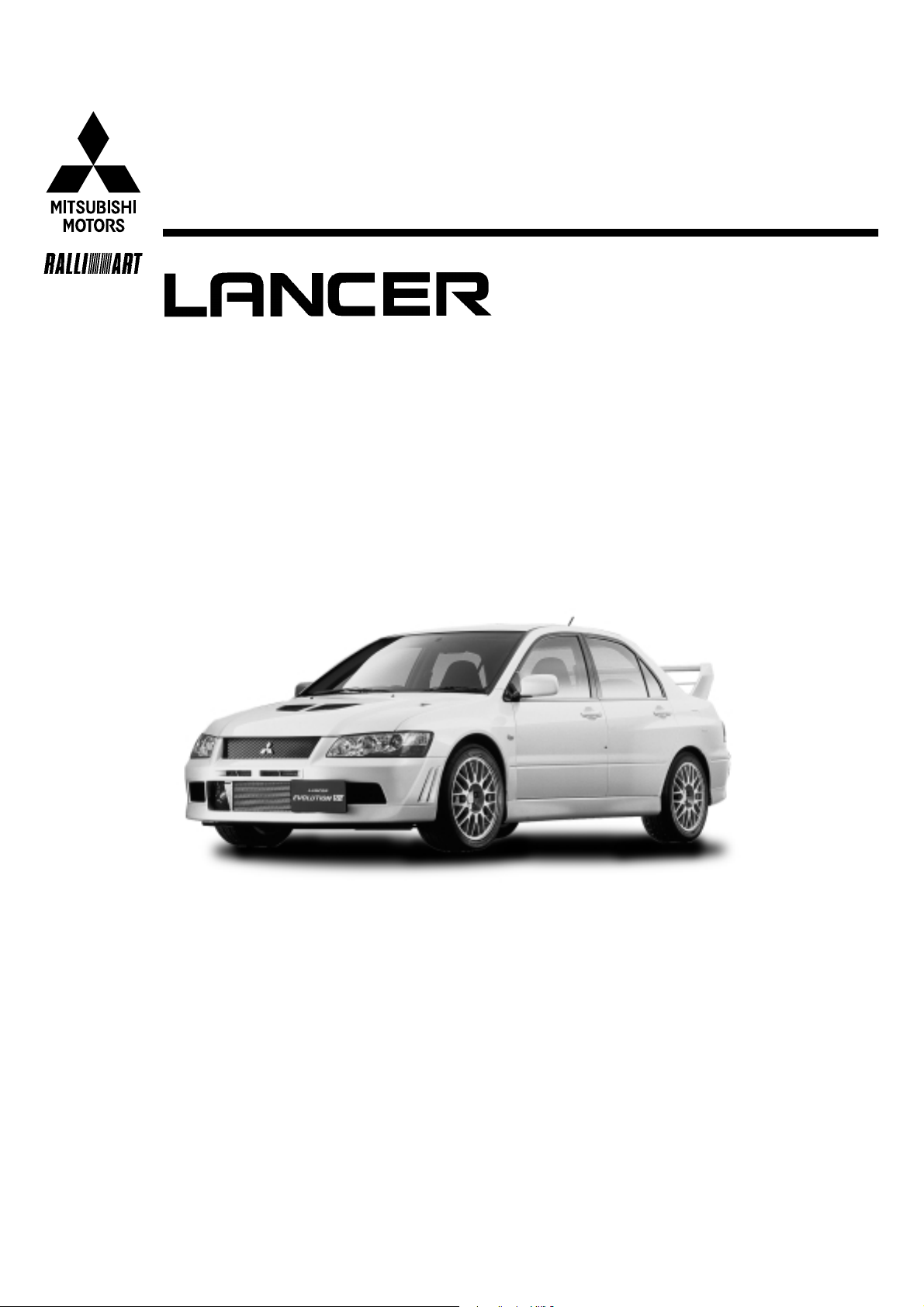

Page 1

TECHNICAL INFORMATION MANUAL

EVOLUTION-VII

Pub. No. N0104CT9A

www.TuningEvo.Club

Page 2

GROUP INDEX

TECHNICAL

INFORMATION

MANUAL

FOREWORD

This manual has been prepared as an introduction

to the specifications, features, construction, functions, etc. of the newly developed LANCER EVOLUTION-VII. Please read this manual carefully so that

it will be of assistance for your service activities.

Please note that the following service manuals are

also available and should be used in conjunction

with this manual.

WORKSHOP MANUAL S0105CT9A

All information, illustrations and product descriptions contained in this manual are current as of the

time of publication. We, however, reserve the right

to make changes at any time without prior notice or

obligation.

GENERAL .......................

ENGINE .........................

POWER TRAIN ..................

DRIVE-CONTROL

COMPONENTS ..................

BODY ...........................

EXTERIOR ......................

INTERIOR .......................

EQUIPMENT .....................

0

1

2

3

4

5

6

7

The EVOLUTION-VII is sold exclusively through

RALLIART Inc. Since the EVOLUTION-VII is a rallybased model, it will not be warranted and will not be

homologated for general production. Therefore, any

service matters on the EVOLUTION-VII should be

inquired to RALLIART Inc. as usual.

E Mitsubishi Motors Corporation April 2001

Page 3

NOTES

Page 4

GENERAL

CONTENTS

0-1

HOW TO USE THIS MANUAL 2..............

Model Indications 2............................

TARGETS OF DEVELOPMENT 2..............

PRODUCTS FEATURES 2....................

TECHNICAL FEATURES 4....................

Exterior 4.....................................

Interior 5......................................

Body Dimensions and Spacious Cabin 6.........

Aerodynamic Performance 6....................

Active Center Differential (ACD), Active Yaw

Control (AYC) 7................................

Engine 8......................................

Transmission 8.................................

All-wheel Independent Suspensions 8............

Safety 10......................................

Equipments 13.................................

Serviceability and Reliability 13..................

VEHICLE IDENTIFICATION 14.................

MAJOR SPECIFICATIONS 15.................

Page 5

0-2

GENERAL -

How to Use This Manual/Targets of Development/Product Features

HOW TO USE THIS MANUAL

MODEL INDICATIONS

The following abbreviations are used in this manual for identification of model types.

MPI: Indicates the multipoint injection, or engine equipped with the multipoint injection.

DOHC: Indicates an engine with the double overhead camshaft, or models equipped with such an engine.

M/T: Indicates the manual transmission, or models equipped with the manual transmission.

A/C: Indicates the air conditioner.

TARGETS OF DEVELOPMENT

A new competitive device in addition to technology established in the previous motor sport events to

improve potential performance as well as outward and inward appearance with a sophisticated view to

represent a high performance sedan of the next generation has been featured to improve the image

of Mitsubishi brand.

Furthermore, enhancement of competitiveness as well as driving performance in various motor sport

events has been sought.

PRODUCT FEATURES

Outward and inward appearance

to represent a

high performance sedan of

the next generation

The most outstanding engine

and power performance in the

class

(1) Exterior with sophisticated and fearless expression

D Multi-lighted headlamp and rear combination lamp exclusively used

for EVOLUTION-VII

D Front bumper with large cooling air inlet

D Incorporate blister fender and overwhelming large - sized tyre

D Large- sized and light weight rear spoiler with variable elevation angle

that can be adjusted at 4 points

D Front bumper extension and side sill extension

D Large- sized under cover equipped (for improvement of aerodynamic

and cooling performance in drive system)

(2) Interiors with athletic feeling

D Light weight backet newly designed by RECARO seat (adoption of

silk waving cloth with functionality)

D Steering wheel newly designed by MOMO

D Multi- functional sports meter (with permanent illumination to be visible

in the day light)

(1) Fine tuned engine that provides improved output at all ranges:Maximum

output 280 PS (206 kW) and maximum torque 39 kgfSm (383 NSm)

D mprovement of turbo charger

D Enlarged Intercooler and oil cooler

D Automatic injection control 3 -nozzle intercooler spray

(2) Drive system with high reliability to deal with increased engine torque

D Reinforcement of transfer, propeller shaft, and drive shaft

Page 6

GENERAL -

Product Features

0-3

Further improvement in handling

performance

made by enhancement of the

marginal performance

(1) Mitsubishi original revolutionary technology with all wheel control

D Newly developed active center differential system (ACD) (to be

compatible with steering response to cornering and rising traction

performance)

D Improvement of marginal performance in cornering made by integrated

control of ACD{active yawing control (AYC)

(2) Optimally tuned suspension to be adjusted to the new dimensions has

improved cornering performance.

D Extended length of wheel base (+115 mm), enlarged width of treads

(front: +5 mm, rear: +10 mm)

D Increased suspension stroke in the compression side

(front:+15 mm, rear: +5 mm)

D 235/45ZR17 tyres adopting half- radial structure and newly developed

high performance high grip compounds

NOTE

Figures in the parentheses indicate the numbers compared with those

of EVOLUION-VI.

(3) High rigidity body to sustain high marginal performance

(bend rigidity: increased by 50 %, torsion rigidity: equal to that of

EVOLUTION-VII)

D Suspension mounting, fortification of body frame connections, addition

of reinforcements (approximately 20 locations), and addition of welding

spots

D High rigidity 3- point mounting strut tower bar

D Rear end cross bar<RS>

D Aluminum hood and fender attached

Revolutionary

braking system

to correspond

with high marginal performance

(1) Sporty type 4ABS (improved braking stability derived from braking control

in both sides at driving in sports mode)

(2) EBD system for EVOLUTION-VII (improvement in deceleration

performance)

(3) Featuring Brenvo made front 17- inch ventilated disc (opposite differential

diameter 4 - piston type) and rear 16- inch ventilated disc (opposite

2- piston type)

Page 7

0-4

GENERAL - Technical Features

TECHNICAL FEATURES

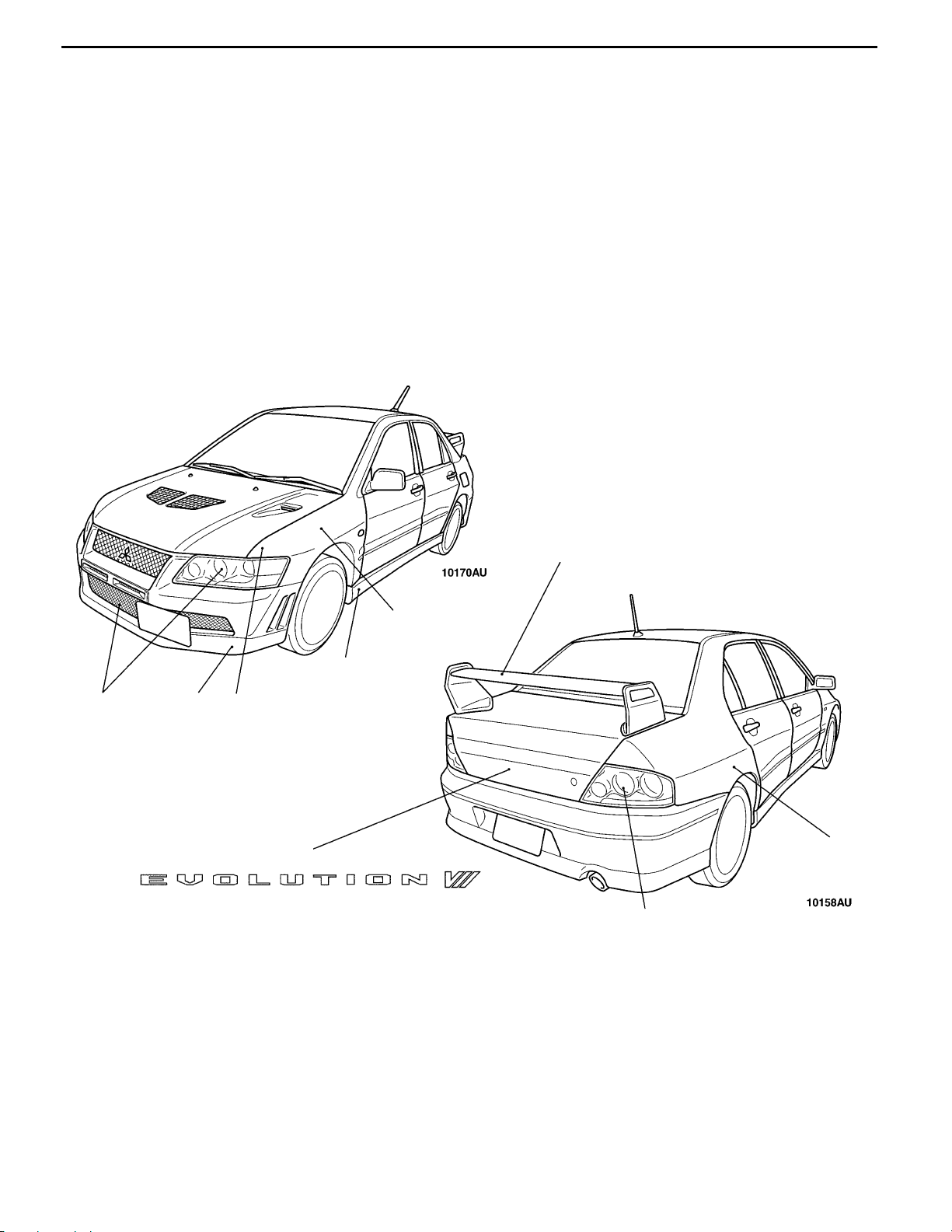

EXTERIOR

DESIGN FEA TURES

The 7th generation EVOLUTION has acquired the

image of “high performance sports sedan” equipped

with guaranteed quality and fearless determination

as “high quality driving sedan” in addition to the

rally image of the previous generations.

(1) Aggressive and overwhelming front mask with

multi- lighted headlamps, large-sized inlet

bumper grill, and side outlet

(2) Improved maneuvering capability of the vehicle

at the corners by cutting a large portion of the

front corner

(3) Exclusive blister fender to appeal good road

hanging (traction characteristics) and brisk

driving capability

(4) Front -side sill extension and wing - type rear

spoiler to emphasize the high aerodynamic

performance

(5) Clear type rear combination lamp to appeal

sporty feeling and guaranteed quality

(6) Attaching the newly designed “EVOLUTION

VII” emblem with sharp and sporty image

(1)

(4)

(4)

(3)

(4)

(2)

(3)

(6)

(5)

Page 8

GENERAL - Technical Features

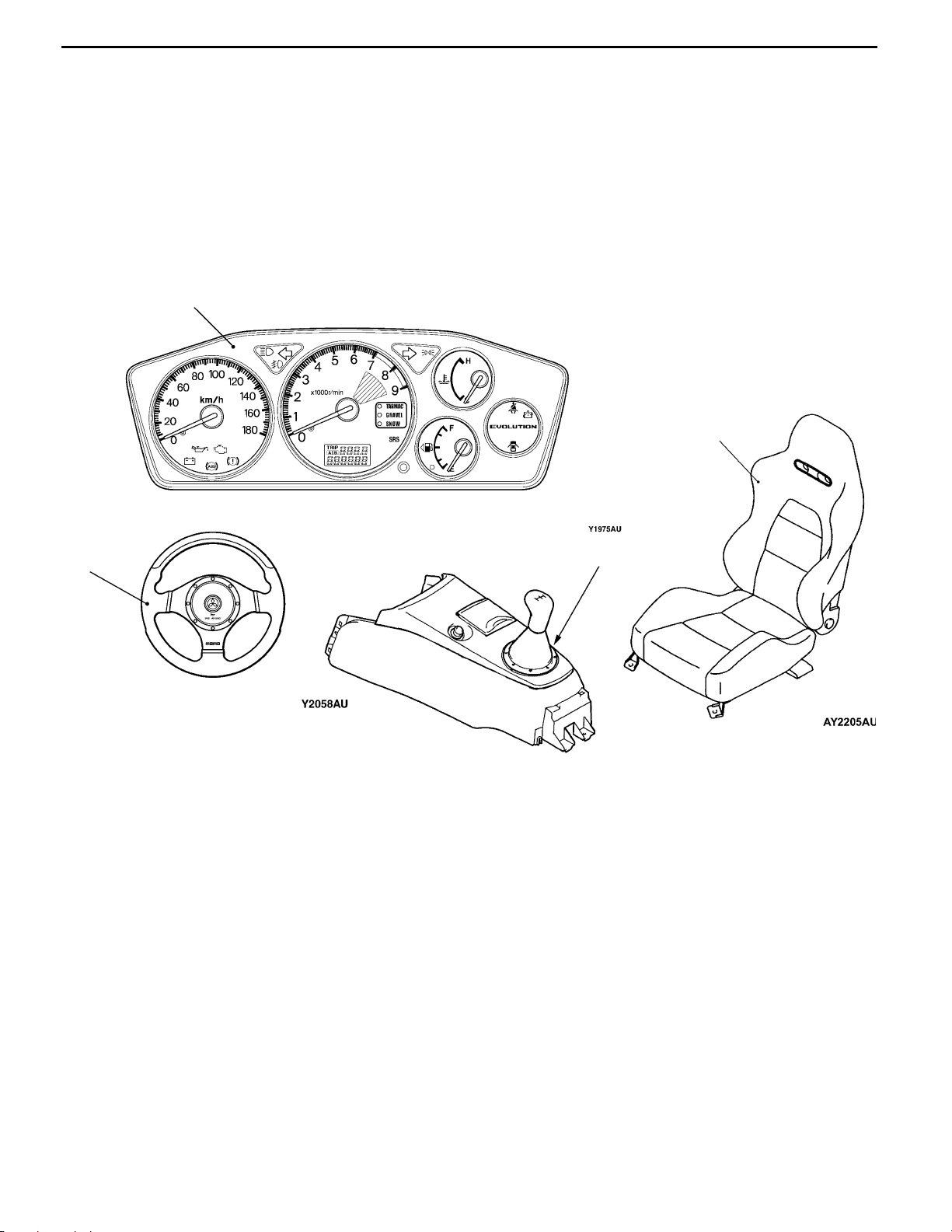

INTERIOR

DESIGN FEA TURES

High performance interior to provide an impression

of sports minded vehicle as the 7th generation

EVOLUTION

(1) Combination meter exclusively for EVOLU-

TION-VII with a configuration of a circular

tachometer in the center and thick bezels

(partitions between meters) with discreet design

create appeal for fearless determination and

sporty feelings.

