Page 1

Lossnay

Models:

LGH-150RVXT-E

LGH-200RVXT-E

LGH-250RVXT-E

1509876HC8401

Installation Instructions

Page 2

Lossnay Energy Recovery Ventilator

MODELS:

LGH-150RVXT-E

LGH-200RVXT-E

LGH-250RVXT-E

English

Installation Instructions

(For use by dealer/contractor)

Contents

Safety precautions ............................................... 1

Outline drawings .................................................. 3

Before installation ................................................ 3

Standard installation examples............................4

Installation method ..............................................4

Function settings ...............................................13

Check points after installation work ................... 22

Trial operation ....................................................22

This product needs to be installed properly in order to ensure maximum functionality as well as safety.

Please make sure to read this installation manual before starting the installation.

l Installation must be performed by a dealer or installation contractor. Please note that improper installation may cause malfunction or accident.

“Operating Instructions” and this manual must be handed over to the customer after completing the installation.

Safety precautions

The following signs indicate that death or serious injury may be caused by failure to heed the precautions described below.

WARNING

Do not modify or disassemble.

Do not

disassemble

Prohibition of use in

bath or shower room

Connect the

grounding wire.

The instructions

given must be

followed.

(It could cause re, electric shock or injury.)

The Lossnay unit and remote controller should

not be installed where it is highly humid, like a

bathroom, or other wet place.

(It could cause electric shock or power leakage.)

Connect the product properly to ground.

(Malfunctioning or power leaks can cause electrical

shock.)

Use the specied power supply and voltage.

(Use of incorrect power supply or voltage could cause

re or electric shock.)

Select a place with sufcient strength and install

the main unit securely.

(It could cause injury if it falls.)

The instructions

given must be

followed.

Wiring work must be performed by qualied

professionals, and be implemented safely and

securely in accordance with the engineering

standards and the extension wiring rules for

electrical equipment.

(Poor connection or improper wiring work could cause

electric shock or re.)

Install a power supply isolator at the power supply

side as per local electrical regulations. All supply

circuits must be disconnected before obtaining

access to the terminal devices. Use the specied

cable size and connect the cables securely to

prevent disconnection when they are pulled.

(If there is a defect in the connection, there is a

possibility of re.)

Select an adequate place for the opening to

introduce outdoor air, where it will not intake the

exhaust fumes like combustion gas, or others, and

there is no risk of blockage.

(Shortage of fresh air could put the room in a state of

oxygen deciency.)

A duct made of steel must be installed with care

not to be connected electrically with metal, wire,

stainless steel plate, or others.

(It could cause re when power leakage occurs.)

Eng-1

Page 3

Safety precautions (continued)

CAUTION

Prohibited

The instructions

given must be

followed.

Do not place a burning appliance in a place where

it is exposed directly to the air from the Lossnay

unit.

(It could cause an accident as a result of incomplete

combustion.)

Do not use at a place where it is exposed to high

temperatures (40˚C or higher), naked ames, or in

environment with combustible fumes.

(It could cause re.)

Do not use in an environment such as a chemical

factory, where hazardous gases such as acidic

gases, alkaline gases, organic solvent fumes, paint

fumes, or gases containing corrosive components

are generated.

(It could malfunction.)

Do not install this product in a place where it is

exposed to ultraviolet light.

(UV may damage covering insulation.)

Put on gloves during installation.

(It could cause injury.)

Make sure the power supply isolator is turned off

on the power distribution panel when Lossnay

is not used for a long period of time after the

installation.

(It could cause electric shock, power leakage, or re as

a result of deteriorated insulation.)

Always use the specied suspension bolts,

nuts and washers or correctly rated wire / chain

hangers.

(Use of hardware with insufcient strength could result

in the product dropping.)

The outside ducts must be tilted at a gradient (1/30

or more) down toward the outdoor louvres from

Lossnay, and properly insulated.

(The entry of rain water may cause power leakage, re,

or damage to household property.)

The instructions

given must be

followed.

The control box cover must be closed after the

installation.

(Dust or humidity may cause power leakage or re.)

When connecting external devices (electric heater,

damper, lamp, monitoring unit, etc.) using output

signals of the Lossnay unit, make sure to install

safety equipment for the external devices.

(It could cause re, damage, etc. without safety

equipment.)

Select a duct heater in compliance with local and

national laws, ordinances, and standards.

Select a duct heater that has obtained the CE mark.

Install the duct heater separated from the product

by a distance of 2 m or more.

(Failure to do so may result in re or equipment

damage due to the transmission of residual heat from

the heater.)

This appliance is not intended for use by persons

(including children) with reduced physical sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they

do not play with the appliance.

(This appliance can be used by children aged

from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack

of experience and knowledge if they have been

given supervision or instruction concerning use

of the appliance in a safe way and understand the

hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall

not be made by children without supervision.)

CAUTION

lWhen using the product where it is exposed to high temperatures

and humidity (40˚C or higher, RH 80% or higher), or where fog

occurs frequently, moisture is likely to condense in the core, and

may result in condensation build up in the unit. The product should

not be used under such conditions.

lOutdoor air may enter the Lossnay owing to the pressure

difference between indoor and outdoor or external winds even

when the product is not operated. It is recommended to install an

Electrically operated damper to block the outdoor air.

lIn a cold weather area, an area with strong external winds or

where fog occurs frequently, cold outdoor air, external winds or fog

may be introduced into the product when its operation is stopped. It

is recommended to install an Electrically operated damper.

lWhen using the product in an environment where there is a

window, or opening near the outdoor louvre , where insects are

likely to gather around the interior or exterior light , take note that

small insects may intrude into the product.

lIn a cold weather area, or others, dewing or freezing could occur

on the main unit, where the duct is connected, or other sections,

depending on the conditions of outdoor air and indoor temperature

and moisture, even if they are within the range of operating

conditions. Make sure to conrm the operating conditions and

other precautions, and do not use the product if dewing or freezing

is anticipated.

*Example of dewing condition - Outdoor air: -5˚C or lower, dew-

point temperature at installation place: 10˚C or higher (When the

indoor temperature is 22˚C or higher with the relative humidity

higher than 50%, or other)

