Page 1

LOSSNAY

HAND BOOK

Model: LGH-50RSDC-E

August 2009 No. U162-A

FOR DEALERS

Nameplate

Repair work should be performed by

the manufacturer, its service agent or

similarly qualified person in order to

avoid hazards.

Page 2

Contents

1. Safety precautions ................................................................. 3

2. Names of components ......................................................... 4

3. Specifications ....................................................................... 5

4. Outside dimensions ............................................................... 6

5. Electrical wiring diagram ...................................................... 7

6. Basic circuit diagrams ....................................................... 8-9

7. Fundamentals of operation ............................................ 10-15

8. Troubleshooting ............................................................. 16-22

9. Overhaul procedure ....................................................... 23-27

10. Parts catalog ................................................................. 28-34

Page 3

1. Safety precautions

Please be sure to read the following precautions thoroughly before commencing with the maintenance work, and

conduct the inspection and repair of the product in a safe manner.

The types and levels of danger that may arise if the product is handled incorrectly are described by using the

warning symbols shown below.

Incorrect handling of the product may result in serious injury

Warning

or death.

Electric shock

If you must inspect the circuitry while the power is

on, do not touch the live parts.

(Failure to heed this warning may result

in electric shock.)

Caution for

electric shock

Modification is prohibited

Do not modify the product.

(Failure to heed this warning may result

in electric shock, fire and/or injury.)

Prohibited

Proper electric work

Use the electric wires designated for electric work,

and conduct electric work in accordance with the

"Electric Installation Engineering Standard", the

"Indoor Wiring Regulations" and the installation

instructions.

(Improper connection or wiring installation

may result in electric shock and/or fire.)

Be sure to follow

this instruction.

Turn off the power supply

Be sure to shut off the power supply isolator before

disassembling the product for repair.

(Failure to heed this warning may result

in electric shock.)

Be sure to follow

this instruction.

Use proper parts and tools

For repair, be sure to use the parts listed in the

service parts list of the applicable model and use the

proper tools.

(Failure to heed this warning may result in

electric shock, fire and/or bodily injury.)

Be sure to follow

this instruction.

Replace damaged and/or degraded parts

Be sure to replace the power-supply cord and lead

wires in the event that they are damaged and/or

degraded.

(Failure to heed this warning may result

in electric shock and/or fire.)

Be sure to follow

this instruction.

Check insulation

Upon completing repair work, always measure the

insulation resistance. Verify that it is at least 10 M

(with a 500 V DC insulation resistance tester), and

then turn on the power.

(Inadequate insulation may cause electric

shock.)

Be sure to follow

this instruction.

Incorrect handling of the product may result in serious injury

Caution

Caution for injury

Do not conduct any work at a location where you do

or damage to properties including buildings and equipment.

Wear gloves

Wear gloves when conducting work.

not have a sure footing.

(Failure to heed this caution may result in

(Failure to heed this caution may result in

a fall.)

Prohibited

injury to your hands from sharp metal or

other edges.)

Be sure to follow

this instruction.

Request for repair

Inspect the grounding, and repair it if incomplete. Make sure that a power supply isolator or an overload

protection device is being installed, if not, recommend the dealer to install one.

Make sure that the product operates properly upon completion of repair. Clean the product as well as the

surrounding area, and then notify the customer of the completion of repair.

3

Page 4

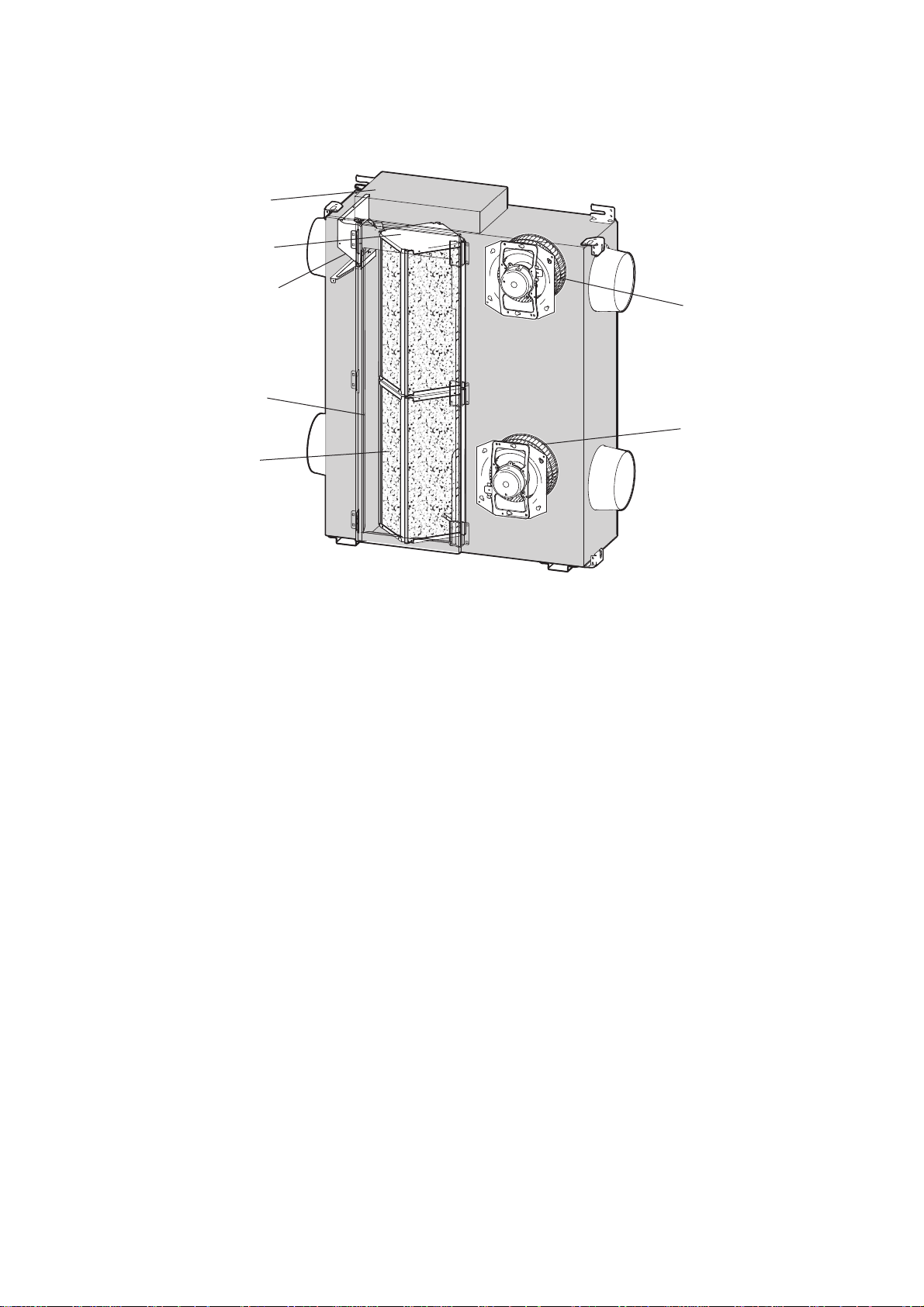

2. Names of components

Control box

Lossnay core

Damper plate

Maintenance cover

Air filter

(4 filters)

Air exhaust fan

(EA fan)

Air supply fan

(SA fan)