(1)

0-5

(2) The Mitsubishi original design made by MOMO

used for the steering has the same design used

for horn pad as the shift lever to express

integration of the image and high performance

interior.

(3) The Mitsubishi original design made by Recaro

used for the front seat has a sewing line

surrounding circumference of the sides to

emphasize the good holding.

(3)

(2)

(2)

Page 9

0-6

ith

ith

GENERAL - Technical Features

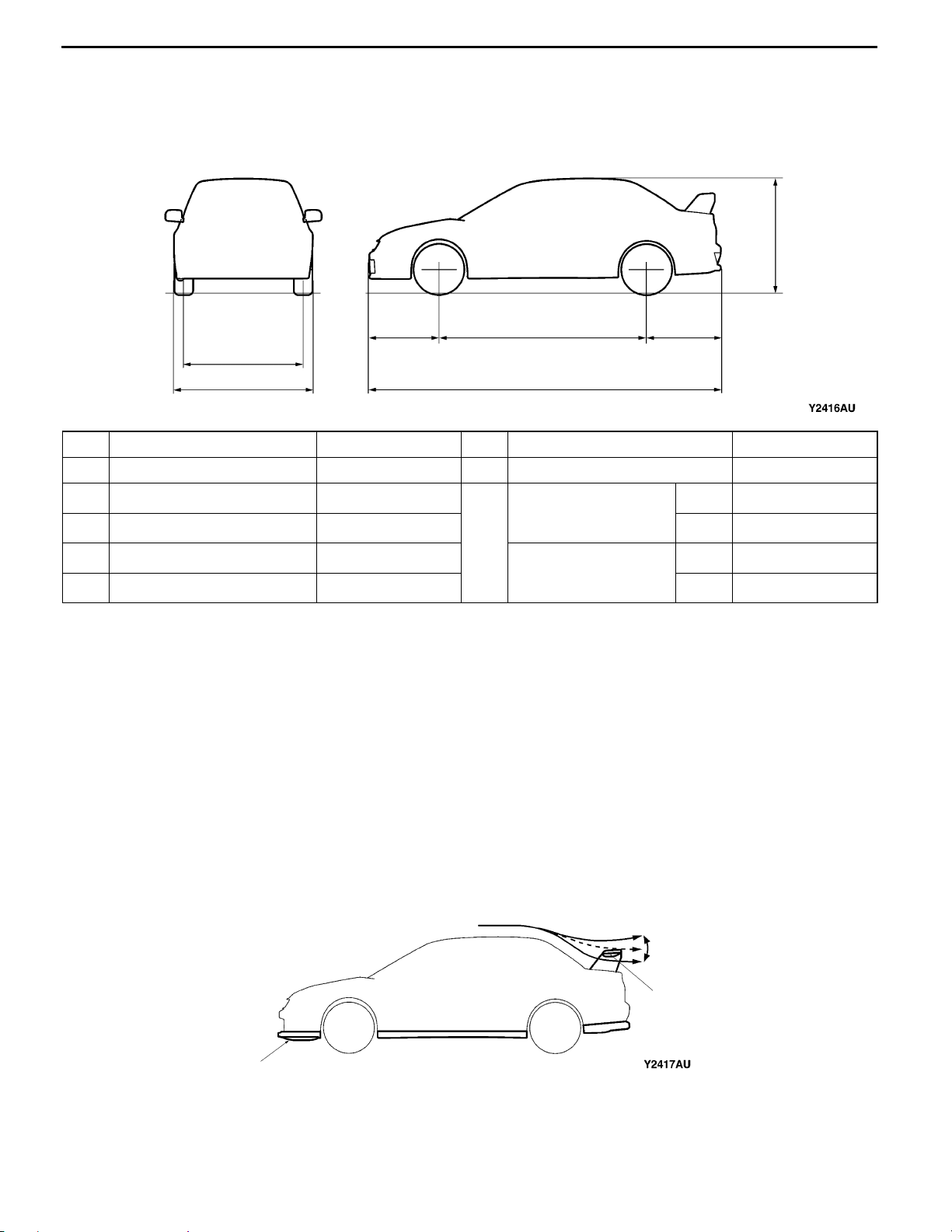

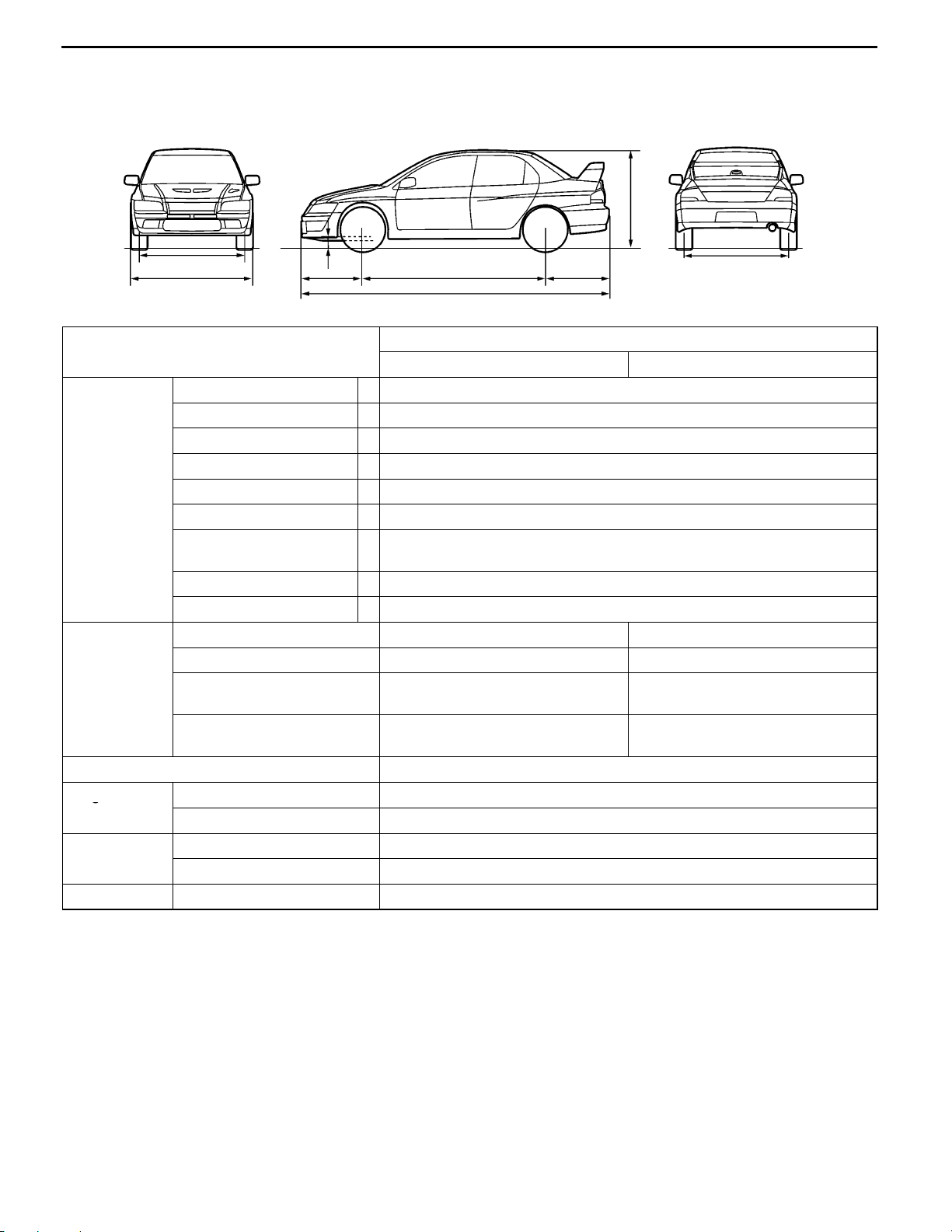

BODY DIMENSIONS AND SPACIOUS CABIN

Body Dimensions

The dimensions of the EVOLUTION-VII except for the overall width have been altered in comparison

with those of EVOLUTION-VI.

3

5

7

2

No. Item Dimensions mm No. Item Dimensions mm

1 Overall length 4 455 (+105) 6 Rear overhang 935 ( - 15)

2 Overall width 1 770 (±0)

3 Overall height 1 450 (+45)

4 Wheel base 2 625 (+115)

5 Front overhang 895 (+5)

7 Tred

4

1

<Vehicles w

235/45ZR17tyres>

Tred

<Vehicles w

205/65R15tyres>

6

Front 1 515 (+5)

Rear 1 515 (+10)

Front 1 500 (+5)

Rear 1 500 (+10)

NOTE

Figures in the parentheses indicate the values in comparison with those of EVOLUTION-VI.

AERODYNAMIC PERFORMANCE

Deterioration of aerodynamic performance accompanied with enlargement of the body size has been

suppressed by attaching a large -sized under cover on the lower part of the engine compartment, optimizing

elevation angle setting of rear spoiler.

(1) Under cover

A large -sized under cover is designed for compatibility of reduction of air resistance and reduction

of lift.

(2) Rear spoiler

Lift control by attaching elevation angle adjustable rear spoiler and optimizing attached position of

the spoiler are designed for reduction of air resistance.

(2)

(1)

Page 10

GENERAL - Technical Features

0-7

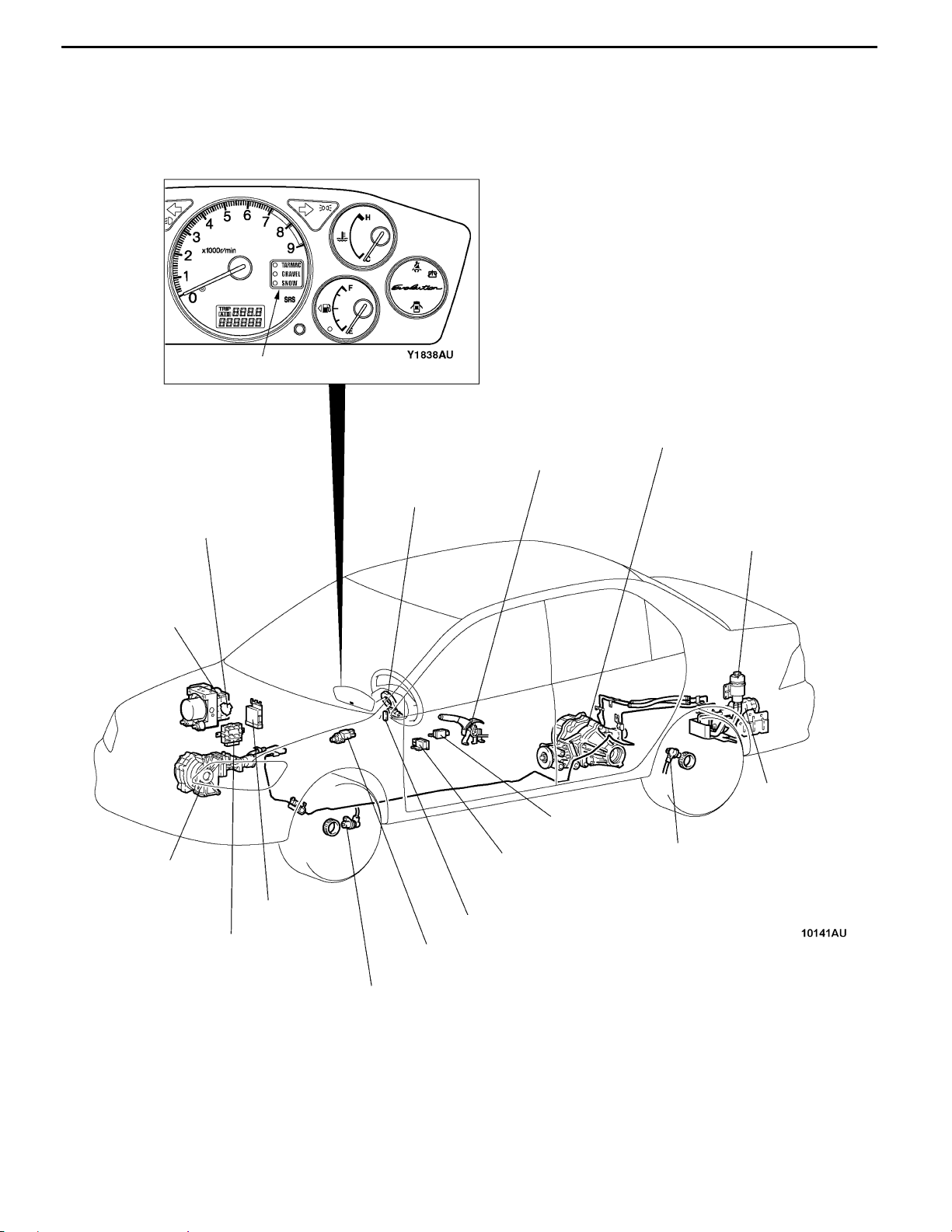

ACTIVE CENTER DIFFERENTIAL (ACD), ACTIVE YAW CONTROL (AYC)

ACD, which is designed for improving drive characteristics by electronically controlling center

differential movement, and AYC, which has been adopted since EVOLUTION-IV are featured by

combing two systems for integrated control so that further improvements in driving performance can

be achieved.

ACD mode indicator lamp

AYC torque transfer

differential

Parking brake switch

Steering wheel

sensor

Throttle position sensor (TPS)

ABS-ECU

ACD transfer

Engine- ECU

4WD-ECU

Longitudinal

G sensor

ACD mode switch

Stop lamp switch

Reserve tank

Hydraulic unit

assembly

Lateral G sensor

Wheel speed sensor

Wheel speed sensor

Page 11

0-8

GENERAL - Technical Features

ENGINE

The turbo charger specifications have been

optimized by reducing the size of the turbine nozzle

diameter to increase the engine torque at

low- middle speed range as well as high speed

range.

TRANSMISSION

Implementation of fortifying each part to deal with

the increased engine torque and revision of the gear

ratio of the standard transmission are intended for

further improvement in power performance.

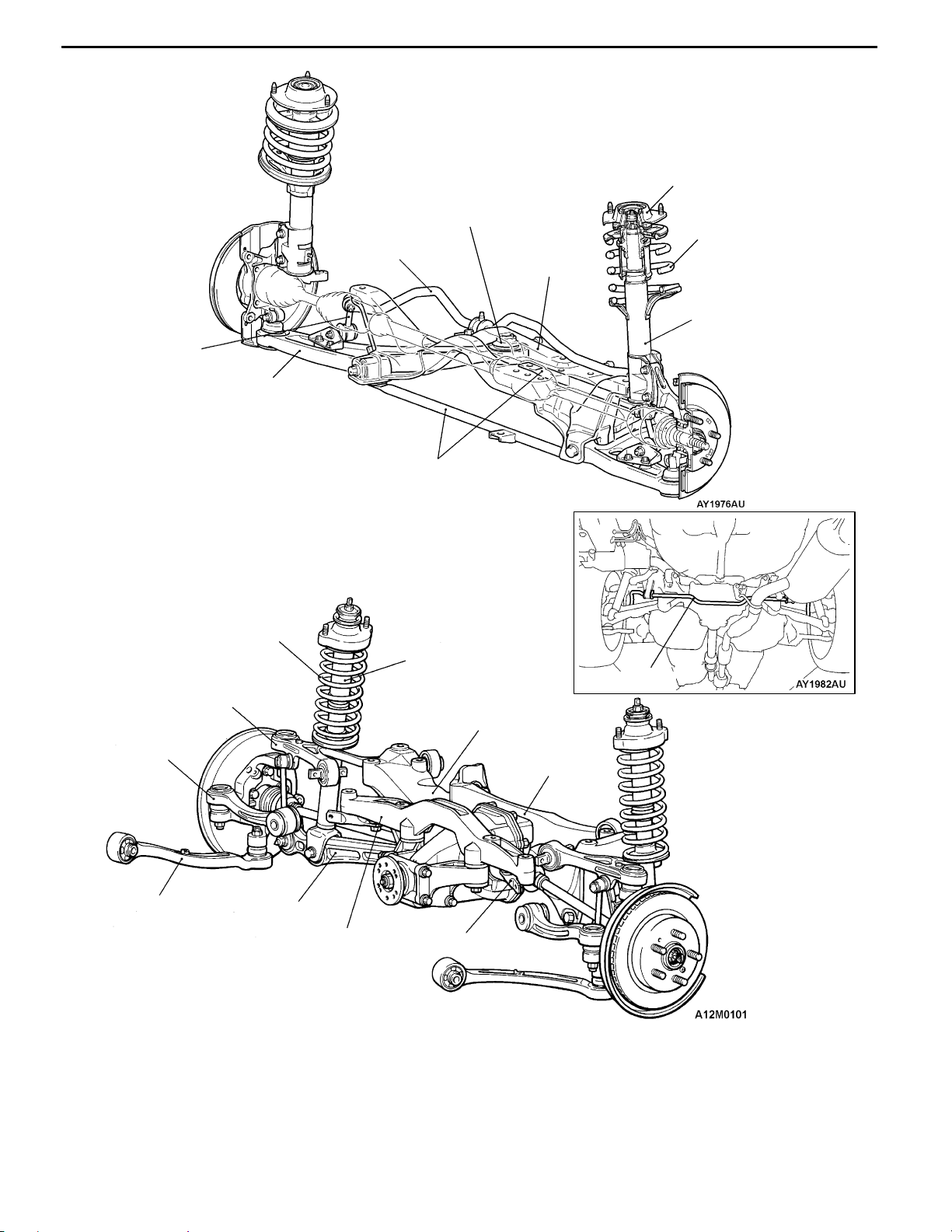

ALL-WHEEL INDEPENDENT SUSPENSIONS

While the popular and rally-proven McPherson strut

front and multi-link rear suspension systems have

basically been retained, they were optimized for

the new model.