Eng-2

Page 4

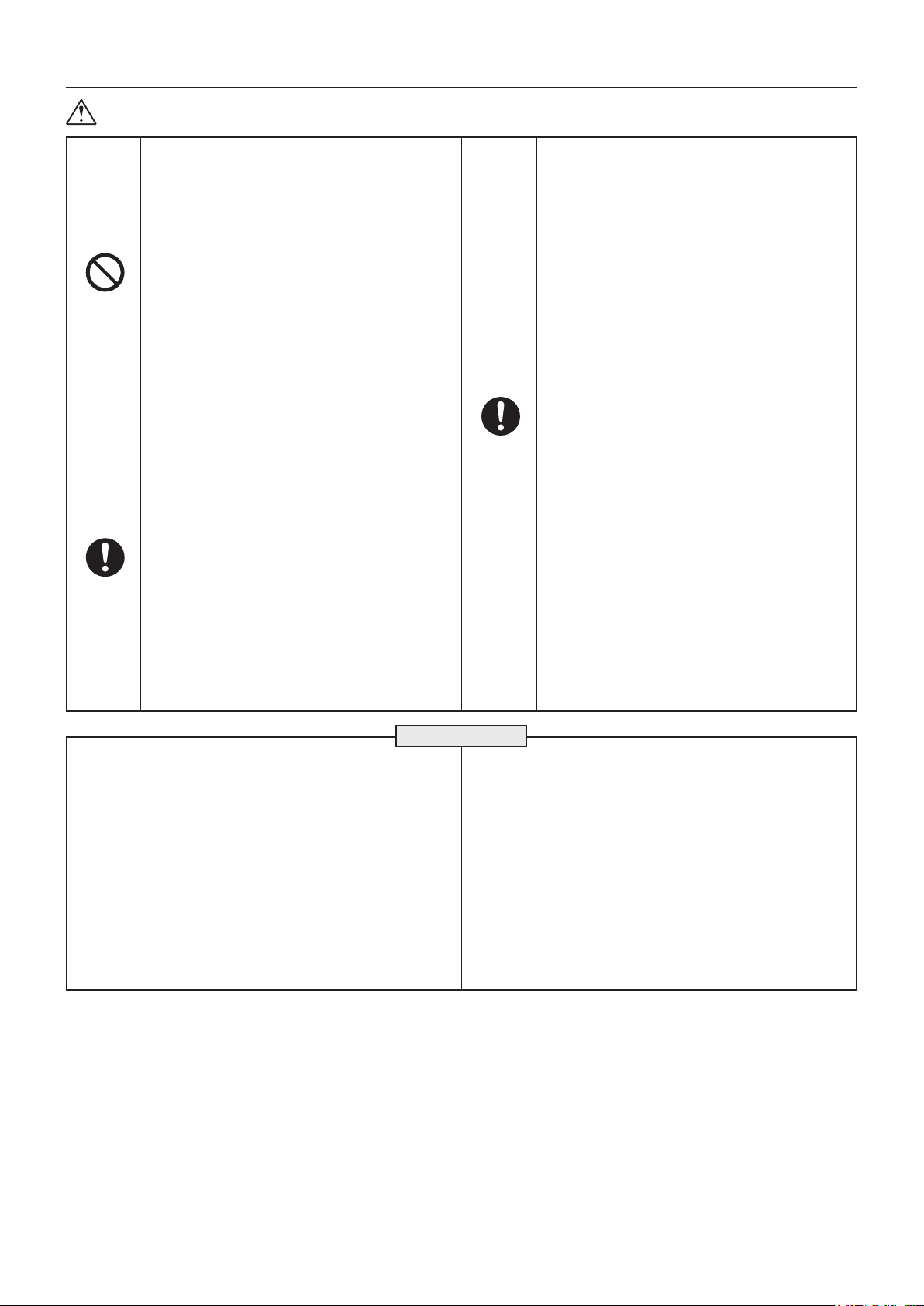

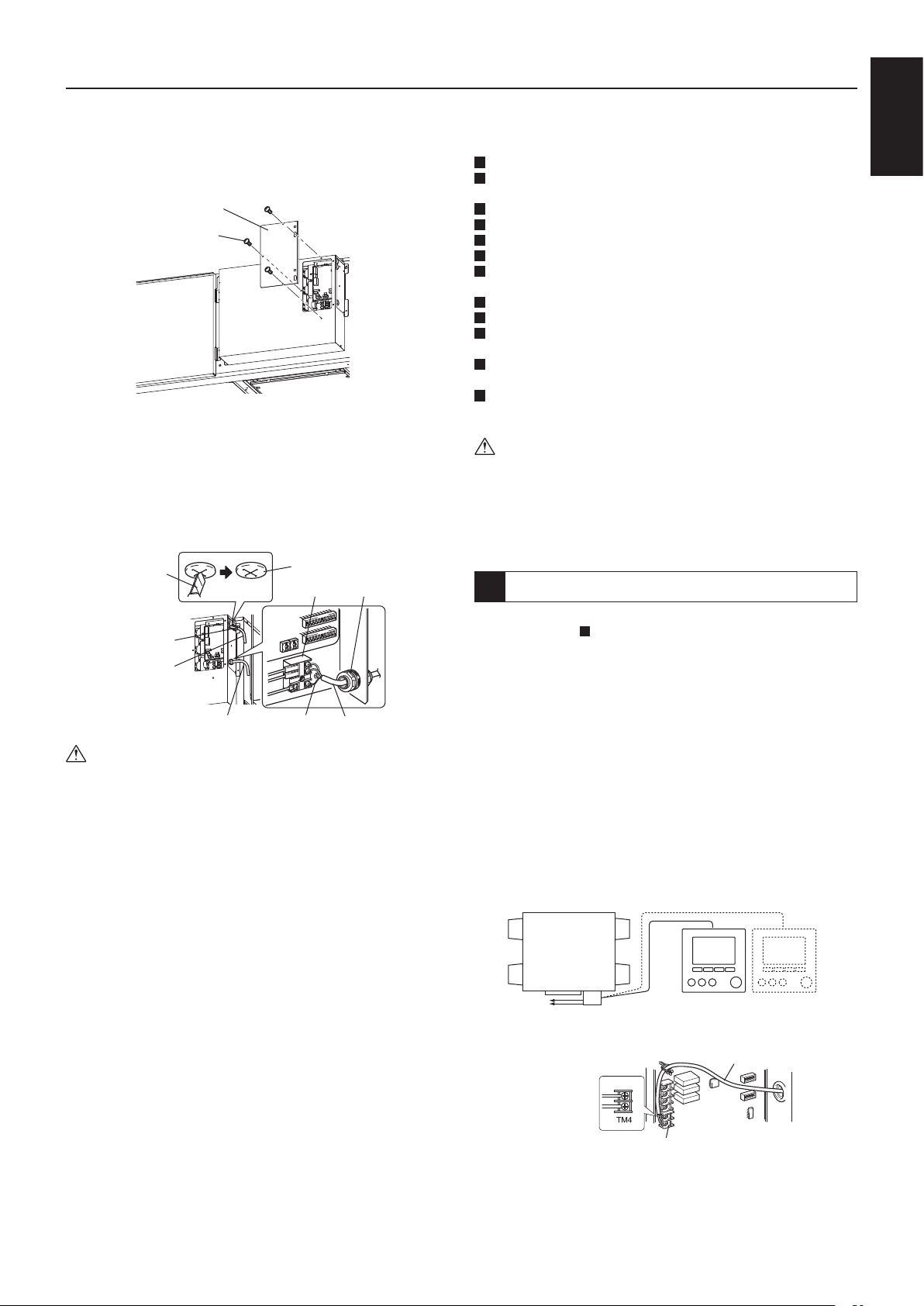

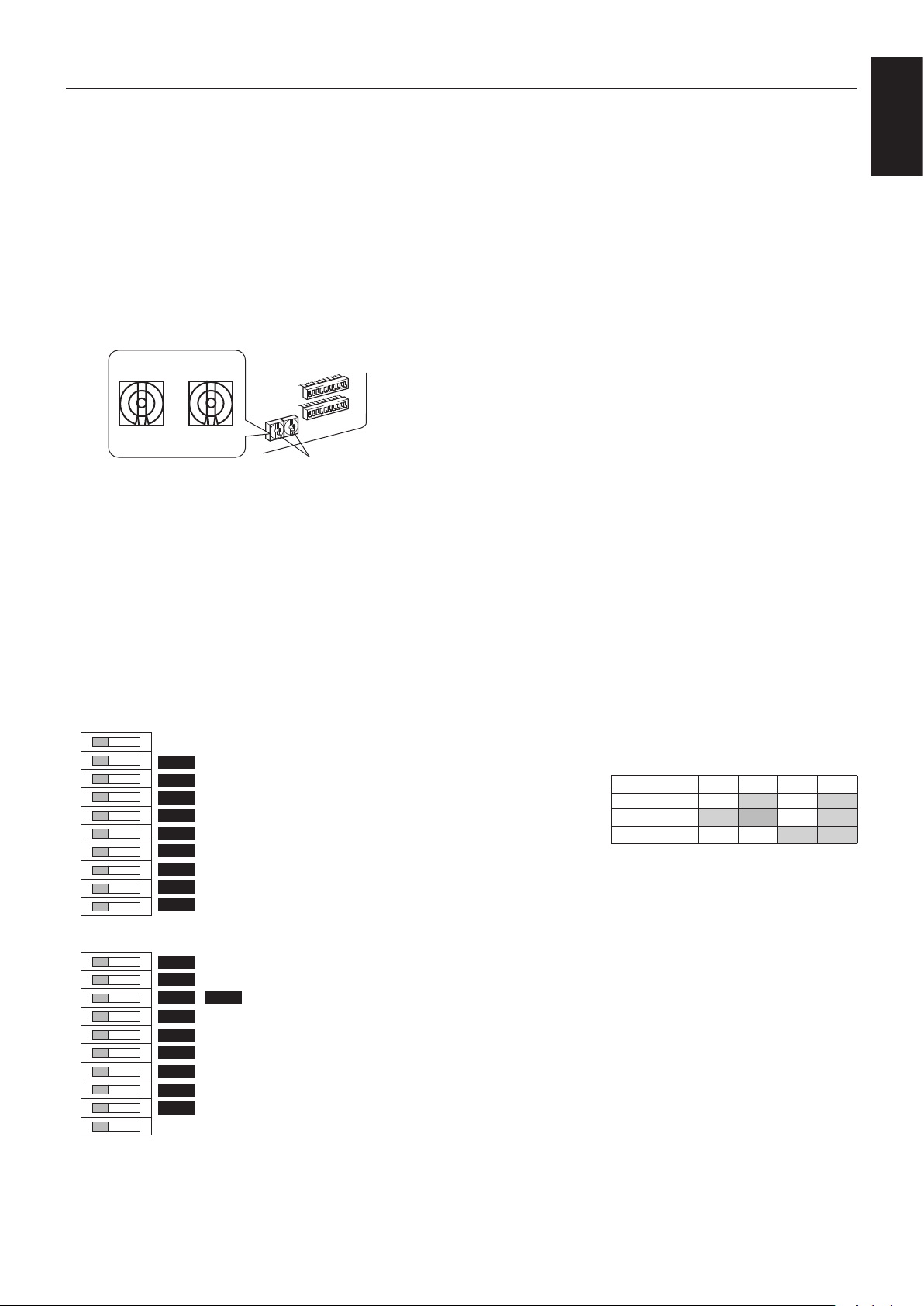

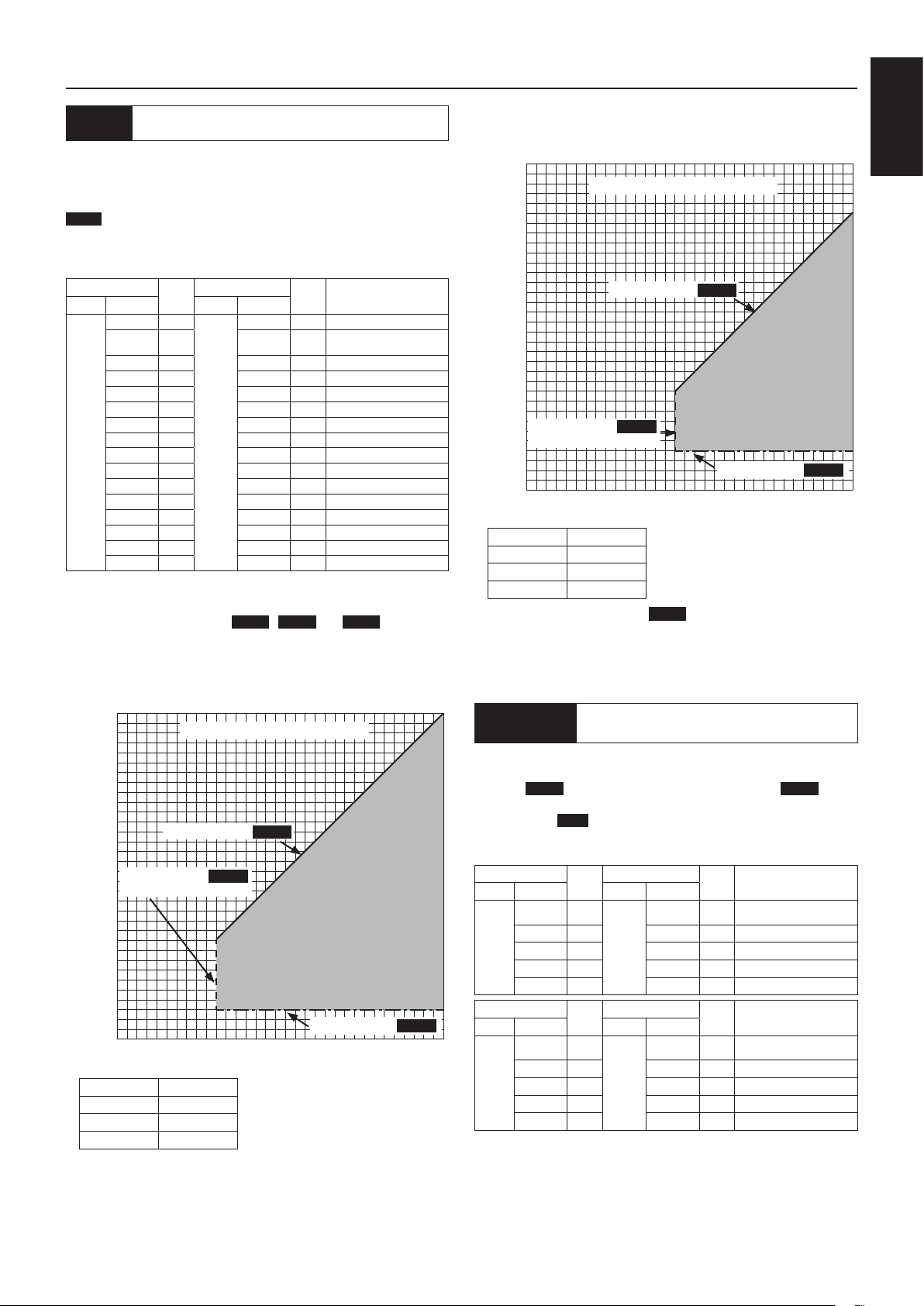

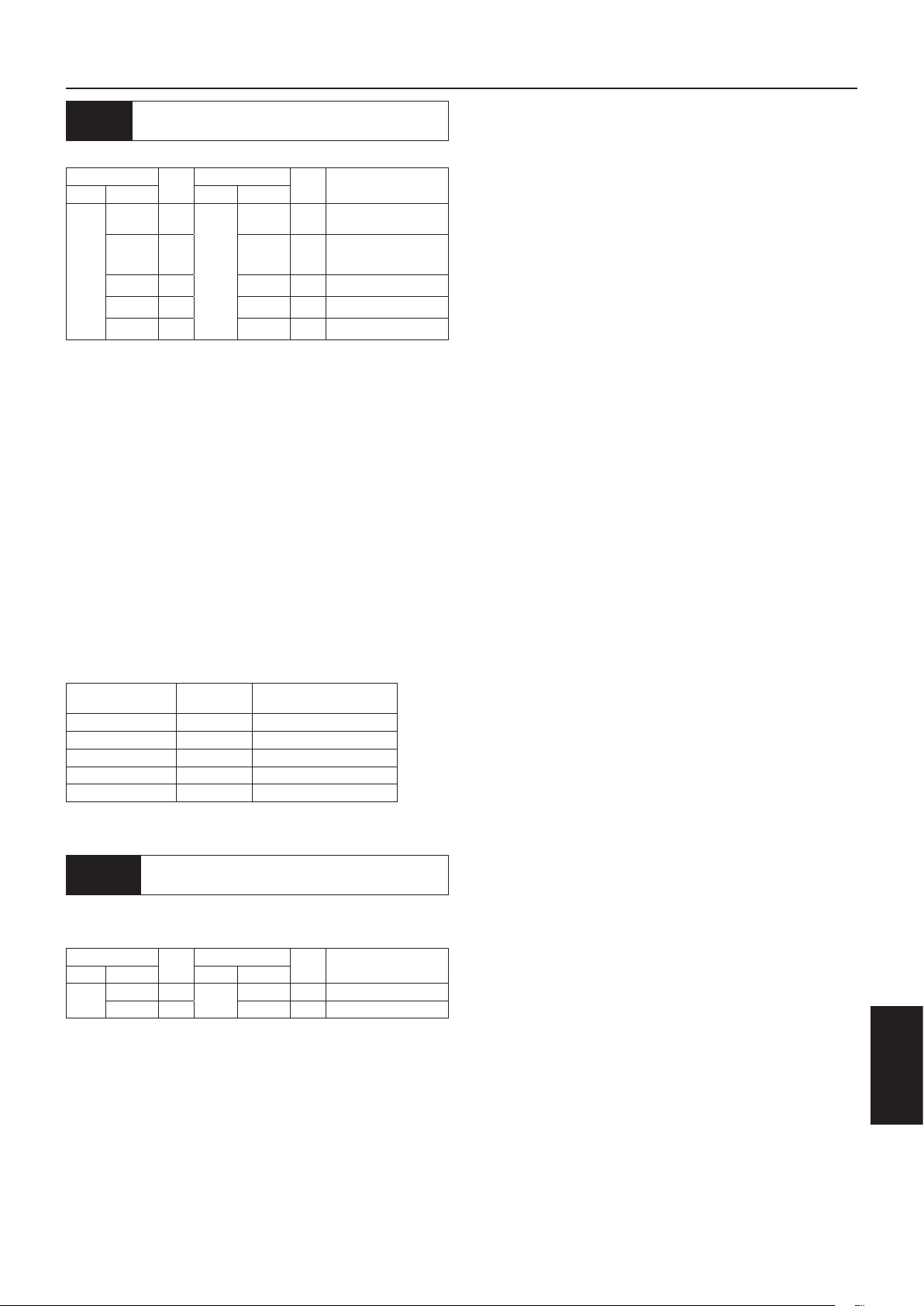

Outline drawings

250

60

Flange

By-pass damper plate

1500

Air exhaust fan (Outside)

Air exhaust fan (Inside)

Ceiling suspension xture

(6-15 X 30 oval)

Flange

English

When using φ250 duct

287

58

227

OA EA

(outside air

intake)

750

215

250

255

RA SA

(return air) (supply air)

75090

1980

945.7 945.7

Lossnay cores

By-pass damper plate

50 1450

Model Weight

LGH-150RVXT-E 156 kg

LGH-200RVXT-E 159 kg

LGH-250RVXT-E 198 kg

Reference for maintenance space

RA air lters

OA air lters

Maintenance cover

for fan (470 x 450)

Exhaust

(exhaust air

outlet)

945.7 945.7

Flange

Air supply fan (Inside)

Air supply fan (Outside)

Control box

750750115

250

250

424

500

Pipe guide

Supply

Power supply

cable opening

116

132

Accessory parts

• Mounting screws 4-8 for duct anges ................. x50

(2 pcs are spare)

560560210

440

φ

242

φ

258

Unit (mm)

1200390

Inspection opening

600 x 600

150 to 250

More than 750

Maintenance cover for

Maintenance space

600

317

- Cores

- Air lters

Before installation

- Accessory parts are in the Lossnay unit (OA duct place) together

with manuals. Please remove all accessory parts before starting

installation.

- Damper plate is xed against transportation vibration. Please make

it free before starting installation.

• Duct connecting anges (φ250) ........................... x4

• L shape pieces for 250 x 750 duct anges ........... x8

• Slim-Lossnay connection cable

(gray: two wires) ................................................... x1

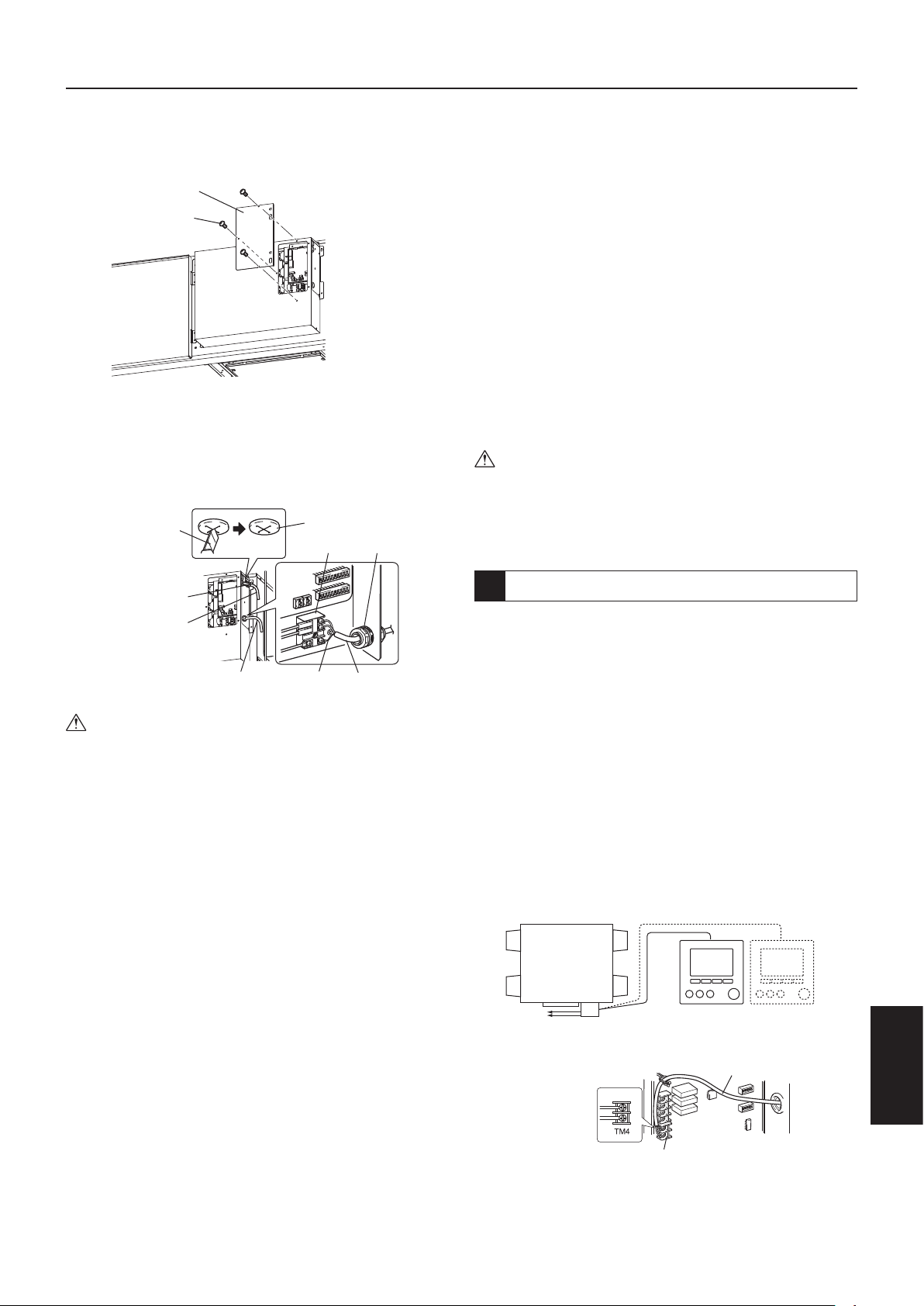

- If carrying the product into the building is difcult due to the

product’s size, it is possible to stand the product up like the picture

below.

CAUTION

• Before standing the product up, remove the Lossnay cores and

lters (See page 3 of the operating instructions.)