4

Page 5

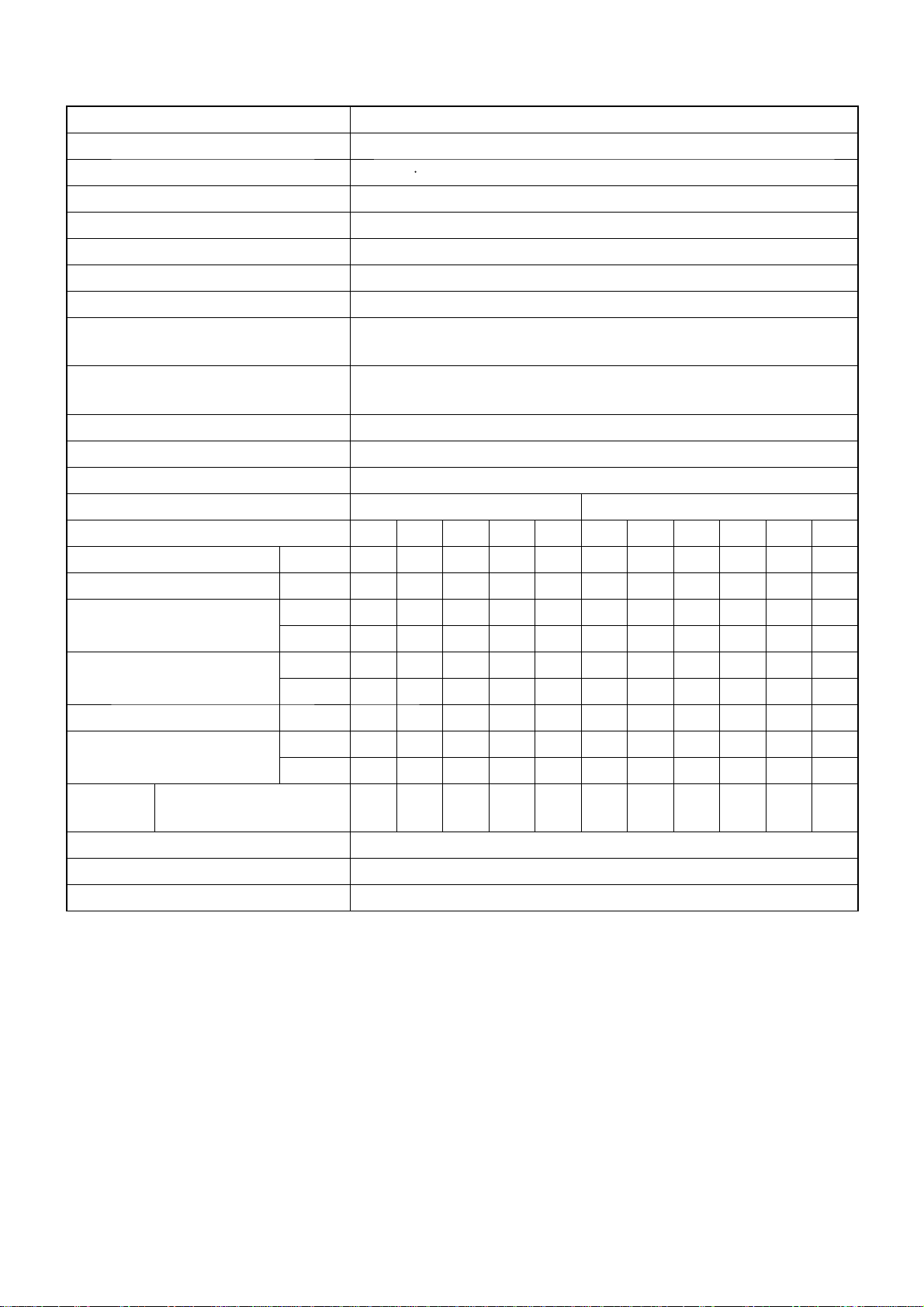

3. Specifi cations

Model LGH-50RSDC-E

Heat exchange system Air-to-air Total heat exchange (sensible heat + latent heat exchange)

Heat exchange element material Partition spacing plate-special treated paper

Cladding Galvanized steel sheet

Heat insulating material Self-extinguishing urethane foam

Motor DC brushless motor. Two units

Blower 220 mm diameter. Centrifugal fan

Filter material Non-woven fabrics fi lter (Gravitational method 82%, EU-G3)

Applicable air condition of setting environment

Applicable air condition range of outdoor

and indoor

The setting air condition shall be between -10°C to 40°C, 80%RH or less.

OA temperature shall be -15°C to 40°C, 80%RH or less, with general air

conditioning room environment.

Functions

Lossnay ventilation fi ve speeds / Bypass ventilation (fi ve speeds + power)

Weight 48 kg

Frequency / Power source 50 Hz / Single phase 220-240 V

Ventilation mode

Fan speed (230 V) 12345

Lossnay (Energy recovery) ventilation

Power

Bypass ventilation

12345

Current [A] 1.17 0.67 0.35 0.20 0.13 1.80 1.20 0.70 0.35 0.20 0.13

Power Consumption [W] 165 90 41 22 14 265 164 90 40 21 14

3

/h] 395 305 215 144 90 468 395 305 215 144 90

[m

Air volume

[l/s] 110 85 60 40 25 130 110 85 60 40 25

2O] 10.2 6.1 3.1 1.5 0.7 13.8 10.2 6.1 3.1 1.5 0.7

[mmH

External static pressure

[Pa] 100 60 30 15 7 135 100 60 30 15 7

Temperature exchange effi ciency

Enthalpy exchange

effi ciency [%]

Noise [dB]

Measured at 1.5 m under the center

of panel in an anechoic chamber

[%] 77.5 81.5 85.5 88 90 - - - - - Heating 71 75 79 82 84 - - - - - Cooling 68 72.5 77 80.5 83 - - - - - -

31 26.5 21 18 18 35 31 26.5 21 18 18

Starting current 2.5 A or less

Insulation resistance 10 M

or more (500 V megger)

Dielectric strength AC 1500 V 1 minute

5

Page 6

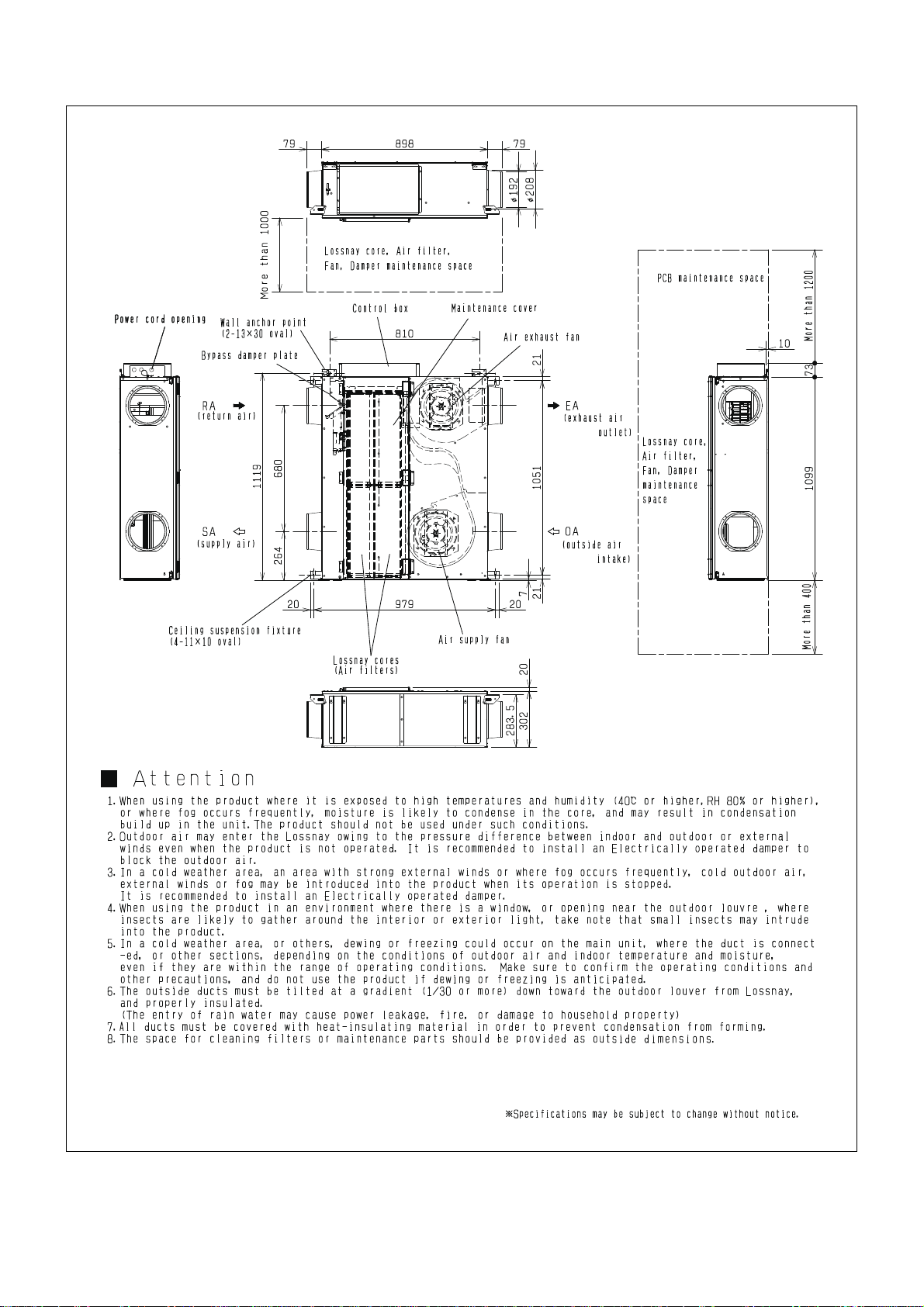

4. Outside dimensions

6

Unit (mm)

