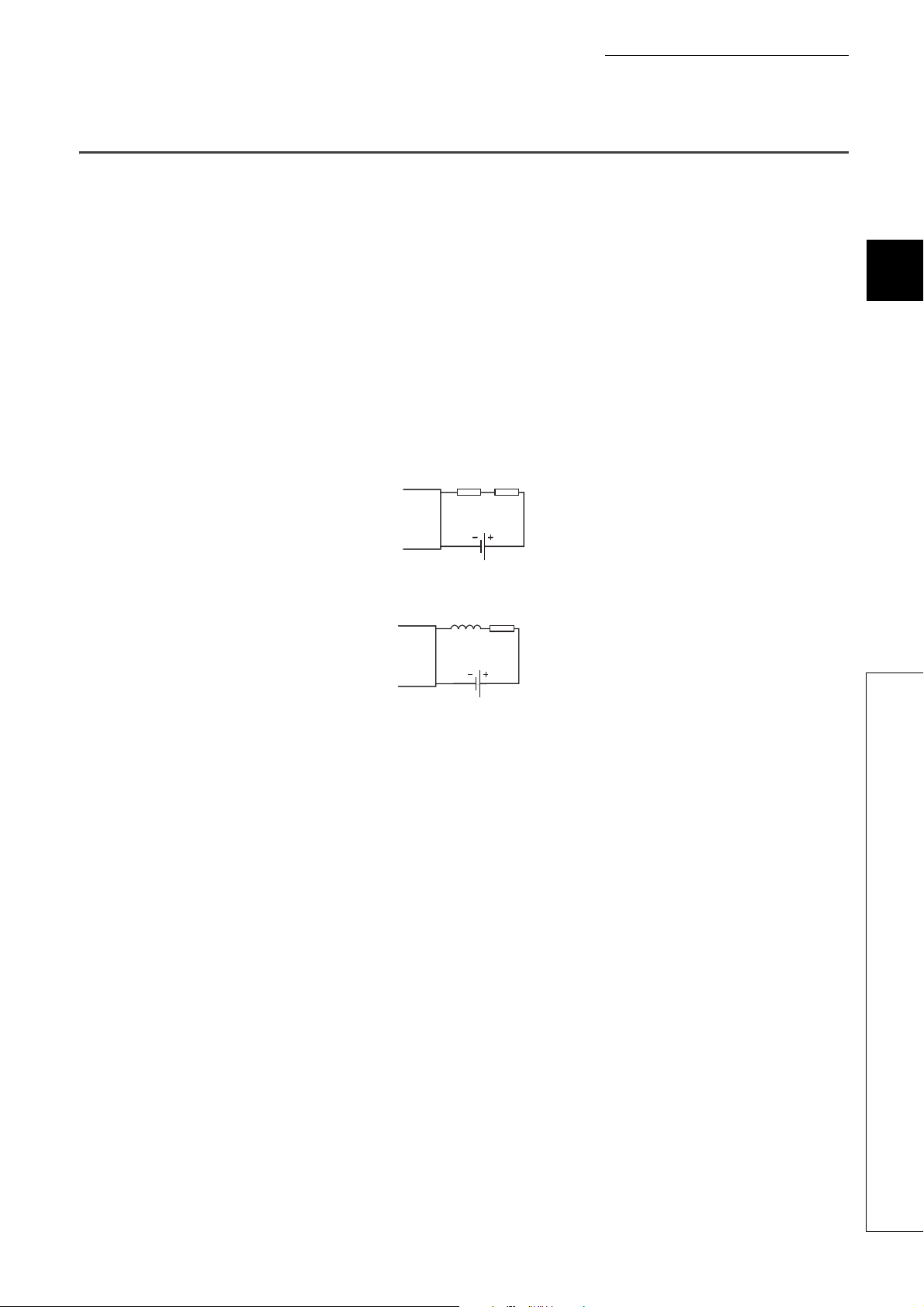

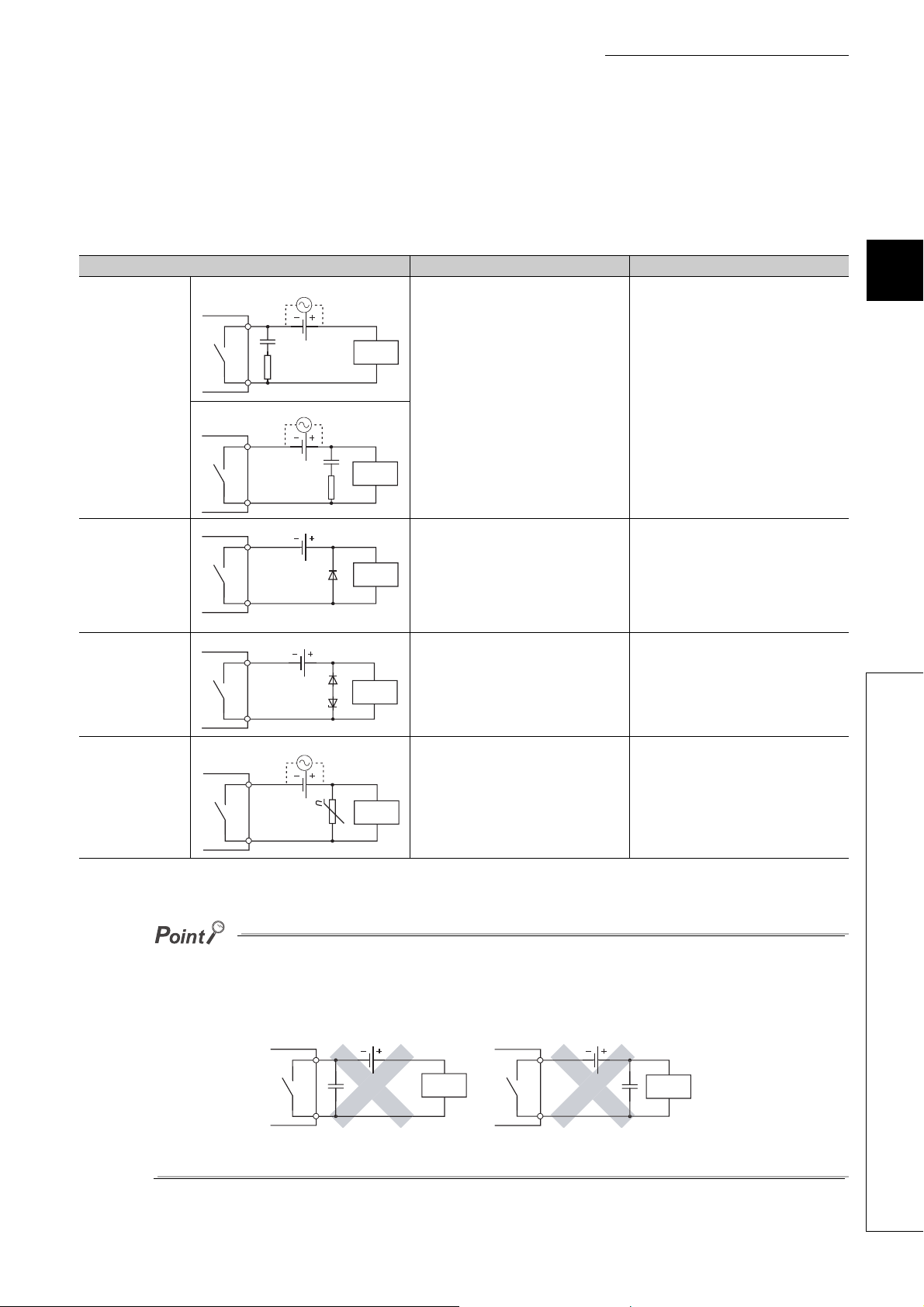

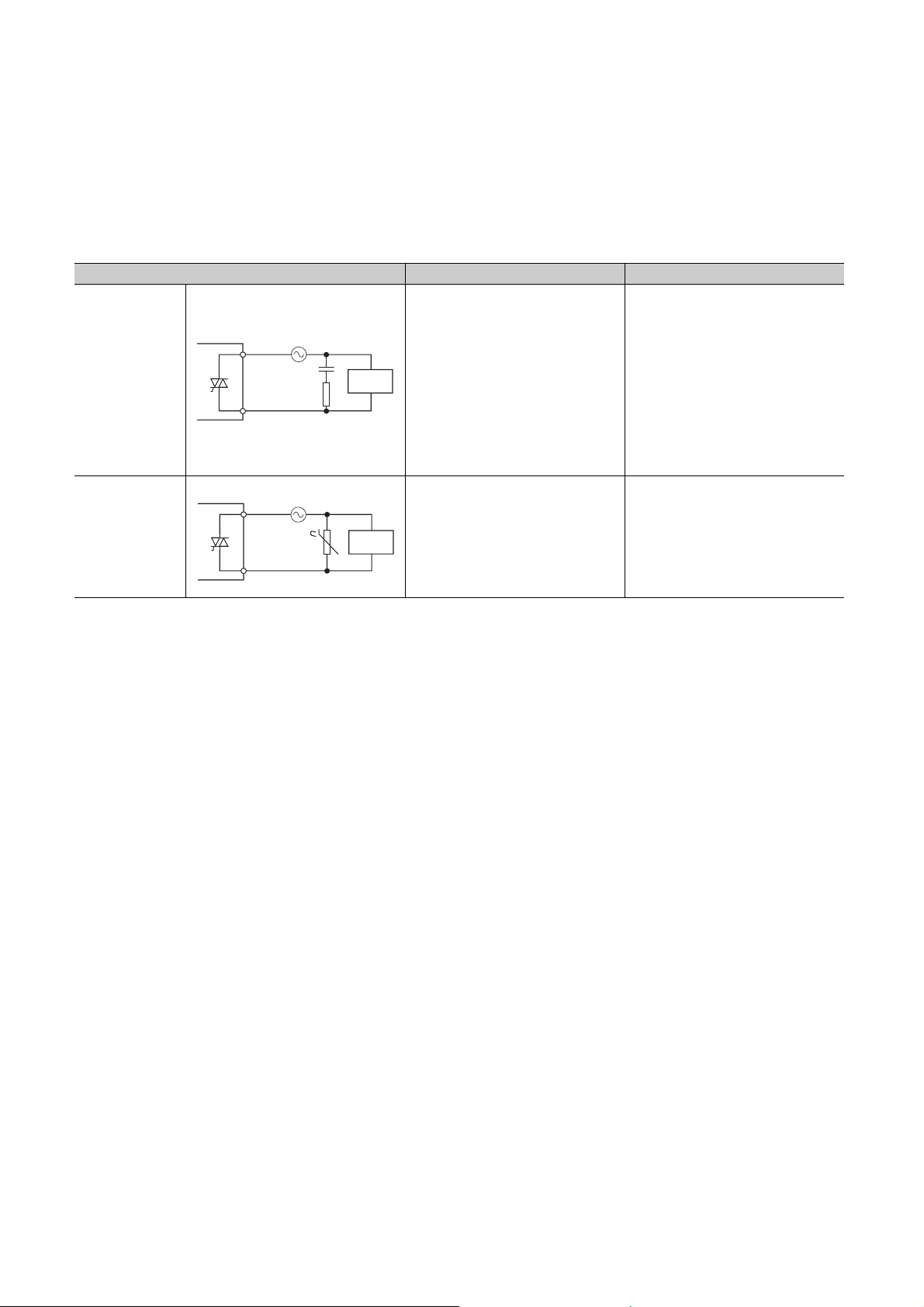

(c) Measures against back EMF

*1

Capacitor

Resistor

Inductive

load

Diode

Inductive

load

Capacitor

Inductive

load

Capacitor

Inductive

load

Configure a contact protection circuit for extending the contact life, preventing noise when the contact is cut off,

and suppressing the generation of carbide and nitric acid due to arc discharge.

An Incorrect contact protection circuit may cause contact welding.

Also, when using the contact protection circuit, the recovery time may be long.

The following table shows the representative examples of the contact protection circuit.

Capacitor + Resistor

method (CR

method)

CHAPTER 3 BEFORE USING I/O MODULE

Example Method for selecting elements Remarks

Refer to the following for constants of the

capacitor and resistor. Note that the

following values may differ depending on a

Capacitor

Resistor

Inductive

load

nature of the load and a variation of

characteristics of it.

• Capacitor: 0.5 to 1(µF) against load

current of 1A

• Resistor: 0.5 to 1() against power

supply voltage of 1V

Use a capacitor whose withstand voltage is

equal to or more than the rated voltage. In

AC circuit, use a capacitor having no

polarity.

If a load is a relay or solenoid, the recovery

time delays.

A capacitor suppresses electric discharge

while a contact is off, and a resistor

restricts a flow of current while a contact is

on.

3

Diode method

Diode + Zener diode

method

Varistor method

*1 When using AC power, impedance of CR must be larger enough than it of the load (prevention of a malfunction due to

● Avoid providing a contact protection circuits shown below.

Use a diode that meets both conditions