The improvements to the front include adding a

crossmember brace to the lower arm mount for

more rigidity, flattening the chassis crossmember,

and realigning the roll center to an ideal height.

As a result, the suspension delivers enhanced

handling and straight-line stability, ride comfort,

grounding characteristics, and roll feel, as well as

less vibrations and noise.

Since adoption of magnesium diecasting rocker

cover and hollow camshaft is intended for light

weight of the upper part of the engine, vibration

of engine- transmission at acceleration can be

reduced to improve the response of the body.

The steering gear’s optimal position ensures

predictably linear toe-in changes.

Each arm of the rear multi-links with trailing arms,

as well as its linkage point and length, was

reevaluated to achieve optimal alignment.

Combined with the wider tracks, higher body rigidity,

and improved damping characteristics of the

bushings and bump rubbers, the suspensions

deliver a supple ride with superb handling stability

for relaxing, effortless control.

Page 12

Stabilizer link

Lower arm

GENERAL - Technical Features

Lower arm bushing

(Pillow ball bushing with rubber)

Stabilizer bar

Crossmember bar

<RS (option), RS-II>

Crossmember

0-9

Strut insulator

Coil spring

Strut assembly

(shock absorber)

Toe control arm

Trailing arm

Coil spring

Upper arm

Lower arm

Differential support

member

Shock absorber

Stabilizer bar

Crossmember

Differential

support arm

Toe control bar <RS>

Page 13

0-10

GENERAL - Technical Features

SAFETY

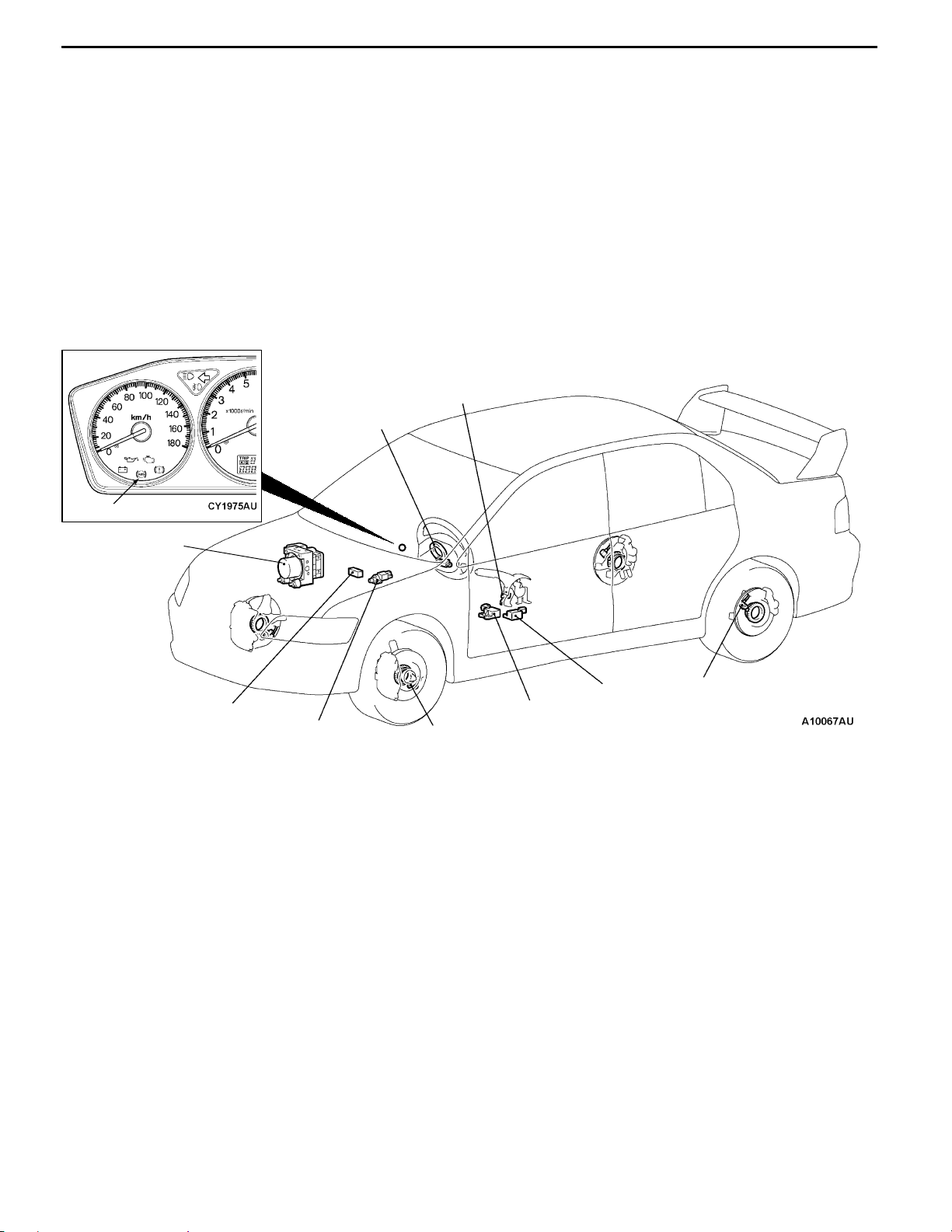

ACTIVE SAFETY

BRAKING SYSTEM

All models feature fade-resistant 14-inch ventilated

discs up front and rear 8-inch drums for sure, linear

stopping power.

A 4-sensor, 3-channel ABS (Anti-lock Braking

System) with EBD (Electronic Brake-force

Distribution) is available. ABS adjusts the braking

pressure of the front wheels independently and

rear wheels together for controlled emergency

braking.

Parking brake switch

Steering wheel sensor

New for the Lancer, EBD works with the ABS

computer to evenly modulate each channel’s

braking pressure for ideal braking force regardless

of load or surface conditions at all times.

ABS warning lamp

Hydraulic unit

(integrated in

ABS-ECU)

Diagnosis connector

Stop lamp switch

Longitudinal G sensor

Wheel speed sensor

Lateral G sensor

Wheel speed sensor

Page 14

GENERAL - Technical Features

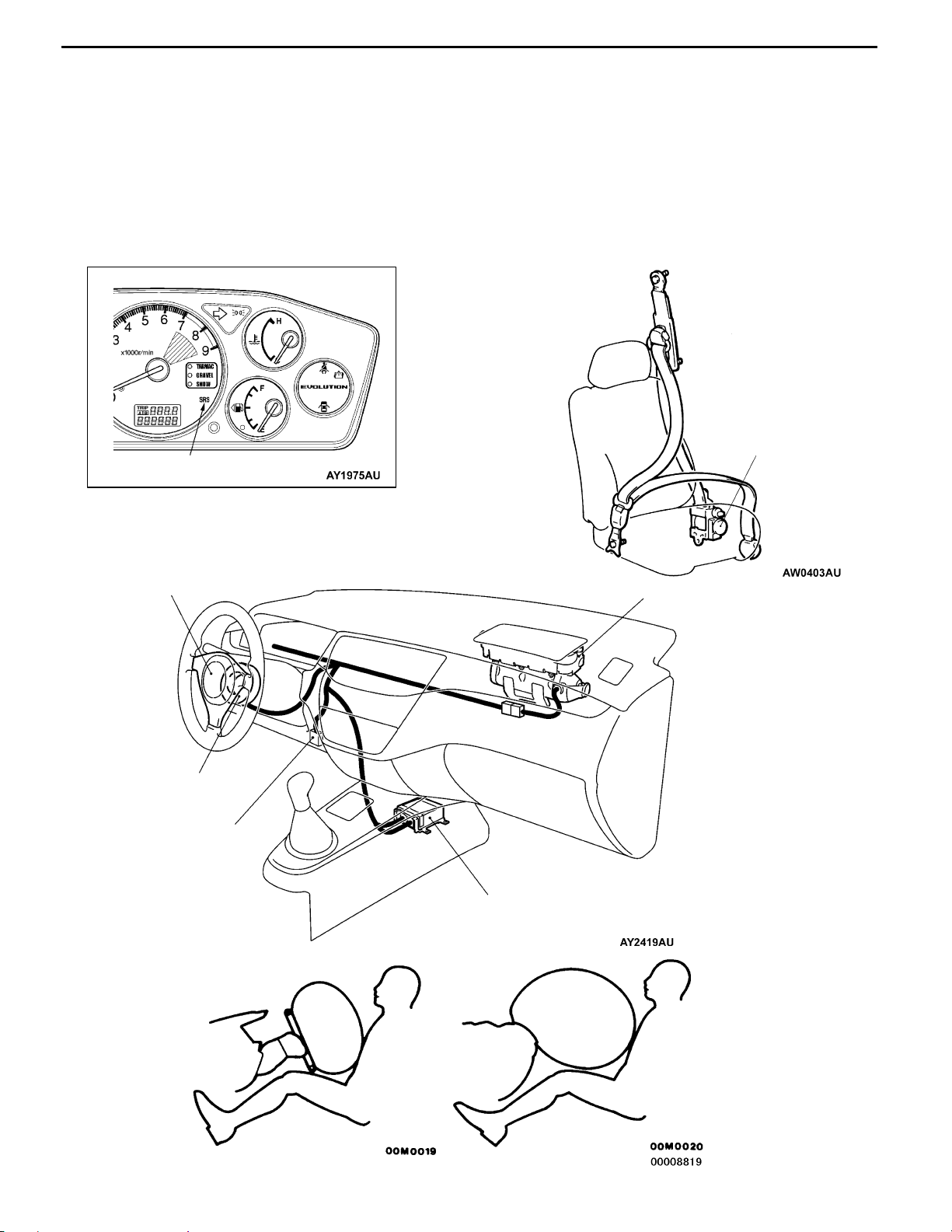

PASSIVE SAFETY

SRS AIR BAGS

Dual SRS (Supplemental Restraint System) front

airbags deploy only upon detection of frontal impact.

When used in combination with the 3-point ELR

seatbelts, they significantly mitigate head and upper

torso injury to front-seat occupants.

SRS warning lamp

0-11

Seat belt with pretensioner featured for the driver’s

and front passenger’s seats is designed for instantly

taking up the slack in the seat belt at the time

of impact to improve restraint effect on a passenger.

It is activated approximately at the same time as

SRS airbag is activated to improve protection effect

on a passenger.

Seat belt with pretensioner

Driver’s side air bag module

Clock spring

Diagnosis connector

Driver’s side Passenger’s side

Front passenger’s side air bag module

SRS- ECU

Page 15

0-12

GENERAL - Technical Features

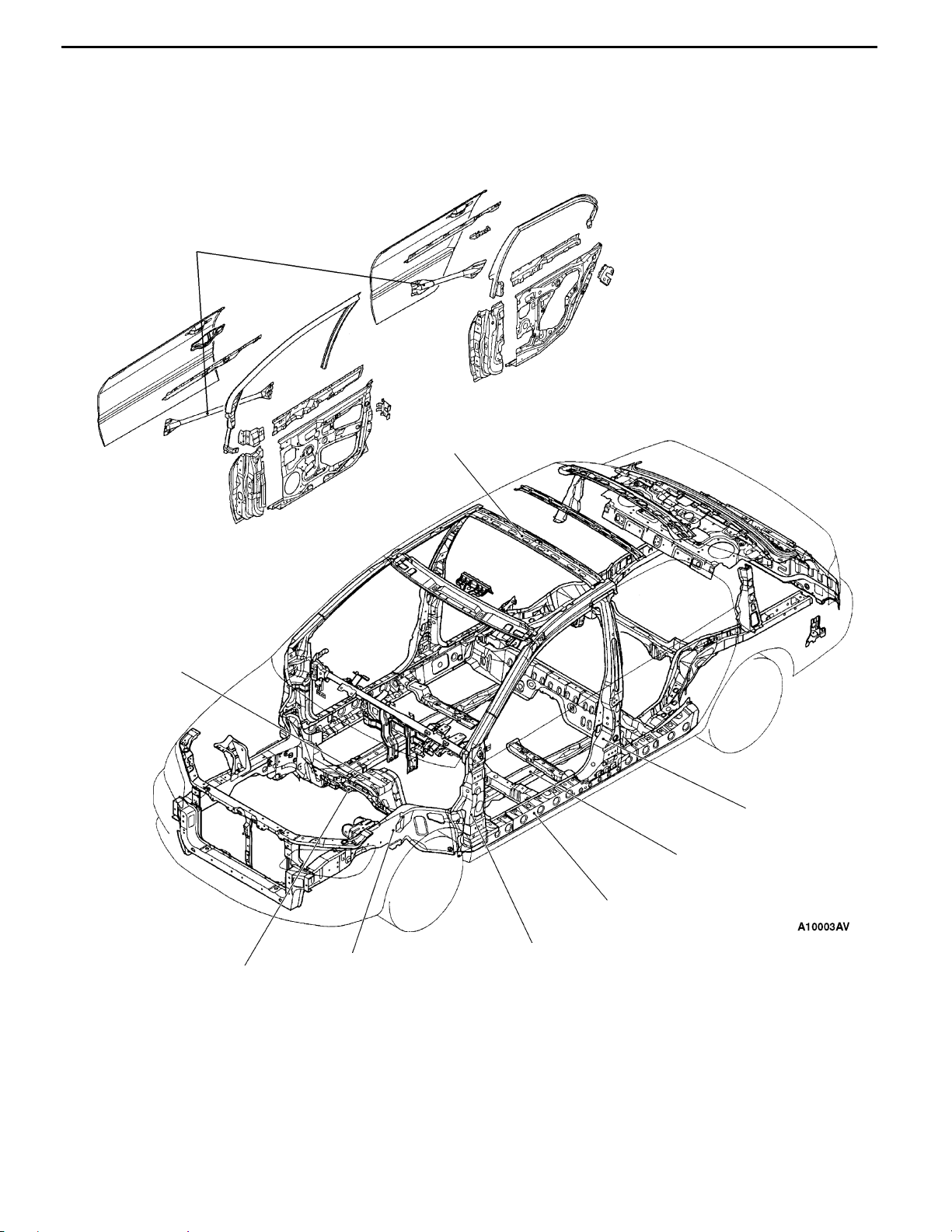

BODY CONSTRUCTION

The EVOLUTION-VII safety-enhanced body

structure comprises front and rear crushable zones

that effectively absorb the impact energy of front

and rear collisions.

Enlarged impact bars

Enlarged cross-section of roof bow

Adding to all-round occupant protection is a

deformation-resistant, highly rigid cabin structure

that features strategic reinforcements plus large

side-door impact bars.

Thicher dash panel lower

Added dash crossmember

Enlarged cross-section and

extended front side member

Reinforced center pillar

Enlarged cross-section and

minimised vertical offset of

front floor side member

Enlarged cross-section

of side sill

Reinforced front pillar

Page 16

GENERAL - Technical FeaturesGENERAL - Technical Features

SAFETY-ENHANCED FRONT SEATS

The front seats are designed to minimise the risk

of whiplash in a collision from the rear.

The headrestraints have been ideally angled

forward, while the seat frame was moved toward

the rear.

OTHER SAFETY FEATURES

D 3-point ELR seatbelts

D Front fog lamps

EQUIPMENTS

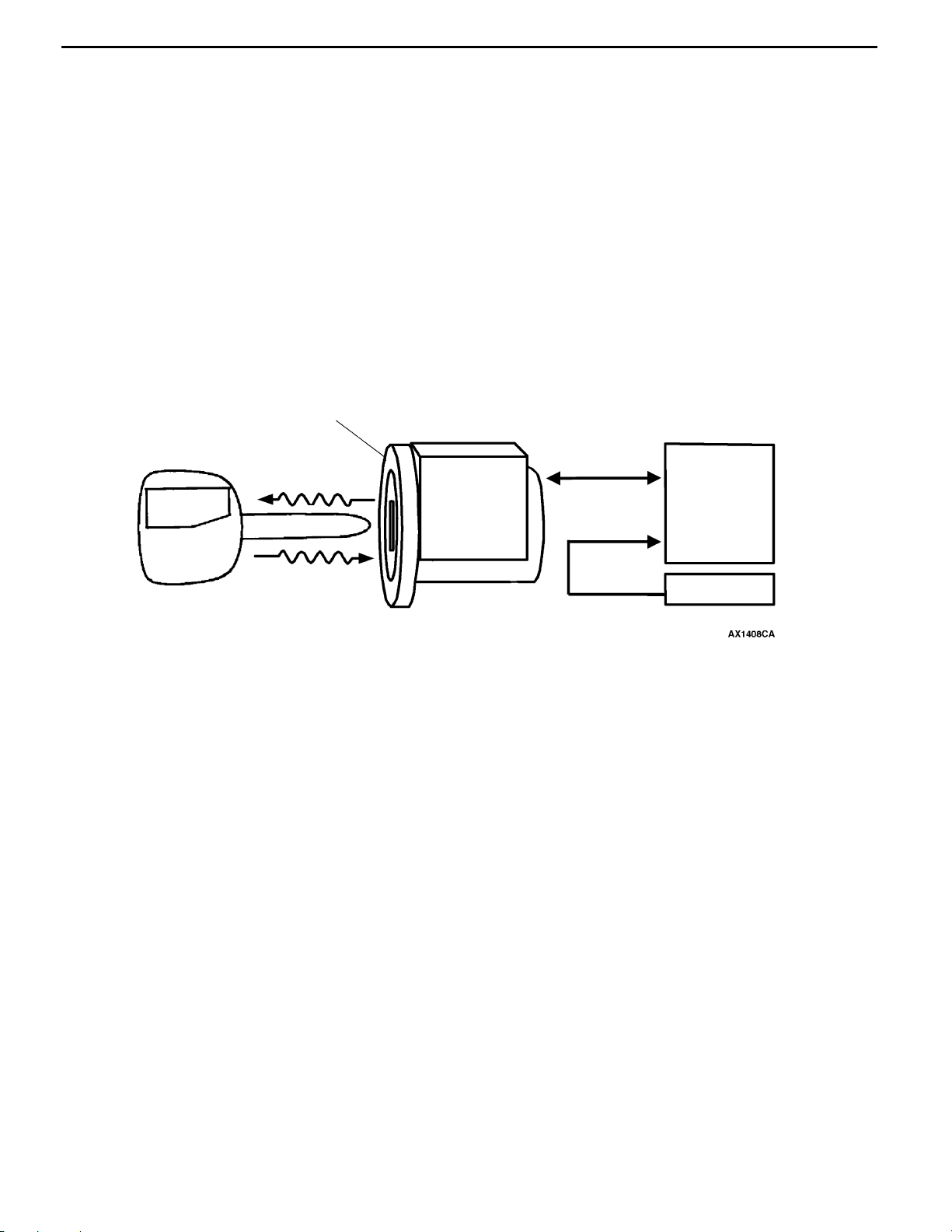

IMMOBILIZER SYSTEM

This system lets the engine be started only when

an encrypted code that is recorded in the ignition

key is the same as an encrypted code that is

Integrated immobilizer-ECU and antenna

Ignition key

Power

Transponder

0-13

In-house tests show a roughly 40% improvement

in occupant injury figures.

