Page 1

Lossnay Energy Recovery Ventilator

Model:

0902874HN5301

LGH-50RSDC-E (220-240V 50Hz

Installation Instructions

)

(For use by dealer/contractor)

Contents

Safety precautions.............................................1

Outline drawings................................................2

Standard installation examples..........................3

Installation method.............................................4

Function settings................................................7

Trial operation....................................................8

This product needs to be installed properly in order to ensure maximum functionality as well as safety.

Please make sure to read this installation manual before starting the installation.

lInstallation must be performed by a dealer or installation contractor. Please note that improper installation may cause malfunction or accident.

Separate booklet “Operating Instructions” is provided for the customer.

The booklet and this manual must be handed over to the customer after completing the installation.

Safety precautions

The following signs indicate that death or serious injury may be caused by failure to heed the precautions described below.

Do not modify or disassemble.

(It could cause fire, electric shock or injury.)

Do not

disassemble

The Lossnay unit should not be installed where it is highly

humid, like a bathroom, or other wet place.

Prohibition of use in

bath or shower room

Connect the

grounding wire

The instructions

given must be

followed.

(It could cause electric shock or power leakage.)

Connect the product properly to ground.

(Malfunctioning or power leaks can cause electrical shock.)

.

Use the specified power supply and voltage.

(Use of incorrect power supply or voltage could cause fire or electric

shock.)

Select a place with sufficient strength and install the main unit

securely.

(It could cause injury if it falls.)

WARNING

The instructions

given must be

followed.

Wiring work must be performed by qualified professionals,

and be implemented safely and securely in accordance with

the engineering standards and the extension wiring rules for

electrical equipment.

(Poor connection or improper wiring work could cause electric

shock or fire.)

Install a power supply isolator at the power supply side as per

local electrical regulations.

(It could cause fire if power leakage occurs.)

All supply circuits must be disconnected before obtaining

access to the terminal devices.

Use the specified cable size and connect the cables securely to

prevent disconnection when they are pulled.

(If there is a defect in the connection, there is a possibility of fire.)

Select an adequate place for the opening to introduce outdoor air,

where it will not inhale the exhaust fumes like combustion gas, or

others, and there is no risk of blockage by snowfall or others.

(Shortage of fresh air could put the room in a state of oxygen deficiency.)

A duct made of steel must be installed with care not to be

connected electrically with metals such as metal, wire, stainless

steel plate, or others.

(It could cause fire when power leakage occurs.)

Prohibited

CAUTION

Do not place a burning appliance in a place where it is exposed

directly to the air from the Lossnay unit.

(It could cause an accident as a result of incomplete combustion.)

Do not place an object on or sit on the Lossnay unit.

(It could cause electric shock, fire, or other damage.)

Do not use at a place where exposed to high temperatures (40°C or

higher), naked flames, or in environment with combustible fumes.

(It could cause fire.)

Do not use in an environment such as a chemical factory, where

hazardous gases such as acidic gases, alkaline gases, organic

solvent fumes, paint fumes, or gases containing corrosive

components are generated.

(It could malfunction.)

Insulation failure caused by salt or sulphur air and hot spring

steam, Rust, fire or malfunction may occur.

Installing high quality filters inside outdoor air duct if the

Lossnay operates in salt or sulphur air conditions.

Do not install this product in a place where it is exposed to

ultraviolet light.

(UV may damage covering insulation.)

The instructions

given must be

followed.

Put on gloves during maintenance.

(It could cause injury.)

Make sure the power supply isolator is turned off on the power

distribution panel when Lossnay is not used for a long period

of time after the installation.

(It could cause electric shock, power leakage, or fire as a result of

deteriorated insulation.)

Always use the specified suspension bolts, nuts and washers.

(Use of hardware with insufficient strength could result in the product

dropping.)

The outside ducts must be tilted at a gradient (1/30 or more) down

toward the outdoor louvres from Lossnay, and properly insulated.

(The entry of rain water may cause power leakage, fire, or damage

to household property.)

The control box cover must be closed after the installation.