Page 7

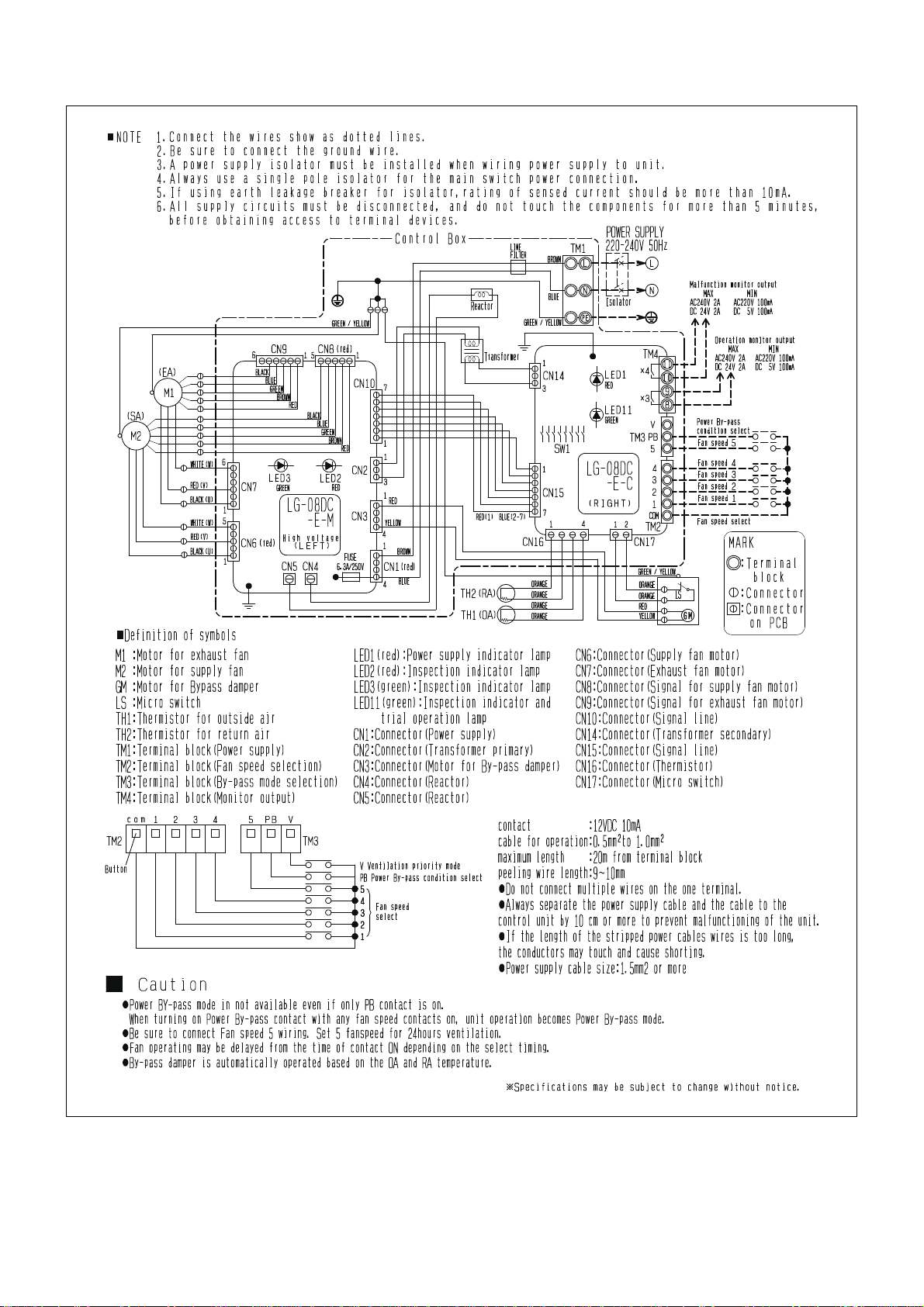

5. Electrical wiring diagram

7

Page 8

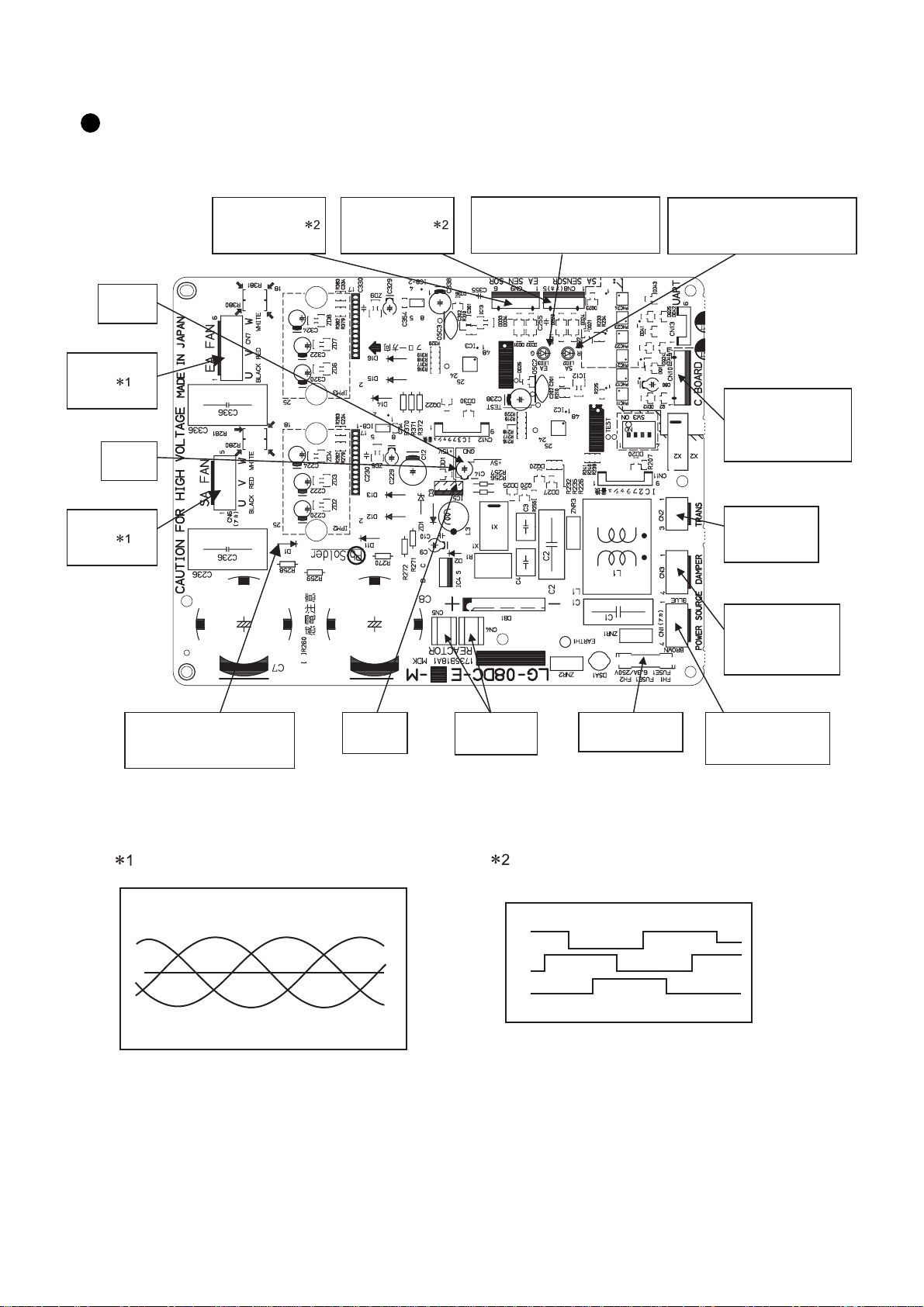

6. Basic circuit diagrams

Circuit board diagrams and check points

(1) Large PCB (printed circuit board) (Left)

5 V DC

(C14)

EA fan drive

output

(CN7)

GND

(C14)

SA fan drive

output

(CN6)

EA fan motor

sensor signal

(CN9)

SA fan motor

sensor signal

(CN8)

LED 3 (green)

䍃During EA fan operation: lit

䍃During an error: blinking

LED 2 (red)

䍃During SA fan operation: lit

䍃During an error: blinking

Communication

signal between

the circuit boards.

(CN10)

Transformer

input

(CN2)

Motor for

Bypass damper

220-240 V AC

(CN3)

300-340 V DC

(D1)

Fan drive power supply

15 V DC

(IC5)

Current waveform of the fan drive output

(Current of each line)

Reactor

(CN4, CN5)

Voltage waveform of the fan motor sensor signal

(Voltage between the lead wires of the

Fuse

(6.3 A / 250 V)

connectors 2, 3, 4 and GND)

U Line current V Line current W Line current

Although the current cycle and value varies

with the operational status, each current waveform

is a sine wave with a phase difference by 120 degrees.

Note) Noise is included in the actual waveform.

CAUTION

●

5 V

U

V

W

The voltage cycle varies with the operational

status (rotational frequency).

Each signal has 50% duty cycle of H (5 V) and L (0 V),

and there is a phase difference by 120 degrees.

Note) Noise is included in the actual waveform.

0 V

Live parts of the large PCB is not insulated from the power supply.

Even after turning off the power, the capacitors on the circuit boards are still charged.

Wait more than 5 minutes before servicing.

Power supply

220-240 V 50 Hz

(CN1)