Eng-3

Page 5

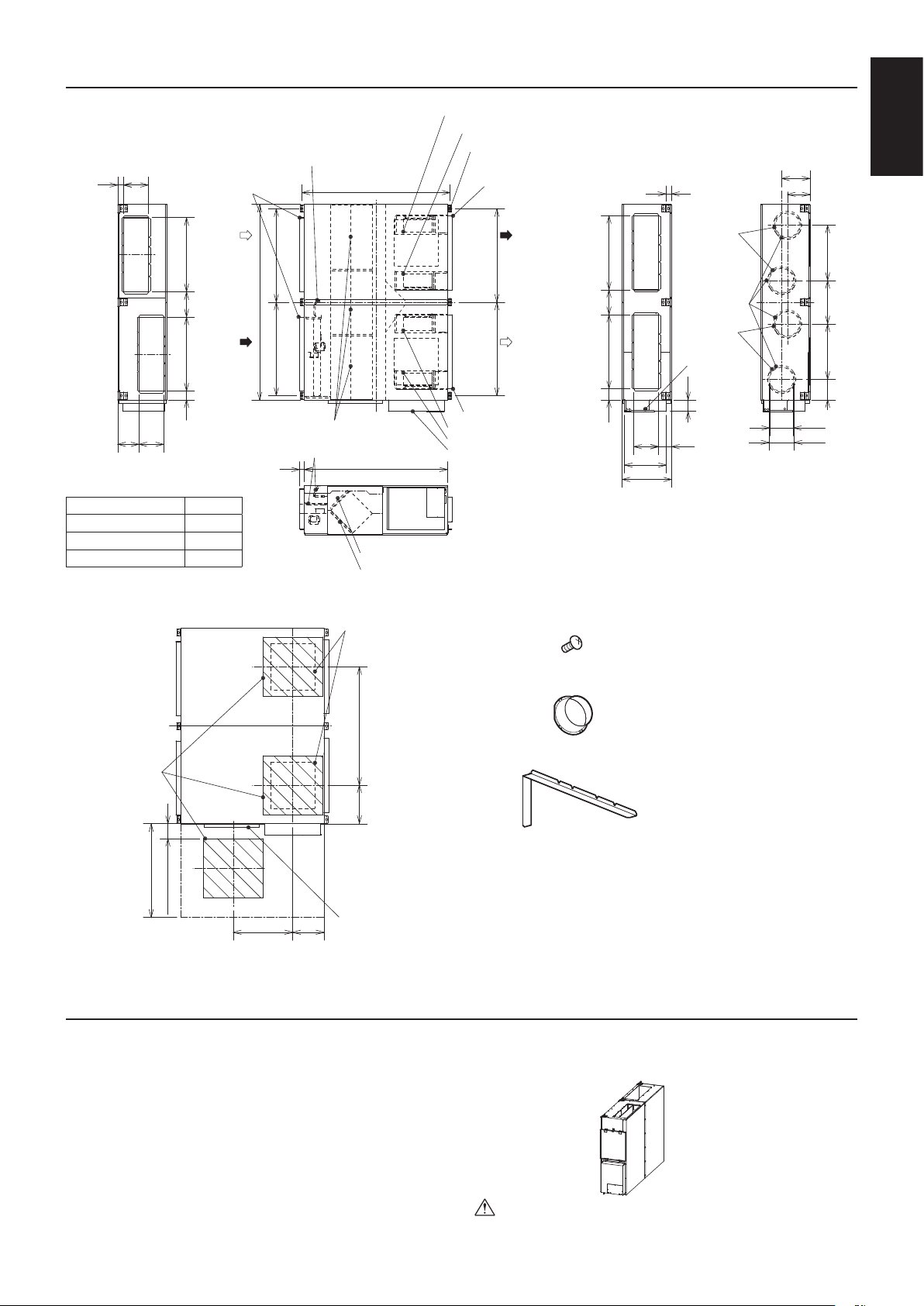

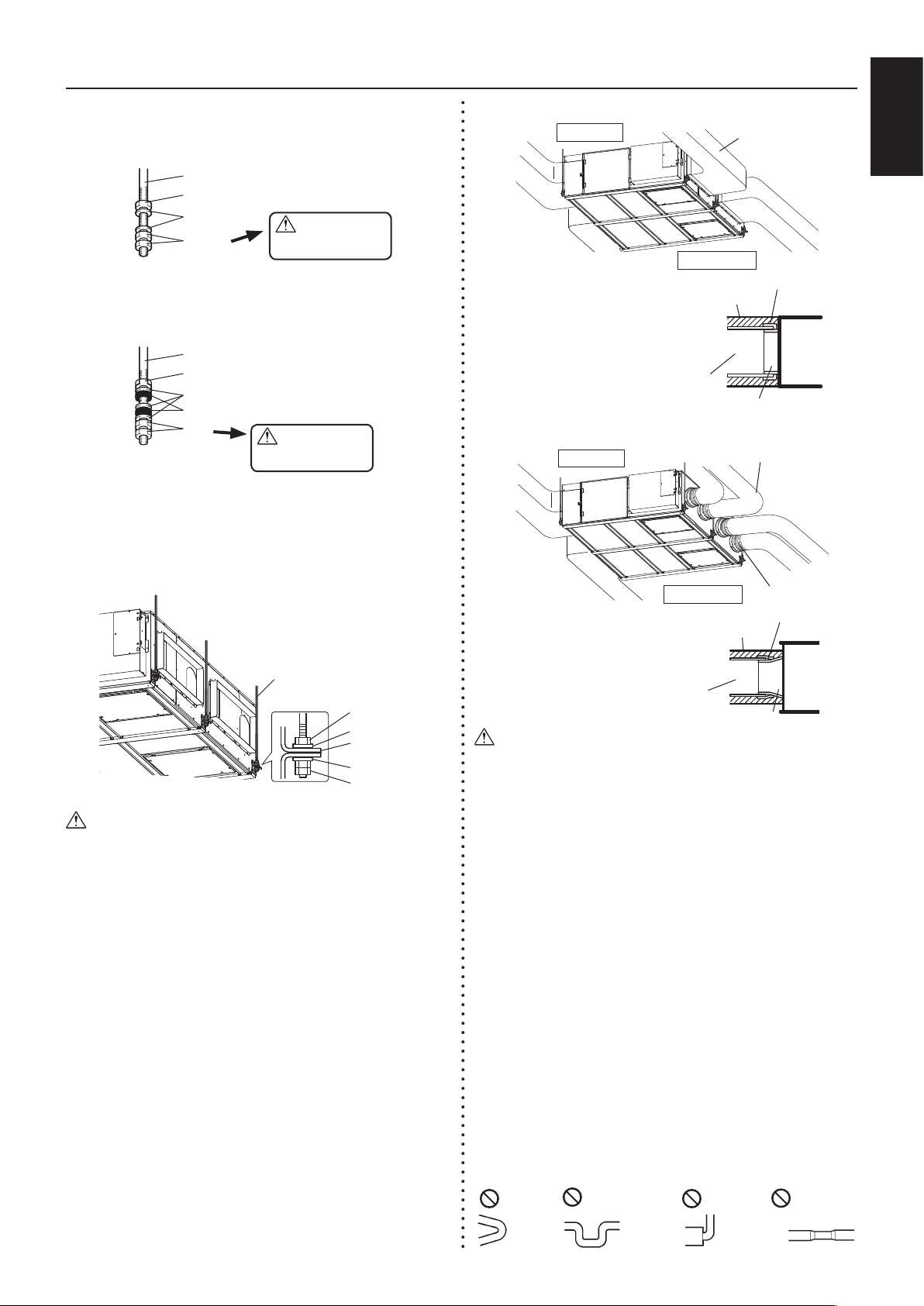

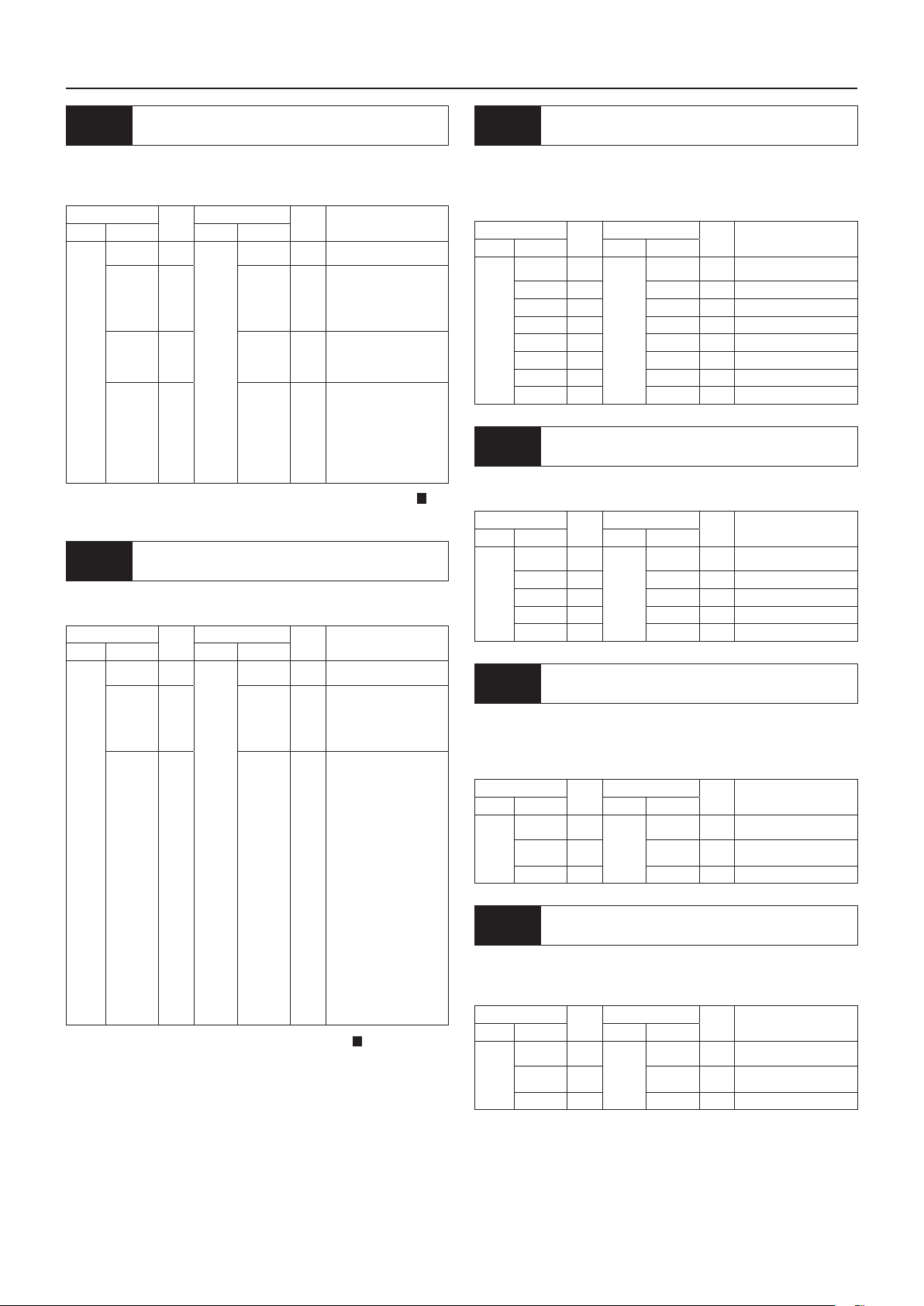

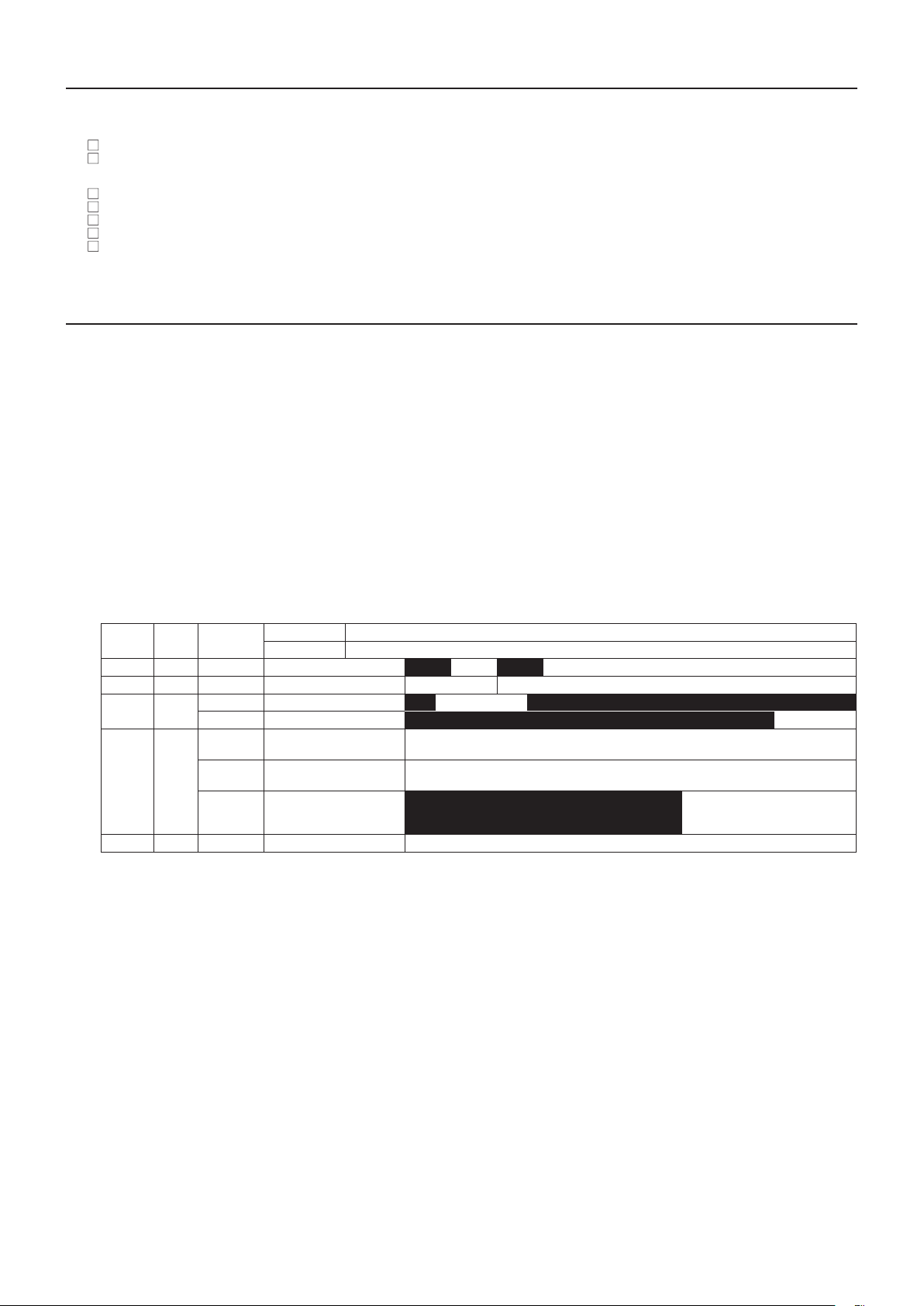

Standard installation examples

Inspection opening for

exhaust fan motors

EA

(exhaust air

outlet)

3 m or more

(recommended)

OA

(outside air

intake)

Downward gradient of duct:

1/30 or more (toward wall side) and provision of distance

in table below (to prevent rain water from seeping in)

Deep hood

(to prevent

rain water from

seeping in)

OA

(outside air

intake)

EA

(exhaust air

outlet)

Remote controller

(optional parts)

Duct

Inspection opening for

exhaust fan motors

(600 x 600)

Inspection opening

for supply fan motors

Lossnay unit

Anchor bolt (to be provided by user)

Lossnay unit

Inspection opening

for supply fan motors

(600 x 600)

Inspection opening for

Lossnay cores, lters and PCB

(600 x 600)

Inspection opening

for Lossnay cores,

lters and PCB

(600 x 600)

Maintenance space

Return air grille

(not included)

RA

(return air)

Return air grille

(not included)

Supply air grille

(not Included)

SA

(supply air)

Supply air grille

(not included)

EA

(exhaust

air outlet)

OA

(outside

air intake)

Electrically operated damper

(Protection against the intrusion of cold

air while Lossnay is stopped in winter)

(To be provided by the customer)

EA

(exhaust

air outlet)

OA

(outside

air intake)

Lossnay

unit

• In a region where there is risk of freezing

in winter, it is recommended to install an

Electrically operated damper, or the like,

in order to prevent the intrusion of (cold)

outdoor air while Lossnay is stopped.

CAUTION

• Do not install Lossnay unit vertically or on

an incline.

• Do not install Lossnay unit up-side-down.

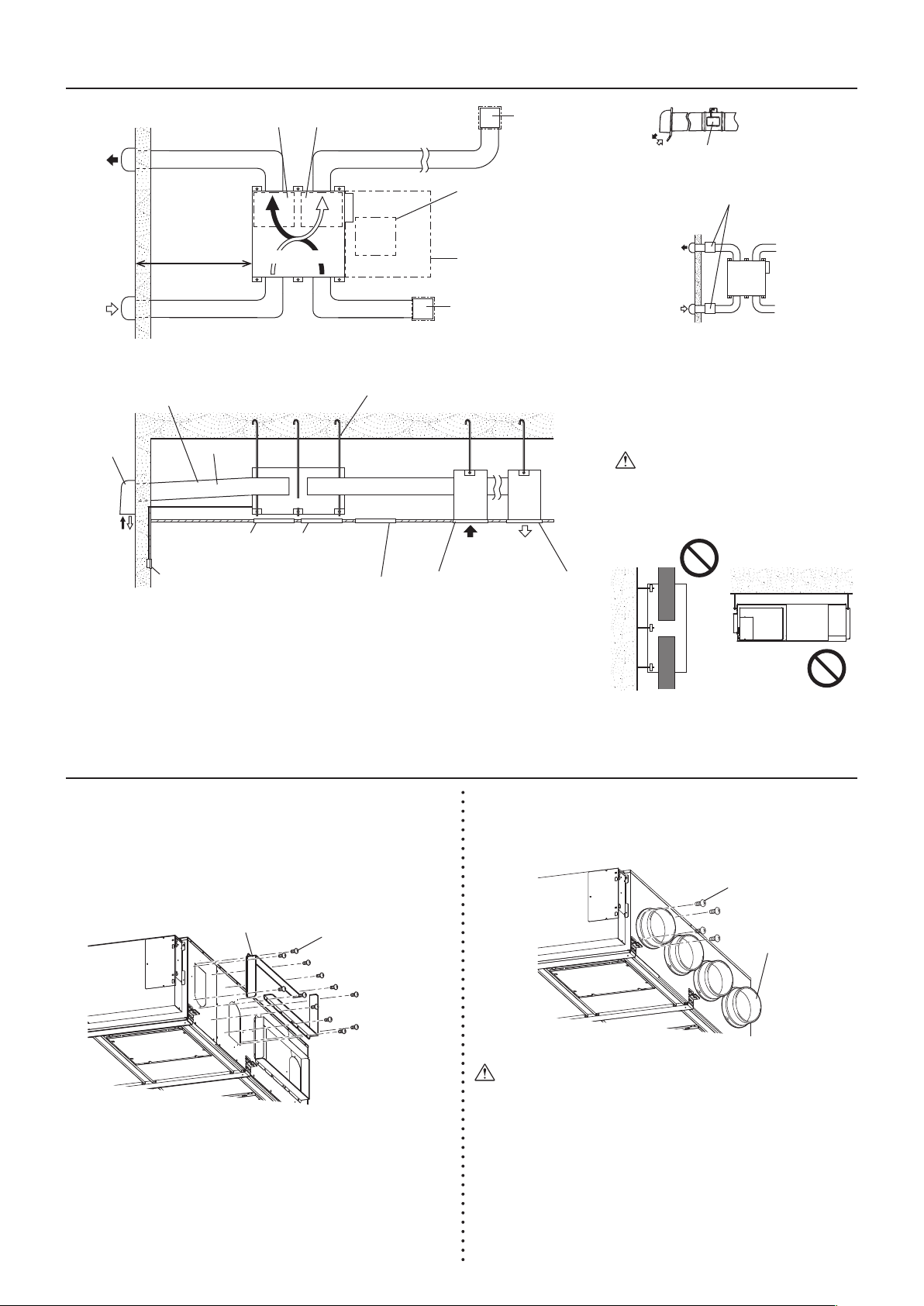

Installation method

Installing the Lossnay unit

1. Attaching the duct connecting anges

1) 250 x 750 duct anges

Use the supplied screws (size:4-8) to x L shape pieces and form

250 x 750 anges to the Lossnay unit.

L shape piece

(Accessory parts)

Mounting screw (size:4-8)

(Accessory parts)

2) φ250 duct anges

For supply and exhaust path, φ250 duct x 2 can be used. Use

the supplied screws (size:4-8) to secure φ250 duct connecting

anges to the Lossnay unit.

Mounting screw (size:4-8)

(Accessory parts)

Duct connecting ange

(Accessory parts)

CAUTION

• Before attaching the duct connecting anges, check that no

foreign matter (scraps of paper, vinyl, etc.) has found its way

inside to Lossnay unit.

Eng-4

Page 6

Installation method (continued)

English

2. Preparing the anchor bolts (M12)

Mount the washers (outer diameter of >24 mm) and nuts onto the

pre-recessed anchor bolts (M12), as shown in the gure below.

Anchor bolt (M12)

Nut

Washer

CAUTION

Nut

[When using (customer-prepared) vibration isolation rubber]

When using (customer-prepared) vibration isolation rubber, there

is a possibility of this causing a decrease in strength, so we

recommend the following type of construction.

Anchor bolt (M12)

Nut

Washer

Vibration isolation rubber

Nut

USE TWO NUTS

CAUTION

USE TWO NUTS

3. Mounting Lossnay unit

(1) Hang the ceiling suspension xtures on the anchor bolts and

adjust in such a way that Lossnay unit is level.

(2) Tighten up securely using double nuts.

250 x 750 duct anges

Room Side

φ250 duct anges

Room Side

Outdoor Side

Heat-insulating material

Outdoor duct

Duct connecting ange

Outdoor Side

Heat-insulating material

Duct

Aluminium tape

Duct

Taping

Aluminium tape

Lossnay

unit

Anchor bolt

(M12)

Nut

Washer

Ceiling suspension

xture

Washer

Nut

CAUTION

•

When suspending Lossnay unit from the ceiling, do not handle

it in such a way that force will be applied to the control box.

• Install the anchor bolts to ensure the product's weight or

earthquake load. (Correctly rated wire/chain may also be used)

4. Connecting the ducts

(1) Fasten the duct securely to the duct connecting ange, and

wrap aluminium tape (eld supply) around the joints so that

there is no air leakage.

(2) Suspend the ducts from the ceiling so that their weight will not

be applied to the Lossnay unit.

(3) The two outdoor ducts must be covered with heat-insulating

material in order to prevent condensation from forming.

Lossnay

Outdoor duct

Duct connecting ange

unit

CAUTION

• When on-site commissioning is planned, a straight duct

length more than 10xD (D=duct diameter or equivalent)

from the source of turbulence like bends, contractions and

dampers etc, to the measurement point is recommended for

correct measurement.

In the United Kingdam, on-site measurment should

therefore be measured in accordance with BSRIA guideline

(Commissioning Air System. Application procedures for

buildings AG3/89.3(2001))

•

Before attaching the ducts, check that no (debris or any other)

foreign matter (scraps of paper, vinyl, etc.) has found its way

inside the ducts.

• Do not touch the damper plate inside Lossnay unit when

connecting the ducts. (When the rectangular duct is secured

with screws, check that the screws are not collided to the

damper plate.)

• If it is expected that the ambient temperature around the place

where the Lossnay unit is installed will be high during the

summer air conditioning season, it is recommended that the

indoor duct work be covered with insulation material.

• Do not place the auxiliary blower to the exhaust side air

passage.

Do not carry out the following types of duct construction. (Doing so

could cause a drop in the air volume and generate abnormal noises.)

• Extremely

sharp bends

• Multiple bends • Bends right next

to the outlet

• Extreme reduction in

the diameter of the

connected ducts

Eng-5

Page 7

Installation method (continued)

Electrical installation

With this product, the wiring installation method will vary according to

the design of the system.

Perform electrical installation to meet local electrical regulations.

* Always use double insulated PVC cable for the transmission cables.

* Wiring work must be performed by qualied professionals.

* All supply circuits must be disconnected before obtaining access to

the terminal devices.