(Dust or humidity may cause power leakage or fire.)

When connecting external devices (electrically operated damper,

lamp, monitoring unit, etc.) using output signals of the Lossnay unit,

make sure to install safety equipment for the external devices.

(It could cause fire, damage, etc. without safety equipment.)

Page 2

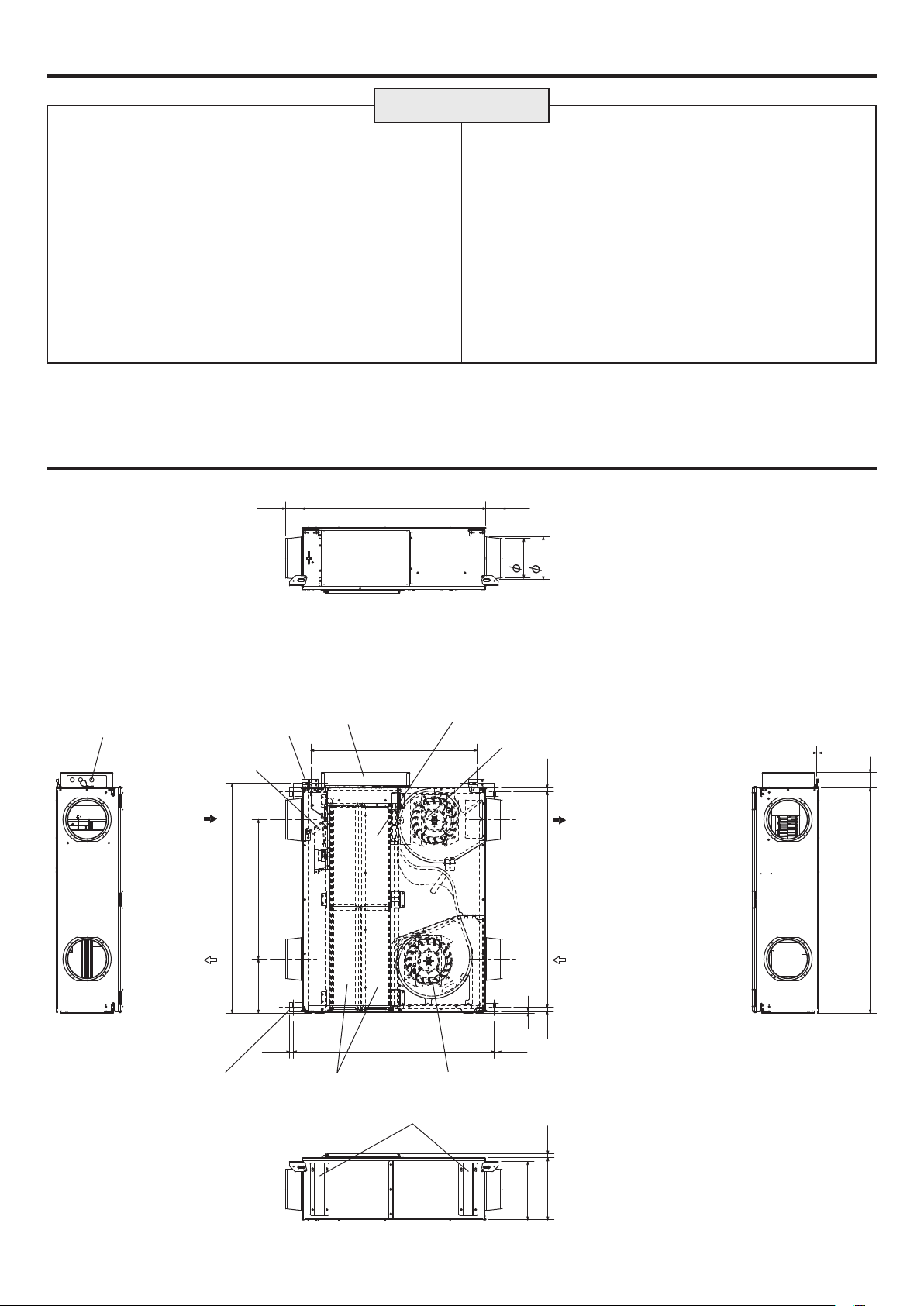

10

73

1099

810

21

979 2020

21

7

1051

680

264

1119

283.5

302

20

89879 79

192

208

Safety precautions (continued)

lWhen using the product where it is exposed to high

temperatures and humidity (40°C or higher, RH 80% or higher),

or where fog occurs frequently, moisture is likely to condense

in the core, and may result in condensation build up in the unit.

