Page 1

WORKSHOP MANUAL

EVOLUTION-VI

Pub. No. S9806CNCP9-A

Page 2

General . . . . . . . . . . . . . . . . . . . . . . . .

.

.

00

EVOLUTION-VI

WORKSHOP MANUAL

SUPPLEMENT

FOREWORD

This Workshop Manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and

installation. Use the following manuals in

combination with this manual as required.

TECHNICAL INFORMATION MANUAL

N9806CNCP9

N9806CNCP9-A

WORKSHOP MANUAL

S9806CNCP9

Engine . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Transmission . . . . . . . . . . .

Front Axle . . . . . . . . . . . . . . . . . . . . . .

Rear Axle . . . . . . . . . . . . . . . . . . . . . .

Front Suspension . . . . . . . . . . . . . . .

Service Brakes . . . . . . . . . . . . . . . . .

Steering . . . . . . . . . . . . . . . . . . . . . . . .

Body . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior . . . . . . . . . . . . . . . . . . . . . . . .

Interior and Supplemental

Restraint System (SRS) . . . . . . . . .

Chassis Electrical . . . . . . . . . . . . . .

Heater, Air Conditioner and

V entilation . . . . . . . . . . . . . . . . . . . . .

Electrical Wiring . . . . . . . . . . . . . . . .

11

13

21

22

26

27

33

35

37

42

51

52

54

55

All information, illustrations and product

descriptions contained in this manual are current

as at the time of publication. We, however, reserve

the right to make changes at any time without prior

notice or obligation.

The EVOLUTION -VI is sold exclusively through

RALLIART Inc. Since the EVOLUTION-VI is a rallybased model, it will not be warranted and will not be

homologated for general production. Therefore, any

service matters on the EVOLUTION-VI should be

inquired to RALLIART Inc. as usual.

E Mitsubishi Motors Corporation March 1999

Page 3

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component,

can lead to personal injury or death to service personnel (from inadvertent firing of the air

bag) or to the driver and passenger (from rendering the SRS inoperative).

(2) SRS components should not be subjected to heat over 93_C, so remove the SRS-ECU, air

bag module and clock spring before drying or baking the vehicle after painting.

(3) Service or maintenance of any SRS component or SRS-related component must be performed

only at an authorized MITSUBISHI dealer.

(4) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP

52B – Supplemental Restraint System (SRS), before beginning any service or maintenance

of any component of the SRS or any SRS-related component.

NOTE

Section titles with asterisks (*) in the table of contents in each group indicate operations requiring warnings.

Page 4

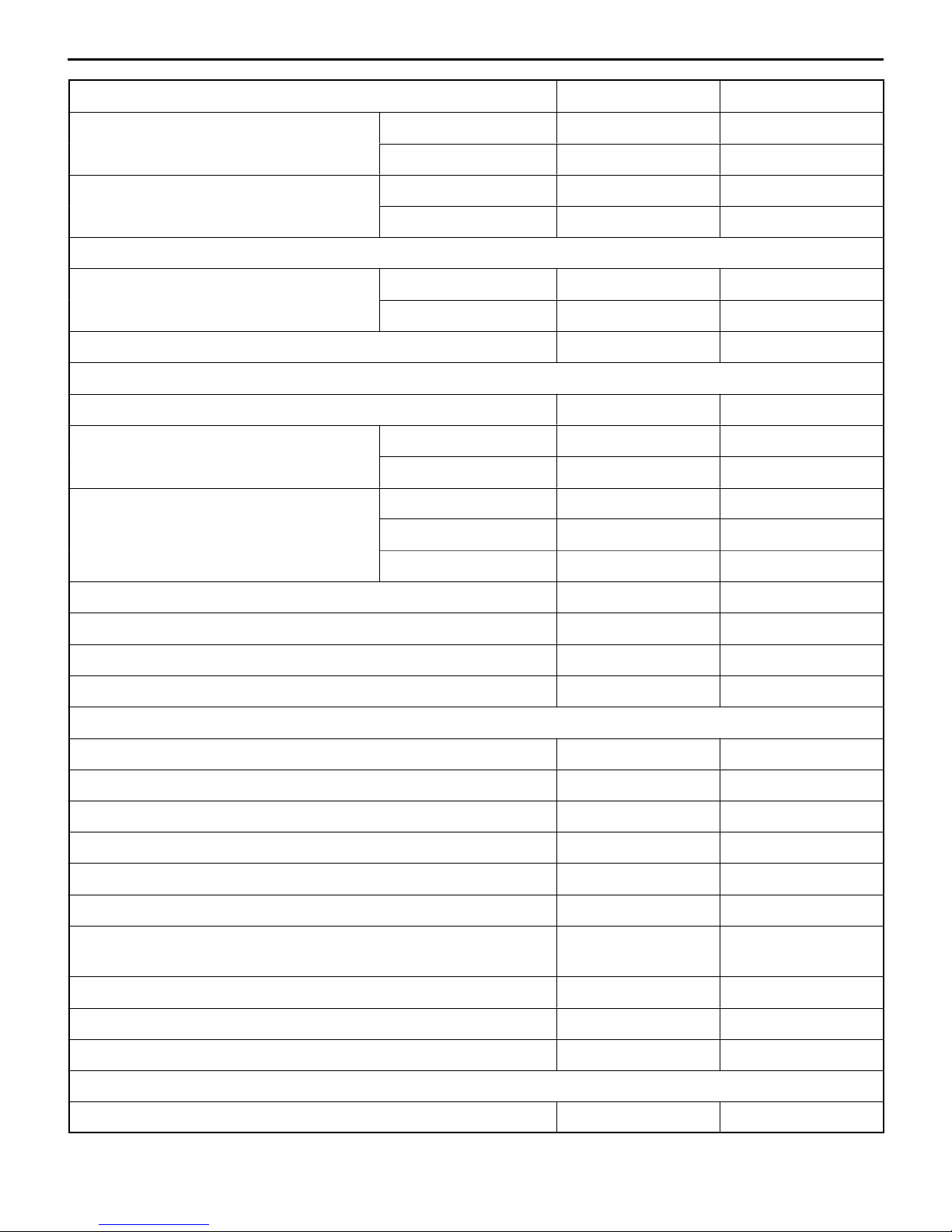

GENERAL

CONTENTS

00-1

HOW TO USE THIS MANUAL 3. . . . . . . . . . . . . .

Scope of Maintenance, Repair and Servicing

Explanations 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definition of Terms 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Indication of Tightening Torque 3. . . . . . . . . . . . . . . .

Explanation of Manual Contents 4. . . . . . . . . . . . . . .

HOW TO USE

TROUBLESHOOTING/INSPECTION SERVICE

POINTS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Contents 6. . . . . . . . . . . . . . . . . . . . .

Diagnosis Function 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Use the Inspection Procedures 10. . . . . . .

Connector Measurement Service Points 11. . . . . . .

Connector Inspection 12. . . . . . . . . . . . . . . . . . . . . . . .

Inspection Service Points for a Blown Fuse 13. . .

Points to Note for Intermittent Malfunctions 13. . . .

MODELS 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRECAUTIONS BEFORE SERVICE 15. . . . . . .

SUPPORT LOCATIONS FOR LIFTING AND

JACKING 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Garage Jack 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Stands 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single-post and Double-post Lift 19. . . . . . . . . . . . . .

SPECIAL HANDLING INSTRUMENTS FOR

TOWING 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE TEST 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIGHTENING TORQUE 22. . . . . . . . . . . . . . . . . . .

Page 5

GENERAL – How to Use This Manual

HOW TO USE THIS MANUAL

00-3

SCOPE OF MAINTENANCE, REPAIR

AND SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Note, however,

that for engine and transmission-related component

parts, this manual covers only on-vehicle

inspections, adjustments, and the removal and

installation procedures for major components.

For detailed information concerning the inspection,

checking, adjustment, disassembly and reassembly

of the engine, transmission and major components

after they have been removed from the vehicle,

please refer to separate manuals covering the

engine and the transmission.

ON-VEHICLE SERVICE

“On-vehicle Service” is procedures for performing

inspections and adjustments of particularly

important locations with regard to the construction

and for maintenance and servicing, but other

inspection (for looseness, play, cracking, damage,

etc.) must also be performed.

INSPECTION

Under this title are presented inspection and

checking procedures to be performed by using

special tools and measuring instruments and by

feeling, but, for actual maintenance and servicing

procedures, visual inspections should always be

performed as well.

DEFINITION OF TERMS

STANDARD VALUE

Indicates the value used as the standard for judging

the quality of a part or assembly on inspection

or the value to which the part or assembly is

corrected and adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a

part or assembly on inspection and means the

maximum or minimum value within which the part

or assembly must be kept functionally or in strength.

It is a value established outside the range of

standard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be

completed in a shorter time).

CAUTION

Indicates the presentation of information particularly

vital to the worker during the performance of

maintenance and servicing procedures in order to

avoid the possibility of injury to the worker, or

damage to component parts, or a reduction of

component or vehicle function or performance, etc.

INDICATION OF TIGHTENING TORQUE

The tightening torque shown in this manual is a

basic value with a tolerance of ±10% except the

following cases when the upper and lower limits

of tightening torque are given.

(1) The tolerance of the basic value is within ±10%.

(2) Special bolts or the like are in use.

(3) Special tightening methods are used.

Page 6

00-4

GENERAL – How to Use This Manual

EXPLANATION OF MANUAL CONTENTS

Maintenance and Servicing Procedures

The numbers provided within the diagram indicate the sequence for maintenance and servicing procedures.

D Removal steps:

The part designation number corresponds

to the number in the illustration to indicate

removal steps.

D Disassembly steps:

The part designation number corresponds

to the number in the illustration to indicate

disassembly steps.

Indicates procedures to be performed

before the work in that section is started,

and procedures to be performed after

the work in that section is finished.

Component Diagram

A diagram of the component parts is

provided near the front of each section

in order to give a reader a better understanding of the installed condition of

component parts.

Indicates (by symbols) where lubrication is necessary.

D Installation steps:

Specified in case installation is impossible

in reverse order of removal steps. Omitted

if installation is possible in reverse order of

removal steps.

D Reassembly steps:

Specified in case reassembly is impossible

in reverse order of disassembly steps.

Omitted if reassemby is possible in reverse

order of disassembly steps.

Classifications of Major Maintenance/Service Points

When there are major points relative to maintenance and servicing procedures

(such as essential maintenance and service points, maintenance and service standard values, information regarding the use of special tools, etc.), these are arranged together as major maintenance and service points and explained in detail.

AA" : Indicates that there are essential points for removal or disassembly.

"AA : Indicates that there are essential points for installation or reassembly.

Symbols for Lubrication, Sealants and Adhesives

Information concerning the locations for lubrication and for application of sealants and adhesives is provided, by using symbols, in the diagram of component parts or on the page following the component parts page, and explained.

: Grease

(multipurpose grease unless there is a

brand or type specified)

: Sealant or adhesive

: Brake fluid or automatic transmission fluid

: Engine oil, gear oil or air conditioner com-

pressor oil

: Adhesive tape or butyl rubber tape

Page 7

GENERAL – How to Use This Manual

00-5

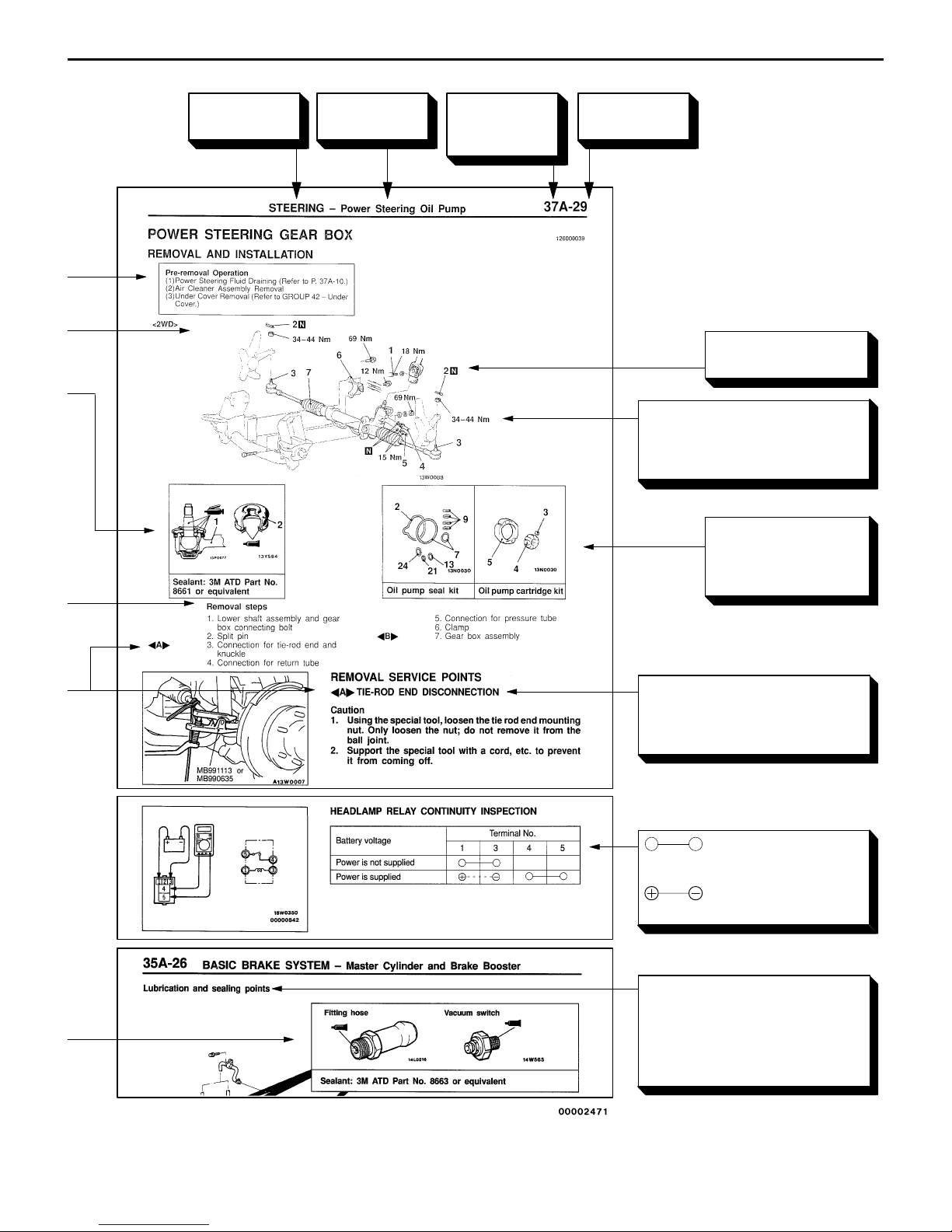

Indicates the

group title.

Indicates the

section title.

Indicates the

group number.

Indicates the

page number.

Denotes non-reusable part.

Denotes tightening torque.

For bolts and nuts which do not

have a tightening torque listed,

refer to the “Tightening torque”.

Repair kit or set parts

are shown. (Only very

frequently used parts

are shown.)

Operating procedures, cautions, etc. on removal, installation, disassembly and reassembly are described.

indicates that there is

a continuity between the terminals.

indicates terminals to

which battery voltage is applied.

The title of the page (following

the page on which the diagram

of component parts is presented) indicating the locations of

lubrication and sealing procedures.

Page 8

00-6

GENERAL – How to Use Troubleshooting/Inspection Service Points

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE

POINTS

Troubleshooting of electronic control systems for which the MUT-II can be used follows the basic outline

described below. Furthermore, even in systems for which the MUT-II cannot be used, part of these systems

still follow this outline.