8

Page 9

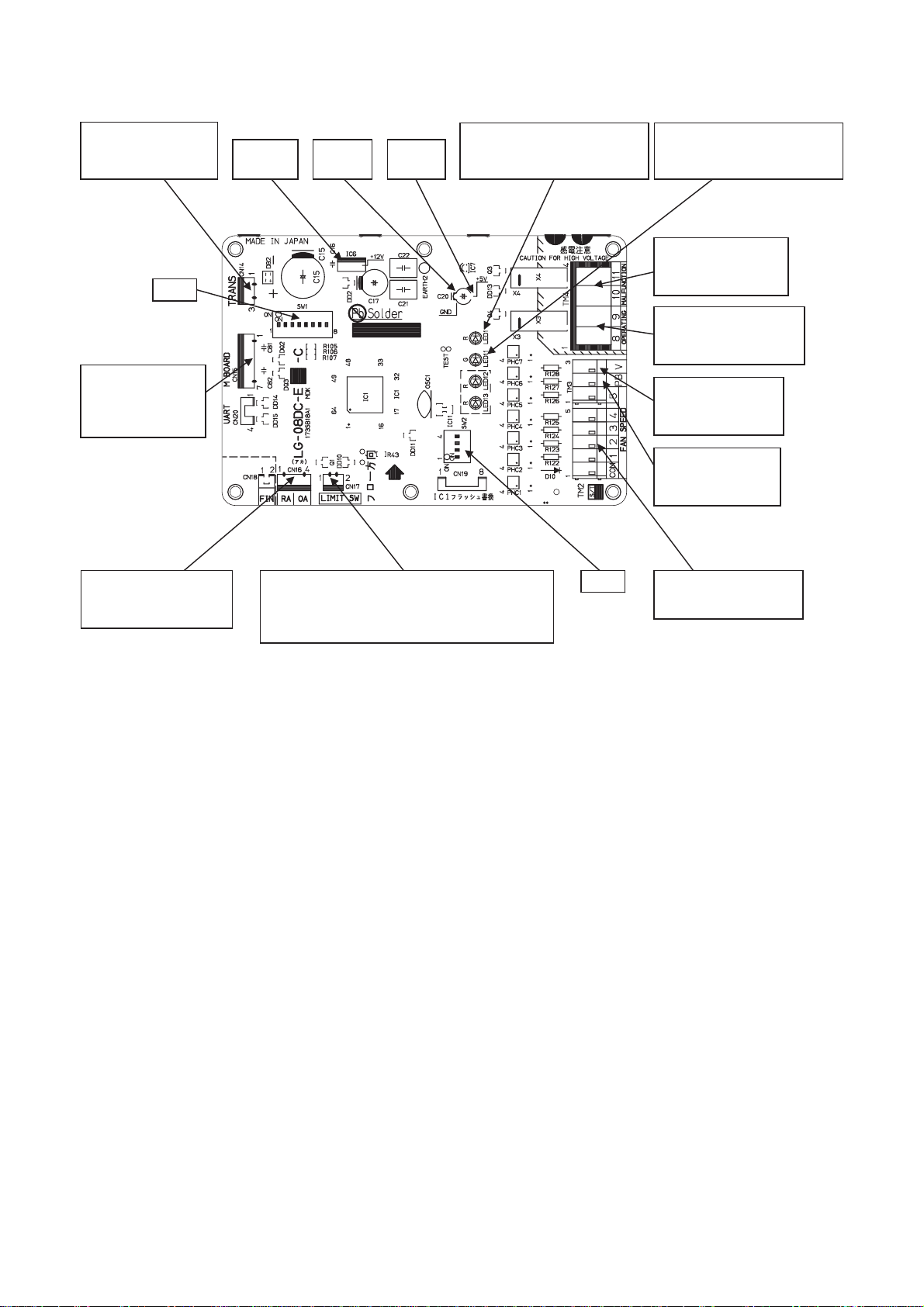

(2) Small PCB (right)

Transformer output

11 V to 20 V AC

(CN14)

SW1

Communication

signal between

the circuit boards.

(CN15)

Thermistor

(return air, outside air)

(CN16)

LED 1 (red)

12 V DC

(IC6)

Damper position detector

(CN17)

䍃during energy recovery ventilation: 12 V DC

䍃during bypass ventilation: 0 V

GND

(C20)

5 V DC

(C20)

䍃Normal: lit

䍃During an error: blinking

SW2

LED 11 (green)

䍃During trial operation: lit

䍃During an error: blinking

During an error: 0 Ω

Normal: Open

(TM4 10, 11)

During operation: 0 Ω

When stopped: Open

(TM4 8, 9)

Ventilation priority

mode selection

(TM3 V)

Power bypass

condition selection

(TM3 PB)

Fan speed selection

(TM2 1-4, TM3 5)

9

Page 10

7. Fundamentals of operation

Description of the PCB

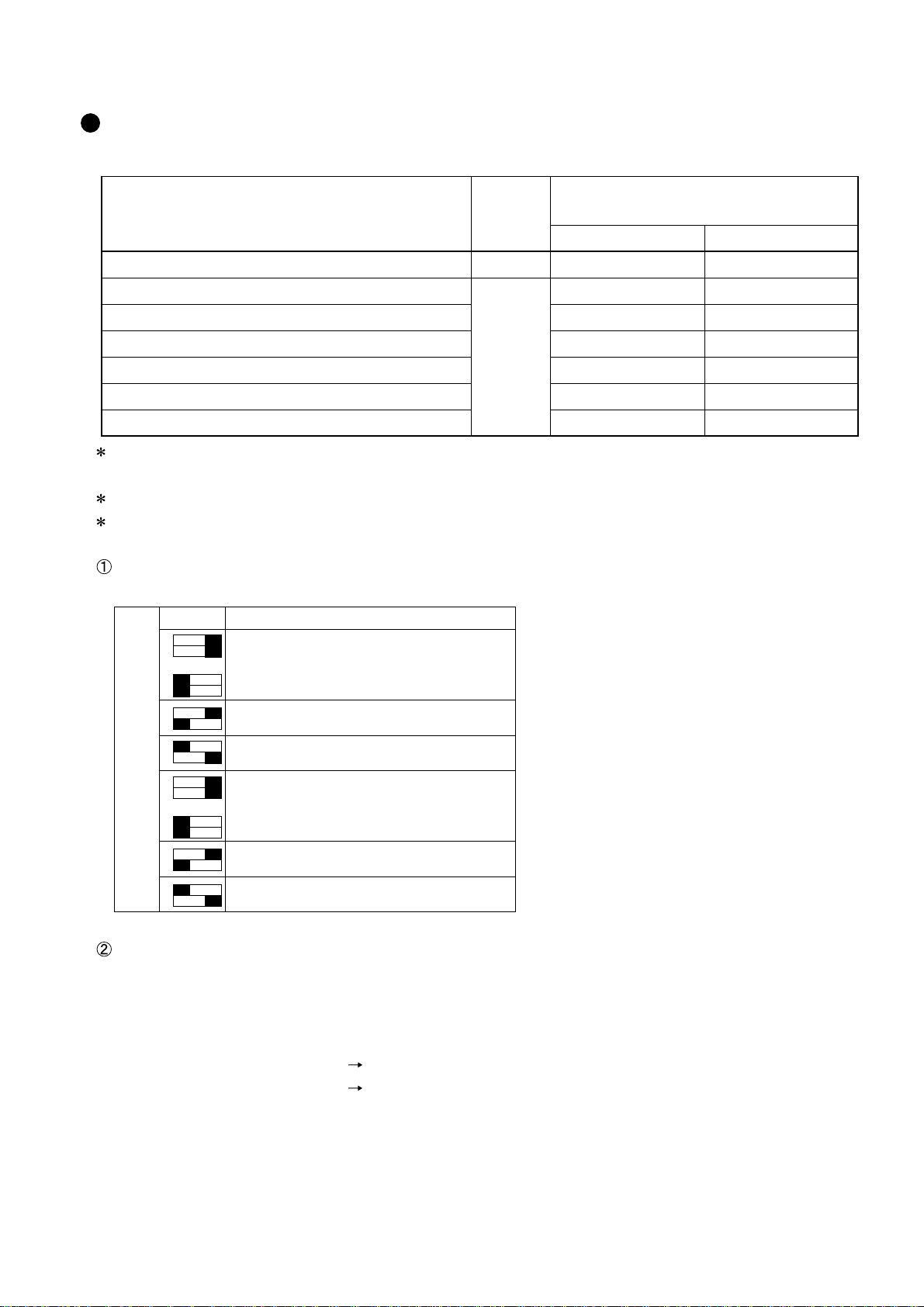

(1) Air volume control

Fan speed selection

(TM2, TM3)

Operation

(Reference value under rated static pressure)

(m3/h) (l/s)

All contacts : OFF Stop 0 0

Air volume

Speed 1 (Contact between 1 and COM) : ON

395 110

Speed 2 (Contact between 2 and COM) : ON 305 85

Speed 3 (Contact between 3 and COM) : ON 215 60

Running

Speed 4 (Contact between 4 and COM) : ON 144 40

Speed 5 (Contact between 5 and COM) : ON 90 25

Power bypass (Contact between PB and COM) : ON 468 130

1 Power bypass will be enabled when any of fan speed contacts (1 to 5) are ON. (The fan will not operate

when only the power bypass contact is turned ON.)

2 It needs 5 seconds to change air volume (including OFF) after the fan speed is selected.

3 When multiple fan speeds are selected simultaneously, the higher fan speed will be performed.

Fan speed fi ne-tuning

Fan speed can be fi ne-tuned by the dip switch SW 2 on the circuit board.

ON OFF Operation

2

1

or

All supply air fan speeds are default settings.

Each of the supply air fan speed settings except

power bypass mode is increased.

Each of the supply air fan speed settings is

decreased.

or

All exhaust fan speeds are default settings.

Each of the exhaust fan speed settings except

power bypass mode is increased.

Each of the exhaust fan speed settings is

decreased.

SW 2

2

1

2

1

2

1

4

3

4

3

4

3

4

3

Automatic air volume increasing during bypass setting

Fan speed will automatically increase 1 step higher than its present speed if both conditions are met:

• The dip switch SW 1-7 on the circuit board is ON.

• Operation mode is switched to bypass ventilation from energy recovery ventilation (with a summer criteria)

in automatic ventilation mode.

Example 1 : Speed 3 operation Speed 2 operation

Example 2 : Speed 1 operation Power bypass operation

( If the operation mode is switched to energy recovery ventilation from bypass ventilation, fan speed will

return to its original speed.)