The product should not be used under such conditions.

lOutdoor air may enter the Lossnay owing to the pressure

difference between indoor and outdoor or external winds even

when the product is not operated. It is recommended to install

also an Electrically operated damper to block the outdoor air.

lIn a cold weather area, an area with strong external winds or

where fog occurs frequently, cold outdoor air, external winds

or fog may be introduced into the product when its operation is

stopped. It is recommended to install an Electrically operated

damper to shut them out.

Outline darawings

CAUTION

lWhen using the product in an environment where there is a

window, or opening near the outdoor louvre , where insects

are likely to gather around the interior or exterior light , take

note that small insects may intrude into the product.

lIn a cold weather area, or others, dewing or freezing could

occur on the main unit, where the duct is connected, or other

sections, depending on the conditions of outdoor air and

indoor temperature and moisture, even if they are within

the range of operating conditions. Make sure to confirm the

operating conditions and other precautions, and do not use

the product if dewing or freezing is anticipated.

*Example of dewing condition – Outdoor air: -5°C or lower,

dew-point temperature at installation place: 10°C or higher

(When the indoor temperature is 22°C or higher with the

relative humidity higher than 50%, or other)

Accessory parts

lMounting screws.....................................x24

lDuct connecting flanges...........................x4

(double flanges at SA and EA sides)

Power cord opening

RA

(return air)

SA

(supply air)

Wall anchor point

(2-13x30 oval)

Bypass damper plate

Control box Maintenance cover

Air exhaust fan

EA

(exhaust air outlet)

OA

(outside air intake)

Ceiling suspension fixture

(4-11x10 oval)

(Air filters)

Foot plate

Air supply fanLossnay cores

Weight : 46 kg

Unit (mm)