TROUBLESHOOTING CONTENTS

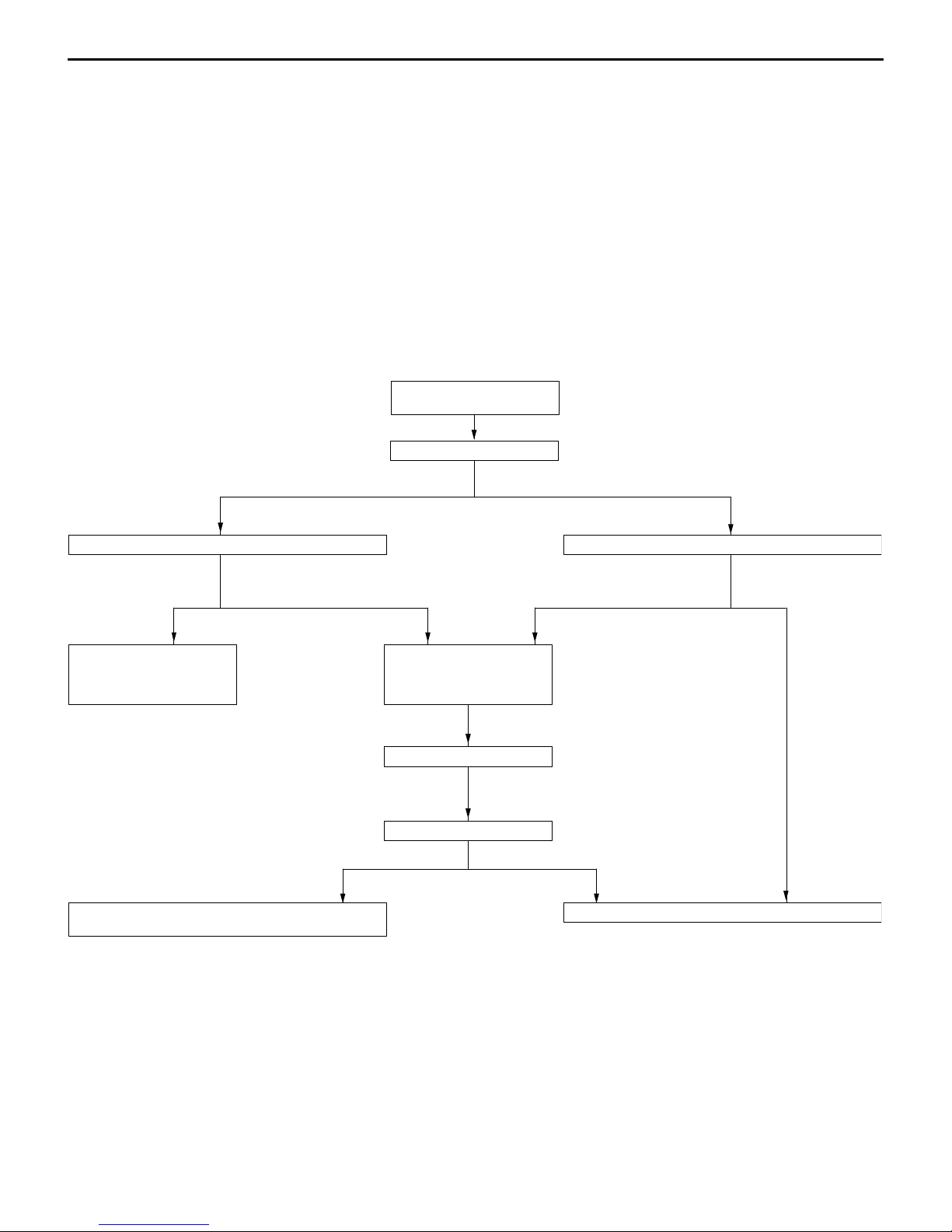

1. STANDARD FLOW OF DIAGNOSIS TROUBLESHOOTING

The troubleshooting sections follow the basic diagnosis flow which is given below. If the diagnosis

flow is different from that given below, or if additional explanation is required, the details of such

differences or additions will also be listed.

Diagnosis method

Gathering information

from the customer.

Check trouble symptom.

Reoccurs Does not reoccur.

Read the diagnosis code

No diagnosis code

or communication

with MUT-II not

possible

Refer to the INSPECTION

CHART FOR TROUBLE

SYMPTOMS (Refer to

applicable group.)

Diagnosis code

displayed.

Refer to the INSPECTION CHART FOR DIAGNOSIS

CODES (Refer to applicable group.)

Diagnosis code

displayed.

After taking note of the

malfunction code, erase

the diagnosis code

memory

Recheck trouble symptom.

Read the diagnosis codes.

Read the diagnosis code

Diagnosis code

displayed.

No diagnosis

code

INTERMITTENT MALFUNCTIONS (Refer to P.00-13.)

No diagnosis

code

2. SYSTEM OPERATION AND SYMPTOM VERIFICATION TESTS

If verification of the trouble symptoms is difficult, procedures for checking operation and verifying

trouble symptoms are shown.

3. DIAGNOSIS FUNCTION

Details which are different from those in the “Diagnosis Function” section on the next page are listed.

Page 9

GENERAL – How to Use Troubleshooting/Inspection Service Points

4. INSPECTION CHART FOR DIAGNOSIS CODES

5. INSPECTION PROCEDURE FOR DIAGNOSIS CODES

Indicates the inspection procedures corresponding to each diagnosis code. (Refer to P.00-10 for how

to read the inspection procedures.)

6. INSPECTION CHART FOR TROUBLE SYMPTOMS

If there are trouble symptoms even though the results of inspection using the MUT-II show that all

diagnosis codes are normal, inspection procedures for each trouble symptom will be found by means

of this chart.

7. INSPECTION PROCEDURE FOR TROUBLE SYMPTOM

Indicates the inspection procedures corresponding to each trouble symptoms classified in the Inspection

Chart for Trouble Symptoms. (Refer to P.00-10 for how to read the inspection procedures.)

8. SERVICE DATA REFERENCE TABLE

Inspection items and normal judgement values have been provided in this chart as reference information.

9. CHECK AT ECU TERMINALS

Terminal numbers for the ECU connectors, inspection items and standard values have been provided

in this chart as reference information.

00-7

10. INSPECTION PROCEDURES USING AN OSCILLOSCOPE

When there are inspection procedures using an oscilloscope, these are listed here.

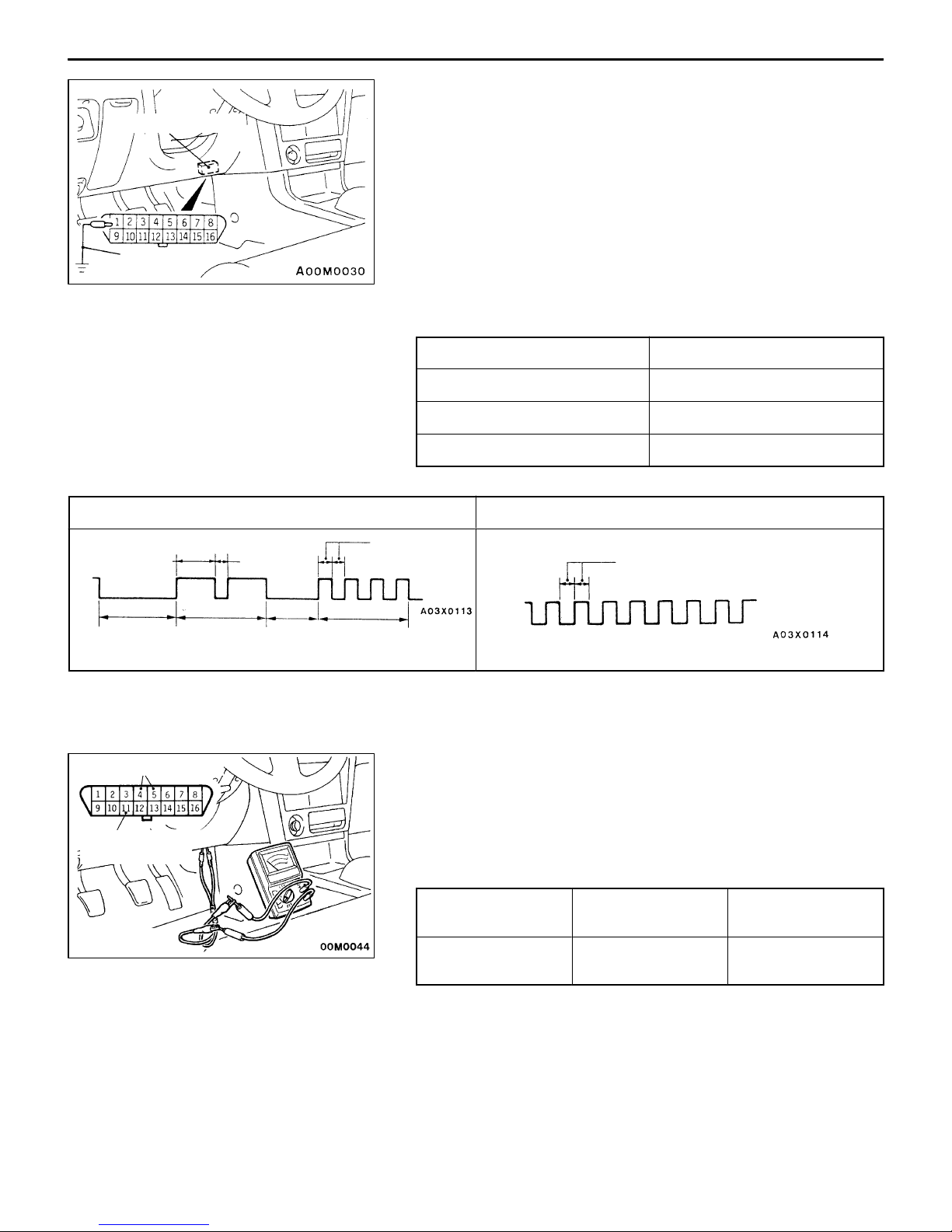

DIAGNOSIS FUNCTION

MUT-II

METHOD OF READING DIAGNOSIS CODES

WHEN USING THE MUT-II

Connect the MUT-II to the diagnosis connector and take a

reading of the diagnosis codes.

Caution

Turn off the ignition switch before connecting or

disconnecting the MUT-II.

Page 10

00-8

GENERAL – How to Use Troubleshooting/Inspection Service Points

WHEN USING THE WARNING LAMP

Diagnosis connector

1. Use the special tool to earth No.1 terminal (diagnosis

control terminal) of the diagnosis connector.

2. To check ABS system, remove the valve relay.

NOTE

That is because the valve relay is off and the warning

lamp remains illuminated if there is a fault in the ABS

system.

MB991529

3. Turn on the ignition switch.

4. Read out a diagnosis code by observing how the warning

lamp flashes.

Applicable systems

System name Warning lamp name

MPI Engine warning lamp

AYC A YC warning lamp

ABS ABS warning lamp

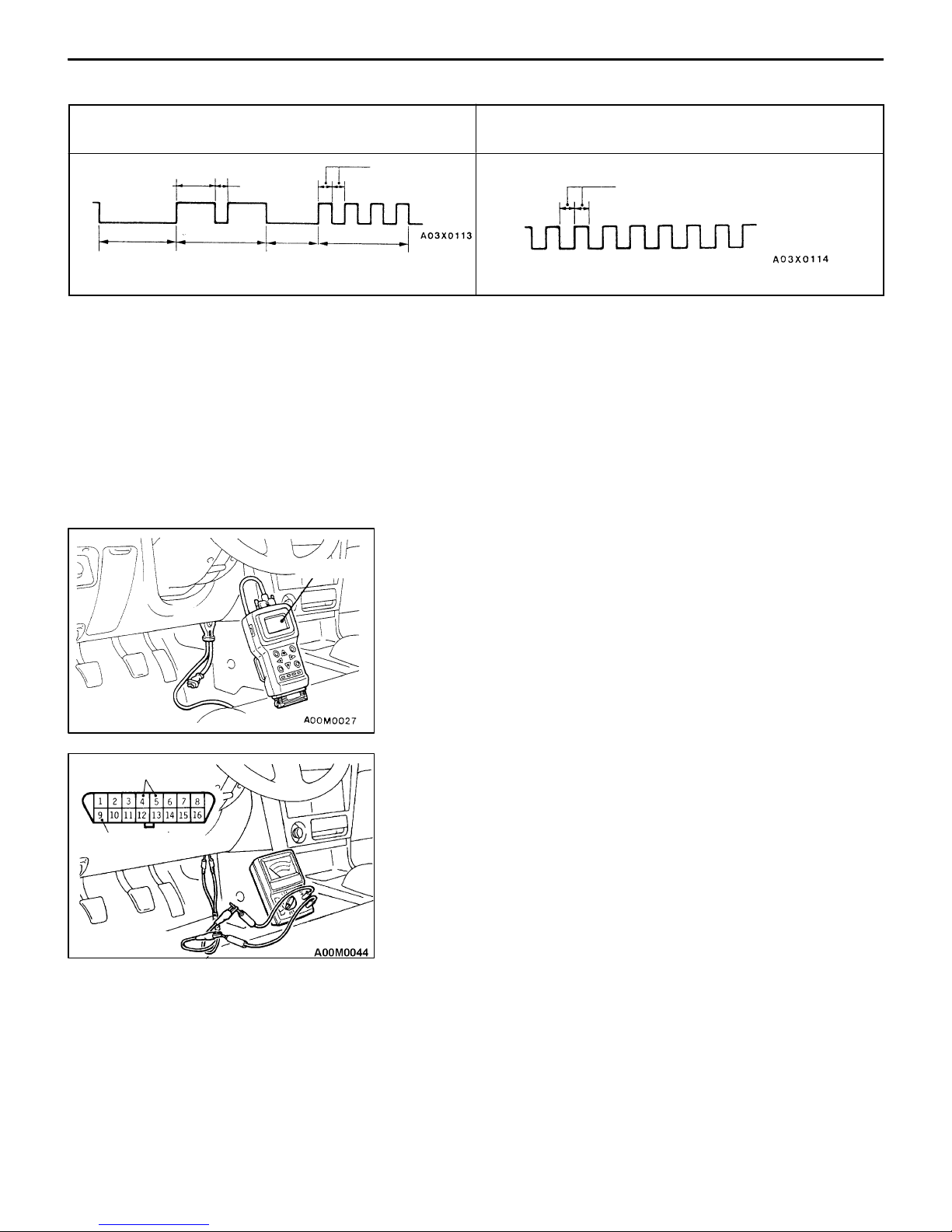

Indication of diagnosis code by warning lamp

When the diagnosis code No.24 is output When no diagnosis code is output*

On

Off

1.5 secs.

Pause

time 3

secs.

Tens

signal

0.5 sec.

Place

division

2 secs.

Units

signal

0.5 sec.

On

Off

0.5 sec.

NOTE

*: Even if the ABS system is normal, removing the valve relay causes the diagnosis code No.52 to

be output.

Earth terminal

WHEN USING THE VOLTMETER

Use the special tool to connect the diagnosis output terminals

and the earth terminal of the diagnosis connector to a voltmeter

and take a reading of the diagnosis codes from the movement

Full-auto air conditioner terminal

of the needle.

Voltmeter connection terminals

MB991529

System name Positive connection

terminal

Full-auto air

conditioner

11 4 or 5

Negative connection terminal

Page 11

GENERAL – How to Use Troubleshooting/Inspection Service Points

Diagnosis result display method when using a voltmeter

00-9

Example of diagnosis code voltage wave pattern for

diagnosis code No. 24

0.5 sec.

Units

signal

12V

0 V

1.5 secs.

Pause

time 3

secs.

Tens

signal

0.5 sec.

Place

division

2 secs.

Normal voltage wave pattern

0.5 sec.

12 V

0 V

METHOD OF ERASING DIAGNOSIS CODES

WHEN USING THE MUT-II

Connect the MUT-II to the diagnosis connector and erase the diagnosis code.

Caution

Turn off the ignition switch before connecting or disconnecting the MUT-II.

WHEN NOT USING THE MUT-II

(1) Turn the ignition switch to OFF.

(2) After disconnecting the battery cable from the battery (–) terminal for 10 seconds or more, reconnect

the cable.

(3) After the engine has warmed up, run it at idle for about 15 minutes.

INPUT SIGNAL INSPECTION POINTS <VEHICLES

MUT-II

WITH ETACS-ECU>

WHEN USING THE MUT-II

1. Connect the MUT-II to the diagnosis connector.

Earth terminal

ET ACS terminal

MB991529

Caution

The MUT-II should be connected or disconnected after

turning the ignition switch to the OFF position.

2. If buzzer of the MUT-II sounds once when the each switch

is operated (ON/OFF), the ETACS-ECU input signal for

that switch circuit system is normal.