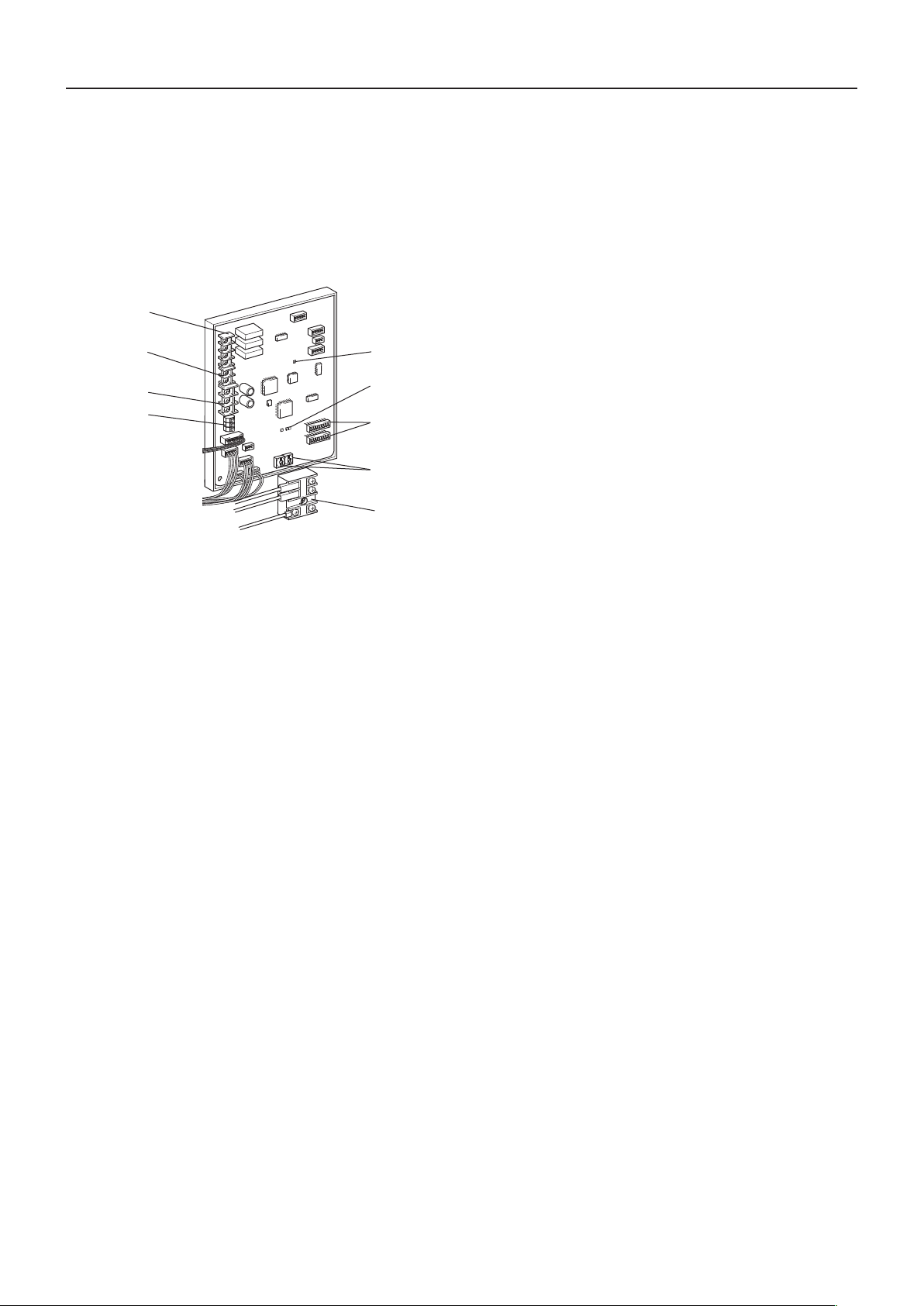

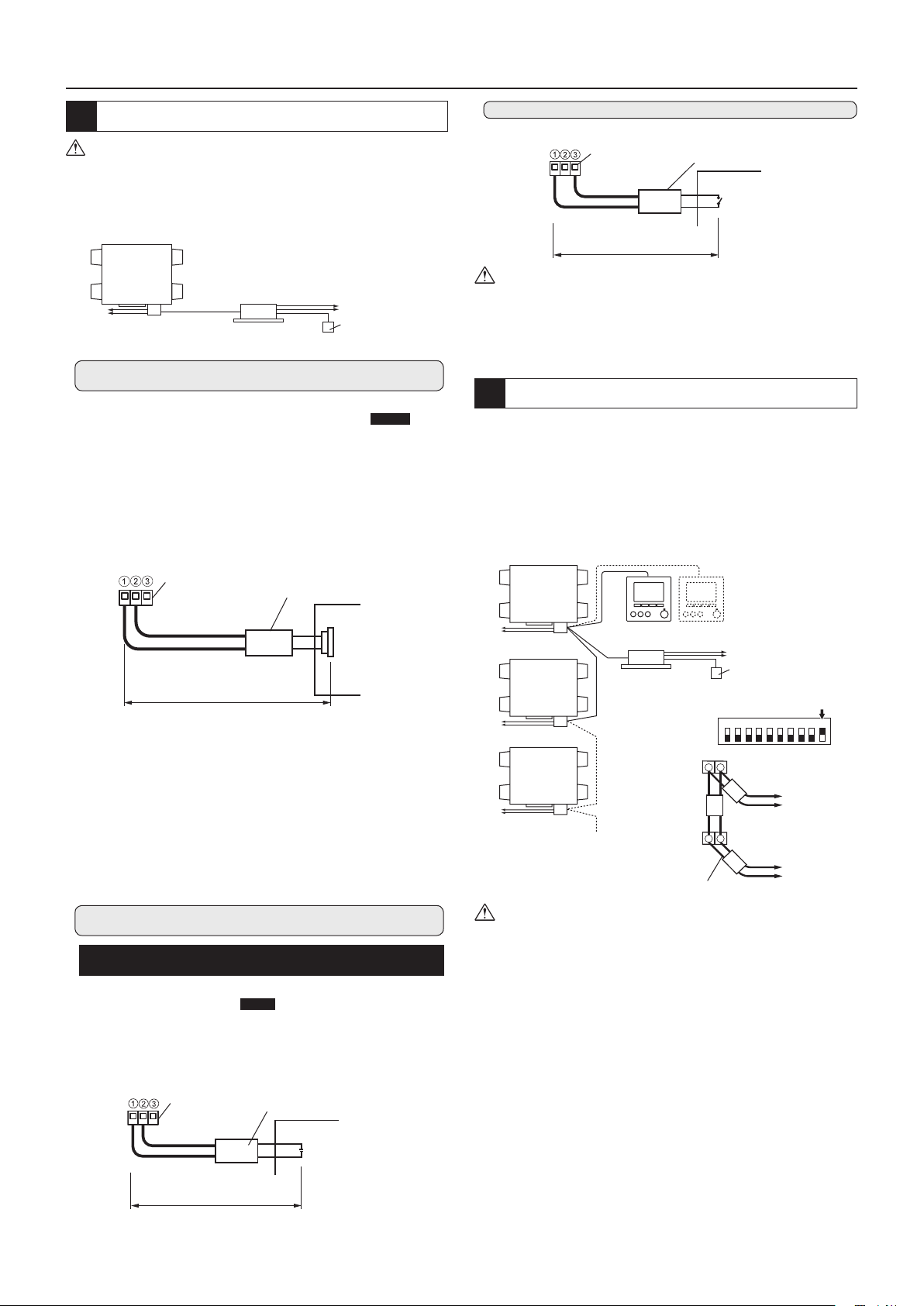

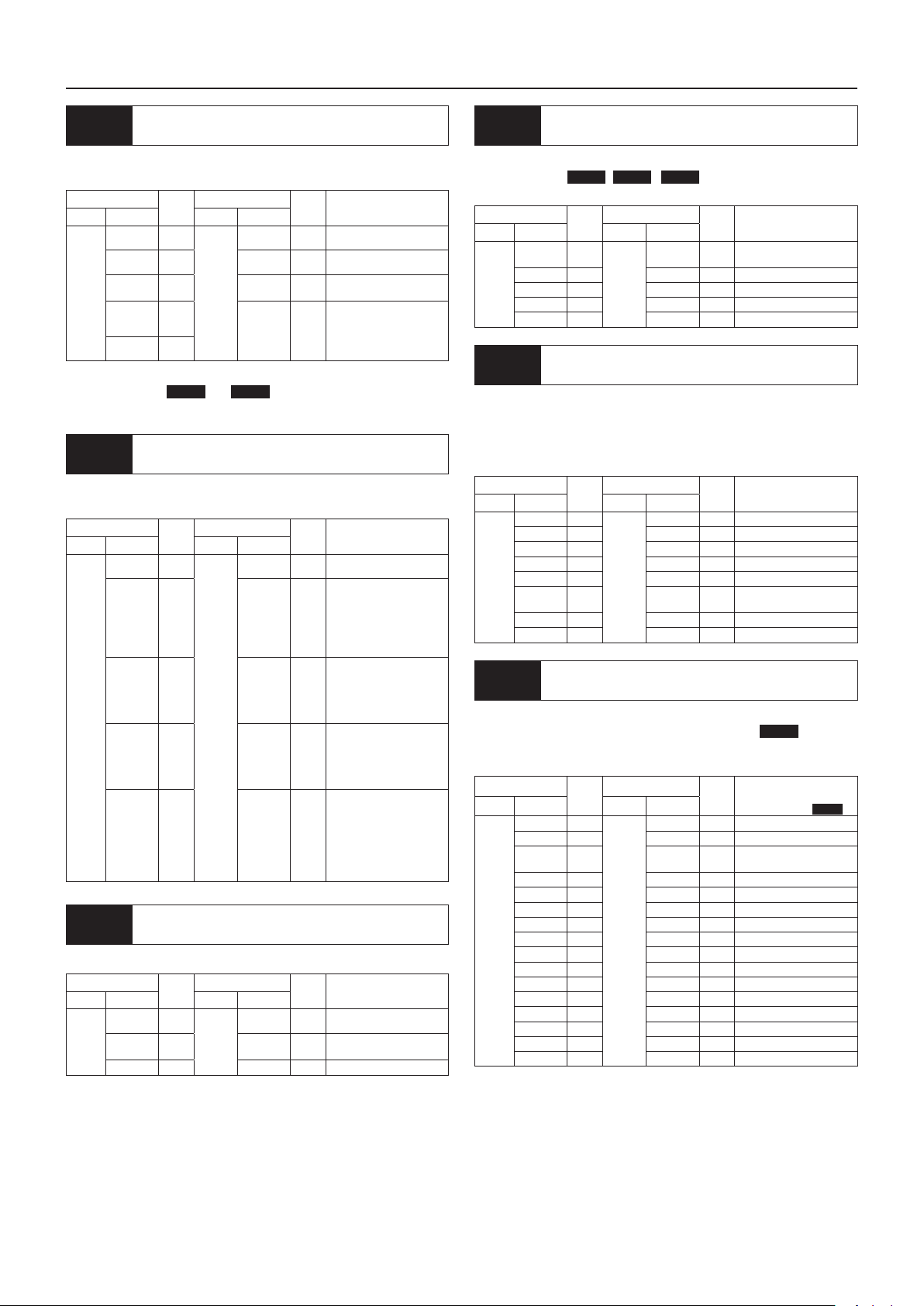

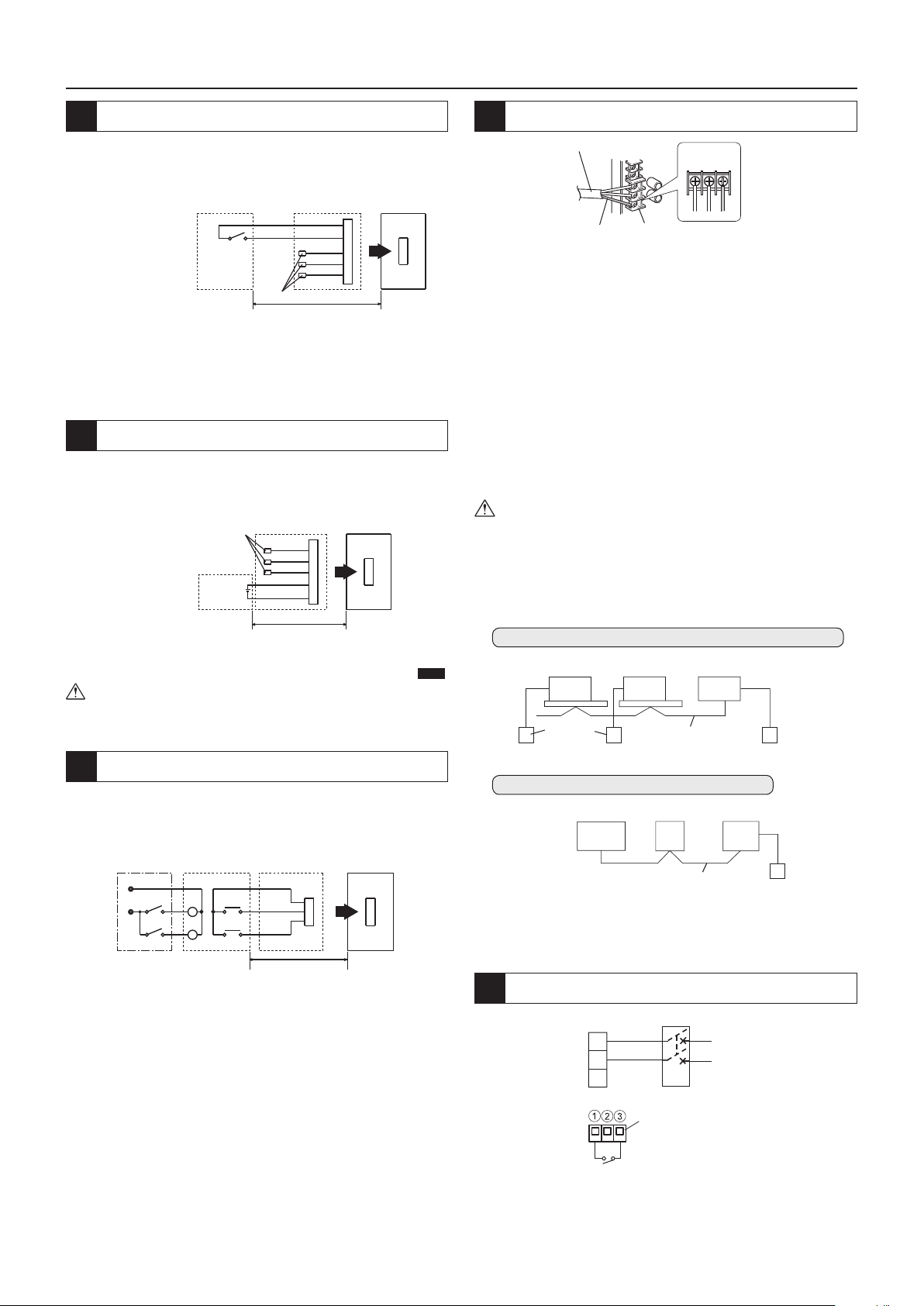

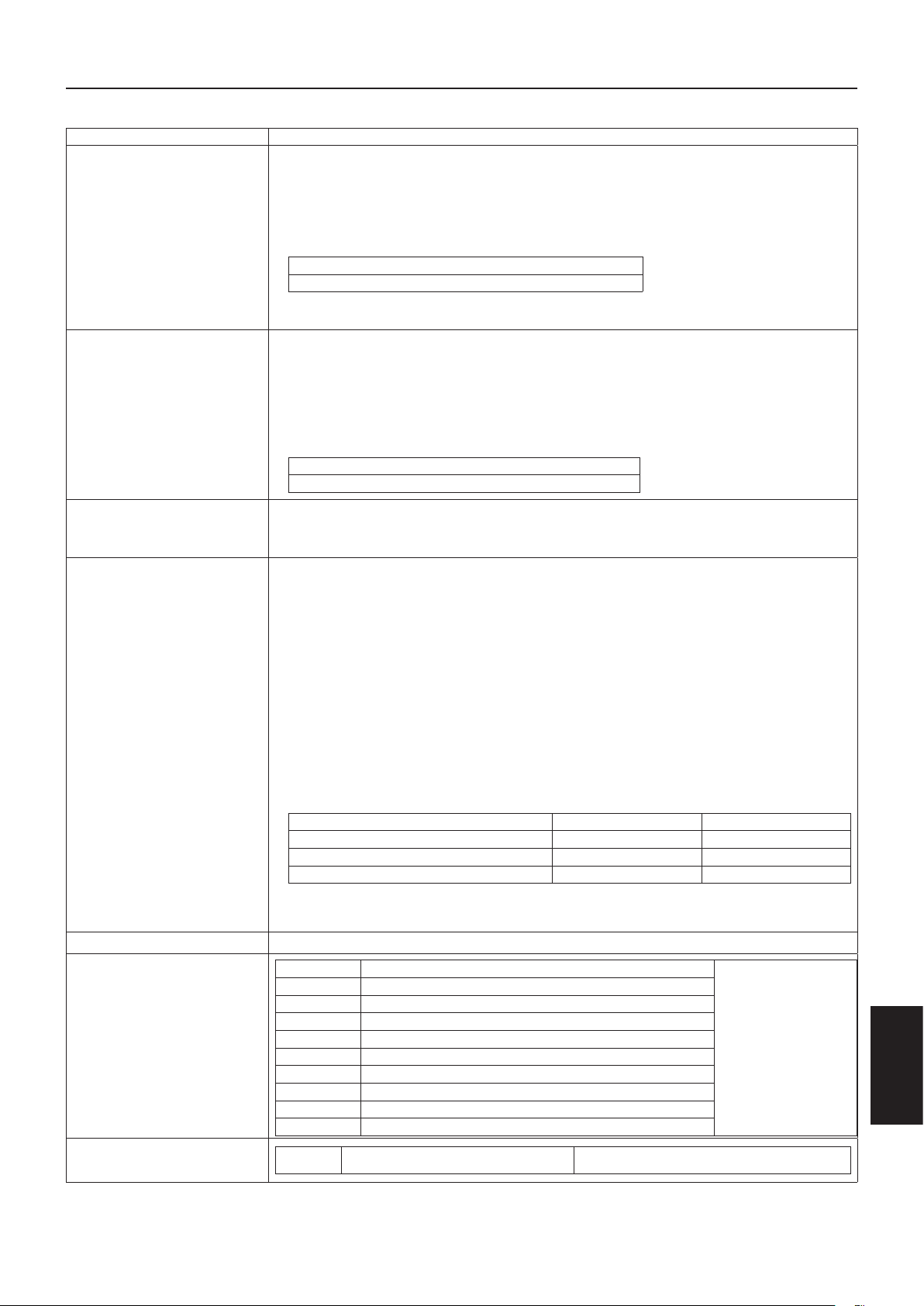

Names of components in control box

TM3

TM4

TB5

TM2

LED3

LED1, 2, 4

SW2, SW5

SA1, SA2

TM1

Eng-6

Page 8

Installation method (continued)