shown below.

Diode

Zener Diode

Varistor

Inductive

load

Inductive

load

• Reverse breakdown voltage is equal to

or more than 10 times as large as the

circuit voltage.

• The forward current is equal to or more

than 2 times as large as the load current.

Use zener voltage for the zener diode

equal to or more than the power supply

voltage.

Select a cut voltage (Vc) for the varistor to

meet the following condition.

• Vc > Power voltage × 1.5(V)

• Vc > Power supply voltage × 1.5(V) × √2

(when using AC power supply)

This method is not effective when the Vc is

too high

The recovery time is slower than the CR

method.

This method is effective when the recovery

time delays considerably by the diode

method.

The recovery time delays slightly.

leak current from the CR).

These circuit are effective for preventing an arc at shut-off. However, the contact welding may occur because the charge

current flows to capacitor when the contact turns on or off.

A DC inductive load is usually harder for switching than a resistor load, but if a proper protection circuit is configured, the

performance will be similar to the resistor load.

3.2 Output Module

● A protection circuit must be provided closely to a load or contact (module). If their distance is far, the protection circuit

may not be effective. Appropriate distance is within 50 cm.

25

Page 28

(4) Precautions for using the triac output module

Varistor

Inductive

load

(a) Measures against back EMF

Take measures against back EMF to the side where the load is connected if the wiring distance from the output

module to the load is long.

If not, the surge suppressor in the output module may not work effectively.

Example Method for selecting elements Remarks

Refer to the following for constants of the