WHEN USING VOLTMETER

1. Use the special tool to connect a voltmeter between

the earth terminal (No. 4 or 5) and the ETACS terminal

(No. 9) of the diagnosis connector.

2. If the voltmeter indicator deflects once when the each

switch is operated (ON/OFF), the ETACS-ECU input signal

for that switch circuit system is normal.

Page 12

00-10

GENERAL – How to Use Troubleshooting/Inspection Service Points

HOW TO USE THE INSPECTION PROCEDURES

The causes of a high frequency of problems occurring in electronic circuitry are generally the connectors,

components, the ECU and the harnesses between connectors, in that order. These inspection procedures

follow this order, and they first try to discover a problem with a connector or a defective component.

1. Comments on the diagnosis code or trouble

CHECKING PROCEDURE 4

symptom above.

D Indicator does not turn on or off even if control

mode switch is pressed.

D Indicator switch should not be illuminated is

illuminated.

In the above cases, the ECS switch circuit is defective or the indicator

circuit is defective.

MUT-II Data list

17 Control mode selection switch

OK: Voltage changes between approx. 0V → approx.

2.5V → approx. 5V when the switch is operated.

NG

ECU switch component inspection (Refer to P.3-44.)

OK

Measure at switch connector A-44

D Disconnect the connector, and measure at the harness

side.

D Voltage between terminal 6 – earth and terminal 8 –

earth

OK: Approx. 5V

OK

Check the following connector. A-44

OK

Check trouble symptom.

Replace the ECS-ECU.

OK

4. Indicates voltage and resistance to be measured at a particular

NG

OK

NG

5. Inspect the contact condition at each connector terminal.

Probable cause

2. Indicates inspection carried out using the

MUT-II.

Indicates the operation and inspection procedures.

Indicates the OK judgement conditions.

3. Detailed inspection procedures (methods)

such as component inspection and circuit

inspection are listed on a separate page, and

are given here for reference.

connector.

(Refer to Connector Measurement Service Points.)

The connector position can be located in the wiring diagram in the

electrical wiring manual by means of this symbol.

Indicates operation and inspection procedures, inspection terminals

and inspection conditions.

Indicates the OK judgement conditions.

Repair

(Refer to Connector Inspection Service Points.)

The connector position can be located in the wiring diagram in the

electrical wiring manual by means of this symbol.

Caution

After carrying out connector inspection, always be sure to

reconnect the connector as it was before.

HARNESS INSPECTION

Check for an open or short circuit in the harness between the terminals which were defective according

to the connector measurements. Carry out this inspection while referring to the electrical wiring manual.

Here, “Check harness between power supply and terminal xx” also includes checking for blown fuses.

For inspection service points when there is a blown fuse, refer to “Inspection Service Points for a Blown

Fuse.”

MEASURES TO TAKE AFTER REPLACING THE ECU

If the trouble symptoms have not disappeared even after replacing the ECU, repeat the inspection procedure

from the beginning.

6. Confirm that there are trouble symptoms. If trouble symptoms have

disappeared, the connector may have been inserted incorrectly and the

trouble symptom may have disappeared during inspection.

If it seems that trouble symptoms still remain, proceed to the next page of

instructions.

7. If trouble symptoms still remain up to this stage, there is a possibility that there is an

open or short circuit in the harness between the connectors, so check the harness.

Alternatively , the cause may be a defective ECU, so try replacing the ECU and check

if the trouble symptom disappears.

Page 13

GENERAL – How to Use Troubleshooting/Inspection Service Points

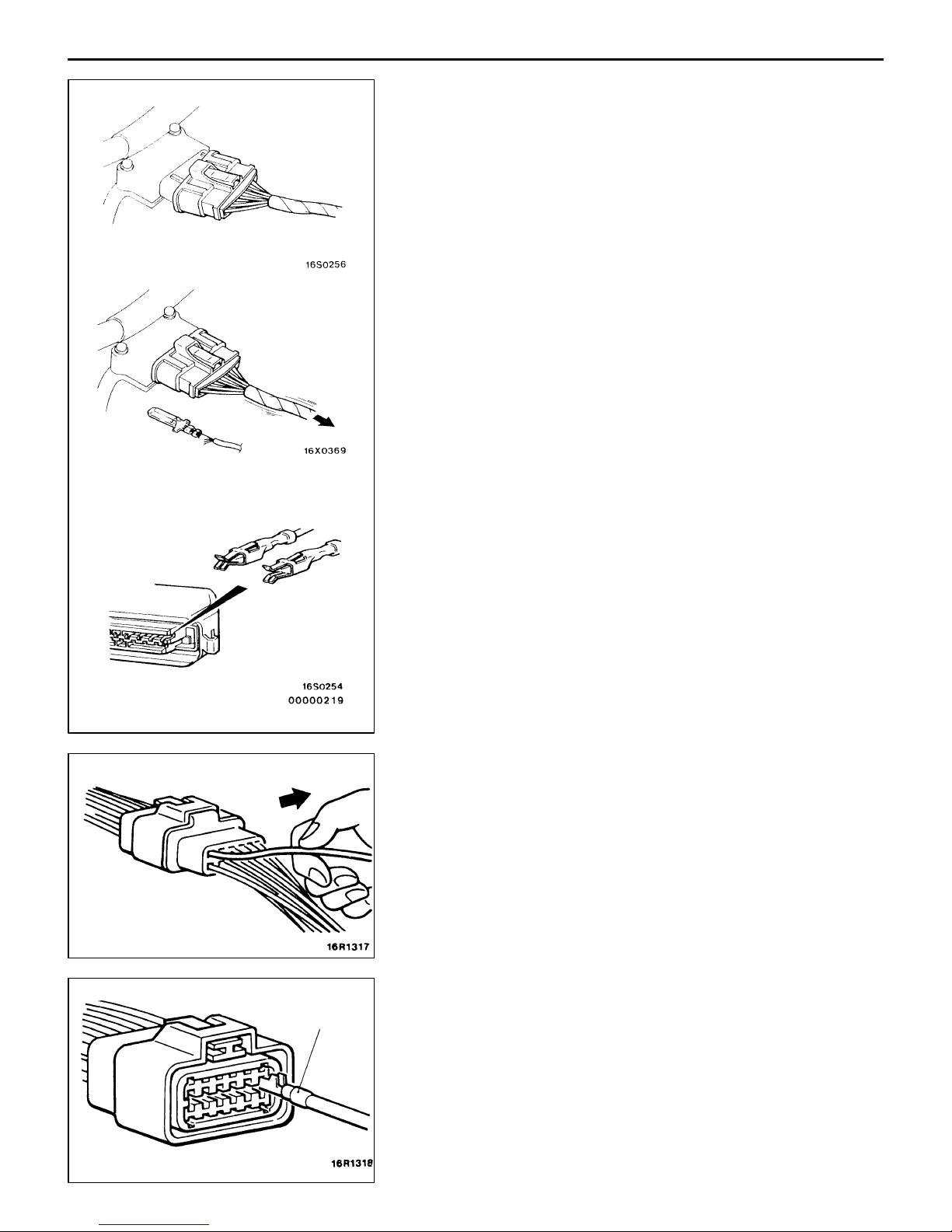

CONNECTOR MEASUREMENT SER VICE POINTS

Turn the ignition switch to OFF when connecting disconnecting

the connectors, and turn the ignition switch to ON when

measuring if there are no instructions to be contrary.

00-11

Extra-thin probe

Test bar

Connector

Inspection harness

for connector pin

contact pressure

Harness connector

IF INSPECTING WITH THE CONNECTOR CONNECTED

(WITH CIRCUIT IN A CONDITION OF CONTINUITY)

Waterproof Connectors

Be sure to use the special tool (harness connector). Never

insert a test bar from the harness side, because to do so

will reduce the waterproof performance and result in corrosion.

Ordinary (non-waterproof) Connectors

Check by inserting the test bar from the harness side. Note

that if the connector (control unit, etc.) is too small to permit

insertion of the test bar, it should not be forced; use a special

tool (the extra-thin probe in the harness set for checking

for this purpose.

IF INSPECTING WITH THE CONNECTOR DISCONNECTED

<When Inspecting a Female Pin>

Use the special tool (inspection harness for connector pin

contact pressure in the harness set for inspection).

The inspection harness for connector pin contact pressure

should be used. the test bar should never be forcibly inserted,

as it may cause a defective contact.

<When Inspecting a Male Pin>

Touch the pin directly with the test bar.

Caution

At this time, be careful not to short the connector pins

with the test bars. To do so may damage the circuits

inside the ECU.

Page 14

00-12

GENERAL – How to Use Troubleshooting/Inspection Service Points

Connector disconnected or improperly

connected

Defective connector contact

Harness wire breakage

at terminal section

Low contact pressure

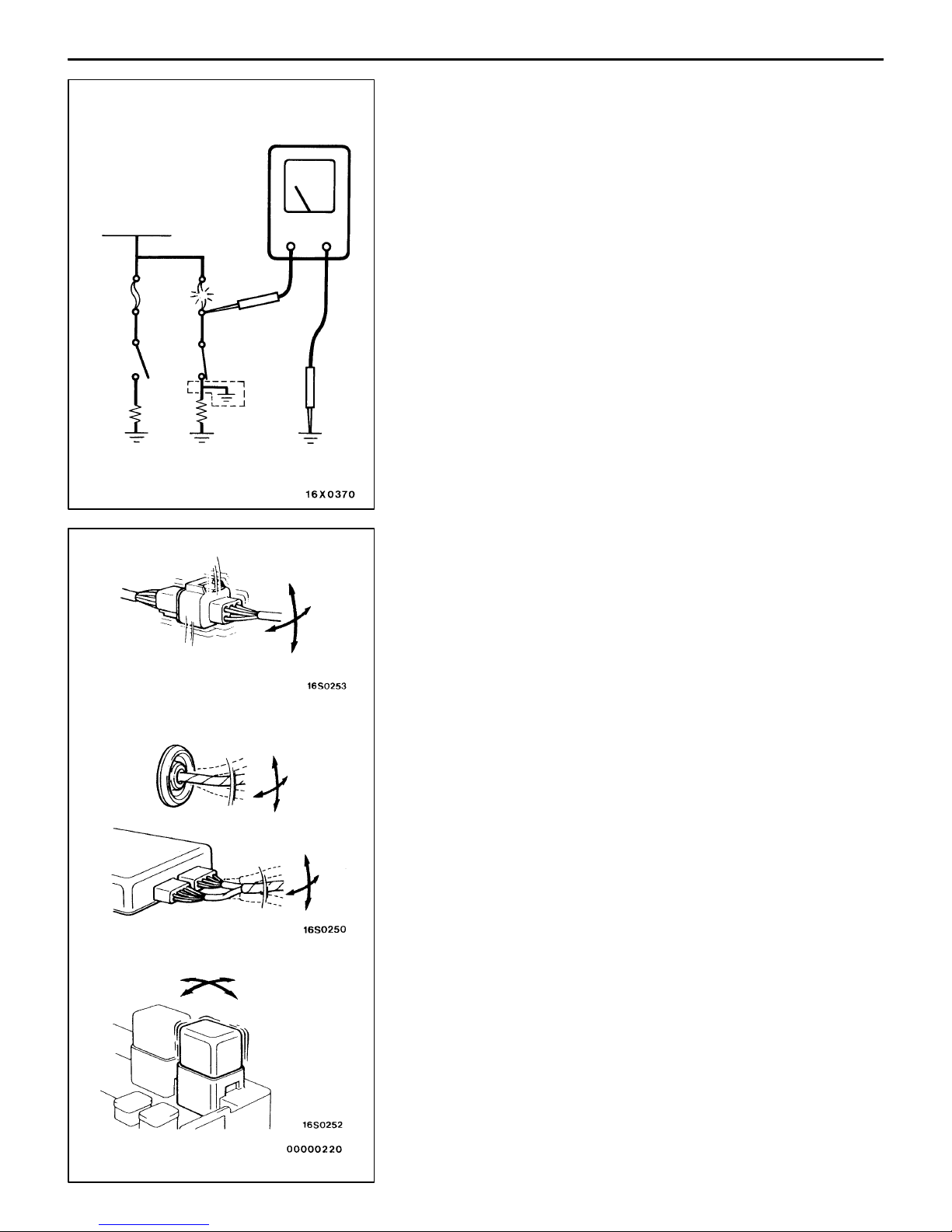

CONNECTOR INSPECTION

VISUAL INSPECTION

D Connector is disconnected or improperly connected

D Connector pins are pulled out

D Due to harness tension at terminal section

D Low contact pressure between male and female terminals

D Low connection pressure due to rusted terminals or foreign

matter lodged in terminals

MB991219

CONNECTOR PIN INSPECTION

If the connector pin stopper is damaged, the terminal

connections (male and female pins) will not be perfect even

if the connector body is connected, and the pins may pull

out of the reverse side of the connector. Therefore, gently

pull the harnesses one by one to make sure that no pins

pull out of the connector.

CONNECTOR ENGAGEMENT INSPECTION

Use the special tool (connector pin connection pressure

inspection harness of the inspection harness set) to inspect

the engagement of the male pins and females pins. (Pin

drawing force : 1 N or more)

Page 15

GENERAL – How to Use Troubleshooting/Inspection Service Points

INSPECTION SERVICE POINTS FOR A BLOWN

FUSE

Remove the fuse and measure the resistance between the

load side of the fuse and the earth. Set the switches of all

0 Ω

Battery

circuits which are connected to this fuse to a condition of

continuity. If the resistance is almost 0 Ω at this time, there

is a short somewhere between these switches and the load.

If the resistance is not 0 Ω, there is no short at the present

time, but a momentary short has probably caused the fuse

to blow.

00-13

Fuse

Load

switch

Load

Connector

inspection

The main causes of a short circuit are the following.

D Harness being clamped by the vehicle body

D Damage to the outer casing of the harness due to wear

or heat

D Water getting into the connector or circuitry

D Human error (mistakenly shorting a circuit, etc.)

POINTS TO NOTE FOR INTERMITTENT

MALFUNCTIONS

Intermittent malfunctions often occur under certain conditions,

and if these conditions can be ascertained, determining the

cause becomes simple. In order to ascertain the conditions

under which an intermittent malfunction occurs, first ask the

customer for details about the driving conditions, weather

conditions, frequency of occurrence and trouble symptoms,

and then try to recreate the trouble symptoms. Next, ascertain

whether the reason why the trouble symptom occurred under

these conditions is due to vibration, temperature or some

other factor. If vibration is thought to be the cause, carry

out the following checks with the connectors and components

to confirm whether the trouble symptom occurs.

The objects to be checked are connectors and components

which are indicated by inspection procedures or given as

probable causes (which generates diagnosis codes or trouble

symptoms.)

D Gently shake the connector up, down and to the left and

right.

D Gently shake the wiring harness up, down and to the

left and right.

D Gently rock each sensor and relay, etc. by hand.

D Gently shake the wiring harness at suspensions and other

moving parts.

NOTE

If determining the cause is difficult, the flight recorder function

of the MUT-II can also be used.

Page 16

00-14

16 valves-intercooler

(4WD-5M/T)

controlled fuel

16

(4WD-5M/T)

turbo)

MODELS

<LANCER EVOLUTION-IV>

GENERAL – Models

Model

code

E-CN9A SNDF ’97 RS 4G63 (2,000-DOHC –-W5M51

Class

code

SRGF ’97 GSR

Model

year

Grade Engine model Transmission

model

turbo)

Applicable serial numbers

E-CN9A: CN9A – 0000001 Y

<LANCER EVOLUTION-V>

Model

code

GF-CP9A SNDF ’98 EVOLUTION-V RS 4G63 (2,000-DOHC –

Class

code

SNGF ’98 EVOLUTION-V

Model

year

Grade Engine model Transmission

GSR

model

W5M51

valves-intercooler

turbo)

Applicable serial numbers

GF-CP9A: CP9A – 0000001 Y

<LANCER EVOLUTION-VI>

Model

code

Class

code

Model

year

Grade Engine model Transmission

model

Fuel supply

system

Electronically

injection (MPI)

Fuel supply

system

MPI

Fuel supply

system

f

GF-CP9A SNDF ’99 EVOLUTION-VI

RS

SNGF ’99 EVOLUTION-VI

GSR

Applicable serial numbers

GF-CP9A: CP9A – 0100001 Y

4G63 (2,000-DOHC –

16 valves-intercooler

W5M51

(4WD-5M/T)

MPI

Page 17

GENERAL – Precautions Before Service

00-15

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

1. Items to follow when servicing SRS

(1) Be sure to read GROUP 52B – Supplemental Restraint System (SRS).