D Child-protection rear door locks

recorded in the immobilizer-ECU. Immobilizer

system is equipped as an option.

Start

permission

signal

Engine - ECU

or

Engine A/T-ECU

Encrypted code

Steering lock key

cylinder and immobilizer - ECU

SERVICEABILITY AND RELIABILITY

MAINTENANCE-FREE FEATURES

D Adoption of an auto-tensioner eliminates the

need for timing belt adjustment

ENHANCED DIAGNOSIS SYSTEM

Diagnosis functions have been included for the

following systems, so that it is possible to use the

MUT-II to read the diagnosis codes and service

data and to carry out actuator tests. In addition,

it is also possible to read the diagnosis codes by

the flashing of the warning lamp in some systems.

IMPROVED SERVICEABILITY AND HANDLING

D A one-touch joint type plastic tube has been

adopted for fuel main lines, which makes

removal and installation easier.

MUT- II

Registration

of ignition

key

D Adoption of auto lash adjusters eliminates the

need for valve clearance adjustment

D MPI

D ACD

D AYC

D 4ABS

D SRS air bag

D Simplified Wiring System (SWS)

D A small wiper module, which includes wiper

motor and linkage, has been adopted to

facilitate removal and installation.

Page 17

0-14

16val

)

GENERAL - Vehicle Identification

VEHICLE IDENTIFICATION

MODELS

Model code Class code Grade Engine model Transmission model Fuel supply

system

CT9A SNDFZL/R RS 4G63 (1,997 mL-DOHC-

ves-intercoolerturbo

SNGFZL/R RS-II

MODEL CODE

CT 9 A S N D F L

Z

123456789

No. Items Contents

1 Development CT: MITSUBISHI LANCER

2 Engine type 9: 1,997 mL petrol engine

3 Sort A: Passenger car

4 Body style S: 4-door sedan

5 Transmission type N: 5-speed manual

6 Trim level D: RS

7 Specification engine

feature

W5M51 <4WD-5M/T> MPI

EVOLUTION-VII

transmission

G: RS-II

F: MPI-DOHC

8 Special feature Z: 4WD

9 Steering wheel location L: Left hand

R: Right hand

Page 18

GENERAL - Major Specifications

mm

g

MAJOR SPECIFICATIONS

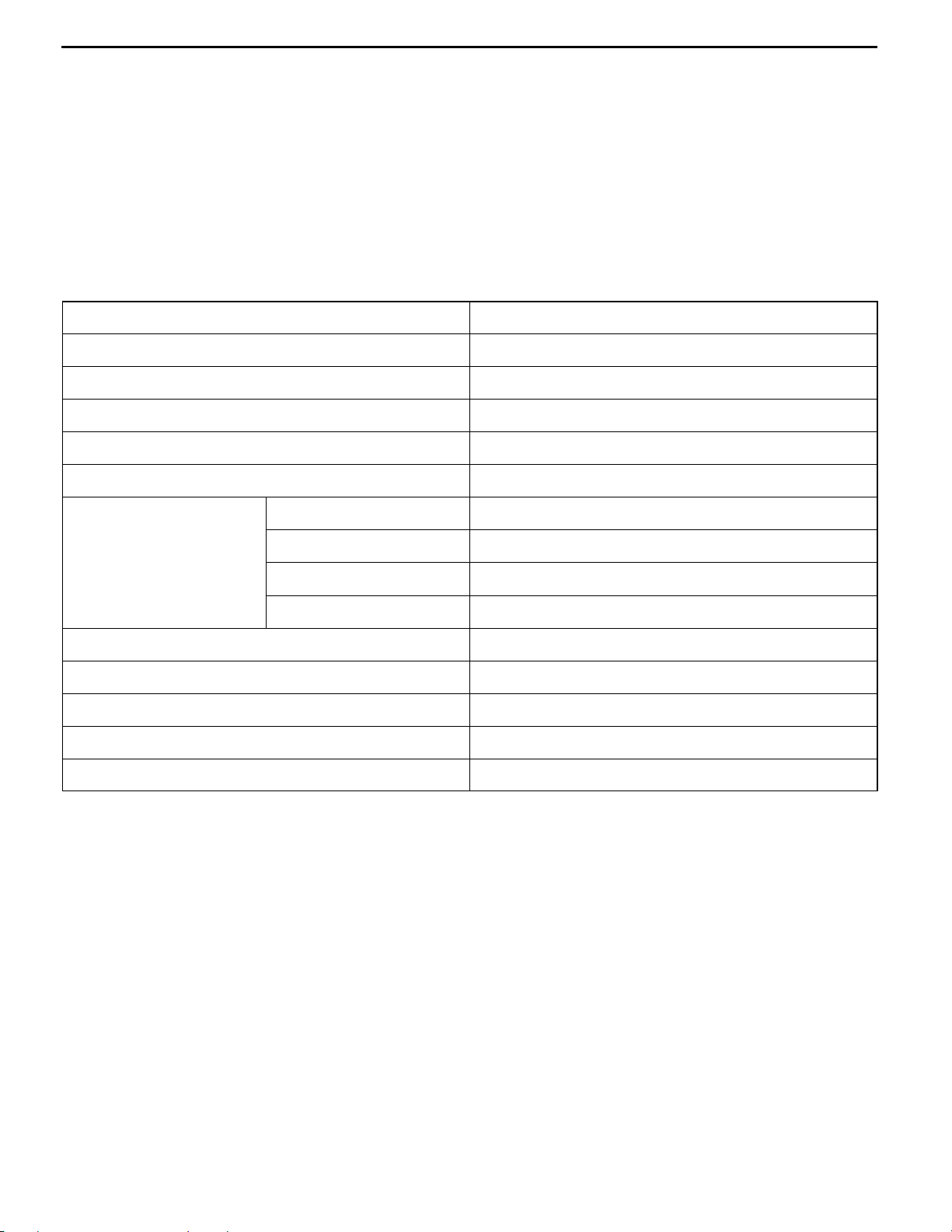

0-15

8

1

2

Items

Vehicle

dimensions

Vehicle

weight kg

Seating capacity 5

Engine Model No. 4G63

Transmission

Fuel System Fuel supply system MPI

Front track 1 1,500, 1,515

Overall width 2 1,770

Front overhang 3 855

Wheel base 4 2,625

Rear overhang 5 975

Overall length 6 4,455

Ground clearance

(unladen)

Overall height (unladen) 8 1,450

Rear track 9 1,500, 1,515

Kerb weight 1,380 1,420

Max. gross vehicle weight 1,655 1,695

Max. axle weight

rating-front

Max. axle weight

rating-rear

Total displacement mL 1,997

Model No. W5M51

Type 5-speed manual

7

3

CT9A

SNDFZL/R SNGFZL/R

7 140

950 970

705 725

9

4

5

6

*1

*1

NOTE

1

: Vehicles with 17 inch wheels.

*

Page 19

NOTES

Page 20

ENGINE

CONTENTS

1-1

GENERAL INFORMATION 2................

Major Specifications 2.......................

BASE ENGINE 3..........................

Piston 3....................................

Piston Ring 3...............................

LUBRICATION SYSTEM 4..................

Engine Oil Cooler 4.........................

COOLING SYSTEM 5......................

Specifications 5.............................

Construction Diagram 5......................

INTAKE AND EXHAUST 6.................

Air Intake System 6.........................

Exhaust System 9...........................

FUEL SYSTEM 11.........................

Specifications 11............................

Construction Diagram 11.....................

Fuel Tank 12...............................

CONTROL SYSTEM 13....................

System Block Diagram 14....................

Control System Diagram 15..................

List of Component Functions 16..............

Fuel Injection Control 19......................

Idle Speed Control 19.......................

Ignition Timing and Distribution Control 20.....

Radiator Fan Motor Control 20...............

Power Supply and A/C Condenser Fan Relay

Control, Oxygen Senser Heater Control, Air Flow

Senser Filter Reset Control, Alternator Control,

Fuel Pressure Control, Supercharging Pressure

Control, Secondary Air Control 20.............

Fuel Pump Relay Control 21..................

EGR Control and Purge Control 22............

Diagnosis System 22.........................

EMISSION CONTROL SYSTEM 23..........

Emission Control System Diagram 23.........

MOUNT 24................................

Construction Diagram 24.....................

ACCELERATOR SYSTEM 26...............

Construction Diagram 26.....................

Page 21

1-2

ENGINE - General Information

GENERAL INFORMATION

This engine has the same basic structure as the previous 4G63-T/C engine, however, the following

enhancements have been added in order to provide improved performance.

D The piston shape has been changed.

D The width of the piston rings has been reduced in order to reduce engine friction.

D The turbocharger type has been changed.

D An EGR valve has been added.

MAJOR SPECIFICATIONS

Items 4G63-T/C

Total displacement mL 1,997

Bore × stroke mm 85.0 × 88.0

Compression ratio 8.8

Combustion chamber Pentroof type

Camshaft arrangement DOHC

Valve timing Intake opening BTDC 21_

Intake closing ABDC 59_

Exhaust opening BBDC 58_

Exhaust closing ATDC 18_

Maximum output kW/r/min 206/6500

Maximum torque N·m/r/min 383/3500

Fuel system Electronic controlled multipoint fuel injection

Rocker arm Roller type

Auto-lash adjuster Equipped

Page 22

ENGINE - Base Engine

1-3

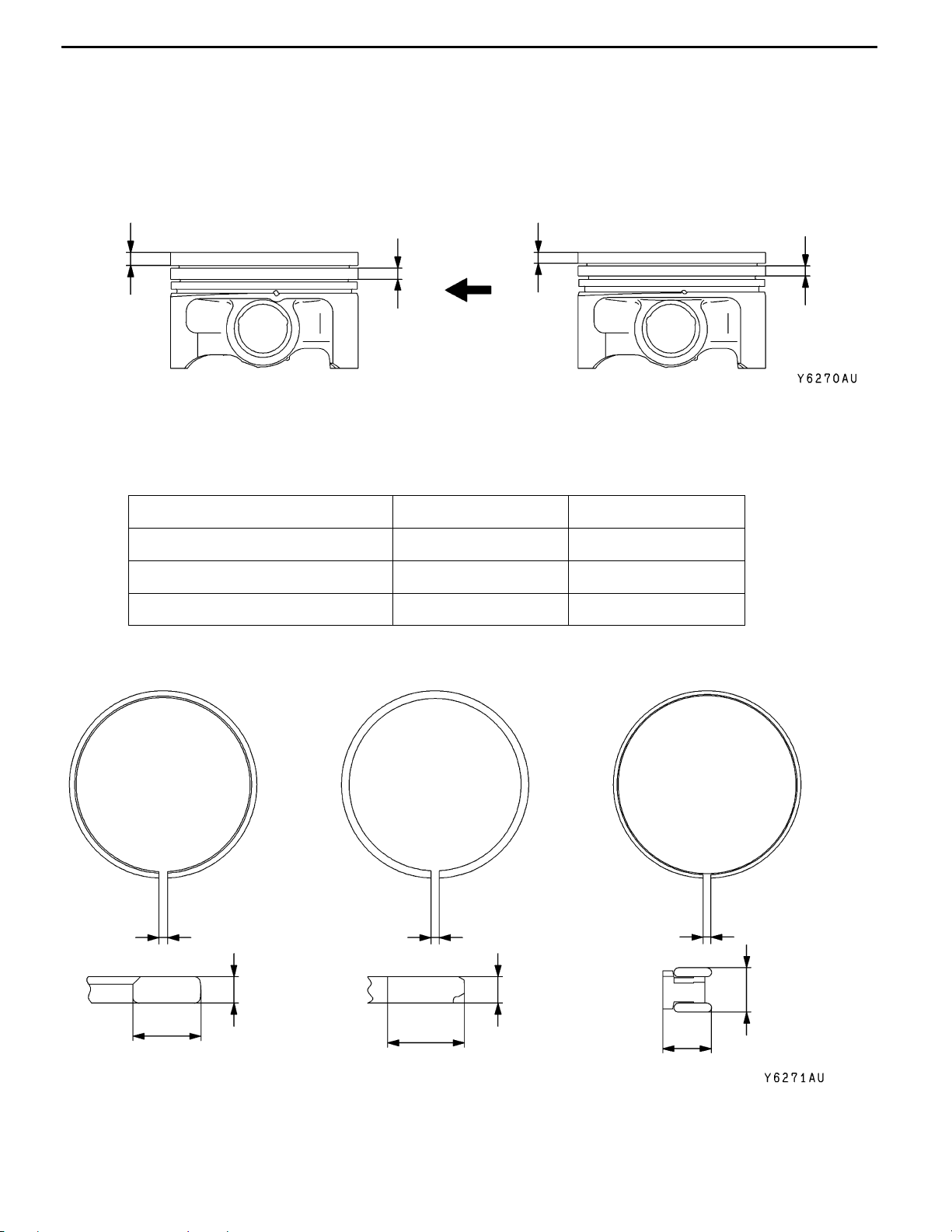

BASE ENGINE

PISTON

The top land height has been changed from 5 mm to 6 mm, and the second land height has been

changed from 4.5 mm to 5 mm.

<OLD>

4.5 mm

6mm

<NEW>

5mm

5mm

PISTON RING

The tension of the rings has been changed as shown in the table below, and the thicknesses of the

No. 2 ring and the oil ring have been reduced in order to provide reduced engine friction.

NEW OLD

PISTON RING No. 1 9.5 N 8.34 N

PISTON RING No. 2 7.0 N 10.49 N

OIL RING 25.0 N 33.34 N

PISTON RING No. 1 PISTON RING No. 2 OIL RING

0.20 ∼ 0.30 mm (New models)

0.25 ∼ 0.35 mm (Old models)

1.2 mm

3.1 mm

3.5 mm (New models)

3.8 mm (Old models)

0.35 ∼ 0.50 mm (New models)

0.40 ∼ 0.55 mm (Old models)

1.2 mm (New models)

1.5 mm (Old models)

2.2 mm (New models)

2.5 mm (Old models)

0.10 ∼ 0.40 mm

2.0 mm (New

models)

2.8 mm (Old

models)

Page 23

1-4

ENGINE - Lubrication System

LUBRICATION SYSTEM

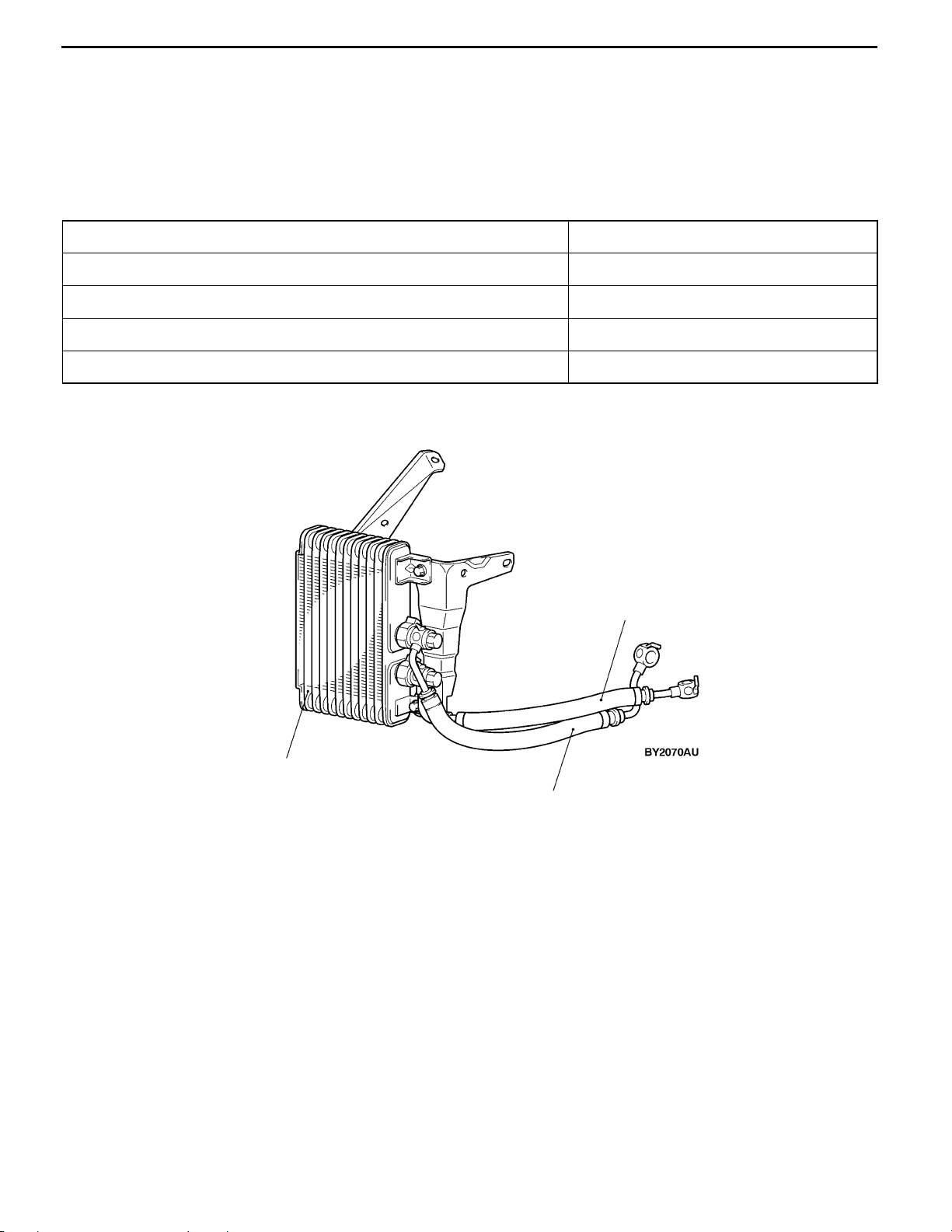

ENGINE OIL COOLER

The drawn cup air-cooled type engine oil cooler has been adopted. The engine oil cooler is installed

below the right head lamp assembly and brings in the air through the oil cooler duct of the front bumper

to cool the engine oil.