capacitor and resistor. Note that the

following values may differ depending on a

nature of the load and a variation of

Capacitor + Resistor

method (CR

method)

Varistor method

Capacitor

Resistor

Inductive

load

characteristics of it.

• Capacitor: 0.5 to 1(µF) against load

current of 1A

• Resistor: 0.5 to 1() against power

supply voltage of 1V

Use a capacitor whose withstand voltage is

equal to or more than the rated voltage.

Use a capacitor having no polarity.

Select a cut-off voltage (Vc) for the varistor

to meet the following condition.

• Vc > Power supply voltage × 1.5(V) × √2

This method is not effective when the Vc is

too high.

If a load is a relay or solenoid, the recovery

time delays.

The recovery time delays slightly.

26

Page 29

CHAPTER 3 BEFORE USING I/O MODULE

3.3 I/O Combined Module

This section describes the precautions for using the I/O combined module.

The precautions not described below are common to that for the input module and output module. ( Page 20,

Section 3.1, Page 21, Section 3.2)

(1) I/O numbers of the I/O combined module

The I/O combined module uses same I/O number for input and output.

Because same number is used for input and output, the I/O numbers to be used can be saved.

Input (X) Output (Y)

X00

X1F

Y00

32 points

Y1F

(2) Applicable software

Use GX Works2 with version 1.492N or later.

The following cannot be set using GX Developer and GX Works2 whose version is earlier than 1.492N.

• "I/O Mix" cannot be selected in I/O Assignment.

• Input response time cannot be set.

• Error Time Output Mode cannot be set.

3

3.3 I/O Combined Module

27

Page 30

CHAPTER 4 SPECIFICATIONS

4.1 General Specifications

For the general specifications of the I/O modules, refer to the following manual.