For safe operations, please follow the directions and heed all warnings.

(2) Always use the designated special tools and test equipment.

(3) Wait at least 60 seconds after disconnecting the battery cable before doing any further work.

The SRS system is designed to retain enough voltage to deploy the air bag even after the battery

has been disconnected. Serious injury may result from unintended air bag deployment if work

is done on the SRS system immediately after the battery cable is disconnected.

(4) Never attempt to disassemble or repair the SRS components. (SRS air bag control unit, air bag

module and clock spring.) If faulty, replace it.

(5) Warnings labels must be needed when servicing and handling SRS components. Warning labels

are located in the following locations.

D Sun visor

D Glove box

D SRS air bag control unit

D Steering wheel

D Steering gear and linkage

D Air bag module

D Clock spring

(6) Store components removed from the SRS in a clean and dry place.

The air bag module should be stored on a flat surface and placed so that the pad surface is

facing upwards.

(7) Be sure to deploy the air bag before disposing of air bag module or disposing of a vehicle equipped

with an air bag. (Refer to GROUP 52B – Air Bag Module Disposal Procedures.)

(8) Whenever you finish servicing the SRS, check the SRS warning lamp operation to make sure

that the system functions properly.

2. Observe the following when carrying out operations on place where SRS components are installed,

including operations not directly related to the SRS air bag.

(1) When removing or installing parts do not allow any impact or shock to the SRS components.

(2) SRS components should not be subjected to heat over 93_C, so remove the SRS components

before drying or baking the vehicle after painting.

After re-installing them, check the SRS warning lamp operation to make sure that the system

functions properly.

Page 18

00-16

GENERAL – Precautions Before Service

SERVICING THE ELECTRICAL SYSTEM

Before replacing a component related to the electrical system

and before undertaking any repair procedures involving the

electrical system, be sure to first disconnect the negative

(–) cable from the battery in order to avoid damage caused

by short-circuiting.

Caution

Before connecting or disconnecting the negative (–) cable,

be sure to turn off the ignition switch and the lighting

switch.

(If this is not done, there is the possibility of

semiconductor parts being damaged.)

APPLICATION OF ANTI-CORROSION AGENTS

AND UNDERCOATS

If oil or grease gets onto the oxygen sensor, it will cause

a drop in the performance of the sensor.

Cover the oxygen sensor with a protective cover when applying

anti-corrosion agents and undercoats.

Approx.

40 cm

PRE-INSPECTION CONDITION

“Pre-inspection condition” refers to the condition that the

vehicle must be in before proper engine inspection can be

carried out. If you see the words “Set the vehicle to the

pre-inspection condition.” in this manual, it means to set the

vehicle to the following condition.

D Engine coolant temperature: 80–90_C

D Lamps, electric cooling fan and all accessories: OFF

D M/T: Neutral

VEHICLE WASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to note the

following information in order to avoid damage to plastic

components, etc.

D Spray nozzle distance: Approx. 40 cm or more

D Spray pressure: 3,900 kPa or less

D Spray temperature: 82_C or less

D Time of concentrated spray to one point: within 30 sec.

Page 19

GENERAL – Precautions Before Service

00-17

MUT-II

sub-assembly

ROM pack

MUT-II

Refer to the MUT-II INSTRUCTION MANUAL for instructions

on handling the MUT-II.

Connect the MUT-II to the diagnosis connector as shown

in the illustration.

Caution

Connection and disconnection of the MUT-II should

always be made with the ignition switch in the OFF

position.

Page 20

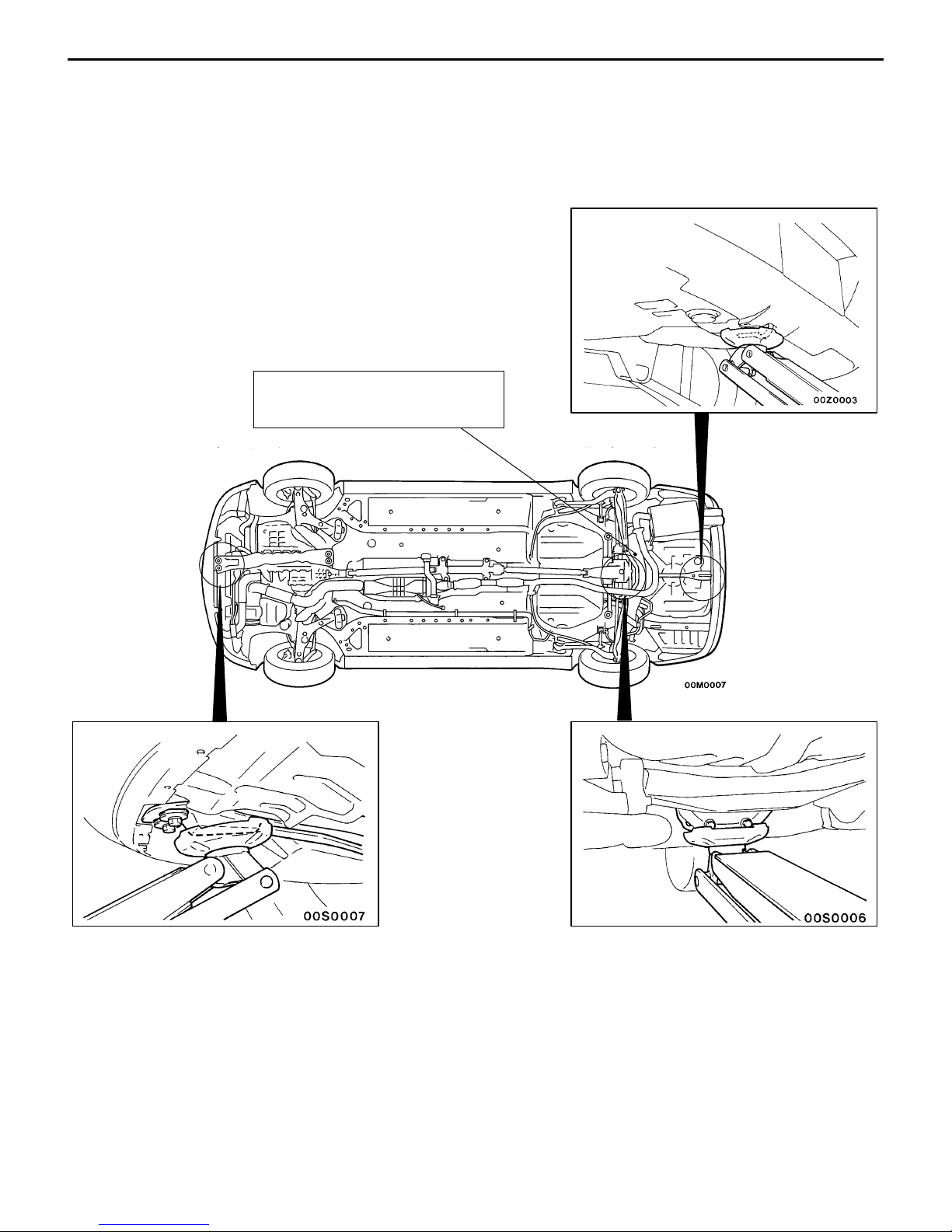

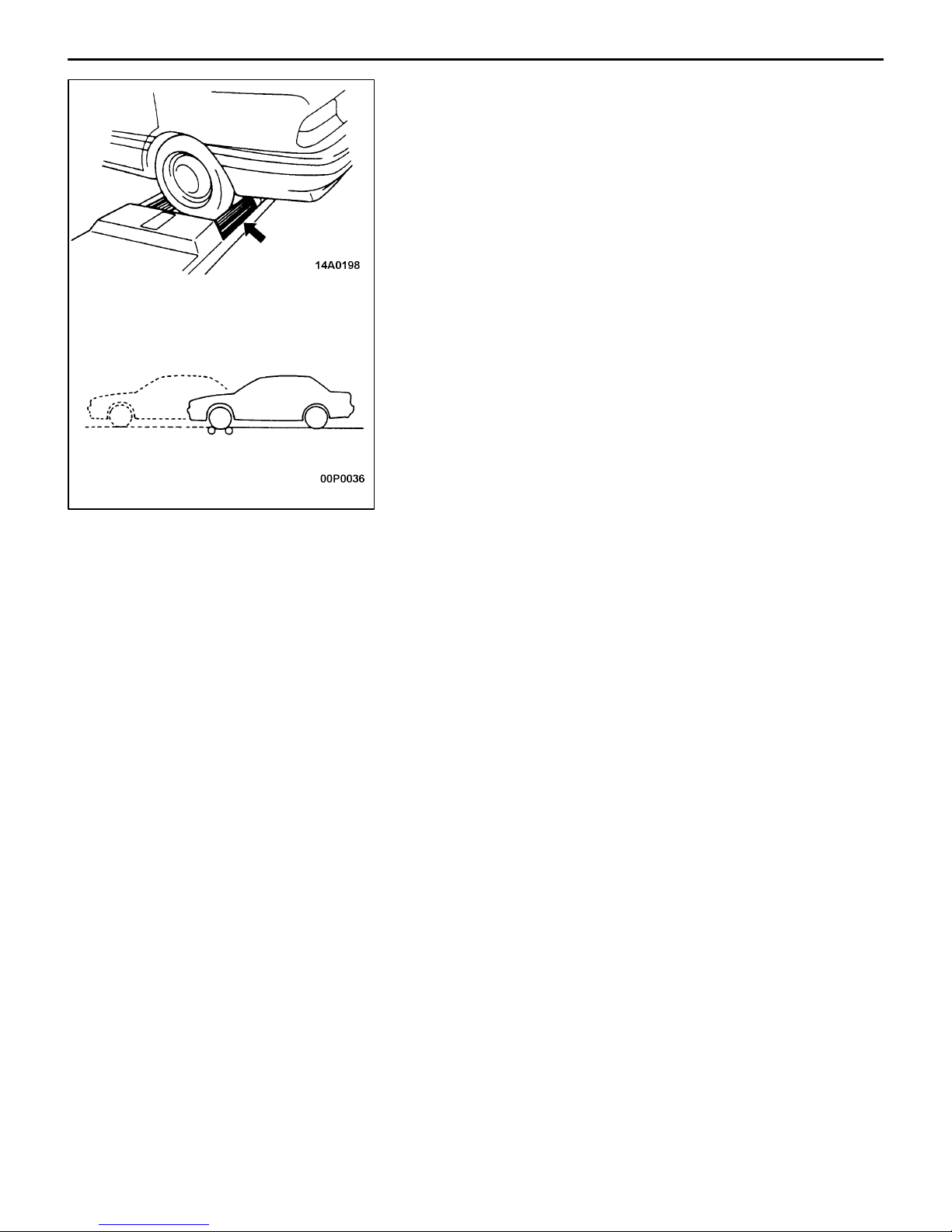

00-18

GENERAL – Support Locations for Lifting and Jacking

SUPPORT LOCATIONS FOR LIFTING AND JACKING

GARAGE JACK

Caution

Do not support the vehicles at locations other than specified supporting points. Neglecting this

will cause damage, etc.

Caution

Never support the rear floor

crossmember.