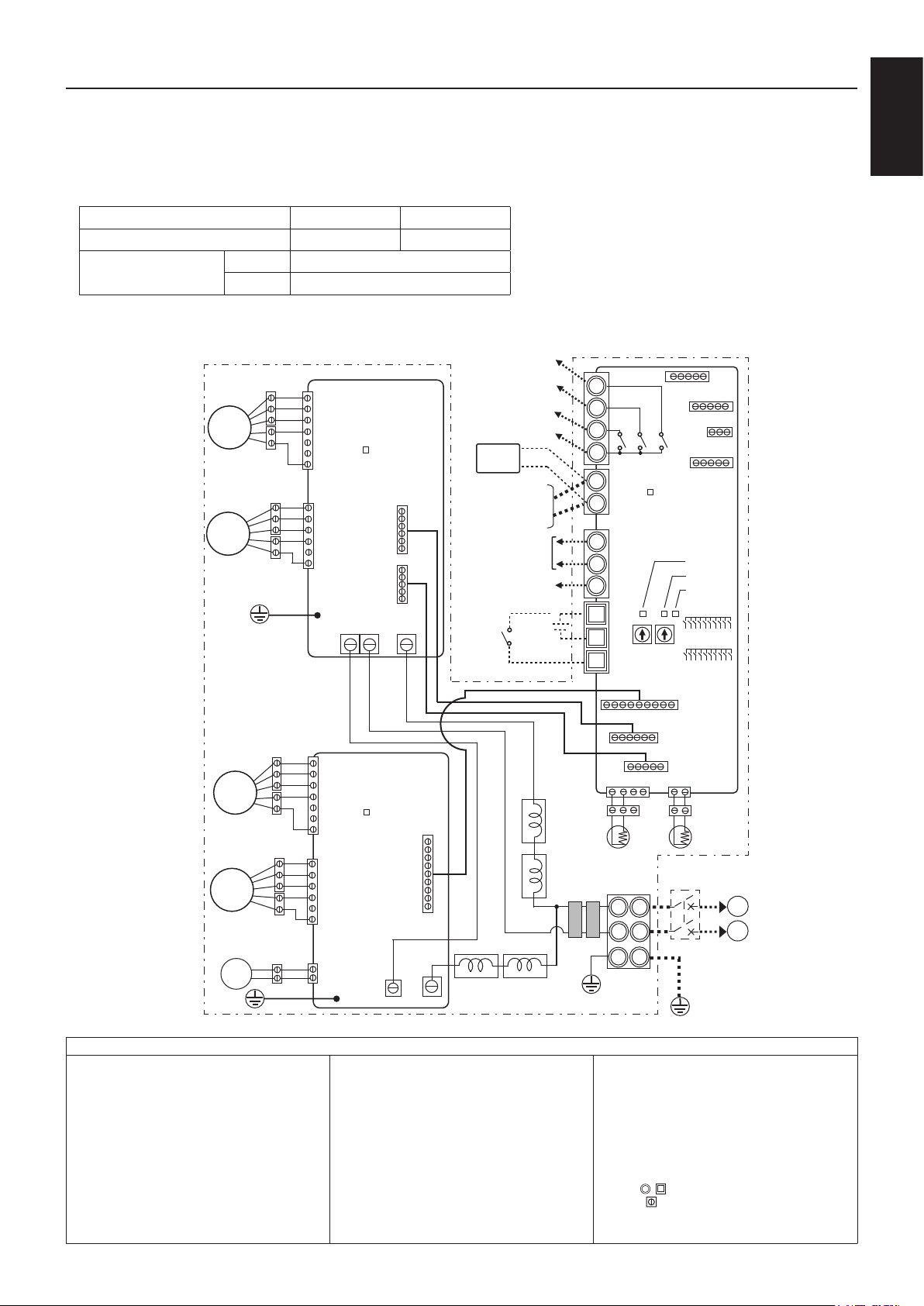

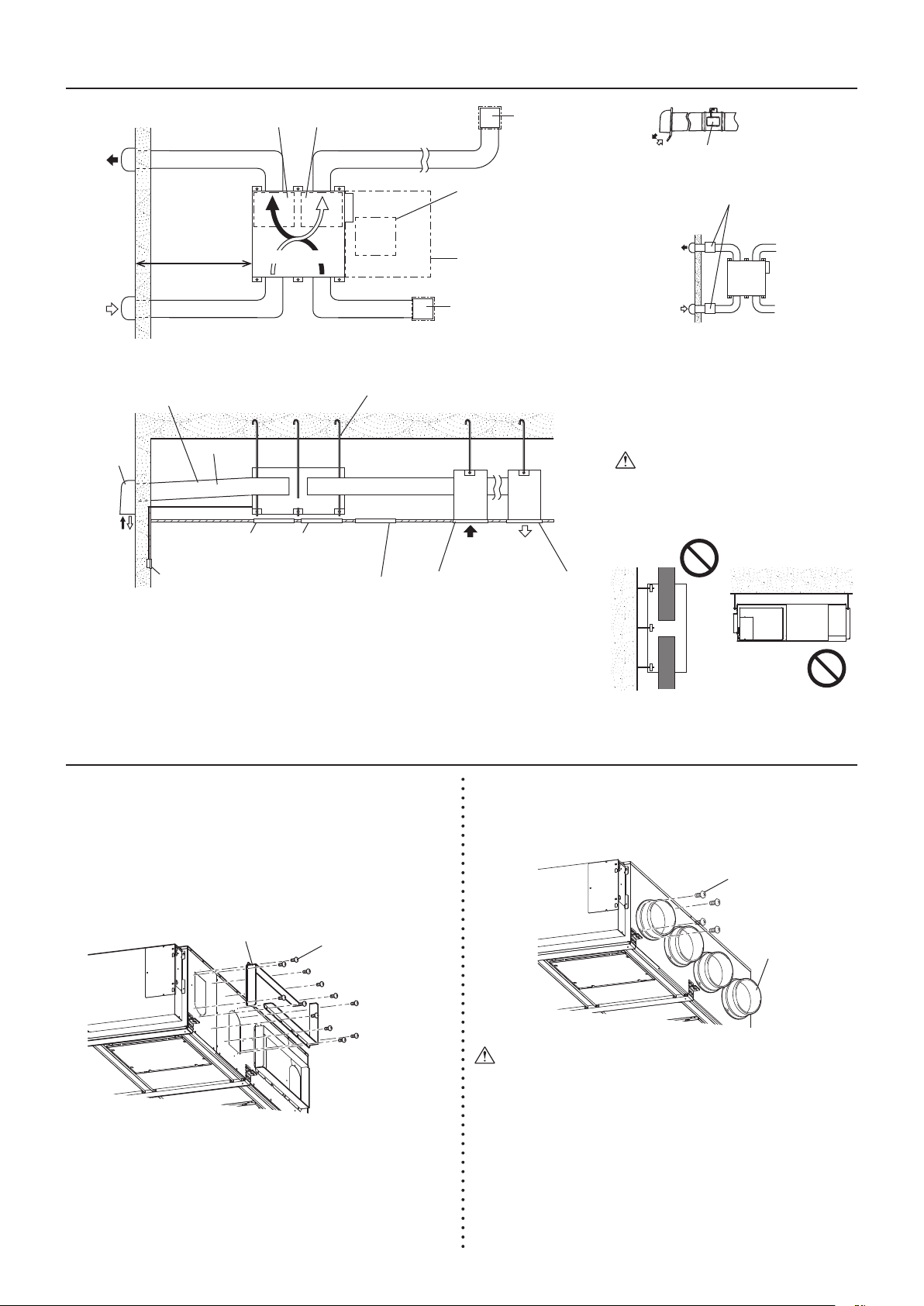

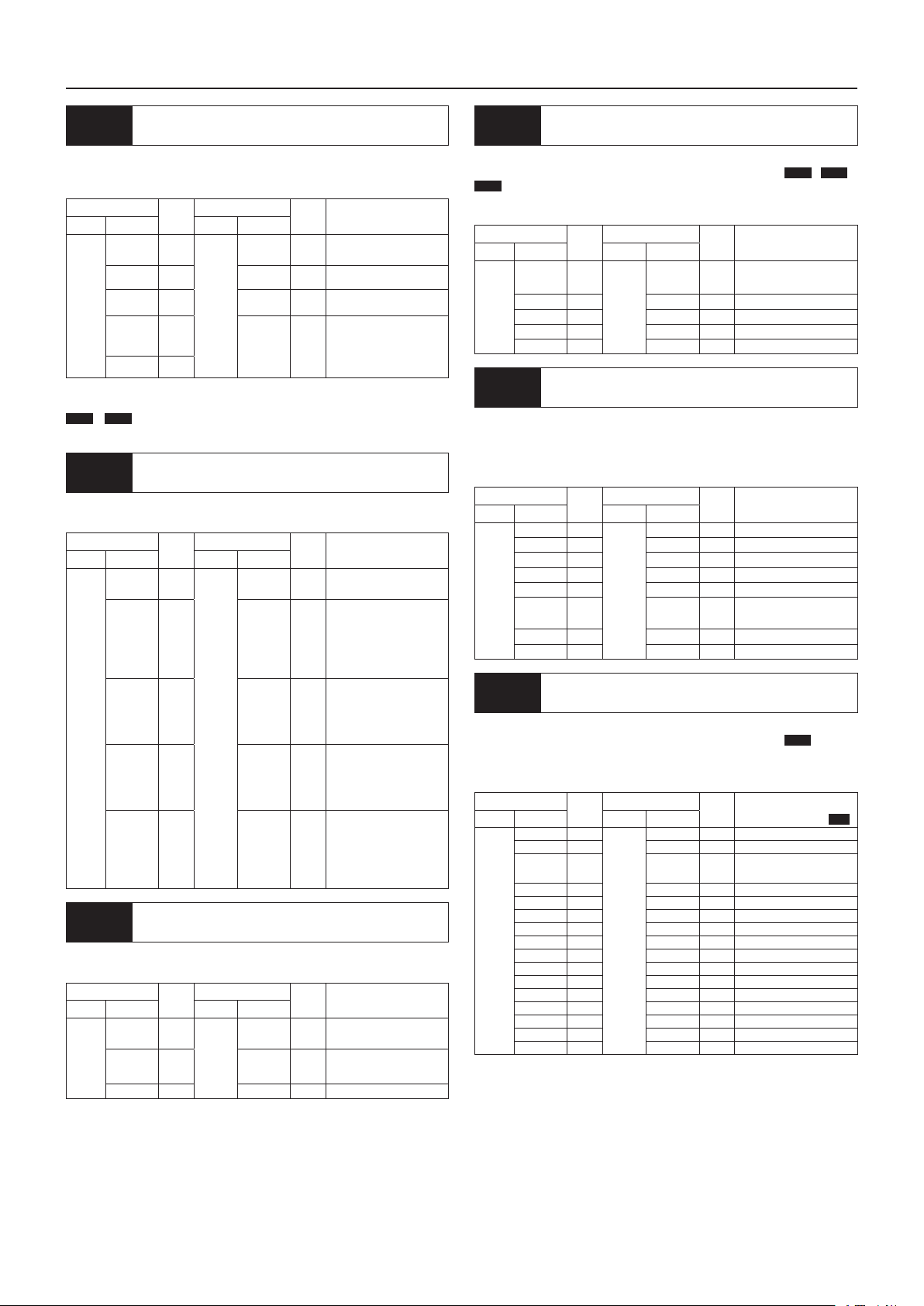

Wire connection diagram ----- Model LGH-150 and 200 RVXT-E

* TM1, TM2, TM3, TM4, TB5 shown in dotted lines are eld work.

* Be sure to connect the ground wire.

* A power supply isolator must be installed.

* Always use an isolator for the main switch power connection.

* Select proper circuit breaker according to the electrical current information in the chart below.

Model LGH-150RVXT-E LGH-200RVXT-E

Maximum current when operating [A] 5.6 6.4

Inrush current after power

supply ON [A]

10 ms 12.1

100 ms 6.6

Printed Circuit

Board 1

M

3

EXHAUST

FAN MOTOR

(Inside)

M

2

SUPPLY

FAN MOTOR

(Inside)

CN9

CN10

CN119

CN118

TAB2 TAB1

TAB5

LED6

Bypass monitor or Pre-

heater signal output (*1)

Malfunction monitor

output (*1)

Operation monitor

output (*1)

COM

PZ61DR-E

2nd remote controller

(Max. 2 controllers)

2nd Lossnay unit

(Max. 15 units)

M-NETtransmission cable

Shielded Wire

Volt-free

contact

12V or

24VDC

Mr .Slim

(non-polar)

(*1)

MAX 240 VAC 1 A MIN 220 VAC 100 mA

24 VDC 1 A 5 VDC 100 mA

TM3

7

8

9

10

1

X15

TM4

X14

CN20(GR)

CN26(WH)

CN32(WH)

X13

CN17(RE)

LED3

2

Printed Circuit

Board for control

A

TB5

B

S

TM2

1

2

3

LED4

LED2

LED1

SW2

SA2 SA1

SW5

CN21

English

M

4

EXHAUST

FAN MOTOR

(Outside)

M

1

SUPPLY

FAN MOTOR

(Outside)

GM

M1: Motor for supply fan (outside)

M2: Motor for supply fan (inside)

M3: Motor for exhaust fan (inside)

M4: Motor for exhaust fan (outside)

GM: Motor for By-pass damper

TH1: Thermistor for outside air

TH2: Thermistor for return air

SW2,5: Switch (Function selection)

TM1:

Terminal block (Power supply)

TM2: Terminal block (External control input)

TM3: Terminal block (Monitor output)

TM4: Terminal block (Transmission cable)

TB5: Terminal block (M-NET Transmission cable)

Printed Circuit

Board 2

CN9

LED6

CN121

CN10

CN7

TAB2

TAB1

REACTOR

Denition of symbols

TAB1, TAB2, (TAB5)

TAB3,TAB4

X13: Relay contact

X14: Relay contact

X15: Relay contact

CN5: Connector (Thermistor RA)

CN7: Connector (Motor for By-pass damper)

CN9: Connector (Fan motor)

CN10: Connector (Fan motor)

CN17: Connector (Fan speed 1/2/3/4)

CN18: Connector

CN118: Connector

CN19: Connector

: Connector (Power supply)

: Connector (Reactor)

REACTOR

LINE

FILTER

CN19

CN18

CN5

CN22

TH1(OA)

TH2(RA)

Isolator

(Field supply)

L

N

PE

L

N

POWER SUPPLY

TM1

CN119: Connector

CN20: Unused

CN22: Connector (Thermistor OA)

CN26: Connector (

CN32: Connector (Remote control selection)

SA1: Address setting rotary switch (tens digit)

SA2: Address setting rotary switch (ones digit)

LED1 to LED3: Inspection indicator lamp

LED4, LED6: Power supply indicator lamp

SYMBOL

:

:

By-pass, 0 - 10 VDC Fan speed control

Terminal block

Connector on PCB

)

Eng-7

Page 9

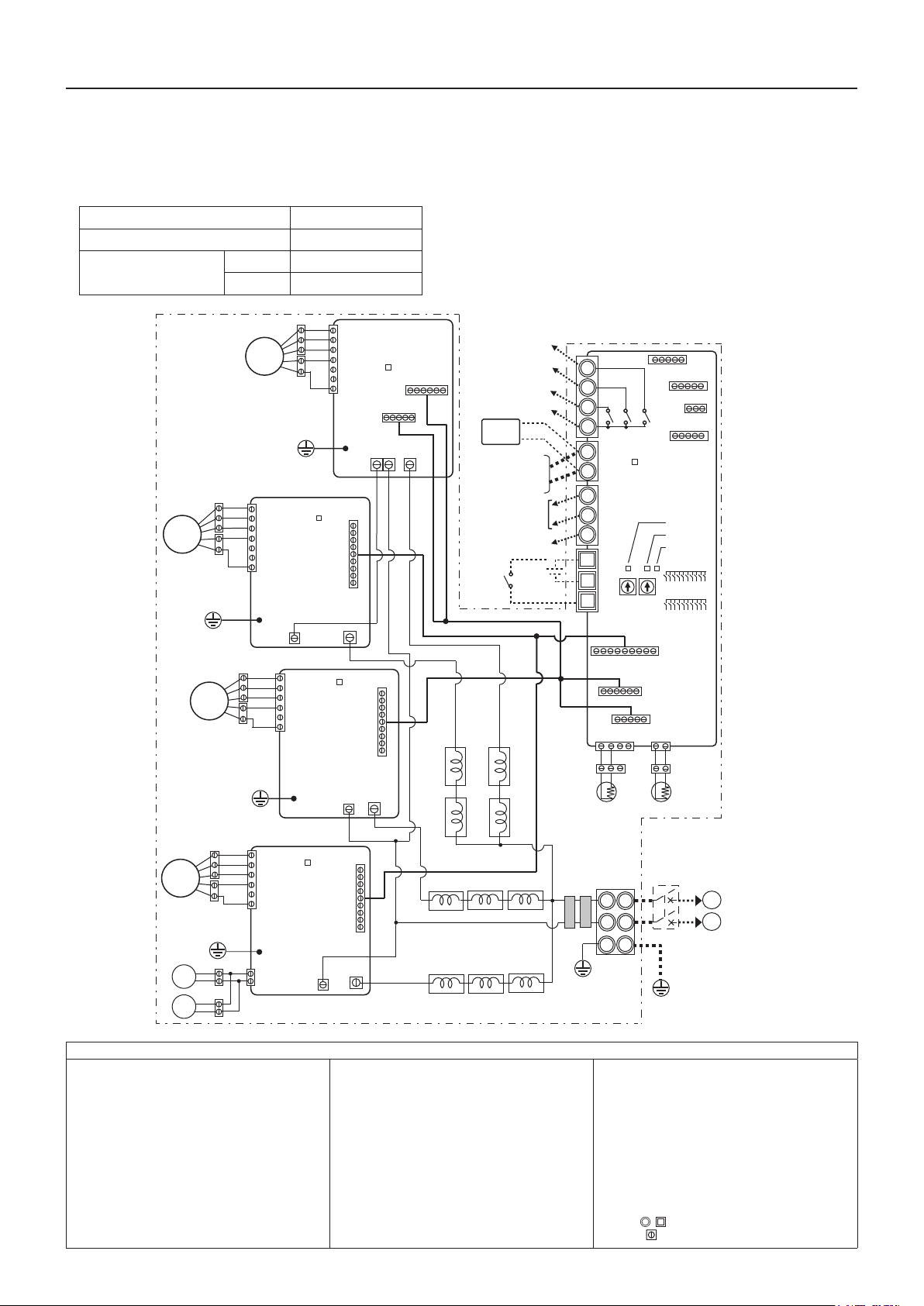

Installation method (continued)

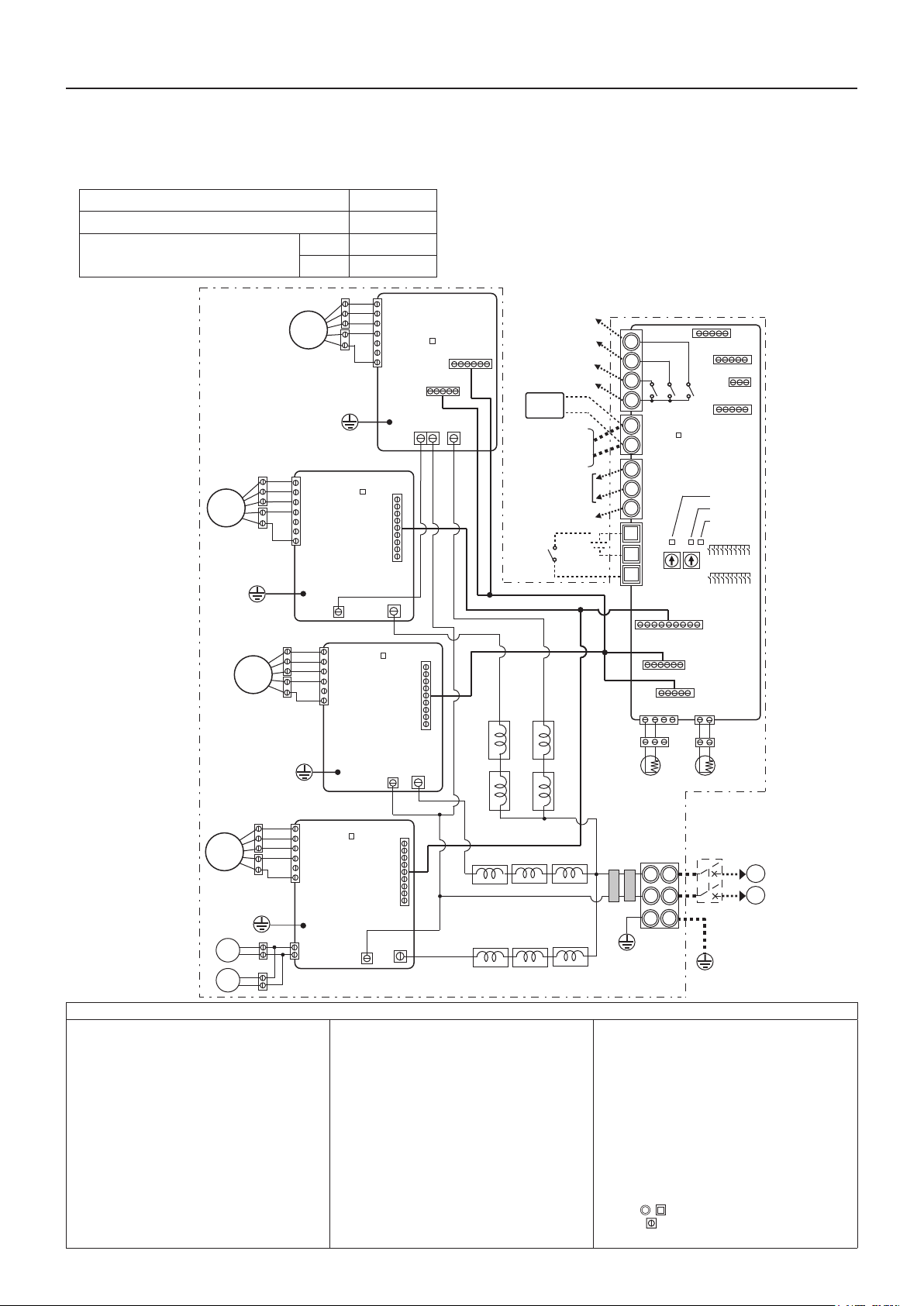

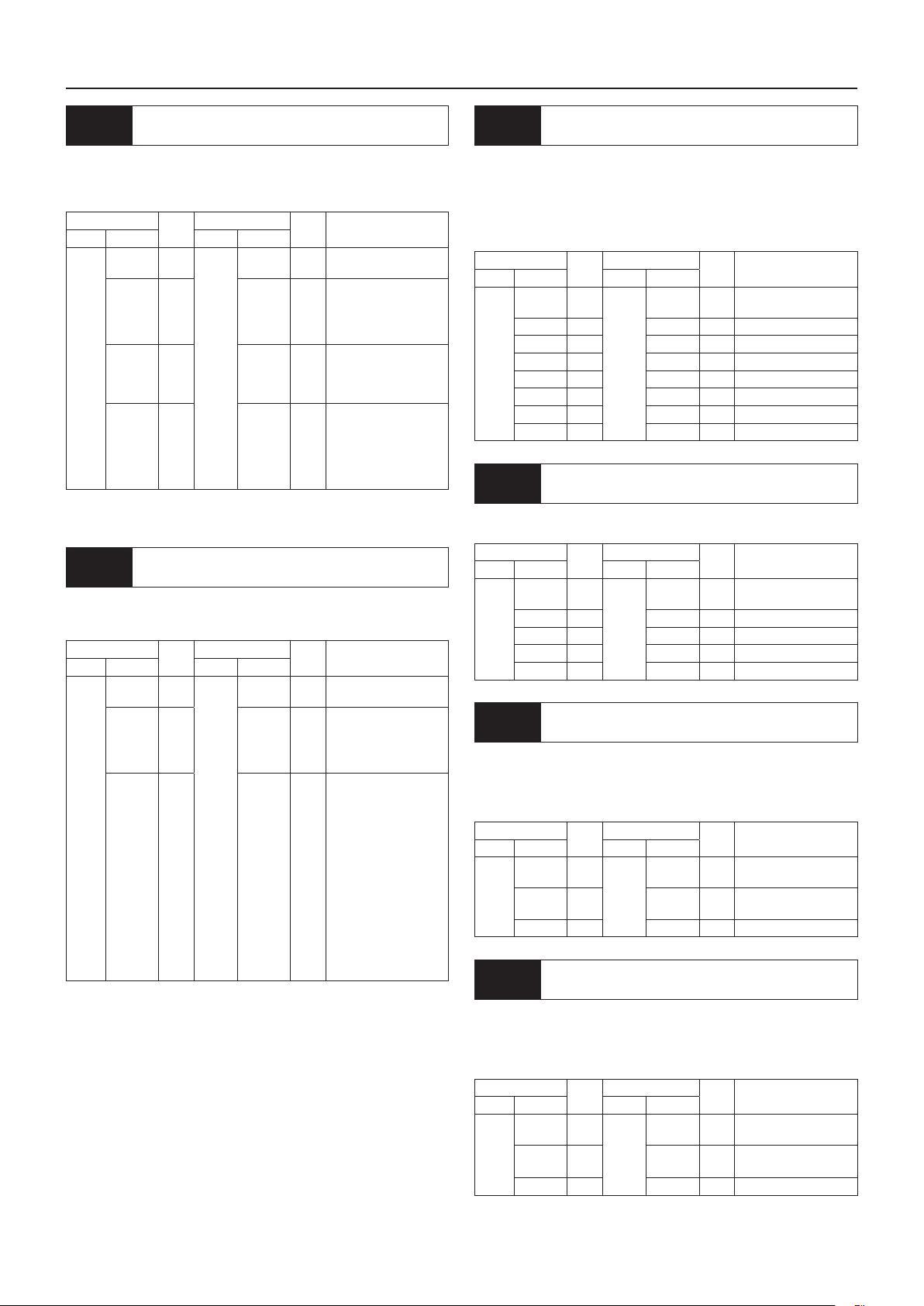

Wire connection diagram ----- Models LGH-250RVXT-E

* TM1, TM2, TM3, TM4, TB5 shown in dotted lines are eld work.

* Be sure to connect the ground wire.

* A power supply isolator must be installed.

* Always use an isolator for the main switch power connection.

* Select proper circuit breaker according to the electrical current information in the chart below.