─10─

Page 11

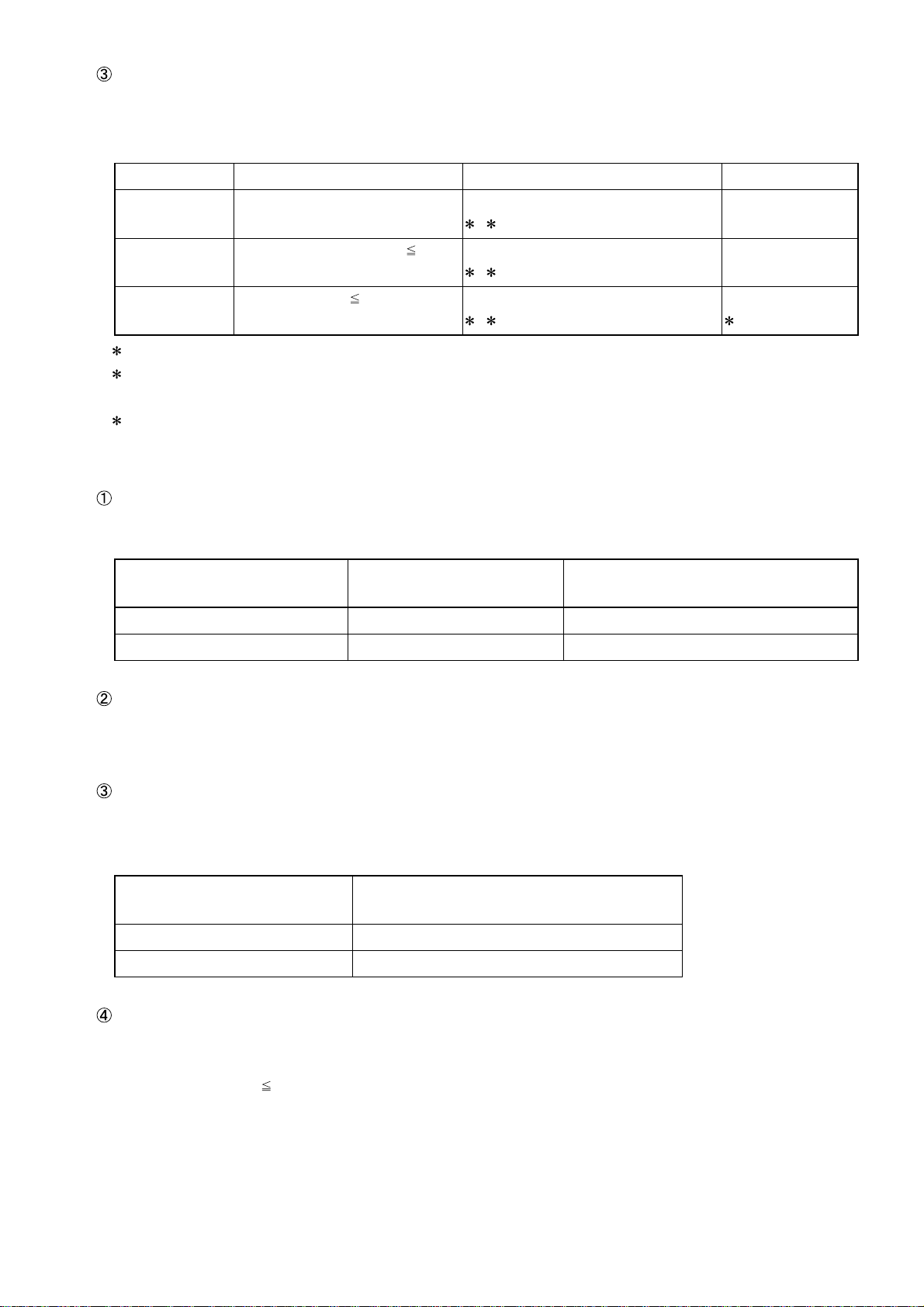

Cold region operation mode

When using the unit in cold region, set the air supply (SA)fan in the SA intermittent operation mode to prevent the energy recovery core from freezing. The fan operation is based on the measured outside air (OA)

temperature as below.

Operation mode OA temperature SA fan EA fan

Normal -10°C < OA temperature Continuous running

1

2

SA intermittent -15°C <OA temperature -10°C

SA stopped OA temperature -15°C Repeat 55 min. stop / 5 min. running

1 The operation mode will be decided 5 minutes after the normal operation during startup.

2 The running condition does not change while the SA fan stops or 1 minute after startup. (OA temperature

is voided.)

3 When the switch SW 1-3 is on, the EA fan operates at fan speed 5 during 55-minute stop of the SA fan.

Repeat 10 min. stop / 60 min. running

1 2

1 2

Continuous running

Continuous running

Continuous running

3

(2) Damper motor control

Automatic ventilation mode

Automatic ventilation algorithm patterns are switched by the OA • RA (return air) thermistor and function setting switch SW 1-6.

Function setting switch SW1-6

OFF (factory setting) 17°C or higher Automatic ventilation pattern 1 (chart 1)

ON 28°C or higher Automatic ventilation pattern 2 (chart 2)

Power bypass mode

When turning on the TM3 PB contact with any fan speed contacts (1 to 5) on, operation mode will be

switched to bypass ventilation. Then, fan speed will be also increased to Power bypass speed.

Ventilation priority mode

When turning on the TM3 V contact with any fan speed contacts (1 to 5) on, operation mode (energy recovery or bypass) can be fi xed by the function setting switch SW 1-4. (Fan speed will not be changed in the

bypass ventilation mode.)

Function setting switch SW1-4 Ventilation priority mode

OFF (factory setting) Bypass ventilation fi xed

ON Energy recovery ventilation fi xed

Prohibition of the bypass ventilation

In case of the situations below, bypass ventilation will be disabled, and energy recovery ventilation setting

will be activated.

a. OA temperature 8°C (for dew condensation prevention)

b. OA • RA thermistor failure.

OA temperature criteria

in the summer season

Automatic ventilation algorithm

─11─

Page 12

Automatic ventilation algorithm temperature chart

< Pattern 1>

Chart 1. Automatic ventilation algorithm temperature chart during the switch SW 1-6 OFF setting.

When an outdoor temperature has not reached 17ºC

within 24 hours

Undetermined area

30

28

26

24

22

20

Energy recovery

18

16

14

12

10

Outdoor temperature °C

8

6

ventilation

6 8 10 12 14 16 18 20 22 24 26 28 30

Indoor temperature °C

ventilation

Bypass

When an outdoor temperature has reached 17ºC or higher

within 24 hours

Bypass

Undetermined area

30

28

26

24

22

20

Energy recovery

18

16

14

12

10

Outdoor temperature °C

8

6

ventilation

6 8 10 12 14 16 18 20 22 24 26 28 30

Indoor temperature °C

ventilation

<Pattern 2>

Chart 2. Automatic ventilation algorithm temperature chart during the switch SW 1-6 ON setting.

When an outdoor temperature has not reached 28ºC

within 24 hours

When an outdoor temperature has reached 28ºC or higher

within 24 hours

Bypass

Undetermined area

30

28

26

24

22

20

Energy recovery

18

16

14

12

10

Outdoor temperature °C

8

6

ventilation

6 8 10 12 14 16 18 20 22 24 26 28 30

Indoor temperature °C

ventilation

Undetermined area

30

28

26

24

22

20

Energy recovery

18

16

14

12

10

Outdoor temperature °C

8

6

ventilation

6 8 10 12 14 16 18 20 22 24 26 28 30

Indoor temperature °C

Undetermined area

When operation starts under this condition, energy recovery ventilation will be activated.

When this condition is reached after operation starts, the current ventilation mode is maintained.

Bypass

ventilation

─12─

Page 13

(3) Operation monitor output

When the function setting switch SW 1-2 (for operation monitor output with delay function) is set to OFF, and

the switch SW 1-5 (for operation monitor output) is set to ON, the operation monitor signal can be output from

the monitor terminal block

SW 1-2 OFF

SW 1-5 ON

Signal type Uncharged a-contact

Contact specifi cations

and (TM4) on the circuit board.

Maximum load

Minimum load 5 V DC 100 mA

220-240 V AC 2 A

24 V DC 2 A

Operation

Stopping Monitor output : Off (contact : open)

Running Monitor output : On (contact : close)

(4) Operation monitor output with delay function

When the function setting switch SW 1-2 (for operation monitor output with delay function) is set to ON, the operation monitor signal from the monitor terminal block and (TM4) on the circuit board is shown as below.

SW 1-2 ON

Signal type Uncharged a-contact

220-240 V AC 2 A

24 V DC 2 A

Monitor output : On (contact : close) 10 seconds after air

supply fan operates

Contact specifi cations

Operation

Maximum load

Minimum load 5 V DC 100 mA

OA temperature

OA temperature 15°C Monitor output : Off (contact : open)

The fan continues to operate for 3 minutes, after operation monitor output has been

OFF by the Lossnay stopping control.

-5°C

(5) Malfunction monitor output

The malfunction monitor signal can be output from the monitor terminal block and (TM4) on the circuit

board.

Signal type Uncharged a-contact

Contact specifi cations

Maximum load

Minimum load 5 V DC 100 mA

Normal Monitor output : Off (contact : open)

Operation

During an error Monitor output : On (contact : close)

─13─

220-240 V AC 2 A

24 V DC 2 A

Page 14

(6) Trial operation function

This is a function for operating the Lossnay without external signals (contact signals). With this function, con-

necting condition of the AC power supply line and the wirings can be confi rmed. Also, the Lossnay can be

forced to operate in case of system down.

How to set Turn on the trial operation switch SW 1-1.

SA fan operation Speed 1

EA fan operation Speed 1

Operation mode Energy recovery ventilation, after 1 minute bypass ventilation

LED 11 Lit

Operation monitor output

(TM4 and )

When SW 1-2 (Operation monitor output with delay function) is ON, or

SW 1-5 (Operation monitor output) is ON,

Monitor output : On (contact : close)

(7) LED display

Small PCB (right) Large PCB (left)

LED Display Condition LED Display Condition

1 No power supplied

Unlit

LED 1 (red)

LED 11 (green)

1 When one of LED 1 and LED 11 is blinking, the other one will be unlit.

2 In case multiple errors have occurred at the same time, each LED will blink simultaneously.

Lit Power supplied Lit SA fan running

Blinking Error Blinking Error

Unlit 1 Normal

Lit In trial operation Lit EA fan running

Blinking Error Blinking Error

LED 2 (red)

LED 3 (green)

Unlit SA fan stopping

Unlit EA fan stopping

─14─

Page 15

(8) Function setting switches

SW1

Trial operation

Operation monitor output with delay function

Setting for exhaust fan in cold region operation mode

Ventilation priority mode during ventilation setting input on

Operation monitor output

Bypass auto ventilation priority setting

Automatic air volume increasing during bypass setting

Not to used

SW2

Decreasing exhaust fan power

Increasing exhaust fan power

Decreasing supply fan power

Increasing supply fan power

All switches are OFF at factory setting.