Manual "Safety Guidelines" included in the CPU module or head module

28

Page 31

4.2 Input Module Specifications

4.2.1 LX10 AC input module

Item Specifications Appearance

Number of input points 16 points

Rated input voltage, frequency 100 to 120VAC (+10%/-15%), 50/60Hz(±3Hz)

Input voltage distortion Within 5%

Rated input current 8.2mA (100VAC, 60Hz), 6.8mA (100VAC, 50Hz)

Inrush current Max. 200mA within 1ms

ON voltage/ON current 80VAC or higher/5mA or higher (50Hz, 60Hz)

OFF voltage/OFF current 30VAC or lower/1.7mA or lower (50Hz, 60Hz)

Input resistance 12.2k (60Hz), 14.6k (50Hz)

Response time

Dielectric withstand voltage 1400VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP1X

Common terminal arrangement 16 points/common (common terminal: TB17)

Number of occupied I/O points 16 points (I/O assignment: input 16 points)

External interface

5VDC internal current consumption 90mA (TYP. all points ON)

Weight 0.17kg

OFF to ON 15ms or less (100VAC 50Hz, 60Hz)

ON to OFF 20ms or less (100VAC 50Hz, 60Hz)

By noise simulator of 1500Vp-p noise voltage, 1µs noise width and 25 to 60Hz

noise frequency

18-point screw terminal block (M3 × 6 screws) ( Page 62, Section 6.2.1)

Derating chart

CHAPTER 4 SPECIFICATIONS

4

4.2 Input Module Specifications

Simultaneous

on input

points

(points)

16

12

8

4

0

16 points, 50

Input voltage

50Hz 60Hz

to 132VAC to 120VAC

- to 132VAC

Ambient temperature( )

16 points, 55

15 points, 55

6002040

29

Page 32

External connections Terminal connections

X01

X03

X05

X07

X09

X0B

X0D

X0F

X00

X02

X04

X06

X0A

X0C

X0E

COM

1

3

5

7

9

11

13

15

17

2

4

6

8

10

12

14

16

18

Empty

X08

100 to 120VAC

Terminal

number

Signal

name

Signal

name

Viewed from the front of the module.

TB1

TB16

TB17

100 to 120VAC

Photocoupler

Photocoupler

Internal

circuit

LED

LED

30

Page 33

4.2.2 LX28 AC input module

6002040

0

Input voltage

8 points, 50

Ambient temperature ( )

Simultaneous

on input

points

(points)

8 points, 55

7 points, 55

5 points, 55

2

8

6

4

to 200VAC to 132VAC

to 240VAC to 220VAC

to 264VAC to 264VAC

50Hz 60Hz

LED

LED

Internal

circuit

TB1

TB15

TB17

Photocoupler

Photocoupler

100 to 240VAC

1

3

5

7

9

11

13

15

17

2

4

6

8

10

12

14

16

18

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

100 to 240VAC

Terminal

number

Signal

name

Viewed from the front of the module.

X00

X01

X02

X03

X05

X06

X07

COM

X04

Item Specifications Appearance

Number of input points 8 points

Rated input voltage, frequency 100 to 240VAC (+10%/-15%), 50/60Hz(±3Hz)

Input voltage distortion Within 5%

Rated input current

Inrush current Max. 950mA within 1ms

ON voltage/ON current 80VAC or higher/5mA or higher (50Hz, 60Hz)

OFF voltage/OFF current 30VAC or lower/1.7mA or lower (50Hz, 60Hz)

Input resistance 12.2k (60Hz), 14.6k (50Hz)

Response time

Dielectric withstand voltage 2300VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP1X

Common terminal arrangement 8 points/common (common terminal: TB17)

Number of occupied I/O points 16 points (I/O assignment: input 16 points)

External interface

5VDC internal current consumption 80mA (TYP. all points ON)

Weight 0.15kg

OFF to ON

ON to OFF 20ms or less (100/200VAC 50Hz, 60Hz)

16.4mA (200VAC, 60Hz), 13.7mA (200VAC, 50Hz)

8.2mA (100VAC, 60Hz), 6.8mA (100VAC, 50Hz)

15ms or less (100VAC 50Hz, 60Hz)

10ms or less (200VAC 50Hz, 60Hz)

By noise simulator of 1500Vp-p noise voltage, 1µs noise width and 25 to 60Hz

noise frequency

18-point screw terminal block (M3 × 6 screws) ( Page 62, Section 6.2.1)