SPECIFICATIONS

Items Specifications

Type Drawn cup type

Core size mm (Width × Hight × Thickness) 160 × 200 × 49

Engine oil cooler oil amount L 0.35

Performance kJ/h 29,900

CONSTRUCTION DIAGRAM

Engine oil cooler

Engine oil cooler

return hose

Engine oil cooler

feed hose

Page 24

ENGINE - Cooling System

1-5

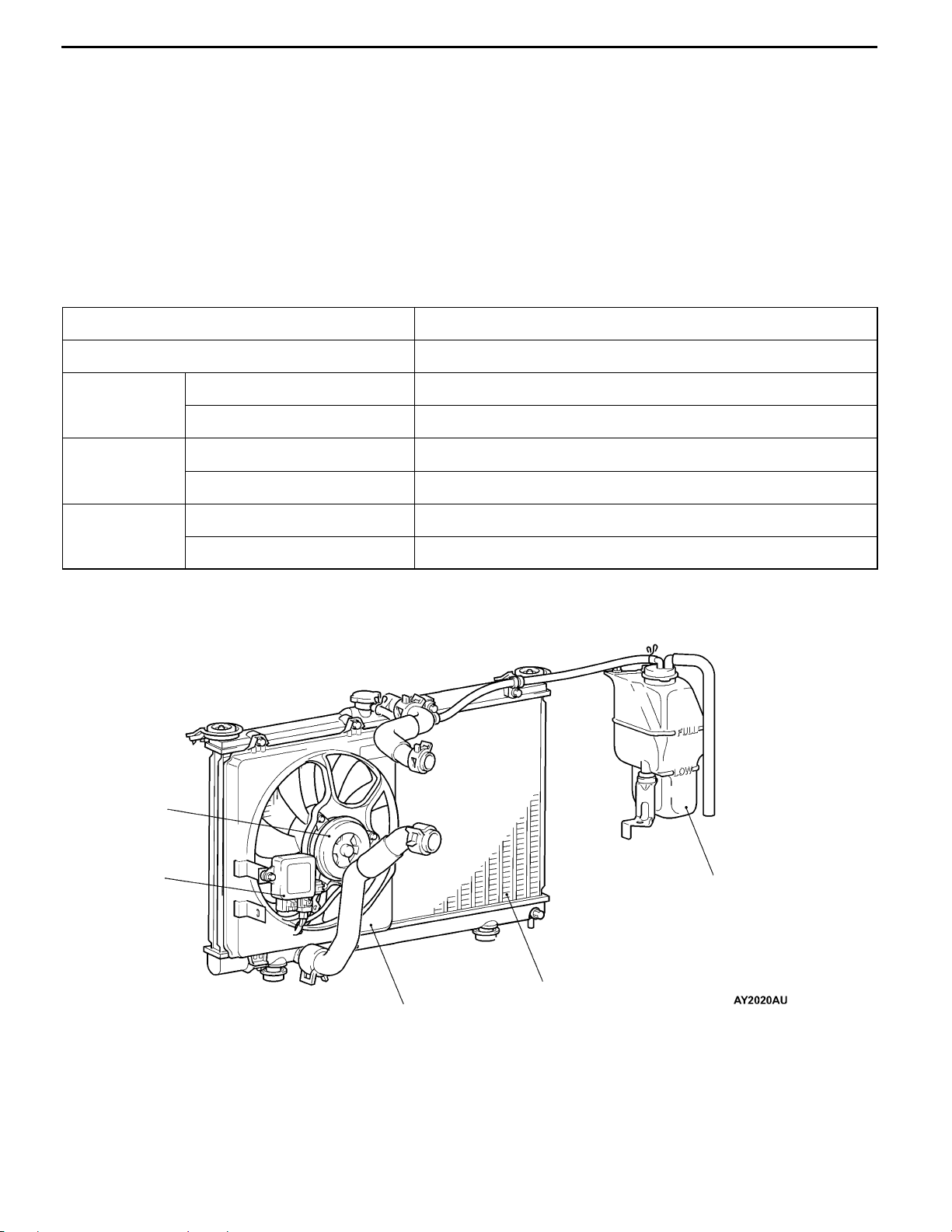

COOLING SYSTEM

The cooling system is a water-cooled pressurized, forced circulation type which offers the following features.

D To improve the reliability of cavitation at a high engine speed and to increase the amount of engine

coolant, output control system in which a thermostat is installed at the outlet of engine coolant from

the engine to the radiator has been adopted.

D To improve the engine cooling performance and save weight, a plastic tank and an aluminium radiator

fins have been introduced.

D The speed of electric cooling fan is optimally controlled by a radiator fan controller and the engine-ECU

according to driving conditions so that the fan operating noise is minimized and the fuel efficiency

is improved.

SPECIFICATIONS

Items Specifications

Cooling method Water-cooled pressurized, forced circulation with electrical fan

Radiator Type Pressurized corrugate type

Performance kJ/h 216,700

Water pump Type Impeller of centrifugal type

Drive method Drive belt

Thermostat Type Wax pellet type with jiggle valve

Valve open temperature _C 80 ± 1.5

CONSTRUCTION DIAGRAM

Radiator fan

motor

Radiator fan

controller

Reserve tank

Shroud

Radiator

Page 25

1-6

ENGINE - Intake and Exhaust

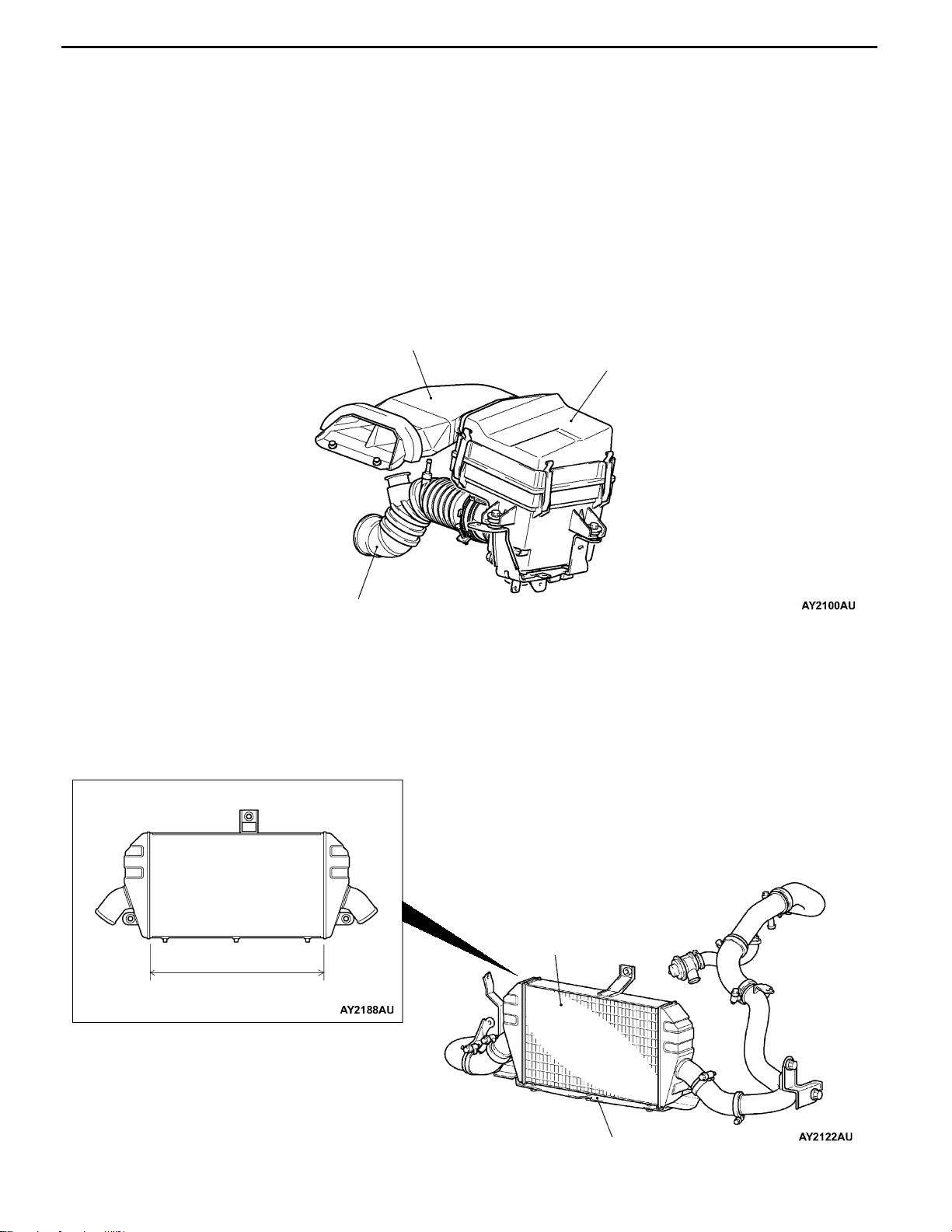

INTAKE AND EXHAUST

AIR INTAKE SYSTEM

AIR DUCT, AIR CLEANER

D By introducing fresh cool air from the top of the radiator efficiently, the engine performance has been

enhanced and intake air noise has been reduced.

D Burnable used paper mixed with plastic materials have been adopted in consideration for reduction

of industrial wastes and protection of global environment.

AIR INTAKE HOSE

Unleaded rubber materials have been adopted for air intake hose in consideration for protection of global

environment.

CONSTRUCTION DIAGRAM

Air duct

Air cleaner assembly

Air intake hose

INTER COOLER

By mounting an air cooled intercooler to reduce the intake air temperature after boosting, engine output

has been improved. The features of the air cooled intercooler are as follows.

D Large intercooler (Core size: 289.5×490×65 mm)

D Air guides are mounted to the bottom of the intercooler.

CONSTRUCTION DIAGRAM

Inter cooler assembly

490 mm

Air guide

Page 26

ENGINE - Intake and Exhaust

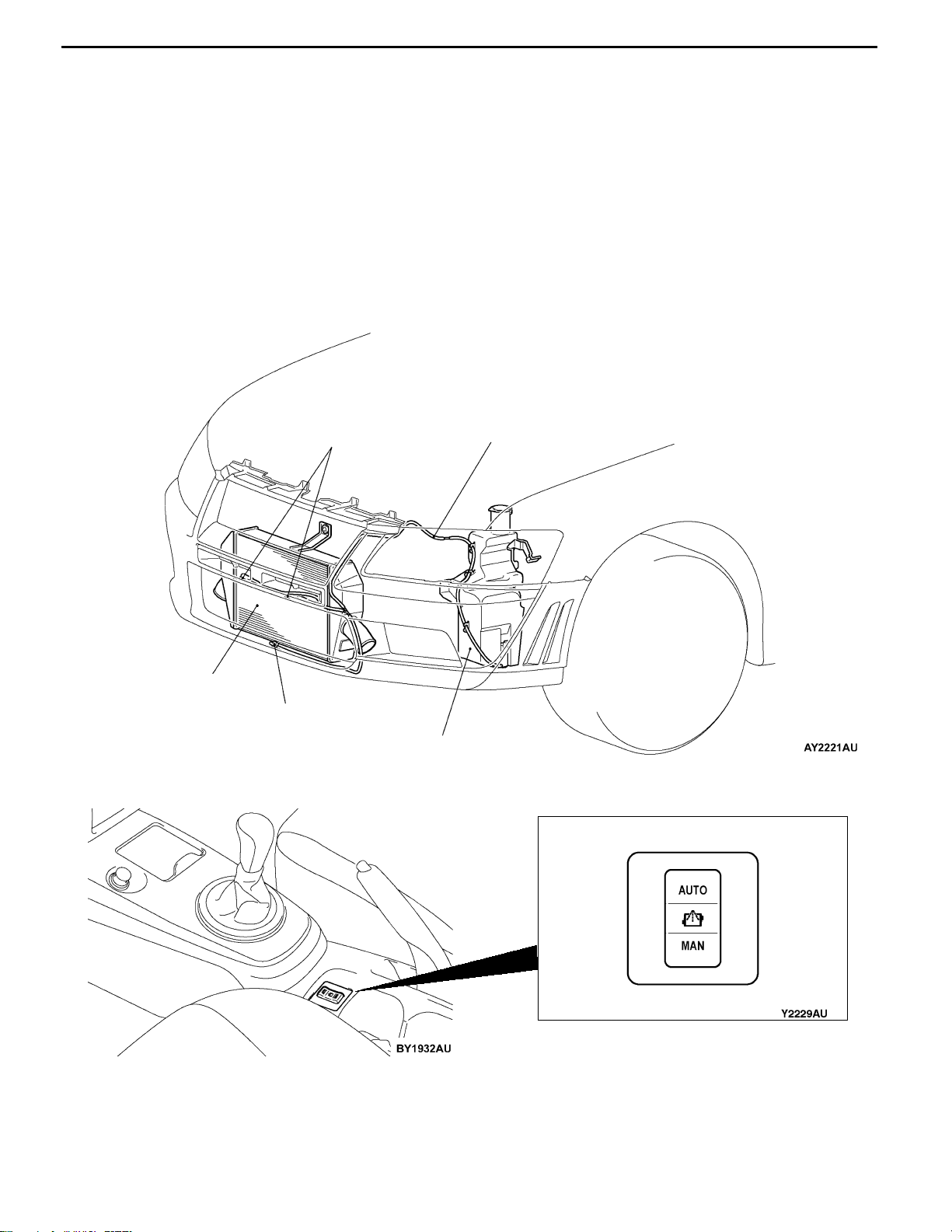

1-7

INTER COOLER WATER SPRAY

To complement the intercooler efficiency in ranges where the cooling efficiency of the air cooled intercooler

is insufficient, and attain high performance in various operating environments, a system which cools by

spraying water from a special washer tank for the intercooler to the front of the intercooler has been

adopted.

The features of the intercooler water spray system is as follows.

D Sprays water when the water spray switch on the floor console is operated.

D Adopts a system which enables switching between the auto mode which automatically sprays water

at the optimum operating conditions by signals from the ECU according to the engine state, and

the manual mode which is operated by the driver.

D Three water spray nozzles are located at optimum positions to enhance the intercooler efficiency.