1 Trial operation (Refer to (6) (page 14).)

OFF ON Operation

SW1

1 Normal operation

1 Trial operation

7 Automatic air volume increasing during bypass setting

OFF ON Operation

7 Not increasing.

SW1

7

When unit is in bypass operation except power

bypass mode, the unit fan speed is automatically

increased 1 step.

8 Fan speed fine-tuning

ON OFF Operation

2

1

or

All supply air fan speeds are default settings.

Each of the supply air fan speed settings except

power bypass mode is increased.

Each of the supply air fan speed settings is

decreased.

or

All exhaust fan speeds are default settings.

Each of the exhaust fan speed settings except

power bypass mode is increased.

Each of the exhaust fan speed settings is

decreased.

SW2

2

1

2

1

2

1

4

3

4

3

4

3

4

3

2

Operation monitor output with delay function (TM4 )

OFF ON Operation

SW1

2 Not available

2 Available (Refer to (4) (page 13).)

3

Exhaust fan speed setting in cold region operation mode

(Refer to (1) (page 11).)

OFF ON Operation

SW1

3 Not fixed

3 Exhaust fan : speed 5 fixed

4

Ventilation priority mode during ventilation setting input on

(Refer to (2) (page 11).)

OFF ON Operation

SW1

4 Bypass ventilation mode fixed

4 Lossnay (Energy recovery) ventilation mode fixed

* Below 8°C, even SW1-4 is fixed any setting, ventilation mode should be Lossnay

(Energy recovery) ventilation.

5 Operation monitor output (TM4

OFF ON Operation

SW1

5 Not available

5 Available (Refer to (3) (page 13).)

* During SW1-2 on, operation monitor output is prior to “ 2 operation monitor output

with delay function”.

)

6 Bypass automatic ventilation priority setting (Refer to (2)

(page 12).)

OFF ON Operation

6

SW1

6

When outdoor temperature is 17°C or higher

within 24 hours, then bypass ventilation starts by

comparison OA and RA.

When outdoor temperature is 28°C or higher

within 24 hours, then bypass ventilation starts by

comparison OA and RA.

─15─

Page 16

8. T roubleshooting

Work precautions

• When removing or touching a transformer, printed circuit board or other parts, make sure to turn off the

power supply isolator. Even after disconnecting the power supply isolator, the voltage is still high in the capacitors on the printed circuit boards. Wait more than 5 minutes, and make sure a voltage is low by using a

tester, before servicing.

• When removing the circuit board, always hold it at both ends and remove carefully so as not to apply force to

the surface mounted parts.

• When removing the circuit board, be careful of the metal edges on the board.

• When removing or inserting the connectors for the circuit board, hold the entire housing section. Never pull

on the lead wires.

• When servicing, be sure to recreate the malfunction two or three times before starting repairs.

• When reconnecting the power supply, wait more than 5 minutes after power-off, and then turn it on again.

• If it is thought that there is a printed circuit board malfunction, check for disconnected wires in the print pattern, burnt parts or discoloration.

• If the printed circuit board is replaced, make sure that the switch settings on the new board are the same as

the old board.

Part names used in the following text correspond to those listed in the parts catalog.

(1) Checkpoints for installation condition

No. Checkpoints

1 Do the wiring diameters and capacity of the motor breaker and the ground-fault interrupter meet specifi -

cations?

2 Is the specifi ed power (220-240 V AC 50 Hz) supplied to the power terminal (TM1)?

3 Do the wirings for the fan speed and bypass condition selections meet specifi cations?

• Contact: 12 V DC 10 mA

• Diameter of cables : 0.5 mm

• Maximum length : 20 m from terminal block

• Wire peeling length : 9-10 mm

4 Are the wirings for fan speed and bypass condition selections correct?

5 Are the wires for fan speed and bypass condition selections more than 10 cm away from the power sup-

ply cable?

6 Are the connected terminal blocks of the wires for fan speed and bypass condition selections correct?

(TM2 1-4 and TM3 5 are for fan speed selection. TM3 PB and V are for bypass condition selection.)

7 Is each wire securely connected to the terminal blocks?

8 Are external signals correctly input to TM2 and TM3 on the circuit board?

9 Is the output capacity of the operation and malfunction monitors within rated range?

Operation monitor output : Maximum 220-240 V AC/ 24 V DC 2 A, minimum 5 V DC 100 mA

Malfunction monitor output : Maximum 220-240 V AC/ 24 V DC 2 A, minimum 5 V DC 100 mA

2

to 1.0 mm2

─16─

Page 17

(2) Troubleshooting and repair method

When any LEDs on the circuit boards are blinking

The type of failure is shown by the number of blinking times of LED 1 (red), LED 11 (green), LED 2 (red) and

LED 3 (green) on the circuit boards. The LED blink interval is 0.25 seconds for both lit and unlit. The display

duration is approximately 5 seconds.

0.25s 0.25s0.25s

Lit

Unlit

5s

Failure display example (2 blinks)

Checklist of LED failure displays

LED 1

LED 1 1

LED 2

(red)

2

blinks

-

2

blinks

2

blinks

2

blinks

(green)

-

2

blinks

-

-

-

(red)

1

blink

-

3

blinks

4

blinks

5

blinks

LED 3

(green)

-

1

blink

-

-

-

Symptom Cause Corrective action

SA fan overcurrent failure

EA fan overcurrent failure

Fan drive

voltage failure

(Undervoltage)

Fan drive

voltage error

(Overvoltage)

SA fan operation failure

Overcurrent occurred

at the SA fan motor.

SA fan motor malfunction

Large circuit board

malfunction

Overcurrent occurred

at the EA fan motor.

EA fan motor malfunction

Large circuit board

malfunction

The power supply

voltage is low (150 V

AC or lower).

Large circuit board

malfunction

The power supply

voltage is high (320 V

AC or higher).

Large circuit board

malfunction

The SA fan does not

rotate properly.

SA fan motor wire

connection error

SA fan motor malfunction

SA fan motor sensor

malfunction

Large circuit board

malfunction

Turn off the power supply, wait more than 5

minutes, and then turn it on again.

Check the coil resistance of the fan motor.

If it has a defect, replace the fan motor.

Replace the circuit board if none of above

related actions works.

Turn off the power supply, wait more than 5

minutes, and then turn it on again.

Check the coil resistance of the fan motor.

If it has a defect, replace the fan motor.

Replace the circuit board if none of above

related actions works.

Check the power supply voltage.

(220-240 V AC 50 Hz)

Replace the circuit board if none of above

related actions works.

Check the power supply voltage.

(220-240 V AC 50 Hz)

Replace the circuit board if none of above

related actions works.

Check whether the fan turns by hand.

Check the wiring of the connector (CN6) on

the circuit board and the fan motor.

Check the coil resistance of the fan motor.

If it has a defect, replace the fan motor.

Check the signal voltage of the fan motor sensor. If it has a defect, replace the fan motor.

Replace the circuit board if none of above

related actions works.

In case multiple errors have occurred at the same time, each LED will blink simultaneously.

When reconnecting the power supply, wait more than 5 minutes after power-off, and then turn it on again.

─17─

Page 18

LED 1

LED 1 1

LED 2

LED 3

(red)

-

2

blinks

-

(green)

blinks

blinks

2

-

2

(red)

-

6 or 7

blinks

-

(green)

5

blinks

-

6 or 7

blinks

9

blinks9 blinks9 blinks9 blinks

Symptom Cause Corrective action

EA fan operation failure

SA fan motor

sensor failure

EA fan motor

sensor failure

Communication

failure between

the circuit

boards 1

The EA fan does not

rotate properly.

EA fan motor wire

connection error

EA fan motor malfunction

EA fan motor sensor

malfunction

Large circuit board

malfunction

Wire connection error

of SA fan motor sensor

SA fan motor sensor

malfunction

Large circuit board

malfunction

Wire connection error

of EA fan motor sensor

EA fan motor sensor

malfunction

Large circuit board

malfunction

Connection error

between the circuit

boards

The external signal

wires and power supply cable are too close.

Connection error of

transformer

Transformer malfunction

Connection error of

reactor

Check whether the fan turns by hand.

Check the wiring of the connector (CN7) on

the circuit board and the fan motor.

Check the coil resistance of the fan motor.

If it has a defect, replace the fan motor.

Check the signal voltage of the fan motor sensor. If it has a defect, replace the fan motor.

Replace the circuit board if none of above

related actions works.

Check the wiring of the connector (CN8) on

the circuit board and the fan motor sensor.

Check the signal voltage of the fan motor sensor. If it has a defect, replace the fan motor.

Replace the circuit board if none of above

related actions works.

Check the wiring of the connector (CN9) on

the circuit board and the fan motor sensor.

Check the signal voltage of the fan motor sensor. If it has a defect, replace the fan motor.

Replace the circuit board if none of above

related actions works.

Check the connections of the connectors

(CN10, CN15) on the circuit boards.

Keep the wires for fan speed and bypass

condition selections more than 10 cm away

from the power supply cable.

Check the connection of the connectors

(CN2, CN14) on the circuit boards.

Check the output of the transformer. If it has

a defect, replace the transformer.

Check the connection of the connectors

(CN4, CN5) on the circuit board.

Reactor malfunction Check the resistance of the reactor. If it is

open, replace the reactor.