Model LGH-250RVXT-E

Maximum current when operating [A] 10.8

Inrush current after power

supply ON [A]

M

EXHAUST

FAN MOTOR

(Outside)

10 ms 21.8

100 ms 11.9

M

3

EXHAUST

FAN MOTOR

(Inside)

4

CN9

Top Left Printed

Circuit Board

(EA Outside)

TAB2

Top Right Printed

Circuit Board

(EA Inside)

CN9

TAB5

LED6

CN121

TAB1

CN118

TAB2

LED6

CN119

TAB1

(*1)

Bypass monitor or Pre-

heater signal output (*1)

Malfunction monitor

output (*1)

Operation monitor

output (*1)

PZ61DR-E

2nd remote controller

(Max. 2 controllers)

2nd Lossnay unit

(Max. 15 units)

M-NETtransmission cable

Shielded Wire

12V or

Volt-free

24VDC

contact

Mr .Slim

(non-polar)

MAX 240 VAC 1 A MIN 220 VAC 100 mA

24 VDC 1 A 5 VDC 100 mA

COM

7

8

9

10

1

2

A

B

S

1

2

3

TM3

X15

TM4

TB5

TM2

CN20(GR)

CN26(WH)

CN32(WH)

X14

X13

CN17(RE)

LED3

CN17 (Red)

Printed Circuit

Board for Control

CN21

LED4

LED2

LED1

SW2

SA2 SA1

SW5

M

SUPPLY

FAN MOTOR

(Inside)

M

1

SUPPLY

FAN MOTOR

(Outside)

GM

GM

2

CN10

Bottom Right

Printed Circuit

Board

(SA Inside)

CN10

Bottom Left Printed

Circuit Board

(SA Outside)

CN7

TAB2

M1: Motor for supply fan (outside)

M2: Motor for supply fan (inside)

M3: Motor for exhaust fan (inside)

M4: Motor for exhaust fan (outside)

GM: Motor for By-pass damper

TH1: Thermistor for outside air

TH2: Thermistor for return air

SW2, 5

: Switch (Function selection)

TM1:

Terminal block (Power supply)

TM2: Terminal block (External control input)

TM3: Terminal block (Monitor output)

TM4: Terminal block (Transmission cable)

TB5: Terminal block (M-NET Transmission cable)

LED6

CN121

TAB2

LED6

TAB1

REACTOR

CN121

TAB1

REACTOR

Denition of symbols

TAB1, TAB2, TAB5

TAB3, TAB4

: Connector (Power supply)

: Connector (Reactor)

X13: Relay contact

X14: Relay contact

X15: Relay contact

CN5: Connector (Thermistor RA)

CN7: Connector (Motor for By-pass damper)

CN9: Connector (Fan motor)

CN10: Connector (Fan motor)

CN17: Connector (Fan speed 1/2/3/4)

CN18: Connector

CN118: Connector

CN19: Connector

CN19

CN18

CN5

TH2(RA)

LINE

FILTER

L

N

PE

TM1

CN22

TH1(OA)

Isolator

(Field supply)

POWER SUPPLY

L

N

CN119: Connector

CN20: Unused

CN21: Connector

CN121: Connector

CN22: Connector (Thermistor OA)

CN26: Connector (

By-pass, 0 - 10 VDC Fan speed control

)

CN32: Connector (Remote control selection)

SA1: Address setting rotary switch (tens digit)

SA2: Address setting rotary switch (ones digit)

LED1 to LED3: Inspection indicator lamp

LED4, LED6: Power supply indicator lamp

SYMBOL

:

:

Terminal block

Connector on PCB

Eng-8

Page 10

Installation method (continued)

English

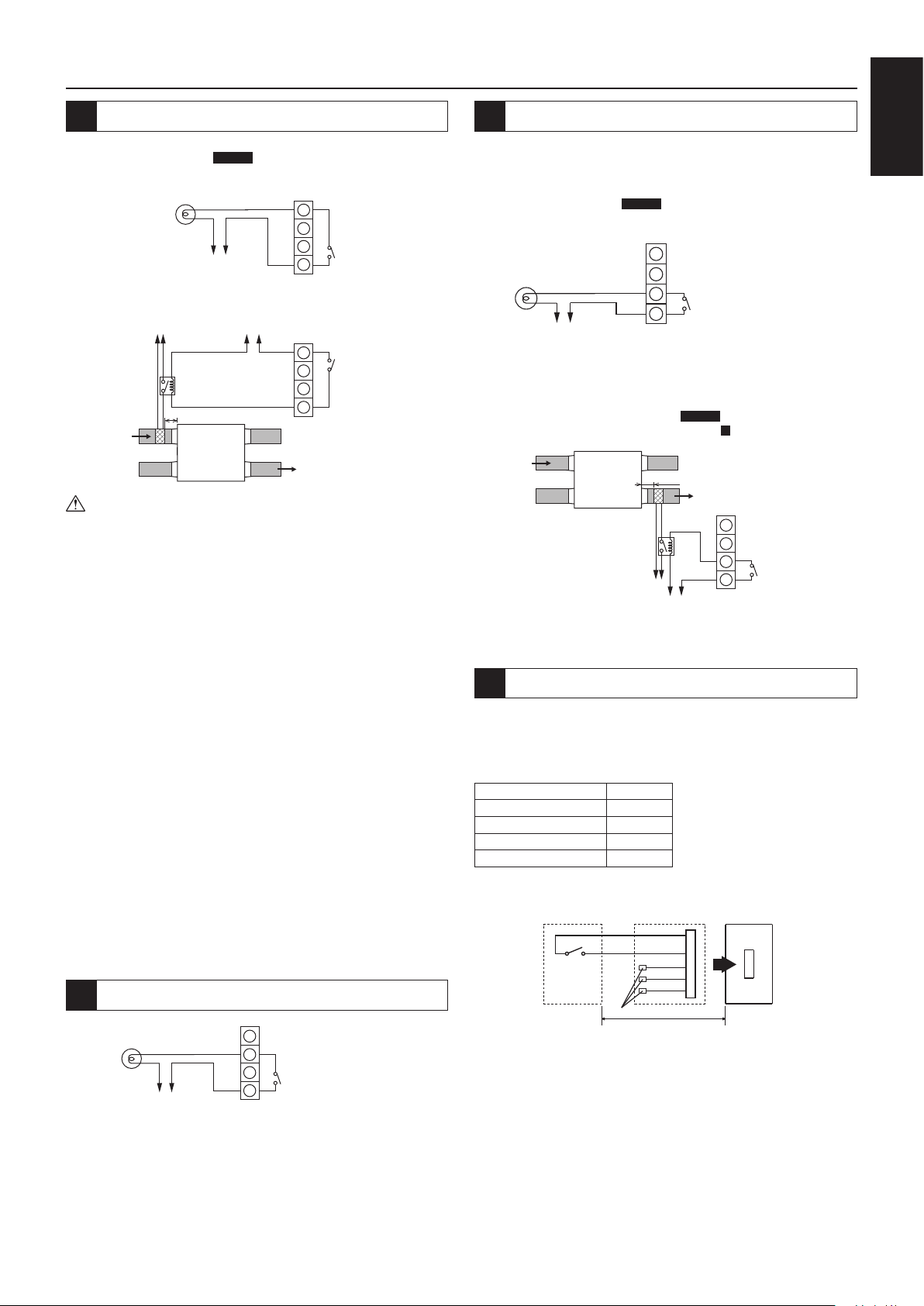

Connecting the power supply cable

1. Remove the black screws and the control

box cover

Control box cover

Black screws

2. Connecting the power supply cable and

transmission cable

Pass the Power supply cable through the bush* and connect to the

TM1 terminal block using the round terminals. Connect the ground

wire to the ground terminal and secure tightening the bush. (* Use

an item that can rmly secure the cable such as a PG connector.)

The following system conguration can

be created. Connect the necessary parts.

1 When connecting with remote controller (PZ-61DR-E).

2 When interlocked with indoor unit of air conditioner or other

external device including other manufactures.

3 When operating multiple Lossnay units.

4 By-pass monitor or Pre-heater signal output.

5 Malfunction monitor output.

6 Operation monitor output

7 When switching fan speed externally (when a sensor or other

device is connected).

8 When switching By-pass externally.

9 To change fan speed by 0 - 10 VDC input

10

When using the remote/local switching and the ON/OFF input

(level signal)

11

When connecting to the City Multi or Mitsubishi Electric Air-

Conditioner Network System (MELANS).

12

To start/stop Lossnay stand-alone operation without using the

remote control

CAUTION

• When connecting external devices (electric heater, damper,

lamp, monitoring unit, etc.) using output signals of the

Lossnay unit, make sure to install safety equipment for the

external devices.

(It could cause re, damage, etc. without safety equipment.)

Insert the cutting

Cord clip

Transmission cable

Bush

TM1

Ground wire

PG connector

Power supply cablePower supply cable

CAUTION

• Always separate the power supply cable and transmission

cable by 5 cm or more to prevent malfunctioning of the unit.

• If the length of the stripped Power supply cable is too long,

the conductors may touch and short out.

• Power supply cable size : 1.5 mm

(1) Tighten the ground wire and transmission cables to the

terminal block.

(2) Secure the transmission cables using the cord clips.

Upon completion of the wiring connections, replace the control box

cover.

2

(ø9)or more.

When connecting with remote controller (PZ-61DR-E)

1

* When controlling Lossnay units with MELANS, connect wires

according to 11 .

Securely connect the transmission cable from the remote controller

to 1 and 2 of the input terminal block (TM4). (No polarity)

Wire type: two-core sheathed cable

Wire diameter: 0.3 mm

•

If there are two remote controllers, connect them in the same way.

• Keep the overall length of the transmission cable between

Lossnay and the remote controller within 200 m.

2

Note

• Do not tighten screws of terminal block with a torque larger

than 0.5 Nm. It could damage the PCB.

• Take care not to connect the power supply cable or M-NET

transmission cable.

•

Number of transmission cables which can be connected to

single input terminal is up to 4 wires.

• Single wires such as PVC wires cannot be connected.

Lossnay

Power supply

Up to two remote controllers

Transmission cables

2

1

Remote controller input terminal

Eng-9

Page 11

Installation method (continued)

When interlocked with indoor unit of air conditioner or

2

other external device including other manufactures

CAUTION

• The connection may vary according to the output signal type

of the external unit.

• Don’t tighten screws of terminal block with a torque larger

than 0.5 Nm. It could damage the PCB.

Lossnay

Power supply

TM2

External

device

Power supply

Operating switch for

external device

When using Mitsubishi Mr. Slim air conditioner with MA

Remote controller

Conrm that the pulse input switch (SW2-2) is set to “OFF”.

(Factory setting is “OFF”.) (Refer to function settings No. 28 )

Connect the interlocking cable connector side to CN2L on the

circuit board for the Mr. Slim indoor unit, then connect the lead

wire side to the 1 and 2 of the input terminal block (TM2) for the

Lossnay external controller input. (No polarity)

• Always separate the power supply cable and the Slim-Lossnay

connection cable by 5 cm or more to prevent the unit from

malfunctioning.

• The Slim-Lossnay connection cable is 100 mm long. When

wiring, extend it as far as necessary.

Lossnay external

control input

(TM2)

Maximum 500 m

Slim-Lossnay connection cable

(Accessory parts)

CN2L

Mr. Slim (Indoor unit)

Printed circuit board

Note

• The Lossnay remote controller (PZ-61DR-E) cannot be used

with this system.

• Use MA remote controller of Mr. Slim for switching Lossnay

ON/OFF or the fan speed.

• The ventilation mode is “automatic ventilation”.

• Ensure that all connections are secure and that the appropriate

insulation is provided.

Use extension cable sheathed PVC cable or cable 0.5 mm

1.5 mm2.

2

to

When the external device has an uncharged a-contact signal

• The wiring should be the following picture.

Lossnay external

control input

(TM2)

Maximum 500 m

2

to 1.5 mm2 sheathed PVC cable

0.5 mm

External device

Uncharge a-contact

CAUTION

• If an optocoupler or any other type of polar coupler is used at

the uncharged a-contact, connect the positive side to 3 and

the negative side to 1.

When operating multiple Lossnay units

3

1) Connect from Lossnay Unit 1 to Lossnay Unit 2, and from Unit 2 to

Unit 3 and so on up to a maximum of 15 units using a transmission

cable.

Wire type: two-core sheathed cable

Wire diameter: 0.3 mm

2) When it is interlocked with an external device, turn ON the setting

switch (SW5-10) of main Lossnay where the external signal is

input.

Lossnay

Power supply

Lossnay

Power supply

Lossnay

Power supply

MAX 15 units

2

External

device

Remote controller

(PZ-61DR-E)

Power supply

Operating switch for

external device

1 2

SW5

First

21

TM4

TM4

Transmission cable

21

Lossnay

Second

Lossnay

3 4 5 6 7 8 9 10

Connect to

remote controller

(PZ-61DR-E)

Connect to

third Lossnay

ON

ON

OFF

When the external device has a charged operating signal

of 12 VDC or 24 VDC

[SW2-2] setting vary depending on the types of output signal of

external device.

• Move the pulse input switch [SW2-2] to the ON position.

(Refer to function settings

No. 28 )

• When interlocking with a pulse output device, a pulse width is

at least 200 m sec. to turn Lossnay ON, and 10 sec. interval is

necessary to next output.

• The wiring should be the following picture.

Lossnay external

control input

(TM2)

Overall connection extension length

(Follow the operation manual for the external equipment.)

2

to 1.5 mm2 sheathed PVC cable

0.5 mm

External device

12 or 24 VDC

Eng-10

CAUTION

Don’t tighten screws of terminal block with a torque larger

than 0.5 Nm. It could damage the PCB.

Note

• Up to four transmission cables can be connected to one input

terminal.

• Single wires such as PVC wires cannot be connected.

• Only one unit can be set as main Lossnay. The operating

signal and pulse signal of the external device can be

connected to main Lossnay only.

• When the external signal is not input, main-unit setting is not

required even for operation of multiple units.

• Connect the power supply cable to each Lossnay unit.

Page 12

Installation method (continued)

English

By-pass monitor or Pre-heater signal output.

4

By-pass monitor or Pre-heater signal can be selected at SW5-6.

(Refer to function settings No. 58 )

Always check that it is the intended setting.

By-pass monitor SW5-6 OFF

By-pass operation

indicator

Max 240 VAC, 1 A

24 VDC, 1 A

Min 220 VAC, 100 mA

5 VDC, 100 mA

Pre-heater output SW5-6 ON

Power Supply

for heater

Relay

2 m or more

OA

Pre-heater

Power

Supply

Lossnay

Power Supply

for relay

TM3

7

8

9

10

TM3

7

8

9

10

SA

X13

X13

Max 240 VAC, 1 A

24 VDC, 1 A

Min 220 VAC, 100 mA

5 VDC, 100 mA

CAUTION

• Select a duct heater in compliance with local and national

laws, ordinances, and standards.

Select a duct heater that has obtained the CE mark.

• Always select a heater that is equipped with a non-self-

resetting safety device.

Do not directly supply power from the Lossnay unit to the

duct heater.

(Doing so could cause re.)

• Install a circuit breaker for the duct heater in compliance with

all applicable laws, ordinances, and standards.

• Install the duct heater separated from the product by a

distance of 2 m or more.

(Failure to do so may result in equipment damage due to the

transmission of residual heat from the heater.)

• When using a heater without a temperature control function,

select a heater with a capacity that is matched to the air

volume.

• Do not use the heater outside the set air volume.

(If the heater’s capacity is too larger, this may result in the

heater frequently turning ON/OFF.)

(If the heater’s capacity is too small, this may result an

inability to heat.)

• Ensure that the duct heater and Lossnay are wired and that

the Lossnay function settings have been congured, and then

always check operation by trial operation.

• For the duct heater output, see function setting SW5-6.

Malfunction monitor output.

5

TM3

Malfunction indicator

Power

Supply

Max 240 VAC, 1 A

24 VDC, 1 A

Min 220 VAC, 100 mA

5 VDC, 100 mA

7

8

9

10

X14

Operation monitor output

6

Operation monitor output can be selected to sympathize with exhaust

fan or supply fan at SW 5-2.

SW5-2 OFF: Exhaust fan operation monitor output

SW5-2 ON: Supply fan operation monitor output

(Refer to function settings No. 57 )

Always check that it is the intended setting.

TM3

Operation

indicator

Power Supply

Max 240 VAC, 1 A

24 VDC, 1 A

Min 220 VAC, 100 mA

5 VDC, 100 mA

7

8

9

10

X15

To use operation monitor output for a supply after-heater, turn SW2-8

ON, and use the supply fan operation monitor output with delayed

operation. (Refer to function settings No. 57 )

For the heater, observe the cautions listed in 4 .

OA

When switching fan speed externally

7

(when a sensor or other equipment is connected)

Lossnay

Power Supply

for heater

2 m or more

SA

Relay

Power Supply

for relay

TM3

7

8

9

X15

10

Max 240 VAC, 1 A

24 VDC, 1 A

Min 220 VAC, 100 mA

5 VDC, 100 mA

Using a eld supply sensor, etc., make connection by inserting the

optional remote display adaptor (PAC-SA88HA-E) in the connector

CN17 (Red) as shown by the gure.

Lossnay will operate the fan speed following the table below,

regardless of the remote controller setting.

CN17 (Red) Fan speed

1-2 (Brown-Red) 4

1-3 (Brown-Orange) 3

1-4 (Brown-Yellow) 2

1-5 (Brown-Green) 1

nExample “Fan speed 4”

Field supply sensor, etc.

SW1

Remote display adaptor

(Optional) PAC-SA88HA-E

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Not used. Insulate completely.

Max wiring length 10 m

Lossnay

control board

CN17

Fan speed

selection

Use this in such a way that it ventilates at low fan speed normally,

and when the external sensor detects contamination of indoor air,

it changes to high fan speed operation.

Eng-11

Page 13

Installation method (continued)

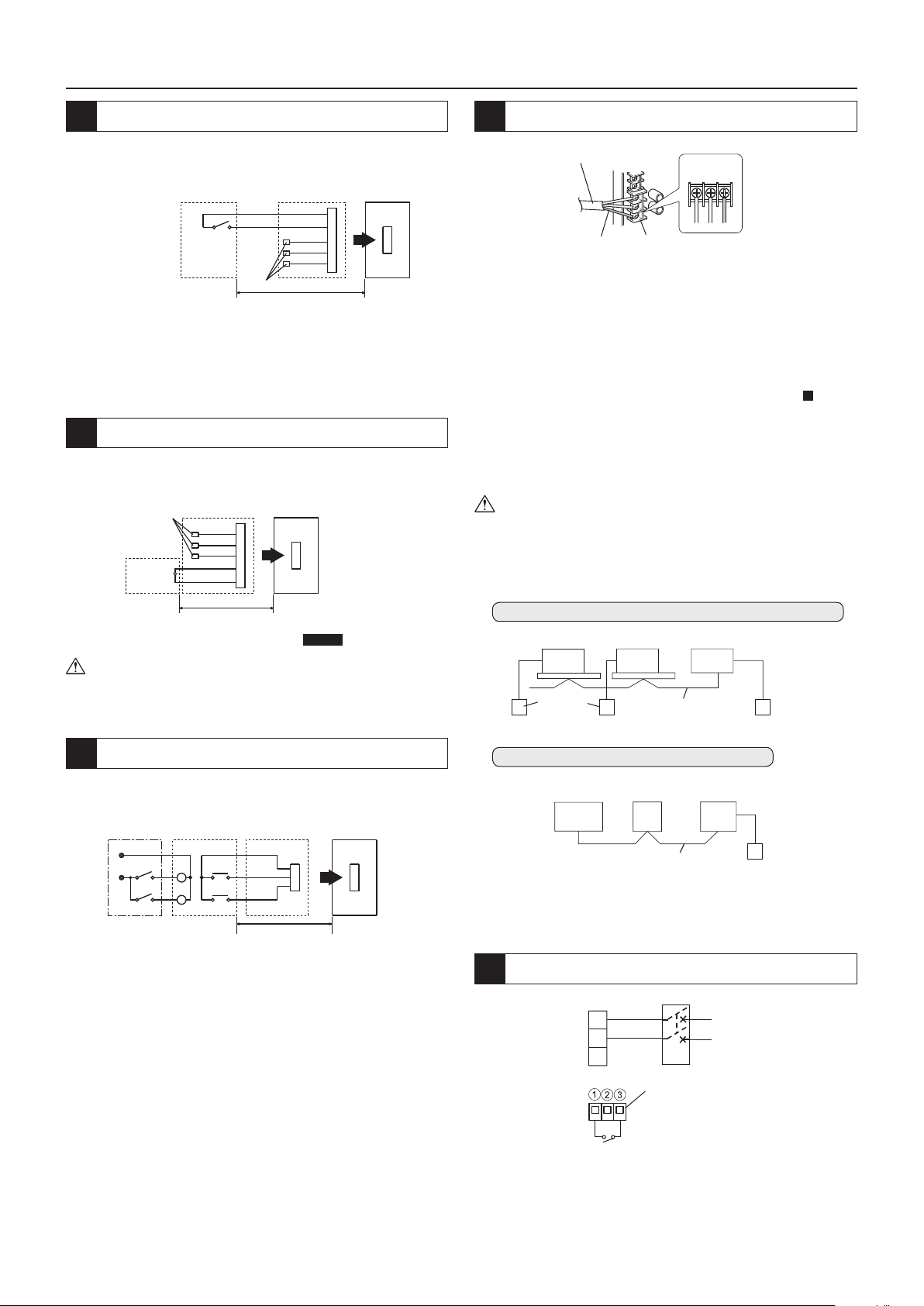

When switching By-pass externally.