CONSTRUCTION DIAGRAM

<Water Spray Nozzle/Water Spray Hose/Washer Tank>

Inter cooler

<Water Spray Switch>

Water spray nozzle

Water spray nozzle

Water spray hose

Washer tank

Water spray switch

Page 27

1-8

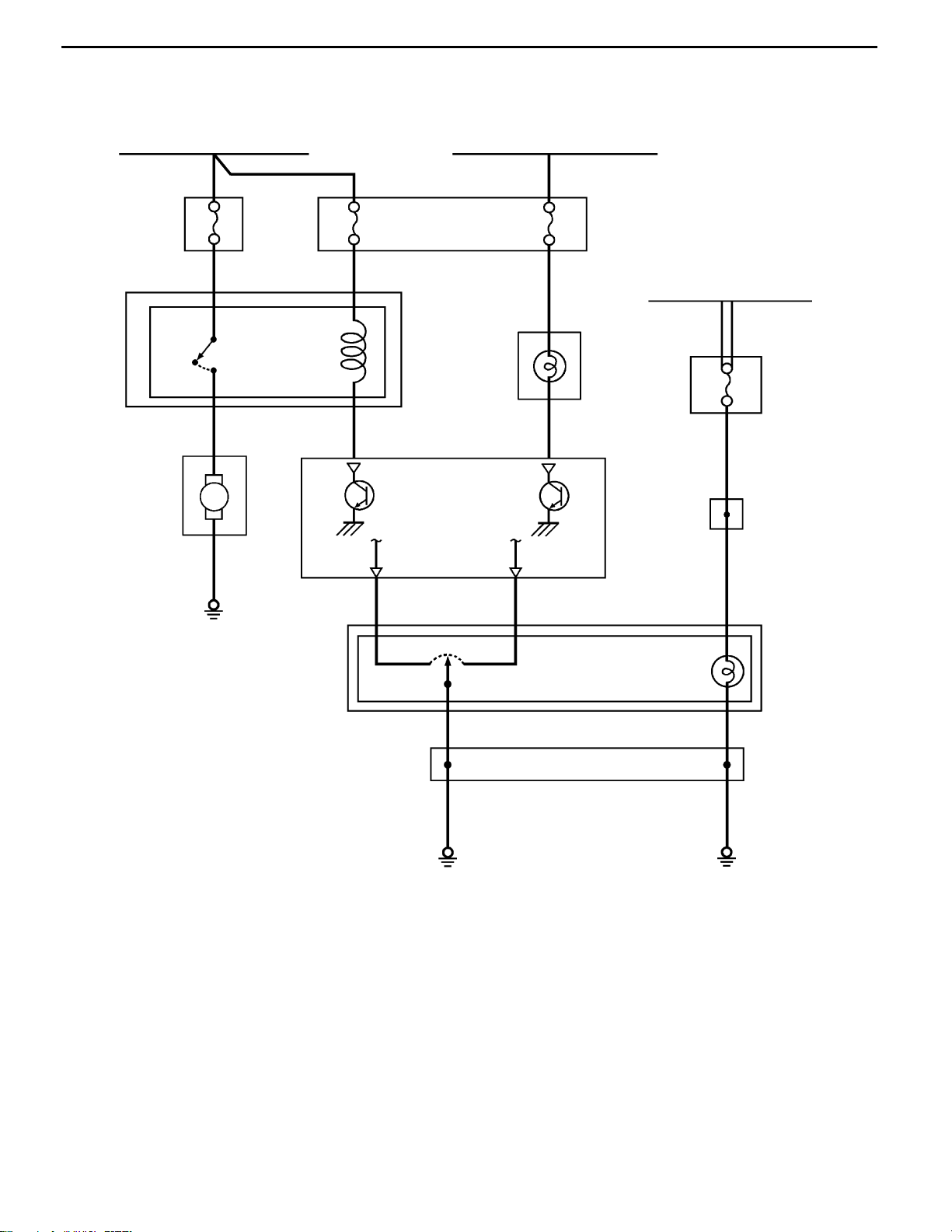

SYSTEM DIAGRAM

ENGINE - Intake and Exhaust

Ignition switch (IG2)

Fuse

20A

J/B

Water spray

motor

Water spray relay

OFF ON

M

7.5A

J/B

Engine-ECU

Ignition switch (IG1)

7.5A

Combination

meter

Front-ECU

(Tail lamp relay)

Fuse

7.5A

J/C

MANUAL AUTO

Water spray switch

J/C

Page 28

Exhaust fitting

Exhaust fitting bracket

ENGINE - Exhaust System

Exhaust manifold

heat protector

1-9

EXHAUST SYSTEM

EXHAUST FITTING BRACKET

An exhaust fitting bracket has been added in order to provide

greater rigidity.

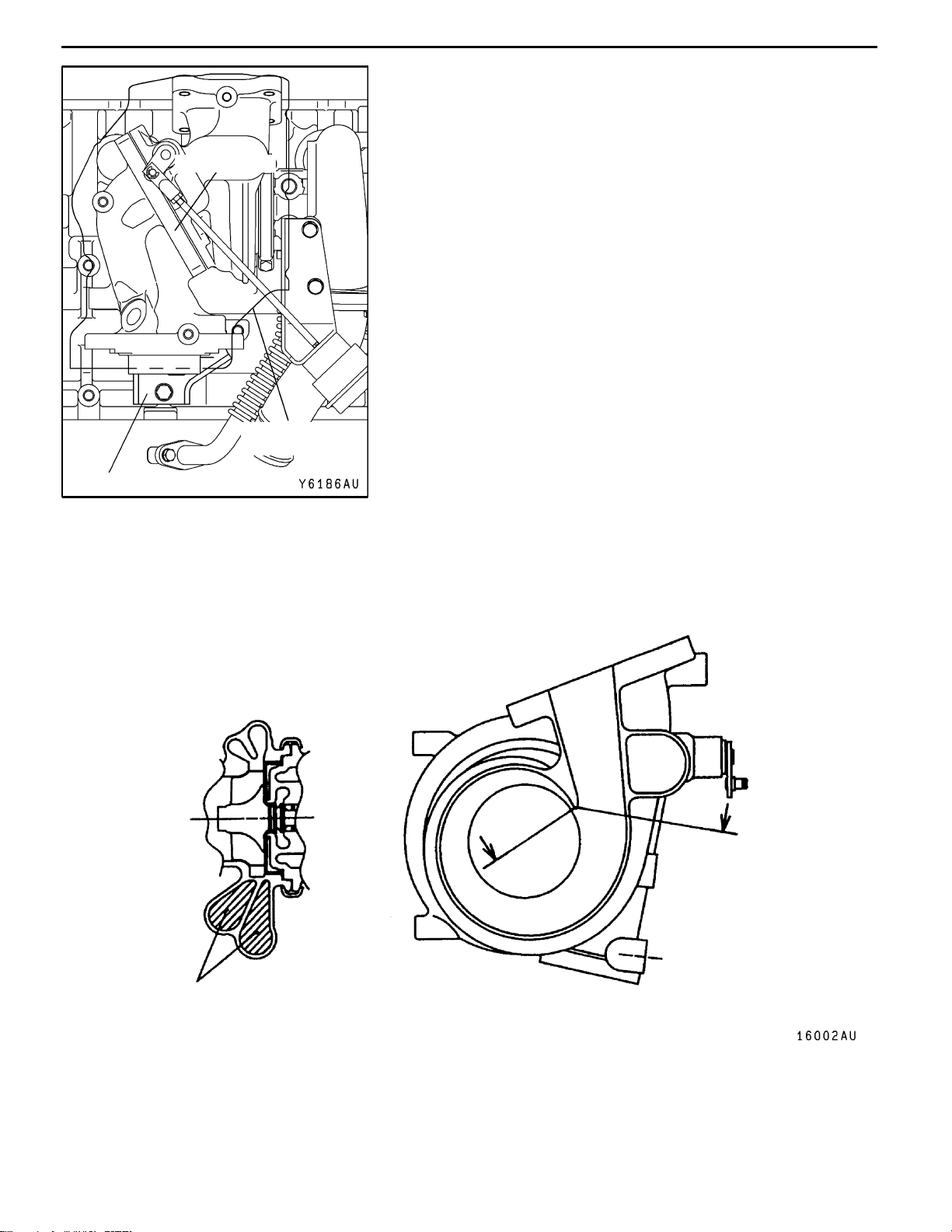

TURBOCHARGER

The turbocharger type TD05HR-16G6-9.8T and TD05HRA-16G6-9.8T have been adopted.

Compared to previous types of turbocharger, these new types have a smaller turbine housing nozzle

area which improves response at medium to low speeds.

A

A

Nozzle area

Section A - A

Page 29

1-10

ENGINE - Intake and Exhaust

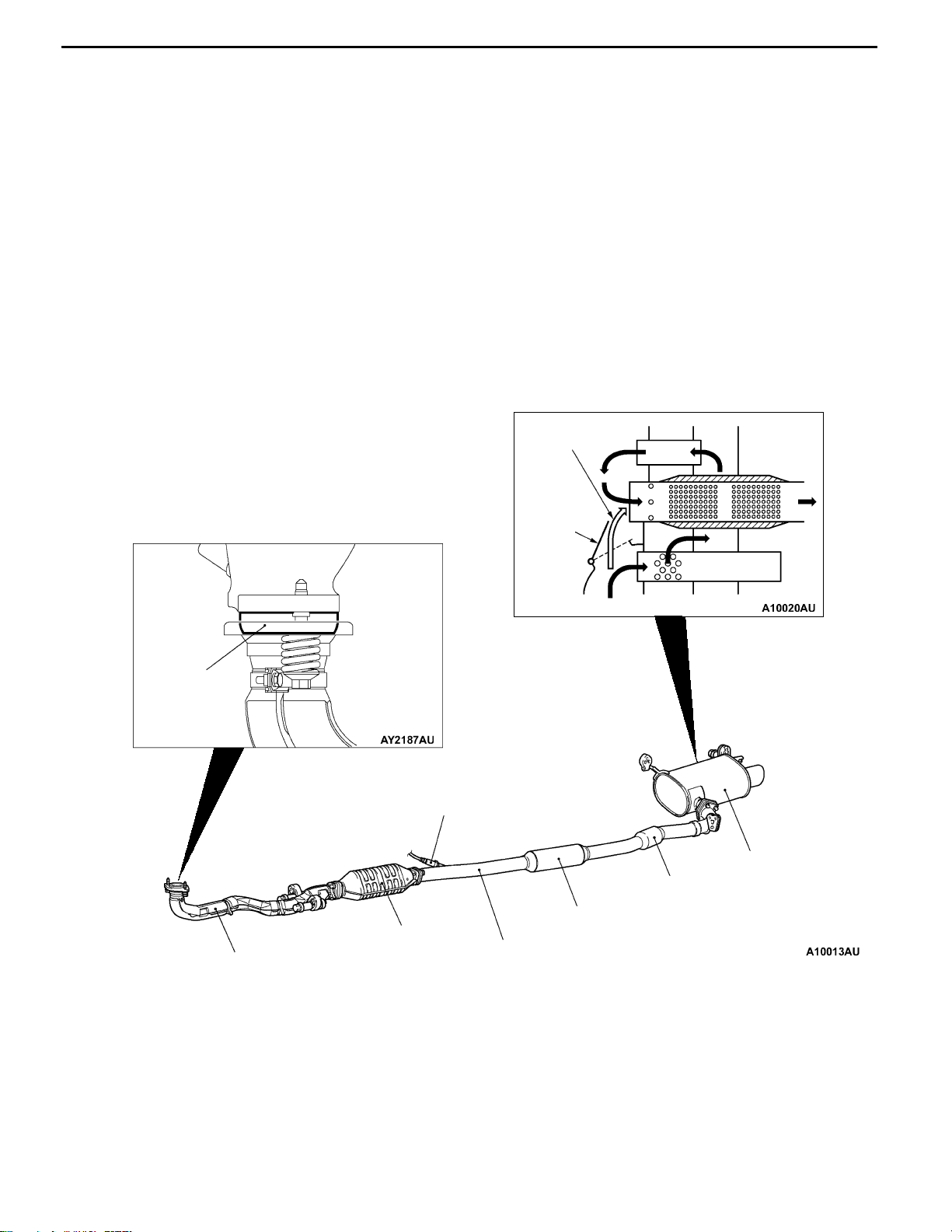

EXHAUST PIPE AND MUFFLER

Exhaust pipe consisting of 3 separation system: front exhaust pipe, center exhaust pipe, and exhaust

main muffler, has the following features:

D The adoption of a seal ring has reduced vibrations during idling and driving noise.

D A main muffler incorporating a back pressure variable valve is adopted.

D Straight layout of exhaust piping has reduced vibration and exhaust pressure in exhaust system.

D The adoption of hanger rubber with lower spring constant and the decreased number of hangers

have reduced vibration in exhaust piping.

D The adoption of all stainless exhaust piping has enhanced resistance to corrosion and heat.

D Installation of thermal insulating cover and materials on front pipe has improved emission control

performance.

CONSTRUCTION DIAGRAM

When valve

is open

Seal ring

Front exhaust pipe

Back

pressure

variable

valve

Flow of exhaust gas

Oxygen sensor

Main muffler

Pre-muffler (sub)

Pre-muffler

Catalytic converter

Center exhaust pipe

Page 30

ENGINE - Fuel System

Fuel

tank

L48Fuel

Electri

Fuel

294

j

1-11

FUEL SYSTEM

The fuel system consists of parts such as electromagnetic-type fuel injectors, a delivery pipe and a fuel

pressure regulator. In addition, a fuel pressure control solenoid valve has been provided in order to maintain

idling stability after the engine is re-started when it is hot. This system is basically the same as the

previous system used in the 4G63-DOHC-Turbocharger engine for the EVOLUTION-VI.

SPECIFICATIONS

Items Specification

capacity

pumptype

Fuel filter type Cartridge (filter-paper type)

Fuel return system Fuel pressure regulator return

pressure regulator controlpressurekPa

Injectors

Evaporative emission control system Canister type

Type Electromagnetic

Quantity 4

c

CONSTRUCTION DIAGRAM

Fuel pump resistor

Injector resistor

Delivery pipe

Fuel pressure regulator

Injector

Fuel tank

Evaporative canister

Fuel cut-off valve assembly

Fuel pump and gauge assembly

Pipe and gauge assembly

Fuel pump relay

Page 31

1-12

ENGINE - Fuel System

FUEL TANK

A steel fuel tank is located under the floor of the

rear seats to provide increased safety and increase

the amount of luggage compartment space.

D The fuel tank has been equipped with a valve

assembly which incorporates a fuel cut-off valve

to prevent fuel from leaking out in the event

of a collision for adjusting the pressure inside

the fuel tank.

CONSTRUCTION DIAGRAM

Fuel high-pressure hose

Suction hose

D For better serviceability, the fuel tank has been

coupled with the main line by a one-touch joint

method, not the conventional double flare nut

method.

Fuel pump and gauge assembly

Pipe and gauge assembly

Fuel high-pressure hose

Fuel cut-off valve assembly

Fuel tank

Page 32

ENGINE - Control System

1-13

CONTROL SYSTEM

The control system is based on the system for 4G63-DOHC-Tubocharger which has been installed in

the EVOLUTION-VI, with the following improvements added.

Improvements/Additions Remarks

Adoption of compact throttle position sensor D Smaller size and light weight

D Higher resistance to vibration

D Idle position switch disused

D Basically the same as that used in the SPACE

WAGON

Adoption of compact stepper motor for idle speed control

servo

Adoption of PWM (pulse width modulation) method of

radiator fan motor control

Adoption of dual oxygen sensor D Higher reliability of air fuel ratio control

Adoption of intercooler water spray control D Improved intercooler cooling efficiency

D Improved ignition performance

D Basically the same as that used in the LANCER

D Reduced fuel consumption

D Reduced fan noise

D Basically the same as that used in the LANCER

D Basically the same as that used in the GALANT

Page 33

1-14

SYSTEM BLOCK DIAGRAM

ENGINE - Control System

Air flow sensor

Intake air temperature sensor

Barometric pressure sensor

Engine coolant temperature sensor

Throttle position sensor

A/C switch

A/C load signal

Camshaft position sensor

Crank angle sensor

Vehicle speed sensor

Power steering fluid pressure switch

Detonation sensor

Intercooler water spray (auto)

Engine-ECU

Fuel injection control

Idle speed control

Ignition timing control

Engine control relay control

Fuel pump relay control

A/C relay control

Fan motor control

(radiator)

Fan relay control

(A/C condenser)

Alternator control

Air flow sensor filter reset control

Fuel pressure control

Turbochanger control

No.1 injector

No.2 injector

No.3 injector

No.4 injector

Idle speed control servo

(stepper motor)

No.1, No.4 ignition coil

No.2, No.3 ignition coil

Engine control relay

Fuel pump relay 2

Fuel pump relay 3

Tachometer

A/C relay

Fan controller

(radiator)

Fan motor relay (HI, LOW)

(A/C condenser)

Alternator G terminal

Air flow sensor

Fuel pressure control solenoid valve

Waste gate solenoid valve

Intercooler water spray (manual)

Oxygen sensor (front)

Oxygen sensor (rear)

Ignition switch-IG

Ignition switch-ST

Alternator FR terminal

Power supply

Diagnosis control terminal

Secondary air control

Intercooler water spray control

Engine warning lamp control

Oxygen sensor heater control

EGR control

Purge control

Diagnosis output

RAM data transmission

Secondary air control solenoid valve

Intercooler water spray relay

Intercooler water spray lamp

Engine warning lamp

(check engine lamp)

Oxygen sensor heater (front)

Oxygen sensor heater (rear)

EGR control solenoid valve

Purge control solenoid valve

Diagnosis output terminal

Diagnosis output terminal

(for MUT-II)

Page 34

ENGINE - Control System

CONTROL SYSTEM DIAGRAM

1-15

L1 Oxygen sensor (front)

L2 Oxygen sensor (rear)

L3 Air flow sensor

L4 Intake air temperature sensor

L5 Throttle position sensor

L6 Camshaft position sensor

L7 Crank angle sensor

L8 Barometric pressure sensor

L9 Engine coolant temperature sensor

L10 Detonation sensor

D Power supply

D Ignition switch-IG

D Ignition switch-ST

D Vehicle speed sensor

D A/C switch

D A/C load signal

D Power steering fluid pressure switch

D Alternator FR terminal

Check

l7 Secondary

air control

solenoid

valve

valve

Canister

By-pass

valve

Engine-ECU

From

fuel tank

L5 Throttle

position

sensor

l1 Injector

l2 Idle speed control servo

l3 Fuel pressure control solenoid valve

l4 Waste gate solenoid valve

l5 EGR control solenoid valve

l6 Purge control solenoid valve

l7 Secondary air control solenoid valve

D Engine control relay

D Fuel pump relay 2, 3

D A/C relay

D Ignition coil

D Fan controller

D Condenser fan relay (HI)

D Condenser fan relay (LOW)

D Engine warning lamp

D Diagnosis output

D Alternator G terminal

l2 Idle

speed

control

servo

Vacuum

tank

L8 Barometric

L3 Air flow

Air

inlet

Secondary

air valve

pressure

sensor

sensor

L4 Intake air

temperature

sensor

l6 Purge

control

solenoid

valve

L1 Oxygen

sensor

(front)

l4 Waste gate

solenoid valve

l3 Fuel pressure

Waste gate

actuator

control

solenoid valve

Fuel

pressure

regurator

To fuel tank

L6 Camshaft

PCV valve

l5 EGR control

solenoid valve

l1 Injector

position sensor

From

fuel pump

EGR

valve

L9 Engine coolant

temperature sensor

L7 Crank angle sensor

L10 Detonation sensor

L2 Oxygen sensor (rear)

Three-way

catalytic converter

Page 35

1-16

ENGINE - Control System

LIST OF COMPONENT FUNCTIONS

Name Function

ECU Engine-ECU Uses the signals input from the various sensors to control operation of

actuators in accordance with the driving conditions.