2

Page 3

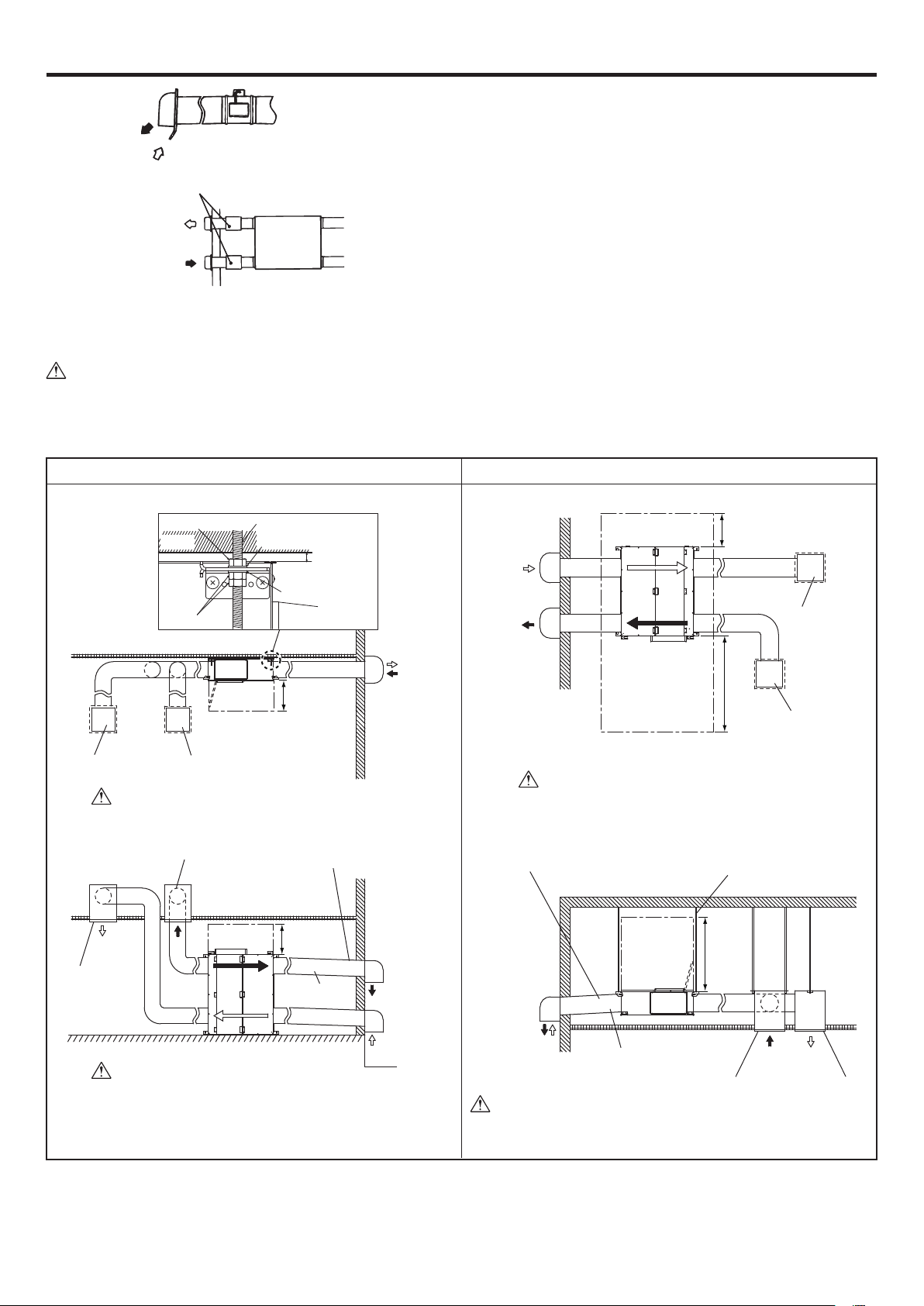

Standard installation examples

EA

(exhaust air outlet)

OA

(outside air intake)

OA (outside air intake)

EA (exhaust air outlet)

lIn a region where there is risk of freezing in winter, it is recommended

to install an Electrically operated damper, or the like, in order to

prevent the intrusion of (cold) outdoor air while Lossnay is stopped.

lThis product is designed to use horizontally as the figure or upside

down. Do not install vertically with the product suspension fixture.

lThe outside sir intake must be located where no rainwater or fog

comes in to prevent the intake of water.

Example

Electrically operated damper

(Protection against the intrusion of cold air while Lossnay is stopped in winter)

(To be provided by the customer)

Lossnay unit

<Installation horizontally><Installation vertically>

Anchor bolt

(to be provided by user)

Washer

Unit

Maintenance

space

Washer

More than

400

Supply air grille

Nut

Wall

Unit

Nut

Return air grille

Keep the unit more than 5mm away from the wall.

Downward gradient of duct:

1/30 or more (toward wall side, provide

1m or more) (to prevent rain water from

seeping in)

Maintenance

space

Unit

More than

400

SA

(supply air)

Supply air grille

Return air grille

RA

(return

air)

More

than 5

Duct

OA

(outside air intake)

EA

(exhaust air outlet)

EA

(exhaust air outlet)

OA

(outside air intake)

EA

(exhaust air outlet)

Maintenance space

Top/bottom reverse installation is not available

for this unit

Downward gradient of duct:

1/30 or more (toward wall side, provide

1m or more) (to prevent rain water from

seeping in)

Maintenance

space

Unit

Unit

More than

400

Supply air grille

More than

1200

Anchor bolt

(to be provided by user)

More than

1000

Return air grille

Floor

Unit should be on the floor by foot plate.