8

Establish the wire connection by inserting the optional remote display

adaptor (PAC-SA88HA-E) in the connector CN26 (White).

SW1

SW1: By-pass ventilation operation switch

(When closed: For By-pass ventilation operation)

Remote display adaptor

(Optional) PAC-SA88HA-E

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Not used. Insulate completely.

Max wiring length 10 m

Lossnay

control board

CN26

Fan speed/

Ventilation

mode selection

With SW1 is “ON”, the ventilation mode of Lossnay is changed to the

By-pass ventilation regardless of the setting on the remote controller.

* When the outdoor air temperature drops lower than 8˚C, it

changes to the heat exchanger ventilation. (Display of the

remote controller does not change.)

To change fan speed by 0 - 10 VDC input

9

Establish the wire connection by inserting the optional remote display

adaptor (PAC-SA88HA-E) in the connector CN26 (White).

Not used. Insulate

completely.

External

device

Remote display adaptor

(Optional) PAC-SA88HA-E

Brown 1

Red 2

Orange 3

Yellow 4 (0 - 10 VDC)

Green 5 (COM)

Max wiring length 10 m

Lossnay

control board

CN26

Fan speed/

Ventilation

mode selection

To change fan speed by 0 - 10 VDC input, the wiring should be the

above picture. Refer to function settings No. 63 for more details.

CAUTION

• Make sure of correct polarity.

When connecting to the City Multi, Mitsubishi Electric Air-

11

Conditioner Network System (MELANS)

M-NET transmission cable

Shielded wire M-NET transmission cable input terminal block

TB5

S

BA

• One shielded wire is connected to terminal TB5 S on the PCB.

Address setting is required. (Refer to function setting section.)

M-NET transmission cable: Connect any of the City Multi indoor

unit, or Mitsubishi Electric AirConditioner Network System (MELANS)

- to the Lossnay.

• Remote Controller

PZ-61DR-E:

Connect to TM4 1, 2 on the PCB. (See Section 1 “When

connecting with Remote Controller (PZ-61DR-E)”.)

• Securely connect the M-NET transmission cables to TB5 AB.

(No-Polar)

Type: (Shielded wire, CVVS/CPEVS)

Wire diameter: 1.25 mm2 to 2.0 mm2

CAUTION

• Don’t tighten screws on the terminal block with a torque larger

than 0.5 Nm. It may damage the PCB.

• Always use shielded wires only for the M-NET transmission

cables, and nish the shield properly.

When interlocking with Mitsubishi M-NET air conditioner

• Incase of PZ-61DR-E

Air

conditioner

MA remote

controller

Air

conditioner

M-NET transmission cable

Lossnay

PZ-61DR-E

When using the remote/local switching and the ON/OFF

10

input (level signal)

Insert the optional remote ON/OFF adaptor (PAC-SE55RA-E) in

CN32 on the Lossnay control PCB.

Remote control

board

SW2

SW1

Relay power supply

Relay circuit

X

Y

Remote ON/OFF adaptor

(Optional) PAC-SE55RA-E

Orange 1

X

Red 2

Y

Brown 3

Max wiring length 10 m

Lossnay

control board

CN32

SW1: When this is ON, Lossnay cannot turn ON/OFF by the

Remote Controller (PZ-61DR-E).

SW2: When SW1 is ON, Lossnay can be turned ON by setting

SW2 at ON or turned OFF by setting SW2 at OFF.

SW1: Remote/local selector switch

SW2: ON/OFF switch

X, Y : Relay (Contactor rating DC 1 mA)

When connecting to PZ-61DR-E and MELANS

• Connect the power feeding unit.

(Optional)

Power

supply unit

MELANS

M-NET transmission cable

Lossnay

PZ-61DR-E

* Limit the total length of transmission cables no longer than

500 m. Limit the wiring length between Lossnay and the power

supply unit (Optional) or the outdoor unit no longer than 200 m.

To start/stop Lossnay stand-alone operation without

12

using the remote control

TM1

Isolator

L

N

PE

TM2

Start/stop the unit by a switch connected to TM213.

When turned the unit ON, it operates at fan speed 4 and

automatic ventilation mode.

Do not start/stop the unit by turning the power supply to the unit

ON/OFF.

Lossnay external

control input

Switch

Eng-12

Page 14

Function settings

English

Address setting is required when connecting to City Multi and MELANS.

Setting the address

Use the following procedure when setting the address for dedicated

Lossnay.

(The method in determining the addresses will depend on the existing

system. Refer to the appropriate technical documents for details.)

(1) Remove the control box cover.

(2) Use a at blade screwdriver to turn the address setting switch on

the circuit board.

• SA1 indicates the tens digit and SA2 indicates the ones digit.

• The factory setting is “00”.

SA1 SA2

10s digit 1s digit

Address setting switch

* When the address number has been changed, the data in the

memory is automatically reset.

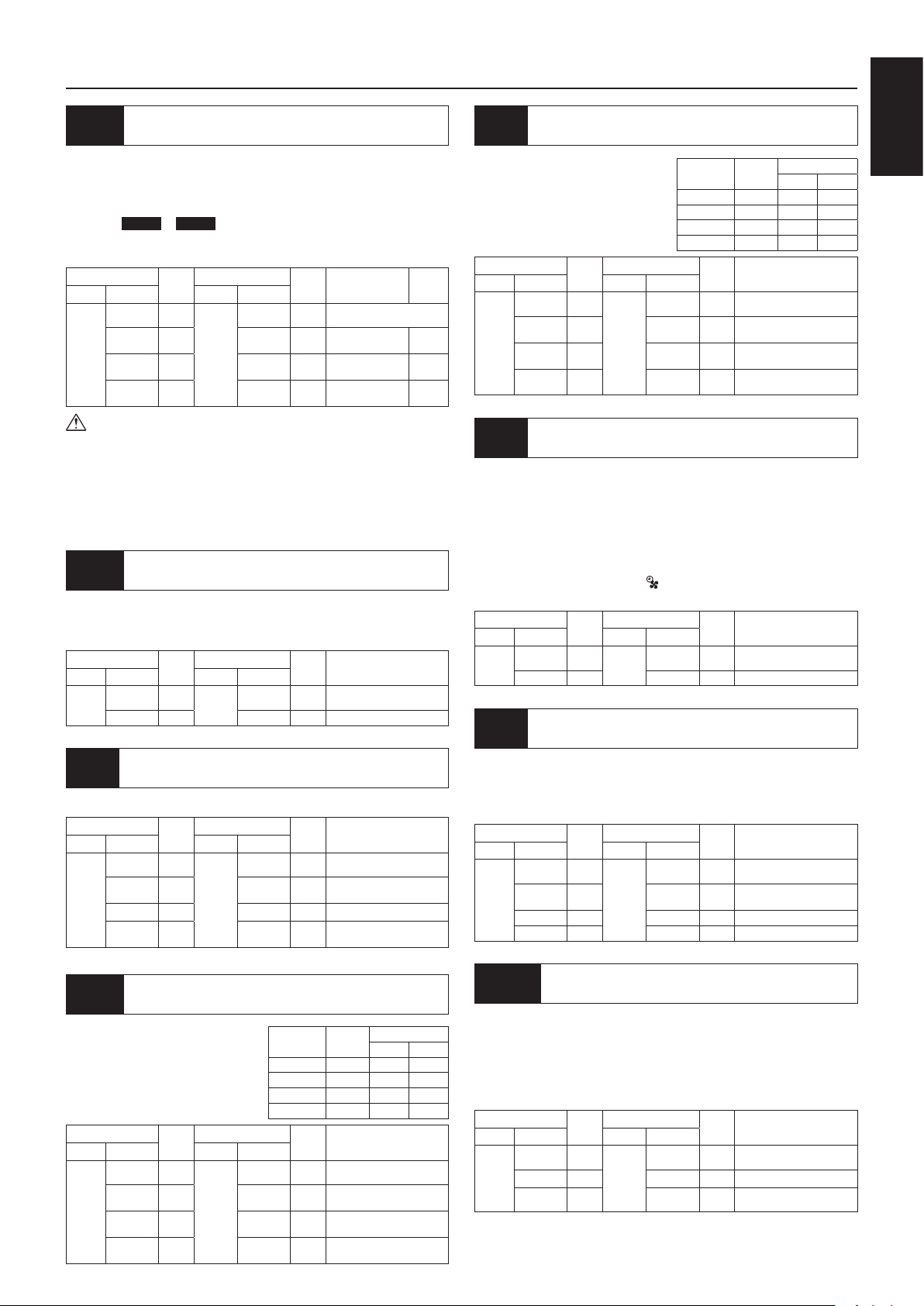

Changing the function selection

switches (SW-2, 5 and 6)

Set the selection switches (SW-2 and 5) to perform the appropriate

function.

* All function except “Trial operation” and “Main unit setting” can be

set also from the remote controller (PZ-61DR-E). If the function is

switched later using the remote controller, it operates according to

the setting on the remote controller.

Change the function settings from the

remote controller PZ-61DR-E.

Please refer to the Instruction book of PZ-61DR-E for how to set the

function settings.

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

(SW2)

OFF ON

(SW5)

OFF ON

Trial operation

No. 28 Pulse input setting

No. 63 External fan speed input setting (0 - 10 VDC)

No. 6 Indoor negative pressure setting

No. 7 Indoor positive pressure setting

No. 63 External fan speed input setting (0 - 10 VDC)

No. 51 Automatic ventilation mode setting

No. 57

Operation monitor output synchronized with exhaust fan or supply fan

No. 61 Fan speed for air volume “High” input

No. 62 Fan speed for air volume “Low” input

No. 9 Delay start setting for air conditioner starting

No. 57 Operation monitor output synchronized with exhaust fan or supply fan

No. 13 , No. 14 Exhaust fan setting

No. 5 Automatic recovery setting after power interruption

No. 1 Filter maintenance and fan power up setting against lter choking

No. 58 By-pass monitor output or Pre-heater output setting

No. 15 Interlock mode setting

No. 15 Interlock mode setting

No. 14 Exhaust fan setting at OA temperature lower than -15˚C

Main unit setting (refer to page 10)

DIP-SW 6 is to idenify the model for PCB.

When replacing to new PCB, set the same

setting as old one.

(SW6)

SW6-1 SW6-2 SW6-3 SW6-4

LGH-150RVXT-E OFF ON OFF ON

LGH-200RVXT-E ON ON OFF ON

LGH-250RVXT-E OFF OFF ON ON

* Do not change from factory setting.

If changed,please set as factory setting.

Eng-13

Page 15

Function settings (continued)

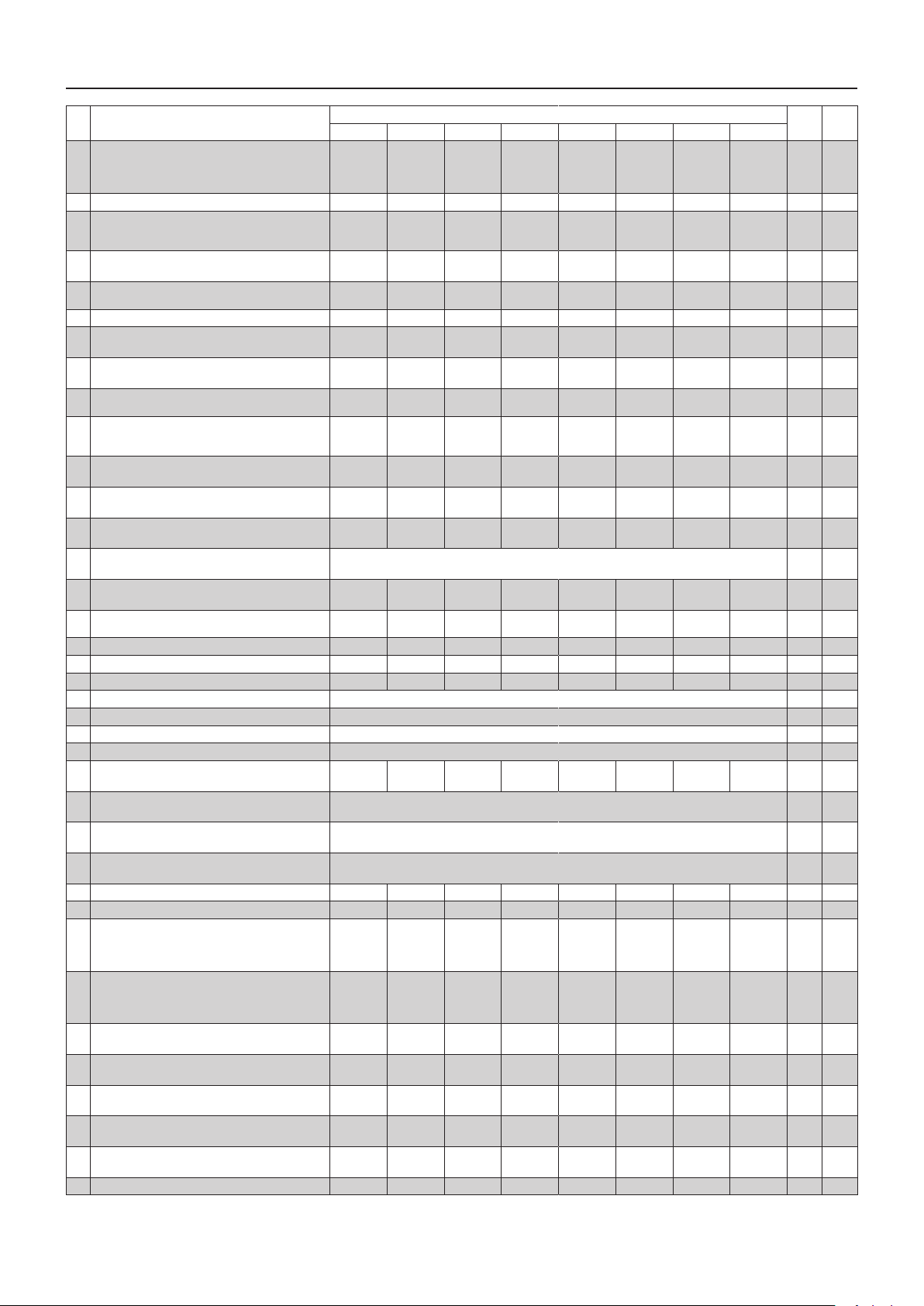

No Function

Filter maintenance and fan power up setting

*1

against lter choking

2 Lossnay core maintenance indicator setting N/A Available - - - - - - 0 N/A

Automatic recovery setting after power interruption

5

6 Indoor negative pressure setting

7 Indoor positive pressure setting

Max. fan speed setting during the rst 30 minutes

8

9 Delay start setting for air conditioner starting

Exhaust fan setting during air conditioner defrosting

13

Exhaust fan setting at OA temperature lower

14

than -15 ˚C

15 Interlock mode setting

28 Pulse input setting

Night-purge setting 1)

*30

Air volume

Night-purge setting 2)

*31

Outdoor and indoor temperature gap

Night-purge setting 3)

*32

Threshold of outdoor temperature

Night-purge setting 4)

*33

Time span for memorizing

*34 Input priority setting

36 Outdoor temperature display setting N/A Available - - - - - - 0 N/A

37 Indoor temperature display setting N/A Available - - - - - - 0 N/A

38 Calculated supply air temperature display setting N/A Available - - - - - - 0 N/A

Temperature exchange efciency setting (10 digit)

39

40 Temperature exchange efciency setting (1 digit) Setting Data 0 to 9 --> 1 digit of temperature exchange efciency 0 to 9 0 N/A

*41 Outdoor temperature correction Setting Data 0 to 14 --> Outdoor temperature correction -7 ˚C to 7 ˚C 7 N/A

*42 Indoor temperature correction Setting Data 0 to 14 --> Room temperature correction -7 ˚C to 7 ˚C 7 N/A

*51 Automatic ventilation mode setting

Automatic ventilation mode setting 1)

*52

Outdoor and indoor temperature gap

Automatic ventilation mode setting 2)

*53

The lowest outdoor temperature setting

Automatic ventilation mode setting 3)

*54

The lowest indoor temperature setting

*55 Supply fan power up setting N/A 1 level up 2 level up 3 level up 4 level up - - - 0 N/A

*56 Exhaust fan power up setting N/A 1 level up 2 level up 3 level up 4 level up - - - 0 N/A

Operation monitor output synchronized with

57

exhaust fan or supply fan

By-pass monitor output or Pre-heater output set-

58

ting

Pre-heater setting 1)

*59

ON temperature

Pre-heater setting 2)

*60

OFF interval

*61 Fan speed for air volume “High” input

*62 Fan speed for air volume “Low” input

*63 External fan speed input setting (0 - 10 VDC)

100 Initialization - Initialize - - - - - - 0 N/A

This table shows the summary of function settings. Please refer to the following pages for more details.

The functions indicated with * are newly added or modied from Lossnay LGH-RX

The functions indicated with “N/A” in the “DIP-SW No.” column are available only when using with remote controller PZ-61DR-E.

0 1 2 3 4 5 6 7

Indicator

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

Setting Data 0 to 15 --> The lowest outdoor temperature for Night-purge 15 ˚C to 30 ˚C 2 N/A

Main unit

input priority

Setting Data 0 to 9 --> 10 digit of temperature exchange efciency 0 to 9 7 N/A

Dip-SW

priority

Setting Data 0 to 7 --> Temperature gap 0 ˚C to 7 ˚C 0 N/A

Setting Data 0 to 15 --> Lowest outdoor temperature 10 ˚C to 25 ˚C 6 N/A

Setting Data 0 to 15 --> Lowest indoor temperature 15 ˚C to 30 ˚C 1 N/A

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

Dip-SW

priority

available

Fan power

up N/A

Stop when

the power

is On

N/A Available - - - - - - 0 N/A

ON/OFF

interlock

Non-pulse

Fan speed 1 Fan speed 2 Fan speed 3 Fan speed 4

N/A

0 ˚C 1 ˚C 2 ˚C 3 ˚C 4 ˚C 5 ˚C 6 ˚C 7 ˚C 5 N/A

24 hrs 48 hrs 72 hrs - - - - - 0 N/A

Individual

input priority

Pattern A Pattern B

EA fan

monitor

output

By-pass

monitor

output

0 ˚C -1 ˚C -2 ˚C -3 ˚C -4 ˚C -5 ˚C -6 ˚C -7 ˚C 0 N/A

1 hr 2 hrs 3 hrs 4 hrs 5 hrs - - - 0 N/A

Fan speed 4Fan speed

Fan speed 2Fan speed

Indicator N/A

Fan power

up N/A

Start when

the power

is On

Supply 1

N/A

N/A

N/A 15 min 30 min - - - - 0 5-1

Stop No change - - - - - 0 5-3

Stop

input

N/A Pattern X Pattern Y Pattern Z - - - 0

down

Exhaust 1

down

Fan speed

1 or 2

ON inter-

lock

Pulse

input

- - - - - - 0 N/A

SA fan

monitor

output

Operation

monitor

output for

Pre-heater

3

1

-E series.

5

Setting Data

Indicator

available

Fan power

up available

Return to the

state before

interruption

Supply 2

down

Exhaust 2

down

No change - - - - 0

OFF inter-

lock

- - - - - 0 2-2

Free

setting

SA fan

monitor

with delay

operation

- - - - - 0 5-6

- - - - - 0 2-9

- - - - - 0 2-10

- - - - 0 5-5

- - - - 0 5-4

- - - - 0 2-4

- - - - 0 2-5

External

input given

priority

- - - - 0 2-7

- - - - 0

- - - 0

- - - 0 N/A

Factory

setting

DIP-SW

No.