CHAPTER 4 SPECIFICATIONS

4

Derating chart

External connections Terminal connections

4.2 Input Module Specifications

31

Page 34

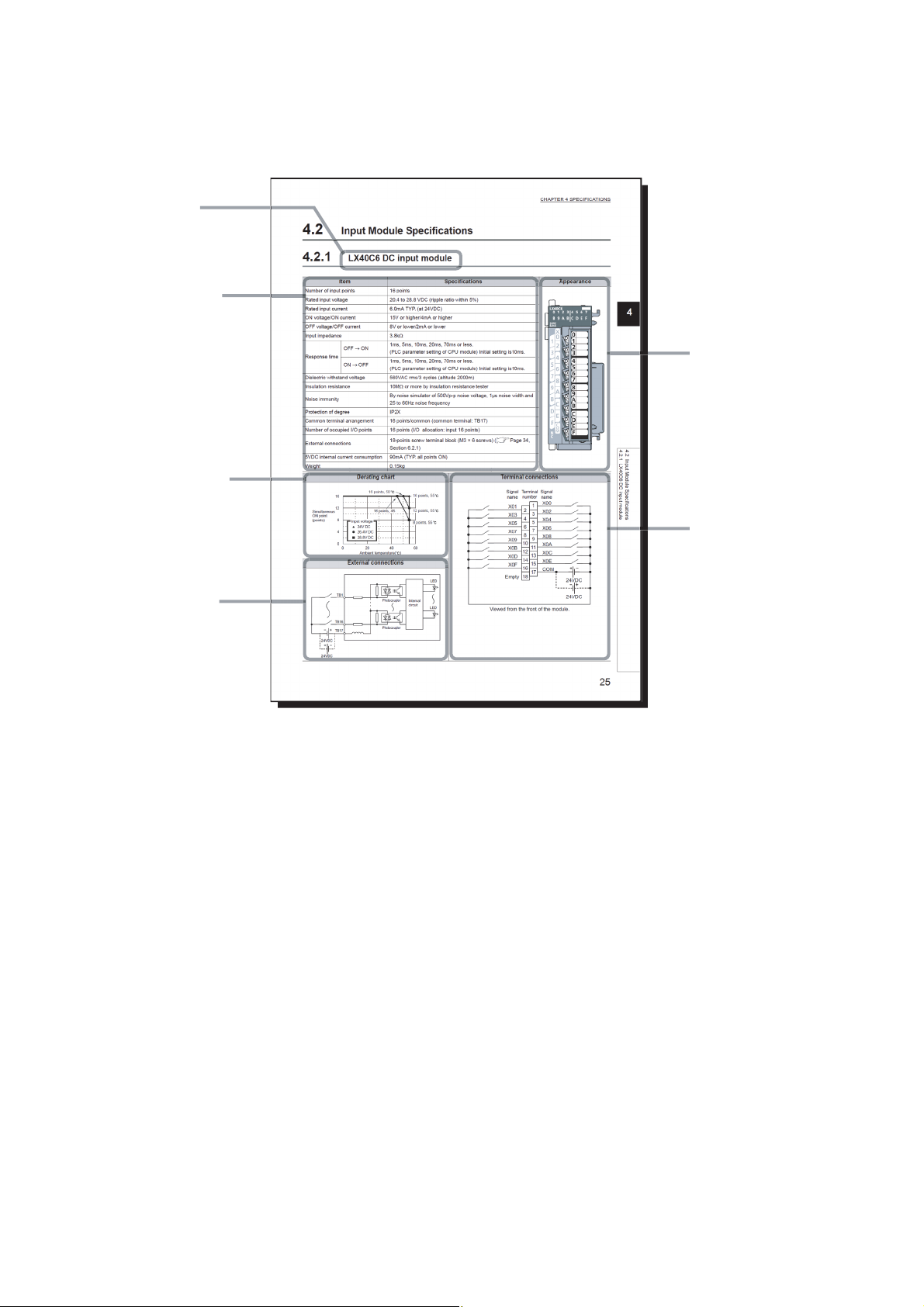

4.2.3 LX40C6 DC input module

Item Specifications Appearance

Number of input points 16 points

Rated input voltage

Rated input current 6.0mA TYP. (at 24VDC)

ON voltage/ON current 15V or higher/4mA or higher

OFF voltage/OFF current 8V or lower/2mA or lower

Input resistance 3.8k

OFF to ON

Response time

ON to OFF

Dielectric withstand voltage 510VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP2X

Common terminal arrangement 16 points/common (common terminal: TB17)

Number of occupied I/O points 16 points (I/O assignment: input 16 points)

External interface

5VDC internal current consumption 90mA (TYP. all points ON)

Weight 0.15kg

24VDC (ripple rate: 5% or less)

(Allowable voltage range: 20.4 to 28.8VDC)

1ms, 5ms, 10ms, 20ms, 70ms or less

(PLC parameter setting of CPU module) Initial setting is 10ms.

1ms, 5ms, 10ms, 20ms, 70ms or less

(PLC parameter setting of CPU module) Initial setting is 10ms.

By noise simulator of 500Vp-p noise voltage, 1µs noise width and 25 to 60Hz

noise frequency

18-point screw terminal block (M3 × 6 screws) ( Page 62, Section 6.2.1)

Simultaneous

on input

points

(points)

Derating chart

16

12

8

4

0

16 points, 50

16 points, 45

Input voltage

24V DC

26.4V DC

28.8V DC

Ambient temperature ( )

16 points, 55

12 points, 55

8 points, 55

6002040

32

Page 35

24VDC

24VDC

TB1

TB16

TB17

CHAPTER 4 SPECIFICATIONS

External connections Terminal connections

Terminal

Photocoupler

Photocoupler

Internal

circuit

LED

LED

Signal

name

X01

X03

X05

X07

X09

X0B

X0D

X0F

Empty

number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Signal

name

X00

X02

X04

X06

X08

X0A

X0C

X0E

COM

Viewed from the front of the module.

4

24VDC

24VDC

4.2 Input Module Specifications

33

Page 36

4.2.4 LX41C4 DC input module

Item Specifications Appearance

Number of input points 32 points

Rated input voltage

Rated input current 4.0mA TYP. (at 24VDC)

ON voltage/ON current 19V or higher/3mA or higher

OFF voltage/OFF current 9V or lower/1.7mA or lower

Input resistance 5.7k

OFF to ON

Response time

ON to OFF

Dielectric withstand voltage 510VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP2X

Common terminal arrangement 32 points/common (common terminal: B01, B02)

Number of occupied I/O points 32 points (I/O assignment: input 32 points)

External interface

5VDC internal current consumption 100mA (TYP. all points ON)

Weight 0.11kg

24VDC (ripple rate: 5% or less)

(Allowable voltage range: 20.4 to 28.8VDC)

1ms, 5ms, 10ms, 20ms, 70ms or less

(PLC parameter setting of CPU module) Initial setting is 10ms.