OA

(outside air intake)

OA

(outside air intake)

EA

(exhaust air outlet)

Duct

RA

(return air)SA(supply air)

Return air grille

Do not install the unit on the ceiling plate directly to prevent

the unit from falling, and making vibration and noise.

3

Supply air grille

Unit (mm)

Page 4

Installation method

Installing the Lossnay unit

1) Preparing the anchor bolts

Mount the washers (outer diameter of >21 mm for M10) and nuts onto

the pre-recessed anchor bolts (M10), as shown in the figure below.

Anchor bolt (M10)

Nut

Washer

Nut

2) Attaching the duct connecting flanges

Use the supplied screws to secure the duct connecting flanges to the

Lossnay unit.

Duct connecting ange

(Accessory parts)

Mounting screw

lAll mounting screws for the ceiling suspension fixture should be

tighten even if the unit is installed vertically.

CAUTION

lIf wall material is wood, tighten up by wood screws. Confirm

whether strength of wall is enough.

lWhen suspending Lossnay unit from the ceiling, do not handle it

in such a way that force will be applied to the control box.

lInstall the anchor bolts to ensure the product's weight or

earthquake load. (Correctly rated wire / chain may also be used)

4) Connecting the ducts

(1) Fasten the duct securely to the duct connecting flange, and wrap

aluminum tape (not included) around the joints so that there is no

air leakage.

(2) Suspend the ducts from the ceiling so that their weight will not be

applied to the Lossnay unit.

(3) All ducts must be covered with heat-insulating material in order to

prevent condensation from forming.

Heat-insulating

material

Outdoor

duct

Aluminum

tape

Lossnay

unit

CAUTION

lBefore attaching the duct connecting flanges, check that no

foreign matter (scraps of paper, vinyl, etc.) has found its way

inside to Lossnay unit.

lAttach the duct connecting flanges with the packing at the SA

and RA sides.

3) Mounting Lossnay unit

<Installation horizontally>

(1) Loose the screw on the ceiling suspension fixture.

(2) Turn the fixture around the loosened screw by 90 degrees to set it

at level.

(3) Fix the fixtures securely on the fan body by tightening the loosened

screw and accessory mounting screws.

(4) Hang the ceiling suspension fixtures on the anchor bolts and adjust

in such a way that Lossnay unit is level.

(5) Tighten up securely using double nuts.

<Installation vertically>

(1) Wall anchor point should be hang by M10 anchor bolt.

(2) Tighten up securely using washar (more than p26mm) and M10

nut.

Ceiling suspension xture

Mounting screw

<Installation horizontally>

Anchor bolt

Washer

Nut

Loosen

Duct connecting

ange

CAUTION

lBefore attaching the ducts, check that no (debris or any other)

foreign matter (scraps of paper, vinyl, etc.) has found its way

inside the ducts.

lDo not touch the damper plate inside Lossnay unit when

connecting the ducts.

lIf it is expected that the ambient temperature around the place

where the Lossnay unit is installed will be high during the

summer air conditioning season, it is recommended that the

indoor duct work be covered with insulation material.

Do not carry out the following types of duct construction. (Doing so

could cause a drop in the air volume and generate abnormal noises.)

• Extremely

sharp bends

• Multiple bends • Bends right next

to the outlet

• Extreme reduction

in the diameter of

the connected ducts

Wall anchor point

<Installation vertically>

Anchor bolt

Washer

Nut

Ceiling suspension xture

(Not, in use)

4

Page 5

Installation method (continued)

LINE

FILTER

Isolator

POWER SUPPLY

High voltage

(LEFT)

RED(1) BLUE(2-7)

CN15

(RIGHT)

CN16 CN17

LG-08DC

-E-M

1

3

1

7

1

4

2

1

4

4

3

7

1

1

1

1

1

5

1

6

5

1

5

1

Control Box

GREEN / YELLOW

(SA)

(EA)