5-3

5-9

5-7

5-8

2-8

5-2

2-3

2-6

Eng-14

Page 16

Function settings (continued)

English

No. 1

Filter maintenance and fan power up

setting against lter choking

Set the schedule for lter cleaning based on the estimated

concentration of dust in the air.

When fan power up is available, exhaust and supply fans power up at

1,000 hrs and 2,000 hrs gradually .

If function No. 55 or No. 56 is already worked, fan power up function

may not available.

Estimated hour differs by actual operated fan speed.

DIP-SW

SW No.

SW5-5

Setting

Setting

(Factory setting)

check

- -

- - 1

OFF

ON 3

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

1

Setting

Filter maintenance

check

indicator

0

2 N/A N/A

DIP-SW priority

Indicate at

estimated 3,000 hrs

Indicate at

estimated 3,000 hrs

Fan power

UP

N/A

Available

CAUTION

• When the setting for the cumulative operation time of the

Lossnay is exceeded, the lter cleaning icon will appear

on the indoor unit remote controller or the Lossnay remote

controller. After cleaning the lter, the lter cleaning icon

can be reset. Refer to the Instruction book for the remote

controller.

No. 2

Set to enable Lossnay core maintenance display. Estimated hour

differs by actual operated fan speed.

This function is N/A from Lossnay unit DIP-SW.

SW No.

N/A

Lossnay core maintenance indicator

setting

DIP-SW

Setting

Setting

check

- -

- - 1

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

2

Setting

check

0

Lossnay core

maintenance indicator

N/A

Indicate at estimated 6,000 hrs

No.7

Supply fan speed becomes bigger

than exhaust fan speed.

Remote controller indicates fan

speed of supply fan.

SW No.

SW2-5

No.8

Indoor positive pressure setting

DIP-SW

(Factory setting)

Setting

Setting

check

- -

OFF

ON 2

- - 3

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

7

Fan speed

Display

0

1 N/A

Supply

fan

4 4 3 2

3 3 2 1

2 2 1 1

1 1 1 1

Setting

Down level of exhaust

check

fan speed

DIP-SW priority

Exhaust fan speed is 1

down to supply fan speed

Exhaust fan speed is 2

down to supply fan speed

Max. fan speed setting during the rst 30

minutes

Exhaust fan

1 down 2 down

This sets the fan to run forcibly for 30 minutes when operation starts

to ventilate the indoor area. After 30 minutes, fan speed can be

changed.

Use this setting if the indoor air is contaminated at night when the

system is shut down and you desire to ventilate the indoor area

quickly when operation is started in the morning.

This function is N/A from Lossnay unit DIP-SW.

During this function is working, is displayed at PZ-61DR-E and

selected fan speed is displayed.

DIP-SW

SW No.

N/A

No.9

Setting

Setting

check

- -

- - 1 Available

Delay start setting for air conditioner starting

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

8

Setting

Max. fan speed setting

check

during the rst 30 minutes

0

N/A

No.5

Automatic recovery setting after power

interruption

Sets for automatic recovery following power interruption.

DIP-SW

SW No.

SW5-4

No. 6

(Factory setting)

Setting

Setting

check

- -

OFF

- - 2

ON 3

Indoor negative pressure setting

Exhaust fan speed becomes

bigger than supply fan speed.

Remote controller indicates fan

speed of exhaust fan.

DIP-SW

SW No.

SW2-4

(Factory setting)

Setting

Setting

check

- -

OFF

ON 2

- - 3

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

5

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

6

Setting

Automatic recovery

check

0

1

Fan speed

Display

0

1 N/A

DIP-SW priority

Stop when the power is on

Start when the power is on

Lossnay returns to the

state before interruption

Exhaust

fan

4 4 3 2

3 3 2 1

2 2 1 1

1 1 1 1

Setting

Down level of supply fan

check

speed

DIP-SW priority

Supply fan speed is 1

down to exhaust fan speed

Supply fan speed is 2

down to exhaust fan speed

Supply fan

1 down 2 down

Delays Lossnay operation for 30 minutes when City Multi or Mr. Slim

starts operating or when a external device starts operating.

This function is available only when Lossnay is interlocked with air

conditioners. This function is N/A during Night-purge.

DIP-SW

SW No.

SW5-1

(Factory setting)

No.13

Setting

Setting

check

- -

OFF

- - 2 15 min

ON 3 30 min

Exhaust fan setting during air conditioner

defrosting

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

9

Setting

Lossnay delay start

check

0

1 N/A

DIP-SW priority

This function can be used under the condition Lossnay supply duct is

connected to Mr. Slim or City Multi indoor unit.

Sets the operation of the exhaust fan during defrosting of the air

conditioner (when supply fan stop).

To enable this function, it is necessary to set the DIP-SW of the

indoor unit also. Please refer to its manual.

DIP-SW

SW No.

SW5-3

Setting

Setting

(Factory setting)

check

- -

ON 1 Stop

OFF

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

13

Setting

Exhaust fan operation during

check

air conditioner defrosting

0

2 No change

DIP-SW priority

Eng-15

Page 17

Function settings (continued)

No.14

Exhaust fan setting at OA temperature

lower than -15 ˚C

Sets the operation of the exhaust fan when the outdoor air is lower

than -15 ˚C (when supply fan stop).

DIP-SW

SW No.

SW5-3

SW5-9

Setting

Setting

5-3 OFF

5-9 ON

5-3 ON

5-9 OFF

5-3 OFF

5-9 OFF

(Factory setting)

5-3 ON

5-9 ON

check

- -

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

14

Setting

Exhaust fan operation at

check

outdoor temp. -15 ˚C or less

0

1 Stop

2

3 No change

DIP-SW priority

Forced to fan speed 2

or less*

* In case Lossnay is operating fan speed 1, exhaust fan keeps fan

speed 1. Function No. 13 and No. 14 are included in DIP-SW 5-3,

then it is impossible to set independently without PZ-61DR-E.

No.15

Interlock mode setting

These settings indicate how Lossnay should operate when external

devices are started or stopped.

DIP-SW

SW No.

5-7 OFF

5-8 OFF

(Factory setting)

5-7 ON

5-8 OFF

SW5-7

SW5-8

5-7 OFF

5-8 ON

5-7 ON

5-8 ON

No.28

Setting

Setting

check

- -

Pulse input setting

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

15

Setting

Interlock setting

check

0

1

2

3

4

DIP-SW priority

The Lossnay will start and stop

according to the operation of the

external devices. Subsequent

operation will be possible using

the remote controller for the

Lossnay or MELANS.

The Lossnay will start whenever

external devices are operated.

Lossnay stop operation will

be possible using its remote

controller or MELANS.

The Lossnay will stop whenever

external devices are stopped.

Lossnay start operation will

be possible using its remote

controller or MELANS.

The Lossnay will start and stop

according to the operation of

the external devices. Control

via the Lossnay remote

controller or MELANS will only

be possible when external

devices are stopped.

Set external input signal type from external device for TM2.

DIP-SW

SW No.

SW2-2

Setting

Setting

(Factory setting)

check

- -

OFF

ON 2 Pulse input

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

28

Setting

Pulse input setting

check

0

1 NOT pulse input

DIP-SW priority

No.30

Night-purge setting 1)

Air volume

Set fan speed during Night-purge. To use Night-purge function, it is

necessary to set No. 30 , No. 31 , No. 32 correctly.

This function is N/A from Lossnay unit DIP-SW.

DIP-SW

SW No.

N/A

No.31

Setting

Setting

check

- -

- - 1 Fan speed 1

- - 2 Fan speed 2

- - 3 Fan speed 3

- - 4 Fan speed 4

Night-purge setting 2)

Outdoor and indoor temperature gap

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

30

Setting

Night-purge setting 1)

check

Air volume

0

N/A (Night-purge

function is not available)

Set one of conditions for Night-purge start, temperature gap between

indoor and outdoor.

When the actual gap between indoor and outdoor becomes bigger

than the setting, Night-purge starts.

This function is N/A from Lossnay unit DIP-SW.

DIP-SW

SW No.

N/A

No.32

Setting

Setting

check

- -

- - 1

- - 2

- - 3

- - 4

- -

- - 6

- - 7

Night-purge setting 3)

Threshold of outdoor temperature

PZ-61DR-E

Function No.

Setting Data

31

(Factory setting)

Setting

Indoor temperature -

check

outdoor temperature

0

5

0 ˚C or more

1 ˚C or more

2 ˚C or more

3 ˚C or more

4 ˚C or more

5 ˚C or more

6 ˚C or more

7 ˚C or more

Set one of conditions for Night-purge start, maximum outdoor

temperature within the last setting hours at function No.33 .

When this setting temperature is low, it is likely to start Night-purge.

This function is N/A from Lossnay unit DIP-SW.

The maximum outdoor

Setting

temp. within the last setting

check

hours at function No.33

or more

17 ˚C

or more

or more

or more

or more

or more

or more

or more

or more

or more

or more

or more

or more

or more

or more

SW No.

N/A

DIP-SW

Setting

Setting

check

- -

- - 1 16 ˚C

- -

- - 3 18 ˚C

- - 4 19 ˚C

- - 5 20 ˚C

- - 6 21 ˚C

- - 7 22 ˚C

- - 8 23 ˚C

- - 9 24 ˚C

- - 10 25 ˚C

- - 11 26 ˚C

- - 12 27 ˚C

- - 13 28 ˚C

- - 14 29 ˚C

- - 15 30 ˚C

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

32

0 15 ˚C or more

2

Eng-16

Page 18

Function settings (continued)

English

No.33

Night-purge setting 4)

Time span for memorizing

Set one of conditions for Night-purge start, time span for memorizing

the threshold of outdoor temperature.

For example;

If Lossnay unit operates everyday, please set “24 hrs (factory

setting)”.

If Lossnay unit stops during weekend, please set “72 hrs” so that

Lossnay can start Night-purge in the Monday morning.

This function is N/A from Lossnay unit DIP-SW.

DIP-SW

SW No.

N/A

No.34

Setting

Setting

check

- -

- - 1 48 hrs

- - 2 72 hrs

Input priority setting

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

33

Time span for memoriz-

Setting

ing

check

0

24 hrs

Set to follow input to the main unit from air conditioner, fan speed

controller, etc.

This function is N/A from Lossnay unit DIP-SW.

DIP-SW

SW No.

N/A

No.36

Setting

Setting

check

- -

- - 1 Individual input priority

Outdoor temperature display setting

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

34

Setting

Input priority setting

check

0

Main unit input priority

No.39, 40

Temperature exchange efciency

setting

Set the 10 digit of temperature exchange efciency which is used to

calculate supply air temperature.

This function is N/A from Lossnay unit DIP-SW.

SW No.

N/A

SW No.

N/A

DIP-SW

DIP-SW

Setting

Setting

Setting

check

- -

- - 1 1

- - 2 2

- - 3 3

- - 4 4

- - 5 5

- - 6 6

- -

- - 8 8

- - 9 9

Setting

check

- -

- - 1 1

- - 2 2

- - 3 3

- - 4 4

- - 5 5

- - 6 6

- - 7 7

- - 8 8

- - 9 9

PZ-61DR-E

Function No.

Setting Data

39

(Factory setting)

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

40

Setting

check

0 0

7

Setting

check

0

10 digit of temperature

exchange efciency

7

1 digit of temperature

exchange efciency

0

Set to display outdoor temperature detected by Lossnay unit

thermistor or not.

This function is N/A from Lossnay unit DIP-SW.

DIP-SW

SW No.

N/A

No.37

Setting

Setting

check

- -

- - 1

Indoor temperature display setting

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

36

Setting

Outdoor temperature

check

display

0

N/A

Display on the screen of

PZ-61DR-E

Set to display indoor temperature detected by Lossnay unit thermistor

or not.

This function is N/A from Lossnay unit DIP-SW.

DIP-SW

SW No.

N/A

No.38

Setting

Setting

check

- -

- - 1

Calculated supply air temperature display

setting

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

37

Setting

Indoor temperature

check

display

0

N/A

Display on the screen of

PZ-61DR-E

Set to display calculated supply air temperature or not.

This function is N/A from Lossnay unit DIP-SW.

DIP-SW

SW No.

N/A

Setting

Setting

check

- -

- - 1

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

38

Setting

Calculated supply

check

temperature display

0

N/A

Display on the screen of

PZ-61DR-E

No.41

Outdoor temperature correction

Set the correction for the outdoor temperature displayed on the

PZ-61DR-E screen by function No. 36 .

This function is N/A from Lossnay unit DIP-SW.

SW No.

N/A

DIP-SW

Setting

Setting

check

- -

- - 1 -6 ˚C

- - 2 -5 ˚C

- - 3 -4 ˚C

- - 4 -3 ˚C

- - 5 -2 ˚C

- - 6 -1 ˚C

- -

- - 8 +1 ˚C

- - 9 +2 ˚C

- - 10 +3 ˚C

- - 11 +4 ˚C

- - 12 +5 ˚C

- - 13 +6 ˚C

- - 14 +7 ˚C

PZ-61DR-E

Function No.

Setting Data

41

(Factory setting)

Setting

The correction to

check

thermistor detection

0 -7 ˚C

7

0 ˚C

Eng-17

Page 19

Function settings (continued)

No.42

Indoor temperature correction

Set the correction for the indoor temperature displayed on the

PZ-61DR-E screen by function No. 37 .

This function is N/A from Lossnay unit DIP-SW.

DIP-SW

SW No.

N/A

No.51

Setting

Setting

check

- -

- - 1 -6 ˚C

- - 2 -5 ˚C

- - 3 -4 ˚C

- - 4 -3 ˚C

- - 5 -2 ˚C

- - 6 -1 ˚C

- -

- - 8 +1 ˚C

- - 9 +2 ˚C

- - 10 +3 ˚C

- - 11 +4 ˚C

- - 12 +5 ˚C

- - 13 +6 ˚C

- - 14

Automatic ventilation mode setting

PZ-61DR-E

Function No.

Setting Data

42

(Factory setting)

Setting

The correction to

check

thermistor detection

0 -7 ˚C

7

0 ˚C

+7 ˚C

Set the pattern of conditions to go into By-pass mode in automatic

ventilation operation.

When setting Data is set “3” by PZ-61DR-E, function No. 52 , No. 53 ,

and No. 54 are available.

DIP-SW

SW No.

SW2-7

Setting

Setting

(Factory setting)

check

- -

OFF

ON 2

- - 3 Free setting

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

51

Setting

Conditions to go into

check

By-pass mode

0

1

DIP-SW priority

Pattern A

Indoor temperature is 16 ˚C or more

Outdoor temperature is 16 ˚C or more

Indoor temperature -

outdoor temperature ≥ 0 ˚C

Pattern B

Indoor temperature is 22 ˚C or more

Outdoor temperature is 18 ˚C or more

Indoor temperature -

outdoor temperature ≥ 2 ˚C

* Pattern A is more likely to become By-pass mode than pattern B.

Note;

The ventilation mode follows the table below.

Remote controller

Energy recovery

ventilation mode

By-pass ventilation

mode

Automatic

Interlocked air conditioner

(Mr. Slim or City Multi)

Either Yes or No

Cooling/Stop Automatic (Follows the map)

Other than above

Lossnay

Energy recovery ventilation

mode

By-pass ventilation mode

Always energy recovery

ventilation mode

No.52

Automatic ventilation mode setting 1)

Outdoor and indoor temperature gap

Set one of conditions for By-pass mode in auto ventilation operation,

temperature gap between indoor and outdoor.

This function is N/A from Lossnay unit DIP-SW.

This function is available when setting Data 3 is selected at function

No. 51.

DIP-SW

SW No.

N/A

No.53

Setting

Setting

check

- -

- - 1 1 ˚C or more

- - 2 2 ˚C or more

- - 3 3 ˚C or more

- - 4 4 ˚C or more

- - 5 5 ˚C or more

- - 6 6 ˚C or more

- - 7 7 ˚C or more

Automatic ventilation mode setting 2)

The lowest outdoor temperature

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

52

Setting

Indoor temperature -

check

outdoor temperature

0

0 ˚C or more

Set one of conditions for By-pass mode in auto ventilation operation,

minimum outdoor temperature which comes in indoor directly.

This function is N/A from Lossnay unit DIP-SW.

This function is available when setting Data 3 is selected at function

No. 51.

SW No.

N/A

DIP-SW

Setting

Setting

check

- -

- - 1 11 ˚C or more

- - 2 12 ˚C or more

- - 3 13 ˚C or more

- - 4 14 ˚C or more

- - 5 15 ˚C or more

- -

- - 7 17 ˚C or more

- - 8 18 ˚C or more

- - 9 19 ˚C or more

- - 10 20 ˚C or more

- - 11 21 ˚C or more

- - 12 22 ˚C or more

- - 13 23 ˚C or more

- - 14 24 ˚C or more

- - 15 25 ˚C or more

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

53

Setting

Outdoor temperature

check

0 10 ˚C or more

6

16 ˚C or more

Eng-18

Page 20

Function settings (continued)

English

No.54

Automatic ventilation mode setting 3)

The lowest indoor temperature setting

Set one of conditions for By-pass mode in auto ventilation operation,

minimum indoor temperature.

This function is N/A from Lossnay unit DIP-SW.

This function is available when setting Data 3 is selected at function

No. 51.

When Lossnay is interlocked to Mr. Slim or City Multi indoor unit, the

target temperature of the indoor unit is the lowest indoor temperature

for By-pass mode

DIP-SW

SW No.

N/A

Setting

Setting

check

- -

- -

- - 2 17 ˚C or more

- - 3 18 ˚C or more

- - 4 19 ˚C or more

- - 5 20 ˚C or more

- - 6 21 ˚C or more

- - 7 22 ˚C or more

- - 8 23 ˚C or more

- - 9 24 ˚C or more

- - 10 25 ˚C or more

- - 11 26 ˚C or more

- - 12 27 ˚C or more

- - 13 28 ˚C or more

- - 14 29 ˚C or more

- - 15 30 ˚C or more

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

54

Setting

Indoor temperature

check

0 15 ˚C or more

1

16 ˚C or more

Free By-pass setting

User can set conditions to go into By-pass mode in automatic

ventilation mode by function No. 52 , No. 53 and No. 54.

Setting examples are shown below.

Example 1*

By-pass/Energy recovery ventilation map in automatic ventilation

mode

40

38

36

34

32

30

28

26

24

Set by function No. 54

22

(Terget temp. of air conditioner)

20

Outdoor temperature (˚C)

18

16

14

12

10

8

8

Energy recovery ventilation area

Set by function No. 52

By-pass ventilation area

Set by function No. 53

1210 14 1816 20 22 24 26 28 30 32 34 36 38 40

Indoor temperature (˚C)

Function No. Setting Data

52 0 (0 ˚C)

53 0 (10 ˚C)

54 2 (17 ˚C)

Example 2

By-pass/Energy recovery ventilation map in automatic ventilation

mode

40

38

36

34

32

30

28

26

24

22

20

Outdoor temperature (˚C)

18

16

14

Set by function No. 54

12

(Terget temp. of air conditioner)

10

8

8

Energy recovery ventilation area

Set by function No. 52

By-pass ventilation area

Set by function No. 53

1210 14 1816 20 22 24 26 28 30 32 34 36 38 40

Indoor temperature (˚C)

Function No. Setting Data

52 5 (5 ˚C)

53 1 (11 ˚C)

54 7 (22 ˚C)

When the setting of Function No. 53 is low, with using the pre-

heater function, the outdoor temperature may be detected as

higher and the mode may change to By-pass mode even in winter.

Set the setting 16 ˚C or more, or use energy recovery ventilation

mode.

No.55, 56

Supply fan power up setting

Exhaust fan power up setting

Use these functions when the air volume is needed to be up after

installation.

Function No. 55 is for supply fan power up and function No. 56 is for

exhaust fan power up.

When function No. 1 is on and fan speed already reached the

maximum power, this function is N/A.

These functions are N/A from Lossnay unit DIP-SW.

SW No.

N/A

SW No.

N/A

DIP-SW

DIP-SW

Setting

Setting

Setting

check

- -

- - 1 1 level up

- - 2 2 level up

- - 3 3 level up

- - 4 4 level up

Setting

check

- -

- - 1 1 level up

- - 2 2 level up

- - 3 3 level up

- - 4 4 level up

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

55

PZ-61DR-E

Function No.

Setting Data

(Factory setting)

56

Setting

Supply fan power up