1ms, 5ms, 10ms, 20ms, 70ms or less

(PLC parameter setting of CPU module) Initial setting is 10ms.

By noise simulator of 500Vp-p noise voltage, 1µs noise width and 25 to 60Hz

noise frequency

40-pin connector ( Page 64, Section 6.2.2)

Simultaneous

on input

points

(points)

30

20

10

0

Derating chart

32 points, 40

Input voltage

24V DC

26.4V DC

28.8V DC

Ambient temperature( )

32 points, 50

32 points, 55

24 points, 55

20 points, 55

6002040

34

Page 37

CHAPTER 4 SPECIFICATIONS

A20B20

A19

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B09

B08

B07

B06

B05

B04

B03

B02

A12

A04

A02

B01

A18

A17

A16

A15

A14

A13

A11

A10

A09

A08

A07

A06

A05

A03

A01

24VDC

24VDC

Pin

number

X01

X02

X03

X04

X05

X06

X07

X08

X09

X0A

X0B

X0C

X0D

X0E

X0F

X00

Signal

name

X11

X12

X13

X14

X15

X16

X17

X18

X19

X1A

X1B

X1C

X1D

X1E

X1F

X10

Empty

Empty

Empty

Empty

Empty

Empty

COM

COM

Signal

name

Viewed from the front of

the module.

External connections Terminal connections

LED

24VDC

24VDC

B20

A05

B01,B02

Photocoupler

Photocoupler

Internal

circuit

LED

4

4.2 Input Module Specifications

35

Page 38

4.2.5 LX42C4 DC input module

6002040

Ambient temperature( )

64 points, 35

64 points, 10

0

60

40

20

28.8V DC

26.4V DC

24V DC

Input voltage

Simultaneous

ON point

(points)

16 points/common

(total 32 points), 55

11 points/common

(total 22 points), 55

9 points/common

(total 18 points), 55

64 points, 24

Item Specifications Appearance

Number of input points 64 points

Rated input voltage

Rated input current 4.0mA TYP. (at 24VDC)

ON voltage/ON current 19V or higher/3mA or higher

OFF voltage/OFF current 9V or lower/1.7mA or lower

Input resistance 5.7k

OFF to ON

Response time

ON to OFF

Dielectric withstand voltage 510VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP2X

Common terminal arrangement 32 points/common (common terminal: 1B01, 1B02, 2B01, 2B02)

Number of occupied I/O points 64 points (I/O assignment: input 64 points)

External interface

5VDC internal current consumption 120mA (TYP. all points ON)

Weight 0.12kg

24VDC (ripple rate: 5% or less)

(Allowable voltage range: 20.4 to 28.8VDC)

1ms, 5ms, 10ms, 20ms, 70ms or less

(PLC parameter setting of CPU module) Initial setting is 10ms.

1ms, 5ms, 10ms, 20ms, 70ms or less

(PLC parameter setting of CPU module) Initial setting is 10ms.

By noise simulator of 500Vp-p noise voltage, 1µs noise width and 25 to 60Hz

noise frequency

40-pin connector ( Page 64, Section 6.2.2)

Derating chart

36

Page 39

CHAPTER 4 SPECIFICATIONS

sw

1B20

1B01,1B02

24VDC

24VDC

LED

1A05

Internal

circuit

Photocoupler

Photocoupler

Left side connectors

(first half )

Right side connectors

(last half )

Indication

selector

circuit

1

The above diagram shows the first half of 32 points (F).

The last half of 32 points (L) are similar.

1A201B20

1A19

1B19

1B18

1B17

1B16

1B15

1B14

1B13

1B12

1B11

1B10

1B09

1B08

1B07

1B06

1B05

1B04

1B03

1B02

1A12

1A04

1A02

1B01

1A18

1A17

1A16

1A15

1A14

1A13

1A11

1A10

1A09

1A08

1A07

1A06

1A05

1A03

1A01

24VDC

24VDC

24VDC

24VDC

Pin

number

X01

X02

X03

X04

X05

X06

X07

X08

X09

X0A

X0B

X0C

X0D

X0E

X0F

X00

Signal

name

X11

X12

X13

X14

X15

X16

X17

X18

X19

X1A

X1B

X1C

X1D

X1E

X1F

X10

2A202B20

2A19

2B19

2B18

2B17

2B16

2B15

2B14

2B13

2B12

2B11

2B10

2B09

2B08

2B07

2B06

2B05

2B04

2B03

2B02

2A12

2A04

2A02

2B01

2A18

2A17

2A16

2A15

2A14

2A13

2A11

2A10

2A09

2A08

2A07

2A06

2A05

2A03

2A01

COM2

COM2

X21

X22

X23

X24

X25

X26

X27

X28

X29

X2A

X2B

X2C

X2D

X2E

X2F

X20

X31

X32

X33

X34

X35

X36

X37

X38

X39

X3A

X3B

X3C

X3D

X3E

X3F

X30

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

COM1

COM1

Signal

name

Pin

number

Signal

name

Signal

name

Left side connector Right side connectors

Viewed from the front of

the module.

Viewed from the front of

the module.

External connections Terminal connections

4

*1 Switching left side (F) provides the first half (X00 to X1F) LED indications, and switching right side (L) provides the latter

half (Y20 to Y3F) LED indications.