Page 21

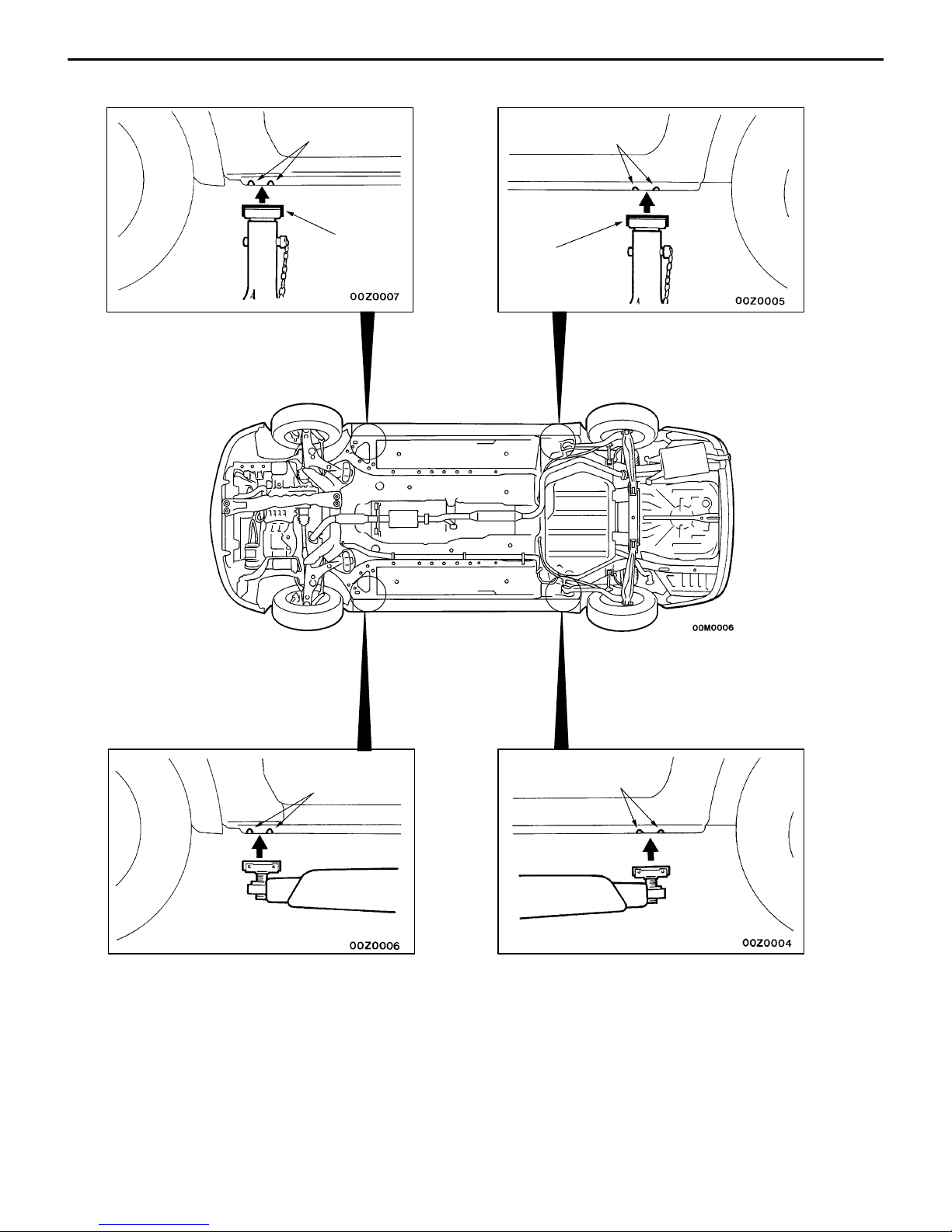

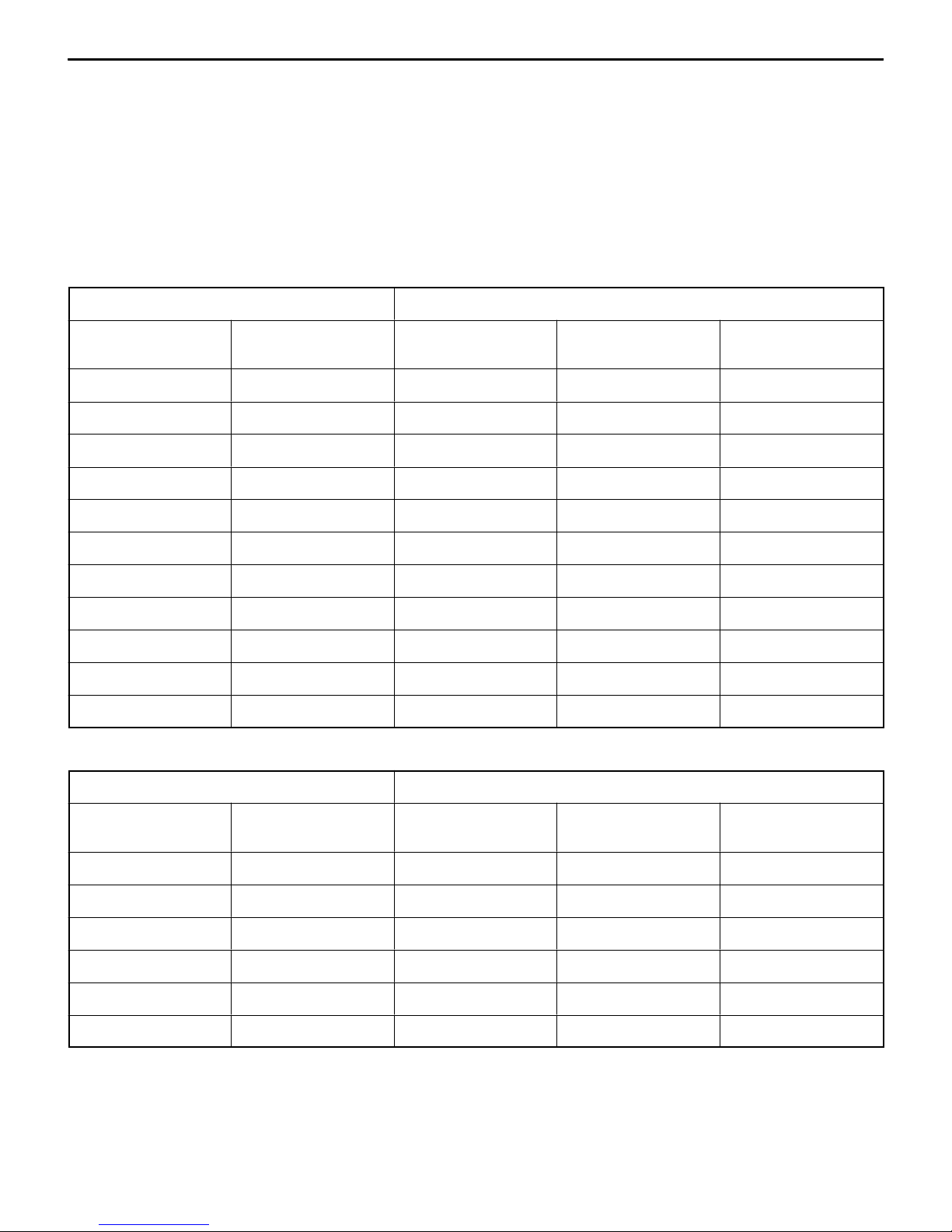

AXLE STANDS

GENERAL – Support Locations for Lifting and Jacking

00-19

Notch

Rubber

Notch

Rubber

SINGLE-POST AND

DOUBLE-POST LIFT

Notch

Notch

Page 22

00-20

GENERAL – Special Handling Instruments for Towing

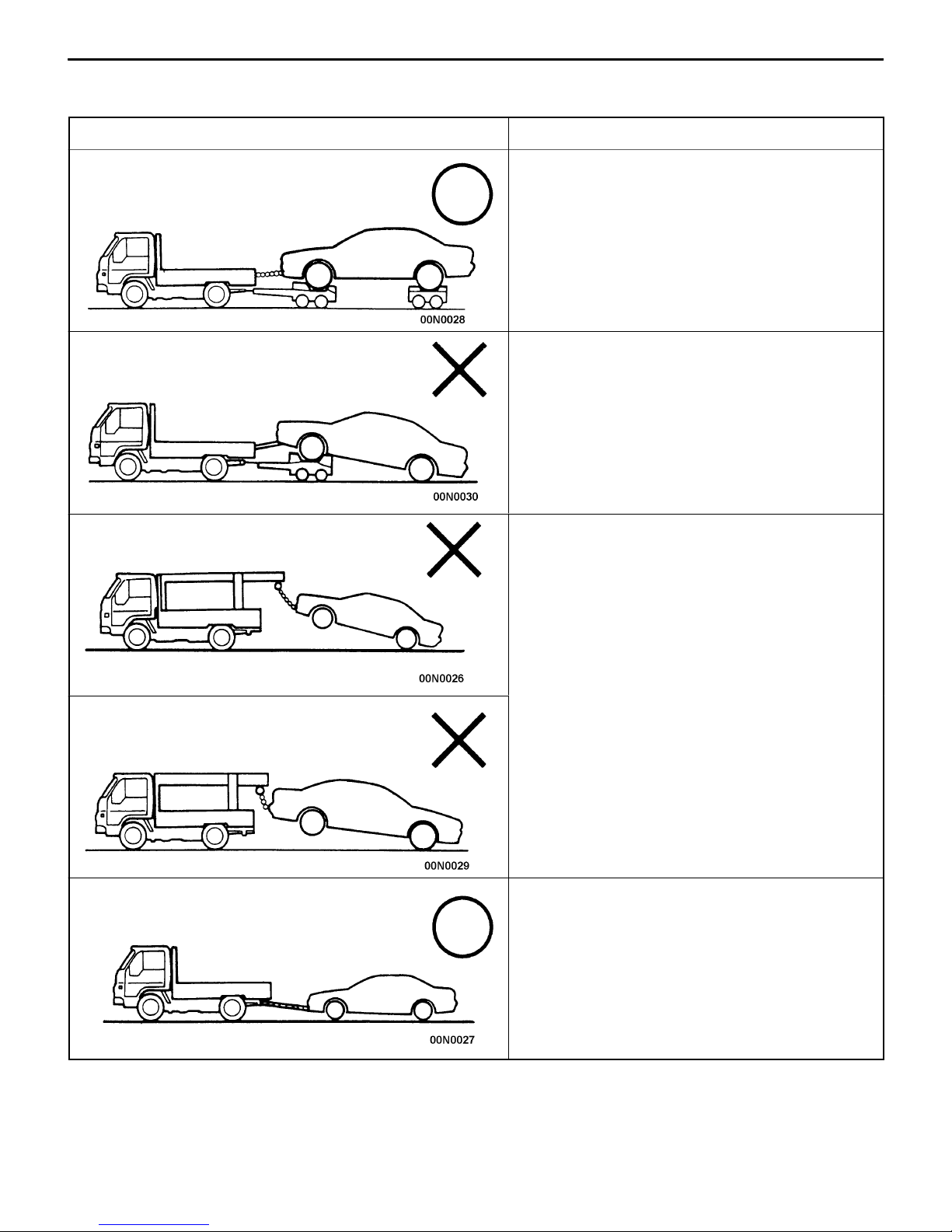

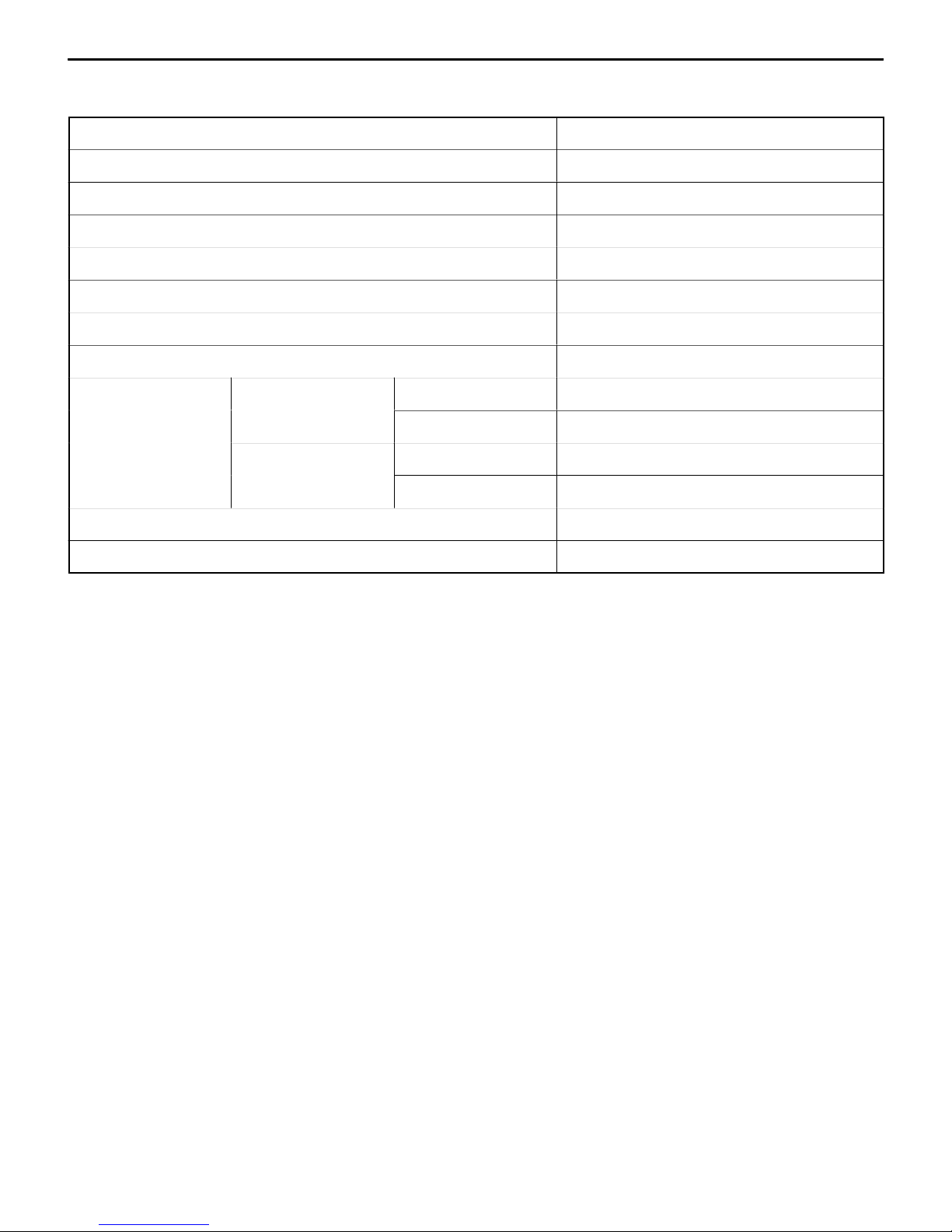

SPECIAL HANDLING INSTRUMENTS FOR TOWING

Towing methods Remarks

If a tow truck is used

Lifting method for 4 wheels – Good

Front wheels lifted – No good

Front wheels lifted – No good

D For 4WD models, the basic principle is that all

four wheels are to be raised before towing.

D The shift lever should be set to 1st gear and

the parking brake should be applied.

D The vehicle must not be towed by placing only

its front wheels or only the rear wheels on a

rolling dolly, because to do so will result in

deterioration of the viscous coupling and result

in the viscous coupling causing the vehicle to

jump forward suddenly.

D If only the front wheels or only the rear wheels

are lifted for towing, the bumper will be damaged.

In addition, lifting of the rear wheels causes

the oil to flow forward, and may result in heat

damage to the rear bushing of the transfer, and

so should never be done.

Rear wheels lifted – No good

Towing by rope or cable – Good

D The front and rear wheels must rotate normally.

D Both running and driving systems must function

normally.

D The shift lever must be set to the neutral position

and the ignition key must be set to “ACC”.

Page 23

Brake tester

GENERAL – Brake Test

BRAKE TEST

In order to stabilize the viscous coupling’s dragging force,

the brake test should always be conducted after the

speedometer test.

FRONT WHEEL MEASUREMENTS

1. Place the front wheels on the brake tester.

2. Perform the brake test.

Caution

The rear wheels should remain on the ground.

3. If the brake dragging force exceeds the specified value,

jack up the vehicle and manually rotate each wheel to

check the rotation condition of each wheel.

NOTE

If the brake dragging force exceeds the specified value,

the cause may be the effect of the viscous coupling’s

dragging force, so jack up the front wheels and check

the rotation condition of the wheels in this state for no

effect by the viscous coupling’s dragging force.

REAR WHEEL MEASUREMENTS

After placing the rear wheels on the brake tester, follow the

same procedures as for the front wheel measurements.