Circuit boards malfunction

Replace both circuit boards if none of above

related actions works.

1 Each LED does not blink simultaneously in some cases.

In case multiple errors have occurred at the same time, each LED will blink simultaneously.

When reconnecting the power supply, wait more than 5 minutes after power-off, and then turn it on again.

─18─

Page 19

LED 1

(red)

3

blinks

4

blinks

5

blinks

8

blinks

LED 1 1

LED 2

LED 3

(green)

(red)

(green)

---

---

---

---

Symptom Cause Corrective action

Damper failure Damper plate opera-

tion error

Remove the rod, and then check whether

the damper plate moves by hand.

For removing the rod, open the maintenance

cover and remove the guards from the unit.

Wire connection error

of the damper unit

Check the wiring of the connectors (CN3,

CN17) on the circuit boards and the damper

unit.

Connection error

between the circuit

Check the connection of the connectors

(CN10, CN15) on the circuit boards.

boards

OA thermistor

failure

RA thermistor

failure

External device error

(when the

switch SW 1-2

is ON)

Connector connection

error of thermistor

Thermistor malfunction

Connector connection

error of thermistor

Thermistor malfunction

The following conditions developed.

•

OA temperature is

still -10°C or lower, 60

minutes after the TM4

Check the wiring of the connector (CN16) on

the circuit board and the thermistor.

Check the resistance of the thermistor.

If it has a defect, replace the thermistor.

Check the wiring of the connector (CN16) on

the circuit board and the thermistor.

Check the resistance of the thermistor.

If it has a defect, replace the thermistor.

When external devices are connected,

check the external devices.

When external devices are not connected,

check the switch SW 1-2.

8,9 output started.

•

OA temperature is 15

°C or higher within 15

minutes after the TM4

8,9 output started.

In case multiple errors have occurred at the same time, each LED will blink simultaneously.

When reconnecting the power supply, wait more than 5 minutes after power-off, and then turn it on again.

LED displays (Normal)

LED 1

LED 1 1

LED 2

(red)

Lit

2

-

LED 3

(green)

(red)

(green)

---

Lit

2

--

Power supplying to the circuit board Lit when the power is supplying to the circuit

Trial operation Lit during trial operation (SW 1-1 ON).

Contents Descriptions

board.

- - Lit - SA fan operation Lit during the SA fan operation.

- - - Lit EA fan operation Lit during the EA fan operation.

2 When one of LED 1 and LED 11 is blinking (during an error), the other one will be unlit.

All LEDs are temporarily lit just after power-on.

─19─

Page 20

When the unit does not operate or operates irregularly

No. Symptom Cause Corrective action

1 The fans do not

operate.

Power is not supplied to the unit. Check the power supply.

(200-240 V AC 50 Hz)

Power supply voltage is out of rated

range.

• Improper connection or wiring of the

external signals.

• The type of external signals does not

match the connected terminal block.

Check the power supply.

(220-240 V AC 50 Hz)

Check the connections of the external signal

wires and the terminal blocks (TM2, TM3).

TM2 1-4 and TM3 5 are for fan speed selection.

TM3 PB is for bypass condition selection.

TM3 V is for ventilation priority mode.

The type of external signals is incorrect.

Check the type of external signals.

(Uncharged a-contact)

The external device signals are not input. Check the external devices.

The signal cables from the external devices are longer than specifi ed.

Check the wiring length of the signal

cables. (Make sure the wiring length from

the external devices is within 20 m.)

The external signal wires and the power

supply cable are too close.

Keep the wires for fan speed and bypass

condition selections more than 10 cm

away from the power supply cable.

2• The fans do not

stop.

•

The fan speed

does not change.

Malfunction of the circuit board, or the fan

motor

The trial operation switch SW 1-1 is ON. Check the trial operation switch SW 1-1.

The external device signals are input. Check the external devices.

The external signal wires and the power

supply cable are too close.

See the "Checklist of LED failure displays"

(page 17).

Keep the wires for fan speed and bypass

condition selections more than 10 cm

away from the power supply cable.

The signal cables from the external devices are longer than specifi ed.

Check the wiring length of the signal

cables. (Make sure the wiring length from

the external devices is within 20 m.)

3 Air volume chang-

es by itself.

The function setting switch SW 1-7

(Automatic air volume increasing during

bypass setting) is ON.

If energy recovery ventilation mode is au-

tomatically switched to bypass ventilation

with the switch SW 1-7 is ON, fan speed

will increase 1 step higher than its present

speed (with a summer criteria).

If the operation mode is switched to en-

ergy recovery ventilation, fan speed will

return to its original speed.

Refer to 7. (1) (page 10).

(This is not a failure.)

4 The SA fan pe-

riodically stops

operating.

When -15°C < OA temperature -10°C,

•

the SA fan regularly stops for 10 minutes

to prevent the Lossnay core from freez-

Refer to 7. (1) (page 11).

(This is not a failure.)

ing.

• When OA temperature is -15°C or lower,

The SA fan stops to prevent the Lossnay

core from freezing.

─20─

Page 21

No. Symptom Cause Corrective action

5 The SA fan pe-

riodically stops

operating, and the

EA fan air volume

decreases.

6 After operation

has been stopped,

the fan continues

to run for a while.

When OA temperature is -15°C or lower,

the SA fan stops operating to prevent the

Lossnay core from freezing.

Then, the EA fan runs at speed 5 if the

switch SW 1-3 is ON.

The function setting switch SW 1-2

(Operation monitor output with delay function) is ON.

Refer to 7. (1) (page 11).

(This is not a failure.)

When the switch SW 1-2 is ON, the fan

continues to operate for 3 minutes after

Lossnay operation has been stopped.

Refer to 7. (4) (page 13).

(This is not a failure.)

7 The damper plate

does not operate.

When OA temperature is 8°C or lower, energy recovery ventilation mode is turned on.

Check the OA temperature.

Trial operation switch SW 1-1 is ON. Turn off the trial operation switch SW 1-1.

When the bypass

condition selection signal (TM3

PB, V) is being

used.

Malfunction of the circuit board, or the

damper motor

The type of external signals does not

match the connected terminal block.

The type of external signals is incorrect.

See the "Checklist of LED failure displays"

(page 17).

Check the connections of the external sig-

nal wires and the terminal blocks (TM2,

TM3). (TM3 PB or V is for bypass condi-

tion selection)

Check the type of external signals.

(Uncharged a-contact)

8 Operation moni-

tor or malfunction

monitor is not correctly output.

9 LED 1 on the cir-

cuit board is not lit

in spite of power

supplying.

The external device signals are not input. Check the external devices.

The signal cables from the external devices

are longer than specifi ed.

Check the wiring length of the signal

cables. (Make sure the wiring length from

the external devices is within 20 m.)

The external signal wires and the power

supply cable are too close.

Keep the wires for fan speed and bypass

condition selections more than 10 cm

away from the power supply cable.

The function setting switch SW 1-4

(Ventilation priority mode during ventilation setting input on) is ON.

When the switch SW 1-4 and TM3 V input

is ON, operation mode is fi xed in energy

recovery ventilation.

Refer to 7. (2) (page 11).

The connected terminal block is incorrect.

•

• Check the connections of the terminal

blocks (TM4).

• Connection error

• The function setting switch SW 1-2 or

SW 1-5 is not set to ON.

• Check the switch SW 1-2 (Operation

monitor output with delay function) or

SW 1-5 (Operation monitor output).

Connection error of the power supply lead

wires

Check the wiring of the connector (CN1)

and the power supply terminal block

(TM1) on the circuit board.

Connection error of the transformer Check the connection of the connectors

(CN2 and CN14) on the circuit board.

Transformer malfunction Check the transformer output. If it has a

defect, replace the transformer.

Disconnection of the fuse Replace the circuit board.

Malfunction of the small circuit board Replace the circuit board if none of above

related actions works.

─21─

Page 22

Temperature and thermistor resistance table

Temperature

(°C)

-30

-20 32.8 18 6.5

-19 31.3 19 6.2

-18 29.8 20 6.0

-17 28.4 21 5.8

-16 27.1 22 5.6

-15 25.9 23 5.4

-14 24.7 24 5.2

-13 23.5 25 5.0

-12 22.5 26 4.8

-11 21.5 27 4.7

-10 20.6 28 4.5

-9 19.6 29 4.3

-8 18.8 30 4.2

-7 18.0 31 4.0

Resistance value (kΩ)

(TYP)

53.9 -

∞

Temperature

(°C)

16 7.0

17 6.7

Resistance value (kΩ)

(TYP)

-6 17.2 32 3.9

-5 16.4 33 3.8

-4 15.7 34 3.6

-3 15.1 35 3.5

-2 14.4 36 3.4

-1 13.9 37 3.3

0 13.3 38 3.2

1 12.8 39 3.1

2 12.2 40 3.0

3 11.7 41 2.9

4 11.2 42 2.8

5 10.8 43 2.7

6 10.4 44 2.6

7 9.9 45 2.5

8 9.5 46 2.4

9 9.2 47 2.4

10 8.8 48 2.3

11 8.5 49 2.2

12 8.1 50 2.1

13 7.8

14 7.5 90 0-0.7

15 7.3

─22─

Page 23

9. Overhaul procedure

Work precautions

• When touching the electric components such as circuit boards and fan motors, do not touch the components

for more than 5 minutes after power-off, and then start servicing.

• Before replacing parts, repair troubled sections according to the instructions described in the troubleshooting.

• When servicing, always keep proper footing.

• When servicing, make sure that the cord is pulled out of the outlet, or the power supply isolator is off if no

mains connector is built in the product, so as no electrical shock or injury to occur. Pay suffi cient attention

when working on the product.