Sensors Ignition switch-IG Detects the ON/OFF position of the ignition switch. When this signal

is input to the engine-ECU, power is supplied to components such as

the injectors, air flow sensor, idle speed control servo and crank angle

sensor.

Ignition switch-ST Detects whether the engine is cranking. The engine-ECU controls the

fuel injection, throttle valve opening angle and ignition timing to the

appropriate settings based on this signal.

Air flow sensor Detects the amount of intake air (volumetric capacity) by means of a

Karman vortex meter. The engine-ECU controls the basic injector drive

time based on this signal and on the engine speed.

Barometric pressure sensor Detects the barometric pressure by means of a semiconductor

diffusion-type pressure sensor. The engine-ECU detects the vehicle’s

altitude based on this signal, and uses this to correct the fuel injection

amount so that the optimum air/fuel mixture ratio is obtained for that

altitude.

Oxygen sensor Detects the concentration of oxygen in the exhaust gas by means of

zirconia and platinum electrodes. The engine-ECU judges whether the

air/fuel mixture ratio is at the optimum theoretical ratio based on this

concentration.

Intake air temperature sensor Detects the temperature of the intake air by means of a thermistor. The

engine-ECU corrects the fuel injection amount to the correct amount

corresponding to the intake air temperature based on the voltage

output from this sensor.

Engine coolant temperature

sensor

Throttle position sensor Detects the throttle valve opening angle by means of a potentiometer.

Vehicle speed sensor Detects the vehicle speed by means of a magnetic rheostatic element.

Camshaft position sensor Detects the No. 1 cylinder compression top dead centre position by

Crank angle sensor Detects the crank angle by means of a hall element. The engine-ECU

Detects the temperature of the engine coolant by means of a

thermistor. The engine-ECU detects how warm the engine is based on

the signal from this sensor, and uses this to control the fuel injection

amount, idle speed and ignition timing.

The engine-ECU controls the throttle valve and also determines the

optimum fuel injection for the vehicle’s degree of acceleration based

on the voltage output from this sensor.

means of a hall element.

controls the injectors based on the signal from this sensor.

Alternator FR terminal Detects the energising duty ratio of the alternator field coil.

Power steering fluid pressure

switch

A/C switch Detects the ON/OFF condition of the A/C.

Detects whether there is a power steering load present by means of a

contact switch.

Page 36

ENGINE - Control System

Name Function

Sensors A/C load signal Inputs the compressor drive state (low load/high load) to the

engine-ECU. The engine-ECU controls the A/C idle-up revolution

speed using this signal.

1-17

Intercooler water spray switch

(automatic)

Intercooler water spray switch

(manual)

Diagnosis control terminal Notifies the engine-ECU that the MUT-II has been connected to the

Actuators Engine control relay Turns the engine-ECU power circuit on and off.

Injector Drives the fuel injection by means of drive signals from the

Ignition coil

(integrated power transistor)

Idle speed control servo The throttle valve bypass air amount during idling and deceleration is

Fuel pump relay 1 Supplies power to the fuel pump when the ignition switch is at the ON

Fuel pump relay 2 Controls the supply of power to the fuel pump in accordance with the

Sprays water when certain driving conditions are satisfied.

Sprays water while the switch is being pressed by the driver.

diagnosis connector, and enables communication between the MUT-II

and the engine-ECU.

engine-ECU.

Interrupts the ignition coil primary current in accordance with the

ignition signals from the engine-ECU, in order to generate a high

voltage for ignition.

controlled with the signal from the engine-ECU.

position.

signal from the engine-ECU.

Fuel pump relay 3 Controls the supply of power to the fuel pump when driving at low loads

and when driving at high loads, in accordance with the signal from the

engine-ECU.

Fan controller Controls the smooth operation of the radiator fan in accordance with

the signal from the engine-ECU.

Condenser fan relay (HI) Controls the condenser fan operation (high speed) in accordance with

the signal from the engine-ECU.

Condenser fan relay (LOW) Controls the condenser fan operation (low speed) in accordance with

the signal from the engine-ECU.

Intercooler water spray relay Controls the driving of the intercooler spray motor in accordance with

the signal from the engine-ECU.

Waste gate solenoid valve Controls the supercharging pressure which acts on the waste gate

actuator in accordance with the signal from the engine-ECU.

Purge control solenoid valve Controls the purge air flow amount which is introduced into the surge

tank in accordance with the signal from the engine-ECU.

EGR control solenoid valve Controls the negative pressure which operates the EGR valve in

accordance with the signal from the engine-ECU.

Secondary air control solenoid

valve

Controls the pressure which is introduced into the secondary air valve

in accordance with the signal from the engine-ECU.

Fuel pressure control solenoid

valve

Controls the fuel pressure in accordance with the signal from the

engine-ECU.

Page 37

1-18

Name Function

Actuators Alternator G terminal Controls the current generated by the alternator in accordance with the

A/C relay Controls the A/C compressor operation.

ENGINE - Control System

signal from the engine-ECU.

Engine warning lamp

(check engine lamp)

Intercooler water spray lamp Illuminates when the intercooler is being sprayed in accordance with

Illuminates when a sensor malfunction is detected to warn the driver

of the problem.

the signal from the engine-ECU.

Page 38

ENGINE - Control System

1-19

FUEL INJECTION CONTROL

The fuel injection control system is basically the same as the control system for the 4G63-DOHC-Turbocharger

engine installed in the Evolution-VI.

SYSTEM CONFIGURATION DIAGRAM

Air flow sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Throttle position sensor

Camshaft position sensor

Crank angle sensor

Ignition switch-ST

Oxygen sensor

Vehicle speed sensor

Detonation sensor

To fuel

tank

Fuelpressure

regulator

Fuel pressure control

solenoid valve

Engine-ECU

From

fuel

pump

Injector

IDLE SPEED CONTROL

The idle speed control system is basically the same as the control system for the 4G63-DOHC-Turbocharger

engine installed in the Evolution-VI.

SYSTEM CONFIGURATION DIAGRAM

Air flow sensor

Barometric pressure sensor

Bimetal type limiter

To intake

manifold

Idle speed control servo

(Stepper motor)

From air

cleaner

Speed adjusting screw

Engine-ECU

Intake air temperature sensor

Engine coolant temperature sensor

Throttle position sensor

Crank angle sensor

A/C switch

A/C load signal

Vehicle speed sensor

Power steering fluid pressure switch

Alternator FR terminal

Ignition switch-IG

Ignition switch-ST

Diagnosis control terminal

Page 39

1-20

ENGINE - Control System

IGNITION TIMING AND DISTRIBUTION CONTROL

The ignition timing and distribution control system is basically the same as the control system for the

4G63- DOHC-Turbocharger engine installed in the Evolution-VI.

SYSTEM CONFIGURATION DIAGRAM

Air flow sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Camshaft position sensor

Crank angle sensor

Detonation sensor

Ignition switch-ST

Vehicle speed sensor

EngineECU

To tachometer

Ignition switch

Ignition

coil A

Spark plug

Cylinder No. 4 1 32

Battery

Ignition

coil B

RADIATOR FAN MOTOR CONTROL

The radiator fan motor control system is basically the same as the control system for 4G6-MPI engine

installed in the GALANT.

POWER SUPPLY AND A/C CONDENSER FAN RELAY CONTROL, OXYGEN

SENSOR HEATER CONTROL, AIR FLOW SENSOR FILTER RESET CONTROL,

ALTERNATOR CONTROL, FUEL PRESSURE CONTROL, SUPERCHARGING

PRESSURE CONTROL, SECONDARY AIR CONTROL

These control systems are basically the same as those for 4G63-DOHC-Turbocharger engine installed

in the EVOLUTION-VI.

Page 40

ENGINE - Control System

1-21

FUEL PUMP RELAY CONTROL

D The fuel injection amount is controlled by the fuel pump relay 3 in order to reduce the amount of

return fuel when the engine is running at low speeds and fuel consumption is low, and also to reduce

noise.

Battery

Ignition switch

Fuel pump relay 1

Engine-ECU

Fuel

pump

relay 3

Fuel pump relay 2

Fuel pump resistor

To fuel pump

Page 41

1-22

ENGINE - Control System

EGR CONTROL AND PURGE CONTROL

Refer to the EMISSION CONTROL SYSTEM.

DIAGNOSIS SYSTEM

The engine-ECU is prvided with the following functions to make system inspection easier.

D Engine warning lamp control

D Diagnosis function

D Service data output

D Actuator test

NOTE

Refer to the Workshop Manual for details on each item.

Page 42

ENGINE - Emission Control System

1-23

EMISSION CONTROL SYSTEM

The following improvements in the control details have been made to the system, which is basically

the same as the previous system used in the 4G63-DOHC-Turbocharger engine for the EVOLUTION-VI.

D An electronically-controlled EGR system utilizing an EGR control solenoid valve has been adopted.

D An electronically-controlled purge control system utilizing purge control solenoid valve has been adopted.

System Remarks

Evaporative emission control system Electronic control type

(Duty cycle type purge control solenoid valve)

Exaust gas recirculation (EGR) system Electronic control type

(Duty cycle type EGR control solenoid valve)

EMISSION CONTROL SYSTEM DIAGRAM

From

fuel

Check

valve

Canister

tank

Air

inlet

Purge

control

solenoid

valve

Oxygen

sensor

(front)

Fuel pressure

control

solenoid valve

Fuel

pressure

regurator

To fuel

tank

PCV valve

EGR control

solenoid valve

Injector

From fuel

pump

EGR

valve

Oxygen sensor (rear)

Three-way

catalytic converter

Page 43

1-24

ENGINE - Mount

MOUNT

The inertia axial system based on the past achievements in COLT/LANCER has been adopted for the

engine mount system.

D Longitudinal installation type of cylindrical liquid-filled engine mount has been adopted for reduction

of idle vibration and improvement of ride feeling.

D The liquid-filled mount system has been adopted for transmission mount to improve ride feeling by

optimizing the insulator.

D Installation of roll mount in the upper area has reduced engine rolling. Furthermore, enlargement

of insulator diameter has reduced idle vibration.

CONSTRUCTION DIAGRAM

<Engine mount/Transmission mount>

Engine mount

Transmission mount

Page 44

ENGINE - MountENGINE - Mount

<Engine roll stopper/Crossmember/Centermember : L.H. drive vehicles>

Rear roll mount bracket

Rear roll rod assembly

Front roll mount bracket

Front roll stopper

1-25

Rear roll rod bracket

Crossmember

Crossmember bar

Centermember

<Engine roll stopper/Crossmember/Centermember : R.H. drive vehicles>

Rear roll mount bracket

Front roll mount bracket

Front roll stopper

Rear roll stopper

Crossmember

Centermember

Crossmember bar

Page 45

1-26

ENGINE - Accelerator System

ACCELERATOR SYSTEM

The accelerator system is a cable and suspended

pedal combination.

Plastic bushing and rubber damper have been attached to the end of the accelerator cable, to pre-

CONSTRUCTION DIAGRAM

Accelerator

cable

Accelerator arm

vent noise and vibration when the cable and accelerator arm contact.

Plastic bushing

Rubber

dumper

<L.H. drive vehicles>

Accelerator cable

Accelerator

pedal bracket

Accelerator arm

<R.H. drive vehicles>

Accelerator cable

Accelerator

pedal bracket

Accelerator arm

Page 46

POWER TRAIN

CONTENTS

2-1

CLUTCH 2................................

Specifications 2.............................

MANUAL TRANSMISSION 3................

Specifications 3.............................

Sectional View 4............................

4WD System 8.............................

Power Train 9..............................

Transmission Control 11.....................

ACTIVE CENTER DIFFERENTIAL (ACD)

AND ACTIVE YAW CONTROL (AYC)

Description of Structure and Operations 16....

System Structure 16.........................

Oil Pressure Unit 18.........................

Electronic Control System 20.................

PROPELLER SHAFT 27....................

FRONT AXLE 28..........................

REAR AXLE 29............................

DIFFERENTIAL 30.........................

12........

DIFFERENTIAL MOUNT 33.................

Page 47

2-2

POWER TRAIN - Clutch

CLUTCH

SPECIFICATIONS

Items Specifications

Engine model 4G63-DOHC-Intercooler Turbocharger

Clutch disc type Dry single plate type

Clutch disc facing diameter O.D.×I.D. mm 240×160

Clutch cover type Diaphragm spring pull type

Clutch cover set load N 9,320 ± 750

Control system Hydraulic type

Release cylinder I.D. mm 20.64

Master cylinder I.D. mm 15.87

Clutch fluid Brake fluid DOT 3 or DOT 4

CLUTCH CONTROL CONFIGURATION

<L.H.drive vehicles>

Clutch hose

Clutch pipe

Clutch master cylinder

Clutch release

cylinger

<R.H.drive vehicles>

Master cylinder member assemblyReservoir hose

Clutch pedal

Reservoir hose

Clutch master cylinder

Master cylinder member assembly

Clutch pipe

Clutch pipe

Clutch release cylinger

Clutch pedal

Clutch hose

Page 48

POWER TRAIN - Manual Transmission

2-3

MANUAL TRANSMISSION

The manual transmission is a W5M5 transmission. This transmission incorporates the following changes

from the F5M4 type transmission mounted to GALANT.

D With the incorporation of 4WD, the center differential has been positioned at the front differential

of the 2WD, and the front differential has been positioned inside the transfer.

D The kinetic performance has been improved by setting a helical gear LSD for the front differential.

<RS, RS II: Option>

D With the adoption of the active center differential (ACD), an hydraulic multi plate clutch has been

adopted for the transfer limited slip differential. <RS, RS II: Option> (Refer to P.2-17 for details

of the hydraulic multi plate clutch.)

SPECIFICATIONS

Item Specifications

Classification RS, RS II RS, RS II (Super cross gear specifications)

Transmission type W5M51

Engine type 4G63-DOHC-T/C

Transmission type 5 steps forward, 1 step reverce, always in contact)

Gear ratio

Final deceleration ratio 4.529 ←

Helical gear LSD (Front differential) No Yes

Transfer

1st 2.785 ←

2nd 1.950 ←

3rd 1.407 1.444

4th 1.031 1.096

5th 0.720 0.825

Reverse 3.416 ←

Deceleration ratio 3.307 ←

Limited slip differential VCU or hydraulic multi

plate clutch (ACD)

←

Page 49

2-4

SECTIONAL VIEW

W5M51 <Vehicle with VCU>

POWER TRAIN - Manual Transmission

12

4

5

3

6

7

8

9

15

19

18

17

16

14

20

1. 4th gear

2. 3rd - 4th synchronizer

3. 3rd gear

4. Transmission case

5. Clutch housing

6. Clutch release bearing retainer

7. Input shaft

8. Output shaft

9. Front differential

10. Viscous coupling unit (VCU)

10

11

13

12

11. Transfer cover

12. Hypoid pinion

13. Center differential

14. 1st gear

15. 1st - 2nd synchronizer

16. 2nd gear

17. 5th gear

18. 5th - reverse synchronizer

19. Reverse gear

20. Reverse idler gear

Page 50

W5M51 <Vehicle with ACD>

POWER TRAIN - Manual Transmission

2-5

4

1

2

3

5

6

7

8

9

21

20

19

18

17

16

22

1. 4th gear

2. 3rd - 4th synchronizer

3. 3rd gear

4. Transmission case

5. Clutch housing

6. Clutch release bearing retainer

7. Input shaft

8. Output shaft

9. Front differential

10. Clutch housing

11. Transfer cover

15

10

11

12

13

14

12. Piston

13. Transfer hydraulic case

14. Hypoid pinion

15. Center differential

16. 1st gear

17. 1st - 2nd synchronizer

18. 2nd gear

19. 5th gear

20. 5th - reverse synchronizer

21. Reverse gear

22. Reverse idler gear

Page 51

2-6

POWER TRAIN - Manual Transmission

W5M51 <Vehicle with Helical Gear LSD and VCU>

4

1

2

3

5

6

7

8

9

19

18

17

16

15

14

20

1. 4th gear

2. 3rd - 4th sychronizer

3. 3rd gear

4. Transmission case

5. Clutch housing

6. Clutch release bearing retainer

7. Input shaft

8. Output shaft

9. Front differential (Helical gear LSD)

10. Viscous coupling unit (VCU)

13

10

11

12

11. Transfer cover

12. Hypoid pinion

13. Center differential

14. 1st gear

15. 1st - 2nd sychronizer

16. 2nd gear

17. 5th gear

18. 5th - reverse synchronizer

19. Reverse gear

20. Reverse idler gear

Page 52

POWER TRAIN - Manual Transmission

W5M51 <Vehicle with Helical Gear LSD and ACD>

2-7

4

1

2

3

5

6

7

8

9

17

21

181920

16

22

1. 4th gear

2. 3rd - 4th sychronizer

3. 3rd gear

4. Transmission case

5. Clutch housing

6. Clutch release bearing retainer

7. Input shaft

8. Output shaft

9. Front differential (Helical gear LSD)

10. Clutch housing

11. Transfer cover

15

10

11

12

13

14

12. Piston

13. Transfer hydraulic case

14. Hypoid pinion

15. Center differential

16. 1st gear

17. 1st - 2nd sychronizer

18. 2nd gear

19. 5th gear

20. 5th - reverse synchronizer

21. Reverse gear

22. Reverse idler gear

Page 53

2-8

POWER TRAIN - Manual Transmission

4WD SYSTEM

The 4WD system is a center differential full-time 4WD with limited slip differential.