M1

M2

LG-08DC

-E-C

GREEN

LED11

LED1

RED

RED

GREEN

LED2

LED3

Fan speed 1

Fan speed 2

Fan speed 3

Fan speed 4

Fan speed select

Power By-pass

condition select

Malfunction monitor output

MAX MIN

AC240V 2A AC220V 100mA

DC 24V 2A DC 5V 100mA

Operation monitor output

MAX MIN

AC240V 2A AC220V 100mA

DC 24V 2A DC 5V 100mA

WHITE(W)

BLACK(U)

RED(V)

RED

BROWN

GREEN

BLUE

BLACK

RED

BROWN

GREEN

BLUE

BLACK

BLACK(U)

RED(V)

WHITE(W)

RED

YELLOW

Reactor

Transformer

RED

YELLOW

BROWN

BLUE

CN6(red)

CN7

CN9

TM4

TM3

CN4CN5

6.3A/250V

FUSE

LS

ORANGE

ORANGE

TH2(RA)

ORANGE

ORANGE

ORANGE

ORANGE

TH1(OA)

×3

×4

SW1

TM2

BLUE

BROWN

CN1(red)

CN3

CN2

CN10

CN8(red)

CN14

TM1

220-240V 50Hz

GREEN / YELLOW

Fan speed 5

GREEN / YELLOW

PB

GM

4

1

COM

3

2

5

8

9

10

11

L

N

MARK

:Connector on PCB

:Terminal block

:Connector

L

N

PE

V

Electrical installation

With this product, the wiring installation method will vary according to the design of the system.

Perform electrical installation to meet local electrical regulations.

* Always use double insulated PVC cable for the transmission cables.

* Wiring work must be performed by qualified professionals.

* All supply circuits must be disconnected before obtaining access to the terminal devices.

Names of components in control box

Line lter

Transformer

CN14

CN10

LED2

CN8

CN9

LED3

CN2

AC Reactor

TM1

LED1

TM4

CN3

TM3

CN7

TM2

LED11

CN6

Fuse

CN1

CN15

CN16

SW1

CN17

SW2

Wire connection diagram

CAUTION

lConnect the wires shown as dotted lines.

lBe sure to connect the ground wire.

lA power supply isolator must be installed when wiring power supply to unit.

lAlways use a single pole isolator for the main switch power connection.

lAll supply circuits must be disconnected, and do not touch the components for more than 5 minutes, before obtaining access to the

terminal devices.

lIf using earth leakage breaker for isolator, rating of sensed current should be more than 10mA.

Symbol explanation

M1: Motor for exhaust fan

M2: Motor for supply fan

GM: Motor for Bypass damper

LS: Micro switch

TH1: Thermistor for outside air

TH2: Thermistor for return air

TM1: Terminal block (Power supply)

TM2: Terminal block (Fan speed selection)

TM3: Terminal block (By-pass mode selection)

TM4: Terminal block (Monitor output)

LED1(red): Power supply indicator lamp

LED2(red): Inspection indicator lamp

LED3(

green

): Inspection indicator lamp

): Inspection indicator and trial operation lamp

5

LED11(green

CN1: Connector (Power supply)

CN2: Connector (Transformer primary)

CN3: Connector (Motor for By-pass damper)

CN4: Connector (Reactor)

CN5: Connector (Reactor)

CN6: Connector (Supply fan motor)

CN7: Connector (Exhaust fan motor)

CN8: Connector (Signal for supply fan motor)

CN9: Connector (Signal for exhaust fan motor)

CN10: Connector (Signal line)

CN14: Connector (Transformer secondary)

CN15: Connector (Signal line)

CN16: Connector (Thermistor)

CN17: Connector (Micro switch)

Page 6

Installation method (continued)

PB

V

Connecting the power supply cable

1) Remove the screws and the control box cover

Control box coverScrew

2) Connecting the power supply cable

Pass the power cable through the bush* and connect to the TM1

terminal block using the round terminals. Connect the ground wire to

the ground terminal and secure tightening the bush.

(*: for PG connector or the like)

Ground wire

TM1

PG connector (customer preparation)

Power supply cable

Unit operating method

nFan speed select

Operated fan speed is followed as below table by the fan speed select

contacts.