• Always connect the power wire properly.

• After completing repairs, confi rm that the main unit operates normally.

• Always wear gloves when servicing.

Part names used in the following text correspond to those listed in the parts catalog.

(1) Turning power off

Shutdown the unit.

Turn off the power supply isolator on the distribution board.

Precaution

All supply circuit must be disconnected, and do not touch

the components for more than 5 minutes, before obtaining access to the terminal devices.

(2) Fan parts

Open the maintenance cover.

Maintenance cover

Unscrew the fi xing screws (25 PTT screws 4 x 8, indicated by ) for the casing (upper).

Unscrew the fi xing screws (four screws indicated by , and two special screws indicated by ) for the guards.

Precaution

DO NOT REMOVE the maintenance cover, although the picture shows the unit without the cover for easy understanding. When you remove the casing (upper), close the maintenance cover after unscrewing all the screws.

Casing (upper)

─23─

Guard

(Maintenance cover)

Page 24

Remove the casing (upper).

Air Exhaust (EA) fan

Unscrew the screws (two PTT screws 4 x 8, indicated by

) for the connector cover next to the EA fan.

EA fan SA fan

These parts are drawn translucently to show inner parts.

Disconnect all the connectors for the fans.

Unscrew the screws (six PTT screws 5 x 10, indicated

by ).

EA fan

Connectors for the EA fan and SA fan

Power supply wiring

Signal wiring

─24─

Page 25

Air Supply (SA) fan

Unscrew the screws (six PTT screws 5 x 10, indicated

by ).

(3) Circuit board parts

Unscrew the screws (four screws, indicated by ) for the

control cover.

When replacing the lead wires or damper parts, unscrew the fi xing screws (two PTT screws 4 x 8, indicated

by ) for the fi x plate.

Fix plate

Lead wires

(power)

Lead wires

(signal)

*GM=Geared Motor

Lead wires

(GM)

Transformer Reactor

─25─

Terminal blockCircuit board

Page 26

(4) Lossnay core

Unscrew the screws (two screws, indicated by ) for the core holder.

Core holder

Draw the Lossnay core from the unit by holding the

handles.

Lossnay core Handles

(5) Damper parts and Damper motor

Remove the fi x plate for the lead wires and disconnect the wires from the circuit board. (Refer to (3) (page 25)).

Unscrew the screws (two screws, indicated by ) for the damper, and draw the damper from the unit.

Damper GM cover

─26─

A

B

Page 27

Unscrew the screws (three screws, indicated by ) for

the GM cover.

Remove the GM cover.

Unscrew the screws (two screws, indicated by ) for the

damper motor.

GM cover

When assembling

Assemble the unit in the reverse order of disassembly.

Always make sure that the unit works properly when

reassembled.

Damper motor (GM)

─27─

Page 28

10. Parts catalog

Please note the following when using the parts catalog.

1. When ordering parts, always indicate the part number, part name, and the number of

parts required.

2. Parts are not always available, and it may take time for you to receive them.

3. There may be specifi cation improvements.

4. Specifi cations are correct as of August 2009.

5. Parts marked are critical for safety. To maintain safety and performance, always

replace these parts with the parts prescribed.

6. The numbers that are circled in the exploded view are the same as the reference

number for the part being indicated.

Description of screw abbreviations

Screw

Abbreviation Description

PC screw Cross recess fl at head machine screw

PRC screw Cross recess oval head machine screw

PP screw Cross recess pan head machine screw

SW · PP screw Cross recess pan head screw with spring washer

PPT screw Cross recess tapping screw

PCT screw Cross recess fl at head tapping screw

PTT screw Cross recess truss head tapping screw

PT screw Cross recess truss head machine screw

SET screw Slotted head stop screw

SQ · SET screw Square head stop screw

P · SET screw Pan head stop screw

PMT screw Primer truss head screw

HS · SET screw Hexagon head stop screw

P · R · W screw Cross recess round wood screw

4

Screw diameter Length

×

16

P · C · W screw Cross recess fl at head wood screw

P · R · C · W screw Cross recess round and fl at wood screw

R · W screw Slotted round wood screw

PW · PP screw Cross recess pan head screw with small washer

SW-PW · PP screw Cross recess pan head machine screw with spring washer and fl at washer

─28─

Page 29

Model LGH-50RSDC-E

No. Parts No. Name of part Critical Remarks Price

1. H00 000 487 PTT screw 4×8 99

2. R50 028 610 Flange 4

3. Y55 001 223 Cord clip 1

4. H00 000 244 PT screw 6×12 4

5. R50 095 380 Hanger 2

6. Y50 123 369 Wiring diagram 1

7. R50 399 223 Cord clip 2

8. R50 399 224 Cord clip 8

9. K81 540 384 Fix plate 2

10. H00 000 390 PT screw 5×10 4

11. K81 540 385 Fix plate 2

12. Y50 123 722 Fix piece 3

13. Y50 057 344 Wire 1

14. Y50 123 721 Maintenance cover 1

15. Y50 123 830 Casing(upper) 1

16. Y50 123 717 Core holder 1

17. Y50 123 723 Guard 2

18. H00 000 332 PTT screw 4×10 4

19. A33 391 045 Special screw 4×12 2 Black

20. Y50 123 345 Fix piece 3

21. Y50 123 344 Hinge 3

22. Y50 123 724 Lossnay core 2

23. Y50 123 730 Filter 4

Q'ty

pcs/unit

for safety

29

Page 30

1

*

*

1

2

3

4

5

10

11

6

4

5

2

*

1

10

9

8

7

2

9

12

10

11

10

2

*

1

18

19

16

17

23

22

15

14

23

13

23

1

23

17

*

21

22

1

24pcs.

1

20

* shows accessory parts.

─30─

Page 31

Model LGH-50RSDC-E

No. Parts No. Name of part Critical Remarks Price

31. R50 488 713 Motor fix plate 2

32. Y50 123 453 Motor 1

33. Y50 031 608 Flinger 2

34. K81 417 102 U ring 2

35. M45 649 226 Bush 5

36. M35 164 224 Cord clip 10

37. Y50 123 708 Fan base 1

38. H00 056 075 Spring washer(4) 2

39. H00 189 007 PTT screw 5×10 20

40. Y50 123 720 Connector cover 1

41. D41 123 223 Lead wire clip 2

42. Y50 123 710 Connector case 1

43. Y50 123 711 Fix plate(earth) 1

44. M34 706 465 Special washer 2 φ10

45. R50 542 480 Centrifugal fan 2 φ220

46. M34 398 077 Tab washer 2

47. R50 331 067 Special nut(8) 2 Left-handed

48. Y50 123 718 Fan casing 1

49. Y50 123 709 Fix pieces 2

50. Y50 123 454 Motor 1

51. H00 172 076 Lock washer 1

52. Y50 123 712 Motor fix plate 1

53. Y50 123 713 Separator 1

54. Y50 123 719 Fan casing 1

Q'ty

pcs/unit

for safety

31

Page 32

35

49

36

36

37

36

34

35

1

33

40

35

35

41

41

42

1

44

43

45

1

1

48

47

46

Air exhaust fan assembly

32

1

31

1

1

39

1

38

52

1

51

36

50

31

1

38

1

39

33

39

34

A

54

1

45

44

─32─

53

47

46

Air supply fan assembly

A

49

1

Page 33

Model LGH-50RSDC-E

No. Parts No. Name of part Critical Remarks Price

61. Y50 123 732 Damper fix plate 1

62. Y50 123 727 Fix plate 1

63. Y50 123 156 Pull spring 1

64. D40 072 225 Bush 1

65. Y50 123 729 Damper 1

66. Y50 123 716 Damper support 1

67. Y50 115 225 Bush 1

68. Y50 123 726 GM cover 1

69. Y50 061 260 Damper motor (GM) 1 AC220・240V

70. R50 054 225 Special bush 2

71. Y50 123 725 GM fix plate 1

72. Y50 123 728 Rod 1

73. M31 234 089 Special bush 2

74. H00 000 003 PP screw 4×8 2

75. Y50 123 715 Control cover 1

76. Y50 123 221 Lead wire 1

77. D41 006 363 Cord band 1

78. Y50 123 172 Circuit board 1 LG-08DC-E

79. Y50 123 714 Fix plate 1

80. K83 223 225 Bush 3

81. Y50 138 216 Transformer 1 AC230V

82. Y50 123 179 Reactor 1

83. H00 000 349 PT screw 4×8 9

84. M13 100 242 Terminal block 1 3P

85. H00 154 005 PPT screw 4×12 1

86. H00 011 008 PT screw 4×8(BS) 1

87. H00 013 076 Lock washer(4) 2

88. D42 019 095 Spacer 3

89. X40 139 095 Spacer 10

90. Y50 123 733 Circuit fix plate 1

91. Y50 123 216 Lead wire(GM) 1

92. Y50 123 214 Lead wire(sigunal) 1

93. Y50 123 213 Lead wire(poewr) 1

94. Y50 123 731 Fix plate 1

Q'ty

pcs/unit

for safety

33

Page 34

61

62

63

64

66

65

67

68

69

70

7

8

70

71

1

72

73

73

10

35

83

8

79

81

80

74

80

82

80

83

84

85

86

1

36

87

88

83

89

94

90

75

76

77

78

91

1

92

93

─34─

Page 35

Printed in Japan

June, 2009

24 <MEE>

Page 36

Revision record

Revision Date Overview

U162-1

A 2009-08-19 Page 33

Parts No. of No.63 was R50 069 156.

Loading...

Loading...