00-21

Page 24

00-22

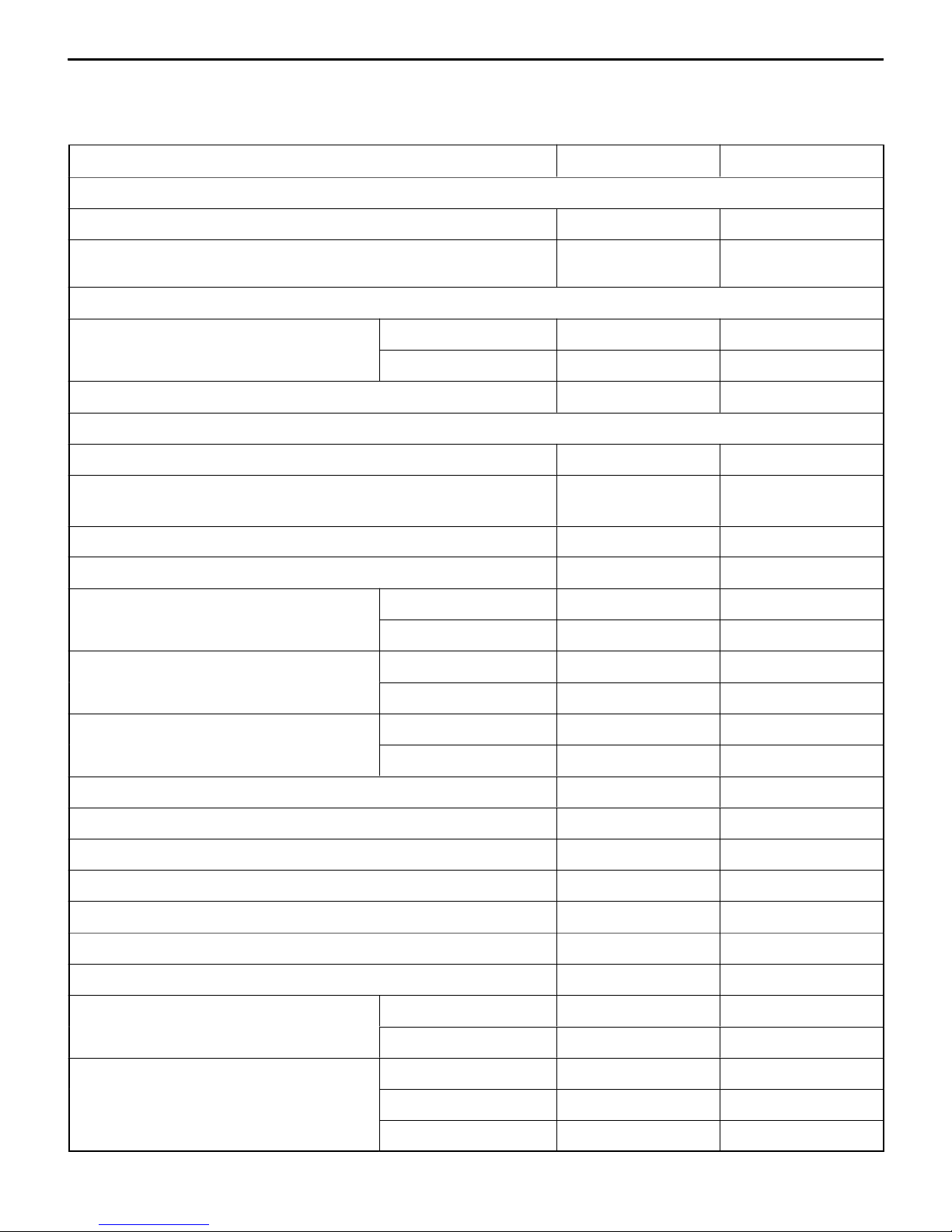

GENERAL – Tightening Torque

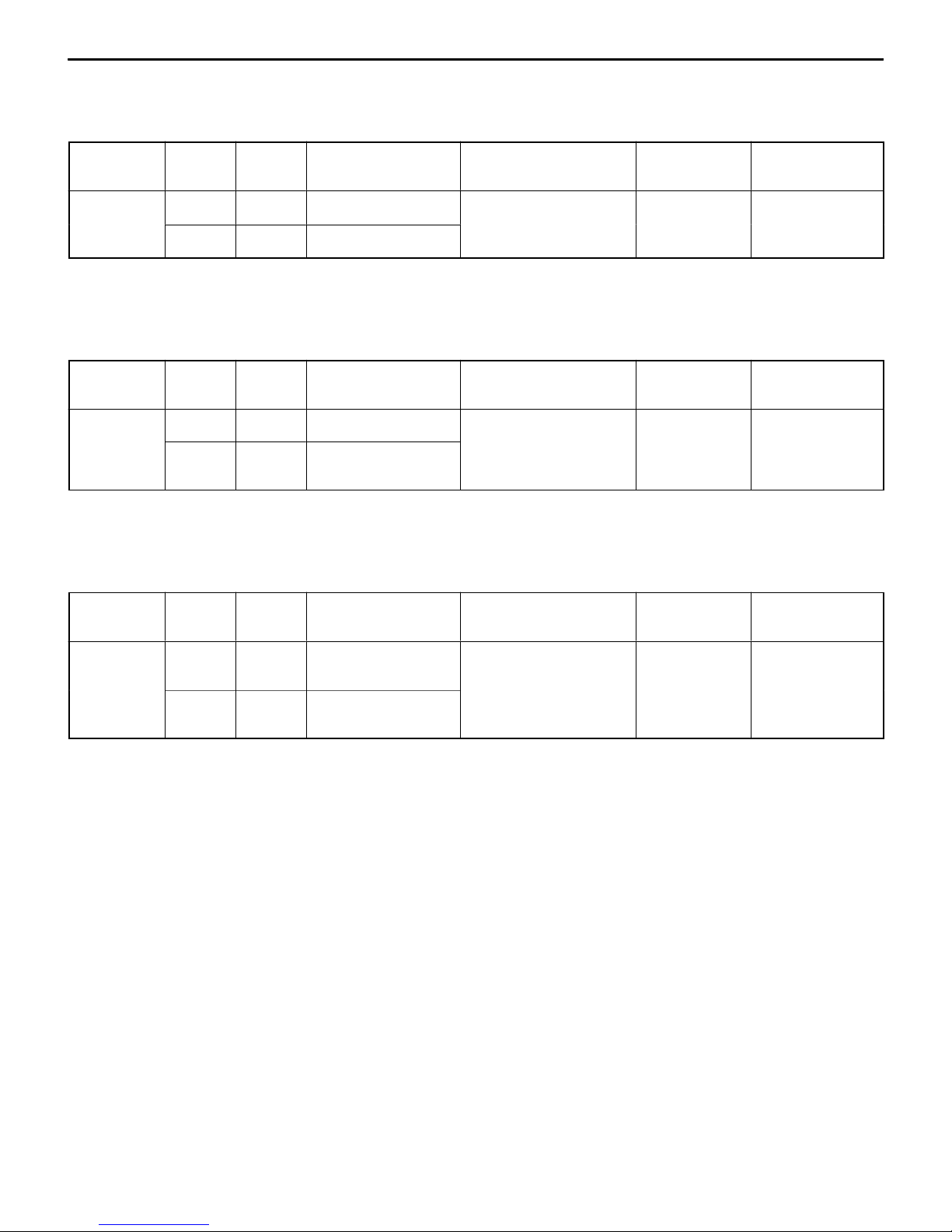

TIGHTENING TORQUE

Each torque value in the table is a standard value

for tightening under the following conditions.

(1) Bolts, nuts and washers are all made of steel

and plated with zinc.

(2) The threads and bearing surface of bolts and

nuts are all in dry condition.

The values in the table are not applicable:

(1) If toothed washers are inserted.

(2) If plastic parts are fastened.

(3) If bolts are tightened to plastic or die-cast

inserted nuts.

(4) If self-tapping screws or self-locking nuts are

used.

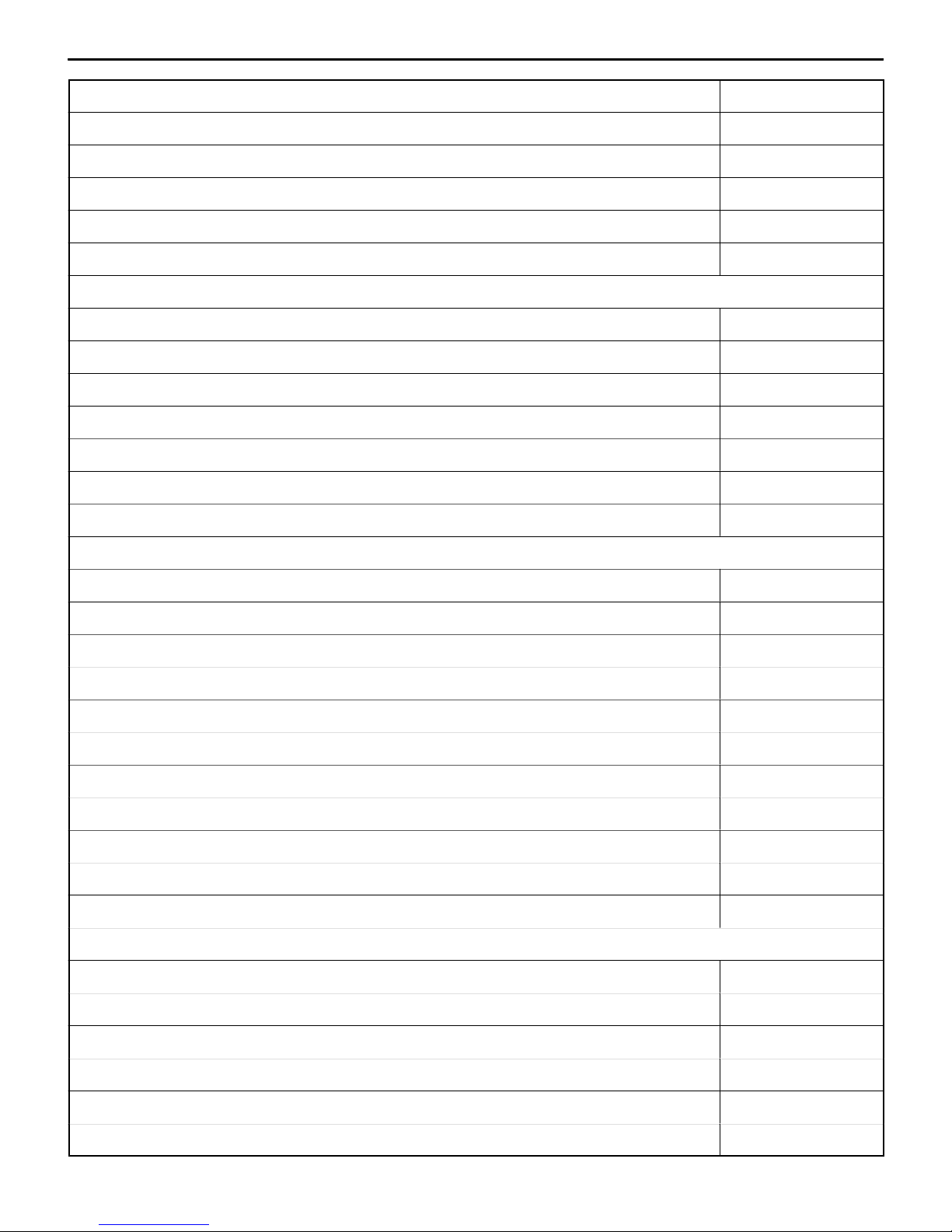

Standard bolt and nut tightening torque

Thread size Torque Nm

Bolt nominal

diameter (mm)

M5 0.8 2.5 4.9 5.9

M6 1.0 4.9 8.8 9.8

M8 1.25 12 22 25

M10 1.25 24 44 52

M12 1.25 41 81 96

M14 1.5 72 137 157

Pitch (mm) Head mark “4” Head mark “7” Head mark “8”

M16 1.5 111 206 235

M18 1.5 167 304 343

M20 1.5 226 412 481

M22 1.5 304 559 647

M24 1.5 392 735 853

Flange bolt and nut tightening torque

Thread size Torque Nm

Bolt nominal

diameter (mm)

M6 1.0 4.9 9.8 12

M8 1.25 13 24 28

M10 1.25 26 49 57

M10 1.5 24 44 54

M12 1.25 46 93 103

M12 1.75 42 81 96

Pitch (mm) Head mark “4” Head mark “7” Head mark “8”

Page 25

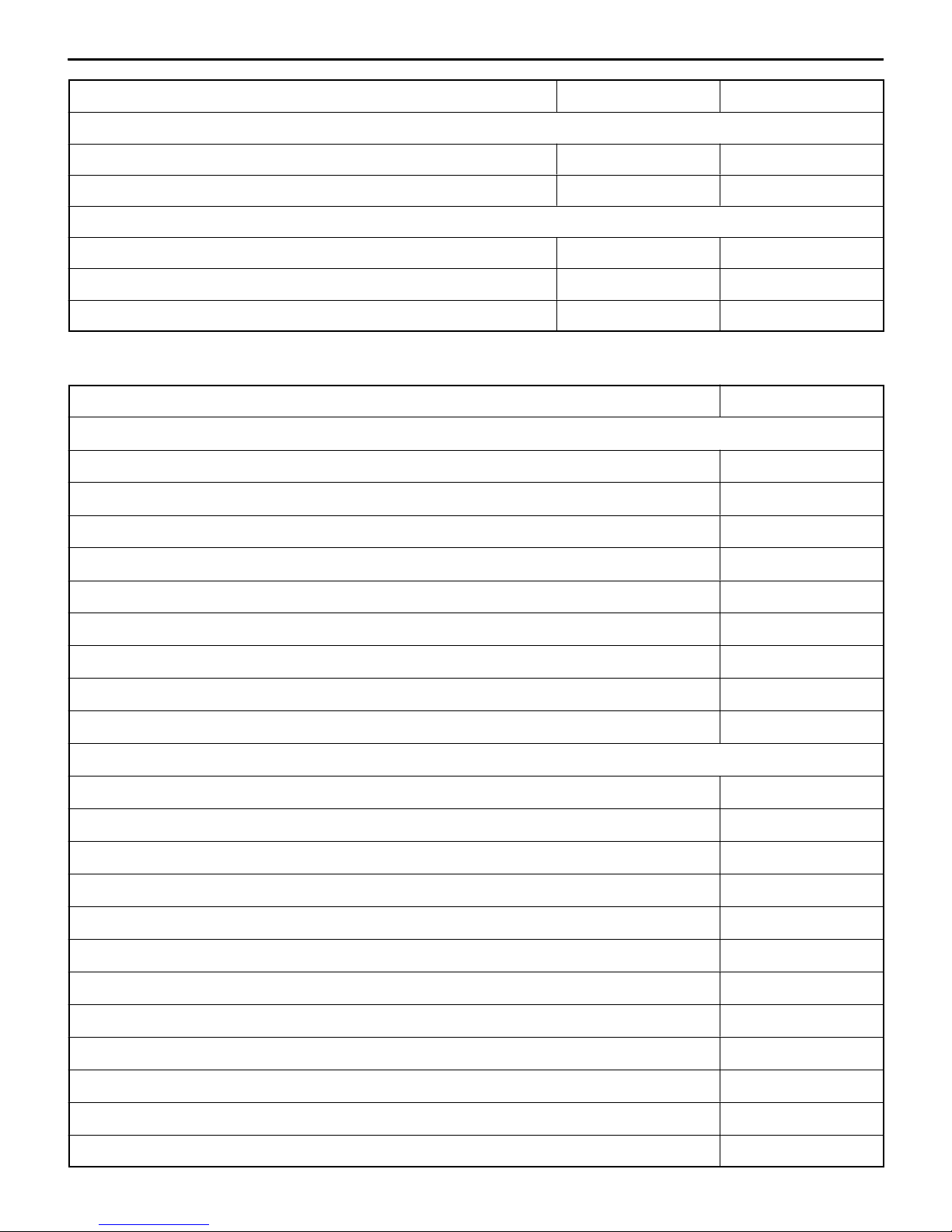

ENGINE

CONTENTS

11-1

GENERAL INFORMATION 2. . . . . . . . . . . . . . . .

SPECIFICATIONS 3. . . . . . . . . . . . . . . . . . . . . . . .

Service Specifications 3. . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 5. . . . . . . . . . . . . . . . . . . . . .

New Tightening Method by Use of Bolts

to Be Tightened in Plastic Area 9. . . . . . . . . . . .

Sealants 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Form-In-Place Gasket 10. . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 11. . . . . . . . . . . . . . . . . . . . . . .

ALTERNATOR AND IGNITION SYSTEM 14.

TIMING BELT 15. . . . . . . . . . . . . . . . . . . . . . . . .

FUEL AND EMISSION CONTROL PARTS 27

SECONDARY AIR SYSTEM AND INTAKE

MANIFOLD 29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXHAUST MANIFOLD 31. . . . . . . . . . . . . . . . .

WATER PUMP AND WATER HOSE 34. . . . .

ROCKER ARMS AND CAMSHAFT 37. . . . . .

CYLINDER HEAD AND VALVES 43. . . . . . . .

FRONT CASE, COUNTERBALANCE

SHAFT AND OIL PAN 51. . . . . . . . . . . . . . . . .

PISTON AND CONNECTING ROD 59. . . . . .

CRANKSHAFT AND FLYWHEEL 67. . . . . . . .

THROTTLE BODY 73. . . . . . . . . . . . . . . . . . . . .

TURBOCHARGER 75. . . . . . . . . . . . . . . . . . . . .

ALTERNATOR 79. . . . . . . . . . . . . . . . . . . . . . . . .

STARTER MOTOR 83. . . . . . . . . . . . . . . . . . . . .