Fan speed select contact Fan speed

All contacts : OFF OFF

1 : ON Fan speed 1

2 : ON Fan speed 2

3 : ON Fan speed 3

4 : ON Fan speed 4

5 : ON Fan speed 5

Multi contacts : ON Higher fan speed operate

CAUTION

lFan operating may be delayed from the time of contact ON

depending on the select timing.

nBy-pass condition select

By-pass damper is automatically operated based on the OA and RA

temperature.

nPower By-pass condition select

When turning on Power By-pass contact with any fan speed contacts on,

unit operation becomes power By-pass mode.

(*1)

Insert the cutting

Bush

TM3

TM2

Transmission

Cable

Bush

Cord clip

CAUTION

lAlways separate the power supply cable and the cable to the

control unit by 10 cm or more to prevent malfunctioning of the

unit.

lIf the length of the stripped power cables wires is too long, the

conductors may touch and short out.

lPower supply cable size : 1.5 mm2 or more.

(1) Refer to the wiring diagram and screw down the ground wire and

the cables to the terminal block.

(2) Secure the power supply cable with the PG connector and the

Transmission cables with the cord clip.

Upon completion of the wiring connections, replace the control box cover.

3) Connecting the cables for fan speed select and Bypass condition select

Connect the cables and the contacts as below.

Put the wires deeply to the holes of contact with pushing the button.

Confirm no unconnected wire.

com 1 2 3 4 5 PB V

TM2

Button

TM3

Ventilation priority mode

Power By-pass condition select

4) The following system configuration can be created.

Connect the necessary parts.

(1) If you would like to connect to a Electrically operated damper, etc.,

or would like to fetch operation monitor output.

(2) If you would like to fetch Malfunction monitor output.

(1) When connect to an Electrically operated damper, etc.,

or take operation monitor output:

Connect the power supply from the Electrically operated damper

to 8 and 9 of the monitor output terminal block (TM4) with

reference to the wire connection diagram.

x3

TM4

Power supply

Electrically

operated

damper

(2) When take Malfunction monitor output:

Connect to 0 and a of the monitor output terminal block (TM4)

with reference to the wire connection diagram.

x4

TM4

Power supply

Lamp or monitoring unit

Lamp or monitoring unit

Fan speed

select

contact: 12VDC 10 mA

cable for operation: 0.5mm2 to 1.0mm

maximum length: 20m from terminal block

peeling wire length: 9~10mm

CAUTION

l

Power By-pass mode is not available even if only PB contact is on. (*

lBe sure to connect Fan speed 5 wiring.

2

It is recommended to connect Malfunction monitor output to check

the malfunction externally.

1)

6

Page 7

Function settings

SW1

Trial operation

Operation monitor out put with delay function

Setting for exhaust fan in cold region operation mode

Ventilation priority mode during ventilation setting input on

Operating monitor output

By-pass auto ventilation priority setting

Auto air volume increasing during bypass setting

Not to used

SW2

Decreasing exhaust fan power

Increasing exhaust fan power

Decreasing supply fan power

Increasing supply fan power

lAll switches are OFF at factory setting.

1 Trial operation

OFF ON Operation

1 Normal operation

SW1

1 Trial operation

7 Auto air volume increasing during bypass setting

OFF ON Operation

7 Not increasing.

SW1

7

When unit is in by-pass operation except power

by-pass mode, the unit fan speed is automatically

increased 1 step.

8 Fan speed fine-tuning

ON OFF Operation

2

1

or

All supply air fan speeds are default settings.

Each supply air fan speed settings except power

bypass mode are increased.

Each supply air fan speed settings are decreased.

or

All exhaust fan speeds are default settings.

Each exhaust fan speed settings except power

bypass mode are increased.

Each exhaust fan speed settings are decreased.