4.2 Input Module Specifications

37

Page 40

4.3 Output Module Specifications

The following output module equips the overload protection function and the overheat protection function.

Applicable model LY40NT5P, LY41NT1P, LY42NT1P, LY40PT5P, LY41PT1P, LY42PT1P

Function Description

• If the output module detects overcurrent, it limits output current by the current limiter operation

Overload protection function

Overheat protection function

*1 This function is for protecting the internal circuit of the module, not for protecting external devices.

Also, leaving the failure too long may rise the internal temperature of the module, resulting in deterioration of output

elements and/or discoloration of a case and printed circuit board. When the failure occurs, turn off the corresponding

outputs immediately to remove the causes.

*2 This operation limits overcurrent to a constant value and keeps outputting it.

*1

*1

• For the overcurrent detection value and the limited current, refer to "Overload protection function" on the

module specifications.

• When the load current becomes lower than the overcurrent detection value, the module returns to normal

operation.

• If overcurrent keeps flowing due to overload, heat is generated inside the module. When high heat is

detected inside the module, the output is turned off.

• The number of output points that the overheat protection function simultaneously operates differs depending

on the module. For the number, refer to "Overheat protection function" on the module specifications.

• After heat goes down, the module returns to normal operation.

*2

38

Page 41

4.3.1 LY10R2 contact output module

TB1

Load

Load

LED

TB17

TB16

LED

100/200VAC

or

24VDC

Internal

circuit

Relay

Relay

1

3

5

7

9

11

13

15

17

2

4

6

8

10

12

14

16

18

Y01

Y03

Y05

Y07

Y09

Y0B

Y0D

Y0F

Y00

Y02

Y04

Y06

Y08

Y0A

Y0C

Y0E

COM

Empty

The following diagram shows the external load power supply.

100/200VAC

or

24VDC

External load

power supply

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Terminal

number

Signal

name

Signal

name

Viewed from the front of the module.

Item Specifications Appearance

Number of output points 16 points

Rated switching voltage, current

Minimum switching load 5VDC 1mA

Maximum switching load 264VAC 125VDC

Response time

Life

Maximum switching frequency 3600 times/hour

Surge suppressor None

Fuse None

Dielectric withstand voltage 2300VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP1X

Common terminal arrangement 16 points/common (common terminal: TB17)

Number of occupied I/O points 16 points (I/O assignment: output 16 points)

External interface

5VDC internal current

consumption

Weight 0.21kg

OFF to ON 10ms or less

ON to OFF 12ms or less

Mechanical 20 million times or more

Electrical

External connections Terminal connections

24VDC 2A (resistance load)/point, 8A/common

240VAC 2A (COS = 1)/point, 8A/common

Page 23, Section 3.2 (3) (a)

By noise simulator of 1500Vp-p noise voltage, 1µs noise width and 25 to 60Hz

noise frequency

18-point screw terminal block (M3 × 6 screws) ( Page 62, Section 6.2.1)

460mA (TYP. all points ON)

CHAPTER 4 SPECIFICATIONS

4

4.3 Output Module Specifications

39

Page 42

4.3.2 LY18R2A contact output module (All points independent)

TB1

Load

Load

LED

TB16

TB15

LED

100/200VAC

or

24VDC

TB2

100/200VAC

or

24VDC

Internal

circuit

Relay

Relay

Item Specifications Appearance

Number of output points 8 points

Insulation method Relay

Rated switching voltage, current

Minimum switching load 5VDC 1mA

Maximum switching load 264VAC 125VDC

Response time

OFF to ON 10ms or less

ON to OFF 12ms or less

Mechanical 20 million times or more

Life

Electrical

Maximum switching frequency 3600 times/hour

Surge suppressor None

Fuse None (Attaching a fuse to each external wiring is recommended.)

Dielectric withstand voltage 2300VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP1X

Common terminal arrangement No common (all-point independent contact)

Number of occupied I/O points 16 points (I/O assignment: output 16 points)

External interface

5VDC internal current

consumption

Weight 0.18kg

24VDC 2A (resistance load)/point, 8A/module

240VAC 2A (COS = 1)/point, 8A/module

Page 23, Section 3.2 (3) (a)

By noise simulator of 1500Vp-p noise voltage, 1µs noise width and 25 to 60Hz

noise frequency

18-point screw terminal block (M3 × 6 screws) ( Page 62, Section 6.2.1)

260mA (TYP. all points ON)

External connections Terminal connections

Terminal

number

2

4

6

8

10

11

12

13

14

15

16

17

18

Signal

name

Y00

1

Y01

3

Y02

5

Y03

7

Y04

9

Y05

Y06

Y07

Empty

100/200VAC

or 24VDC

Signal

name

External load power supply

External load power supply

External load power supply

External load power supply

External load power supply

External load power supply

External load power supply

External load power supply

Y00

Y01

Y02

Y03

Y04

Y05

Y06

Y07

Empty

Viewed from the front of the module.

The following diagram shows the external load power supply.

Load

Load

Load

Load

Load

Load

Load

Load

40

Page 43

4.3.3 LY20S6 triac output module

Load

Load

TB16

LED

TB17

100 to 240VAC

LED

TB1

Internal

circuit

Item Specifications Appearance

Number of output points 16 points

Rated load voltage,

frequency

Maximum load current 0.6A/point, 4.8A/common

Load voltage distortion ratio Within 5%

Maximum load voltage 264VAC

Minimum load

voltage/current

Maximum inrush current 20A/cycle or less

Leakage current at OFF 3mA or lower (at 240V, 60Hz), 1.5mA or lower (at 120V, 60Hz)

Maximum voltage drop at ON 1.5V or lower (at load current of 0.6A)

Response

time

Surge suppressor CR absorber

Fuse None (Attaching a fuse to each external wiring is recommended.)