Page 26

11-2

ENGINE – General Information

GENERAL INFORMATION

Descriptions Specifications

Type In-line OHV, SOHC

Number of cylinders 4

Combustion chamber Pentroof + curved top piston type

Total displacement dm

Cylinder bore mm 85.0

Piston stroke mm 88.0

Compression ratio 8.8

V alve timing Intake valve Opens (BTDC) 21°

Lubrication system Pressure feed, full-flow filtration

Oil pump type Involute gear type

3

Closes (ABDC) 59°

Exhaust valve Opens (BBDC) 58°

Closes (ATDC) 18°

1,997

Page 27

ENGINE – Specifications

hol

SPECIFICATIONS

SERVICE SPECIFICATIONS

Items Standard value Limit

Timing belt

Auto-tensioner rod projection length mm 12 –

11-3

Auto-tensioner rod pushed-in amount [when pushed with a force of 98

– 196 N] mm

Rocker arms and camshaft

Camshaft cam height mm Intake 35.79 35.29

Exhaust 35.49 34.99

Camshaft journal outer diameter mm 26 –

Cylinder head and valves

Cylinder head flatness of gasket surface mm Less than 0.05 0.2

Cylinder head grinding limit of gasket surface mm

Total resurfacing depth of both cylinder head and cylinder block

Cylinder head overall height mm 131.9 – 132.1 –

Cylinder head bolt shank length mm – Maximum 99.4

V alve thickness of valve head (margin) mm Intake 1.0 0.5

Exhaust 1.5 1.0

Overall valve length mm Intake 109.5 109.0

Exhaust 109.7 109.2

1.0 or less –

– 0.2

Valve thickness to valve guide clearance

mm

V alve face angle 45° – 45.5° –

Valve spring free length mm 48.3 47.3

Valve spring load/installed height N/mm 294/40.0 –

Valve spring out-of-squareness 1.5° or less Maximum 4°

Valve seat contact width mm 0.9 – 1.3 –

Valve guide inner diameter mm 6.6 –

Valve guide projection from cylinder head upper surface mm 20.5 –

Valve stem projection mm Intake 49.20 49.70

Oversize rework dimensions of valve guide

e mm

Intake 0.02 – 0.05 0.10

Exhaust 0.05 – 0.09 0.15

Exhaust 48.40 48.90

0.05 O.S. 12.05 – 12.07 –

0.25 O.S. 12.25 – 11.27 –

0.50 O.S. 12.50 – 12.52 –

Page 28

11-4

Items LimitStandard value

ENGINE – Specifications

Intake oversize rework dimensions of valve

guide hole mm

Exhaust oversize rework dimensions of

valve guide hole mm

Front case and oil pan

Oil pump side clearance mm Drive gear 0.08 – 0.14 –

Oil pressure at curb idle speed kPa [Oil temperature is 75 to 90°C] 78 or more –

Piston and connecting rod

Piston outer diameter mm 85.0 –

Piston ring side clearance mm No. 1 ring 0.04 – 0.075 –

Piston ring end gap mm No. 1 ring 0.25 – 0.35 0.8

0.3 O.S. 35.30 – 35.33 –

0.6 O.S. 35.60 – 35.63 –

0.3 O.S. 33.30 – 33.33 –

0.6 O.S. 33.60 – 33.63 –

Driven gear 0.06 – 0.12 –

No. 2 ring 0.02 – 0.06 –

No. 2 ring 0.40 – 0.55 0.8

Oil ring 0.10 – 0.40 1.0

Piston pin outer diameter mm 21.0 –

Piston pin press-in load N (Room temperature) 7,350 – 17,200 –

Crankshaft pin oil clearance mm 0.02 – 0.05 0.1

Connecting rod big end side clearance mm 0.10 – 0.25 0.4

Crankshaft and flywheel

Crankshaft end play mm 0.05 – 0.25 0.40

Crankshaft journal outer diameter mm 57.0 –

Crankshaft pin outer diameter mm 44.0 –

Crankshaft journal oil clearance mm 0.02 – 0.04 0.1

Bearing cap bolt shank length mm – Maximum 71.1

Piston to cylinder clearance mm 0.02 – 0.04 –

Cylinder block grinding limit of gasket surface mm

Total resurfacing depth of both cylinder head and cylinder block

Cylinder block overall height mm 284 –

Cylinder block inner diameter mm 85.0 –

– 0.2

Cylinder block cylinder mm 0.01 –

Turbocharger

Waste gate actuator operation check kPa 100 113.3

Page 29

ENGINE – Specifications

Items LimitStandard value

Alternator

Rotor coil resistance Ω Approx. 3 – 5 –

Protrusion length of brush mm – 2

Starter motor

Commutator runout mm 0.05 0.1

Commutator outer diameter mm 32.0 31.4

Commutator undercut mm 0.5 –

TORQUE SPECIFICATIONS

Items Nm

Alternator and ignition system

Oil level gauge guide 13

11-5

Water pump pulley 9

Alternator brace (Alternator side) 21

Alternator brace (Tightened with water pump) 23

Alternator pivot bolt 44

Crankshaft pulley 25

Center cover 3

Spark plug 25

Ignition coil 10

Timing belt

Timing belt cover (Flange bolt) 11

Timing belt cover (Washer bolt) 9

Power steering pump bracket 49

Tensioner pulley 49

Tensioner arm 24

Auto tensioner 24

Idler pulley 48

Crank angle sensor 9

Oil pump sprocket 54

Camshaft bolt 118

Tensioner “B” 19

Counterbalance shaft sprocket 45

Page 30

11-6

Items Nm

Rocker cover 3.5

Engine support bracket 49

Camshaft sprocket bolt 88

Timing belt rear right cover 11

Timing belt rear left upper cover 11

Fuel and emission control parts

Throttle body 18

Fuel pressure regulator 9

Delivery pipe 11

Vacuum tank bracket 9

Solenoid valve bracket 9

Solenoid valve 9

ENGINE – Specifications

Vacuum hose and vacuum pipe 11

Secondary air intake manifold

Heat protector 13

Vacuum hose and vacuum pipe 11

Air pipe (Heat protector side) 13

Air pipe (Cam position sensor side) 11

Air pipe (Eye bolt) 49

Air pipe (Control valve side) 24

Air control valve 21

Air control valve bracket 24

Intake manifold stay 30

Intake manifold (M8) 19

Intake manifold (M10) 35

Exhaust manifold

Engine hanger 12

Heat protector (Turbocharger side) 14

Oxygen sensor 54

Exhaust fitting bolt 59

Exhaust fitting nut 59

Air outlet fitting 19

Page 31

ENGINE – Specifications

Items Nm

OIl return pipe (Turbocharger side) 9

Oil return pipe (Oil pan side – Head mark 7) 9

Oil return pipe (Oil pan side – Head mark 10) 13

Oil pipe 11

Oil pipe eye bolt (Cylinder head side) 16

Oil pipe eye bolt (Turbocharger side) 30

Water pipe 11

Water pipe eye bolt 41

Exhaust manifold (M8) 29

Exhaust manifold (M10) 49

Exhaust manifold (Turbocharger side) 59

Water pump and water hose

11-7

Water temperature sensor 29

Water temperature gauge unit 11

Water inlet fitting 24

Water outlet fitting (M6) 10

Water outlet fitting (M8) 13

Thermostat housing 24

Thermostat housing (Clamp) 11

Water inlet pipe (Cylinder block) 13

Water inlet pipe (Outlet fitting) 10

Water pump 14

Knock sensor 22

Rocker arms and camshaft

Camshaft position sensor 9

Camshaft position sensor cover 10

Camshaft position sensing cylinder 21

Camshaft position sensing support 13

Camshaft bearing cap 20

Oil delivery body 11

Cylinder head and valves

Cylinder head bolt [Tighten to 78 Nm and then completely before tightening to final torque

specification]

20 ! 90° + 90°

Page 32

11-8

Items Nm

Front case and oil pan

Drain plug 39

Oil pan 7

Oil screen 19

Buffle plate 22

Oil pressure switch 10

Oil cooler by-pass valve 54

Relief plug 44

Plug 24

Front case 24

Oil pump cover (Screw) 10

Oil pump cover (Bolt) 16

ENGINE – Specifications

Piston and connecting rods

Connecting rod nut 20 + 90° to 94°

Crankshaft and flywheel

Flywheel bolt 132

Rear plate 11

Bell housing cover 9

Oil seal case 11

Beam bearing cap bolt 25 + 90°

Check valve 32

Throttle body

Throttle position sensor 3.5

Idle speed control body assembly 3.5

Turbocharger

Waste gate actuator 11

Page 33

ENGINE – Specifications

11-9

NEW TIGHTENING METHOD – BY USE OF BOLTS TO BE TIGHTENED IN

PLASTIC AREA

A new type of bolts, to be tightened in plastic area, is currently used some parts of the engine. The

tightening method for the bolts is different from the conventional one. Be sure to observe the method

described in the text when tightening the bolts.

Service limits are provided for the bolts. Make sure that the service limits described in the text are strictly

observed.

D Areas where the bolts are in use:

(1) Cylinder head bolts

(2) Main bearing cap bolts

(3) Connecting rod cap bolts

D Tightening method

After tightening the bolts to the specified torque, tighten them another 90° or 180° (twice 90°). The

tightening method varies on different areas. Observe the tightening method described in the text.

SEALANTS

Item Specified sealant Quantity

Engine support bracket bolt 3MTM AAD Part No. 8672 or equivalent As required

Semi-circular packing 3MTM AAD Part No. 8672 or equivalent As required

Rocker cover 3MTM AAD Part No. 8672 or equivalent As required

Oil return pipe gasket 3MTM AAD Part No. 8731 or equivalent As required

Thermostat housing Mitsubishi Genuine Part No. MD970389 or

equivalent

Water outlet fitting Mitsubishi Genuine Part No. MD970389 or

equivalent

Engine coolant temperature gauge unit 3MTM AAD Part No. 8672 or equivalent As required

Engine coolant temperature sensor 3MTM AAD Part No. 8731 or equivalent As required

Cam position sensor support Mitsubishi Genuine Part No. MD970389 or

equivalent

Oil pressure switch 3MTM AAD Part No. 8672 or equivalent As required

Oil pan Mitsubishi Genuine Part No. MD970389 or

equivalent

Oil seal case Mitsubishi Genuine Part No. MD970389 or

equivalent

As required

As required

As required

As required

As required

Page 34

11-10

ENGINE – Specifications

FORM-IN-PLACE GASKET

The engine has several areas where the form-in-place gasket (FIPG) is in use. To ensure that the gasket

fully serves its purpose, it is necessary to observe some precautions when applying the gasket. Bead

size, continuity and location are of paramount importance. Too thin a bead could cause leaks. Too thick

a bead, on the other hand, could be squeezed out of location, causing blocking or narrowing of the

fluid feed line. To eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary to

apply the gasket evenly without a break, while observing the correct bead size.

The FIPG used in the engine is a room temperature vulcanisation (RTV) type and is supplied in a 100-gram

tube (Part No. MD970389). Since the RTV hardens as it reacts with the moisture in the atmospheric

air, it is normally used in the metallic flange areas. The FIPG, Part No. MD970389, can be used for

sealing both engine oil and coolant, while Part No. MD997110 can only be used for engine oil sealing.

Disassembly

The parts assembled with the FIPG can be easily disassembled without use of a special method. In

some cases, however, the sealant between the joined surfaces may have to be broken by lightly striking

with a mallet or similar tool. A flat and thin gasket scraper may be lightly hammered in between the

joined surfaces. In this case, however, care must be taken to prevent damage to the joined surfaces.

For removal of the oil pan, the special tool “Oil Pan Remover” (MD998727) is available. Be sure to use

the special tool to remove the oil pan.

Surface Preparation

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper

or wire brush. Check to ensure that the surfaces to which the FIPG is to be applied is flat. Make sure

that there are no oils, greases and foreign substances deposited on the application surfaces. Do not

forget to remove the old sealant remained in the bolt holes.

Form-in-Place Gasket Application

When assembling parts with the FIPG, you must observe some precautions, but the procedures is very

simple as in the case of a conventional precut gasket.

Applied FIPG bead should be of the specified size and without breaks. Also be sure to encircle the

bolt hole circumference with a completely continuous bead. The FIPG can be wiped away unless it is

hardened. While the FIPG is still moist (in less than 15 minutes), mount the parts in position. When

the parts are mounted, make sure that the gasket is applied to the required area only. In addition, do

not apply any oil or water to the sealing locations or start the engine until a sufficient amount of time

(about one hour) has passed after installation is completed.

The FIPG application procedure may vary on different areas. Observe the procedure described in the

text when applying the FIPG.

Page 35

ENGINE – Special Tools

SPECIAL TOOLS

Tool Number Name Use

MD998781 Flywheel stopper Holding of flywheel and drive plate

11-11

MD998778 Crankshaft

sprocket puller

MD998719 Pulley holder pin Holding camshaft sprocket

MB990767 Crankshaft pulley

holder

MD998785 Sprocket stopper Holding silent shaft sprocket

Removal of crankshaft sprocket

MD998767 Tensioner puller

socket wrench

MD998738 Set screw

MD998713 Camshaft oil seal

installer

MD998442 Lash adjuster wire Air bleeding of lash adjuster

Adjustment of timing belt tension

Installation of camshaft oil seal

Page 36

11-12

Tool UseNameNumber

ENGINE – Special Tools

MB991654 Cylinder head bolt

wrench (12)

MD998772 Valve spring

compressor

MD998735 Valve spring

compressor

MD998737 Valve stem seal

installer

Removal and installation of cylinder head bolt

Removal and installation of valve and related

parts

Installation of valve stem seal

MD998727 Oil pan remover Removal of oil pan

MD998162 Plug wrench Removal and installation of front case cap plug

Use with MD998783.

MD998783 Plug wrench

retainer

MD998371 Silent shaft bearing

puller

Removal and installation of front case cap plug

Removal of counterbalance shaft front bearing

MD998372 Silent shaft bearing

Removal of counterbalance shaft rear bearing

puller

Page 37

Tool UseNameNumber

ENGINE – Special Tools

11-13

MB991603 Silent shaft bearing

puller stopper

MD998705 Silent shaft bearing

installer

MD998375 Crankshaft front

seal installer

MD998285 Crankshaft front oil

seal guide

Guide stopper for removal and installation of

counterbalance shaft rear bearing

Use with MD998372.

Installation of counterbalance shaft front and

rear bearing

Installation of crankshaft front oil seal

Guide for installation of crankshaft front oil seal

Use with MD998375.

MD998780 Piston setting tool Removal and installation of piston pin

MB990938 Handle Installation of crankshaft rear oil seal

MD998776 Crankshaft rear oil

seal installer

Page 38

11-14

ENGINE – Alternator and Ignition System

ALTERNATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

3 Nm

1

10

2

9

10 Nm

11

13 Nm

21 Nm

23 Nm

25 Nm

15

12

16

14

44 Nm

4

3

7

13

6

5

9 Nm

25 Nm

Removal steps

1. Oil level gauge

2. O-ring

3. Oil level gauge guide

4. O-ring

5. Water pump pulley

6. Alternator brace

7. Alternator

8. Crankshaft pulley

8

9. Center cover

10. Spark plug cable

11. Ignition coil

12. Spark plug

13. Breather hose

14. PCV hose

15. PCV valve

16. PCV valve gasket

Page 39

TIMING BELT

REMOVAL AND INSTALLATION

ENGINE – Timing Belt

11-15

11 N m

9 Nm

29

1

49 Nm

8

22

7

23

26

24

2

13

24 Nm

118 Nm

14

11 N m

27

49 Nm

24 Nm

9

30

25

11 N m

31

3

4

19

6

45 Nm

19 Nm

18

3.5 Nm

30 Nm

5

28

88 Nm

15

48 Nm

10

Removal steps

1. Timing belt front upper cover

2. Timing belt front center cover

3. Rubber plug

4. Timing belt front lower cover

5. Power steering pump bracket

AA""LA 6. Timing belt

"KA 7. Tensioner pulley

8. Tensioner arm

"JA 9. Auto tensioner

10. Idler pulley

11. Crank angle sensor

AB""IA 12. Oil pump sprocket

AC""HA 13. Crankshaft sprocket bolt

AD" 14. Crankshaft sprocket

15. Crankshaft sensing blade

16. Tensioner B

16

12

54 Nm

17

32

11

21

20

9 Nm

AE""GA 17. Timing belt B

AF""FA 18. Counterbalance shaft sprocket

"EA 19. Crankshaft spacer

AG" 20. Crankshaft sprocket B

21. Crankshaft key

22. Oil filler cap

"DA 23. Rocker cover

24. Rocker cover gasket A

25. Rocker cover gasket B

"CA 26. Semi-circular packing

"BA 27. Engine support bracket

AH""AA 28. Camshaft sprocket bolt

29. Camshaft sprocket

30. Timing belt rear right cover

31. Timing belt rear left upper cover

32. Timing belt rear left lower cover

49 Nm

Page 40

11-16

ENGINE – Timing Belt

REMOVAL SERVICE POINTS

AA" TIMING BELT REMOVAL

(1) If the timing belt is to be reused, chalk an arrow mark

on the back surface of the belt so that the belt can be

reinstalled in the same direction.

(2) Place the exhaust camshaft sprocket in a position where

the timing mark for No. 1 cylinder is positioned about

one tooth before the top dead center of the compression

stroke.

Timing mark

Caution

The camshaft sprocket on the exhaust side can turn

very easily because of the valve spring tension. Use

care not to allow your fingers to get caught by the

sprocket.

(3) Loosen the lock nut of the tensioner pulley, then remove

the timing belt.

AB" OIL PUMP SPROCKET REMOVAL

(1) Remove the plug on the left side of cylinder block.

(2) Insert a screwdriver (shank diameter 8 mm) to block the

counterbalance shaft.

(3) Remove the nut.

(4) Remove the oil pump sprocket.

AC" CRANKSHAFT BOLT LOOSENING

(1) Hold the drive plate with the special tool as shown.

(2) Remove the crankshaft bolt.

AD" CRANKSHAFT SPROCKET REMOVAL

If it is difficult to remove the sprocket, use the special tool.

Page 41

6EN1322

MD998785

ENGINE – Timing BeltENGINE – Timing Belt

AE" TIMING BELT “B” REMOVAL

Make a mark on the back of the timing belt indicating the

direction of rotation so it may be reassembled in the same

direction if it is to be reused.

NOTE

(1) Water or oil on the belt shortens its life drastically, so

the removed timing belt, sprocket, and tensioner must

be free from oil and water. These parts should not be

washed. Replace parts if seriously contaminated.

(2) If there is oil or water on each part check front case

oil seals, camshaft oil seal and water pump for leaks.