The center differential has been positioned at the front differential of the 2WD transmission, and the

front differential has been positioned inside the transfer. The limited slip differential of the center differential

has been positioned at the back of the front differential in the transfer.

For the limited slip differential of the center differential, a viscous coupling unit (VCU) or active center

differential (ACD) has been adopted.

Engine

Transfer

Center differential

Limited slip

differential

Front differential

Rear differential

Page 54

POWER TRAIN - Manual Transmission

2-9

POWER TRAIN

Helical Gear LSD

The helical gear LSD is composed of four long pinions, four short pinions, three thrust washers, side

gears A and B, and cases A and B.

The long pinions are in contact with the side gear B and short pinions, while the short pinions are in

contact with the side gear A and long pinions.

Case B

Short pinion

Thrust washer

Side gear B

Long pinion

Side gear A

Case A

Power Flow

Operations in forward driving

During forward driving, as the differential case and and drive shaft rotate at the same speed, they

rotate at the assembly without the inside of the differential moving.

The driving force at this time will be transmitted as follows.

Differential case

Short pinion

→ Long and short pinions → Side gears A and B → Drive shaft

Driving power

Differential case

Side gear B

Side gear A

Long pinion

Page 55

2-10

POWER TRAIN - Manual Transmission

Operations during differential (when there is rotational difference between the left and right

wheels)

When the frictional coefficient of the left and right wheels are more or less equal, and a slight rotational

difference occurs at the left and right wheels (normal turning), rotational difference will also occur

between side gears A and B. In this case, while the long pinions and short pinions mutually rotate

in the reverse direction, the vicinity of side gears A and B revolves and absorbs the speed difference.

In this way, like normal differential, the high speed side accelerates for the revolved amount in respect

to the revolution speed of the differential case,while the low speed side rotates in the decelerated

state and performs differential.

Differential case

Revolution

Autorotation

High speed side

Side gear A

Autorotation

Driving power

Side gear B

Low speed

side

Long pinion

Short pinion

Operations during Limited Slip Differential

When the loads of the left and right wheels become unbalanced due to changes in road surface

conditions and sudden turning, the driving torque of side gears A and B will differ.

As mentioned earlier, because side gears A and B are in contact via the respective long and short

pinions, the gears influence each other, resulting in contact reaction force (F and f) between the

long pinion and side gear B, and the short pinion and side gear A.

The separating force (Ft and ft) in the axial direction of the contact reaction force causes side gears

A and B to be pushed and extended. From this force, side gears A and B are pushed against the

thrust washer (case) and friction occurs.

The separating force (Fr and f r) in the radial direction of the contact reaction force causes the long

pinion and short pinion to be pushed against the differential case (cases A and B). This force generates

a large friction between the long pinion, short pinion, and differential case (cases A and B).

Friction also occurs on the gear with the generation of contact reaction force (F and f) of the four

gears (pinions).

These frictional forces cause the generation of frictional torque at each section according to the

size of the driving torque input to the differential case, and the generation of limited slip differential

torque proportionate to the input torque.

Page 56

POWER TRAIN - Manual Transmission

2-11

Driving power

Torque

High speed

side

Long pinion

Differential case

Short pinion

TRANSMISSION CONTROL

D The shift lever construction adopted the

spherical rotary shaft fulcrum type to assure

a non-rickety.

D The base bracket material adopted a synthetic

resin for the weight reduction.

Forward direction

Thrust washer

FFr

Ft

Low speed

side

Side gear A

f

fr

ft

Thrust washer

Side gear B

D The shift and select cable securing portions

have been elastically supported to reduce

contained sound.

D A mass-filled shift knob has been adopted to

minimize the binding touch at the time of a

shift.

CONSTRUCTION DIAGRAM

Select cable

Shift lever assembly

Shift cable

Base bracket

Page 57

2-12

POWER TRAIN - ACD and AYC

ACTIVE CENTER DIFFERENTIAL (ACD) AND ACTIVE YAW CONTROL (AYC)

The LANCER EVOLUTION-VII adopts the newly developed active center differential (ACD).

The driving performance of the ACD has been improved by varying the center differential drive by electronic

control.

The yaw moment is directly controlled by the active yaw control (AYC) adopted from EVOLUTION-V

onwards to improve the turning performance.

By combining and integratedly controlling these two systems, the driving performance has been further

improved.

RS, RS II

ACD Option

ACD and AYC Option

OUTLINE OF CONTROL

The following effects are obtained by equipping the ACD or ACD and AYC.

State of vehicle ACD AYC Integrated control effects

1. During deceleration

(Before

corners)

2. First half of

turning

(Corner entrance)

3. Latter half

of turning

(Corner

exit)

Similar to the direct engagement

4WD by increasing the center

differential during sharp deceleration to improve stability in deceleration.

The center differential restriction is

reduced according to the steering

angle and operation speed to set

the center differential as close as

possible to the free state and

improve turning performance.

The center differential restriction is

enhanced according to the amount

the acceleration is stepped to set

similar effects as the direct engagement 4WD and improve the acceleration performance.

[When decelerated during

turning]

The driving power is moved to

the inside turning wheel to

reduce the tack in.

The driving power is moved to

the outside turning wheel

according to the steering

angle and operation speed to

improve the turning performance.

The driving power is moved to

the outside turning wheel

according to the amount the

acceleration is stepped to

decrease the acceleration

understeer and improve turning performance.

Stability against various

external influences such as

poor road conditions and

driver operations have been

improved.

The response to steering

operations (brisk movement) is improved as much

as possible.

Two elements (acceleration

and turning) have been

improved simultaneously.

2. First half of turning

AYC: Turning

1. During deceleration

AYC: Tack in deceleration

(During deceleration when turning)

ACD: Free

ACD: Direct

engagement

3. Latter half of turning

AYC: Under steer deceleration

ACD: Direct engagement

Page 58

COMPONENT VIEW

ACD mode indicator lamp

POWER TRAIN - ACD and AYC

Parking brake switch

Steering

wheel sensor

2-13

AYC torque transfer

differential

Throttle position sensor (TPS)

ABS-ECU

ACD transfer

Engine-ECU

4WD-ECU

Longitudinal

G sensor

ACD mode switch

Stop lamp switch

Reserve tank

Hydraulic unit

assembly

Lateral G sensor

Wheel speed sensor

Wheel speed sensor

Page 59

2-14

p

y

LIST OF MAIN COMPONENTS

POWER TRAIN - ACD and AYC

Components

ACD transfer Controls the transmission torque of the hydraulic multi plate clutch by the

4WD-ECU Processes information of various sensors and switches, calculates the hydraulic

Engine-ECU Sends the engine idling state to the 4WD-ECU.

ABS-ECU Outputs the ABS monitor signal to the 4WD-ECU.

Throttle position sensor (TPS) Sends the throttle valve opening angle to the 4WD-ECU.

Longitudinal G sensor Sends the acceleration in the front and rear directions of the vehicle to the

Lateral G sensor Sends the acceleration along the side of the vehicle to the 4WD-ECU.

Steering wheel sensor Sends the steering angle and neutral position to the 4WD-ECU.

Wheel speed sensor Sends the wheel speed to the 4WD-ECU.

Stop lamp switch Sends the brake operating state to the 4WD-ECU.

Parking brake switch Sends the operating state of the parking brake to the 4WD-ECU.

ACD mode indicator lamp

ACD mode switch Switches the ACD control mode (TARMAC, GRAVEL, SNOW).

Hydraulic

unit

Electric pump relay Supplies the power to the electric pump.

AYC torque transfer differential Controls the transmission torque of the left and right clutches according to the

Pressure sensor Sends the pressure of the accumulator to the 4WD-ECU.

Electric pump Generates oil pressure for clutch operations.

Directional valve Controls whether to supply the oil pressure to the left or right AYC clutch.

Proportional valve

<ACD>

Proportional valve

<AYC>

Outline of function

hydraulic unit, and adjusts the center differential.

multi plate clutch transmission torque and amount of AYC torque movement and

direction, and controls the hydraulic unit on the basis of them.

4WD-ECU.

Displays the ACD control mode (TARMAC, GRAVEL, SNOW).

Lights the all mode lamp during fail. (Lights for about1.5 seconds after the ignition

switch is turned ON)

Controls hydraulic supplied to hydraulic multi plate clutch of the ACD.

Controls oil pressure supplied to the AYC clutch.

oil pressure from the hydraulic unit, and adjusts the left and right driving power

difference of the rear wheels.

Page 60

OUTLINE OF ACD AND AYC

POWER TRAIN - ACD and AYC

2-15

<ACD and AYC

Equipped Vehicle>

ABSECU

ABS monitor signal

Wheel speed sensor <FL>

Wheel speed sensor <RL>

Wheel speed sensor <RR>

Wheel speed sensor <FR>

Wheel speed sensor <FL>*

Wheel speed sensor <RL>*

Wheel speed sensor <RR>*

Wheel speed sensor <FR>*

Longitudinal G sensor

Lateral G sensor

Stop lamp

Steering wheel sensor

Pressure sensor

Throttle position sensor

ECU power supply

1

1

1

1

4WD-ECU

Idling information

ACD mode switch

Parking brake switch

ACD mode indicator lamp

Diagnostic connector

Direction valve*

2

Proportional valve*2(AYC)

Proportional valve (ACD)

Engine-ECU

Wheel speed

sensor <FR>

ACD transfer

Hydraulic

multi

plate clutch

Center

differential

Wheel speed sensor <FL>

NOTE

1

1.

*

indicates equipped with only ACD.

2

*

indicates equipped with ACD and AYC.

2.

Steering wheel sensor

Stop lamp switch

Wheel speed sensor <RR>

Lateral G sensor

Longitudinal G sensor

Wheel speed sensor <RL>

Right clutch*

Left clutch*

Electric

pump

Reservoir

tank relay

Pressure

sensor

2

2

Proportional

valve

(ACD)

Accumulator

Electric

Proportional

2

valve*

(AYC)

Direction al

2

valve*

pump

Hydraulic unit

AYC torque transfer

differential *

2

Page 61

2-16

POWER TRAIN - ACD and AYC

DESCRIPTION OF STRUCTURE AND OPERATIONS

The ACD system adopts a transfer limited slip differential as the hydraulic multi plate clutch, and electronically

controls it using sensors, 4WD-ECU, and hydraulic unit.

NOTE

Refer to P.2-30 for details on the AYC structure and operations.

SYSTEM STRUCTURE

AYC torque transfer

ACD transfer

Hydraulic unit

(Electric pump with

accumulator)

Engine

4WD-ECU

differential

T/M

Steering wheel sensor

TPS

Wheel speed sensor

Longitudinal G sensor

Lateral G sensor

Sensors

Page 62

POWER TRAIN - ACD and AYC

TRANSFER LIMITED SLIP DIFFERENTIAL

2-17

During acceleration and deceleration, the piston is moved in the right direction according to the oil pressure

from the hydraulic unit to connect the hydraulic multi plate clutch (friction plate and disc) and set the

center differential to the direct engagement state as much as possible. This improves the acceleration

performance and stability during deceleration.

During turning, the oil pressure from the hydraulic unit stops, the piston operates in the left direction

to release the hydraulic multi plate clutch and free the center differential to improve the turning performance.

If the parking brake is pulled while driving at a vehicle speed above 5 km/h, the hydraulic multi plate

clutch will also be released and the center differential set as close as possible to the free state.

Hydraulic unit

assembly

ACD transfer

A

A

Section A - A

Transfer hydraulic case

Piston

Thrust bearing

Hydraulic multi plate clutch

(Friction plate and disk)

<During acceleration

and deceleration>

<During turning>

Page 63

2-18

POWER TRAIN - ACD and AYC

HYDRAULIC UNIT

The hydreaulic unit is composed of the accumulator (electric pump, pressure sensor, accumulator) and

pressure controller (proportional valve, directional valve).

The pressure accumulator intermittently operates the pump, and accumulates the control pressure required

in the accumulator.

The pressure controller operates the proportional valve and directional valve, and supplies the appropriate

oil pressure to the ACD transfer or AYC torque transfer differential according to the signals from the

4WD-ECU.

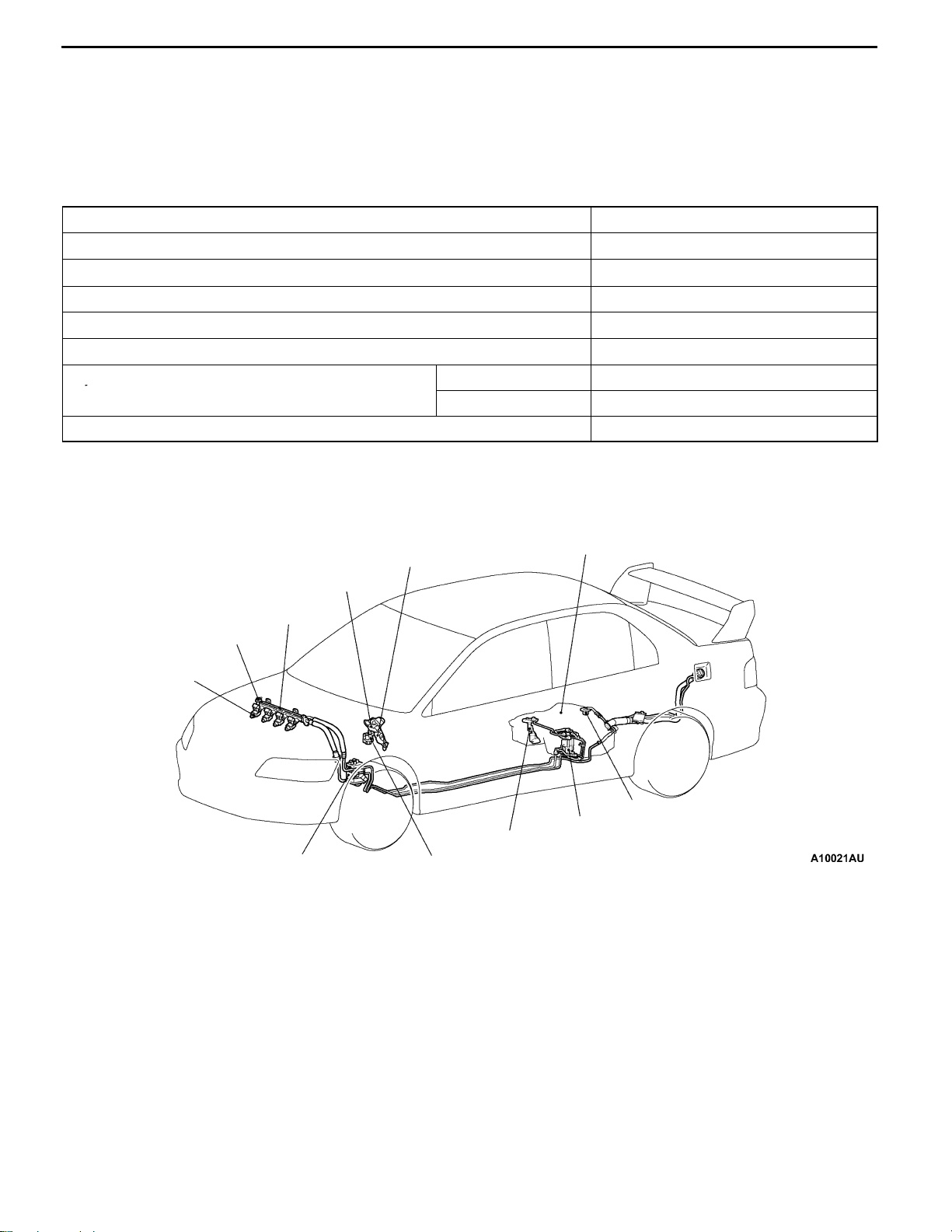

SPECIFICATIONS

Specifications Specifications

Electric pump Trochoidal type

Operating oil ATF SP III

Proportional valve Current proportional control type

Directional valve 3 position electromagnetic switching method

TPS

Stop lamp switch

Wheel speed sensor

Longitudinal G sensor

Lateral G sensor

Steering wheel sensor

Engine-ECU

ABS-ECU

ACD mode switch

Parking brake switch

Electronic control system

Oil pressure control system

4WD-ECU

Electric pump relay

ACD mode

indicator lamp

Hydraulic unit assembly

Pressure sensor

Electric

pump

Proportional

valve (AYC)

Directional

valve

Left

AYC clutch

Accumulator

Proportional

valve (ACD)

Right

ACD transfer

Hydraulic multi

plate clutch

Proportional

valve <ACD>

Proportional

valve <AYC>

Proportional valve

Supplies the oil pressure required for ACD or AYC control

according to the instructions of the 4WD-ECU.

Page 64

Proportional

valve (OFF)

POWER TRAIN - ACD and AYC

From electric pump

2-19

When the proportional valve is OFF, the oil pressure from

the electric pump will be cut off by the proportional valve.

For this reason, oil pressure will be supplied to the ACD

or AYC and each system will be set into the non-operating

state.

Proportional

valve (ON)

To ACD hydraulic multi plate

clutch or AYC directional valve

Directional

valve (OFF)

From electric pump

Return

From proportional

valve <AYC>

When the proportional valve turns ON, the proportional valve

opens, and the oil pressure from the electric pump will be

supplied to the ACD hydraulic multi plate clutch or AYC

directional valve.

Directional valve

Supplies the oil pressure required for controlling the AYC

clutch according to the instructions of the 4WD-ECU.

Directional

valve

When the directional valve is OFF, the oil pressure from the

proportional valve <AYC> will be cut off by the directional

valve. For this reason, the clutch will set into the non-operating

state without oil pressure supplied to each clutch of the AYC.

Directional valve

(Right side: ON)

To clutch

<Left side>

From proportional valve

<AYC>

To clutch

<Left side>

To clutch

<Right side>

To clutch

<Right side>

When oil pressure supply signal for the AYC clutch <Right