Dielectric withstand voltage 2300VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP1X

Common terminal

arrangement

Number of occupied I/O

points

External interface

5VDC internal current

consumption

Weight 0.22kg

OFF to ON Total of 1ms and 0.5 cycles or less

ON to OFF Total of 1ms and 0.5 cycles or less (rated load, resistive load)

100 to 240VAC (+10%/-15%), 50/60Hz(±3Hz)

24VAC/100mA, 100VAC/25mA, 240VAC/25mA

By noise simulator of 1500Vp-p noise voltage, 1µs noise width and 25 to 60Hz noise

frequency

16 points/common (common terminal: TB17)

16 points (I/O assignment: output 16 points)

18-point screw terminal block (M3 × 6 screws)( Page 62, Section 6.2.1)

300mA (TYP. all points ON)

CHAPTER 4 SPECIFICATIONS

4

4.3 Output Module Specifications

External connections Terminal connections

Terminal

Load

Load

Load

Load

Load

Load

Load

Load

Signal

name

Y01

Y03

Y05

Y07

Y09

Y0B

Y0D

Y0F

Empty

number

10

12

14

16

18

Signal

name

Y00

1

2

4

6

8

11

13

15

17

Y02

3

Y04

5

Y06

7

Y08

9

Y0A

Y0C

Y0E

COM

Viewed from the front of the module.

Load

Load

Load

Load

Load

Load

Load

Load

100 to 240VAC

41

Page 44

4.3.4 LY28S1A triac output module (All points independent)

Item Specifications Appearance

Number of output points 8 points

Insulation method Photocoupler isolation

Rated load voltage,

frequency

Maximum load current 1A/point, 8A/module

Load voltage distortion ratio Within 5%

Maximum load voltage 264VAC

Minimum load

voltage/current

Maximum inrush current 20A/cycle or less

Leakage current at OFF 3mA or lower (at 240V, 60Hz), 1.5mA or lower (at 120V, 60Hz)

Maximum voltage drop at ON 1.5V or lower (at load current of 0.6A)

Response

time

Surge suppressor CR absorber

Fuse None (Attaching a fuse to each external wiring is recommended.)

Dielectric withstand voltage 2300VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP1X

Common terminal

arrangement

Number of occupied I/O

points

External interface

5VDC internal current

consumption

Weight 0.19kg

OFF to ON Total of 1ms and 0.5 cycles or less

ON to OFF Total of 1ms and 0.5 cycles or less (rated load, resistive load)

100 to 240VAC (+10%/-15%), 50/60Hz(±3Hz)

24VAC/100mA, 100VAC/25mA, 240VAC/25mA

By noise simulator of 1500Vp-p noise voltage, 1µs noise width and 25 to 60Hz noise

frequency

No common (all points independent)

16 points (I/O assignment: output 16 points)

18-point screw terminal block (M3 × 6 screws) ( Page 62, Section 6.2.1)

200mA (TYP. all points ON)

Module

total output

current

(A)

8

6

4

2

0

Derating chart

8A, 45

3A, 55

Load voltage

132VAC/264VAC

6002040

Ambient temperature ()

42

Page 45

CHAPTER 4 SPECIFICATIONS

Load

Load

TB15

LED

TB16

100 to 240VAC

100 to 240VAC

LED

TB1

Internal

circuit

TB2

External connections Terminal connections

Terminal

number

2

4

6

8

10

12

14

16

18

Signal

name

Y00

1

Y01

3

Y02

5

Y03

7

Y04

9

Y05

11

Y06

13

Y07

15

Empty

17

Signal

name

External load power supply

External load power supply

External load power supply

External load power supply

External load power supply

External load power supply

External load power supply

External load power supply

Y00

Y01

Y02

Y03

Y04

Y05

Y06

Y07

Empty

Viewed from the front of the module.

The following diagram shows the external load power supply.

100 to 240VAC

Load

Load

Load

Load

Load

Load

Load

Load

4

4.3 Output Module Specifications

43

Page 46

4.3.5 LY40NT5P transistor output module (Sink type)

Internal

circuit

LED

LED

TB1

TB16

TB17

TB18

12/24VDC

Constant-voltage

circuit

Load

Load

Photocoupler

Photocoupler

Item Specifications Appearance

Number of output points 16 points

Rated load voltage 10.2 to 28.8VDC

Maximum load current 0.5A/point, 5A/common

Maximum inrush current Current is limited by the overload protection function.

Leakage current at OFF 0.1mA or less

Maximum voltage drop at ON 0.2VDC (TYP.) 0.5A, 0.3VDC (MAX.) 0.5A

Response

time

Surge suppressor Zener diode

Fuse None

External

power

supply

Dielectric withstand voltage 510VAC, 1 minute (altitude 2000m)

Insulation resistance 10M or more by insulation resistance tester

Noise immunity

Protection degree IP2X

Common terminal

arrangement

Number of occupied I/O

points

Protection

function

External interface

5VDC internal current

consumption

Weight 0.15kg

OFF to ON 0.5ms or less

ON to OFF 1ms or less (rated load, resistance load)

Voltage 12/24VDC (ripple rate: 5% or less) (Allowable voltage range: 10.2 to 28.8VDC)

Current 9mA (at 24VDC)/common