SW2

2

1

2

1

2

1

4

3

4

3

4

3

4

3

2

Operation monitor out put with delay function * (TM4 89)

OFF ON Operation

2 Not available

SW1

2 Available

3

Exhaust fan speed setting in cold region operation mode *

OFF ON Operation

SW1

3 Not fixed

3 Exhaust fan : speed 5 fixed

4

Ventilation priority mode during ventilation setting input on

OFF ON Operation

SW1

4 Bypass ventilation mode fixed

4 Lossnay ventilation mode fixed

* Below 8°C, even SW1-4 is fixed any setting, ventilation mode should be Lossnay

ventilation.

5 Operating monitor output (TM4 89)

OFF ON Operation

SW1

5 Not available

5 Available

* During SW1-2 on, operating monitor out is prior to “ 2 operation motor out put with

delay function”.

6 By-pass auto ventilation priority setting

OFF ON Operation

When outdoor temperature is 17°C or higher

6

SW1

6

within 24 hours, then bypass ventilation starts by

comparison OA and RA.

When outdoor temperature is 28°C or higher

within 24 hours, then bypass ventilation starts by

comparison OA and RA.

* Operation monitor out put with delay function

Corresponds to operation mode output (TM4 89)

Supply fan with following function

- Start the output (TM4 89) 10 seconds after supply fan operates

but also when the thermistor for outside air (TH1) detect -5

lower.

- Stop the output (TM4 89) when thermistor for outside air (TH1)

detects a temperature higher than -15

malfunction of TH1.

- Lossnay continues to operate for 3 minutes, after stopping the

output (TM4 89)

- Error code is shown on the remote controller and stop the output in

case of followings.

1) TH1 detects higher than 15°C within 15 minutes after the output

starts.

2) TH1 detects -10°C or lower, 60 minutes after the output starts.

3) TH1 detects continuously 70°C or higher for more than 1 minute.

*Cold region operation mode

The unit operation is based on the measured OA temperature as

below.

Operation mode OA temperature

Normal -10°C<OA

SA intermittent -15°C<OA<-10°C

SA stopped OA<-15°C

SA : supply air EA : exhaust air OA : outside air

Continuous running Continuous running

Repeat 10min. Stop

/ 60min.

Repeat 55min. Stop

/ 5min. running

°C

or stop the supply fan or

SA fan EA fan

running

Continuous running

Continuous running

Fan speed 5 is fixed

in SA fan stopped

operation in the case

of SW1-3.

°C

or

7

Page 8

Trial operation

After the system has been installed and before the ceiling panel is installed, make sure that wires are properly connected, then test the system’s

operation.

(1) Remove the control box cover.

(2) Turn the trial operation switch (SW1-1) “On”.

lLED11 will be on with the Fan speed 1 setting and with By-pass ventilation operating for 1 min.

Then, it will change to energy recovery ventilation mode.

(3) Turn the trial operation switch (SW1-1) “Off

(4) Install the cover in its original position on the control box.

Trouble shooting

Cause of failure

Supply fan over current failure Twice - Once -

Exhaust fan over current failure - Twice - Once

Shortage of power supply voltage Twice - 3times -

Over voltage of power supply Twice - 4times -

Supply fan motor operating failure Twice - 5times -

Exhaust fan motor operating failure - Twice - 5times

Supply fan motor sensor failure Twice - 6 or 7times -

Exhaust fan motor sensor failure - Twice - 6 or 7times

Communication failure between

upper and lower PCB

Damper failure 3times - - -

Outside air sensor failure 4times - - -

Room air sensor failure 5times - - -

External interlocked unit failure 8times - - -

If troubles occur as above, turn off all fan speed contacts immediately and contact to your dealer.

The unit may not operate properly if the power supply voltage is lower than the rating voltage. (220-240V)

”.

LED indication (Blinking)

Small PCB (right) Large PCB (left)

LED1

(red)

9times 9times 9times 9times

LED11

(green)

LED2

(red)

LED3

(green)

Motor operation

stop

running

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

AUTHORIZED REPRESENTATIVE IN EU:

MITSUBISHI ELECTRIC EUROPE B.V.

HARMAN HOUSE, 1 GEORGE STREET, UXBRIDGE, MIDDLESEX UB8 1QQ, U.K.

Loading...

Loading...