AF" COUNTERBALANCE SHAFT SPROCKET

REMOVAL

(1) Set the special tool as shown to prevent the

counterbalance shaft sprocket from turning together.

(2) Loosen the bolt and remove the sprocket.

11-17

AG" CRANKSHAFT SPROCKET “B” REMOVAL

If it is difficult to remove the sprocket, use the special tool.

AH" CAMSHAFT SPROCKET BOLT LOOSENING

Use a wrench to hold the hexagonal part of the camshaft,

and then remove the camshaft sprocket mounting bolt.

INSTALLATION SERVICE POINTS

"AA CAMSHAFT SPROCKET BOLT TIGHTENING

Using a wrench, hold the camshaft at its hexagon and tighten

the bolt to the specification.

Page 42

11-18

ENGINE – Timing Belt

"BA ENGINE SUPPORT BRACKET INSTALLATION

Coat the bolts illustrated with sealant before tightening.

Specified sealant: 3M

"CA SEALANT APPLICATION TO SEMI-CIRCULAR

PACKING

Specified sealant: 3M

TM

AAD Part No. 8672 or equivalent

TM

AAD Part No. 8672 or equivalent

Semicircular

packing

10 mm

10 mm

Cylinder head

Page 43

10 mm

Apply sealant

10 mm

10 mm

ENGINE – Timing Belt

"DA SEALANT APPLICATION TO ROCKER COVER

Apply sealant to the areas indicated in the illustration.

Specified sealant: 3M

11-19

TM

AAD Part No. 8672 or equivalent

Apply sealant

Sharp

edge

10 mm

Apply sealant

Apply sealant

"EA SPACER INSTALLATION

Install the spacer with the chamfered end toward the oil seal.

Counterbalance

shaft

MD998785

"FA COUNTERBALANCE SHAFT SPROCKET

INSTALLATION

(1) Install the counterbalance shaft sprocket and screw the

bolt.

(2) Install special tool MD998785 as shown in the illustration

to lock the counterbalance shaft.

(3) Tighten the bolt, and then remove the special tool.

Page 44

11-20

Timing

marks

(on front

case)

Timing

marks

ENGINE – Timing Belt

"GA TIMING BELT “B” INSTALLATION

(1) Align timing marks on the crankshaft sprocket “B” and

counterbalance shaft sprocket with the marks on the front

case respectively.

(2) Install the timing belt “B” on the crankshaft sprocket “B”

and counterbalance shaft sprocket. There should be no

slack on the tension side.

(3) Make sure that the relationship between the tensioner

pulley center and the bolt center is as shown in the

illustration.

(4) Move the tensioner “B” in the direction of arrow while

lifting with a finger to give a sufficient tension to the tension

side of timing belt. In this condition, tighten bolt to secure

tensioner “B”. When the bolt is tightened, use care to

prevent shaft from turning together. If shaft is turned

together, belt will be overtensioned.

(5) Check to ensure that timing marks on sprockets and front

case are in alignment.

(6) Press with index finger the center of span on the tension

side of timing belt “B”. The bolt must deflect 5 – 7 mm.

"HA CRANKSHAFT BOLT TIGHTENING

(1) Using the special tool, hold the flywheel or drive plate.

(2) Install the crankshaft pulley in position.

Page 45

ENGINE – Timing Belt

11-21

"IA OIL PUMP SPROCKET INSTALLATION

(1) Insert a Phillips screwdriver (shank diameter 8 mm shaft)

through the plug hole on the left side of the cylinder

block to block the left counterbalance shaft.

(2) Install the oil pump sprocket.

(3) Apply a proper amount of engine oil to the bearing surfaces

of the nuts.

(4) Tighten the nuts to the specified torque.

6EN0564

"JA AUTO TENSIONER INSTALLATION

(1) If the auto tensioner rod is in its fully extended position,

A

B

reset it as follows.

(2) Clamp the auto-tensioner in the vise with soft jaws.

(3) Push in the rod little by little with the vise until the set

hole A in the rod is aligned with the hole B in the cylinder.

(4) Insert a wire (1.4 mm in diameter) into the set holes.

(5) Unclamp the auto tensioner from the vise.

(6) Install the auto tensioner to front case and tighten to

the specified torque.

Caution

Leave the wire installed in the auto tensioner.

"KA TENSIONER PULLEY INSTALLATION

Install the tensioner pulley in such direction that its two small

holes are arranged vertically.

Small holes

6EN1323

Page 46

11-22

Timing mark

Timing mark

ENGINE – Timing Belt

"LA TIMING BELT INSTALLATION

(1) Place the exhaust side camshaft sprocket in a position

where its timing mark is one tooth offset from the timing

mark on the rocker cover in the counterclockwise direction.

NOTE

Even if the timing marks on the sprocket and the rocker

cover are brought into alignment, the exhaust camshaft

is forced back by the valve spring tension. It is stabilized

at a position one tooth before the timing mark.

(2) Align the timing mark on the intake side camshaft sprocket

with that on the rocker cover.

NOTE

Even if the timing marks on the sprocket and the cover

are brought into alignment, the intake camshaft is forced

to turn one tooth in the clockwise direction by the valve

spring tension and stabilized there.

Oil pump

sprocket

timing marks

Plug

6EN1327

Screwdriver

6EN1026

(3) Place the timing mark on the crankshaft sprocket one

tooth this side from the mated timing mark as in the case

of the camshaft sprocket.

(4) Align the timing mark on oil pump sprocket with its mating

mark.

(5) Remove the plug on cylinder block and insert a Phillips

screwdriver (shank diameter 8 mm) through the hole

(Engine with counterbalance shafts).

If it can be inserted as deep as 60 mm or more, the

timing marks are correctly aligned. If the inserted depth

is only 20 – 25 mm, turn the oil pump sprocket one turn

and realign timing marks. Then check to ensure that the

screwdriver can be inserted 60 mm or more. Keep the

screwdriver inserted until installation of timing belt is

finished.

Page 47

Timing mark

ENGINE – Timing Belt

(6) Remove the Phillips screwdriver. Place the oil pump

sprocket in a position where its timing mark is one tooth

offset from the mated timing mark in the counterclockwise

direction.

6EN1327

(7) Fit the timing belt over the exhaust side camshaft sprocket,

and secure it at the illustrated position using a paper

clip.

11-23

Timing mark

(8) Turn the intake side camshaft sprocket as shown to a

position where its timing mark is one tooth offset from

the mated timing mark in the counterclockwise direction.

Then, fit the timing belt over the sprocket and secure

it with a paper clip.

NOTE

The intake camshaft will be turned a little clockwise by

the valve spring tension and stabilized in position even

if the belt is clipped at one tooth offset position.

(9) Check to ensure that the timing marks on the intake

camshaft sprocket side are in alignment when the exhaust

camshaft sprocket is turned clockwise to align the timing

marks.

NOTE

The timing belt span between the intake and exhaust

sprockets will have 17 cogs.

(10)Fit the timing belt over the idler pulley, oil pump sprocket

and crankshaft sprocket in this order.

Oil pump

Crankshaft

sprocket

sprocket

NOTE

Be careful that the belt does not become slack.

Page 48

11-24

ENGINE – Timing Belt

(11)Fit the timing belt over the tensioner pulley.

NOTE

When fitting the timing belt over the tensioner pulley,

turn the intake side camshaft sprocket a little

counterclockwise, as this will facilitate the work.

Crankshaft

sprocket

MD998767

MD998738

(12)Turn the crankshaft pulley a little in the illustrated direction

to pull up the timing belt at the idler pulley side.

(13)Check to ensure that the timing marks on the crankshaft

sprocket, oil pump sprocket and exhaust camshaft

sprocket are all offset one tooth from the corresponding

timing marks in the counterclockwise direction.

(14)Using the special tool, turn the tensioner pulley in the

illustrated direction to strain the timing belt. Then, secure

the tensioner temporarily by tightening the retaining bolt

lightly.

NOTE

There must be no slack in the timing belt between the

intake and exhaust camshafts.

(15)Turn the crankshaft to align the timing mark with the mark

for No. 1 cylinder top dead center in the compression

stroke.

(16)Set the special tool as shown and screw it in up to the

position where the wire inserted in the auto-tensioner

when installing it can be moved lightly.

Page 49

MD998767

ENGINE – Timing Belt

(17)Loosen the retaining bolt of the tensioner pulley.

Caution

Loosening the retaining bolt can cause the intake

and exhaust camshafts to turn, resulting in slackened

timing belt. Use care that the timing belt does not

come off the sprockets at this time.

(18)Pull up the slack of the timing belt by turning the tensioner

in illustrated direction using the special tool and a torque

wrench (0 – 5 Nm).

(19)From this position, turn back the tensioner until the torque

wrench reading becomes 3.5 Nm, then secure it by

tightening the retaining bolt.

(20)Remove the special tool attached in step (16).

(21)Rotate the crankshaft clockwise 2 turns. Then, leave it

intact 15 minutes.

(22)Check to see that the wire inserted when installing the

auto-tensioner can be pulled out lightly. If it can be pulled

out lightly, the timing belt is being tensioned properly.

If so, remove the wire. In addition, check that the rod

protrusion from the auto-tensioner meets the standard

value, which is also an indication of properly tensioned

timing belt.

11-25

Standard value: 3.8 – 4.5 mm

(23)If the wire cannot be removed with a light force, repeat

steps (16) through (21) until the proper belt tensioner

is obtained.

INSPECTION

TIMING BELT

Replace belt if any of the following conditions exist.

(1) Hardening of back rubber.

Back side is glossy without resilience and leaves no indent

when pressed with fingernail.

(2) Cracks on rubber back.

(3) Cracks or peeling of canvas.

(4) Cracks on rib root.

(5) Cracks on belt sides.

Page 50

11-26

ENGINE – Timing Belt

(6) Abnormal wear of belt sides. The sides are normal if

they are sharp as if cut by a knife.

(7) Abnormal wear on teeth.

(8) Missing tooth.

98 to 196 N

12 mm

Movement

AUTO TENSIONER

(1) Check the auto tensioner for possible leaks and replace

as necessary.

(2) Check the rod end for wear or damage and replace as

necessary.

(3) Measure the rod protrusion. If it is out of specification,

replace the auto tensioner.

Standard value: 12 mm

(4) Press the rod with a force of 98 to 196 N and measure

its protrusion.

(5) If the measured value is 1 mm or more shorter than the

value obtained in step (3), replace the auto tensioner.

Page 51

ENGINE – Fuel and Emission Control Parts

FUEL AND EMISSION CONTROL PARTS

REMOVAL AND INSTALLATION

11 N m

11-27

11 N m

15

9 Nm

16

9 Nm

12

11

3

1

18 Nm

9

10

8

5

6

4

14

7

2

13

Removal steps

1. Throttle body

"CA 2. Throttle body gasket

3. Fuel return pipe

"BA 4. Fuel pressure regulator

5. O-ring

6. Insulator

7. Insulator

"AA 8. Injector

9. O-ring

10. Grommet

11. Delivery pipe

12. Vacuum hose and vacuum pipe

13. Vacuum tank

14. Vacuum tank bracket

15. Solenoid valve

16. Solenoid valve bracket

Page 52

11-28

Grommet

ENGINE – Fuel and Emission Control Parts

INSTALLATION SERVICE POINTS

"AA INJECTORS INSTALLATION

(1) Before installing an injector, the rubber O-ring must be

lubricated with a drop of clean engine oil to aid in

installation.

(2) Install injector top end. Be careful not to damage O-ring

during installation.

O-ring

1EN0388

"BA FUEL PRESSURE REGULATOR INSTALLATION

(1) Apply a small amount of new engine oil to the O-ring.

Insert the fuel pressure regulator into the delivery pipe

being careful not to damage the O-ring.

Caution

Be sure not to let engine oil get into the delivery

pipe.

(2) Check that the fuel pressure regulator turns smoothly.

If it does not turn smoothly, the O-ring may be trapped.

Remove the fuel pressure regulator and check the O-ring

for damage, and then re-insert it into the delivery pipe

and check once again.

Projection

"CA GASKET INSTALLATION

Position the projection as shown in the illustration.

Page 53

ENGINE – Secondary Air System and Intake Manifold

SECONDARY AIR SYSTEM AND INTAKE MANIFOLD

REMOVAL AND INSTALLATION

11-29

35 Nm

19 Nm

10

5

21 Nm

21 Nm

24 Nm

4

6

11 N m

35 Nm

24 Nm

2

11 N m

35 Nm

7

49 Nm

13 Nm

3

1

9

30 Nm

Removal steps

1. Exhaust manifold heat protector

2. Vacuum hose and vacuum pipe

"BA 3. Air pipe assembly

4. Air control valve gasket

5. Air control valve assembly

6. Engine hanger

11

8

"AA 7. Air control valve bracket

8. Intake manifold stay

9. Alternator brace stay

10. Intake manifold

11. Intake manifold gasket

Page 54

11-30

(1)

ENGINE – Secondary Air System and Intake Manifold

INSTALLATION SERVICE POINTS

"AA AIR CONTROL VALVE BRACKET INSTALLATION

(1) Attach the air control valve bracket and the engine hanger

to the intake manifold using bolts and nuts with which

the intake manifold is also installed to the engine.

(2) Tighten the bolts and nuts to the specified torque in the

sequence given in the illustration.

(2)

(3)

(2)

(1)

(3)

(4)

"BA AIR PIPE ASSEMBLY INSTALLATION

(1) Install the air pipe assembly to the exhaust manifold and

to the air control valve and secure it provisionally by

tightening the fasteners handtight.

(2) Tighten the fasteners to the specified torque in the

sequence given in the illustration.

Page 55

ENGINE – Exhaust Manifold

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION

11-31

16 Nm

59 Nm

19

59 Nm

1

12 Nm

18

11 N m

29 Nm

30 Nm

14

15

49 Nm

41 Nm

4

12

10 Nm

13

16

10 Nm

5

17

14 Nm

11

41 Nm

59 Nm

3

2

54 Nm

Removal steps

1. Engine hanger

2. Turbocharger heat protector

3. Oxygen sensor

4. Exhaust fitting

5. Exhaust fitting gasket

6. Air outlet fitting

"CA 7. Air outlet fitting gasket

8. Oil return pipe

"BA 9. Gasket

"BA 10. Oil return pipe gasket

(Oil pan side)

10

8

9 Nm

9

Head mark 7: 9 Nm

Head mark 10: 13 Nm

11. Oil return pipe gasket

12. Turbocharger assembly

13. Turbocharger gasket

14. Oil pipe

15. Water pipe

16. Water pipe

17. Turbocharger

"AA 18. Exhaust manifold

19. Exhaust manifold gasket

7

19 Nm

6

(Turbocharger side)

Page 56

11-32

3456

ENGINE – Exhaust Manifold

INSTALLATION SERVICE POINTS

"AA EXHAUST MANIFOLD INSTALLATION

Tighten the exhaust manifold mounting nuts to the specified

torque in the sequence given in the illustration.

12

789

Timing belt side

Oil pan

"BA GASKET / OIL RETURN GASKET INSTALLATION

EVOLUTION IV AND V

Install the gasket with the silicon-printed side toward the oil

pan and with the tabbed end directed as shown.

Silicon print

Timing belt side

Oil pan

Oil return

pipe gasket

EVOLUTION VI

(1) Install the gasket with the tabbed end directed as shown.

Gasket

Oil pan

Oil return

pipe gasket

Oil return

pipe

(2) Apply sealant to both sides of the oil return pipe gasket

and leave it for 20 minutes to dry before installing. T ighten

the mounting bolts to the specified torque.

Specified sealant:

TM

3M

AAD Part No. 8731 or equivalent

NOTE

If mounting bolts with head mark 7 have been used,

be sure to replace them with bolts having head mark

10.

Page 57

Projection

ENGINE – Exhaust Manifold

"CA GASKET INSTALLATION

Position the projection as shown in the illustration.

11-33

Page 58

11-34

ENGINE – Water Pump and Water Hose

WATER PUMP AND WATER HOSE

REMOVAL AND INSTALLATION <EVOLUTION VI>

11

1

13

16

22 Nm

2

13 Nm

12

9.8 Nm

29 Nm

10 Nm

4

8

7

24 Nm

5

9

6

11 N m

24 Nm

11 N m

3

10

15

14